Patents

Literature

143 results about "Corrosive acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

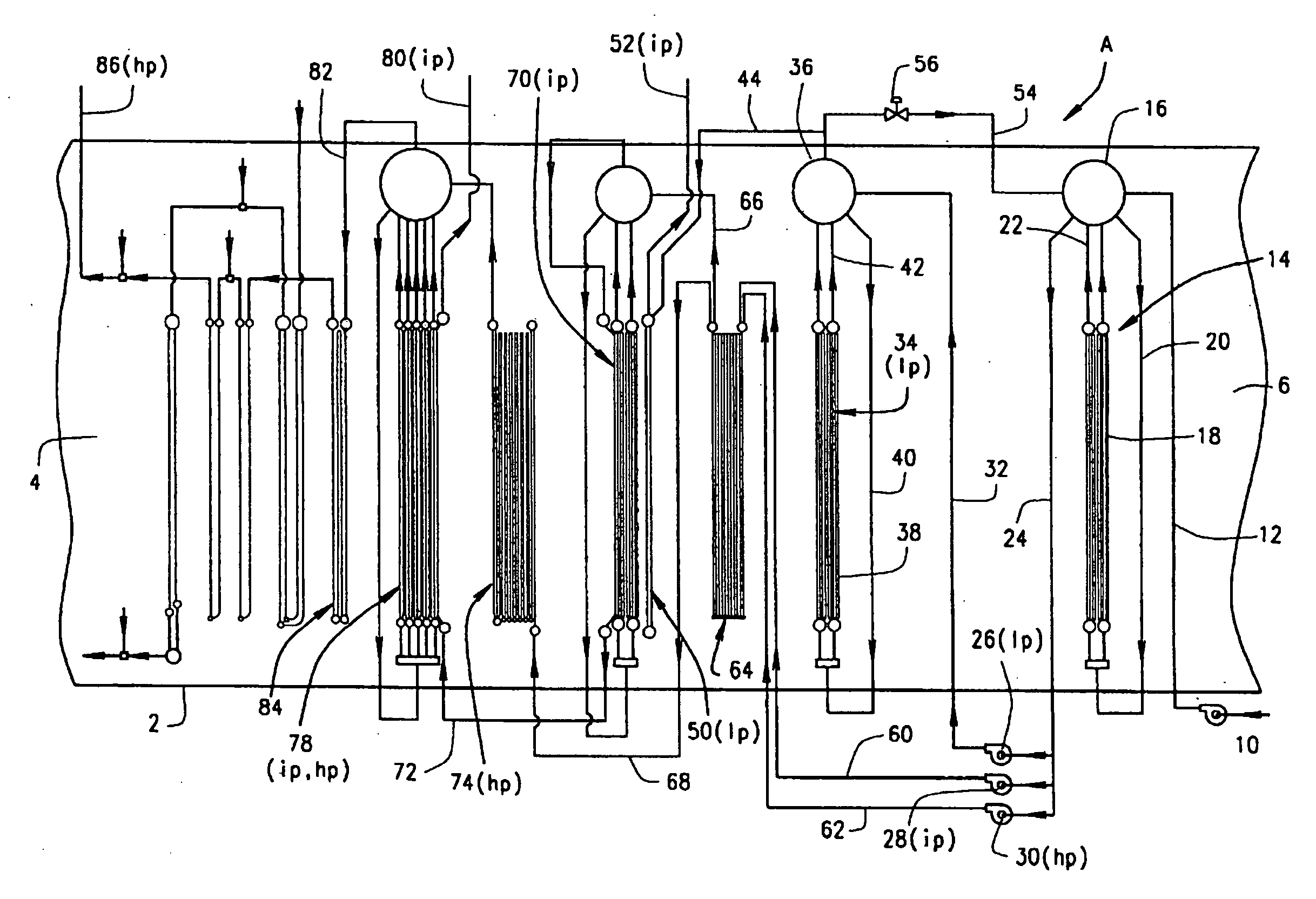

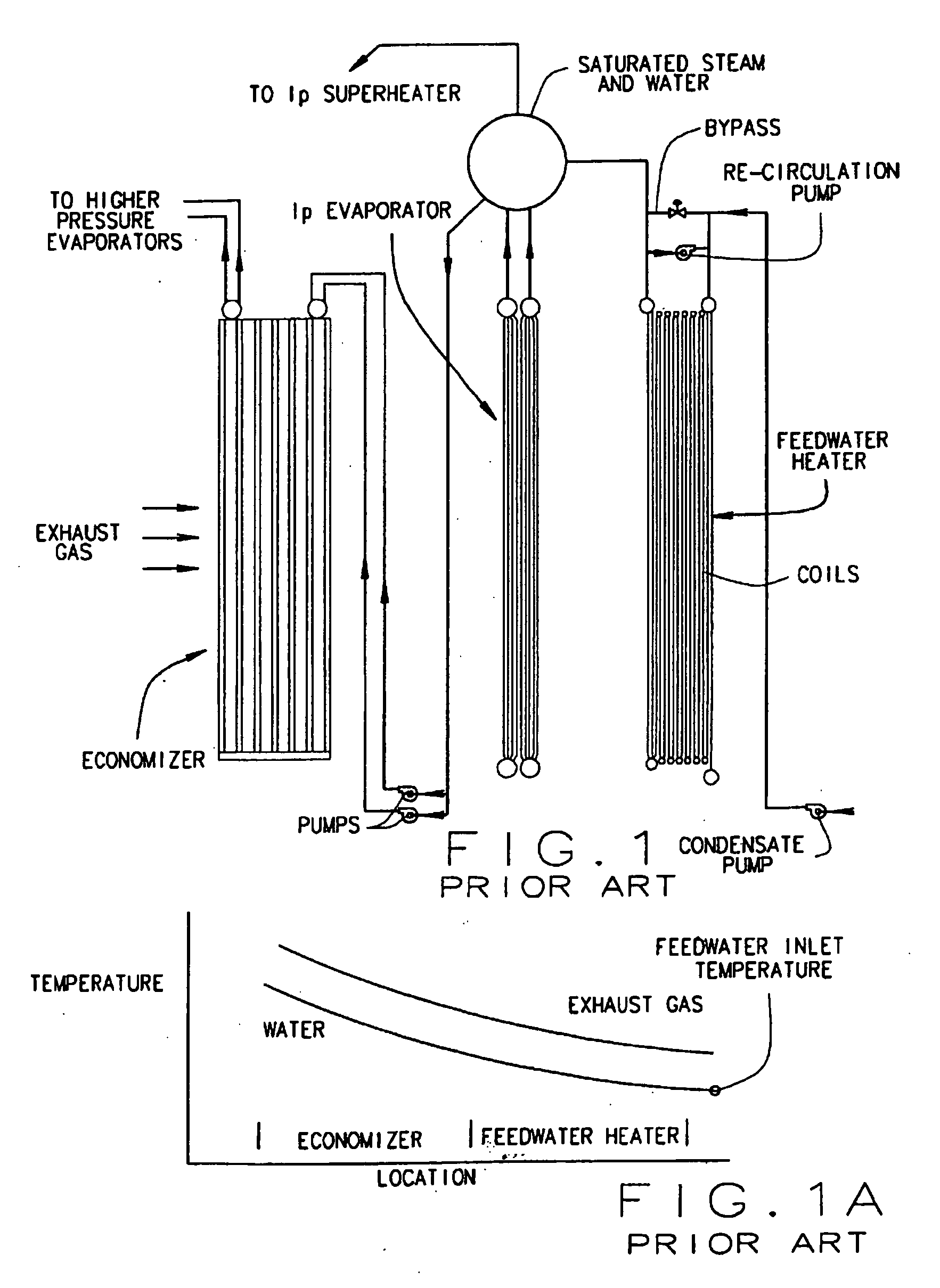

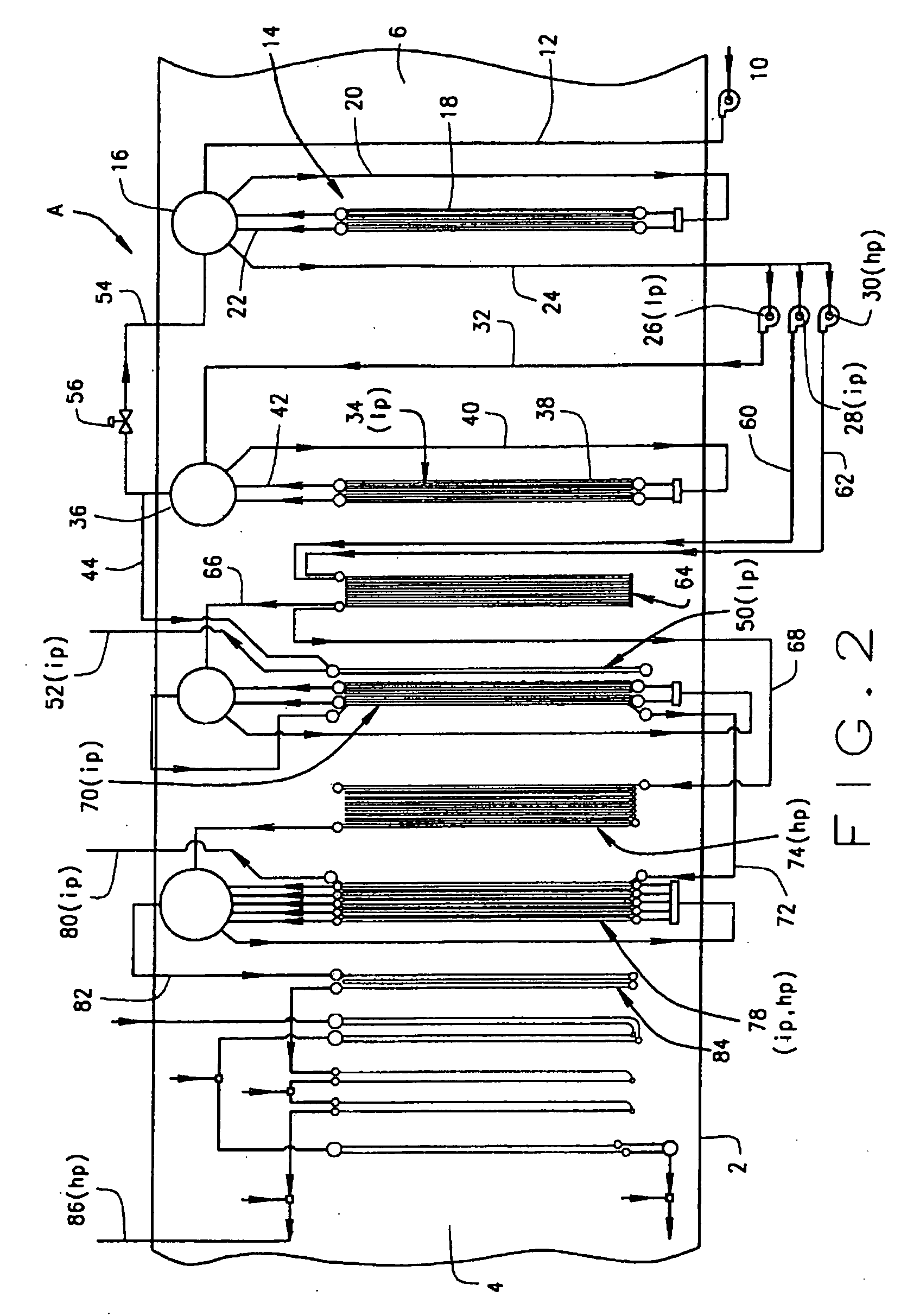

Process and apparatus for heating feedwater in a heat recovery steam generator

InactiveUS20120312019A1Steam generation heating methodsSteam accumulatorsCorrosive acidExhaust fumes

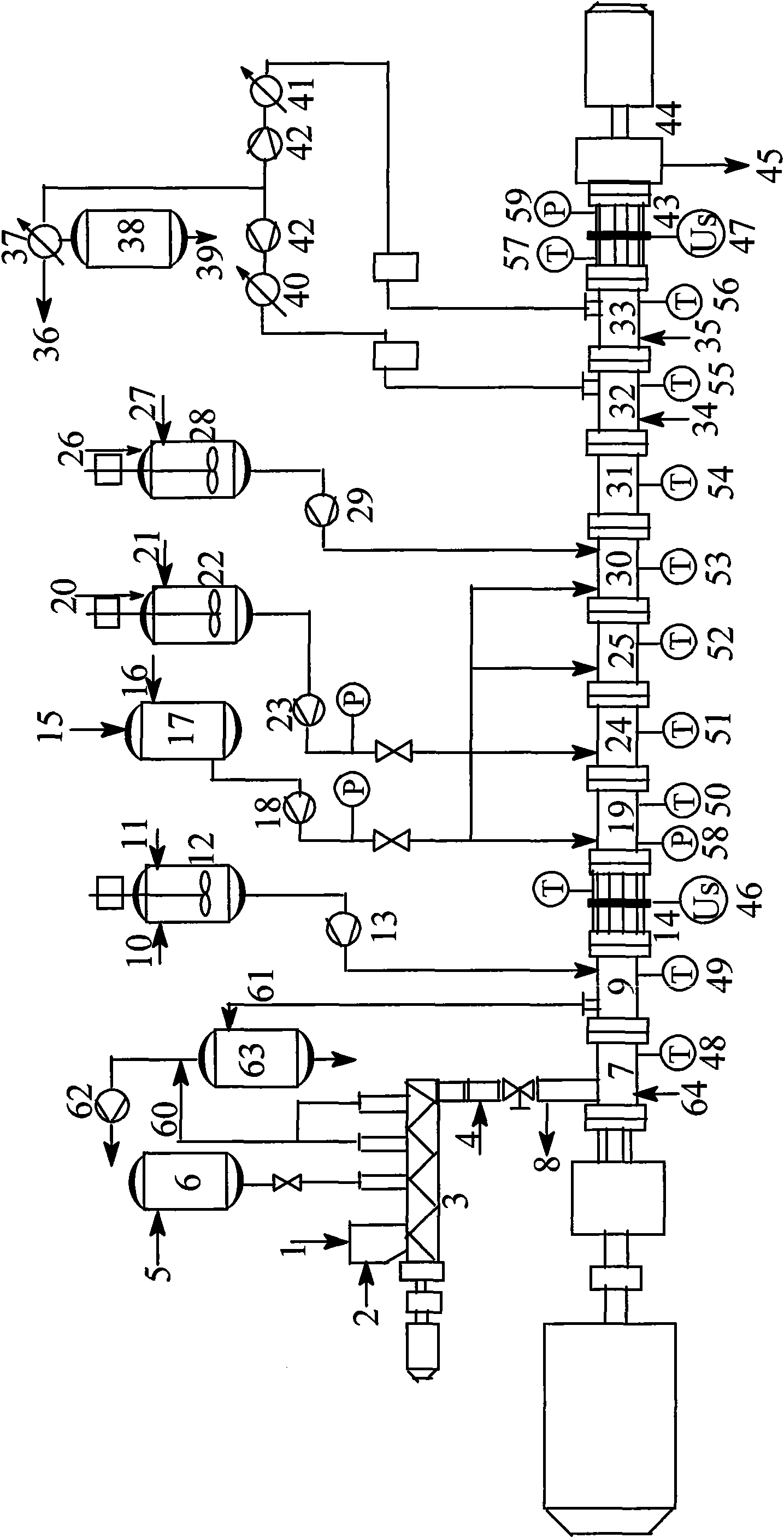

A feedwater heater (14) in a heat recovery steam generator (A,B) lies within a flow of hot exhaust gas. The feedwater heater (14) converts subcooled feedwater into saturated feedwater water, the temperature of which is only lightly above the acid dew point temperature of the exhaust gas so that corrosive acids do not condense on coils (18) of the feedwater heater (14). Yet the temperature of the saturated feedwater lies significantly below the temperature of the exhaust gas at the coils (18), so that the coils (18) operate efficiently and require minimal surface area. Pumps (26, 28, 30) elevate the pressure of the saturated feedwater and direct it into an economizer (64, 90) where, owing to the increase in pressure, the water is again subcooled. The economizer (64, 90) elevates the temperature still further and delivers the higher pressure feedwater to evaporators (34, 70, 78) that convert it into saturated steam that flows on to the superheaters (50, 78, 84). Higher pressure pegging stem admitted to the feedwater heater (14) controls the pressure—and temperature—of saturated steam and water in the feedwater heater (14).

Owner:NOOTER ERIKSEN INC

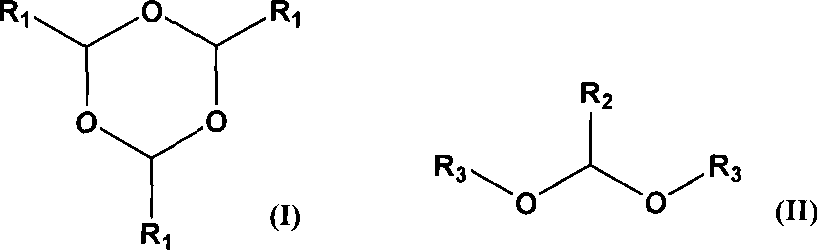

Method for preparing acetal compound by room-temperature ionic liquid catalyst

InactiveCN101544628AReduce pollutionEasy to manufactureOrganic chemistryOrganic compound preparationOrganic solventRoom temperature

The invention discloses a method for synthesizing an acetal compound by taking a room-temperature ionic liquid as a catalyst. The method comprises the following step: taking aldehyde or aldehyde-ethanol as a reactant, and synthesizing the acetal compound in the presence of no other organic solvent and dehydrating agent. Compared with the prior synthesizing method, the method has mild reaction conditions, does not use strongly corrosive acid, such as sulfuric acid, hydrochloric acid, and the like as catalyst, and does not use other organic solvent and dehydrating agent any longer. The method has the characteristics of simple operation, high catalytic activity, good selectivity, reusage, and the like. Thus, the method has good application prospect.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing silicon dioxide aerogel by normal pressure drying method using rice hull ash as raw material

A method for dry producing the silica dioxide aerogel from rice husk ash as raw material in atmosphere pressure, belongs to the technical field of chemical industry materials producing, which comprises the following steps: leaching the rice husk ash formed by rice husk burning in the inorganic strongly basic aqueous solution and inorganic corrosive acid neutralizing basic solution to get the silica dioxide hydrosol, treating the hydrosol with organo-silicon compound to get the hydrogel, then ageing, water scrubbing, replacing the moisture in hydrogel with a organic solvent, and drying in atmosphere pressure to get the silica dioxide aerogel with the specific surface area about 400-800 m.

