Bearing steel ball sorting equipment capable of automatically measuring diameters

A technology of automatic measurement and bearing steel balls, which is applied in sorting and other directions, can solve the problems affecting the factory's profit, deviation of measurement results, and reduced work efficiency, and achieve the effect of simple and reasonable design structure, improved work efficiency, and avoiding material jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

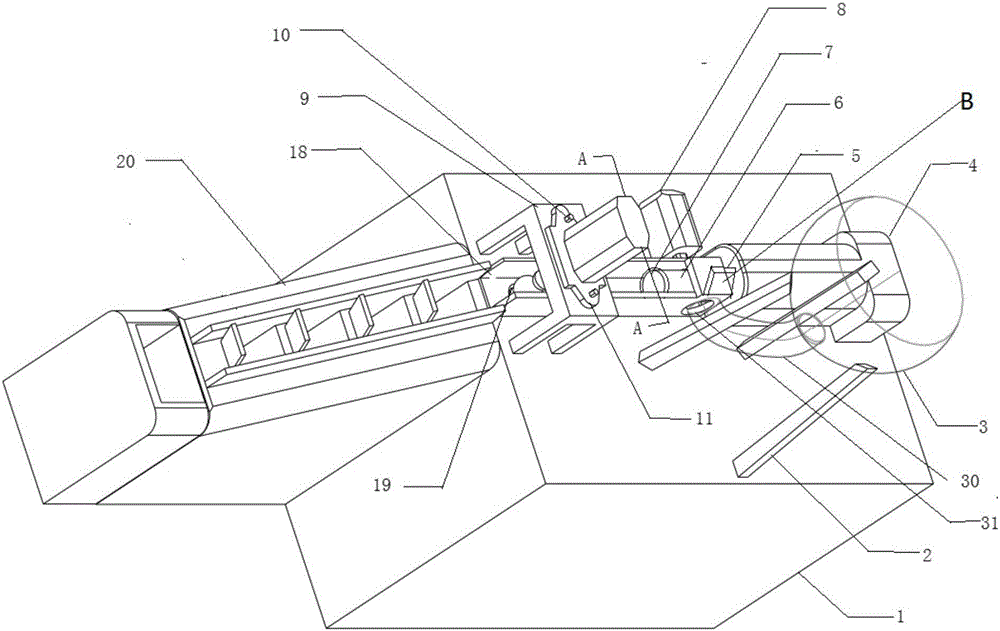

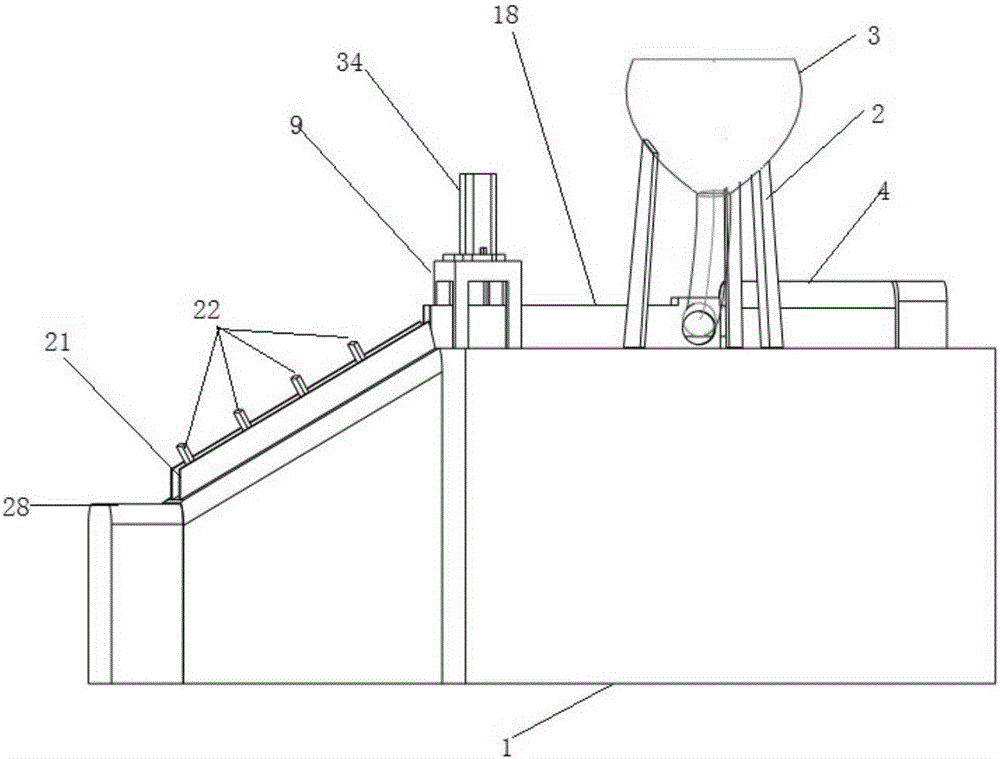

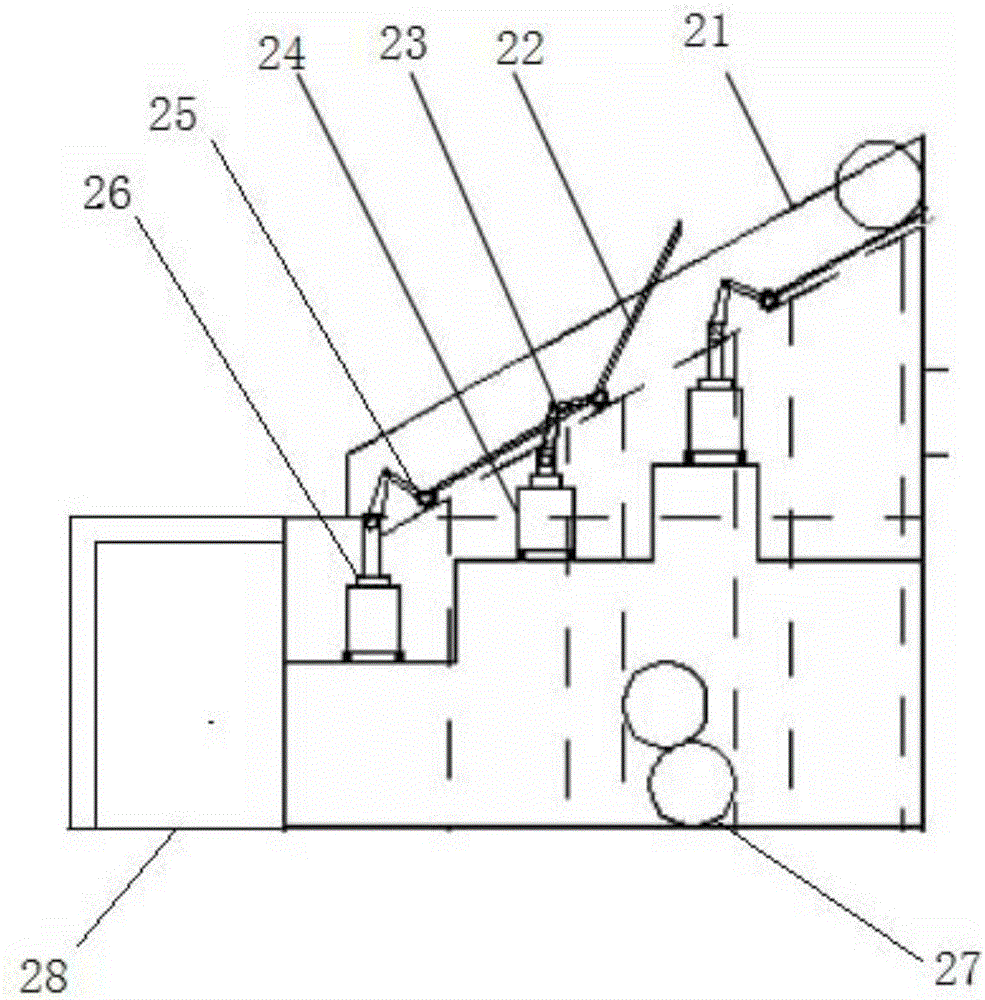

[0018] Specific implementation mode one: combine figure 1 As shown, including control cabinet 1, hopper bracket 2, hopper 3, cylinder 4, steel ball baffle 5, pneumatic cylinder telescopic arm 6, rubber sleeve 7, photoelectric sensor 8, sensor bracket 9, sensor level adjustment seat 10, hexagonal screws 11. A tested steel ball 17, steel ball chute 18, steel ball concave hole 19, steel ball sorting box 20, steel ball slideway 30, slideway connection port 31, baffle electromagnet 32, spring baffle 33 , the inductance sensor 34; the control cabinet 1 is a rectangular shell; the bottom end of the hopper support 2 is welded on one side of the central axis of the top surface of the control cabinet 1; the hopper 3 is a funnel-shaped welded on the top of the hopper support 2; the cylinder 4 is connected by bolts On the central axis of the top surface of the control cabinet 1; the steel ball chute 18 is located at the front end of the cylinder 4, welded on the central axis of the top su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com