Patents

Literature

316 results about "Illite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

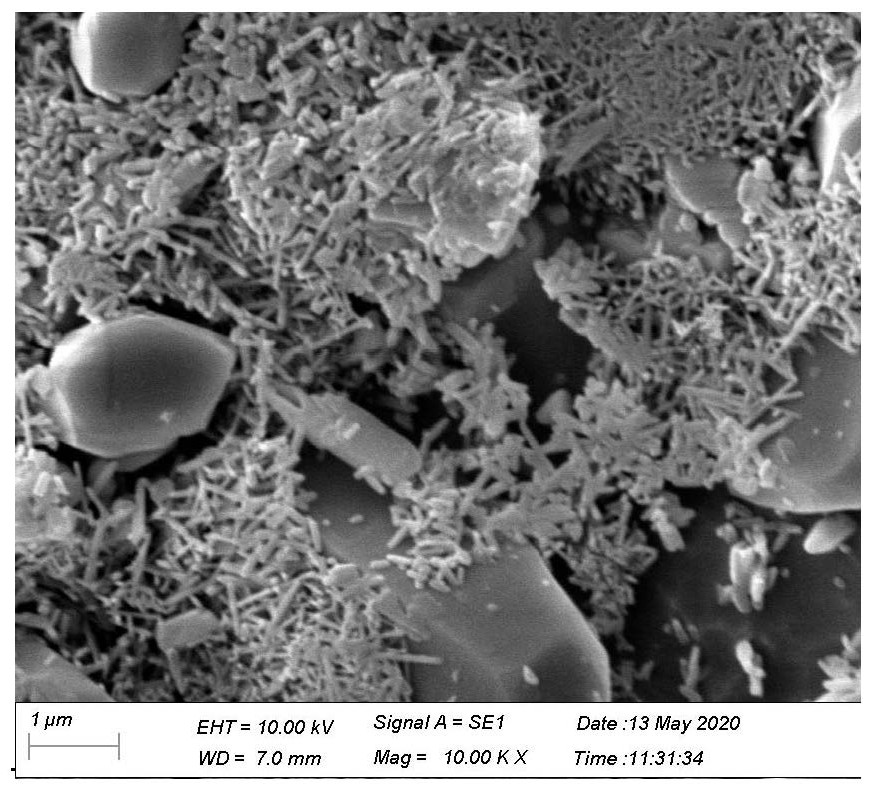

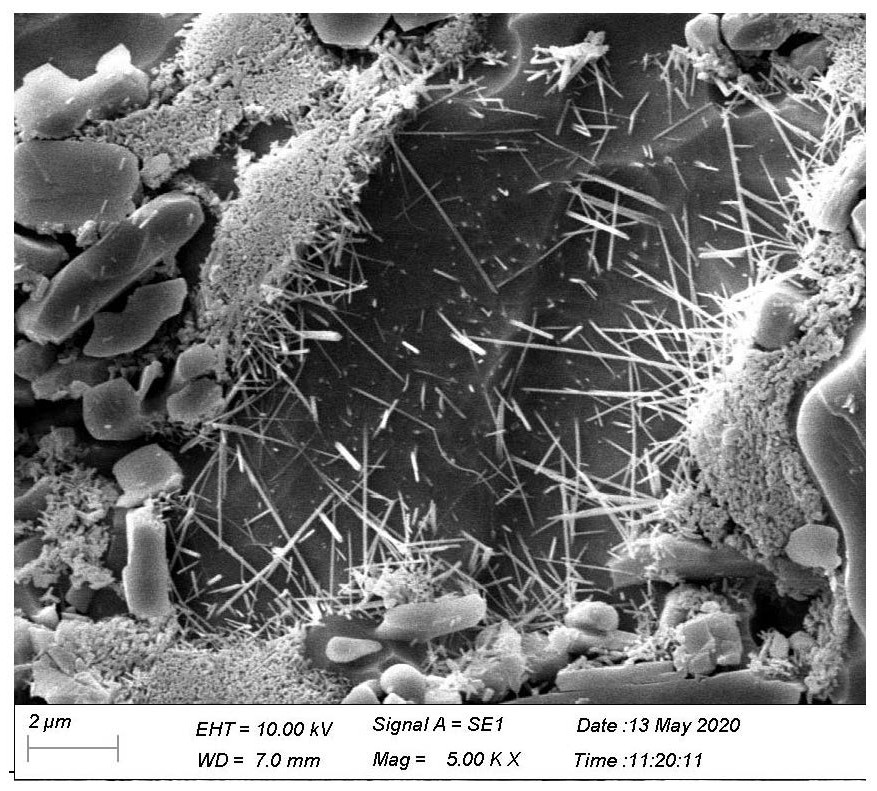

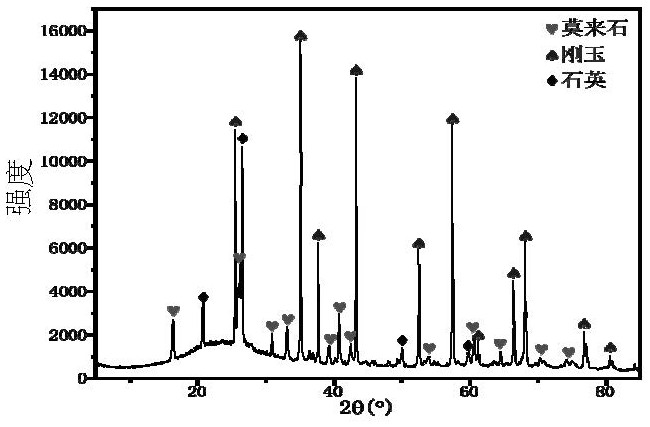

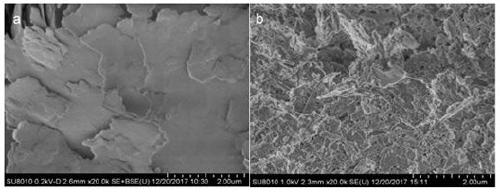

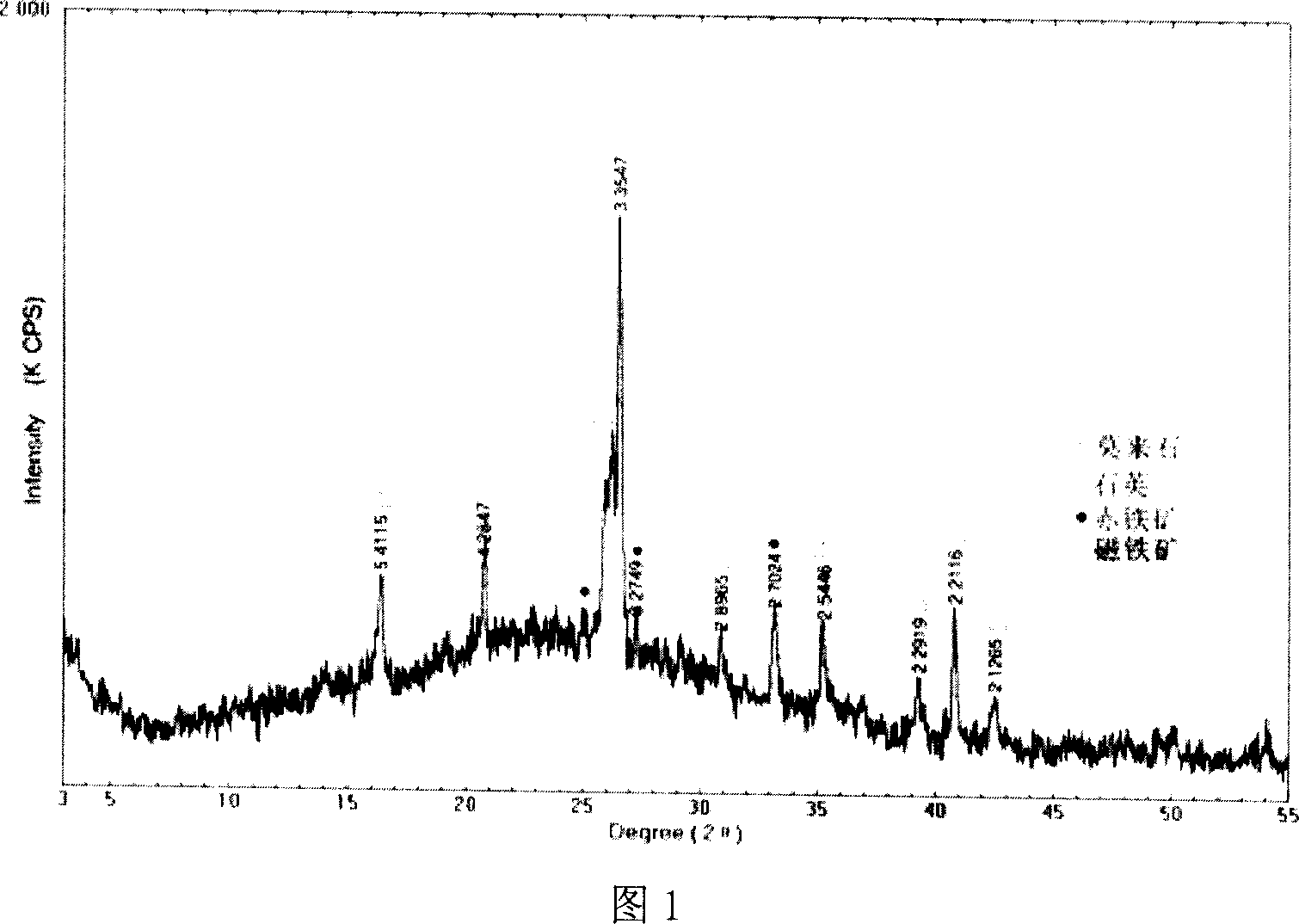

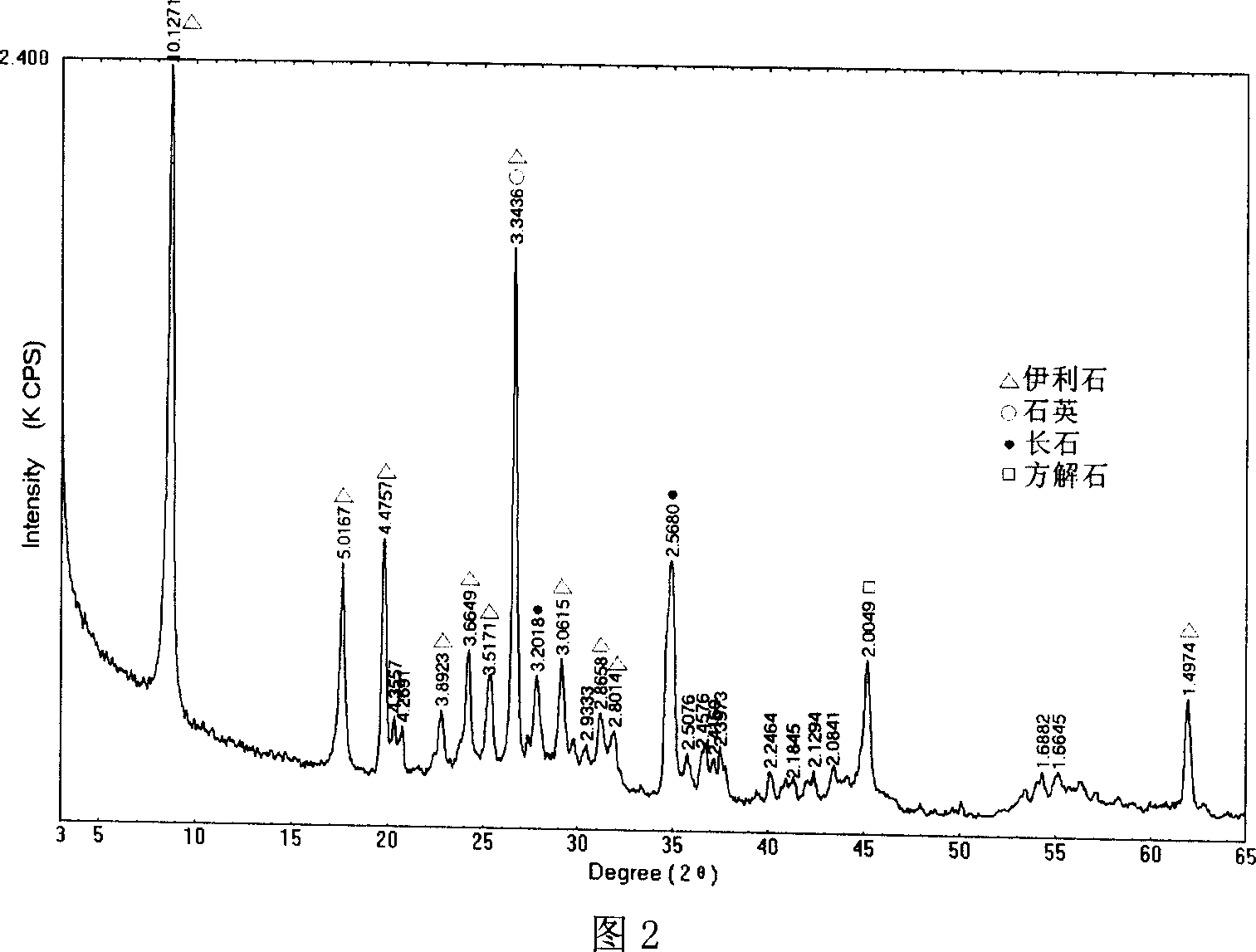

Illite is a group of closely related non-expanding clay minerals. Illite is a secondary mineral precipitate, and an example of a phyllosilicate, or layered alumino-silicate. Its structure is a 2:1 sandwich of silica tetrahedron (T) – alumina octahedron (O) – silica tetrahedron (T) layers. The space between this T-O-T sequence of layers is occupied by poorly hydrated potassium cations which are responsible for the absence of swelling. Structurally, illite is quite similar to muscovite with slightly more silicon, magnesium, iron, and water and slightly less tetrahedral aluminium and interlayer potassium. The chemical formula is given as (K,H3O)(Al,Mg,Fe)2(Si,Al)4O10[(OH)2,(H2O)], but there is considerable ion (isomorphic) substitution. It occurs as aggregates of small monoclinic grey to white crystals. Due to the small size, positive identification usually requires x-ray diffraction or SEM-EDS (automated mineralogy) analysis. Illite occurs as an altered product of muscovite and feldspar in weathering and hydrothermal environments; it may be a component of sericite. It is common in sediments, soils, and argillaceous sedimentary rocks as well as in some low grade metamorphic rocks. The iron rich member of the illite group, glauconite, in sediments can be differentiated by x-ray analysis.

