Patents

Literature

440results about How to "Avoid material jams" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

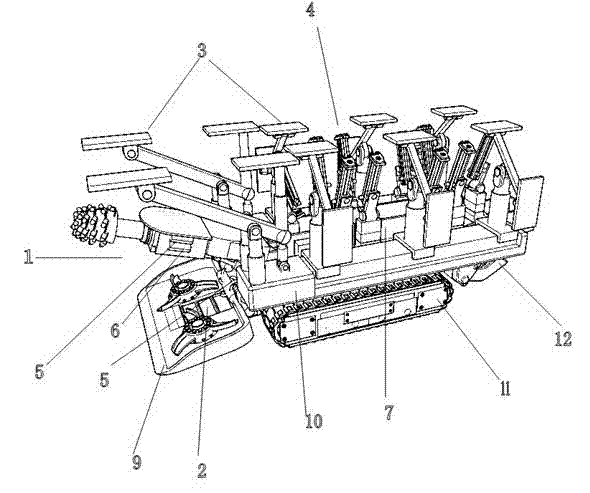

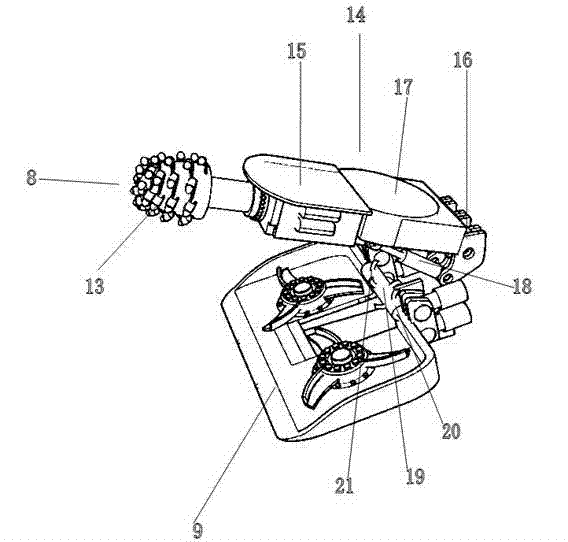

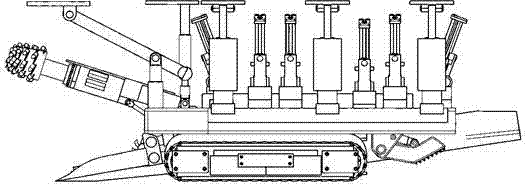

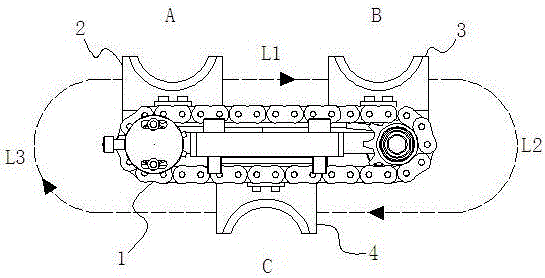

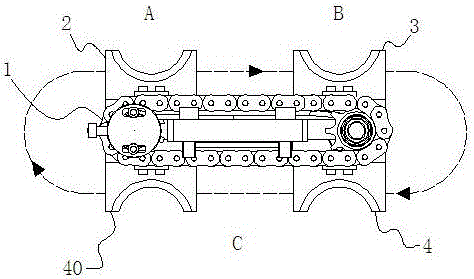

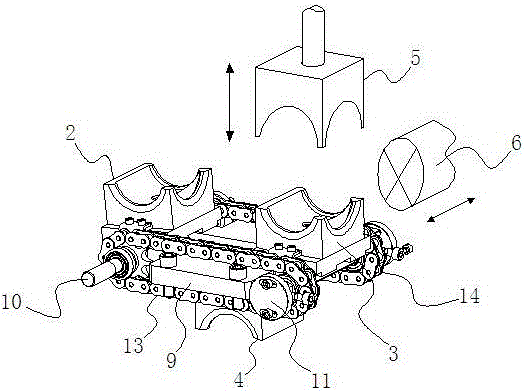

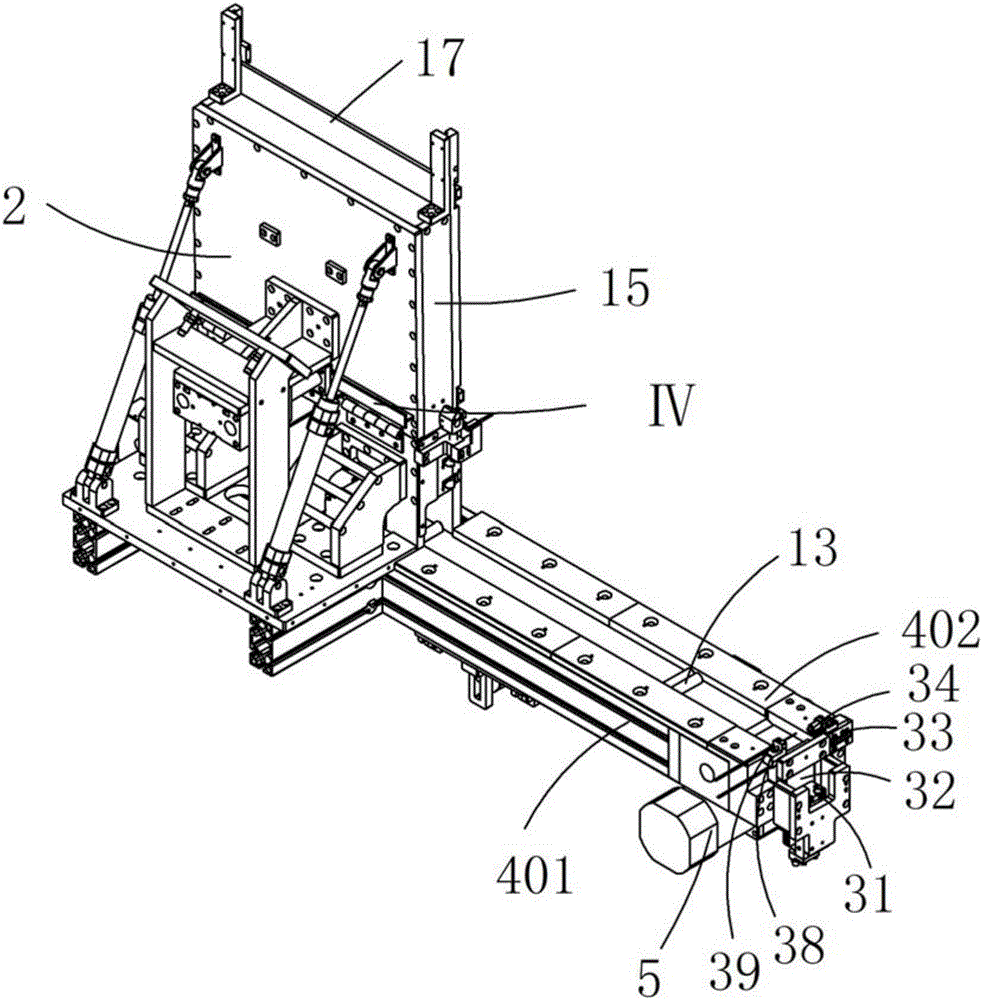

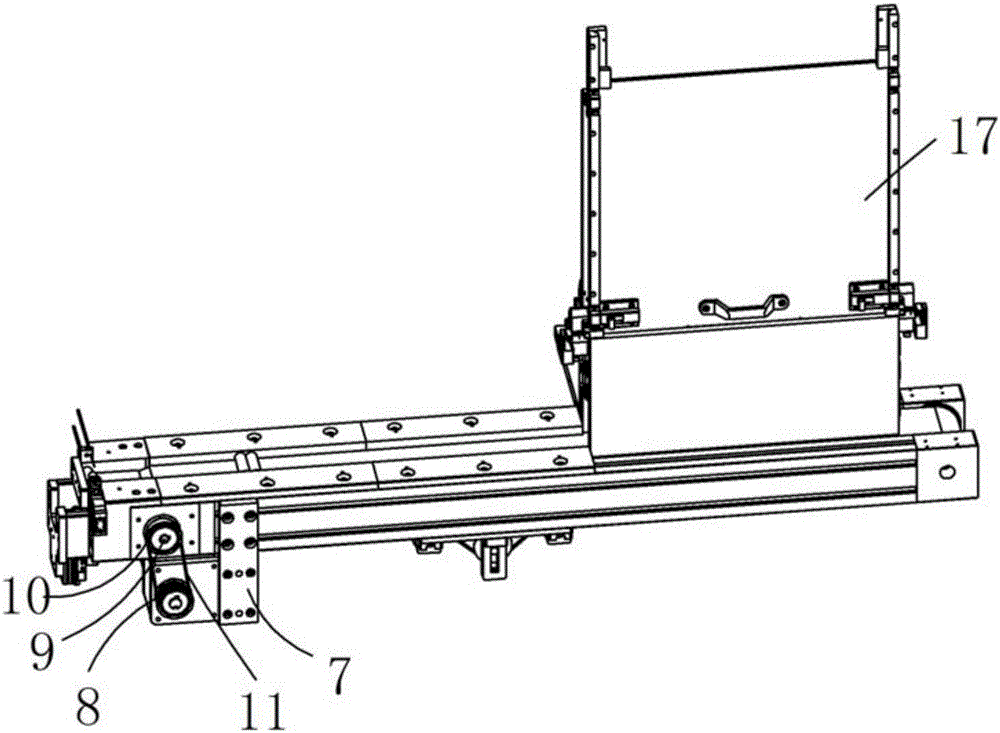

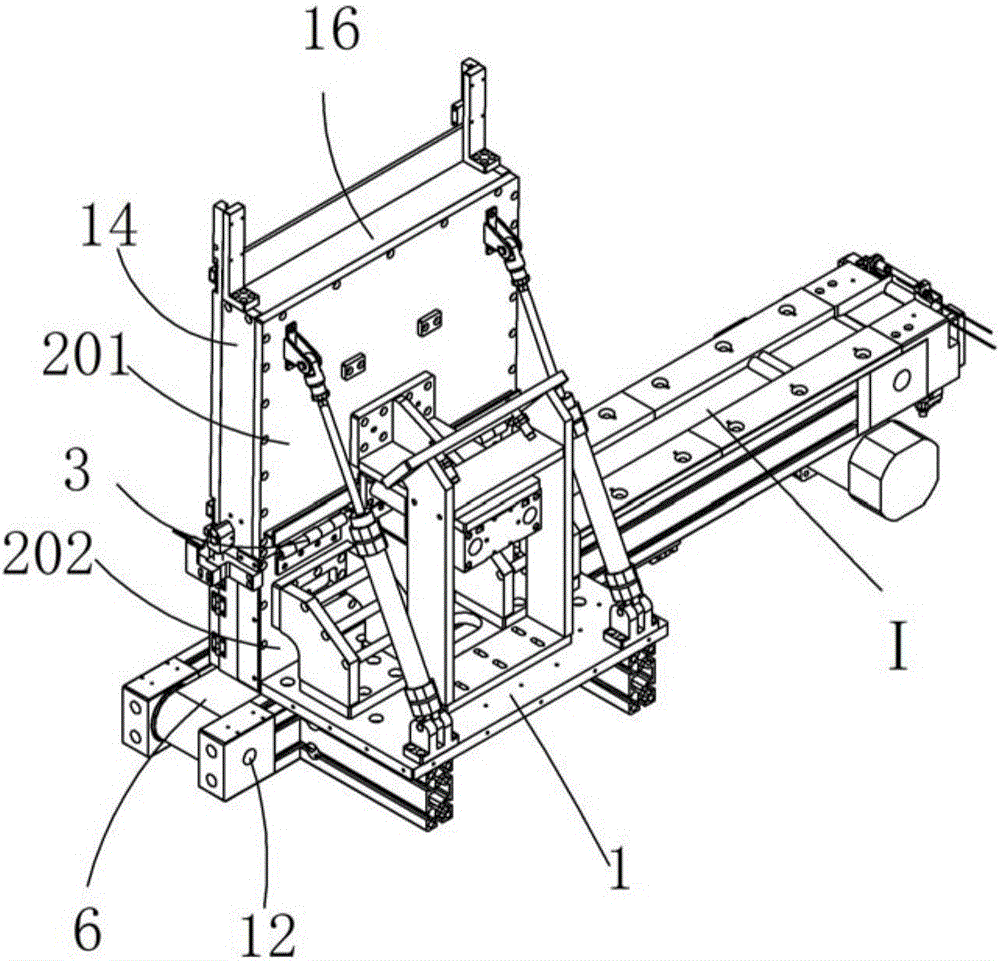

Unmanned roadway driving and anchoring all-in-one machine

InactiveCN104500086AImprove adjustabilityFlexible cuttingMine roof supportsTunnelsSupporting systemControl system

The invention discloses an unmanned roadway driving and anchoring all-in-one machine. The unmanned roadway driving and anchoring all-in-one machine comprises a driving system, a conveying system, a temporary support system, an anchoring system, a driving all-in-one machine water system, a sensing system and an electrical control system. A feed moving roller at the connection portion between a shovel of the driving system and the front end of the conveying system can prevent feed clogging at the shovel and the front end of a scraper conveyor. The temporary support system is uniform in supporting, can move relative to the driving and anchoring all-in-one machine to achieve no-deferring synchronization of driving, supporting and anchoring and can be adapted to the round, uprightly oval, approximately oval or rectangular cross section of a roadway to be applicable to driving and supporting operations of roadways of a variety of ground pressure and directions. The sensing system and the electrical control system of the driving and anchoring all-in-one machine can effectively collect and process information such as, light, distance, humidity and gas and the electrical control system performs automatic or remote manual analysis so as to achieve unattended operations in the working process and greatly improve the safety factor of the operations.

Owner:SHANXI DATONG UNIV

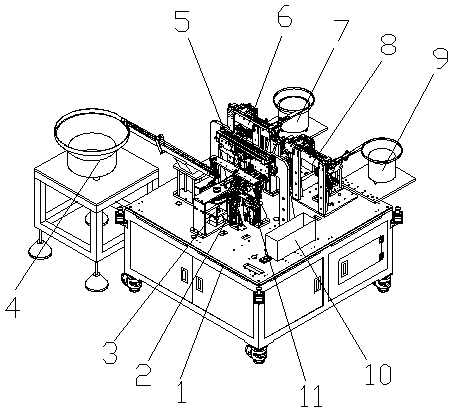

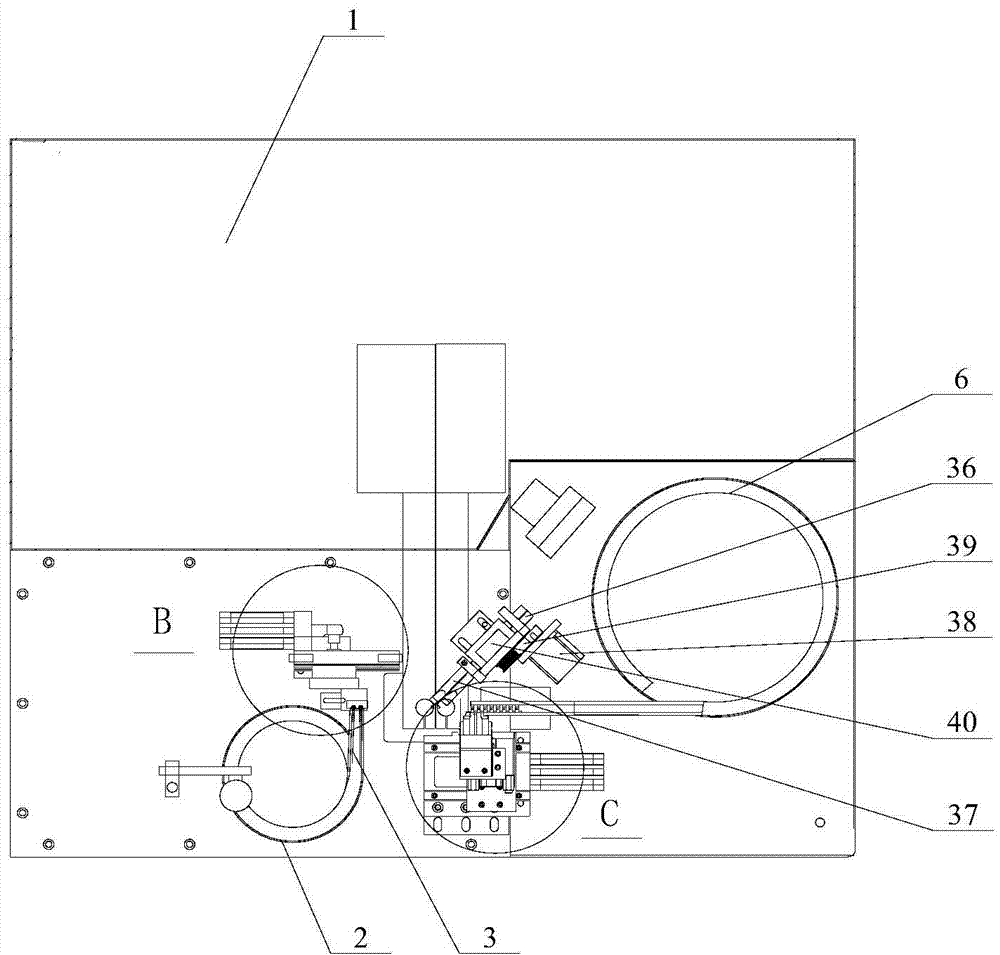

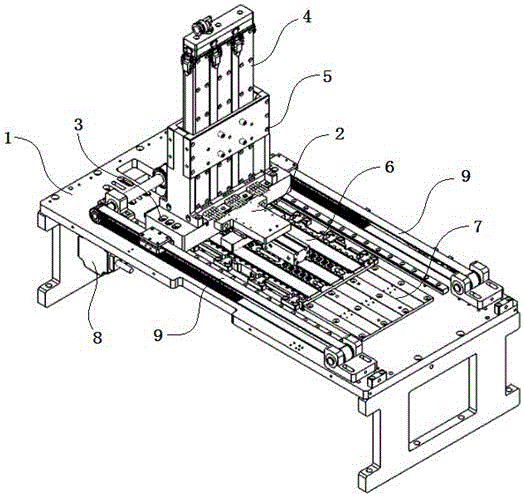

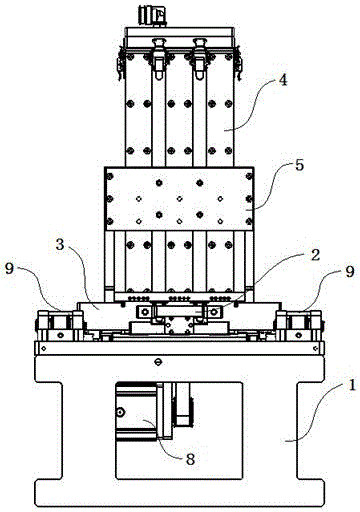

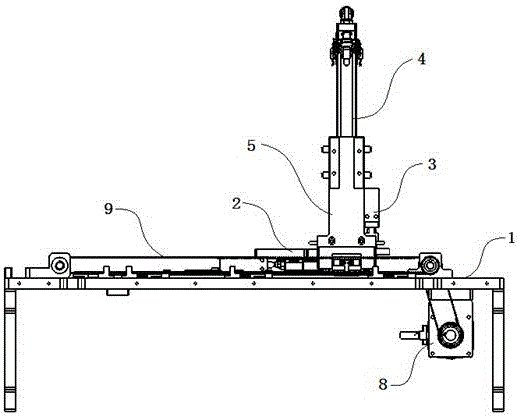

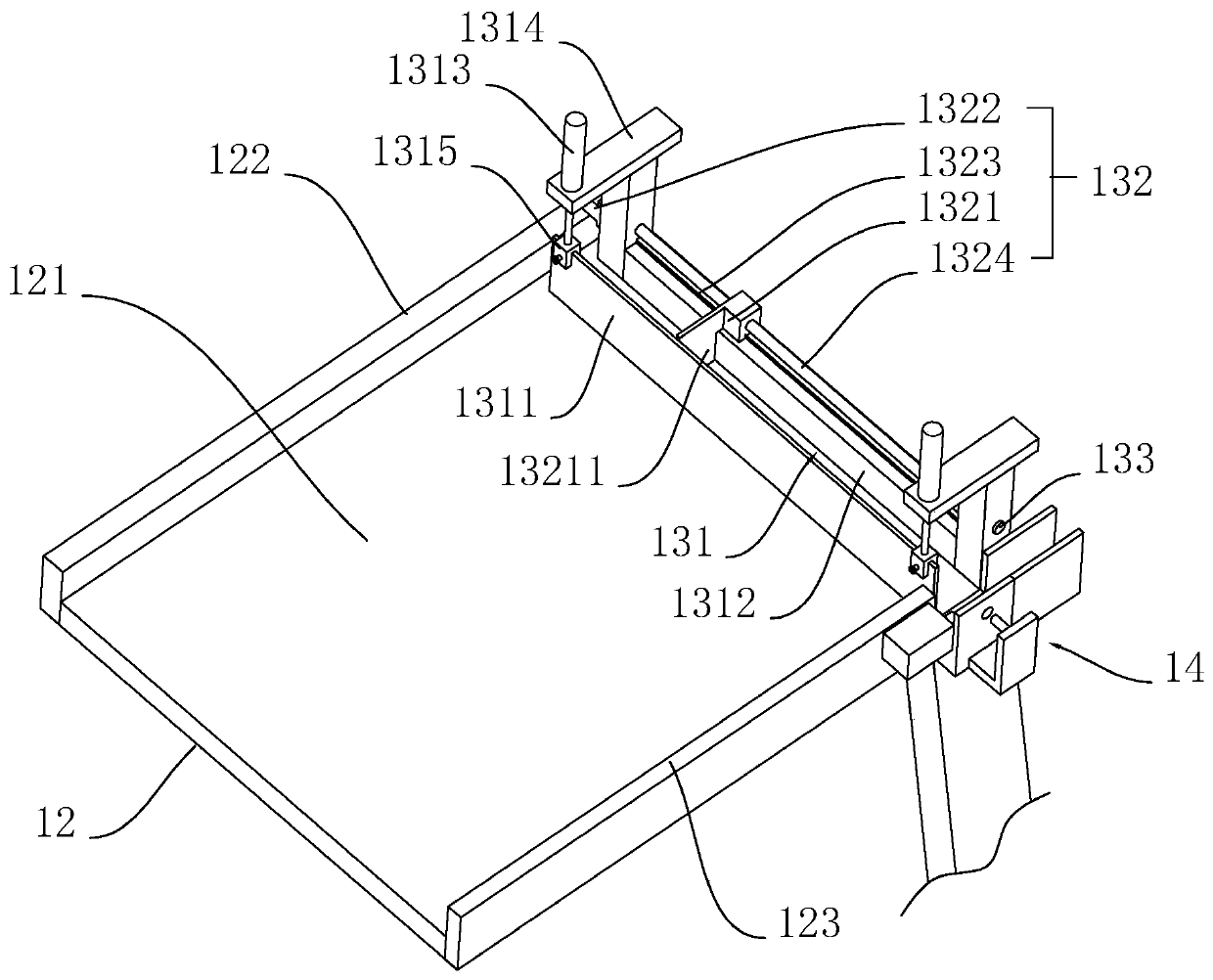

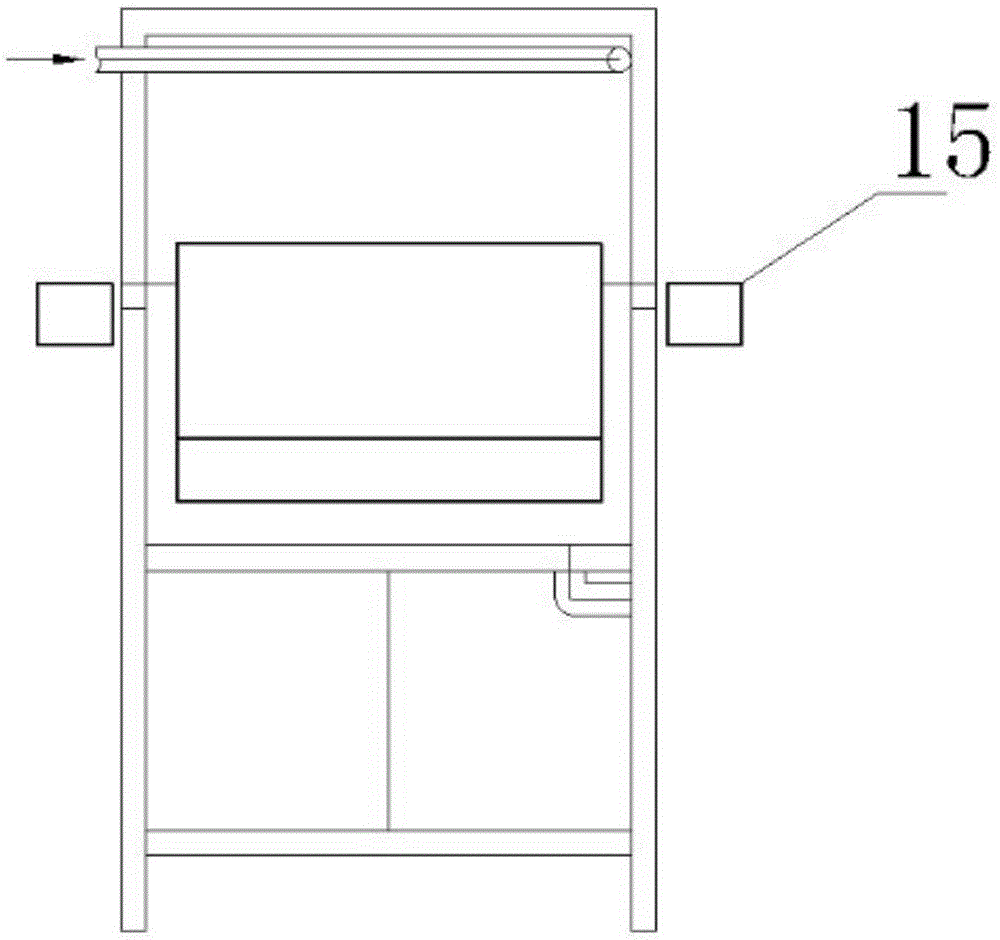

Fully automatic assembling machine for spring fasteners

InactiveCN108390236AQuick and automatic assemblyHigh efficiency of one-time assemblyContact member assembly/disassemblyAssembly machinesDistribution controlMaterial distribution

The invention relates to a fully automatic assembling machine for spring fasteners. The fully automatic assembling machine comprises a rack and a power distribution control box. The rack is provided with a circulation conveying device, a rubber shell feeding device, a fastener feeding device and a spring feeding device, wherein the rubber shell feeding device, the fastener feeding device and the spring feeding device are sequentially arranged on the periphery of the circulation conveying device. The rubber shell feeding device comprises a rubber shell feeding vibration disc disposed on the left front side of the circulation conveying device, and the rubber shell feeding vibration disc is communicated with a rubber shell material distribution block through a rubber shell conveying track; arubber shell conveying manipulator matched with the rubber shell material distribution block is disposed above the circulation conveying device, a rubber shell clamping device is arranged on the portion, below the rubber shell conveying manipulator, of the right front side of the circulation conveying device, and a fastener pushing-in device matched with the circulation conveying device is arranged under the rubber shell clamping device. The circulation conveying device is adopted for feeding and conveying materials, and the fasteners are pushed into insertion holes in a rubber shell from bottom to up through the fastener pushing-in device. The one-time assembling efficiency is high, the operation is convenient, fast and automatic assembly of the spring fasteners is achieved, and the production efficiency is improved.

