Patents

Literature

187results about How to "Shorten the drilling cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-element synergic plugging agent and application thereof

ActiveCN104232039AReduce penetrationLimit penetrationDrilling compositionStrong bindingUltimate tensile strength

The invention provides a multi-element synergic plugging agent and application thereof. The multi-element synergic plugging agent comprises the component 1 or the component 2, wherein the component 1 comprises the following components in parts by weight: 40-50 parts of rigid particles, 15-20 parts of a flexible material, 15-20 parts of an ultrafine filling material, and 15-20 parts of an expansive type polymer: the component 2 comprises the following components in parts by weight: 50-70 parts of rigid particles, 10-25 parts of a flexible material, 10-25 parts of an ultrafine filling material, and 10-30 parts of an expansive type polymer. The multi-element synergic plugging agent disclosed by the invention combines the rigid material with the flexible material, incorporates the elastoplasticity, fully utilizes the synergistic function of the materials, can effectively plug the cracks with different widths, has the performances of high bearing strength, high temperature resistance, deformability and strong binding powder of the cracked stratum, and can be applied to the leaking stoppage operation for the drilling engineering to solve the leakage problem at different degrees.

Owner:PETROCHINA CO LTD

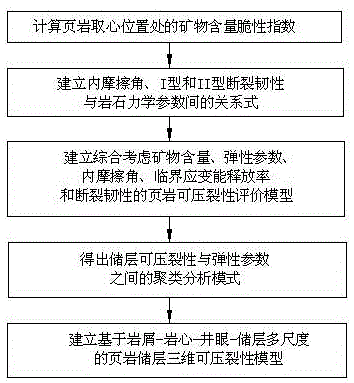

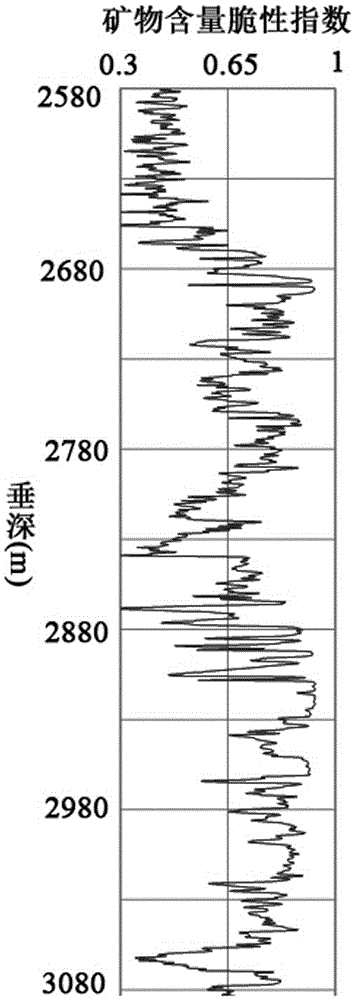

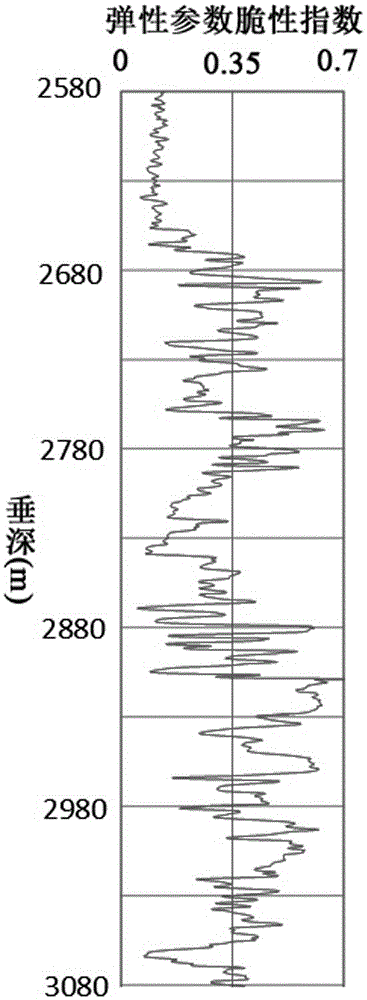

Debris-core-borehole-reservoir multiscale shale reservoir three-dimensional fracturing evaluation method

ActiveCN105156103ALarge capacityQuantification of fracabilityBorehole/well accessoriesType fractureWell placement

The invention relates to a debris-core-borehole-reservoir multiscale shale reservoir three-dimensional fracturing evaluation method. The method comprises the steps of: (S1) calculating mineral content brittleness indexes in a shale coring position; (S2) building relations among an internal friction angle, I type and II type fracture toughness and rock mechanical parameters; (S3) building shale fracturing evaluation models comprehensively considering a mineral content, elastic parameters, the internal friction angle, a critical strain energy release rate and the rapture toughness; (S4) applying a support vector machine algorithm to obtain a cluster analysis mode between a reservoir fracturing performance and the elastic parameters; and (S5) applying the cluster analysis mode and a reservoir three-dimensional elastic parameter data body to obtain a debris-core-borehole-reservoir multiscale shale reservoir three-dimensional fracturing model. The method can be applied to obtain the fracturing performance of any space position in a shale reservoir, so that the well position selection blindness is prevented, and the fracturing modification effect and the after-pressing yield are improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

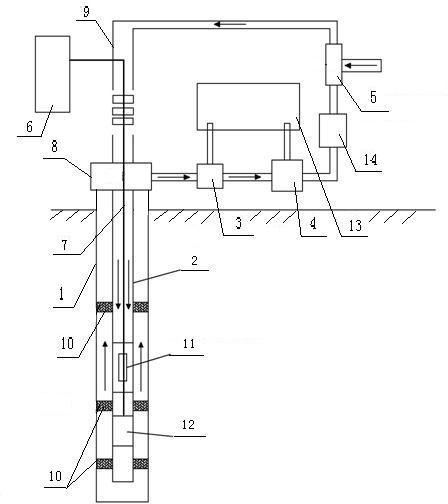

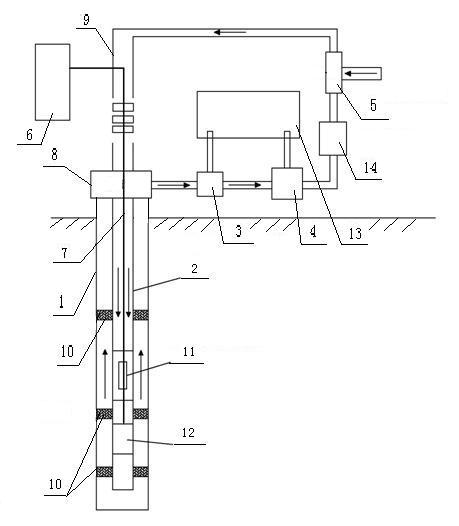

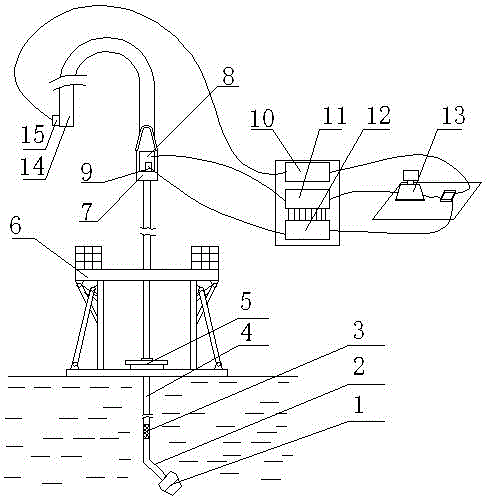

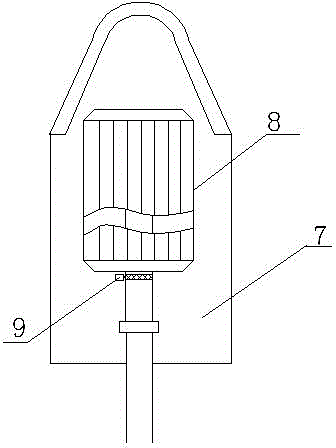

Laser drilling device

InactiveCN102322216AIncrease drilling speedShorten the drilling cycleDrilling machines and methodsAir compressionInlet channel

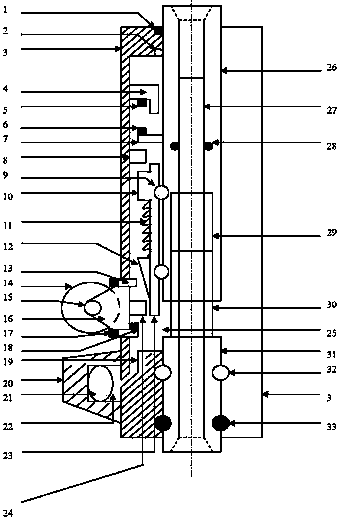

The invention relates to a laser drilling device, comprising a ground part and an underground part, wherein in an underground pit shaft, a communicated duct extends downwards into the pit shaft from the ground and reaches the bottom of the pit shaft; an MWD (Measurement While Drilling) guide instrument and a laser are arranged in the duct; a cable extends downwards into the pit shaft and is connected with the MWD guide instrument and the laser respectively; a stabilizer is arranged in an annular cavity between the duct and the pit shaft; a sleeve head is arranged at the pit opening on the ground; the duct is connected to an air outlet hole of an air compression booster station through the sleeve head so as to form an air inlet channel; the pit shaft is connected with the sleeve head through a superficial sleeve; the sleeve head is connected with another duct; and the another duct is connected to the air inlet hole of the air compression booster station after passing through a sand remover, a dust remover and a liquid-gas separator so as to form a circulation channel for dust removal, purification and boosting. The laser drilling device disclosed by the invention has high drilling speed, saves the drilling cycle and improves the drilling benefits.

Owner:NORTHEAST GASOLINEEUM UNIV

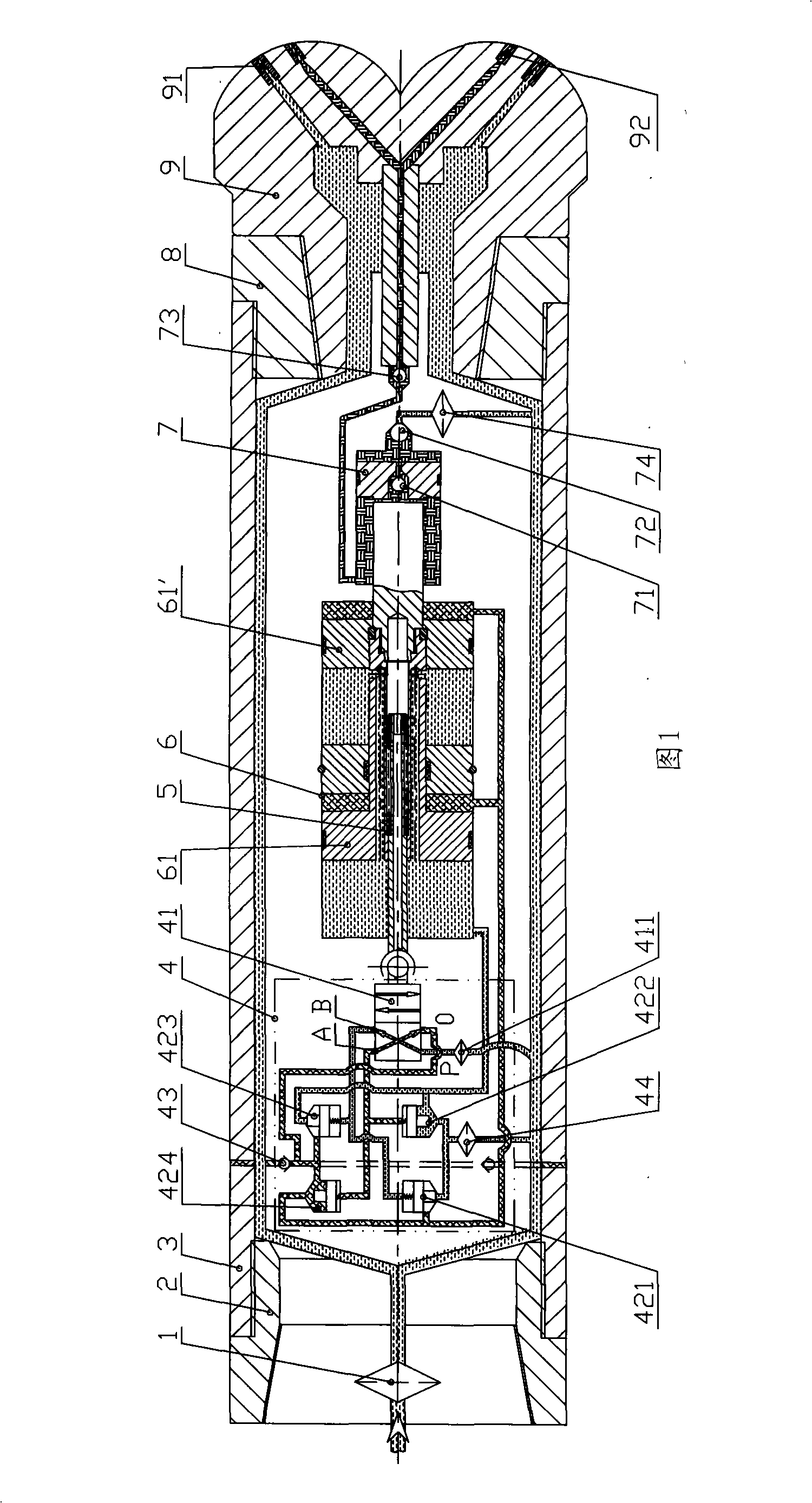

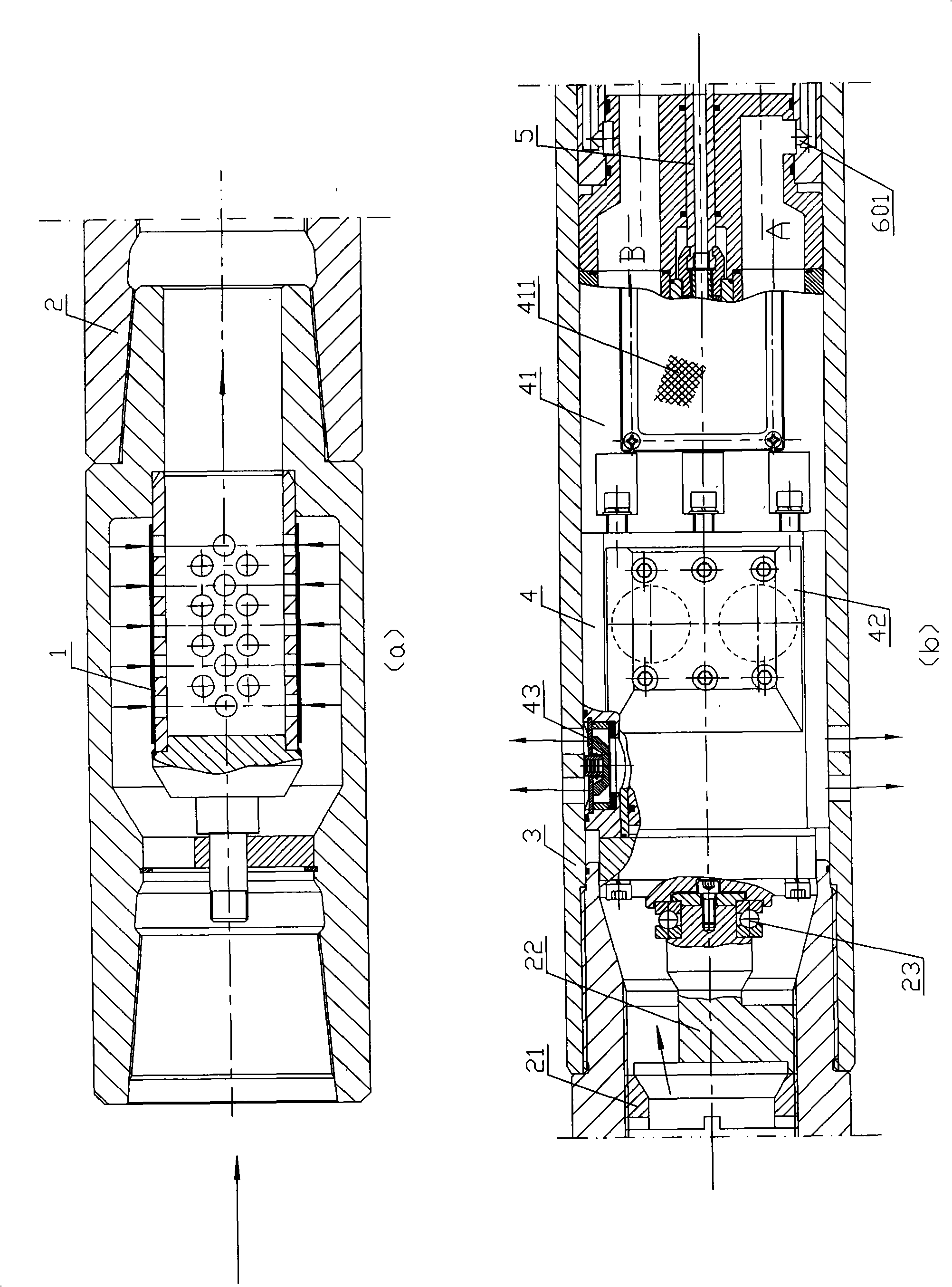

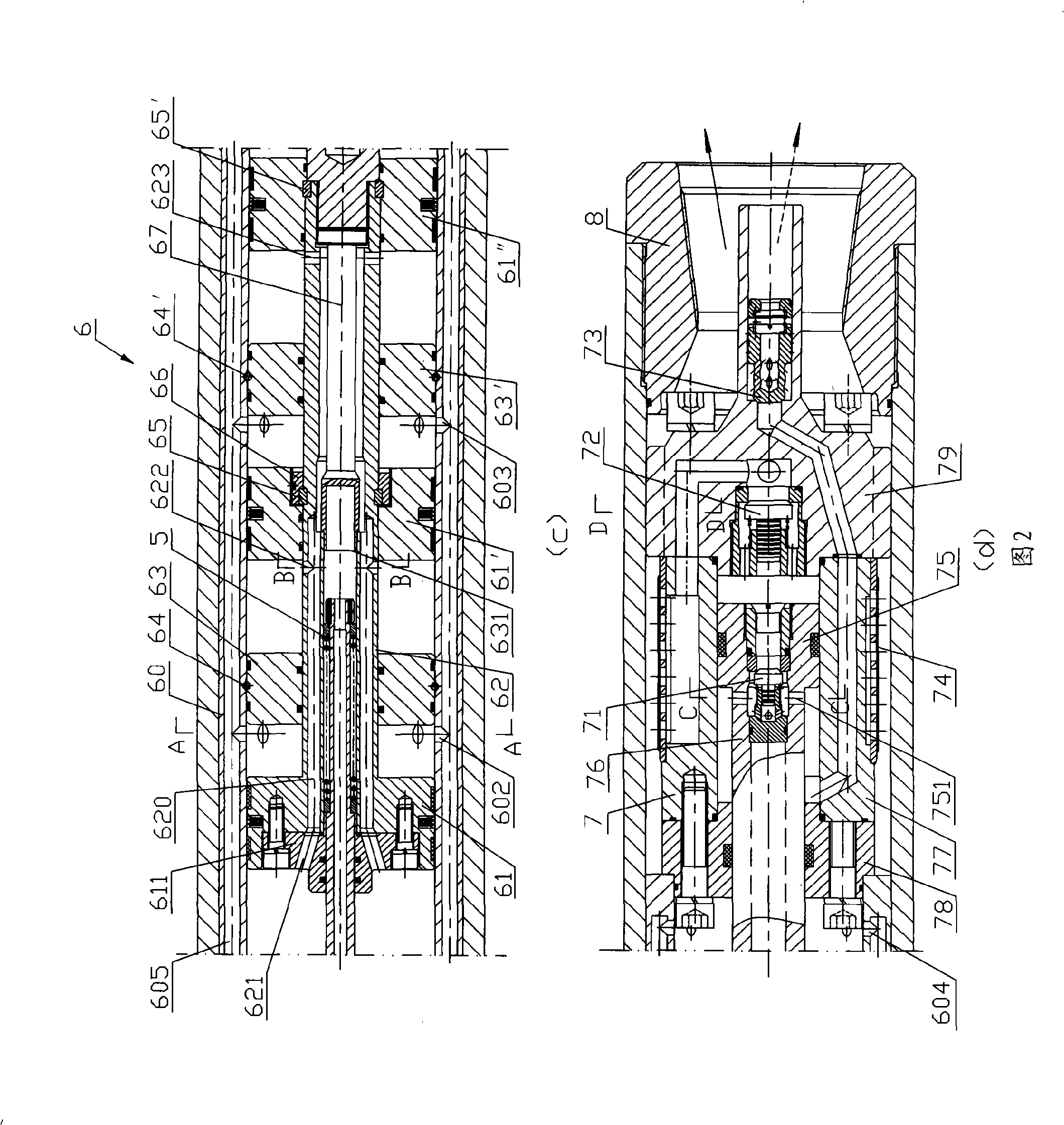

Well bottom booster pump and its supercharging method

ActiveCN101403279AIncrease drilling speedGood value for moneyFluid-pressure convertersFlushingBottom hole pressurePrice ratio

The invention discloses a bottom hole pressure pump and a pressurizing method thereof, wherein, the pressure pump mainly comprises a filter screen assembly, an upper end connector, a shell, a lower end fastening and an assorted double-channel drill bit. A change valve, a reversing control device, a power cylinder and a pressure cylinder are arranged in the shell sequentially, the lower end of the filter screen assembly is connected with the upper end connector by threads, the lower end of the upper end connector is connected with the shell by threads and sealed, the lower end fastening is connected with the shell by threads and sealed, and the left end of the lower end fastening props against the right end of the pressure cylinder, and presses and connects the change valve, the power cylinder and the pressure cylinder in the shell with a locking part arranged in the upper end connector. The invention can drastically improve the drilling speed, reduce the drilling cost and shorten the drilling period, and has relatively simple structure, short total length, low movement velocity, long service life, low manufacturing cost and high performance-price ratio.