Passivator for remediation of farmland soil subjected to combined pollution of heavy metals, and preparation method and use method of passivator

InactiveCN106800933AImprove adsorption capacityImprove water retentionAgriculture tools and machinesMagnesium fertilisersIon exchangeBinding state

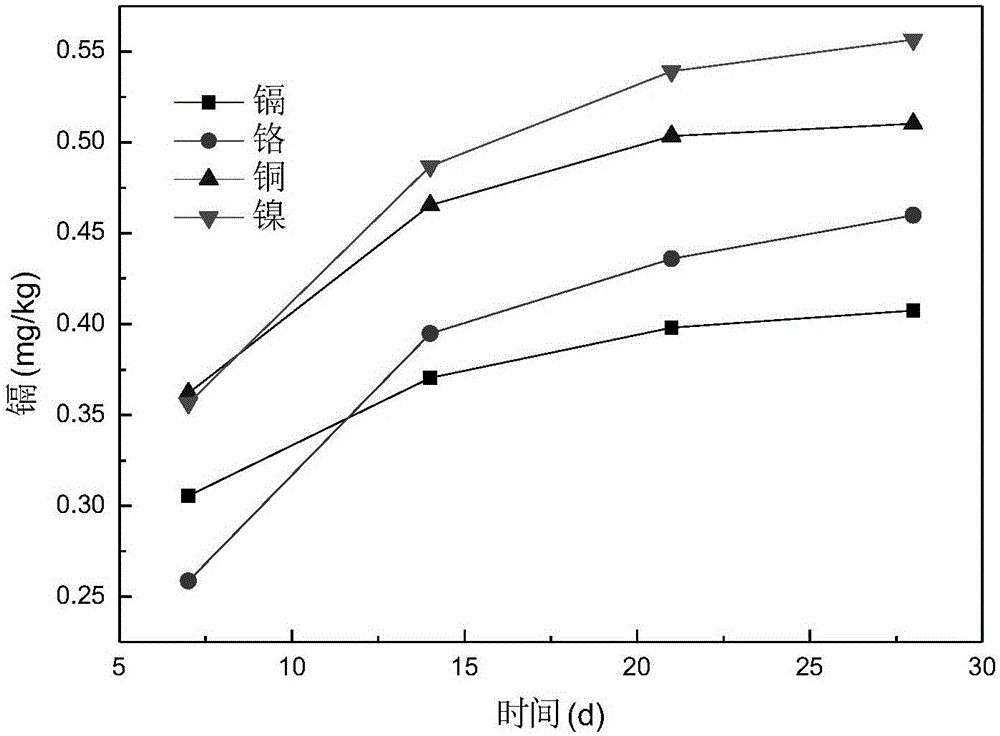

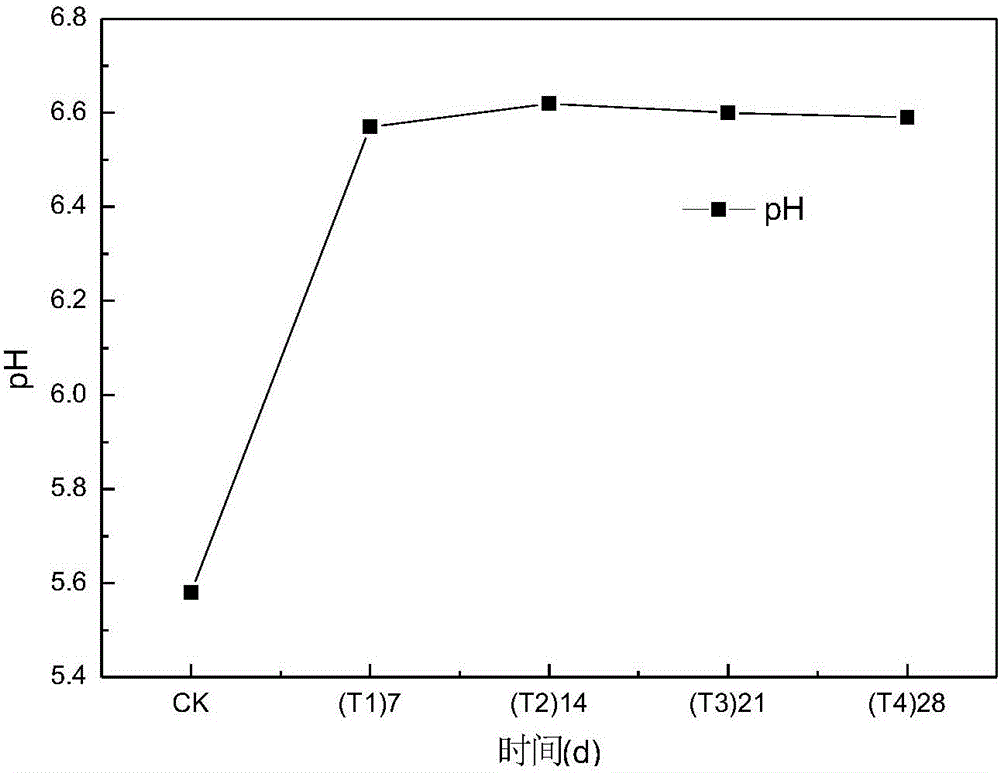

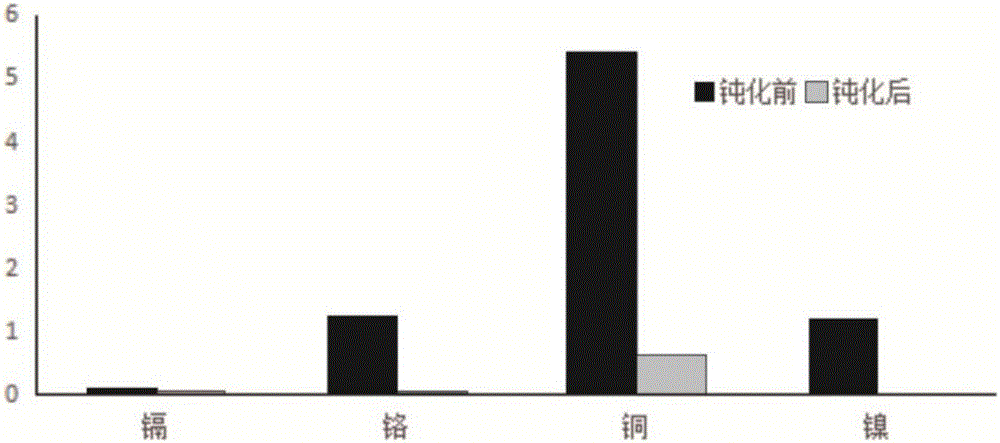

The invention relates to a passivator for remediation of farmland soil subjected to combined pollution of heavy metals such as cadmium, chromium, copper and nickel, and a preparation method and a use method of the passivator. The passivator is prepared from a passivator A and a passivator B, wherein the passivator A is prepared from montmorillonite, kieselguhr, sepiolite, illite and ferrous sulfate; the passivator B is prepared from periclase, calcite, calcium magnesium phosphate fertilizer, plant ash and calcium hydroxide; the passivator is suitable for the farmland soil subjected to the combined pollution of the cadmium, the chromium, the copper and the nickel, and is prepared from the multiple different porous absorption materials with specific contents and a passivation material; the components of the passivator have complementary advantages, and the principles such as absorption and stabilization are combined; the combination forms of the heavy metals are effectively enhanced by ion exchange, complexing, chelating and adsorption methods, and the combination forms are converted into more stable strong organic binding states and residue states, so that the effective state contents of the heavy metals in the farmland soil are effectively reduced, and the passivation effect is long-acting and stable; therefore, the passivator has a great repair effect for the farmland soil subjected to combined pollution of the cadmium, the chromium, the copper and the nickel.

Owner:SICHUAN YIKE ENVIRONMENTAL PROTECTION SCI ANDTECH

Antimicrobial mildew-proof ceramic tile and preparation method thereof

The invention discloses an antimicrobial mildew-proof ceramic tile and a preparation method thereof. The ceramic tile is prepared from the following raw materials in parts by weight: 40-50 parts of quartz sand, 20-30 parts of fluorite, 15-25 parts of gravel dust, 10-20 parts of illite, 16-28 parts of loess, 14-22 parts of mullite, 8-16 parts of furnace slag, 4-12 parts of a chalk powder, 24-32 parts of modified clay, 5-15 parts of bone meal, 2-4 parts of zinc silicate, 1-3 parts of copper oxide, and 3-8 parts of silver-loaded zirconium phosphate. Zinc silicate, copper oxide, silver-loaded zirconium phosphate and other inorganic antibacterial agents are added into the ceramic tile, and besides, the modified clay also has the sterilization efficacy, so that the ceramic tile has quite good antibacterial mildew-proof properties, has the sterilizing rate reaching 90% or more, and can effectively inhibit propagation of mildew; and the prepared ceramic tile has the characteristics of being high in strength, low in water absorption rate, good in abrasion resistance, good in weather resistance and durable in use.

Owner:安徽省亚欧陶瓷有限责任公司

High-strength foundry casting sand and preparation method thereof

InactiveCN104801655AHigh strengthHigh tensile strengthFoundry mouldsFoundry coresFoundrySodium Bentonite

The invention discloses high-intensity foundry casting sand and a preparation method thereof. The high-intensity foundry casting sand comprises the following raw materials in parts by weight: 45 to 65 parts of quartz sand, 20 to 30 parts of desert sand, 15 to 20 parts of illite, 12 to 18 parts of calcium carbonate powder, 5 to 10 parts of silicon boride, 2 to 3 parts of 3-isocyanatopropyltriethoxysilane, 8 to 12 parts of modified bentonite, 5 to 10 parts of emery powder, 4 to 8 parts of shale ash, 5 to 10 parts of malthacite, 3 to 5 parts of sodium alginate, 6 to 9 parts of light calcined powder, 3 to 7 parts of carbon nanofiber, 4 to 6 parts of polyethylene imine, 2 to 3 parts of polyvinyl butyral, and a proper amount of water. Compared with the traditional casting sand, the casting sand provided by the invention is relatively high in wet compression strength and tensile strength, further is excellent in heat resistance, plasticity and air permeability, is easy for pattern drawing and modeling, has the effect of bearing various external forces and high temperature, can improve casting quality obviously, and avoids defect of air holes produced by castings.

Owner:江守仲

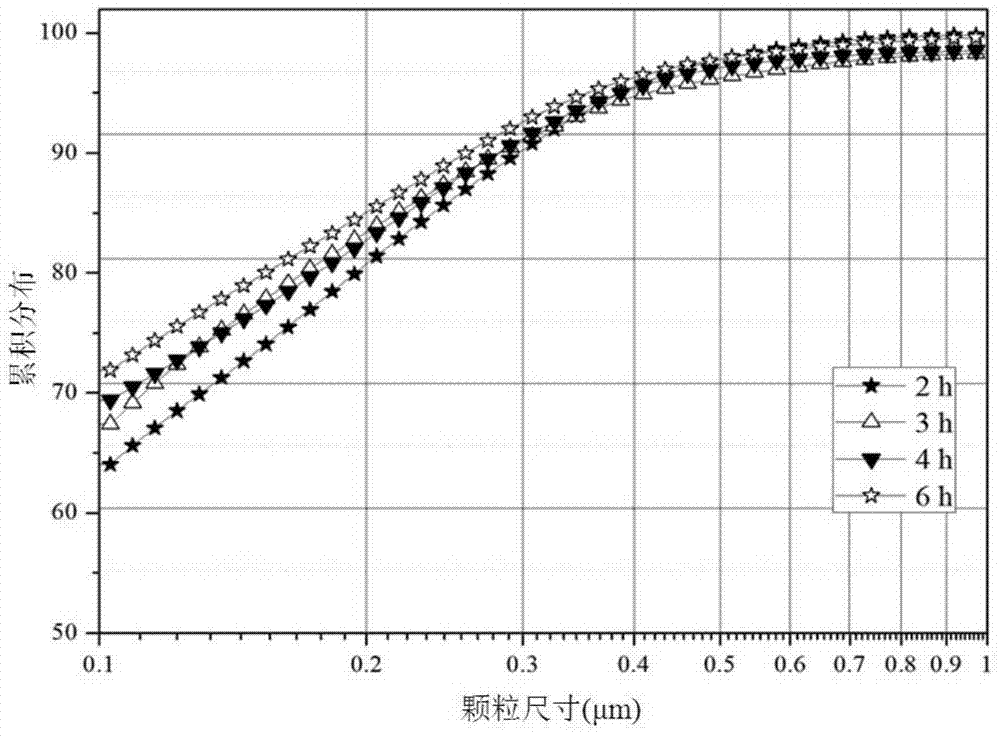

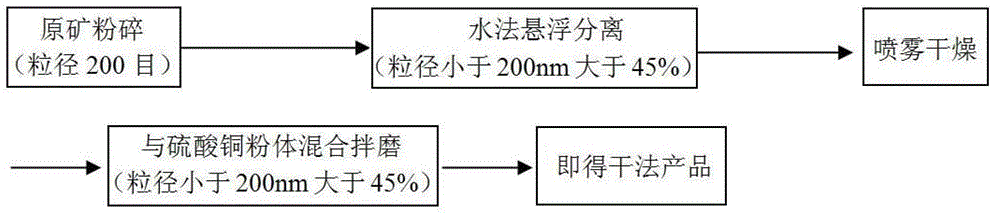

Preparation methods of illite/montmorillonite clay nanometer slurry and illite/montmorillonite clay nanometer powder

InactiveCN103588214AImprove stabilityGood anti-sedimentationMaterial nanotechnologySilicon compoundsDispersityHigh energy

