Patents

Literature

816 results about "Diameter measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hole Measurement Apparatuses

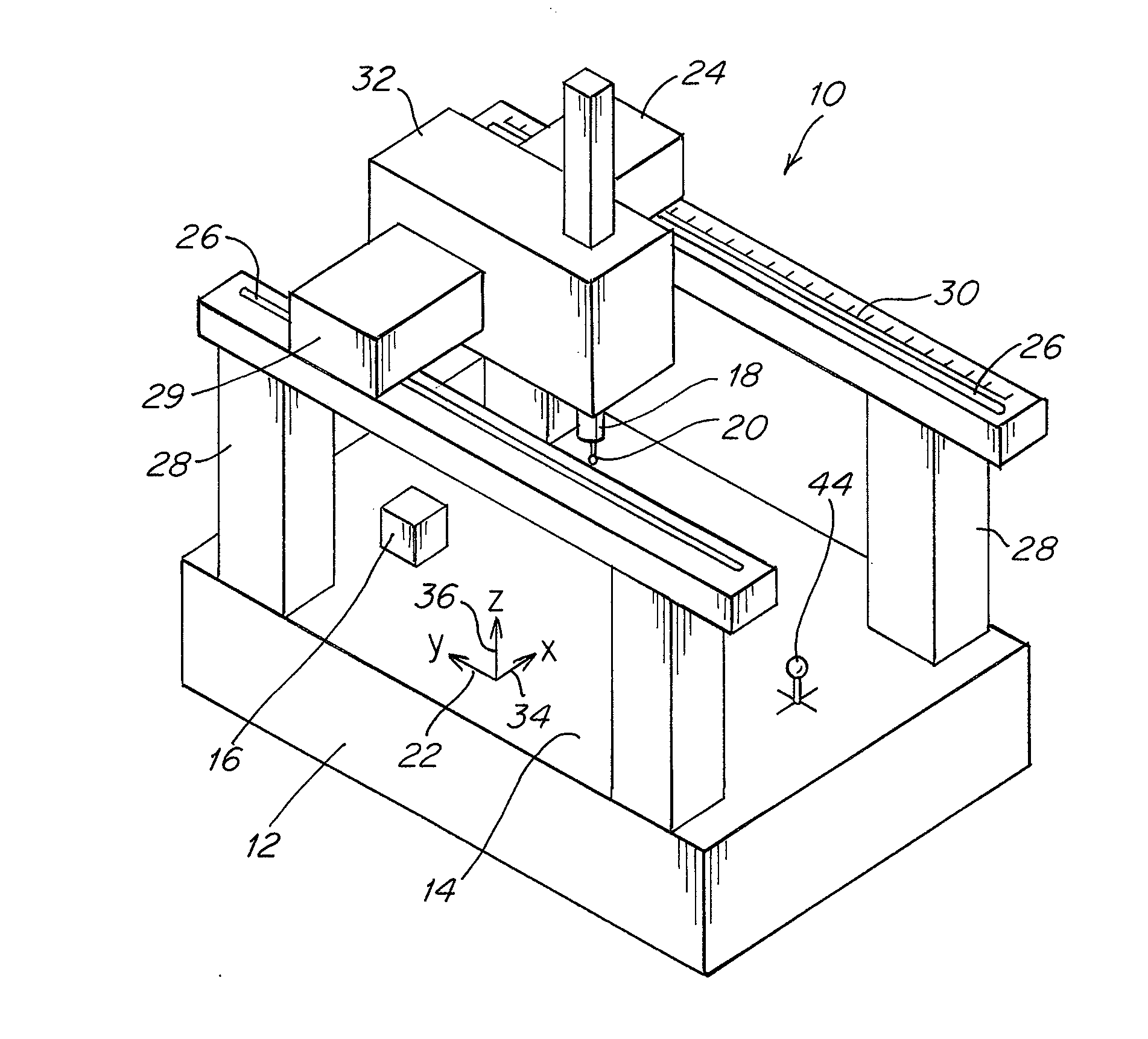

ActiveUS20110166824A1Increase productionIncrease workforceElectric/magnetic depth measurementElectrical/magnetic diameter measurementsEngineeringDiameter measurement

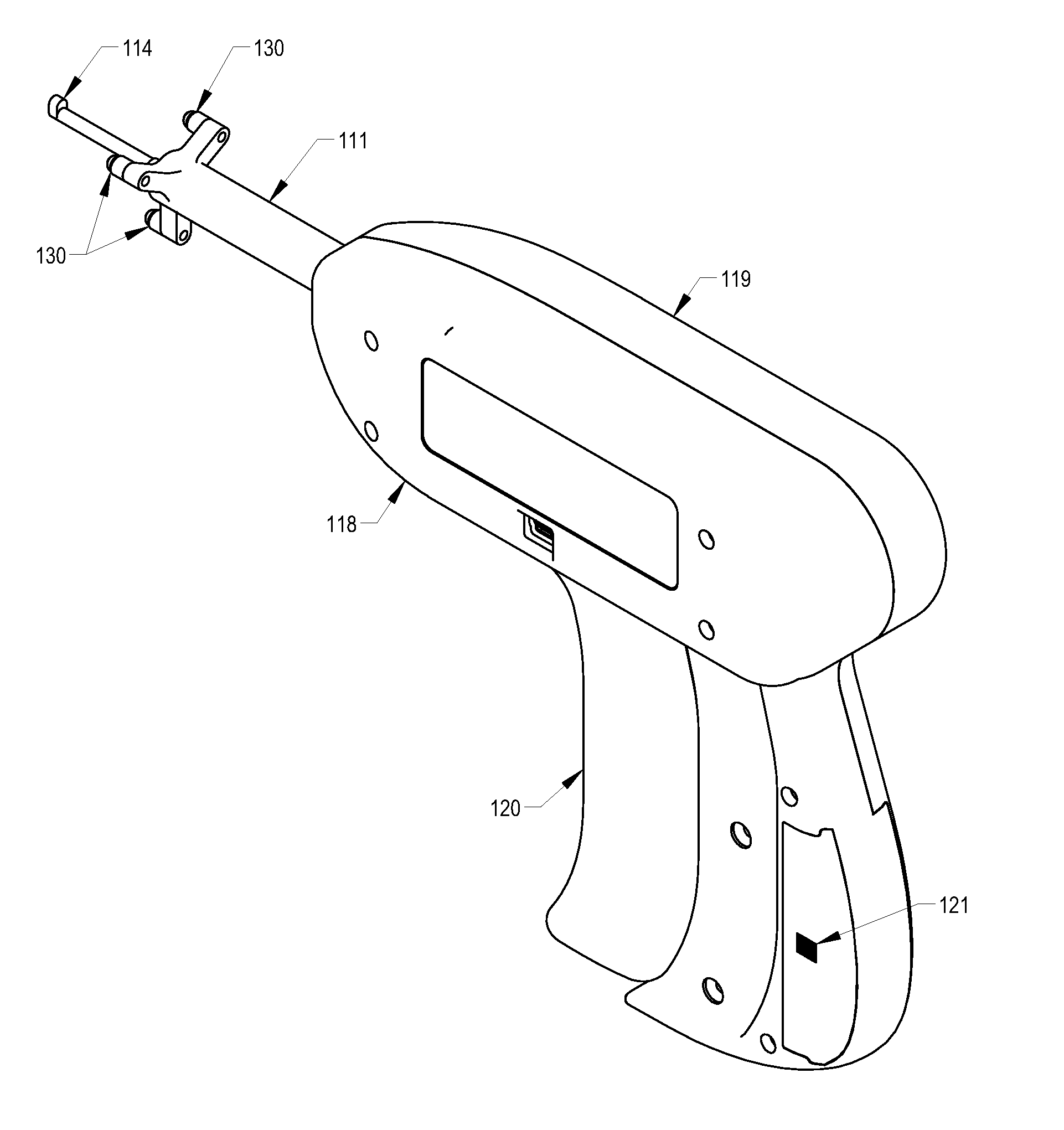

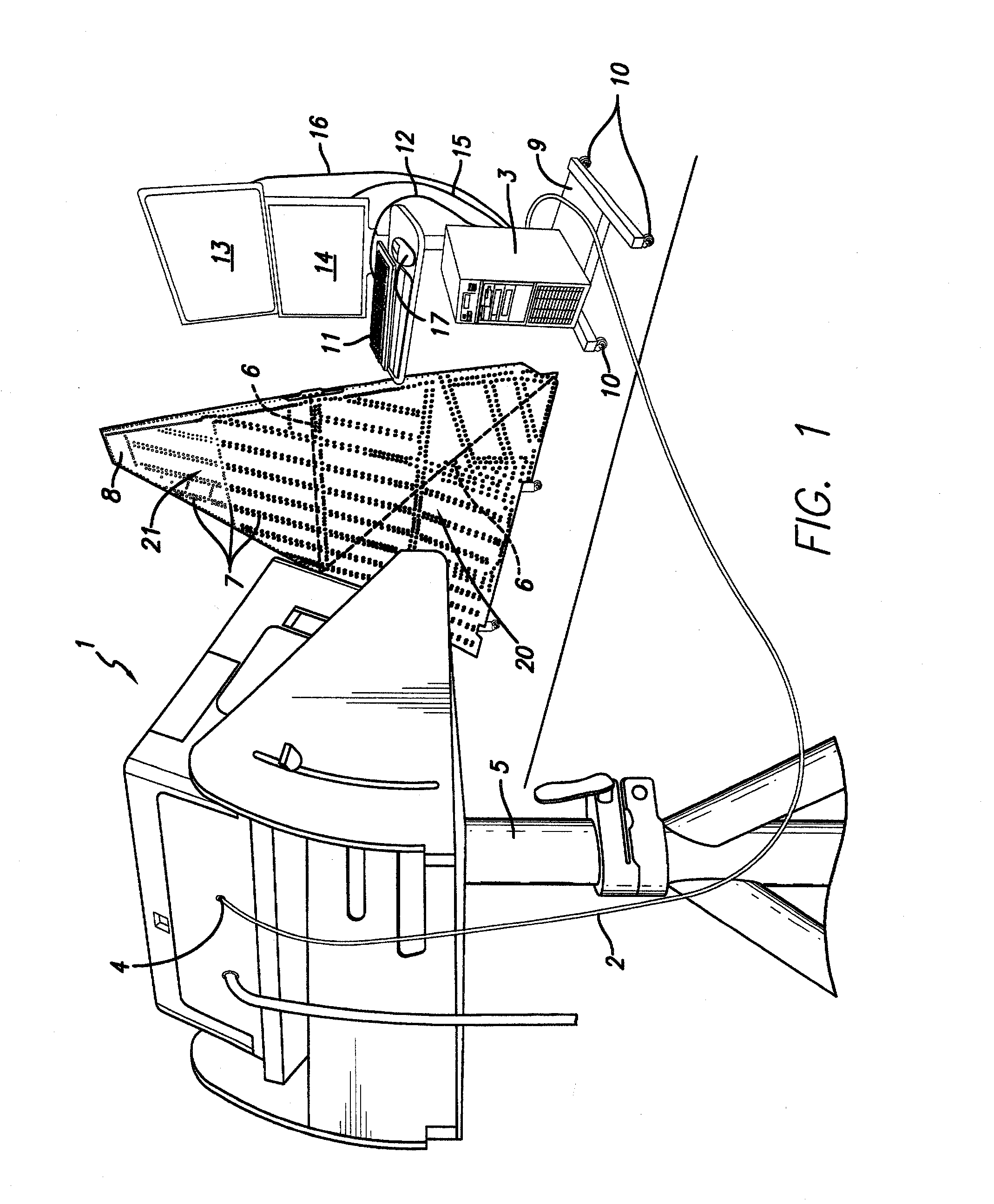

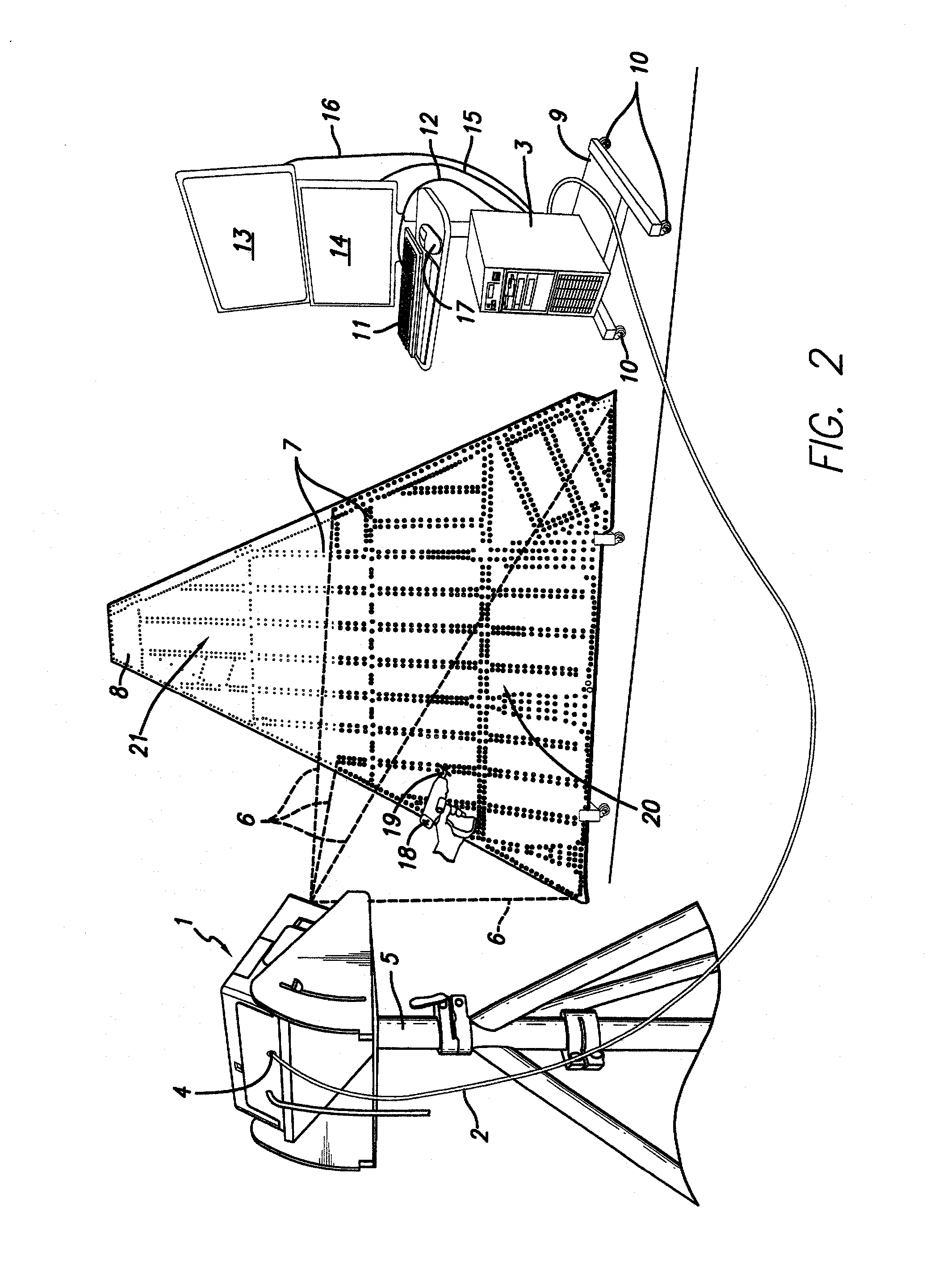

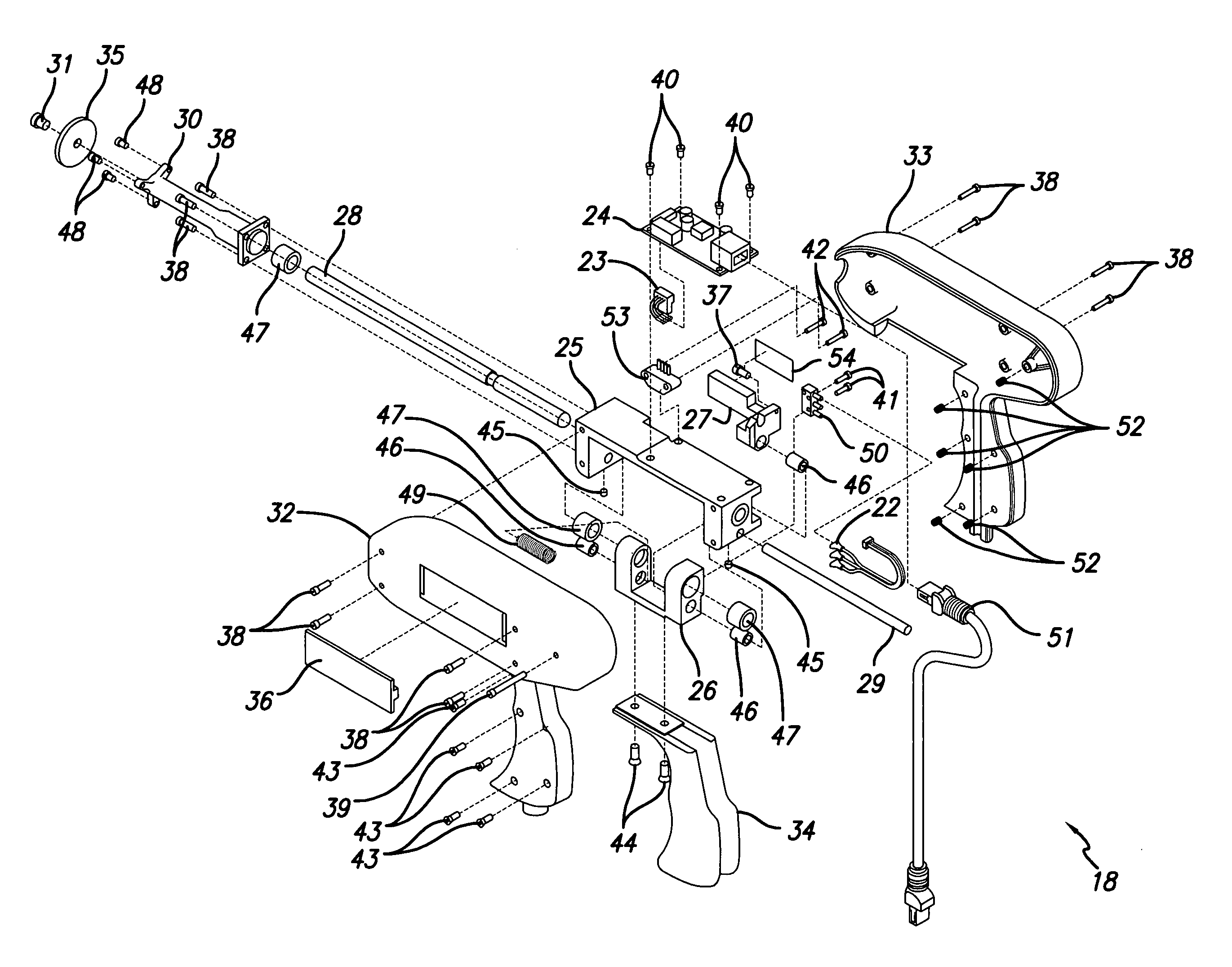

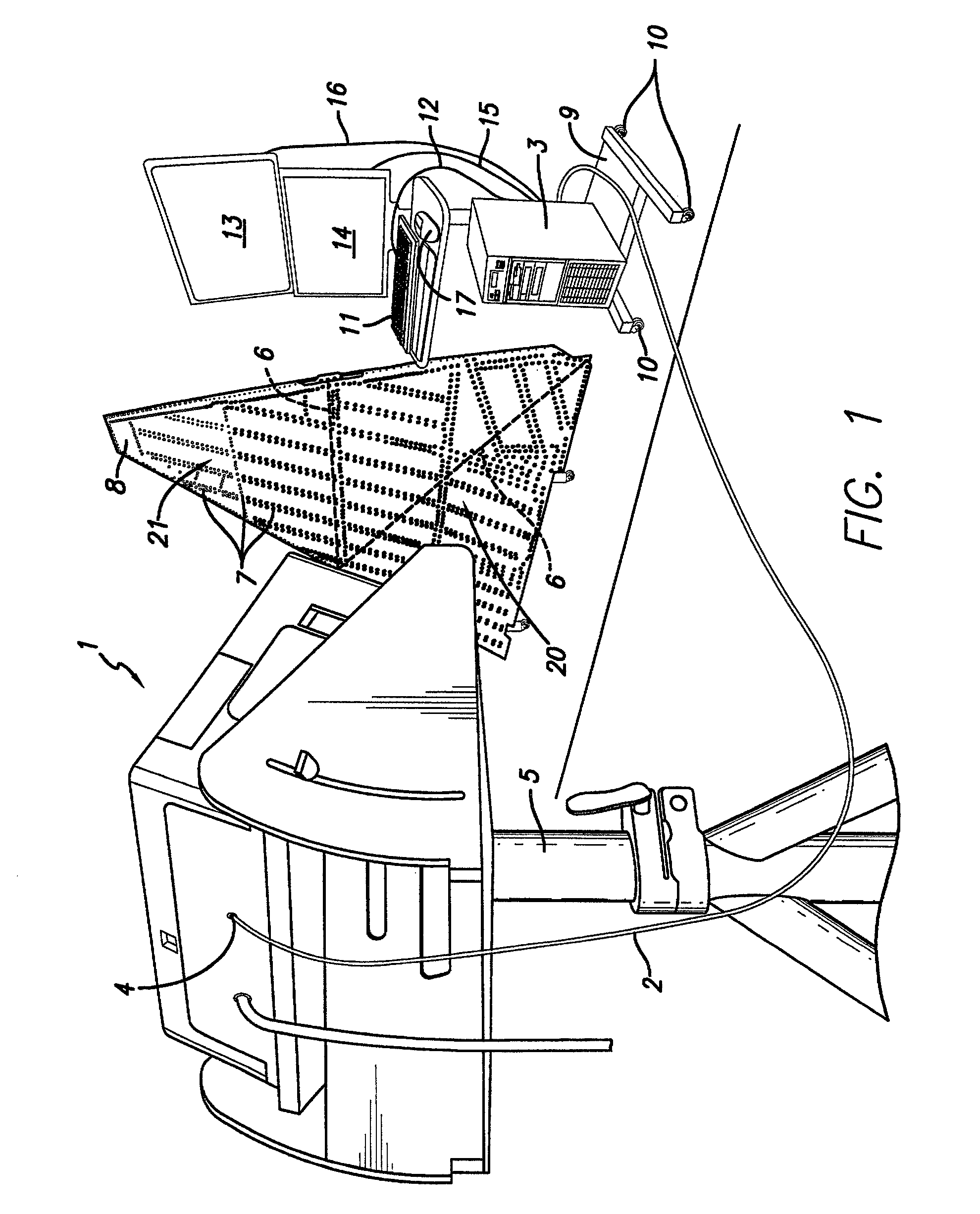

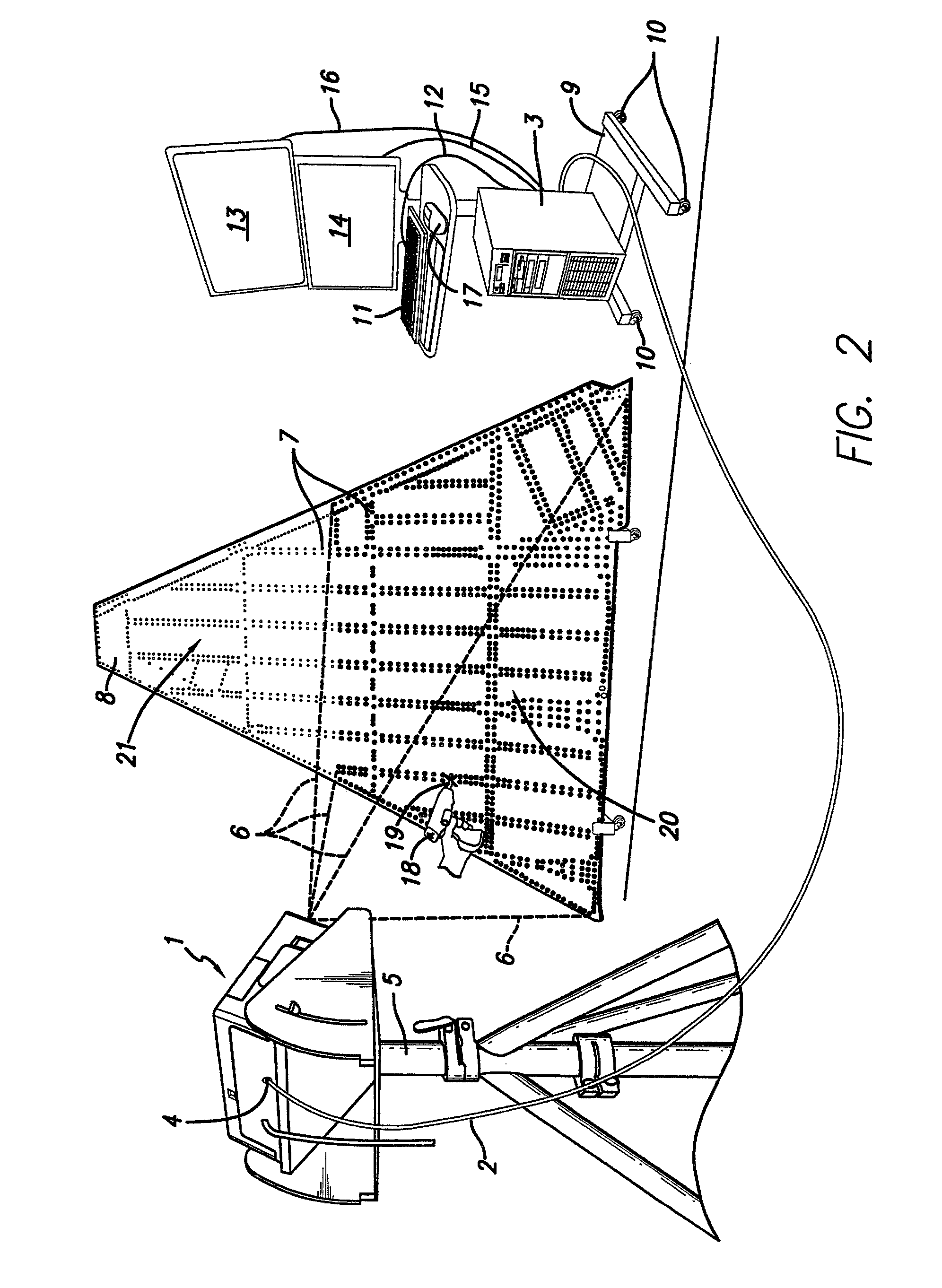

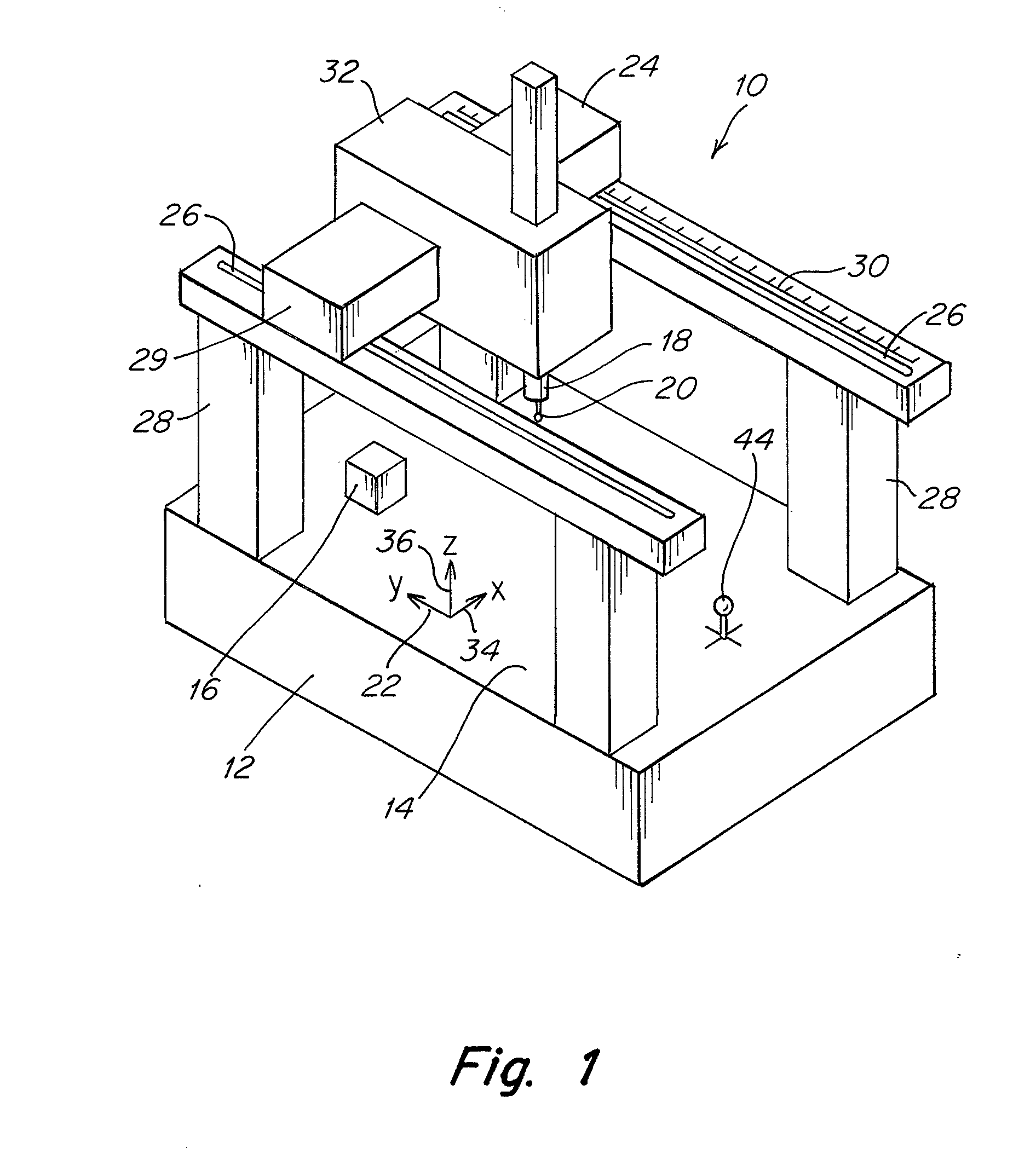

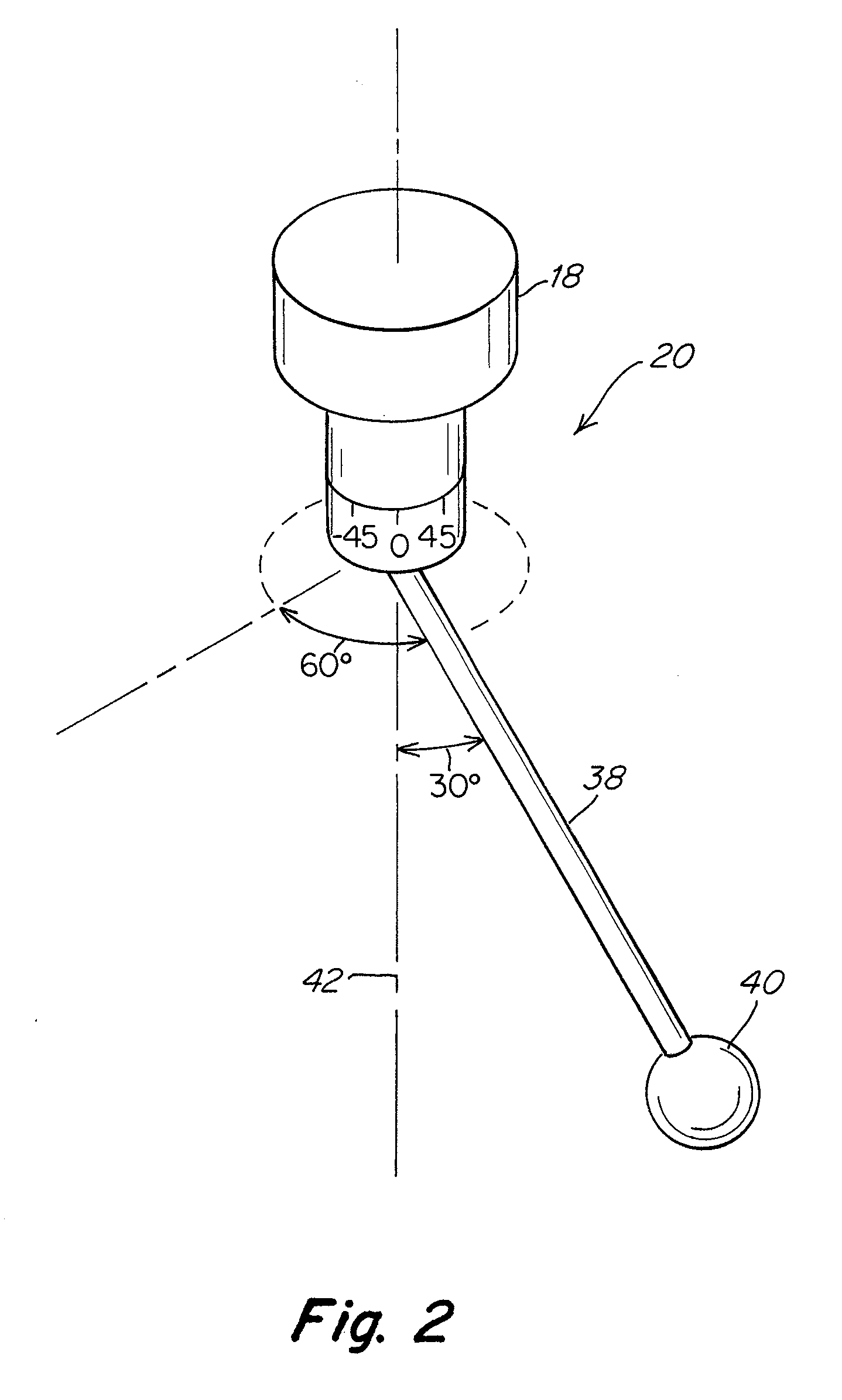

The present invention is directed to automated apparatuses and methods for measuring fastener hole depth, fastener length, countersink depth and / or hole diameters in a workpiece (or other object) in an automated and extremely rapid, efficient and accurate manner. The apparatuses may be operably connected with a power source and with one or a plurality of computers or other data collection devices to transmit fastener hole depth, countersink depth and / or hole diameter measurement data and / or information to them each time that a fastener hole is measured, while the apparatus is continuously measuring fastener holes (i.e., with no interruptions). Extremely advantageously, using only one hand, and by only squeezing a trigger only one time, an operator of such an apparatus may successfully and very rapidly and accurately perform more than one, or all three, of the following functions: (i) normalize the apparatus relative to one or a plurality of fastener holes and / or workpiece surfaces; (ii) make one or a plurality of accurate measurements; and (iii) transmit the one or more measurements from the apparatus to one or a plurality of computers and / or other data collection devices for, for example, recordation, storage, manipulation, other use and / or the like.

