Patents

Literature

159results about How to "Efficient plugging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

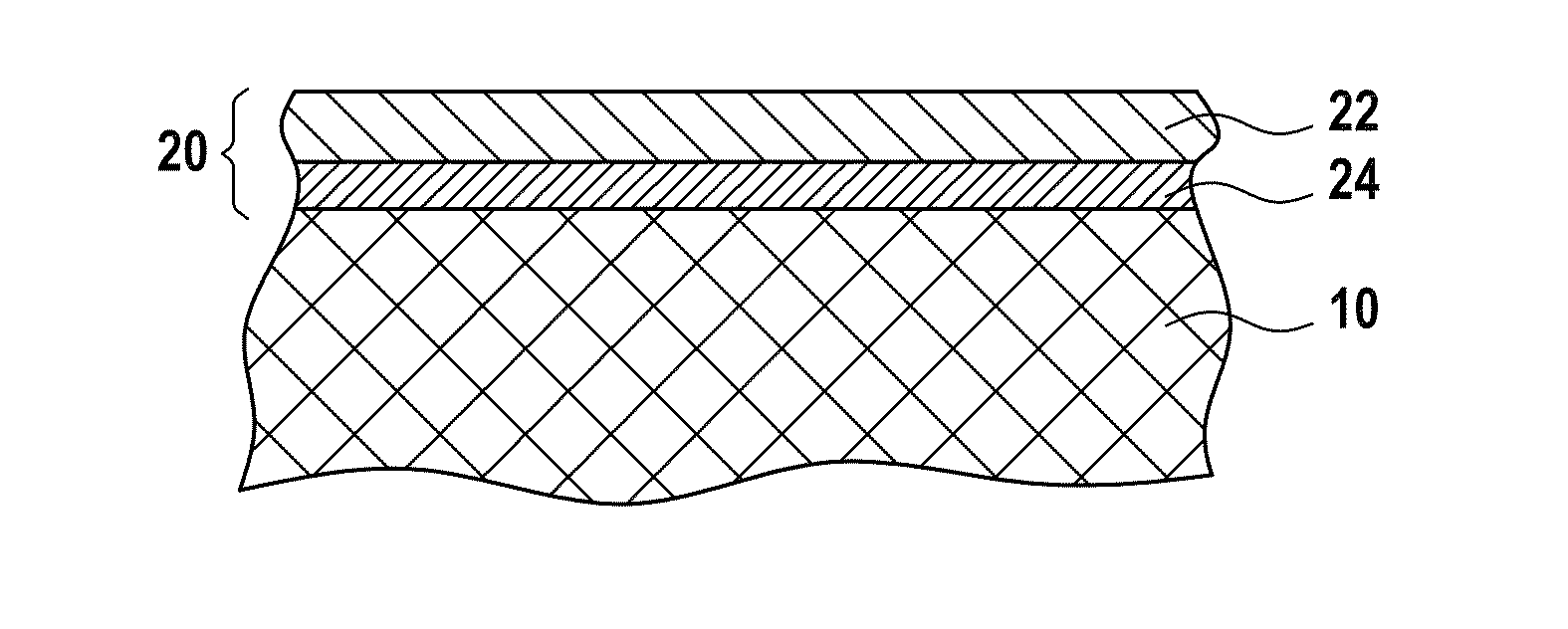

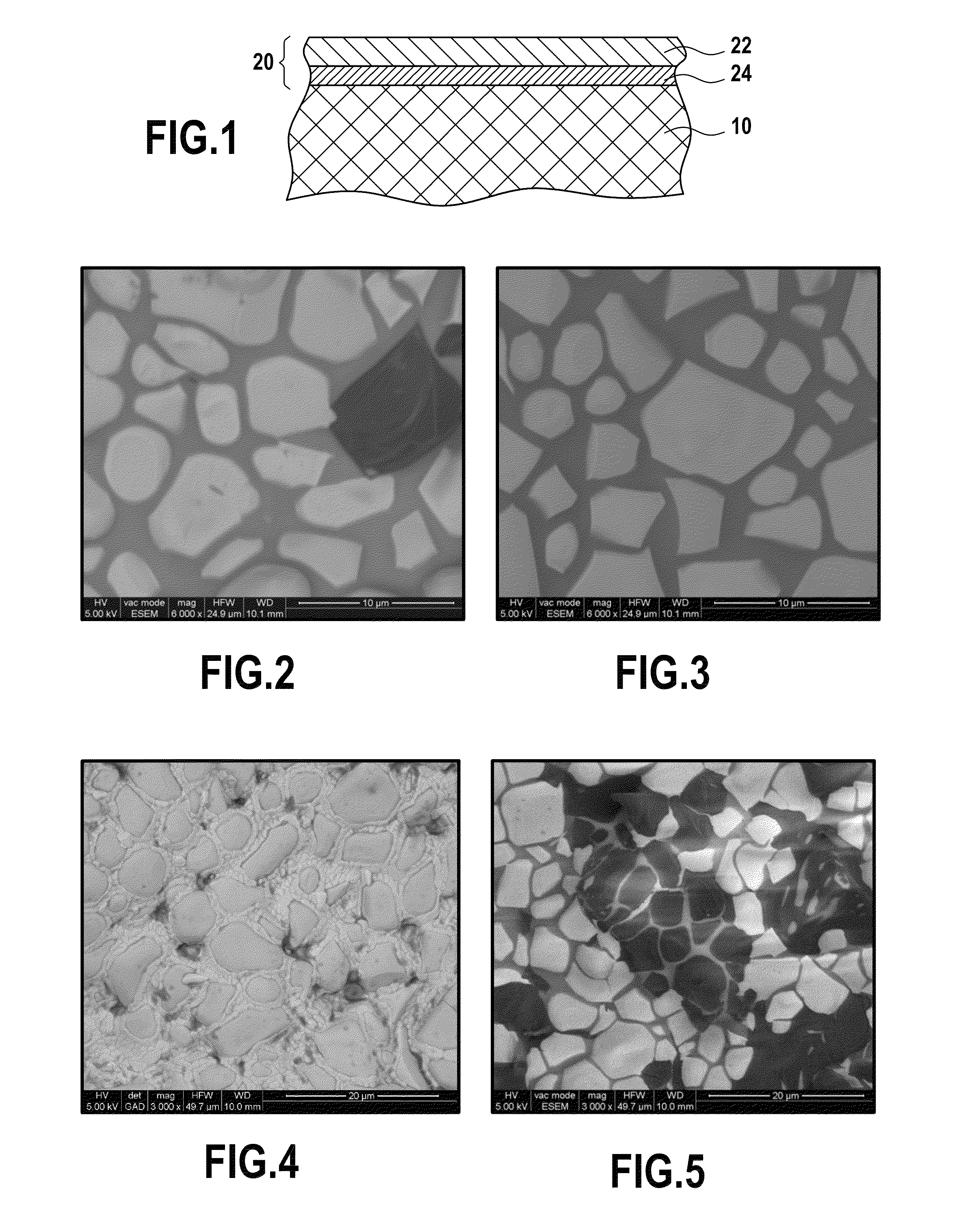

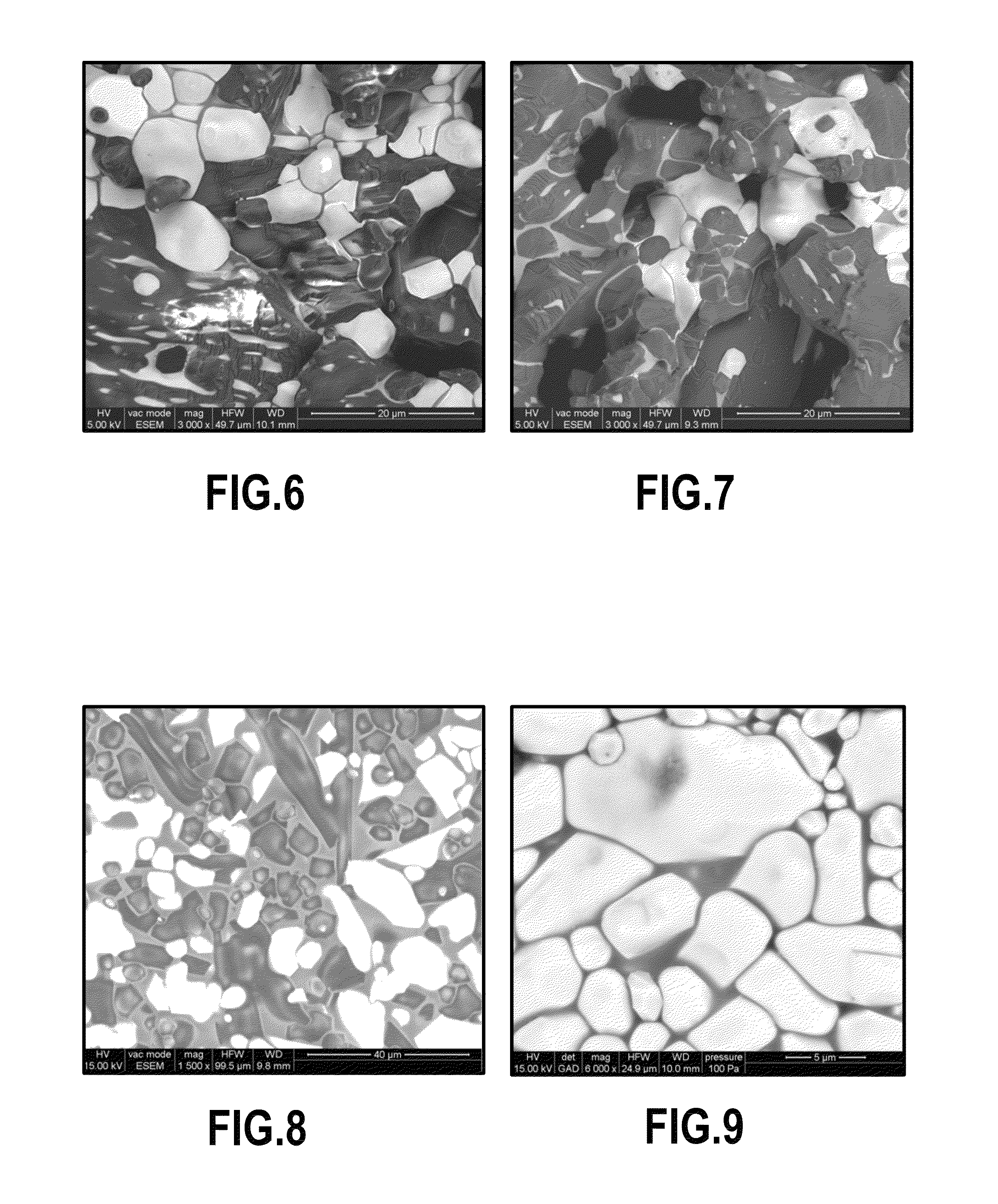

Environmental barrier for a refractory substrate containing silicon

ActiveUS20110256411A1Conserving its effectivenessImprove abilitiesLiquid surface applicatorsMolten spray coatingSelf-healingRare earth

In order to protect a substrate having at least a portion adjacent to a surface that is made of a refractory material containing silicon, while the substrate is in use at high temperature in a medium that is oxidizing and wet, there is formed on the surface of the substrate an environmental barrier that contains no boron and that has at least one layer that is essentially constituted by a system of oxides formed by at least one rare earth oxide, silica, and alumina, and that is capable of self-healing by maintaining the presence of at least one solid phase in a temperature range extending up to at least 1400° C. approximately.

Owner:UNIV DE BORDEAUX +1

Method for preparing intra-operative hemostatic material by cross emulsification of plant starch

ActiveCN102139123ANot easy to decomposeExtended shelf lifeAbsorbent padsBandagesTissue CompatibilityBiology

The invention discloses a method for preparing an intra-operative hemostatic material by cross emulsification of plant starch. The method comprises the following steps of: taking plant starch as a raw material; gelatinizing; carrying out enzymolysis; emulsifying and cross-linking; carrying out solvent extraction; washing; spray-drying; sieving; sterilizing; and packaging to obtain the hemostatic material. The hemostatic material prepared by adopting the method disclosed by the invention has excellent biological barrier properties and tissue compatibility, can directly act on a hemorrhagic wound surface, and is especially convenient for organs and tissues with complex shapes. The selected material is plant starch which has the advantages of no toxicity, no irritation, rich sources, low price, simple and feasible production processes, high water absorption speed, short hemostatic time, good using effect and wide clinical application prospect.

Owner:杜宝堂

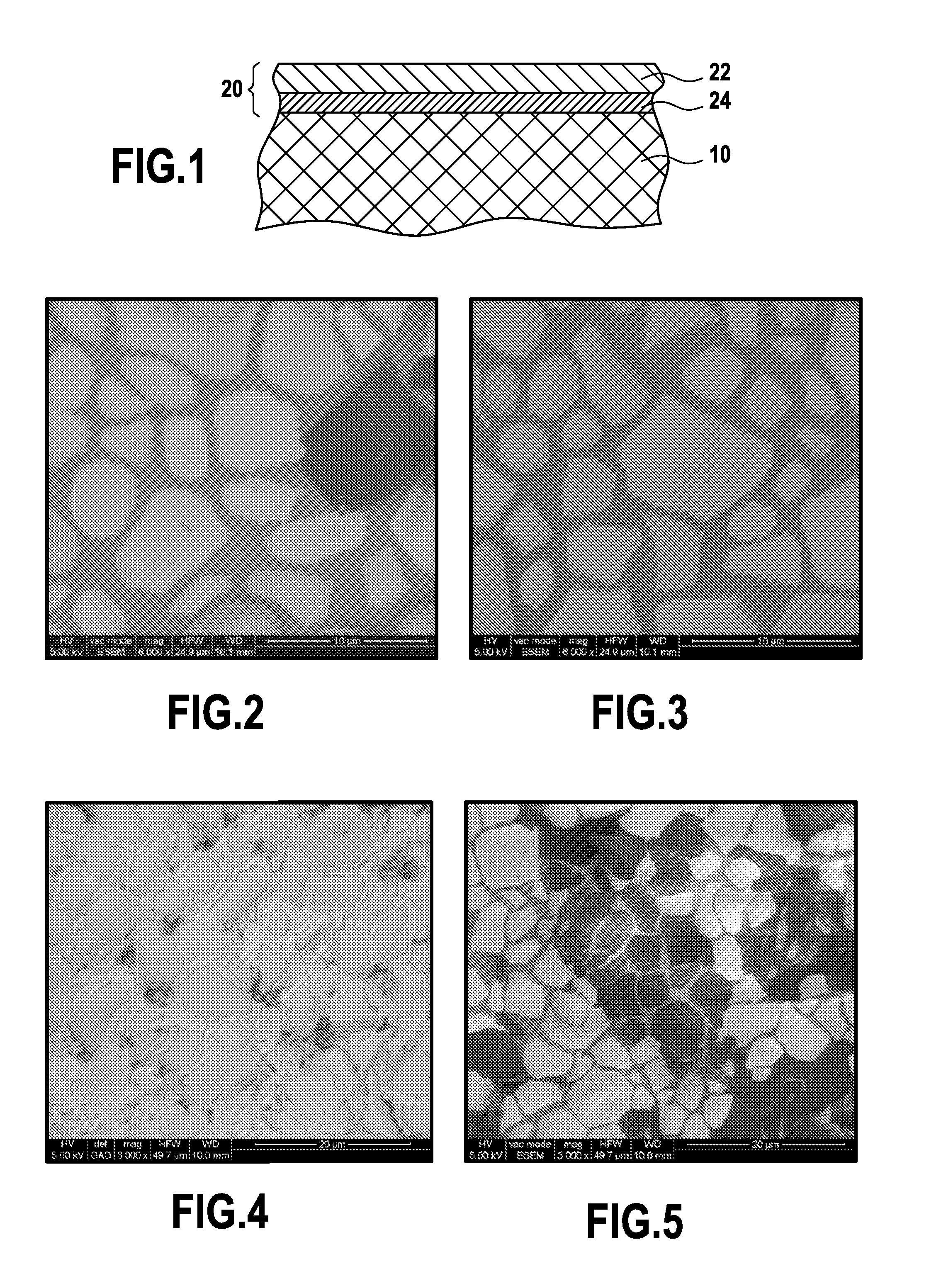

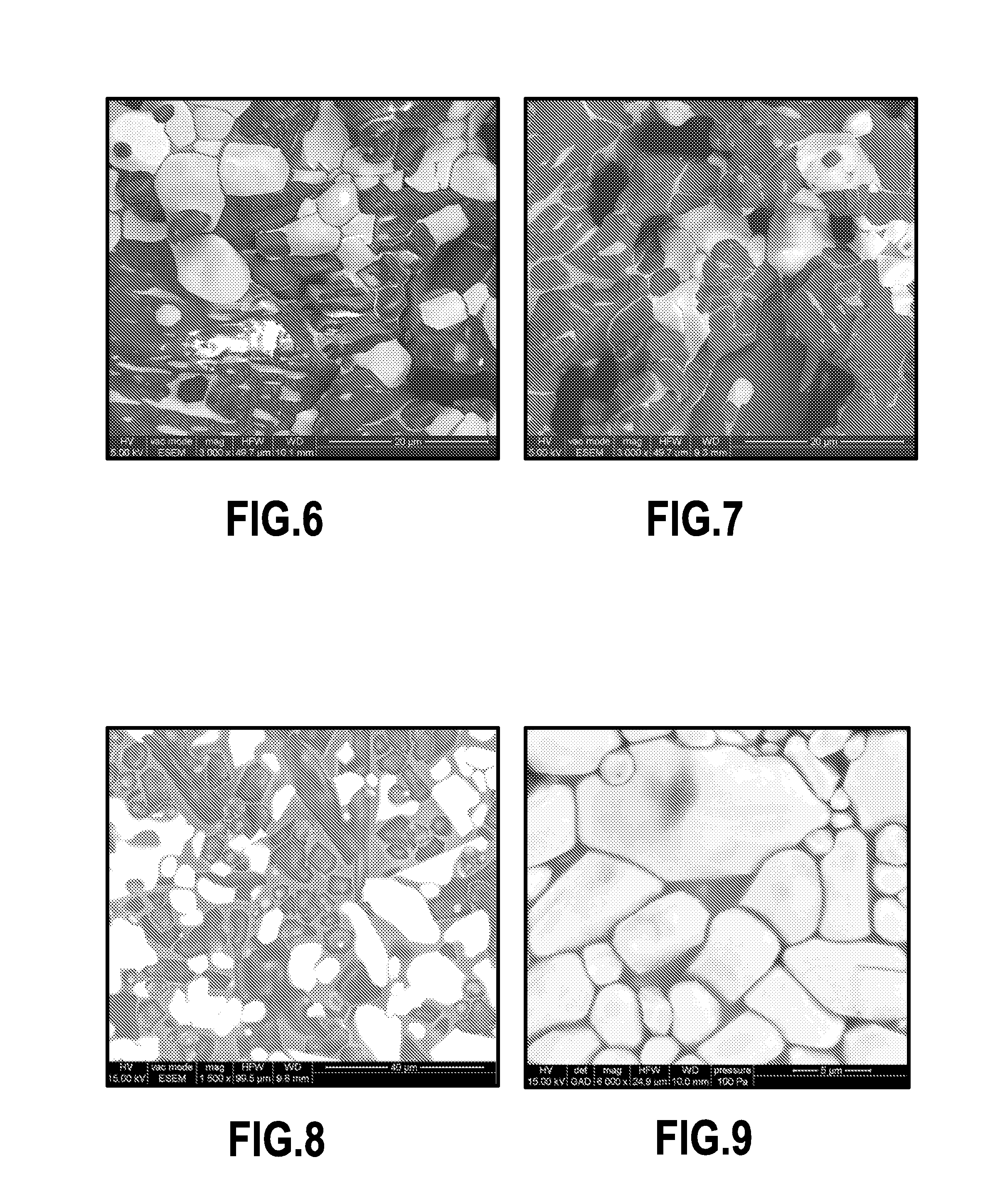

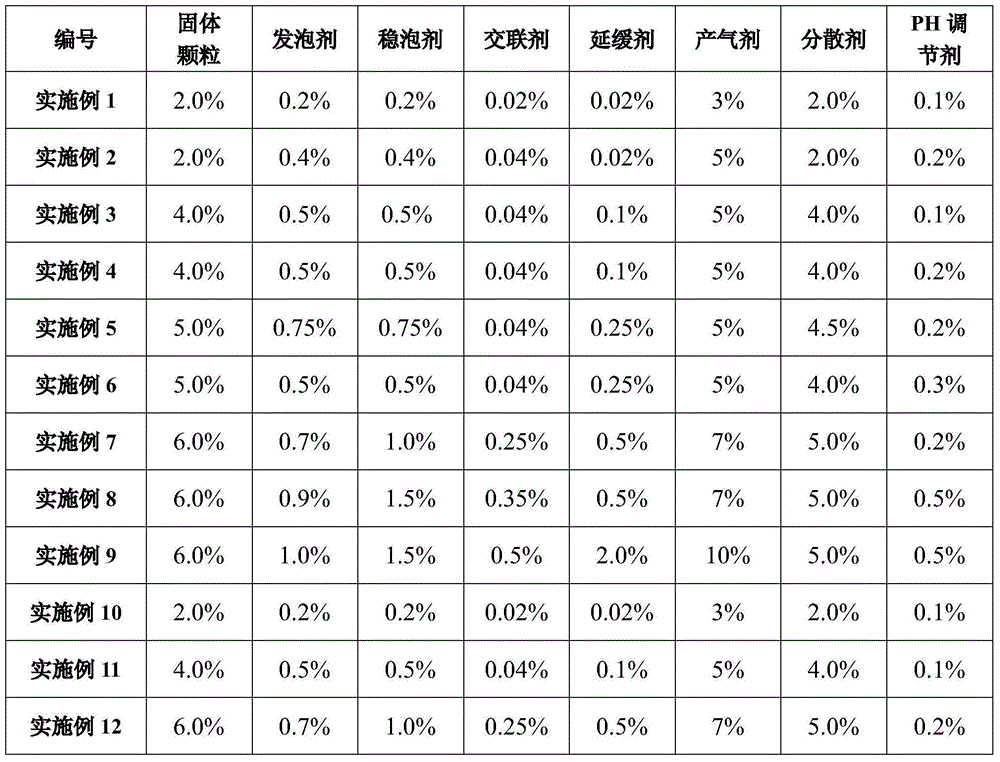

Three-phase self-foaming water-plugging agent

The invention discloses a three-phase self-foaming water-plugging agent, and belongs to the field of petroleum chemistry. The provided water-plugging agent comprises the following components: solid particles, a foaming agent, a foam stabilizing agent, a crosslinking agent, a delaying agent, and a gas producing agent. Compared with the prior art, the provided water-plugging agent has the advantages of high foam quality and good stability, the gel crosslinking and gas production can be achieved at the same time, the water-plugging agent can tolerate high temperature, has a strong residue blocking performance and a long water-plugging period, and can achieve efficient plugging and depth profile control. Moreover, the preparation technology of the provided water-plugging agent is simple, the injection cost is low, and the water-plugging agent is safe and reliable, thus has a good market prospect and high economic value, and is especially suitable for the development of high temperature heavy oil steam stimulation wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