Owner:DONGGUAN UNIV OF TECH

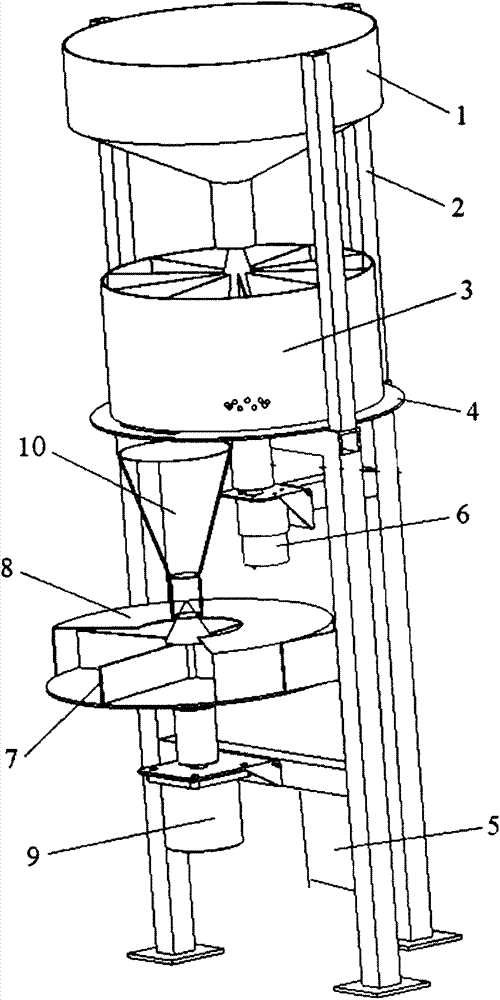

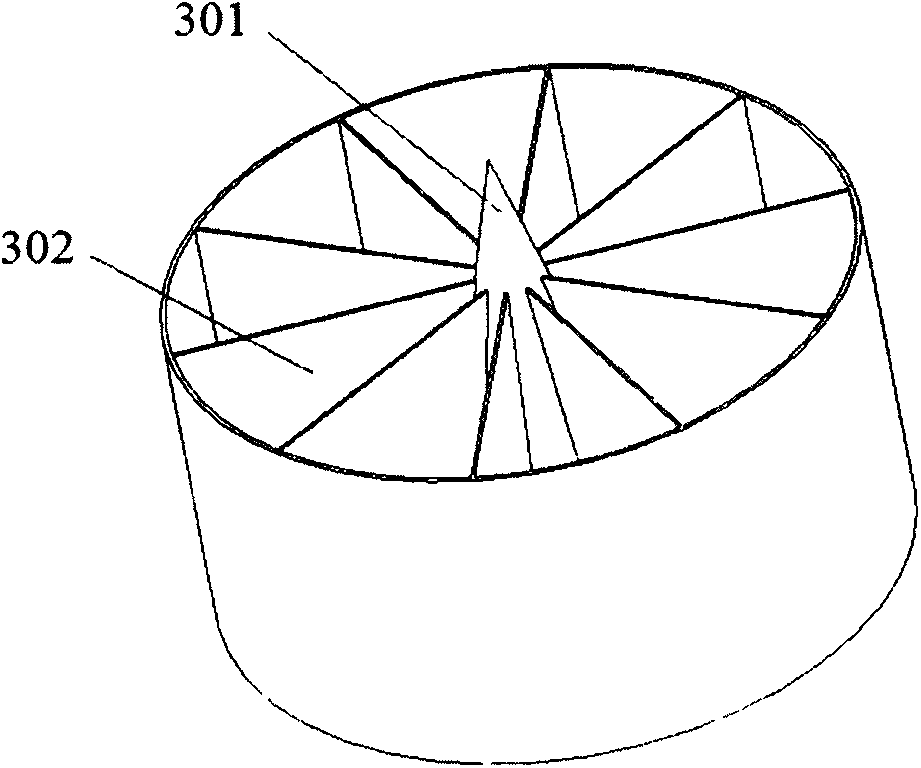

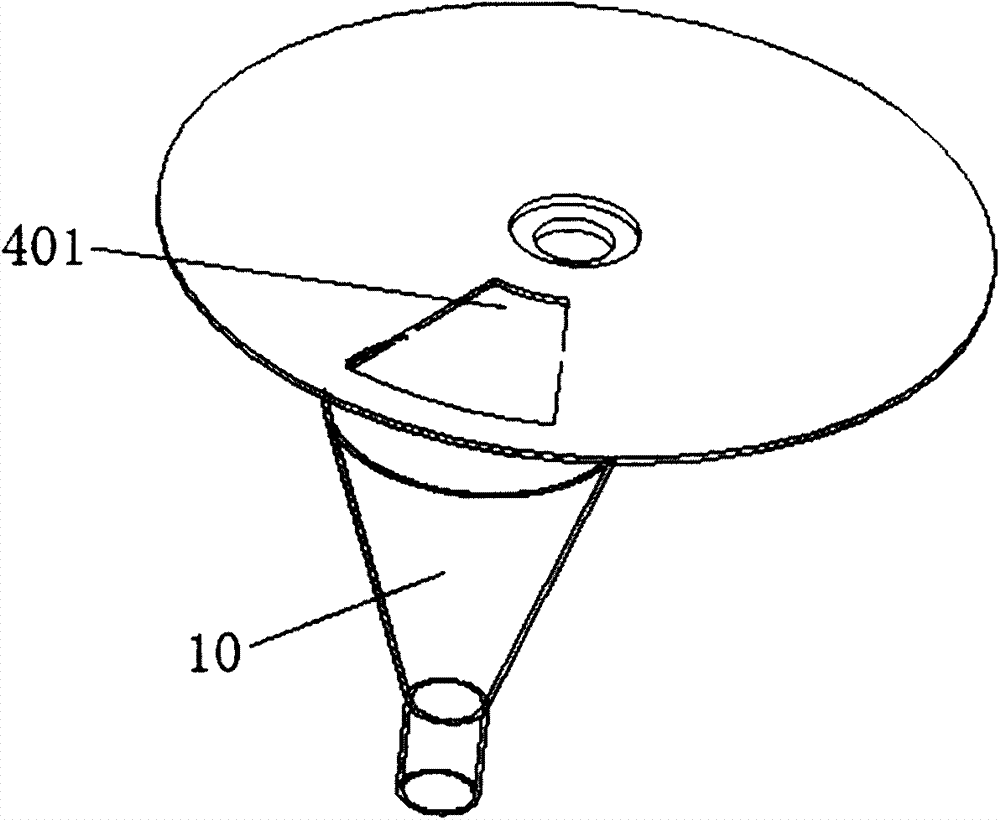

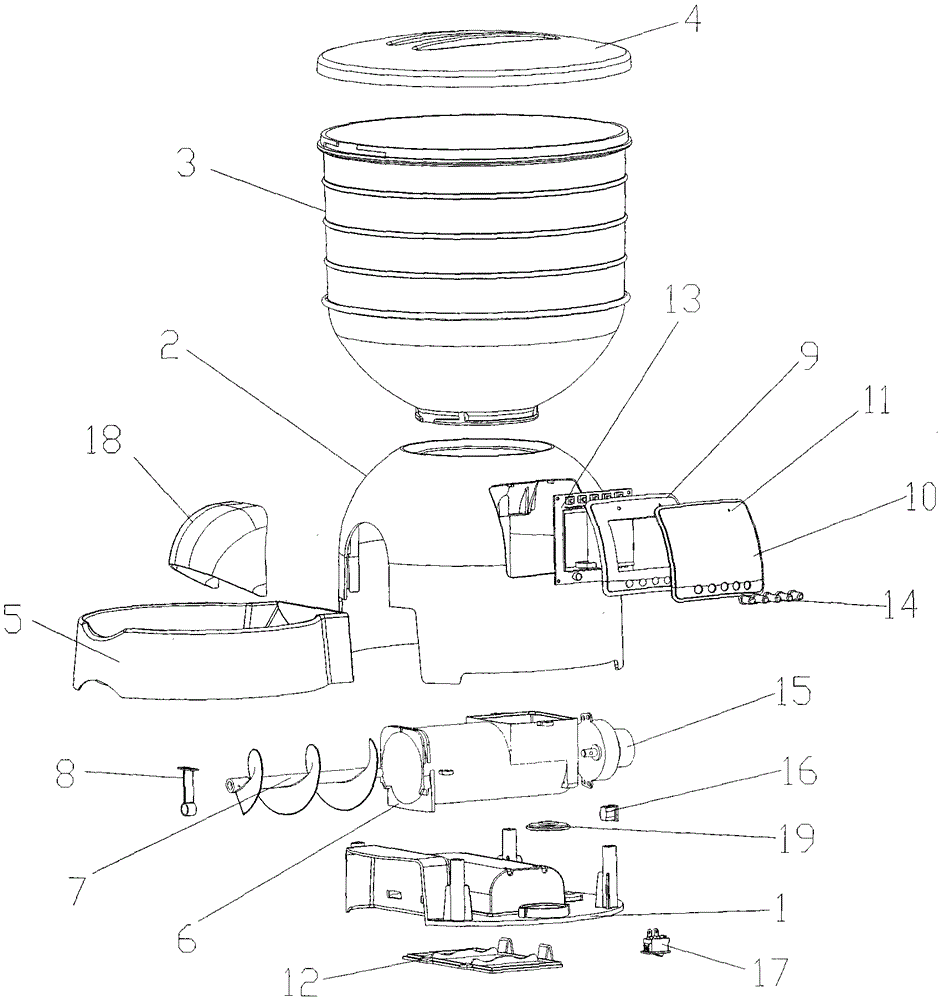

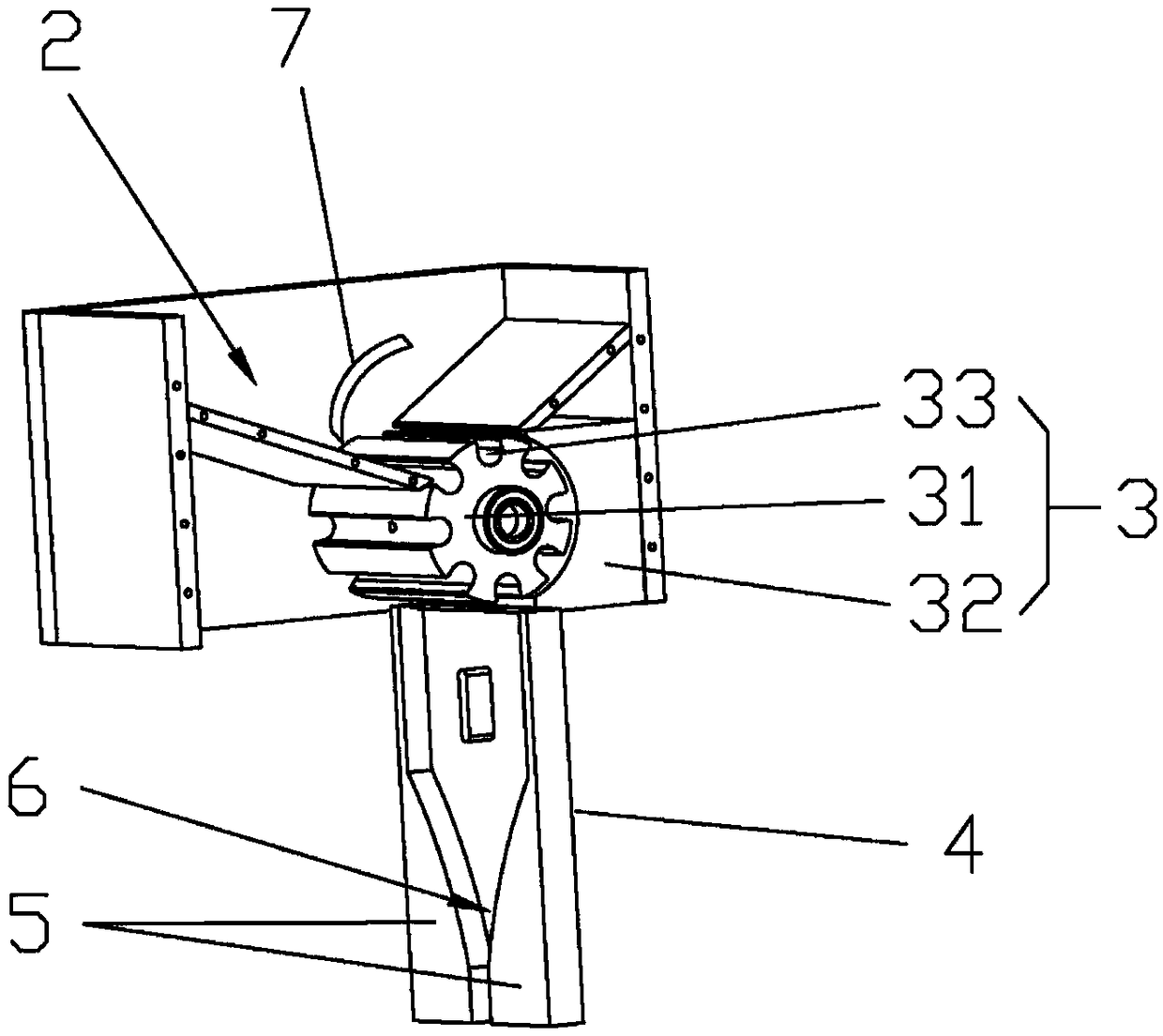

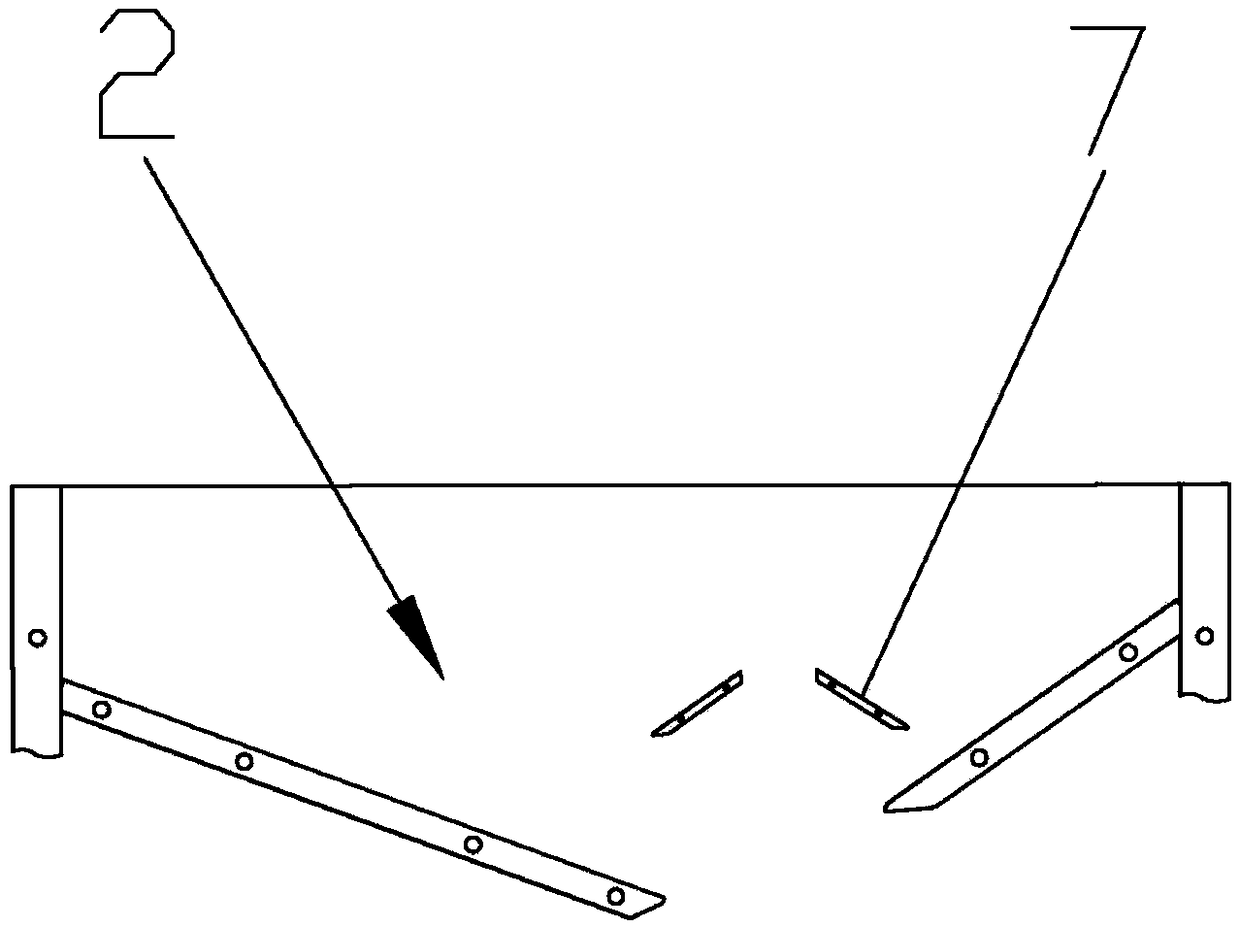

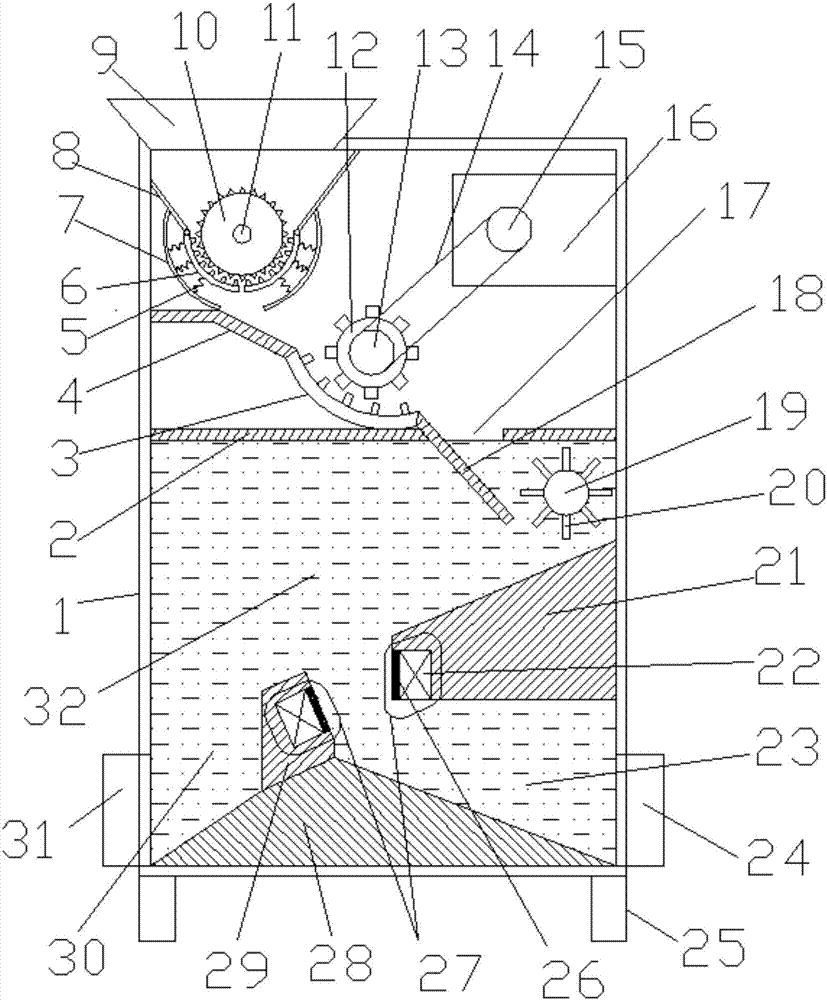

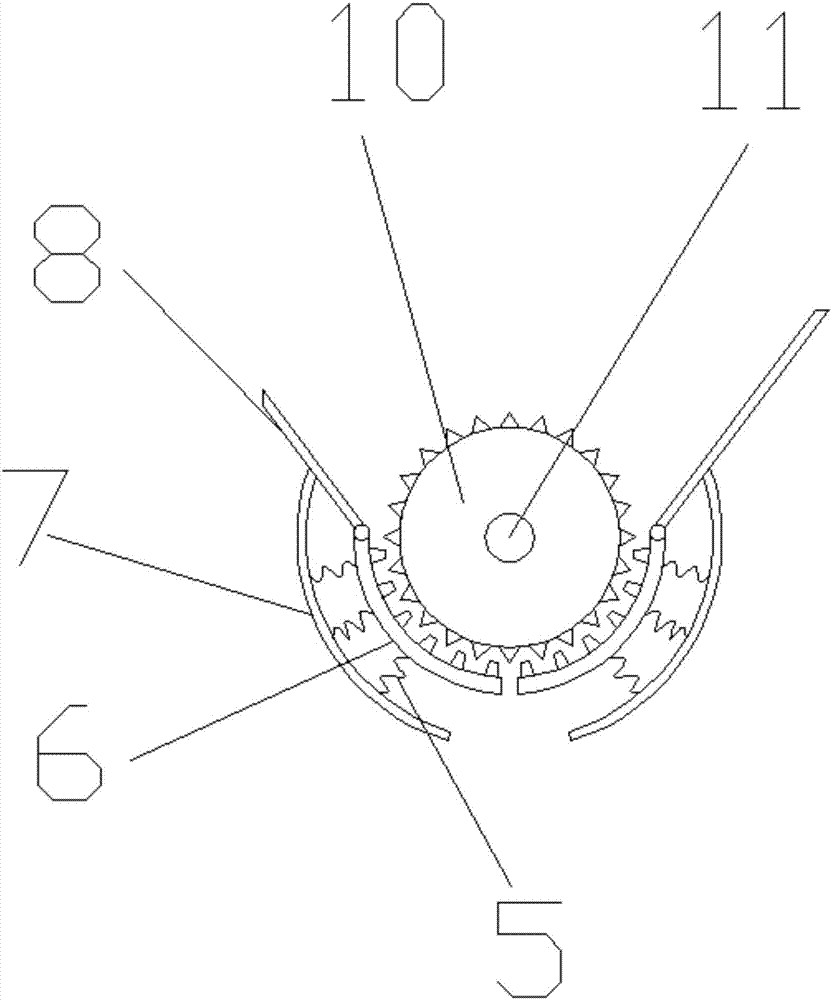

Quantitative material throwing device for aquaculture

InactiveCN103875579ASimple structureLow manufacturing costPisciculture and aquariaEngineeringAquaculture

The invention discloses a quantitative material throwing device for aquaculture and belongs to the field of aquaculture equipment. The device comprises a storage bin, a support, a quantitative bin, a quantitative tray, a conveying pipe, a feeding motor, a throwing tray, a throwing protection cover and a throwing motor, wherein the storage bin is fixedly installed on the top of the support, the quantitative bin is installed below the storage bin and is connected with the feeding motor, the quantitative tray is arranged on the bottom of the quantitative bin and is fixedly installed on the support, a quantitative hole is formed in the quantitative tray, the conveying pipe is arranged below the quantitative hole, the throwing tray is arranged below the conveying pipe and is connected with the throwing motor, and the throwing protection cover is arranged on the throwing tray in a covering mode. According to the device, the problem of uneven feed throwing is solved, even throwing all over the pond is realized in the true sense, the use efficiency of feed is improved, and the influence of aquaculture on the environment is reduced. Furthermore, the device is simple in structure and low in manufacturing cost and is worth popularization.

Owner:常州智能农业装备研究院有限公司

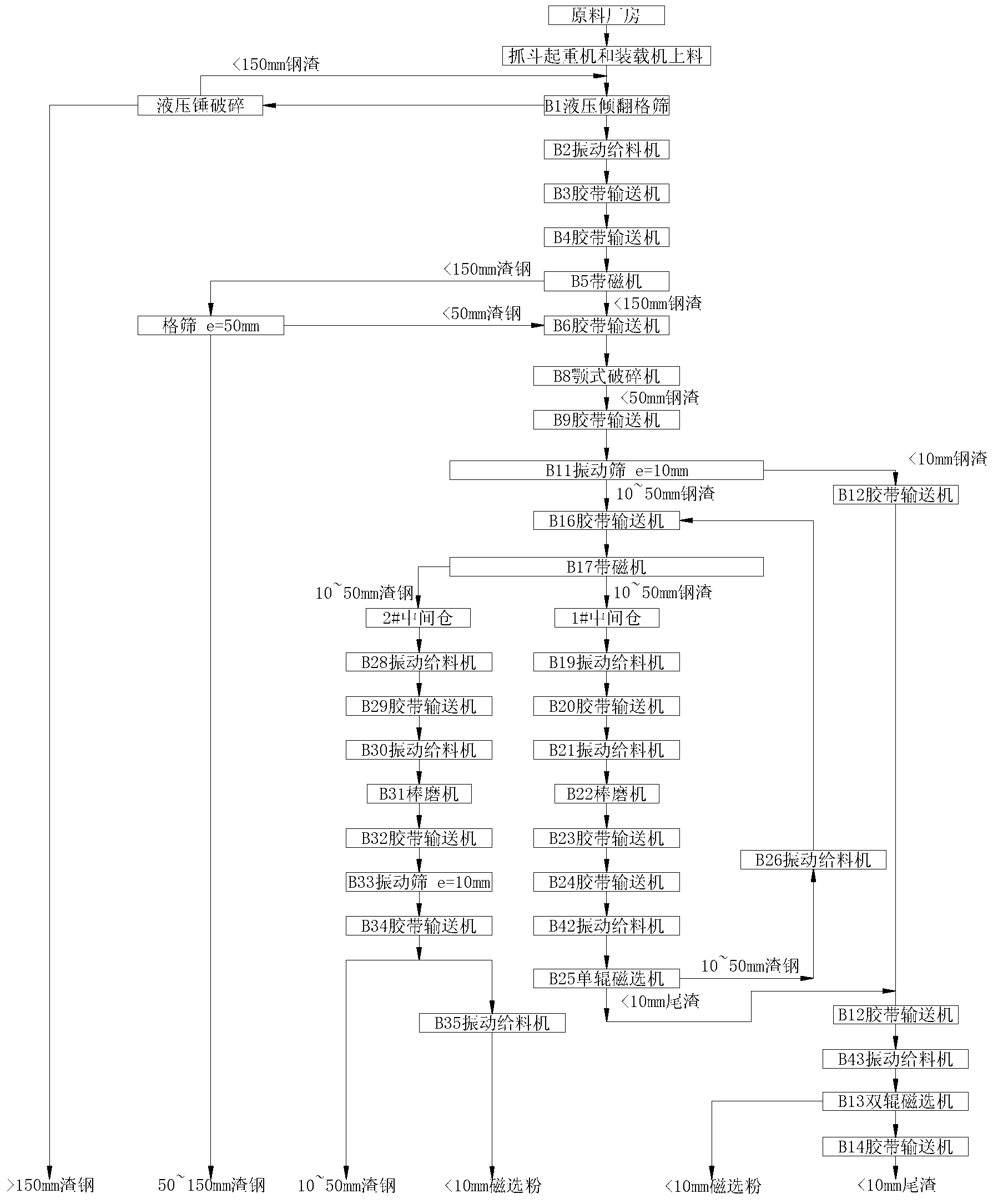

Steel slag treating technology

ActiveCN103290153AIncrease added valueFor subsequent useRecycling and recovery technologiesSteelmakingClosed loop

The invention relates to a steel slag treating technology which can be used for treating steel slag after which is stabilized by adopting a hot and stuffy method. According to the technology, the steel slag is treated by the procedures of screening, crushing, magnetic separation, purification and the like through utilizing the mode of combining an open loop and a closed loop circulation to obtain five high-value-added high-quality products, namely first-type bulk slag steel with the grade of more than or equal to 80% and particle size of 150mm, a second-type bulk slag steel with the grade of more than or equal to 80% and particle size of 50-150mm, slag steel with grade of more than or equal to 85% and particle size of 10-50mm, magnetic separation powder with grade of more than or equal to 42% and particle size of 10mm, and metal iron content (2% of tailings with the particle size of 10mm), wherein the first-type bulk slag steel and the second-type bulk slag steel and the slag steel with the grade of more than or equal to 85% can be returned for steelmaking, the magnetic separation powder can be used for sintering, and the tailings can be used for producing steel slag micropowder as high-activity admixture of cement and concrete and the like. Through the technology, the zero emission of the steel slag can be realized, the defects that the steel slag stored occupies a large area and pollutes the environment can be solved, and the economic benefits of a steel mill can be increased.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

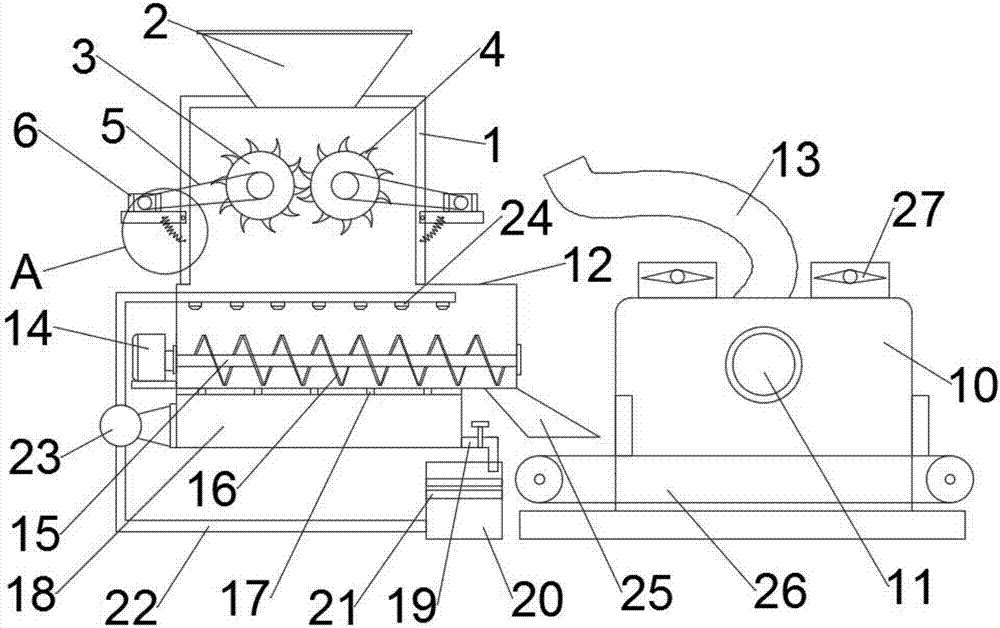

Continuous integrated waste plastic garbage crushing and cleaning treatment device

InactiveCN107116725ASmooth entryImprove cleanlinessPlastic recyclingMechanical material recoveryPull forceWater vapor

The invention discloses a continuous integrated waste plastic garbage crushing and cleaning treatment device. The device comprises a crushing machine body; a feed hopper is arranged at the top of the crushing machine body; a poking turntable is arranged in the feed hopper; a pair of rotating circular rollers is arranged in the middle position of an inner cavity of the crushing machine body in parallel; a movable support plate is hinged to the outer side wall, opposite to the rotating circular rollers, of the crushing machine body; a transmission motor is mounted above the movable support plate; an output shaft of the transmission motor is connected to center rotating shafts of the rotating circular rollers through transmission conveying belts; and the top position of a box body of a quick drying box communicates with a water vapor discharge pipe. The transmission motor enables the transmission conveying belts to always keep in a tensioned state through self weight and tension of a powerful tension spring; and dissipated water vapor is discharged through the water vapor discharge pipe, so that subsequent finished products are directly used in a dried state.

