Patents

Literature

1112results about "Aluminium oxide/hydroxide preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

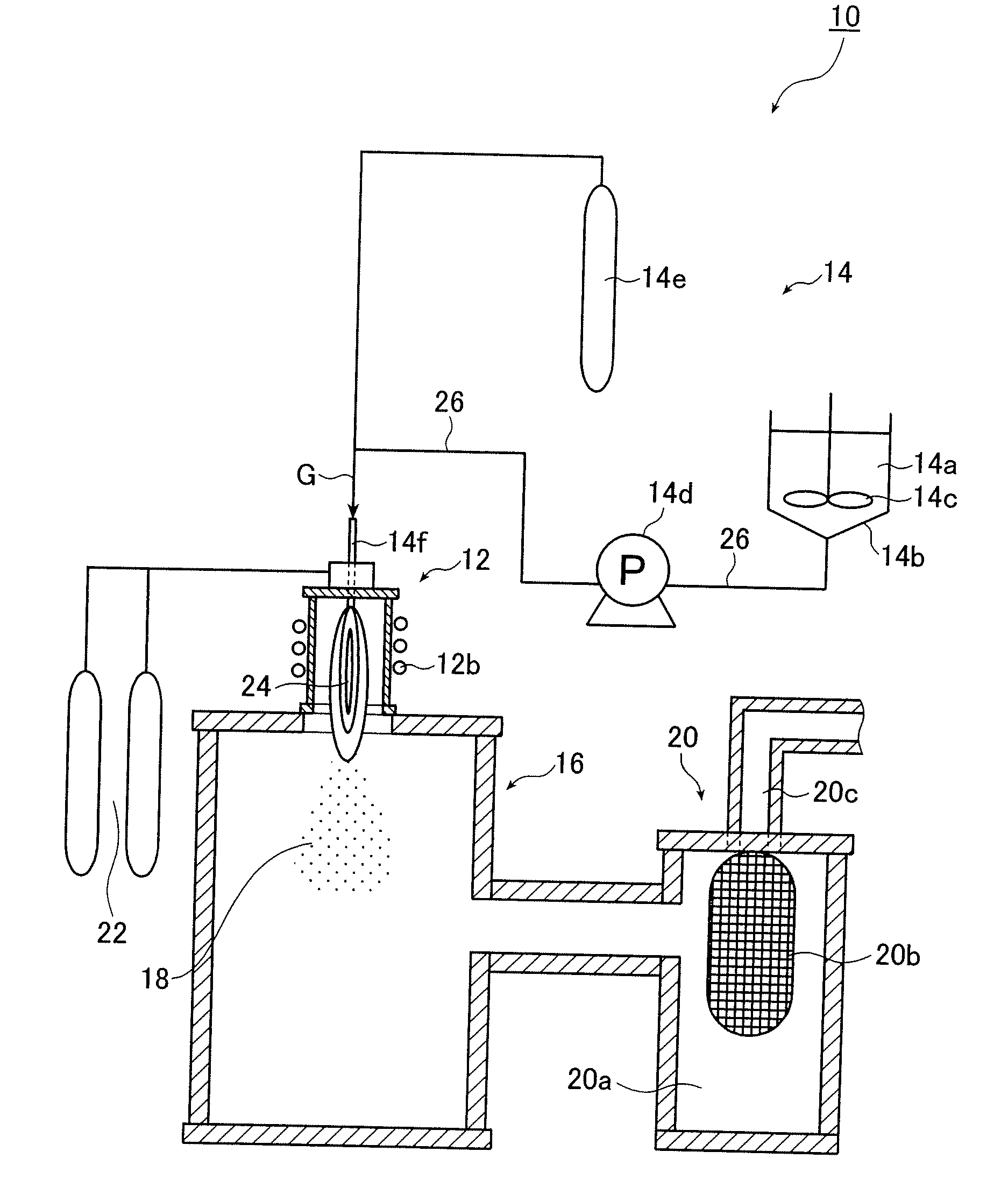

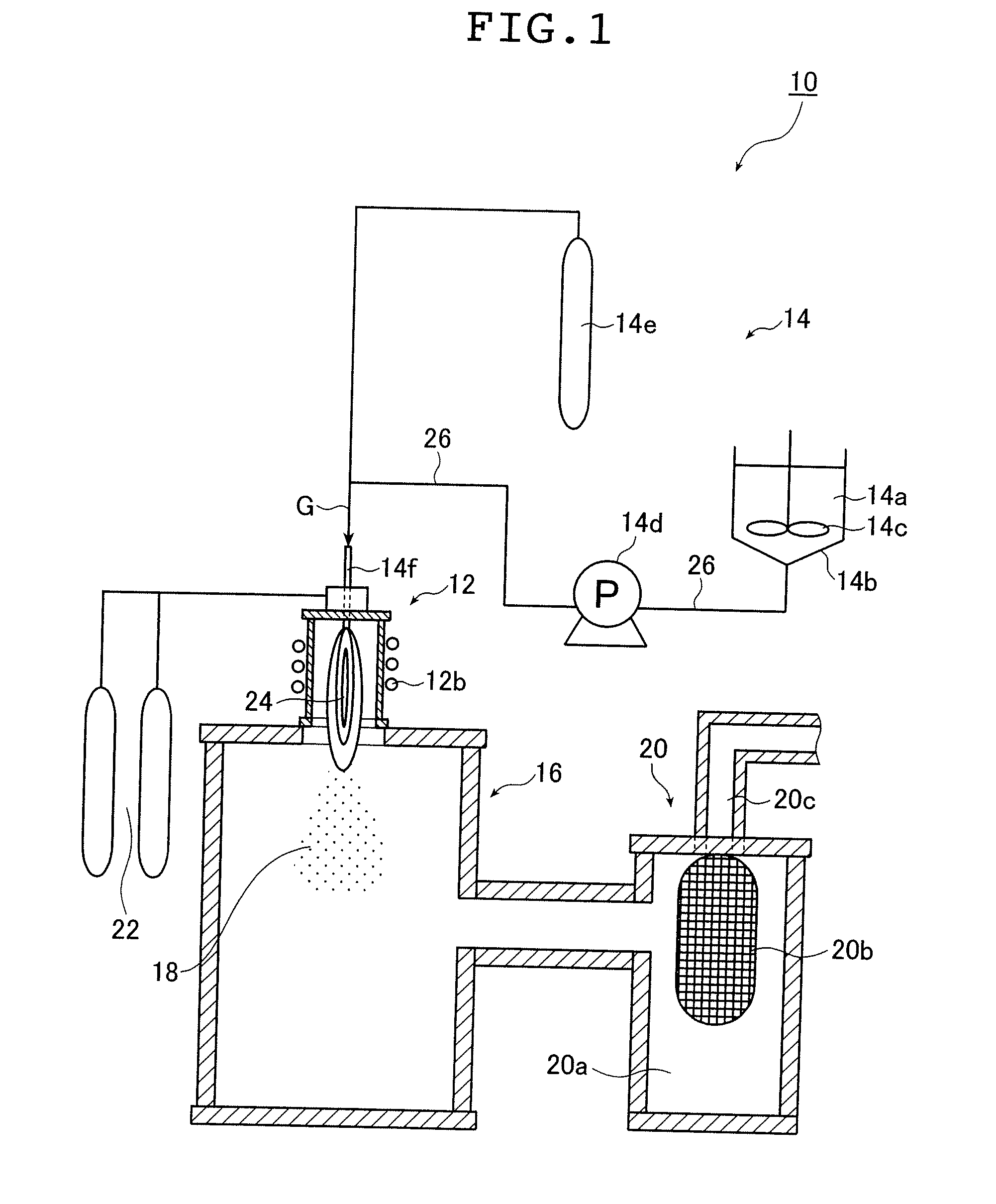

Process and Apparatus for Producing Fine Particles

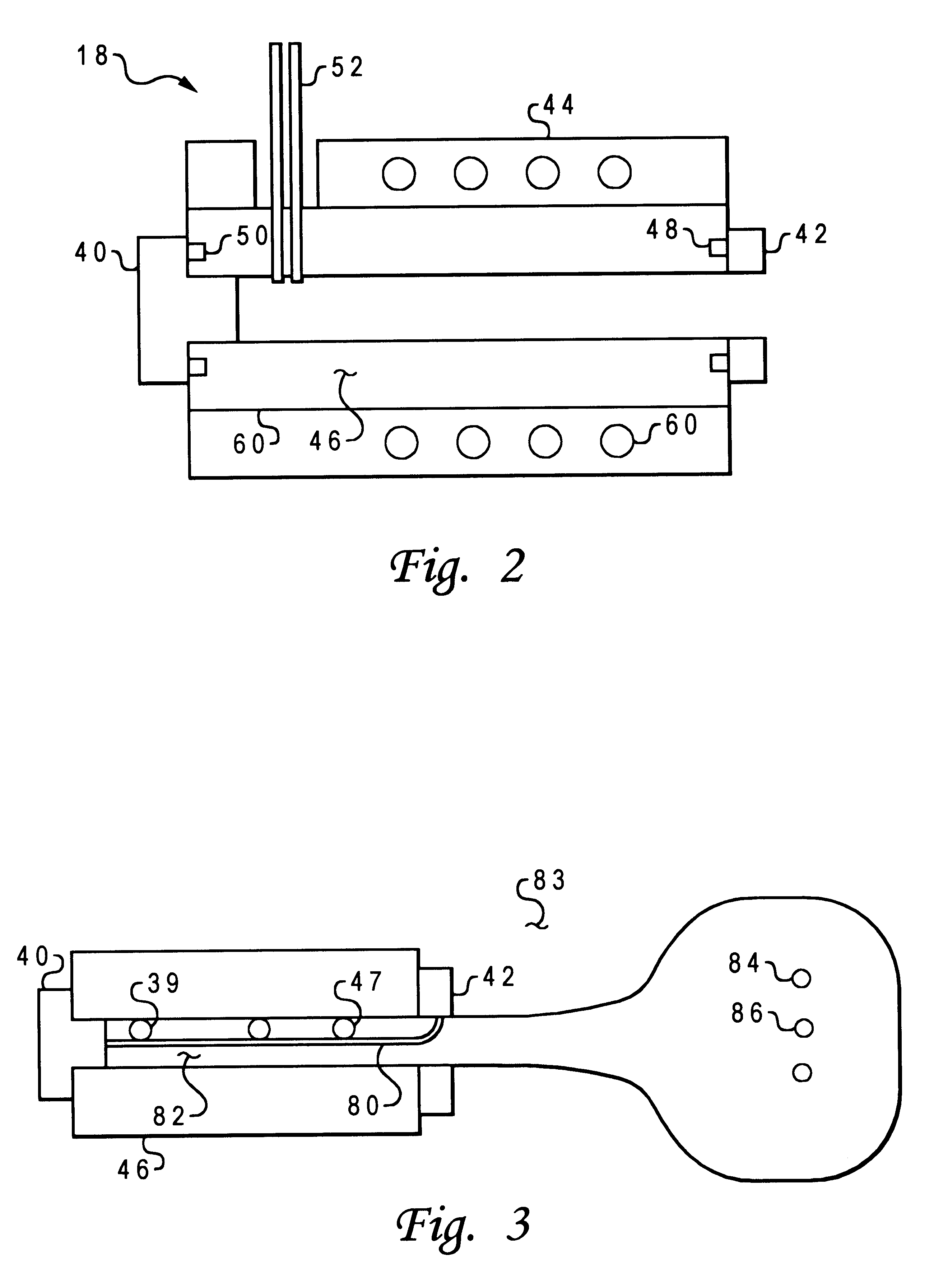

ActiveUS20080006954A1Improve productivityFunction increaseAlkaline earth titanatesMaterial nanotechnologyGas phaseSlurry

A fine particle producing process introduces a material for producing fine particles into a thermal plasma flame to make a vapor-phase mixture and quenches the vapor-phase mixture to form the fine particles. In the process, the material for producing the fine particles is dispersed or dissolved in a dispersion medium or solvent, preferably containing a combustible material to prepare a dispersion such as a slurry, a colloidal solution or a dissolution solution, the dispersion is made into a form of droplets, or the material for producing the fine particles is dispersed with a carrier gas and a combustible material and the dispersion in a droplet form or the dispersed material is introduced into the thermal plasma flame. In the fine particle producing process and apparatus, a gas of an amount sufficient to quench the vapor-phase mixture is supplied toward a tail of the thermal plasma flame. In the process and apparatus, primary fine particles are introduced into a cyclone to be subjected to cooling and classification and secondary fine particles having a particle size of 100 nm or less which are left upon removal of coarse particles are recovered.

Owner:NISSHIN SEIFUN GRP INC +1

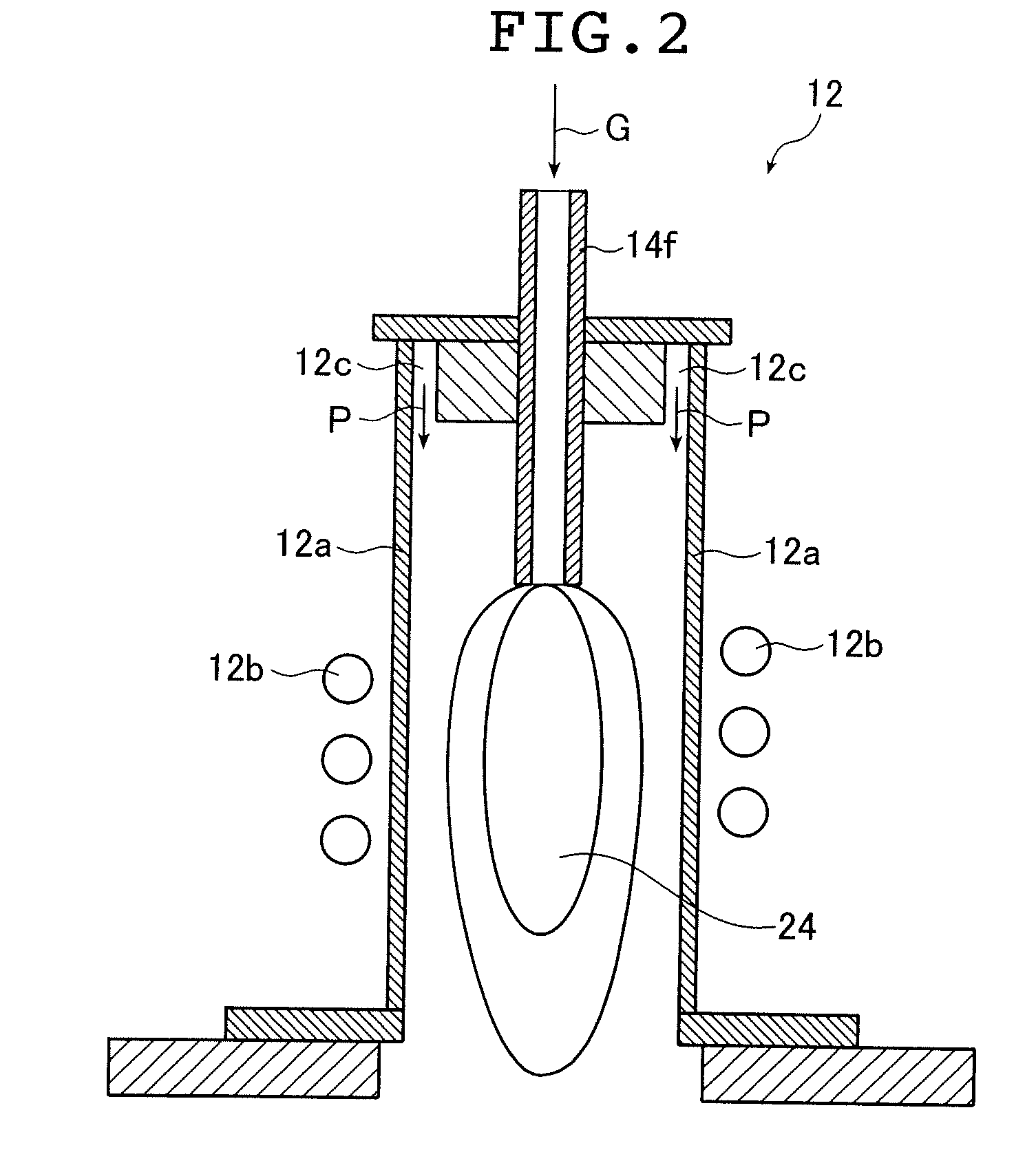

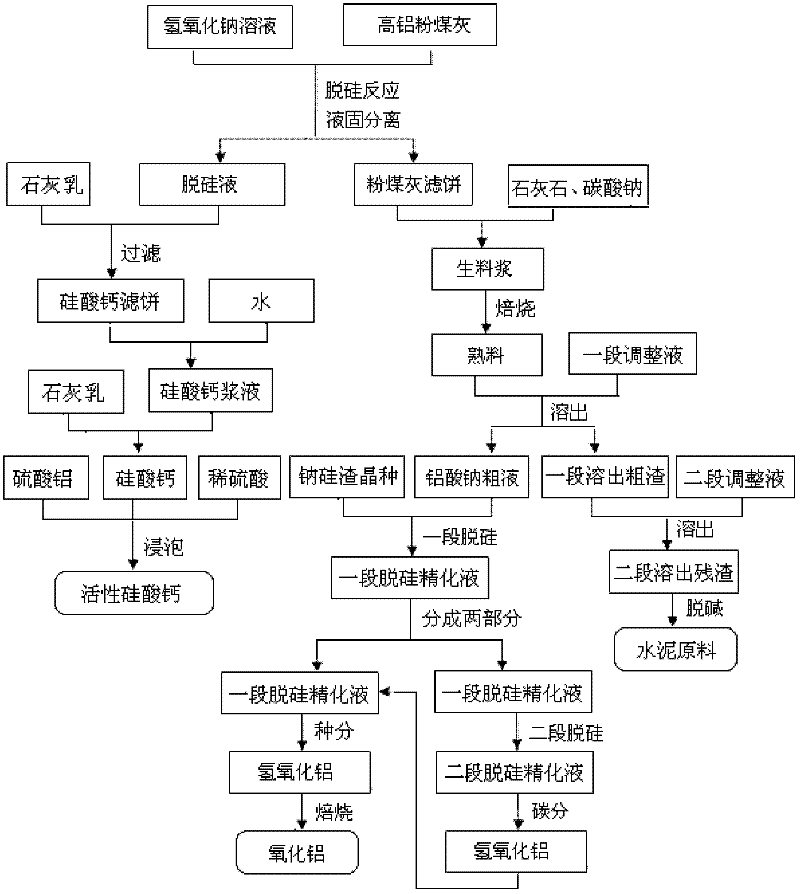

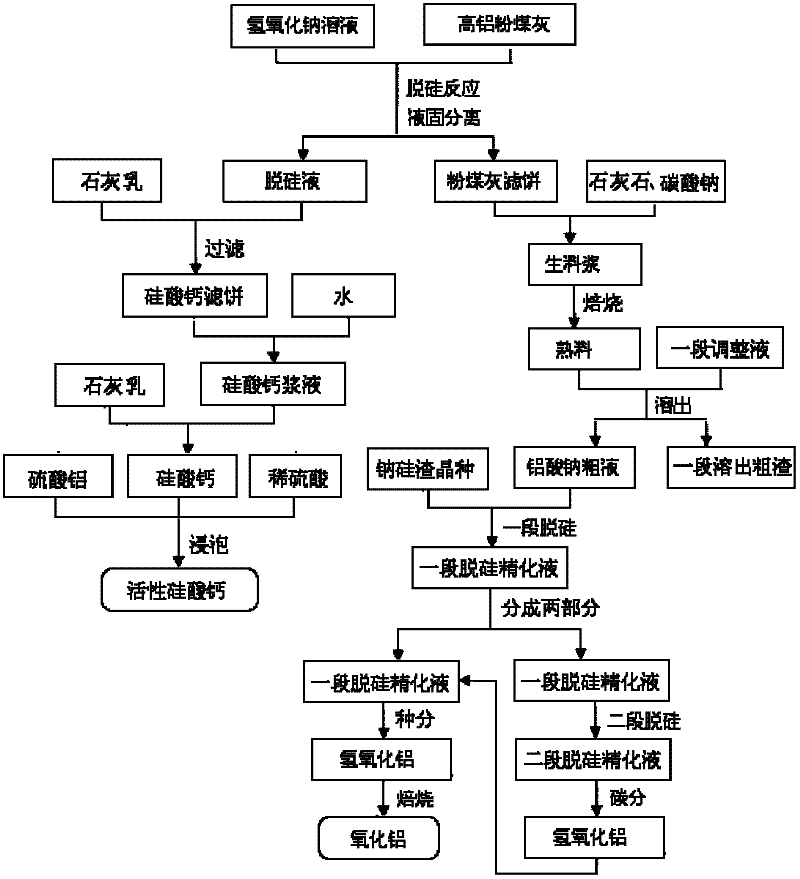

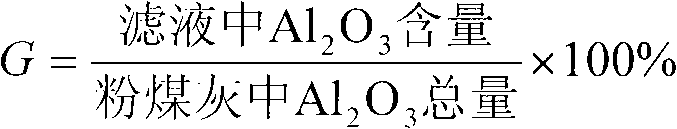

Method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash

ActiveCN102249253AExtraction is effective and cheapIncrease Al-Si RatioAlkaline-earth metal silicatesAluminium oxide/hydroxide preparationCalcium silicateSodium aluminate

