Patents

Literature

714 results about "Drilling engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drilling engineering is a subset of petroleum engineering. Drilling engineers design and implement procedures to drill wells as safely and economically as possible. They work closely with the drilling contractor, service contractors, and compliance personnel, as well as with geologists and other technical specialists. The drilling engineer has the responsibility for ensuring that costs are minimized while getting information to evaluate the formations penetrated, protecting the health and safety of workers and other personnel, and protecting the environment.

Intelligent drilling expert system

ActiveCN104806226AAccurate discoveryReal-timeAutomatic control for drillingEarly predictionAutomatic control

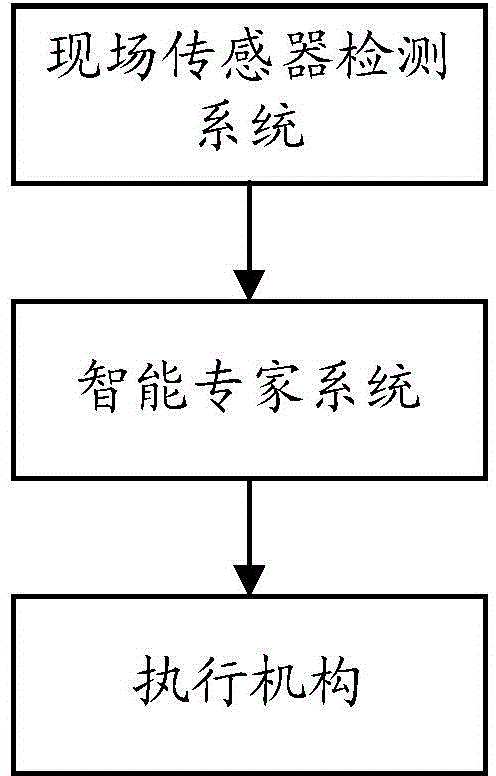

The invention provides an intelligent drilling expert system. The intelligent drilling expert system comprises a field sensor detection system, an intelligent expert system and an execution mechanism. An automatic closed-loop drilling regulation and control system is formed. Data in a whole drilling process are acquired through a field sensor; then, the acquired data are transmitted into a computer for processing, monitoring, prediction, analysis, explanation, control and the like. Most importantly, through the researched cross-specialty and cross-industry intelligent expert control models for drilling hydraulic control, well wall stability control, friction resistance and torque control, drilling speed and cost control, drilling complexity and accident control and the like, instantaneity, early discovery, early prediction, interpretation while drilling and an automatic control function can be realized, and accurate information is provided for drilling engineering; moreover, the intelligent drilling expert system has the advantages of reducing the drilling cost, increasing the drilling speed, avoiding sudden accidents and discovering oil and gas accurately.

Owner:北京四利通控制技术股份有限公司

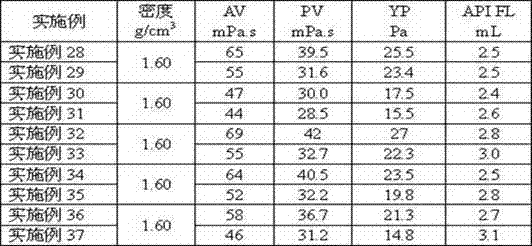

Deep-water low-temperature low-density early-strength cementing slurry for well cementation

ActiveCN101747880ARapid development of strengthImprove early strengthDrilling compositionVolumetric Mass DensityCement slurry

The invention relates to deep-water low-temperature low-density early-strength cementing slurry for well cementation in petroleum drilling engineering, which contains 100 parts of low-temperature early-strength cement, 10 to 30 parts of low-temperature reinforcing material, 10 to 80 parts of low-density light-weight material, 0.5 to 4 parts of drag reducer, 2.5 to 8 parts of fluid loss additive, 0.1 to 5 parts of retarder, 0.15 to 1.2 parts of defoamer, 2.5 to 8 parts of early strength agent and 57 to 95 parts of water, and slurry with the density of 1.2g / cm3 to 1.7g / cm3 can be prepared. The slurry system at least has the following advantages that: the maximum early strength (24 hours) can reach 14.7MPa, the long-term strength stability is good, the static gelling transition time is short, and the system is stable. The invention provides technical support for the quality of deep-water well cementation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

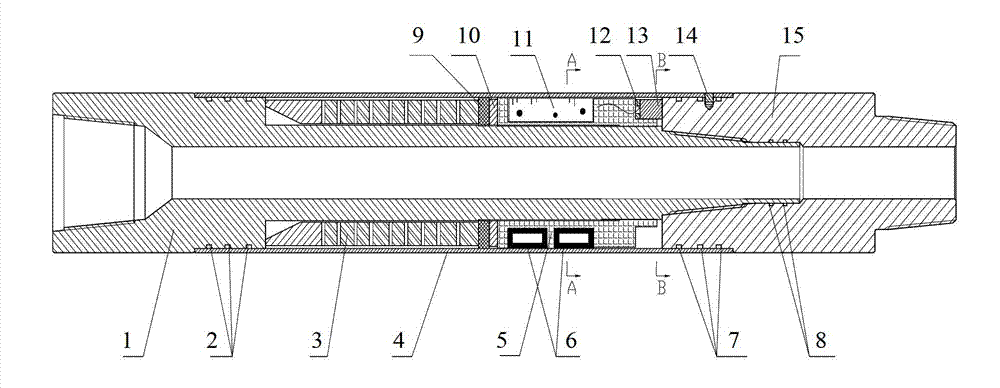

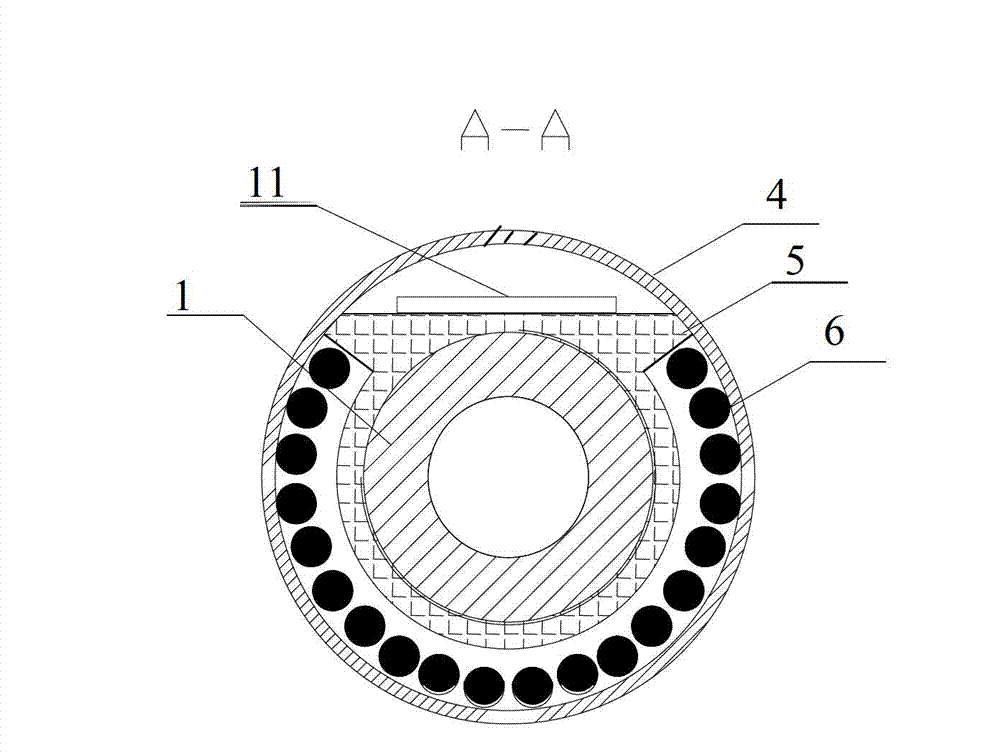

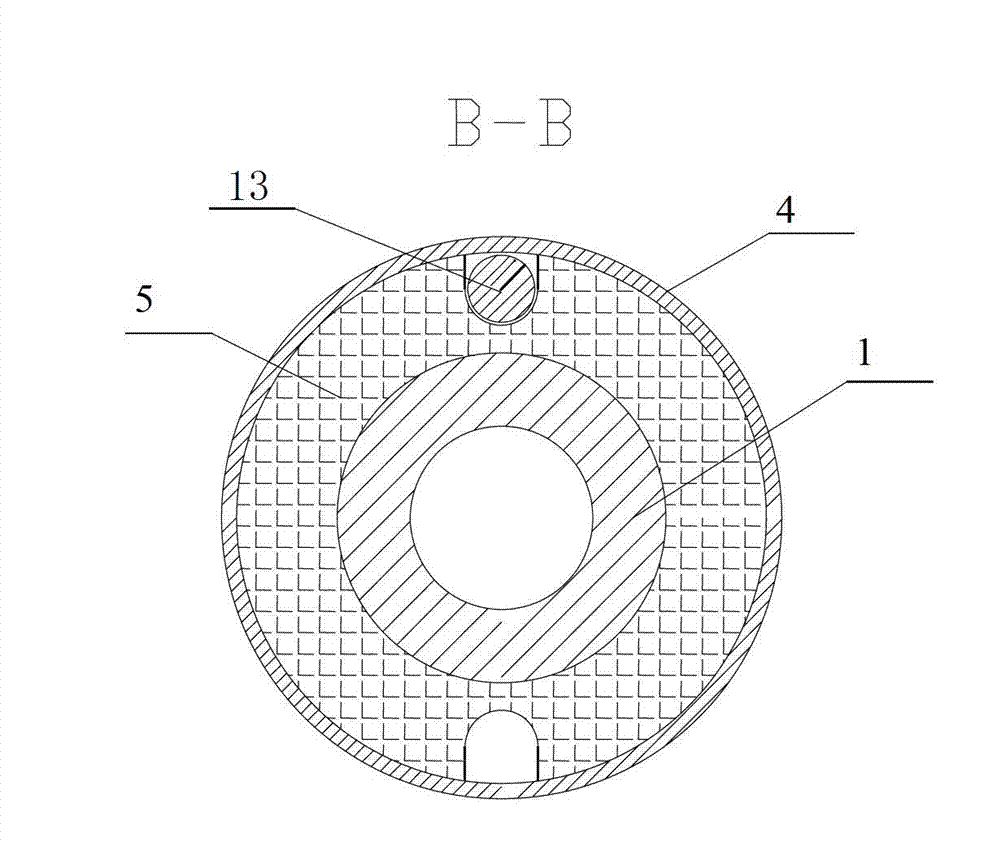

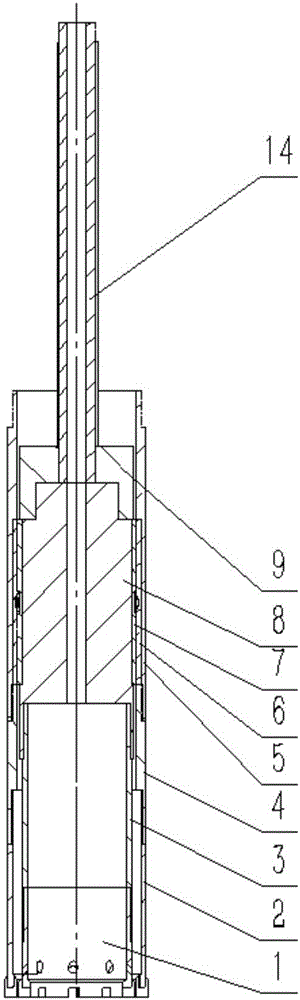

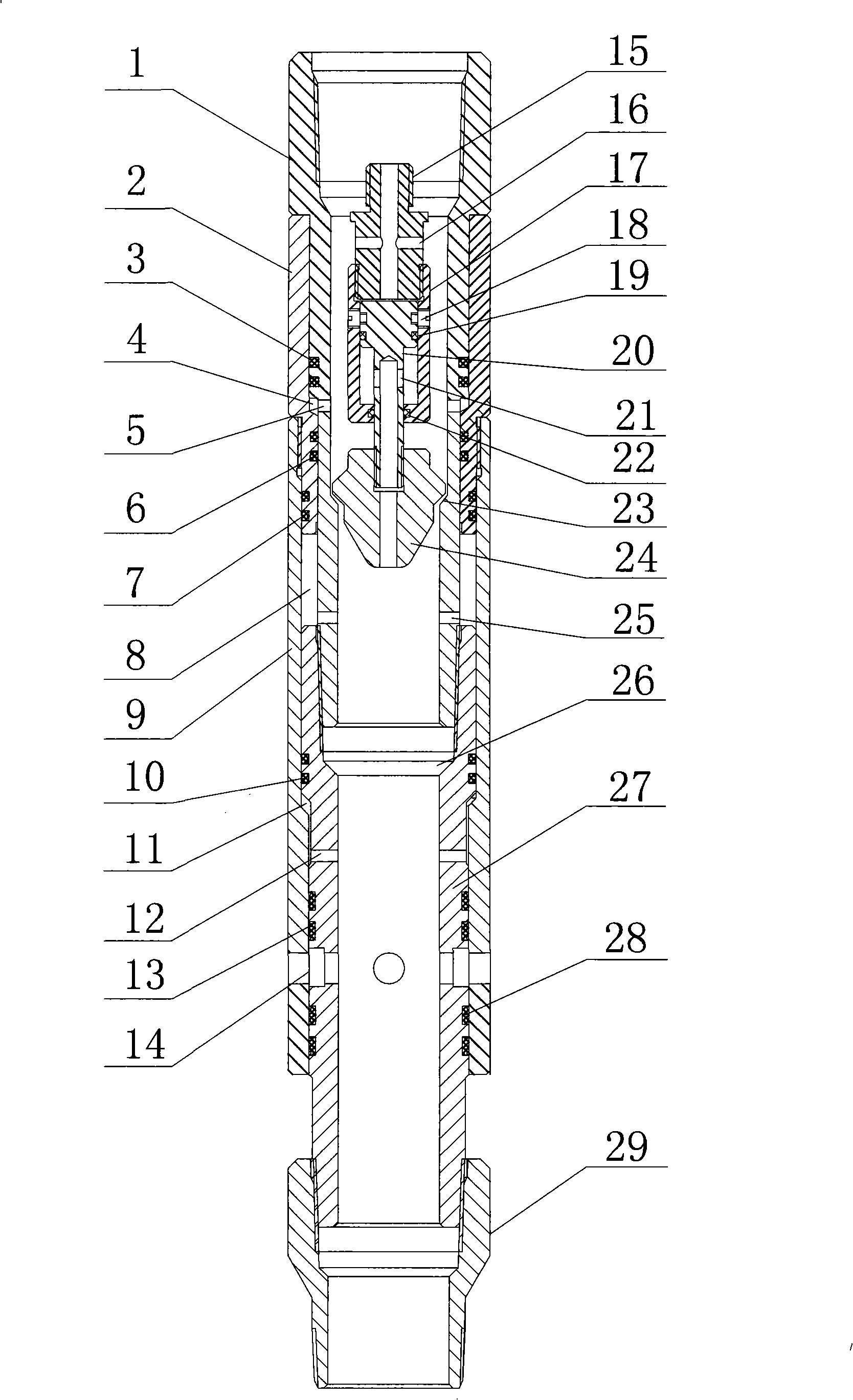

Well drilling information acoustic wave transmission relay device based on drilling string information channel

ActiveCN102733799AReduce distractionsImprove versatilitySurveyWell drillingSurface acoustic wave sensor

The invention relates to a drilling information transmitting device in the field of petroleum and natural gas drilling engineering, in particular to a well drilling information acoustic wave transmission relay device based on a drilling string information channel. The well drilling information acoustic wave transmission relay device comprises an acoustic wave sensor, a modulator circuit, a power source and a transmitting transducer assembly, wherein the modulator circuit receives electric signals outputted from the acoustic wave sensor; effective data are obtained after the electric signals are processed, and are transmitted to the transmitting transducer assembly; and the power source is used for supplying power for the acoustic wave sensor, the modulator circuit and the acoustic wave transmitting transducer assembly. The well drilling information acoustic wave transmission relay device can effectively work in an underground complex environment for a long time, the transmission distance of acoustic waves in a drilling string is lengthened, effective detection and directional signal transmission are ensured, and interference of a ring is decreased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