Owner:DELTA SIGMA

Hole measurement apparatuses

ActiveUS8606540B2Fast, efficient and accurate measurementEasy transferElectric/magnetic depth measurementElectrical/magnetic diameter measurementsDiameter measurementBiomedical engineering

The present invention is directed to automated apparatuses and methods for measuring fastener hole depth, fastener length, countersink depth and / or hole diameters in a workpiece (or other object) in an automated and extremely rapid, efficient and accurate manner. The apparatuses may be operably connected with a power source and with one or a plurality of computers or other data collection devices to transmit fastener hole depth, countersink depth and / or hole diameter measurement data and / or information to them each time that a fastener hole is measured, while the apparatus is continuously measuring fastener holes (i.e., with no interruptions). Extremely advantageously, using only one hand, and by only squeezing a trigger only one time, an operator of such an apparatus may successfully and very rapidly and accurately perform more than one, or all three, of the following functions: (i) normalize the apparatus relative to one or a plurality of fastener holes and / or workpiece surfaces; (ii) make one or a plurality of accurate measurements; and (iii) transmit the one or more measurements from the apparatus to one or a plurality of computers and / or other data collection devices for, for example, recordation, storage, manipulation, other use and / or the like.

Owner:DELTA SIGMA

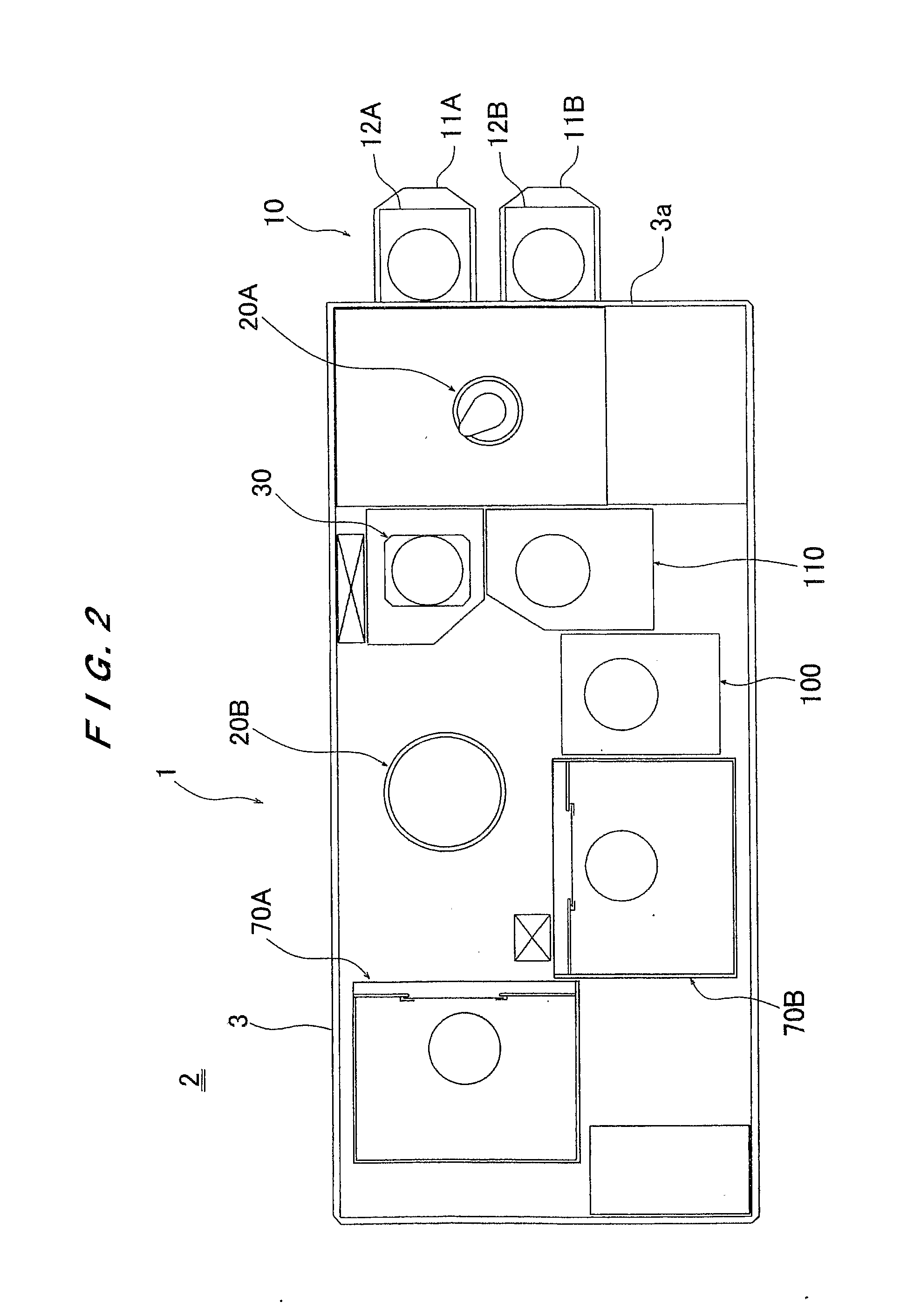

Substrate Processing Apparatus

ActiveUS20080200100A1Easy to polishEdge grinding machinesPolishing machinesSurface conditionsDiameter measurement

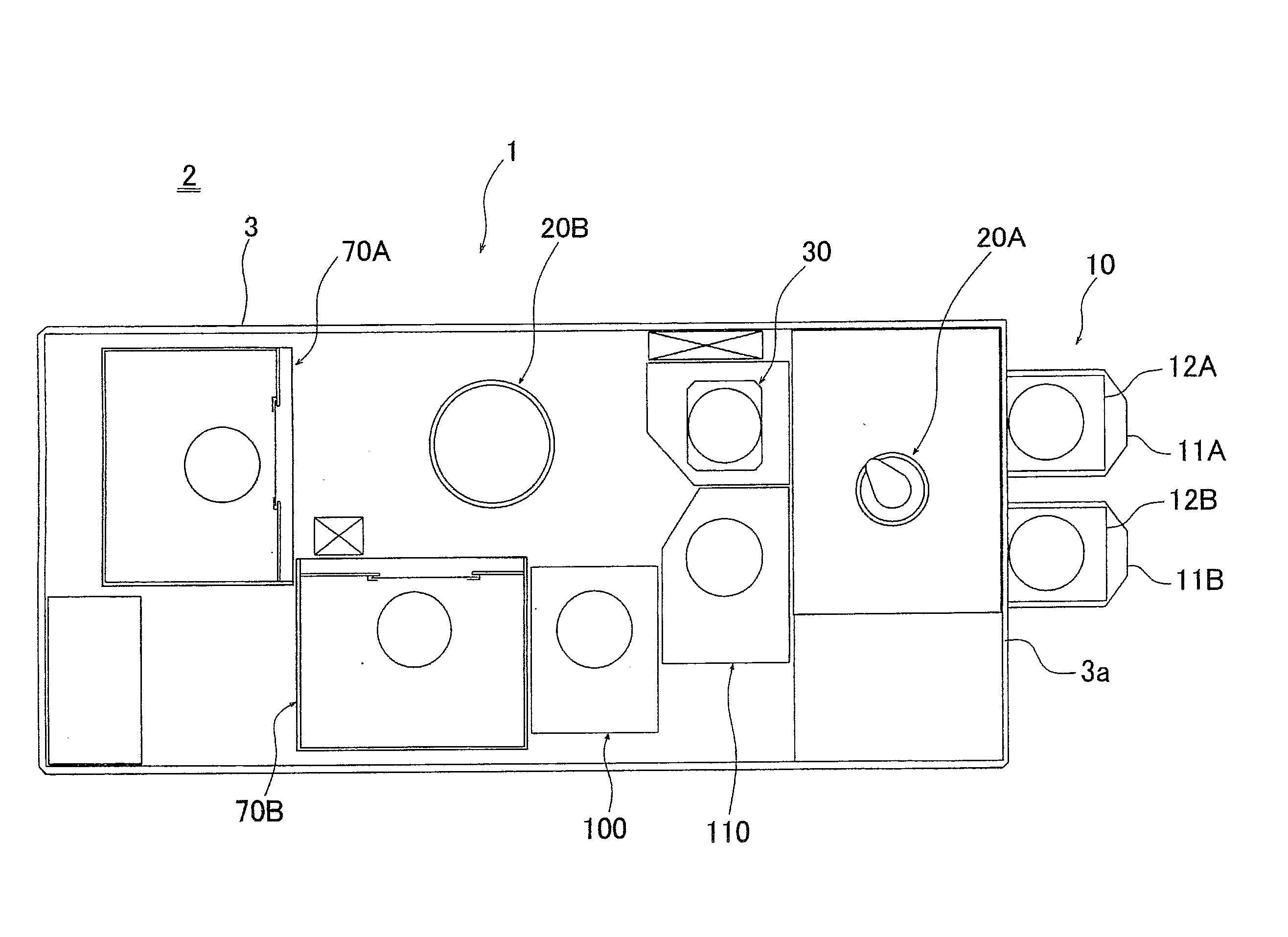

A substrate processing apparatus (1) includes first and second polishing units (70A, 70B) for polishing a peripheral portion of a substrate (W), a primary cleaning unit (100) for cleaning the substrate (W), a secondary cleaning and drying unit (110) for drying the substrate (W) cleaned in the primary cleaning unit (100), and a measurement unit (30) for measuring the peripheral portion of the substrate (W). The measurement unit (30) includes a mechanism for measurement required for polishing in the first and second polishing units (70A and 70B), such as a diameter measurement mechanism, a cross-sectional shape measurement mechanism, or a surface condition measurement mechanism.

Owner:EBARA CORP

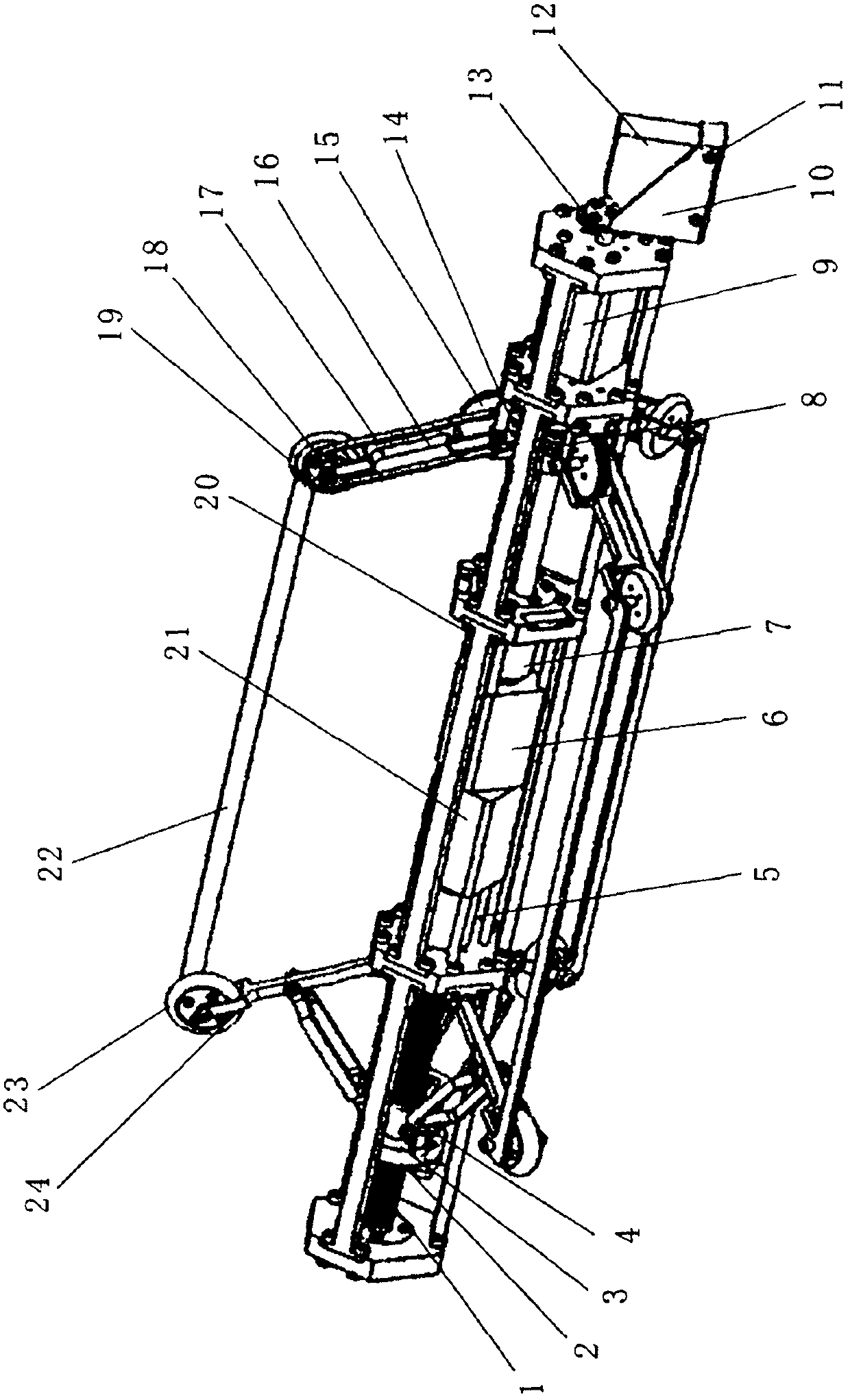

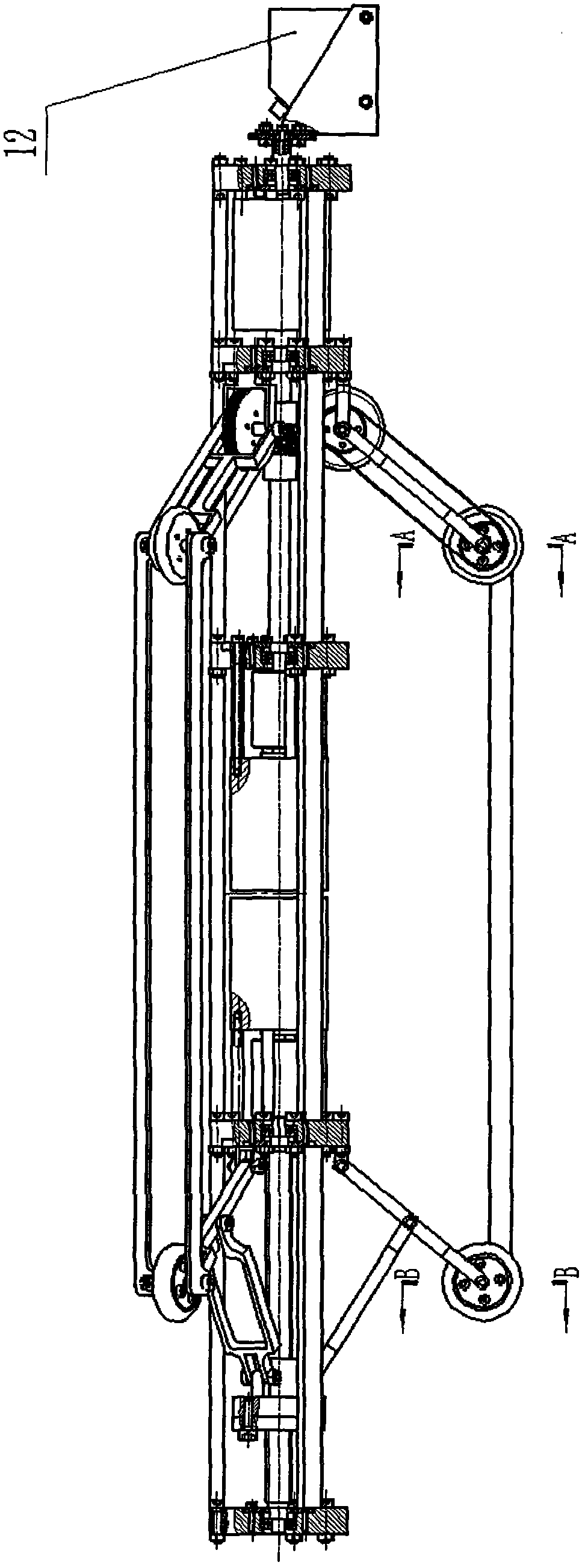

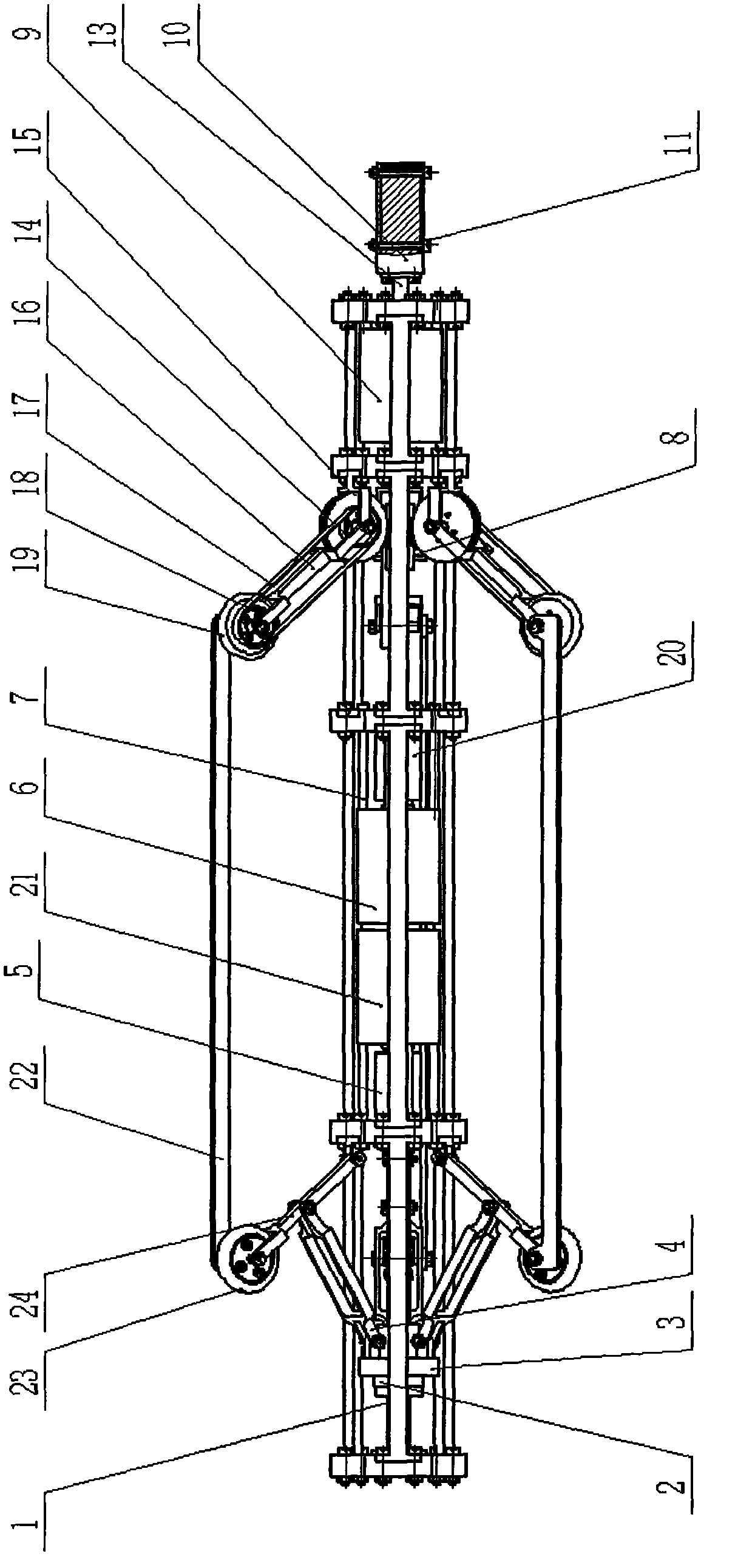

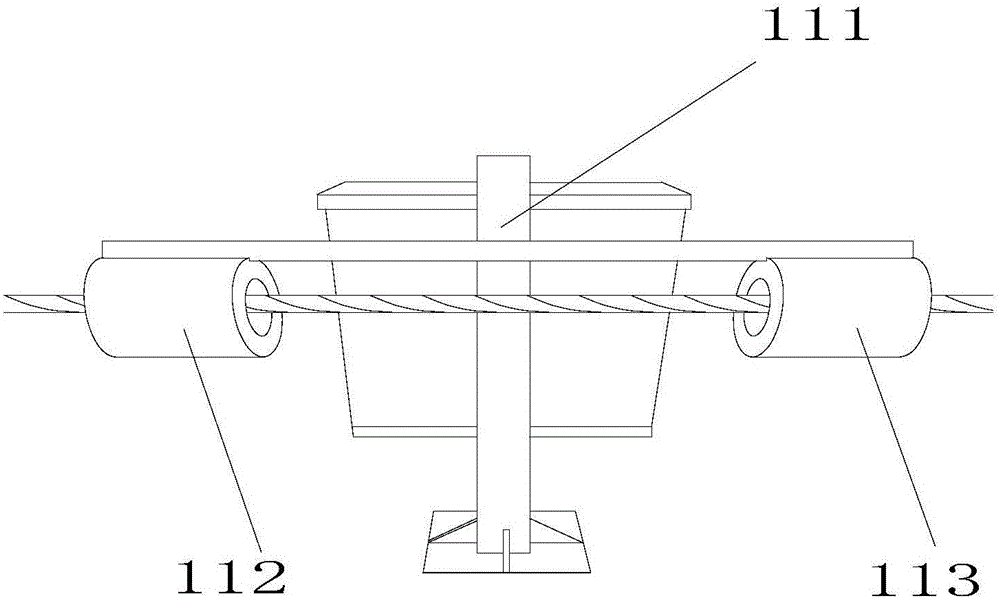

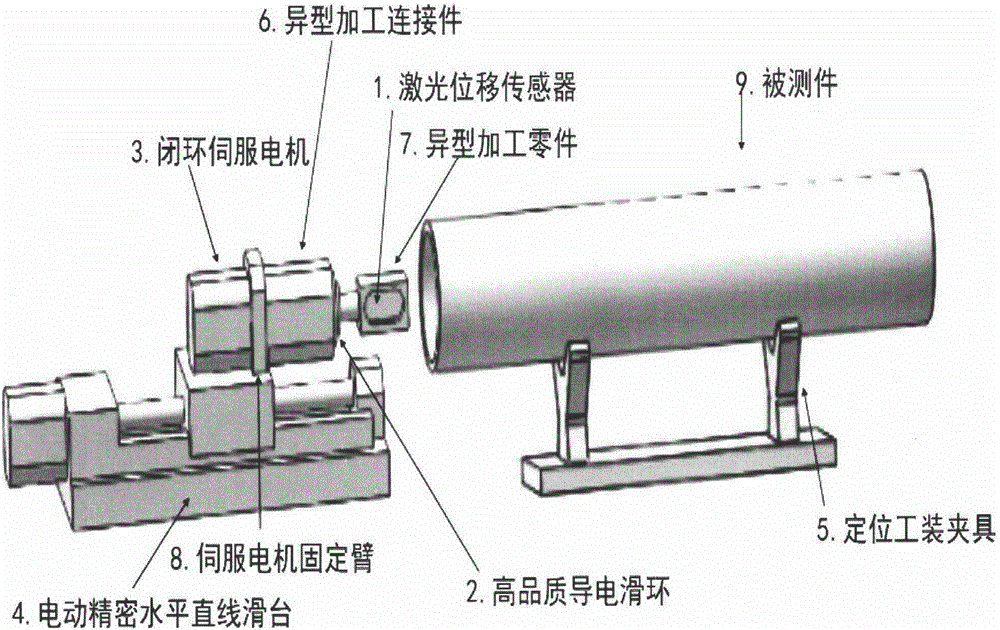

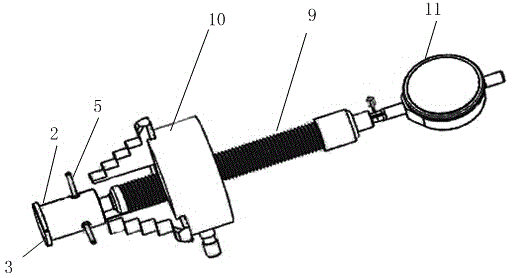

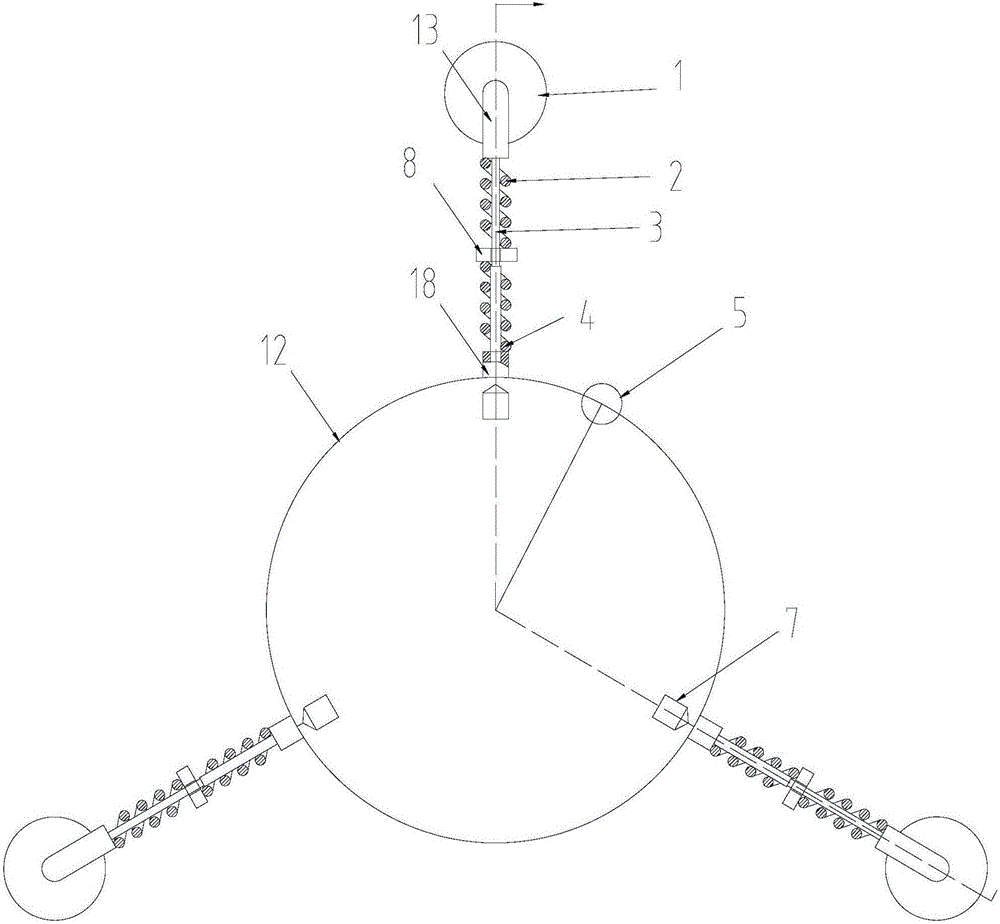

Pipeline robot for internal diameter measurement

InactiveCN103398665ASuitable for measurement requirementsHigh measurement accuracyUsing optical meansPigs/molesTransmission beltBall screw

The invention relates to a pipeline robot for internal diameter measurement. The pipeline robot for the internal diameter measurement comprises a supporting mechanism, a main driving mechanism and a laser measurement mechanism, wherein the supporting mechanism mainly consists of a nut for a ball screw, a step motor I, wheels, a connection rod, a push rod and the like; the main driving mechanism mainly consists of a worm gear, a worm rod, a belt wheel, a transmission belt and the like; and the linear movement of the pipeline robot can be realized through the driving of a step motor II. The laser measurement mechanism is mainly composed of a sensing measuring head, a sensor bracket and a step motor III. The pipeline robot provided by the invention can be used for measuring an internal diameter of a long pipeline, and can particularly meet the measurement requirement of thin and long pipes with the larger range of the internal diameter. The pipeline robot provided by the invention not only can be used for carrying out non-contact measurement on the internal diameters of the pipelines with different sizes but also can realize various measurements by means of replacing a measurement head of a sensor, such as flaw detection and the like. The pipeline robot has the advantages of high measurement precision and convenience in use.