The invention provides a method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash. The method comprises the following steps that: the high-alumina fly ash firstly reacts with a sodium hydroxide solution to carry out pre-desilication to obtain a liquid-phase desiliconized solution and a solid-phase desiliconized fly ash; lime cream is added to the liquid-phase desiliconized solution to carry out a causticization reaction, the resulting solid phase is active calcium silicate which is prepared through carrying out filter pressing, flash evaporation and drying to obtain the finished product; limestone and a sodium carbonate solution are added to the desiliconized fly ash to blend qualified raw slurry, then the blend qualified raw slurry is subjected to baking into the clinker, the liquid phase generated from dissolution of the clinker is a crude solution of sodium aluminate; the crude solution of the sodium aluminate is subjected to processes of first-stage deep desilication, second-stage deep desilication, carbonation, seed precipitation, baking and the like to obtain the metallurgical grade aluminum oxide meeting requirements. According to the present invention, the defects in the prior art are overcome; purposes of less material flow and small amount of slaggling are achieved; energy consumption, material consumption and production cost are relative low; extraction rate of the aluminum oxide is high; the calcium silicate with high added value is co-produced; the method provided by the present invention can be widely applicable for the field of chemical engineering.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

Preparation method for aluminum oxide by direct forming method

InactiveCN102923744AReduce drynessReduce stepsAluminium oxide/hydroxide preparationAluminium hydroxide preparationHydrated aluminaAluminium hydroxide

The invention discloses a preparation method for aluminum oxide by a direct forming method. The method is characterized in that the aluminum oxide is directly formed by a wet filter cake, wherein pore volume is 0.3-0.8ml / g; a specific surface area is 150-300 m<2> / g; and crushing strength is 30-120 N / particle; the preparation process comprises the steps: a) meta-aluminate containing aluminum or a strong acid salt compound is neutralized with a precipitator solution at a temperature of 30-80 DEG C and pH of 6-9; accessory ingredient is added in a neutralizing process; mixture is aged for at least 10min after neutralizing; b) prepared aluminium hydroxide gel is washed by de-ionized water for 4-10 times; dosage of the de-ionized water for each time is 10-40 times of mass of a dried substrate of prepared aluminium hydroxide; a hydrated alumina filter cake is obtained after washing and filtering; content of the aluminium hydroxide in the filter cake is controlled to be 5-50%; and c) the accessory ingredient is added into one or various liquid in the step a) and step b); the filter cake after washing is formed by a normal forming method; and the formed filter cake is dried at a temperature of 80-120 DEG C and calcined at a temperature of 450-1000 DEG C to obtain a finished product of the aluminum oxide.

Owner:CHINA NAT OFFSHORE OIL CORP +1

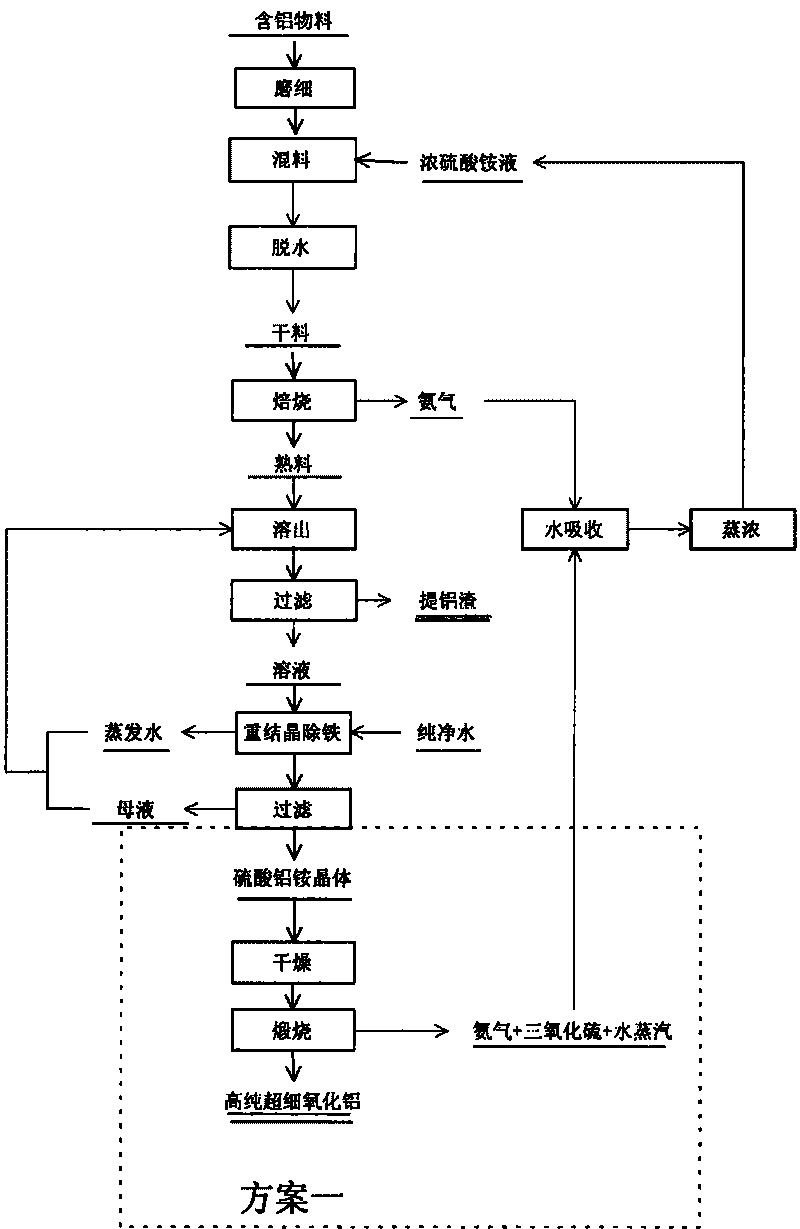

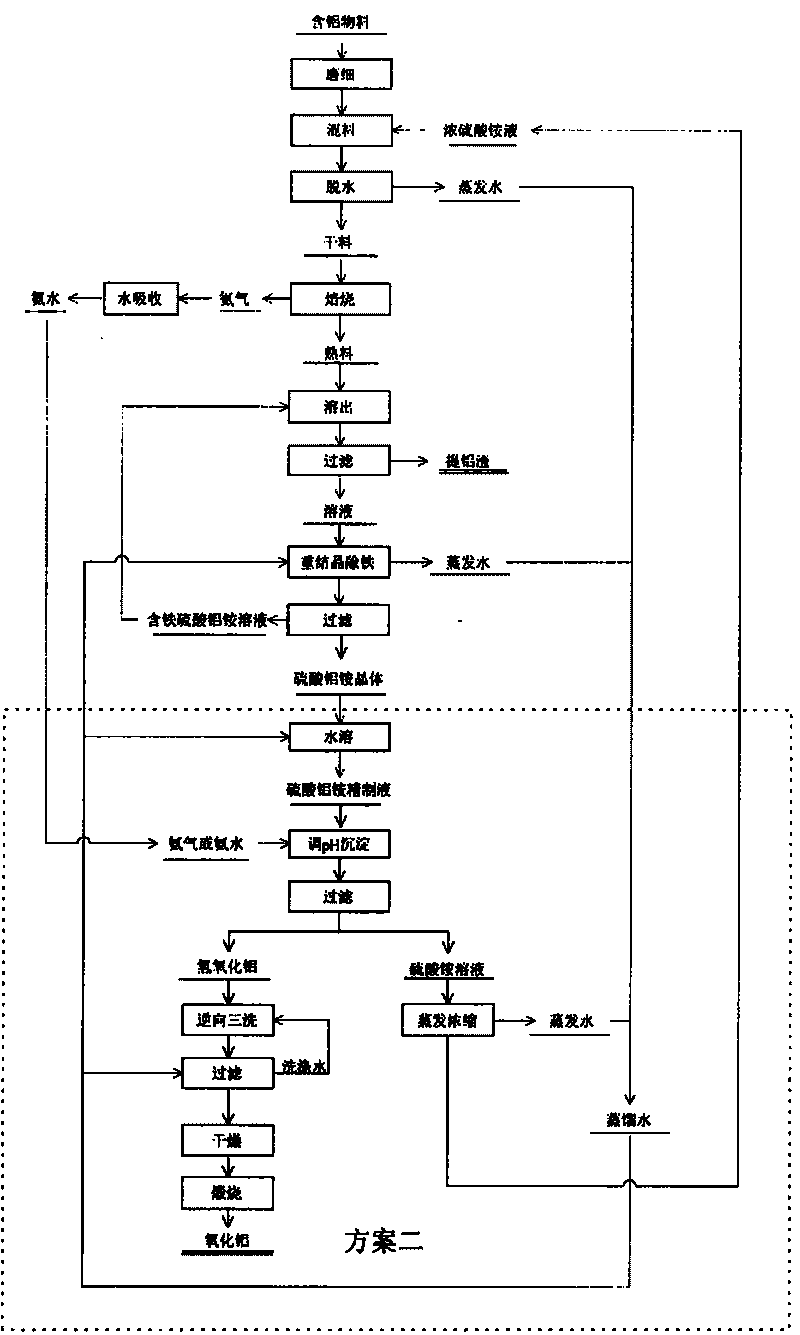

Method for preparing aluminum oxide from aluminiferous material

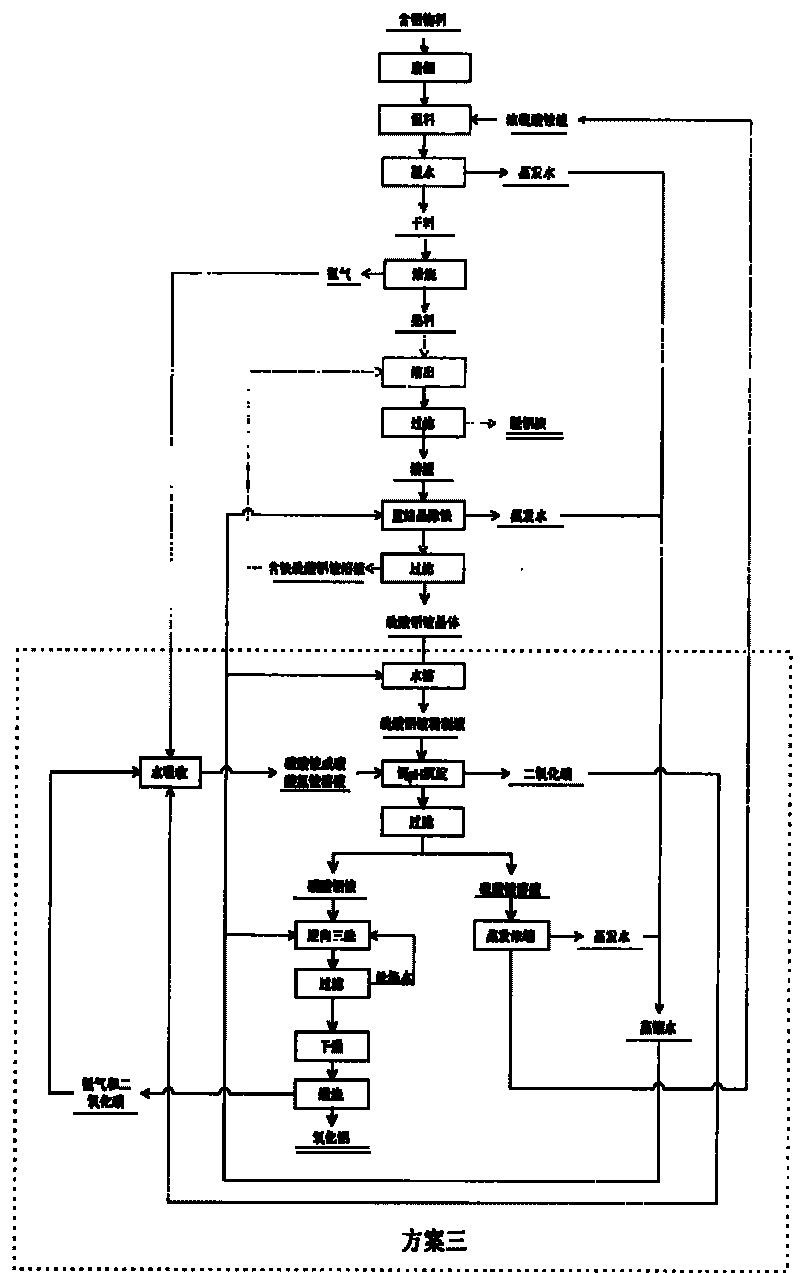

InactiveCN101734698AHigh value-added comprehensive utilizationCause secondary pollutionAluminium oxide/hydroxide preparationAluminium hydroxide preparationAluminum ammonium sulfateAlunite

The invention provides a method for preparing aluminum oxide and other products from aluminiferous materials such as bauxite, high iron bauxite, alunite, kaoline, alumina, fly ash, coal gangue, aluminum ash, nepheline, clay and the like. The method comprises the following steps: (1) crushing, grinding and mixing the aluminiferous materials with ammonium sulfate and then roasting; (2) dissolving the roasted product (clinker aggregate) in water, and filtering to obtain aluminum ammonium sulfate solution and filter residues; (3) carrying out deferrization, aluminum deposition or recrystallization on the aluminium ammonum sulfate solution with ammonia to prepare aluminum oxide, and meanwhile, recycling the ammonium sulfate; (4) preparing silicon dioxide from the filter residues, and taking the remaining residues containing ferrum as the raw material for ironmaking. The method is suitable for treating various aluminiferous materials, has the advantages of simple technical process, simple equipment, no emission of solid, liquid and gas wastes, and no secondary pollution, and realizes the high-added-value green complex utilization of the aluminiferous materials such as bauxite, high ironbauxite, alunite, kaoline, alumina, fly ash, coal gangue, aluminum ash, nepheline, clay and the like.