Owner:TSINGHUA UNIV

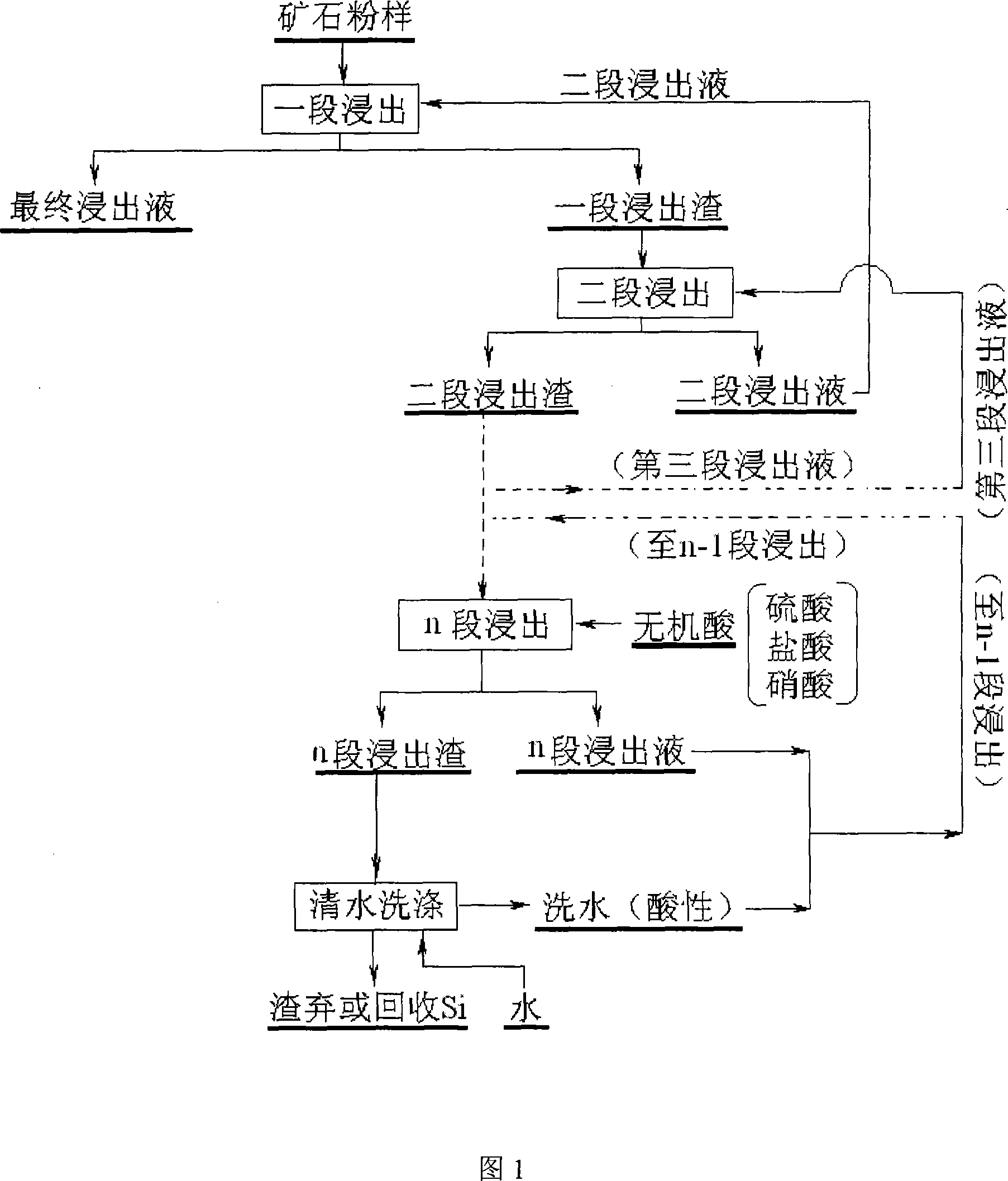

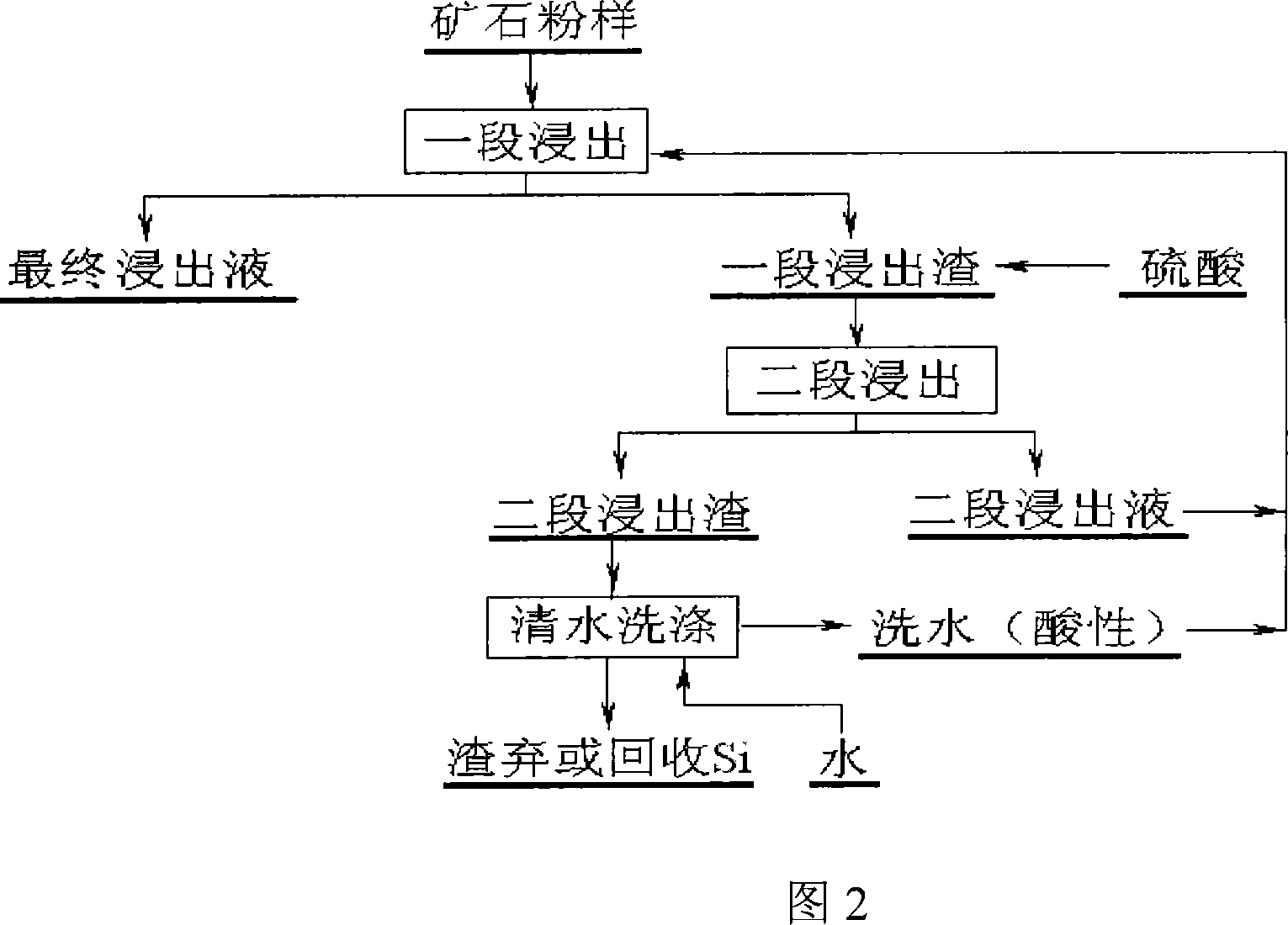

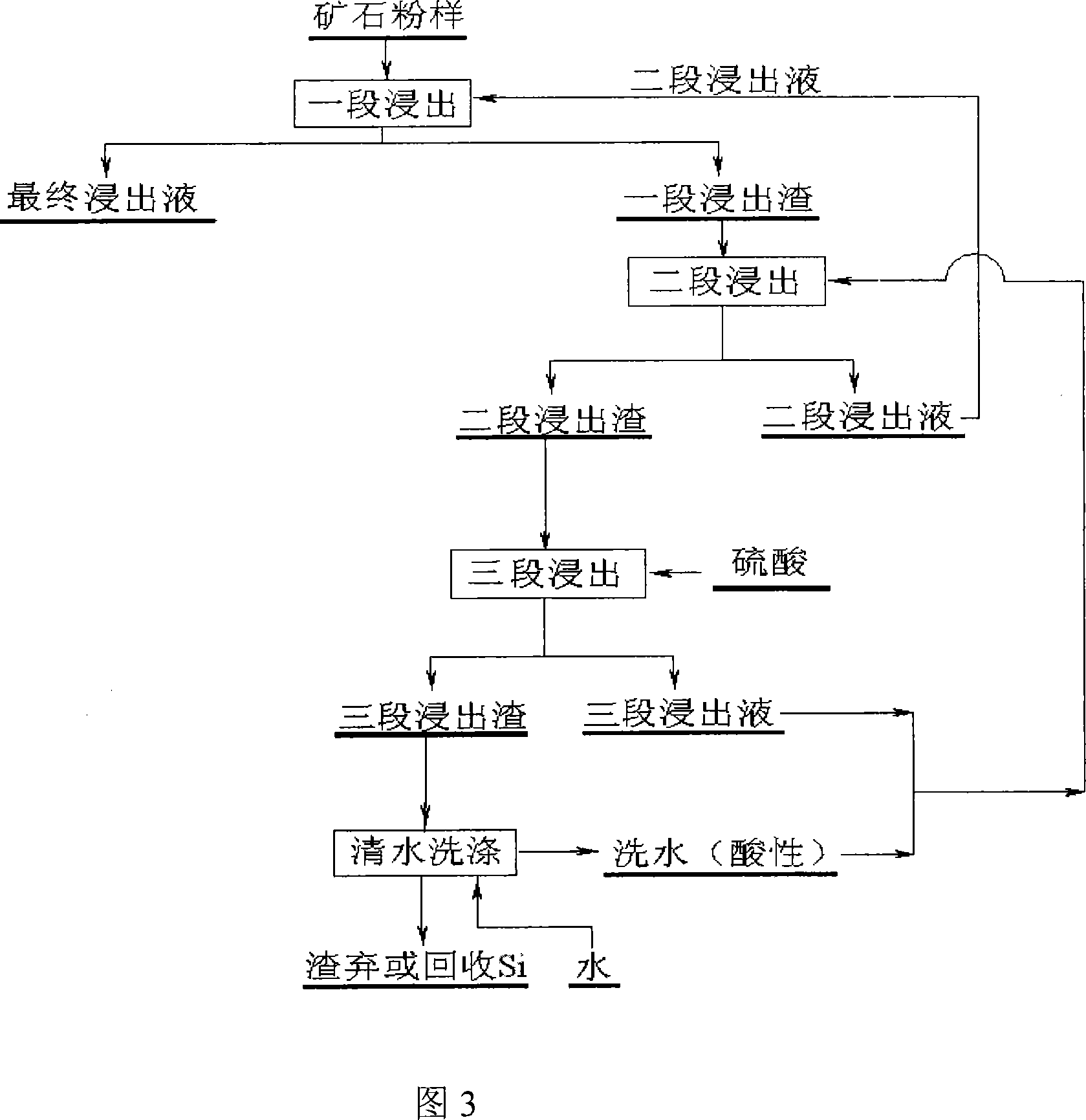

Multistage counter current acid leaching process containing nickel serpentine ore

InactiveCN101058852AReduce leachingReduce consumptionProcess efficiency improvementPregnant leach solutionReverse current

The invention discloses a nepouite with the multi-stage reverse-current acid-dipping technology, which comprises the following steps : grinding the nepouite; reacting with mixing the primary immersion liquid and water; reacting the leach residues a plurality of times endlessly; getting the K extract after finishing filtering the reaction of the k times; making the K extract liquor and the K extract react cyclically the k+1 times; regarding the k extract liquor as the extract liquor of the k-1 leaching reaction; regarding a corrosive acid as the extract liquor of the last leaching reaction; regarding the last extract liquor as a liquor containing Ni and Mg after n times reaction (k is between 1 and n and n is not less than 2). The invention reduces the cost, which recovers the Ni and Mg highly effectively.