Owner:ZHONGCHAO LIANHE ENERGY SCI & TECH BEIJING CO LTD

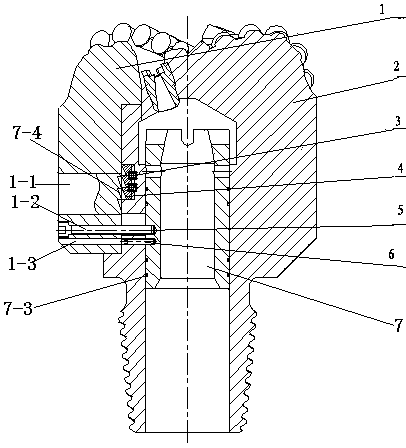

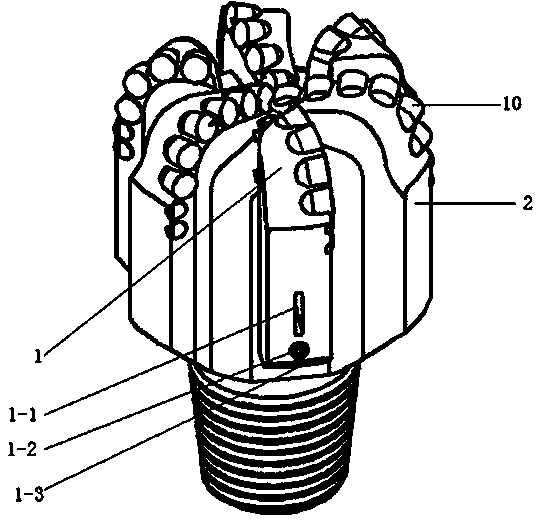

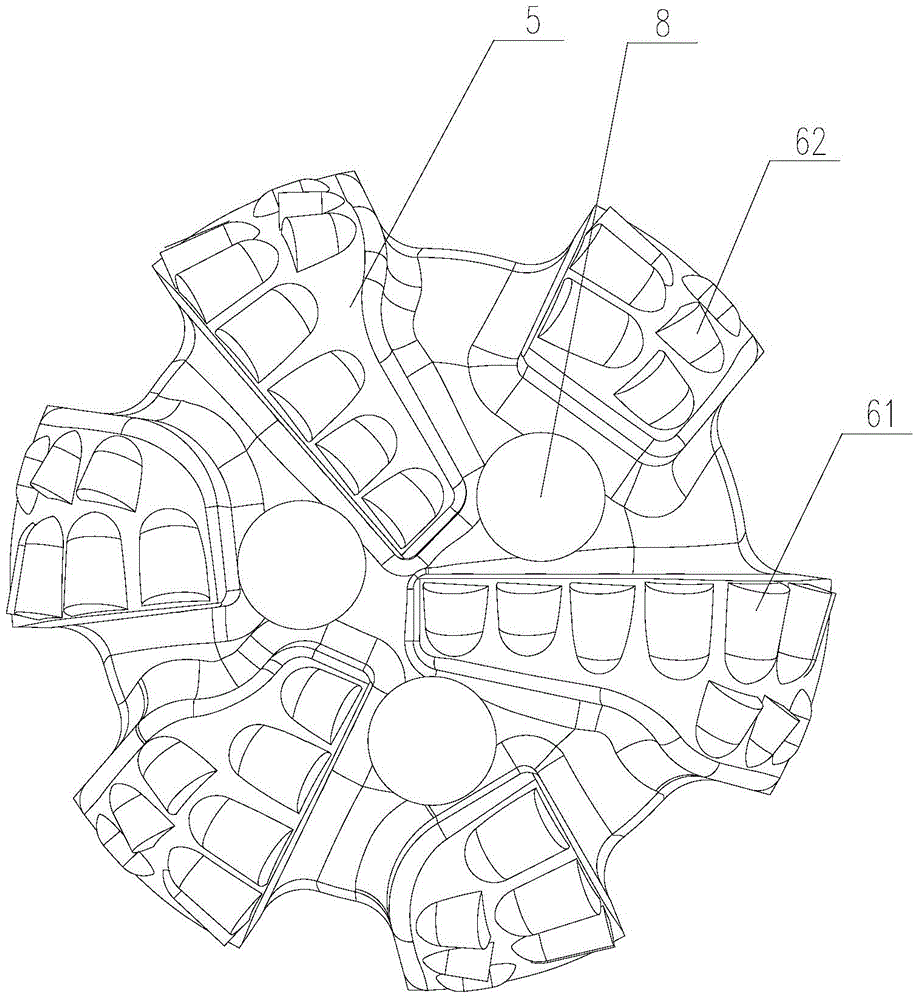

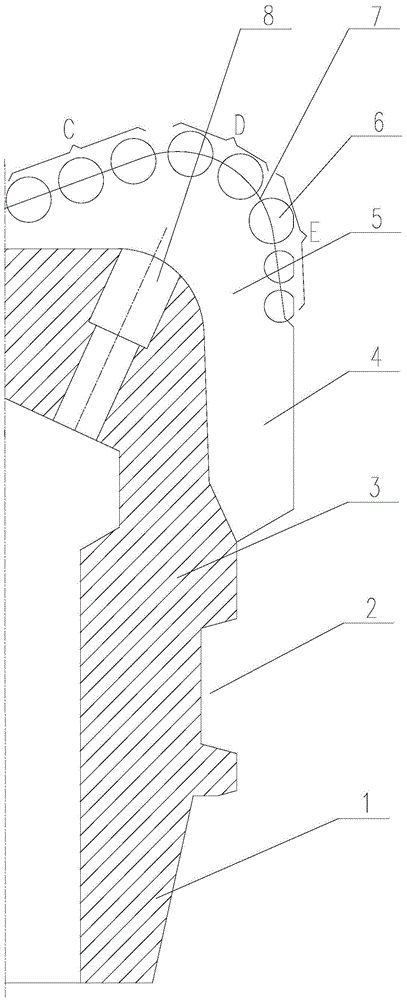

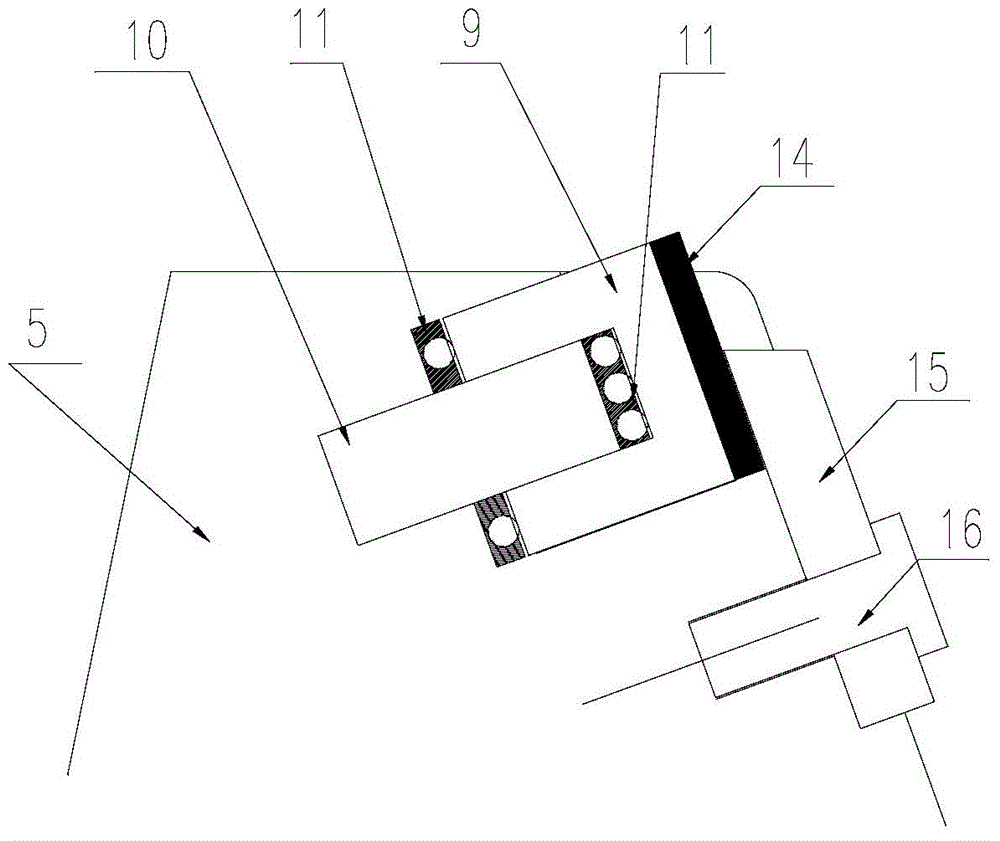

Drill bit with telescopic blades

The invention relates to a drill bit with telescopic blades. The drill bit can increase mechanical drilling speed and is long in service life. The drill bit comprises a drill bit body, fixed blades, cutting teeth and a nozzle, wherein the fixed blades and the cutting teeth are fixed to the drill bit body, the nozzle is arranged at the outer ends of the fixed blades and is communicated with a cylindrical cavity in the drill bit body, and the telescopic blades are movably connected between the fixed blades on the drill bit body. In drilling for oil, gas and geological prospecting, particularly in deep wells, ultra-deep wells and horizontal wells, compared with a conventional PDC drill bit, the drill bit can greatly improve mechanical drilling speed, meanwhile, the drill bit is longer in service life, and according the aims of shortening a drilling cycle and reducing drilling cost are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

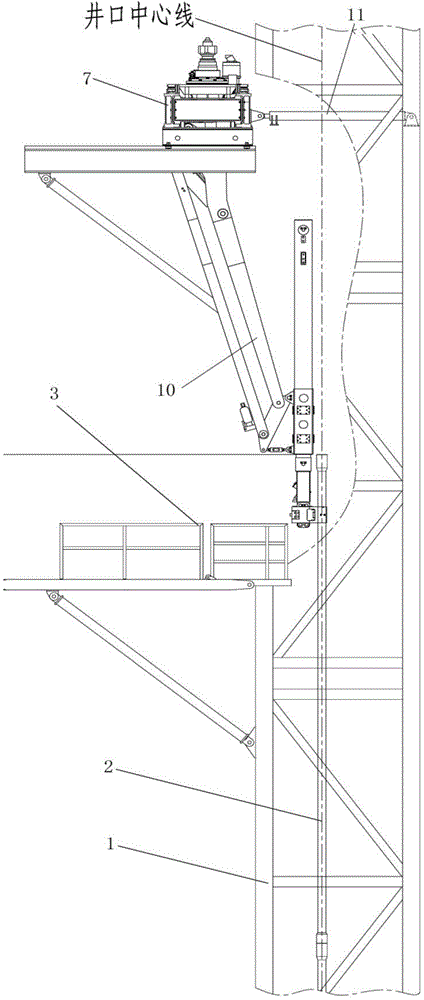

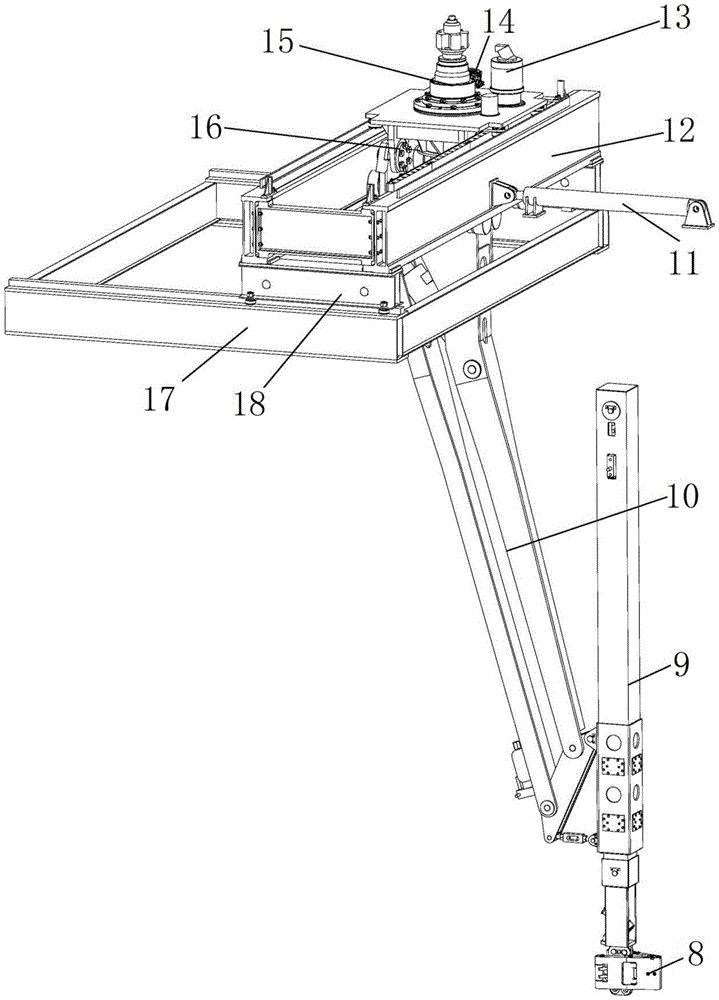

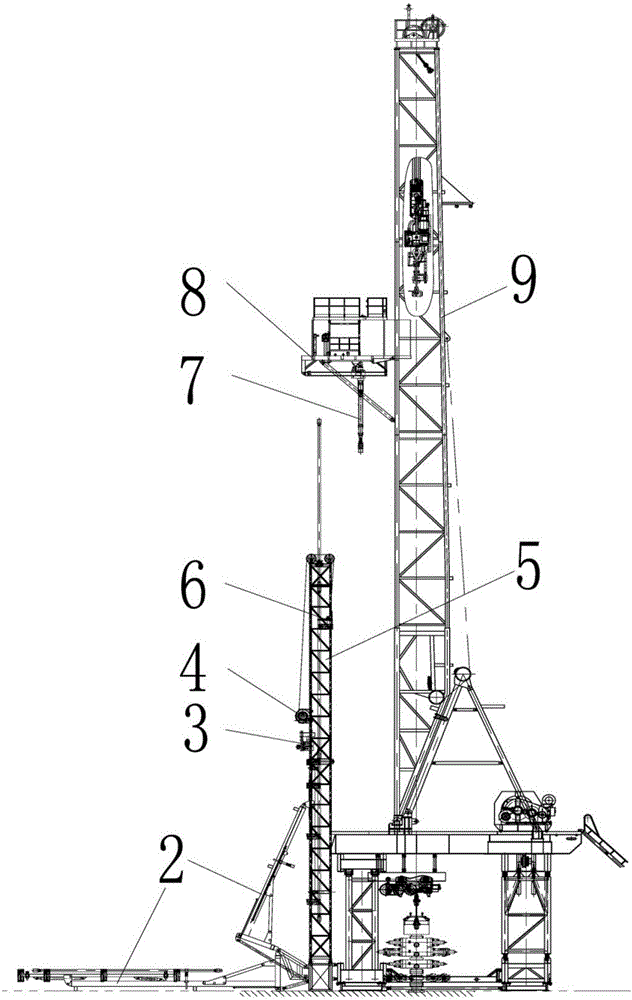

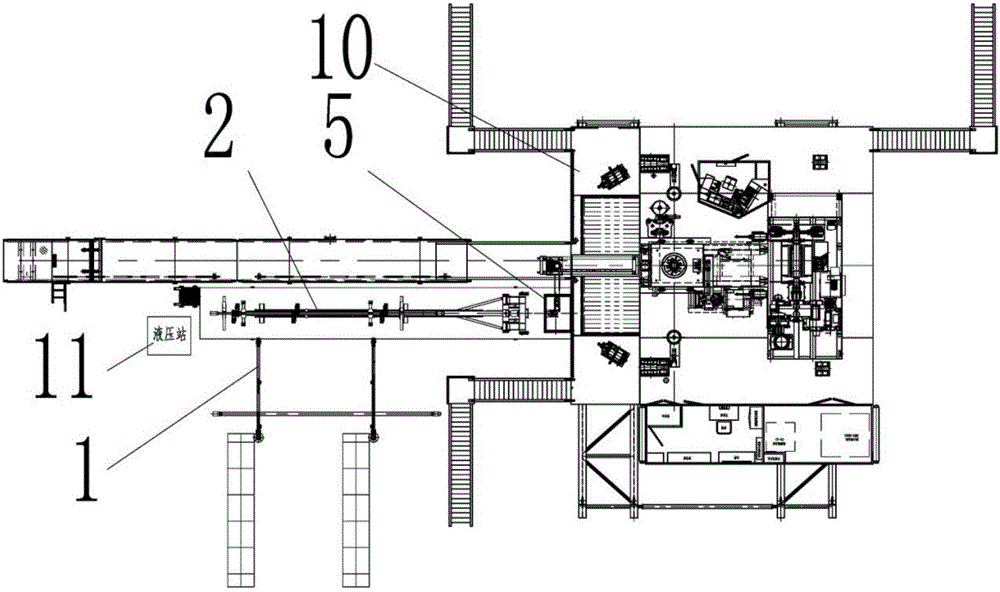

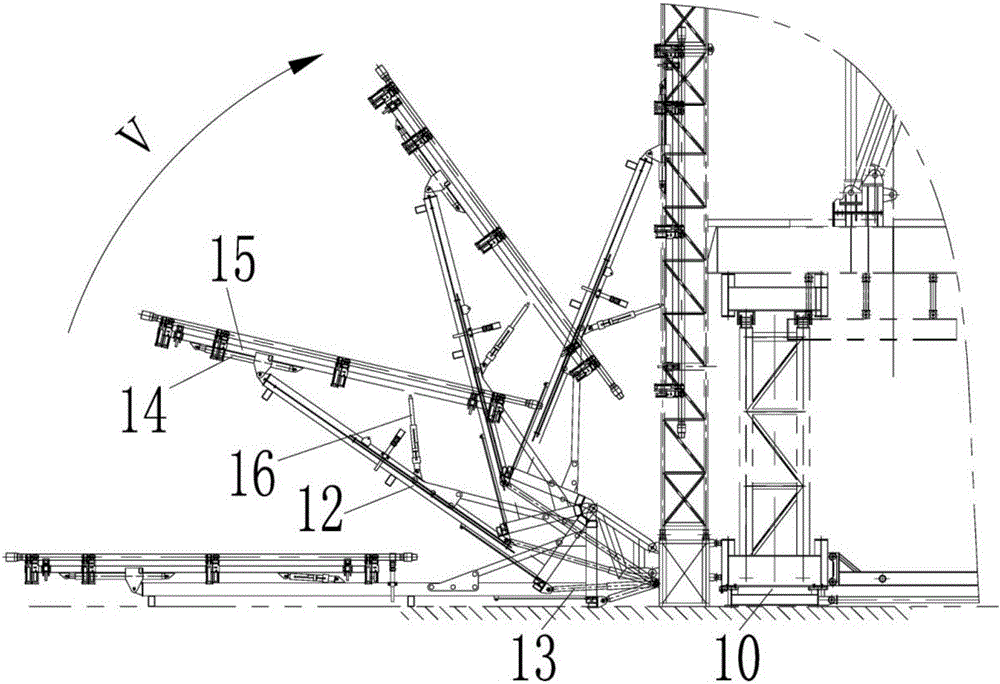

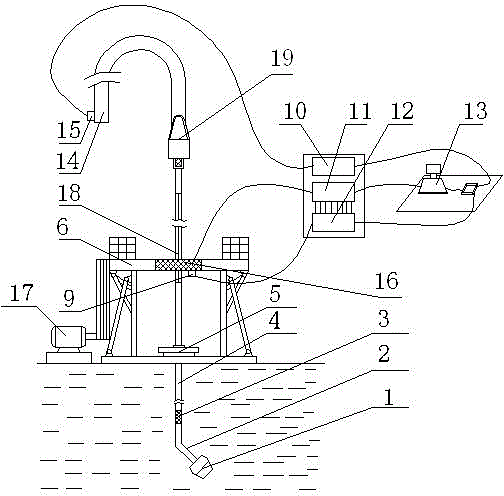

Automatic derrick device suitable for double-wellhead pipe arrangement operation and method

ActiveCN104594829AReduce handling operationsShorten the drilling cycleDrilling rodsDrilling casingsHydraulic cylinderEngineering

The invention discloses an automatic derrick device suitable for double-wellhead pipe arrangement operation. The automatic derrick device comprises a pair of longitudinal rails. The longitudinal rails are each provided with a longitudinal moving pulley. A transverse rail is fixedly connected to the upper portions of the two longitudinal moving pulleys. The middle of the transverse rail is connected with a derrick of a drilling machine through a longitudinal driving hydraulic cylinder. A transverse moving pulley is mounted in the transverse rail. A slewing mechanism is mounted on the transverse moving pulley and is in transmission connection with a transverse driving motor. The lower end of the slewing mechanism is fixedly connected with the upper portion of an inclined arm. The lower portion of the inclined arm is hinged to an outer cylinder of a telescopic arm. A pair of gripping pliers is mounted at the lower end of an inner cylinder of the telescopic arm. The invention further discloses a method for stand arrangement through the automatic derrick device. The device and method meet the requirement of the double-wellhead drilling machine for simultaneously conducting stand establishing, tripping, casing running and other operation.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

Curable low-density leaking stoppage working fluid and preparation method thereof

InactiveCN106967393AReduce hydrostatic injection pressureExtended stayDrilling compositionFiberWorking fluid

