Method for preparing mesoporous gamma-Al2O3 by dynamic hydrothermal method

A dynamic hydrothermal and mesoporous technology, applied in the preparation of alumina/hydroxide, etc., can solve the problems of high roasting temperature, long time, and easy self-agglomeration of particles, and achieve simple experimental steps, increase the contact area, and prepare short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

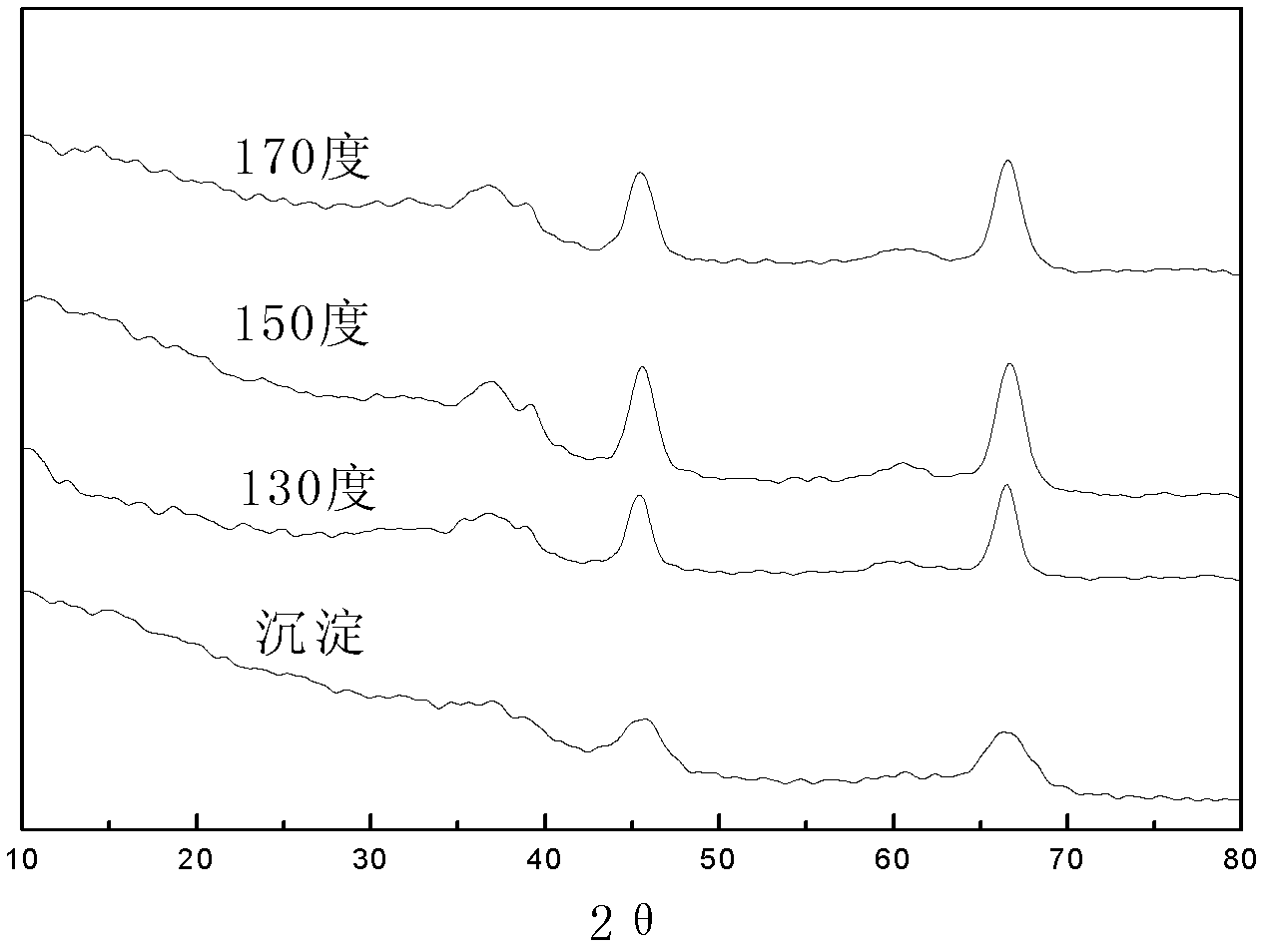

[0029] combine figure 1 This embodiment will be described.

[0030] The aqueous solution that is dissolved with 3.75g aluminum nitrate 5.25g urea is added respectively in the cetyl trimethyl ammonium bromide solution (the quality of cetyl trimethyl ammonium bromide 0.1g), its mass ratio is aluminum nitrate : urea: hexadecyltrimethylammonium bromide=1: 1.4: 0.027, continuously stirred for 1h at 30°C to make it uniformly mixed, then the mixed solution was transferred to an autoclave, and distilled water was added in the autoclave, Make its volume 1 / 2 of the volume of the whole inner tank (the volume of the whole inner tank is 300mL); then heat to 170°C and continuously stir for 4h; after the reaction is finished, the reaction product is suction filtered, and washed with distilled water until neutral, Dry at 100°C to constant weight, and bake at 600°C for 4 hours to obtain γ-Al 2 o 3 .

