Patents

Literature

3549results about How to "Improve sorting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

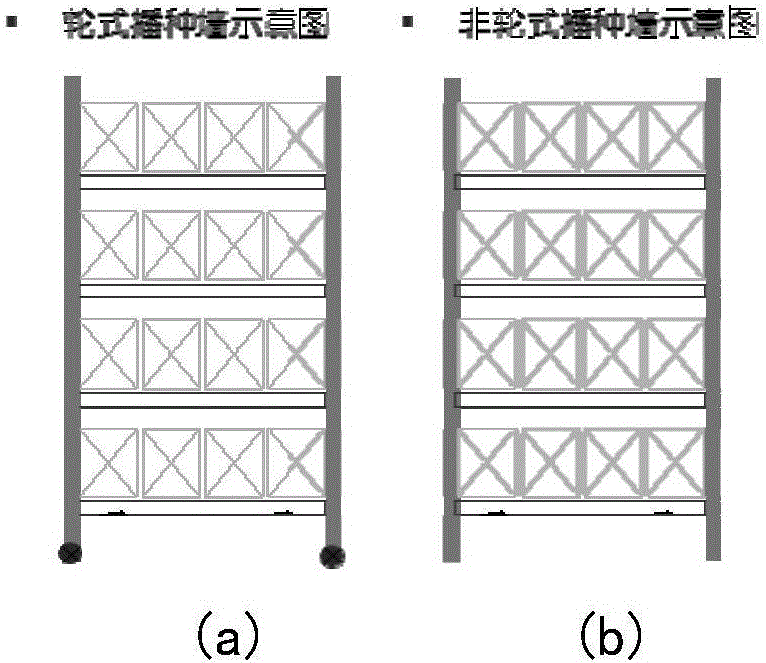

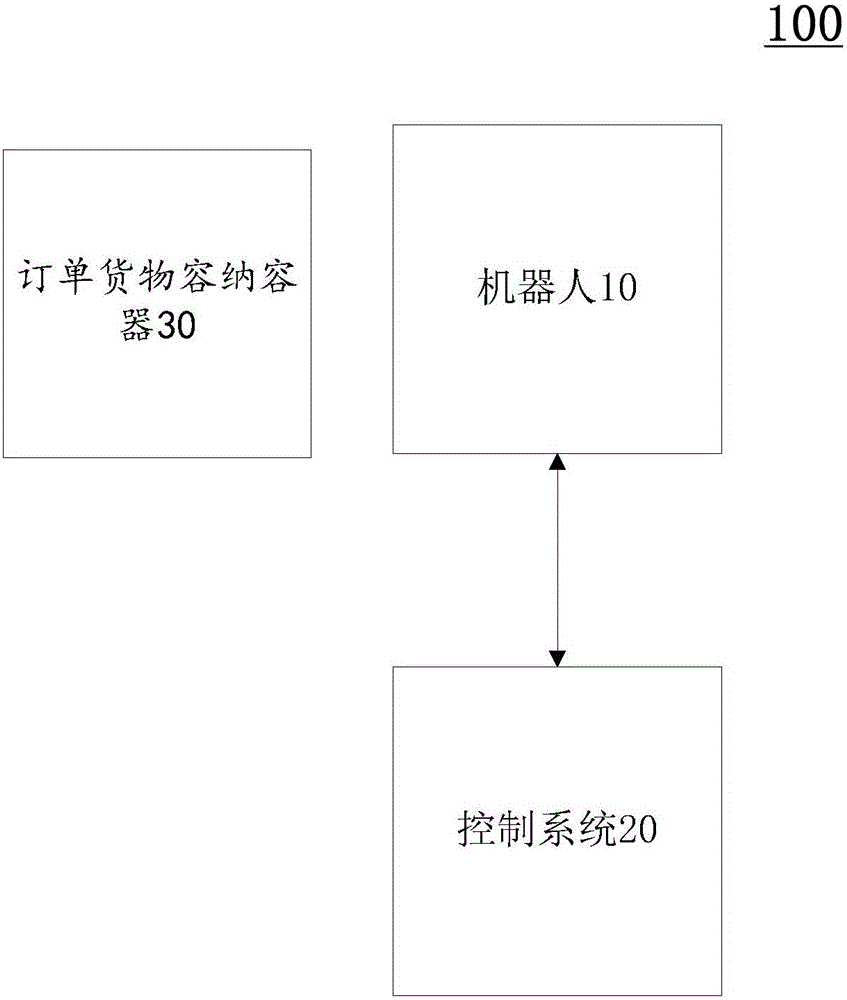

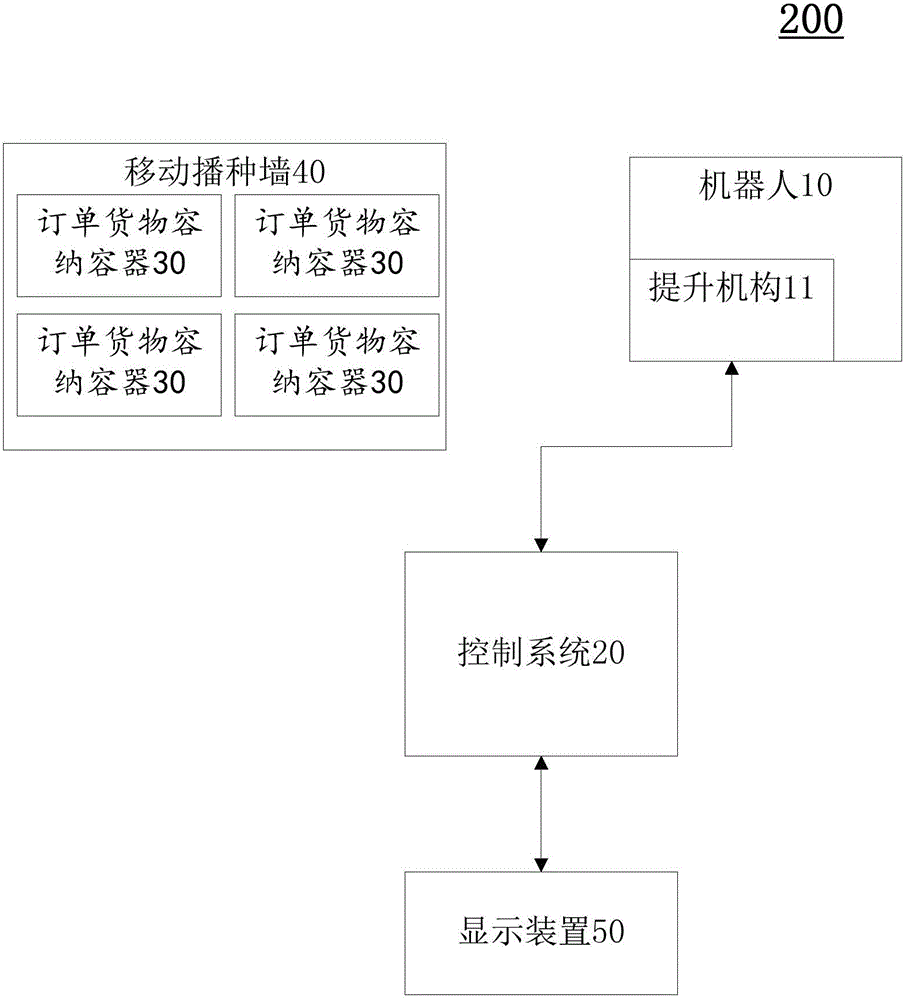

Automatic cargo picking system and automatic cargo picking method

Provided are an automatic cargo picking system and method. The automatic cargo picking system comprises a transfer robot, a control system and multiple ordered cargo containing containers; each ordered cargo containing container is arranged to contain one or more cargoes corresponding to an order; the control system and the transfer robot conduct wireless communication, the automatic cargo picking process comprises the steps that the control system distributes a task order for the transfer robot; the transfer robot obtains empty ordered cargo containing containers, transfers the ordered cargo containing containers to all cargo placing areas where the cargoes corresponding to the order are located to collect the cargoes and transfers the ordered cargo containing containers which complete cargo picking to the designated place. An automatic cargo picking technology is a scheme that the orders are assigned to people, and an original cargo shelf can be used; the cargo-to-people mode can adopt the method of conducting full container and full tray cargo storing on the original cargo shelf, and therefore the problem of frequent shelving is solved; the intelligent transfer robot is utilized for replacing manual transferring, and the labor intensity of picking personnel is reduced.

Owner:BEIJING JIZHIJIA TECH CO LTD

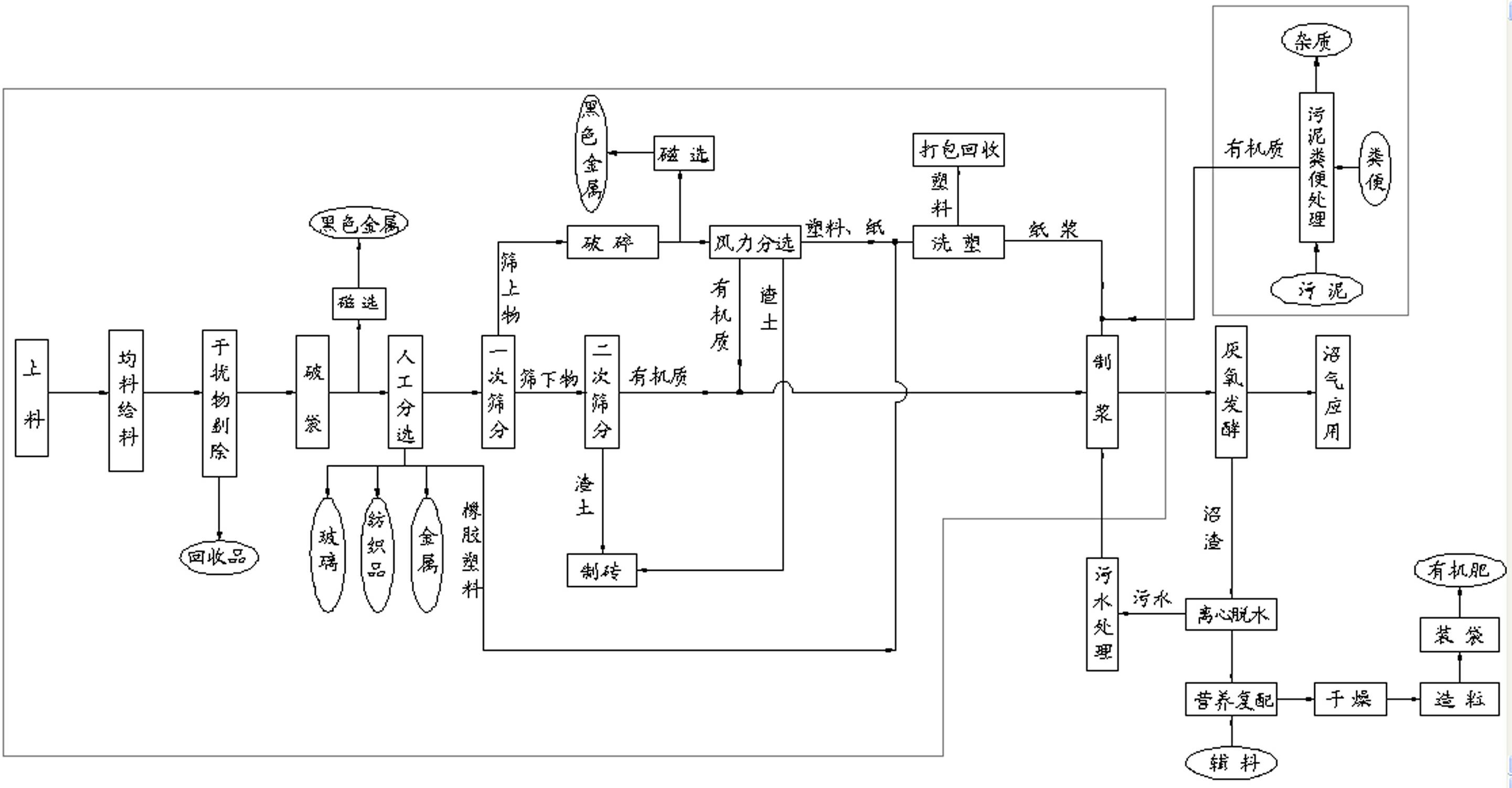

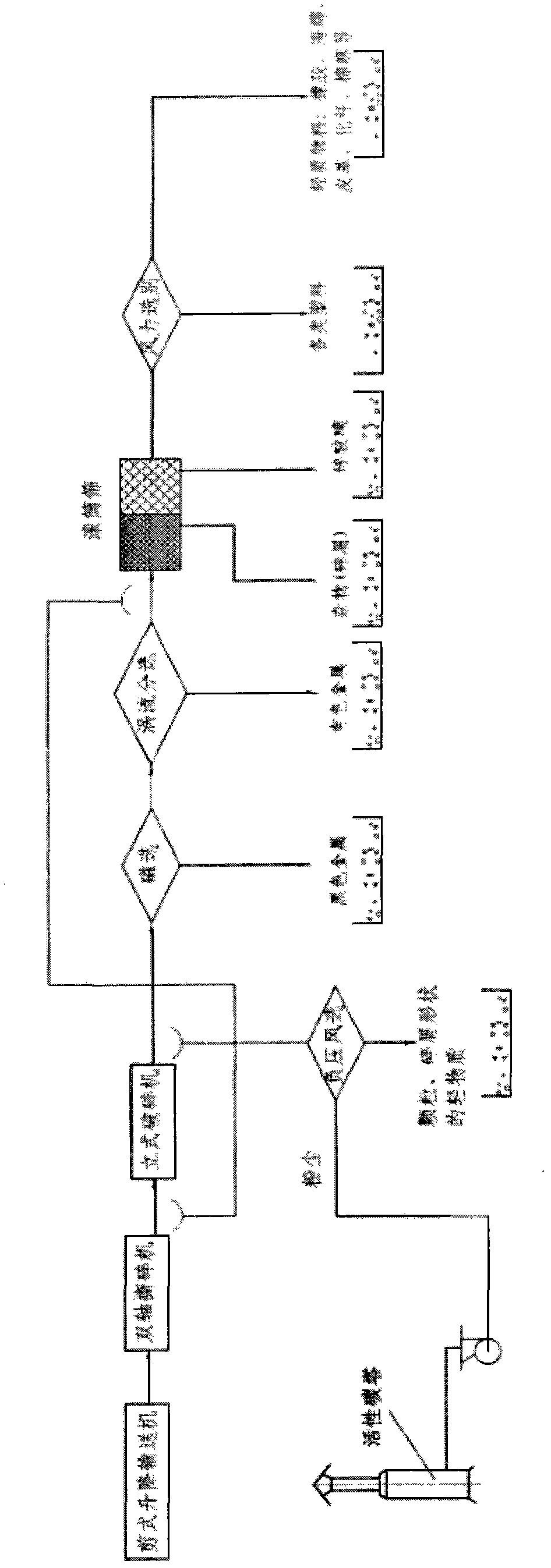

Comprehensive treating system for domestic wastes

InactiveCN102527701AIncrease productionImprove qualityBio-organic fraction processingWaste processingSludgeOrganic manure

The invention discloses a comprehensive treating system for domestic wastes. Reutilizing comprehensive treatment for mixed wastes is realized by the system according to a comprehensive sorting technology and a combined anaerobic fermentation technology, wherein the advanced sorting techniques, such as, crushing, magnetic separating, sieving, air classifying, and the like, are adopted in the comprehensive sorting technology; reutilized products, such as metal, plastics, organic matters, and the like, are screened out; the screened organic matters are prepared into slurry together with sludge and excrements and are then subjected to the combined anaerobic fermentation; the reutilized products, such as methane, organic fertilizer, and the like, can be produced under the action of anaerobic fermentation; and after the methane is purified, the methane is used for generating power, domestic fuel or vehicle-mounted fuel. According to the technology, the intensified treatment for organic wastes, such as domestic wastes, sludge, excrements, kitchen wastes, and the like, can be realized. The comprehensive treating system is high in mechanical and automated degree. Compared with the prior art, the comprehensive treating system has the advantages of simplification, effectiveness, less labor power, and the like.

