Preparation method of ZSM-11 molecular sieve

A technology of ZSM-11 and molecular sieve, which is applied in the field of preparation of ZSM-11 molecular sieve, can solve the problems of low production efficiency, low crystallinity, and long crystallization time, and achieve the effect of reducing synthesis cost and shortening crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

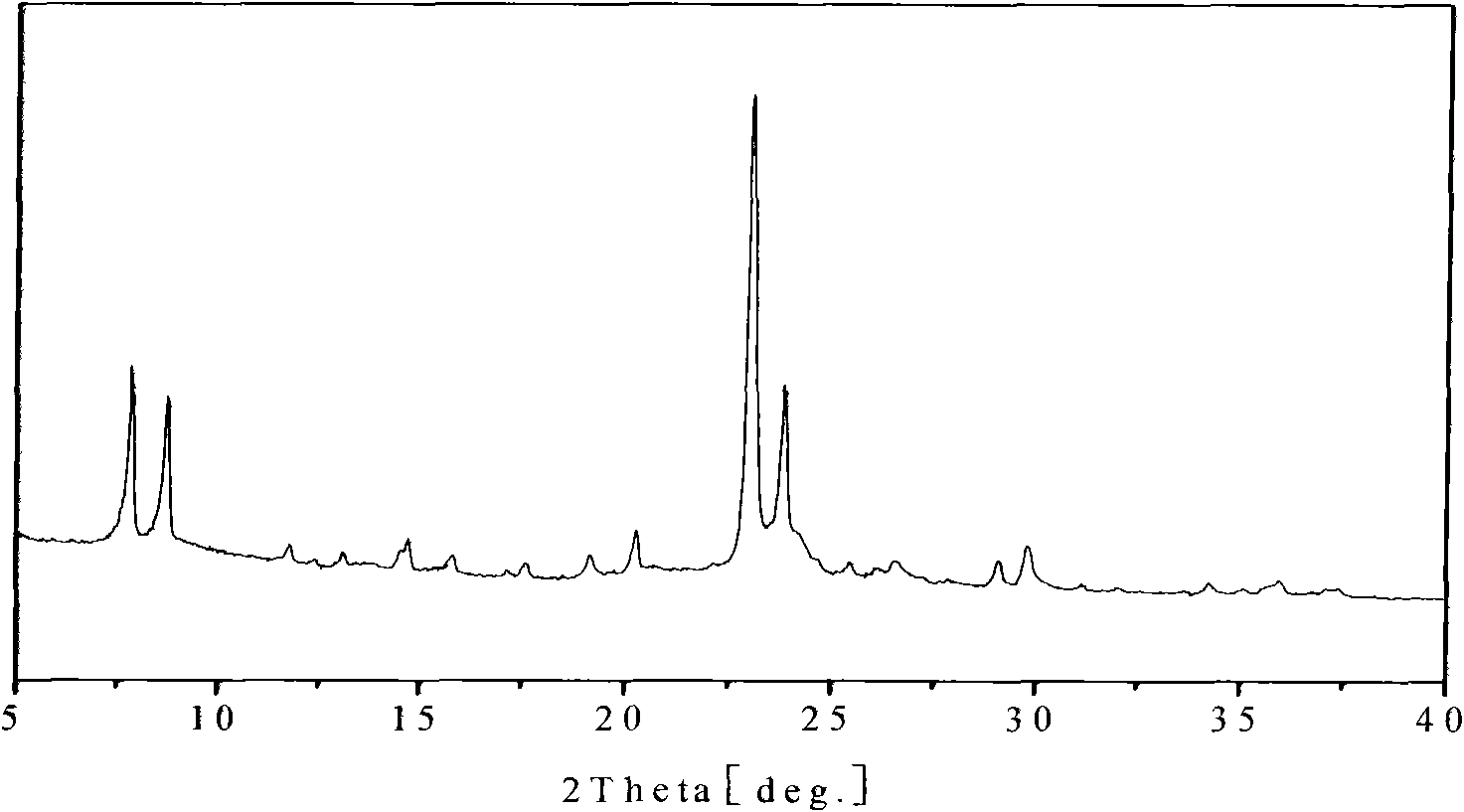

Image

Examples

Embodiment 1

[0014] Weigh 1.8g sodium hydroxide and 5.0g tetrabutylammonium bromide and dissolve in 50.0ml deionized water, then add 7.5g EU-1 molecular sieve while stirring at room temperature, stir for 0.5 hours, then add 5.0g white carbon black , After stirring for 0.5 hours, move to a closed stainless steel reaction kettle. Crystallize at 140°C for 48 hours to obtain ZSM-11 molecular sieve.

[0015] Proportion: 0.3Na 2 O: 1.1SiO 2 : 0.10 (TBA) 2 O: 100EU-1(g): 37H 2 O.

