Patents

Literature

817results about How to "Easy to adjust control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

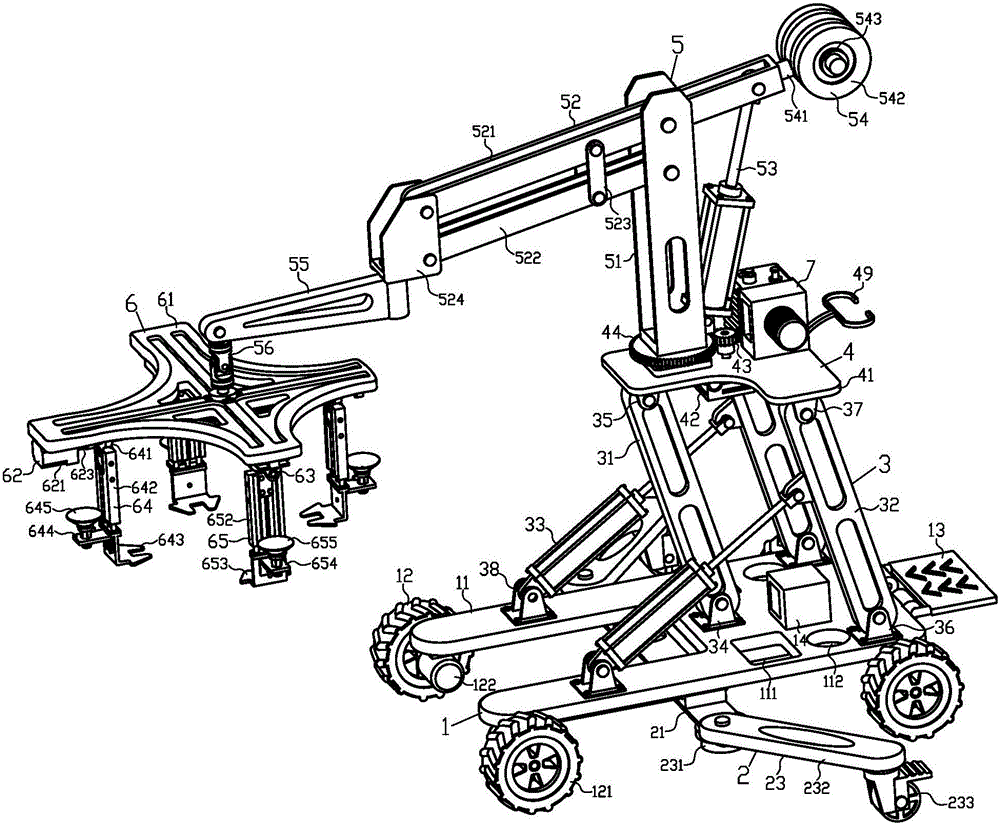

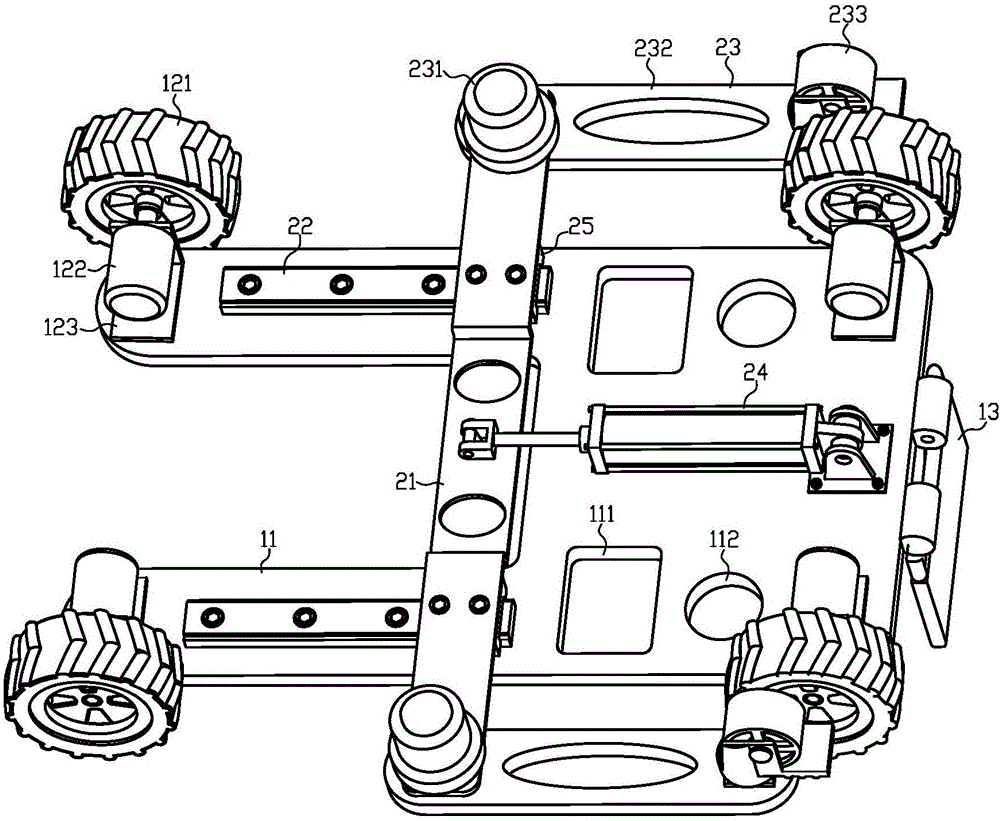

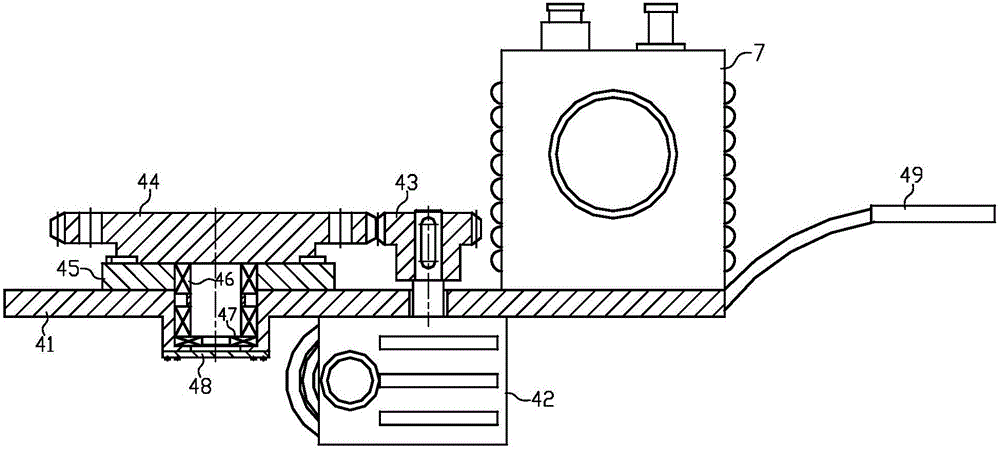

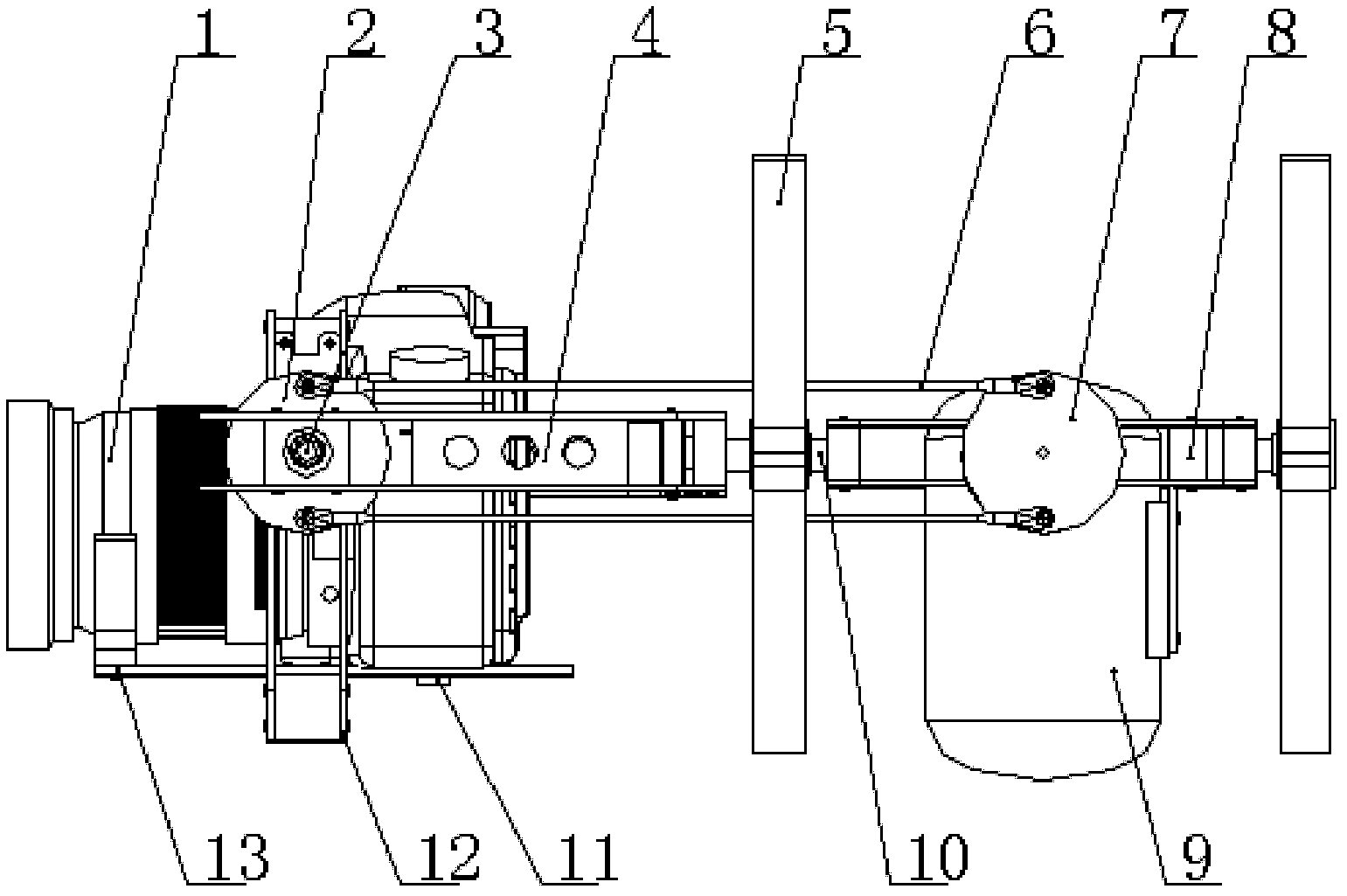

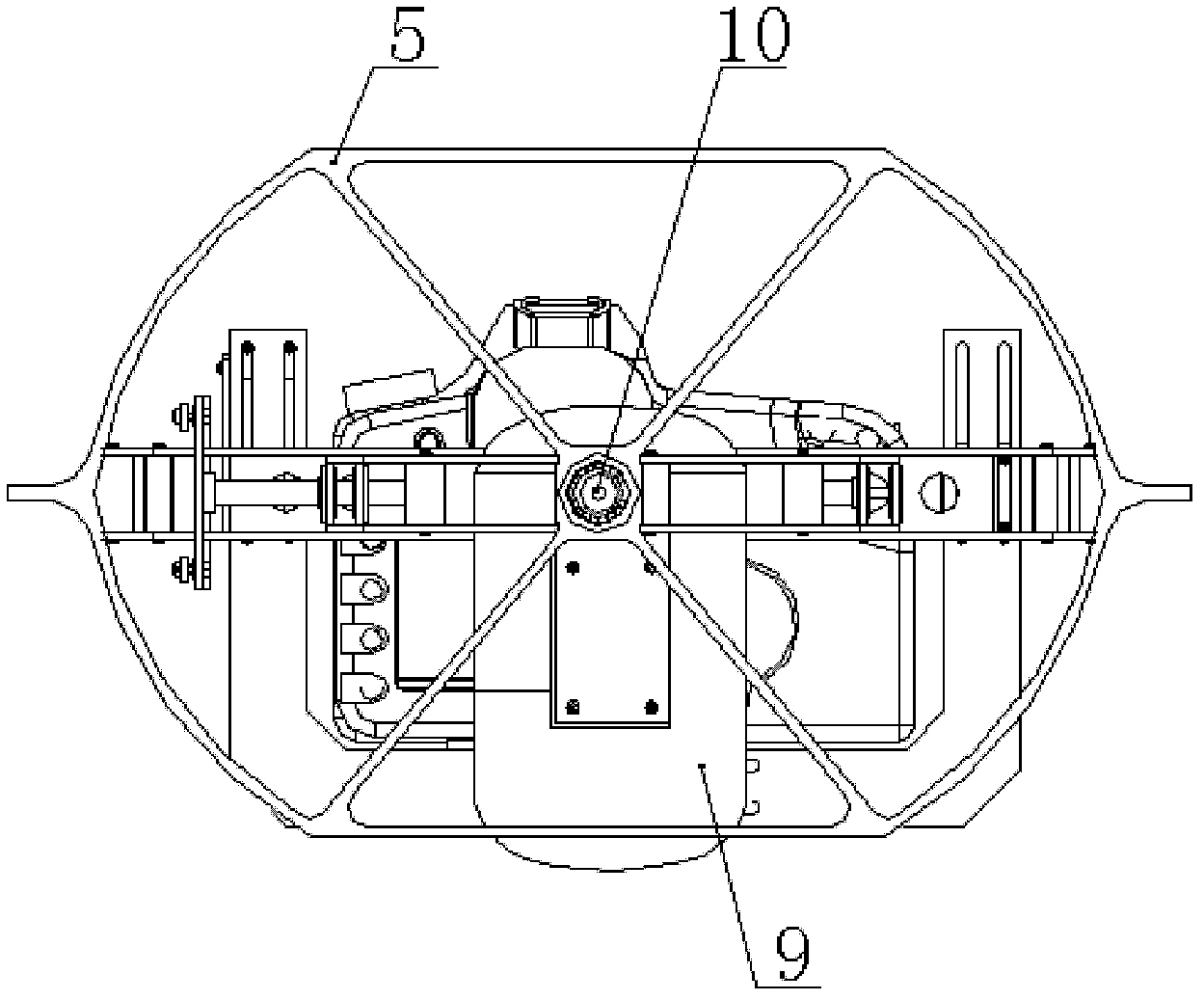

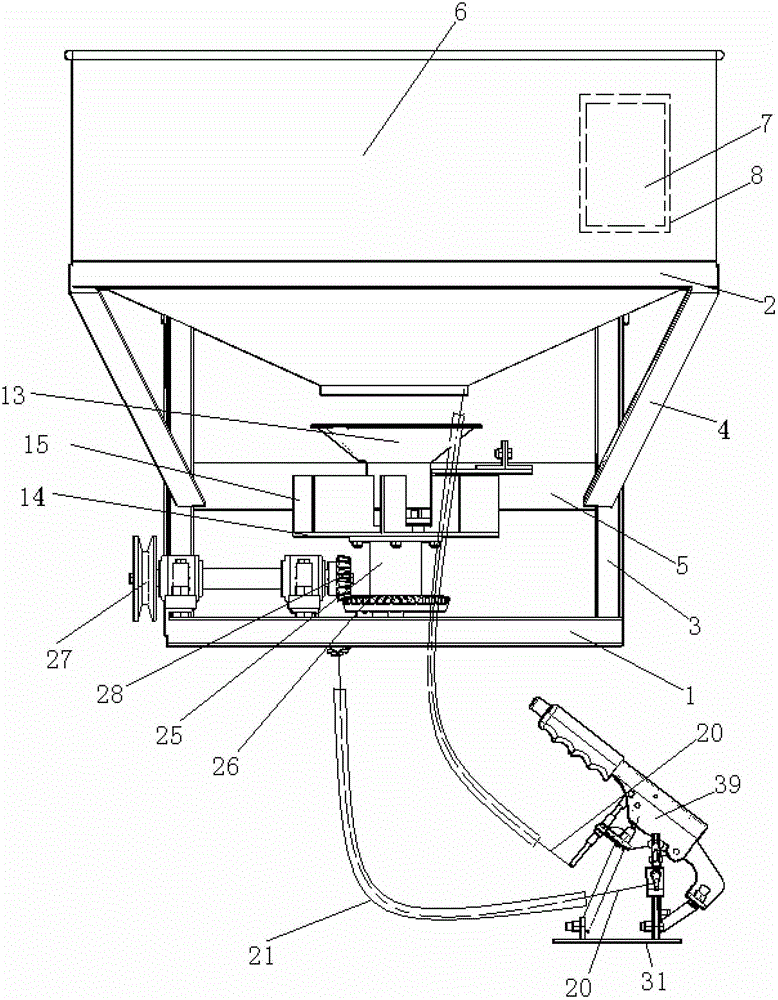

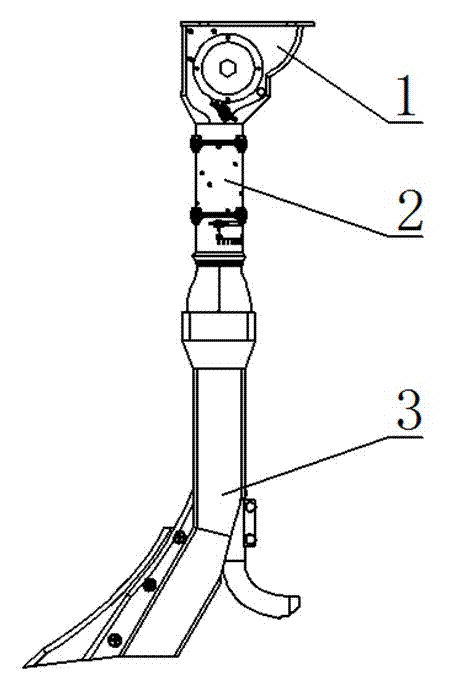

Six-degree-of-freedom multi-function loading and transporting robot

ActiveCN106112999AIncrease stiffnessHigh movement precisionProgramme-controlled manipulatorGripping headsDegrees of freedomEngineering

The invention discloses a six-degree-of-freedom multi-function loading and transporting robot. The six-degree-of-freedom multi-function loading and transporting robot comprises a mobile chassis, an anti-overturning device, an adjustable supporting seat, a rotating device, a motion executing arm, a grasping device and an electric air pump. The anti-overturning device mounted under the mobile chassis is used for preventing the robot from overturning during executing the loading and transporting tasks; the adjustable supporting seat can be used for adjusting the height and the fore-and-aft horizontal displacement of the grasping device; the rotating device is used for adjusting the left-right rotation of the grasping device; the motion executing arm is mainly used for executing the lifting and lowering tasks; and the grasping device is capable of executing the material grasping task by mechanical clamping or negative pressure adsorbing. The robot can be used for the works as material moving and carrying, material loading and unloading and the like in the logistics or industrial production and has the advantages of being high in flexibility of motion, strong in adaptability, large in anti-overturning torque, compact in structure, capable of saving storage space, convenient to adjust and control and the like. The robot is capable of overcoming the technical defects in the prior loading and transporting robot and more applicable to popularization.

Owner:ANHUI UNIV OF SCI & TECH +1

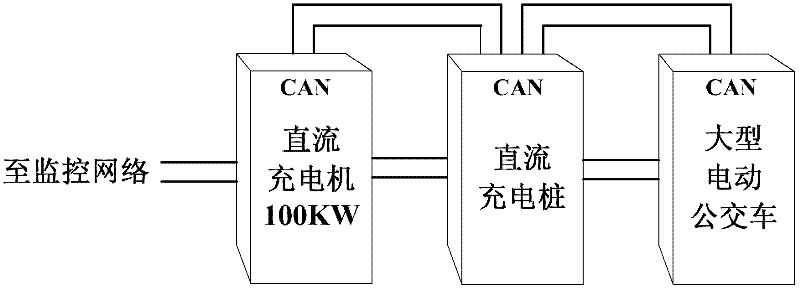

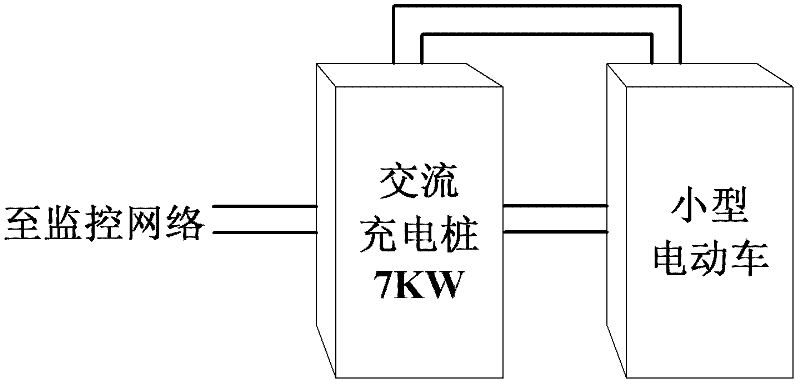

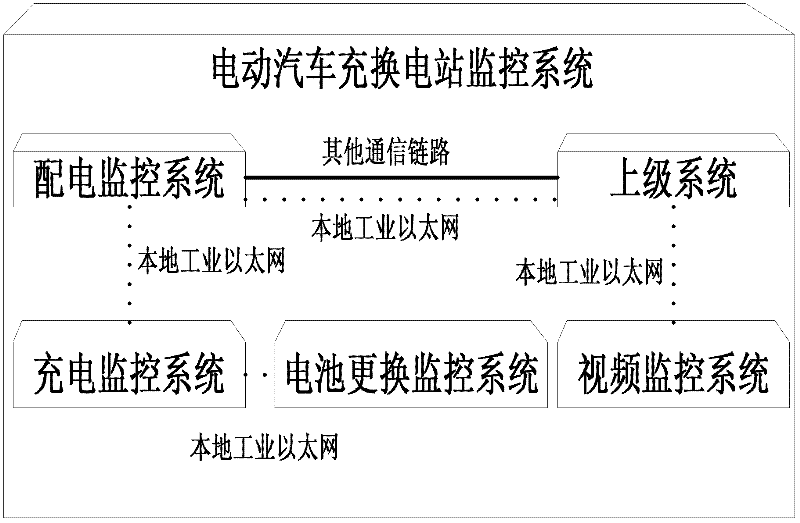

Monitoring system for electric automobile battery charging and replacing station

InactiveCN102315677ASolve the monitoring problem of compatible charging and swapping of large and small carsMeet the requirementsBatteries circuit arrangementsClosed circuit television systemsVideo monitoringDistribution power system

The invention relates to a monitoring system for an electric automobile battery charging and replacing station. The system comprises a superior system, an electricity distribution monitoring system, a charging monitoring system, a battery replacement monitoring system and a video monitoring system; a monitoring work station, a server, a printer, an electricity distribution system communication management machine and an electricity utilization information collecting terminal are connected with a network exchanger of the charging monitoring system through a local industrial Ethernet; a network exchanger of the electricity distribution monitoring system is connected with a communication gateway of the superior system through the local industrial Ethernet; an intelligent communication terminal of the battery replacement monitoring system is connected with the network exchanger of the charging monitoring system through the local industrial Ethernet; and a video server of the video monitoring system is connected with the communication gateway of the superior system through the local industrial Ethernet. The system can meet the requirement of electric energy complement of large commercial vehicles and small passenger vehicles and can realize omnibearing, effective and real-time monitoring on the battery charging and replacing of electric automobiles.