Owner:BEIJING HAOHAI TIANJI TECH +1

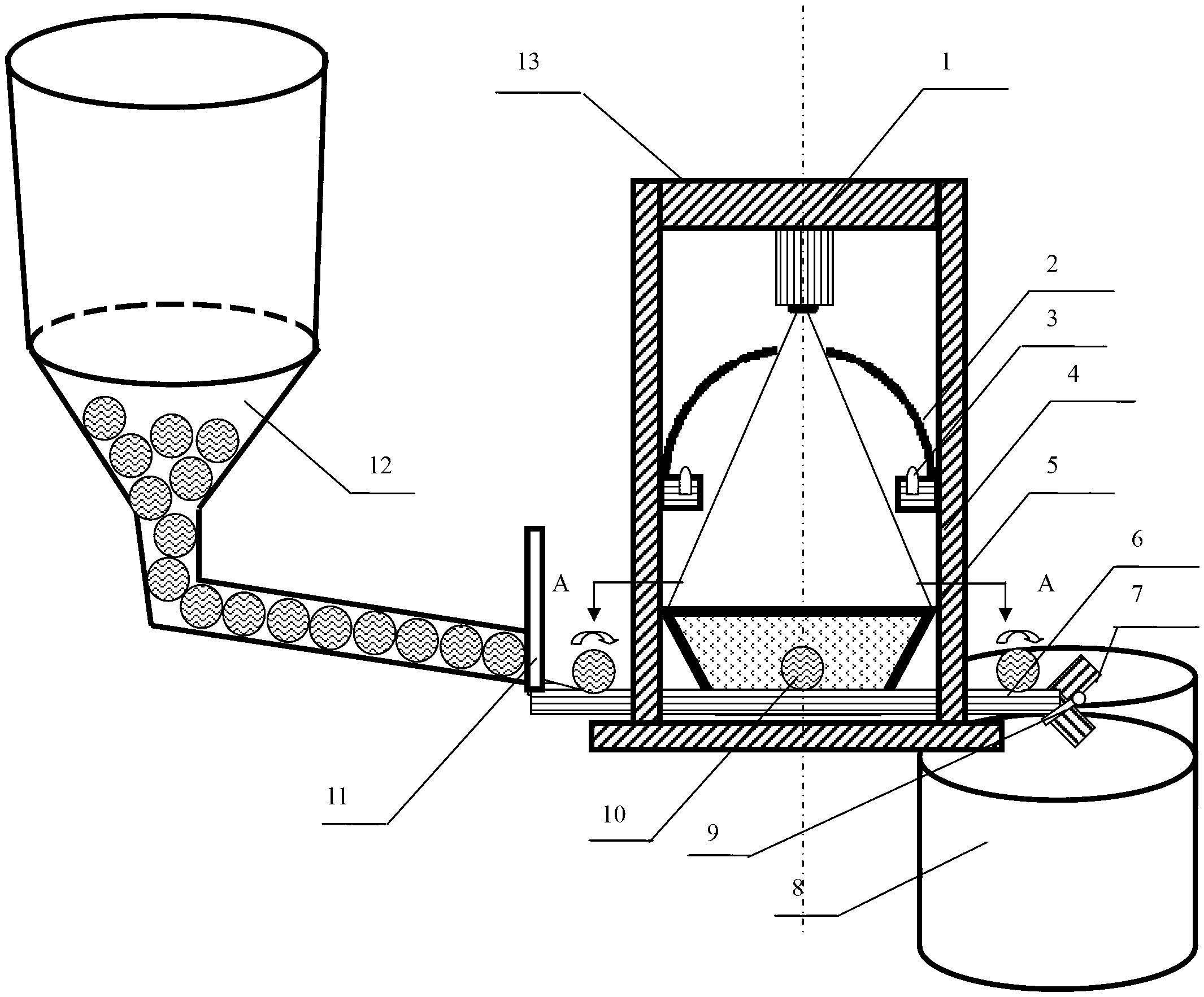

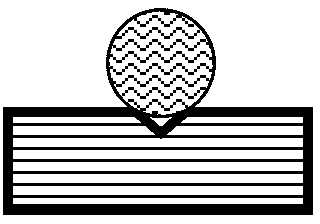

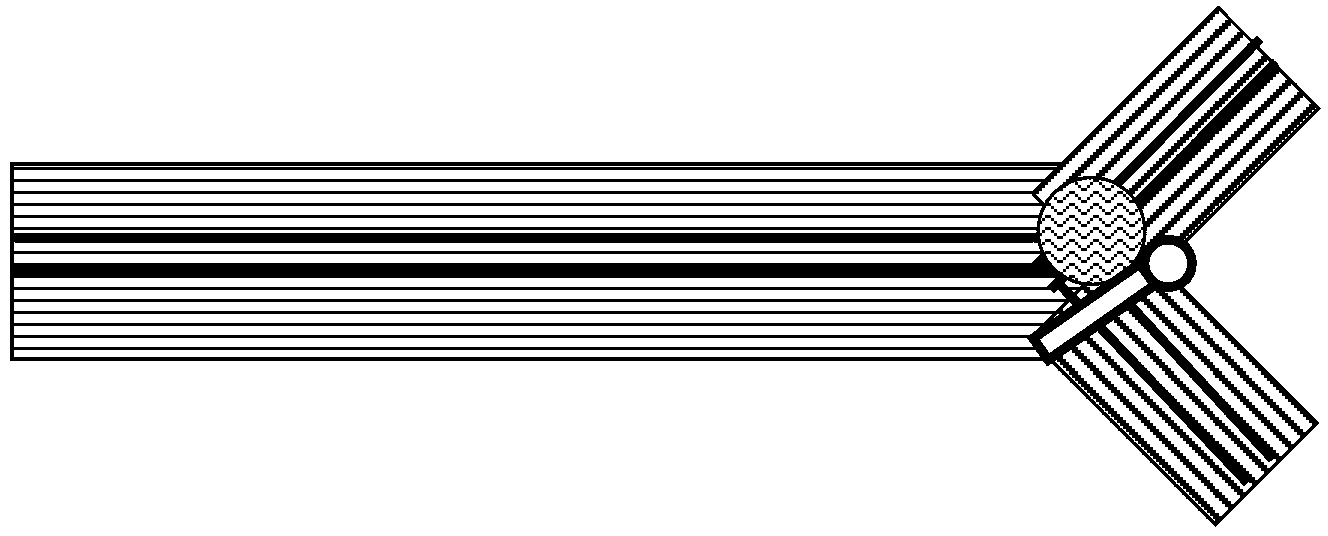

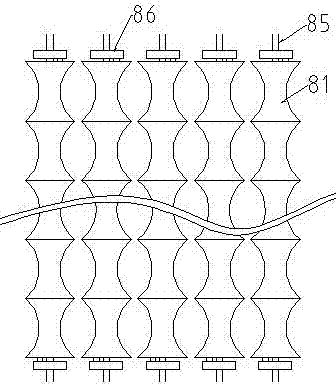

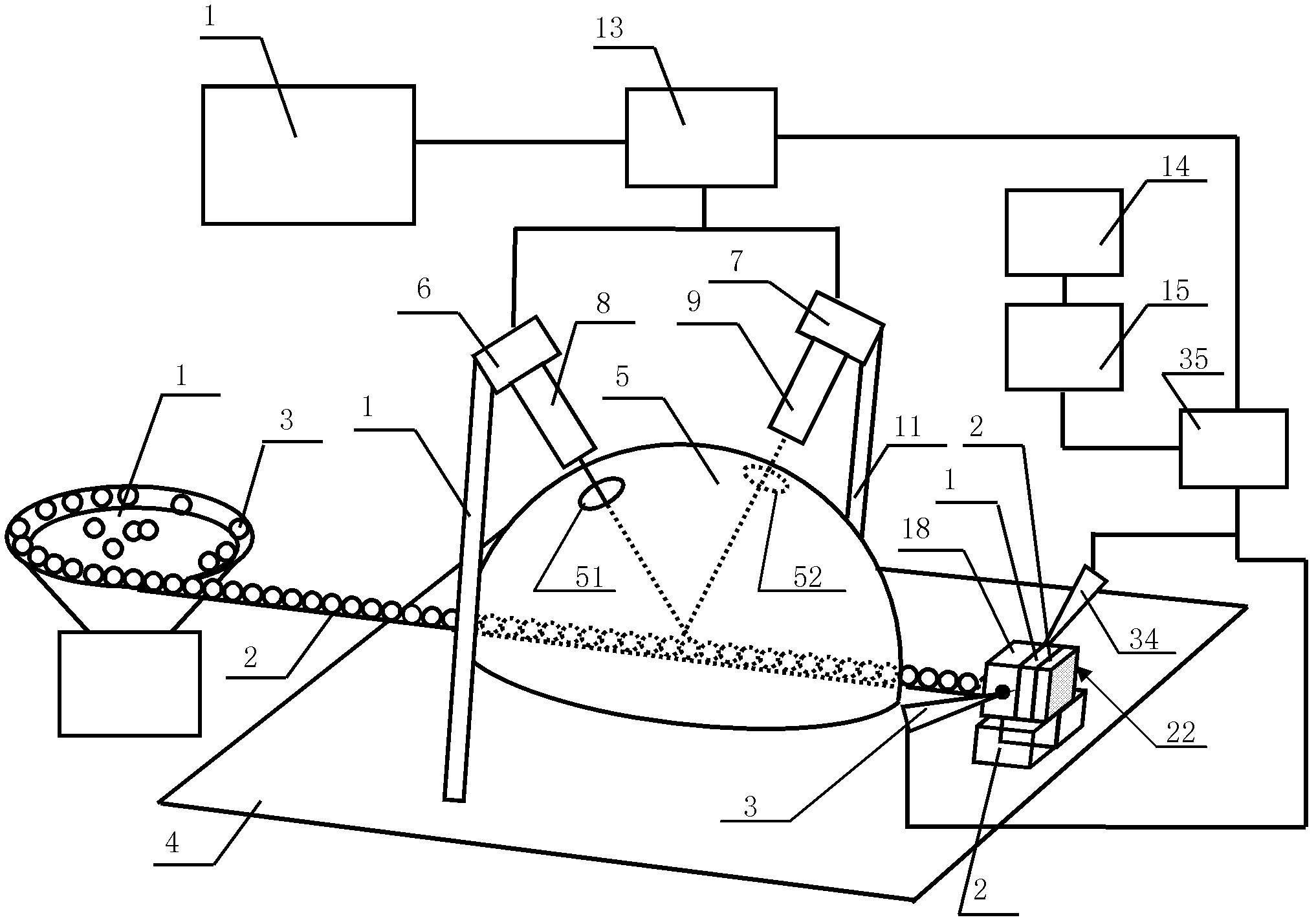

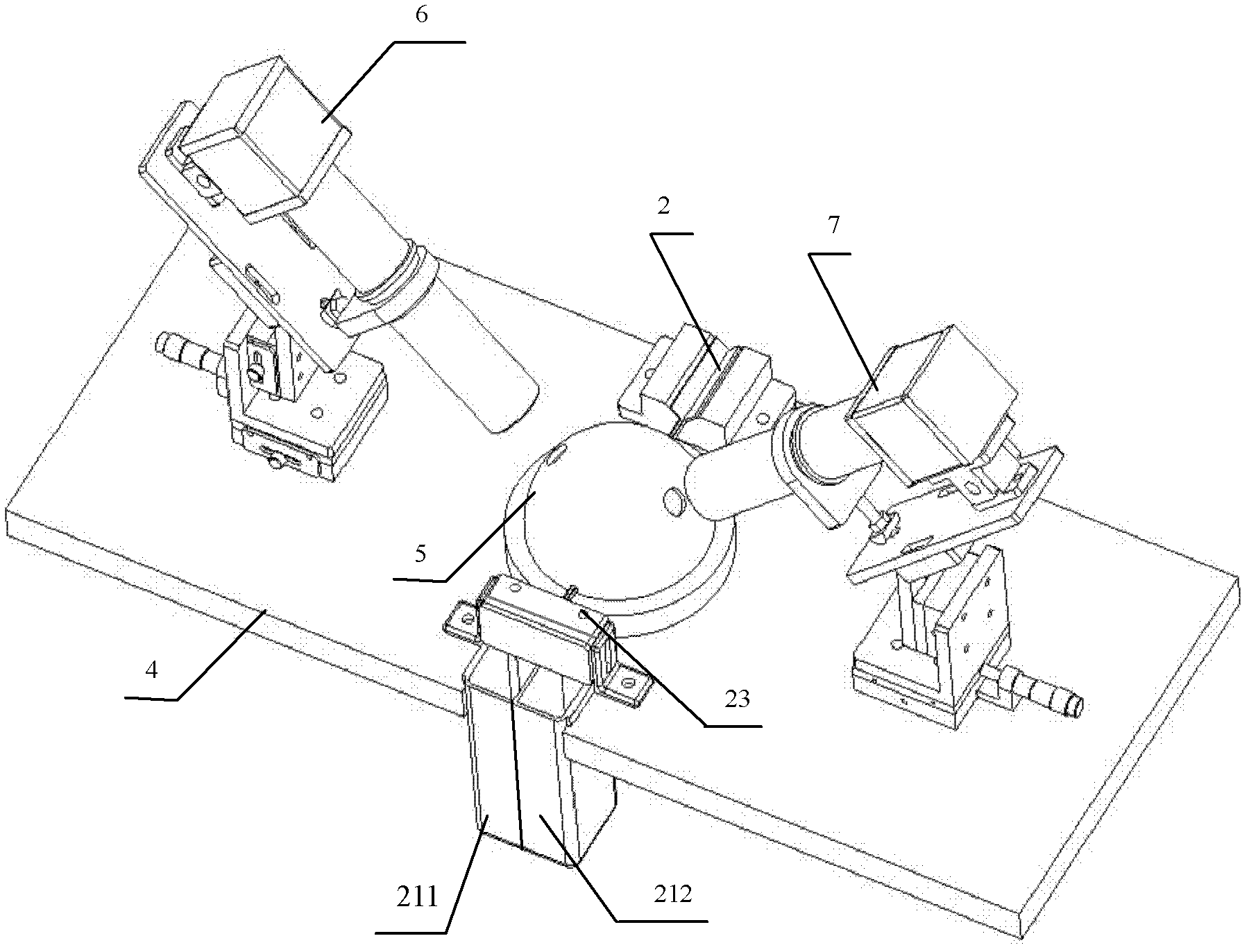

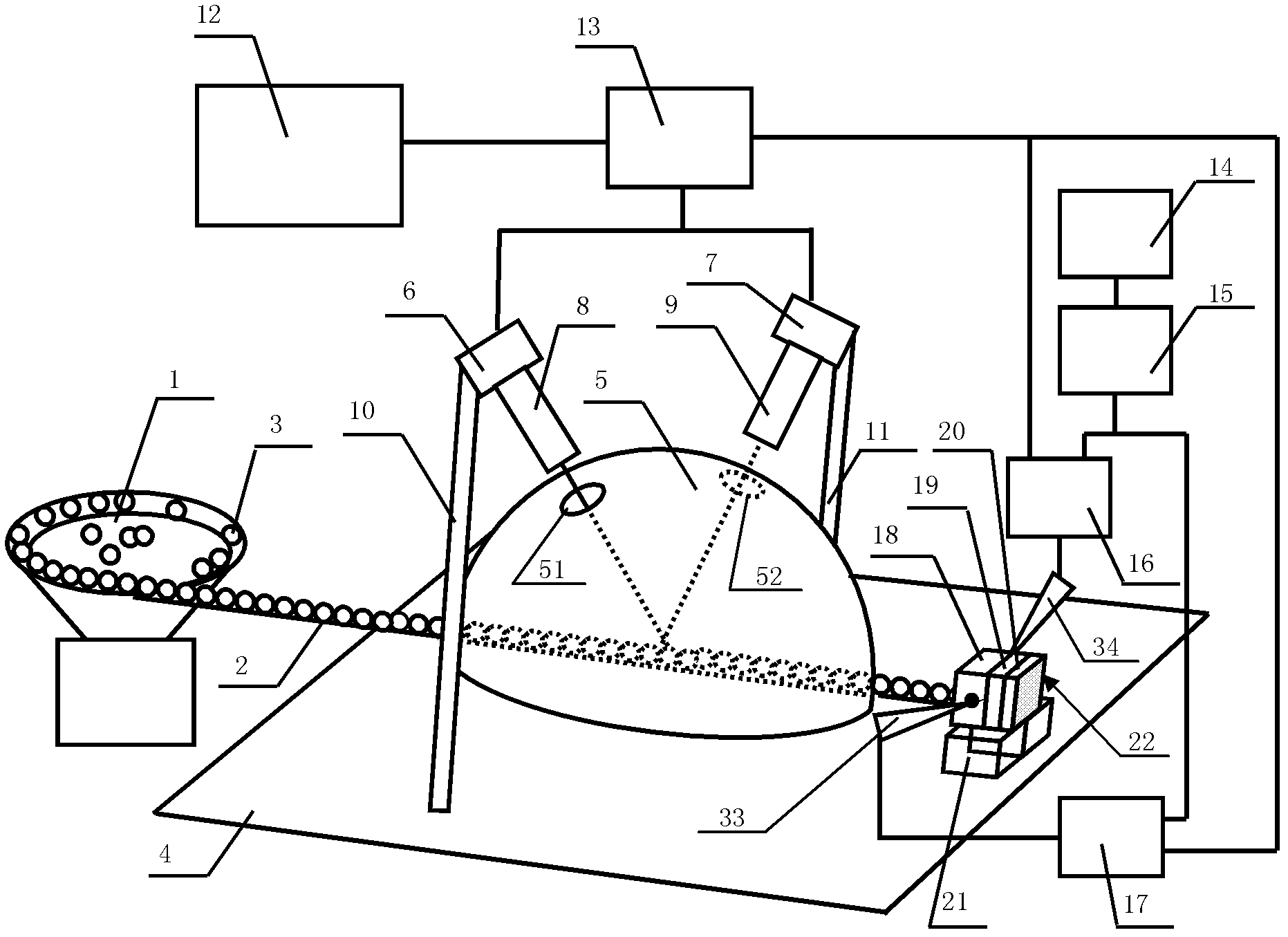

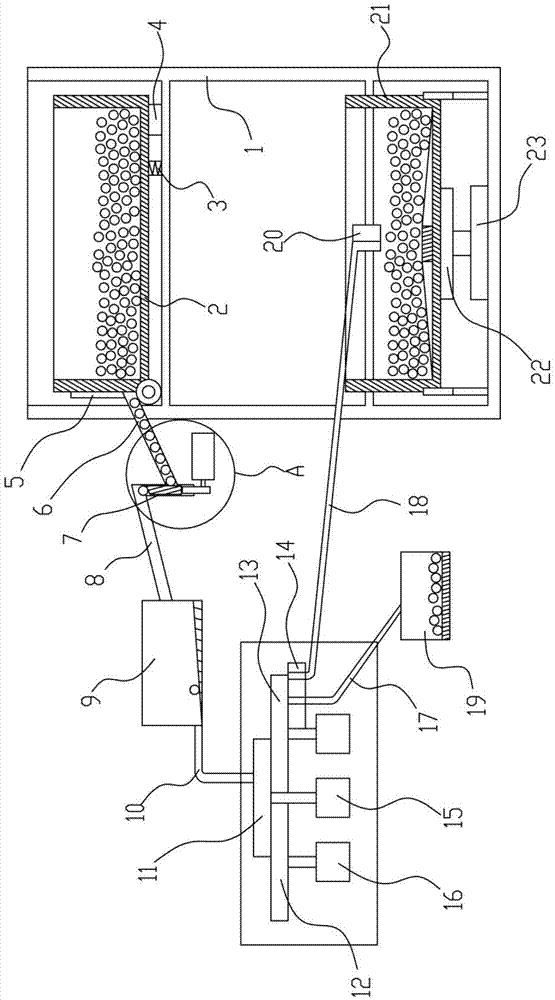

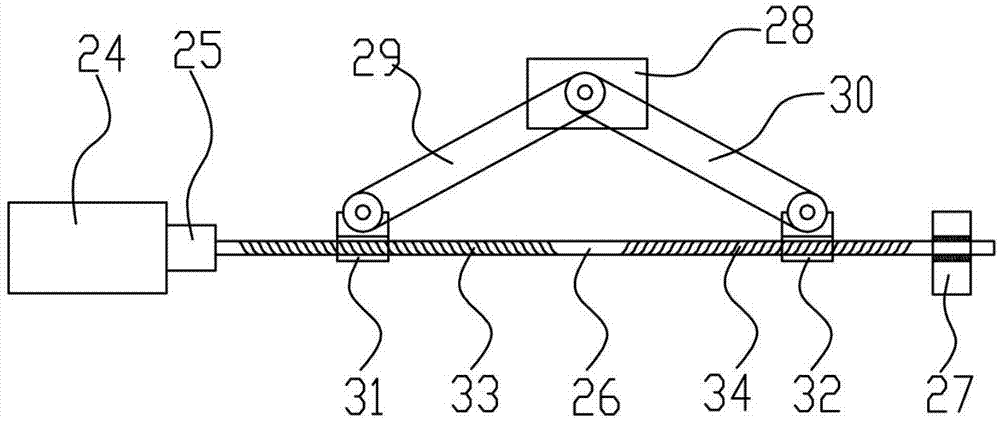

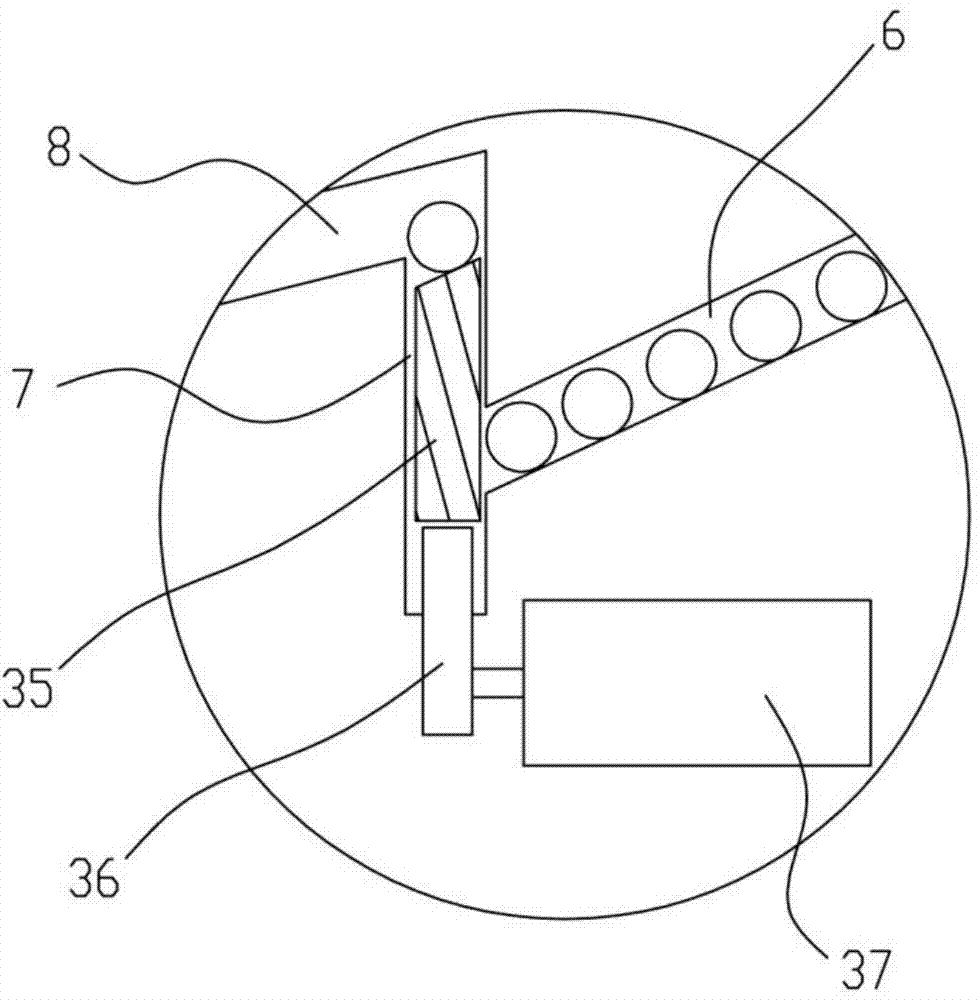

Monocular multi-perspective machine vision-based online automatic sorting device for steel ball surface defect

ActiveCN103286081ASimplify complexityImprove detection efficiencyMaterial analysis by optical meansSortingMachine visionImaging processing

The invention relates to a monocular multi-perspective machine vision-based online automatic sorting device for steel balls. The online automatic sorting device comprises an assembly line, a monocular multi-perspective machine vision device and a microprocessor, wherein the assembly line is used for automatically detecting and sorting the steel balls, the monocular multi-perspective machine vision device is used for shooting images of the detected steel balls, the microprocessor is used for performing image processing, detection, identification and classification on the images of the detected steel balls and coordinately controlling each actuating mechanism on the assembly line to coordinately move, and the assembly line comprises a feeding actuating mechanism, a transmission mechanism and a sorting actuating mechanism. The invention provides the monocular multi-perspective machine vision-based online automatic sorting device for the steel balls based, which has the advantages of simple mechanism, low manufacturing cost, high sorting efficiency and convenience in operation and maintenance.

Owner:ZHEJIANG UNIV OF TECH

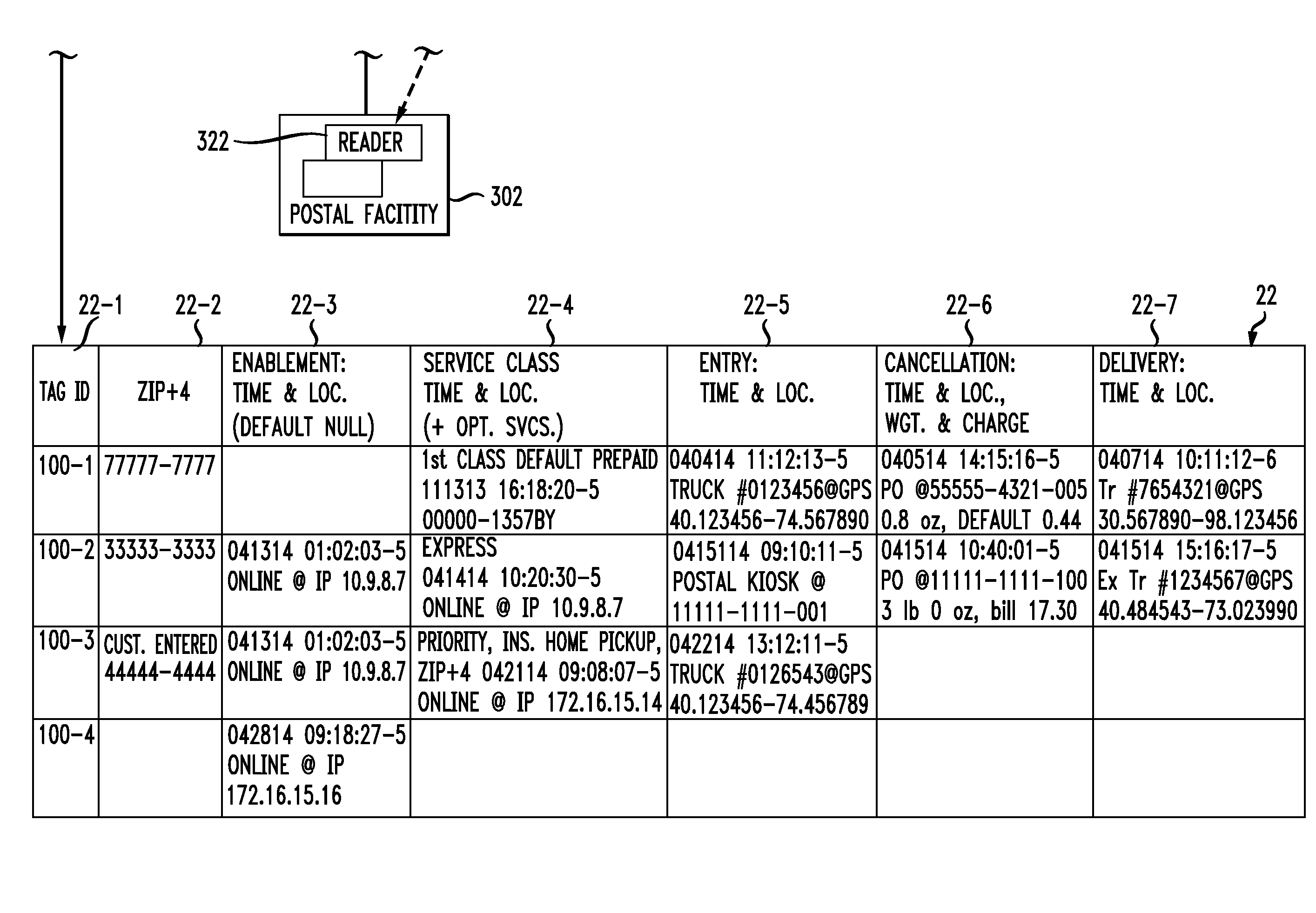

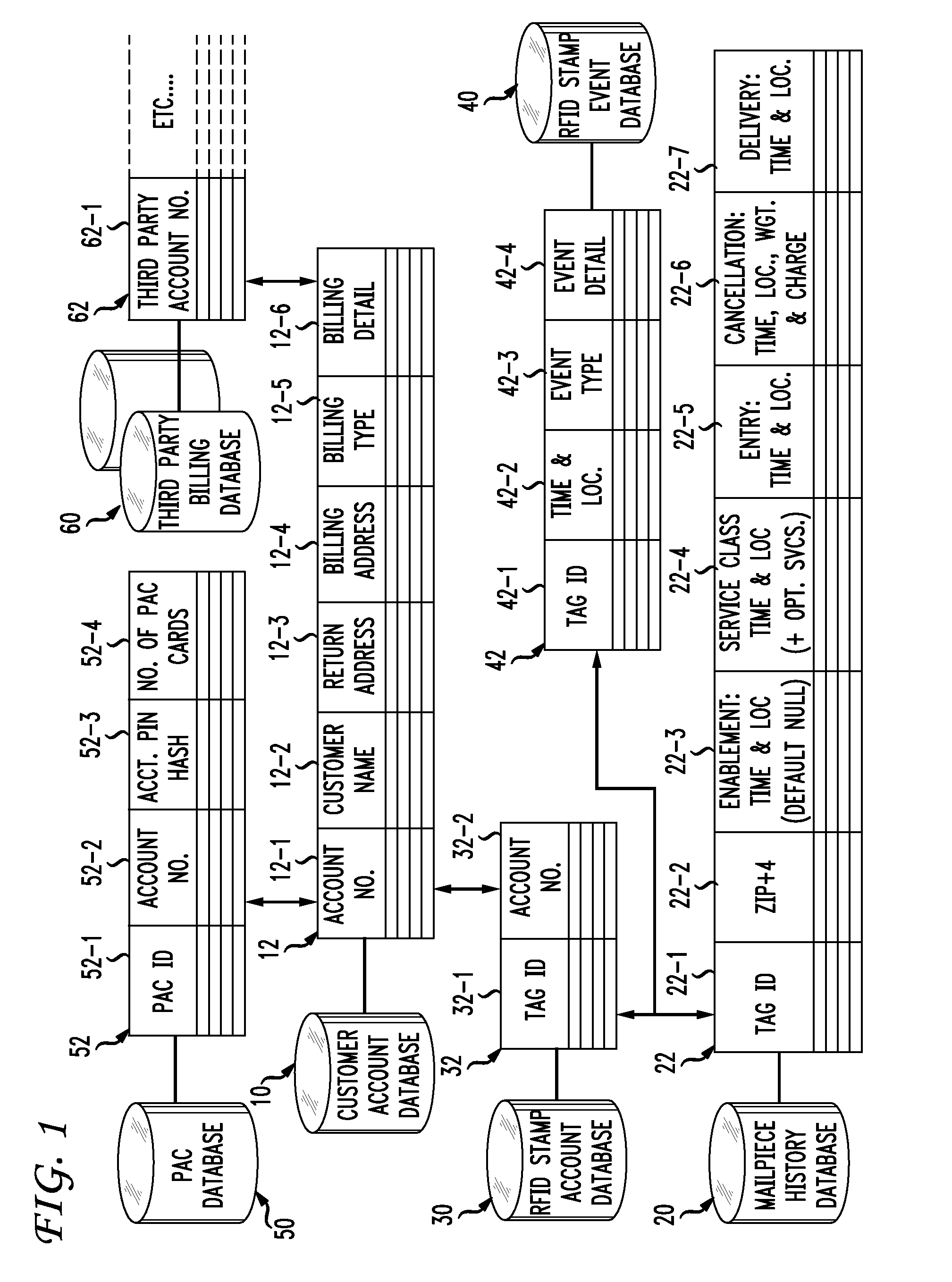

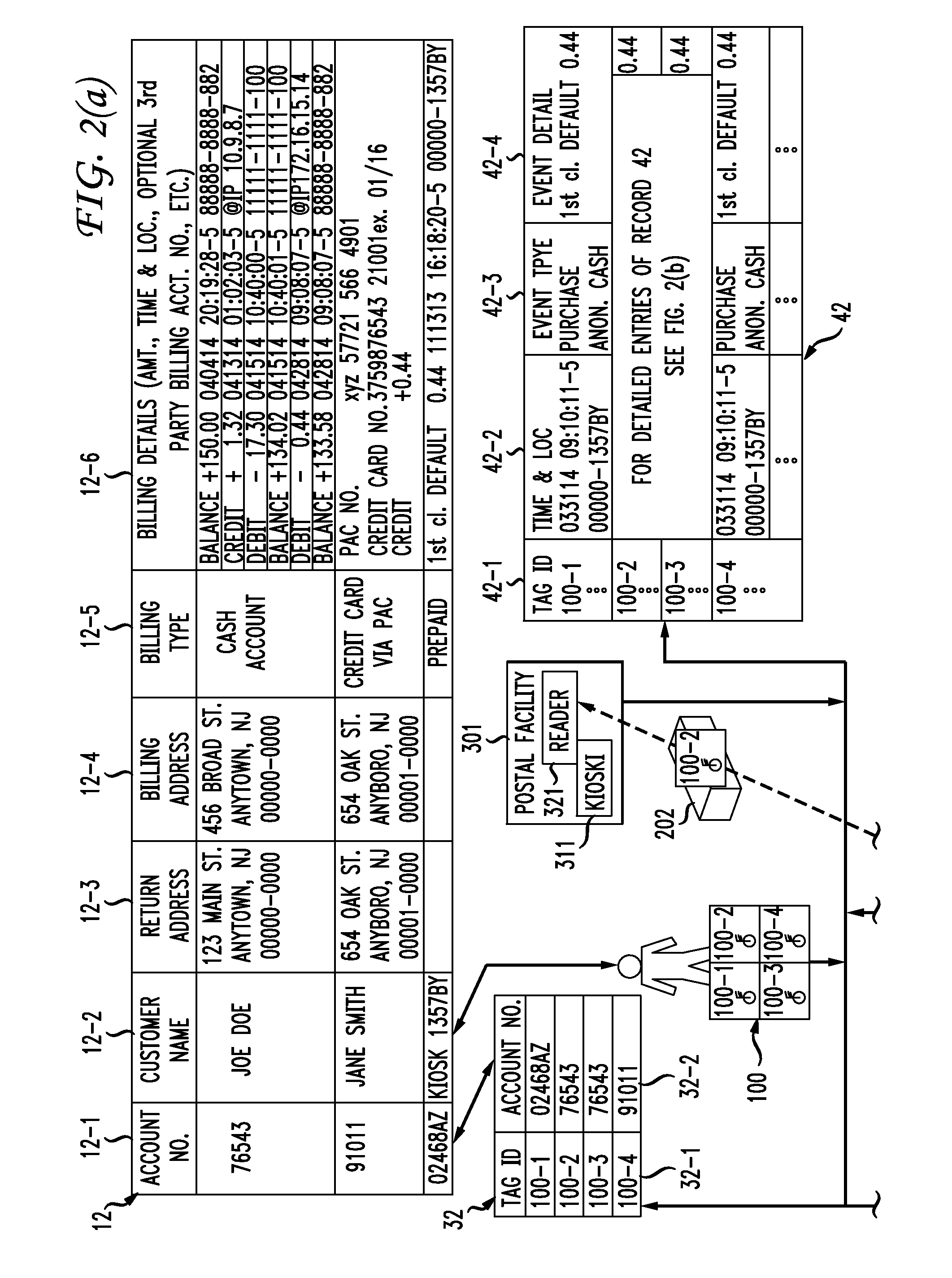

Passive RFID postage stamps and method of using the same

ActiveUS20110137775A1Easy to detectImprove service reliabilityElectric signal transmission systemsDigital data processing detailsPaymentComputer science

A system and method for postage payment utilizes passive RFID tags as postage “stamps”, with the amount of the postage automatically billed to a previously-established customer account. The tags are stored in a separate stamp database and are “enabled” by linking the individual tag to a customer account. The use of the RFID stamps eliminates the need for the customer to know the proper postage beforehand. The existence of a customer account with a proper return address reduces the likelihood of a dead letter. Also, a special category of stamps may be used for automatic reply mail. By virtue of using an RFID tag, the mailed item's progress through the postal delivery system may be tracked from dispatch to delivery.

