Patents

Literature

30results about How to "Improve grade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

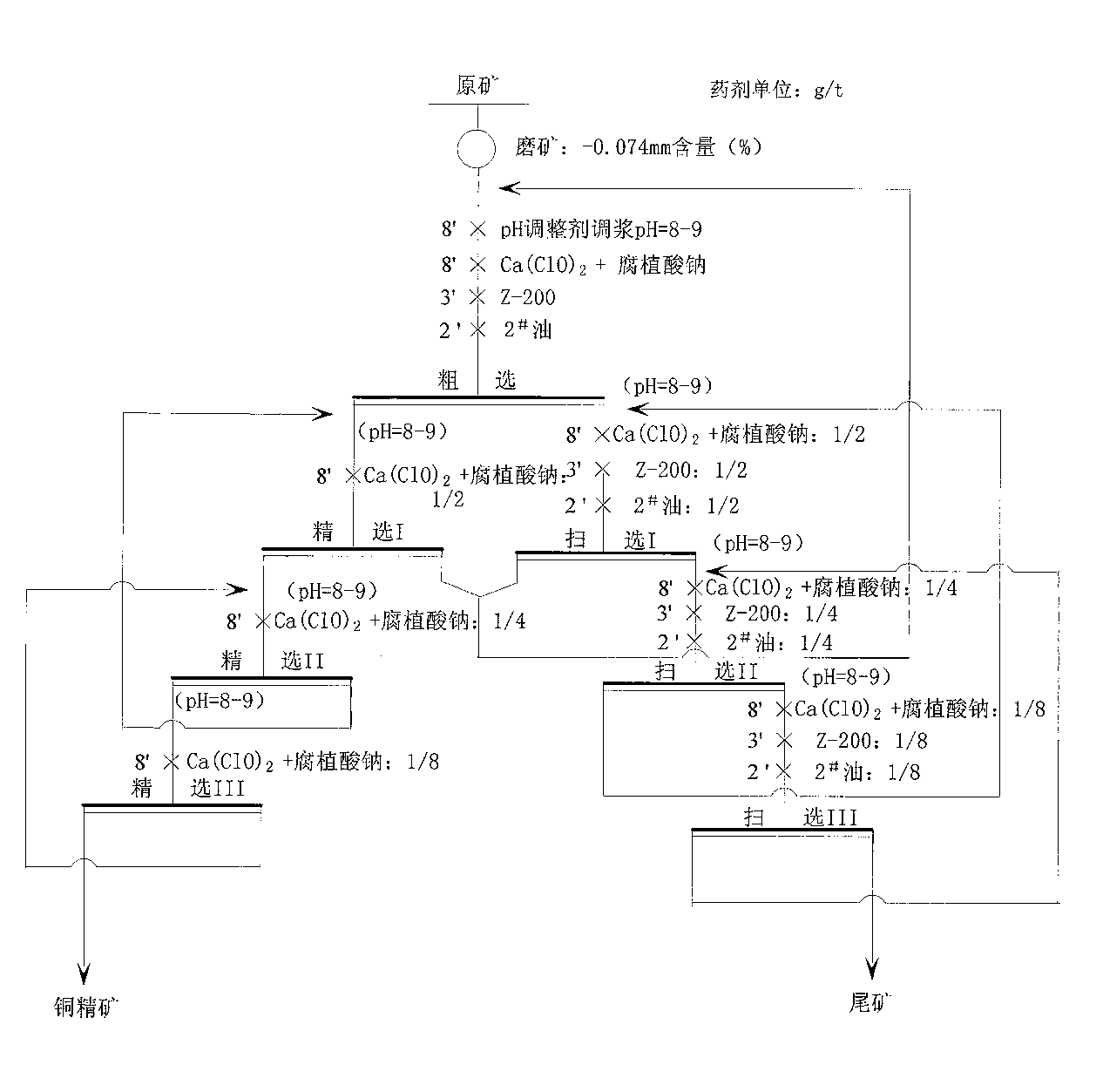

Compound inhibiting agent capable of effectively separating copper and sulfur at low-alkalinity condition

The invention discloses a compound inhibiting agent capable of effectively separating copper and sulfur at a low-alkalinity condition, which is prepared by mixing calcium chlorate and sodium humate according to a weight ratio. The ratio of sodium hypochlorite to the sodium humate is equal to 1-50. The copper and sulfur separation can be effectively realized at the low-alkalinity condition, so that the grade of copper concentrate ore is promoted and the problems that the easiness of scaling and solidifying, pipeline blocking, equipment etching, serious mine wastewater which are caused by high alkalinity of the conventional copper and sulfur separation and a large amount of added lime are solved; and compared with a cyaniding method and a heating oxidization method, the compound inhibiting agent disclosed by the invention has the advantages of no pollution, simple process flow, strong operability and the like.

Owner:CHANGCHUN GOLD RES INST +1

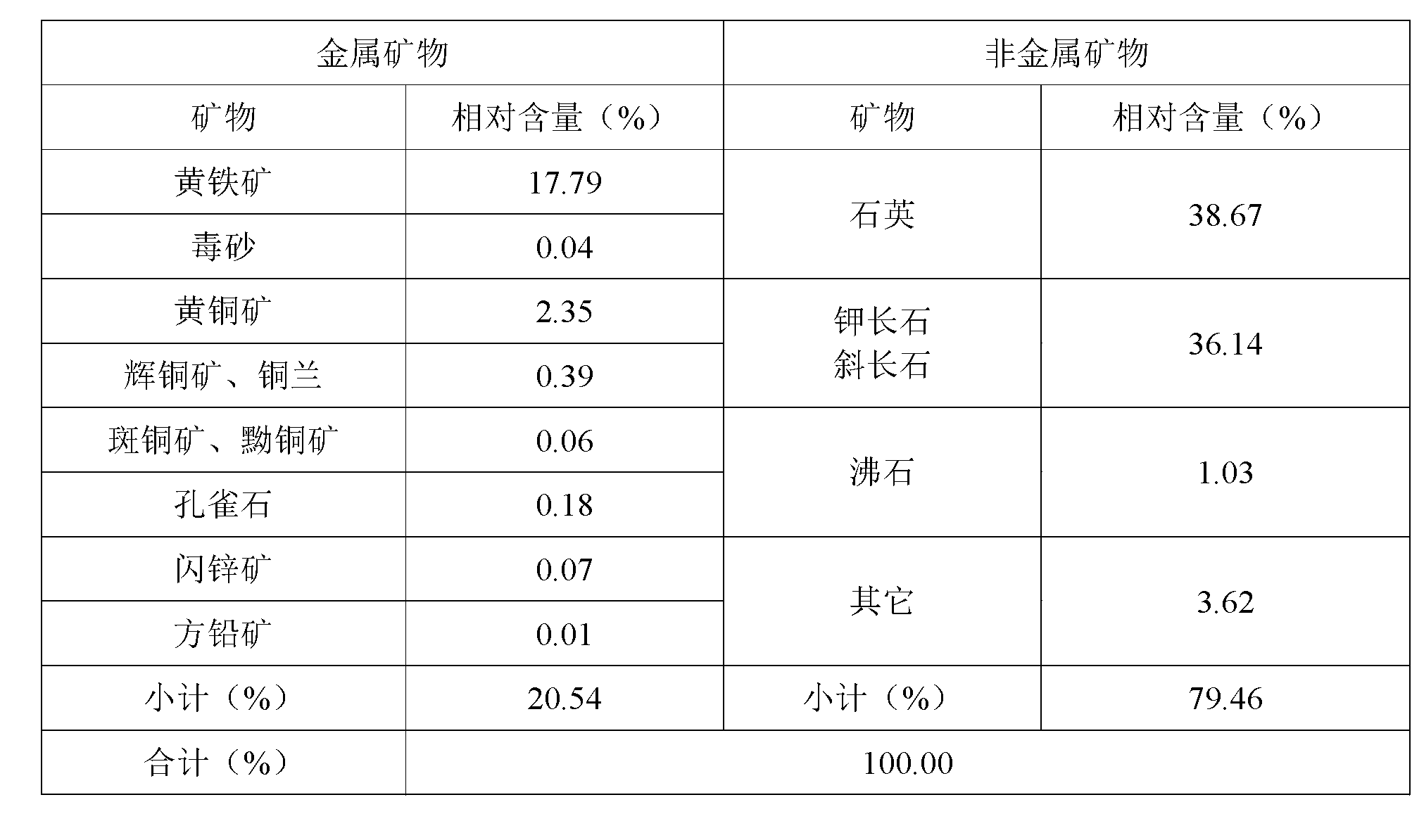

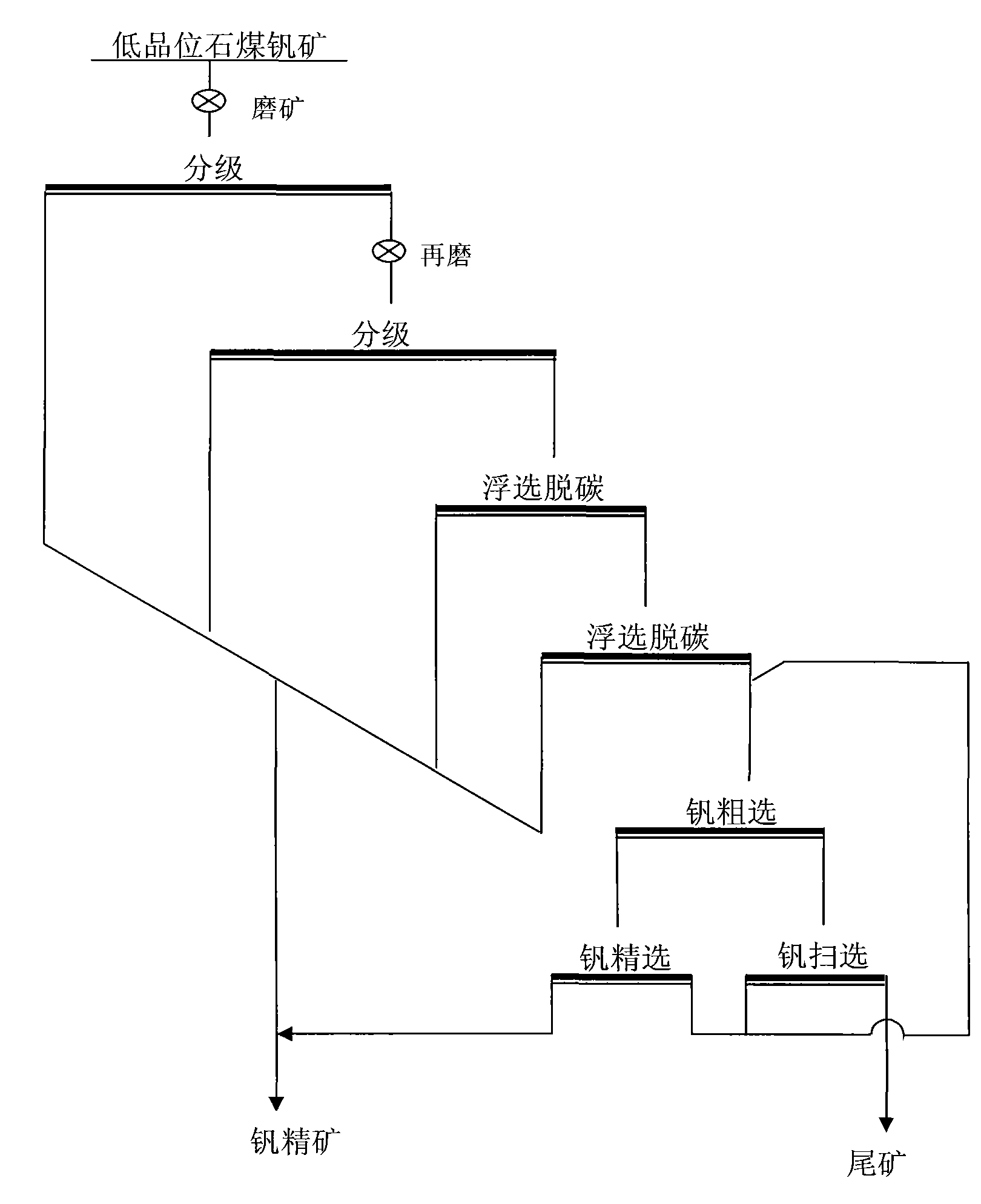

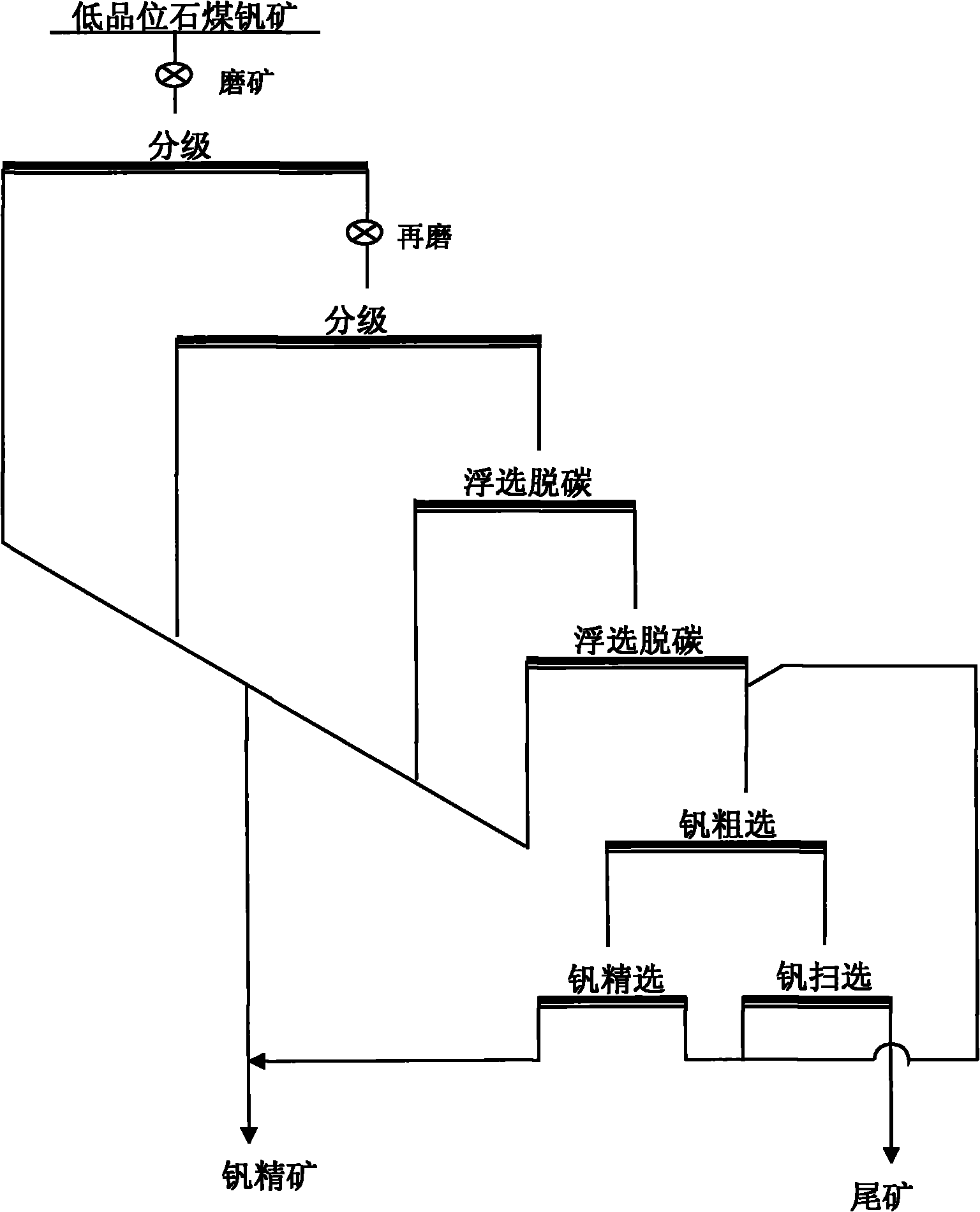

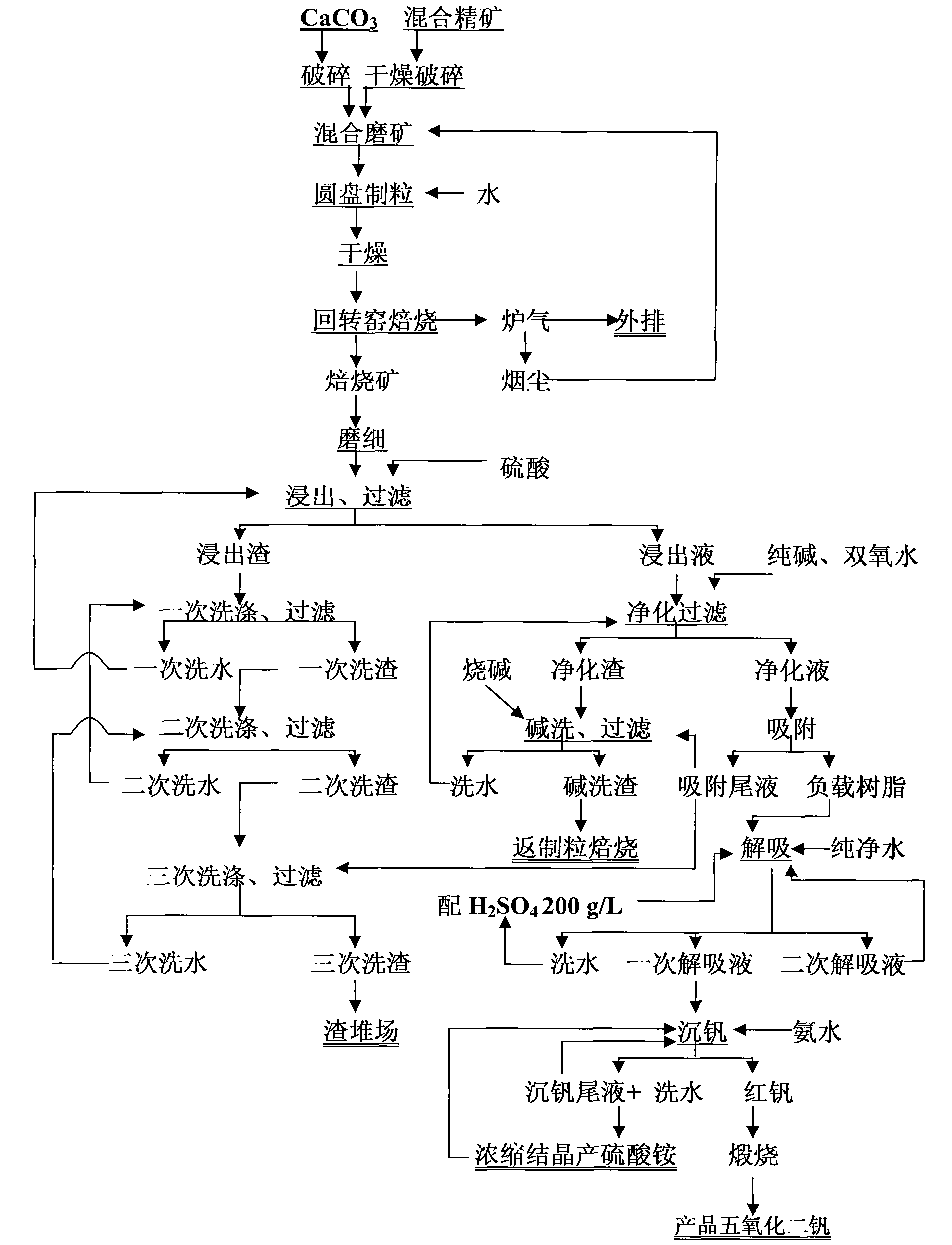

Metallurgical method for extracting vanadium pentexide from low-grade stone coal vanadium ores

