Chemical preparation method of novel porous titanium

A technology of porous titanium and titanium sheets, which is applied in the field of preparation of porous titanium, can solve the problems of reduced corrosion resistance, achieve stable properties, good application prospects, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

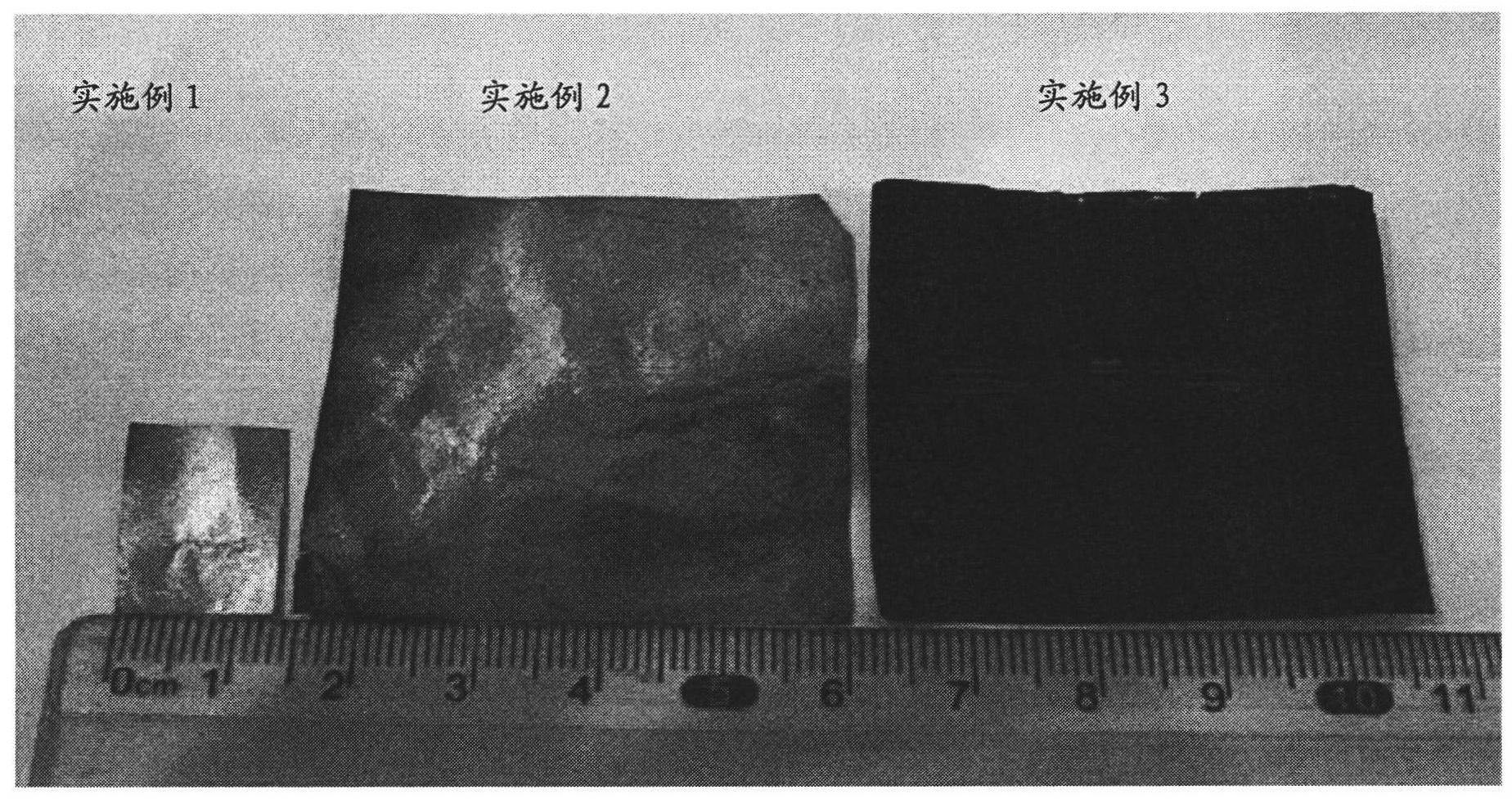

Embodiment 1

[0022] (1) Cut the 100um thick titanium sheet into an area of 1.4*1.9cm 2 Ultrasonic cleaning with detergent, water, and absolute ethanol for 10 minutes, rinsed with water and dried, then placed in 10w% oxalic acid aqueous solution at 100°C for 3 hours, rinsed with water, and dried to obtain a clean surface with microscopic unevenness titanium sheet.