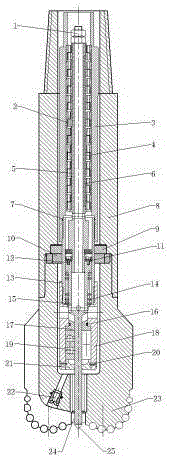

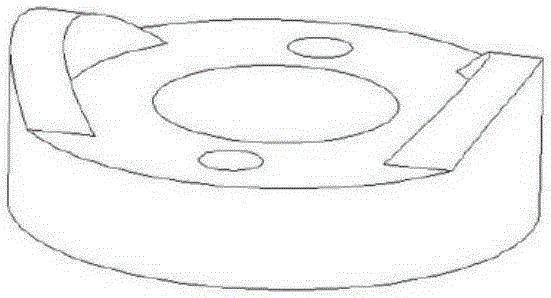

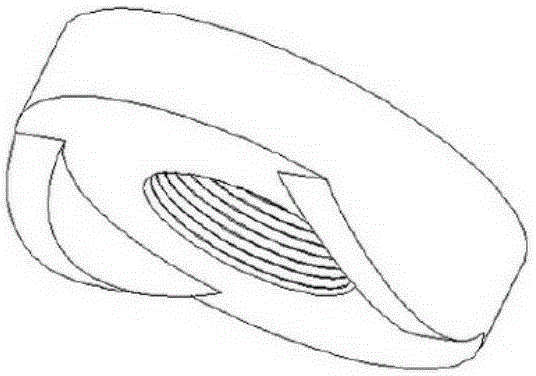

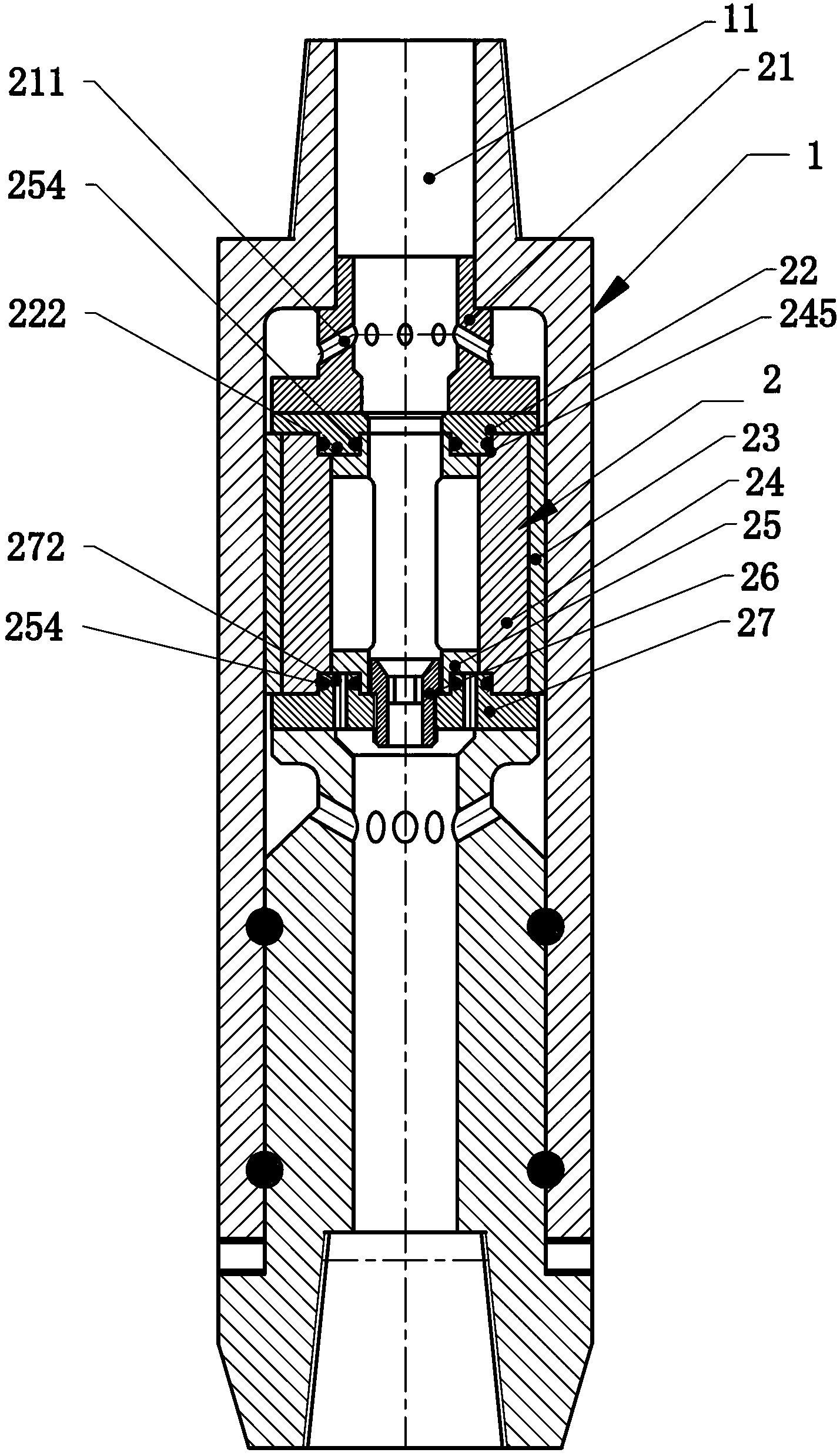

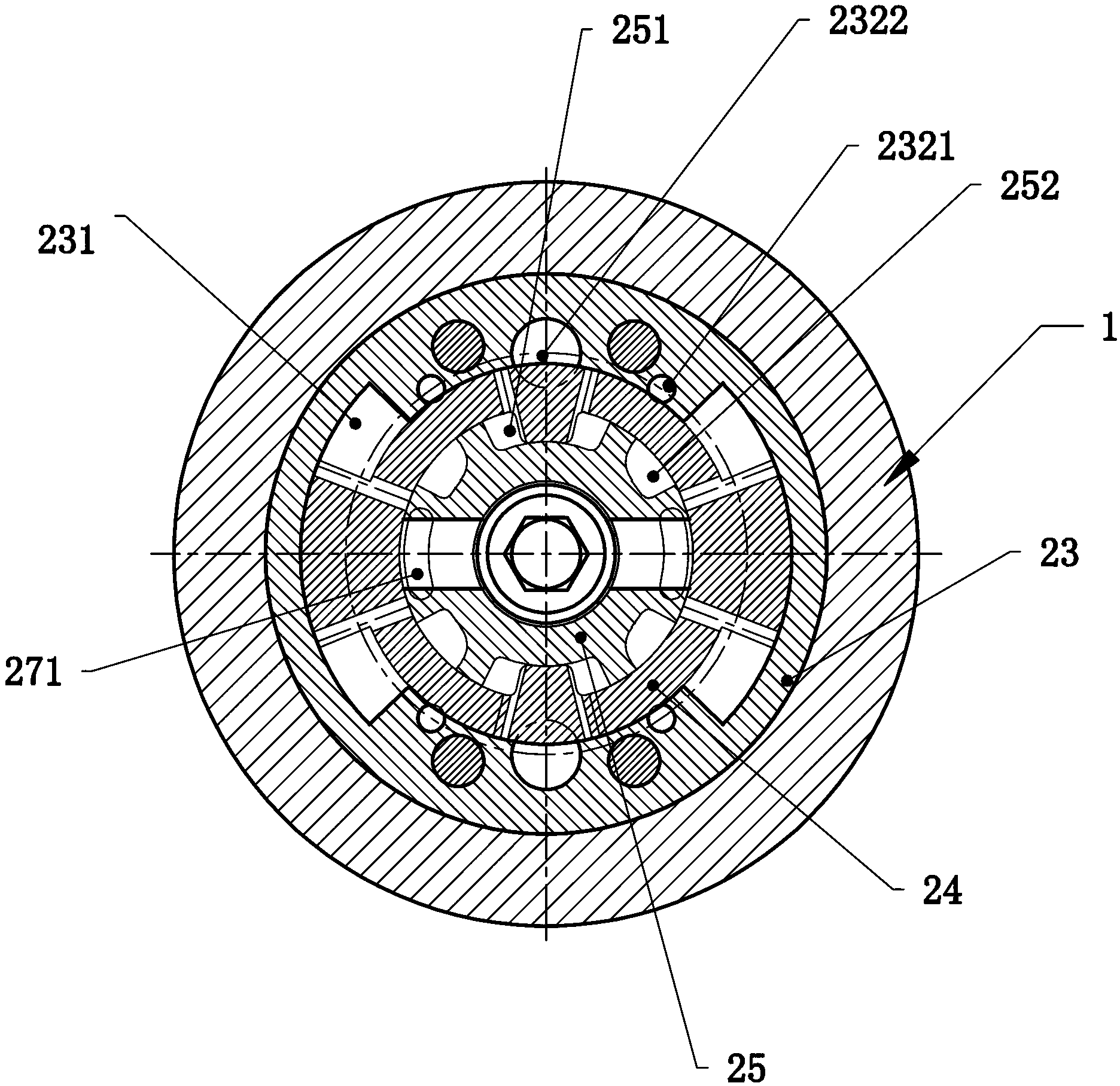

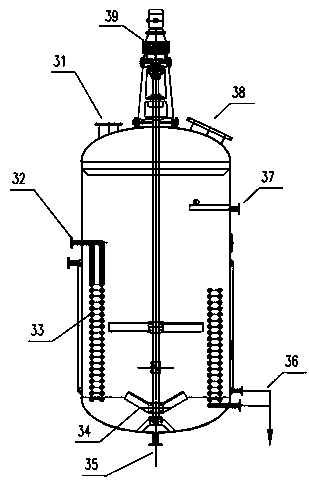

Torsional impact drilling tool

ActiveCN102454364ATorque stability and balanceReduce torsional oscillationsVibration drillingImpact hammerPetroleum engineering

The invention discloses a torsional impact drilling tool which can apply high-frequency torsion impact to a drilling bit in the drilling engineering. The technical scheme of the torsional impact drilling tool is as follows: the torsional impact drilling tool mainly comprises a short section of a drill collar, a torsional impact generator and a connecting body, wherein the short section of the drill collar and the torsional impact generator are in clearance connection through the connecting body and are located by splines; a diversion cover is fixed on a hammer seat; a cavity is formed inside the diversion cover; a closure nozzle, a sieve tube, a locating sleeve and an impact hammer are sequentially arranged in the cavity from inside to outside; the sieve tube is fixed with the hammer seat; the impact hammer, the locating sleeve, the sieve tube and the hammer seat are provided with through holes in the circumferential direction; and an impact hammer head and a starting hammer head are processed on the impact hammer. The torsional impact drilling tool is arranged between the drill collar and the drilling bit; and the drilling bit receives the high-frequency torsional impact generated by the impact hammer under the driving of fluids while receiving the rotational torsion of a drill column. Compared with other drilling tools, the torsional impact drilling tool disclosed by the invention has the advantages that the high-frequency torsional impact can be generated, the sticking-sliding phenomenon of the drilling bit is eliminated, the mechanical drilling rate of harder or abrasive formation is increased, the service life of matched components, such as the drilling bit and the like of the drill column is prolonged, the drilling efficiency is improved and the drilling cost is reduced.

Owner:CHINA PETROCHEMICAL CORP +3

Multi-element synergic plugging agent and application thereof

ActiveCN104232039AReduce penetrationLimit penetrationDrilling compositionStrong bindingUltimate tensile strength

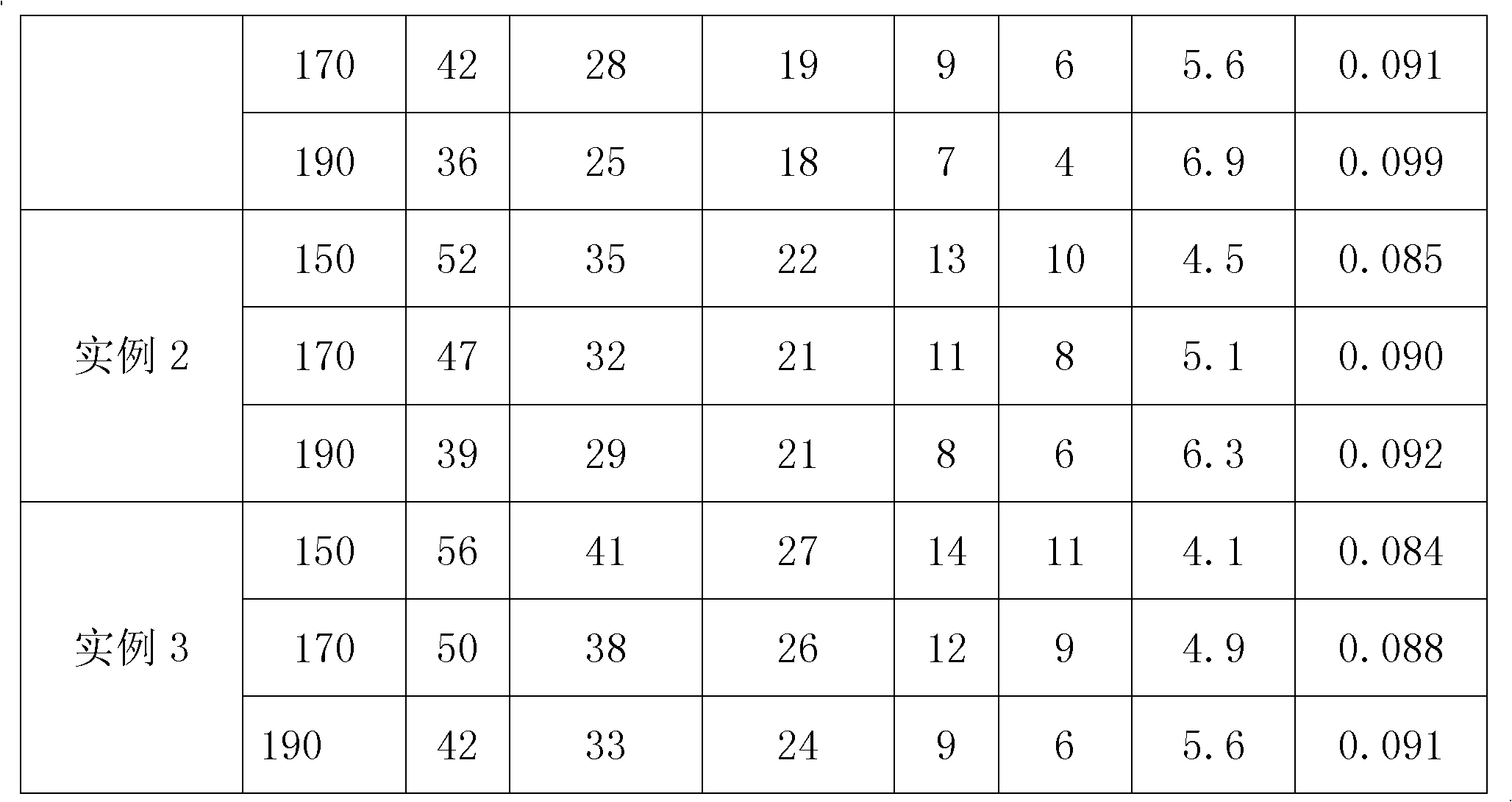

The invention provides a multi-element synergic plugging agent and application thereof. The multi-element synergic plugging agent comprises the component 1 or the component 2, wherein the component 1 comprises the following components in parts by weight: 40-50 parts of rigid particles, 15-20 parts of a flexible material, 15-20 parts of an ultrafine filling material, and 15-20 parts of an expansive type polymer: the component 2 comprises the following components in parts by weight: 50-70 parts of rigid particles, 10-25 parts of a flexible material, 10-25 parts of an ultrafine filling material, and 10-30 parts of an expansive type polymer. The multi-element synergic plugging agent disclosed by the invention combines the rigid material with the flexible material, incorporates the elastoplasticity, fully utilizes the synergistic function of the materials, can effectively plug the cracks with different widths, has the performances of high bearing strength, high temperature resistance, deformability and strong binding powder of the cracked stratum, and can be applied to the leaking stoppage operation for the drilling engineering to solve the leakage problem at different degrees.

Owner:PETROCHINA CO LTD

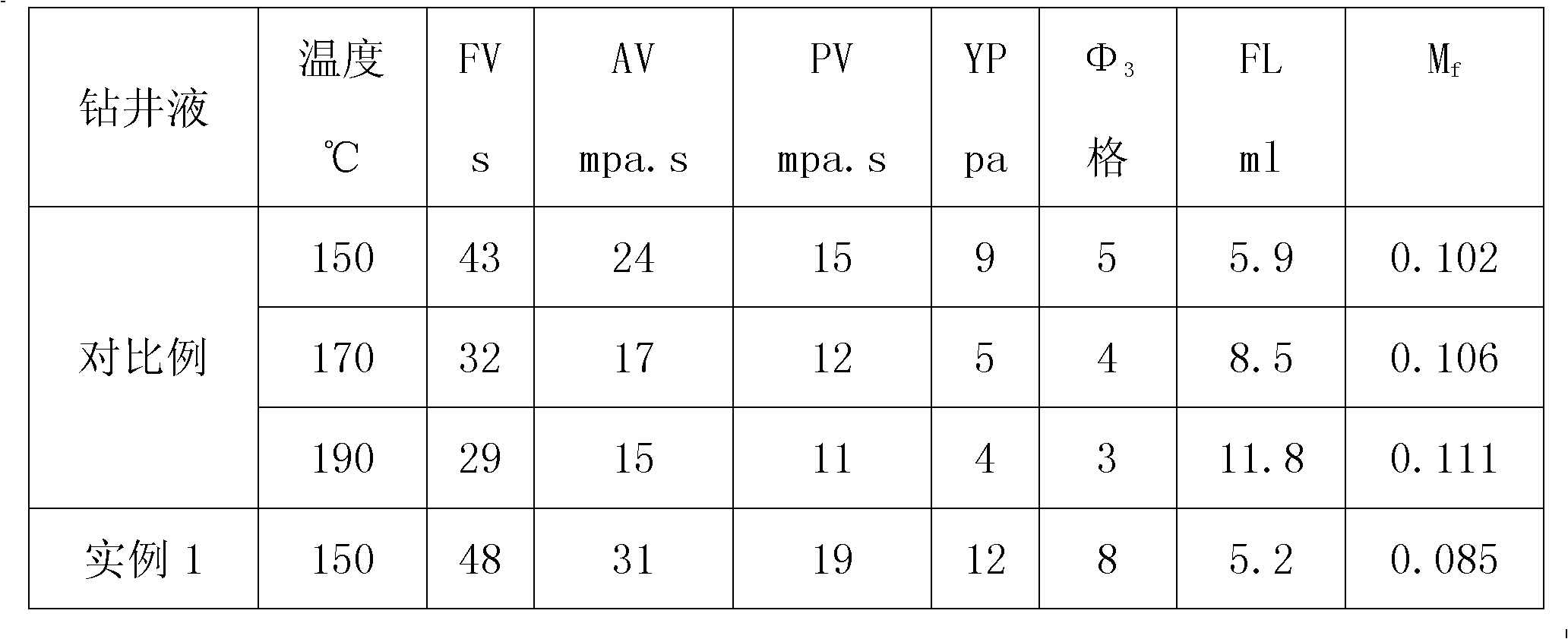

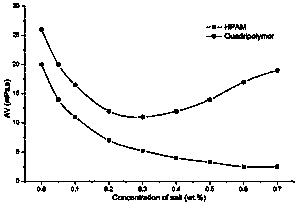

Polyamine drilling fluid

ActiveCN102391842AImprove rheologyImprove high temperature resistanceDrilling compositionWell drillingPetrochemical

The invention belongs to the field of petrochemical drilling technology, and relates to polyamines drilling fluid used in the petroleum drilling process. The polyamines drilling fluid mainly contains 0.1-5% of shale inhibitor, 0.1-5% of fluid loss additive, 0.1-5% of coating agent, 0.1-5% of lubricating agent, 0-5% of thickening agent, 0-5% of plugging agent, 1-10% of slurry compounding soil, and pH regulator and weighting agent which are blended and added according to the need; and the polyamines drilling fluid also contains the balance of water used for preparing the drilling fluid. The polyamines drilling fluid has stronger capability of inhibiting hydrous expansion and hydrous disintegration of bentonite, has good rheological property and high-temperature resistance, and is applicable to oil reservoir and oil gas drilling engineering with high water sensitivity and higher clay content.

