Mineral processing method for enriching vanadium pentoxide from graphite vanadium ore

A technology of vanadium pentoxide and beneficiation method, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of low grade, waste of vanadium resources, high cost, and achieve short process, concentrate grade and recovery rate Improved, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

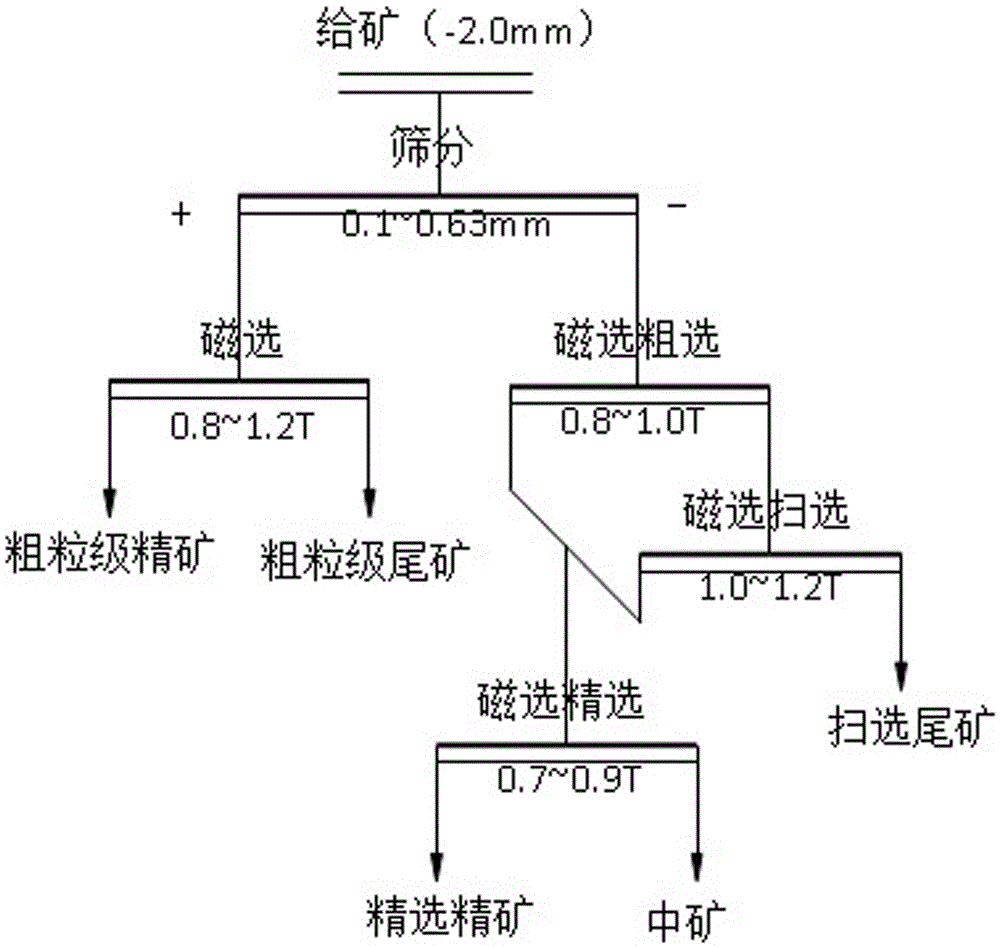

[0018] Raw ore vanadium grade V of a graphite-type vanadium mine 2 o 5 0.52%, the main vanadium-containing mineral is vanadium-containing limonite, followed by vanadium-containing mica, and a small amount of vanadium-containing kaolin and vanadium-containing illite. The other main minerals are graphite, quartz, pyroxene, hornblende, etc. Enriched V 2 o 5 The beneficiation method according to figure 1 shown. The raw ore is all crushed to -2.0mm, screened with a 1.0mm sieve, and the +1.0mm particle size adopts a Φ3mm+Φ2mm multi-gradient media box, and a magnetic separation with a magnetic field strength of 1.0T is performed to obtain a coarse-grained concentrate and coarse-grained Tailings, -1.0mm particle size products use Φ2mm+Φ1.0mm multi-gradient media box for one roughing and one sweeping. The roughing and sweeping field strengths are 0.9T and 1.0T respectively, and the roughing concentrate is obtained. The scavenging concentrate and scavenging tailings, roughing conce...

Embodiment 2

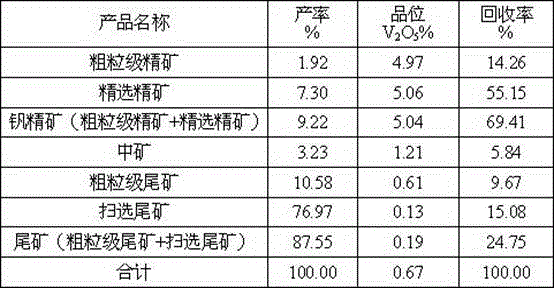

[0022] The tailings in a tailings pond are tailings after graphite-type vanadium ore flotation graphite, V 2 o 5 The grade is 0.67%. The main vanadium-containing minerals are vanadium-containing limonite, vanadium-containing hematite and vanadium mica. The gangue minerals are mainly quartz, clay, feldspar, pyroxene, garnet, etc. Because the tailings are the tailings after graphite flotation, there is grinding during graphite flotation, so that the particle size composition of the tailings is finer than that of the original ore, and its particle size composition is 100% less than 2.0mm. tailings according to figure 1 As shown, use a 0.63mm sieve to sieve, +0.63mm grain grade products use Φ3mm+Φ2mm multi-gradient media boxes, and perform a magnetic separation with a magnetic field strength of 1.0T to obtain coarse-grained concentrates and coarse-grained tailings, - The 0.63mm particle size product adopts Φ2mm+Φ1.0mm multi-gradient medium box to conduct one roughing, one sweepi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com