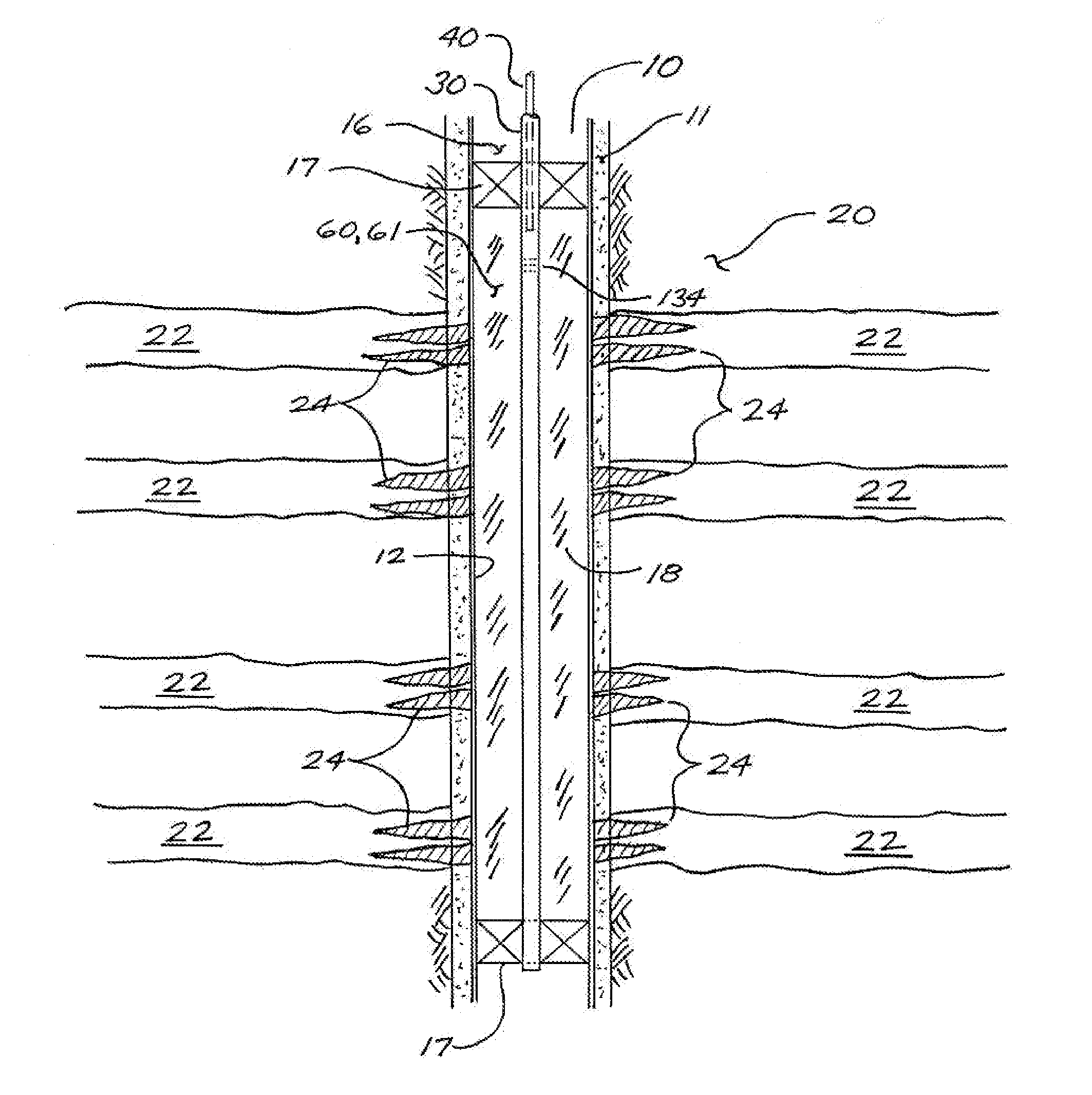

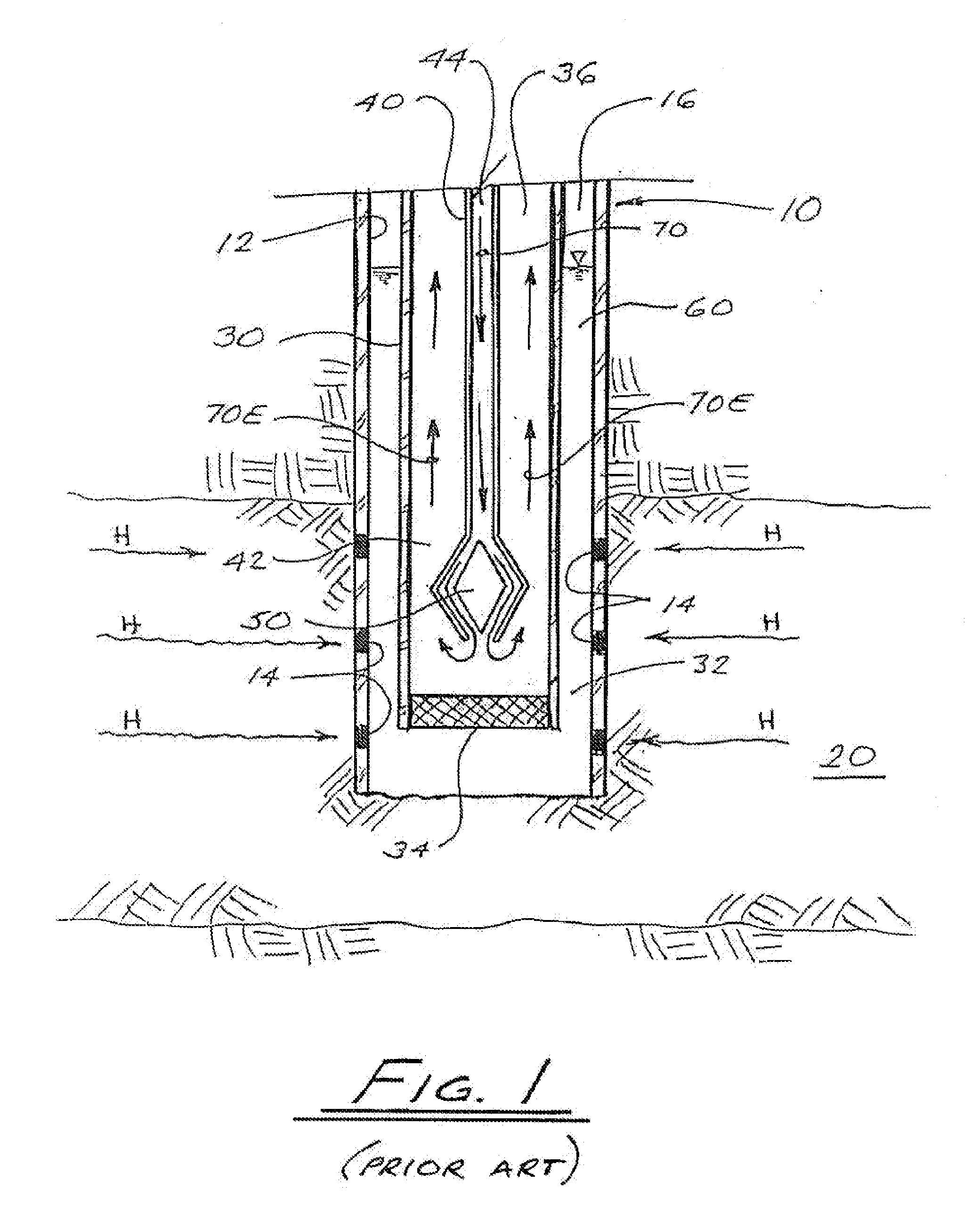

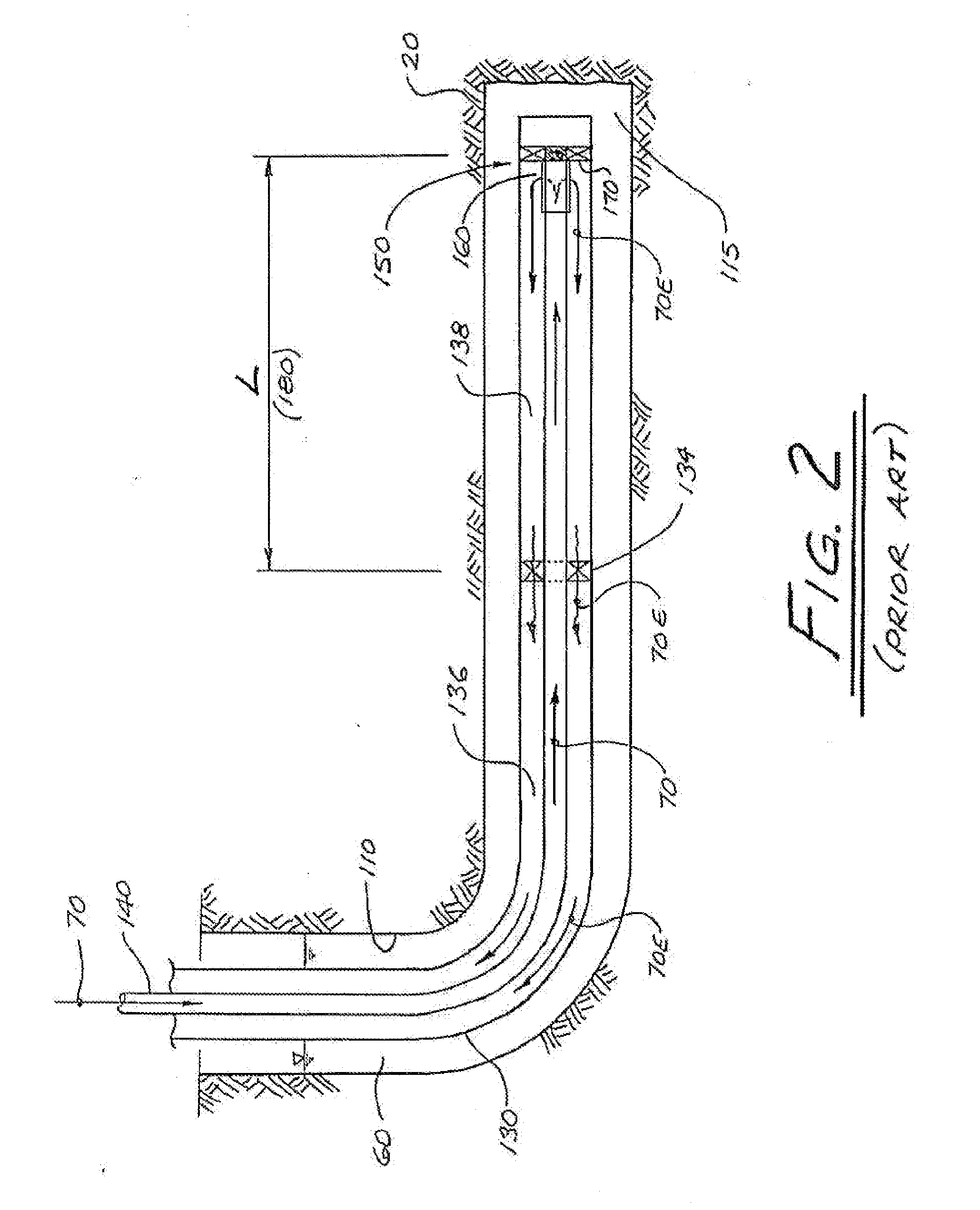

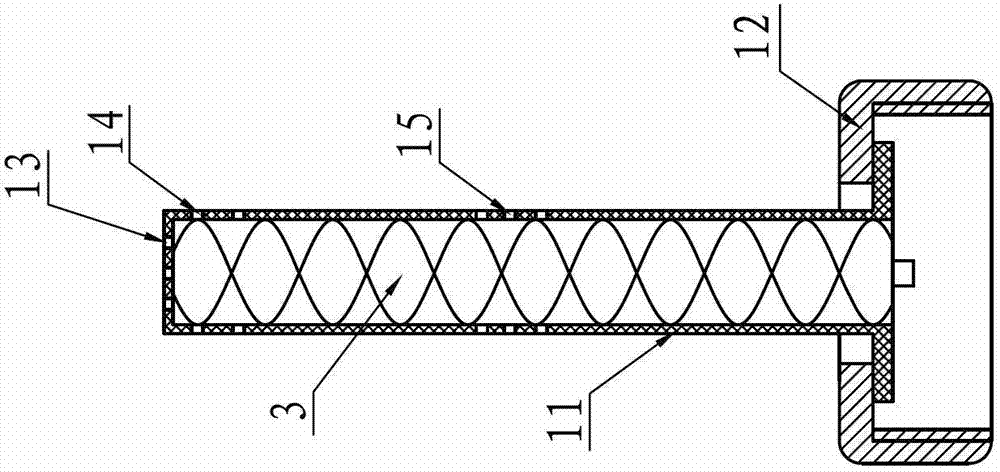

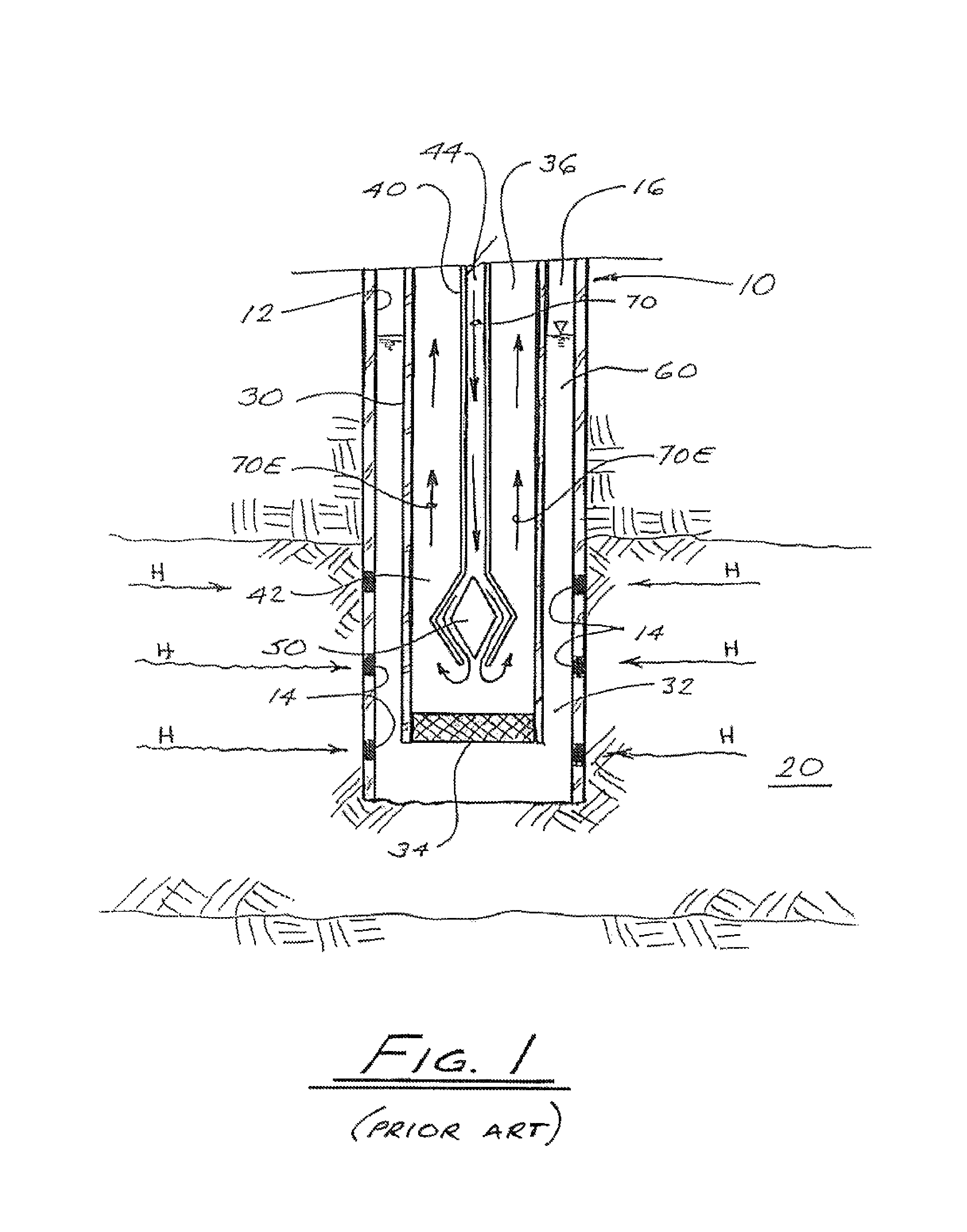

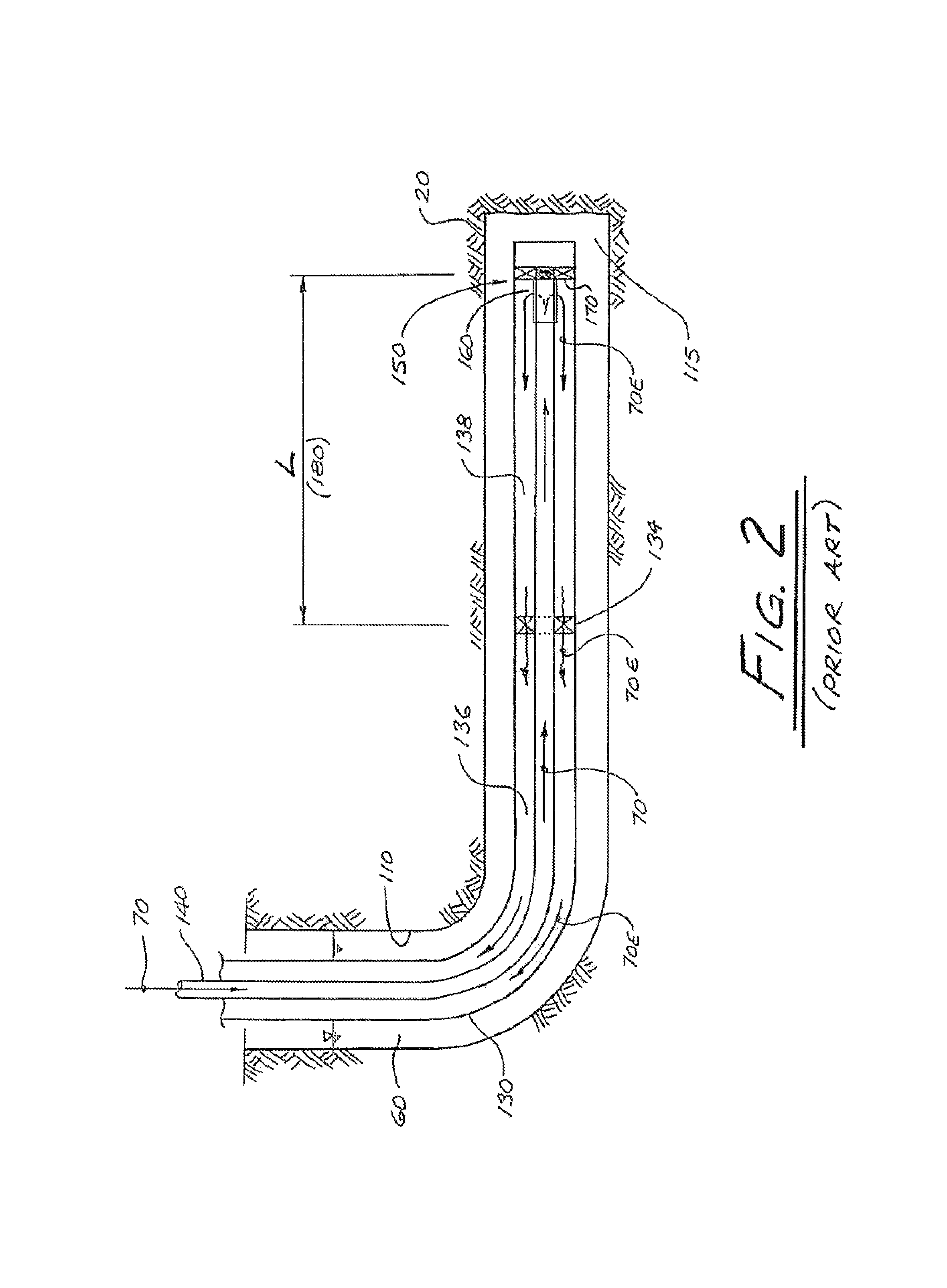

Method and apparatus for freeze-thaw well stimulation using orificed refrigeration tubing

InactiveUS20100263874A1Long processPromote uniform refrigerant effectivenessDomestic cooling apparatusLighting and heating apparatusFreeze thawingWell stimulation

A method and apparatus for introducing refrigerant into a wellbore, for freeze-fracturing a selected region of a subsurface formation, uses refrigerant diffuser pipe having multiple orifices in a selected pattern along a designated section of its length. The orificed supply tubing is disposed within a refrigerant return conduit, thereby forming a tubing annulus. A flow of liquid refrigerant is introduced into the diffuser pipe and flows through the orifices into the tubing annulus, with the orifices acting as expander means creating a pressure drop and causing vaporization of the refrigerant as it passes into the annulus. To facilitate use of the same diffuser pipe in different wells having different requirements, a helical orifice-isolation wrap may be disposed around the diffuser pipe, with the orifice-isolation wrap having orifice-plugging elements arrayed to effectively block fluid flow through selected orifices, while leaving other orifices open as required. In this way, it is possible to design diffuser pipes with particular orifice arrangements that will accommodate two or more different isolation wraps, with each different wrap plugging different patterns of orifices.

