Method for preparing high-pruity alumina powder

A technology of high-purity alumina and alumina, which is applied in the preparation of alumina/hydroxide, alkali metal aluminate/aluminum oxide/aluminum hydroxide, alumina/aluminum hydroxide, etc., which can solve the problems of purity limitation, Serious environmental pollution, low purity and other problems, to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

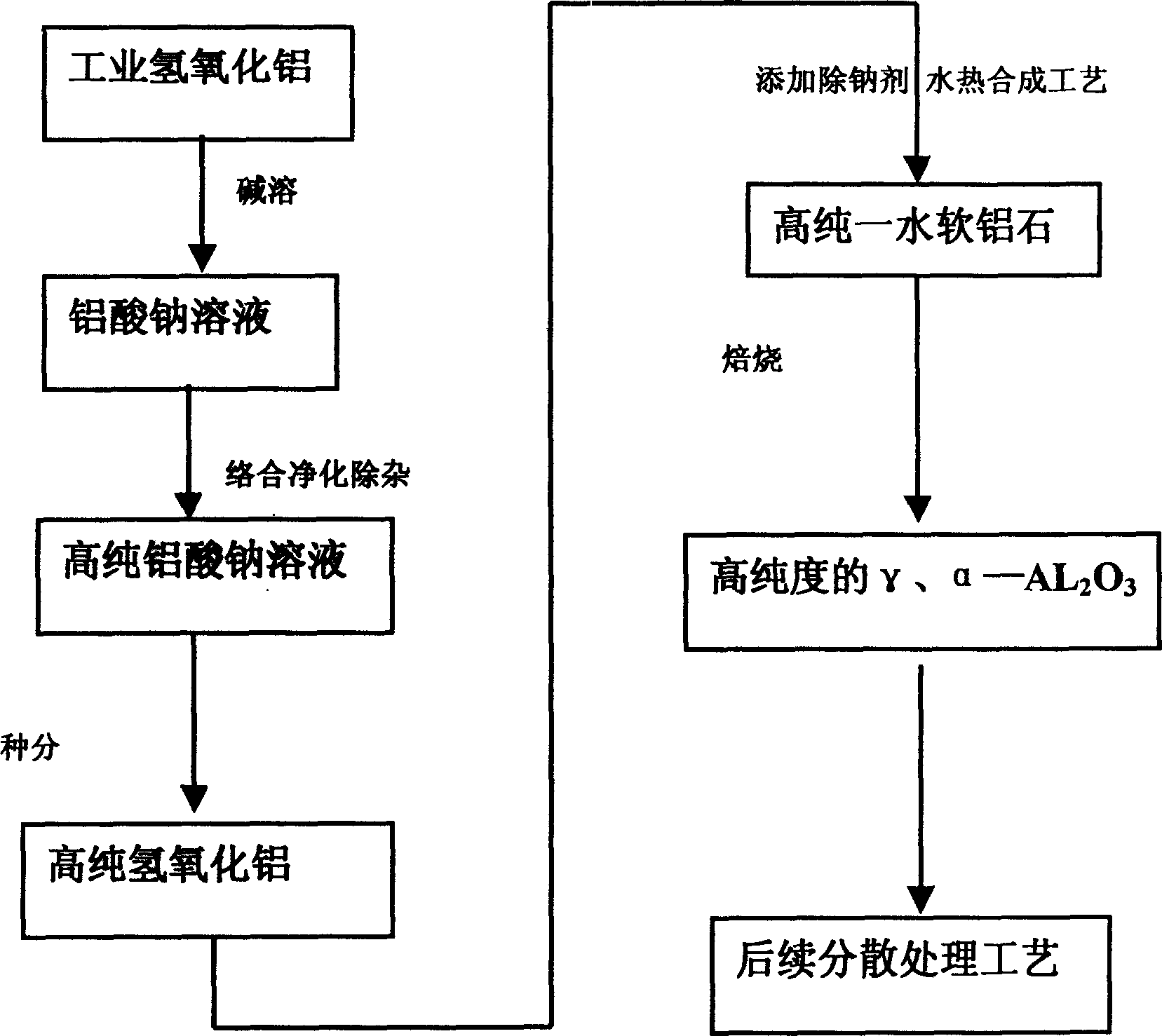

Image

Examples

Embodiment 1

[0020] The preparation method of the high-purity alumina powder of the present invention uses the intermediate product aluminum hydroxide (which can be the middle stage product of seed or carbon aluminum hydroxide) of the alumina production process by the sintering method as a raw material, and prepares aluminum by dissolving Sodium aluminate solution, adding 9% aluminum hydroxide by weight of aluminum hydroxide as impurity remover, used to adsorb harmful impurities in the sodium aluminate solution, stirred for 45 minutes, and separated liquid-solid to prepare high-purity sodium aluminate solution. This solution is used as the decomposition mother solution, the decomposition temperature is controlled at 60°C, and the concentration of alumina in the solution is 100g / l, 7% active aluminum hydroxide is added as the seed crystal for carbonation and decomposition of the seeds to prepare high-purity aluminum hydroxide. The decomposition time Controlled within 5 hours, carbon dioxide ...

Embodiment 2

[0023] The preparation method of the high-purity alumina powder of the present invention uses the intermediate product aluminum hydroxide of the alumina production process by the sintering method as a raw material, prepares a sodium aluminate solution by dissolving, and adds 7% of the weight of aluminum hydroxide Aluminum micropowder was used as impurity remover, and after stirring for 40 minutes, liquid-solid separation was carried out to prepare high-purity sodium aluminate solution. This solution is used as the decomposition mother solution, the decomposition temperature is controlled at 65°C, and the concentration of alumina in the solution is 110g / l, 8% active aluminum hydroxide is added as the seed crystal for carbonation and decomposition of the seeds to prepare high-purity aluminum hydroxide. The decomposition time Controlled in 6 hours, carbon dioxide flow 0.05m 3 / h·l, the decomposition rate of the carbonation decomposition process is controlled at 83%. After the dec...

Embodiment 3

[0026] The preparation method of the high-purity alumina powder of the present invention uses the intermediate product aluminum hydroxide of the alumina production process by the sintering method as a raw material, prepares a sodium aluminate solution by dissolving, and adds 10% of the weight of aluminum hydroxide Aluminum was used as impurity remover, and after stirring for 48 minutes, liquid-solid separation was carried out to prepare high-purity sodium aluminate solution. This solution is used as the decomposition mother solution, the decomposition temperature is controlled at 65°C, and the concentration of aluminum oxide in the solution is 120g / l. Add 9% high-purity aluminum hydroxide as a seed crystal for carbonation and decomposition of the seeds to prepare high-purity aluminum hydroxide. Decomposition The time is controlled at 6 hours, carbon dioxide is introduced, and the decomposition rate of the carbonation decomposition process is controlled at 80%. After the decompo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com