Owner:AT&T INTPROP I L P

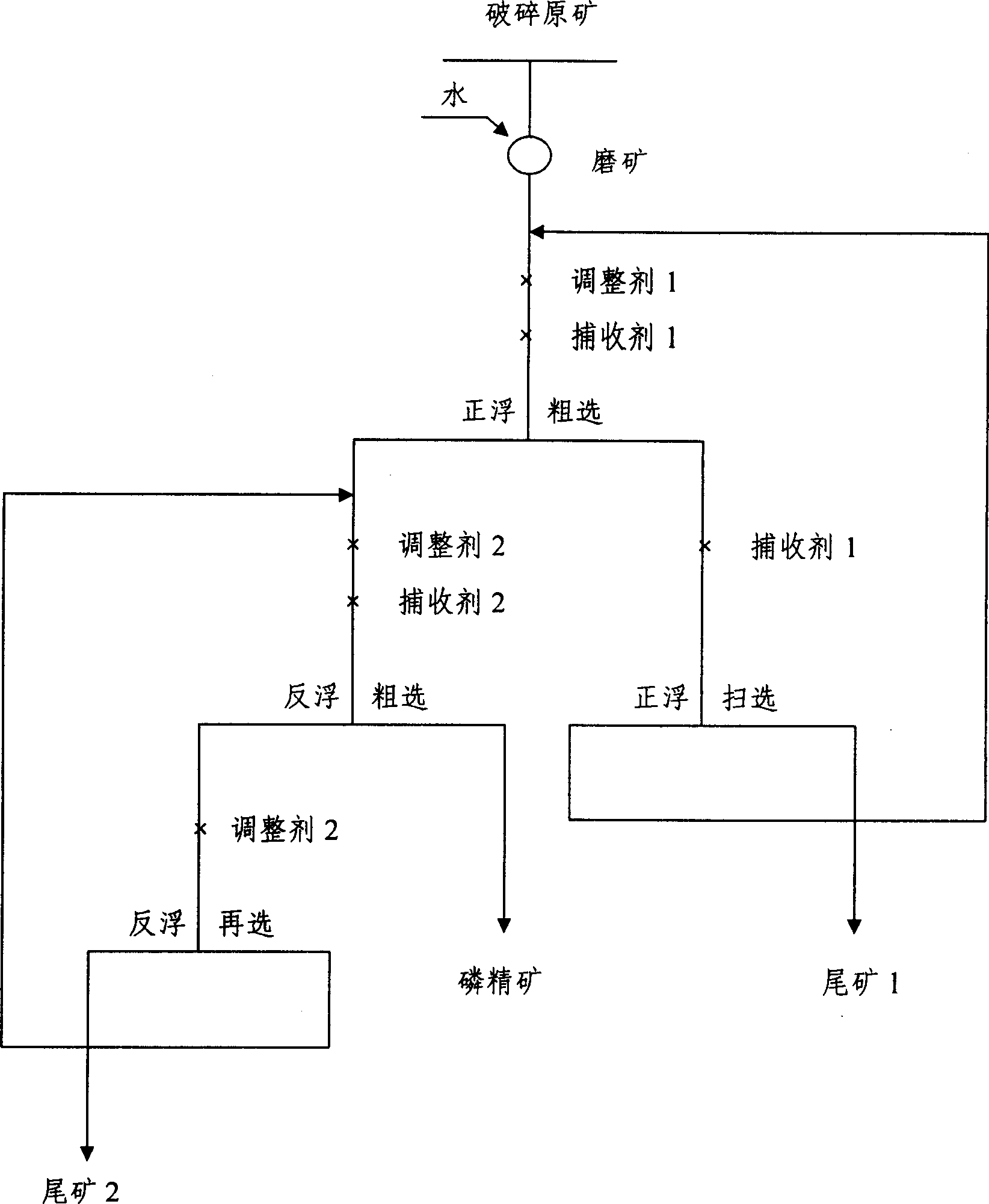

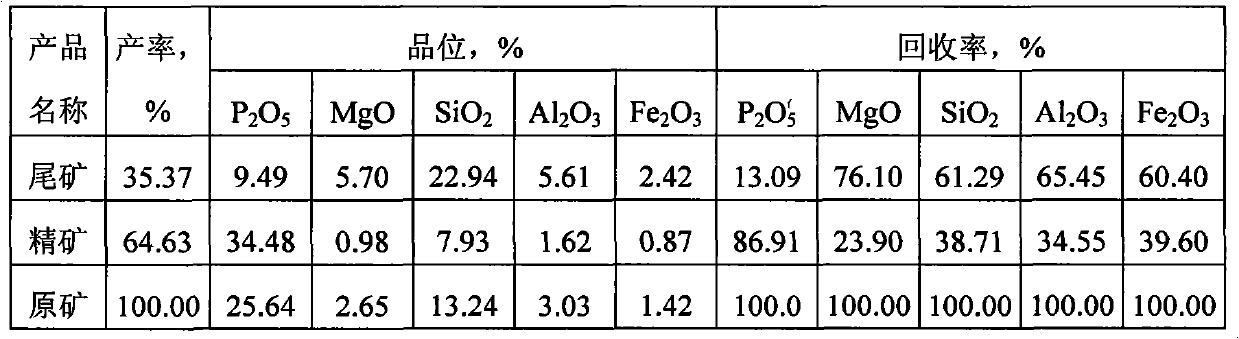

Collophanite direct flotation and reverse flotation technique

The invention relates to a positive-negative floatation technology for cellophane, which comprises the following steps: subjecting siliceous-calcareous collophane ore to breaking and grinding process to dissociate ore monomer; adding water to it get ore pulp with concentration of 20 -50%; Leading the mixture to agitated tank; adding modifying agent sodium silicate and positive collector agent to ore pulp; processing the mixture in positive floating system to get foamed product; adding negative floatation agent inorganic acid and collector agent to the foamed product in negative flotation agitated tank; processing the mixture in negative floating system with carbonate vein mineral negative flotation to get foamed product as negative flotation debris and product in tank as clean ore. The invention can simplify process, deduce cost and recycle the water.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

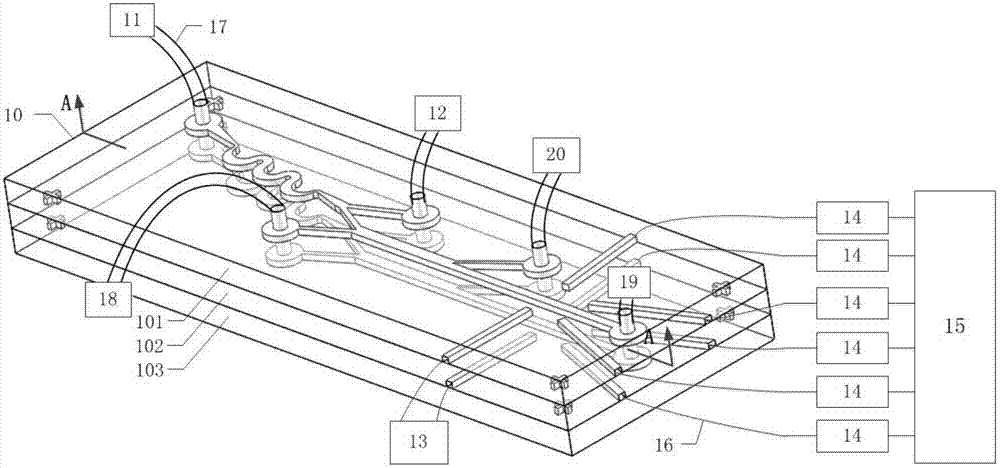

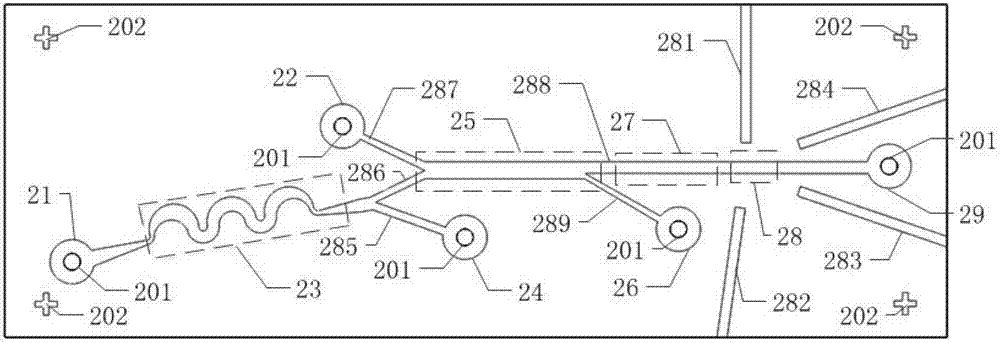

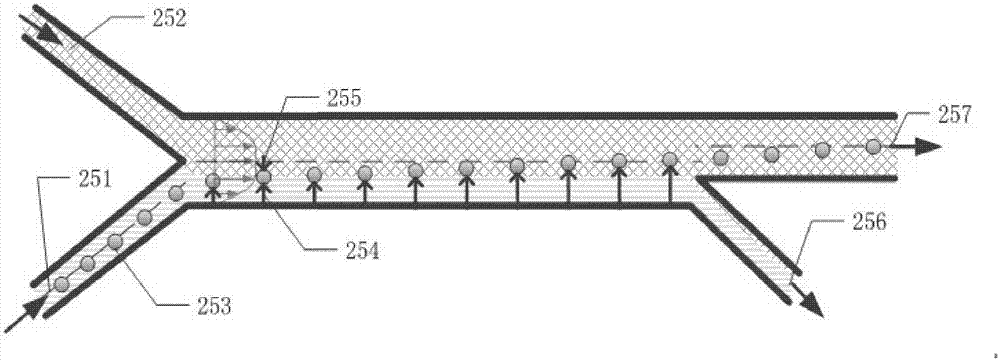

Integrated chip system for high-throughput sorting and counting detection of biological particles, and application

ActiveCN103191791AMeet the damageNo damageMaterial analysis by optical meansLaboratory glasswaresInertial effectLiquid Change

The invention discloses an integrated chip system for high-throughput sorting and counting detection of biological particles, and an application. The chip system comprises a main microfluidic chip, a micropipe, a sample liquid micropump, an exchange liquid micropump, a first waste liquid collecting device, a second waste liquid collecting device, a third waste liquid collecting device, laser emitters, photoelectric conversion devices, optical fibers and a computer, wherein the main microfluidic chip comprises an asymmetric curved flow path, a first branch channel, a second branch channel, a third branch channel, a main flow path, a branch flow path, aligning marks, etc. The system utilizes the asymmetric curved flow path to realize pre-focusing and sorting for the particles, utilizes a liquid changing flow channel to realize change of a carrier liquid of to-be-tested particles and particle cleaning, and utilizes a viscoelastic effect and an inertial effect of a viscoelastic fluid to realize focus of single equilibrium position of section centers of the particles. The system does not need a sheath liquid, complex pre-cleaning of the particles, and optical alignment, has advantages of high speed, high precision, integration, miniaturization, automation, low cost, simple production process, easy batch production, etc.

Owner:SOUTHEAST UNIV

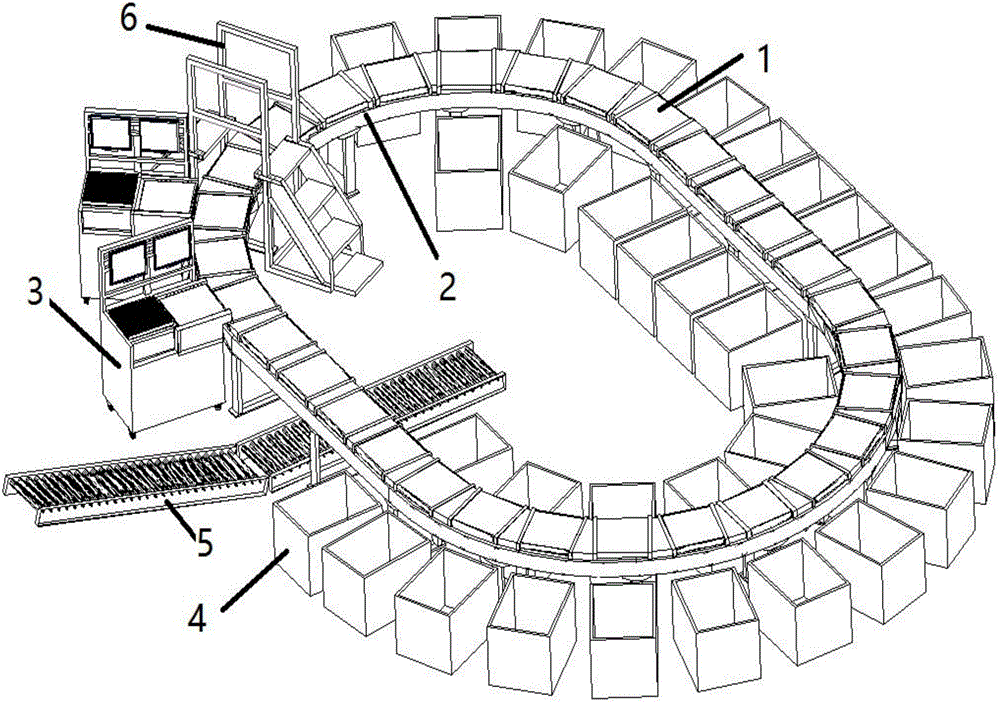

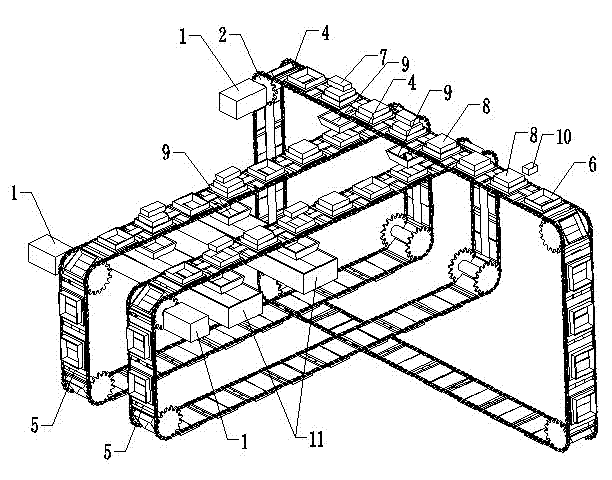

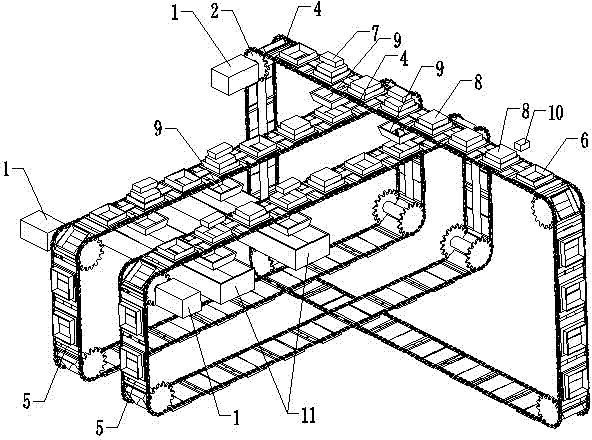

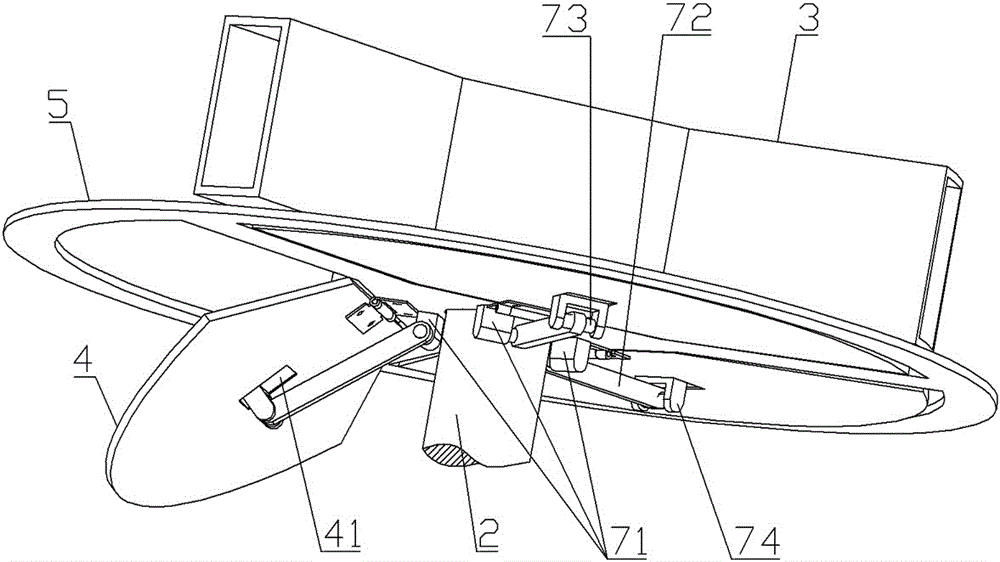

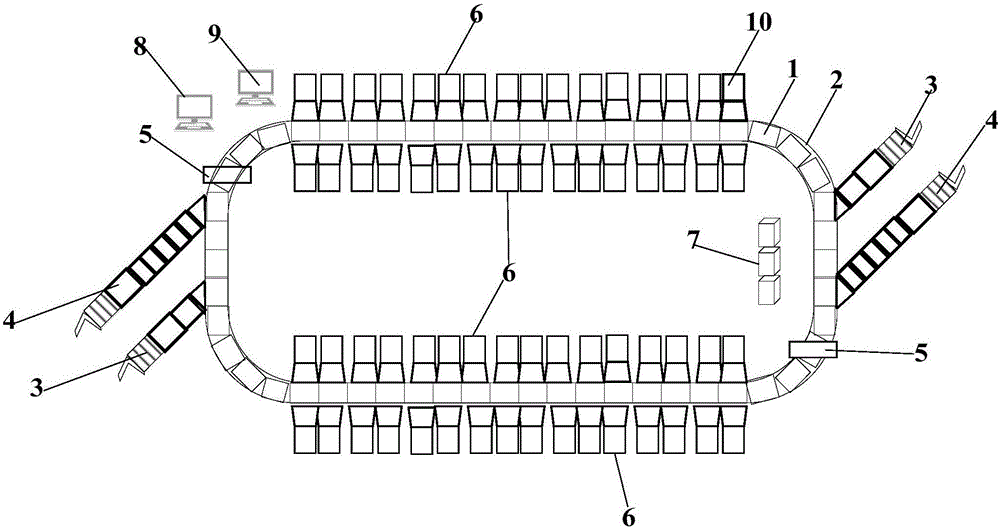

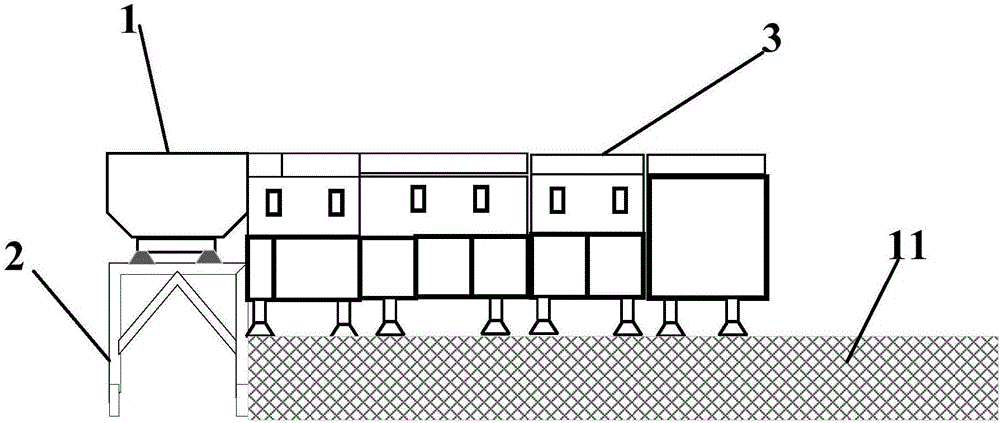

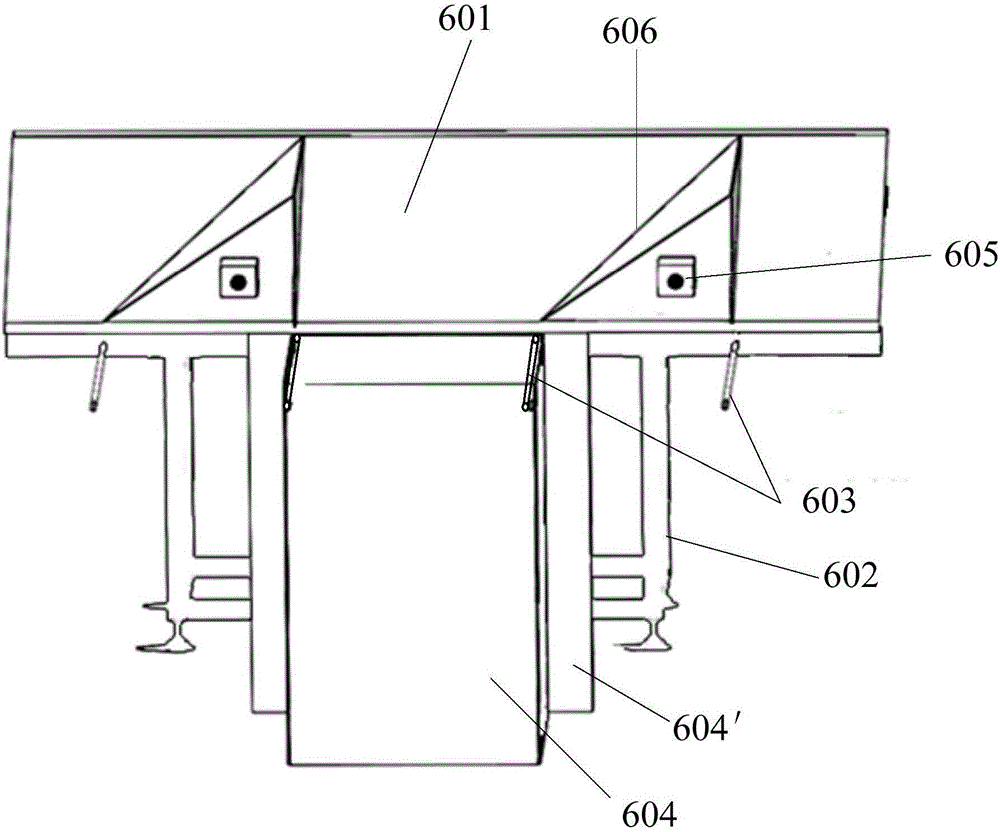

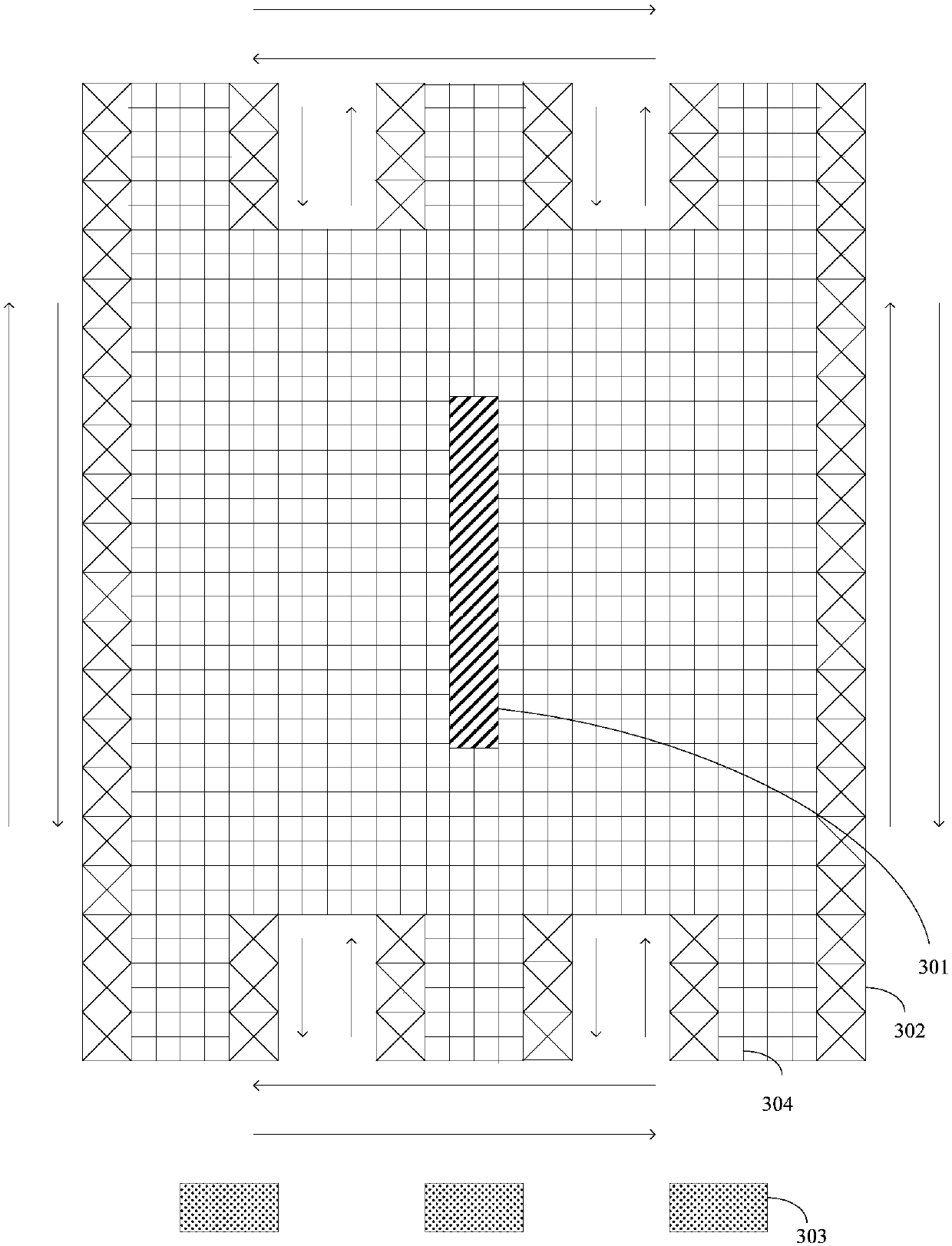

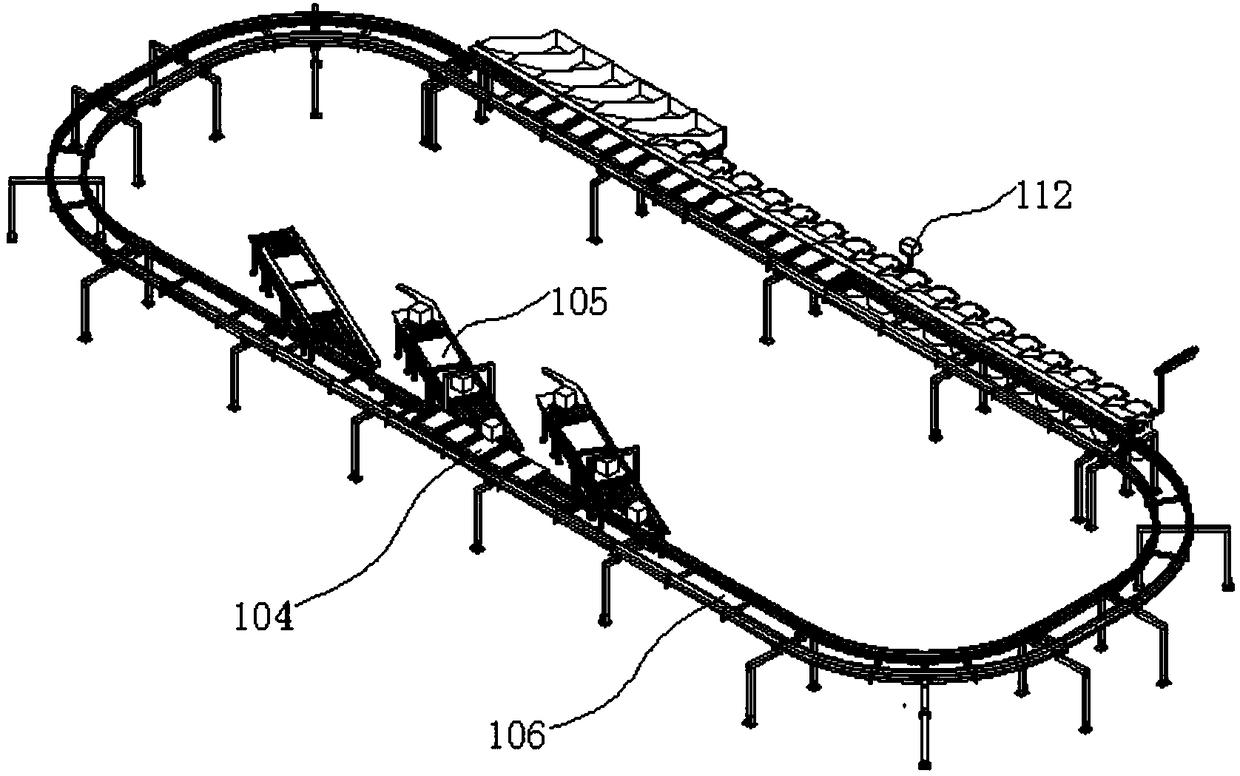

Small halved belt type sorting system and method

The invention discloses a small halved belt type sorting system and method. The system comprises a rail mechanism, a conveying mechanism, storage mechanisms and an operating mechanism. The rail mechanism is arranged annularly, the conveying mechanism is arranged on the rail mechanism and rotates in the annular direction of the rail mechanism, the storage mechanisms are arranged on the two sides of the rail mechanism, and the operating mechanism is arranged on the outer side of the rail mechanism. Small express packages or small flexible packaging objects or small irregular objects can be sorted, and sorting efficiency can be greatly improved.

