Patents

Literature

870results about How to "Lower Drilling Costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

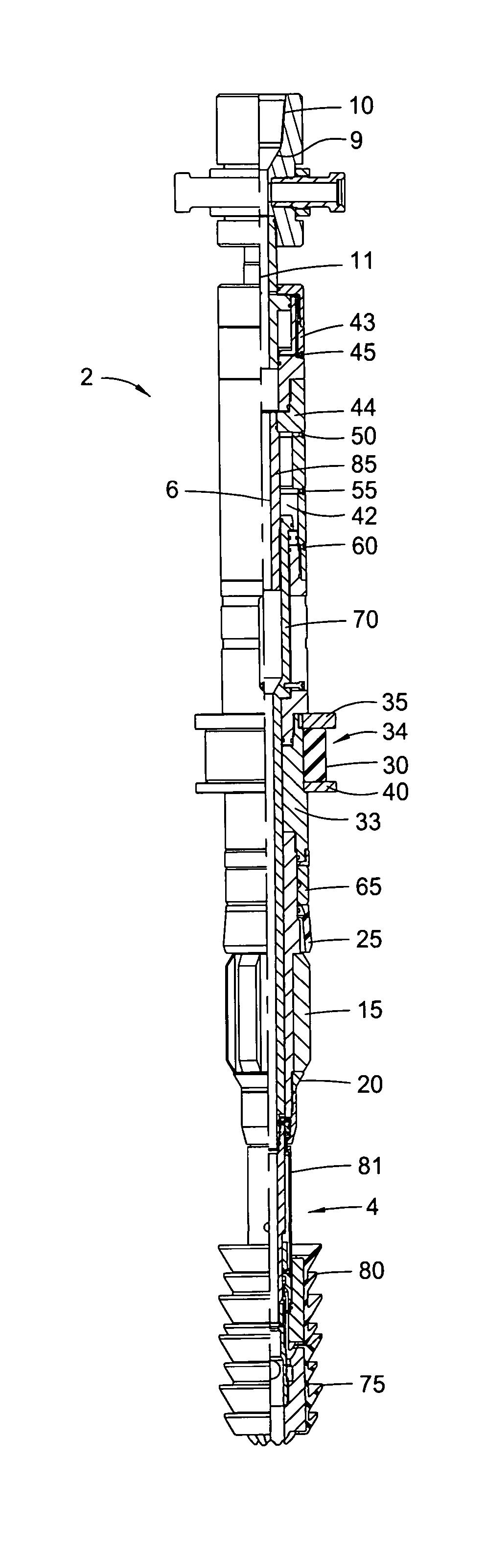

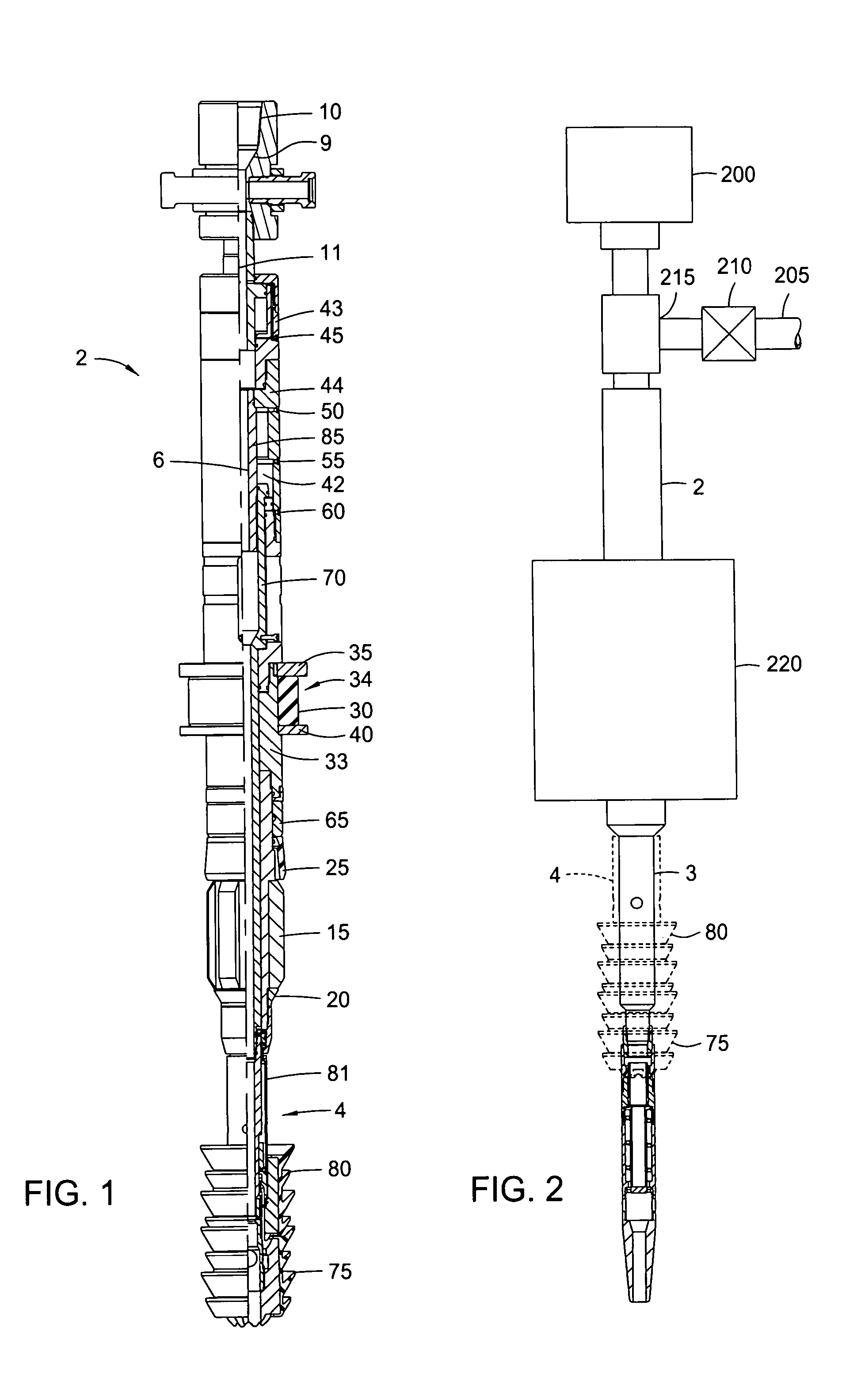

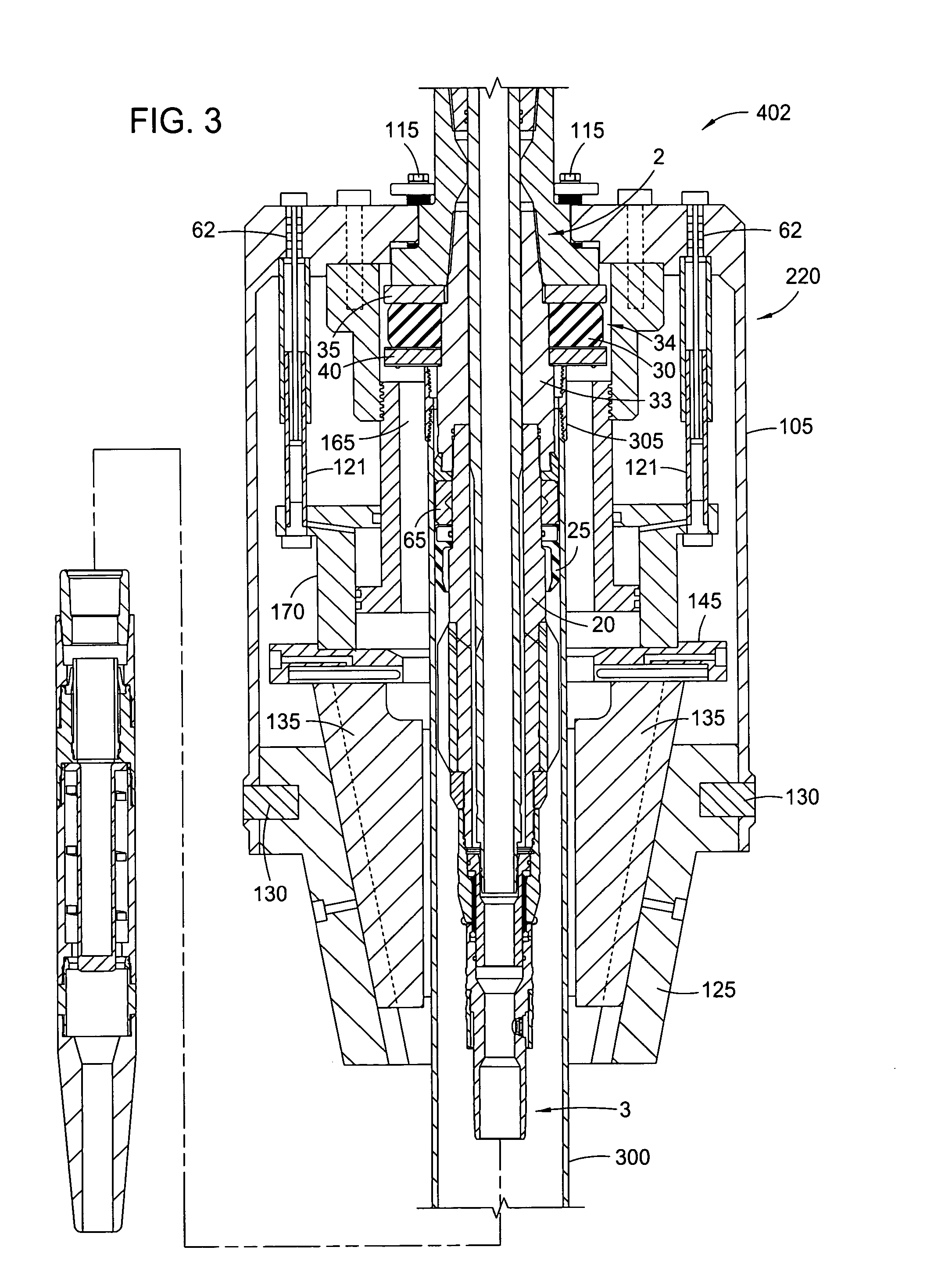

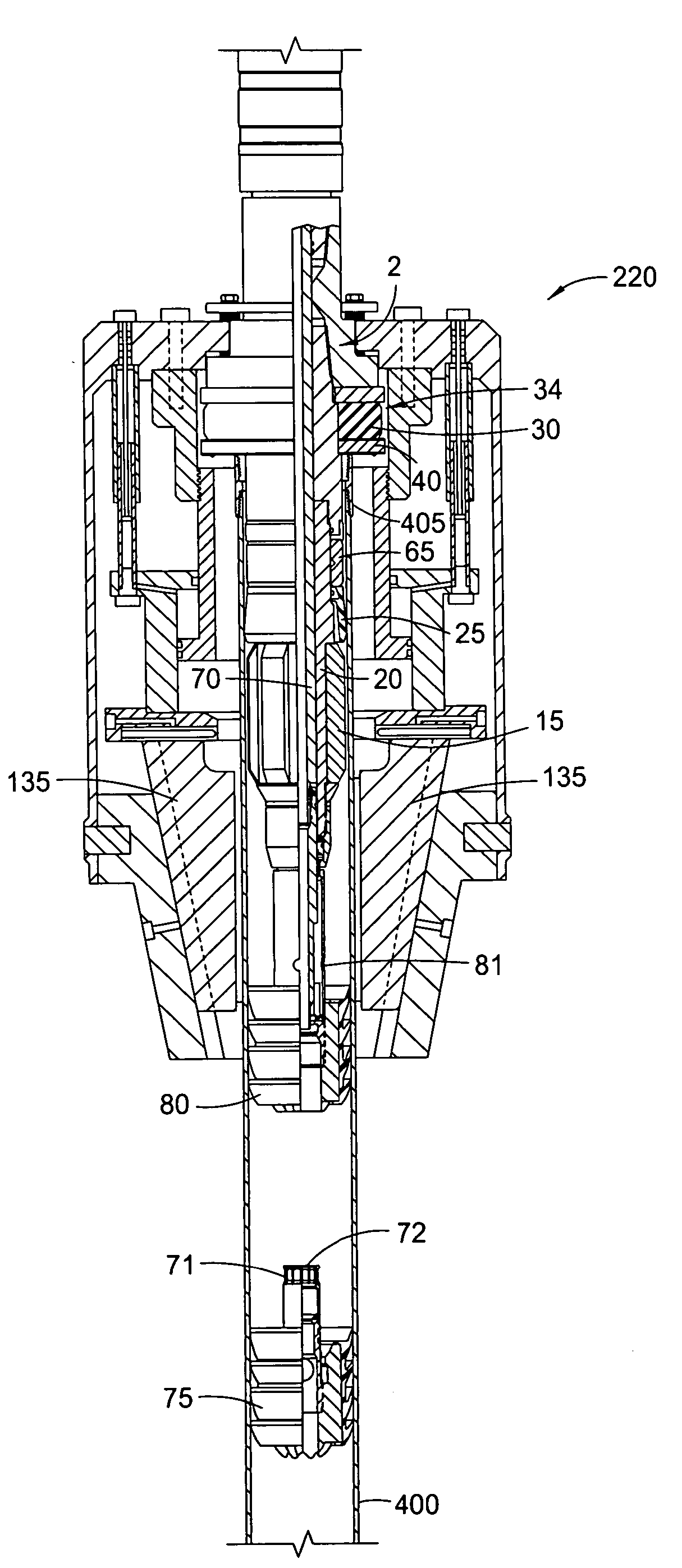

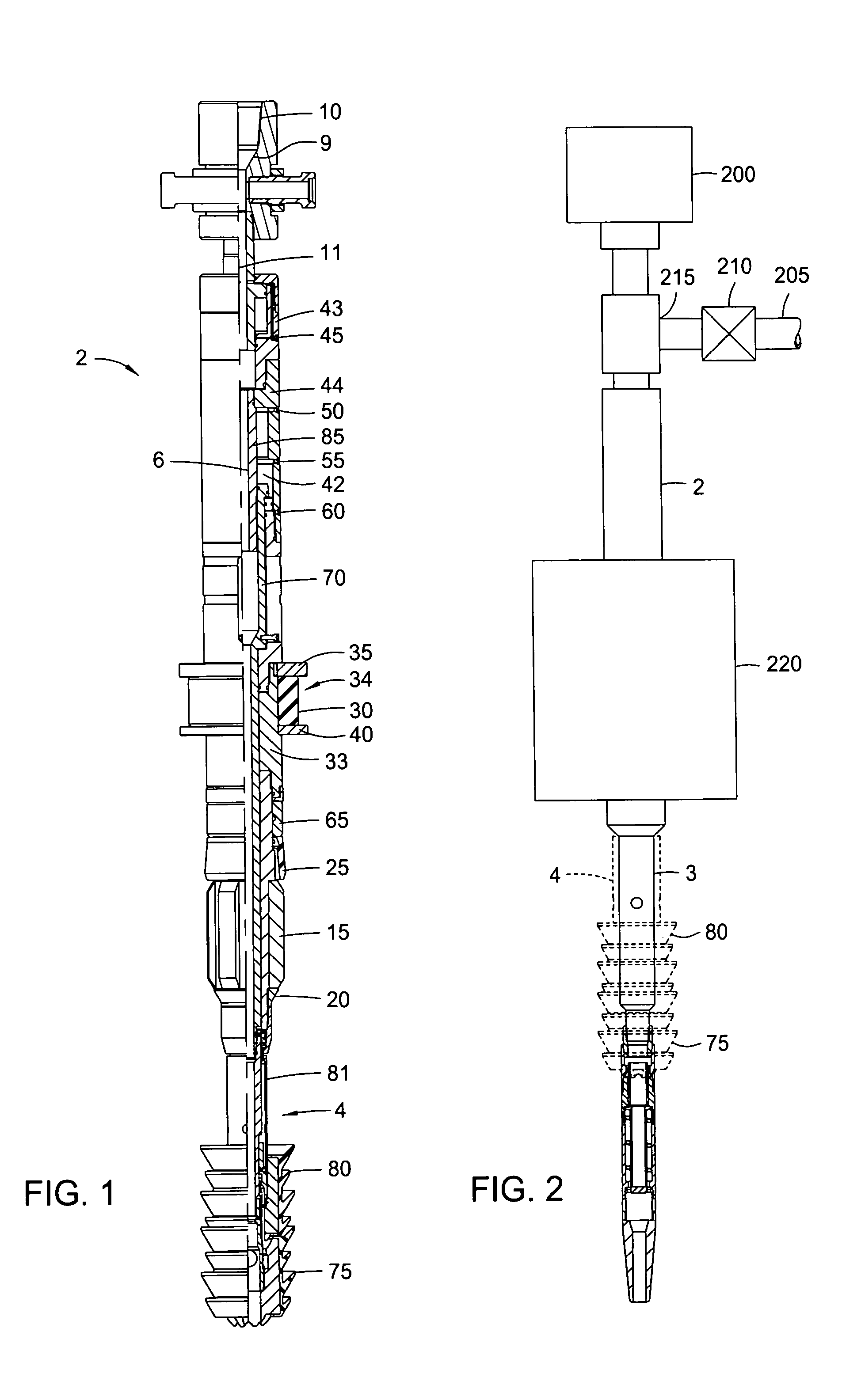

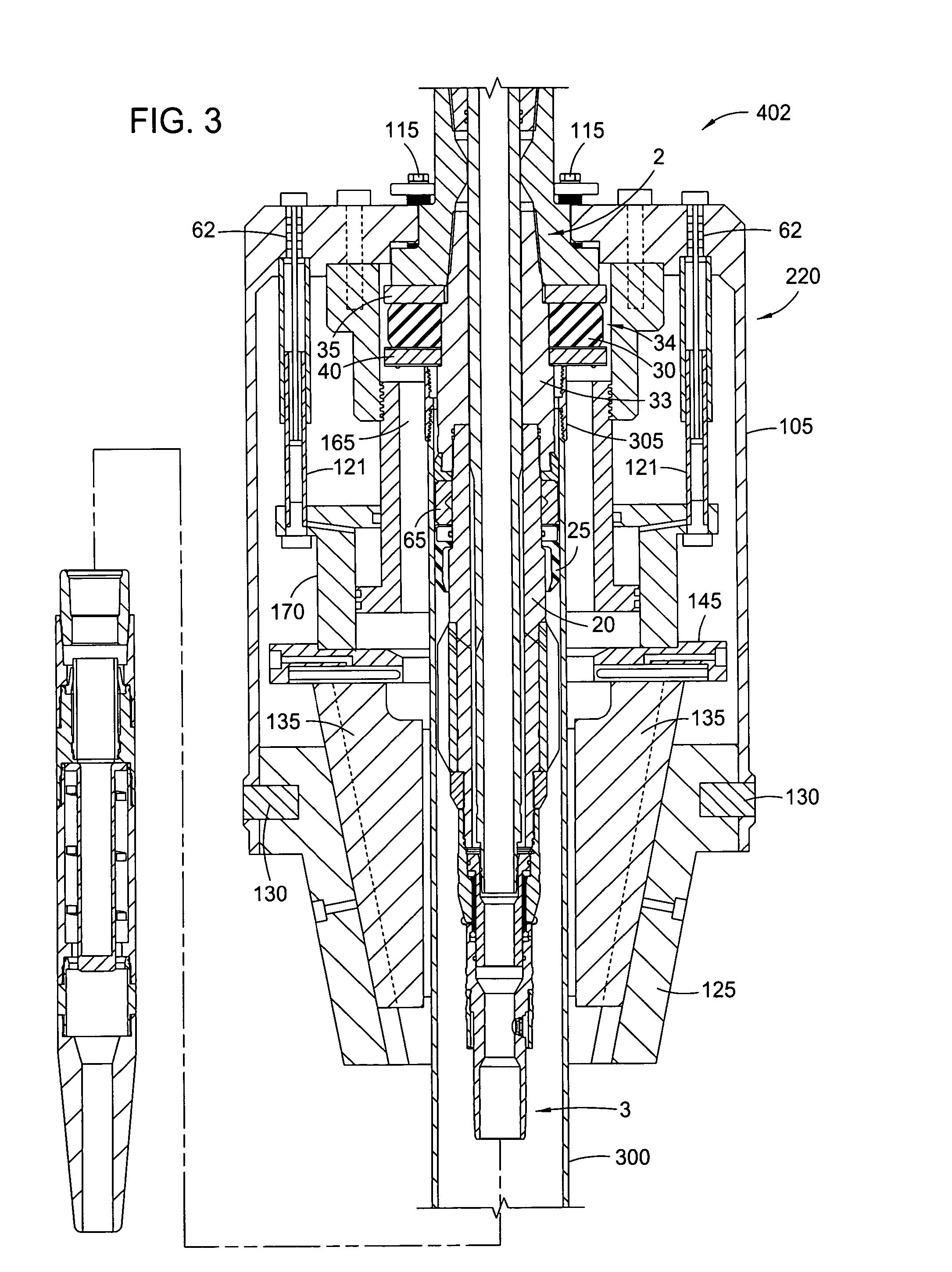

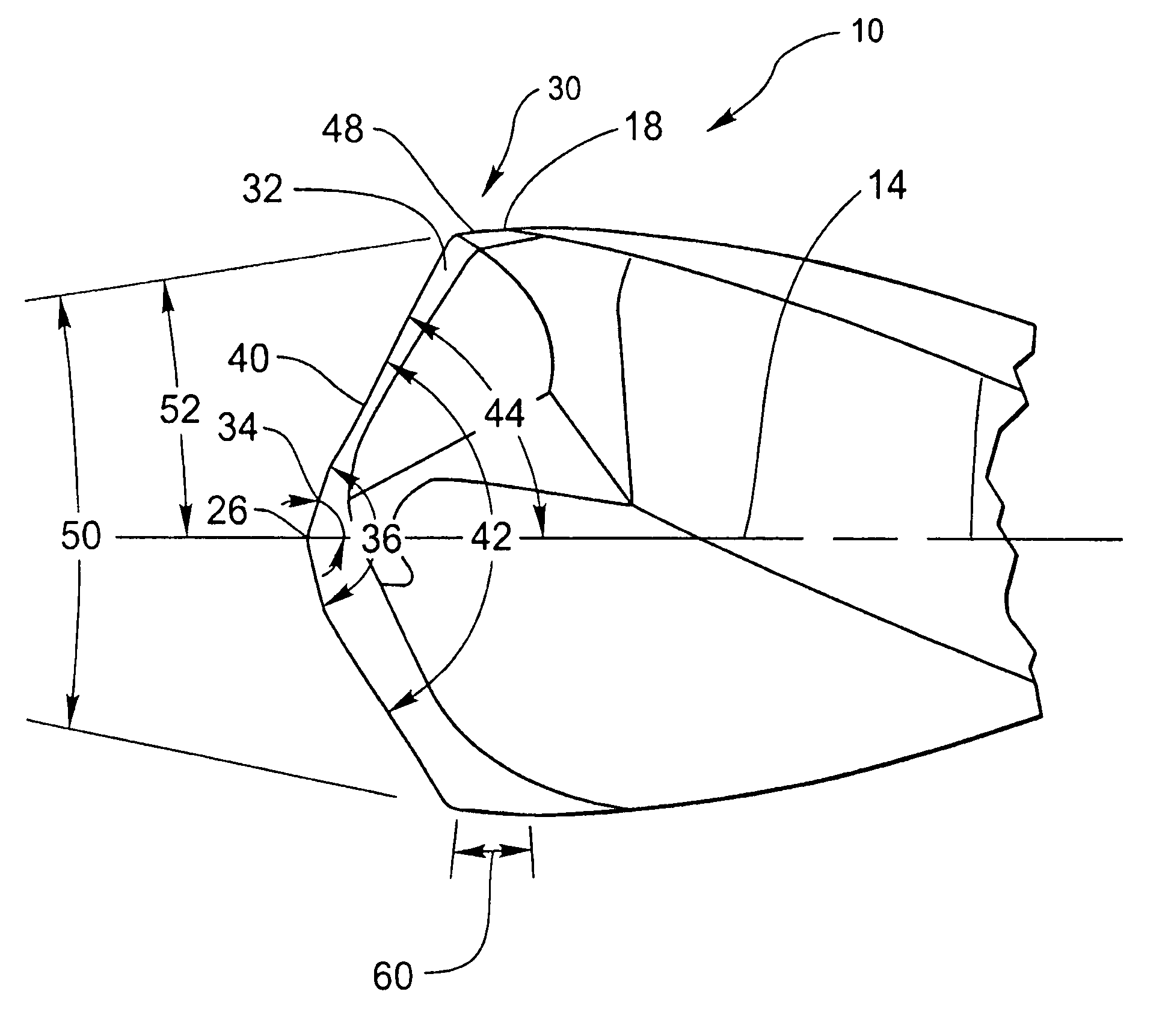

Methods and apparatus for handling and drilling with tubulars or casing

InactiveUS20050000691A1Shorten the timeReduce laborMechanical apparatusDrilling rodsTop driveWell drilling

The present invention provides a method and apparatus for handling tubulars and drilling with tubulars such as casing into a formation. In one aspect of the invention, the apparatus comprises a circulating head and a cementing head operatively connectible to a gripping member. The circulating head is used to circulate drilling fluid while drilling with casing, and the cementing head is used to cement the casing string within the formation at a desired depth. The present invention also relates to methods and apparatus for isolating a tensile load from a drilling apparatus rotated by a top drive. In one aspect, the present invention provides a load isolator apparatus having an isolator body operatively connected to the top drive and a torque body at least partially disposed in the isolator body. In operation, the bearing assembly transfers the tensile load from the torque body to the isolator body.