Owner:CENT SOUTH UNIV

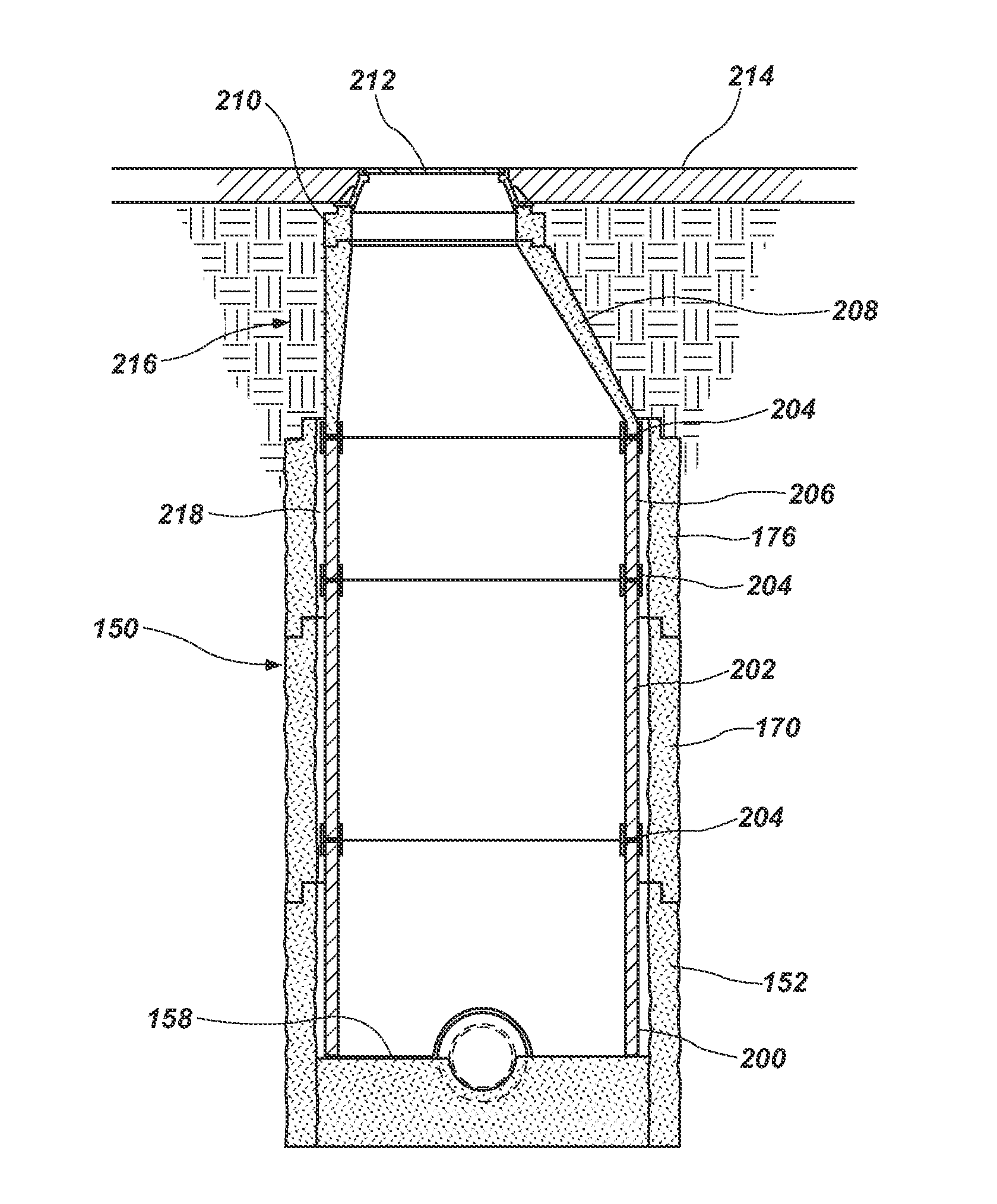

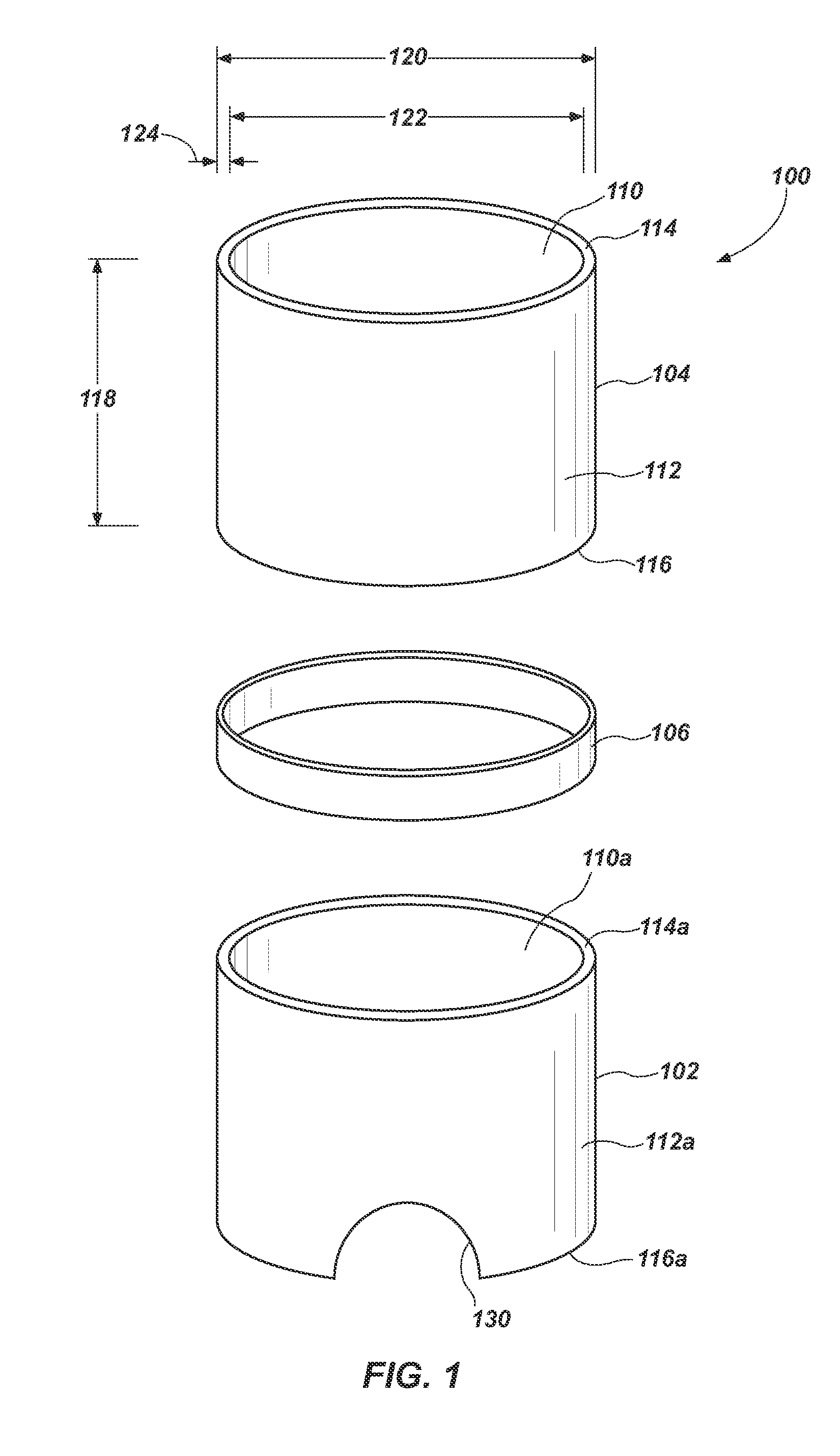

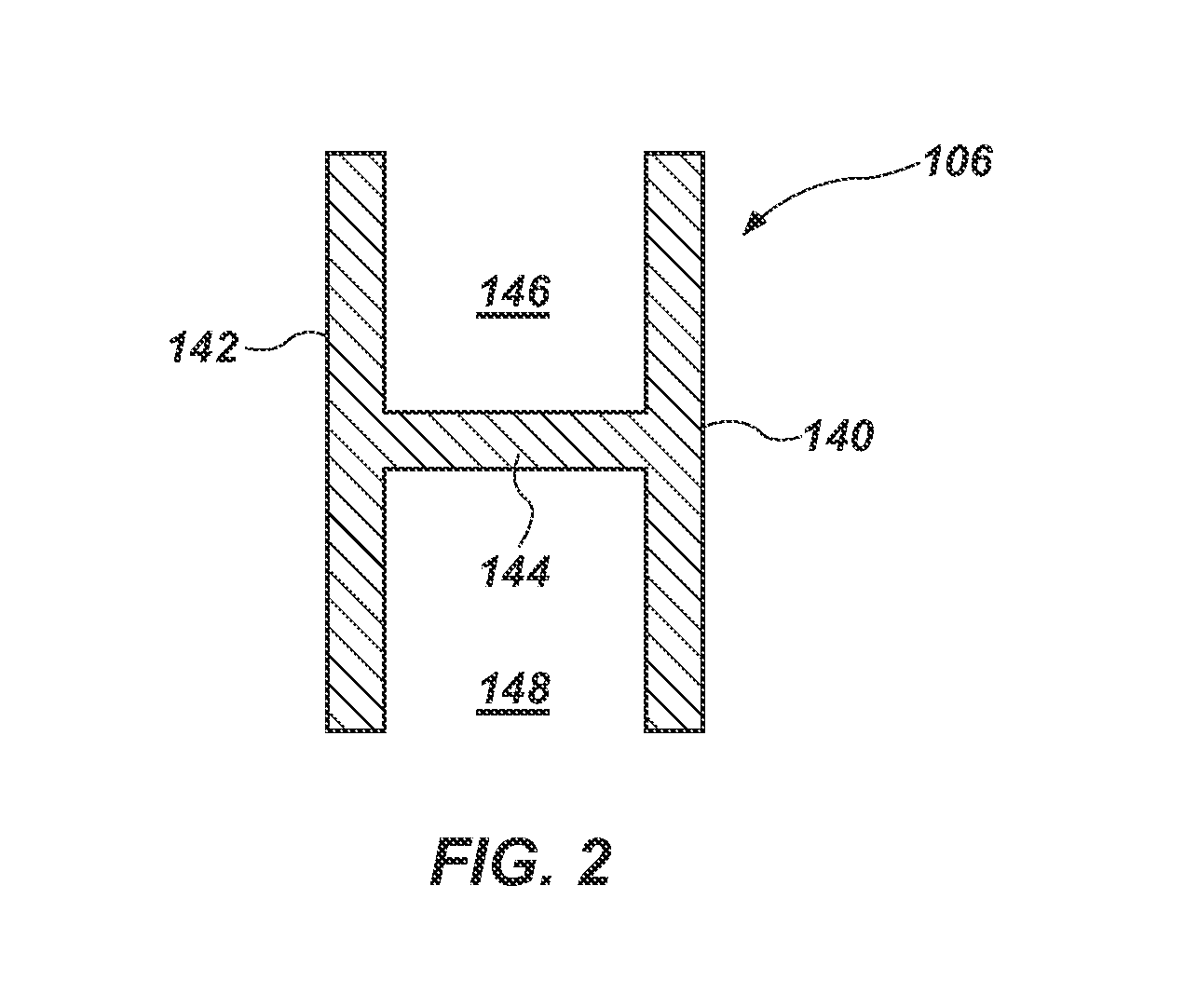

Rehabilitation of deteriorated manhole and other sewer structures

A new inner passageway through a pre-cast concrete structure damaged by corrosion may be formed by stackable inserts formed of polymer concrete. The inserts may be stacked in the old passageway through the pre-cast concrete structure such that an inner surface of the stacked inserts forms a new passageway through the pre-cast concrete structure. A grout may be poured between an outer surface of the stacked inserts and an inner surface of the pre-cast concrete structure forming the old passageway. The surfaces of the stackable inserts may have superior resistance to corrosive acids such that the need for future repair is greatly reduced. Suitable pre-cast concrete structures for rehabilitation include pre-cast concrete structures utilized in wastewater systems, including manholes and other similar structures. In this manner, the damaged pre-cast concrete structures do not need to be removed during the rehabilitation.

Owner:GENEVA POLYMER PROD

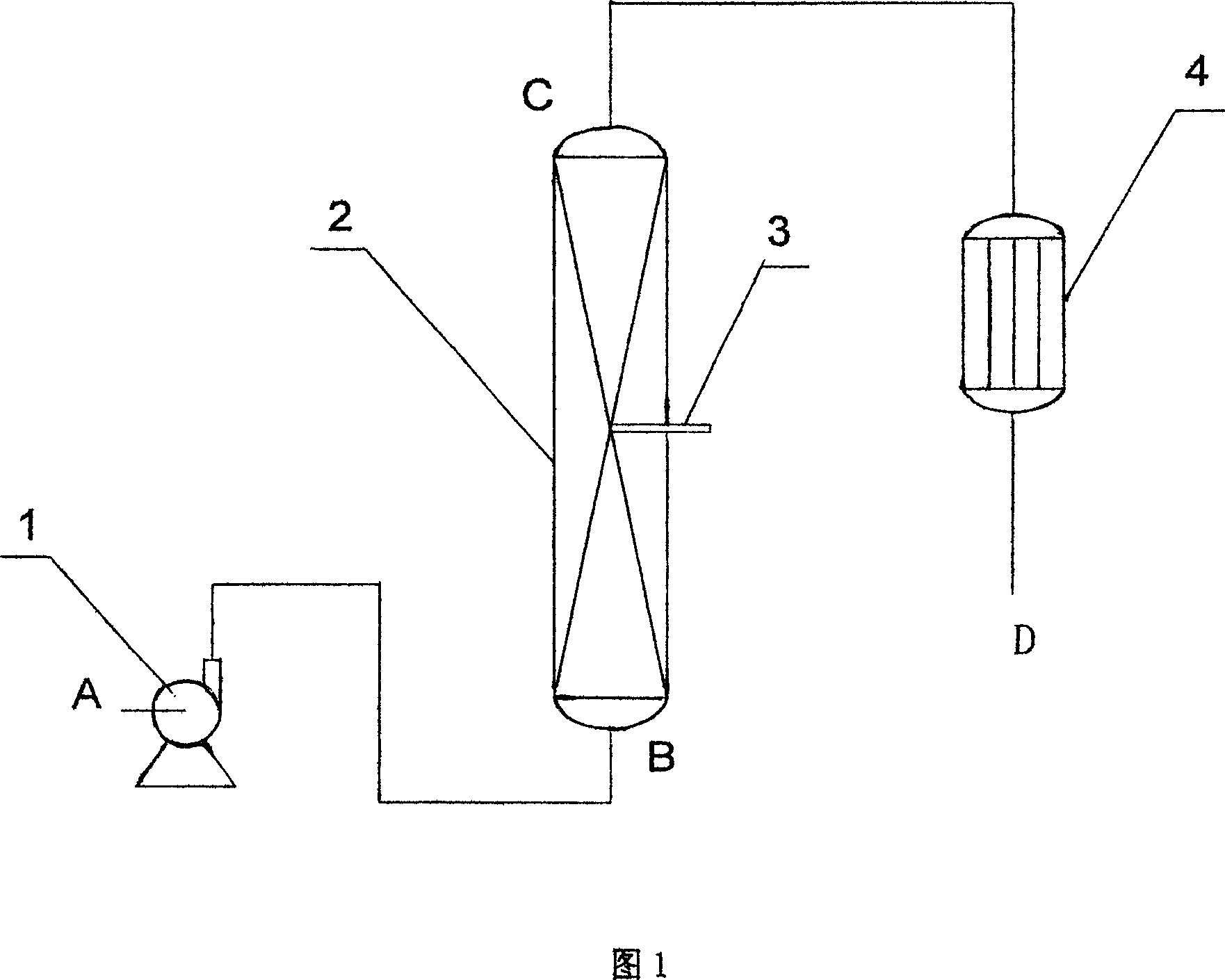

1-polyolefin halogenation production method

InactiveCN101671412AMeet the needs of halogenation reactionIncreased macroscopic reaction ratePolyolefinProcess equipment

The invention relates to a 1-polyolefin halogenation production method which is characterized in that continuous plastication (mixing), degasification, ultrasonic wave visbreaking, softening, multistage halogenation, neutralization and stabilization, devolatilization, ultrasonic wave temperature reduction and stripping and slicing measurement are realized in a sealing drying system in a double-screw extruder reactor to produce the halogenated polyolefin. Compared with the traditional process, the process flow is shortened by three fourth, which saves investment and energy power consumption; the halogen content of the halogenated polyolefin can be controlled, and does not contain corrosive acid gas, so that the equipment can not be corroded severely, is the modern green engineering, and canwidely replace the process equipment of the current halogenated polyolefin.

Owner:江苏圣杰实业有限公司

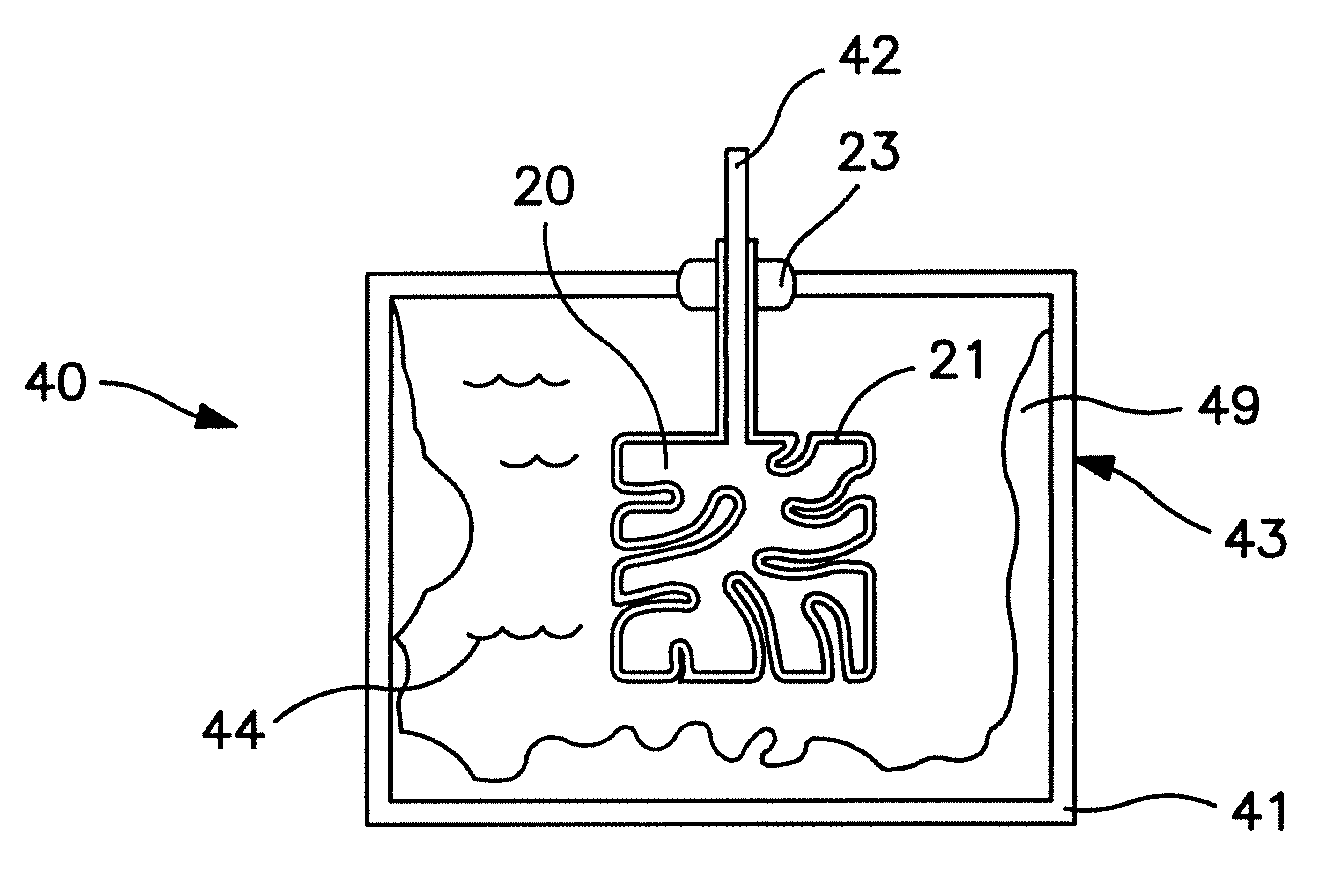

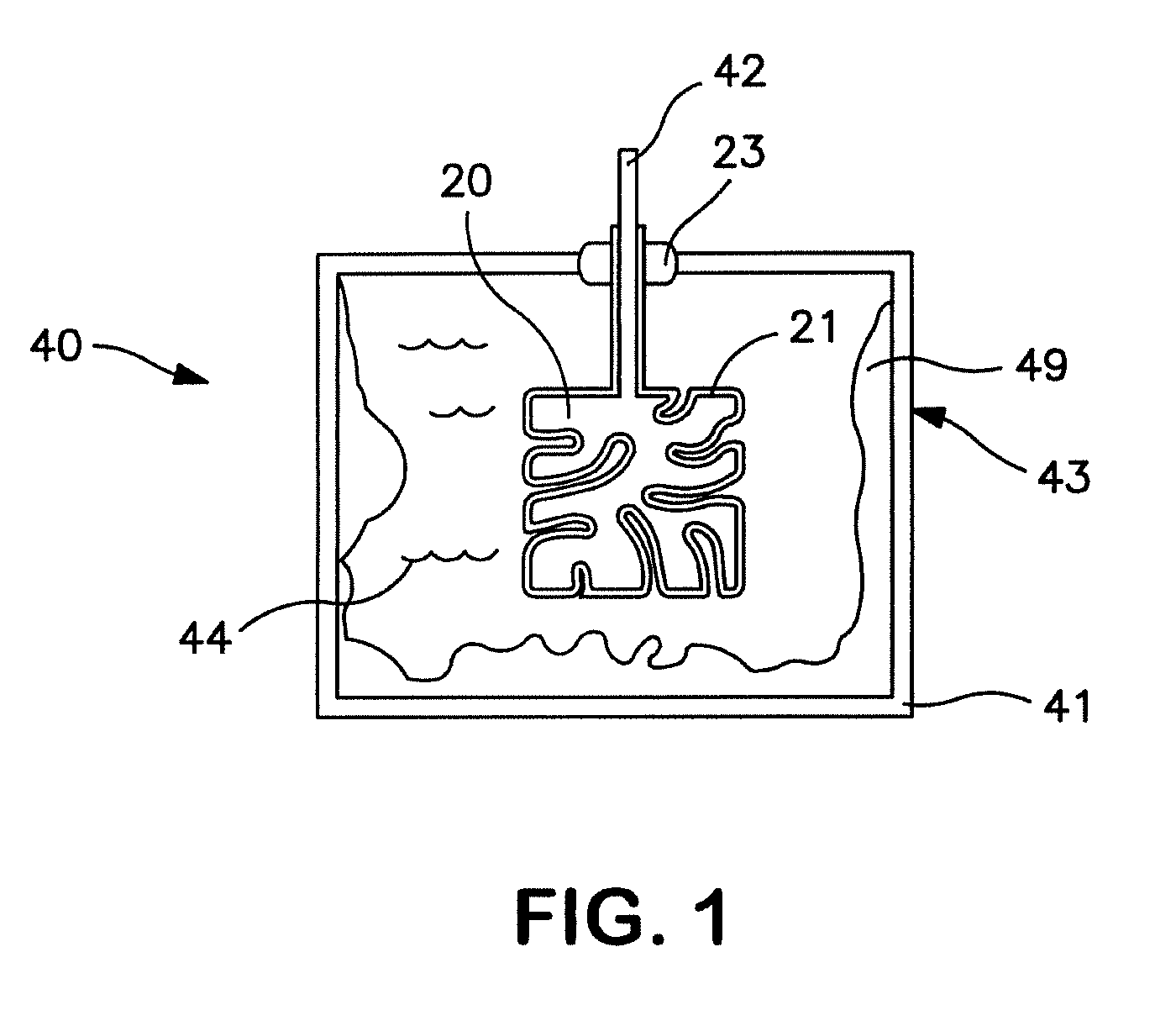

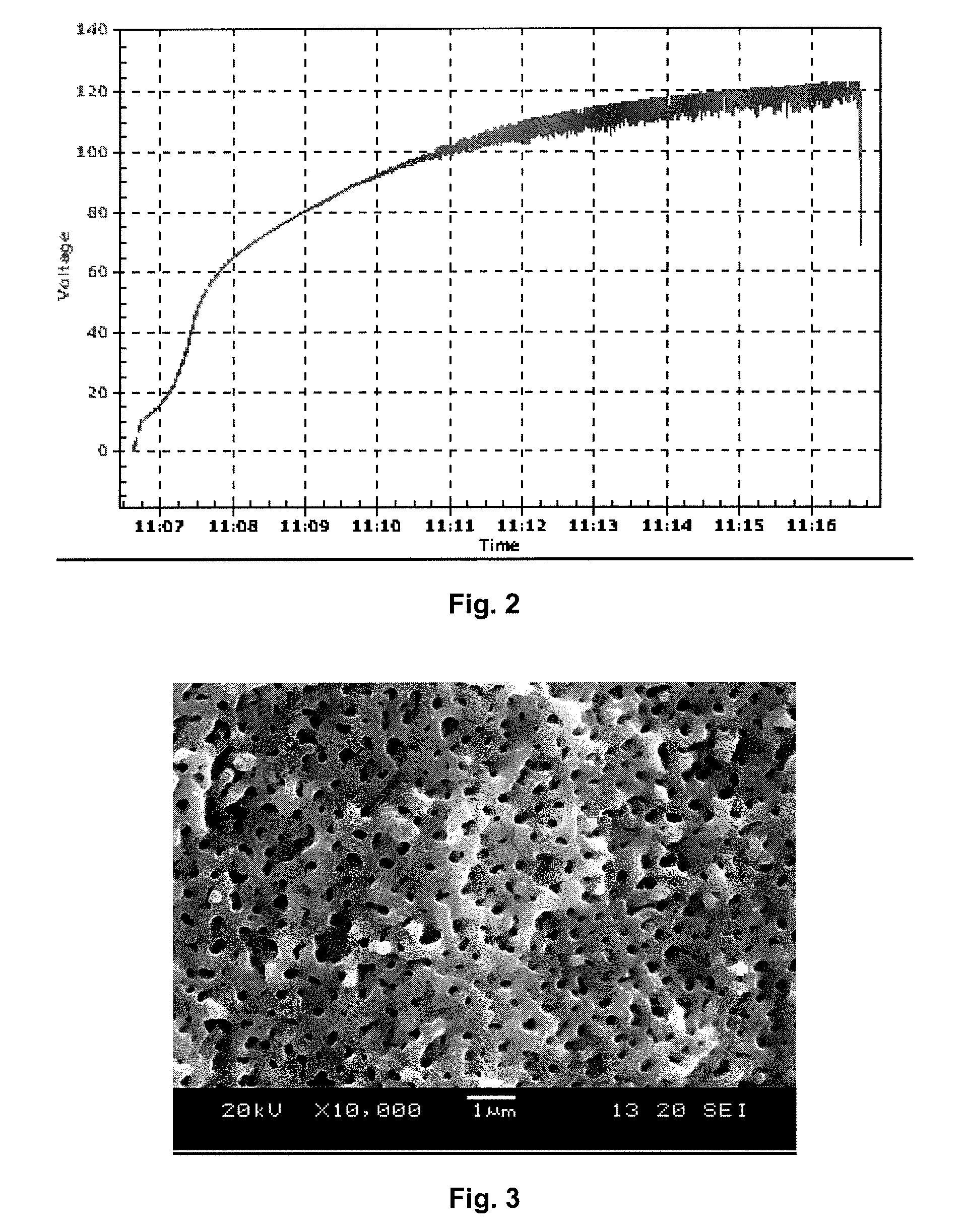

Substrate for use in wet capacitors

A porous substrate for use in a wide variety of applications, such as wet capacitors, is provided. The substrate is formed by subjecting a metal substrate to a voltage while in solution to initiate anodic formation of an oxide film. Contrary to conventional anodization processes, however, the newly created oxide quickly breaks down to once again expose the metal surface to the electrolytic solution. This may be accomplished in a variety of ways, such as by raising the voltage of the solution above a critical level known as the “breakdown voltage”, employing a corrosive acid in the solution that dissolves the oxide, etc. Regardless of the mechanism employed, the nearly simultaneous process of oxide growth / breakdown results in the formation of a structure having pores arranged at substantially regular intervals. The resulting structure is highly porous and can exhibit excellent adhesion to electrochemically-active materials and stability in aqueous electrolytes.