Owner:INNER MONGOLIA UNIV OF TECH

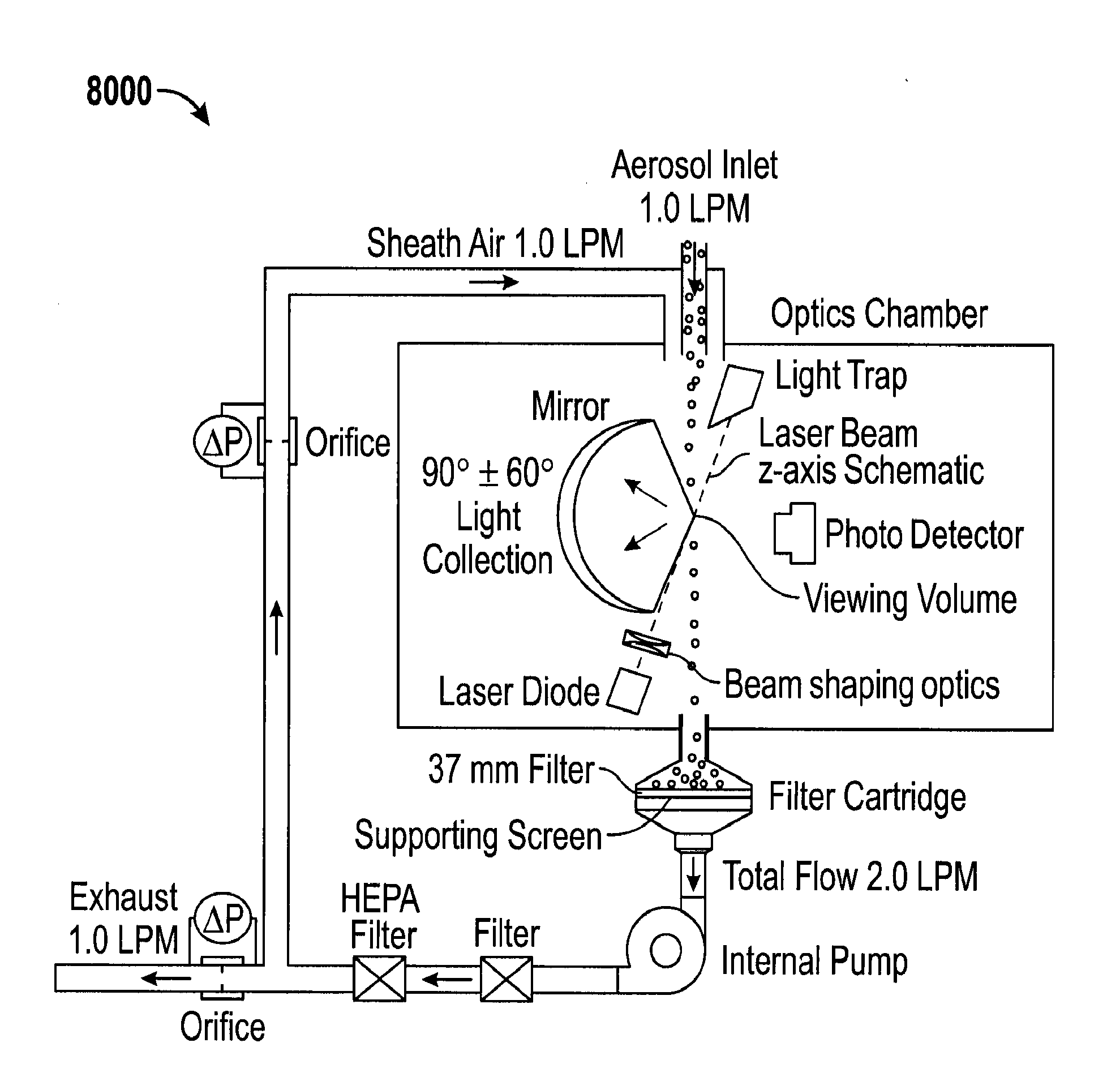

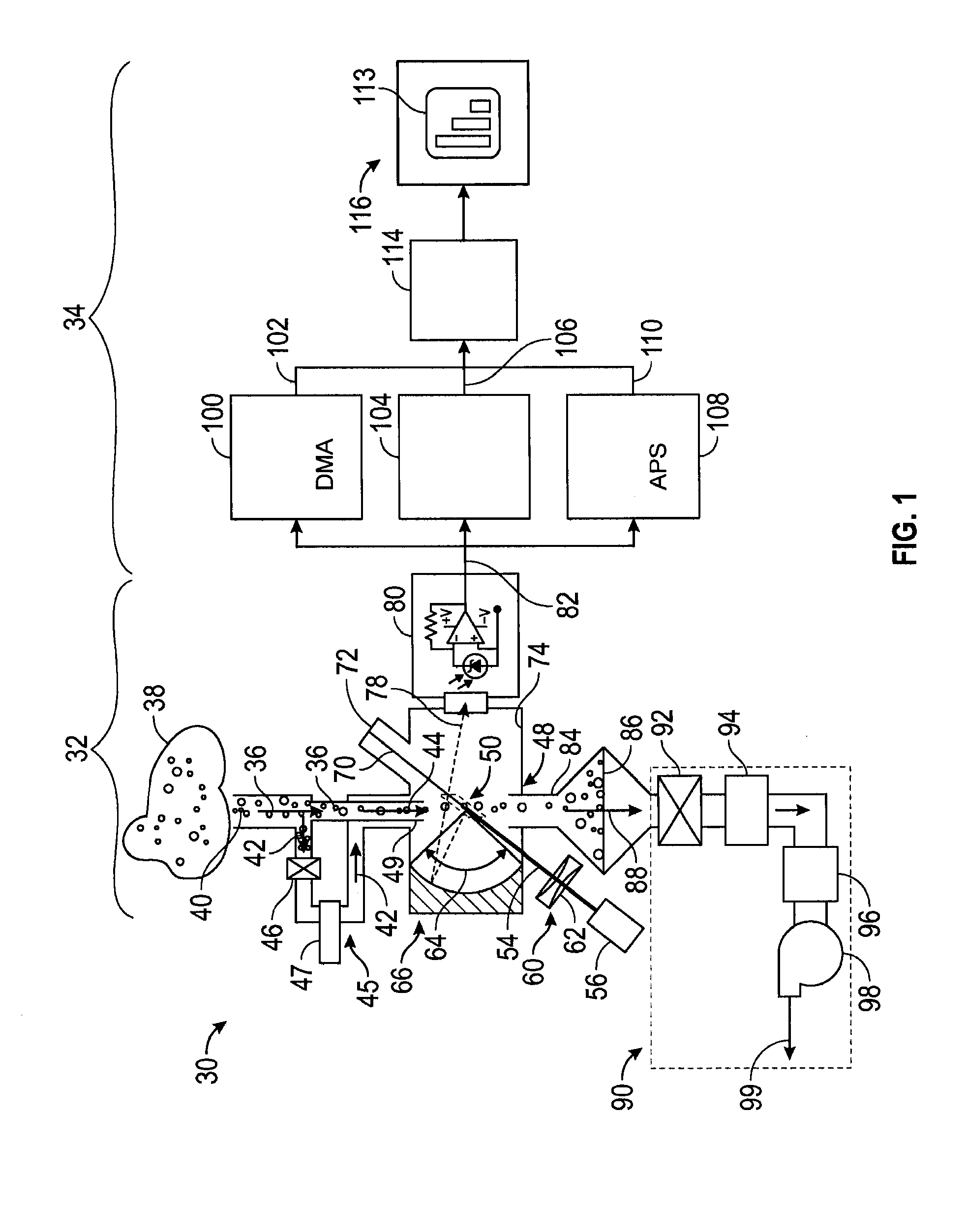

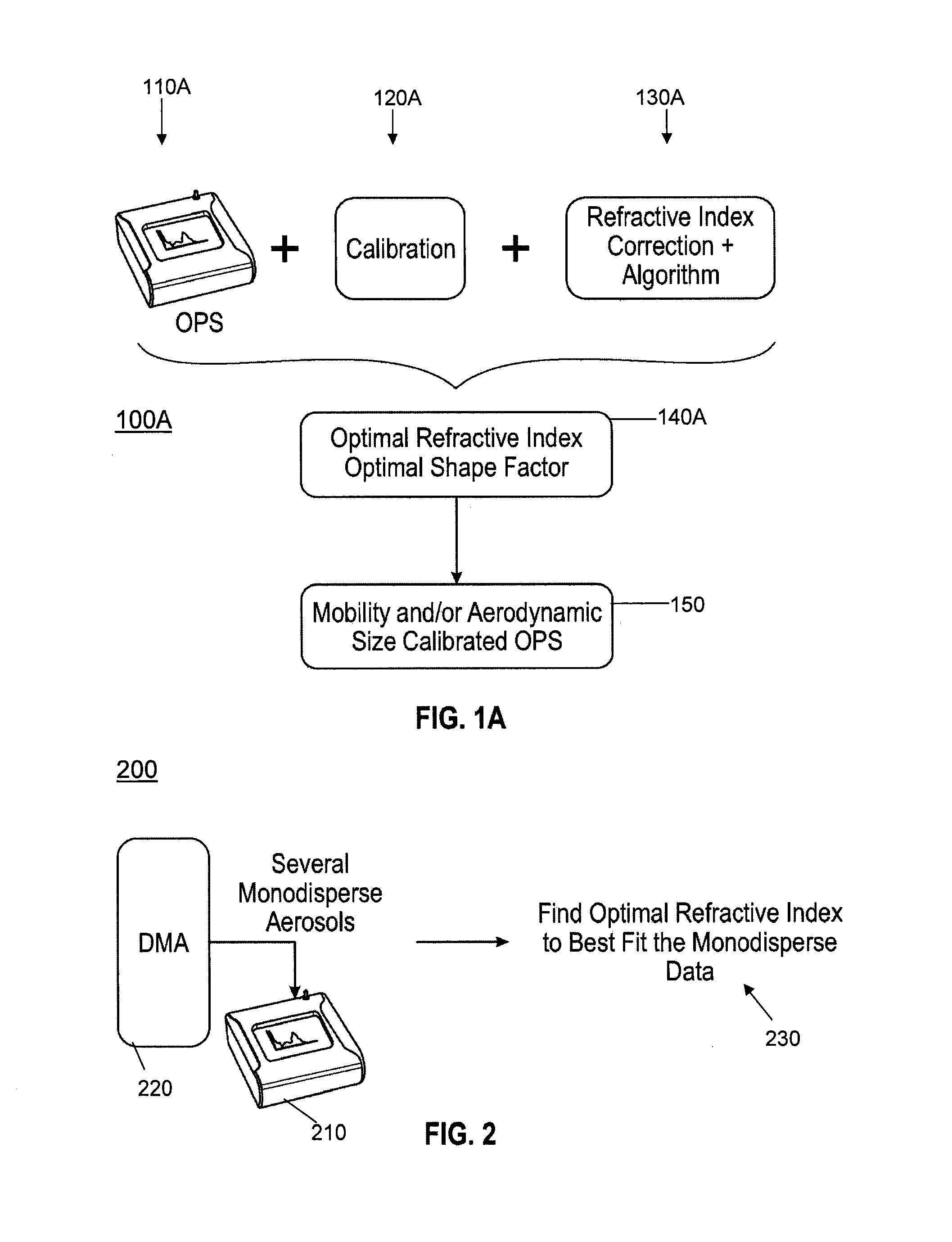

System and method for converting optical diameters of aerosol particles to mobility and aerodynamic diameters

ActiveUS20140247450A1Low costProvide quicklyMaterial analysis by optical meansParticle size analysisOptical propertyRefractive index

A system and a method of measuring a particle's size in a select aerosol using the optical diameter of the particle to perform a mobility and / or aerodynamic diameter conversion without any knowledge about the particle's shape and its optical properties in the aerosol being characterized. In one example embodiment of the invention, the method includes generating a set of calibration data and finding the optimal refractive index and shape that best fits the calibration data. In addition, the method includes creating a new calibration curve that provides a mobility-equivalent or aerodynamic-equivalent diameter.

Owner:TSI INC

Method and apparatus for probe tip diameter calibration

ActiveUS20110000277A1Improve accuracy and reliabilityHigh measurement accuracyTesting/calibration of speed/acceleration/shock measurement devicesMechanical measuring arrangementsDiameter measurementPhysics

A method for determining probe tip diameters with improved accuracy and reliability that includes performing a routine for determining probe tip diameter multiple times with the arm of the coordinate measurement machine in different machine positions. Diameter values associated with each of the calibration routines may be combined in a manner that provides more accurate diameter measurements.

Owner:HEXAGON METROLOGY INC

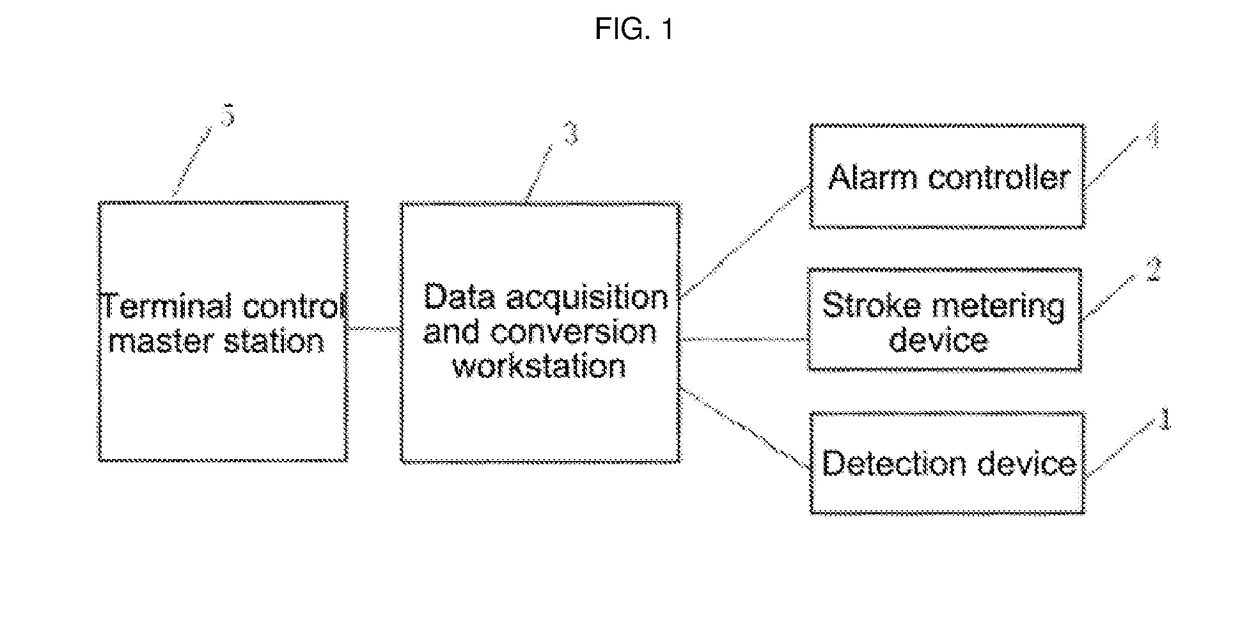

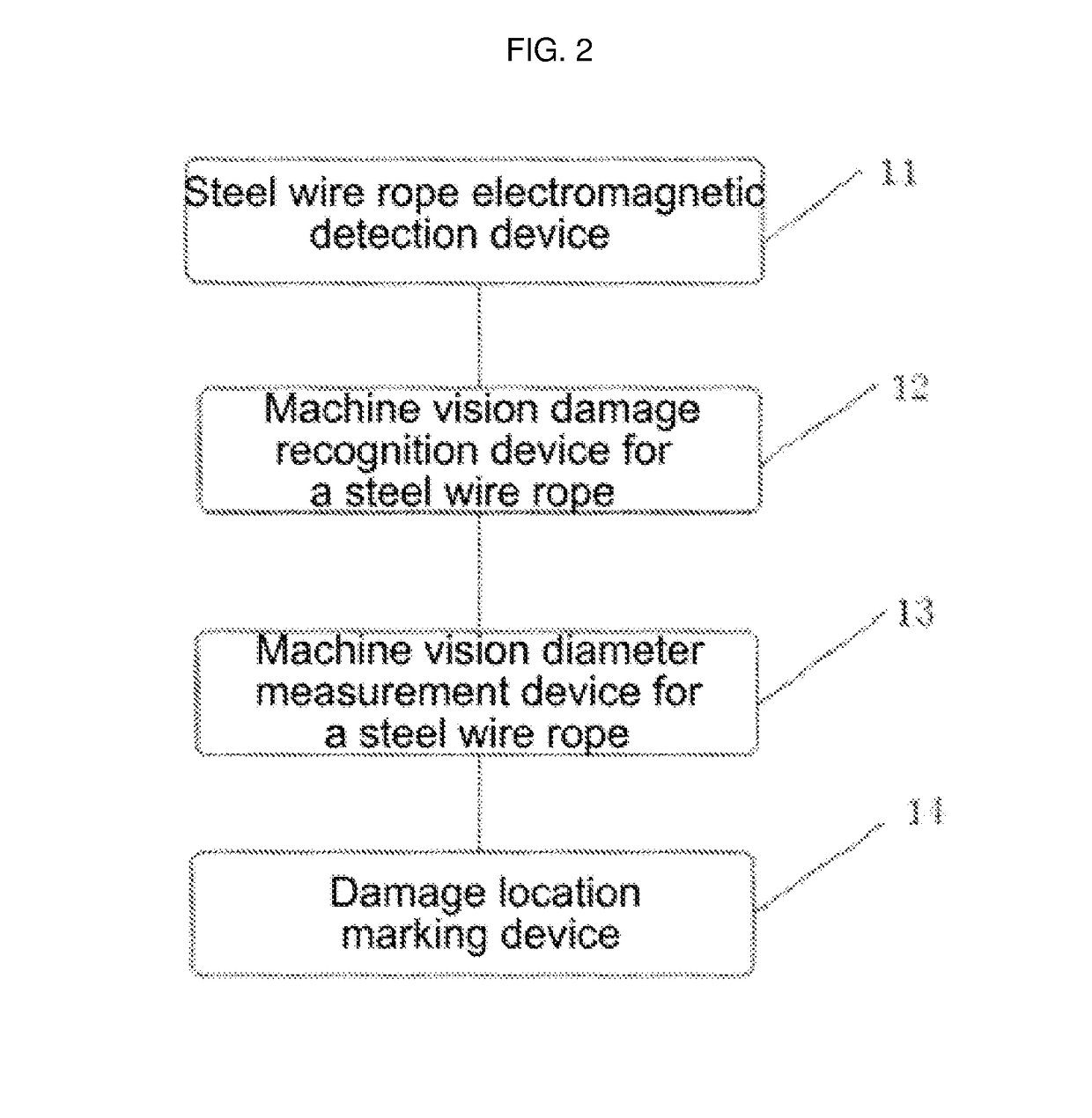

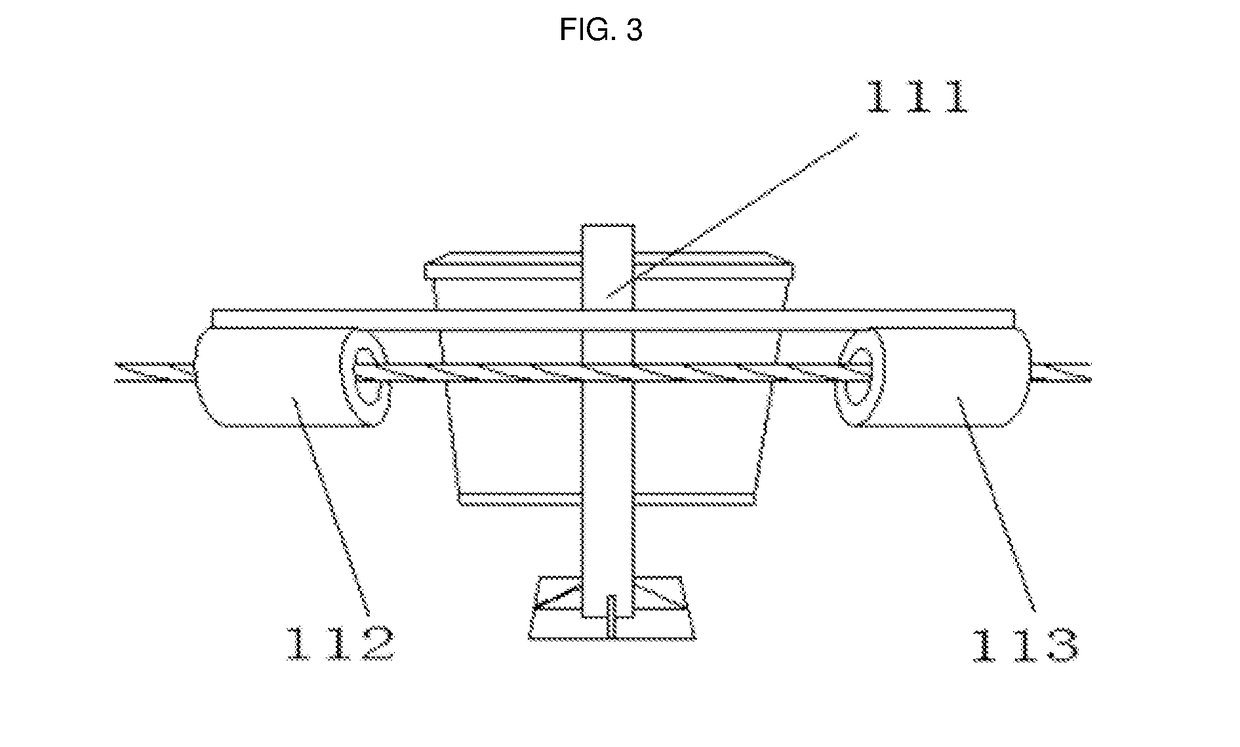

Holographic detection system for steel wire rope

ActiveCN106018544AQuality assuranceImprove reliabilityUsing electrical meansOptically investigating flaws/contaminationMachine visionEconomic benefits

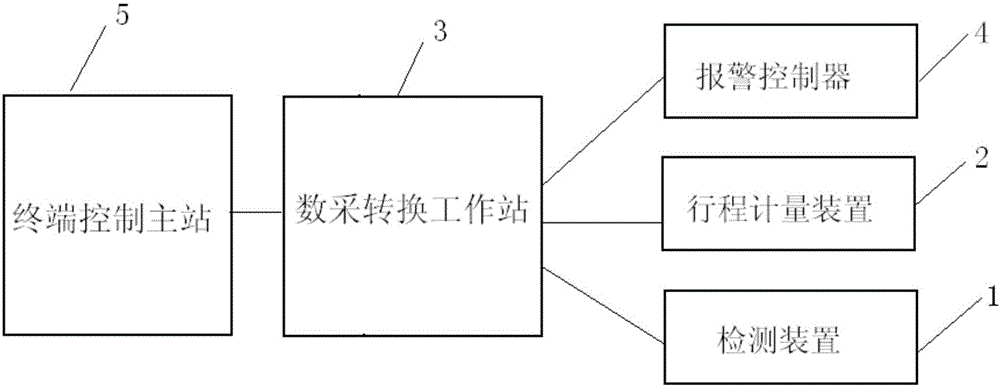

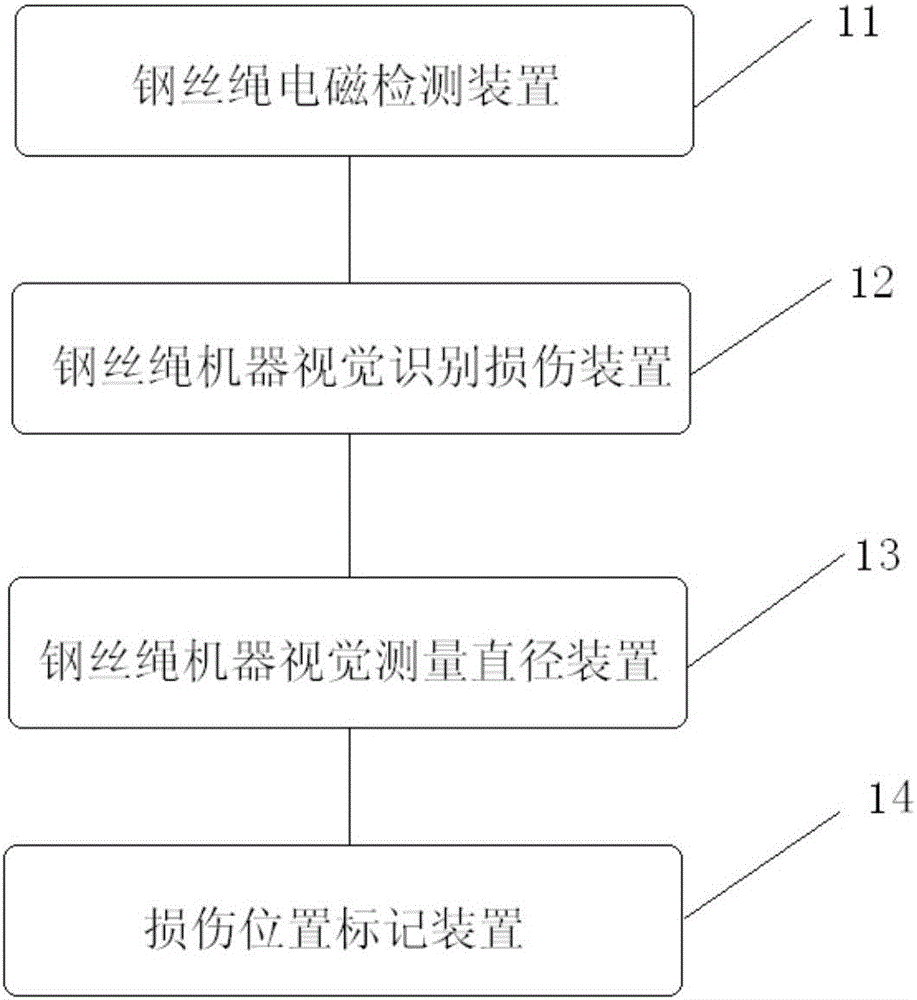

The invention discloses a holographic detection system for a steel wire rope. The holographic detection system for the steel wire rope comprises a detection device, a journey metering device, a data acquisition transition work station, an alarm controller, a terminal control master station and the like. The detection device comprises a steel wire rope electromagnetic detecting device, a steel wire rope damage machine vision device, a steel wire rope diameter measurement machine vision device, a damage position marking device and the like. The holographic detection system for the steel wire rope has technical advantages in many aspects and will bring good market prospects and economic benefits.

Owner:LUO YANG WIRE ROPE INSPECTION TECH CO LTD

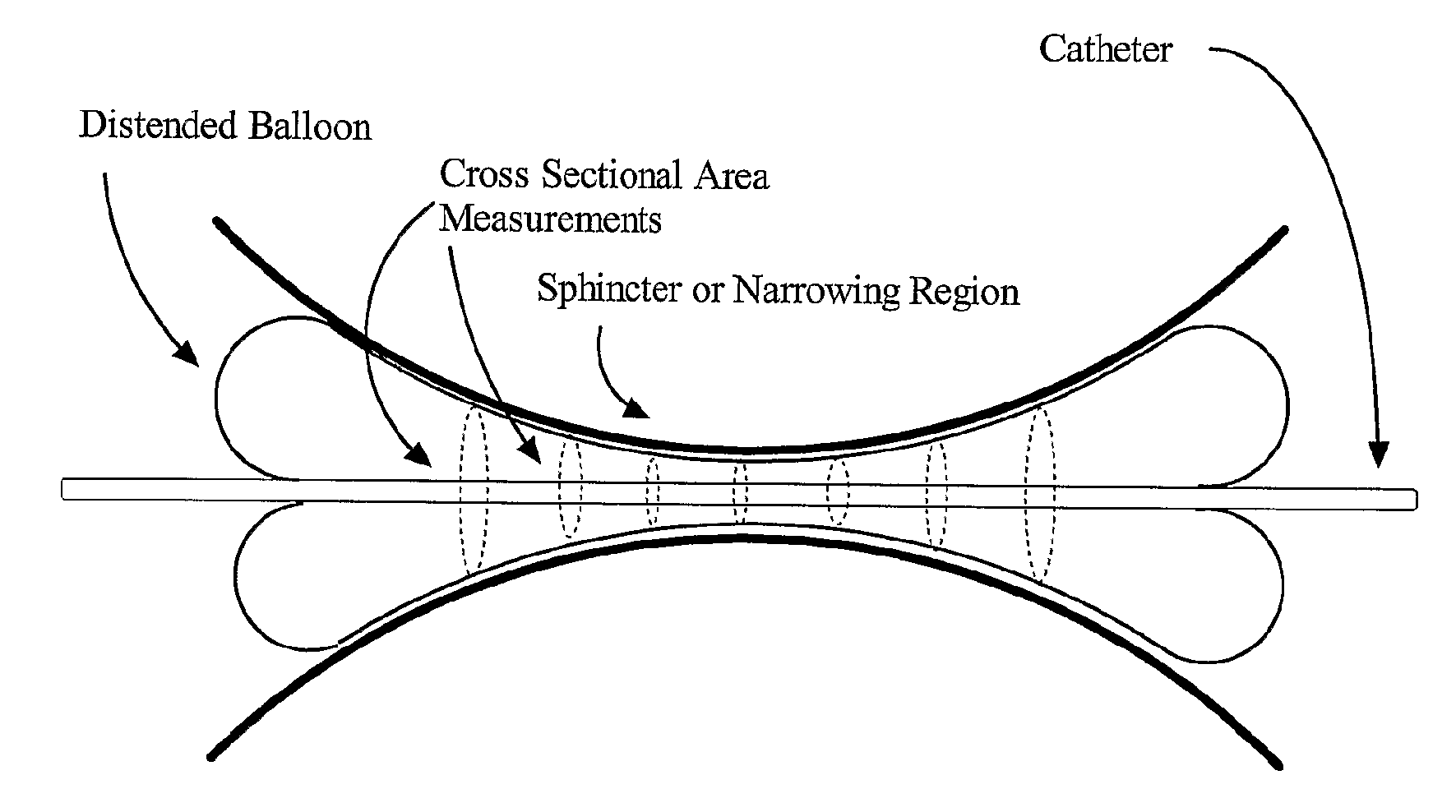

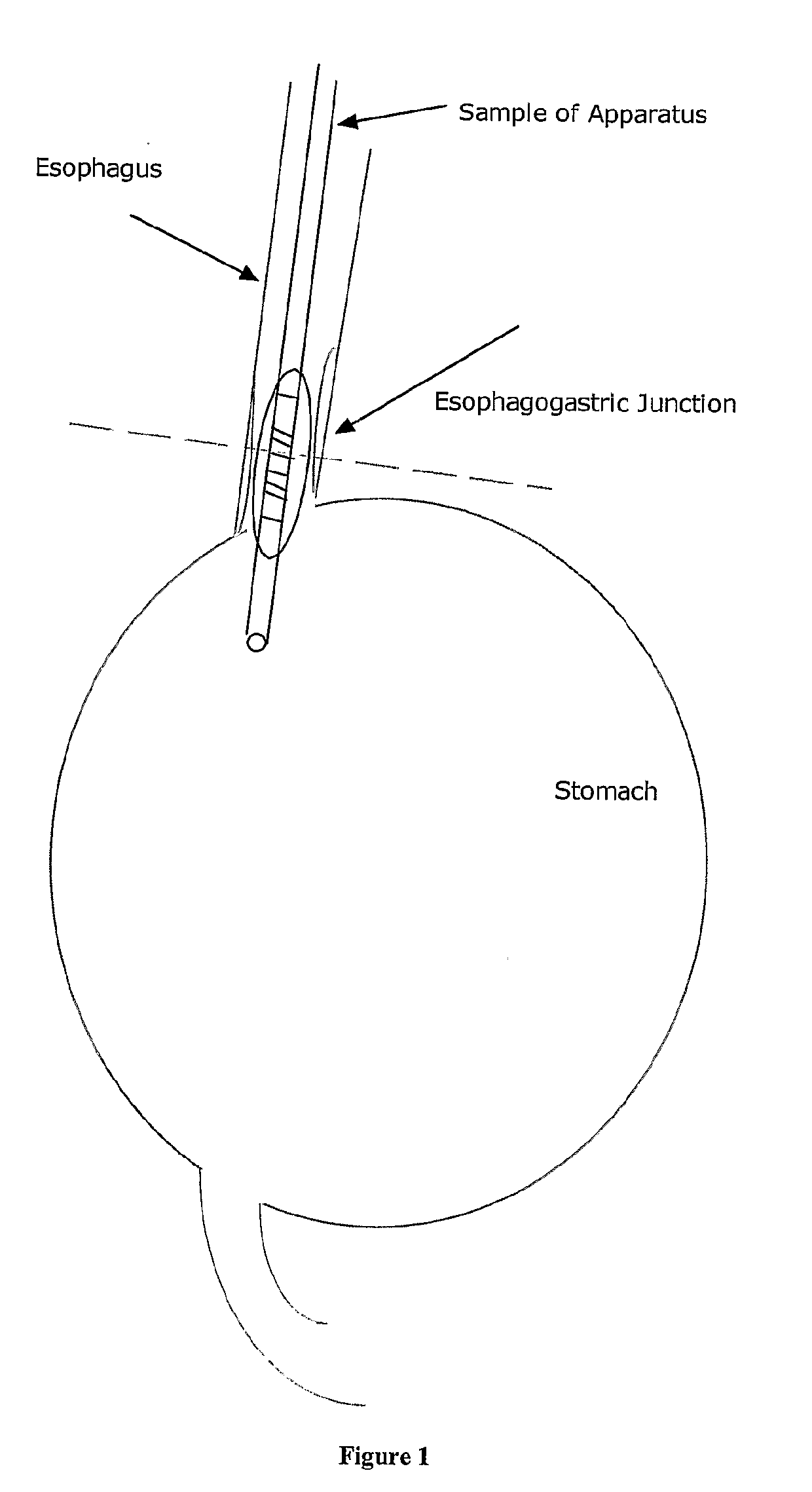

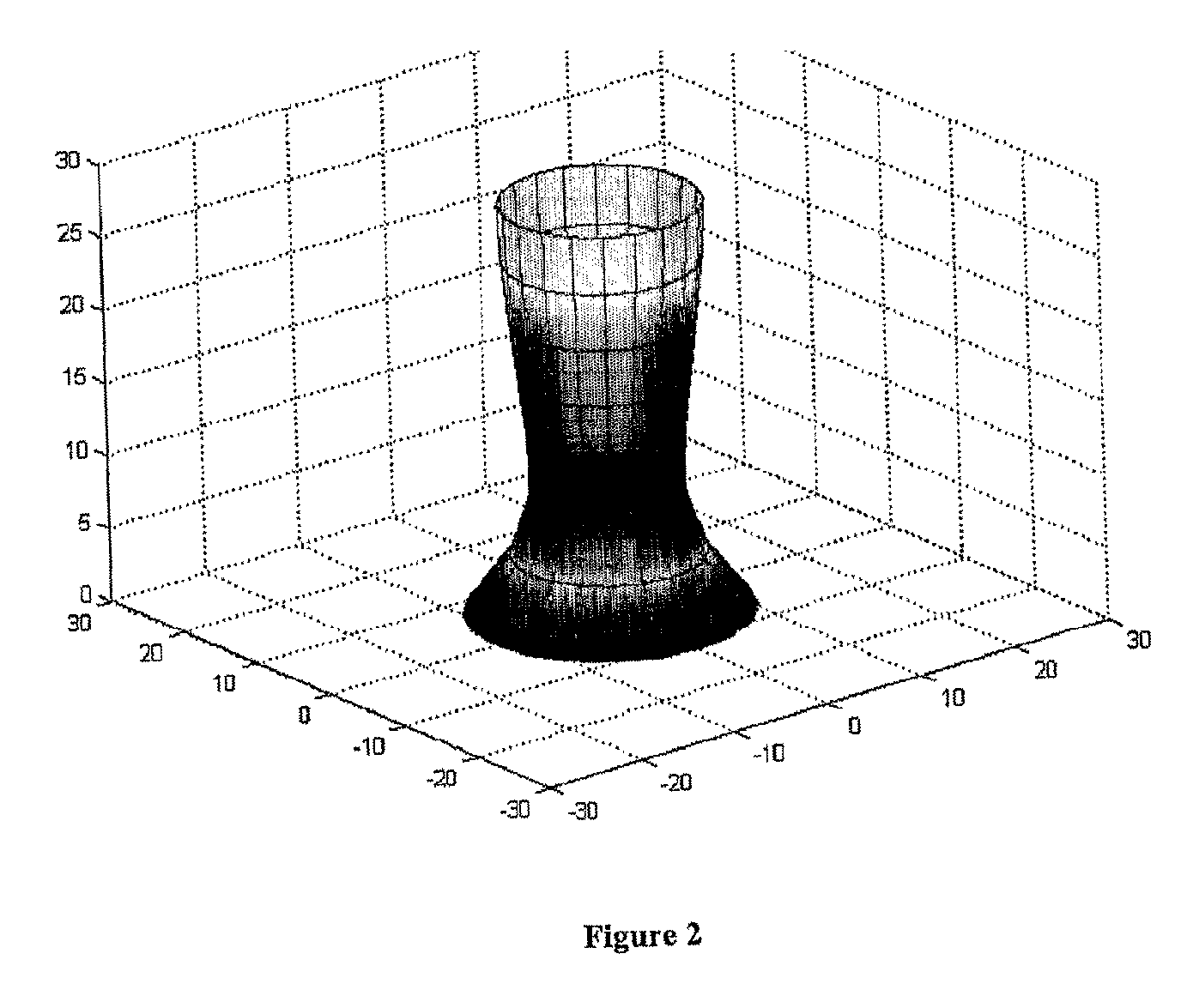

Method and Apparatus For Chemical Measurement of Sphincters and Narrowing Regions in Hollow Biological Organs

InactiveUS20080161730A1Increase volumeMinimize discomfortPerson identificationCatheterSphincterElectrical impedance

A method and apparatus are disclosed for measuring geometry and compliance in sphincters and other narrowing regions. The apparatus comprises a catheter with an inflatable balloon to be inserted and inflated in the narrowing region. Inside the balloon it is possible to make multiple cross-sectional area or diameter measurements in an axial direction such that a three-dimensional profile of the balloon can be obtained. Preferably multiple sets of electrodes are provided inside the balloon and the cross-sectional recordings are based on measurements of the electrical impedance of an electrically conducting fluid inside the balloon.

