Spliced stamping mould

A stamping die and splicing technology, applied in the field of stamping die, can solve the problems of damage to the die surface, hidden dangers, low production efficiency, etc., to avoid material jams and ensure production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

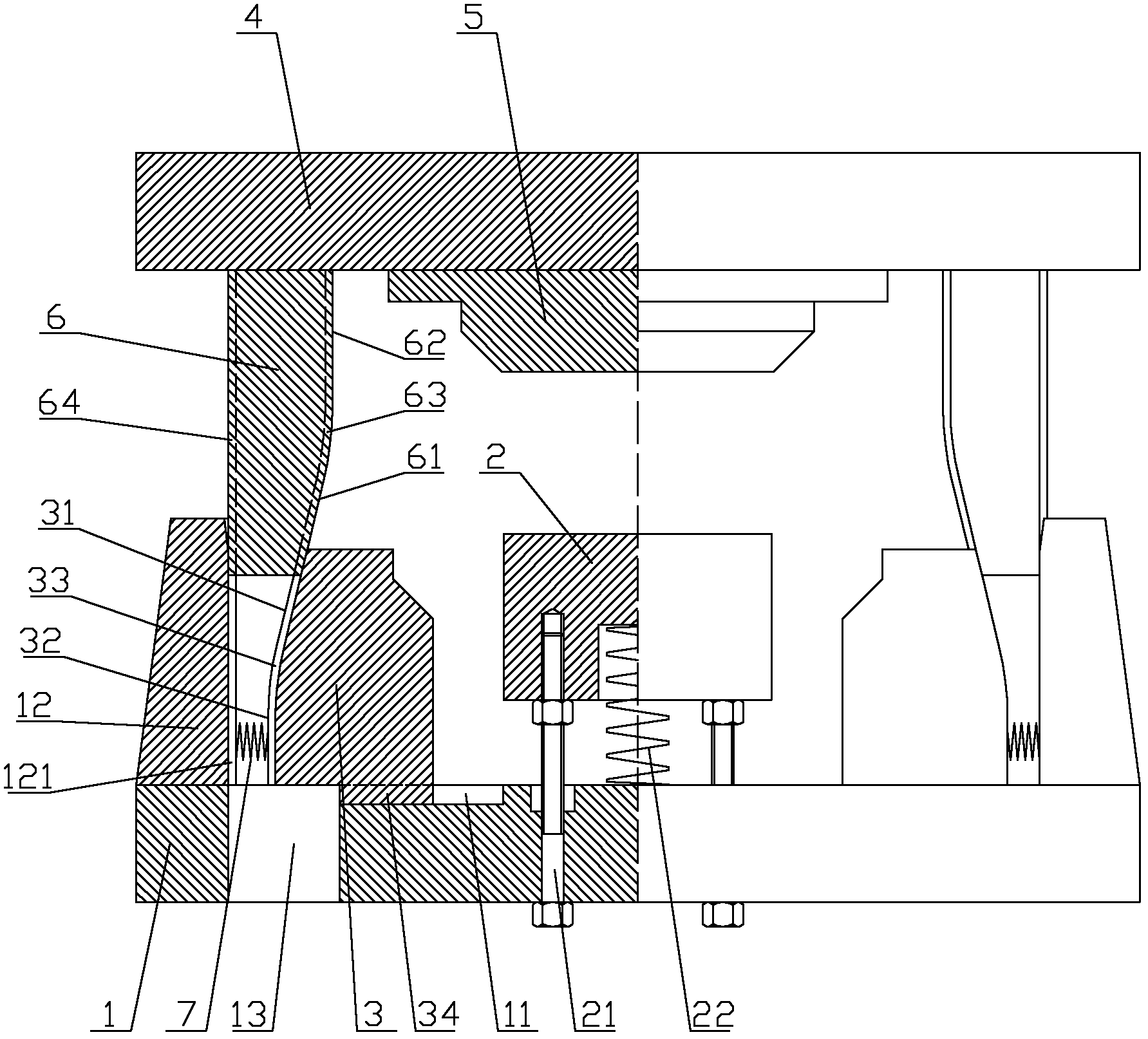

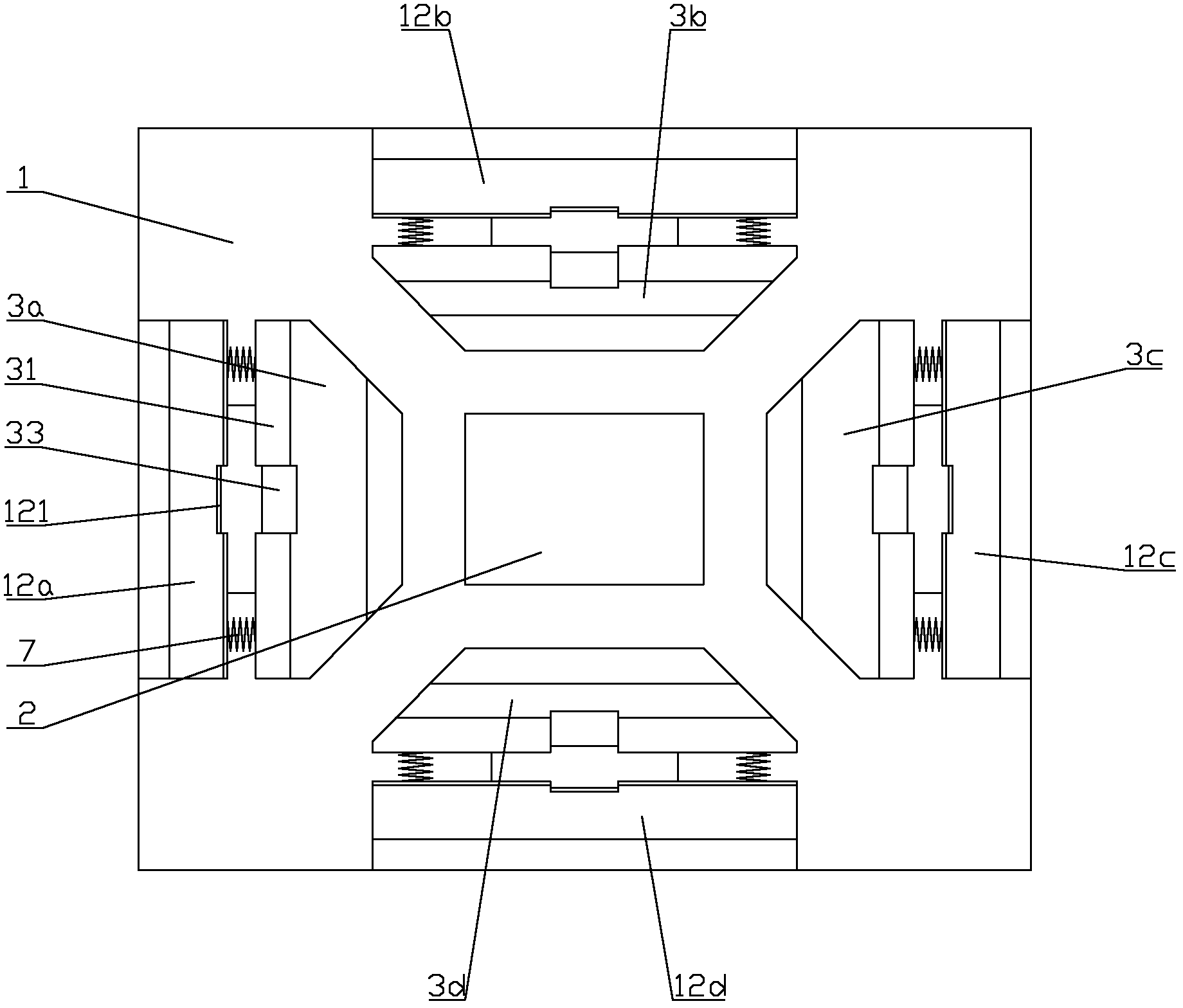

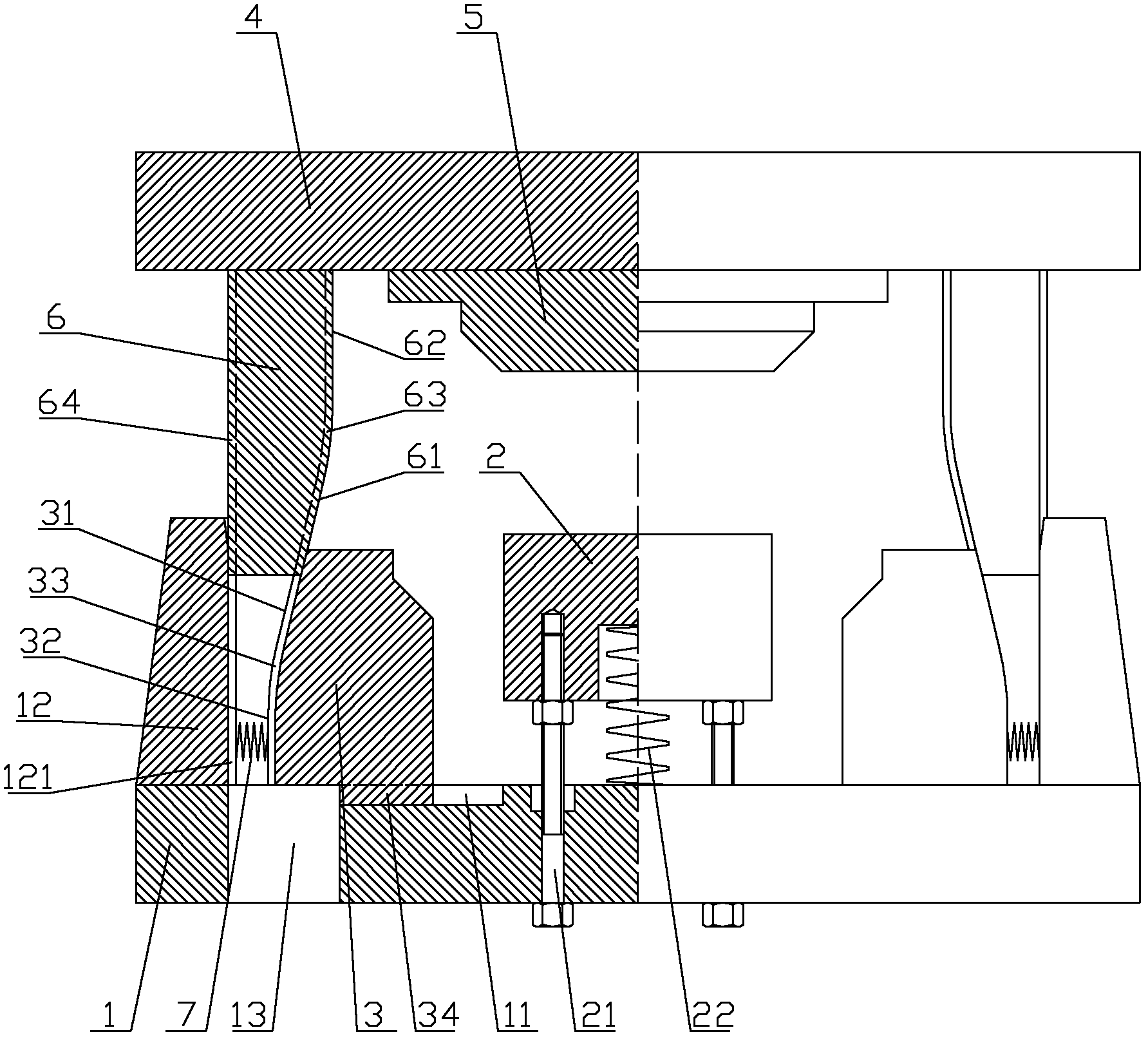

[0017] figure 1 It is a half sectional view of the present invention, figure 2 It is a plan view of the lower die of the present invention, as shown in the figure: the split stamping die of the present invention includes an upper die assembly and a lower die assembly, and the lower die assembly includes a lower die base 1, a supporting block 2 and a surrounding At least two lower die splicing blocks 3 that can be combined on the outside of the supporting block 2 and are slidably connected to the lower die base 1; the supporting block 2 is a liftable structure, and its top surface is a part of the lower die surface. The inner surface surrounded by the die splicing block 3 and the top surface of the supporting block 2 can be spliced to form a complete lower die surface; the upper die assembly includes an upper die base 4, an upper die 5 and a push block 6, and the upper die 5 is fixedly arranged on the bottom surface of the upper mold base 4, and the bottom surface of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com