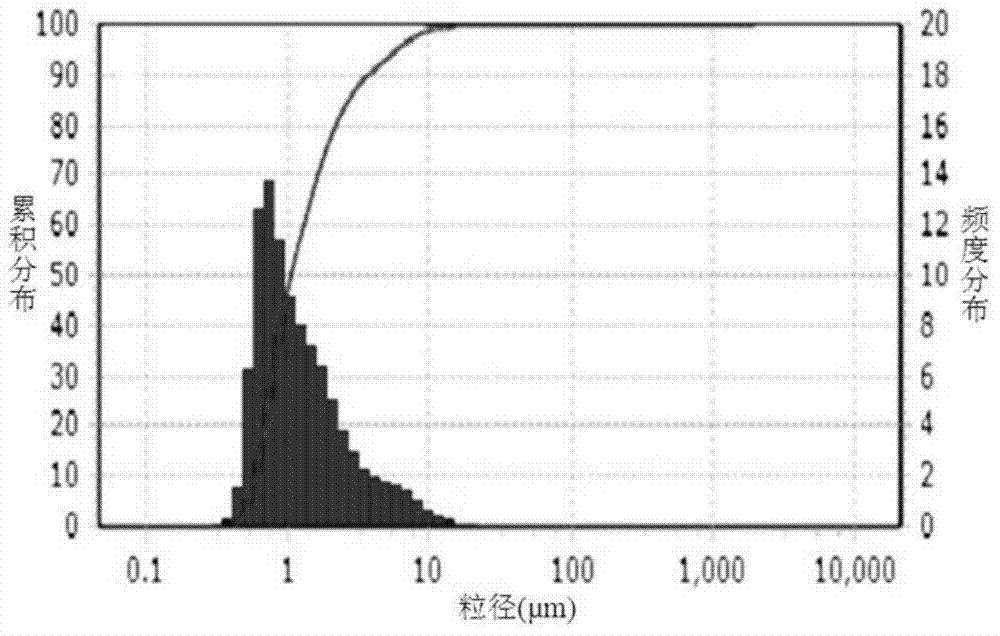

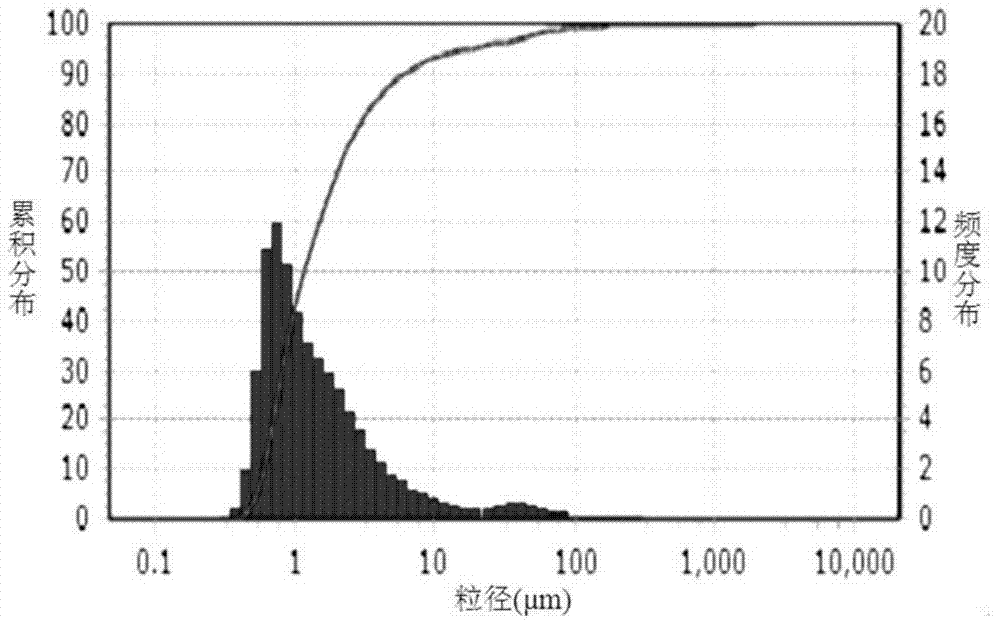

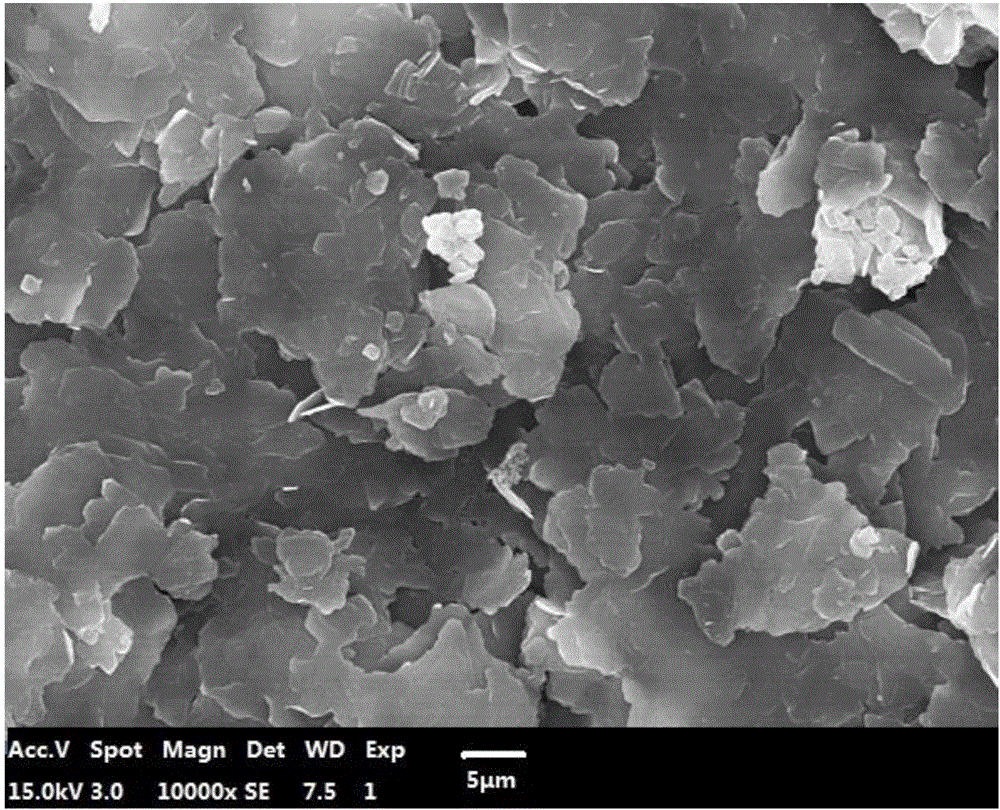

The invention discloses preparation methods of illite / montmorillonite clay nanometer slurry and illite / montmorillonite clay nanometer powder and belongs to the field of development and preparation of nanometer materials. The preparation method of the illite / montmorillonite clay nanometer powder comprises the following steps: (1) mechanically breaking natural illite / montmorillonite clay mineral; (2) soaking in water so as to obtain illite / montmorillonite clay slurry; (3) adjusting the pH value of the illite / montmorillonite clay slurry, puddling and dispersing; (4) sieving the puddled and dispersed slurry by using a 50-mesh sieve; (5) removing iron from the slurry; (6) chemically bleaching the slurry; (7) grinding the bleached slurry by adopting a high-energy density stirred mill so as to obtain nanometer slurry; (8) adding a dispersing agent to the nanometer slurry to carry out dispersing treatment; (9) adding a modifying agent to the slurry to carry out swelling treatment; (10) evaporating and drying; and (11) carrying out mechanical pulverization so as to obtain the illite / montmorillonite clay nanometer powder in the end. The illite / montmorillonite clay nanometer powder prepared by the method can reach the nanoscale and has good powder uniformity and dispersity.

Owner:SOUTH CHINA UNIV OF TECH +1

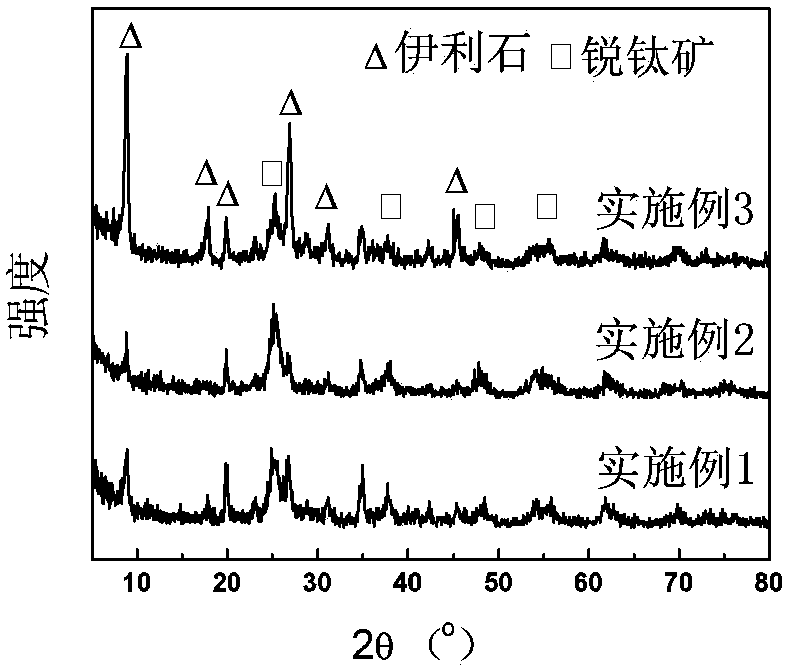

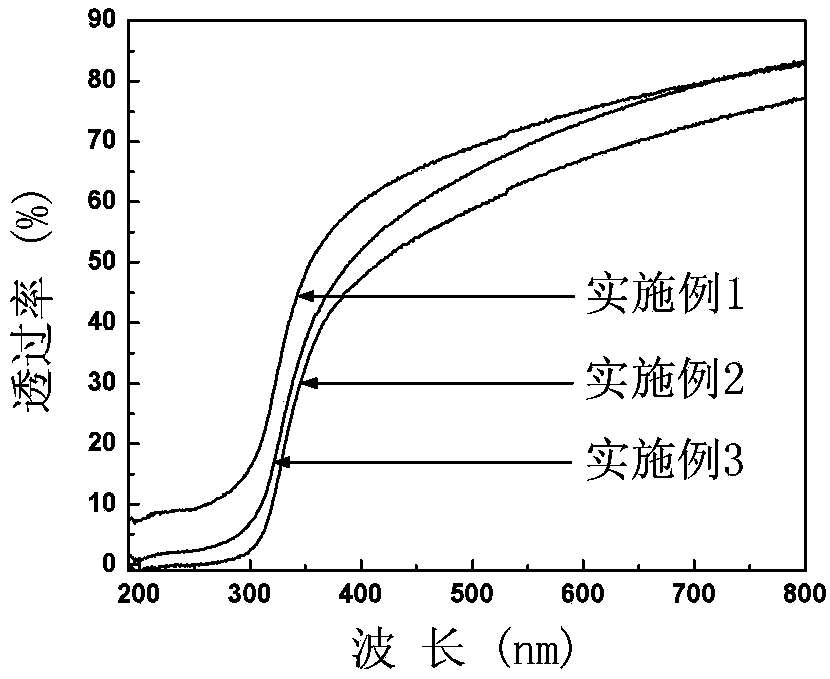

Preparation method of TiO2/illite inorganic UV-blocking agent

The invention relates to a preparation method of a TiO2 / illite inorganic UV-blocking agent, which belongs to the technical field of a novel mineral functional material. The method fully uses high reflecting rate and surface charge of illite, and takes high-purity illite as a raw material, in a titanium sulfate hydro-thermal system, full dispersion and composition of nano-level TiO2 on the surfaceof illite are realized, and the problems of easy agglomeration and poor adhesive force of the nano TiO2 / illite inorganic UV-blocking agent can be solved. The method can obviously reduce the productioncost, the process flow is simple, calcining is not required for products, the energy consumption is low, the obtained composite powder has good water phase dispersibility, and has good UV-blocking performance, and the TiO2 / illite inorganic UV-blocking agent can be widely used for the fields of textile finishing and protection of a high-molecular material having high weatherability requirement such as an exterior coating.

Owner:JILIN UNIV

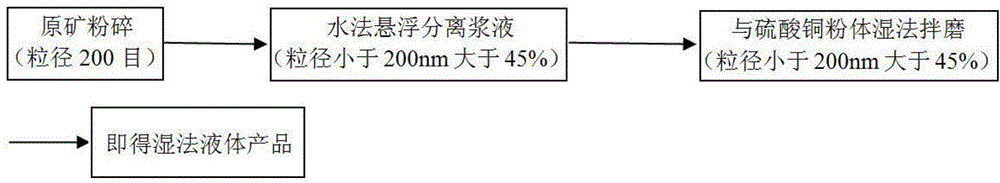

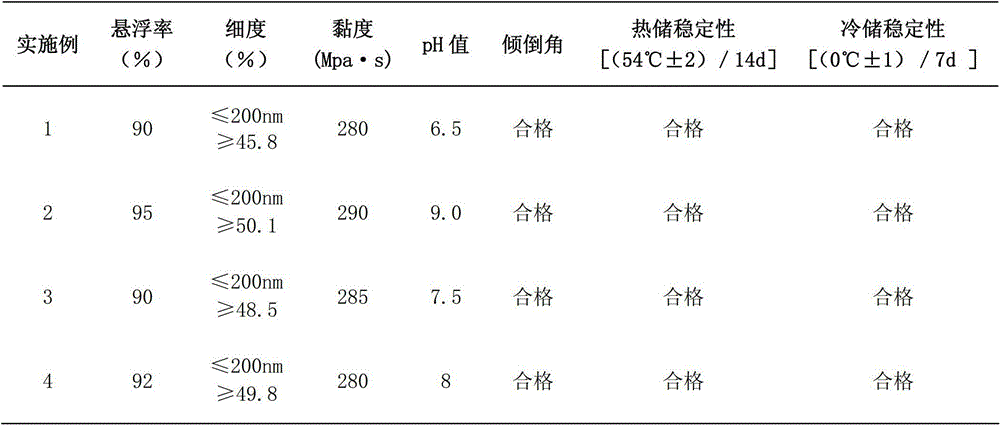

Illite/montmorillonite mixed-layer clay sterilization suspending agent

InactiveCN102742573APermanent suspensionPermanent dispersionBiocideDisinfectantsPesticide residueSuspending Agents

The invention discloses an illite / montmorillonite mixed-layer clay sterilization suspending agent, which is prepared from the following raw materials in percentage by weight: 40-70 percent of illite clay mineral, 15-40 percent of montmorillonite clay mineral and 5-30 percent of inorganic sterilization additive. Since the raw materials are natural nanomaterials which have the performance of permanent suspension property and dispersibility, and copper sulfate, carboxymethyl cellulose and alkyl quaternary ammonium salt powder are added, the unique dispersibility and strong suspension property of the clay micro / nano level powder in water are kept, and the sterilization capacity is also achieved. The inorganic suspending agent has the characteristics of high efficiency, low toxicity, environmental friendliness and safety, the suspension rate reaches over 90 percent, the dispersibility and the suspension property of the pesticide can be kept for long time, the problem of super-standard pesticide caused by the conventional organic suspending agent is solved, and pollution to environment and serious injury to human bodies caused by pesticide residue in crop products can be effectively reduced.

Owner:上思县文德矿业科技咨询服务有限公司 +2

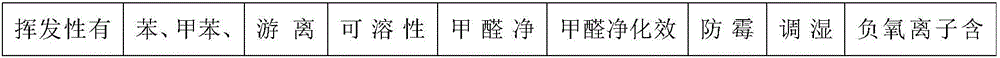

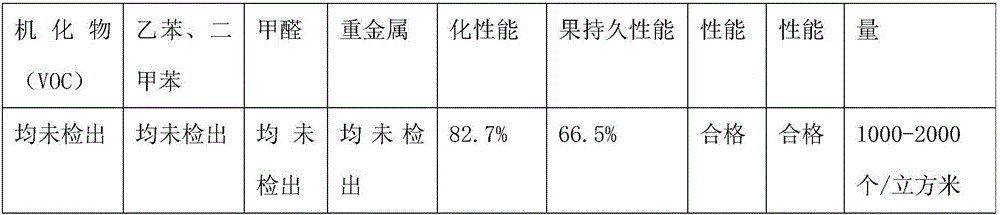

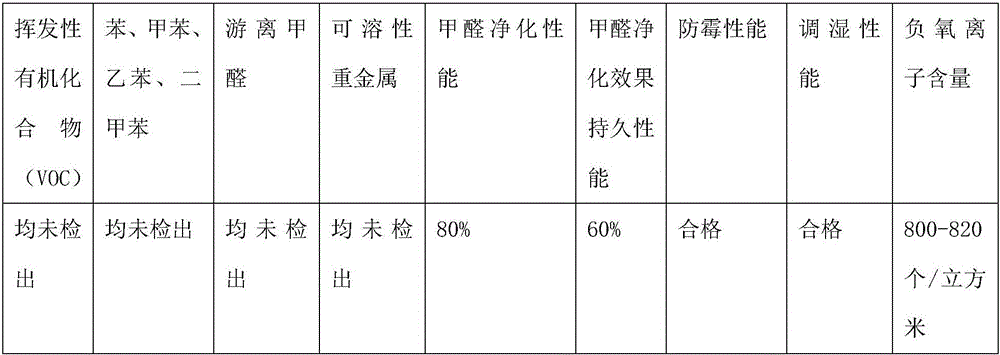

Roller coating type diatom ooze environment-friendly interior wall powder material and preparation method thereof

The invention discloses a roller coating type diatom ooze environment-friendly interior wall powder material and a preparation method thereof. The material is prepared from, by mass, 30 parts of diatomite, 15 parts of coarse whiting powder, 8 parts of titanium dioxide, 0.3 part of antifoaming agent, 5 parts of white cement, 4 parts of attapulgite, 5 parts of kaolin, 10 parts of talcum powder, 5 parts of illite, 0.4 part of mildew preventive, 15 parts of sepiolite, 0.3 part of wood fibers and 2 parts of natural inorganic mineral pigments. The attapulgite and kaolin form a binding agent. The material can improve the usability of a diatom ooze product, the construction performance of the material is improved to the maximum extent, meanwhile, the health performance of the product is improved, the concentration of indoor negative oxygen ions is improved, the material has an extremely strong antibacterial effect and can adsorb and decompose multiple kinds of harmful heavy metal, formaldehyde benzene VOC and other harmful gases in indoor air, the lasting performance of formaldehyde purification is improved, the catalytic ability of the product at normal temperature and even low temperature is improved, and indoor air quality is effectively improved.