Owner:FLIP TECH LTD

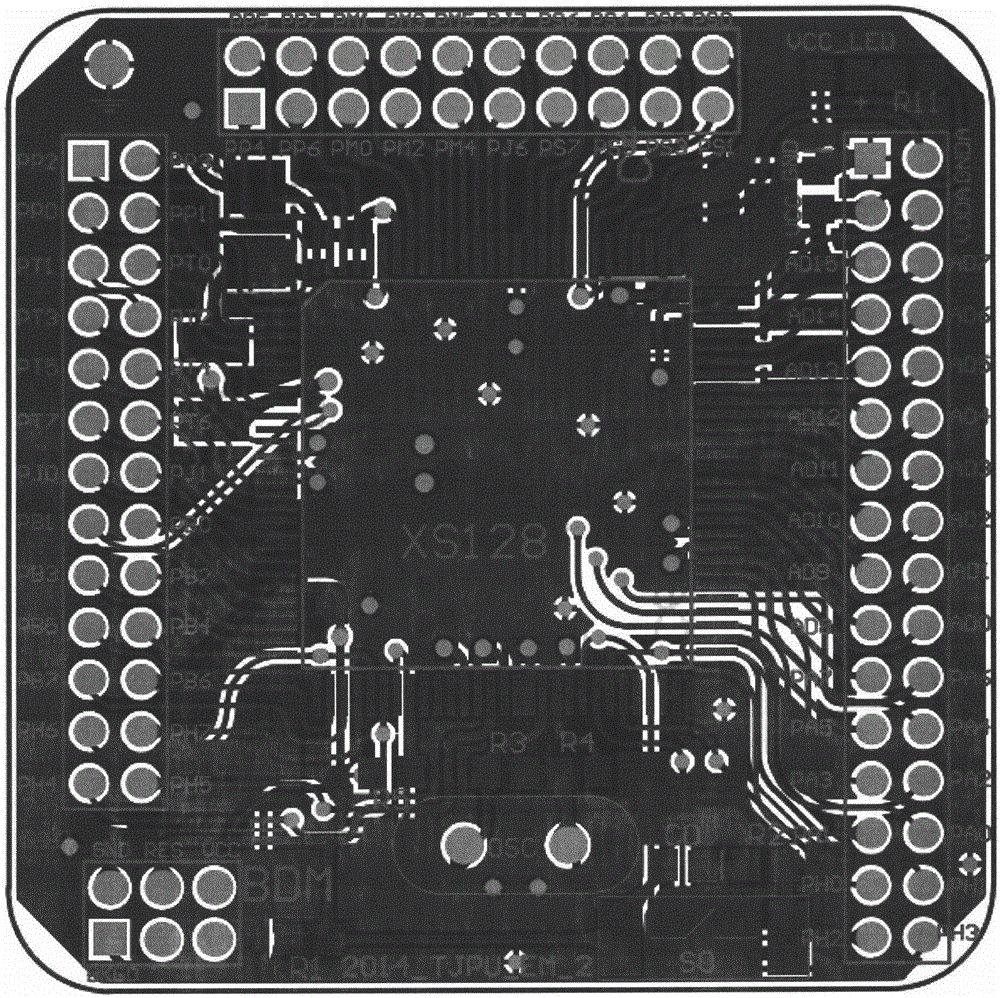

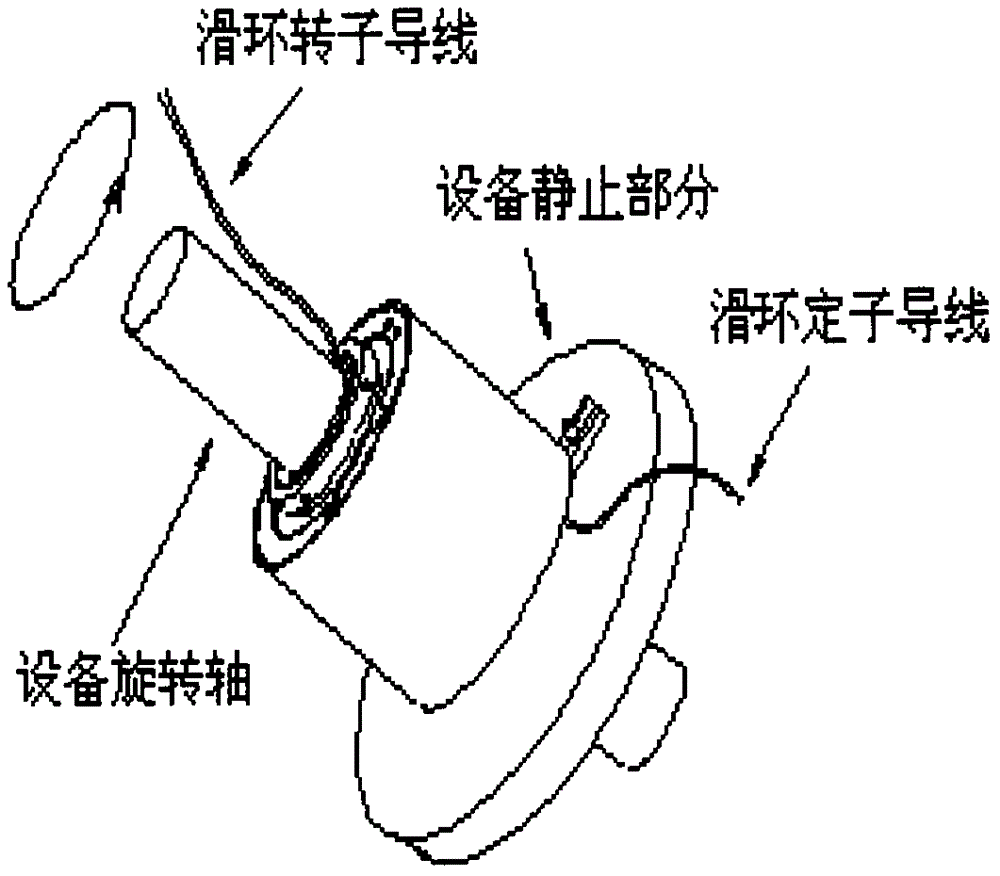

High-speed laser internal diameter detection system

InactiveCN106091961ARealize acquisitionEasy to detectUsing optical meansMeasurement pointElectric control

The invention belongs to the field of intelligent instruments and devices and relates to a high-speed laser internal diameter detection system. The good detection effect of laser on surfaces of objects such as metal is utilized, and relative coordinate information of the measurement point position of a detected internal diameter is obtained using a laser triangulation method. In order to ceaselessly, effectively and stably 360-degree collect various data required in internal diameter detection, a laser range finding probe is innovatively combined with a slip ring, so that the laser range finding probe can be directly connected to a motor and achieves 360-degree high-speed rotation. A high-precision electric control linear guide rail is utilized to achieve comprehensive acquisition of internal diameter data, thereby conducting high-precision internal diameter measurement. Through verification, the laser internal diameter detection method meets requirements of internal diameter nondestructive testing, a host computer platform is friendly, and correlated data can be fed back remotely and wirelessly. The measurement method provided by the method can be popularized into other high-precision dimension detection systems capable of reflecting object internal walls.

Owner:TIANJIN POLYTECHNIC UNIV

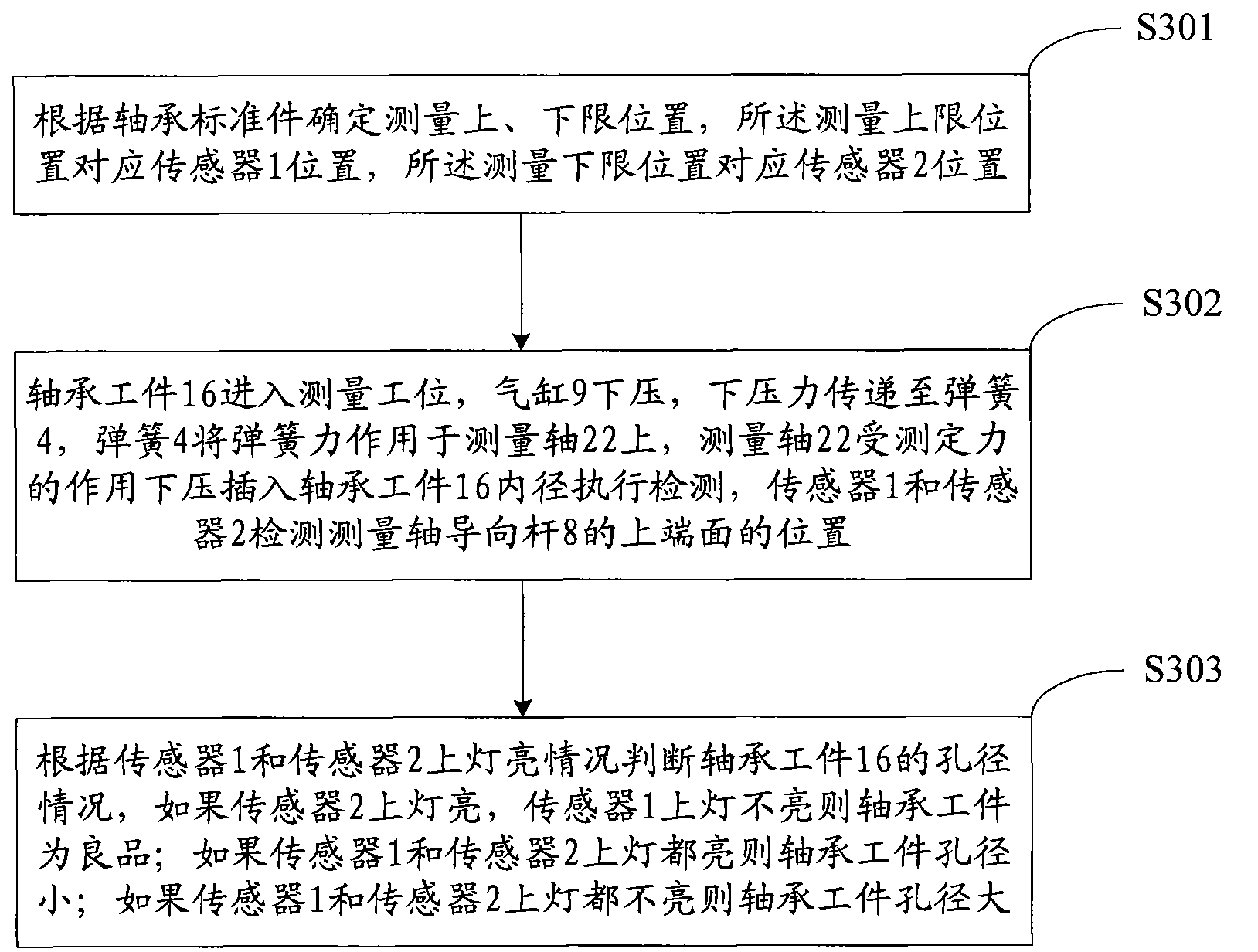

Hole diameter detection apparatus and method

InactiveCN101586952AReliable measurementReduce manufacturing costMachine bearings testingCouplingEngineering

The invention embodiment provides a hole diameter detection apparatus and method. An embodiment of hole diameter detection apparatus comprises: a transmission part including a cylinder fixed on a cylinder fixing block for providing telescopic motion along the measurement shaft, and a coupling shaft connected with the cylinder and a fastening coupling block connected with the coupling shaft; an induction part including a sensor fixing bar fixed on the fastening coupling block, two sensors mounted on the top of the sensor fixing bar on adjustable positions, a spring shielding sheet mounted under the lower sensor, and a spring disposed between the spring shielding sheet and the limiting block in the measurement part; a measurement part including a limiting block, a measurement shaft guide rod fixed on the limiting block, and a measurement shaft which is connected with the measurement shaft guide rod and has a convergent lower end and a round cross section; and a base used for fixing bearing workpiece for measuring. The invention embodiment improves the stability and reliability of the hole diameter measurement, and reduces production cost.

Owner:王乃明

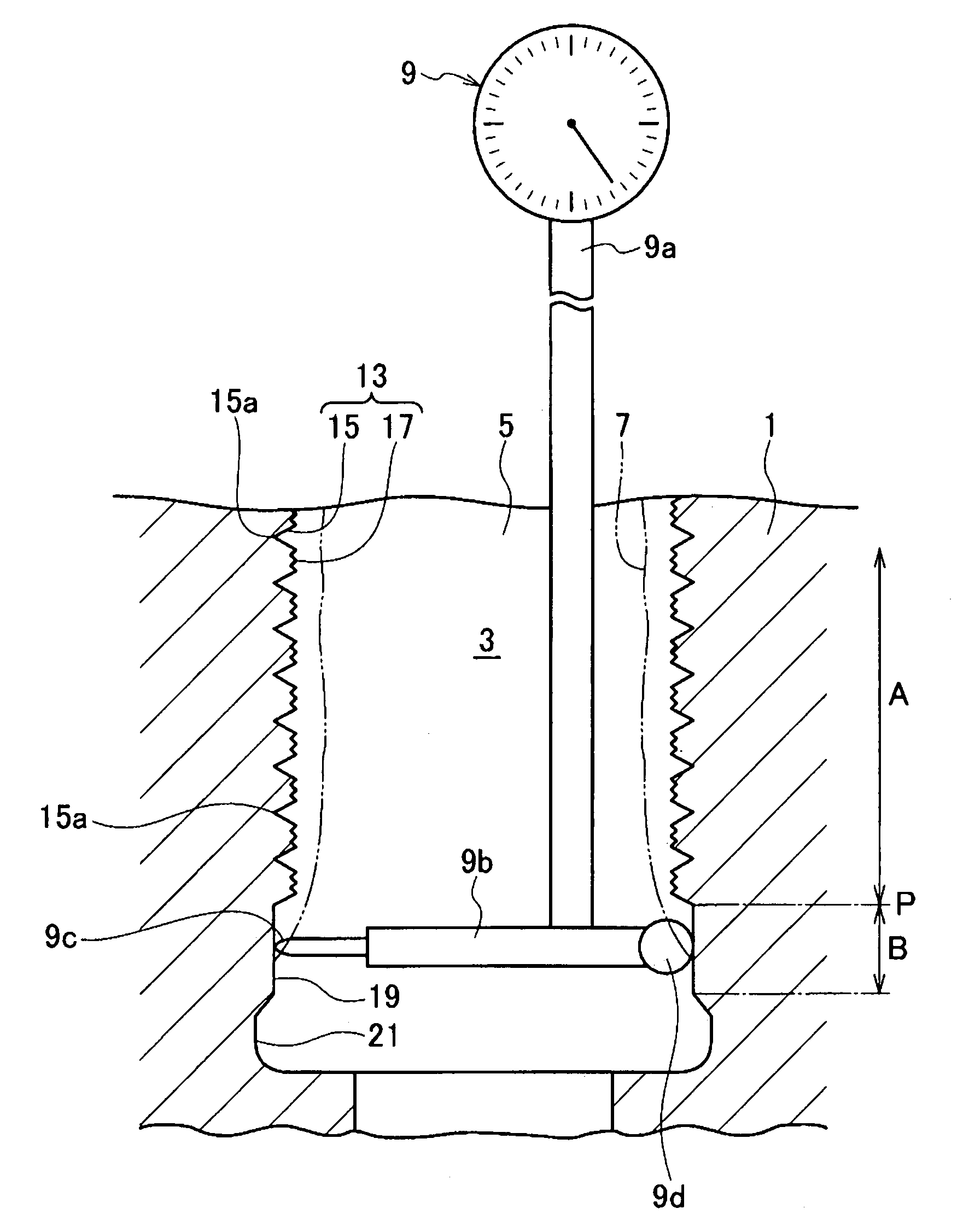

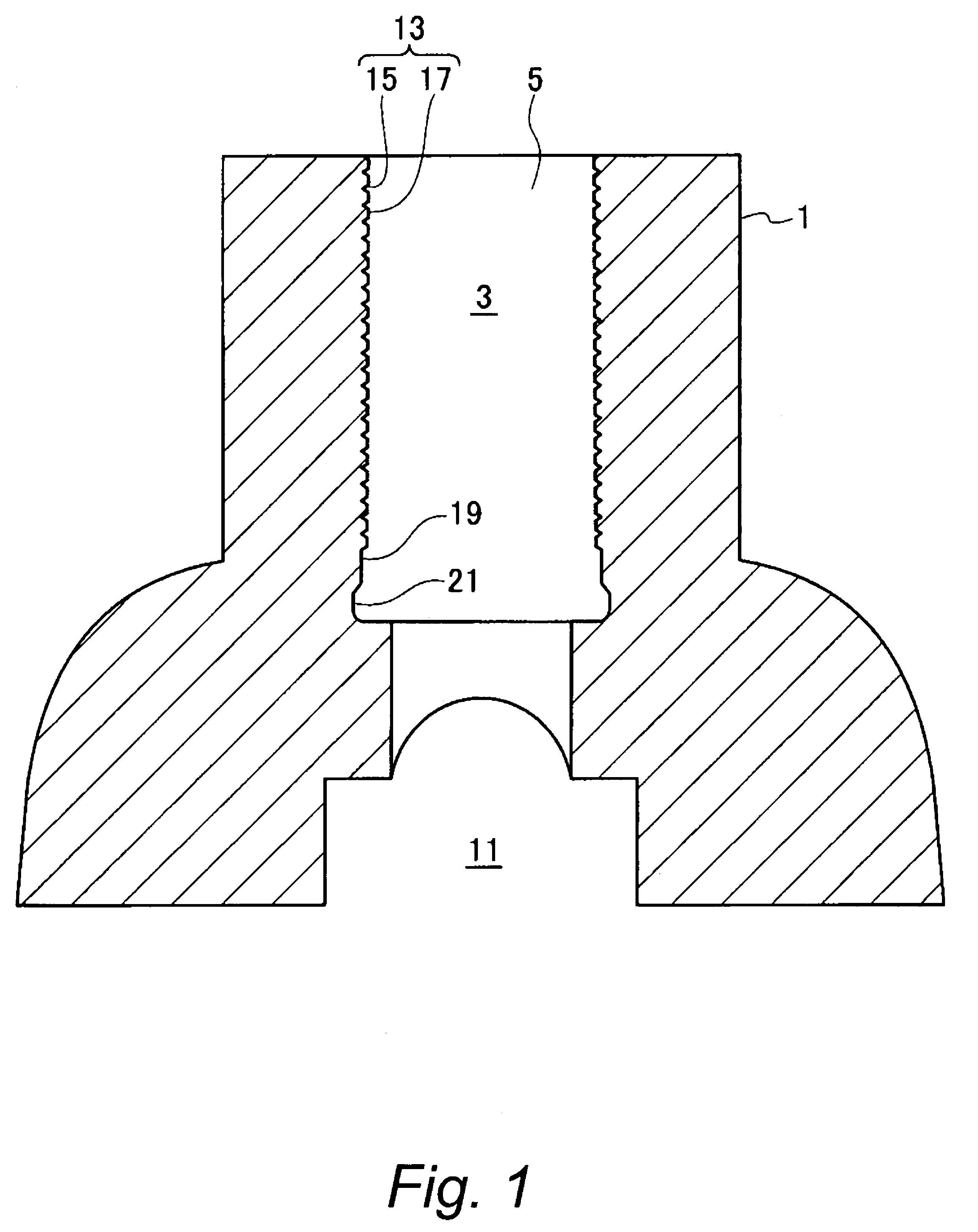

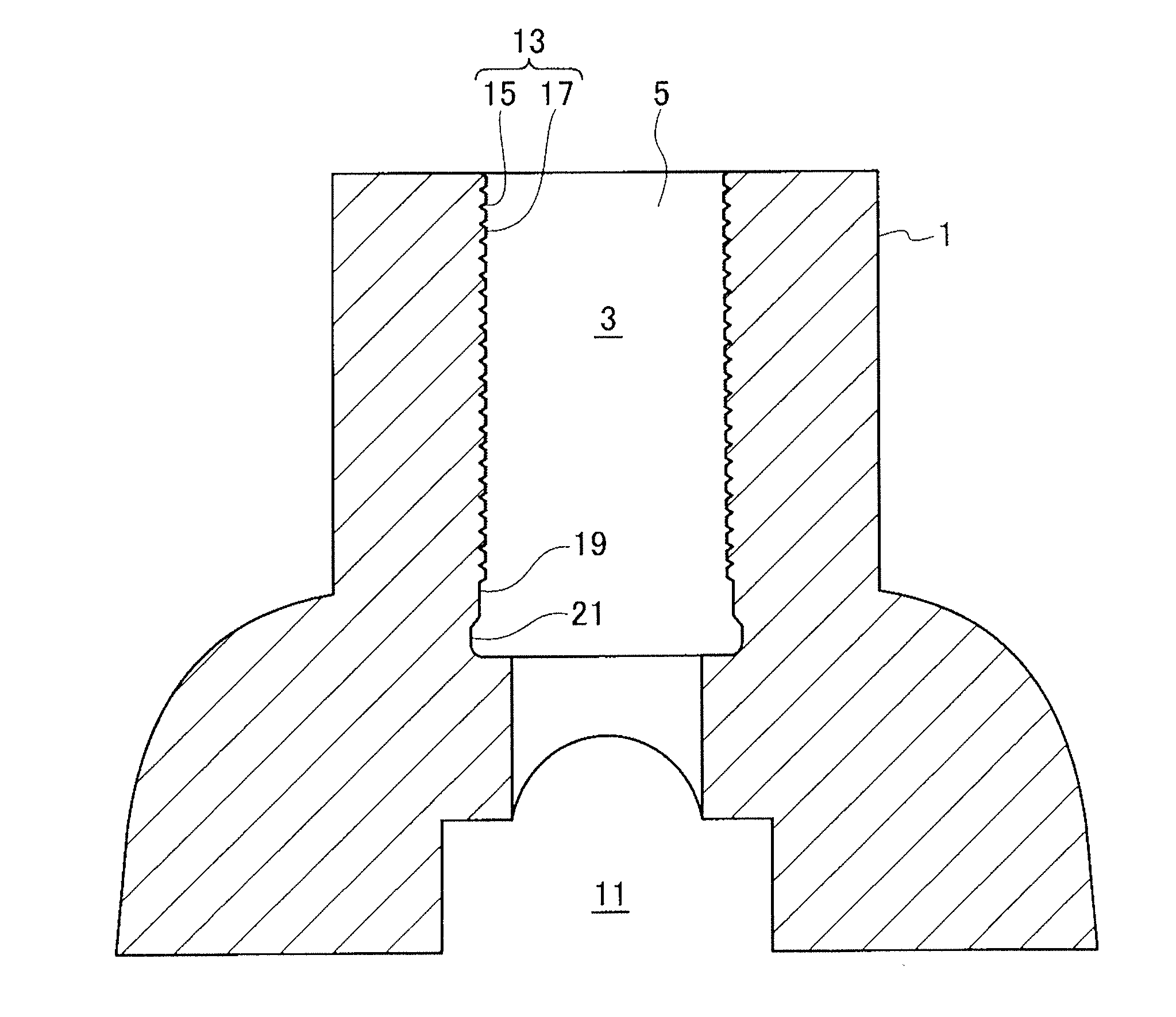

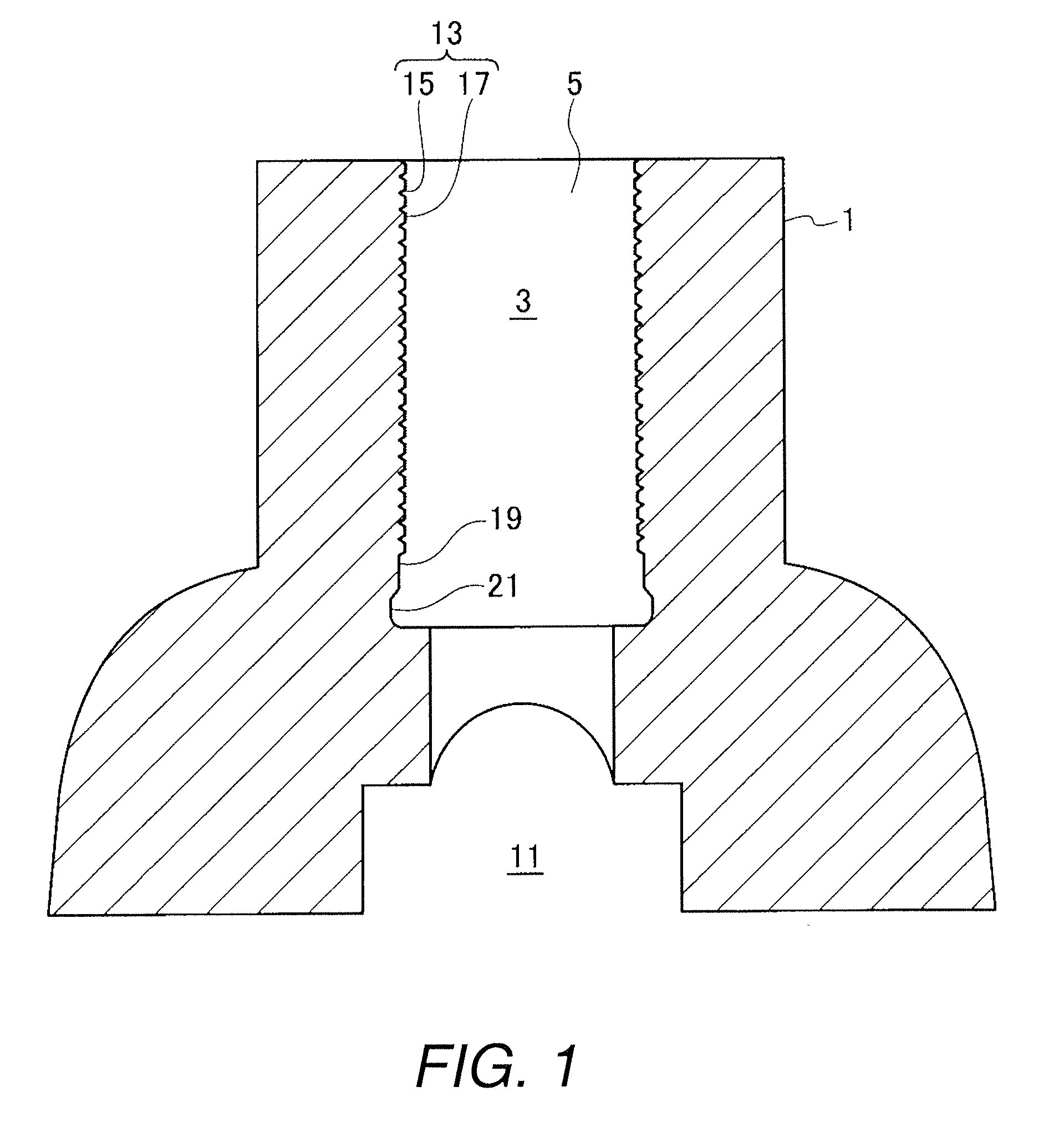

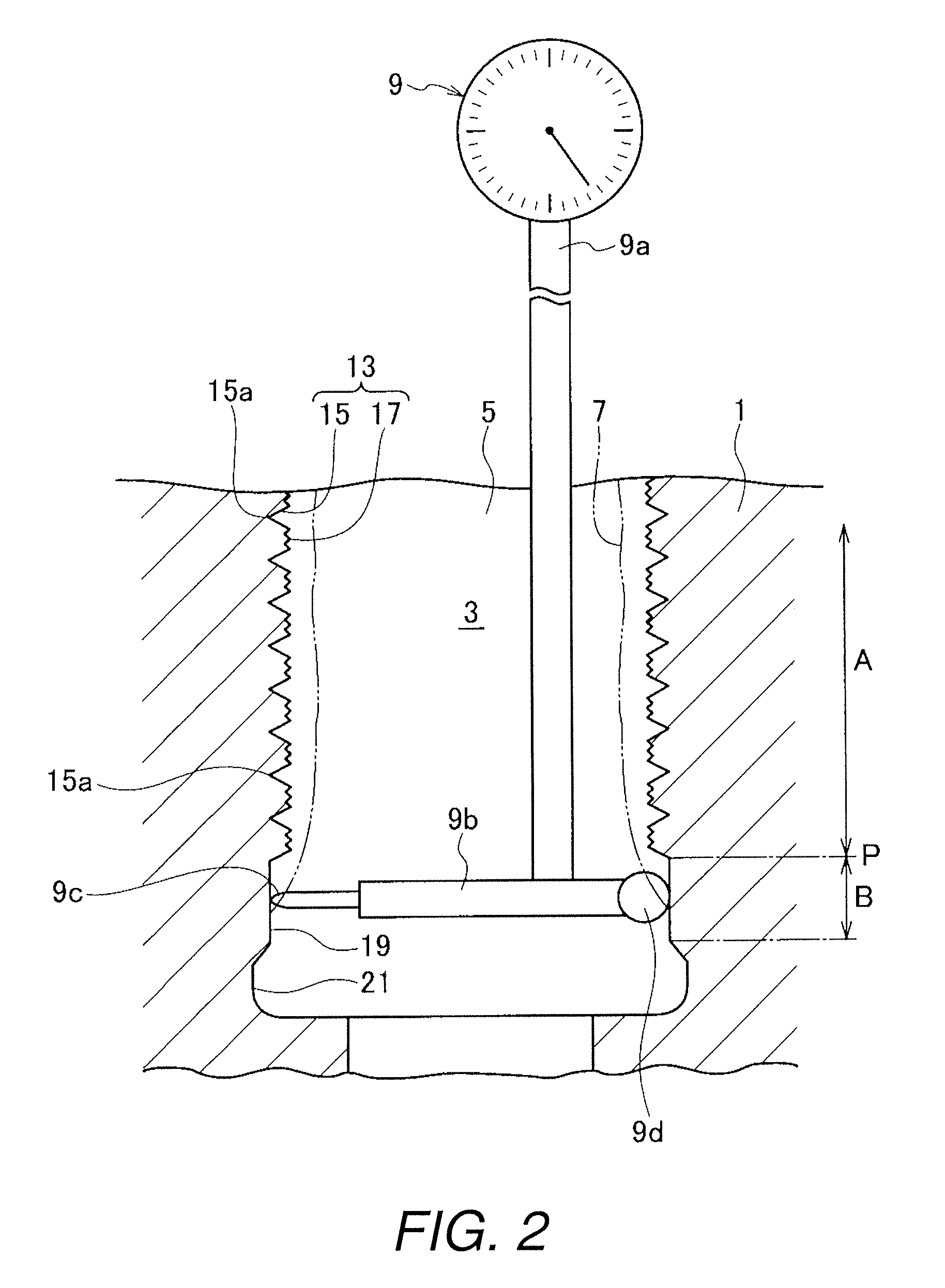

Cylindrical internal surface with thermally spray coating

ActiveUS7851046B2Accurate measurementMolten spray coatingLayered productsRough surfaceThermal spraying

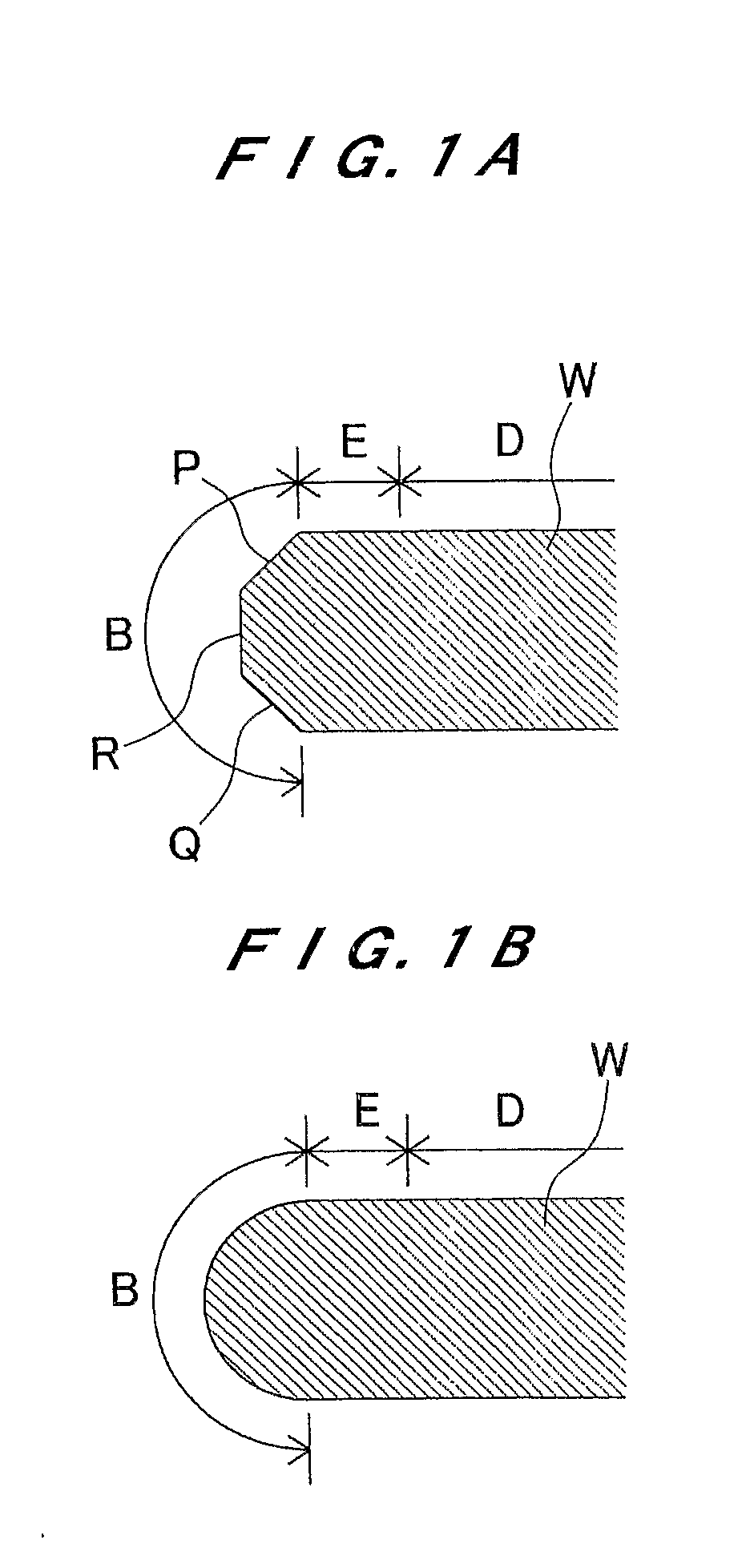

Before a thermally sprayed coating is deposited onto a cylindrical internal surface of a cylinder bore 3a rough surface 13 is formed to increase the adhesion of the thermally sprayed coating. After forming the rough surface is completed, an internal diameter measurement surface that is smoother than the rough surface is formed on an axial end section of the internal cylindrical surface. The internal diameter of the cylinder bore is measured at the internal diameter measurement surface with an internal diameter measuring instrument. An appropriate thickness for the thermally sprayed coating is determined based on the measurement result.