Owner:CHINA PETROCHEMICAL CORP +1

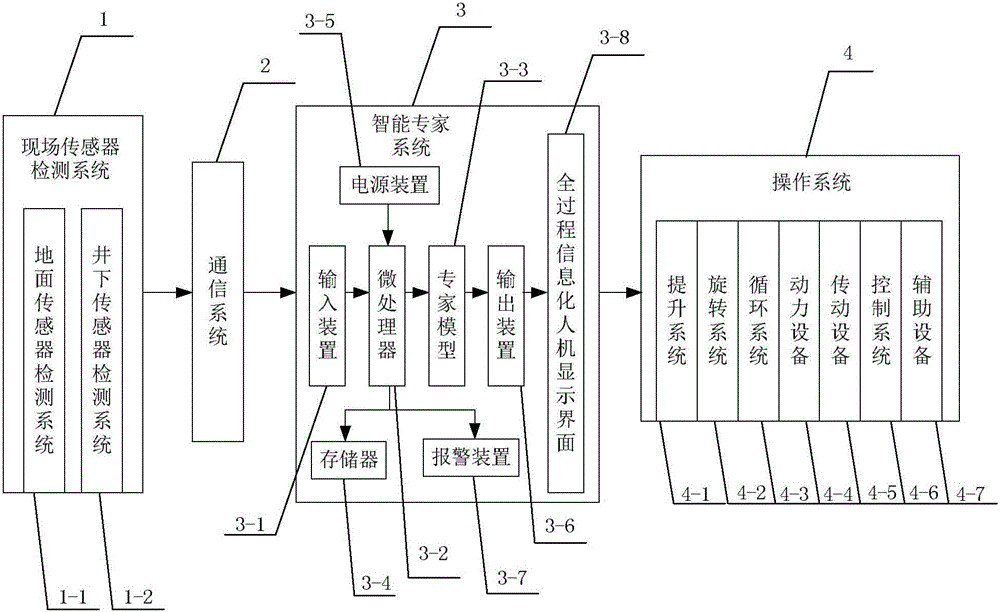

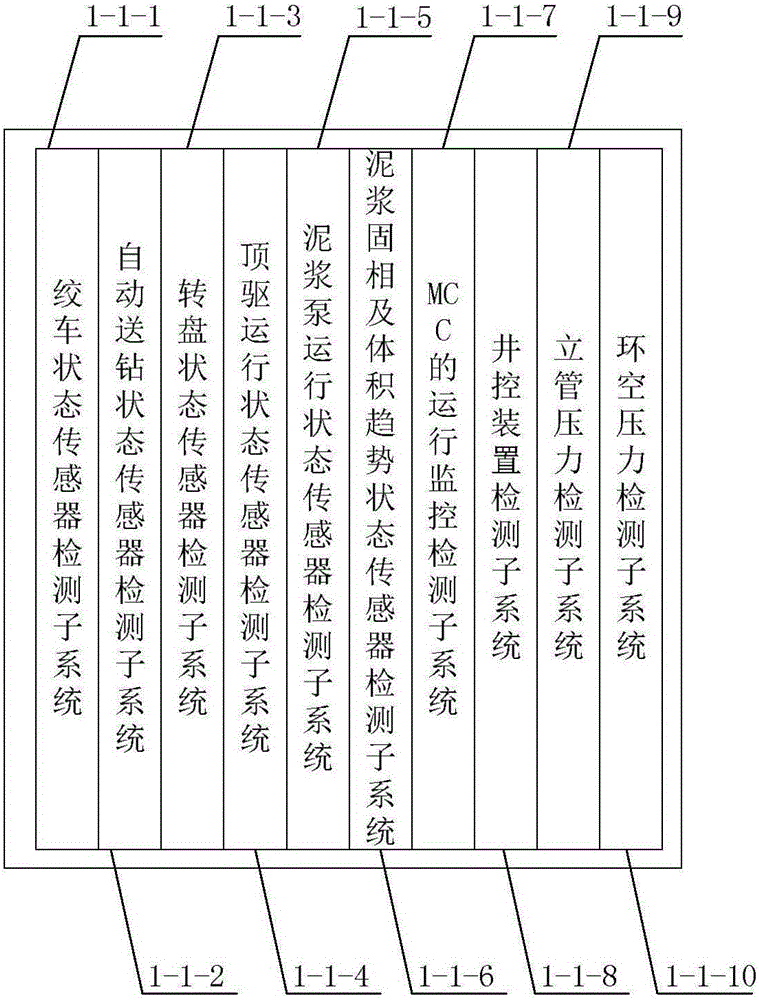

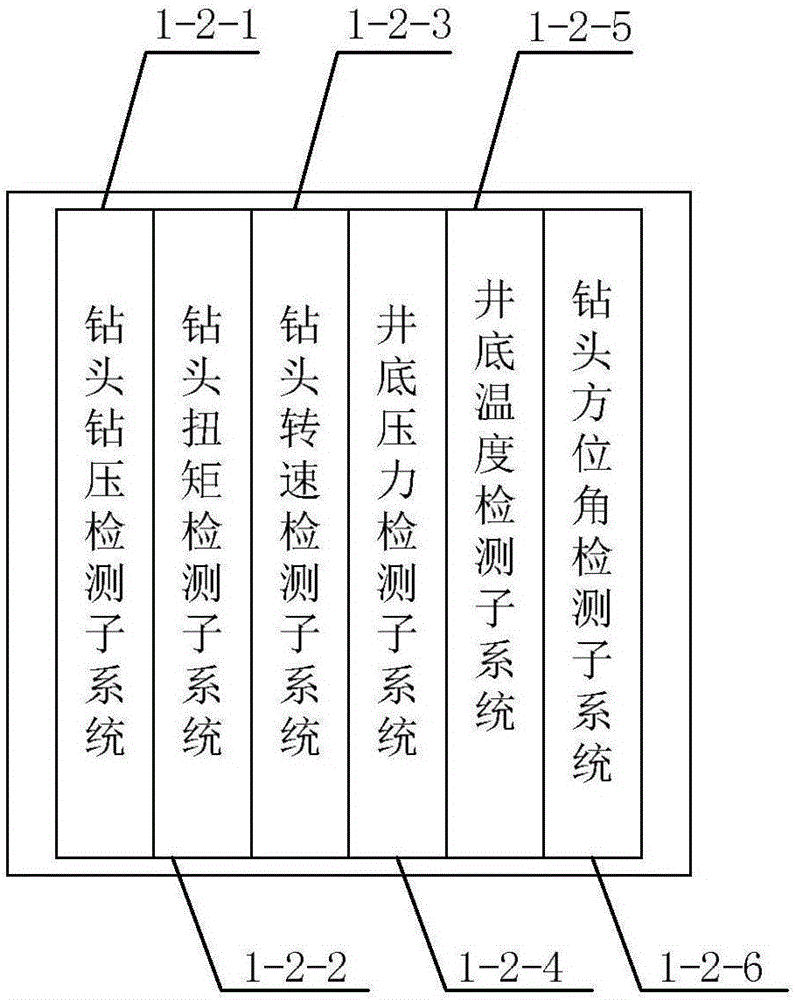

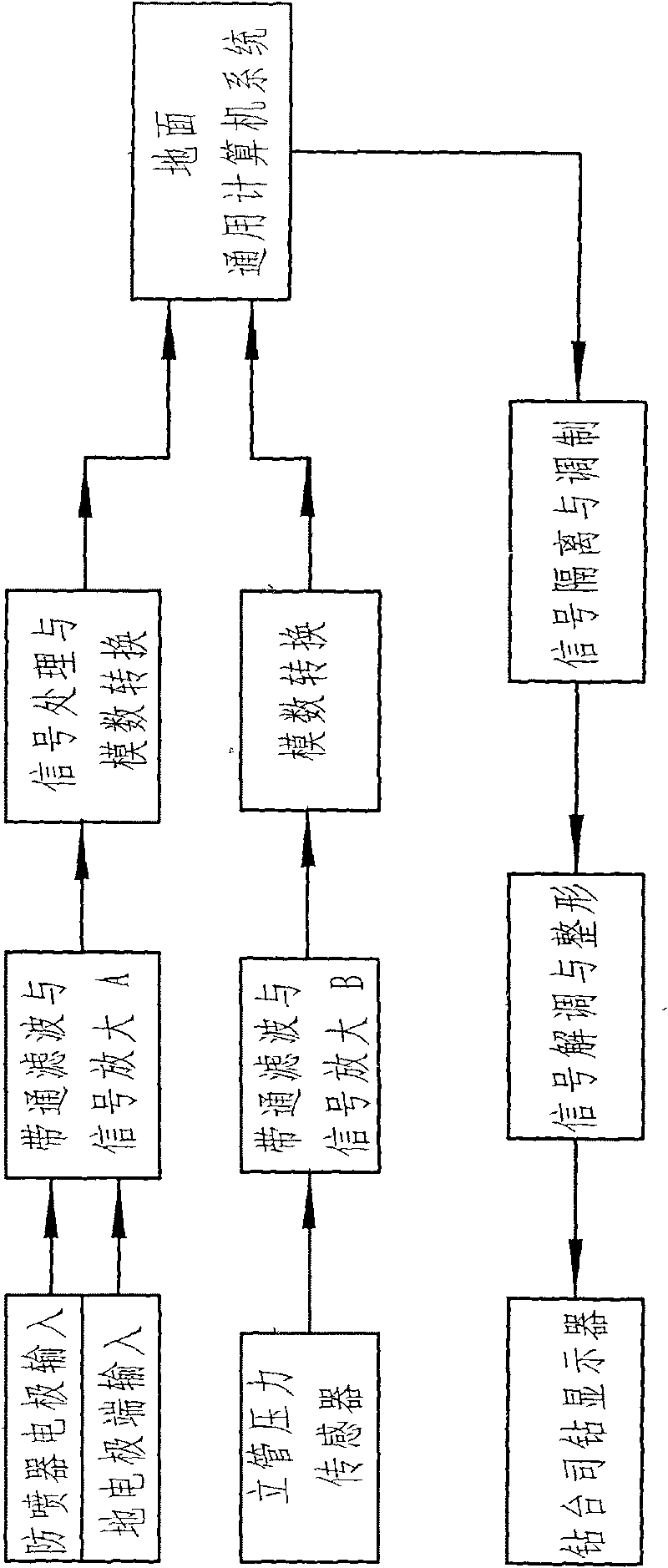

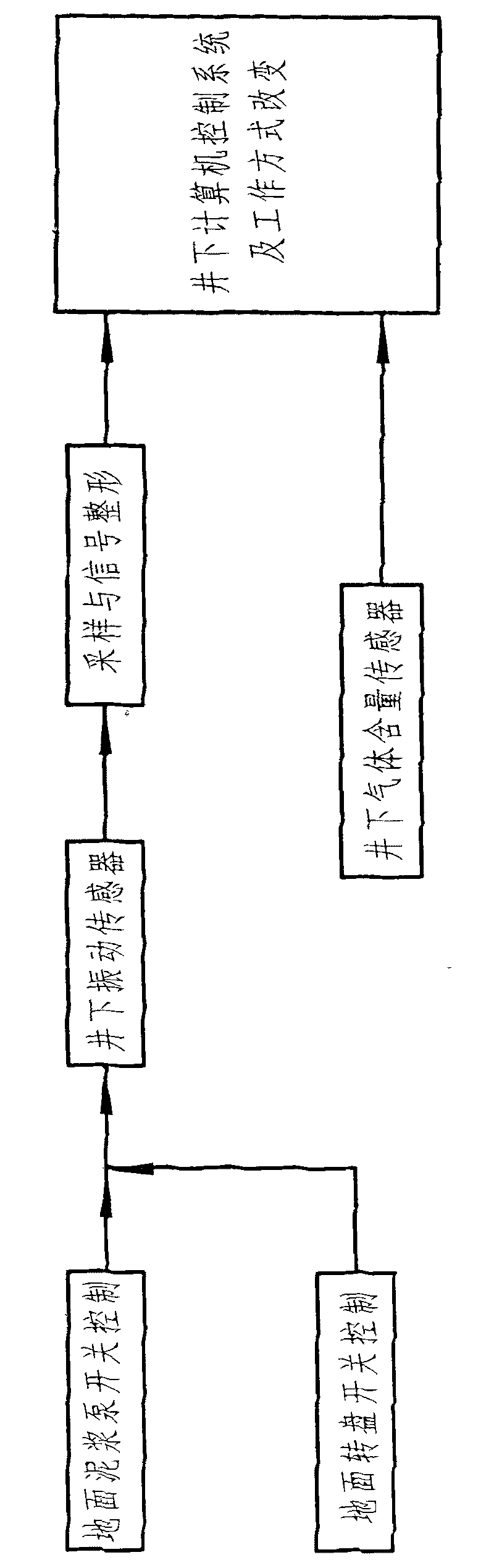

Intelligent well drilling expert system

InactiveCN106121621AAccurate discoveryReal-timeAutomatic control for drillingCommunications systemAutomatic control

The invention discloses an intelligent well drilling expert system. The intelligent well drilling expert system comprises an on-site sensor detection system, a communication system, an intelligent expert system and an operation system. The on-site sensor detection system is connected with the intelligent expert system through the communication system, the intelligent expert system is connected with the operation system, and thus the automatic closed loop well drilling adjusting and controlling system is formed. The on-site sensor detection system acquires data of the whole well drilling process. The acquired data are transmitted to the intelligent expert system through the communication system, so that processing monitoring, forecasting, analyzing, controlling and processing are conducted, and finally the operation system executes an operation instruction sent by the intelligent expert system after analyzing. The intelligent well drilling expert system can achieve real-time performance and the functions of early finding, early forecasting, explanation at any time and automatic control, and not only provides accurate information for well drilling engineering but also has the advantages of reducing well drilling cost, increasing well drilling speed, completely preventing accidents, and finding oil and gas accurately.

Owner:SOUTHWEST PETROLEUM UNIV

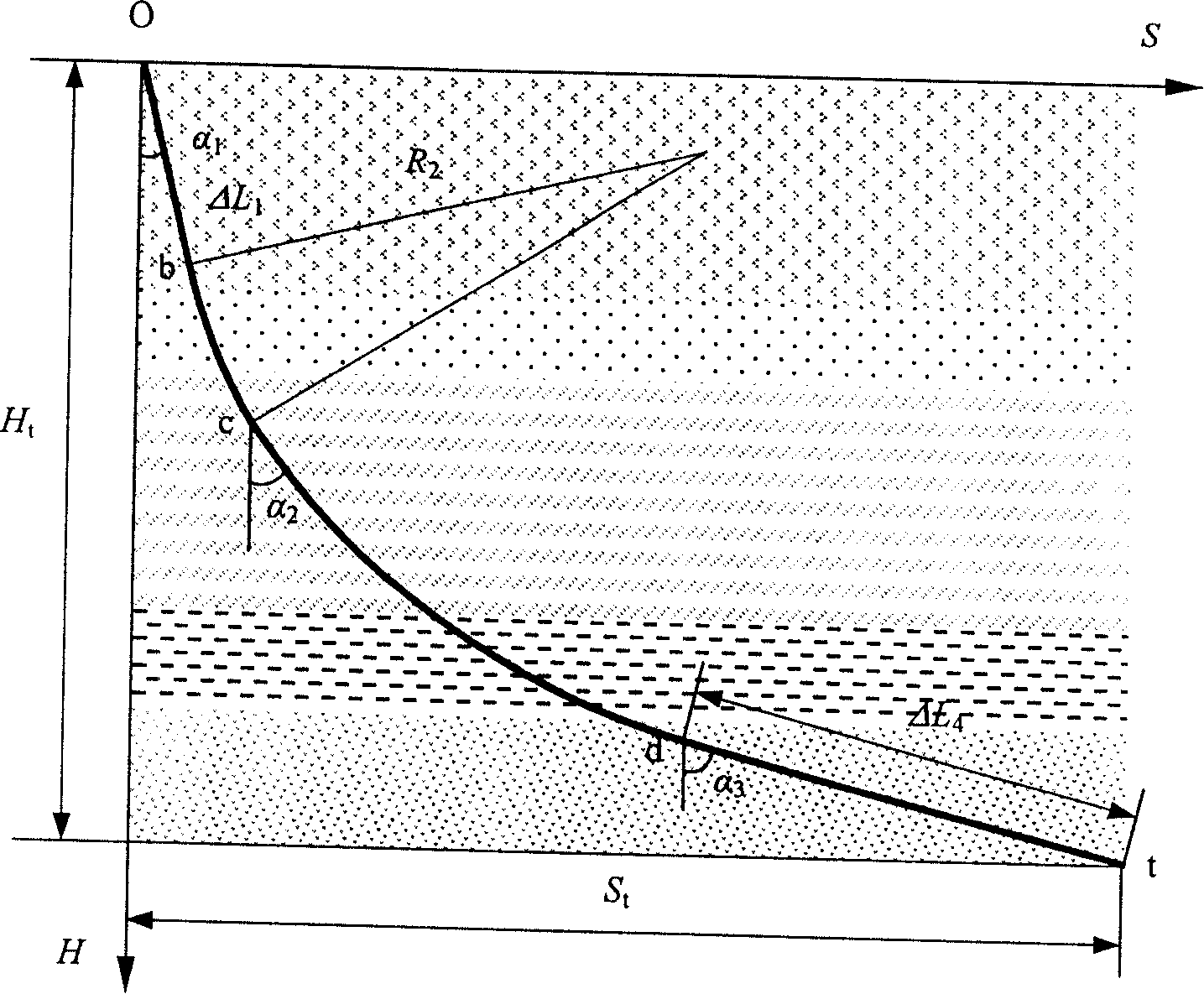

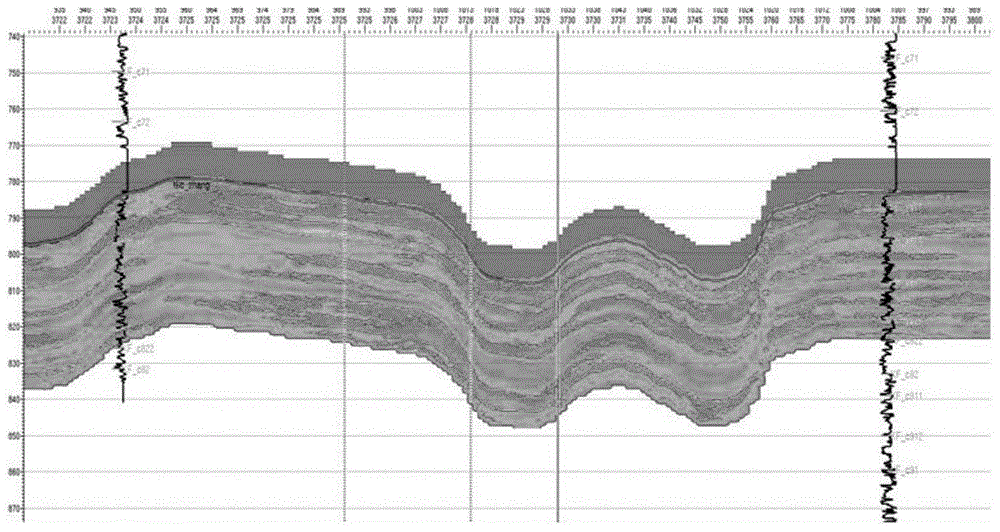

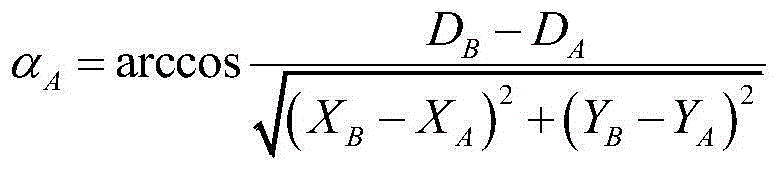

Monitoring method for drilled wellbore trajectories

InactiveCN101387198AIn line with the actual situationImprove monitoring accuracySurveyTracking modelHorizontal wells

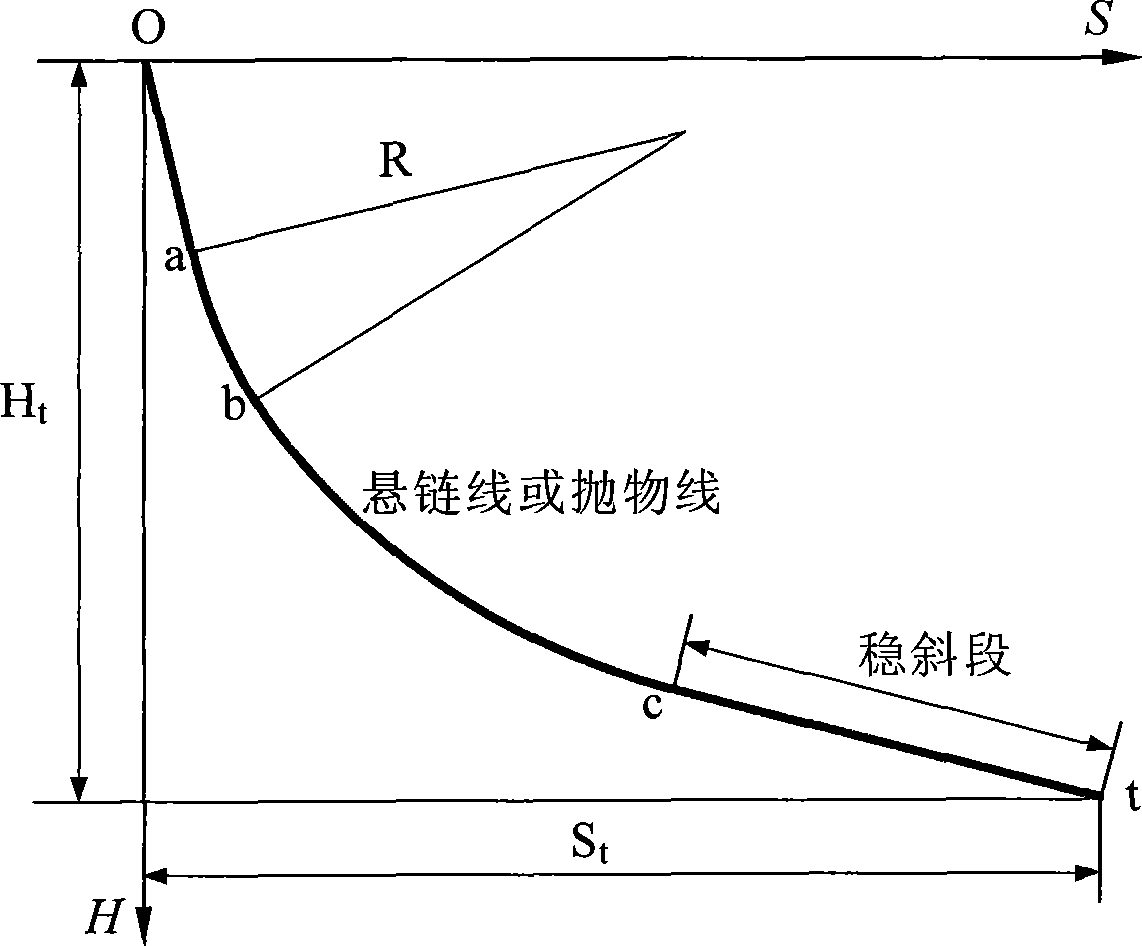

The invention relates to a drilling engineering technology in petroleum engineering, in particular to a method for monitoring the track of an actually drilled wellbore. The method comprises the following steps: acquisition of inclination survey data and naturalization treatment; determination of characteristic parameters of a wellbore track model; determination of a hole inclination equation and an azimuth equation; calculation of coordinate increment; calculation of surveying point coordinates; and so on. As for large-displacement wells containing catenary or parabola tracks and various directional wells and horizontal wells, the method can accurately monitor the coordinates of various surveying points, so as to make the monitoring result accord with the practice of the drilling engineering, thereby effectively improving the construction precision and the reliability of catenary drilling and parabola drilling.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polymer drilling fluid with high temperature resistance

InactiveCN102851011AImprove rheologyImprove fermentation performanceDrilling compositionTemperature resistancePetroleum

Owner:YANGTZE UNIVERSITY

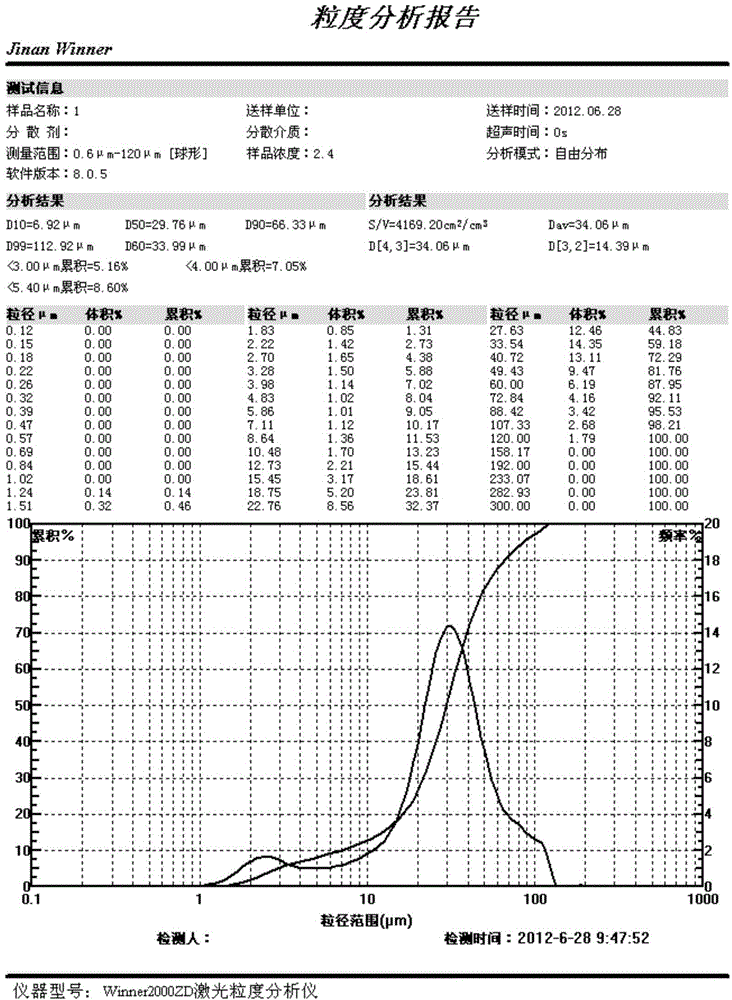

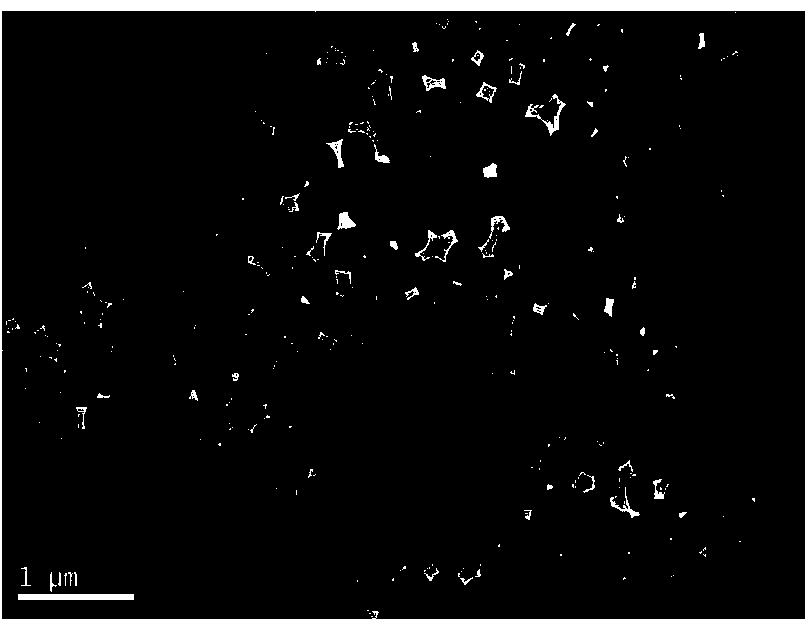

Preparation method of while-drilling plugging fluid for oil-based drilling fluid

ActiveCN104448136AGood compatibilityNo change in rheological propertiesDrilling compositionSludgeWell drilling

The invention relates to a preparation method of a while-drilling plugging fluid for oil-based drilling fluid, belonging to the technical field of drilling fluid treatment in petroleum drilling projects. The preparation method of the while-drilling plugging fluid for oil-based drilling fluid comprises the following steps: dropwise adding an aqueous phase which contains a propylene water-soluble organic monomer A, a water-soluble crosslinking agent B and a powder-like organic material C into oil D which contains a dispersing agent E; and after emulsification, initiating by using an oxidation-reduction initiating system to obtain a stable suspension plugging agent. According to the while-drilling plugging fluid, a deformation function is realized, the fluid has good compatibility with the oil-based drilling fluid, and can resist the temperature which reaches 150 DEG C, the particle size is 1 micron-100 microns, and the permeable loss of the nano-micron-grade cracks and pores in oil-based sludge drilling can be rapidly and effectively blocked, so that the drilling operation cost is reduced; and according to the oil-based while-drilling plugging agent prepared through the method, drying and granulation are not needed, and the agent can be directly used for while-drilling plugging in the oil-based drilling fluid, and is convenient to use and easy to popularize.