The invention provides a curable low-density leaking stoppage working fluid and a preparation method. The curable low-density leaking stoppage working fluid is prepared from, by weight, 100 parts of G-grade oil well cement, 44-60 parts of slag, 23-67 parts of lightening admixture, 8-12 parts of micro silicon, 0.4-1.2 parts of dispersant, 4-5 parts of fluid loss agent, 0.4 part of retarder, 1 part of fiber, 131-214 parts of water and 0.5 part of foaming agent. The density of the curable low-density leaking stoppage working fluid is 1.20-1.50 g / cm<3>, the curable low-density leaking stoppage working fluid is high in early strength and thixotropy, free of free water and good in system stability, and the technical problem that a curing body cannot be formed due to bridge plug leaking stoppage in a conventional leaking stoppage method and the cement leaking stoppage cutting body difficultly stays at a leaking layer is solved. After leaking stoppage is carried out, the formation pressure bearing capacity at the leaking layer can be improved, and the technical defects of the existing conventional leaking stoppage method are overcome.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

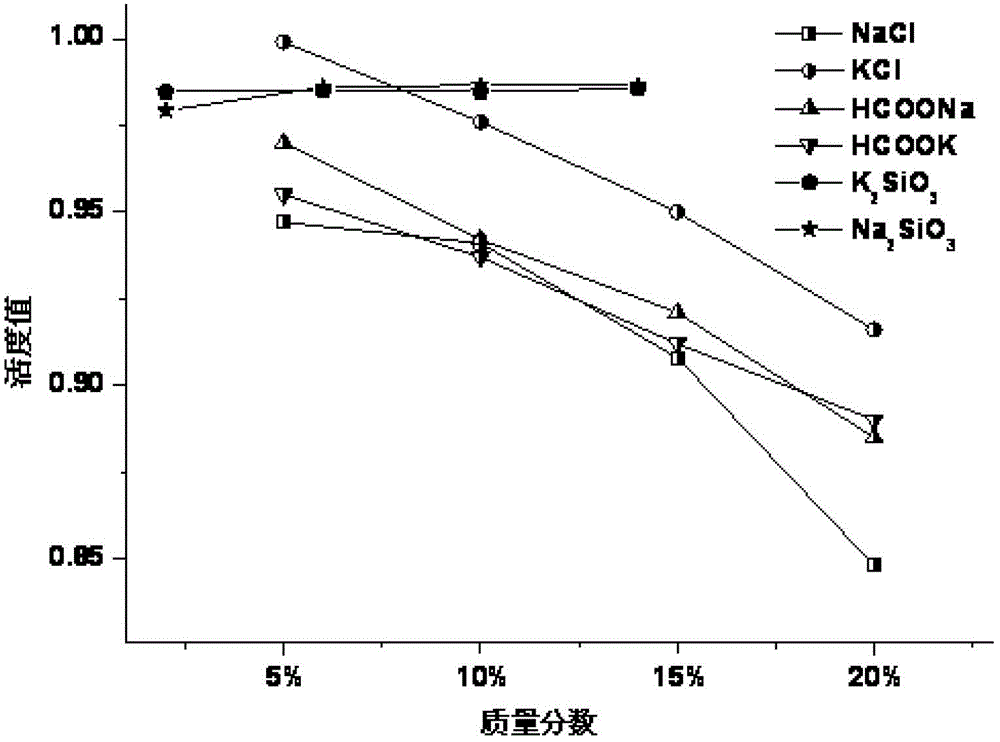

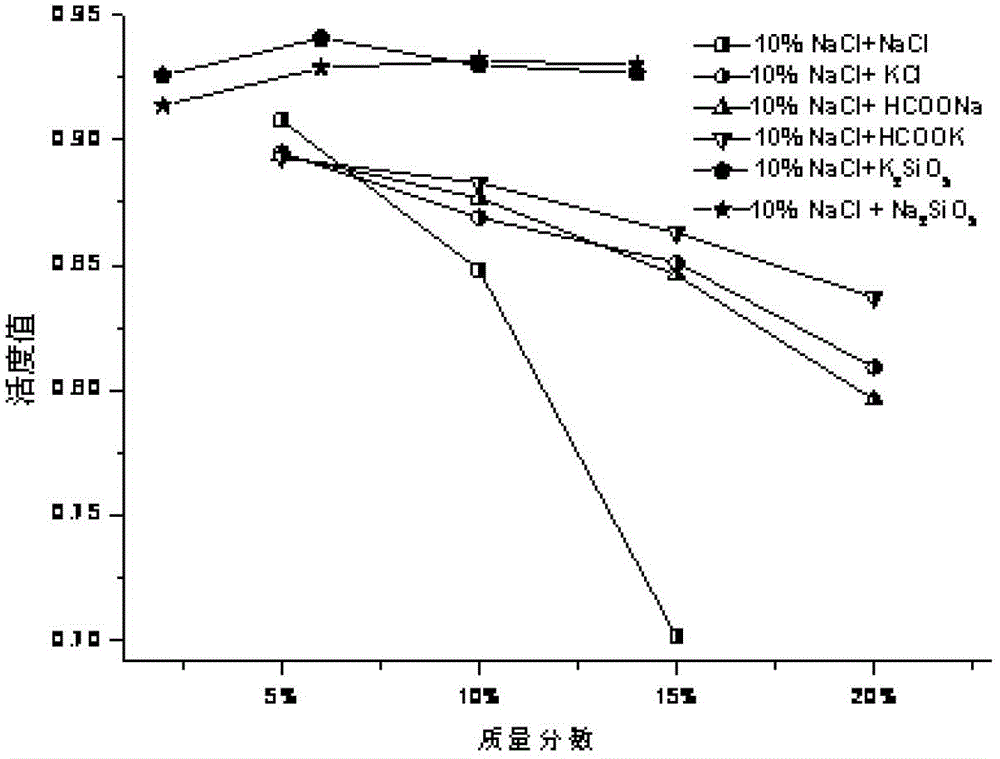

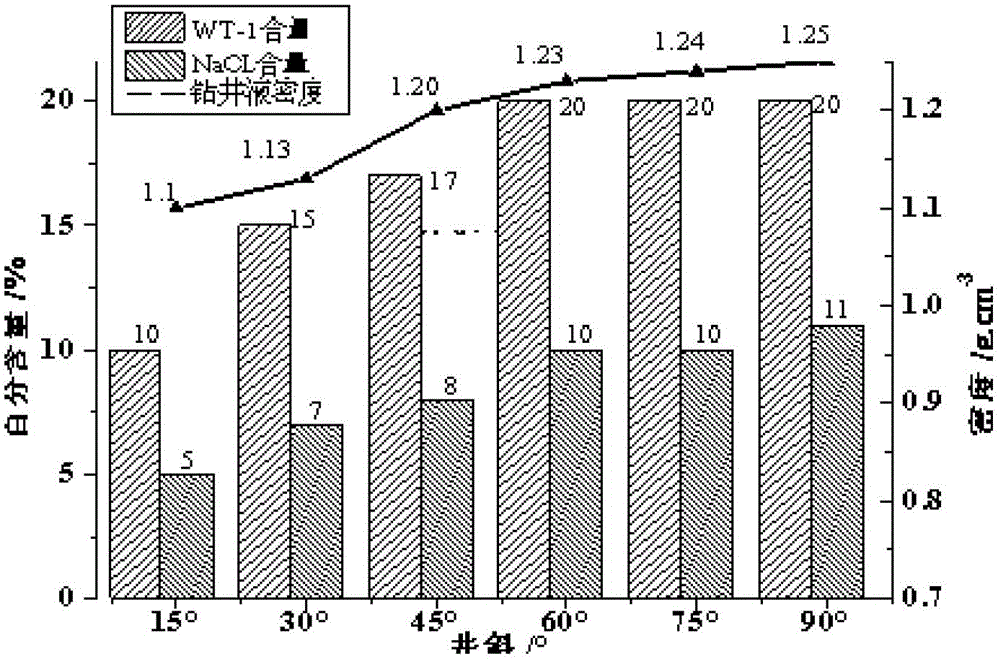

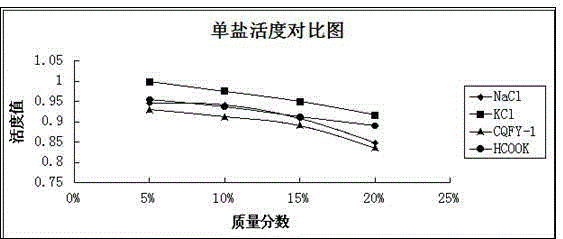

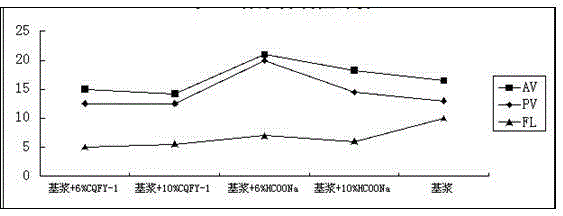

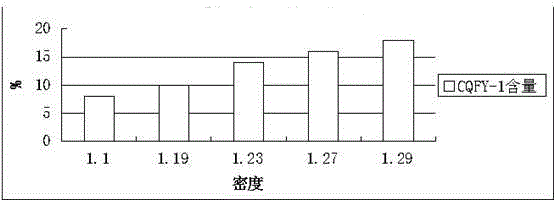

Composite salt low-activity anti-sloughing drilling fluid and construction method thereof

InactiveCN103146363AAvoid differential pressure lossThe system has strong chemical inhibition and anti-collapse effectDrilling compositionSealing/packingFriction reductionMass ratio

The invention discloses a composite salt low-activity anti-sloughing drilling fluid and a construction method thereof. The composite salt low-activity anti-sloughing drilling fluid consists of the following raw materials in percentage by mass: 0.2-0.3% of drilling fluid viscosifier, 2-3% of carboxymethyl starch, 1.5-2% of aqueous dispersion cation emulsified asphalt, 0.2-0.3% of anti-salt anti-calcium filtrate reducer, 1% of sulfonated phenolic resin, 2% of acid-soluble temporary seal reservoir protective agent, 1% of superfine calcium, 0.1% of caustic soda and the balance of clean water. In construction, the composite salt accounting for 5-15% of the dosage of the composite slat low-activity anti-sloughing drilling fluid is added, and the composite salt is formed by mixing sodium formate and sodium chloride at a mass ratio of 2:1. By utilizing the composite salt, the function of chemically suppressing mudstone and preventing sloughing in the drilling fluid as well as the density of the drilling fluid are improved. With strong chemical suppression and low solid phase, the composite salt low-activity anti-sloughing drilling fluid completely meets the strict high-quality requirements of a long open-hole section for friction reduction and resistance reduction of the drilling fluid.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

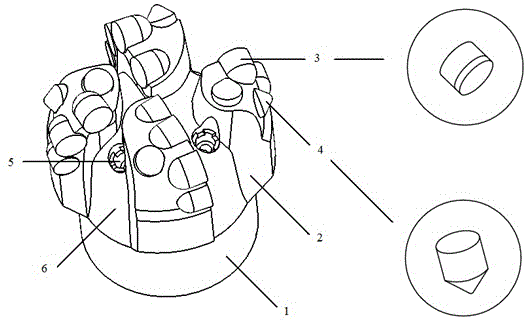

Rotary-tooth drilling bit

ActiveCN103556952AImprove cutting performanceExtended service lifeConstructionsWell drillingEngineering

The invention discloses a rotary-tooth drilling bit which comprises a connector, a basal body, blades and cutting teeth, wherein the cutting teeth are arranged on the blade surfaces of the blades, the advancing direction of the drilling bit in use is taken as the front, each blade is provided with an inner cone part, a nose part and an outer cone part in sequence from a position of each front part blade surface, which is nearly close to the center of the end surface of the front end of the basal body, to each rear part blade surface; at least one rotary tooth is arranged on the blade surface of each blade, the rotary tooth is a cutting tooth capable of rotating around the self axle wire, and the rotary tooth is mounted inside a rotary tooth hole on the blade through a rotation device. According to the rotary-tooth drilling bit, through arranging at least one rotary tooth on the blade surface of each blade, the entire circumference of the cutting end surface of the rotary tooth is enabled to participate in cutting to stratum during the stratum cutting process through the drilling bit, the use ratio of the cutting end surface of the rotary tooth is improved, the service life of the drilling bit is prolonged greatly, the depth drilling capability of a single drilling bit is enhanced remarkably, the drilling speed of the drilling bit is kept to be higher, the drilling period is shortened, and the drilling cost is reduced.

Owner:CHENGDU BEST DIAMOND BIT

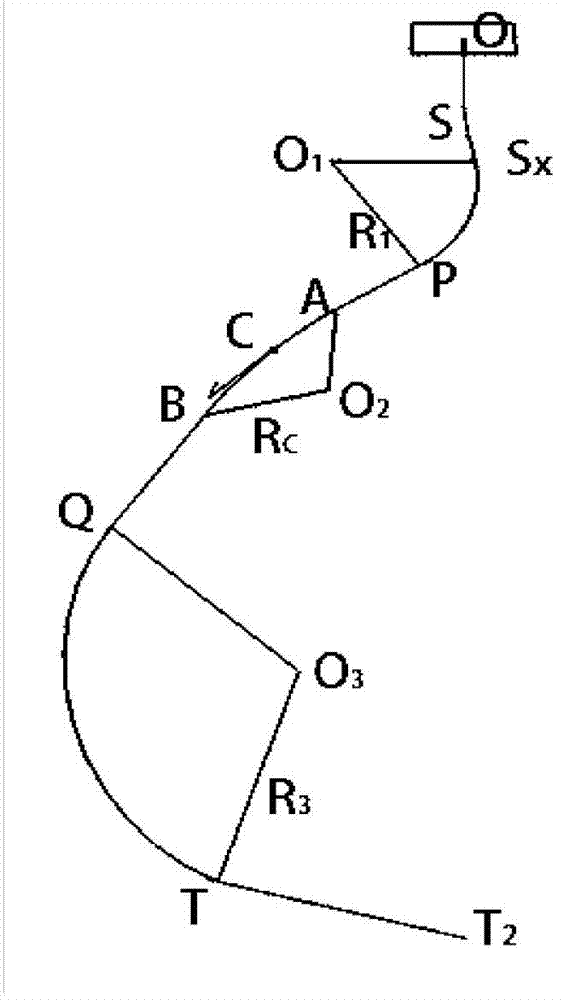

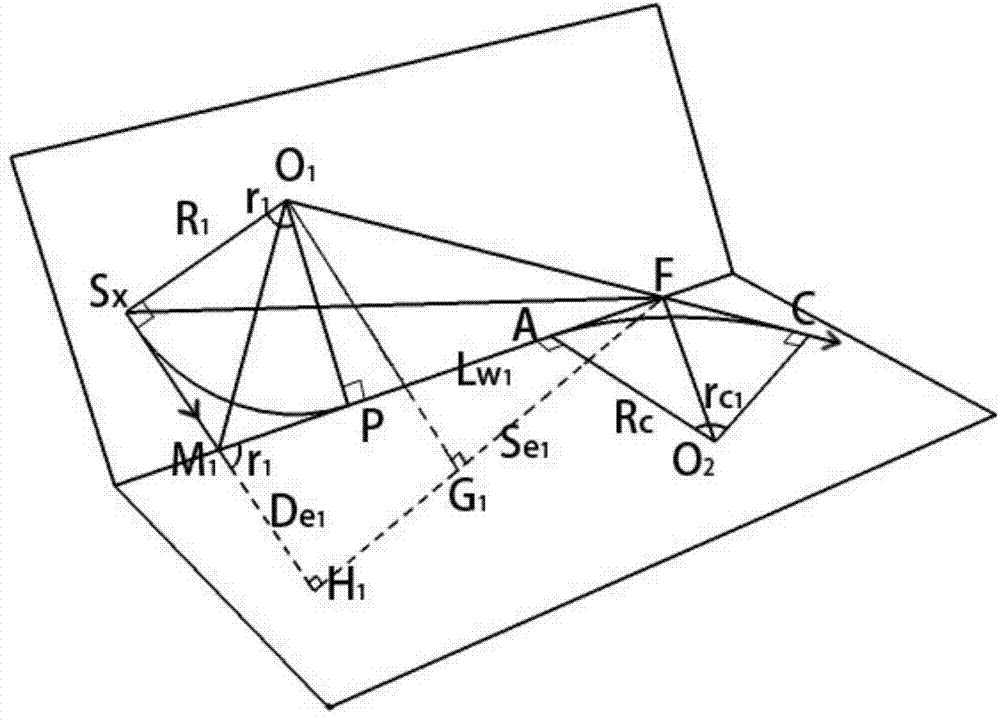

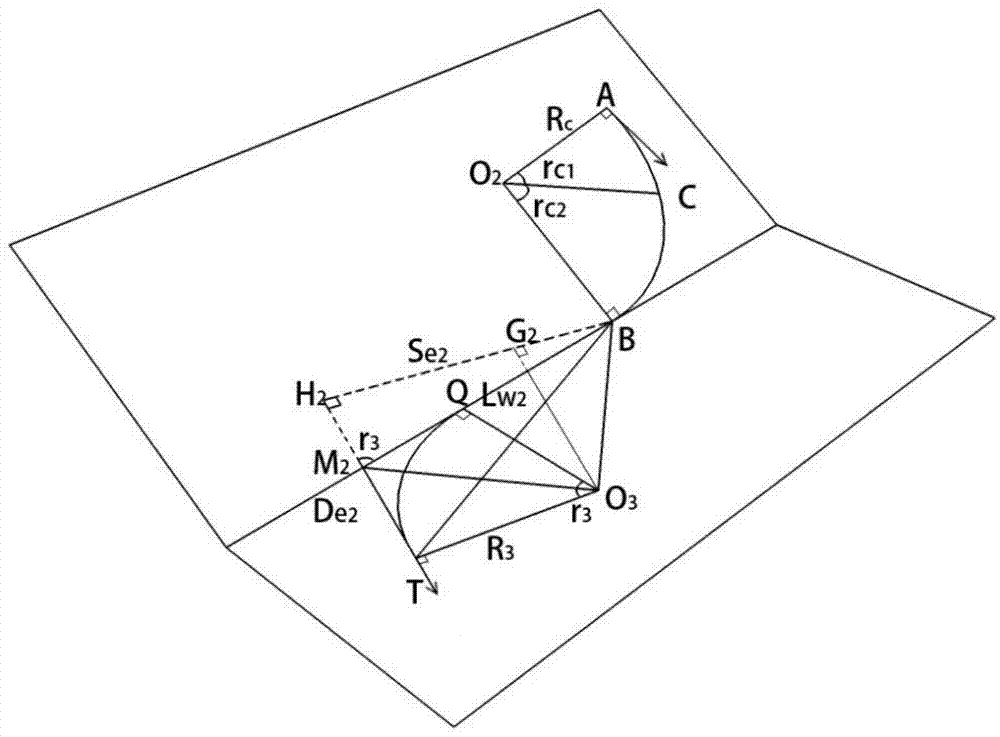

Sidetrack horizontal well track design method under control point constraint condition

InactiveCN103699738AShorten the lengthShorten the drilling cycleSpecial data processing applicationsWell drillingDesign methods

The invention discloses a sidetrack horizontal well track design method under control point constraint condition. The sidetrack horizontal well track design method comprises the following steps: determining known parameters; modeling well tracks; setting a hole deviation angle and an azimuth angle at a control point; solving the parameters of key points in a model; sieving a well track with the shortest total length. According to the sidetrack horizontal well track design method under control point constraint condition provided by the invention, the design models of the well tracks are given out, the hole deviation angle and the azimuth angle at the control point in the well tracks are selectively adopted, thus the well direction of the track at the control point is optimized, and then the method of the whole track is optimized; the design method is simple, tentative calculation is not required, the track with shorter length can be designed by inputting known conditions of design, so that the method is beneficial to shortening the drilling period and reducing the drilling cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

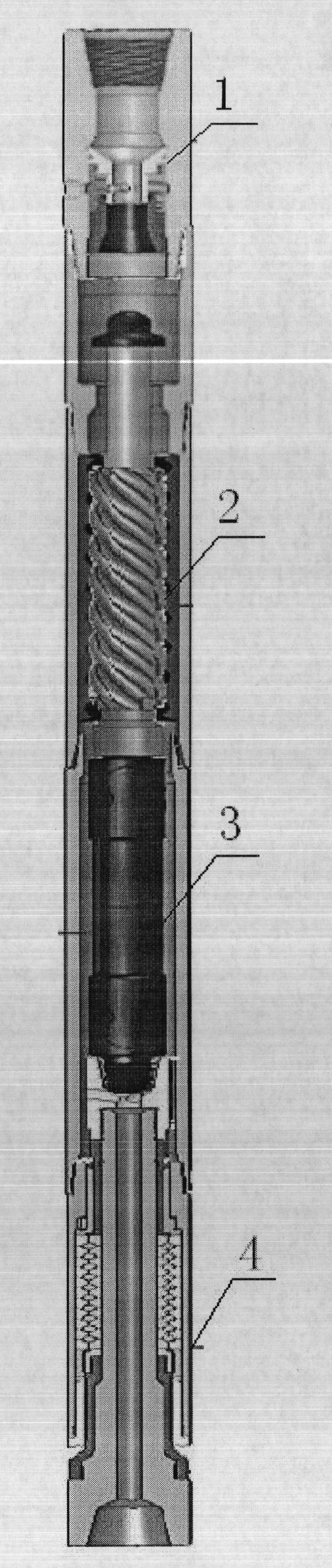

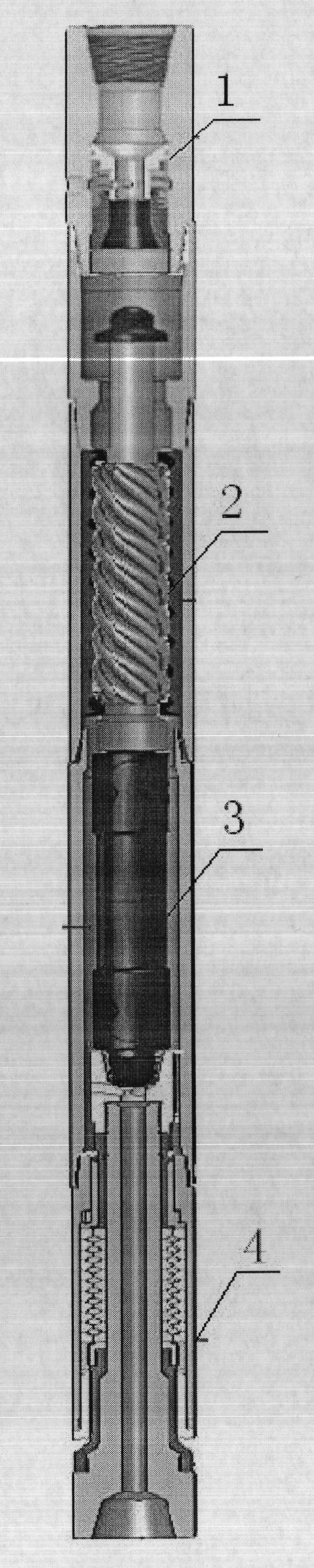

Novel spiral drilling rig structure

InactiveCN102465667ASimple structureReduce manufacturing costDirectional drillingBorehole drivesDrive shaftManufacturing systems

The invention discloses a novel spiral drilling rig structure. The novel spiral drilling rig structure mainly comprises a by-pass valve assembly (1), a motor assembly (2), a universal shaft assembly (3) and a transmission shaft assembly (4) which are connected sequentially. The novel spiral drilling rig structure is simple and low in manufacturing cost and later maintenance cost, improves the drilling efficiency, shortens the drilling period, reduces the drilling cost, and has very obvious economic significance.