Owner:KYOCERA AVX COMPONENTS CORP

Substrate for Use in Wet Capacitors

ActiveUS20100067174A1Machining electrodesLiquid electrolytic capacitorsPorous substrateCritical level

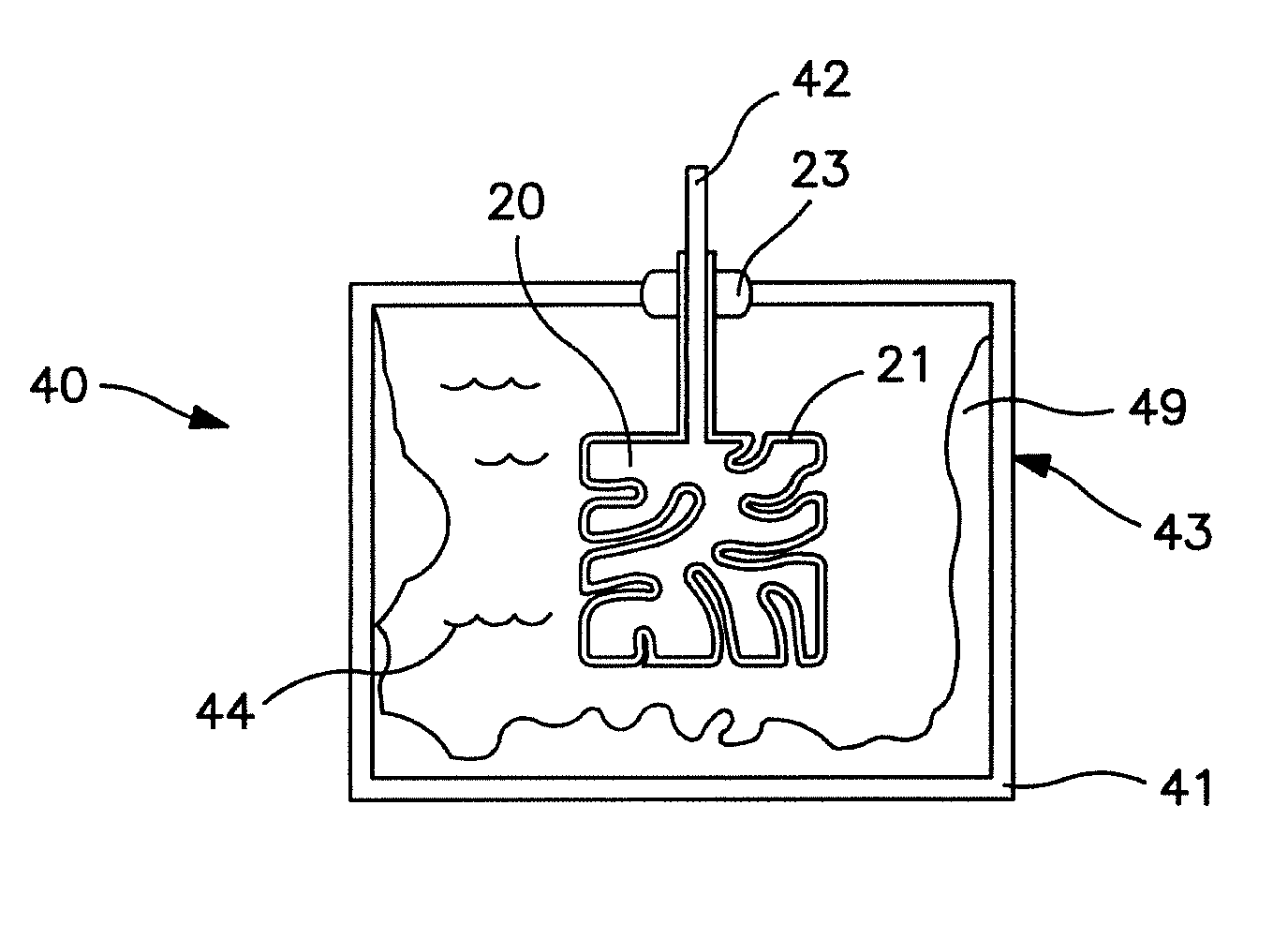

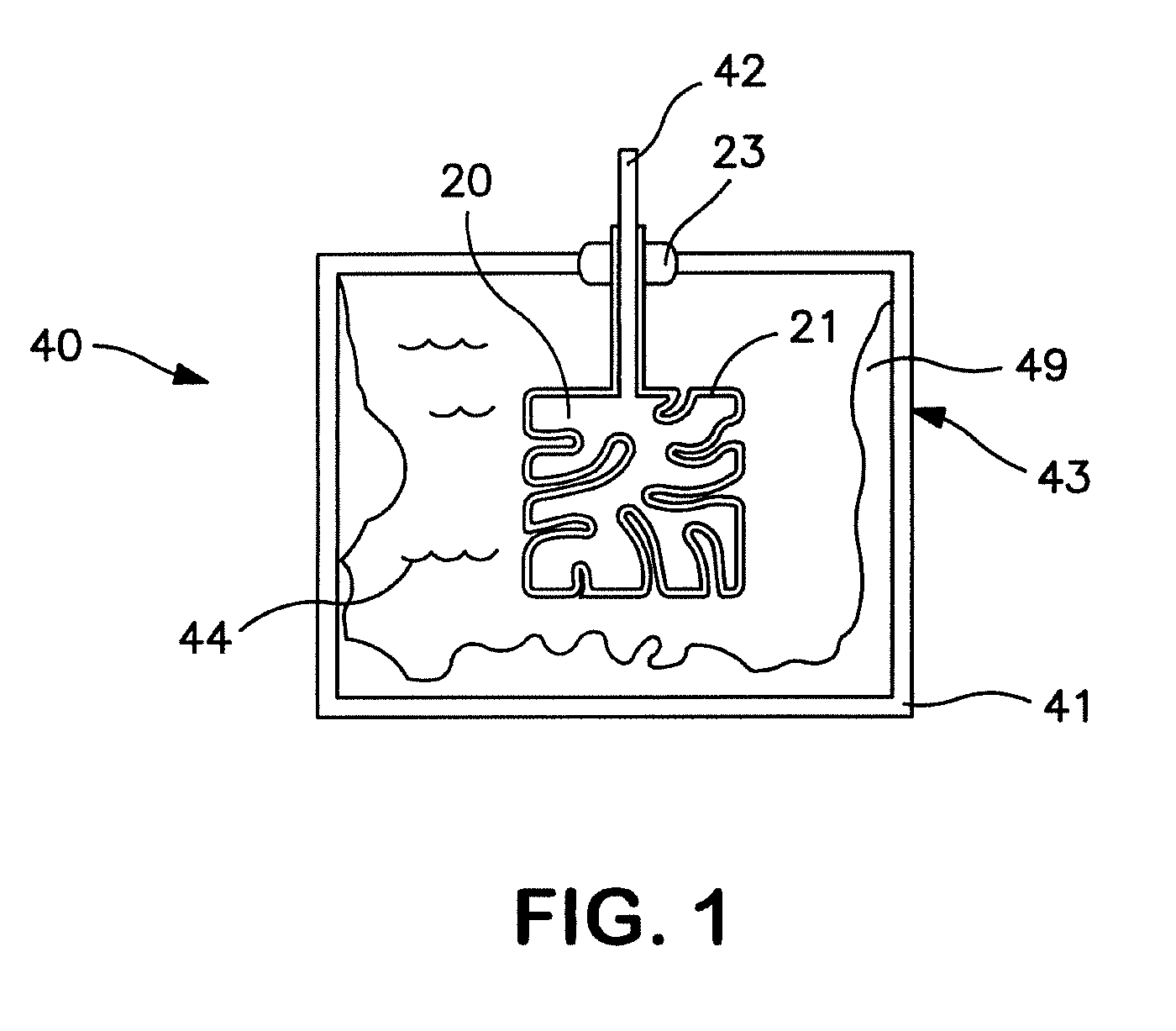

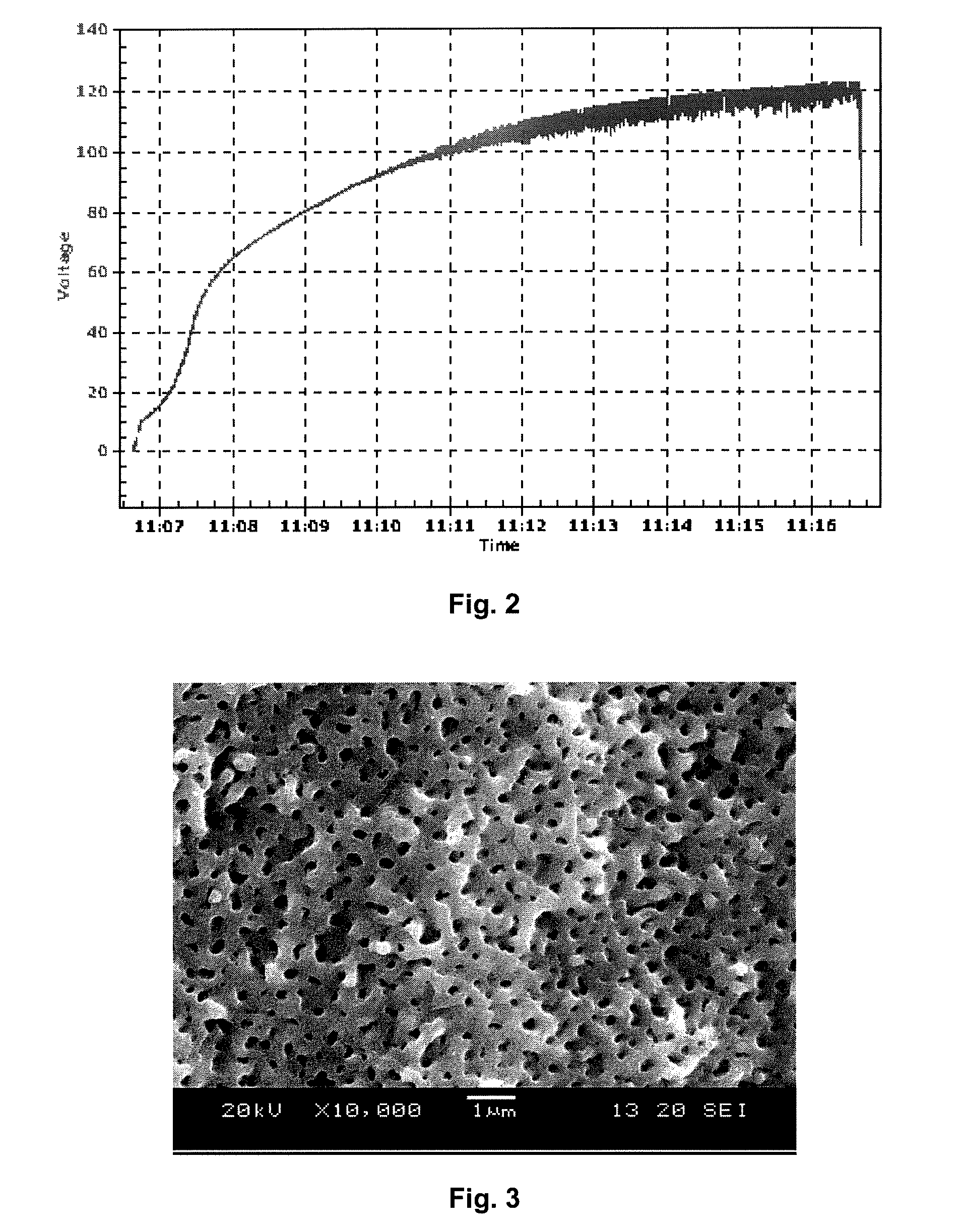

A porous substrate for use in a wide variety of applications, such as wet capacitors, is provided. The substrate is formed by subjecting a metal substrate to a voltage while in solution to initiate anodic formation of an oxide film. Contrary to conventional anodization processes, however, the newly created oxide quickly breaks down to once again expose the metal surface to the electrolytic solution. This may be accomplished in a variety of ways, such as by raising the voltage of the solution above a critical level known as the “breakdown voltage”, employing a corrosive acid in the solution that dissolves the oxide, etc. Regardless of the mechanism employed, the nearly simultaneous process of oxide growth / breakdown results in the formation of a structure having pores arranged at substantially regular intervals. The resulting structure is highly porous and can exhibit excellent adhesion to electrochemically-active materials and stability in aqueous electrolytes.

Owner:KYOCERA AVX COMPONENTS CORP

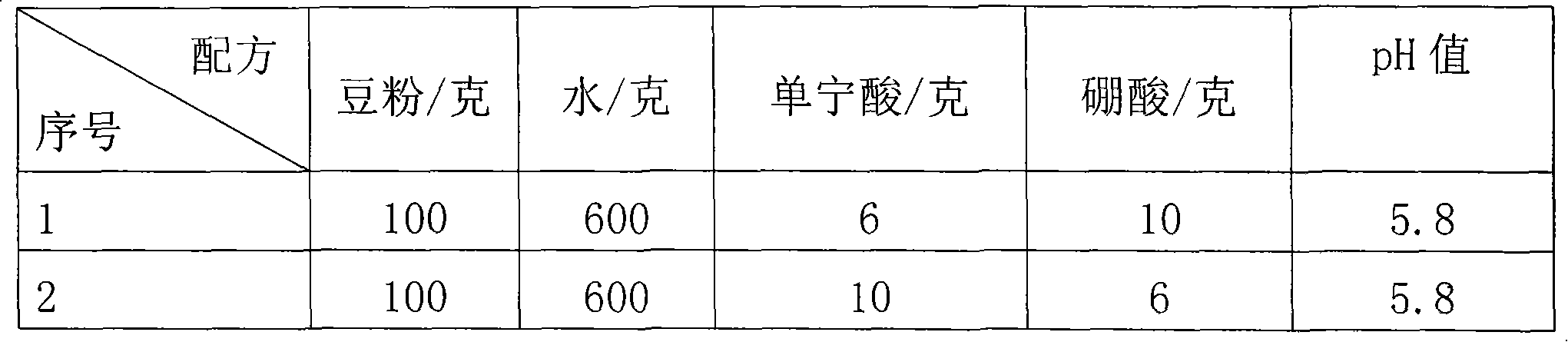

Tannic acid and boric acid modified bean powder adhesive and preparation method thereof

InactiveCN101126008AReduce acidityHigh bonding strengthNon-macromolecular adhesive additivesProtein adhesivesWater bathsCorrosive acid

A tannic acid and boric acid modified soybean flour adhesives and preparation method thereof relates to an adhesive and a preparation method thereof. The invention solves the problems in the prior art such as poor water resistance, high PH value and strongly corrosive acid. The compositions of the invention are made according to a weight proportion of 100 shares of soybean flour, 600 shares of water, 2 to 10 shares of tannic acid and 2 to 10 shares of boric acid. The preparation method comprises the steps that: the soybean flour is dissolved into the water at the temperature between 30 DEG C and 35 DEG C and then kept in a water bath at a temperature between 30 DEG C and 35 DEG C for 3 to 8 minutes; the soybean flour was mixed with the boric acid solution after the soybean flour is stirred for even mixture; at intervals of 10-20 minutes, the tannic acid solution is add and stirred until even mixture and subjects to a reaction for 10 to 20 minutes. Compared with the prior art, the PH value of the adhesive of the invention is low; thereby the stimulated corrosion towards the adhesive material and production workers is reduced and the bonding strength is improved. The soybean flour made by the invention is applicable to plywood production and other packaging materials. The invention has the advantages of releasing no formaldehyde, low corrosive acid, good water resistance, high bonding strength, and simple producing technique. The invention belongs to an environmental-friendly adhesive.