Owner:CHINA PETROCHEMICAL CORP +1

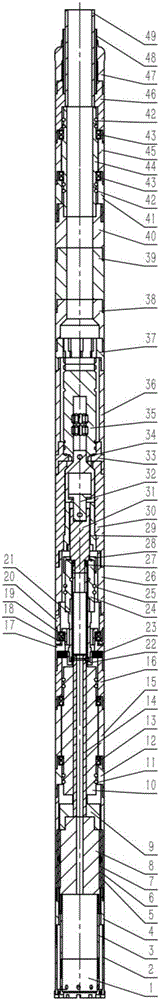

Downhole torque self-balance cable drilling tool system

ActiveCN106761480ARealize disturbance drillingDisturbance reachesSurveyDrill bitsWell loggingWell drilling

The invention relates to a downhole torque self-balance cable drilling tool system, and belongs to the technical field of drilling engineering equipment. The drilling tool system is composed of an inner and outer drill bit assembly, a power assembly, an inner and outer drill bit pressure adjustment system, a slurry circulation system and a blockage release system. An inner drill bit and an outer drill bit are used for crushing rock in a reverse rotation mode, and micro-disturbance drilling of surrounding rock is realized. A stator set and a rotor set of a power motor are used for driving the outer drill bit and the inner drill bit separately, the drill bits and a power system realize torque self-balance overall, and no torque action is generated on an upper drilling tool. A power source, the slurry circulation system, a logging system and the like are integrated to the drilling tool, and normal operations such as drilling, trip-out and trip-in operation and well logging during drilling can be realized on the ground only through winch equipment for drilling tool trip-out and trip-in. When drilling blockage occurs, the drilling tool is lifted up through a winch, and through forward and reverse alternate rotation of a blockage release drill bit, rock granules at the blockage position are removed to realize blockage release.

Owner:JILIN UNIV

Oil-based drilling fluid for development drilling of shale gas

ActiveCN103614122AGood application effectHigh ratio of dynamic plasticDrilling compositionOil phasePetroleum

The invention relates to an oil-based drilling fluid for development drilling of a shale gas, and belongs to the technical field of drilling fluids for petroleum drilling engineering. The oil-based drilling fluid is characterized by being prepared from the following components by weight percent: 0.2% to 2% of main emulsifier, 0.1% to 1% of auxiliary emulsifier, 0% to 1.5% of wetting agent, 0.2% to 1.5% of alkalinity regulating agent, 0% to 1.5% of organic soil, 0% to 1.5% of tackifier, 0.2% to 2% of filtrate reducer, 0% to 80% of weighting agent, 0% to 20% of water phase and the balance of oil phase. The oil-based drilling fluid can be used for meeting a special requirement of the shale gas drilling to the drilling fluid, and is good in stability, inhibitory capability and lubricity even under low and high temperatures. The oil-based drilling fluid has the characteristics of high dynamic plastic ratio, low plastic viscosity, wide application range and good economic benefit.

Owner:JINGZHOU JIAHUA TECH

Strong inhibition type anti-collapse foam liquid for drilling

InactiveCN101798499AIncreased water carrying capacityPrevent immersionDrilling compositionFoaming agentCarrying capacity

The invention relates to foam liquid for drilling, in particular to strong inhibition type anti-collapse foam liquid for drilling, which is characterized by being prepared with the following components in parts by weight: 0.09-0.11 part of foam stabilizer, 0.36-0.44 part of foaming agent, 2.34-2.86 parts of anti-collapse agent, 2.7-3.3 parts of fluid loss additive and 94.51-93.29 parts of water. When complex situations such as formation water occur to gas drilling, the foam liquid of the invention can effectively improve the rock carrying capacity and the water carrying capacity and simultaneously protect the stability of the upper well wall. Laboratory studies shown that the foam liquid has high foaming capacity, the foaming capacity is more than or equal to 500 percent, the half-life is moderate, and the foam liquid can be easily controlled and is conducive to drilling engineering construction.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

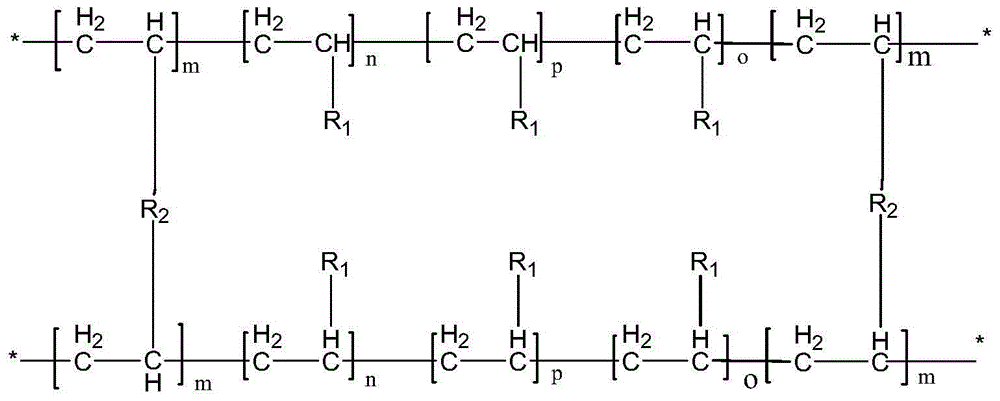

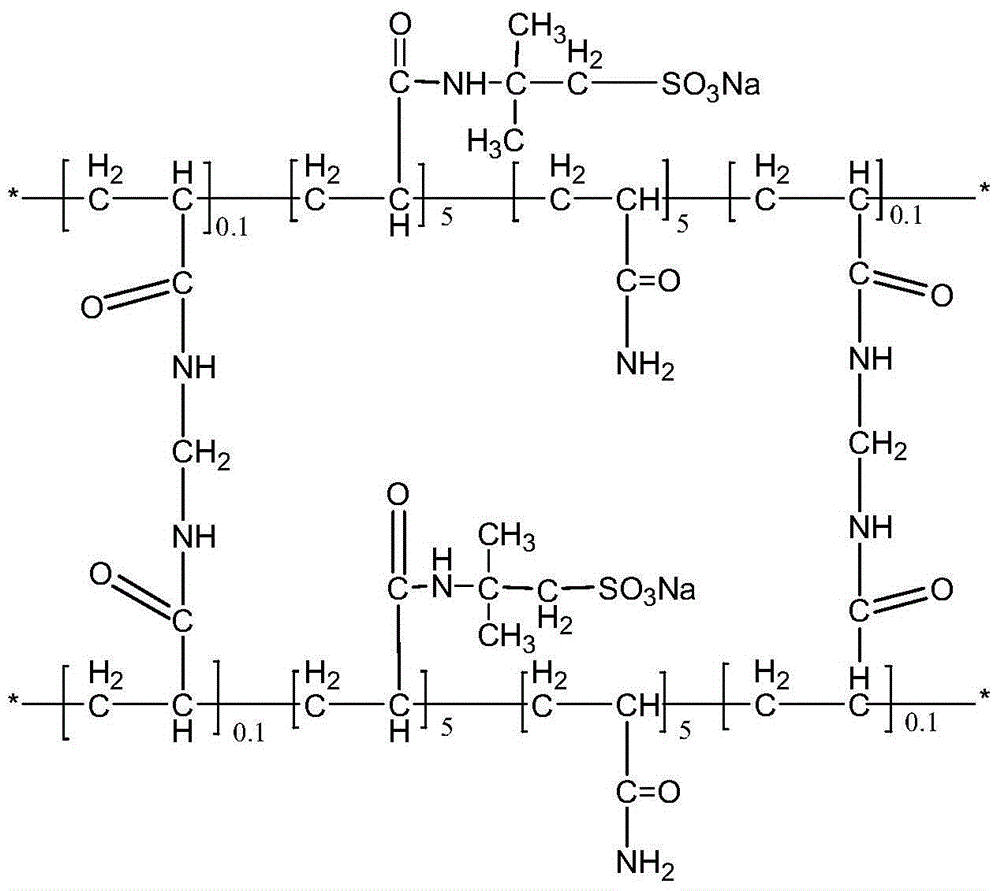

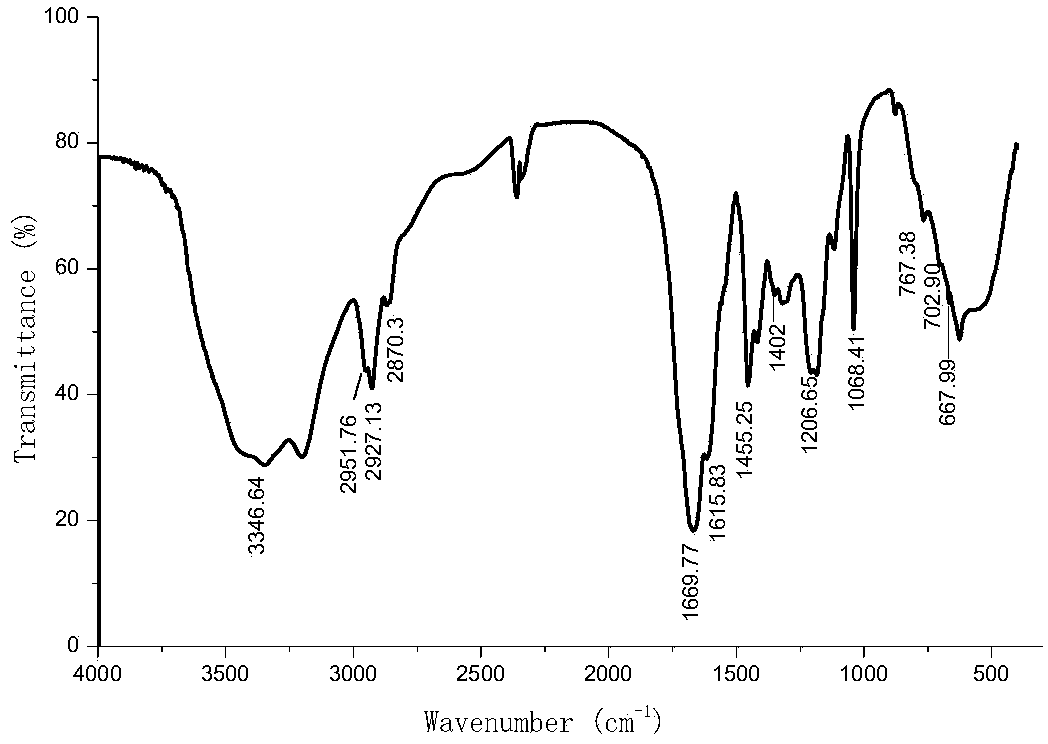

Polymer nano-silica temperature-resistant, salt-tolerant and fluid loss reducing agent and preparation method thereof

InactiveCN103525379ANew features of strong high temperature resistanceGood temperature and salt resistanceDrilling compositionPolymer scienceEmulsion polymerization

The invention discloses a polymer nano-silica temperature-resistant, salt-tolerant and fluid loss reducing agent and a preparation method thereof. According to the preparation method, in the presence of nano-silica, a polymer-base nanometer composite material with amphiphilic block hydrophobic associating polymer wrapping inorganic nano-silica is successfully synthesized by virtue of a micellar emulsion polymerization method and combines the rigidity and the heat stability of the inorganic nano-silica and the characteristics of the amphiphilic block hydrophobic associating polymer together, and the temperature resistance, the salt tolerance and the thickening property of the polymer are obviously improved by virtue of the polymer-base nanometer composite material on the basis of the existing good performances of the amphiphilic block hydrophobic associating polymer. As a temperature-resistant, salt-tolerant and fluid loss reducing agent for a drilling fluid in the drilling engineering, the polymer nano-silica temperature-resistant, salt-tolerant and fluid loss reducing agent has a remarkable fluid loss reducing effect under high temperature and high salinity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

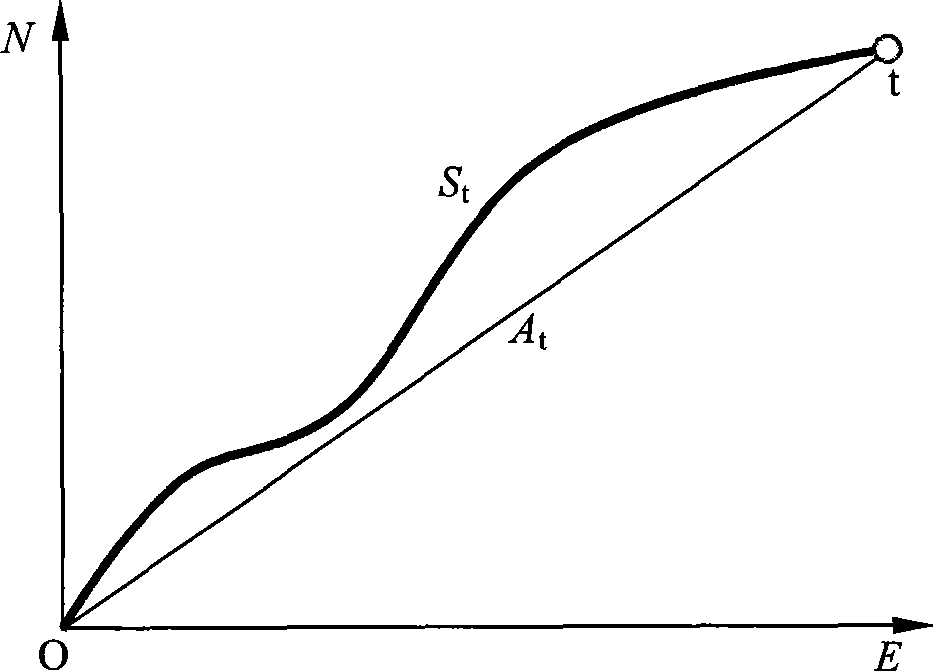

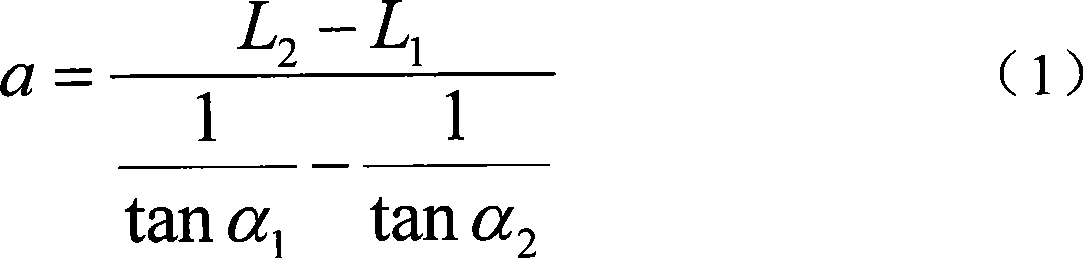

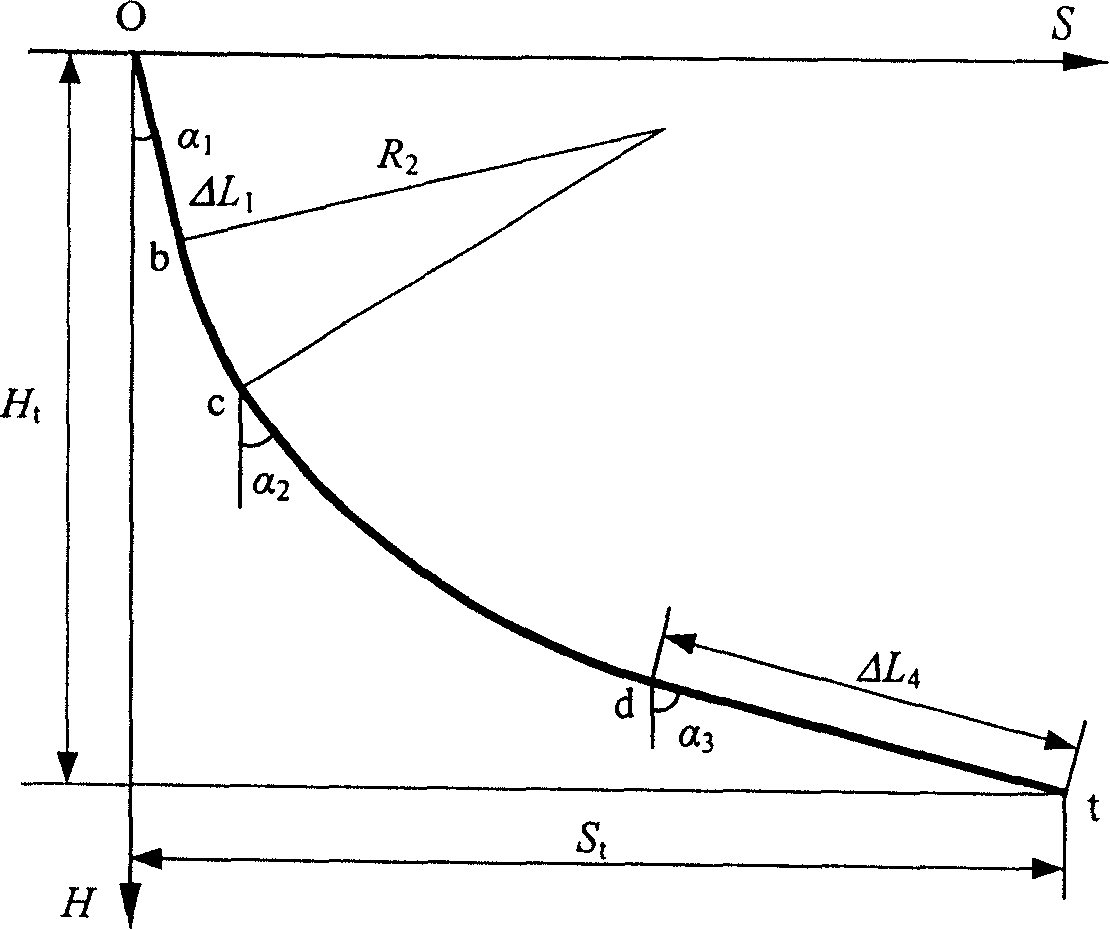

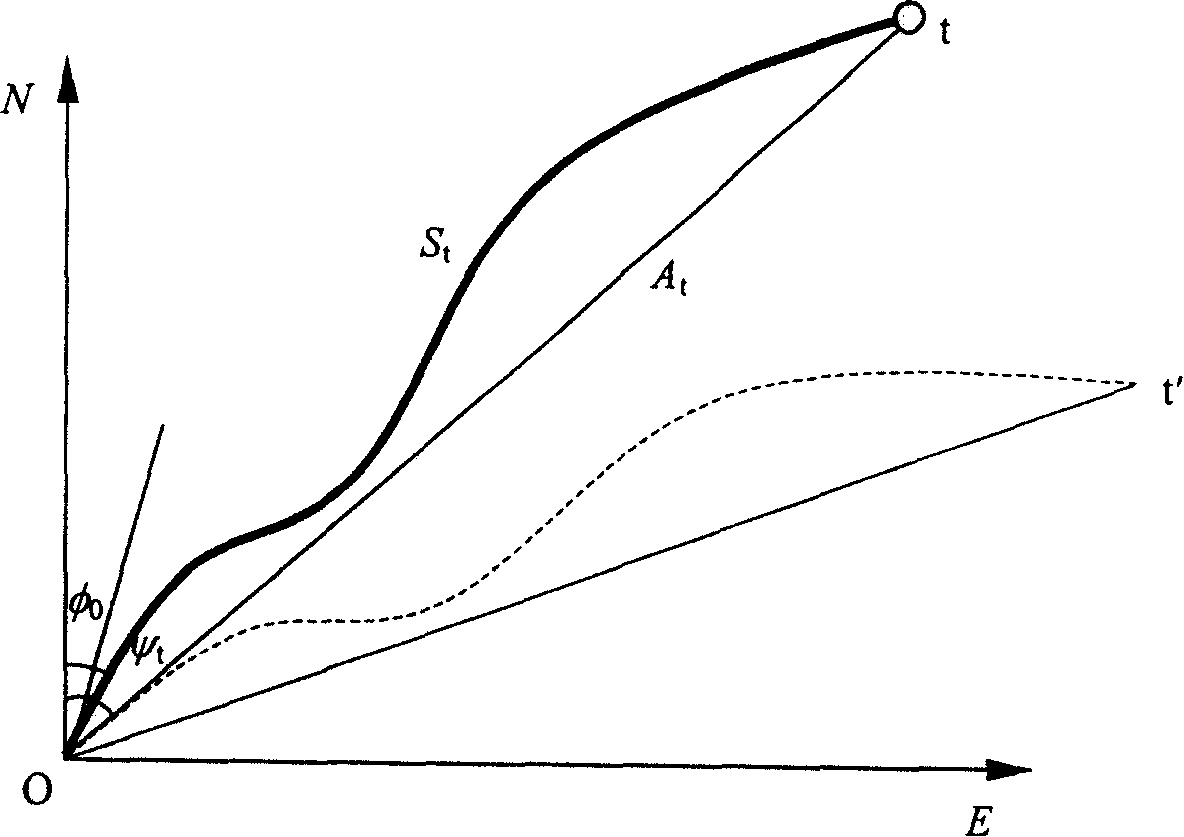

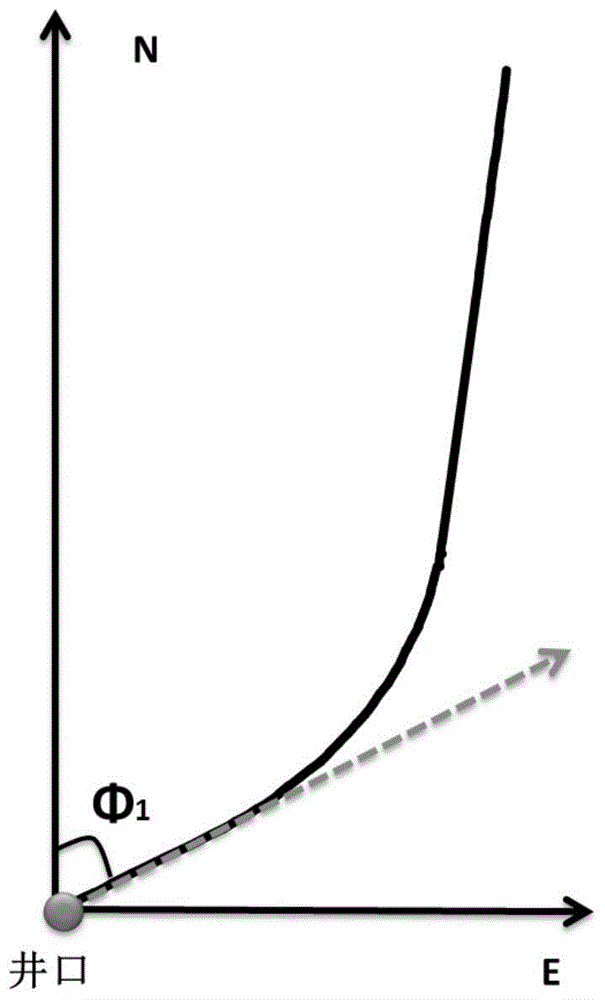

Funicular curve well drilling rail design method using stratum natural deflecting rule

ActiveCN101173598AIn line with formation conditionsRealize the designDirectional drillingSection planeThree stage

The invention relates to a drilling engineering design in the petroleum drilling engineering, in particular to wellbore trajectory optimized design and control in the highly-displacement well. For three-stage and four-stage catenary sections, the design of wellbore trajectory is finished through 12 steps. The invention puts forward a new method of two-dimensional catenary trajectory design. A plurality of units with different azimuth wander ratio is divided according to natural deviating rule of formation, which is combined to the formation condition that conforms to the actual situations of drilling engineering. On the basis of maintaining the characteristics and advantages of catenary trajectory and regarding to the influence of natural deviating rule of formation, a method of three-dimensional catenary trajectory design is put forward, which can not only scientifically work out the azimuth lead angle and initial azimuth, but also work out the trajectory parameters of every point inthe wellbore trajectory. The realization of three-dimensional wander trajectory design of catenary section has real meaning of guidance for the drilling design and construction of the highly-displacement well. The invention is used in the field of petroleum and geological exploration.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel PDC drill bit utilizing impact effect for improving heart rock breaking efficiency

The invention belongs to the field of technical equipment used in oil and natural gas drilling engineering, mine exploiting, geological drilling, constructional engineering, tunnel engineering, shielding and non-excavation, and relates to a novel PDC drill bit utilizing the impact effect for improving heart rock breaking efficiency. The PDC drill bit solves the problems that in the drilling process, a center rock column left in the center part influences drilling efficiency, and the position deviating from the center of a well hole shakes left and right. According to the technical scheme, the upper end of a turbine is fixed through a nut, the lower end of the turbine is fixed through a boss on a turbine shaft, an upper cam is connected to the turbine shaft through threads, a lower cam is fixed to a punch hammer through a sunk screw, the upper section of the punch hammer is hollow, a pore passage enabling drilling fluid to flow out is formed in the upper end of a shell on the lower portion, a pressing head with the top end provided with a tip-shaped PDC tooth is added to the tail end of a connecting cavity, as a main impact part, the lower end of the punch hammer becomes thin, and a bi-directional thrust ball bearing is placed at the lower end. The equipment enables the heart to generate longitudinal impact, improves the rock breaking efficiency and reduces drilling cost.

