Patents

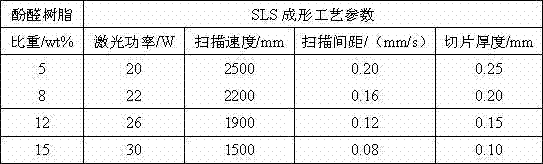

Literature

874 results about "Porous titanium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

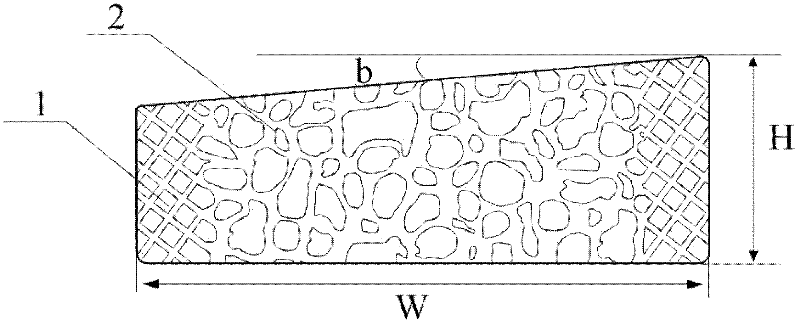

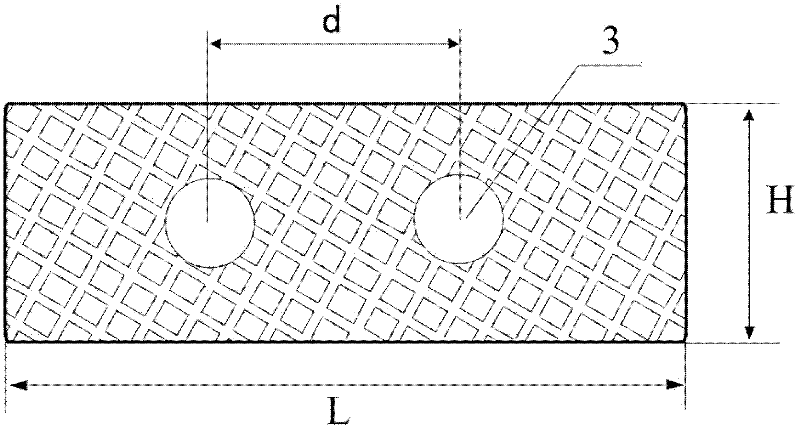

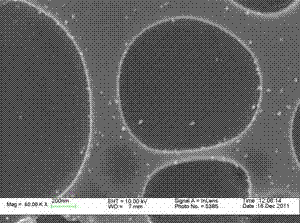

Porous Titanium Disc We provide porous titanium disc with wide range of filtration precision and dimensions.Porous titanium is used as filter & Gas Diffusion Layer in new generation fuel cells (PEMFC). Porous Titanium Tube We provide porous titanium tube with wide range of filtration precision and dimensions.

Method for preparing complexly shaped biomedical porous titanium molybdenum alloy implant body

InactiveCN102335742ADesign personalizationHigh dimensional accuracyIncreasing energy efficiencyProsthesisNatural boneMetallic materials

The invention provides a method for preparing a complexly shaped biomedical porous titanium molybdenum alloy implant body and belongs to the technical field of biomedical porous metallic material preparation. The method comprises the following steps of: taking a mixture of titanium and molybdenum metallic element powder and organic polymer powder as raw materials, and then preparing the biomedical porous titanium molybdenum alloy implant body by adopting the processes, such as three-dimensional modeling, selective laser-firing rapid forming, thermal de-greasing, vacuum sintering, and the like. The processing steps are simple, the period is short, the use ratio of materials is high, the cost is low, any complexly shaped porous titanium alloy implant body can be conveniently manufactured, and the method has efficiency and economic advantages in individual design and rapid manufacturing of the implant body. A titanium molybdenum alloy material prepared by using the method has the advantages that pore space is uniform, adjustment scopes of porosity, aperture ratio and aperture are wide, elasticity modulus and compression strength are in close proximity to natural bone, and the demand on biomechanical compatibility required by a biomedical material is met.

Owner:UNIV OF SCI & TECH BEIJING

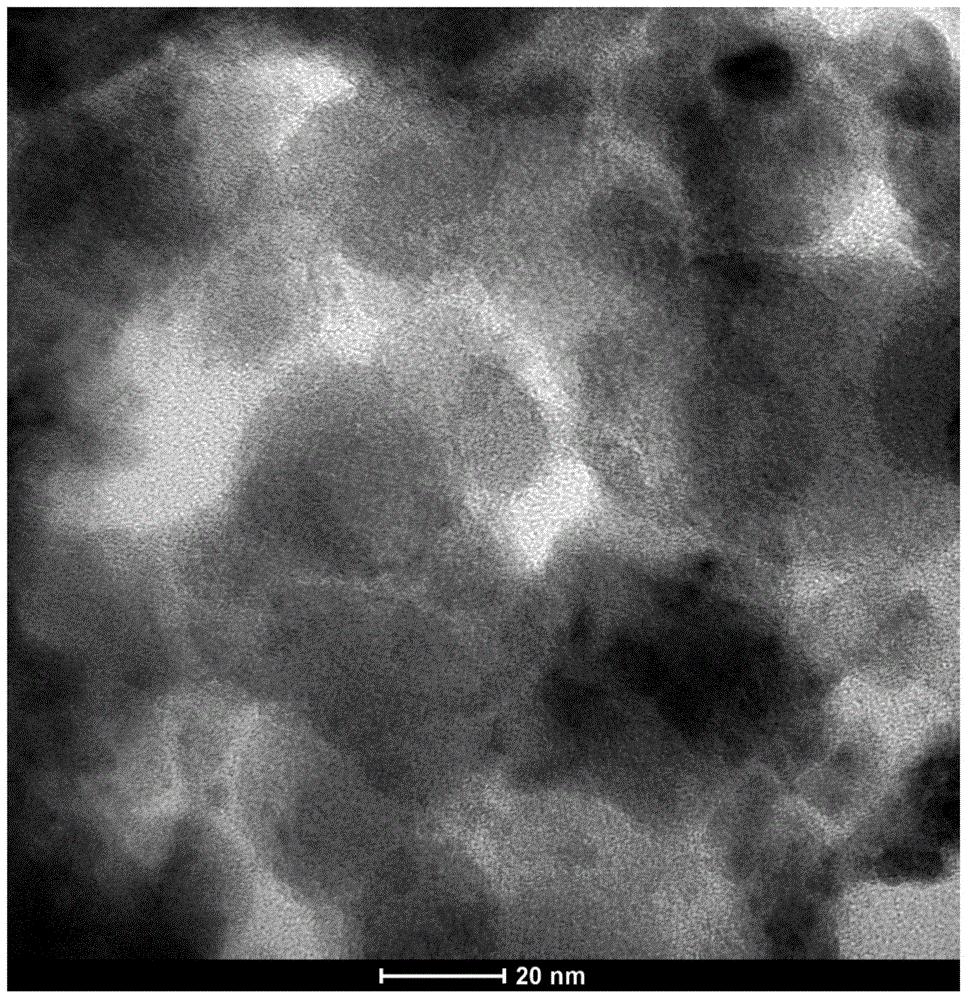

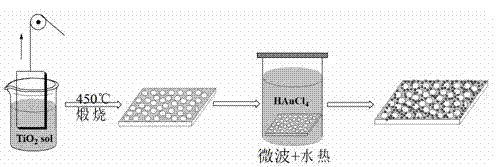

Porous titanium dioxide/graphene composite material and preparation method thereof

InactiveCN103143338ANarrowing of the forbidden bandLarge specific surface areaPhysical/chemical process catalystsIn situ polymerizationAniline

The invention discloses a porous titanium dioxide / graphene composite material and a preparation method thereof. The preparation method comprises the steps of: adding aniline and graphene into a surfactant-containing protonic acid solution according to a certain ratio; preparing a nanometer polyaniline / graphene composite material through an in-situ polymerization method; preparing titanium dioxide sol by using a sol-gel method; adding 0.05-0.20g of nanometer polyaniline / graphene composite material into 50mL of sol, uniformly mixing; standing and aging the sol for 3-5 days; drying in a drying oven at the temperature of 60-120 DEG C; milling; calcining the obtained composite for 30 minutes -2 hours at the temperature of 200-550 DEG C; and removing the polyaniline, thereby obtaining the porous titanium dioxide / graphene composite material. According to the invention, the porous titanium dioxide / graphene is prepared by utilizing the nanometer polyaniline and the titanium dioxide is deposited on the graphene, so that the contact area of the titanium dioxide and pollutants is increased, the separating efficiency of photo-generated electrons and holes is improved and the photocatalytic efficiency is improved.

Owner:SICHUAN AGRI UNIV

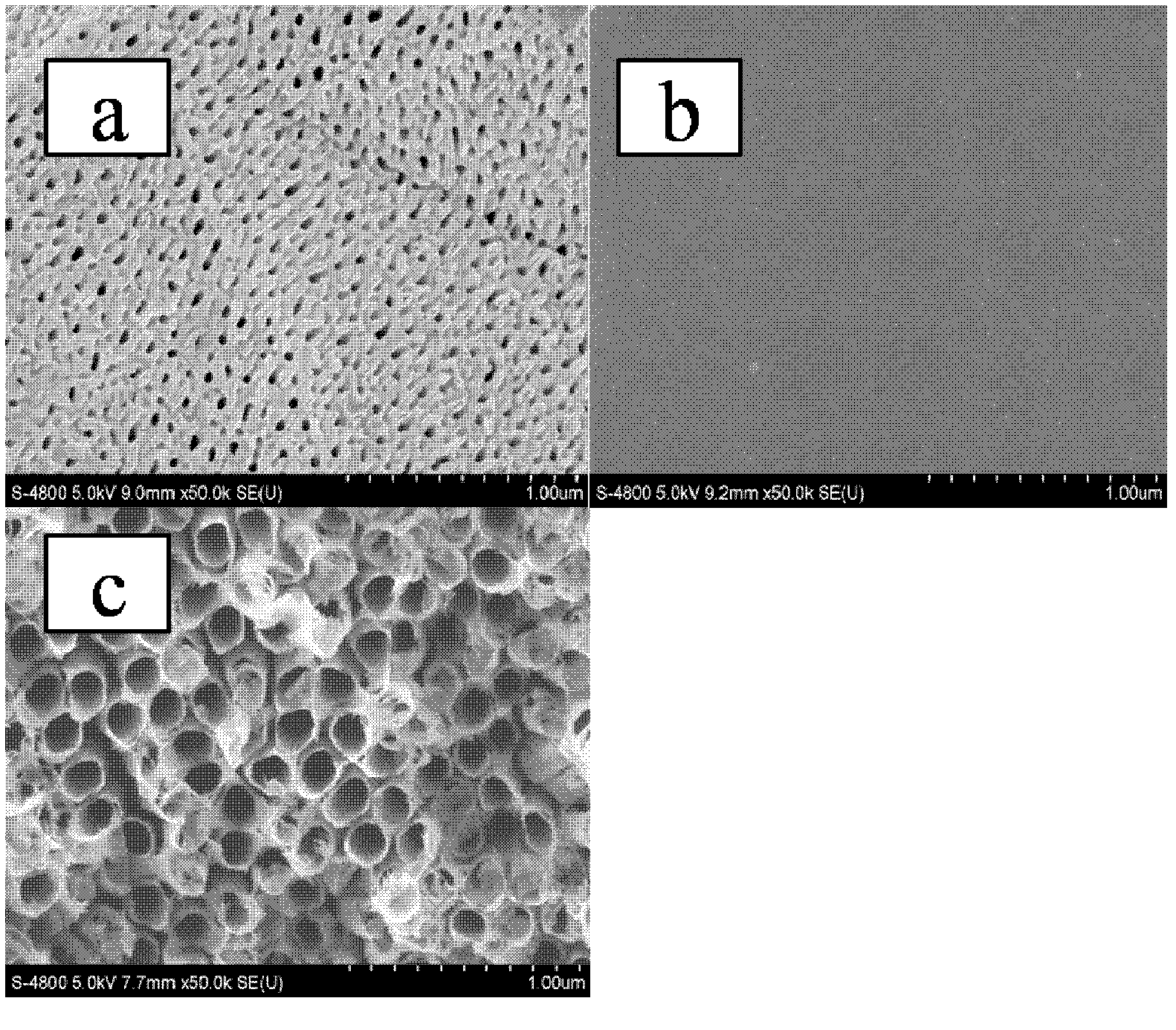

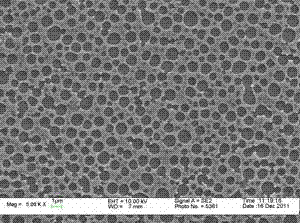

Method for preparing porous titanium dioxide nanotube array

InactiveCN101748463AControllable growthEffective peelingPolycrystalline material growthSurface reaction electrolytic coatingTio2 nanotubeTitanium oxide

The invention relates to a method for preparing an ordered porous anodic titanium dioxide nanotube array. The method can prepare an ultra-large area defect-free titanium dioxide nanotube array film, the surface layer is the porous shape like an anodic aluminum oxide template, and the lower layer is a nanotube ordered array, thereby overcoming the common problems of easy lodging and aggregation of tubes in the prior art of preparing the anodic titanium dioxide nanotube array and simultaneously solving the problems that the prepared nanotube array film has more surface defect corrosion pits and the sediment blocks tube mouths. The nanotube array can realize the controllable growth by controlling the preparation conditions and the process and obtain the ordered array films with different tube diameters, different wall thicknesses and different tube lengths. The diameter range of the nanotubes is 20-200nm, the wall thickness range is 5-30nm, and the length range of the titanium dioxide tubes is 100nm-1mm. The invention particularly relates to a technology which can effectively and completely strip the titanium dioxide array film, effectively strip a titanium substrate from the TiO2 nanotube array and obtain the different sizes of porous nanotube array self-support films.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Perovskite solar cell and manufacturing method of perovskite solar cell

ActiveCN104576930AInsulationImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingSilanesEvaporation

The invention discloses a perovskite solar cell. The perovskite solar cell is characterized by sequentially comprising a conductive glass layer, a compact titanium dioxide film, a porous titanium dioxide film, a methylamine lead iodine polycrystalline film, a hole-transport material layer and an evaporation silver electrode layer. Interface modification is carried out on the methylamine lead iodine polycrystalline film through long-chain alkyl silane coupling agents, and the number of carbon atoms of the long-chain alkyl silane coupling agents is larger than six and smaller than sixteen. The invention further discloses a manufacturing method of the perovskite solar cell. Compared with the prior art, the perovskite solar cell and the manufacturing method have the advantages that as interface modification is carried out through the long-chain alkyl silane coupling agents, the recombination of electrons in the cell can be suppressed, and the stability of the cell in the wet environment can be improved.