Owner:苏天平

Full-automatic spot welding machine

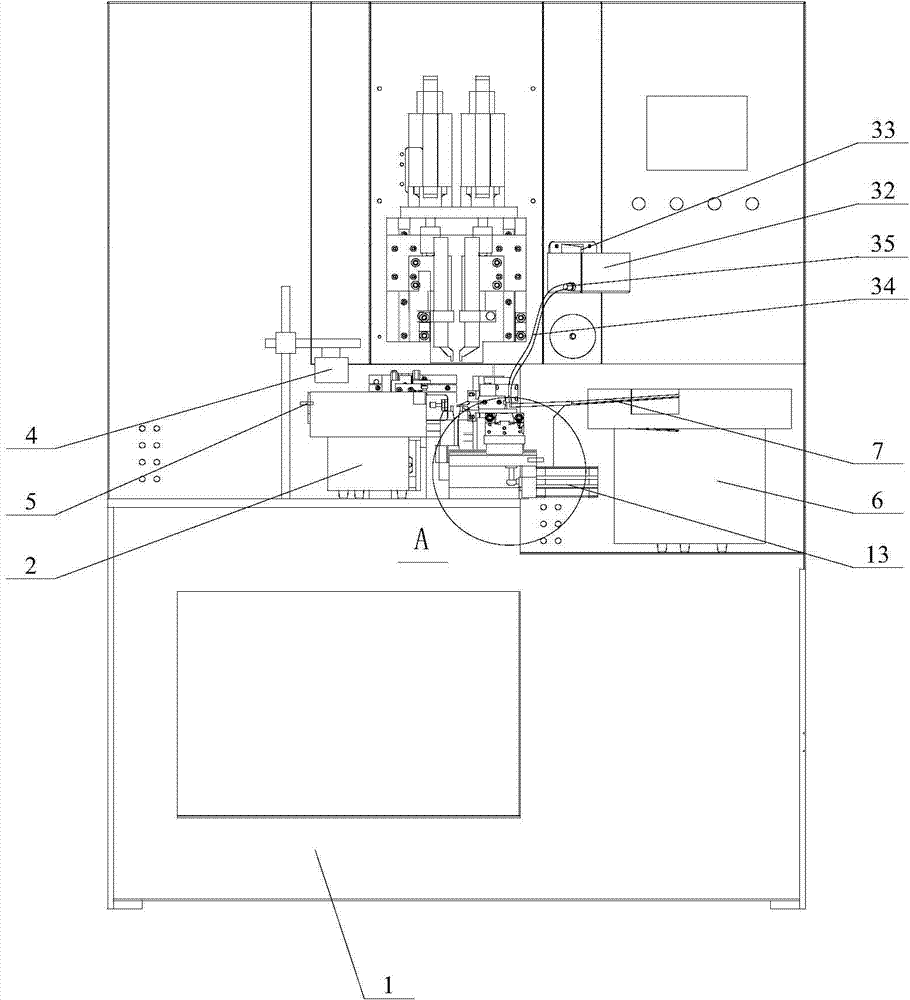

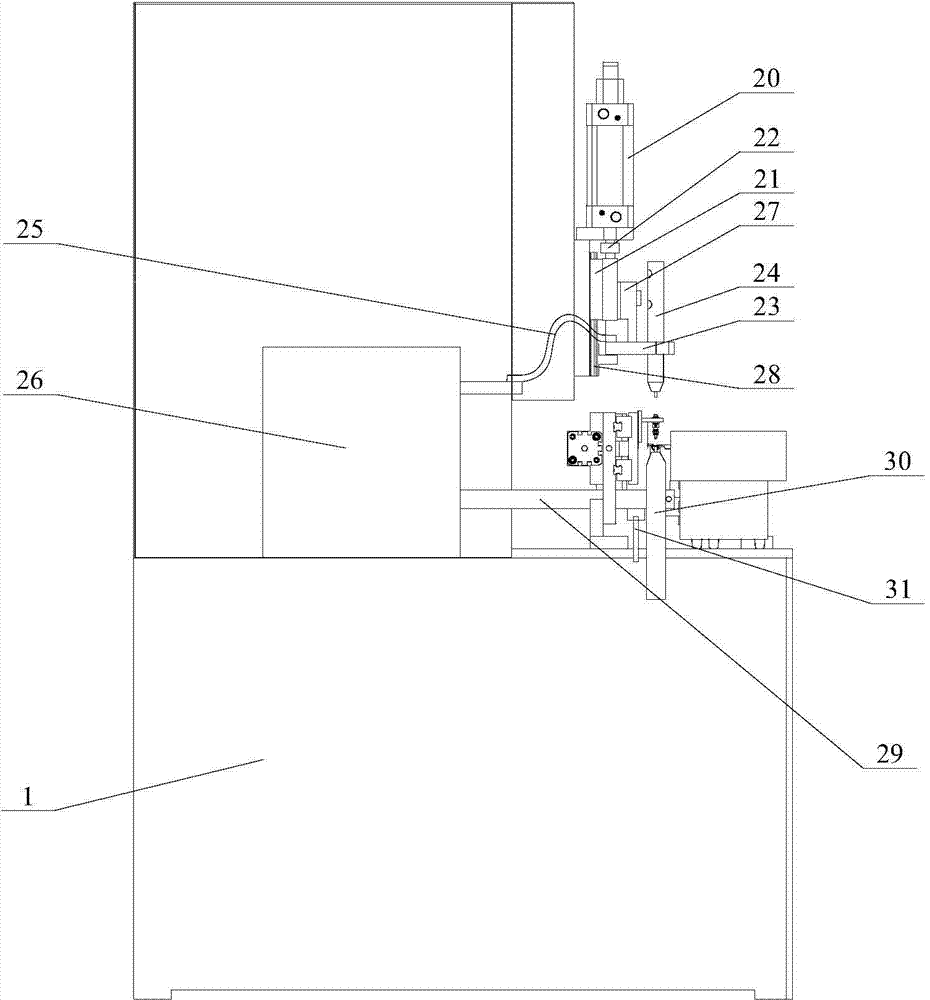

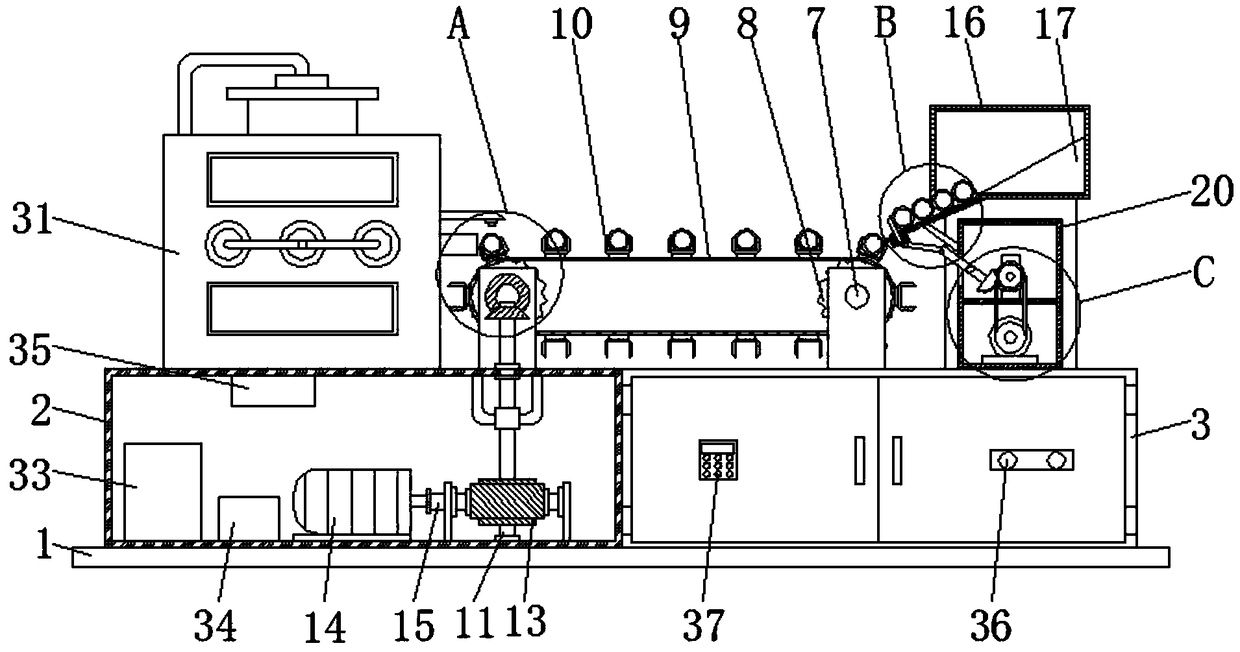

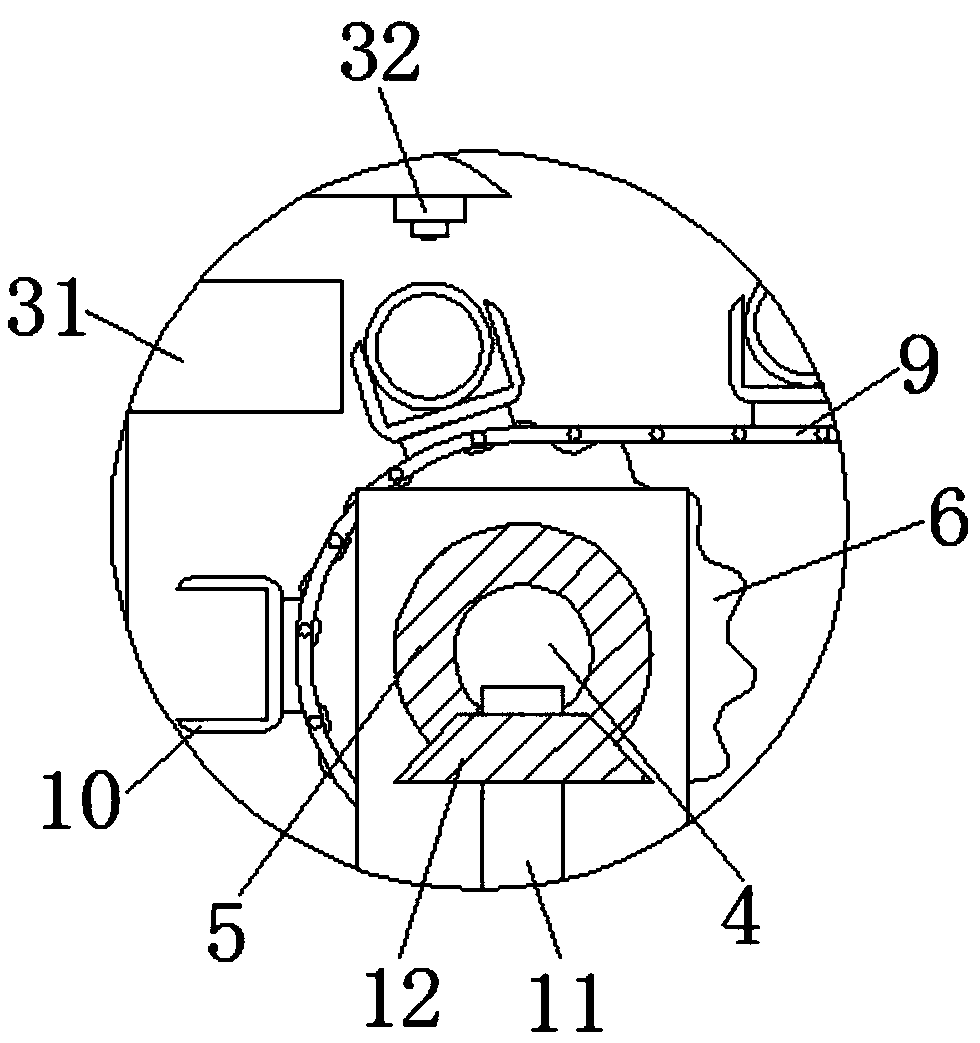

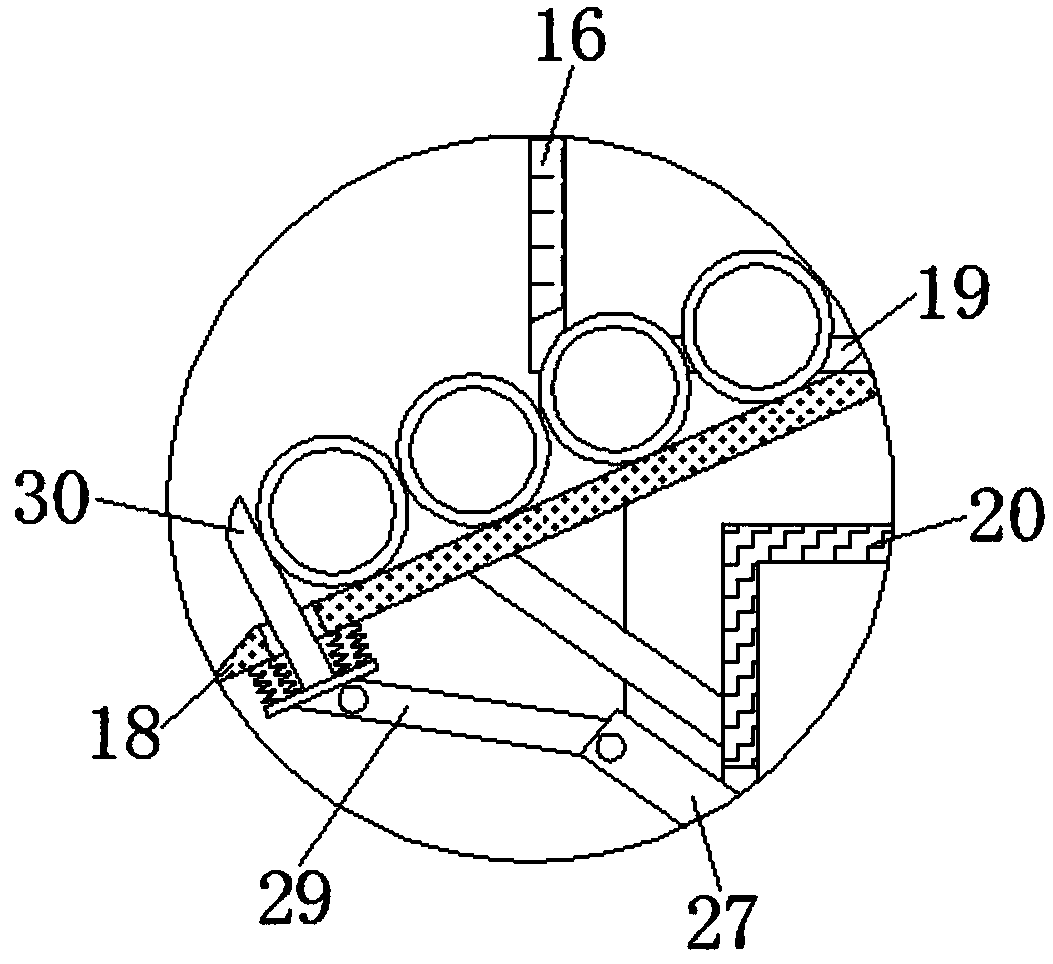

InactiveCN104493350AGuaranteed uptimeReasonable structural designResistance welding apparatusAutomatic controlControl system

The utility model discloses a full-automatic spot welding machine which comprises a spot welding machine body, a first material distributing device, a second material distributing device, a first feeding device, a second feeding device, a welding device, a flux adding device, a tin belt adding device and a control system, wherein the control system comprises a control panel arranged on the spot welding machine body, and the control system controls the running or stopping of the full-automatic spot welding machine by controlling the control panel. The full-automatic spot welding machine is reasonable in structural design and adopts full-automatic control, effectively avoids material blocking and material leakage through a sensor, and can meet normal and stable running, so that high production efficiency, good stability and high welding quality are ensured, and full-automatic welding for small accessories such as contactors, contact pieces, small electrical accessories and artware can be realized.