Owner:北京南极海新材料股份有限公司

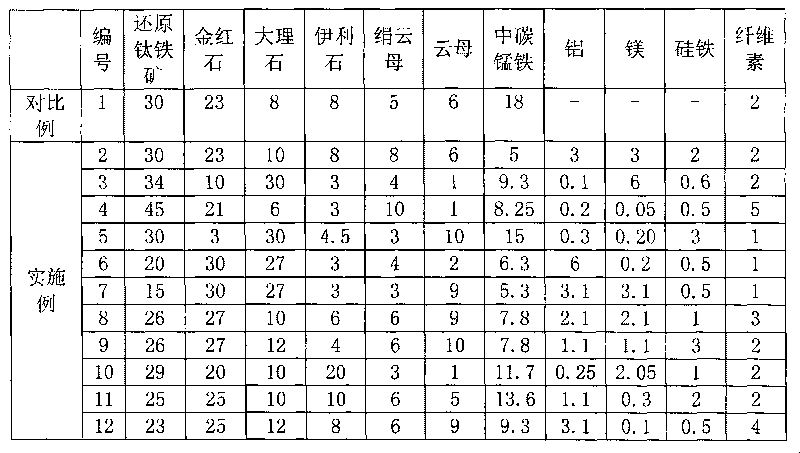

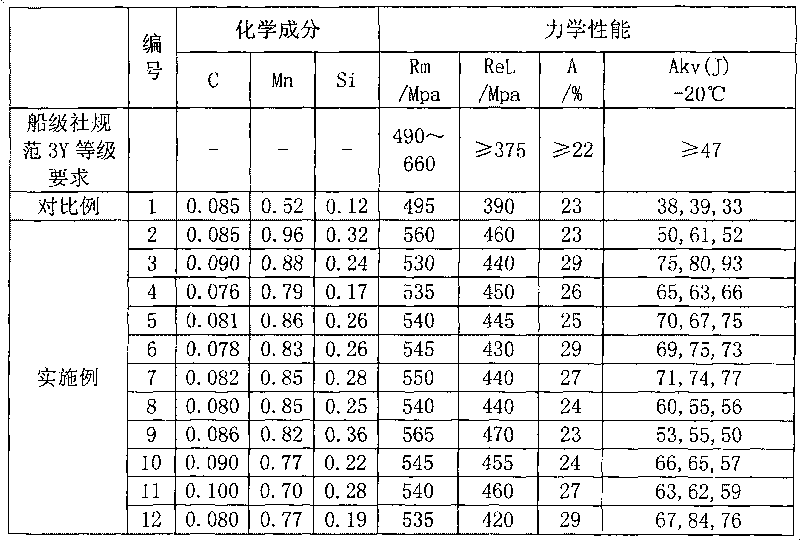

High-strength and high-flexible acid electrode for ships

InactiveCN101733574ASimple welding processImprove transition efficiencyWelding/cutting media/materialsSoldering mediaCelluloseFerrosilicon

The invention discloses a high-strength and high-flexible acid electrode for ships, belonging to the technical field of welding materials and welding. The high-strength and high-flexible acid electrode comprises a welding core and a coating, wherein the welding core is H08A steel; and the coating comprises the following components in mass percentage: 15-45 of reduced ilmenite, 3-30 of rutile, 6-30 of marble, 3-20 of illite, 3-10 of sericite, 1-10 of mica, 5-15 of mid-carbon fe-mn, 0.1-6 of aluminum, 0.05-6 of magnesium, 0.5-3 of ferrosilicon and 1-5 of cellulose. By adopting a manganese and aluminum-magnesium-silicon combined deoxidation mode, the oxidation of manganese is reduced, thereby improving the efficiency of manganese as an alloy agent being transmitted to a welding seam; and the usage amount of manganese and the material cost in the coating are decreased and the manganese content in welding fly dust is reduced, thereby decreasing the toxicity of the welding fly dust, protecting the health of a welder and saving the manganese resources at the same time. The invention has excellent welding process property and excellent deposited metal and welded joint comprehensive property, and is particularly suitable for the steel plate 3Y-level welding seam welding and the assembly spot welding and repairing for DH36 and EH36 ships.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Activating acid leaching method for extracting vanadium from bone coal

InactiveCN102392126ALower manufacturing requirementsHigh activityProcess efficiency improvementChemical reactionSlag

The invention discloses an activating acid leaching method for extracting vanadium from bone coal. The method is innovative that a bone coal grinding step employs mechanical force for activation; clay minerals containing vanadium like illite in the bone coal bone coal are treated with mechanical force chemical reaction and activated through controlling rotating speed and vibration frequency of a planet mill or a vibromill of a jaw breaker and a hammer mill, ball milling time and particle size in each operation, but carbonaceous structure is not destroyed, so as to lay foundation for increasing yield of vanadium and obtain carbon rich acid leaching slag. The invention also has innovation that a normal pressure acid leaching method is employed to realize an extraction rate of 90-98%.

Owner:森松(江苏)海油工程装备有限公司

Green body for high-strength thin ceramic plate, high-strength thin ceramic plate and preparation method thereof

The invention discloses a green body for a high-strength thin ceramic plate, a high-strength thin ceramic plate and a preparation method thereof. The green body is obtained by pressing and molding green body powder; and the green body powder comprises the following raw materials ins percentage by weight: 4.0%-18.0% of potassium feldspar, 2.0%-8.0% of albite, 16.0%-24.0% of illite, 28.0%-34.0% of calcined aluminum oxide, 2.0%-4.0% of talc mud, 24.0%-30.0% of acicular kaolin and 2.0%-4.0% of bentonite.

Owner:MONALISA GRP CO LTD

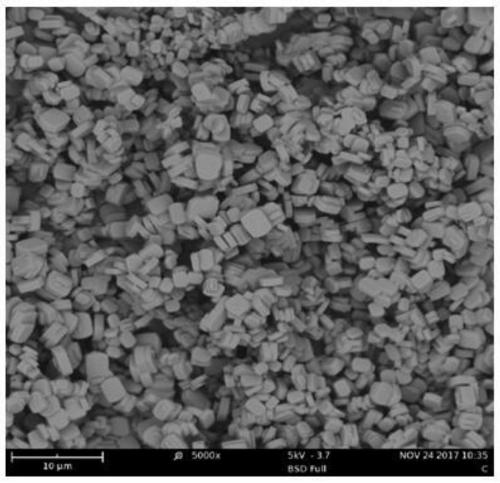

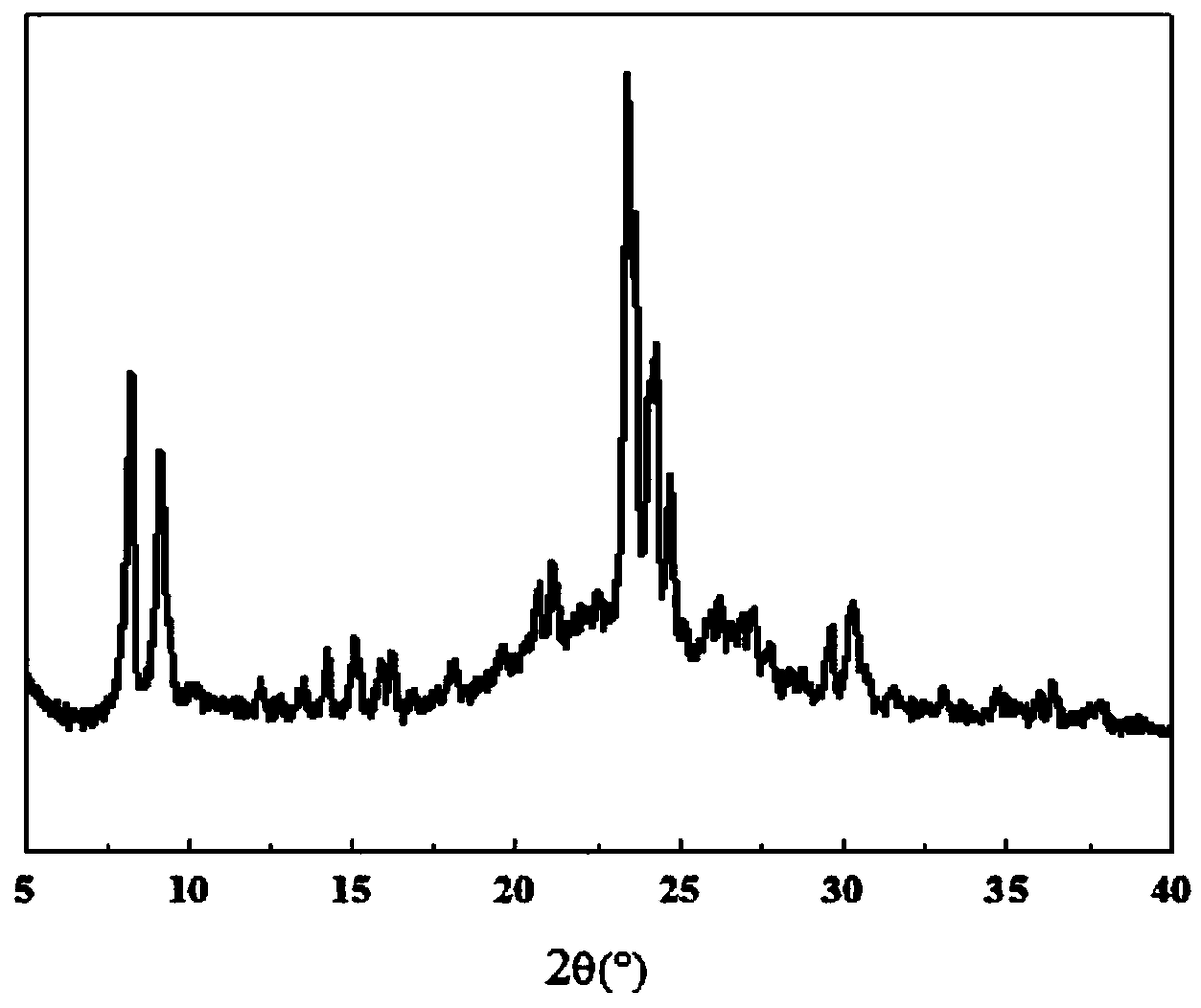

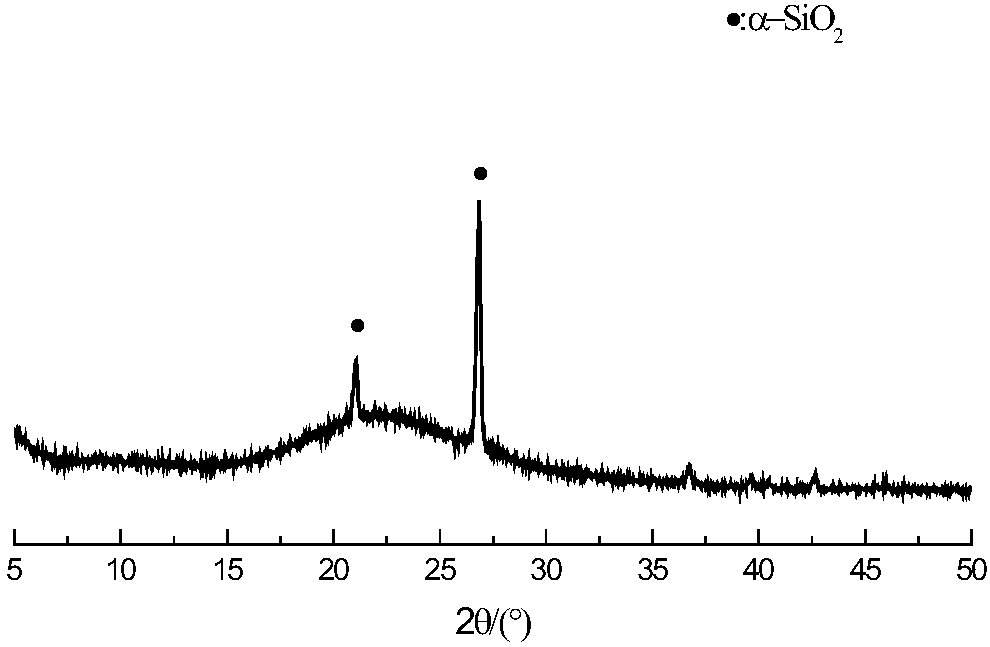

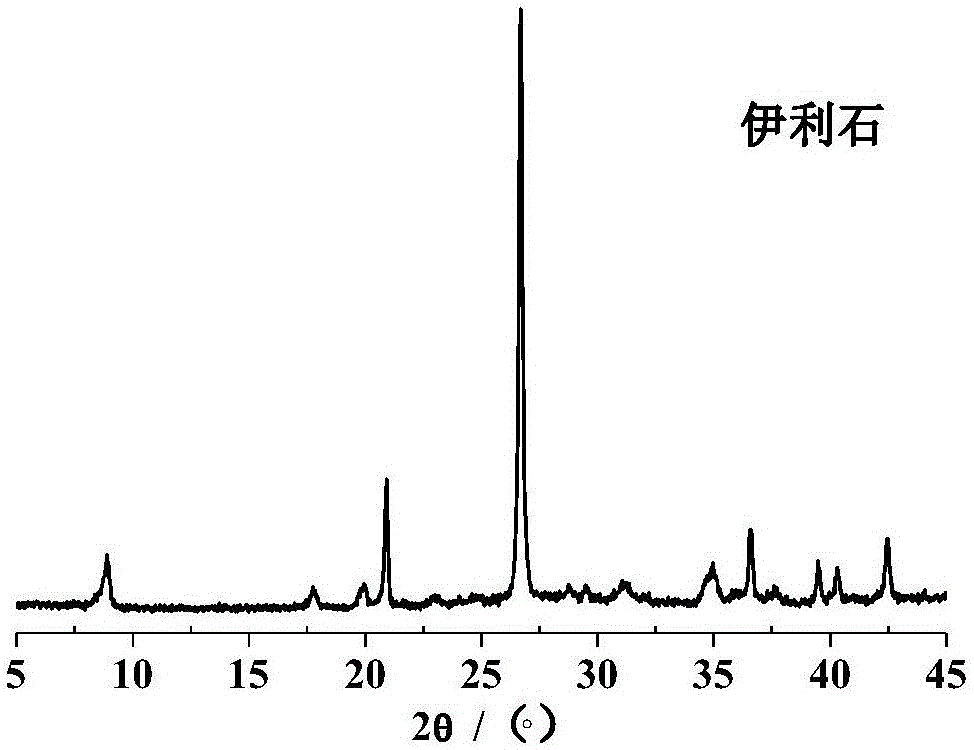

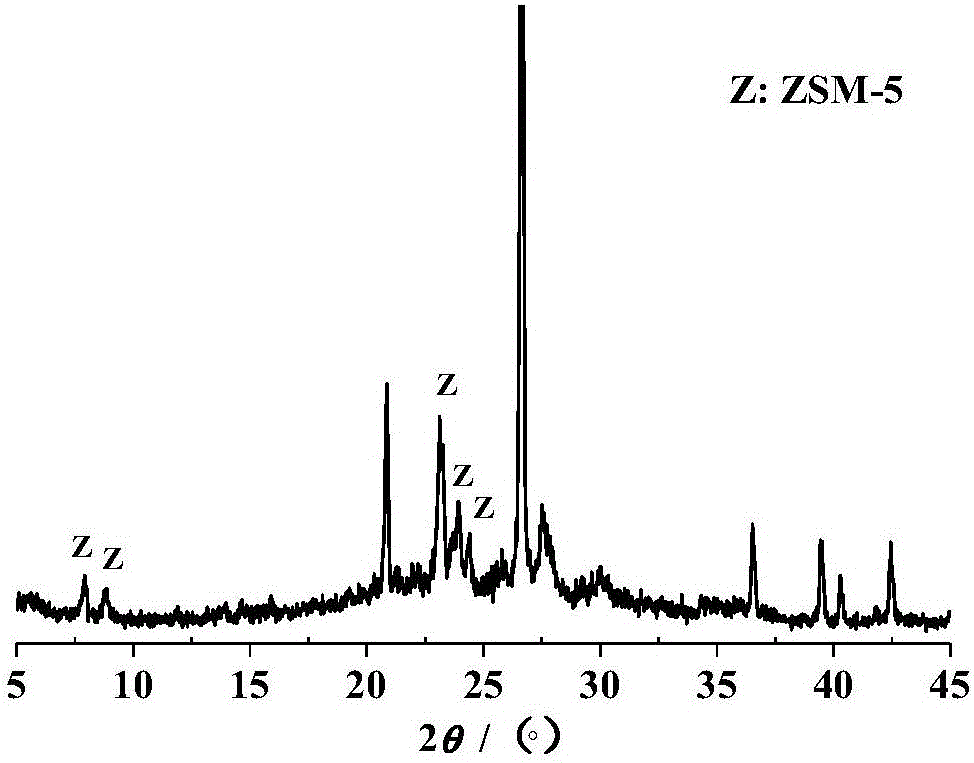

Template-free method for synthesizing hierarchical pore ZSM-5 zeolite molecular sieve from illite

ActiveCN109336129ALower synthesis costAvoid pollutionPentasil aluminosilicate zeoliteMolecular sieveSlag

The invention discloses a template-free method for synthesizing a hierarchical pore ZSM-5 zeolite molecular sieve from illite. The method comprises the following steps: taking illite as a raw materialto obtain mesoporous silicon dioxide active silicon slag through acid pickling, wherein the purity of the active silicon slag is greater than 98%; and carrying out a reaction on the active silicon slag generated by pickling illite as a silicon aluminum source in a condition of adding an alkali source and regulating a rule ratio to obtain a hierarchical pore ZSM-5 zeolite molecular sieve catalyst.The method has the advantages of being short in synthetic period, low in synthetic cost, low in synthesized pollutant, high in catalytic ability of synthesized product and the like.