Owner:CHINA ELECTRIC POWER RES INST +1

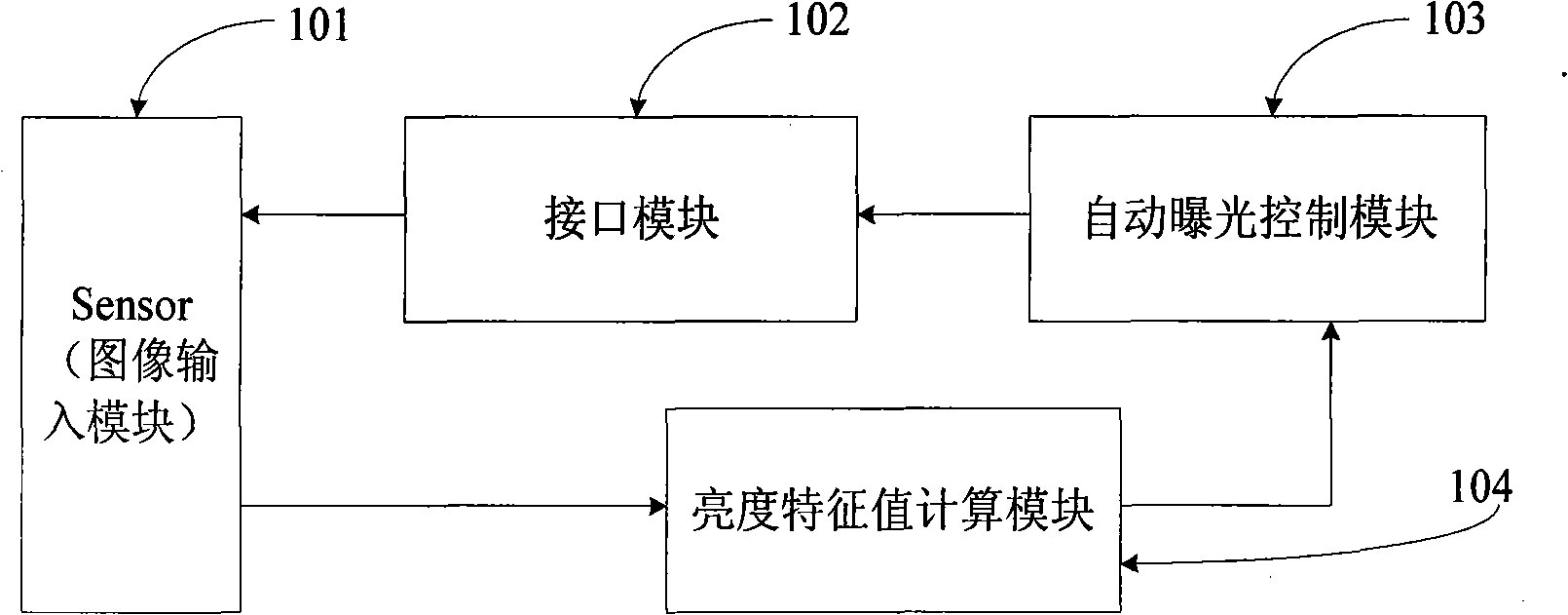

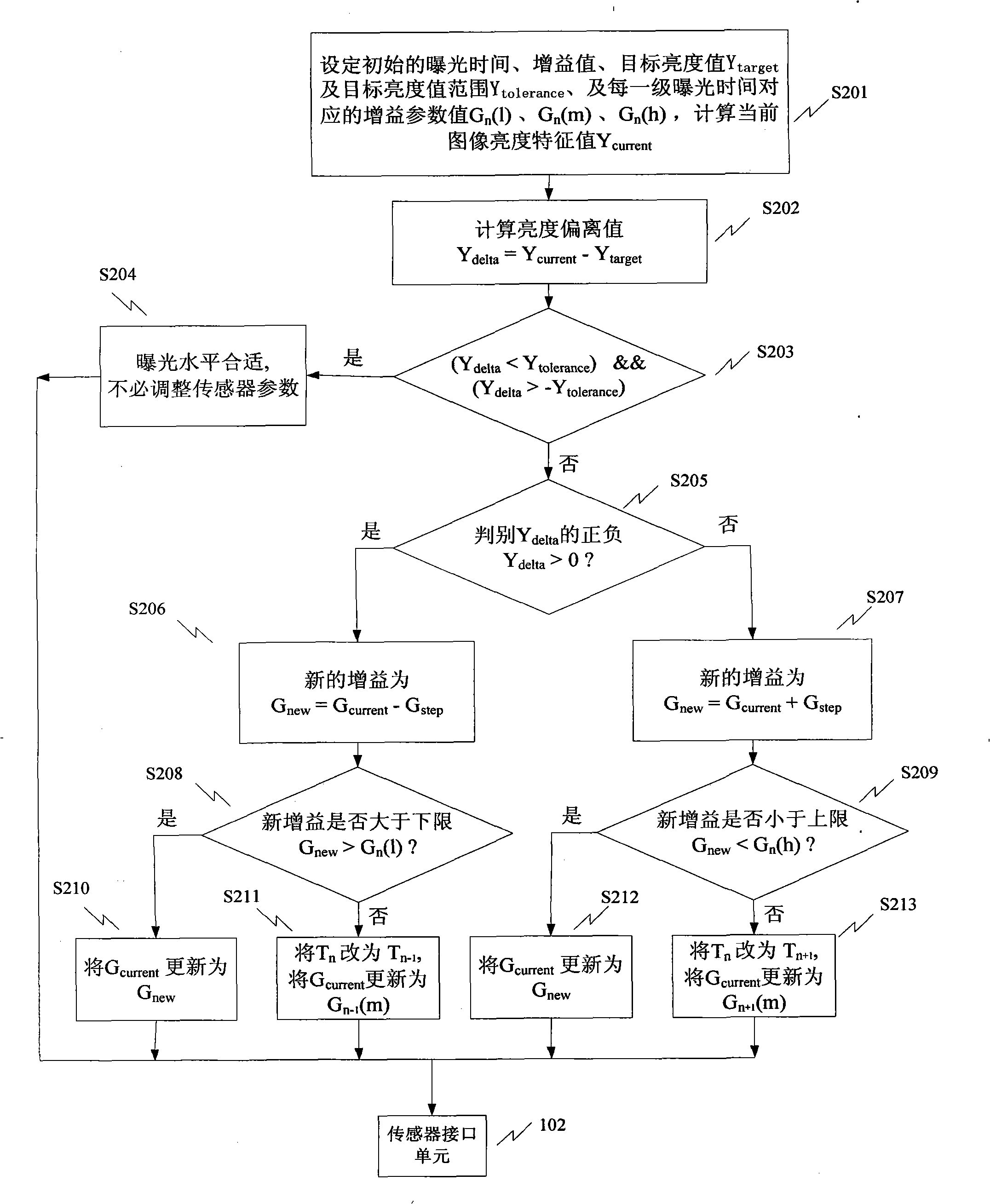

Method for automatic exposure regulation and control system

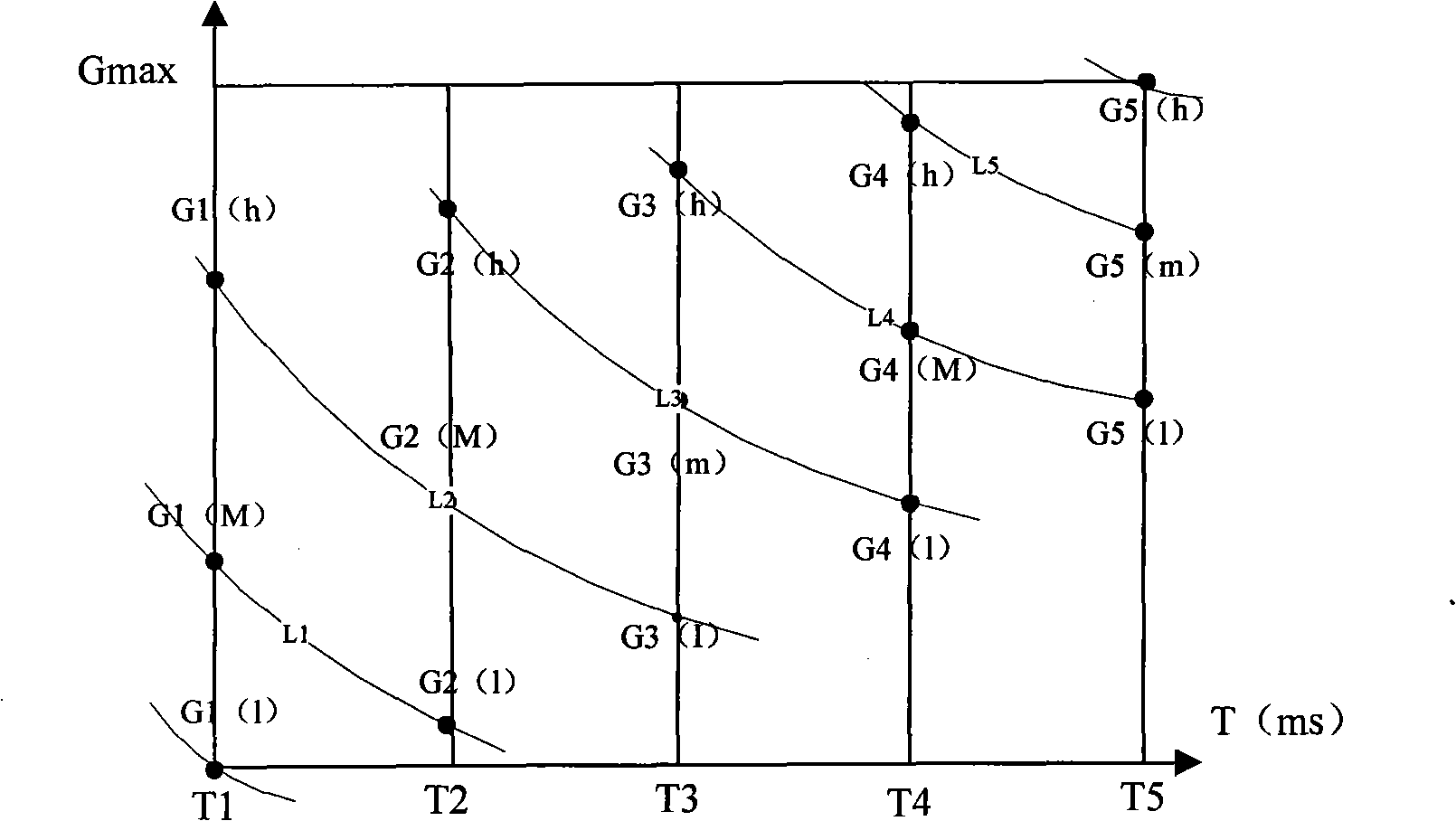

InactiveCN101359148AFlexible adjustmentEasy to adjust controlTelevision system detailsColor television detailsAutomatic exposure controlControl system

The invention discloses an automatic exposure adjustment method and a control system, comprising the following steps: first, setting the initial exposure parameters and determining the scope of the target brightness; secondly, judging whether the average brightness value of the image in the initial state is within the target brightness scope, and if so, do not change the exposure time and the gain value; the invention is characterized in that if the average brightness value of the image in the initial state is not within the target brightness scope, the exposure time is divided into n-levels, gained in each level and gradually adjusted based on a certain step length; the exposure time jumps from one level to another level on the equal-brightness curves so as to achieve the optimal exposure effect through the method of gradually adjusting the gain and the exposure time. The control system comprises a sensor (101), an interface module (102), an automatic exposure control module (103) and a brightness characteristic value calculation module (104); the method and the system are simple and flexible to realize so as to reduce the chip cost; and the adjustment on the equal-brightness curves enables the entire automatic exposure process to be very smooth, without the brightness-darkness staggered flashing situations.

Owner:ARKMICRO TECH

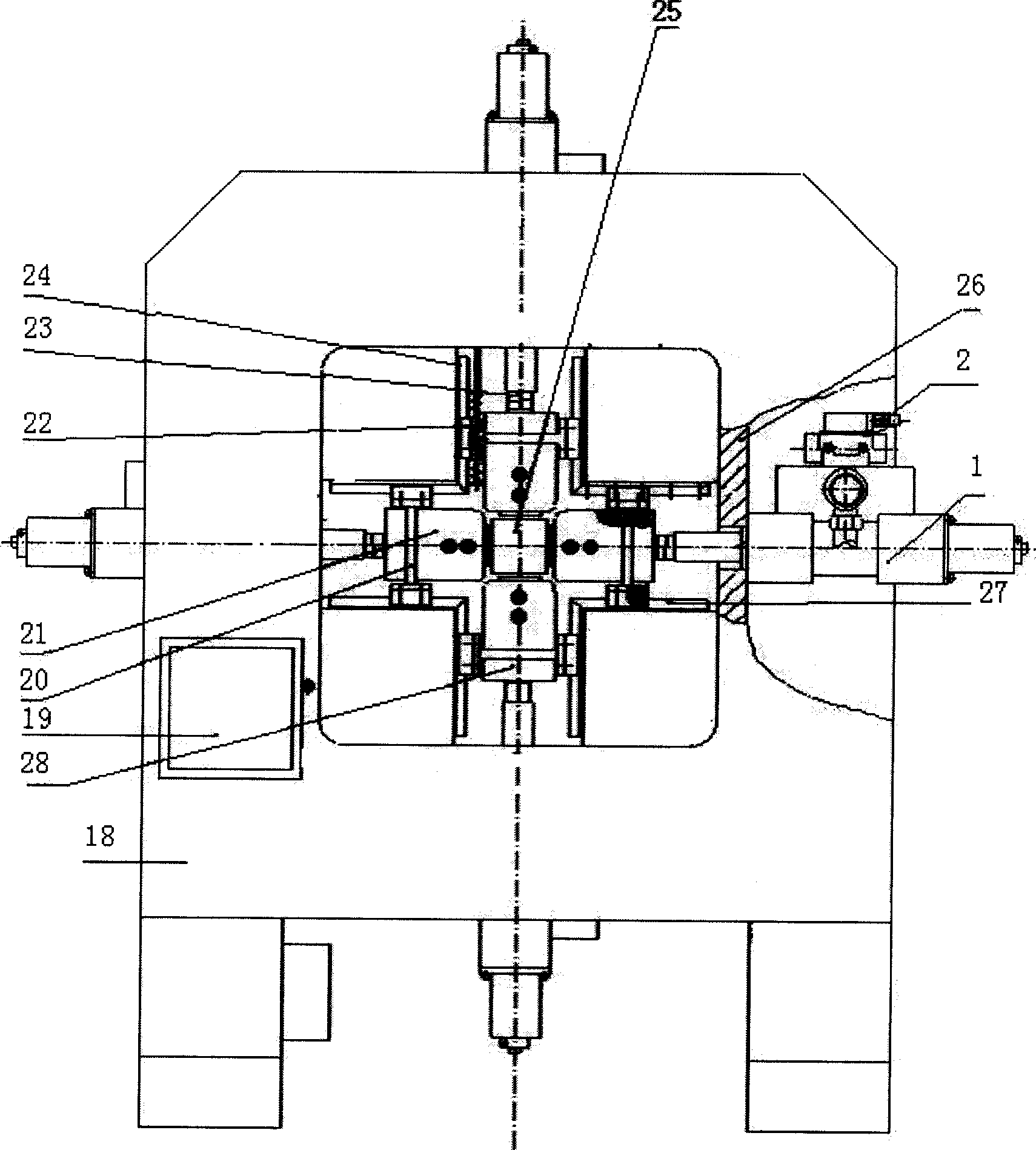

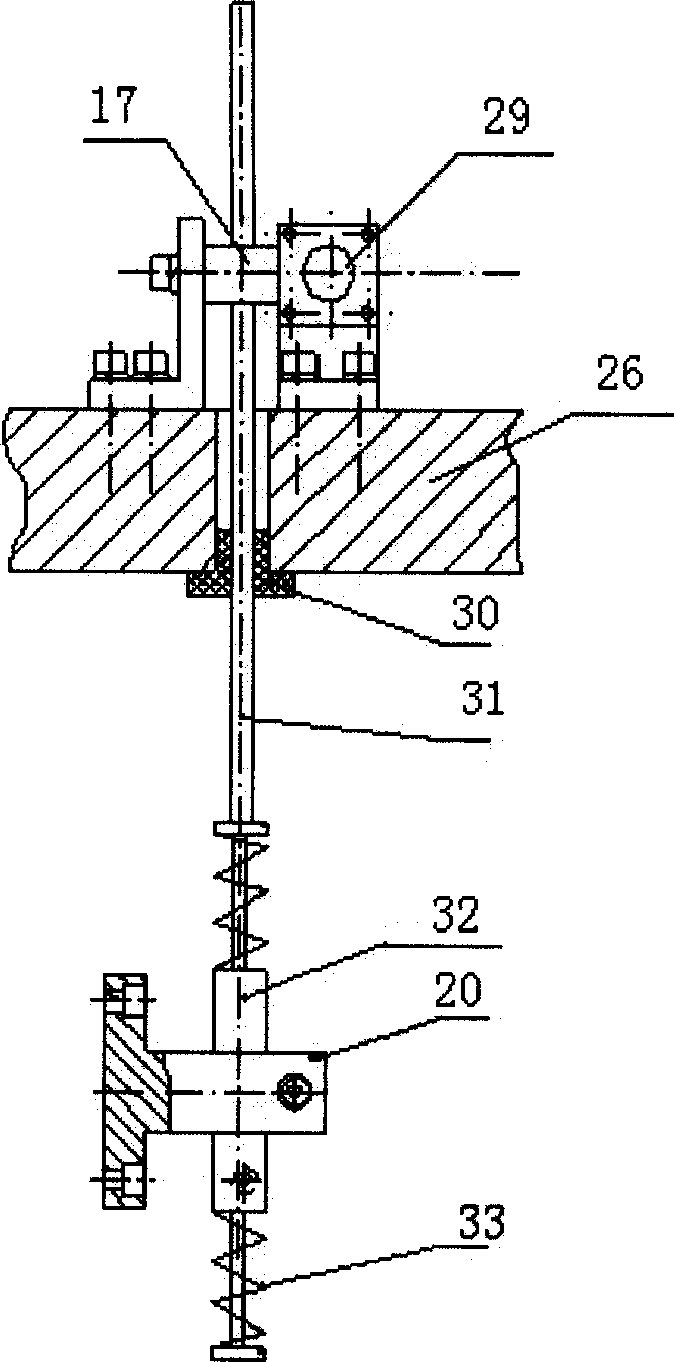

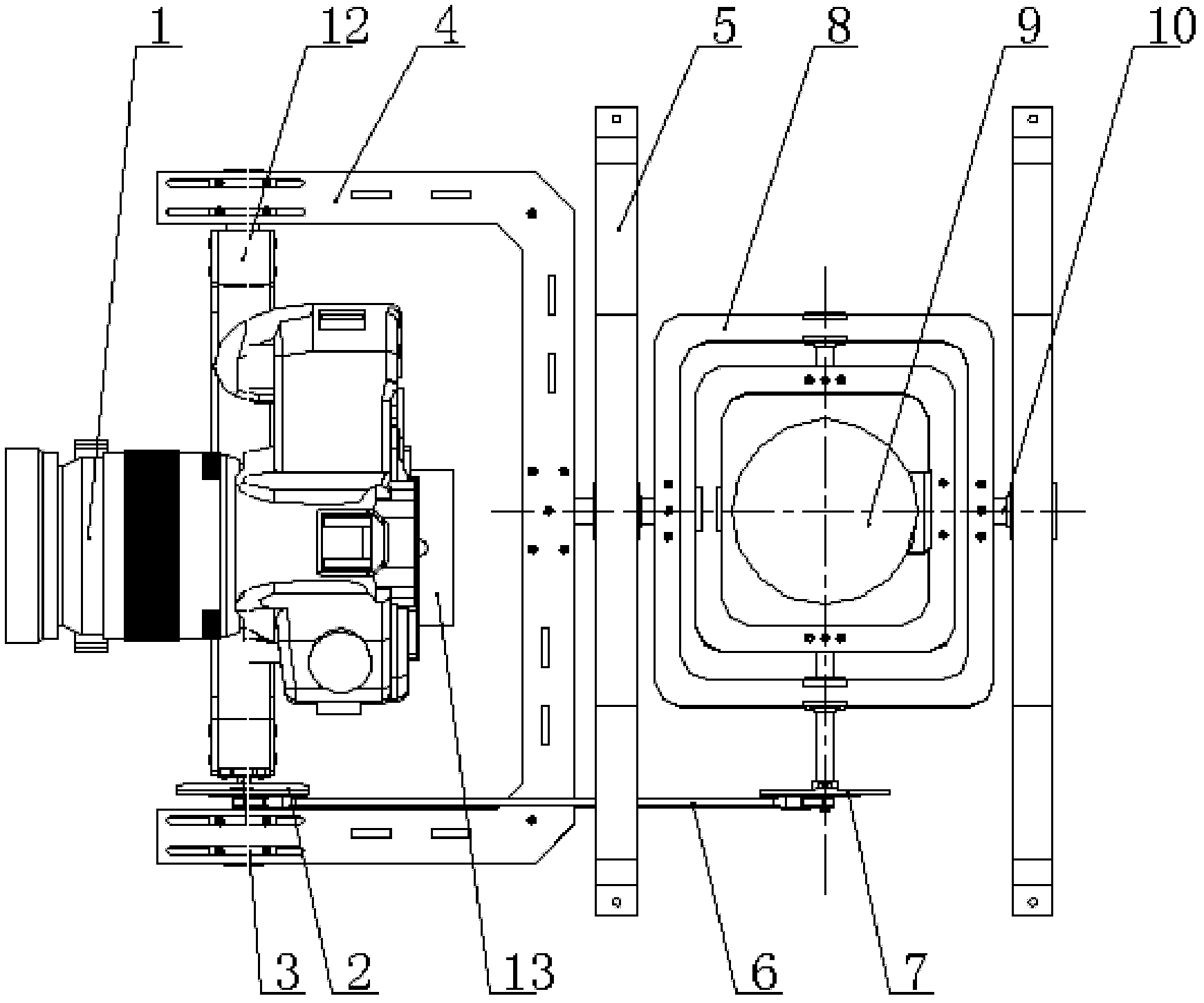

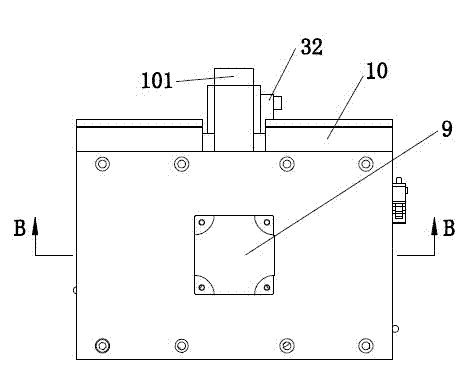

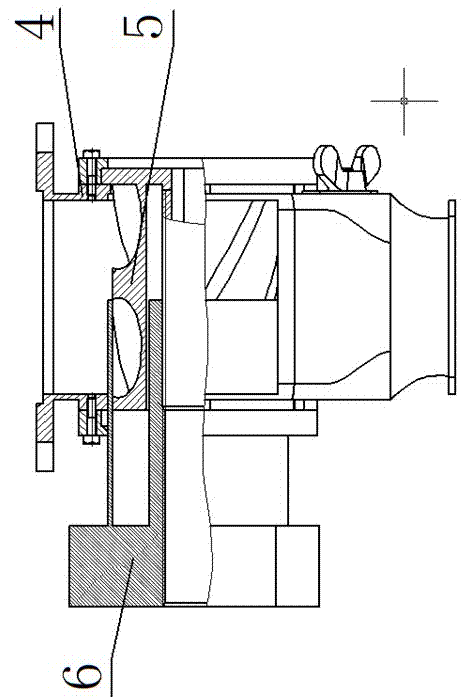

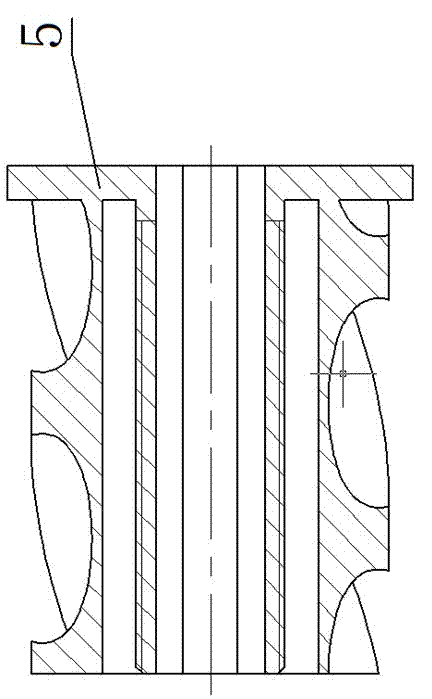

Vertical double-shaft four-cylinder electro-hydraulic servo testing machine

InactiveCN1865910ARapid responseQuick change shockMaterial strength using tensile/compressive forcesControl systemElectro hydraulic

The vertical dual-shaft four-cylinder electrohydraulic servo testing machine comprises: a hydraulic pressure drive for dual-direction stress filed, a four-cylinder drive fit to any loading path, a differential close-loop servo system, a function generator fit to different waves, a position transfer device fit to assemble the test piece, a guide plate and linear rail to ensure co-shaft and avoid bending. This invention is very convenient.

Owner:TSINGHUA UNIV +1

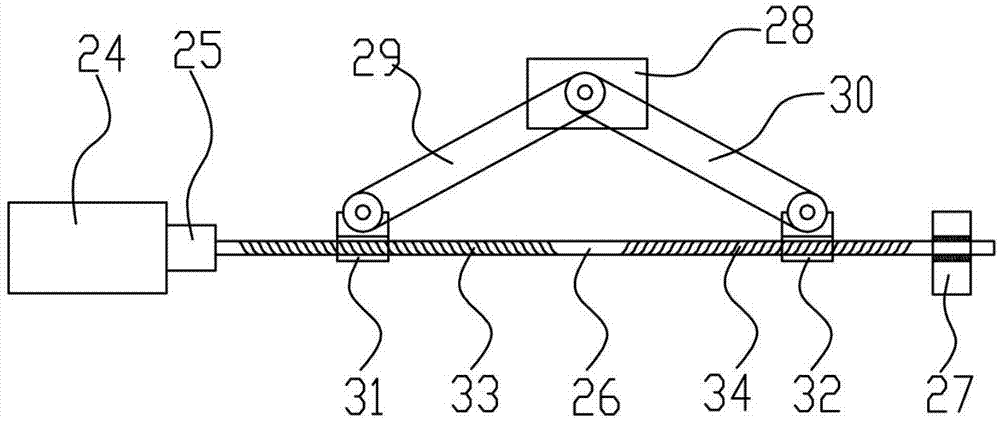

Powder sending and laying device for quickly shaping device

ActiveCN101362202APrevent dispersalAvoid wandering situationsAdditive manufacturing apparatusLoading/unloadingHigh rateReciprocating motion

The invention discloses a powder feeding and laying device applied to a high rate former, which consists of a powder storing case and a movable hopper, wherein, the powder storing case is an upper powder storing case positioned above the movable hopper and provided with a power outlet at the bottom; the powder storing case is fixed and stable; a movable baffle capable of automatically opening and closing the powder outlet is arranged at the bottom of the powder outlet; a movable bracket is fixed outside the movable hopper which moves to and fro from left to right along a horizontal line on a forming working platform of a high rate former by a driving mechanism; an unlocking component which is matched to be used with the movable bracket is arranged on the movable baffle; a receiving port at the upper part of the movable hopper corresponds to the powder outlet; a powder laying port is arranged at the bottom of the movable hopper, which is a rectangular port enclosed by two lateral baffles in the front and the back and two flexible doctor blades on the left and the right. The powder feeding and laying device applied to a high rate former has simple structure, handy assembly and deinstallation of all parts and easy regulation and control, the capability of modular working independently, rapid powder laying, and high reliability.

Owner:西安赛隆增材技术股份有限公司

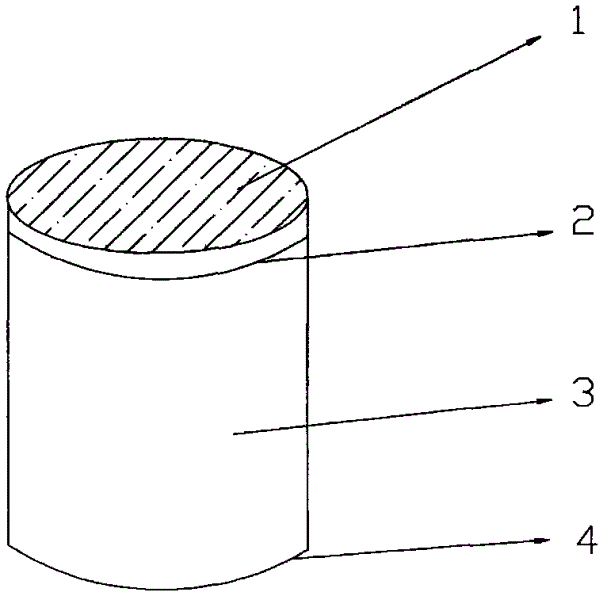

Rubber conductive particle and preparation method thereof

ActiveCN102623196AImprove conductivity and stabilityEasy thicknessContact materialsMetal layered productsTotal thicknessLaser cutting

The invention provides a rubber conductive particle, comprising a rubber base material and metal plated film on the surface of the particle. The metal plated film can comprise one layer or a plurality of layers, and has a total thickness of 0.05mum to 1mm. The rubber conductive particle has a cylindrical shape or a platform shape, has a cross section of a circular shape, an elliptical shape, or a polygon shape, and has a cross section diameter of 1mm to 10mm. The preparation method of the rubber conductive particle comprises: first preparing a rubber sheet material with moulding, injecting, extruding, or calendering methods; then plating the metal plated film on the surface of the rubber sheet material by employing plating technique; and carrying out punching, shearing or laser cutting on the sheet material to obtain the rubber conductive particle. The rubber conductive particle of the invention is characterized by good conductivity of metal coating, thin thickness of the coating, reduction of raw material consumption, low manufacturing cost, and no pollution basically, and can be used as a conduction contact component of a push-button circuit board.

Owner:NANTONG MEMTECH TECH

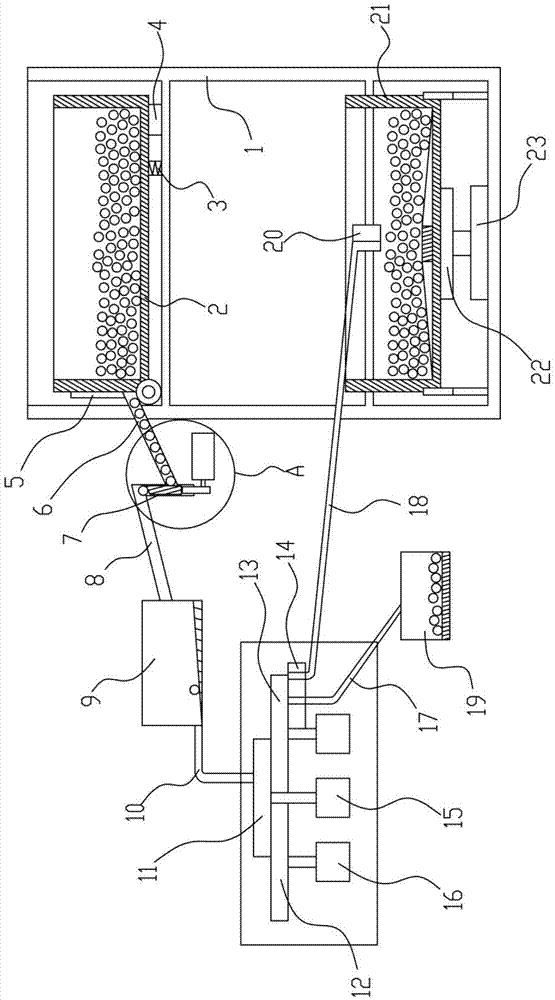

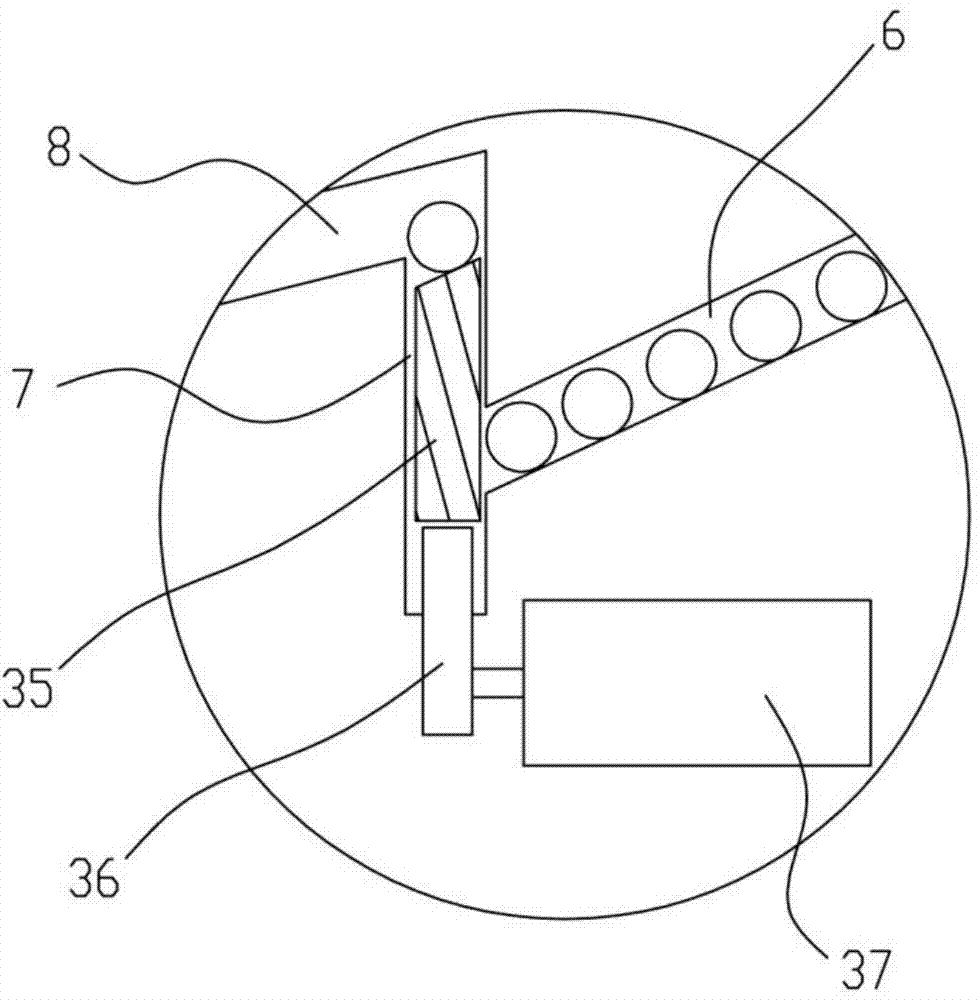

Automatic steel ball sorting device

The invention discloses an automatic steel ball sorting device, which comprises a frame, a loading bucket, a discharging bucket, a waste ball cabin, a quantitative ball supply device, a feeding box, a detection device and a control device, wherein the lower end of the loading bucket is provided with a gravity sensor; one side of the loading bucket is hinged to the frame; a single-side elevating device is arranged on the other side of the loading bucket; the loading bucket is connected with the quantitative ball supply device and the feeding box through a loading channel; the feeding box is connected with the detection device through a feeding channel; the detection device is connected with the waste ball cabin and the discharging bucket respectively through a discharging channel; a distance sensor is arranged above the discharging bucket; the lower end of the discharging bucket is provided with a horizontal elevating device. The automatic steel ball sorting device has the advantages of no need of manual attendance for a long time, lower processing cost, constant loading frequency, higher sorting efficiency and avoidance of secondary defects caused by falling of steel balls into the discharging bucket.