Owner:张校阳

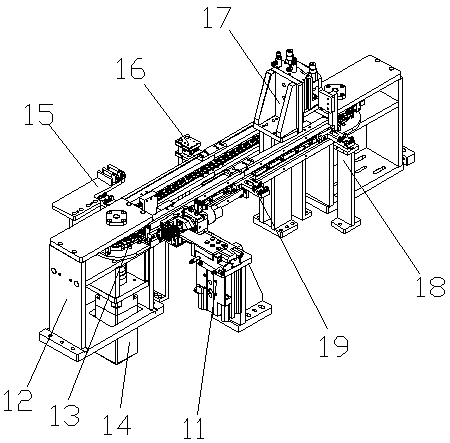

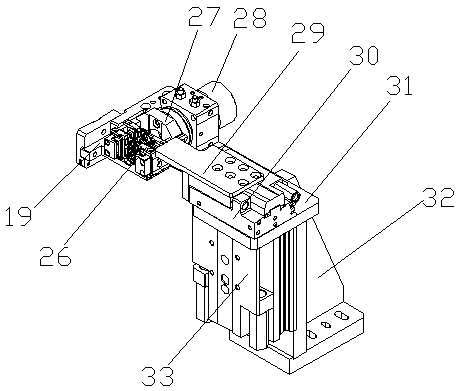

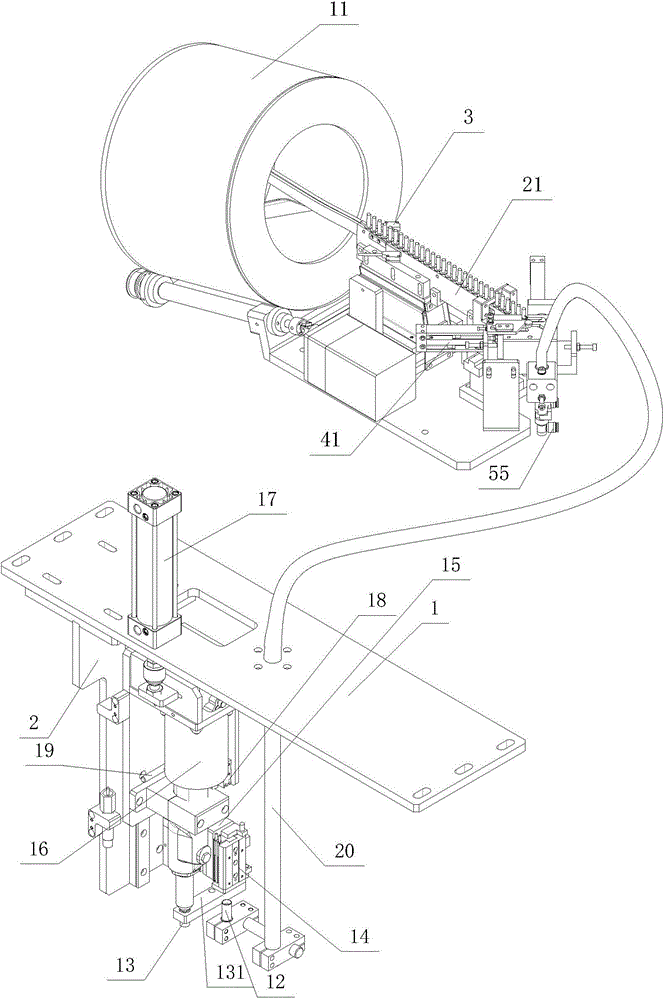

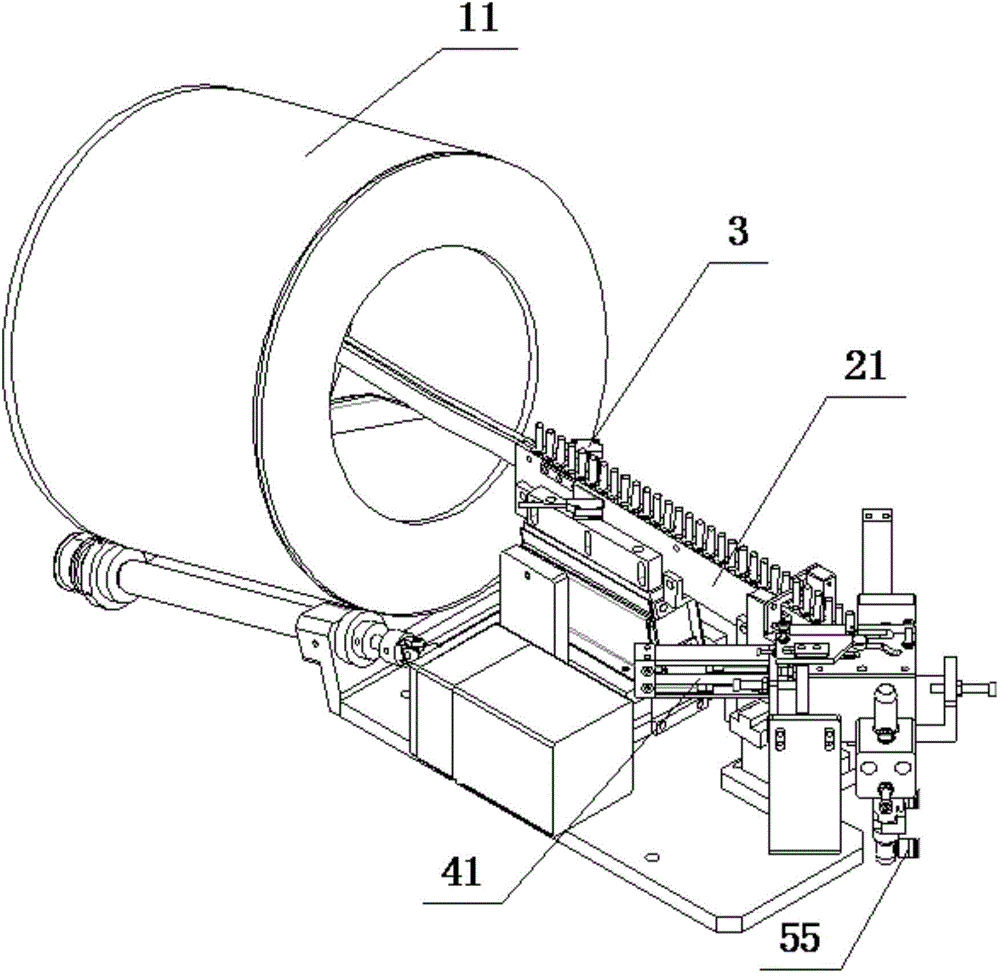

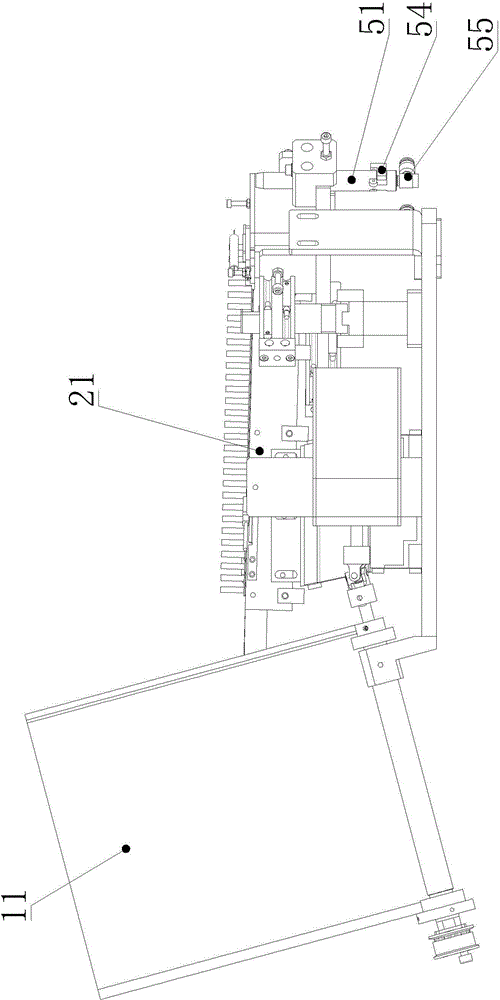

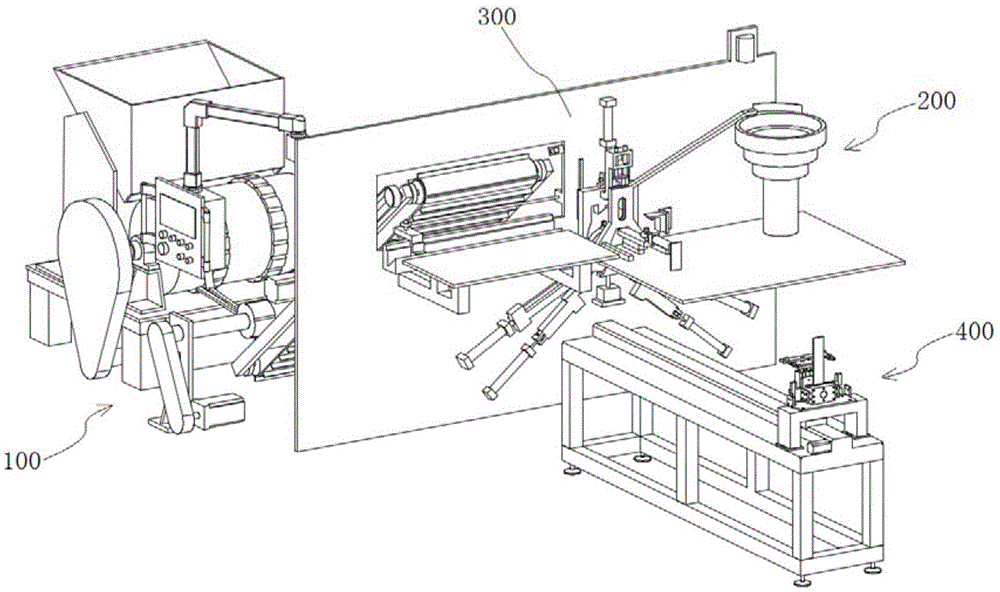

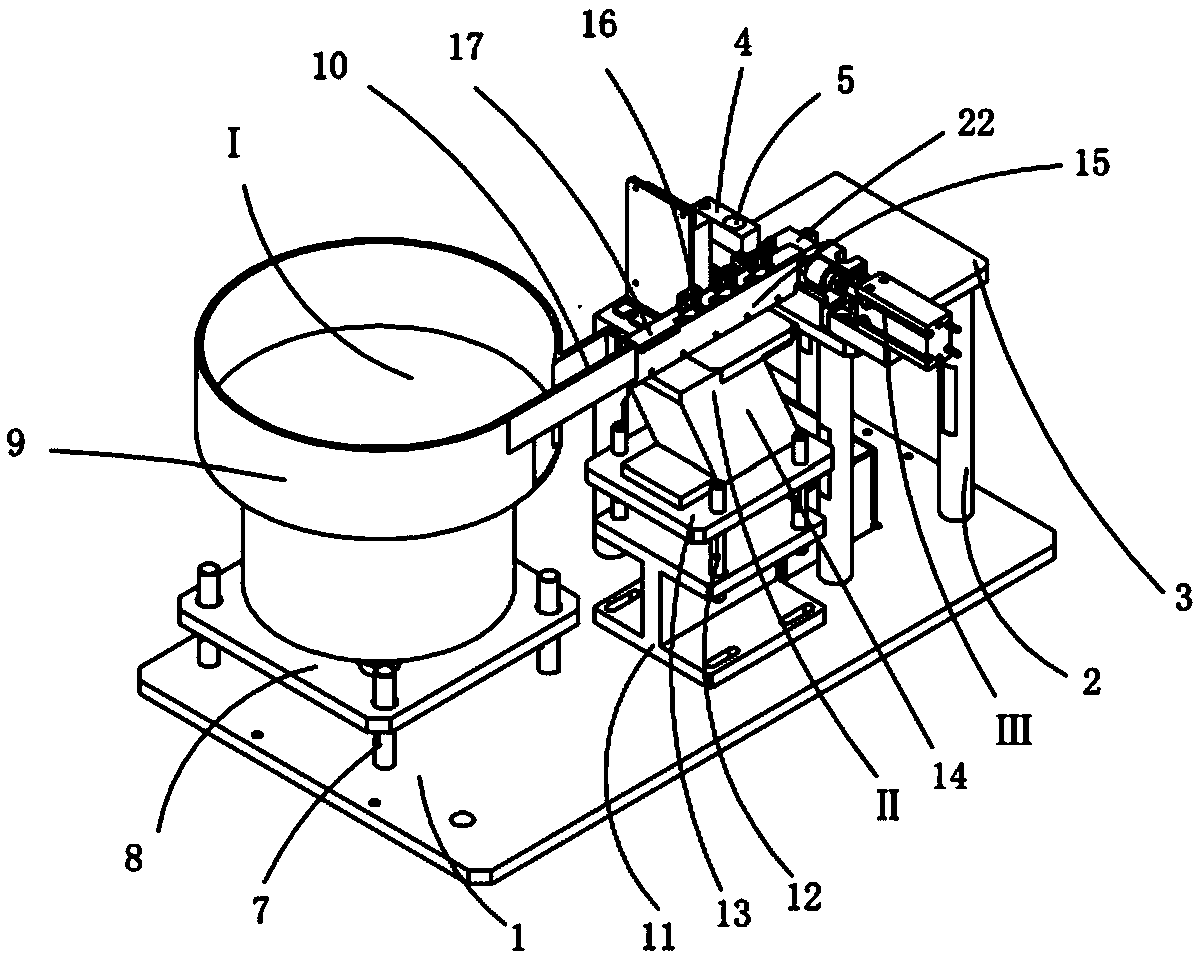

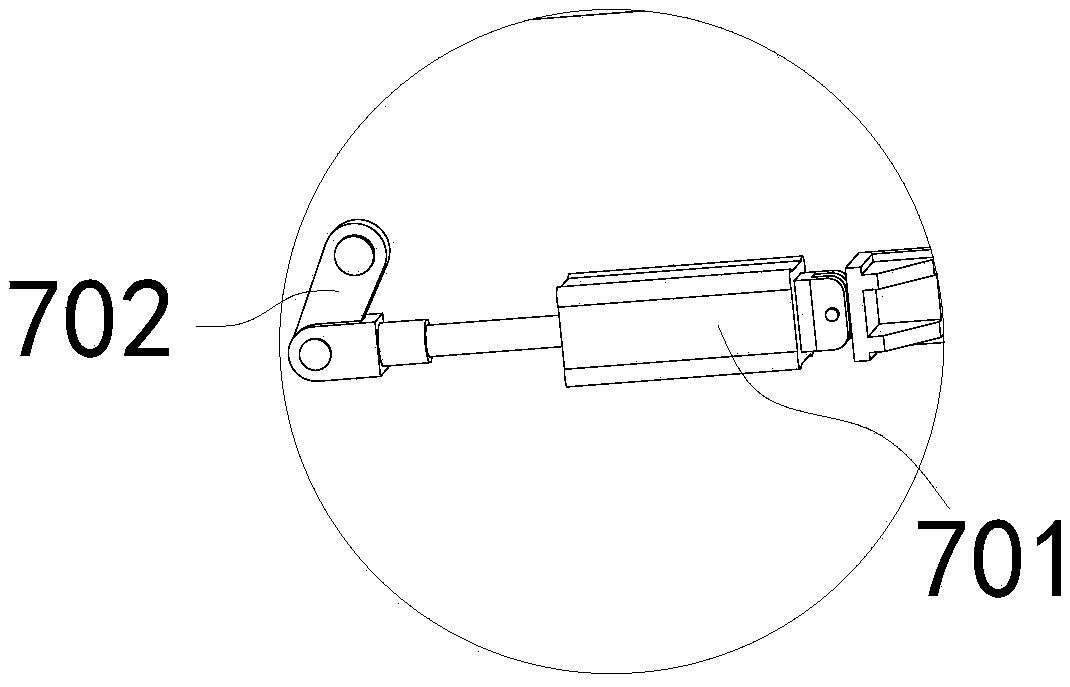

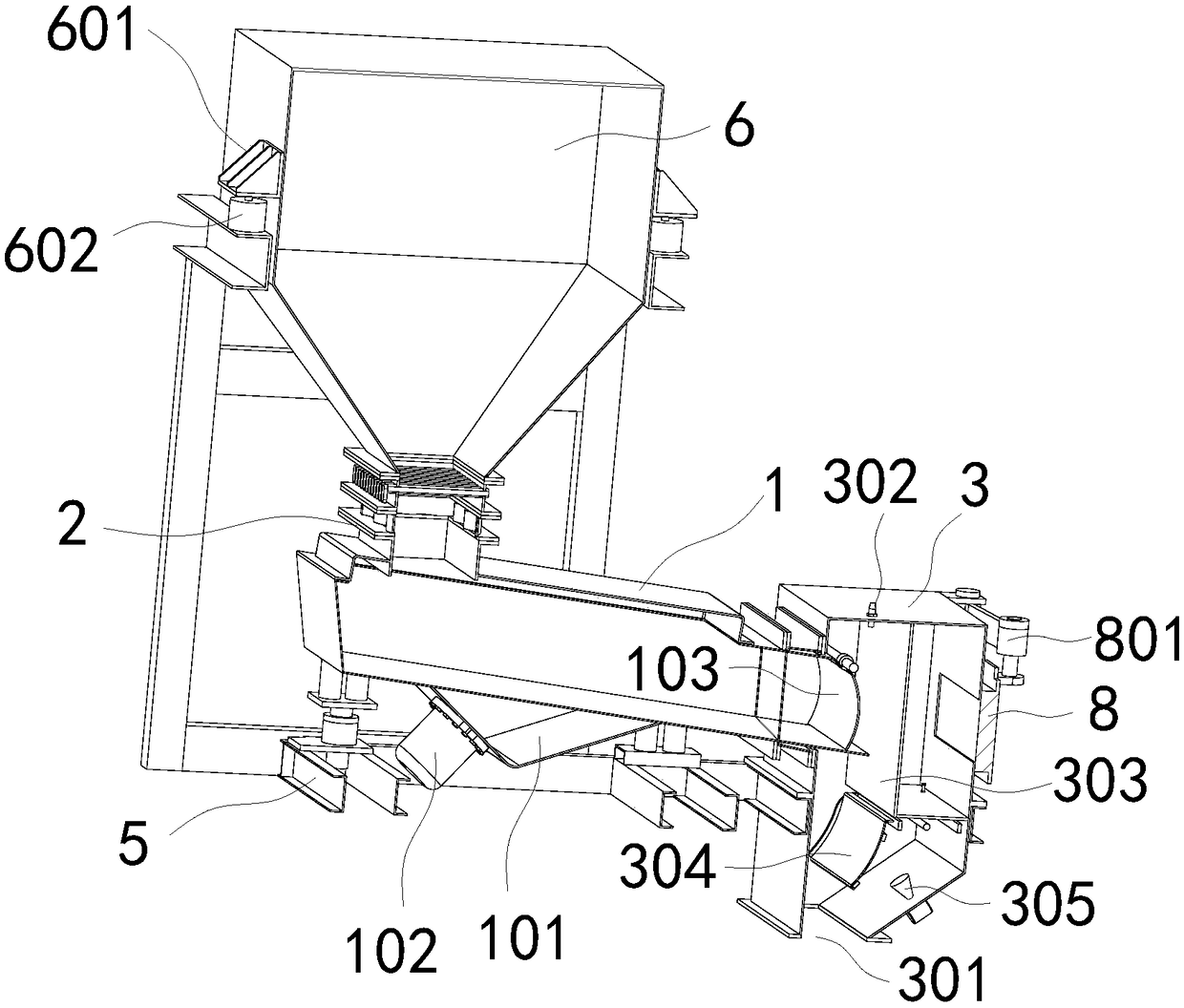

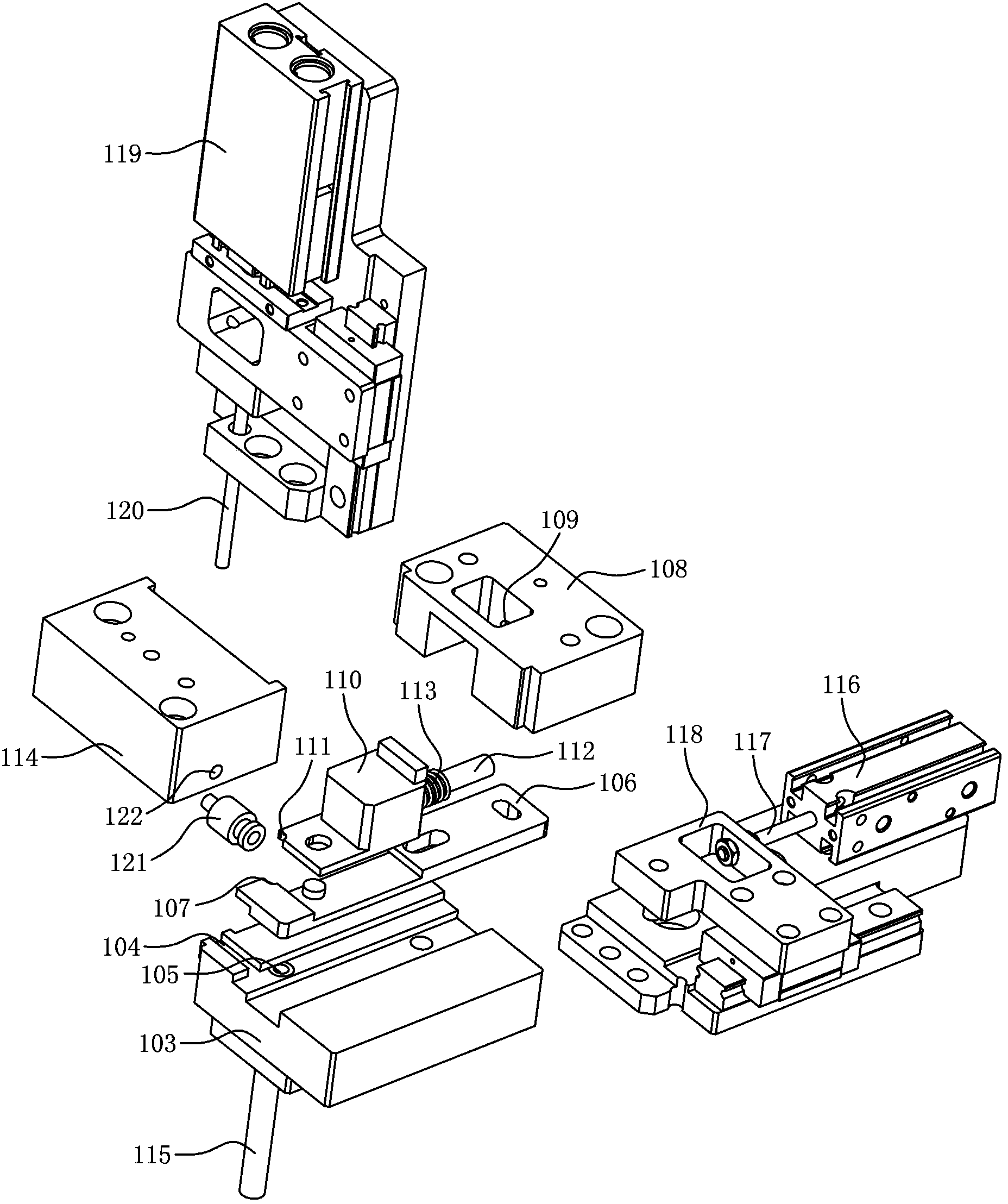

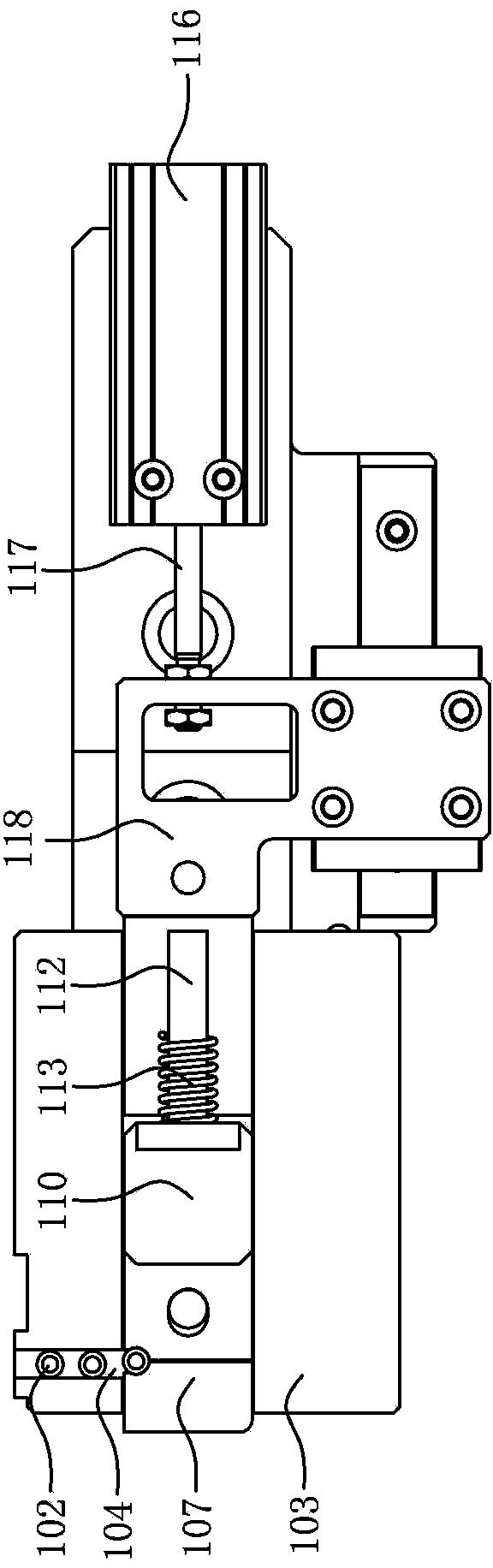

High-speed intelligent automatic rivet distributing and supplying and automatic riveting device for rivet gun

The invention provides a high-speed intelligent automatic rivet distributing and supplying and automatic riveting device for a rivet gun. The device comprises a rivet distributing and supplying device, and an automatic rivet supplying and riveting device which is connected with the rivet distributing and supplying device; the rivet distributing and supplying device comprises a supplying unit, a conveying unit, a pushing unit and a feeding unit; the automatic rivet supplying and riveting device comprises a base, a riveting mechanism, a supplying mechanism and a feeding mechanism; the rivet distributing and supplying device is used for supplying rivets; the automatic rivet supplying and riveting device is used for receiving the rivets and drilling the rivets. The high-speed intelligent automatic rivet distributing and supplying and automatic riveting device for the rivet gun is simple in structure, achieves the functions of automatically distributing the rivets, supplying the rives, feeding and riveting, is high in automation degree, greatly decreases the labor intensity of workers, and increases the production efficiency.

Owner:王承刚 +1

Fully-automatic round-head barrel hook forming machine

ActiveCN105414415AMeet production requirementsFulfill production requirementsWire articlesProduction lineControl system

The invention discloses a fully-automatic round-head barrel hook forming machine belonging to the field of wire bending machines. The fully-automatic round-head barrel hook forming machine comprises a steel wire feeding device, a handle tube feeding device, a forming device, a fetching and shaping device and a control system, wherein the handle tube feeding device is arranged in front of the forming device; the steel wire feeding device is arranged at the rear of the forming device; the fetching and shaping device is arranged in front of the forming device, is located below the handle tube feeding device and is composed of a grabbing mechanism, a locating mechanism and a shaping mechanism; and all the steel wire feeding device, the handle tube feeding device, the forming device and the fetching and shaping device are automatically controlled by the control system to sequentially finish the actions of handle tube feeding, steel wire feeding, barrel hook forming as well as fetching and shaping. By using the fully-automatic round-head barrel hook forming machine, a barrel hook not only can be fully-automatically produced, but also can be corrected and shaped after being formed to make preparation for the next installation of the barrel hook, so that the requirement of an automatic installation production line of the barrel hook is met, and the automatic level and production efficiency of vessels such as barrels and tanks are greatly increased.

Owner:CHANGZHOU PUHE PLASTIC

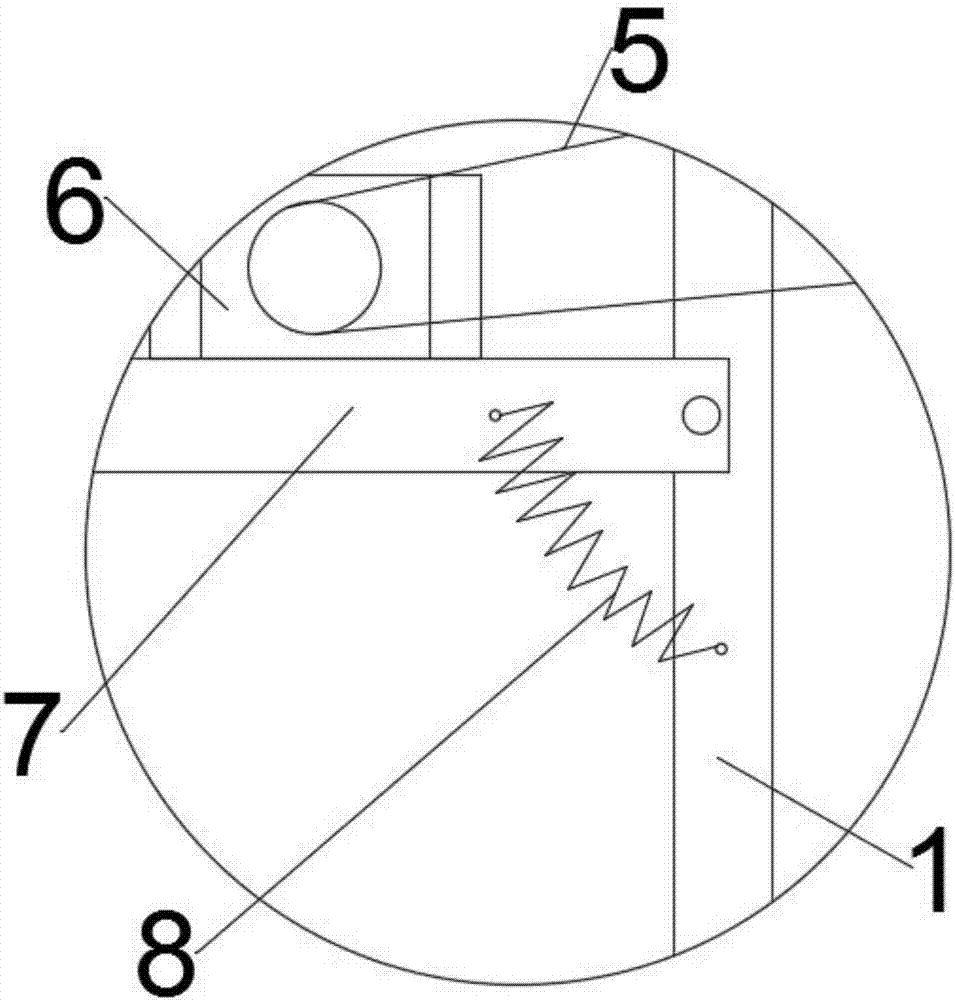

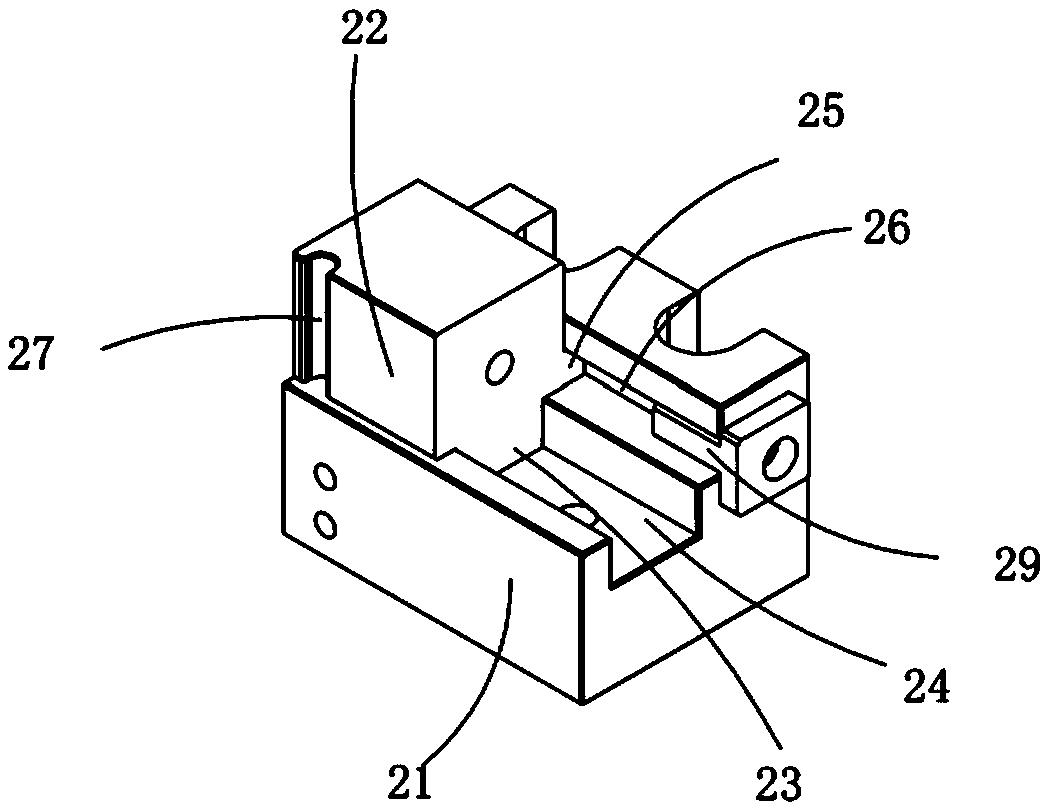

Staggered feeding mechanism

InactiveCN105501901AAvoid material jamsJigging conveyorsConveyor partsEngineeringMechanical engineering

The invention relates to a staggered feeding mechanism. A feeding component and a direct vibration component are mounted on a bottom plate, and a material feeding track of the feeding component is communicated with a direct vibration track of the direct vibration component; a material slitting bottom plate is mounted on the bottom plate through material spitting pillars; a staggered feeding component is mounted on the material slitting bottom plate; a blanking base is mounted on the material spitting bottom plate, and a screw butting block is mounted on the front side of the blanking base; a staggered cylinder fixing block and a staggered slider groove are formed in the material slitting bottom plate, a staggered cylinder is mounted on the staggered cylinder fixing block, and a staggered slider is mounted inside the staggered slider groove in a matched manner; the front end of the piston rod of the staggered cylinder is connected with the staggered slider through the staggered cylinder joint; a half-cylinder groove used for positioning screws is formed in the left rear side of the staggered slider, and an avoidance notch for preventing material blockage is formed in the front side inside the screw butting block. The feeding component is used for supplying material continually; and the staggered cylinder drives the staggered slider to move, and under the effect of the screw butting block, screws are staggered on by one and moved to adsorption positions.

Owner:BOZHON PRECISION IND TECH CO LTD

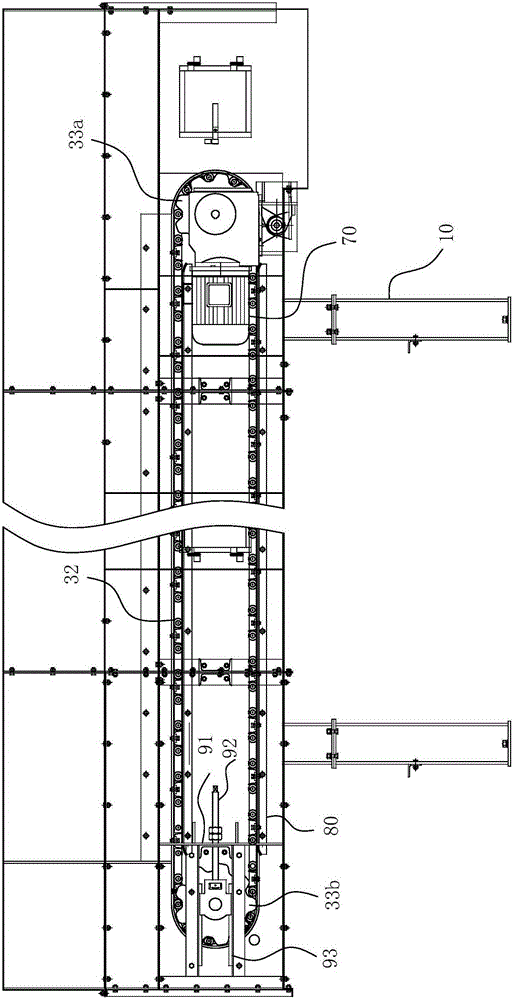

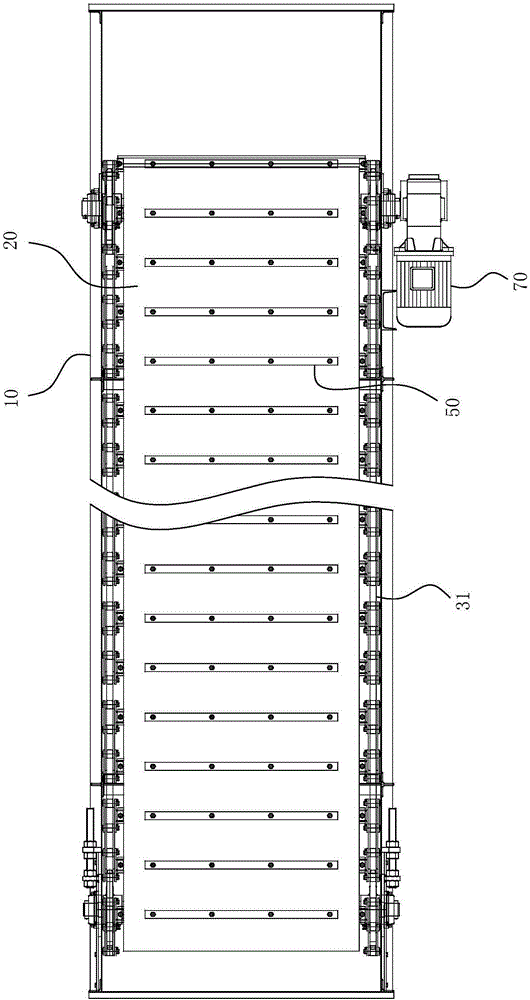

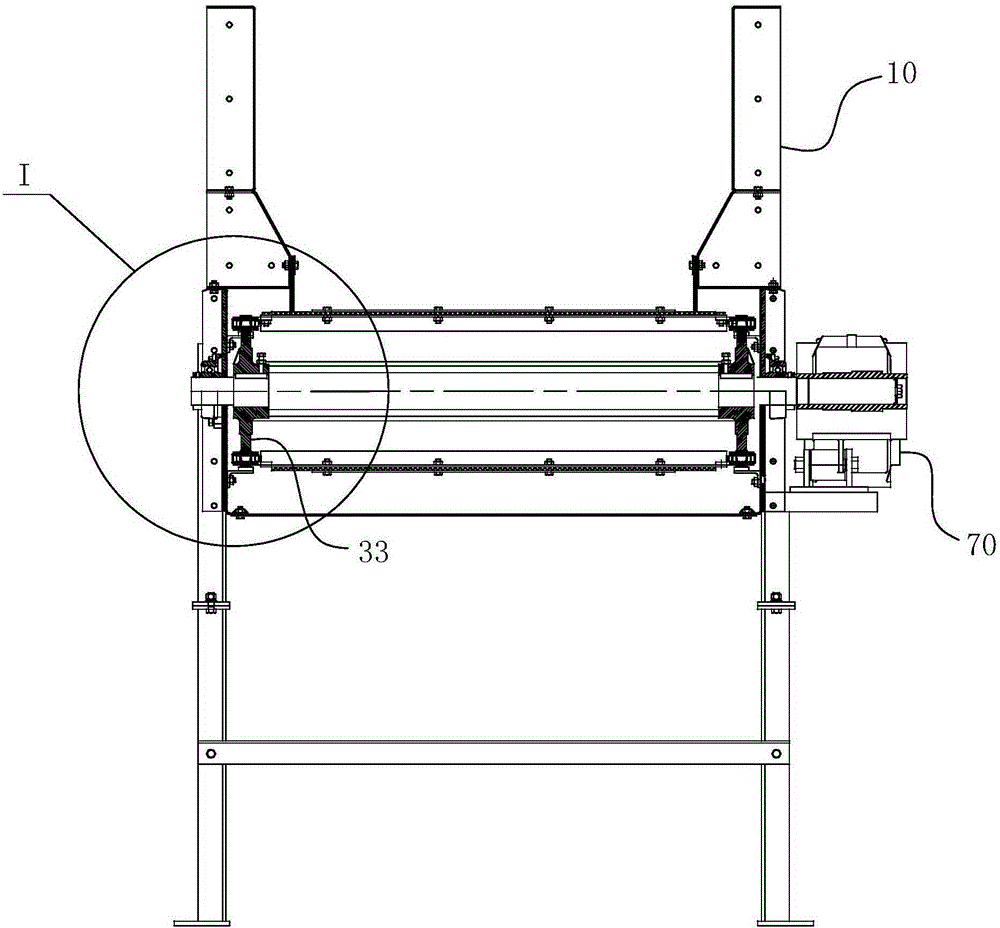

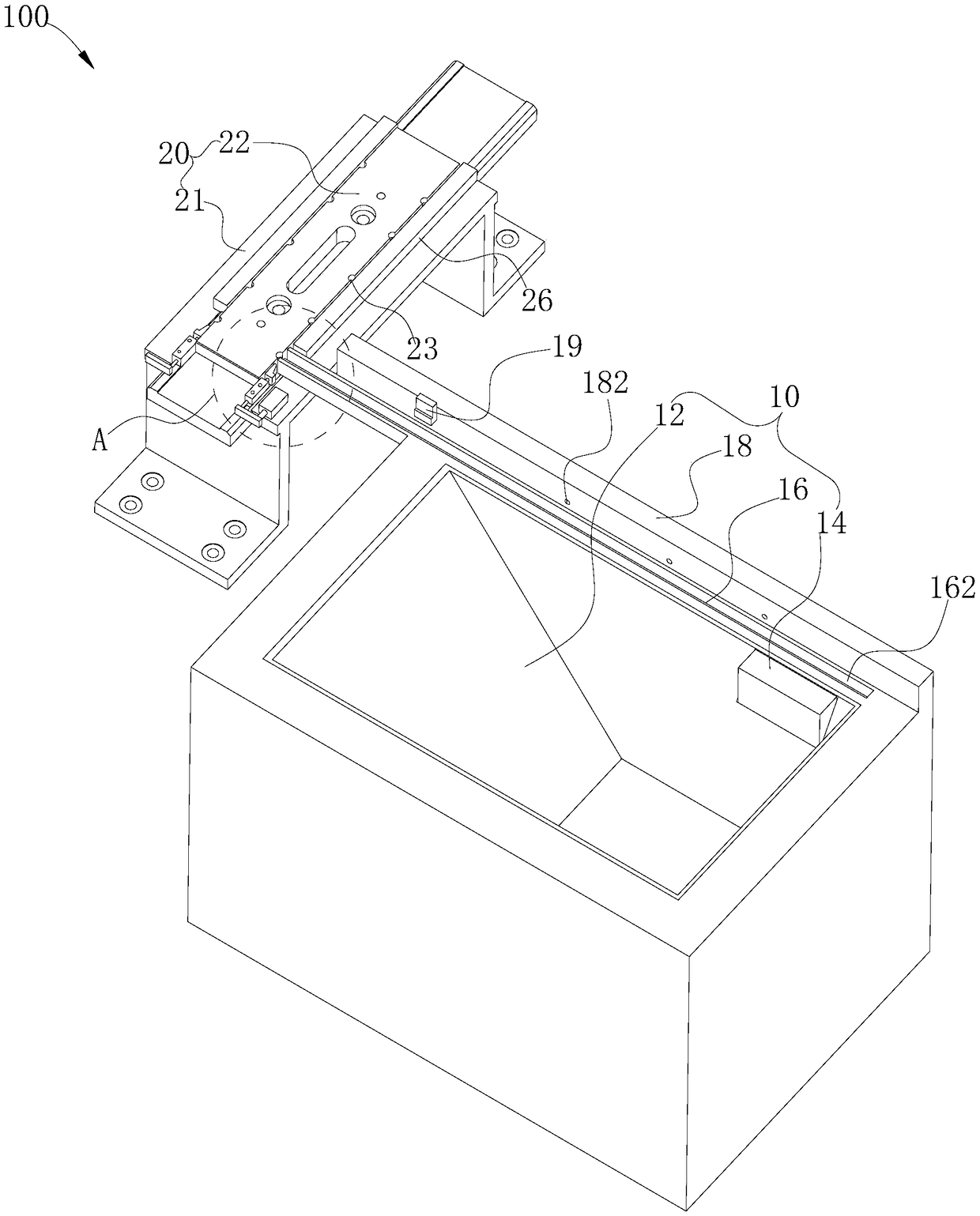

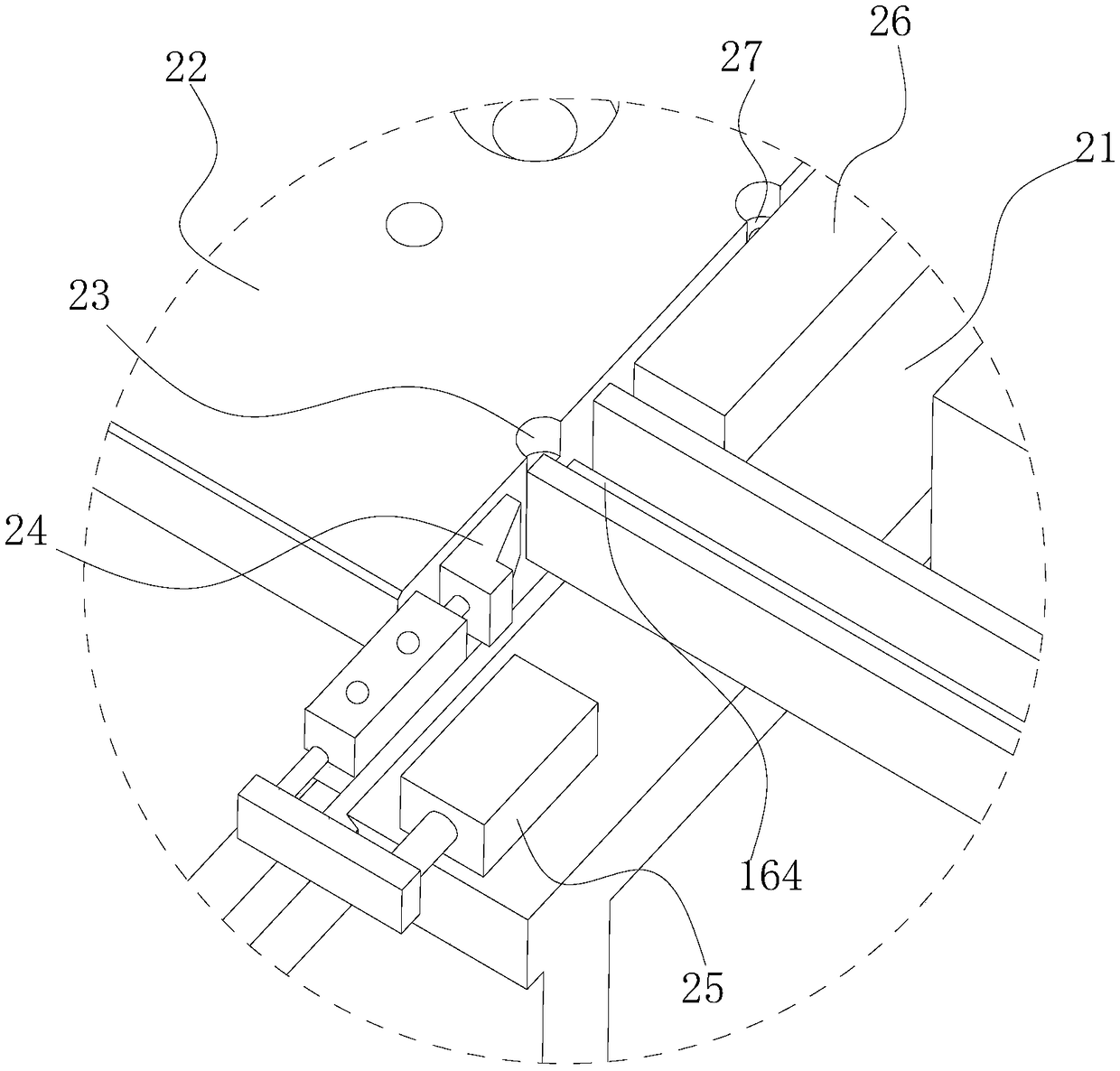

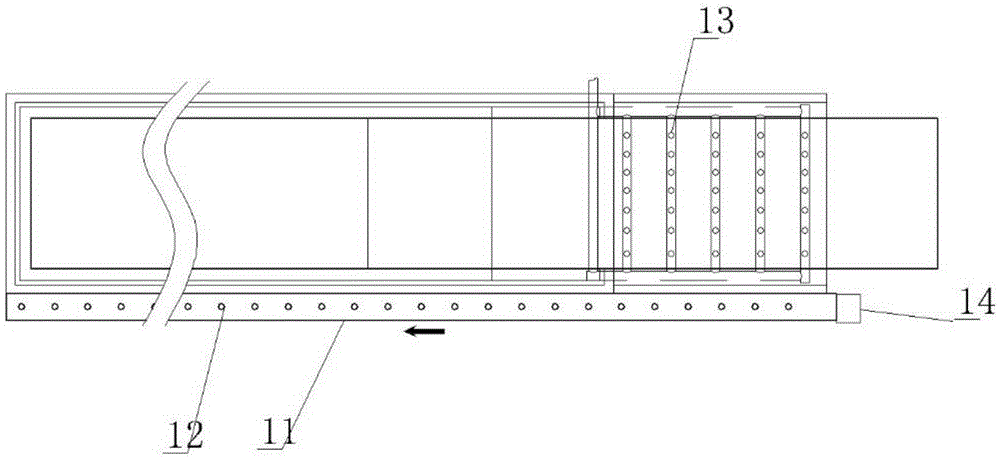

Feed and discharge processing method and feed and discharge processing device of flat-head machine and flat-head machine

ActiveCN106112659AReduce processing timeImprove processing efficiencyMetal working apparatusTransmission beltEngineering

The invention discloses a feed and discharge processing method and a feed and discharge processing device of a flat-head machine and the flat-head machine. According to the feed and discharge processing method, a belt transmission mechanism is arranged, three or more than three lower fixtures are arranged on a transmission belt of the belt transmission mechanism, a feed position of a pipe is set in one end of the upper part of the transmission belt, a processing position of the pipe is set on the other end of the upper part of the transmission belt, and a discharge position of the pipe is set in an area of the lower part of the transmission belt. During processing, each lower fixture is driven to pass through the feed position, the processing position and the discharge position and then return to the feed position by the transmission belt, so as to form a circulation, so that the feed, processing and discharge steps of the pipe are completed on the same transmission belt at the same time. According to the feed and discharge processing method, the feed and discharge processing device and the flat-head machine, the processing efficiency of the pipe flat-head machine is greatly improved.