The invention provides a metallurgical method for extracting vanadium pentexide from low-grade stone coal vanadium ores. The method comprises the following steps of: breaking and grinding the stone coal vanadium ores, grading the stone coal vanadium ore particles to a coarse particle grade and a fine particle grade, grinding and grading the coarse particles to the coarse particle grade, adding kerosene and terpenic oil(C10H17OH) into the obtained products at the coarse particle grade for flotation decarburization to obtain the charcoal concentrate, and adding a gangue inhibitor and a vanadium mineral collector into the obtained products at the coarse particle grade to obtain the vanadium concentrate; using the products at the fine particle grade obtained in two gradations, the flotation charcoal concentrate and the vanadium concentrate as the mixed concentrate, and the floated underflow as tailings; adding CaO into the mixed concentrate, performing granulation, baking and wet-grinding of the mixture, adding sulfuric acid into the mixture for leaching, performing purification, resin adsorption and analysis of the leaching solution, performing vanadium deposition and calcining of the product of the vanadium deposition to obtain V2O5, and washing the leaching mud which can be used as a building additive. In the method, the ore dressing of vanadium-enriched minerals and the pollution-free smelting process are combined, so that the smelting processing capacity is lowered, the smelting investment and the production cost are lowered, the V2O5 yield of the metallurgical method reaches 74.23 percent; and the production cost is reasonable, and the metallurgical method is environmentally-friendly.

Owner:中钢矿业开发有限公司 +2

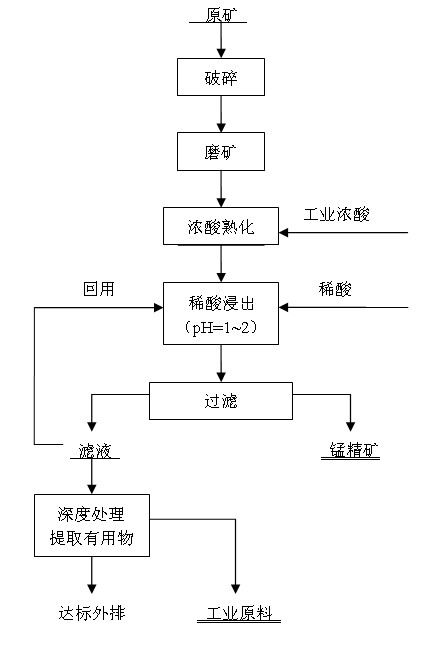

Method for treating primary low-grade high-phosphorus manganese ore by acid blending curing

InactiveCN102181627AImprove gradeReduce phosphorus contentProcess efficiency improvementManganiteLow graded

The invention relates to a method for treating primary low-grade high-phosphorus manganese ore by acid blending curing, and belongs to the field of wet metallurgy of metallurgical technology. The low-grade primary high-phosphorus manganese ore, the manganese grade of which is 13 to 24 percent, is used as a raw material. The method comprises the following steps of: crushing the manganese ore into primary ore powder before the low-grade primary high-phosphorus manganese ore is leached, adding industrial concentrated acid (nitric acid, hydrochloric acid, sulfuric acid and the like), curing the primary high-phosphorus manganese ore at normal temperature, leaching the cured manganese ore by using diluted acid (the pH value is 1 to 2) under the conditions that the concentration of slurry is 50 to 200g / L and the temperature is 25 to 60 DEG C, filtering, separating and washing, wherein the slag is high-quality manganese-rich ore, P / Mn of which is less than or equal to 0.003 and the manganese grade of which is 30 to 45 percent. The method can be used for reducing the flow of the traditional ore dressing process, removing most phosphorus and greatly improving the grade of manganese; the recovery rate of the manganese is more than 80 percent, and the leaching rate of the phosphorus is more than 90 percent; and the method can be used for large-scale and intensive production of the manganese-rich ore for metallurgy, and gives rise to good economic benefit and social benefit.

Owner:KUNMING UNIV OF SCI & TECH

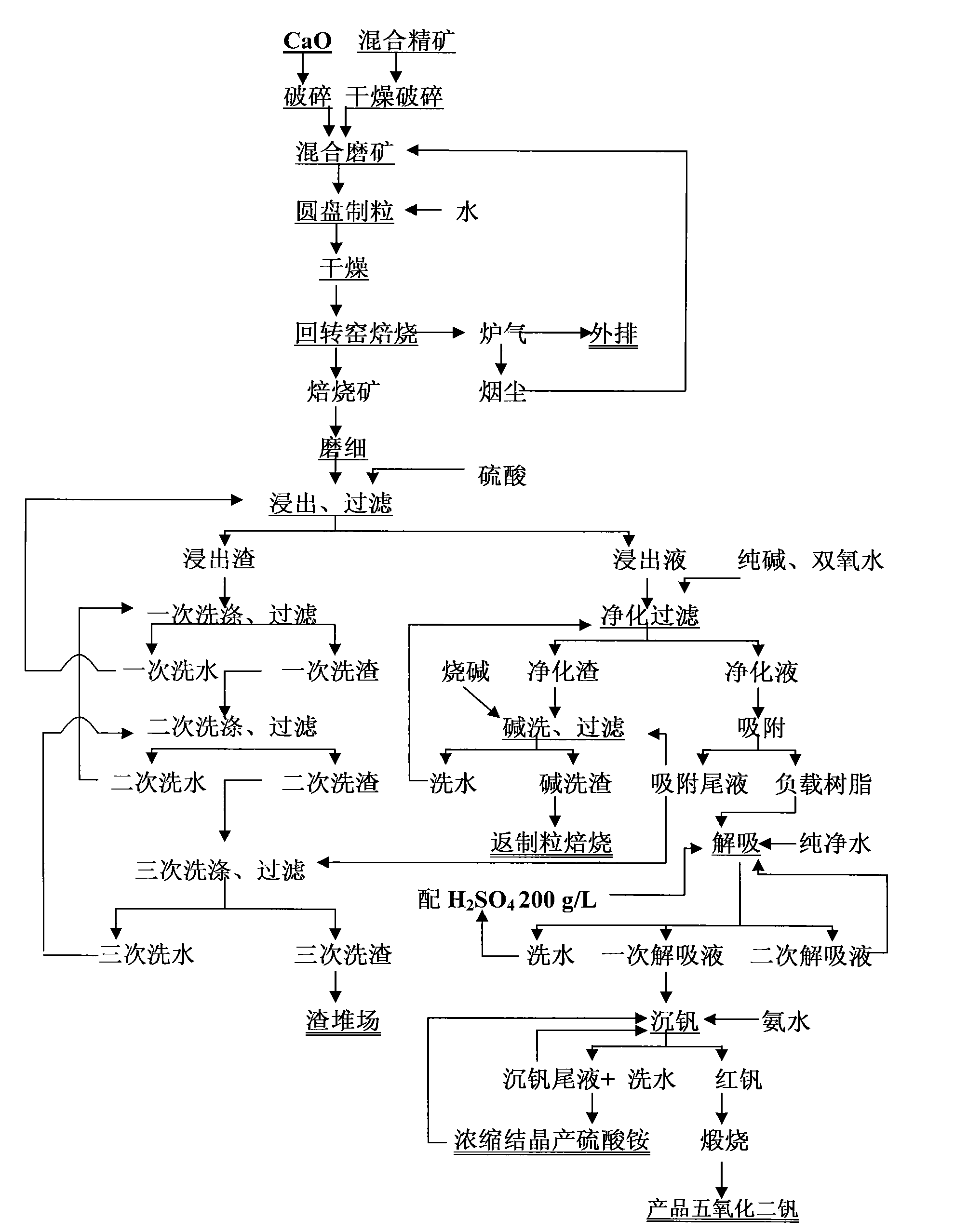

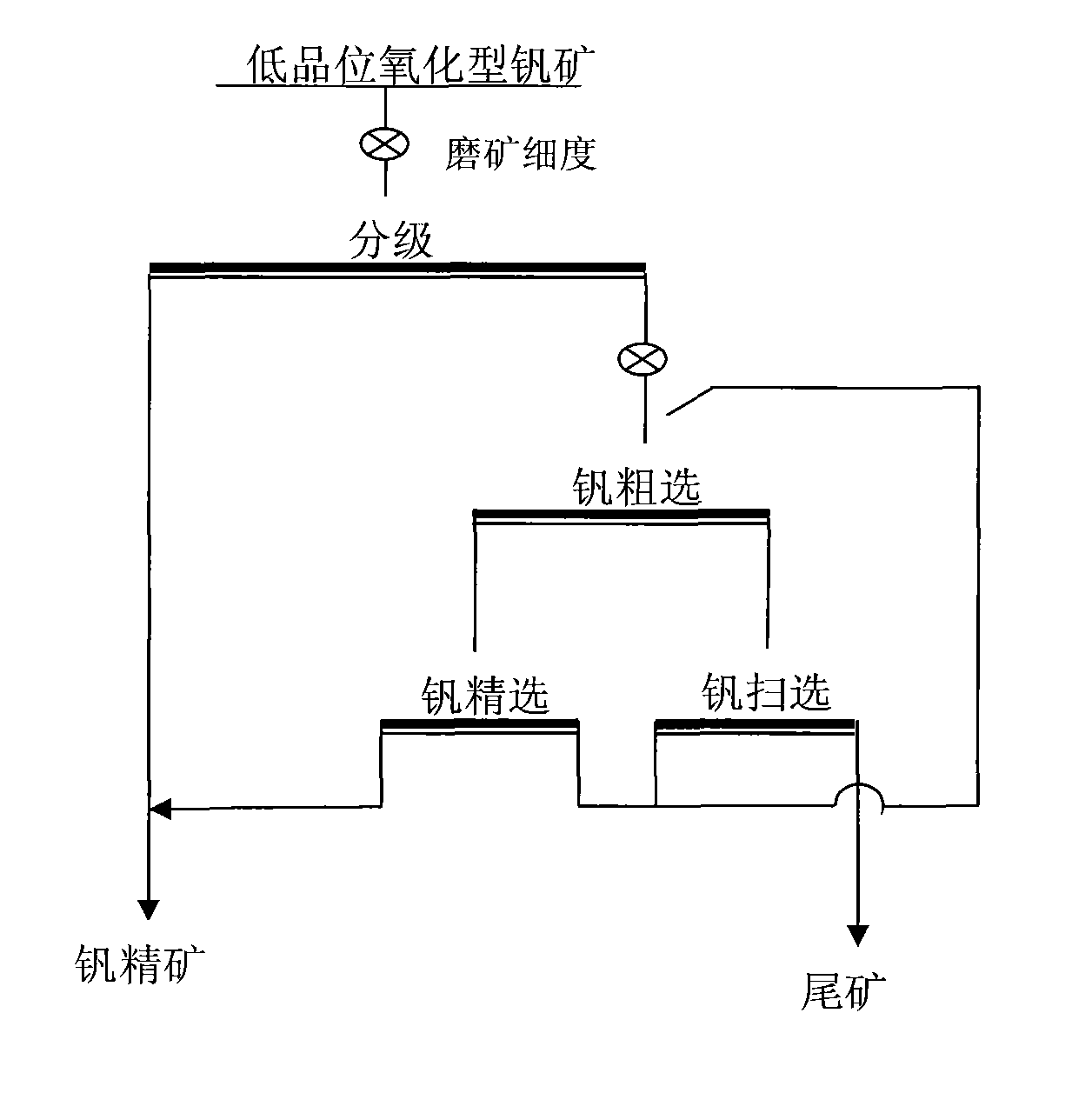

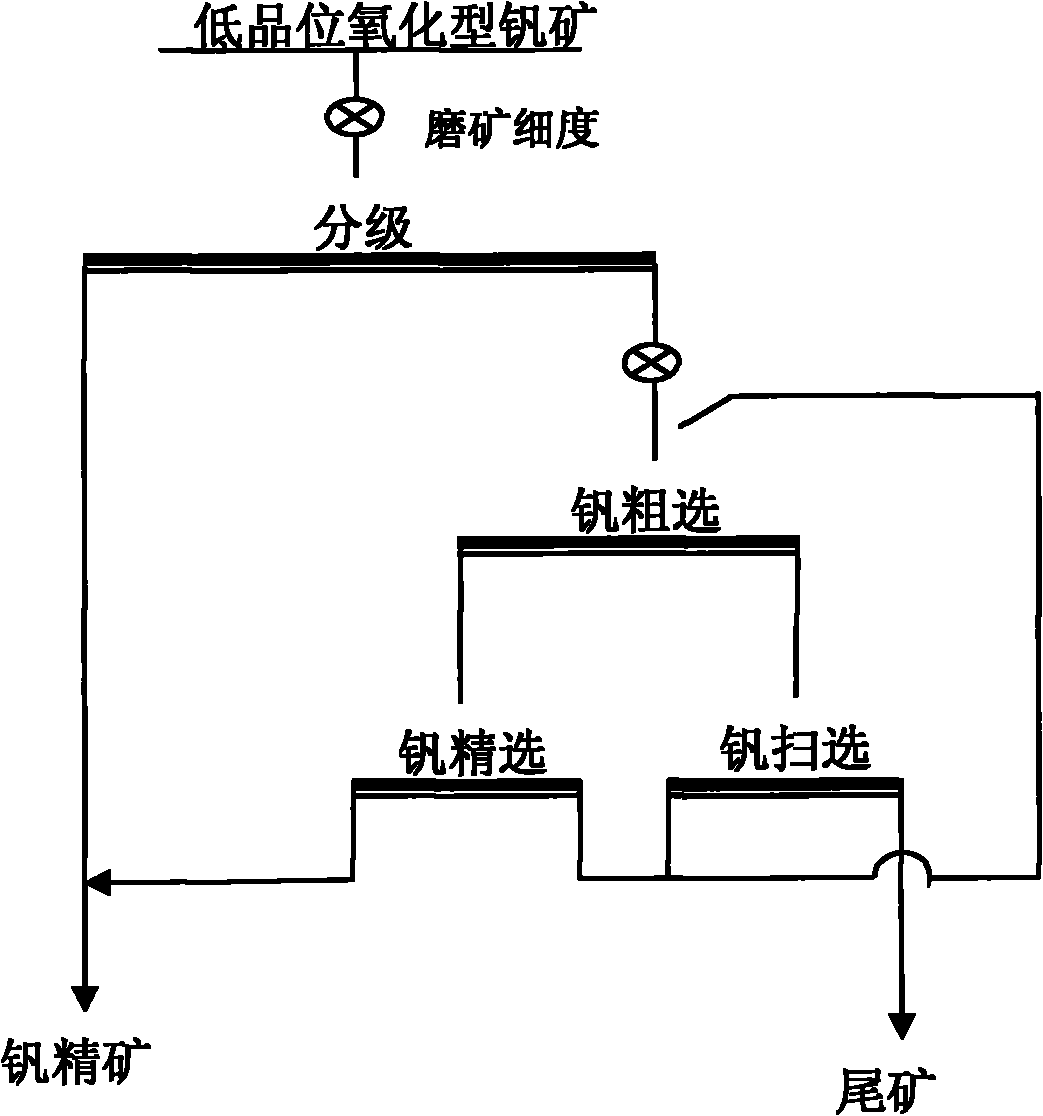

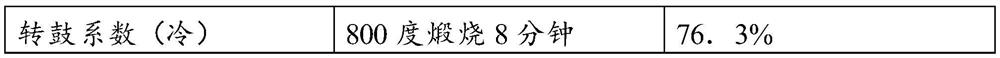

Extraction method for extracting vanadium pentoxide from low grade oxidized type navajoite

InactiveCN101775507AImprove gradeReduce processingVanadium oxidesProcess efficiency improvementWet grindingRotary kiln

The invention provides an extraction method for extracting vanadium pentoxide from low grade oxidized type navajoite. The method is as follows: crushing and grinding raw ores of the oxidized type navajoite, grading the crushed and grinded raw ores into coarse fraction products and fine fraction products; selecting mineral containing vanadium from the coarse fraction products by flotation to obtain vanadium concentrate, combining the fine fraction products with the vanadium concentrate to service as bulk concentrate, and taking the underflow of flotation as final tailings; drying the bulk concentrate, adding CaCO3 into the dried bulk concentrate, evenly mixing the CaCO3 with the bulk concentrate, placing the mixture into a disk granulator for pelletizing, leading particles into a rotary kiln for roasting, discharing and cooling calcined ores, leading the calcined ores into a lattice ball mill for wet grinding, levigating ore pulp, adding sulfuric acid the calcined ore quantity of which is 3%-5% into the ore pulp, performing agitation leach in an agitator bath for 4-6h, keeping the pH value within 2.0-2.5, leading lixivium produced by filtering the ore pulp to the purification procedure, washing leaching residues for three times so as to be prepared into building materials, and performing purification, resin adsorption, resolving, vanadium sinking and roasting on the lixivium to obtain a vanadium pentoxide product. The process of the invention adopts a technique of preparing with low cost, thereby effectivly improving the grade of vanadium raw materials, lowering the production cost and solving the problem of enviromental pollution.