Owner:常萍

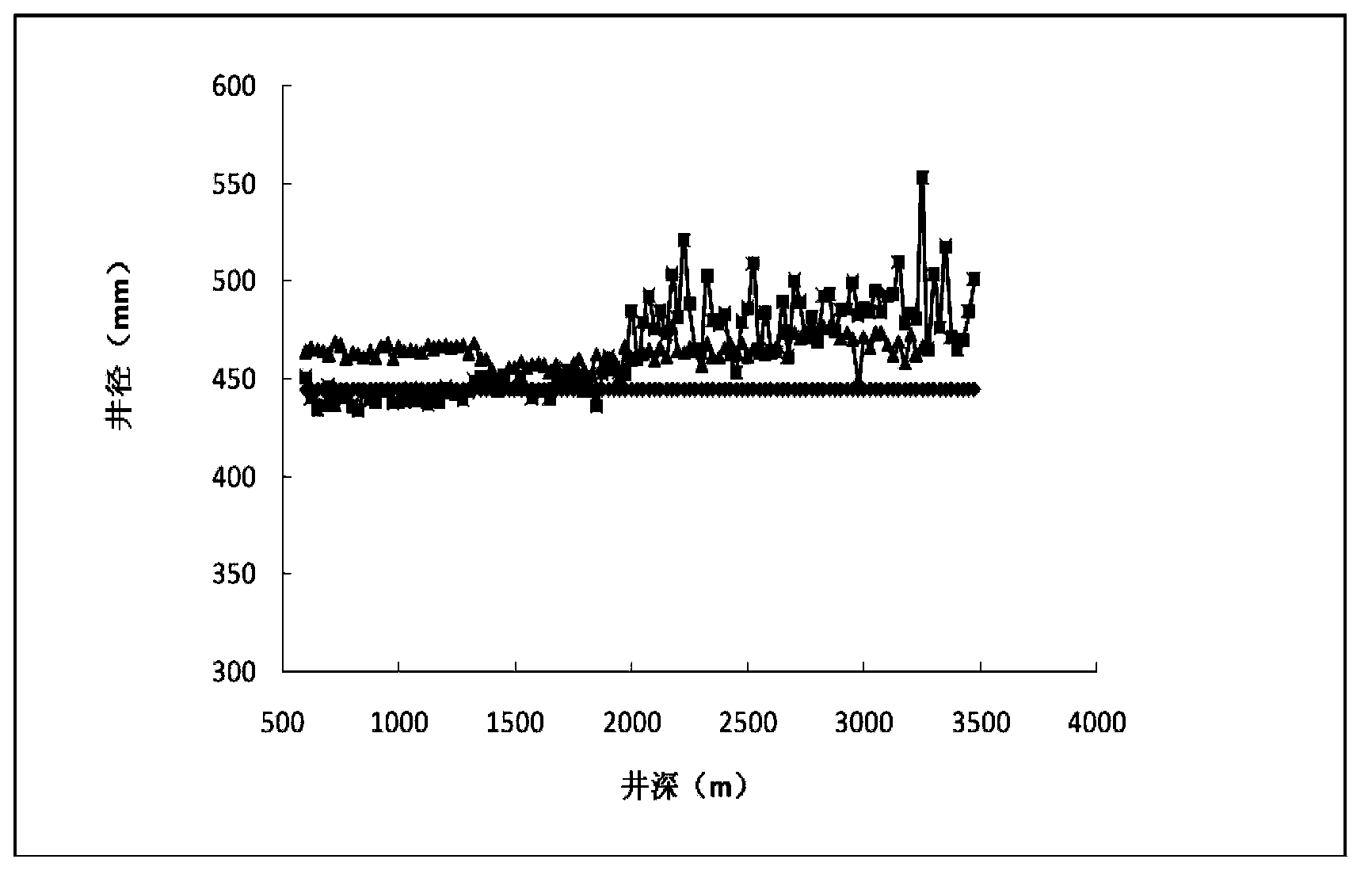

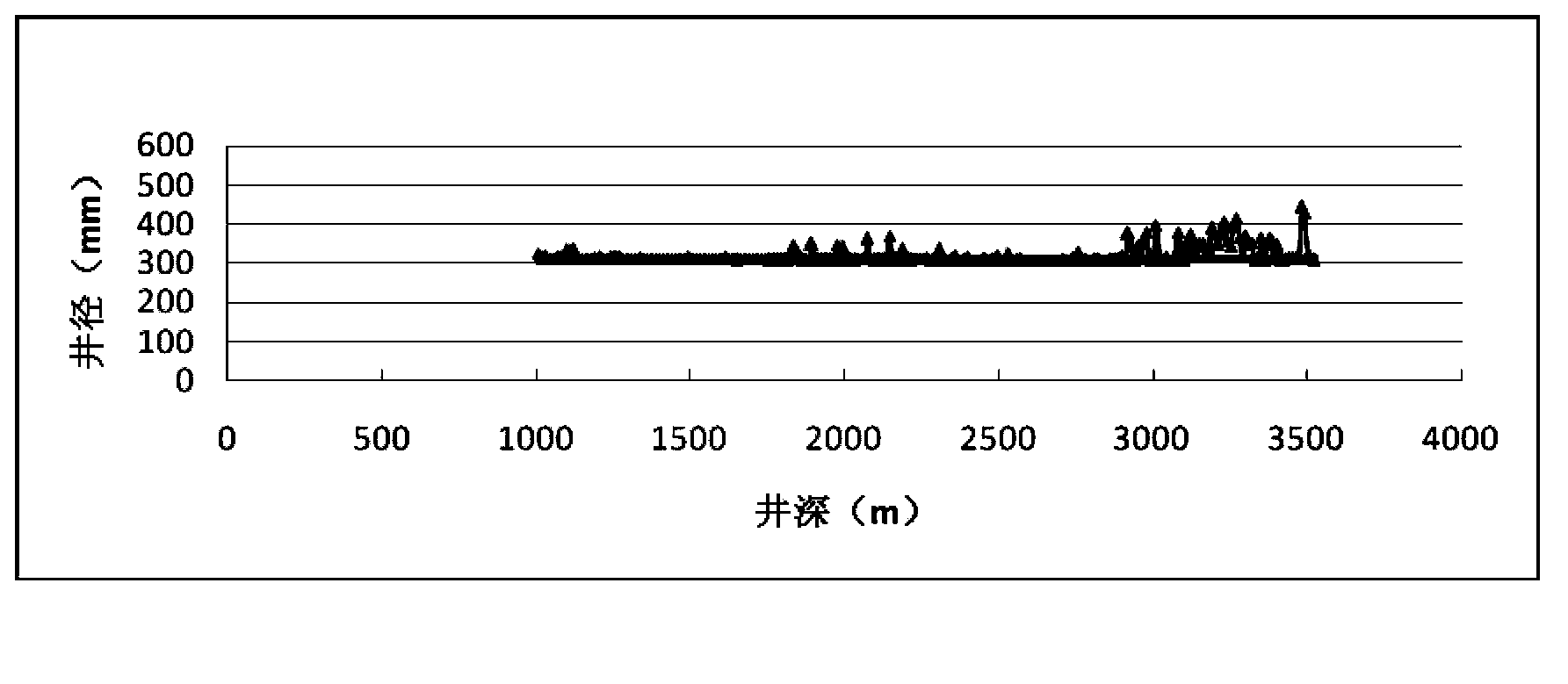

Dendritic multi-amino polymer drilling fluid used for mud rock well drilling

ActiveCN104130758AEnhanced inhibitory effectReduce plasticityDrilling compositionPotassiumWell drilling

The invention relates to a dendritic multi-amino polymer drilling fluid used for mud rock well drilling. The drilling fluid is characterized by consisting of a dendritic multi-amino polymer, drilling fluid bentonite, sodium carbonate, a polymer coating agent, potassium polyacrylate, a hydrolyzed polyacrylonitrile ammonium, a bit balling resistant lubricant and water. The dendritic multi-amino polymer drilling fluid can improve an inhibitive performance of the drilling fluid, can greatly improve the inhibitive performance on clay and drilled chips of the drilling fluid, can reduce plasticity of daub rock, can avoid water-absorption swelling and dispersing of the daub rock, can reduce friction resistance, can prevent bit balling, can increase a penetration rate and can ensure safety of a downhole operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

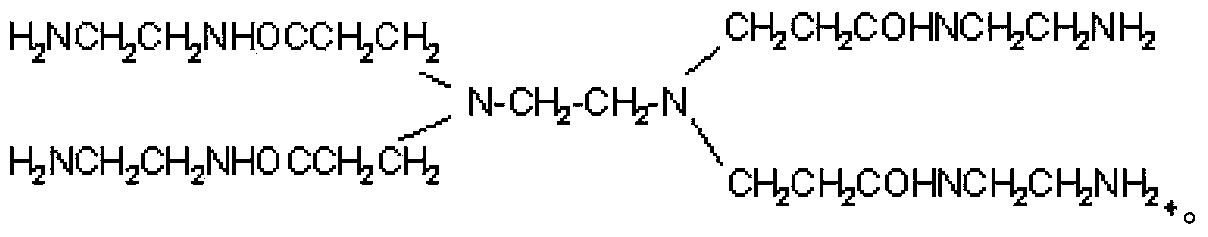

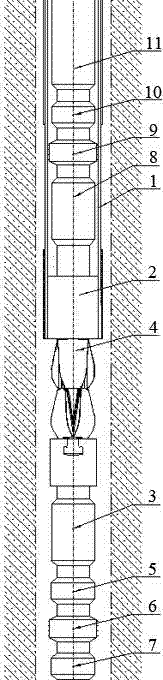

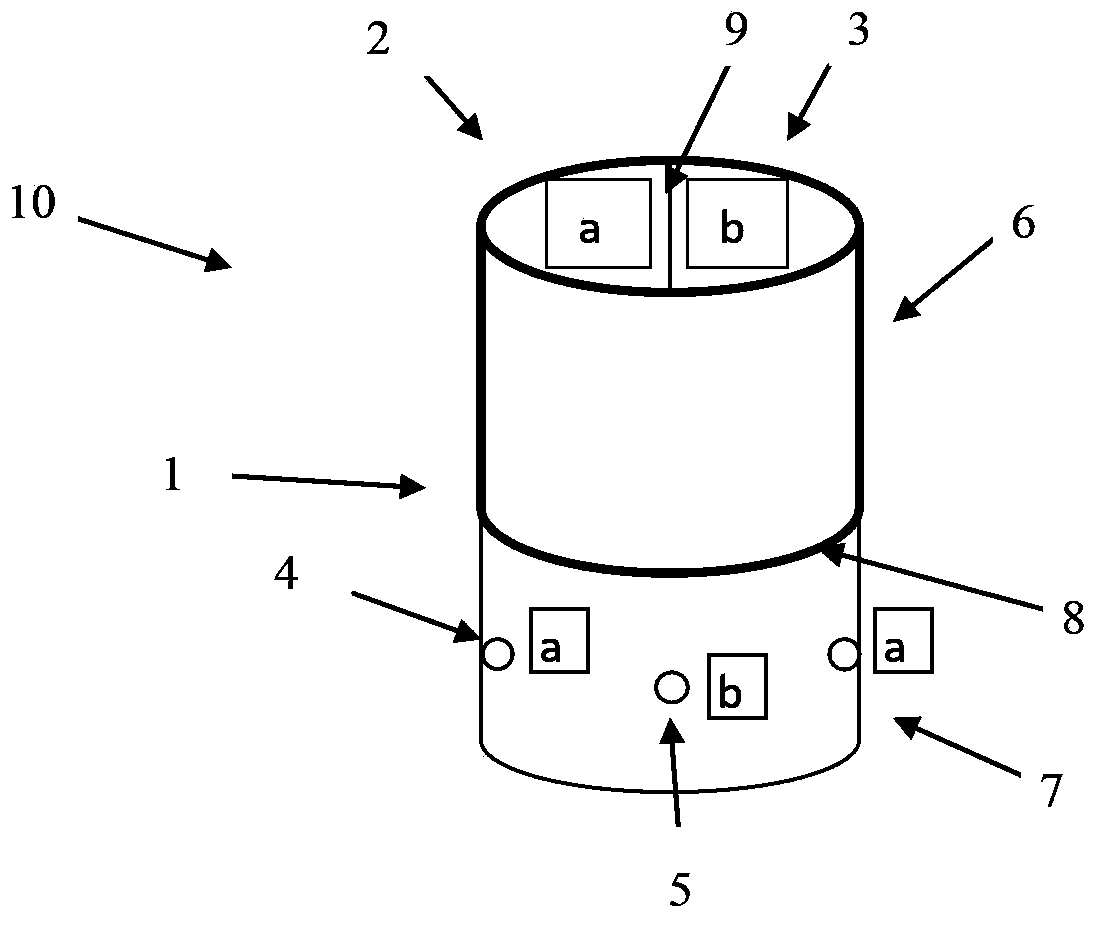

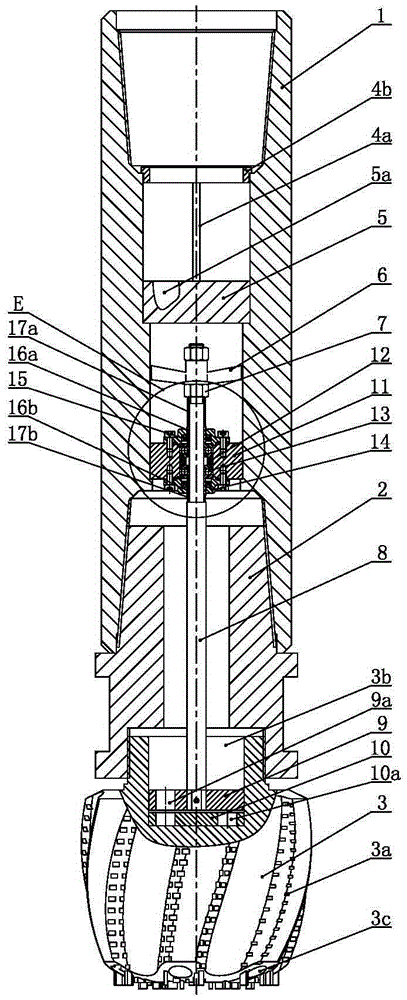

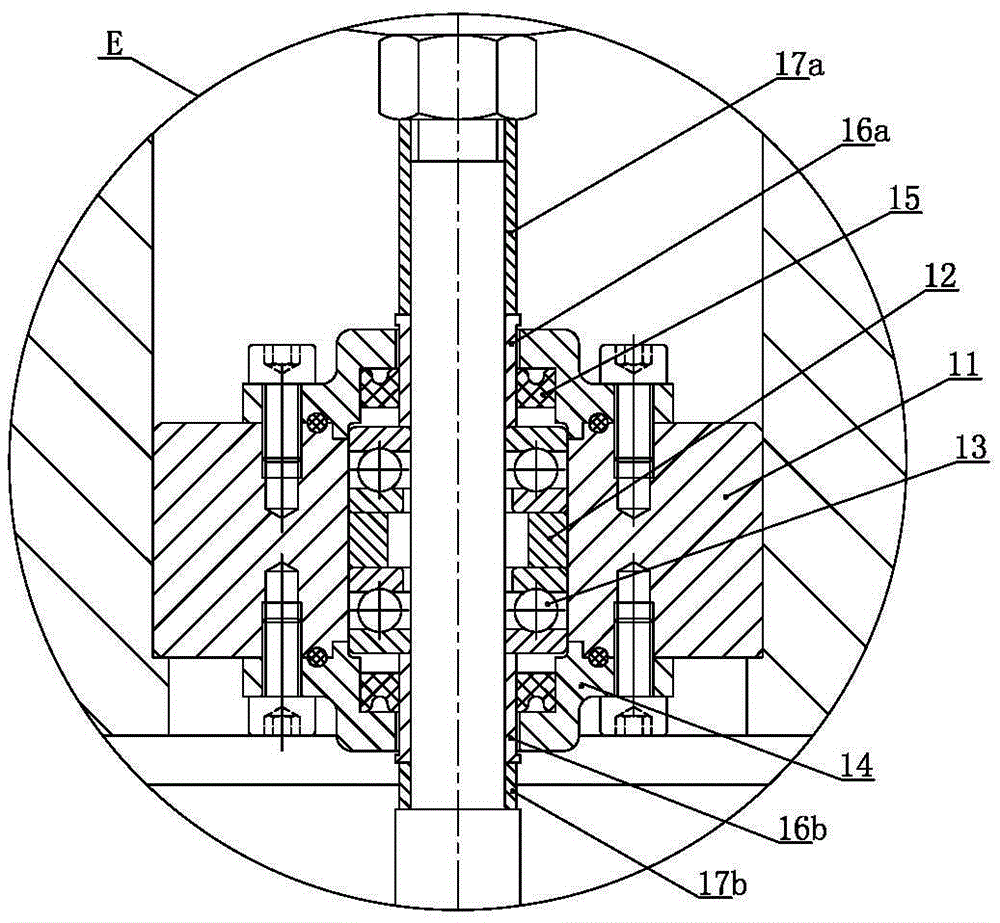

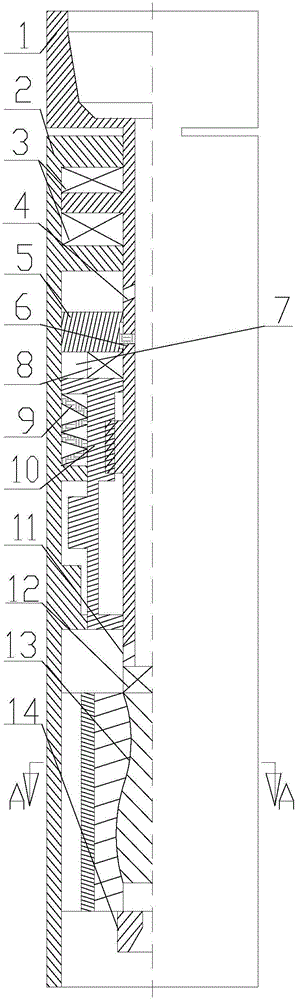

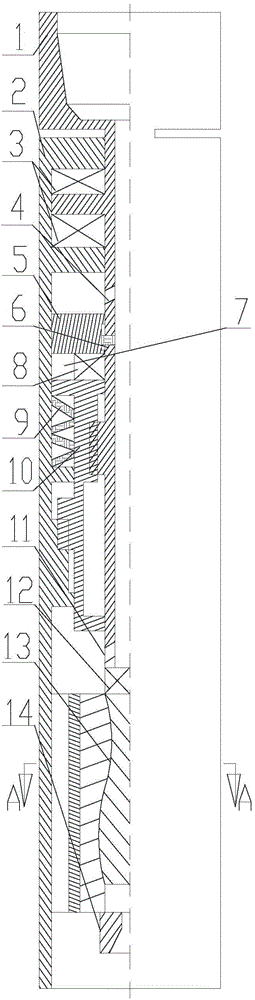

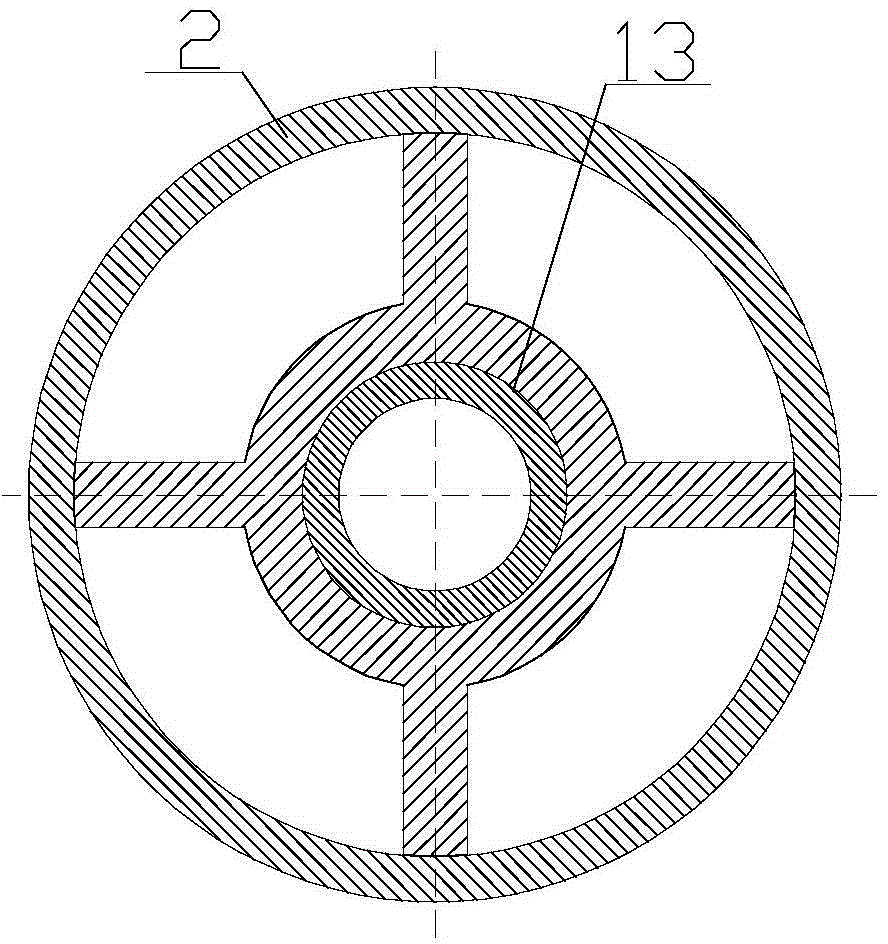

High-expansibility naked eye suspension adhering system and method

InactiveCN102777123AMeet expansion requirementsReduce accidentsSealing/packingDrilling machines and methodsHydraulic cylinderControl engineering

The invention discloses a high-expansibility naked eye suspension adhering system, comprising an adhering pipe (1) and a tool pipe string. The tool pipe string consists of a secondary hydraulic cylinder (2), a lower hydraulic cylinder (3), a hydraulic reducing expansion drill (4), a lower drill rod conversion joint (5), a lower hydraulic anchor (6), a lower pressure holding ball base (7), an upper hydraulic cylinder (8), an upper hydraulic anchor (9), an upper drill rod conversion joint (10), a drill pipe (11) and an upper pressure holding ball base (14). The invention further discloses a high-expansibility naked eye suspension adhering method. The high-expansibility naked eye suspension adhering system and the high-expansibility naked eye suspension adhering method provided by the invention have the advantages that when naked eye adhesion is carried out, the expansibility is high, the reliability is strong, and the construction efficiency is high. The continuous suspension adhesion operation can be completed by casing off the adhering system for one time.