Owner:SOUTHWEST PETROLEUM UNIV

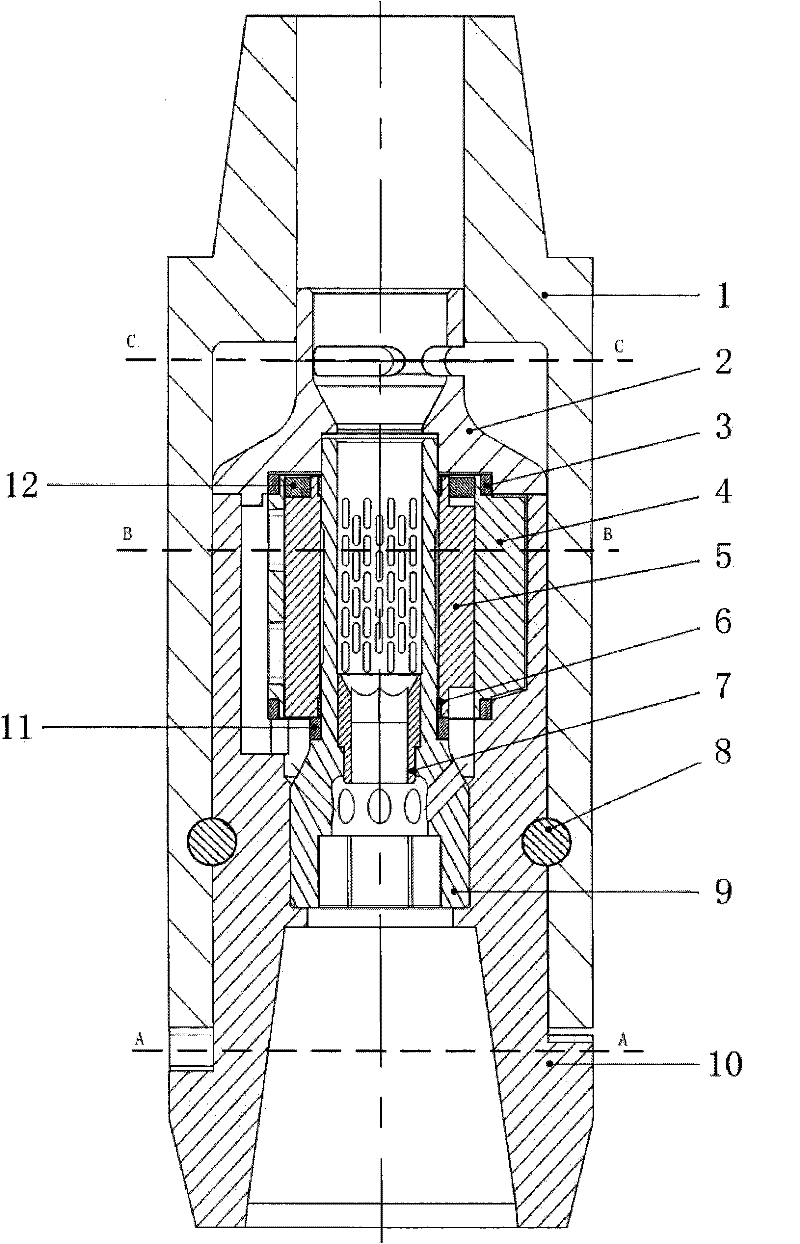

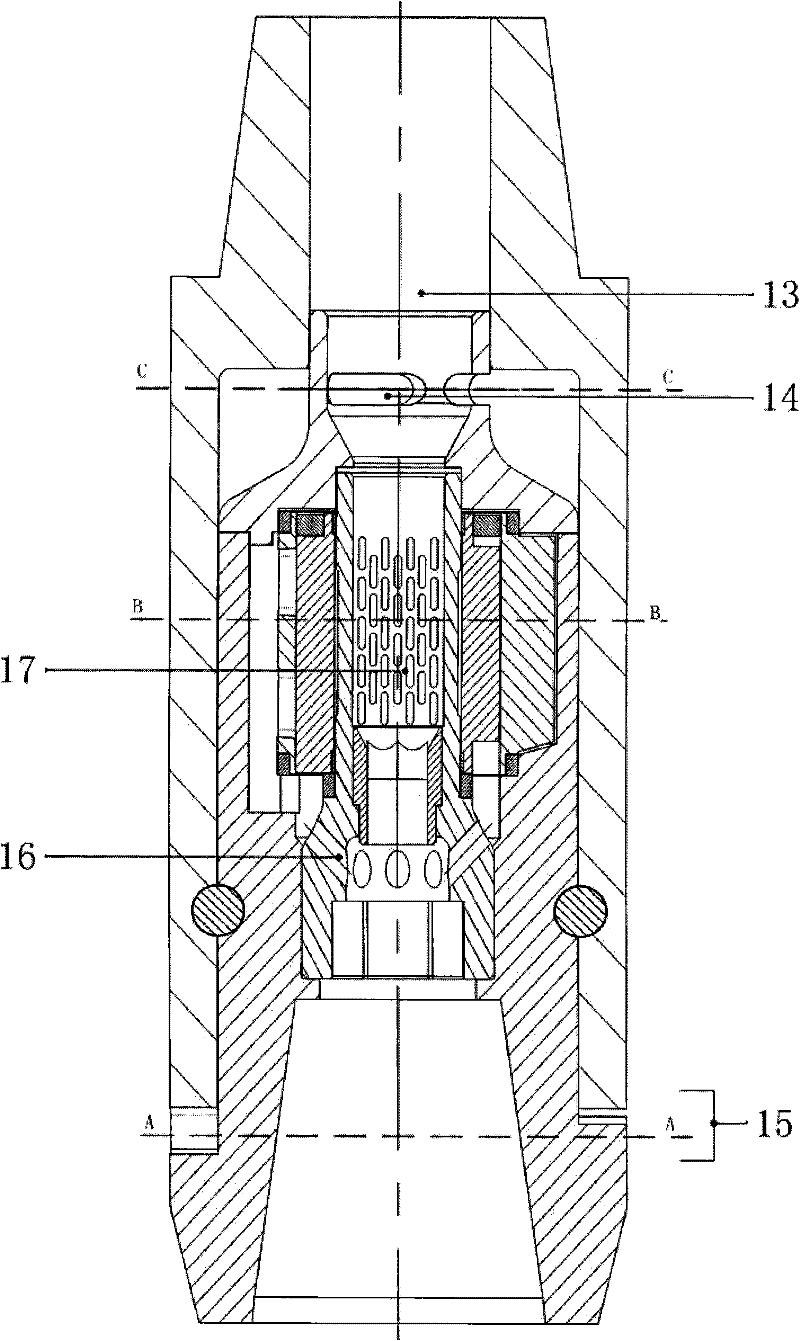

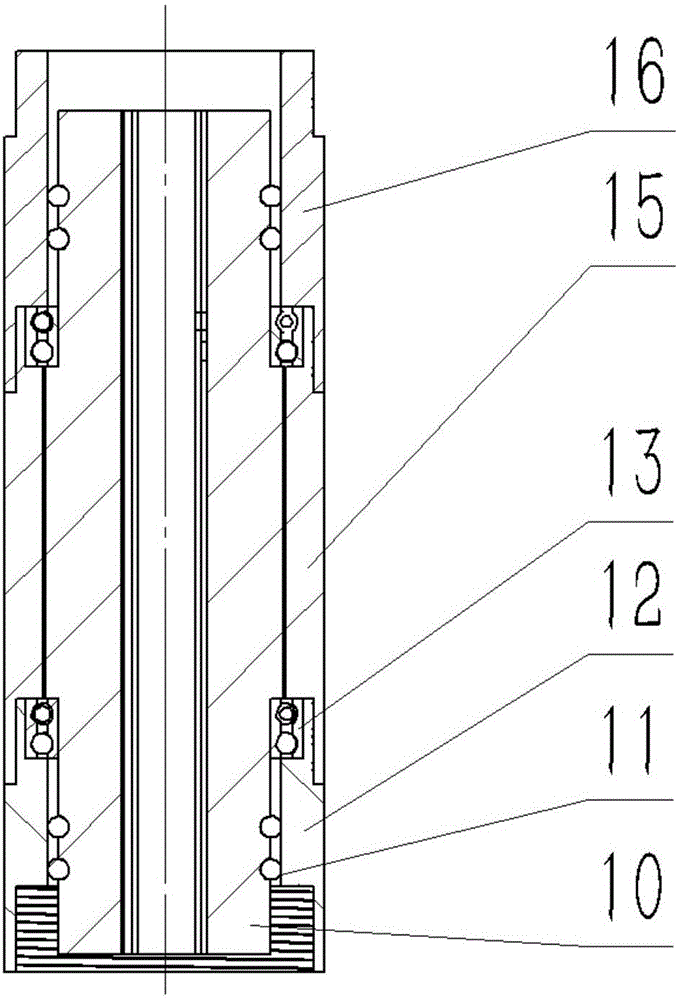

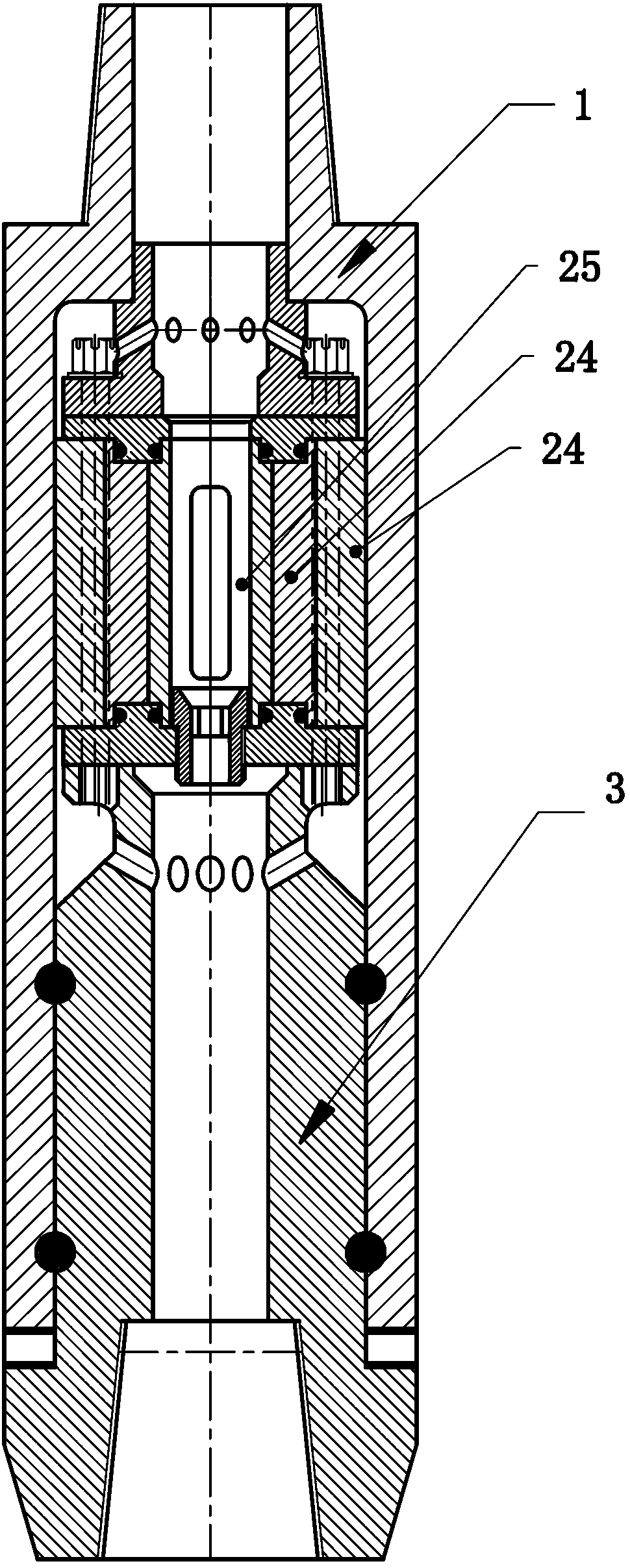

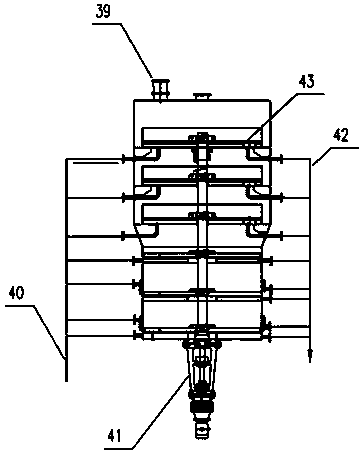

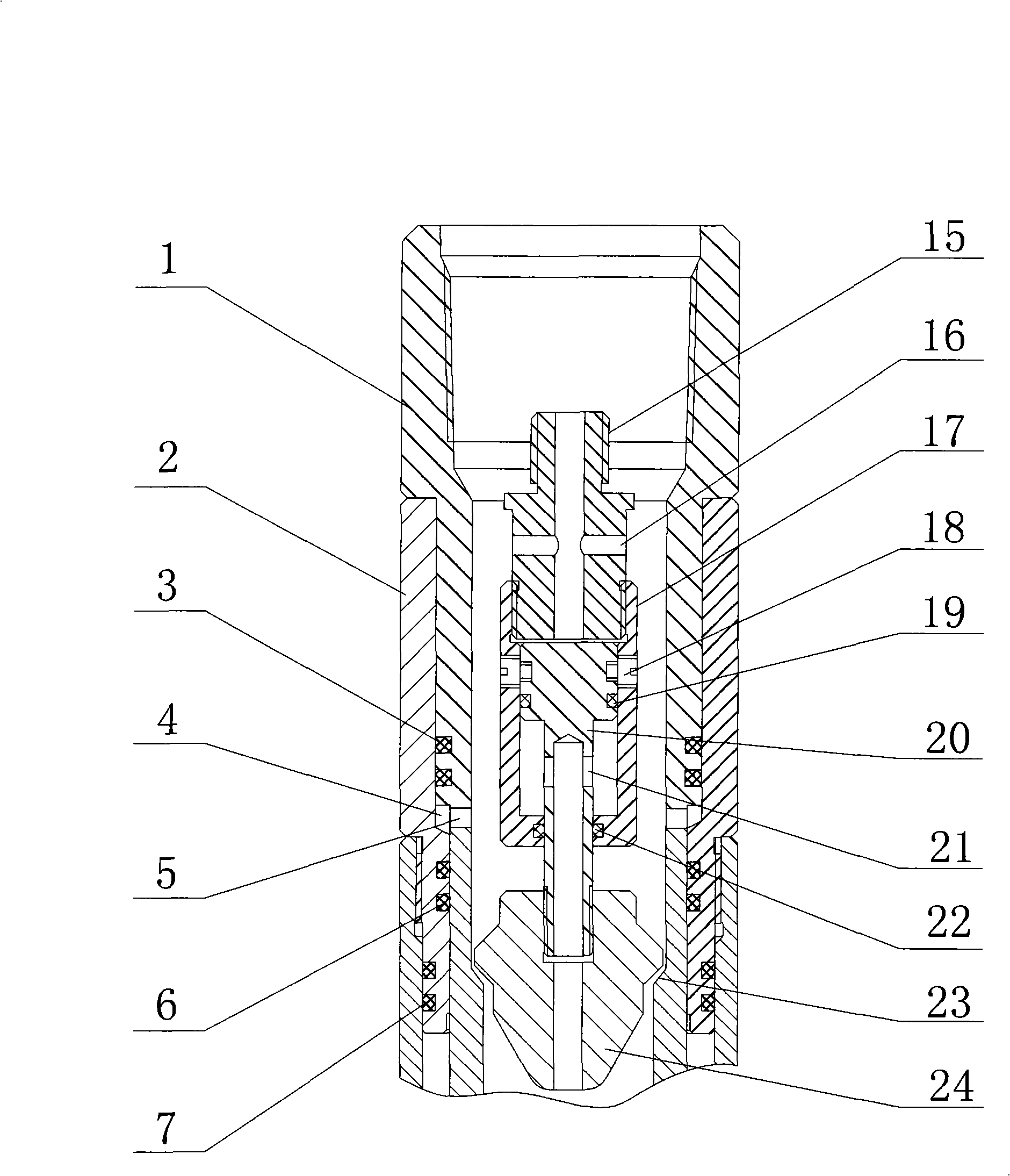

Water pressure torsional impact device for well drilling

The invention relates to a water pressure torsional impact device for drilling engineering. The water pressure torsional impact device adopts the technical scheme that the water pressure torsional impact device for the well drilling is characterized in that a water pressure torsional impact generator mainly comprises a flow guide location cover, an upper rotating gland, an impact rammer, an impact rammer seat, a steering divider, a cutoff nozzle and a lower rotating gland, wherein the flow guide location cover, the upper rotating gland, the impact rammer seat and the lower rotating gland are fastened with a drilling bit mounting seat by bolts; through holes are formed in axes of the impact rammer, the impact rammer seat and the steering divider; the through hole in the axis of the impact rammer is sleeved with the steering divider; the impact rammer is arranged on the through hole in the axis of the impact rammer seat; with the adoption of the scheme, the water pressure torsional impact device overcomes defects in the prior art, and a downhole tool capable of increasing the rate of penetration in a harder or abrasive stratum and avoiding stick-slip of a PDC (polycrystalline diamond compact) drilling bit is provided.