Owner:WEATHERFORD TECH HLDG LLC

Methods and apparatus for handling and drilling with tubulars or casing

InactiveUS7325610B2Reduce laborShorten the timeMechanical apparatusDrilling rodsTop driveWell drilling

The present invention provides a method and apparatus for handling tubulars and drilling with tubulars such as casing into a formation. In one aspect of the invention, the apparatus comprises a circulating head and a cementing head operatively connectible to a gripping member. The circulating head is used to circulate drilling fluid while drilling with casing, and the cementing head is used to cement the casing string within the formation at a desired depth. The present invention also relates to methods and apparatus for isolating a tensile load from a drilling apparatus rotated by a top drive. In one aspect, the present invention provides a load isolator apparatus having an isolator body operatively connected to the top drive and a torque body at least partially disposed in the isolator body. In operation, the bearing assembly transfers the tensile load from the torque body to the isolator body.

Owner:WEATHERFORD TECH HLDG LLC

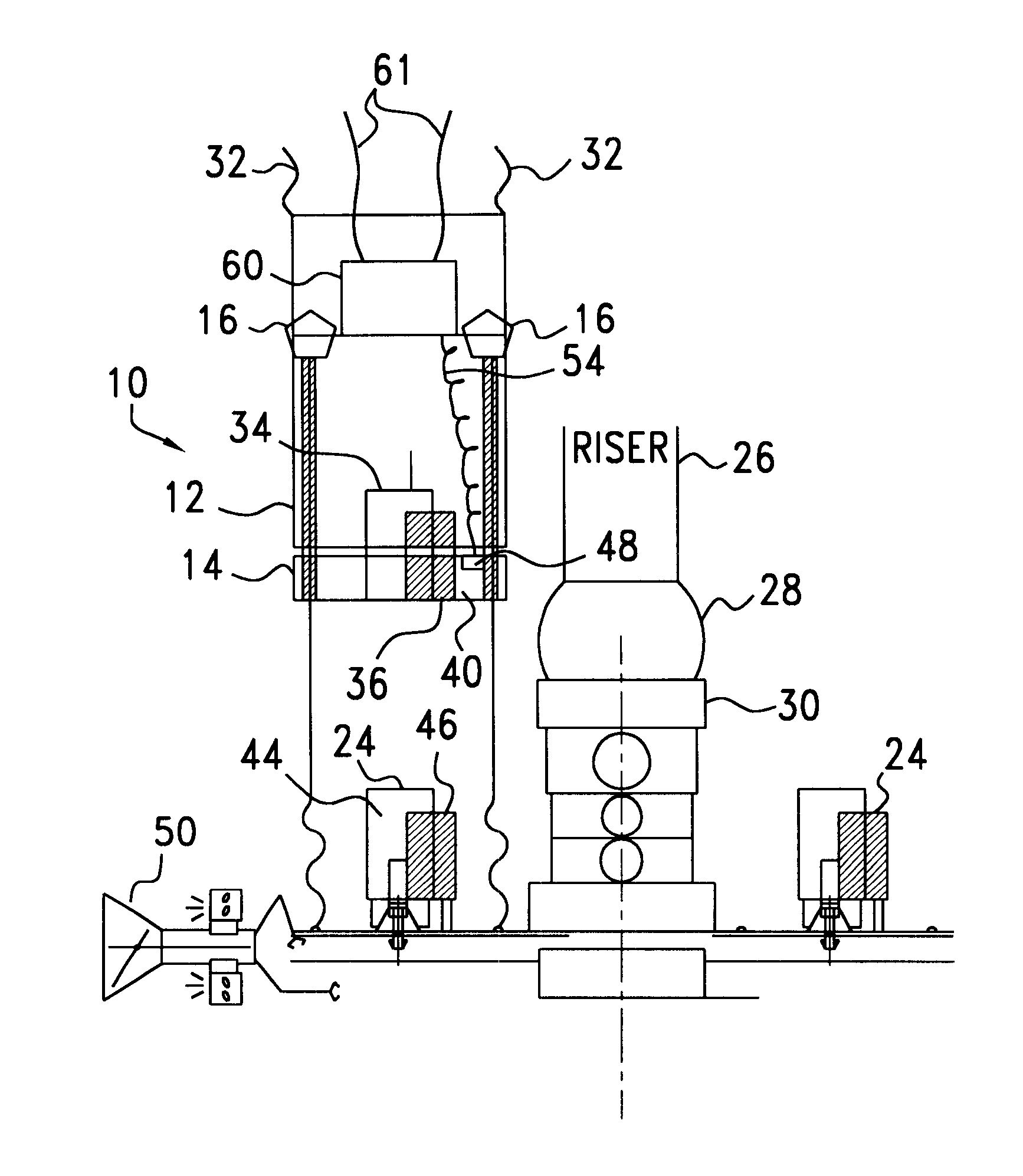

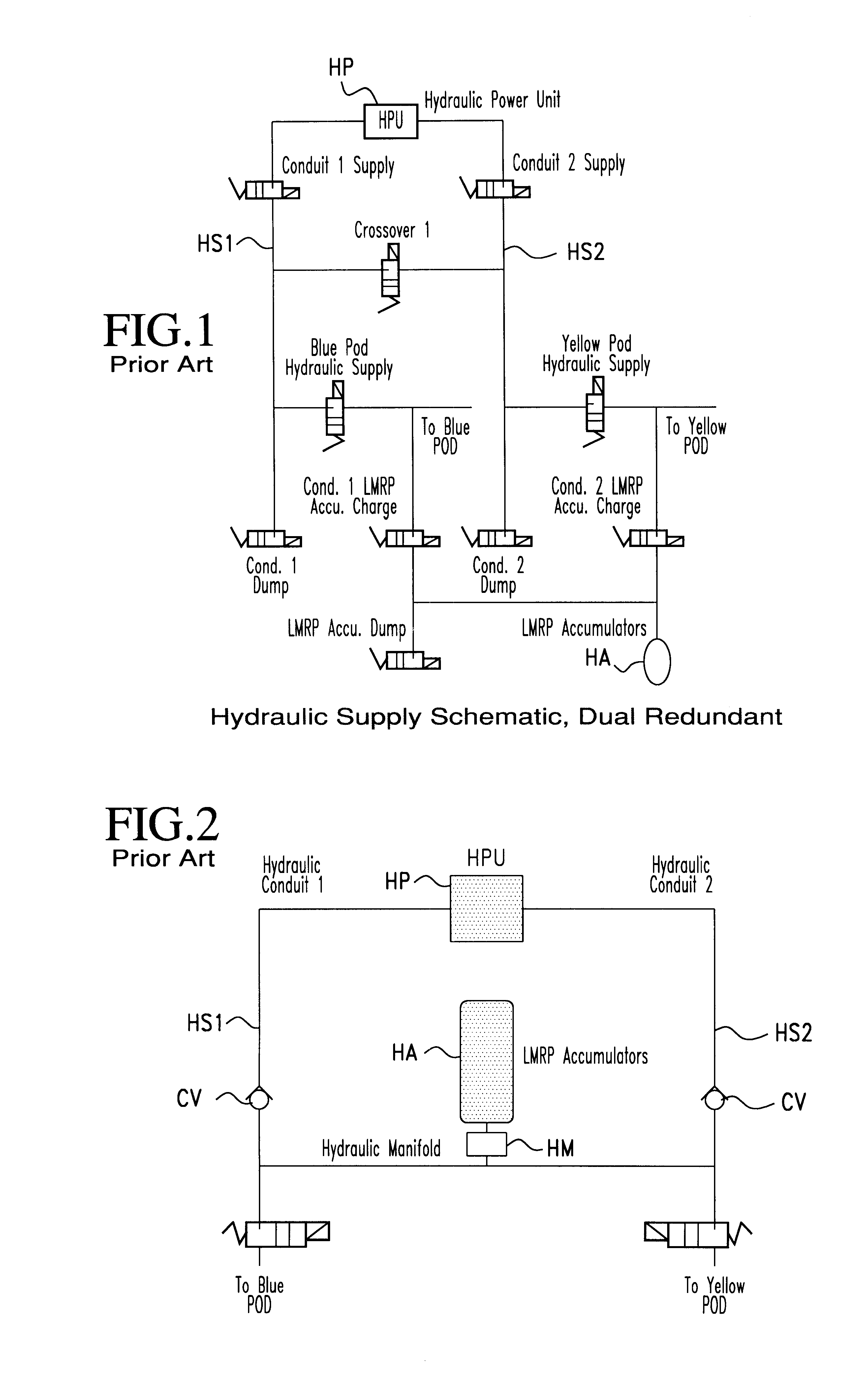

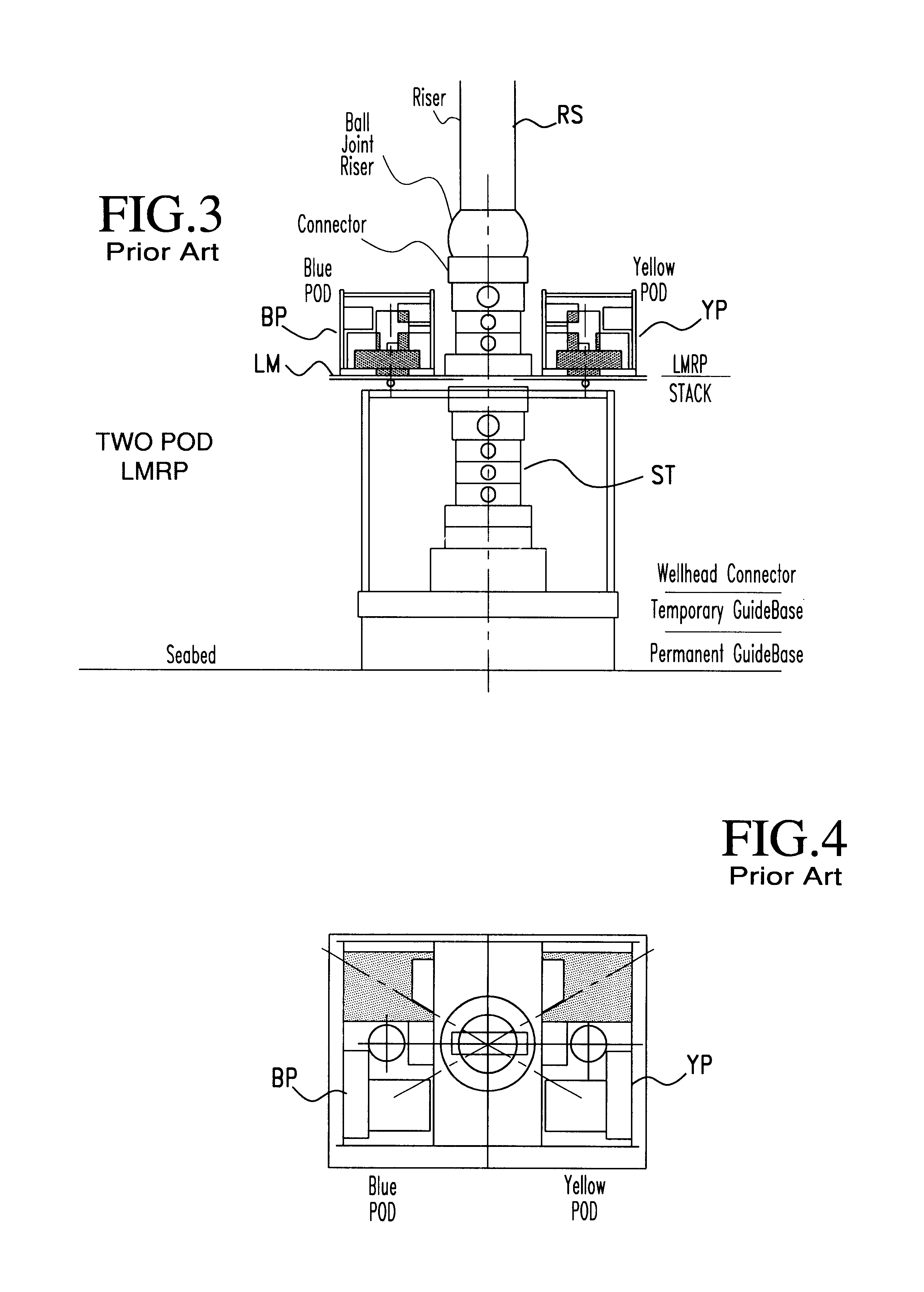

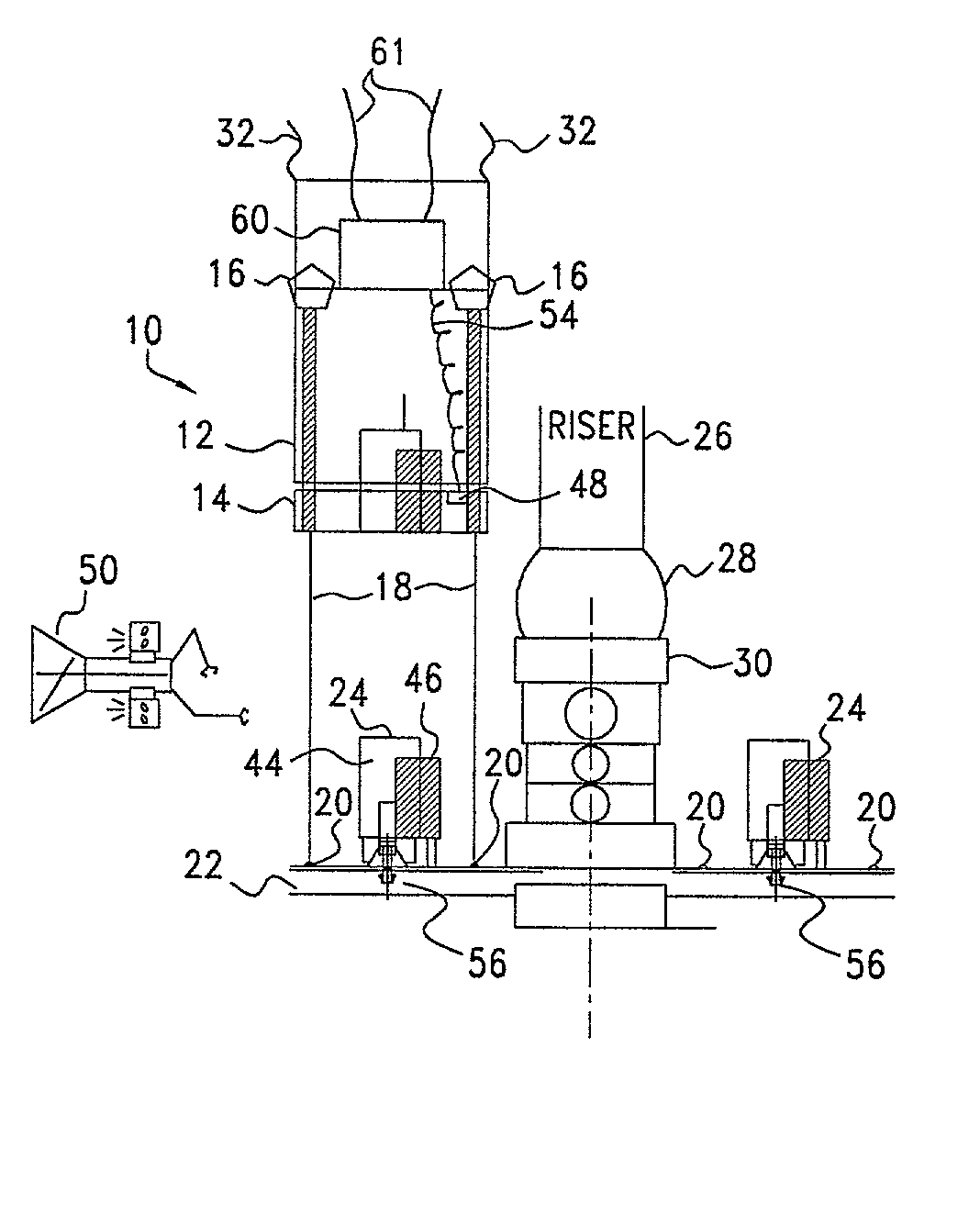

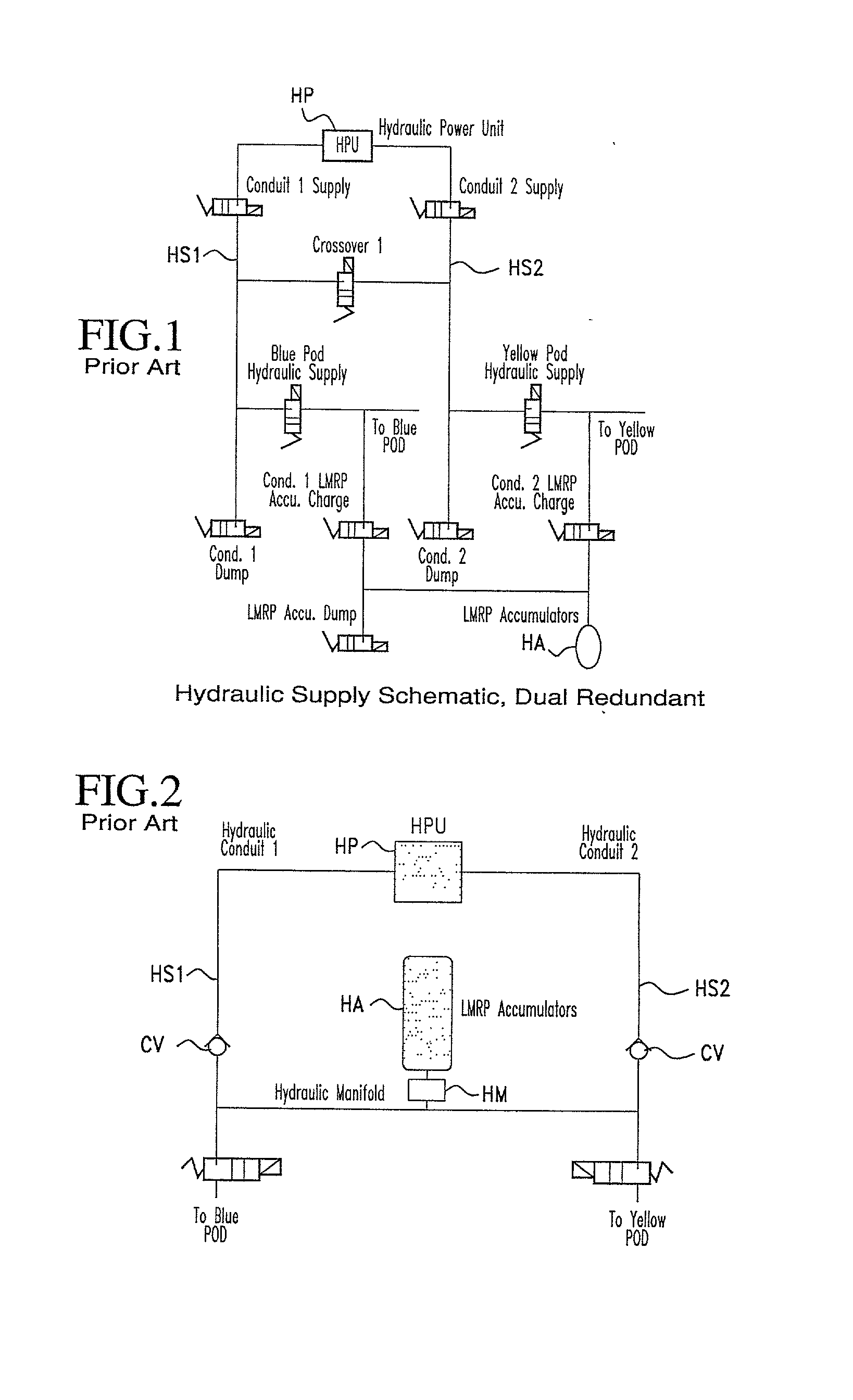

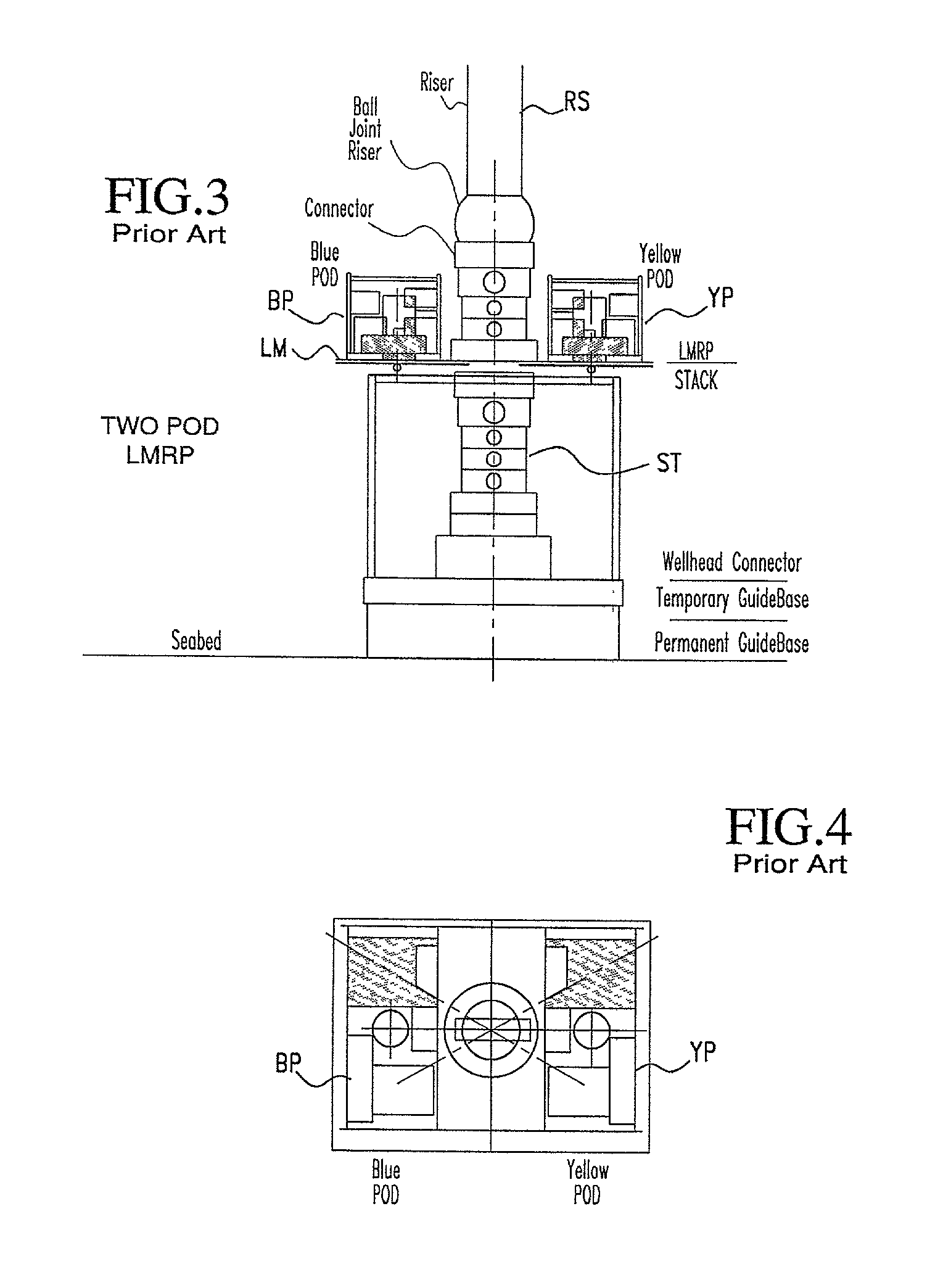

Subsea drilling operations

InactiveUS6422315B1Multiple redundancyLower Drilling CostsDerricks/mastsFluid removalSea bottomControl system

A method for retrieving a subsea pod from a lower marine riser package platform by connecting a buoyant pod retriever to the subsea pod and raising the subsea pod to the surface. In certain aspects, such a method is accomplished without an interruption of associated subsea drilling operations and / or without disconnecting the lower marine riser package from an associated subsea stack. Such a method, in certain aspects, includes: positioning a retrieval module above the pod container, the retrieval module having a pod holder releasably connected thereto; disconnecting the pod holder from the retrieval module; lowering the pod holder to the pod container and releasably connecting the pod holder to the pod container; releasing the pod container from the subsea lower marine riser platform; raising the pod holder to the retrieval module and releasably connecting the pod holder with the pod container to the retrieval module; and raising the retrieval module with the pod container to a location at the surface. Such pod containers are, in certain aspects, part of a multiply redundant control system.

Owner:DEAN QUENTON WAYNE

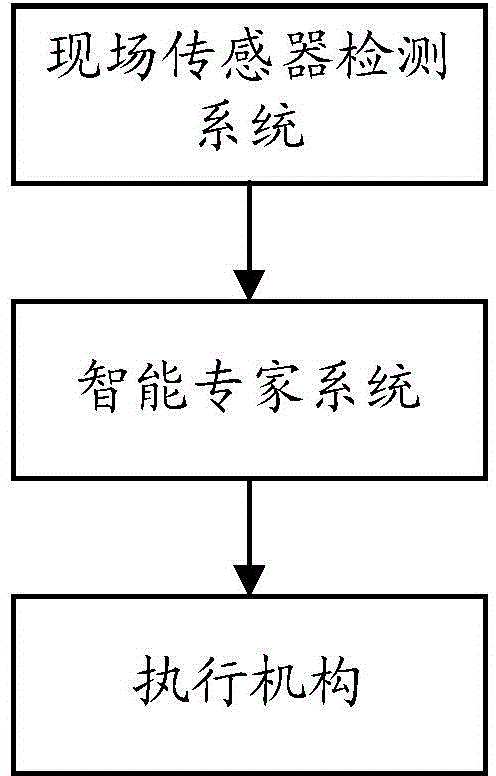

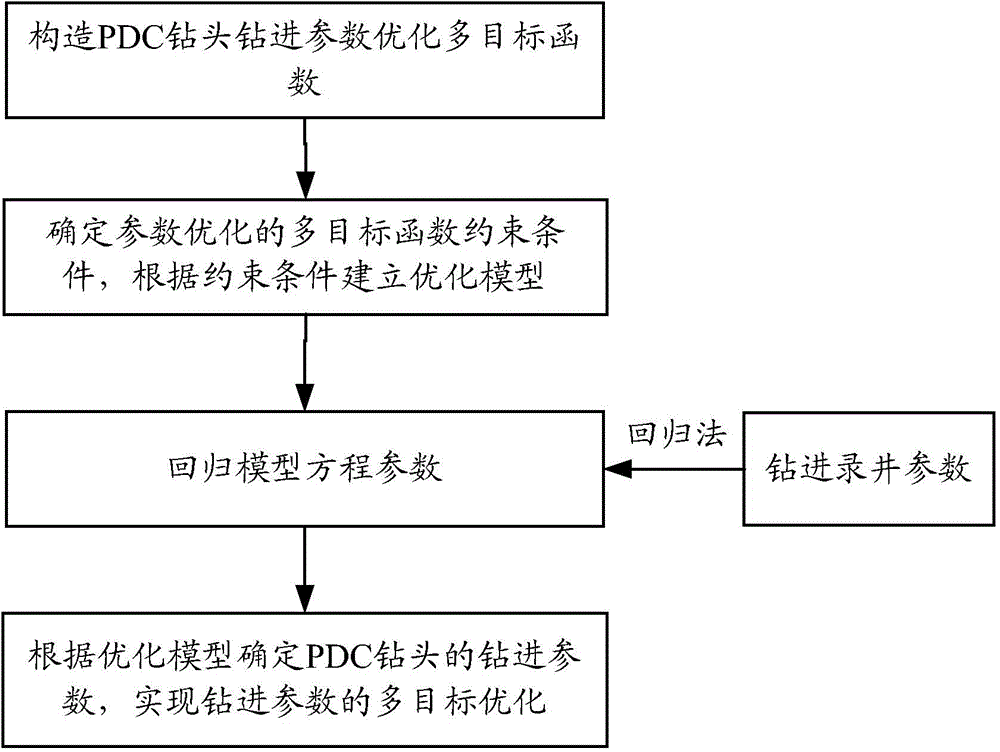

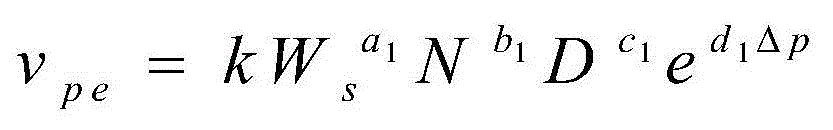

Intelligent drilling expert system

ActiveCN104806226AAccurate discoveryReal-timeAutomatic control for drillingEarly predictionAutomatic control