Owner:上海久是信息科技发展有限公司

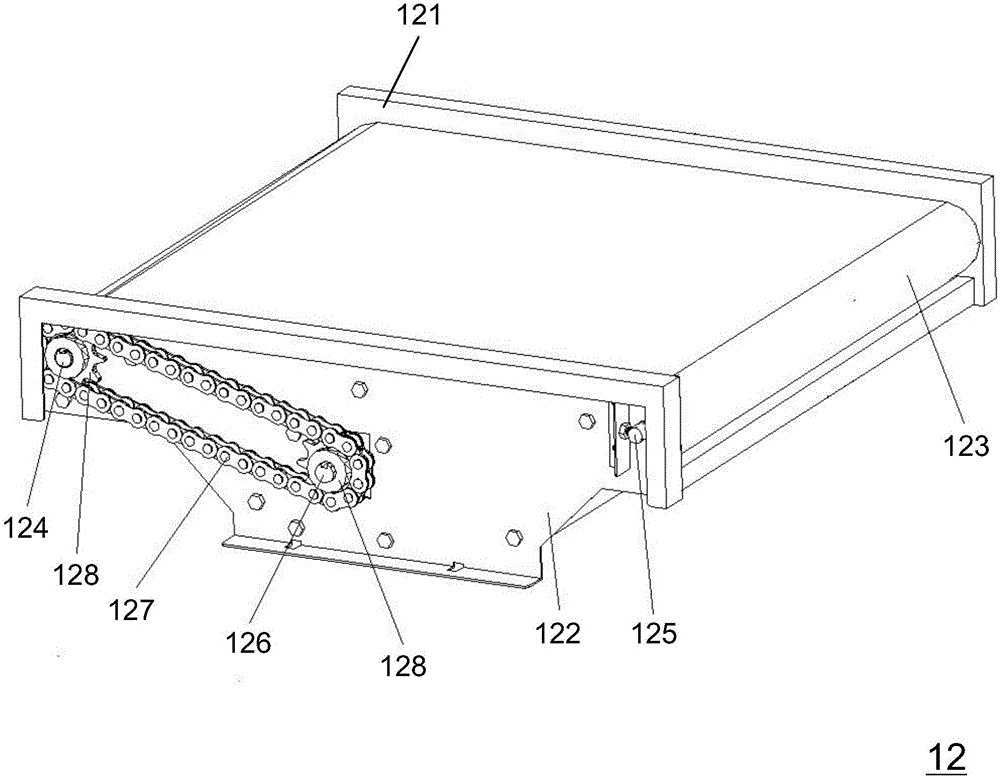

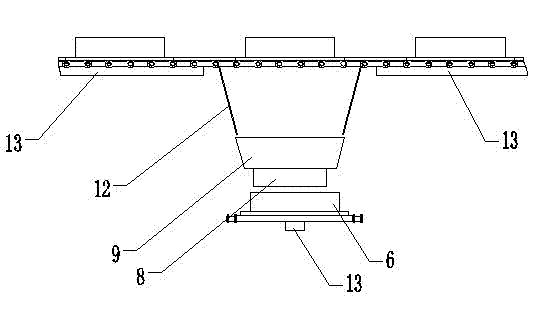

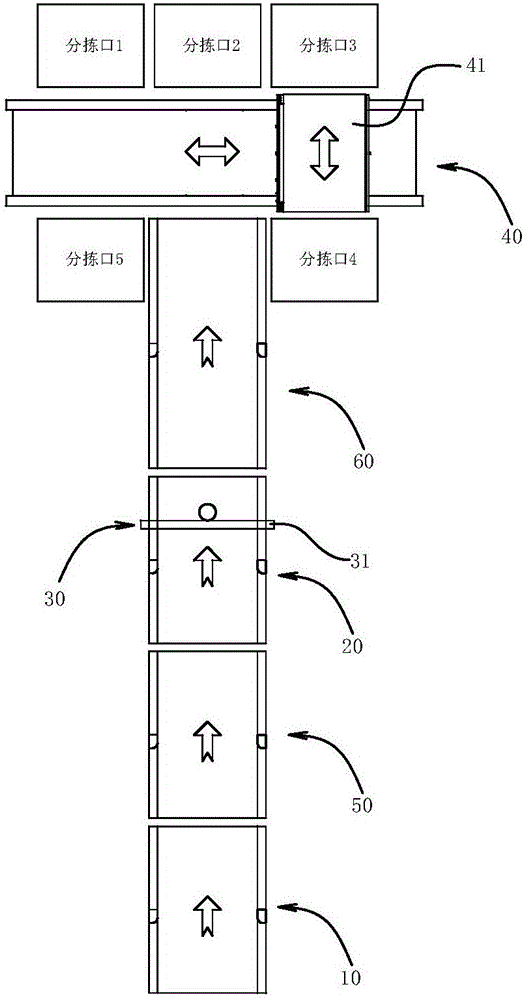

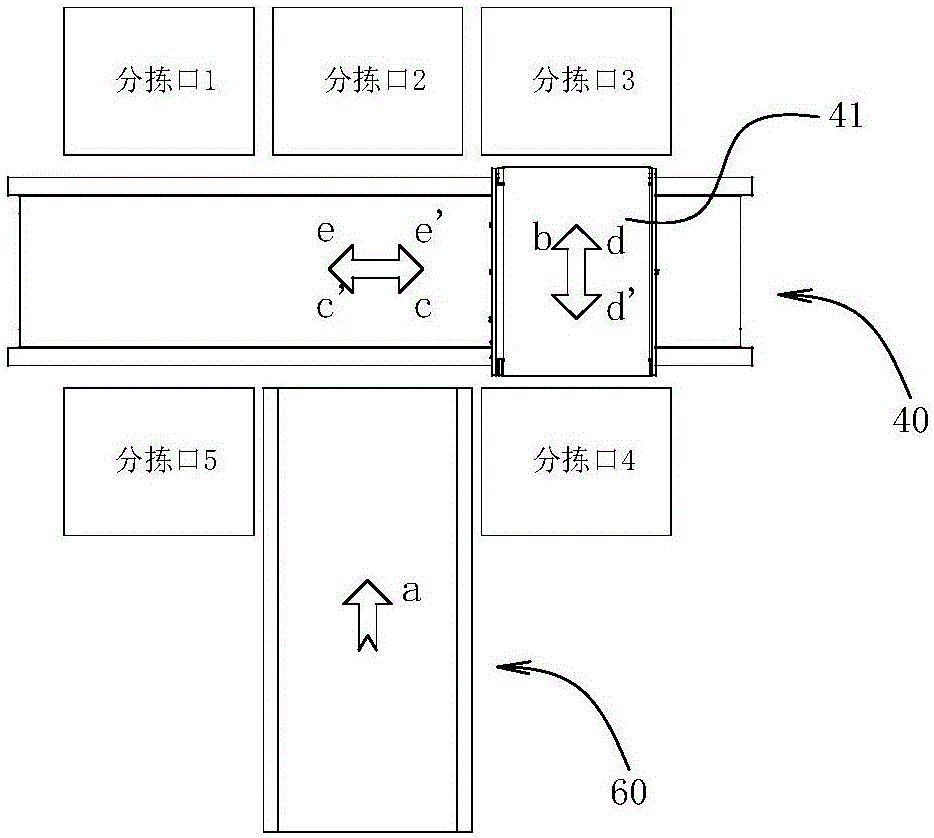

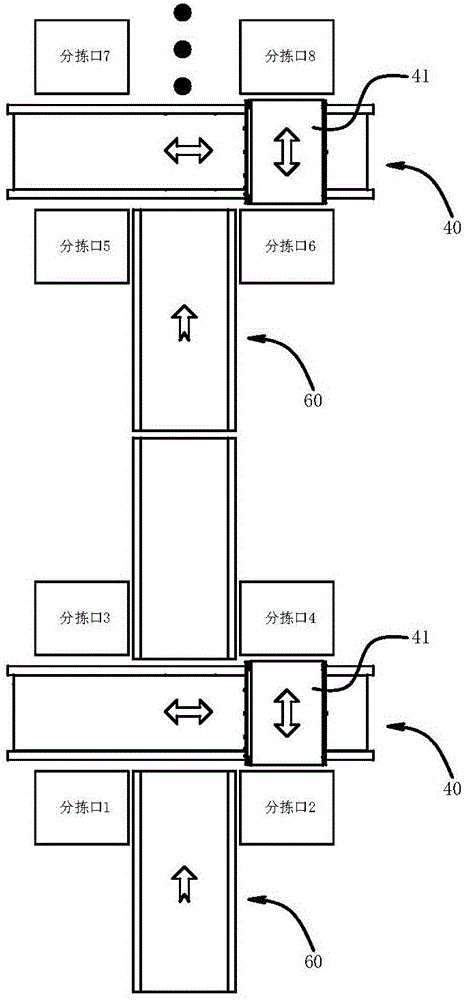

Straight-falling secondary sorting system

The invention discloses a straight-falling secondary sorting system, which can precisely finish the sorting work of a plurality of varieties of micro or small objects, improve sorting efficiency and reduce error rate. The system comprises a primary sorting device and a secondary sorting device, wherein the secondary sorting device is positioned below the primary sorting device and is arranged vertical to the primary sorting device in a cross way. In the system, a vertical sorting mode is adopted, the sorting work of the plurality of varieties of micro or small objects can be finished precisely; moreover, the varieties of objects to be sorted can be rapidly increased by setting the number of secondary sorting chains; and simultaneously, the postures of the objects in a sorting process can be ensured. Therefore, the sorting efficiency is improved and the error rate is reduced.

Owner:SHANDONG UNIV OF SCI & TECH

Logistics sorting system and method based on radio frequency and video and infrared recognition and tracking

ActiveCN102218404ALow costImprove sorting efficiencySortingInformation processingLogistics management

The invention discloses a logistics sorting system and a method based on radio frequency and video and infrared recognition and tracking. The system is provided with a plurality of sent goods transporting units, a convergence conveyer and a goods transporting roller way; each sent goods transporting unit is provided with a second infrared transmitting and receiving device, a cross beam which is provided with a radio frequency card reader, an information processing unit, a printer, a mark labeling device and a sorting port conveyer; a camera is arranged above the goods transporting roller way; each sent goods transporting unit comprises a sent goods conveyer and a goods collating device; the sent goods conveyer is provided with a first infrared transmitting and receiving device and a blocking beam; and the good inlet part of each sorting port conveyer is provided with an LED (light emitting diode) mark and a goods delivery device. The logistics sorting system and the method provided by the invention have the advantages of low cost and high sorting efficiency, goods of different types of goods can be sorted, and the like.

Owner:安徽省一一通信息科技有限公司

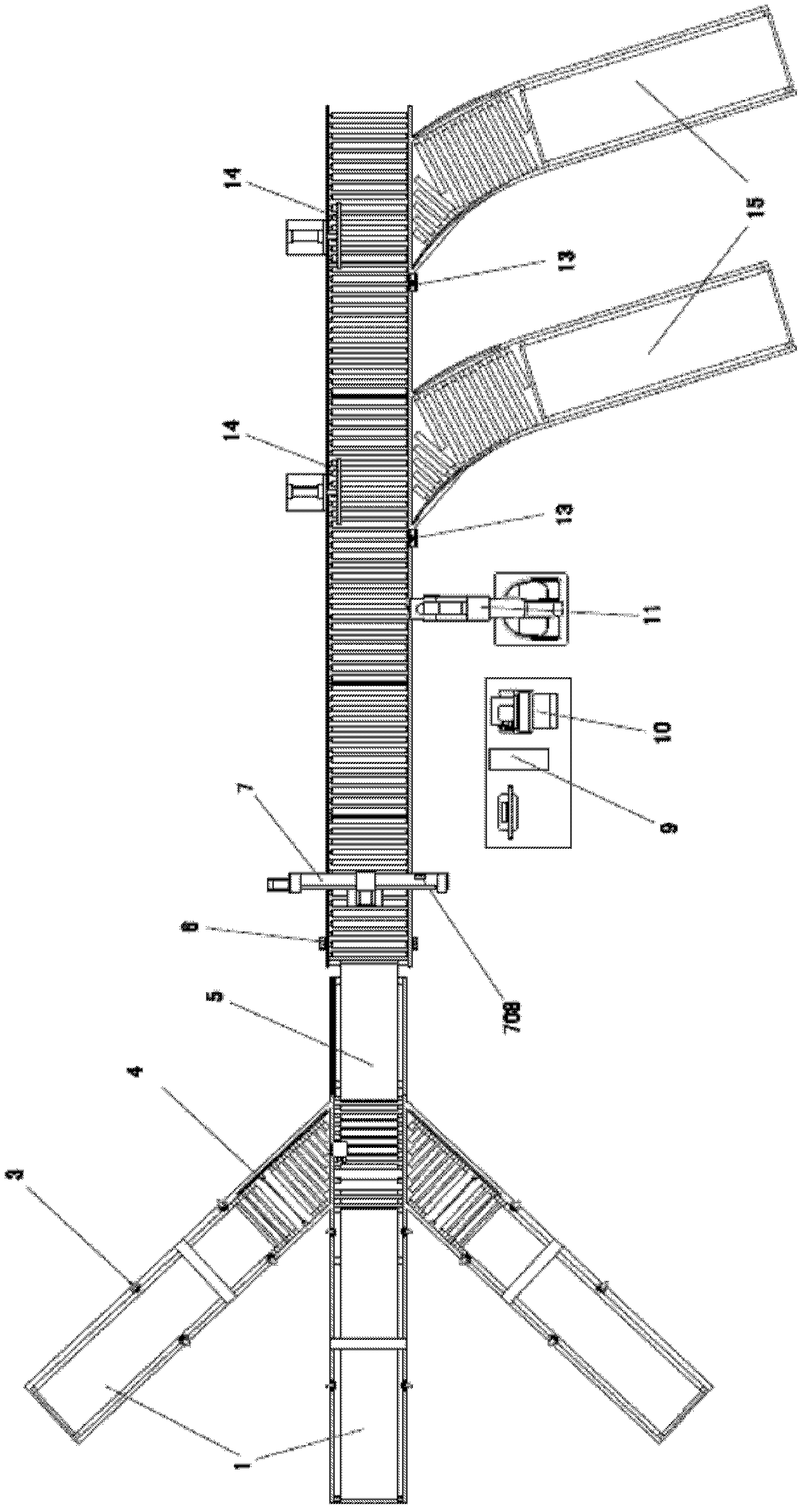

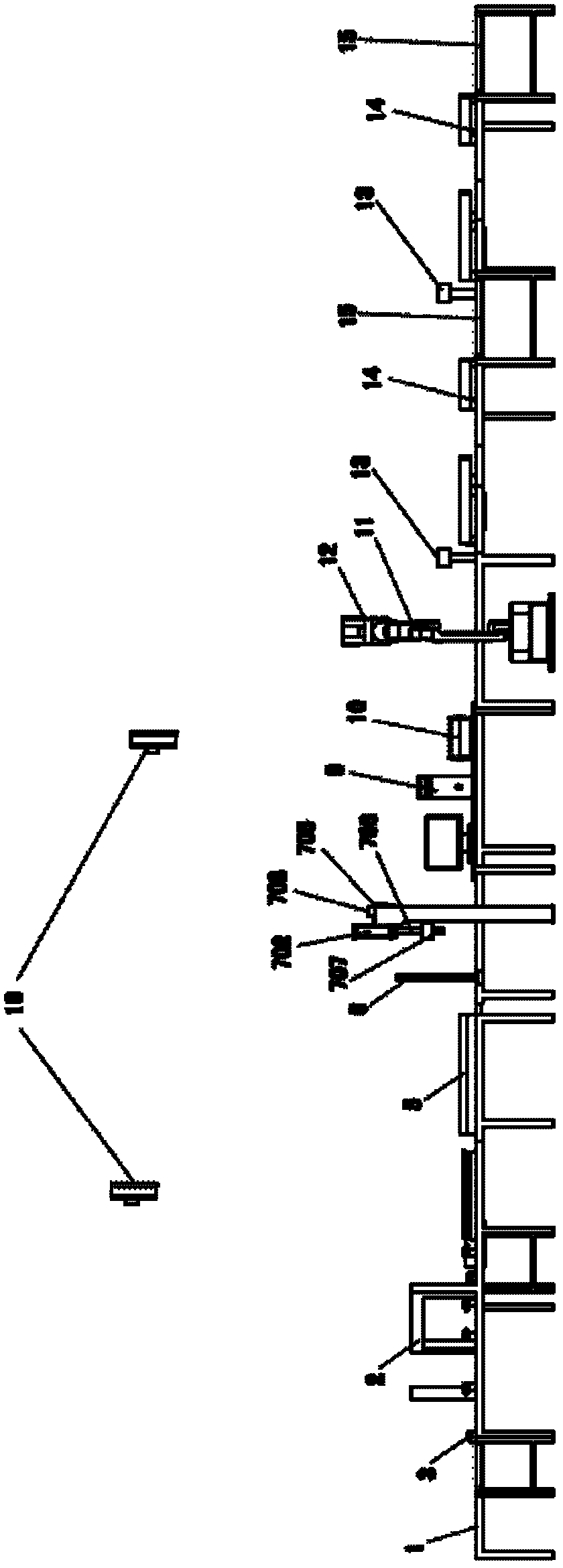

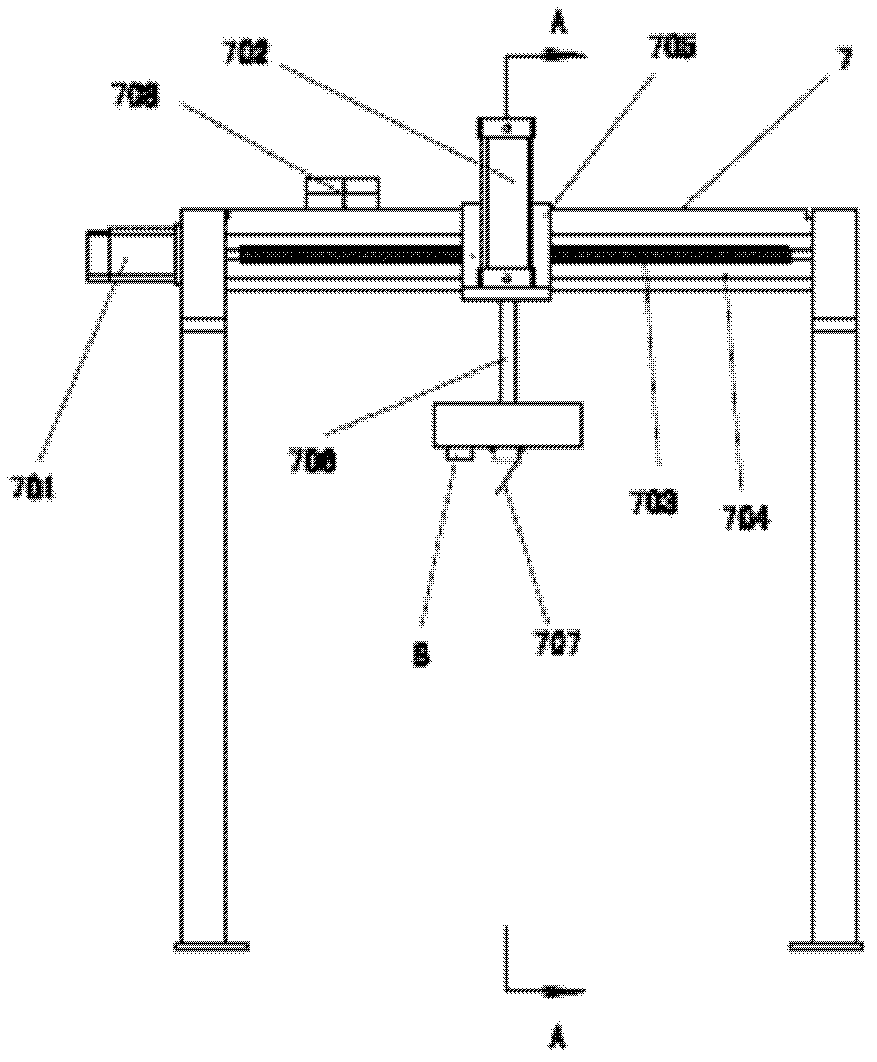

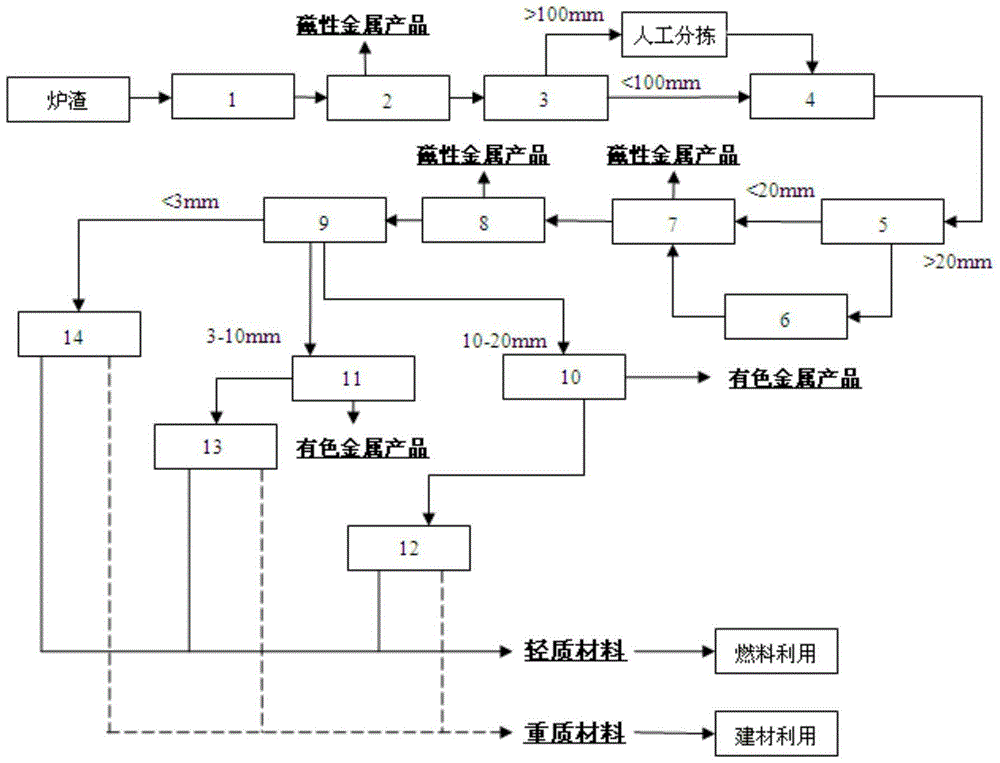

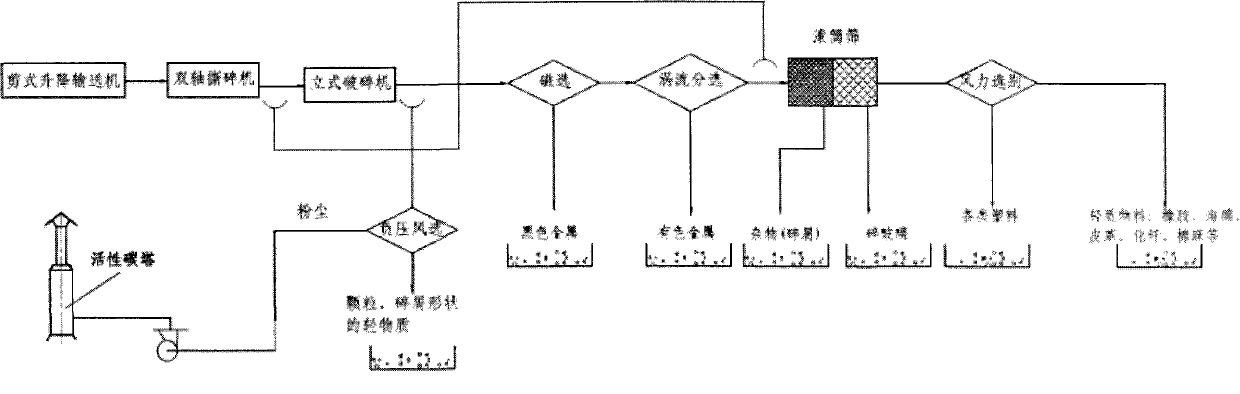

Method for recycling metal and combustibles from domestic waste incineration slag

The invention relates to a method for recycling metal and combustibles from domestic waste incineration slag, and belongs to the field of the solid waste harmless and recycling technology. By means of multi-stage gradient magnetic separation, separation of magnetic metal in the slag is achieved. By means of two-stage eddy current, nonferrous metal in the slag is separated and recycled. According to the grain size distribution and chemical morphological characteristics of the metal in the slag, the metal is crushed and screened in multiple steps so that separated slag particles can be uniform, the recycling rate of magnetic separation and eddy current separation is effectively increased, and finally, according to the density difference of materials, air separation is used for recycling the combustibles in the slag. Finally, the magnetic separation recycling rate of iron in the technological process is 60-80%, the recycling rate of the nonferrous metal aluminum is 60-70%, the recycling rate of the nonferrous metal copper is 40-50%, and separation of the metal in the slag and slag particles can be effectively achieved. The separated metal products can be directly sold or sold after refining, the combustibles can serve as waste incinerator fuel, and the remaining slag can be used as building materials.

