Template-free method for synthesizing hierarchical pore ZSM-5 zeolite molecular sieve from illite

A ZSM-5, zeolite molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of synthesis pollution, long synthesis cycle, and high synthesis cost, and achieve synthesis time. The effect of reducing, enriching silanol groups, and reducing synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

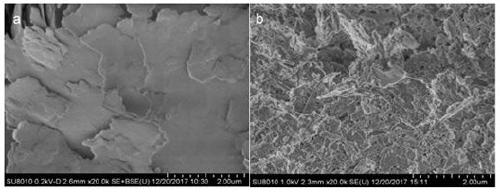

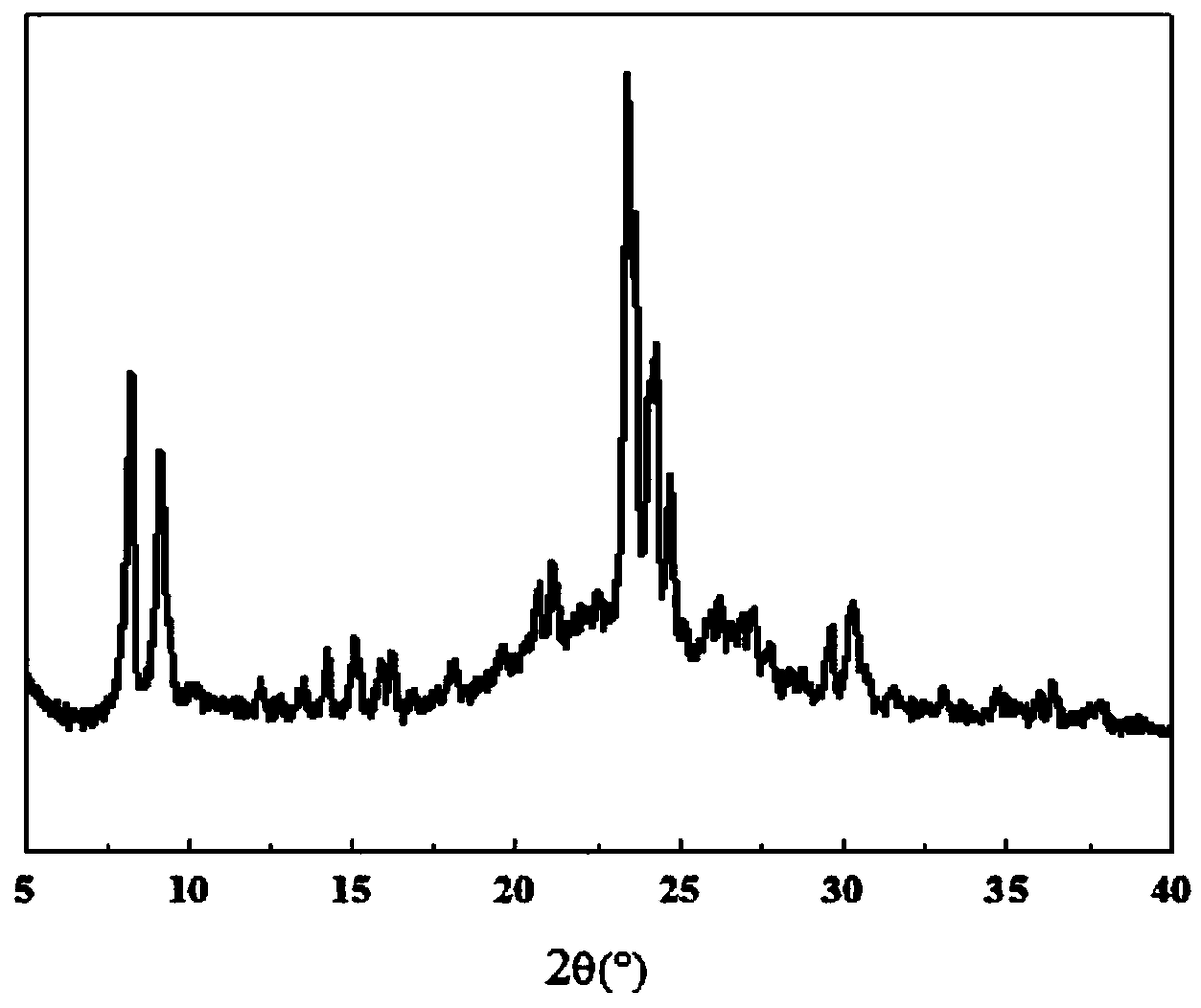

[0029] A method for illite template-free synthesis of hierarchically porous ZSM-5 zeolite molecular sieves, specifically comprising the following processes:

[0030] Preparation of illite active silica slag:

[0031] Step 1, the illite raw material ore is simply ball-milled to powder;

[0032] Step 2, mix illite powder and hydrochloric acid with a concentration of 4mol / L at a ratio of 1:7.5g / mL, and put it into a hydrothermal reaction kettle;

[0033] Step 3, put the hydrothermal reaction kettle in an oven, and react at a temperature of 170 degrees Celsius for 4 hours;

[0034] Step 4: After taking out the reaction kettle, after suction filtration, the reaction product is washed with distilled water until it is neutral, and then dried, and the product is acid-washed illite slag material.

[0035] Synthesis of illite-based hierarchically porous ZSM-5 molecular sieve:

[0036] Step 1: Grind pickling illite slag, aluminum source and alkali source in a mortar for 10 minutes.

...

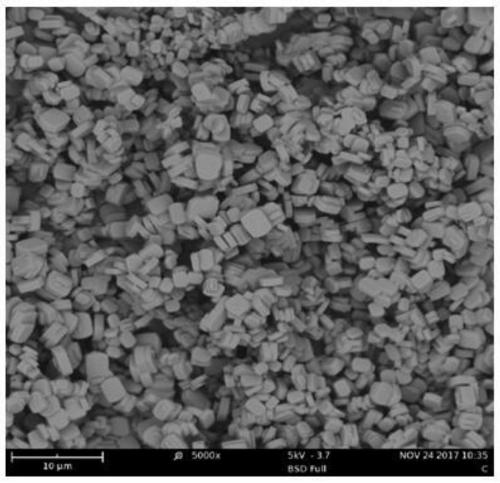

Embodiment example 2

[0041] Preparation of illite active silica slag: same as implementation case 1

