Goods sorting system and method

A sorting system and cargo technology, applied in the field of robots, can solve the problems of low accuracy of cargo sorting and low efficiency of cargo sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

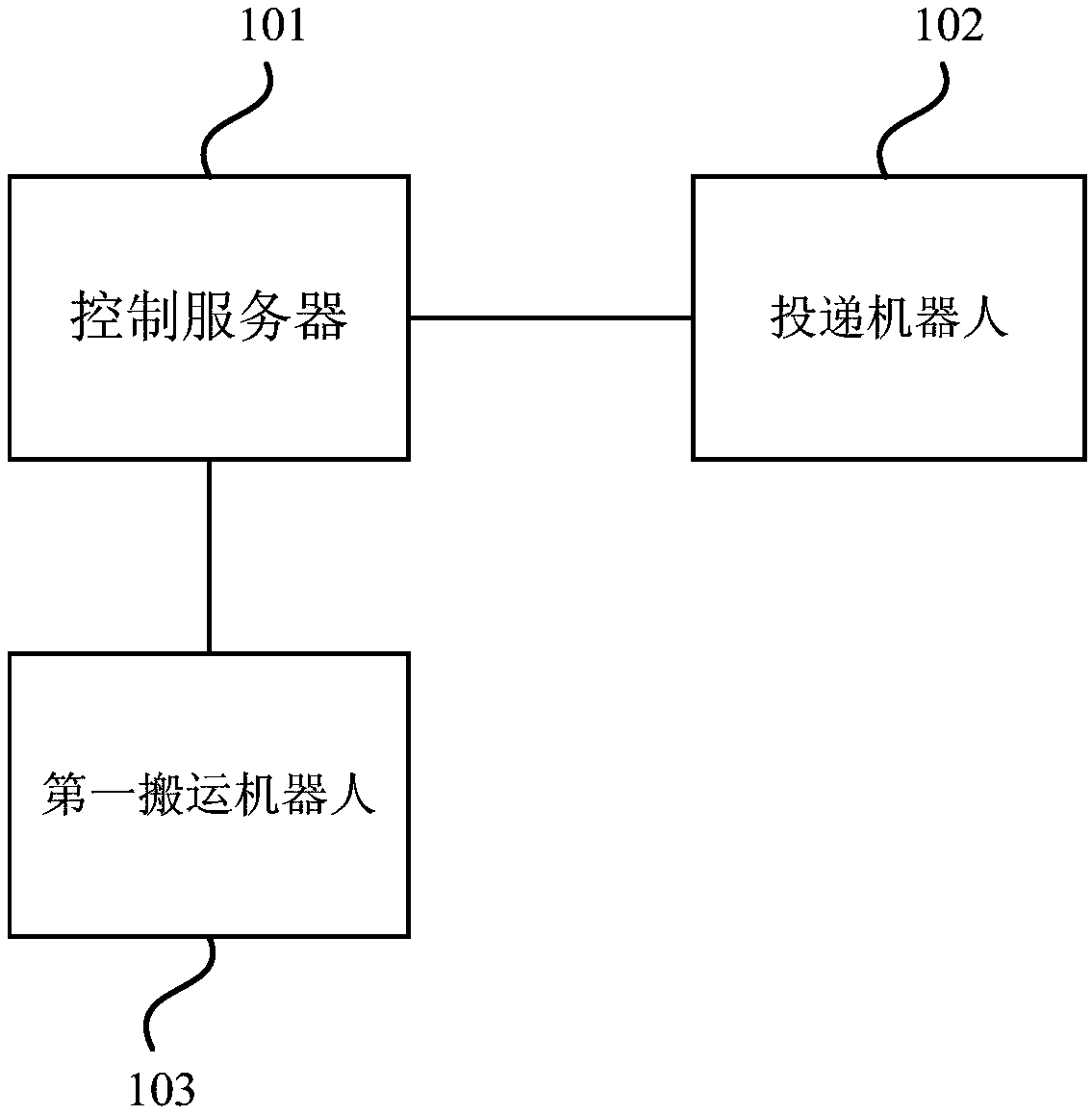

[0045] figure 1 It is a schematic structural diagram of the cargo sorting system in Embodiment 1 of the present invention. This embodiment is applicable to the situation of cargo sorting. The cargo sorting system mainly includes the following parts: control server 101, delivery robot 102 and first handling Robot 103.