Owner:POLAR WELL STIMULATIONS LTD

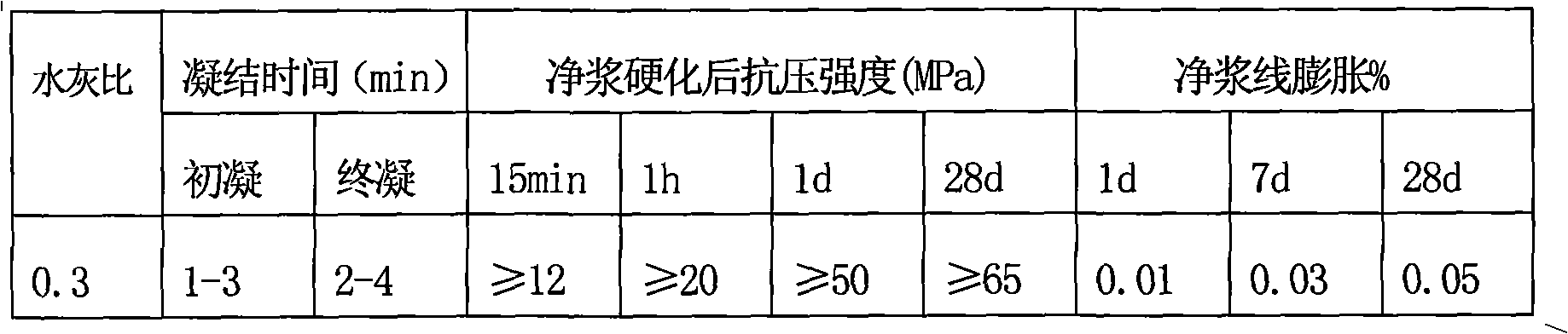

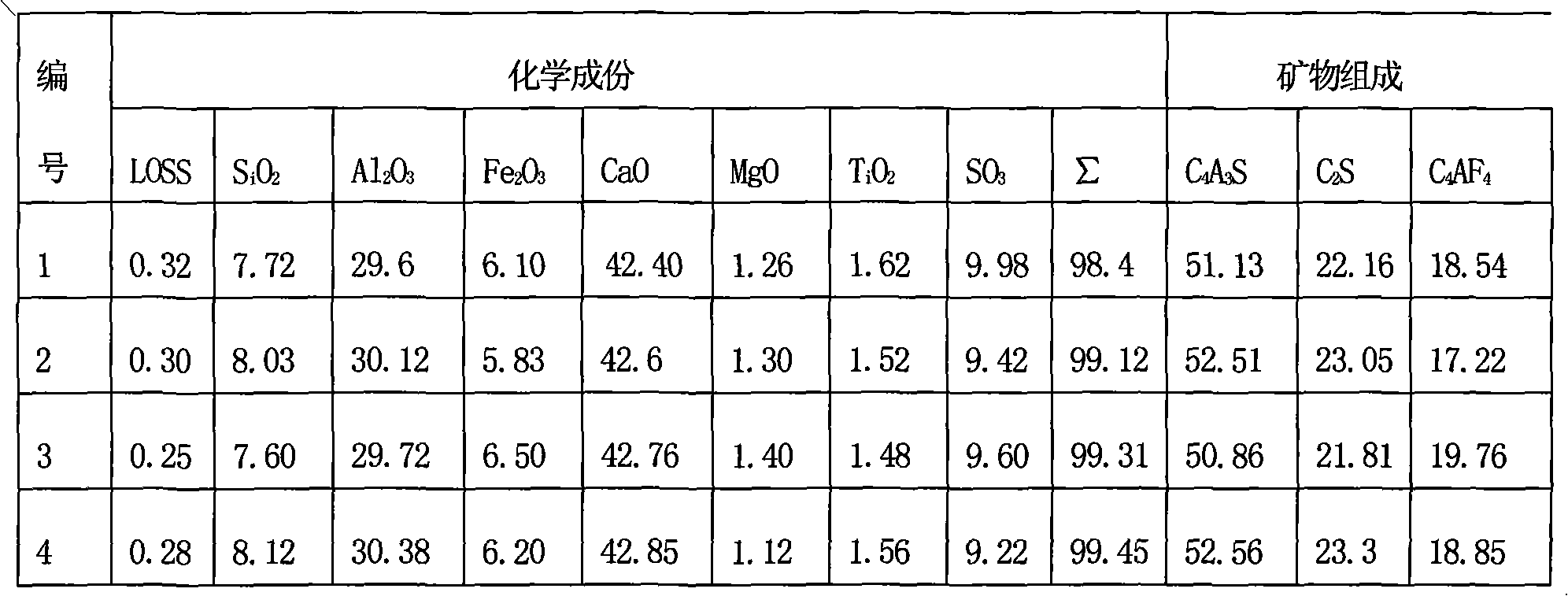

Highly efficient plugging material

The invention discloses a highly efficient plugging material, which adopts the following components by weight percent: 86-92% of sulphate aluminum cement clinkers, 4-8% of anhydrite, 3-6% of lime stones, 0.02-0.05% of plasticizing agent, 0.06-0.15% of hardening accelerator and 0.12-0.15% of short and thin polypropylene fiber. The highly efficient lost circulation material has the characteristics of fast solidification, high hour strength, strong adhering capability, high anti-seepage grade, lower cost, convenient construction operation, safety and environment protection.

Owner:YONGZHOU ZHONGDA SPECIAL CEMENT

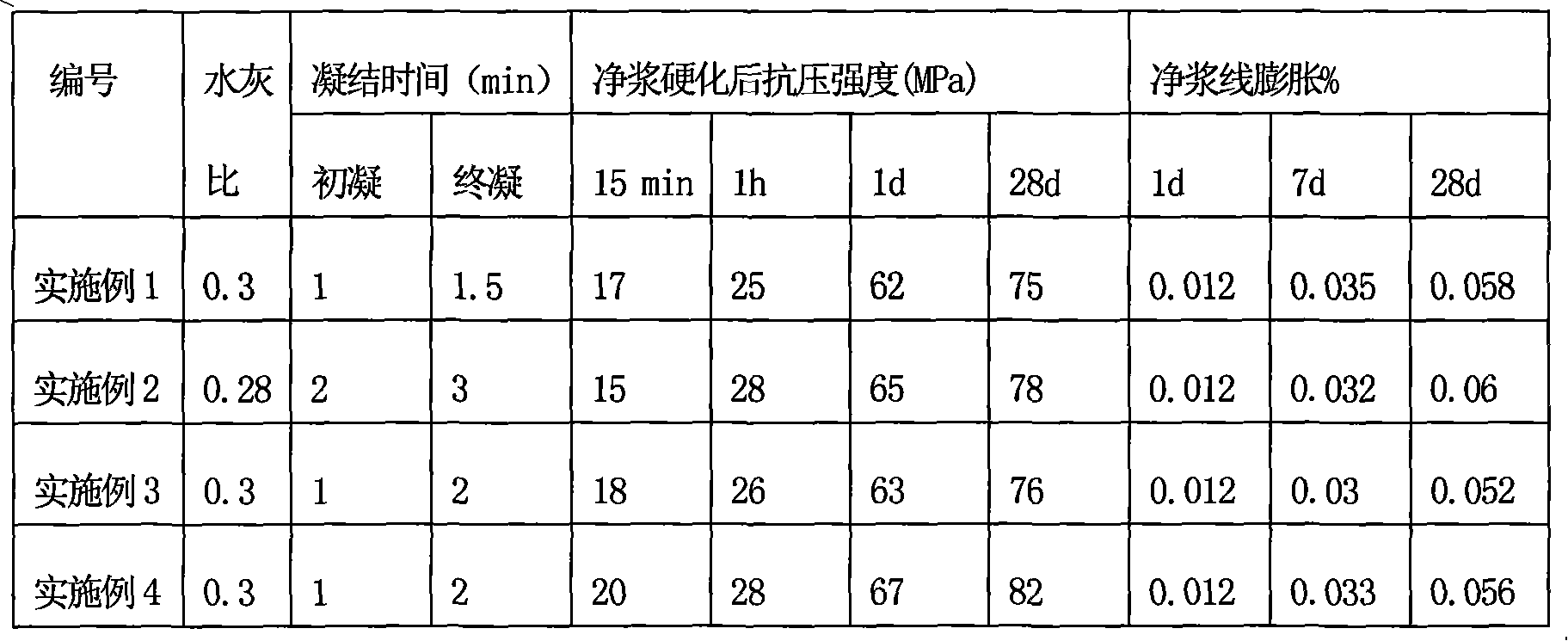

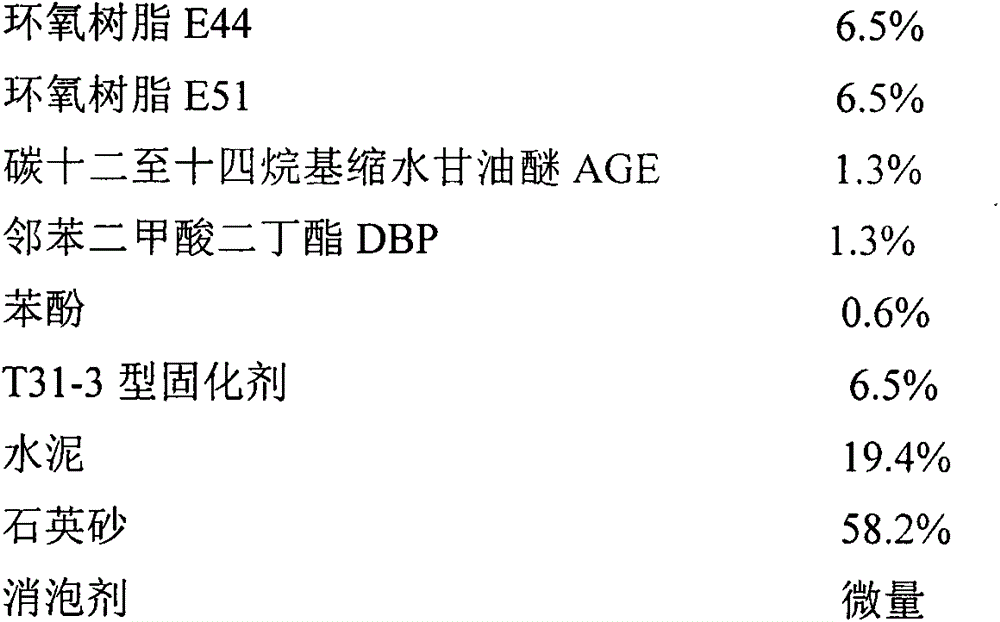

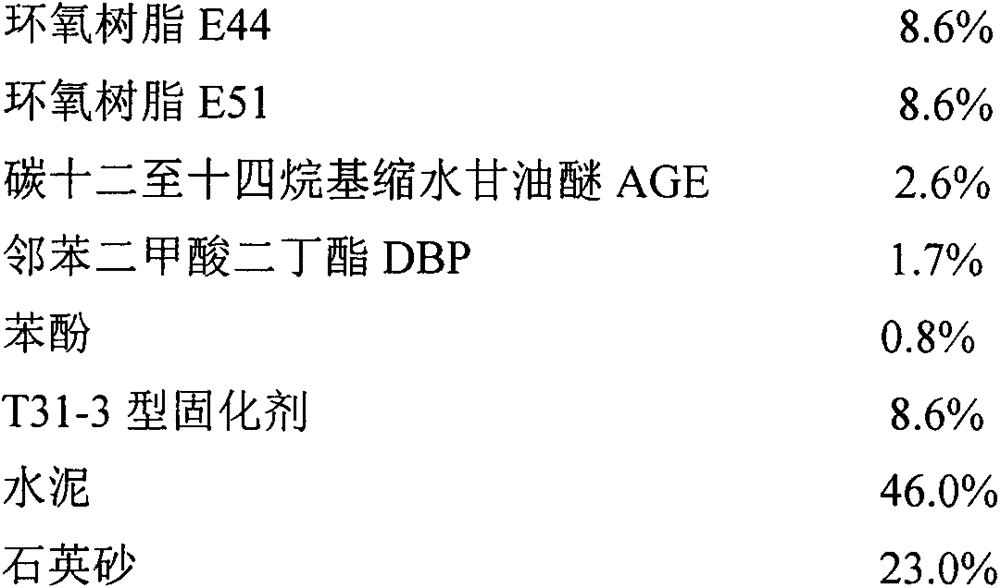

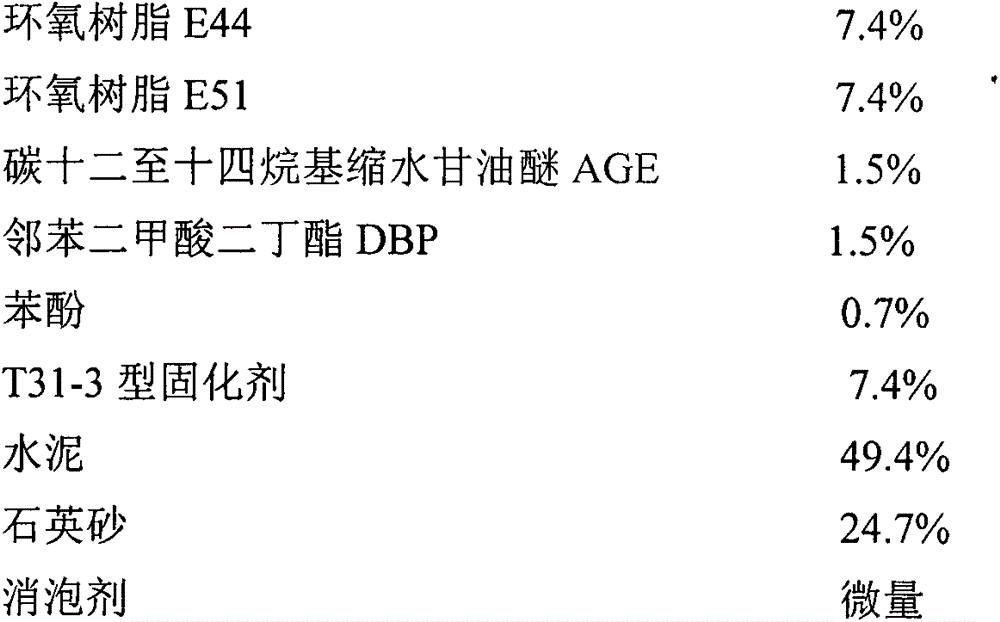

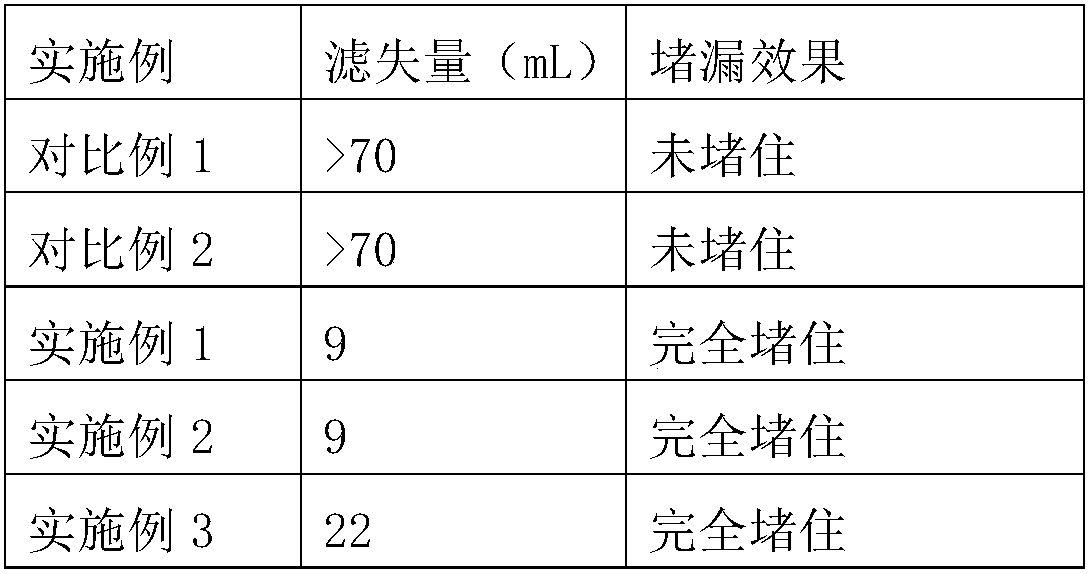

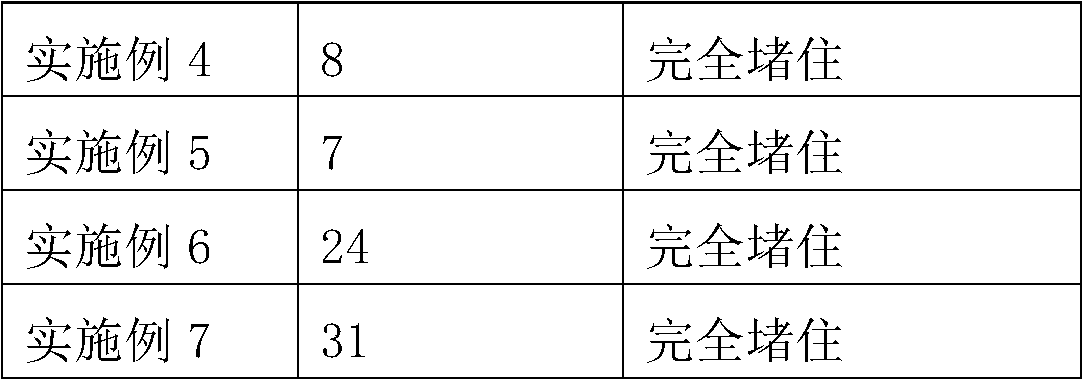

Preparation method of epoxy mortar for filling ocean oil and gas pipeline

InactiveCN103819144ASimple preparation processMeet the replacement requirementsShock resistanceSeawater

The invention belongs to the technical field of application of polymer mortar and particularly relates to a preparation method of epoxy mortar for filling an ocean oil and gas pipeline. The epoxymortar consists of a component A, a component B and a component C, wherein the component A is prepared by defoaming after blending epoxy resin, a reactive diluent, a plasticizer, an accelerator and pigments according to the proper proportion and; the component B is a special underwater T31-3 type curing agent; the component C is aggregate formed by mixing cement with quartz sand according to a certain proportion. When the epoxymortar is used for construction, the component A is heated to 30-50DEG C and stirred to homogeneousphase, and then the component A and the component B are mixed according to certain proportion and uniformly stirred; the component C is subsequently added into the mixture for uniformly blending to obtain an epoxymortar mixture for filling the ocean oil and gas pipeline. The mortar mixture is simple in preparation process; the prepared mixture has the advantages of high curing speed and strong cohesiveness as well as excellent compress and shock resistance and seawater corrosion resistance. The mortar mixture can be used for filling and strengthening an anode protection anticorrosive structure of the ocean oil and gas pipelines.

Owner:TIANJIN UNIV OF SCI & TECH +1

Temperature-control shape memory plugging agent and preparation method thereof

InactiveCN109517588AWith temperature control shape memory functionImprove toughnessDrilling compositionTemperature controlRoom temperature

The invention discloses a temperature-control shape memory plugging agent and a preparation method thereof. The plugging agent is a shape memory particle; the shape memory particle comprises: hollow high-elasticity foam sponge and a temperature-sensitive type shape memory polymer coated on the hollow high-elasticity foam sponge, wherein the content of the temperature-sensitive type shape memory polymer is 20 to 99.99 weight percent of the shape memory particle; and the grain diameter of the shape memory particle is less than or equal to 8mm. The preparation method comprises the following steps: crushing, heating and melting the temperature-sensitive type shape memory polymer; uniformly coating the uncompressed hollow high-elasticity foam sponge with a temperature-sensitive type shape memory polymer hot melt solution; compressing to prepare a compressed flake; and cooling to room temperature, and cutting and granulating. According to the temperature-control shape memory plugging agent,an organic hollow high-elasticity foam sponge compound structure is adopted, and the temperature-sensitive type shape memory polymer is used for bonding and granulating. The temperature-control shapememory plugging agent is added into well cementation cement slurry or drilling mud and is stimulated by a suitable downhole temperature rising environment and the volume is expanded for a plurality oftimes; and a volume steric effect is utilized to realize the aim of plugging rock fractures.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environmental barrier for a refractory substrate containing silicon

ActiveUS8940417B2Conserving its effectivenessImprove abilitiesPropellersMolten spray coatingSelf-healingRare earth

In order to protect a substrate having at least a portion adjacent to a surface that is made of a refractory material containing silicon, while the substrate is in use at high temperature in a medium that is oxidizing and wet, there is formed on the surface of the substrate an environmental barrier that contains no boron and that has at least one layer that is essentially constituted by a system of oxides formed by at least one rare earth oxide, silica, and alumina, and that is capable of self-healing by maintaining the presence of at least one solid phase in a temperature range extending up to at least 1400° C. approximately.

Owner:UNIV DE BORDEAUX I +1

Nanometer plugging agent for water-based drilling fluid, preparing method of nanometer plugging agent and drilling fluid

The invention relates to a nanometer plugging agent for a water-based drilling fluid, a preparing method of the nanometer plugging agent and the drilling fluid. The nanometer plugging agent for the water-based drilling fluid is obtained in a manner that multi-walled carbon nanotubes are covalently coated with sodium polystyrenesulfonate, wherein the tube diameter of the multi-walled carbon nanotubes is 20 nm to 30 nm, and the tube length of the multi-walled carbon nanotubes is 10 microns to 30 microns; the number-average molecular weight of the grafted sodium polystyrenesulfonate is 75 kDa, and the degree of polymerization (DOP) is 900; the drilling fluid is prepared from 100 parts by weight of water, 1-8 parts by weight of bentonite, 4-10 parts by weight of a flow-pattern adjusting agent,0.2-1.2 parts by weight of a thickening agent, 4-10 parts by weight of a fluid loss agent, 30-60 parts by weight of a plugging agent, 10-50 parts by weight of a weighting agent, 0.1-4 parts by weightof a lubricating agent and 0.1-0.4 part by weight of a pH adjusting agent. According to the nanometer plugging agent for the water-based drilling fluid, the preparing method of the nanometer pluggingagent and the drilling fluid, the sodium-polystyrenesulfonate-modified multi-walled carbon nanotubes are used as the plugging agent, micron-and-nanometer-size pores of the mud shale well wall can beeffectively plugged, and the nanometer plugging agent is particularly suitable for drilling construction of stratums with low porosity, low permeability, micro-pore micro-crack development and a remarkable capillary effect.