Owner:NORTHEAST FORESTRY UNIVERSITY

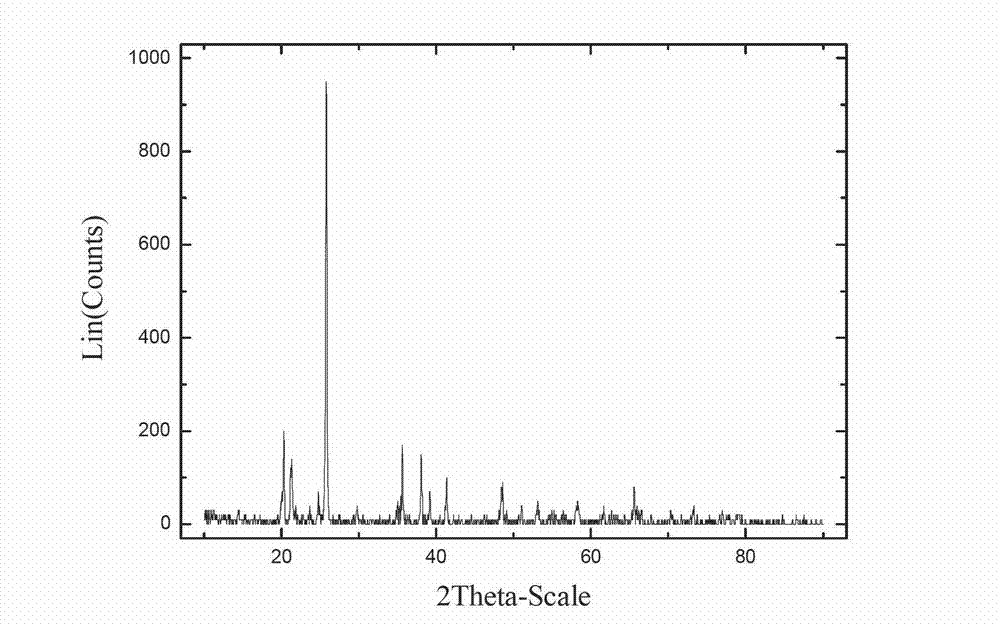

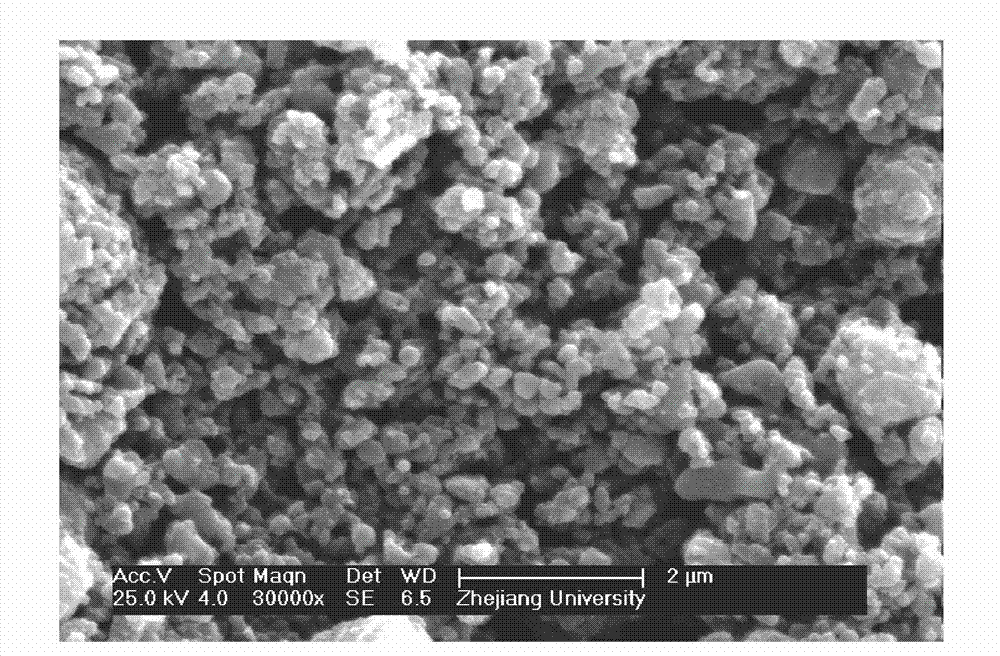

Novel process for preparing battery-grade iron phosphate material by using iron hydroxide

InactiveCN102897739ALow self-discharge rateReduced processing performancePhosphorus compoundsPhosphoric acidIndustrial scale

The invention discloses a novel process for preparing a low-cost battery-grade iron phosphate material by using iron hydroxide. The process comprises the following steps: mixing a zero-valent iron source and corrosive acid in a molar ratio, and adding a certain amount of primary water and ammonia water; stirring to react for 0 to 24 hours, and slowly adding hydrogen peroxide until the iron source disappears and the solution turns to orange; adding surfactant which is 1 to 5 percent that of the mass of the iron source into the solution; adding a reagent containing phosphate radicals into the solution according to a certain molar ratio of iron element to phosphor element under a stirring condition to obtain iron phosphate precipitate; filtering and washing the product 3 to 5 times with the primary water which is 3 to 7 times the weight of the iron phosphate; drying in vacuum for 4 to 12 hours at 50 and 80 DEG C to obtain FePO4.2H2O. The process for preparing battery grade iron phosphate is simple and easy to carry out and low in cost; and the prepared product has good product crystal structure, few impurities and uniform granularity and is suitable for industrial scale production; moreover, the lithium iron phosphate prepared by the process has high specific capacity, low self-discharge, high tap density, stable product performance and good processing performance.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +2

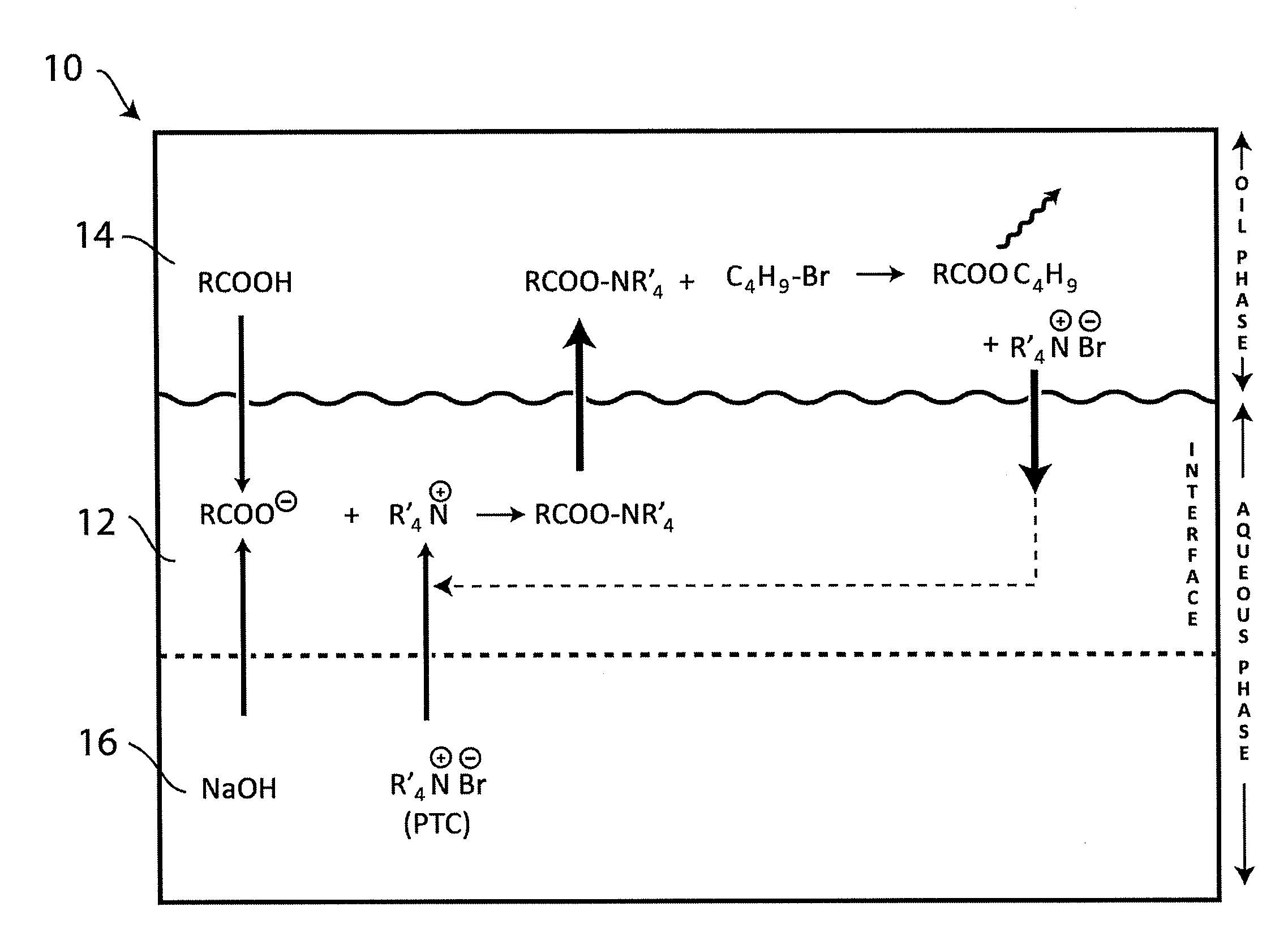

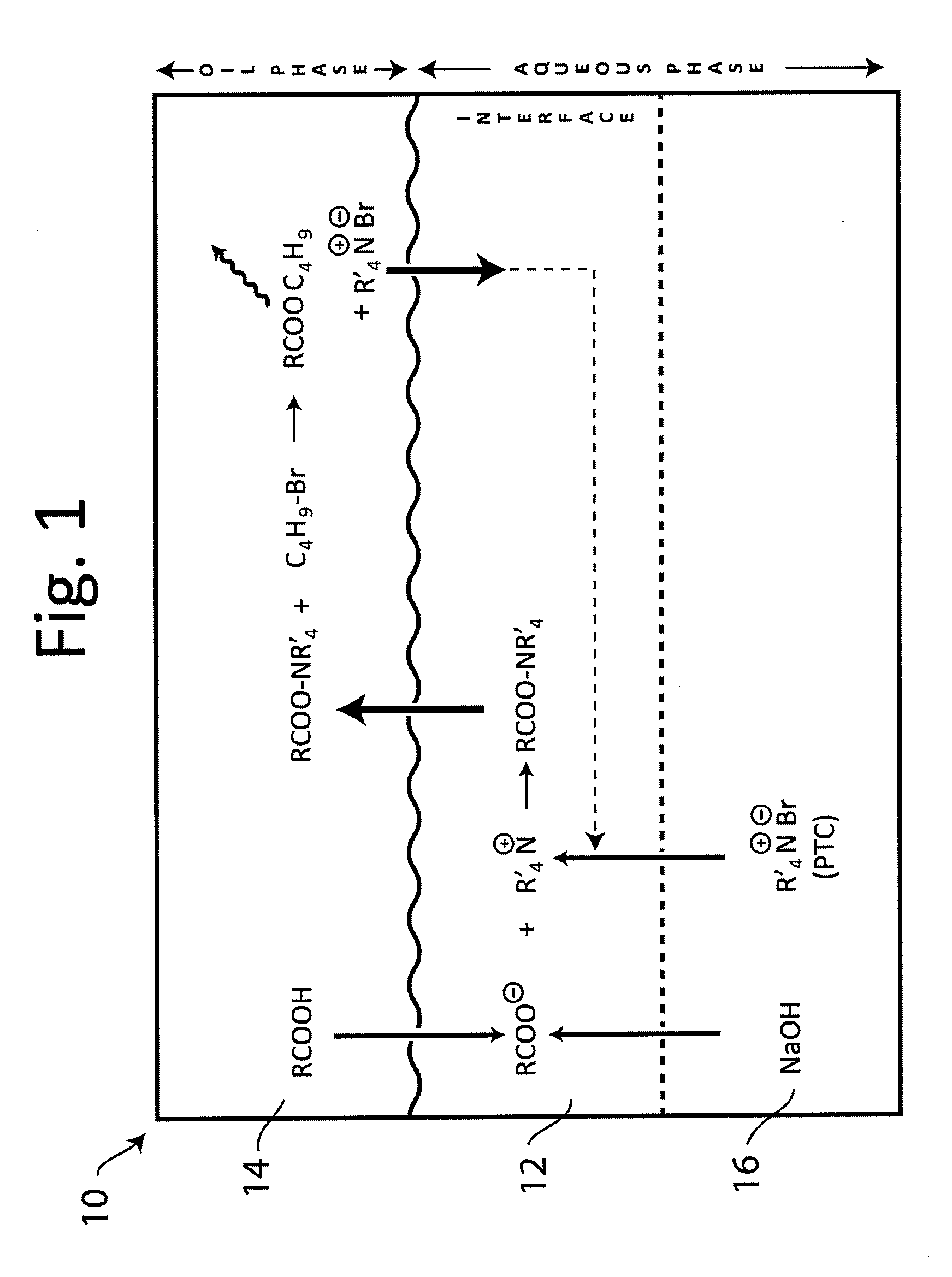

Treatment of hydrocarbons containing acids

InactiveUS20100155304A1Easy to operateMinimizes eliminates corrosionRefining with aqueous alkaline solutionsTreatment apparatus corrosion/fouling inhibitionLiquid hydrocarbonsCorrosive acid

The invention relates to a method of treating a liquid hydrocarbon (e.g. heavy oil, bitumen, etc.) containing naphthenic acids or other corrosive acids in order to partially or fully convert such acids into non-corrosive compounds. The method comprises adding an alkylating agent to the hydrocarbon, bringing the hydrocarbon into contact with an aqueous liquid containing an alkaline compound and a phase transfer catalyst to form an immiscible two-phase system, maintaining the contact to allow conversion of the naphthenic acids to non-corrosive oil-soluble esters, and separating the aqueous phase from the liquid hydrocarbon. Naphthenic acids are highly corrosive to plant and equipment and the method enables them to be converted to non-corrosive compounds in an economic manner.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

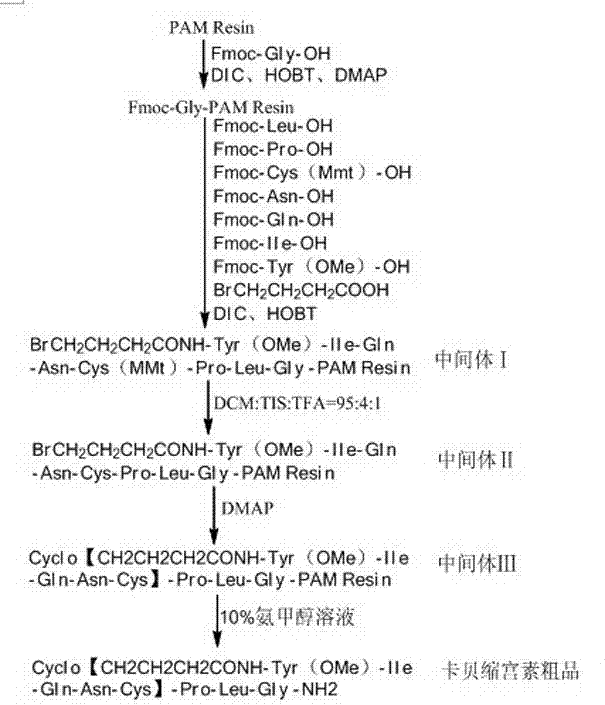

Method for preparing carbetocin

ActiveCN104262464AReduce usageLow costOxytocins/vasopressinsPeptide preparation methodsHigh concentrationFreeze-drying

The invention relates to a solid-phase synthesis method of carbetocin, which comprises the following steps: reacting a PAM (polyacrylamide) resin and Fmoc-Gly-OH to obtain an Fmoc-Gly-PAM resin; sequentially connecting amino acid with Fmoc protective group by solid-phase synthesis to obtain a BrCH2CH2CH2CONH-Tyr(OMe)-Ile-Gln-Asn-Cys(Mmt)-Pro-Leu-Gly-PAM resin; removing the Mmt protective group in the Cys; carrying out cyclization reaction by using DMAP (dimethylaminopyridine) as a cyclization reagent to obtain Cyclo[CH2CH2CH2CO-Tyr(OMe)-Ile-Gln-Asn-Cys]-Pro-Leu-Gly-PAM; carrying out ammonolysis on the cyclization product with an ammonia methanol solution to obtain a carbetocin crude product; and purifying and freeze-drying to obtain the carbetocin. The total yield is up to higher than 45%. Compared with the conventional preparation method, the method provided by the invention avoids using abundant high-concentration strongly-corrosive acid and flammable and explosive aether, has the advantages of high yield, low cost, mild reaction conditions and small environmental pollution, and is beneficial to industrialized production.

Owner:ZHEJIANG PEPTITES BIOTECH CO LTD

Composite function resin, preparation method thereof, and method for treating phthalate pollution of water body

InactiveCN101186719AEnhanced acidic hydrolysis catalytic activityImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionNitrobenzeneStrong acids

The invention discloses a complex function resin and process for preparation, and a method used for dealing with phthalate ester water body pollution. The process for preparation comprises the following procedures: swelling chlorine ball in the organic solvent; sulfonating in the mixing condition; getting the sulfonated chlorine ball after reacting; charging nitrobenzene or o-dichlorobenzene in order to swell in the air-tight condition after drying the sulfonated chorine ball; charging the accelerant in order to react; filtering the resin; washing the resin sequentially with distilled water, alcohol and chlorhydric acid 2%-5%; washing the resin with the distilled water until the washed water is neutral; getting the complex function resin. The specific surface area of the complex function resin is 900-1500m2 / g, the exchange capacity of corrosive acid is 2.1-5.5mmol / g, and the sulfonic group is distributed in the micropore section, the mesopore section and the big pore section of the resin. The complex function resin is applied to deal with water body polluted by phthalate ester. The invention solves the problem that the corrosive acid of the prior complex function resin is concentrated in the mescopore and the big pore of the resin and is distributed less in the micropore, which enhances the absorption effect of the resin for phthalate ester, and enhances the acid hydrolysis catalytic activity of the resin.