Owner:WENZHOU JIADA MACHINERY MFG

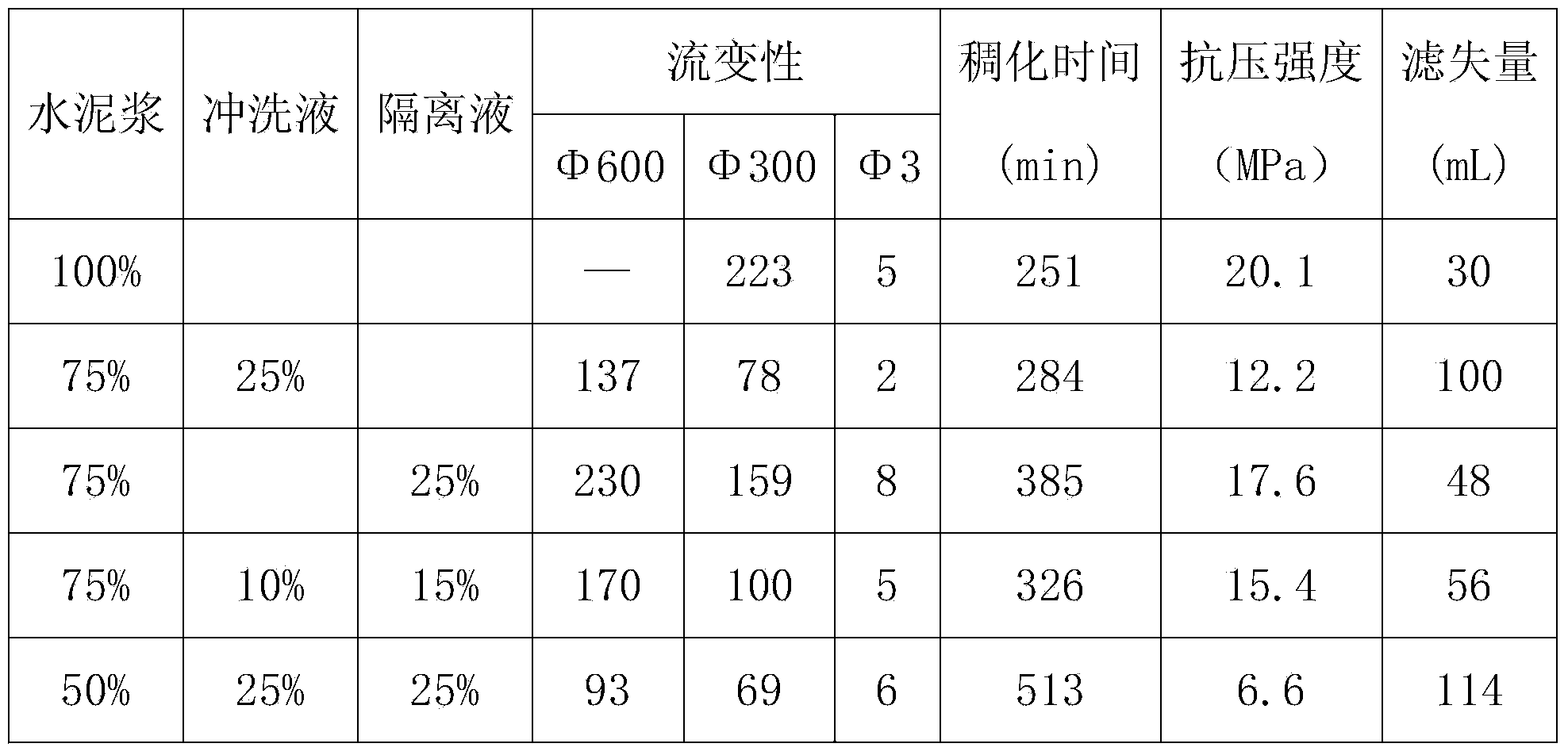

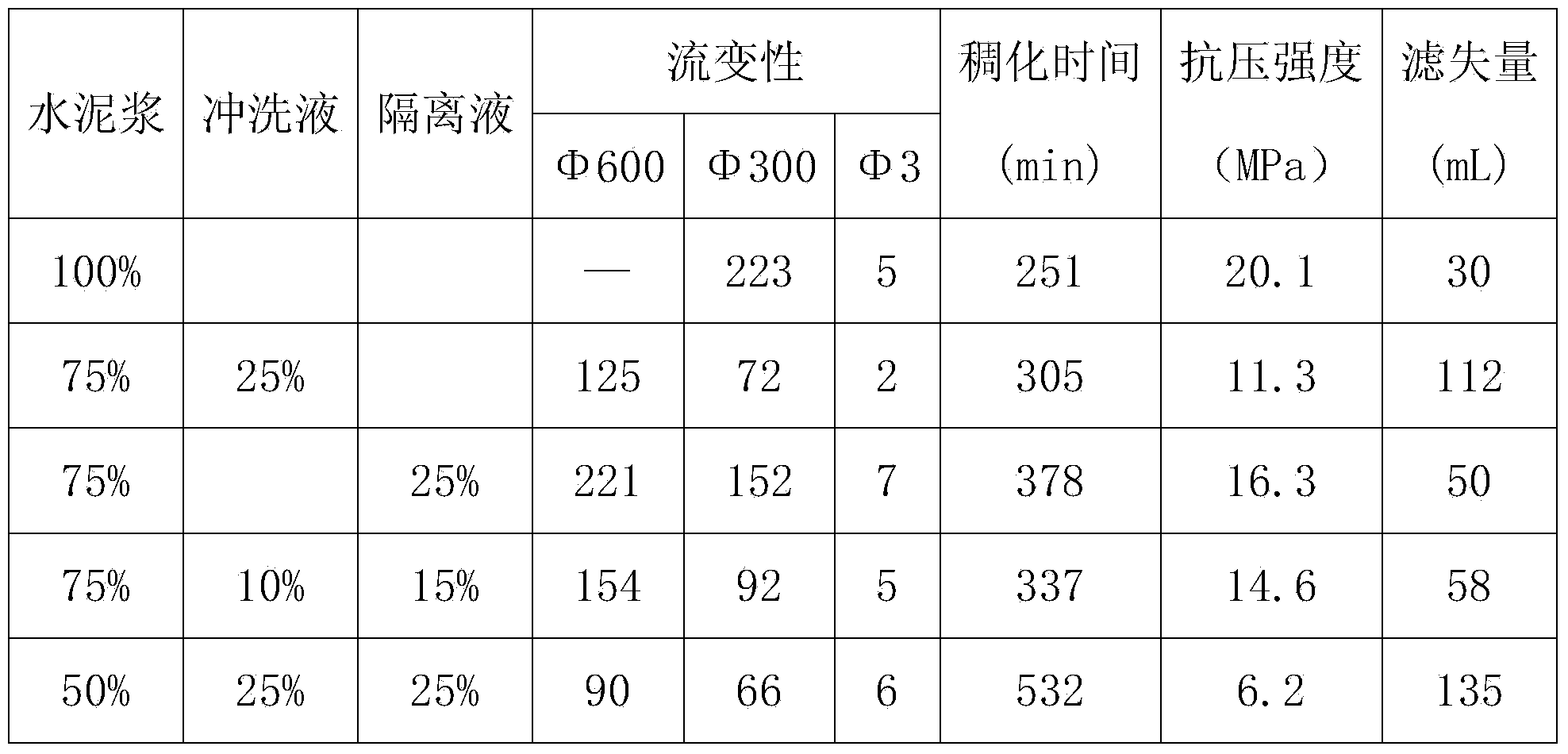

Shale gas exploitation oil-based drilling fluid well-cementing prepad fluid

The invention relates to shale gas exploitation oil-based drilling fluid well-cementing prepad fluid, and belongs to the technical field of petroleum drilling engineering chemistry. The well-cementing prepad fluid is characterized by comprising the following components by volume percent: 30-50% of cleaning fluid, 30-50% of flushing fluid and 0-40% of spacer fluid; the cleaning fluid is composed of a cleaning fluid additive, a weighting agent and water; the flushing fluid is composed of a flushing fluid additive, a weighting agent and water; the spacer fluid is composed of a spacer fluid additive, a weighting agent and water; the cleaning fluid additive is composed of a non-ionic surfactant and a mutual solvent, the flushing fluid additive is composed of a surfactant and a mutual solvent, and the spacer additive is composed of a tackifier and a filtrate reducer. The prepad fluid is capable of effectively eliminating an oil-based drilling fluid mud cake, effectively tidying a well wall and effectively isolating the drilling fluid from the cement mortar; the aims of effectively replacing and isolating are achieved, so that the well-cementing quality is improved.

Owner:JINGZHOU JIAHUA TECH

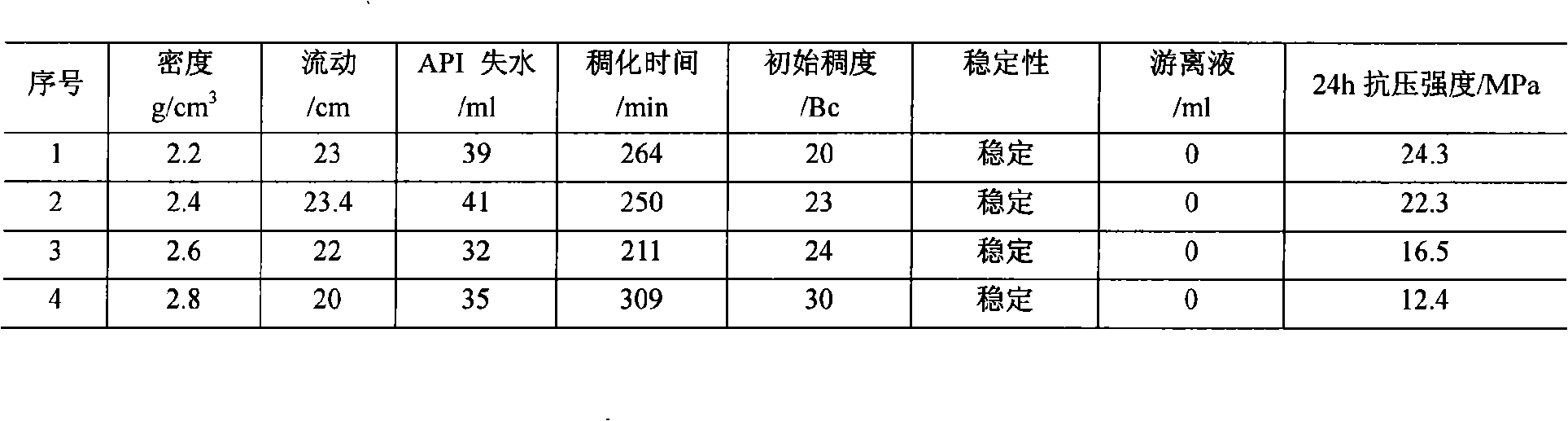

Anti-salt high-density cement mortar

InactiveCN101338183APacked tightlyGuaranteed solid phaseDrilling compositionHigh densityWell cementing

The invention relates to a cement slurry system used for solidifying a well in a petroleum drilling engineering: 50-300 percent of well cement aggravating agent A, 10-100 percent of well cement aggravating agent B, 0.5-4 percent of drag reducing agent, 2.5-8 percent of fluid loss additive, 0.1-5 percent of retarder and 0.15-1.2 percent of defoaming agent. The mixture of wet mixed additive occupies 50-100 percent of the cement quality. According to a salt layer, NaCl can be added during the solidifying of the well. 30-40 percent of high temperature resisting declining agent is added at high temperature. The cement slurry, the density of which reaches to 2.8g / cm3, can be prepared.

Owner:CNPC RES INST OF ENG TECH +1

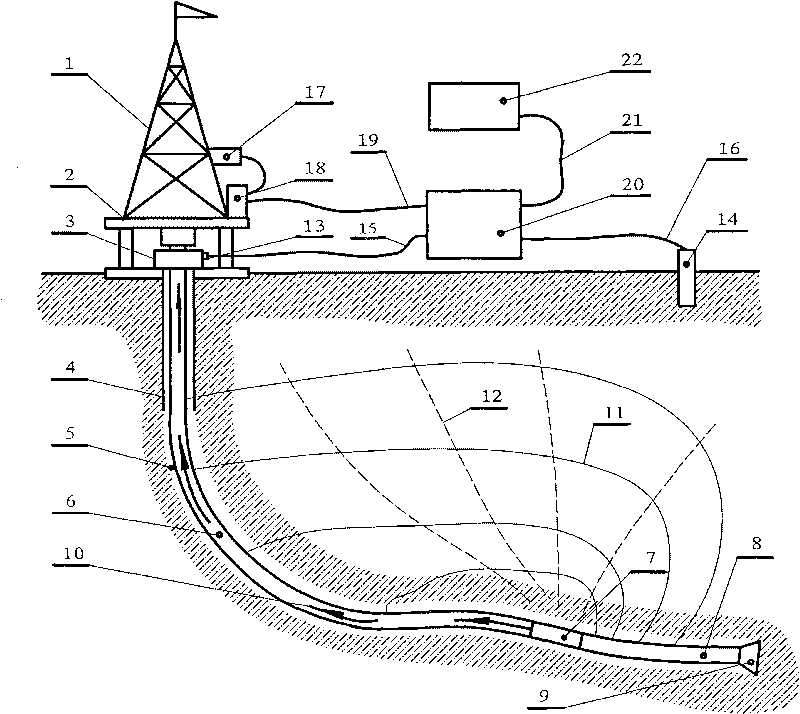

Geometry steerable drilling system driven by liquid and gas phase drilling media rotary disc

The invention relates to a geometry steerable drilling system driven by a liquid and gas phase drilling media rotary disc, which comprises two parts i.e. a ground part and an underground part, wherein the ground part consists of a derrick, a drilling floor, a blowout prevention device, a blowout prevention device electrode, a ground electrode, an electrical conductor, a vertical pipe pressure sensor, a drilling floor driller display, a drilling floor communication cable, a signal processing interface box, a standard serial communication cable and a universal computer system; and the underground part consists of an underground while-drilling directional tool and an underground while-drilling directional instrument. The geometry steerable drilling system driven by the liquid and gas phase drilling media rotary disc can use both a pure liquid phase and mixture media of a pure gas phase or the liquid phase, not only can be used for guide drilling of a rotary disc, but also can be used for measuring a formation natural gamma and the resistivity of the rotary disc while drilling and is suitable for popularizing and applying in petroleum drilling engineering.

Owner:CNPC GREATWALL DRILLING ENG

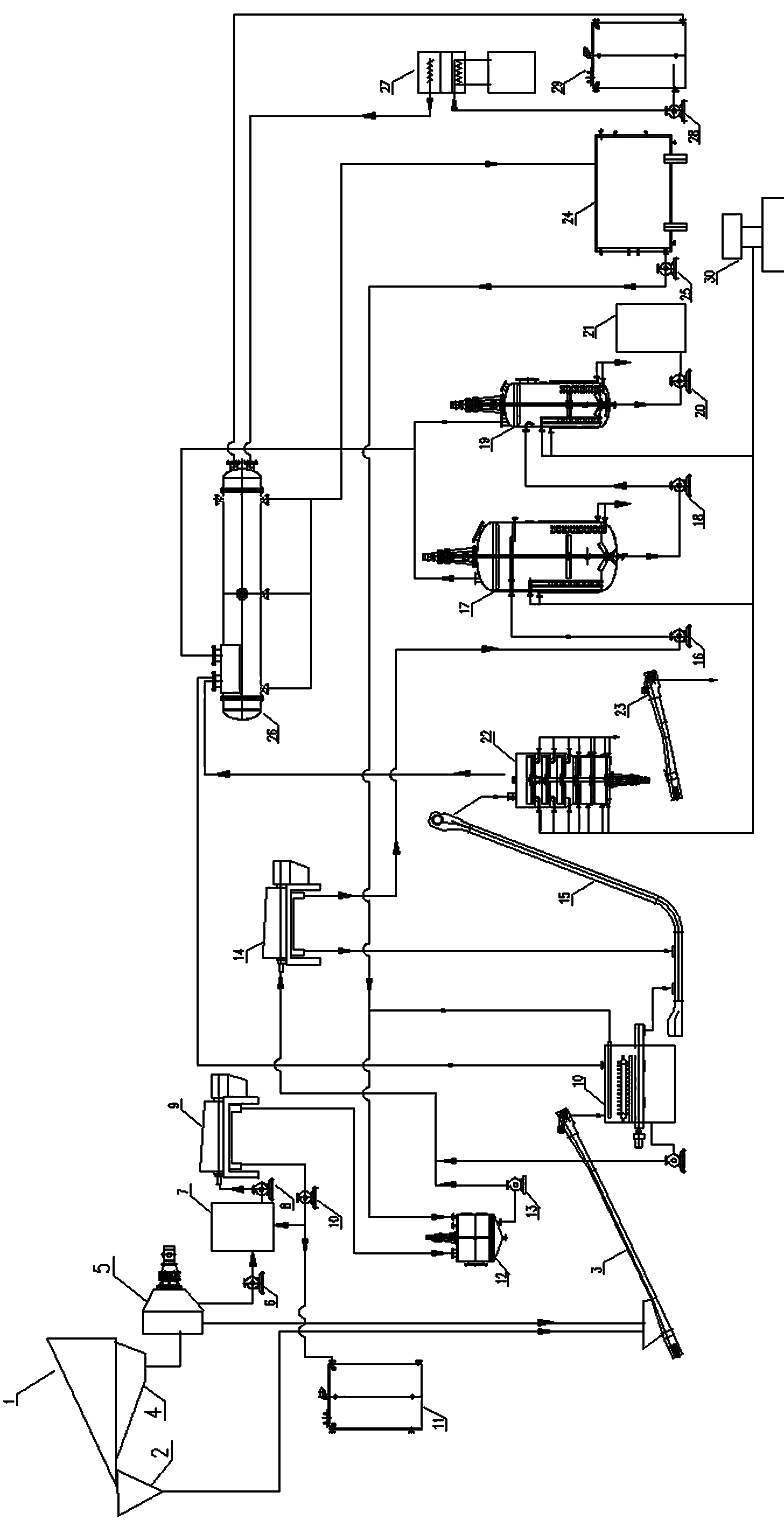

Device for recycling mud and diesel oil base from waste oil-base mud

The invention discloses a device for recycling mud and a diesel oil base from waste oil-base mud and belongs to the technical field of processing of pollutants generated in the process of oil and gas drilling. By the adoption of the device for recycling the mud and the diesel oil base from the waste oil-base mud, the oil-base mud is recycled from oil-containing refuse, such as the waste oil-base mud and drilling cuttings containing oil, generated in the oil-base mud drilling process through the centrifugal filtration-centrifugal sedimentation coupling technology, and the diesel oil base is recycled from a separated low-oil-content solid phase through a leaching-evaporation separating device. The recycled oil-base mud can be reused in drilling engineering. The recycled diesel oil base can be used for re-preparation of the oil base mud. According to the device for recycling the mud and the diesel oil base from the waste oil-base mud, resource recycling and harmless treatment of the oil-containing refuse generated in the oil-base mud drilling process are achieved, cost is low, no secondary pollution is caused, resources can be recycled, operation is easy, the oil-base mud and the diesel oil base are recycled from the oil-containing refuge as much as possible, and the recycled oil-based mud can be reused.

Owner:四川博盛永业工程技术有限公司

Lubricant for drilling fluid

InactiveCN105368410AImprove the lubrication effectImprove wear resistanceDrilling compositionAdjuvantVegetable oil

The invention discloses a lubricant for drilling fluid and belongs to the technical field of chemical agents for petroleum drilling engineering. The lubricant for the drilling fluid contains the following ingredients in parts by weight: 35-90 parts of vegetable oil, 10-25 parts of synthesized ester type oily agent, 9-21 parts of emulsifier, 3-8 parts of extreme-pressure antiwear agent, 6-18 parts of organic molybdenum compound, 10-12 parts of nano metal powder, 7-15 parts of dispersant, 5-9 parts of graphite powder, 3-8 parts of antifoamer, 4-7 parts of surfactant and 4-8 parts of antioxidant. According to the lubricant for the drilling fluid, disclosed by the invention, the vegetable oil serves as a main raw material, and other additives are added as adjuvants, so that the lubricating property of the drilling fluid can be remarkably improved after the lubricant is added into the drilling fluid; and meanwhile, the lubricant has high-temperature and high-pressure resisting characteristics and antiwear and antifriction properties and is free of a mineral oil ingredient, and the additives are also free of sulfur and phosphorus, so that the lubricant is environment-friendly.