Owner:NISSAN MOTOR CO LTD

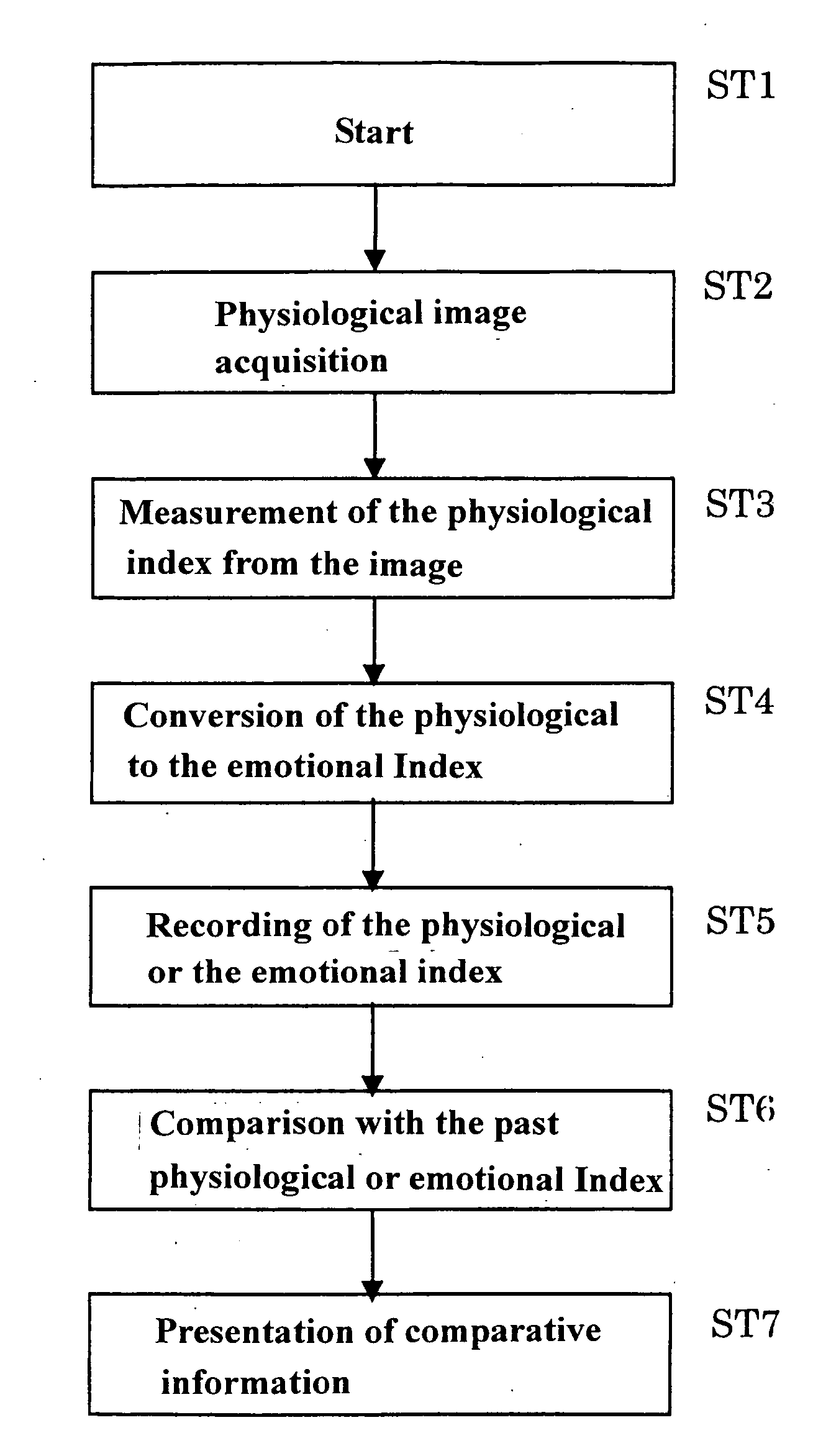

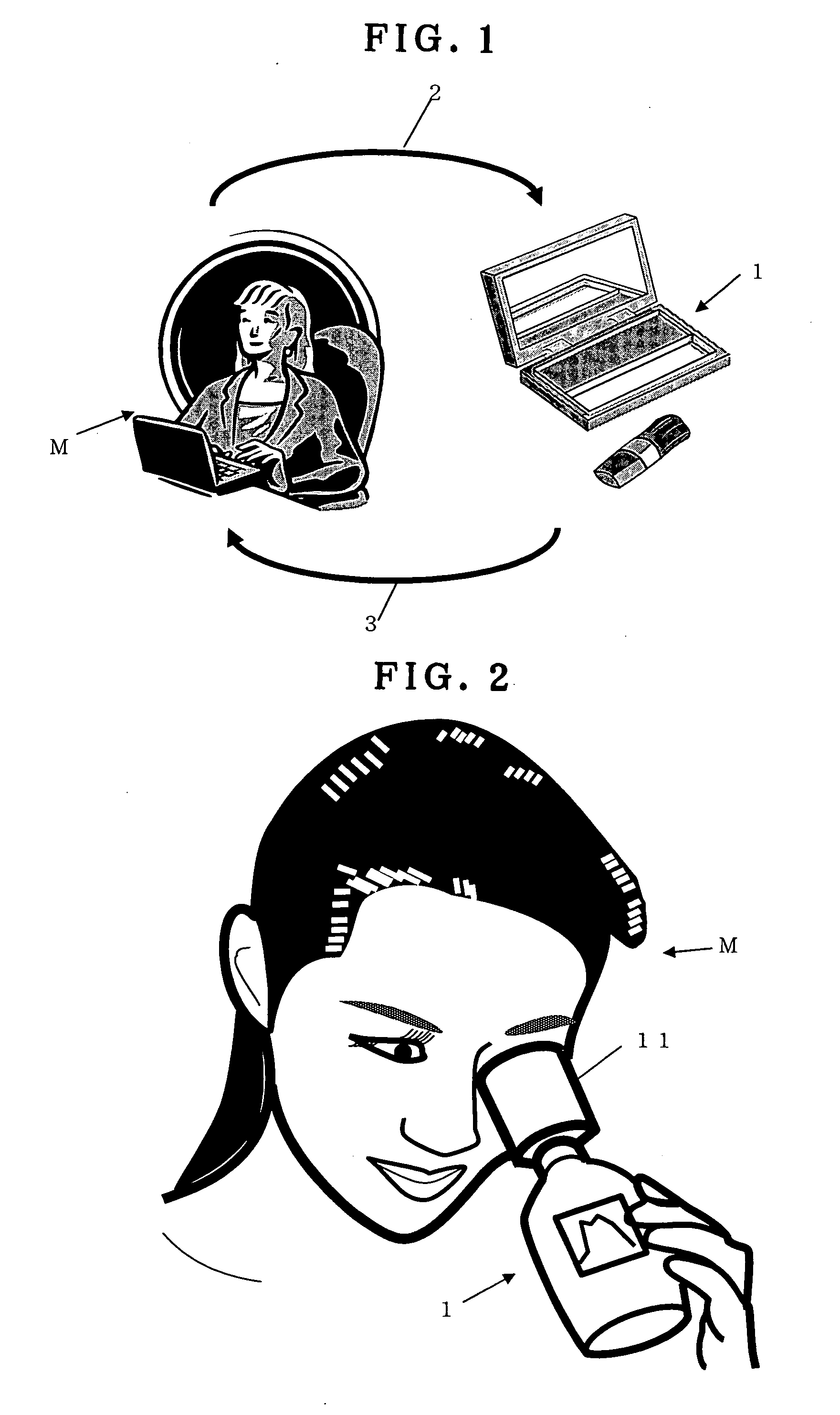

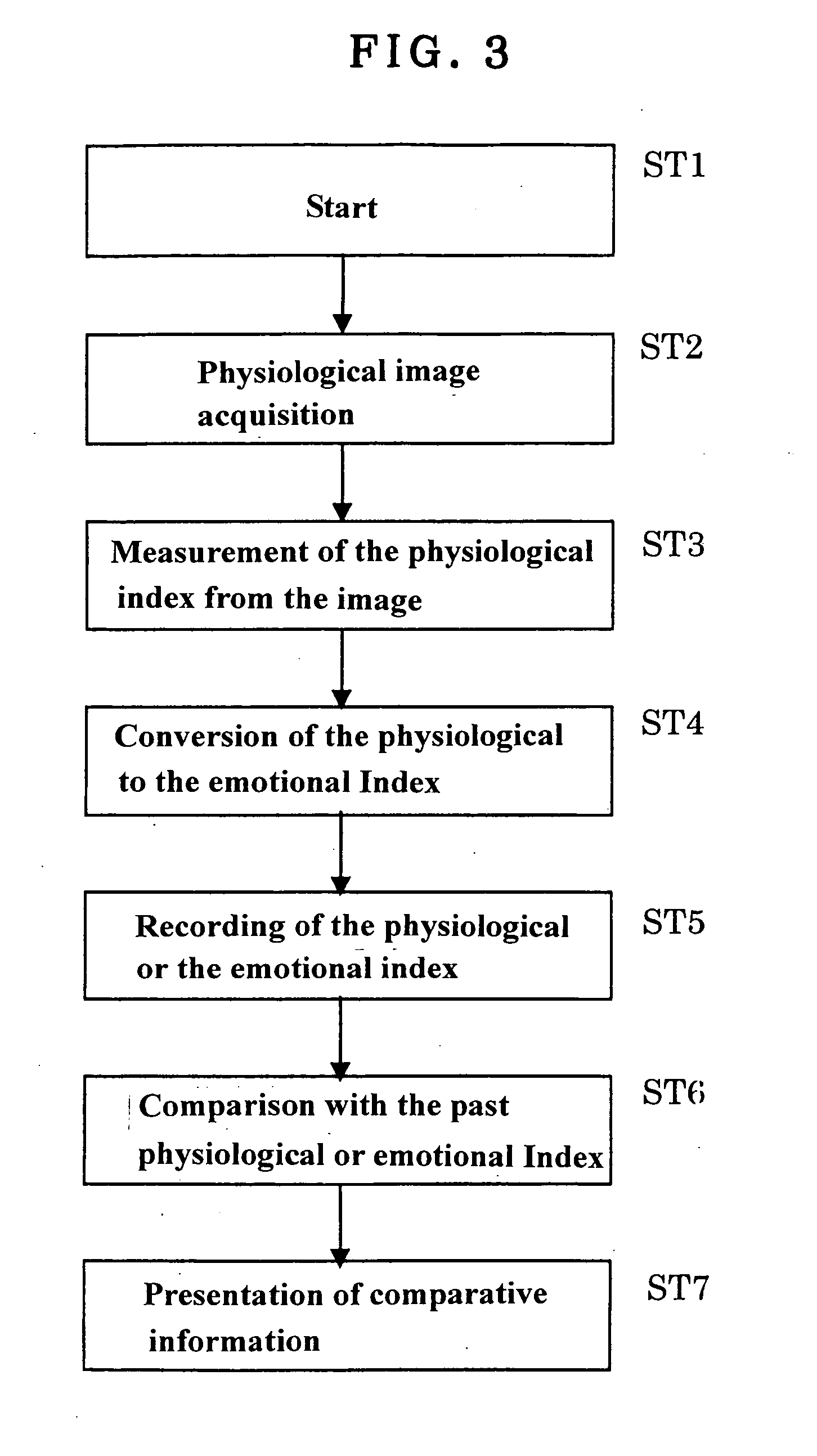

Biological information acquisition and presentation kit, and pupillary diameter measurement kit

InactiveUS20070123794A1Easy to measureImprove accuracyPerson identificationSensorsMeasurement deviceClinical psychology

The invention relates to a biological information acquisition and presentation kit that enables a general able-bodied person or subject to measure the subject's own biological or emotional index in a ready way. The kit 1 is characterized by comprising a positioning means capable of being positioned on an axial focus position of a taking optical system that allows a subject to take an image of a subject's eyeball by herself or himself, an imaging means adapted to take an image of the subject's eyeball, a measurement means adapted to measure a physiological index from the image taken of the eyeball, a conversion means adapted to convert the physiological index detected by said measurement means into an emotional index, and a recording means adapted to record said physiological index or said emotional index, and further comprising a presentation means adapted to present comparative information with a recorded past emotional index.

Owner:OLYMPUS CORP

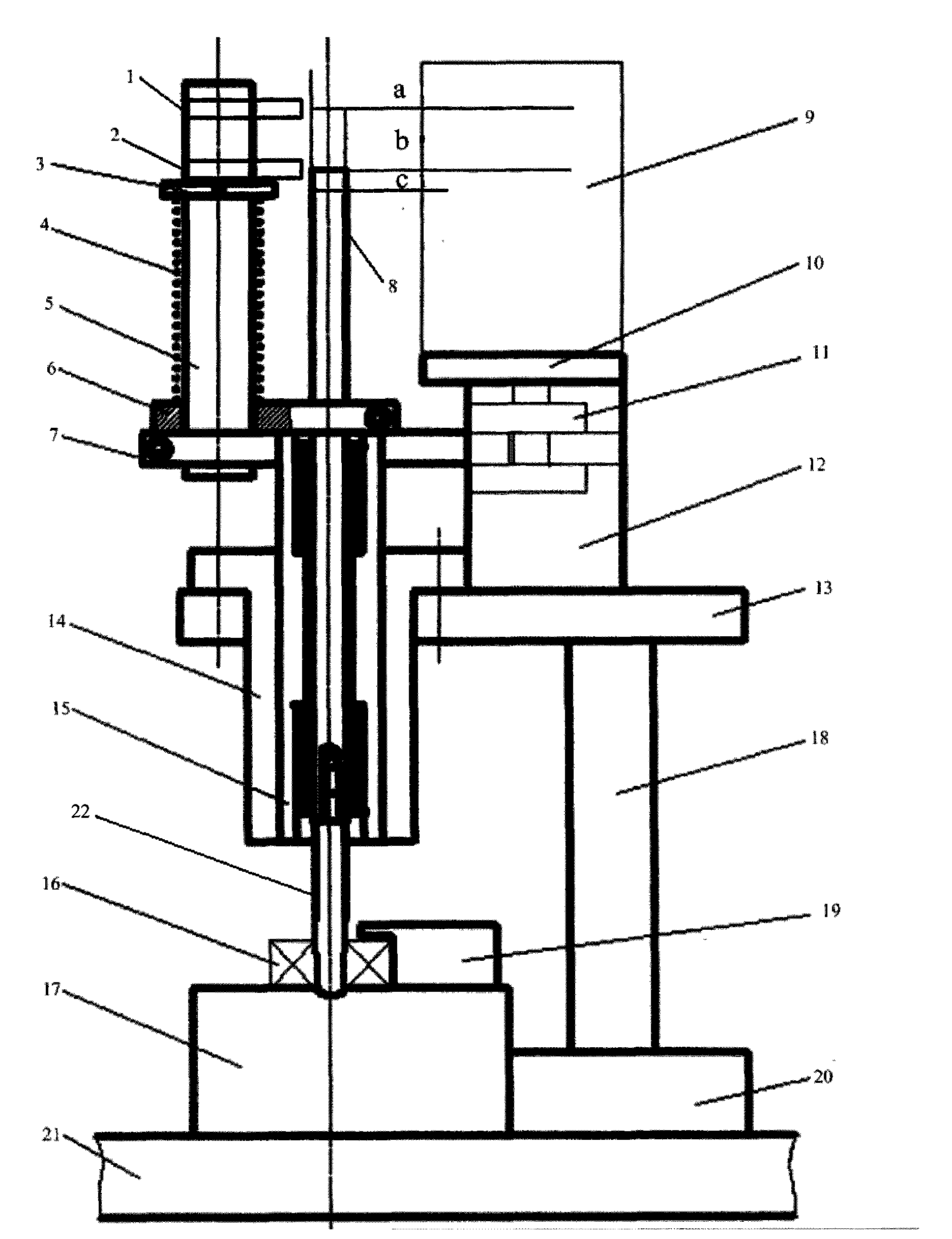

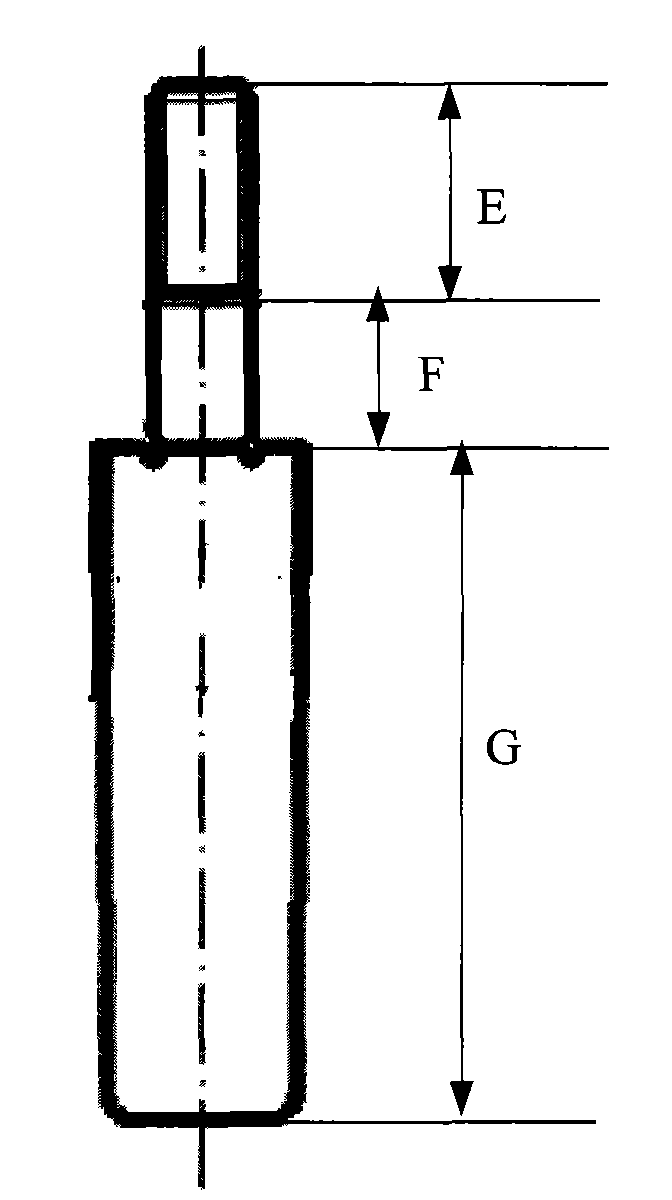

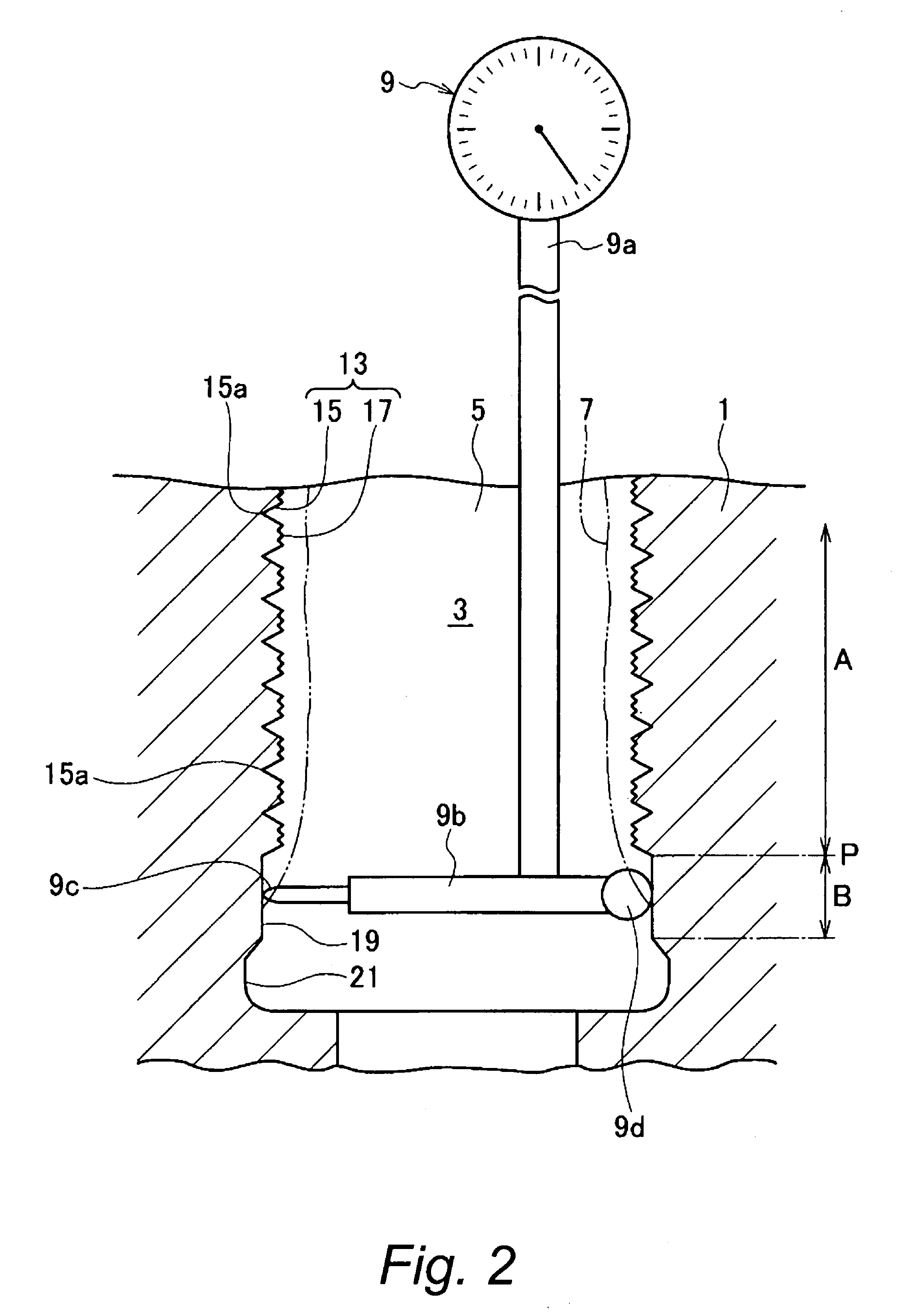

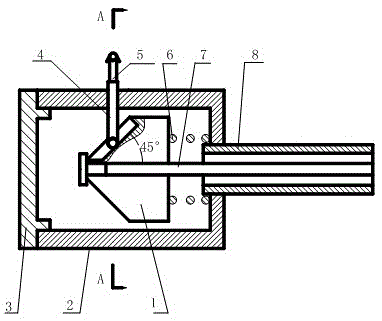

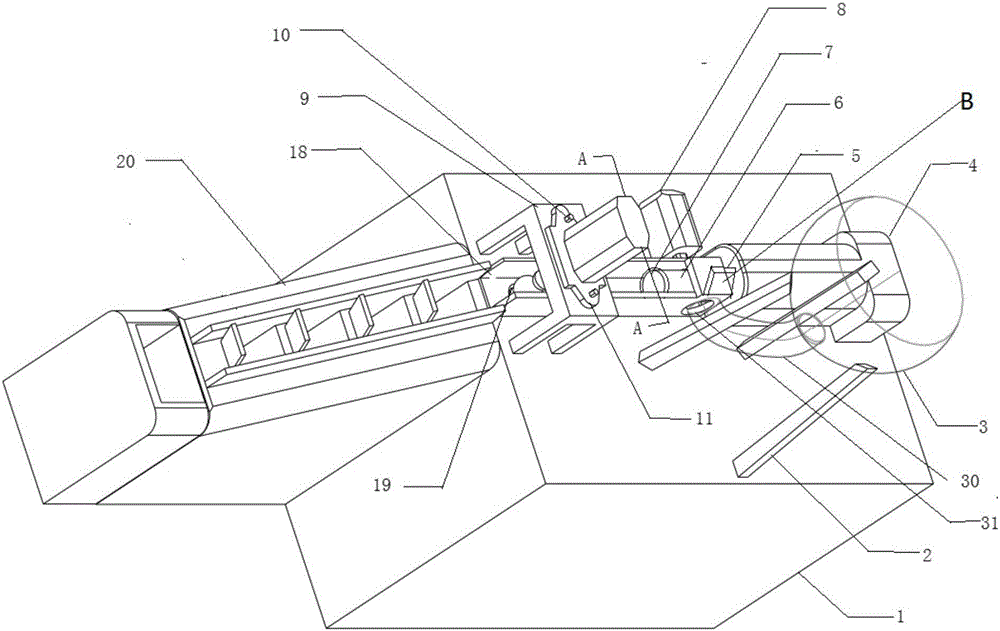

Depth aperture internal diameter measurement device

ActiveCN105547106AGuaranteed backingGuaranteed measurement accuracyMechanical diameter measurementsMeasurement deviceCircular cone

The invention discloses a depth aperture internal diameter measurement device, comprising a tapered block, a sleeve, three measurement rods, a spring, a push rod, a sleeve rod, a thread sleeve rod, a three-claw chuck and an internal diameter dial indicator. The conical surface of the tapered block is uniformly provided with three sliding grooves which are formed along the generatrix direction of the tapered block; the included angle between each sliding groove and the axis of the tapered block is 45 degree; the wall of the sleeve is provided with three through holes which are uniformly distributed along the circumference; three measurement rods pass through the through hole in the wall of the sleeve; and one end of the measurement rod is clamped inside a sliding groove. In the invention, the included angle between the sliding groove and the axis of the tapered block is 45 degrees and the displacement of the measurement rod along the radial direction is turned into an axial direction, which avoids the intermediate transfer between the levers in the traditional measurement, has more accurate measurement and can measure the maximum and minimum diameter of any cross section.

Owner:NANJING COLLEGE OF INFORMATION TECH

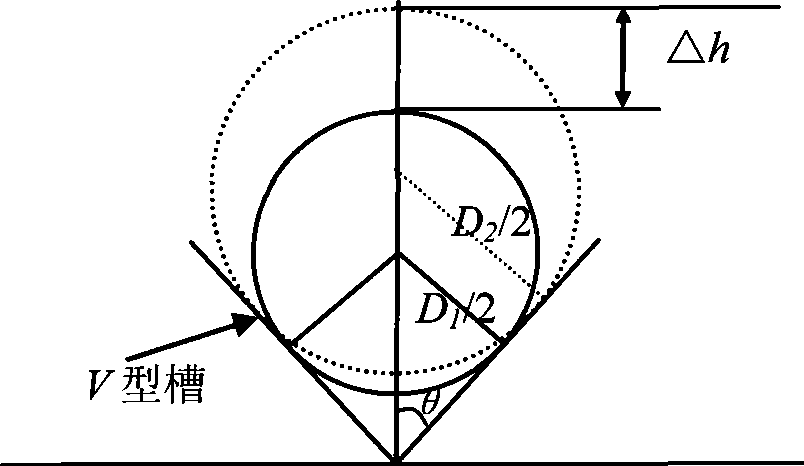

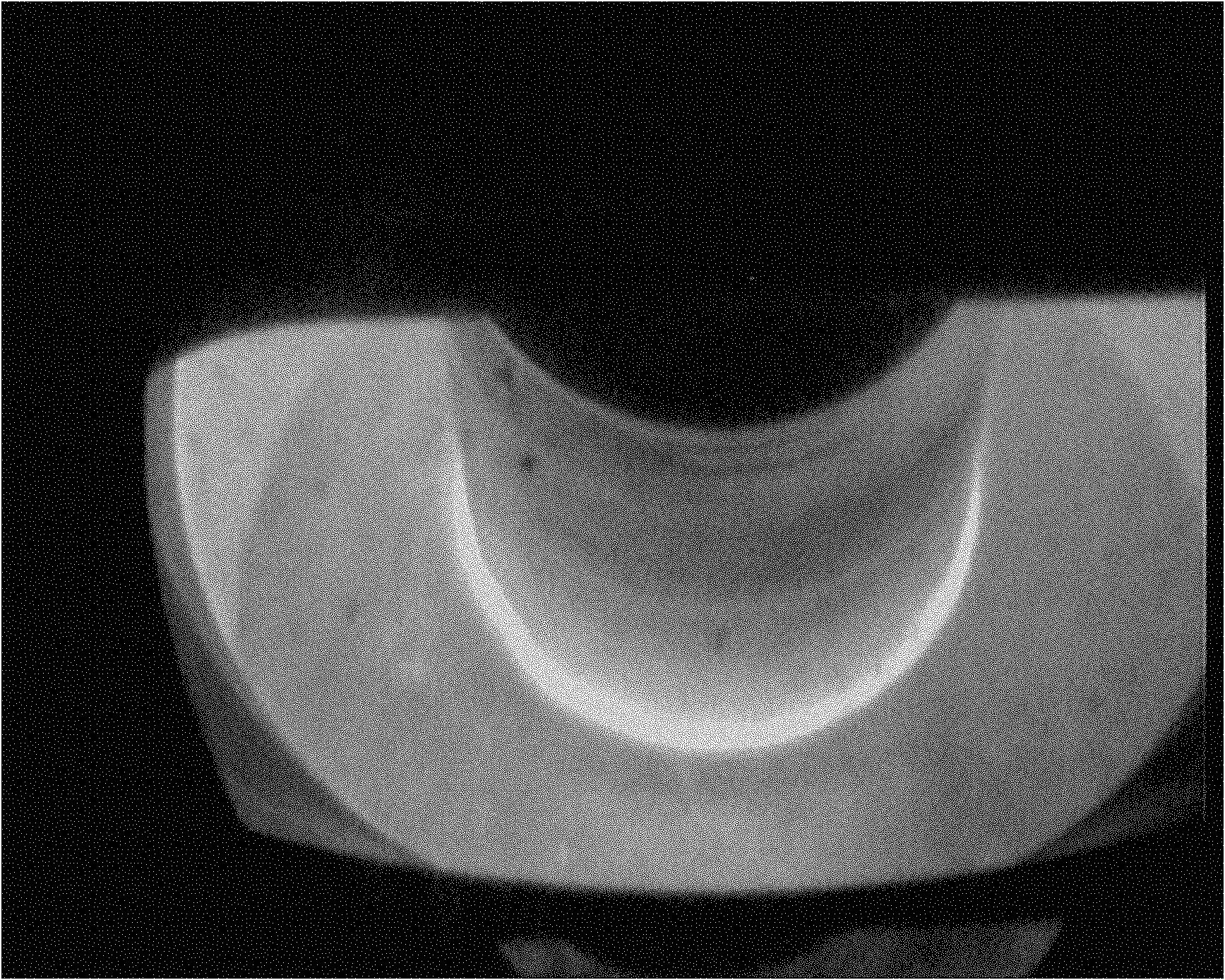

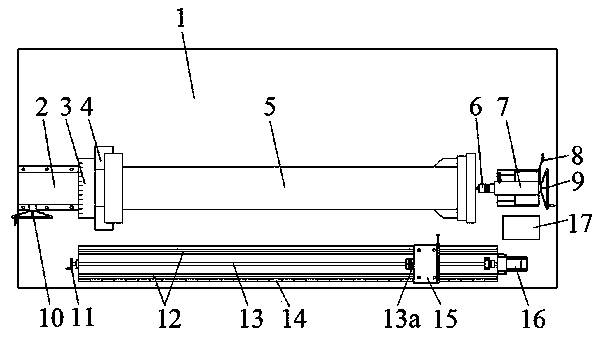

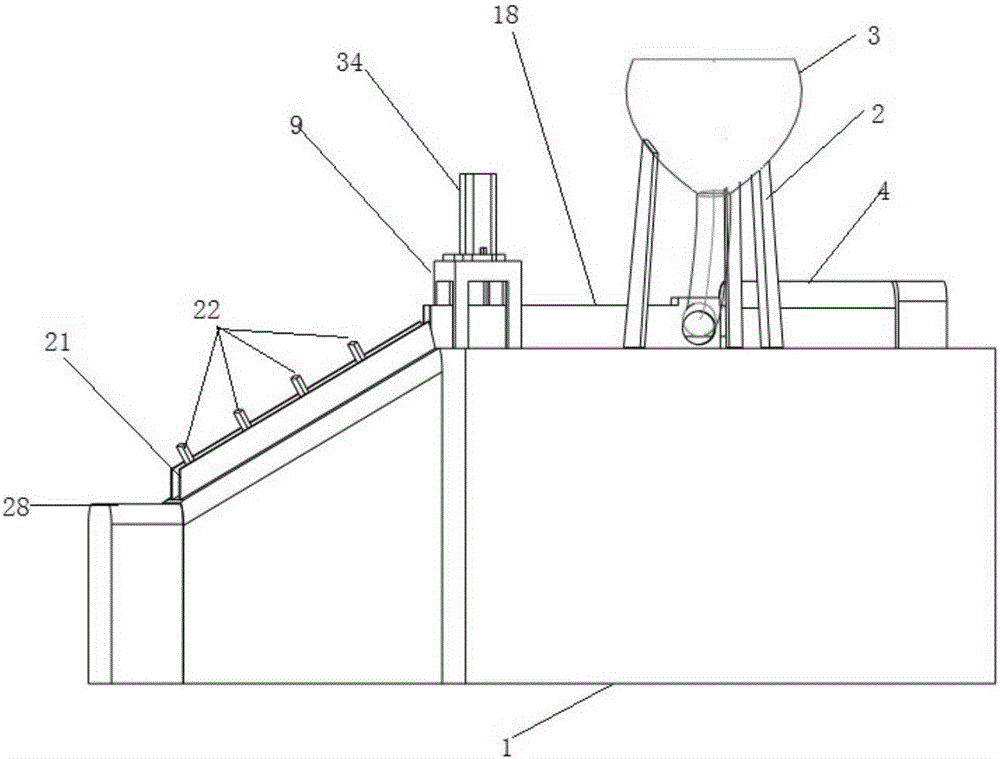

Cylinder on-line diameter measurement apparatus and measurement method thereof

InactiveCN101387499AAchieve precise positioningImprove diameter measurement accuracyUsing optical meansVision inspectionMeasurement device

The invention belongs to the technical field of computer vision inspection and image test, and relates to a device for measuring the diameter of a column on line. The device comprises a V-shaped groove conveyor belt for placing the column to be tested, an electric motor and an electric motor driver for driving the V-shaped groove conveyor belt to move uniformly in a straight line, and a video camera for acquiring images of the column to be tested. The video camera has a micro camera positioned on a tripod head, and the images acquired by the video camera are transmitted to a computer. Meanwhile, the invention provides a measuring method adopted by the device. The device and the method can carry out quick high-precision online measurement for the column. The device has a simple structure, can be regulated conveniently, and is suitable for the measurement of the columns with various diameters.