Owner:NANJING UNIV

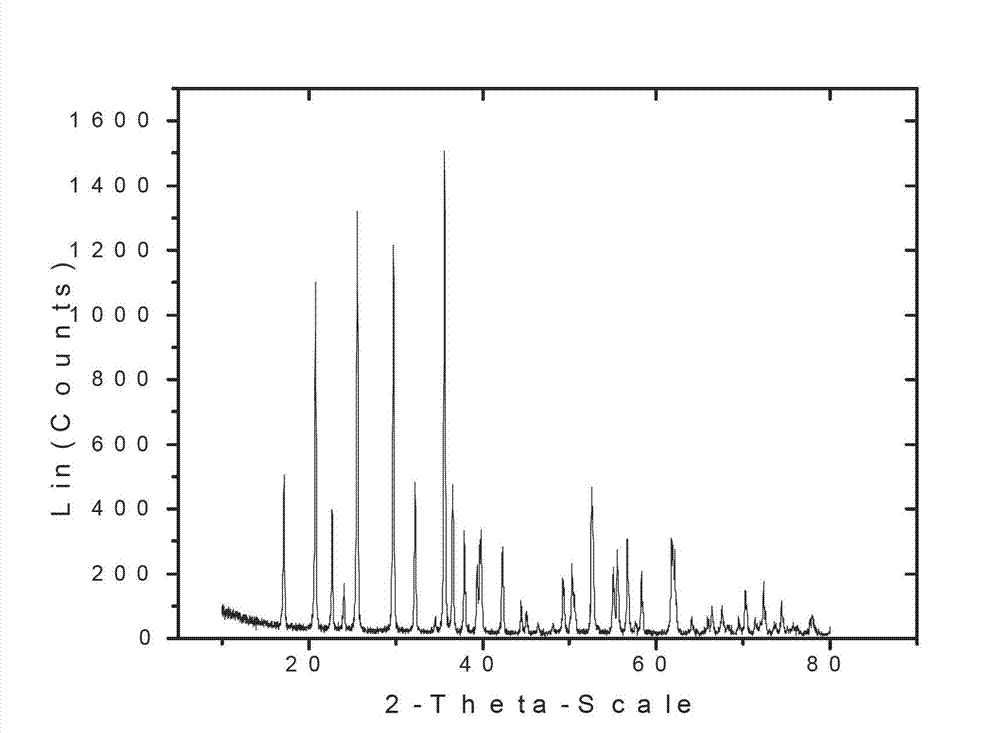

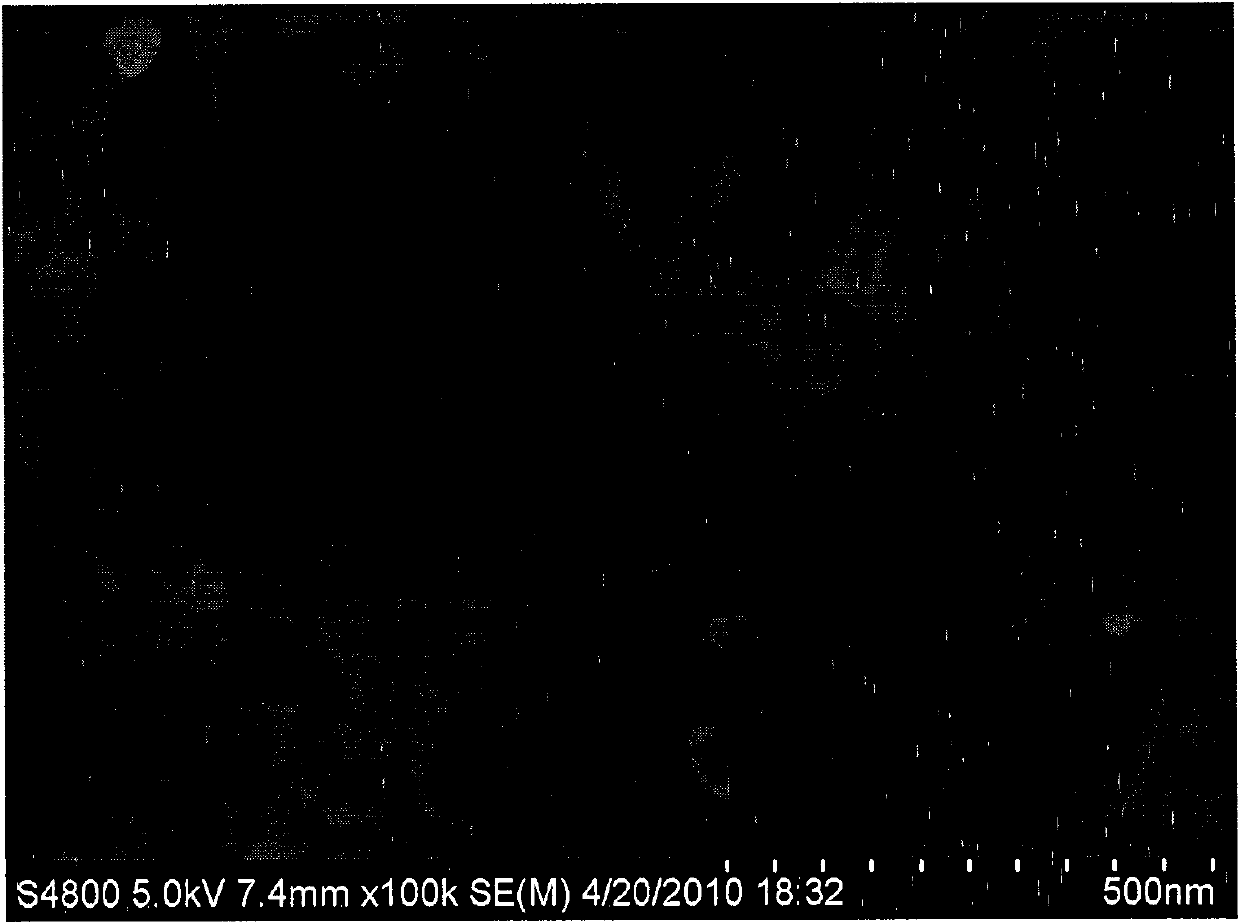

Ionic liquid solution for preparing nano-porous silver and using method thereof

The invention relates to ionic liquid solution for preparing nano-porous silver. In the ionic liquid solution, choline chloride-based ionic liquid is used as a solvent, and each liter of choline chloride-based ionic liquid comprises 0.001 to 0.1mol of AgCl. A method for preparing the nano-porous silver by using the solution comprises the following steps of: cleaning the surface of copper or a copper alloy serving as a substrate, soaking the substrate into the ionic liquid solution after drying, depositing at the temperature of between 20 and 100 DEG C to obtain the nano-porous silver on the surface of the substrate, cleaning with methanol and water in turn, drying and putting the substrate with the nano-porous silver on the surface into aqueous solution of FeCl3 to remove the substrate so as to obtain the narno-porous silver unsupported by the substrate. The ionic liquid solution has simple components and is convenient to prepare. The method for preparing the nano-porous silver by using the solution has the advantages of simple and controllable process, no need of strong corrosive acid and environmental friendliness by using the ionic liquid as an electrolyte solvent. The prepared nano-porous silver has the advantages of high purity and contribution to mass production.

Owner:ZHEJIANG UNIV

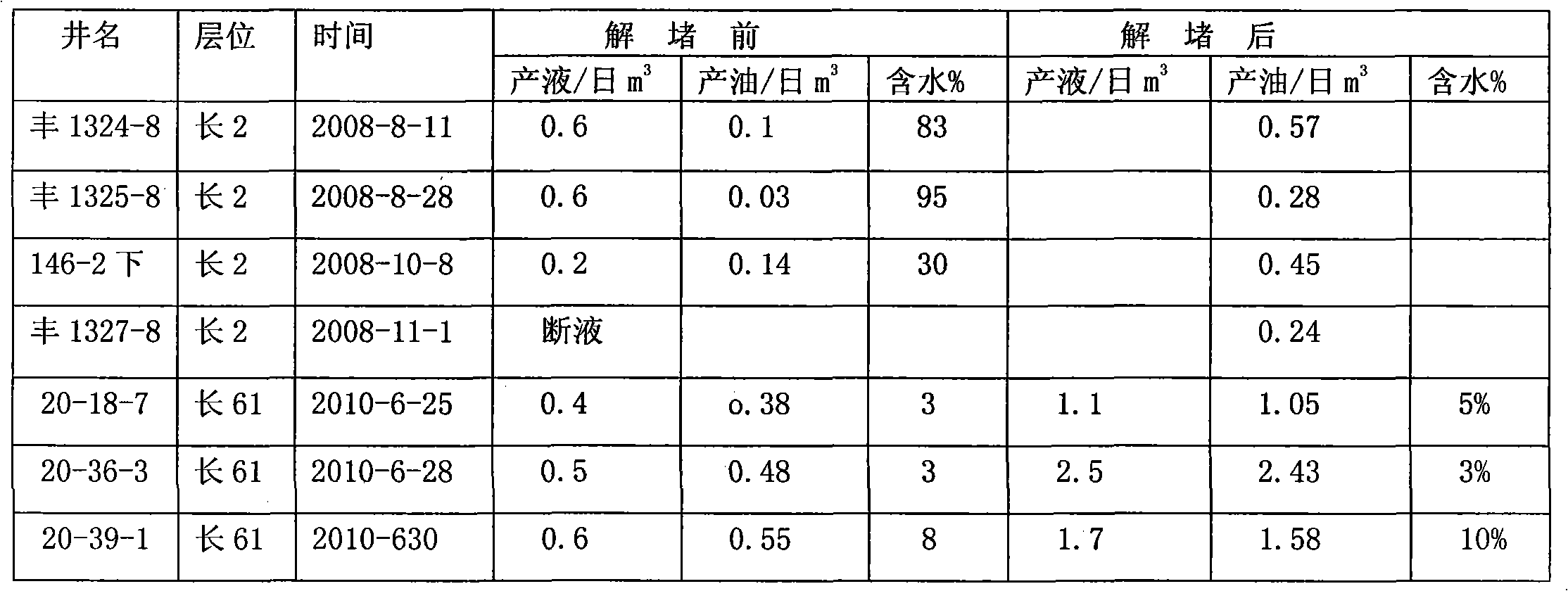

Environment-friendly composite blocking remover composition for oil fields

InactiveCN102399546ANo toxicitySection Tension ReductionDrilling compositionChlorine dioxideCorrosive acid

The invention discloses an environment-friendly composite blocking remover composition for oil fields, comprising 5-10 weight portions of surface active oil displacement agent, 6-11 weight portions of solid chlorine dioxide, and 4-8 weight portions of solid disinfection type activator. The composite blocking remover composition has the characteristics of cleaning and containing no corrosive acid,increases wetting and percolating capacity of the blocking remover, reduces the interfacial tension of the oil-water surface, increases the sweep capacity of the blocking remover, and has the advantages of high efficiency, safety and environmental protection.

Owner:SHAANXI HAIAN IND

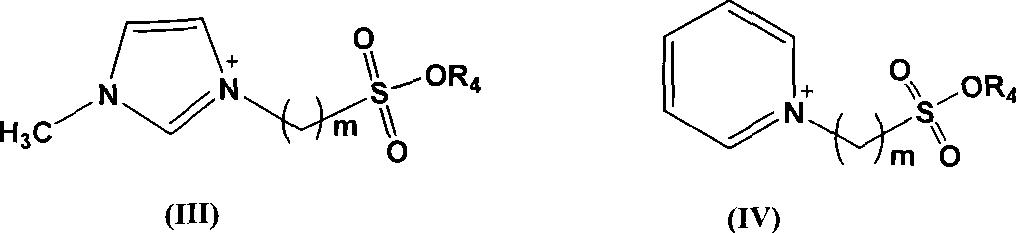

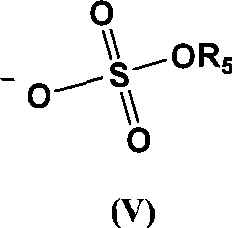

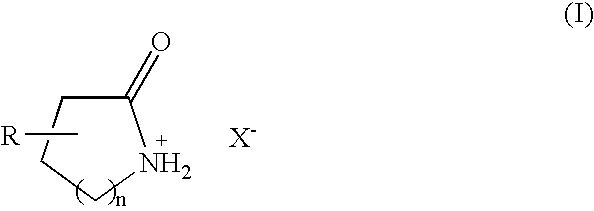

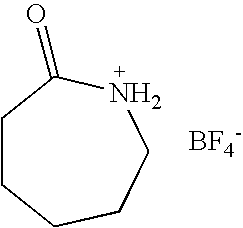

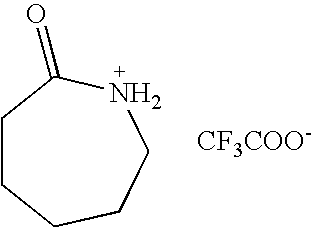

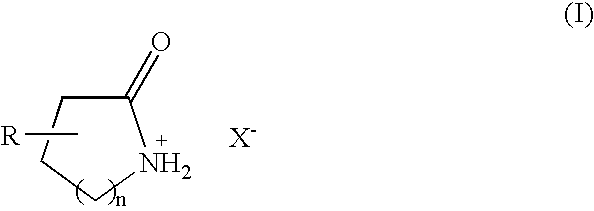

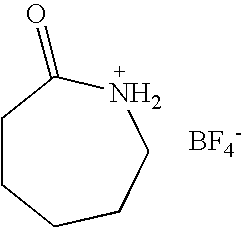

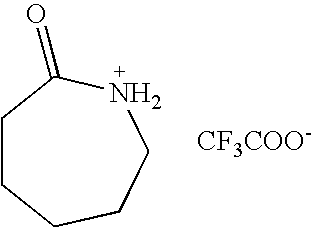

Bronsted acidic room temperature ionic liquids each having a N-protonated lactam cation and method for preparing the same

InactiveUS20070021604A1The material is lowLow raw material costOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsProtonationIonic liquid

The invention relates to a class of novel Brønsted acidic ionic liquids each having a lactam cation, and to a method for preparing the same through simple neutralization reaction of a lactam, which is available in large scale from industry, with a Brønsted inorganic or organic acid under room temperature. The properties of the lactam Brønsted acidic ionic liquids are as follows: they are water- and moisture-stable; they are more environmentally benign and lower cost than that of dialkylimidazolium salts; they have stronger Brønsted acidity and can be used as acidic catalysts and media instead of inorganic corrosive acids, such as concentrated sulfuric acid and hydrofluoric acid, in many acid-catalyzed reactions; and they can also be used as green media for extraction and separation.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Zirconium dioxide loaded microsphere type silica gel superstrong acid catalyst

InactiveCN1966151AImprove conversion rateNo emissionsOrganic compound preparationCarboxylic acid esters preparationProtonationMicrosphere

The invention relates to a ball silica gel solid corrosive acid catalyst which loads zirconia used in esterification and dehydration, wherein said silica gel solid corrosive acid has 1000 times protonation ability then dense sulfuric acid. And the ball silica gel solid corrosive acid uses porous ball silica gel as carrier, and absorbs zirconia and sulfuric acid in the inner hole of silica gel, with the properties of powder corrosive acid and the application in solid bed reactor, to process esterification at high pressure and temperature, to improve its transfer rate.

Owner:上海中远化工有限公司

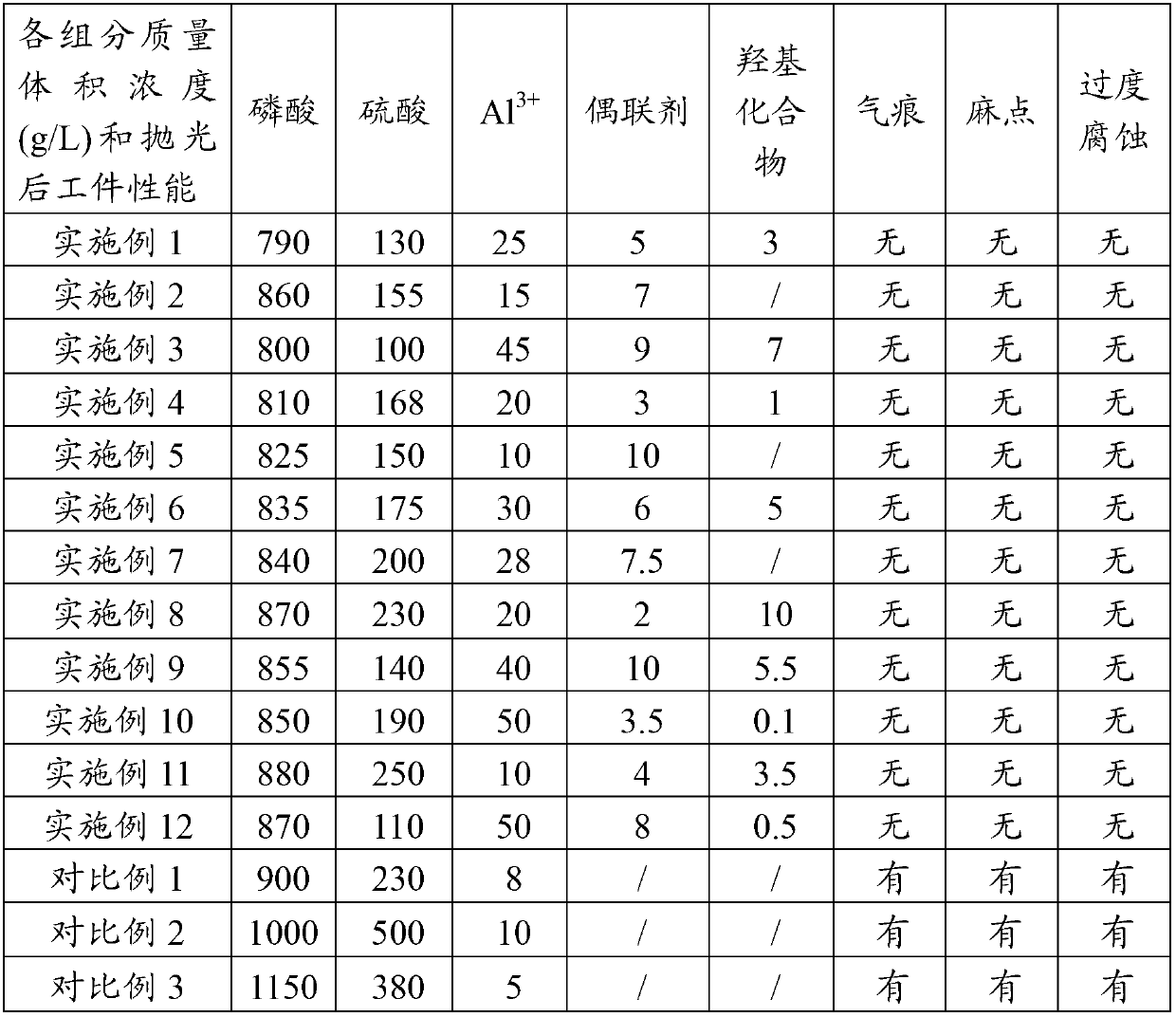

Chemical polishing agent

The invention discloses an aluminum alloy chemical polishing agent applicable to automatic production. The chemical polishing agent comprises aqueous solutions of the following substances: according to mass-volume concentration, 790g / L to 880g / L of phosphoric acids, 100g / L to 250g / L of sulfuric acids, 10g / L to 50g / L of aluminum ions and 2g / L to 10g / L of coupling agents. According to the chemical polishing agent, the proportion of the phosphoric acids and the sulfuric acids is adjusted, and aluminum ions are further added, so that the corrosion of the polishing agent is reduced. The viscosity of the polishing agent is added by the adding of the coupling agents, so that the flow speed of gas released in the polishing process is changed, and the gas cannot leave gas marks on workpieces after the polishing; besides, as the coupling agents can be attached onto the workpiece surface, a layer of protection film is formed between highly corrosive acids and alloy surfaces, so that excessive corrosion caused by the continuous reaction of workpieces after the workpieces leave polishing grooves (during the slow transfer of the automatic production) is avoided, and further, the production stability is guaranteed, and requirements of automatic production is met.

Owner:广州波耳化工科技有限公司

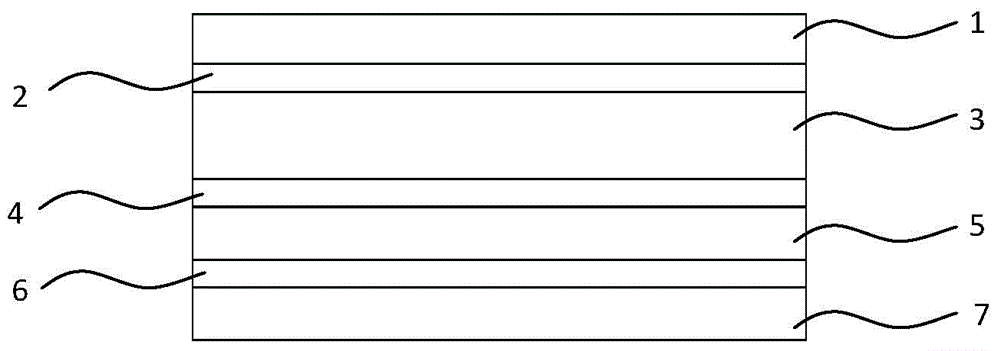

Functional composite packaging aluminum plastic film for lithium battery

InactiveCN104966800AImprove barrier propertiesCorrosion resistanceCell component detailsMetal layered productsWater vaporFluoropolymer

The invention relates to a functional composite packaging aluminum plastic film for a lithium battery. The functional composite packaging aluminum plastic film comprises a modified polypropylene layer, a nanopartice layer, a first binder layer, a fluorocarbon coating layer, an aluminum foil layer, a second binder layer and a nylon layer, wherein the aluminum plastic film is formed by sequentially laminating the modified polypropylene layer, the nanopartice layer, the first binder layer, the fluorocarbon coating layer, the aluminum foil layer, the second binder layer and the nylon layer from inside to outside. According to the functional composite packaging aluminum plastic film disclosed by the invention, due to the fact that the nanoparticle layer with high water absorptivity is added, the condition that water vapor enters into electrolyte to generate corrosive acids such as hydrofluoric acid and other gases can be effectively inhibited, and further the comprehensive barrier property of the aluminum plastic film is improved; besides, an inner layer of an aluminum foil in the aluminum plastic film is coated with fluorocarbon coating, so that the corrosion of the electrolyte to the aluminum foil can be effectively resisted, and the corrosion resisting property of the aluminum foil is enhanced. The functional composite packaging aluminum plastic film disclosed by the invention is produced by adopting a multilayer bonding and laminating composite technique, is simple in processing and easy to implement, and has excellent barrier property, heat sealing property, extending property and corrosion resisting property.