Owner:NINGBO BAIJIABAI MEASUREMENT & CONTROL EQUIP

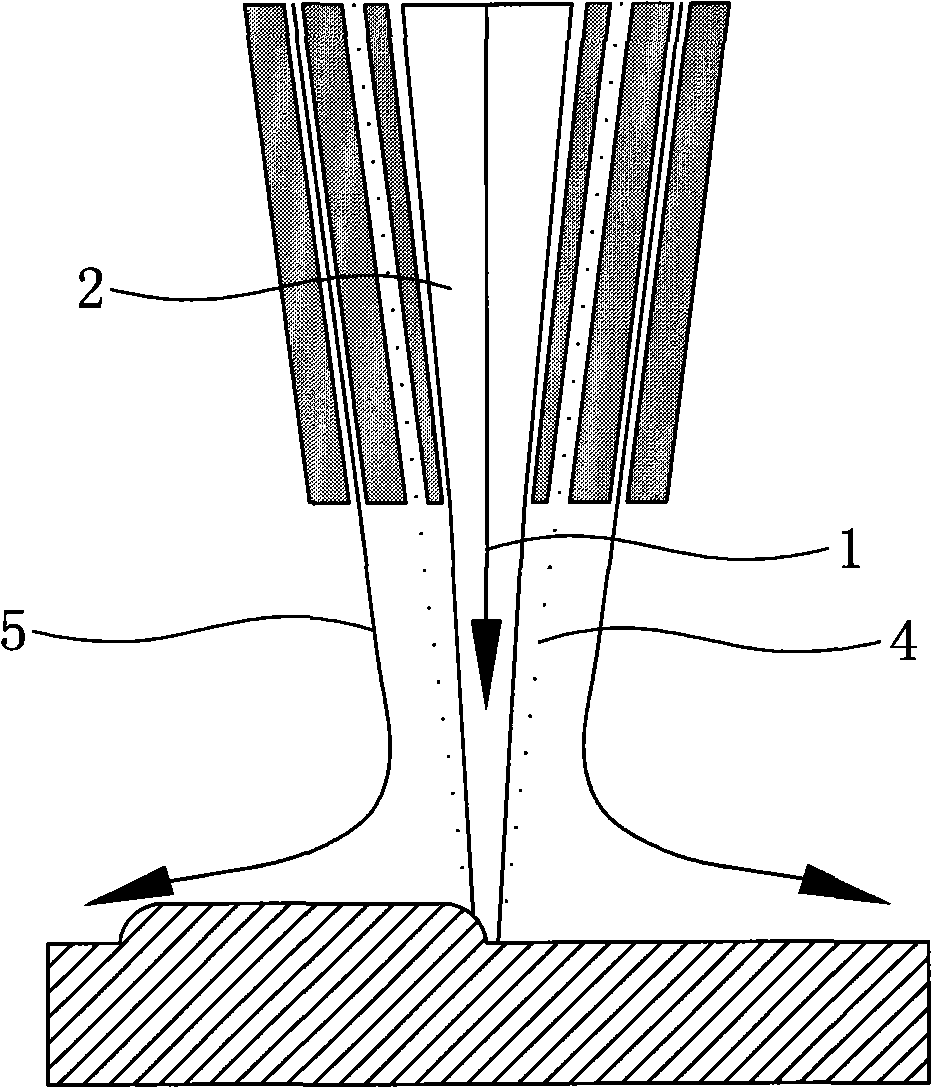

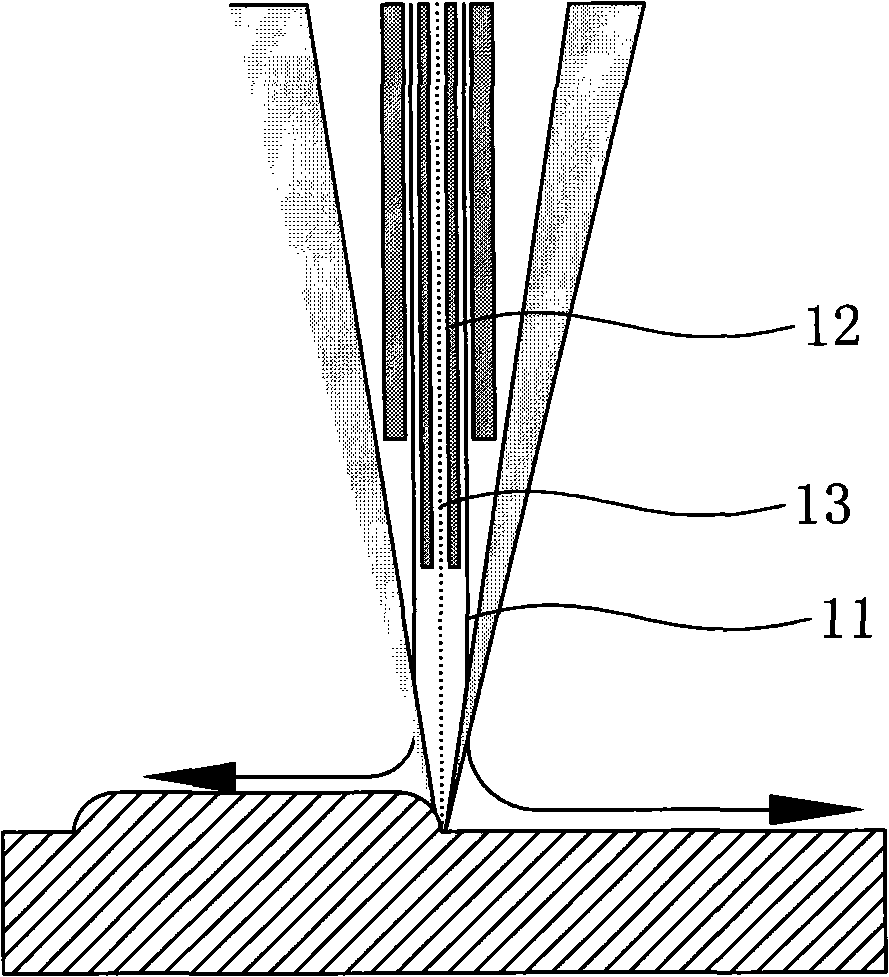

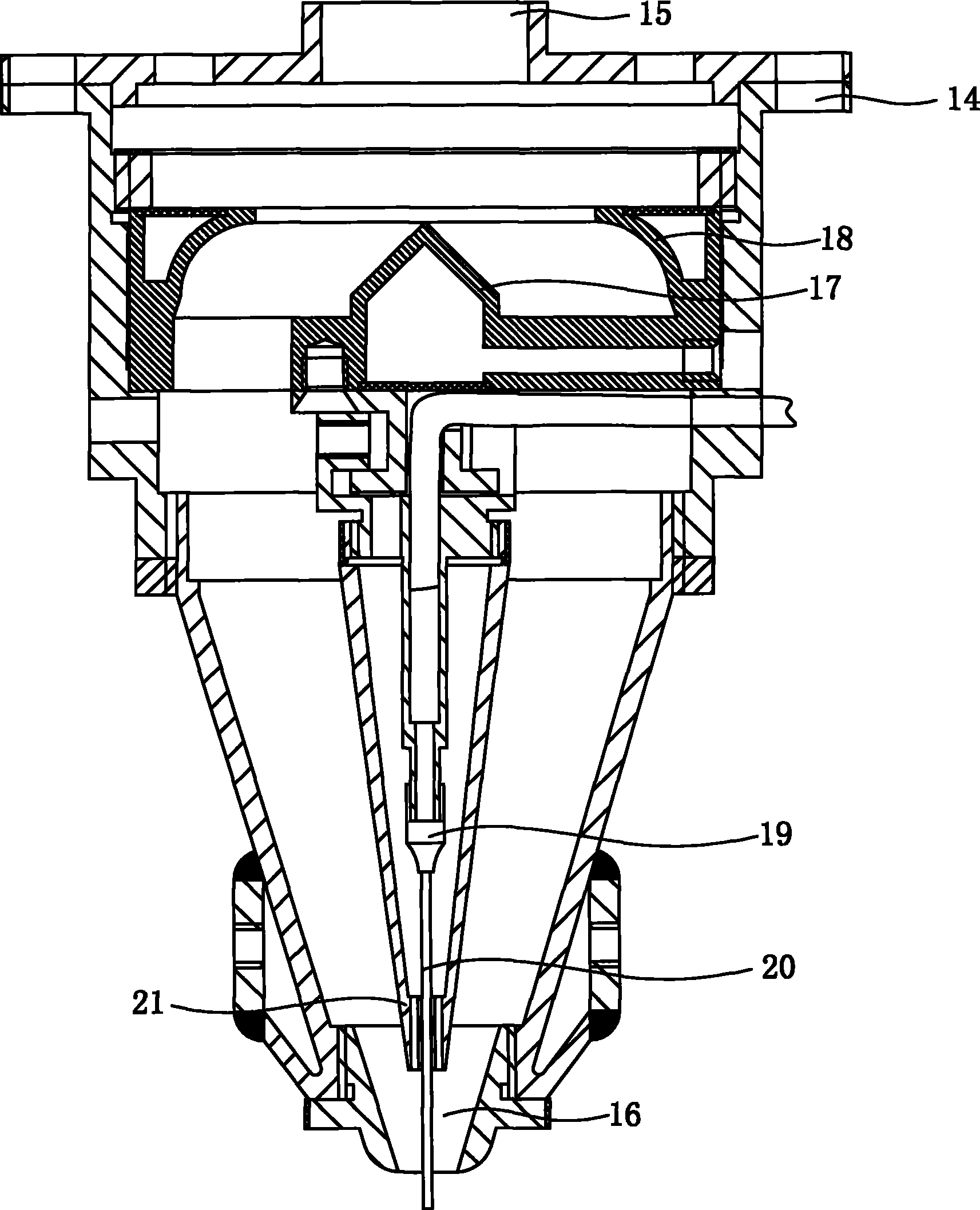

Method and device for light, powder and gas coaxial transmission laser cladding forming manufacturing

InactiveCN101774084AGood rigidityReduce divergenceMetallic material coating processesLaser beam welding apparatusOptical pathCircular section

The invention discloses a method for light, powder and gas co-axial transmission laser cladding forming manufacturing, which is characterized in that: a circular section solid laser beam emitted by a laser is subjected to transformation and beam expansion by the optical path transformation to become a circular laser beam; the circular laser beam is focused to become a hollow circular cone focused laser beam; a powder spraying nozzle is arranged on the hollow part of the circular cone focused laser beam; the powder spraying nozzle and the circular cone focused laser beam are coaxial; the periphery of a single powder beam sprayed by the powder spraying nozzle is provided with a circle of collimation shielding gas curtain; and the collimation shielding gas curtain, the circular cone focused laser beam and the single powder beam sprayed by the powder spraying nozzle are coaxial. By arranging the collimation shielding gas curtain on the periphery of the powder beam, the method realizes the coaxial transmission of light, powders and gas and solves the defects in the prior art.

Owner:SUZHOU UNIV

Gyroscope holder of unmanned aerial vehicle

ActiveCN102353365AReduce or eliminate shakingReduce or eliminate vibrationSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesGyroscopeDrive wheel

The invention relates to a gyroscope holder of an unmanned aerial vehicle. The gyroscope holder comprises a gyroscope part and a camera part, wherein a gyroscope bracket is composed of an inner frame and an outer frame with the same diameter, a mechanical gyroscope is fixed on the inner frame, a driving wheel is fixed at the end part of an output end of a rotating shaft; a central shaft at an axial side of the holder bracket extends out of the holder bracket, a camera frame with a front opening is fixedly mounted at the end part of the central shaft to be coaxial with the central shaft, a driven wheel is fixedly mounted at the end part of a hinged shaft of a camera support; the driving wheel of the outer frame of the gyroscope part and the driven wheel of the camera support of the camera part are in the same direction, and two synchronous transmission rods are articulately mounted on the surface of an axial disk of the driving wheel, to be in symmetry along the axial direction. The gyroscope holder provided by the invention has a simple and reliable structure and good stability, is easy to regulate and control, has a wide range of applications, and can effectively eliminate shakesin the shooting process, maintain the picture stable, lock the shooting object, obtain clear pictures with high quality and effectively improve the shooting quality.

Owner:天津全华时代航天科技发展有限公司

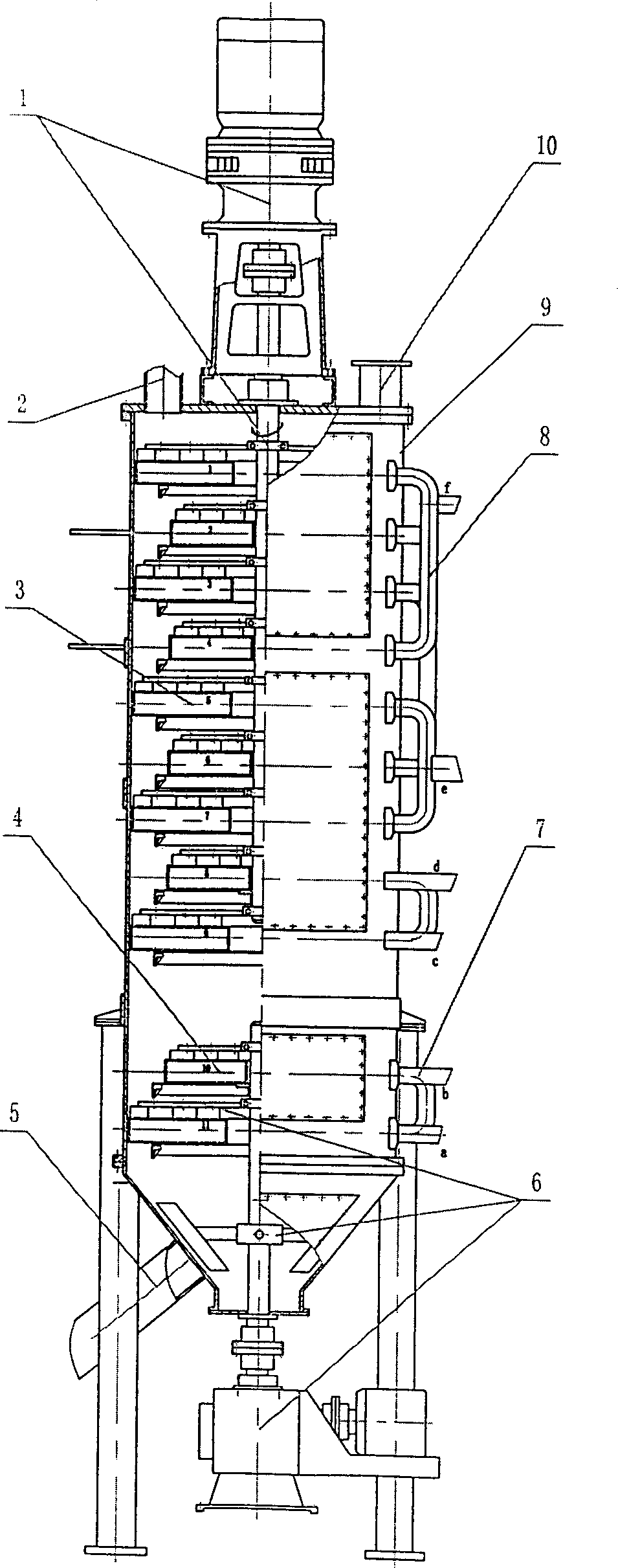

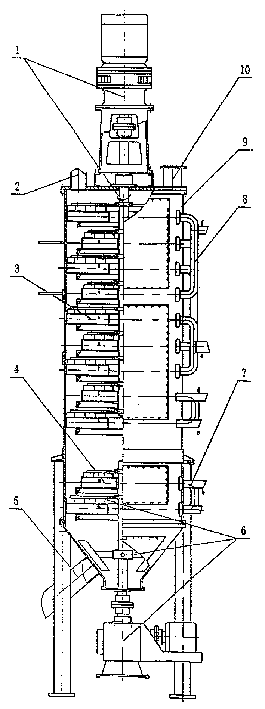

Vetical cracking tower for cracking used tyre and recovering industrial carbon black and fuel oil

InactiveCN1391088AReduce energy consumptionRealize energy savingWeighing apparatus using counterbalancePigmenting treatmentSmall footprintFuel oil

A vertical cracking tower for cracking used tyre and recovering industrial carbon black and fuel oil is composed of sealed vertical tower body, upper scrape stirrer, tyre feeding port, cracked gas outlet, upper hollow heating disc, lower hollow cooling disc, lower scrape stirrer and carbon black discharging port. Its advantages are convenient regulation and control, high quality and safety, liguht weight, and high crakcing performance.

Owner:ZHEJIANG UNIV

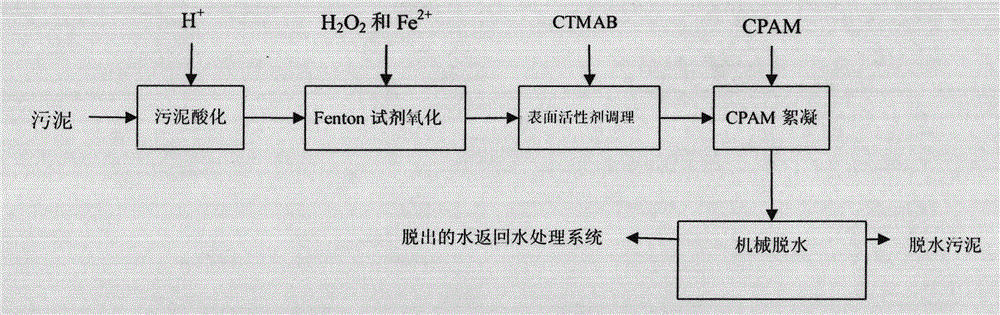

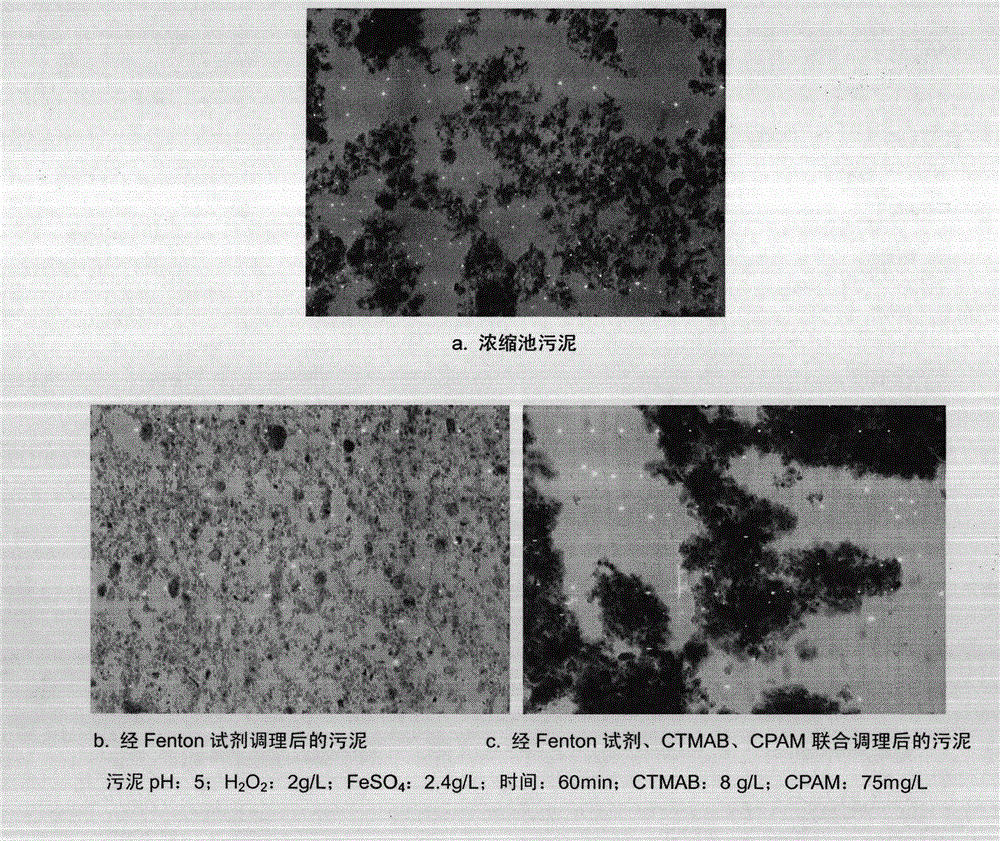

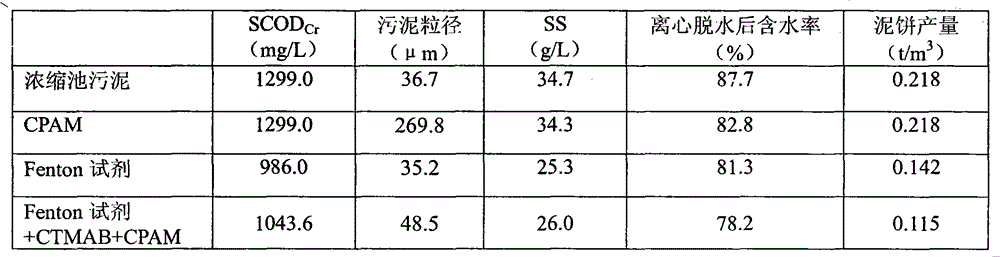

Joint-conditioning dehydration method for sludge

InactiveCN102910793AImprove dehydration effectIncrease solid contentSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationParticulatesFenton reagent

The invention is named as 'a joint-conditioning dehydration method for sludge', belonging to the technical field of environmental engineering and sludge treatment. The joint-conditioning dehydration method comprises the following steps of: adding H202 and FeSO4 into the sludge (with pH being equal to 5) acidified by mineral acid, degrading organic matter by virtue of strong oxidation of a Fenton reagent, and dissolving and cracking microbial cells and extracellular polymeric substances in the sludge; adding a surfactant CTMAB (Cetyl Trimethyl Ammonium Bromide) into the sludge to reduce the surface tension of the sludge and change the surface characteristics of the sludge, and transforming a part of interstitial water into free water; and flocculating sludge particulates with disperse structure, small particle diameter and large specific surface area by virtue of flocculation action of polyacrylamide (CPAM) to the sludge particulates. After the sludge is subjected to joint conditioning of the Fenton reagent, the surfactant and the CPAM, the moisture content of the sludge after being centrifugally dewatered is reduced to 78.2% from 87.7%, and the output of mud cakes is reduced to 0.115t / m<3> from 0.218t / m<3>, therefore, the dehydration property of the sludge can be improved remarkably, the investment and operation costs are reduced effectively, and an ideal sludge reduction goal is reached.

Owner:BEIJING NORMAL UNIVERSITY

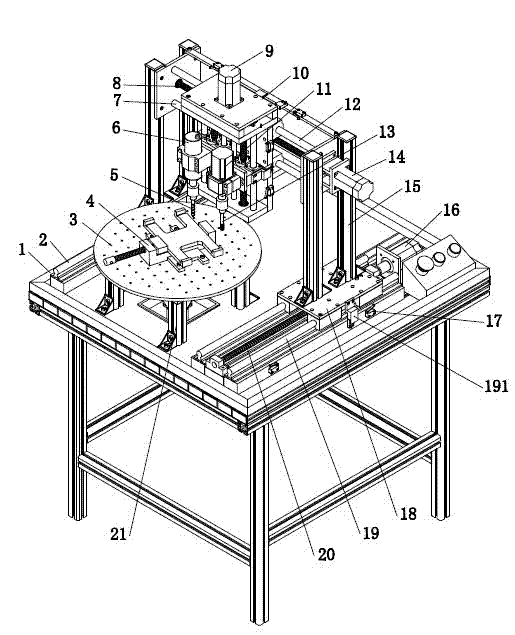

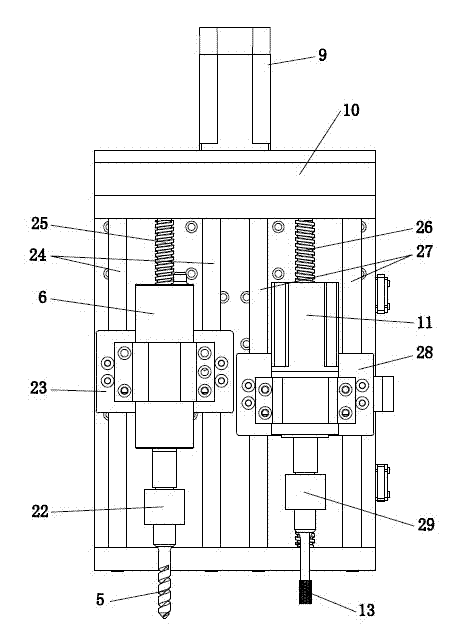

Numerical control drilling and tapping all-in-one machine and control method thereof

InactiveCN103192265AVersatileHigh degree of automationOther manufacturing equipments/toolsLarge fixed membersElectric machineryDrill bit

The invention relates to a numerical control drilling and tapping all-in-one machine and a control method thereof. The numerical control drilling and tapping all-in-one machine is characterized by comprising a frame, a left Y-direction slide rail structure, a right Y-direction slide rail structure, a workpiece clamping table, a portal type mounting rack, a left slide block structure, a right slide block structure, a Y-direction driving structure, a slide framework, an X-direction driving structure, a left slider, a right slide, a Z-direction driving structure, a drill bit motor assembly, a screw tap motor assembly, a drill bit and a screw tap. The numerical control drilling and tapping all-in-one machine has the advantages as follows: multiple functions are achieved; cutting, edging and tapping can be fulfilled on one machine; the degree of automation and the machining precision are high; complex linear interpolation, circular interpolation, feed speed regulation, rough machining, finish machining and the like can be carried out; the control and regulation are easy; the operating efficiency is high; and the manipulation is more convenient.

