Friction and wear test device for variable load cylinder liner and piston ring

A friction and wear test, piston ring technology, applied in the direction of measuring devices, wear resistance testing, instruments, etc., can solve the problems of the occurrence of alternating loads and the inability to measure, the inability to realize continuous changes in loads, and the impact on the accuracy of measurement results, etc. , to achieve the effect of easy operation, reduced lever swing, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

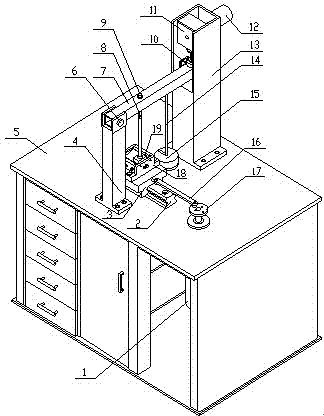

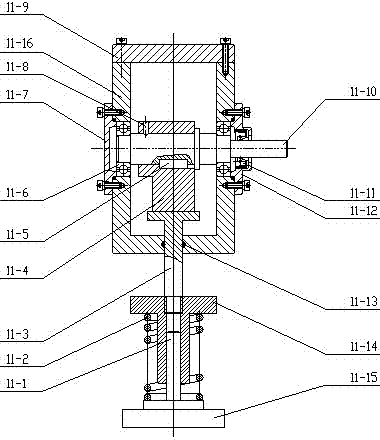

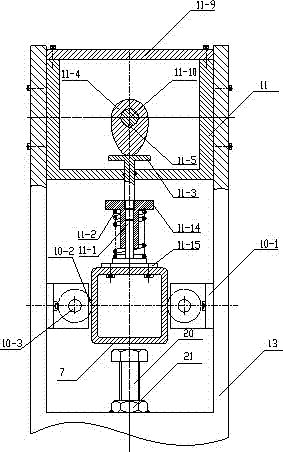

[0022] like figure 1 As shown, the variable load cylinder liner piston ring friction and wear test machine is mainly composed of a spindle motor 1, a guide rail 2, a slide table 3, a left column 4, a workbench 5, a lever 7, a loading rod 9, a swing limiter 10, and a load changer 11 , load-changing motor 12, right column 13, clamp 18 under the concave arc surface, and clamp 19 on the convex arc surface. Guide rail 2, slide table 3, left column 4, right column 13 are arranged on the workbench 5, and main shaft motor 1 is arranged in the workbench 5; Weight 15 on the weight hook, one side of slide table 3 is provided with connecting rod 16, and the outer end of connecting rod 16 is connected with crankshaft disk 17, and crankshaft disk 17 is connected with the spindle motor 1 that is located in the workbench 5 through the shaft. Connected, the slide table 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com