The invention provides an intelligent drilling expert system. The intelligent drilling expert system comprises a field sensor detection system, an intelligent expert system and an execution mechanism. An automatic closed-loop drilling regulation and control system is formed. Data in a whole drilling process are acquired through a field sensor; then, the acquired data are transmitted into a computer for processing, monitoring, prediction, analysis, explanation, control and the like. Most importantly, through the researched cross-specialty and cross-industry intelligent expert control models for drilling hydraulic control, well wall stability control, friction resistance and torque control, drilling speed and cost control, drilling complexity and accident control and the like, instantaneity, early discovery, early prediction, interpretation while drilling and an automatic control function can be realized, and accurate information is provided for drilling engineering; moreover, the intelligent drilling expert system has the advantages of reducing the drilling cost, increasing the drilling speed, avoiding sudden accidents and discovering oil and gas accurately.

Owner:北京四利通控制技术股份有限公司

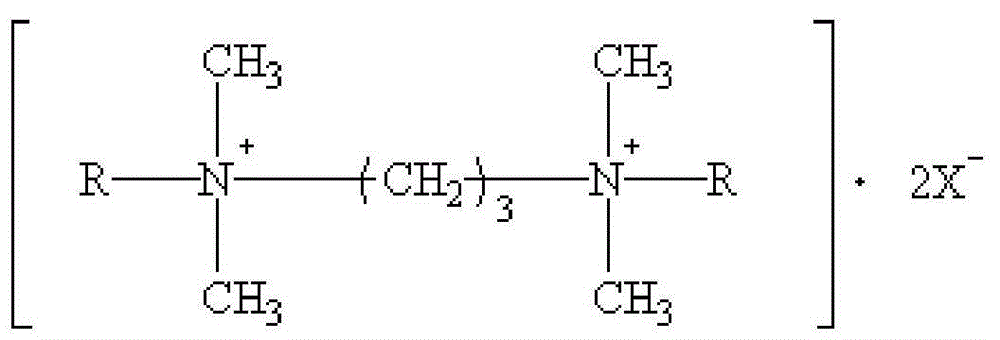

High-efficiency hydrate inhibitive environment-friendly drilling fluid

ActiveCN104531106AGenerate good effectLow cloud pointDrilling compositionInorganic saltsSodium Bentonite

The invention relates to high-efficiency hydrate inhibitive environment-friendly drilling fluid, and particularly relates to the drilling fluid containing water, bentonite, hyamine dimeric surfactant, inorganic salt, sodium carboxymethyl starch, cationic polyacrylamide and solid anti-sloughing lubricating agent GFRH. The high-efficiency hydrate inhibitive environment-friendly drilling fluid can be used for exploiting continental or ocean oil-gas resources and can effectively inhibit the generation of hydrate; moreover, the components of the drilling fluid are small in environment harm, and the drilling fluid has the advantages of high efficiency and environmental protection.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

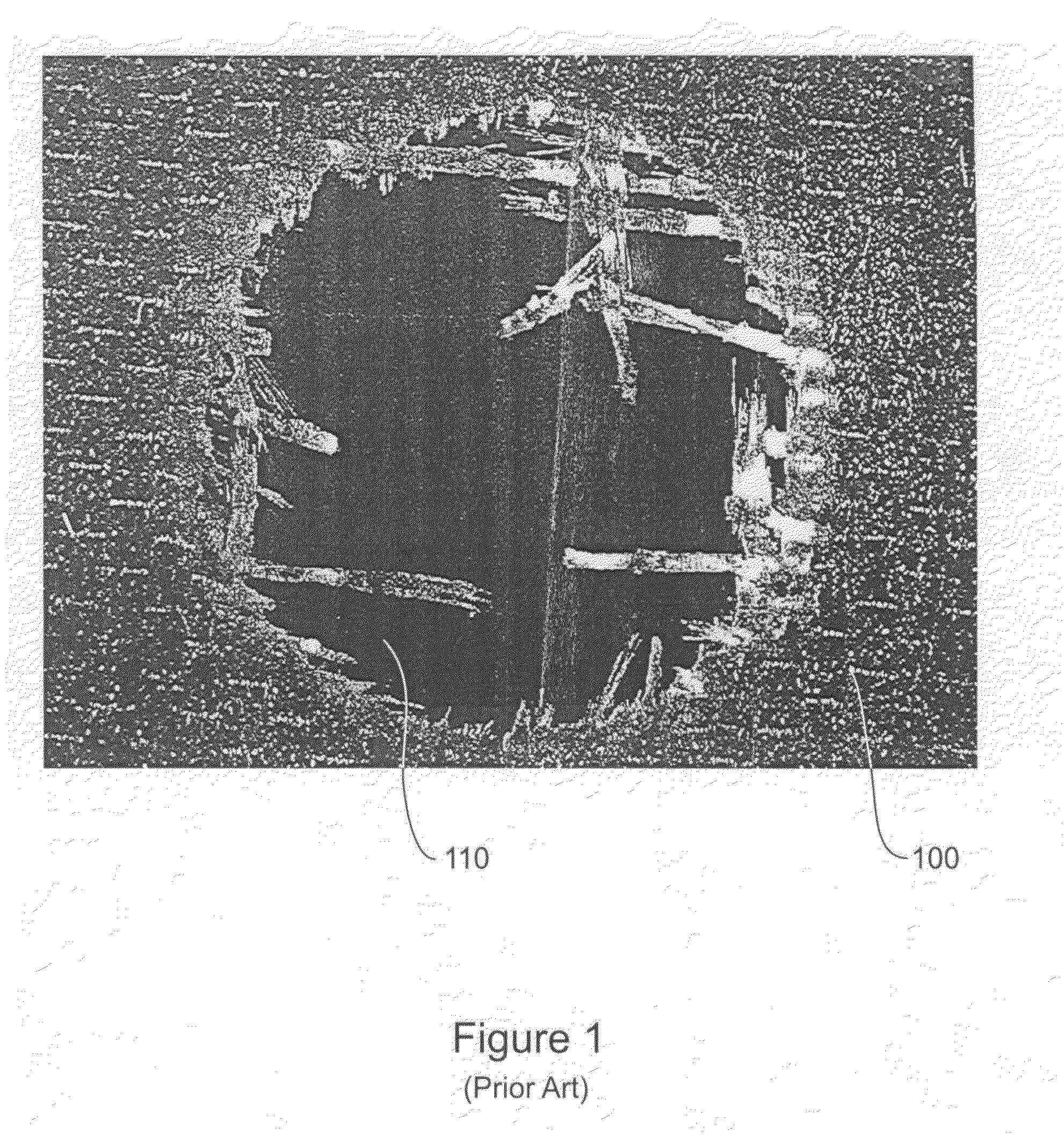

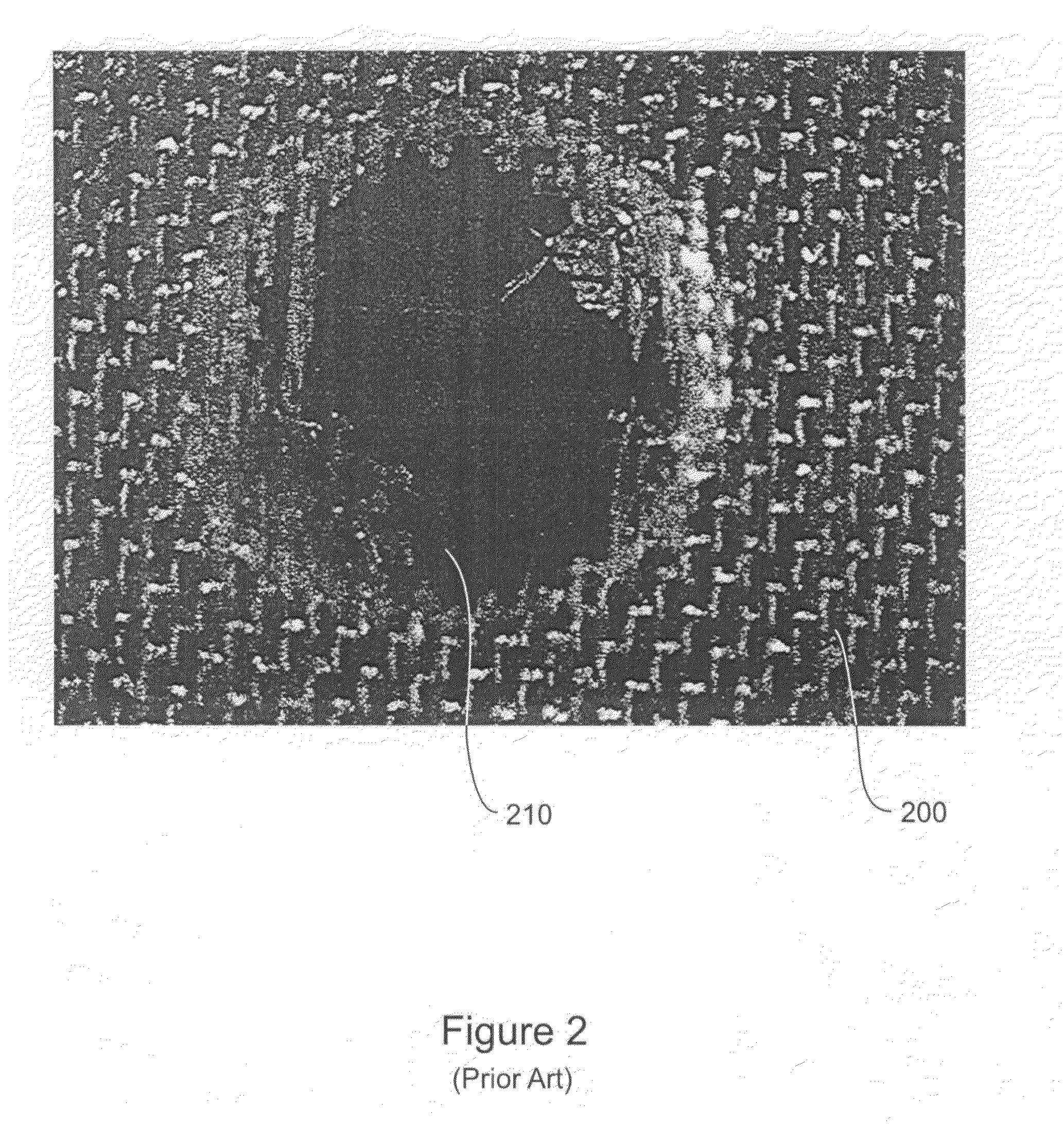

PCD drill for composite materials

ActiveUS7575401B1Increase chanceMinimal delaminationWood turning toolsTransportation and packagingFiberProduction rate

A PCD drill for producing close tolerance holes in multi layer laminates, such as carbon fiber reinforced composites, with minimum fraying of the fibers on both entrance and exit from the hole is provided. The drills provided include a symmetrical cutting point with a self-centering split point and a high shear second cutting lip positioned at the outer diameter of the drill. The drills of the invention may allow for increased cutting speeds and feeds when used with such advanced composite materials, thus increasing tool productivity and providing increased performance.

