Patents

Literature

4484results about "Automatic control for drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

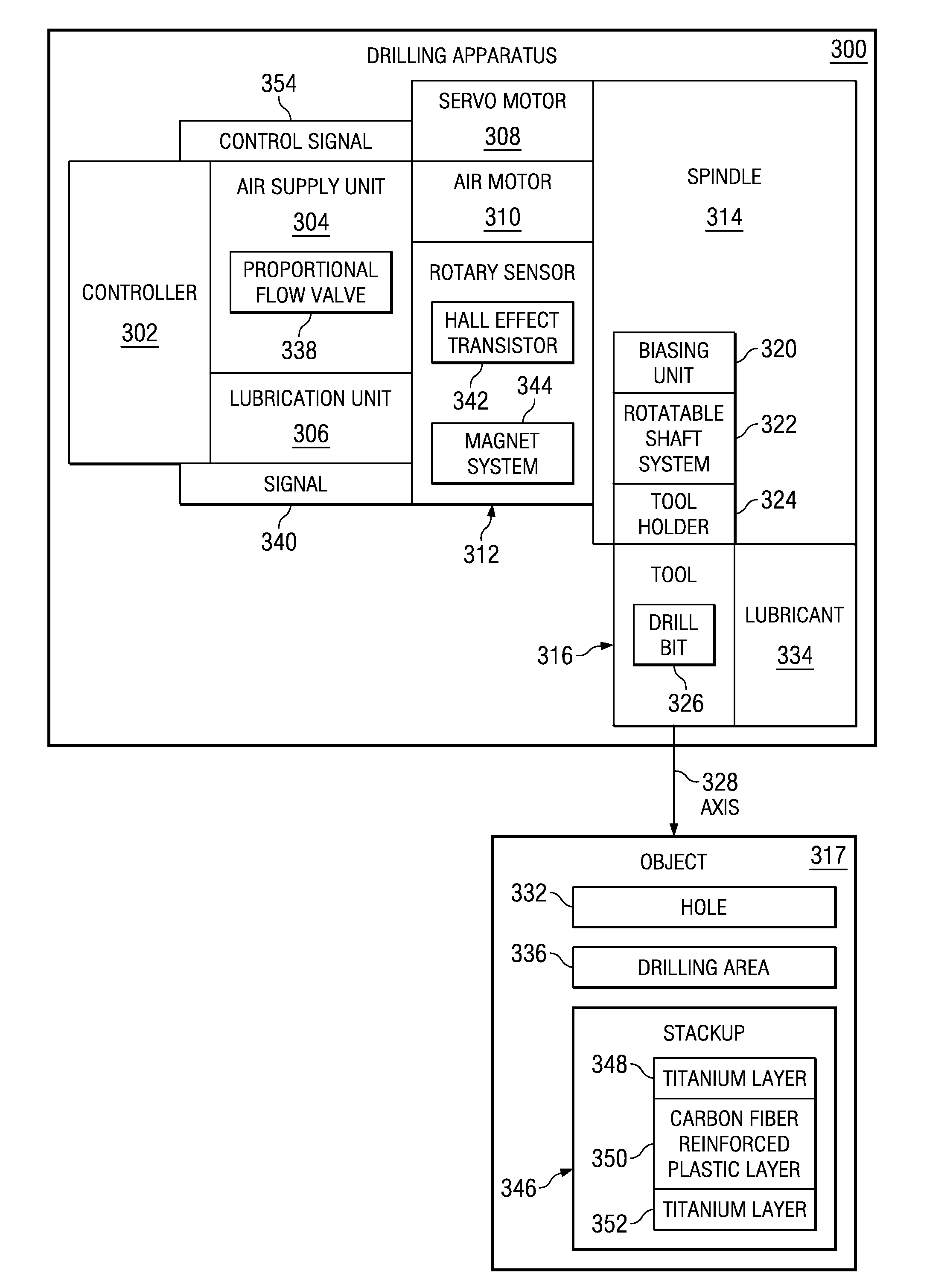

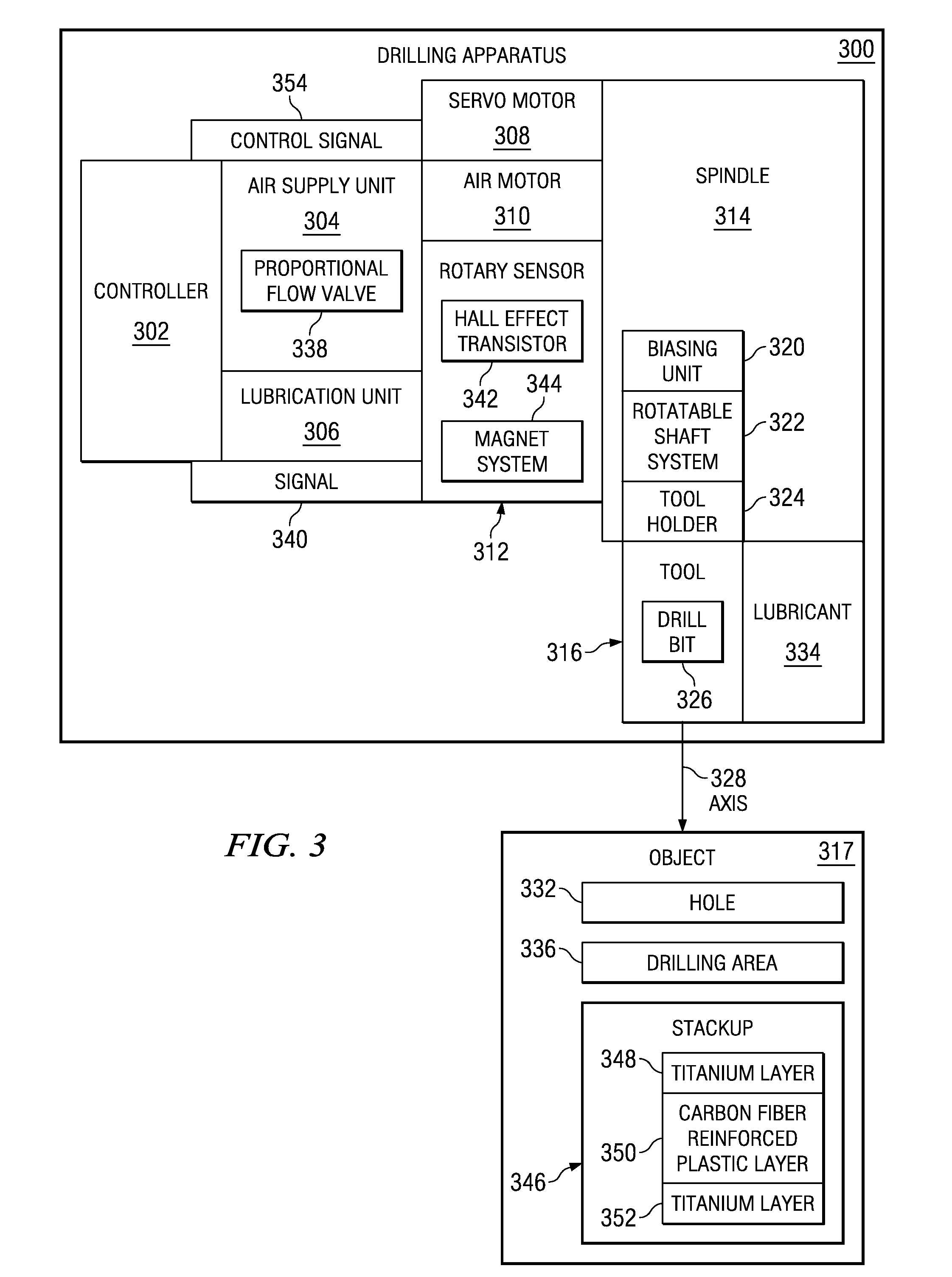

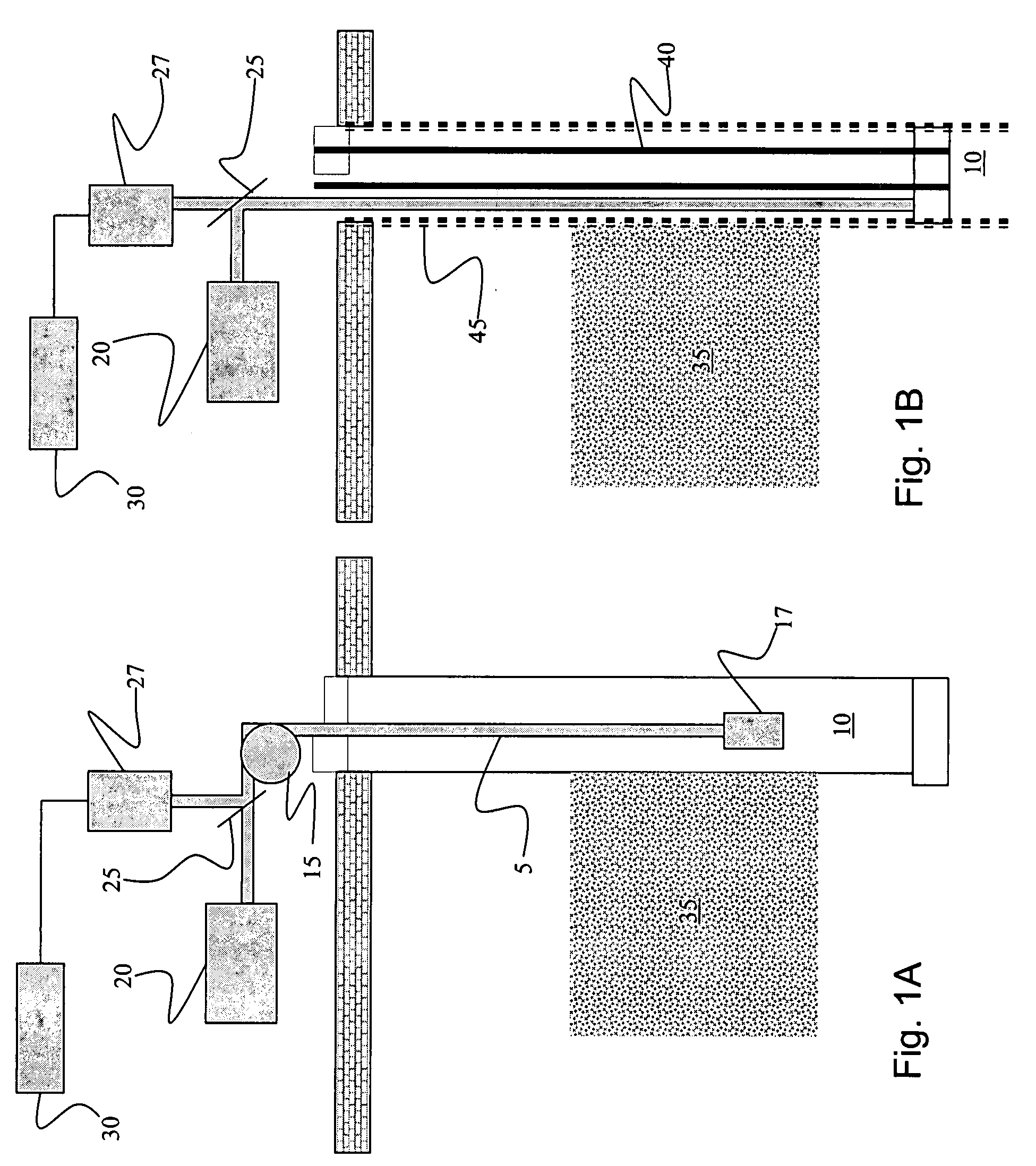

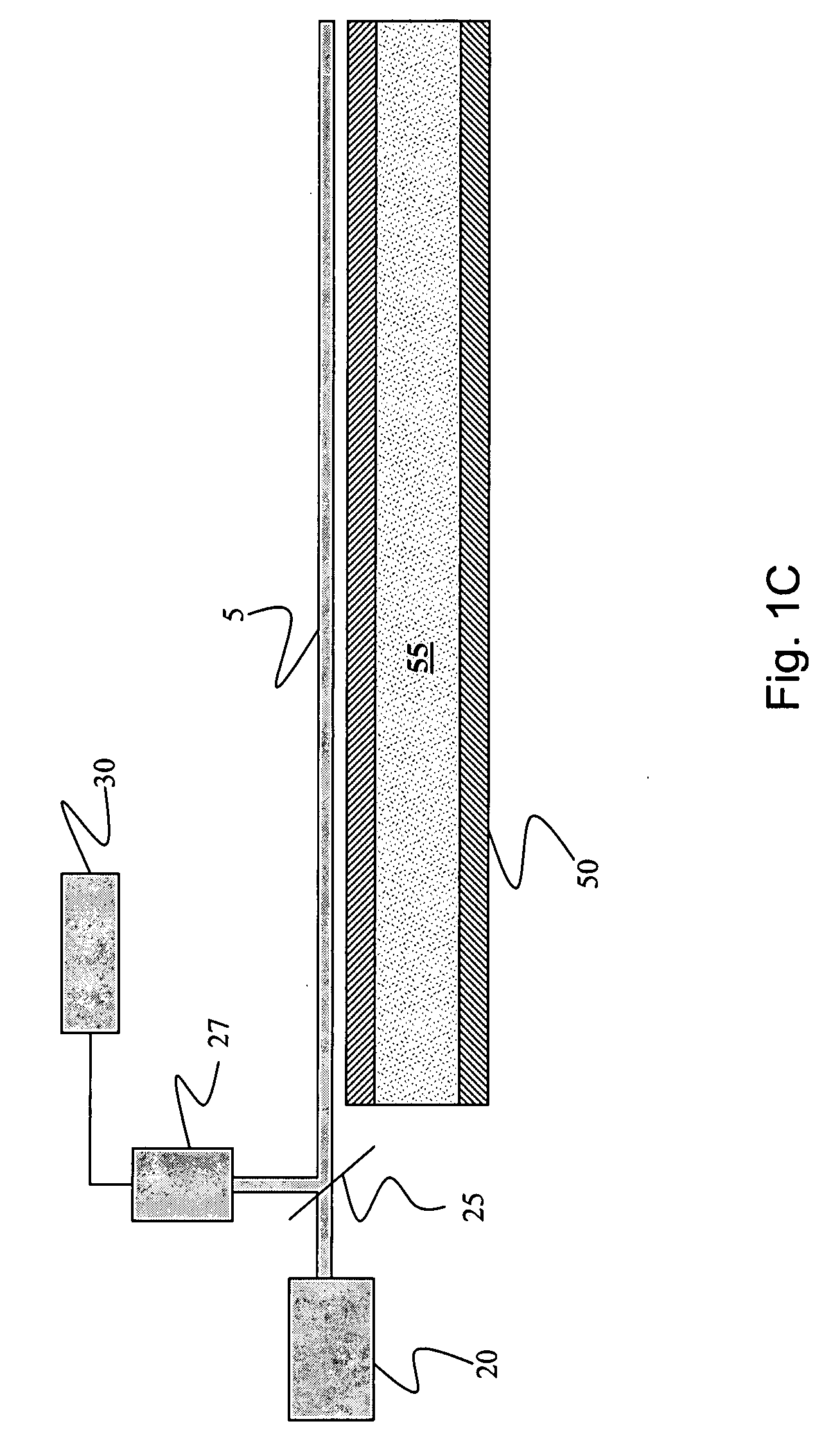

Adaptive positive feed drilling system

An apparatus for a drilling operation. In one advantageous embodiment, the drilling operation includes a motor, a rotary sensor, and a controller connected to the rotary sensor. The rotary sensor may be capable of generating a signal in response to rotary movement of the drill motor. The controller may be capable of monitoring a speed of the air motor from the signal generated by the rotary sensor and may be capable of identifying a change from a current layer in a stackup to a new layer in the stackup using the signal.

Owner:THE BOEING CO

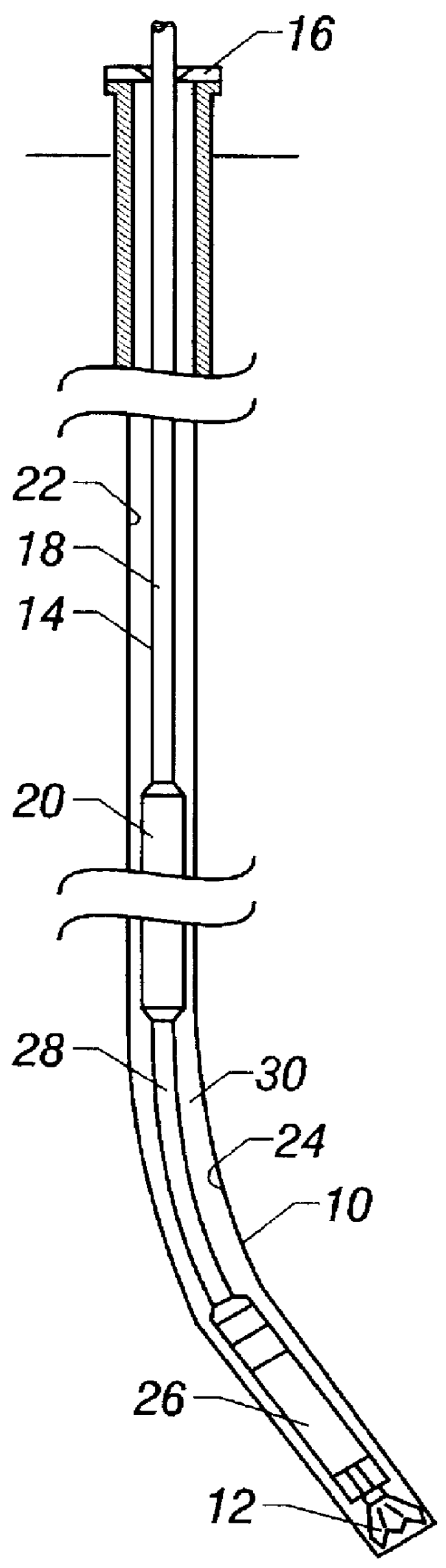

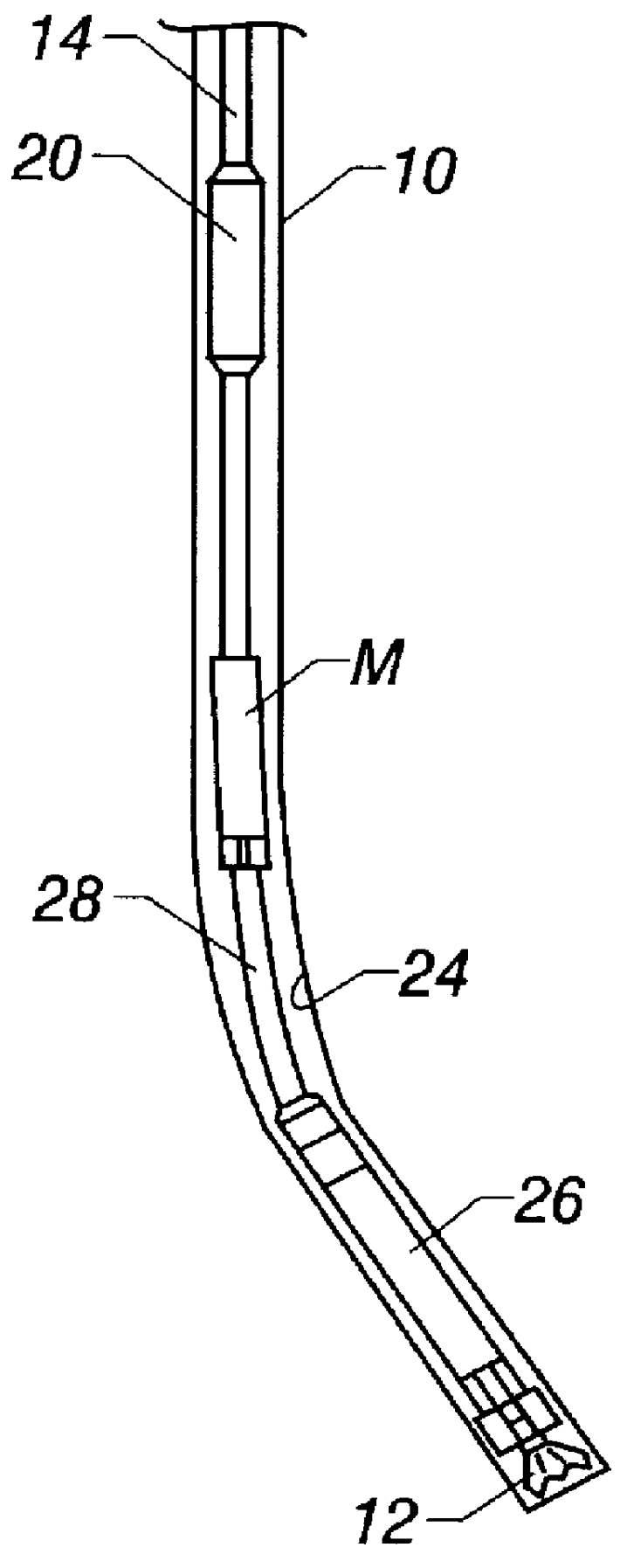

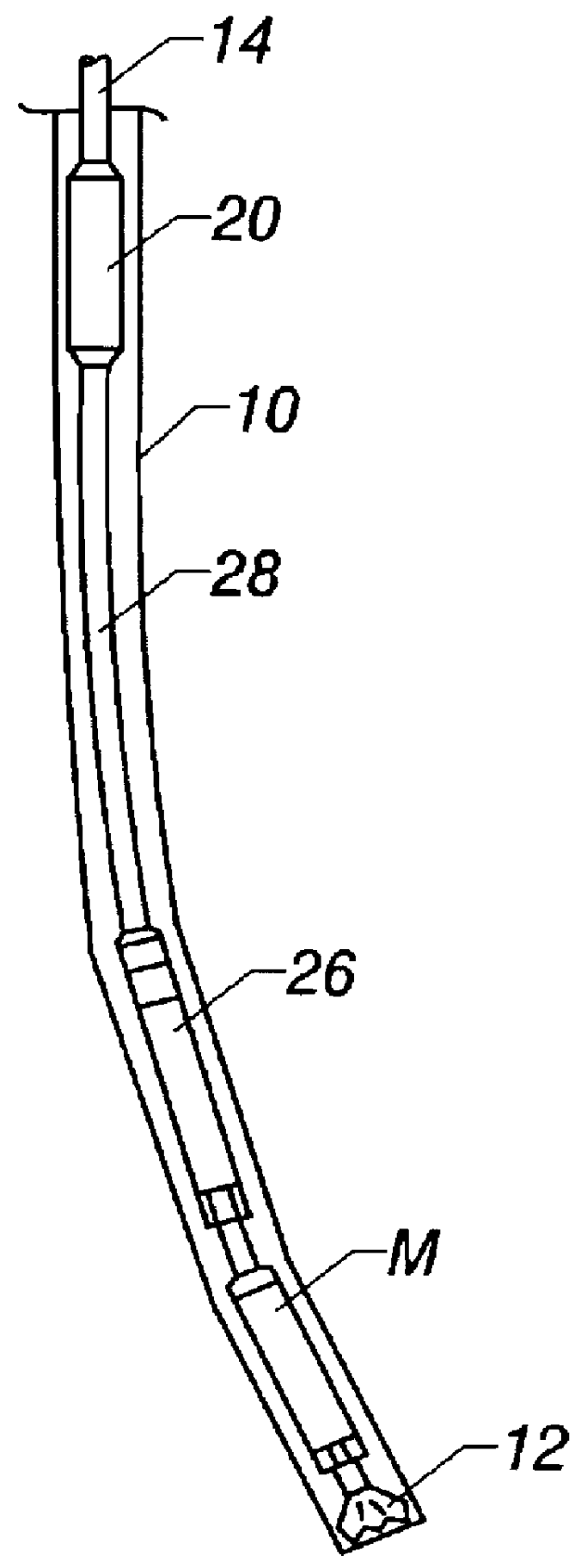

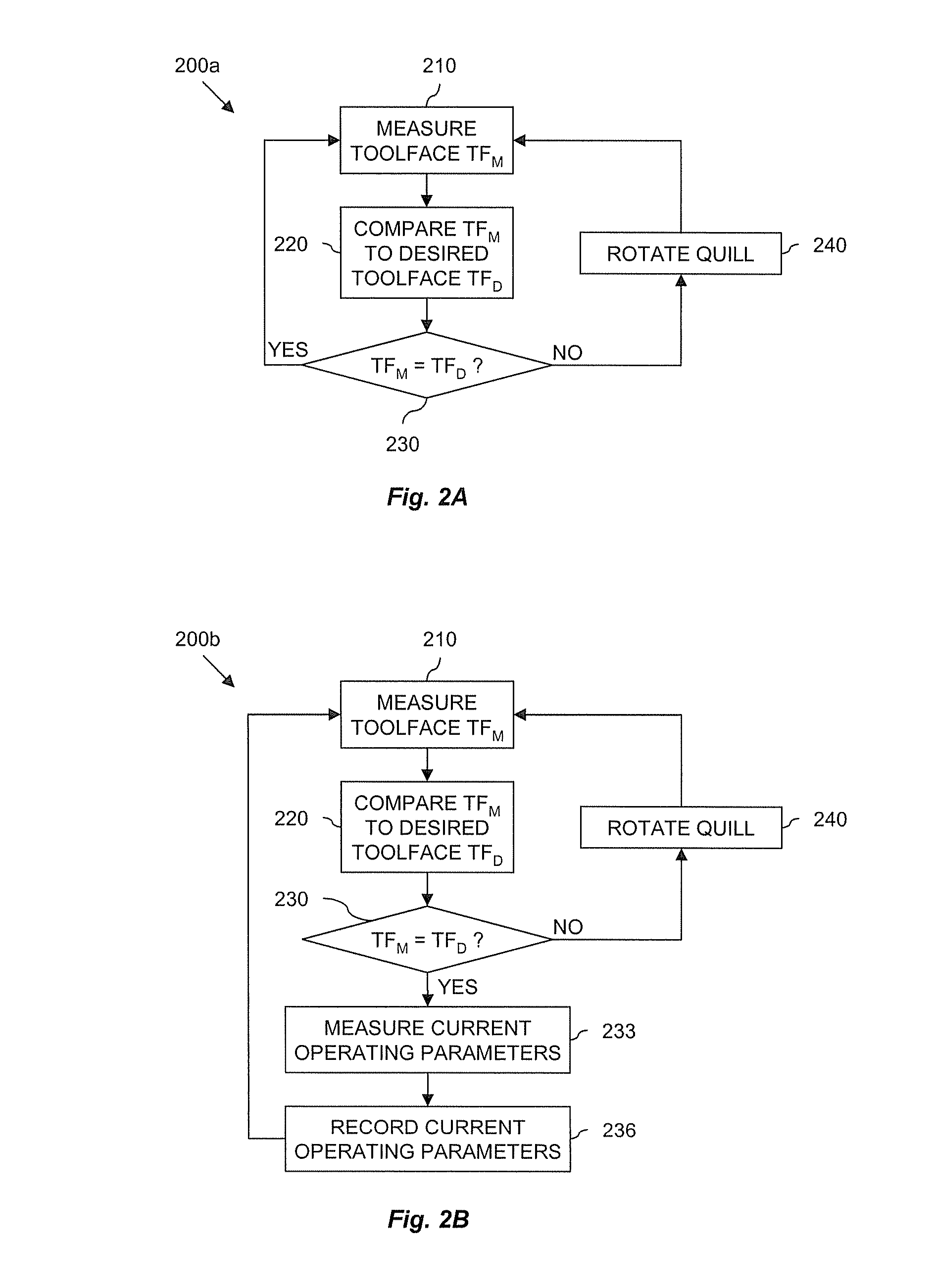

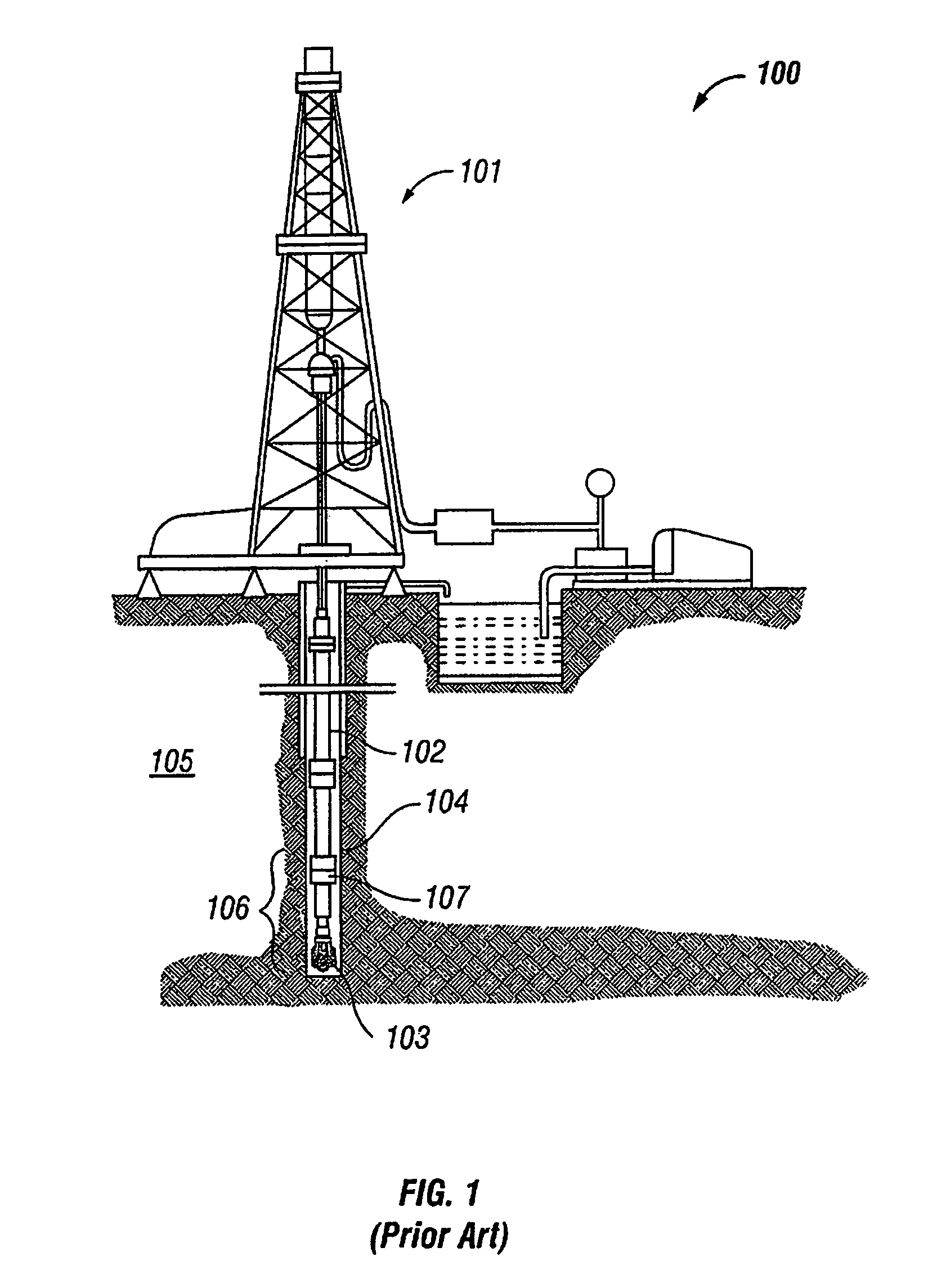

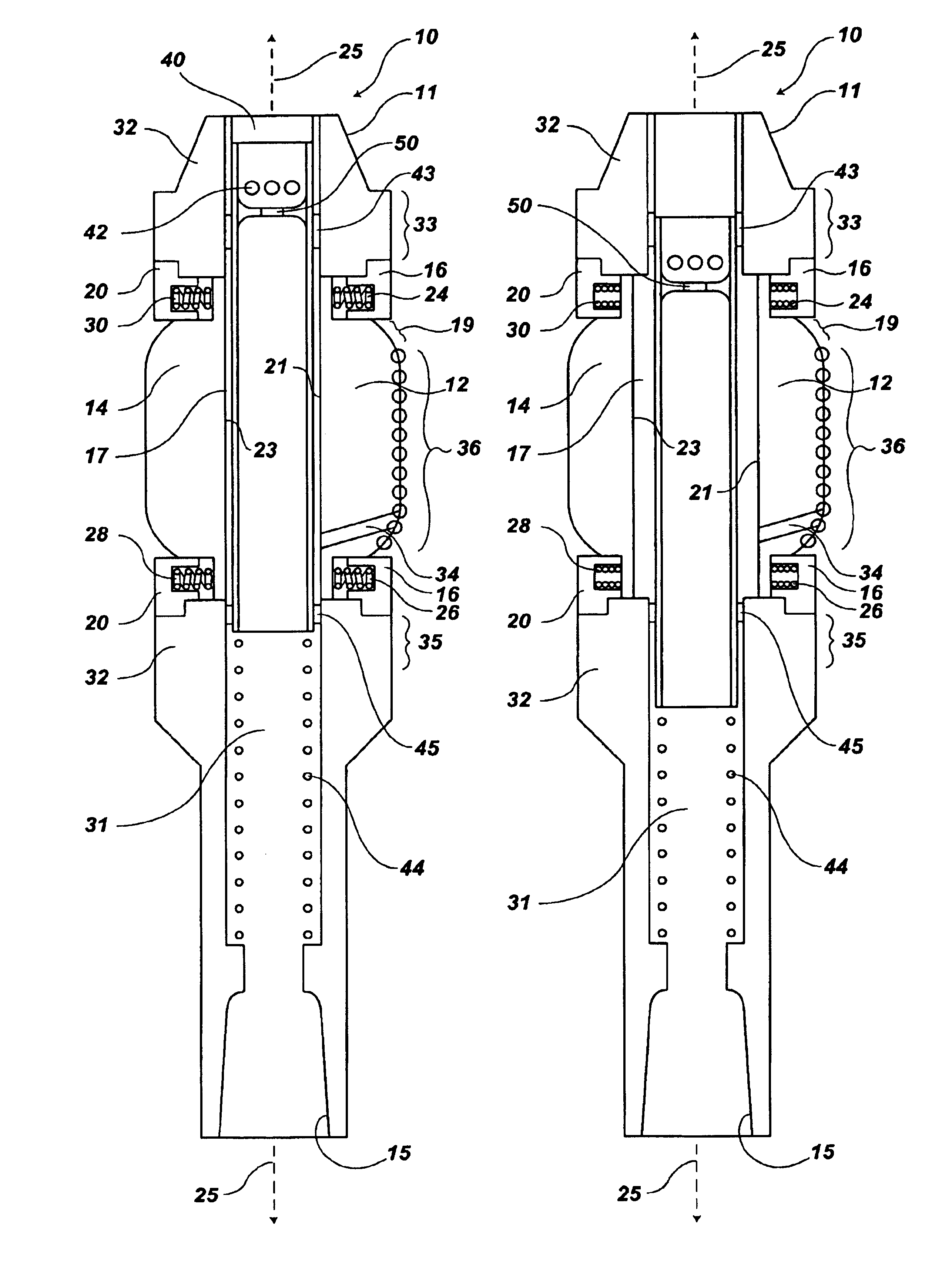

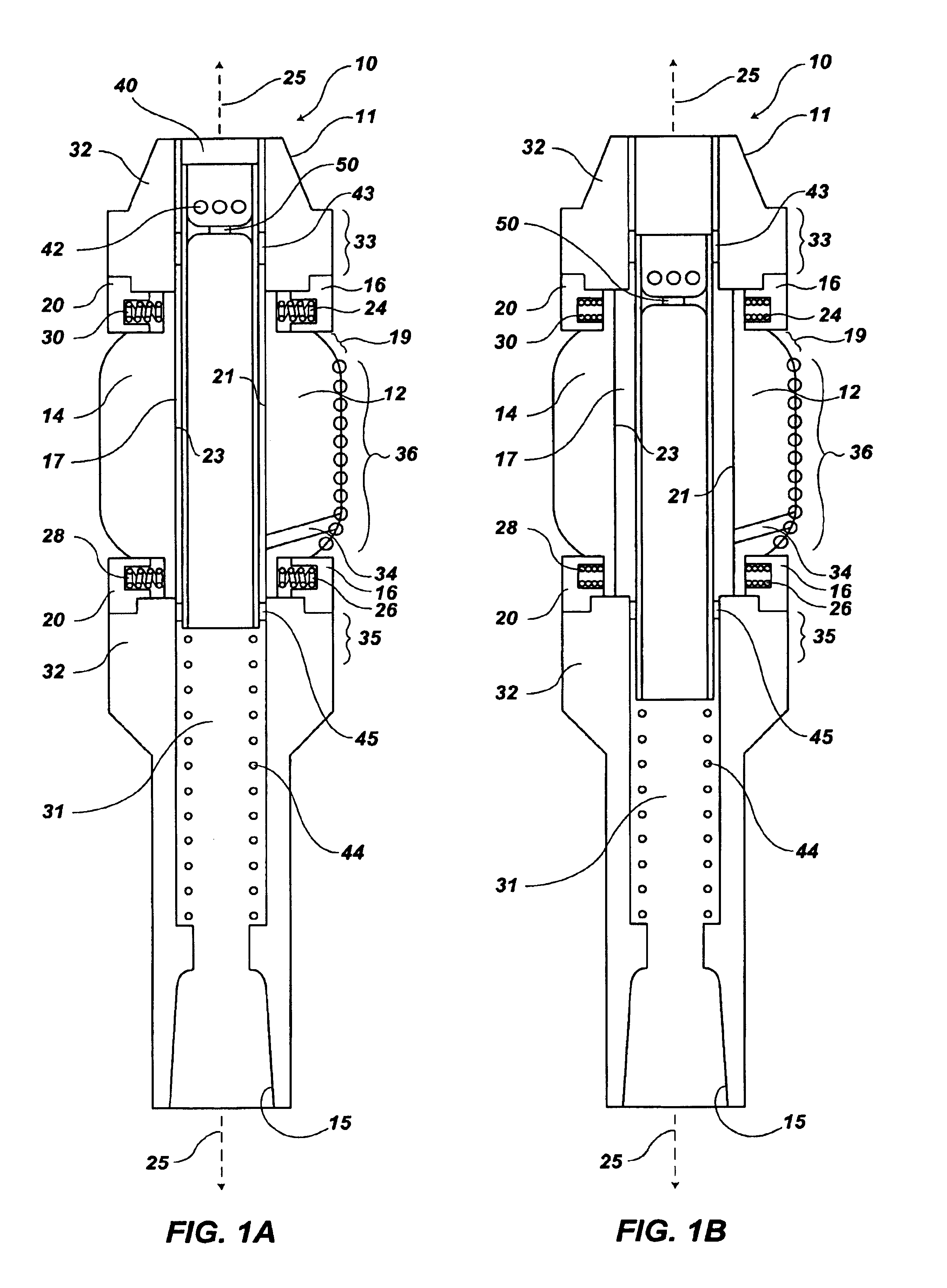

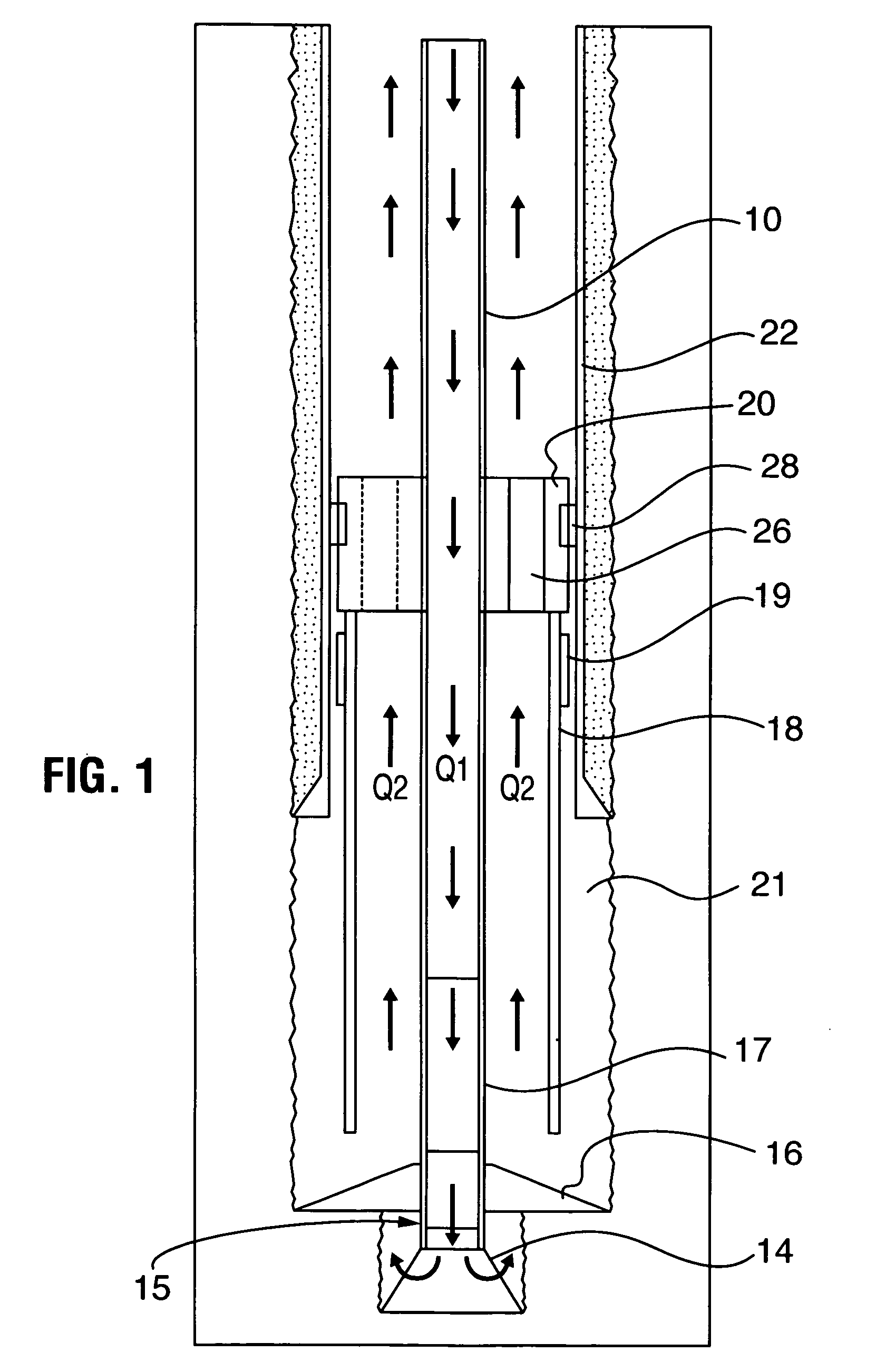

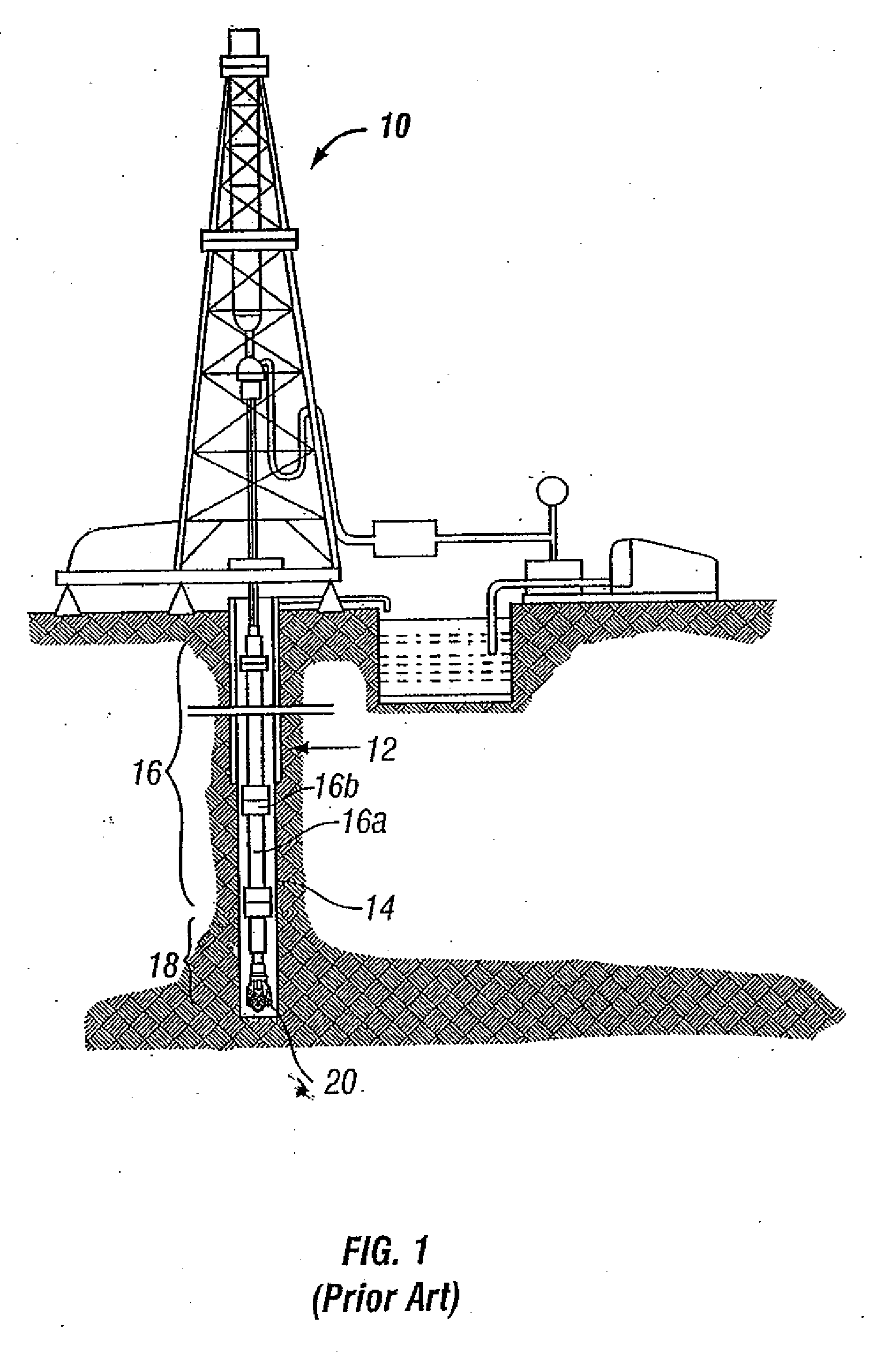

Actively controlled rotary steerable system and method for drilling wells

InactiveUS6092610AEfficient rotary speedPromote productionDrilling rodsConstructionsAccelerometerDirectional drilling