Owner:YANBIAN UNIV

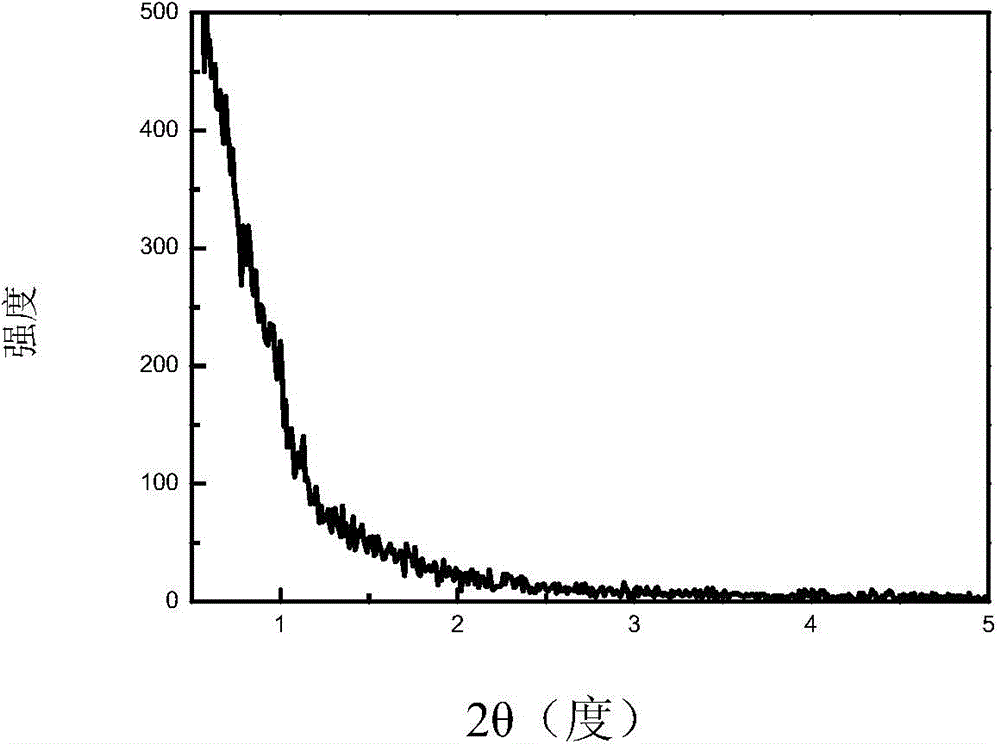

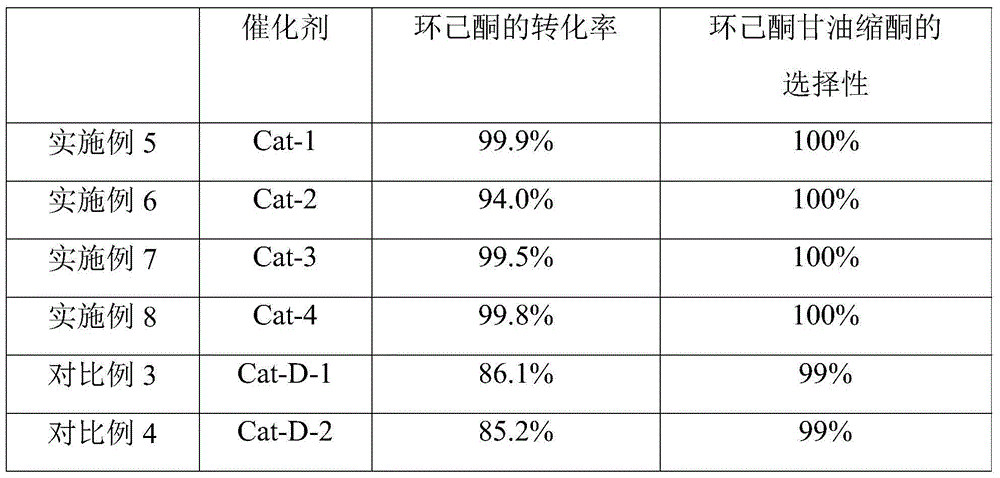

Illite mesoporous composite material and supported catalyst, preparation method and application thereof, and preparation method of cyclohexanone glycerol ketal

ActiveCN105214734AHigh catalytic activityLess side effectsCatalyst carriersOrganic chemistryMolecular sieveCyclohexanone

The invention relates to a spherical illite mesoporous composite material, a preparation method of the spherical illite mesoporous composite material, a spherical illite mesoporous composite material prepared with the method, a supported catalyst comprising the spherical illite mesoporous composite material, a preparation method of the supported catalyst, a supported catalyst prepared with the method, an application of the supported catalyst in a ketalation reaction, and a method for preparing cyclohexanone glycerol ketal with the supported catalyst. The spherical illite mesoporous composite material comprises illite, a mesoporous molecular sieve material with a three-dimensional cubic pore structure, and a mesoporous molecular sieve material with a hexagonal pore structure. When the supported catalyst prepared with the spherical illite mesoporous composite material as a carrier is applied in the ketalation reaction, the conversion rate of reaction raw materials can be substantially improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

High performance electric ceramic

InactiveCN104402400AGood acid and alkali resistanceGood resistance to rain corrosionClaywaresAluminateTin dioxide

The invention relates to a high performance electric ceramic, which is prepared from the following raw materials by weight: 3-9 parts of kaolin, 6-10 parts of illite powder, 5-9 parts of hornblende powder, 3-8 parts of nano-tin dioxide, 3-8 parts of MuO2, 4-9 parts of borocalcite, 1-4 parts of alumina, 1-3 parts of yttrium oxide, 6-10 parts of silicon carbide, 5-9 parts of aluminate cement, 8-13 parts of composite silicon oxide powder, 6-10 parts of waste ceramic slag, 4-6 parts of barium oxide, 3-5 parts of clay, 7-10 parts of quartz, and 9-14 parts of talc. The high performance electric ceramic provided by the invention has good acid and alkali resistance, high rainwater corrosion resistance, also has good insulativity, and is low in cost.

Owner:QINGDAO TOPLINK INFORMATION TECH

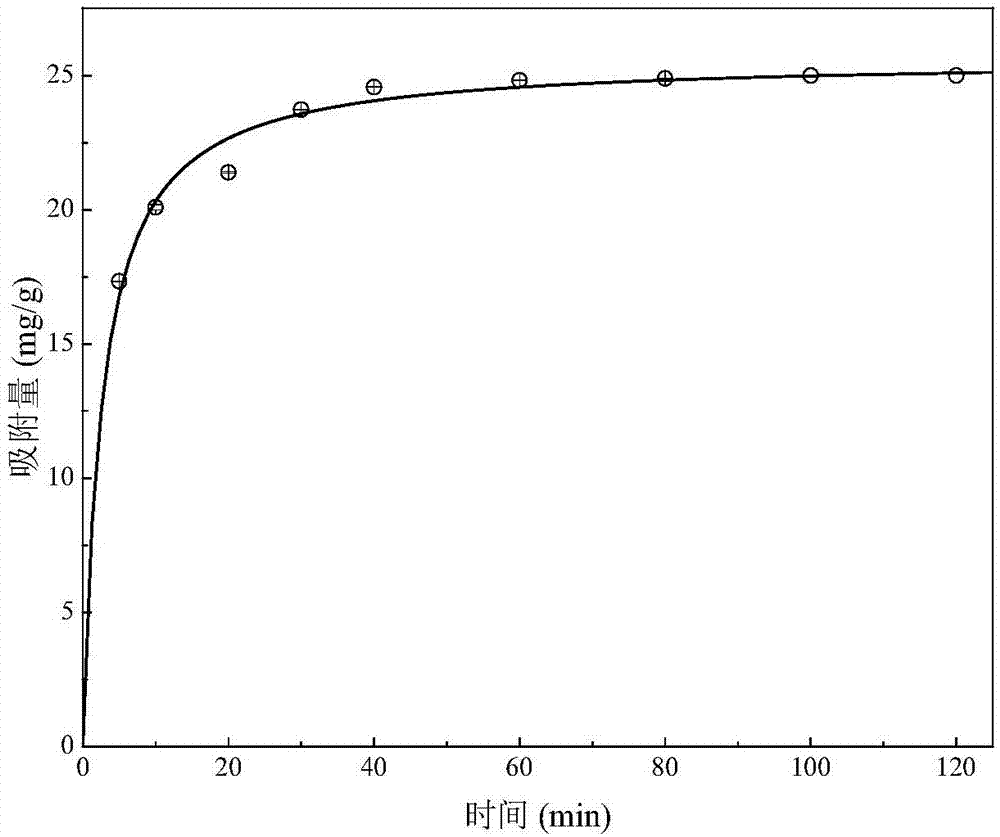

Modification method of illite adsorbent for removing heavy metal ions in wastewater

InactiveCN104525102AGood removal effectLow investment and energy consumptionOther chemical processesWater contaminantsSorbentWastewater

The invention relates to a modification method of an illite adsorbent for removing heavy metal ions in wastewater. The method comprises the following steps: crushing illite raw ore, mixing the crushed illite raw ore with zinc sulfate according to a ratio of 1:1, uniformly mixing, placing the obtained mixture in a muffle furnace, setting the roasting temperature at 600DEG C, roasting for 2h, taking out the roasted mixture, fully milling to obtain mixed powder, washing the mixed powder by using diluted hydrochloric acid with the pH value of 5.3 until a detect result shows that the aqueous solution of the mixed powder has no sulfate ions, centrifuging, and drying to prepare a finished product. The illite adsorbent obtained in the invention is mainly used for removing heavy metal ions in wastewater, and has the advantages of wide application prospect, good removal effect, small investment and energy consumption, economy and practicality.

Owner:HENAN UNIV OF URBAN CONSTR

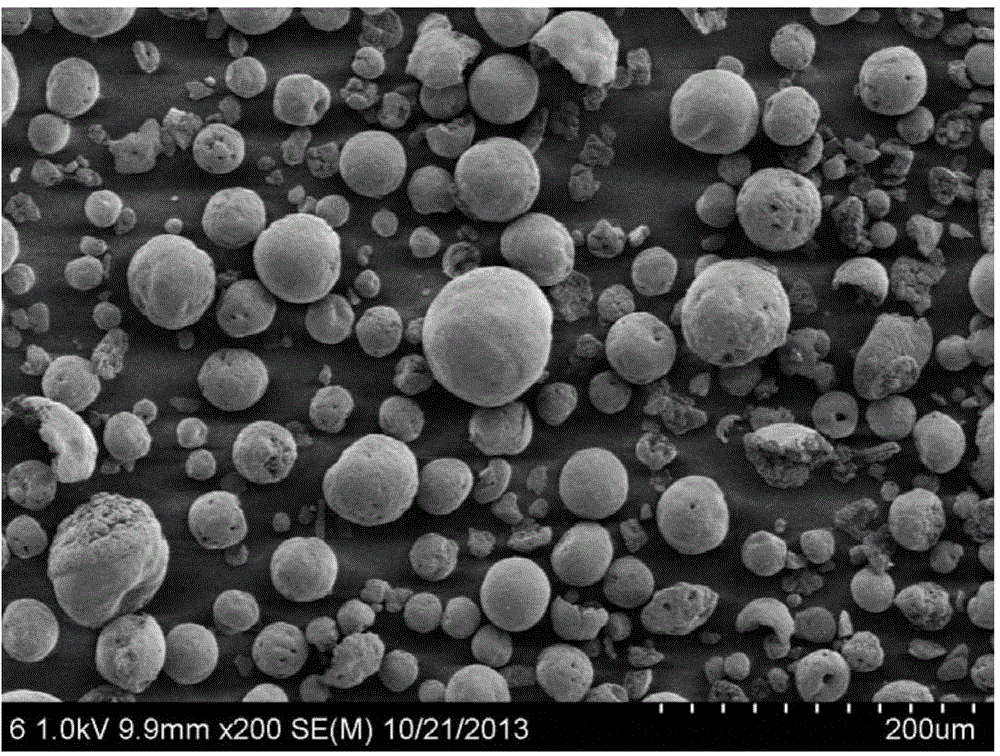

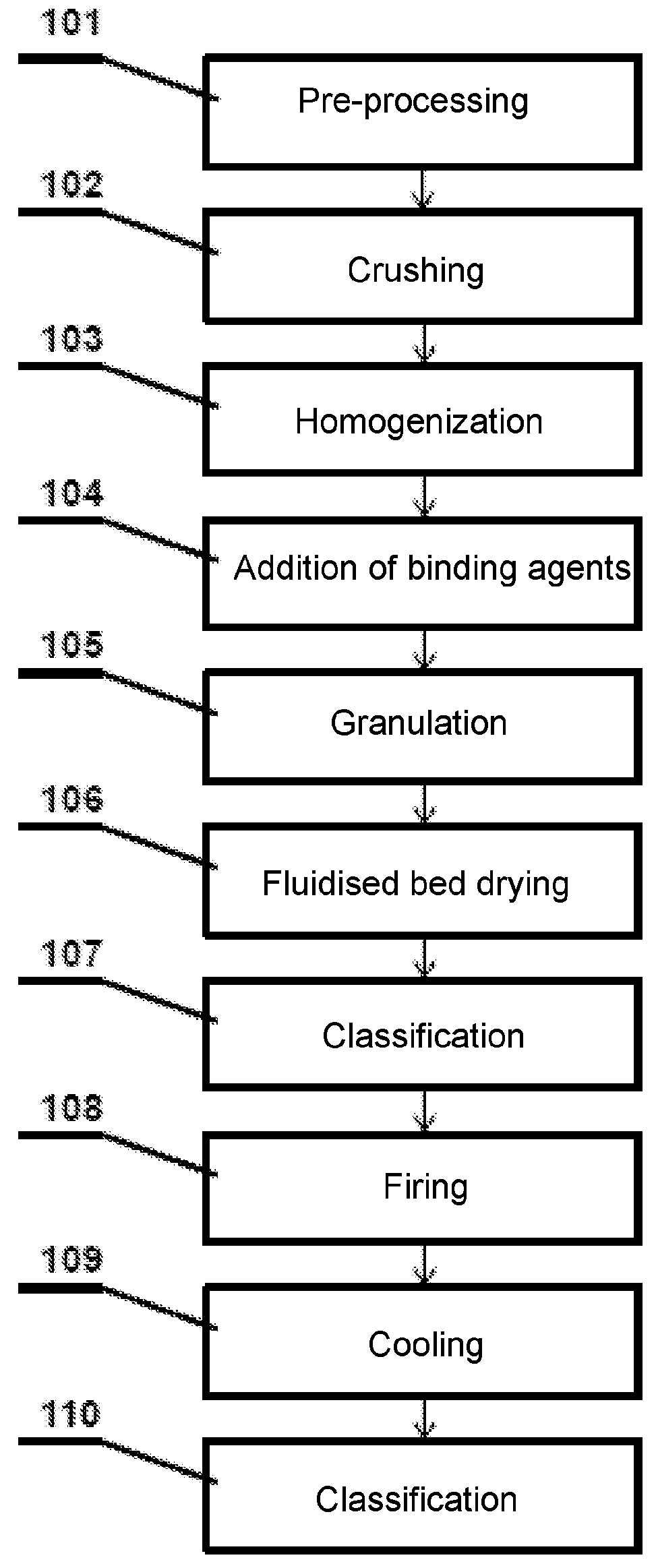

Method of manufacturing of light ceramic proppants and light ceramic proppants

InactiveUS20160053162A1High strengthLow specific gravityFluid removalFlushingFluidized bed dryingMoisture

A method for manufacturing of light ceramic proppants made from a mixture of raw materials that is mechanically granulated in a granulator or that is granulated in a spray dryer from a pourable ceramc mass, to obtain granulate having a granule size of 150-1700 μm (12-100 U.S. Mesh, ASTM E11-04, ISO 13503-2), and next the granulate is fired and the fired granulate is fractioned. The mixture of raw materials is prepared from: illite-beidellite-ka-olinite high-plastic clays of the Poznan series in the amount of 10% to 40% by weight; kaolinite clays in the amount of 10% to 45% by weight; kaolin in the amount of 20% to 40% by weight; fly ash from brown coal combusted in a power plant in the amount of 10% to 35% by weight; and treatment agents in the amount of up to 10% by weight. The mixture of raw materials is mixed and homogenized in a homogenizer, and the obtained granulate is fed to a fluidised bed dryer, in which it is dried to a moisture content below 3%, and the granulate is fired in a rotary furnace in a temperature from 1150° C. up to 1410° C. in time from 120 to 600 min, obtaining proppants which contain from 18% to 32% by weight of Al203, from 40% to 76% by weight of SiO2, and have a specific gravity from 2.15 Mg / m3 to 2.90 Mg / m3 and a bulk density from 1.35 Mg / m3 to 1.70 Mg / m3, depending on the firing time.