Owner:ZHUZHOU KAIFENG IND

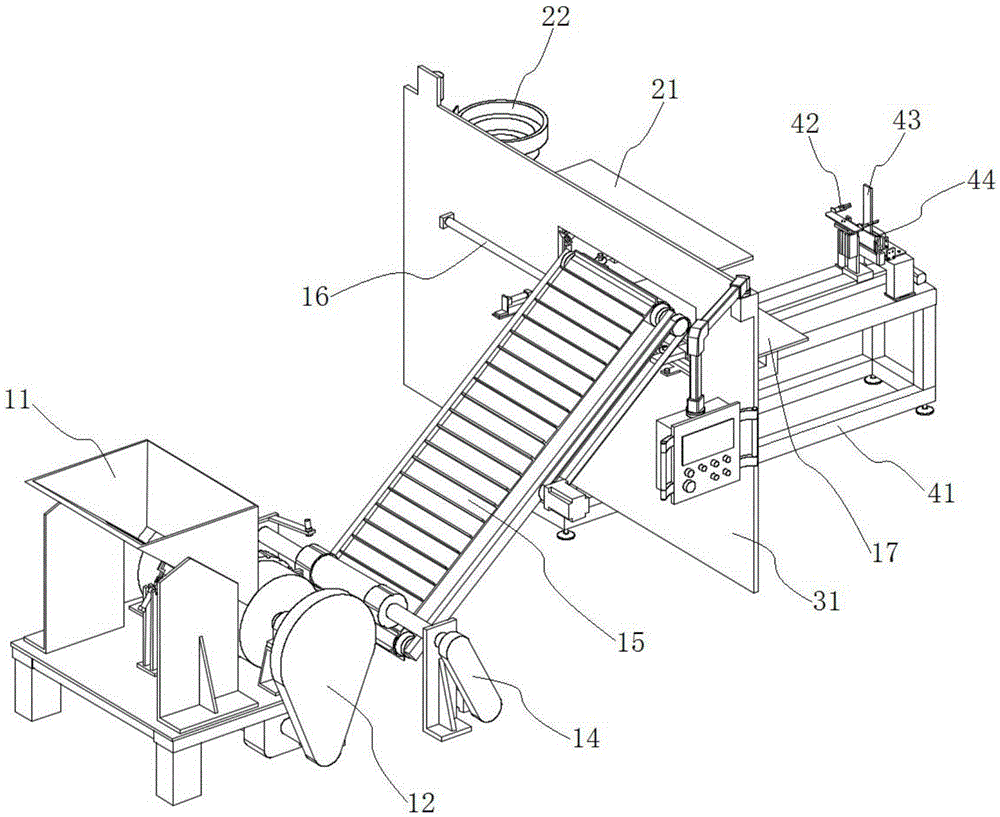

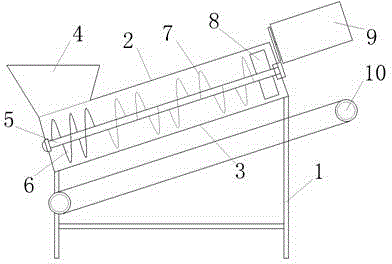

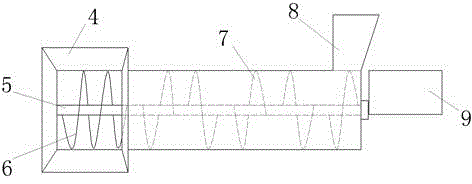

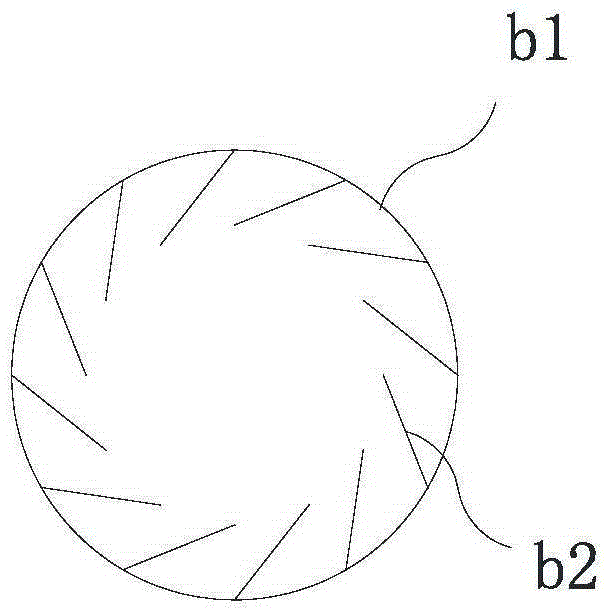

Edible fungus cultivation package and plastic bag separating device

The invention discloses a separating device for a substrate and a plastic thin film bag of an edible fungus cultivation package and belongs to the technical fields of agricultural machinery equipment. The edible fungus cultivation package and plastic bag separating device comprises a barrel body obliquely arranged on a machine frame, wherein the upper barrel wall of the barrel body adopts a sealing structure, the lower barrel wall of the barrel body adopts a grid mesh structure, a feeding opening is formed in the end part on one lower side of the barrel body, a bag outlet is formed in the end part on one higher side of the barrel body, a rotatable rotating shaft is arranged on the axis in the barrel body, a spiral feeding plate is arranged on the feeding opening section of the rotating shaft, material crushing blades are arranged in a spiral manner, are arranged on the rotating shaft on the feeding opening rear section and are arranged in the axial direction of the rotating shaft at intervals, and the spiral direction of the material crushing blades is consistent with the material conveying direction of the barrel body. The edible fungus cultivation package and material bag separating device disclosed by the invention has the benefits that the concept is skilful, the structure is reasonable, a cultivating substrate package for fungus cultivation can be directly crushed, and meanwhile, the automatic separation of the plastic thin film bag from organic materials can be realized, so that the utilization cost of the cultivating substrate is greatly reduced.

Owner:SICHUAN KAIERFENG AGRI TECH CO LTD

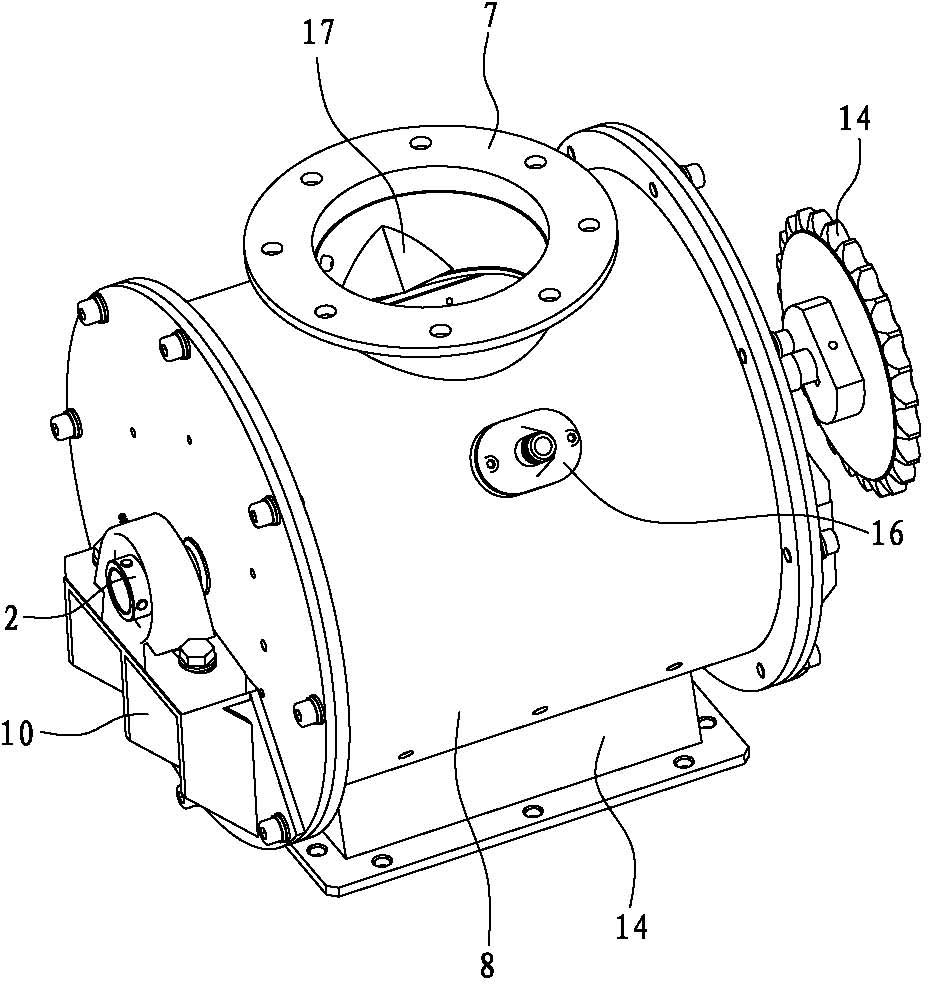

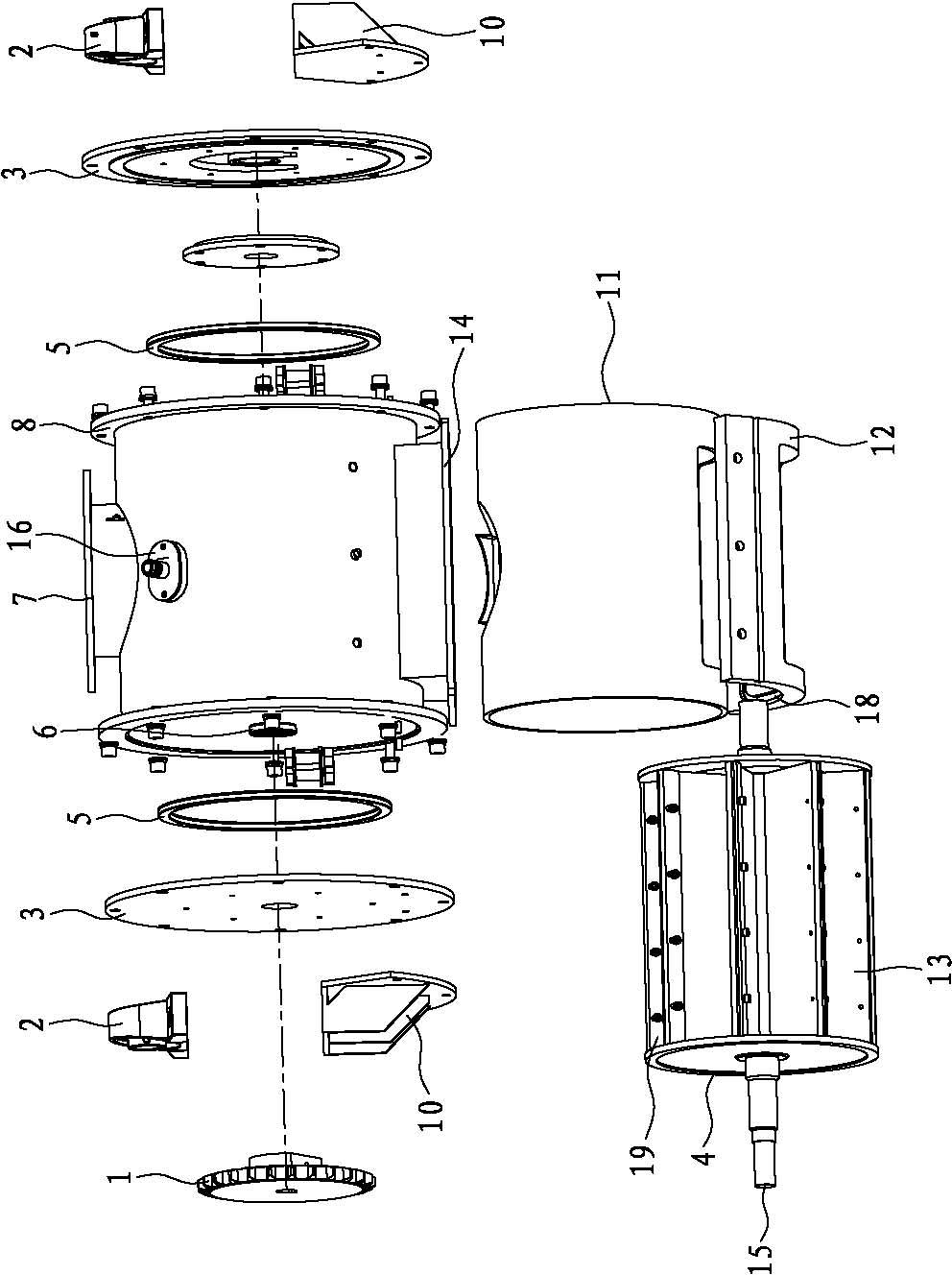

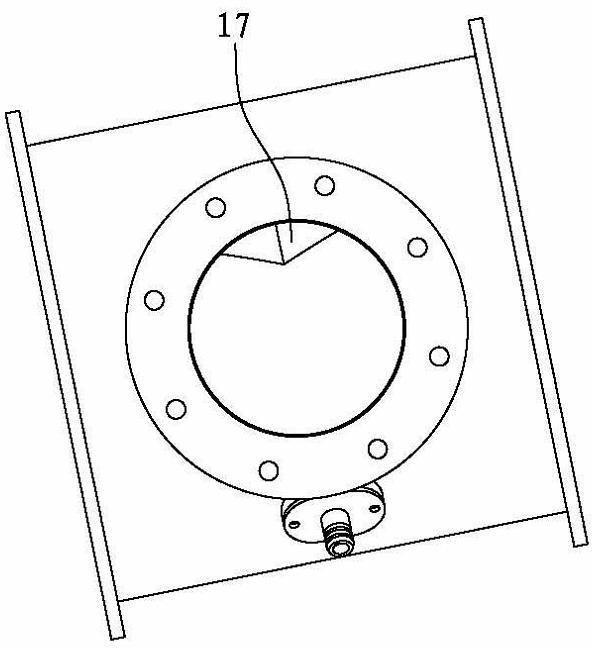

Suspended type gas locking discharge valve

The invention discloses a suspended type gas locking discharge valve. The suspended type gas locking discharge valve adopts a double-shell structure and comprises an outer shell, an inner shell, an impeller, a bearing block, a rotating shaft, a transmission assembly, end covers, gas guiding ports, a blocking prevention structure and a sealing element, wherein the outer shell and the inner shell are sheathed with each other coaxially, a material inlet arranged at the upper end of the cylinder wall of the outer shell is connected with a hopper, and the material inlet is provided with the blocking prevention structure; a discharge valve outlet arranged below the inner shell extends to the outside of the outer shell; the inner shell is axially fixed on the outer shell by an arc-shaped support pad and the end covers; the impeller with a side baffle plate is arranged in the inner shell, the rotating shaft of the impeller is fixed by the bearing block, and the impeller is driven to rotate by the transmission assembly; the gas guiding ports are arranged on the outer shell and the inner shell; the inner shell and the outer shell are sealed by the end covers, and the rotating shaft of the impeller passes through the end covers; and the sealing element is arranged between members. The discharge valve is light weight, good in bearing performance and strong in gas tightness, the gas in the inner shell can be prevented from leaking, the gas transmission capability is improved, the work energy consumption in a gas transmission system is reduced, material blockage is prevented, and the material loading quantity is large, the maintenance is convenient and the service life is long.

Owner:XIAMEN MEIGANQIDONG MATERIAL CONVEYING ENG

Plate link chain belt conveyor

ActiveCN105217228AReduced Integrity Coverage PurposeGuaranteed integrity coverageConveyorsClosed loopEngineering

The invention relates to the field of car dismounting conveying devices, in particular to a plate link chain belt conveyor. The device at least comprises a rack and a conveying assembly, and the conveying assembly comprises a conveying belt and a power part; the conveying belt is a plate link chain conveying belt, the surface of the conveying belt is covered with a rubber mat layer serving as the working face of the conveying belt, and the rubber mat layer at least covers fit clearances which form link plates of the conveying belt; the conveying belt comprises chains and a driving tooth roller, the link plates are erected between two closed loop chains, and a gap is reserved between every two adjacent link plates; the appearance of the rubber mat layer is of a closed loop belt-shaped structure, the inner annular face of the rubber mat layer is attached to the surfaces of the link plates and is sequentially connected with the link plates to form an integrated structure, and installation holes are formed in the link plates; and fastening bolts penetrate the installation holes of the link plate and penetrate the rubber mat layer to be fixedly connected through threads. By means of the plate link chain belt conveyor, on-line conveying requirements of waste after a car is dismounted can be stably achieved, and the self service life and the working efficiency can be effectively guaranteed.

Owner:TONGLING MIRACLE MECHANICAL EQUIP

Magnet assembling mechanism

ActiveCN106041465AEasy to processEasy maintenanceMetal working apparatusProduction lineElectric machinery

The invention discloses a magnet assembling mechanism. The magnet assembling mechanism comprises an assembling working table, a conveying mechanism, a separating mechanism, a filling mechanism, a rapid disassembling magazine, a magazine holding mechanism and a tray, wherein a carrier plate used for placing the tray is arranged in the center of the table surface of the assembling working table; the conveying mechanism comprises two conveyor belts driven by a motor, and the two conveyor belts are separately arranged on the table surface, on the left and right sides of the carrier plate, of the assembling working table; and the filling mechanism is arranged on the two conveyor belts, the separating mechanism is arranged at the front part of the filling mechanism, the magazine holding mechanism is arranged at the upper part of the filling mechanism, and the rapid disassembling magazine is perpendicularly plugged on the magazine holding mechanism. The mechanism has the advantages of being simple to machine, simple to maintain, rapid to disassemble and assemble, low in cost, high in efficiency and the like, can be widely applied to various mobile phone production lines, and has advantages over the existing structures on the market in machining, assembly and later maintenance due to novel structural design and magnet assembling mode.