Owner:PRECORP INC

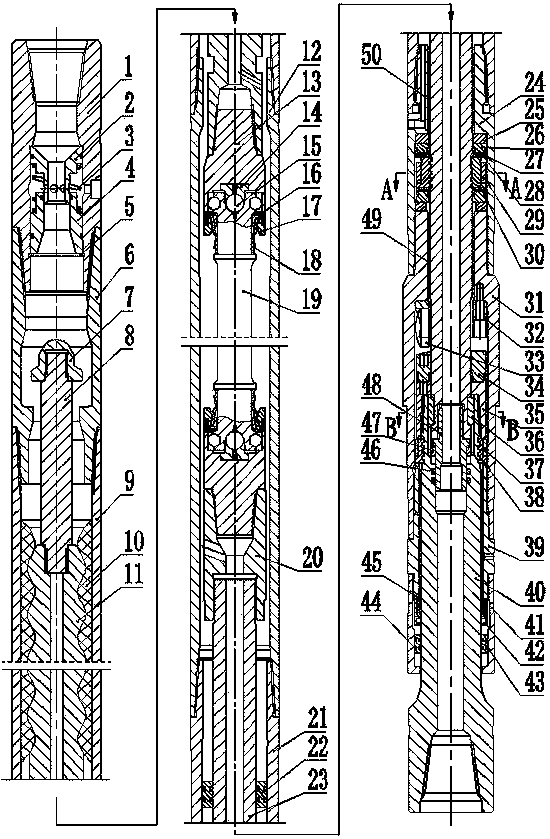

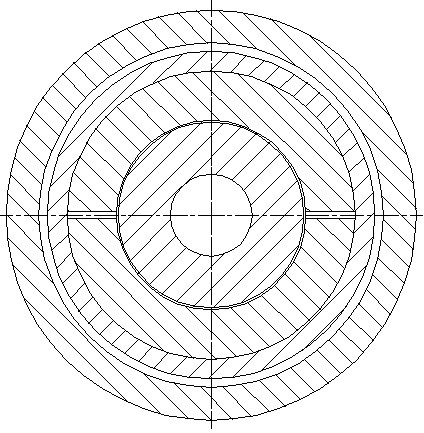

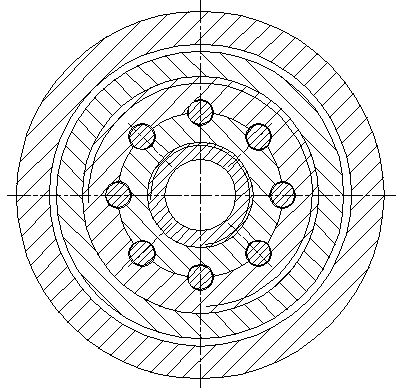

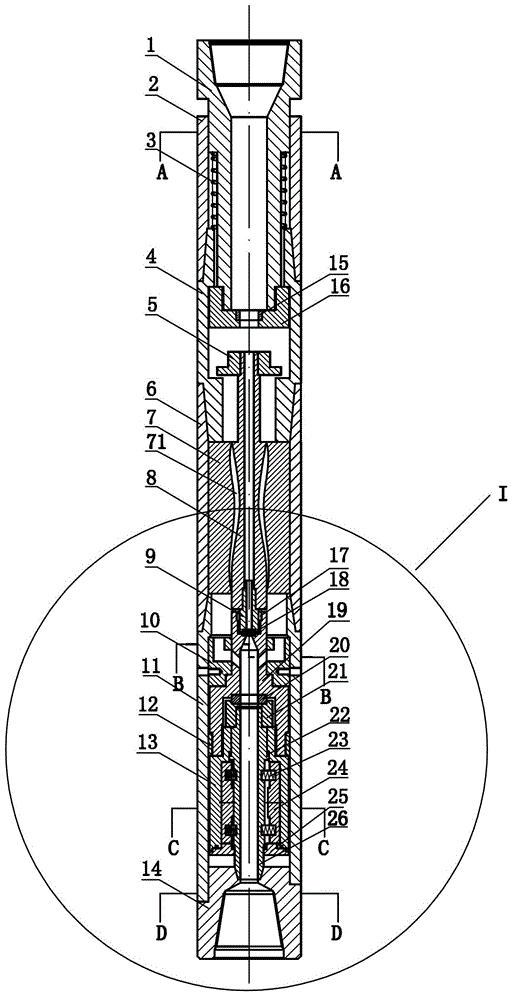

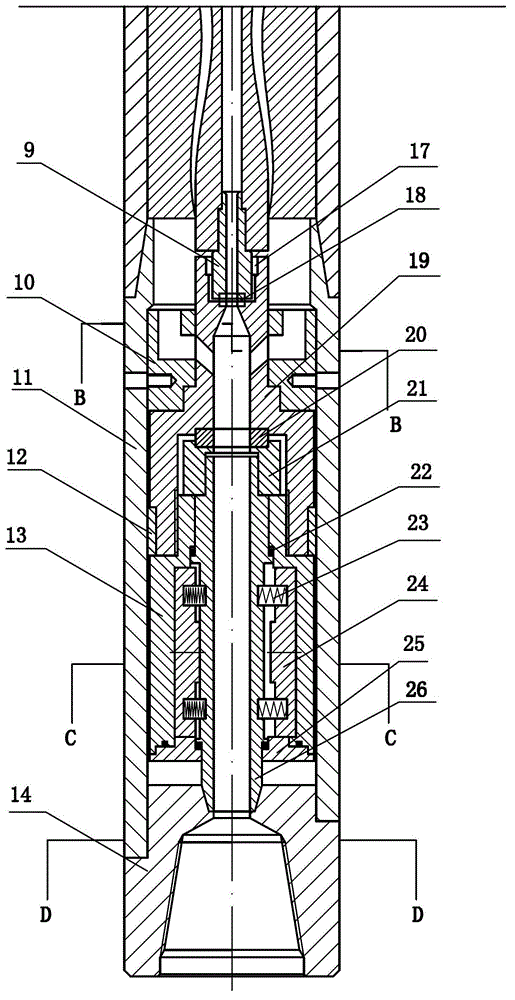

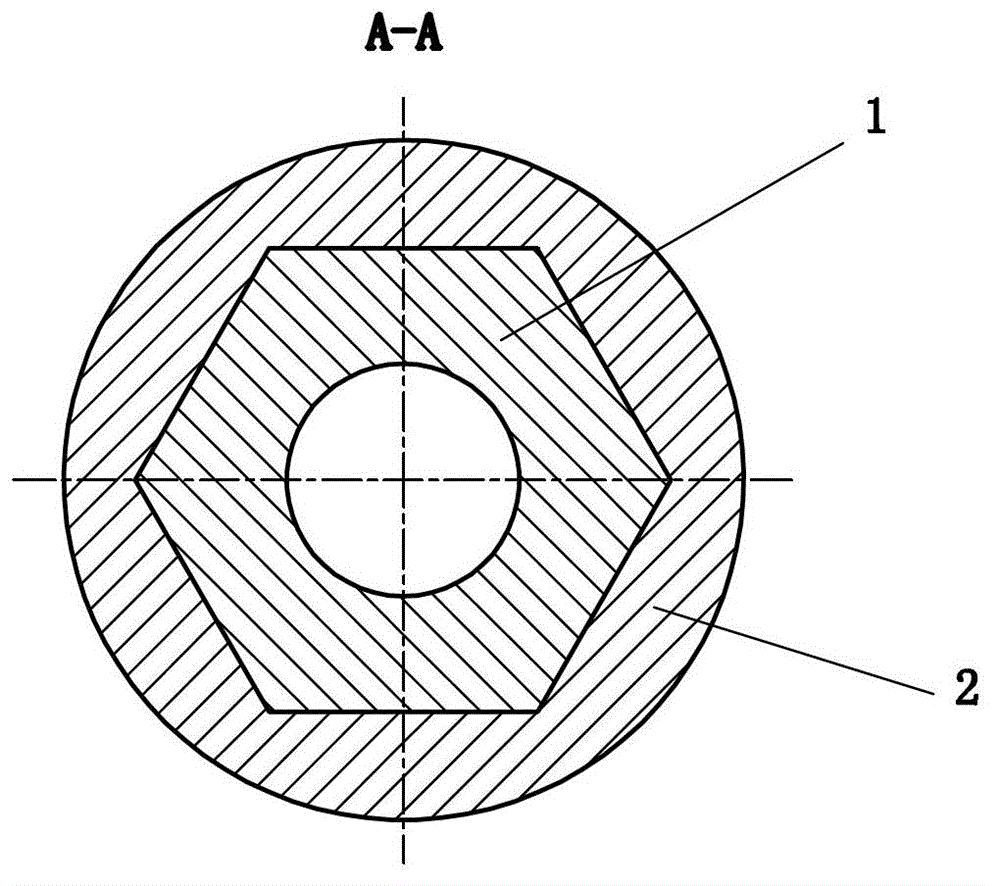

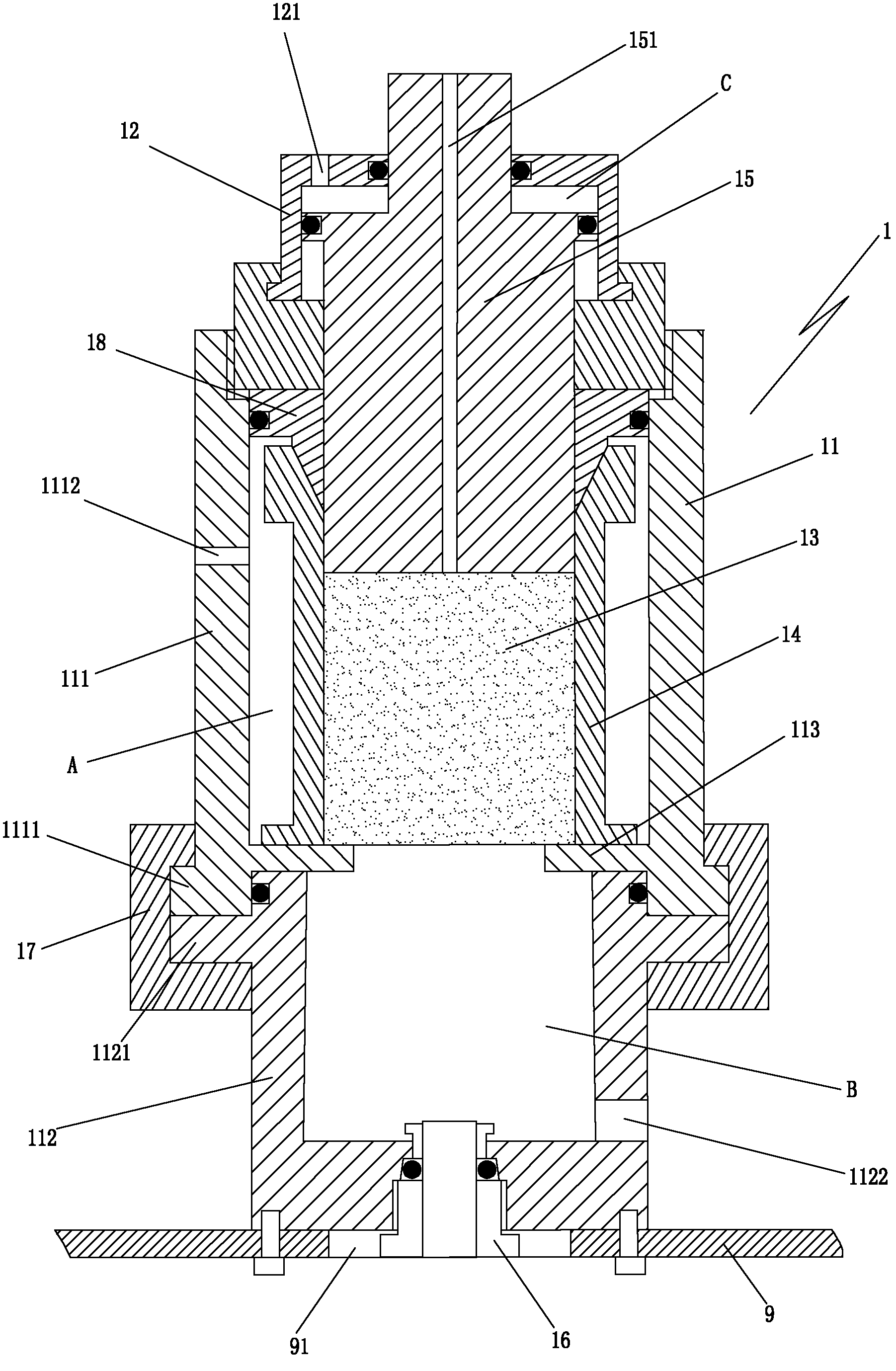

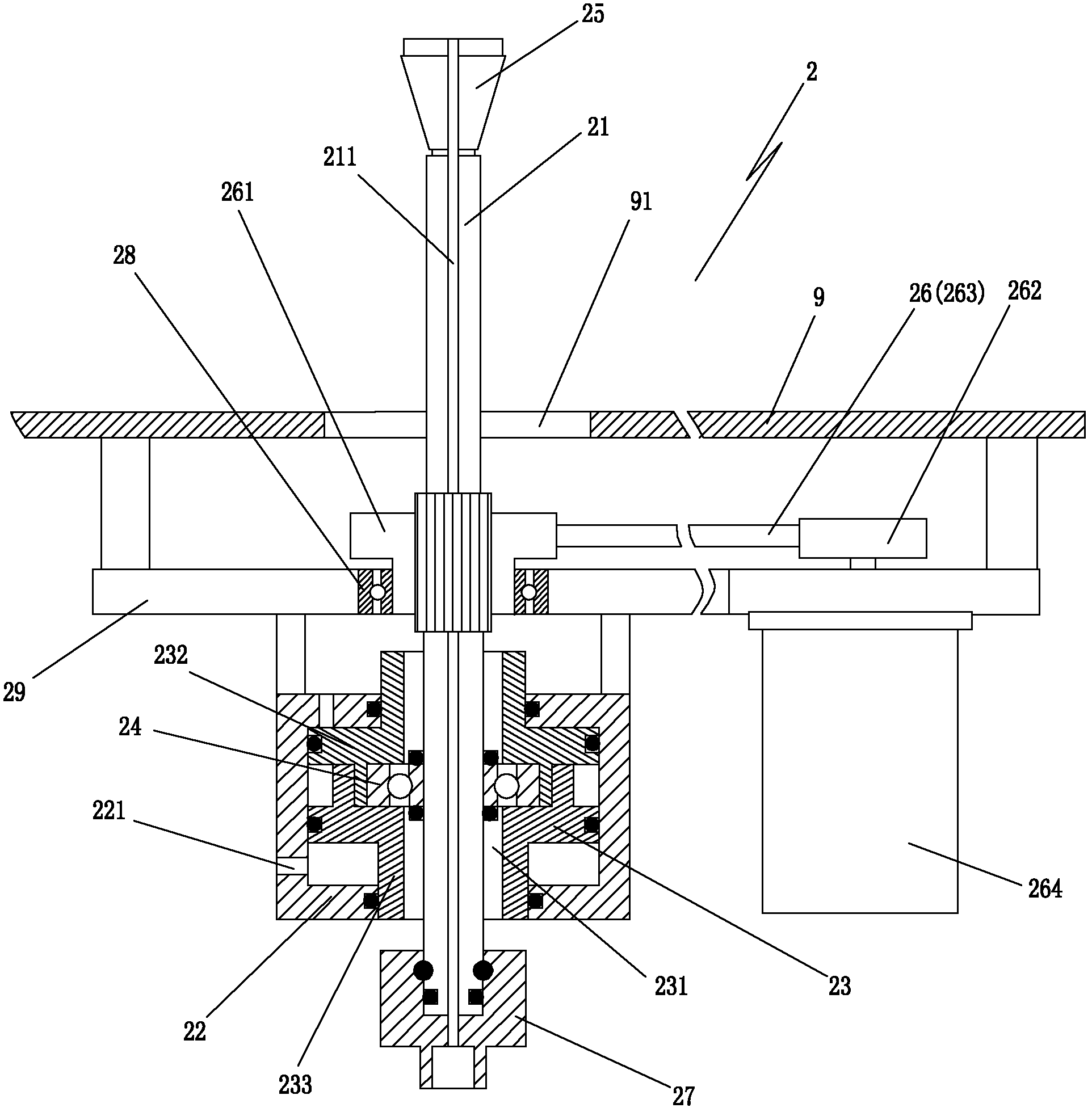

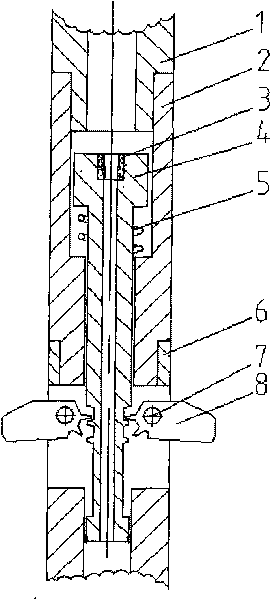

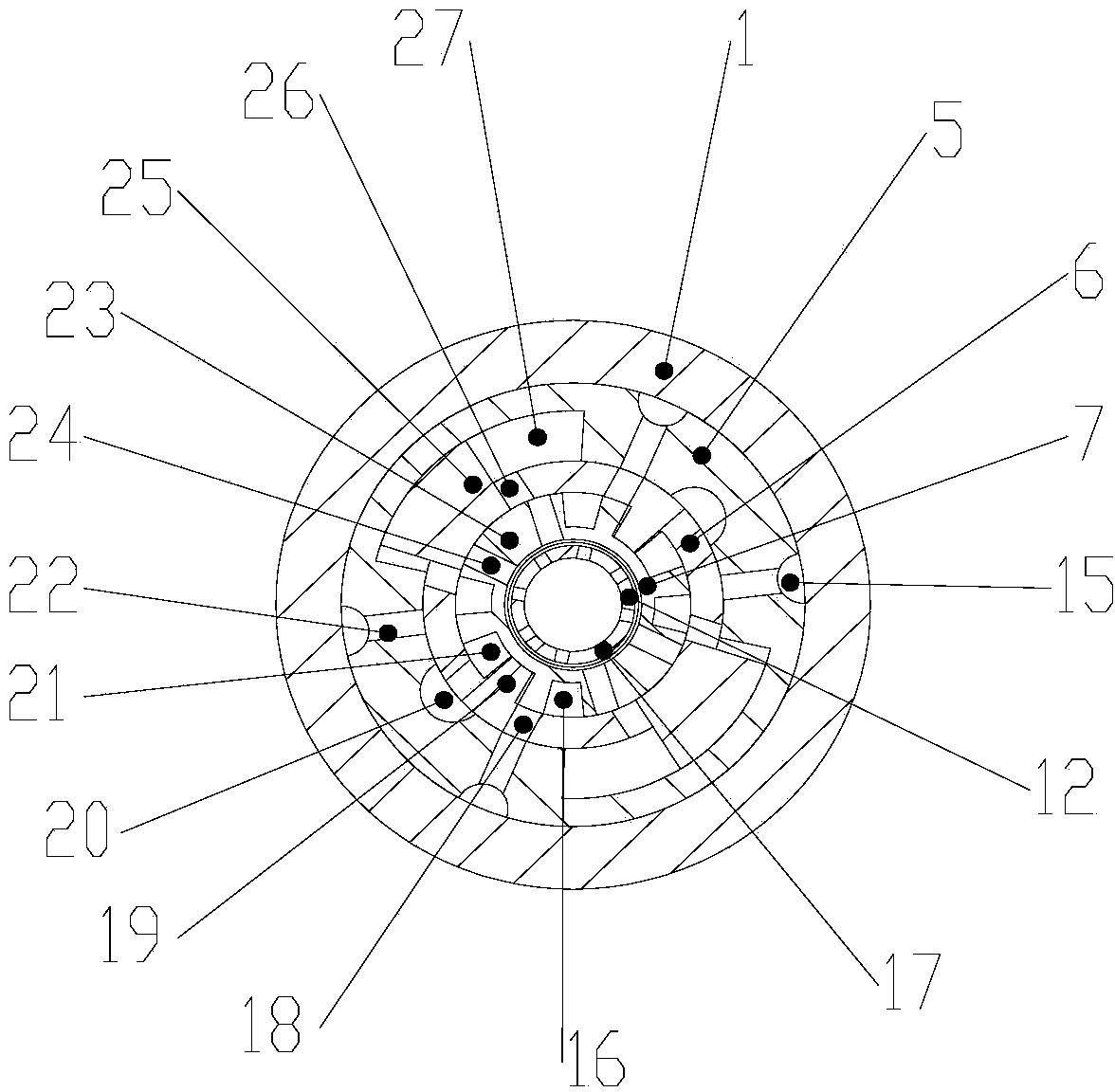

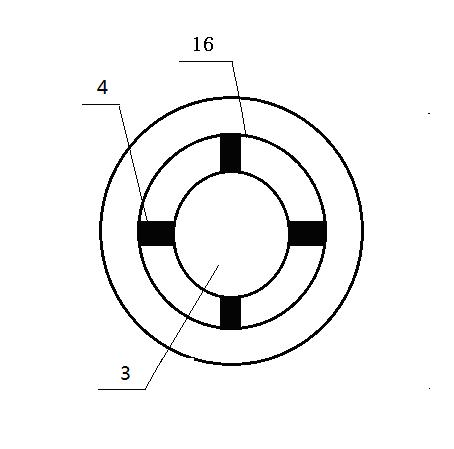

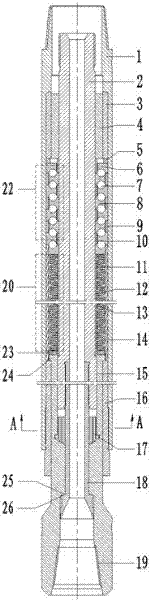

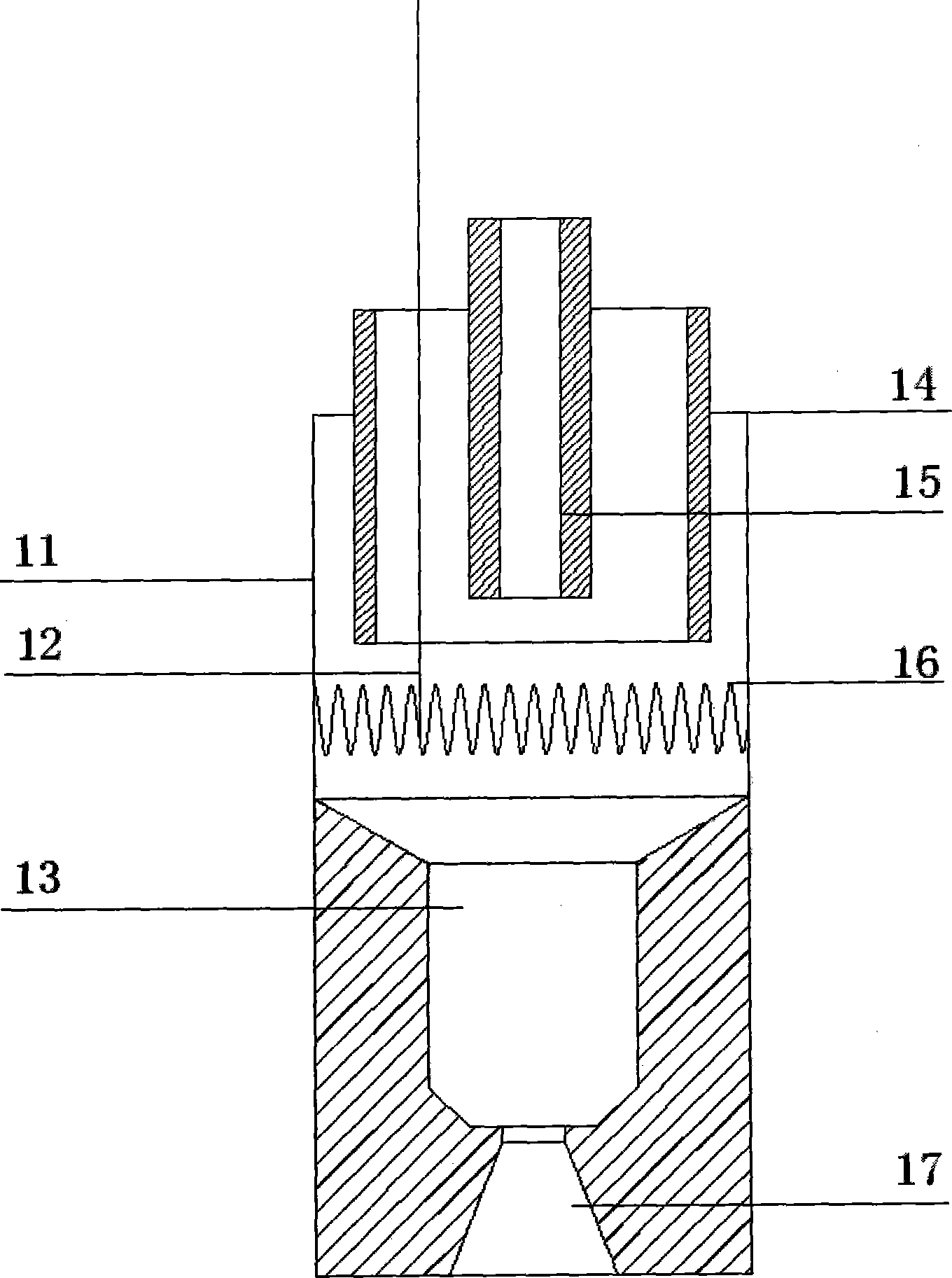

Rotary screw drill tool

InactiveCN104033113AImprove rock breaking abilityExtended service lifeDrilling rodsDrilling casingsSplit ringWell drilling

The invention discloses a rotary screw drill tool used in fields of petroleum drilling and the like and solves the problem about crushing efficiency of hard rocks in extradeep wells. The technical scheme includes that a bypass valve shell, a fall prevention joint, a motor shell, a universal shaft shell, an outer shell, a bearing shell, an outer cam shell, a bottom piston shell and a lower shell are sequentially connected through screw threads; an upper shaft and a lower shaft are connected through a spline, and eight spline pins are evenly and circumferentially distributed between the upper shaft and the lower shaft; a roller holder is fixed on the outer cam shell through three bolts which are circumferentially and evenly distributed, a cam is circumferentially fixed on the cam bushing through three evenly distributed bolts, a roller is mounted on a roller holder, the cam bushing is connected to the lower shaft in a threaded manner, and a lower split ring is clamped in the lower shaft through a serrated trough and is fixed through a lower retaining ring. By the arrangement, the lower shaft of the screw drill tool is enabled to generate soft axial impact with a certain frequency and stable in size, efficiency of rock breaking of a drill is improved, mechanical drilling rate is increased, and drilling cost is thereby lowered.