Owner:TONGJI UNIV

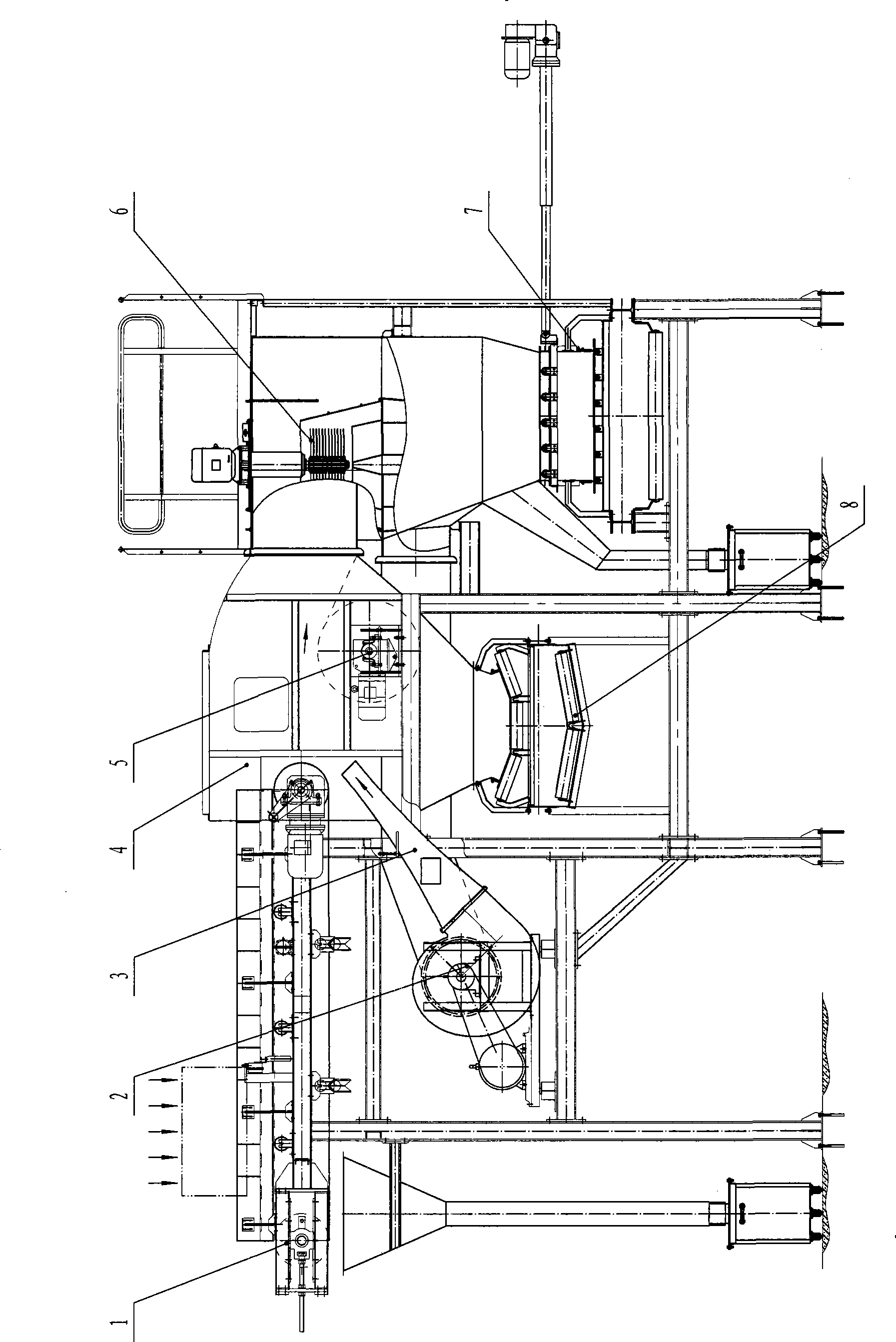

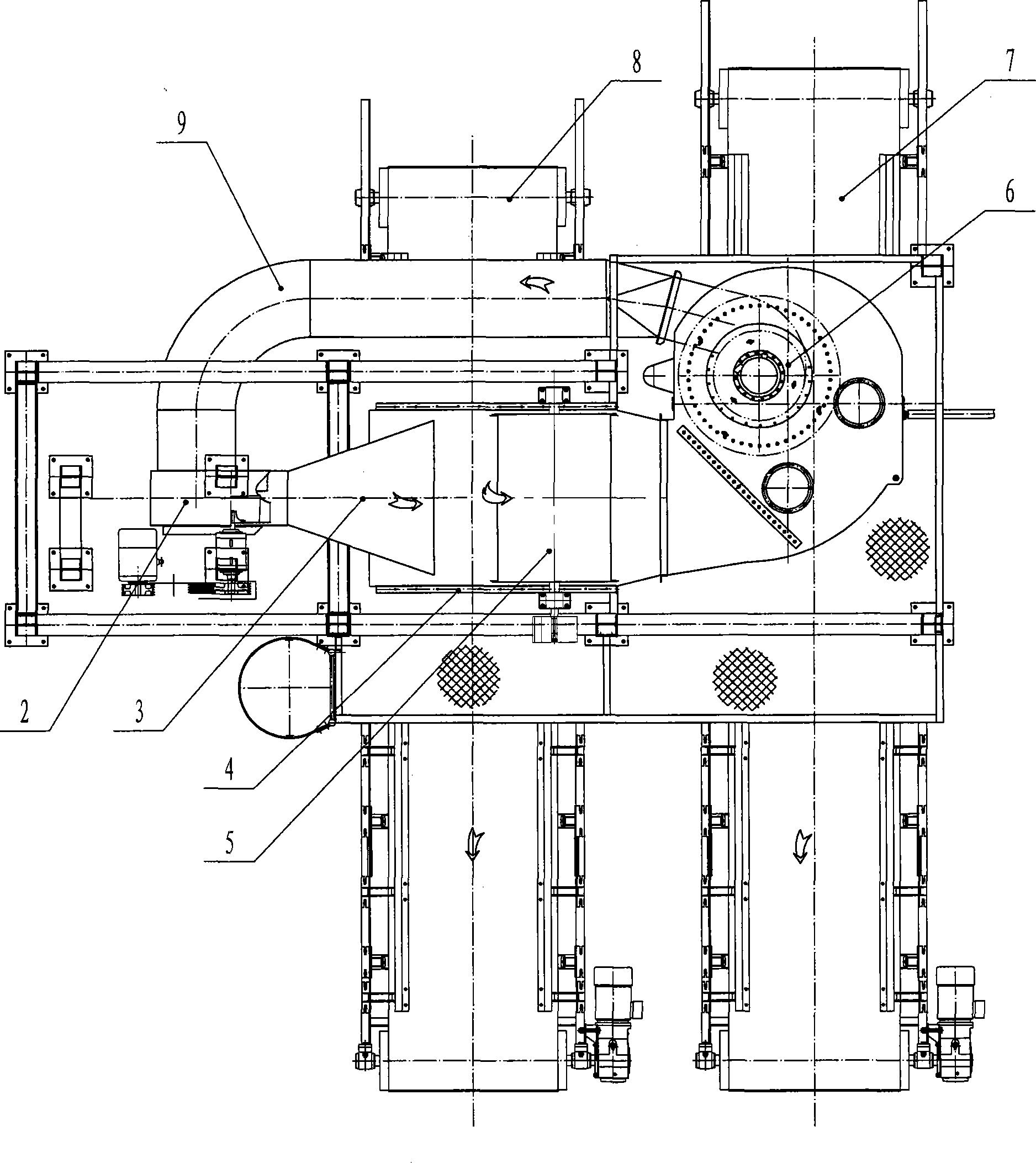

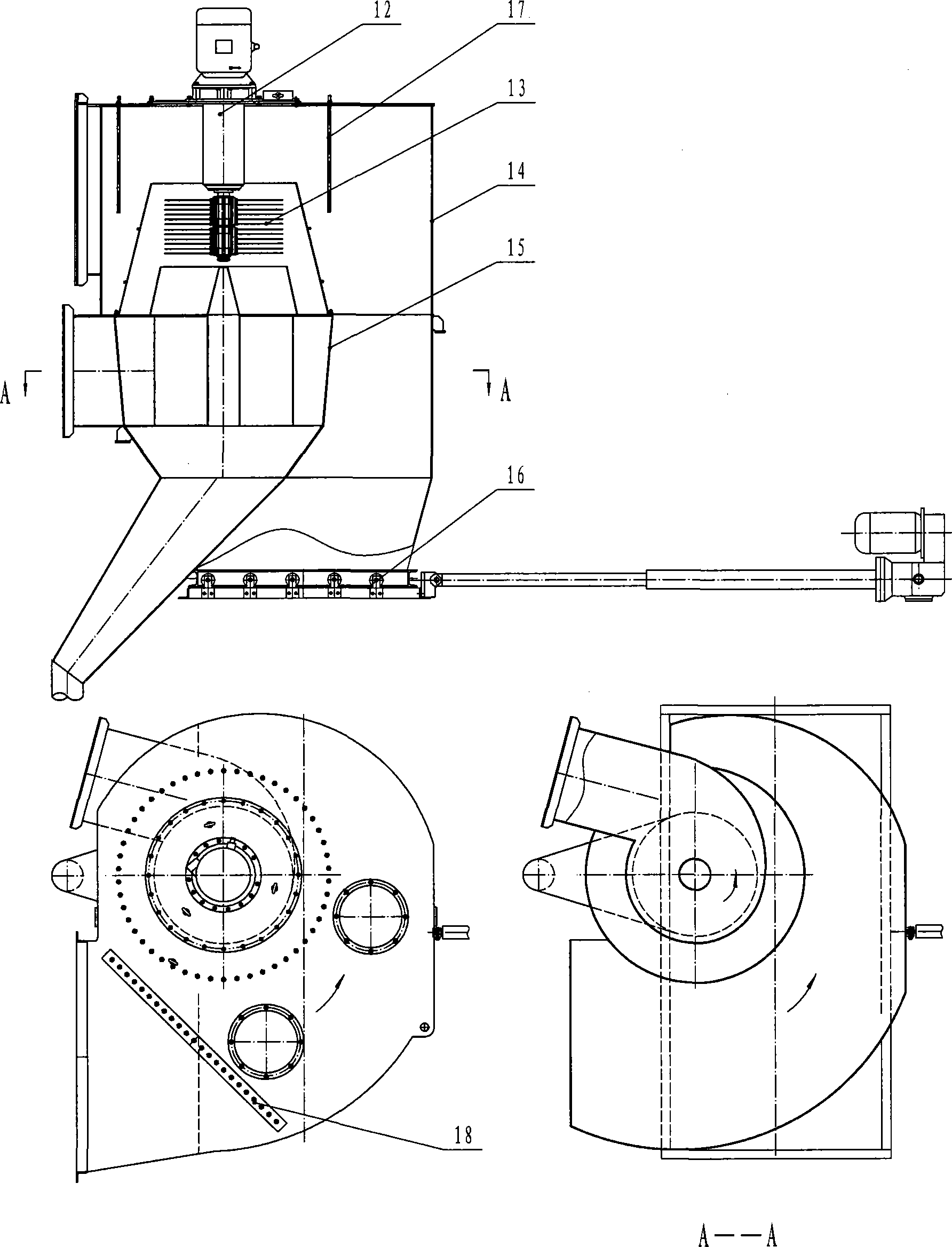

Wind power sorting device

InactiveCN101249494AReduce pollutionReduced wind pressure requirementsGas current separationControl systemUnit device

The invention relates to an air sorting device, which belongs to the field of air sorting technology for chemical material. The system comprises an air blower (2), an air register (3), an air sorting chamber (4), a relay drum (5), a settling centrifuge (6), an input material conveyor (1), a heavy material output conveyor (8), a light material output conveyor (7), an air return pipe (9), a stand, a dust remover and a control system. The settling centrifuge (6) includes a transmission device (12), a pin wheel (13), a ring grate (17) and a bar grate (18). The system adopts the relay drum (5) to reduce the air active section to compensate for the short migration distance of light material under the action of air force, thus obviating the secondary falling back and mixing of the sorted light material. Additionally, an intensely centrifugal air flow is used for separating particles and dust, and high-speed rotation energy can be converted into dynamic pressure by discharging air through a volute. The system has the advantages of compact structure, less occupied area, short pipe, less resistance, strong air power of the air sorting chamber, high sorting efficiency and stable and reliableoperation. The air sorting unit device can be used for sorting oversize plastics of urban life garbage and for sorting other industrial mixed materials.

Owner:BEIJING GOLDEN STATE ENG CO LTD

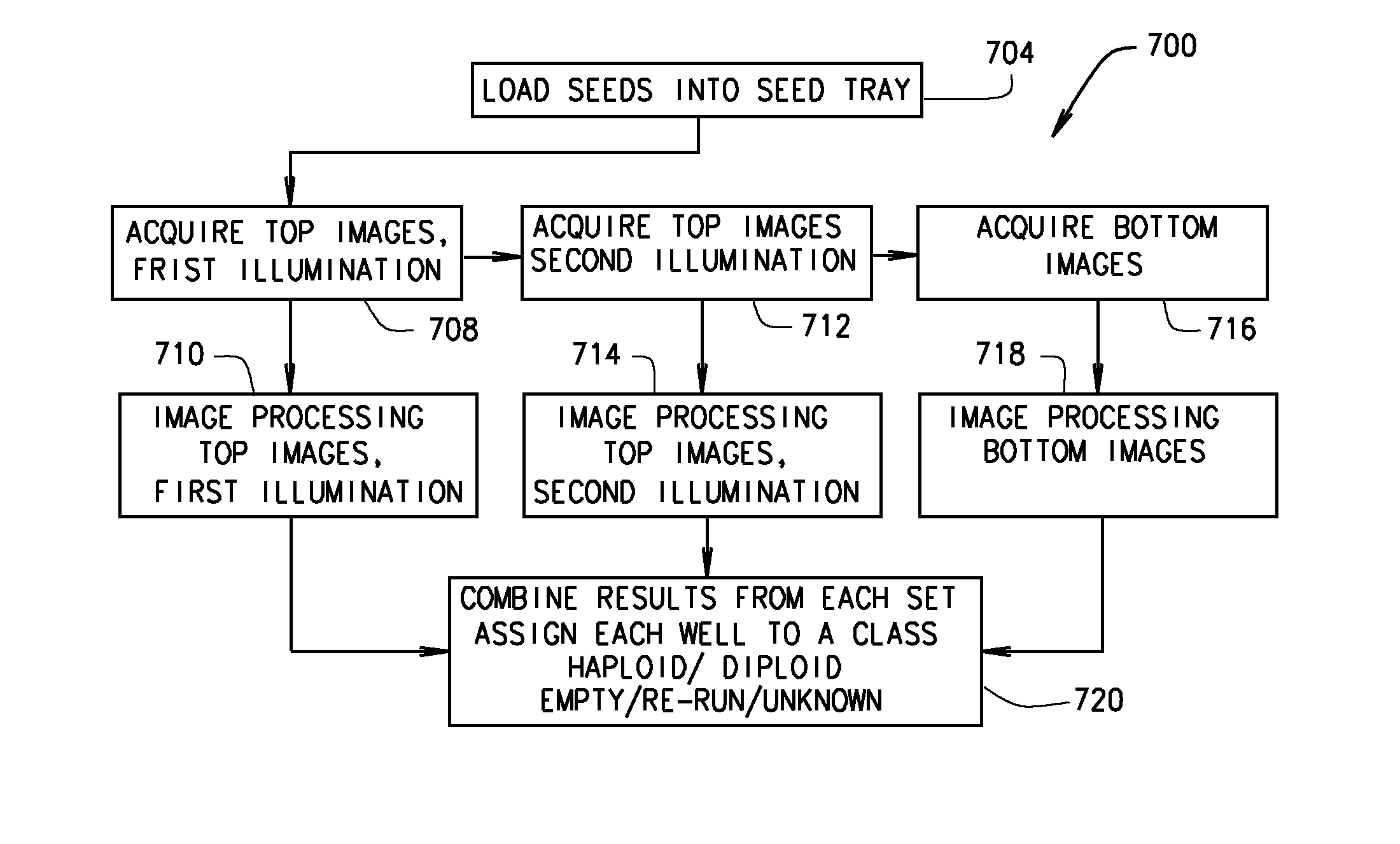

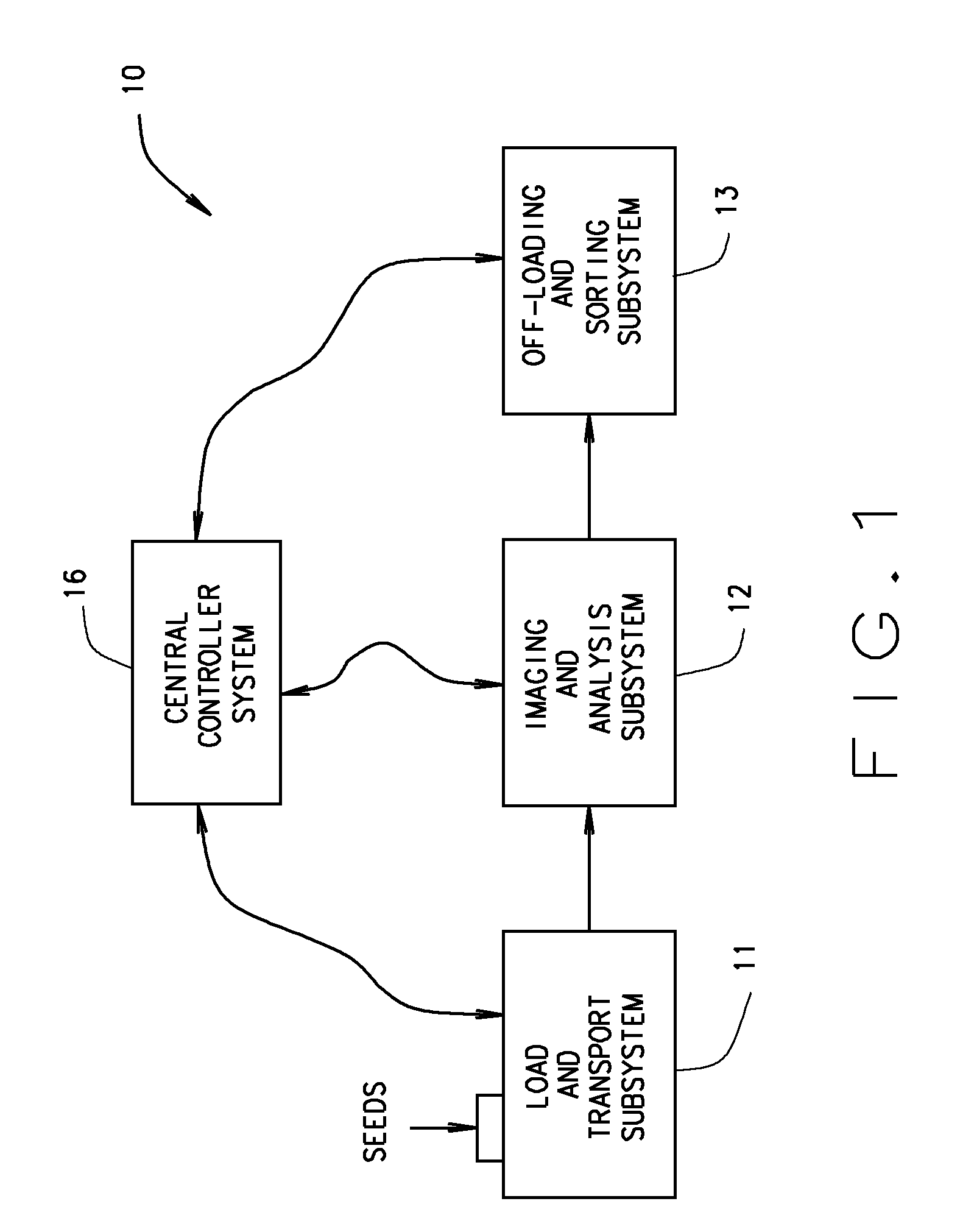

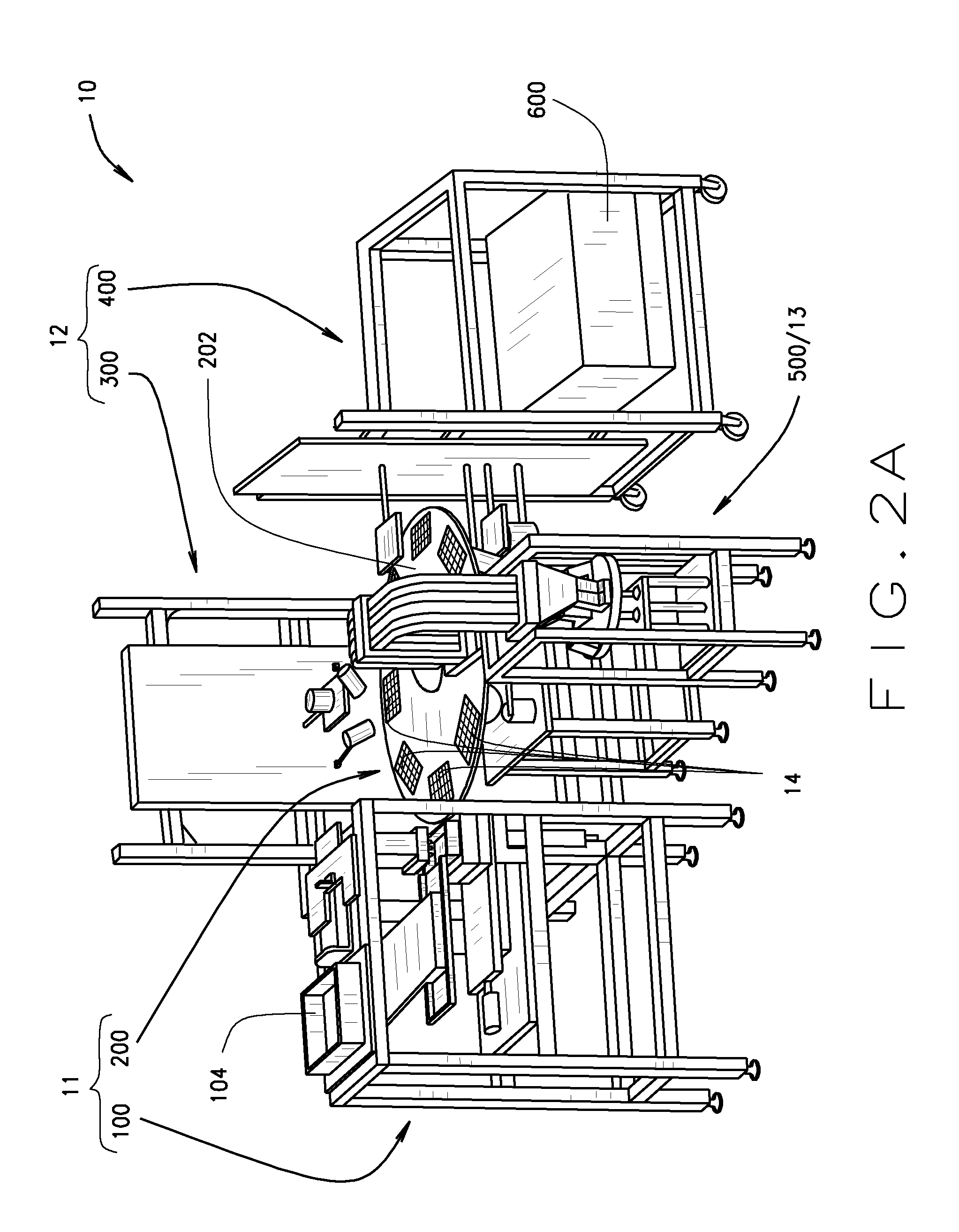

Seed sorter

ActiveUS8189901B2Improve sorting efficiencyGreat throughput rateRadiation pyrometrySeed and root treatmentComputer scienceImaging data

The present disclosure provides systems and methods for sorting seeds based on identified phenotypes of the seeds. In various embodiments, the system includes an optics and controller station structured and operable to collect image data of a top portion, a bottom portion and a plurality of side portions of each respective seed in a set of seeds, and to analyze the collected image data to determine whether each seed exhibits a desired phenotype. The system further includes a seed loading, transporting and sorting station structured and operable to singulate each seed of the set of seeds from a plurality of seeds in a bulk seed hopper, transport the set of seeds to the optics and controller station, and selectively sort each seed to a respective one of a plurality of seed repositories based on whether each respective seed exhibits the desired phenotype.

Owner:MONSANTO TECH LLC

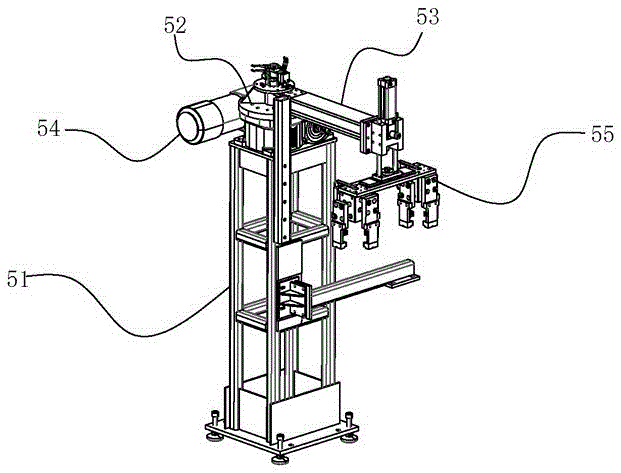

Multi-channel intelligent cargo sorting device

ActiveCN106733675ARealize three-dimensional transportation and sortingImprove sorting efficiencySortingEngineeringMechanical engineering

The invention relates to a multi-channel intelligent cargo sorting device. The multi-channel intelligent cargo sorting device comprises a conveying device, a cargo information recognition device, a classification guiding device, a cargo collection device and a control device, wherein the conveying device comprises a loading zone arranged at the front end and at least three sorting zones which are arranged at the back end, are connected with the loading zone and are distributed in different directions, wherein the sorting zones and the loading zone are distributed in a branch shape; the sorting zones comprise a main sorting zone and a plurality of sub sorting zones; the main sorting zone is used for boxing and arranging object cargo; the sub sorting zones are used for collecting cargo requiring to be sorted again; the classification guiding device is arranged at the connection part of the loading zone and the sorting zones, and is used for allowing cargo to flow to the different sorting zones; and the cargo information recognition device is a scanning box. According to the multi-channel intelligent cargo sorting device with the structure, multi-channel three-dimensional transportation sorting is achieved, the sorting efficiency is effectively improved, and the labor cost is reduced.

Owner:吴朋翰

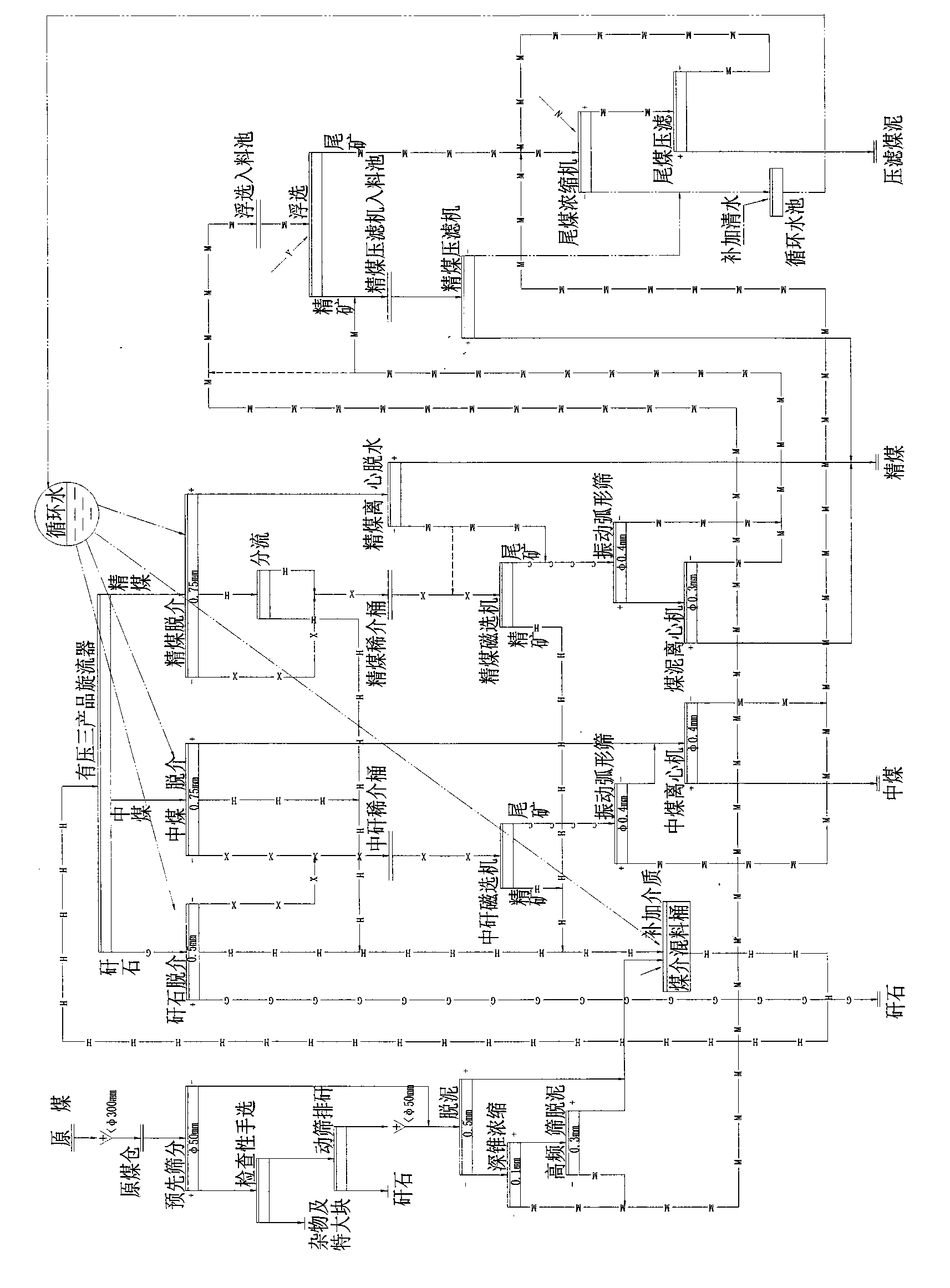

Classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process

InactiveCN103350027AImprove sorting efficiencyFlexible structureWet separationThermodynamicsMagnetic separator

Provided is a classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process. The process comprises the steps that wet classification and primary desliming are carried out on raw coal after prescreening, gangue predischarging and breaking are carried out on the raw coal, secondary desliming is carried out on the screen underflow of the raw coal after the screen underflow is concentrated, the oversize products of the secondary desliming and the screen underflow of the primary desliming are together fed in a pressurized three-product cyclone, three products are obtained after separation, and clean coal, middle coal and gangue are obtained after medium separation and dehydration are carried out on the three products. Part of qualified suspension liquid and dilute suspension liquid are obtained when the medium separation is carried out on the three products, magnetic concentrate is obtained after the dilute suspension liquid is recovered by a magnetic separator, and the magnetic concentrate and the qualified suspension liquid are directly fed in a medium blending barrel. The magnetic tailings of the dilute suspension liquid and the undersize mixtures of pre-desliming, the overflow of concentration classifying equipment and a secondary desliming screen enter a coal slime recovery processing system together. The process is high in separation efficiency, flexible in product structure, low in producing and operating cost and prone to achieving the large-scale single system, the modularization and the integrating intellectualization of plant layout.