Owner:中钢矿业开发有限公司 +2

Production process of inorganically combined fluorite balls

The invention discloses a production process of inorganically combined fluorite balls. The production process of inorganically combined fluorite balls includes the steps of mixing well fluorite floatation powder, fluorite powder, inorganic binder, water and sodium fluosilicate, feeding the mixture into a high-power double-roller ball press to press the mixture into balls, and baking and cooling the balls. The inorganically combined fluorite balls have high grade (content of CaF2 is not less than 85wt%), stable quality and reasonable reaction specific surface area, and have performance and mechanical strength required by stainless steel and high-strength pressure-resisting (blast furnaces and nonferrous metals) smelting of superlow-carbon 300 series and above. By applying the inorganically combined fluorite balls to smelting of special steel, the stainless steel, the blast furnaces and the nonferrous metals, slagging speed can be increased, smelting time can be shortened, and production cost can be lowered.

Owner:FOGANG DEYU FLUORITE BALL

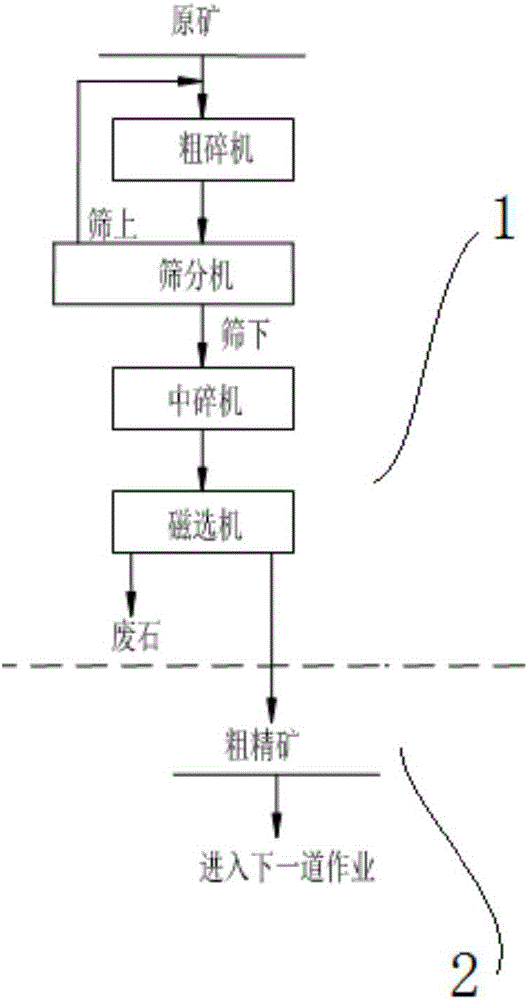

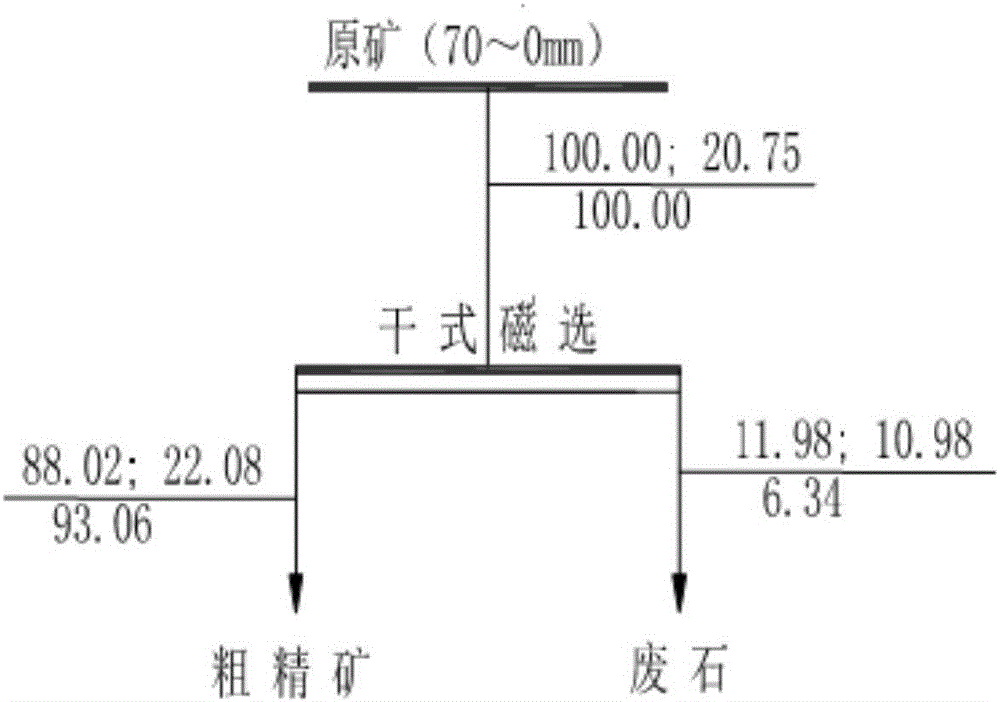

Beneficiation process of lean magnetite ores and production system thereof

ActiveCN106111297AImprove gradeReduce ore transportationMagnetic separationGrain treatmentsMagnetic separatorIronstone

The invention discloses a beneficiation process of lean magnetite ores and a production system thereof, and belongs to the technical field of beneficiation. The beneficiation process comprises the following steps: coarse crushing, intermediate crushing, magnetic separation and transferring. An intermediate crushing device is placed at the front of an ore stope, coarse crushing, intermediate crushing and dry magnetic separation are directly carried out on the stope, the purpose of 'early throwing and discarding' tailings and waste rock is achieved, the grade of rough concentrates is improved, the conveyance amount of the ores is reduced, the conveyance cost of the ores is also reduced, the service lives of a belt and a funnel lining plate of a magnetic separator are prolonged, and therefore, the operation cost of a mine is reduced effectively. The production system comprises a coarse crusher, a screening machine, an intermediate crusher, the magnetic separator, a belt conveyor I and a belt conveyor II, wherein the coarse crusher, the screening machine, the intermediate crusher and the magnetic separator are successively arrayed according to a production line in the ore stope; the belt conveyor I conveys the tailings and the waste rock to a dumping site after the tailings and the waste rock are separated magnetically; and the belt conveyor II conveys magnetically separated rough concentrates to a follow-up process. An iron ore extraction region is expanded, and for the actual situation that lean iron ores are main iron ores in China, the beneficiation process of the lean magnetite ores and the production system thereof are particularly worthy of being popularized and used.

Owner:马钢集团设计研究院有限责任公司

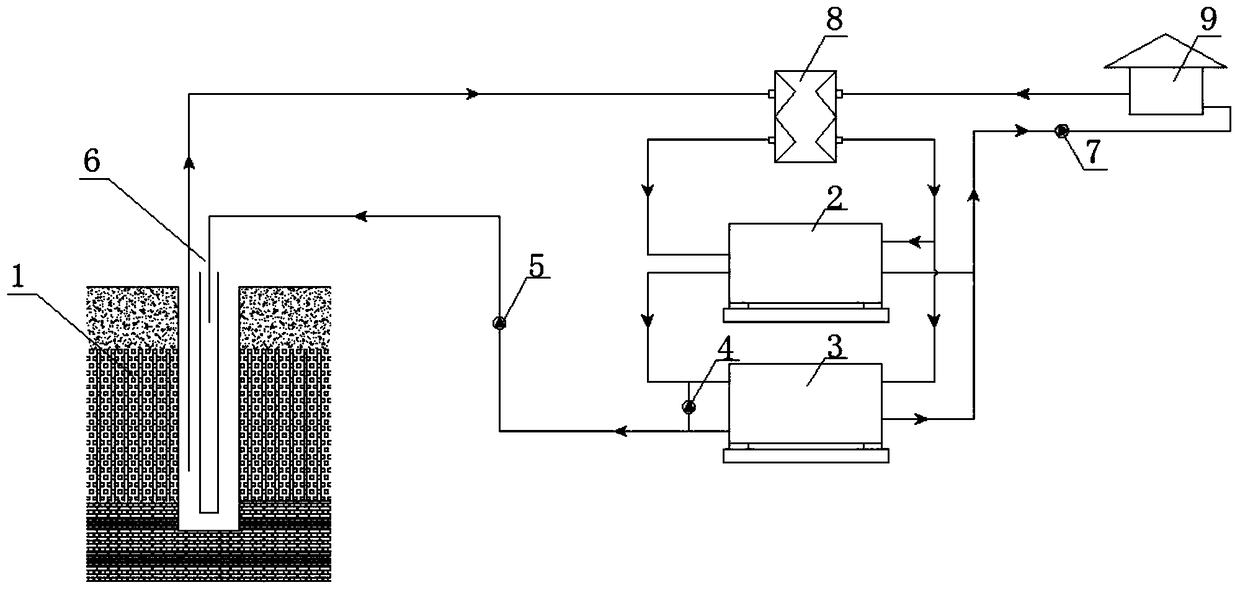

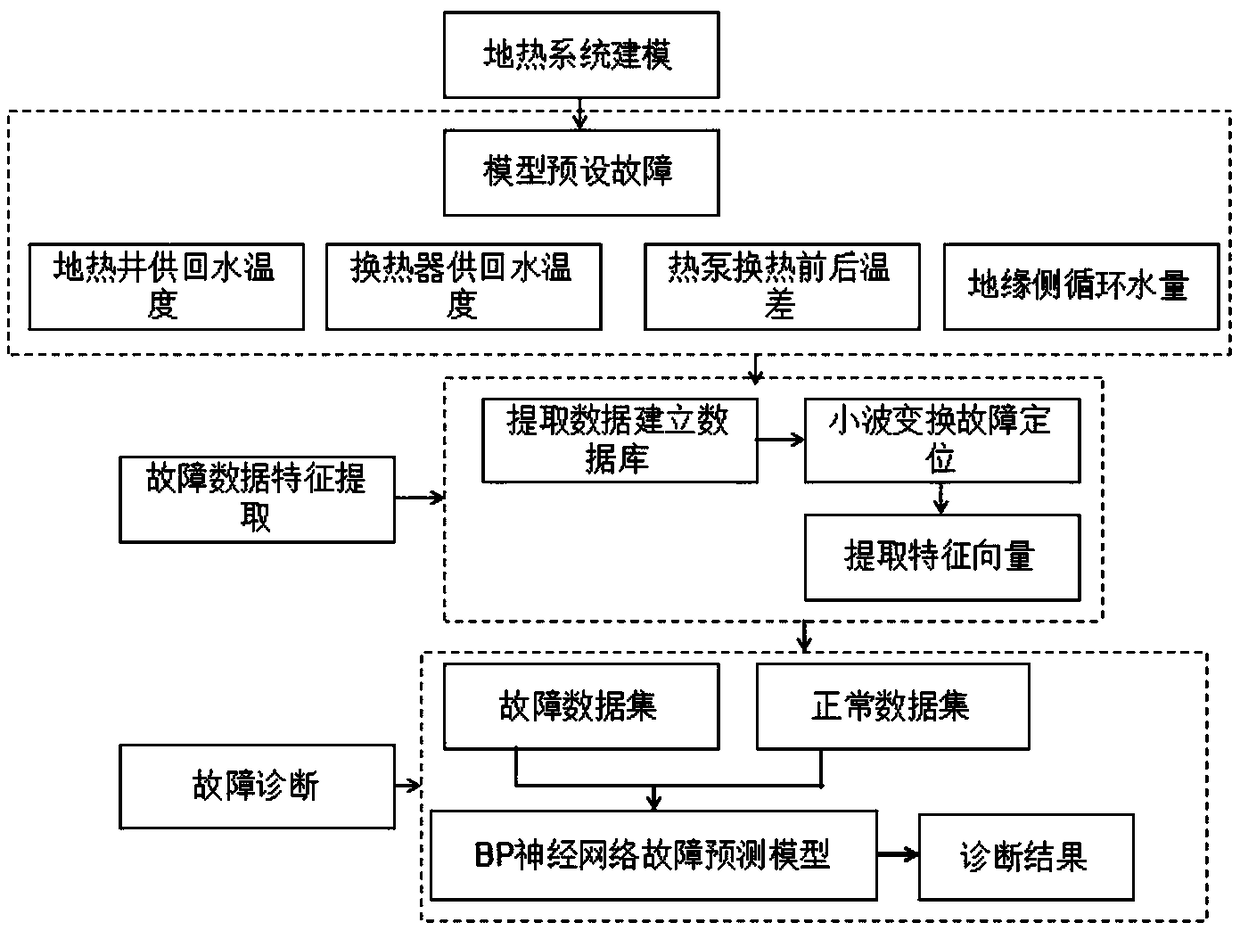

Middle-deep strata non-interference rock thermal heating supply system gradient utilization system and monitoring system and method

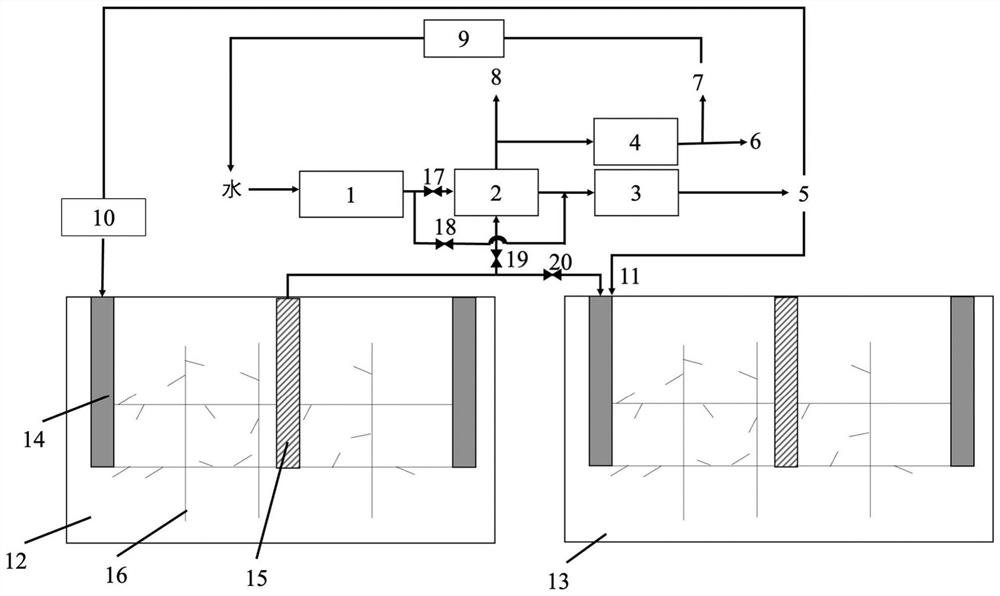

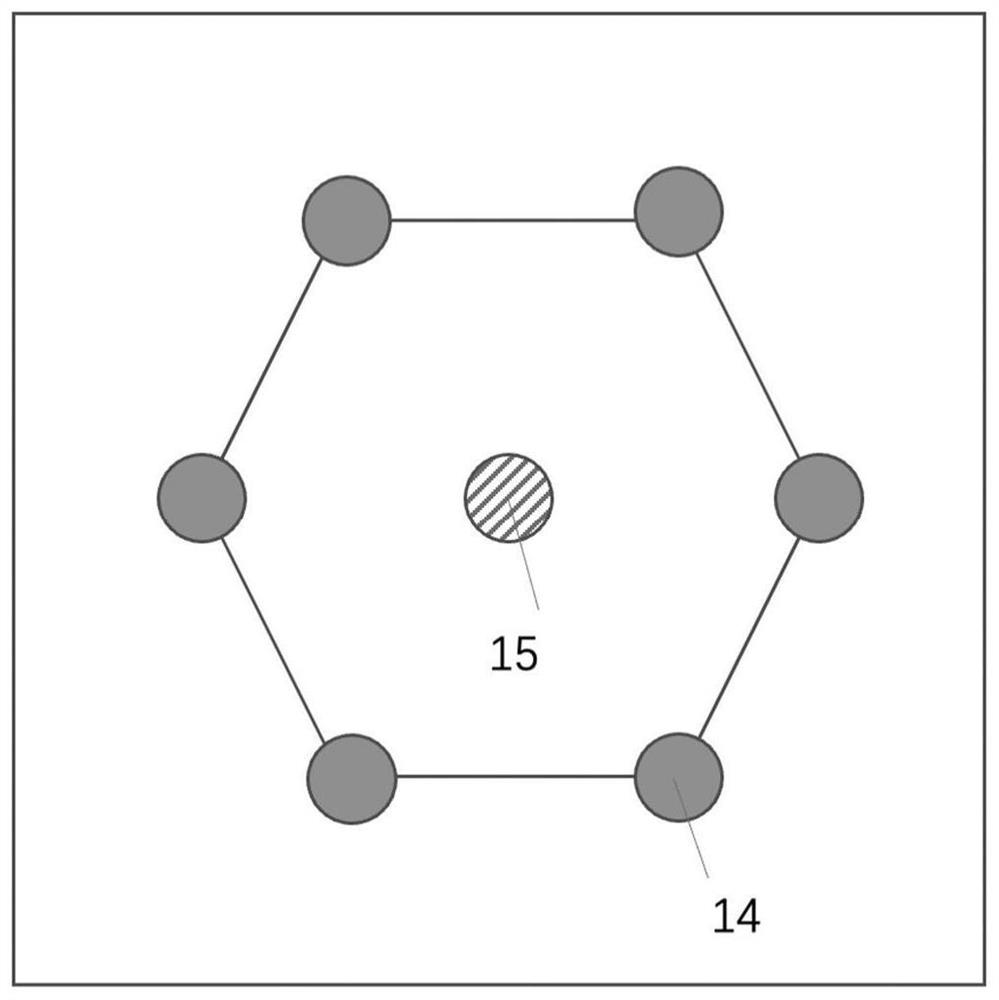

ActiveCN109297077AImprove utilization efficiencyImprove gradeHeat pumpsGeothermal energy generationWater deliveryEvaporator