Owner:SOUTHWEST PETROLEUM UNIV

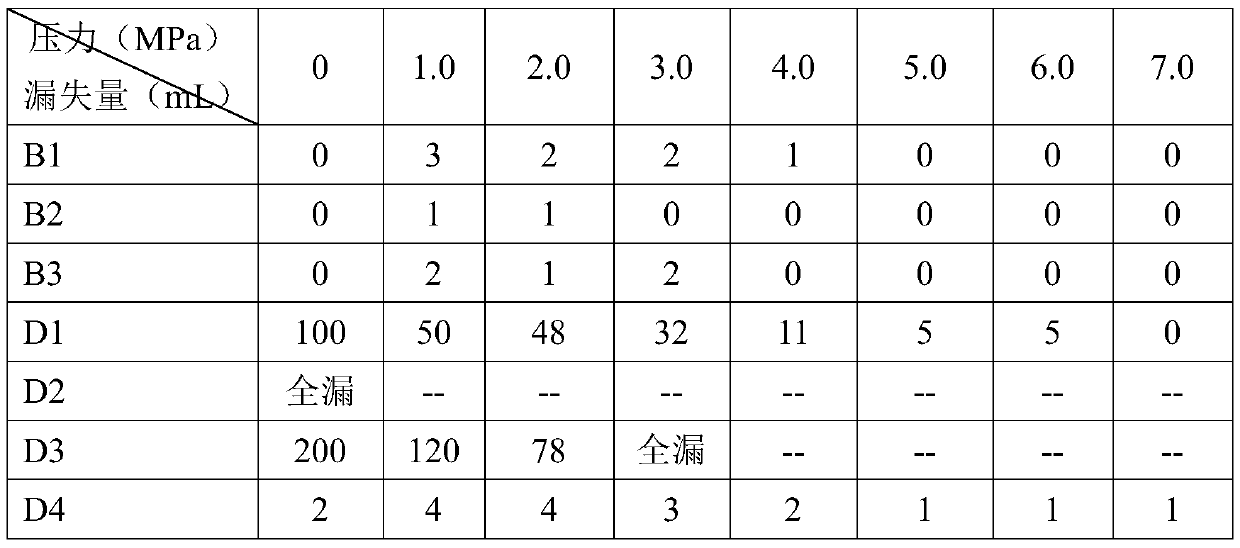

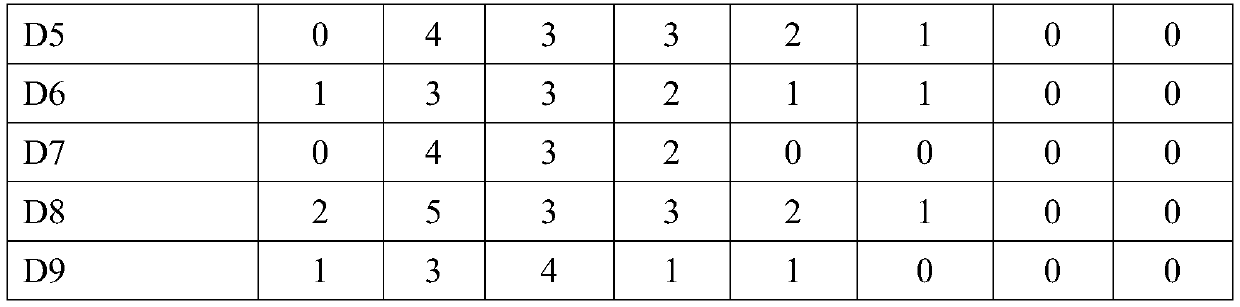

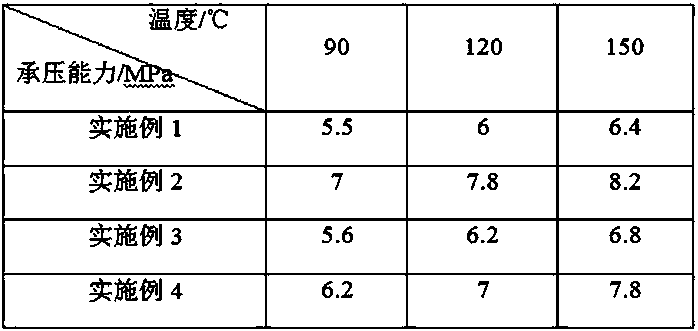

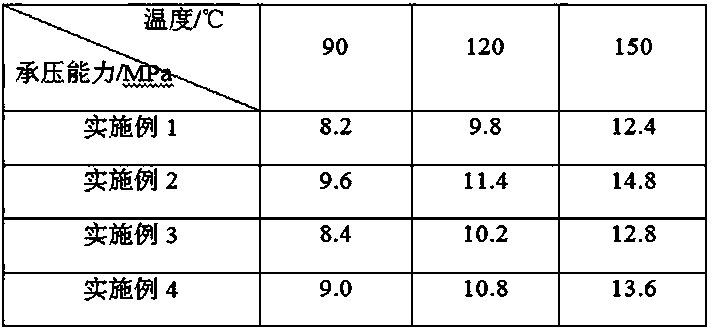

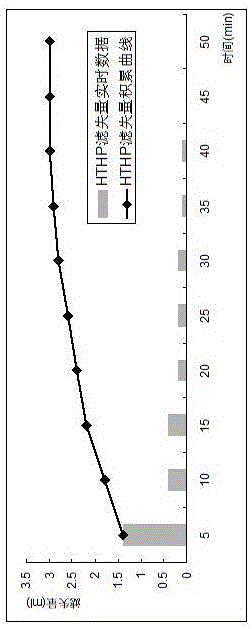

Temperature-sensitive hydrogel leak-plugging agent and preparation method and application thereof

ActiveCN110183579AAvoid repeated lossesEffective pluggingDrilling compositionCross-linkTemperature sensitive

The invention discloses a temperature-sensitive hydrogel leak-plugging agent. The leak-plugging agent is composed of the following raw materials in parts by weight: 3-8 parts of natural starch, 5-10 parts of a nonionic monomer, 1-3 parts of an anionic monomer, 0.06-0.10 part of a cross-linking agent, 0.1-0.3 part of an initiator, 4-8 parts of a pH adjuster, and 85 parts of deionized water. Meanwhile, the invention also discloses a preparation method of the leak-plugging agent and a leak-plugging application of the leak-plugging agent in leakage formations. The provided temperature-sensitive hydrogel leak-plugging agent can be subjected to a reaction in response to temperature to realize phase transformation, the leak-plugging agent is a flowable liquid before being injected into a formation, and after the leak-plugging agent is injected into a formation of 60-150 DEG C, the formation has a certain temperature, the leak-plugging agent is subjected to a reaction to becomes a solid leak-plugging agent with strong adhesion and elastic characteristics when reaching a bottom temperature, the effective plugging of a leakage channel is realized, and the bearing pressure is relatively high,a pressure of a pore and crack pressure-bearing test can reach 5 MPa or more, and thus the repeated leakage of the formation is prevented.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Electronically controlled single-loop water-plugging overburden strata fracture detection method

The invention discloses an electronically controlled single-loop water-plugging overburden strata fracture detection method. The method comprises the following steps that: an electronically controlled single-loop water-plugging overburden strata fracture detector is prepared firstly, wherein the detector is provided with an upper hole sealing capsule and a lower hole sealing capsule respectively at the two ends of a connecting tube; an electronically controlled water flow control device is arranged in the lower hole sealing capsule; and when the detector is used, the operation of detection can be performed just by directly connecting a water inlet pipe of the detector to a drill pipe of a drilling machine, pressing the water inlet pipe of the detector into a drilled hole by using the drill pipe, and connecting an injected water observation device to a water inlet pipe of the drill pipe. According to the invention, hole plugging and water injection are implemented by using the same loop and without using an external high-pressure air duct, so that the situation that an effect of effective hole plugging can not be achieved due to the occurrence of fractures caused by that the high-pressure air duct is rubbed and extruded with the wall of a drilled hole is avoided, a detection system is simplified, operation steps are simplified, and the reliability of water plugging is greatly improved.

Owner:SHANDONG UNIV OF SCI & TECH

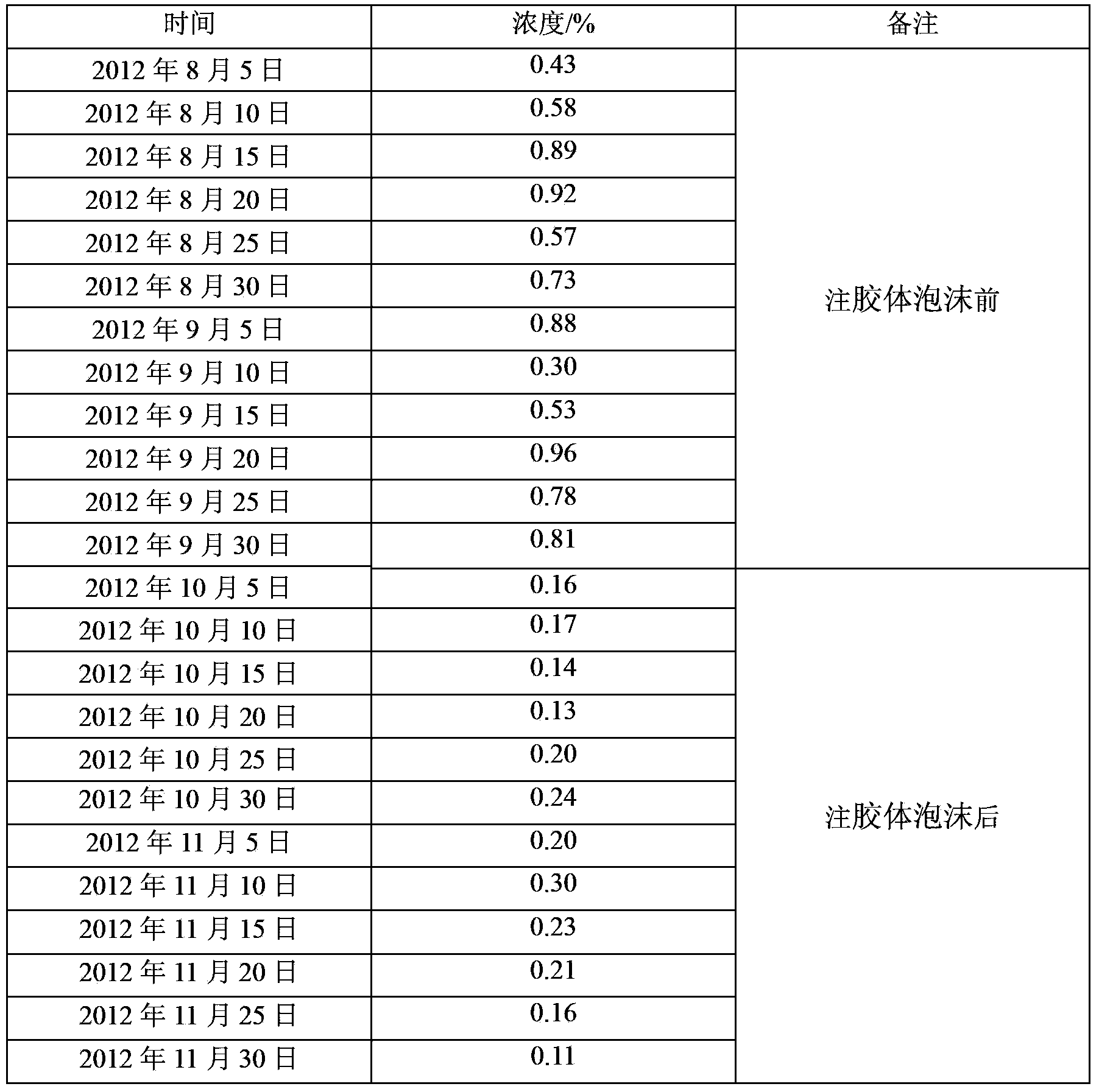

Method for preparing active-carbon-containing colloid gas foam for preventing gas emission in gob

InactiveCN103362532AIncrease in sizeGood shear thinning propertiesDust removalFire preventionActivated charcoal powderCross-link

Active-carbon-containing colloid gas foam for preventing gas emission in a gob is provided, wherein active carbon powder is dispersed into water and is added with certain amount of thickener to prepare an active-carbon-containing thick solution at a certain concentration, and small amount of cross linking agent and foaming agent are added into the solution and is physically and mechanically stirred and foamed under the action of air to prepare the active-carbon-containing colloid gas foam. After the colloid gas foam is injected into the gob through a slip casting pipeline of a mine, a large area of float coal in the gob can be covered and the coal crack can be blocked, the active carbon is used to fully adsorb the free gas in the gob, and meanwhile, a film-shaped colloid covering material like cloth is formed on the surface of the coal to achieve the purpose of long-lasting effective inhibition of emission of the coal gas. The effect of the active-carbon-containing colloid gas foam on preventing gas emission in the gob is remarkable, the cost is low, and the prospect of application is wide.

Owner:CHINA UNIV OF MINING & TECH

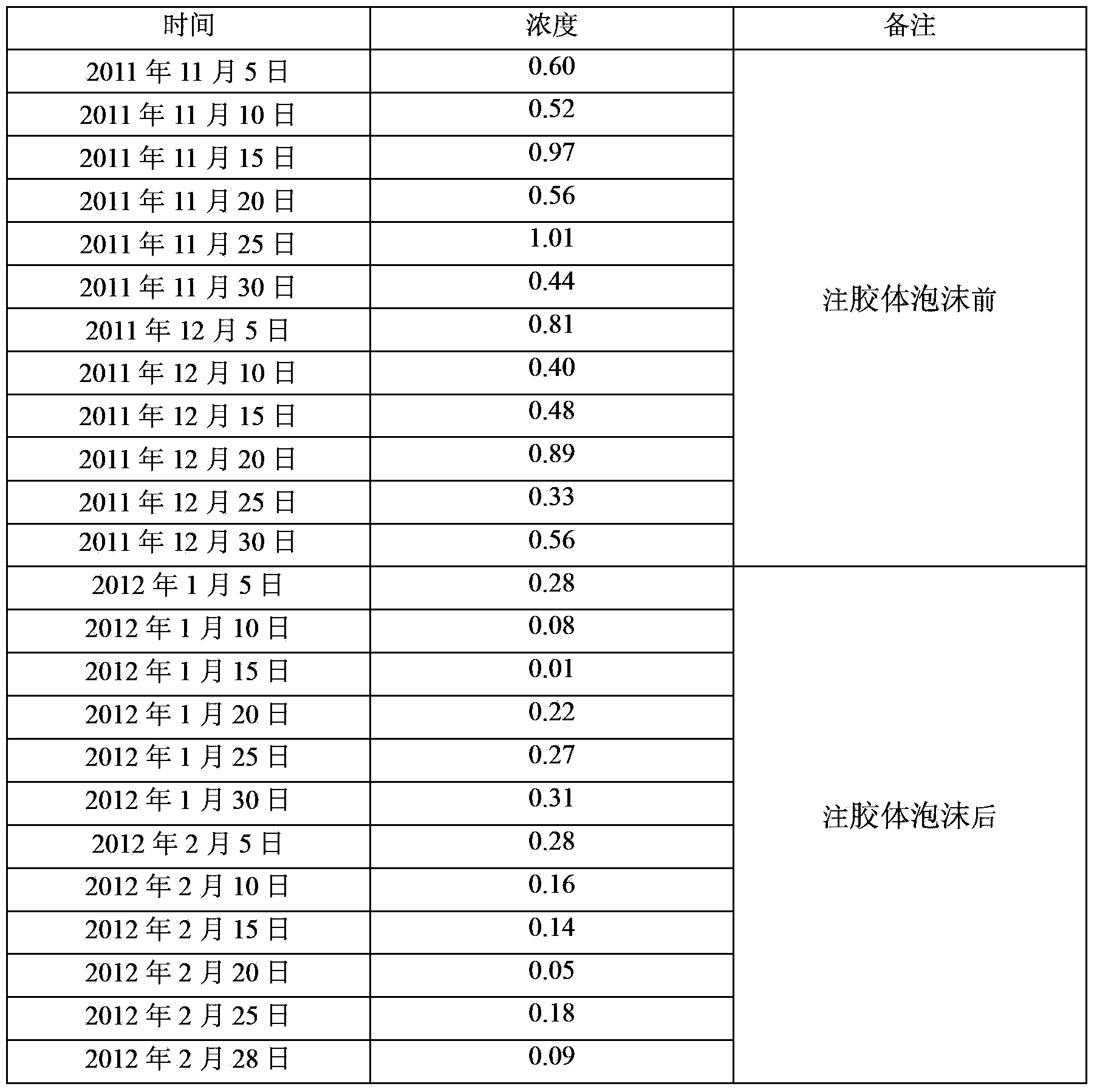

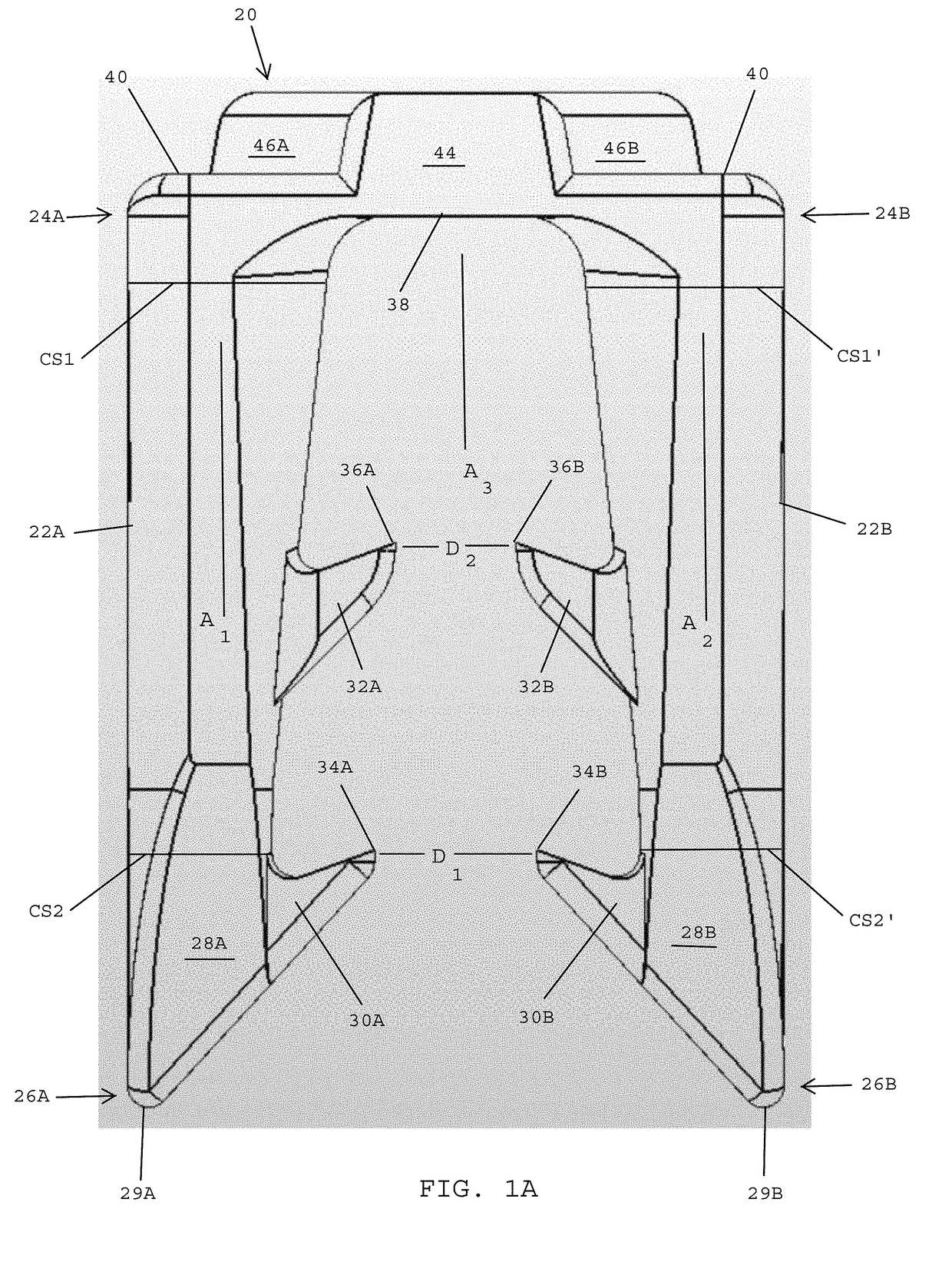

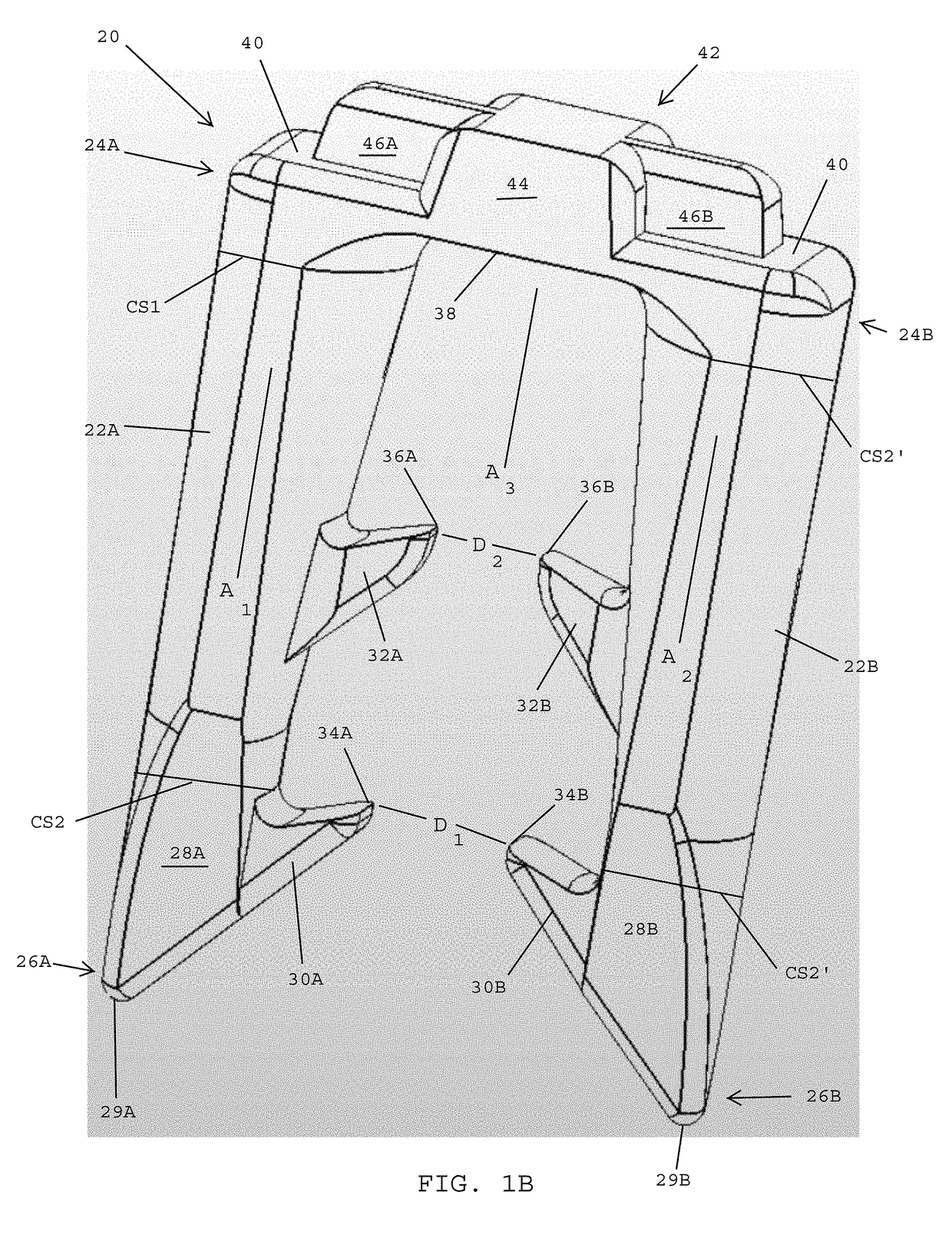

Surgical fasteners for mesh and tissue fixation

A surgical fastener includes a first leg having a first distal barb and a first proximal barb that extend inwardly, and a second leg having a second distal barb and a second proximal barb that extend inwardly. A bridge interconnects proximal ends of the first and second legs. A first distance between opposing inner tips of the first and second distal barbs is greater than a second distance between opposing inner tips of the first and second proximal barbs. The first leg tapers inwardly between the proximal and distal ends thereof and has a cross-sectional area that is greater at the proximal end than at the distal end. The second leg tapers inwardly between the proximal and distal ends thereof and has a cross-sectional area that is greater at the proximal end than at the distal end. An insertion tool engages a crown on the proximal side of the bridge.