Owner:CHONGQING YANJIN ENVIRONMENTAL PROTECTION TECH CO LTD

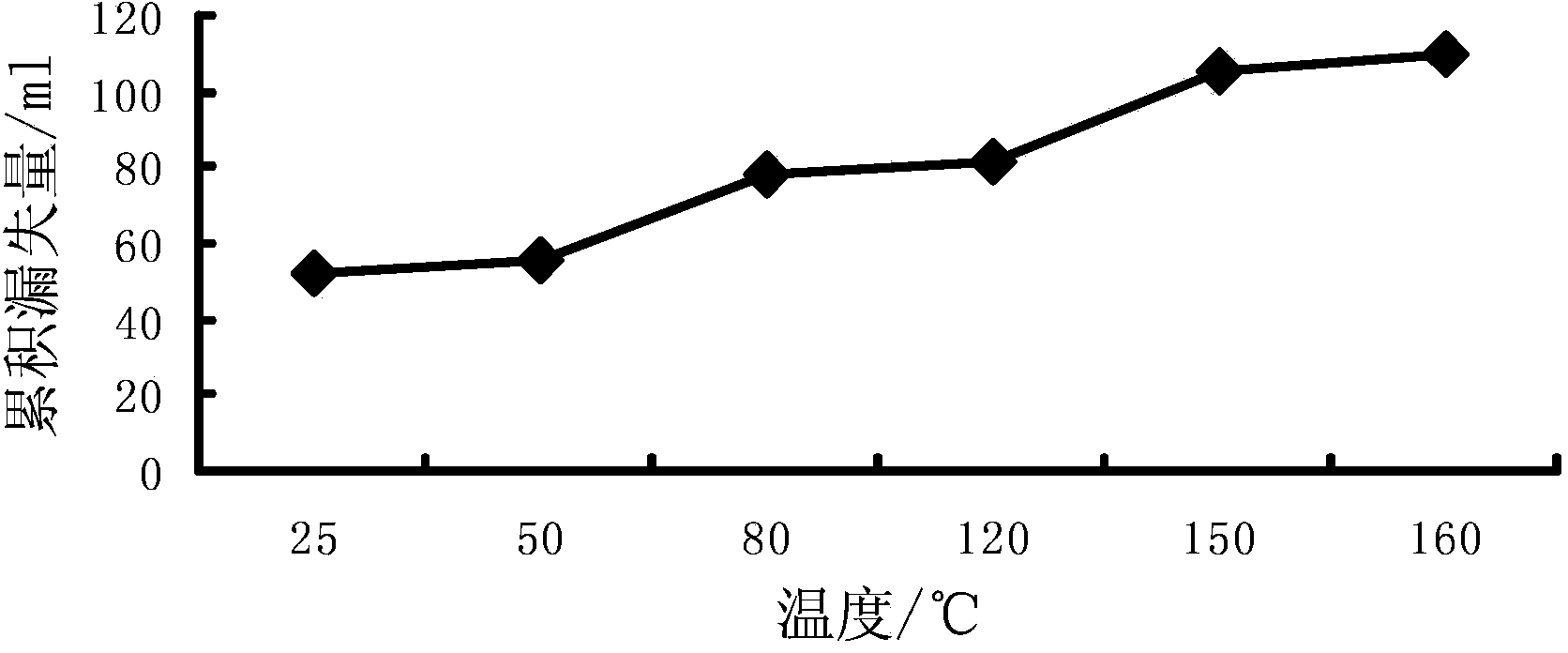

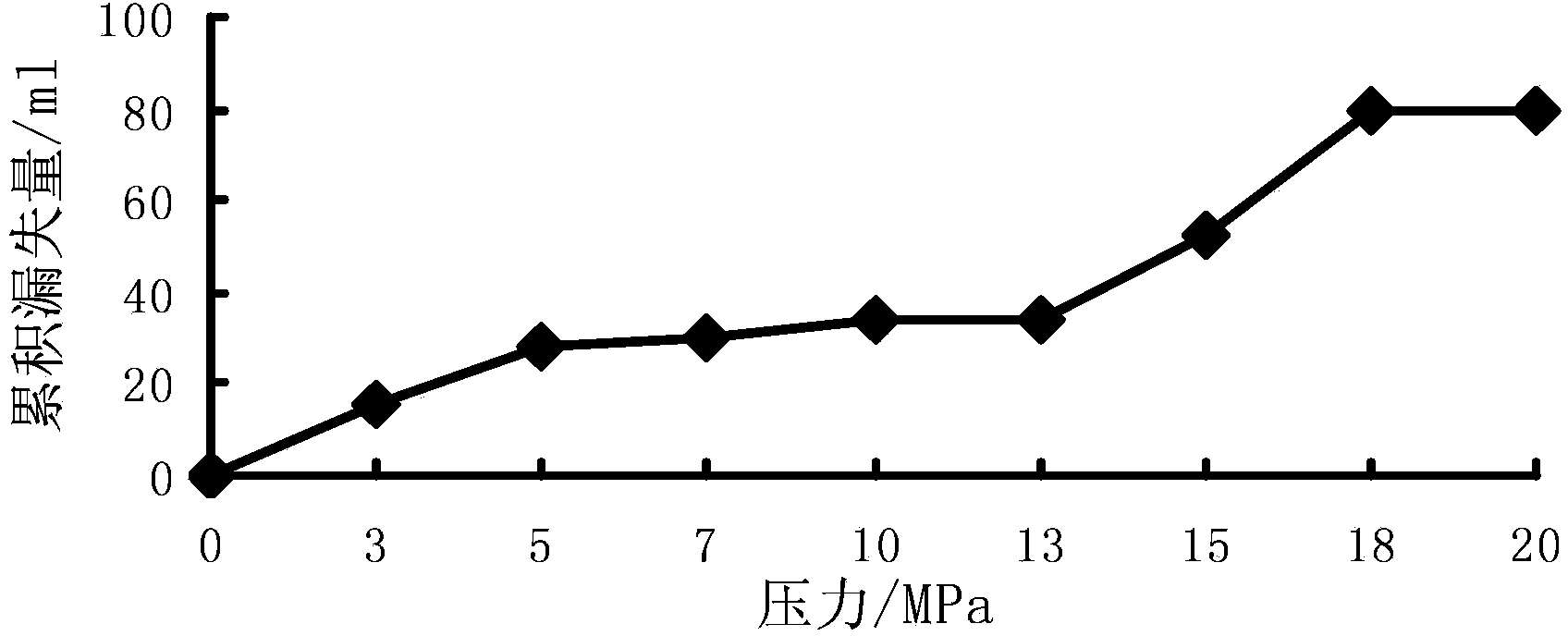

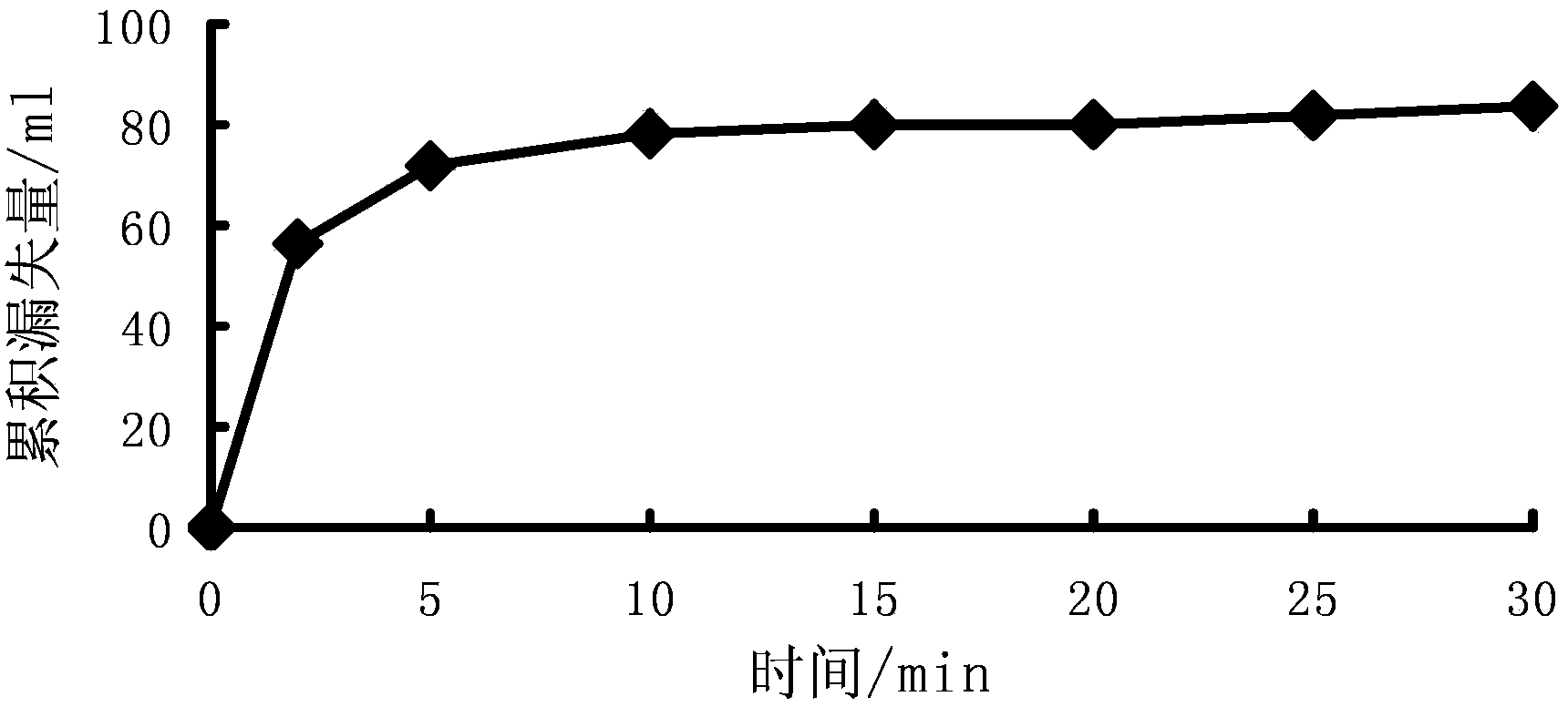

Shearing cross-linking sensitive plugging agent and preparation method thereof

The invention provides a shearing cross-linking sensitive plugging agent used for the drilling engineering. The plugging agent comprises the following components: 40 to 60 parts of organic titanium coal-oil solution, 40 to 60 parts of modified guar gum solution and 2 to 5 parts of emulsifier, wherein the organic titanium coal-oil solution is the mixture of coal oil and organic titanium, the organic titanium is any one of the titanate compounds, the modified guar gum solution is obtained by the graft copolymerization of acrylamide, hydroxymethyl acrylamide monomer and guar gum, and the emulsifier is fatty acid polyoxyethylene ether. The preparation method comprises the following steps: the 2 to 5 parts of the emulsifier is added to the 40 to 60 parts of the organic titanium coal-oil solution, the emulsifier and the organic titanium coal-oil solution are evenly stirred, then the 40 to 60 parts of the modified guar gum solution is added into the mixture slowly and stirred for 1 hour at the temperature of 30 to 35 DEG C to form stable reversed emulsion through a colloid mill, and the finished product of the shearing cross-linking sensitive plugging agent is further obtained. The shearing cross-linking sensitive plugging agent is used for plugging a drilling, the cross-linking agent can be immediately mixed with macromolecule under the action of the high shearing rate of the bit port to generate cross-linking, and the gelling stemming similar to the plastic solid is formed so as to rapidly block the serious leakage layer.

Owner:JINZHOU HONGLI CHEM TECH

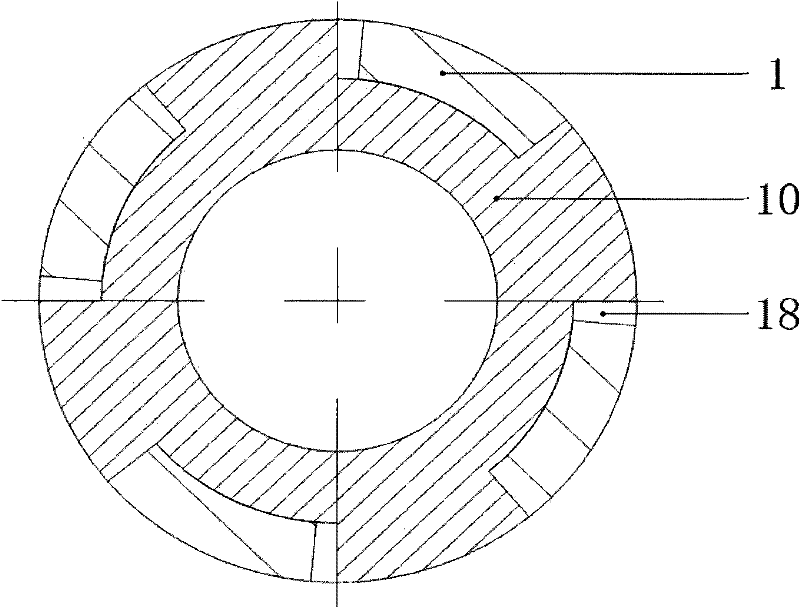

Hydraulic switch sliding bush

ActiveCN101265792ARealize on or offIncrease the effective internal diameterWell/borehole valve arrangementsSealing/packingHydraulic cylinderManufacturing technology

The invention discloses a sliding sleeve for a hydraulic switch, which belongs to the manufacture technology field of underground tool for cementing operation in the oil and natural gas drilling engineering, and comprises a sliding sleeve structure for switch and a control structure. The sliding sleeve structure for switch comprises an upper joint, a piston sleeve, a switch sleeve, a central tube and a lower joint, wherein the piston sleeve is sleeved outside the upper joint, the switch sleeve is sleeved outside the central tube, and the lower joint is connected with the lower end of the central tube; the control structure comprises a connecting joint, a cylinder sleeve, a piston rod and a sealing plug, wherein the connecting joint is connected with the cylinder sleeve, the sealing plug is arranged on the lower end of the piston rod, and the control structure is arranged in the upper joint of the sliding sleeve structure for switch. The invention provides a sliding sleeve for hydraulic switch that can realize repetitious on / off actions through providing hydraulic force on the ground and setting different hydraulic cylinders on the sliding sleeve to realize the on-off mode of the sliding sleeve; the sliding sleeve for hydraulic switch can realize the switch-on or switch-off state of the sliding sleeve repetitiously and is characterized in simple structure, convenient operation and reliable performance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Determination method for initial well deviation azimuth angle of three-dimensional horizontal well borehole trajectory

ActiveCN104653172ALow costReduce Orientation WorkloadSurveyDirectional drillingPetroleumPetroleum engineering

The invention relates to a determination method for an initial well deviation azimuth angle of a three-dimensional horizontal well borehole trajectory and belongs to the technical field of petroleum natural gas drilling. The determination method comprises the following steps: determining a final target-entering deviation angle and a well deviation azimuth angle according to parameters of a target point A and a target point B; determining a minimum stable deviation section length and a well deviation angle behind a twisting direction by using a vertical depth error of the target point A; determining a deviation change rate of a deviation change tool according to a deviation change capability of a drilling tool needing to be used; determining a borehole curve rate needed by a needed entering sleeve according to a sleeve type needing to be adopted; predicating a natural deviation change rate of a stratum according to adjoining well data; determining a first two-dimensional deviation increasing section maximum well deviation rate and a three-dimensional deviation increasing and twisting direction finishing point maximum deviation increasing rate; and combining the parameters to determine the initial well deviation azimuth angle of the three-dimensional horizontal well borehole trajectory. The quantified design is realized, and field drilling and oriented construction are convenient to realize; the oriented working amount is reduced and the drilling engineering cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

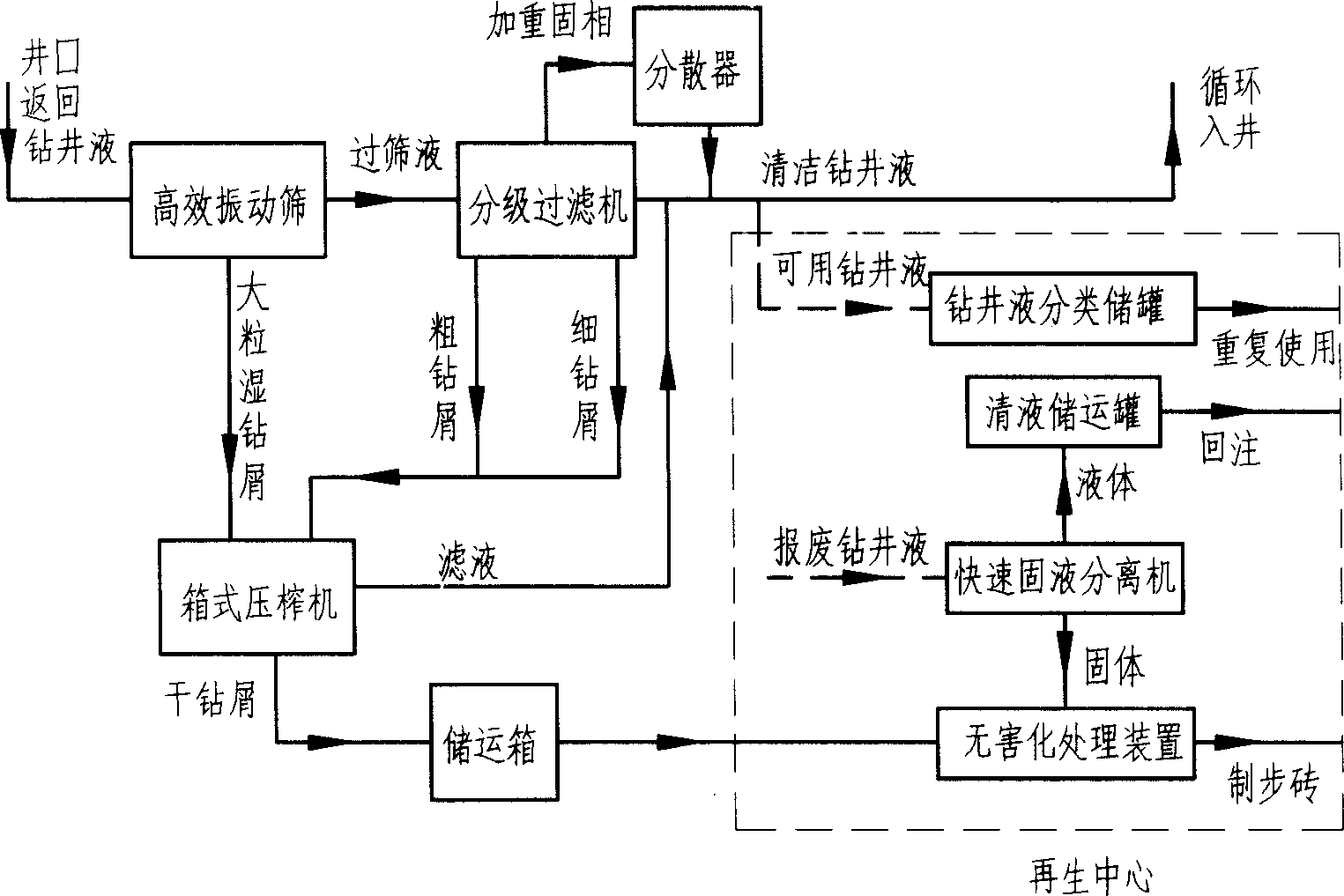

Technique for parallel processing drilling fluid and zero discharge of drill cuttings

The present invention belongs to the field of oil and gas field drilling engineering technology, and relates to a kind of drilling fluid and drill cuttings zero-discharge parallel treatment process. Said treatment process includes the portions of drilling fluid selective solid-phase control, drill cuttings on-line treatment and recovery utilization and drilling fluid regeneration and utilization. Said process utilizes high-effective vibration sieve and sorting filter to make selective solid-phase control of drilling fluid, at the same time utilizes one-box type press filter to make discharged wet drill cuttings undergo the process of drying treatment and further recover the drilling fluid. The dried drill cuttings can be used for making bricks.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

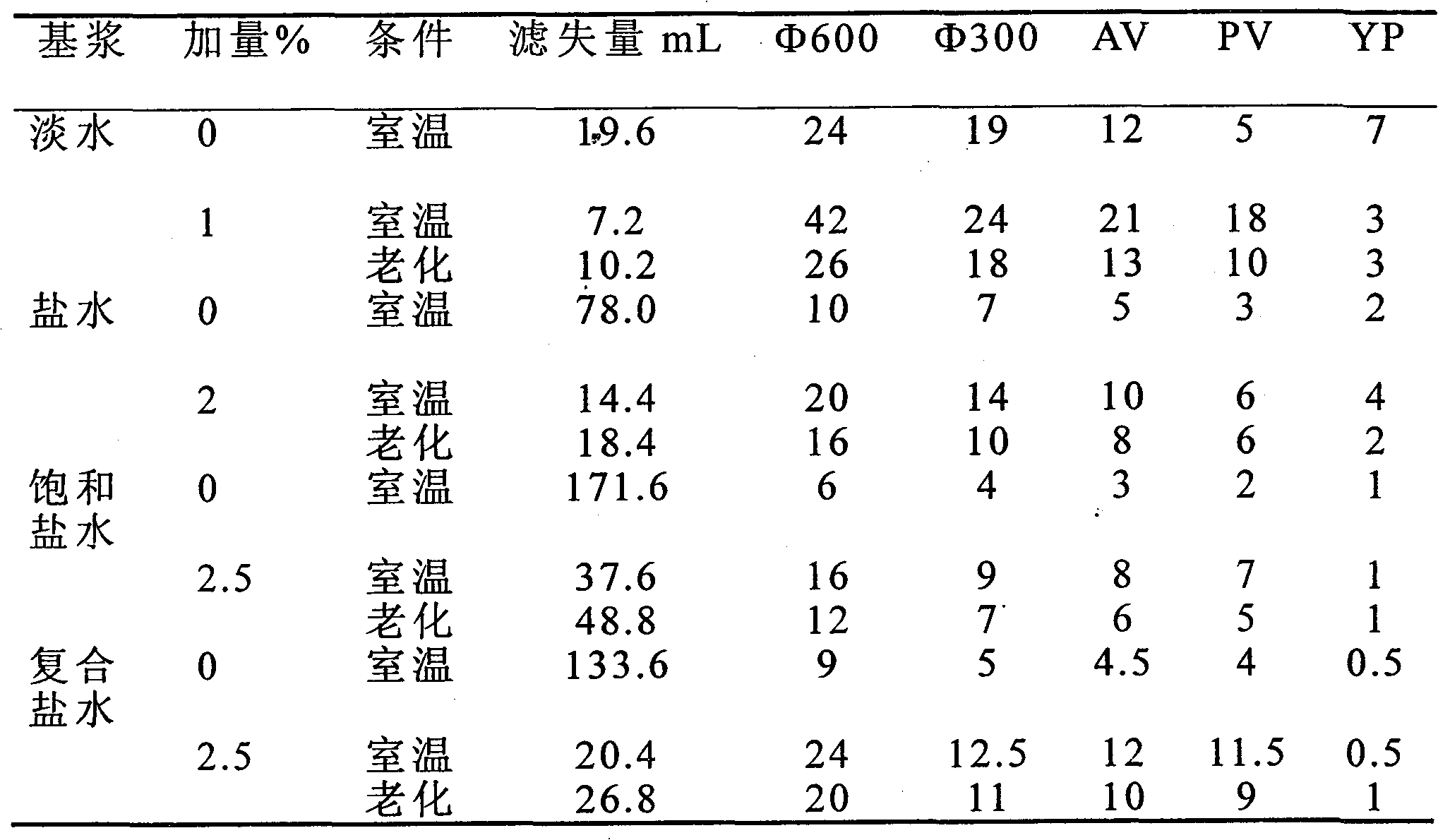

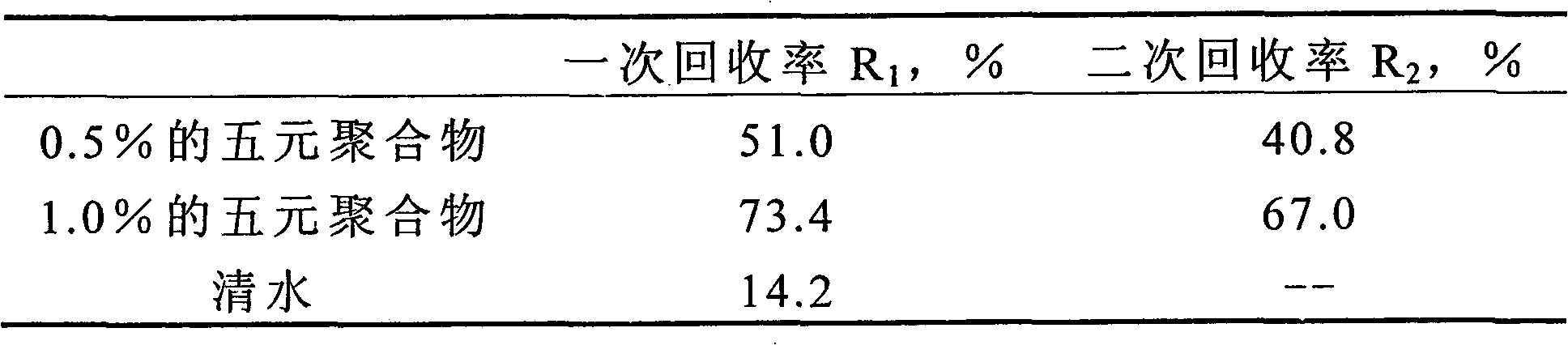

Five-membered copolymer fluid loss agent and preparation method thereof

InactiveCN101928556AIncreased chance of clogged poresImprove filtration loss reduction effectDrilling compositionAlcoholAcrylonitrile

The invention relates to a five-membered copolymer fluid loss agent and a preparation method thereof, which is used for drilling fluid and completion fluid in the drilling engineering of oil and gas fields. The five-membered copolymer fluid loss agent can improve the high-temperature resistant performance, performance for inhibiting shale expansion, salt tolerant performance and the like for fluid loss agent. The technical scheme is as follows: the raw materials for preparing the fluid loss agent comprise acrylamide A, acrylonitrile B, crylic acid C, 2-acrylamide-2-methylpropanesulfonic acid D and vinyl ammonium salt cation monomer E. Water is served as solvent, NaOH solution is pH value modifier, and (NH4)2S2O8 and NaHSO3 are served as initiators. C, D and E are dissolved in water according to the molar ratio of 13-15:10:8, and NaOH solution is used for regulating pH to 6-8; then, A and B are added at the molar ratio of 66-63:3-4; mixed liquor is heated to 40-55 DEG C; the initiators are added to be stirred for 10min; the obtained mixture stands and reacts at the constant temperature for 3-5h; finally, alcohol is adopted for purifying; and the product is cut, prilled and dried to obtain the five-membered copolymer fluid loss agent. The five-membered copolymer fluid loss agent has good temperature resistant performance and salt tolerant performance. The method has high yield and can be used for drilling fluid and completion fluid.