Owner:SOUTHWEST PETROLEUM UNIV

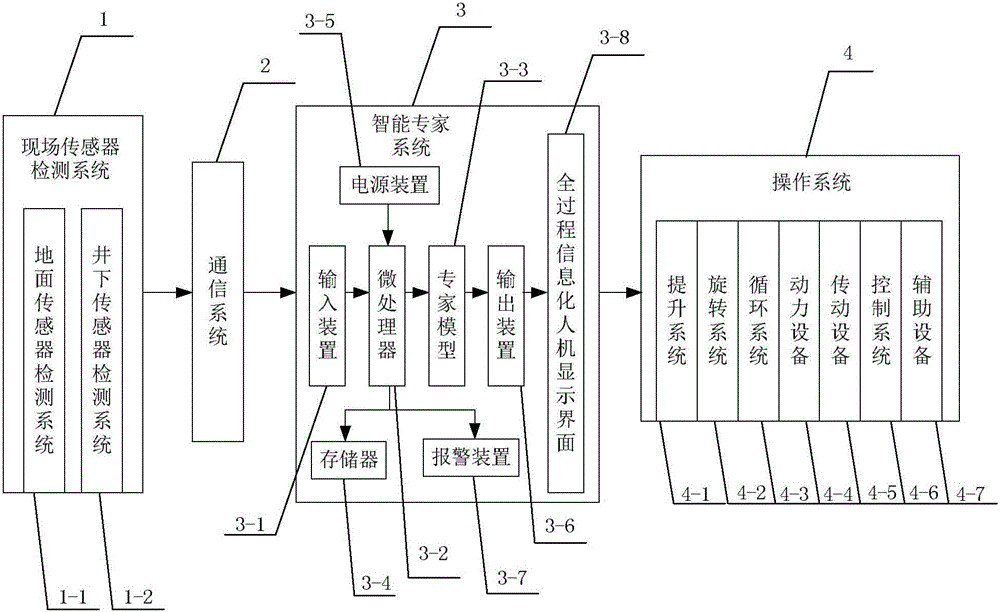

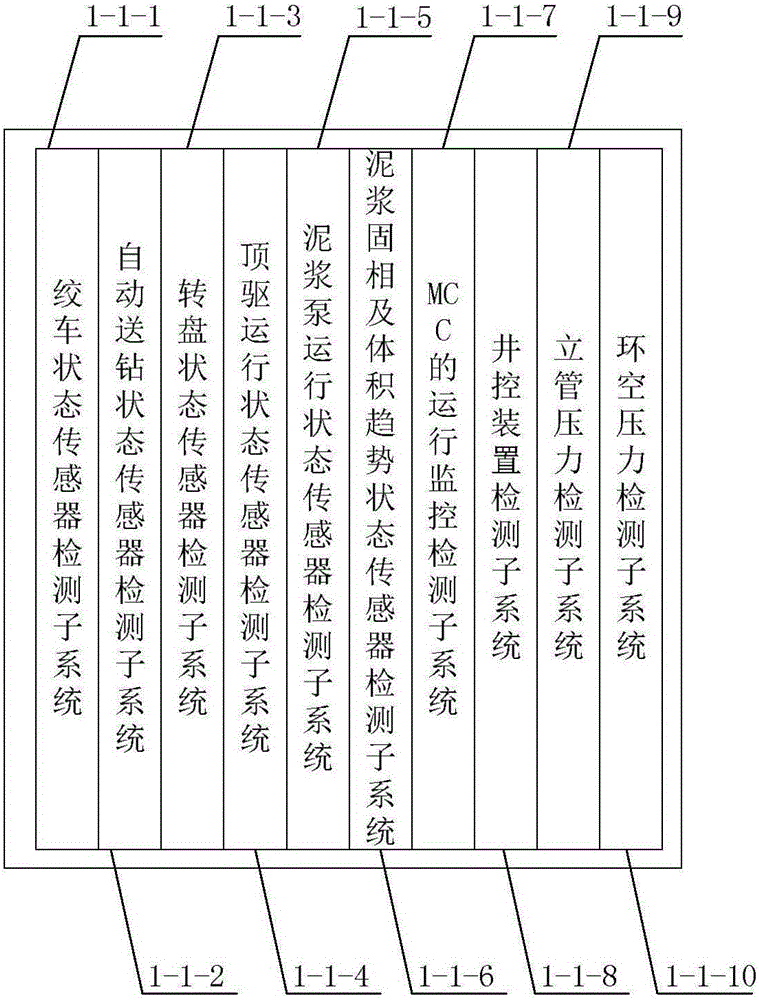

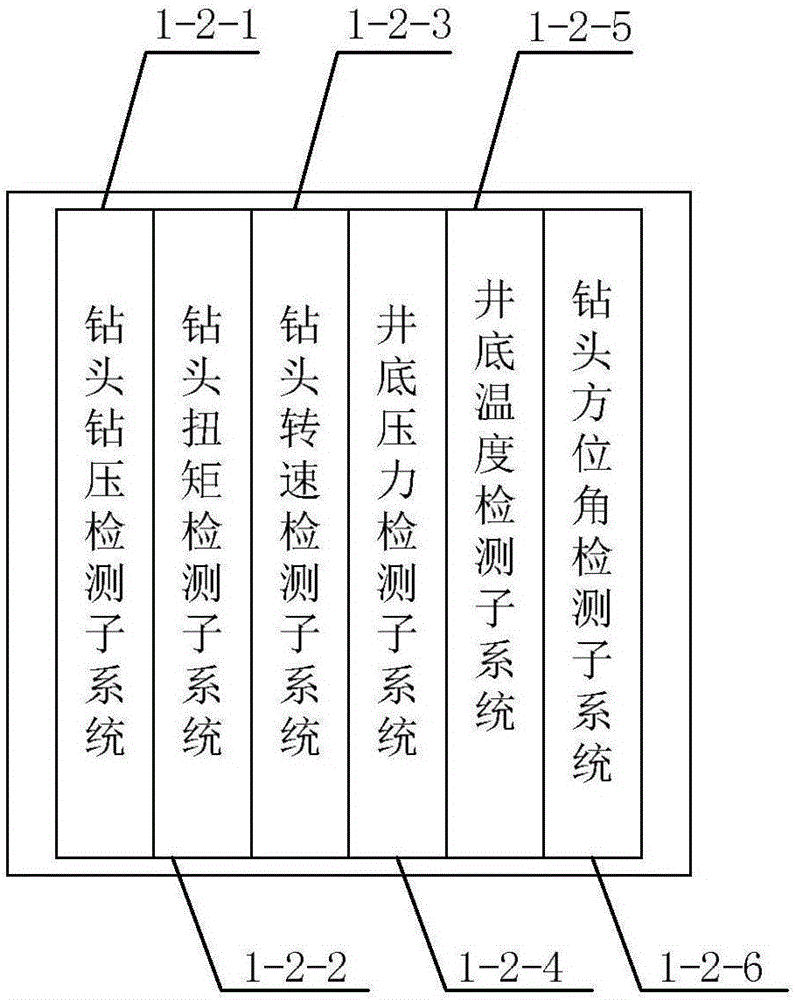

Intelligent well drilling expert system

InactiveCN106121621AAccurate discoveryReal-timeAutomatic control for drillingCommunications systemAutomatic control

The invention discloses an intelligent well drilling expert system. The intelligent well drilling expert system comprises an on-site sensor detection system, a communication system, an intelligent expert system and an operation system. The on-site sensor detection system is connected with the intelligent expert system through the communication system, the intelligent expert system is connected with the operation system, and thus the automatic closed loop well drilling adjusting and controlling system is formed. The on-site sensor detection system acquires data of the whole well drilling process. The acquired data are transmitted to the intelligent expert system through the communication system, so that processing monitoring, forecasting, analyzing, controlling and processing are conducted, and finally the operation system executes an operation instruction sent by the intelligent expert system after analyzing. The intelligent well drilling expert system can achieve real-time performance and the functions of early finding, early forecasting, explanation at any time and automatic control, and not only provides accurate information for well drilling engineering but also has the advantages of reducing well drilling cost, increasing well drilling speed, completely preventing accidents, and finding oil and gas accurately.

Owner:SOUTHWEST PETROLEUM UNIV

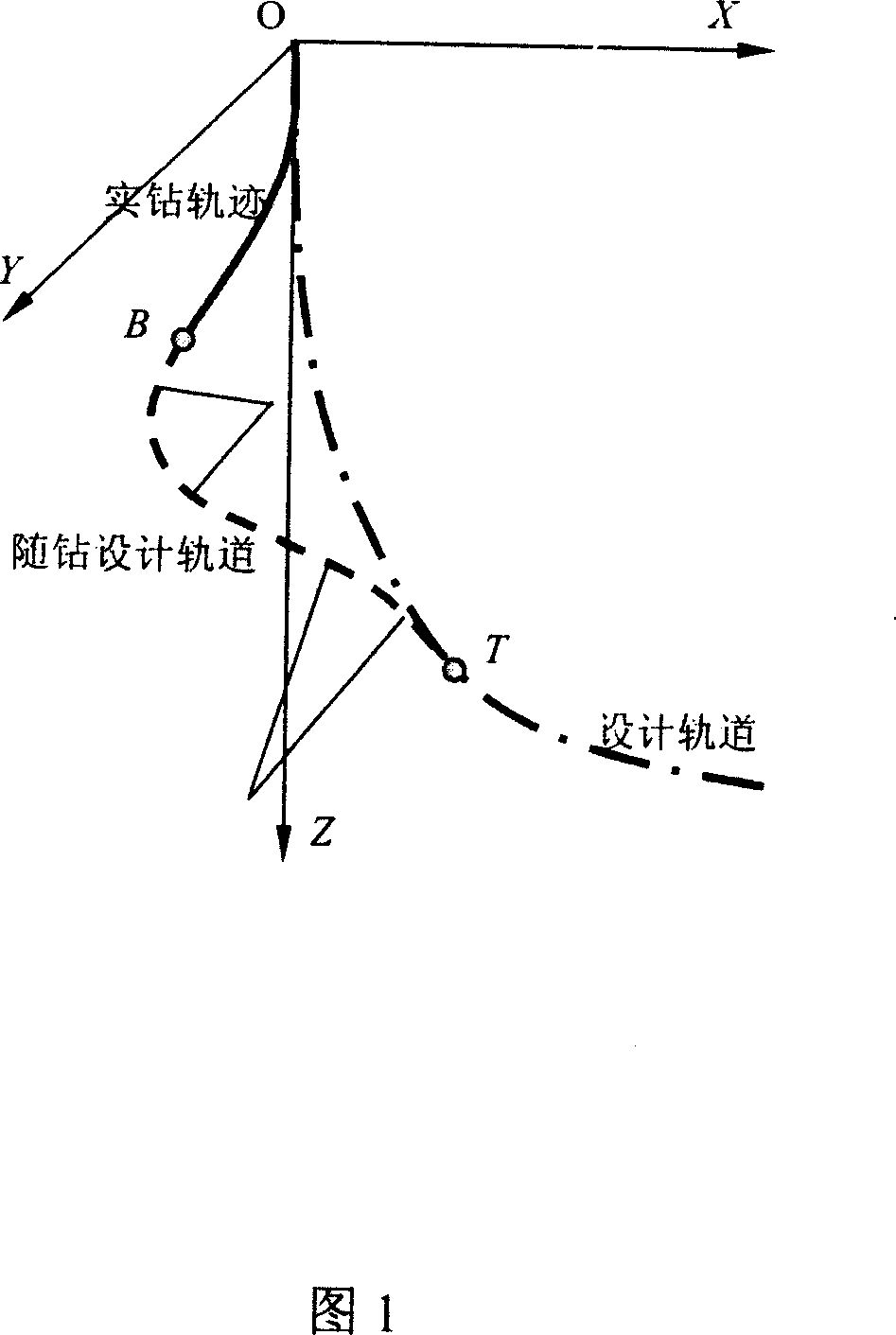

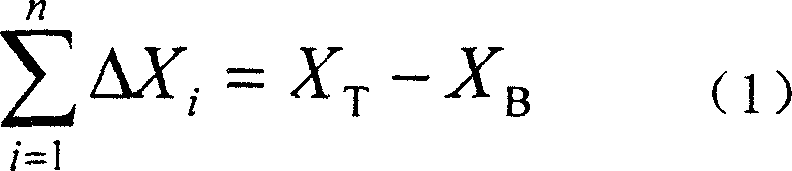

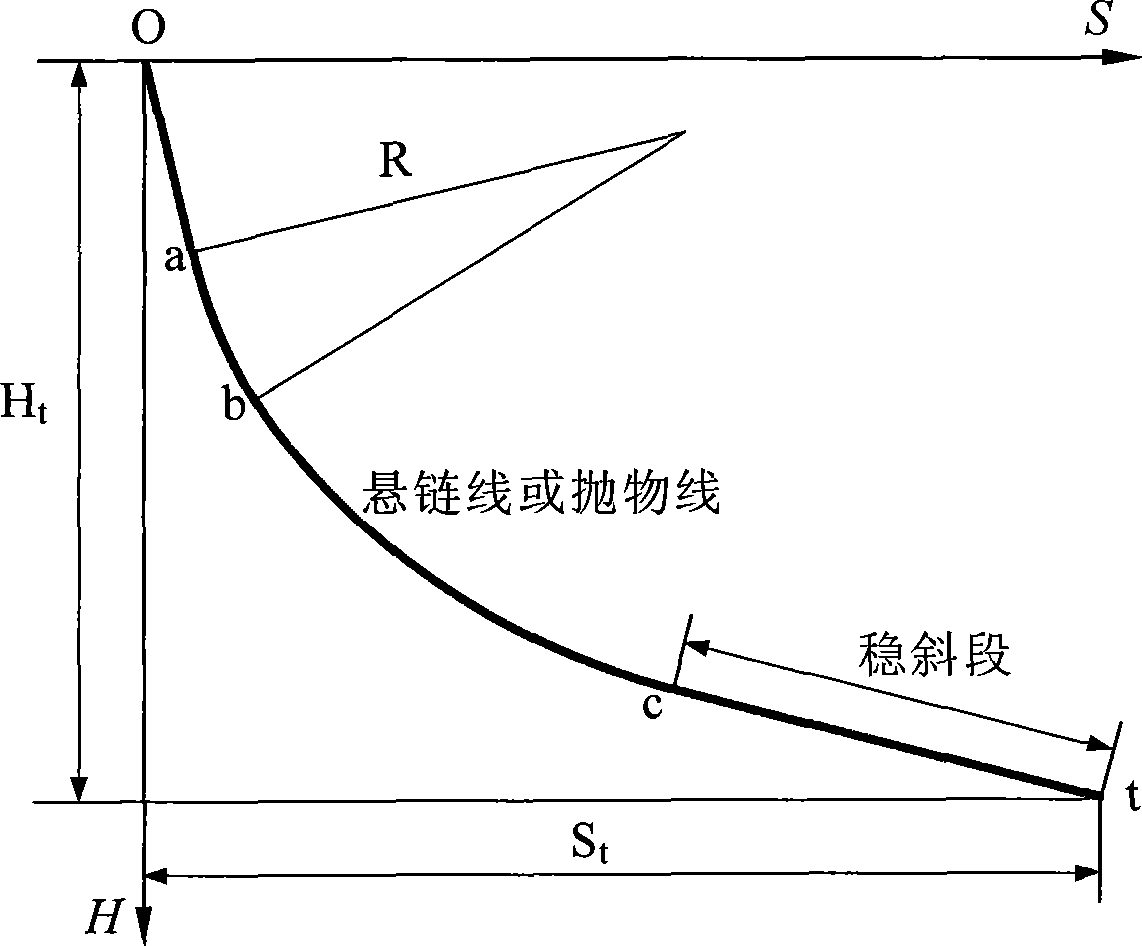

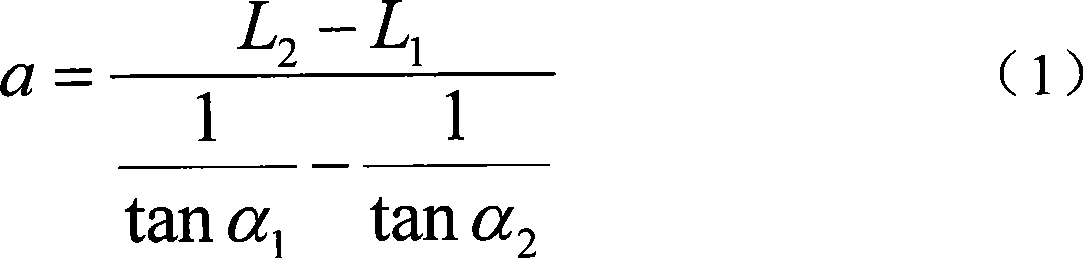

Design-while-drilling method for controlling borehole track while drilling well

InactiveCN1936263AIdeal control targetSafe completionSurveyDirectional drillingSection planePetroleum

The invention relates to well bore rail control and design that includes the process of determining well bore section shape, building equation set, expanding equation set, giving known parameters, and solving the equation set. It could meet the request of target intake direction and coordinate location, and could select 4 random feature parameters as the indeterminate parameters. The invention could improve drilling speed and wellbore quality, lower drilling cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