Owner:ETHICON INC

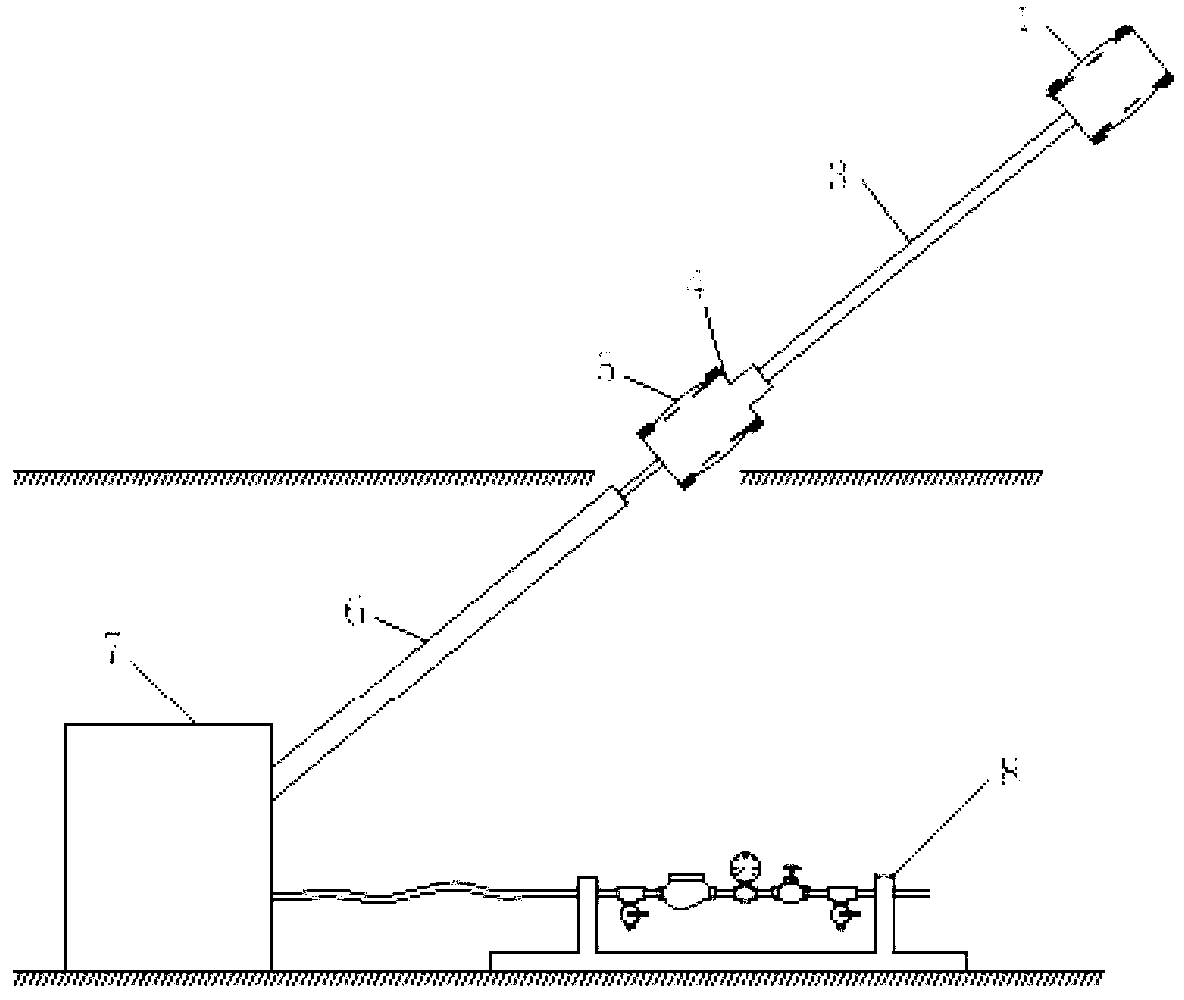

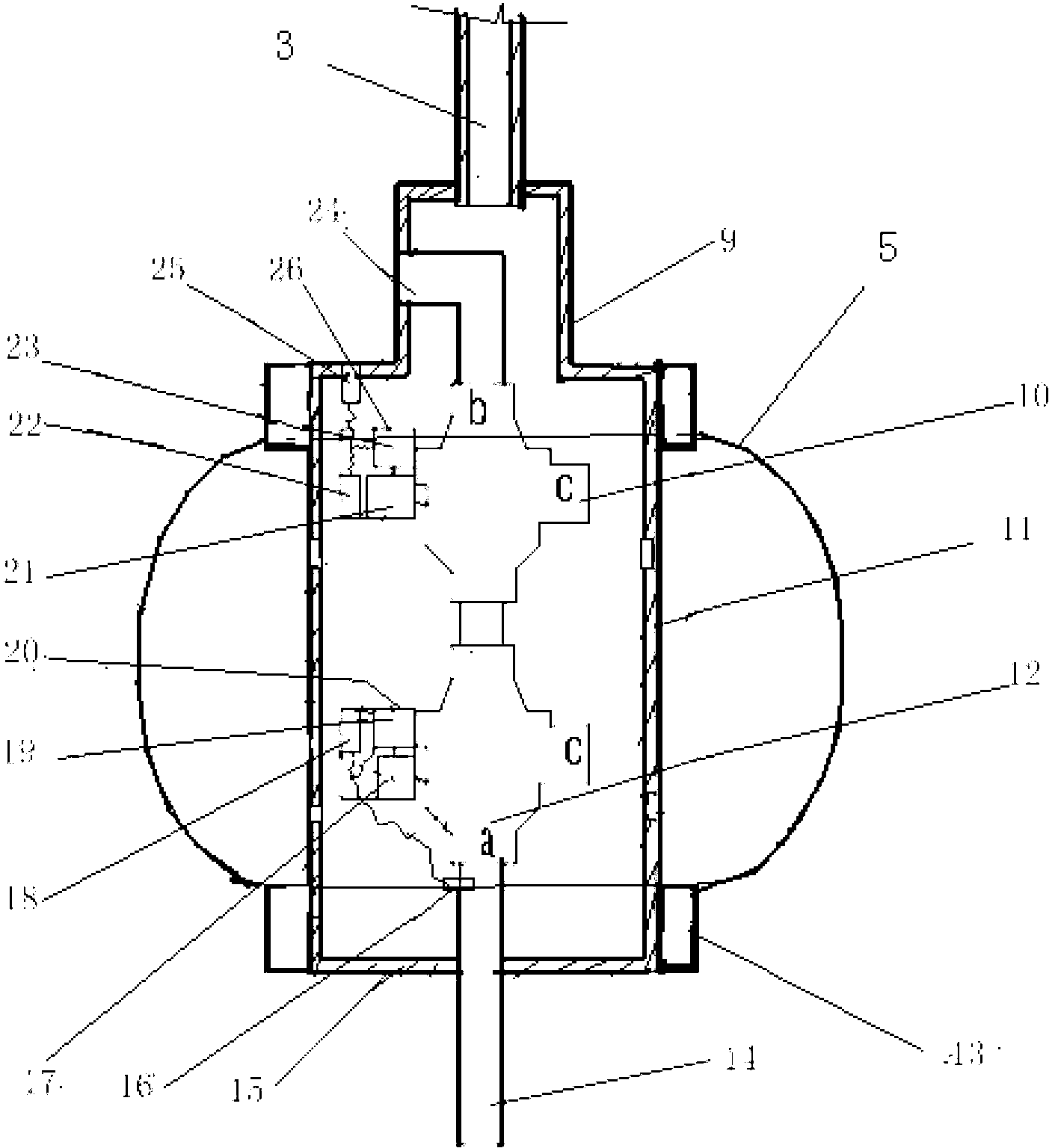

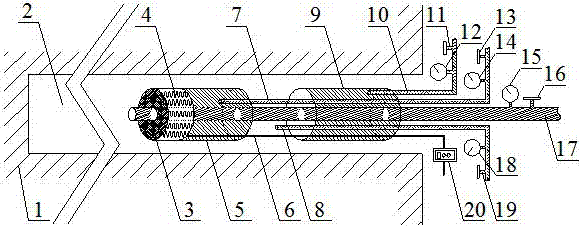

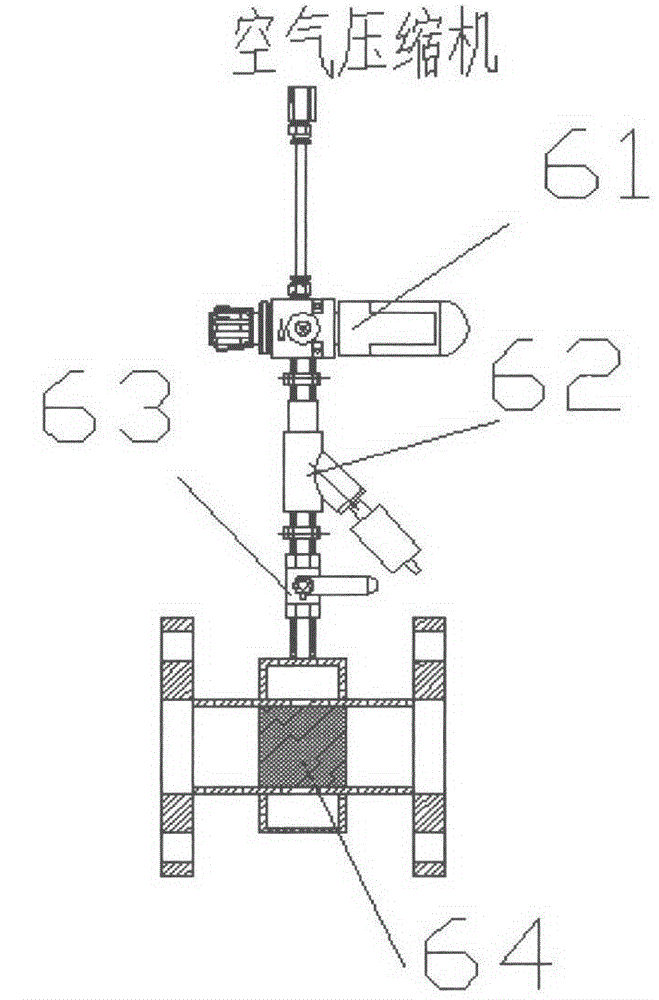

Coal seam super-critical carbon dioxide plugging device and method

The invention discloses a coal seam super-critical carbon dioxide plugging device and method. The device comprises a front-end hole packer, a rear-end hole packer, a grouting pipe, a super-critical carbon dioxide injection pipe and a temperature controller; the front-end hole packer is composed of a front-end hole packer metal end head, a front-end hole packer heating device, a front-end hole packer capsule and a front-end hole packer water injection pipe; the rear-end hole packer is composed of a rear-end hole packer capsule and a rear-end hole packer water injection pipe; the front-end hole packer and the rear-end hole packer are connected with the super-critical carbon dioxide injection pipe through quick sealing connectors, and the super-critical carbon dioxide injection pipe is connected with a super-critical carbon dioxide air source; the grouting pipe is arranged between the front-end hole packer capsule and the rear-end hole packer capsule; and the water injection pipe is connected with a high-pressure water source. The plugging method is high in reliability and good in plugging effect; and efficient plugging of super-critical carbon dioxide in a coal seam is achieved, it is ensured that the carbon dioxide injected into a drill hole is in a super-critical state, and application and promotion of the super-critical carbon dioxide in coal-seam gas yield increasing are facilitated.

Owner:TAIYUAN UNIV OF TECH

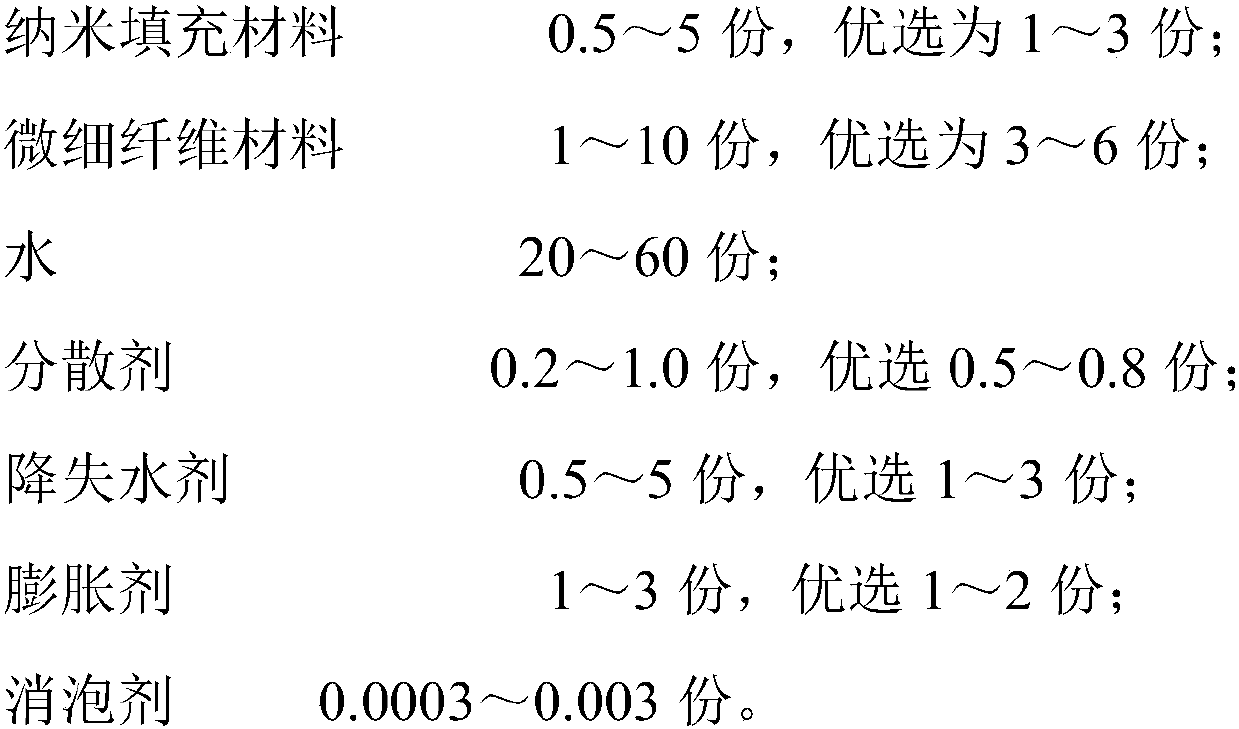

Plugging agent with high bearing strength for deep drilling and preparation method thereof

InactiveCN109868125AHigh compressive strengthImprove flexural strengthDrilling compositionFiberFlexural strength

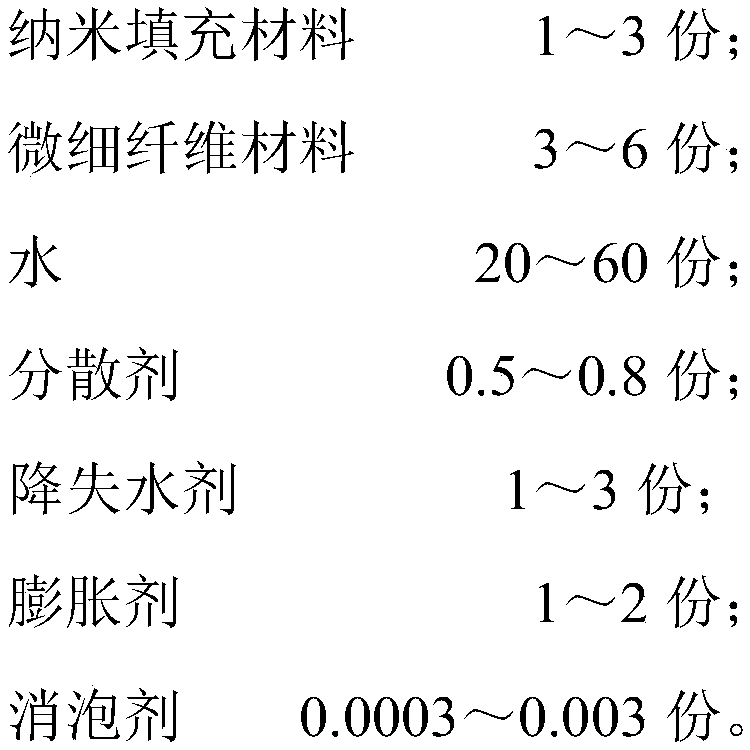

The invention relates to a plugging agent with high bearing strength for deep drilling and a preparation method thereof, belonging to the field of ultra-deep petroleum drilling engineering. The plugging agent with high bearing strength for deep drilling comprises cement, a cement additive, a nanometer filling material, a micro-fine fiber material and water; on the basis of 100 parts by weight of the cement, the content of the nanometer filling material is 0.5 to 5 parts by weight, preferably 1 to 3 parts by weight; the content of the micro-fine fiber material is 1 to 10 parts by weight, preferably 3 to 6 parts by weight; and the content of the water is 20 to 60 parts by weight. According to the invention, the plugging agent with high bearing strength can greatly improve compressive strength and flexural strength of a plugging slurry, and has significant plugging effect. The plugging agent provided by the invention is applicable to plugging lateral cracks, malignant leakage caused by broken rock strata and long open hole segments of multi-pressure series of strata; cementation performance between the plugging agent and a leakage channel wall and the impact crushing resistance of formed cement stone are improved; and the construction requirements of plugging for long open hole segments and plugging under high strength of 30 MPa or above can be solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

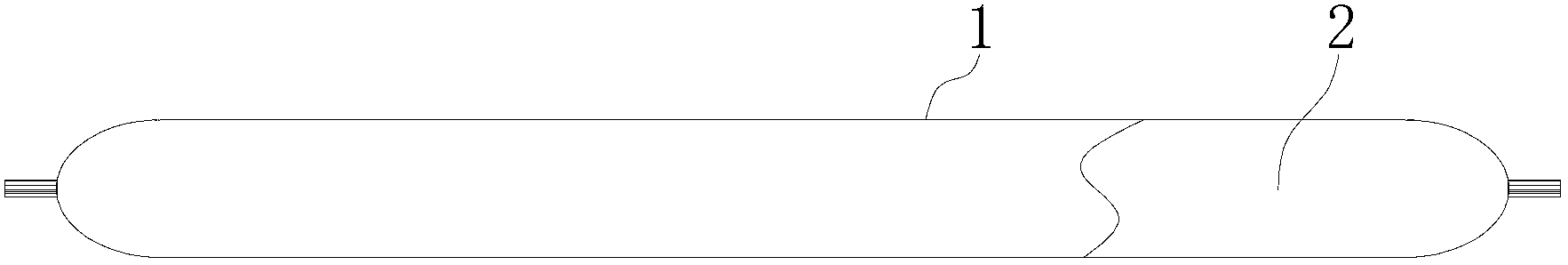

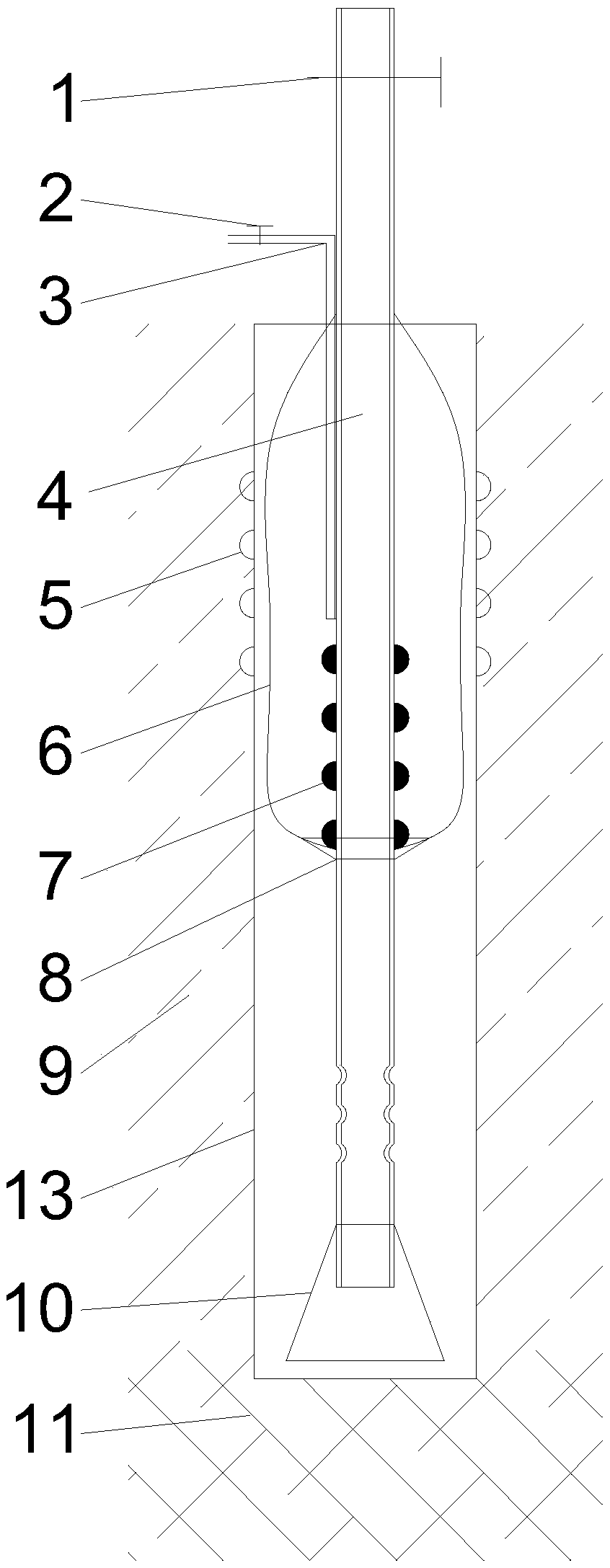

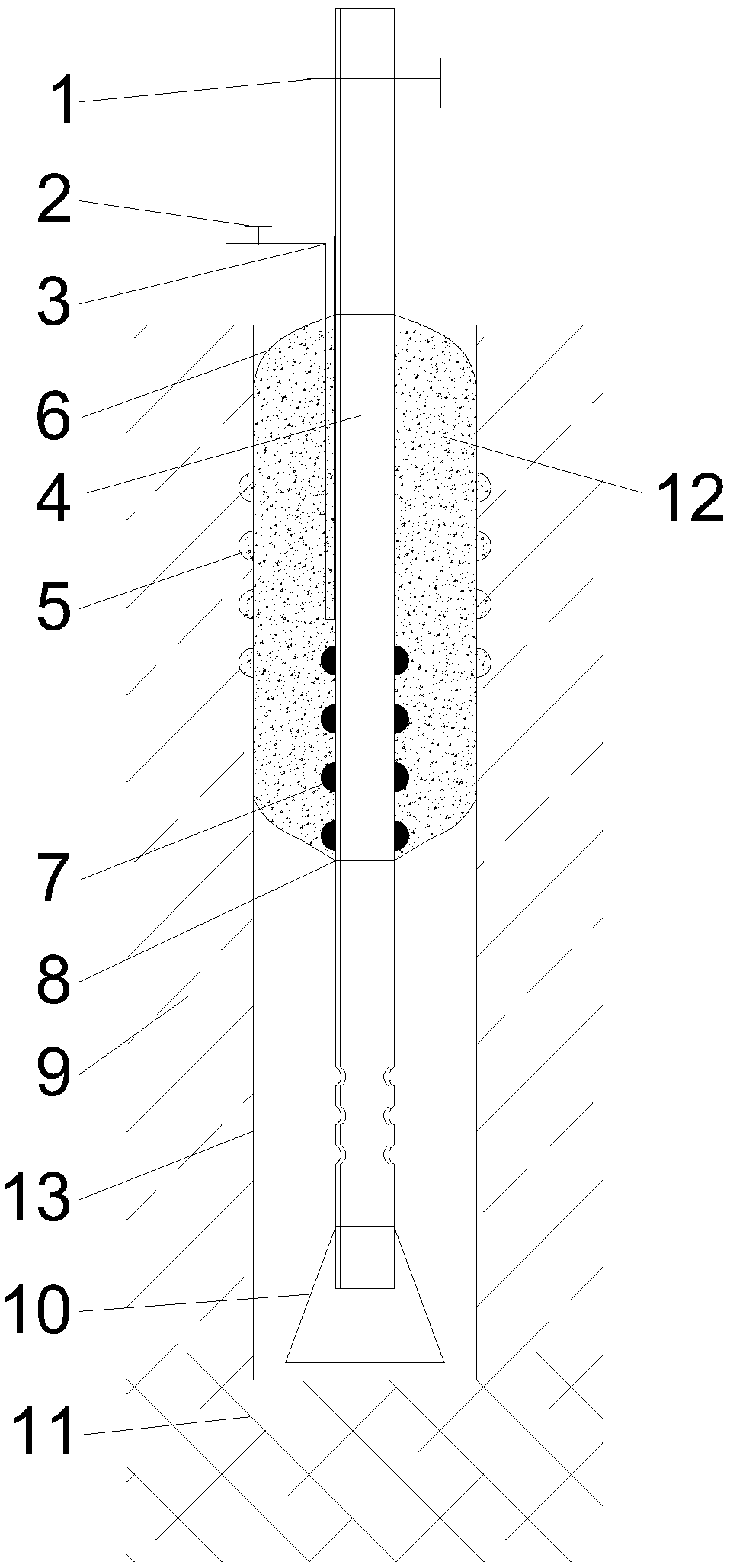

Water stemming containing foaming agent

The invention discloses water stemming which enables mining blasting to be safer. The water stemming comprises an outer packaging film (1) and liquid (2) which is sealed in the outer packaging film (1); the liquid (2) is an aqueous solution; and the aqueous solution contains 0.2 percent to 0.7 percent of foaming agent by the weight. The aqueous solution also contains 0.5 percent to 5 percent of sodium bicarbonate by the weight. The liquid in traditional water stemming is water, so that the effects of cooling, reducing dust, damping flame and reducing accident occurring rate are quite poor. According to the water stemming containing the foaming agent, the foaming agent or the sodium bicarbonate is additionally arranged in the water, so that the accident occurring rate can be reduced, the cooling, dust reducing and flame damping effects of the water stemming are better, and good popularization and application value as well as large-scale production are realized.

