Intelligent warehouse system

A warehouse and intelligent technology, applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of low efficiency in automated warehouses, achieve the effects of saving labor, realizing intelligence, and improving sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

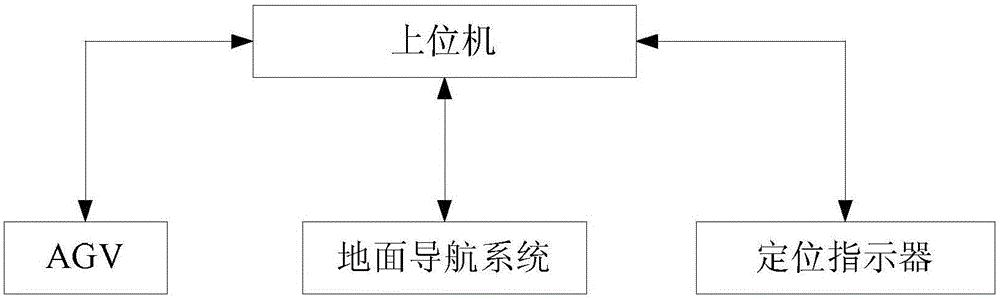

[0029] Specific implementation mode one: combine figure 1 Describe this embodiment, the smart warehouse system described in this embodiment, the warehouse system includes a host computer, an AGV, a positioning indicator and a ground navigation system;

[0030] The upper computer is used for coordinated control of AGV, positioning indicator and ground navigation system, so that the goods in the outbound list are transported from the shelf to the sorting station;

[0031] The positioning indicator is used to determine the position of the corresponding shelf and goods in the inventory data of the goods in the outbound order according to the host computer, and indicate the specific position of the goods;

[0032] The ground navigation system is used to plan the path according to the location of the AGV, the specific location of the goods on the shelf, and the location of the sorting station to find the shortest path;

[0033] AGV, according to the planned shortest path, goes to t...

specific Embodiment approach 2

[0034] Embodiment 2: This embodiment is a further limitation of the smart warehouse system described in Embodiment 1. The upper computer includes the following modules:

[0035] It is used to enter the outbound order information and the location of the sorting station. And send the position of the sorting station to the module of the ground navigation system;

[0036] It is used to find the corresponding shelf and the specific location of the goods in the inventory data according to the outbound goods based on the information of the outbound order, and send them to the module of the positioning indicator and the ground navigation system at the same time;

[0037] It is used to find the nearest AGV among the online AGVs, determine the position of the found AGV, and send the position of the AGV to the module of the ground navigation system;

[0038] A module for receiving the planned shortest path and sending the shortest path to the found AGV;

[0039] A module for inputting ...

specific Embodiment approach 3

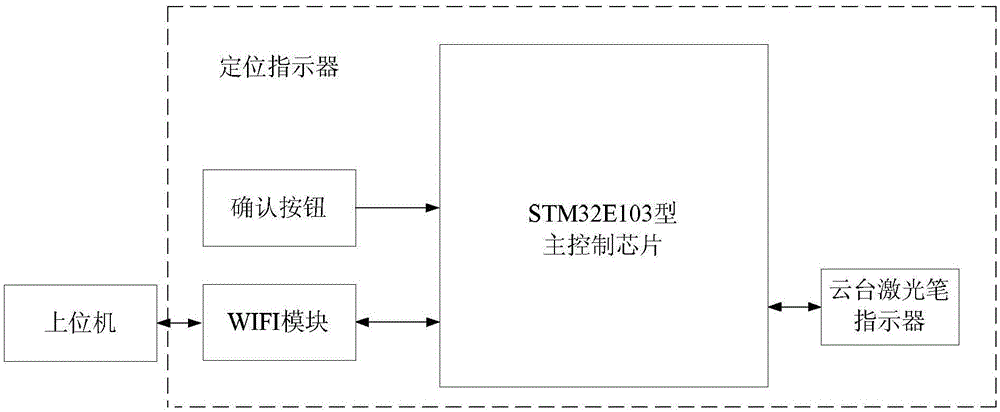

[0041] Specific implementation mode three: combination figure 2 This embodiment is described. This embodiment is a further limitation of the smart warehouse system described in Embodiment 2. The positioning indicator includes a confirmation button, a WIFI module, an STM32E103 type main control chip and a PTZ laser pointer indicator;

[0042] STM32E103 main control chip is used to control the pan-tilt laser pointer indicator according to the specific position of the goods sent by the host computer, and is also used to send the sorting completion signal to the host computer when the sorting completion signal is received;

[0043] The confirmation button is used to input the signal of goods sorting completion and send it to the STM32E103 main control chip;

[0044] WIFI module, used for data communication between STM32E103 main control chip and host computer;

[0045] The PTZ laser pointer indicator is a PTZ with a laser pointer, which is used to rotate the PTZ according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com