Owner:SHUNDE POLYTECHNIC

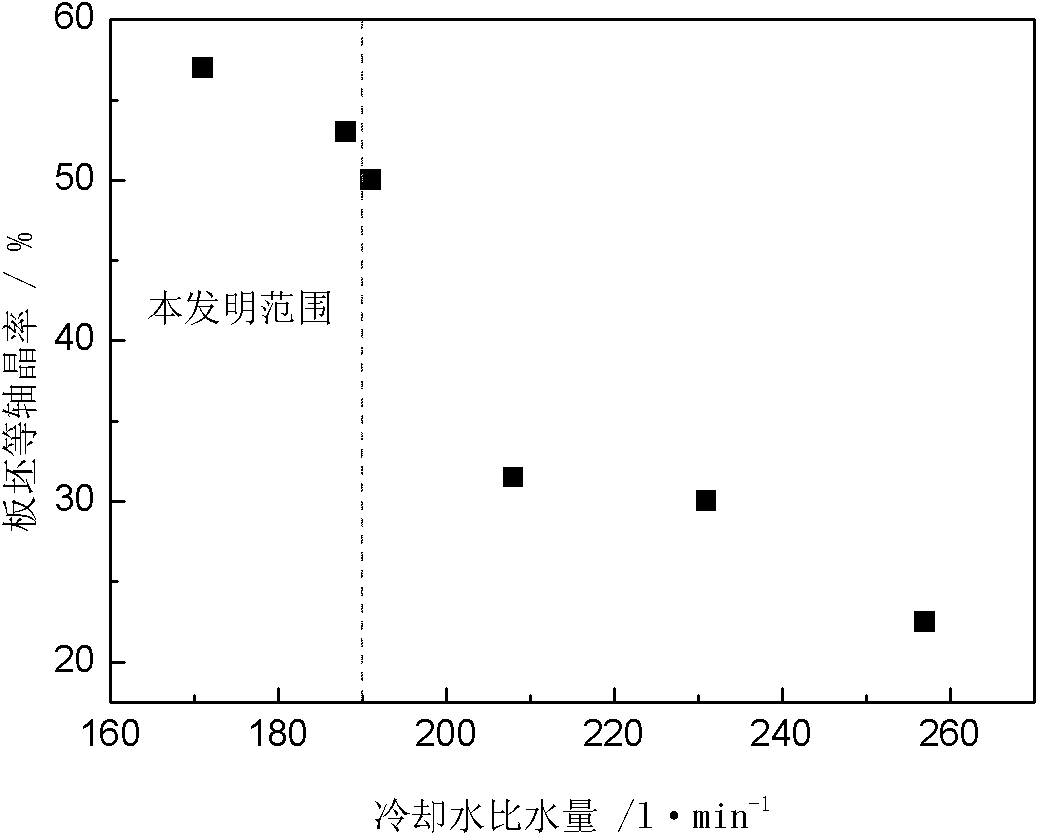

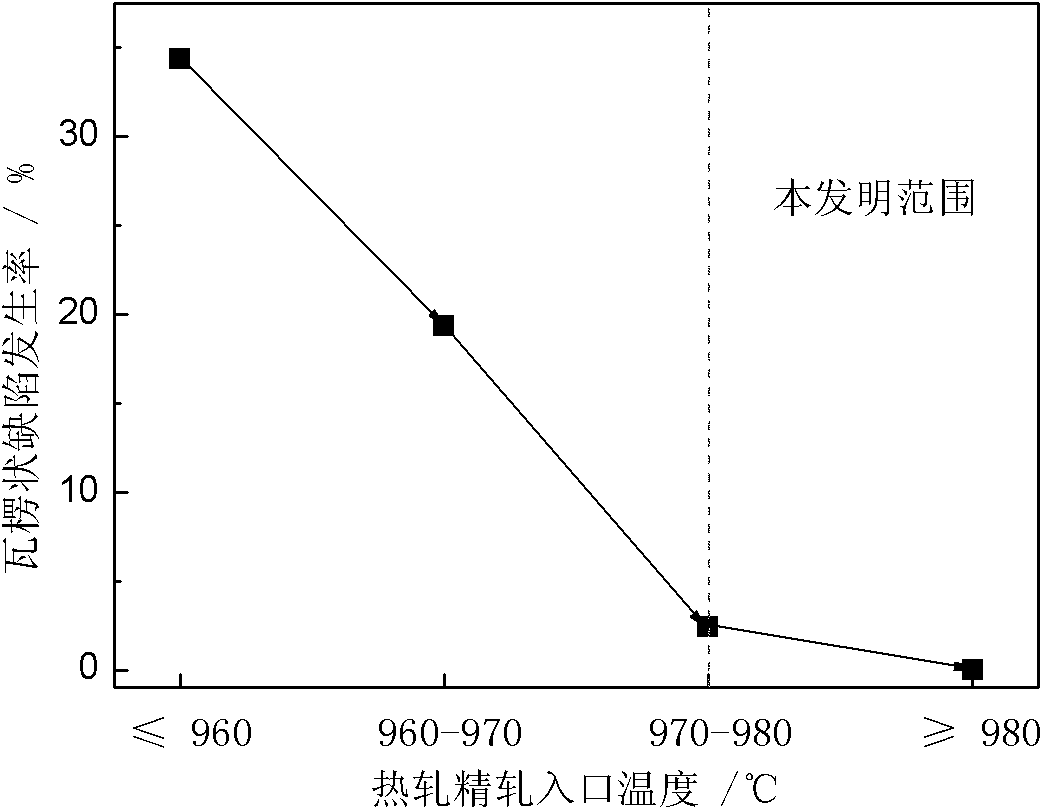

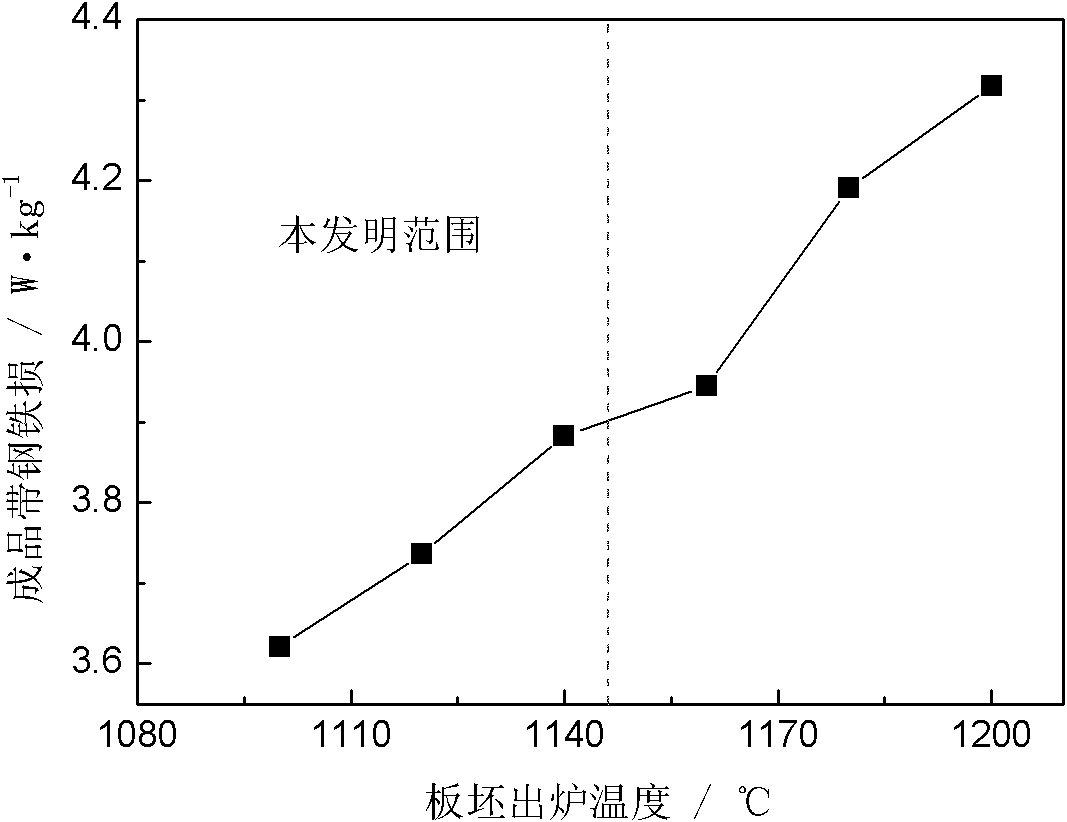

Non-oriented electrical steel plate without corrugated defect and its manufacturing method

ActiveCN102443734AReduce heat flow gradientReduce crystal ratioInorganic material magnetismMaterials scienceCoating

The invention relates to a non-oriented electrical steel plate without a corrugated defect and its manufacturing method. The steel plate is composed of the following chemical components by weight: less than 0.005% of C, 1.2-2.2% of Si, 0.2-0.4% of Mn, less than 0.2% of P, less than 0.005% of S, 0.2-0.6% of Al, less than 0.005% of N, less than 0.005% of O, and the balance Fe. The method comprises the steps of: subjecting the chemical components to molten iron pretreatment, converter smelting, RH refining and continuous casting so as to obtain a plate blank, and controlling the amount of continuous casting secondary cooling water, with the specific water flow of the cooling water maintained at 100-190l / min and the average superheat degree of continuous casting molten steel kept at 10-45DEG C; conducting heating and hot rolling to the plate blank, and making the tapping temperature of the plate blank at 1050-1150DEG C, and keeping the temperature difference between any two points along the length direction of the plate blank lower than 25DEG C during heating, with the hot rolling composed of rough rolling and finish rolling, the inlet temperature of which is controlled higher than orequal to 970DEG C; carrying out pickling, cold rolling, annealing and coating, thus obtaining the finished product of a non-oriented electrical steel plate. By controlling the cooling speed of the plate blank during continuous casting, the temperature difference along the length direction of the plate blank inside a heating furnace, as well as the temperature drop before finish rolling of the plate blank, the method of the invention realizes no corrugated defect.

Owner:BAOSHAN IRON & STEEL CO LTD

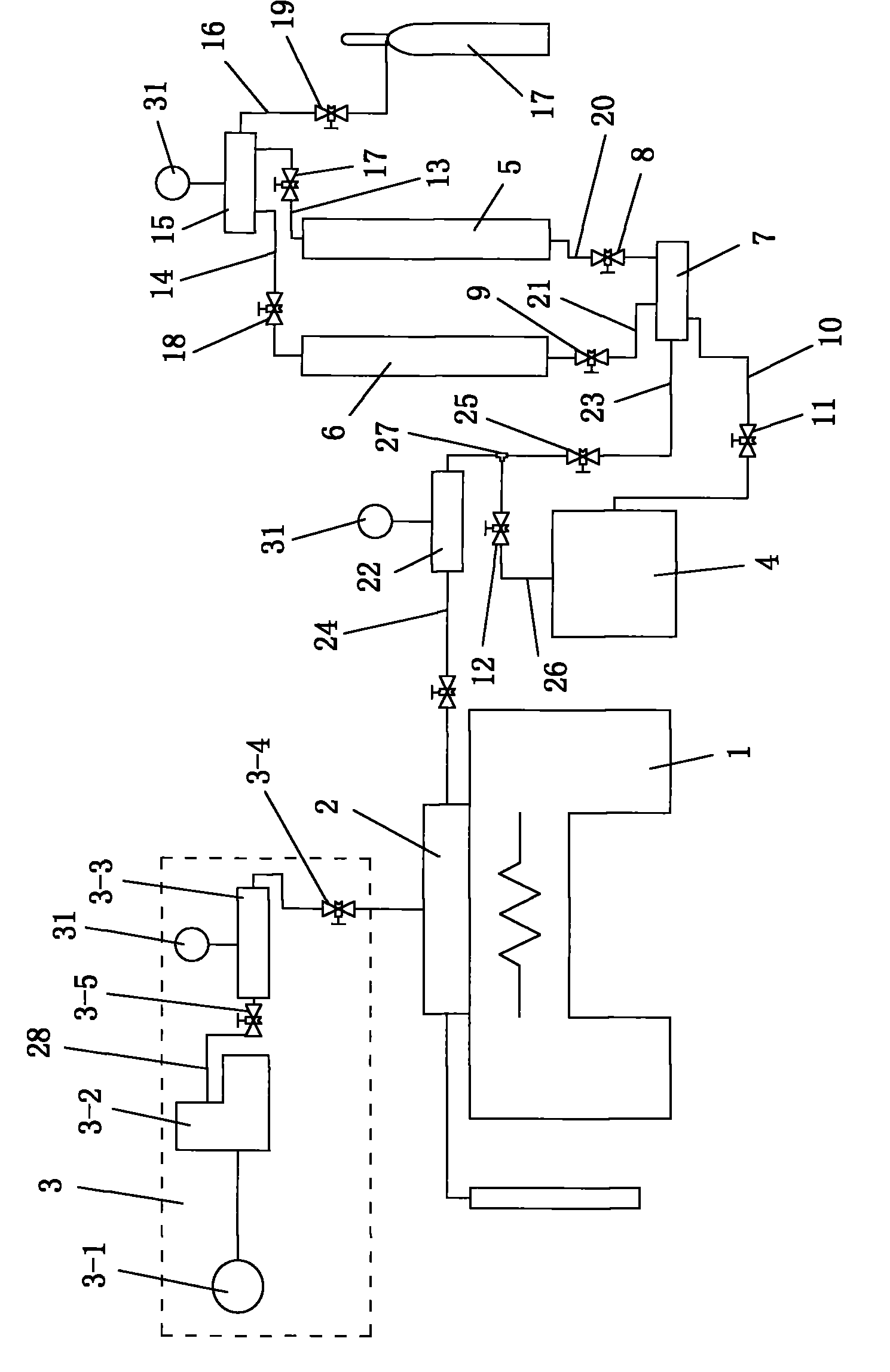

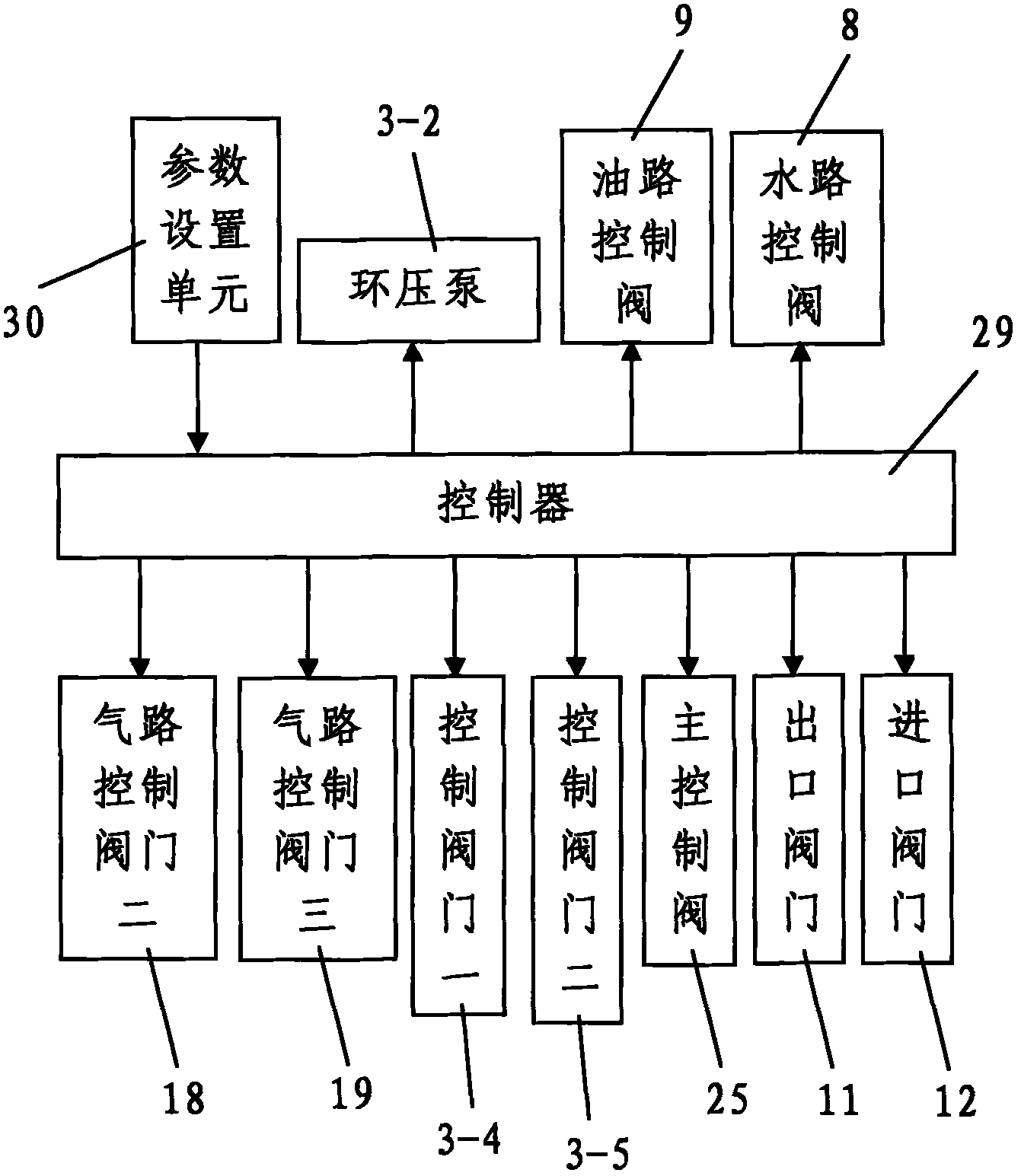

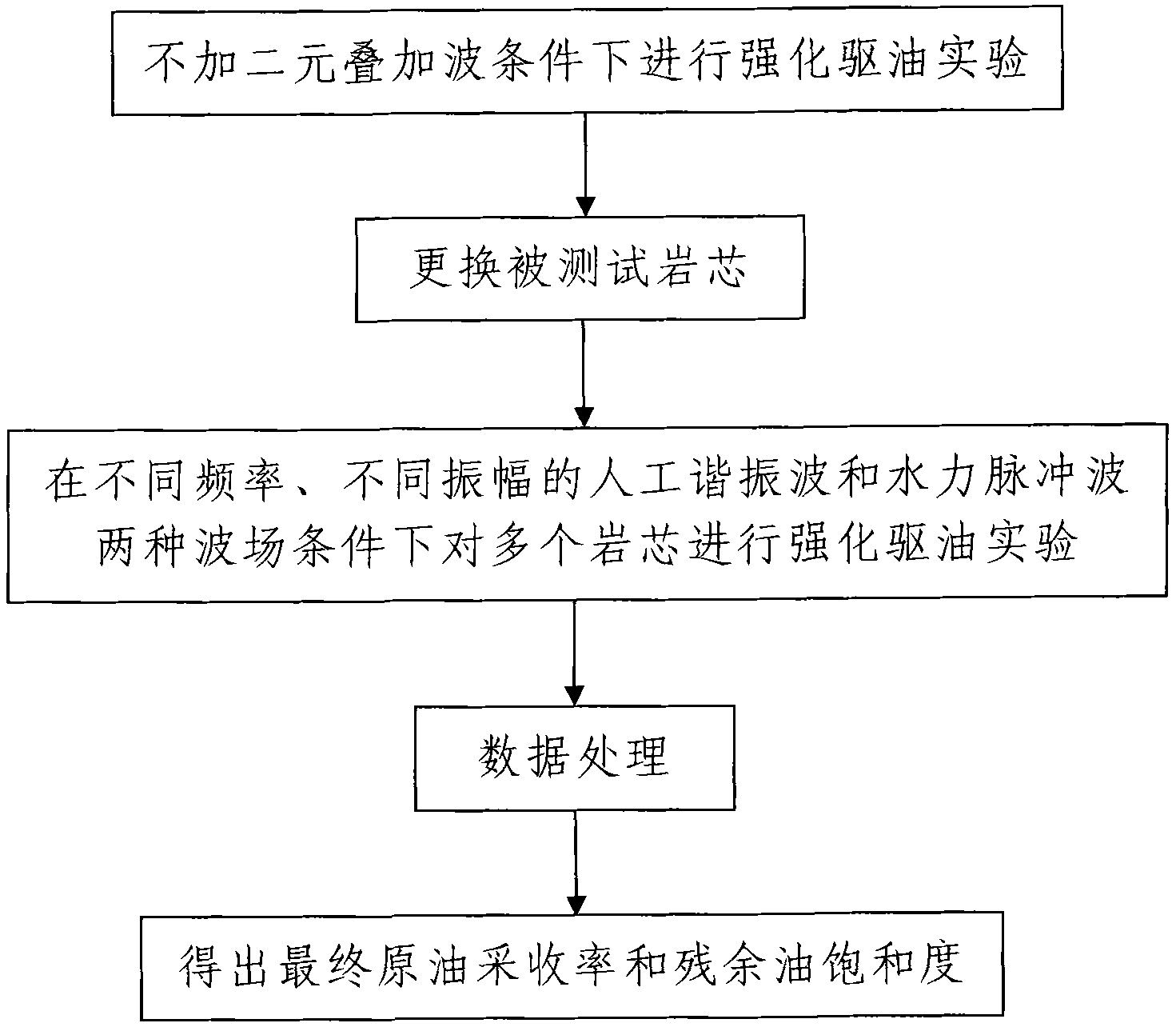

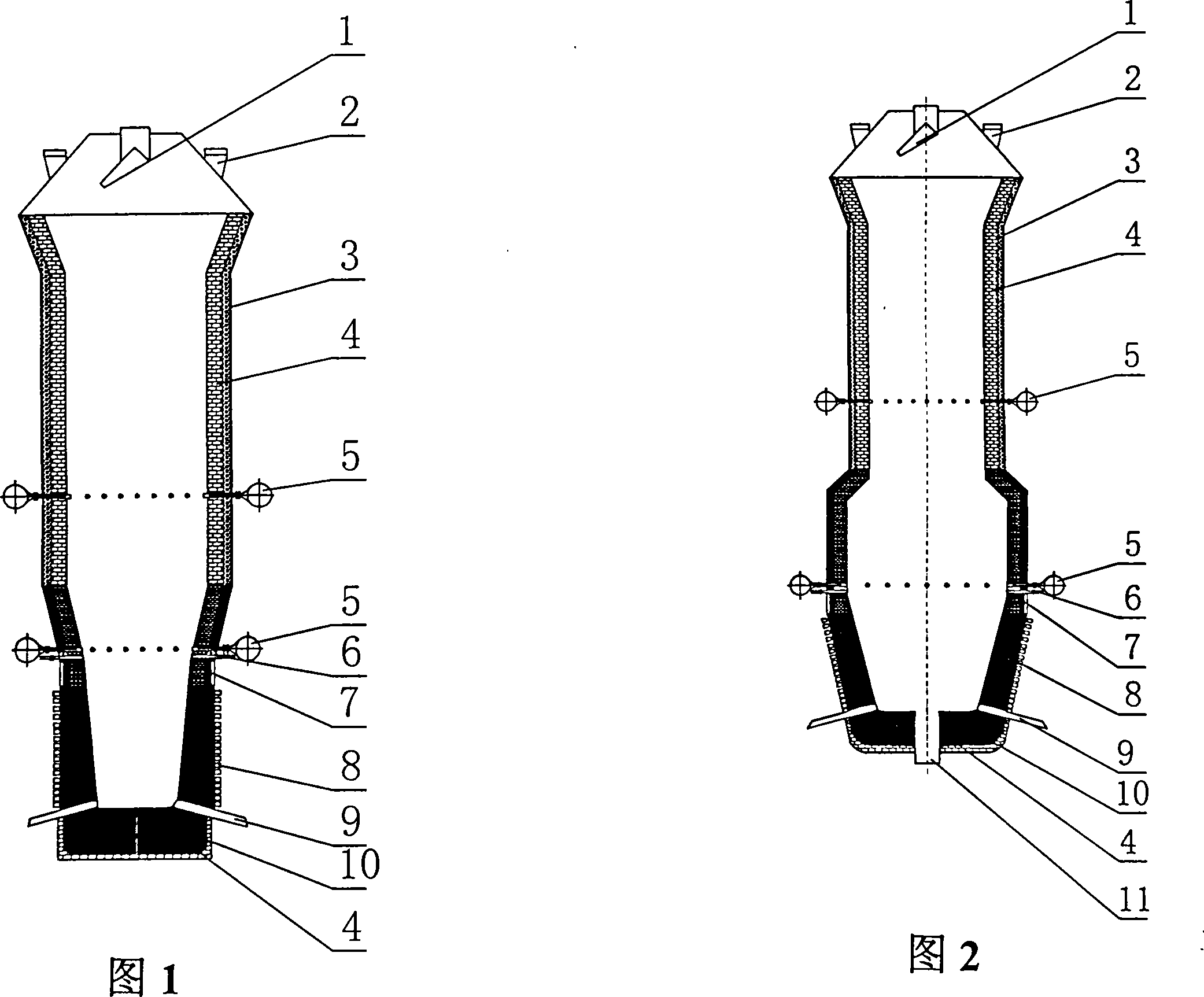

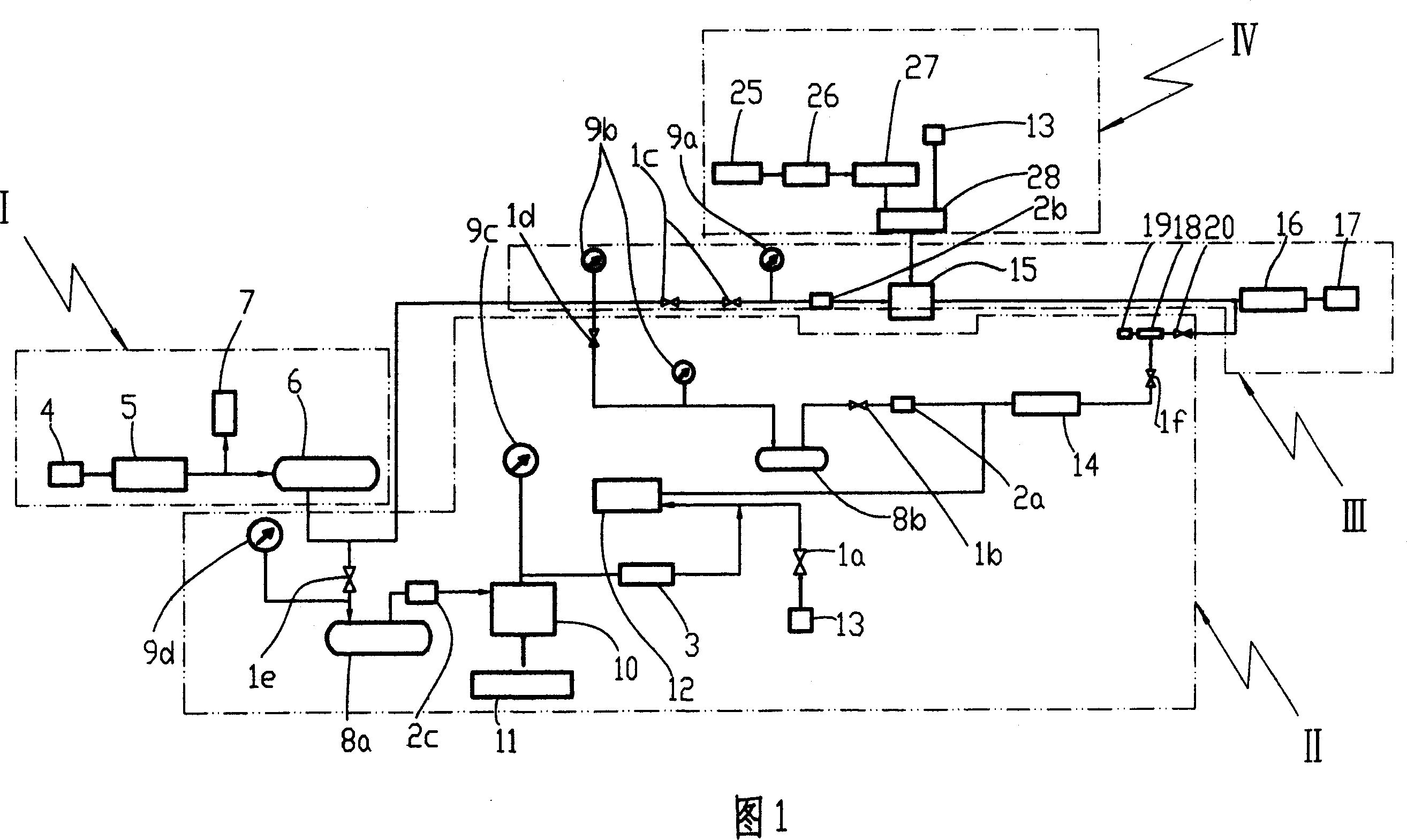

Dualistic superposed wave reinforced oil displacing experiment device and experiment method