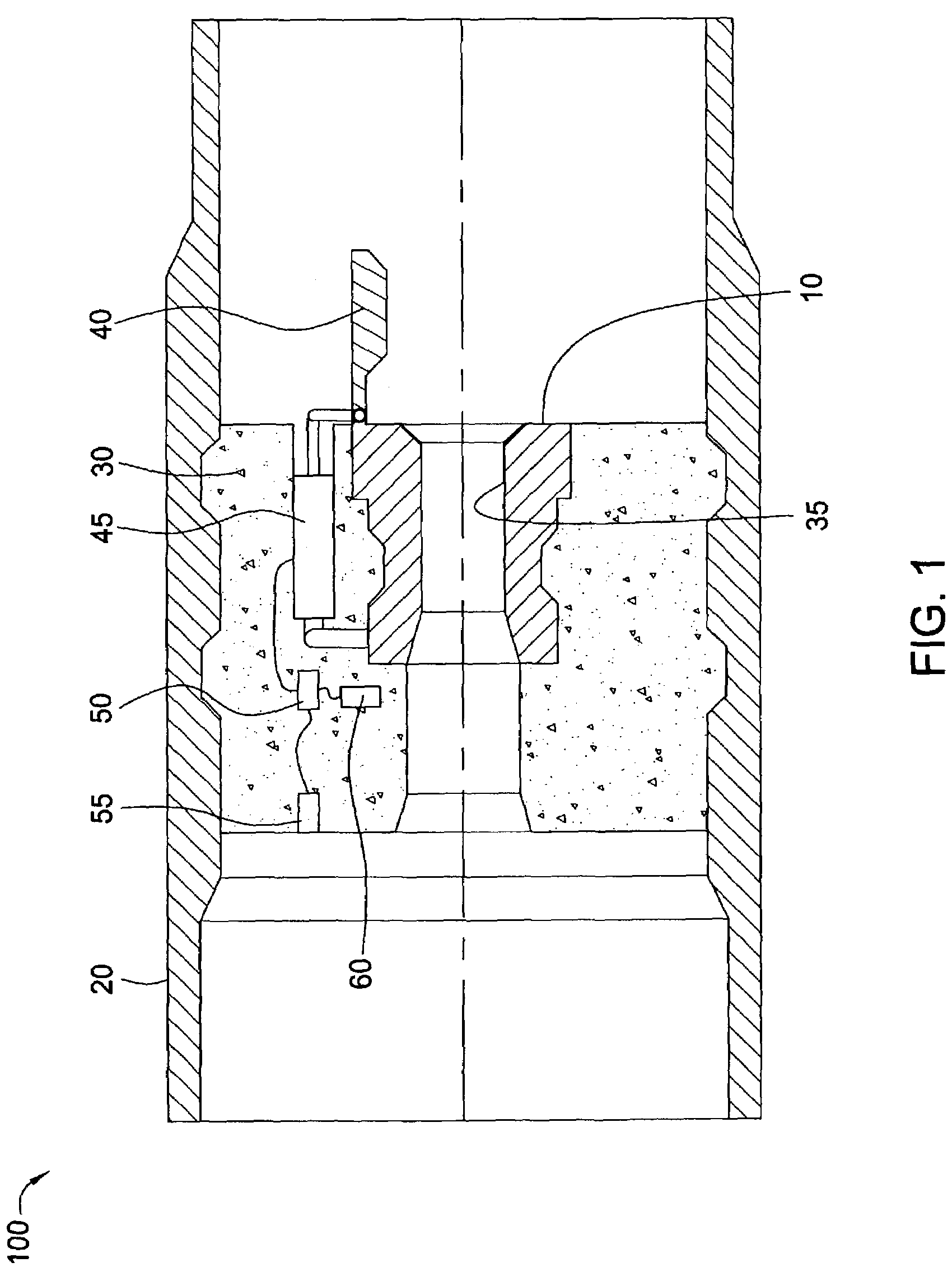

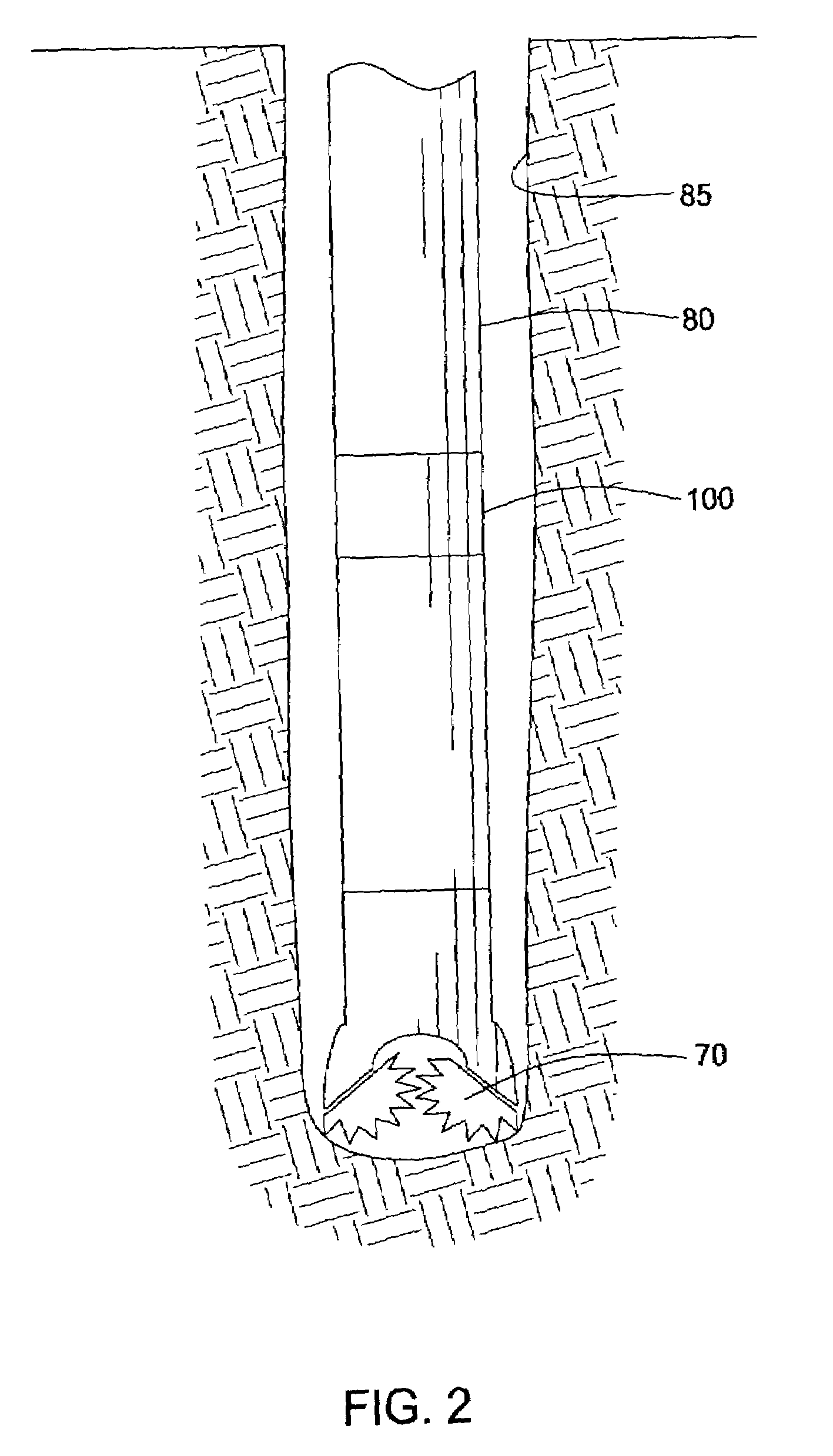

An actively controlled rotary steerable drilling system for directional drilling of wells having a tool collar rotated by a drill string during well drilling. A bit shaft has an upper portion within the tool collar and a lower end extending from the collar and supporting a drill bit. The bit shaft is omni-directionally pivotally supported intermediate its upper and lower ends by a universal joint within the collar and is rotatably driven by the collar. To achieve controlled steering of the rotating drill bit, orientation of the bit shaft relative to the tool collar is sensed and the bit shaft is maintained geostationary and selectively axially inclined relative to the tool collar during drill string rotation by rotating it about the universal joint by an offsetting mandrel that is rotated counter to collar rotation and at the same frequency of rotation. An electric motor provides rotation to the offsetting mandrel with respect to the tool collar and is servo-controlled by signal input from position sensing elements such as magnetometers, gyroscopic sensors, and accelerometers which provide real time position signals to the motor control. In addition, when necessary, a brake is used to maintain the offsetting mandrel and the bit shaft axis geostationary. Alternatively, a turbine is connected to the offsetting mandrel to provide rotation to the offsetting mandrel with respect to the tool collar and a brake is used to servo-control the turbine by signal input from position sensors.

Owner:SCHLUMBERGER TECH CORP

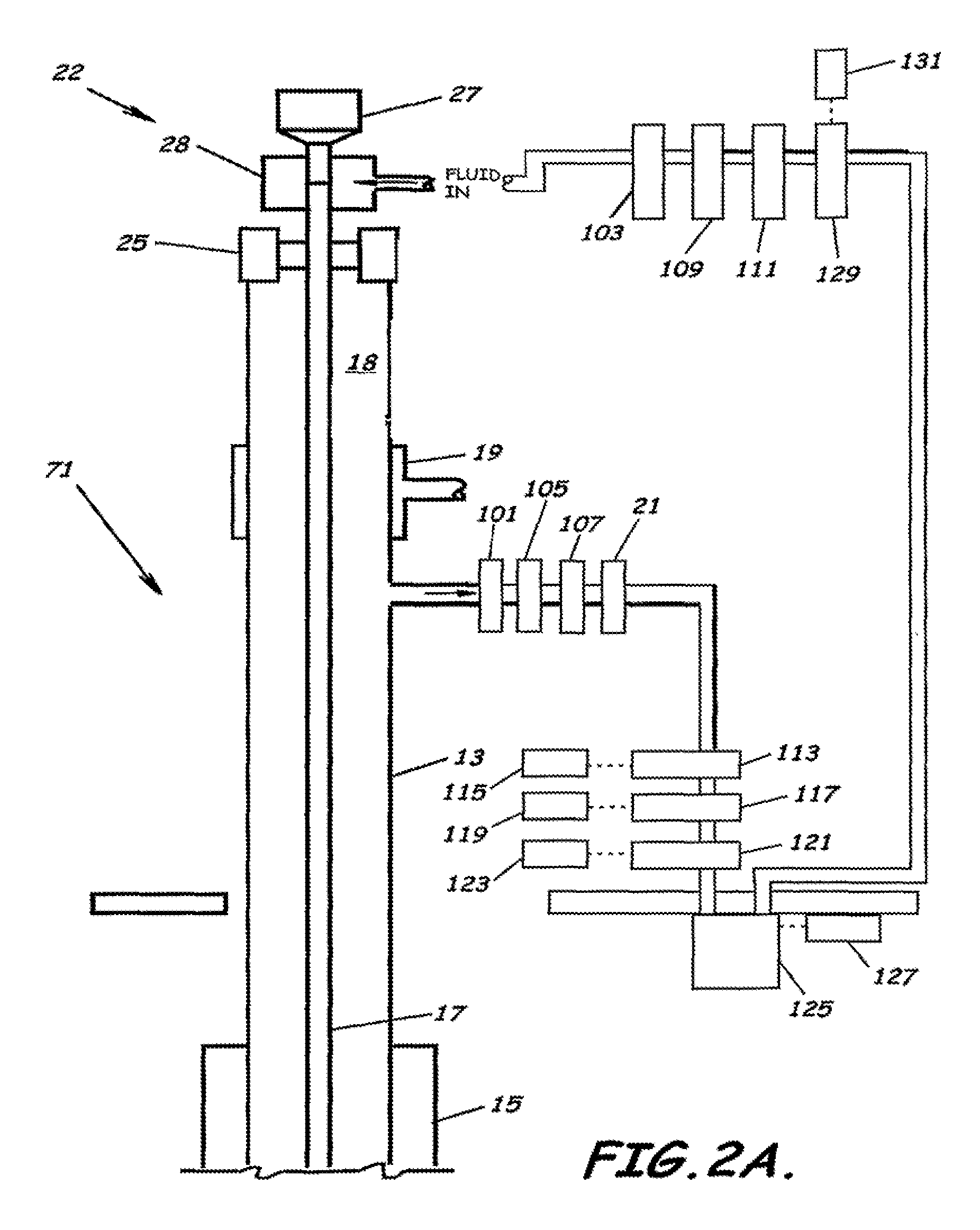

Automated directional drilling apparatus and methods

Methods and systems for drilling to a target location include a control system that receives an input comprising a planned drilling path to a target location and determines a projected location of a bottom hole assembly of a drilling system. The projected location of the bottom hole assembly is compared to the planned drilling path to determine a deviation amount. A modified drilling path is created to the target location as selected based on the amount of deviation from the planned drilling path, and drilling rig control signals that steer the bottom hole assembly of the drilling system to the target location along the modified drilling path are generated.

Owner:NABORS DRILLING TECH USA INC

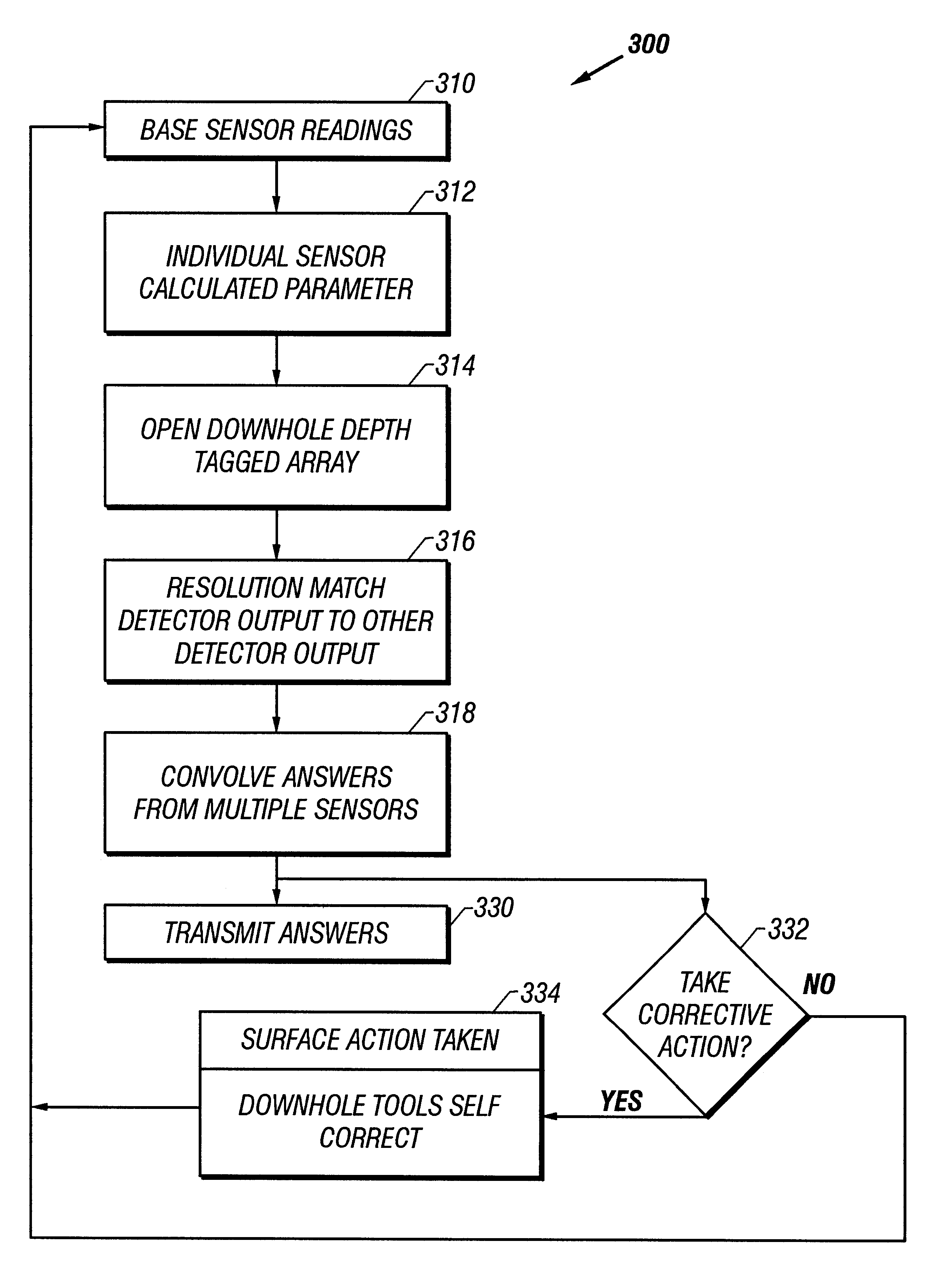

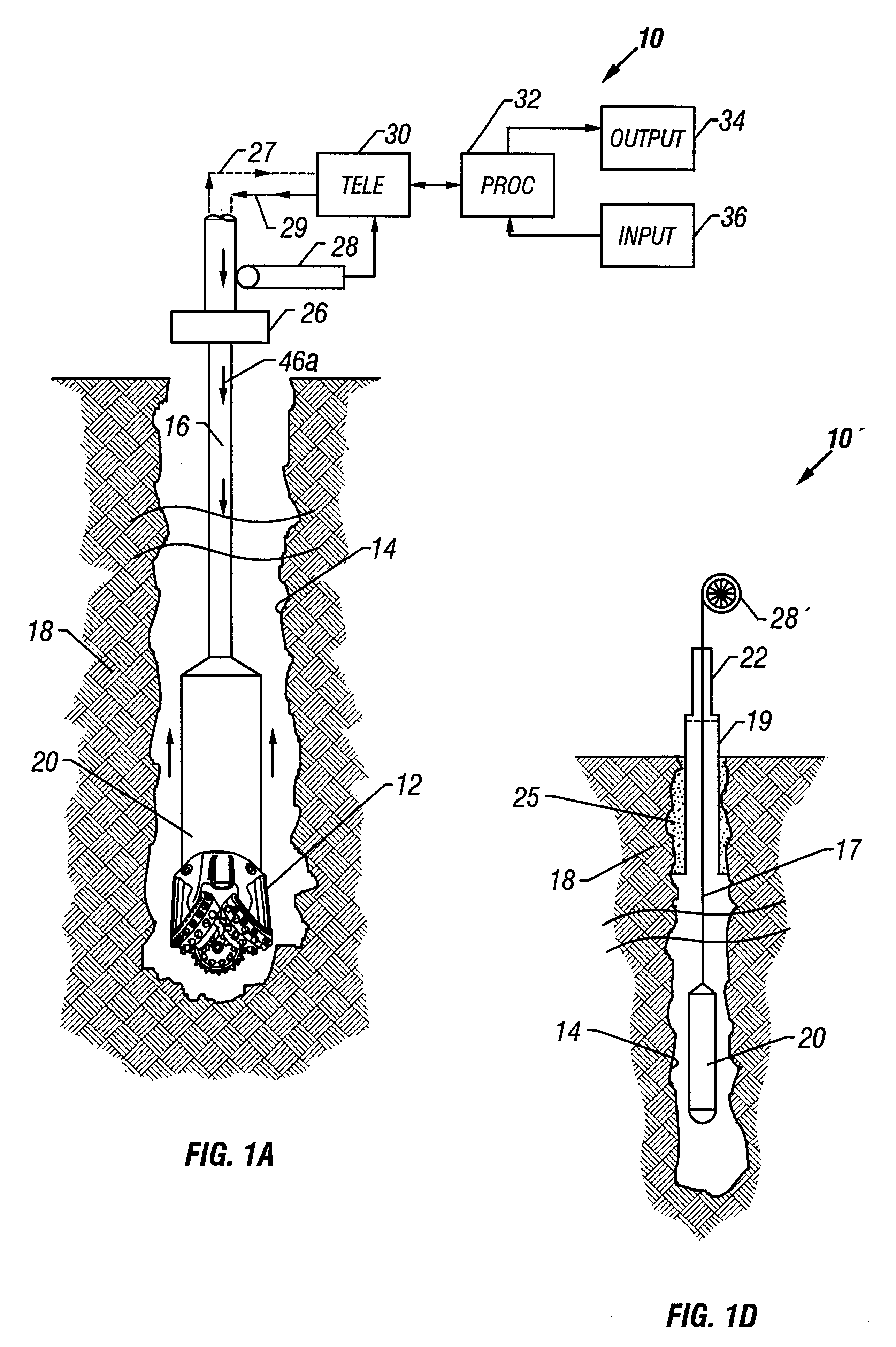

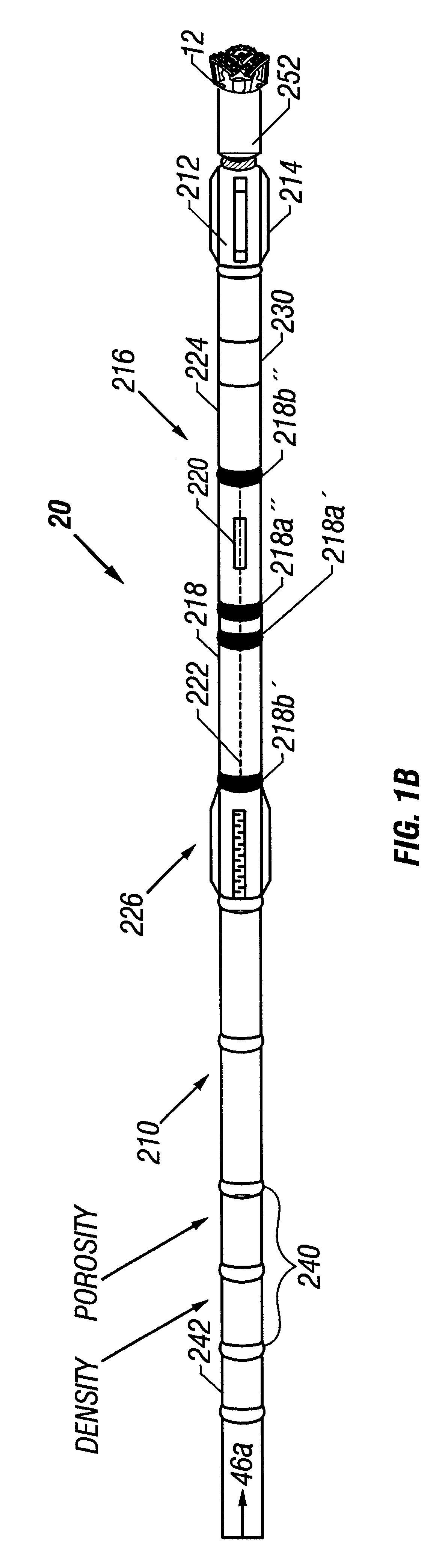

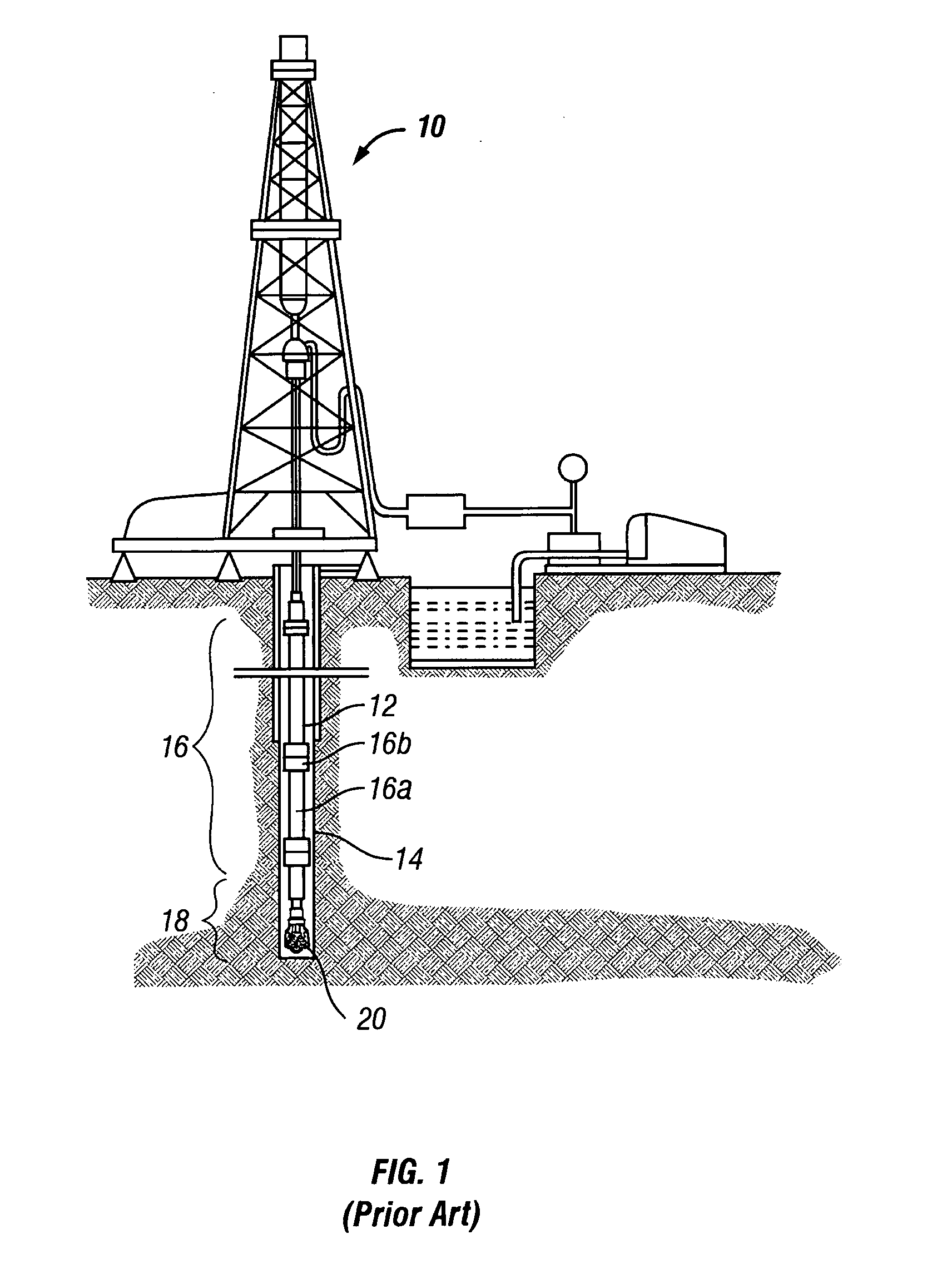

Drilling system with downhole apparatus for determining parameters of interest and for adjusting drilling direction in response thereto

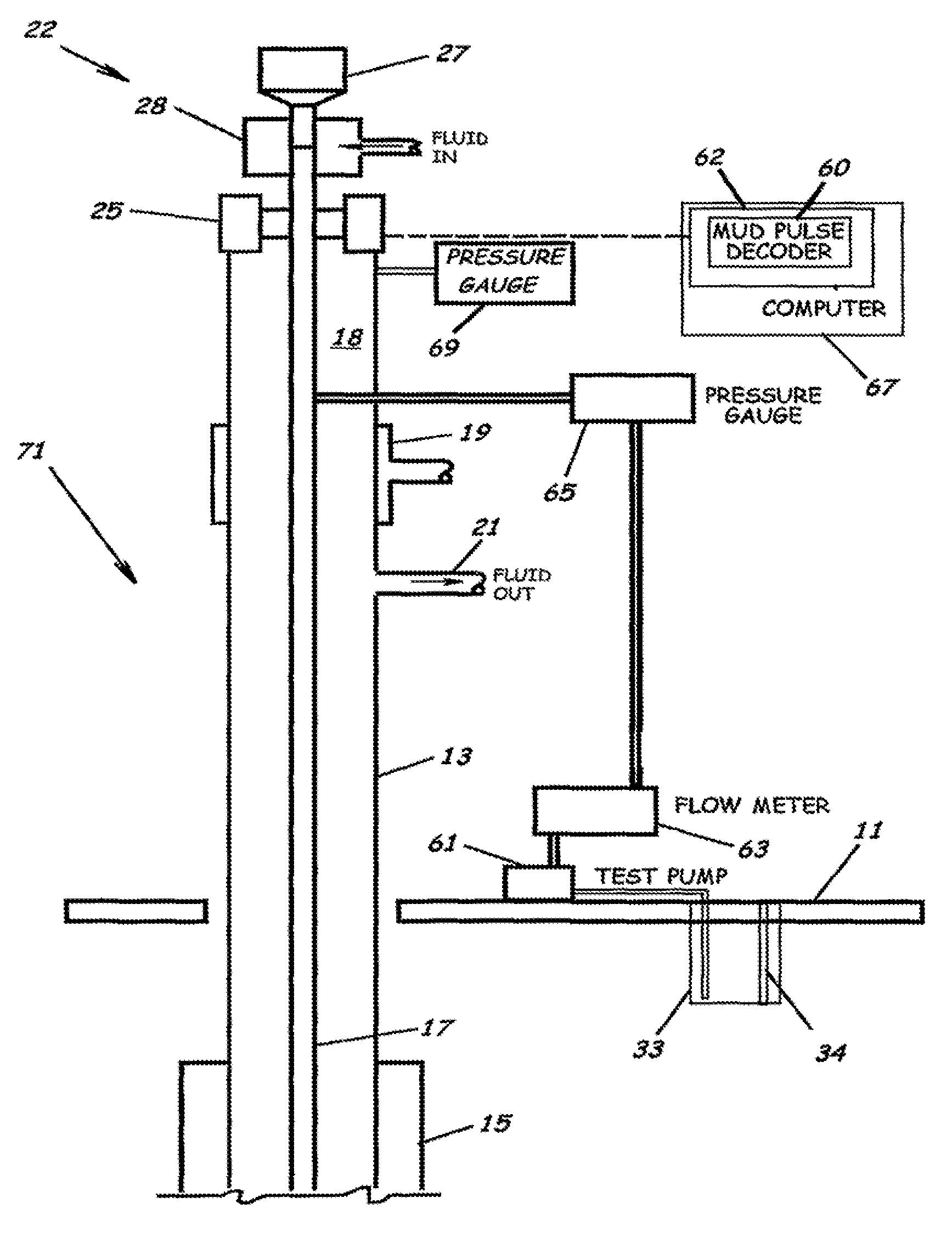

The present invention provides a measurement-while-drilling (MWD) system having a downhole computer and multiple downhole sensors. Relatively large amounts of basic or "raw" data are measured by downhole sensors, and these data are processed within a downhole computer to be reduced to parameters of interest, which may be utilized to control the drilling operation by downhole devices, stored downhole, telemetered to the surface, or both. The measurements may be correlated downhole with stored reference data thereby providing additional information pertaining to the drilling operation. Downhole depth correlation between downhole measured parameters may be made by utilizing surface determined or downhole determined borehole depth.