Owner:苏州茂特斯自动化设备有限公司

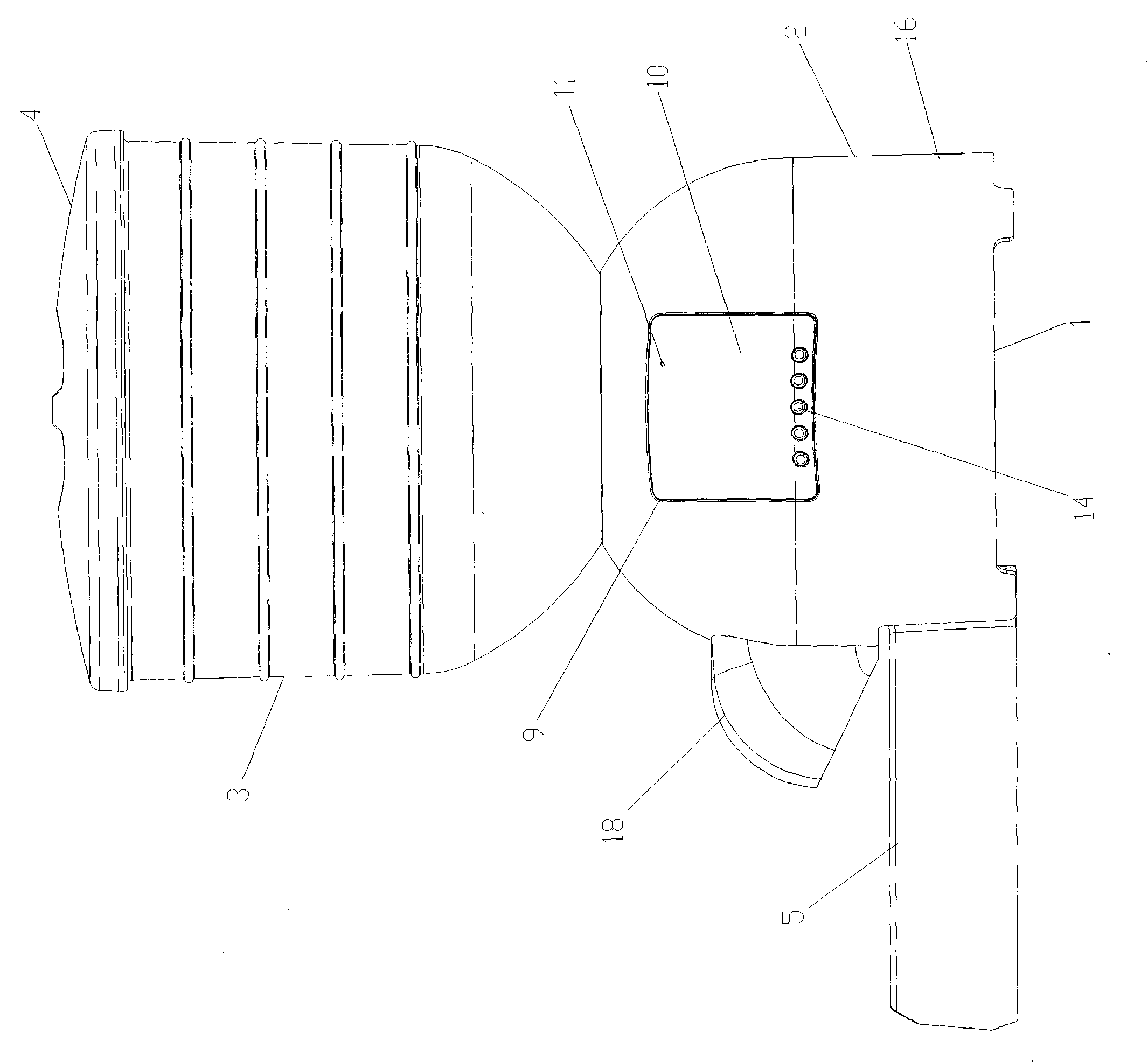

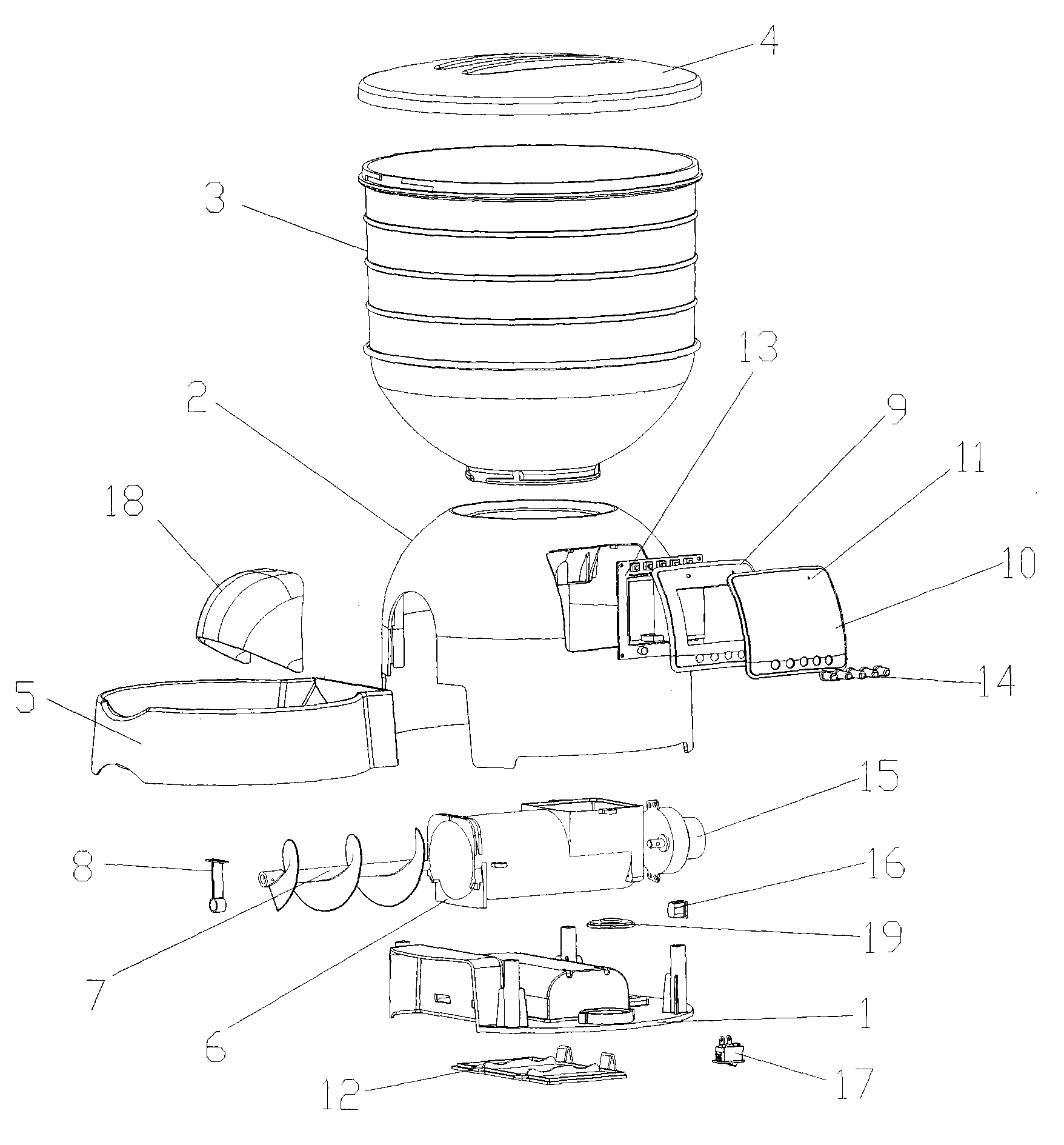

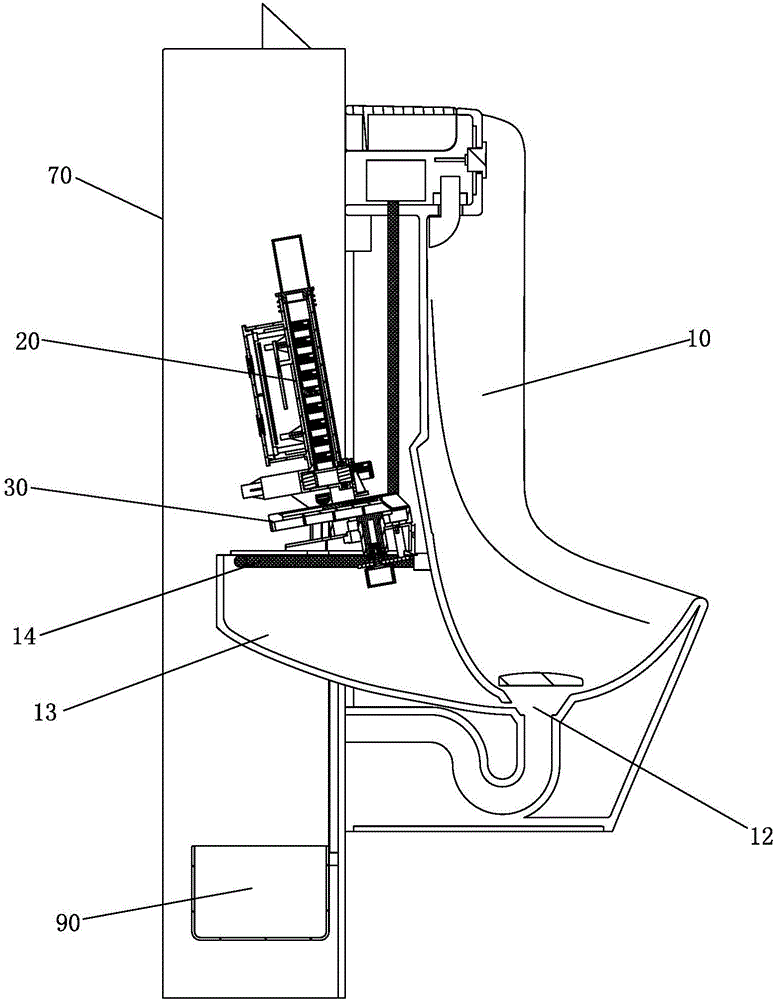

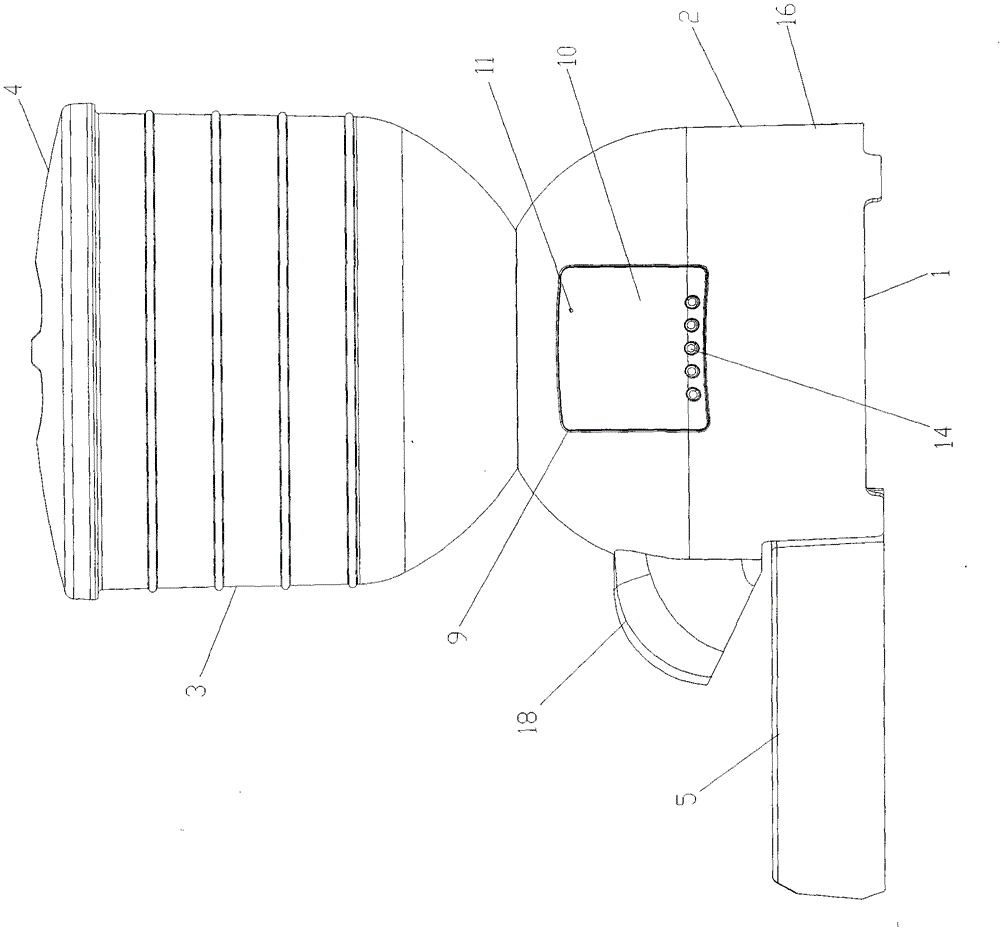

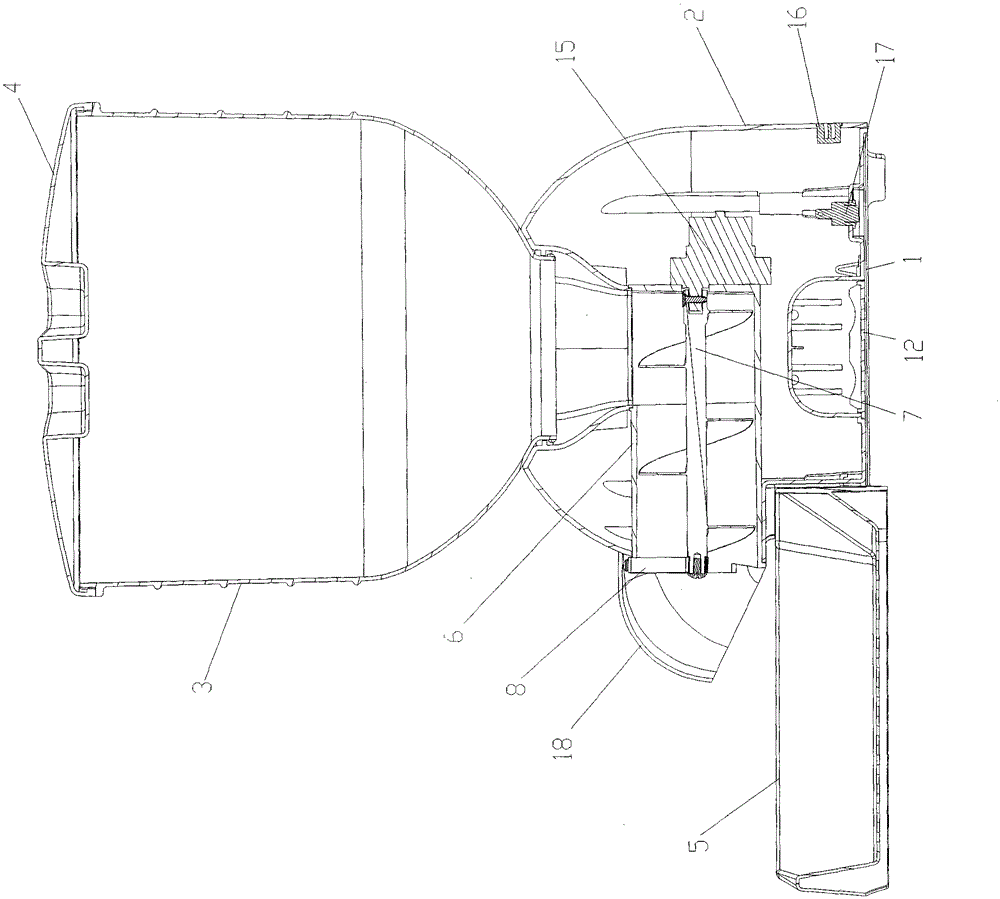

Pet feeder

ActiveCN104067953AAvoid material jamsPrevent leakageAnimal feeding devicesControl systemControl circuit

The invention discloses a pet feeder which is mainly composed of a base casing, a blanking barrel, a food disc, a motor and a power switch. A blanking opening is arranged in the base casing, a spiral sleeve fixedly connected with the blanking opening is arranged below the blanking opening, a screw is installed in the spiral sleeve, one end of the screw is fixedly connected with the motor, the other end of the screw is fixed in the spiral sleeve through a screw supporting device, and the screw is provided with a spiral piece. A nose cover is installed on the outer side of the spiral sleeve and fixedly connected with the base casing through a buckle, a discharging channel bent downwards is positioned in the nose cover, the bottom of the base casing is provided with a base, the base is provided with a groove, the food disc is arranged below the nose cover and positioned in the groove of the base, and the pet feeder further comprises a circuit control system for controlling a circuit to achieve various feeding functions. The pet feeder has the advantages of being simple in structure, working reliably and being rich in functions, capable of achieving continuous automatic feeding many times for many days and capable of automatically stopping feeding when the food disc is filled with food.

Owner:PANJIN HAIXING FINE CHEM TECH

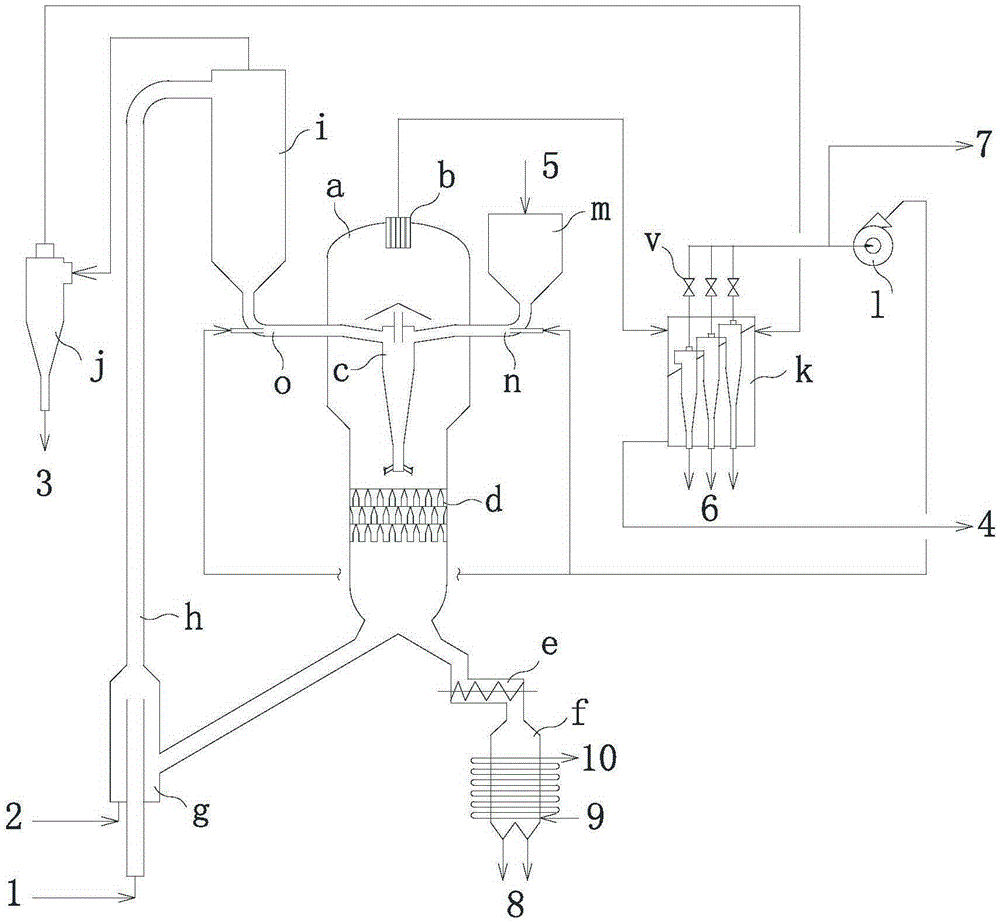

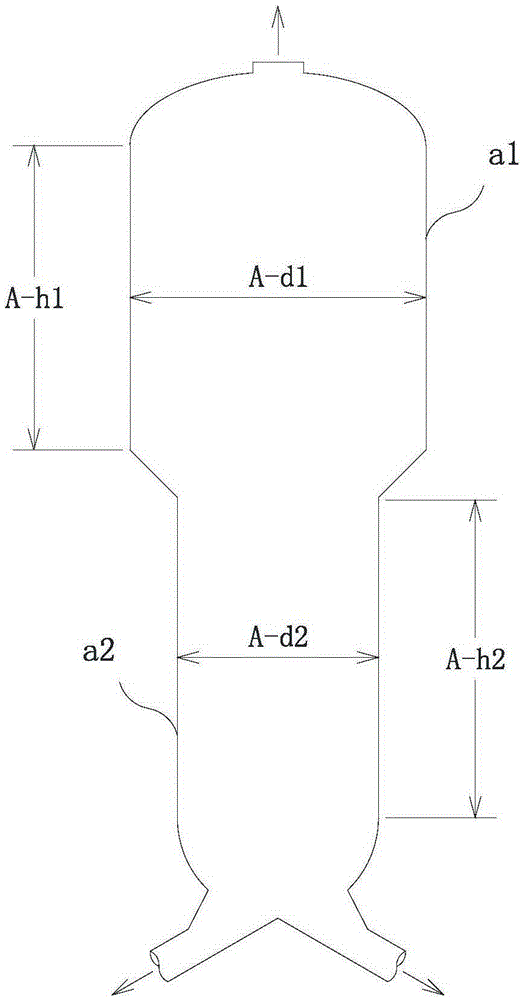

Gas-solid mixed heat carrier quick pulverized coal pyrolysis process and device

InactiveCN105238425AAvoid entrainmentPush breakSpecial form destructive distillationCycloneHeat carrier

The invention discloses a gas-solid mixed heat carrier quick pulverized coal pyrolysis process and a device. The device includes a diameter variable pyrolysis reactor, the top outlet of the pyrolysis reactor is provided with a pyrolytic oil gas collector, a vortex mixer is hidden in the middle part, a breathable heat storage layer is arranged at the lower part, two hot semicoke outlets are arranged at the bottom, one outlet is used for discharging hot semicoke, and the other outlet is connected to a tobacco pipe type refeeder, the tobacco pipe type refeeder is connected to a simple separator through a combustion lift pipe, the bottom of the simple separator is provided with an L-shaped high temperature semicoke control valve, the bottom of a dry raw material coal bunker is equipped with an L-shaped dry raw material coal control valve, outlets of the two valves are respectively connected to two inlets of the vortex mixer, the pyrolytic oil gas collector is in connection with an oil gas inlet manifold box of a box type multi-tube cyclone dust collector, the outlet of the box type multi-tube cyclone dust collector is connected to a high temperature centrifugal fan, the outlet of the high temperature centrifugal fan is connected to the L-shaped dry raw material coal control valve and the L-shaped high temperature semicoke control valve. Therefore, disadvantages of the prior art are overcome.

Owner:SHAANXI MEISILIN ENERGY SCI & TECH RES INST

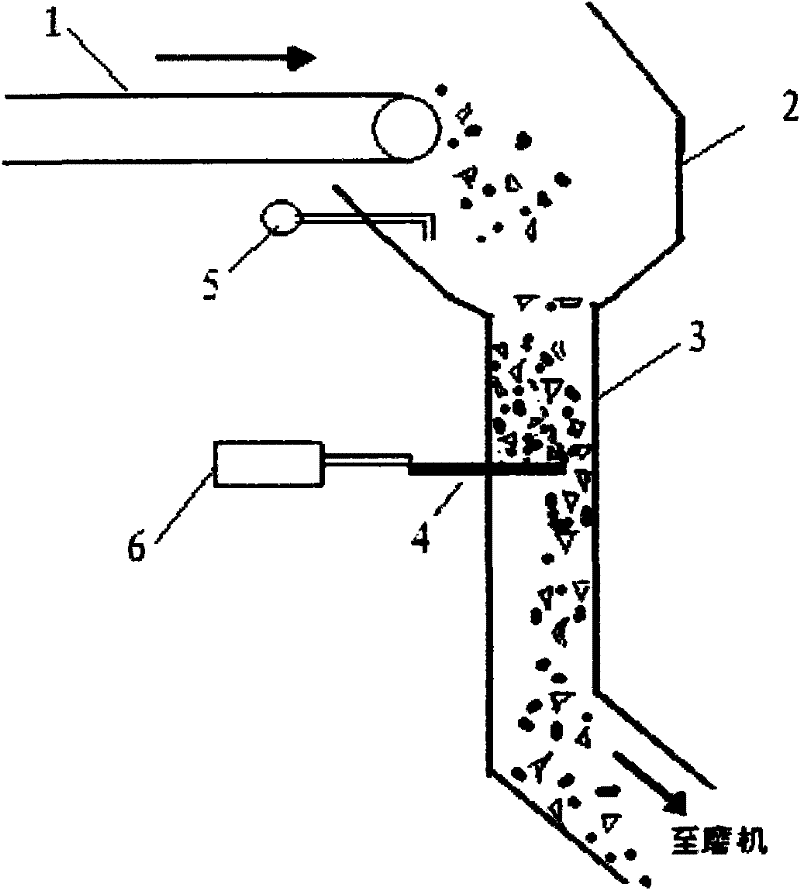

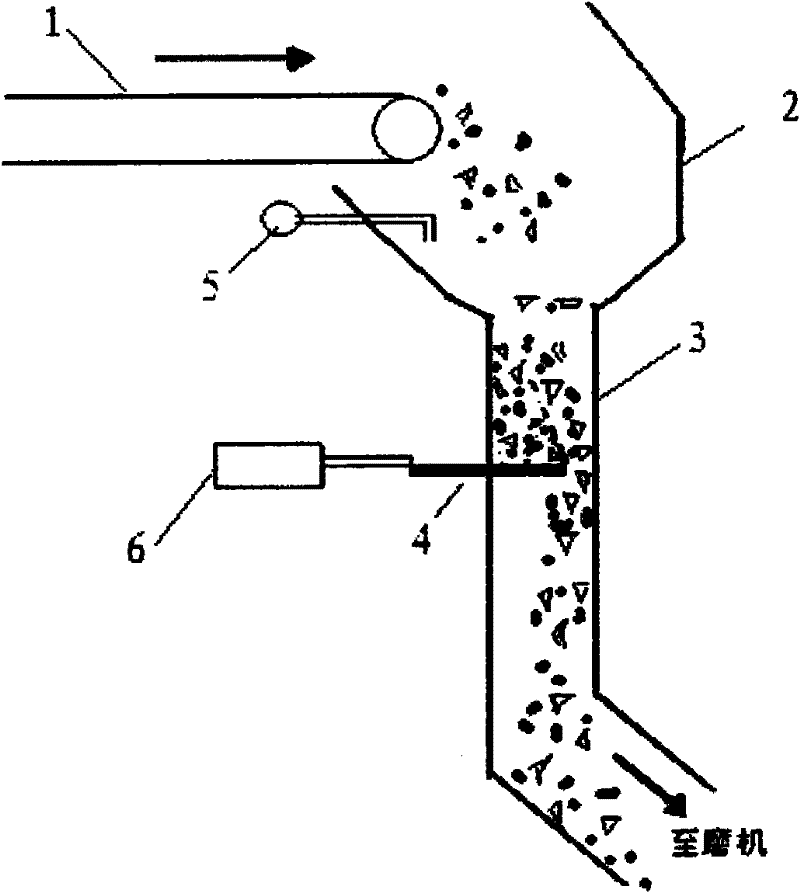

Vertical Mill Sealed Feeder

ActiveCN102259758ASolve the problem of air leakageSolve the vibrationLarge containersConveyor partsLower limitPressure rise

The invention provides a hermetic feeder for a vertical mill. The feeder comprises a mill feed belt, a blanking pipe, a blanking straight pipe, a horizontal insertion plate and a negative pressure meter, wherein the blanking pipe is arranged below the mill feed belt; the blanking straight pipe is connected below the blanking pipe; the horizontal insertion plate is arranged in the middle section of the blanking straight pipe; the length of the horizontal insertion plate stretching into the blanking straight pipe can be adjusted by an actuating mechanism, so that a blanking space is formed by agap between the horizontal insertion plate and the blanking straight pipe and is used for materials to pass through; and the negative pressure meter is arranged above the blanking pipe, is connected with an automatic control system and a central controller, and is provided with an upper limit value and a lower limit value, so that negative pressure starts dropping from a normal value when the blanking straight pipe is blocked, the automatic control system makes the actuating mechanism start acting to open the horizontal insertion plate when the negative pressure reaches the lower limit value,the negative pressure rises due to automatic dredging of material scouring, the automatic control system makes the actuating mechanism close the horizontal insertion plate when the negative pressure reaches the upper limit value, and the negative pressure is restored to the normal value.

Owner:SICHUAN ESHENG CEMENT GROUP

Sealed quantitative feeding machine and control system thereof

PendingCN108861465ARealize airtight air lock functionThe airtight air lock function is satisfiedConveyorsConveyor partsControl systemLevel sensor

The invention discloses a sealed quantitative feeding machine and a control system thereof, and relates to the technical field of vibrating feeding. The machine comprises a vibrating delivering chamber, and the two ends of the vibrating delivering chamber are fixedly communicated with a discharging passage and a measuring chamber through glued canvases; the bottom side face of the vibrating delivering chamber is connected with a fixing frame through two groups of elastic buffering mechanisms, a vibrating motor supporting frame is fixed to the bottom face of the vibrating delivering chamber, and a plurality of vibrating motors are fixed to the vibrating motor supporting frame; a weighing chamber is fixedly communicated with the top of the discharging passage. According to the machine, materials pass through the weighing chamber and the discharging passage and enter the vibrating delivering chamber to be vibrated and discharged, material flow rate is calculated by pulling a pressure sensor in the measuring chamber, and the blockage situation is judged by a damped rotation material level sensor in the measuring chamber; air locking effect of the feeding machine is improved by maintaining the material level of the weighing chamber and flow rate control, the structure is simple, the faulting rate is low, and the size of the feeding machine is effectively reduced.