Owner:NORTHEASTERN UNIV

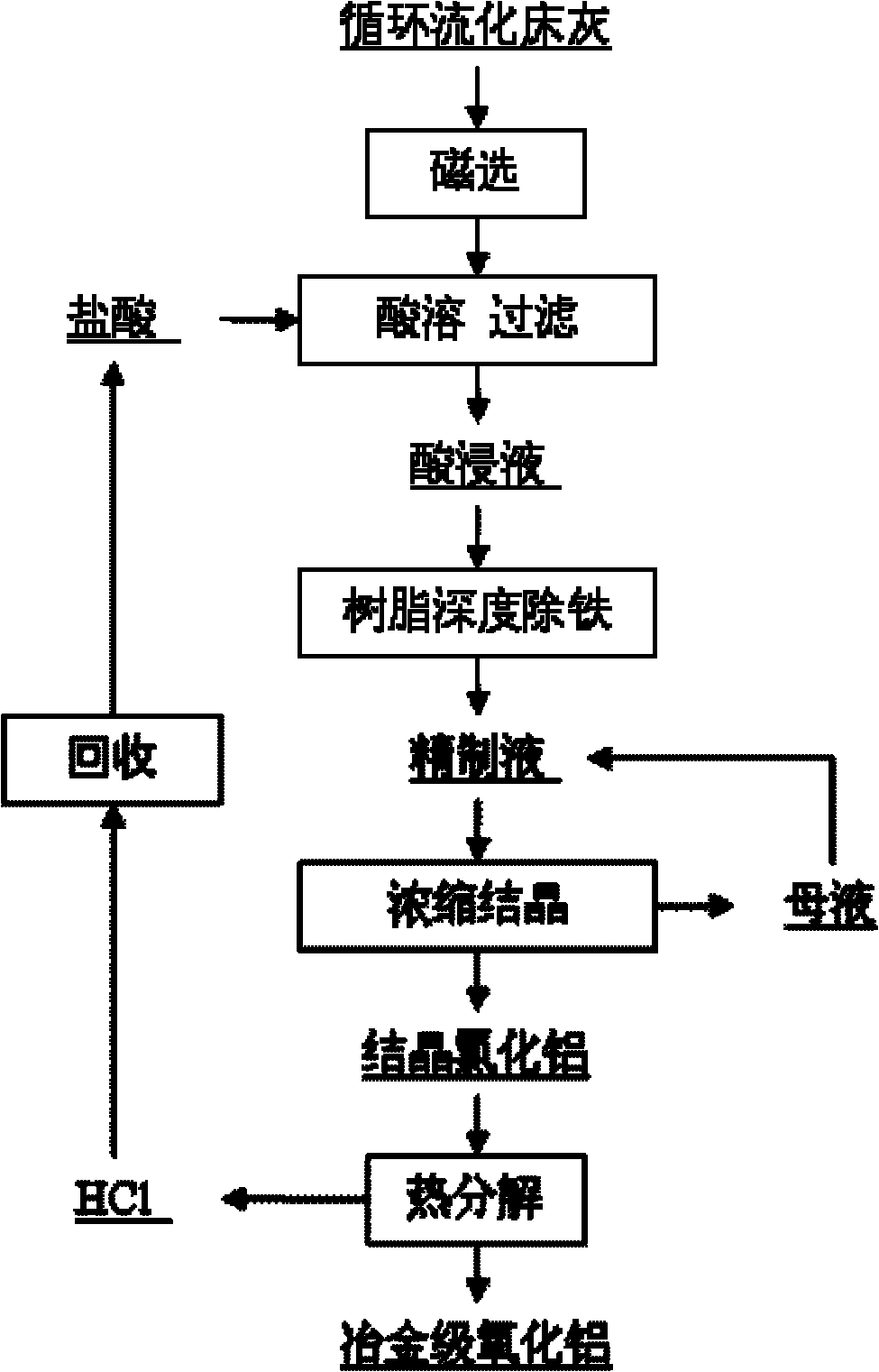

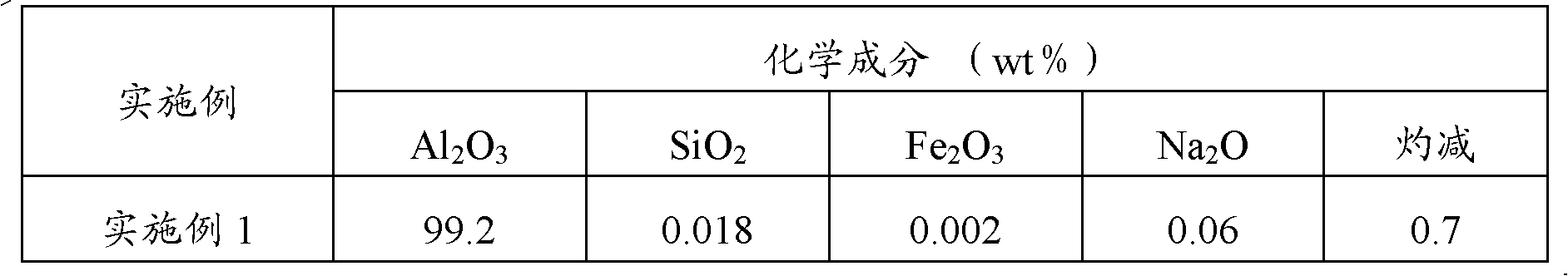

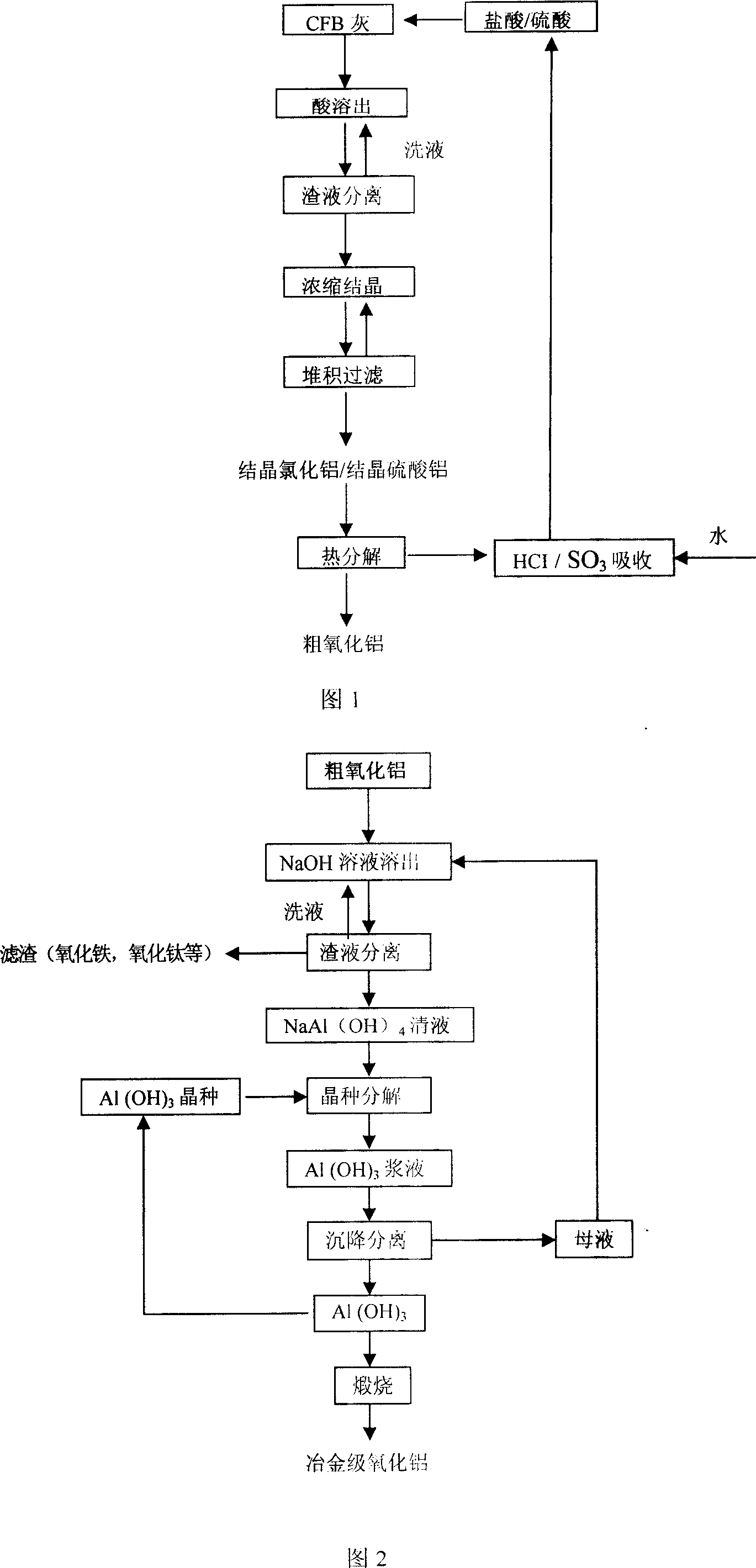

Method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash

ActiveCN102145905AHigh extraction rateReduce manufacturing costSolid waste disposalTransportation and packagingAluminium chloridePulverized fuel ash

The invention discloses a method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash as a raw material. The method comprises the following steps of: a) grinding the pulverized fuel ash, and removing iron by a wet magnetic separation method; b) reacting the pulverized fuel ash subjected to magnetic separation with hydrochloric acid to obtain hydrochloric acid immersion liquid; c) allowing the hydrochloric acid immersion liquid to pass through a large pore type cation resin column for further iron removal to obtain refined aluminum chloride solution; d) concentrating the refined aluminum chloride solution, and crystallizing to obtain an aluminum chloride crystal; and e) calcining the aluminum chloride crystal and decomposing to obtain the metallurgy-level aluminum oxide. The method has a simple process and an easily-controlled production process, and is high in aluminum oxide extraction efficiency, low in production cost and stable in product quality.

Owner:CHINA SHENHUA ENERGY CO LTD

Process for extracting aluminium hydroxide from flyash

InactiveCN1792802AAchieve recyclingEffective leachingAluminium oxide/hydroxide preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium sulfateAluminium hydroxide

A process for extracting aluminum oxide from powdered coal ash includes such steps as grinding, calcining, mixing with H2SO4 solution, heating while reaction for extracting aluminum oxide, boiling in water, concentrating, cooling while educing out aluminum sulfate crystals, heating for dewatering, heating for decomposing to obtain gamma-Al2O3, and further preparing metallurgy-class aluminum oxide.

Owner:朔州市人民政府 +2

Preparation method of alumina

ActiveCN1927716AReduce pollutionReduce consumptionAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium hydroxideDecomposition

The process of preparing alumina includes: the reaction of flyash from circular fluidizing bed and acid to obtain aluminum chloride solution, eliminating silicon impurity, concentrating to crystallize and heating to decompose and to obtain crude alumina product; reaction of crude alumina product and hot alkali solution to obtain sodium aluminate solution; eliminating iron, titanium and other impurity, adding aluminum hydroxide crystal seed into sodium aluminate solution for seed separating decomposition to obtain aluminum hydroxide precipitate; and final calcining aluminum hydroxide to obtain metallurgical alumina. The normal pressure process has no any cosolvent added, and the alumina product has Al2O3 content up to 98 %. The process has small sodium hydroxide consumption, reuse of most of sodium hydroxide, simple operation, low cost, low power consumption, capacity of reducing flyash pollution and other advantages.

Owner:SHENHUA ZHUNGER ENERGY

Method of preparing aluminum oxide from fly ash

ActiveCN1923695AHigh dissolution rateFewer separation stepsAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium sulfateSlag

The invention discloses a preparing method of alumina through fly ash, which comprises the following steps: grinding fly ash; sintering; activating; stirring with H2SO4 evenly to sinter into dried slag; immersing through hot water; stripping aluminum sulfate; condensing; cooling to evolve aluminum sulfate; crystallizing; heating; dehydrating to obtain anhydrous aluminum sulfate; heating; decomposing to obtain gamma-Al2O3.

Owner:PINGSHUO INDAL

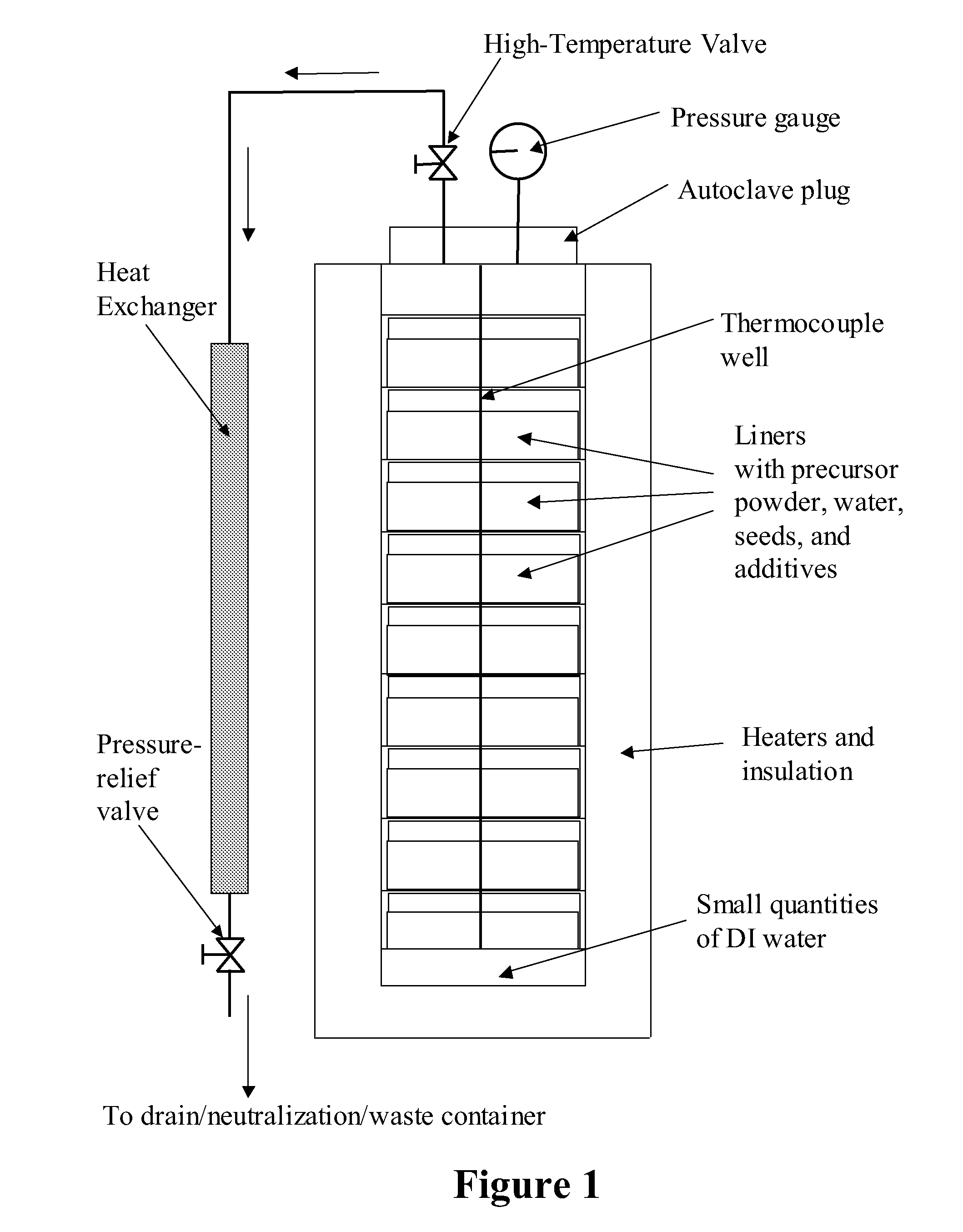

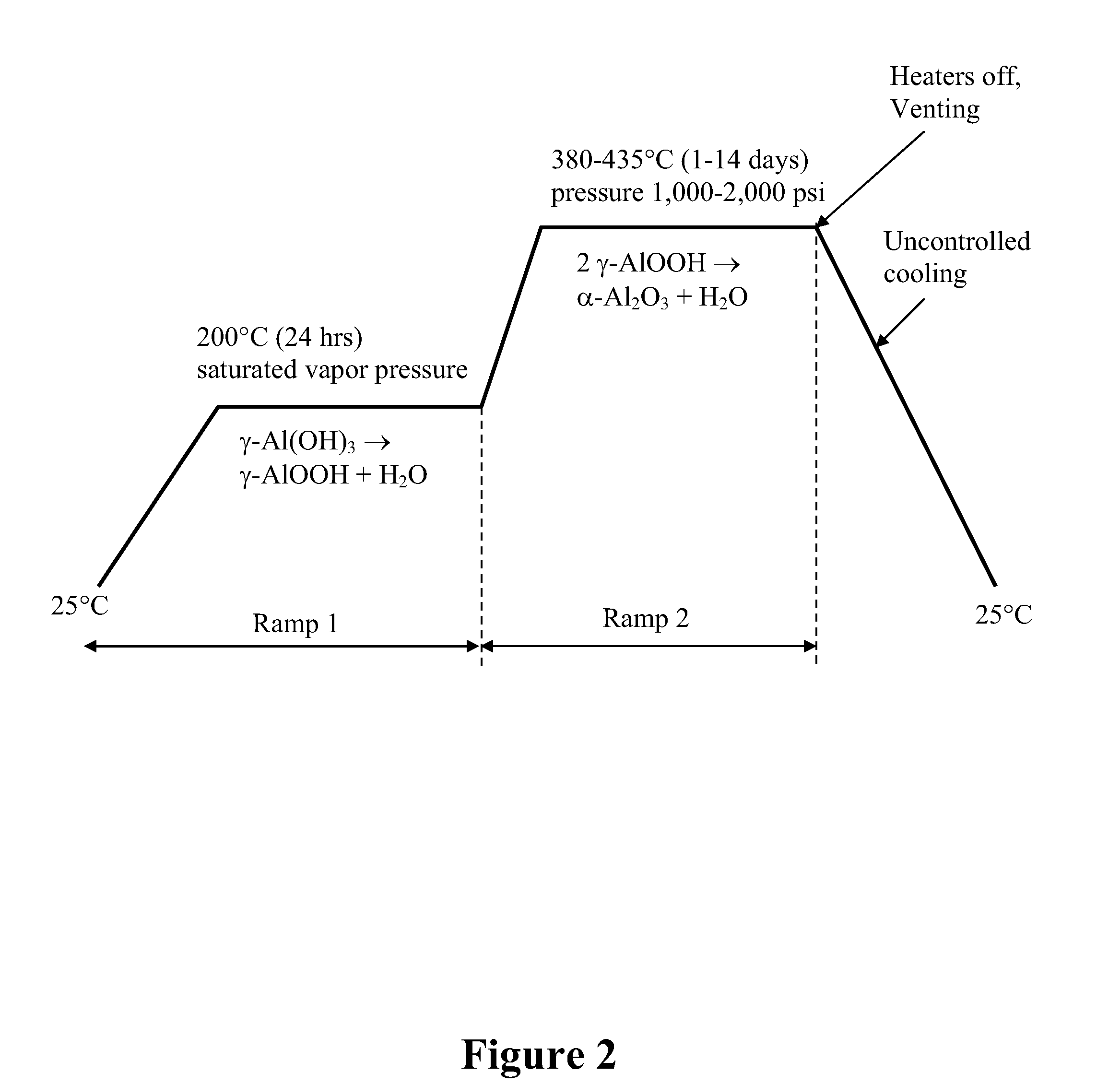

Alpha alumina (corundum) whiskers and fibrous-porous ceramics and method of preparing thereof

InactiveUS20120189833A1High mechanical strengthHigh porosityAluminium oxide/hydroxide preparationAluminium hydroxide preparationWhiskersPorous ceramics

Materials and associated processes for making the materials. For example the material may include alpha alumina crystalline whiskers. The process may include conducting the process as hydrothermal, and producing the whiskers to have a length to diameter aspect ratio of at least two.

Owner:SAWYER TECHN MATERIALS

Method for firstly extracting silicon and secondly extracting aluminum from fly ash

ActiveCN101125656AImprove resource utilization valueIncrease Al-Si RatioAluminium oxide/hydroxide preparationSilicon oxidesSODIUM SILICATE SOLNCarbonation

Owner:PINGSHUO INDAL

Method for preparing alumina by using fly ash

InactiveCN101397146AEffective leachingPromote leachingAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium hydroxideSodium aluminate

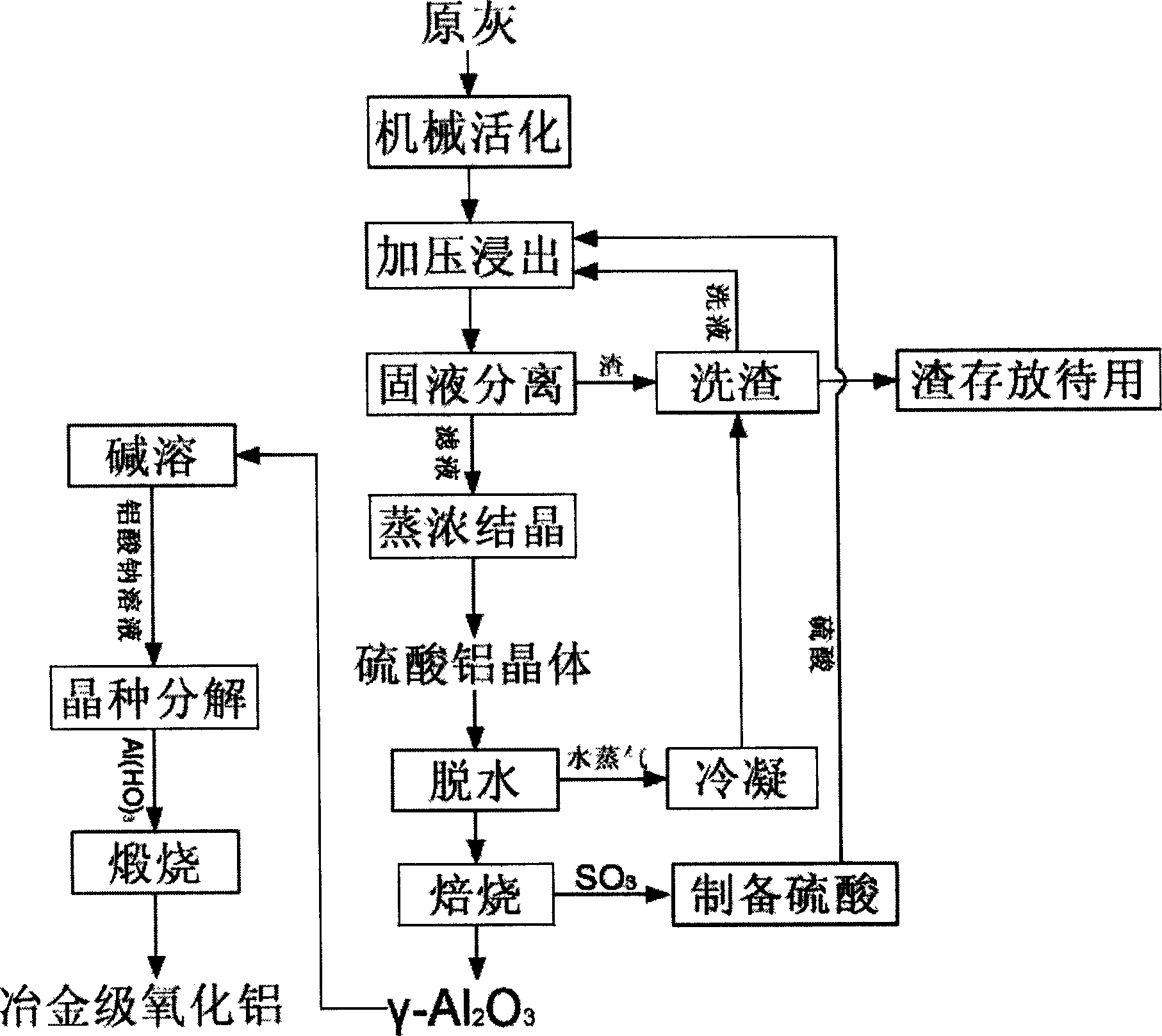

The invention discloses a method for producing alumina by disposing and utilizing industrial solid wastes, in particular to a method for preparing alumina by fly ash, comprising the steps as follows: the fly ash is mechanically activated; the activated fly ash, water and concentrated sulfuric acid react in a reaction kettle under the conditions of heating and pressurizing; the solid is separated from the liquid after the temperature of the reaction is reduced so as to gain aluminium sulfate liquid; the aluminium sulfate liquid is evaporated, concentrated and cooled so as to precipitate aluminium sulphate crystals; the aluminium sulphate crystals are dehydrated and decomposed to gain gama-Al2O3 and SO3; coarse gama-Al2O3 is dissolved in alkaline solution; after the solid is separated from the liquid, the pure sodium aluminate solution is gained; aluminum hydroxide crystal seed is added to the sodium aluminate solution so as to precipitate the aluminum hydroxide; the coarse gama-Al2O3 can be prepared by circularly dissolving the seed-precipitated alkaline solution after vaporization-concentration; the metallurgical alumina can be gained by baking the prepared aluminum hydroxide. The method adds no additive, can lead the alumina in the fly ash to be effectively leached out with the leaching rate more than 90% and saves the energy resource.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