Owner:SOUTHWEST PETROLEUM UNIV

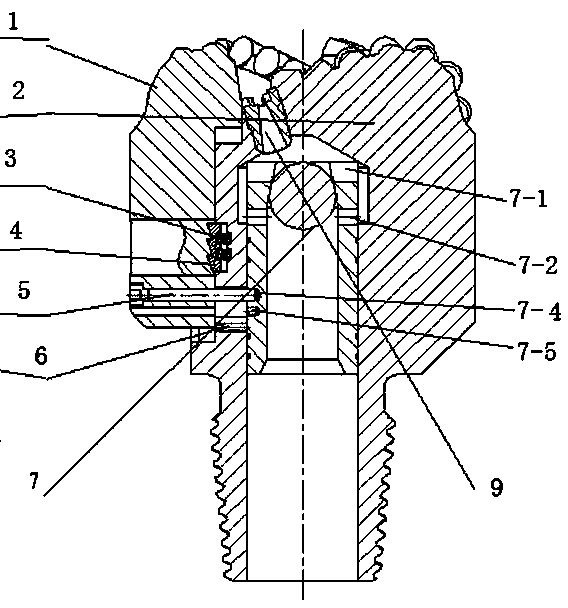

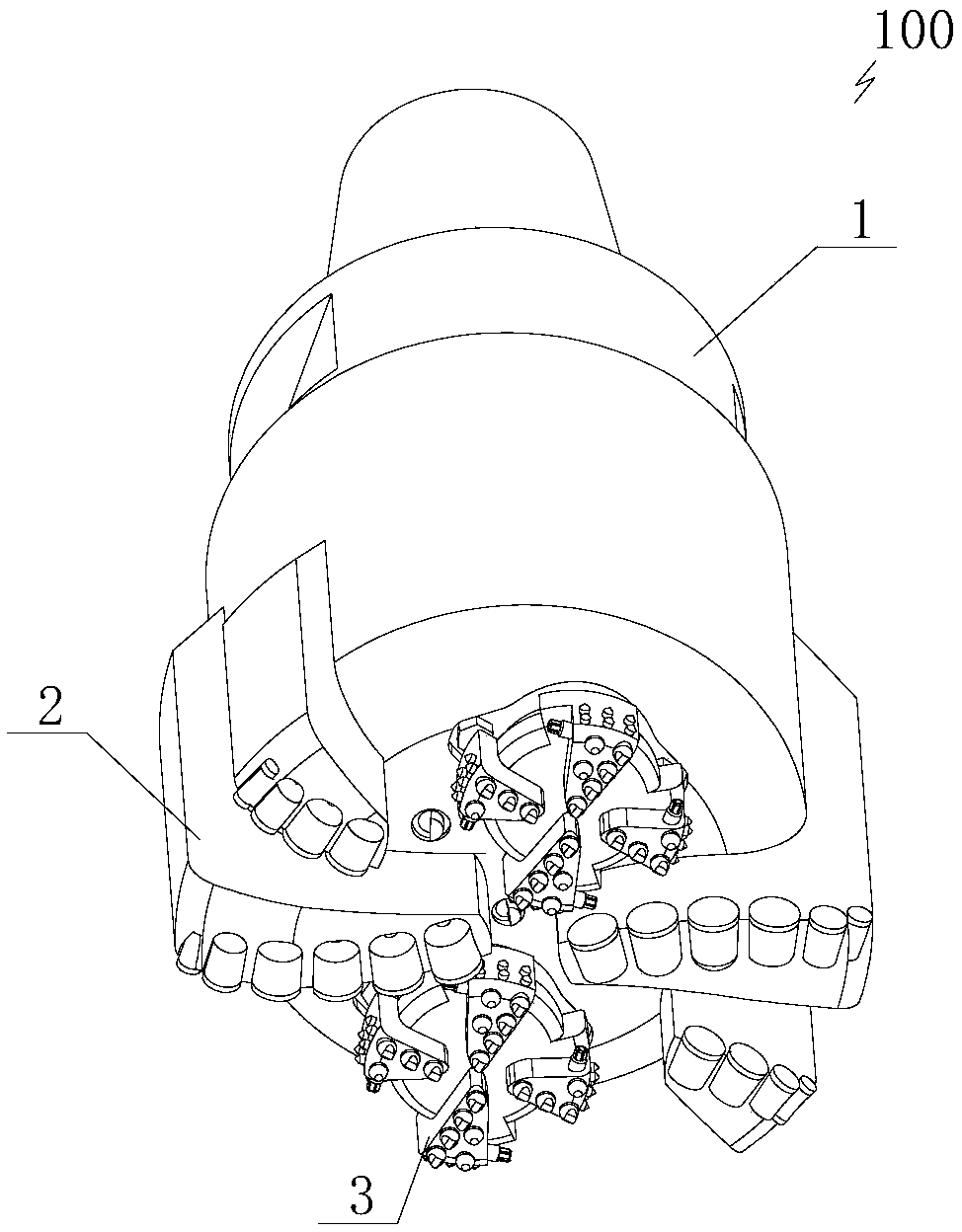

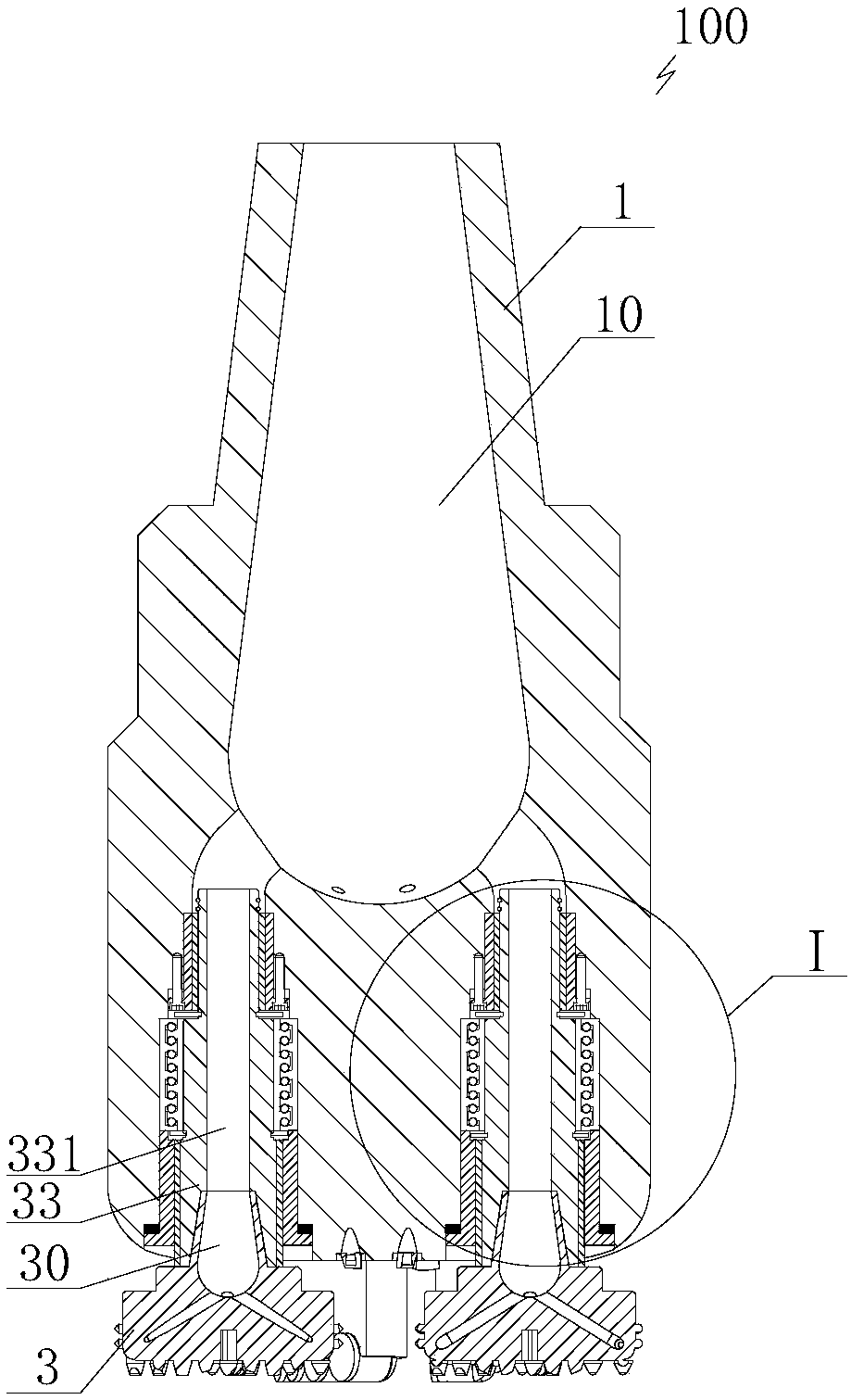

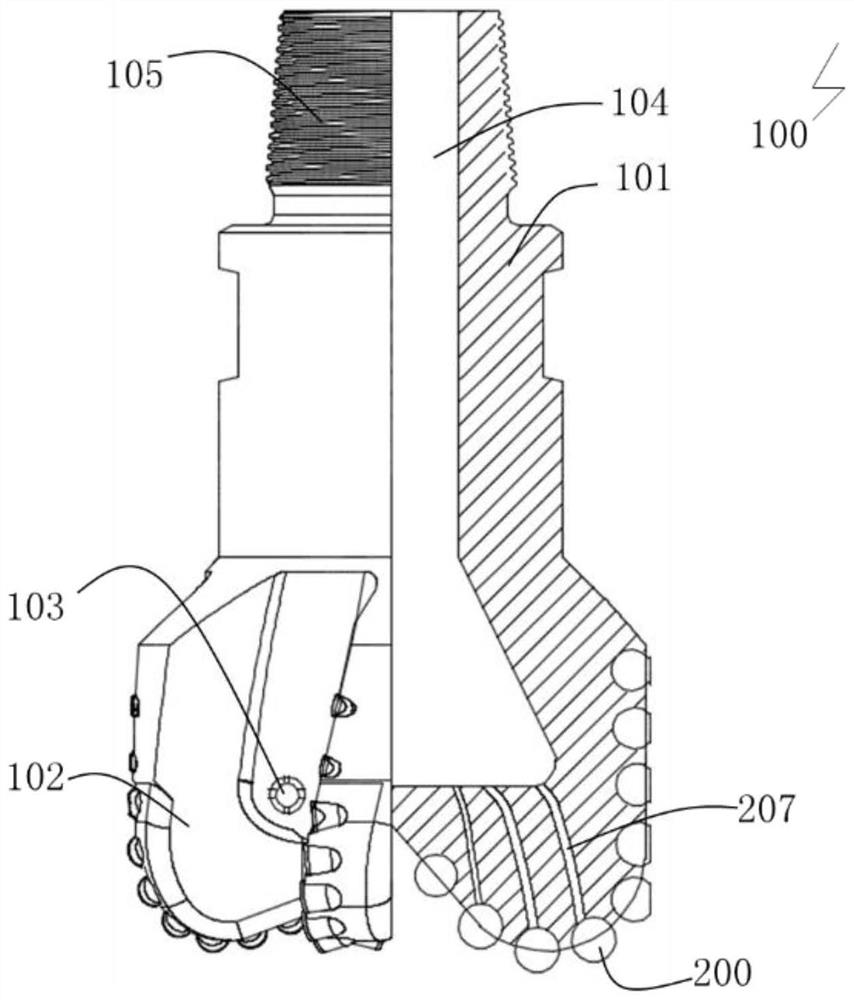

Hybrid power PDC drill bit based on jet flow technology

InactiveCN109025831AExtended service lifeImprove adaptabilityDrill bitsConstructionsWell drillingHigh pressure

The invention relates to a hybrid power PDC drill bit based on jet flow technology, which comprises a drill bit body, one end of the drill bit body is provided with a plurality of drilling fluid nozzles, one end of the drill bit body is provided with at least two drill bit cutter wings, the drill bit cutter wings can rotate in the same direction as the bit body for cutting a rock layer. At least two jet flow power cutter heads are arranged at one end of the drill bit body, the jet flow cutter heads and the drill bit cutter wings are evenly and alternately arranged in the circumferential direction, and a plurality of cutter head cutter wings are evenly arranged on the jet flow power cutter heads at intervals in the circumferential direction, and jet flow nozzles are respectively disposed onone side of each cutter head cutter wing. The jet flow power cutter heads can rotate in the same direction as the drill bit body and can reversely rotate under the driving of a high-pressure jet flow; each cutter head wing can impact the grinding rock formation for a second time and the high pressure jet flow generated by the jet flow nozzle can spray the fracture the rock formation. The drill bit can avhieve mechanical and hydraulic cross rock breaking under the complex and changeable stratum, improves the adaptability of the drill bit to various formations, improves the rock breaking efficiency, shortens the drilling period, reduces the drilling cost and improves the exploration and development benefits.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Modified Leituoshi stone for drilling liquor and its production mehtod

The present invention uses calcium base leituoshi stone ore as raw material, and adopts semi-dry artificial modification process including the steps: breaking clay mineral, adding 1%-5% sodium salt, uniformly mixing them, water-spraying, shearing, pressing, piling and ageing for 7-10 days, drying so as to obtain modified leituoshi stone. Said invention is simple in production method, convenient for operation, less in dosage of modifying agent and low in energy consumption and cost. The phi-600 reading value of drilling fluid prepared with modified leituoshi stone is greater than or equal to 60, mud-making rate is greater than or equal to 18 cu.m / t, filter loss is less than or equal to 13.5 ml and dynamic shear force is less than or equal to 1.2XPVPa. It is superior to sodium base bentonite in all the properties, and is applicable for drilling in the fields of petroleum industry, natural gas engineering, geologic drilling engineering and building engineering, etc.

Owner:湖北名流累托石科技股份有限公司

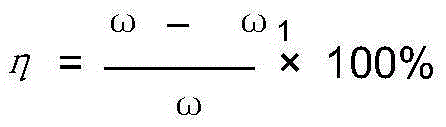

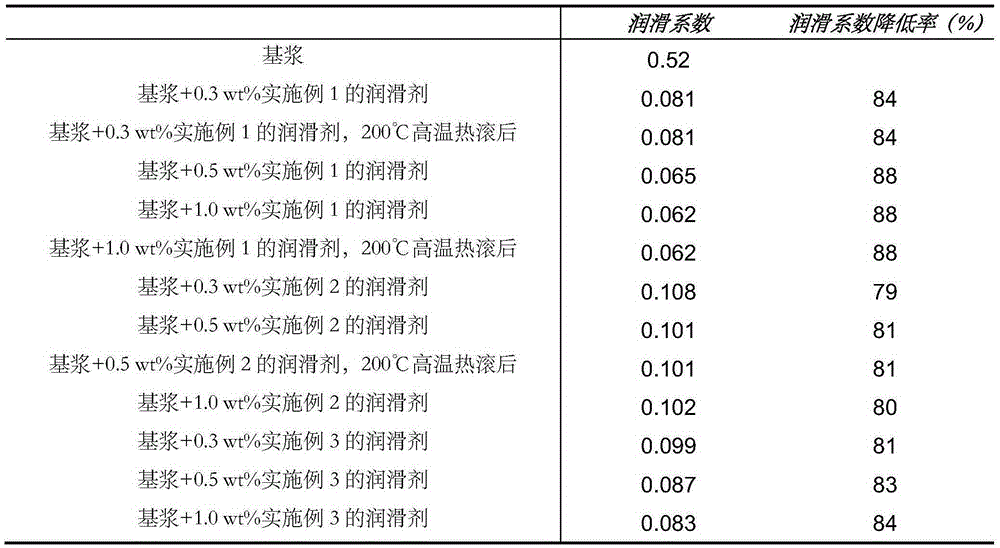

Liquid lubricant for drilling fluid and preparation method of liquid lubricant

InactiveCN105295864AReduce frictional resistanceReduce torqueDrilling compositionWater basedSilicone oil

The invention discloses a liquid lubricant for a drilling fluid and a preparation method of the liquid lubricant. The liquid lubricant is prepared from the following raw materials by weight: 500 to 600 parts of methyl oleate, 170 to 230 parts of silicone oil, 170 to 230 parts of white oil, 30 to 80 parts of backlogged oil, 40 to 80 parts of an emulsifier, 40 to 80 parts of a surfactant, and 15 to 20 parts of a covering agent. The liquid lubricant can be used for a water-based drilling fluid, is approximately not changed in lubricity at 200 DEG C high temperature, can be used for reducing the pulling up force and the torque of a drill stem greatly, and is relatively high in resistance reducing lubricity.