Owner:BALTIC CERAMICS

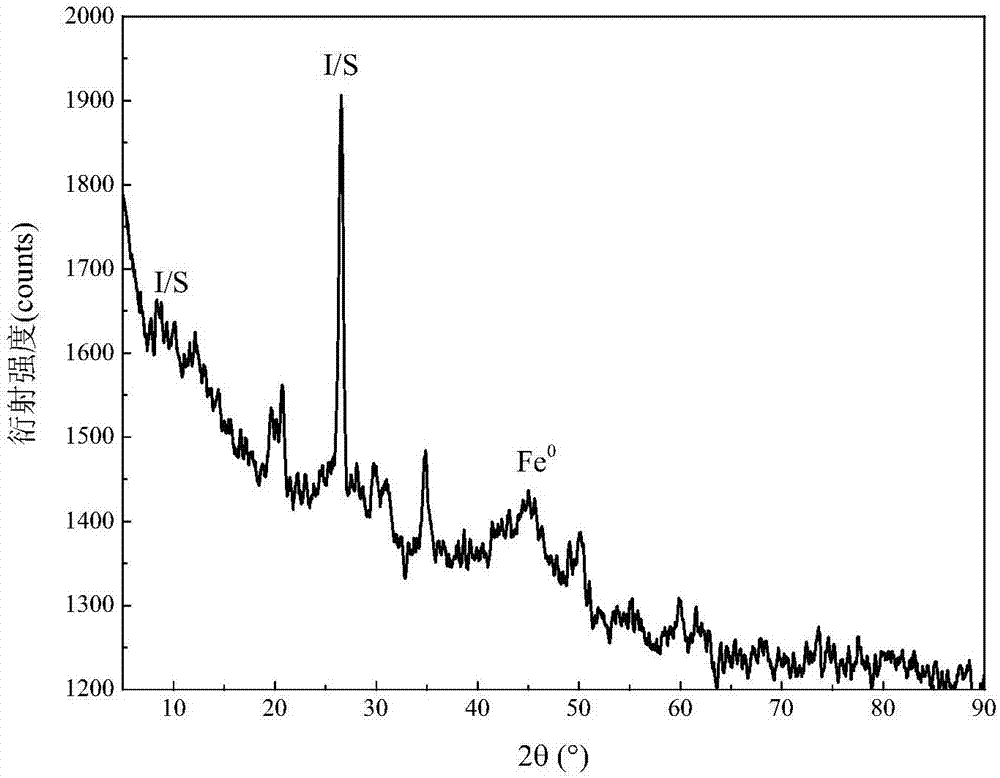

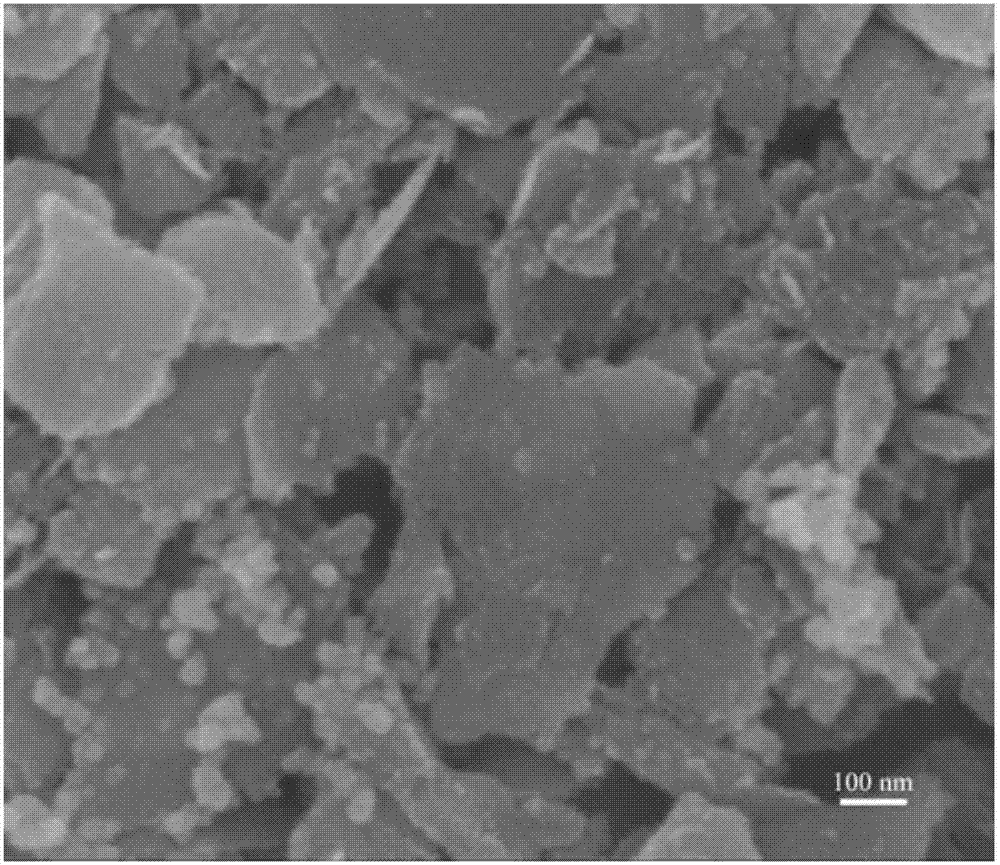

Nano zero-valent iron loaded magnetic nano illite-montmorillonite clay and preparation method and application thereof

InactiveCN106964311AFine particleLamellar morphologyOther chemical processesWater contaminantsPotassium borohydridePotassium

The invention discloses a preparation method of nano zero-valent iron loaded magnetic nano illite-montmorillonite clay. The preparation method includes following steps: (1), adding deionized water into nano illite-montmorillonite clay to obtain a stable suspension; (2), adding ferric trichloride hexahydrate into the suspension, adding anhydrous alcohol, and ultrasonically stirring to obtain a precursor solution; (3), preparing sodium borohydrate or potassium borohydrate solution, and dropwise adding the solution into the precursor solution in a nitrogen atmosphere; (4), using a magnet for gathering to obtain a product, and washing; (5), performing vacuum drying and grinding on the product to obtain nano zero-valent iron loaded magnetic nano illite-montmorillonite clay powder. The invention further discloses the nano zero-valent iron loaded magnetic nano montmorillonite clay prepared by the method and application thereof. The nano zero-valent iron loaded magnetic nano illite-montmorillonite clay prepared by the method has high reaction activity and has remarkable treatment effect on wastewater containing hexavalent chromium, and an outer magnetic field can be utilized for separation after treatment is finished.

Owner:SOUTH CHINA UNIV OF TECH

Method for efficiently releasing potassium from acid-leached illite by aid of microwaves

ActiveCN108409360AWide variety of sourcesTo achieve the purpose of high efficiency and energy savingSilicaPotassium fertilisersPotassiumDissolution

The invention discloses a method for efficiently releasing potassium from acid-leached illite by the aid of microwaves. The method includes the steps: (1) performing flotation and purification on illite raw ores and then grinding the illite raw ores into powder; (2) uniformly mixing acid and illite powder according to a certain proportion; (3) placing mixed materials into a microwave hydrothermaldigester and irradiating the materials at the system temperature of 120-190 DEG C for 5-30 minutes; (4) subsequently treating filtrate. The solid-to-liquid ratio of the illite to the acid is 1:(1-10)mL / g. Illite raw materials are wide in source, early-stage activation is omitted, potassium can be deeply released in an environment of microwave irradiation and acid leaching after flotation and purification, potassium releasing rate is higher than 90%, potassium dissolution rate reaches up to 98% in irradiation in a stepped interval progressive mode, high-purity white carbon black (purity is higher than 95% and iron content is lower than 0.5%) can be acquired by aluminum and iron removal, the average crystallization rate of potassium chloride crystals is 60%, and the purity of the potassium chloride crystals is 85%.

Owner:YANBIAN UNIV

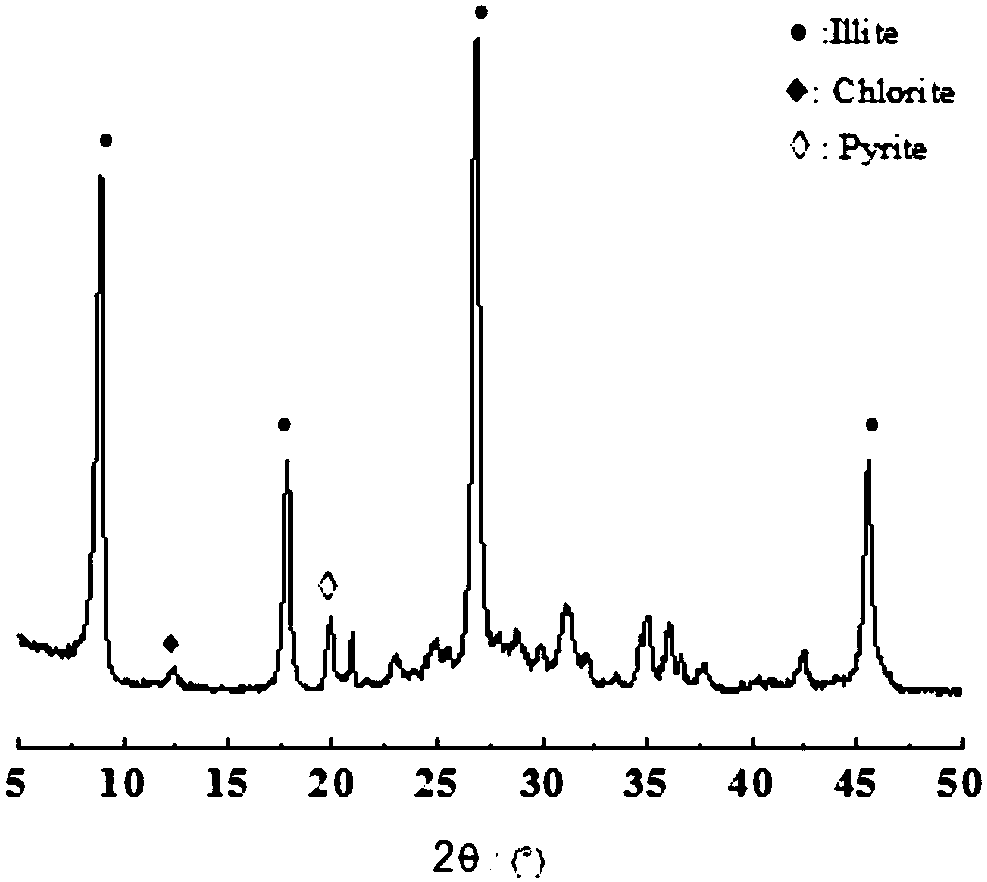

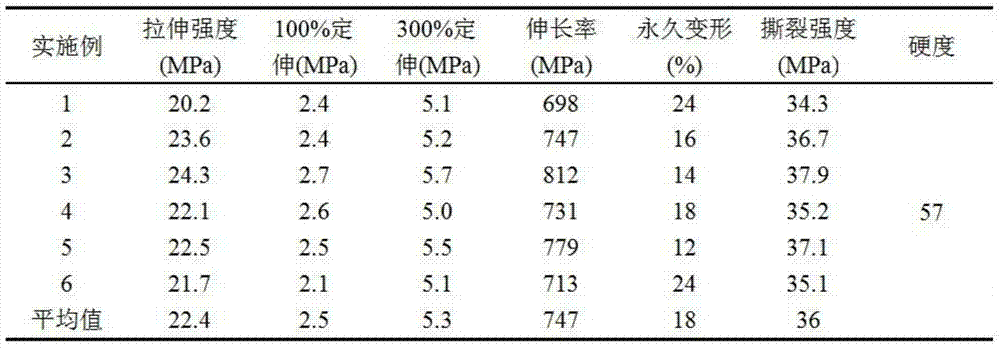

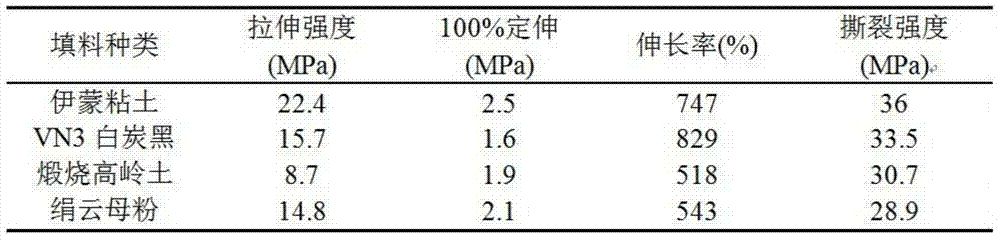

Preparation method of illite/montmorillonite mixed-layer clay/natural rubber compounded rubber

The invention discloses a preparation method of illite / montmorillonite mixed-layer clay / natural rubber compounded rubber and belongs to the technical field of the performance improvement of the compounded rubber. The preparation method comprises the following steps: (1) breaking, dispersing and sieving natural illite / montmorillonite mixed-layer clay so as to obtain slurry; (2) chemically bleaching the slurry; (3) grinding the bleached slurry so as to obtain nanometer slurry; (4) mixing natural latex and water so as to obtain natural latex turbid liquid; (5) mixing the nanometer slurry and the natural latex turbid liquid so as to obtain illite / montmorillonite mixed-layer clay / natural rubber turbid liquid; (6) flocculating the illite / montmorillonite mixed-layer clay / natural rubber turbid liquid and pelleting so as to obtain illite / montmorillonite mixed-layer clay / natural rubber compounded colloidal particles; and (7) drying the colloidal particles so as to obtain the illite / montmorillonite mixed-layer clay / natural rubber compounded rubber. The preparation method is simple in technological process; the production cost is reduced; the emission of dust is reduced; and the illite / montmorillonite mixed-layer clay / natural rubber compounded rubber prepared by the method has relatively strong mechanical property.

Owner:中科纳达新材料(广西)有限公司

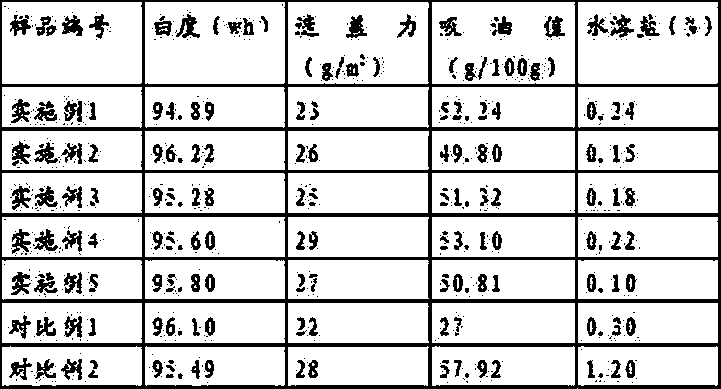

Illite-based composite titanium dioxide and preparation method thereof

The invention provides illite-based composite titanium dioxide and a preparation method thereof. The composite titanium dioxide is obtained by coating the surface of illite with nano titanium dioxide particles, and is prepared from the following components in parts by weight: 60-80 parts of illite, 15-35 parts of titanium dioxide and 0.5-5 parts of dispersing agents. The preparation method comprises the steps of depositing, washing and filtering and calcining. The prepared composite titanium dioxide has the characteristics of low cost, high whiteness, strong covering power, low oil absorption and low water-soluble salt value.