Owner:NINGBO UNIV

Porous Titanium Femoral Sleeves and Their Use in Revision Knee Surgery

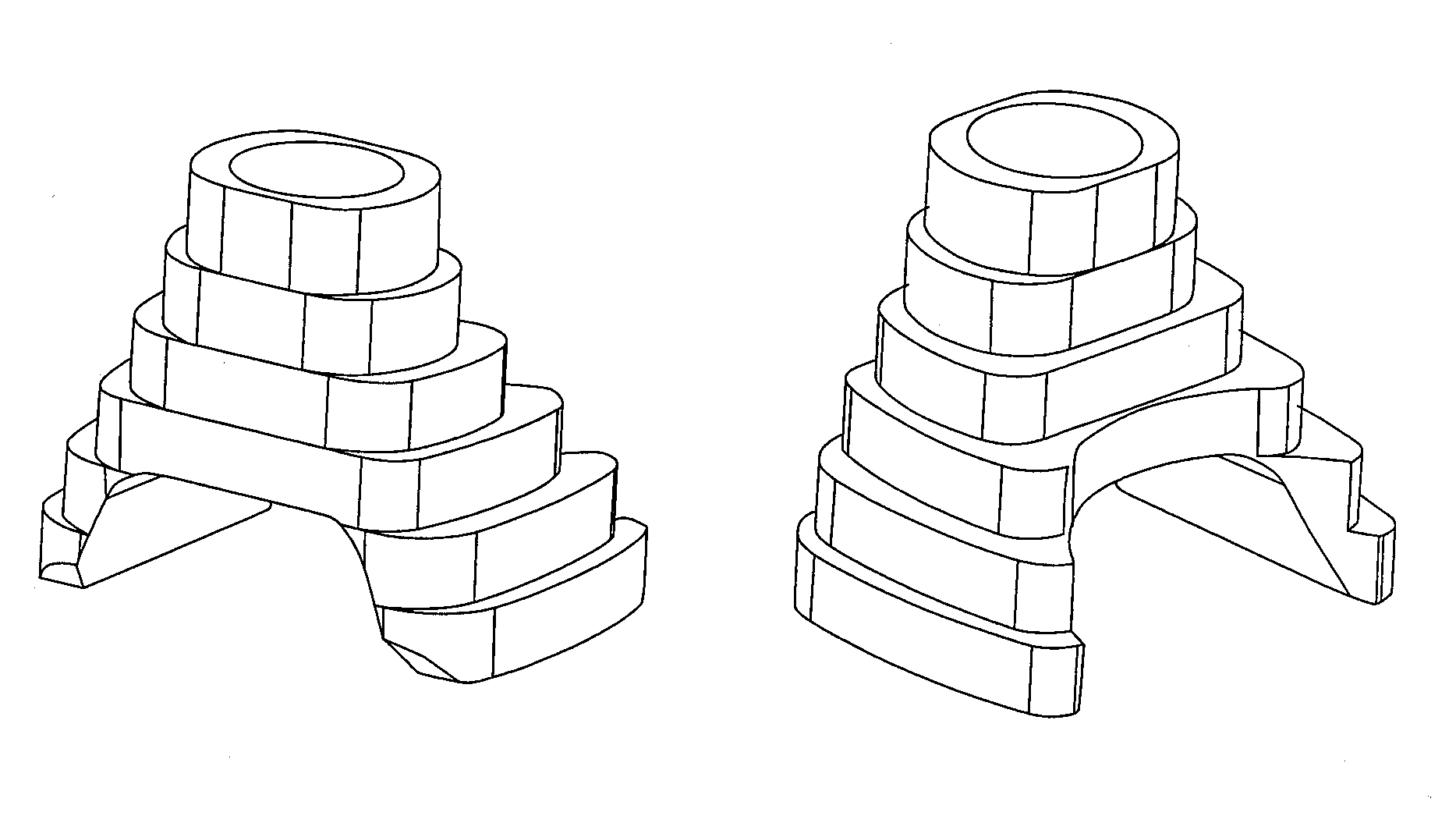

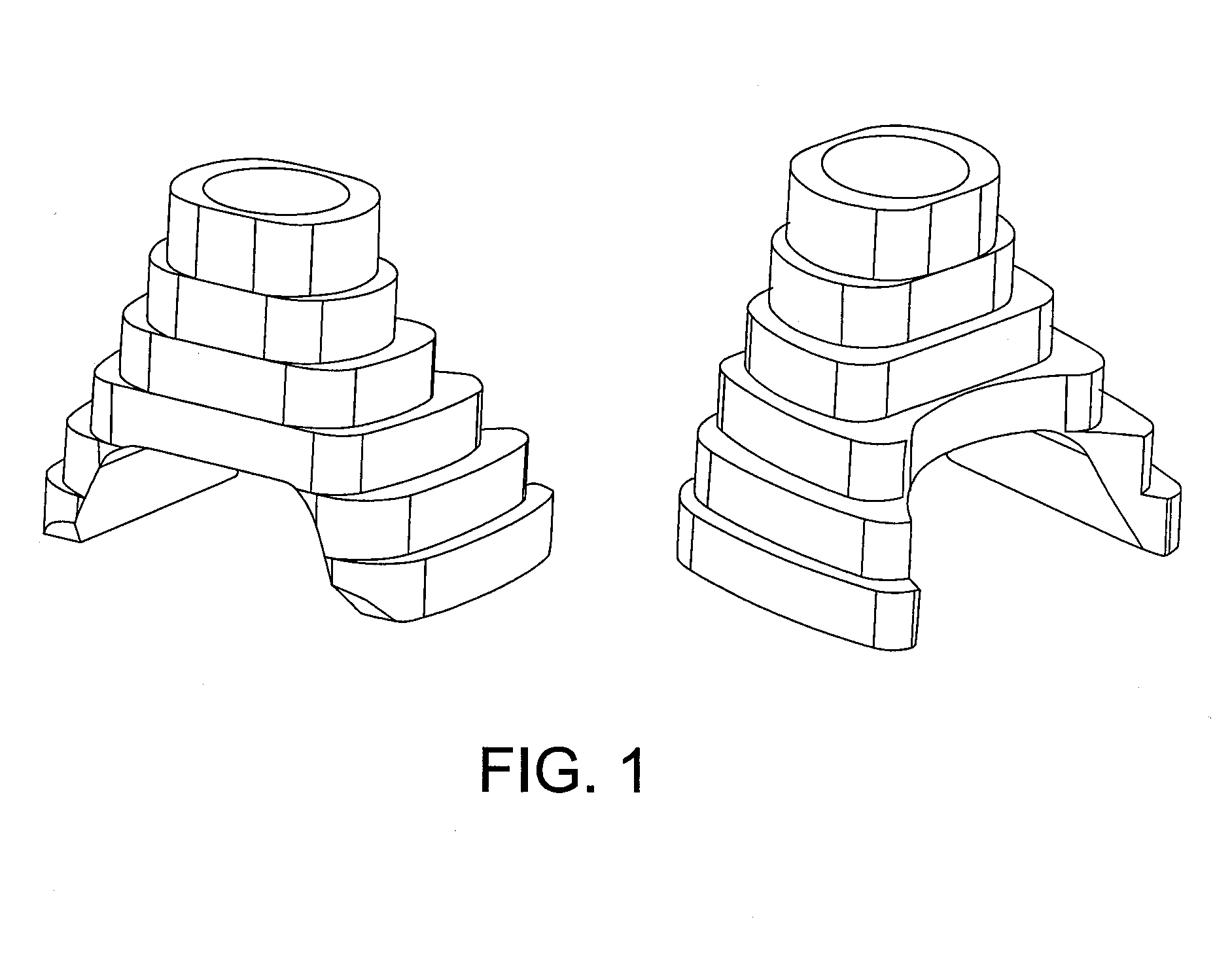

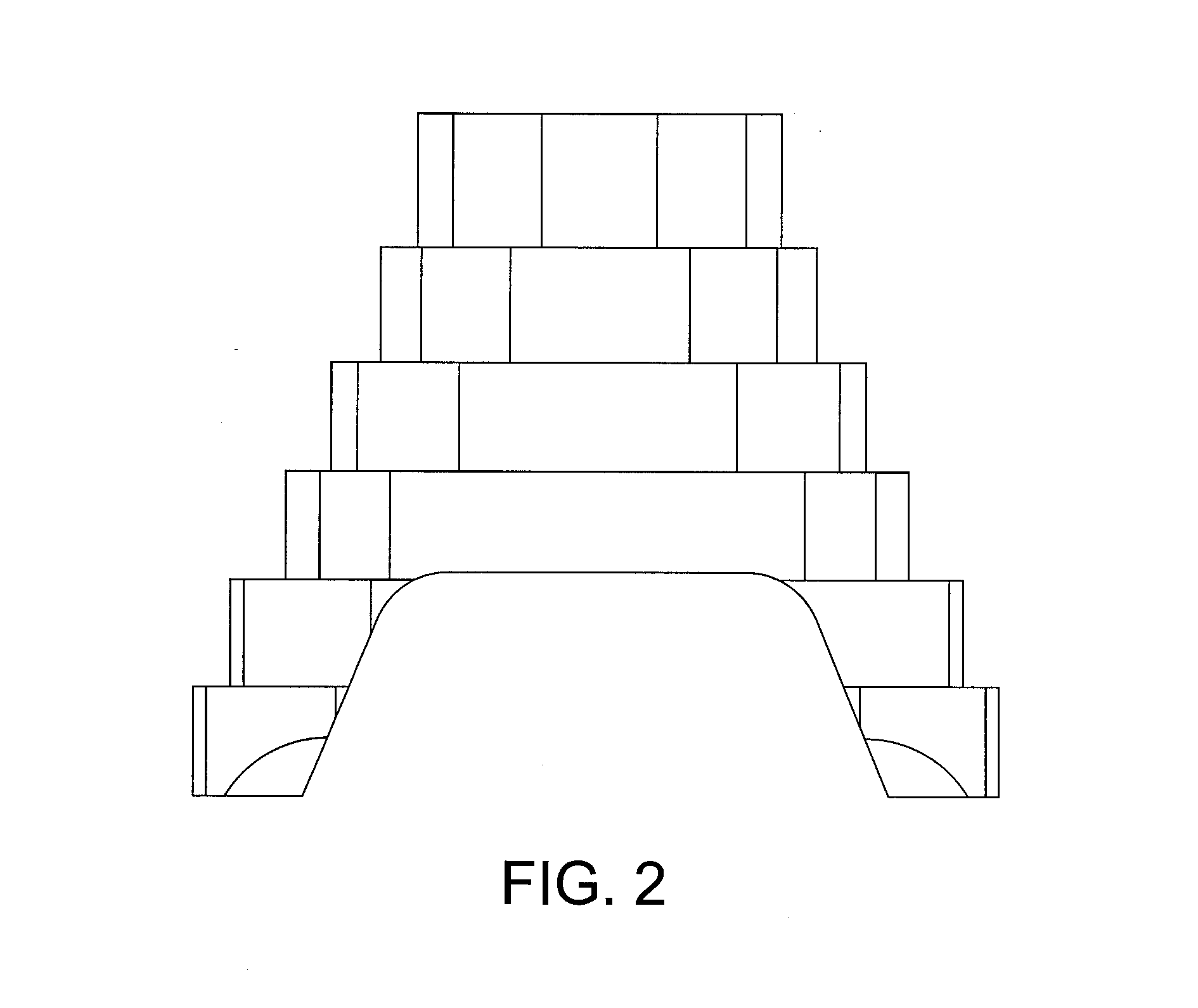

The invention concerns monolithic foam sleeves that comprises titanium or titanium alloy foam having a porosity of 50 to 85% and possess a proximal end, a distal end, an interior wall that defines an interior channel and extends from the proximal end to the distal end; and a terraced outer surface that tapers such that said sleeve is widest at the distal end and most narrow at the proximal end.

Owner:DEPUY (IRELAND) LTD

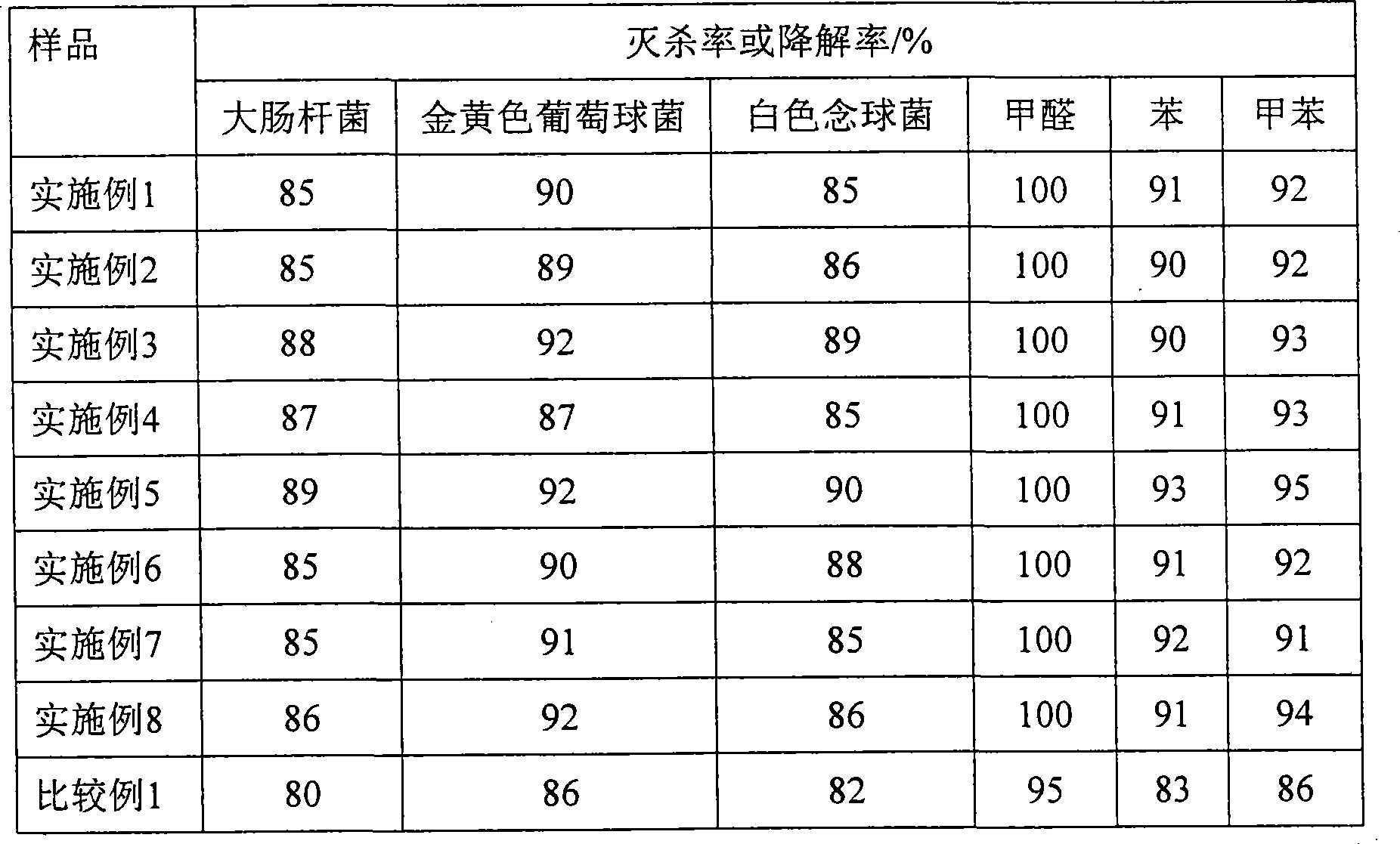

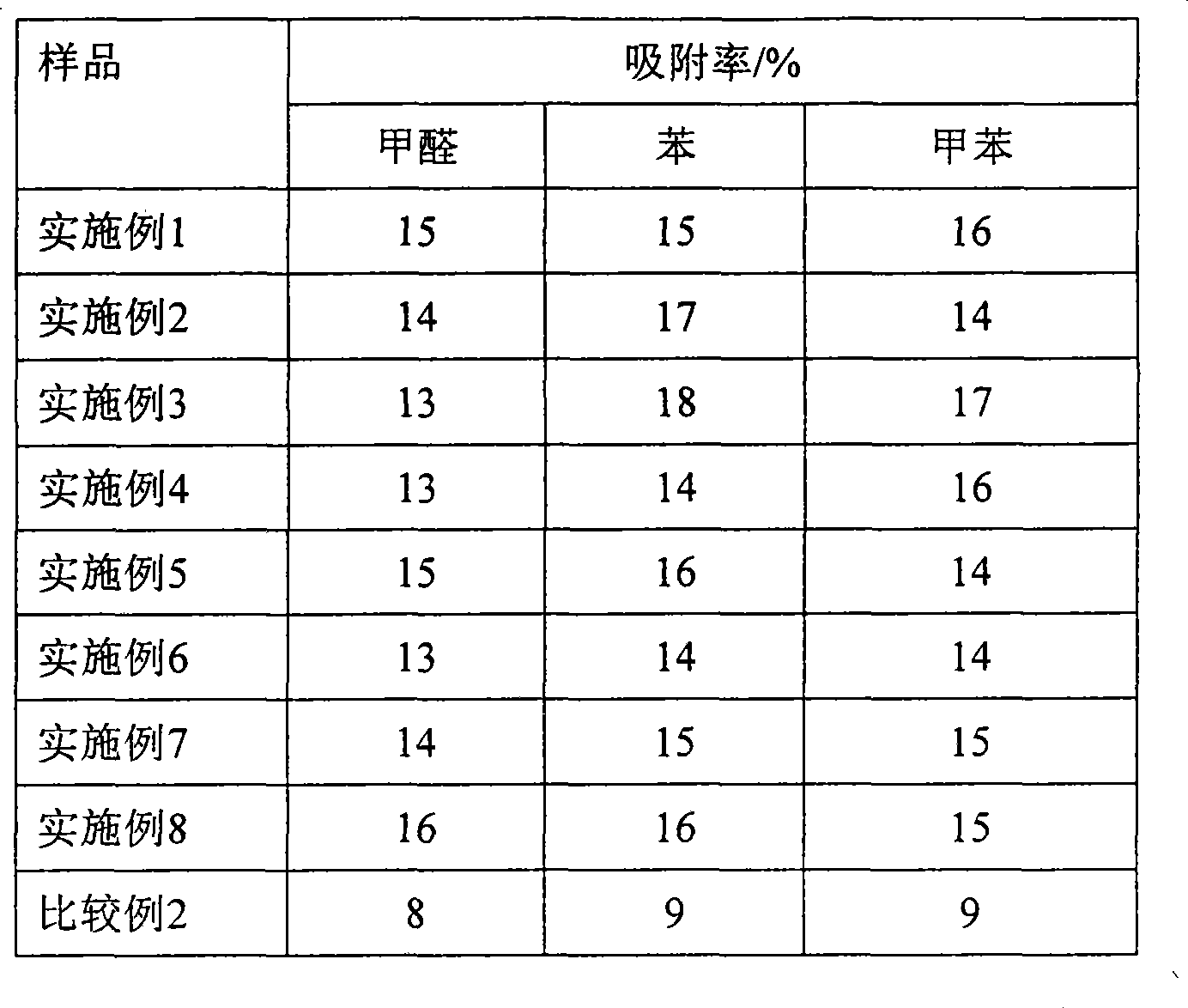

Nano meso-porous titanium dioxide coating having high efficiency antibacterial and air purification function

InactiveCN101418151AEasy to preparePromote degradationAntifouling/underwater paintsPaints with biocidesUltraviolet lightsBULK ACTIVE INGREDIENT

The invention discloses a mesoporous nano titania coating with the functions of high-efficiency antibacterium and air purification. The compositions of the coating in percentage by weight are 1 to 10 percent of mesoporous nano titania, 20 to 60 percent of solvent, 20 to 55 percent of film-forming resin, 0.02 to 10 percent of dispersant and other auxiliary agent, and 10 to 30 percent of inorganic pigment filler. The coating takes the mesoporous nano titania or a modifier of the mesoporous nano titania as an active ingredient, has the functions of high-efficiency antibacterium and air purification after curing and film forming, can be widely applied to an internal wall and an external wall of a building. The mesoporous nano titania coating has simple preparation method and wide pollutant purification scope, has an eradicative rate of more than 85 percent on Escherichia coli, Staphylococcus aureus and Candida albicans within 1 hour, has a degradation rate of more than 90 percent on formaldehyde, benzene and toluene, can be excited to generate photocatalysis by faint ultraviolet light in sunlight or illumination light, and still has obvious effect on degradation of low-concentration pollutant.

