Anti-collapse and leakproof drilling fluid and construction method thereof

A construction method and drilling fluid technology, applied in the field of petroleum drilling, can solve problems such as the inability to use liquid column pressure to support the well wall, the inability to effectively block the leaky layer channel, and the high-inclination well section without increasing the density, so as to achieve the goal of suppressing the well The effect of reducing the occurrence of collapse, shortening the drilling cycle, and reducing the drilling cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

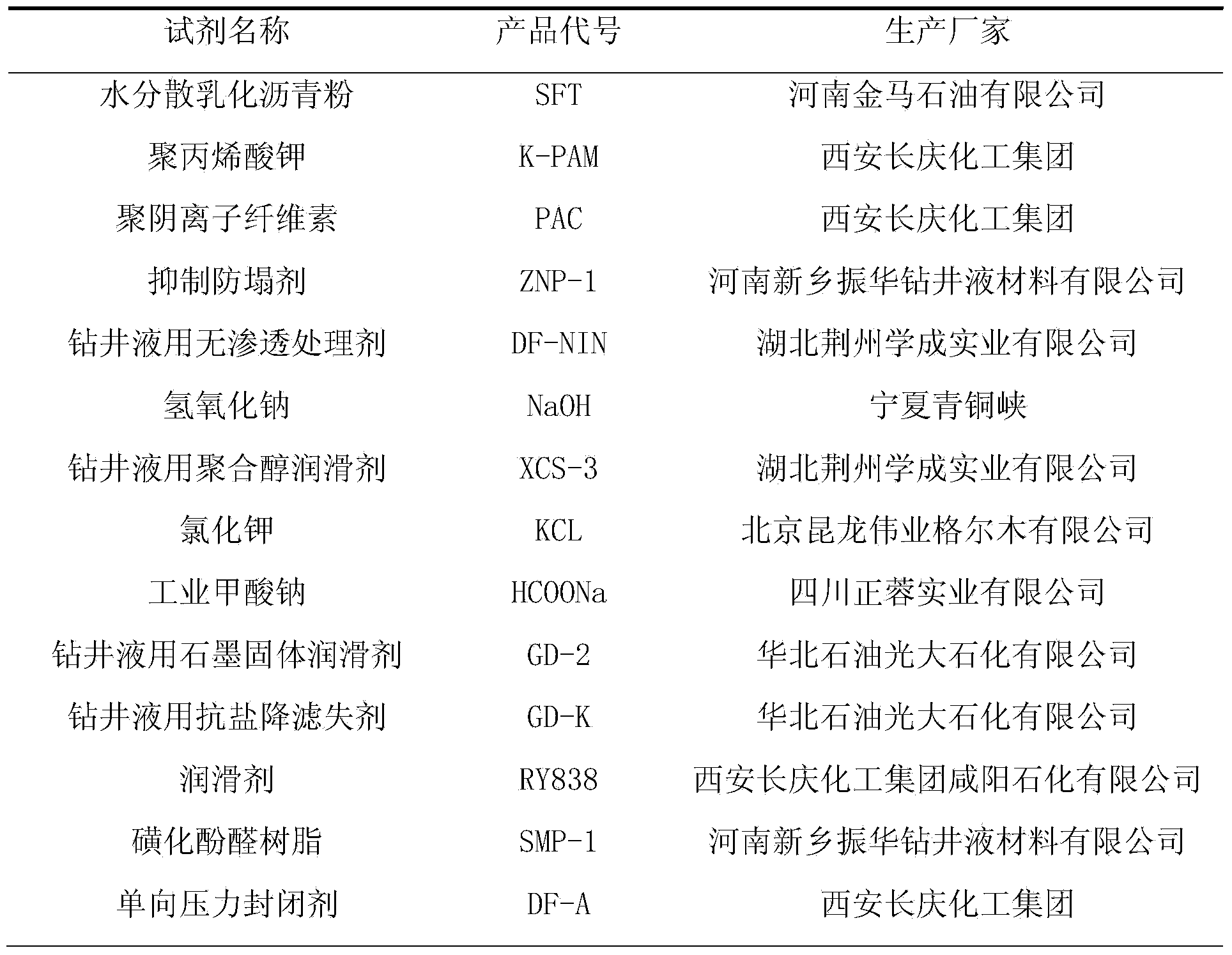

Method used

Image

Examples

Embodiment 1

[0046] Aiming at the geological characteristics of the Mesozoic Triassic strata, the present invention provides an anti-slump and anti-leakage drilling fluid, which is characterized in that: the composition of the drilling fluid per cubic meter is: 1.5-2kg polyanionic cellulose, 20-30kg Drilling fluid anti-salt fluid loss agent, 25-30kg water-dispersed emulsified asphalt powder, 30-40kg superfine calcium carbonate, 50-60kg sodium formate, 1-1.5kg sodium hydroxide, 30-40kg potassium chloride, and the balance is clear water .

[0047] In this embodiment, sodium hydroxide is added to the drilling fluid to adjust the pH of the drilling fluid to 8-9.

[0048] In this embodiment, the drilling fluid is directly compounded and used.

Embodiment 2

[0050] An anti-collapse and anti-leakage drilling fluid is characterized in that: the composition of the drilling fluid per cubic meter is: 1.5kg polyanionic cellulose, 20kg drilling fluid anti-salt fluid loss reducer, 25kg water-dispersible emulsified asphalt powder, 30kg ultrafine Calcium carbonate, 50kg sodium formate, 1kg sodium hydroxide, 30kg potassium chloride, and the balance is clear water.

[0051] In this embodiment, sodium hydroxide is added to the drilling fluid to adjust the pH of the drilling fluid to 8-9.

[0052] In this embodiment, the drilling fluid is directly compounded and used.

Embodiment 3

[0054] An anti-collapse and anti-leakage drilling fluid is characterized in that: the composition of the drilling fluid per cubic meter is: 2kg / m 3 Polyanionic cellulose 30kg drilling fluid anti-salt fluid loss reducer, 30kg water-dispersed emulsified asphalt powder, 40kg superfine calcium carbonate, 60kg sodium formate, 1.5kg sodium hydroxide, 40kg potassium chloride, and the balance is clear water.

[0055] In this embodiment, sodium hydroxide is added to the drilling fluid to adjust the pH of the drilling fluid to 8-9.

[0056] In this embodiment, the drilling fluid is directly compounded and used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com