[0023] (2) Use the above-mentioned treated titanium sheet as a cathode, with an area of 3*3.5cm 2 The titanium sheet is used as the anode, and the center of the two-pole titanium sheet is perpendicular to the center line of the two titanium sheets, and the distance between the two electrodes is 1cm. put into by HF, CH 3 COOH and H 2 O in the electrolyte solution with a volume ratio of 1:5:40, boost the voltage to 20V within 5 minutes, etch the cathode for 25 minutes, rinse with water and dry to obtain a porous titanium mesh.

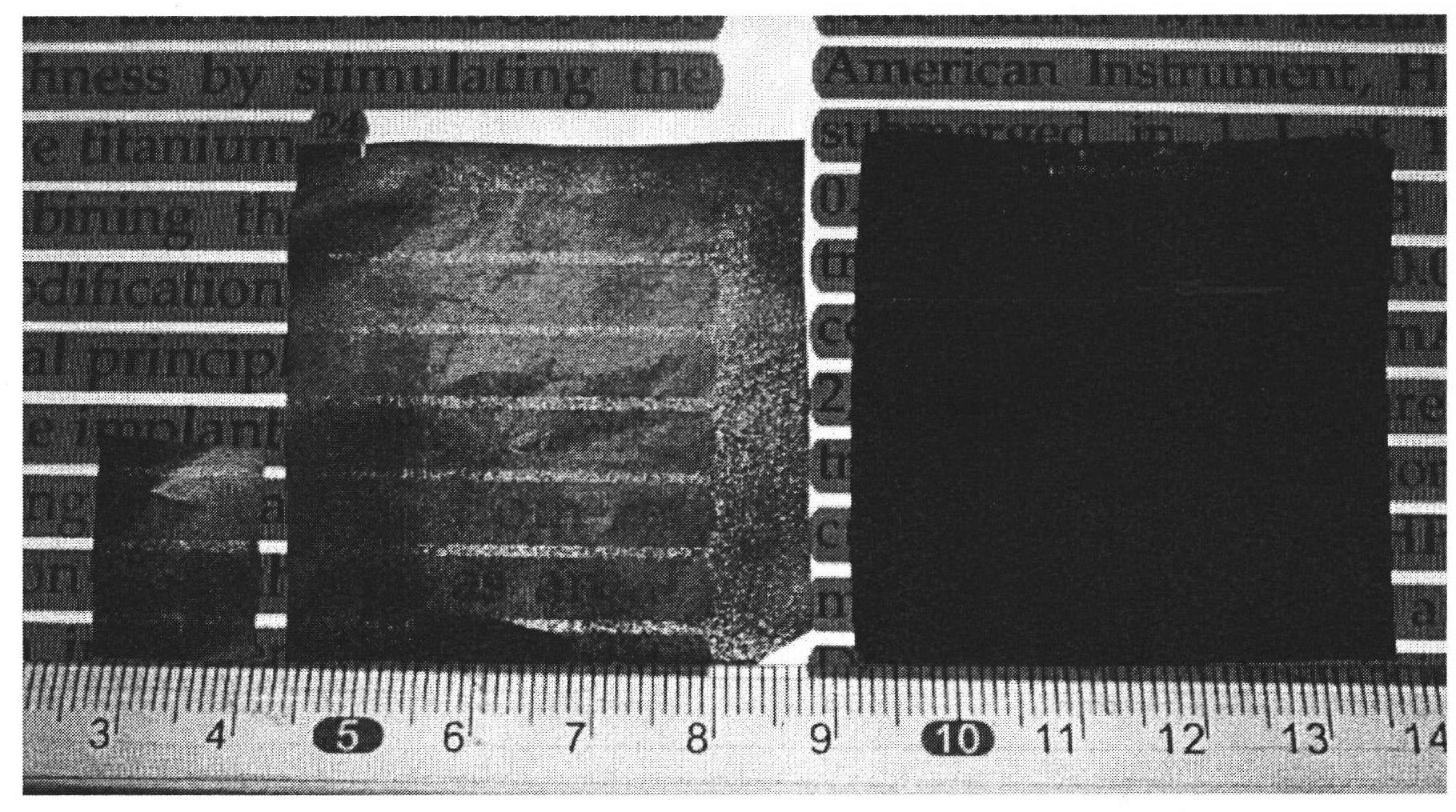

Embodiment 2

[0025] (1) Cut the 100um thick titanium sheet into an area of 4.5*4.5cm 2 Ultrasonic cleaning with detergent, water, and absolute ethanol for 10 minutes, rinsed with water and dried, then placed in 10w% oxalic acid aqueous solution at 100°C for 3 hours, rinsed with water, and dried to obtain a clean surface with microscopic unevenness titanium sheet.