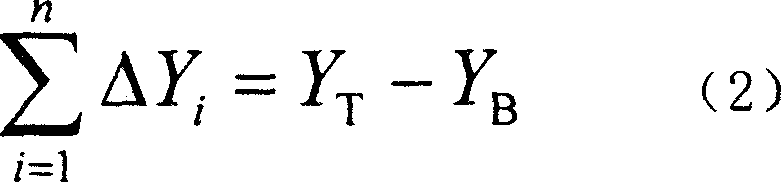

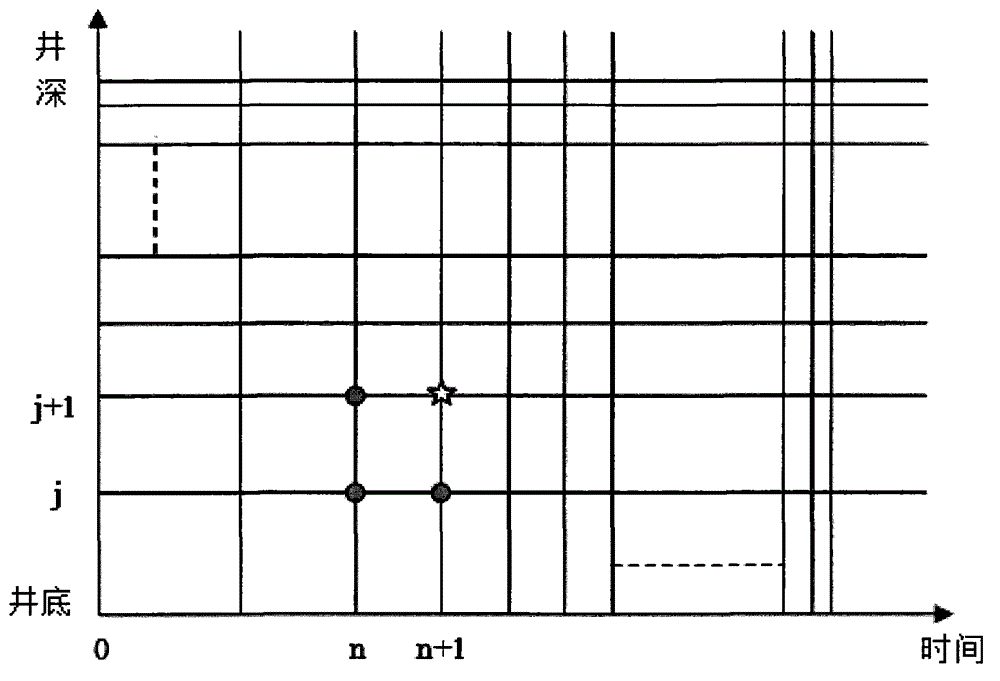

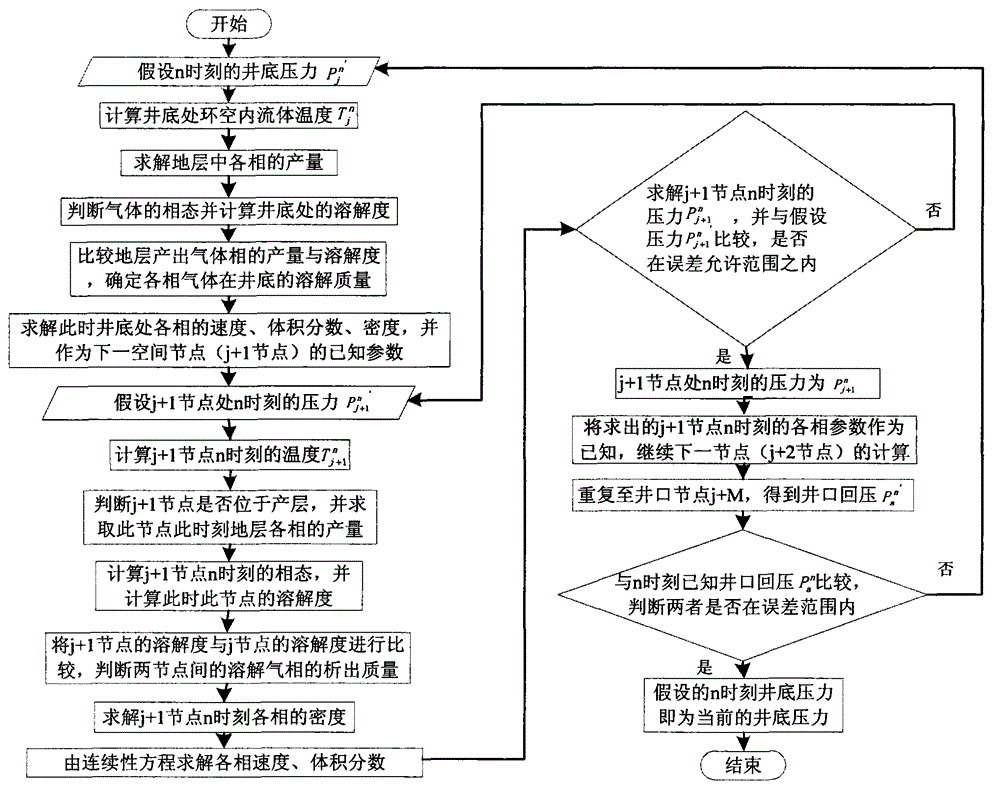

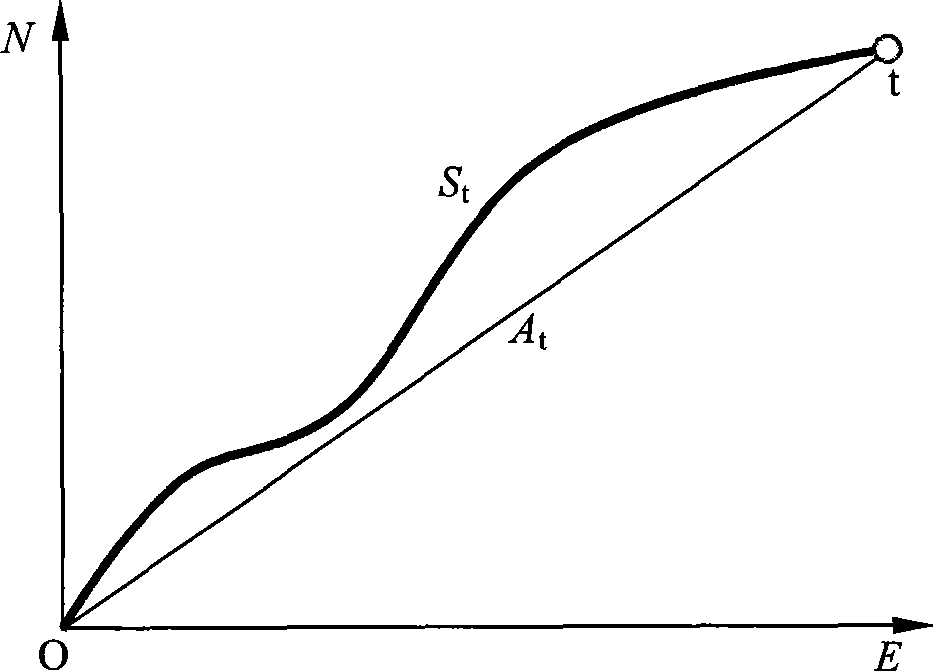

Pressure-controlled drilling method based on drilling annulus wellbore multi-phase flow computing

The invention relates to a pressure-controlled drilling method based on drilling annulus wellbore multi-phase flow computing, which comprises the following steps: obtaining basic parameters for drilling wellbore multi-phase flow computing; determining the variety of fluid in wellbore annulus; considering multi-phase multi-component complex flow factors, and establishing a wellbore annulus internal multi-phase flow control equation group; establishing definite conditions for the multi-phase flow control equation group by combining with technical processes under pressure-controlled drilling different working conditions; carrying out grid division on the time and space domains obtained by multi-phase flow computing; carrying out numerical discretion; solving the wellhead back pressure required by pressure-controlled drilling; and adjusting the wellhead throttling valve based on the computed wellhead back pressure value to realize pressure-controlled drilling. Through the adoption of the method, pressure-controlled drilling can be continued under the condition that the drilling fluid contains gas; the method can be applied to the pressure-controlled drilling process of strata highly containing acidic gases; and the computation accuracy is high, the error is small, the control accuracy of pressure-controlled drilling is improved, and the application range is enlarged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +3

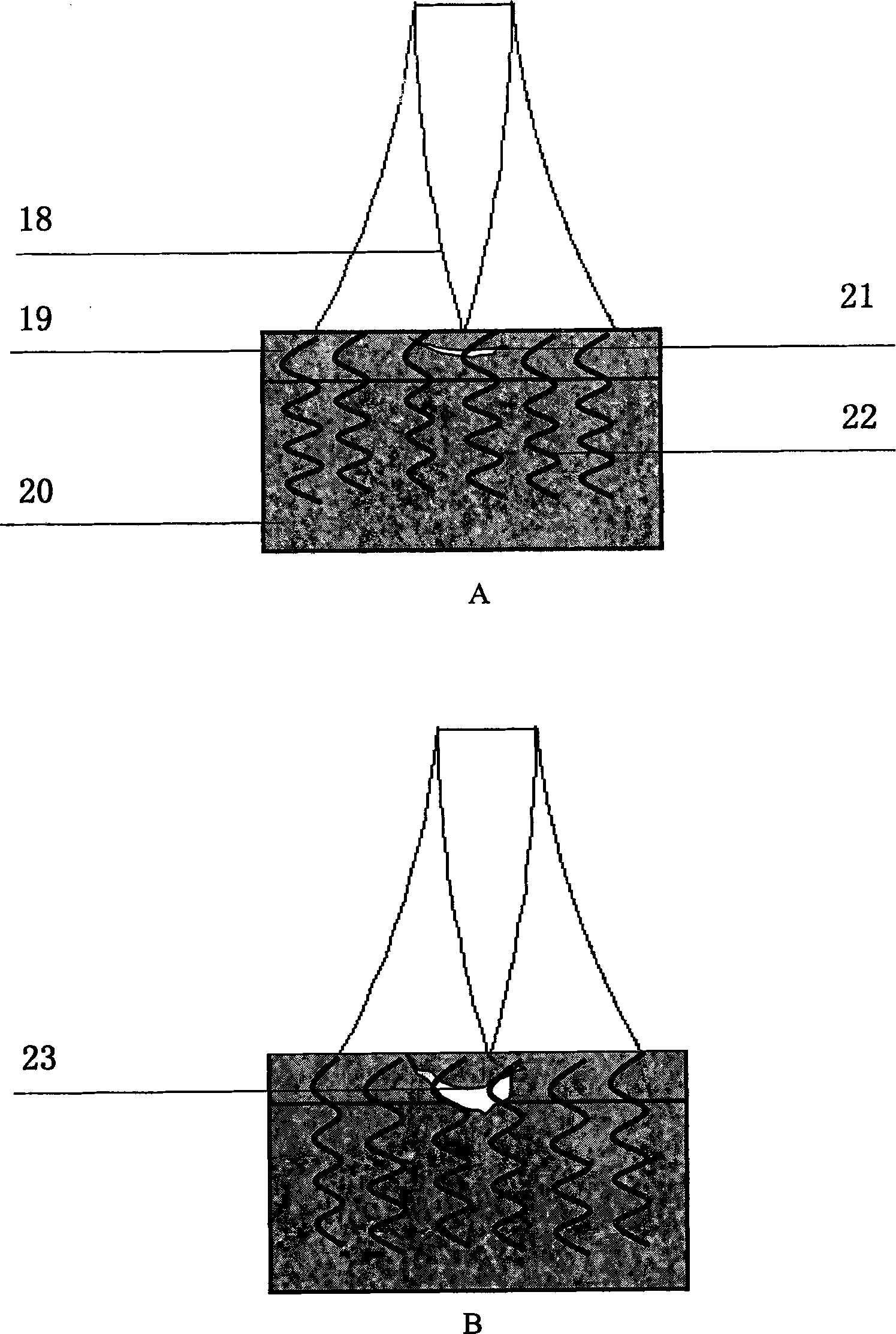

Compound vibrating well-drilling tool

ActiveCN102747958AEliminate \"drag\"Eliminates \"stick-slip\" phenomenonVibration drillingHydraulic cylinderWell drilling

The invention discloses a compound vibrating well-drilling tool which comprises a sleeve, a vibrating short joint, a vibrating short joint chuck, a screw motor, a conversion short joint connected with the lower end of the screw motor, an annular disc sleeved at the upper end of the conversion short joint, a hydraulic cylinder installed at the lower end of the conversion short joint, an impact short joint arranged in an inner cavity of the hydraulic cylinder and a torque transmitting short joint, wherein the vibrating short joint, the vibrating short joint chuck, the screw motor, the conversion short joint, the annular disc, the hydraulic cylinder, the impact short joint and the torque transmitting short joint are arranged in sequence from top to bottom. The well-drilling tool can be installed at different positions in a well-drilling column, the drilling column generate axial and circumferential high frequency compound vibration through the tool, and phenomena including 'pulling press' and 'stick slip' in the large-inclination well drilling process are eliminated, thereby remarkably improving mechanical drilling speed, prolonging the service life of a drill bit and reducing well-drilling cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

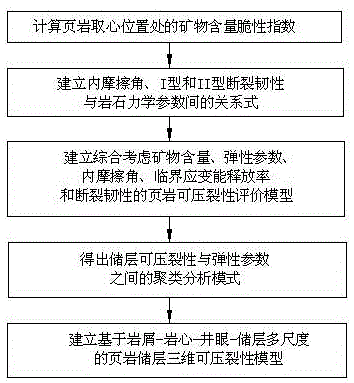

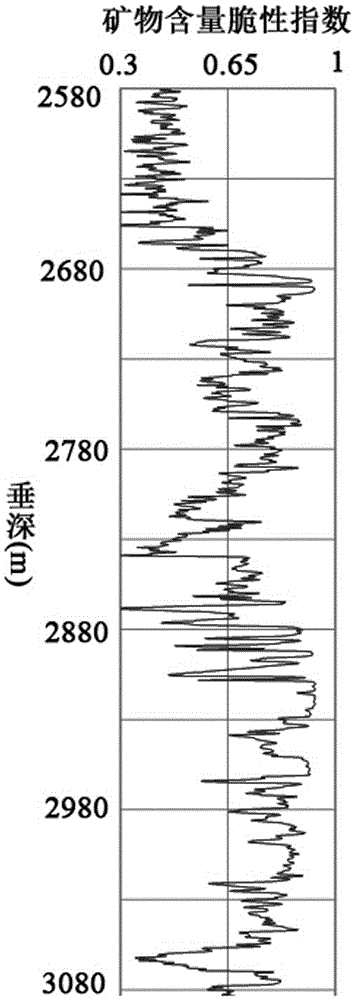

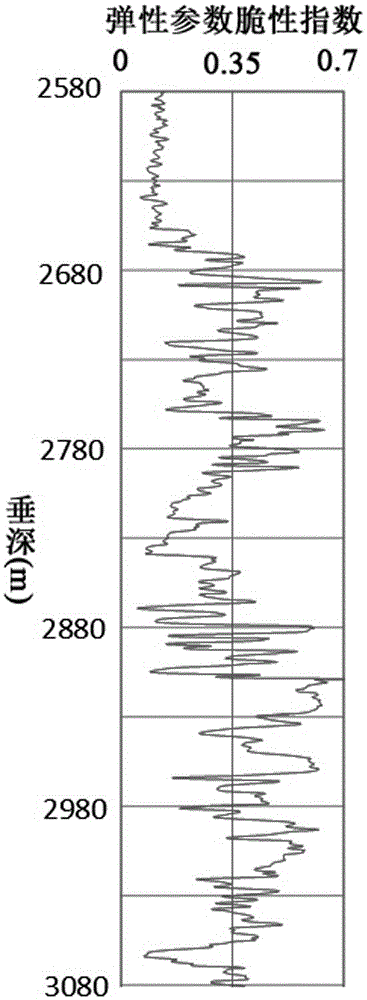

Debris-core-borehole-reservoir multiscale shale reservoir three-dimensional fracturing evaluation method

ActiveCN105156103ALarge capacityQuantification of fracabilityBorehole/well accessoriesType fractureWell placement

The invention relates to a debris-core-borehole-reservoir multiscale shale reservoir three-dimensional fracturing evaluation method. The method comprises the steps of: (S1) calculating mineral content brittleness indexes in a shale coring position; (S2) building relations among an internal friction angle, I type and II type fracture toughness and rock mechanical parameters; (S3) building shale fracturing evaluation models comprehensively considering a mineral content, elastic parameters, the internal friction angle, a critical strain energy release rate and the rapture toughness; (S4) applying a support vector machine algorithm to obtain a cluster analysis mode between a reservoir fracturing performance and the elastic parameters; and (S5) applying the cluster analysis mode and a reservoir three-dimensional elastic parameter data body to obtain a debris-core-borehole-reservoir multiscale shale reservoir three-dimensional fracturing model. The method can be applied to obtain the fracturing performance of any space position in a shale reservoir, so that the well position selection blindness is prevented, and the fracturing modification effect and the after-pressing yield are improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

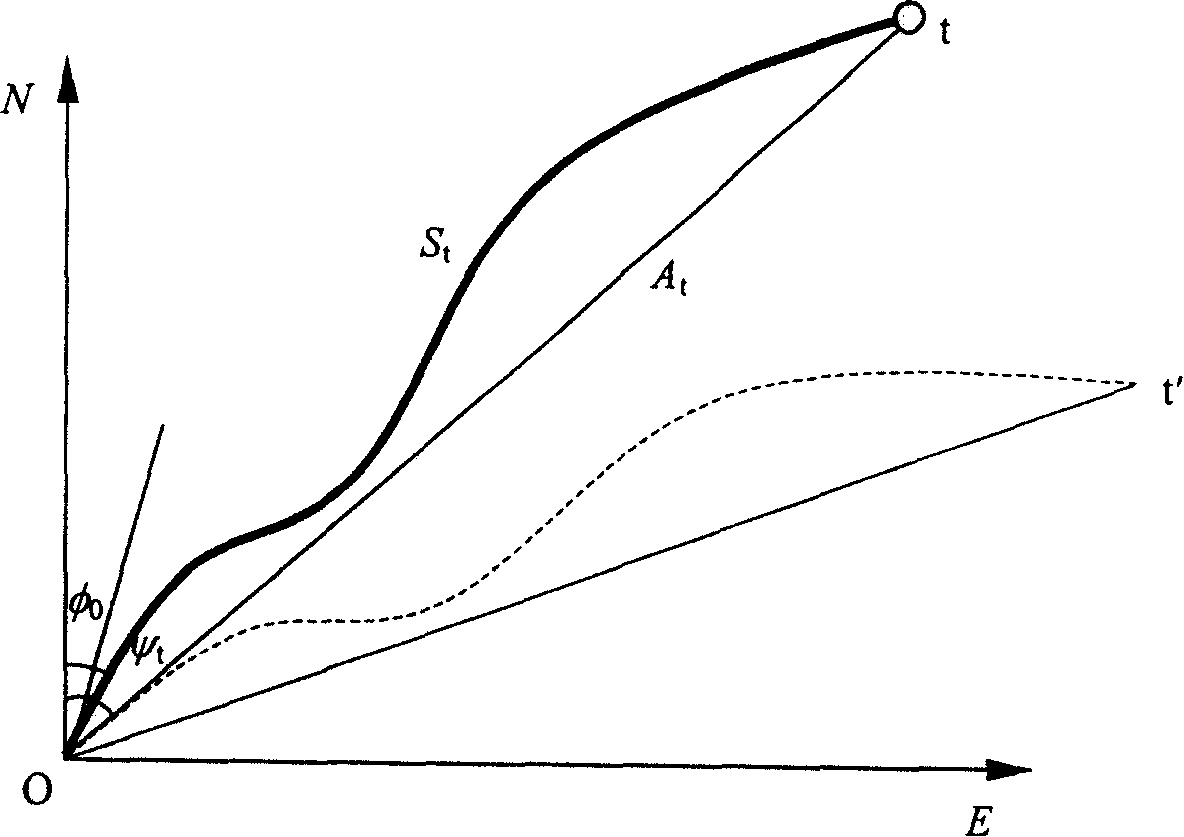

Monitoring method for drilled wellbore trajectories

InactiveCN101387198AIn line with the actual situationImprove monitoring accuracySurveyTracking modelHorizontal wells

The invention relates to a drilling engineering technology in petroleum engineering, in particular to a method for monitoring the track of an actually drilled wellbore. The method comprises the following steps: acquisition of inclination survey data and naturalization treatment; determination of characteristic parameters of a wellbore track model; determination of a hole inclination equation and an azimuth equation; calculation of coordinate increment; calculation of surveying point coordinates; and so on. As for large-displacement wells containing catenary or parabola tracks and various directional wells and horizontal wells, the method can accurately monitor the coordinates of various surveying points, so as to make the monitoring result accord with the practice of the drilling engineering, thereby effectively improving the construction precision and the reliability of catenary drilling and parabola drilling.

Owner:CHINA PETROLEUM & CHEM CORP +1

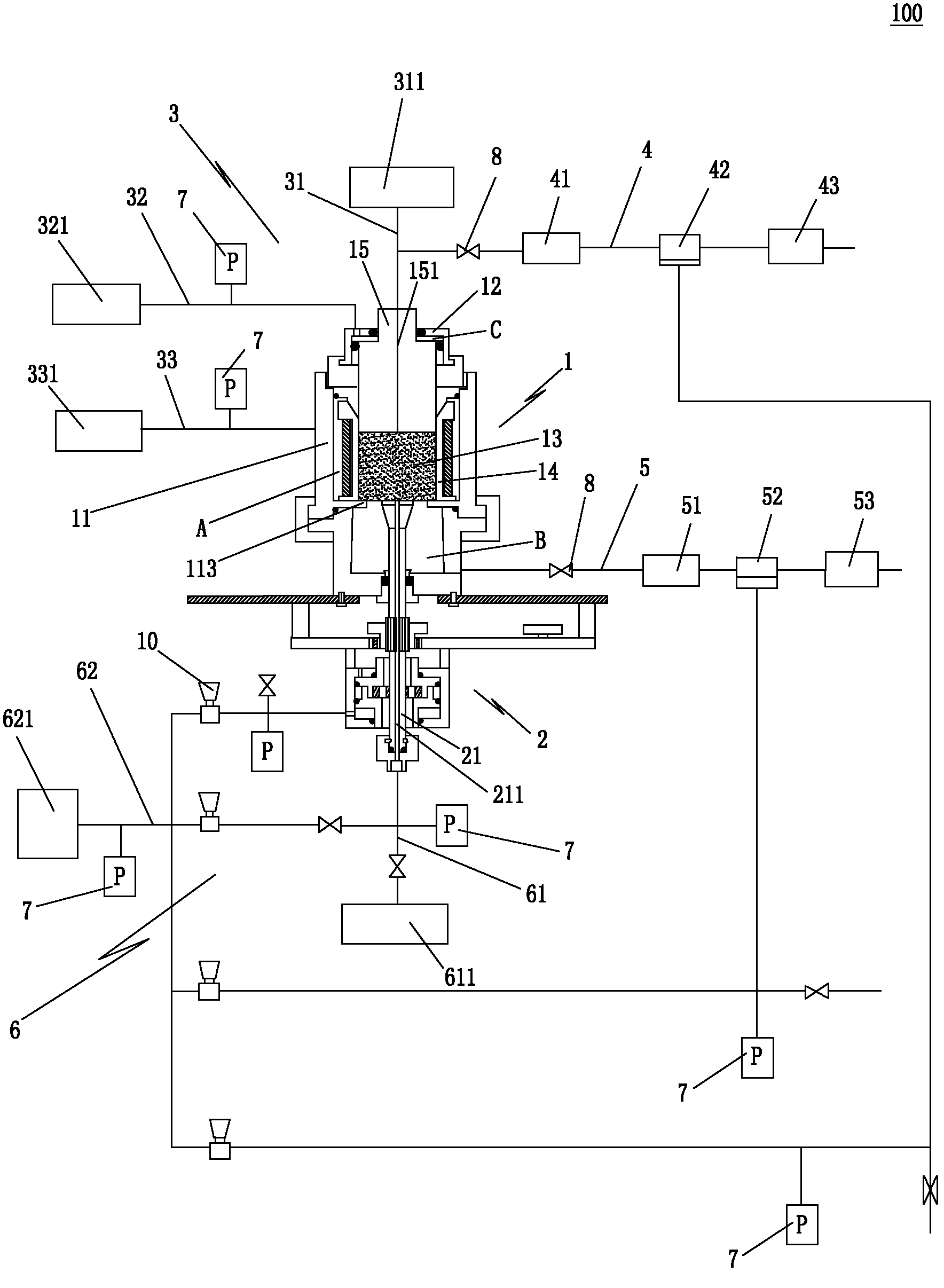

Drilling simulation experiment device

InactiveCN102288742AIncrease drilling speedImprove drilling qualityEarth material testingRock coreWell drilling

The invention relates to a well drilling simulation test device. The well drilling simulation test device comprises a rock core clamping mechanism, a drilling mechanism, a pressing mechanism and a pressing control pipeline, wherein the rock core clamping mechanism and the drilling mechanism are concentrically arranged above and below a test frame; constant pressure liquid which is applied to the upper end of the rock core by a constant pressure pump of the pressing mechanism and constant pressure liquid or high pressure gas which is pressed on the rock core by a constant pressure pump of the drilling mechanism or a high pressure gas source are converged in a simulated cavity at the bottom of the well, and are controlled to flow out by the pressing control pipeline consisting of a filter, a back pressure device and a flowmeter; the back pressure device is connected with the high pressure gas source of the drilling mechanism and controls the pressure of the simulated cavity at the bottom of the well by controlling the gas supply pressure of the high pressure gas source; the pressing mechanism, a pressure sensor of the back pressure device and the flowmeter transmit signals to a computer; and change of related parameters is controlled by the computer program, so that various drilling schemes are simulated and tested, and indoor test data is provided for increasing drilling speed,improving drilling quality and reducing drilling cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for subsea pod retrieval

InactiveUS20030006070A1Lower Drilling CostsMultiple functionsDrilling rodsDerricks/mastsOcean bottomControl system

A method for controlling subsea drilling operations which, in at least certain aspects, includes controlling the subsea drilling operations with a control system having three subsea pod containers of a control system, each with apparatus for controlling the subsea drilling operations, the system also having activation apparatus for activating a chosen one of the subsea pod containers and maintenance apparatus for maintaining the two subsea pod containers other than the chosen one in a standby mode so that triple redundancy of control of the subsea drilling operations is provided, so that the subsea drilling operations are not interrupted during retrieval of a pod whose apparatus for controlling the subsea drilling operations has failed; and methods with such a system for retrieving a subsea pod from a lower marine riser package platform.