Owner:PANZHIHUA HENGWEI CHEM +1

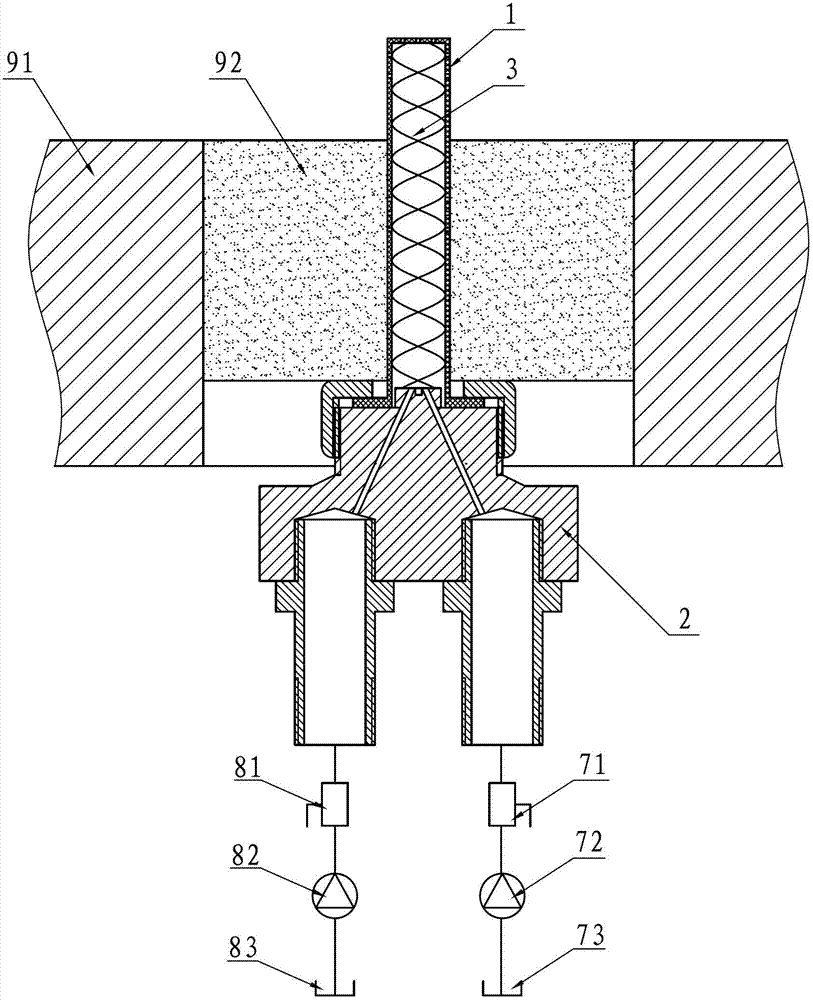

Rapid sealing method for high-pressure water-surge drilling hole

ActiveCN108868825AEfficient pluggingEasy to plug inUnderground chambersSealing/packingHigh pressure waterHigh pressure

The invention discloses a rapid sealing method for high-pressure water-surge drilling hole. The method comprises the following steps: a high-pressure water-surge drilling hole (13) is blocked and designed according to a hydrogeological information of the high-pressure water-surge drilling hole (13), and a drilling hole wall groove (5) is formed on the hole wall of the high-pressure water-surge drilling hole (13) with a drilling tool, the anchor rod bulge (7) is machined on a grouting anchor rod (4), and an assembled bagging anchor rod device is fixed in the high-pressure water-surge drilling hole (13) ; grouting is carried out in an anchor rod bag (6) from a bagging grouting pipe (3), the grouting is stopped when the set pressure is reached, a grouting anchor rod valve (1) is kept open, and after the grouting material in the anchor rod bag (6) is solidified and stabilized, the grouting anchor rod valve (1) is closed, thereby completing the sealing of the high-pressure water-surge drilling hole (13). By the method, the high-pressure water-surge drilling hole can be blocked safely, efficiently and conveniently, and the gushing water can be recycled and reused.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

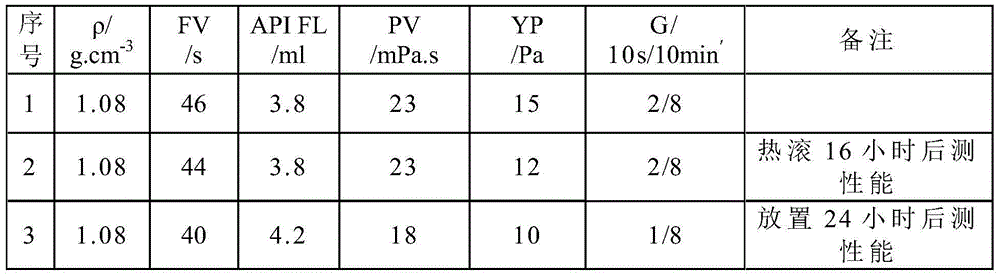

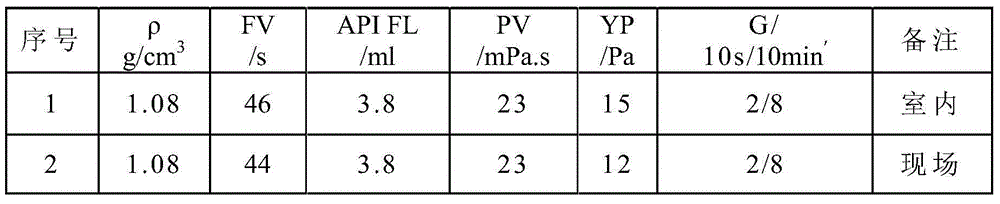

Water-based drilling fluid

The invention discloses water-based drilling fluid. The water-based drilling fluid is prepared from clear water, inhibitor, filtrate reducer, blocking agent, pH regulator and heavy loader according to the weight ratio of 100:(20-25):(15-20):(1-2):(0.5-1):(35-200). By the adoption of the water-based drilling fluid, environmental hazard of oil-based drilling fluid can be avoided, and efficient blocking, multi-phase lubrication, complex inhibition and weak gel property are realized. The water-based drilling fluid is suitable for drilling in a shale gas horizontal well of a long horizontal wellbore which has high hardness and fragility and is prone to collapse, and has high environment friendliness and economical efficiency.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

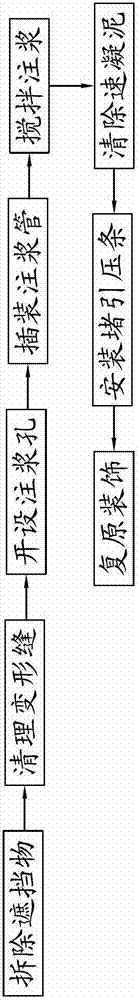

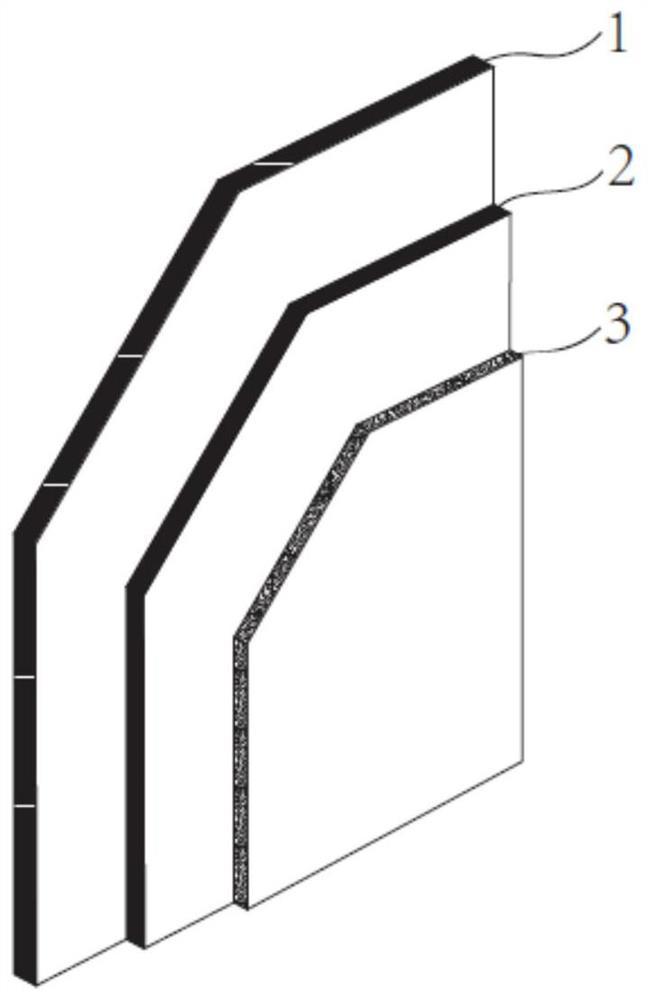

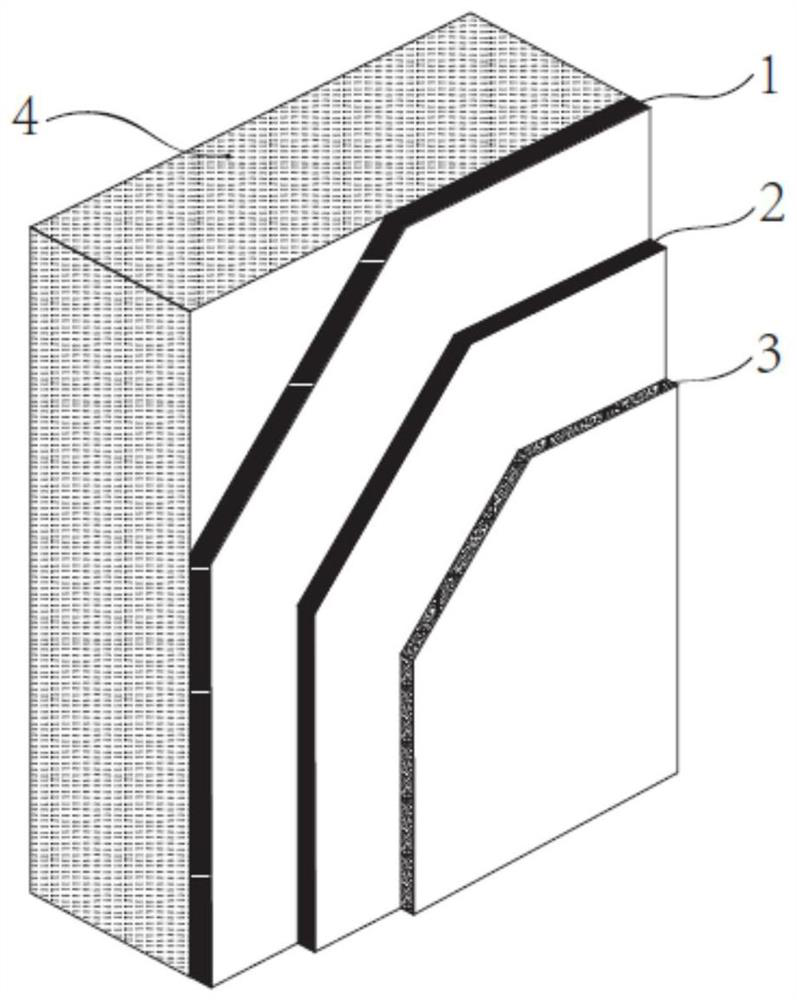

Grouting stoppage and guide repair method for leakage of deformation joint and special grouting device for grouting stoppage and guide repair method for leakage of deformation joint

InactiveCN102776905ASolve the scientific ratioSolve self-mixing problemsArtificial islandsProtective foundationBasementEngineering

The invention discloses a grouting stoppage and guide repair method for leakage of a deformation joint and a special grouting device for the grouting stoppage and guide repair method for the leakage of the deformation joint. The construction comprises the following steps of: clearing the deformation joint; arranging a grouting hole; inserting a grouting pipe; mixing and grouting; removing rapid hardening mud; and installing a stoppage and guide strip. The special grouting device can ensure reasonable ratio of glue solution and water; the mixing and grouting pipe can be used for mixing the synchronously pressed-in glue solution and water before the grouting, so that the mixed liquor can rapidly take reaction to generate a new water stoppage layer in soft puddle shape after being subjected to the grouting, and one-level effective leakage stoppage can be realized; the stoppage and guide strip is installed at the outer side opening of the deformation joint in a sealing way to realize secondary leakage stoppage and leakage guide for the deformation joint, even if trace leakage exists in the deformation joint, trace permeated water is also guided to an underground drainage system, and no influence is caused on normal use of a basement. The repair method provided by the invention not only can thoroughly solve the leakage of the deformation joint, but also is simple in operation, lower in cost and strong in practical applicability.

Owner:江苏金坛建工集团有限公司

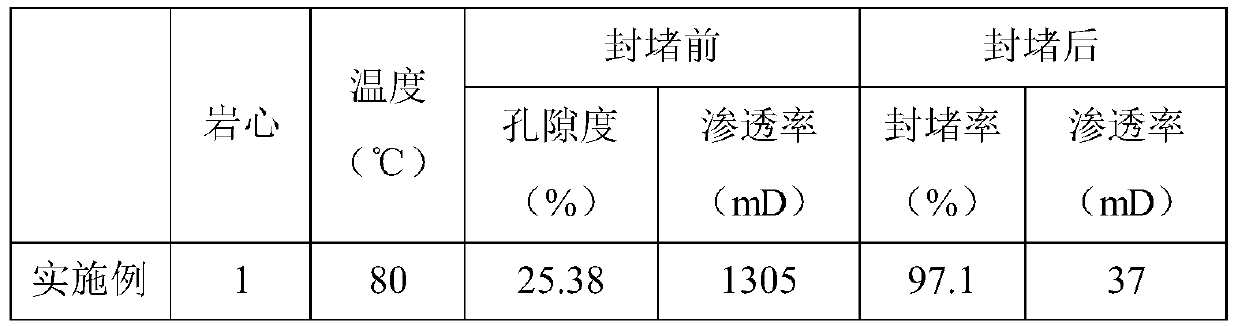

Three-phase foam channel-sealing agent, preparation method thereof, and thickened oil exploiting and plugging method

ActiveCN109971443AImprove plugging efficiencyAdjustable permeabilityDrilling compositionCross-linkFoaming agent

The invention discloses a three-phase foam channel-sealing agent and a preparation method thereof, and a thickened oil exploiting and plugging method by adopting the three-phase foam channel-sealing agent, and belongs to the technical field of oil field chemistry. The three-phase foam channel-sealing agent consists of the following components in percentage by weight: 0.3% of a foaming agent, 3-4%of alpha-starch, 3%-4% of acrylamide, 0.01%-0.02% of an initiator, 0.1%-0.15% of a cross-linking agent, 0.1%-0.2% of a control agent, 0.5%-30% of solid-phase particles and the balance of water. The three-phase foam channel-sealing agent disclosed by the invention is injected into steam channeling pore channels, steam huff and puff is carried out after foam forms gel, the gel is carbonized when encountering steam, and solid particles are left to block the channeling channels. Plugging efficiency is high, permeability is adjustable, a problem of serious steam channeling can be well solved, and the recovery rate of crude oil is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

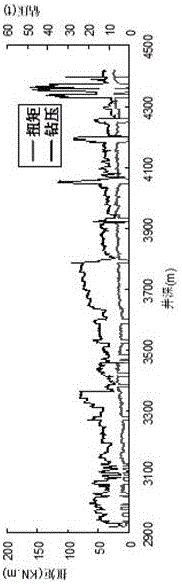

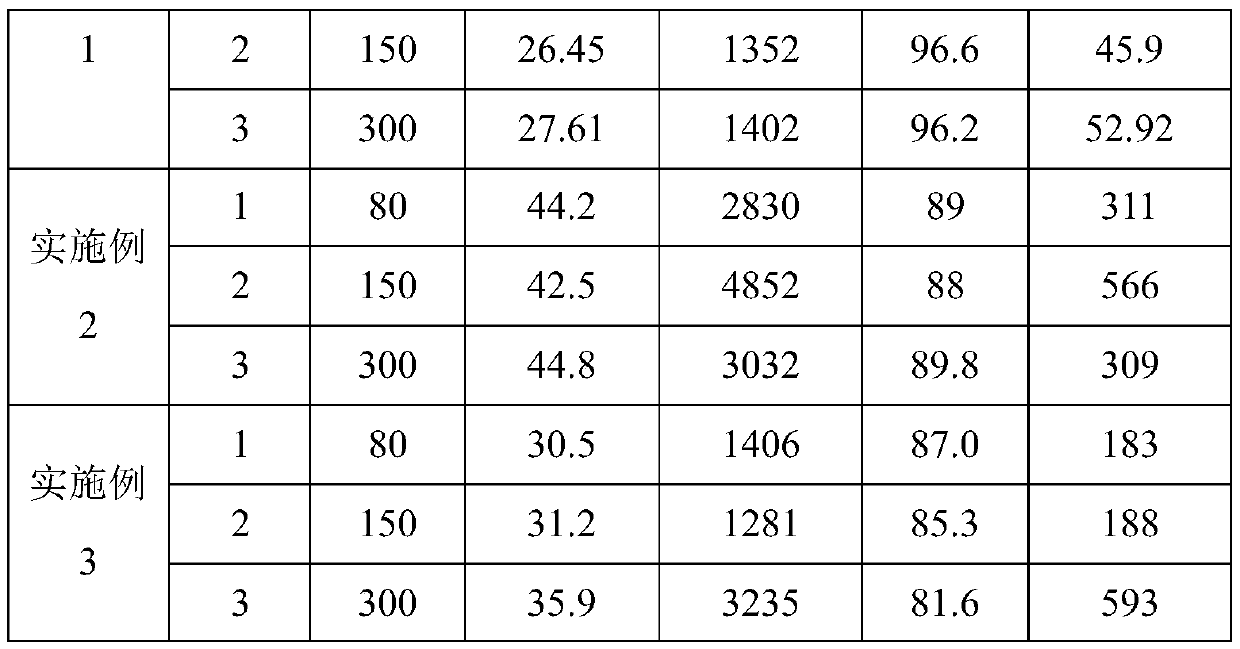

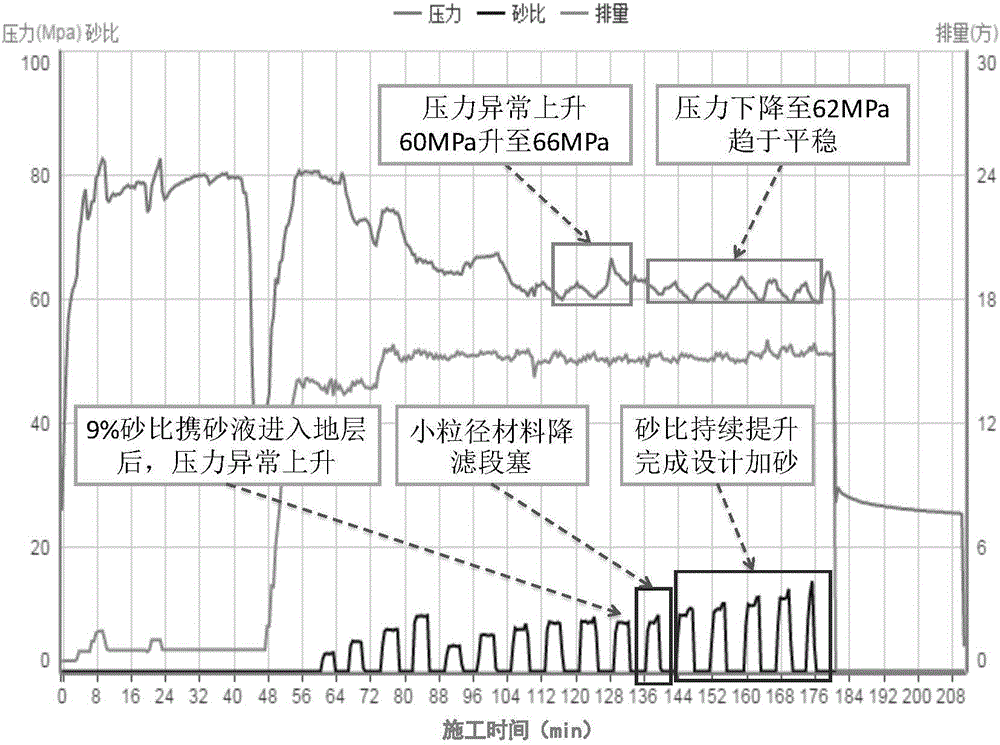

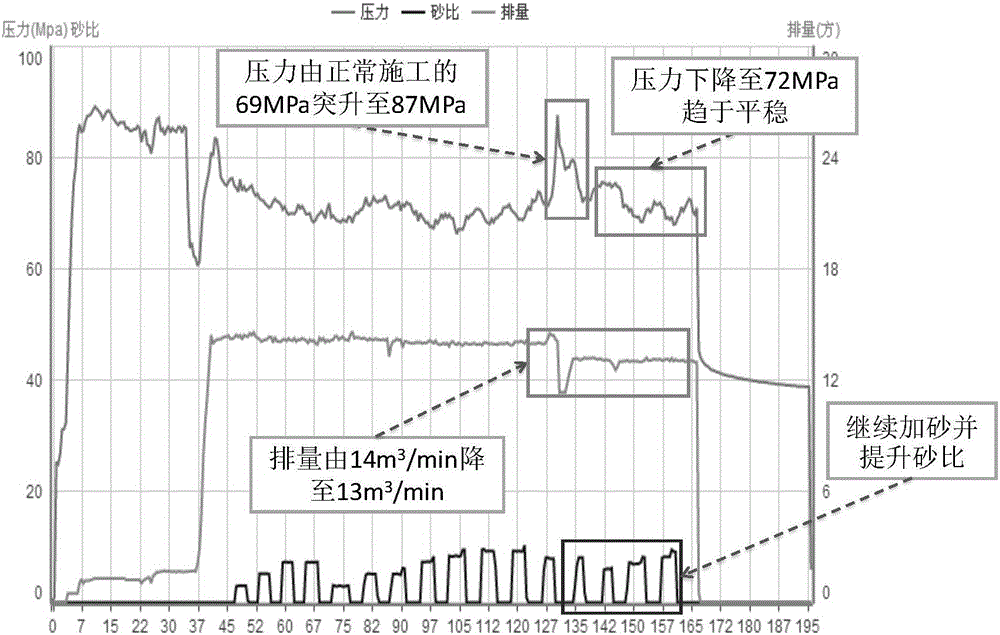

Processing method for controlling abnormal pressure rise in shale fracturing process

InactiveCN106761644ASlow down the rate of formationEfficient pluggingFluid removalPressure riseFracturing fluid

The invention discloses a processing method for controlling abnormal pressure rise in the shale fracturing process. The processing method comprises the following steps that in the middle and later periods of fracturing, a critical sand ratio method is adopted for construction when abnormal pressure rise occurs and comprises the specific steps that 1, the critical sand ratio is determined, wherein a critical sand ratio range is determined as the sand ratio subtracted by 2%-5% at the moment when pressure rises at the slope greater than 1 / 2 in the sand adding process, sand adding is stopped immediately, fracturing fluid injection continues, the injection amount is 1-1.5 times of shaft volume, sand adding is stopped but fluid injection is not stopped; 2, abnormal pressure rise is processed, wherein the point not exceeding the critical sand ratio serves as a starting point to perform pressurized fracturing again after the injection of a fracturing fluid 1-1.5 times of shaft volume is completed, and a sand ratio value in fracturing sand is gradually increased till designed sand adding amount is completed. By adopting the critical sand ratio method, a sandy dyke formation speed can be reduced, the rapid rise situation of construction pressure is effectively controlled, and the method has the advantages that operation is simple and convenient, an existing fracturing process is not changed, the fracturing construction quality can be improved, and a reconstruction effect is ensured.