Owner:煤炭科学研究总院唐山研究院

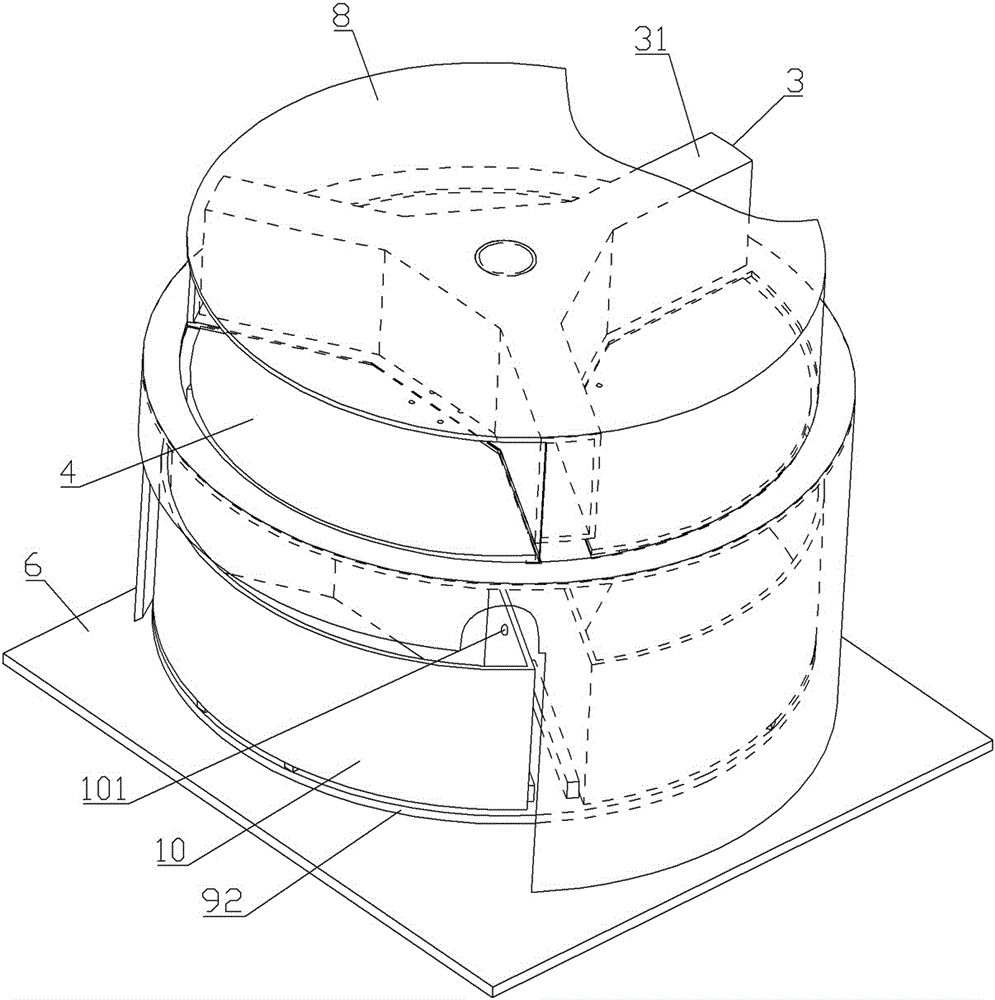

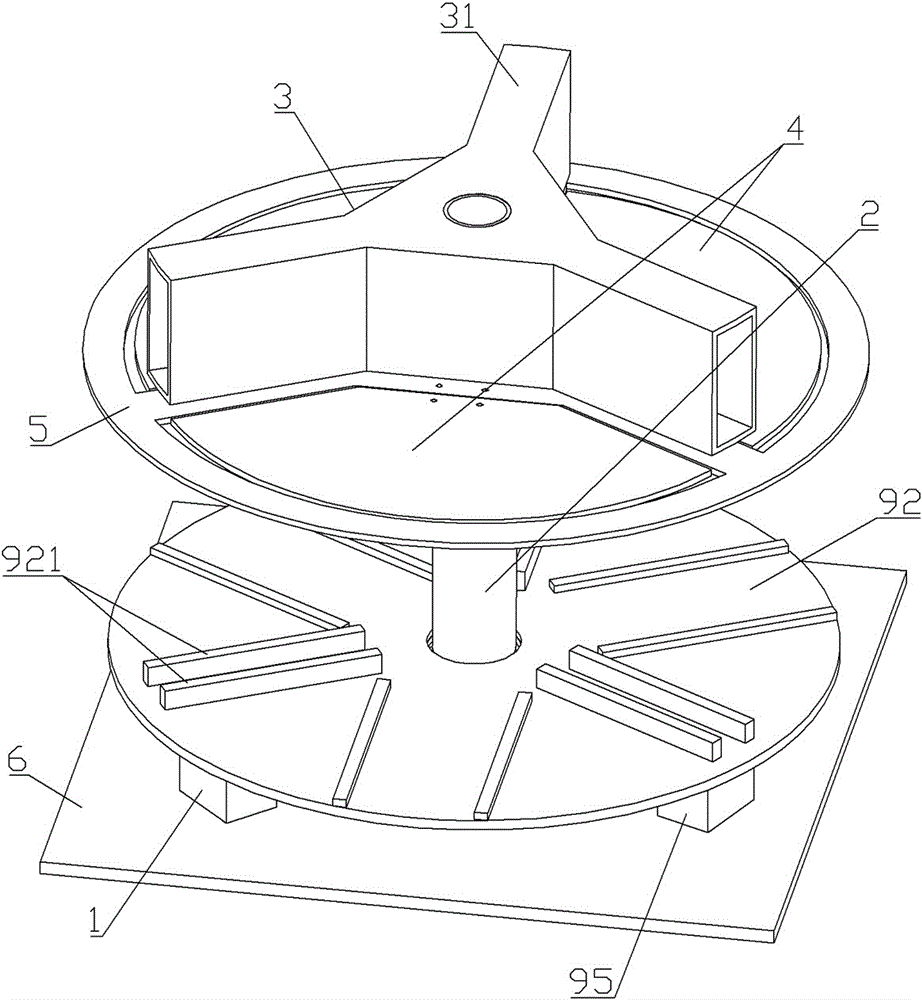

Rotating tower type quick sorting unit

InactiveCN105883370AReduce workloadReduce sorting error rateConveyorsSortingSmall footprintEngineering

The invention discloses a rotating tower type quick sorting unit which comprises a stepping motor A, a vertical rotating shaft, a horizontal sweep plate, a movable plate, an upper base, a lower base and a driving mechanism C for driving the movable plate to move, wherein the stepping motor A drives the vertical rotating shaft to rotate; the two ends of the vertical rotating shaft are movably mounted on the upper base and the lower base respectively; at least three sweep arms are arranged on the horizontal sweep plate; the upper base is divided into a plurality of stations by the sweep arms of the horizontal sweep plate; a region between every two adjacent sweep arms is one station; the stations comprise a material feeding station and a plurality of rotary conveying stations; a package falling opening is formed in each rotary conveying station; the movable plate moves under the driving of the driving mechanism C, to open or close the package falling opening. The rotating tower type quick sorting unit has the advantages of capability of sorting packages in the vertical direction and conveying the packages into package collection cases corresponding to addresses on the packages under the control of a main control computer. Compared with a conventional automatic sorting system, the rotating tower type quick sorting unit occupies a small area, and is high in intelligence degree and high in sorting efficiency.

Owner:NANHUA UNIV

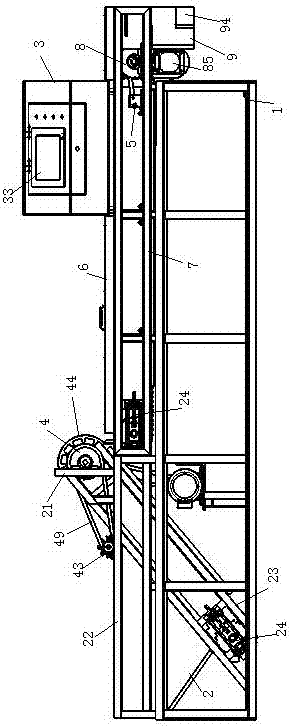

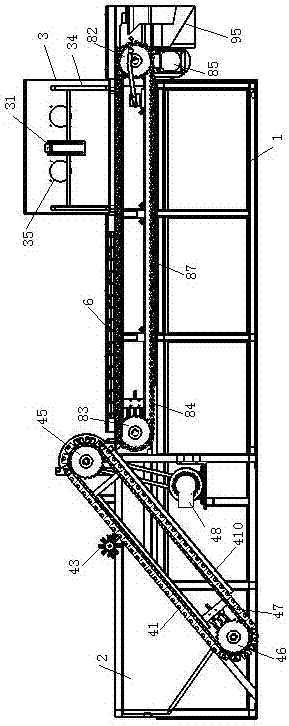

Red date intelligent selection equipment

ActiveCN107413678AImprove sorting efficiencyImprove detection accuracyClimate change adaptationSortingImaging processingControl engineering

The invention provides red date intelligent selection equipment. The red date intelligent selection equipment comprises a bottom supporting frame, a transmission supporting frame, a control box, a hopper, a feeding transmission device, a horizontal conveying device, a pneumatic mechanism and a division box. The transmission supporting frame is fixed to the upper portion of the bottom supporting frame. The horizontal conveying device is arranged in the transmission supporting frame and provided with a horizontal conveying belt composed of rollers. The hopper is arranged on one side of the bottom support frame. An inclined feeding plate is arranged in the hopper, and the feeding plate is connected with the feeding transmission device. The division box is fixed to the other side of the horizontal conveying belt. The control box is fixed to the middle of the transmission supporting frame. The pneumatic mechanism is arranged at the position, between the control box and the division box, of the transmission supporting frame. Industrial cameras and an industrial personal computer are arranged in the control box. An optical fiber sensor is arranged on one side of a chain wheel of the horizontal conveying device. According to the red date intelligent selection equipment, good dates and bad dates are separated through the image processing technology and the pneumatic mechanism, the detection precision is high, the red data sorting efficiency is improved, and the labor intensity is reduced.

Owner:郑州市中昕智能设备有限公司

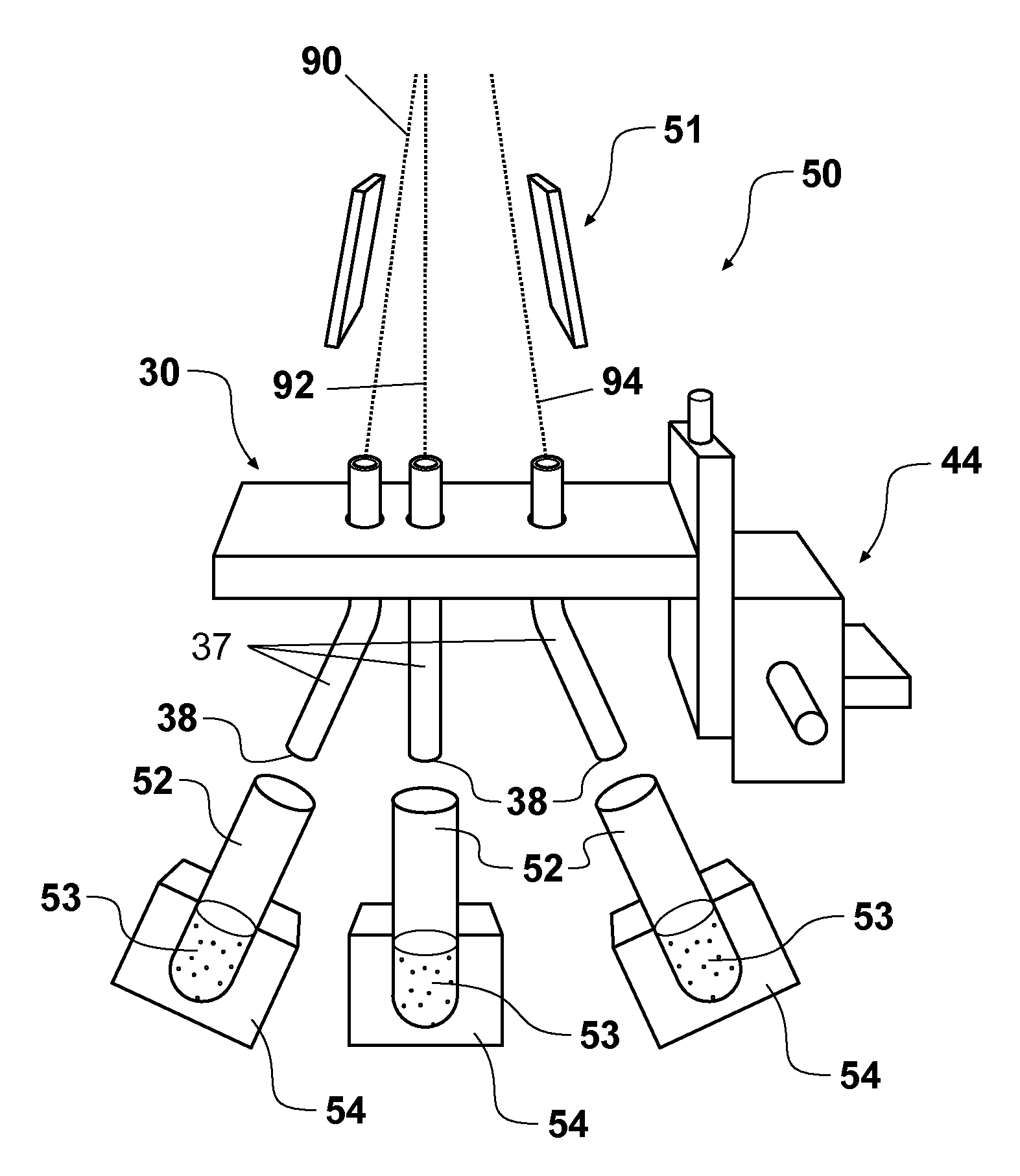

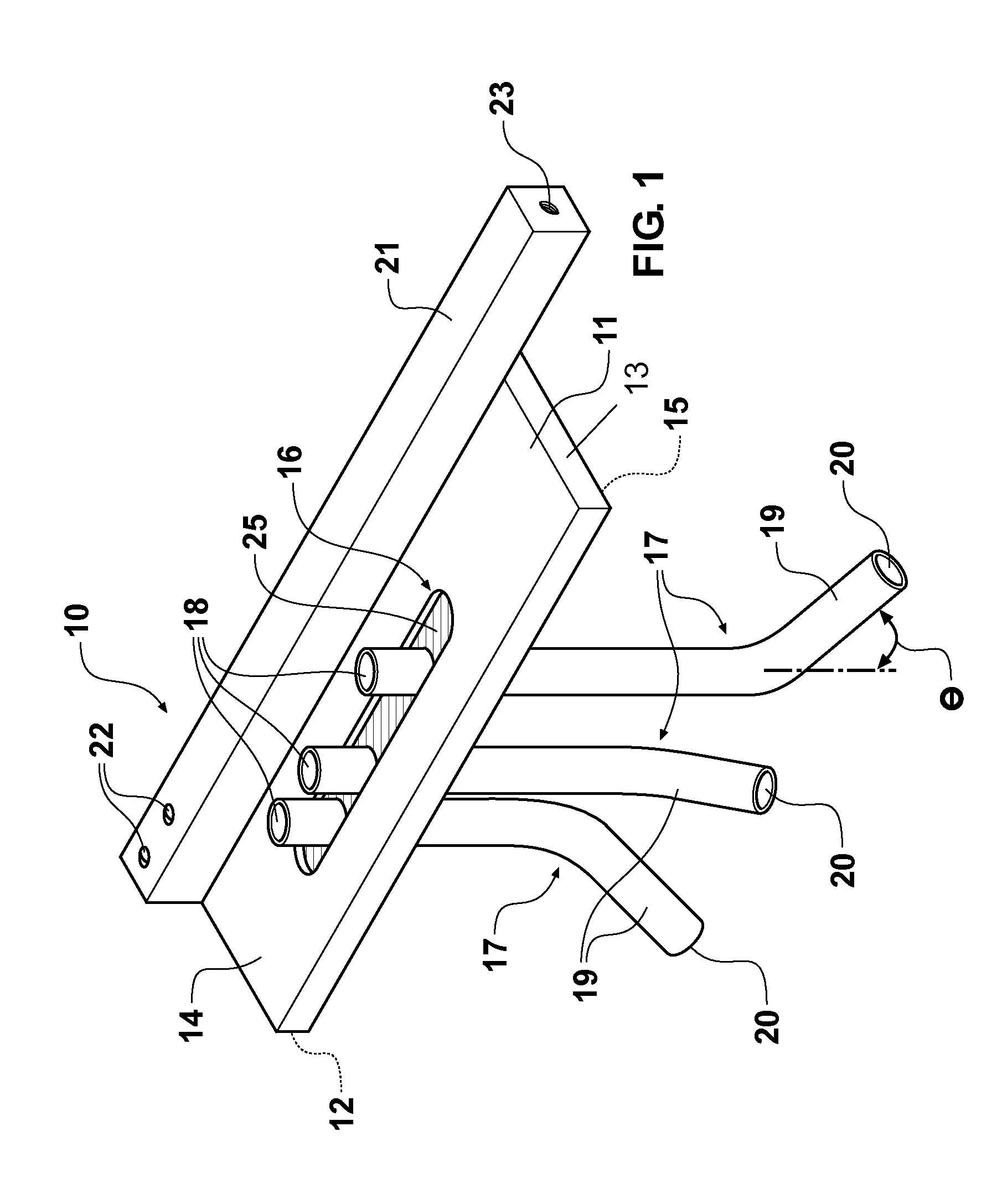

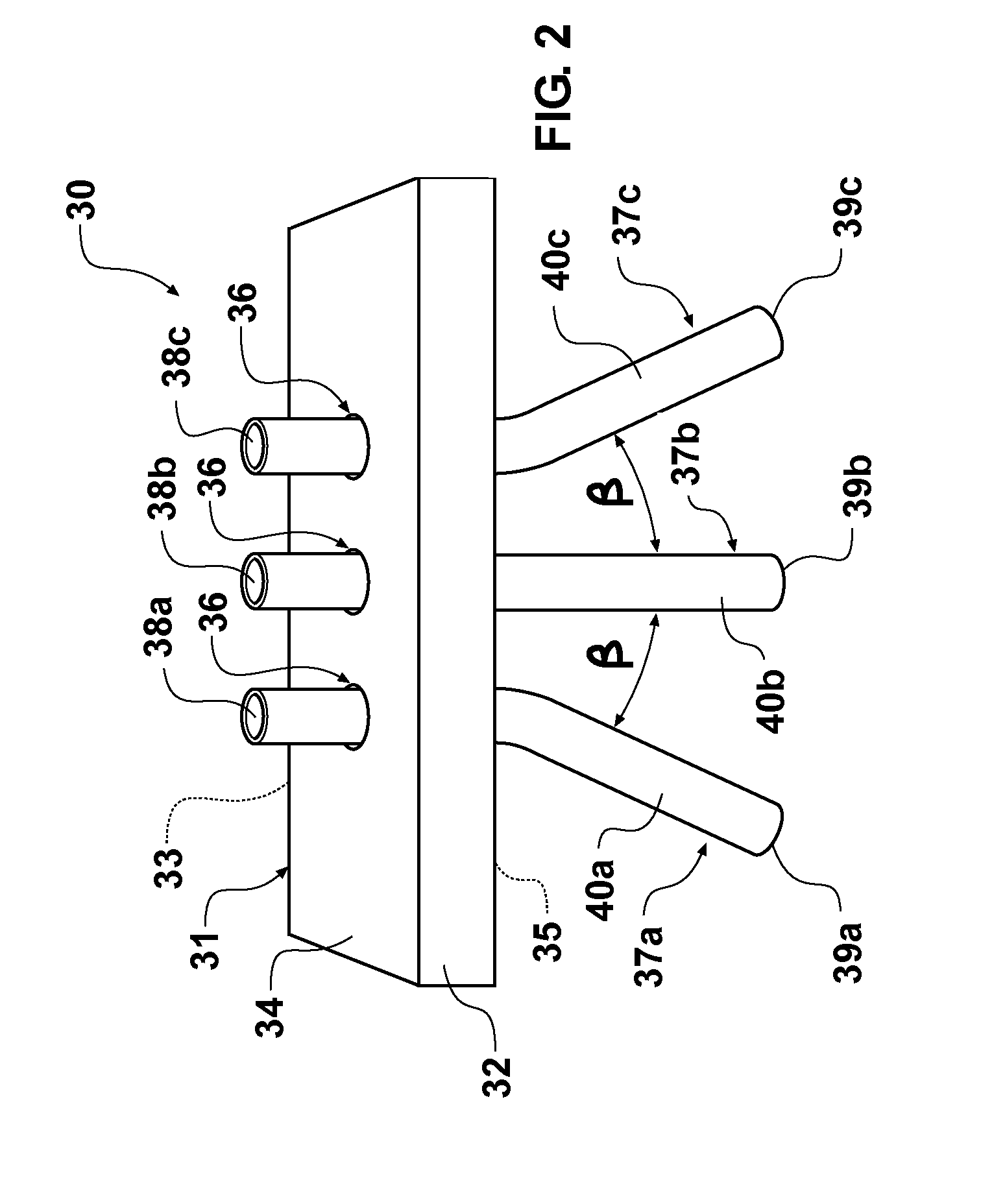

Particle separation devices, methods and systems

InactiveUS20120301869A1Improve sorting efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringParticle separation

A device, system and method for the separation and collection of sperm cells into multiple subpopulations based upon sperm characteristics and for facilitating the collection of multiple subpopulations in limited space. The device can be a redirection device including one or more spaced apart tubes, where each tube has a tube inlet for collecting particles in a flow path, a tube outlet for dispensing the collected particles, and a tube body connecting the tube inlet to the tube outlet for redirecting the particles in the flow path. The device can further include a support for holding each tube in a spaced apart relationship and a securing element for securing the one or more spaced apart tubes to the support.

Owner:INGURAN LLC

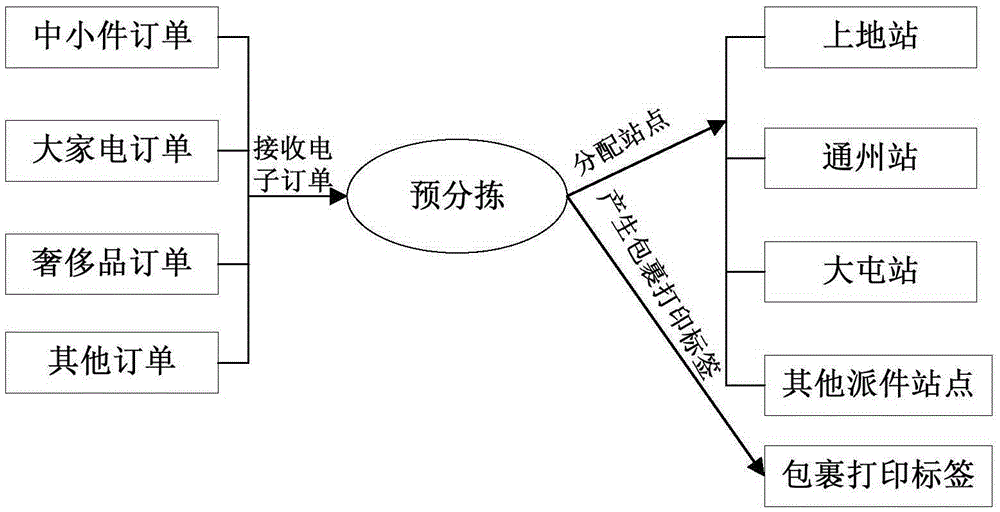

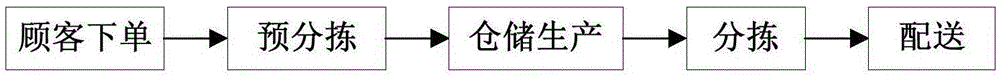

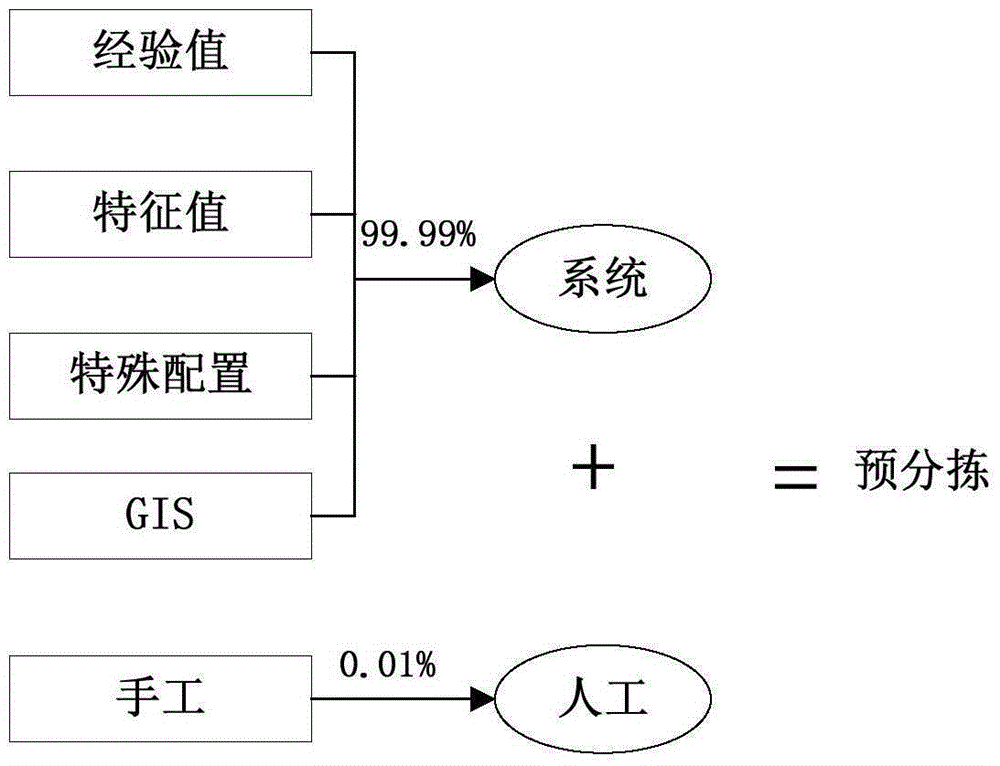

Method and system for automatically sorting parcels

The invention provides a method and system for automatically sorting parcels. The method includes the steps of receiving electronic order information of users, wherein the electronic order information comprises receiver addresses; converting the receiver addresses in the electronic order information into corresponding destination longitudes and latitudes through a map geocoding interface; generating two-dimensional codes containing the electronic order information and the destination longitudes and latitudes, printing the two-dimensional codes, and pasting the two-dimensional codes to the corresponding expressage parcels; scanning the two-dimensional codes, extracting the destination longitudes and latitudes contained in the two-dimensional codes, reading preset longitudes and latitudes corresponding to multiple parcel delivery stations, and respectively calculating the distances between the destination longitudes and latitudes and the longitudes and latitudes corresponding to the multiple parcel stations; and selecting the parcel delivery stations corresponding to the longitudes and latitudes with the smallest distances as destinations where the expressage parcels are sent, and sorting the expressage parcels to the selected parcel delivery stations. By means of the method, the pre-sorting step and the manual processing step can be omitted, and the parcel sorting automation degree and the parcel sorting efficiency can be improved.