[0031] Carry out XRD detection on the product, detection conditions: application of X-ray...

specific Embodiment approach 2

[0033] combine figure 2 , image 3 To illustrate this embodiment, the aqueous solutions of 3.75g aluminum nitrate and 5.25g urea are added to the cetyltrimethylammonium bromide solution (the quality of cetyltrimethylammonium bromide is 0.05g) , its mass ratio is aluminum nitrate: urea: cetyltrimethylammonium bromide=1: 1.4: 0.0133, continuously stirred for 1h at 30°C, so that it can be uniformly mixed, and then the mixed solution is transferred into an autoclave, And add distilled water in the still, make its volume 1 / 2 of the volume of the whole inner tank (the volume of the whole inner tank is 300mL); then heat to 100 ℃ and continue to stir for 4h; Wash with distilled water until neutral, dry at 100°C to constant weight, and roast at 500°C and 550°C for 4 hours to obtain mesoporous γ-Al 2 o 3 The results are listed in Table 1, and Table 1 shows the properties of mesoporous alumina with different calcination temperatures.

[0034] Table 1

[0035]

[0036] Table 1 sh...

specific Embodiment approach 3

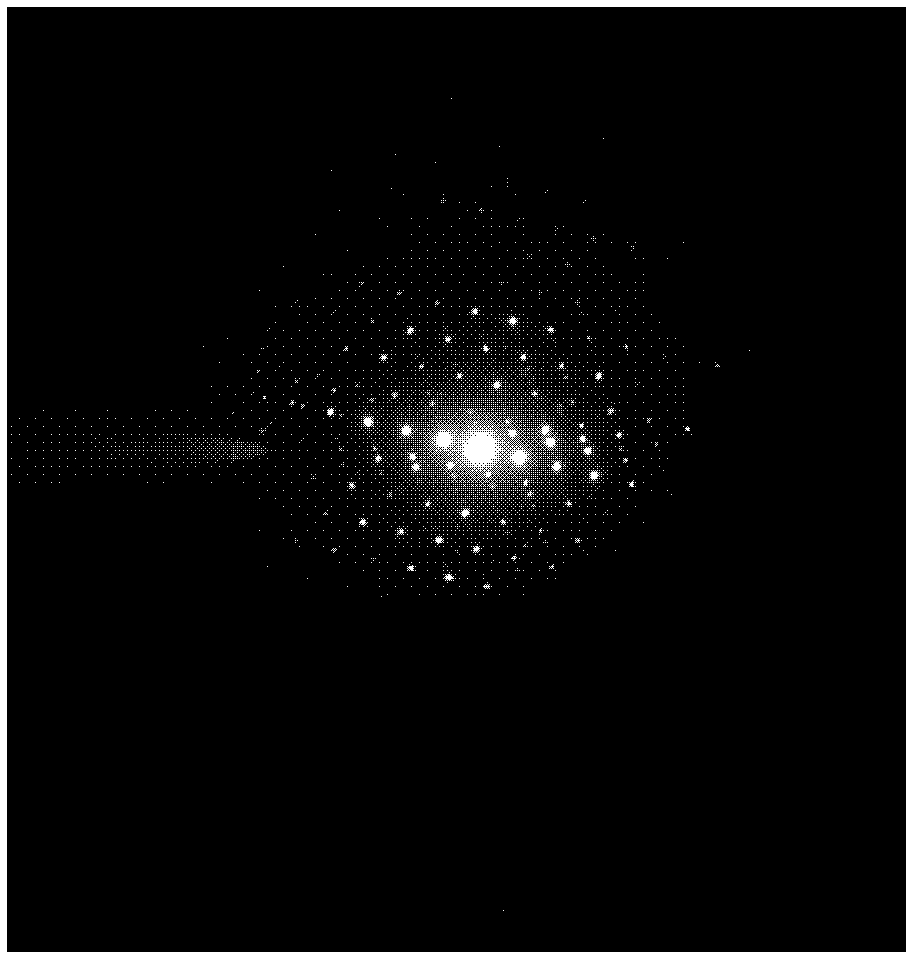

[0039] combine Figure 4 , Figure 5 , Figure 6To illustrate this embodiment, the aqueous solutions of 3.75g aluminum nitrate and 5.25g urea are added to the cetyltrimethylammonium bromide solution (the quality of cetyltrimethylammonium bromide is 0.05g) , its mass ratio is aluminum nitrate: urea: cetyltrimethylammonium bromide=1: 1.4: 0.0133, continuously stirred for 1h at 30°C, so that it can be uniformly mixed, and then the mixed solution is transferred into an autoclave, And add distilled water in the still, make its volume 1 / 2 of the volume of the whole inner tank (the volume of the whole inner tank is 300mL); then heat to 130 ℃ and continue to stir for 4h; after the reaction is finished, the reaction product is suction filtered, And washed with distilled water until neutral, dried at 100°C to constant weight, and calcined at 500°C for 4h to obtain mesoporous γ-Al 2 o 3 .

[0040] The XRD detection conditions of this embodiment are the same as those of Embodiment 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com