Owner:BAKER HUGHES INC

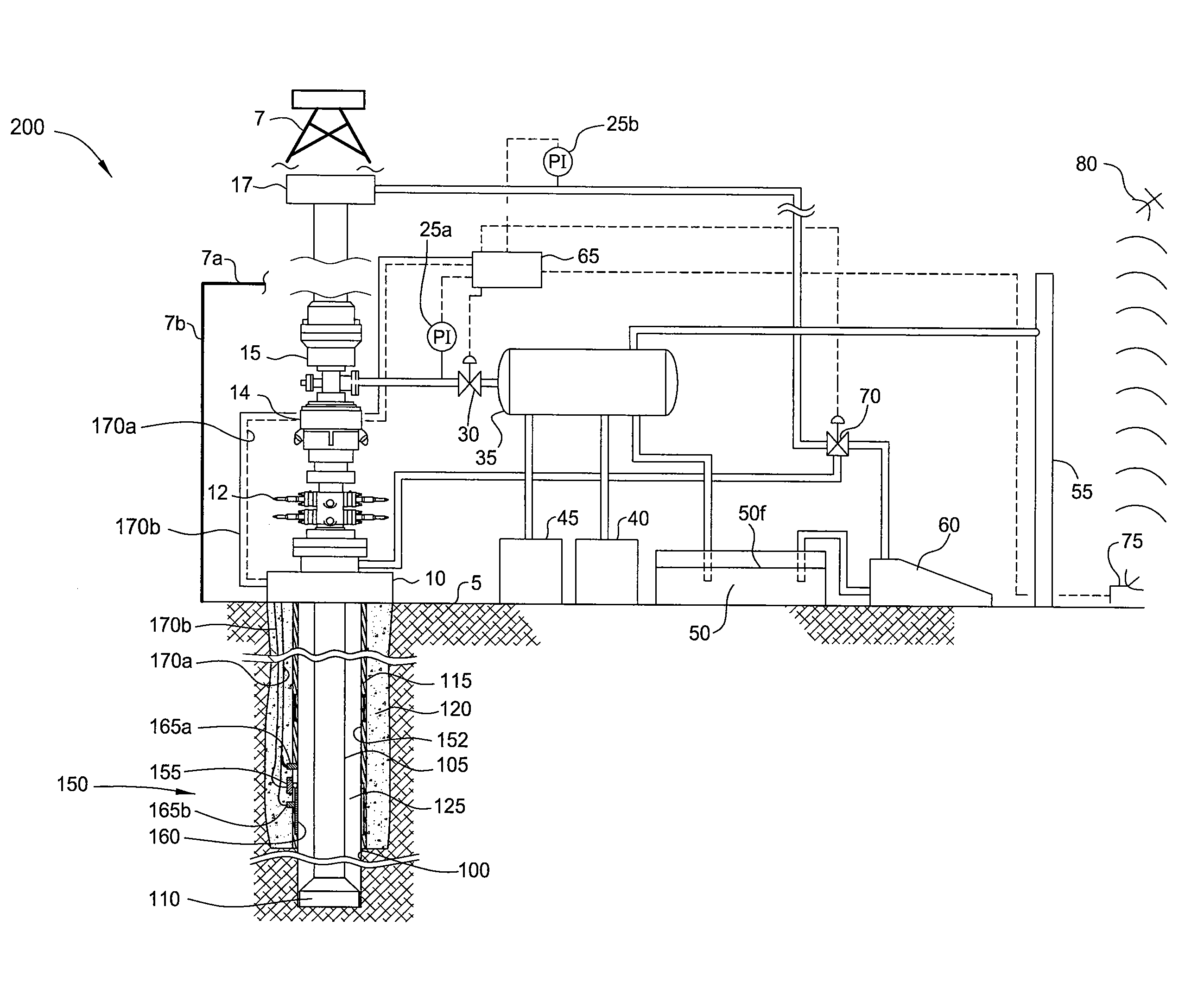

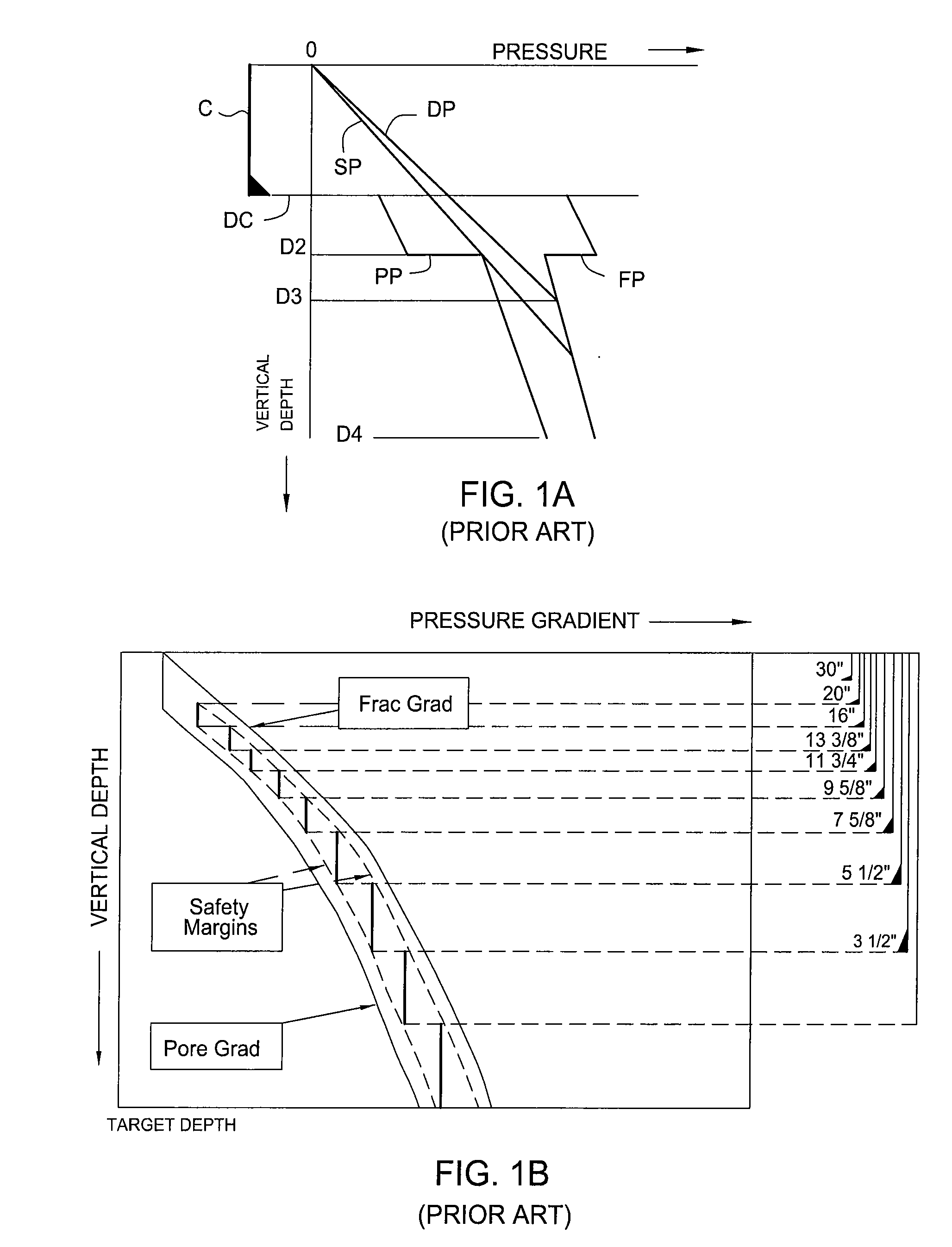

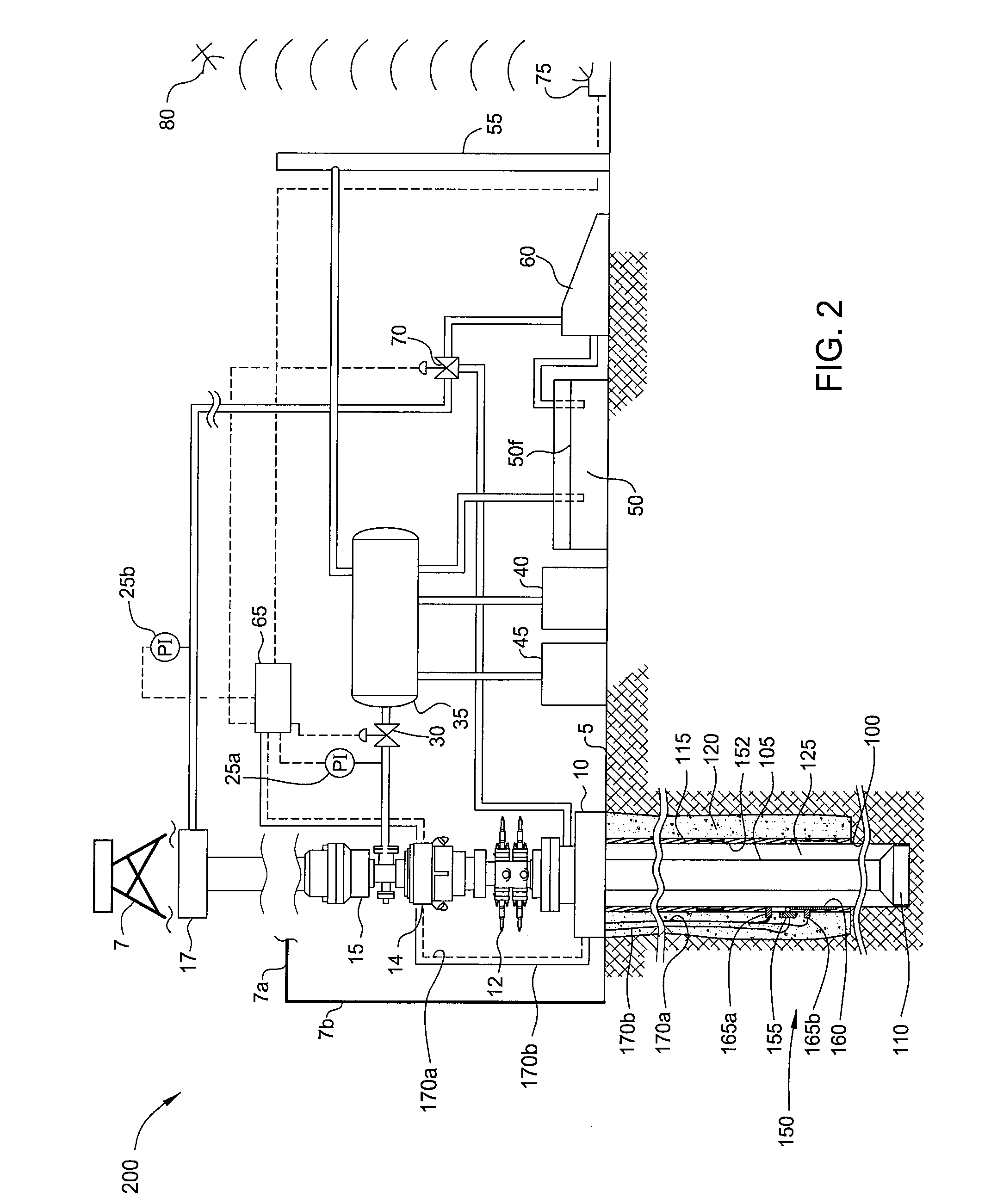

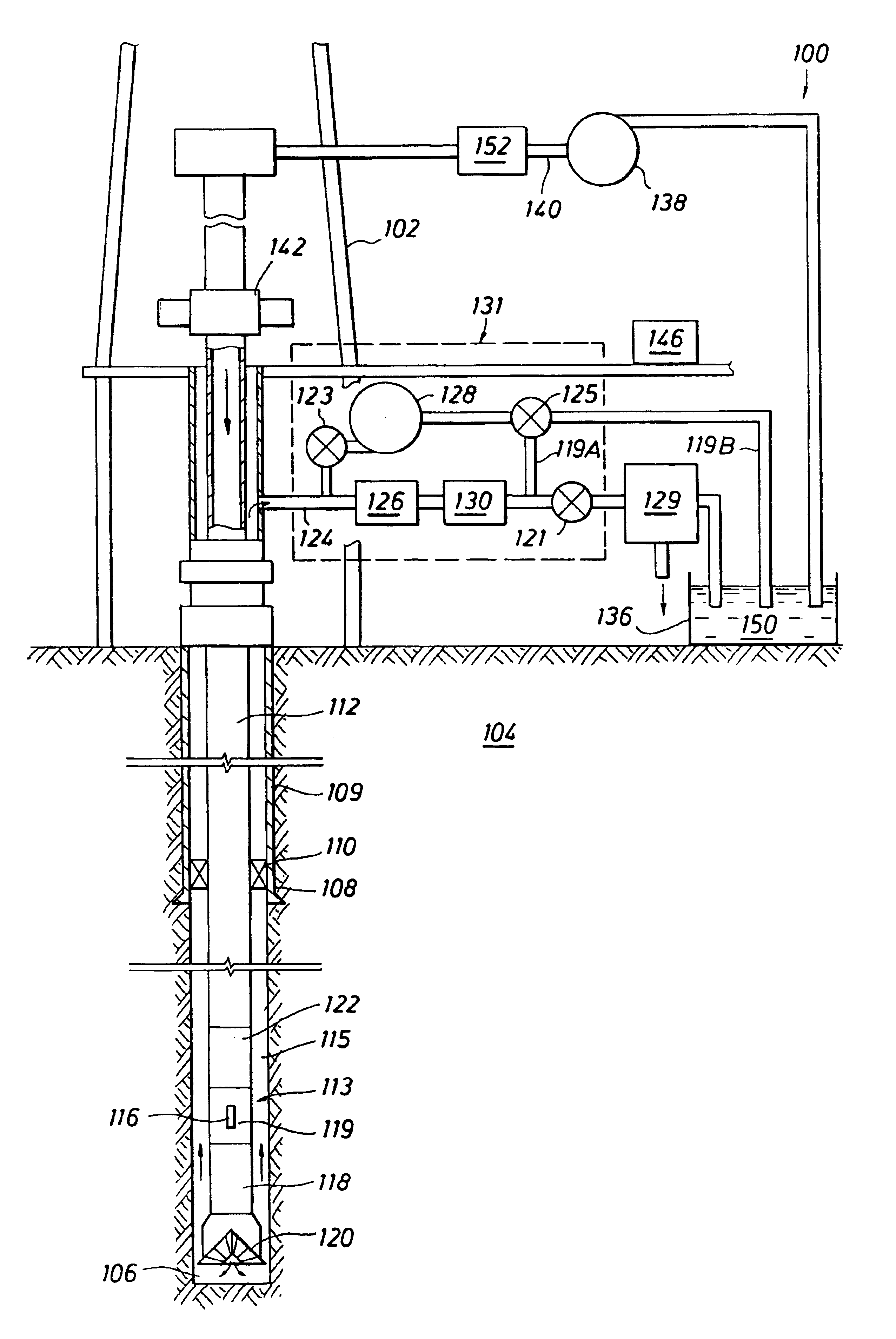

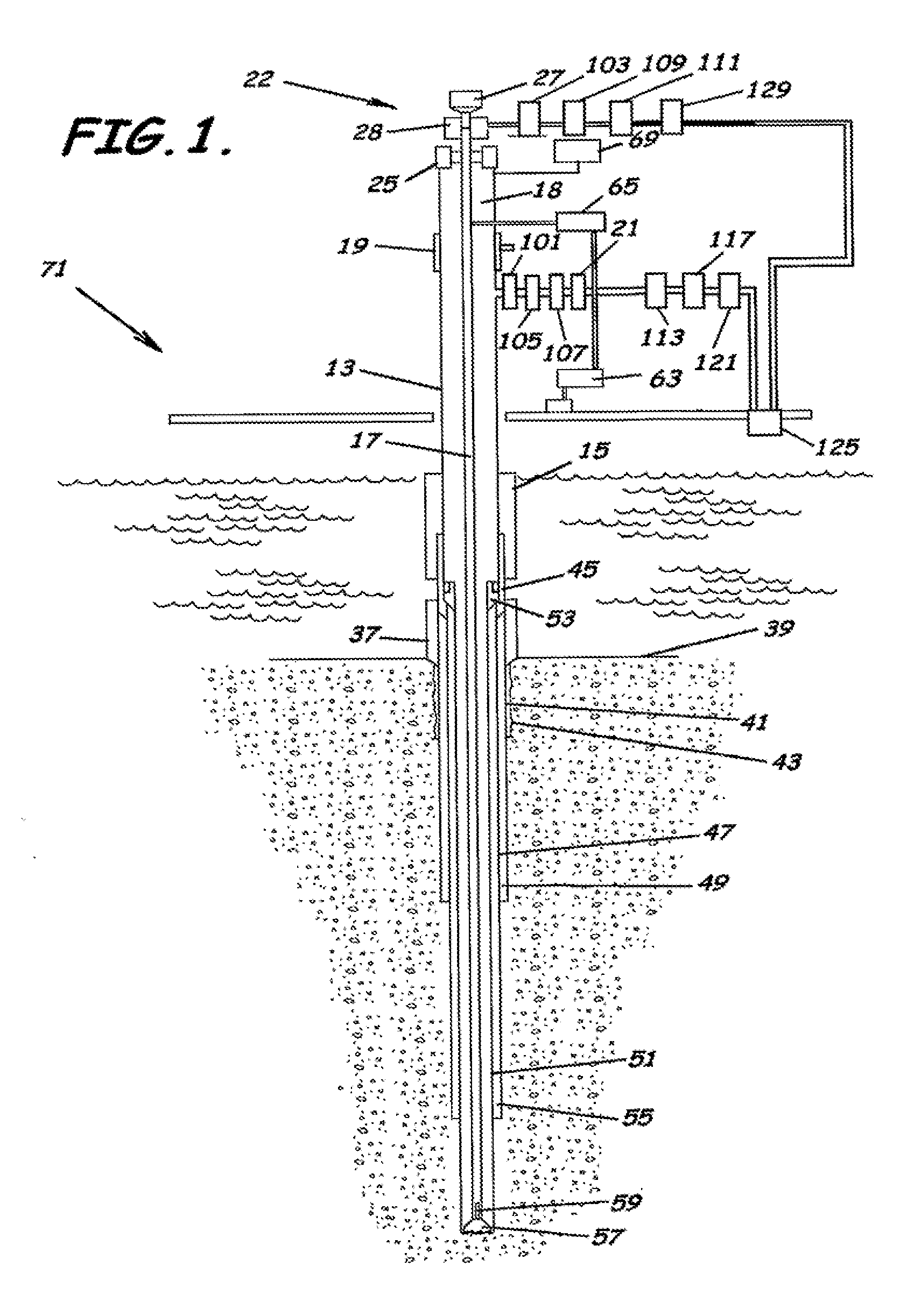

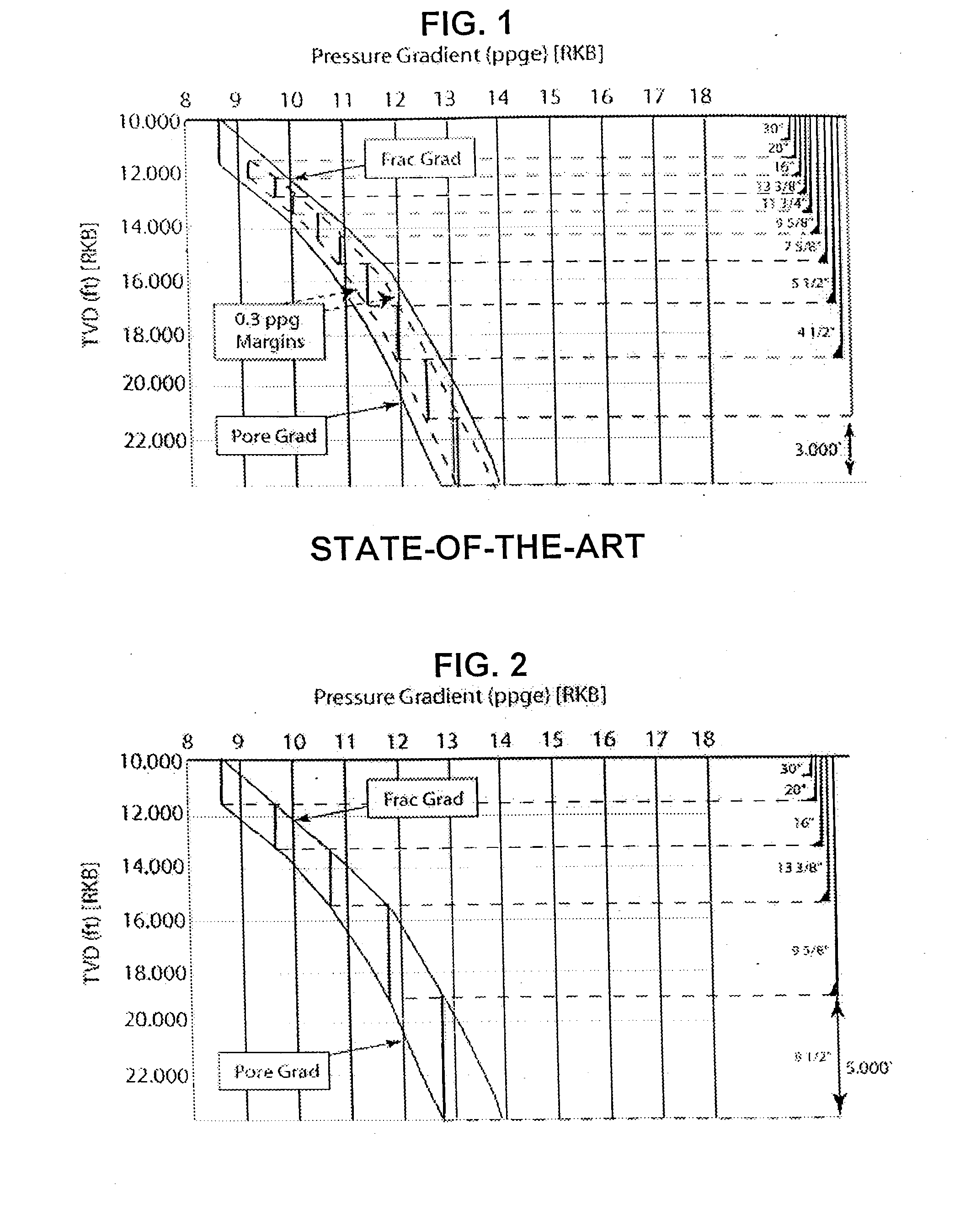

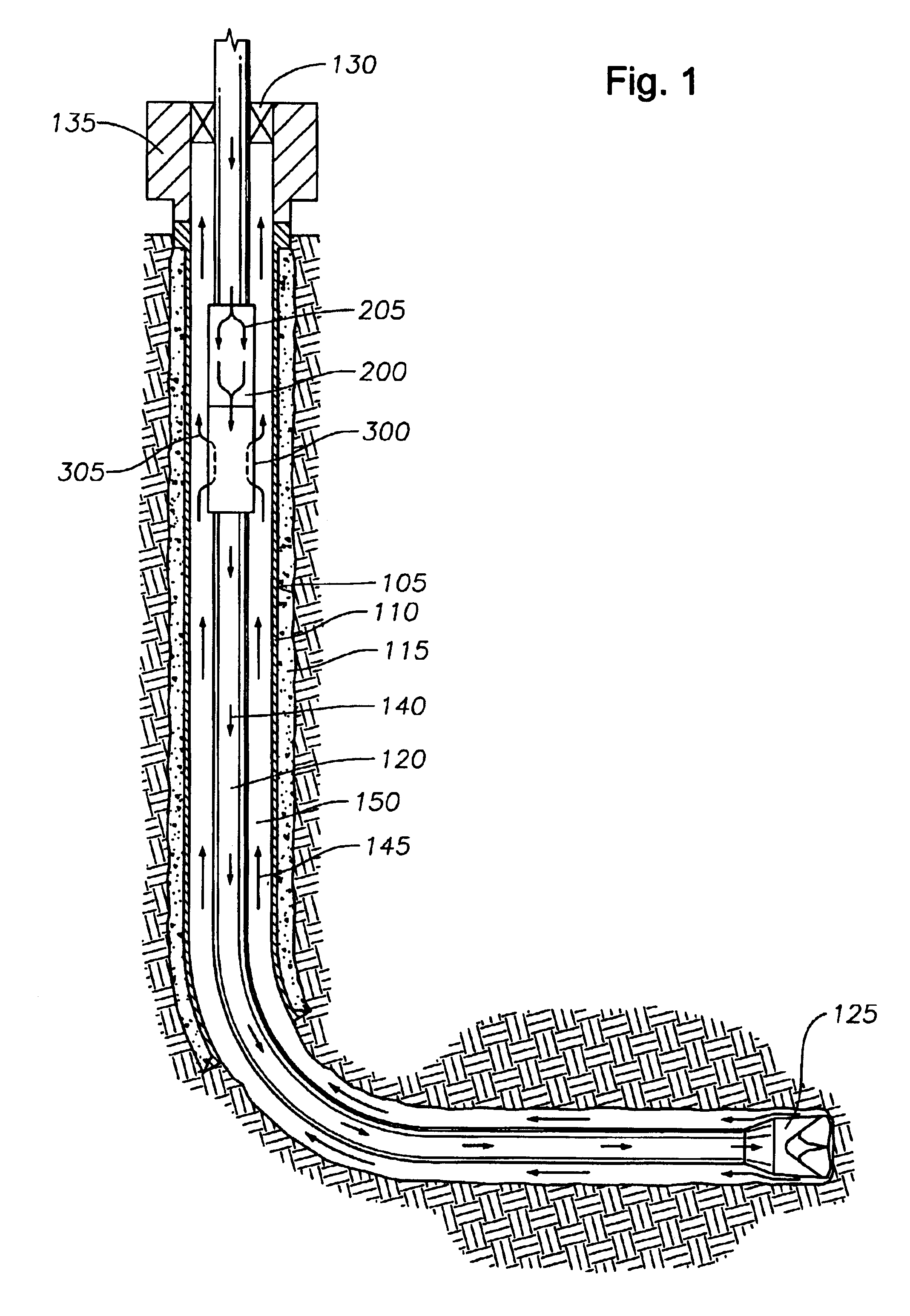

Annulus pressure control drilling systems and methods

In one embodiment, a method for drilling a wellbore includes an act of drilling the wellbore by injecting drilling fluid through a tubular string disposed in the wellbore, the tubular string comprising a drill bit disposed on a bottom thereof. The drilling fluid exits the drill bit and carries cuttings from the drill bit. The drilling fluid and cuttings (returns) flow to a surface of the wellbore via an annulus defined by an outer surface of the tubular string and an inner surface of the wellbore. The method further includes an act performed while drilling the wellbore of measuring a first annulus pressure (FAP) using a pressure sensor attached to a casing string hung from a wellhead of the wellbore. The method further includes an act performed while drilling the wellbore of controlling a second annulus pressure (SAP) exerted on a formation exposed to the annulus.

Owner:WEATHERFORD TECH HLDG LLC

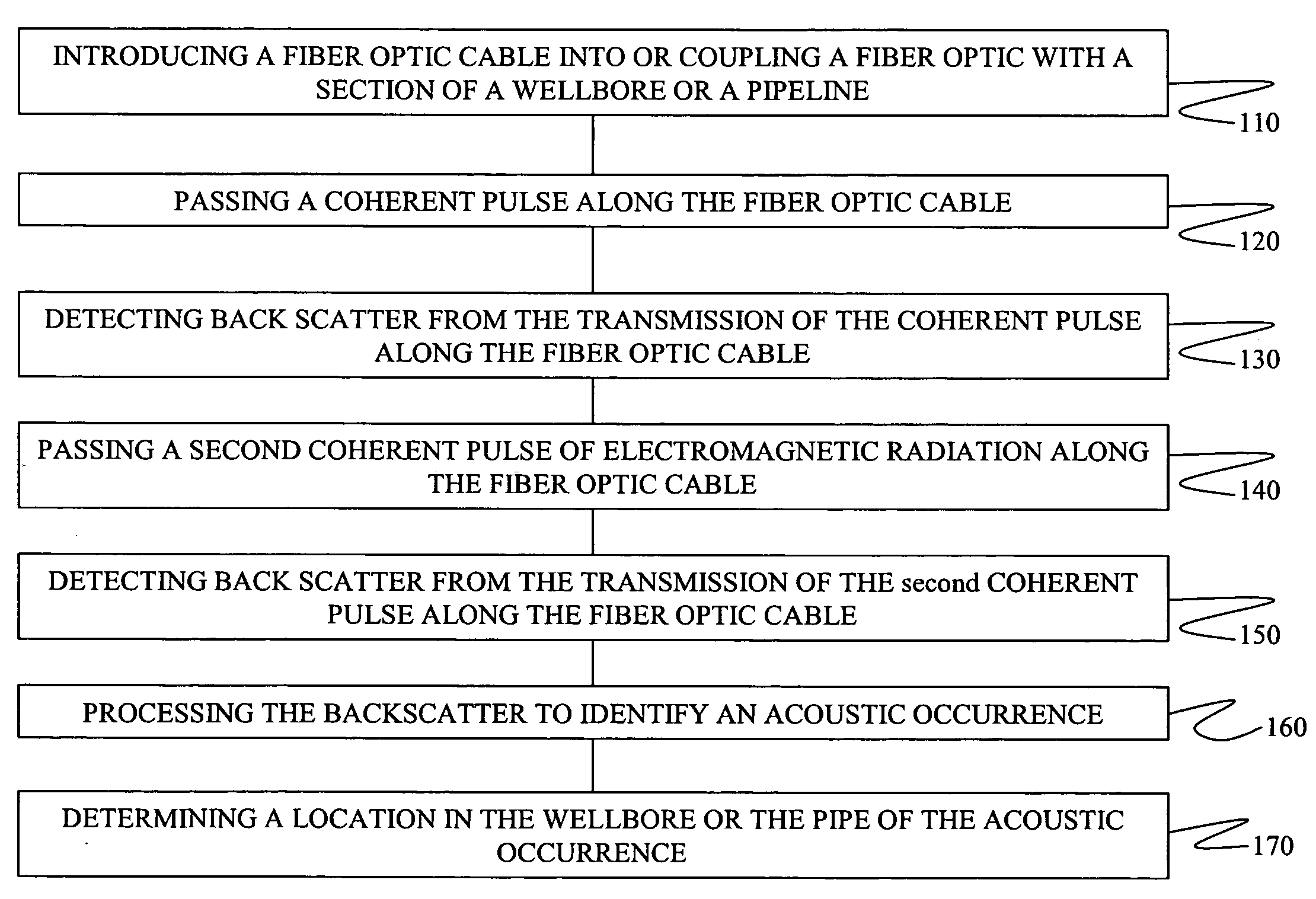

Systems and methods for distributed interferometric acoustic monitoring

This disclosure relates in general to a method and system for monitoring a conduit, a wellbore or a reservoir associated with hydrocarbon production or transportation and / or carbon dioxide sequestration. More specifically, but not by way of limitation, embodiments of the present invention provide for using an optical fiber as a distributed interferometer that may be used to monitor the conduit, wellbore or reservoir. In certain aspects, the distributed interferometric monitoring provides

Owner:SCHLUMBERGER TECH CORP

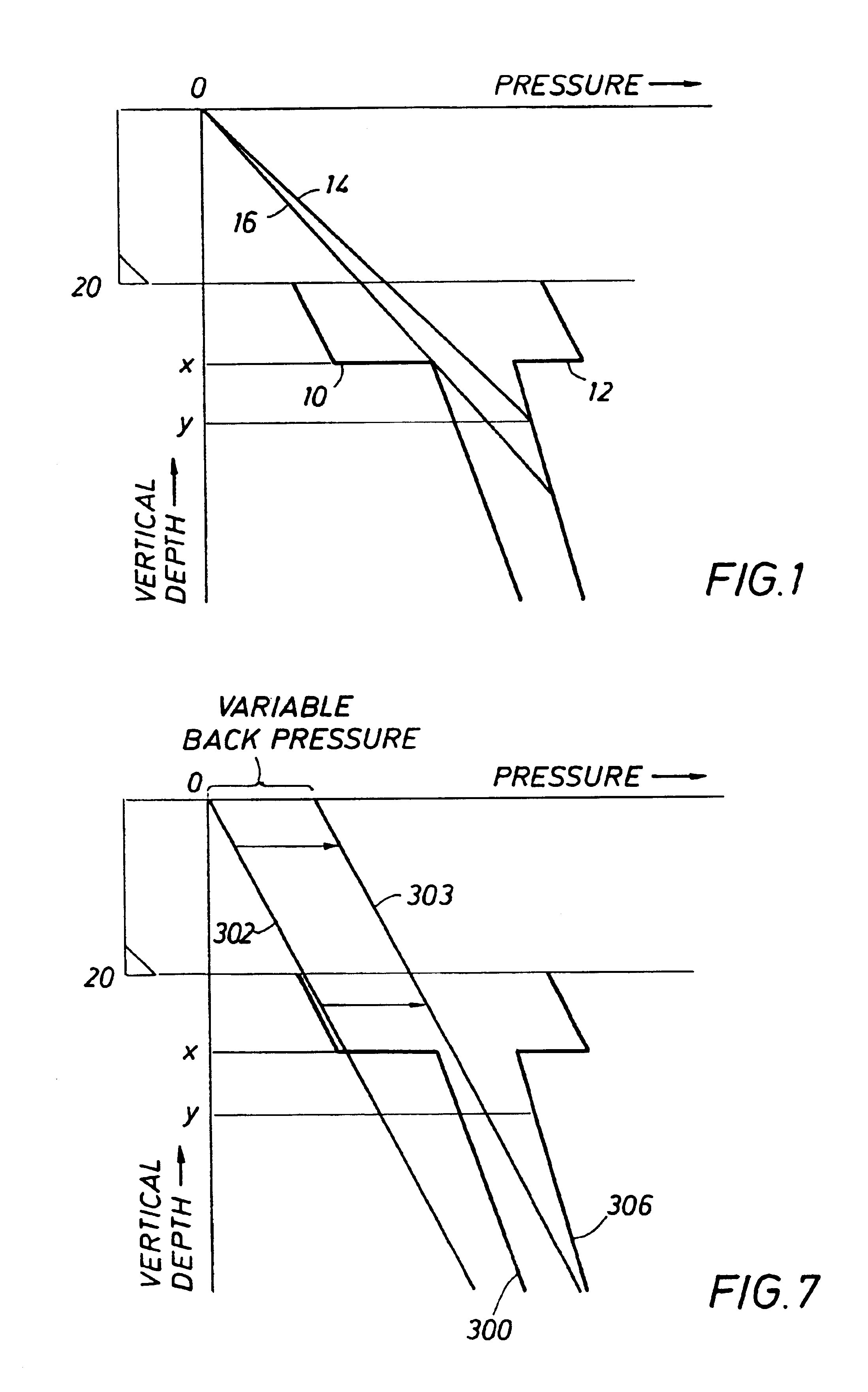

Dynamic annular pressure control apparatus and method

InactiveUS6904981B2Increased annular pressureBuildFluid removalFlushingPressure controlled ventilationPressure control

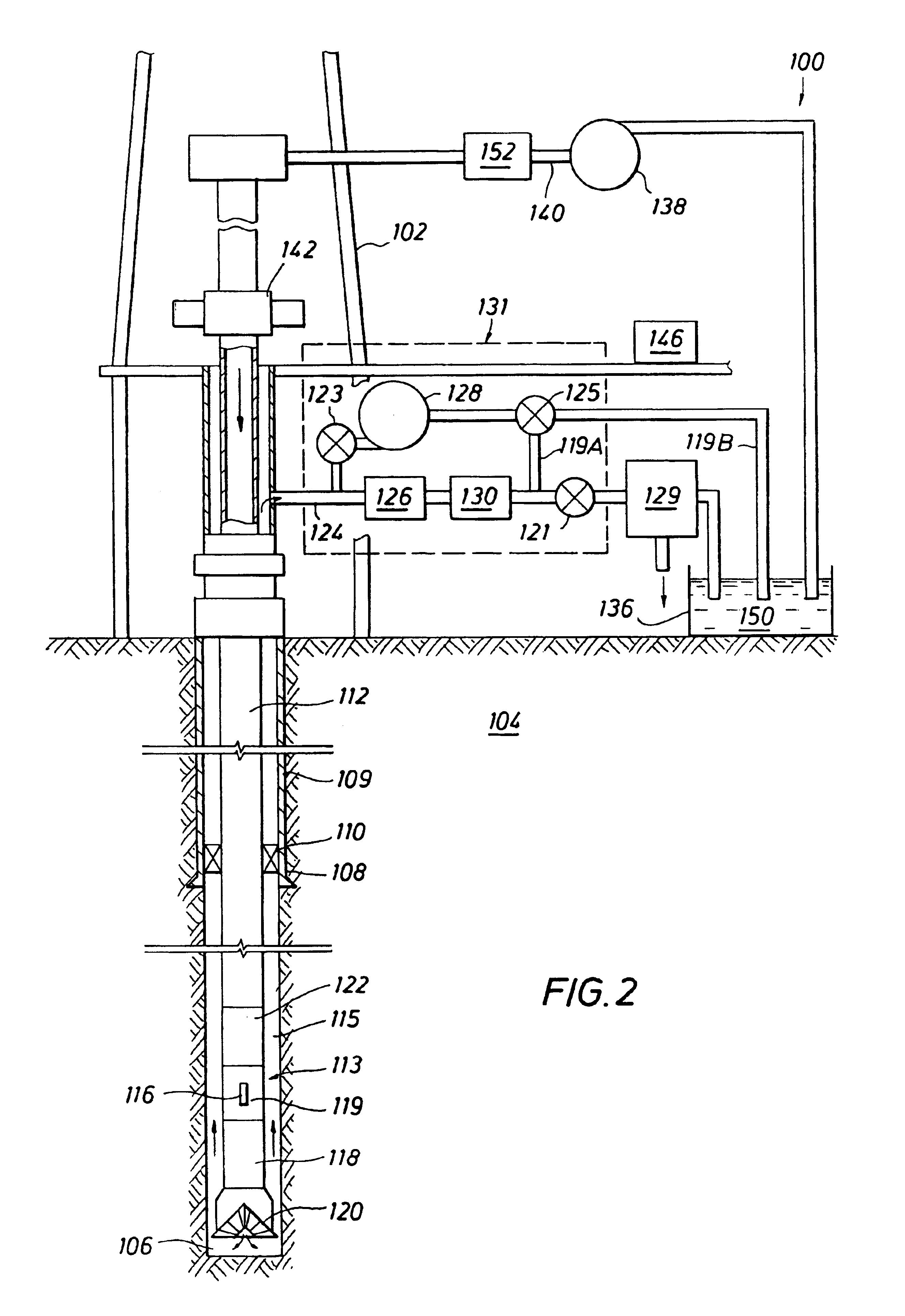

A system and method for controlling formation pressures during drilling of a subterranean formation utilizing a selectively fluid backpressure system in which fluid is pumped down the drilling fluid return system in response to detected borehole pressures. A pressure monitoring system is further provided to monitor detected borehole pressures, model expected borehole pressures for further drilling and control the fluid backpressure system.

Owner:SHELL OIL CO

Well pressure control system

The present invention contemplates a choke control system that provides for local and off-site monitoring and control of the annulus flow pressure of a well. The choke control system includes a choke manifold connected to at least one choke and its associated actuator; a variety of instrumental drilling sensors, pump stroke counter switches, and choke position indicators; a local choke and hydraulic pressure control console; and a programmable controller in communication with the local choke and hydraulic pressure control console. The programmable controller handles the logical operations of the choke control system, including processing instrument measurements and operator input data to produce control signals for operating the choke, the choke actuator and the various valves associated with the choke manifold. The programmable controller is typically either an electronic digital computer and / or a programmable logic controller (PLC). The present invention further contemplates the two-way communication between the choke control system and the Internet via a satellite linkage.

Owner:EXPRO AMERICAS

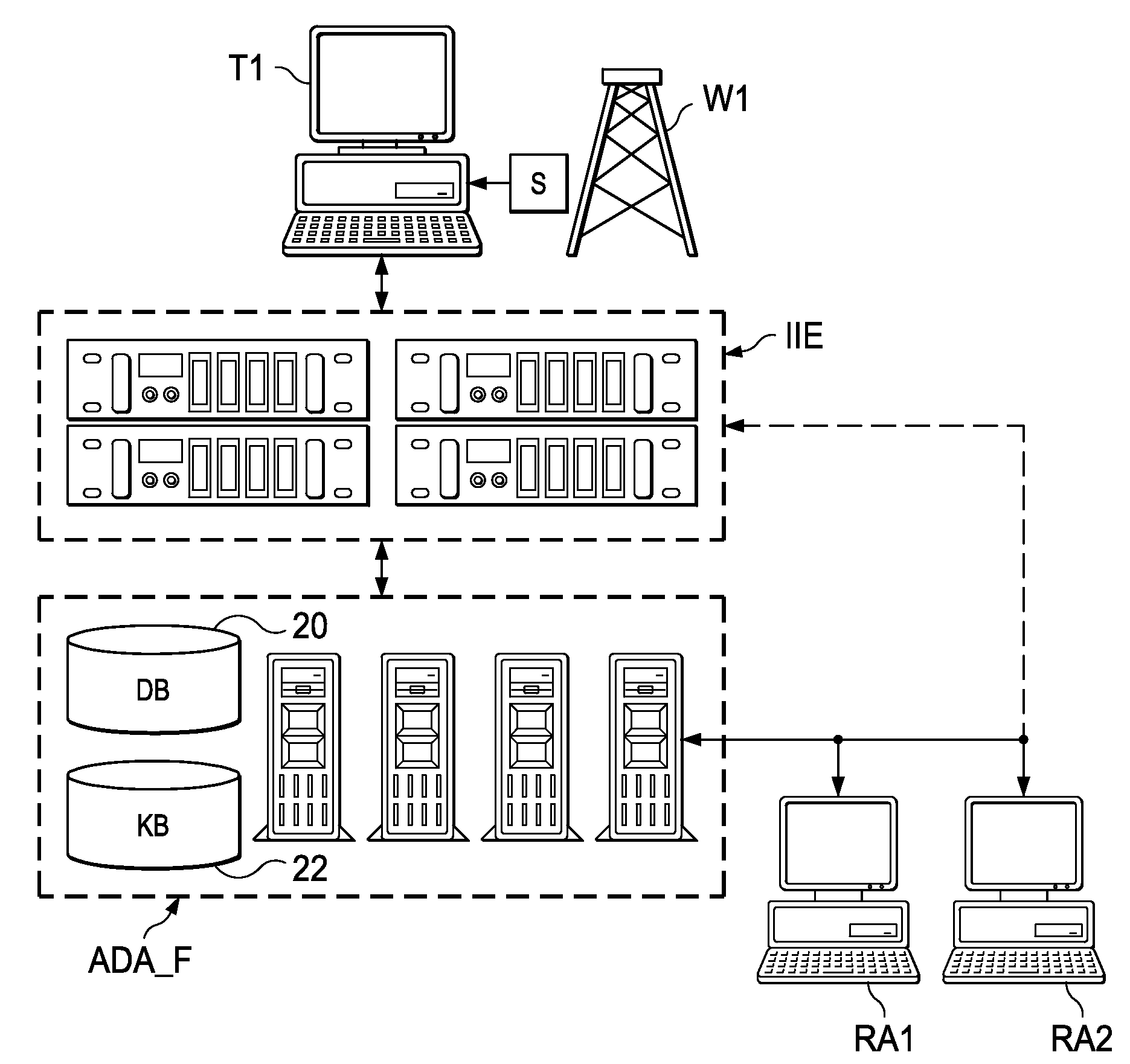

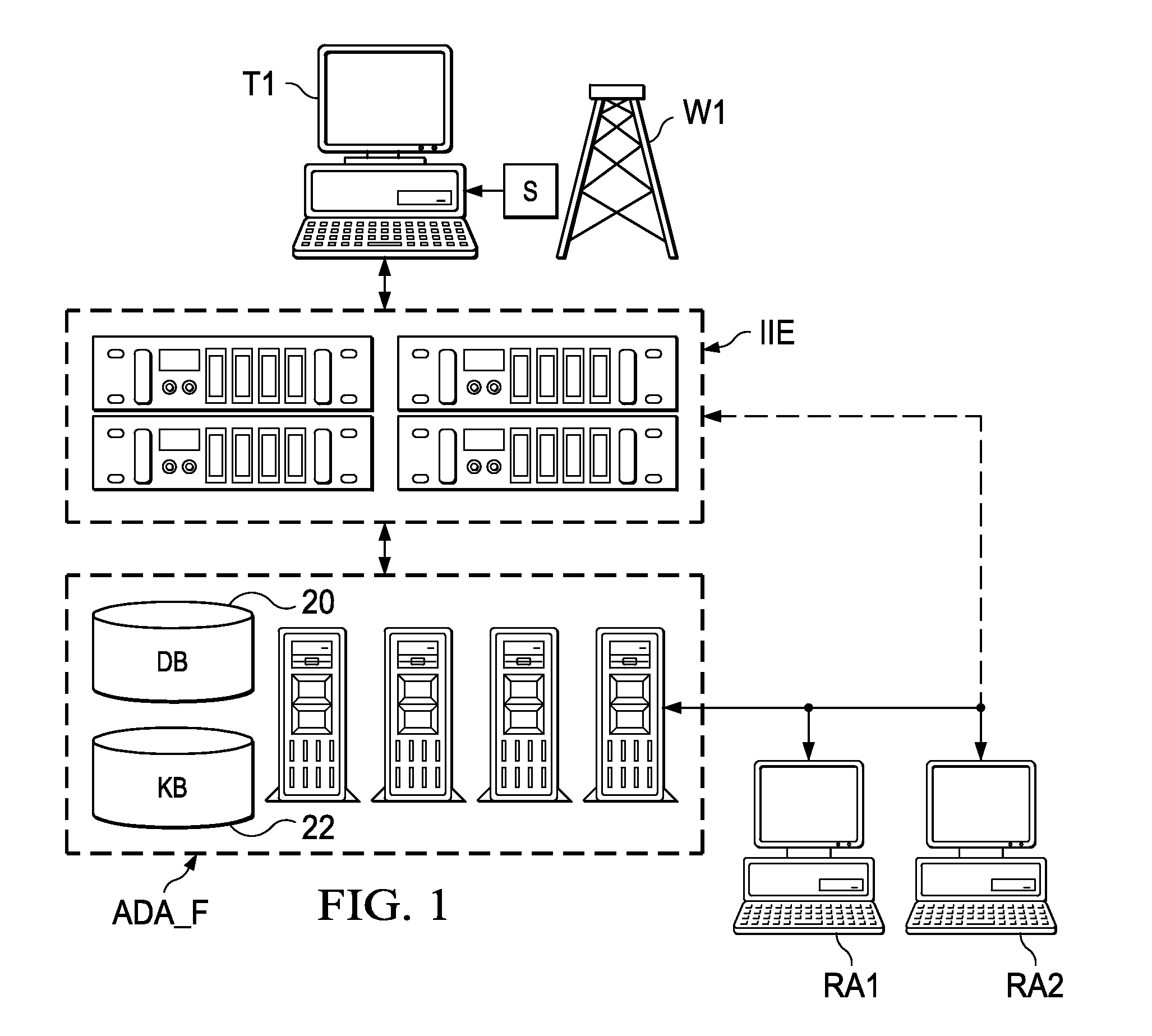

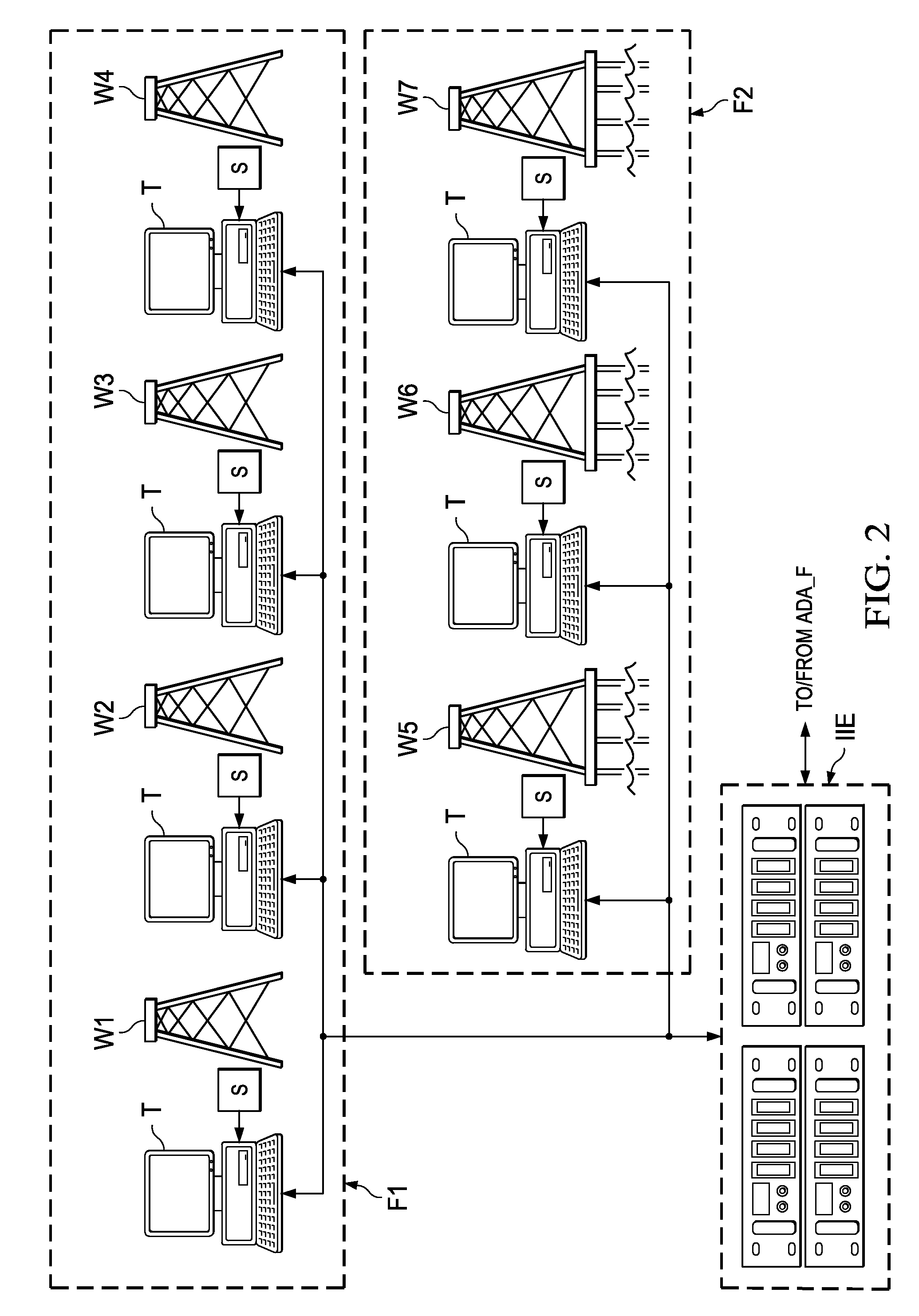

Intelligent Drilling Advisor

ActiveUS20090132458A1Loss of circulationEasy to operateElectric/magnetic detection for well-loggingKnowledge representationComputer sciencePerformance rate

A method, apparatus, and program storage device for integrating and implementing rule-based, heuristic, wellbore key performance rate of penetration indicators advising drilling operations personnel based on the situational awareness of trended earth properties and real time wellbore sensor data, is disclosed.