Owner:DEAN QUENTON WAYNE

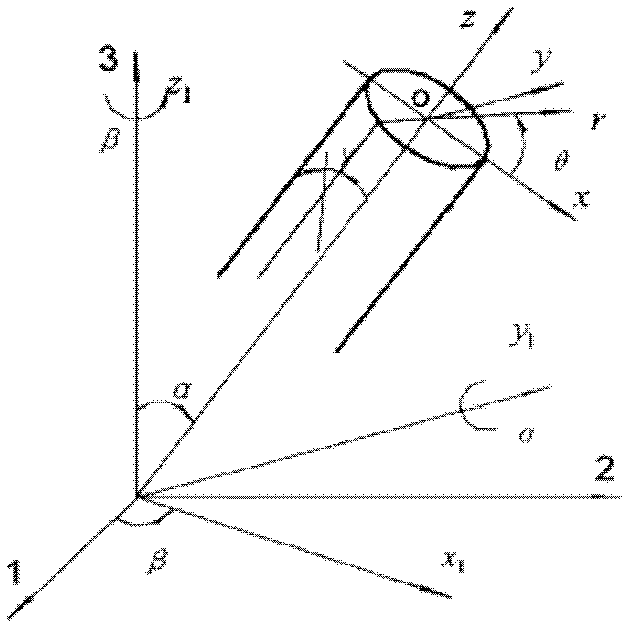

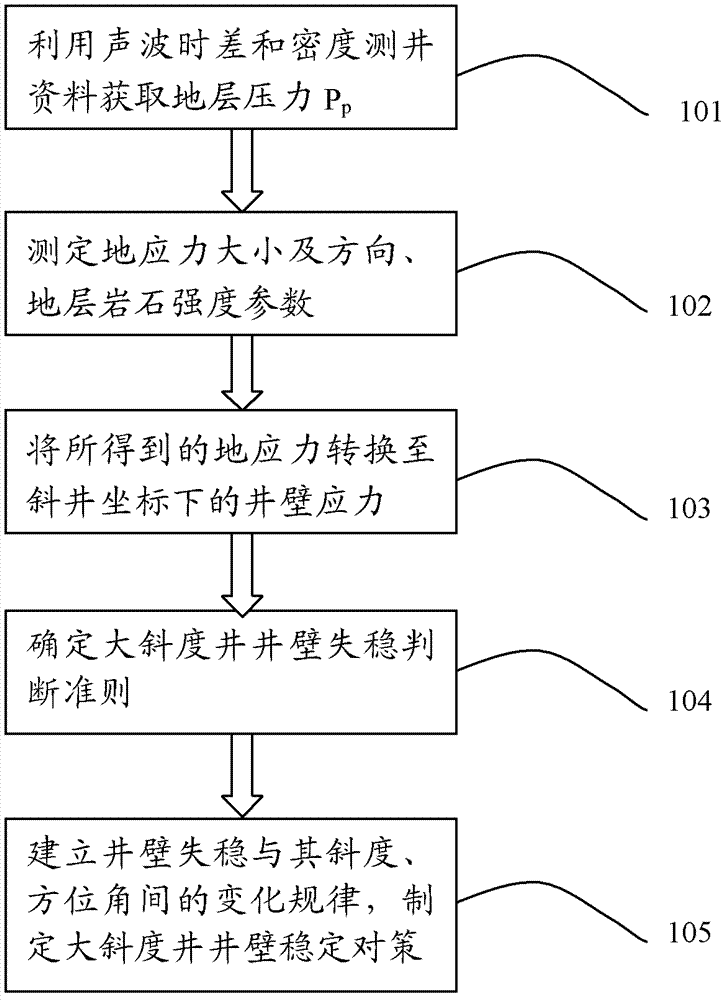

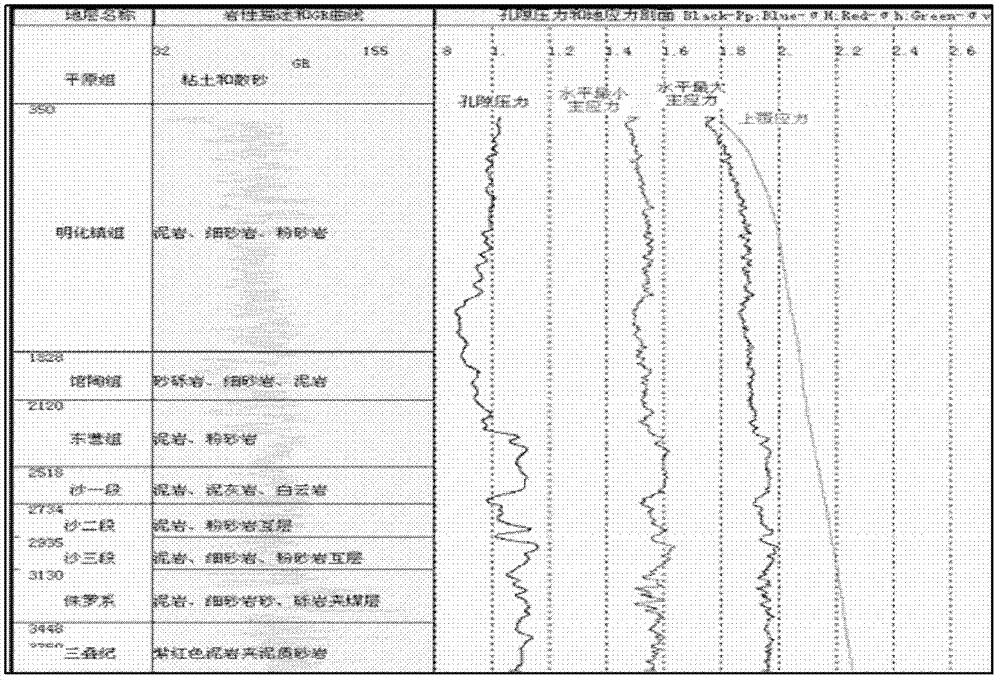

Borehole stability evaluation method for highly-deviated well

InactiveCN103362503ARealize evaluationEasy to moveBorehole/well accessoriesInstabilityLaboratory test

The invention discloses a borehole stability evaluation method for a highly-deviated well. The borehole stability evaluation method includes steps of adopting interval transit time and density logging information to obtain formation pressure Pp, and determining the magnitude and direction of ground stress and formation rock strength parameters; converting the obtained ground stress into borehole stress of deviated well coordinates; determining the criterion of borehole instability judgment of the highly-deviated well; establishing a variation rule between borehole instability and deviation and azimuth angles thereof, and formulating borehole stability countermeasures of the highly-deviated well. In the borehole stability evaluation method, a set of complete and assorted mechanical evaluation methods combined with geology, well drilling, logging, core, laboratory tests and mechanics analysis methods takes shape, mechanical mechanism of borehole stability of the highly-deviated well can be evaluated, so that reliable basis is provided for determination of platform displacement optimization, borehole track optimization and a safe drilling fluid density window determination of the highly-deviated well.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

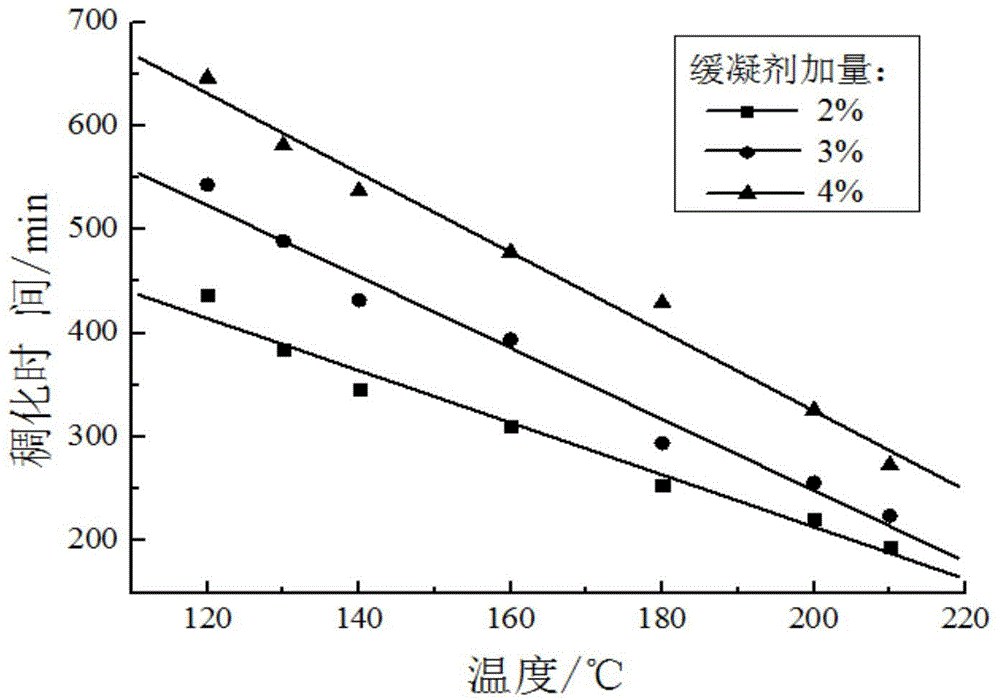

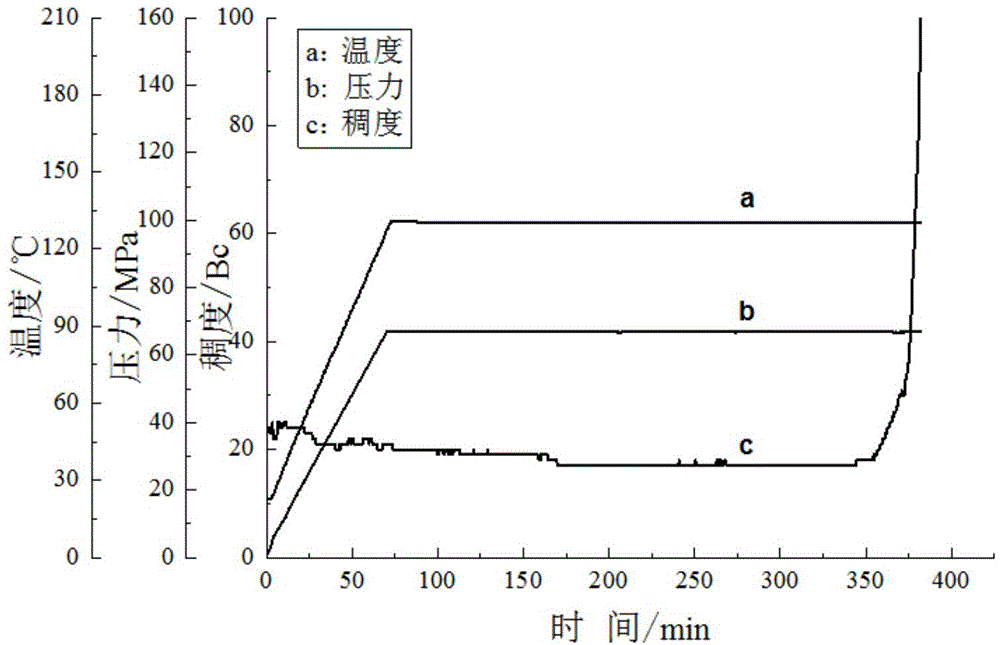

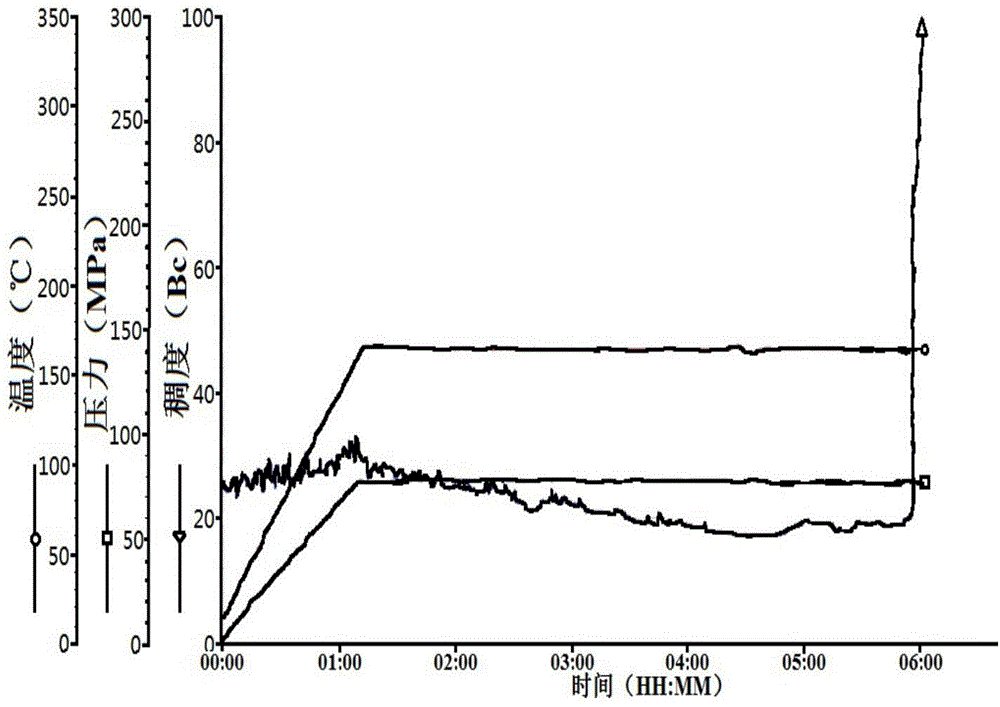

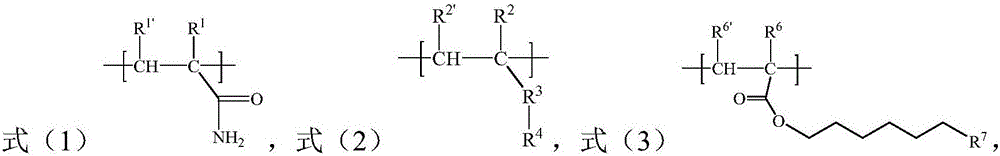

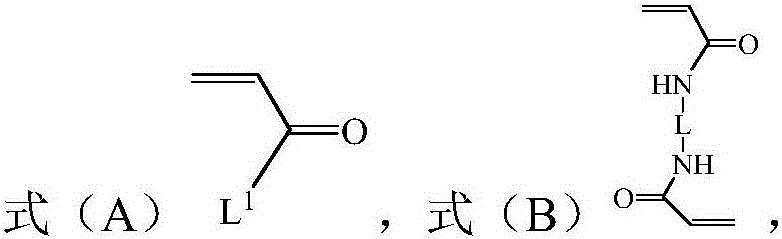

High-temperature-resistant copolymer oil well cement retarder and preparation method thereof

ActiveCN104403056AImprove performanceSolve the problem of severe subsidence at high temperatureDrilling compositionPolymer scienceFumaric acid

The invention relates to a high-temperature-resistant copolymer oil well cement retarder and a preparation method thereof. The preparation method comprises: respectively weighing four polymerization monomers such as 2-acrylamide-2-methylpropanesulfonic acid, diallyldimethylammonium chloride, maleic anhydride or itaconic acid or fumaric acid, and acrylic acid or methacrylic acid according to the mass ratio of 45-80:5-17:7-18:8-20, dissolving the first three monomers in water, then adding sodium polyphosphate and diphenylcarbazide, then successively adding a chain transfer reagent and an initiator, and finally dropwise adding the forth monomer, performing heating reaction and adjusting the pH value, so as to obtain the copolymer retarder. The invention also provides the high-temperature-resistant copolymer oil well cement retarder prepared by the above preparation method. The retarder is resistant to a high temperature up to 230 DEG C and is weak in dispersibility at a high temperature, the cement paste strength develops fast at a low temperature, the addition amount of the retarder has good linear relation with the cement paste hardening time, and the cement paste comprehensive performance is good.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Drill-following reamer

A drill-following reamer comprises an upper joint, a reamer body, a piston nozzle, a piston, a compression spring, a blade, a pin shaft and a limit stop. The upper part of the whole set of device is connected with a drilling tool through the upper joint, while the lower part is connected with a drill bit through a screw thread. During drill-following reaming operation, the liquid piston nozzle pumped on the ground produces pressure drop to push the piston to move downwards, a groove on the piston pushes a gear structure on the blade to rotate the blade outwards by using the pin shaft as the center when the piston moves downwards till the blade is limited by the limit stop, and then the blade is expanded to reach the maximum outside diameter to start the drill-following reaming operation. 78.6 percent of drill hole expansion rate can be achieved by using the drill-following reamer, so the drill hole expansion rate is high; the blade has the mechanical locking function and is not retracted due to the extrusion of the well wall, so the diameter of the reamed drill hole is regular; and because the drilling and the reaming are carried out at the same time, the drilling cost is saved.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