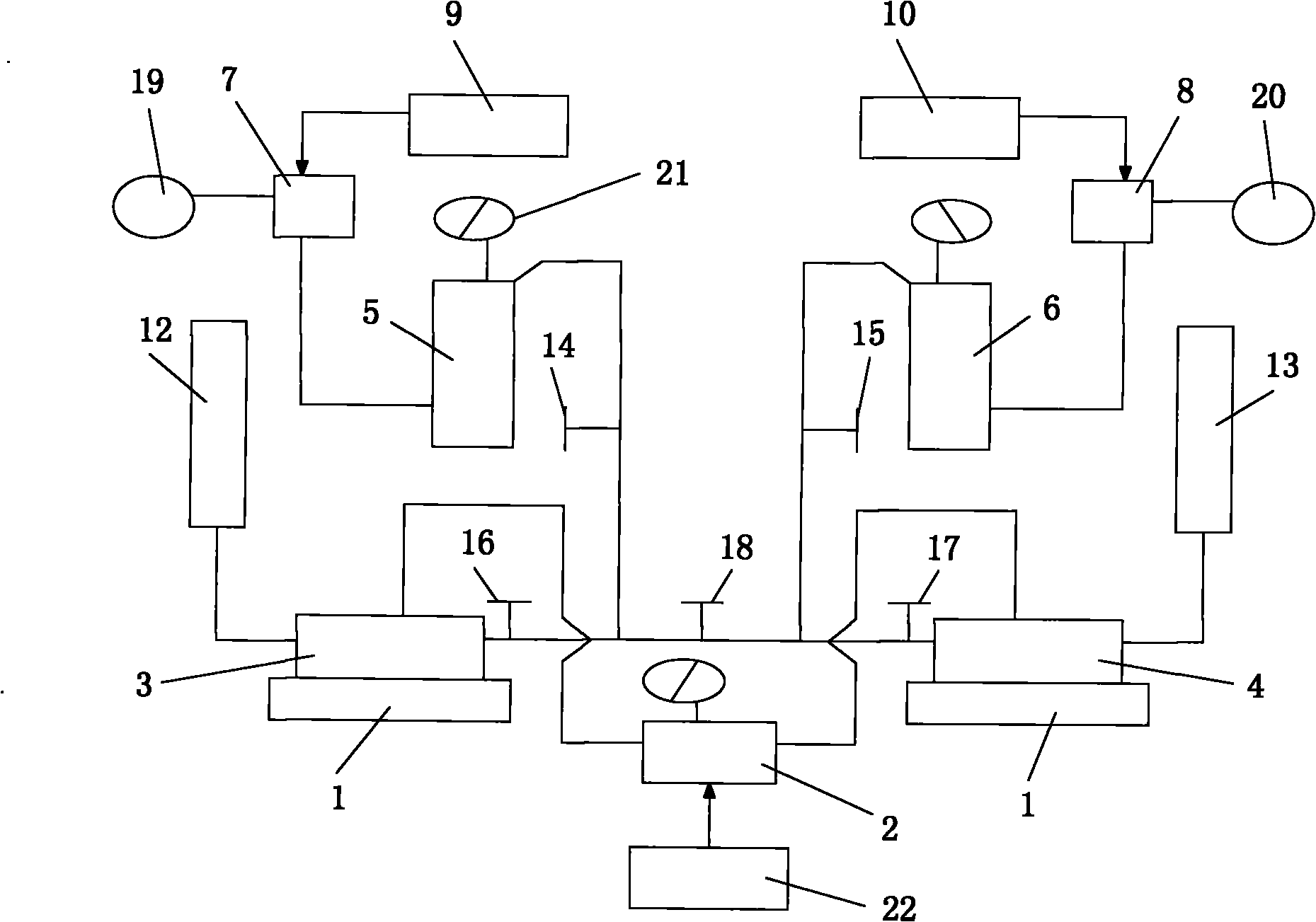

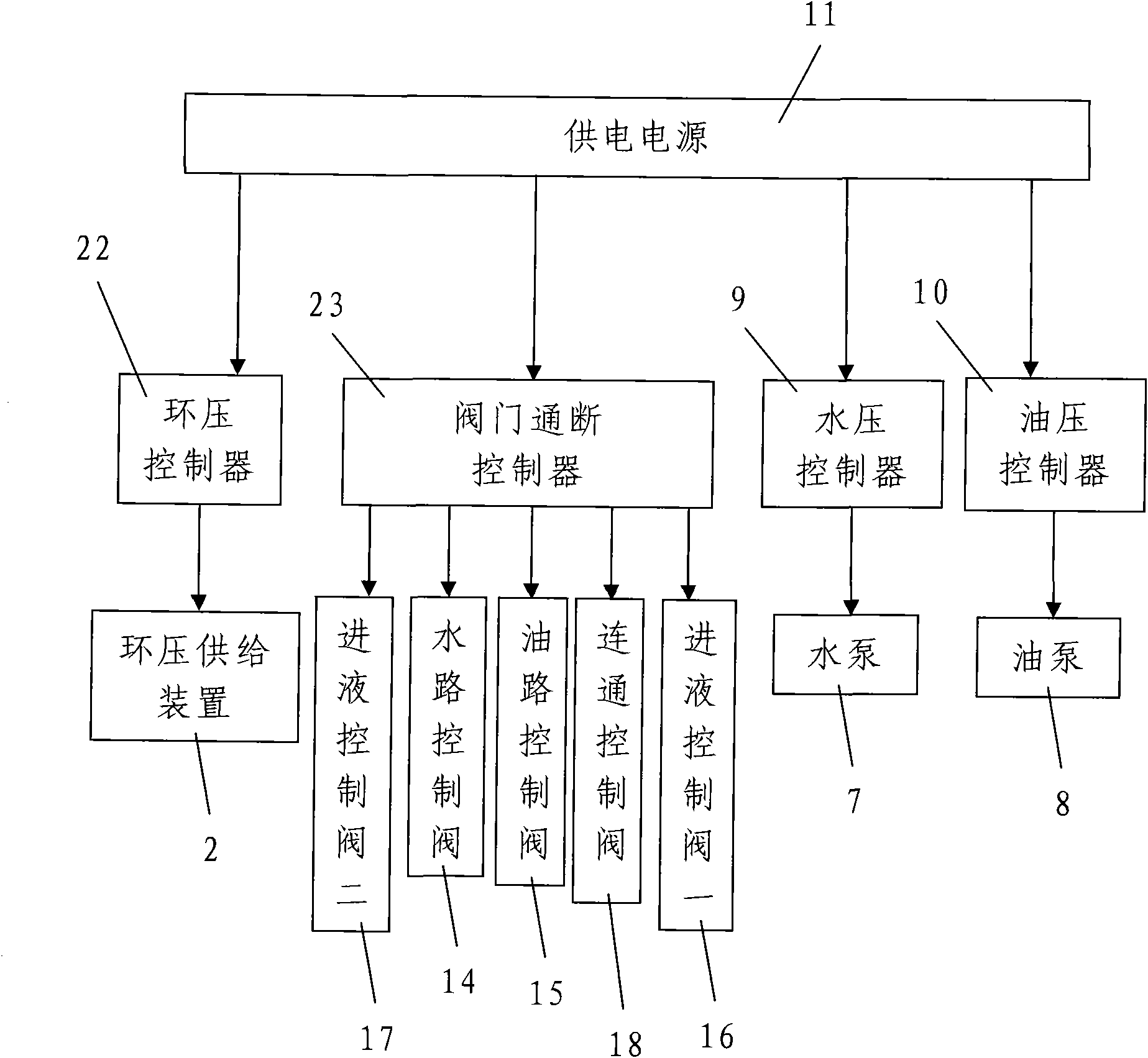

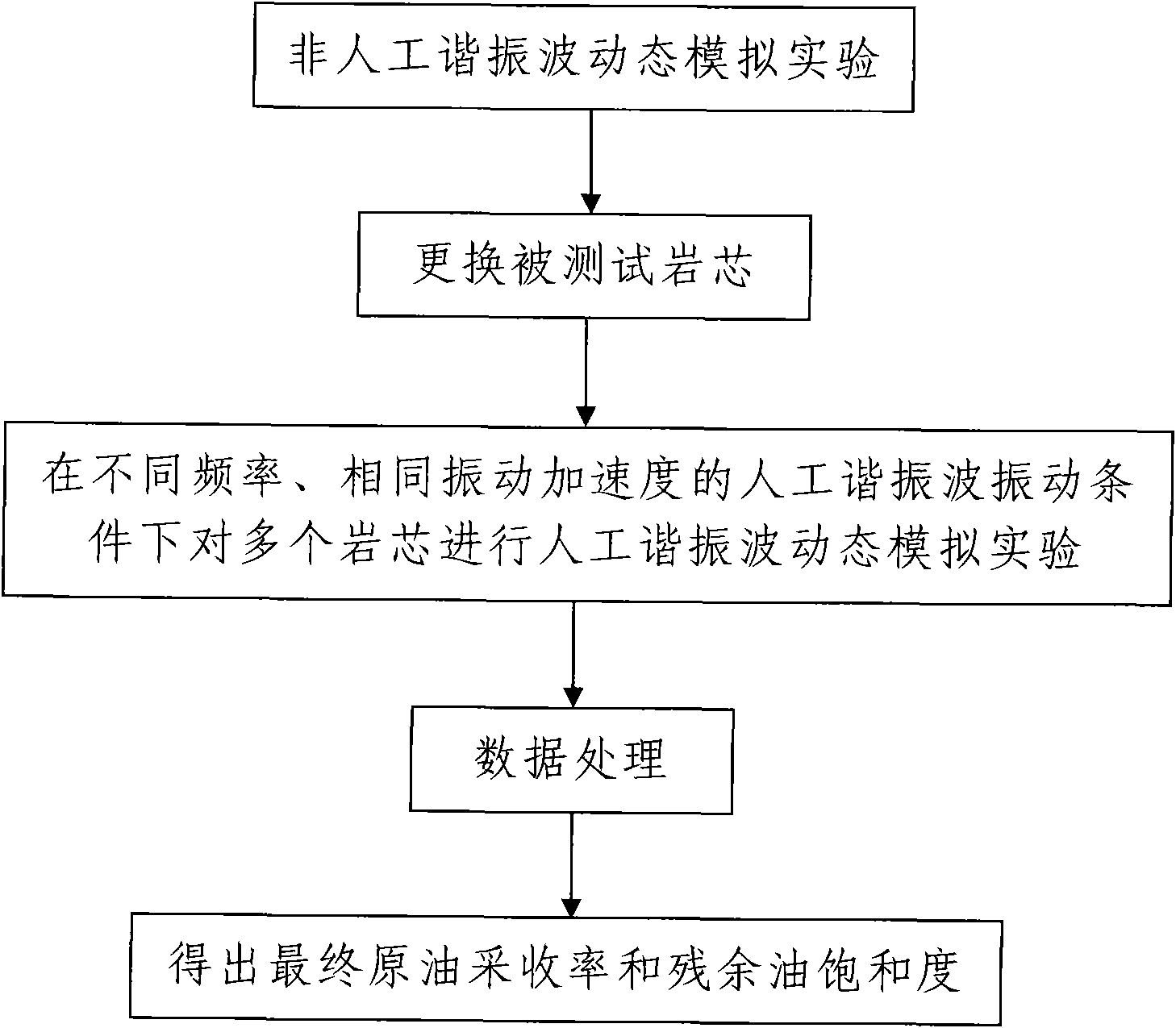

The invention discloses a dualistic superposed wave reinforced oil displacing experiment device and an experiment method. The dualistic superposed wave reinforced oil displacing experiment device comprises an artificial resonance wave test table, a rock core holder, a ring-pressure supplying device, a hydraulic impulse wave generator, a high-pressure water tank, a high-pressure oil tank and a liquid container, wherein the hydraulic impulse wave generator is arranged between a liquid outlet of the high-pressure water tank and the rock core holder, the high-pressure water tank and the high-pressure oil tank are connected with a liquid inlet of the rock core holder through a water pipeline and an oil pipeline, the liquid container is connected with the liquid outlet of the rock core holder, middle transition containers are respectively arranged on the water pipeline and the oil pipeline. The experiment method comprises the following steps of: firstly, under the condition of no dualistic superposed waves, carrying out a reinforced oil displacing experiment; secondly, replacing a rock core and carrying out the reinforced oil displacing experiment on a plurality of rock cores under two wave field conditions of artificial resonance waves and hydraulic impulse waves which have different frequencies and amplitudes; and thirdly, processing data. The method has the advantages of rationaldesign, convenient distribution, complete functions, simple and convenient operation and good simulation effect and can test the final recovery ratio and the residual oil saturation of different rockcores under the conditions of two wave fields.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

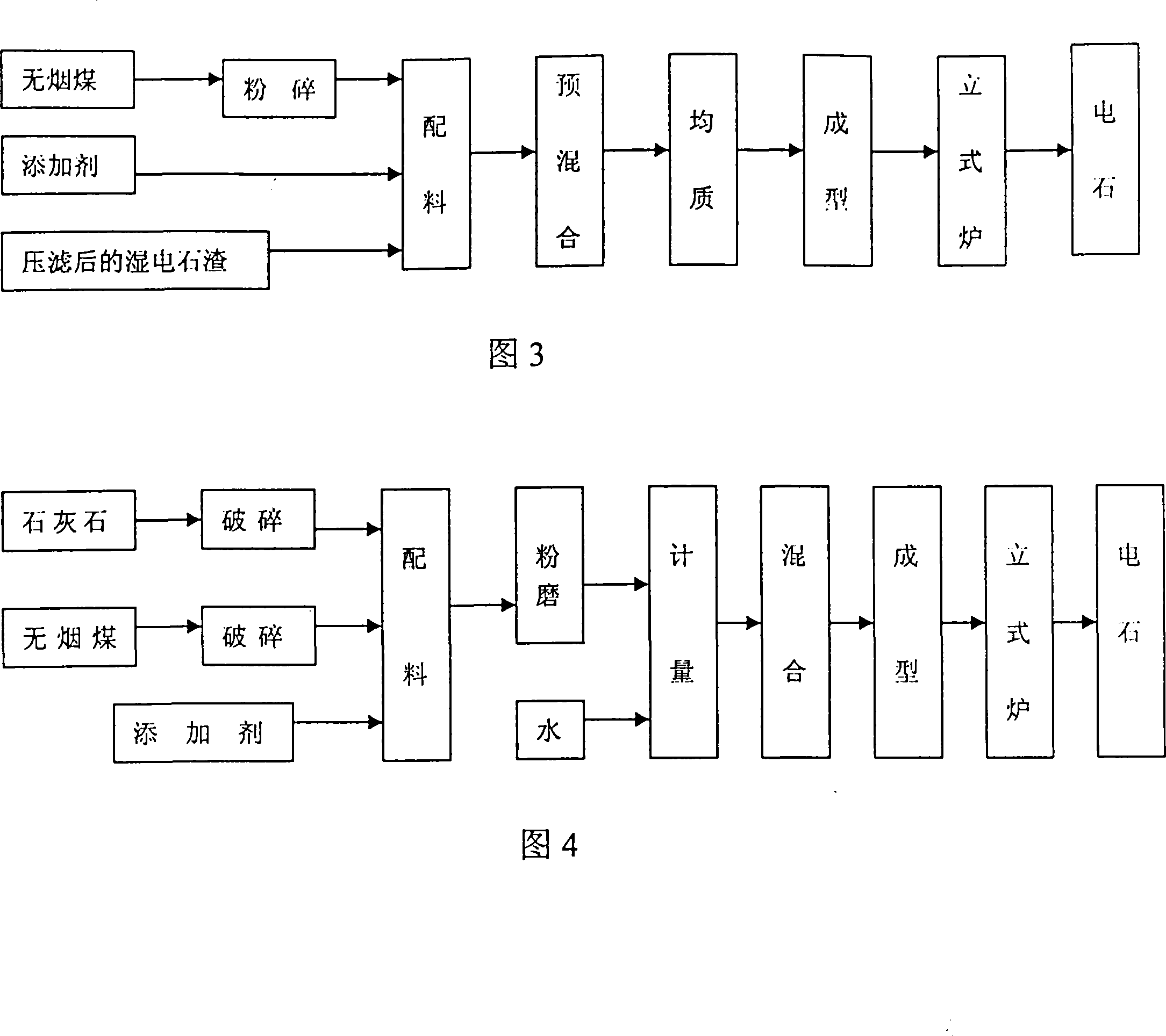

Novel multilevel heat source calcium carbide production technique and device

InactiveCN101172604AReduce energy consumptionReduce manufacturing costEnergy inputCalcium carbideHeat supplyEnergy consumption

A novel processing art and a device for producing calcium carbide with multi-level heat sources adopts an erect furnace with heat supply by oxidizing and burning at the middle-upper part and heat supply by an electric furnace at the lower part; wherein, materials are added from the upper part and pre-heated, decomposed, partially melted, performed the melting reaction, purified by the calcium carbide, discharged by calcium carbide liquid from up to down under the effect of the gravity. The upper part of the erect furnace can be supplied with pre-heating air or oxygen-rich air by a wind supplier to oxidize and burn to raise the temperature in the furnace up to over 1400 DGE C; and the lower part of the erect furnace is mainly supplied with heat sources by the electric furnace to raise the temperature up to between 1800 DGE C and 2400 DGE C. The invention can feed and unload the materials continuously, with high yield, low investment, low energy consumption, and high-tenor calcium carbide.

Owner:长沙紫宸科技开发有限公司

Sowing and fertilizer application machine with characteristic of convenient adjustment control

InactiveCN102742399AHeavy loadReasonable structural designFertiliser distributersSowingEngineeringMechanical engineering

The invention discloses a sowing and fertilizer application machine with a characteristic of convenient adjustment control. The machine comprises a fixation frame, a material loading box, a material discharging hopper, a sowing turntable, a handle control mechanism and a sowing rotation drive mechanism. The fixation frame is provided with a bottom frame, a material loading box fixation frame, a fixation beam and an adjustable pull rod. A side surface of the box body of the material loading box is provided with an observation window and a transparent plastic plate. Both sides of a material outlet of the box body are provided with a clamping groove, wherein movable baffles are arranged in the clamping groove, and movement of the baffle is driven by pull thread on the other end. The material discharging hopper and the sowing turntable are erected below the material outlet, wherein inclined blades are distributed on periphery of an upper end surface of the sowing turntable. A rotation shaft penetrates through the sowing turntable, wherein an upper end of the rotation shaft is fixed with the material discharging hopper. A side wall of a material discharging pipe on the lower end of the material discharging hopper is provided with a material casting port. The lower end of the rotation shaft is connected with the pull thread through a connection rod, wherein the pull thread is driven by the handle control mechanism. According to the present invention, the supporting weight of the fixation frame is large, on / off of the material outlet, the material discharging amount, and the material discharging direction can be adjusted at any moments during the use process, and the adjustment control is convenient.

Owner:罗丙伍

Artificially resonant wave strengthened oil displacement dynamic simulation experimental device and experimental method

ActiveCN101967967ASimple structureEasy to operateFluid removalVibration accelerationWater storage tank

The invention discloses an artificially resonant wave strengthened oil displacement dynamic simulation experimental device and an experimental method. The experimental device comprises an artificially resonant wave test bed, core grippers fixed on the artificially resonant wave test bed, thermotanks distributed outside the core grippers, an intermediate transitional water-delivery container, an intermediate transitional oil delivery container, a water storage tank, an oil storage tank, and liquid containers connected with liquid outlets of the core grippers. The experimental device comprises the following steps of: 1, performing an unartificially resonant wave dynamic simulation experiment; 2, replacing cores and performing an artificially resonant wave dynamic simulation experiment on the plurality of cores under the artificially resonant wave vibration conditions of different frequency and identical vibration acceleration; and 3, performing data processing. The device and the methodensure rational design, convenience of distribution, use and operation, perfect functions and good simulation effect; and the single-phase and two-phase seepage characteristics of the cores, the saturation of residual oil and the final oil recovery factor can be tested under the conditions of artificially resonance waves and different displacing mediums.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Producing process for alkali proof glass beads

InactiveCN1500753AHigh clarityQuality improvementGlass furnace apparatusGlass shaping apparatusGlass ballBrick

The present invention is production process of glass ball for producing alkali resisting glass fiber. The materials including quartzite, calcite, zirconite, rutile, fluorite, potassium nitrate, sodium carbonate and chamotte are crushed and mixed to form the mixed material; and the mixed material is smelted in natural gas burning smelting furnace with zircon corundum brick lining and further processed through cooling, clarification, ball making and annealing to produce alkali resisting glass ball with high zirconia content. The said production process has high product output, low production cost and high product quality and low power consumption, and is easy to control.

Owner:自贡市宏洋新型材料制品有限公司

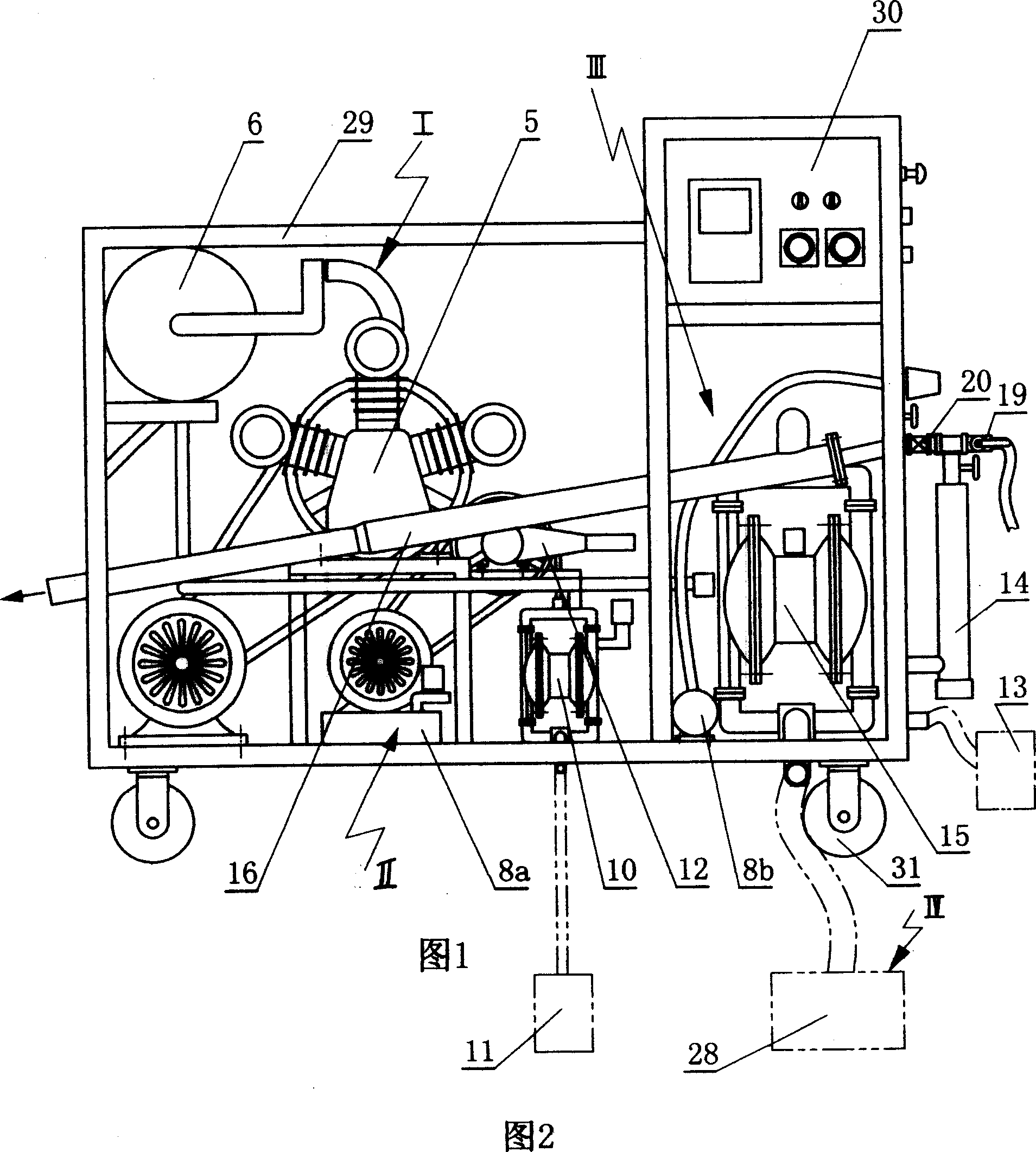

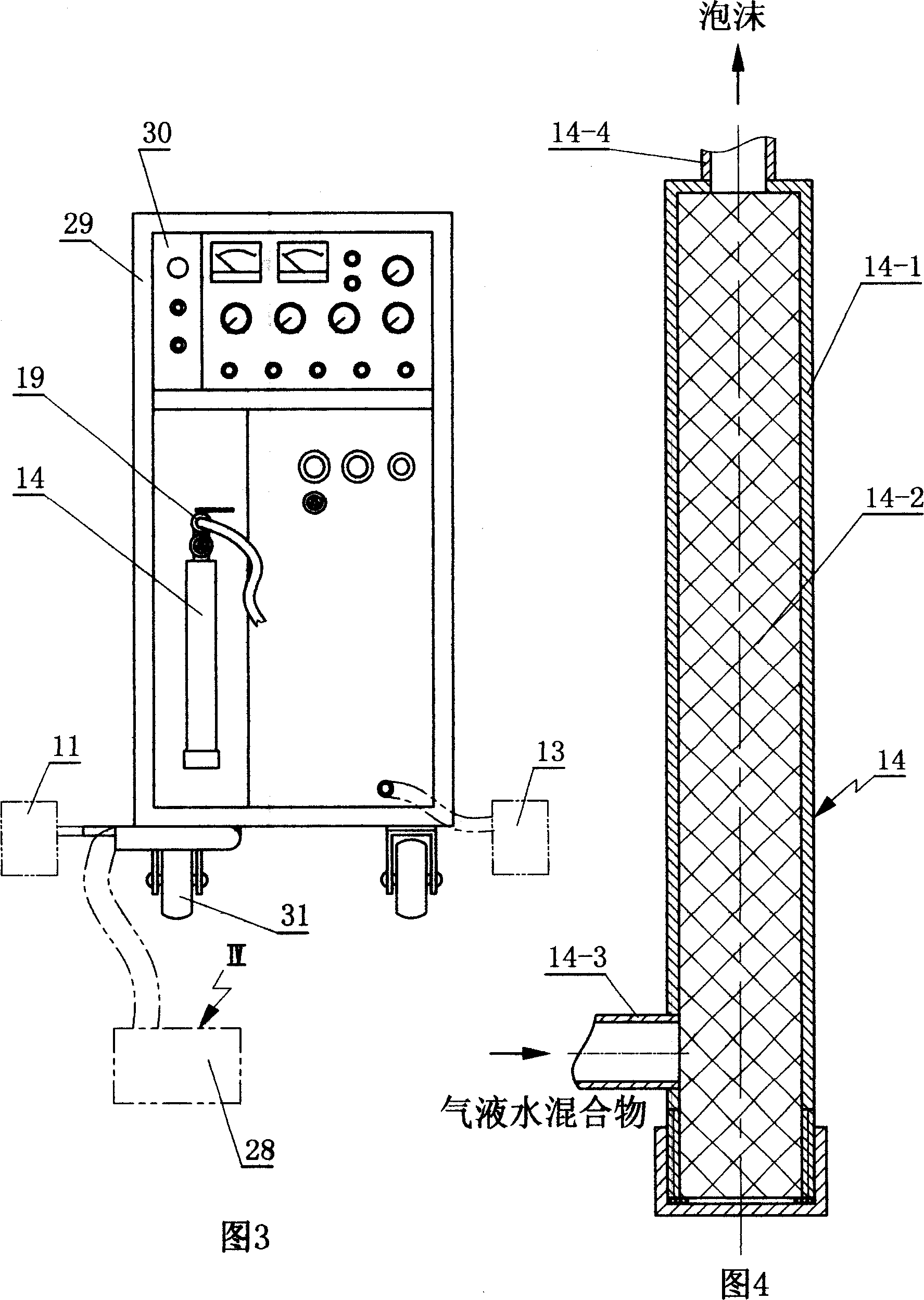

Preparation method of light foam concrete and its main machine

InactiveCN100999099ACompact structureEasy to moveDischarging apparatusMixing operation control apparatusFoam concreteRaw material

The present invention discloses a preparation method of light foamed concrete and its main machine. Said light foamed concrete is made up by using concrete, foaming agent and compressed air through a certain preparation method. Said preparation method includes metering and mixing regulation control technique by adopting combination of manual regulation valve and adjustable electronic regulation valve and pneumatic diaphragm pump slurry conveying technique. Its main machine includes compressed air supply device, foam preparation device and slurry and foam mixing device, etc.

