Water pressure torsional impact device for well drilling

A technology of impact device and hydraulic pressure, which is applied to the driving device for drilling in the borehole, drilling equipment, earthwork drilling and production, etc., which can solve the adverse effects of drill bit sticking, drill bit, drill string supporting parts service life, and many wearing parts And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

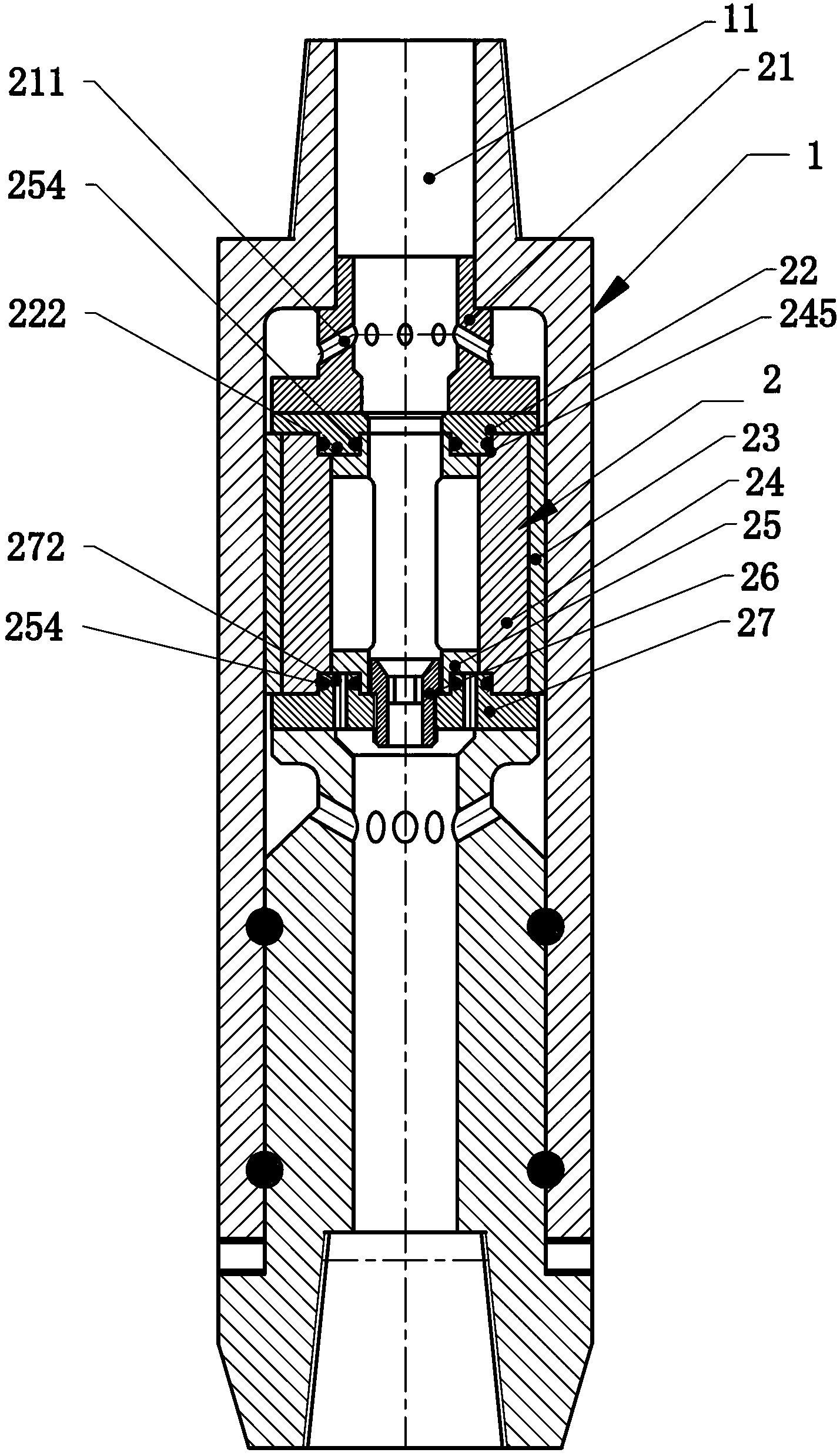

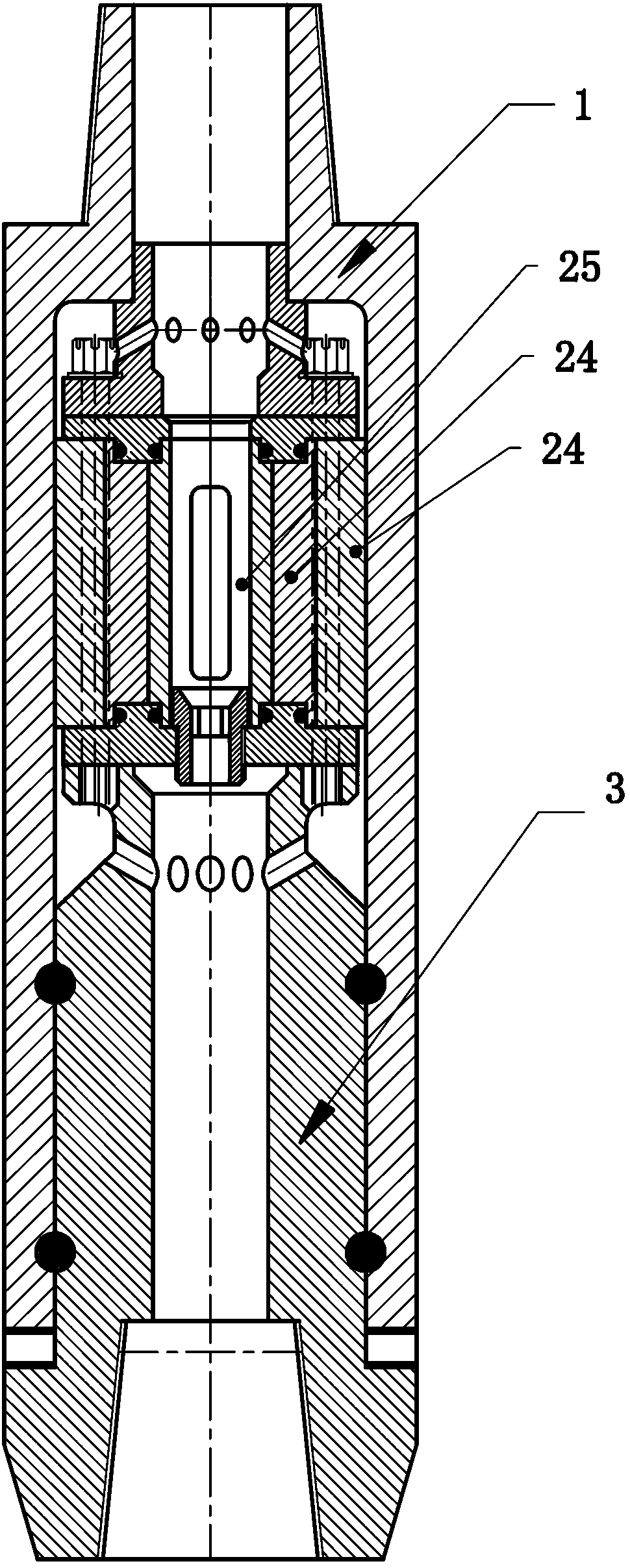