Owner:浙江锂盾储能材料技术有限公司

Brønsted acidic room temperature ionic liquids each having a N-protonated lactam cation and method for preparing the same

InactiveUS7220869B2The material is lowLow raw material costOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsHydrofluoric acidOrganic acid

The invention relates to a class of novel Brønsted acidic ionic liquids each having a lactam cation, and to a method for preparing the same through simple neutralization reaction of a lactam, which is available in large scale from industry, with a Brønsted inorganic or organic acid under room temperature. The properties of the lactam Brønsted acidic ionic liquids are as follows: they are water- and moisture-stable; they are more environmentally benign and lower cost than that of dialkylimidazolium salts; they have stronger Brønsted acidity and can be used as acidic catalysts and media instead of inorganic corrosive acids, such as concentrated sulfuric acid and hydrofluoric acid, in many acid-catalyzed reactions; and they can also be used as green media for extraction and separation.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

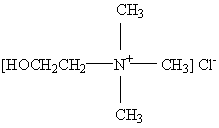

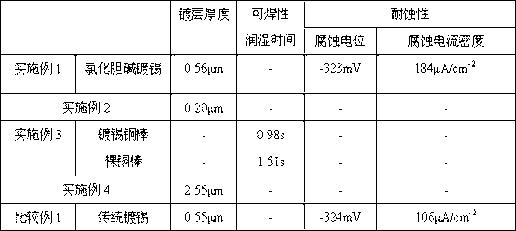

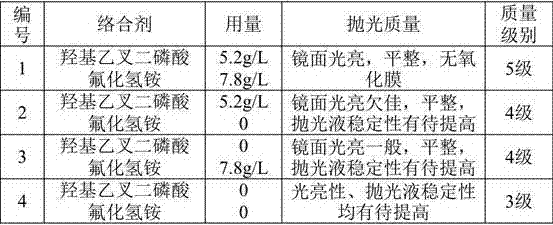

Choline-chloride-based chemical tinning solution and application method thereof

InactiveCN102797001ALow costImprove wettabilityLiquid/solution decomposition chemical coatingTinningCorrosive acid

The invention discloses a choline-chloride-based chemical tinning solution and an application method thereof, belonging to the technical field of tinning. The choline-chloride-based chemical tinning solution comprises choline chloride, water, 5-40g / L tin salt, 50-150g / L complexing agent and a right amount of acidity regulator, wherein the mol ratio of choline chloride to water is 1:2-1:8. The invention also discloses a tinning technique based on the chemical tinning solution, which comprises the following steps: 1) pretreating a copper workpiece to be plated; 2) putting the pretreated copper workpiece into the choline chloride chemical tinning solution to carry out tinning; and 3) drying the tinned workpiece, and inspecting the finished product. The choline chloride chemical tinning water solution disclosed by the invention has the advantages of simple formula and components, high preparation convenience and easily operated technique, does not need strongly-corrosive acid, and can implement continuous deposition.

Owner:CHANGZHOU UNIV +1

Preparation method of lubricating oil detergent

ActiveCN103265995AExcellent detergency and dispersibilityStrong ability to neutralize corrosive acidsAdditivesSolventTemperature treatment

The invention discloses lubricating oil detergent and a preparation method thereof. The detergent is prepared from the following raw materials in parts by weight: 1 part of linoleic acid, 1-2 parts of neutral oil, 1-6 parts of calcium hydroxide, 0.2-1 part of calcium oxide, 0-0.1 part of calcium chloride, 3-10 parts of solvent, 0.2-1 part of methanol, 0.1-0.5 part of water and 0.1-0.4 part of carbon dioxide. The preparation method of the lubricating oil detergent comprises the following steps of: a high-alkalinity reaction, a neutralization reaction and the like. The lubricating oil detergent disclosed by the invention has better detergency and dispersibility and strong corrosive acid neutralization capacity, and is uniform in calcium carbonate grain size distribution. In the whole reaction process, the preparation and treatment process is simple, free of a high-temperature treatment process and easy to realize on the device. Moreover, most of the materials are regenerative, higher in biodegradability and capable of satisfying the green and environmentally-friendly requirements.

Owner:江苏德锐润滑油有限公司

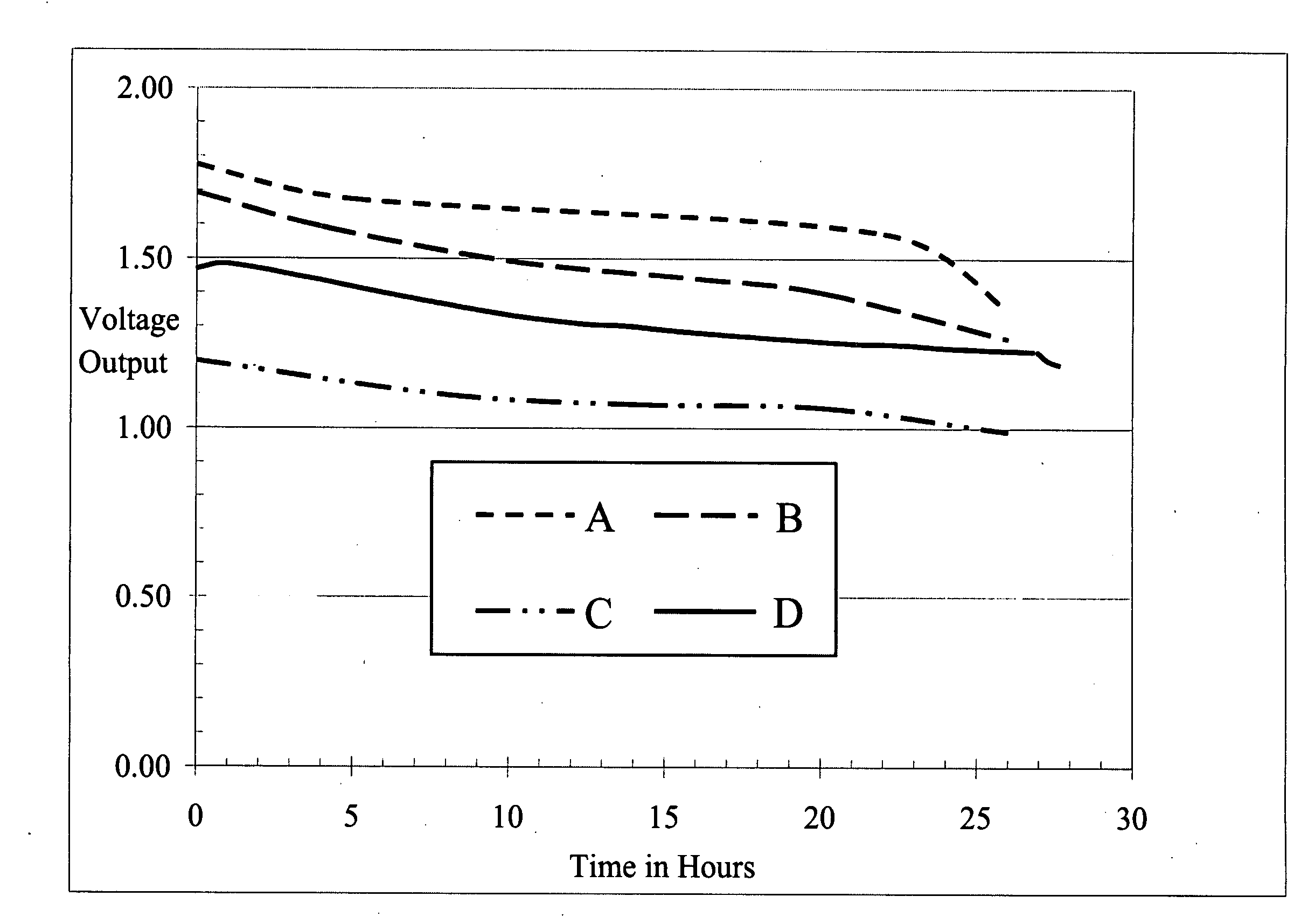

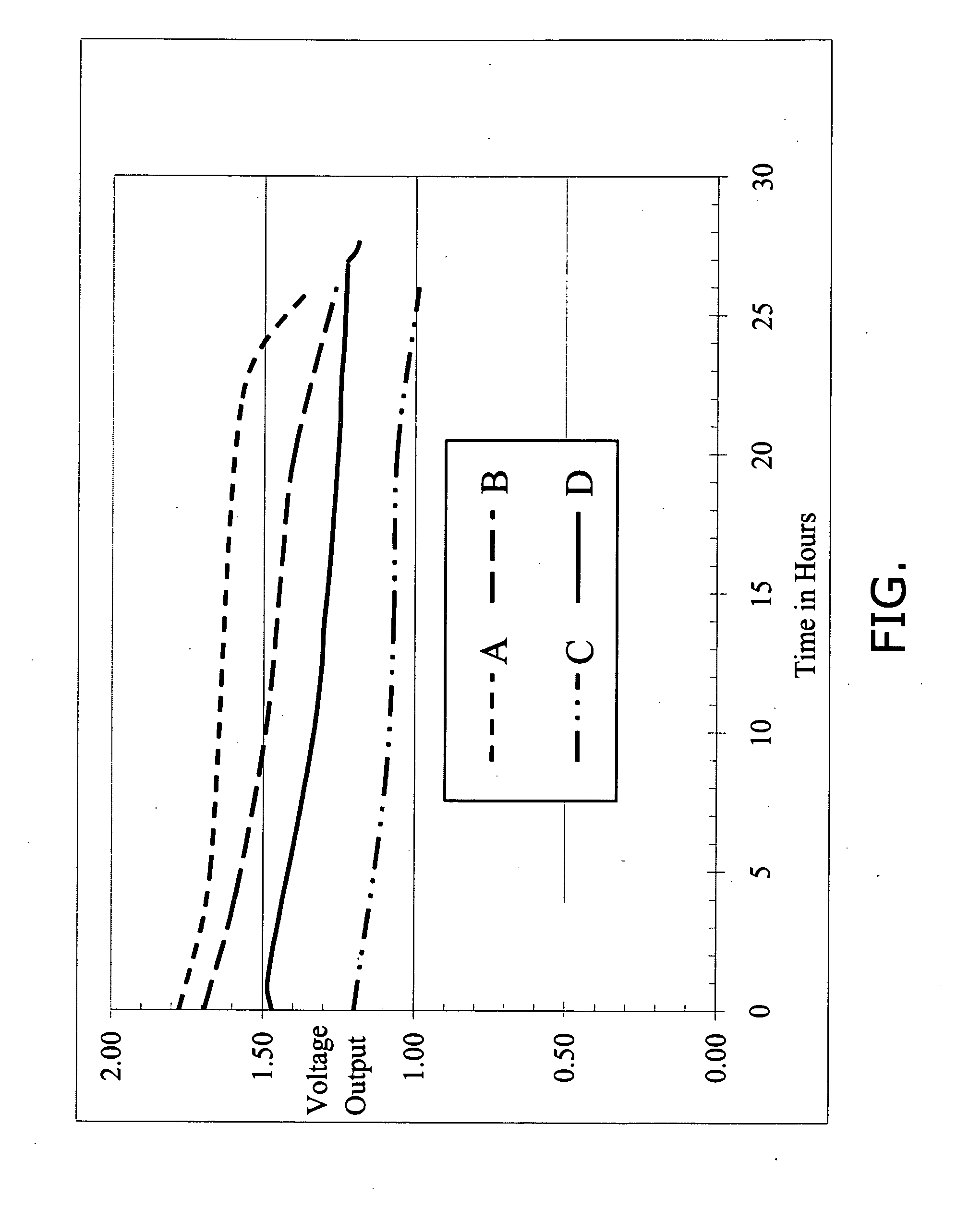

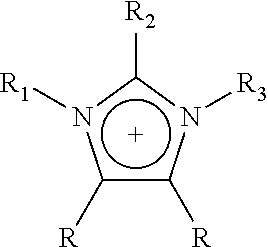

Ionic liquid batteries

Novel electric battery systems are disclosed utilizing selected ionic liquids as electrolytes and selected metals and metal oxides as electrodes. The ionic liquids utilize a substituted imidazolium cation, which does not have the corrosive safety and environmental concerns associated with corrosive acid and alkali electrolytes.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Method for removing boron and phosphorus and purifying industrial silicon by using metallurgic method

The invention discloses a method for removing boron and phosphorus and purifying industrial silicon by using a metallurgic method. The method comprises the steps: (1) placing industrial silicon blocks in the vacuum environment to be heated till the silicon blocks are melted, keeping the temperature for 40-80 minutes so as to refine the silicon blocks; (2) leading protective atmosphere containing oxygen and steam to in the vacuum environment in the step (1) to enable the oxygen and the steam in the protective atmosphere to be fully reacted with impurities in the silicon blocks; and (3) reducing the temperature of the environment in the step (2) till the silicon blocks are in a solid state to obtain silicon ingots, and cutting off slag layers of the silicon ingots. By means of the method, various models of industrial silicon can be purified, samples are not required to be subjected to crushing and ball milling, only simple crushing is required, and the requirement for sample size is low. The method does not comprise any acid-washing steps, usage of a great quantity of strong corrosive acid is avoided, the process if simplified, and the cost is reduced. The impurities including phosphorus, arsenic, antimony, calcium and the like can be removed so as to meet the requirements of solar grade silicon by means of the process. The boron is reduced to be 1.5-0.3 ppmw, and the standard of the solar grade silicon is met.

Owner:SOUTH CHINA NORMAL UNIVERSITY

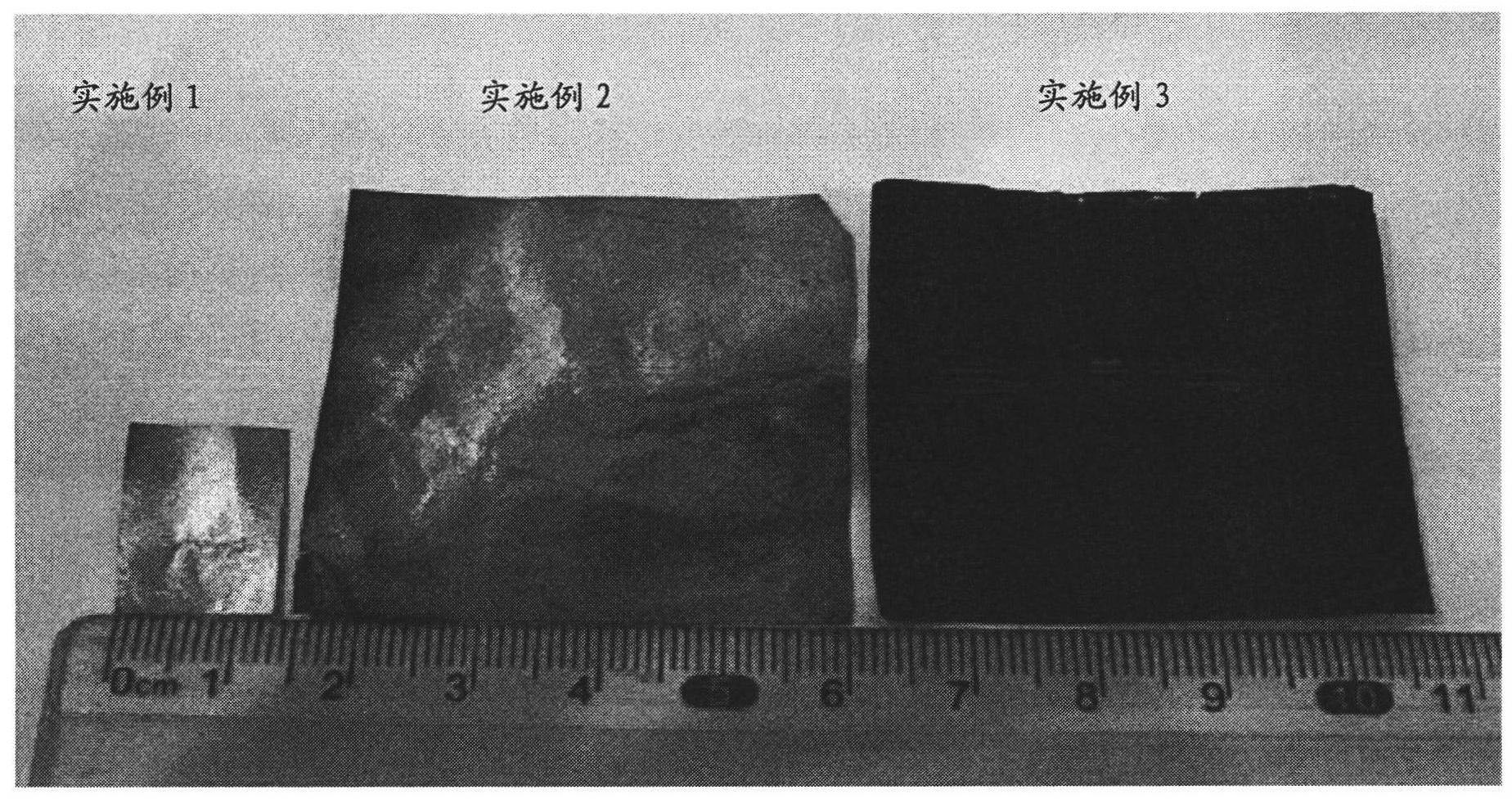

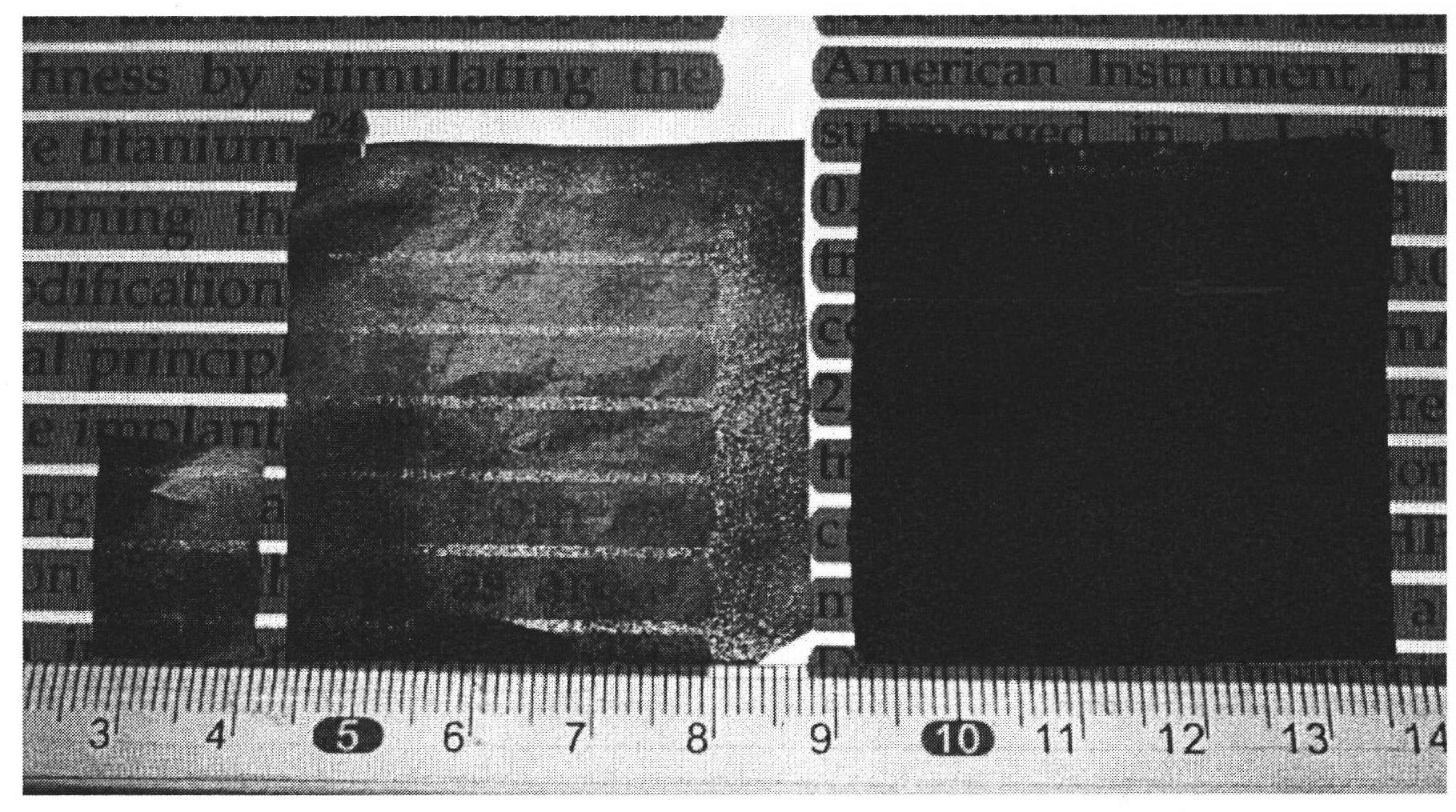

Chemical preparation method of novel porous titanium

InactiveCN102660765ASignificant mesoporous structure featuresLarge specific surface areaSolventElectrochemistry