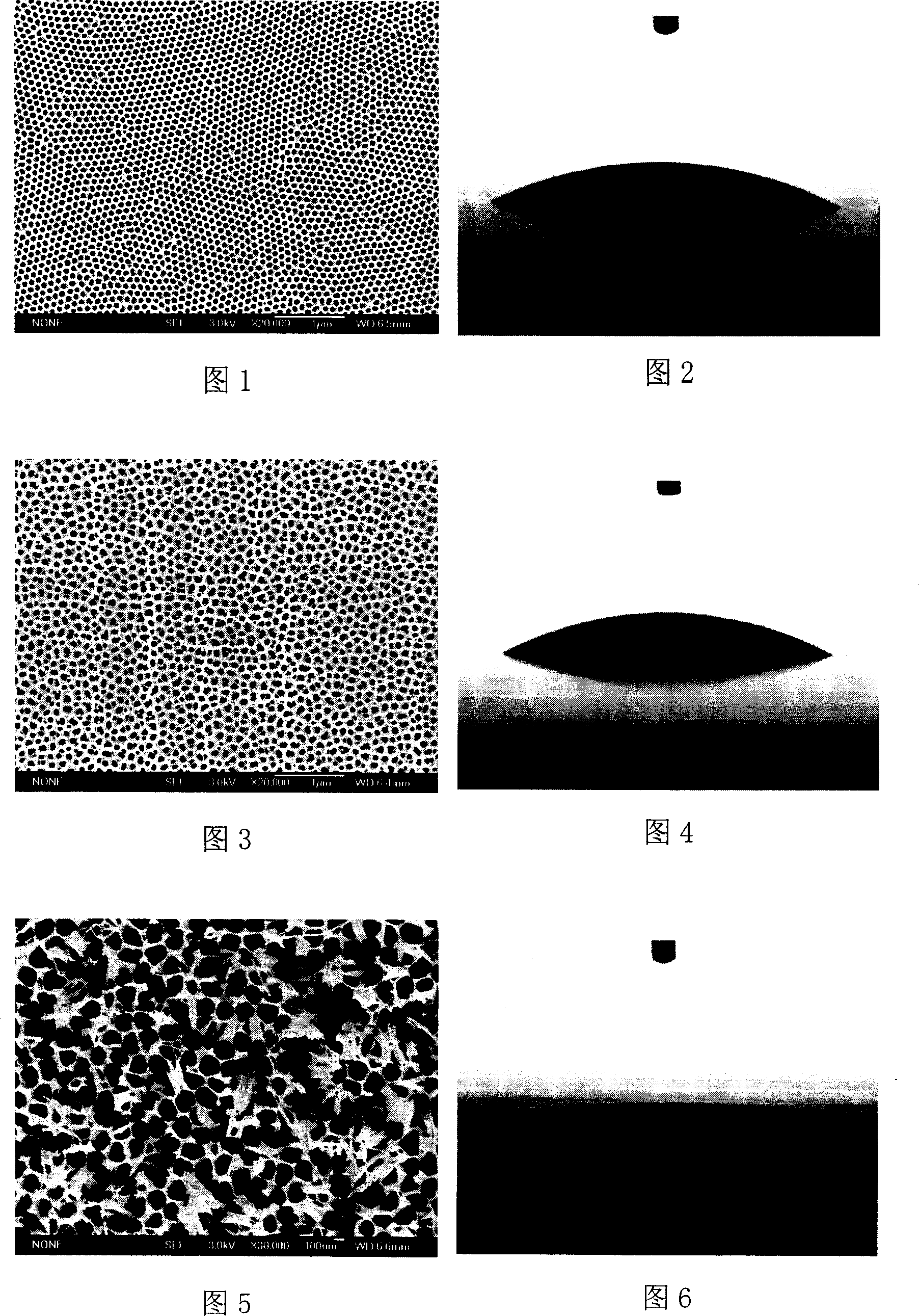

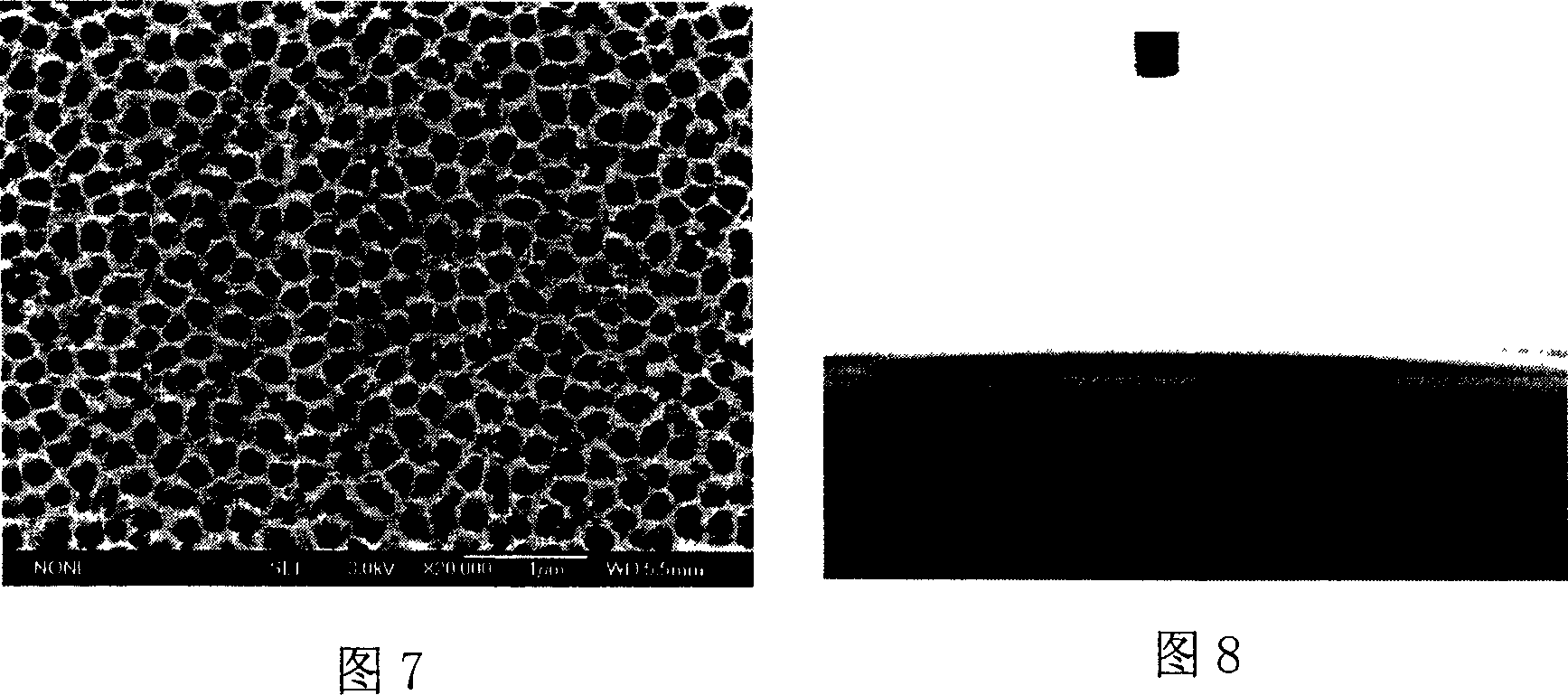

Process for preparing highly-hydrophilic alumina film material

InactiveCN101007645AImprove stabilityShape is easy to controlAluminium oxide/hydroxide preparationPhosphoric acidElectrochemistry

The invention discloses a making method of high-hydrophilicity alumina film, which comprises the following steps: adopting electrochemical polished aluminium foil as anode and platinum piece as cathode; selecting one of sulfuric acid, oxalic acid phosphoric acid with water or poor water (the composite solution of oxalic alcohol and water) as electrolyte solution; using electrochemical oxidizing method to strip aluminium base; removing damping layer; obtaining the product with different shapes and areas.

Owner:BEIJING ZHONGKE NANO THINK PRINT TECH

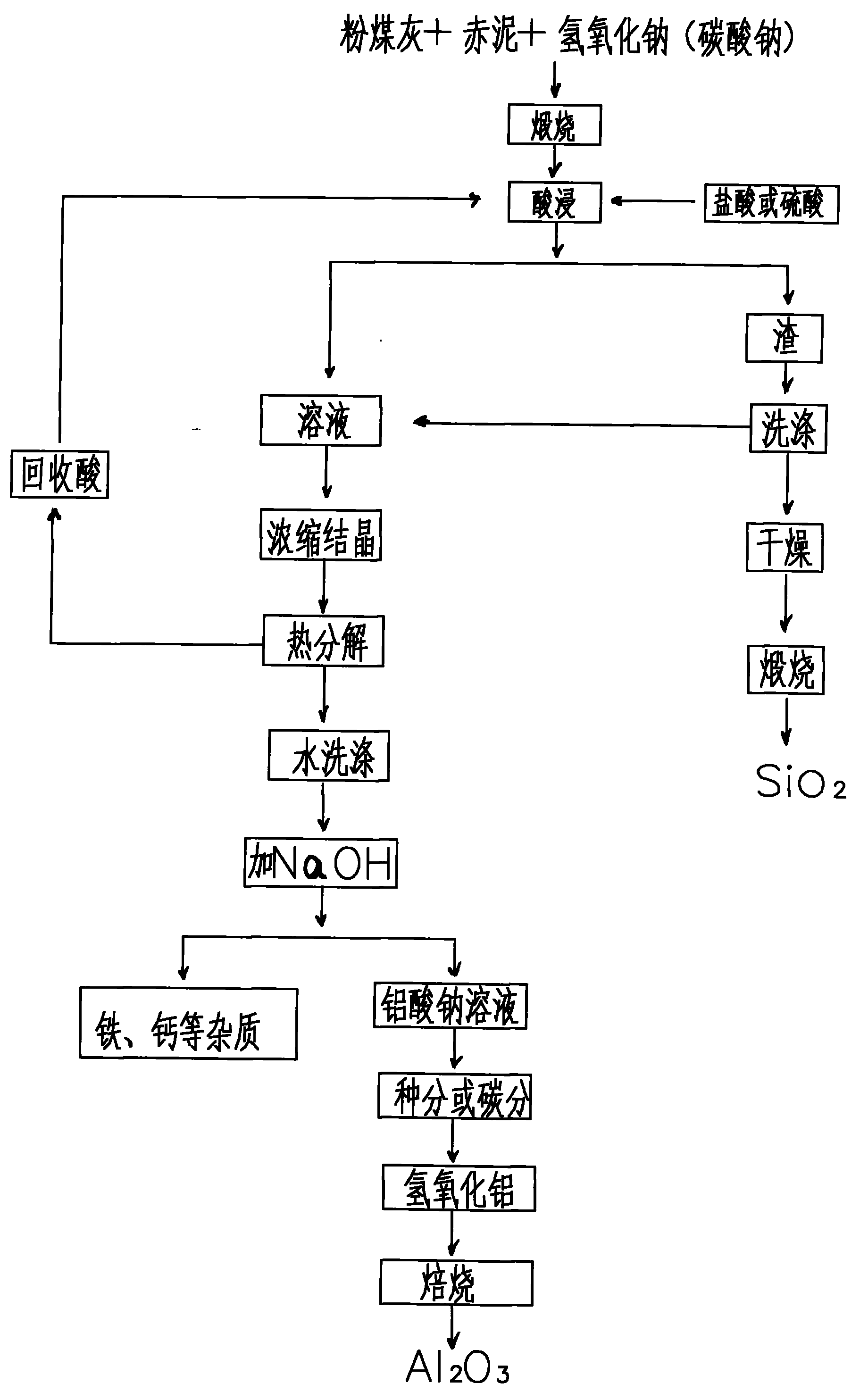

Method for producing alumina and white carbon black by utilizing red mud and flyash

InactiveCN101891224AEmission reductionReduce pollutionSilicaAluminium oxide/hydroxide preparationChemistryCarbon black

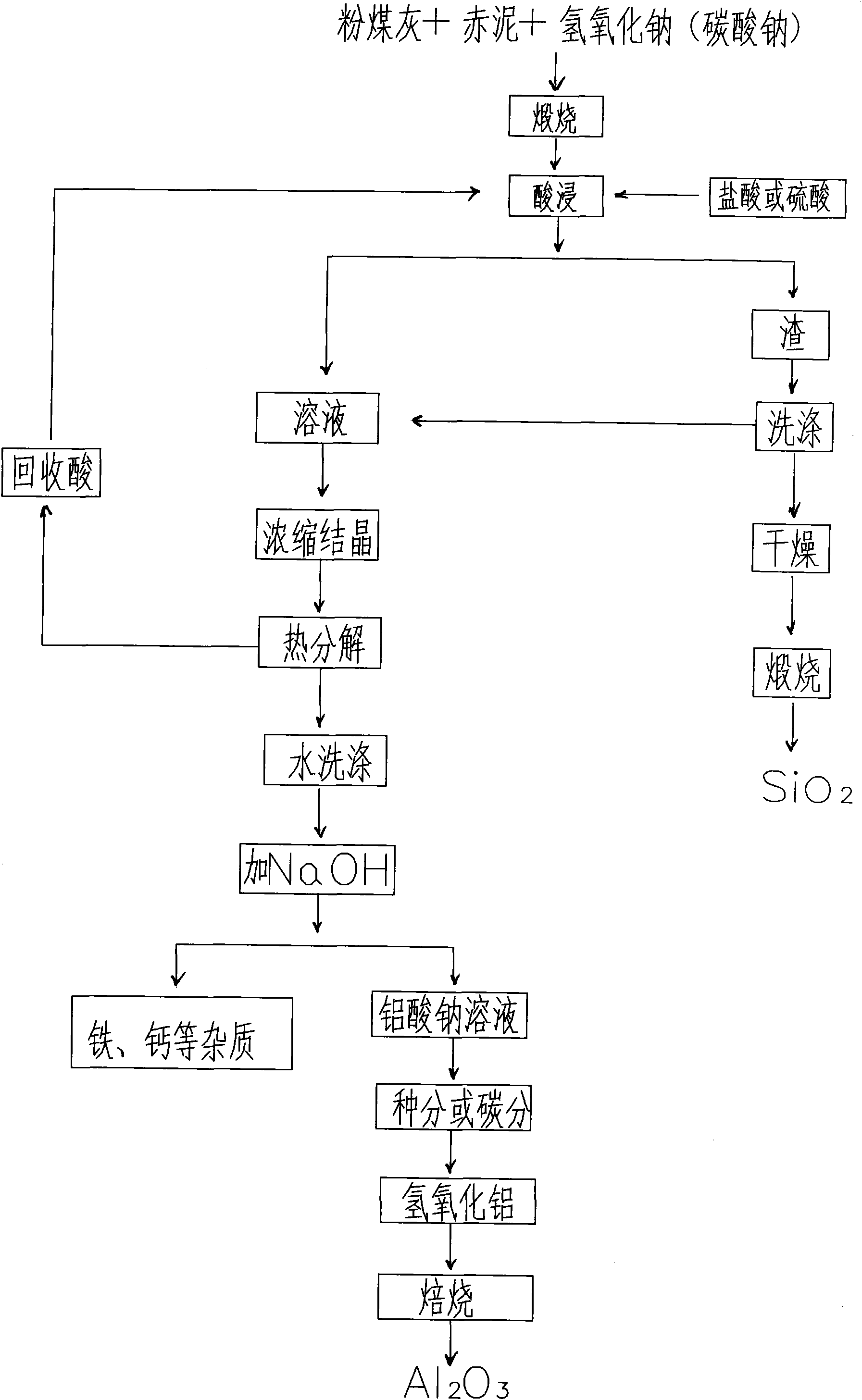

The invention discloses a method for producing alumina and white carbon black by utilizing red mud and flyash, which is characterized by taking the flyash and the red mud as the raw materials, fully utilizing the resources of Al2O3, SiO2 and Na2O in the flyash and the red mud, mixing the flyash and the red mud with sodium hydroxide or sodium carbonate according to certain proportion and preparing the alumina and the white carbon black through calcining, acid leaching, concentrating, crystallizing, thermal decomposition, water washing, seed precipitation, roasting, etc. The acid in the process is recycled and the waste residues can be used as the raw materials of the cement and ironmaking. The method realizes changing wastes into valuables and changing harm into valuables and reduces the pollution of the red mud and the flyash to the environment. China is short of alumina resources. The development and utilization of the flyash and the red mud lay the foundation for sustainable development of the aluminum industry in China. The method is a new breakthrough in red mud resource utilization, is simple in the process flow of producing the alumina and the white carbon black, utilizes the wastes and is low in production cost.

Owner:HENAN ENERGY AND CHEMICAL INDUSTRY

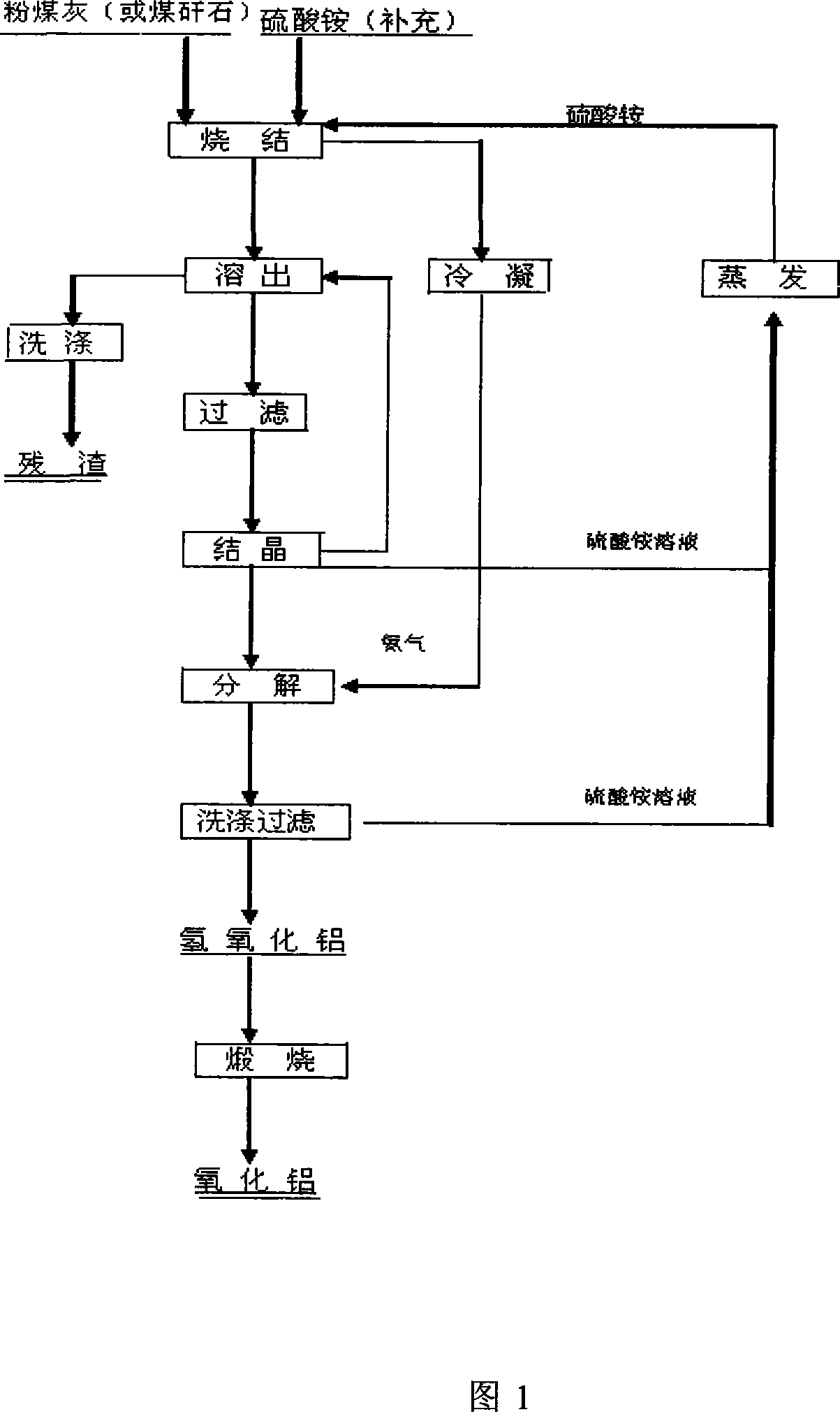

Method for extracting aluminium oxide from coal ash

ActiveCN101117228AEfficient use ofLess corrosiveAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium hydroxideAmmonium aluminium sulfate

The invention provides a method to extract aluminum oxide from a fly ash, and relates to a technological method which is to extract aluminum oxide from the fly ash and comprehensively utilize the residue after extracting aluminum oxide. The invention is characterized in the method which is as follows: ammonium sulfate is mixed into the fly ash to sintering, and the solid is dissolved to obtain the solution containing aluminum-ammonium sulfate; the solution is crystallized to form solid aluminium-ammonium sulfate; solid aluminium-ammonium sulfate reacts with ammonia gas to obtain aluminium hydroxide and ammonium sulfate, and aluminium hydroxide and ammonium sulfate are washed and filtrated to obtain solid aluminium hydroxide; solid aluminium hydroxide is calcined to obtain aluminum oxide; ammonium sulfate can be circularly used after being evaporated in the liquid phase. The ammonium sulfate which is used by the method of the invention is weak acidic, the corrosiveness on the equipment is small, and the ammonium sulfate can be used circularly. The whole process is easy to industrial application. The requirement of the corrosion resistance on the equipment is low. The amount of the residue is small which is beneficial to the comprehensive utilization of the residue after extracting the aluminum oxide.