[0026] (2) Use the above-mentioned treated titanium sheet as a cathode, with an area of 5*5cm 2 A titanium sheet is used as the anode, the centers of the two poles are aligned and the parallel spacing of the titanium sheets is 1 cm. put into the initial by HF, CH 3 COOH and H 2 O in the electrolyte solution with a volume ratio of 1:15:100, by continuously changing the voltage and adding a small amount of HF, the current is kept constant at 0.5A, and the cathode is etched for 50min. Rinse and dry to obtain a porous titanium mesh.

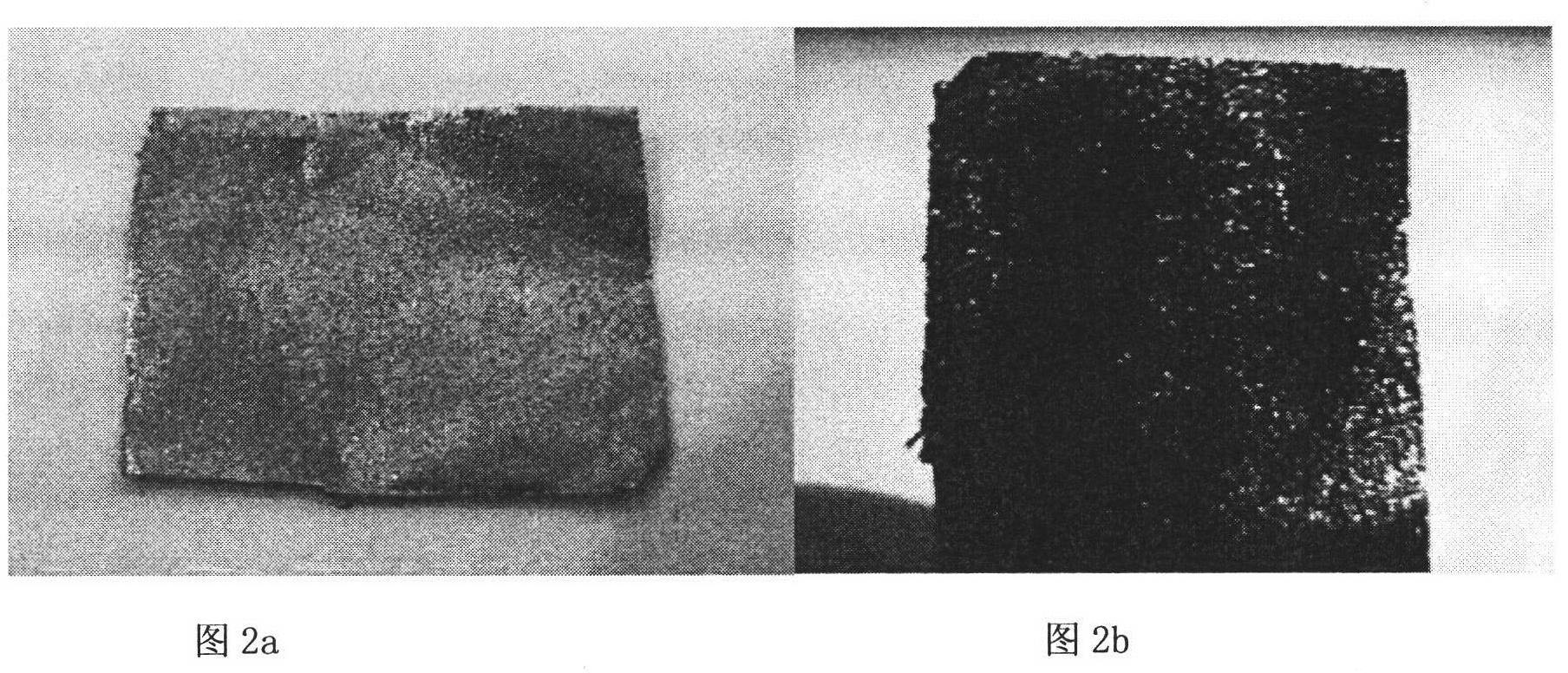

Embodiment 3

[0028] (1) Cut the 100um thick titanium sheet into an area of 4.5*4.5cm 2 Ultrasonic cleaning with detergent, water, and absolute ethanol for 10 minutes respectively, rinsed with water and dried, then placed in 15w% oxalic acid aqueous solution at 100°C for 5 hours, rinsed with water, and dried to obtain a clean and microscopic surface. Uneven titanium sheet.

[0029] (2) The above-mentioned treated titanium sheet is used as a cathode, with an area of 5*5cm 2 A titanium sheet is used as the anode, the centers of the two poles are aligned and the parallel spacing of the titanium sheets is 1 cm. put into by HF, CH 3 COOH and H 2 O in the electrolyte solution with a volume ratio of 1:10:80, boost the voltage to 20V at a boost rate of 2V / min, etch the cathode for 100min, rinse with water, and dry to obtain the corresponding porous titanium mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com