[0046] In this embodiment, the control server 101 respectively establishes a communication connection with the delivery robot 102 and the first handling robot 103 for controlling and scheduling the entire cargo sorting system. Furthermore, the control server 101 refers to a software system with data storage and information processing capabilities, which can be connected with the delivery robot 102, the first transport robot 103 and other hardware input systems or software systems in the system through wired or wireless. The control server 101 can issue tasks to the delivery robot 102 and the first handling robot 103, deliver information to workers, collect stat...

Embodiment 2

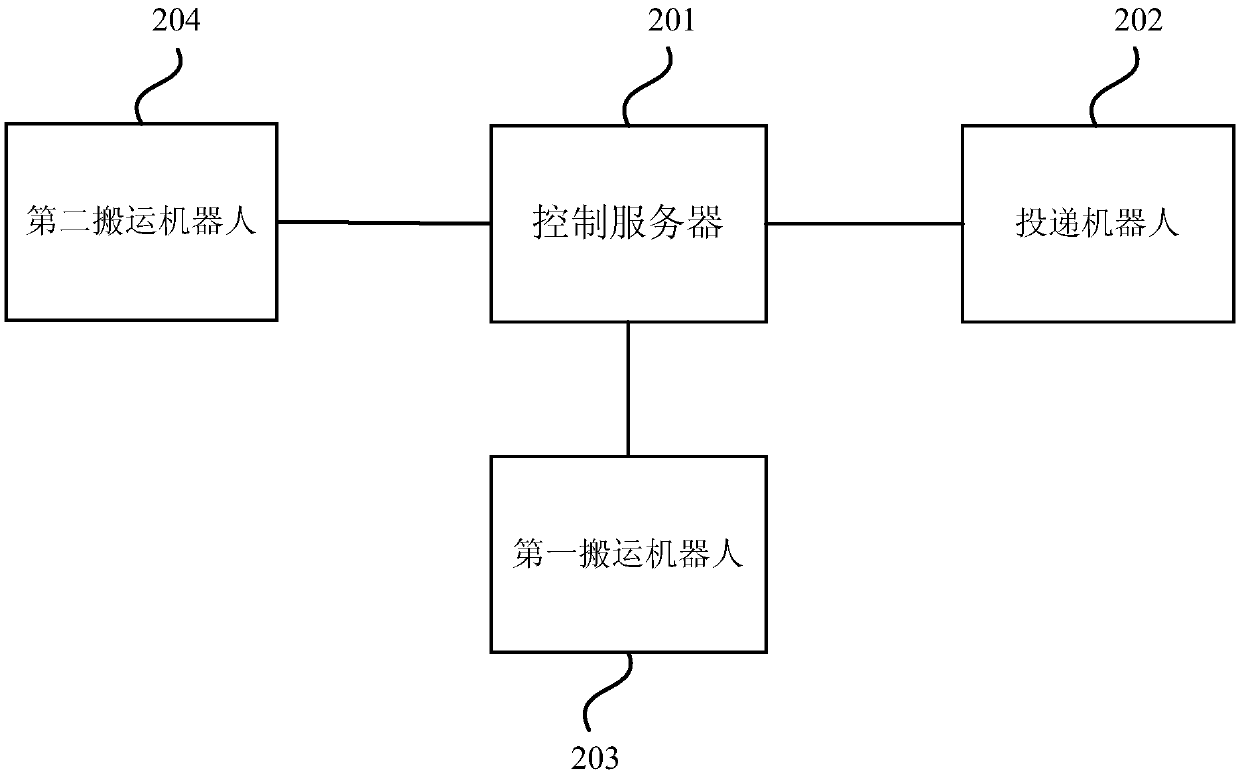

[0063] This embodiment further optimizes the cargo sorting system on the basis of the foregoing embodiments. figure 2 It is a schematic structural diagram of the cargo sorting system in Embodiment 2 of the present invention, as figure 2 As shown, the cargo sorting system mainly includes the following parts: a control server 201 , a delivery robot 202 , a first handling robot 203 and a second handling robot 204 .

[0064] The control server 201 is used to determine the delivery port according to the receiving address of the goods to be delivered, allocate a delivery robot for the goods to be delivered and plan a travel path for the delivery robot, generate a delivery instruction corresponding to the goods to be delivered, and send the delivery instruction to the delivery robot, The delivery instruction includes the travel path of the delivery robot.

[0065] In this embodiment, the receiving address of the goods to be delivered corresponds to different delivery ports, and th...