Owner:ANHUI WEIQIONG DRIVING TECH CO LTD

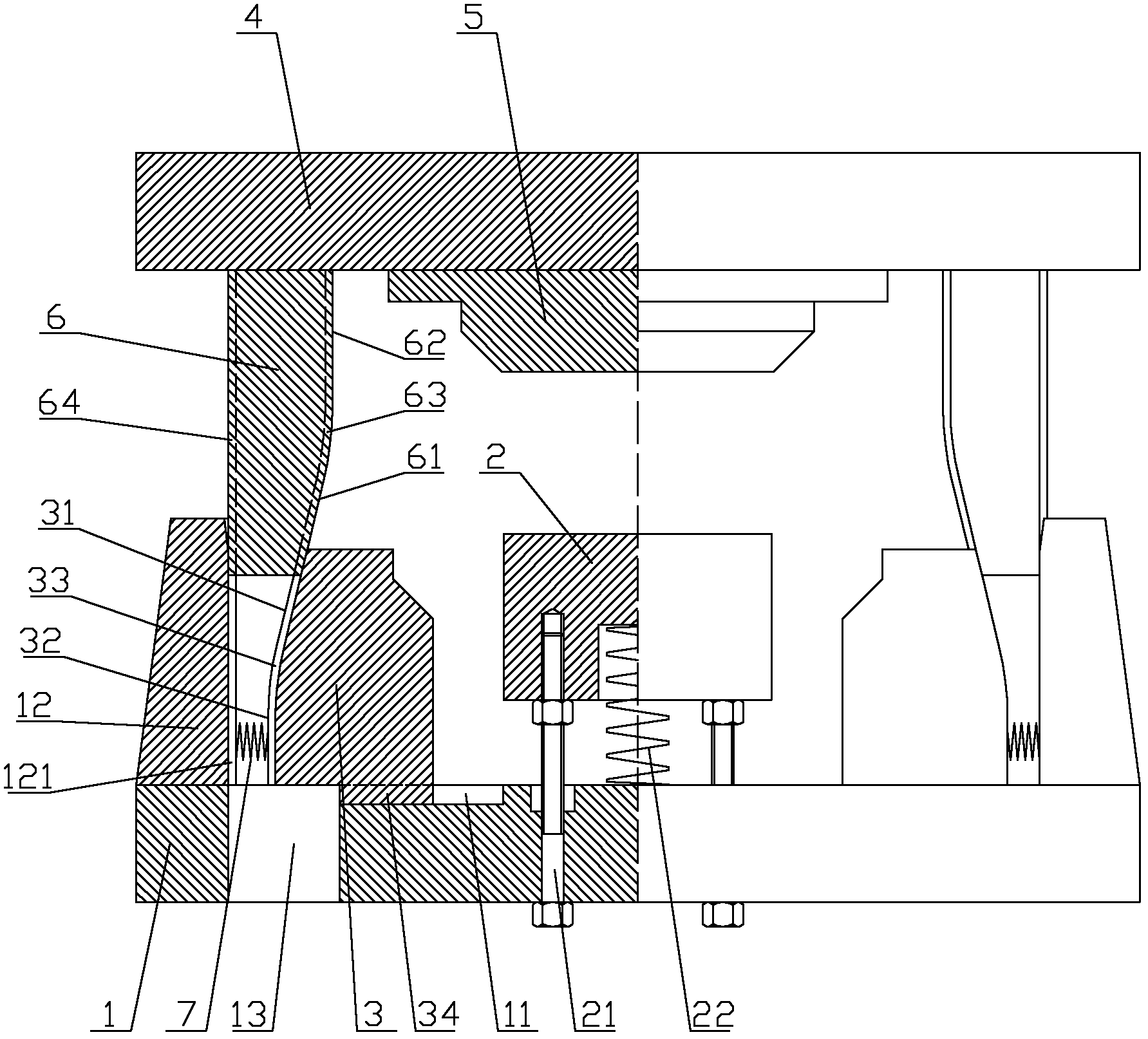

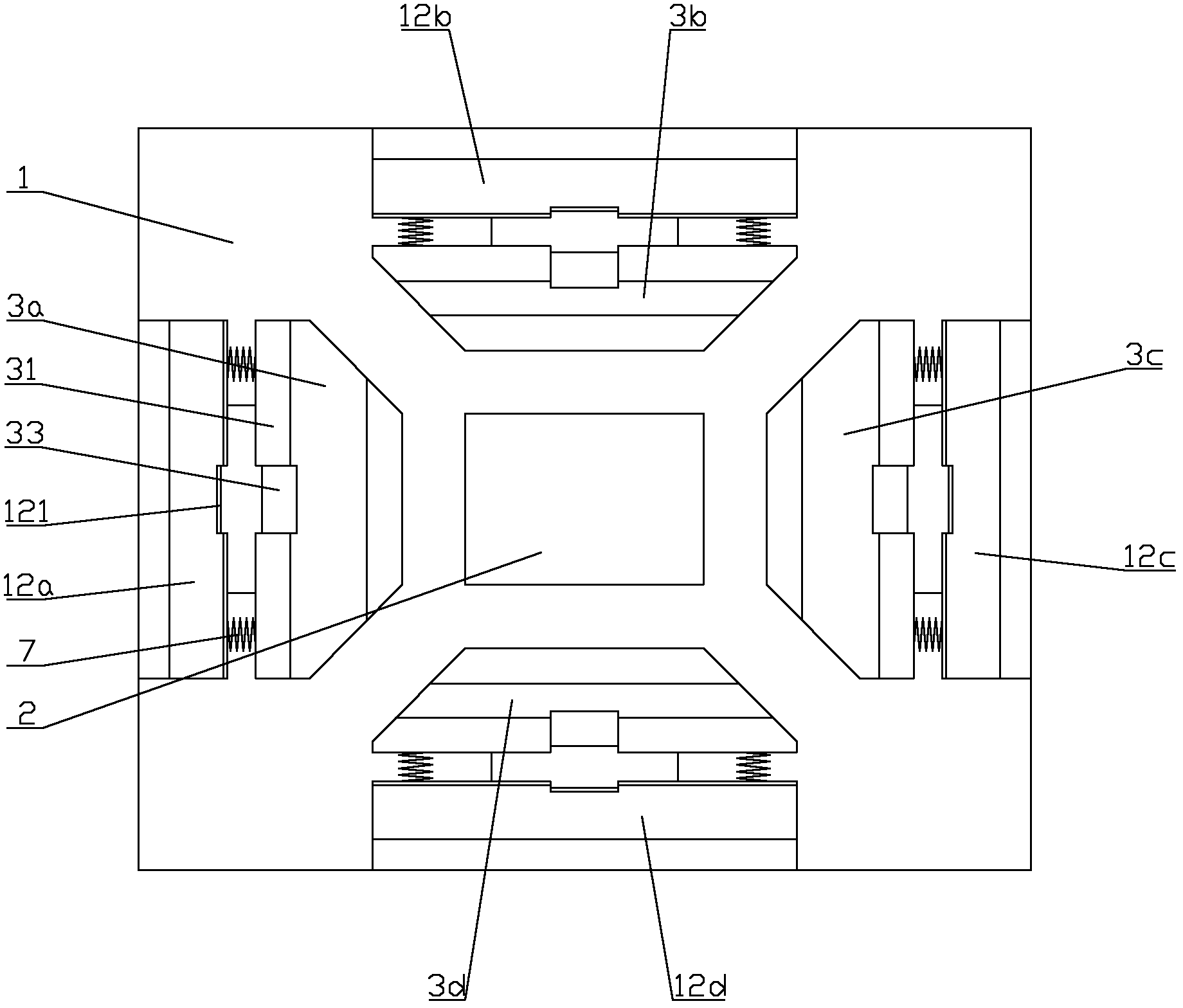

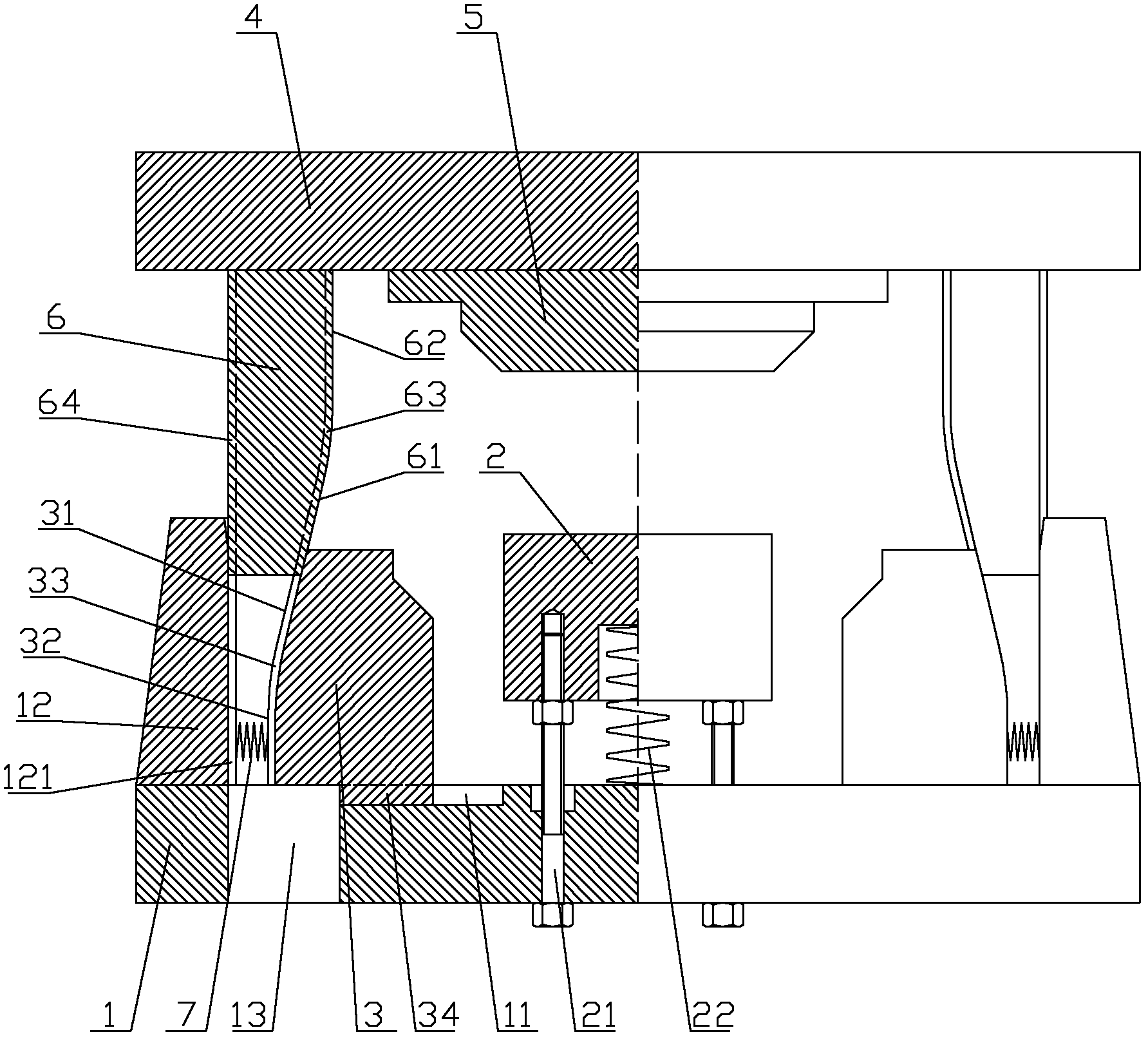

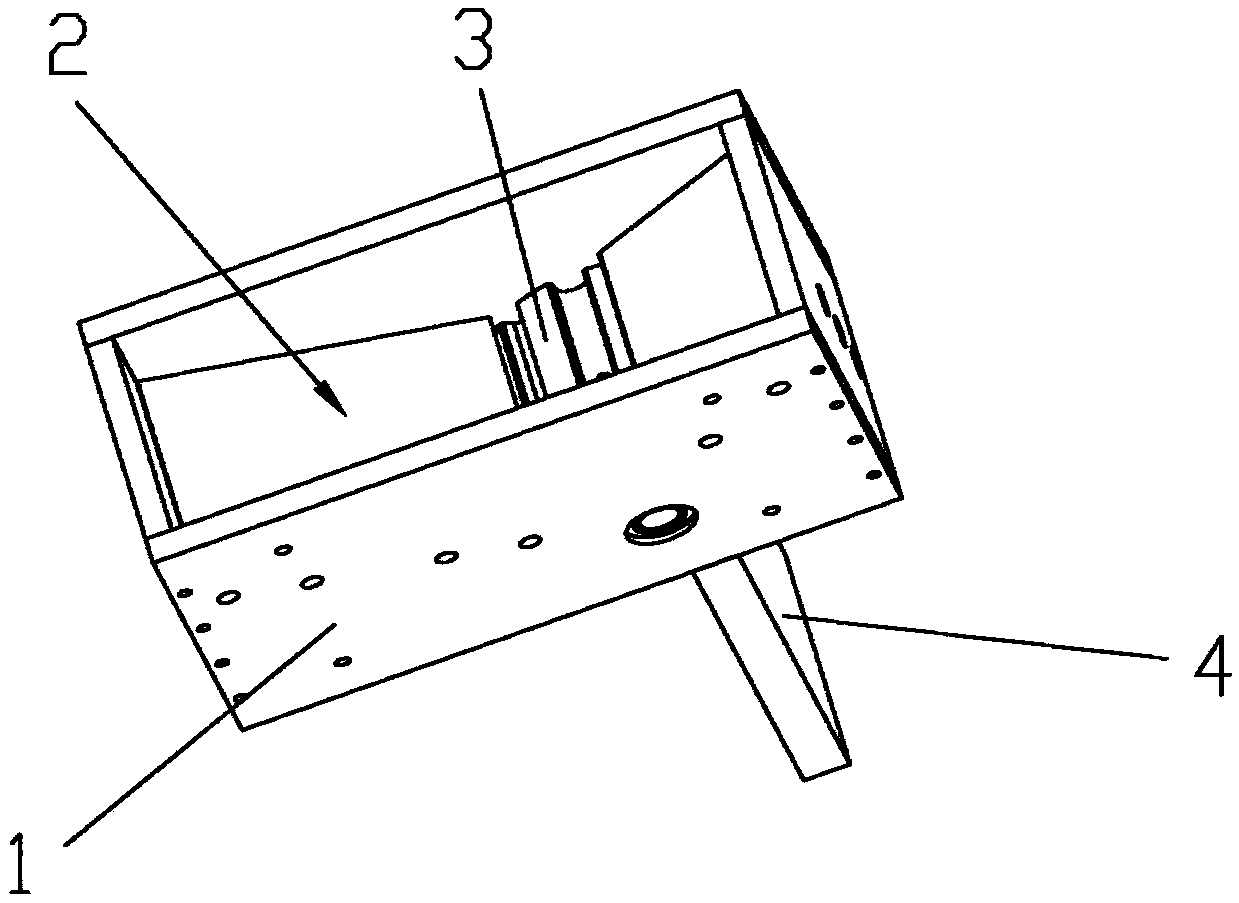

Spliced stamping mould

InactiveCN102397951AEasy to take outReduce contact areaShaping toolsEjection devicesSurface structureMaterials science

The invention discloses a spliced stamping mould. The mould comprises an upper mould component and a lower mould component, wherein the lower mould component comprises a lower mould seat, a material supporting block and at least two splicable lower mould splicing blocks which encircle the outer side of the material supporting block and are connected to the lower mould seat in a sliding mode; the material supporting block has a liftable structure; inner side surfaces encircled by splicing the lower mould splicing blocks and the top surface of the material supporting block can be spliced to form a complete lower mould surface; the upper mould component comprises an upper mould seat, an upper mould and push blocks; the upper mould is fixedly arranged on the bottom surface of the upper mould seat; and the push blocks encircle the outer side of the upper mould, correspond to the lower mould splicing blocks one to one and are used for pushing the corresponding lower mould splicing blocks for splicing when a workbench on a stamping machine descends. The lower mould of the spliced stamping mould has a spliced structure, each lower mould splicing block can move to the outer side to be separated from a workpiece along the horizontal direction after stamping forming, the workpiece is supported by the material supporting block, the top surface of the material supporting block is a part of lower mould surface, and the contact area of the material supporting block and the workpiece is relatively small, so that the workpiece with a complex surface structure is easy to take out, material blocking can be effectively avoided, and production efficiency can be ensured.

Owner:CHONGQING HUAQING AUTOMOBILE PARTS

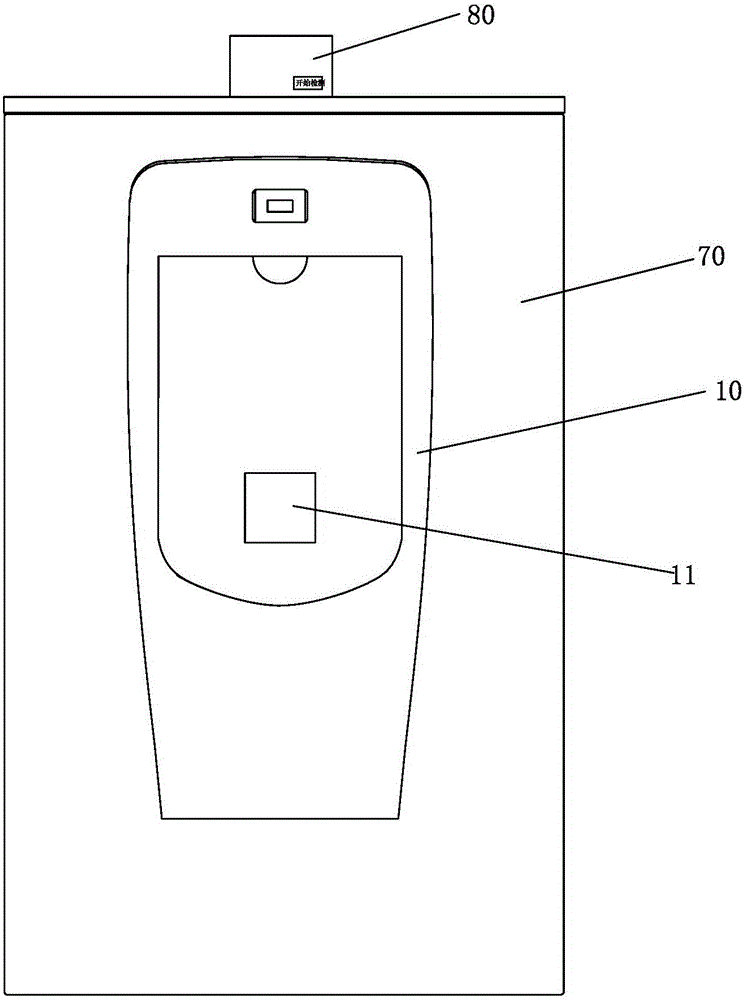

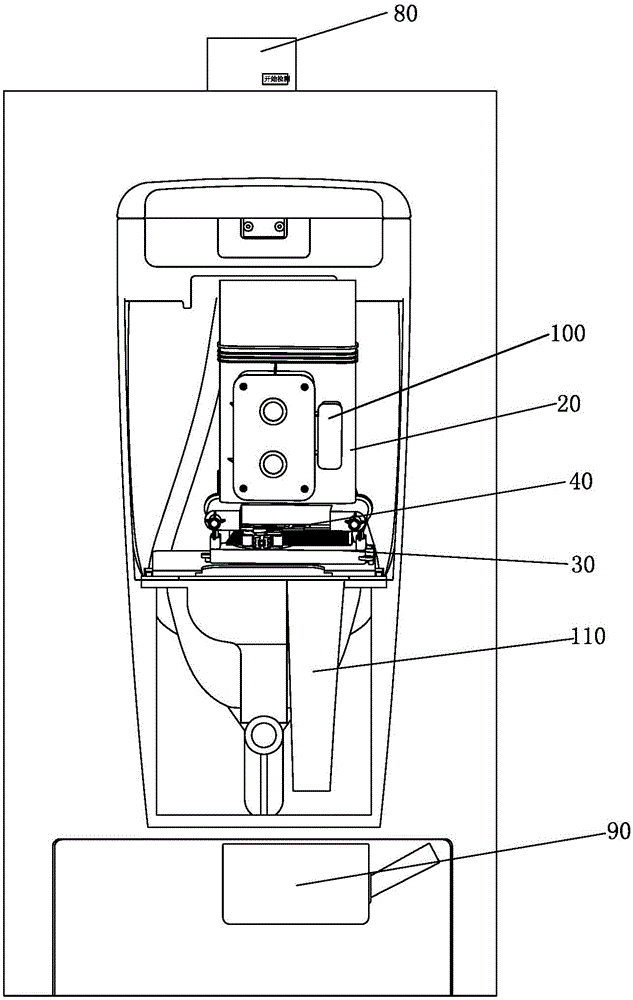

Urine detection device and method

ActiveCN106248920AHigh degree of automationImprove work efficiencyMaterial analysisComputer scienceTest strips

The invention discloses a urine detection device and method. The urine detection device comprises a urine detection assembly. The urine detection assembly comprises a feeding module, a conveying module and a data obtaining module, wherein the feeding module comprises a storage box, the storage box is provided with a plurality of test paper boxes, the test paper boxes contain urine detection test paper, the storage box is provided with a test paper box outlet, the conveying module drives the test paper boxes output from the outlet of the storage box to move so as to achieve urine sampling or urine detection data obtaining or discharging, and the data obtaining module is used for obtaining urine detection data of urine detection test paper soaked with urine in the test paper boxes. The device can automatically complete test paper box feeding, urine sampling, urine detection data obtaining, and is high in automation degree and working efficiency, more intelligent, low in overall cost, high in practicability and easier to popularize.

Owner:JOMOO KITCHEN & BATHROOM

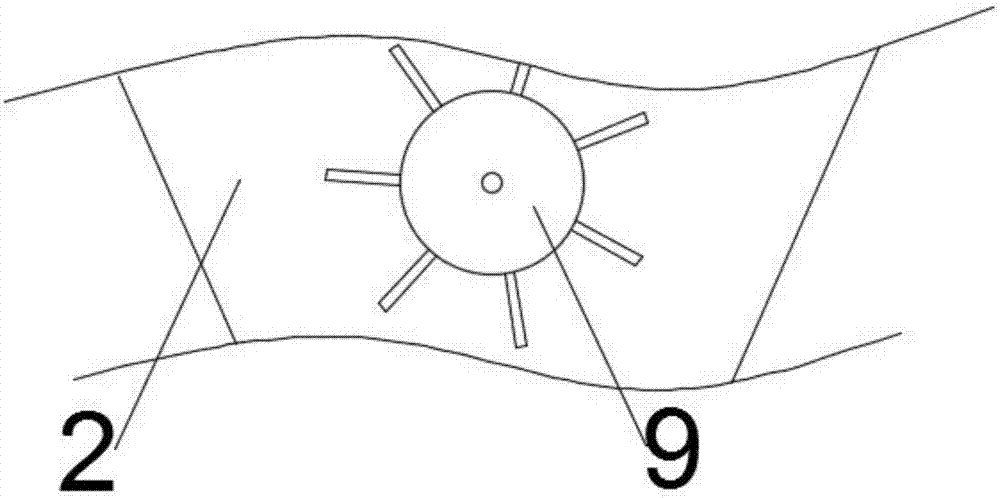

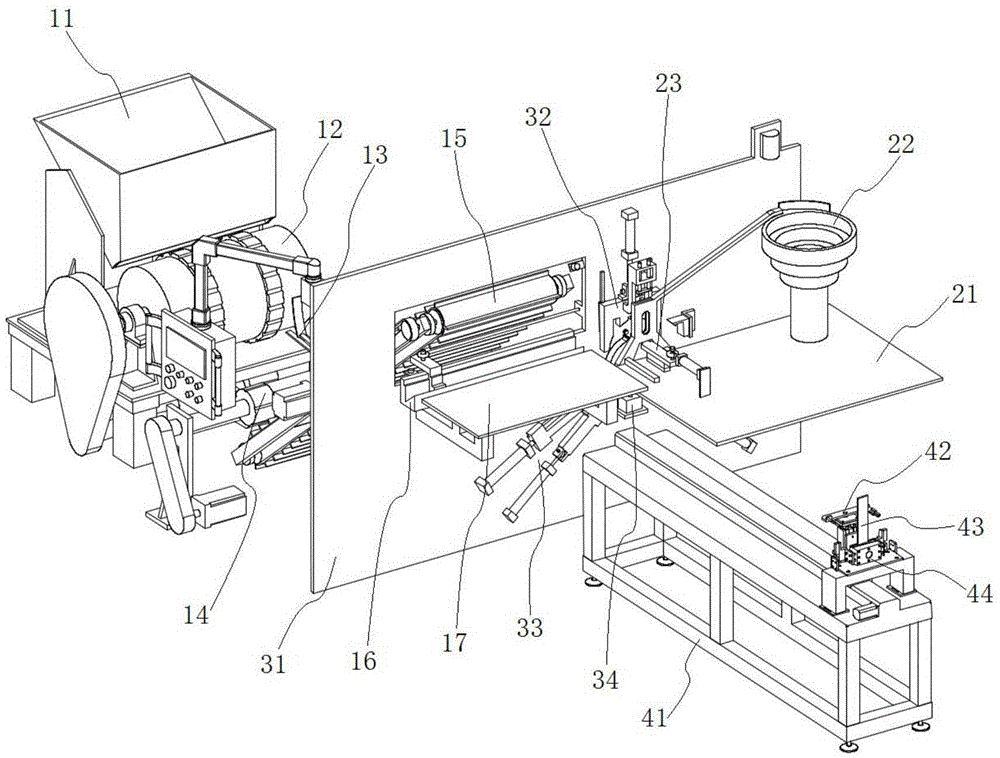

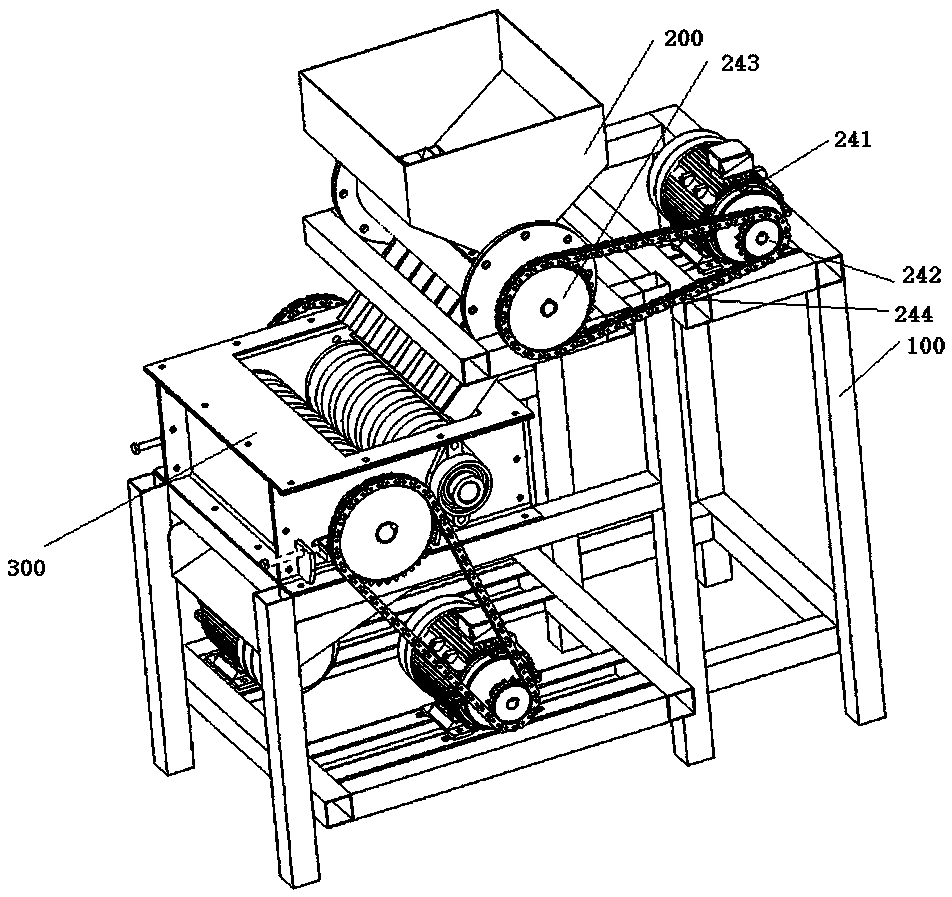

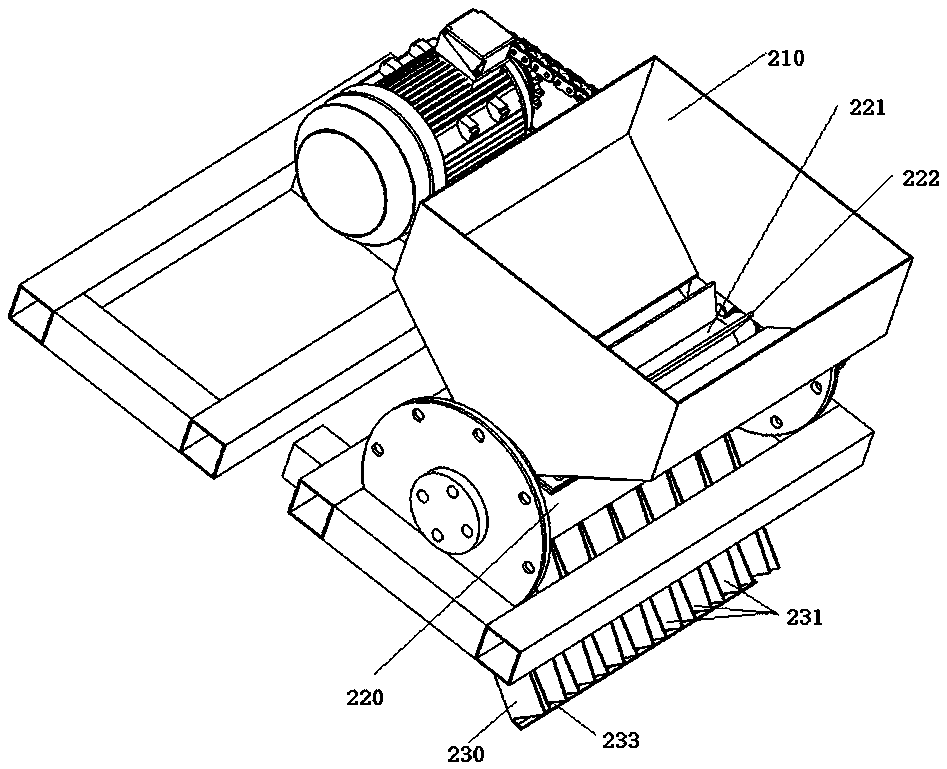

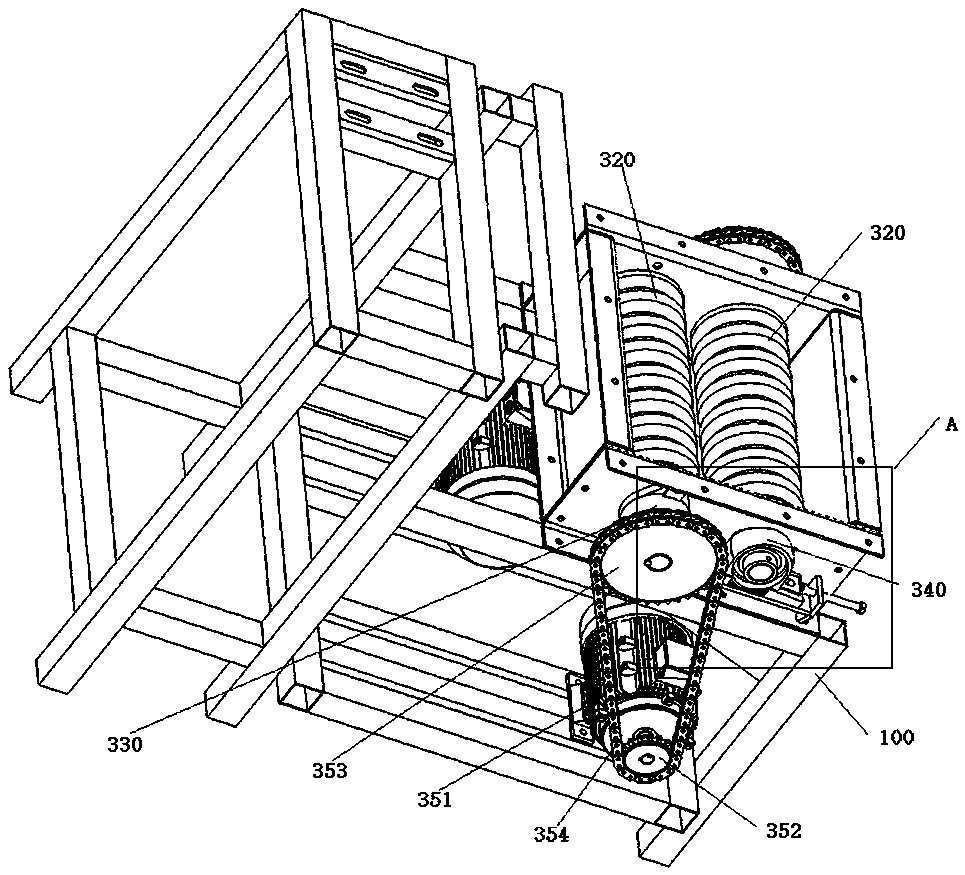

Hull breaking machine based on pretreated walnuts

The invention discloses a hull breaking machine based on pretreated walnuts, and relates to the field of walnut deep processing equipment. The hull breaking machine comprises a rack, an impeller feeding device and an opposite roller extrusion device; the impeller feeding device conducts feeding through an impeller to enable the walnuts to fall into the opposite roller extrusion device orderly, sothat the feeding efficiency is ensured; rollers of the opposite roller extrusion device are structurally optimized, V-shaped annular grooves in the rollers of the opposite roller extrusion device areformed alternately with roller sections to avoid mutual interference of the walnuts and improve the hull breaking efficiency, meanwhile one of the rollers is fixedly arranged, and the other roller isadjustable so as to adapt to hull breaking of the walnuts with different sizes and increase the kernel exposure rate; the impeller feeding device and the opposite roller extrusion device are both driven in a chain transmission mode, the driving speed of the impeller feeding device and the driving speed of the opposite roller extrusion device are matched to enable the materials to be smooth, the work continuity of the hull breaking machine is ensured, and the efficiency is improved; the outer surfaces of the rollers are wrapped with a PVC belt, jumping of the walnuts during falling is reduced,the extrusion efficiency is improved, meanwhile the adaptability of the walnuts in an extrusion work area is improved through the PVC belt, and the high kernel exposure rate is achieved.

Owner:SHIHEZI UNIVERSITY

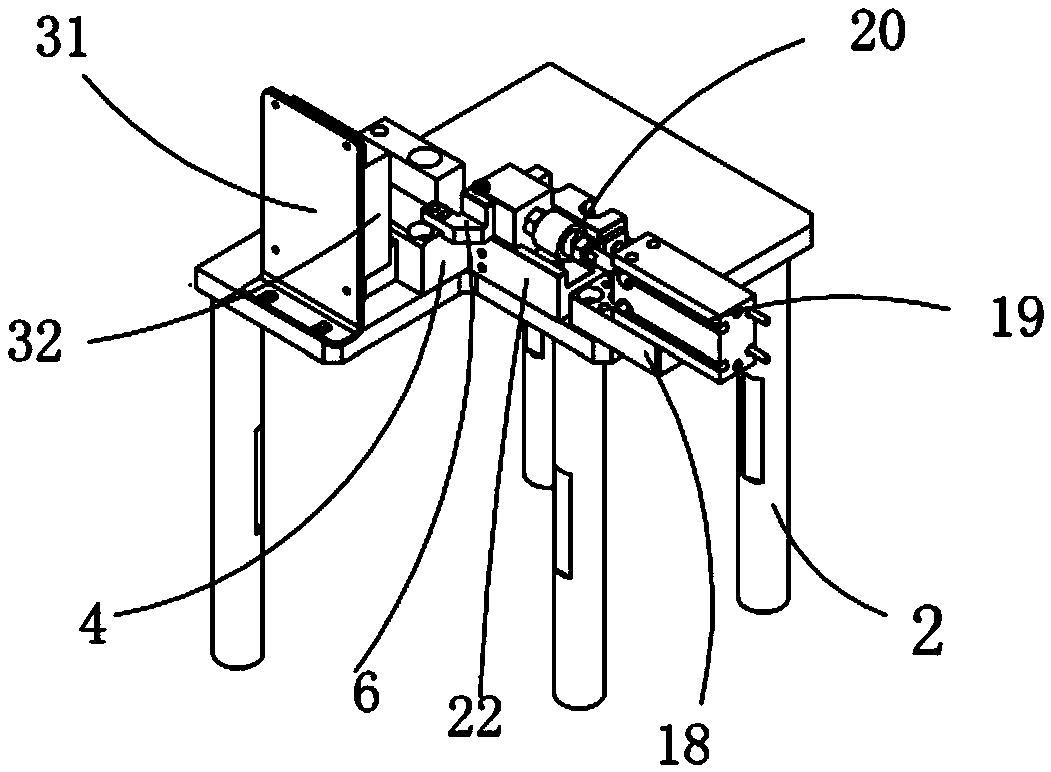

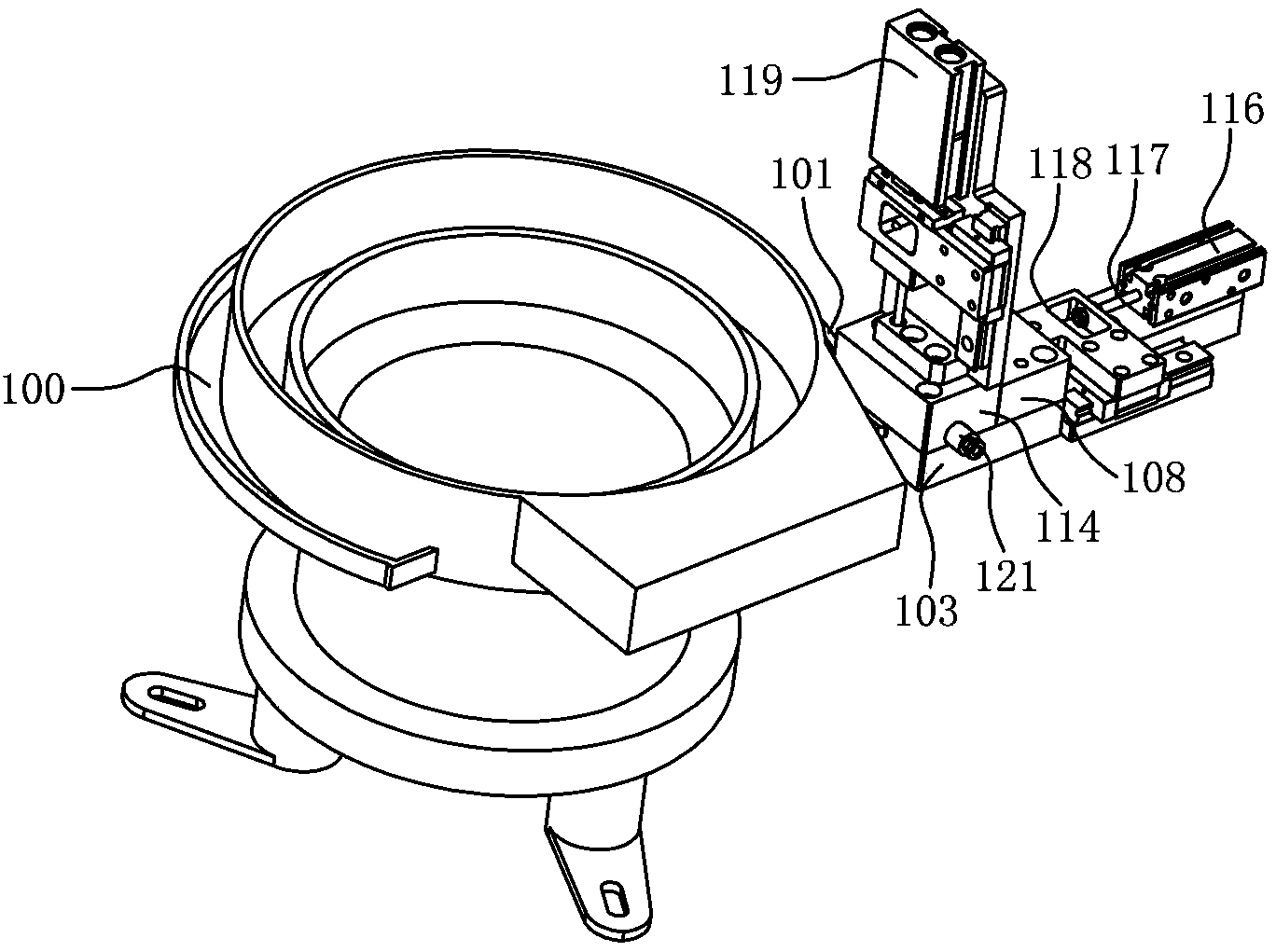

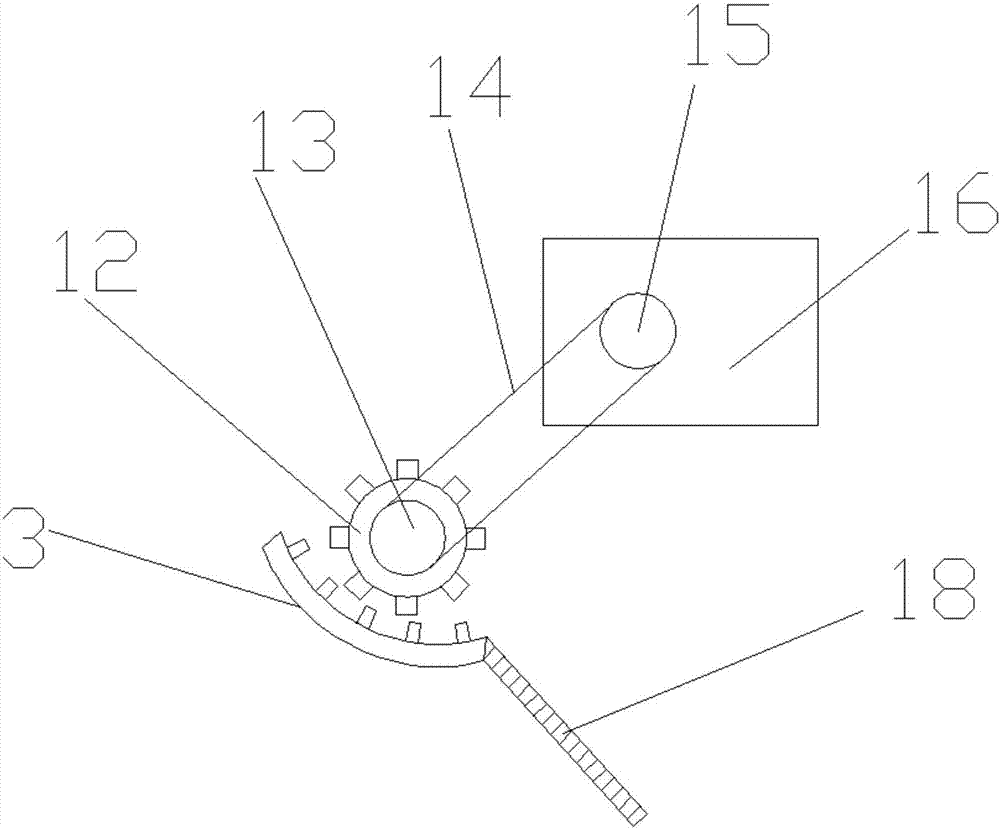

Nut distribution device

The invention discloses a nut distribution device. The nut distribution device comprises a vibration plate which is provided with a discharge opening in one side and internally placed with nuts to be distributed, a first distribution block provided with a feed chute and a blanking opening in one side, a first clamping block provided with a first clamping portion, a second distribution block provided with a spring hole and a guide column hole which are communicated with each other, a second clamping block which is provided with a second clamping portion matched with the first clamping portion for clamping the nuts and a guide column on one side, a spring, a third distribution block, a feed collection tube, a mismatch cylinder provided with a push rod at one end, and a pressing cylinder which is arranged above the third distribution block and provided with an ejection pin. By means of the nut distribution device, the nuts are clamped between the first clamping portion and the second clamping portion to be free from inclination, so that the phenomenon of nut reverse and blocking can be avoided.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