Owner:TIANJIN UNIV

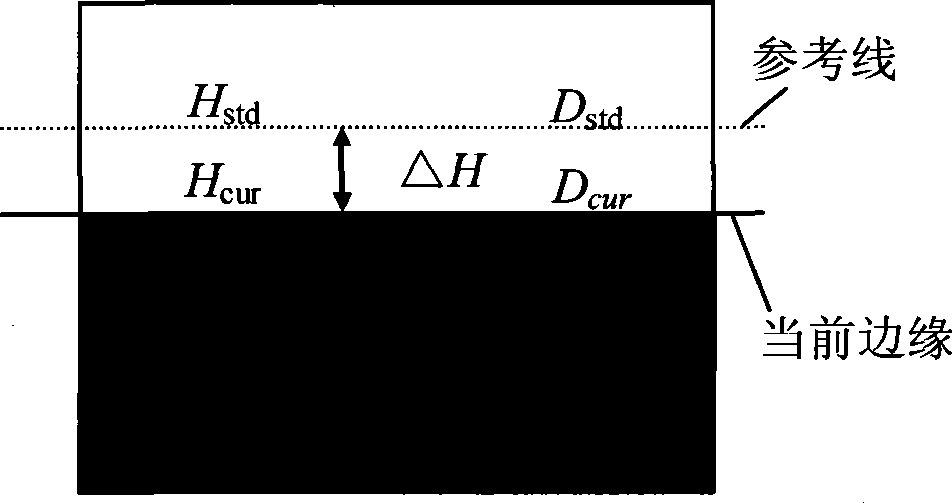

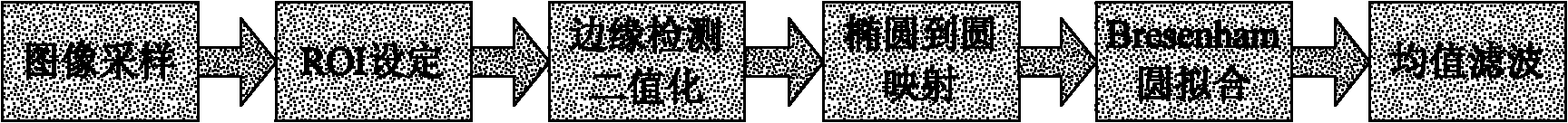

Czochralski single crystal silicon diameter measurement method

InactiveCN102061517AGuaranteed measurement accuracyLow costBy pulling from meltSingle crystalComputer vision

The invention discloses a Czochralski single crystal silicon diameter measurement method, which comprises the following steps of: synchronously acquiring single crystal growth images by using a camera, performing pre-processing and edge detection on the acquired images of each frame, performing sub-pixel optimal approximation and fit of a circle on the images of each frame by adopting a midpoint Bresenham circle drawing algorithm, and performing mean filter on the basis of a fit arc to acquire the accurate diameter of single crystal. The method can perform the sub-pixel optimal approximation of the circle by adopting the midpoint Bresenham circle drawing algorithm and can accurately calculate the diameter of the single crystal by using the common analog industrial camera so as to achieve the measurement effect of the high-resolution industrial camera.

Owner:ZHEJIANG COWIN ELECTRONICS

Holographic detection system for steel wire rope

ActiveUS20190063903A1Improve the degree of refinementDamage detection rateUsing electrical meansOptically investigating flaws/contaminationMachine visionData information

A holographic detection system for a steel wire rope, having a detection device, a stroke metering device, a data acquisition and conversion workstation, an alarm controller, and a terminal control master station is provided. The detection device further specifically has a steel wire rope electromagnetic detection device, a steel wire rope machine vision damage recognition device, a steel wire rope machine vision diameter measurement device, and a damage location marking device. The holographic detection system for a steel wire rope may perform comprehensive evaluation on the damage situation of the steel wire rope and refine damage data information, thereby comprehensively improving the refinement degree of detection and the detection accuracy.

Owner:LUO YANG WIRE ROPE INSPECTION TECH CO LTD

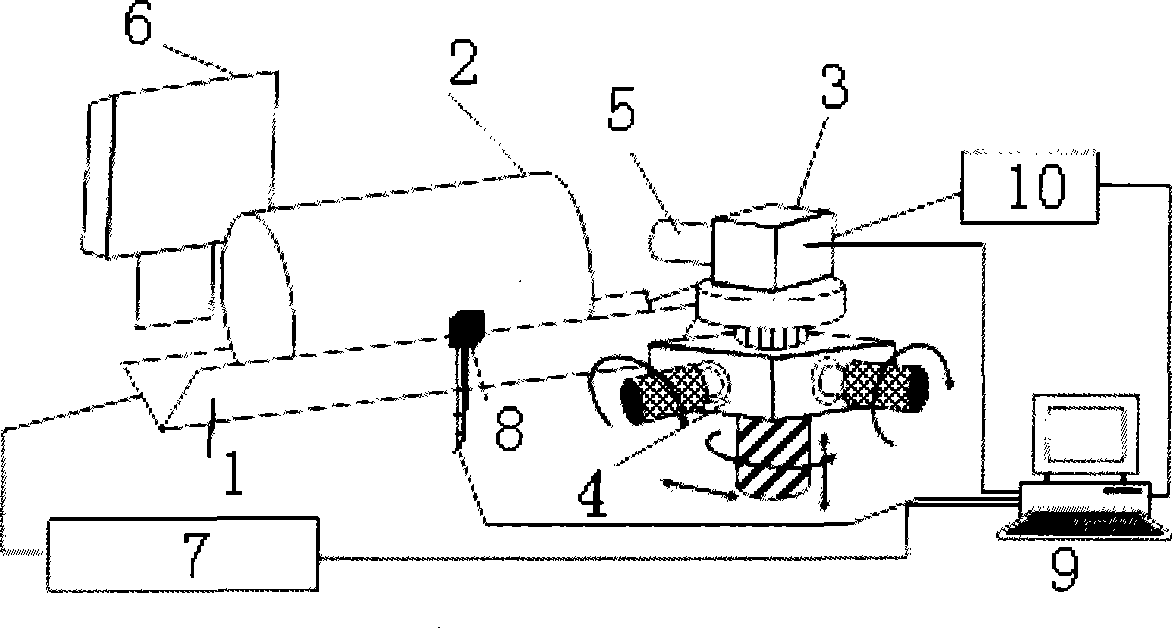

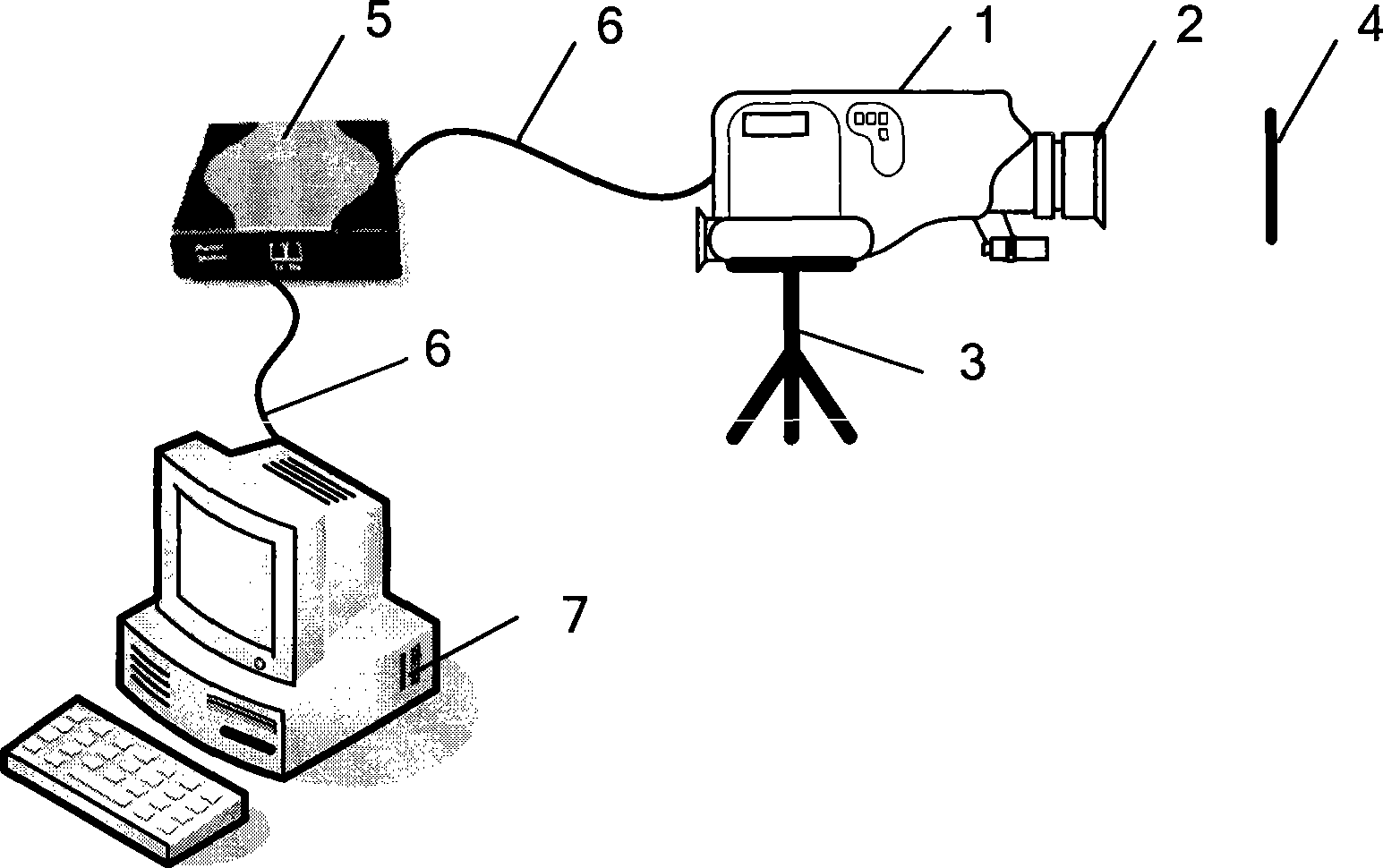

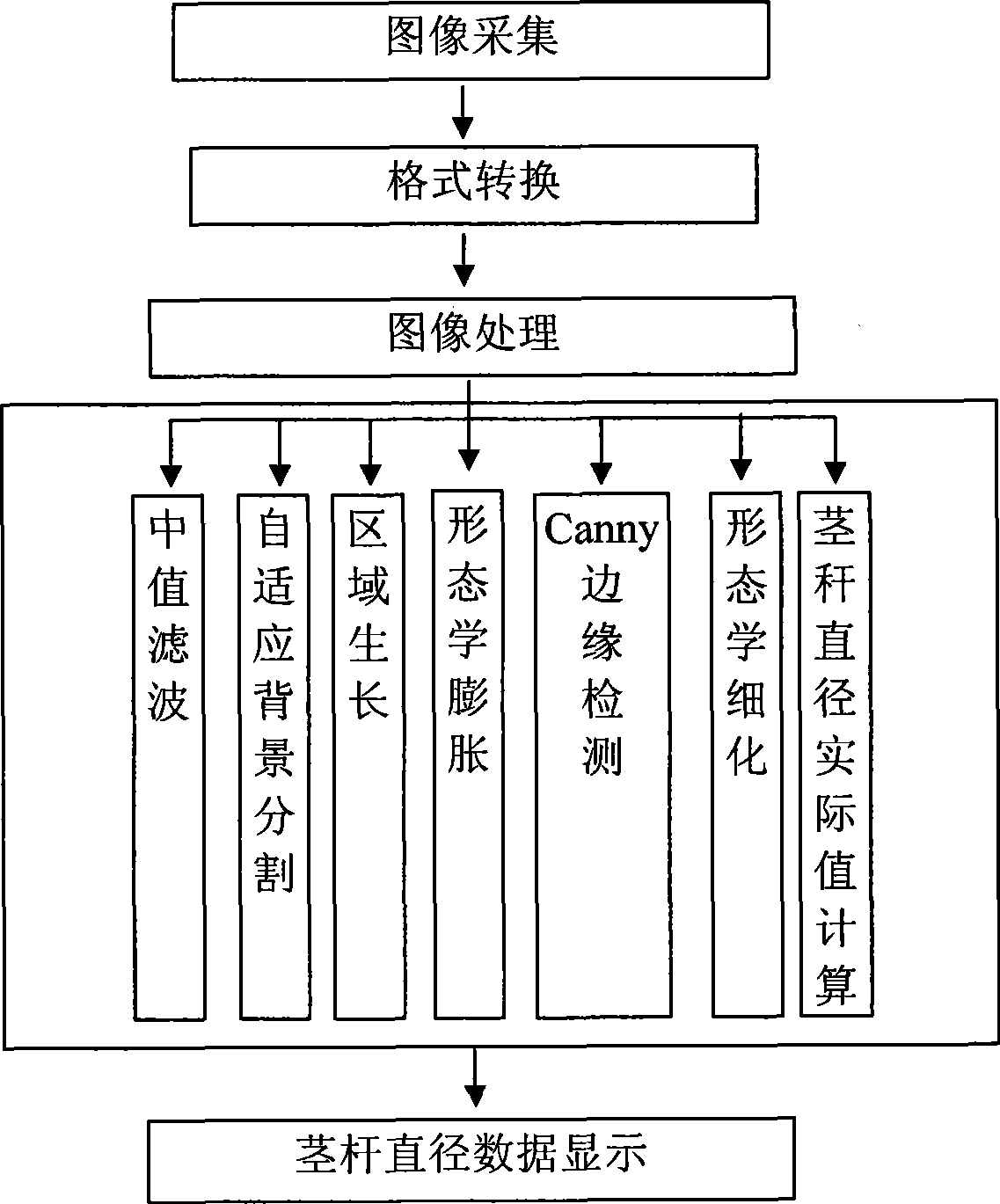

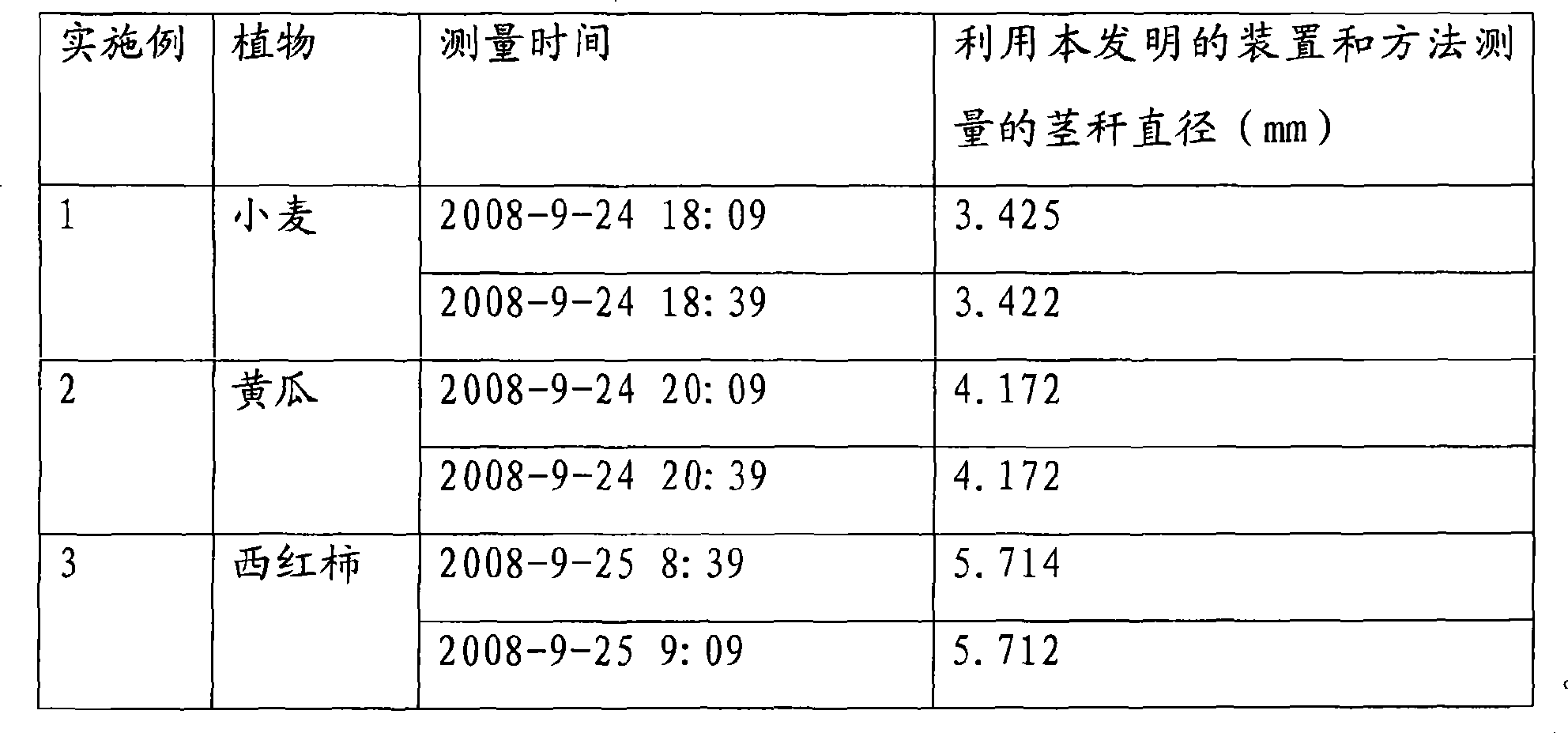

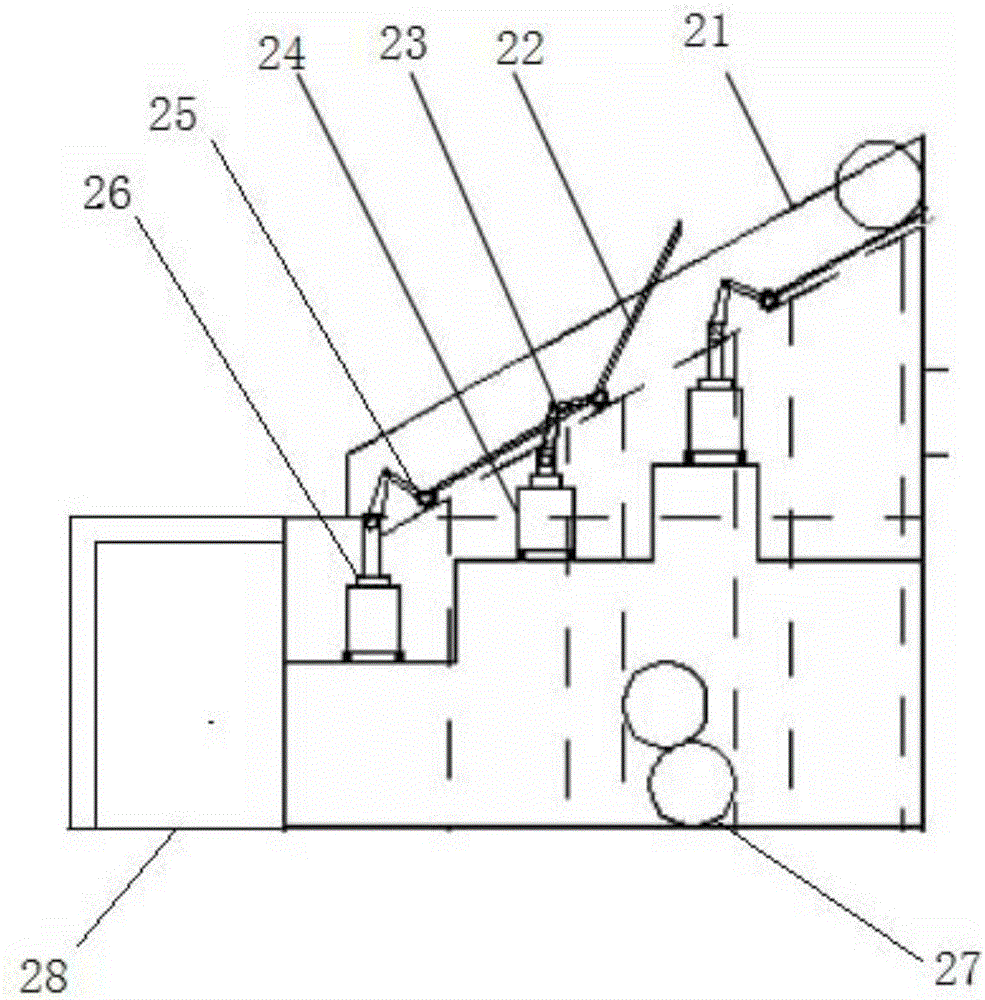

Plant haulm diameter measurement device and measurement method based on machine vision

InactiveCN101419058ASatisfies the requirements of small diameter change measurementHigh measurement accuracyUsing optical meansMeasurement deviceDiameter measurement

The invention provides a device and a method for measuring the diameter of plant stems based on machine vision. The measurement device comprises a camera (1), an annular LED light source (2), a support frame (3), a cylindrical reference object (4), an IEEE 1394 signal fiber transmission device (5), a data transmission cable (6) and a computer (7). The measurement method comprises the following steps of utilizing the camera (1) to acquire images of a to-be-measured plant stem and the cylindrical reference object (4) within a certain time interval, transmitting the images to the computer (7) through the IEEE 1394 signal fiber transmission device (5) and the data transmission cable (6) and utilizing image processing software installed in the computer to calculate the diameter of the plant stem. The invention effectively solves the constraint influence of the prior measurement tool on the diameter changes of the plant stem, avoids the trouble of replacing different range sensors for measuring different plant stems, and can be used for nondestructively monitoring the diameter of the plant stem and small variable quantity of diameter within a certain period of time on line.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

Cylindrical internal surface processing apparatus

ActiveUS20110023777A1Accurate measurementLiquid surface applicatorsMolten spray coatingRough surfaceThermal spraying

A cylindrical internal surface processing apparatus has an internal diameter measuring device and a controller. The internal diameter measuring device measures an internal diameter of an internal cylindrical bore formed in a base member to obtain a measurement result of the internal diameter of the internal cylindrical bore. The controller includes a surface roughening control section and a quality determining section. The surface roughening control section controls operation of a surface roughening equipment to form a rough surface section and an internal diameter measuring surface section on the internal cylindrical bore. The internal diameter measuring surface section is smoother than the rough surface section. The quality determining section determines if the rough surface section is acceptable to allow a subsequent thermally sprayed coating to be applied on the rough surface section based on the internal diameter measurement result at the internal diameter measuring surface section of the internal cylindrical bore.

Owner:NISSAN MOTOR CO LTD

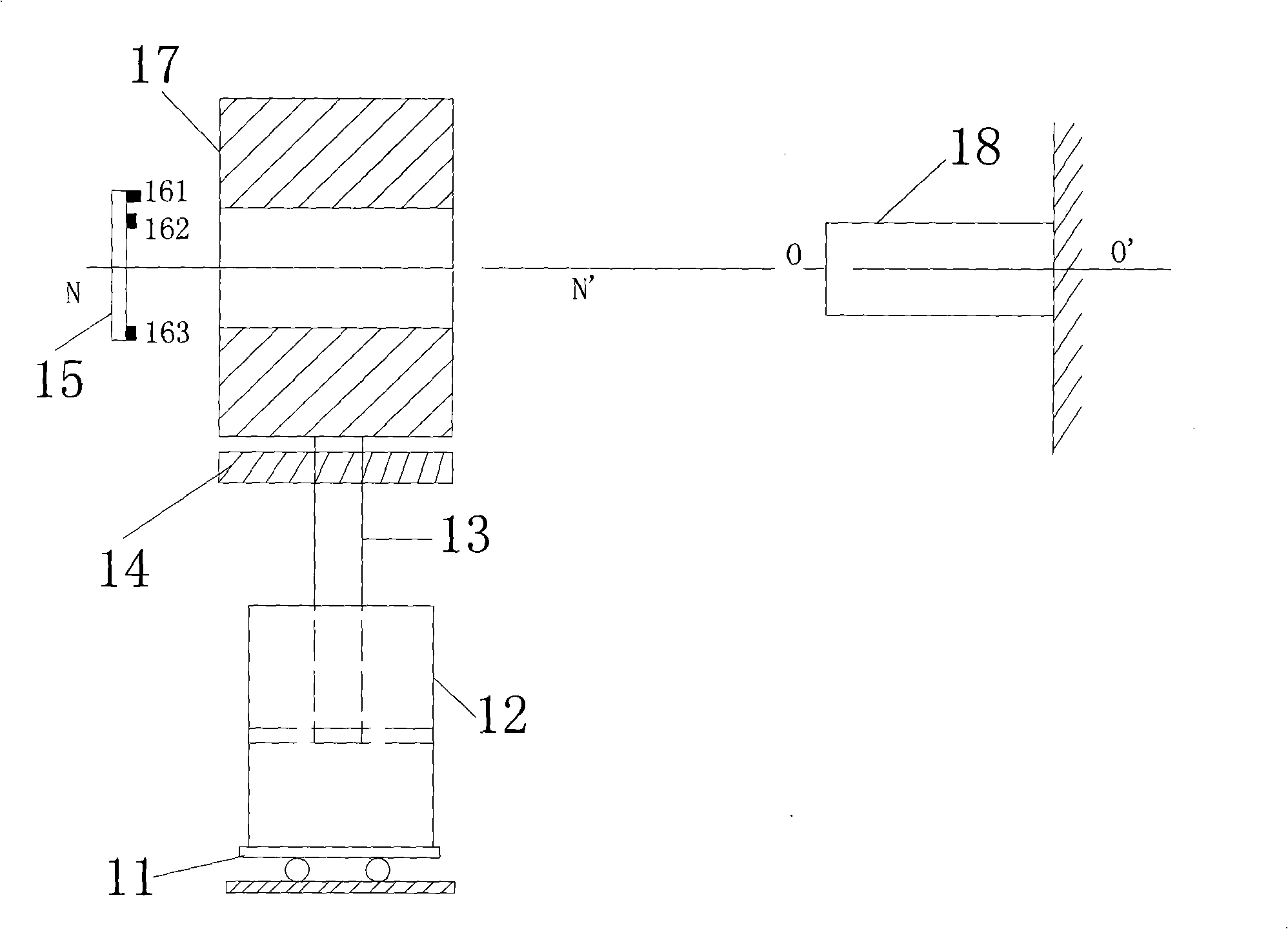

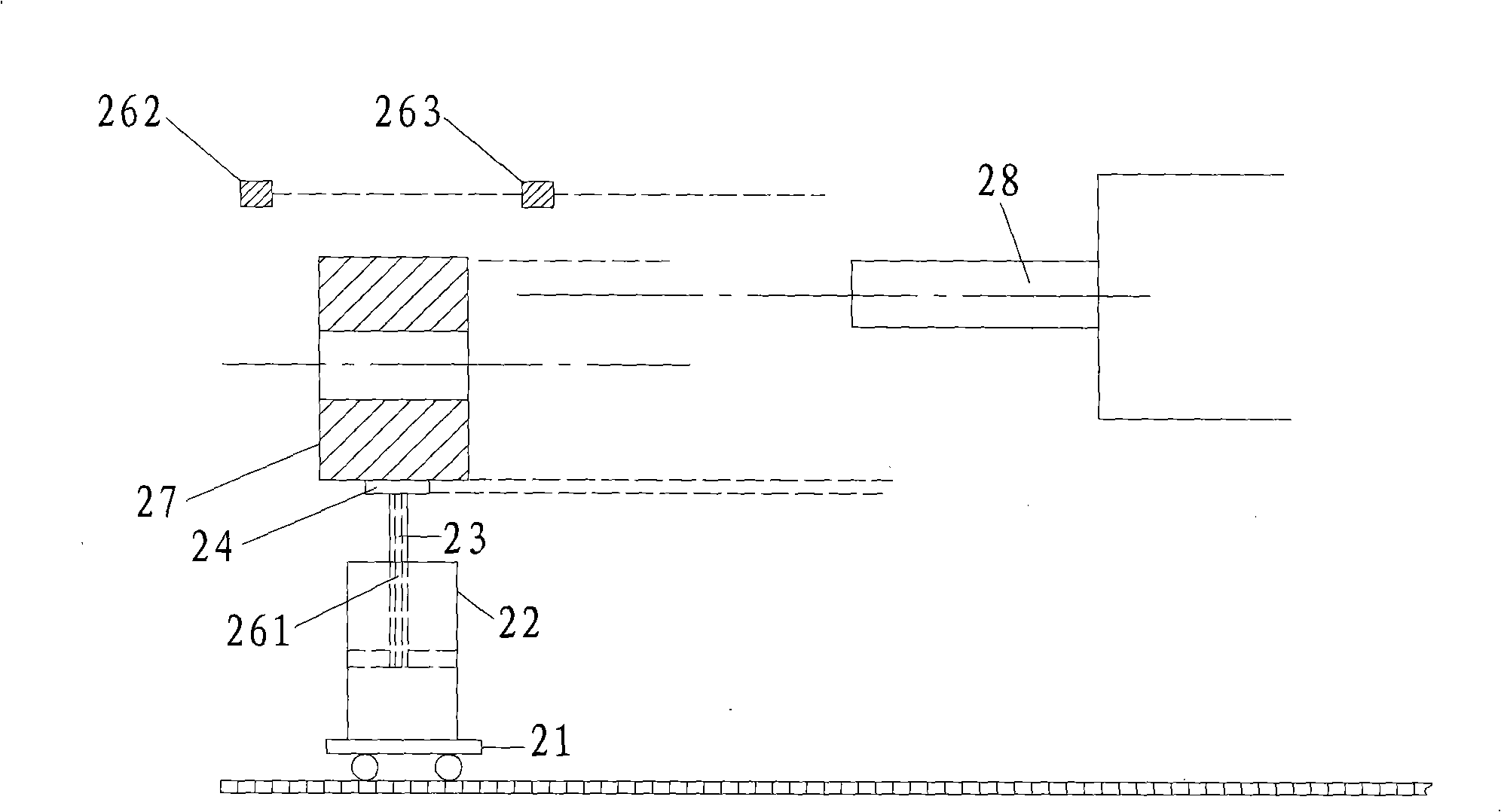

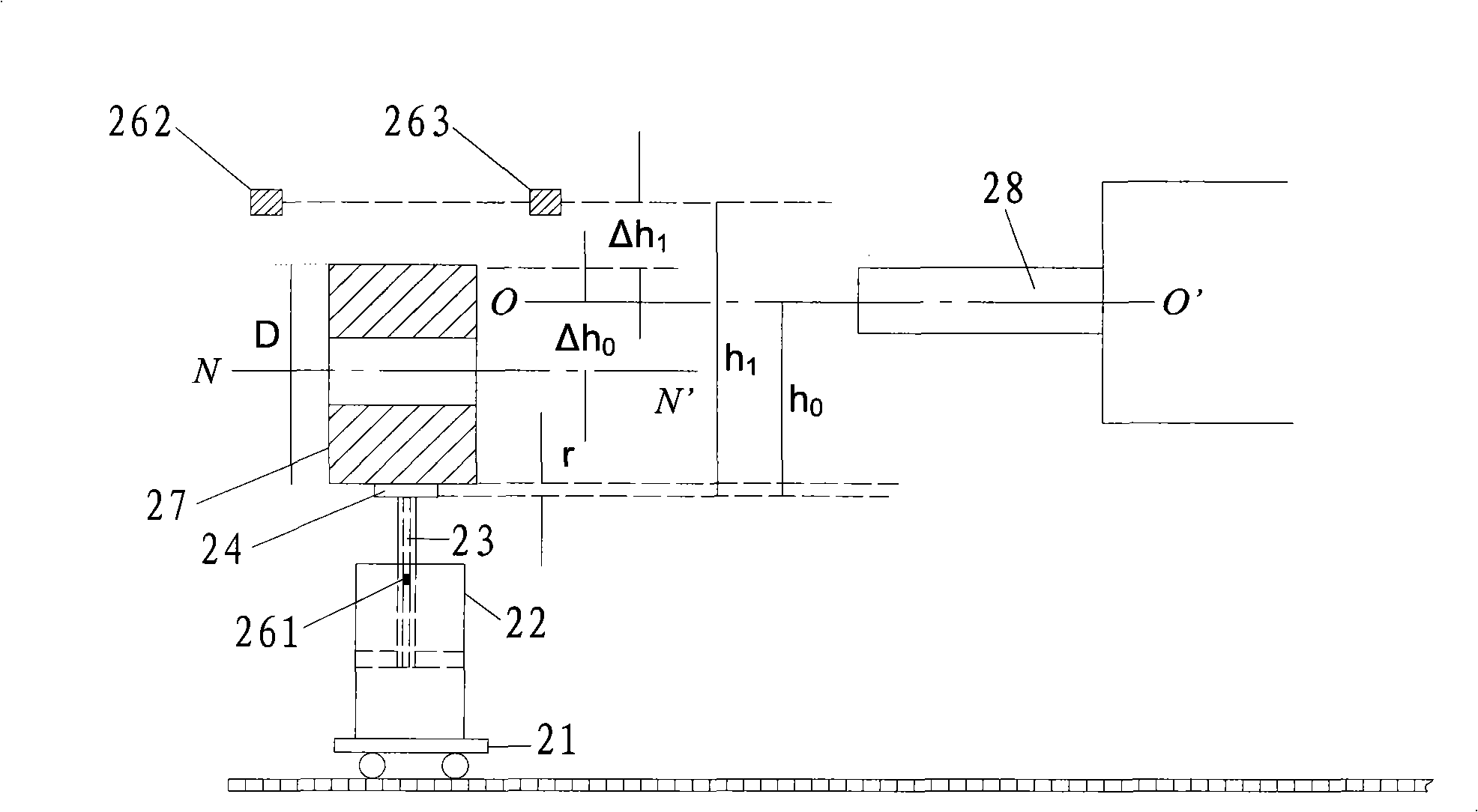

Device and method for coiled material centering and diameter measuring

InactiveCN101537445AHigh precisionDoes not take up spaceUsing optical meansMetal working apparatusHydraulic cylinderEngineering

The invention relates to the filed of coiled profile supplied to a machine and diameter measurement, in particular to a device and a method for coiled material centering and diameter measuring. The device comprises a dolly, a hydraulic cylinder, a mandril and a bracket. The hydraulic cylinder is fixed on the dolly which can move leftwards and rightwards; the mandril is fixed on the piston of the hydraulic cylinder; and the bracket is fixed on the top of the mandril. The device is characterized by also comprising a displacement sensor A, a photoelectric sensor B, a photoelectric sensor C, an analog / digital converter and a PLC; the displacement sensor A is fixed inside the mandril; linear relation exists between position signals generated by the displacement sensor A and the movement distance of the mandrill; the photoelectric sensor B and the photoelectric sensor C are fixed above the bracket and positioned on the same horizontal line; and the displacement sensor A, the photoelectric sensor B and the photoelectric sensor C are all connected with the PLC through the analog / digital converter. The invention has the advantages of simpleness, reliability, convenient installation and high control and measurement accuracy and is beneficial to quantitative statistic.