The invention discloses a middle-deep strata non-interference rock thermal heating supply system gradient utilization system. A double-working-medium relatively independent structure is adopted, and the gradient utilization system comprises a plate heat exchanger which is connected with a geothermal well central pipe. A ground source side outlet of the plate heat exchanger is connected with a high-temperature heat pump. An evaporator outlet of the high-temperature heat pump is connected with an evaporator inlet of a low-temperature heat pump and an inlet of a water mixing system. An evaporatoroutlet of the low-temperature heat pump and an outlet of the water mixing system are connected with a circulating pump system together, and the circulating pump system is back connected with a geothermal well via a water delivery pipeline. A heat exchange water outlet of the plate heat exchanger is connected with a condenser of the high-temperature heat pump and a condenser of the low-temperatureheat pump. A heated water outlet of the high-temperature heat pump and a heated water outlet of the low-temperature heat pump are connected with users, and return water used by the users is deliveredto a heat exchange water inlet of the plate heat exchanger. The invention further provides a monitoring system and method of the gradient utilization system. According to the middle-deep strata non-interference rock thermal heating supply system gradient utilization system and the monitoring system and method, utilization efficiency of energy sources is improved based on the gradient utilizationsystem, key points of a whole heating supply system can be monitored based on the monitoring system, and operating efficiency of the whole heating supply system can be controlled in a detailed mode.

Owner:XI'AN PETROLEUM UNIVERSITY

Beneficiation method for mixed magnetite and hematite

ActiveCN103386361AEfficient recyclingImprove gradeDifferential sedimentationMagnetic separationBeneficiationMaterials science

The invention provides a beneficiation method for mixed magnetite and hematite. The method comprises the steps of a, performing first section ore grinding and second section ore grinding on the mixed magnetite and hematite to obtain ore pulp; b, grading the ore pulp, and performing first fluctuation and desliming on the obtained overflowing ore pulp to obtain slurry and setting sand; c, grading the setting sand, performing third section ore grinding, and performing second fluctuation and desliming on graded ore pulp obtained by ore grinding from the third section ore grinding to obtain slurry and setting sand; and d, performing reverse flotation on the setting sand obtained from the step c. The beneficiation method for the mixed magnetite and hematite is adopted to process the mixed magnetite and hematite with fine particles, so the higher recovery rate and the higher grade of the iron ore concentrate are realized.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

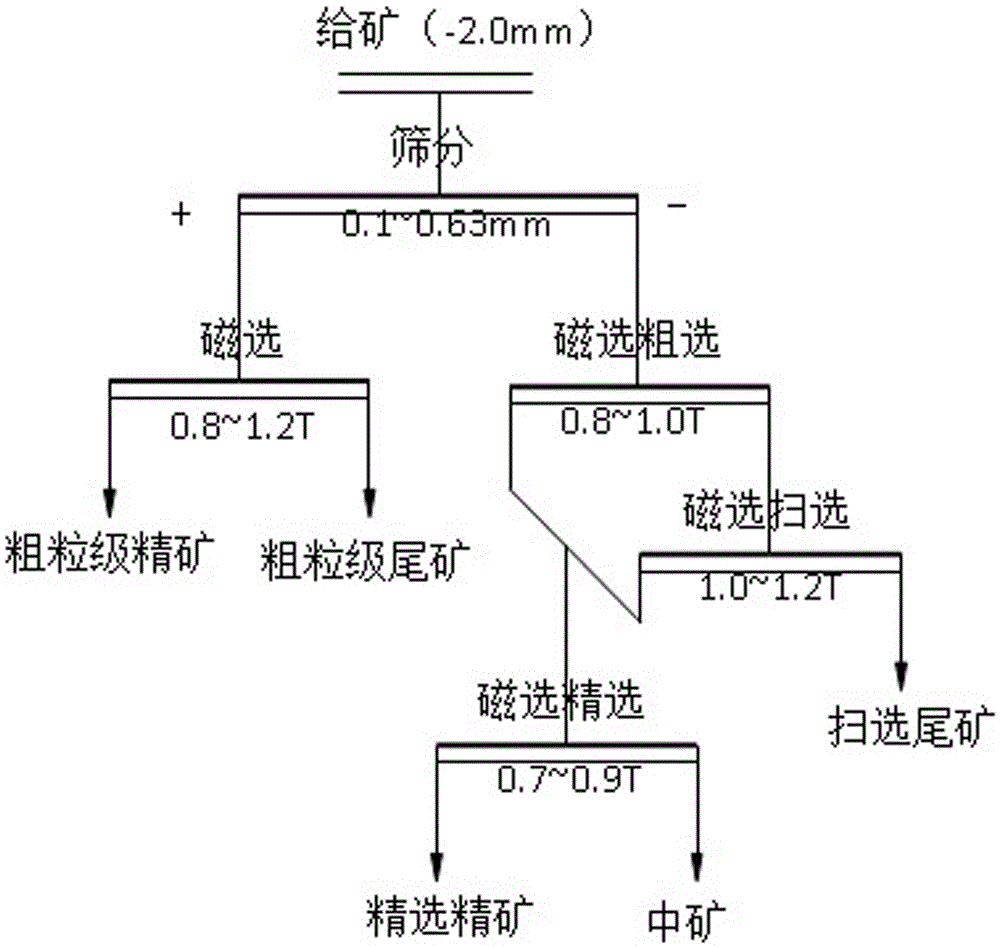

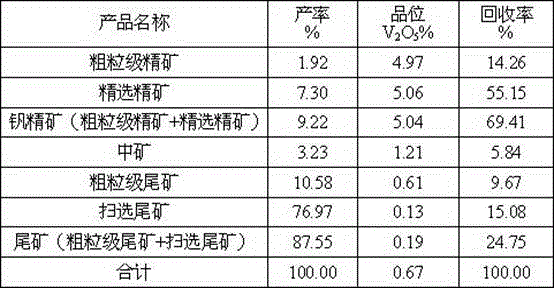

Mineral processing method for enriching vanadium pentoxide from graphite vanadium ore

InactiveCN105478232AImprove gradeSimple processHigh gradient magnetic separatorsOre concentrateVanadium(V) oxide

A mineral processing method for enriching vanadium pentoxide from graphite vanadium ore comprises the following steps: (1) V2O5 raw ore is completely crushed, the grade size of the crushed V2O5 raw ore is -2.0 mm, and the crushed raw ore is sieved to obtain two products of which the grade sizes are +1.0 to +0.63 mm and -1.0 to -0.63 mm; (2) the product of which the grade size is +1.0 to +0.63 mm is magnetically separated to obtain coarse-grain concentrate and coarse-grain tailings; 3) the product of which the grade size is -1.0 to -0.63 is magnetically separated and roughed to obtain roughed concentrate and roughed tailings; the roughed tailings are magnetically separated and scavenged to obtain scavenged concentrate and scavenged tailings; and the roughed concentrate and the scavenged concentrate are merged to be magnetically separated and finished to obtain finished concentrate and middlings, and the finished concentrate and the coarse-grain concentrate adopt vanadium concentrate as metallurgical vanadium extraction raw materials. The grade of V2O5 enriched according to the mineral processing method is higher than 5%, the enrichment ratio of V2O5 is higher than 4.1, the recovery rate of vanadium is higher than 6.7%, and the mineral processing method is suitable for recovering the graphite vanadium ore. The mineral processing method adopting the technical scheme has the advantages that ore grinding is not required, no drugs are adopted, the grade of the metallurgical vanadium extraction raw materials is effectively improved, the flow is simple, the energy consumption is low, no pollution is caused, the cost is low, and the mineral processing method is economic. The mineral processing method is suitable for enriching vanadium pentoxide of which the grade is 0.30-1.20% from graphite vanadium ore.

Owner:佛山市汇广机械制造有限公司

Purification method for coal tar maltha

ActiveCN102965135AEnergy savingImprove gradeWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionChemistryCoal Tar Pitches

A purification method for coal tar maltha aims to save energy and improve grade of coal asphalt raw material. The method provided by the invention comprises the steps of: conducting rough machining on the coal tar, cutting coal tar pitch with a softening point of 30-40 DEG C, and sending into a bulkhead type coal tar pitch extraction column for extraction; respectively heating an aliphatic extraction solvent and an aromatic extraction solvent to 110-250 DEG C; taking 0.5-1 part of an aliphatic solvent and 3-5 parts of an aromatic solvent, and mixing the two into an extractant by a static mixer; thoroughly stirring and mixing the extractant and coal tar pitch by a proportion of 1:0.5-1.3 with the static mixer, and adding the mixture from the upper part of the bulkhead type coal tar pitch extraction column; discharging the sulfur nitrogen compound in coal tar pitch and combined with the extractant from bottom of the extraction column, so as to purify coal tar pitch by removal of sulfur compounds; and discharging the coal tar pitch from the middle part of the bulkhead type coal tar pitch extraction column.

Owner:山西永东化工股份有限公司

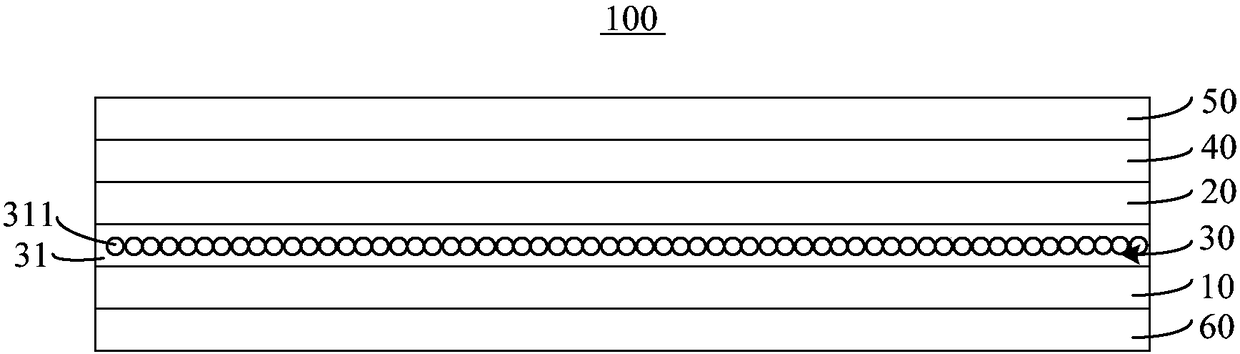

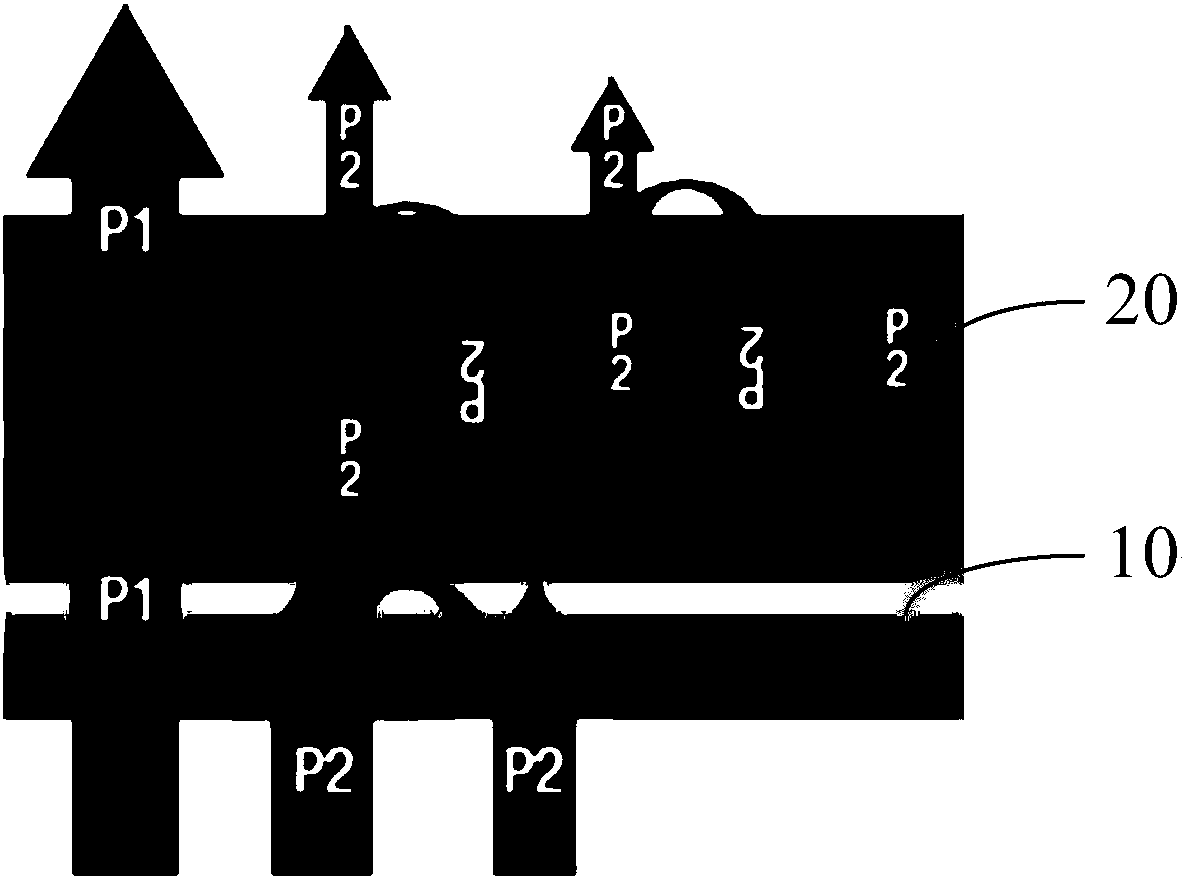

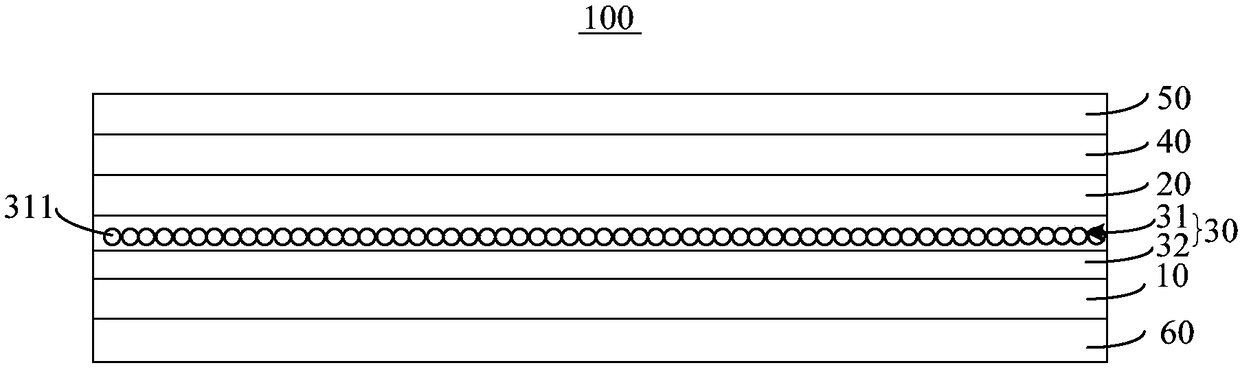

Polarizer and liquid crystal display

InactiveCN108490528AHigh shieldingImprove gradePolarising elementsNon-linear opticsPolarizerLiquid-crystal display

The present invention provides a polarizer comprising a DBEF functional layer, an atomization layer is added to one side of the DBEF layer of the polarizer facing a polarizing layer and / or one side ofthe DBEF layer away from the polarizing layer, and thus the large-angle dark state light leakage of the liquid crystal display including the polarizer is reduced. At the same time, the shading effectof the polarizer is increased through the added atomization layer, thus the shielding property of the polarizer to the backlight is improved, and the taste of the liquid crystal display is improved.