Owner:JIANGSU CONSTR ENG GRP CO LTD +2

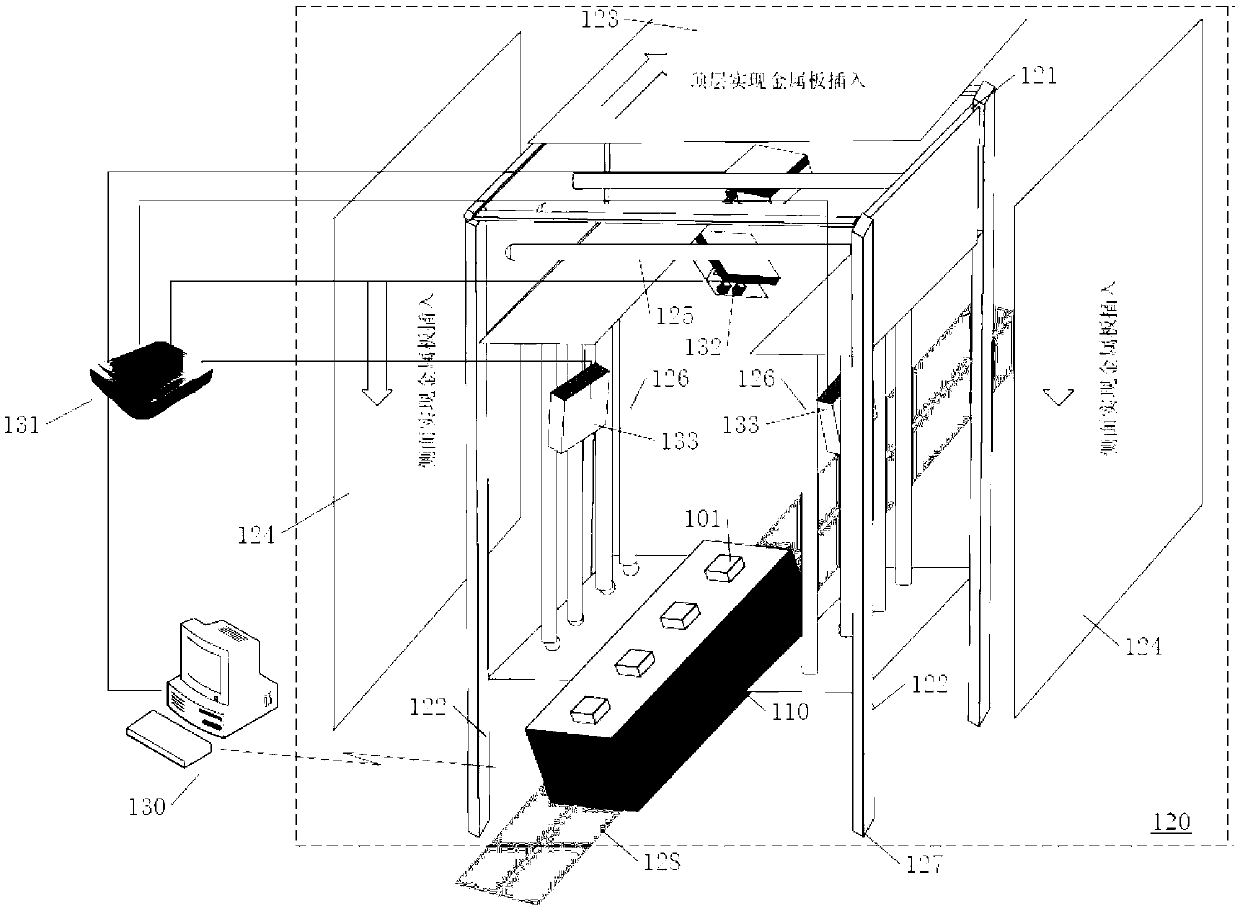

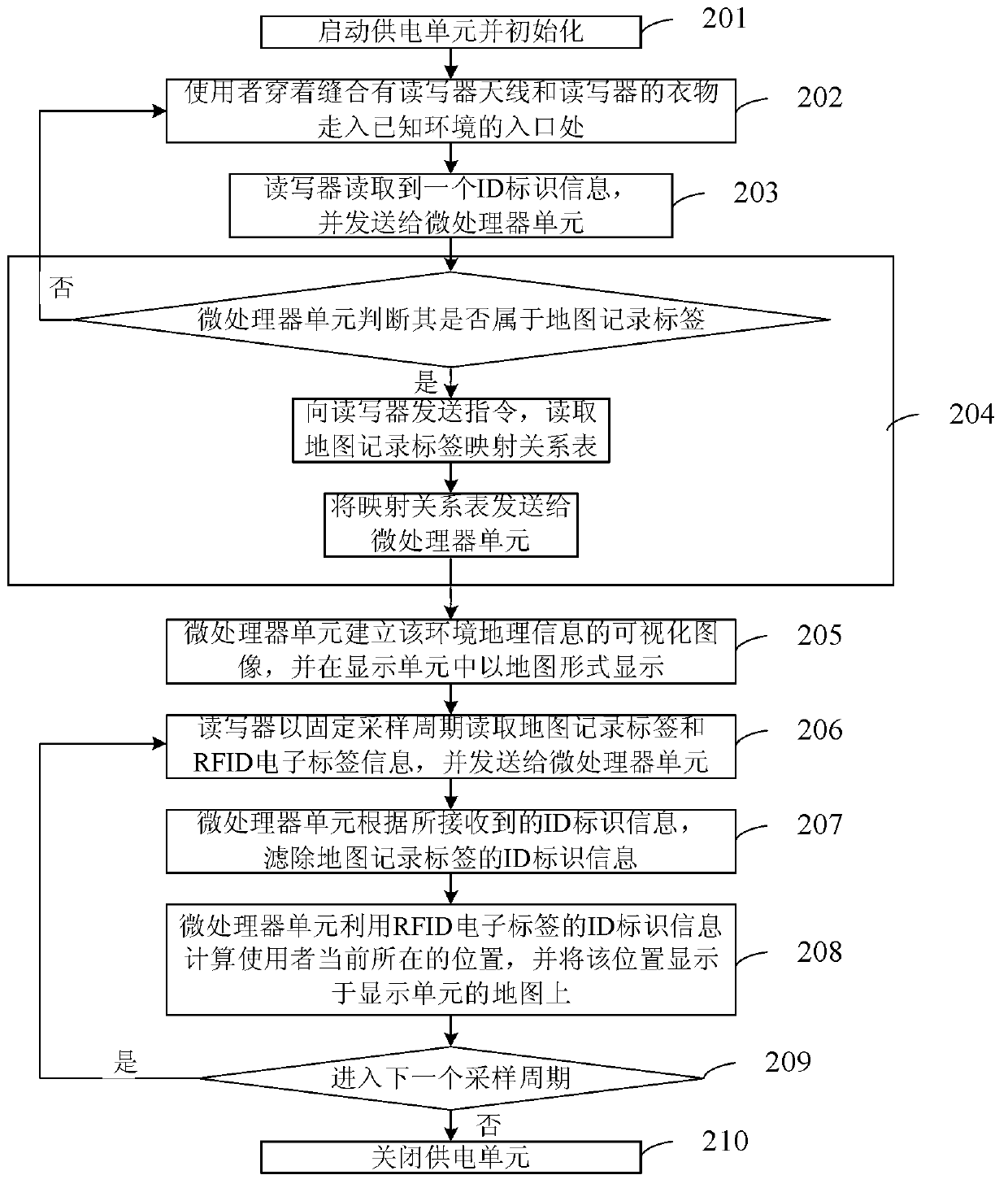

System and method for detecting performance of mobile electronic tags

InactiveCN103279774AMeet the requirements of personalized customizationImprove mobilityTicket-issuing apparatusTesting sensing arrangementsPersonalizationSoftware engineering

The invention discloses a system and method for detecting the performance of mobile electronic tags. The system comprises a testing device, radio-frequency identification electronic tags to be tested and testing equipment, wherein the radio-frequency identification electronic tags to be tested pass through a testing passage; the testing device consists of a mobile trolley and the testing passage; the radio-frequency identification electronic tags to be tested are stuck to objects; and the testing equipment comprises a computer, a read-write device and a read-write device antenna device. The objects with the electronic tags to be tested can pass through the testing passage through the mobile trolley, and a read-write device antenna is mounted in the testing passage; and the positions / states of the read-write device and the antenna and the speed of the mobile trolley are adjusted, and the read-write device reads the electronic tags on the objects through the antenna, so that the optimal electronic tag reading rate can be obtained through repeated testing. Through the system and the method, disclosed by the invention, the position / direction of the antenna and the moving speed of the objects are subjected to individualized customization on the premise that the electronic tags on fixed sticking positions of the objects are subjected to 100% reading, so that a reference is provided for the use of the electronic tags in manufacturing production lines and logistics.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

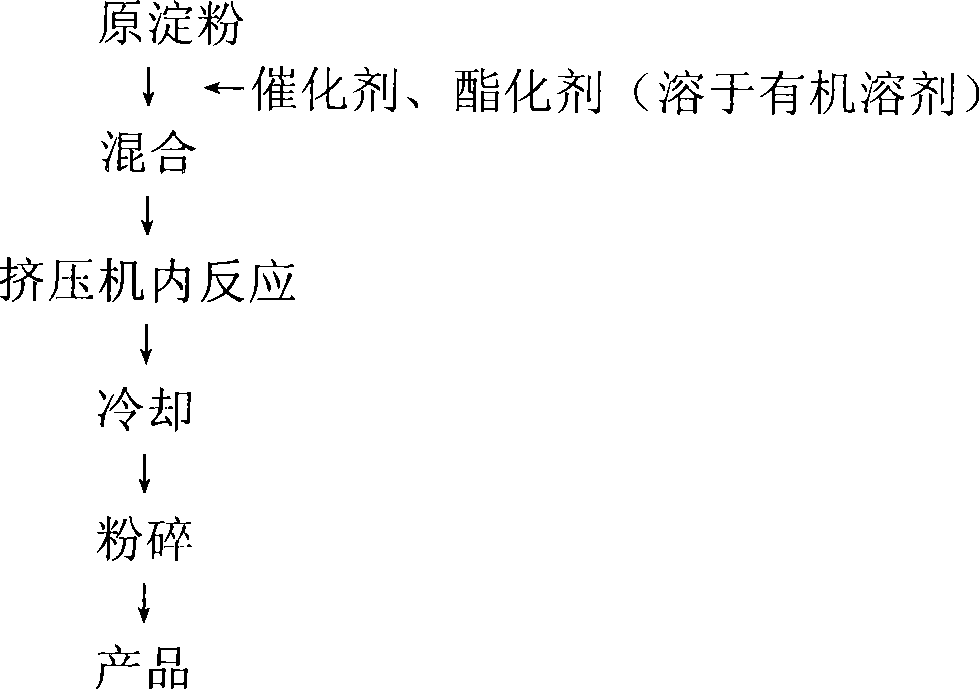

Method for preparing fatty acid starch ester and application

InactiveCN101456916AIncrease choiceImprove freeze-thaw stabilityFood preparationCarbon chainHigh pressure

The invention relates to a preparation method for a fatty acid starch ester and application thereof, which belongs to the technical field of modified starch. According to the invention, starch is adopted as a raw material and fatty acid is taken as an esterification agent; and on the condition of taking an extruder as a chemical reactor, the acidolysis and esterification modification of the starch is carried out to prepare the fatty acid starch ester product with the low substitution degree. The fatty acid which is subjected to the high temperature high pressure high shearing action treatment of the extruder has an esterification reaction with crude starch according to a certain proportion; and due to the introduction of the hydrophobic organic carbon chain, the starch has the lipophilicity and hydrophilicity, and consequently has certain emulsibility. The product can be used as a stabilizer, an emulsifier, a gelling agent, a fat substitute, a microcapsule wall material, and the like in the food industry, and can be applied to the foods such as artificial butter, salad seasoning matter, bakery products, diary products, and the like. The invention has the advantages that the extruder is adopted to prepare the esterified starch; the reaction process is continuous and has simple operation, easy implementation and little environmental pollution; and the obtained product has excellent performance.

Owner:JIANGNAN UNIV

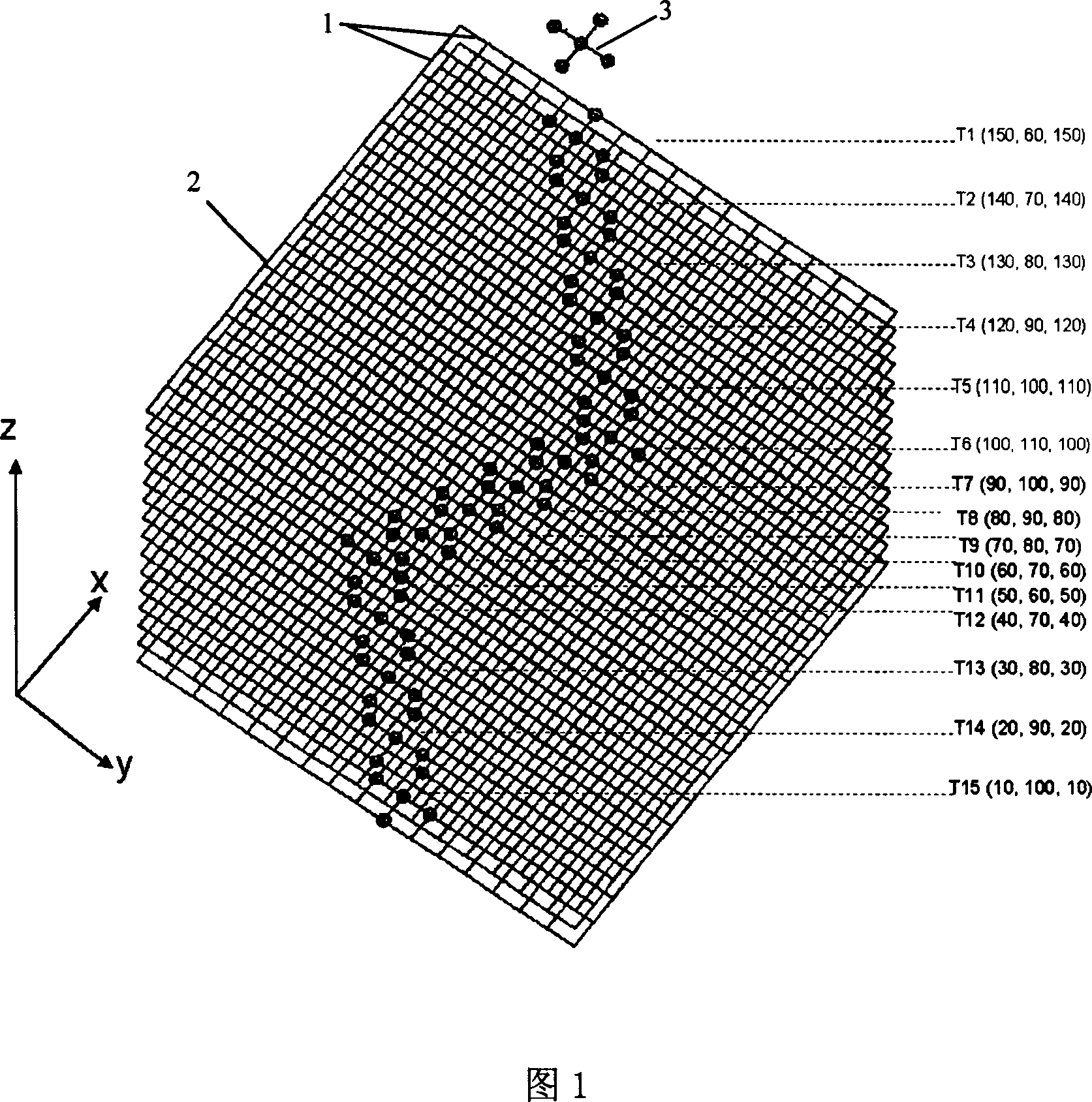

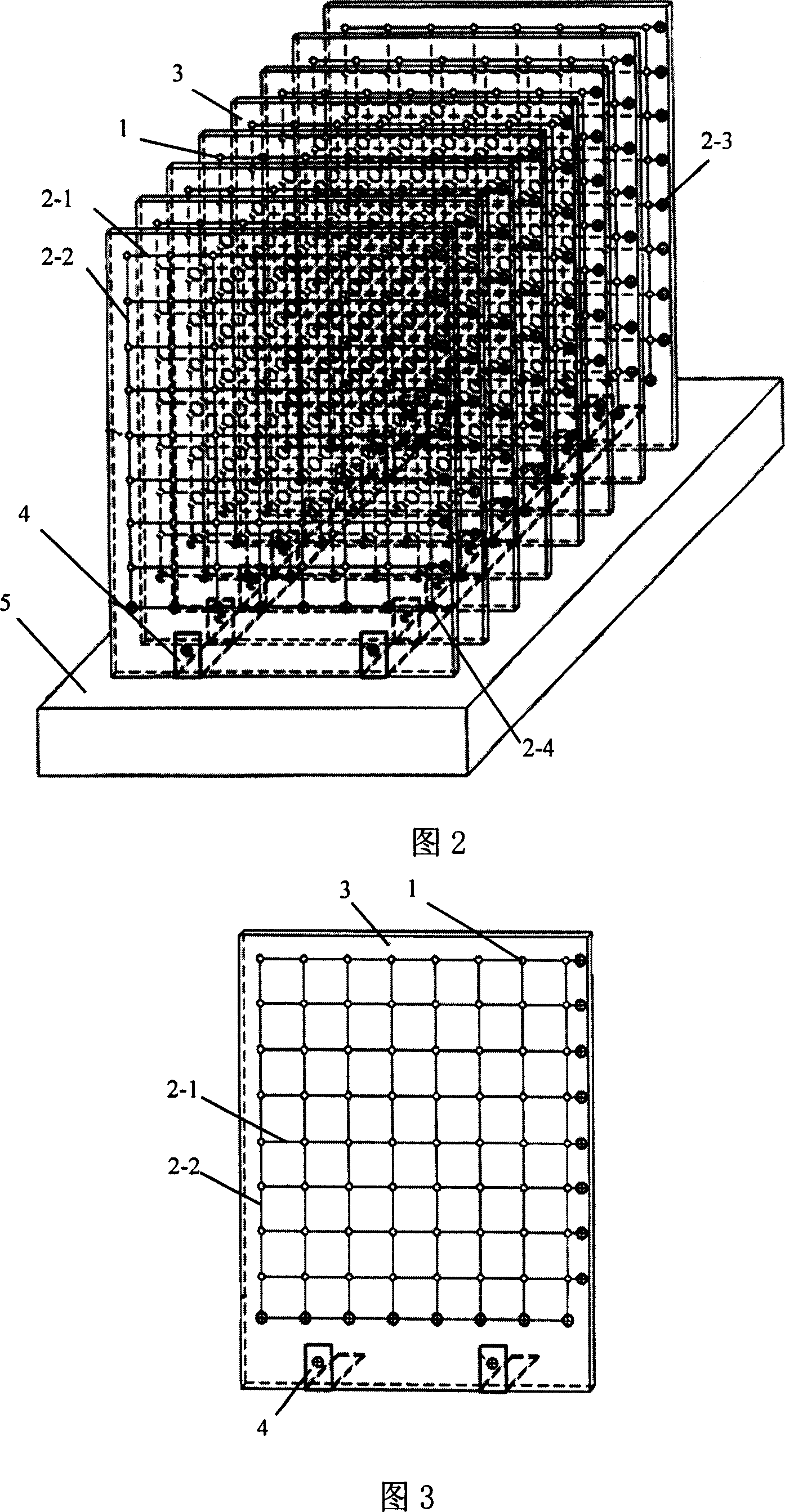

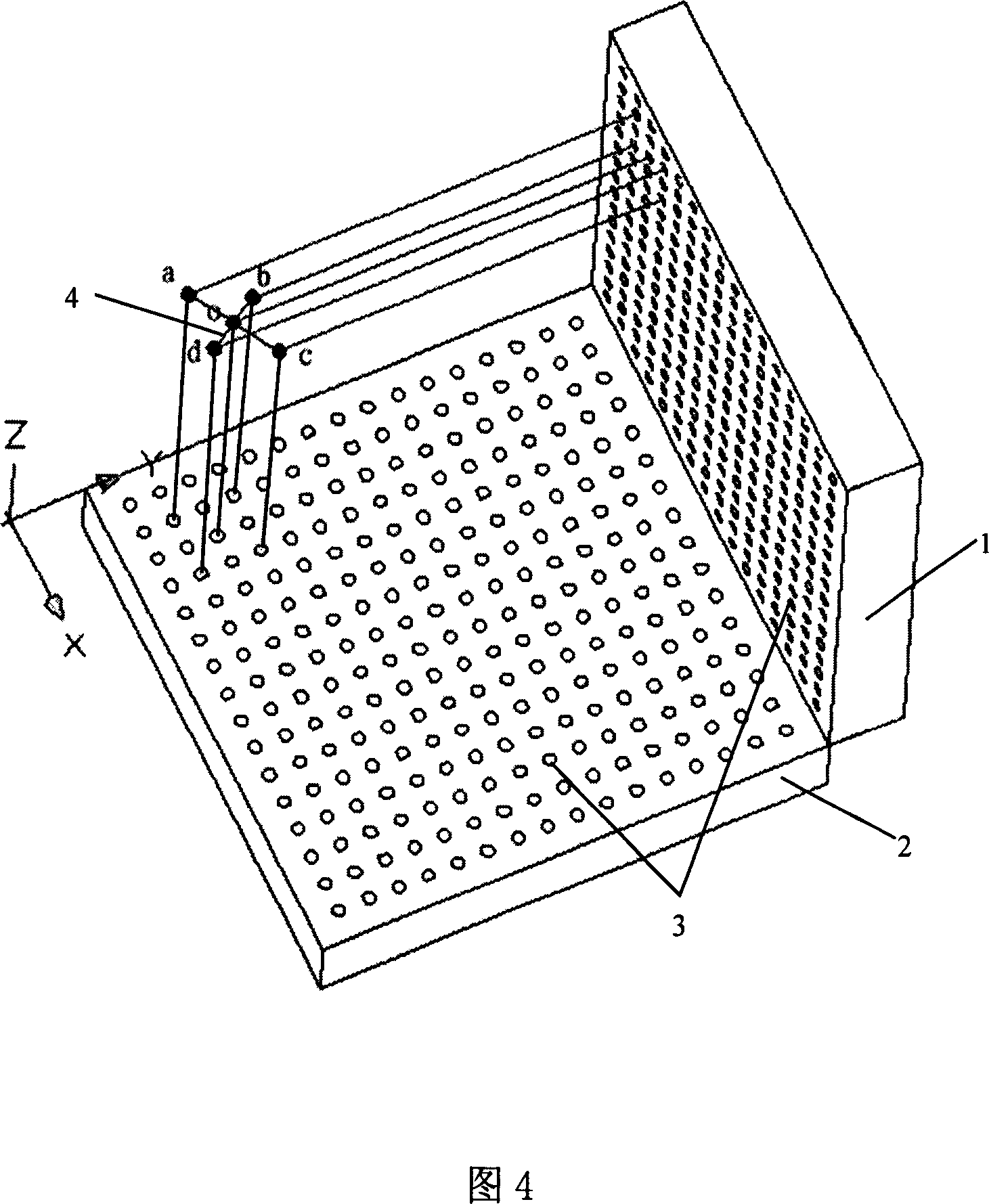

Three-dimensional visual display method and device

InactiveCN101013202AThe display effect is intuitiveThe display is accurate3D modellingOptical elementsData processing systemAnimation

The invention provides a 3D visual display method, with the steps: data processing system uses the 3D object scanning equipment or artificial design, to obtain 3D data; through the calculation, the data processing system produces the node 3D coordinates value of 3D data corresponding to the space lattice (X, Y, Z) of 3D visual display device, in which X>=8, Y>=8, Z>=8; according to the 3D coordinates value, the data processing system outputs signal to 3D visual display device, making the node corresponding to the space lattice (X, Y, Z) to be luminous in the 3D visual display device, so to achieve the 3D visual display. The node luminous method includes LED conductive luminescence, sports particle collisions luminescence. The invention can display 3D composition and animation under no picture or video circumstances, making people viewing 3D results within 360-degree, with good display effect, and accurate, and it can easily control and adjust through data processing system (such as computers, etc.), and have wide application.

