Novel multilevel heat source calcium carbide production technique and device

A new technology, calcium carbide technology, applied in the field of multi-stage heat source calcium carbide production new technology and equipment, can solve the problems of low output, high energy consumption, etc., and achieve the effect of high output, low energy consumption, and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

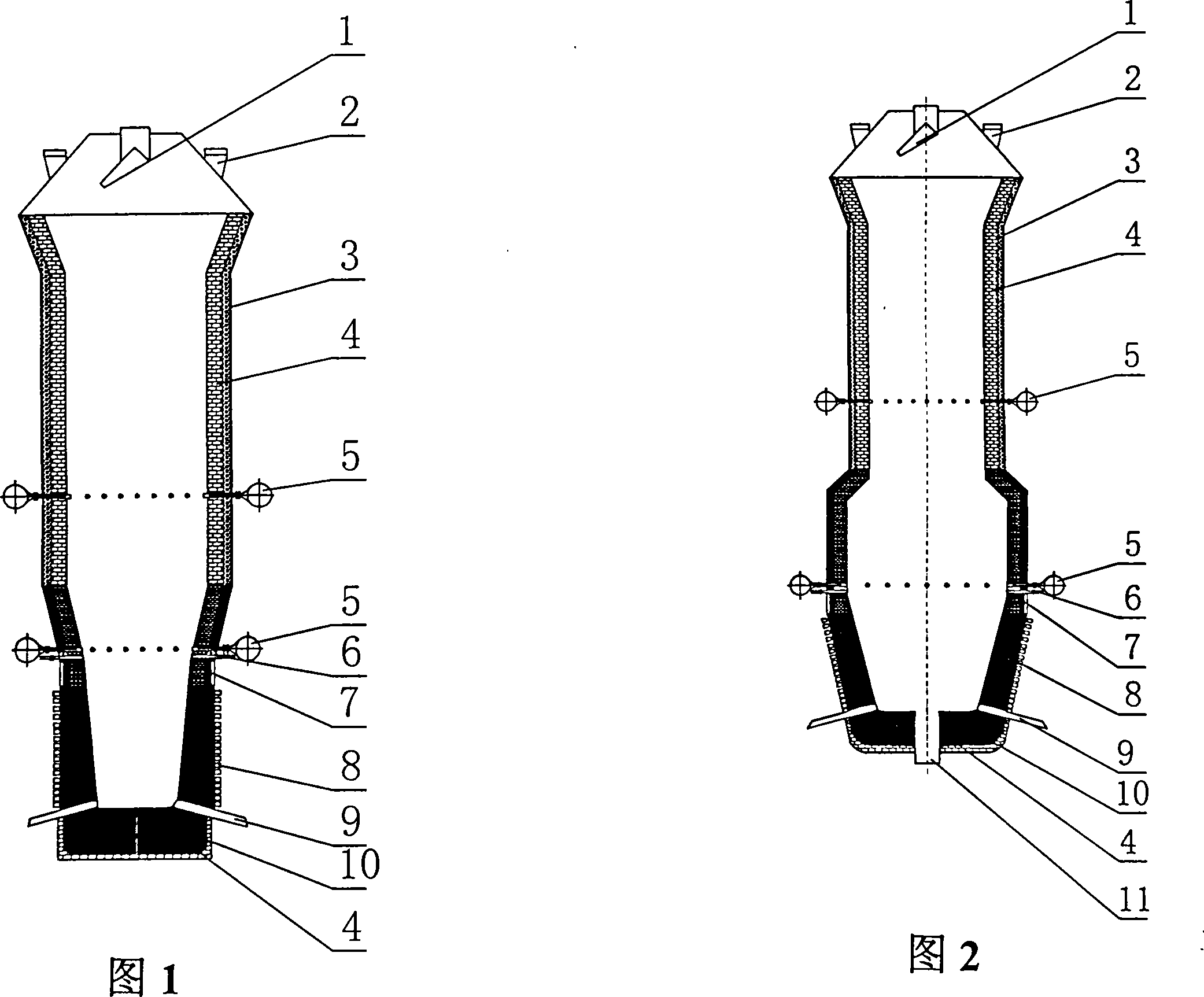

[0033] The vertical furnace used for the test is Φ1.0×5.7m (the height from the bottom of the furnace to the bell mouth is 5.7m, and the diameter of the lower part of the bell mouth is Φ1.0m). The structure is shown in Figure 2.