Owner:PETROLEUM ENG TECH RES INST OF JIANGHAN OILFIELD BRANCH OF

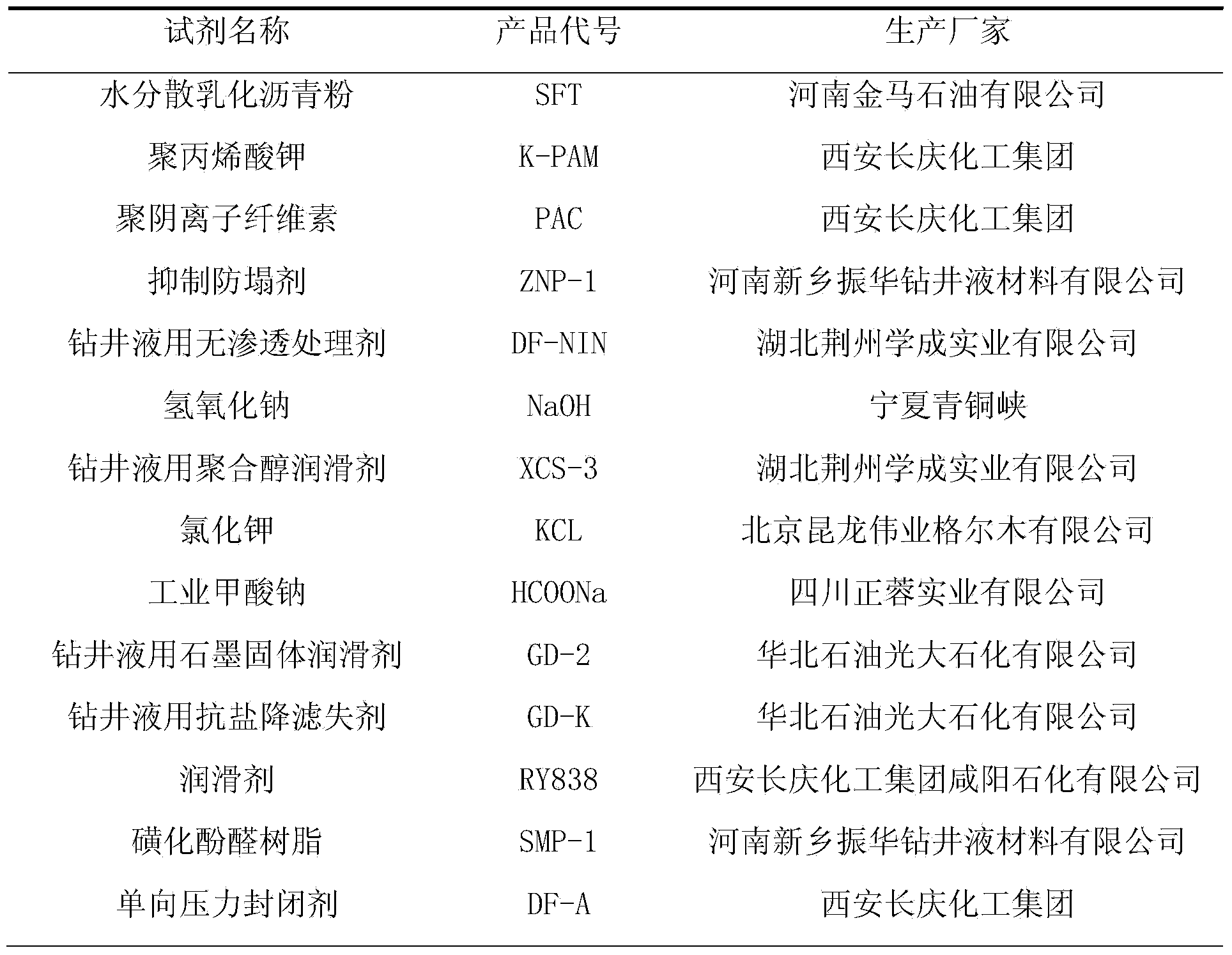

Anti-collapse and leakproof drilling fluid and construction method thereof

ActiveCN104046338AHigh densityHigh solid contentFlushingDrilling compositionCelluloseWater dispersible

The invention relates to the technical field of petroleum drilling, and particularly relates to anti-collapse and leakproof drilling fluid and a construction method thereof, which are applicable to a Mesozoic Triassic stratum having the characteristics of low loading capacity, repeated block leakage and large leaking stoppage difficulty. The drilling fluid is composed of polyanionic cellulose, a drilling fluid salt-resistant filtrate-loss reducer, water dispersible emulsified asphalt powder, ultrafine calcium carbonate, sodium formate, sodium hydroxide, potassium chloride and water. Due to the application of a salt-poor low soil phase, the sealing capacity of a mud cake is improved and the loading capacity of the stratum is enhanced; low density is effectively controlled, and the probability of induced lost circulation is reduced; and the pump delivery is reduced, and the erosion of the drilling fluid to the wall of a well is reduced, thereby protecting the wall of the well from collapsing. According to the invention, through enhancing the loading capacity of the stratum, the low density is effectively controlled, the pump delivery is reduced, the probability of lost circulation is reduced, the drilling cycle of the block is greatly reduced, and the drilling cycle is shortened by over 50%.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

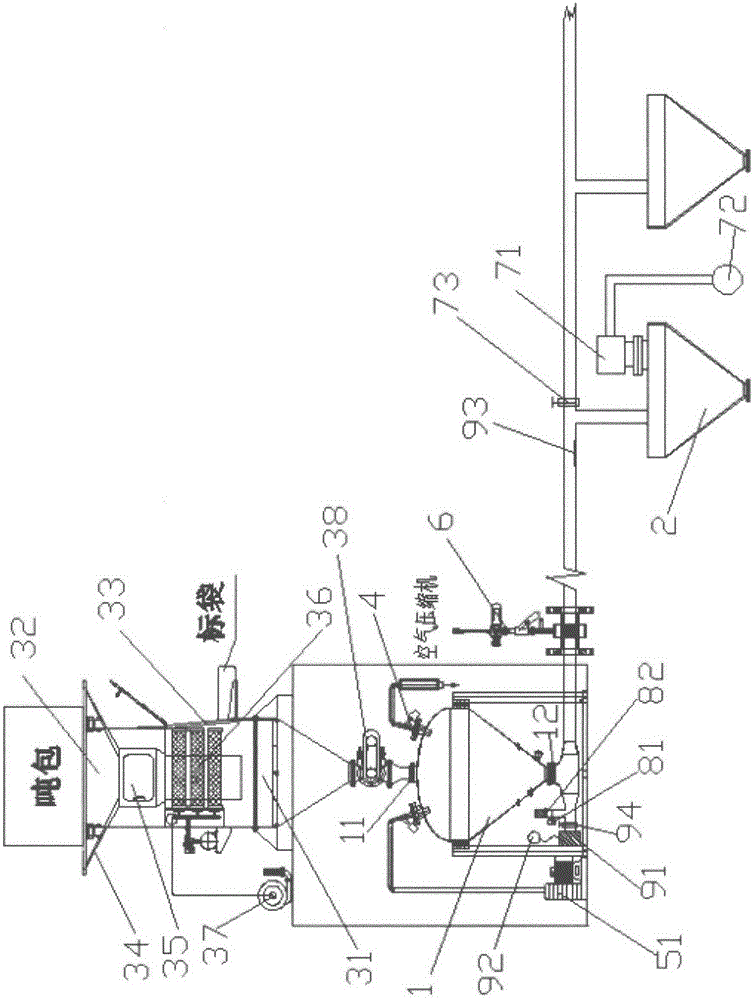

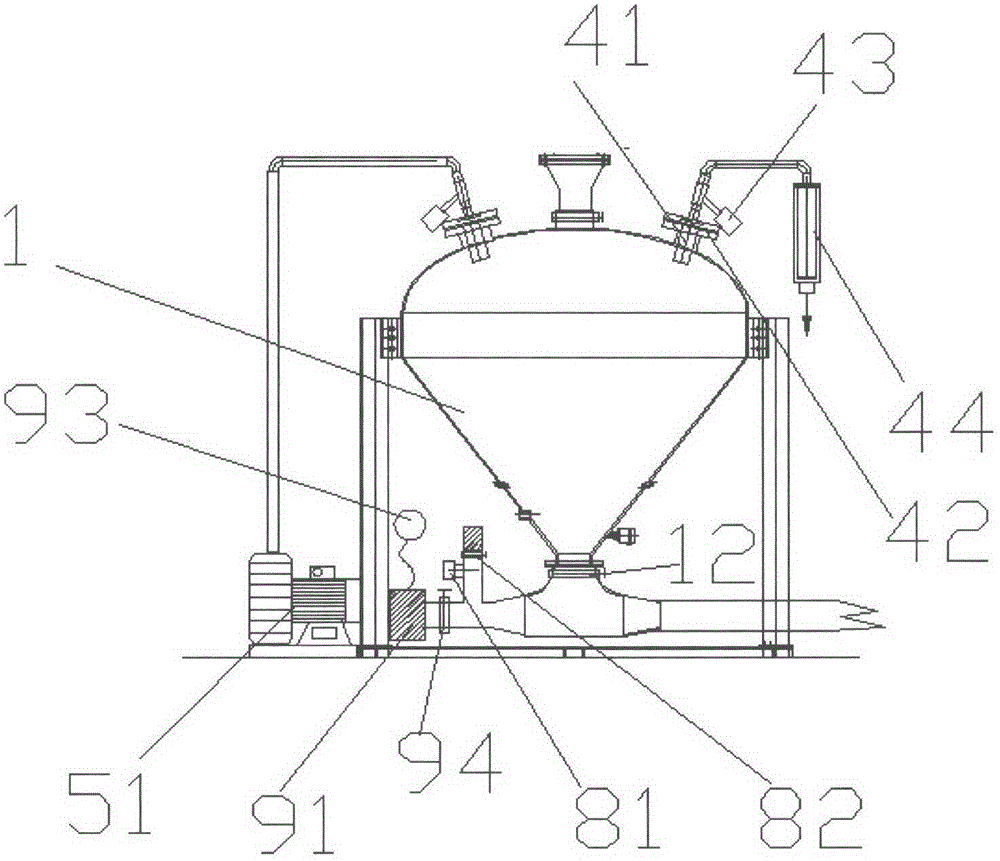

Positive-pressure conveying system device

The invention discloses a positive-pressure conveying system device which comprises a sending tank and a storehouse. The sending tank and the storehouse are connected through a pipeline. Butterfly valves are arranged at the position of a feeding port of the sending tank and the connecting position of the bottom of the sending tank and a discharging pipe. The positive-pressure conveying system device further comprises a tonnage and standard dual-purpose unpacking and material collecting device, an exhaust noise-reduction device, a negative-pressure accelerated feeding device, a material plug forming device, a pipeline cleaning device, a pipeline blocking removing device, and a mixing device with the ratio of fed materials and inlet gas capable of being adjusted. By means of the positive-pressure conveying system device, material conveying can be completed with high efficiency, pollution is reduced, energy consumption is reduced, time and labor are saved, and the production cost is reduced.

Owner:CHANGZHOU CHANGHENG DEYU POWDER INTEGRATIVE SYST

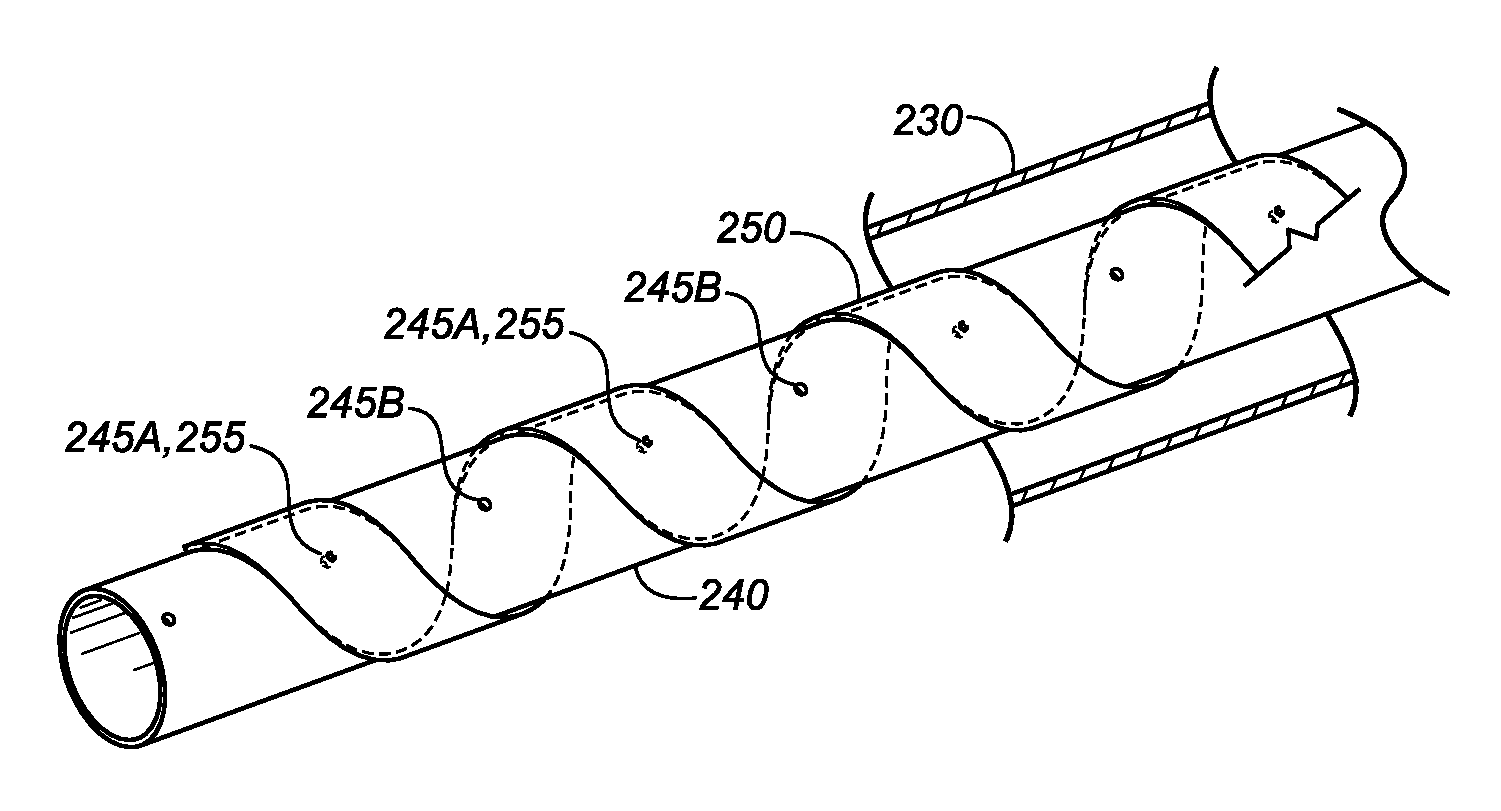

Method and apparatus for freeze-thaw well stimulation using orificed refrigeration tubing

InactiveUS8448708B2Uniform effectivenessEasy to useDomestic cooling apparatusLighting and heating apparatusFreeze thawingVaporization

A method and apparatus for introducing refrigerant into a wellbore, for freeze-fracturing a selected region of a subsurface formation, uses refrigerant diffuser pipe having multiple orifices in a selected pattern along a designated section of its length. The orificed supply tubing is disposed within a refrigerant return conduit, thereby forming a tubing annulus. A flow of liquid refrigerant is introduced into the diffuser pipe and flows through the orifices into the tubing annulus, with the orifices acting as expander means creating a pressure drop and causing vaporization of the refrigerant as it passes into the annulus. To facilitate use of the same diffuser pipe in different wells having different requirements, a helical orifice-isolation wrap may be disposed around the diffuser pipe, with the orifice-isolation wrap having orifice-plugging elements arrayed to effectively block fluid flow through selected orifices, while leaving other orifices open as required. In this way, it is possible to design diffuser pipes with particular orifice arrangements that will accommodate two or more different isolation wraps, with each different wrap plugging different patterns of orifices.