Owner:SOUTHWEST PETROLEUM UNIV

Solid phase-free drilling-in liquid

The invention relates to solid phase-free drilling-in liquid, belonging to the technical field of petroleum drilling engineering chemical agents. The solid phase-free drilling-in liquid is characterized in that: the solid phase-free drilling-in liquid is formed by the following ingredients in percentage by weight: 0.5-1 percent of tackifier, 0.1-0.6 percent of pH regulator, 1-4 percent of fluid loss additive, 3-30 percent of inhibitor, 1-5 percent of lubricant and the balance of sea water. The drilling-in liquid has dual biological and chemical degradation functions, has high viscosity and can meet the requirements of a horizontal well, and particularly a large-displacement horizontal well on the viscosity of low shearing rate; the drilling-in liquid is the solid phase-free drilling-in liquid and does not contain solid phase, the metal ion invading resisting capacity is strong, the shale inhibition is strong, the lubrication is high, the system performance is stable, the maintenance and usage are convenient, thereby having better oil-gas layer protecting effect; the oil field exploitation efficiency can be improved and the normal exploitation life of the oil field can be prolonged.

Owner:YANGTZE UNIVERSITY

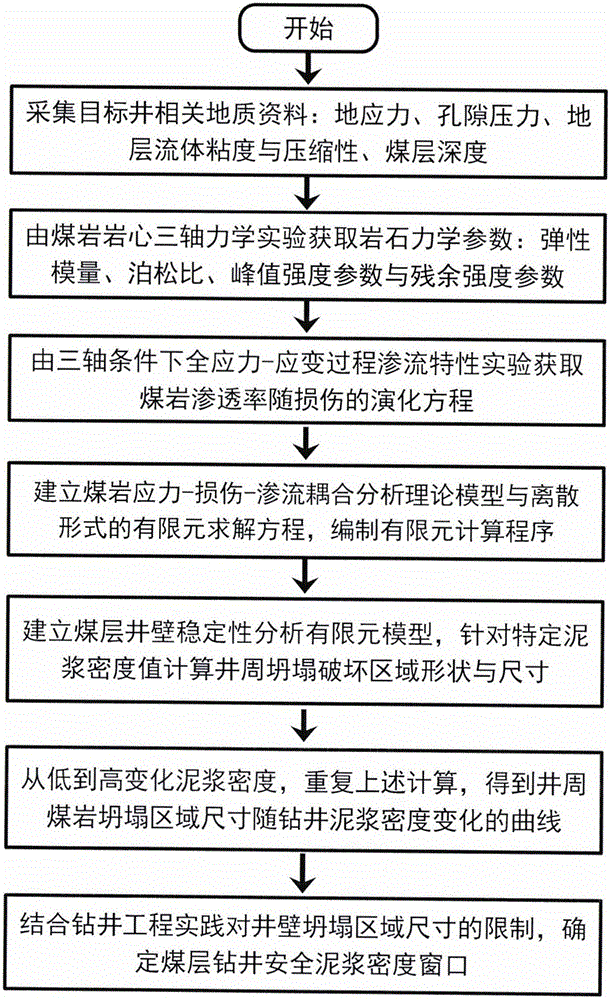

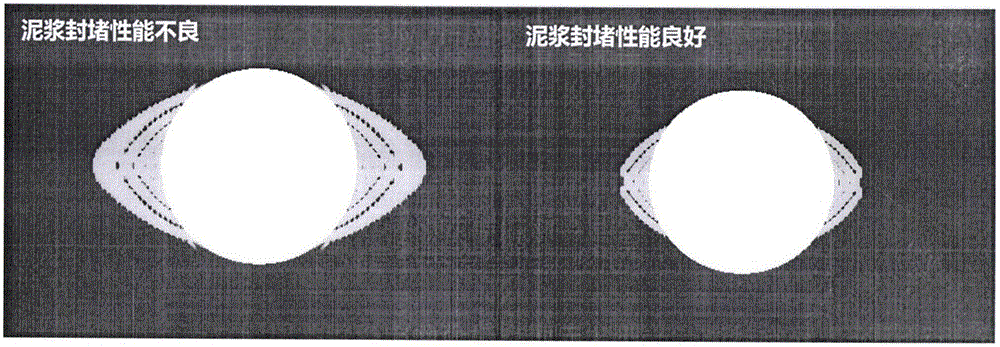

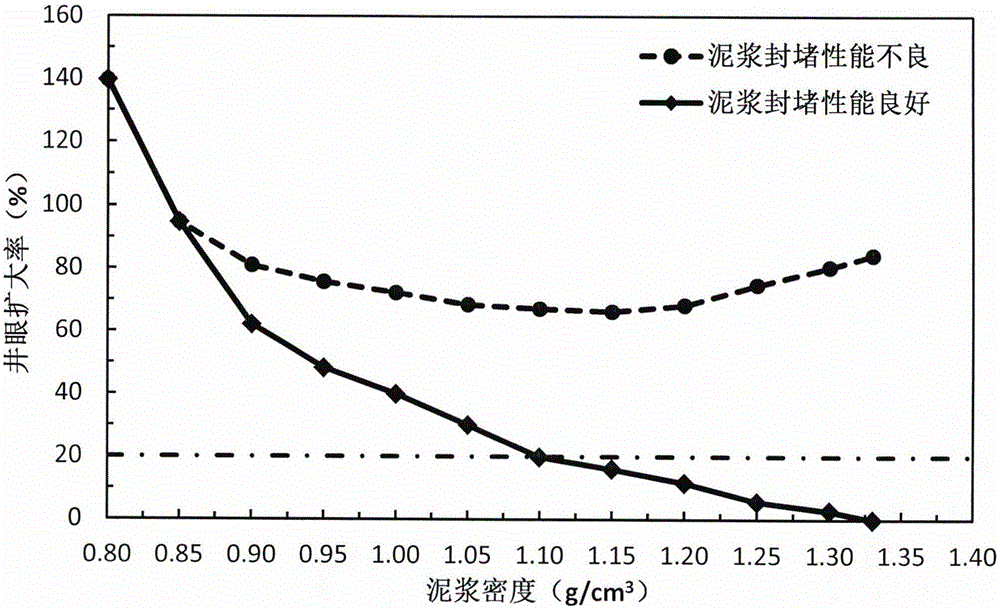

Coal seam well wall stability analysis method under multi-factor coupled effect

InactiveCN105401939AImprove brittlenessImprove stabilityBorehole/well accessoriesPorous mediumWell drilling

The invention discloses a coal seam well wall stability analysis method under a multi-factor coupled effect and belongs to the technical field of coal seam drilling engineering. A well wall is quite unstable because of low strength, large brittleness and remarkable anisotropism of coal rock. An existing coal seam well wall stability analysis method is incapable of reflecting a coal seam stress-damage-seepage coupling process; the calculated mud density is hard to be effective during a practical drilling process. The invention develops the coal seam well wall stability analysis method under the multi-factor coupled effect based on elastoplasticity of a porous medium, a seepage flow theory and a corresponding finite element numerical method; the method is used for accurately predicting the shape and size of collapsed and damaged coal rock around the well under the coupled effect of a plurality of factors such as stress, damages and seepage, providing a limit of the size of a collapsed area of the well wall according to the practical drilling situation of a target coal seam, and determining a corresponding coal seam drilling safe mud density window. The method disclosed by the invention is high in calculation accuracy and good in prediction effect; a designed drilling mud density plays an effect of stabilizing the well wall during on-site drilling and also plays a reservoir protection effect.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

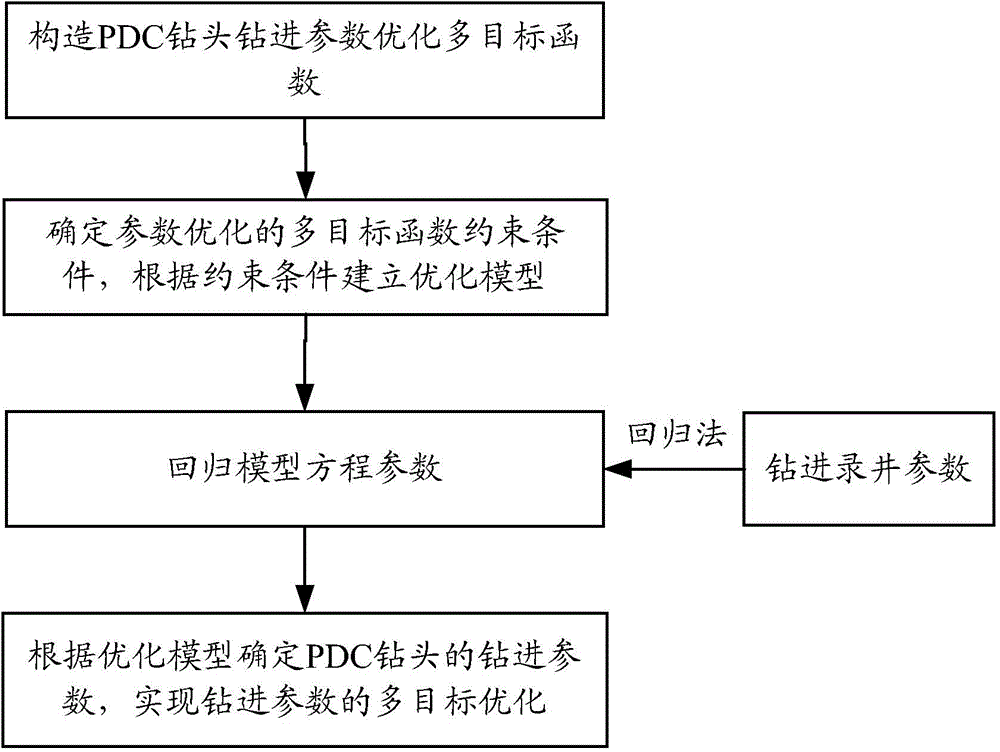

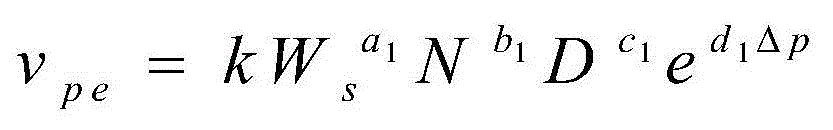

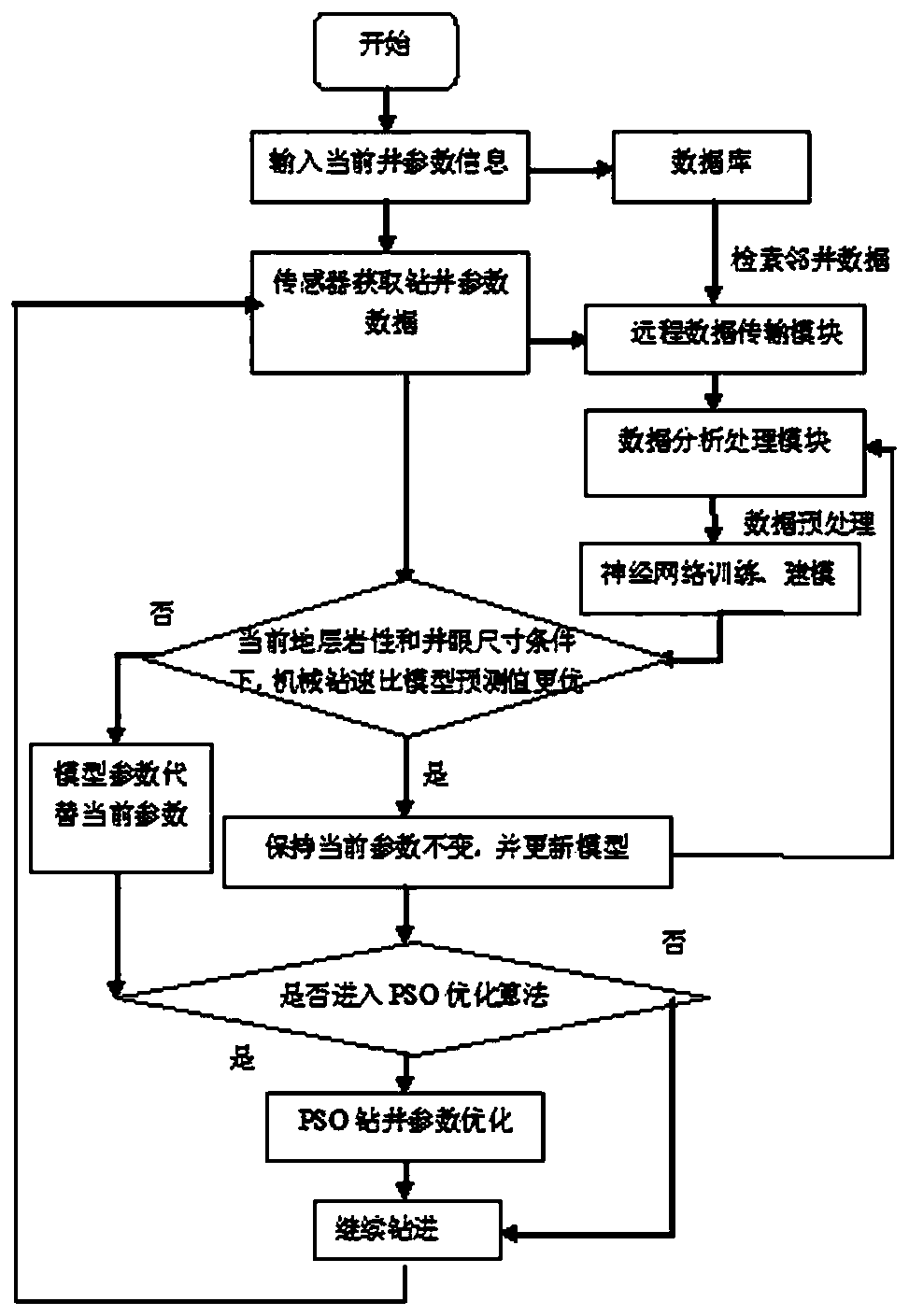

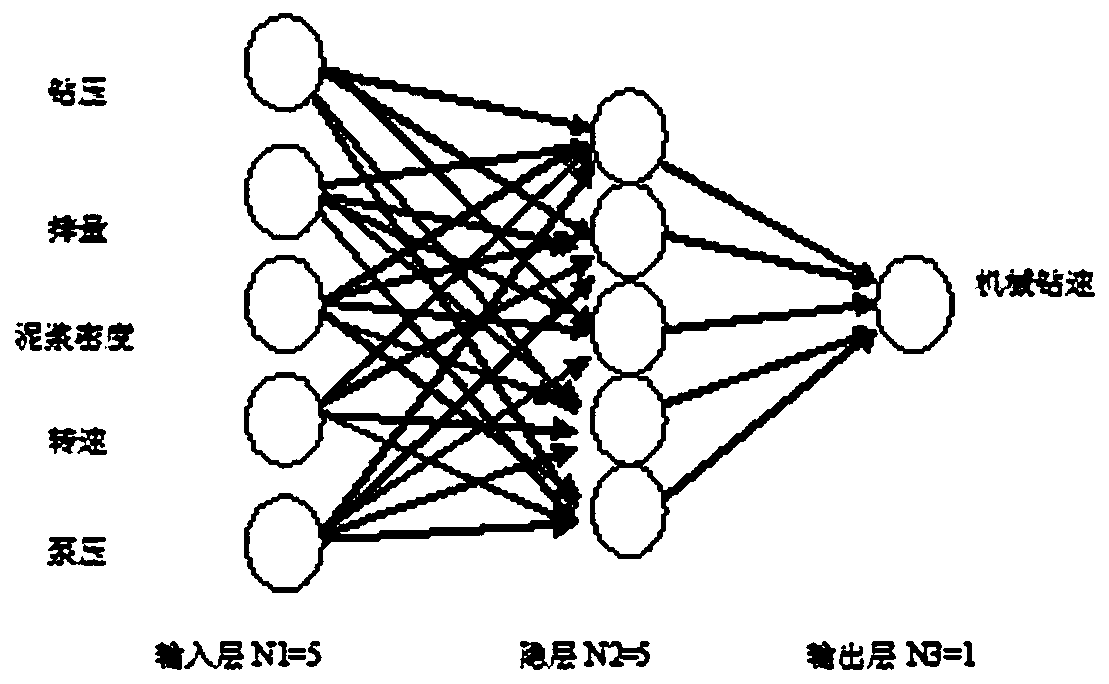

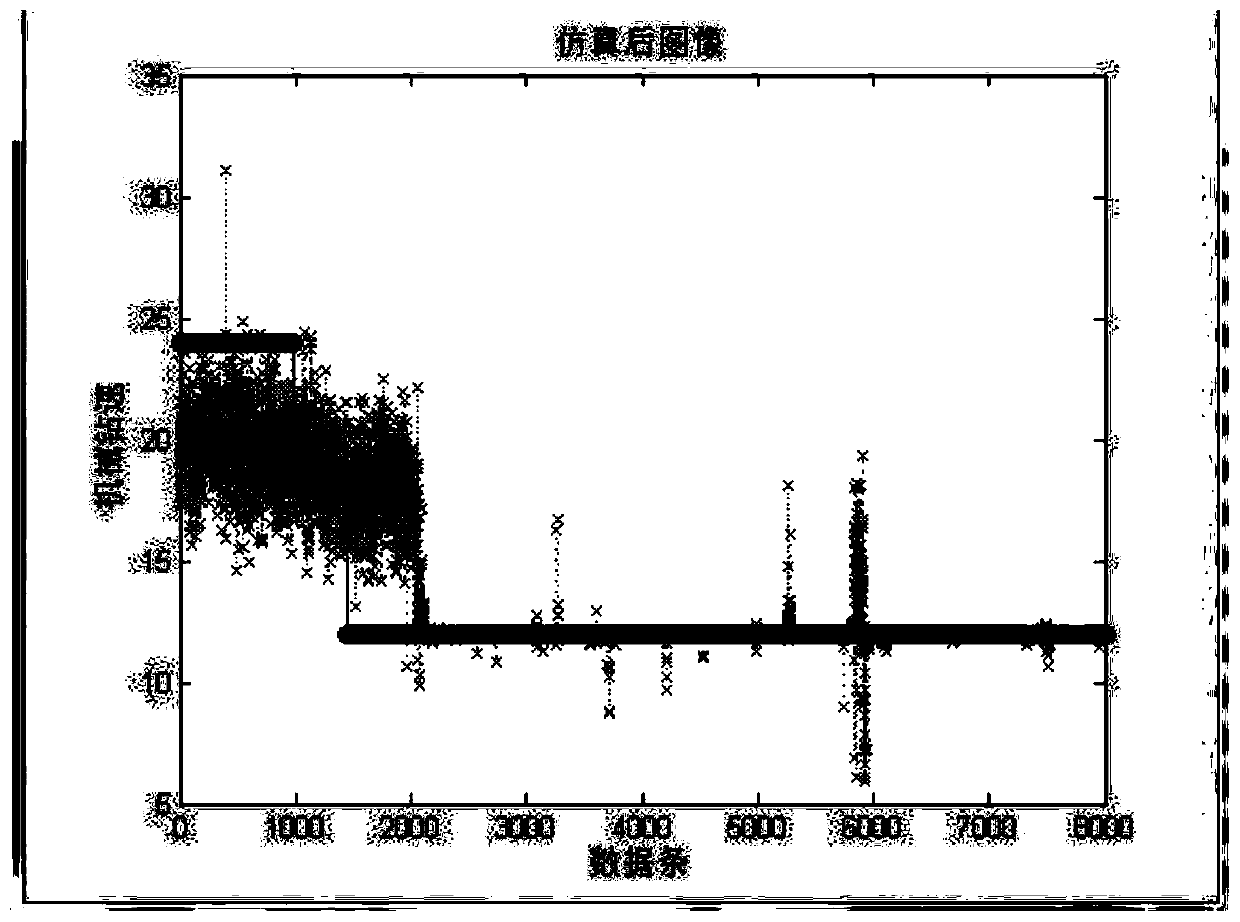

PSO drilling parameter optimization method based on neural network

ActiveCN110852018AFacilitate dynamic optimization requirementsImprove computing efficiencyForecastingArtificial lifeTechnology fusionEngineering

The invention belongs to the technical field of drilling engineering, and particularly relates to a PSO drilling parameter optimization method based on a neural network, which is characterized by comprising the following steps: (1) inputting current design parameters into a drilling parameter optimization system database; (2) querying whether adjacent well historical data of the current well exists or not, transmitting the data to a system data analysis processing module, inputting the preprocessed data into a neural network for model training, and outputting a pre-drilling parameter prediction model; and (3) after drilling, synchronously obtaining current while-drilling data parameters, calculating the current mechanical drilling speed, updating the model, and comparing the mechanical drilling speed under the same stratum lithology and borehole size in the model with the current mechanical drilling speed. Original parameter signals are collected, information data of the whole drillingprocess are processed and analyzed through software, key data are subsequently optimized, and real-time and dynamic intelligent parameter optimization and system comprehensive analysis are achieved through multi-element technology fusion of the whole drilling parameter optimization process.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com