Owner:NANJING UNIV OF TECH

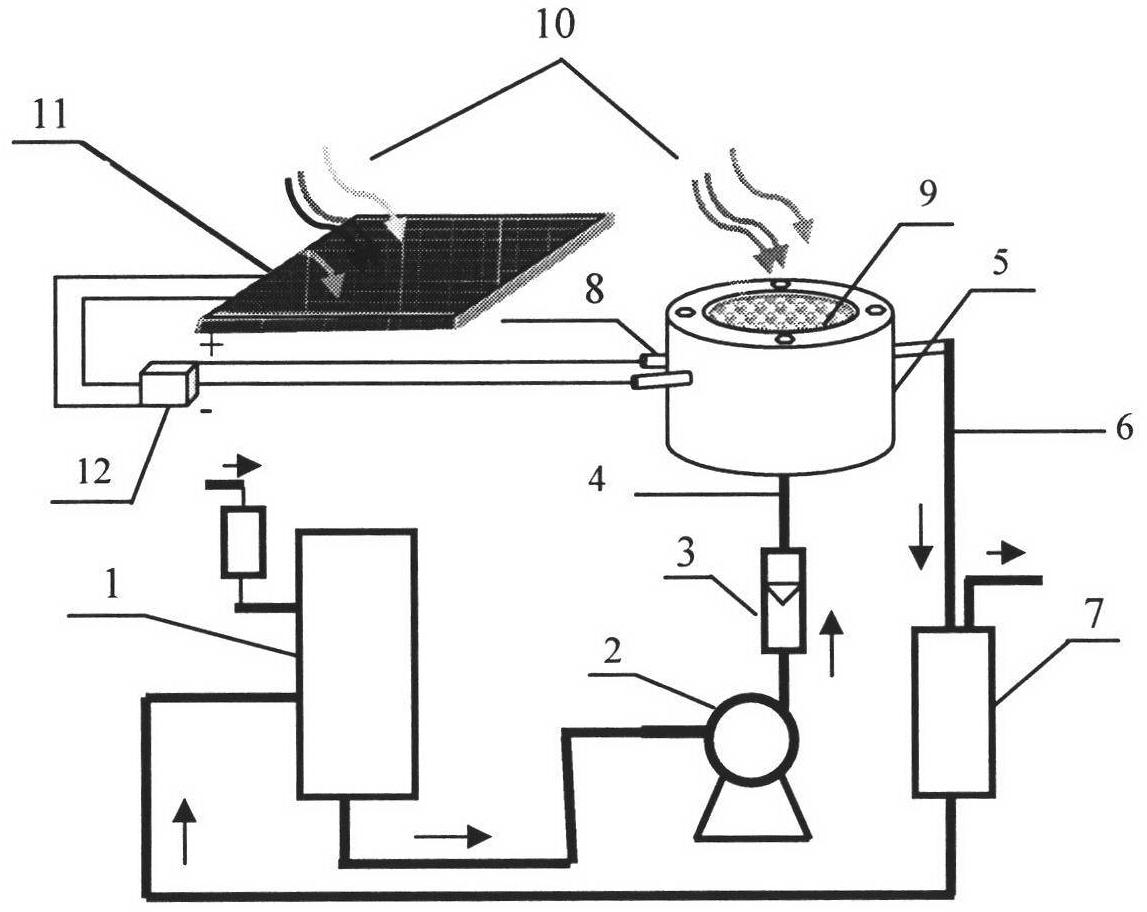

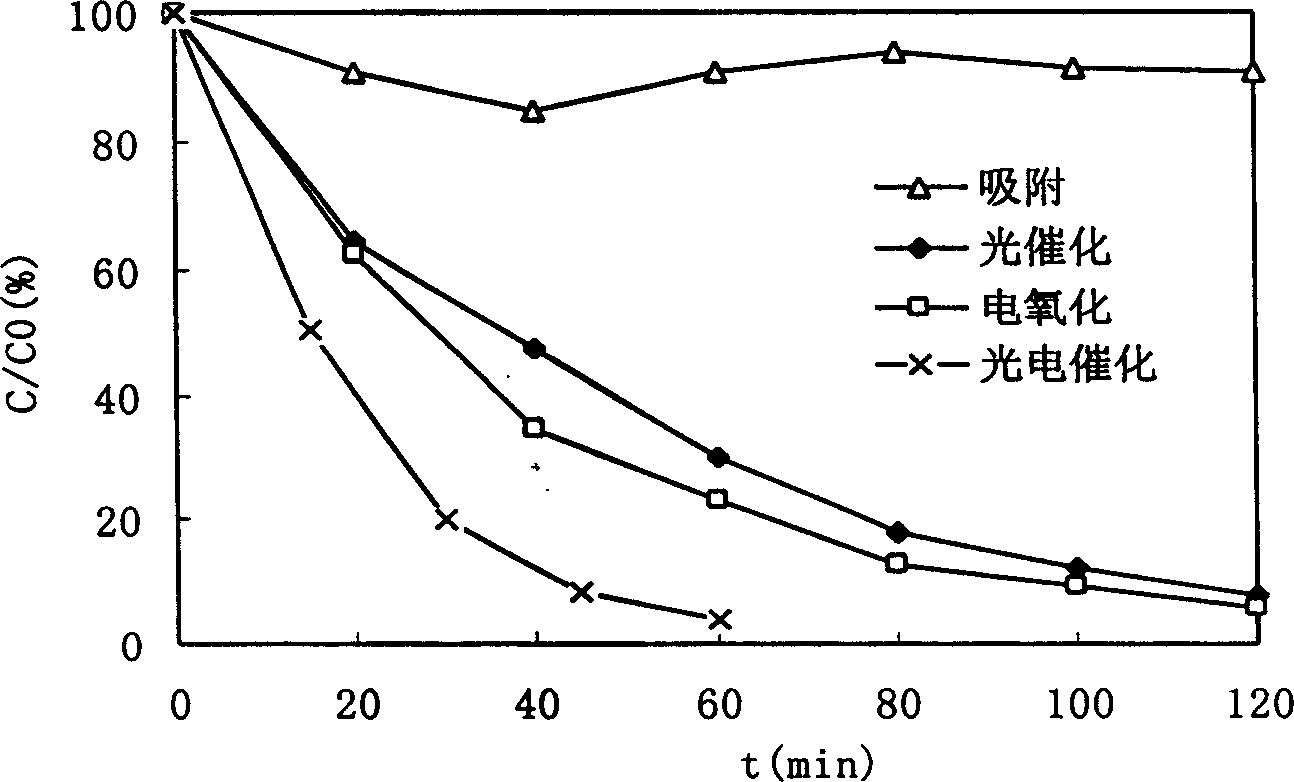

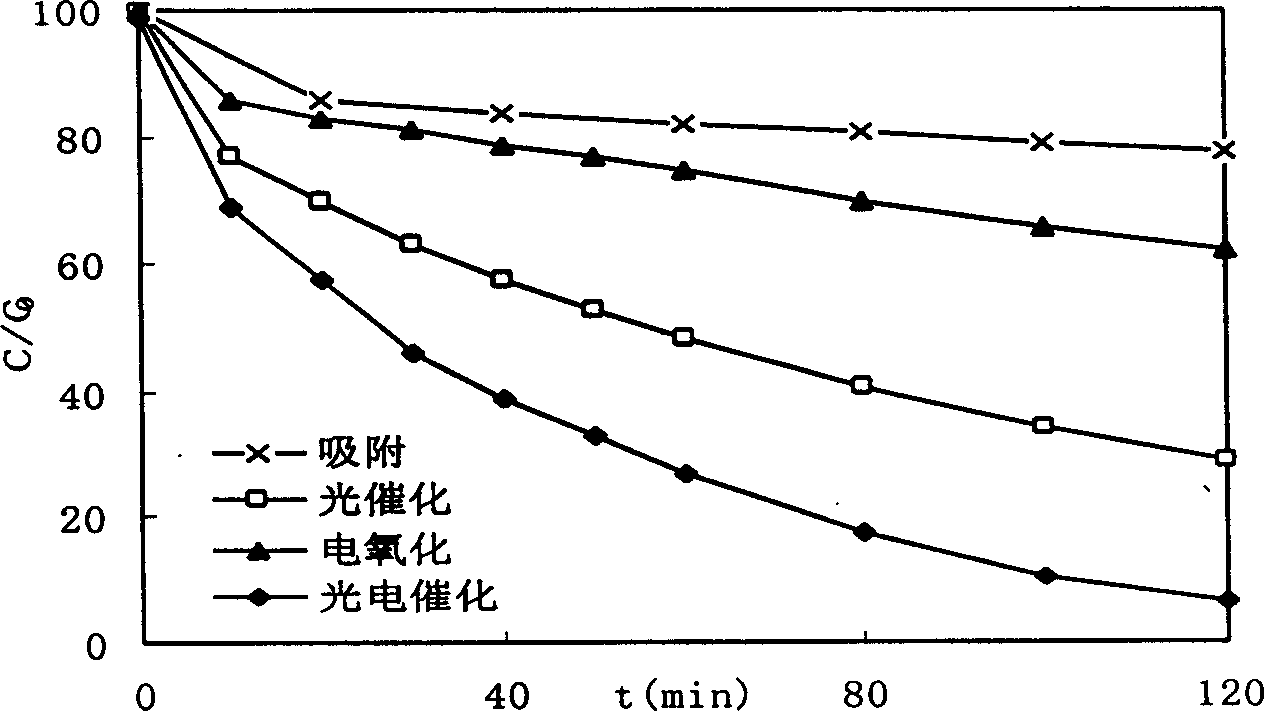

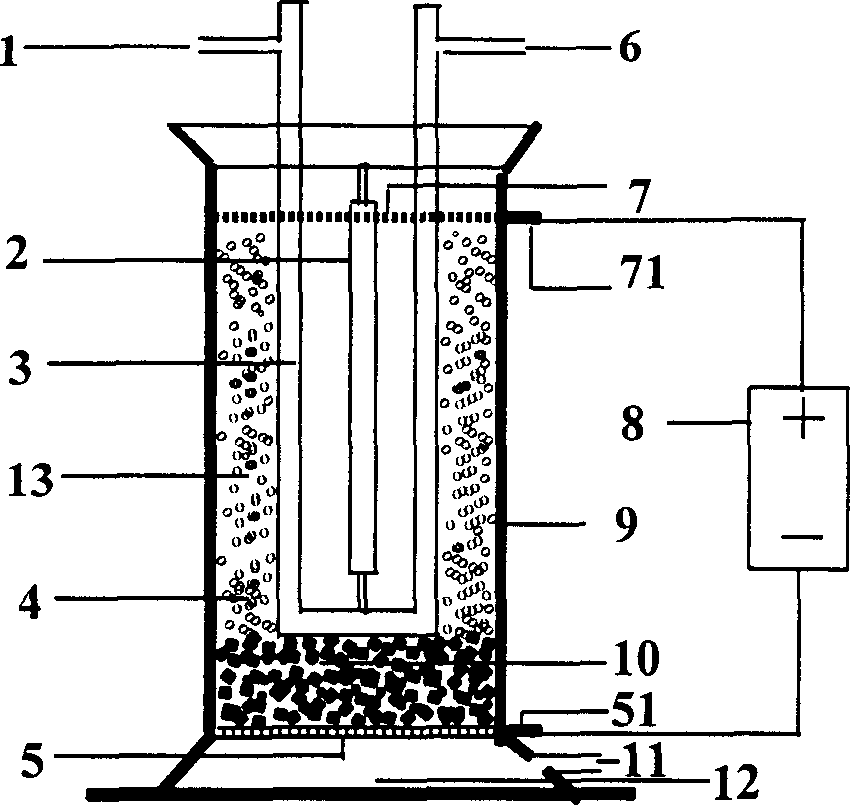

Organic wastewater treatment film reactor utilizing sunlight-assisted electro-catalysis

InactiveCN102603037AAccelerated adsorption/desorption rateThe actual user interface increasesWater/sewage treatment by irradiationEnergy based wastewater treatmentPhoto assistedPorous channel

The invention relates to an organic wastewater treatment film reactor utilizing solar energy photo-assisted electro-catalysis, which comprises a storage tank of water to be processed, a flow controllable constant flow pump, a photoelectric chemical reactor, a clear water storage tank and a solar battery component, wherein a photo anode and a cathode are correspondingly arranged in the reactor; the photo anode takes a porous metal membrane as a base body, and a TiO2 nano tube or a TiO2 mesoporous membrane is formed on the surface of a porous titanium membrane (net) by an electrochemical anisotropic etching technology; a porous channel film is used as the base body; a metal oxide coating electrode with high electrochemical catalytic activity and high electrical conductivity is prepared by a dipping film-forming method, simultaneously, by doping and modifying operations, the electrode material has photo catalytic activity and the reaction efficiency is improved. The reactor integrates electrochemistry, photocatalysis and film separation technologies; the three technologies are coupled to enhance a synergistic effect; the wastewater treatment efficiency can be improved; a solar component is adopted as a power supply; the clean solar energy is utilized to the maximal degree, and the organic wastewater treatment film reactor has social benefits of reducing environment load and economic benefits of reducing cost.

Owner:NANJING UNIV OF TECH

Medicinal porous titanium implant and method for preparing same

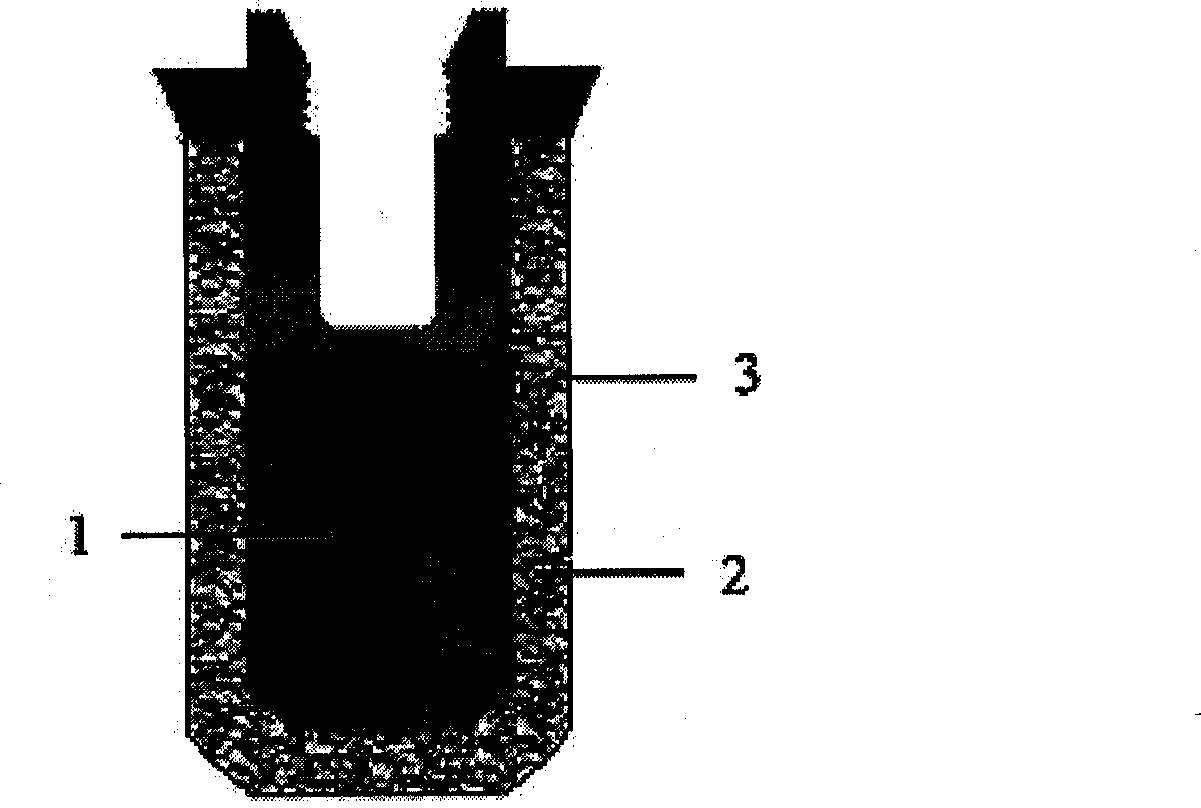

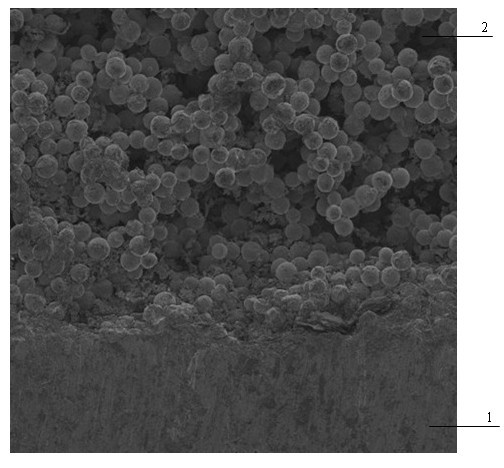

InactiveCN101518467AAchieve long-term stabilityIncrease initiativeDental implantsImpression capsStress concentrationMicrosphere

The invention discloses a medicinal porous titanium implant and a method for preparing the same. The porous titanium implant is prepared by a powder coinjection molding method; and a nano HA and TGF loaded sustained-release gelatin microsphere compound coating is deposited on the porous outer layer of the product. The outer layer of the implant has a communicated porous structure, the thickness of the porous layer is 0.4 to 1.1 millimeters, the porosity of the porous layer is 50 to 70 percent, and the aperture of the porous layer is 50 to 400 mum; the surface of the porous layer is deposited; and the binding strength of the outer layer and an inner core is 150 to 300MPa. Compared with the prior medicinal titanium implant material, the material of the medicinal porous titanium implant has higher mechanical strength, is in accordance with the mechanical performance of osseous tissue, avoids stress concentration and stress shielding, promotes stress transmission and growth of new bones, reduces time for osseointegration, and ensures the long-term stability of the implant. The method adopts once-for-all molding without post machining, thereby considerably reducing the cost.

Owner:CENT SOUTH UNIV

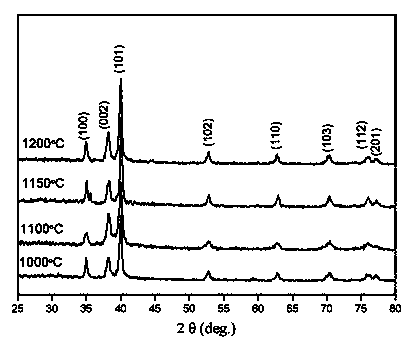

Preparation method of medical porous titanium and titanium alloy

InactiveCN102747245AImprove efficiencyGood mechanical propertiesProsthesisThermal insulationRepair material

The invention discloses a preparation method of medical porous titanium and titanium alloy, which comprises the following steps: proportionally preparing titanium powder, alloy element powder and pore forming agent powder according to needs; carrying out ball milling, mixing and mechanical pressing by a powder metallurgy blank making technique to obtain a blank; putting the blank in a thermal insulation barrel, and putting the thermal insulation barrel into a microwave sintering furnace; and after vacuumizing the furnace chamber to a vacuum degree of 0.1Pa, charging argon with the purity of 99.999% to form cyclic protection, controlling the output power of the microwave sintering furnace at 0.5-3kW, heating to the sintering temperature of 800-1200 DEG C at the heating rate of 5-40 DEG C / minute, keeping the temperature for 5-30 minutes, shutting down the microwave source, and carrying out furnace cooling to obtain the medical porous titanium and titanium alloy. The invention has the advantages of simple preparation method, short sintering period, high efficiency, low sintering temperature and low energy consumption; and the sintered porous titanium and titanium alloy have excellent mechanical properties, and can be used as alternate repair material for bones, joints, artificial radix dentis and other hard tissues.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

A bioactive porous titanium alloy human cervical intervertebral fusion device and its preparation method

ActiveCN102293693AEven by forceSolve the interface binding problemInternal osteosythesisMedical devicesMetallurgyDrug biological activity

The invention provides a porous titanium alloy human cervical interbody fusion cage with bioactivity and a preparation method thereof. The method comprises the following steps: firstly, inputting model data into electron beam melting equipment according to a design requirement to prepare a porous titanium alloy human cervical interbody fusion cage; secondly, preparing gelatin microspheres; and immersing gelatin microsphere dry powder in an rhBMP-2 solution for gelatin coating modification, preparing a gelatin solution A in double distilled water, immersing the porous titanium alloy human cervical interbody fusion cage in the gelatin solution A, mixing the rhBMP-2 gelatin microspheres and absolute ethanol to obtain suspension B, and immersing the gelatin-coating-modified porous titanium alloy human cervical interbody fusion cage in the suspension B to prepare the porous titanium alloy human cervical interbody fusion cage internally containing an rhBMP-2 sustained-release system. The cervical interbody fusion cage prepared with the method has modulus of elasticity close to that of natural bone tissues, and the porous structure and the bioactivity factor sustained-release system inside the cervical interbody fusion cage can induce growth of new bone tissues, so that the binding problem of bone-material interfaces is solved. Therefore, the cervical interbody fusion cage has bettermechanical compatibility and bone integration capability than those of a compact material.