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD

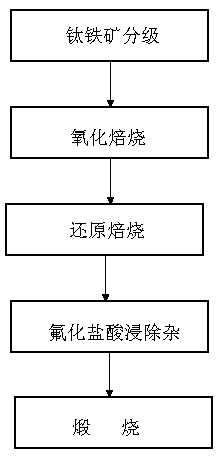

Method for preparing artificial rutile from titanium concentrate

The invention relates to a method for preparing artificial rutile. The method comprises the following steps: ilmenite classification, oxidizing roasting, reduction roasting, fluoride salt staging acidleaching impurity removal, water washing and calcination for obtaining high-grade artificial rutile. The problems of high calcium and magnesium content and low grade of artificial rutile are solved through hydrochloric acid leaching of redox-modified ilmenite, and fluoride salt staging acid leaching impurity removal adopted in the acid leaching process of the method enhances the impurity removalcapability, especially the calcium impurity removal capability, of individually used hydrochloric acid, so the prepared artificial rutile has a high grade and a low calcium and magnesium content, andcan be directly used as a raw material for a chlorination process. The method has the advantages of simple process and device, convenience in operation, low cost, and easiness in realization of industrial production. The grade of the artificial rutile obtained by the method is 90% or more, the impurity removal effect is good, and the total content of calcium and magnesium is 0.5% or less. The rawmaterial used in the invention is ilmenite from Panzhihua and Xichang regions in Sichuan.

Owner:LOMON BILLIONS GRP CO LTD

Molybdenum concentrate decarburization technique

ActiveCN106238214AImprove gradeIncrease varietyFlotationWet separationDecarburizationMolybdenum disulfide

The invention provides a molybdenum concentrate decarburization technique. The molybdenum concentrate decarburization technique comprises the steps that all flotation reagents used in the molybdenum flotation process are replaced by No. 200 megilp, concentration and filter pressing are conducted, and drying treatment is conducted. According to molybdenum concentrate treated through the technique, the mass content of molybdenum is no less than 57%, and the mass content of carbon is no greater than 0.5%. The problems that the carbon content in existing molybdenum concentrate exceeds the standard and the quality is unqualified are solved, the grade of the molybdenum concentrate is improved, the yield of the high-grade molybdenum concentrate is increased, qualified raw materials for downstream molybdenum processing and producing of high-purity molybdenum disulfide are provided, the molybdenum product types are increased, and the comprehensive benefits of molybdenum are increased.

Owner:金堆城钼业汝阳有限责任公司

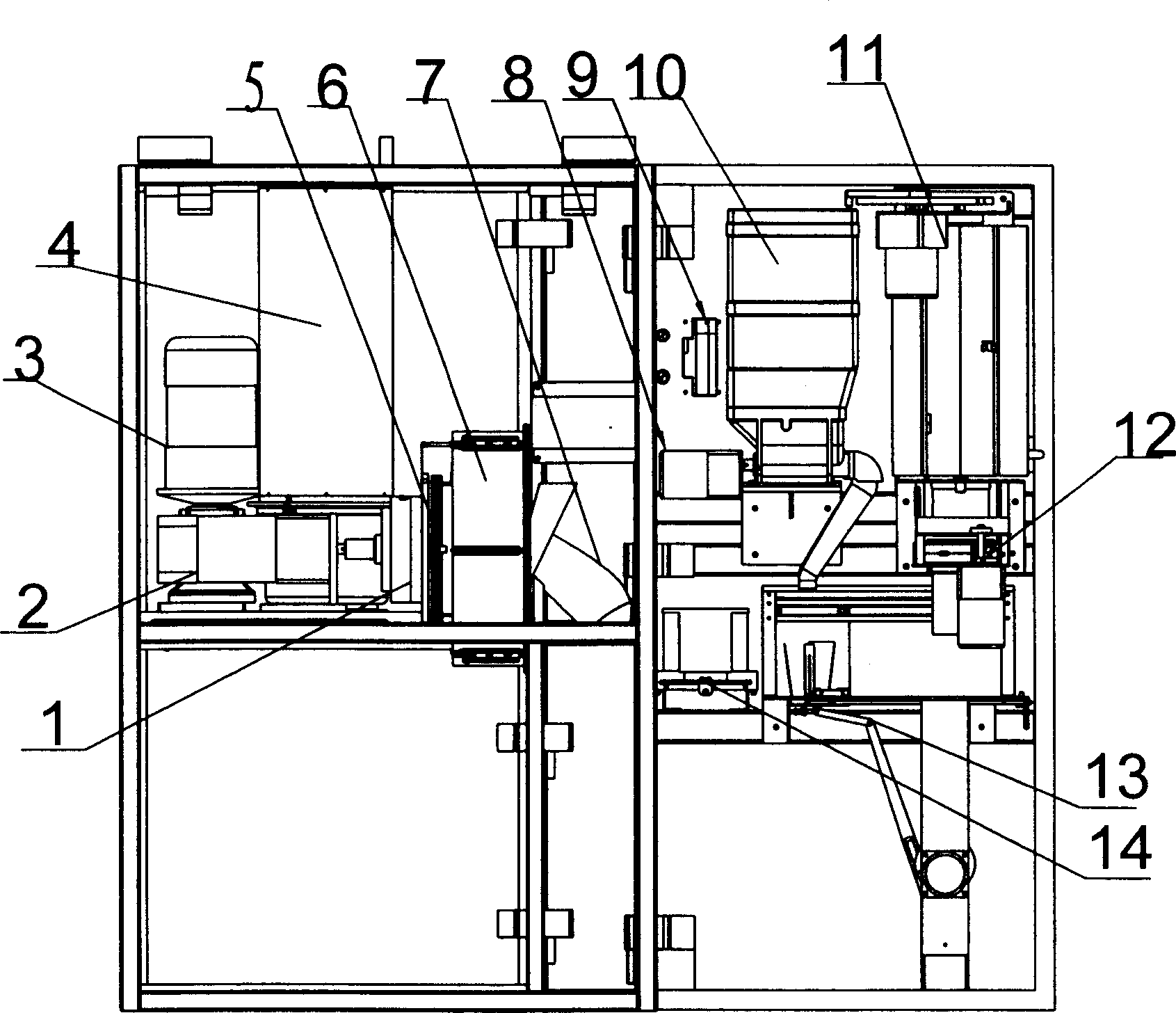

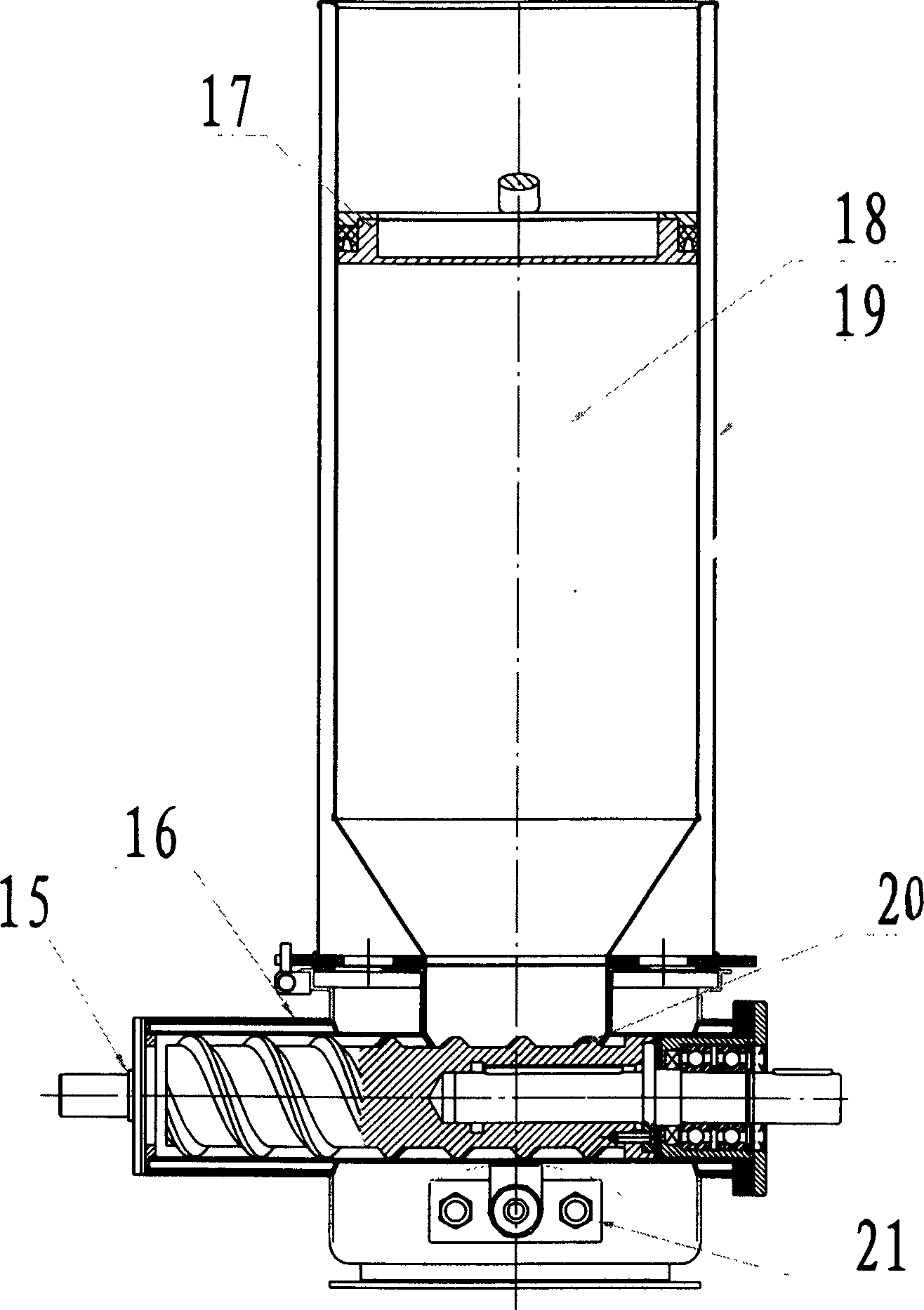

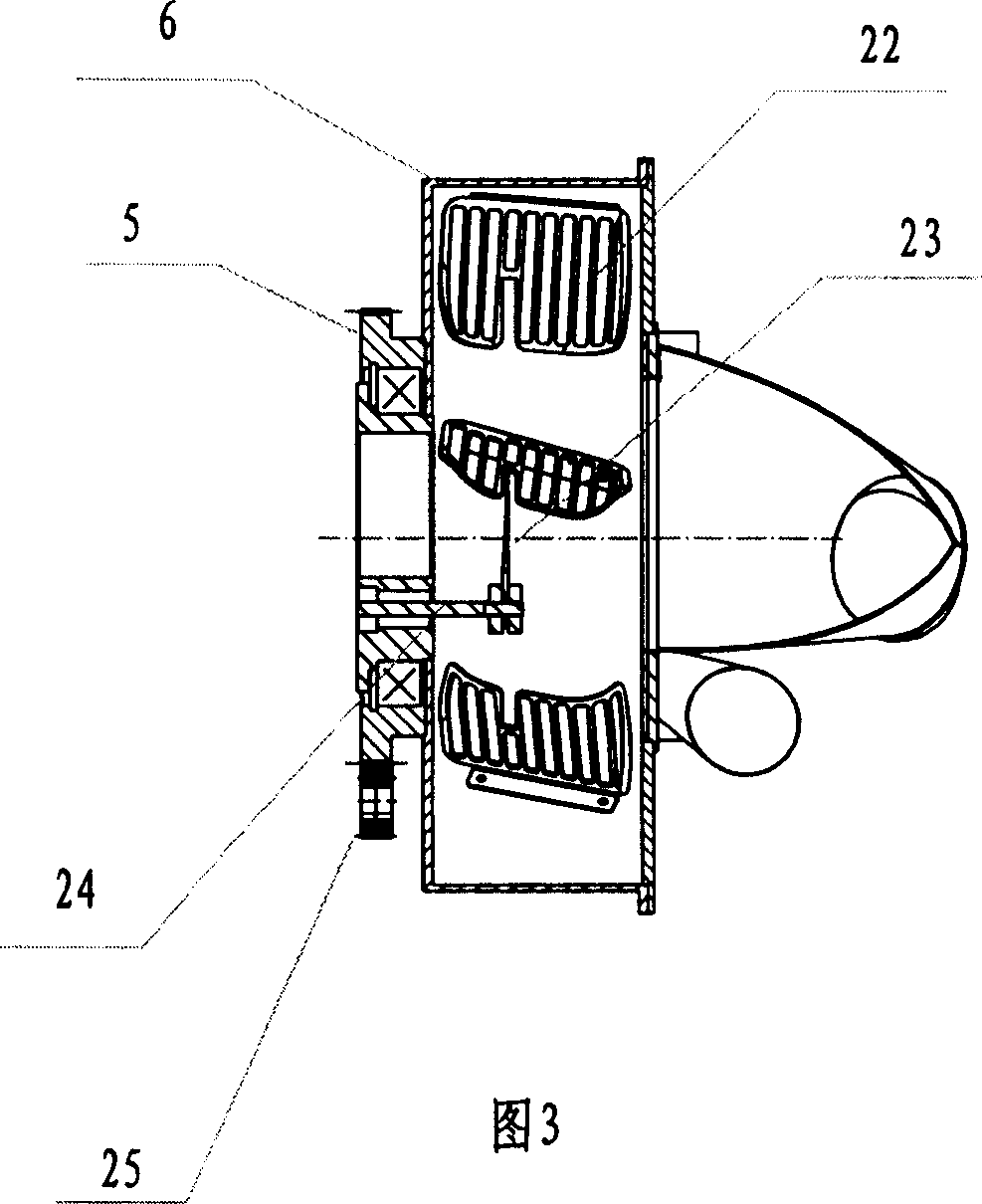

Full-automatic vending machine for instant cake-like food

InactiveCN1866304AImprove sanitationImprove gradeCoin-freed apparatus detailsApparatus for dispensing discrete articlesElectric machineryEngineering

The disclosed full-auto dispenser for immediate-making cake-form food comprises: a heat-insulating storage device with a motor and a stirring barrel with screen plate and cutter and twist dragon on ends, a heating-extruding device under former device, a cutting and stirring device, an acceptation device on dead ahead of the barrel, and a sale device. When purchaser casts some coin into the device, the set circuit board turns on circuit for dropping cup mechanism and sending cup mechanism; the paper cup drops under the accepting funnel to accept the cut food.

Owner:裘斌辉

Iron-base alloy catalyst and its preparing method

InactiveCN1109577CImprove gradeLarge granularityMetal/metal-oxides/metal-hydroxide catalystsSurface finishingIron based alloy

The iron-base alloy catalyst for synthesis of high-grade diamond monocrystal contains Fe, Ni, Mn, Co, Cu and graphite and has a Fe content of 50-76%. The catalyst is prepared through the processes of mixing powder of the components, cold pressing to form, low temperature sintering in sintering furnace, shaping and surface finishing. The preparation process has high finished product rate and the catalyst can be used to produce high-grade diamond with high strength and large size at low cost.

Owner:山东工业大学

Method for producing powdered rock phosphate balls by using powdered rock phosphate

PendingCN111847409AIncrease contentImprove gradeRaw phosphate material treatmentElectric furnacesMineralogy

The invention provides a method for producing powdered rock phosphate balls from powdered rock phosphate. The method comprises the following steps: mixing 100 parts by mass of powdered rock phosphate,1-4 parts by mass of phosphoric acid and 0.5-1 part by mass of calcium carbonate, mixing 0.5-3 parts by mass of sulfuric acid and 0.5-2 parts by mass of a phosphate adhesive, pressing into balls, drying and cooling to obtain powdered rock phosphate balls. According to the method, phosphoric acid, sulfuric acid and a phosphate adhesive are adopted, and P2O5 in the phosphoric acid, sulfuric acid and the phosphate adhesive finally enters the furnace to participate in phosphorus production reaction, so that the content of P2O5 in the phosphate ore is increased, and the grade of the phosphate oreis improved, meanwhile, sulfuric acid is added to further reduce the cost, and reacts with calcium carbonate and other substances to enhance the strength of the final product. The added phosphoric acid and carbonate impurities in phosphorite are subjected to a chemical replacement reaction, a double-roller mixer is used for mixing, CO2 and organic matter harmful to electric furnace production arefully released, the added phosphoric acid is waste phosphoric acid generated in the yellow phosphorus production process, and the utilization value of the waste phosphoric acid is increased.

Owner:重庆雁川化工科技有限公司

System and method for in-situ pyrolysis of oil-rich coal through steam heat injection

PendingCN114790880AImprove gradeReduce ecological environment damageFluid removalInjection wellPollutant

The invention discloses a system and method for in-situ pyrolysis of oil-rich coal through steam heat injection. The system comprises a pressurizing water pump, a condensation heat exchanger, a steam generation device, a centrifugal machine, a water circulation filtering device, a heat injection well, a production well and other components. Aiming at fuel with high tar yield such as oil-rich coal and the like which is easily decomposed to generate oil gas after being heated, water vapor is adopted as a heat injection medium, in-situ pyrolysis of a coal seam is carried out by gradient utilization of heat energy of the water vapor, and the function of co-production of oil gas in the oil-rich coal is achieved. Oil and combustible gas resources generated in the pyrolysis process are extracted, separated water is recycled, pollutants are not directly discharged to the environment, waste heat of products obtained after pyrolysis is comprehensively utilized, and the multi-phase separation process of oil, gas and water is achieved. According to the system, heating and waste heat utilization under different working conditions in the in-situ pyrolysis process are achieved with fewer components, low-energy-consumption and efficient utilization of oil-rich coal is achieved, and the shortage of oil and gas resources in China is relieved.