Owner:上海东大自动化工程有限公司

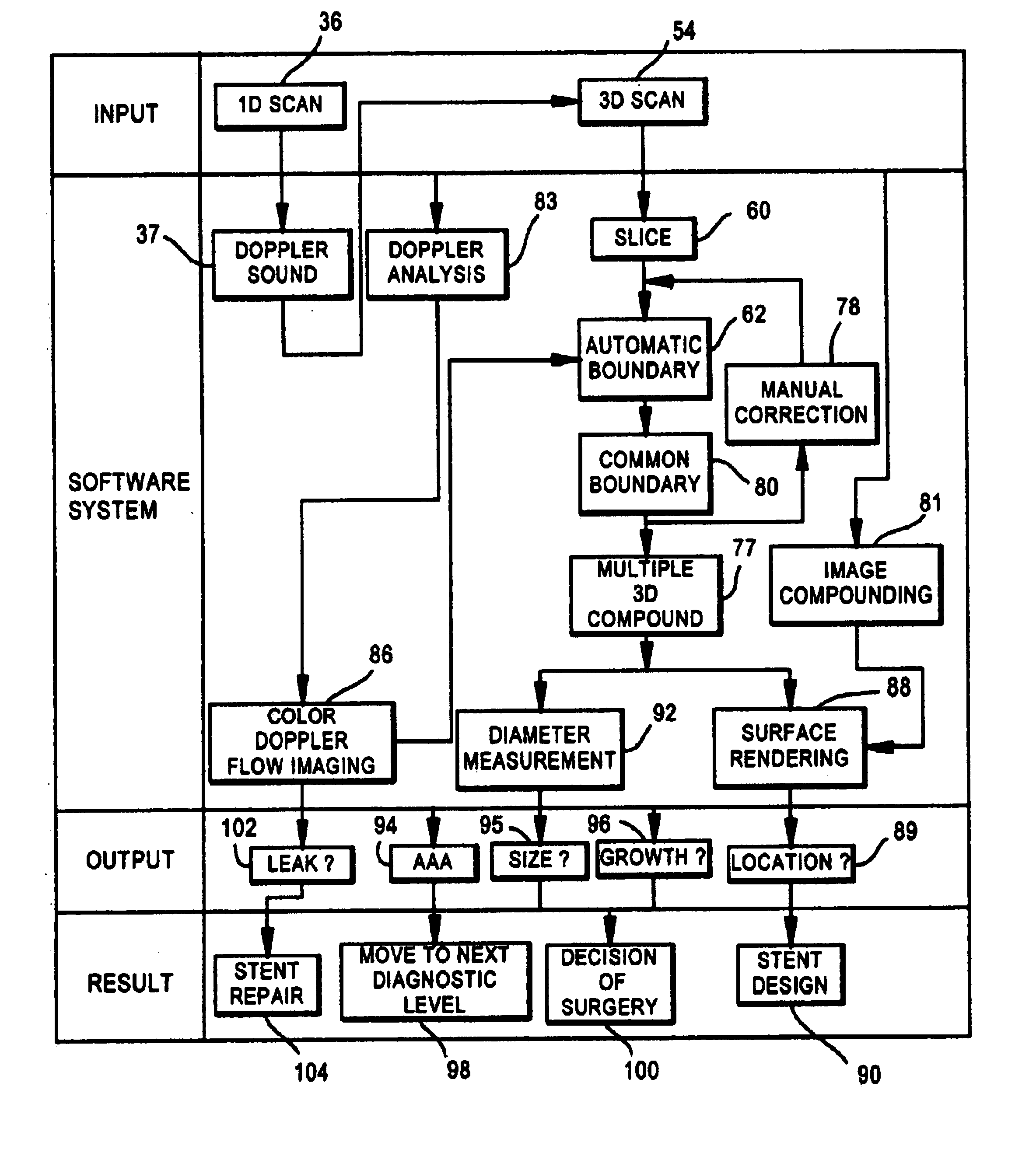

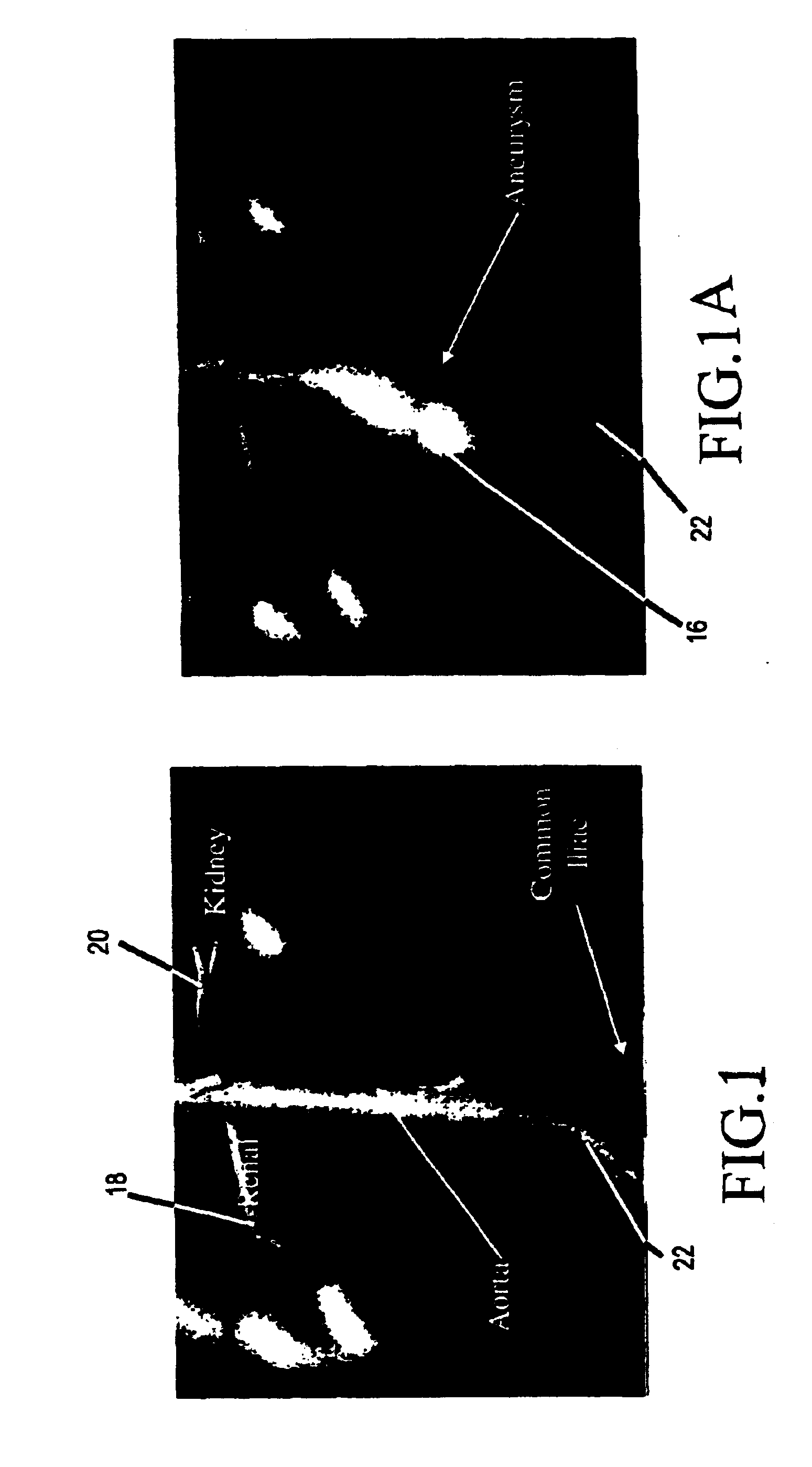

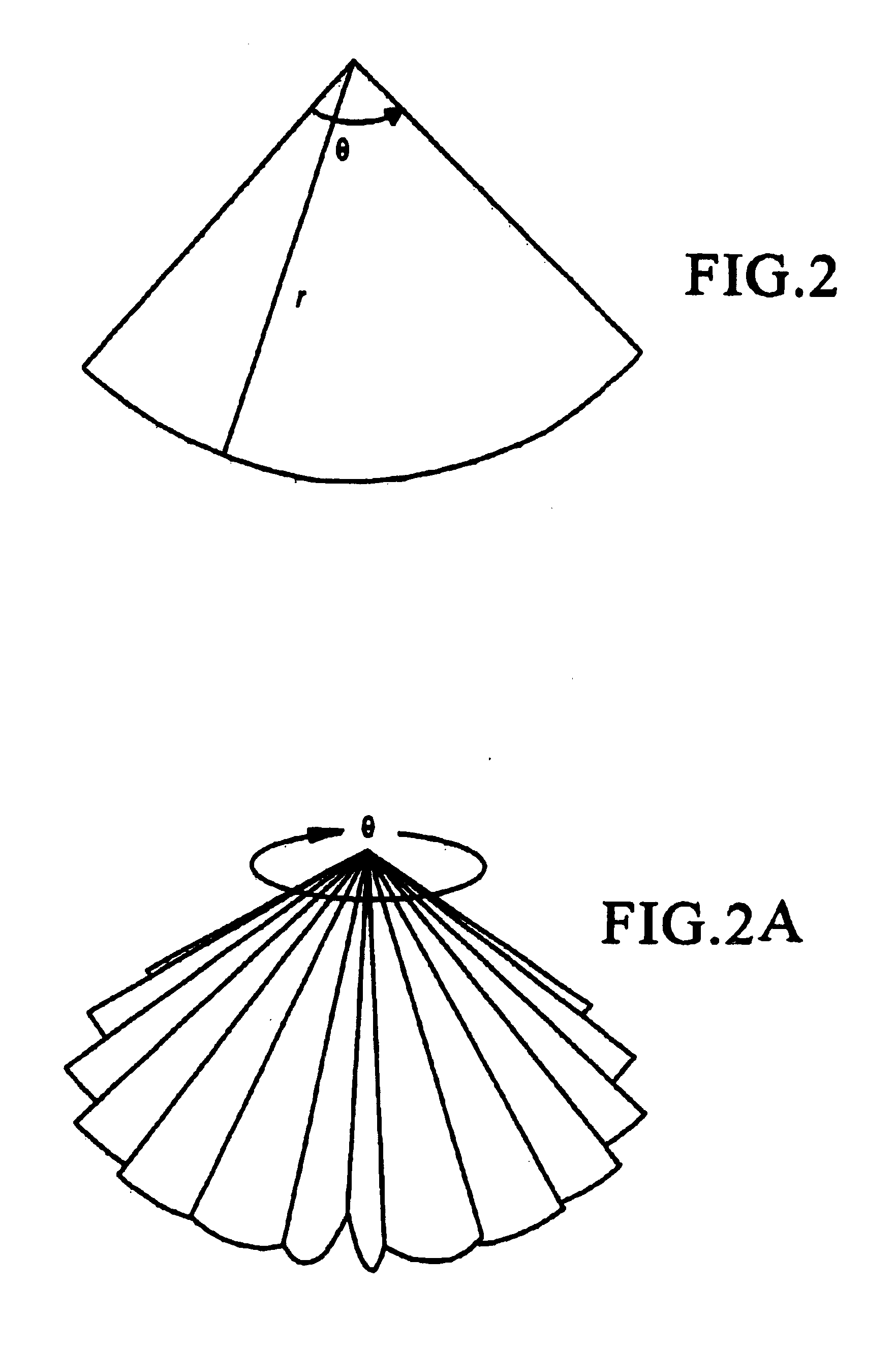

Three-dimensional system for abdominal aortic aneurysm evaluation

A data collection device obtains three-dimensional ultrasound scan information of a portion of the abdominal aorta. A plurality of transducer elements are arranged to provide overlapping coverage. The data collection device is first positioned over the aorta by an operator; a one-dimensional scan with a Doppler sound generator operating on the blood flow is used to verify proper initial positioning of the device. Three-dimensional scan information is then obtained and converted from plane coordinates into spherical coordinates such that the resulting converted scan line planes are perpendicular to the aorta. The information in each converted scan line plane is then processed to determine the boundaries of the aorta, from which diameter information is then calculated. Diameter measurements over a given region of the aorta can be used to determine and monitor an aneurysm in the aorta.

Owner:VERATHON

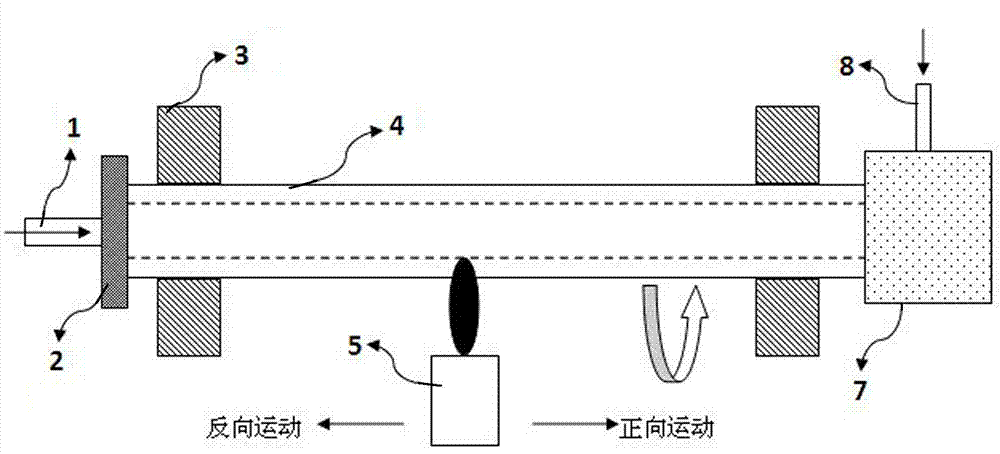

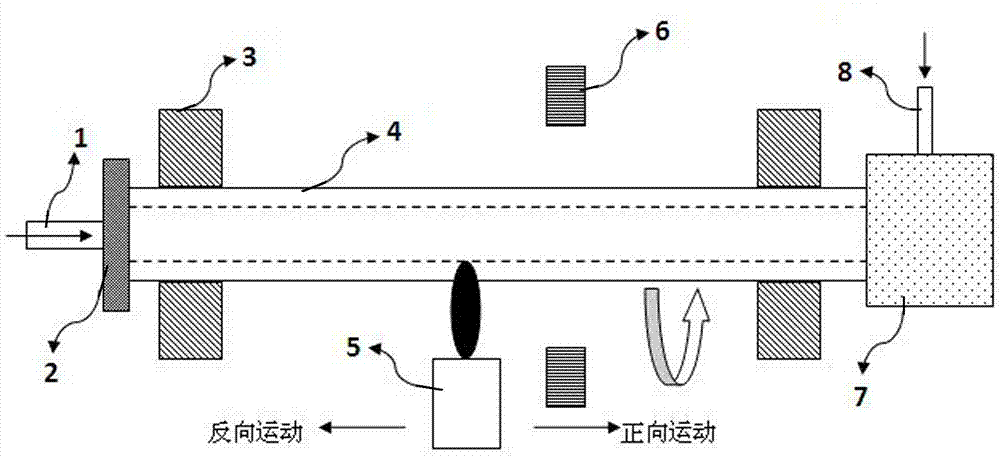

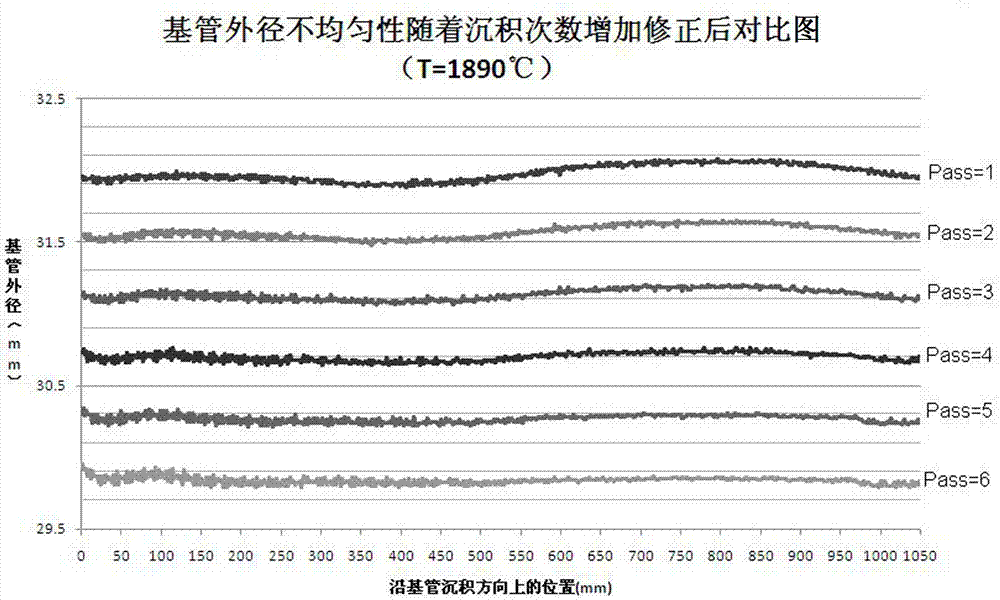

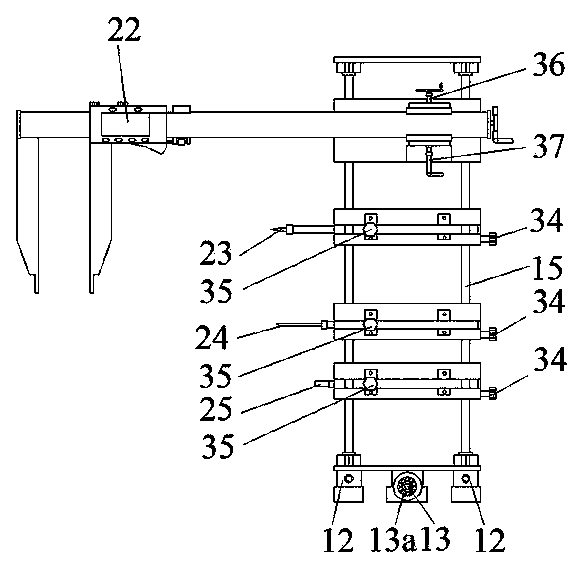

Device for manufacturing prefabricated optical fiber core rod based on base pipe outer diameter maintaining and correcting control and method for manufacturing prefabricated optical fiber core rod by device

ActiveCN103922579AReduce or even eliminate hydroxyl contentReduce biasGlass making apparatusGas phaseNitrogen

The invention relates to a device for manufacturing a prefabricated optical fiber core rod based on base pipe outer diameter maintaining and correcting control and a method for manufacturing the prefabricated optical fiber core rod by the device. In an improved chemical vapor deposition process, the correction of the axial outer diameter change and the maintenance of the outer diameter uniformity and the roundness of a base pipe are realized by controlling the outer diameter of the base pipe during deposition at the high temperature, so that the uniformity of the axial and radial deposition rates is ensured, and the manufactured core rod and a drawn optical fiber have uniform radial and axial geometric characteristics and refractivity profiles. The device comprises a raw material feeding pipeline, a rotary connector, a chuck, a quartz base pipe, an oxyhydrogen flame blow lamp, an outer diameter measurement instrument, a waste residue collection box and a nitrogen pipeline, wherein the raw material feeding pipeline is connected with the rotary connector and is mounted in the quartz base pipe on the chuck of a lathe during chemical vapor deposition; the outer diameter measurement instrument is mounted on a base of the oxyhydrogen flame blow lamp; the waste residue collection box is mounted at the tail end of the chuck of the lathe during chemical vapor deposition; the nitrogen pipeline is connected to the waste residue collection box.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +1

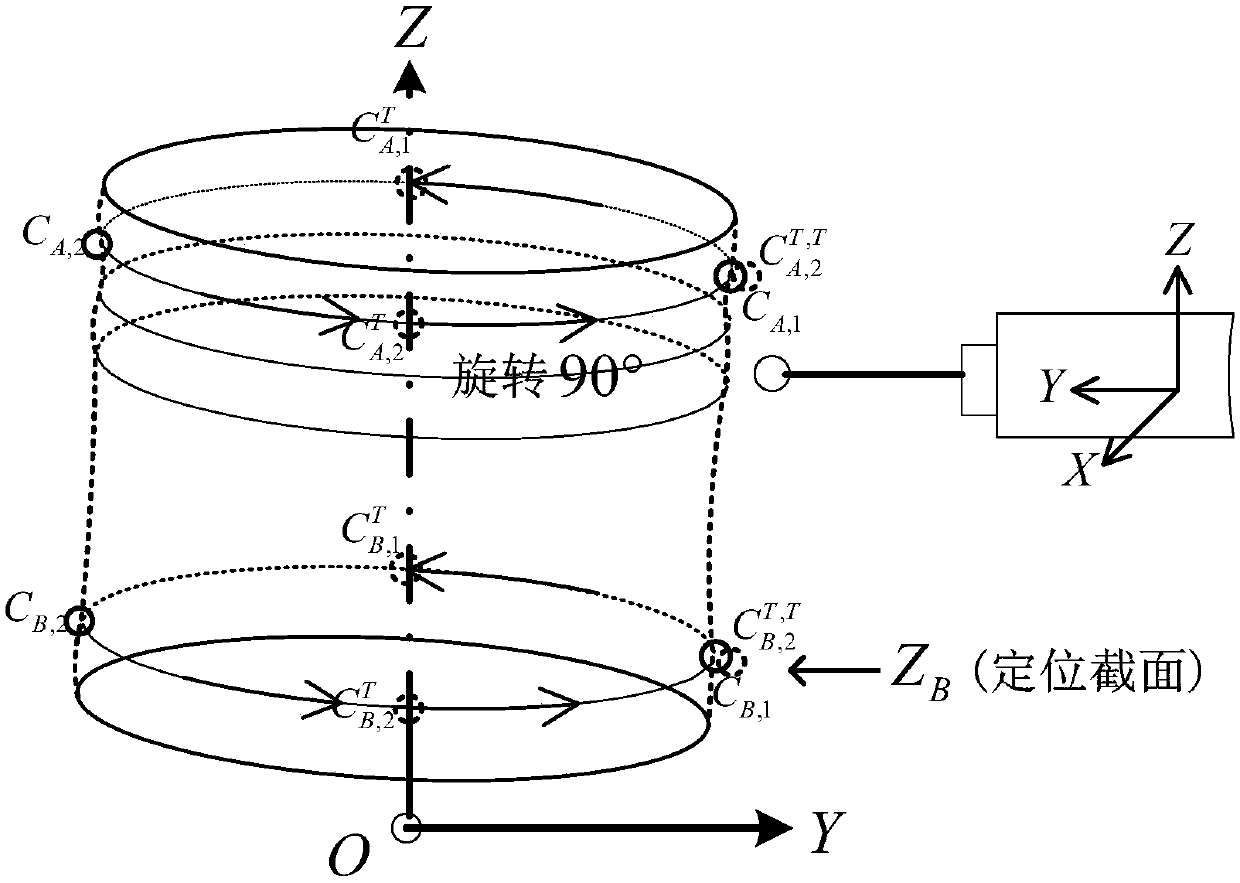

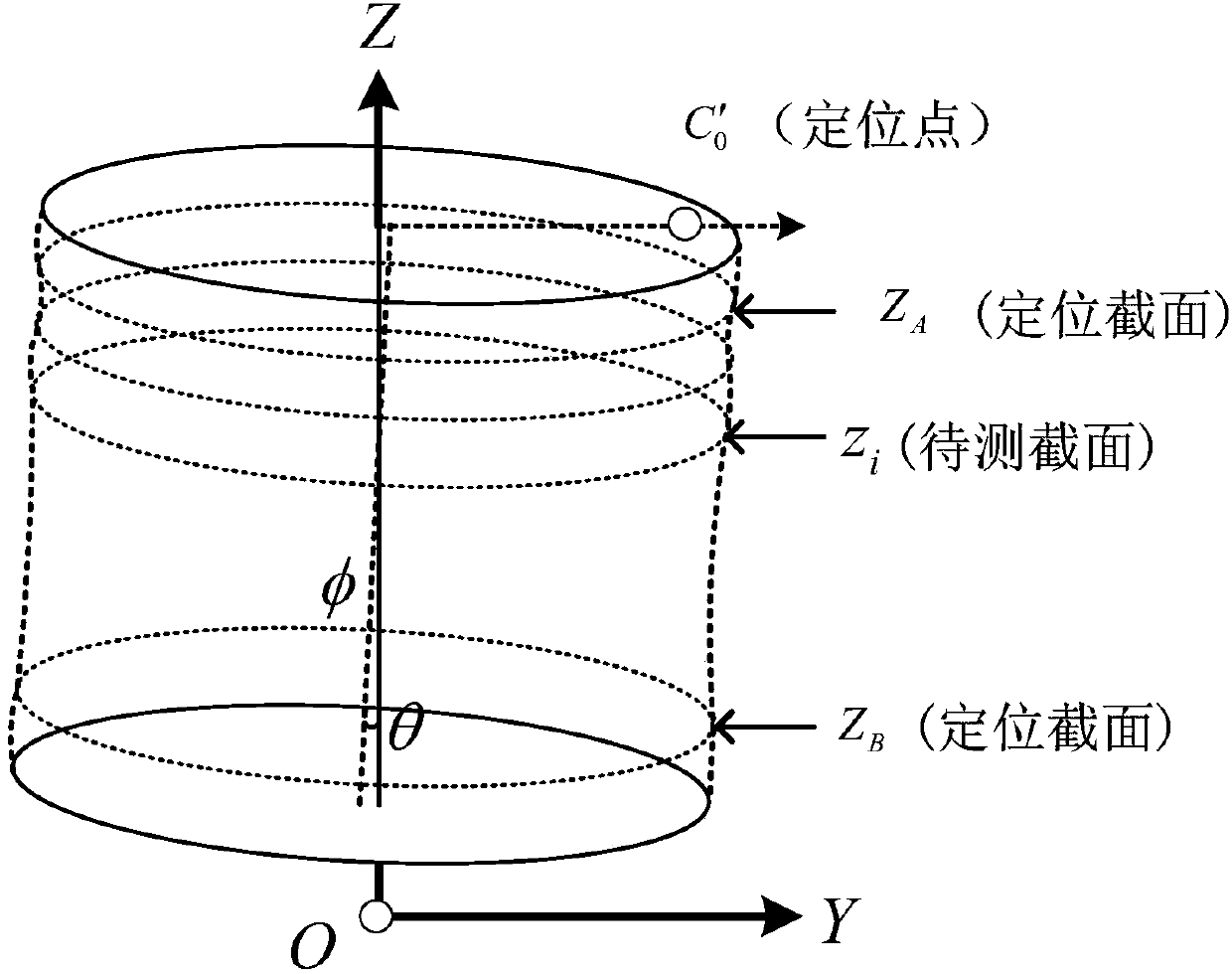

Axial line correction method of cylindrical workpiece and diameter measurement method of sectioned section of cylindrical workpiece

ActiveCN107560583AShorten positioning timeHigh measurement accuracyMeasurement devicesGeometric relationsEngineering

The present invention relates to an axial line correction method of a cylindrical workpiece. According to the method, the spatial relative position of the workpiece under a measurement coordinate system is determined based on the design of the reference point C0 of the end surface of the workpiece; the first correction deltax and deltay of the deviation of a positioning section ZA and a positioning section ZB of the workpiece on an X axis and a Y axis are realized through using two groups of symmetrically-correlated compensation points on the positioning section ZA and the positioning sectionZB of the workpiece; the outlines of the positioning section ZA and the positioning section ZB are resampled, so that sampling points are obtained, a center point O'A and a center point O'B are obtained through fitting calculation; with a straight line determined by the center point O'A and the center point O'B adopted as a reference axis phi of the cylindrical workpiece, a geometric relationshipwith the reference point C0 is built and is solved; and the calibration and correction of a relative deviation angle theta between the reference axis phi and the Z axis of the measurement coordinate system are realized. The present invention also provides a diameter measurement method of the sectioned section of a cylindrical workpiece. According to the diameter measurement method, a geometric relationship between the correction values deltax and deltay of positioning sections and a measured section is built; linear compensation values deltaxi and deltayi are obtained; the coordinates of a probe relative to a sampling point are calculated; integrated and automatic sampling on the outline of the measured section is realized; and a spatial projection and fitting algorithm is adopted to process sampling data to obtain the quantity value of the measured section.