Owner:维度(西安)生物医疗科技有限公司

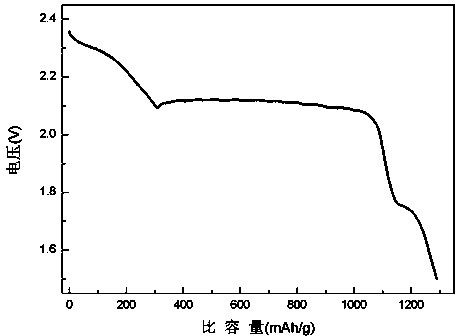

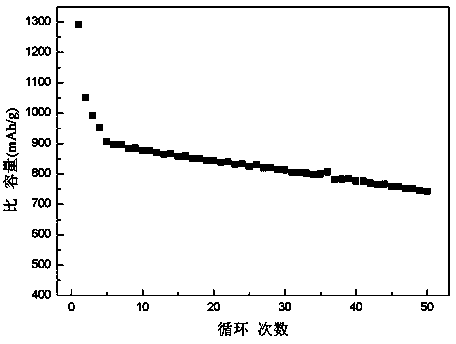

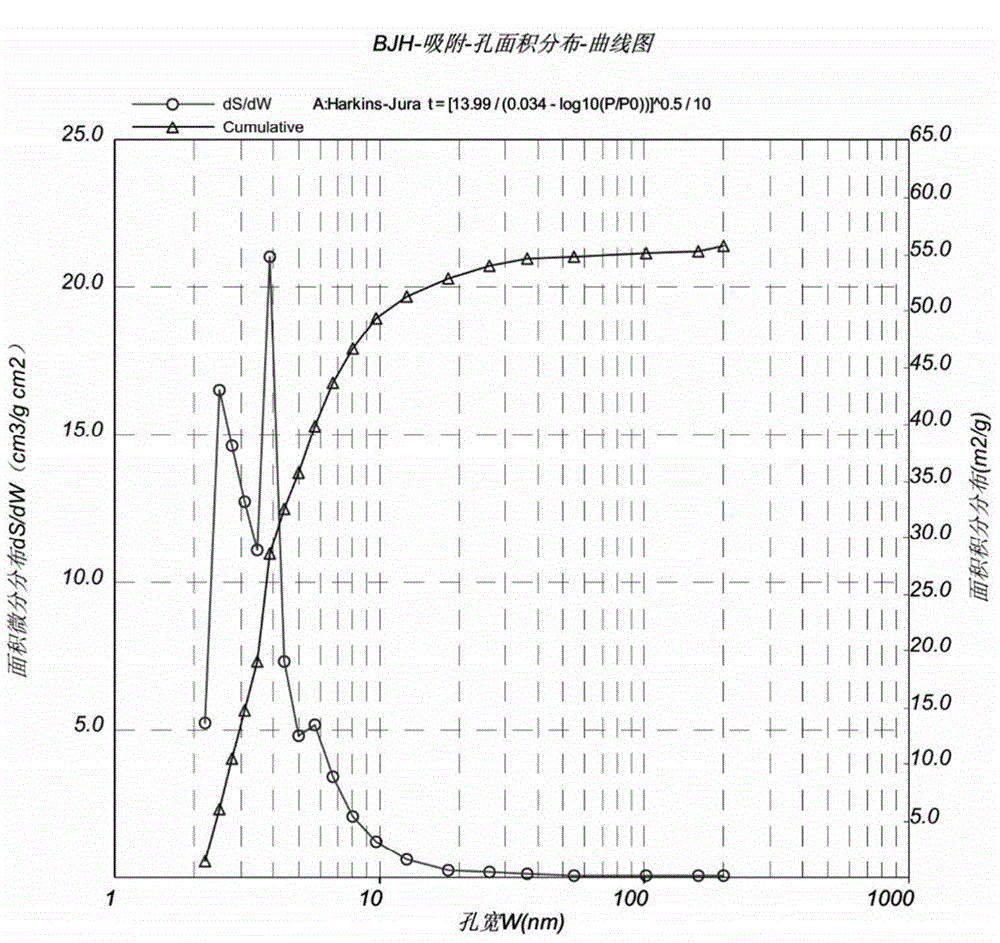

Preparation method of S/TiO2 composite material for anode of sodium-sulfur battery

ActiveCN103840143AImprove conductivityIncrease profitElectrode carriers/collectorsLi-accumulatorsSulfur electrodeHYDROSOL

The invention provides a preparation method of an S / TiO2 composite material for an anode of a sodium-sulfur battery. The preparation method comprises the following steps: dissolving butyl titanate, a template agent and a hydrolysis inhibitor into absolute ethyl alcohol; adding a mixed solution of de-ionized water and the absolute ethyl alcohol to form semi-transparent sol; transferring the sol into a high-pressure reaction kettle to react; calcining a solid product in air to remove the template agent to obtain meso-porous titanium dioxide; dispersing the meso-porous titanium dioxide into a sodium thiosulfate solution dissolved with a surfactant; adding hydrochloric acid to react; washing the solid product by a lot of the de-ionized water and drying; and eating under the protection of an inert atmosphere to obtain the S / TiO2 composite material. The meso-porous titanium dioxide prepared by the preparation method is large in specific surface area, high in porosity and strong in adsorption capability; the electrical conductivity of sulfur can be improved and a lot of nano sulfur and polysulfide can be contained; the polysulfide can be effectively prevented from being dissolved and diffused in electrolyte, and the utilization rate of the sulfur is improved; meanwhile, the structure of the meso-porous titanium dioxide is stable and a pore channel cannot be easily damaged, so as to have buffering effects on volume expansion and retraction in a charging / discharging process of a sulfur electrode.

Owner:CENT SOUTH UNIV

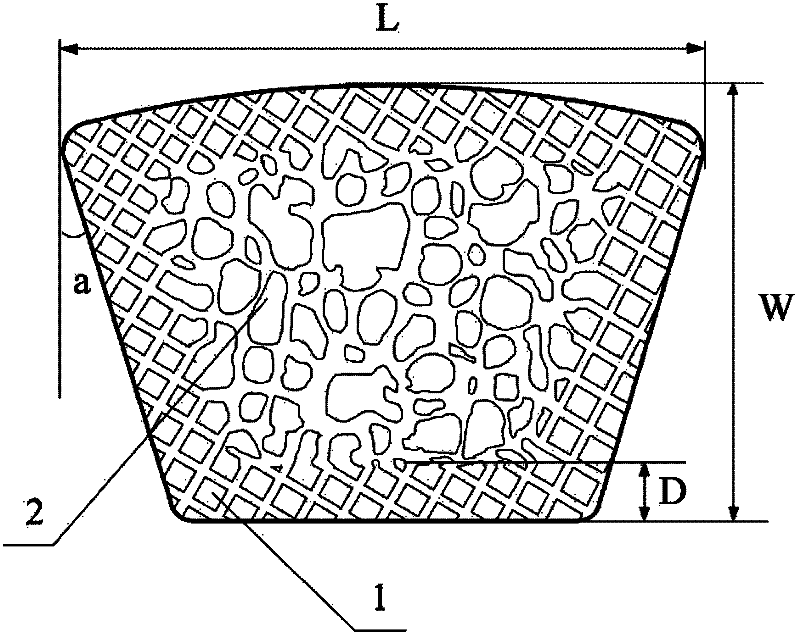

Composite technique of preparing lacunaris titanium coating by using cold spraying and vacuum sintering

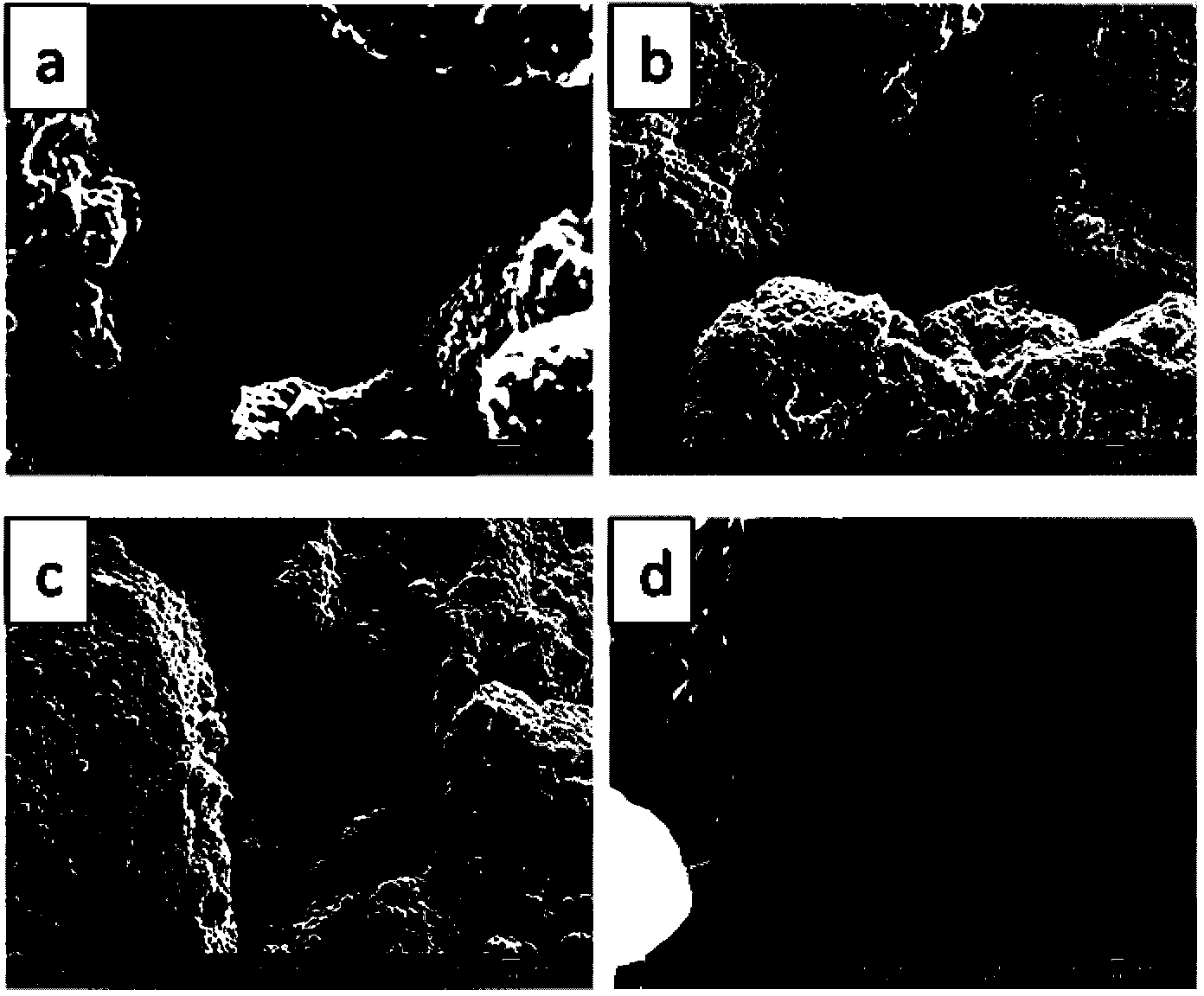

InactiveCN101032633AGood pore uniformityHigh bonding strengthImpression capsSurgeryArtificial boneTitanium alloy

The present invention discloses composite cold spraying and vacuum sintering process for preparing porous titanium coating. Mixed titanium-magnesium powder is first sprayed onto the roughened titanium or titanium alloy substrate to form composite titanium-magnesium coating, which is then sintered at high vacuum and high temperature to obtain porous titanium coating. Thus produced porous titanium coating has no oxide, thickness greater than 0.5 mm, opened and communicated pore structure, pores of 30-200 microns, porosity of 30-65 %, and metallurgical combination with the substrate with combination strength higher than 60MPa and elastic modulus adjustable in 30-50 GPa. The present invention is suitable for making bearing hard tissue implant, such as artificial joint, artificial bone, artificial tooth root, etc. with improved long term stability.