Owner:陕西省煤田地质集团有限公司 +1

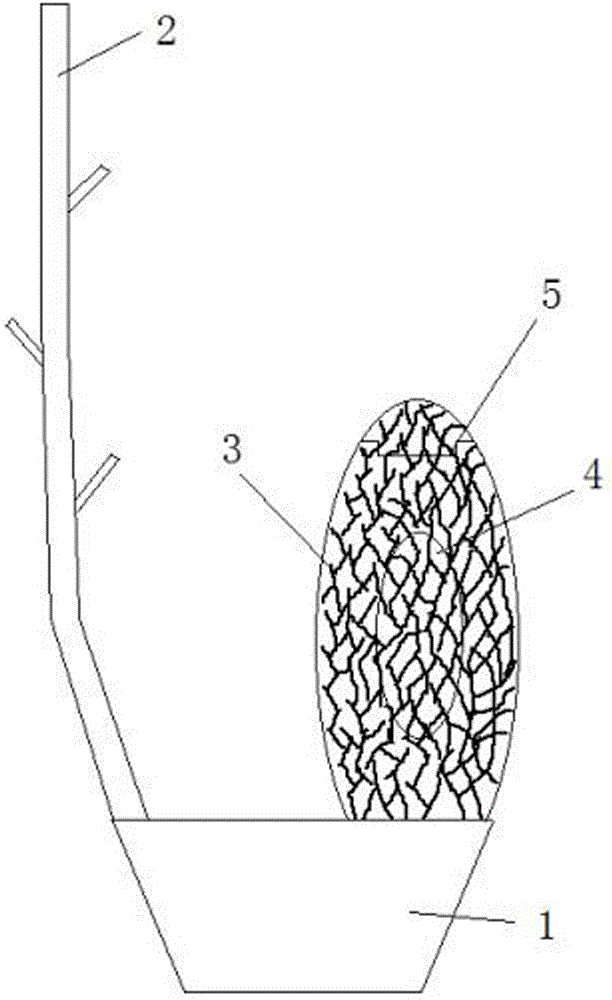

Wood-craft tea branch coat rack illuminating lamp

InactiveCN106704895AImprove gradeStrong aestheticsLighting elementsFree standingEngineeringTree trunk

The invention discloses a wood-craft tea branch coat rack illuminating lamp. The wood-craft tea branch coat rack illuminating lamp comprises a base, wherein a plurality of vertical tree trunk are fixedly mounted on one side of the upper end of the base; a plurality of tea branches which surround in a circle are mounted on the other side of the upper end of the base; the tea branches which surround in a circle surround to form a drum shape, the middle part of the drum is hollow, and a sunken cavity is formed in the top of the drum; a lamp is mounted in the middle hollow part of the drum shape which is formed by the tea branches which surround in a circle; and a potted plant or other adornments can be placed in the sunken cavity. According to the wood-craft tea branch coat rack illuminating lamp disclosed by the invention, the tea branches are arranged beside a rack, so that a space is formed; light can be provided at night; the potted plant and the like are placed to further beautify the environment and improve the artistic grade; and the overall beauty is very intense. The wood-craft tea branch coat rack illuminating lamp is new-generation wood-craft furniture.

Owner:合肥意繁机电科技有限公司

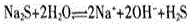

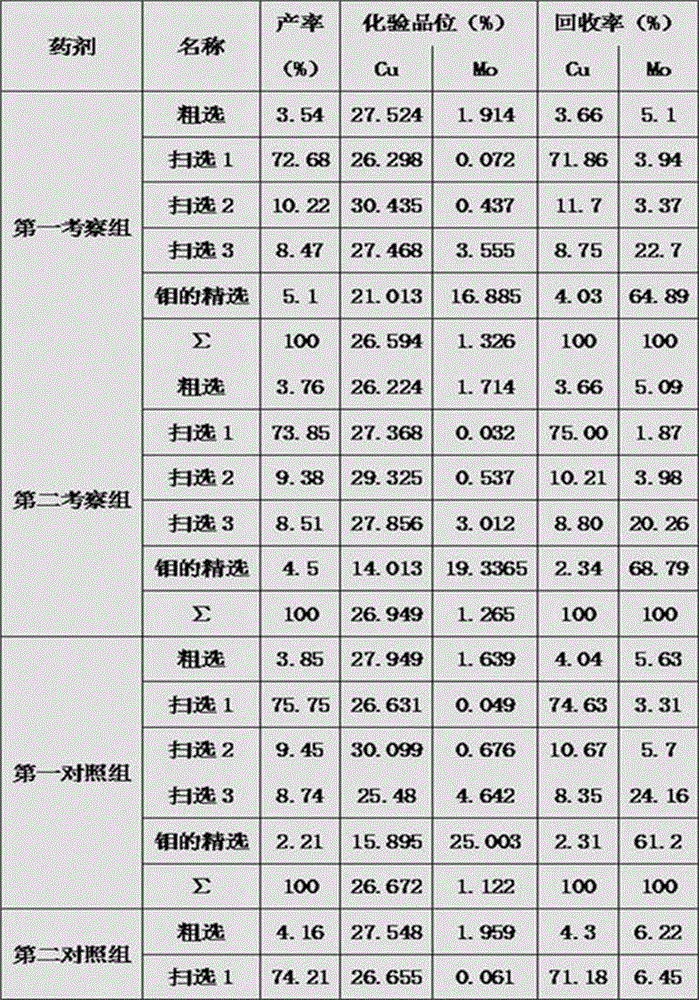

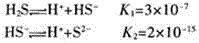

Flotation regulator applied to copper-molybdenum sulphide ore separating flotation and application method thereof

ActiveCN106733207ACopper inhibition effect is obviousImprove gradeFlotationOre concentrateEngineering

The invention discloses a flotation regulator applied to copper-molybdenum sulphide ore separating flotation and an application method thereof. The flotation regulator is a mixed solution obtained by dissolving sodium sulphide in domestic drinking water. The flotation regulator can effectively improve the grade of concentrates obtained after flotation, meanwhile, has high flotation efficiency, and can greatly reduce the usage amount of sodium sulphide.

Owner:LIANGSHAN MINING CO LTD

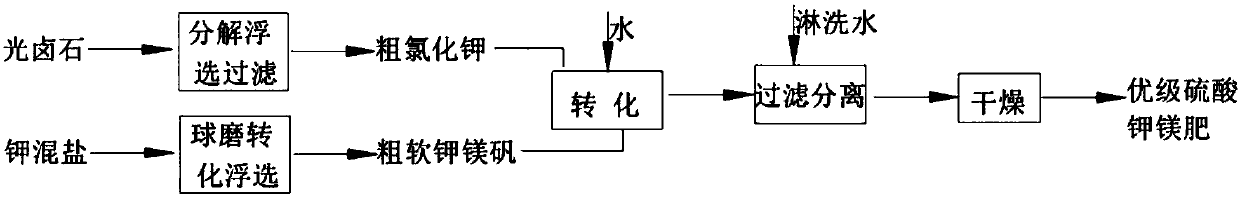

Method for preparation of superior grade potassium magnesium sulfate fertilizer from crude potassium chloride and crude picromerite

InactiveCN107935638AImprove gradeThe principle is simplePotassium fertilisersChloride potassiumDecomposition

Belonging to improvement of superior grade potassium magnesium sulfate preparation technology, the invention specifically relates to a method for preparation of a superior grade potassium magnesium sulfate fertilizer from crude potassium chloride and crude picromerite. The method includes: (1) a decomposition-flotation section; (2) a ball-milling conversion flotation section; (3) a conversion section; (4) a separation-leaching section; and (5) a drying section. The method provided by the invention can obtain high-grade superior potassium magnesium fertilizer, and realizes the zero breakthroughof superior potassium magnesium fertilizer. The method mainly controls the adding dosage and conversion water amount of crude potassium chloride to convert potassium chloride and part of picromeriteinto glaserite, thus improving the product grade. The method provided by the invention has the advantages of simple principle, short process route, easy operation, and a K<+> recovery rate of 60% or more.

Owner:SDIC XINJIANG LUOBUPO POTASH CO LTD

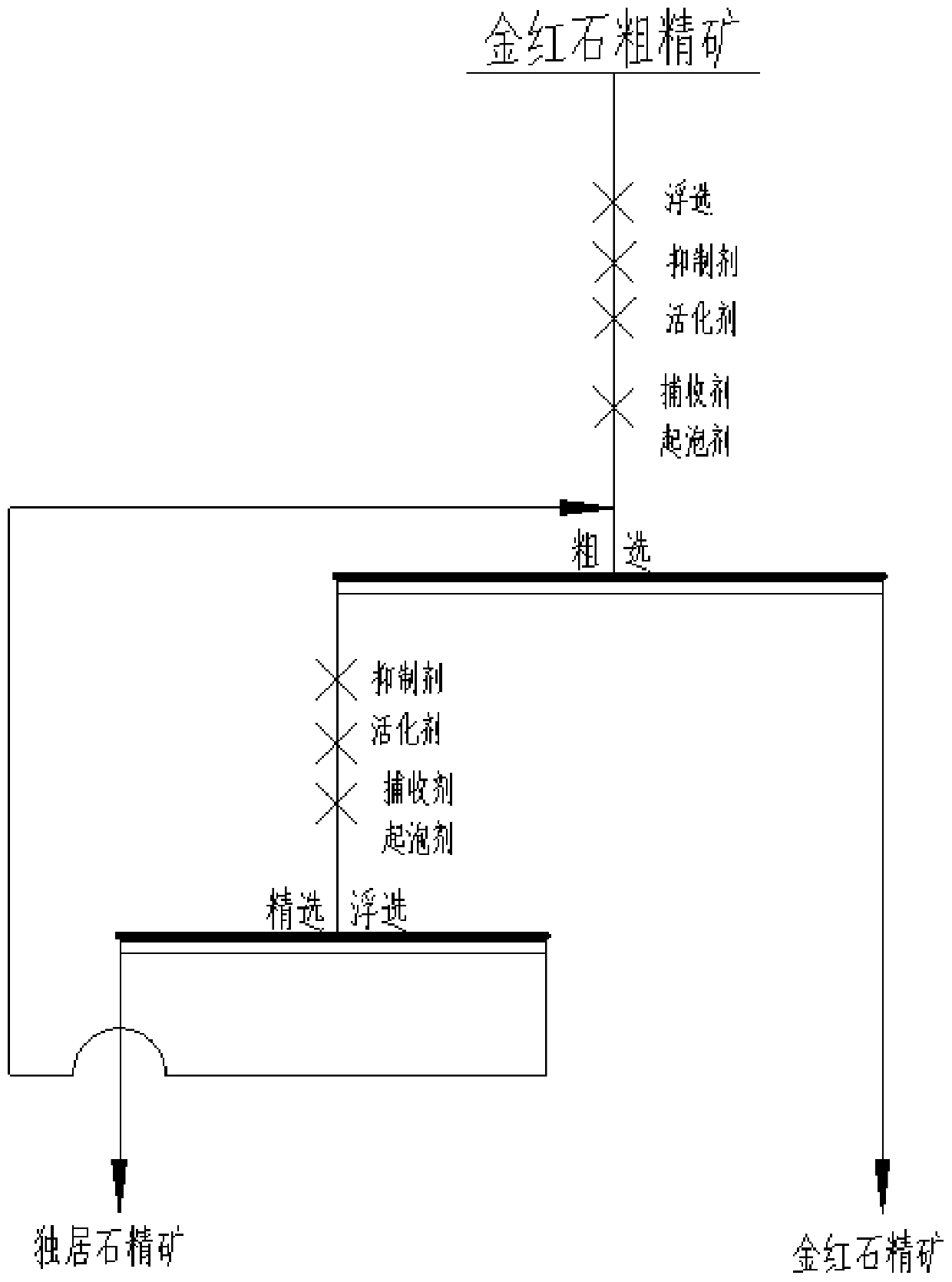

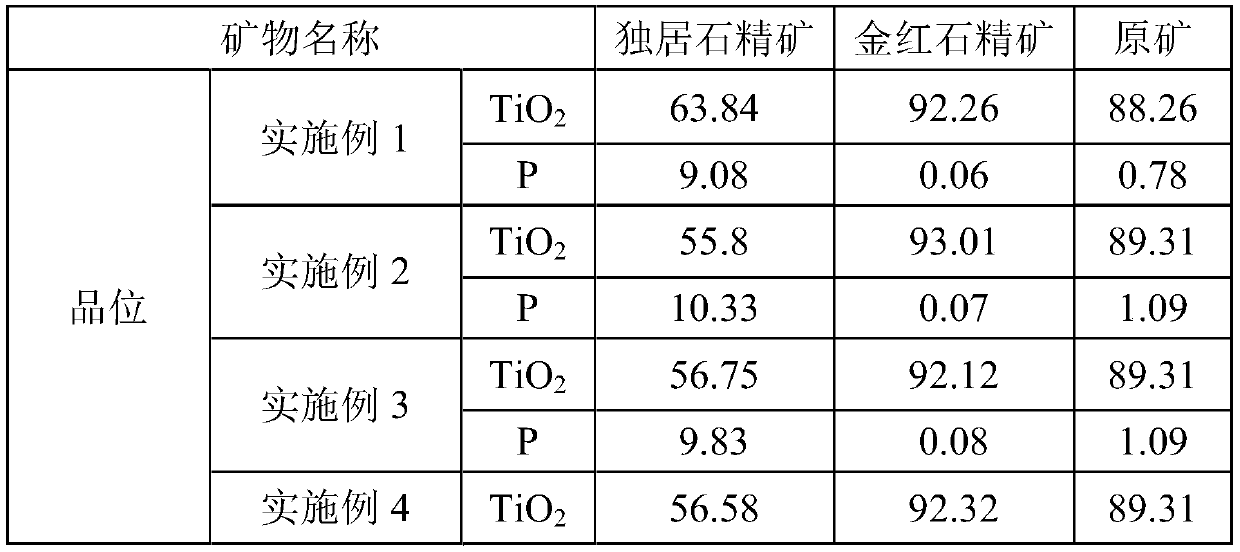

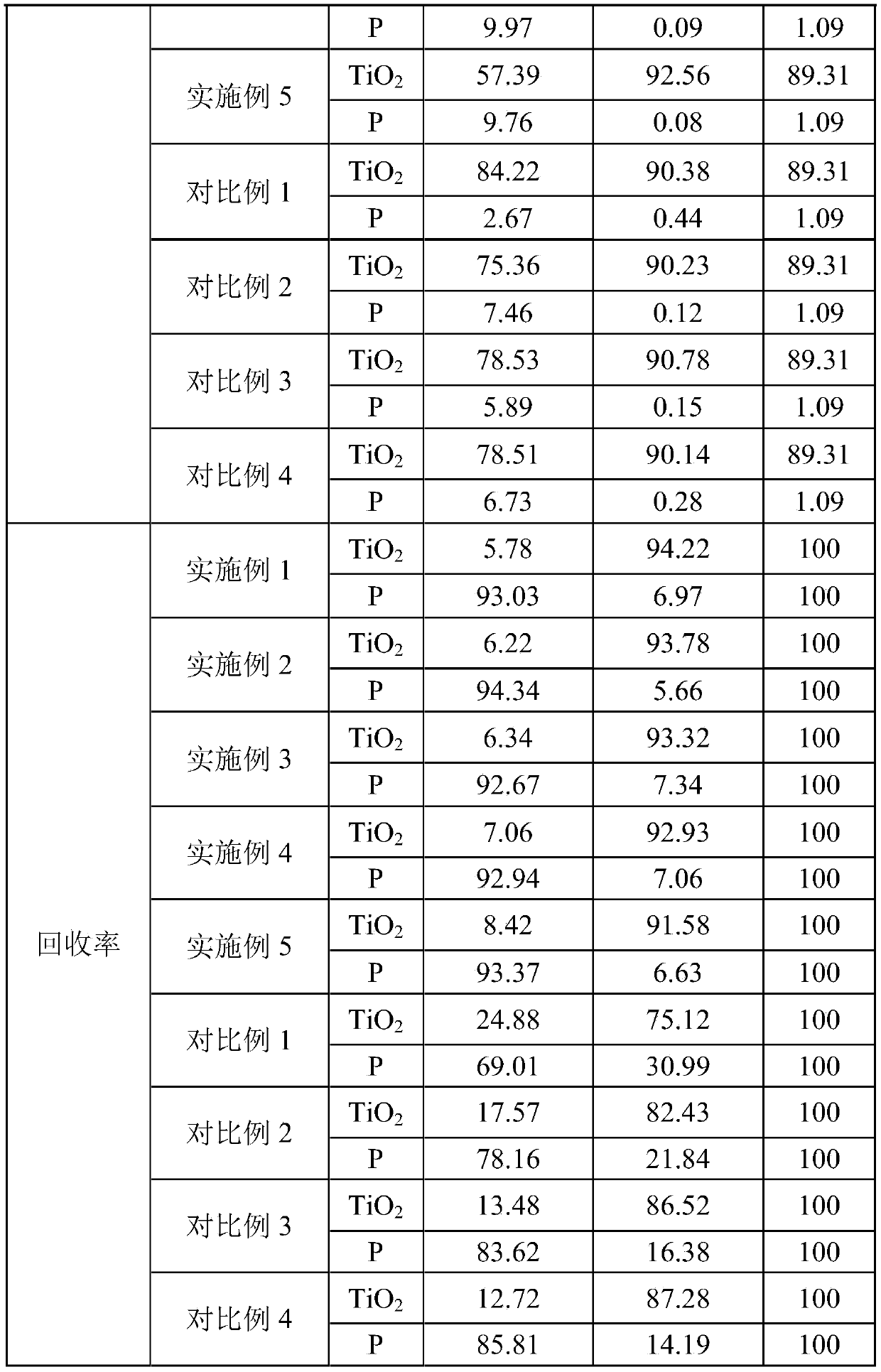

Beneficiation process for sorting monazite and rutile by using composite collecting agent and application thereof

ActiveCN111515030AImprove qualityImprove gradeFlotationProcess efficiency improvementFatty acid methyl esterSodium hydroxide

The invention provides a beneficiation process for sorting monazite and rutile by utilizing a composite collecting agent and an application thereof. The beneficiation process comprises the following steps: (1) mixing 10-15 parts by weight of tall oil, 25-35 parts by weight of oxidized paraffin soap, 40-50 parts by weight of palm oil and 10-15 parts by weight of sodium fatty acid methyl ester sulfonate, and carrying out microwave pre-activation for 5-10 minutes; and adding 8-12 parts by weight of sodium hydroxide after microwave activation, performing saponification for 1.5-2.5 h at the temperature of 85-100 DEG C, and obtaining the target collecting agent. (2) taking a rutile rough concentrate raw material, adding the collecting agent, an inhibitor, an activating agent and a foaming agent,and carrying out primary flotation to obtain monazite rough concentrate and tailings; and (3) adding the collecting agent, the inhibitor, the activating agent and the foaming agent into the monaziterough concentrate, performing secondary flotation, and obtaining monazite concentrate and tailings, wherein the tailings are rutile concentrate. According to the beneficiation process, the rutile rough concentrate is effectively separated, the obtained monazite concentrate product and rutile concentrate product are high in quality, and the beneficiation process is environmentally friendly.