Owner:杨彦明

Reciprocating article sorting system

ActiveCN106269540AImprove efficiencyImprove sorting efficiencySortingEngineeringMechanical engineering

The invention relates to a reciprocating article sorting system, which comprises a conveying unit, wherein the discharging end of the conveying unit is connected with a weighing unit; a scanning unit used for scanning commodities is arranged between the weighing unit and the conveying unit; the discharging end of the weighing unit is connected with the sorting unit; the sorting unit is used for sorting the commodities to be sorted and conveying the commodities to a packaging region; the sorting unit comprises a sorting trolley and a plurality of discharging openings; the sorting trolley is positioned in the discharging openings and does reciprocating movement to put the commodities to be sorted onto the conveying unit; the conveying unit transfers the commodities onto the weighing unit in the conveying process; the weighing is performed on the commodities; the scanning unit also completes the commodity scanning; the efficiency is improved; in addition, the error rate is also reduced; the reciprocating movement of the sorting trolley of the sorting unit between the discharging openings of the sorting unit is used for transferring the commodities to different positions; a plurality of discharging openings can be arranged in the position, so that the sorting efficiency can be further improved.

Owner:安徽省一一通信息科技有限公司

Steel ball surface defect detection automatic sorting device

InactiveCN102680490ARealize automatic feeding processEasy to detectOptically investigating flaws/contaminationSortingSteel ballInterconnection

Disclosed is a steel ball surface defect detection automatic sorting device. A light source is arranged on a work bench, a left camera mounted on a left support and a right camera mounted on a right support are symmetrically arranged on the left side and the right side of a light source bowl cover, camera lenses of the left camera and the right camera are arranged symmetrically and corresponding to a left observation hole and a right observation hole formed on the light source bowl cover, a vibration feed table and a material transferring channel connected to a discharge hole of the vibration feeding table are arranged behind the light source, the material transferring channel penetrates through the power source bowel cover and the front of the light source, a sorting mechanism and a collecting box placed below the sorting mechanism are arranged in front of the light source, a discharge terminal of the material transferring channel is inserted into a feeding hole end of the sorting mechanism, the left camera and the right camera are respectively connected with a peripheral component interconnection (PCI) card, PCI cards are respectively connected with a computer and a pneumatic unit, and an output end of the pneumatic unit is connected with the sorting mechanism. According to the steel ball surface defect detection automatic sorting device, the detecting process can achieve automation completely, no easily-worn part exists, the service life is long, and defect detection is accurate and efficient.

Owner:TIANJIN UNIV

Reverse/direct flotation technology of collophanite

The invention discloses a reverse / direct flotation technology of collophanite. The technology comprises the following steps of: performing ore reduction, ore grinding and size mixing on the silicon calcium type collophanite; adding a carbonate gangue mineral flotation regulator and fatty-acid soap respectively to perform size mixing; performing reverse flotation on the material after the size mixing, wherein the product in the tank is reverse flotation concentrate; dehydrating the reverse flotation concentrate and adding sodium carbonate so as to adjust the pH value to 8-10; performing closed-loop ore grinding and grading on the base flow; enabling the grading overflow to enter a direct flotation stirring tank, and adding water glass and fatty acid soap into the tank respectively to perform size mixing; performing direct flotation on the material subjected to the size mixing, wherein the direct flotation foam product is direct flotation concentrate; and performing concentration, filtration and drying to obtain the finished product of phosphate concentrate. After dehydration (reagent removal), the technology disclosed by the invention can be used for remarkably reducing the amount of sodium carbonate for neutralizing acid water; the sodium carbonate has a dispersion and grinding aid function, and the over-grinding of the material of direct flotation can be reduced; and the fresh surface and proper size composition generated by the ore grinding are favorable for improving the sorted behavior of the direct flotation and improving the sorting efficiency.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

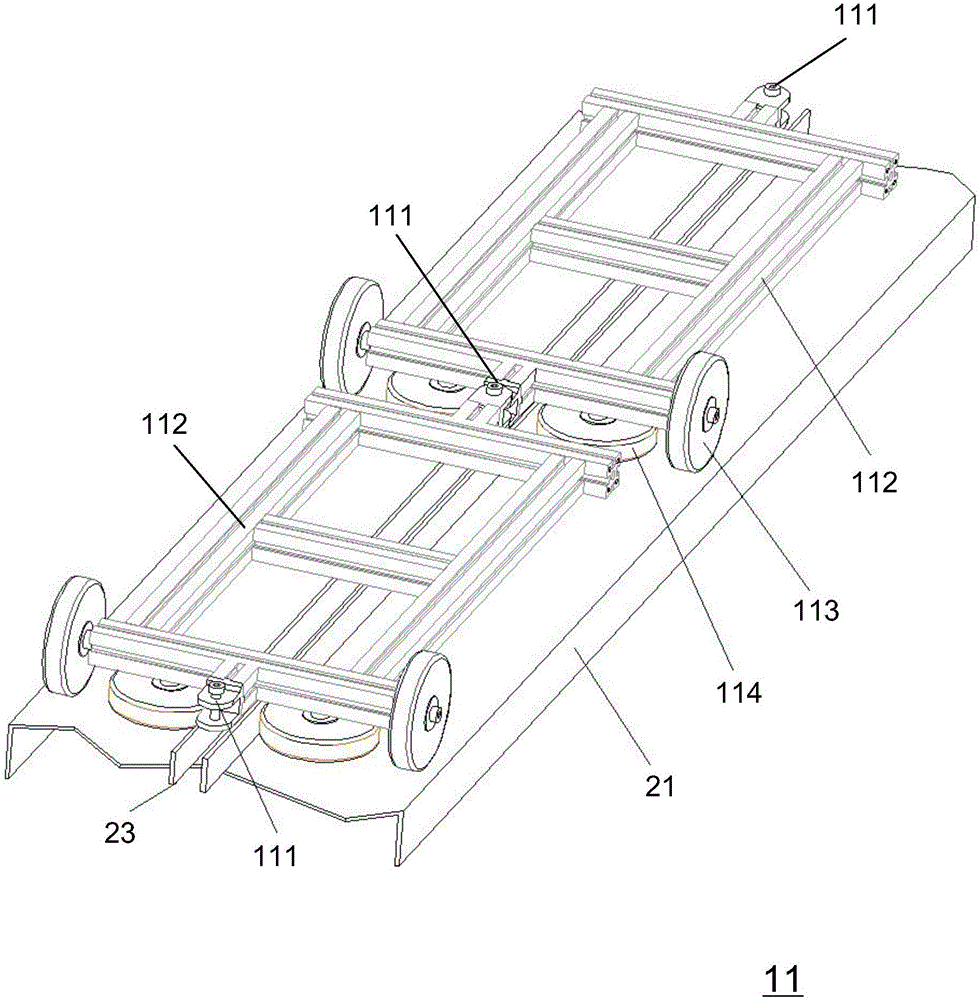

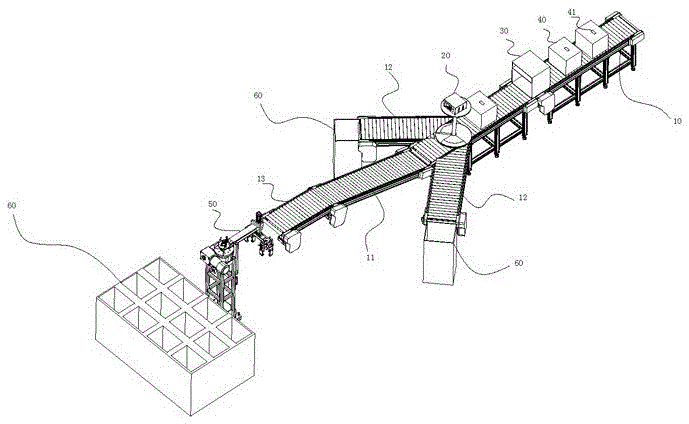

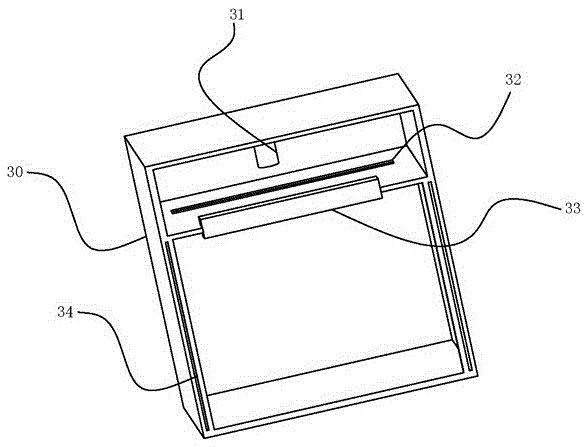

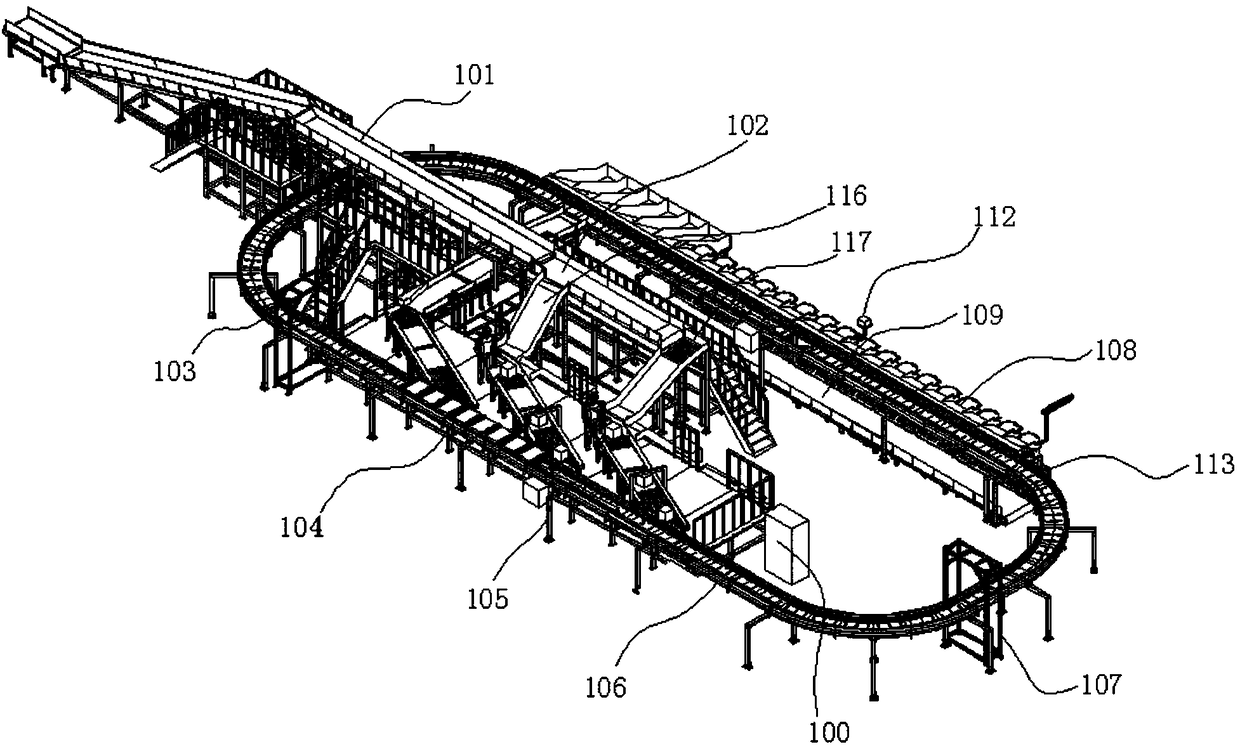

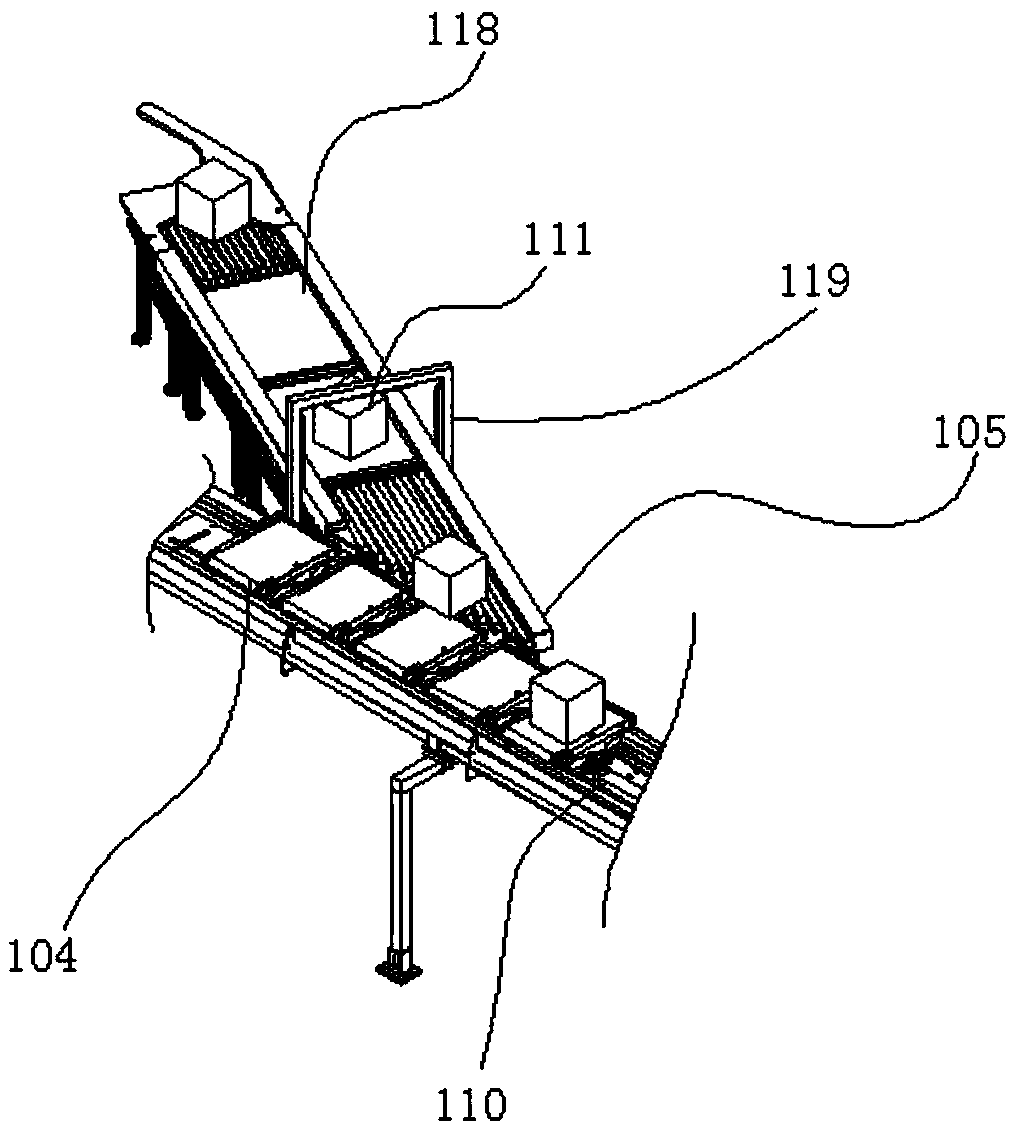

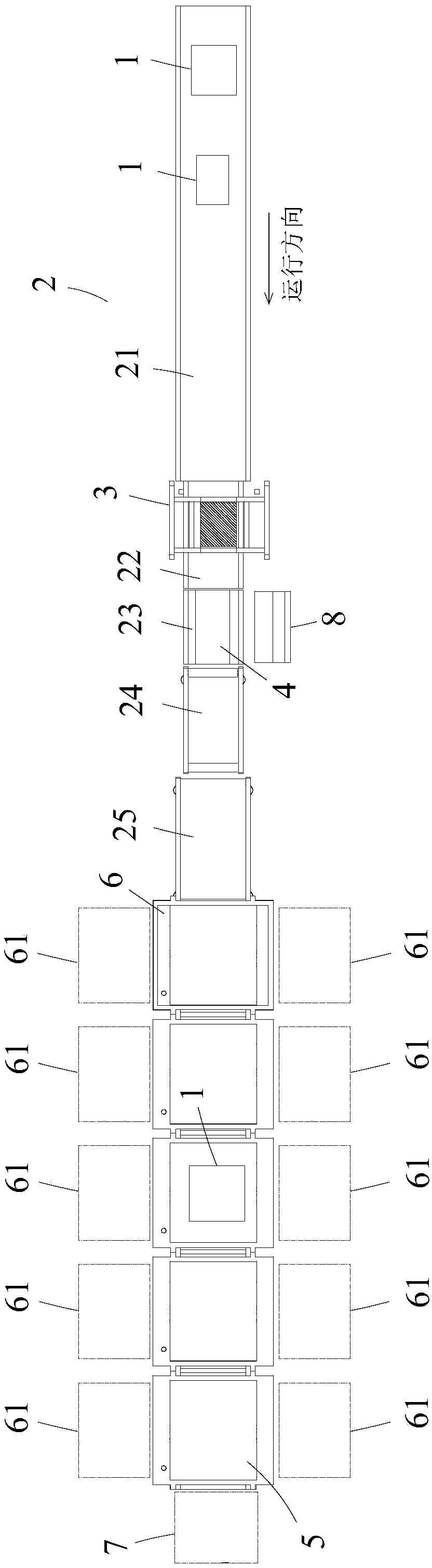

Halved belt sorting system based on automatic feeding

The invention provides a halved belt sorting system based on automatic feeding. The halved belt sorting system based on automatic feeding comprises trolleys, a conveying rail, parcel providing machines, visual recognition devices, discharging grid openings, an electric control cabinet and a control platform; the trolleys are distributed on the conveying rail; parcel conveying units are installed on the trolleys; the parcel conveying units realize lateral feeding or discharging of parcels; vehicle-mounted control systems are installed on the trolleys; the conveying rail is an annular sealed rail and is a motion carrier of the trolleys; the parcel providing machines are installed at the outer side of the conveying rail; the front ends of the parcel providing machines are near the trolleys on the conveying rail; the visual recognition devices are installed above the trolleys on the conveying rail; the visual recognition devices are placed at the back of the parcel providing machines according to the rotation direction of the conveying rail; the discharging grid openings are distributed on the inner side and the outer side of the conveying rail along the conveying rail; and the electric control cabinet is used for supplying power and controlling the speed of a main sorting line. The halved belt sorting system based on automatic feeding can effectively improve efficiency and accuracy of parcel sorting.

Owner:WAYZIM TECH CO LTD

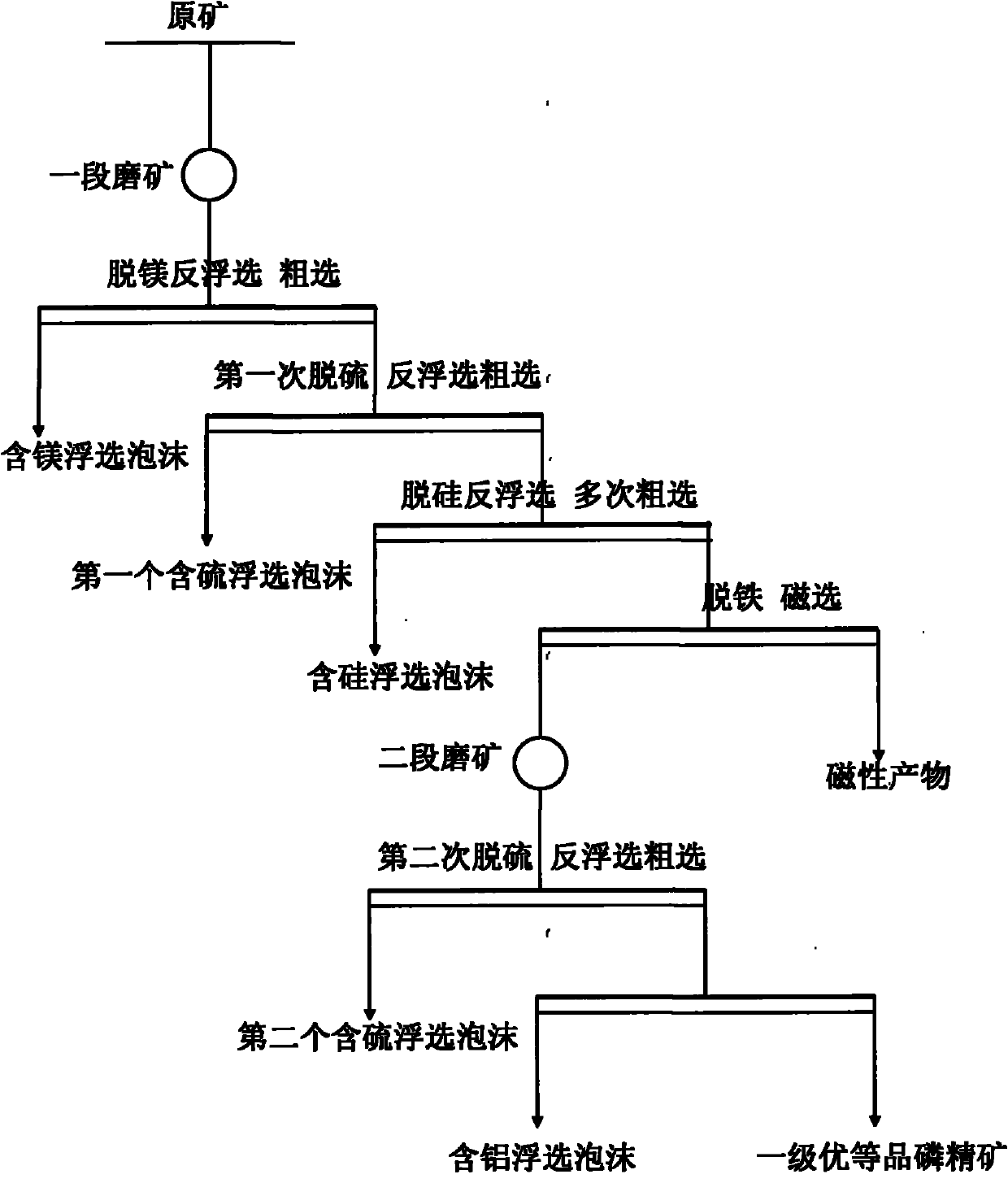

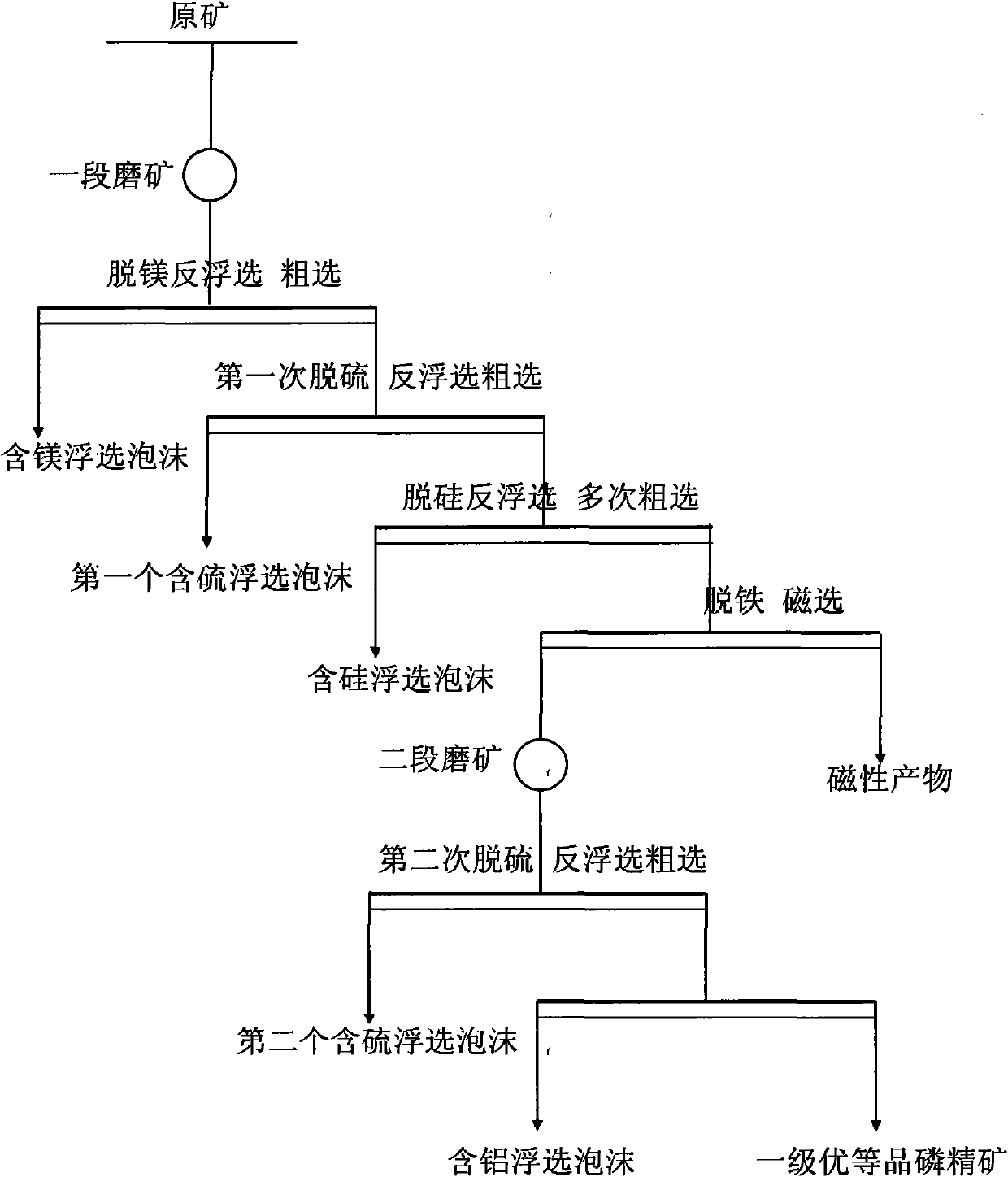

Method for separating collophanite

The invention relates to a method for separating collophanite, which is characterized by comprising the following steps of: (1) coarsely grinding raw collophanite; (2) performing reverse floatation on the grinding product to remove magnesium; (3) reacting floatation base flow of the step (2) with a desulfurization floatation medicament for reverse floatation to remove sulfur; (4) reacting the floatation base flow in the step (3) with a desilicification floatation medicament for reverse floatation to remove silicon; (5) performing intensity magnetic separation on the floatation base flow in the step (4) to remove iron; (6) regrinding a non-magnetic product in the step (5); (7) reacting the grinding product in the step (6) with a desulfurization floatation medicament for reverse floatation to remove sulfur; and (8) reacting the floatation base flow in the step (7) with a dealumnization floatation medicament for reverse floatation to remove aluminum to obtain aluminum-containing floatation foam and the floatation base flow, wherein the floatation base flow is the final phosphorus concentrate. The method can perform floatation at normal temperature and even low temperature to obtain phosphorus concentrate, and has the advantages of high separation property, low energy consumption and effective improvement of the P2O5 recovery rate.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