Owner:李溢雯

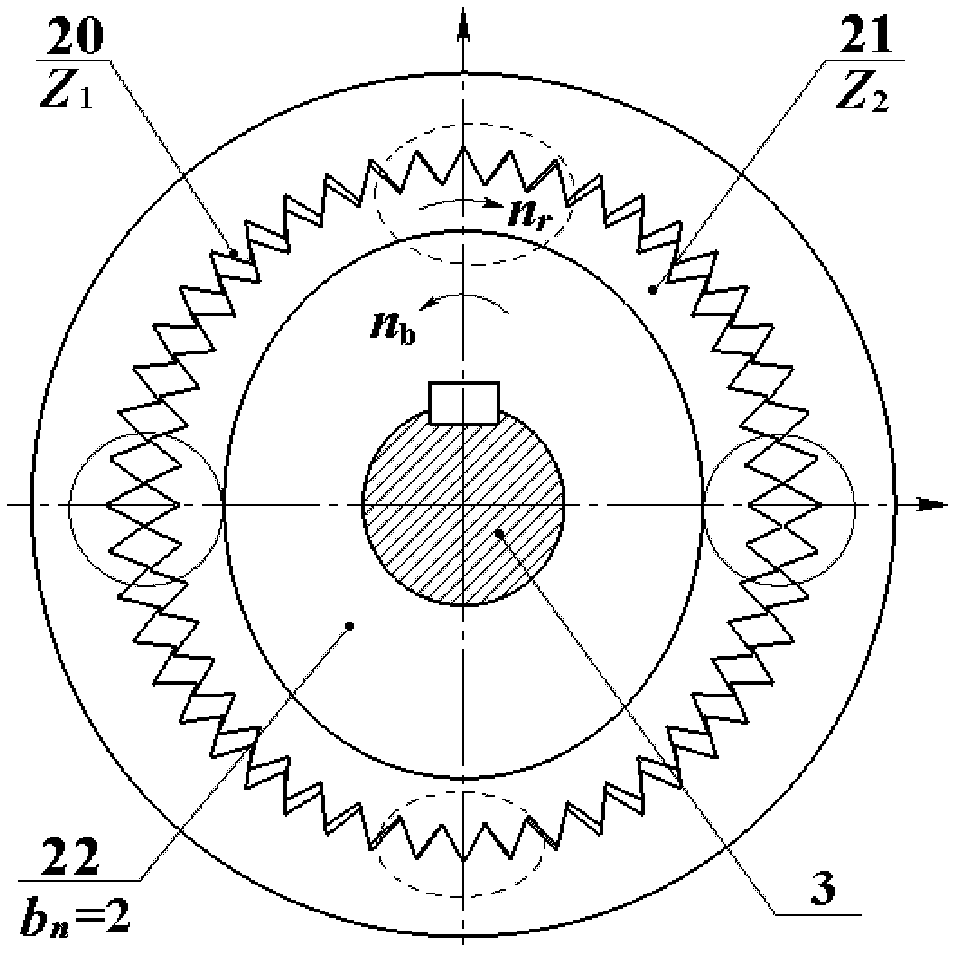

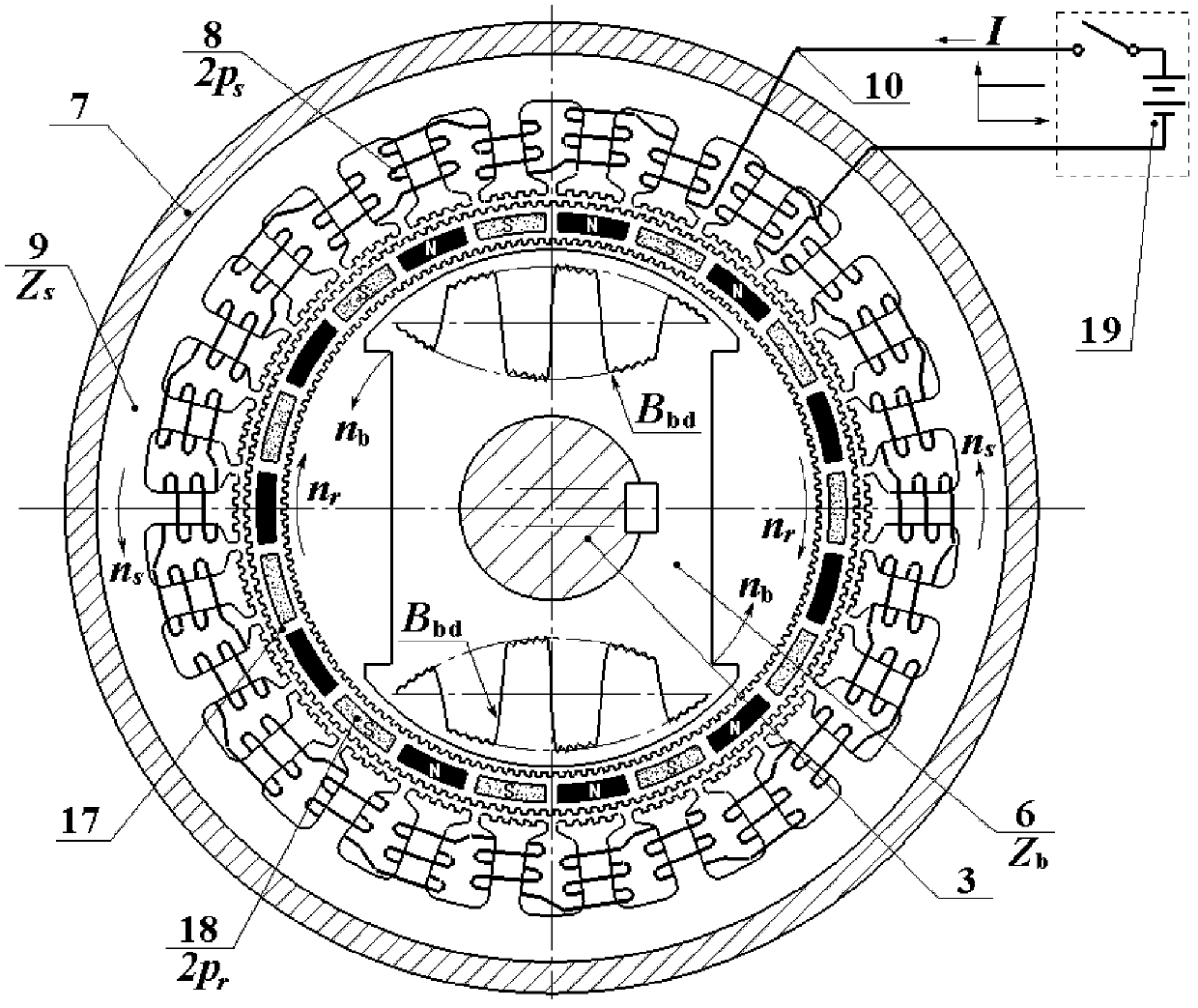

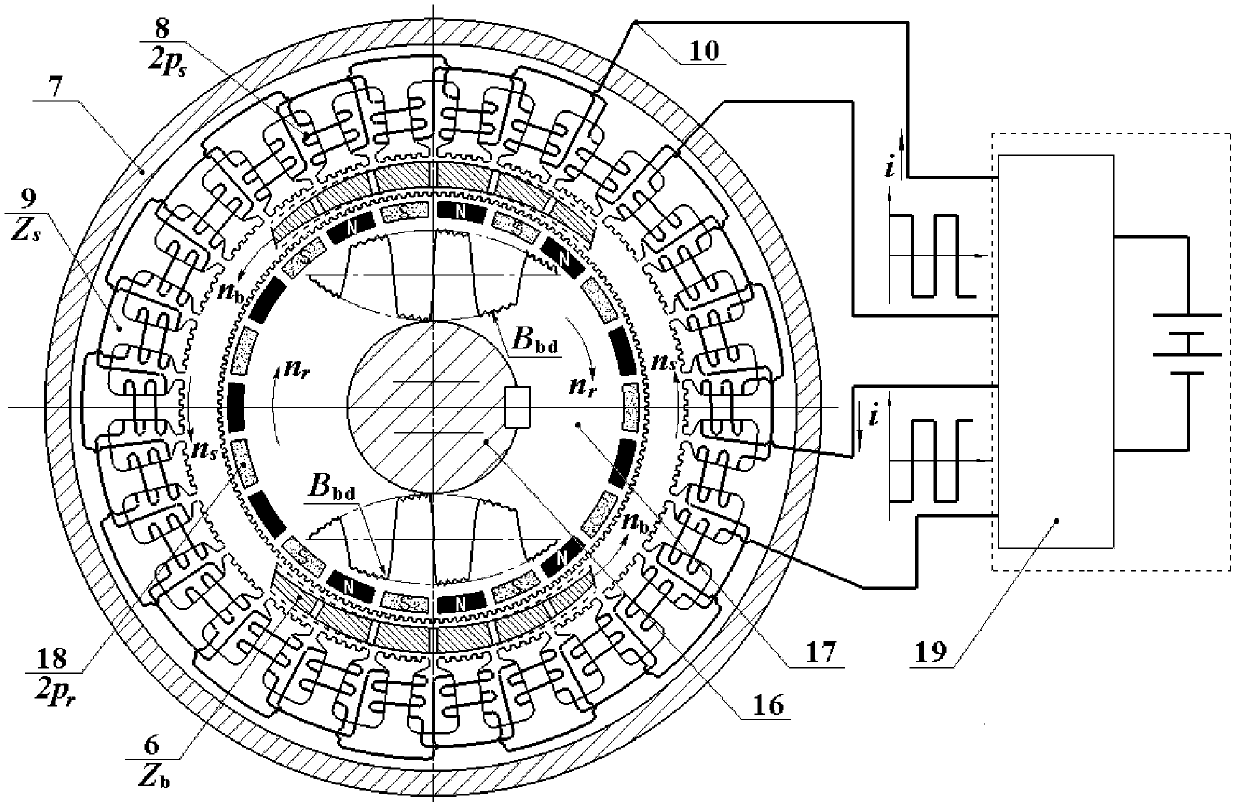

Dual mechanical port magnetic conductance harmonic type electromagnetic gear composite permanent magnet motor

InactiveCN103378711AEliminate contact frictionImprove transmission efficiencyDynamo-electric brakes/clutchesDynamo-electric gearsPermanent magnet rotorLow speed

Provided is a dual mechanical port magnetic conductance harmonic type electromagnetic gear composite permanent magnet motor which can be widely applied to industrial transmission fields such as wind power generation, electric automobiles, ship driving and server driving. The electromagnetic gear composite permanent magnet motor is characterized is that main transmission components of the electromagnetic gear composite permanent magnet motor consists of a stator formed of a stator iron core (9) and a stator winding (8) having 2ps poles, a permanent rotor formed of a rotor iron core (17) equipped with 2pr rotor permanent magnets (18) and an output shaft (16), and a salient pole magnetic conductance wave rotor (6) having Zb salient poles, wherein a numerical difference between the number of pole-pairs ps and pr is relatively small; and the stator, the permanent magnet rotor and the salient pole magnetic conductance wave rotor (6) are coaxially disposed, are mutually coupled through a radial air-gap magnetic field, and are mutually coupled in a salient pole straight axis area of the high-speed rotating salient pole magnetic conductance wave rotor (6) by using a principle of heteropolarity magnetic field attraction with a small pole difference so as to drive the permanent magnet rotor with a small pole difference to rotate at a low speed. Therefore, power speed changed and torque conversion controlled drive with no mechanical contact and no friction is realized.

Owner:余虹锦

Proportional layering fertilizer applying device

InactiveCN102783299AIncrease profitPromote growthFertiliser distributersAgriculture gas emission reductionAgricultural engineeringBarrel Shaped

The invention discloses a proportional layering fertilizer applying device, belonging to agricultural machinery. The proportional layering fertilizer applying device is formed by connecting an outer channel wheel type fertilizer feeder, a fertilizer amount regulating, controlling and distributing assembly and a layering fertilizer applying device, wherein the outer channel wheel type fertilizer feeder comprises a shell, a spiral linear outer channel wheel and a fertilizer amount regulating and controlling sleeve; the spiral linear outer channel wheel is installed in the shell; through the connection and fit of an internal screw thread on the fertilizer amount regulating and controlling sleeve and an external screw thread on the spiral linear outer channel wheel, the fertilizer amount regulating and controlling sleeve is axially and movably arranged on a side part of the spiral linear outer channel wheel, and a cylindrical barrel-shaped outer wall of the fertilizer amount regulating and controlling sleeve entirely covers the spiral linear outer channel wheel; and the layering fertilizer applying device is formed by assembling a fertilizer delivering pipe, a separating plate, a pipe base, an elastic fastener assembly, a rear fertilizer applying tail pipe, a front fertilizer applying pipe and a furrow opener. The proportional layering fertilizer applying device disclosed by the invention achieves the purpose of proportionally applying seed fertilizer and additional fertilizer at one time in a layering way, and has the characteristics of simple and reasonable structure, good working quality, high efficiency, low cost, convenience in regulation and control, high utilization efficiency of fertilizer, and the like.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

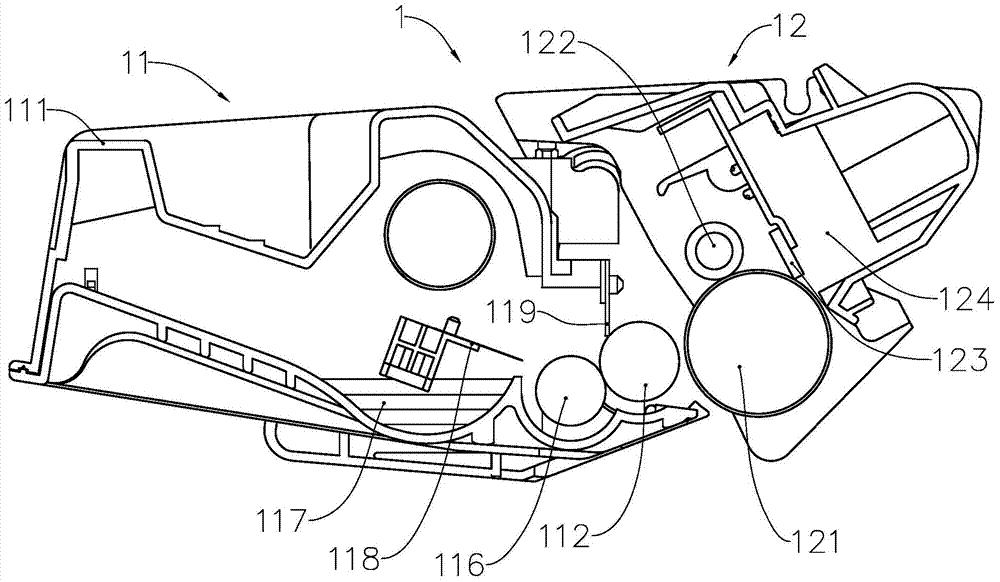

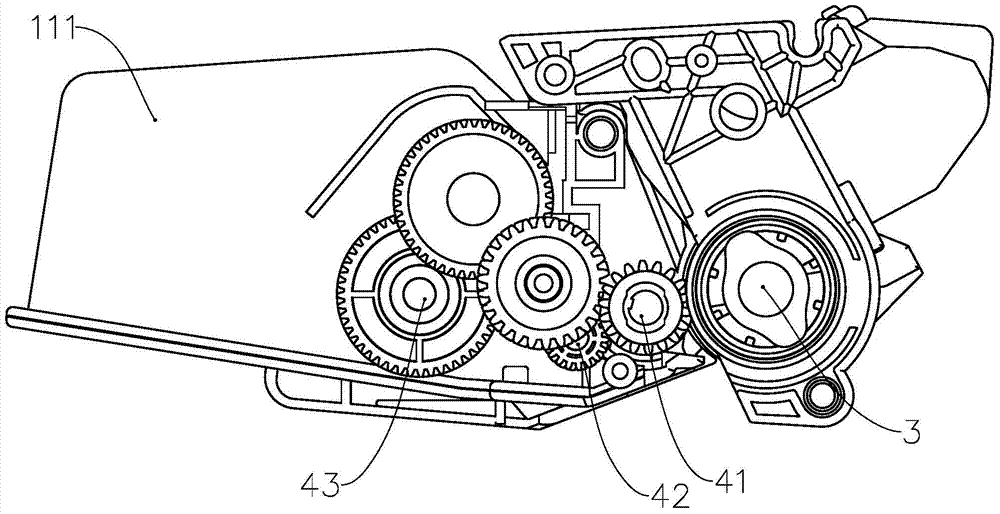

Processing box

ActiveCN103885313AEasy to disassembleEasy to installElectrography/magnetographyEngineeringMechanical engineering

The invention provides a processing box. The processing box comprises a shell, a cavity for containing consumables is defined by the shell, a roller is rotationally arranged in the cavity and comprises a roller body and a driving assembly on one end of the roller body, the driving assembly comprises a gear seat and a driving force receiving part, the gear seat is provided with a containing cavity which is concave inwards axially and comprises a driven part on the inner wall of the containing cavity, the outer wall of the gear seat is provided with a first gear part, the driving force receiving part comprises a driving part in the containing cavity, a driving force receiving part outside the containing cavity and a connecting part connected with the driving part and the driving force receiving part, the driving part is connected with the driven part, the processing box is also provided with a touch control device on the shell, the touch control device is connected with the gear part and drives the first gear part to rotate, and the driven part drives the driving part to rotate. The touch control device is adjusted to solve the problem that the processing box gets stuck, and the processing box can be conveniently disassembled from a printer or installed on the printer.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