Owner:POLAR WELL STIMULATIONS LTD

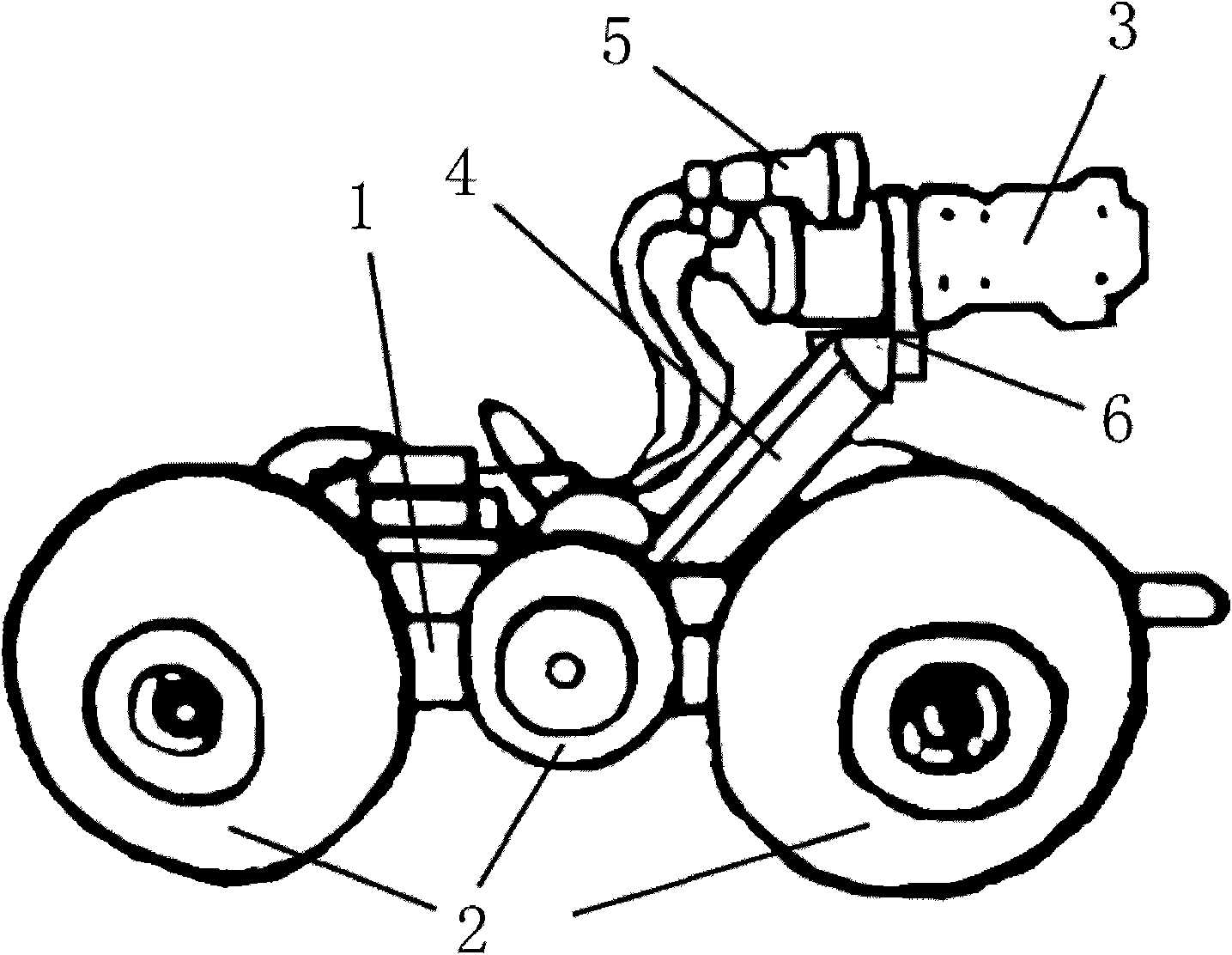

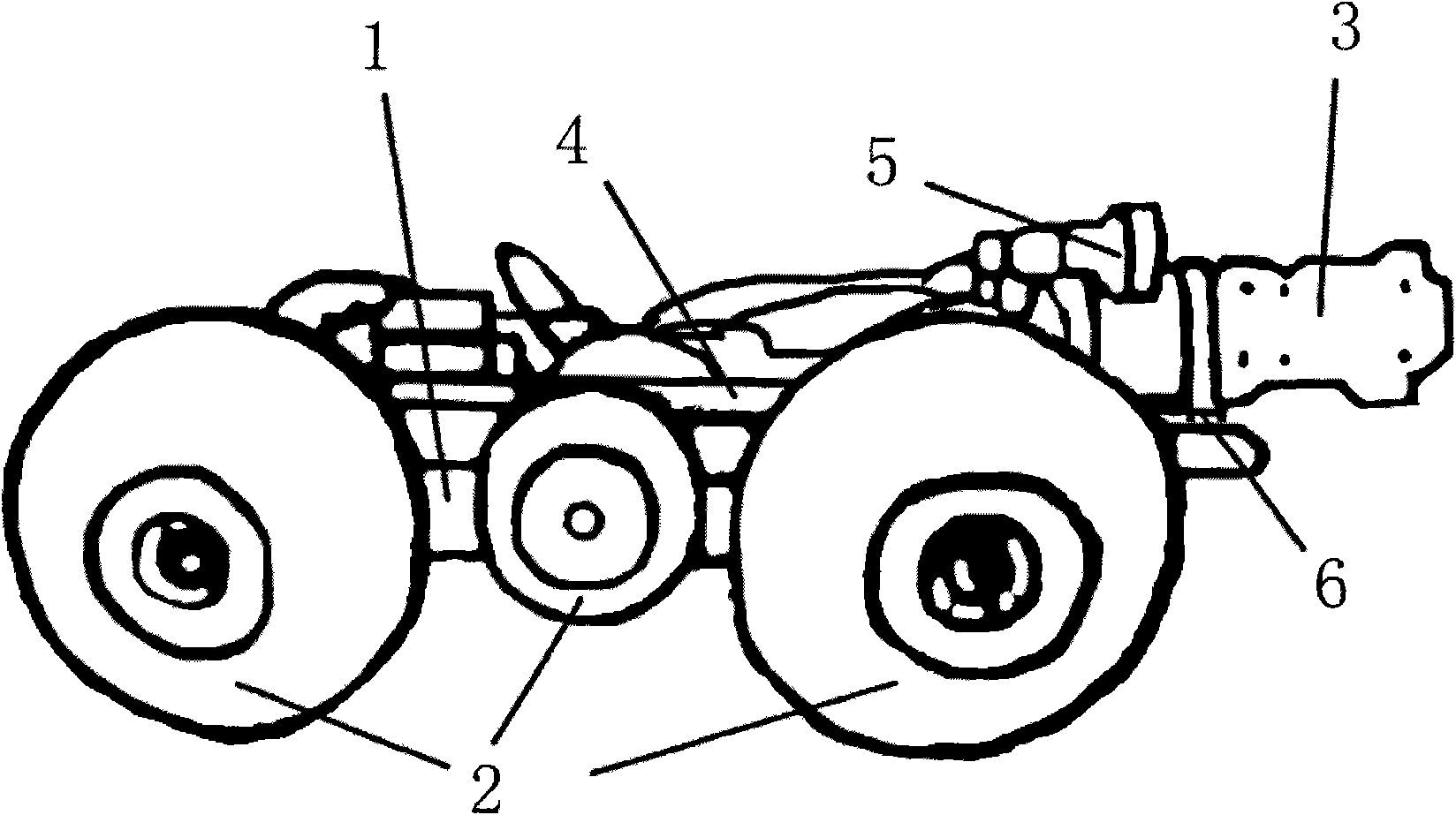

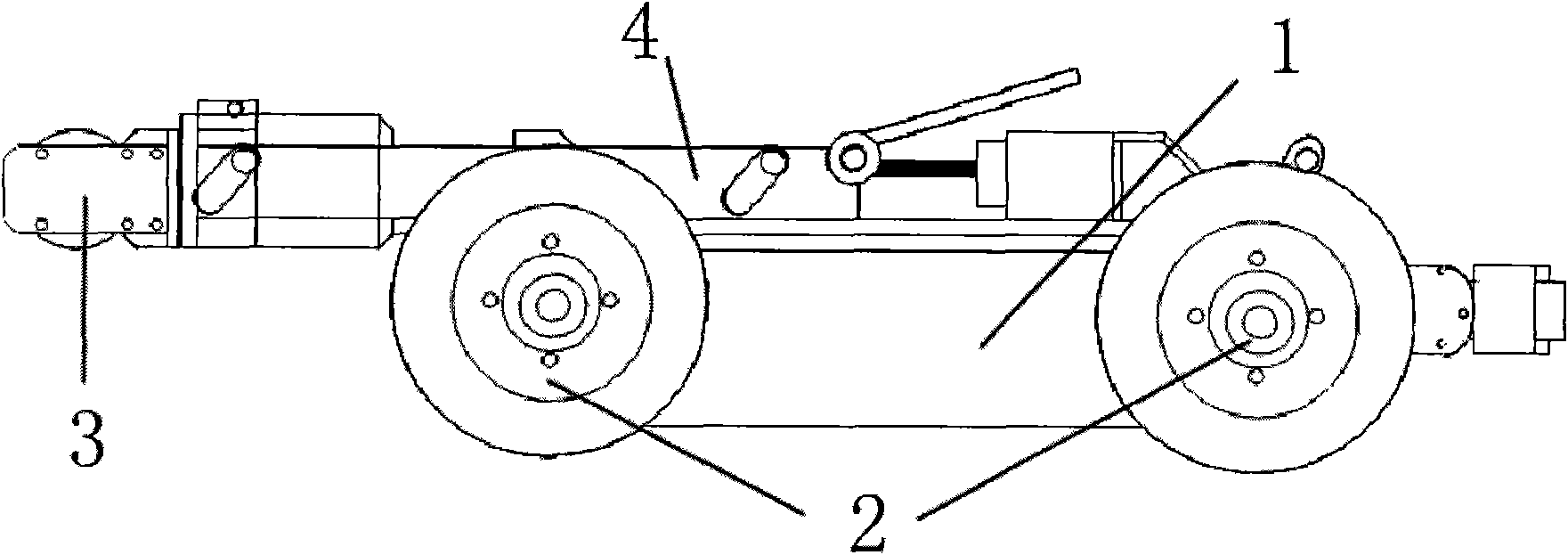

Automatic crawling trolley for detection in pipeline

InactiveCN102155625AEfficient pluggingEffective maintenancePipeline systemsEnvironment effectEngineering

The invention discloses an automatic crawling trolley for detection in a pipeline. The automatic crawling trolley for the detection in the pipeline comprises a frame (1) and travelling wheels (2) which are arranged on two sides of the automatic crawling trolley. The automatic crawling trolley is characterized in that the travelling wheels (2) on the two sides of the automatic crawling trolley can be independently driven respectively. The automatic crawling trolley can be applied to non-ground excavation and monitoring of damage to underground pipelines. The pipeline comprises the underground pipelines such as municipal drainage underground pipelines, agricultural water underground pipelines, industrial water underground pipelines, running water underground pipelines and coal gas underground pipelines. The automatic crawling trolley for the detection in the pipeline is particularly applied to the detection in the underground pipelines without influence on peripheral environments, and can be used for effective de-blocking, maintenance, repair and detection of the underground pipelines. Moreover, the automatic crawling trolley is water-proof, can travel and climb in the underground pipelines which are obstructed, and is anti-skidding.

Owner:管丽环境技术(上海)有限公司 +1

Nano inorganic anti-corrosion, anti-seepage and anti-fouling coating structure for hydraulic concrete

The invention relates to a nano inorganic anti-corrosion, anti-seepage and anti-fouling coating structure for hydraulic concrete, which is characterized by comprising a bi-component high-molecular polymer mortar bonding bottom coating, a bi-component high-strength polymer mortar middle coating and a nano anti-corrosion and anti-fouling protective surface coating, wherein the bi-component high-molecular polymer mortar bonding bottom coating, the bi-component high-strength polymer mortar middle coating and the nano anti-corrosion and anti-pollution protective surface coating are sequentially stacked together. The coating structure has the advantages of corrosion prevention, seepage prevention and pollution resistance, good effect, good stability, easiness in cleaning, lasting effect, good applicability and the like.

Owner:韦尔狄(广州)生物工程科技有限公司

Drilling fluid, preparation method and application thereof

The invention provides a drilling fluid, a preparation method and an application thereof. The drilling fluid includes, by mass, 1-1.5% of a plugging agent, 7-9% of an inorganic salt inhibitor, 0.35-0.45% of an organic salt inhibitor, 1-1.5% of an acid dissolution fluid loss agent, 2.5-4.5% of an acid dissolution temporary plugging agent, 0.3-0.5% of xanthan gum, 0.3-0.6% of high-viscosity polyanionic cellulose, 0.3-0.6% of low-viscosity polyanionic cellulose, and the balanced being water. The drilling fluid solves the technical problems of low drilling speed, long drilling period, poor flowability, long soaking time of well wall in the drilling fluid and high reservoir damage degree since the reservoir is protected by increasing the density of the drilling fluid in the prior art.

Owner:PETROCHINA CO LTD

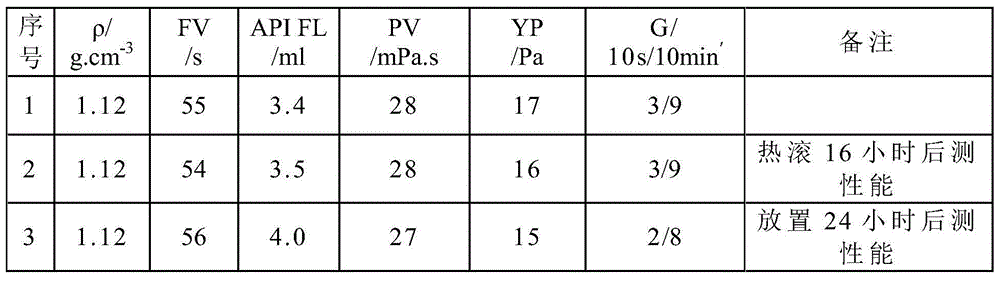

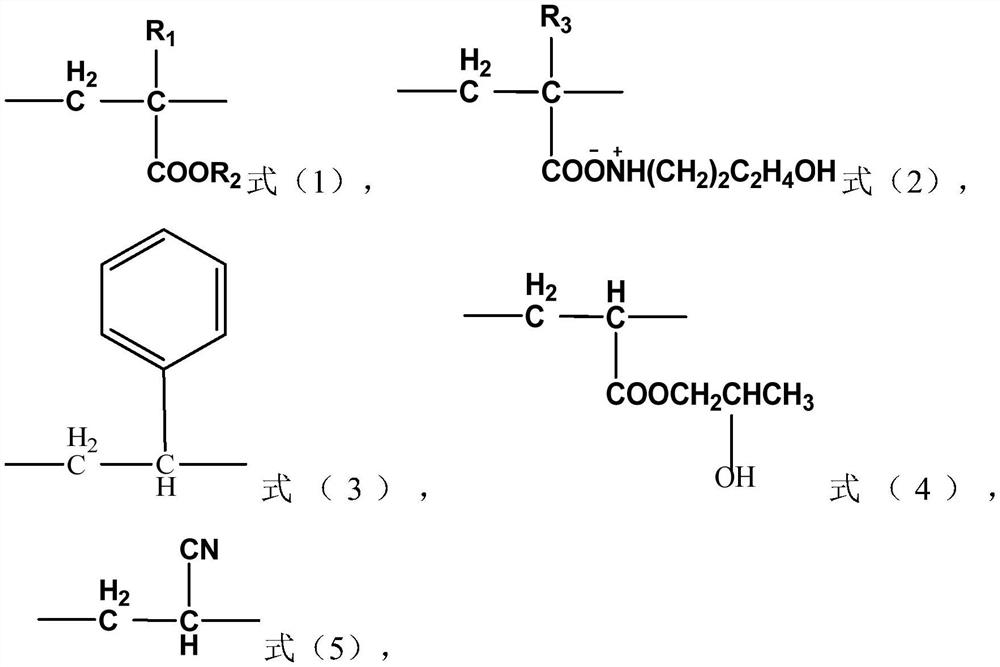

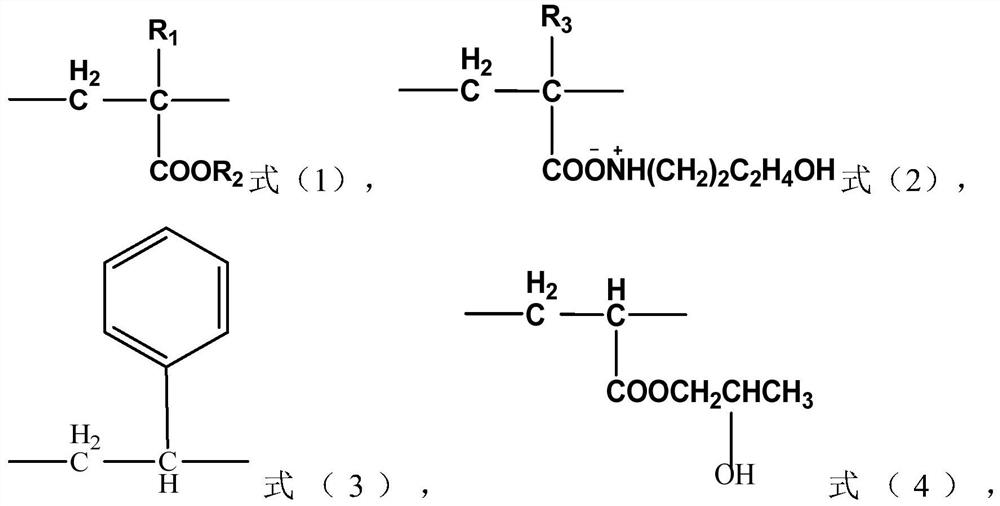

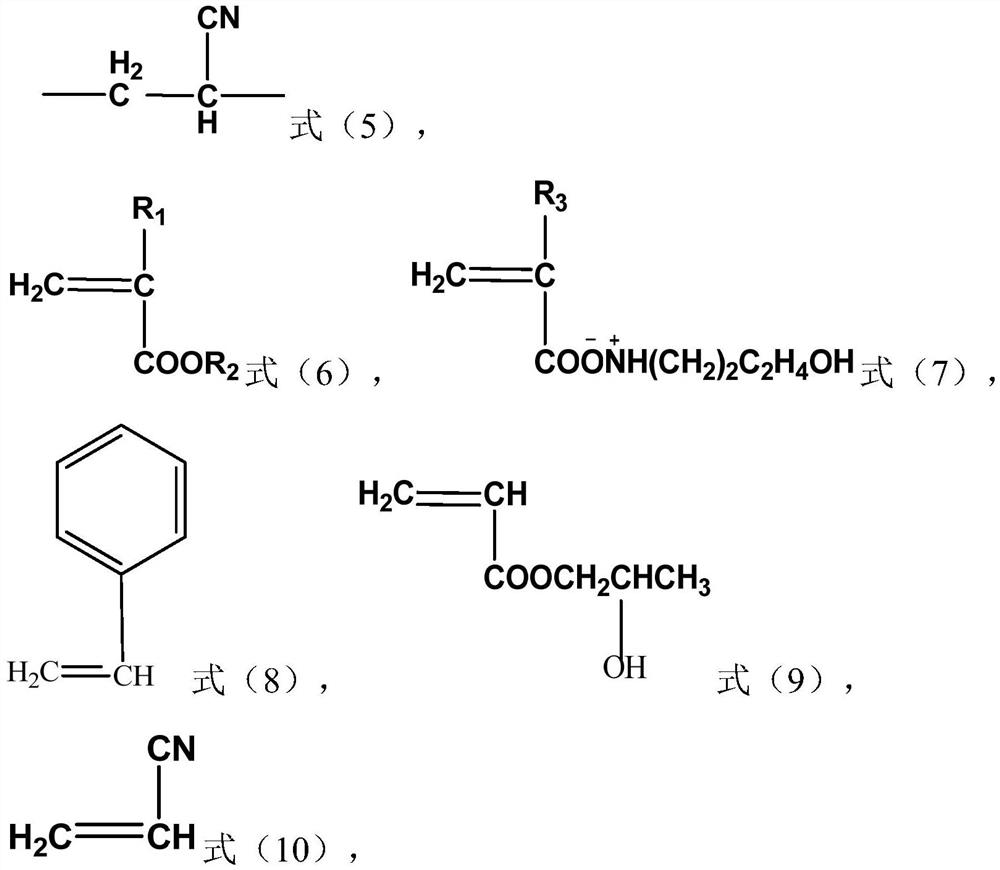

Copolymer, preparation method thereof, application of the copolymer as plugging agent, oil-based drilling fluid and application of oil-based drilling fluid

ActiveCN111808224AGood hydrophilic and lipophilicSolve the missing problemDrilling compositionWell drillingOrganic chemistry

The invention relates to the field of well drilling in the petroleum industry. The invention particularly relates to a copolymer, a preparation method thereof, application of the copolymer as a plugging agent, oil-based drilling fluid and application of the oil-based drilling fluid. The copolymer contains a structural unit A, a structural unit B, a structural unit C, a structural unit D and a structural unit E, wherein the structural unit A is a structural unit with a structure as shown in a formula (1), the structural unit B is a structural unit with a structure as shown in a formula (2), thestructural unit C is a structural unit with a structure as shown in a formula (3), the structural unit D is a structural unit with a structure as shown in a formula (4), and the structural unit E isa structural unit with a structure as shown in a formula (5); R1, R2 and R3 are each independently H or C1-C10 alkyl. When the copolymer provided by the invention is used as a plugging agent, the problem of leakage of underground oil-based drilling fluid can be efficiently solved, and leakage pores and cracks with different sizes can be plugged.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

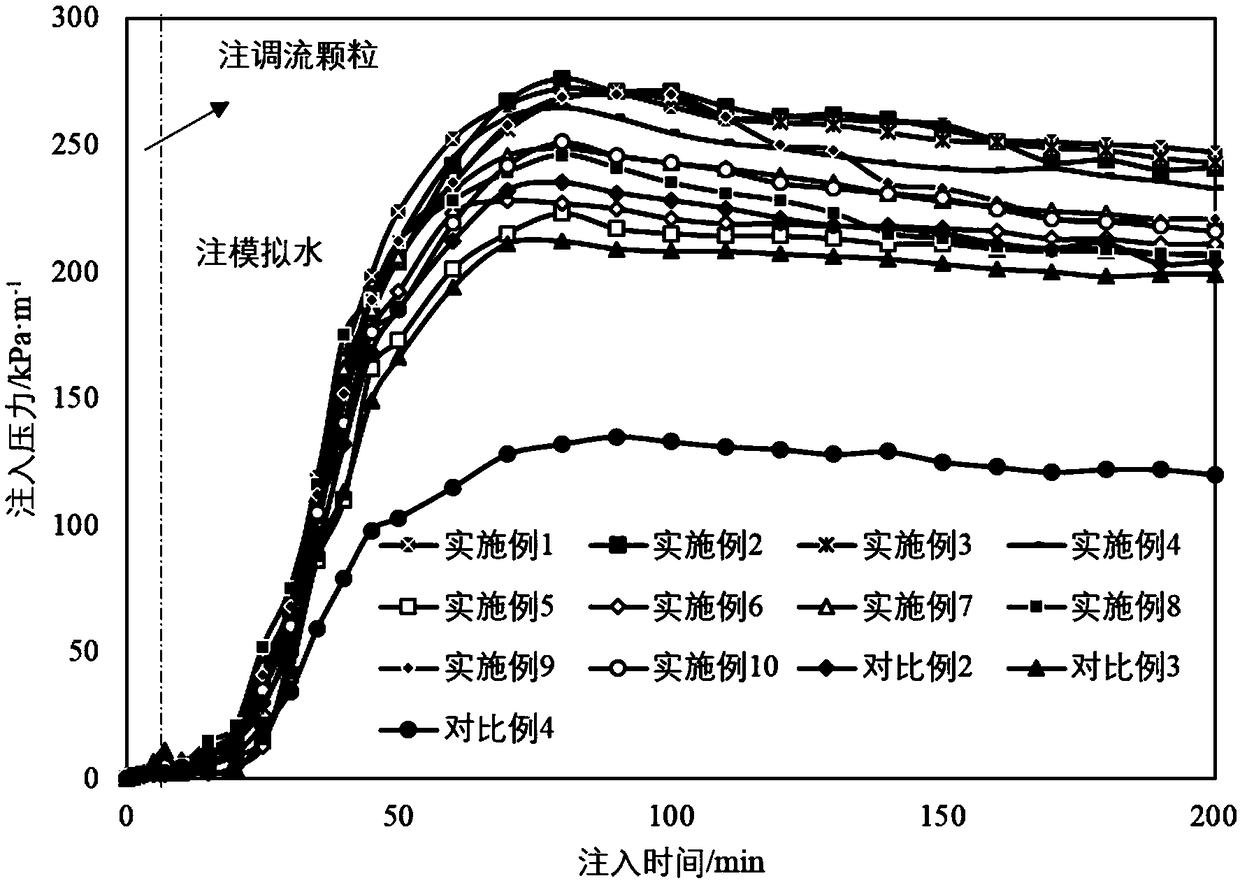

Flow regulating agent particles, flow regulating agent, and preparation method and application of flow regulating agent

ActiveCN109439300AImprove temperature resistanceStrong resistance to mineralizationFluid removalDrilling compositionWater flowVolumetric Mass Density

The invention relates to the field of petroleum exploitation, in particular to flow regulating agent particles, a flow regulating agent, a preparation method of the flow regulating agent, and application of the flow regulating agent particles and the flow regulating agent in development of fractured-vuggy reservoirs. The flow regulating agent particles comprise, by weight, 30-90% of viscoelastic main agents, 3-30% of selective auxiliary solvents, 0.1-30 parts of density adjusting agents, 1-30 parts of swelling agents and 0-10% of toughening agents. The flow regulating agent comprises the flowregulating agent particles and carrier liquid, and the carrier liquid comprises water and surfactants. The obtained flow regulating agent particles have high temperature resistance, adhesion propertyand swelling property, and can selectively adjust deep dominant water flow channels of stratums.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Soluble glass slurry taking water-soluble ester as curing agent

The invention relates to a soluble glass slurry taking water-soluble ester as curing agent. The soluble glass slurry taking water-soluble ester as curing agent uses carbitol acetate as curing agent; the main agent is soluble glass; based on 100 parts of slurry, the volume ratio of each component is as follows: 15-60 parts of soluble glass 38Be', 1-8 parts of carbitol acetate, and water for the rest. The invention is suitable for water plugging of water-bearing layer of quartz sandstone and grouting at the back of the well wall, and is particularly suitable for ground pregrouting and face pregrouting of porous stratum of the pit shaft of mine well; the invention takes carbitol acetate with excellent dissolving performance as curing agent; the grouting material has the characteristics of high permeability, high strength, adjustable gel time, and the like, has simple operation, easy storage and stable performance, and is chemical grouting material with high application value.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com