Owner:天津滨海新区普瑞德石油科技有限公司

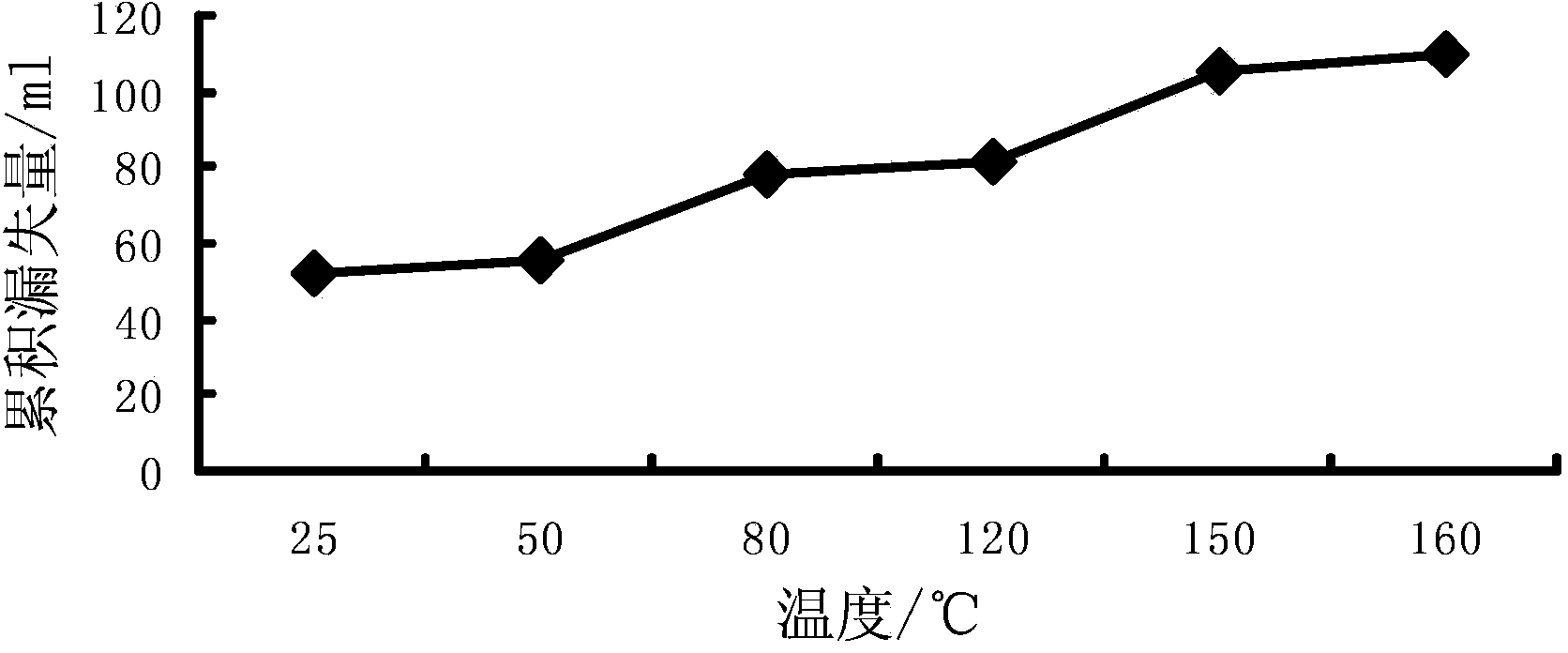

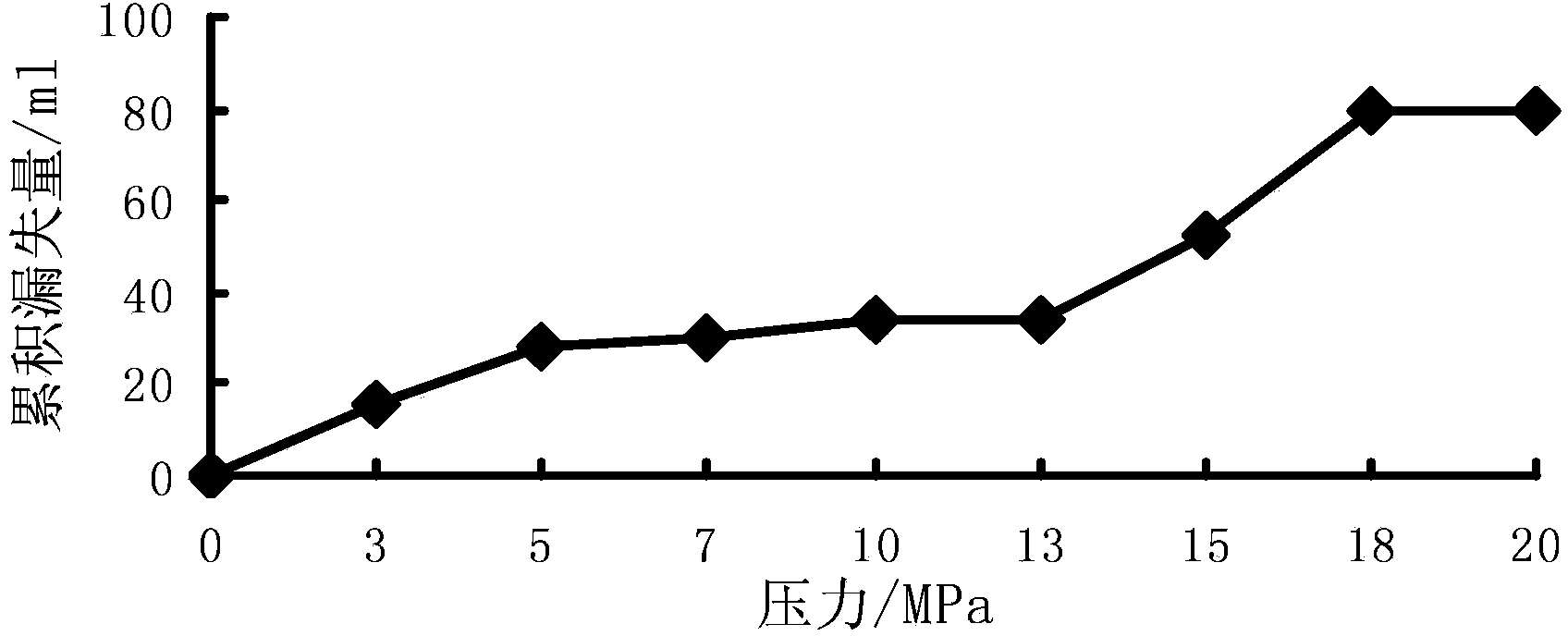

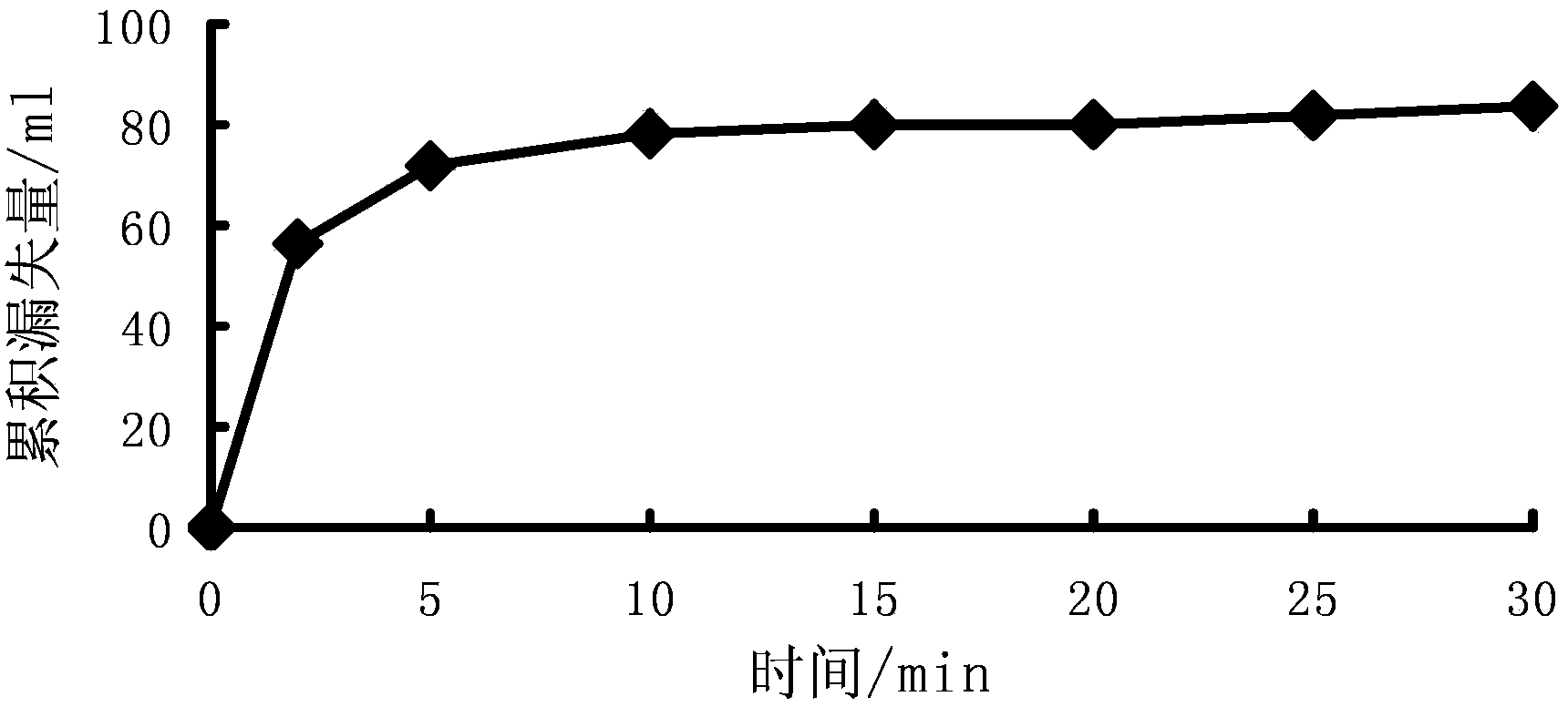

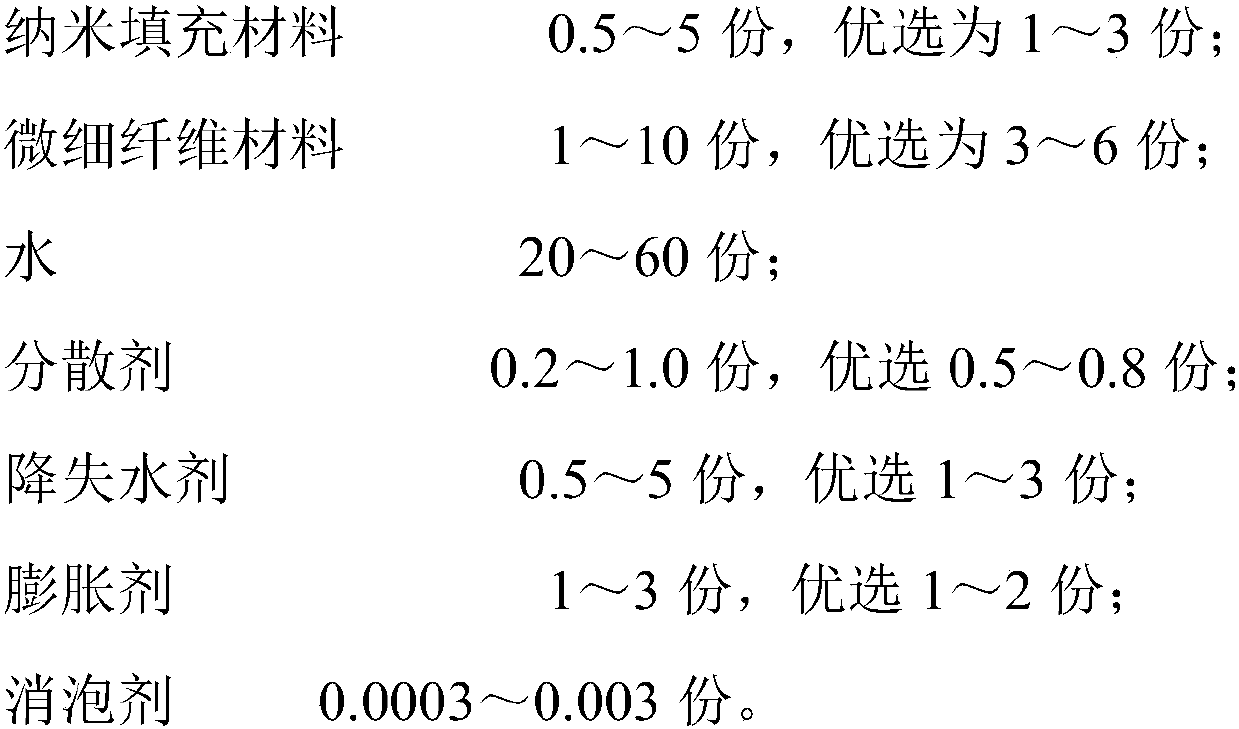

Plugging agent with high bearing strength for deep drilling and preparation method thereof

InactiveCN109868125AHigh compressive strengthImprove flexural strengthDrilling compositionFiberFlexural strength

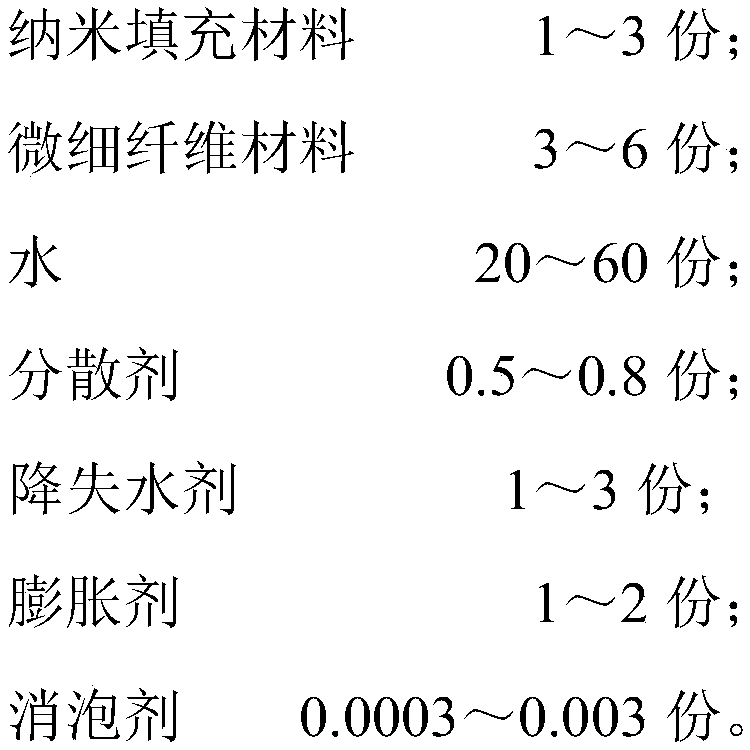

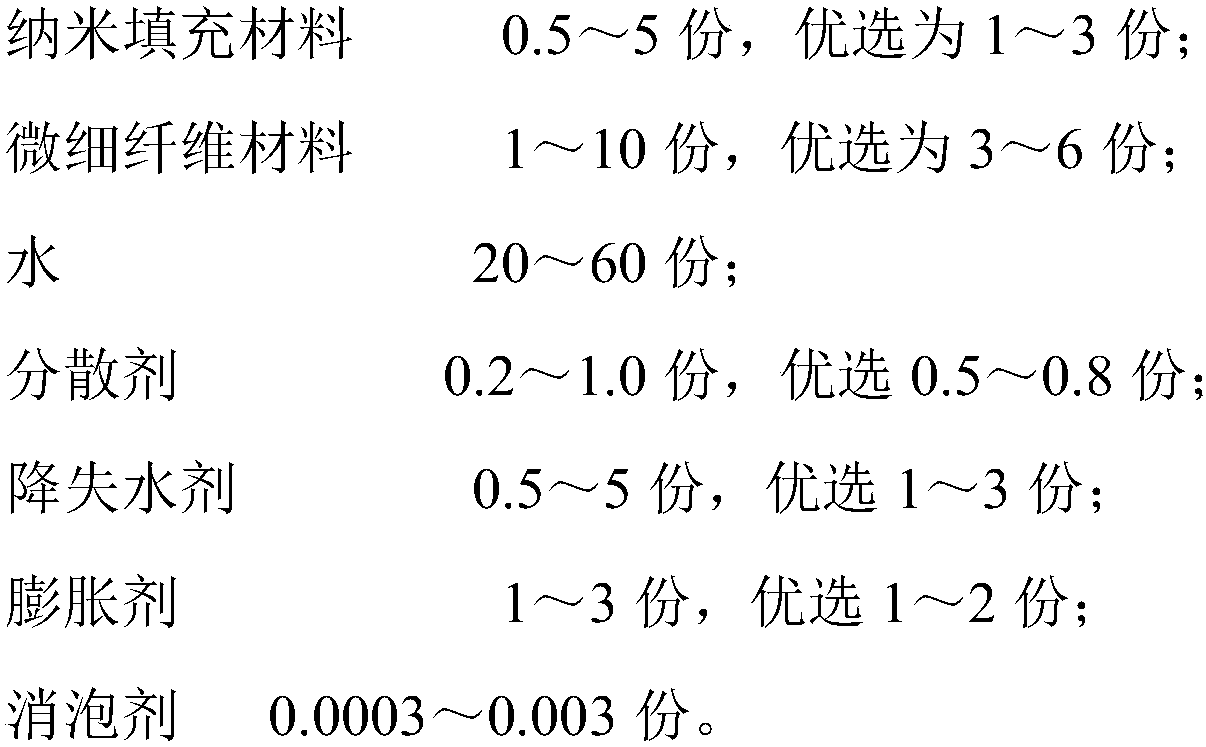

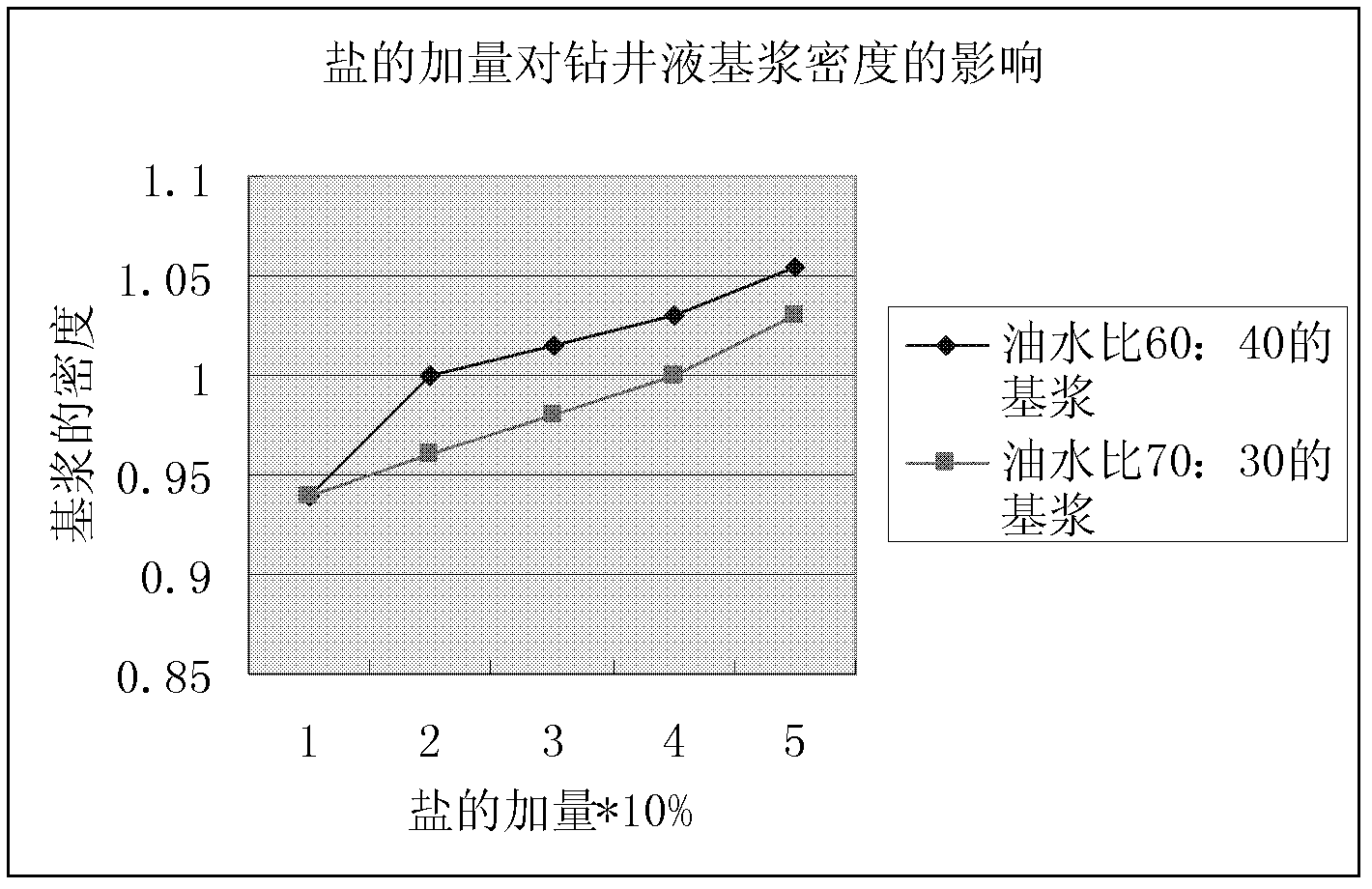

The invention relates to a plugging agent with high bearing strength for deep drilling and a preparation method thereof, belonging to the field of ultra-deep petroleum drilling engineering. The plugging agent with high bearing strength for deep drilling comprises cement, a cement additive, a nanometer filling material, a micro-fine fiber material and water; on the basis of 100 parts by weight of the cement, the content of the nanometer filling material is 0.5 to 5 parts by weight, preferably 1 to 3 parts by weight; the content of the micro-fine fiber material is 1 to 10 parts by weight, preferably 3 to 6 parts by weight; and the content of the water is 20 to 60 parts by weight. According to the invention, the plugging agent with high bearing strength can greatly improve compressive strength and flexural strength of a plugging slurry, and has significant plugging effect. The plugging agent provided by the invention is applicable to plugging lateral cracks, malignant leakage caused by broken rock strata and long open hole segments of multi-pressure series of strata; cementation performance between the plugging agent and a leakage channel wall and the impact crushing resistance of formed cement stone are improved; and the construction requirements of plugging for long open hole segments and plugging under high strength of 30 MPa or above can be solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environment-friendly low solid phase oil-base drilling and completion fluids and preparation methods

InactiveCN103184038AReduce the possibilityHigh permeability recoveryDrilling compositionSolid phasesChemistry

The invention provides an environment-friendly low solid phase oil-base drilling and completion fluids and preparation methods. The oil-base drilling and completion fluids are composed of the following raw materials of, by volume, 55-90 parts of base oil, 1.0-3.0 parts of an oil-based thickener, 3.0-6.0 parts of an emulsifier, 1.0-4.0 parts of a wetting agent, 3-9 parts of an alkalinity regulator and 10-45 parts of saline water. The preparation methods is carried out according to the following steps of a. taking the base oil, adding the emulsifier, the oil-based thickener, the wetting agent and the alkalinity regulator in the base oil; water bathing at a temperature of 40-60 DEG C and stirring for 1-2 h at a speed of 11*1,000 rpm; and b. slowly adding 10-45 parts by volume of the saline water into a solution obtained from the step a and stirring for 3-5 h at a speed of 11*1,000 rpm to obtain products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rotary guiding drilling tool

InactiveCN103527083AReduce the risk of stuck cardsSolve the speed problemDirectional drillingThermodynamicsWell drilling

The invention relates to a downhole guiding drilling tool, and belongs to the technical field of petroleum engineering stratigraphical drilling downhole tools. The downhole guiding drilling tool consists of an irrotational coat, a rotary mandrel and a directed control mechanism, wherein a fixed centralizer and a guiding roller are arranged on the outer surface of the irrotational coat; the directed control mechanism is arranged in an inner cavity; and the guiding roller can be controlled to extend and retract by rotation and vertical movement of the drilling tool. When the guiding roller extends, a lateral thrust is applied to a drill bit, and a well track can forwards move along a certain direction. When extending, the roller is supported on a well wall, and the irrotational coat is prevented from rotating, but can downwards move when the drilling tool is fed, so that the purpose of directed drilling of the drilling tool under the state of rotation is realized. When retracting, the guiding roller does not have a guiding function, and the drilling tool drills like the conventional drilling tool.

