Rotating tower type quick sorting unit

A turret-type, rotating shaft technology, applied in sorting, conveyors, conveyor objects, etc., can solve the problems of high error rate of manual sorting, large floor space, violent sorting, etc., to improve sorting efficiency, The effect of reducing the floor space and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

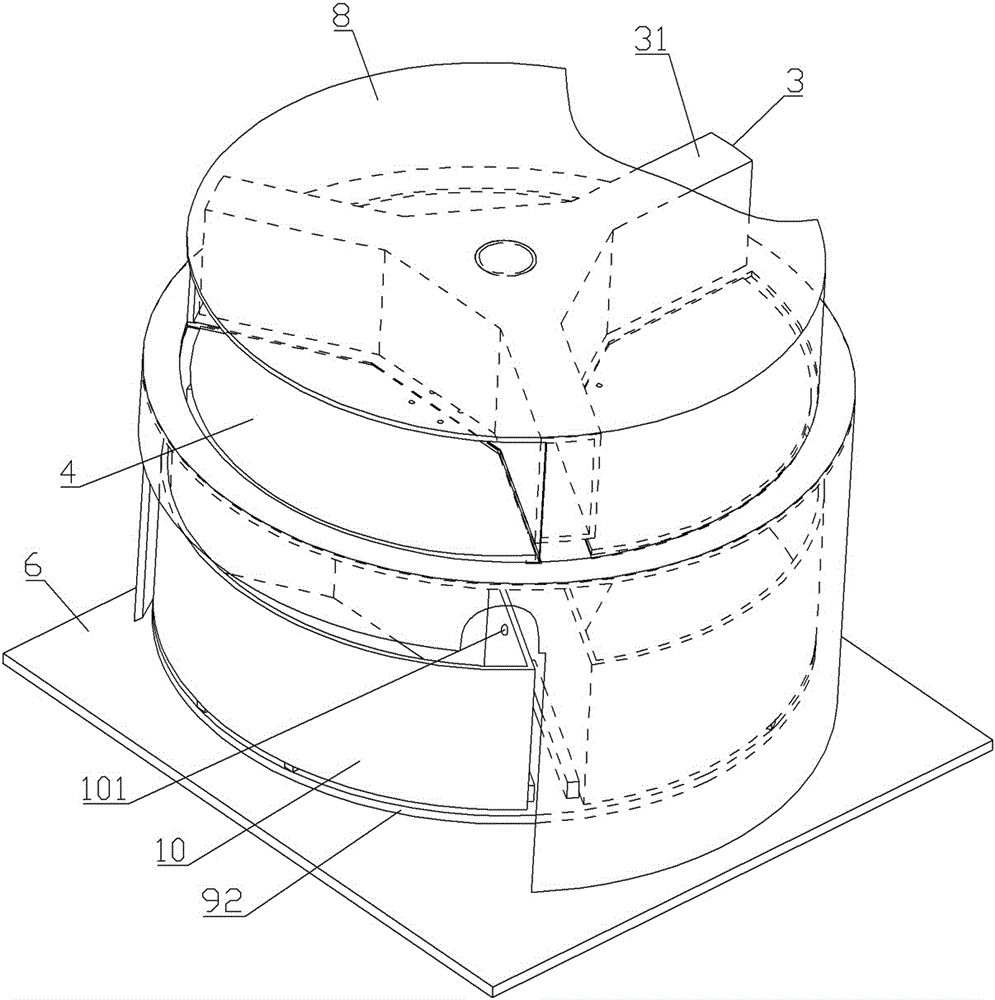

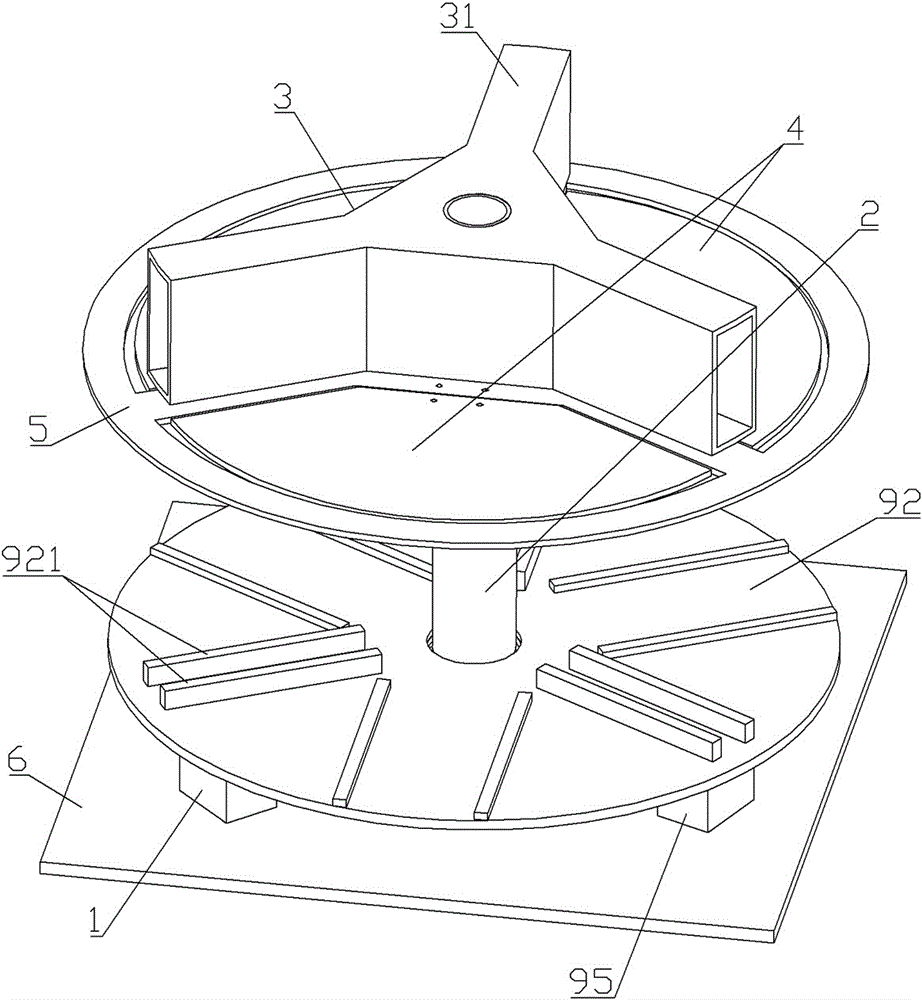

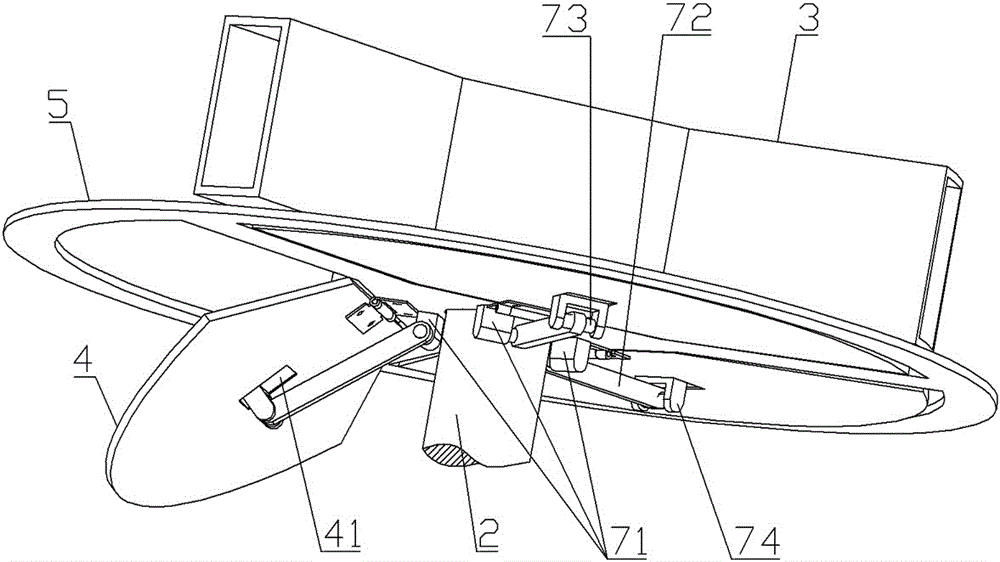

[0042] like Figure 1-6 As shown, the turret-type express sorting unit includes a stepping motor A1, a vertical shaft 2, a horizontal sweeping plate 3, a movable plate 4, an upper base 5, a lower base 6, a driving mechanism C for driving the movable plate, and an outer cover 8 , a turntable mechanism and a package collection box 10.

[0043] The stepper motor A1 is fixed on the lower base 6 and is associated with the vertical shaft 2 to drive the vertical shaft 2 to rotate. Specifically, the stepper motor A1 drives the vertical shaft 2 to rotate through the synchronous wheel set. The synchronous wheel pair includes the active synchronous wheel A111 installed on the crankshaft of the stepping motor A1, the driven synchronous wheel A112 installed on the vertical shaft 2, and the synchronous wheel A112 wound between the active synchronous wheel A and the driven synchronous wheel A. Timing belt A113.

[0044] The two ends of the vertical rotating shaft 2 are movably installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com