Owner:XI AN JIAOTONG UNIV

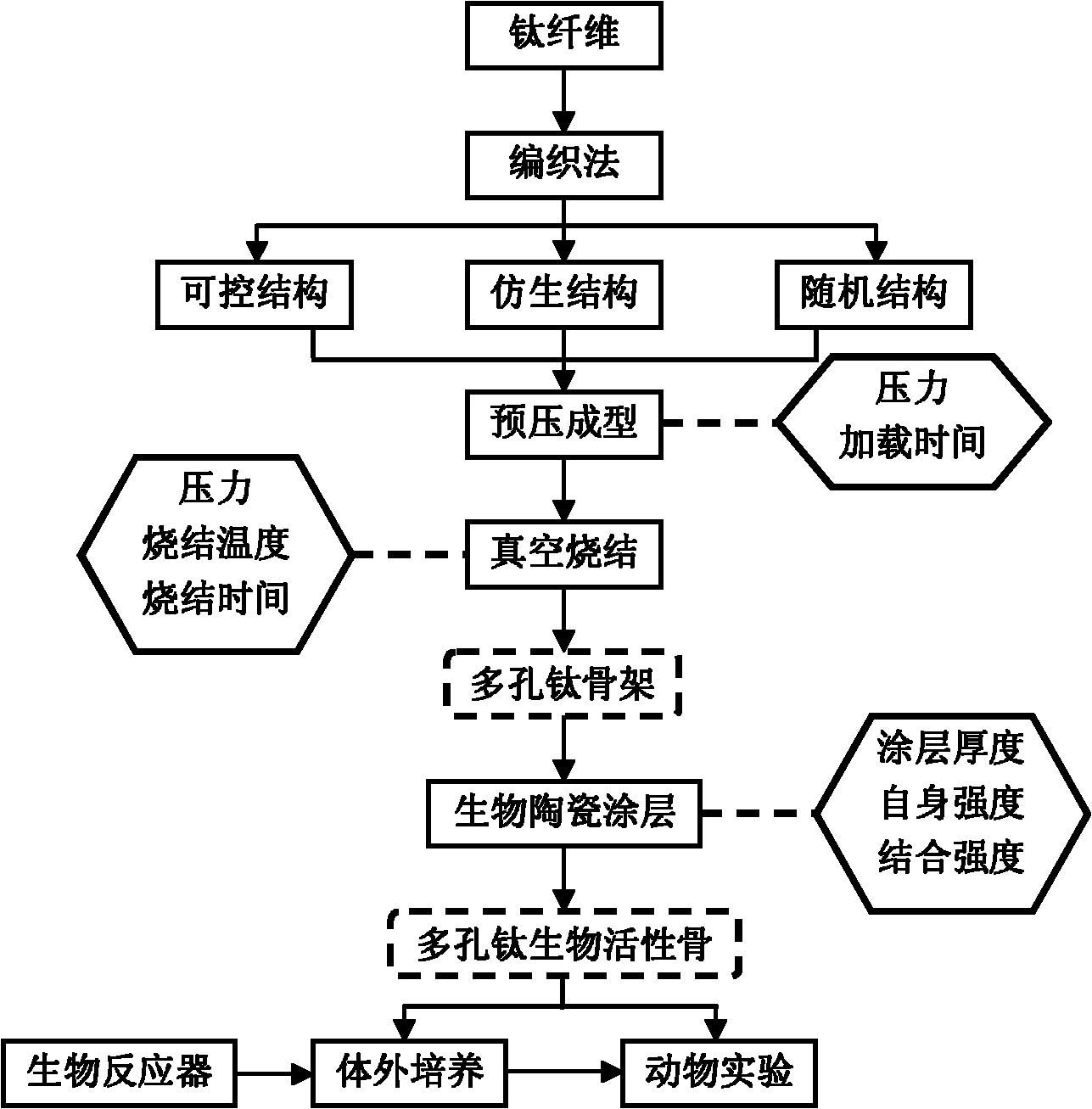

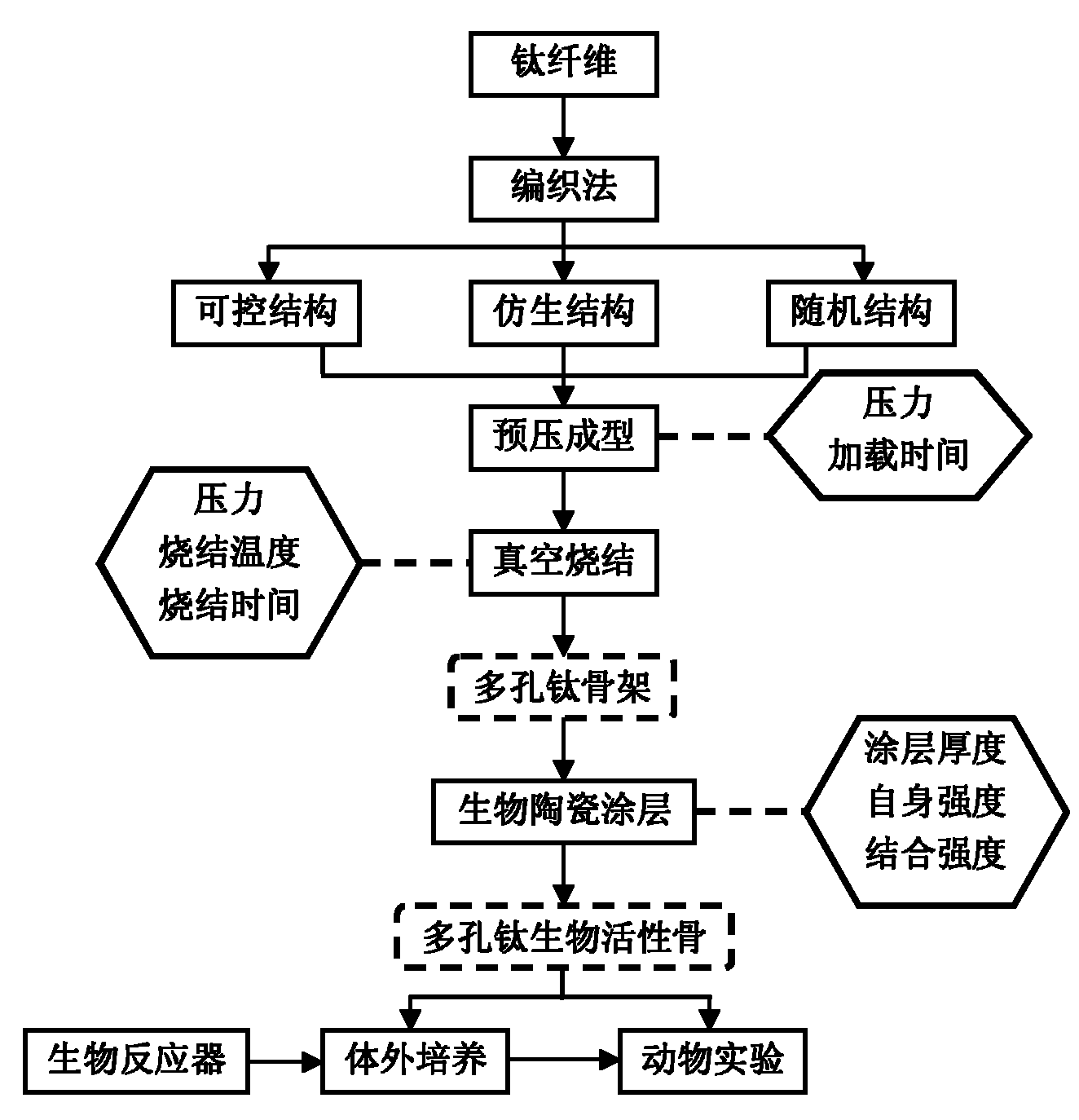

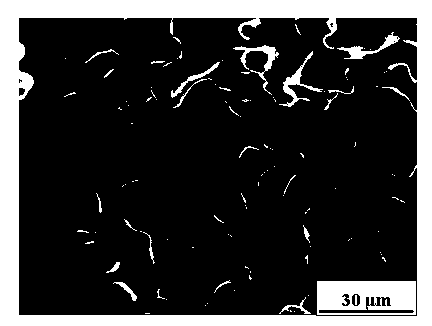

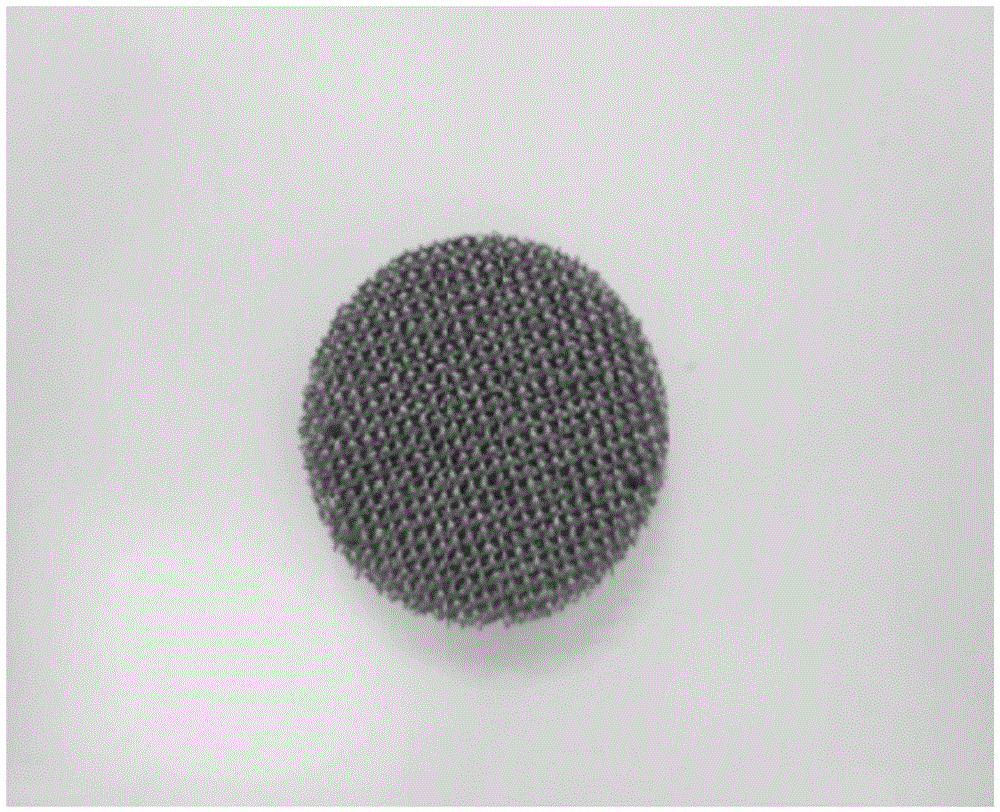

Preparation method of bio-ceramic coating titanium-wire sintering porous titanium artificial bone

InactiveCN101889912AHave biological propertiesBiologically activeBone implantCoatingsFiberPrincipal stress

The invention discloses a preparation method of a bio-ceramic coating titanium-wire sintering porous titanium artificial bone, belonging to the biomedical engineering field. In the invention, a three-dimensional weaving method is utilized, a titanium metal fiber wire is constructed into a controllable structure model, a random structure model and a bionic structure model which can stimulate the bone trabecula and principal stress line of a human bone, and then is prepared into the porous titanium artificial bone through prepressing molding and vacuum sintering, after that, a sol-gel method is utilized to manufacture a gradient coating or a complex coating on the surface of the porous titanium artificial bone, so that the gradient coating transiting from titanium dioxide to bio-ceramics or the bio-ceramics-titanium dioxide complex coating is formed on the surface of the porous titanium artificial bone to obtain the bio-ceramic coating titanium-wire sintering porous titanium artificial bone. The preparation method not only can protect the titanium metal skeleton and prevent titanium ions from dissociating to enter a human body, but also can ensure that the titanium metal skeleton the surface of which is coated with the bio-ceramics has the biological characteristics, therefore, the bio-ceramic coating titanium-wire sintering porous titanium artificial bone can be applied to repairing clinical segmental defect of long bones.

Owner:SHANGHAI JIAO TONG UNIV

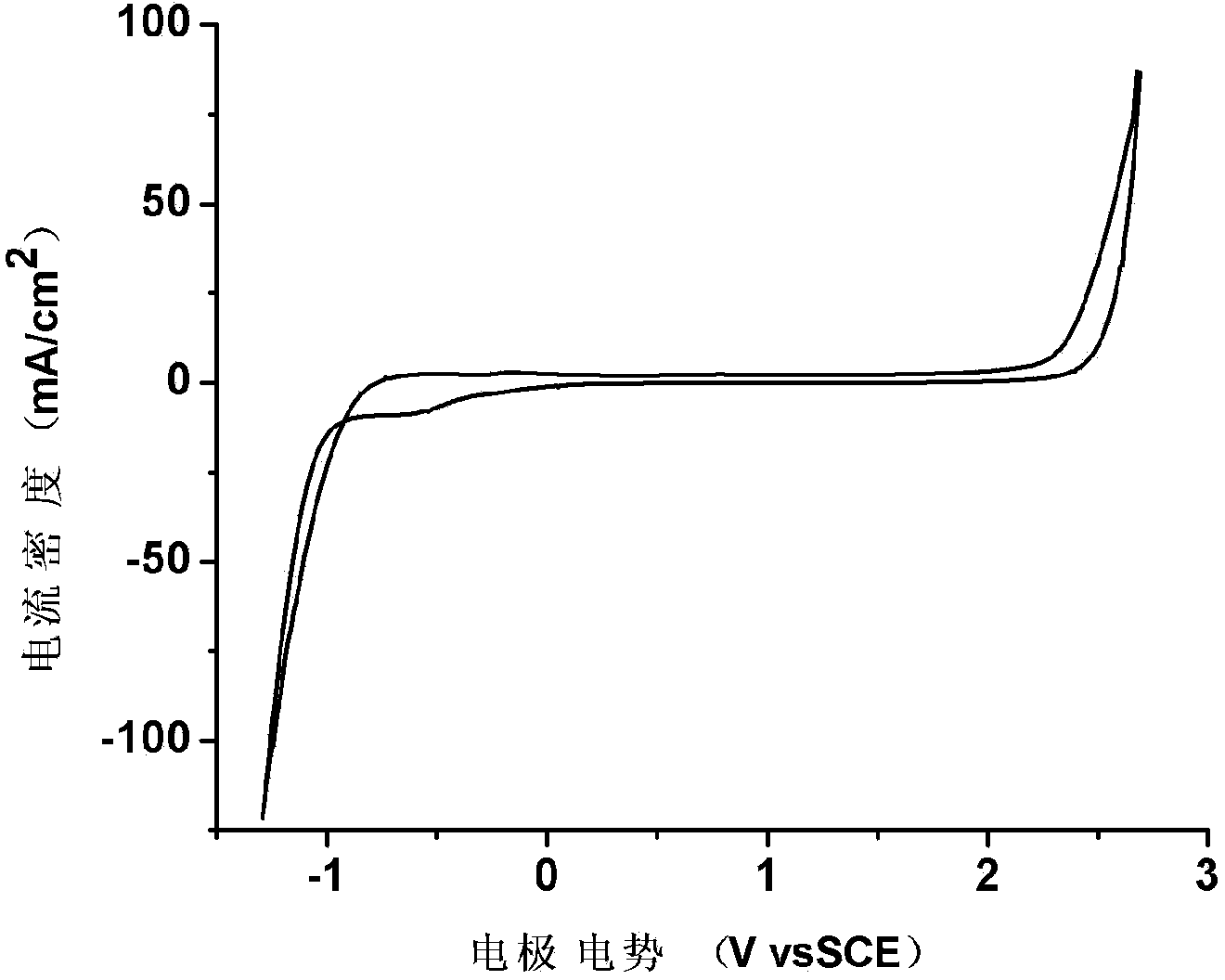

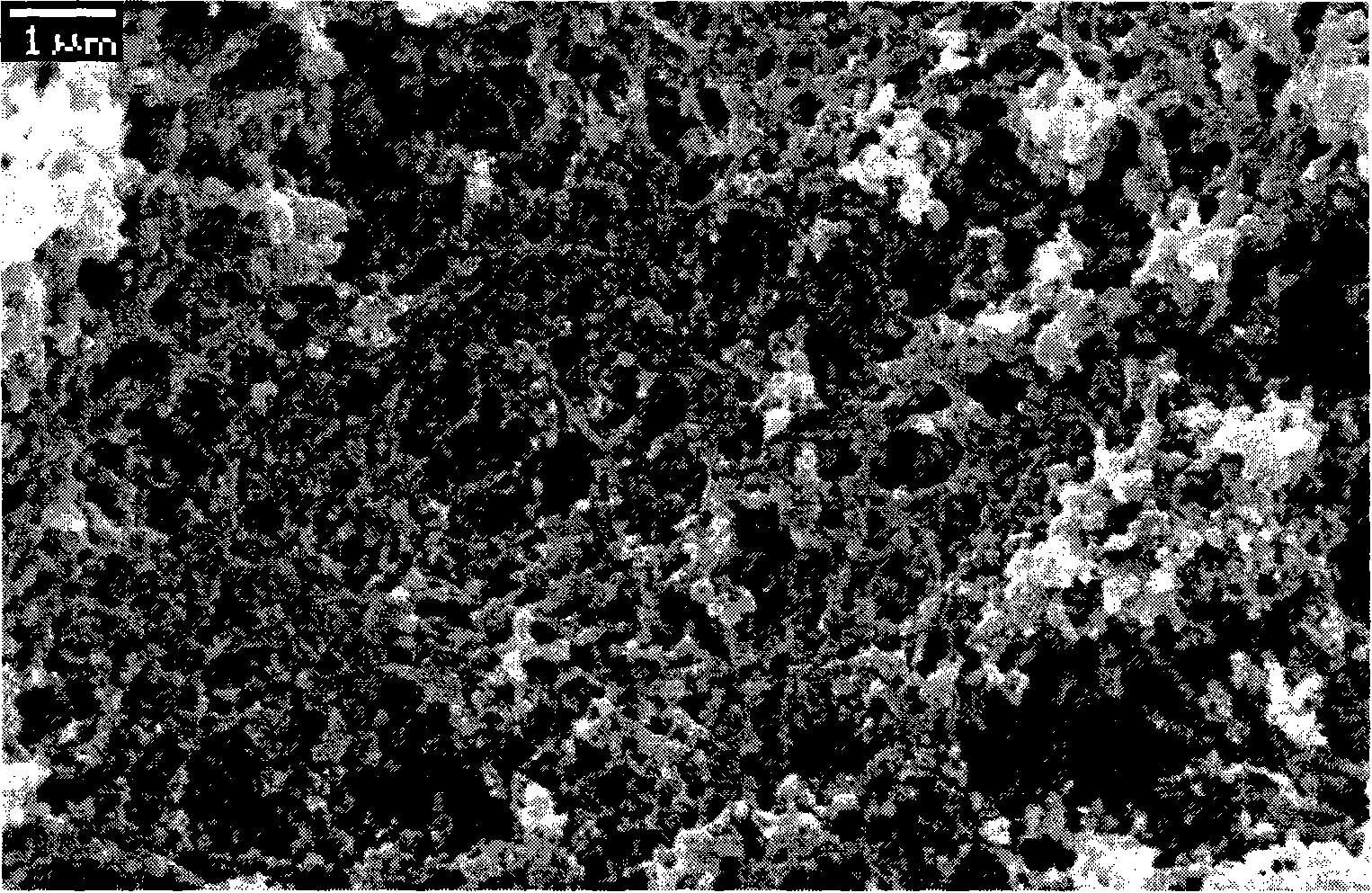

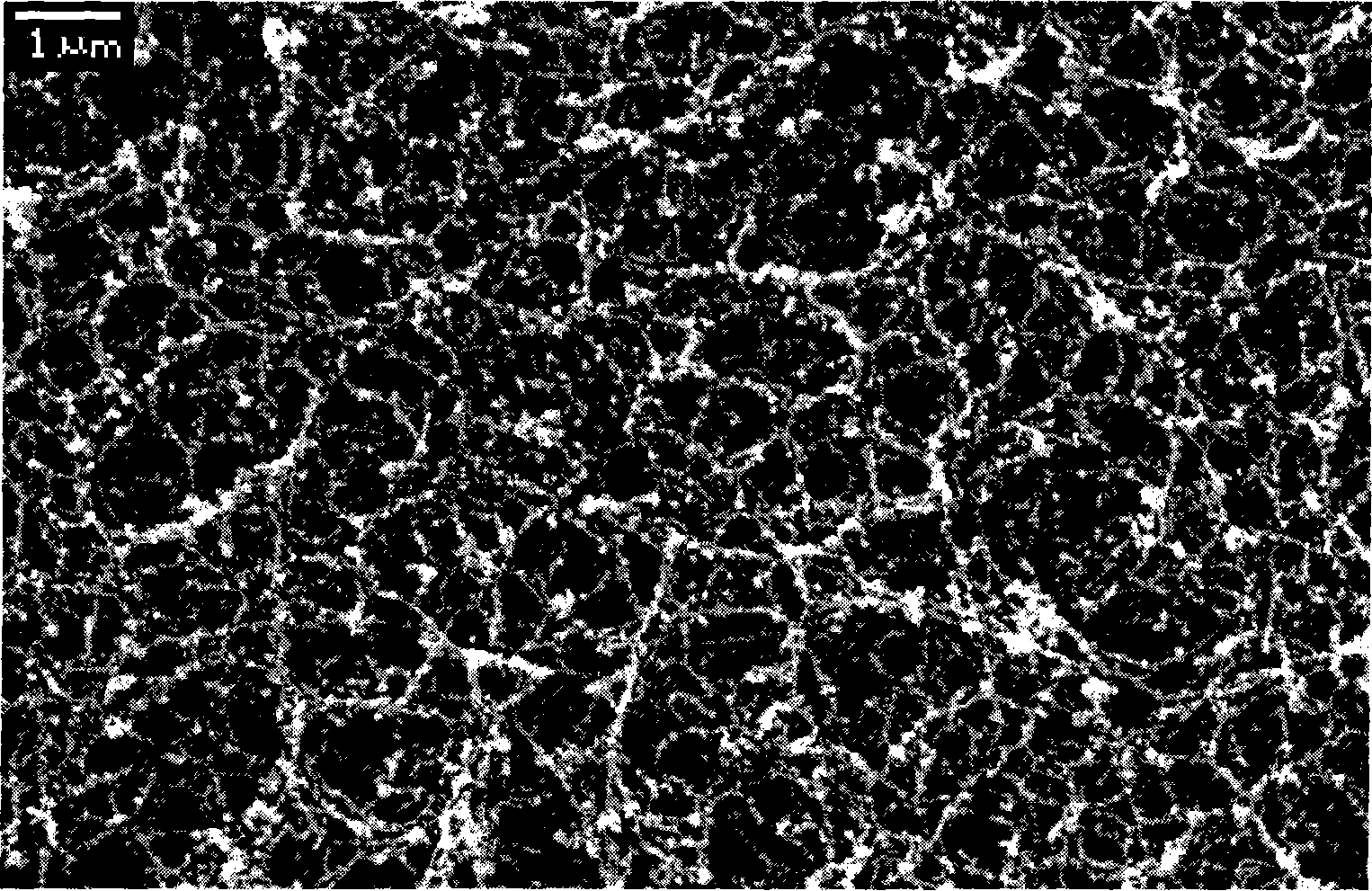

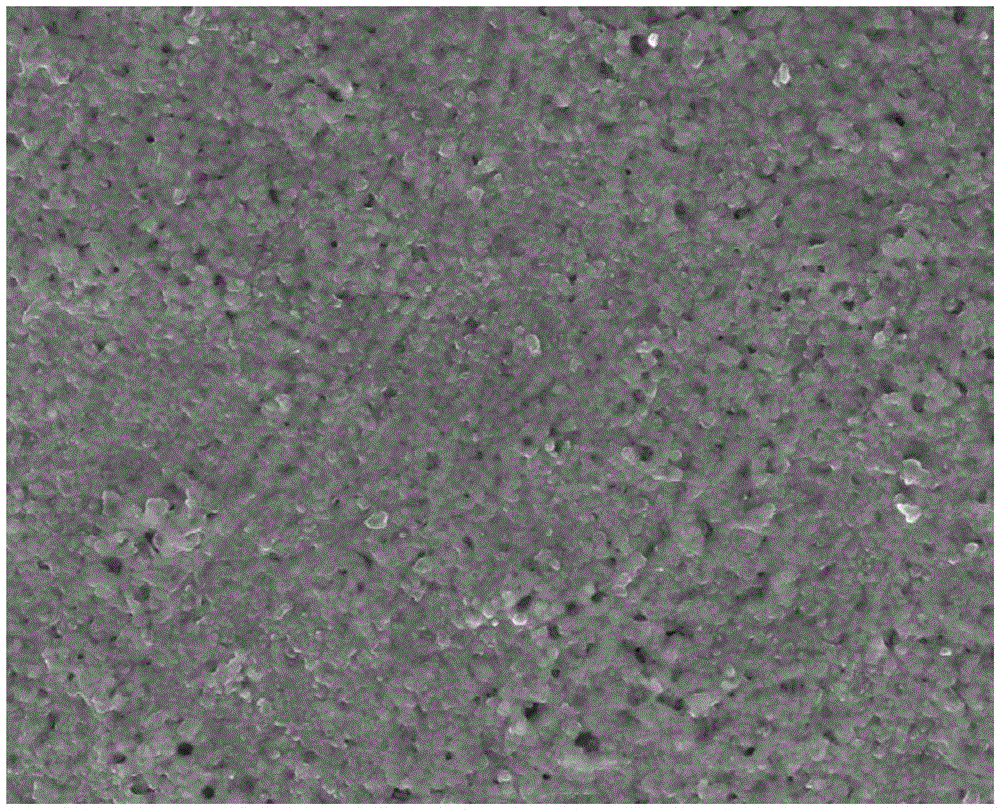

Preparation method of boron-doped diamond film electrode taking porous titanium as matrix