Owner:CHINA PETROCHEMICAL CORP +1

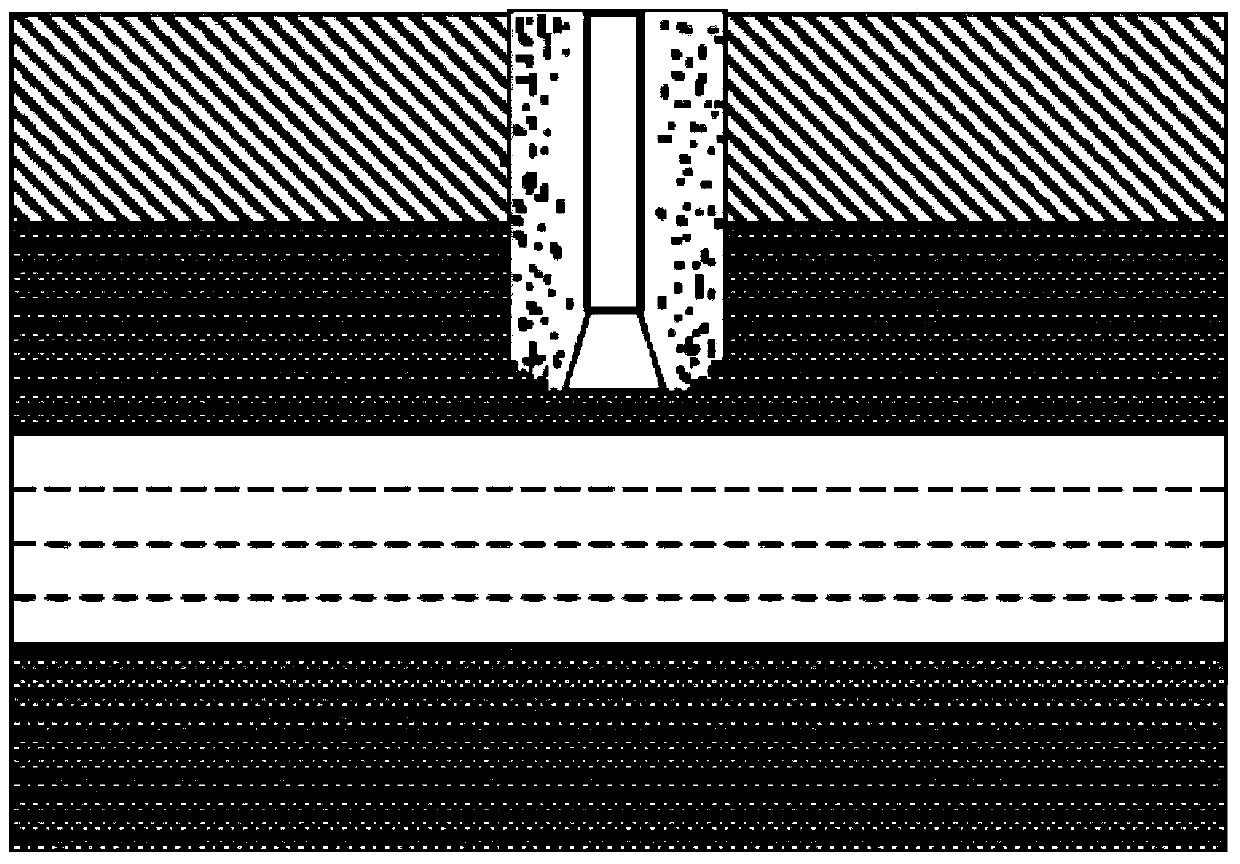

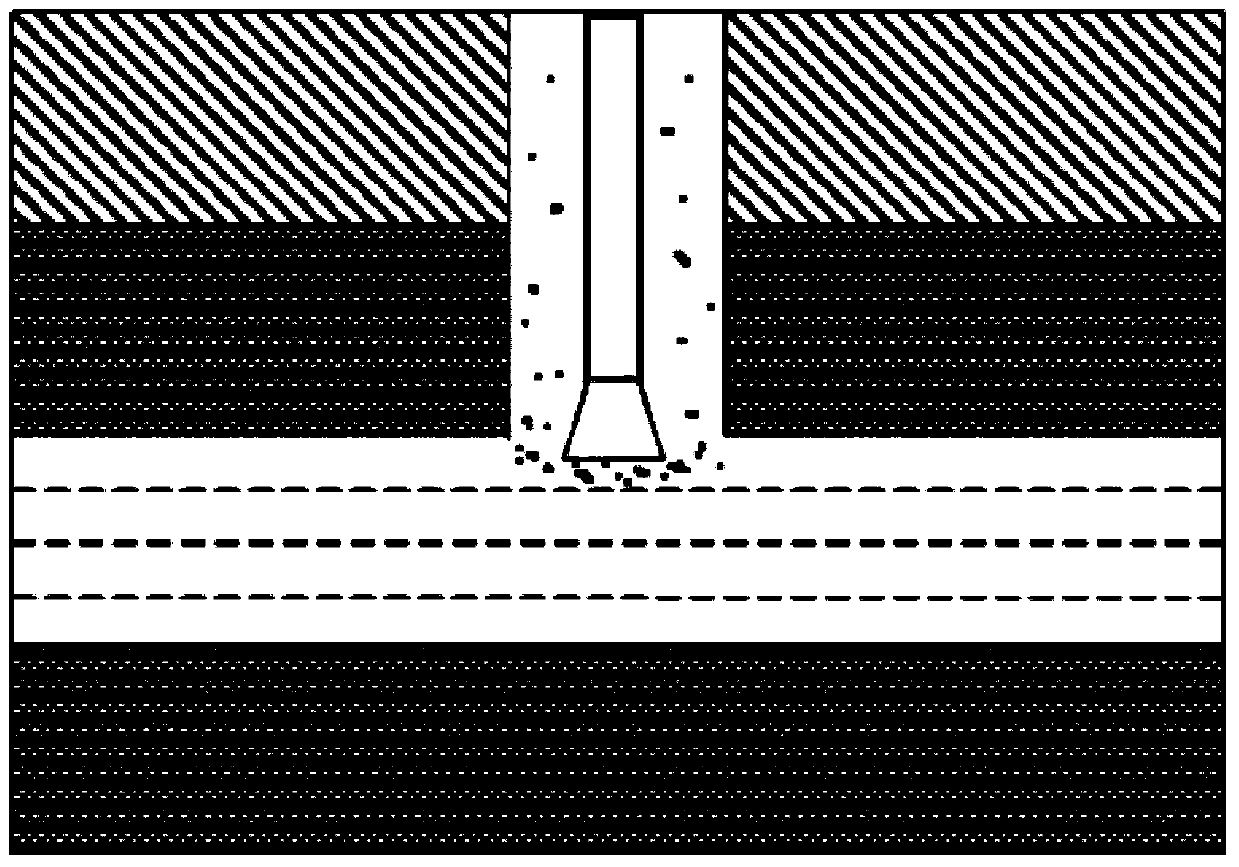

Method for improving well wall stability

The invention provides a method for improving well wall stability. According to the method, in gas drilling, glue is sprayed on a well wall. For example, a first component of a spraying material and a second component of the spraying material are sprayed on the well wall through a spraying device. The spraying device comprises a barrel comprising a first portion and a second portion, two liquid storage tanks arranged in the first portion and containing the first component and the second component respectively, nozzles arranged on the outer peripheral wall of the second portion of the barrel and channels for connecting the liquid storage tanks and the nozzles, wherein the first component and the second component are sprayed out from different nozzles through different channels. Preferentially, the nozzles for spraying out the first component and the nozzles for spraying out the second component are arranged at intervals. According to the method, the stability of the well wall can be effectively improved, and safety and stability of oil drilling are improved. The spraying device used in the method is simple in structure and convenient to operate and enables the components of the spraying material to be fully mixed and solidified on the well wall after the components of the spraying material are sprayed out so as to form a stable blocking layer.

Owner:CHINA PETROLEUM & CHEM CORP +1

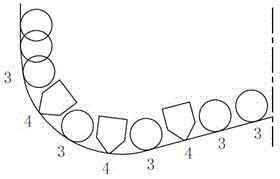

A plowing type PDC drill bit suitable for hard formations

InactiveCN105275403AReduce intensityEfficient crushingDrill bitsConstructionsWell drillingPolycrystalline diamond

The invention provides a plowing type PDC drill bit suitable for hard formations. The plowing type PDC drill bit comprises a drill bit base body, cutter blades and cutting teeth. The drill bit base body is provided with at least two cutter blades and chip grooves are formed between adjacent cutter blades. The cutter blades are provided with the cutting teeth. The cutting teeth include tapered PDC teeth and polycrystalline diamond compacts arranged on the cutter blades. The polycrystalline diamond compacts cut rocks at a rear rake angle and the tapered PDC teeth plow rocks at the positive rake angle. The tops of the tapered PDC teeth are sharp and can cut into rocks easily and form plowing furrows at well bottoms, so that the internal stress of well bottom rocks is released and the rock strength is reduced; the working surfaces of the polycrystalline diamond compacts are large, so that the rocks can be cut in large area; through the organic combination of the PDC teeth of two different structures, the rock breaking efficiency of the drill bit can be greatly improved, the problems of low hard formation drilling speed and short service life of drill bits are effectively solved, and the objectives of increasing the drilling efficiency, shortening the drilling period and reducing the drilling cost are achieved.

Owner:CHINA PETROCHEMICAL CORP +2

Drilling fluid for drilling of fractured igneous rock formation and preparation method of drilling fluid

The invention relates to a drilling fluid for drilling of a fractured igneous rock formation and a preparation method of the drilling fluid in the field of petroleum drilling. The drilling fluid is prepared from components in parts by weight as follows: 1,000 parts of water, 3-4 parts of drilling fluid bentonite, 2-3 parts of sodium carbonate, 2-3 parts of a polymer coating agent, 2-3 parts of potassium polyacrylate or a metal cation polymer, 5-10 parts of an organic amine inhibitor, 20-30 parts of an anti-sloughing reinforced wall fixation agent, 20-30 parts of sulfonated phenol formaldehyderesin, 5-10 parts of a sulfonate copolymer filtrate reducer, 20-30 parts of walchowite, 10-20 parts of an anti-salt and temperature-resistant fluid loss agent, 20-40 parts of superfine calcium carbonate, 50-70 parts of potassium chloride, 0-10 parts of an organic anti-friction compound and 10-20 parts of a nano-micro blocking agent, and the weight is increased to 1.30-1.85 g / cm<3> with a density weighting agent. The drilling fluid has good temperature resistance and lubricating property and excellent inhibition property and anti-sloughing wall fixation property and can effectively prevent thefractured igneous rock formation from collapsing; the rock carrying capability of the drilling fluid can be substantially improved, repeated grinding of larger falling blocks nearby a drill bit is prevented, the frictional resistance is reduced, the mechanical drilling speed is increased, and underground safety is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

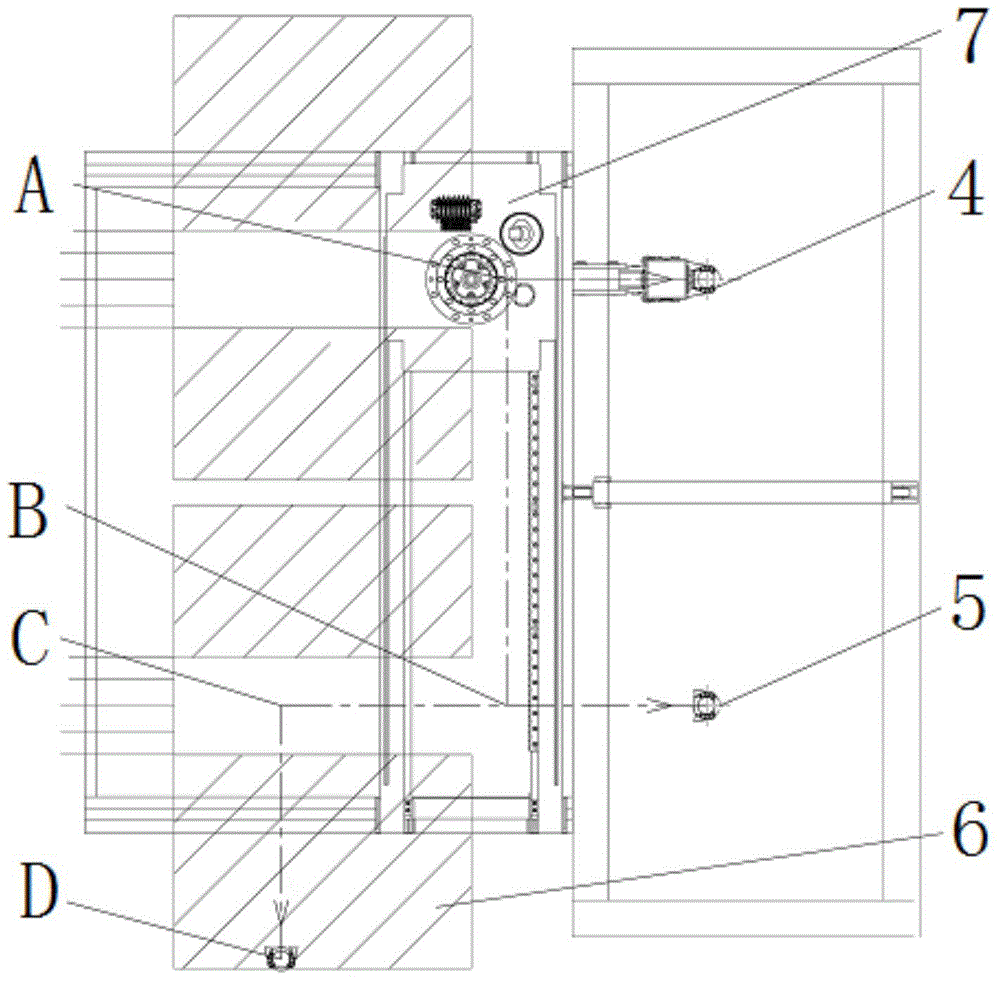

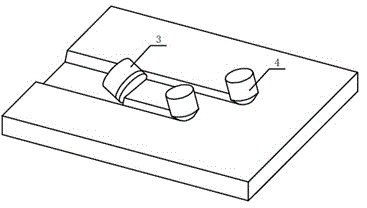

Offline three-joint unit establishing device

InactiveCN106194067AEnable connectivityHigh degree of automationDrilling rodsDrilling casingsWell drillingEngineering

The invention discloses an offline three-joint unit establishing device. The offline three-joint unit establishing device is characterized in that a three-joint unit frame is arranged on a side of a base of a drilling rig, a manipulator is mounted on the outer side surface of a base of the three-joint unit frame, a hydraulic rack pipe frame is arranged along a longitudinal side or two longitudinal sides of the manipulator, a hoisting tackle, a hydraulic winch and hydraulic tongs are mounted on the three-joint unit frame, and an automatic derrick monkey is arranged on the lower end surface of a racking platform of a derrick. Compared with conventional drilling rigs, the offline three-joint unit establishing device has the advantages that the additional offline three-joint unit establishing device independently has three-joint unit establishing functions under the working conditions that normal well drilling is unaffected, accordingly, the well drilling efficiency can be improved, the well drilling cost can be saved, and oil and gas wells can be early started up in an acceleration manner.

Owner:BAOJI PETROLEUM MASCH CO LTD

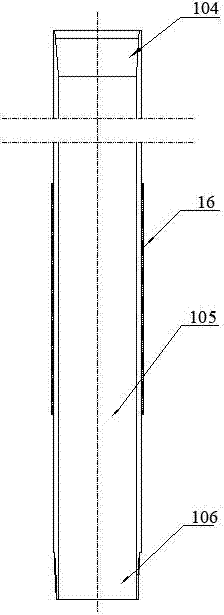

Underground pulsing jet drill bit device

The invention relates to an underground pulsing jet drill bit device. A double-end sleeve, a drill bit connector and a drill bit body are sequentially screwed; the upper end of the drill bit body is provided with a drill bit water cavity; a plurality of drill bit water holes are distributed in the bottom wall of the drill bit water cavity; all of the drill bit water holes are uniformly distributed by using the axial line as the center; each drill bit water hole downwards extends and is communicated with a corresponding spray hole formed in the lower end surface of the drill bit body; the center of the double-end sleeve and the center of the drill bit connector are provided with a center water passage communicated with the drill bit water cavity; a static valve disc is arranged on the bottom wall of the drill bit water cavity; static valve disc water holes are formed in the static valve disc; each static valve water hole has the same hole diameter as the drill bit water hole and is in one-to-one corresponding communication with the corresponding drill bit water hole; a movable valve disc capable of rotating around the axial line covers the static valve disc; at least one movable valve disc water hole is formed in the movable valve disc; and the movable valve disc water hole has the same hole diameter as the static valve disc water hole, and is positioned on the same circumference as the static valve disc water hole. The drill bit device has the advantages that the shaft bottom cleaning effect can be improved; and the hydraulic rock breaking capability can be improved.

Owner:CHINA PETROCHEMICAL CORP +2

Drilling machine angle accurate positioning detection and control system

InactiveCN104632184AReal-time operationAccurate calculationSurveyConstructionsTop driveElectric machine

The invention discloses a drilling machine angle accurate positioning detection and control system. The drilling machine angle accurate positioning detection and control system comprises a driving system, a detection device and an actuator corresponds to the driving system, wherein the driving system comprises a top driving system or a rotary disk driving system. The drilling machine angle accurate positioning detection and control system has the advantages that the adopted angle detection device can automatically calculate the rotating angle of a rotating shaft of a motor, calculation is accurate, the accuracy is high, the anti-seismic property is good, machining is easy, and cost is low; since a dynamic tool face controller is used for achieving dynamic control over a downhole orientation power drilling tool face, when the drilling tool face drifts, the dynamic tool face controller can be operated in real time to adjust the drilling tool face, and the situation that equipment stops drilling and a drilling tool is lifted up is avoided; as a result, loss of the equipment is reduced, manpower and material resources are saved substantially, and downhole accidents are greatly reduced at the same time.

Owner:SICHUAN HONGHUA ELECTRIC

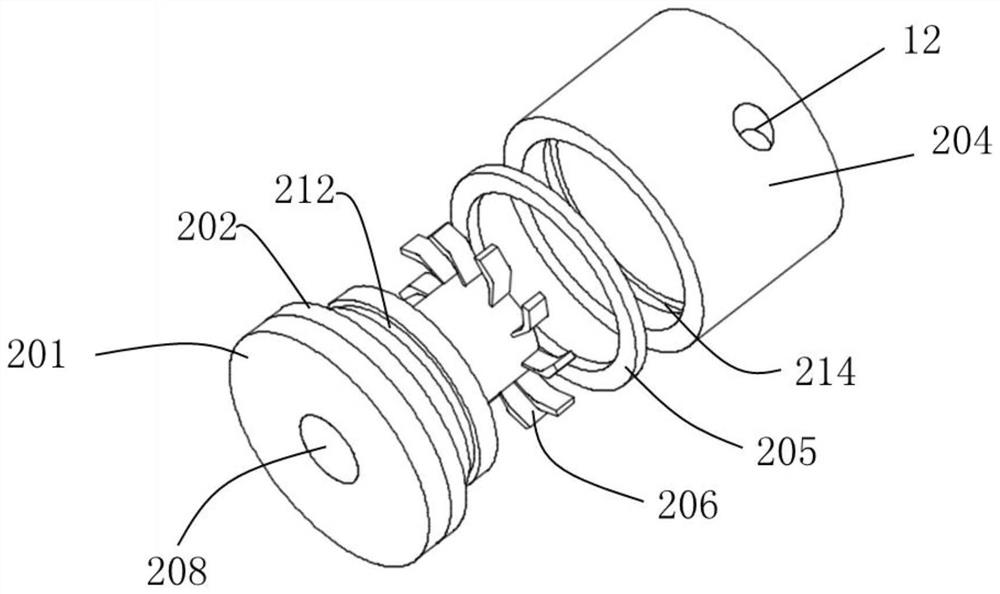

Polycrystalline diamond compact (PDC) bit with rotatable cutting tooth

PendingCN111852342AExtend your lifeAchieve coolingDrill bitsConstructionsPolycrystalline diamondEngineering

A polycrystalline diamond compact (PDC) bit with a rotatable cutting tooth comprises a bit body, the bit body is provided with a tool wing, a nozzle and a main fluid channel, and the cutting tooth isinstalled on the tool wing. The PDC bit is characterized in that a first fluid channel connected with the main fluid channel is arranged in the bit body; the cutting tooth is formed by a central rotating tooth, a bush, a limiting device and a hydraulic drive rotator; the bush is provided with a hole connected with the first fluid channel, and a second fluid channel is formed between the bush and the central rotating tooth; a flow channel space is arranged in the central rotating tooth to form a third fluid channel; the main channel, the first fluid channel, the second fluid channel and the third fluid channel communicate in sequence; and the central rotating tooth is provided with a limiting groove, the bush is provided with a limiting hole or a limiting groove, and the central rotating tooth is connected with the bush through the limiting device. The utilization rate of a cutting tooth diamond layer can be improved through the cutting tool of the structure, meanwhile cooling and cleaning of the cutting tooth can be realized, and the service life of the cutting tool is effectively prolonged.

Owner:刘伟

Hydraulic torque converter

ActiveCN105525871AImprove safety and reliabilityExtended service lifeDirectional drillingWell drillingControl theory

The invention discloses a hydraulic torque converter and mainly relates to the field of oil and gas well drilling. The hydraulic torque converter is installed between a bottom drilling tool combination and a drill column. The hydraulic torque converter is mainly composed of a center shaft, an outer shell, bearing devices, an adjustor, a spring, a hydraulic clutch, a coupler, a torque generator and a nozzle. Due to the special structure and the special connecting function relation among the center shaft, the outer shell, the bearing devices, the adjustor, the spring, the hydraulic clutch, the coupler, the torque generator and the nozzle, the hydraulic torque converter can achieve drill column rotation on the premise that reactive torque of the bottom drilling tool combination is balanced and a tool face is stabilized and can also complete tool face adjustment or composite rotation well drilling work. The drilling speed of a well of a complex structure can be better increased, the well track control precision can be better improved, in addition, a conventional sliding well drilling manner can be changed into a rotation well drilling manner, sliding friction resistance of the drill column is effectively reduced, and the hydraulic torque converter is of great significance in improving the well drilling efficiency of the well of the complex structure. Meanwhile, the hydraulic torque converter has the beneficial effects of being simple in structure, convenient to operate and install, safe and reliable.