Owner:丹东亿龙高科技材料有限公司 +1

Method for microwave synthesis of ZSM-5 molecular sieve through illite

InactiveCN106830002ASolve the external silicon sourceSolving the problem of aluminum sourcesMolecular sieve catalystsPentasil aluminosilicate zeoliteMolecular sieveHigh energy

Owner:YANBIAN UNIV

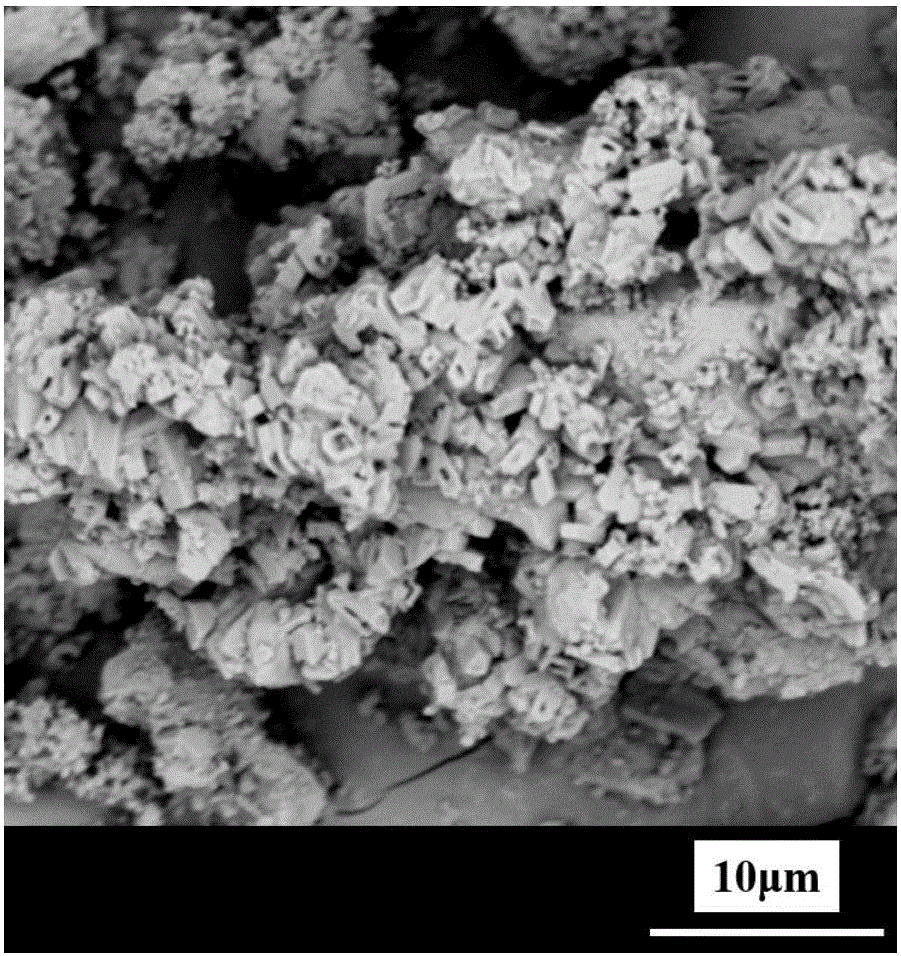

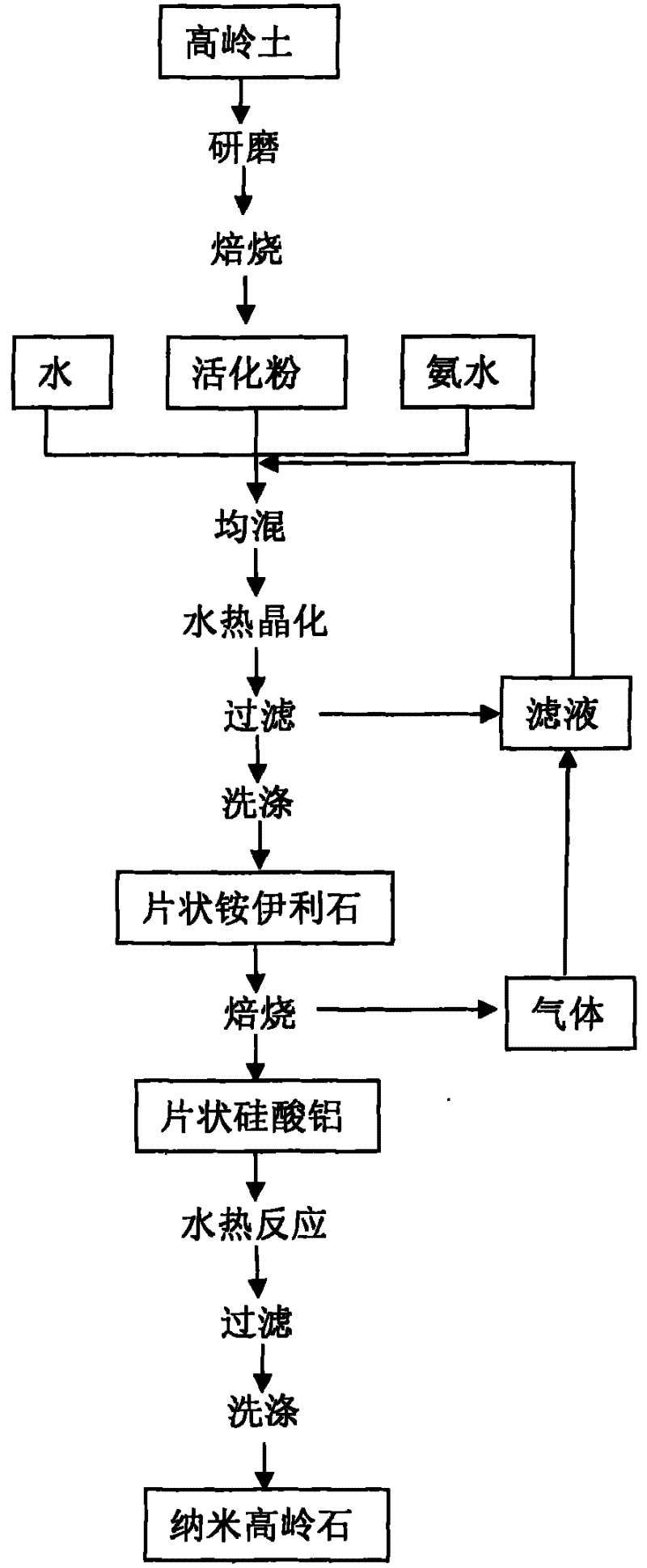

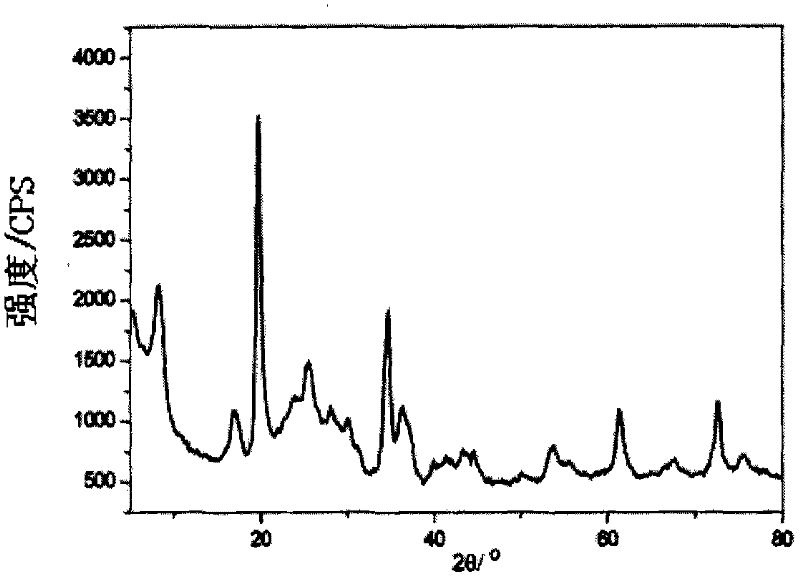

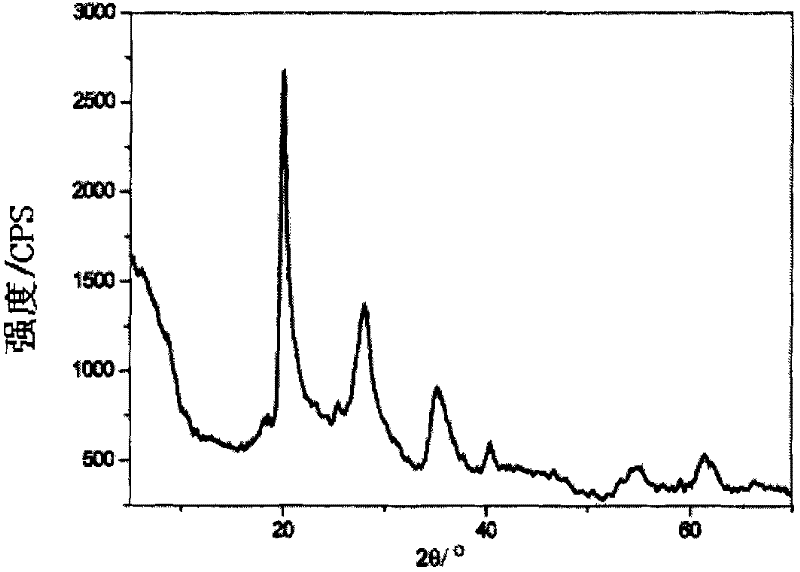

Method for preparing ammonium illite sheets, alumina silicate sheets, and nano-sized kaolinite

InactiveCN102205971ALower requirementEasy to implementNanostructure manufactureAluminium silicatesAluminum silicateKaolin clay

The invention relates to a method for preparing a nano-sized kaolinite from kaolin. The method comprises: (1) crushing and baking kaolin to obtain baked kaolin powder; (2) mixing the baked kaolin powder, strong ammonia liquor and water, such that a slurry is obtained; (3) placing the slurry into a pressure reaction vessel for a hydrothermal crystallization reaction; (4) carrying out a solid-liquid separation upon the slurry, washing and drying the slurry, such that ammonium illite sheets are obtained; (5) baking ammonium illite to obtain alumina silicate sheets; (6) mixing alumina silicate and water into a slurry, and placing the slurry into a pressure reaction vessel for a hydrothermal crystallization reaction; (7) carrying out a solid-liquid separation upon the slurry, washing and drying the slurry, such that nano-sized kaolinite is obtained. According to the present invention, cheap kaolin is adopted as a raw material, and ammonium illite sheets are produced through a crushing-baking-hydrothermal treating method. Therefore, difficulties in synthesizing ammonium illite are reduced, preparation technologies are simplified, and alumina silicate and nano-sized kaolinite with specific surface areas exceeding 150m<2> / g are prepared.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

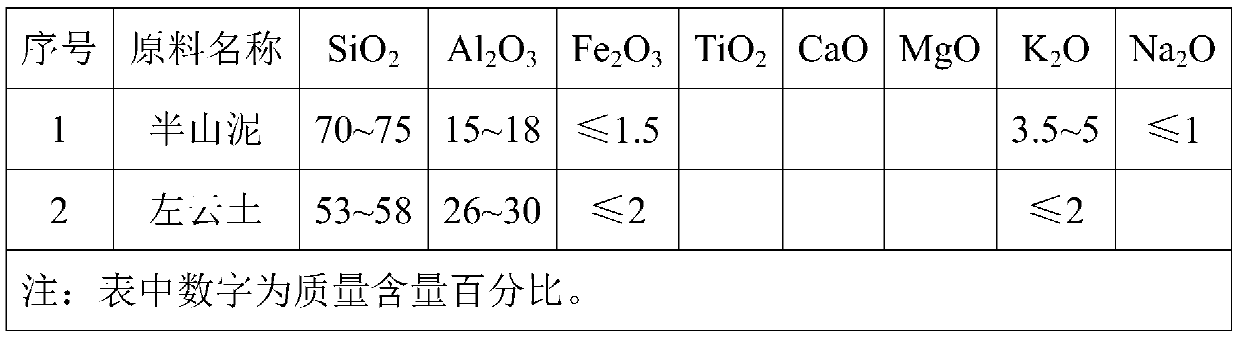

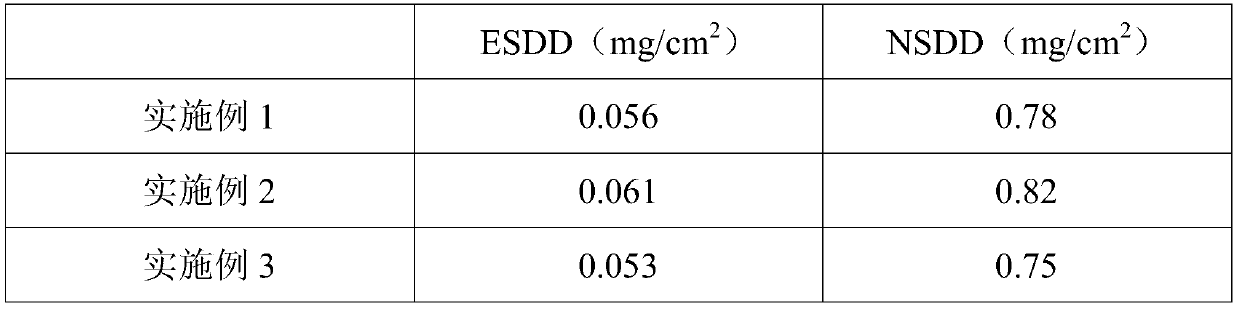

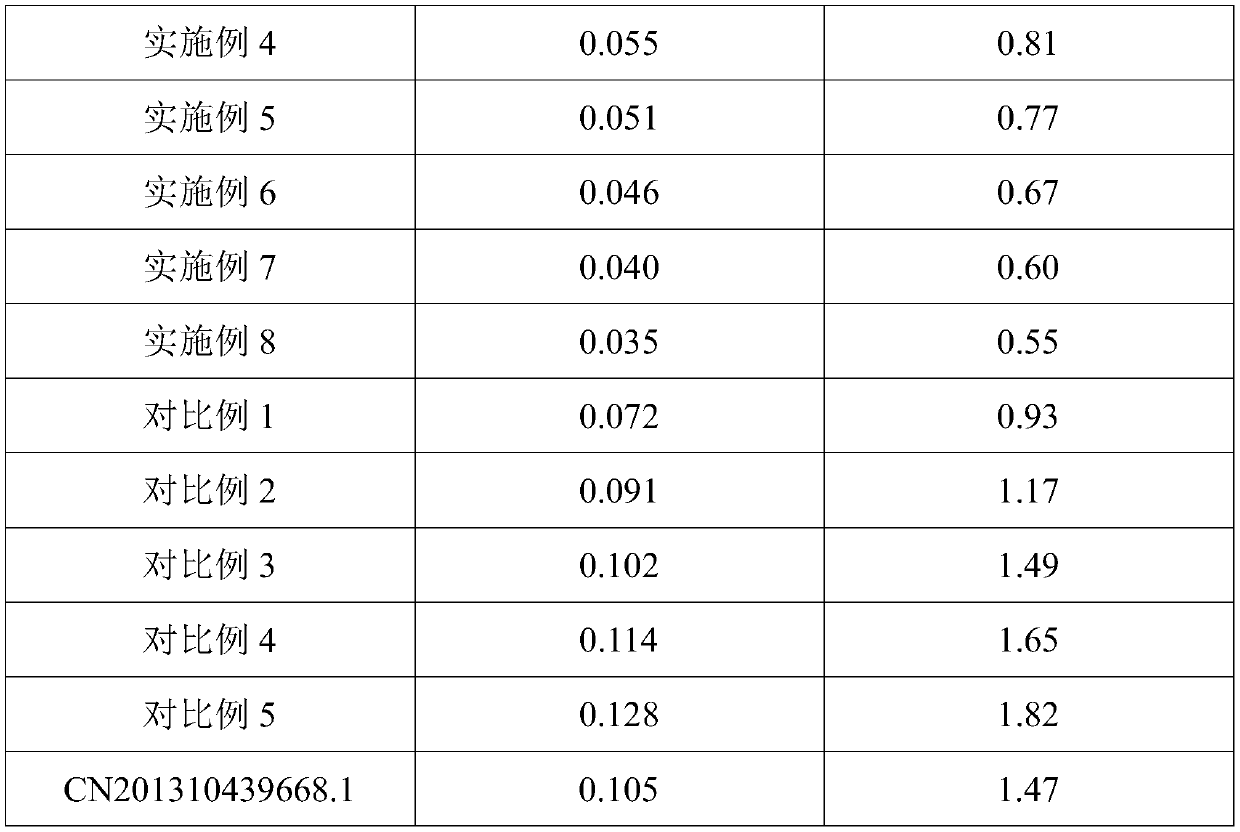

Glaze for extra-high voltage porcelain insulator, and production method thereof

The invention provides a formula and a preparation method of a glaze for an extra-high voltage porcelain insulator, wherein the raw materials of the formula comprise, by weight, 20-33 parts of quartz,10-18 parts of illite, 10-15 parts of semi-mountain clay, 10-15 parts of zirconium silicate micro powder, 4-7 parts of white corundum micro powder, 1-5 parts of nanometer silicon dioxide, 3-6 parts of wollastonite, 1-2 parts of barium carbonate, 7-12 parts of Zuoyun soil, 5-7 parts of manganese oxide, 1-2 parts of iron oxide, 1-2 parts of chromium oxide, 3-5 parts of antimony oxide, 2-8 parts ofsepiolite powder and 2-8 parts of bentonite. The preparation method comprises: preparing nanometer silicon dioxide composite modified sepiolite powder, preparing a solid solution, carrying out wet ball milling, and adjusting the specific gravity of glaze slurry. According to the invention, with the glaze obtained by the formula and the method, the insulator has excellent stain resistance and excellent voltage sharing performance, further has substantially improved mechanical performance and substantially improved electrical performance, and is suitable for extra-high voltage direct current power transmission systems.