Owner:BP CORP NORTH AMERICA INC

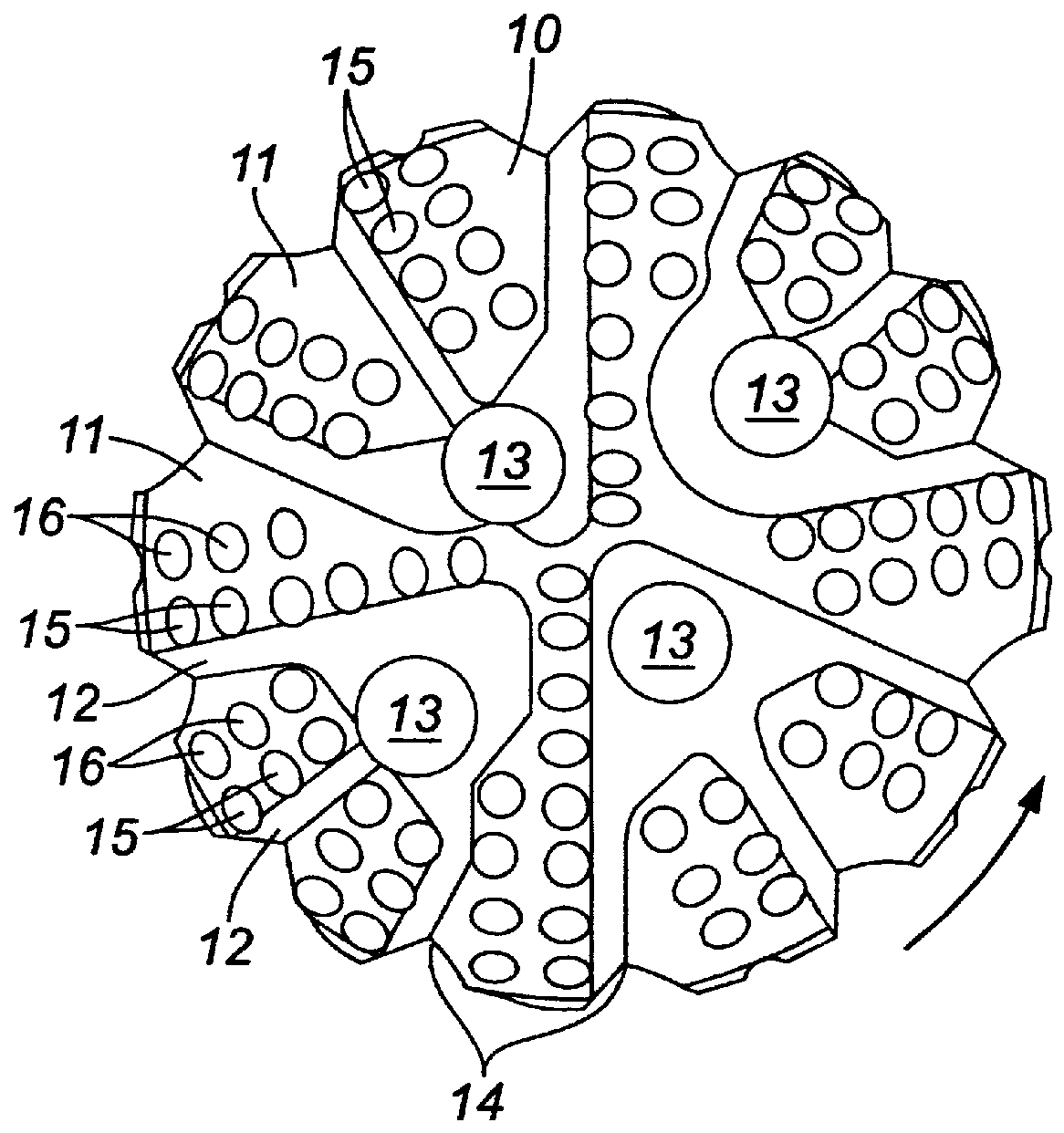

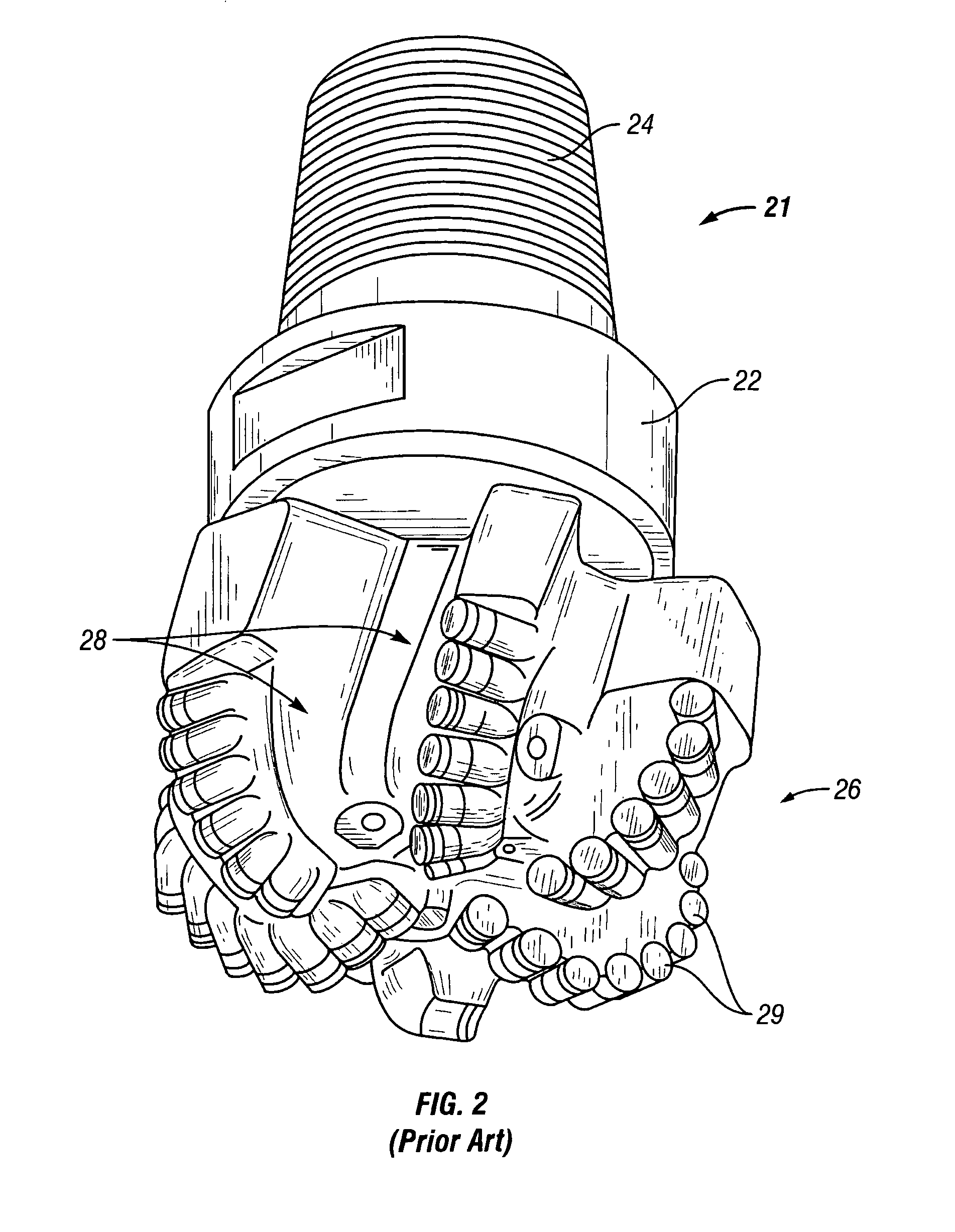

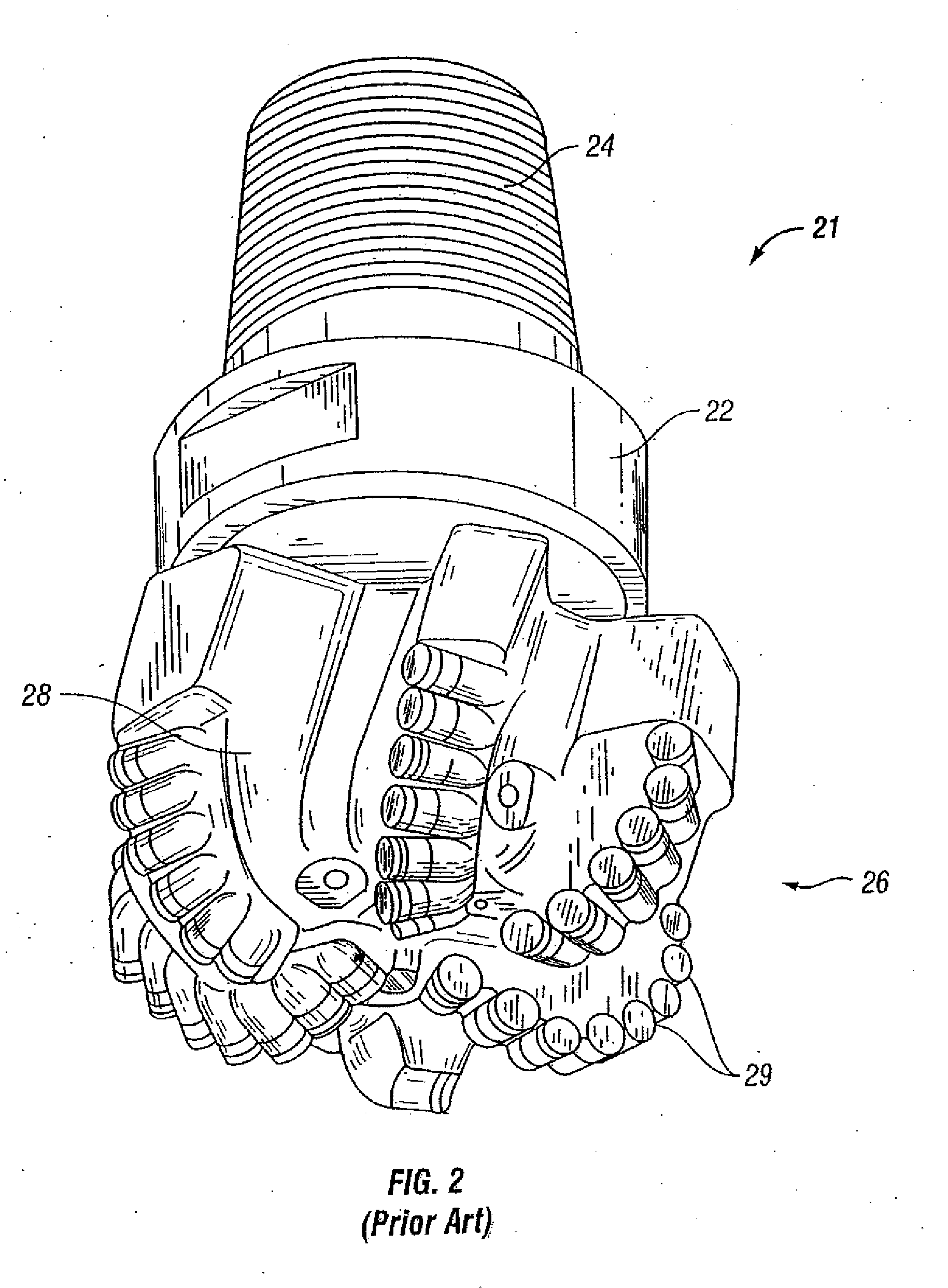

Rotary drill bit having moveable formation-engaging members

Formation engaging elements are moveably mounted onto a drill bit. Such elements may be used to protect other rigidly mounted formation engaging elements from impacts that occur during use of the drill bit, or they may be used to alter the aggressiveness of the drill bit when used in directional drilling operations.

Owner:REEDHYCALOG UK

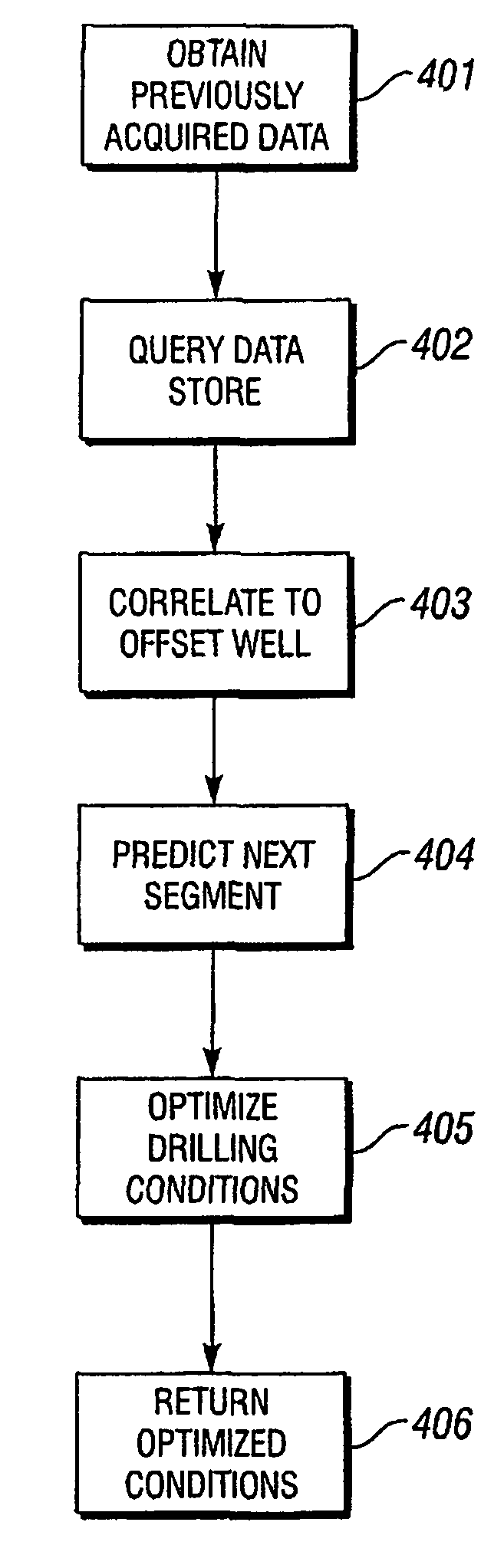

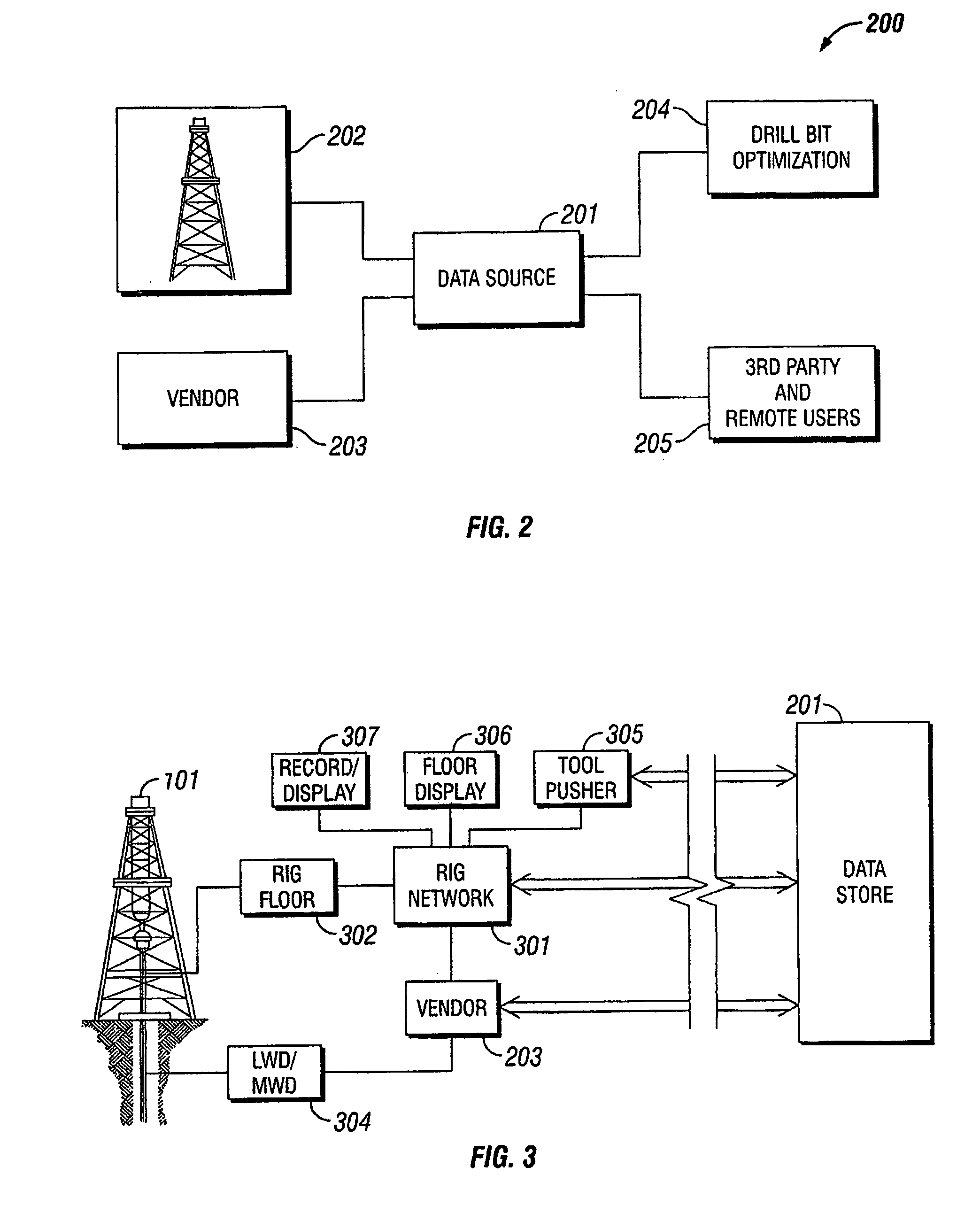

System for optimizing drilling in real time

A method for optimizing drilling parameters includes obtaining previously acquired data, querying a remote data store for current well data, determining optimized drilling parameters, and returning optimized parameters for a next segment to the remote data store. Determining optimized drilling parameters may include correlating the current well data to the previously acquired data, predicting drilling conditions for the next segment, and optimizing drilling parameters for the next segment.

Owner:SMITH INT INC

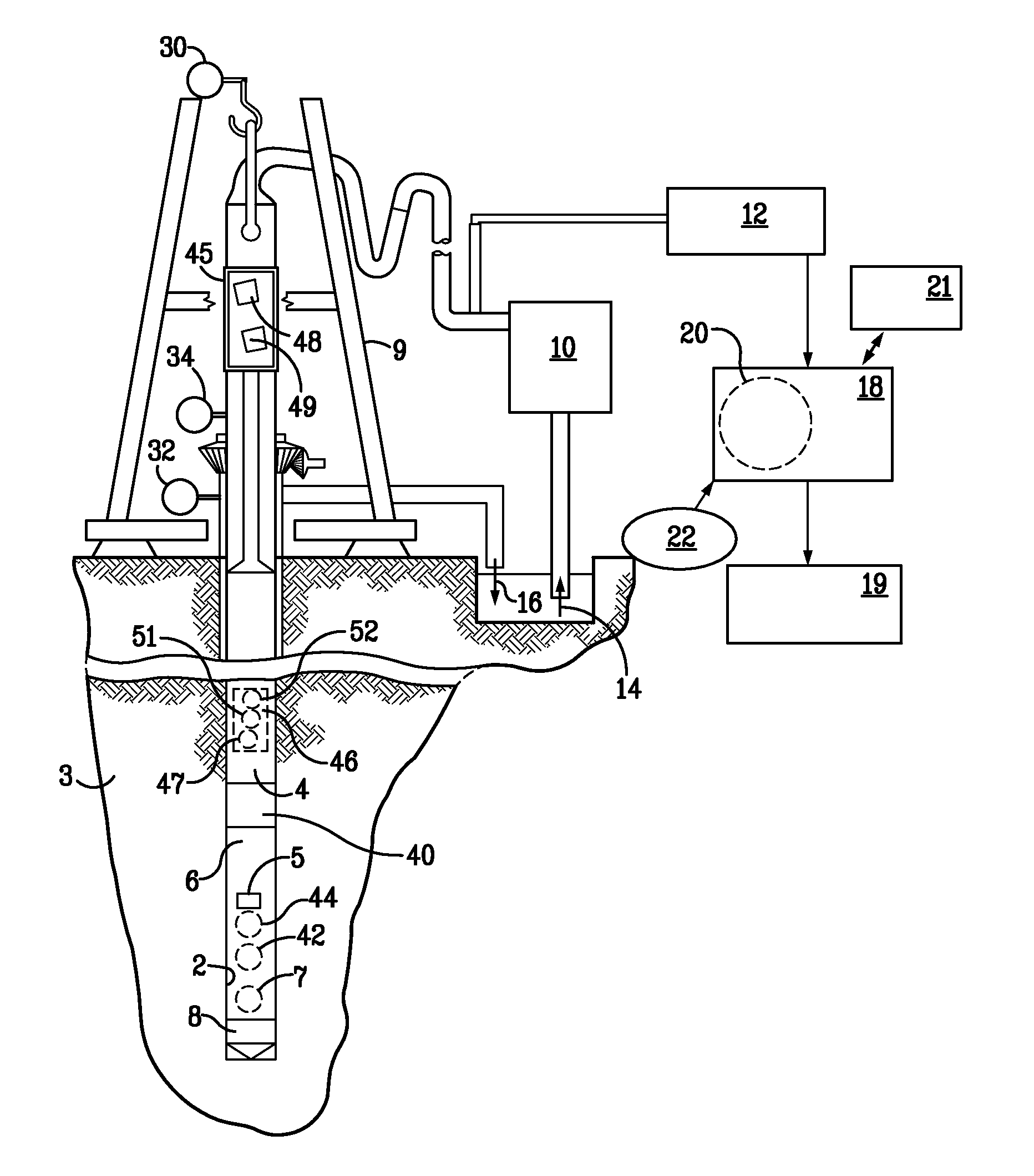

System and Method for Monitoring and Controlling Underground Drilling

ActiveUS20110186353A1Reduce the differenceVibration measurement in solidsMachine part testingFinite element techniqueResonance

A system and method for monitoring underground drilling in which vibration is monitored by creating a model of the drill string using finite element techniques or finite difference techniques and (i) predicting vibration by inputting real time values of operating parameters into the model, and then adjusting the model to agree with measured vibration data, (ii) predicting the weight on bit and drill string and mud motor speeds at which resonance will occur, as well as when stick-slip will occur, so that the operator can avoid operating regimes that will result in high vibration, (iii) determining vibration and torque levels along the length of the drill string based on the measured vibration and torque at one or more locations, (iv) determining the remaining life of critical components of the drill string based on the history of the vibration to which the components have been subjected, and (v) determining the optimum drilling parameters that will avoid excessive vibration of the drill string.

Owner:APS TECH

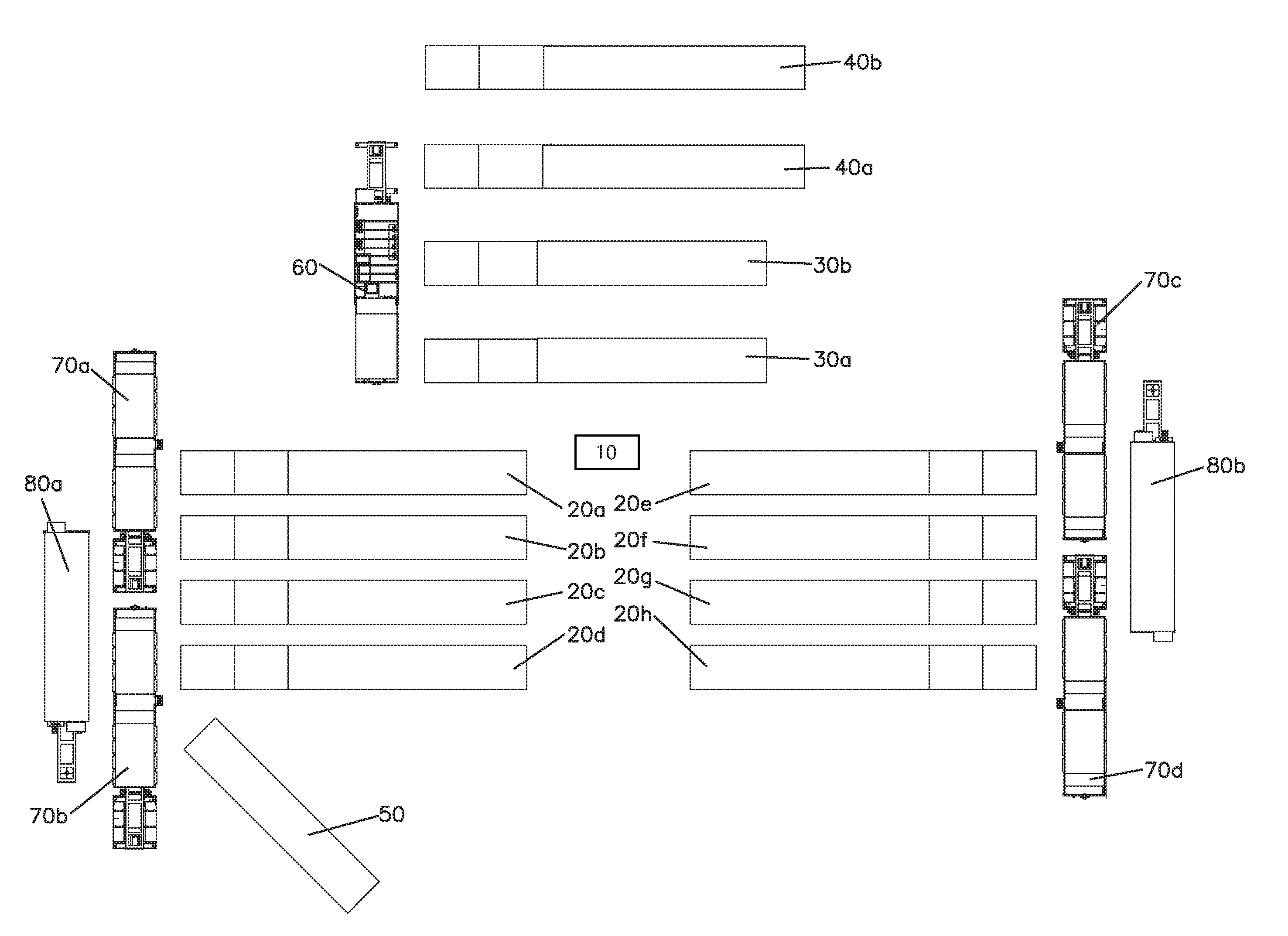

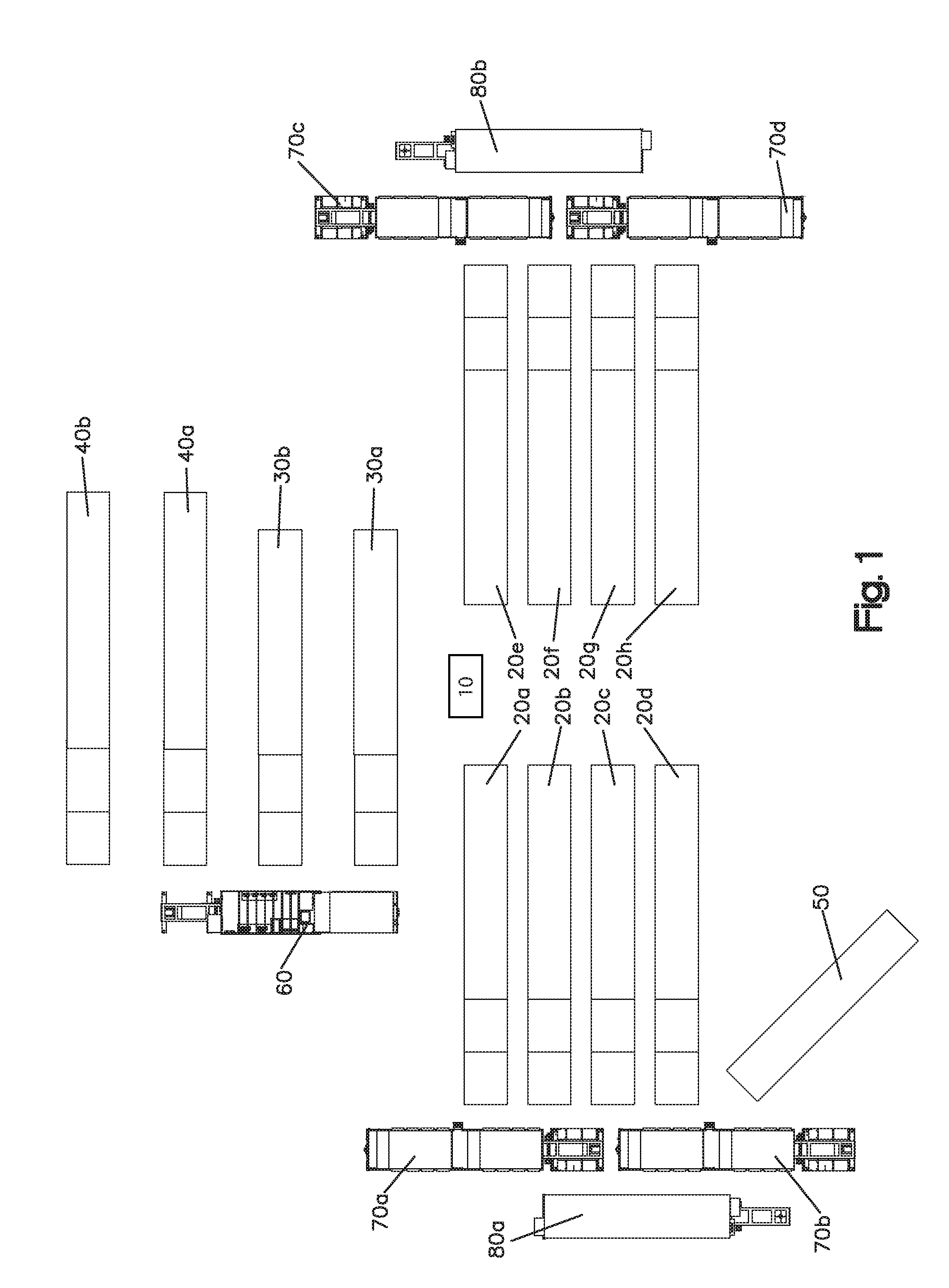

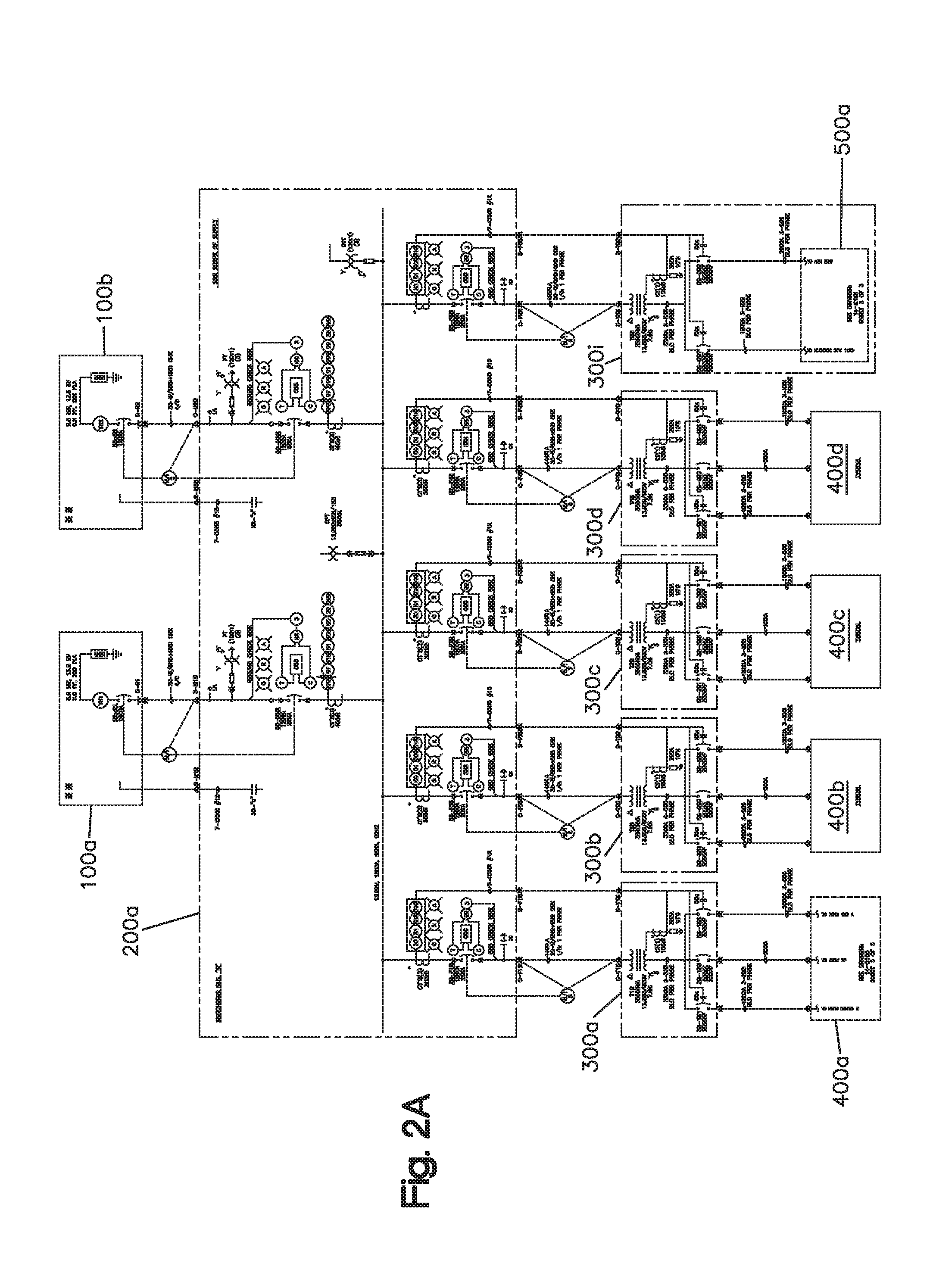

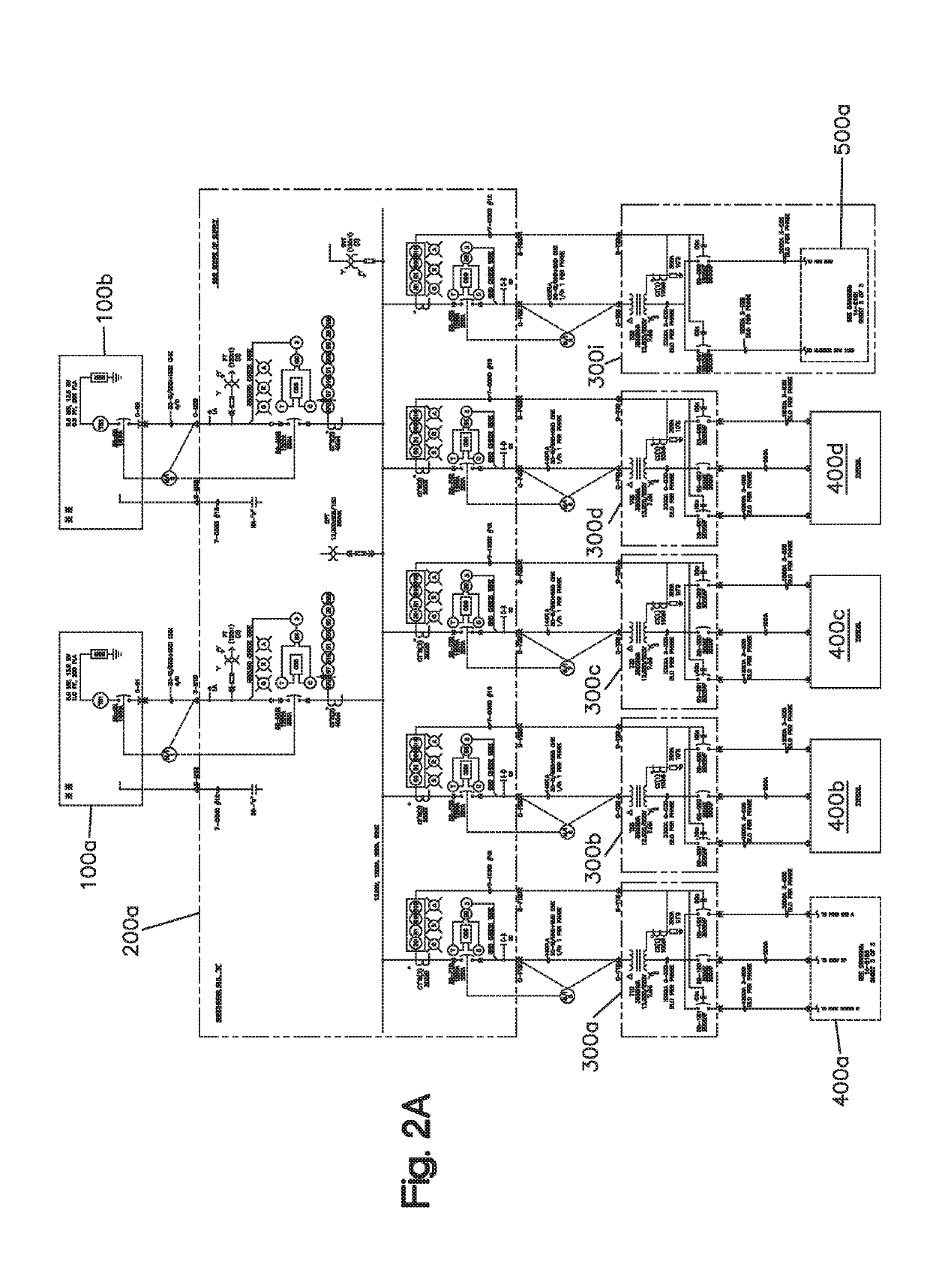

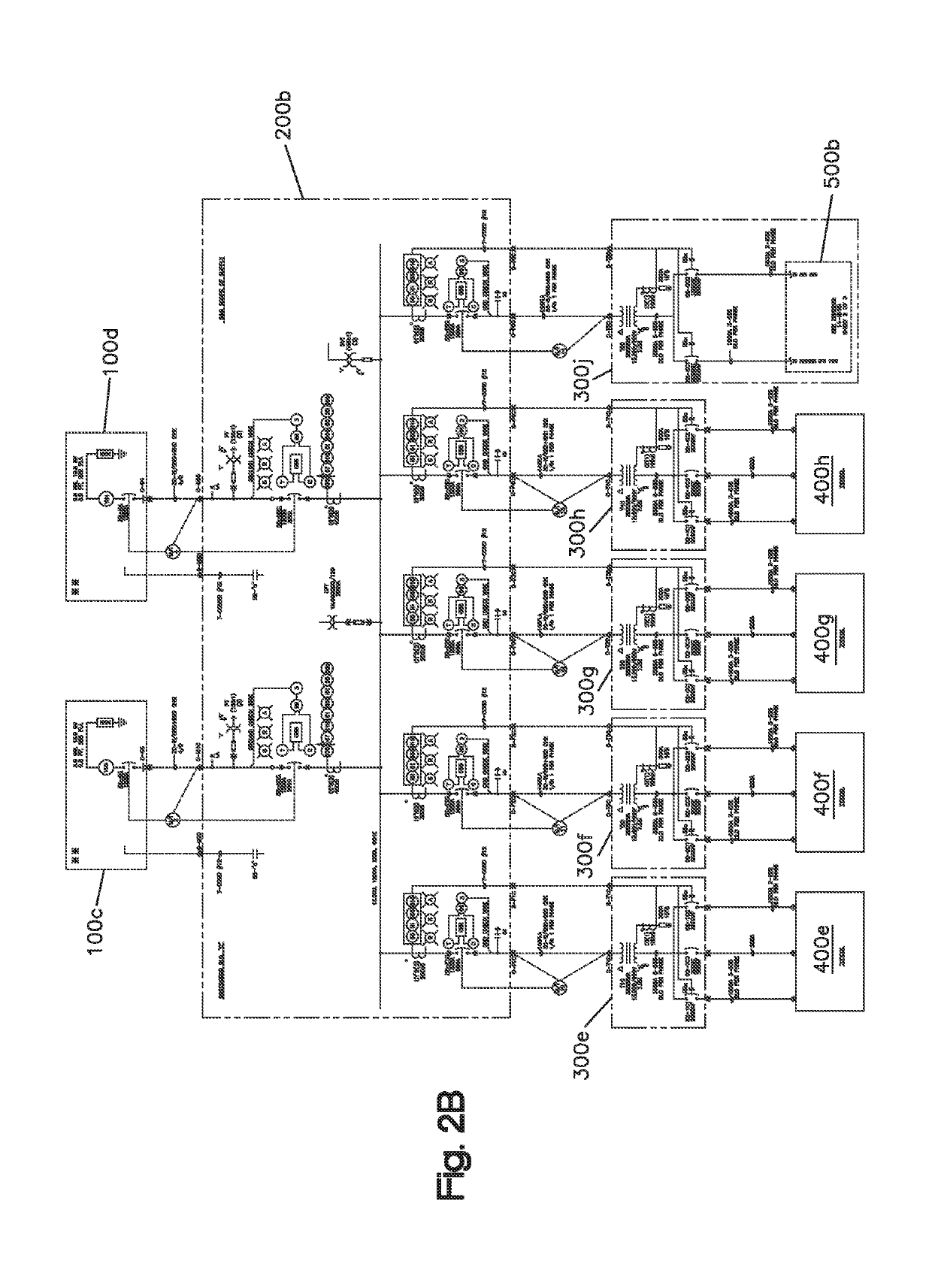

Well fracturing systems with electrical motors and methods of use

A system for stimulating oil or gas production from a wellbore includes a hydraulic fracturing pump unit having one or more hydraulic fracturing pumps driven by one or more electrical fracturing motors, a variable frequency drive (VFD) controlling the electrical fracturing motors, a fracturing pump blower unit driven by a blower motor, and a fracturing pump lubrication unit having a lubrication pump driven by a lubrication motor and a cooling fan driven by a cooling motor. The system may further include a blender unit and a hydration unit. A system control unit may control the operational parameters of the system.