Owner:CHINA PETROCHEMICAL CORP +1

Environment-friendly chlorine-free drilling fluid and preparation method thereof

InactiveCN105255459ANo pollutionEasy to degradeDrilling compositionPhysical chemistryEnvironmental engineering

The invention relates to environment-friendly chlorine-free drilling fluid, which is characterized in that the environment-friendly chlorine-free drilling fluid is prepared from the following components in percentages by weight: 8 to 18 percent of chlorine-free strongly inhibitory compound salt; 0.2 to 0.3 percent of drilling fluid tackifier; 1.5 to 3 percent of water-dispersible cationic emulsified asphalt powder; 0.2 to 0.4 percent of salt-resistant and calcium-resistant filtrate reducer; 0.2 to 0.5 percent of natural polymer filtrate reducer; 2 to 4 percent of acid-soluble temporarily plugged reservoir protection agent; 0.1 percent of caustic soda; and the balance of clean water. The environment-friendly, chlorine-free, low-density, low-solid phase, strong-chemical inhibition and anti-collapse drilling fluid can inhibit the collapse of mudstone sections under the condition of low density, and meets the friction drag reduction of long open hole sections with low solid phase.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

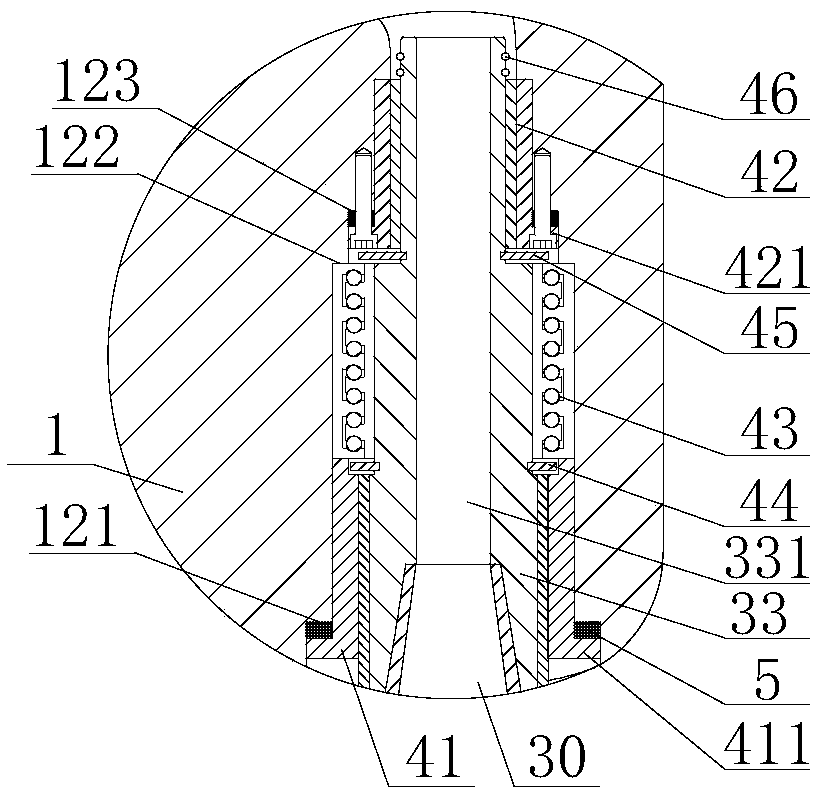

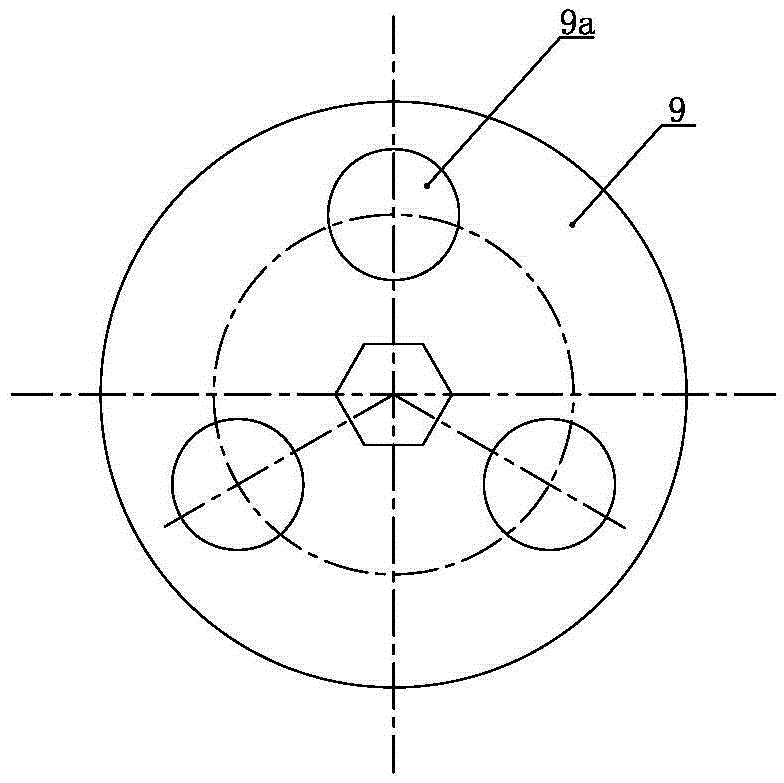

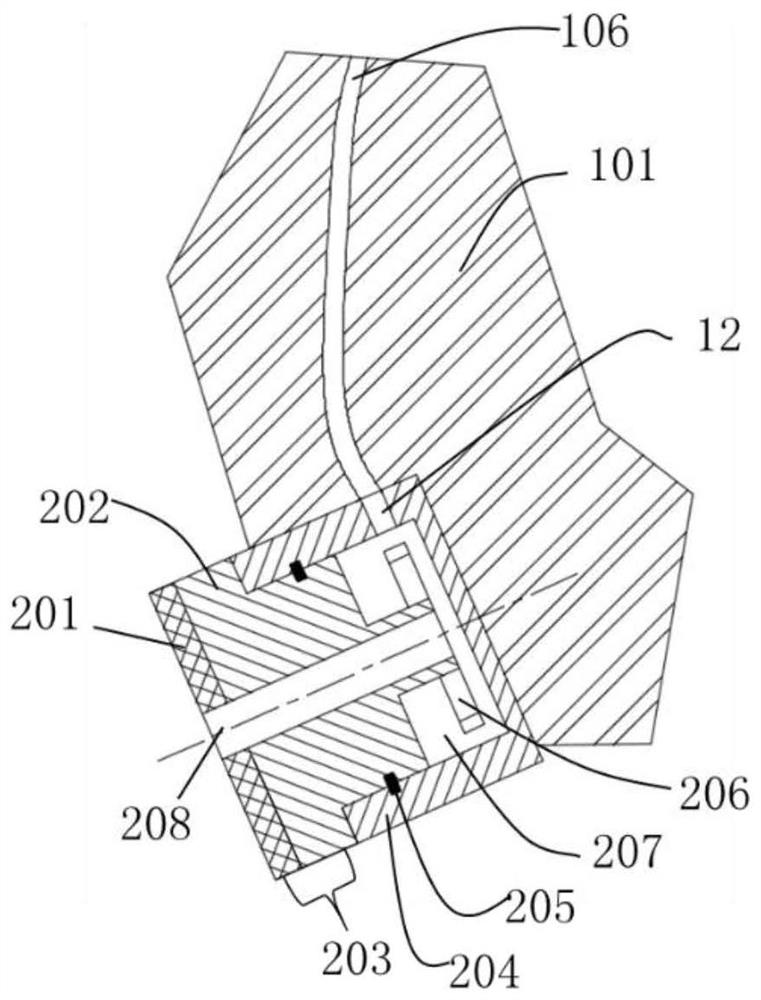

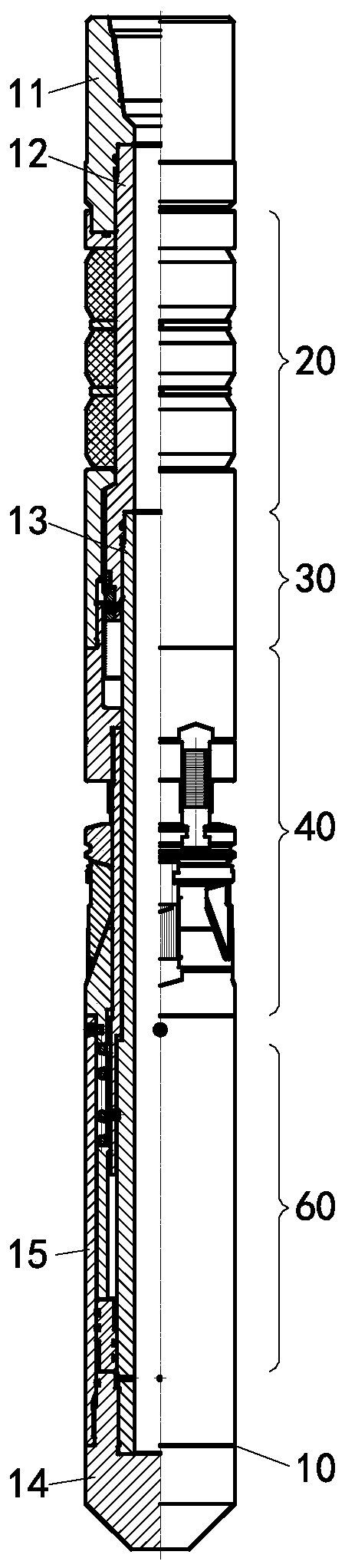

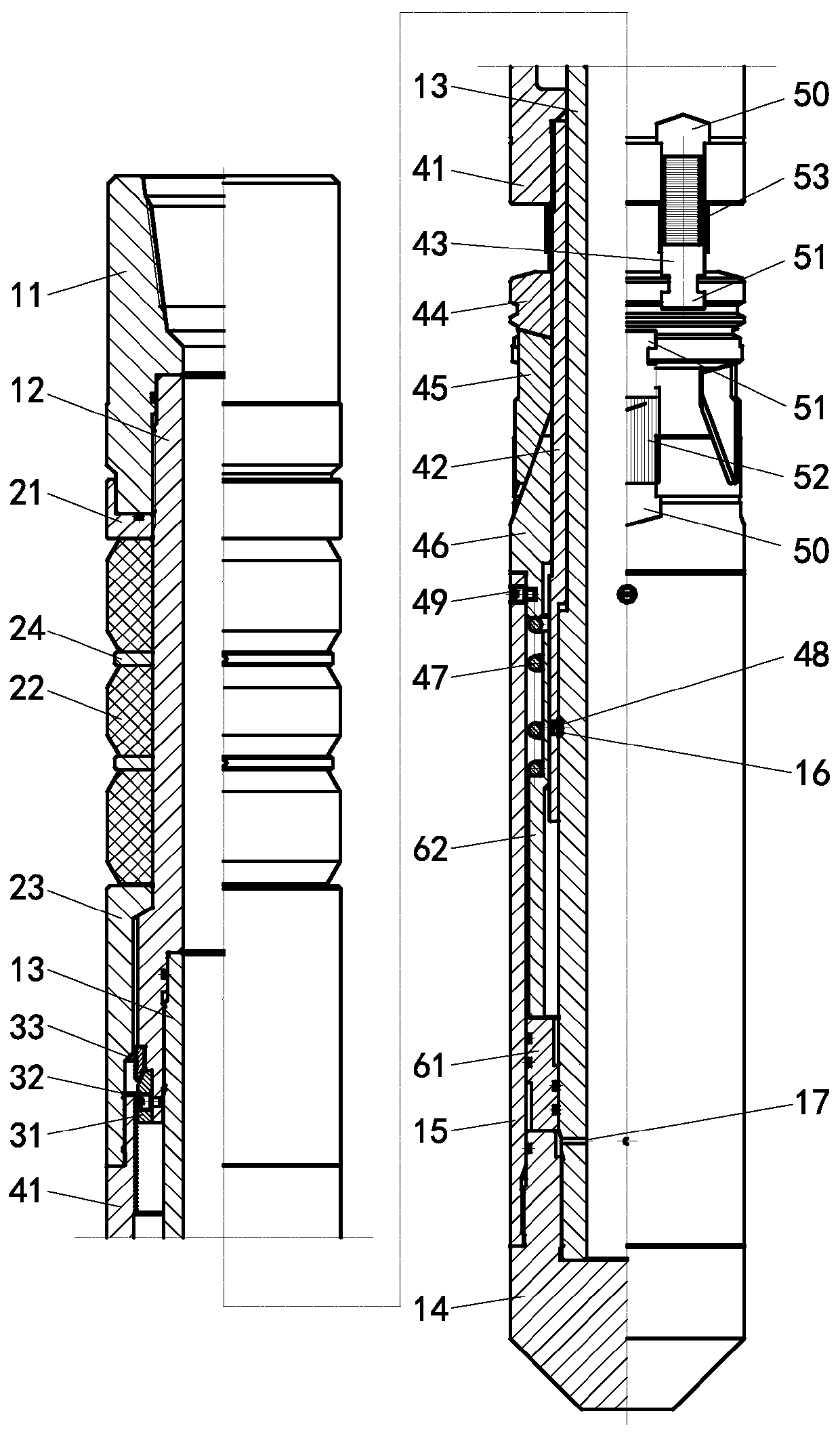

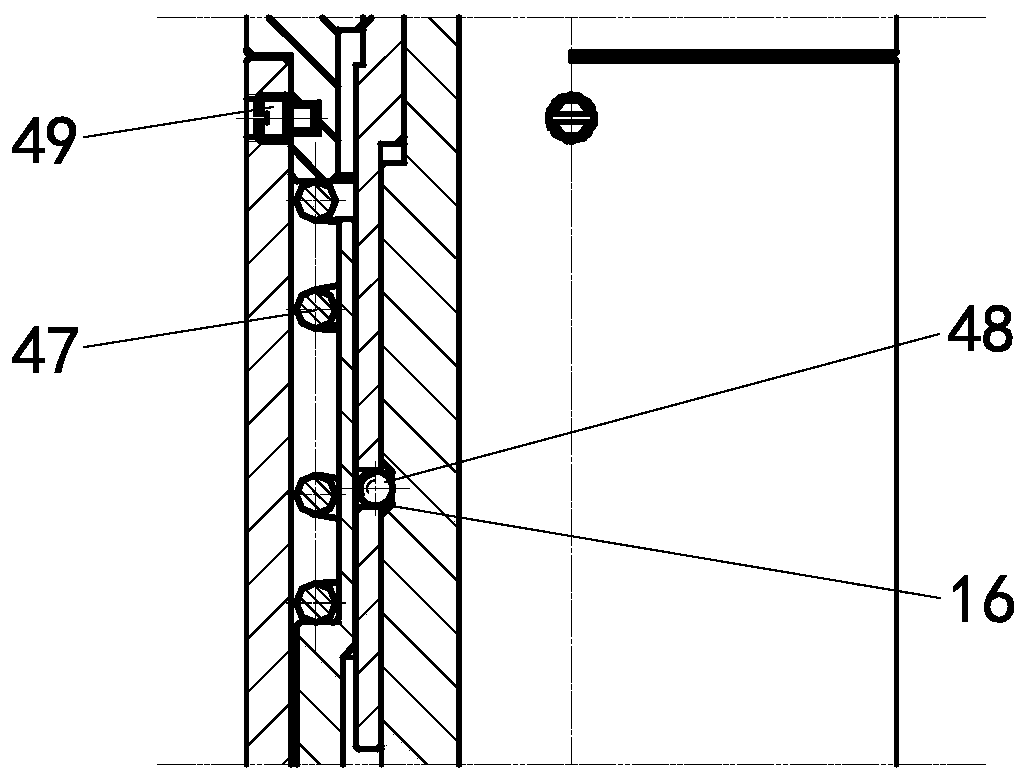

Double-slip hydraulic anchoring sealing device for window sidetrack drilling

PendingCN110863793AEliminate the risk of collusionMeet the technical requirements of window sidetrackingSealing/packingPressure transmissionUpper joint

The invention discloses a double-slip hydraulic anchoring sealing device for window sidetrack drilling. The double-slip hydraulic anchoring sealing device for window sidetrack drilling comprises a suspension unit (10). The suspension unit (10) is provided with a sealing unit (20), a locking and unsealing recovery unit (30), a slip anchoring unit (40) and a force transmission unit (60) in sequencefrom top to bottom. The suspension unit comprises an upper joint (11), an upper core tube (12), a lower core tube (13) and a lower joint (14) which are connected in sequence through threads from top to bottom. The external threads at the upper end of the lower joint is connected with a cylinder sleeve (15). A group of pressure transmission holes (17) which are evenly distributed in the circumferential direction are formed in the lower end of the lower core tube. An annular groove (16) is formed in the position, corresponding to the lower part of the slip anchoring unit, of the lower core tube.According to the double-slip hydraulic anchoring sealing device for window sidetrack drilling, a whipstock can be positioned axially or circumferentially in the window forming process by using hydraulic pressure, it is not necessary to arrange a positioning base beforehand, and the position for forming a window can be adjusted according technological requirements. The double-slip hydraulic anchoring sealing device for window sidetrack drilling is simple in structure, convenient to operate, and safe and reliable to use; and the production efficiency is improved because orientation, sealing, window formation and window repairing can be completed with one time of drilling.

Owner:GUIZHOU GAOFENG GASOLINEEUM MACHINERY

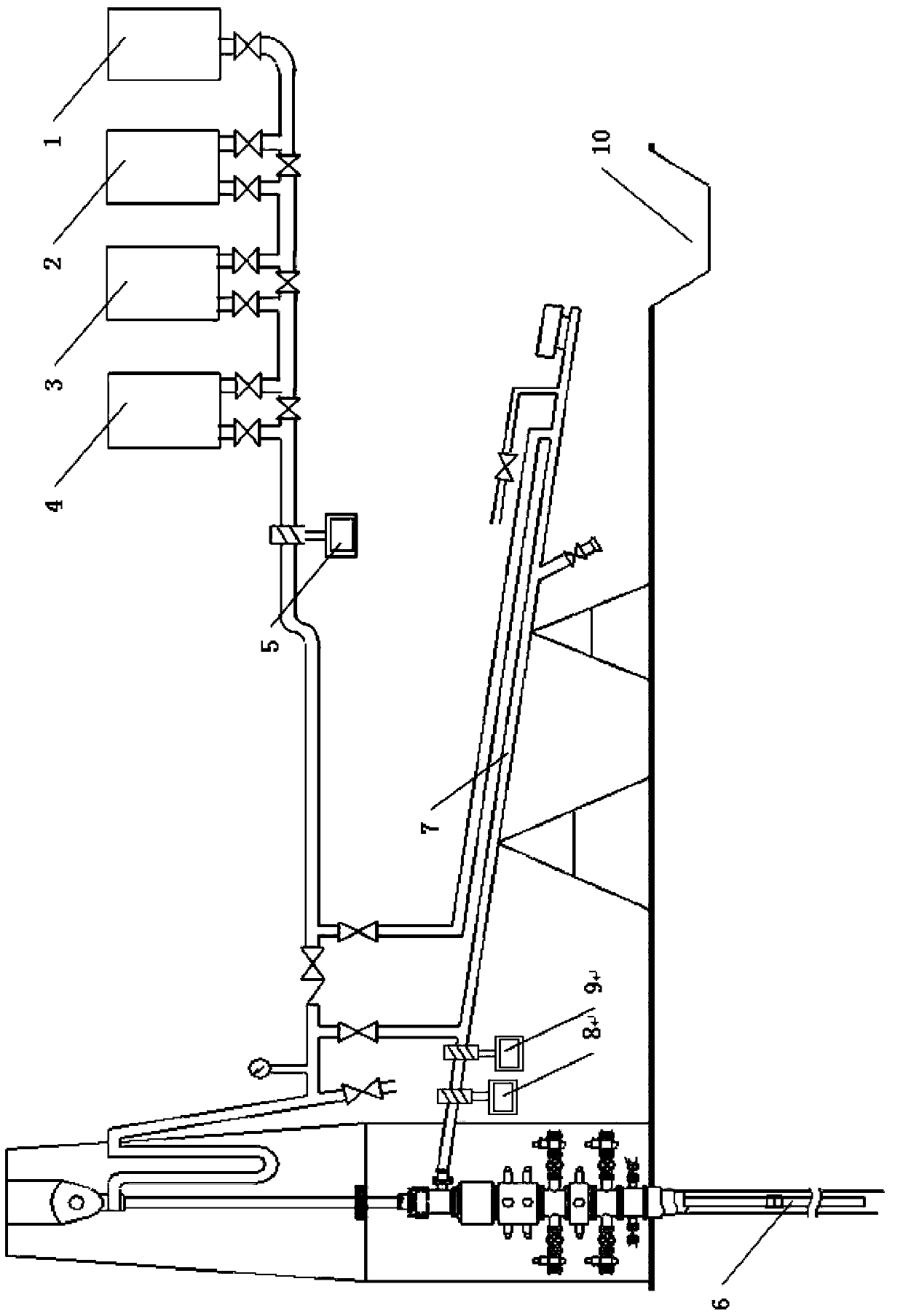

Method for freezing formation water in gas drilling process

InactiveCN105507811AExtend the construction sectionShorten the drilling cycleDrilling rodsInsulationWellheadFormation water

The invention relates to a method for freezing formation water in a gas drilling process. When formation water occurs in a gas drilling period, low-temperature gas that is condensed injected as a circulating medium into a well through a drill pipe and returns along with formation water and drill debris entering a shaft to a wellhead along an annulus when arriving at an outlet position; wherein the low-temperature gas returned up freezes the formation water dispersed in the annulus into particulate solid ice and carries it to the surface while freezing the well wall at the outlet position. The method enables a construction segment of gas drilling to be maximally extended, keeps efficient and safe drilling and high drilling speed and also prevents the problem of environmental pollution by waste water or waste mud caused in a foam drilling process.

Owner:CHINA PETROCHEMICAL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com