The invention provides a chemical preparation method of novel porous titanium. The chemical preparation method is characterized in that a metal titanium plate as a substrate is subjected to surface dirt removal cleaning treatment and then is treated in an oxalic acid solution for a certain time so that the uneven metal titanium plate is obtained; and in a system composed of a common acid or salt, a solvent and a corrosive acid, the uneven metal titanium plate is electrolyzed at a cathode under voltage of 2 to 40V by an electrochemical cathode etching method for a time so that a porous titanium mesh which has apertures having uneven and controllable sizes and has a black-white degree-controllable titanium surface color is obtained. The chemical preparation method has the advantages of simple processes, convenient operation, low equipment requirements and easily controllable conditions. The porous titanium mesh obtained by the chemical preparation method has stable properties and small thickness, is soft and has good application prospects in related fields of photovoltaics, photocatalysis, electrocatalysis and medicine.

Owner:NANJING UNIV OF TECH

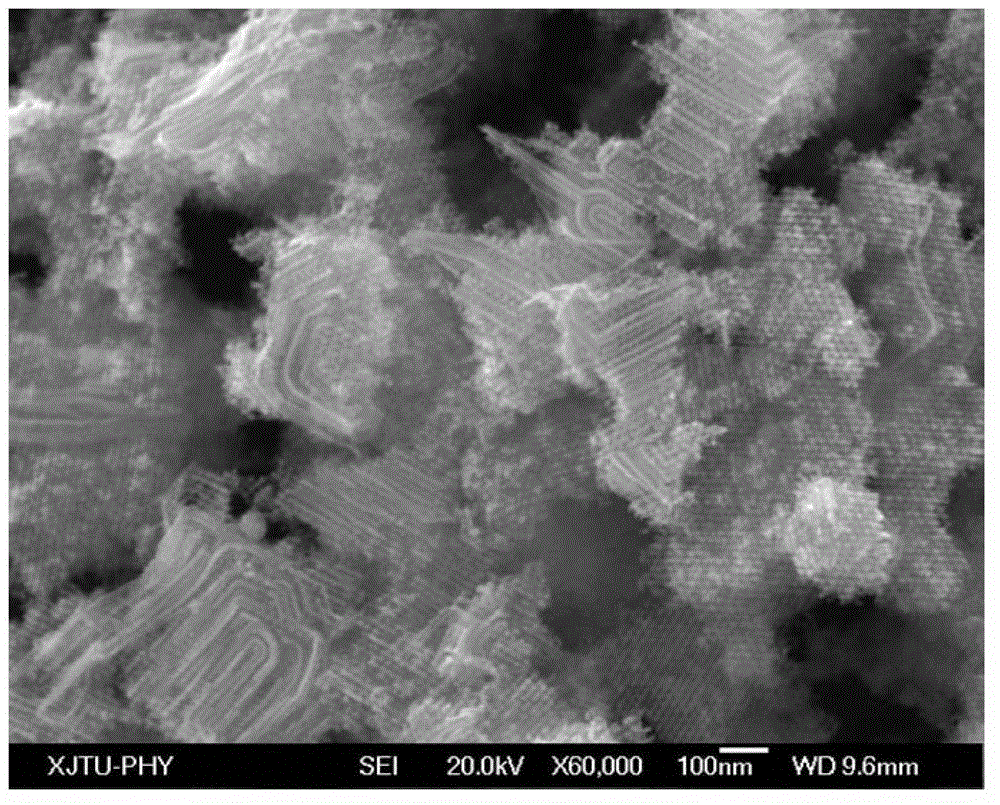

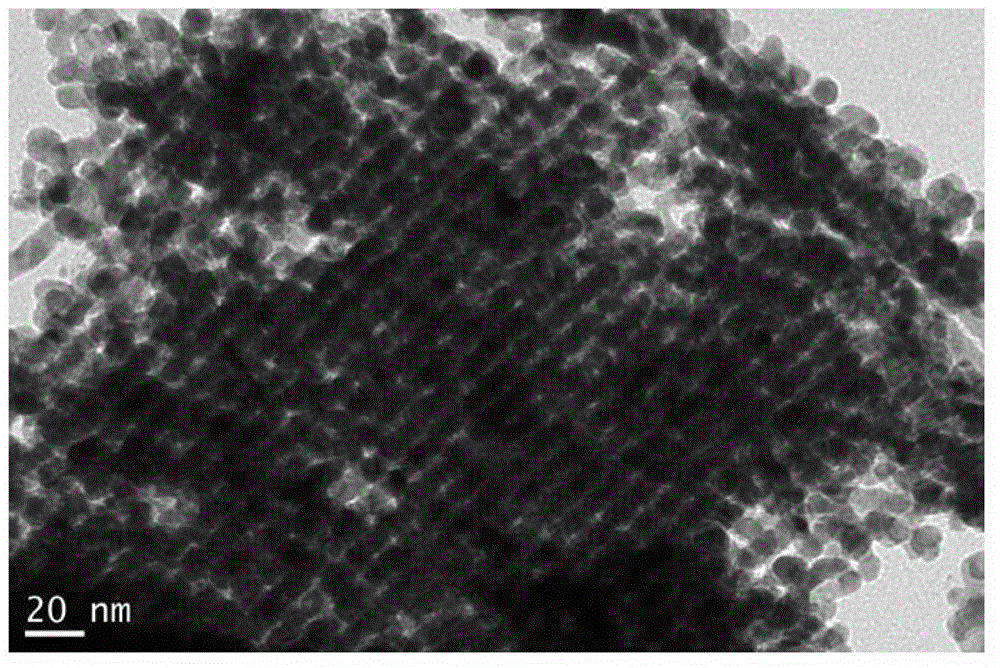

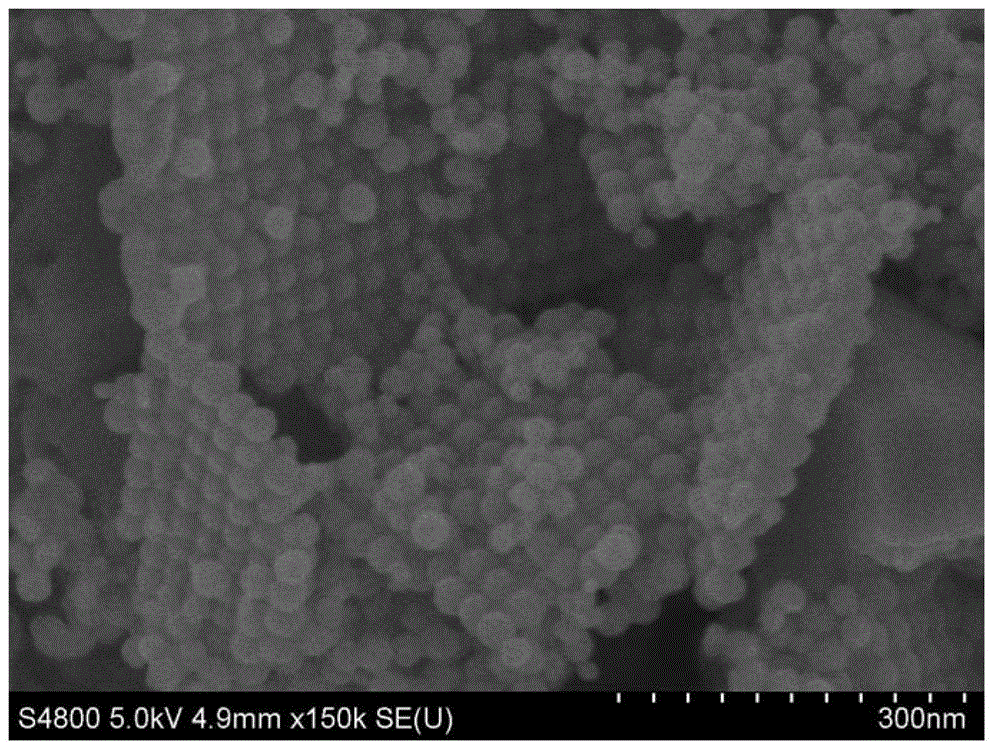

Method for preparing surface-enhanced Raman scattering (SERS) matrix

InactiveCN103149194AParticle size adjustableUniform particle sizeRaman scatteringElectromagnetic couplingMolecular sieve

The invention discloses a method for preparing a surface-enhanced Raman scattering (SERS) matrix. According to the method, precious-metal inorganic salt liquid is filled in a molecular sieve template, the template is removed by using high-concentration corrosive acid or alkaline liquid after calcination or reduction, and a precious-metal mesoporous material with uniformly distributed particle size and gaps is finally obtained. The method has the advantages that the particle diameter and gap size can be effectively controlled; the particle size and the gaps are uniformly distributed, so that the quantitative research on electromagnetic coupling among particles is facilitated; and meanwhile, the repeatability of SERS detection can be improved due to the uniformity of hotspot distribution. The low-concentration molecule detection capability can be effectively increased due to high density and small gaps, so that the SERS matrix has a broad application prospect in fields of biology, chemistry, medicine, environment and the like.

Owner:XI AN JIAOTONG UNIV

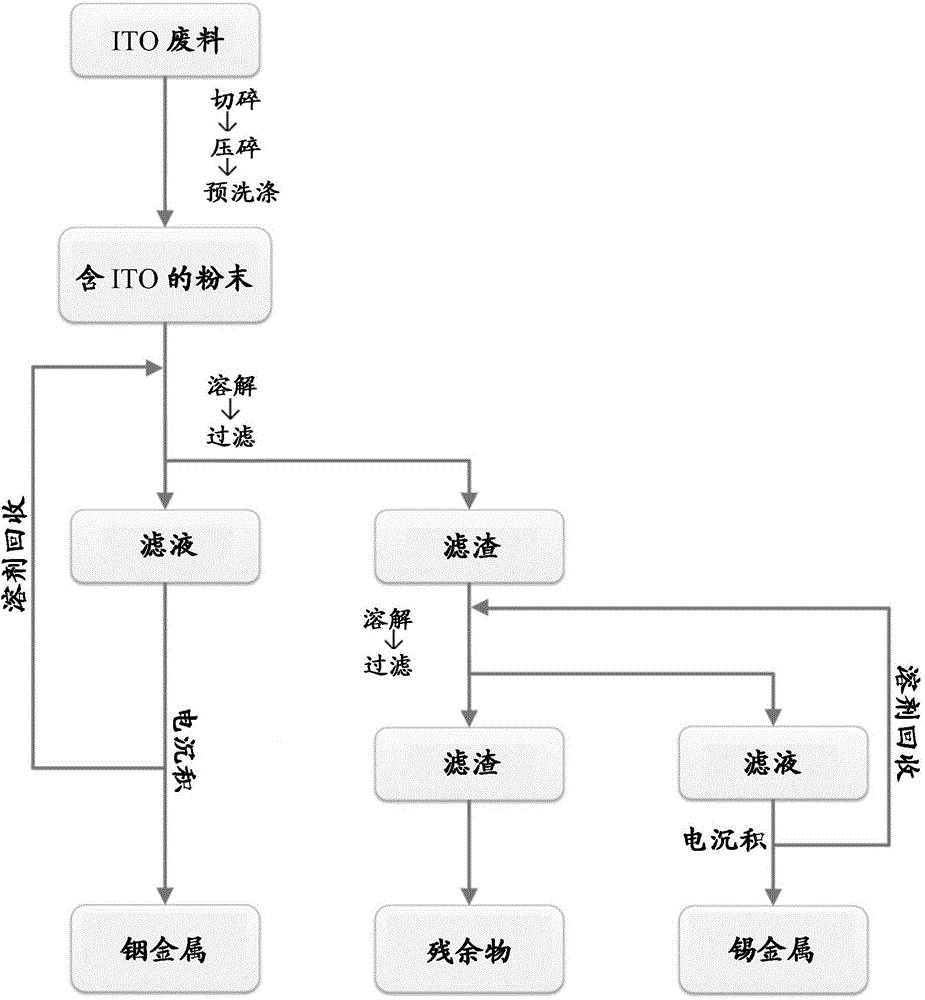

Method of selective recovery of valuable metals from mixed metal oxides

InactiveCN104862482ANo recovery dropPhotography auxillary processesProcess efficiency improvementIndiumCorrosive acid

The present invention relates to a process for recovering metals from indium tin oxide (ITO) scrap. It allows the selective recovery of indium and tin from waste ITO by means of a simple and environmentally benign dissolution-deposition method, with no requirement of using strong corrosive acid / alkaline chemicals (e.g. hydrochloric acid, nitric acid, sulfuric acid and sodium hydroxide) for dissolution and complicated procedures / operation. The dissolution baths can be reused without observable recovery deterioration. It significantly reduces the cost requirement in the recovery process.

Owner:NANO & ADVANCED MATERIALS INST

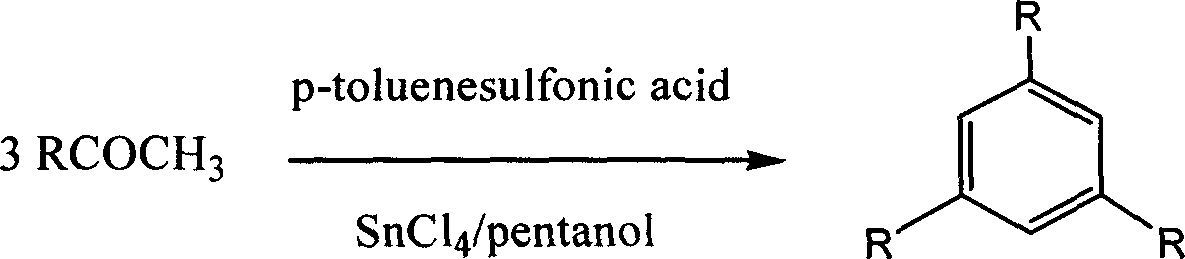

Process for synthesizing1,3,5-triphenyl benzene

InactiveCN1837168AAvoid pollutionReduce manufacturing costHydrocarbonsHydrocarbon preparationCarbonizationAcetophenone

The invention discloses a 1, 3, 5-triphenyl benzene synthesizing method, which comprises the following steps: dissolving acetophenone in n-amyl alcohol; mixing and adding in accelerant tin tetrachloride; putting in accelerant p-toluenesulfonic acid; reacting at 110deg.c for hours; pouring out reactant in absolute ethyl alcohol; mixing; filtering; using carrene-alcohol for recrystallization; getting 1,3,5-diphenylbenzene benzene. The invention solves the problem of the carbonization of corrosive acid catalystsing and synthesizing 1, 3, 5-triphenyl benzene, which reduces the reaction yield and environmental contamination.

Owner:YANGZHOU UNIV

Concrete coloring compositions and methods

ActiveUS20090139435A1Moderate corrosive characteristicEffective coloringBenz-azabenzanthrone dyesDyeing processCorrosive acidConjugate acid

The present invention provides acidic compositions and methods that are adapted to impart color to cementitious or mineral substrate surfaces. Specifically, the present invention relates to acidic compositions and methods adapted to treat cementitious or mineral substrate surfaces that have the advantage of using a less corrosive acid-based solution. The acidic composition incorporates species including a weak base in equilibrium with a conjugate acid. The presence of such species moderates the corrosive behavior of the acid while still allowing excellent coloring action to occur.

Owner:SWIMC LLC

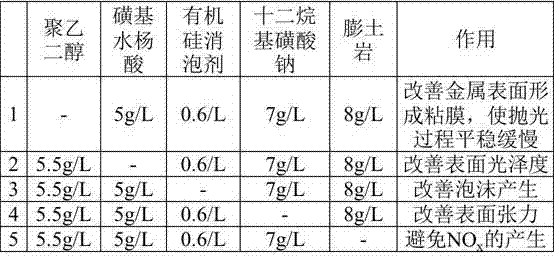

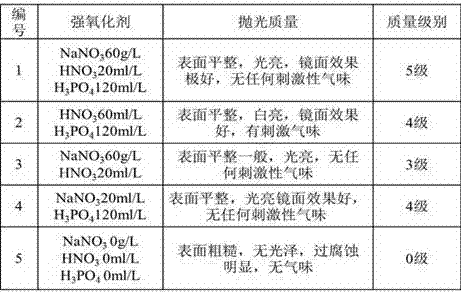

Environment-friendly stainless steel polishing solution and preparation method and polishing process thereof

The invention provides an environment-friendly stainless steel polishing solution and a preparation method and polishing process thereof. The environment-friendly stainless steel polishing solution comprises a strong oxidant, corrosive acid, a compound complexing agent, a corrosion inhibitor, a rare earth additive, a viscosity regulator, a brightening agent, a defoaming agent, a surfactant, a NOx remover and deionized water. The polishing solution is good in stability and long in service life, the polishing solution preparation and stainless steel treatment processes are simple, the surface of treated stainless steel is smooth, oxide films are avoided, point corrosion is avoided, the mirror plane is great, the polishing time is short, no irritant gas is generated in the using process, and the polishing solution can be used repeatedly and circularly.

Owner:无锡市恒利弘实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com