Owner:河南华慧有色工程设计有限公司 +1

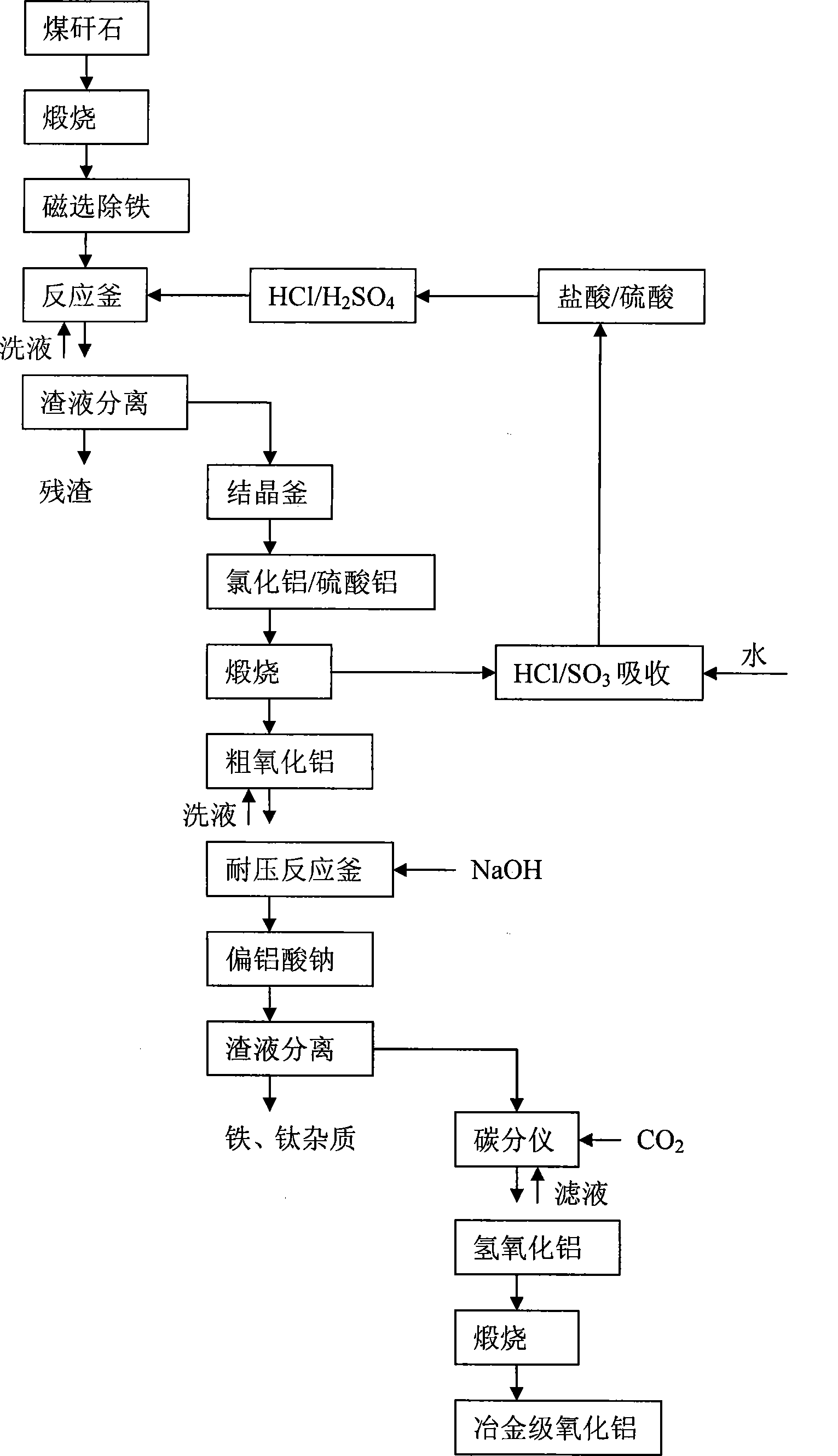

Method for extracting alumina from coal gangue

InactiveCN101450811AAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium hydroxideSodium aluminate

The invention mainly relates to a method for extracting alumina from coal gangue. The coal gangue is ground, and then is calcined through a fluidized furnace and iron is removed through a magnetic separator, the coal gangue with the iron removal reacts with an acid to obtain an aluminum chloride solution without silicon impurities, the solution containing the aluminum is concentrated and crystallized and then is subjected to low-temperature calcination to obtain crude aluminum oxide, then the crude aluminum oxide reacts with sodium hydroxide to obtain a sodium aluminate mother solution, impurities such as iron and titanium are removed, an aluminum hydroxide crystal seed is added to the mother solution, and carbon dioxide gas is introduced for seed precipitation to obtain an aluminum hydroxide precipitate, and metallurgical grade alumina can be obtained through the calcinations. The method does not use any auxiliary agent at normal pressure, and uses hydrochloric acid and sulfuric acid to directly leach and extract alumina; the content of the alumina prepared by the method can reach more than 99 percent; and the method has the advantages of simple process flow, adequate raw material sources, less energy consumption, low cost, and high utilization value of the coal gangue.

Owner:CHANGCHUN CHAOWEI NEW MATERIALS TECH

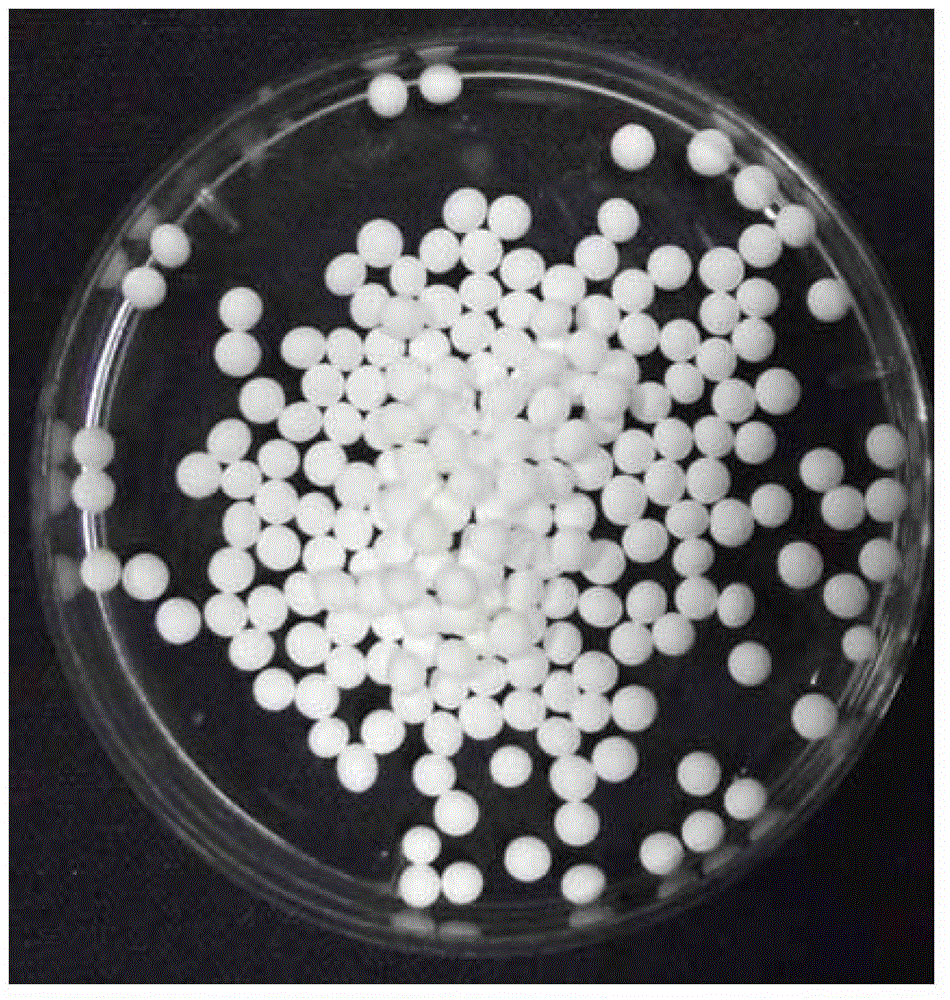

Method for preparing spherical alumina particles by alginic acid auxiliary forming method

ActiveCN102718241AReduce energy consumptionNo pollution in the processAluminium oxide/hydroxide preparationIonComposite pellet

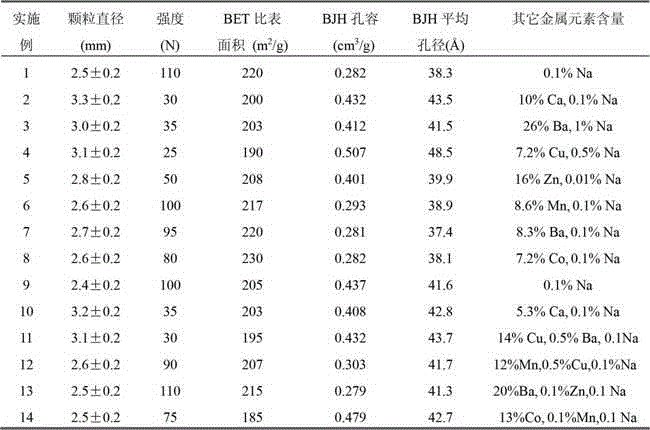

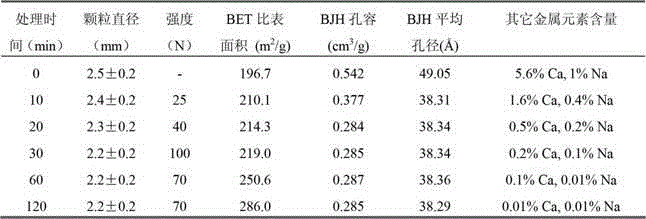

The invention discloses a method for preparing spherical alumina particles by an alginic acid auxiliary forming method. The method includes the following steps of firstly, taking pseudo-boehmite, adding water for dispensing, and then adding a sodium alginate aqueous solution to stir to form a sodium-alginate-pseudo-boehmite suspension; secondly, dropping the sodium-alginate-pseudo-boehmite suspension into an aqueous solution of aluminum, calcium, barium, copper, zinc, manganese or cobalt metal ion, and forming alginic-acid-pseudo-boehmite rubber composite pellets in a gel mode; and thirdly, subjecting the alginic-acid-pseudo-boehmite rubber composite pellets to a washing by water, a drying and a calcination to obtain the spherical alumina particles. According to the method for preparing the spherical alumina particles, the forming of the particles is performed in mild aqueous phase, the energy consumption is low, the pollution is absent during a preparation process, the production efficiency is high, the specific surface area, the pore volume, the pore diameter and the metallic oxide content of the spherical alumina can be conveniently adjusted, the preparation process is simple, the operation is convenient, and the industrial production is easy to achieve.

Owner:TIANJIN UNIV

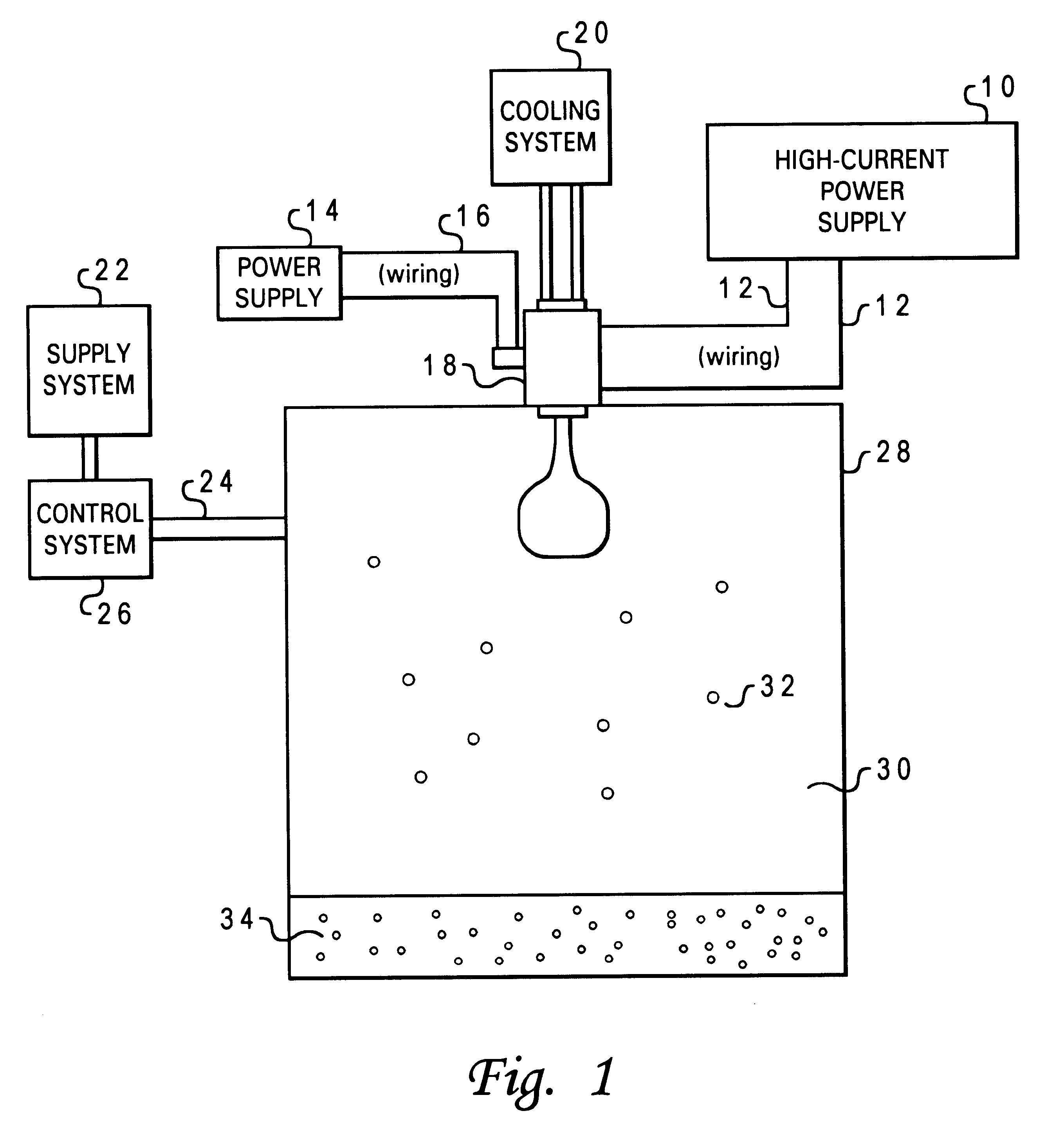

Method and apparatus for direct electrothermal-physical conversion of ceramic into nanopowder

InactiveUS6472632B1More energyMaterialMaterial nanotechnologyTransportation and packagingParticulatesNanocrystal

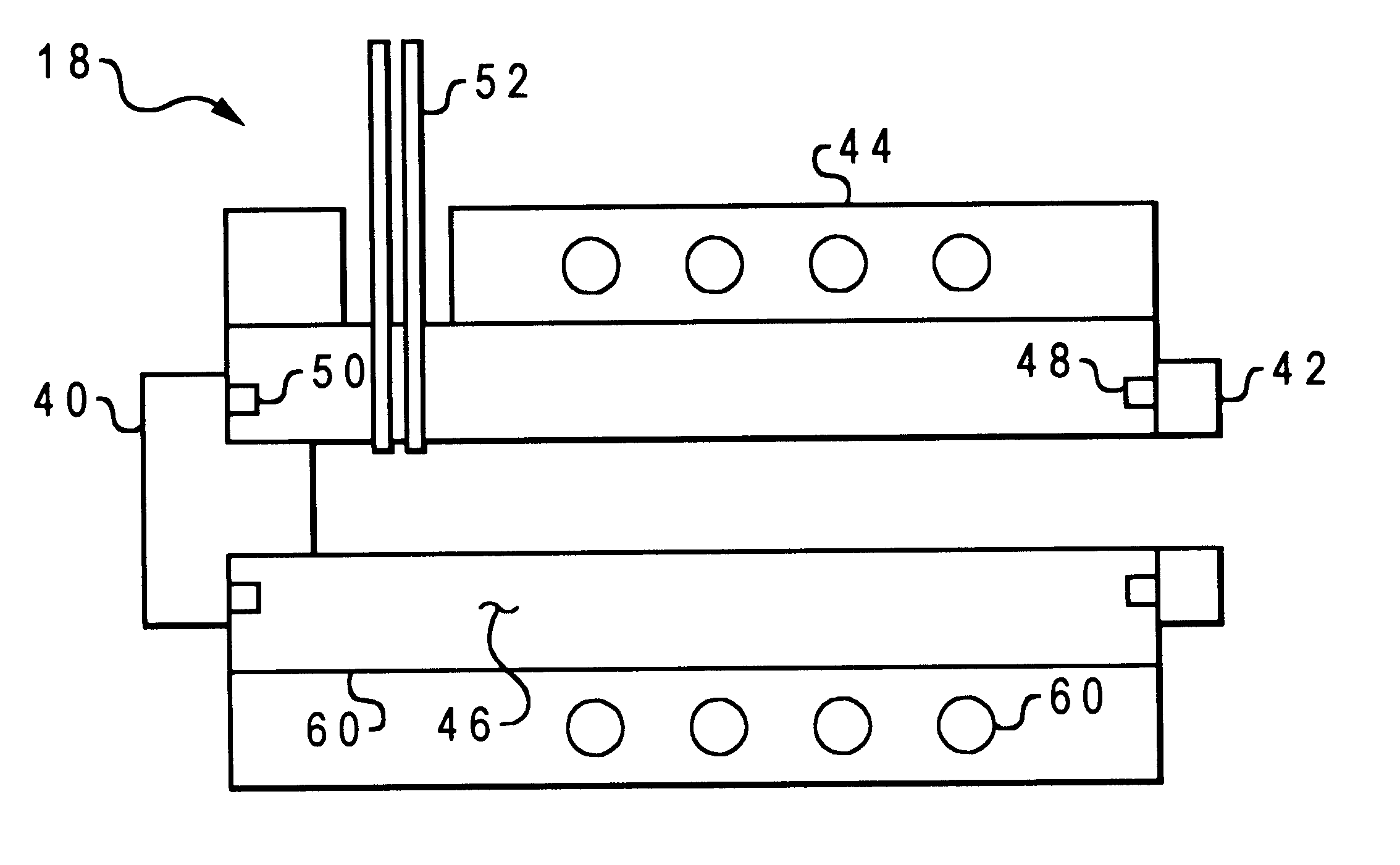

A method of producing nanocrystalline ceramic powder by creating a plasma stream in a reactor vessel, and physically converting a ceramic precursor material into ceramic particles suspended in the vessel, using the plasma stream. A metallic reactant may additionally be introduced into the vessel using the plasma stream, wherein the metallic reactant forms ceramic particles having the same composition as the ceramic particles of the physical converting step. The plasma stream is created using an electrothermal gun. The gun may use a ceramic barrel which is eroded by the plasma stream. Alternatively (or additionally), the ceramic precursor material may be injected as particulates into the plasma stream, wherein the ceramic precursor particulates are micron-sized or larger. A novel electrothermal gun design may optionally use a replaceable insert constructed of the ceramic precursor material.