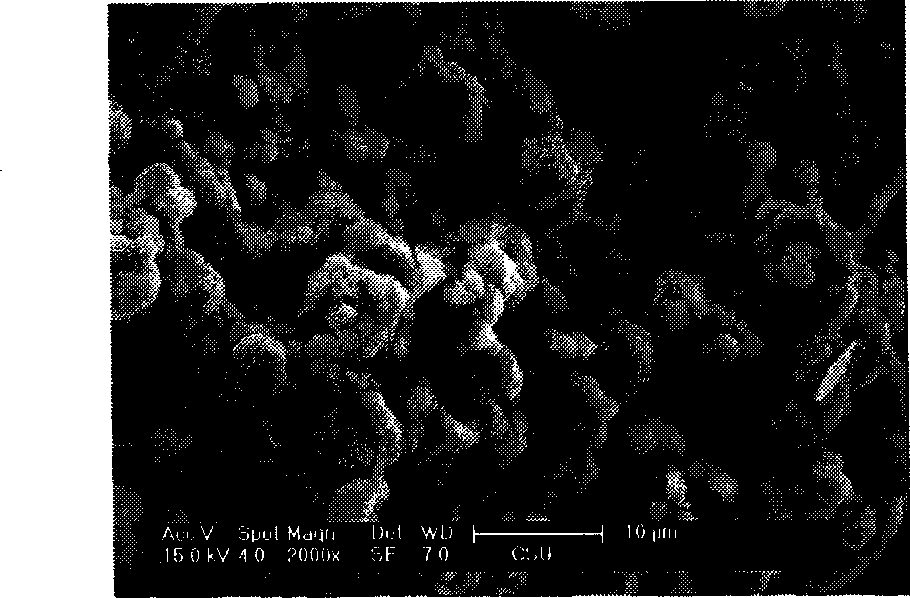

InactiveCN103643219AIncrease growth rateImprove stabilityChemical vapor deposition coatingGas phaseChemical vapor deposition

The invention discloses a preparation method of a boron-doped diamond (BDD) film electrode taking porous titanium as a matrix. The preparation method is characterized in that the titanium matrix is a porous titanium material with the porosity of 20-50%, hot filament chemical vapor deposition equipment is adopted, and a porous titanium base BDD electrode is prepared through chemical vapor deposition by using a second-order boron concentration control mode. By adopting the method, the generation capacity of TiC is controlled by adjusting boron source concentrations of different stages during chemical vapor deposition, namely the formation of TiC is inhibited by using high boron doping at the initial stage to improve the bonding force between a base and a film, and the boron source concentration is reduced in the later period of reaction to perform low boron doping. The porous titanium base BDD electrode prepared by the method disclosed by the invention is uniform and compact in diamond grain, and the porous titanium matrix is completely covered by a diamond film, so that the electrode has good stability and a relatively wide potential window.

Owner:JILIN UNIV

Preparation method of biomedical porous titanium

Owner:KUNMING UNIV OF SCI & TECH

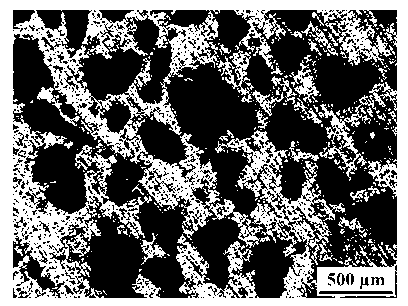

Preparation of porosity controllable porous titanium

The invention provides a preparation method of a porous titanium with controllable porosity, comprising the following steps: Ti powder and 1 wt.%-4 wt.% of binder are well mixed; urea particles are used as a pore forming agent and added into the mixture, the volume fraction between the pore forming agent and the mixture is 30-80 percent: 70-20 percent, and the mixture is mixed fully and evenly; and then the obtained mixture is one-direction pressed into blanks under the pressure of 100MPa to 250MPa; the obtained green compact is heated in a vacuum furnace with the vacuum degree kept between 10<-2> to 10<-3>Pa, thus obtaining porous metal members. The porosity can be determined by the quantity of added urea in the invention, and the size and shape of the pores can be determined according to the size (200Mum to 2mm) and shape of urea particles, thus realizing the target of controllable porosity, pore size and pore shape; the preparation method of the invention also has the advantages of simple technique, low equipment requirement, convenient operation and low cost.

Owner:CHONGQING UNIV

Preparation method and applications of ternary composite material

InactiveCN104324762AEfficient preparationPromote growthOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsSimple Organic CompoundsMaterials preparation

The present invention relates to a ternary composite material preparation method, and belongs to the technical field of material science, nanometer materials, catalysis and the like. According to the present invention, a cyanuric chloride hexahydroxy carboxylic acid ligand and copper nitrate are adopted as raw materials to prepare the hydrothermally stable porous metal organic framework material Cu-MOF, Cu-MOF is adopted as a carrier, nanometer silver is anchored on the surface of the carrier, and a porous titanium dioxide shell layer is coated to prepare the ternary composite material Cu-MOF@Ag@TiO2. The composite material has the excellent performance of catalytic reduction of unsaturated organic compounds, and has good application prospects in heterogeneous catalytic reduction reactions.

Owner:UNIV OF JINAN

Method for preparing biomedical porous titanium and titanium alloy material

InactiveCN101948964ANo need to worry about residueSimple processProsthesisTitanium alloyPorous titanium

The invention provides a method for preparing biomedical a porous titanium and titanium alloy material, belongs to the technical field of the preparation of biomedical materials, and relates to a method for preparing porous materials, in particular the method for preparing the porous titanium and titanium alloy material. The method for preparing the porous titanium and titanium alloy material comprises the following steps of: mixing the mixture of Ti powder and 1 to 40 mass percent of Mg powder serving as a pore-forming agent in a mixer for certain time; filling the mixture in a mould; forming a set shape under certain pressure; putting green bodies into a high temperature furnace; introducing argon; heating to the temperature of between 650 and 750 DEG C; keeping the temperature for 1 to 2 hours; continuously heating the blank to the temperature of between 1,150 and 1,250 DEG C; and keeping the temperature for 3 to 7 hours and cooling to prepare the porous titanium and titanium alloy material. The method has the advantages of simple process, convenient operation, no residue or pollution of the pore-forming agent and high pore-forming quality.

Owner:DALIAN UNIV OF TECH

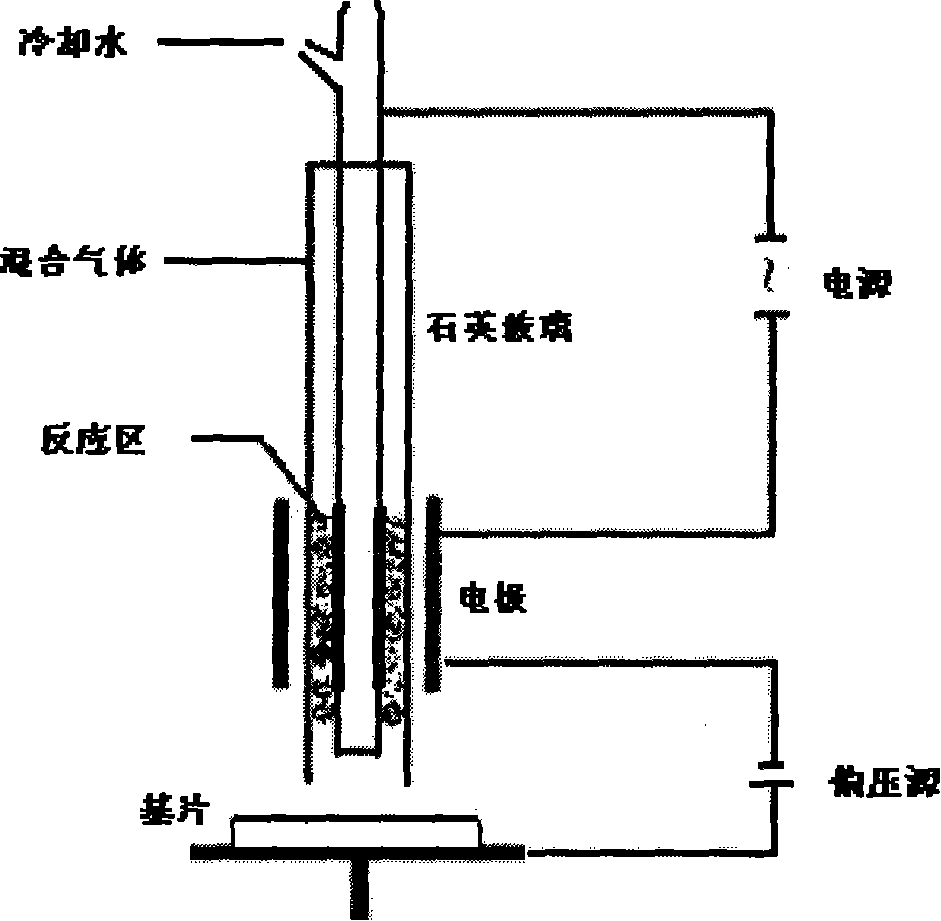

Nanocrystalline porous TiO2 film and preparation method thereof

InactiveCN101164689ACrystalline internal resistance is smallEasy transferPhysical/chemical process catalystsTitanium dioxideCrystal structureHigh pressure

The present invention relates to a nano crystal porous titanium dioxide film and its preparation method. Said film is a film with TiOn structure, in which n is 1.5-2.5, it is a polycrystalline crystal structure, its grain size is 10-500nm and its pore size is 10-500nm. Its preparation method includes the following steps: (1), cleaning matrix material by using ultrasonic wave, drying and placing the cleaned and dried matrix material in the lower portion of plasma reactor, introducing carrier gas inert gas; (2), introducing mixed gas of oxygen gas and titanium-containing gas carried by carrier gas, applying high-votage etectricity, regulating biasing electrode and pulse bias voltage, forming active granules containing titanium, under the action of biased polarization and acceleration forming wire-mesh structure, at the same time making the active granules containing titanium be carried onto matrix material surface and deposited; and (3), after the reaction deposition taking out matrix material, on the surface of matrix material can obtain the nano crystal porous TiO2 film.

Owner:DONGHUA UNIV

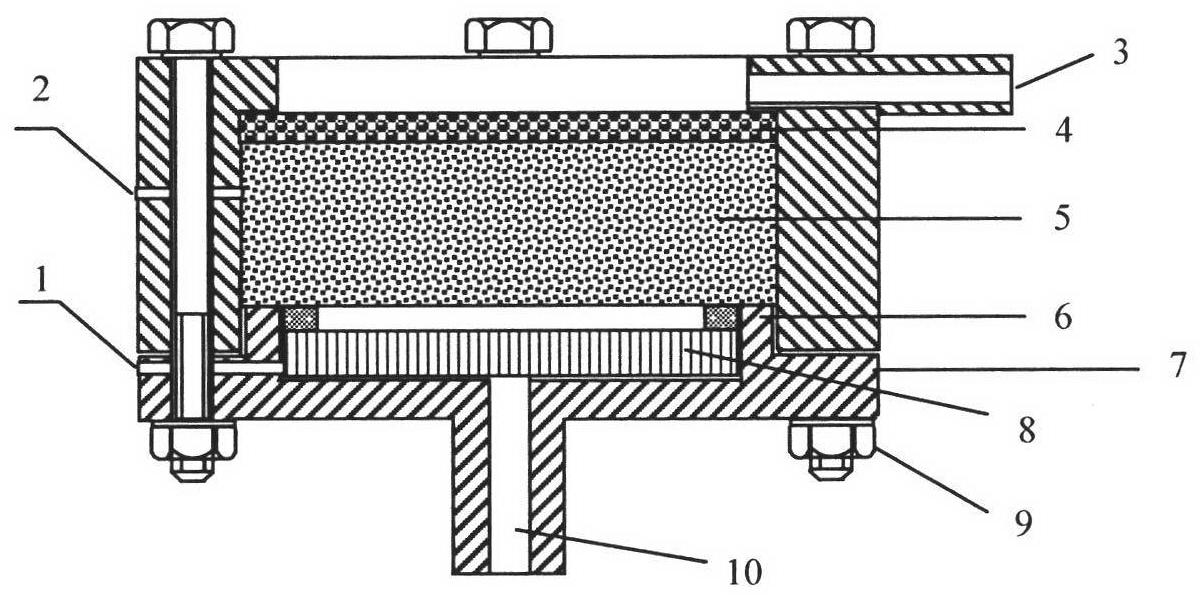

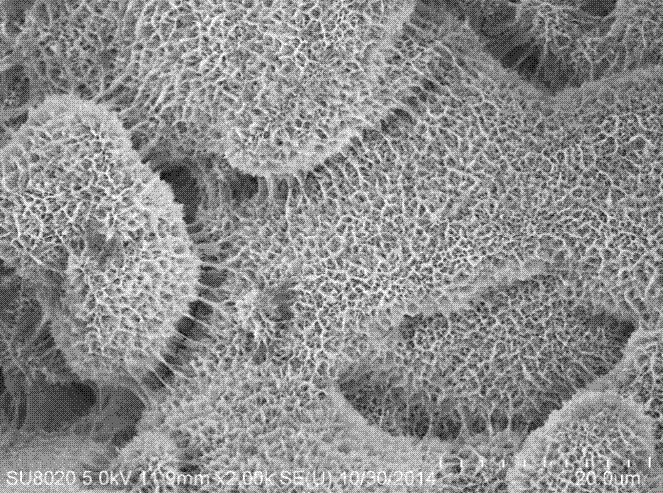

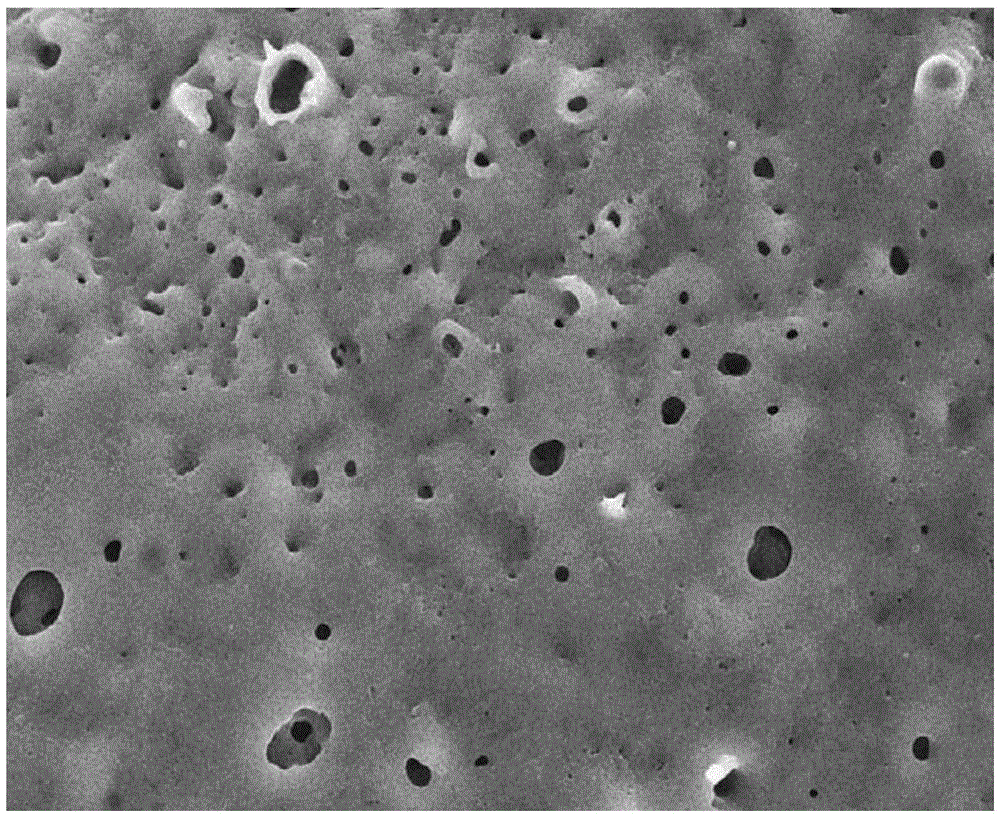

Electrocatalytic porous titanium filter membrane with micro nano structure and preparation method thereof

InactiveCN107020074AImprove electrocatalytic activityGood dispersionSemi-permeable membranesHeterogenous catalyst chemical elementsMicro nanoNanowire

An electrocatalytic porous titanium filter membrane with a micro nano structure and a preparation method thereof are disclosed, the electrocatalytic porous titanium filter membrane comprises a porous titanium film matrix, a TiO2 middle layer with the micro nano structure and an electrocatalytic active layer loaded on the TiO2 middle layer, the TiO2 middle layer with the micro nano structure is TiO2 nano flower, nanowire, nanorod or nanotube aggregates growing in situ on the porous titanium film matrix, and the electrocatalytic active layer is PbO2, SnO2, RuO2, IrO2, Sb2O5, Bi2O3 and other transition metal oxides or a composite comprising the various metal oxides. The method comprises three main steps: pretreatment of the porous titanium matrix, construction of the middle layer with the micro nano structure and loading of the active layer. The electrocatalytic porous titanium filter membrane has excellent mass transfer performance, high electrocatalytic activity, high pollutant removal efficiency, low energy consumption, and the like, thus having a good application prospect in the field of organic wastewater treatment.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