Owner:CHONGQING ACAD OF METROLOGY & QUALITY INST

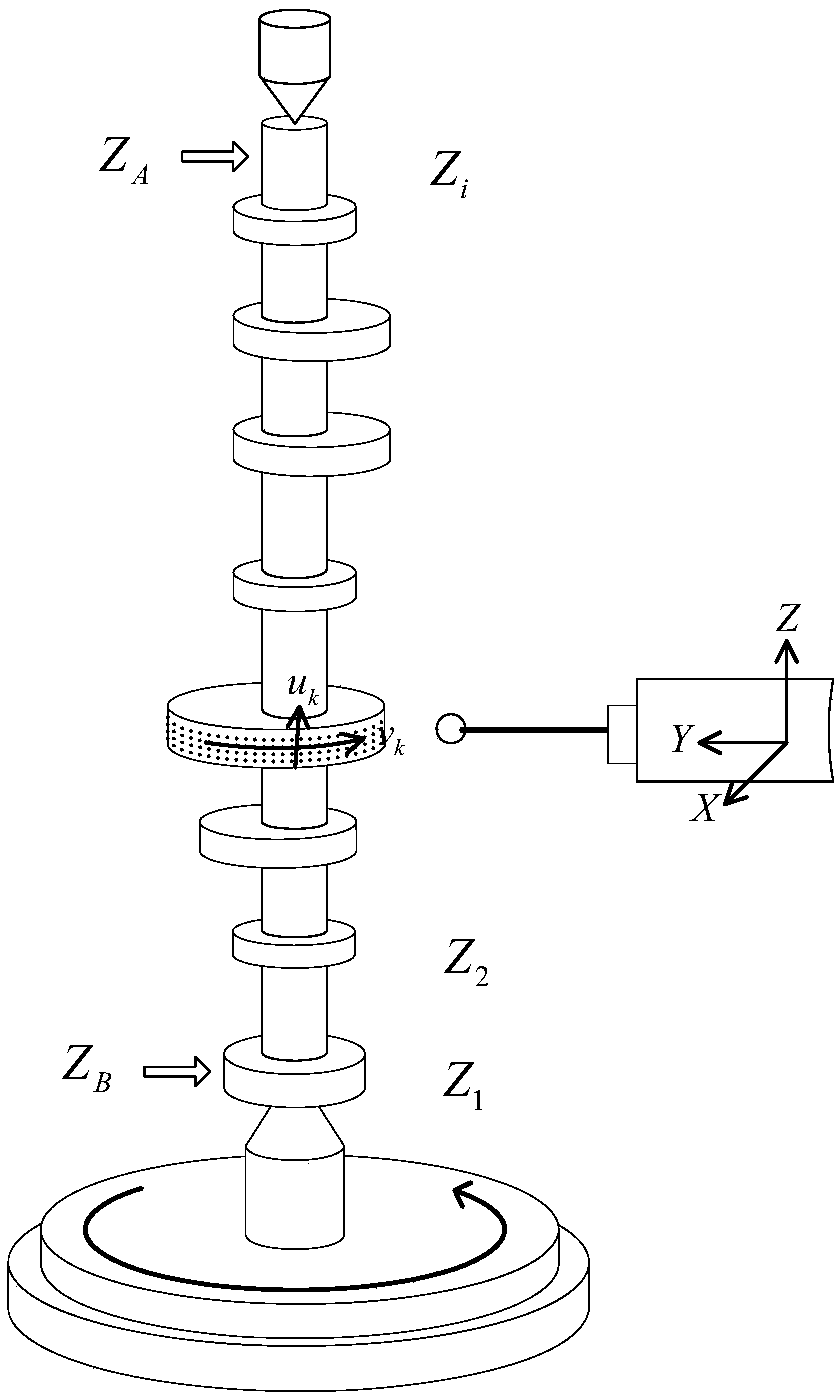

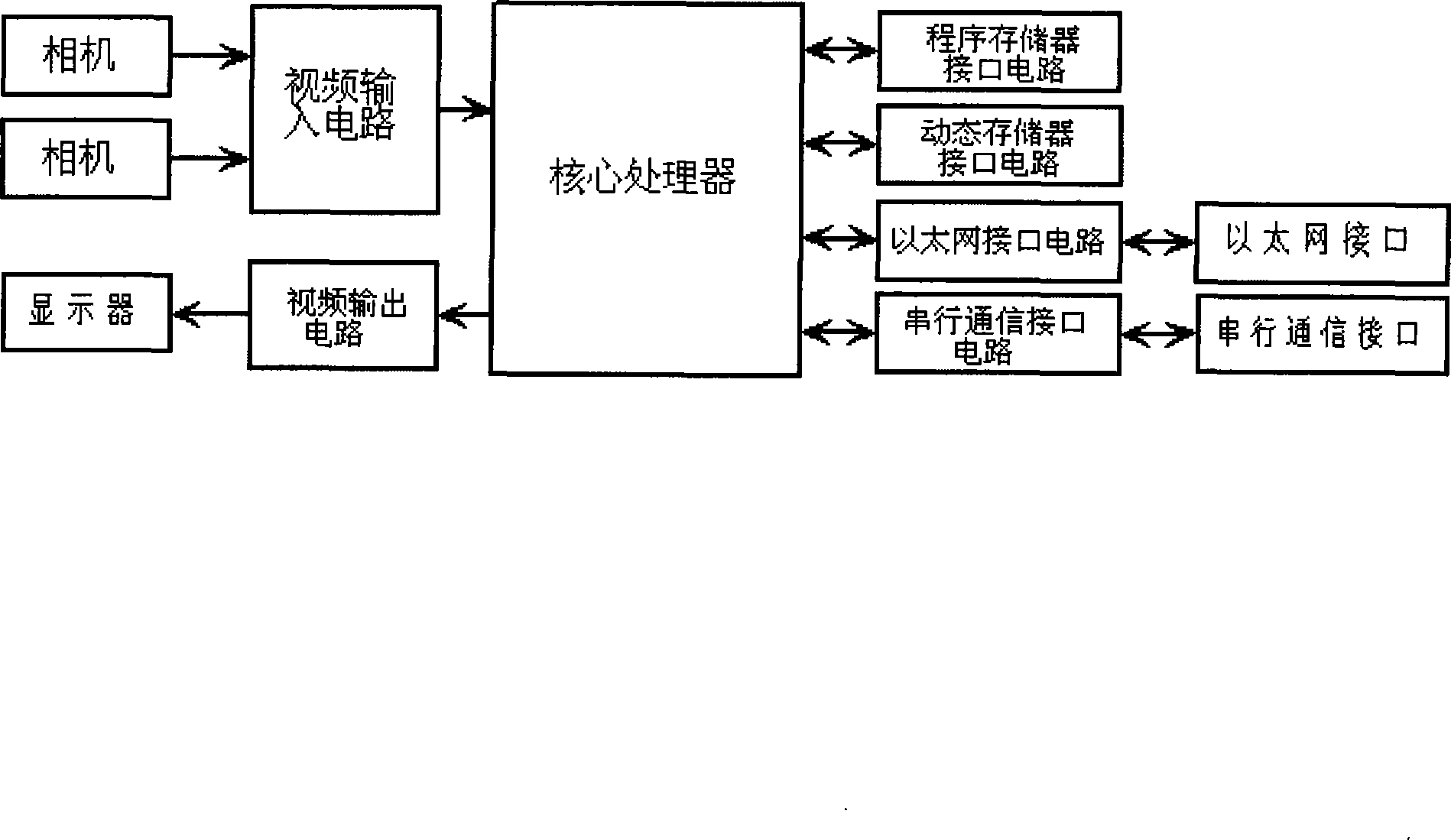

Method for measuring double-camera straight-pulling monocrystal diameter based on digital signal processor

ActiveCN101226050ALow costHigh speedPicture taking arrangementsUsing optical meansDigital signal processingData compression

The invention discloses a two-camera diameter measurement method for Czochralski crystal based on a digital signal processor, which comprises a plurality of steps: collect the image at the stages of crystal growth and equi-diameter by adopting standard industrial double CCD camera; carry on the processes of edge detection, noise removal, data fitting, data filtering and data compression for the image information by utilizing a core processor with embedded structure based on DSP to realize the precise measurement on the diameter of monocrystalline silicon rod; finally, communicate the measurement radius and compressed image information with a host computer through the Ethernet interface and TCP / IP protocol. The two-camera diameter measurement method for Czochralski crystal based on a digital signal processor has the advantages that by utilizing the core processor with embedded structure, the measurement method has high reliability and no host machine resources are occupied; by adopting standard industrial double CCD camera to process the diameters at different stages respectively, the measurement method has high accuracy and low cost; by adopting the techniques of complex edge detection, noise removal, least squares fitting, extreme value filtering, data compression and algorithm level optimization, the measurement method has strong function, high accuracy and fast speed.

Owner:XIAN ESWIN MATERIAL TECH CO LTD +1

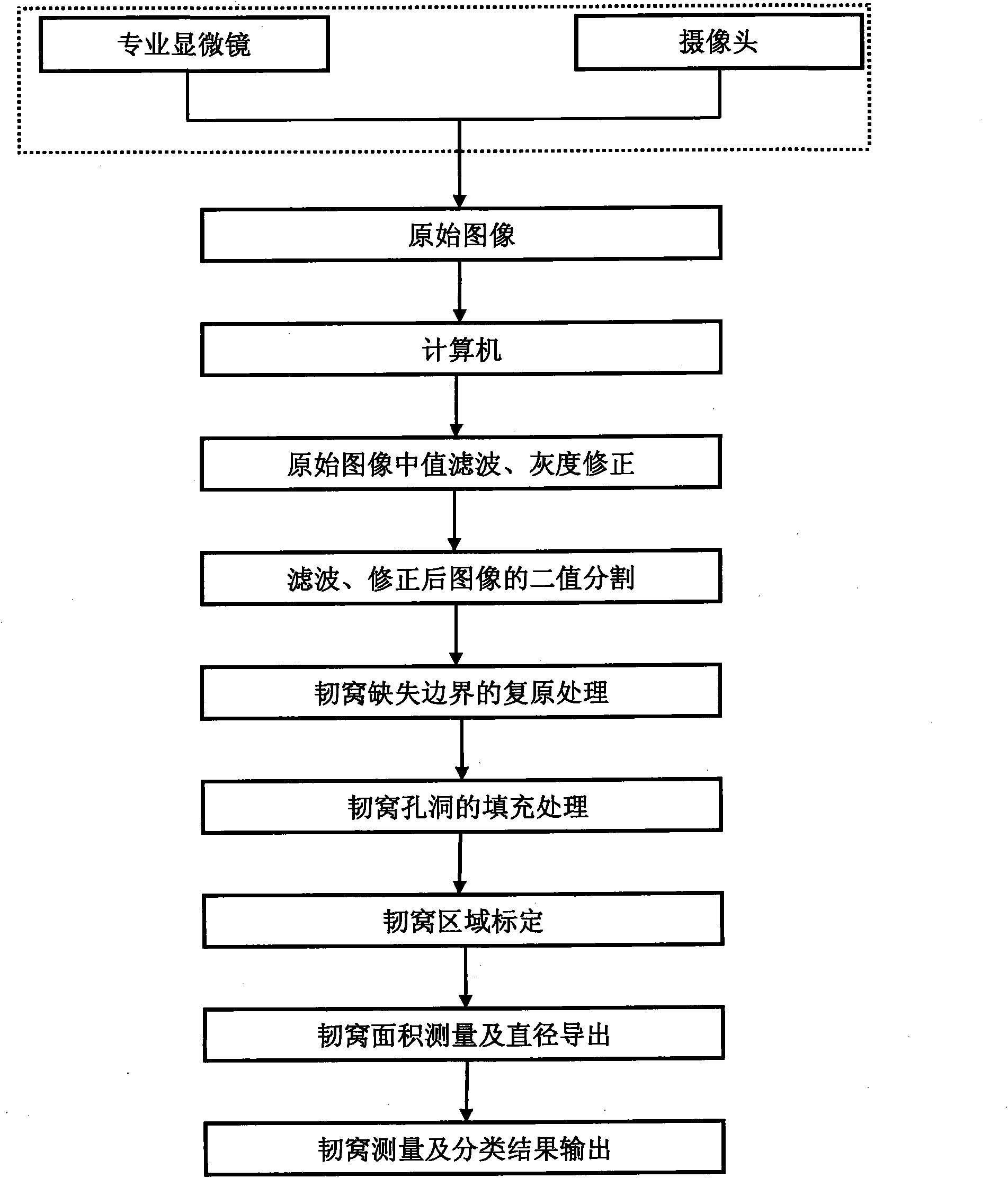

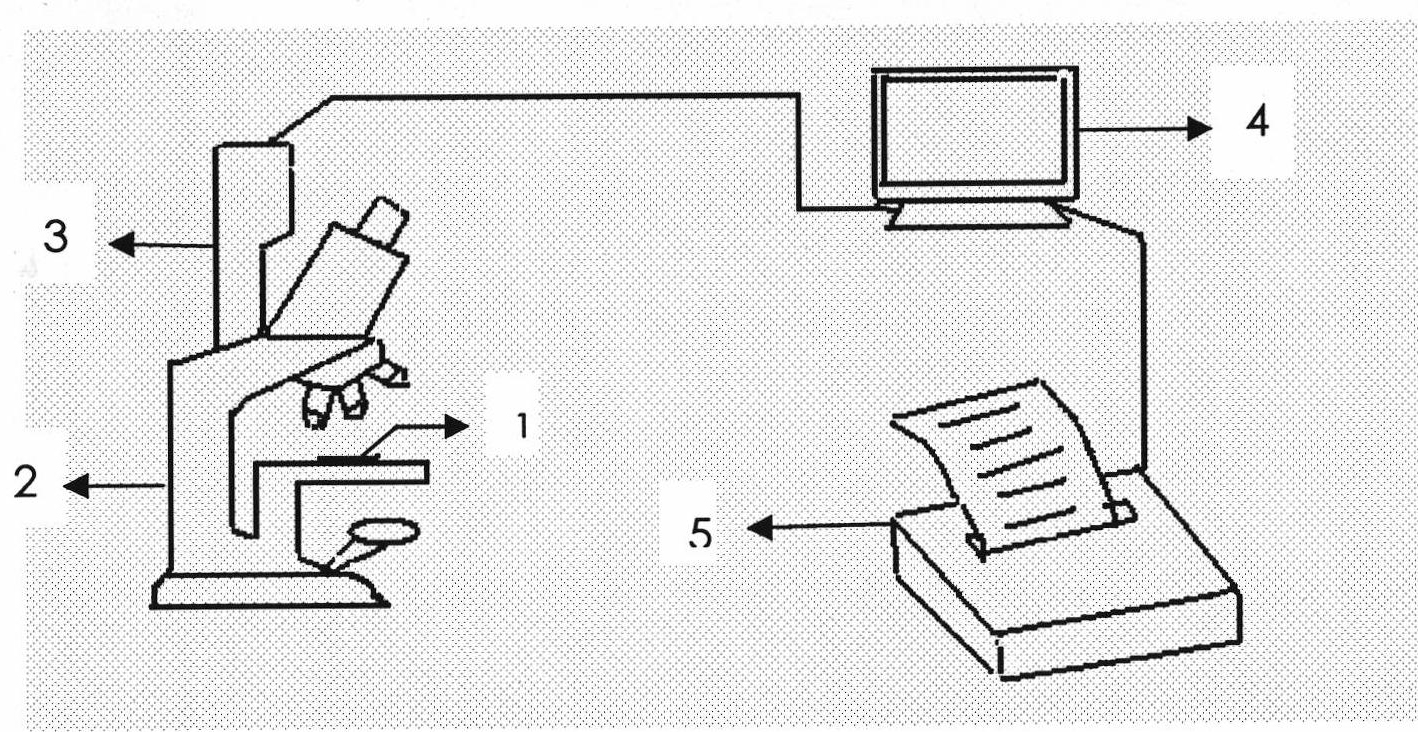

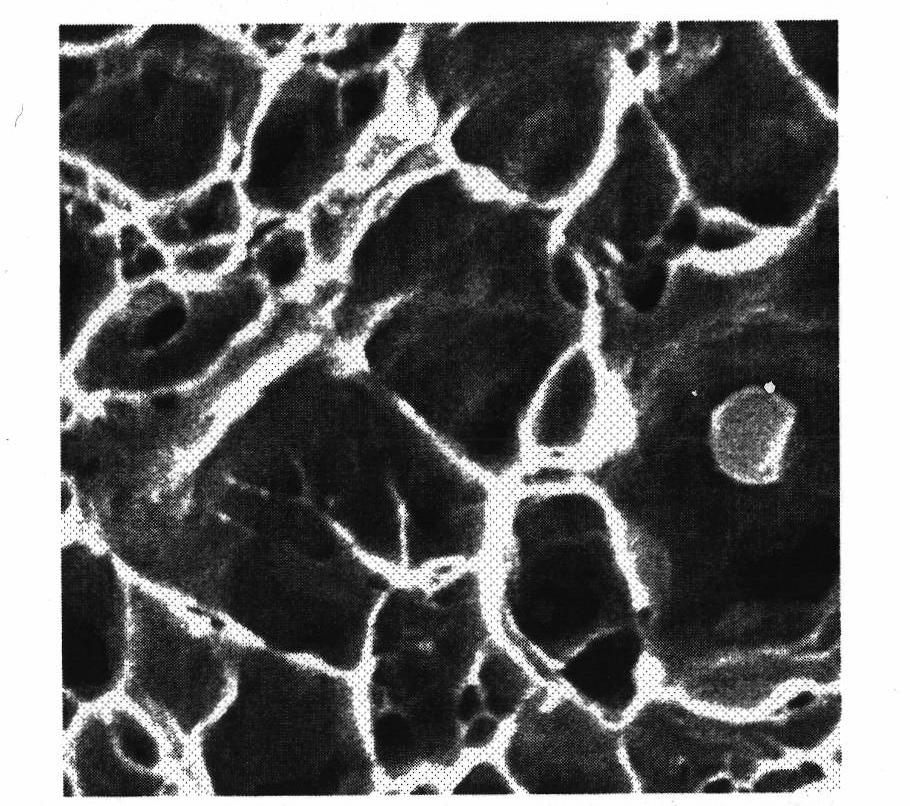

Method and device for automatically restoring, measuring and classifying steel dimple images

InactiveCN101782526AAchieve separationPreserve edge informationImage enhancementImage analysisNoise removalGray level

The invention relates to a method and a device for automatically restoring, measuring and classifying steel dimple images. The device comprises an image acquiring system, an image pretreating part, an image restoring part, an image analyzing part, etc. The image pretreating part is used for performing median filter noise removal and gray level correction on original images acquired by the image acquiring system; the image restoring part is used for performing binary segmentation by using an adaptive fuzzy threshold valve method; boundary deletion and holes in the obtained binary images are processed respectively by using an ultra-erosion and layer-by-layer expansion method and an improved scanning line seed filling algorithm; the image analyzing part is used for performing region calibration on the processed images and setting the dimple diameter as the diameter of the minimum circumcircle of the dimple; and a random dimple region area algorithm is used to measure the dimple area so as to obtain the dimple diameter. After measurement, the measured classification results are output. The invention has the advantages of accuracy, efficiency and convenience, and can be popularized and applied in fracture measurement, analysis and classification with complex backgrounds and shapes in the material filed.

Owner:JIANGSU UNIV

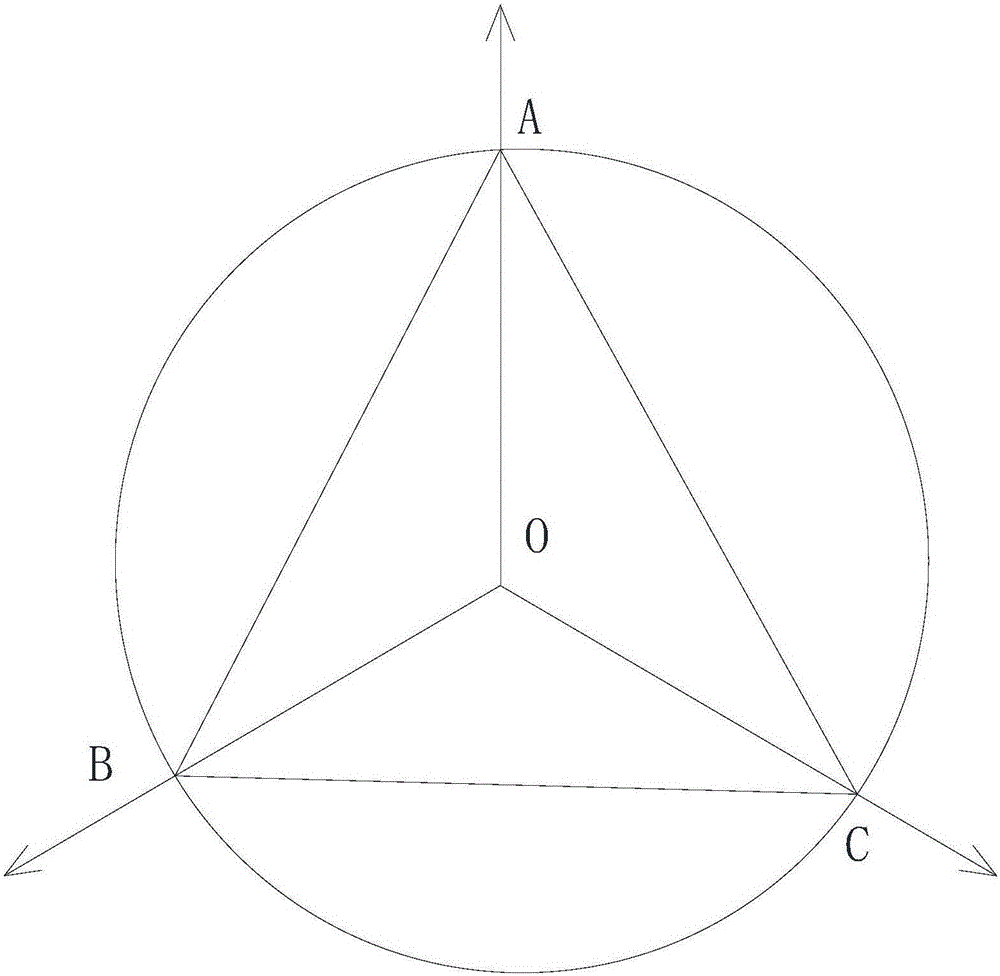

Device and method for detecting wheel diameter of urban rail vehicle through sensors installed on arc in normal direction

ActiveCN103591899ARealize online non-contact measurementHigh measurement accuracyUsing optical meansLight beamEngineering

The invention discloses a device and method for detecting the wheel diameter of an urban rail vehicle through sensors installed on an arc in the normal direction. The device comprises a central processing unit and the plurality of laser sensors connected with the central processing unit. The portion, in a detection section, of a steel rail deflects outward, and a protective rail is arranged inside the portion, in the detection section, of the steel rail. The laser sensors are arranged between an area emptied due to deflection of the steel rail and the protective rail, are arrayed in the direction of the steel rail, and are evenly distributed on the arc with the fixed chord length radius, a probe of each laser sensor conducts measurement in the normal direction of the arc, a detection light beam is aligned with the circle center of the installation arc, and all the laser sensors are located below wheels and in the same plane with wheel circumferences undergoing diameter measurement. The multiple laser sensors are used in the method and arranged below the wheels according to the arc normal relation to simultaneously detect the wheels so that detection points can be obtained, least square fitting is conducted so that initial diameters can be obtained, and the initial diameters are averaged so that the wheel diameter can be obtained. When online non-contact type measurement is conducted, the device and method has the advantages of being high in speed, high in accuracy and large in measurement diameter range.

Owner:NANJING UNIV OF SCI & TECH

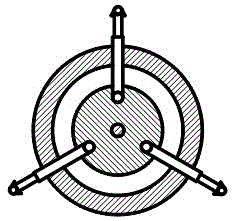

Three-jaw centering internal diameter measurement device and measurement method

ActiveCN106705801AEasy clampingSimplify your measurement workMechanical counters/curvatures measurementsMechanical diameter measurementsEngineeringDiameter measurement

The invention discloses a three-jaw centering internal diameter measurement device and measurement method. The device comprises a cylinder, a plurality of measurement assembly and a driving apparatus. Each measurement assembly comprises a support, a measurement small wheel, a soft spring, a hard spring, a measurement end press rod, a press sheet, a sensor, a press sheet rod and a support rod. The sensor is arranged on the inner side wall of the cylinder; the hard spring, the press sheet, the soft spring and the support are connected in sequence; the hard spring is fixedly arranged on the outer side wall of the cylinder; and the support is movably equipped with the measurement small wheel. One end of the measurement end press rod passes through the hard spring, the press sheet and the soft spring and is fixed to the support, and the other end thereof is a free end, and can pass through the cylinder and extend into the sensor when the soft spring and / or hard spring are / is compressed. One end of the press rod is fixedly arranged on the press sheet, and the other end thereof is fixedly arranged on the outer side wall of the cylinder through the support rod. The driving apparatus comprises a press tube, a stepping press device and a locating shaft. The locating shaft is arranged coaxially with a center shaft of the cylinder; and the press tube is fixedly arranged on the locating shaft and is corresponding to the plurality of press sheet rods.

Owner:HEFEI UNIV OF TECH

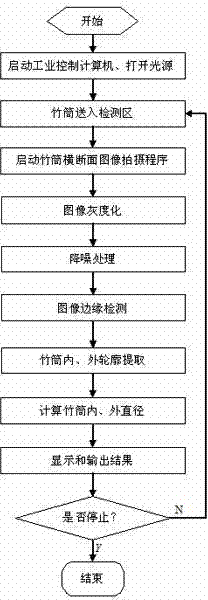

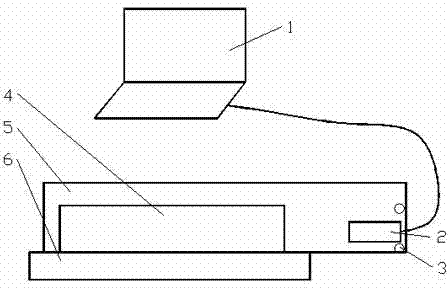

Method and device for measuring bamboo tube diameter based on digital image processing technology

InactiveCN102269571ADistortion and deformation are smallEasy to realize processing automationUsing optical meansImaging processingMaximum diameter

The invention relates to a method and device for measuring the diameter of a bamboo tube based on digital image processing technology. It uses an industrial camera to collect a digital image of the cross-section of the bamboo tube, and automatically processes it through an image processing program to measure the maximum outer diameter, the smallest outer diameter, and the minimum outer diameter of the bamboo tube. Average outer diameter, maximum inner diameter, smallest inner diameter and average inner diameter, and display the measurement results. Because the present invention adopts the industrial camera perpendicular to the bamboo tube cross-section to collect the bamboo tube cross-sectional image, the image distortion is small and the precision is high; through the automatic processing and measurement of the digital image processing program designed, the measurement accuracy can be improved by increasing the number of sampling times; non-contact method The method for measuring the diameter of the bamboo tube has high speed and high efficiency, and is convenient for realizing automation of bamboo processing; the invention is simple to realize, has fast measurement speed, is stable and reliable, has detailed diameter parameters and high precision.

Owner:FUJIAN AGRI & FORESTRY UNIV

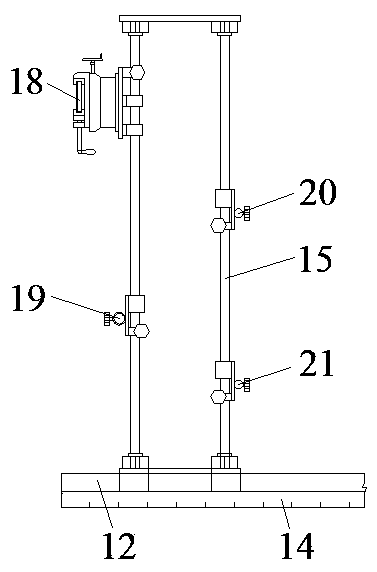

Pipeline geometric size measuring machine

InactiveCN103453823AHigh working reliabilityEasy to operateMechanical counters/curvatures measurementsMechanical diameter measurementsVernier scaleMarking out

The invention discloses a pipeline geometric size measuring machine and belongs to the technical field of measuring equipment. The pipeline geometric size measuring machine comprises a pipeline clamping device, a measuring device and a control box, and the pipeline clamping device, the measuring device and the control box are arranged on an operating platform. The pipeline clamping device is used for supporting a pipeline to be measured through a spindle box mechanism and a tail bracket mechanism. The measuring device is provided with two guide rails on the operating platform, the two guide rails are parallel to the axis of the pipeline clamping device, a measuring framework is driven by a measuring framework driving mechanism to move on the guide rails, and a vernier caliper clamp, an LVDT displacement meter clamp, a hatching pen clamp and a thickness gauge clamp are arranged on the measuring framework. When the pipeline geometric size measuring machine works, the position of the pipeline to be measured and the position of the measuring framework are adjusted electrically or manually, the geometric size of each portion of the pipeline to be measured is measured, or, marking-out is carried out. The pipeline geometric size measuring machine can complete the four operations of marking-out calibration of the pipeline, diameter measurement on any section, thickness measurement on any portion and ellipticity measurement on pipeline sections comprehensively. The pipeline geometric size measuring machine is high in working reliability and convenient to operate, and can improve locating accuracy, enhance measuring effects and improve work efficiency.

Owner:DALIAN UNIV OF TECH

Bearing steel ball sorting equipment capable of automatically measuring diameters

The invention relates to the technical field of bearing production, in particular to bearing steel ball sorting equipment capable of automatically measuring diameters. The bearing steel ball sorting equipment comprises a control cabinet, an automatic feeding mechanism, a differential type inductive-transducer diameter measurement mechanism and an automatic sorting mechanism. Automatic falling of steel balls is achieved through cooperation of a hopper, a steel ball baffle and a photoelectric sensor, a PLC system controls a cylinder to achieve automatic feeding, and a differential type inductive transducer is used for measuring the diameters of the steel balls so as to improve measurement precision. A sorting box is matched with PLC control to achieve automatic graded sorting of the steel balls, and unqualified steel balls are picked out. The automatic measurement and sorting process of the steel balls is achieved through automatic falling, high-precision steel ball diameter measurement through the differential type inductive transducer and the sorting box controlled by a PLC.

Owner:新昌县澄潭镇艺林机械厂

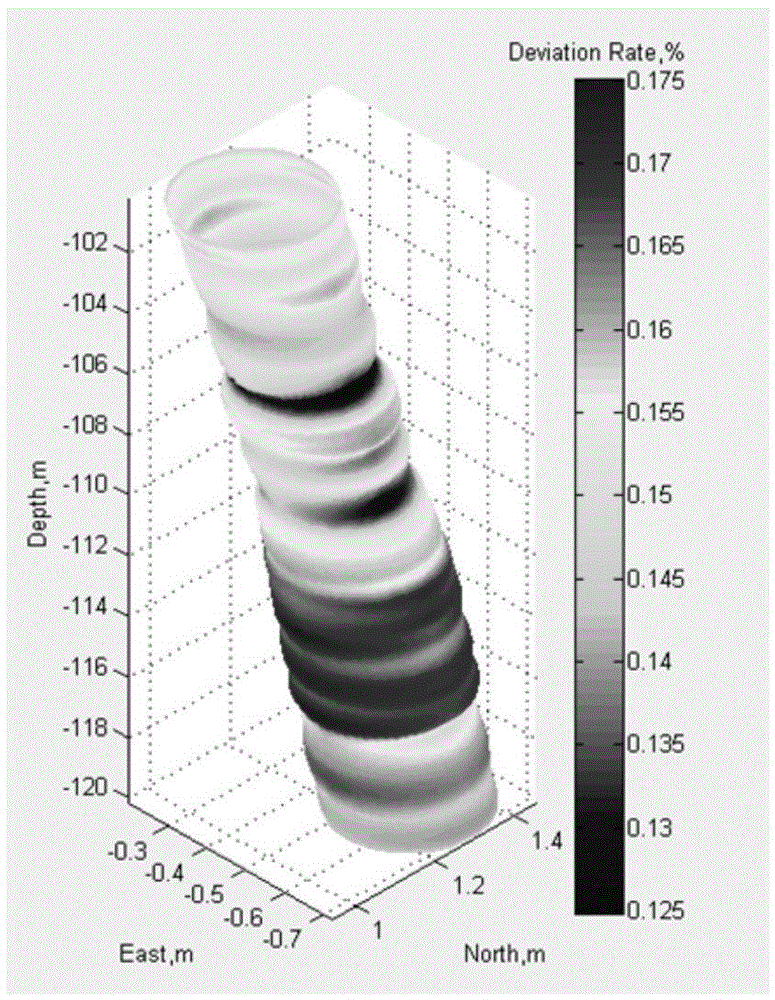

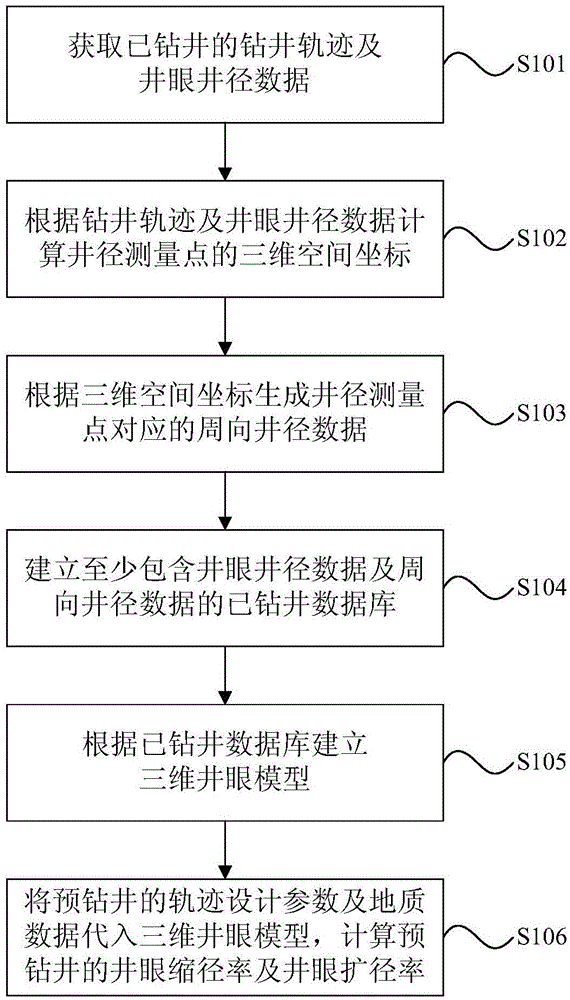

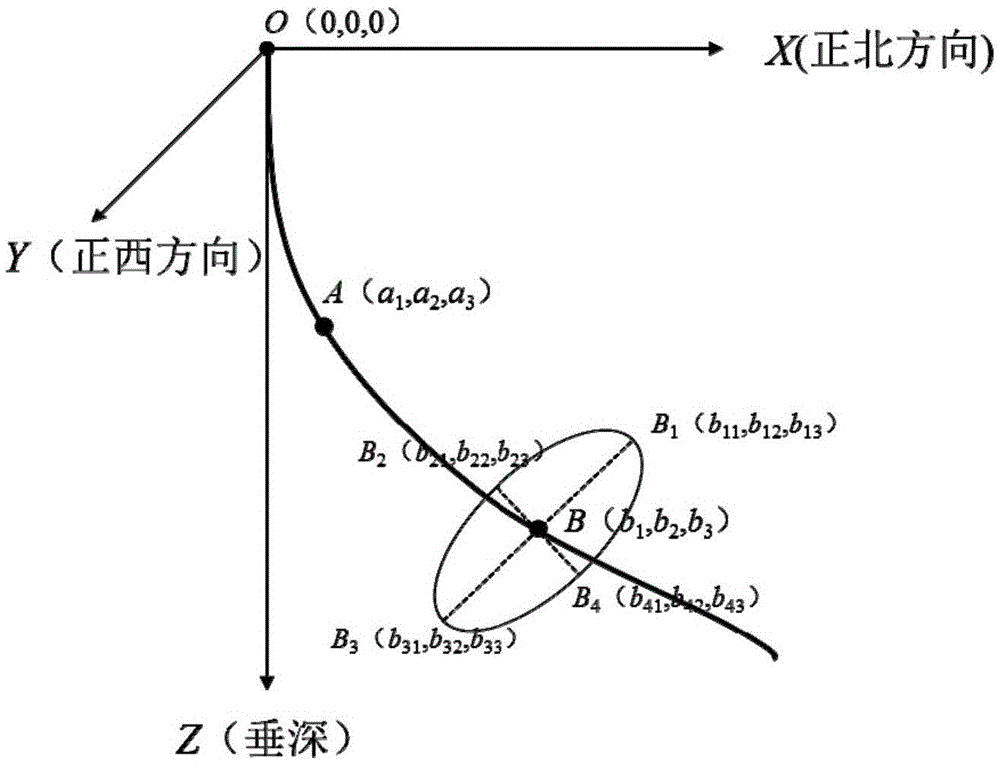

Drilling trajectory design parameter based pre-drilling three-dimensional hole modeling method and apparatus

ActiveCN105550448AAccurately reflectAccurate predictionSurveySpecial data processing applicationsGeomorphologyMeasurement point

The invention provides a drilling trajectory design parameter based pre-drilling three-dimensional hole modeling method and apparatus. The method comprises the steps of obtaining a drilling trajectory and hole diameter data of a drilled well, wherein the drilling trajectory comprises a well depth, an azimuth angle and a hole drift angle of each diameter measurement point; according to the drilling trajectory and the hole diameter data, calculating three-dimensional space coordinates of a hole diameter measurement point; according to the three-dimensional space coordinates, generating circumferential hole diameter data corresponding to the hole diameter measurement point; establishing a drilled well database at least containing the hole diameter data and the circumferential hole diameter data; according to the drilled well database, establishing a three-dimensional hole model; and substituting a pre-drilling trajectory design parameter and geologic data into the three-dimensional hole model to calculate a hole shrinkage rate and a hole diameter expanding rate of pre-drilling. Through the modeling method and apparatus, the hole shrinkage rate and the hole diameter expanding rate of pre-drilling are calculated according to the established three-dimensional hole mathematic model, so that a specific condition of a real hole can be reflected and predicted more accurately and comprehensively, and data support can be provided for hole engineering design work.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com