Owner:STEWART & STEVENSON

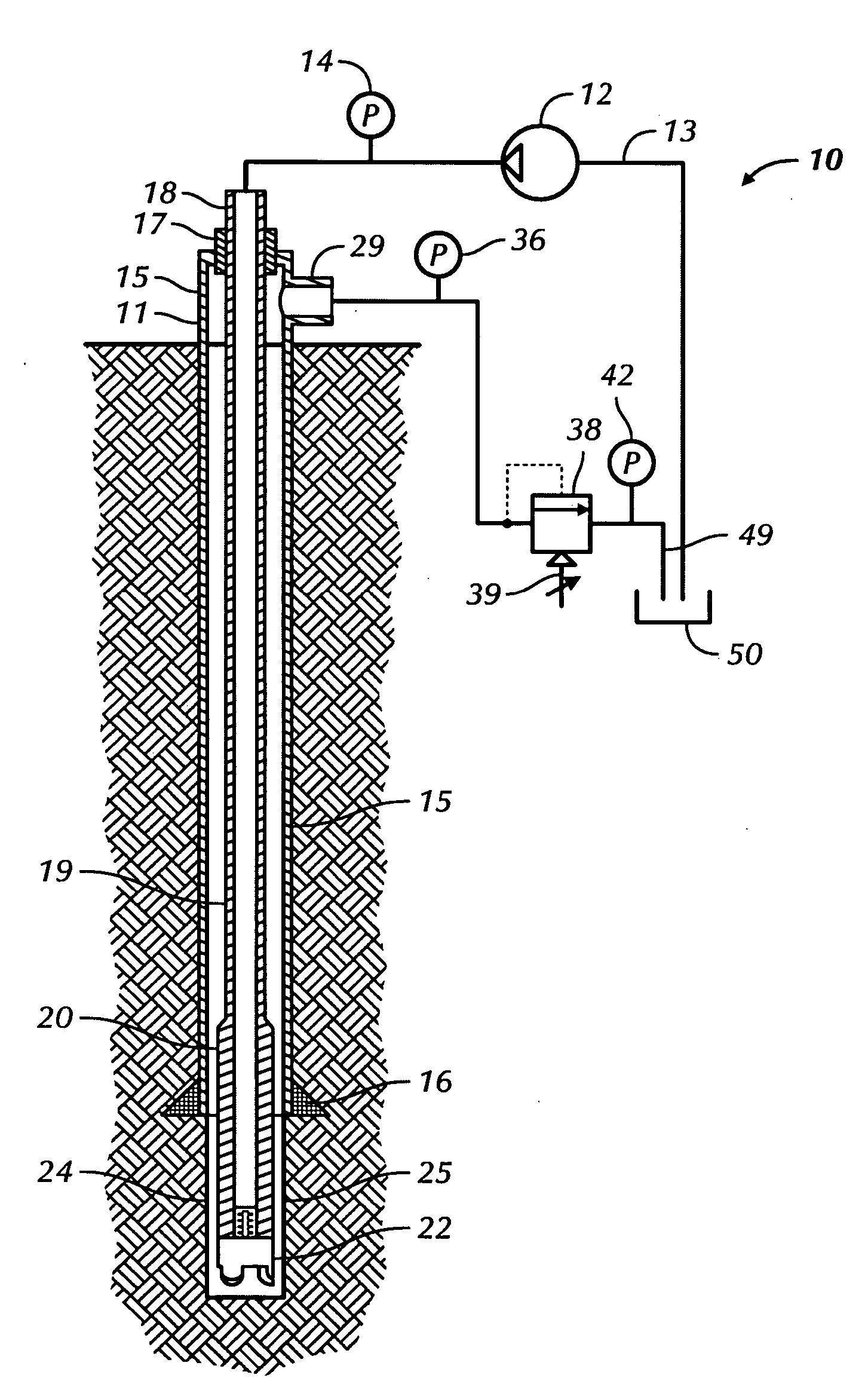

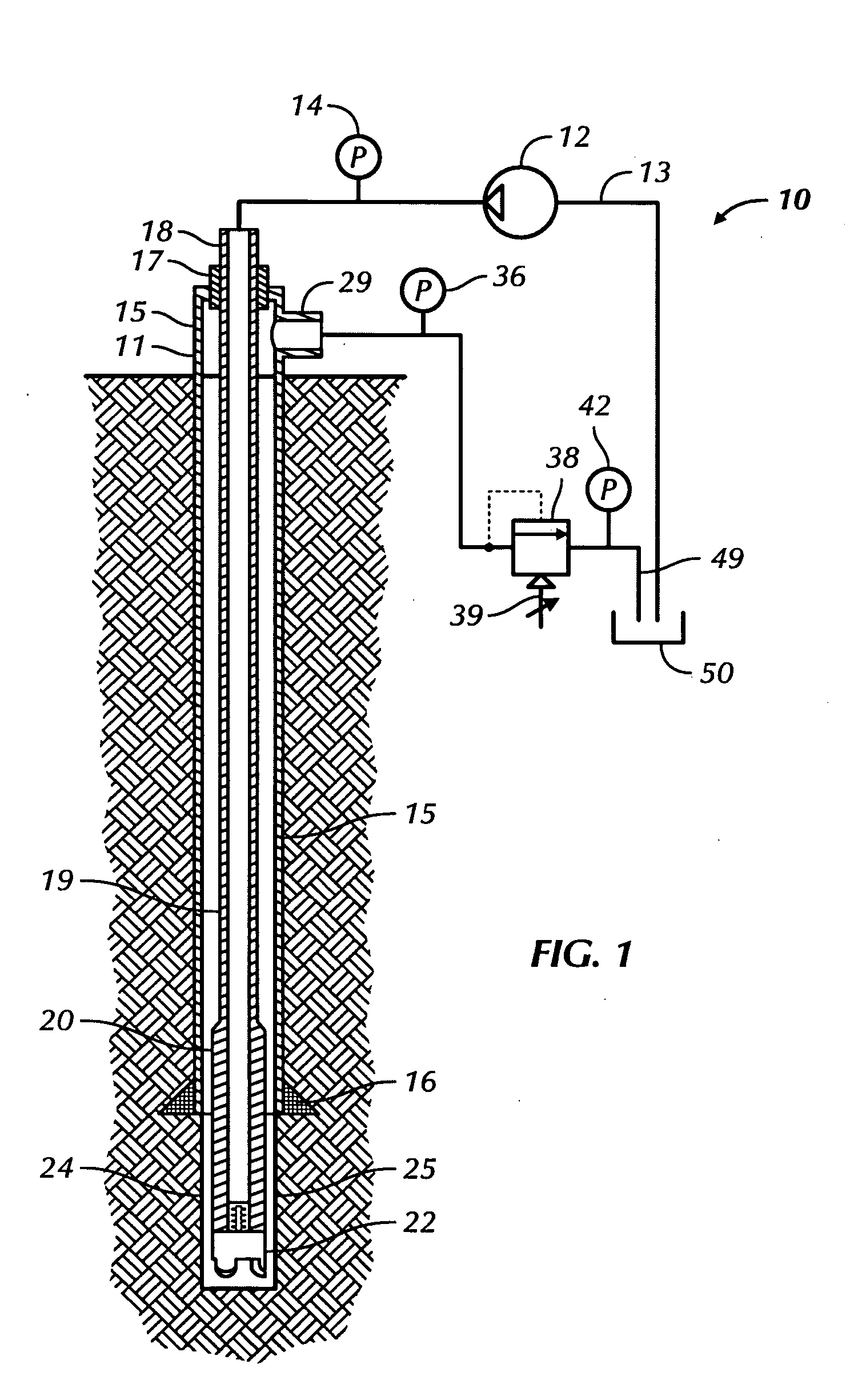

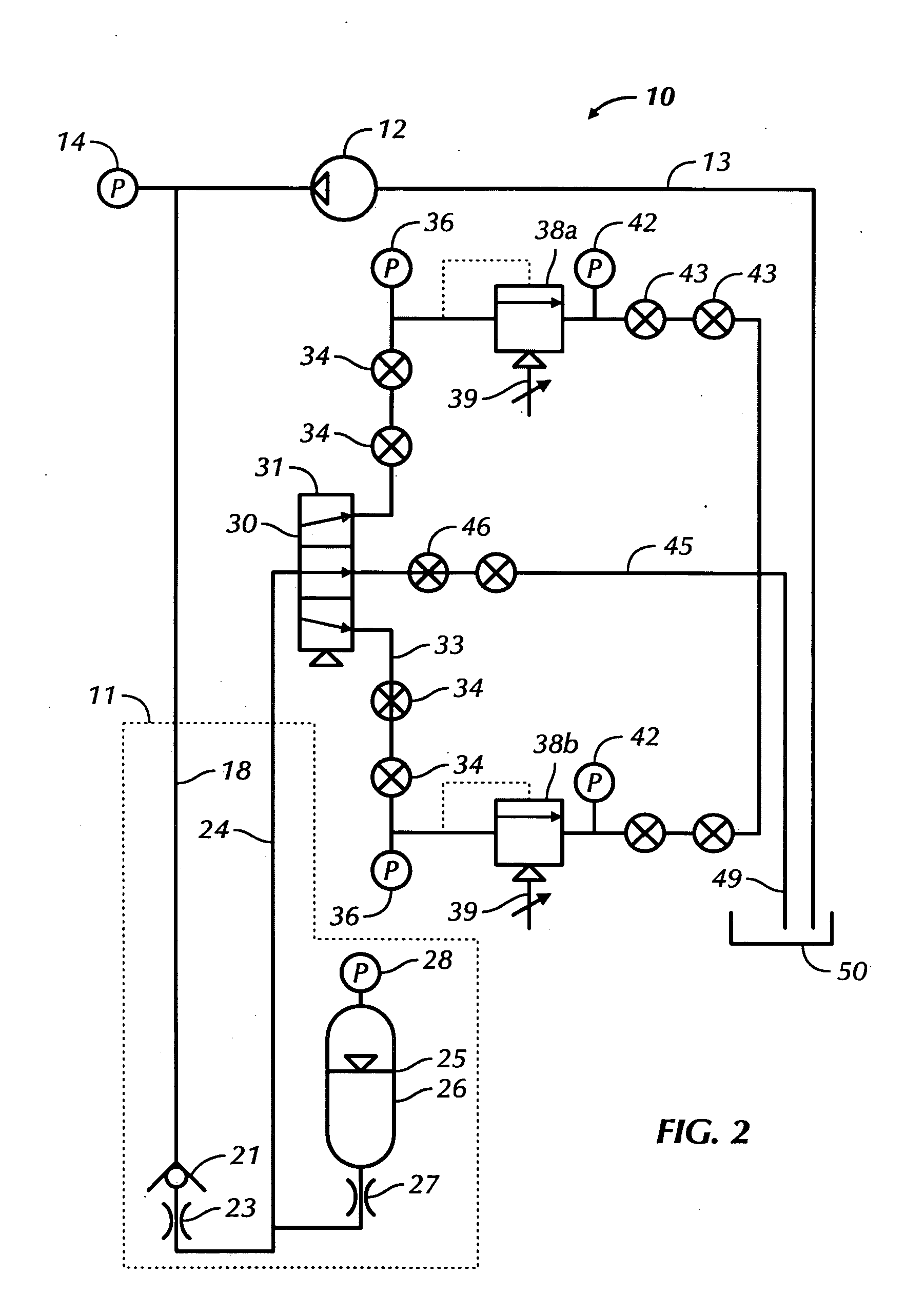

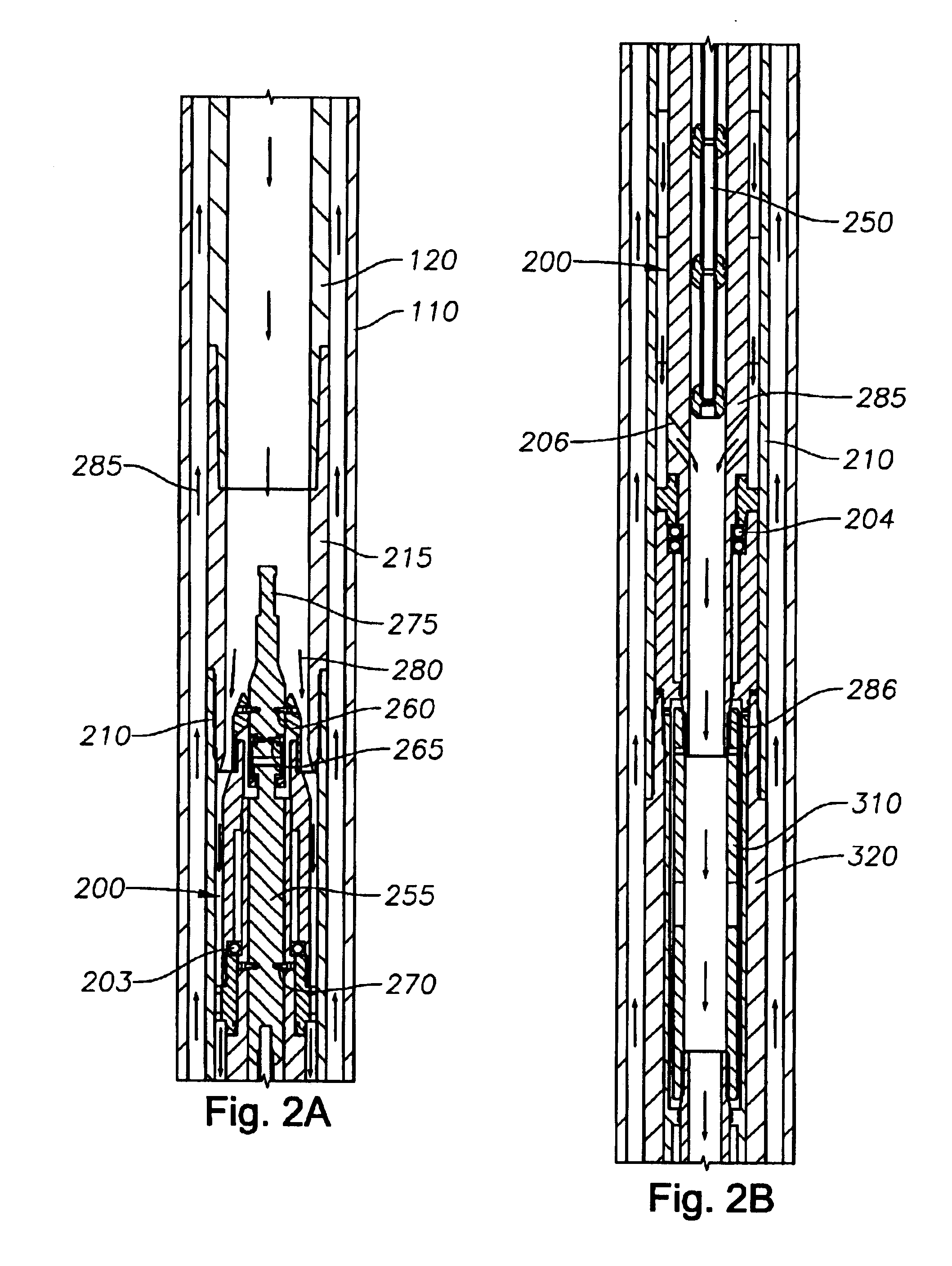

Methods and apparatus for actuating a downhole tool

The present invention relates to apparatus and methods for remotely actuating a downhole tool. In one aspect, the present invention provides an apparatus for activating a downhole tool in a wellbore, the downhole tool having an actuated and unactuated positions. The apparatus includes an actuator for operating the downhole tool between the actuated and unactuated positions; a controller for activating the actuator; and a sensor for detecting a condition in the wellbore, wherein the detected condition is transmitted to the controller, thereby causing the actuator to operate the downhole tool. In one embodiment, conditions in the wellbore are generated at the surface, which is later detected downhole. These conditions include changes in pressure, temperature, vibration, or flow rate. In another embodiment, a fiber optic signal may be transmitted downhole to the sensor. In another embodiment still, a radio frequency tag is dropped into the wellbore for detection by the sensor.

Owner:WEATHERFORD TECH HLDG LLC

System, Program Products, and Methods For Controlling Drilling Fluid Parameters

ActiveUS20110125333A1Easy to controlEconomic securityFlushingDrilling compositionMarine engineeringSelf adaptive

Embodiments of systems, program product, and methods for controlling drilling fluid pressures are provided. These embodiments, for example, can provide dynamic density control with highly adaptive, real-time, process-control and are scalable to any rig, large or small, on land or water. Combined static and dynamic stresses and displacements can be determined continuously at strategic locations in and around the wellbore of a well so that insitu and operational induced pressure window limitations at specific weak-points or other locations of interest are controlled.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

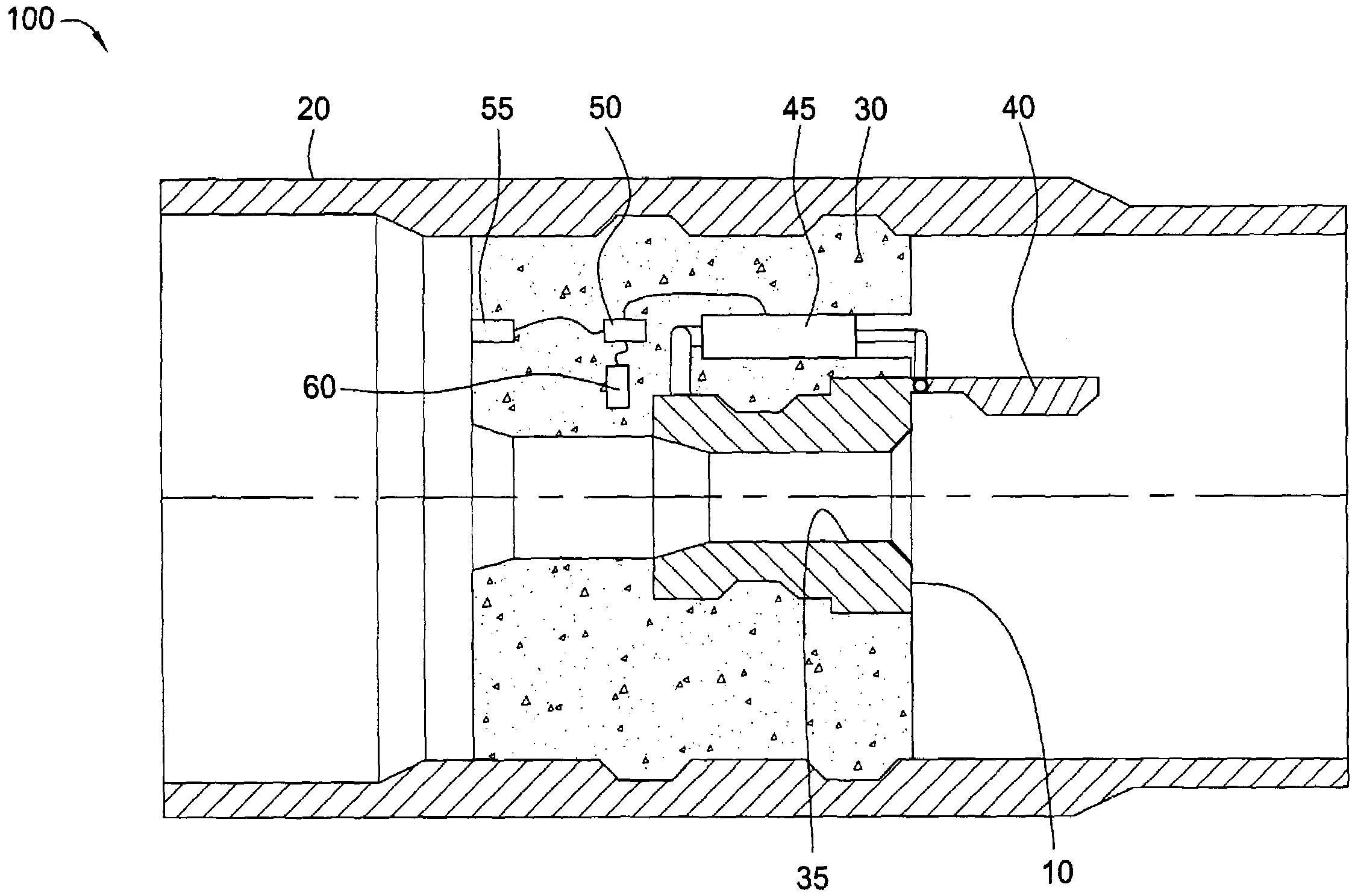

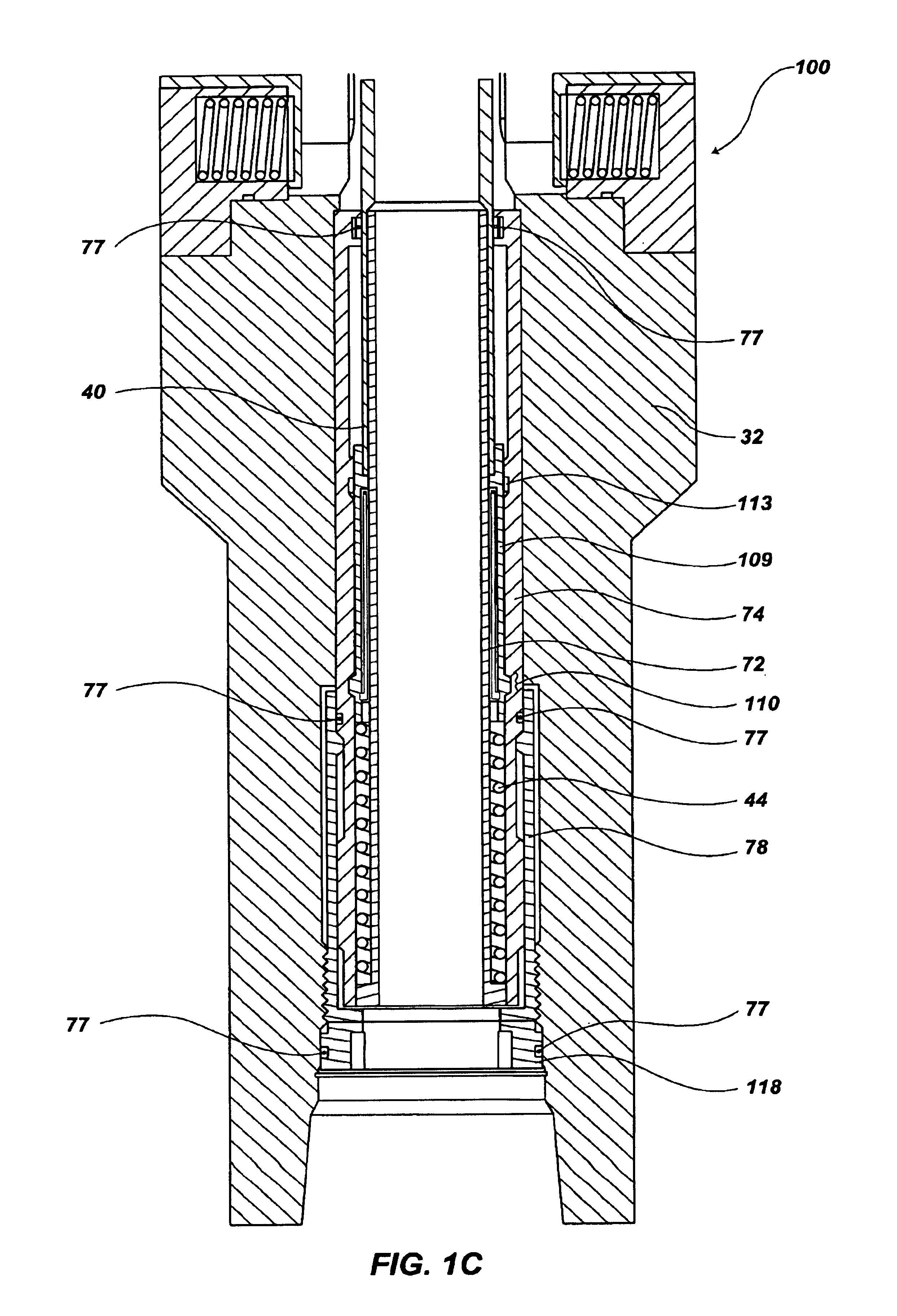

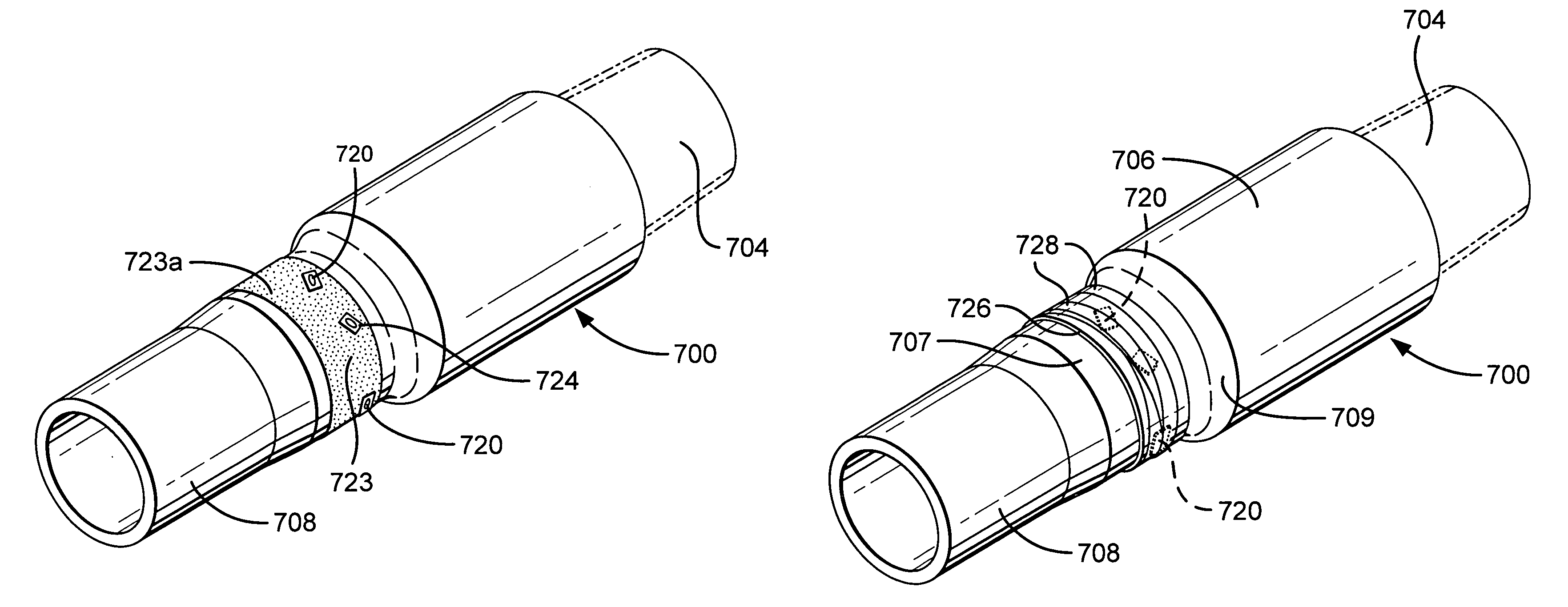

Expandable reamer apparatus for enlarging boreholes while drilling and methods of use

ActiveUS7036611B2Reduce capacityReduce the cross-sectional areaSurveyDrill bitsFixed bearingWell drilling

An expandable reamer apparatus and methods for reaming a borehole, wherein a laterally movable blade carried by a tubular body may be selectively positioned at an inward position and an expanded position. The laterally movable blade, held inwardly by blade-biasing elements, may be forced outwardly by drilling fluid selectively allowed to communicate therewith by way of an actuation sleeve disposed within the tubular body. Alternatively, a separation element may transmit force or pressure from the drilling fluid to the movable blade. Further, a chamber in communication with the movable blade may be pressurized by way of a downhole turbine or pump. A ridged seal wiper, compensator, movable bearing pad, fixed bearing pad preceding the movable blade, or an adjustable spacer element to alter expanded blade position may be included within the expandable reamer. In addition, a drilling fluid pressure response indicating an operational characteristic of the expandable reamer may be generated.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

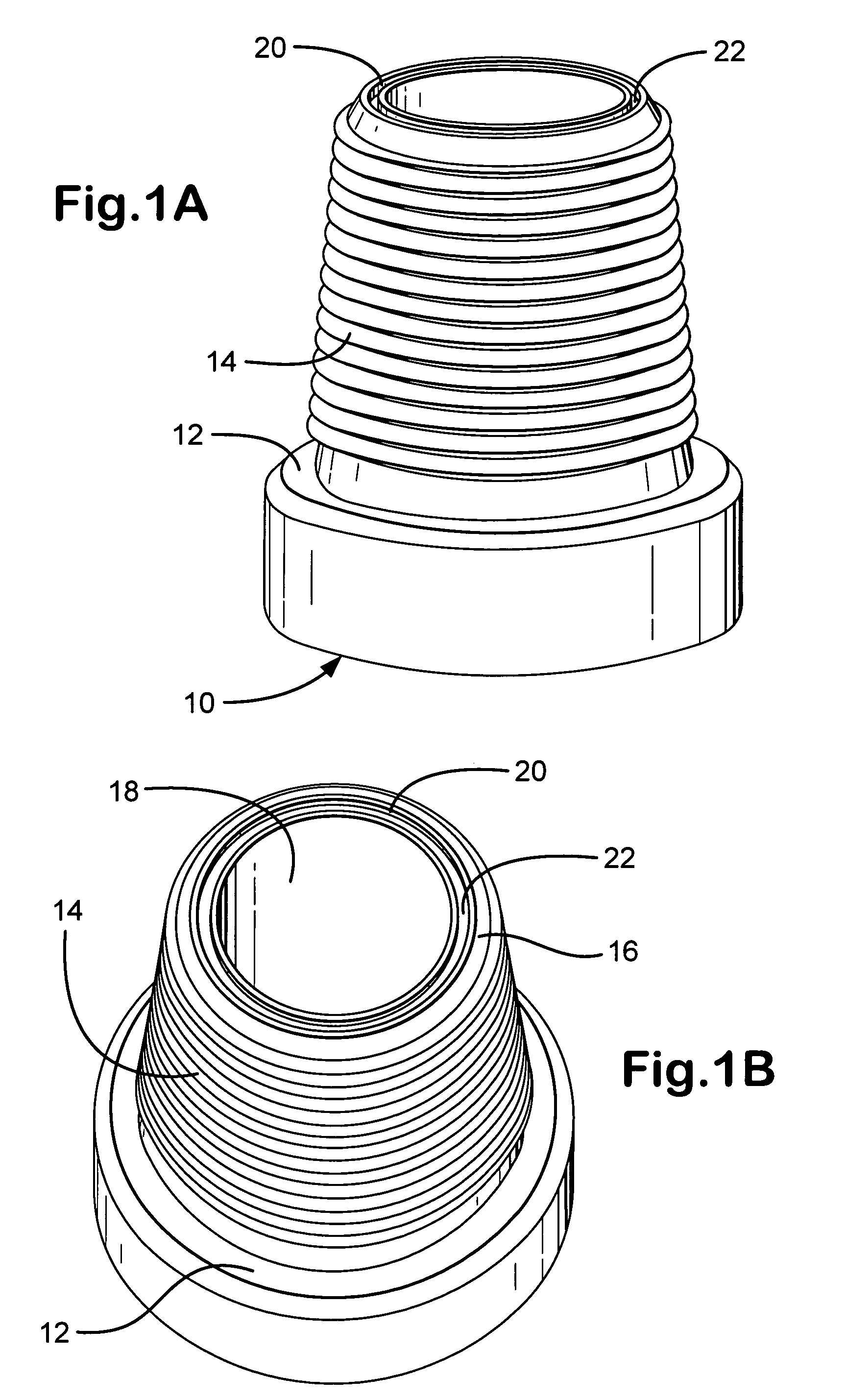

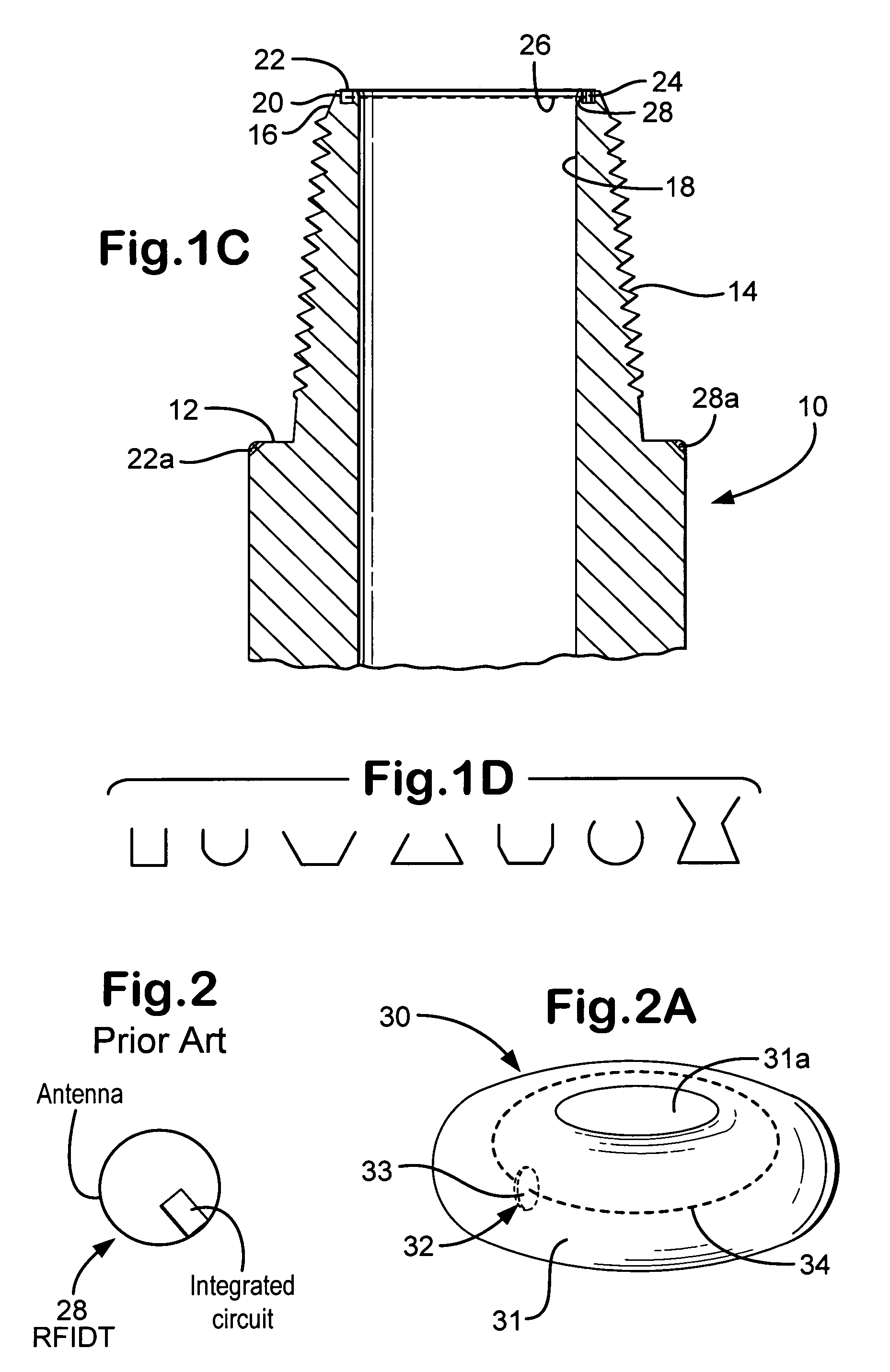

Apparatus identification systems and methods

Owner:VARCO I P INC

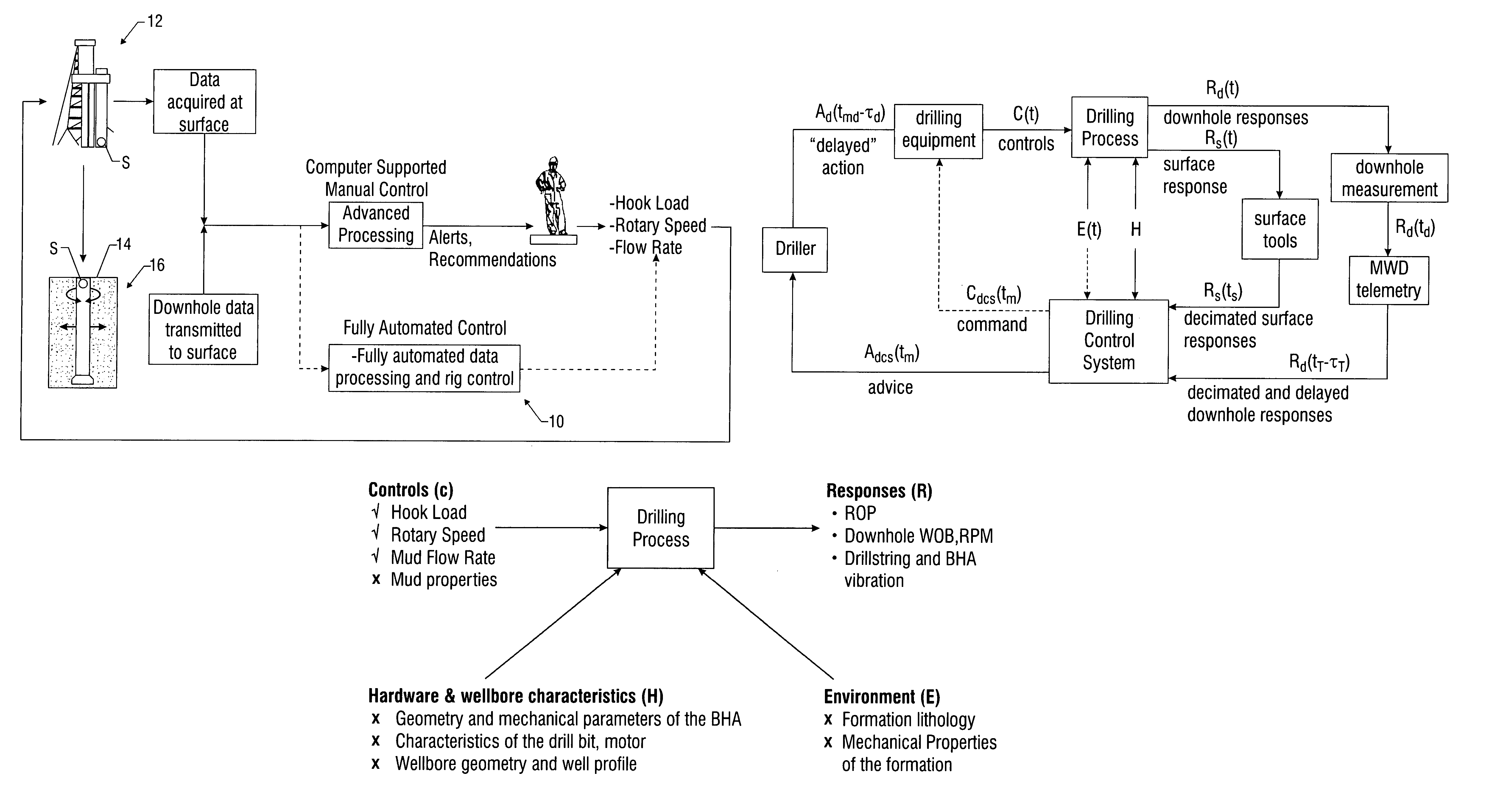

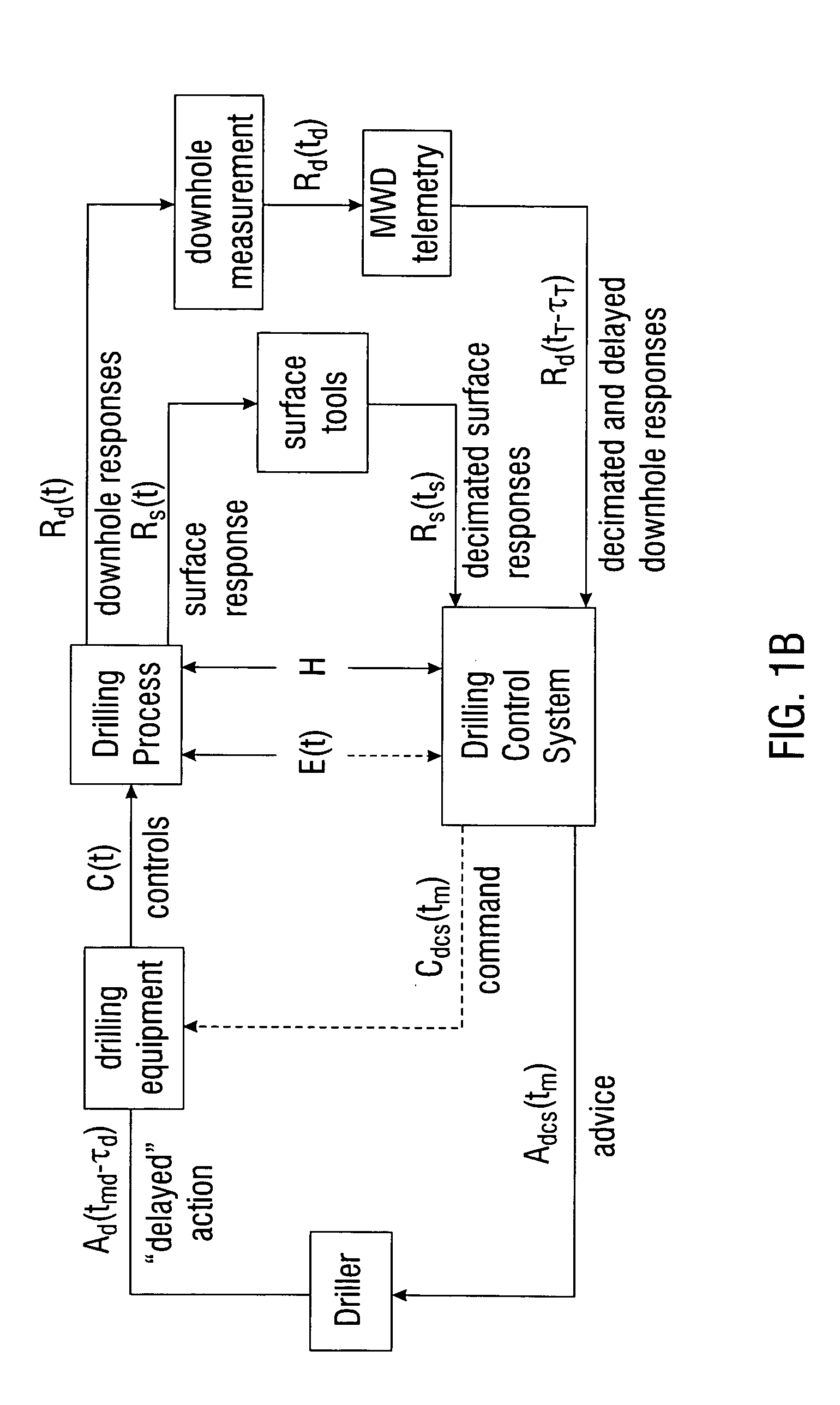

Real-time drilling optimization based on MWD dynamic measurements

A drilling control system provides, in one aspect, advisory actions for optimal drilling. Such a system or model utilizes downhole dynamics data and surface drilling parameters, to produce drilling models used to provide to a human operator with recommended drilling parameters for optimized performance. In another aspect, the output of the drilling control system is directly linked with rig instrumentation systems so as to provide a closed-loop automated drilling control system that optimizes drilling while taking into account the downhole dynamic behavior and surface parameters. The drilling models can be either static or dynamic. In one embodiment, the simulation of the drilling process uses neural networks to estimate some nonlinear function using the examples of input-output relations produced by the drilling process.