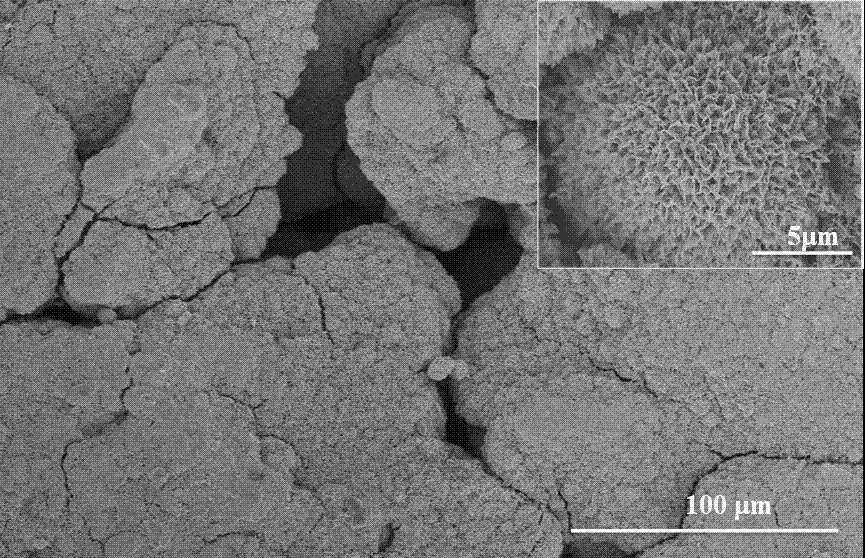

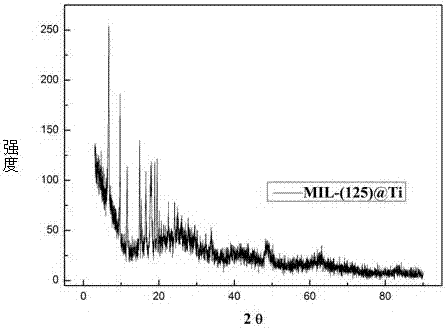

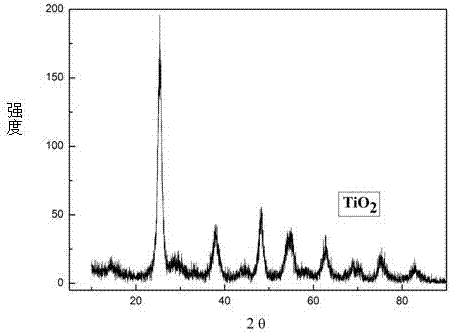

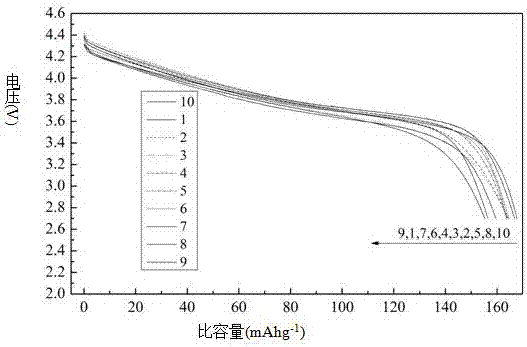

Method for coating and modifying lithium ion battery positive electrode material

InactiveCN107195899AImprove electrochemical performancePromote commercializationCell electrodesNew energyMetal-organic framework

The invention discloses a method for coating and modifying a lithium ion battery positive electrode material, and belongs to the technical field of a new energy lithium battery positive electrode material. The method comprises the steps of uniformly mixing the positive electrode material in a solution of a template agent, an organic solvent, a ligand and an organic titanium salt; transferring the uniformly-mixed solution to a high-pressure reaction kettle, and automatically assembling the organic metal salt and the ligand into a metal organic framework material (MOFs) under high temperature and high pressure and under an effect of the template agent, wherein the MOFs is uniformly coated on a surface of the positive electrode material; and performing calcination on the obtained product after filtering, drying and grinding to obtain the final lithium ion battery positive electrode material coated with porous titanium dioxide. With the lithium ion battery positive electrode material prepared by the method, the high- and low-temperature performance of the battery is improved; and the titanium dioxide with a stable structure is coated on the surface of the positive electrode material, and the cycle stability of the positive electrode material can be remarkably improved.

Owner:KUNMING UNIV OF SCI & TECH

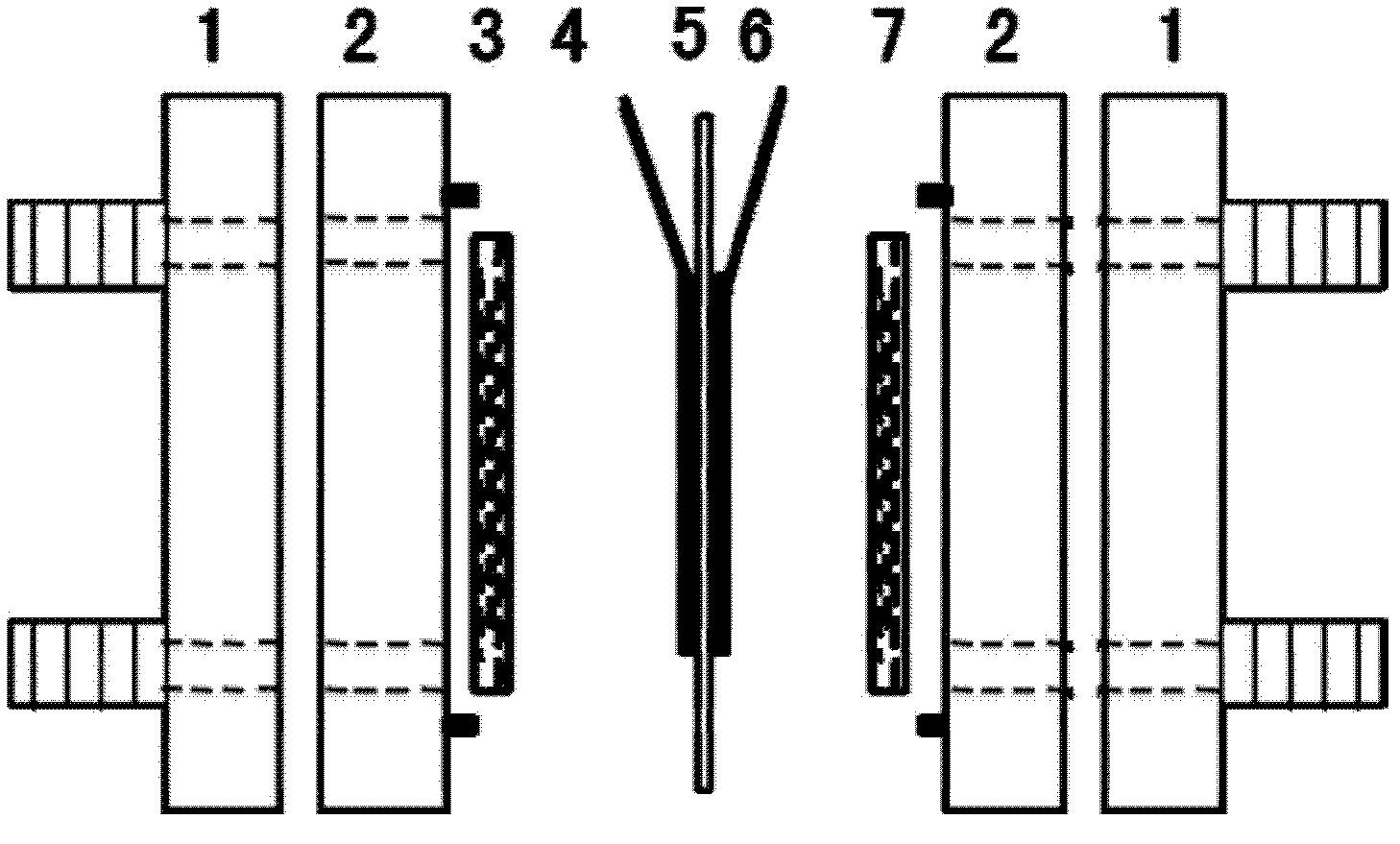

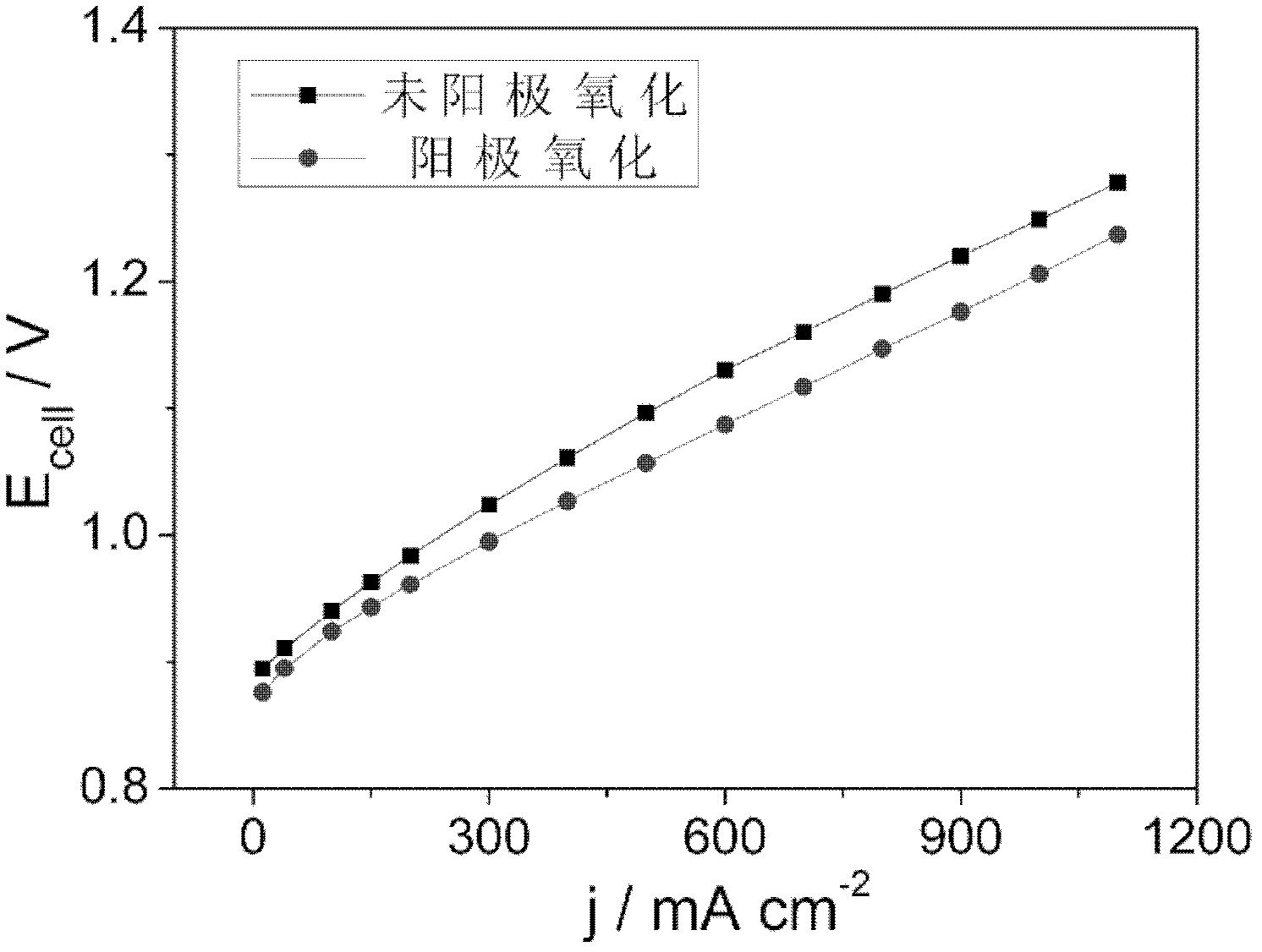

Treating method of metallic titanium material

ActiveCN103173835ASimple preparation processNo complex equipment requiredElectrolytic inorganic material coatingCell electrodesAnodizingFuel cells

The invention provides a treating method of a metallic titanium material. The metallic titanium material is sintered porous titanium, a titanium felt, a titanium mesh or foaming titanium. The treating method of the metallic titanium material comprises the following steps of: purifying the surface of the titanium material; taking the titanium material after purification as an anode to carry out anodizing; and electro-depositing a layer of catalyst or coating a catalyst precursor on the surface of the titanium material after oxidation, and carrying out high-temperature roasting to obtain the titanium material with high catalytic activity. The prepared titanium material with the catalytic activity can be used as a diffusion layer and also an electrode, has the advantages that the preparation method is simple, the catalytic activity is high, the decomposition voltage is greatly lowered, the energy utilization ratio is increased, and the like, is applied to a hydrobromic acid electrolytic cell and can also be used as the diffusion layer or the electrode in a hydrobromic fuel cell and a hydrobromic reproducible energy storage cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

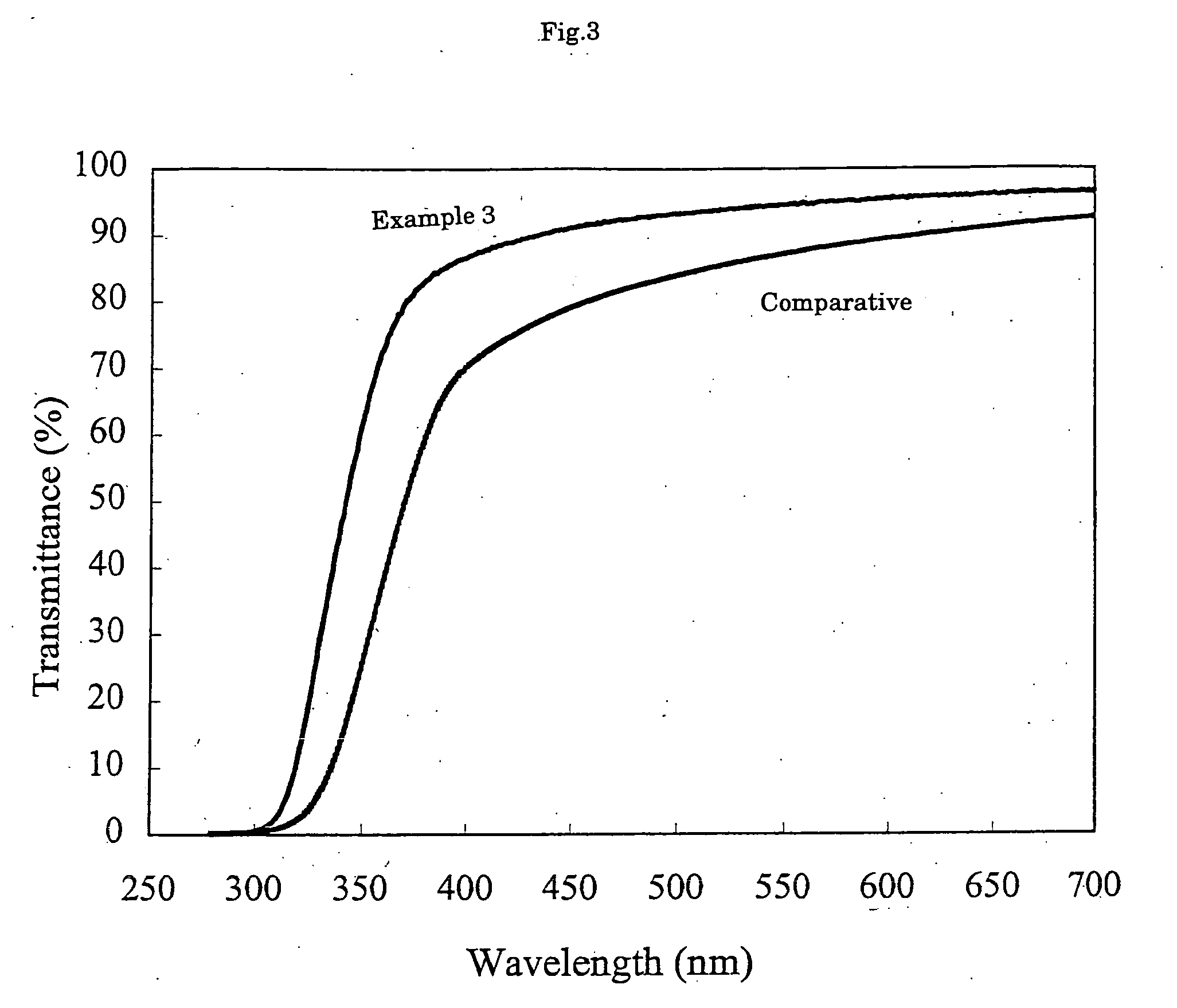

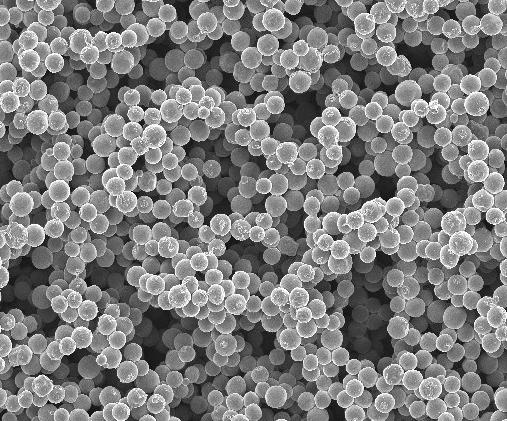

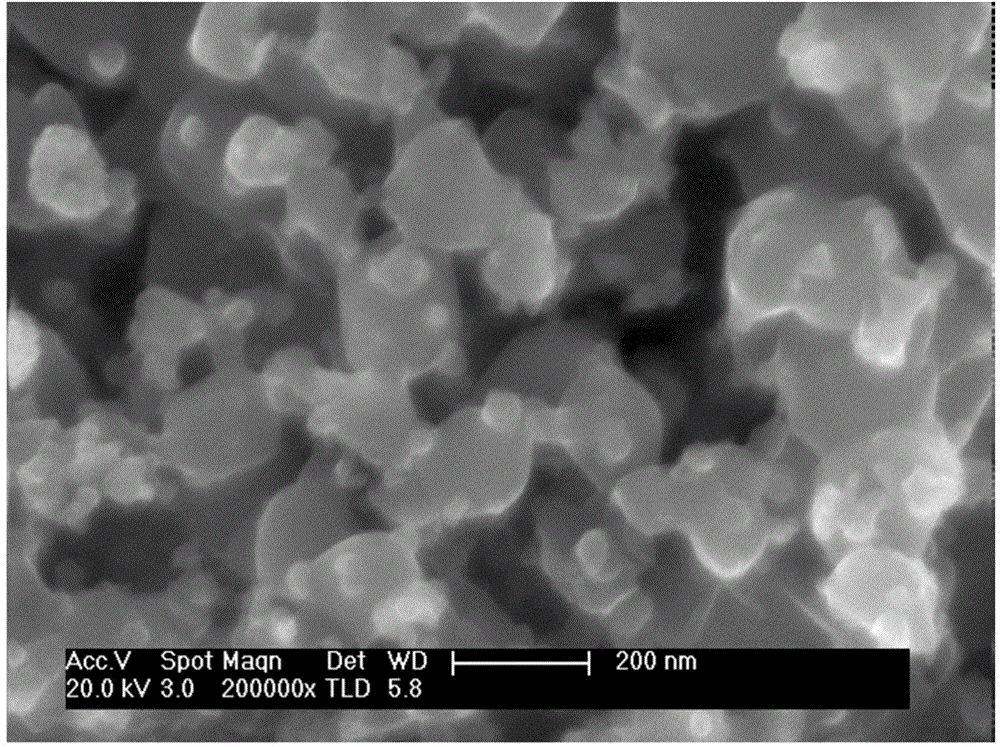

Porous titanium oxide powder and method for production thereof

InactiveUS20060188432A1Excellent ultraviolet-protecting ability and usability and transparencyLarge specific surface areaCosmetic preparationsMaterial nanotechnologyUltravioletSpherical shaped

There is provided a titanium oxide powder having excellent ultraviolet-protecting ability, usability and transparency, and a method of manufacturing the same. The titanium oxide powder provided is a porous titanium oxide powder that is formed from titanium oxide primary particles agglomerated together, has a mean particle diameter of 0.01 to 100 μm, and has a specific surface area of 250 to 500 m2 / g. The porous titanium oxide powder can be obtained by subjecting a titanium salt solution to hydrolysis by heating under the presence of an aliphatic alcohol and / or a substance having a carboxyl group or a carbonyl group, and then further carrying out heating treatment with an acid. The titanium oxide primary particles preferably have a mean particle diameter of 1 to 50 nm, and the powder preferably has an approximately spherical shape with the ratio of the minor axis to the major axis being at least 0.75.