Owner:江西高强电瓷集团有限公司

Illite loaded nanocarbon compound adsorbing material and preparation method thereof

InactiveCN106311147AImprove adsorption and capture performanceGood dispersionOther chemical processesWater contaminantsDispersitySorbent

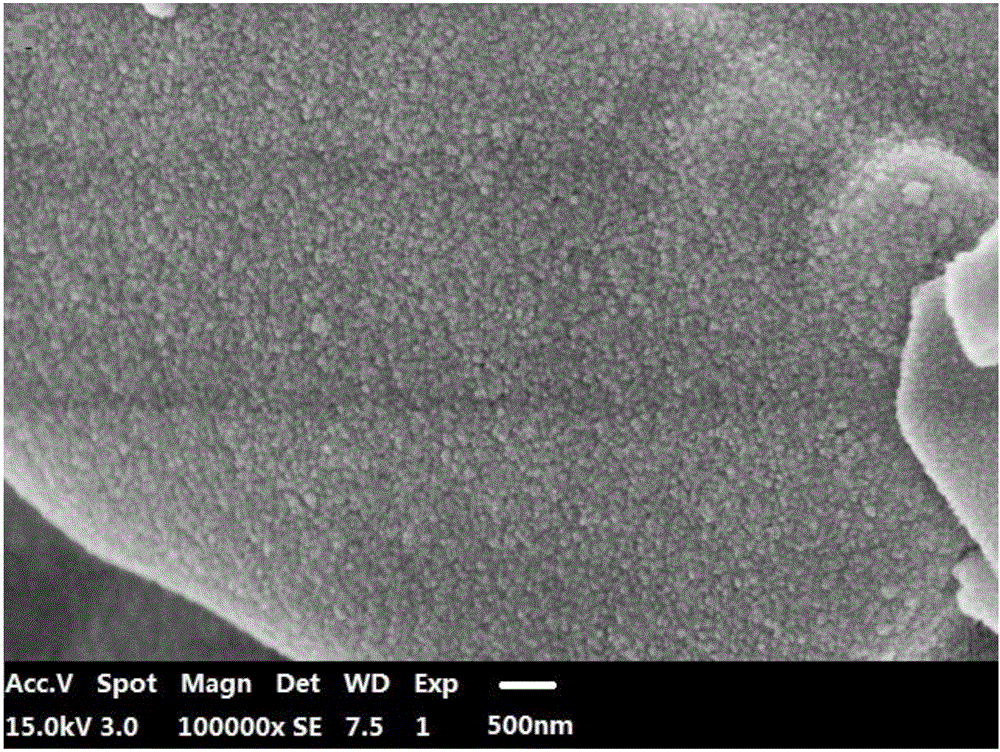

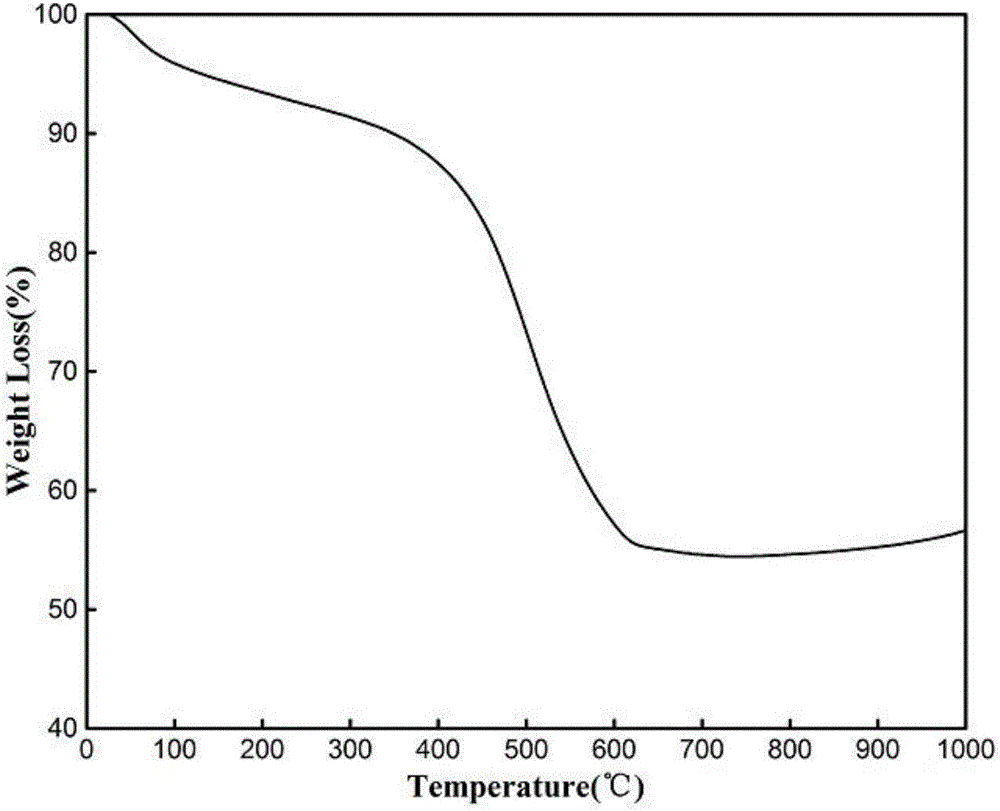

The invention relates to an illite loaded nanocarbon compound adsorbing material and a preparation method thereof and belongs to the field of non-metallic mineral material and environmental engineering. According to the invention, illite is taken as a carrier, soluble saccharide is taken as a carbon source and nanocarbon grains are uniformly loaded on the surface of an illite layer, so that the nanocarbon compound adsorbing material taking illite as the carrier is obtained. In the prepared illite loaded nanocarbon compound adsorbing material, the average grain diameter of the nanocarbon grains is 30-50nm, the nanocarbon grains are uniformly and compactly distributed on the surface of the illite layer and the load volume is 30%-70% of the mass of the compound material. According to the material, the illite carrier effect is utilized to increase the adsorbing capturing performance of the compound material to the pollutant and the dispersity of the adsorbent; the obtained raw materials are easily acquired and are low in cost; the preparation technique is simple and the reaction condition is mild; the illite loaded nanocarbon compound adsorbing material has higher application value in the field of wastewater treatment.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

High water absorbing and retaining composite containing illite clay mineral and method for preparing the same

The water absorbing and maintaining composite material consists of water soluble unsaturated ethylene monomer, illite-clay mineral in the amount of 2-300 wt% of the ethylene monomer, and water soluble free radical polymerization initiator in the amount of 0.001-1 wt% of the ethylene monomer. The preparation process includes adding illite-clay mineral into 5-50 % concentration water soluble unsaturated ethylene monomer solution with water soluble free radical polymerization initiator or water soluble free radical polymerization initiator and crosslinking agent, dispersing, heating to 20-90 deg,c for polymerization of 1-10 hr, drying of the polymerized product at 40-150 deg.c and crushing mechanically to obtain grain product. The water absorbing and maintaining composite material has low cost, high absorption to calcium and magnesium ion aqua and high salt tolerance, and is suitable for use in agriculture and forestry.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

High water absorption composite material and its preparation method

This invention relates to a super hydrating composite and its preparation. A super hydrating composite, its characteristic is that it mainly consist of fly ash, illite, acrylic acid, acrylamide, hydroxide solution, water-solubility radical polymerization initiator and cross linking agent raw material, the addition quality of fly ash is 20%-60% of acrylic acid, the addition quality of illite is 20%-60% of acrylic acid, the addition quality of water-solubility radical polymerization polymerization initiator is 0.01%-1% of acrylic acid, the addition quality of acrylamide is 5%-60% of acrylic acid, the addition quality of cross linking agent is 0%-0.5% of acrylic acid, the addition quality of hydroxide solution is that neutralization degree is 40-100 mole percentage after neutralizing acrylic acid; The stated fly ash is grinded by vibration milling to make mean diameter be 5.0-15.0 mum,illite is grinded by vibration milling to make mean diameter be 5.0-15.0 mum. The characteristics of invented product are super hydrophilia, high potassium content, low cost, environment compatibility is better than sodium polyacrylate super hydrating resin.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Water element stone ceramic ball and preparing method thereof

The invention discloses a water element stone ceramic ball and preparing method thereof. The water element stone ceramic ball is prepared from the following raw materials in parts by weight: 80-100 parts of water element stones, 45-65 parts of green stones, 20-40 parts of garnet, 10-15 parts of carbon stone fiber, 24-36 parts of rectorite, 18-26 parts of diatomite, 14-22 parts of illite, 12-18 parts of ocher, 10-15 parts of Balanophyllia sp, 7-14 parts of nano silver carbon molecular sieves, 15-20 parts of green frontiers stones, 25-45 parts of natural manganese sands and 5-10 parts of titanium dioxide. After being processed by the water element stone ceramic ball, drinking water is weakly alkaline in water quality with small molecules and negative potential, rich in oxygen, minerals and trace elements needed by the body, and beneficial to human health; the water element stone ceramic ball has the functions of killing bacteria and viruses in the drinking water, eliminating odors and adsorbing harmful substances of chlorine dioxide, heavy metals and the like, so as to ensure the good quality of the drinking water.

Owner:徐州雅居乐环保科技有限公司

Production method of illite compressed nutrient soil

ActiveCN104119180BReduce manufacturing costReduce shipping costsFertilizer mixturesEcological environmentPolyvinyl alcohol

The invention discloses a production method for compressed illite nutrient soil. The technical scheme is characterized by firstly carrying out acid treatment on illite and sludge; and then packaging to obtain finished products after stirring, compressing and carrying out micro-wave sterilization on ingredients of the compressed illite sludge nutrient soil at a low temperature. The compressed illite nutrient soil consists of materials such as acidified illite, acidified sludge, sodium silicate hydrate, polyvinyl alcohol, ferrous sulfate, peat, flower ceramsite, high-viscosity attapulgite clay, biogas slurry, crushed plant fiber, expanded vermiculite, expanded perlite and super absorbent resin. The compressed illite nutrient soil contains a great deal of nitrogen, phosphor, potassium, organic matters and various trace elements, can provide nutrient elements needed for plant growth, can reduce harm of pathogenic bacteria and pests on plants, is beneficial to normal growth and development of plants and protects ecological environment, and the production method for the compressed illite nutrient soil is applicable to producing the compressed illite nutrient soil with different formulas.

Owner:度测(上海)科技服务中心

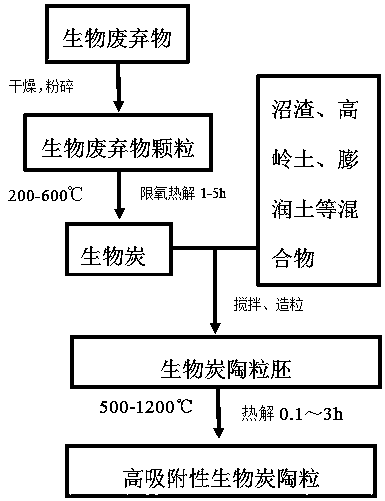

Method for preparing high-adsorption ceramsite by using biochar

InactiveCN110467429ALarge specific surface areaStrong electron exchangeOther chemical processesCeramic materials productionIon exchangeExpanded clay aggregate

The invention discloses a method for preparing high-adsorption ceramsite by using biochar. The method comprises: drying biomass waste, crushing, carrying out oxygen limited pyrolysis for 1-5 h at a temperature of 200-600 DEG C, cooling to a room temperature to obtain biochar, completely mixing biochar and any one or more than two selected from biogas residue powder, kaolin powder, illite, chlorite, dolomite powder, biogas residue powder, montmorillonite, bentonite powder, diatomite powder and perlite powder, stirring, granulating, roasting for 0.1-3 h at a temperature of 500-1200 DEG C, cooling, breaking, and screening to obtain the high adsorption ceramsite. According to the present invention, the high-adsorption porous biochar ceramsite with stable chemical properties can be obtained bycarrying out mixed sintering on biochar, kaolin and the like; and with the method, the pore structure of ordinary ceramsite is optimized, the ion exchange capacity is improved, the adsorption of conventional ceramsite is enhanced, and the obtained product can be efficiently used in the fields of sewage treatment, soil improvement, environmental restoration and the like.

Owner:SHANGHAI ACADEMY OF LANDSCAPE ARCHITECTURE SCI & PLANNING

Raw material formula and method for manufacturing high-alumina porcelain insulator

The invention relates to a raw material formula and method for manufacturing a high-alumina porcelain insulator, and belongs to the technical field of electric porcelain. The formula comprises bauxite, kaolinite, feldspar, mullite, illite, clay, Zuoyun soil, nacrite, garnet and white carbon black, and the high-alumina porcelain insulator is prepared by a sintering process comprising the followingsteps: using a plurality of raw materials and adding a small amount of garnet, white carbon black and methyl silicone resin, grinding into powder with two different particle sizes in the preparation process, mixing, heating in stages, cooling and heating again. And the obtained porcelain insulator has excellent mechanical properties and meets the requirements of the field of electroceramics at present.

Owner:江西省萍乡市宇翔电瓷制造有限公司

Closestool high in strength and low in weight and preparation method thereof

The invention relates to a closestool high in strength and low in weight and a preparation method thereof. A green body of the closestool comprises 24-29 parts of illite, 12-16 parts of potassium feldspar, 18-23 parts of montmorillonite, 20-28 parts of clay, 13-15 parts of sodalite, 7-11 parts of rutile, 21-27 parts of halloysite, 17-20 parts of allophane, 5-7 parts of barium carbonate, 2-4 parts of johnstonotite, 9-13 parts of calcined kieselguhr, 5-9 parts of glauconite, 6-10 parts of rectorite and 1-3 parts of addition agents; Glaze materials are composed of 6-13 parts of feldspar, 7-12 parts of kaolin, 3-9 parts of germanite, 12-17 parts of vermiculite, 11-15 parts of talcum, 4-8 parts of tourmaline powder and 3-5 parts of nano-silver-powder. The closestool high in strength and low in weight is low in weight, high in strength, low in water absorption and capable of releasing anions and resisting against bacteria.

Owner:广东澳丽泰陶瓷实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com