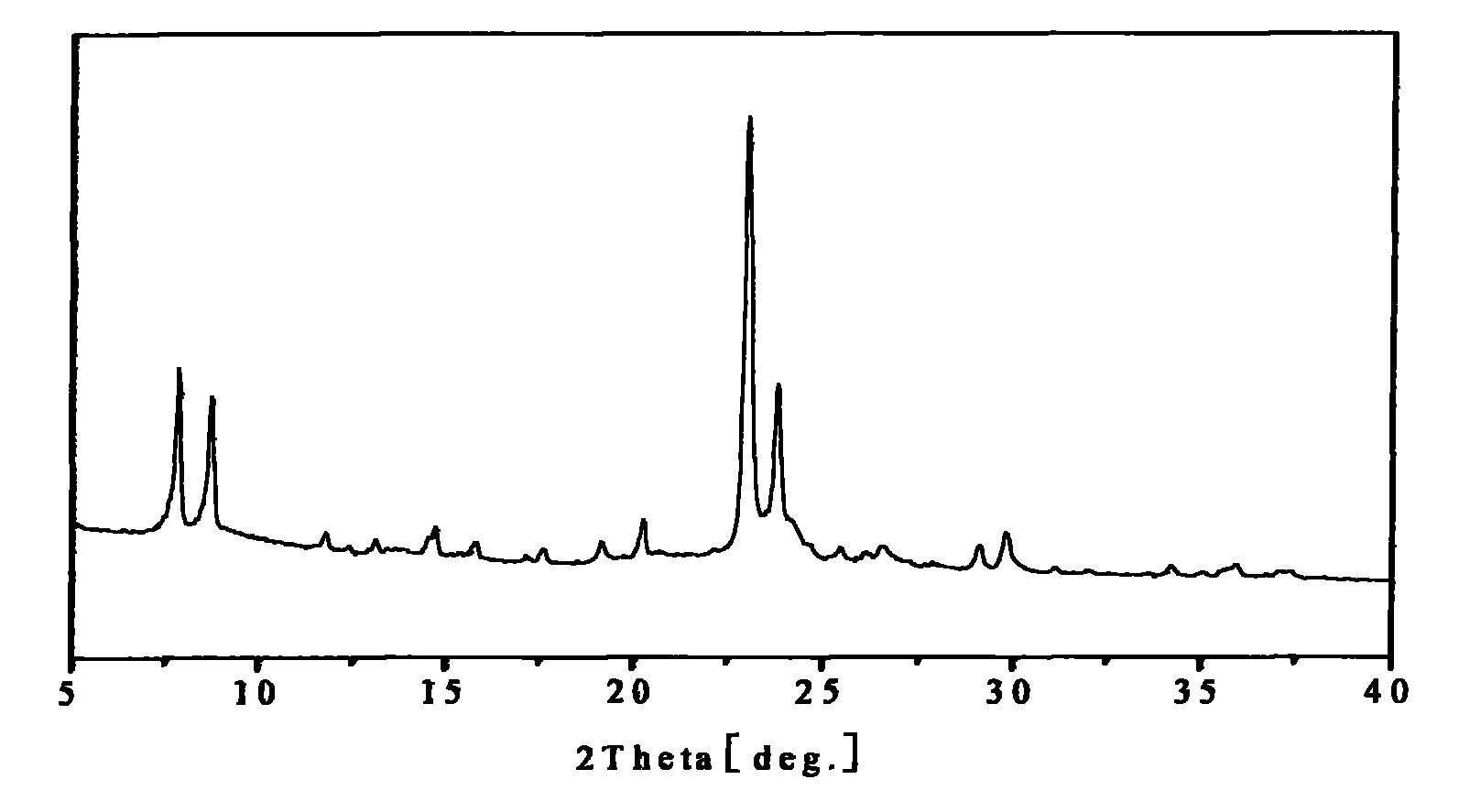

Embodiment 2

[0017] Weigh 1.6g of sodium hydroxide and 6.0g of tetrabutylammonium bromide and dissolve them in 50.0ml of deionized water, then add 5.0g of EU-1 molecular sieve while stirring at room temperature, stir for 0.5 hours, then add 5.0g of white carbon black, After stirring for 0.5 hours, move to a closed stainless steel reaction kettle. Crystallize at 140°C for 48 hours to obtain ZSM-11 molecular sieve.

[0018] Proportion: 0.40Na 2 O: 1.6SiO 2 :0.17(TBA) 2 O: 100EU-1(g): 55H 2 O.

Embodiment 3

[0020] Weigh 1.6g of sodium hydroxide and 6.0g of tetrabutylammonium bromide and dissolve them in 50.0ml of deionized water, then add 5.0g of EU-1 molecular sieve while stirring at room temperature, stir for 0.5 hours, then add 8.0g of white carbon black, After stirring for 0.5 hours, move to a closed stainless steel reaction kettle. Crystallize at 150°C for 36 hours to obtain ZSM-11 molecular sieve.

[0021] Proportion: 0.40Na 2 O: 2.7SiO 2 :0.17(TBA) 2 O: 100EU-1(g): 55H 2 O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com