Owner:SHISEIDO CO LTD

Preparation method of titanium carbide-based cermet powder material for thermal spraying

InactiveCN102166652AImprove wear resistanceReduce coefficient of frictionMolten spray coatingSelf-propagating high-temperature synthesisThermal spraying

The invention provides a preparation method of a titanium carbide-based cermet powder material for thermal spraying, which belongs to the field of powder materials for thermal spraying. The method comprises the following steps of: firstly, weighting titanium powder, graphite powder / soot carbon, and other metal components in a proportion to prepare raw material powder; putting the raw material powder into a ball mill pot for ball milling, briquetting the mixture to form a block after the mixing is finished, placing in a self-propagating high-temperature synthesis reactor, igniting the block after the air in the reactor is removed so that the whole block is ignited to undergo a self-propagating reaction; starting a mechanical pump to vacuumize after the reaction is finished, and cooling reaction products to room temperature with the reactor so as to obtain a loose porous titanium carbide-based cermet block; and finally, after the cermet block is taken out, removing contaminants on the surface of the cermet block, and then crushing and screening residual products to obtain titanium carbide-based cermet powder for thermal spraying in different grain sizes. The preparation method in the invention has the characteristics of short synthesis time, energy saving, environmental protection, low price, and the like, and is suitable for industrial production.

Owner:UNIV OF SCI & TECH BEIJING

Bio-medicinal porous titanium material and preparation method thereof

InactiveCN101912635AReduce Insufficient StrengthReduced stress shieldingProsthesisNatural boneBiocompatibility

The invention discloses a bio-medicinal porous titanium material. The porous titanium material comprises at least two layers, the porosity of the material is enlarged layer by layer from inside to outside, the porosity of the innermost layer is 0 to 50 percent, the porosity of the outermost layer is 30 to 90 percent, and the size of aperture is 50 to 500 microns. The porous titanium material has excellent corrosion resistance and biocompatibility, has the mechanical property matched with natural bones, meanwhile can provide a good transmission passage for growth of bone cells, and can solve the stress shielding phenomenon and the problems of loosening, breakage and the like.

Owner:SICHUAN UNIV

Preparation method of three dimensional nanometer porous titanium and alloy thereof

The invention provides a preparation method of three dimensional nanometer porous titanium and alloy thereof. The method adopts a powder coated solid phase sintering technology, and comprises the following steps: coating a mother alloy block with a dealloying medium material with magnesium metal or magnesium alloy powder as the dealloying medium material, and carrying out heat insulation sintering; and dissolving the surface coating dealloying medium material to prepare nanometer porous pure alpha titanium with a three dimensional block structure or nanometer porous beta titanium alloy. A powder metallurgy magnesium powder coated titanium alloy sintering dealloying technology is adopted, a solid phase dealloying technology adopting the magnesium-based powder as the dealloying medium is used to prepare the nanometer porous pure alpha titanium and beta titanium alloy, so the use amount of the magnesium powder can be stoichiometrically controlled according to the mass of a titanium alloy sample, the porosity of the prepared nanometer alpha titanium and beta titanium alloy is above 60%, and the aperture dimension is 1-100nm.

Owner:SOUTHEAST UNIV

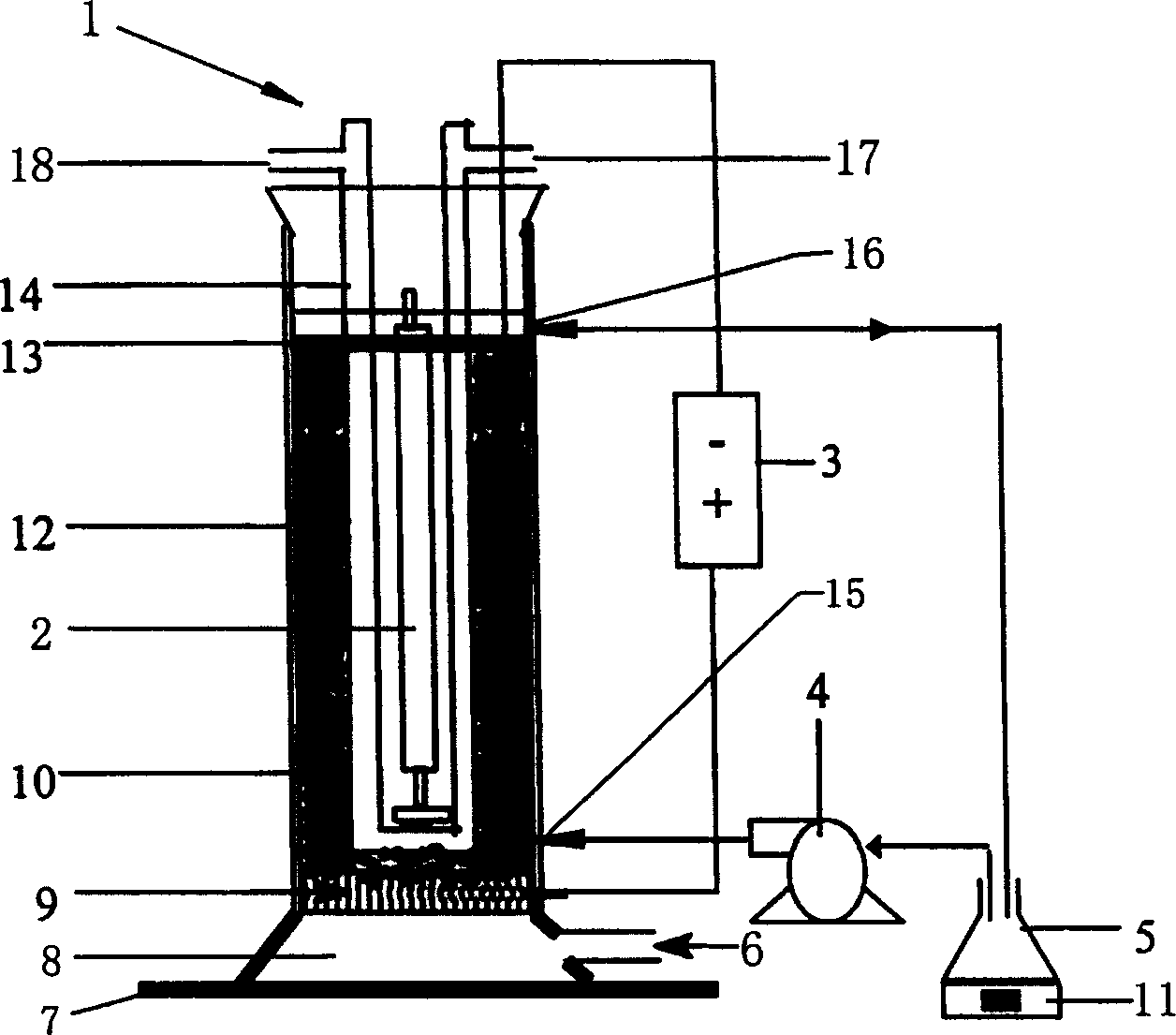

Continuous circular flow-type optoelectric catalytic fixed bed reactor with 3D electrodes and its organic sewage treating method

InactiveCN1526652ALow costGive full play to the efficiency of synergistic catalytic oxidationWater/sewage treatment by irradiationWater/sewage treatment by electrochemical methodsFixed bedTitanium plate

The continuous circular flow-type optoelectric catalytic fixed bed reactor has structure including casing, microporous titanium plate cathode, porous titanium ring anode, double-layer U-shaped quartz tube, UV lamp inside the U-tube as light source, optoelectric catalytic reaction chamber formed between the cathode and the anode, fixed bed 3D particle electrode set inside the reaction chamber and formed via painting nano TiO2 onto SiO2 particle, and continuous circulating unit comprising liquid storage and pump connected between the liquid inlet and liquid outlet of the reaction chamber. The present invention also provides the method and technological conditions of treating organic sewage with the reactor. Inside the reactor, voltage higher than the oxidation potential of the pollutant is applied to raise the photocatalytic and eletrocatalytic oxidation efficiency.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

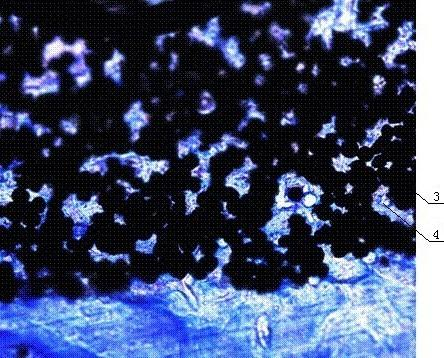

Preparation method and application of bacteriostatic bio-active ceramic membrane for porous titanium or titanium alloy surface of lattice structure

ActiveCN106676604AHeating up fastSimple film formationSurface reaction electrolytic coatingTissue regenerationMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a preparation method and application of bacteriostatic bio-active ceramic membrane for a porous titanium or titanium alloy surface of a lattice structure and belongs to the technical field of metal surface treatment. The preparation method of the bacteriostatic bio-active ceramic membrane for the porous titanium or titanium alloy surface of the lattice structure comprises the steps of chemical polishing, preparation of a prefabricated oxide film at a direct-current voltage and preparation of the bacteriostatic bio-active ceramic membrane at a bidirectional square-wave pulse voltage. Chemical polishing is conducted through a chemical acid pickling method. Preparation of the prefabricated oxide film is conducted through a low-voltage direct-current anodic oxidation method. Preparation of the bacteriostatic bio-active functional ceramic layer is prepared through a micro-arc oxidation preparation method. The ceramic layer obtained by the adoption of the preparation method is firmly combined with a matrix, the surface of the ceramic layer is provided with a micron-level microcellular structure, and the ceramic layer can greatly improve the bacteriostatic performance and biological activity of the porous titanium or titanium alloy surface. When an interbody fusion cage for the orthopedics field and an implant for the dentistry field are manufactured based on the preparation method of the bacteriostatic bio-active ceramic membrane for the porous titanium or titanium alloy surface of the lattice structure, the synosteosis time of the implant is shortened, and the bacteriostatic performance of the implant is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Three phase three-diemsnional electrode photoelectric reactor

InactiveCN1377728AEfficient electro-oxidationImprove photocatalytic oxidation efficiencyWater/sewage treatment by irradiationEnergy based chemical/physical/physico-chemical processesWastewaterThree-phase

The photoelectric reactor used in treating organic waste water consists of casing, 3D particle electrode, porous cathode titanium plate, anode titanium net, light source UV lamp and photocatalyst. Itis one combination of triphase 3D electrode and photocatalytic technology, and it can capture photoelectrons in anode with bias voltage to raise the photocatalytic oxidation efficiency of titania andutilize the indirect electrochemical oxidatino and photocatalytic oxidation of H2O2 as strong oxidant produced in the 3D cathode. In addition, the porous titanium plate as both electrical feeder and aeration unit results in compact and reasonable structure, increased dissolution speed of oxygen of air in water and thus organic pollutant eliminating efficiency.

Owner:SUN YAT SEN UNIV

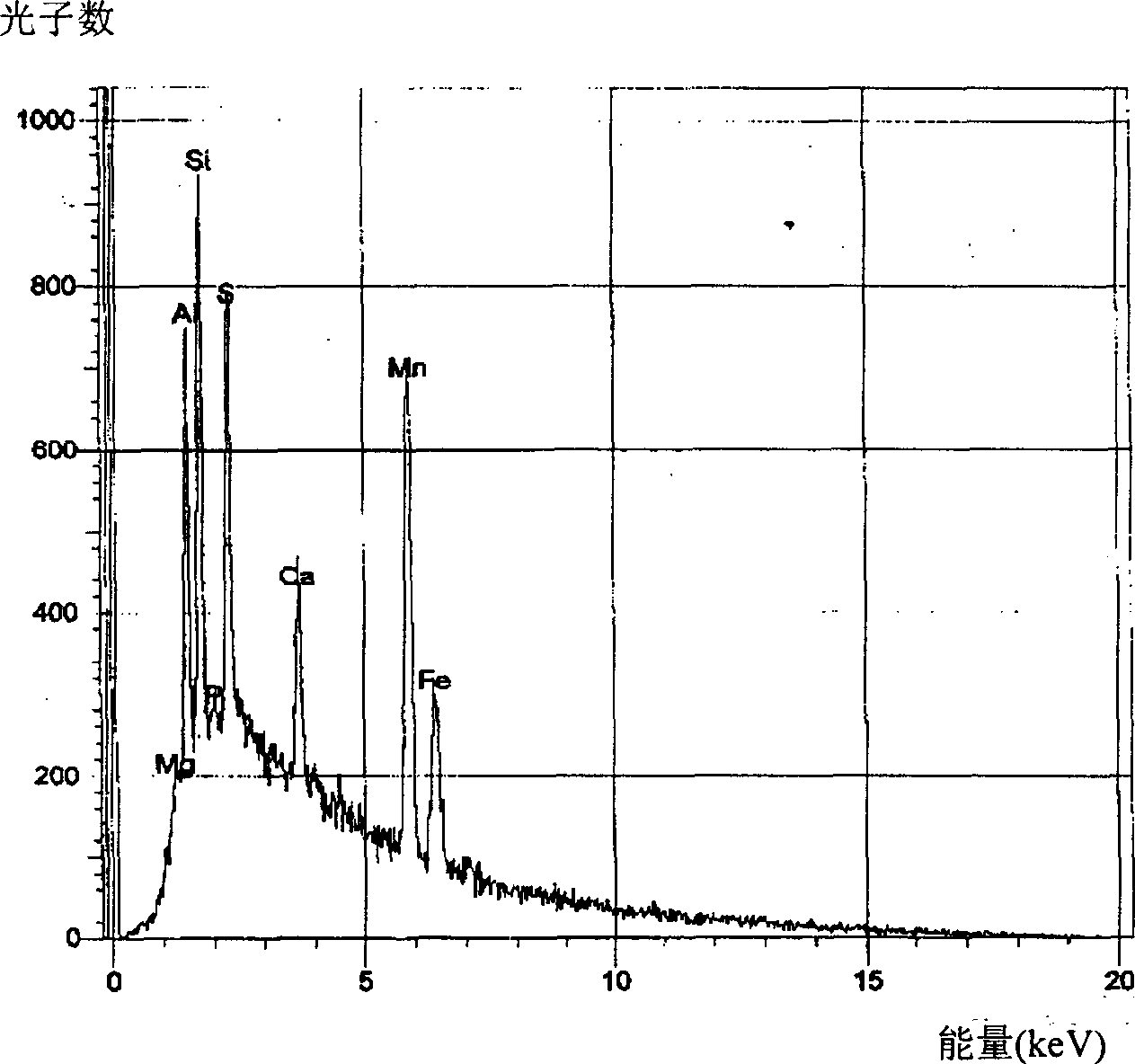

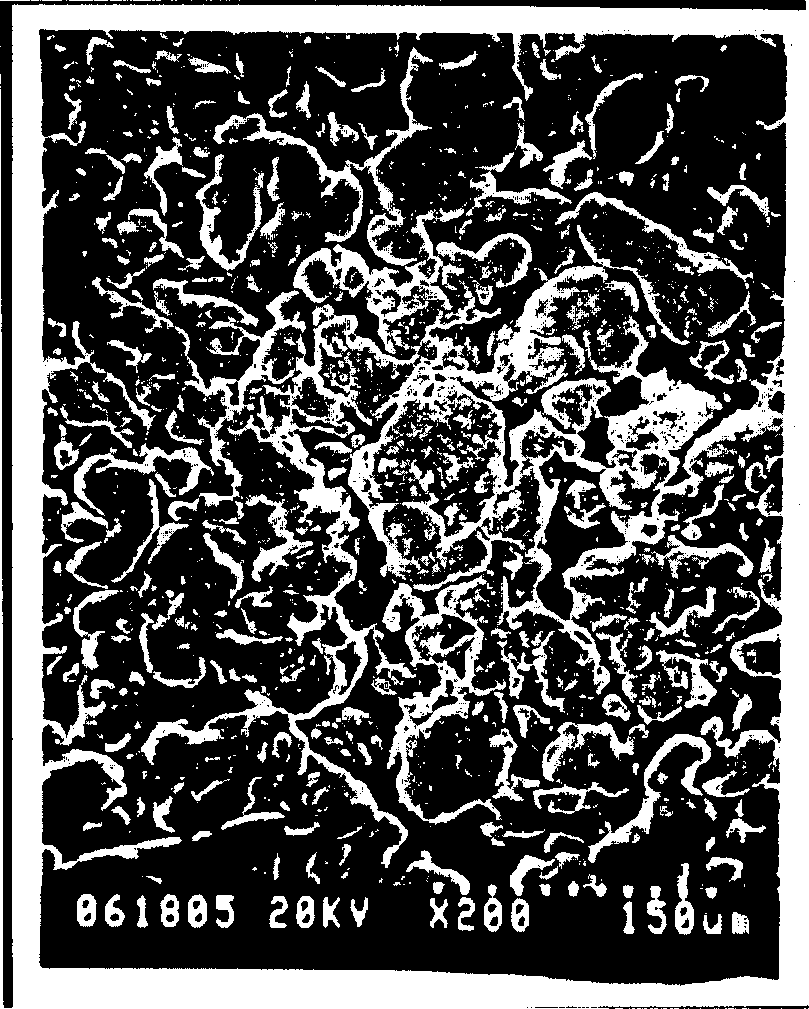

Preparation method of recyclable surface-enhanced Raman-spectrum active substrate

InactiveCN103048304AHigh Raman enhancement effectGet reusable featuresRaman scatteringSurface-enhanced Raman spectroscopyNanoparticle

The invention belongs to the technical field of laser-Raman spectrum detection appliances and Raman spectrum analysis and detection, and in particular relates to a recyclable surface-enhanced Raman-spectrum active substrate with low cost and good reproducibility, and a preparation method thereof. The substrate is characterized in that a porous titanium dioxide film is loaded on the surface of a carrier base sheet through a dipping and lifting method, and then gold nanoparticles grow on the surface of the titanium dioxide film. The composite substrate has an outstanding surface enhanced effect; and chemical compound molecules absorbed on the surface of gold in a previous Raman experiment can be effectively removed through ultraviolet irradiation, and thus the substrate can be recycled.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com