Owner:BAKER HUGHES INC

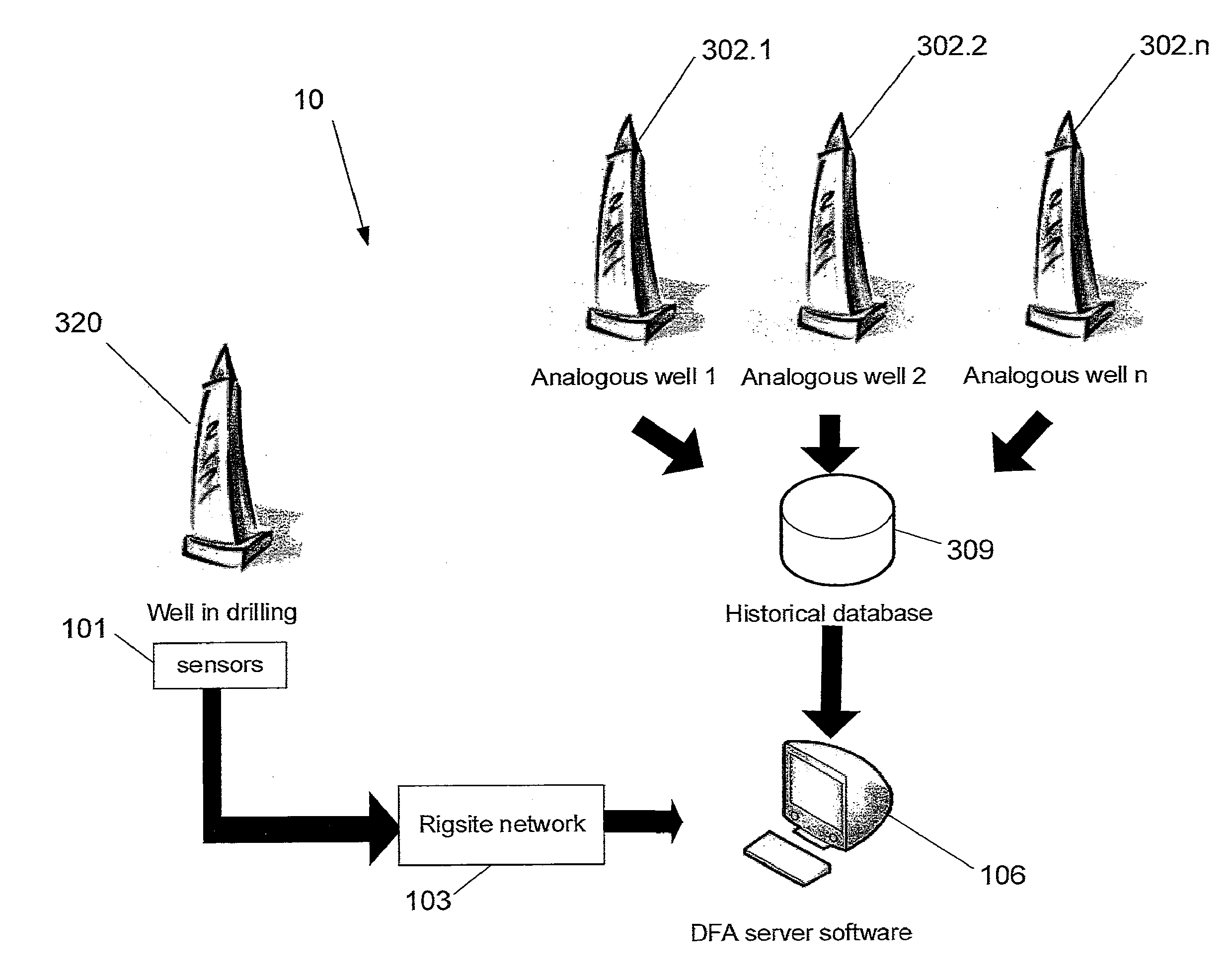

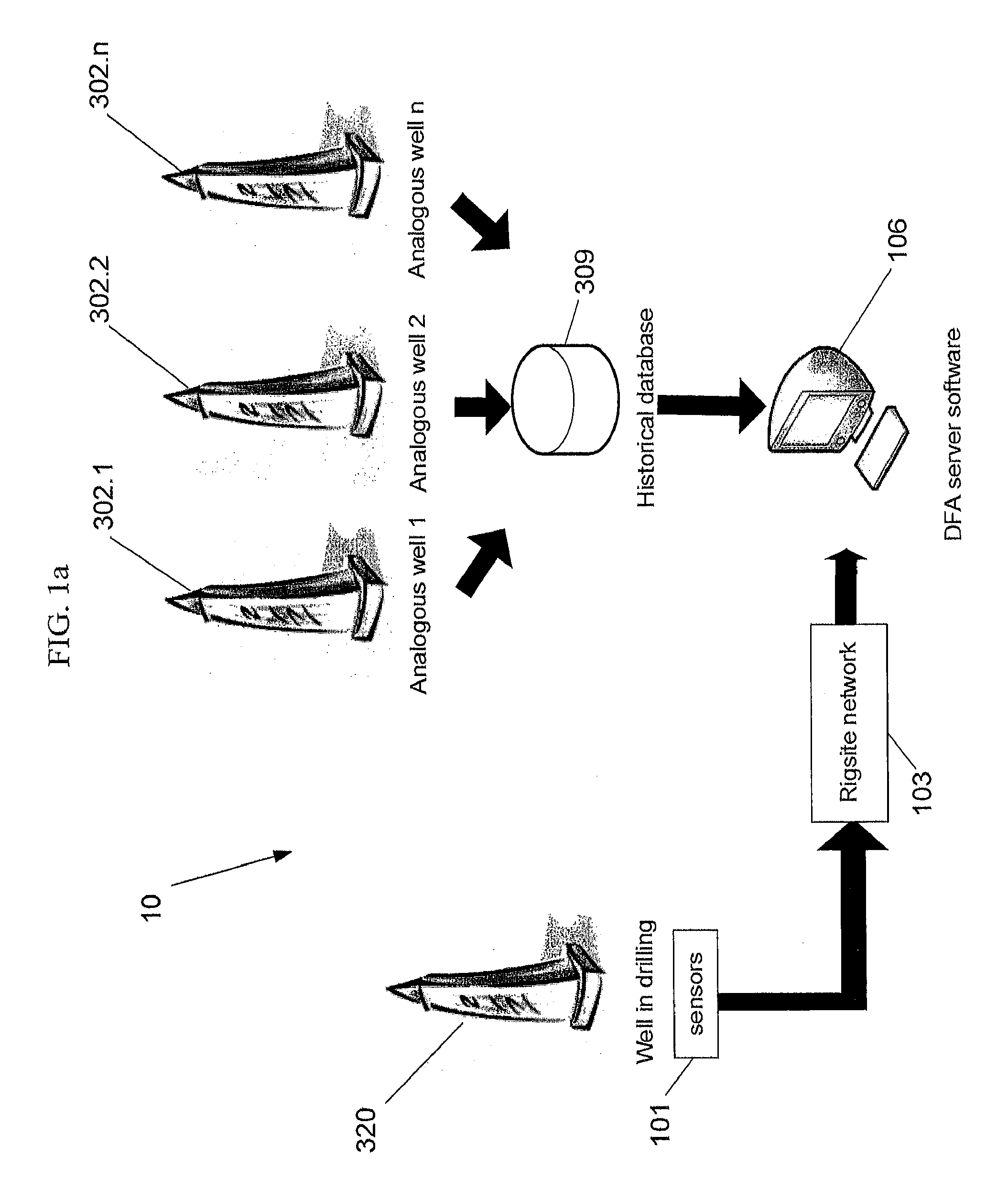

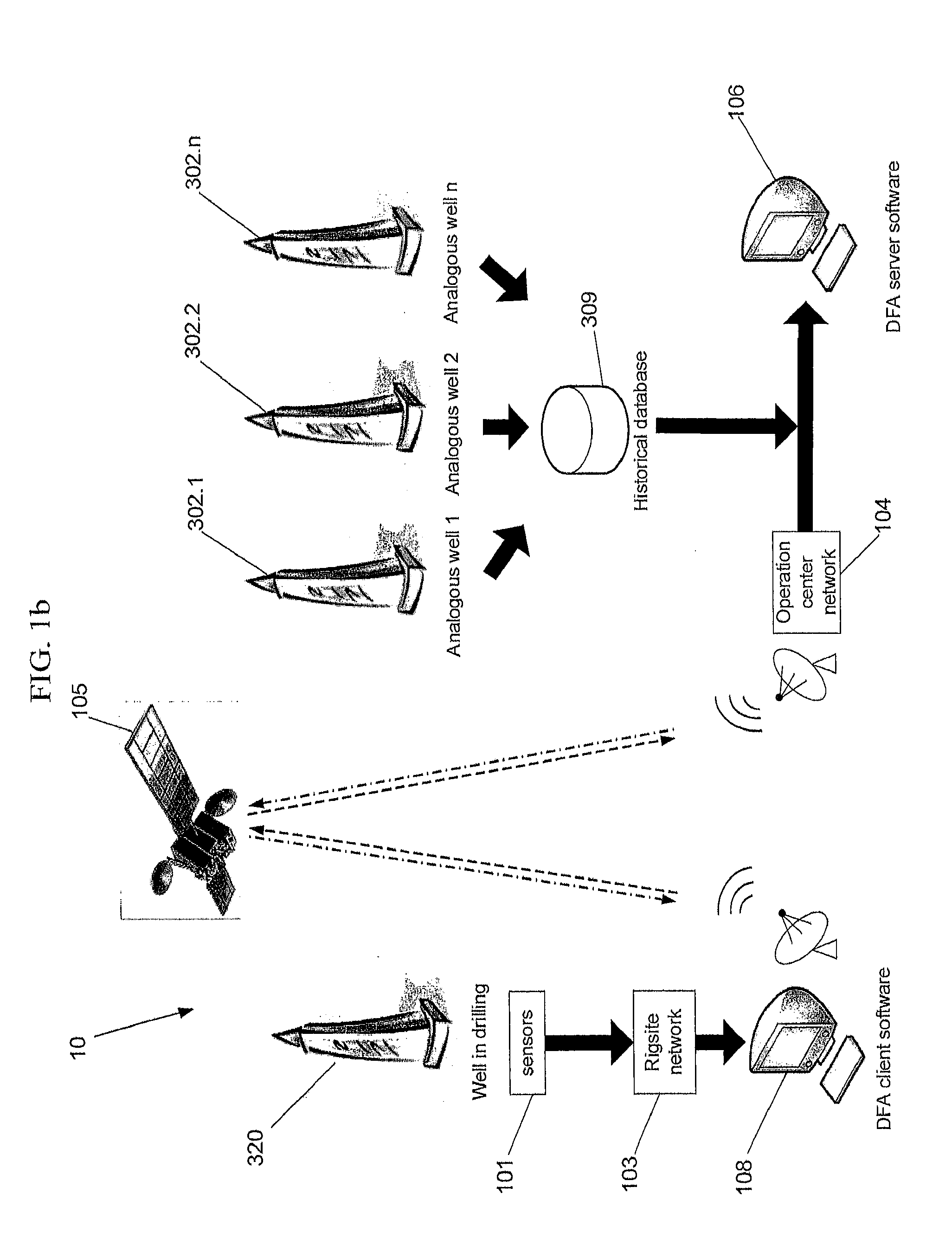

Methods and systems for improved drilling operations using real-time and historical drilling data

ActiveUS20140116776A1Maximized drilling rateLower Drilling CostsEarth drilling toolsMathematical modelsLithologyReal-time data

Methods and systems are described for improved drilling operations through the use of real-time drilling data to predict bit wear, lithology, pore pressure, a rotating friction coefficient, permeability, and cost in real-time and to adjust drilling parameters in real-time based on the predictions. The real-time lithology prediction is made by processing the real-time drilling data through a multilayer neural network. The real-time bit wear prediction is made by using the real-time drilling data to predict a bit efficiency factor and to detect changes in the bit efficiency factor over time. These predictions may be used to adjust drilling parameters in the drilling operation in real-time, subject to override by the operator. The methods and systems may also include determining various downhole hydraulics parameters and a rotary friction factor. Historical data may be used in combination with real-time data to provide expert system assistance and to identify safety concerns.

Owner:RESOURCE ENERGY SOLUTIONS

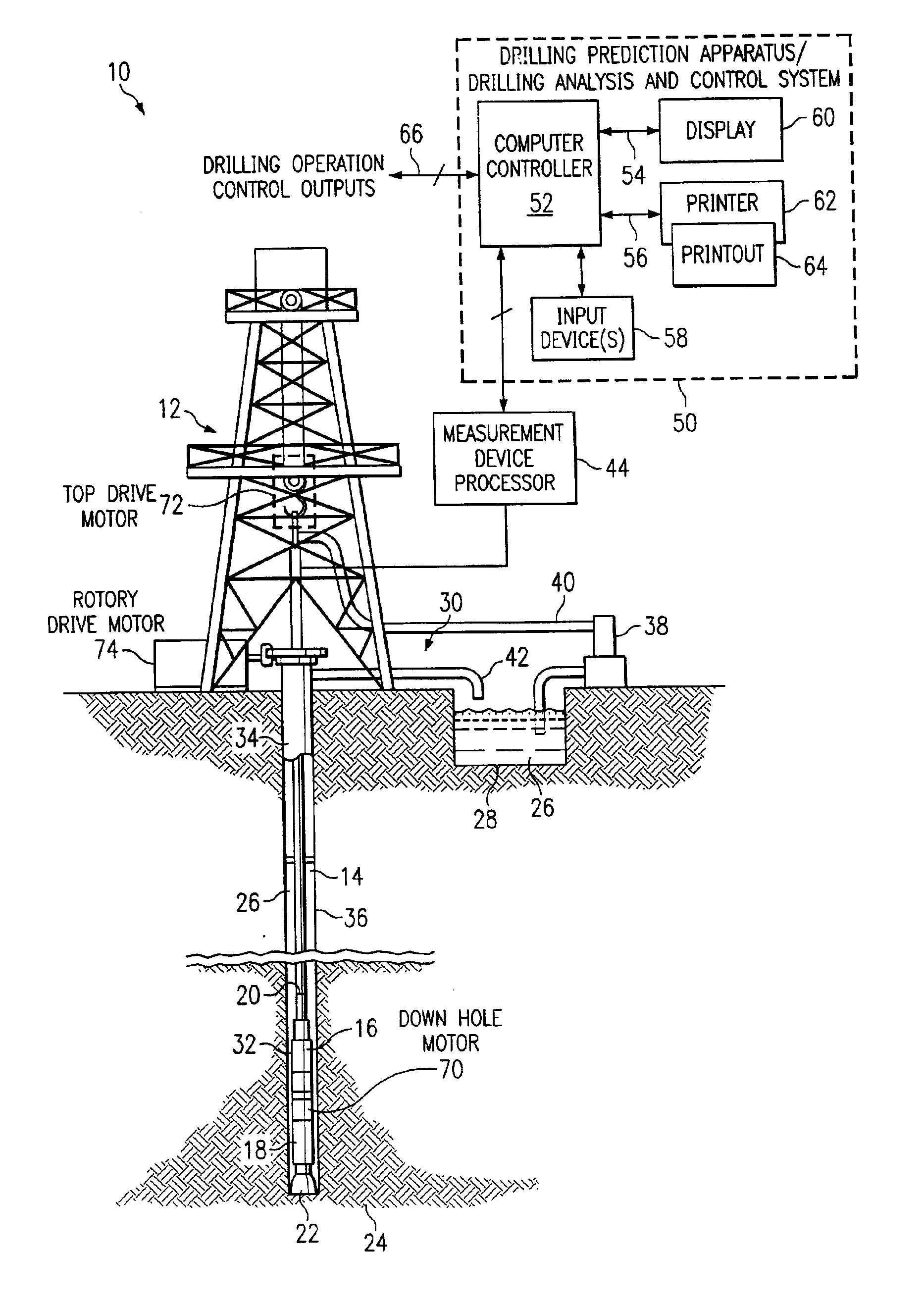

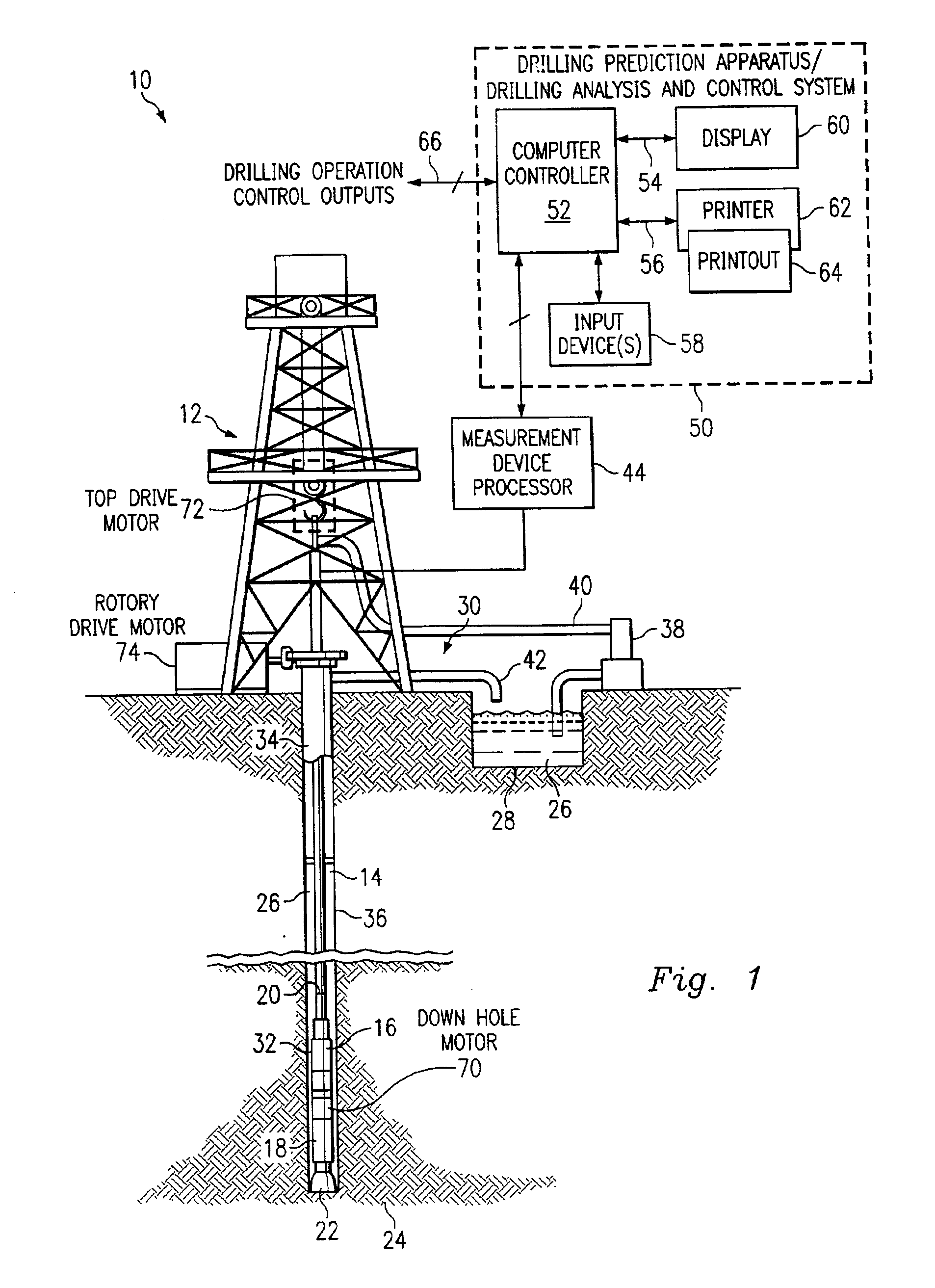

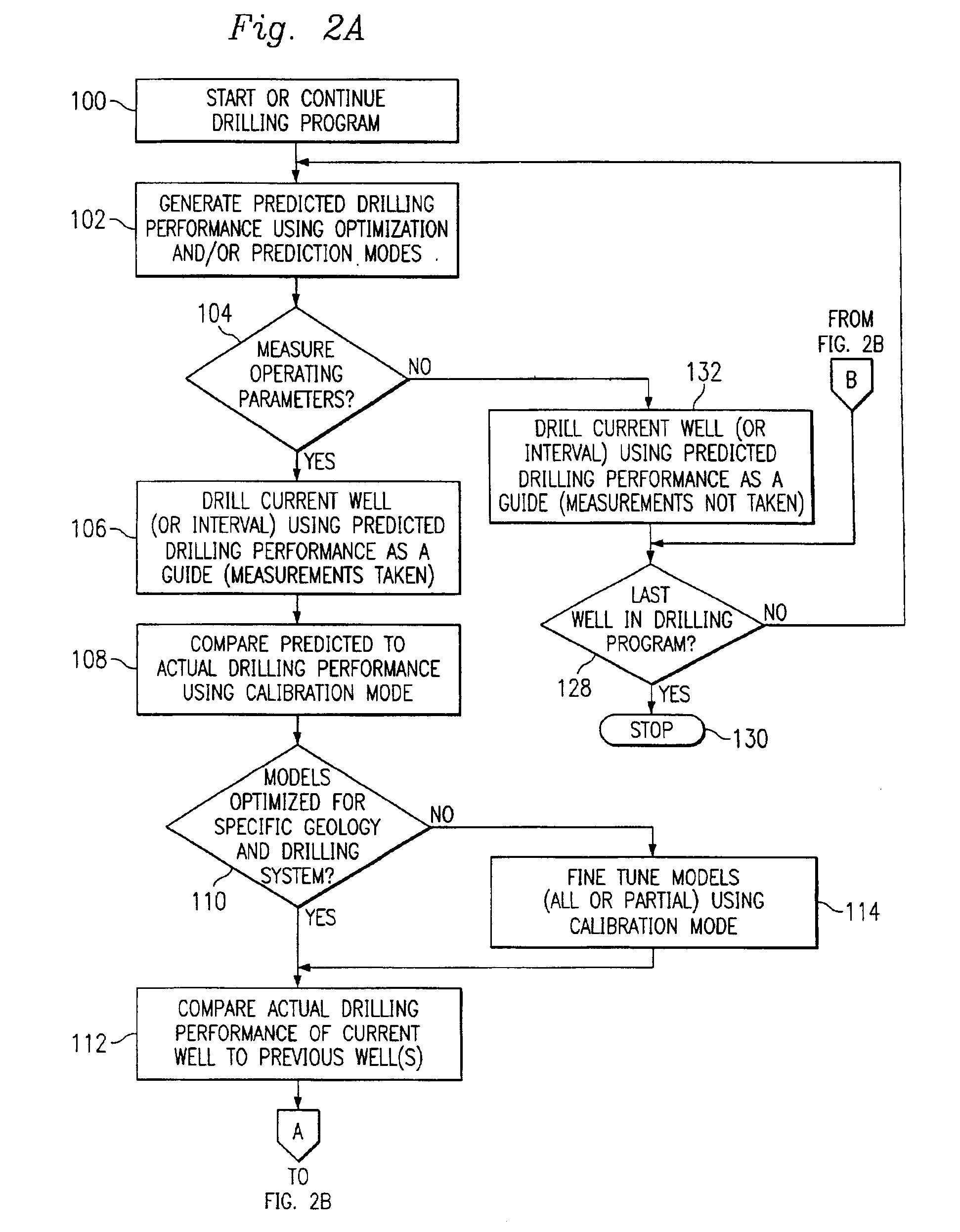

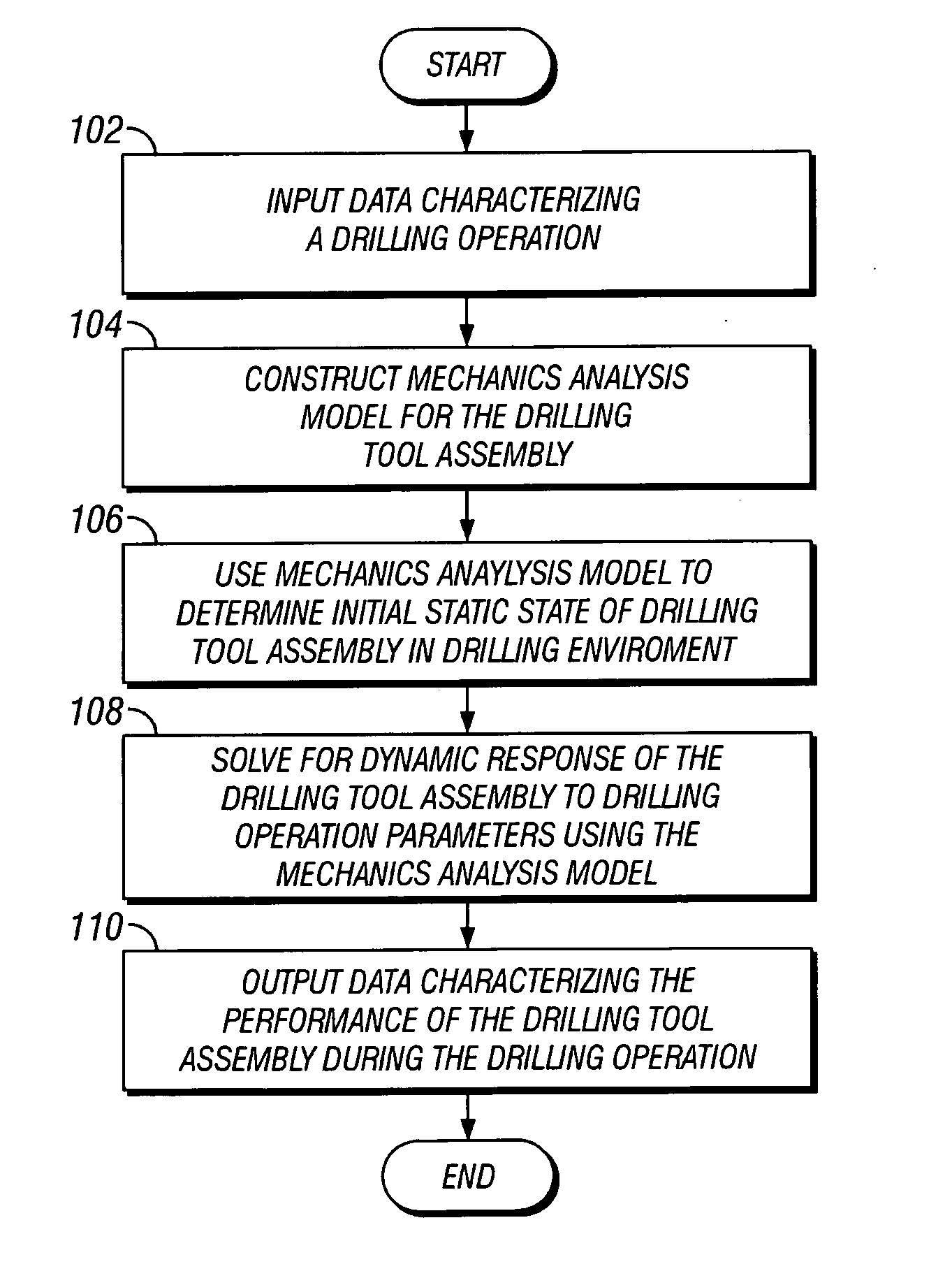

Method and system for predicting performance of a drilling system of a given formation

InactiveUS7032689B2Electric/magnetic detection for well-loggingEarth drilling toolsComputer printingDisplay device

A method and apparatus for predicting the performance of a drilling system for the drilling of a well bore in a given formation includes generating a geology characteristic of the formation per unit depth according to a prescribed geology model, obtaining specifications of proposed drilling equipment for use in the drilling of the well bore, and predicting a drilling mechanics in response to the specifications as a function of the geology characteristic per unit depth according to a prescribed drilling mechanics model. Responsive to a predicted-drilling mechanics, a controller controls a parameter in the drilling of the well bore. The geology characteristic includes at least rock strength. The specifications include at least a bit specification of a recommended drill bit. Lastly, the predicted drilling mechanics include at least one of bit wear, mechanical efficiency, power, and operating parameters. A display is provided for generating a display of the geology characteristic and predicted drilling mechanics per unit depth, including either a display monitor or a printer.

Owner:HALLIBURTON ENERGY SERVICES INC

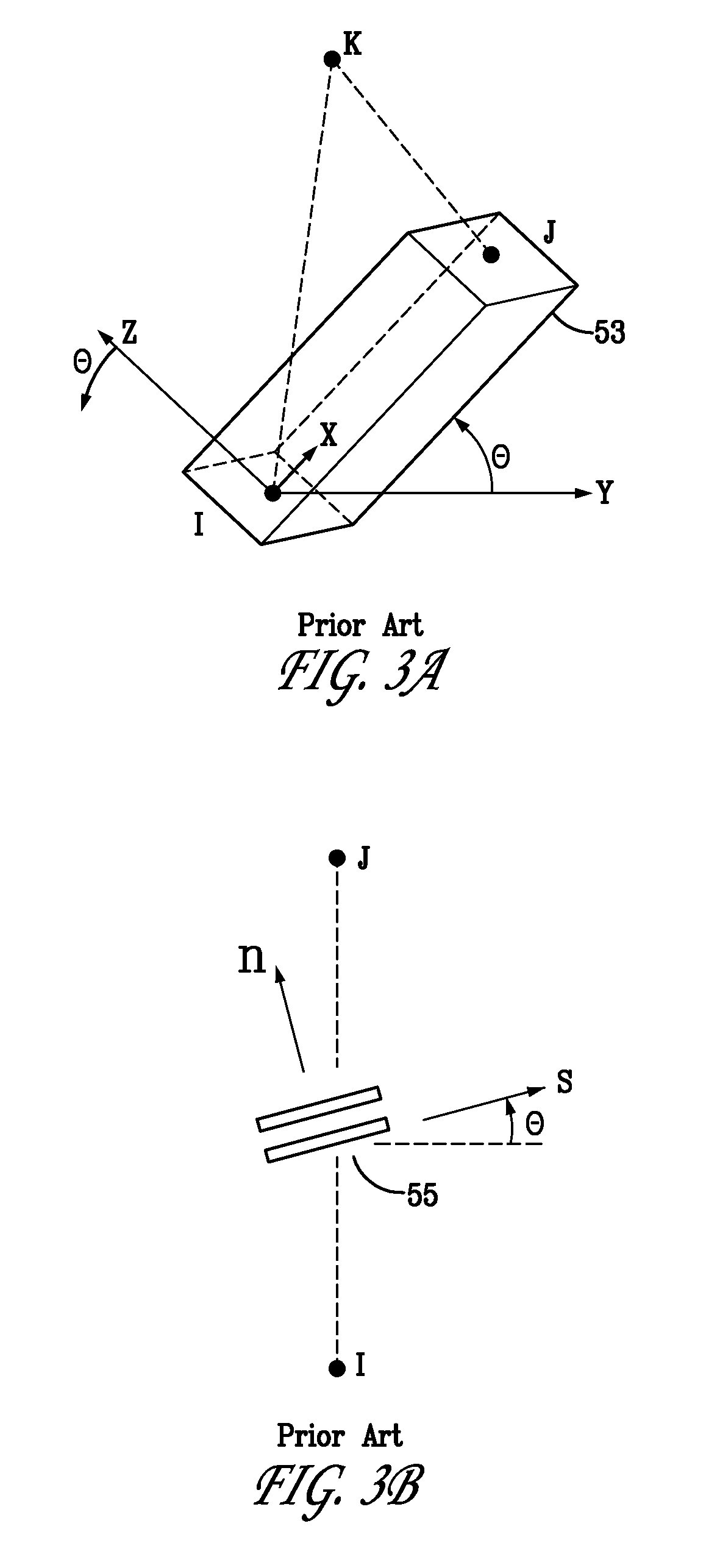

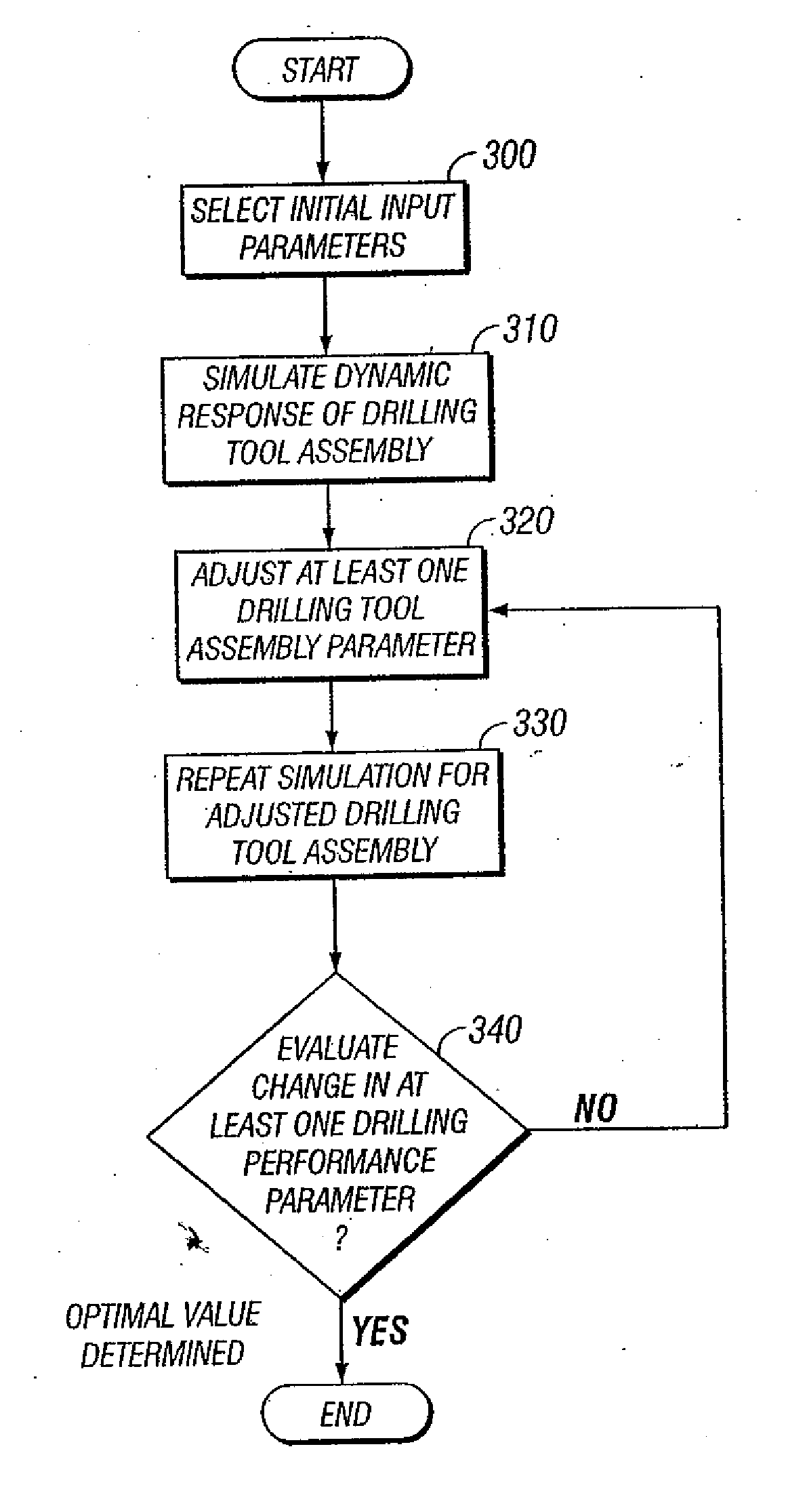

Methods for modeling, designing, and optimizing the performance of drilling tool assemblies

ActiveUS20050096847A1Electric/magnetic detection for well-loggingDrill bitsPetroleum engineeringDrill bit

A method for designing a drilling tool assembly, having a drill bit disposed at one end includes defining initial drilling tool assembly design parameters; calculating a dynamic response of the drilling tool assembly; adjusting a value of a drilling tool assembly design parameter; and repeating the calculating and the adjusting until a drilling tool assembly performance parameter is optimized.

Owner:SMITH INT INC

Well fracturing systems with electrical motors and methods of use

A system for stimulating oil or gas production from a wellbore includes a hydraulic fracturing pump unit having one or more hydraulic fracturing pumps driven by one or more electrical fracturing motors, a variable frequency drive (VFD) controlling the electrical fracturing motors, a fracturing pump blower unit driven by a blower motor, and a fracturing pump lubrication unit having a lubrication pump driven by a lubrication motor and a cooling fan driven by a cooling motor. The system may further include a blender unit and a hydration unit. A system control unit may control the operational parameters of the system.