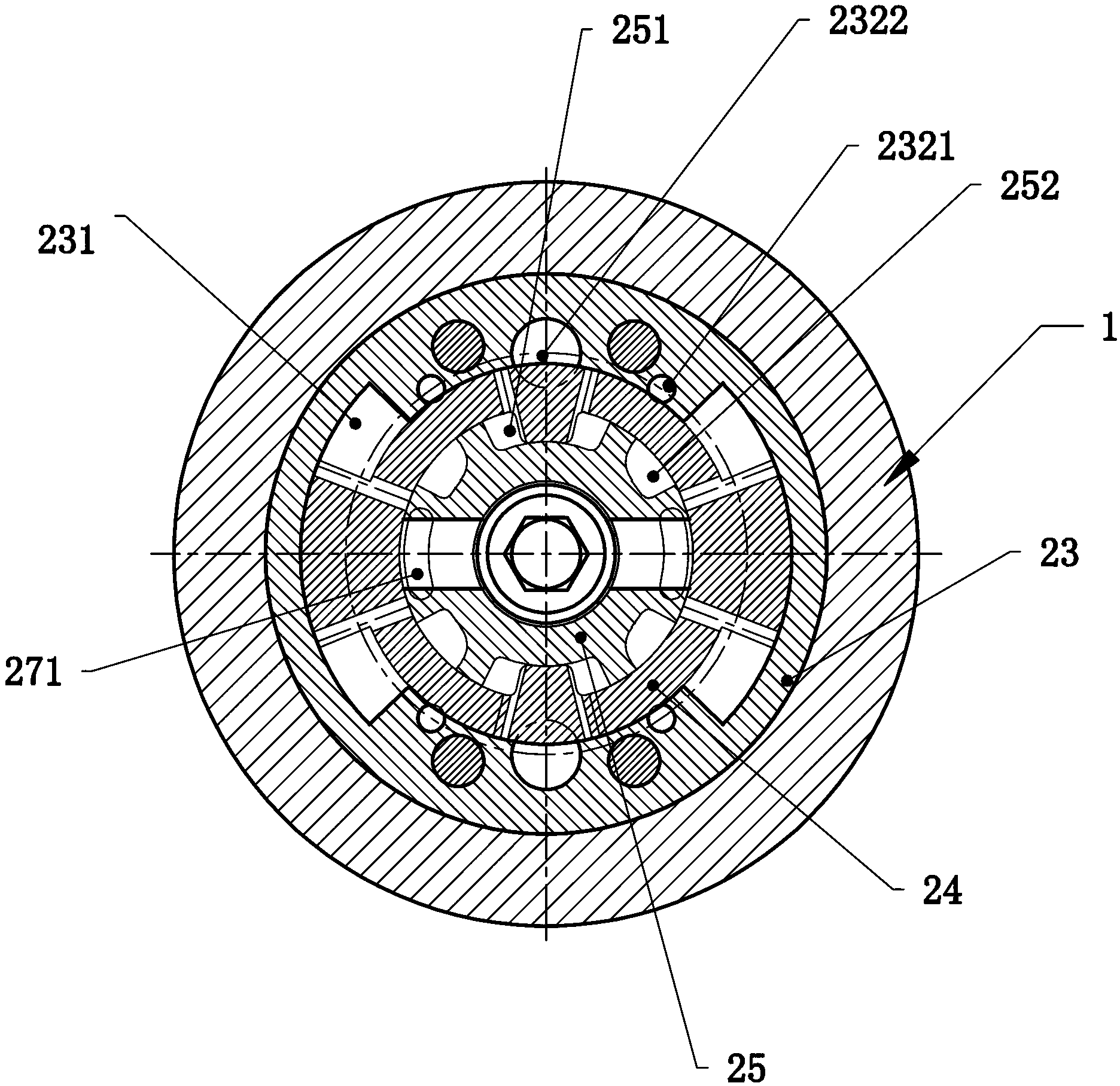

[0022] Such as figure 1 —— Figure 12 As shown, a hydraulic torsional impact device for drilling includes a drill jack sub 1, a hydraulic torsional impact generator 2 and a drill bit mount 3. The hydraulic torsional impact generator 2 is placed in the drill jack sub 1. In the embodiment of the present invention, the hydraulic torsional impact generator 2 is mainly composed of a diversion positioning cover 21, an upper rotary gland 22, an impact hammer 24, an impact hammer seat 23, a steering diverter 25, a shut-off nozzle 26, a lower The rotary gland 27 is composed of a diversion positioning cover 21, an upper rotary gland 22, an impact hammer seat 23 and a lower rotary gland 27 are fastened to the drill bit mounting seat 3 by bolts, and the impact hammer 24, impact hammer Both the shaft centers of the hammer seat 23 and the steering splitter 25 are set through holes, wherein the steering splitter 25 is sleeved on the shaft center through hole of the impact hammer 24, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com