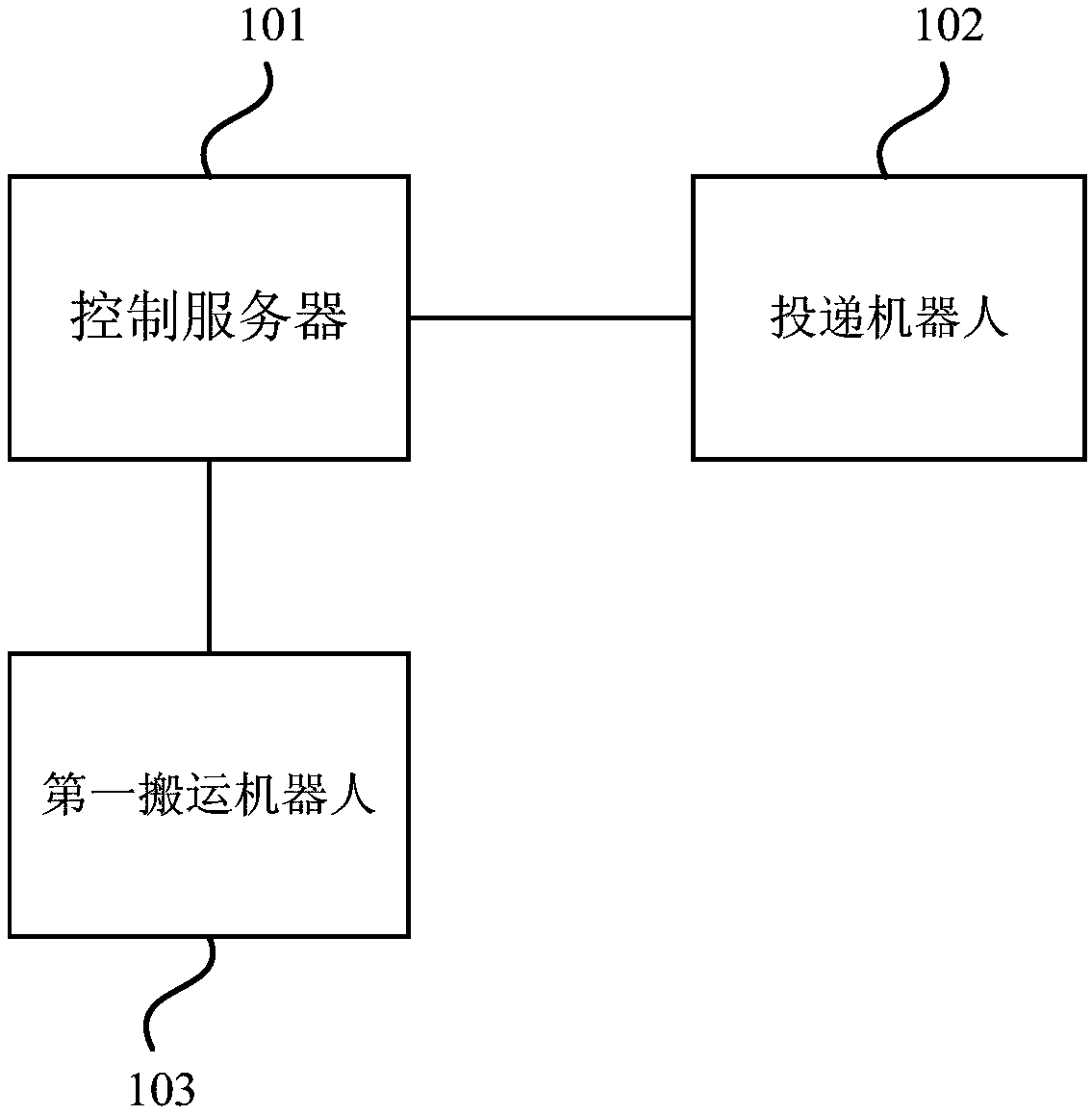

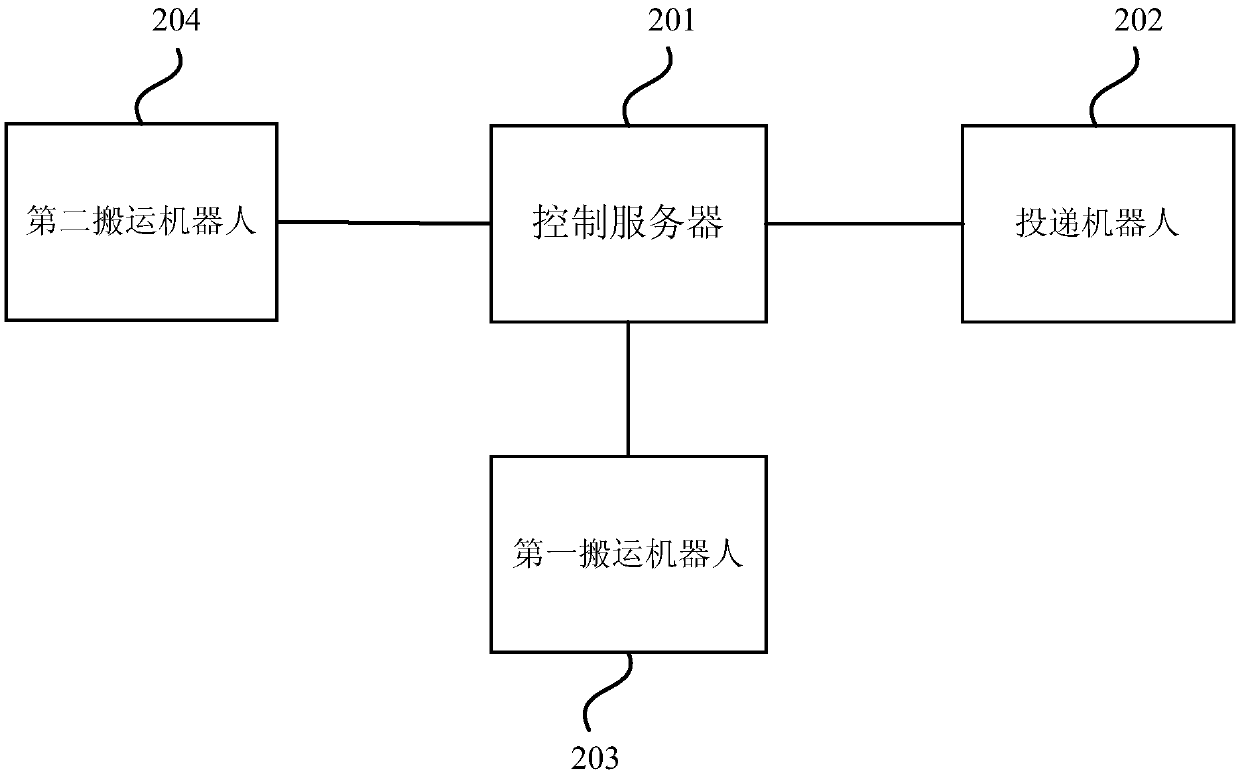

Goods sorting system and method

ActiveCN108672308AImprove sorting efficiencyImprove accuracySortingPosition/course control in two dimensionsEngineeringTransport engineering

The invention discloses a goods sorting system and method. The system comprises a control server, a delivery robot and a first carrying robot, wherein the control server is used for determining a delivery port based on the a delivery address of goods to be delivered, distributing the delivery robot and planning a moving route for the delivery robot and generating a delivery instruction to the delivery robot; the delivery robot is used for moving to the delivery port, delivering the goods to be delivered to the delivery port and then returning to a first specified position; the control server is also used for distributing the first carrying robot and planning the moving route for the first carrying robot when the quantity of the goods collected by a goods collecting container at the lower part of the delivery port is beyond or equal to a preset threshold, and generating a carrying instruction and sending the carrying instruction to the first carrying robot; and the first carrying robotis used for moving to the goods collecting container based on the moving route, carrying the goods collecting container to a goods collecting station and then returning to a second specified position.According to the technical scheme, the goods sorting system and method improve the goods sorting efficiency and improve the goods sorting accuracy.

Owner:BEIJING JIZHIJIA TECH CO LTD

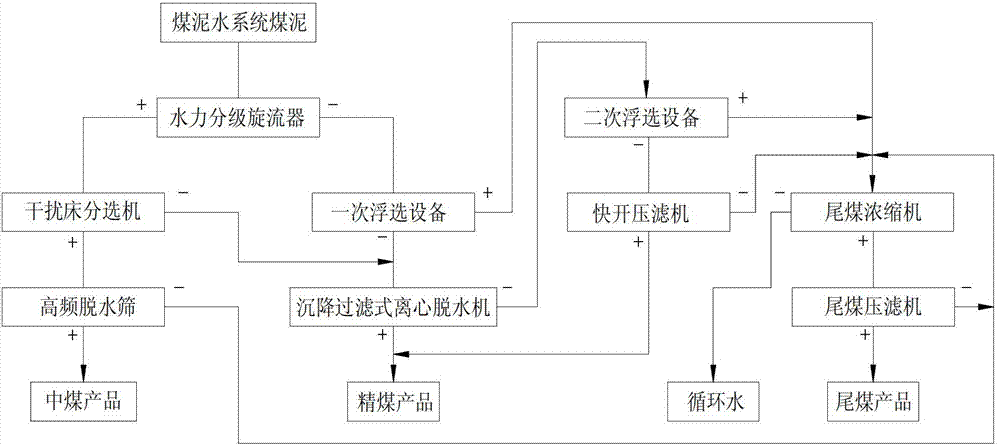

Classifying, separating and dewatering method for high-ash-content difficultly-separated coal slime

ActiveCN103240168AGive full play to the advantages of sortingRealize high-precision sortingFlotationWet separationCycloneFluidized bed

The invention discloses a classifying, separating and dewatering method for high-ash-content difficulty-separated coal slime. The classifying, separating and dewatering method includes: pumping a coal slime water system coal slime to a hydraulic classifying cyclone for classifying, enabling the coal slime to enter primary floatation equipment to separate by overflowing, subjecting bottom flow to entering a separating machine of a liquid-solid fluidized bed to separate, mixing and 'doping' primary floated fine clean coal and coarse-grain clean coal prior to entering a horizontal sedimentation perforated basket centrifuge to dewater and recycle, enabling filtrate and centrifugate of the horizontal sedimentation perforated basket centrifuge to enter secondary floatation equipment to separate, dewatering secondarily-separated clean coal by a quick-opening filter press, doping on-sieve products of coarse-grain tailing coal slime dewatered by a high-frequency sieve into coal products, and mixing backwater of the high-frequency sieve and primarily-separated tailing coal, the secondarily-separated tailing coal and filtrate of a clean coal quick-opening filter press into a tailing coal concentrator and the filter press to dewater and recycle. Therefore, high-quality clean coal low in ash content and water and high in recycling rate is obtained, the problem of 'loss of coarse coal' of floatation of tailing coal is solved, and the technical difficulty of high-precision separation of high-ash-content difficultly-separated coarse and fine coal slime is overcome.

Owner:CHINA UNIV OF MINING & TECH

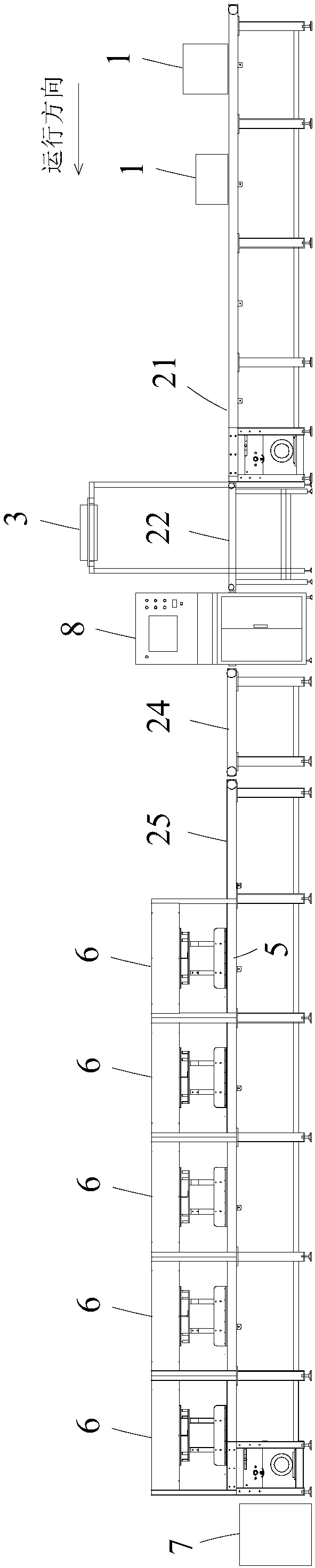

Cross-belt logistic sorting system

The invention discloses a cross-belt logistic sorting system. The cross-belt logistic sorting system comprises a conveying line, a sorting line, distributing tables, a plurality of sorting carts, a cycling rail and an upper computer, wherein the conveying line is used for conveying to-be-sorted packages or cargoes to the sorting line from the lower portion; the sorting line is used for conveying the packages or the cargoes conveyed by the conveying line to corresponding sorting sliding grooves according to the preset classification rule; the distributing tables are used for measuring volumes and weights of the packages or the cargoes conveyed by the sorting line; the sorting carts are used for conveying the packages or the cargoes conveyed by the distributing tables to corresponding sorting openings to be output; the cycling rail is used for guiding the sorting carts to convey and sort the packages or the cargoes through cycling moving; the upper machine is used for controlling sortingand conveying of the packages or the cargoes. According to the cross-belt logistic sorting system, the structure is simpler, sorting efficiency is remarkably improved, transportation and assembling are convenient, and automation of logistic sorting is achieved.

Owner:SHENZHEN YUZHI EQUIP TECH CO LTD

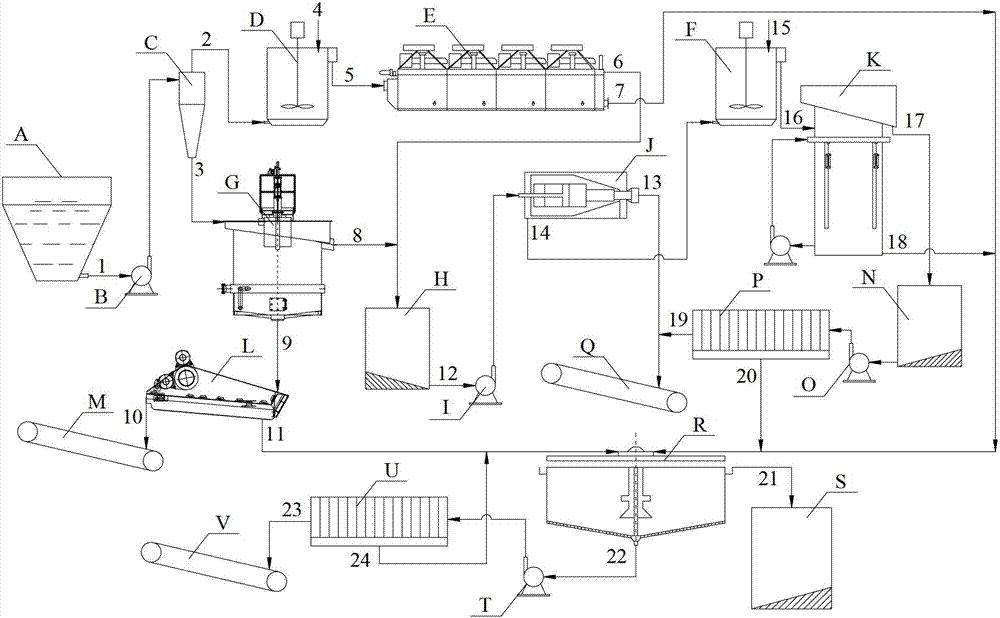

Fragmentation separation process flow for end-of-life automobile body

The invention discloses a fragmentation separation process flow for an end-of-life automobile body. The fragmentation separation process flow for an end-of-life automobile body can realize that an end-of-life automobile body is gradually fragmented into fragments having preset sizes by a two-step fragmentation method so that follow-up material sorting and recovery can be carried out conveniently. A sorting process of the fragmentation separation process flow for an end-of-life automobile body realizes separation and recovery of light materials, magnetic metal materials, non-ferrous metal materials, micro-powder materials, glass, rubber and plastic obtained by automobile body fragmentation by targetedly and orderly carrying out negative pressure-cyclone separation, magnetic sorting, eddy current sorting and drum screening according to material composition of the end-of-life automobile body. The fragmentation separation process flow for an end-of-life automobile body has the advantages of high automation degree, low noise, no dust, no exhaust gas, friendly work environment, high equipment sorting classification efficiency, simple and flexible configuration, and convenient management and maintenance. The fragmentation separation process flow for an end-of-life automobile body is a novel process flow used for an automobile disassembly industry of China.

Owner:HUNAN VARY TECH

Automatic steel ball sorting device

The invention discloses an automatic steel ball sorting device, which comprises a frame, a loading bucket, a discharging bucket, a waste ball cabin, a quantitative ball supply device, a feeding box, a detection device and a control device, wherein the lower end of the loading bucket is provided with a gravity sensor; one side of the loading bucket is hinged to the frame; a single-side elevating device is arranged on the other side of the loading bucket; the loading bucket is connected with the quantitative ball supply device and the feeding box through a loading channel; the feeding box is connected with the detection device through a feeding channel; the detection device is connected with the waste ball cabin and the discharging bucket respectively through a discharging channel; a distance sensor is arranged above the discharging bucket; the lower end of the discharging bucket is provided with a horizontal elevating device. The automatic steel ball sorting device has the advantages of no need of manual attendance for a long time, lower processing cost, constant loading frequency, higher sorting efficiency and avoidance of secondary defects caused by falling of steel balls into the discharging bucket.

Owner:NINGBO BAIJIABAI MEASUREMENT & CONTROL EQUIP

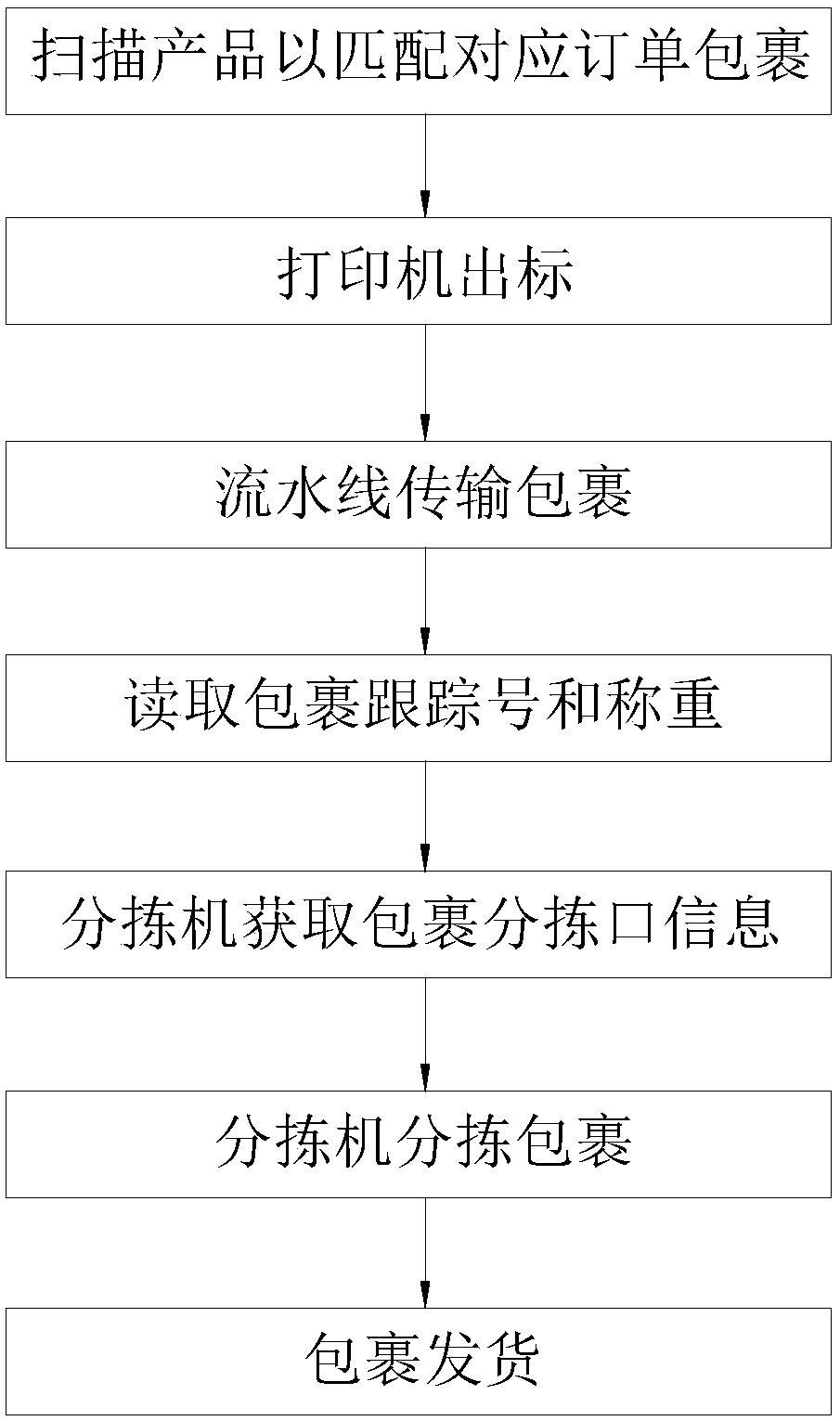

Logistics automatic sorting system and method

InactiveCN107597607ARealize integrationRealize the error phenomenonSortingLogistics managementAssembly line

The invention relates to a logistics automatic sorting system and method. The logistics automatic sorting system comprises an order system server, a printer for printing parcel tag information, an assembly line comprising an acceleration section, a weighing section and a sorting section, a laser code reader reading the parcel tag information, a weighing table for weighing the weight information ofparcels, a sorting machine for sorting different parcels and conveying the parcels to corresponding sorting boxes, and a control device for coordination work of components. According to the logisticsautomatic sorting system, a product warehouse, an order system and a sorting work part can be connected, so that automatic matching of warehouse products, orders and sorting ports is achieved; compared with the existing mode that warehouse product classification, order system operation and sorting are conducted by manpower, through the sorting method, the manual operation work procedures are greatly reduced, the sorting efficiency is improved, and the mistaken phenomena of order omission in sorting, parcel abnormity and the like are greatly reduced; and the method achieves integration of warehouse product classification, order system operation and sorting work.

Owner:深圳市恒之易电子商务有限公司

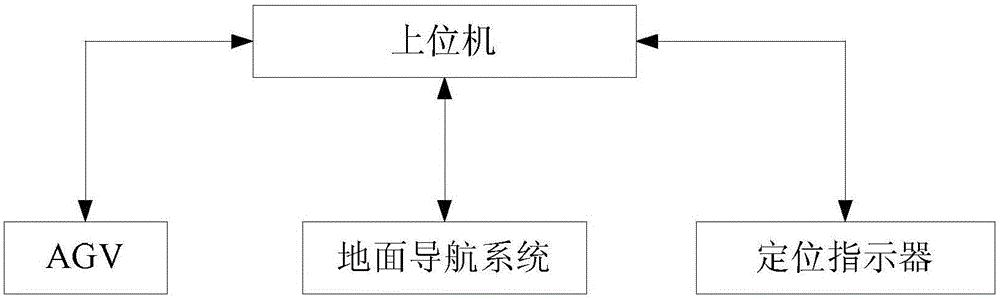

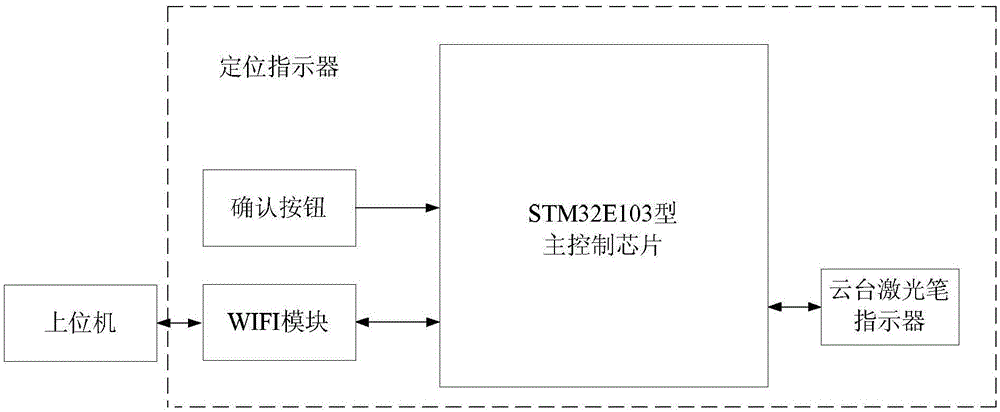

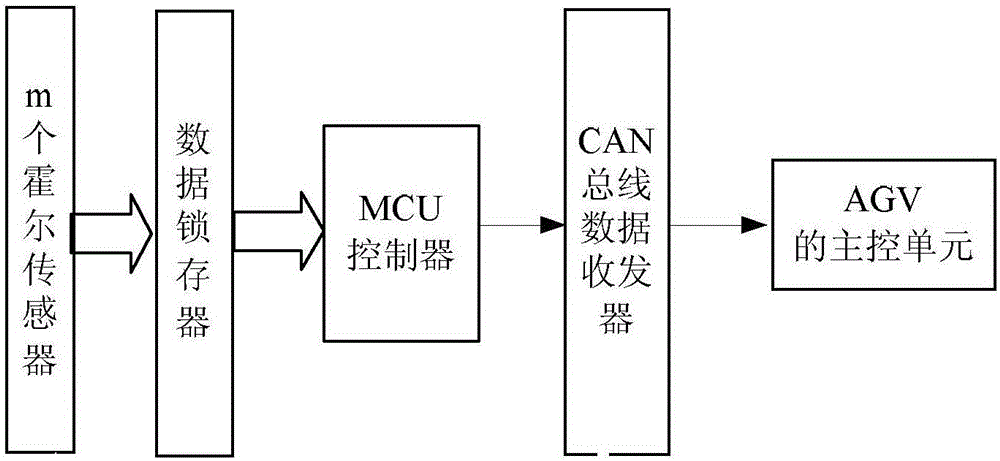

Intelligent warehouse system

ActiveCN105129308AImprove sorting efficiencyRealize intelligenceStorage devicesEngineeringCoordinate control

The invention belongs to the technical field of automatic warehouse systems, and relates to an intelligent warehouse system. The problem that an existing automatic warehouse is low in work efficiency is solved. The warehouse system comprises an upper computer, an AGV, a locating indicator and a ground navigation system. The upper computer is used for coordination control over the AGV, the locating indicator and the ground navigation system, so that cargos in a stock-out sheet are conveyed to a sorting station from storage racks. The locating indicator is used for determining the positions of the corresponding storage racks, of the cargoes in the stock-out sheet, in storage data and the positions of the cargoes according to the upper computer and indicating the specific positions of the cargoes. The ground navigation system is used for carrying out path planning according to the position of the AGV, the specific positions of the storage racks of the cargoes and the position of the sorting station to find a shortest path. The AGV is used for conveying the cargoes indicated by the locating indicator to the sorting station from the storage racks according to the planned shortest path. The intelligent warehouse system is used for warehouse cargo sorting.

Owner:哈尔滨灵翰智能技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com