Medicinal porous titanium implant and method for preparing same

A technology of porous titanium and implants, which is applied in the fields of pharmaceutical formulations, dental implants, medical science, etc., can solve the problems of difficult to achieve near-net shape, decreased strength, inferior strength of porous metal, etc., so as to avoid stress shielding phenomenon and shorten osseointegration. time, the effect of avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

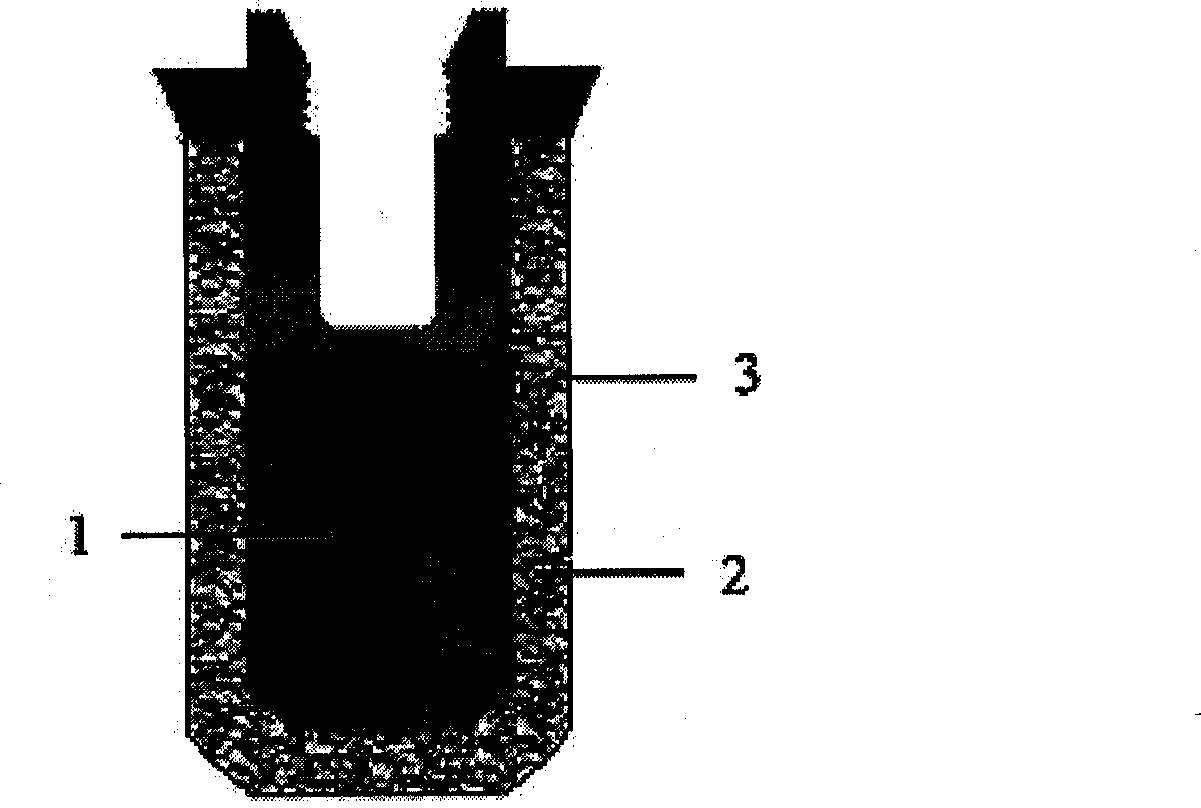

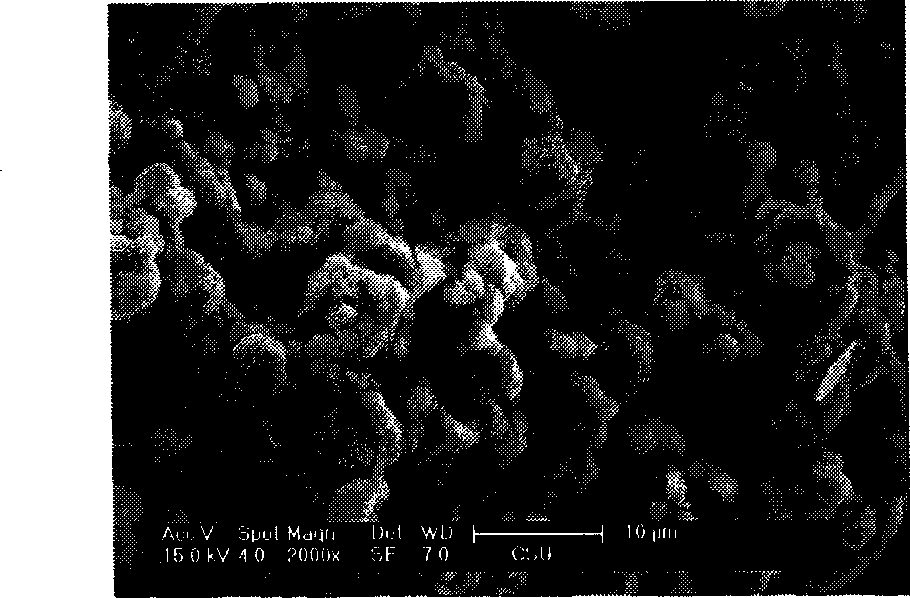

[0027] Example 1 Preparation of nano-HA and growth factor-loaded gelatin-released microcapsule composite coating porous titanium material of the present invention

[0028](1) Prepare the raw material powder: prepare the porous outer layer raw material powder: get 85% of titanium powder and 15% of titanium hydride powder by weight percentage and put the four-pot mixer; then get 45vol% of sodium chloride powder by volume percentage, and mix the powder The raw materials are mixed evenly and prepared into porous outer layer raw material powder. The raw material powder of the inner dense layer is titanium powder.

[0029] (2) Preparation of binding agent: by weight percentage, get polyethylene glycol 30%, vegetable oil 10%, polyethylene 20%, plasticizer 8%, paraffin 32%, put in blade mixer, at 140 ℃ Mix at temperature for 1 hour;

[0030] (3) Ingredients: mix the binder with the mixed porous outer layer raw material powder and titanium powder respectively in a volume ratio of 55:...

Embodiment 2

[0038] Porous outer layer raw material powder: take 90% of titanium powder and 10% of titanium hydride powder according to weight percentage; then take 50vol% of sodium chloride powder according to volume percentage, put it in a four-pot mixer, and mix the powder raw materials evenly. The powder of inner dense layer is titanium powder. Binding agent is with embodiment 1. The binder is mixed with the mixed porous outer layer raw material powder and titanium powder respectively, and the volume is 50:50. The rest of the preparation method and process parameters are the same as in Example 1, and the nano-HA / TGF-β1 slow-release microsphere composite coated titanium implant of the present invention is prepared.

Embodiment 3

[0040] Porous outer layer raw material powder: take 80% of titanium powder and 20% of titanium hydride powder according to weight percentage; then take 40vol% of sodium chloride powder according to volume percentage, put it in a four-pot mixer, and mix the powder raw materials evenly. The powder of inner dense layer is titanium powder. Binding agent is with embodiment 1. The binder is mixed with the mixed porous outer layer raw material powder and titanium powder respectively, and the volume is 45:55. The rest of the preparation method and process parameters are the same as in Example 1, and the nano-HA / TGF-β1 slow-release microsphere composite coated titanium implant of the present invention is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com