Owner:JIANGXI UNIV OF SCI & TECH +3

Method for producing iron ore concentrate by quickly burning siderite through microwave

The invention provides a method for producing iron ore concentrate by quickly burning siderite through microwave, comprising the steps of placing the siderite powders into a microwave reactor and introducing oxygen to heat the siderite to 400-700 DEG C at a frequency of 2450 MHz and an input power of 50-300 W / Kg; and then keeping the temperature for 10-20 minutes to obtain high-grade iron ore concentrate with Fe3O4 being the principal component. The method has the characteristics of cleaning, energy saving, low cost, and small pollution. The iron ore obtained after calcination is of high grade and the high-temperature smog can be further applied to drying the iron ore concentrate after dust extraction.

Owner:KUNMING UNIV OF SCI & TECH

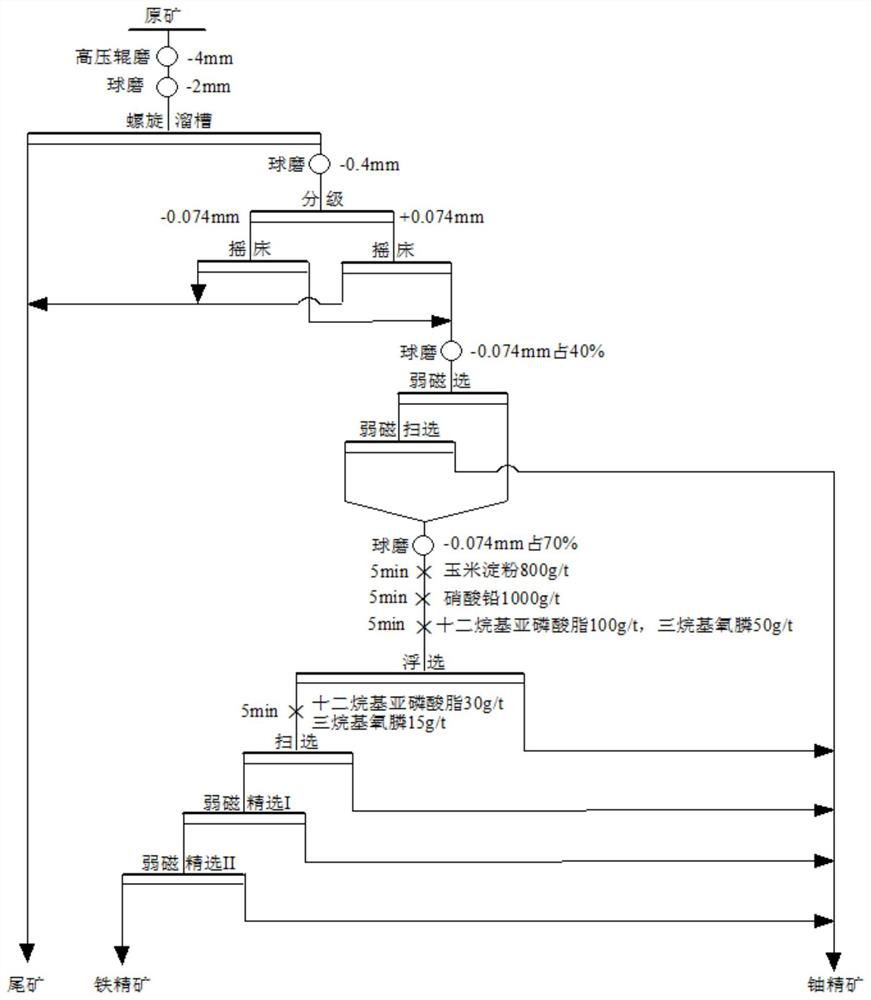

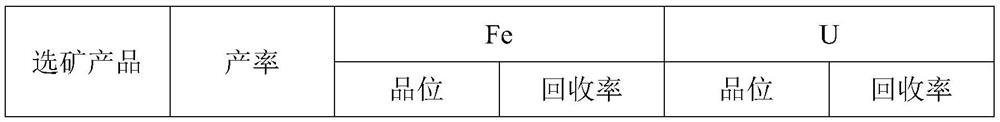

Beneficiation comprehensive recovery method for low-grade iron-containing uranium ore

ActiveCN113333156AImprove the economic benefits of mine depositsImprove gradeSolid separationOre concentrateGravity separation

The invention discloses a beneficiation comprehensive recovery method for low-grade iron-containing uranium ore. The beneficiation comprehensive recovery method comprises the steps that uranium ore and magnetite are enriched in advance through gravity separation of the low-grade iron-containing uranium ore, then a magnetite is separated from gravity separation concentrate through low-intensity magnetic separation, the uranium ore is removed from magnetic separation rough concentrate through flotation and multiple times of low-intensity magnetic concentration, the quality of the iron ore concentrate is improved, the radioactivity is removed, the iron grade in the finally obtained iron ore concentrate is 67.12%, the iron recovery rate is 91.59%, and the radioactivity reaches the national standard; and the uranium grade in the obtained uranium concentrate is 0.261%, the uranium recovery rate is 84.41%, the iron grade is only 1.56%, the uranium grade in the uranium concentrate is improved, and the iron grade in the uranium concentrate is reduced. According to the beneficiation comprehensive recovery method for the low-grade iron-containing uranium ore, comprehensive recovery of the low-grade iron-containing uranium ore is really realized.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

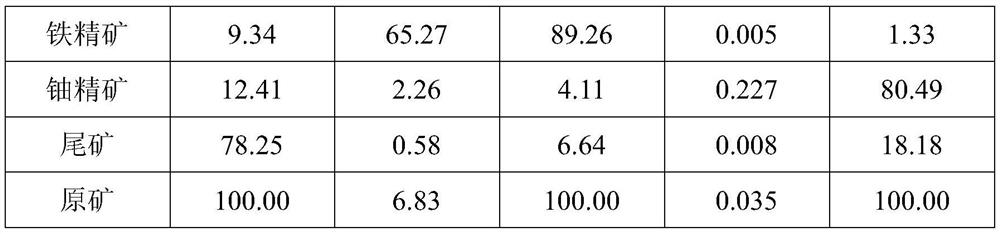

Method for improving grade of fluorite concentrate

The invention discloses a method for improving the grade of fluorite concentrate. The method comprises: adding an adjusting agent into a fluorite ore after ore grinding to obtain a first fluorite oreslurry; adding an inhibitor, an activator and a collector into the first fluorite ore slurry to obtain a second fluorite ore slurry and a first tailings; performing ore grinding treatment on the second fluorite ore slurry to obtain a third fluorite ore slurry; adding an inhibitor, an activator and a collector into the third fluorite ore slurry to obtain a fourth fluorite ore slurry and a second tailings; and adding an inhibitor into the fourth fluorite ore slurry to obtain the fluorite concentrate. In the method provided by the invention, a pH value of the ore slurry is adjusted through the adjusting agent, then the fluorite ore is subjected to concentration and scavenging for several times through addition of the inhibitors, the activators and the collectors, and then the grade of the fluorite concentrate is improved, an impurity content of the fluorite ore is reduced, and at the same time, the problems of large middling circulation amount, low separation efficiency, and unstable flotation in the production can be eliminated.

Owner:西安矿源有色冶金研究院有限公司

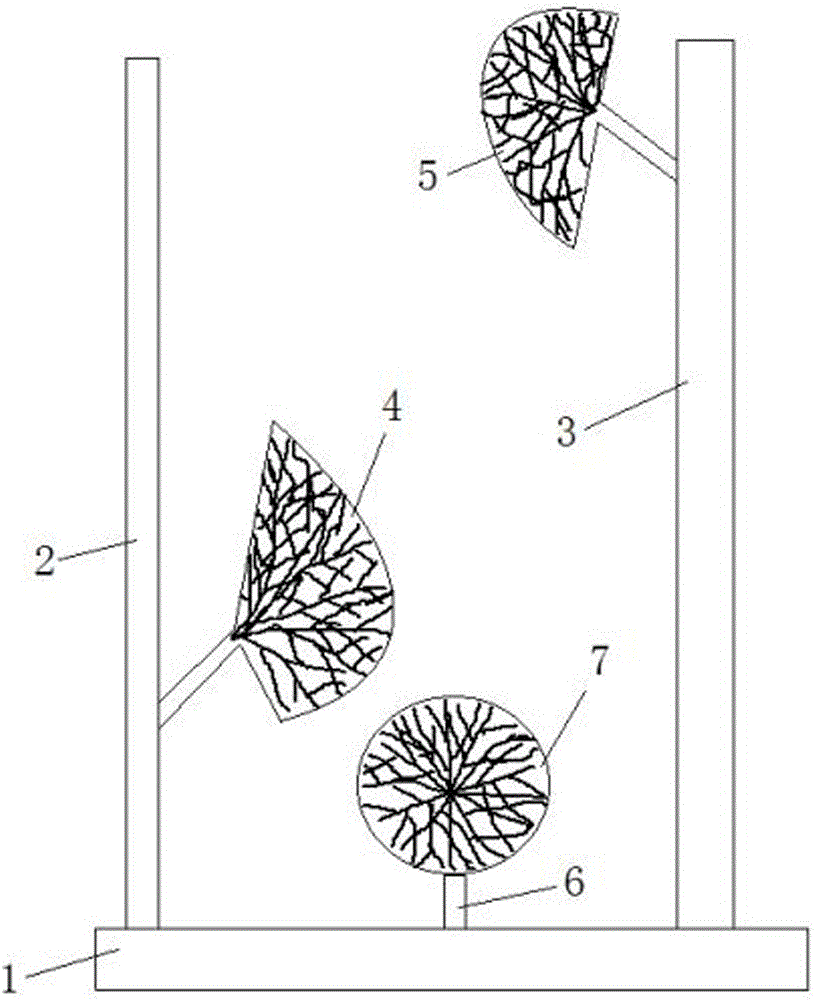

Wooden hat and coat stand with tea tree branch clusters

The invention discloses a wooden hat and coat stand with tea tree branch clusters. The hat and coat stand comprises a base and the tea tree branch clusters, a left vertical trunk and a right vertical trunk are fixedly mounted at the upper end of the base, middle tea tree branch clusters are arranged on the left vertical trunk, upper tea tree branch clusters are arranged on the right vertical trunk, a vertical rod is arranged at the upper end of the base and positioned between the left vertical trunk and the right vertical trunk, lower tea tree branch clusters are arranged on the vertical rod, and a plurality of tea tree branches are integrally bound to form the tea tree branch clusters. According to the hat and coat stand, a plurality of tea tree branch clusters are arranged on the trunks, the hat and coat stand can hang clothes and serve as artworks, the environments can be beautified, taste is improved, and the hat and coat stand is strong in overall aesthetic feeling and new-generation wooden furniture.

Owner:合肥协佳机电科技有限公司

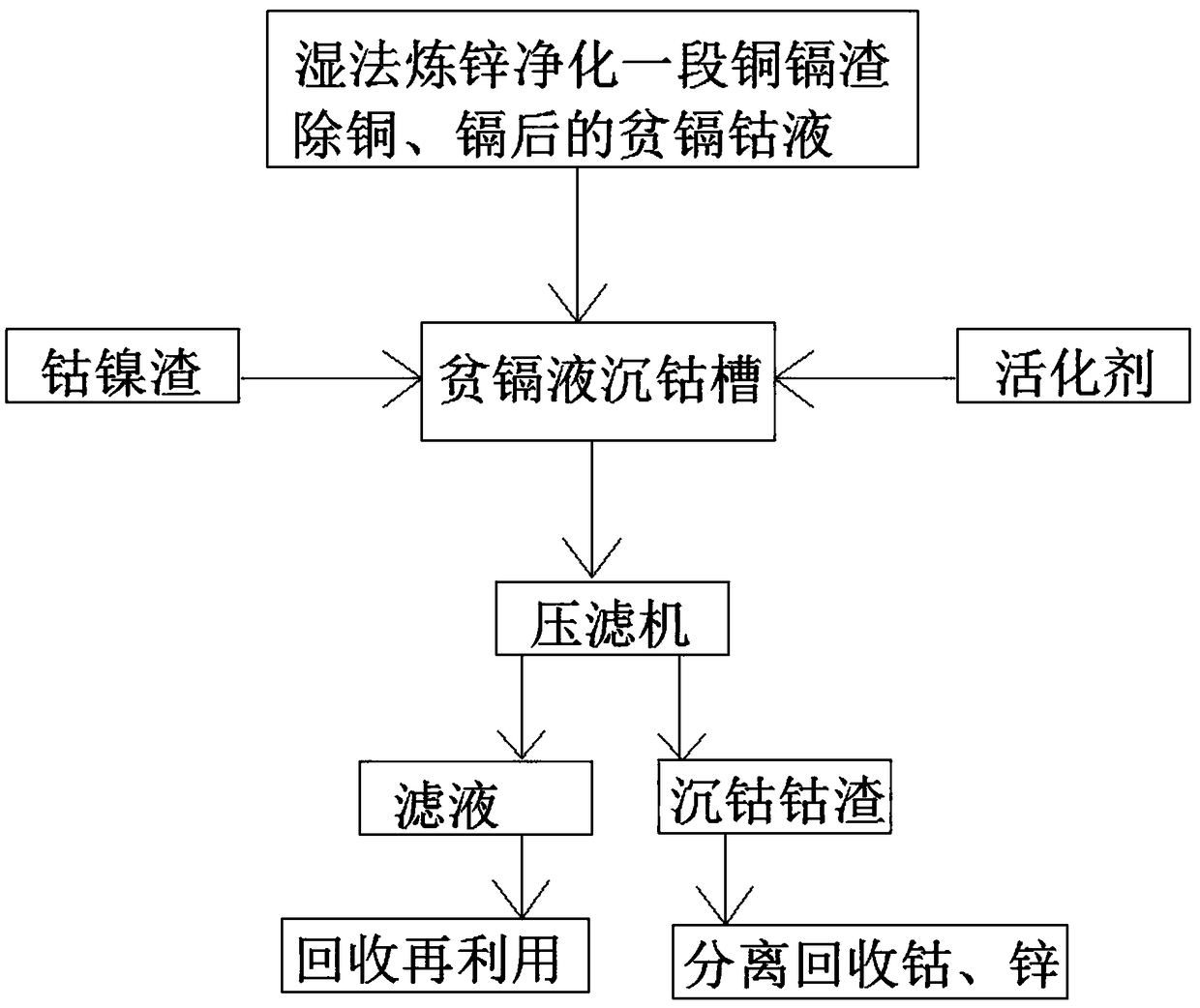

Method for recycling zinc and cobalt in wet-type smelting zinc purifying slag

The invention discloses a method for recycling zinc and cobalt in wet-type smelting zinc purifying slag. The method adopting the technology comprises the following steps of firstly, removing the copper and cadmium in the copper and cadmium slag produced in the first stage of wet type smelting zinc purifying to obtain a lean-cadmium cobalt solution, and putting the lean-cadmium cobalt solution intoa lean-cadmium cobalt precipitating tank; then, pulping the cobalt and nickel slag in the purifying slag at the second stage, and mixing the pulped solution and the lean-cadmium cobalt solution in the lean-cadmium cobalt precipitating tank; under the existence of an activator, precipitating the cobalt in the lean-cadmium cobalt solution by zinc powder in the cobalt and nickel slag through certainreaction time and reaction temperature. The method has the advantages that the zinc powder in the cobalt and nickel slag is reutilized, the cobalt in the lean-cadmium cobalt precipitating solution isfully precipitated, the consumption amount of zinc powder is greatly reduced, and the production cost is reduced; the technology is simple and reasonable, the operation is easy, the waste slag can bewell recycled and reutilized, and the good application prospect is realized.