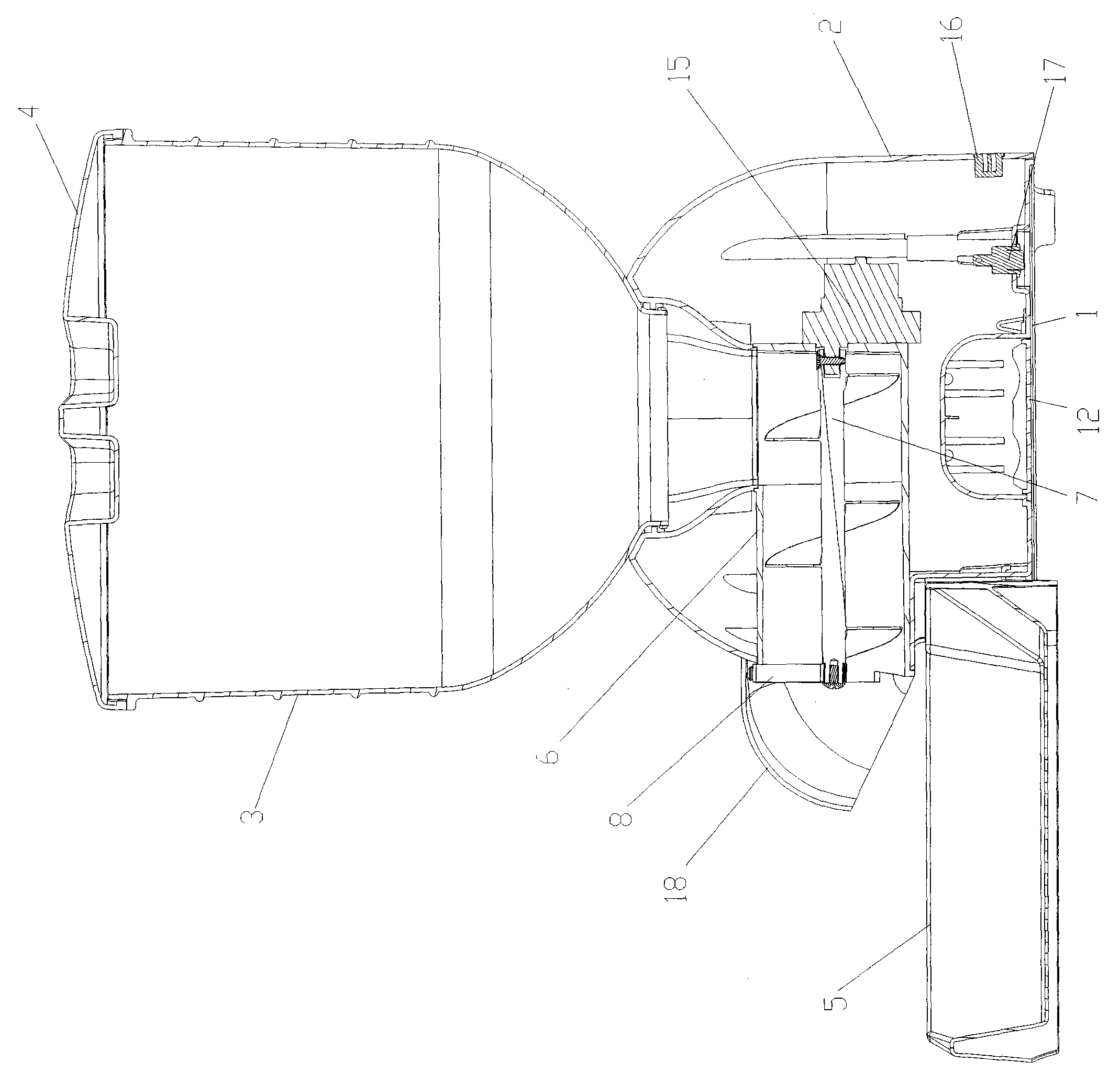

pet feeder

ActiveCN104067953BAvoid material jamsPrevent leakageAnimal feeding devicesControl systemControl circuit

The invention discloses a pet feeder which is mainly composed of a base casing, a blanking barrel, a food disc, a motor and a power switch. A blanking opening is arranged in the base casing, a spiral sleeve fixedly connected with the blanking opening is arranged below the blanking opening, a screw is installed in the spiral sleeve, one end of the screw is fixedly connected with the motor, the other end of the screw is fixed in the spiral sleeve through a screw supporting device, and the screw is provided with a spiral piece. A nose cover is installed on the outer side of the spiral sleeve and fixedly connected with the base casing through a buckle, a discharging channel bent downwards is positioned in the nose cover, the bottom of the base casing is provided with a base, the base is provided with a groove, the food disc is arranged below the nose cover and positioned in the groove of the base, and the pet feeder further comprises a circuit control system for controlling a circuit to achieve various feeding functions. The pet feeder has the advantages of being simple in structure, working reliably and being rich in functions, capable of achieving continuous automatic feeding many times for many days and capable of automatically stopping feeding when the food disc is filled with food.

Owner:PANJIN HAIXING FINE CHEM TECH

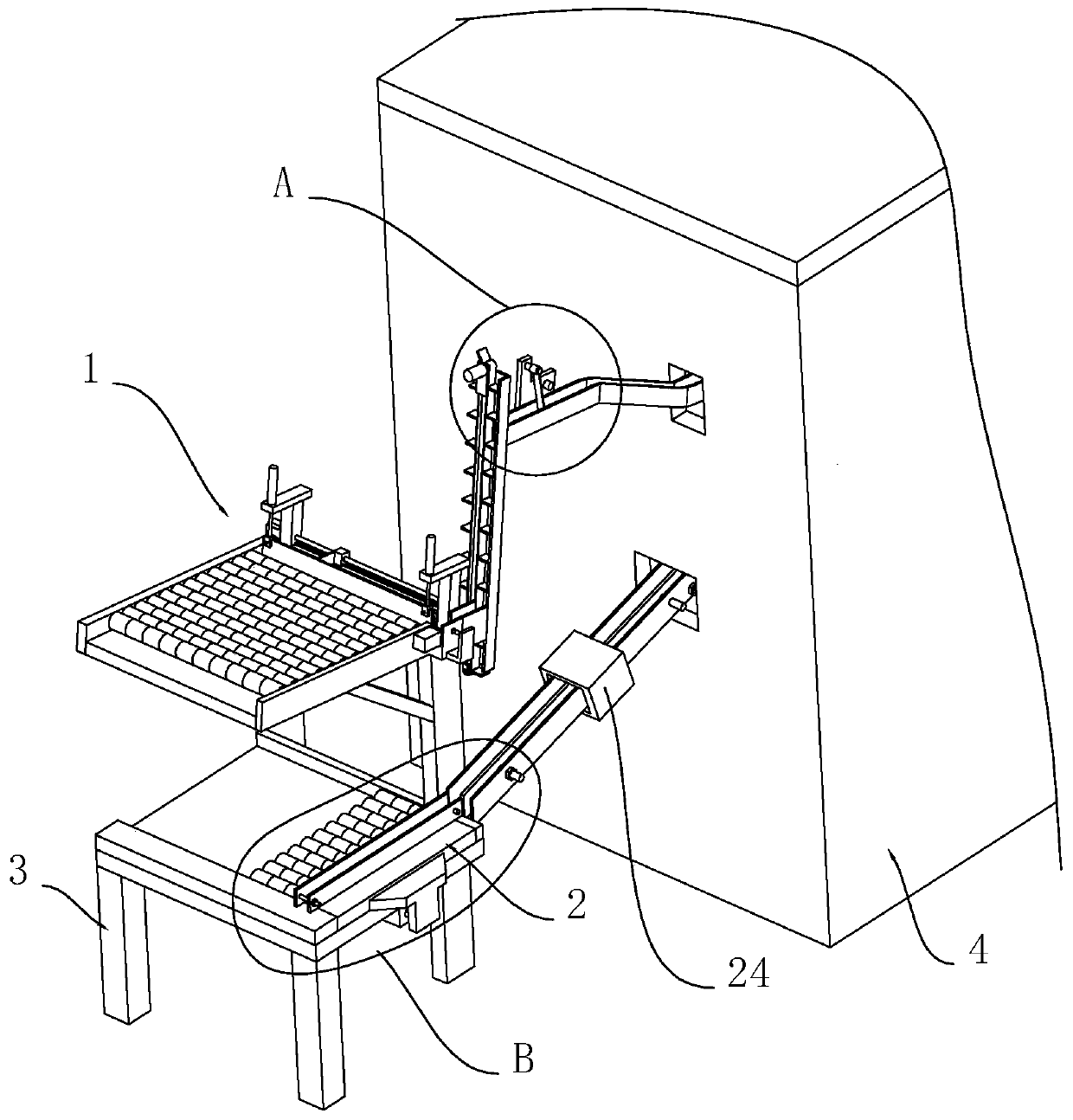

Conveying assembly and automatic feeding device

The invention discloses a conveying assembly and an automatic feeding device. The conveying assembly is used for conveying materials and comprises a material bin, a lifting feeding mechanism and a linear vibrator. The material bin is used for holding materials. The lifting feeding mechanism is used for conveying the materials in the material bin to the linear vibrator. The linear vibrator is arranged on the side wall of the material bin. The upper surface of the linear vibrator is provided with a clamping groove extending in the length direction of the linear vibrator. The clamping groove is used for clamping materials. The linear vibrator drives the materials to move to the output end of the clamping groove in the length direction. A baffle is arranged on the side, away from the materialbin, of the linear vibrator. The baffle is provided with a blowing hole used for being connected with a blowing mechanism, so that materials which are not clamped into the clamping groove are blown into the material bin through the blowing mechanism. In the technical scheme, the blowing mechanism can be installed at the blowing hole, the materials which are on the linear vibrator and are not stably clamped in the clamping groove are blown into the material bin, and the problems of material clamping and not-in-place feeding are avoided in the feeding process.

Owner:TCL KING ELECTRICAL APPLIANCES HUIZHOU

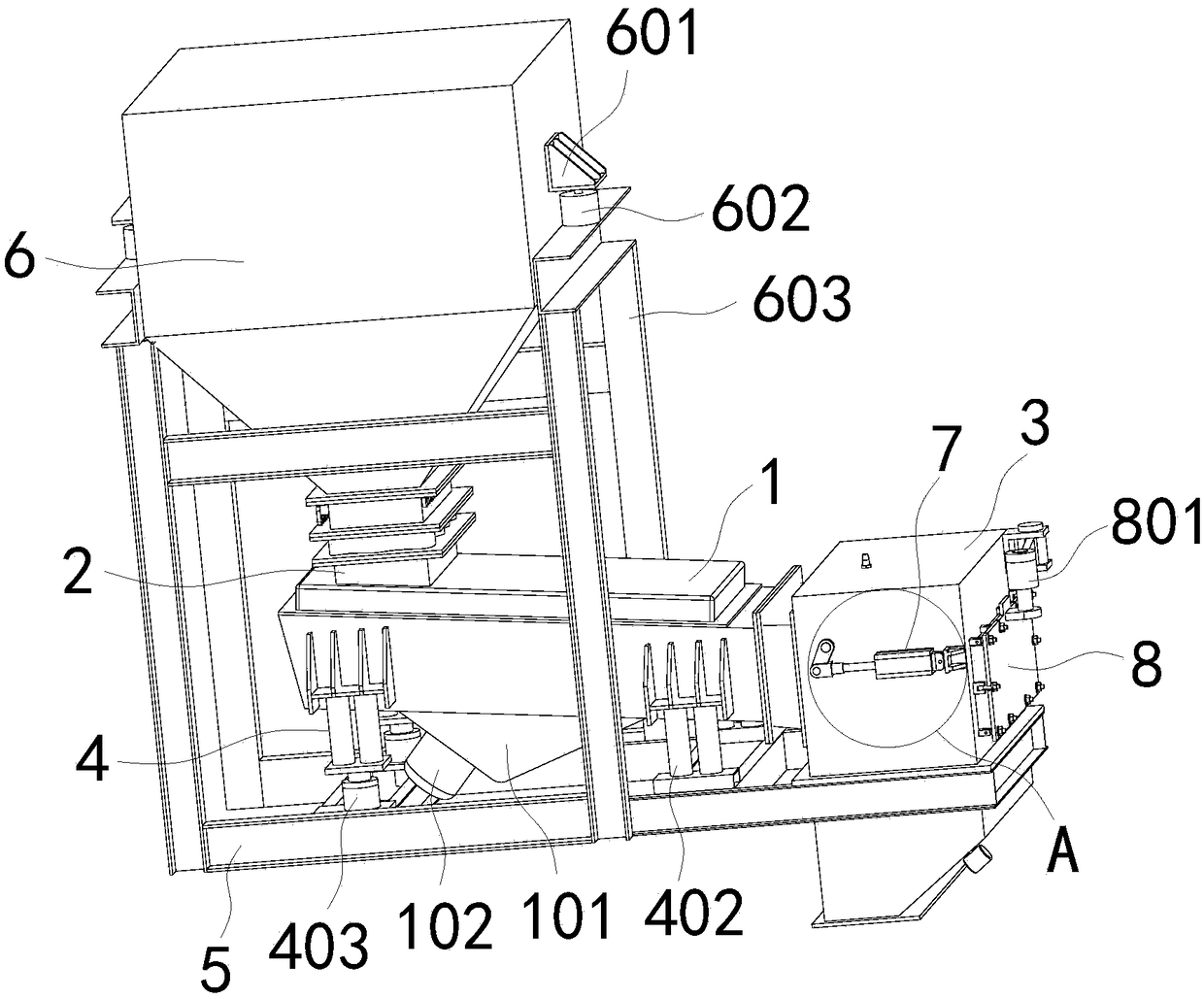

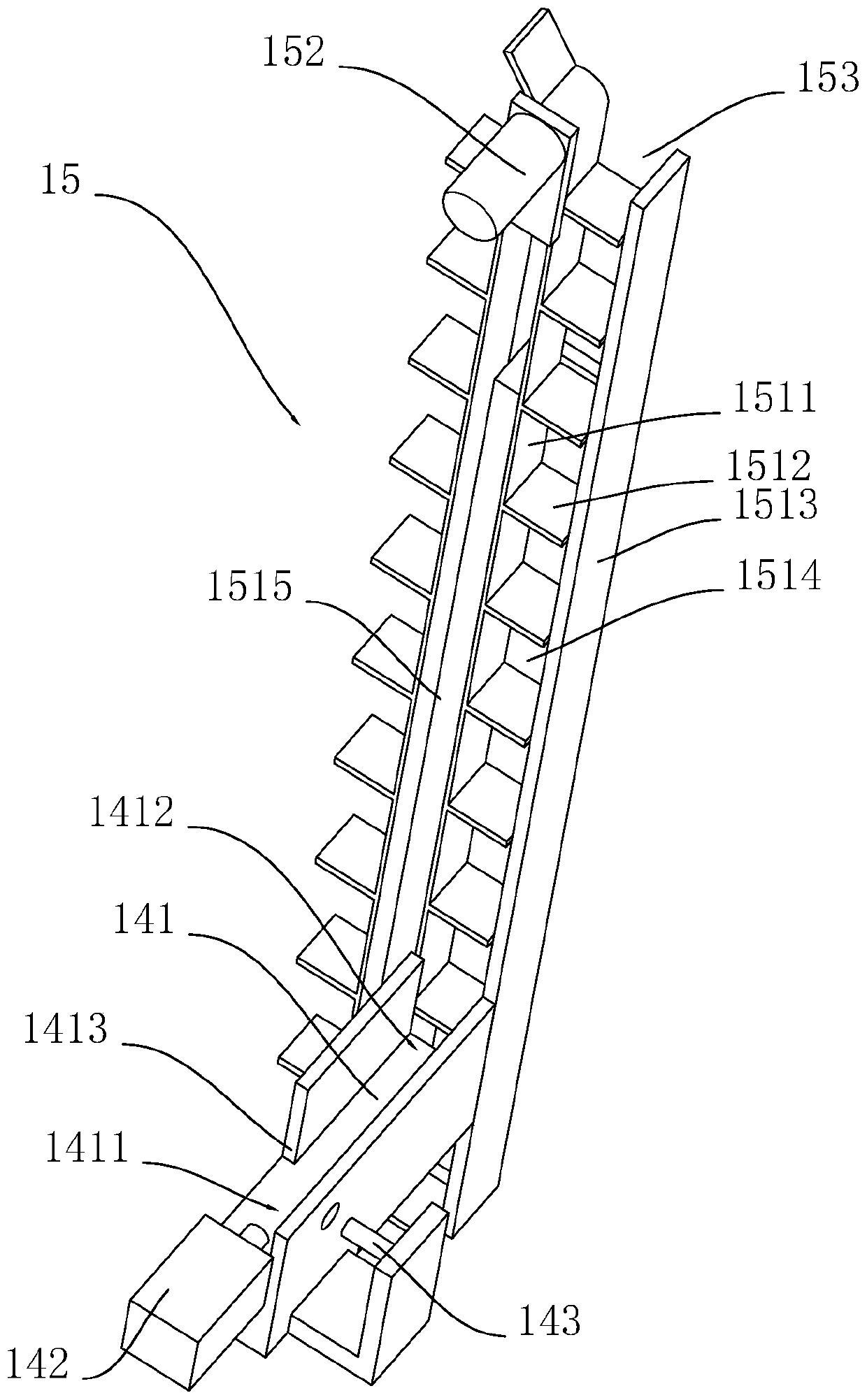

Bearing directional feeding and discharging device

ActiveCN110238717ATimely deliveryAvoid material jamsRevolution surface grinding machinesGrinding drivesEngineeringMechanical engineering

The invention relates to a bearing directional feeding and discharging device. The feeding and discharging device comprises a feeding device and a discharging device, wherein the feeding device comprises a feeding workbench, a pushing mechanism, a lifting feeding mechanism and a feeding material channel; the top surface of the feeding workbench is provided with a feeding area, the feeding area is obliquely arranged, the pushing mechanism comprises a pushing material channel arranged on the lower side of the feeding area and a material pushing driving mechanism for driving a workpiece to transversely move in the pushing material channel, The pushing material channel comprises a movable baffle plate and a fixed baffle plate, wherein the movable baffle plate is close to one side of the feeding area and can ascend and descend, the fixed baffle plate is fixedly arranged on the feeding workbench, the lifting feeding mechanism comprises a lifting material channel and a lifting driving mechanism, wherein the lower end of the lifting channel is connected with the pushing material channel, the lifting driving mechanism drives the lifting material channel to ascend and move, the upper end of the lifting material channel is provided with a material outlet, an input end of a material feeding channel is connected to a material outlet, and the output end of the feeding material channel extends into a grinding machine; the discharging device comprises a discharging material channel which is obliquely arranged, the upper end of the discharging material channel is connected with a discharging end of the grinding machine processing area, and the lower end of the discharging material channel is positioned outside the grinding machine.

Owner:CIXI CTZ BEARING

Loading device

ActiveCN106743739AAvoid the problem of scratching each otherRealize automatic feeding processConveyorsLarge containersAssembly lineElectrical performance

The invention relates to a loading device. The loading device comprises a bottom plate and a material bin vertical plate mounted on the back side of the bottom plate; the material bin vertical plate comprises an upper material bin vertical plate and a lower material bin vertical plate which are connected through hinges; a conveying assembly line component capable of conveying batteries is arranged at the bottom of the bottom plate; a square upper material bin component is mounted on the upper material bin vertical plate; a rotating component capable of driving the square upper material bin component to turn is mounted between the bottom plate and the upper material bin vertical plate; a conical material bin component capable of guiding materials is mounted on the lower material bin vertical plate; a drawing and stopping mechanism is mounted on the upper material bin vertical plate; an eccentric wheel is mounted on the lower material bin vertical plate, is located at a funnel-shaped discharging port of the conical material bin component and is matched with a belt of the conveying assembly line component to convey the batteries separately one by one; and an electrical performance test head component capable of judging positive and negative poles of the batteries is mounted at the tail end of the conveying assembly line component in the conveying direction. With the loading device, automatic loading of the batteries and distinguishing of the positive and negative poles of the batteries can be realized, and the problem of scratching of the surfaces of the batteries can be solved.

Owner:BOZHON PRECISION IND TECH CO LTD

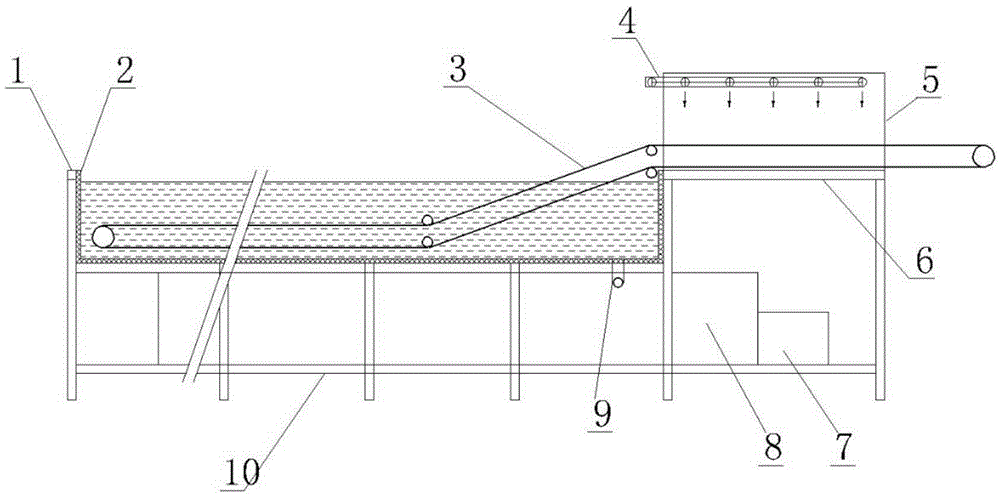

Novel fin evaporator leak detection line

InactiveCN105181260ALow drainage efficiencyImprove drainage efficiencyDetection of fluid at leakage pointWater savingDownspout

The invention discloses a novel fin evaporator leak detection line, which comprises a water tank, an air blowing table, a conveyor belt, a quick connector conveyor chain, and a bench, and is characterized in that the water tank is made of transparent glass; the bottom part of the water tank is provided with a downspout valve; the bottom part of the water tank tilts towards the downspout valve at a certain slope; two sides of the water tank are provided with dual-pipe explosion-proof lighting lamps; the entire water tank is fixed on the bench; the air blowing table is provided with a strong air blowing device and a water receiving device; water collected by the water receiving device can flow back to the water tank; the conveyor belt is connected with the water tank and the air blowing table; the transition section from the water tank to the air blowing table rises at a slope of 20+ / -0.2 DEG; the quick connector conveyor chain and the conveyor belt share one variable-frequency motor to be driven; the bench is made of an aluminum alloy material, and the maximal bearing weight of the bench is no smaller than 3t. The novel fin evaporator leak detection line is economic and practical, the leak detection efficiency is high, water-saving effects are high, and the novel fin evaporator leak detection line can be matched and joined with a drying line and a blunting line for use.

Owner:HEFEI GREAT WALL REFRIGERATION TECH

Steel tube shaping machine automatic feeding control system

The invention discloses a steel tube shaping machine automatic feeding control system which comprises a baseplate. A transmission box and an electromechanical box are correspondingly fixedly connectedwith the top of the base plate. A first rotating shaft is rotatably connected with the top of the transmission box by supporting frames. One end of the first rotating shaft penetrates through the supporting frames and extends to the front of the supporting frames. The end, extending to the front of the supporting frames, of the first rotating shaft is fixedly connected with a first bevel gear. Afirst chain wheel is fixedly connected with the outer surface positioned between the two supporting frames of the first rotating shaft. The invention relates to the technical field of construction material production equipment. The steel tube shaping machine automatic feeding control system greatly enhances accuracy of feeding arrangement, avoids the condition that a steel tube is stuck in a shaping machine andnormal work of the shaping machine is affected, achieves accurate positioning of the steel tube in the taking position of the shaping machine, and achieves the purpose of preventing materials from getting stuck, so that steel tube shaping work of production staff is greatly facilitated.

Owner:XIANGYANG KEWEI ELECTRIC

Slender material automatic loading device

PendingCN109051650AConvenient process operationArrange neatlyConveyorsLoading/unloadingEngineeringProduction quality

The invention relates to the technical field of automatic feeding devices, in particular to a slender material automatic loading device. The slender material automatic loading device comprises a mainbody, a storage bin and an arrangement mechanism mounted in the main body, and a correcting device mounted under the main body; the arrangement mechanism is positioned under the storage bin and abovethe correcting device; the arrangement mechanism is used for transporting slender materials in an outlet of the storage bin to an inlet of the correcting device; the inlet of the correcting device andan outlet of the arrangement mechanism are the same in length, and are oppositely arranged in parallel; a correcting block is arranged at the middle part of the correcting device; and distances fromthe correcting block to the left and right side edges of the correcting device are the same. When the slender material automatic loading device is used for arranging the materials, the automatic direction correction can be realized by using the weight difference of two ends of the slender materials, and then, the slender materials are tidily arranged; the direction is not needed to distinguish inmanual charging, so that the manual operation intensity is reduced, the operation efficiency is improved, the flowing of some returned materials into next procedures cannot occur, and the production quality is improved.

Owner:SHIN TECH ENG

High-efficiency ore crushing and sorting device

InactiveCN107377090AAvoid material jamsImprove crushing efficiencyGrain treatmentsEngineeringMagnetorheological fluid

The invention discloses a high-efficiency ore crushing and sorting device, which includes a shell; the bottom of the shell is symmetrically provided with supporting feet, the left side of the top of the shell is provided with a feeding hopper, and the inner top of the shell corresponds to the lower part of the feeding hopper A primary crushing mechanism is provided, and a secondary crushing mechanism is provided on the lower right side of the primary crushing mechanism. The plate and the lower cavity of the housing form a sorting chamber. The invention provides a high-efficiency ore crushing and sorting device. The invention cleverly sets the primary crushing mechanism and the secondary crushing mechanism, which can avoid material jamming, and the crushing efficiency is high and the effect is good. In addition The invention utilizes the principle that magnetorheological fluid produces rheological phenomena under the action of a magnetic field to cleverly set up a magnetic separation mechanism, which has faster recognition speed, higher separation accuracy, and high separation efficiency. down to work.

Owner:南宁众创空间科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com