Owner:NANOSCALE ENG & TECH CORP

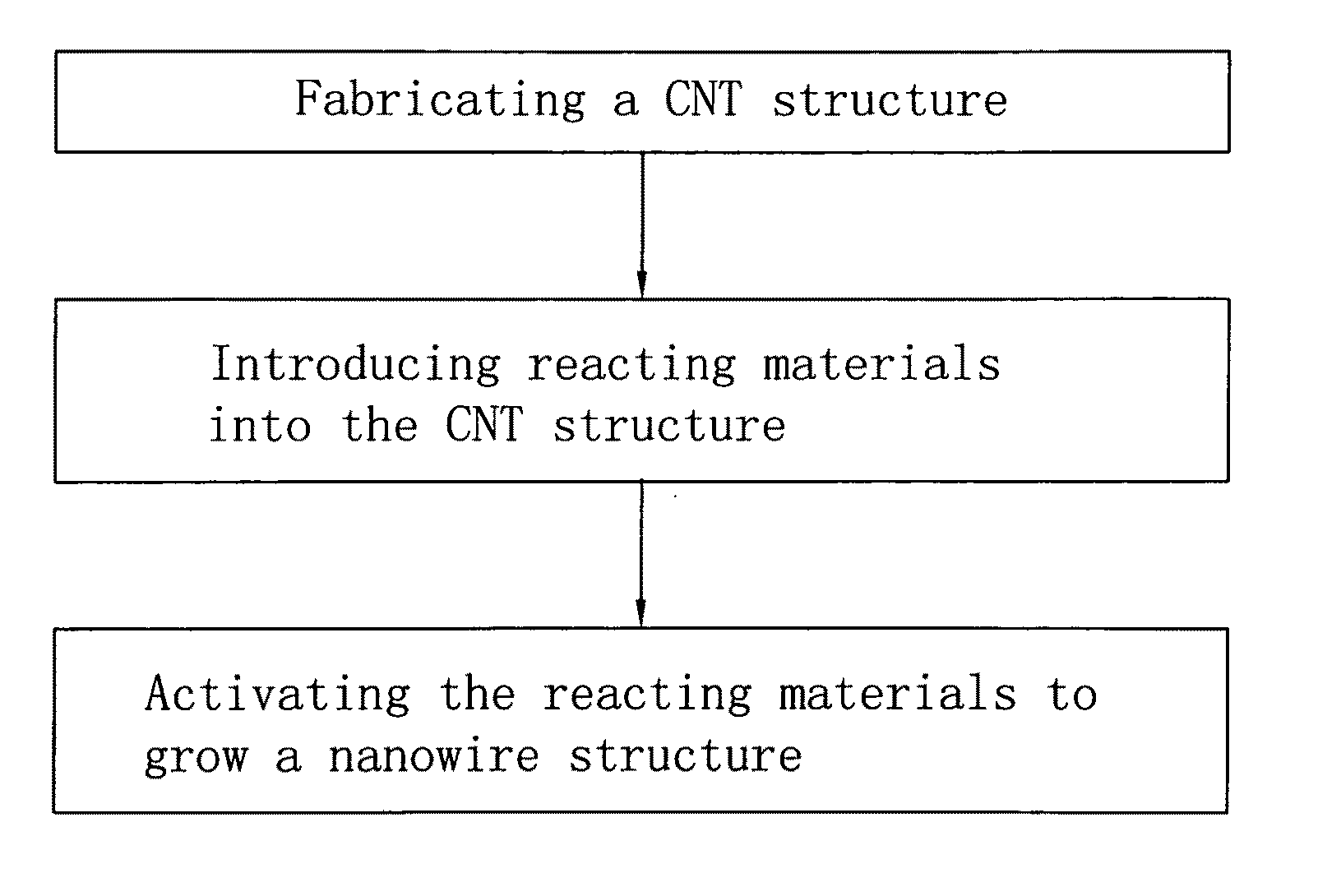

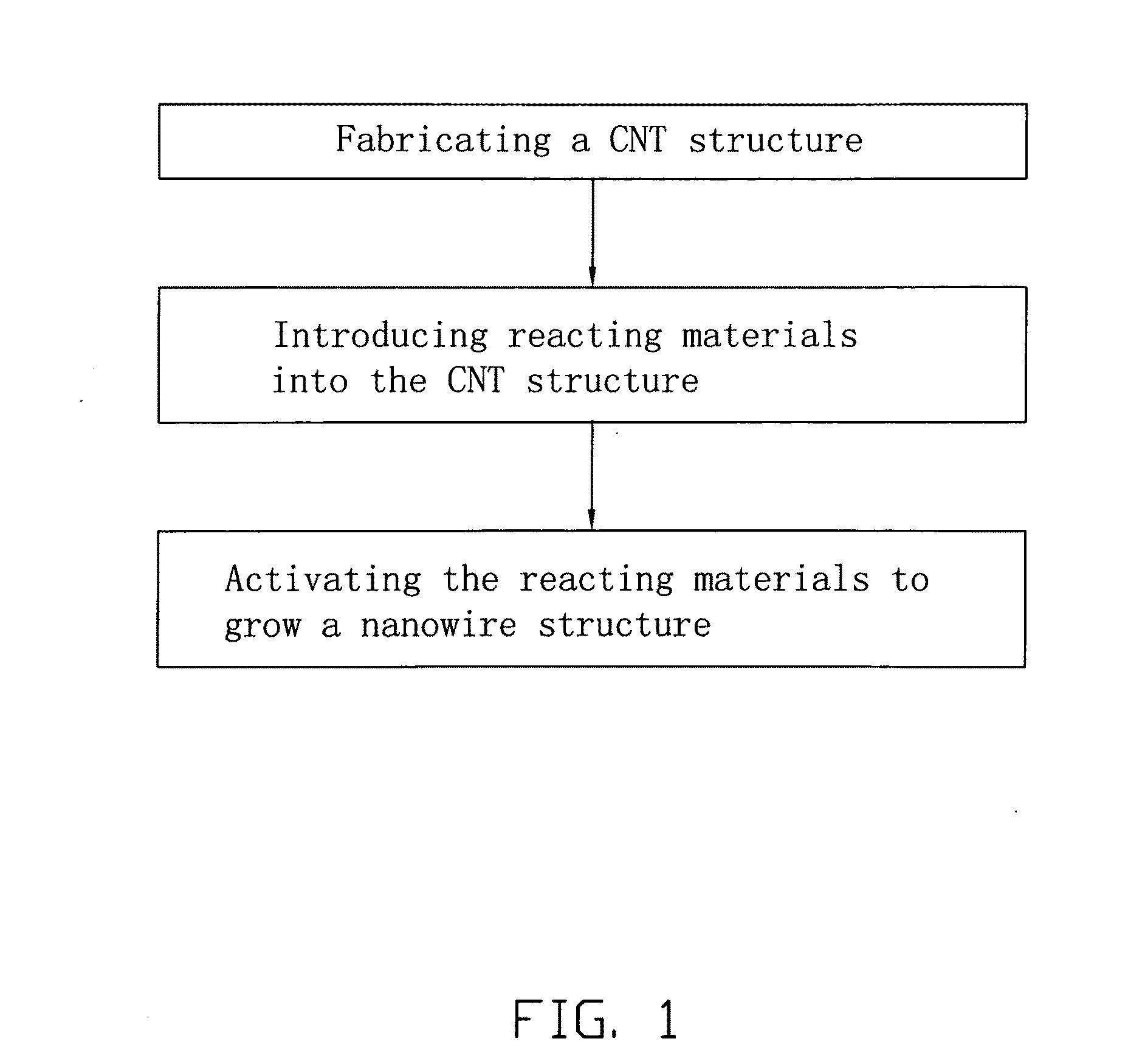

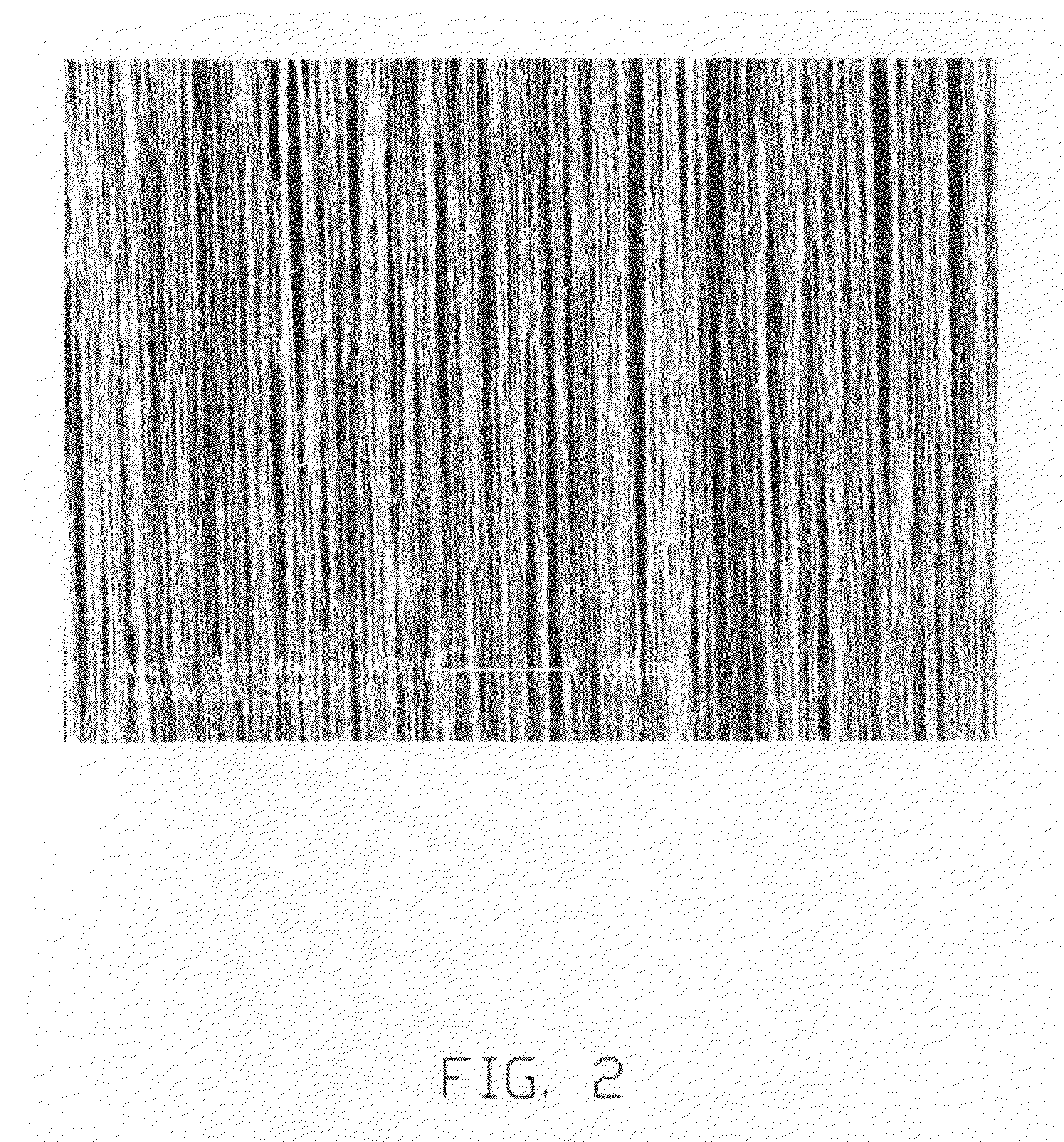

Method for making nanowire structure

The disclosure related to a method for making a nanowire structure. The method includes fabricating a free-standing carbon nanotube structure, introducing reacting materials into the carbon nanotube structure, and activating the reacting materials to grow a nanowire structure.

Owner:TSINGHUA UNIV

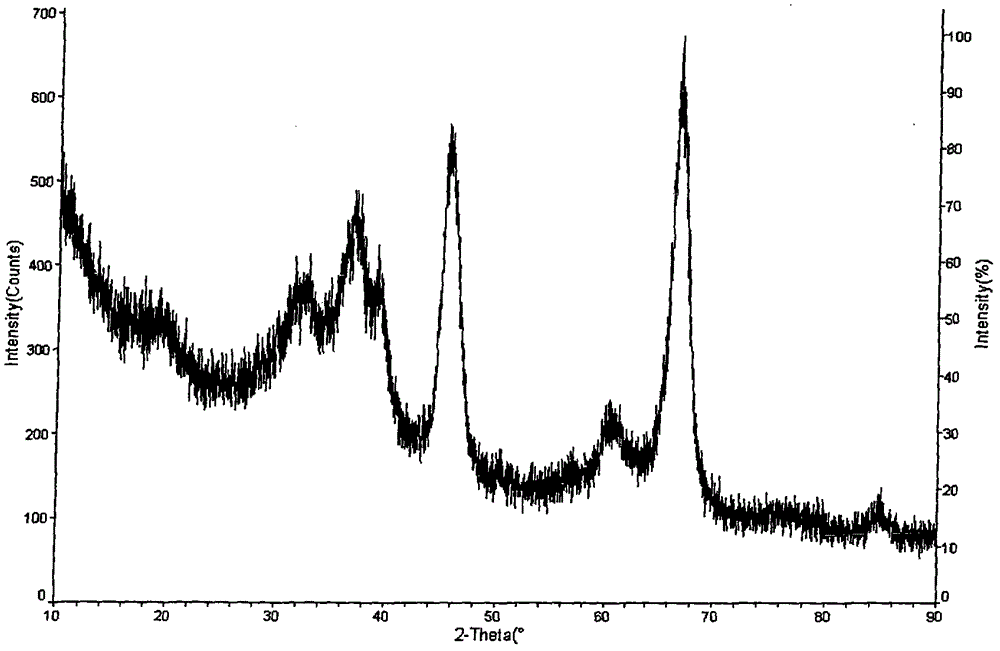

Solid phase preparation method for gamma-alumina with gradient distribution holes

InactiveCN102849763ALow costReduce manufacturing costCatalyst carriersAluminium oxide/hydroxide preparationAluminum CarbonateSolid reaction

The invention relates to a solid phase preparation method for gamma-alumina with gradient distribution holes. The method comprises: adopting a solid phase reaction to obtain a precursor ammonium aluminum carbonate hydroxide, and carrying out calcination to obtain gamma-alumina with a high specific surface area, gradient distribution holes and a large pore volume. The most prominent characteristic of the present invention comprises adopting a raw material solid phase reaction synthesis technology and controlling the property of the resulting gamma-alumina through synthesis conditions. In addition, the method of the present invention has characteristics of simpleness, easy operation, no requirement of addition of a pore-expanding agent, and cost saving, and is suitable for industrial mass production.

Owner:PETROCHINA CO LTD +1

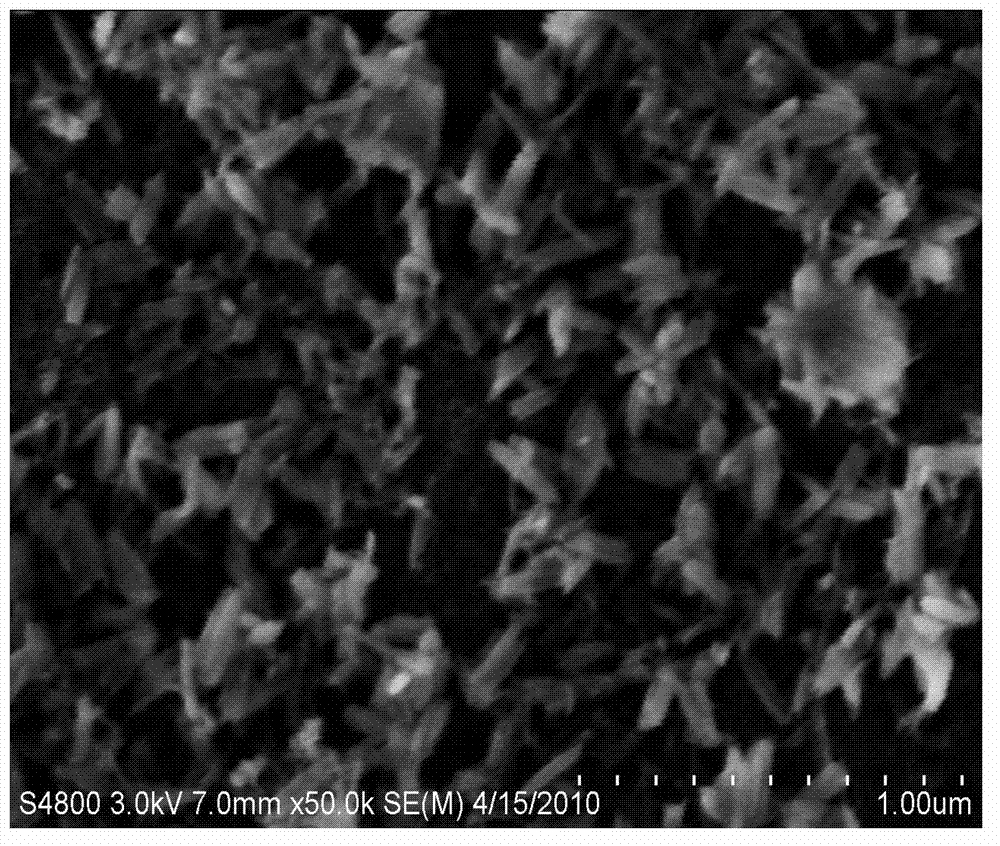

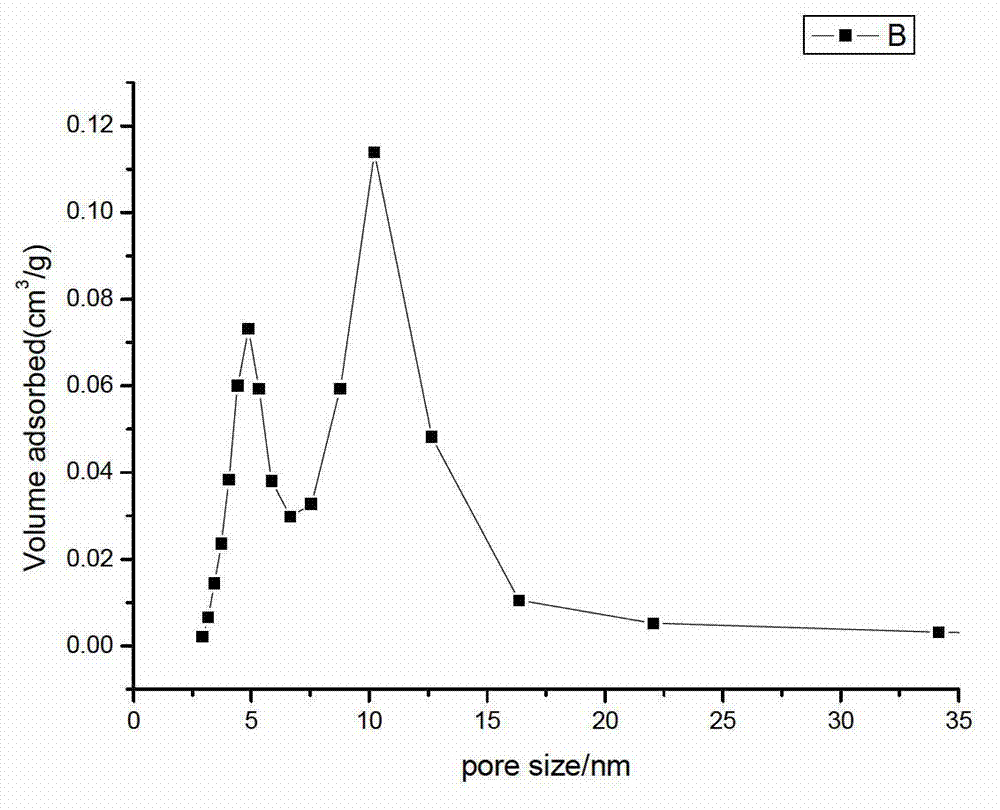

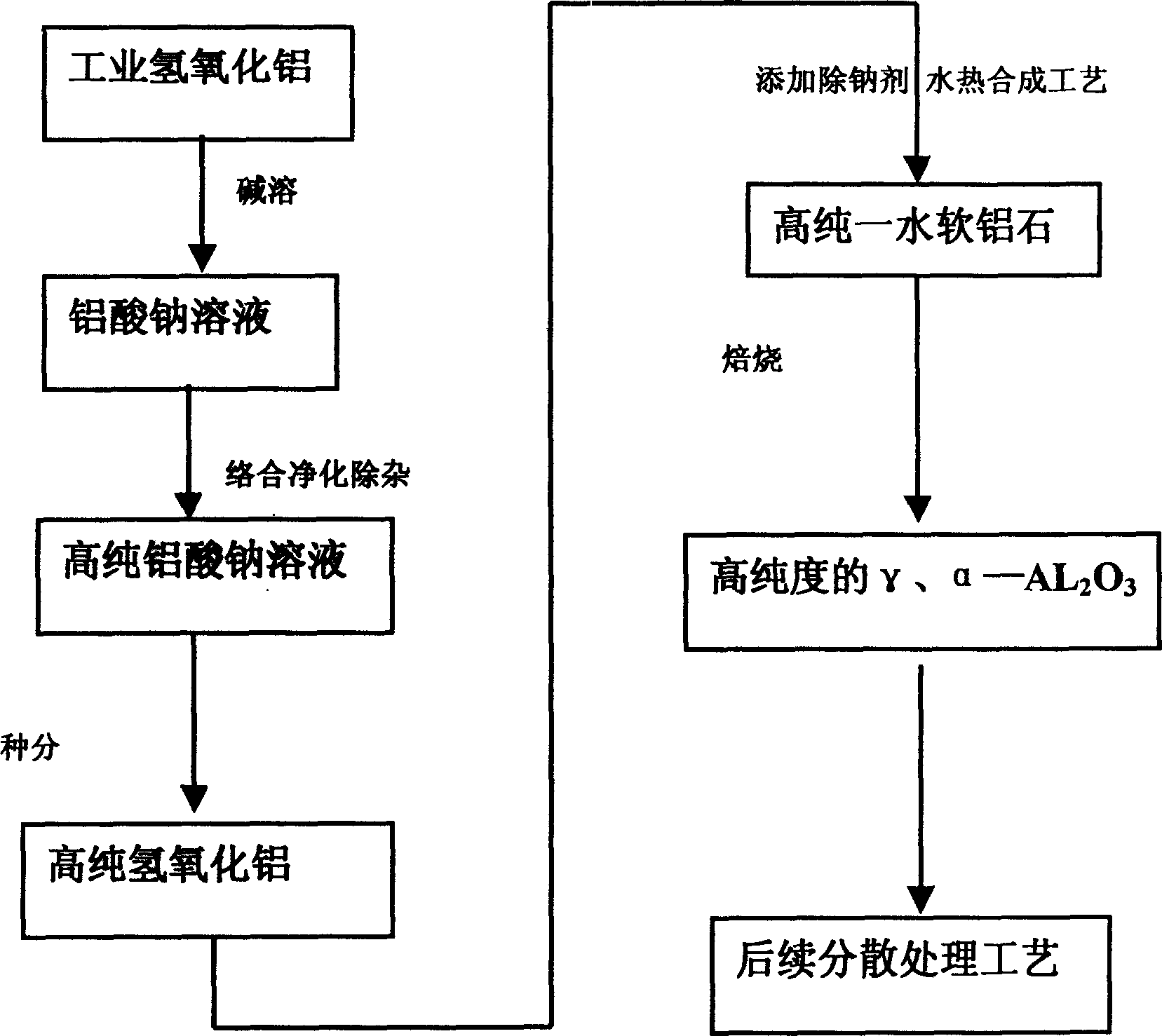

Method for preparing high-pruity alumina powder

ActiveCN1579941ALow costNo pollution in the processAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium oxide/hydroxide preparationAluminium hydroxideFluorescence