Owner:STEWART & STEVENSON

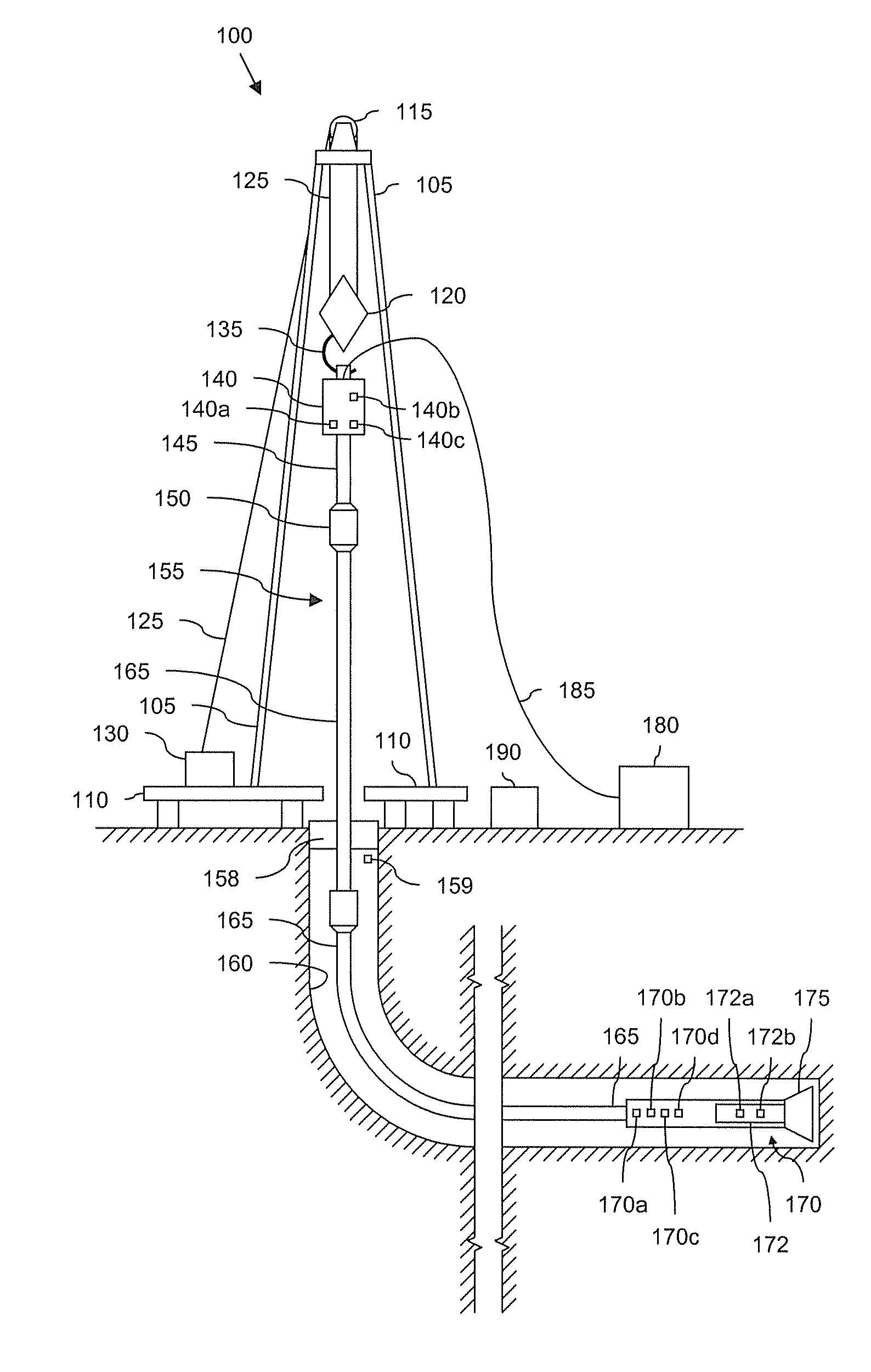

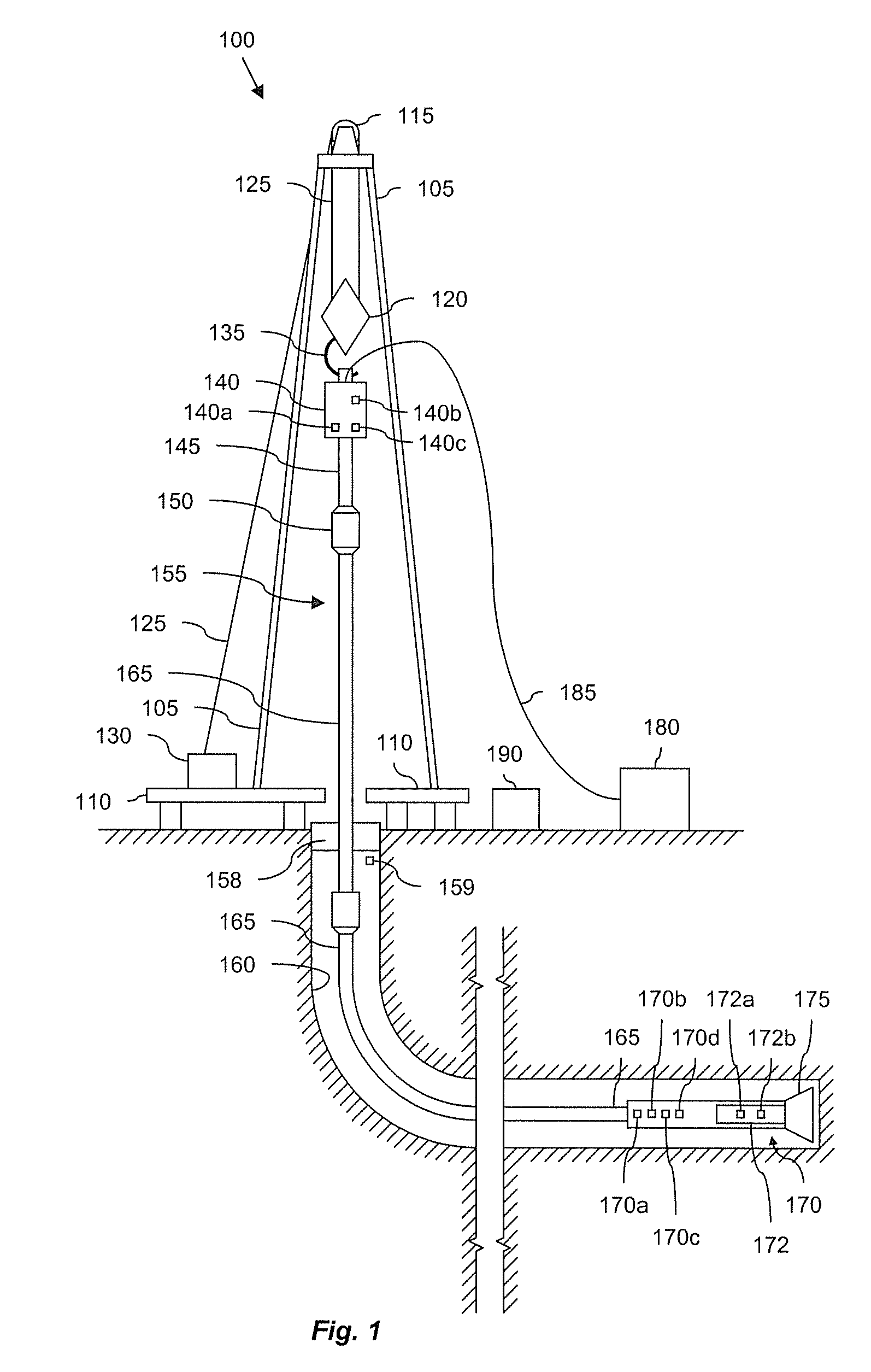

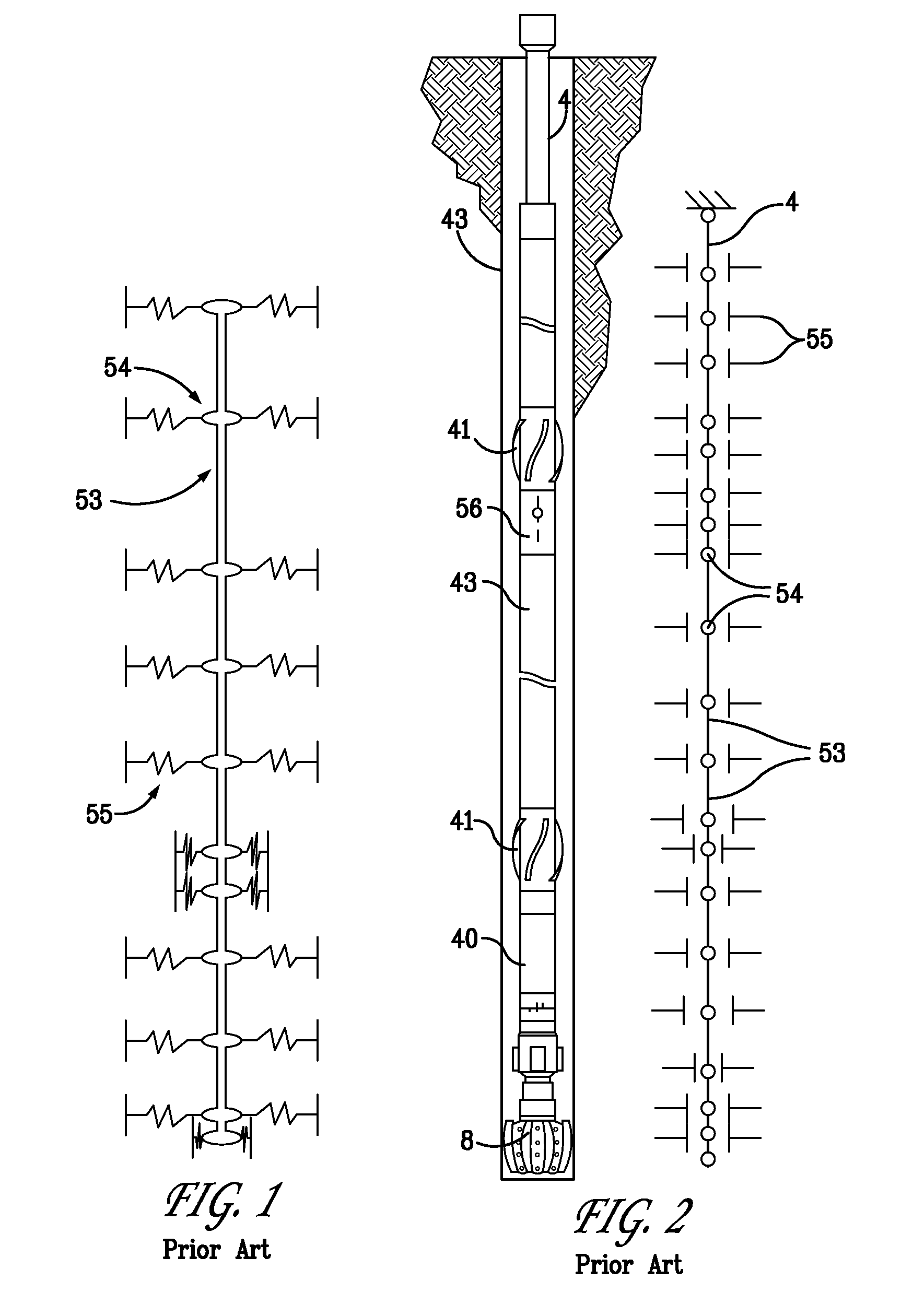

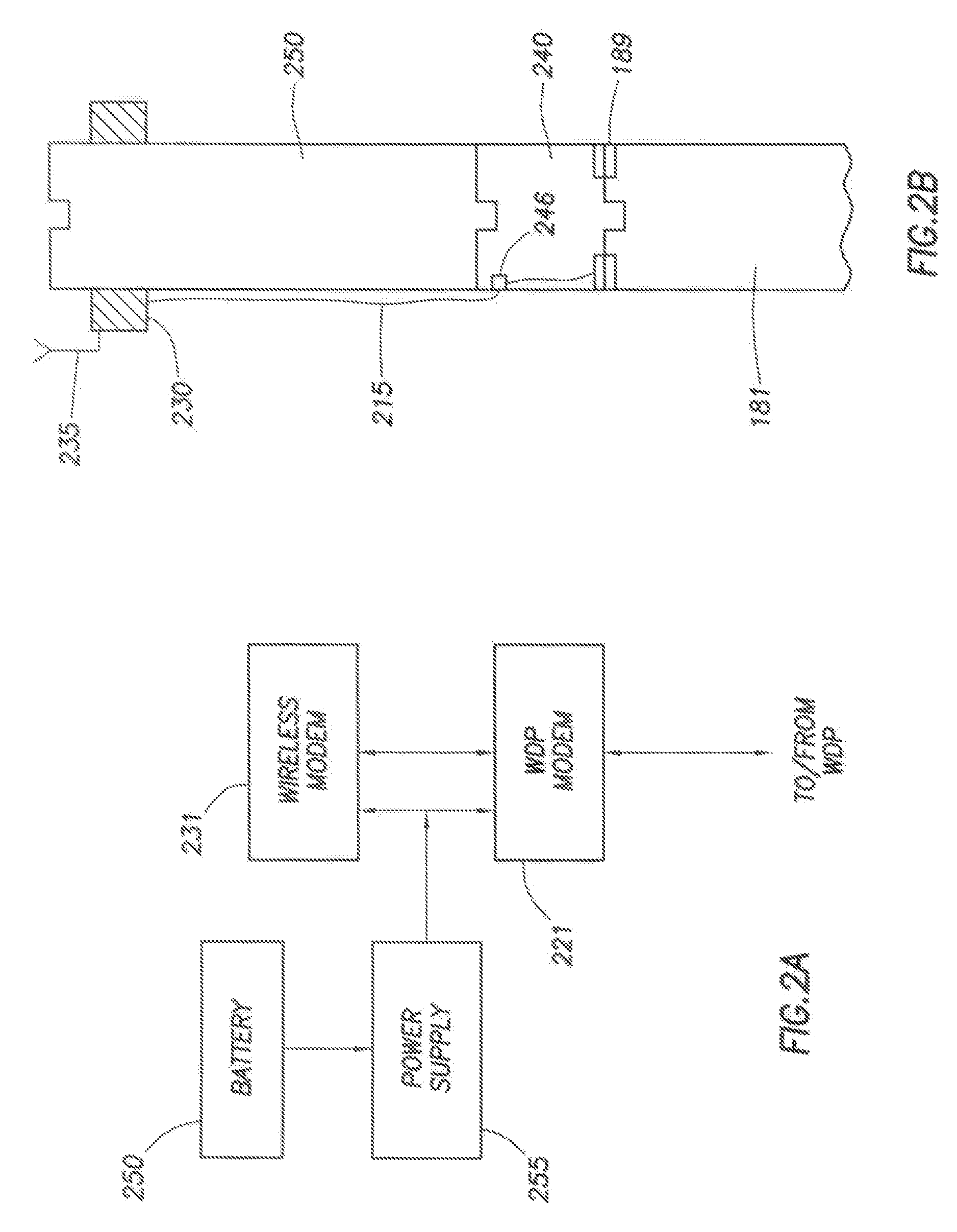

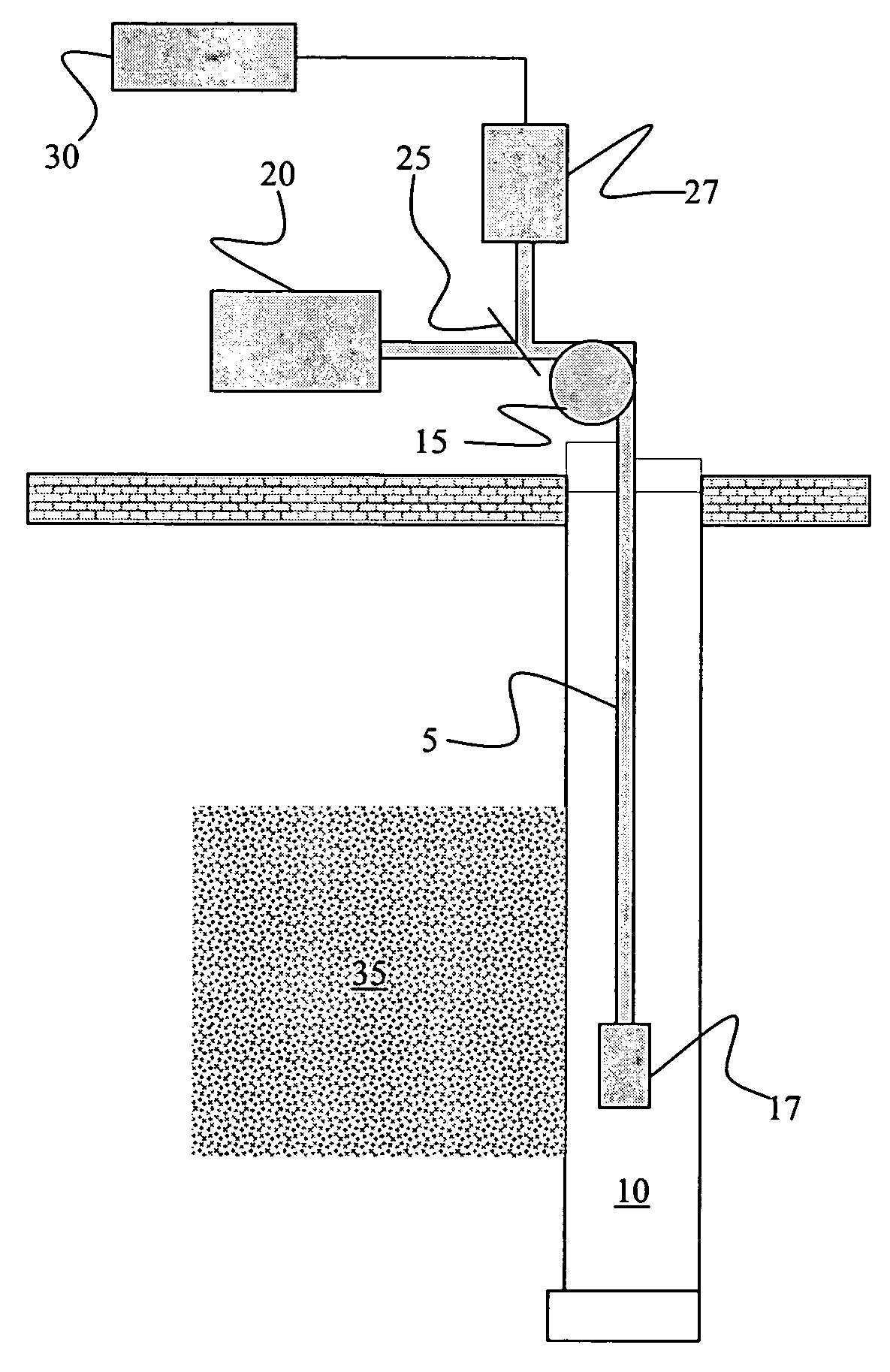

Bidirectional drill string telemetry for measuring and drilling control

The disclosure has application for use in conjunction with an operation of drilling an earth borehole using: a drilling rig, a drill string having its generally upper end mechanically coupleable with and suspendable from the drilling rig, and a bottom hole assembly adjacent the lower end the drill string, the bottom hole assembly including a drill bit at its lower end. A method is set forth for obtaining information about at least one parameter sensed at the bottom hole assembly, including the following steps: providing at least one measuring device in the bottom hole assembly, the at least one measuring device producing measurement data representative of a measured condition at the bottom hole assembly; providing an uphole processor system at the earth's surface; providing a drill string telemetry system coupled with the at least one measuring device and coupled with the uphole processor system; and transmitting the data from the measuring device to the uphole processor system via the drill string telemetry system.

Owner:SCHLUMBERGER TECH CORP

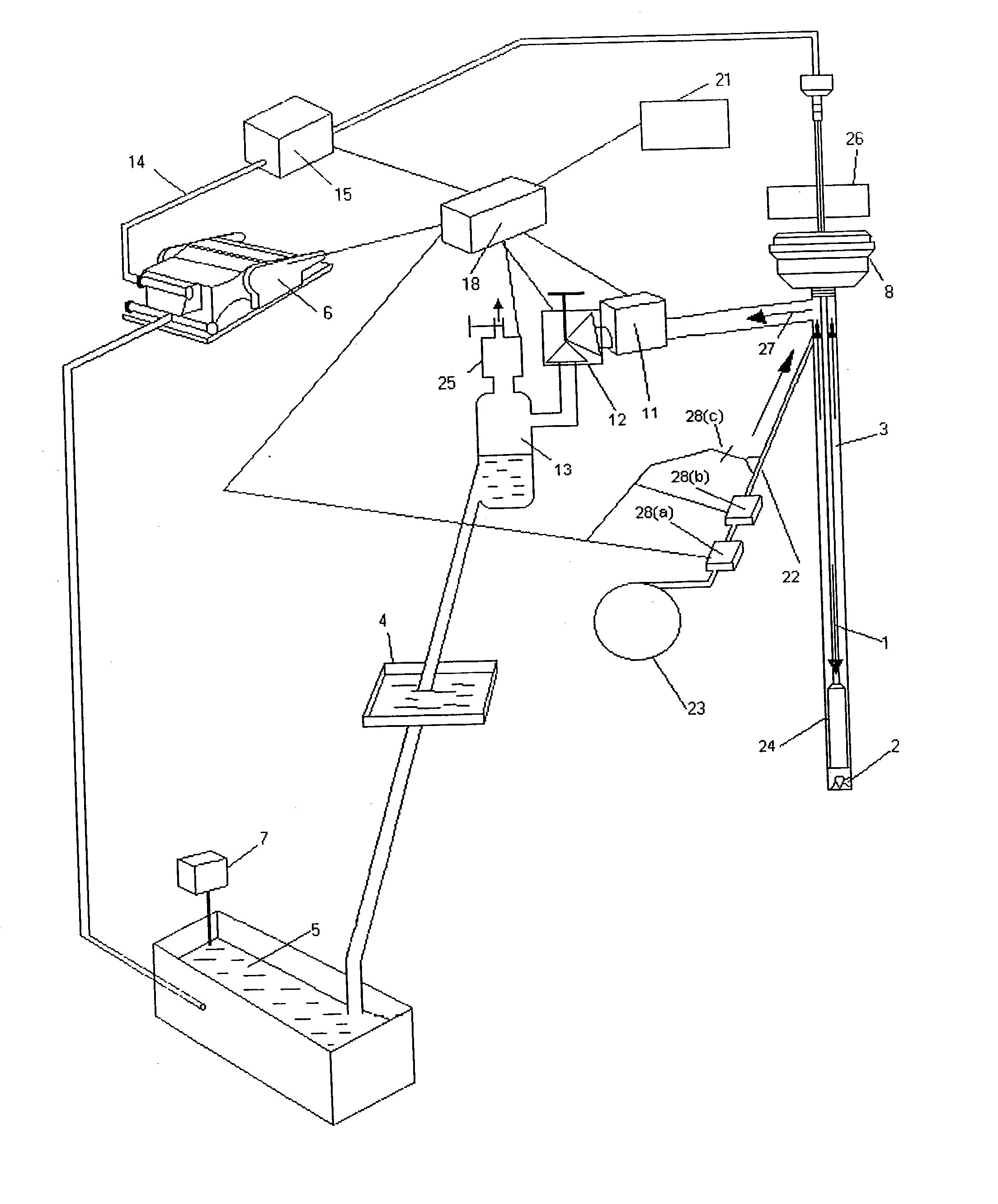

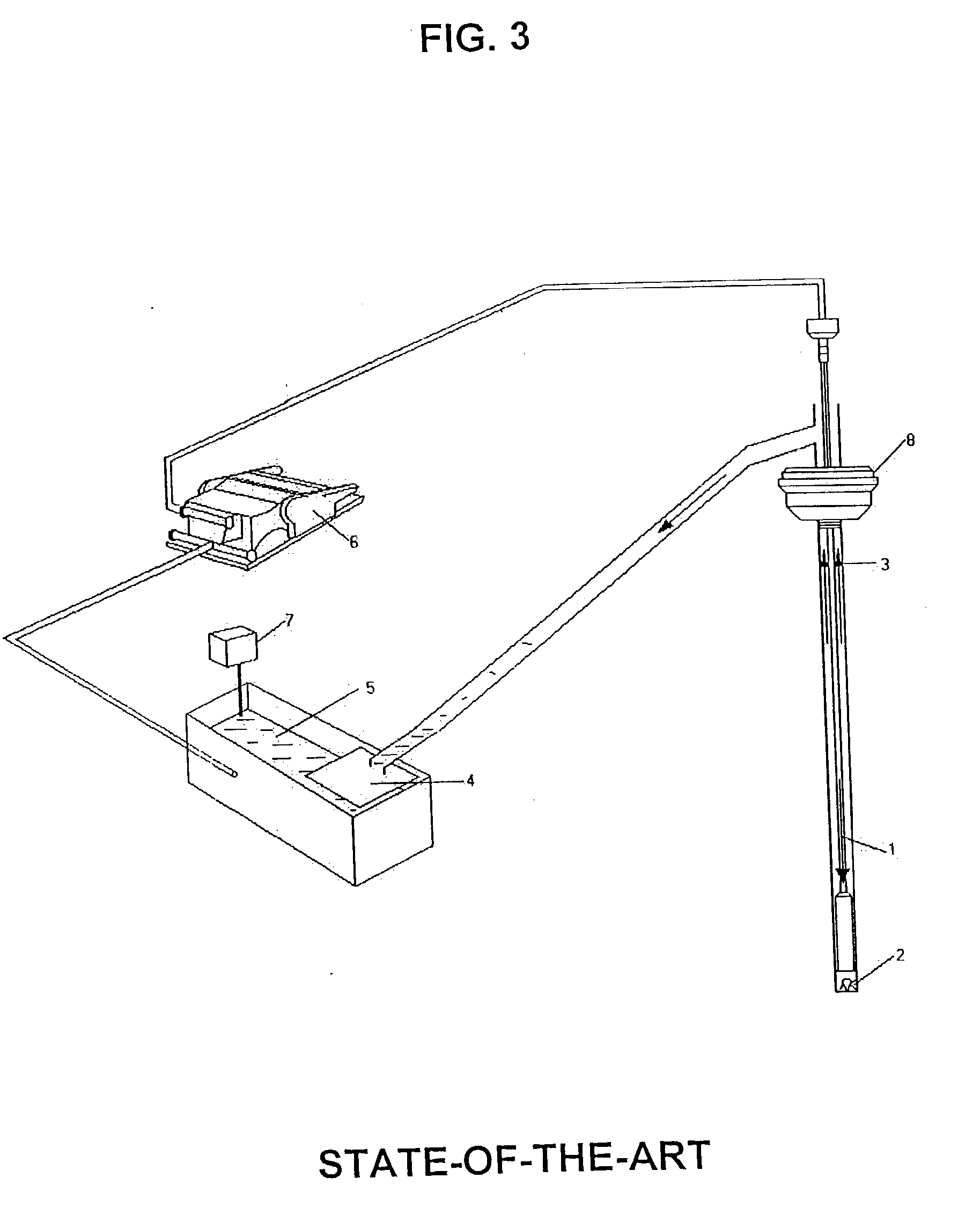

Drilling system and method

InactiveUS20030079912A1Accurate calculationImprove securityConstructionsFlushingWell drillingEngineering

A closed-loop circulating system for drilling wells has control of the flow rates in and out of the wellbore. Kicks and fluid losses are quickly controlled by adjusting the backpressure. Kick tolerance and tripping margins are eliminated by real-time determination of pore and fracture pressure. The system can incorporate a rotating BOP and can be used with underbalanced drilling.

Owner:SECURE DRILLING INT

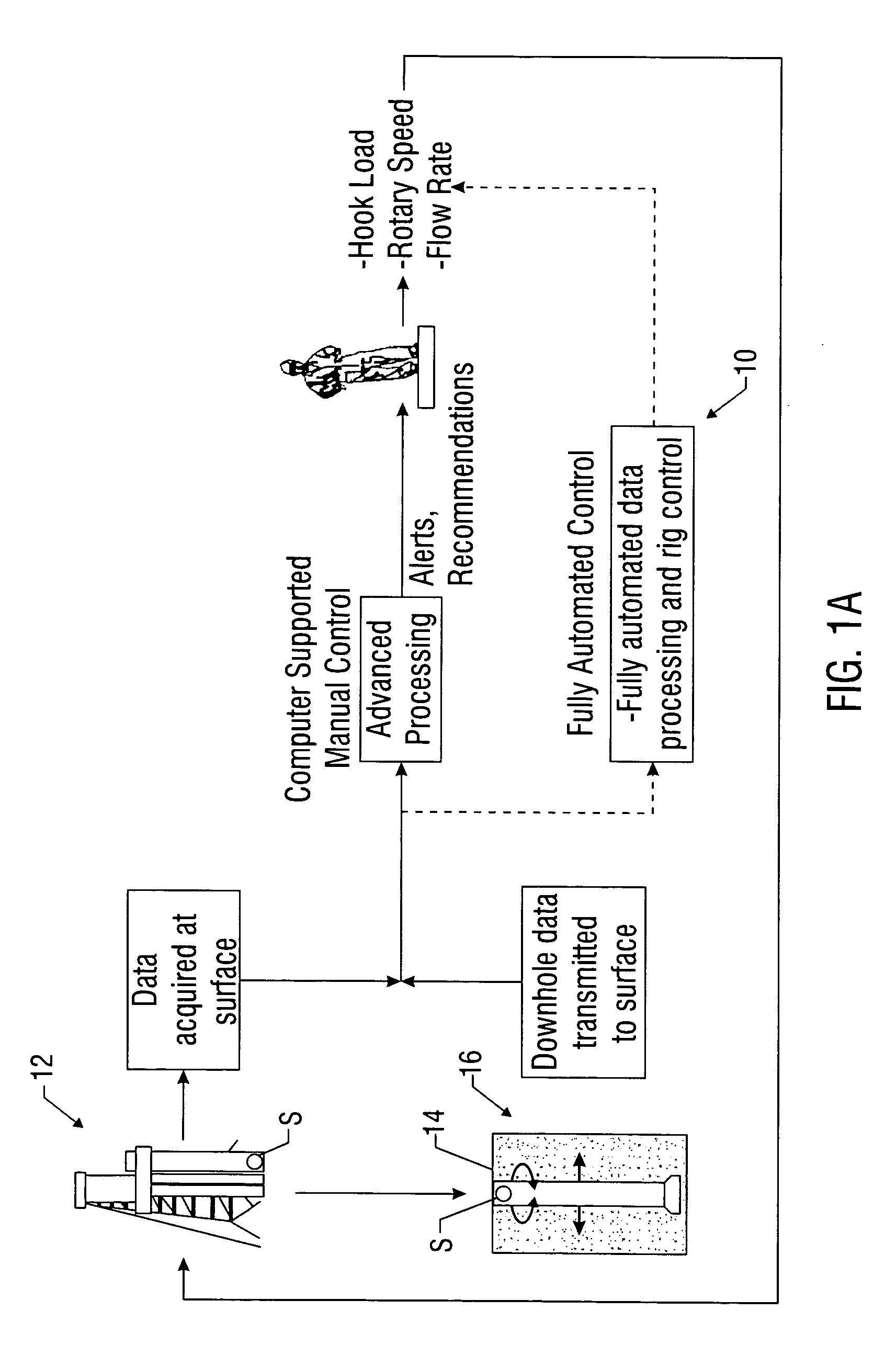

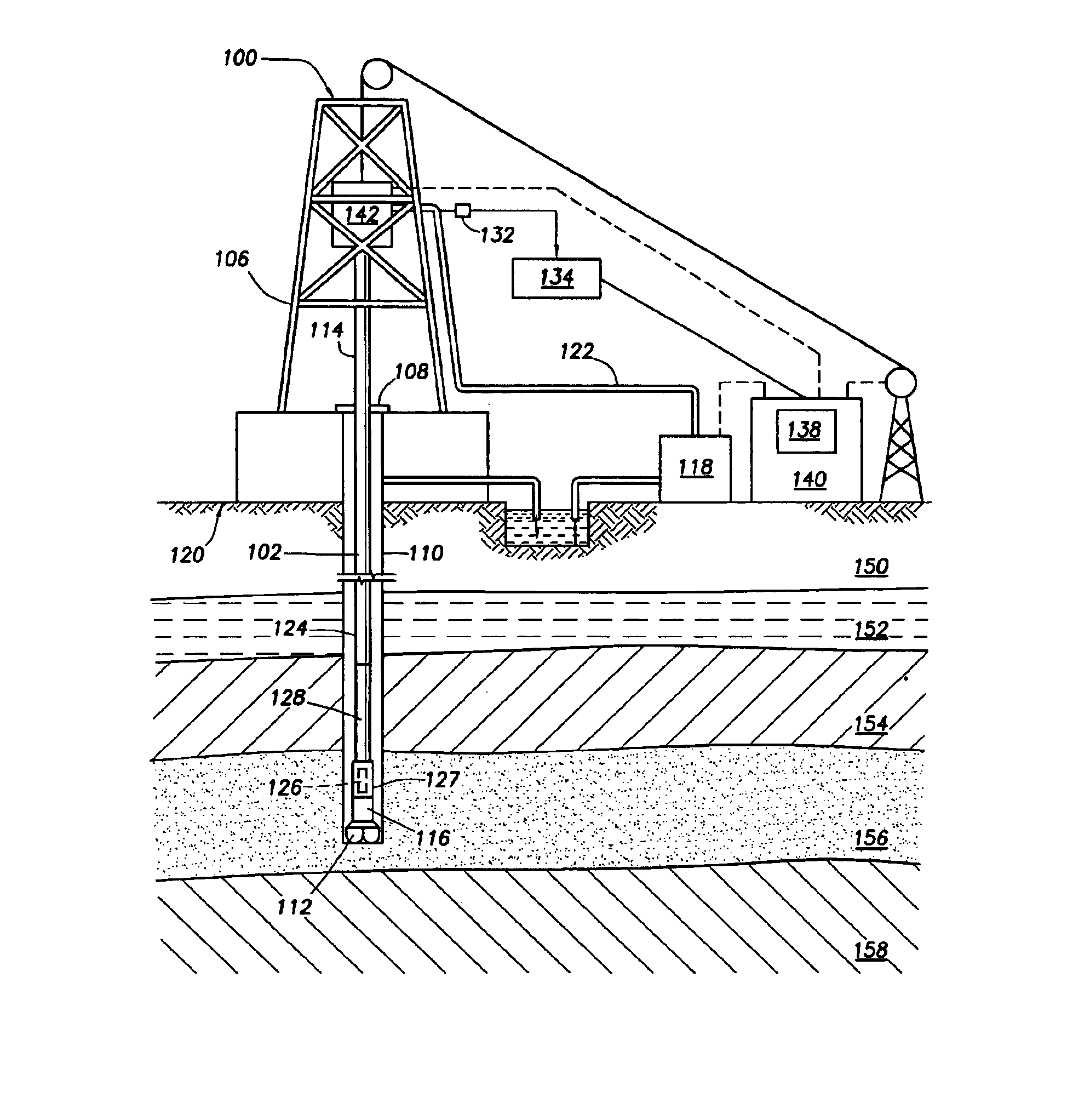

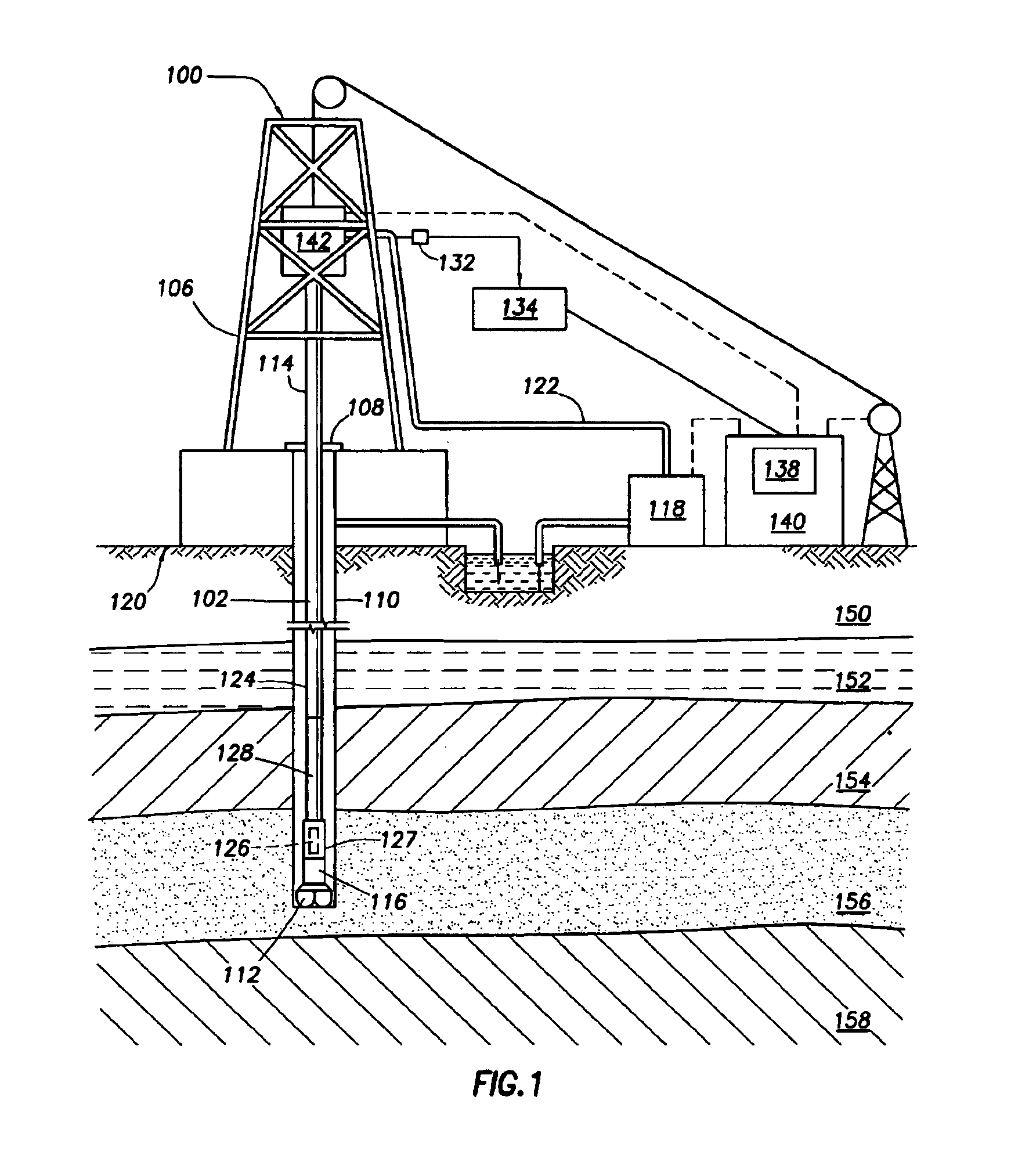

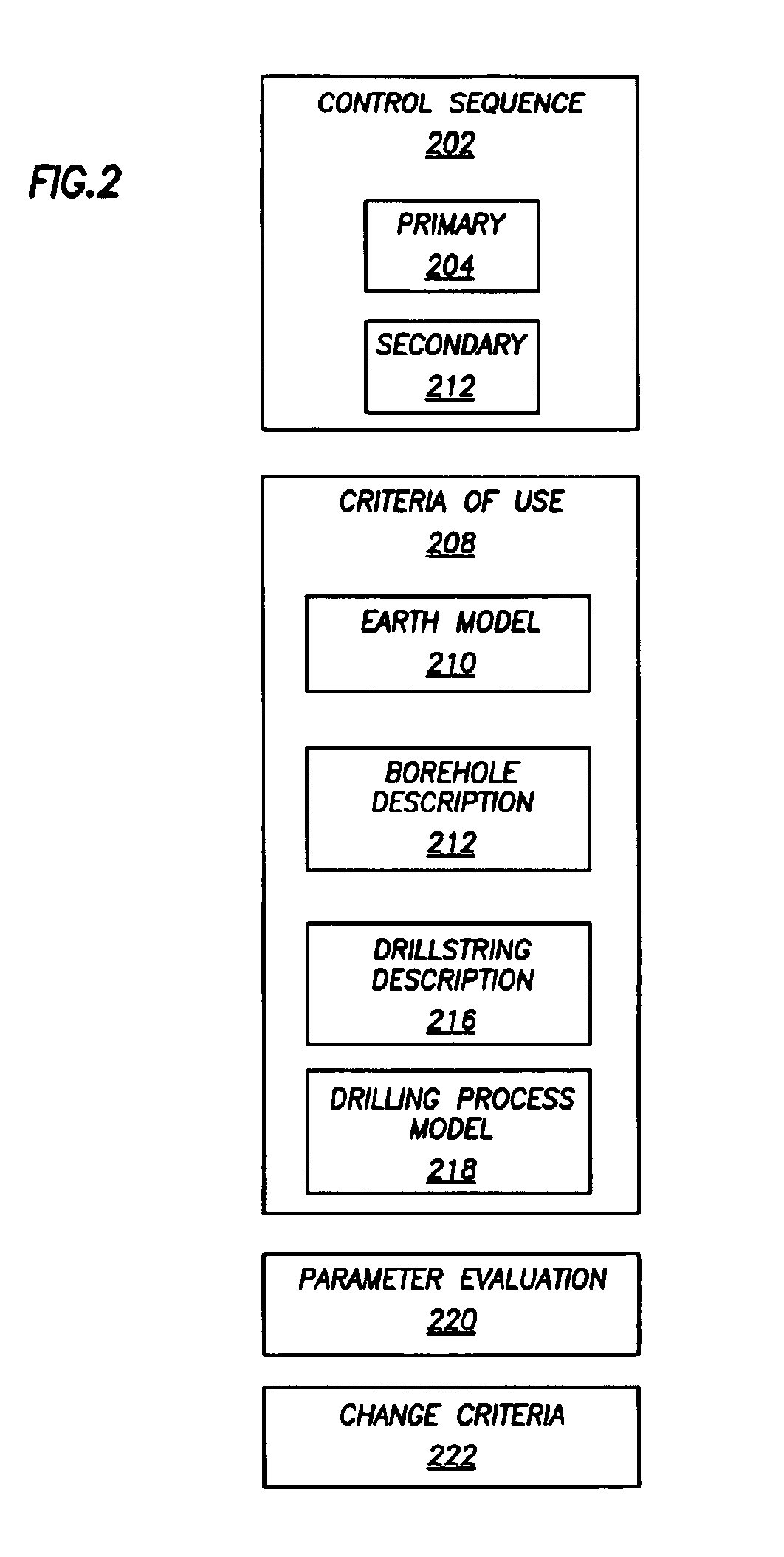

Realtime control of a drilling system using the output from combination of an earth model and a drilling process model

A system is for controlling borehole operations using a computational drilling process model representing the combined effect of downhole conditions and the operation of a drillstring. The drilling process model is continually updated with downhole measurements made during a drilling operation. From the updated drilling process model, a set of optimum drilling parameters is determined and communicated to a surface equipment control system. Further, the system allows the surface equipment control system to automatically adjust current surface equipment control settings based on the updated optimum drilling parameters. Various control scripts are generated and executed to inform the surface equipment control system based on a present drilling mode.