[0034] The raw materials used in the test are limestone, carbide slag, anthracite, additives, limestone CaO content 54.2%, press filter carbide slag dry basis CaO content 69.9%, water content 35%, anthracite volatile content 8.7%, ash 11.4%, low calorific value 6953 ×4.18kJ / kg, the additive uses the existing calcium carbide production ZC-1 special additive.

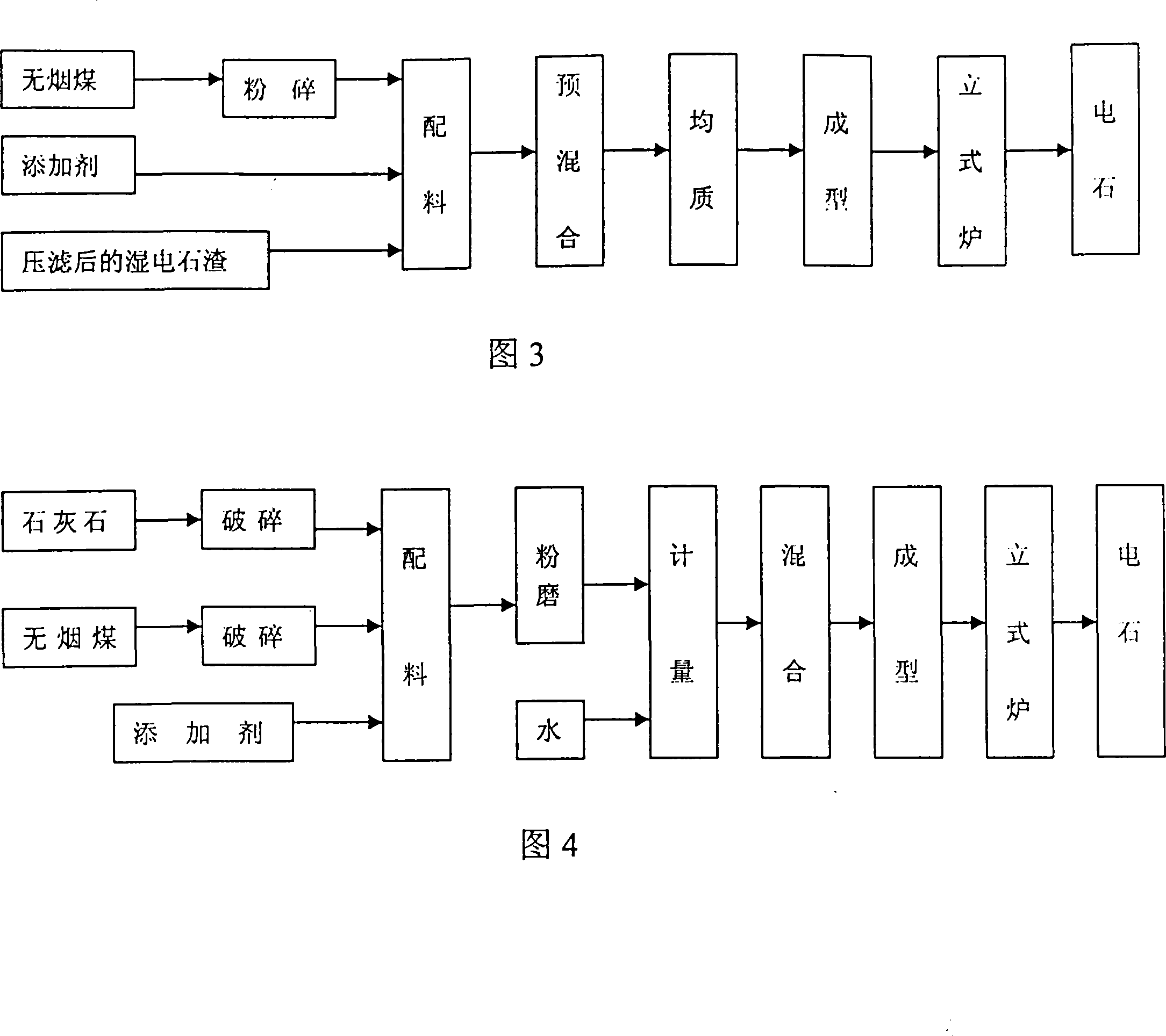

[0035] Test 1: After using the above-mentioned limestone: anthracite: additives according to the weight ratio: 1.5: 1: 0.1, crush and grind to a fineness of 0.08mm and sieve the remaining 18-22% dry powder, add appropriate amount of water to plasticize, use The roller extrusion molding machine is formed into a Φ12mm material rod, which is continuously fed into the vertical furnace. The temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com