Method for improving well wall stability

A technology of stability and wellbore, which is applied in the field of oil drilling, can solve problems such as the accuracy of basic parameters, inconsistent well sections, and no stability assessment, etc., so as to reduce the time of drying the wellbore, reduce the drilling cycle, and improve drilling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 spraying device

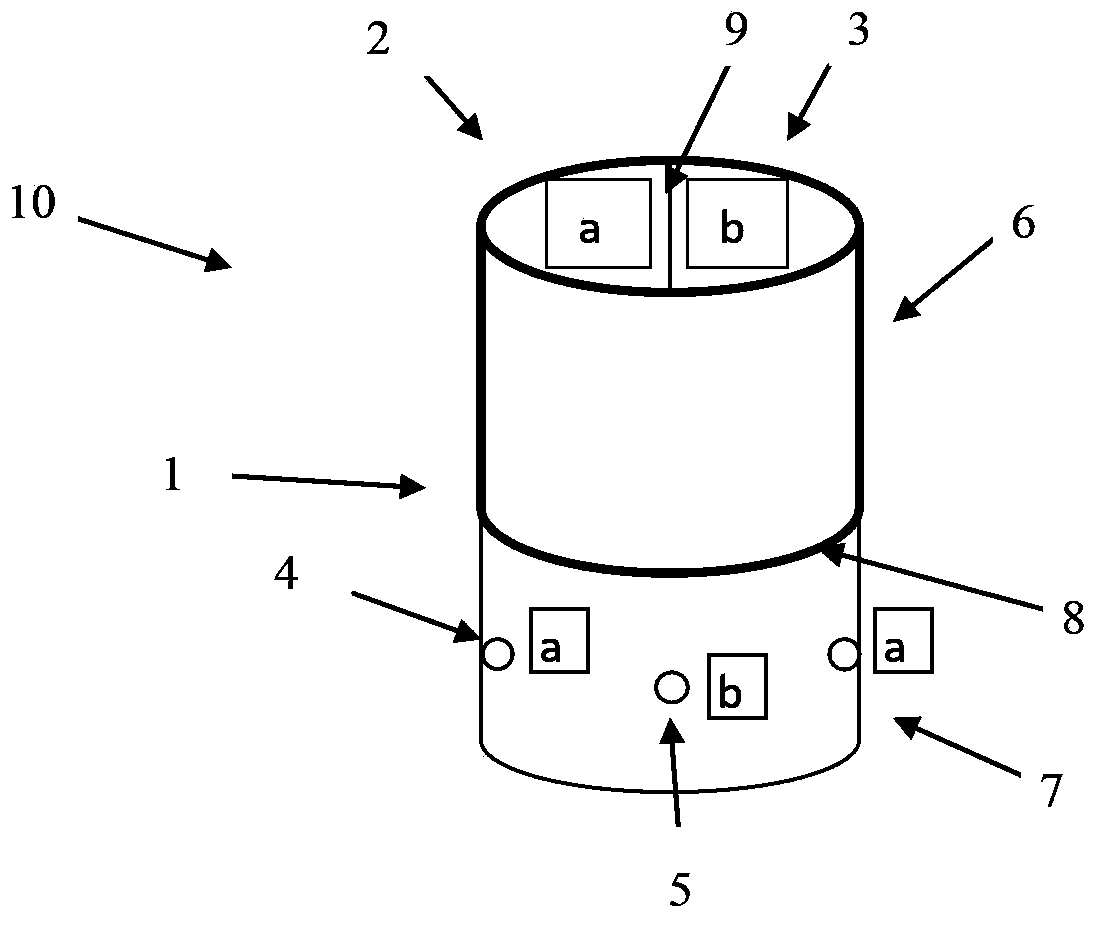

[0030] figure 1 A schematic diagram of a spraying device 10 according to the invention is shown. In this embodiment, the spraying device 10 includes a cylinder body 1, a liquid storage tank 2 and a liquid storage tank 3, and a plurality of non-existing components represented by the nozzle 4 and the nozzle 5. figure 1 The nozzles shown in all, and figure 1 A channel not shown is located in the barrel 1 for connecting the reservoir and the nozzle. Wherein, a baffle 8 is provided inside the cylinder body 1 to divide the cylinder body 1 into a first part 6 and a second part 7 . The liquid storage tank 2 and the liquid storage tank 3 are arranged inside the first part 6 of the cylinder body 1 and separated by another baffle 9 . The nozzles are arranged on the outer walls around the second part 7 of the barrel 1 . Different reservoirs correspond to different delivery pipes and nozzles.

[0031] figure 1 a and b in refer to two different spr...

Embodiment 2

[0033] Embodiment 2 increases the glue spraying method of wall stability

[0034] The spraying device in Example 1 is used for well wall support in oil drilling.

[0035] During the gas drilling process, when encountering formations that are prone to collapse or encountering formation water, the drill should be pulled out, and the air hammer or drill bit should be replaced with the spraying device as described in the embodiment. The first component and the second component of the spraying material are respectively installed in the liquid storage tank 2 and the liquid storage tank 3 . Among them, the first component is epoxy resin A glue, and the second component is epoxy resin B glue (ie curing agent). The first component and the second component alone are not adhesive, and when the two are mixed in a ratio of 1:1, the maximum adhesiveness is produced. Run the spraying device into the target well section, use the drill pipe as the gas channel, flexibly pressurize the sprayin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com