The invention discloses a method to produce highly pure Alumina powder. The steps are as follows: deploying Aluminium hydroxide which is produced in the process of manufacturing alumina using sintering process to be solution, disposing of impurity, adding seed crystal to prepare highly pure aluminium hydroxide; removing Na in the solution, getting highly pure bodhmite after hydrothermal synthesis; and after washing and baking, highly pure Alumina can be obtained. The cost is about 15 thousand per ton, which is far less than current market price, 40-60 thousand per ton. It can put into production in a large scale and it is easy to reach 1-5 thousand ton per year. With a low cost, no pollution and high purity (over 99.99 percent), the production is widely used in rare earth fluorescence materials, high voltage Na lamp and other relative special Alumina fine ceramics field.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for extracting high-purity alumina and silica gel from coal ash

ActiveCN101254933AHigh purityLow equipment requirementsSilicaAluminium oxide/hydroxide preparationSilica gelSilicon dioxide

The invention discloses a method for extracting high-purity alumina and silica gel from the flyash. The method includes calcining and activating the powdered coal at low temperature; water extracting the alumina; acid extracting the alumina and the silica gel; separating the alumina and the silica gel; separating the alumina and the iron; recycling and reutilizing the CO2 generated during the calcining and recycling the alkali, the sodium chloride, the acid and the water during the extractions. The extracted alumina and silica gel have high purity and are used as high added value products. The separation extraction rates of the alumina and the silica gel in the fly ash reach more than 90%. The residue amount obtained after extracting the alumina and the silica gel from the fly ash is less than 10% of the fly ash. The entire technological process is carried out under the normal pressure, therefore the method has low requirement for equipment. Since the CO2 generated during the calcining and the alkali and the acid used in the extraction can be reutilized, the method can realize zero discharge without secondary pollution.

Owner:安岭(陕西)环境科技有限公司

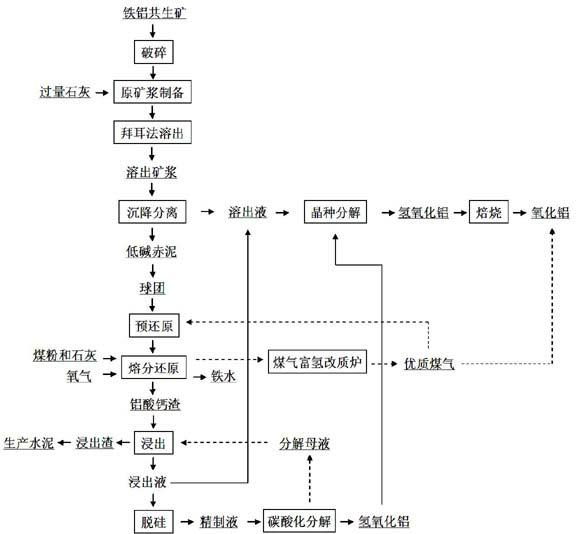

Comprehensive utilization method of high-ferrum and low-grade bauxite

ActiveCN102583477AReduce alkalinityHigh dissolution rateAluminium oxide/hydroxide preparationCarbon captureRotary furnaceCalcium aluminate cements

A comprehensive utilization method of high-ferrum and low-grade bauxite belongs to the technical of metallurgy and is carried out according to the steps as follows: a large proportion of aluminium oxide is extracted through a Bayer process technology that excess lime is added, produced low-alkali red mud is pre-reduced through a coal-based rotary furnace process technology, then high-temperature melting separation of aluminium slag / ferrum is realized by adopting a ferrum bath oxygen coal jetting technology, formed aluminium slag generates calcium aluminate cement after being quenched and tempered, calcium aluminate cement slag is leached with low sodium carbonate solution, a part of leached crude solution and digestion slurry by the Bayer process are mixed and enter a Bayer process system to extract aluminium oxide, and the other part is desilicated and then is resolved in a carbonation manner, aluminum hydrate, which is the decomposition product, is conveyed to the Bayer process system as seed crystal, and resolved mother liquid is used for leaching calcium aluminate cement slag after being mixed. The method provided by the invention can not only ensure efficient dissociation extraction of ferrum and aluminium, but also be practicable in technology and economic benefit, thereby comprehensively utilizing high-ferrum bauxite resource of China effectively.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

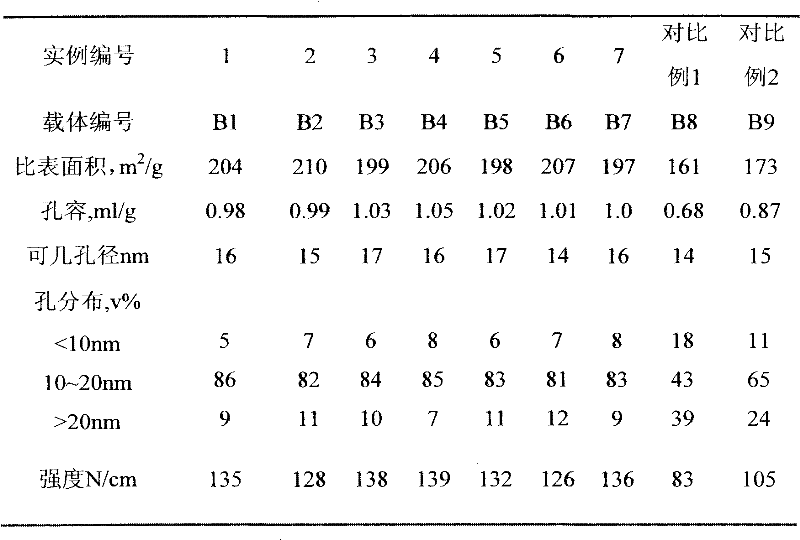

Preparation method for alumina carrier

ActiveCN102441436AWell mixedLarge hole volumeCatalyst carriersAluminium oxide/hydroxide preparationPseudoboehmiteResidual oil

The invention discloses a preparation method for an alumina carrier, which includes the following steps: (1) dry pseudoboehmite gel powder and extrusion aid are uniformly mixed and then added into aqueous solution in which physical pore-expanding agent and chemical pore-expanding agent are dissolved; (2) the material obtained in step 1 is uniformly mixed and molded by extrusion on an extruder; (3) the material obtained in step 2 is dried and baked, and thereby the finished alumina carrier is prepared. The alumina carrier prepared by the method has large pore volume and pore diameter, centrally distributed pores and high mechanical strength, and is applicable to the preparation of heavy oil and residual oil hydrodemetallization catalysts and other fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

High temperature-resistant activated alumina material and preparation method thereof

ActiveCN102745729AEase of mass productionSimple processAluminium oxide/hydroxide preparationRoom temperaturePeptization

The present invention provides a high temperature-resistant activated alumina material and a preparation method thereof. The alumina material is prepared by the following steps: mixing macroporous pseudo-boehmite, high viscosity pseudo-boehmite and an additive by using water; uniformly stirring at a rotation speed of 100-1000 r / min; adding dilute nitric acid with a concentration of 30% to carry out a reaction until the pH value is 2.0-5.5 and the solution is at the peptization state, and then aging for 3-6 hours at a temperature of 80-100 DEG C while stirring; adding a pore-forming agent at a room temperature, and carrying out uniform stirring, pulping, spraying and drying; and carrying out calcination at a temperature of 900 DEG C to prepare the alumina. The alumina material of the present invention has advantages of convenient mass production, high specific surface, and the like, wherein the specific surface of the alumina material of the present invention can be maintained more than 110 m<2> / g for a long time at a temperature of 1000-1100 DEG C. In addition, the preparation method of the alumina material has characteristics of simple process and low cost.

Owner:浙江欧信环保科技有限公司

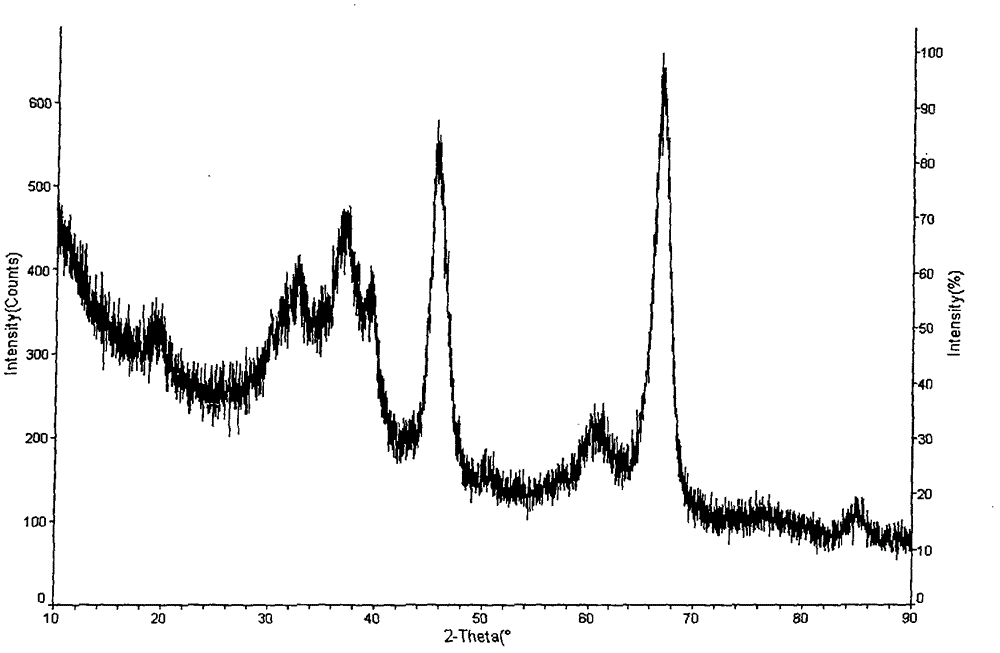

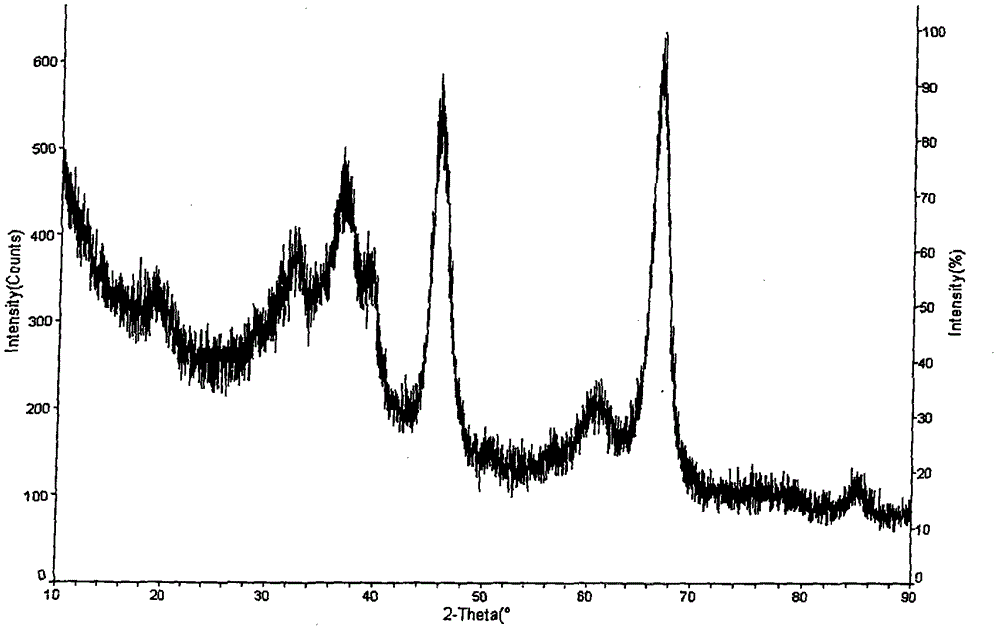

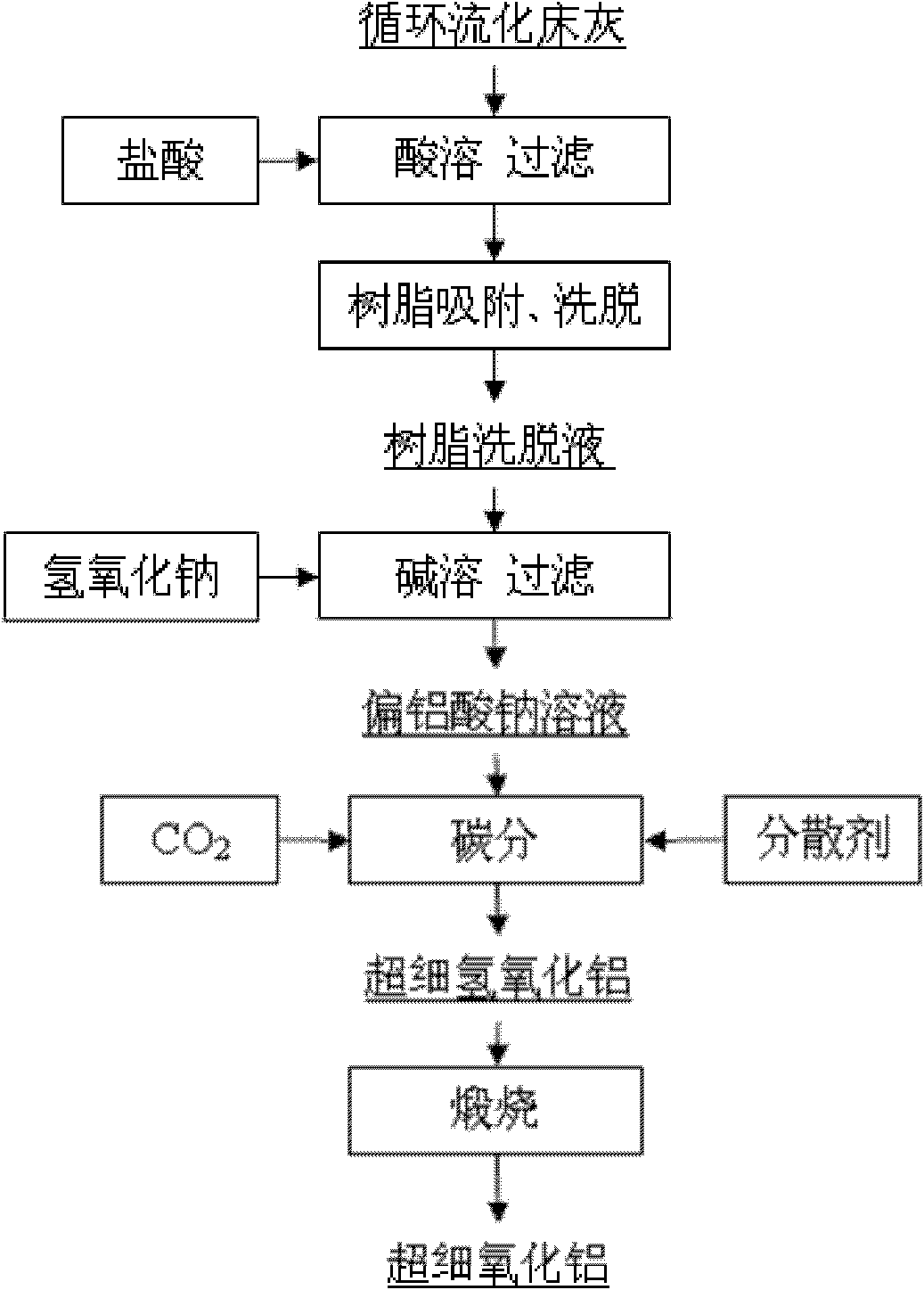

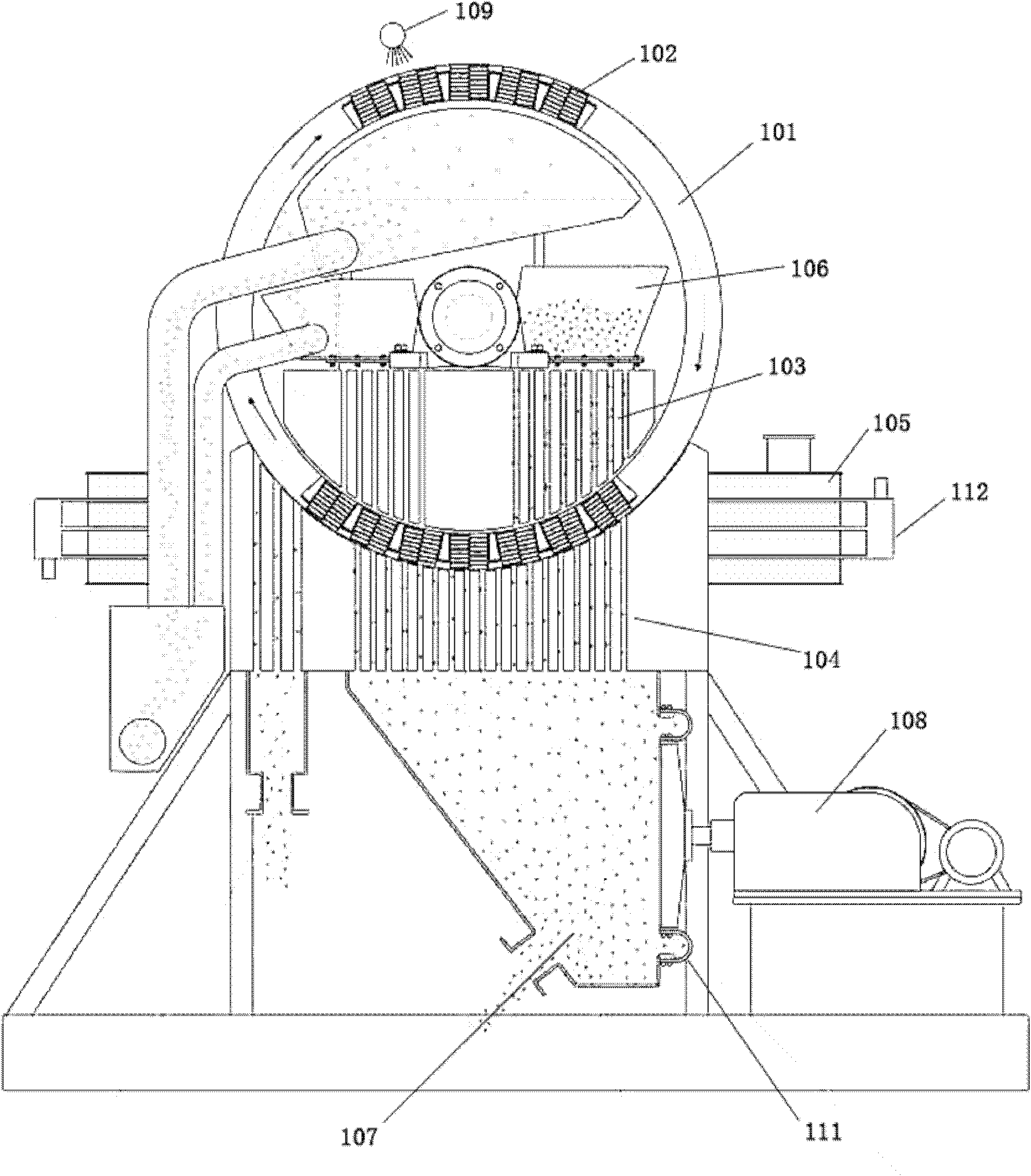

Method for preparing super-fine aluminum hydroxide and alumina from fly ash

ActiveCN102153117AHigh purityEliminate high temperature calcination activation stepsProductsReagentsAluminium chlorideAluminate

The invention discloses a method for preparing super-fine aluminum hydroxide and super-fine alumina by using fly ash of a circulating fluidized bed as a raw material. The method comprises the following steps of: 1, after grinding the fly ash, carrying out wet magnetic separation on the ground fly ash to remove iron and then performing a reaction of the obtained product and hydrochloric acid to obtain immersion liquid of hydrochloric acid; 2, adsorbing the immersion liquid of hydrochloric acid by filling a macroreticular cation resin column and after a resin is adsorbed and saturated, the resin is eluted by eluent to obtain the eluent containing aluminium chloride and ferric chloride; 3, carrying out alkali dissolution iron removal on the eluent to obtain sodium meta-aluminate solution; 4, adding a dispersant into the sodium meta-aluminate solution and uniformly mixing the mixture to obtain dispersion liquid; and 5, carrying out carbon dioxide decomposition on the dispersion liquid to obtain the super-fine aluminum hydroxide. Gamma-alumina and alpha-alumina can be respectively obtained by calcining the super-fine aluminum hydroxide at different temperatures. Compared with other methods, the method has the advantages of wide raw material sources, simple production process and high product purity.