Owner:SCHLUMBERGER TECH CORP

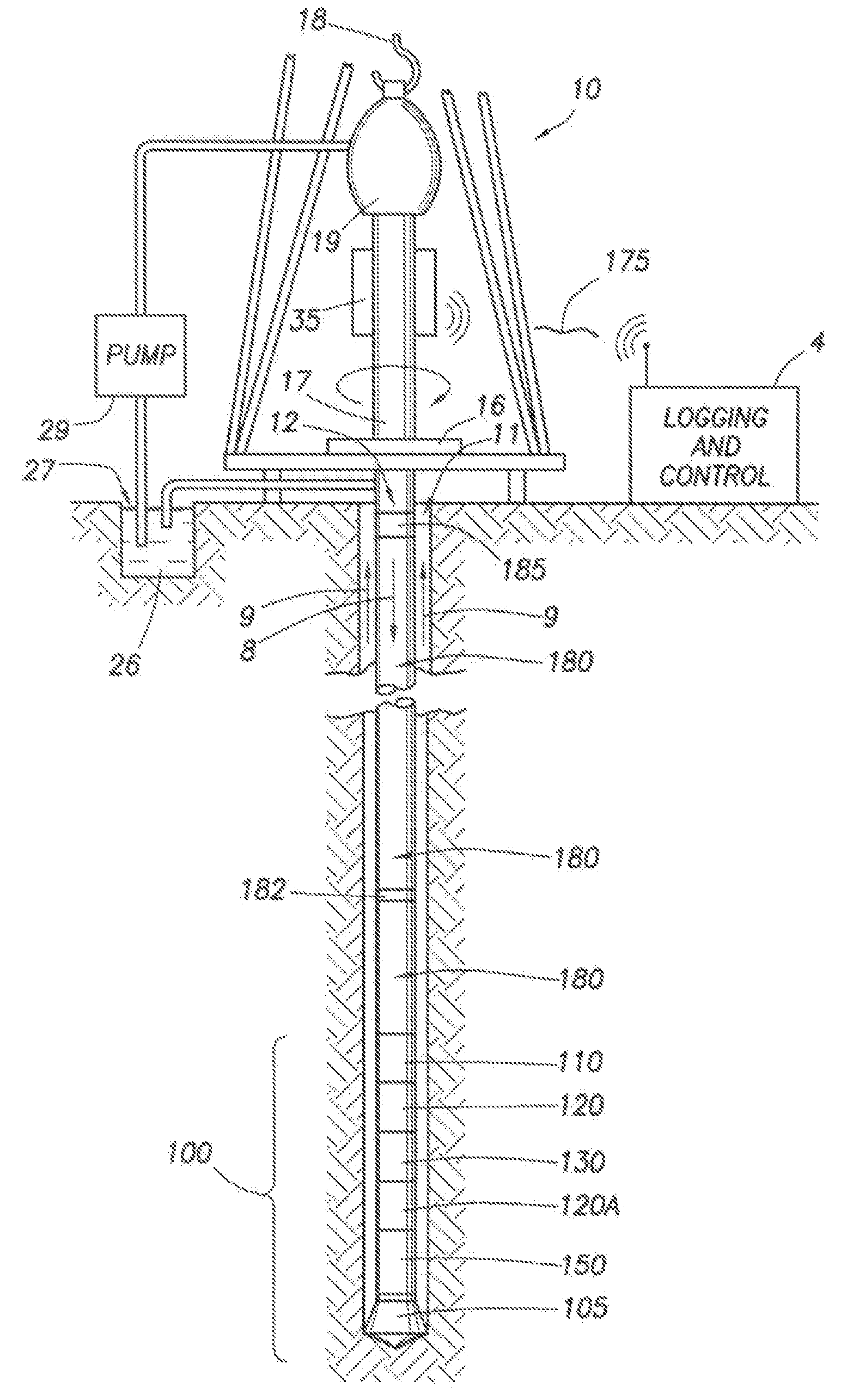

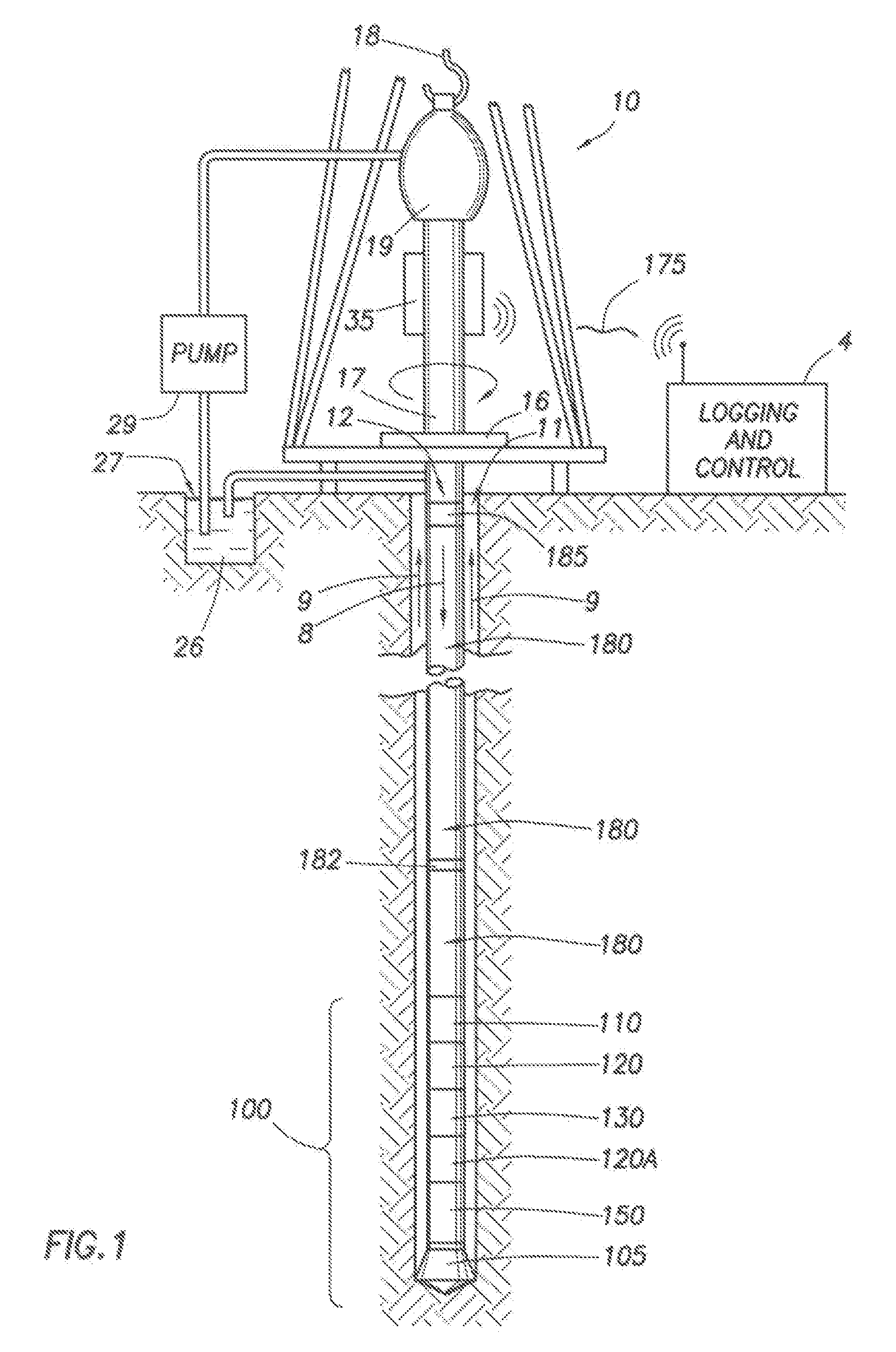

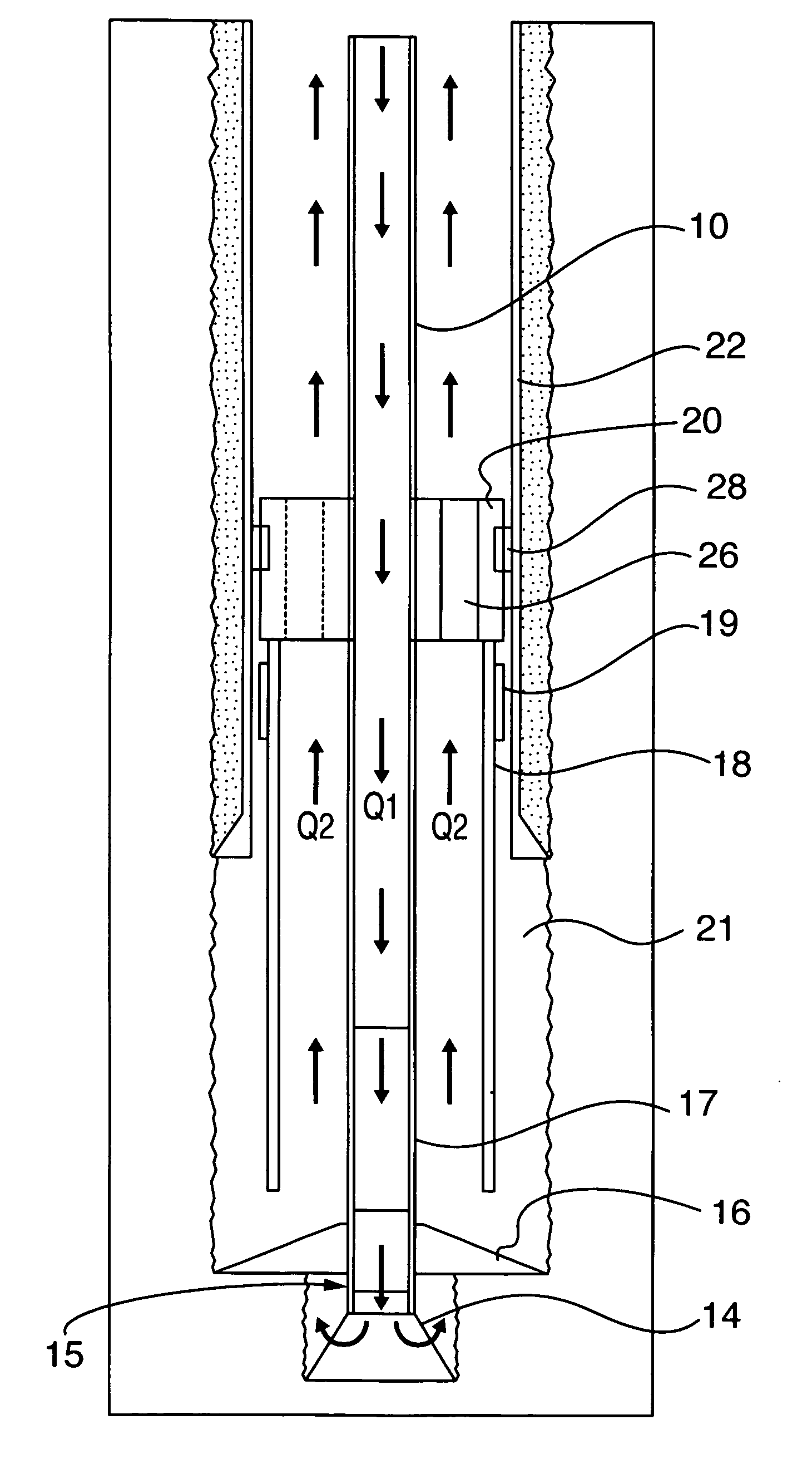

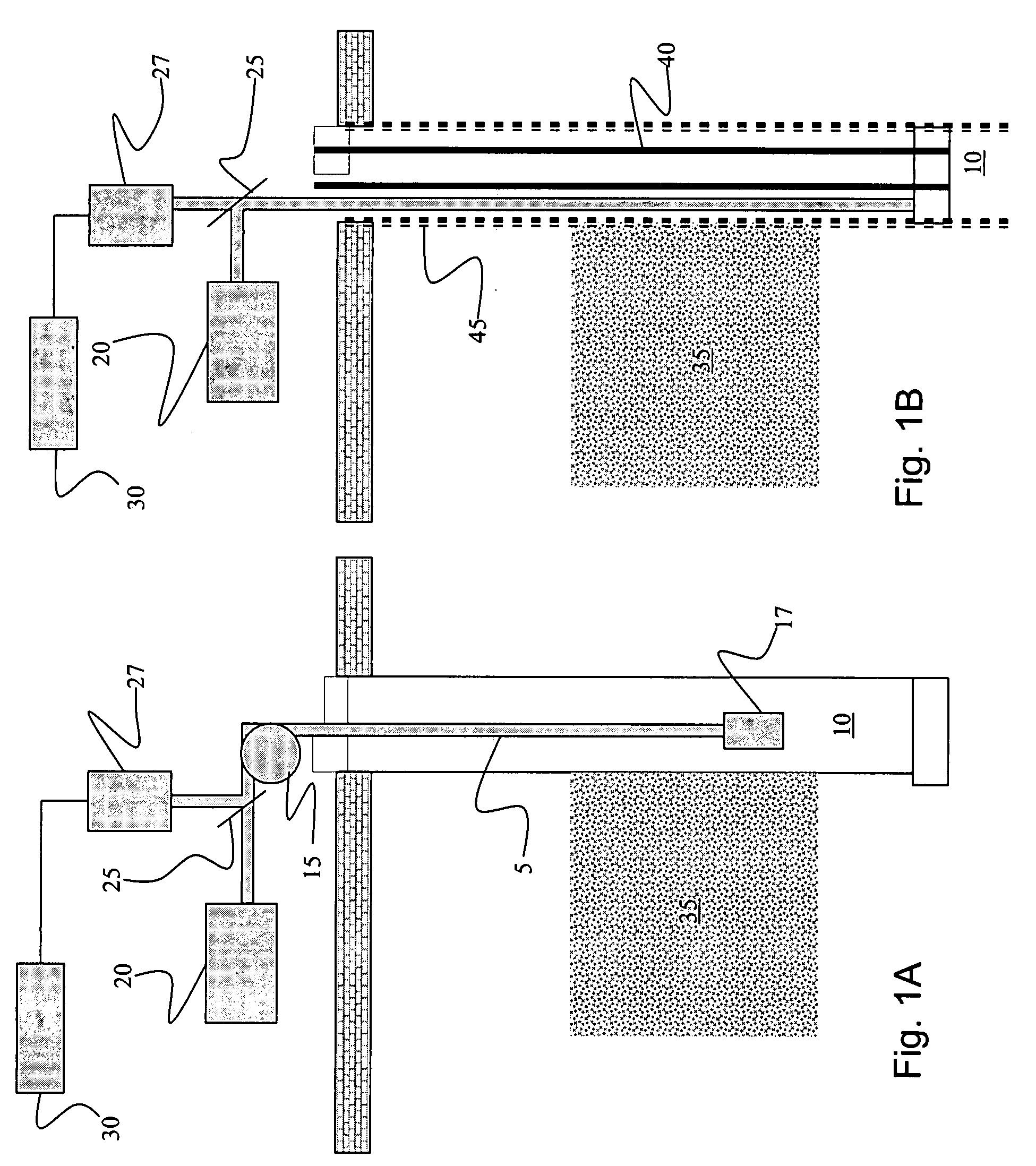

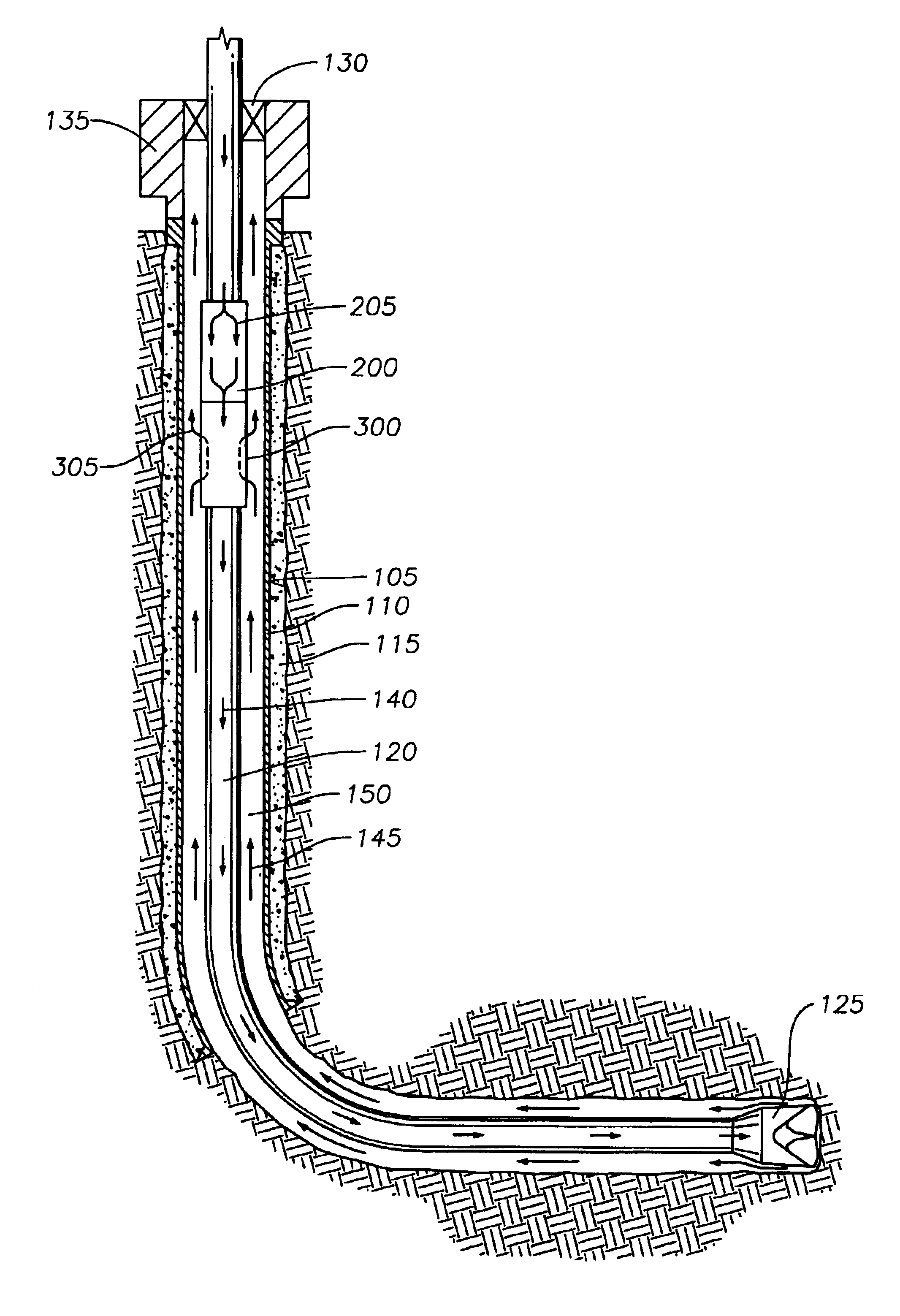

Method and apparatus for drilling a borehole with a borehole liner

A method for drilling a borehole includes; providing a drill string of drill pipe including a center bore, a distal end, a bit assembly at the distal end; hanging a liner from the drill string, thereby forming an annular space between the drill string and the liner and with the bit assembly extending from a lower end of the liner; positioning the drill string with the liner attached thereto in a borehole such that a second annular space is formed between the liner and the borehole wall; operating the bit assembly to proceed with drilling the borehole; and circulating drilling fluid down through the center bore of the drill string out through the bit assembly and down through the second annular space between the liner and the borehole wall, the drilling fluid returning up through the annular space between the drill string and the liner.

Owner:TESCO CORPORATION +1

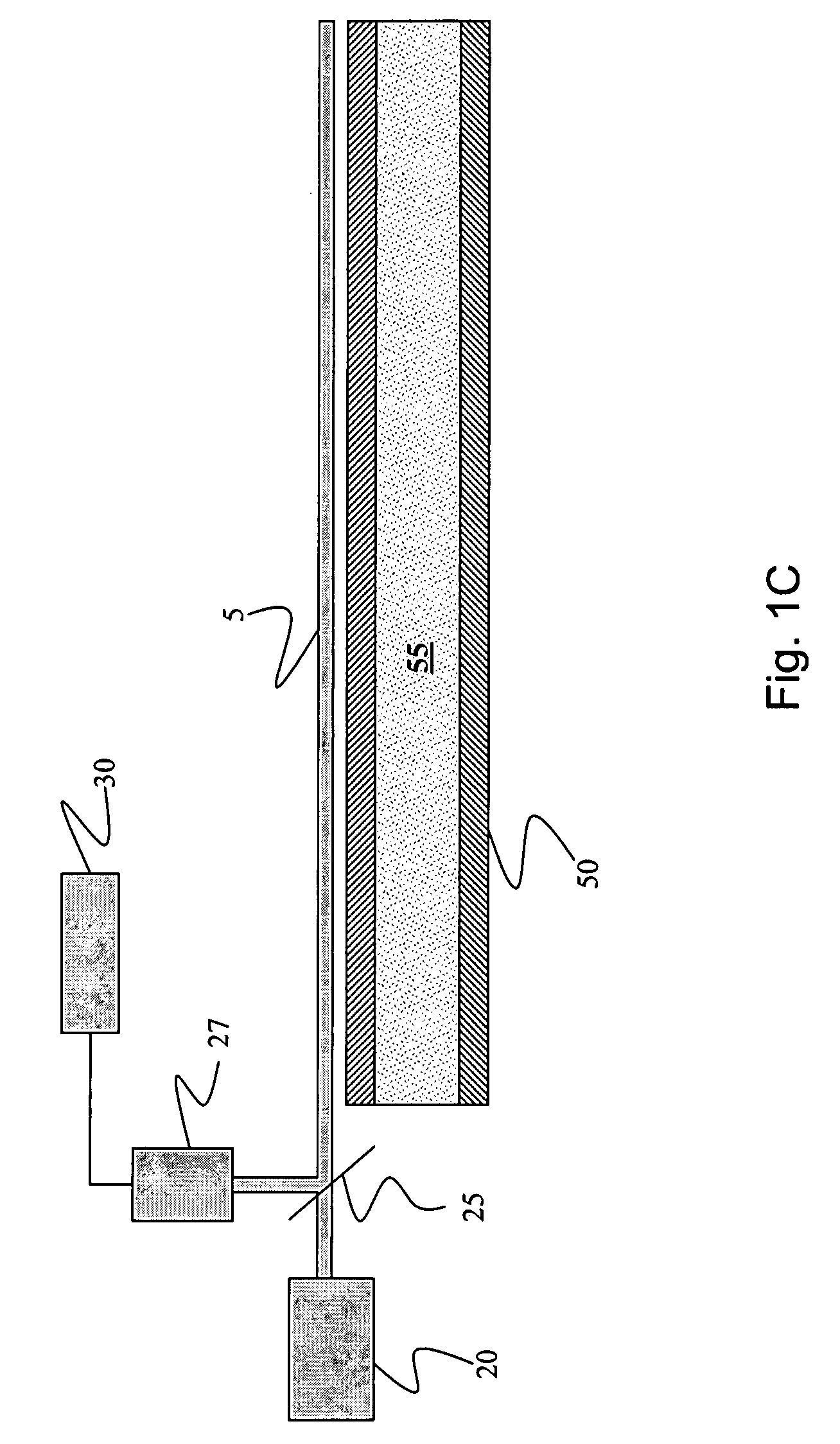

Systems and methods for distributed interferometric acoustic monitoring

Acoustic monitoring of a conduit, a wellbore or a reservoir associated with hydrocarbon production or transportation and / or carbon dioxide sequestration is carried out using a fibre optic cable extending along or appurtenant to it as a distributed interferometer. Coherent Raleigh noise generated by the transmission of the coherent beam of radiation through the fiber optic is detected and processed to identify an acoustic occurrence.

Owner:SCHLUMBERGER TECH CORP

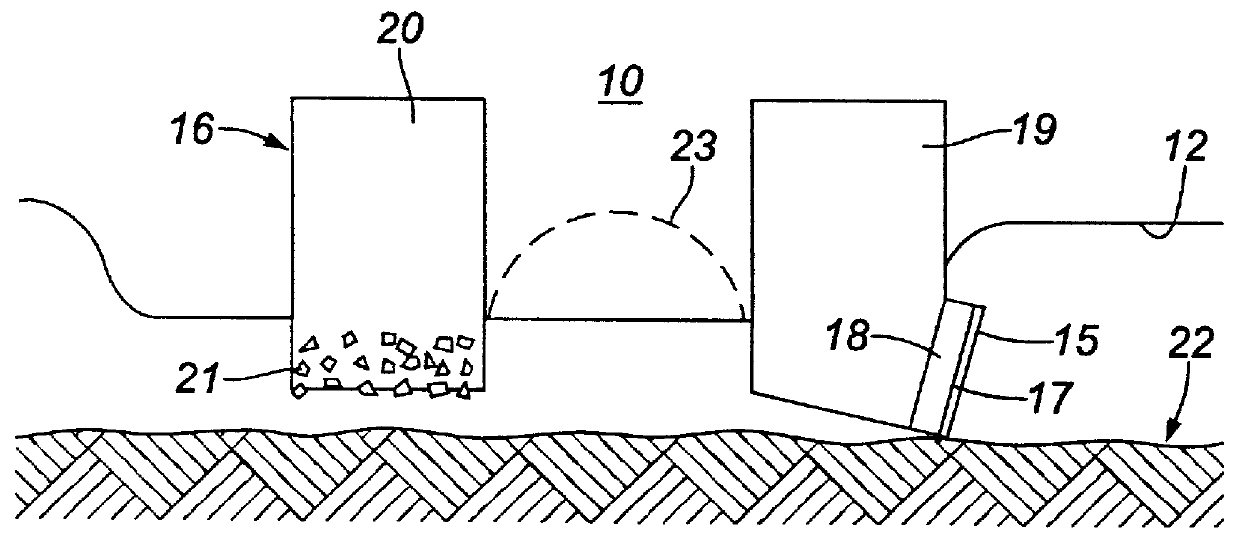

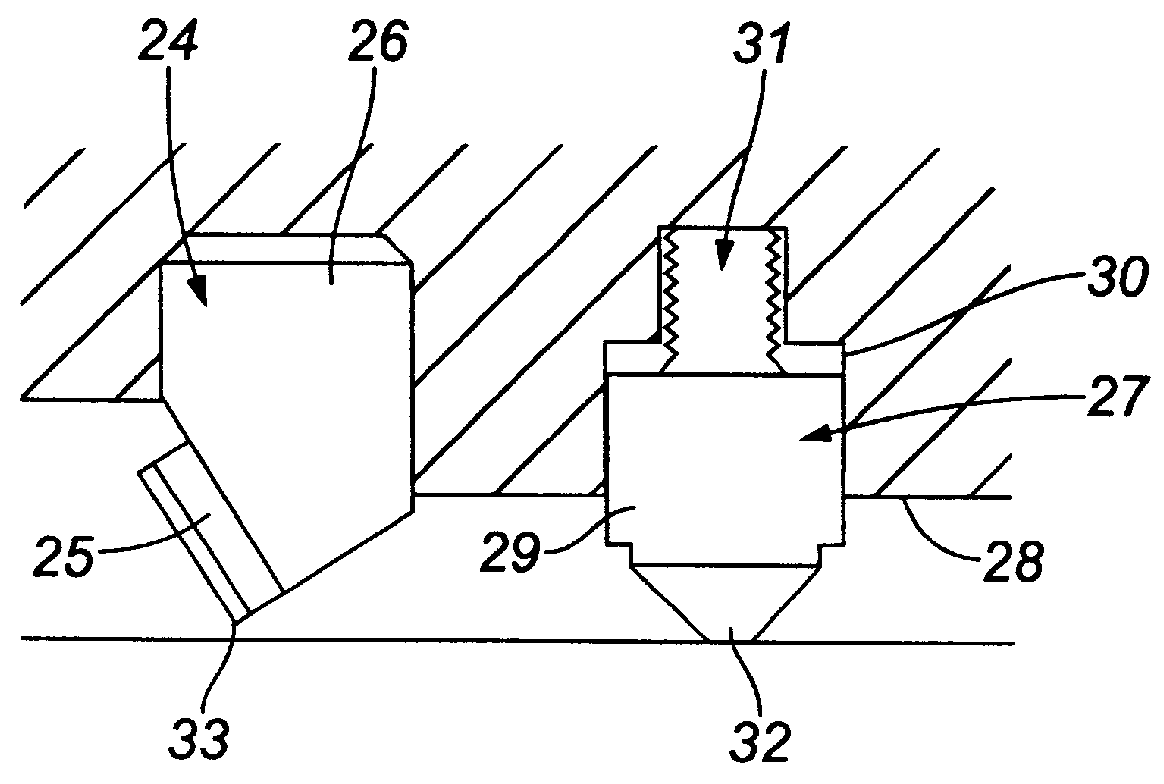

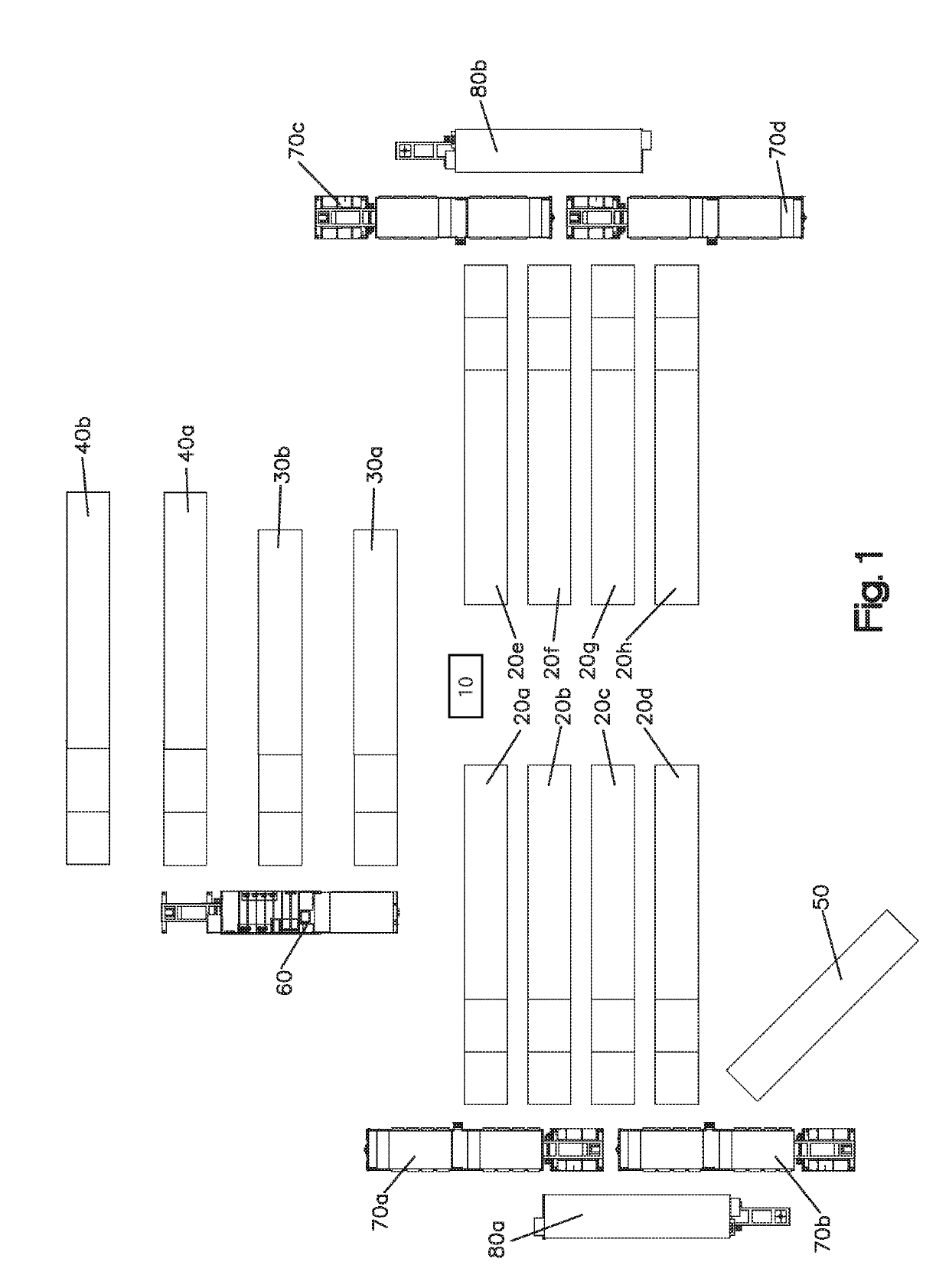

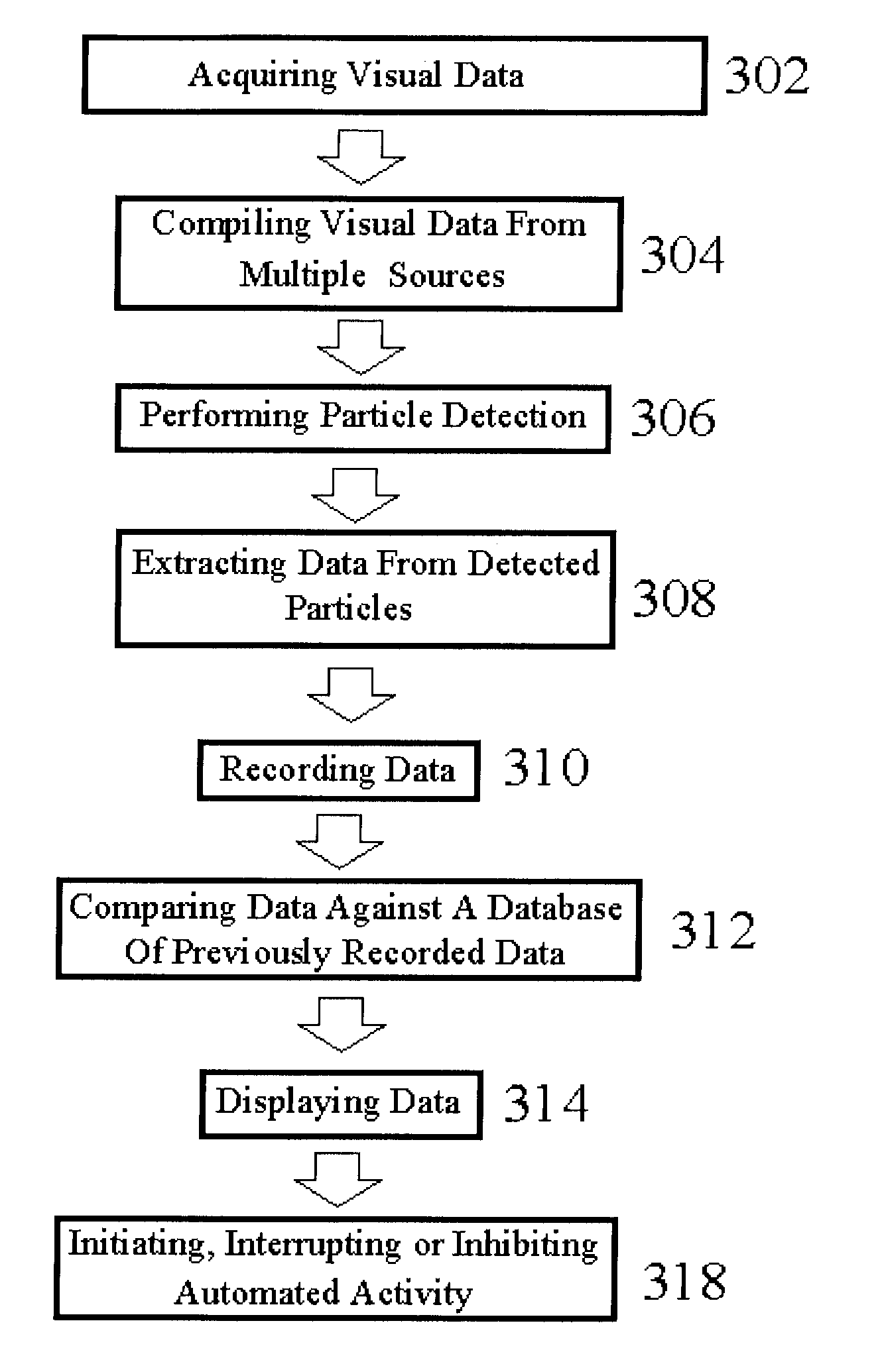

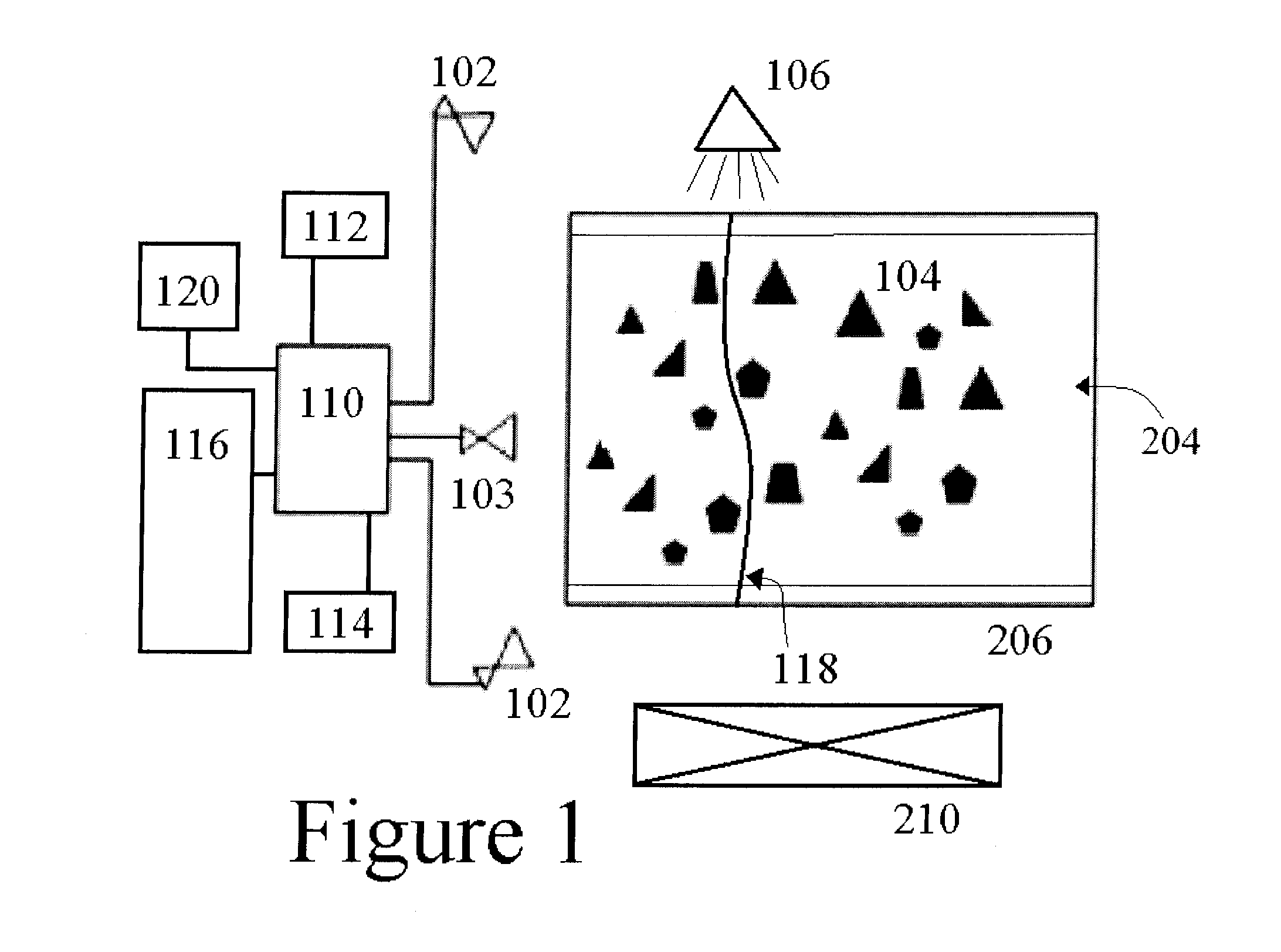

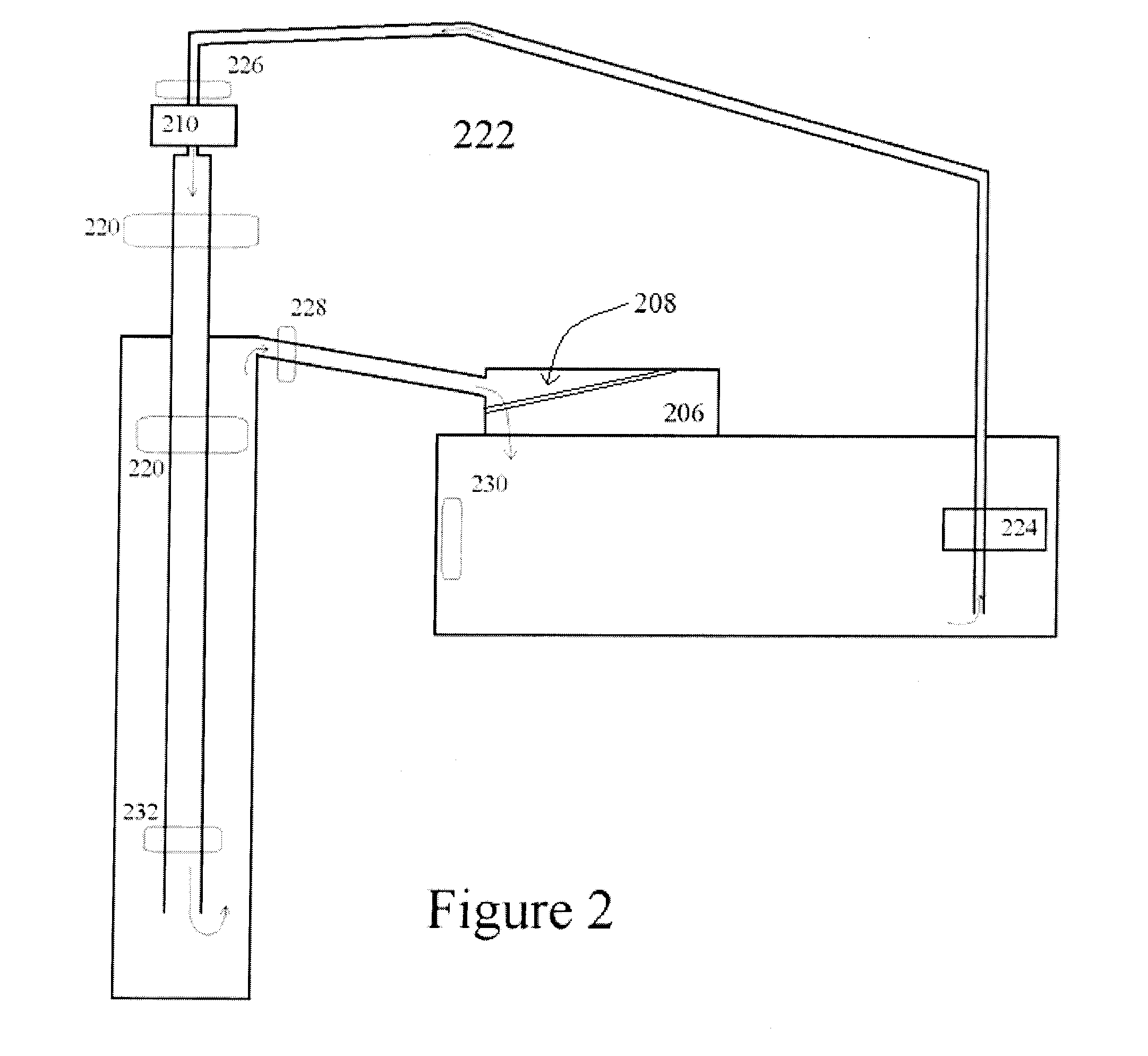

System and method for measuring characteristics of cuttings and fluid front location during drilling operations with computer vision

ActiveUS20160130928A1Improve performanceLow costSampled-variable control systemsComputer controlWell drillingFeature data

The invention relates to a system and method of for measuring the characteristics and volume of drill cuttings. The system comprises at least one camera operably connected to a processor for recording characteristics of drill cutting particles wherein said processor is configured to perform particle detection, extract features of said particles, or both. The processor is typically configured to initiate, interrupt or inhibit an automated activity based on the particle characteristics. The method comprises acquiring visual data from at least one camera, performing particle detection using said data, extracting feature data of any detected particles, alerting an operator and / or initiating, interrupting, or inhibiting automated activity.

Owner:HELMERICH & PAYNE TECH LLC

Simulating the Dynamic Response of a Drilling Tool Assembly and Its Application to Drilling Tool Assembly Design Optimization and Drilling Performance Optimization

InactiveUS20070067147A1Drill bitsAnalogue processes for specific applicationsPetroleum engineeringAssembly design

A method of selecting a drilling tool assembly including selecting components of a first drilling tool assembly and simulating a dynamic response of the first drilling tool assembly. Further, selecting components of a second drilling tool assembly, simulating a dynamic response of the second drilling tool assembly, and graphically illustrating the dynamic responses of the first and second drilling tool assemblies.

Owner:SMITH INT INC

Apparatus and method to reduce fluid pressure in a wellbore

The present invention generally provides apparatus and methods for reducing the pressure of a circulating fluid in a wellbore. In one aspect of the invention an ECD (equivalent circulation density) reduction tool provides a means for drilling extended reach deep (ERD) wells with heavyweight drilling fluids by minimizing the effect of friction head on bottomhole pressure so that circulating density of the fluid is close to its actual density. With an ECD reduction tool located in the upper section of the well, the friction head is substantially reduced, which substantially reduces chances of fracturing a formation.

Owner:WEATHERFORD TECH HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com