[0042] Synthesis of illite-based hierarchically porous ZSM-5 molecular sieve:

[0043] Step 1: Grind pickling illite slag, aluminum source and alkali source in a mortar for 10 minutes.

[0044] Step 2, add distilled water, make material molar ratio be pickling illite slag material (SiO 2 ):Al 2 o 3 : NaOH : H 2 O=40:1:0.155:3.5, so that the materials are mixed evenly.

[0045] Step 3, transfer the mixed material to a hydrothermal reaction kettle, and crystallize at 190°C for 2 hours;

[0046] Step 4: Take out the reaction kettle, and after it returns to room temperature, take out the materials in the reaction kettle, and then filter and dry the reaction product to obtain ZSM-5 zeolite molecular sieve raw powder.

Embodiment example 3

[0048] Preparation of illite active silica slag: same as implementation case 1

[0049] Synthesis of illite-based hierarchically porous ZSM-5 molecular sieve:

[0050] Step 1: Grind pickling illite slag, aluminum source and alkali source in a mortar for 10 minutes.

[0051] Step 2, add distilled water, make material molar ratio be pickling illite slag material (SiO 2 ):Al 2 o 3 : NaOH : H 2 O=40:1:0.28:3.5, so that the materials are mixed evenly.

[0052] Step 3, transfer the mixed material to a hydrothermal reaction kettle, and crystallize at 190°C for 4 hours;

[0053] Step 4: Take out the reaction kettle, and after it returns to room temperature, take out the materials in the reaction kettle, and then filter and dry the reaction product to obtain ZSM-5 zeolite molecular sieve raw powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com