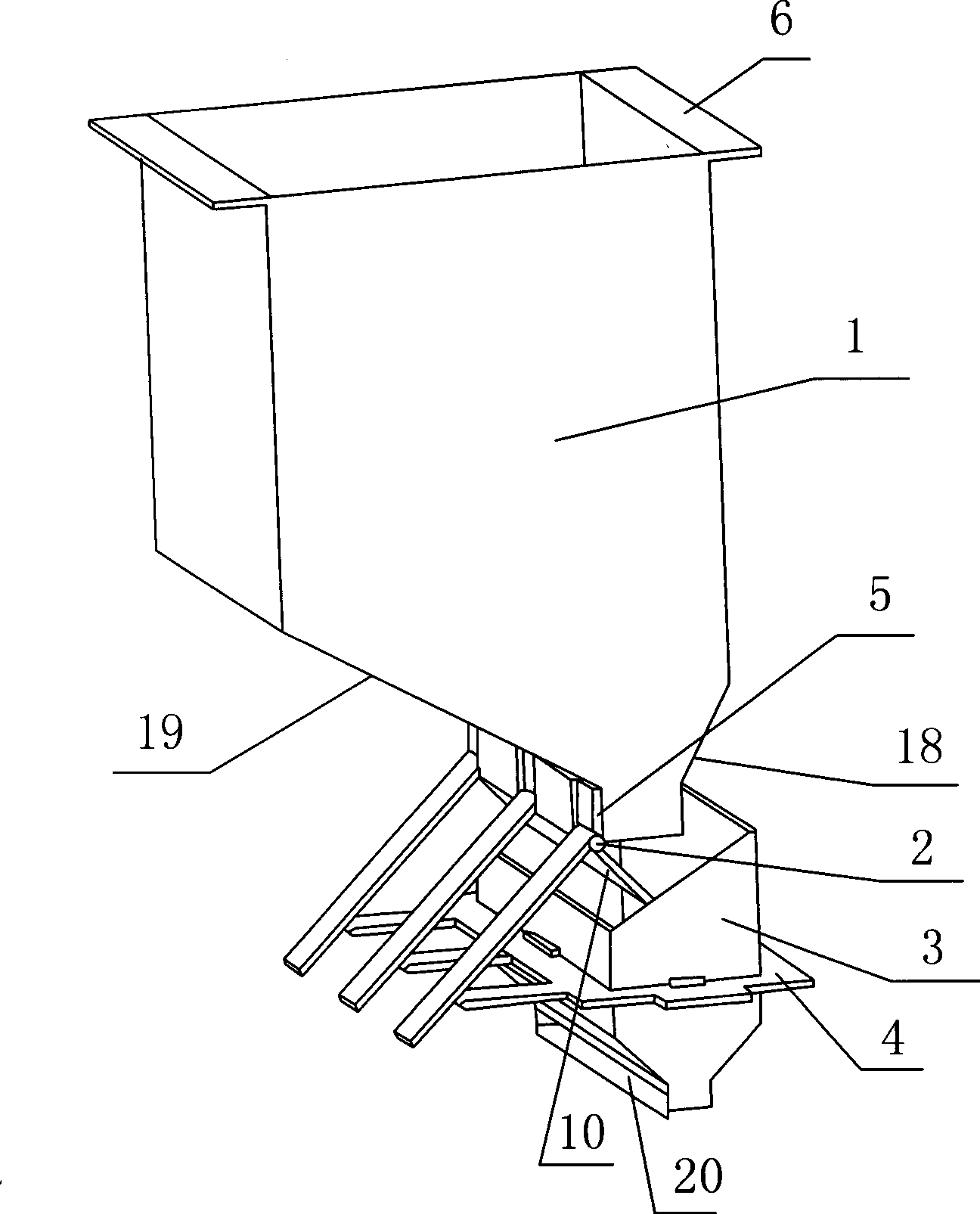

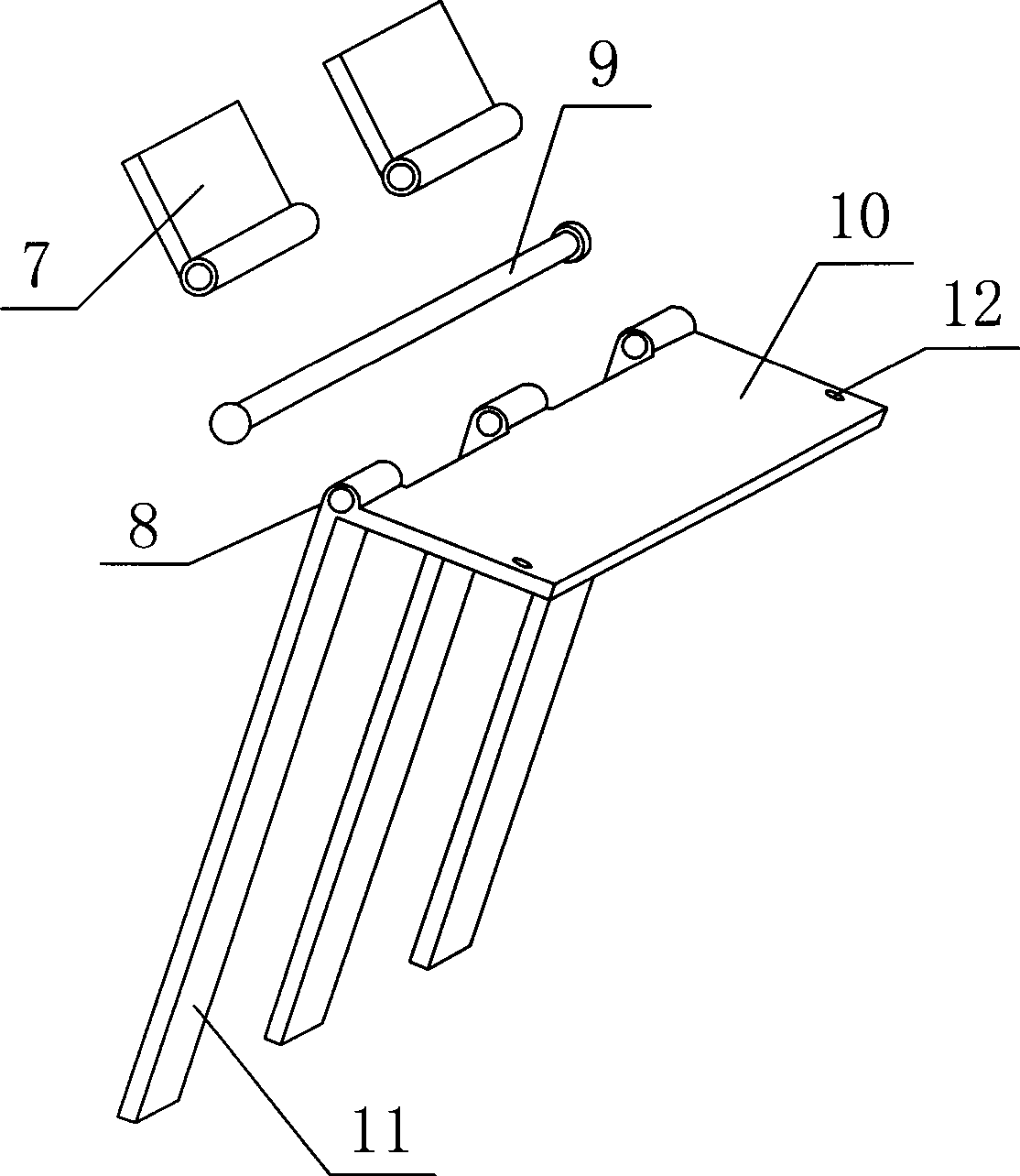

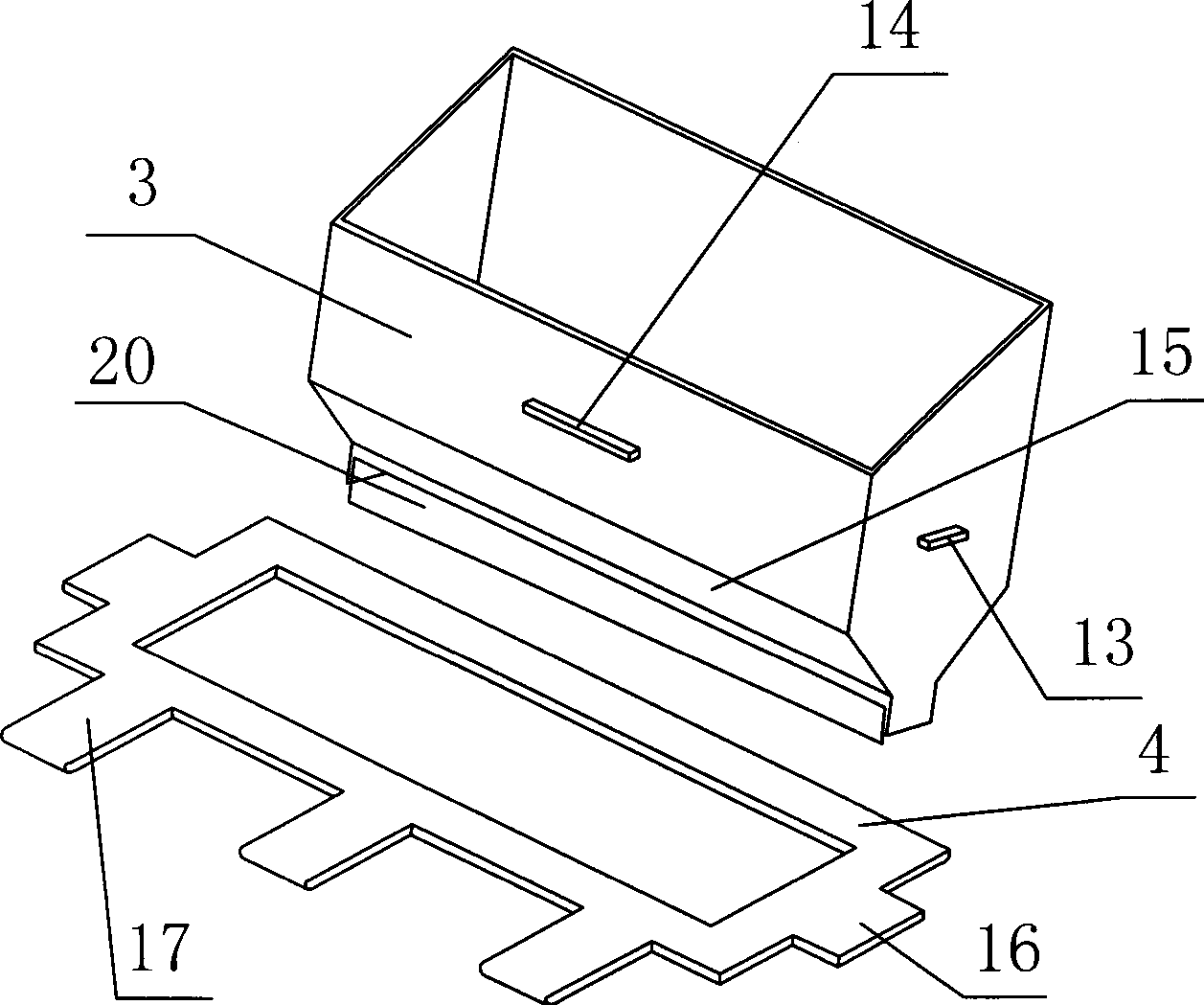

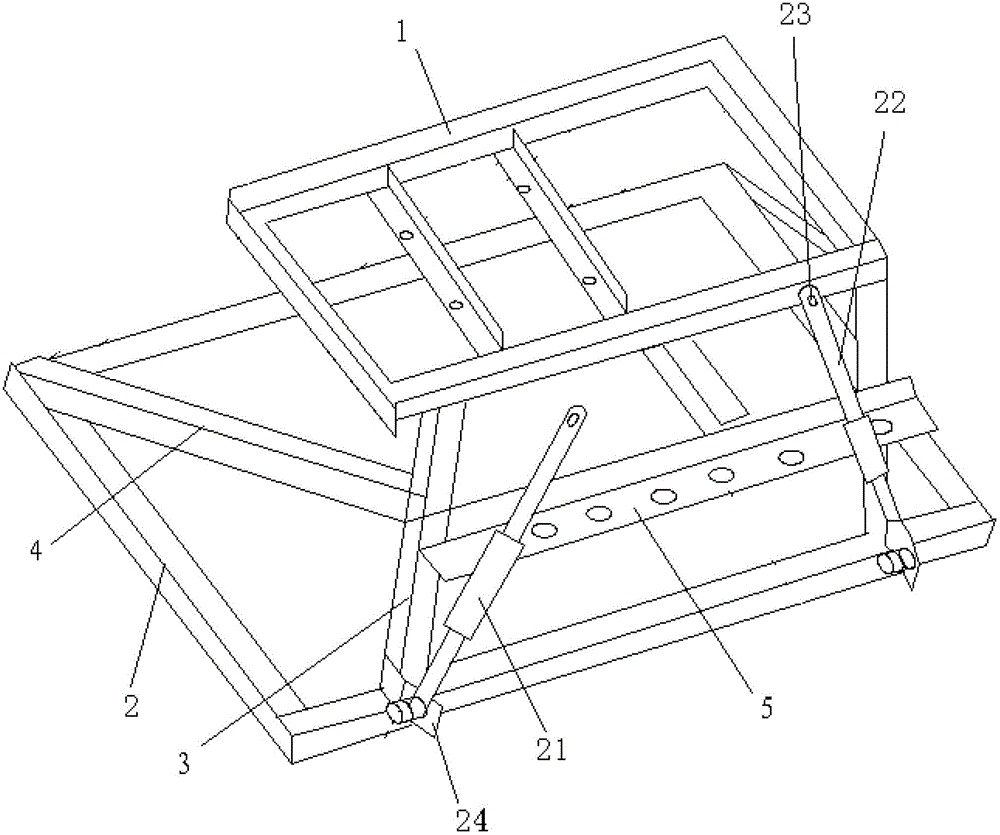

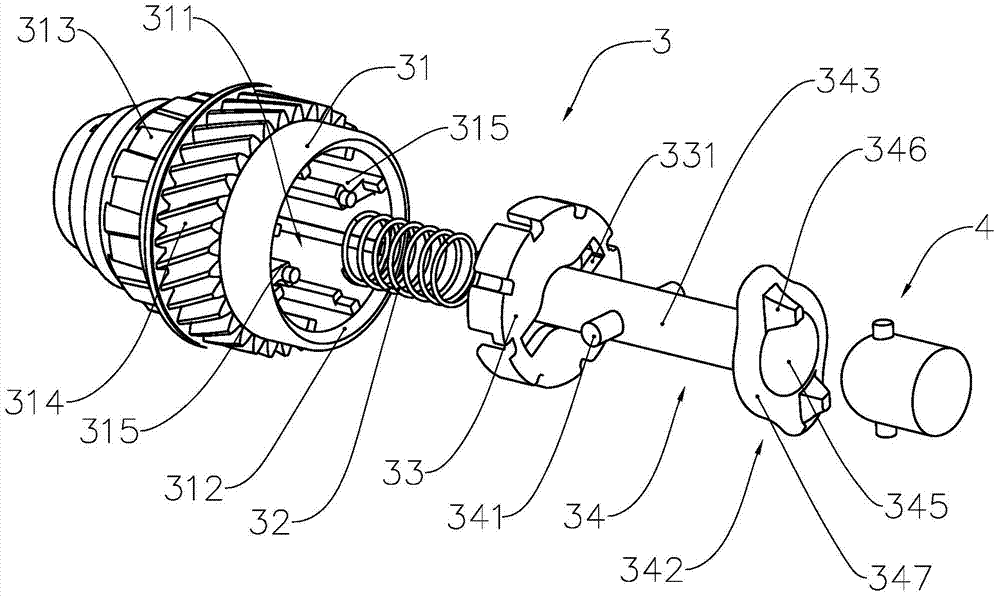

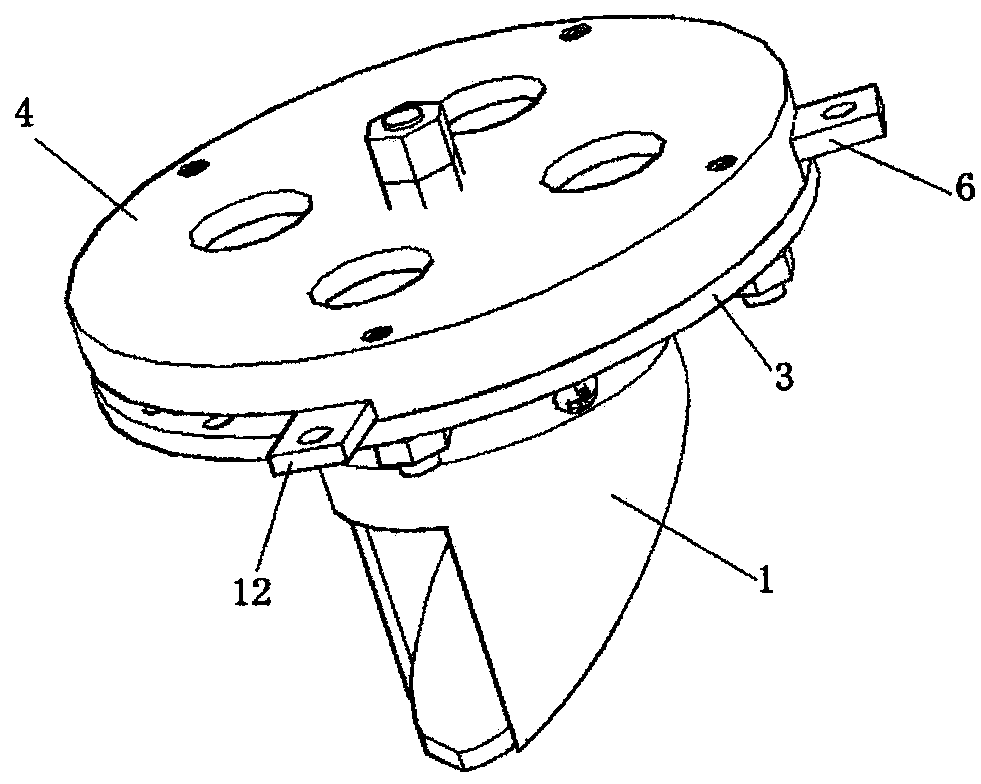

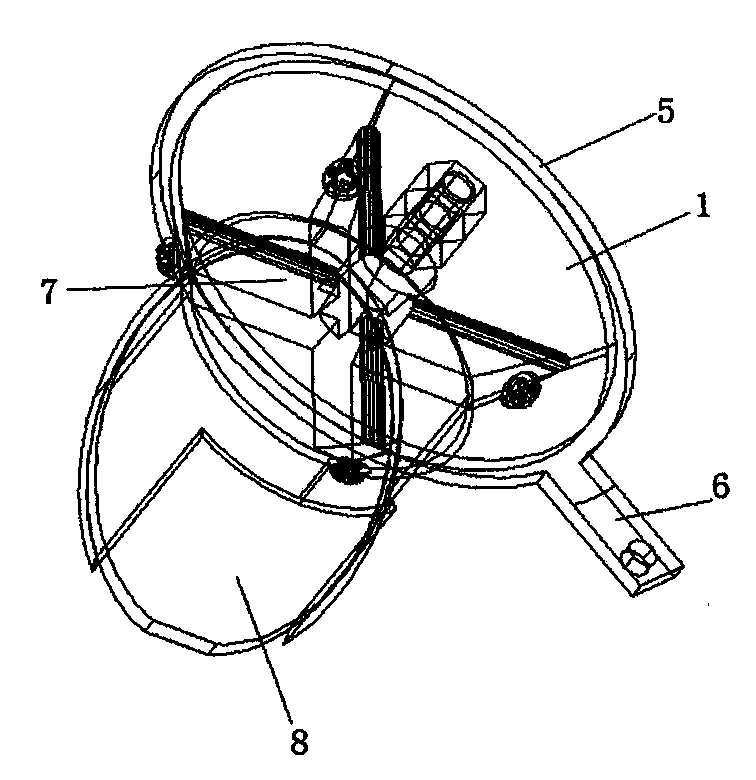

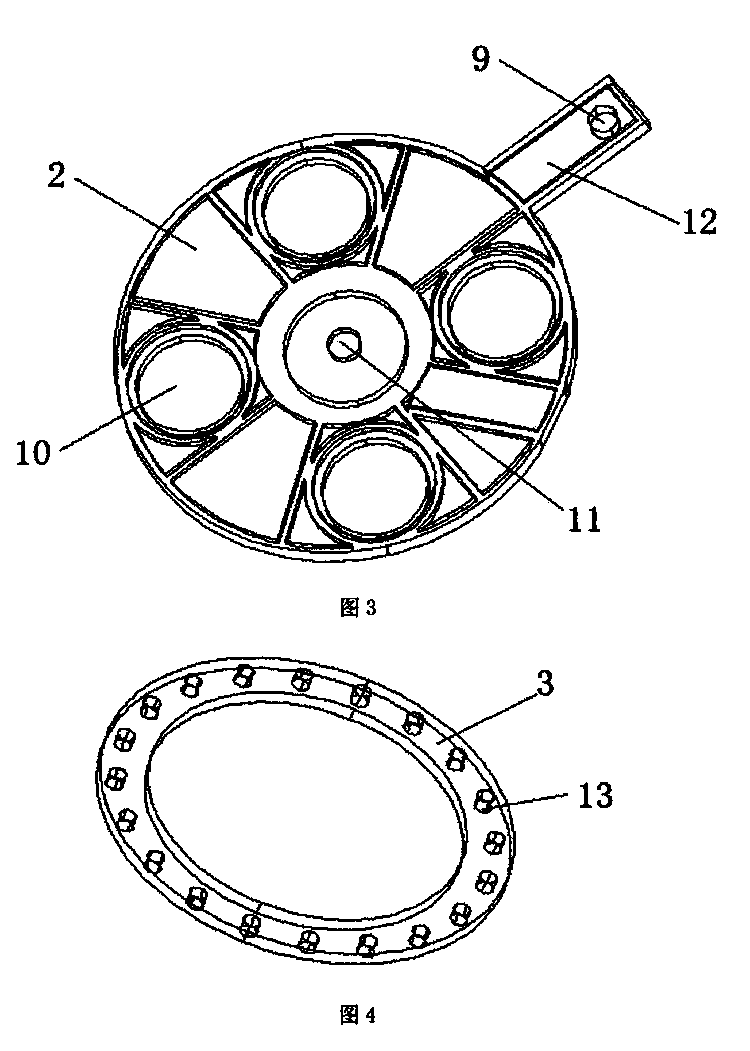

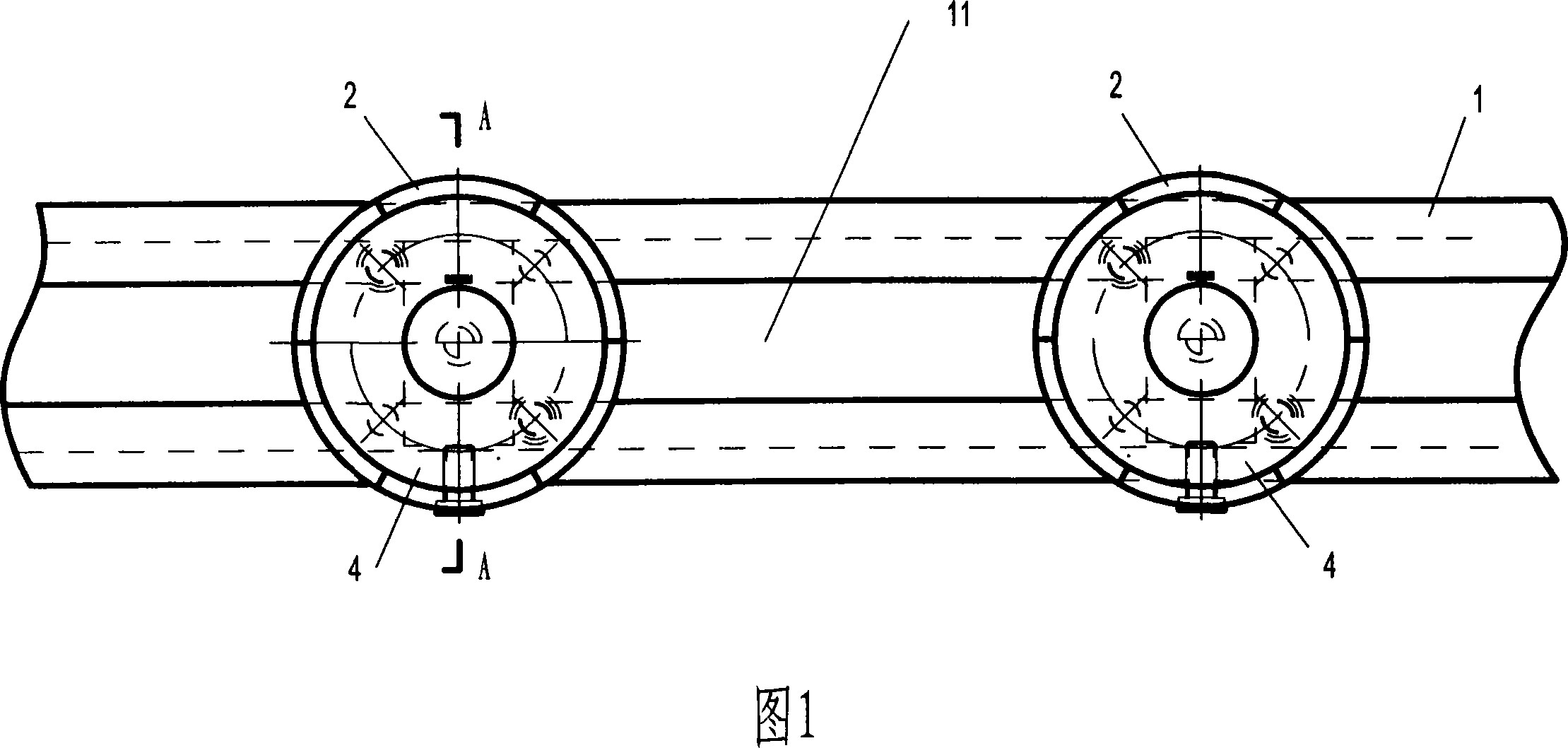

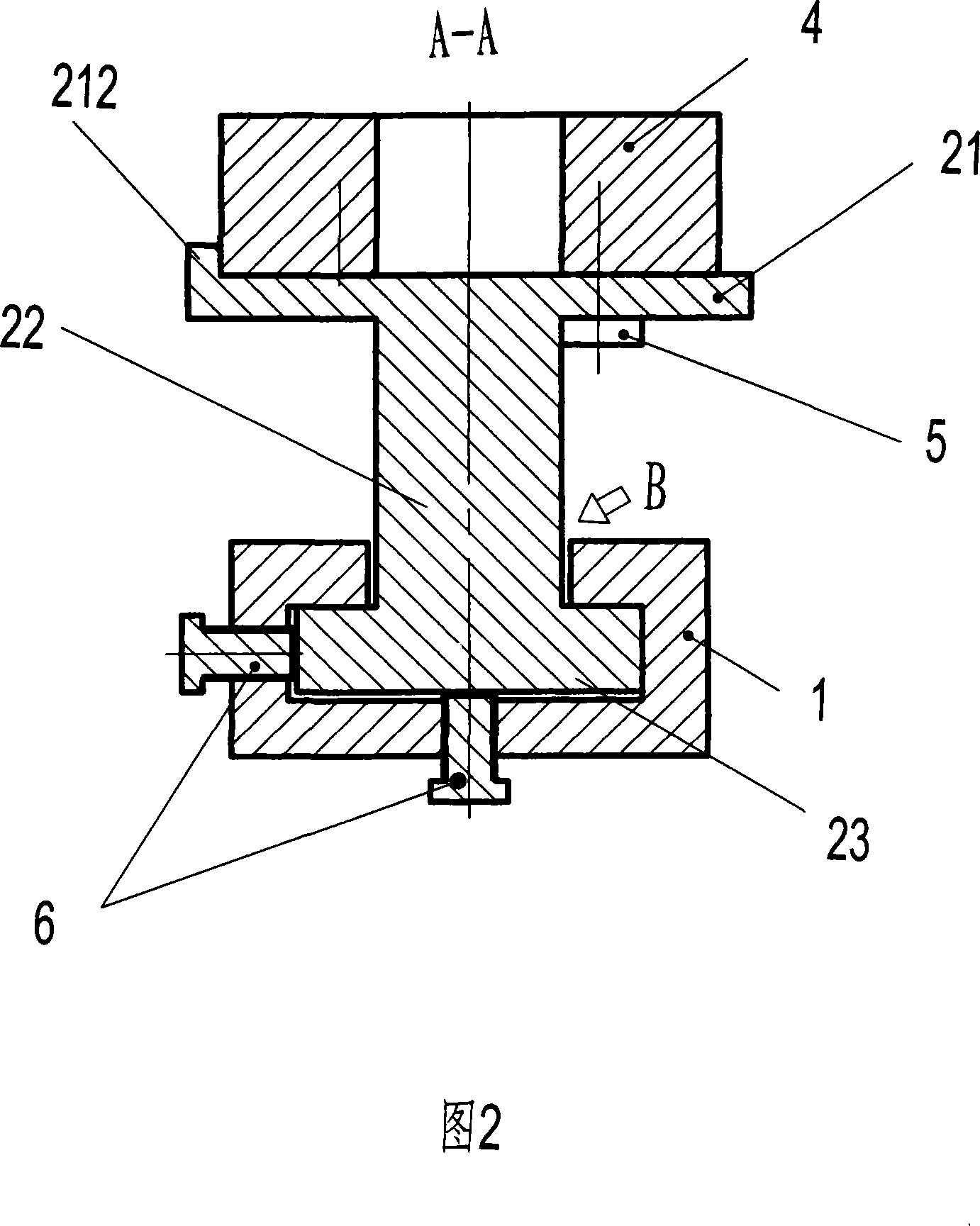

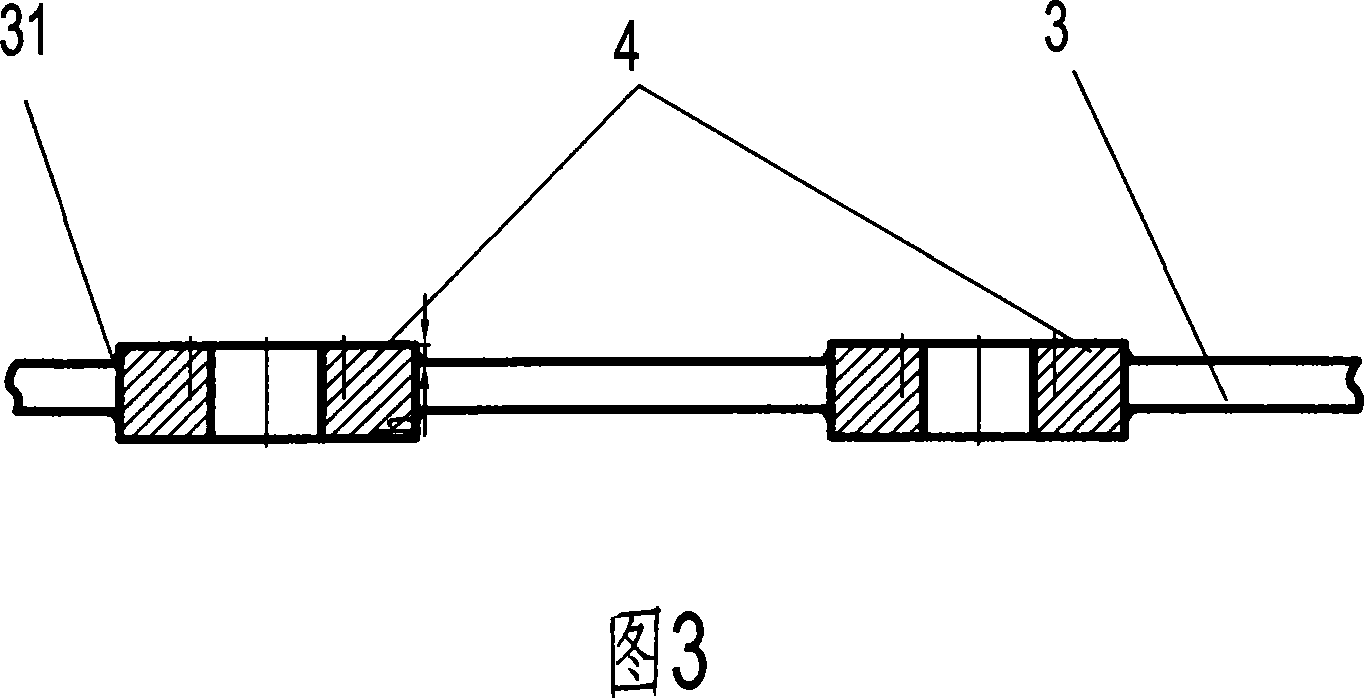

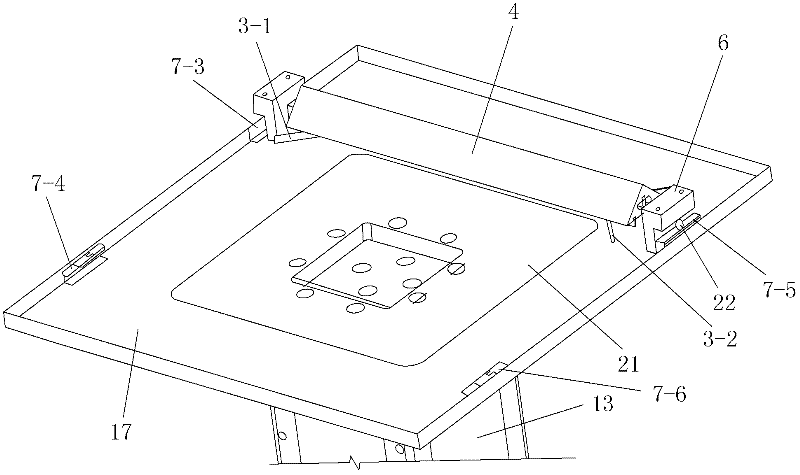

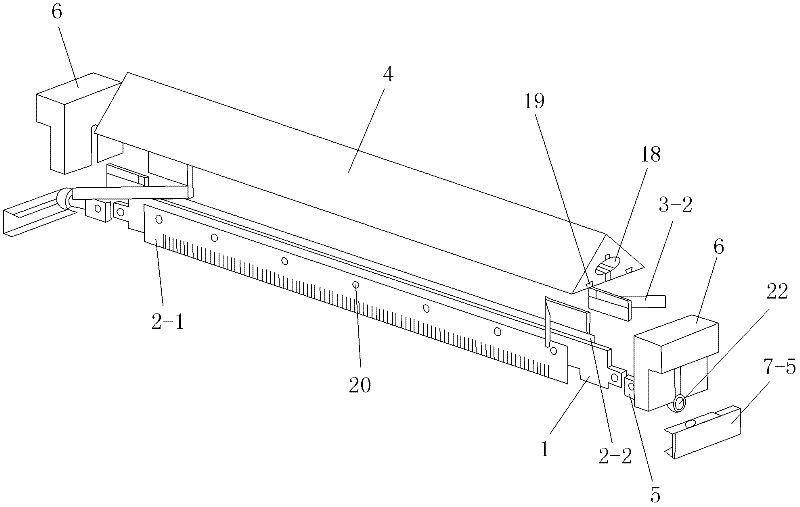

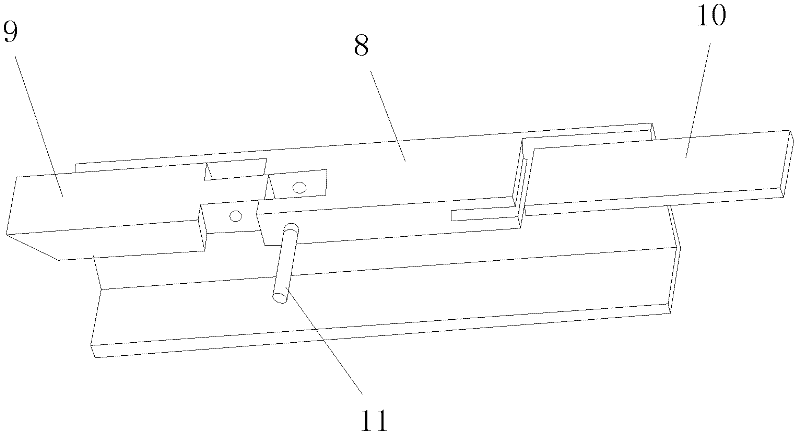

Material sowing rotary adjusting mechanism of adjustable seeding and fertilizer applying machine

ActiveCN103444322AReasonable structural designEasy to adjust controlFertiliser distributersSeed depositing seeder partsEngineeringMechanical engineering

The invention discloses a material sowing rotary adjusting mechanism of an adjustable seeding and fertilizer applying machine. The material sowing rotary adjusting mechanism comprises a blanking hopper, a blanking amount adjusting disc, a fixed ring and a blanking plate, wherein the blanking amount adjusting disc is mounted above the blanking hopper; the fixed ring is mounted below the edge of the blanking hopper; the blanking plate is mounted above the blanking amount adjusting disc; the edge of the blanking hopper and the blanking amount adjusting disc are clamped between the fixed ring and the blanking plate and are located in an annular bulge. The material sowing rotary adjusting mechanism is reasonable in structural design, the four parts are combined, a discharging amount and the direction and width of discharging can be adjusted at any time in the use process and are convenient to adjust and control and the material sowing rotary adjusting mechanism is very suitable for popularization and use in most rural areas of China.

Owner:扬州复道科技有限公司

Welding aid for connecting flange and its welding method

ActiveCN101073867AGuarantee welding qualityShorten the manufacturing cycleWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFixed position

The invention is concerned with the auxiliary welding equipment and the welding method for connecting flange, the equipment includes the main body that is a strip square bar with inverse T-shape slot and several chucks fixing on the main body, the top of the chuck is plate-shape body, the middle of the chuck is shore, the bottom of the chuck is squareness base, sets the location hole crossing the upper surface and bottom of the plate-shape body on the plate-shape body, the upper surface edge of the plate-shape body is the ring protruding table with several gaps, the chuck fixes on the main body by embed the squareness base in the inverse T-shape slot, sets the strainer resisting the squareness base on the chuck fixing position of the main body. The invention can ensure the welding quality, improve the work efficiency, short the manufacturing cycle, reduce the manufacturing cost.

Owner:HUDONG HEAVY MACHINERY

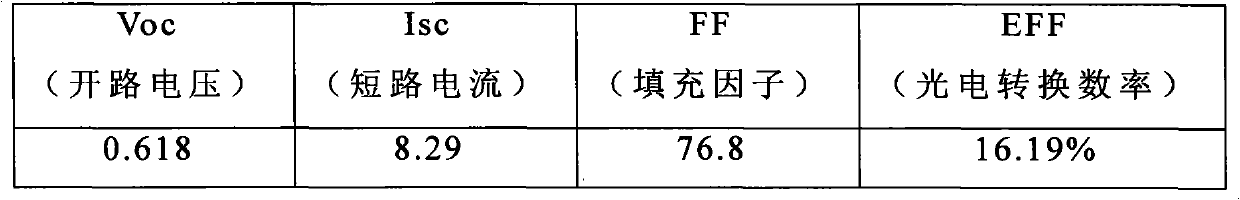

Method for improving phosphorus diffusion uniformity of solar cell

ActiveCN102005502AAvoid uneven diffusionReduce uneven diffusionFinal product manufactureSemiconductor devicesNitrogen atmosphereNitrogen gas

The invention discloses a method for improving phosphorus diffusion uniformity of a solar cell. The method comprises the following steps of: (1) placing a silicon slice in a diffusion furnace and raising the temperature of each region in the furnace to 700 to 780 DEG C, wherein the environment in the furnace is uniform nitrogen atmosphere, and the flow rate of the nitrogen gas is 8 to 30L / minute; (2) simultaneously introducing phosphorus-carrying source gas at the speed of 0.8 to 2L / minute and dry oxygen at the speed of 0.4 to 2.5L / minute after the temperature is stable, ensuring that the gas environment in the furnace is uniform, and diffusing for 10 to 40 minutes; (3) stopping introduction of the phosphorus-carrying source gas source and the dry oxygen, synchronously and uniformly raising the temperature of each region in the furnace at the rate of below 5 DEG C / minute, raising temperature to 810 to 900 DEG C and diffusing for 10 to 40 minutes; and (4) reducing temperature and discharging out of a boat. Through uniform gas and consistent temperature in the furnace, the phosphorus diffusion uniformity during preparation of the battery plate is improved, and the conversion efficiency of the solar cell is improved to a certain extent.

Owner:YANCHENG CANADIAN SOLAR INC

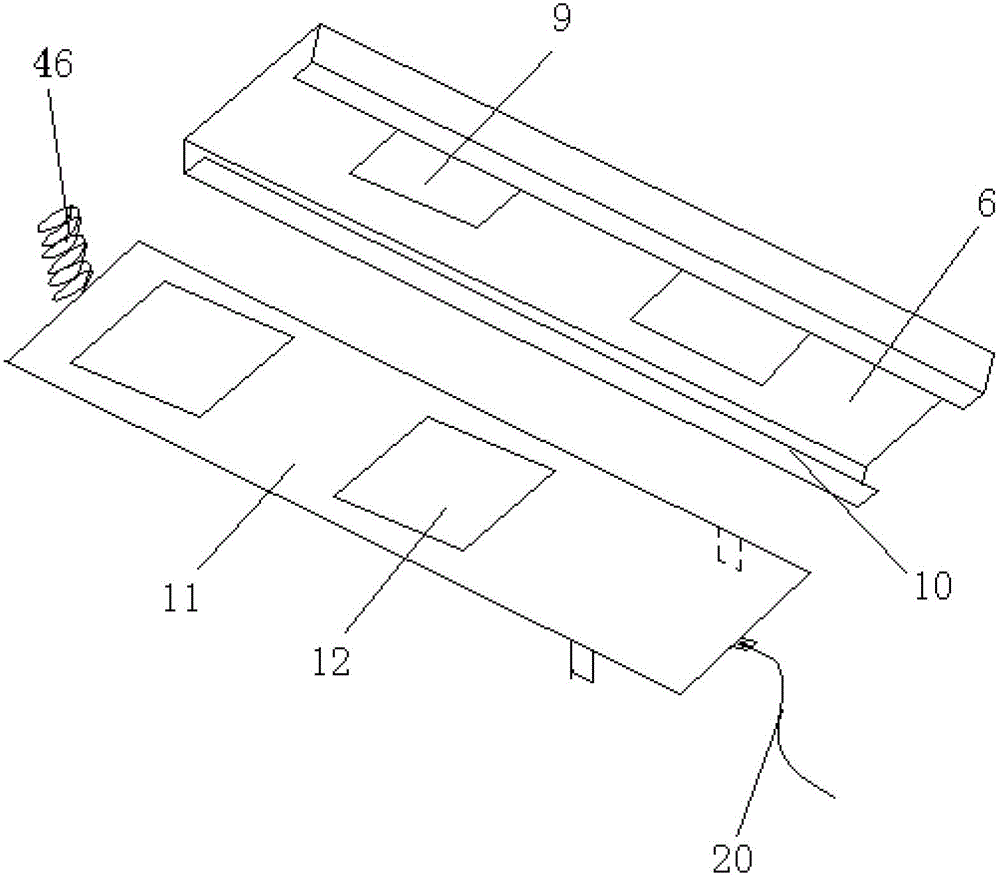

Powder spreading device for rapid forming equipment

The invention discloses a powder spreading device for rapid forming equipment, comprising a moving mechanism, a scraping plate mechanism, a left-side wing and a right-side wing, wherein the moving mechanism does horizontal-linear reciprocating movement back and forth on a forming working platform; the scraping plate mechanism is fixedly arranged at the bottom part of the moving mechanism; the left-side wing and the right-side wing are movably arranged at the left side and the right side of the bottom part of the moving mechanism; the moving mechanism comprises a pushing block, a connecting rod, a left traveling mechanism and a right traveling mechanism, wherein the connecting rod is arranged at the bottom part of the pushing block; the left traveling mechanism and the right traveling mechanism are respectively and symmetrically arranged at the left end part and the right end part; the scraping plate mechanism comprises a front scraping plate and a rear scraping plate which are symmetrically arranged; and both the left-side wing and the right-side wing are splayed side wings II which are consists of two inclined side plates III and can move horizontally towards left and right alongthe scraping plate mechanism. In the powder spreading device, the structure is simple, the assembly and disassembly of all the parts are simple and convenient, the adjustment and control of all the parts are simple and easy, the independent modular working can be realized, the powder spreading is fast, the reliability is high, and the defects of difficult powder confinement, complex structure and difficult adjustment of powder-spreading areas and the like in the existing powder-spreading device can be solved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

High gel protein powder and its production method and uses

ActiveCN101305767AIncrease elasticityEasy to stretchAnimal proteins working-upFood preparationMaillard reactionCompound (substance)

The invention provides a method for preparing high-gelation protein powder combining chemical methods including a Maillard reaction, a fermentation sugar removal method and physical methods such as microwave radiation, dry heat-treating, etc. The prepared high-gelation protein powder has ultrahigh protein powder gel strength and stability with a highest up to2,400g and wide application.

Owner:NANTONG KANGDE BIOLOGICAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com