Owner:CHINA SHENHUA ENERGY CO LTD

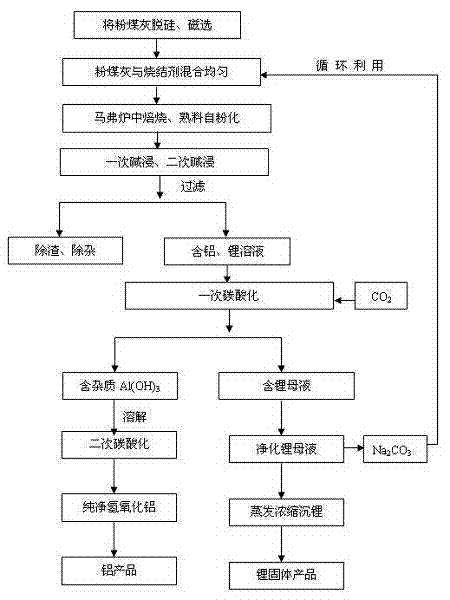

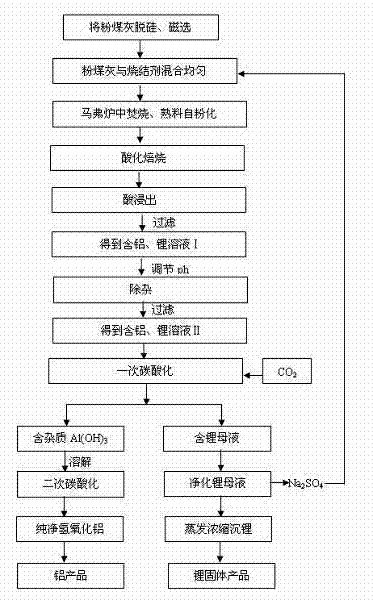

Method for comprehensively extracting aluminum and lithium from coal ash

The invention provides a method for comprehensively extracting aluminum and lithium from coal ash. The method is characterized by comprising the following technological steps which are carried out in sequence: (A) desiliconizing and magnetically separating; (B) roasting; (C) primary dipping by alkali; (D) secondary dipping by alkali; (E) carbonizing, and precipitating aluminum; (F) purifying lithium mother liquor; and (G) evaporating, concentrating and precipitating lithium. The method has the advantages that silicon, iron, aluminum and lithium are sequentially extracted from the industrial coal ash, so that the waste is turned into treasure, the cost of the raw materials is reduced, the technological operation is simple and convenient, and the comprehensive extracting rate of aluminum lithium resources can be maximized; and the method is an ideal method for comprehensively extracting aluminum and lithium from the coal ash.

Owner:HEBEI UNIV OF ENG

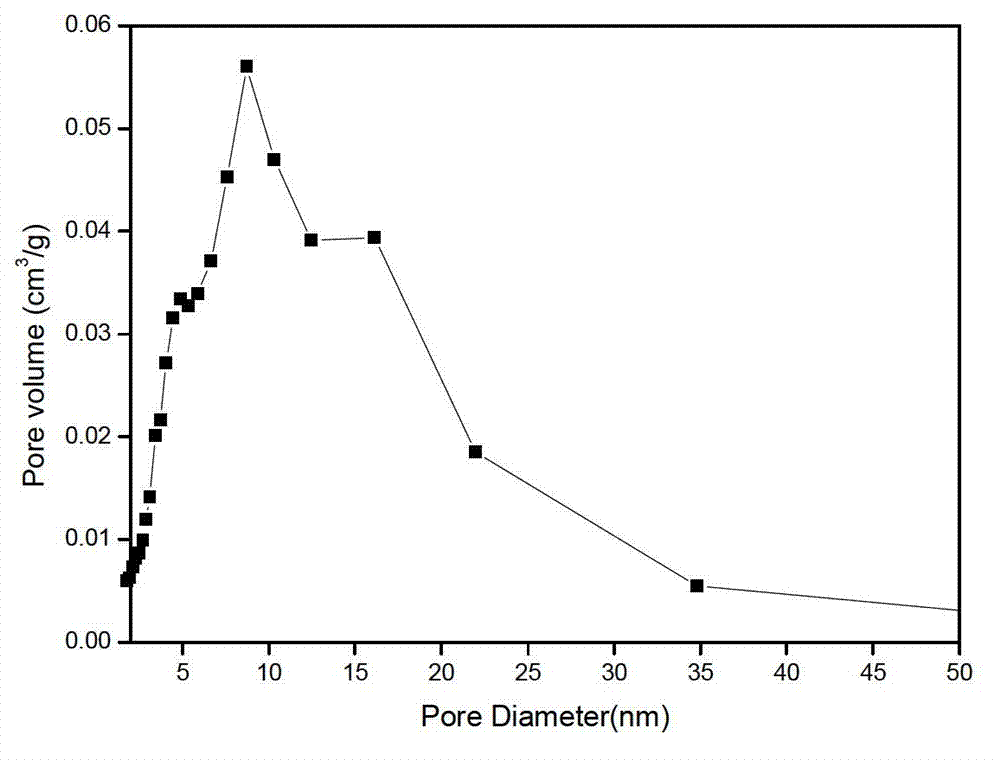

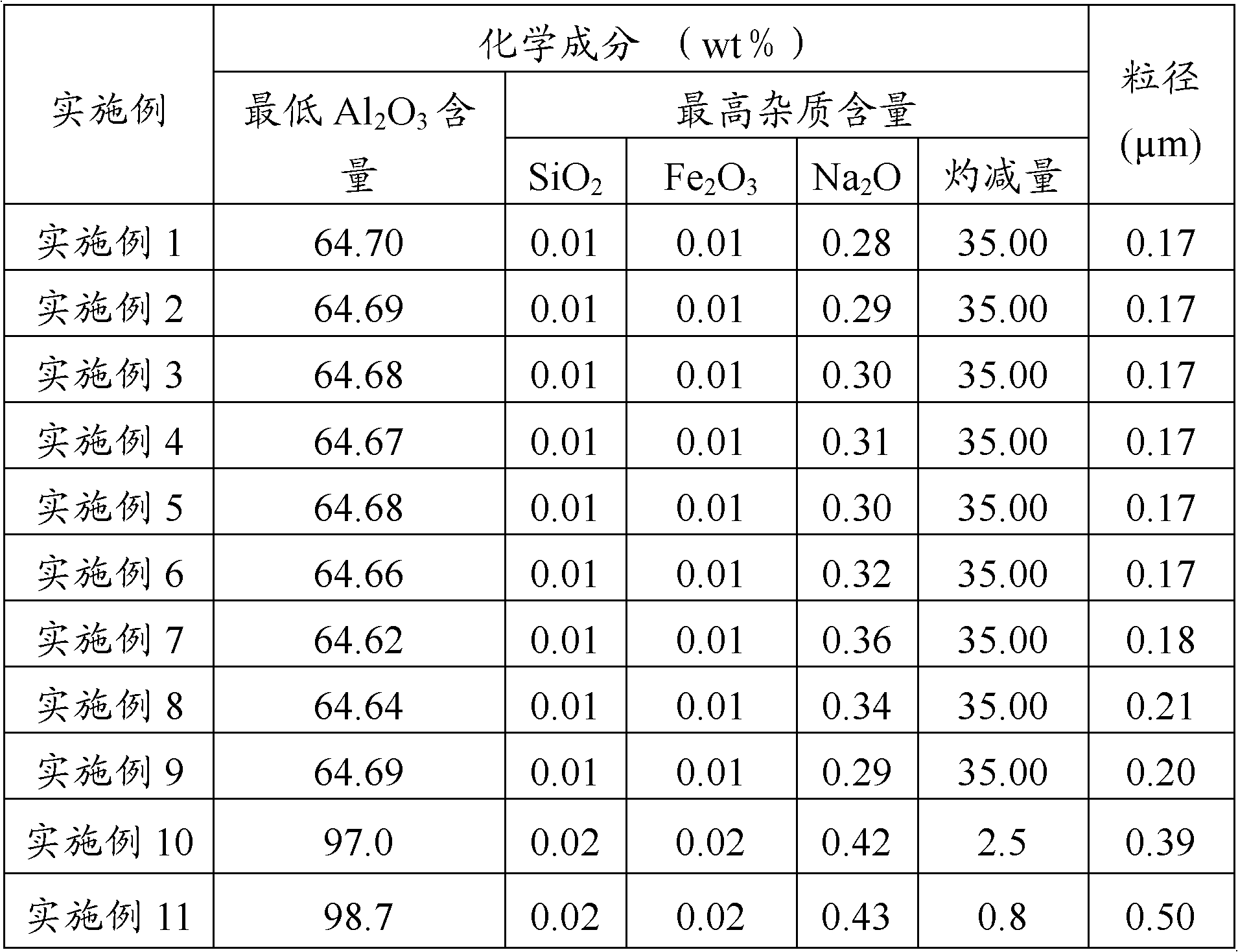

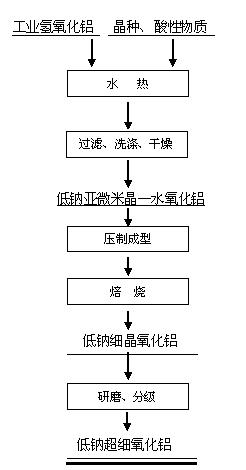

Preparation method of low-sodium fine grain alumina

InactiveCN102320638AWide variety of sourcesSimple production processAluminium oxide/hydroxide preparationBoehmiteLow sodium

The invention relates to a preparation method of low-sodium fine grain alumina, in particular to a preparation method of low-sodium submicro grain alumina used for electronic ceramics, microcrystalline ceramics, fine polishing, catalyst carriers and the like. The preparation method is characterized by taking industrial aluminium hydroxide as a raw material in the preparation process and comprising the following steps of: firstly carrying out hydrothermal phase inversion processing on aluminium hydroxide to obtain low-sodium fine grain alumina monohydrate with sodium oxide content being less than 500ppm; briquetting the obtained low-sodium fine grain alumina monohydrate, and then roasting to obtain low-sodium fine grain alumina; and finally grinding and grading, thus obtaining low-sodium submicro alumina. The preparation method of low-sodium fine grain alumina has the advantages of simple production process, wide raw material sources, low production cost, environment friendliness and the like, and can combine with the existing alumina production process and equipment to carry out hydrothermal processing, thus effectively simplifying the production process and lowering the production cost. The method is ideal for preparing ultra-low-sodium boehmite and alumina.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

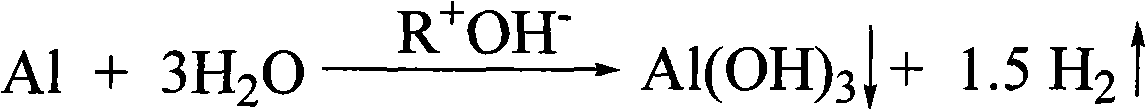

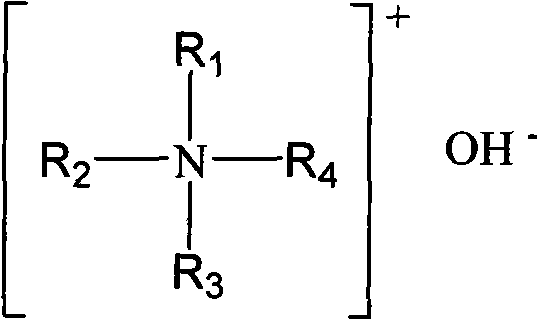

Preparation method of alumina powder

The invention relates to a preparation method of alumina powder. The preparation method of the alumina powder comprises the following steps: metal aluminum and a quaternary ammonium base aqueous solution react in a hot bath to prepare an aluminum hydroxide precipitate, the aluminum hydroxide precipitate is filtered, washed, dried, calcined at high temperature and crushed to prepare alpha-phase alumina powder and gamma-phase alumina powder, and the quaternary ammonium base aqueous solution is still used as filtrate capable of being repeatedly used. A quaternary ammonium base is an organic base with a structural formula of R1R2R3R4NOH, wherein R1, R2, R3 and R4 can be same (or different) alkyl groups (or aromatic groups). The invention has the advantages of low technological condition requirements, environmental protection, low cost and good product repetitiveness, is particularly suitable for mass production and can prepare high-pure ultra-fine alumina powder if high-pure aluminum sheets are adopted as an aluminum source, thereby being applied to the fields, such as high-voltage sodium lighting tubes, long-afterglow luminescent materials, tricolor fluorescent powder, advanced grinding materials, artificial lenses, and the like.

Owner:大连光科纳米材料有限公司

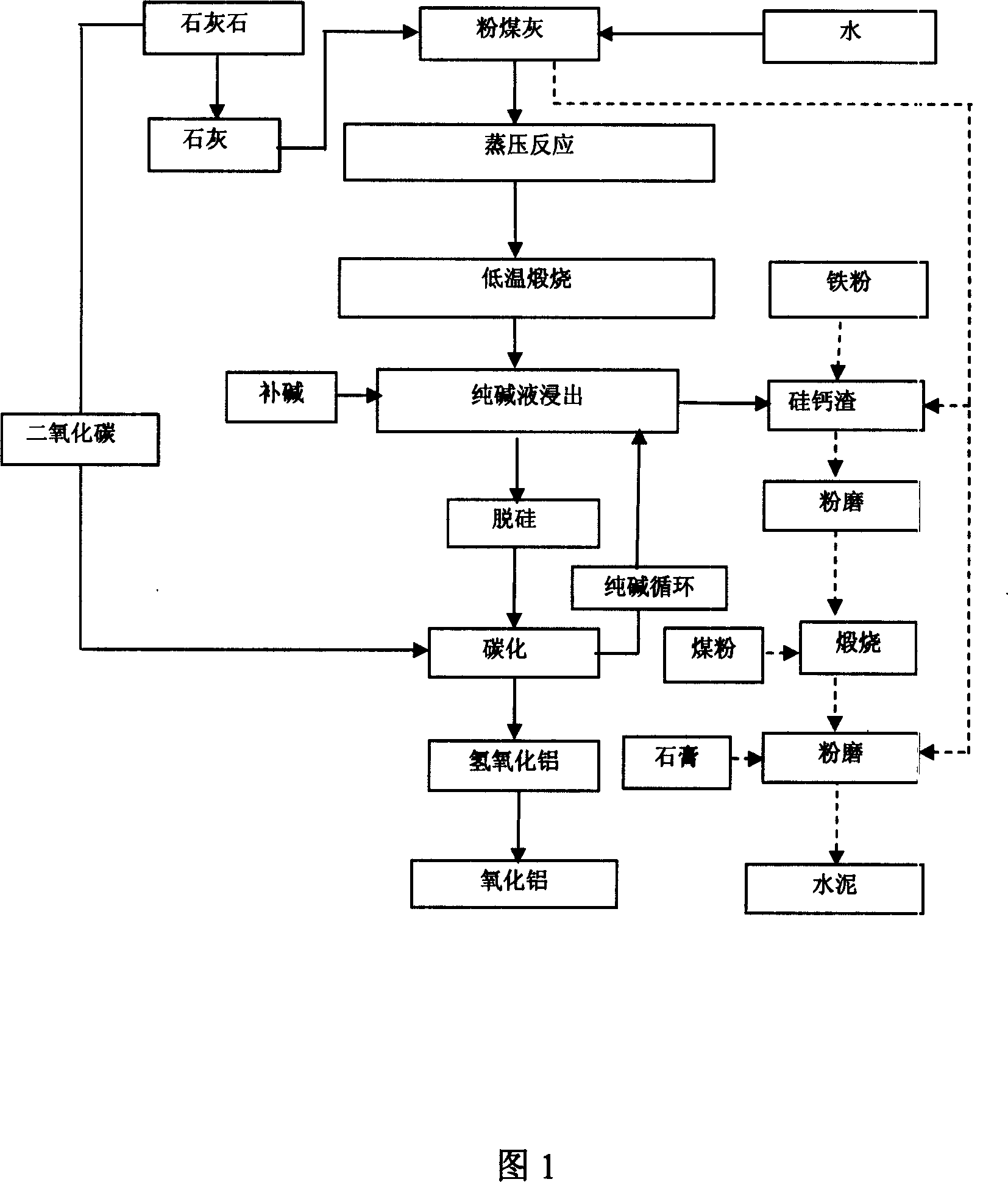

Method for extracting alumin from aluminous fly-ash and method for producing cement from fag end

InactiveCN101028936AReduce manufacturing costAluminium oxide/hydroxide preparationCement productionAl powderSteam pressure

A process for extracting aluminum oxide from high-Al powdered coal ash and using the residual dregs to prepare cement includes such steps as mixing with lime and water, steam pressure reaction to generate the resultant containing hydrated calcium silicoaluminate and calcium hydroxide, calcining, extracting in sodium carbonate solution to obtain aluminum oxide, desiliconizing, carbonizing, calcining to obtain high-purity aluminum oxide, and using the SiCa dregs to prepare cement.

Owner:CHANGAN UNIV

Technical method for comprehensively extracting aluminum and lithium from coal ash through acid process

The invention provides a technical method for comprehensively extracting aluminum and lithium from coal ash through an acid process. The method is characterized by comprising the following technological steps which are carried out in sequence: (A) desiliconizing and magnetically separating; (B) thermally processing; (C) acidizing and roasting; (D) leaching; (E) removing residues; (F) carbonizing, and precipitating aluminum; (G) purifying lithium mother liquor; and (H) evaporating, concentrating and precipitating lithium. The method has the advantages that the silicon, iron, aluminum and lithium are sequentially extracted from the industrial coal ash, so that the waste is turned into treasure, the cost of the raw materials is reduced, the technological operation is simple and convenient, and the comprehensive extracting rate of aluminum source and lithium resources can be maximized; and the method is an ideal method for comprehensively extracting aluminum and lithium from the coal ash through the acid process.

Owner:HEBEI UNIV OF ENG

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com