Owner:HENAN YUGUANG ZINC IND

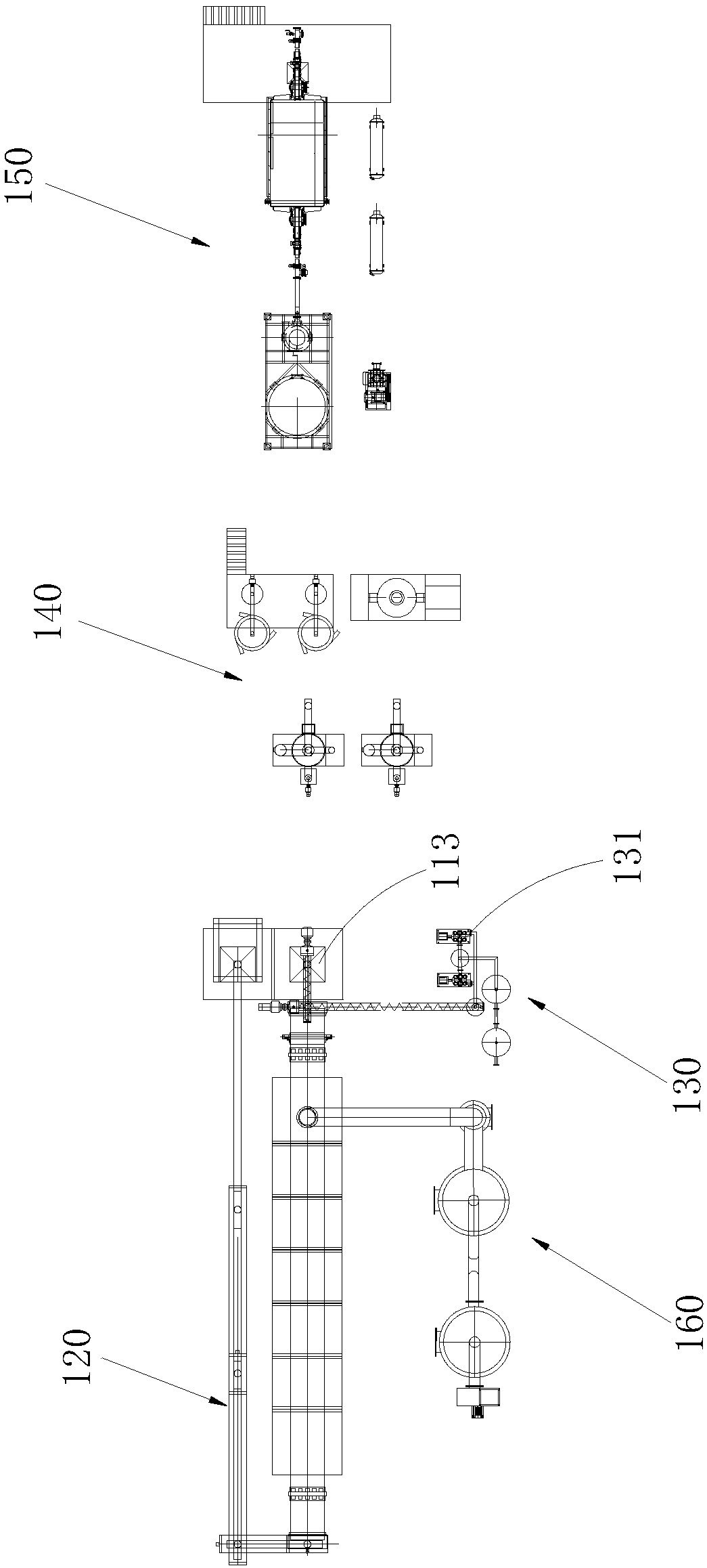

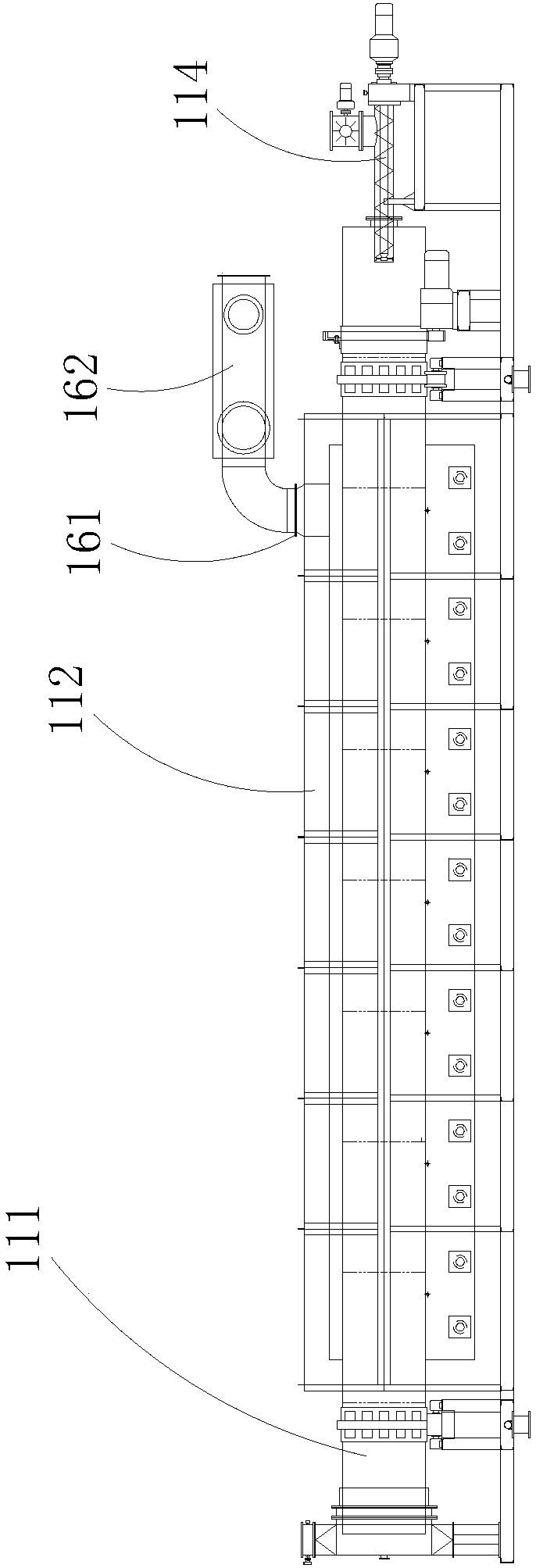

Production system for producing industrial copper powder based on pyrolysis and hydrogen embrittlement principles

The invention relates to the technical field of industrial copper powder production, and discloses a production system for producing industrial copper powder based on pyrolysis and hydrogen embrittlement principles. The production system includes a horizontally rotatably arranged rotary furnace, a multistage-cooling spiral system, a turbine crushing system and a copper fine powder ball mill; the rotary furnace is placed in a heating furnace, a heating ring chamber is formed between the rotary furnace and the heating furnace, and the rotary furnace is heated by fuel combustion in the heating ring chamber; the rotary furnace is connected with the multistage-cooling spiral system, and copper particles formed after heating pyrolysis in the rotary furnace are spirally conveyed and cooled by themultistage-cooling spiral system; the turbine crushing system crushes the copper particles conveyed by the multistage-cooling spiral system, and removes pyrolyzed carbon black; and the copper fine powder ball mill grinds the copper particles processed by the turbine crushing system to form the industrial copper powder. The production method realizes the preparation of high-purity ultrafine copperpowder (1000-1250 meshes), the whole preparation process achieves energy saving and environmental protection, and the prepared industrial copper powder has good quality and high grade.

Owner:阙南平 +1

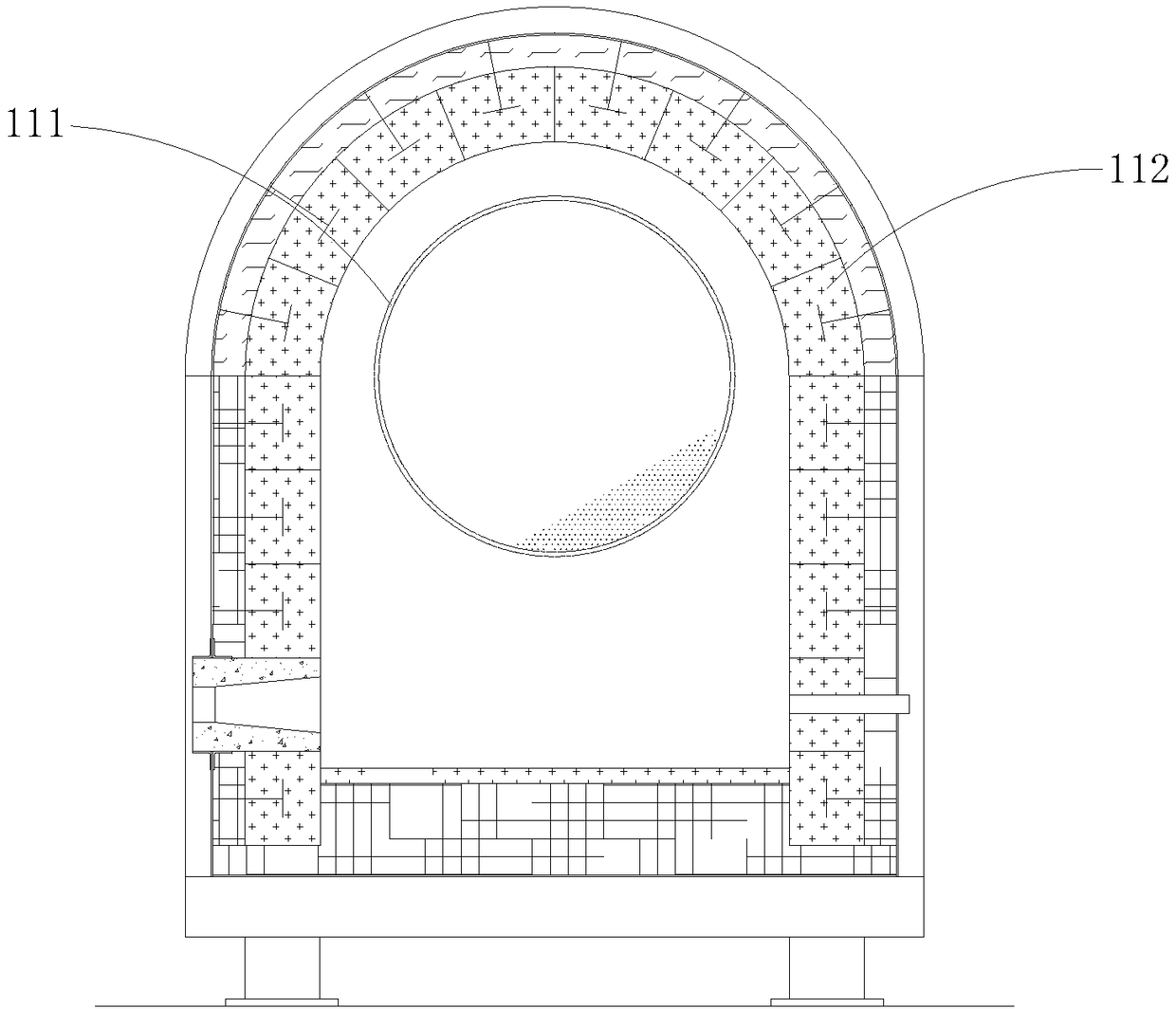

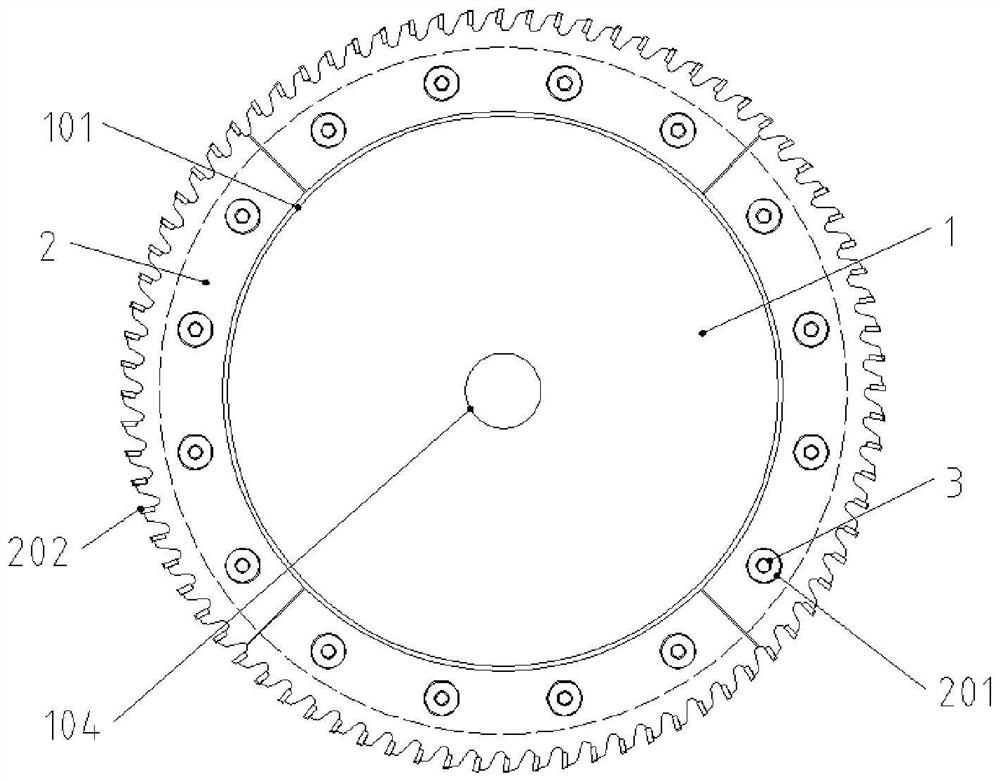

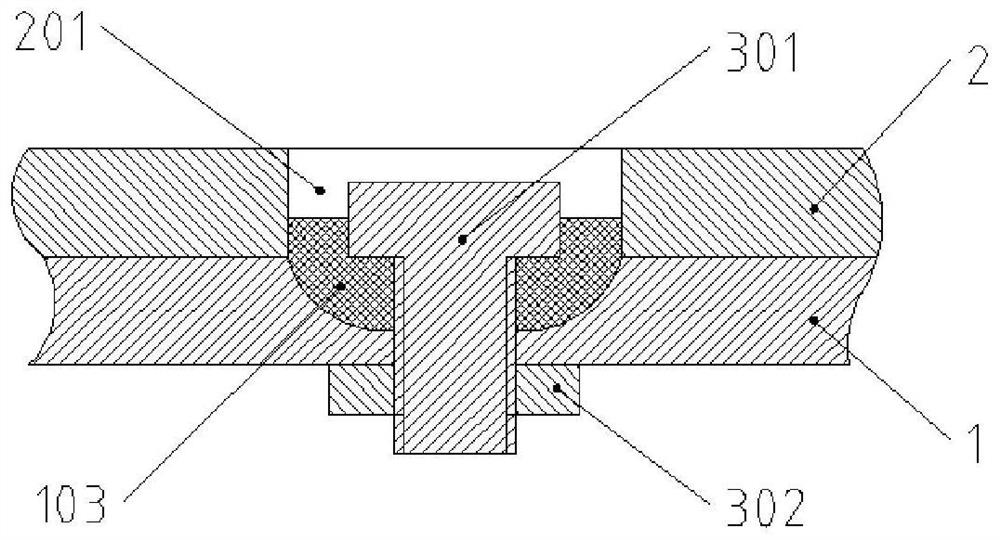

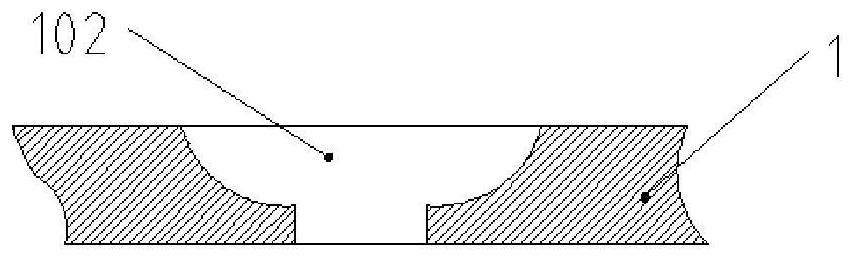

Detachable wood circular saw blade

PendingCN114800705AReduce vibrationImprove gradeCircular sawsSaw bladesFastenerManufacturing engineering

The invention provides a low-vibration detachable circular saw blade for wood. A detachable wood circular saw blade comprises a saw blade body, the saw blade body is provided with a plurality of first mounting holes, the first mounting holes are through holes, the upper contour edge of the projection of the first mounting holes on the side face of the saw blade body is in a symmetrical arc shape, and the lower contour edge of the projection of the first mounting holes on the side face of the saw blade body is in a symmetrical straight line shape. An elastic piece is arranged in each first mounting hole; the detachable saw blades are provided with a plurality of second mounting holes, and each second mounting hole corresponds to one first mounting hole; and the fasteners are arranged in the first mounting holes and the second mounting holes corresponding to the first mounting holes in a penetrating manner. Through cooperation of the first mounting hole and the second mounting hole, vibration transmitted to the saw blade body by the detachable saw blade is gathered, then energy of the vibration is consumed through the elastic piece, and low vibration is achieved during high-speed rotating saw cutting.

Owner:杭州欣胜精密机械有限公司

Application of limonite as adhesive and pellet preparation method

The invention discloses an application of limonite with excellent balling property as an adhesive and a pellet preparation method. The limonite comprises limonite powder, and chemical components of the limonite powder comprise iron, silicon dioxide, calcium oxide, magnesium oxide, aluminum oxide, water, sulfur, phosphorus and the like. The pellet preparation method comprises the steps of raw material preparation and mixing, pelletizing, drying, preheating, roasting, cooling and the like. The drying comprises forced air drying and air draft drying. The balling index of the limonite-based adhesive reaches 1.55, and the balling index is improved by 59.8% compared with the balling index of bentonite in the prior art. By the adoption of the pellet preparation method with the limonite powder as the adhesive, the adding amount of the bentonite in the pelletizing process can be reduced by 40%, the charging grade of iron-containing raw materials of a blast furnace is improved by 0.18%, the slag discharging amount is reduced by 0.27%, the carbon dioxide emission amount is reduced by 0.99%, and the ore blending cost is reduced by 22 yuan / ton or above. The blast furnace smelting has the benefits of cost reduction, efficiency improvement, energy conservation and emission reduction, and has important significance for realizing carbon neutralization when carbon reaches the peak.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com