Embodiment 3

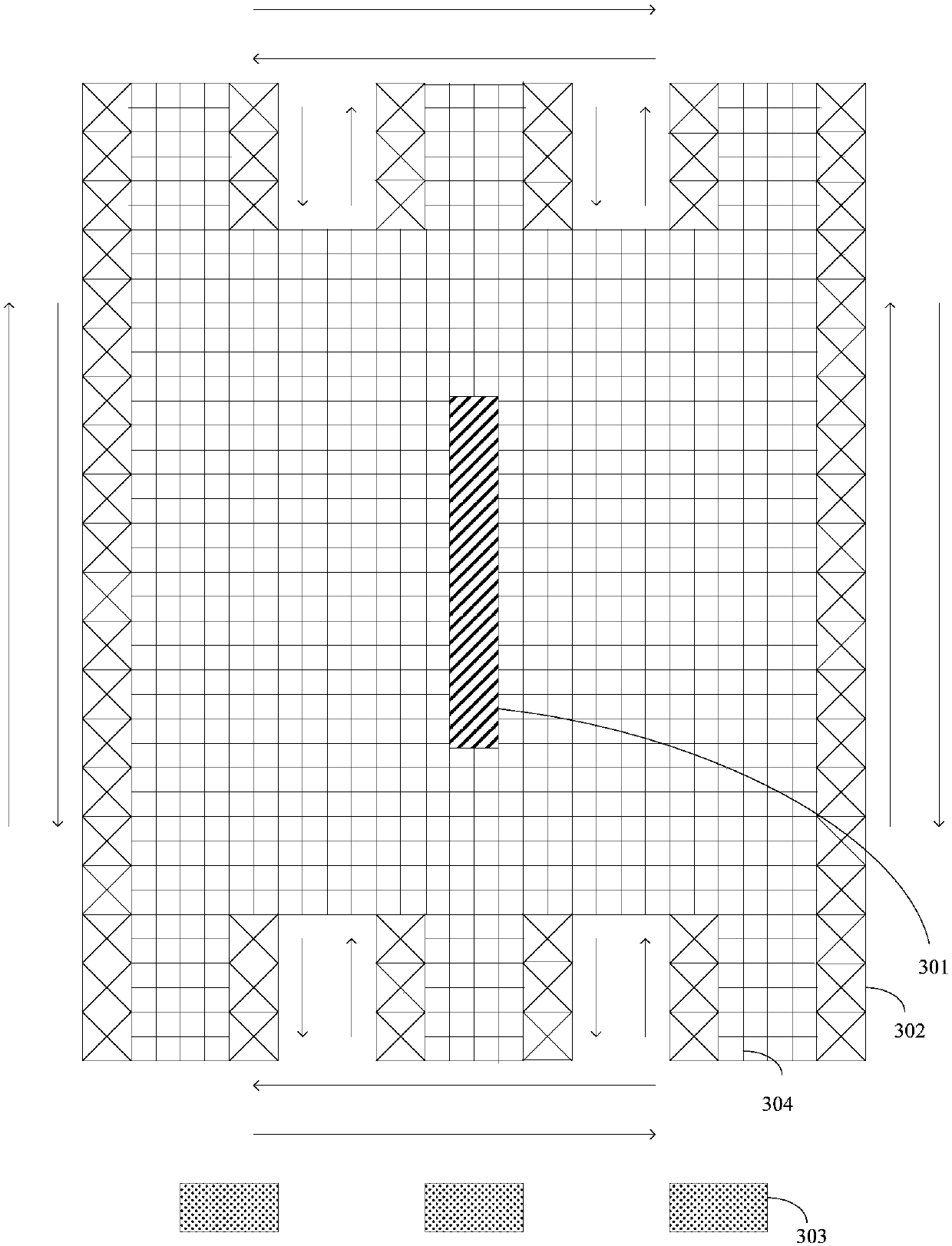

[0081] This embodiment further optimizes the cargo sorting system on the basis of the foregoing embodiments. image 3 It is a schematic diagram of the layout of the sorting system in Embodiment 3 of the present invention. Depend on image 3 It can be seen that the collection containers are arranged in the field in a polygonal outline, the supply platform 301 is located within the polygonal outline, the cargo collection station 303 is located outside the polygonal outline, the area inside the polygonal outline constitutes the walking channel of the delivery robot, and the area outside the polygonal outline It constitutes the walking channel of the first transport robot and the second transport robot. The polygonal outline is a rectangular outline; the polygonal outline partially has openings.

[0082] The delivery platform 301 is arranged in the center of the site, and the cargo container 302 is arranged around the site or on one or more sides of the site. The cargo collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com