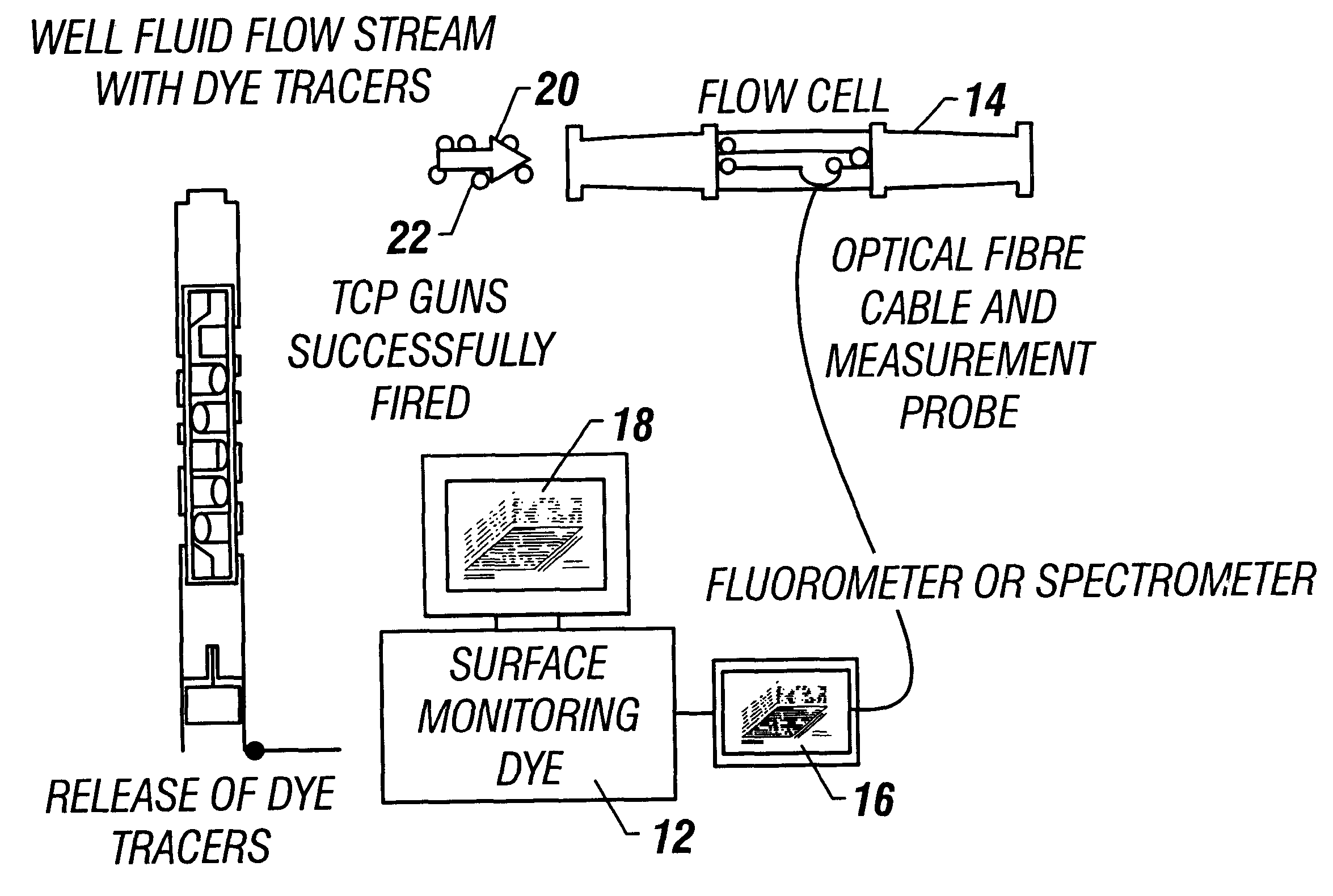

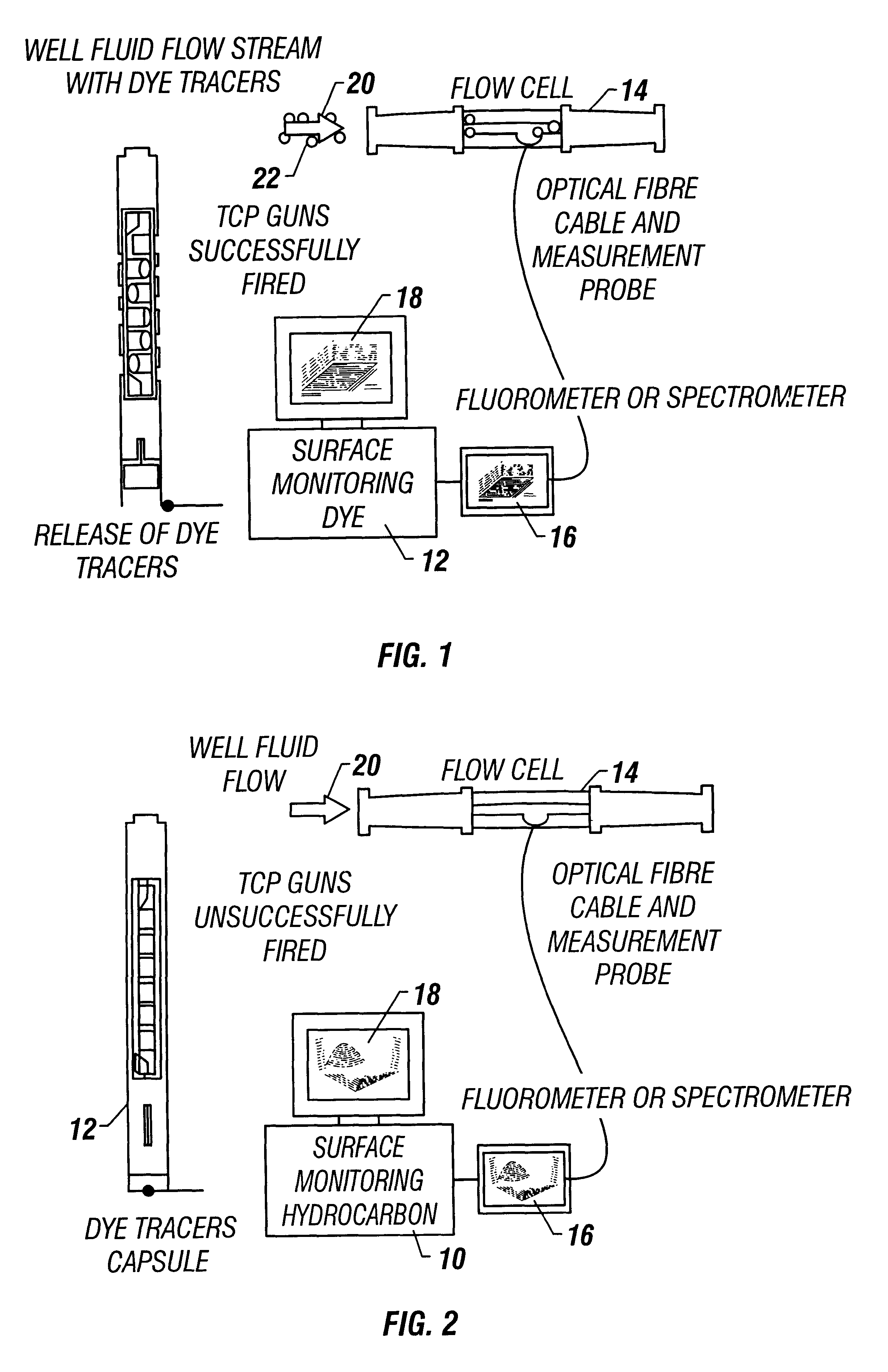

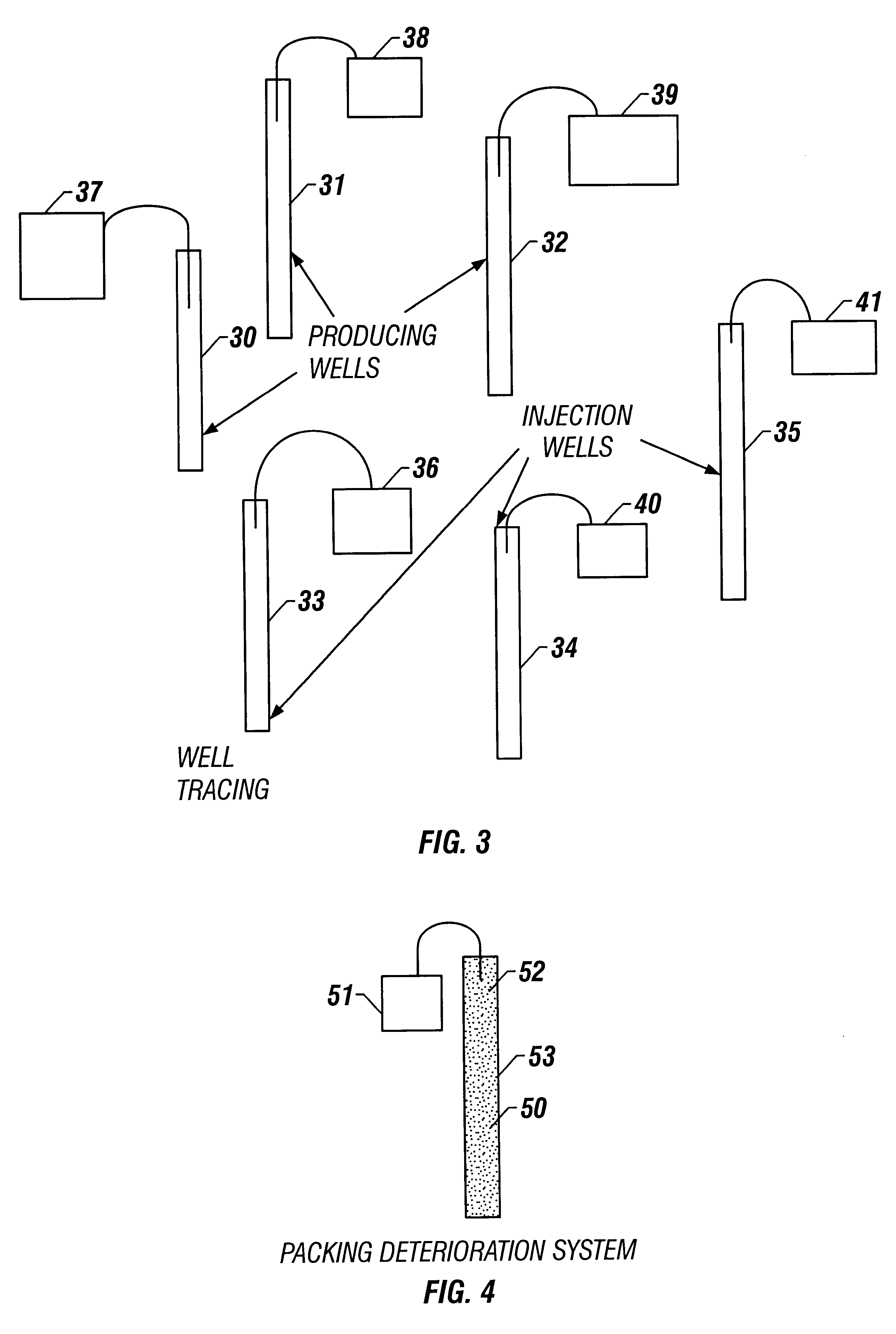

Method and apparatus for a tubing conveyed perforating guns fire identification system using enhanced marker material

A method and apparatus detects the presence of a fluorescent tracer dye, a change in capacitance, or a change in fiber optic electrical properties to determine whether or not a TCP gun has fired. The method and apparatus detects the number of charges fired to determine whether or not all TCP guns have fired and also determines the contributions of injection wells to producing wells by introducing fluorescent tracers into injection wells and detecting the presence of the fluorescent tracers at production wells. The invention places fluorescent dye particles in a gravel pack to sense when a gravel pack is deteriorating by detecting the tracer dye particles in the well flow.

Owner:BAKER HUGHES INC

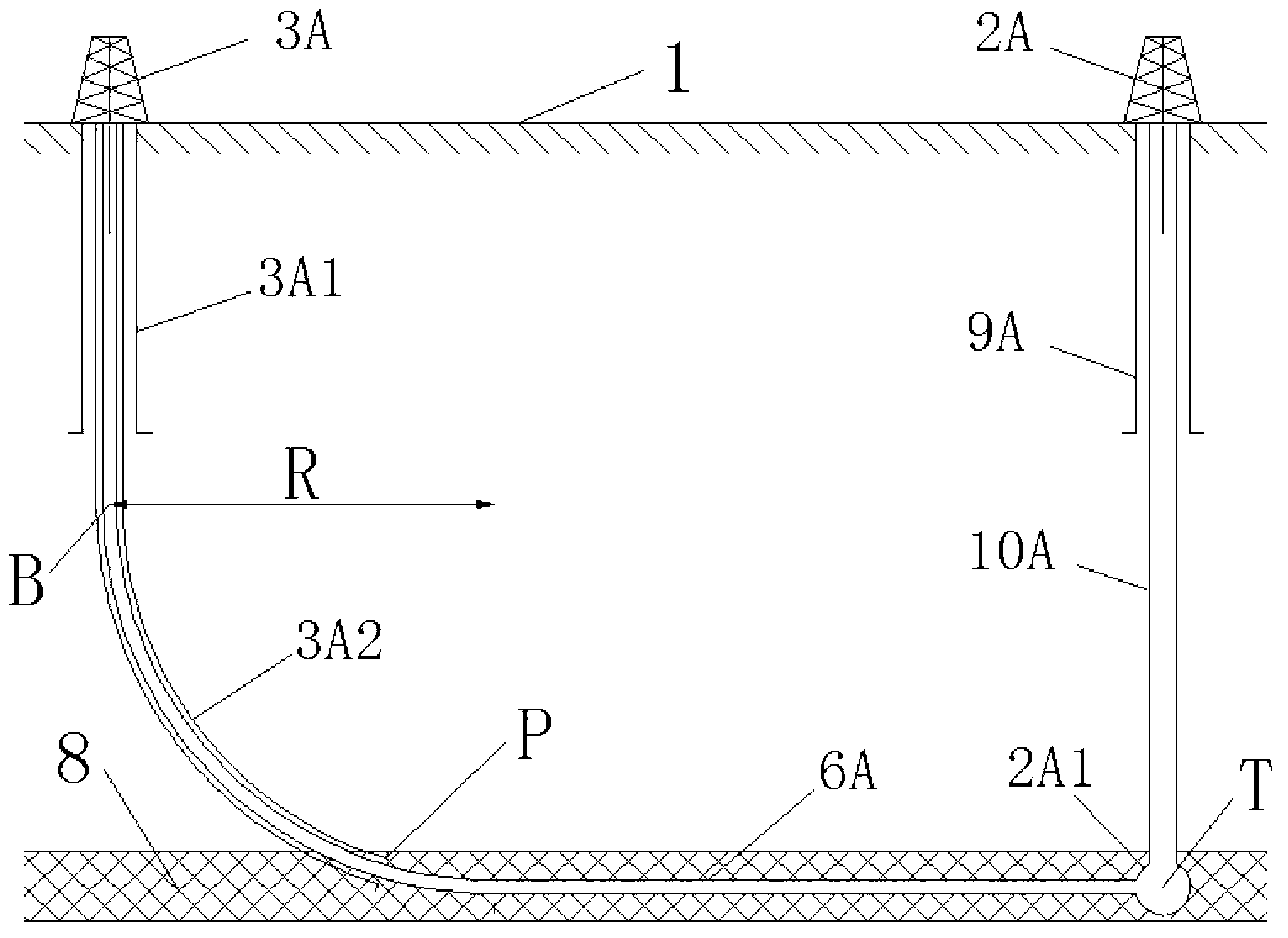

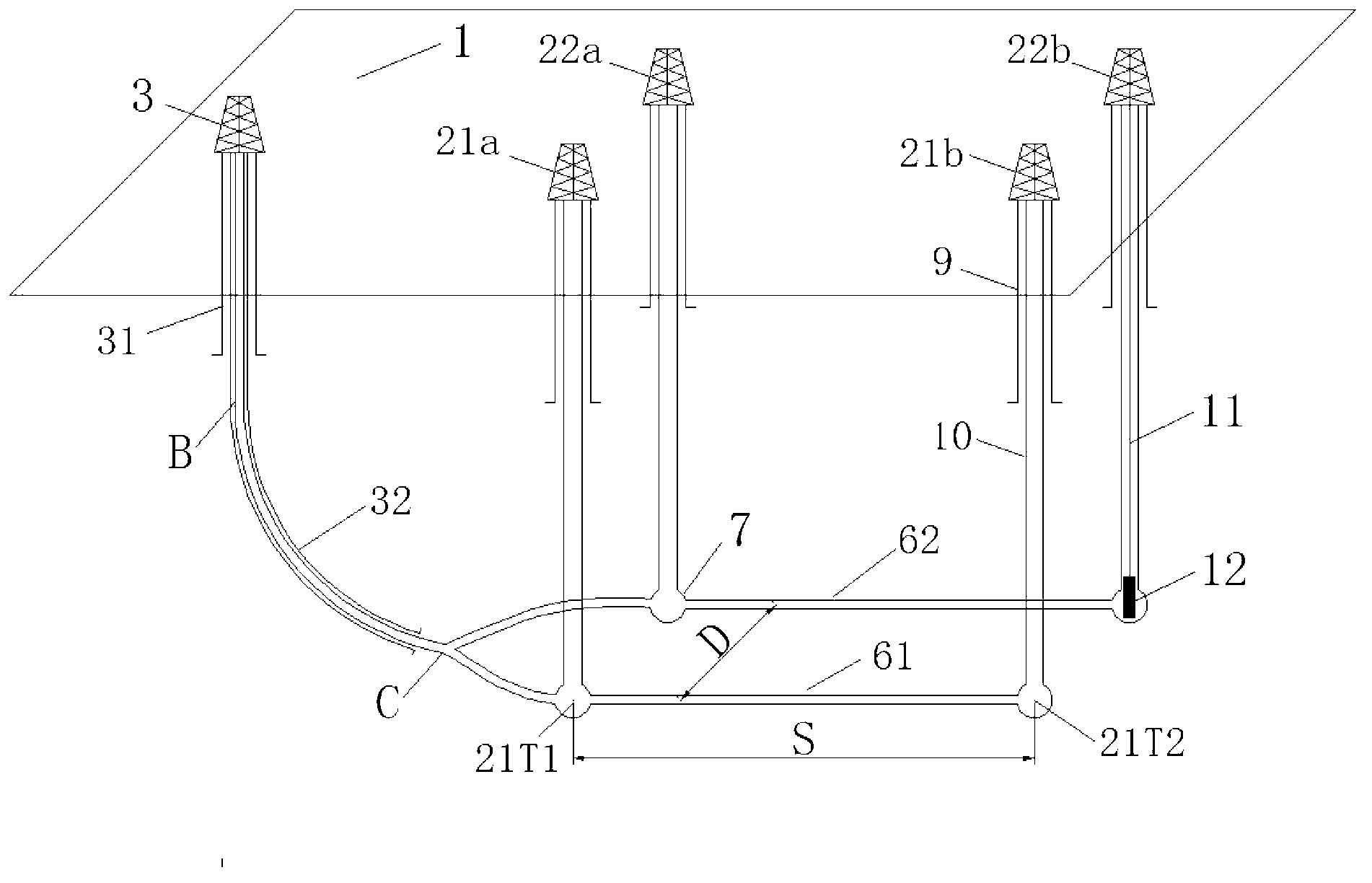

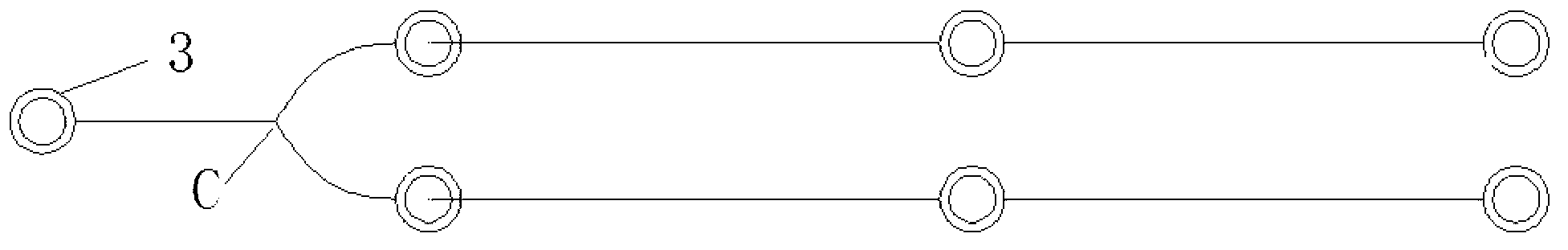

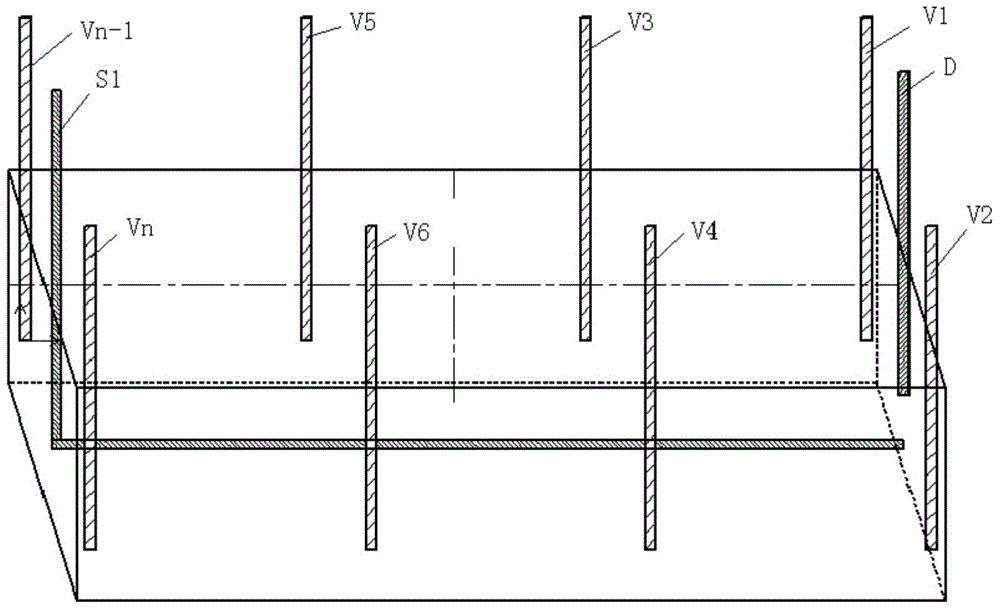

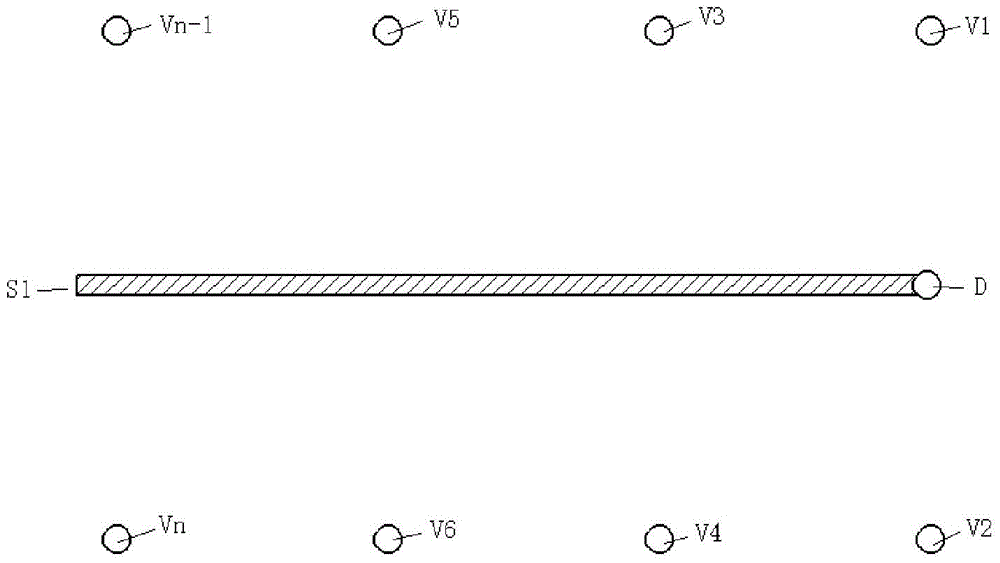

Horizontal branch multi-well-group butted well and construction method thereof

ActiveCN103216234AGuarantee normal implementationAvoid cloggingUnderground miningFluid removalWell drillingHorizontal branch

The invention discloses a horizontal branch multi-well-group butted well and a construction method thereof. The butted well adopts a distribution structure that a horizontal well corresponds to at least two vertical well groups; each vertical well group comprises at least two vertical wells; the vertical wells of each vertical well group are respectively communicated with the horizontal well at the target points respectively arranged at the bottoms of the vertical wells, so that horizontal mining channels which correspond to the vertical well groups one to one can be formed; and the target points arranged at the bottoms of the vertical wells are arranged in a target ore bed. By adopting a novel well drilling distribution form, the horizontal branch multi-well-group butted well enlarges the bare area of the ore bed, improves the mining efficiency, lowers the well drilling cost, reduces the construction period and reduces the mining risk.

Owner:EXPLORATION TECH RES INST OF CHINESE ACADEMY OF GEOLOGICAL SCI +1

Near-bit torsion impactor

InactiveCN103628819AStable jobEliminate stick-slipDrill bitsVibration drillingElectricityWell drilling

The invention discloses a near-bit torsion impactor. The near-bit torsion impactor comprises a drill collar pup joint, a splitter, a torsion impactor body and an impact transmission pup joint. The lower portion of the drill collar pup joint is connected with the impact transmission pup joint, the splitter and the torsion impactor body are installed between the drill collar pup joint and the impact transmission pup joint; a lower port of the splitter is communicated with an inlet of the torsion impactor body; an outlet of the torque impactor body is communicated with the transmission pup joint. The near-bit torsion impactor has the advantages that due to the fact that high-frequency low-amplitude torque impact which is stable in periodicity is generated, impact torque can eliminate the phenomena of PDC bit stick slip and intermittent bit sticking; due to the fact that the near-bit torsion impactor is provided with no electronic part and is of a full-hydraulic mechanical structure, the size is small and the impact process has no interference to an electric instrument which conducts measurement while drilling. The near-bit torsion impactor guarantees that in the drilling process, torque in a drill stem is stable and balanced, drill stem torsion oscillation is reduced and stable work of electric MWD devices, electric LWD devices and the like is facilitated. Parts which are prone to being damaged are few in the near-bit torsion impactor, and the near-bit torsion impactor is stable in work, long in service life and beneficial for lowering well drilling cost.

Owner:CNPC BOHAI DRILLING ENG

Mining method for heavy oil reservoir and well network thereof

The invention relates to a mining method for a heavy oil reservoir and a well network used in the same. The mining method comprises a well network arrangement stage, a preheating stage, a gravity fire flooding stage and a steam flooding stage; the gravity fire flooding stage comprises an ignition stage and a fire wire propulsion stage. The well network comprises a plurality of mining well groups. Each mining well group comprises a horizontal well, a middle vertical well and a plurality of side vertical wells, wherein the plurality of side vertical wells are arranged in two lines; the first line of the side vertical wells and the second line of the side vertical wells are symmetrical about the horizontal well; each line of side vertical wells are arranged at intervals in the direction from the tiptoe to the heel of the horizontal well and are in parallel to the horizontal well. According to the invention, combination of gravity fire flooding and steam flooding is adopted, so that utilization of heat after fire flooding is improved; thermal communication of injection and production wells is established by steam huff and puff auxiliary gravity fire flooding, so that a steam flooring mining effect is improved; well completion cost and drilling cost are reduced.

Owner:PETROCHINA CO LTD

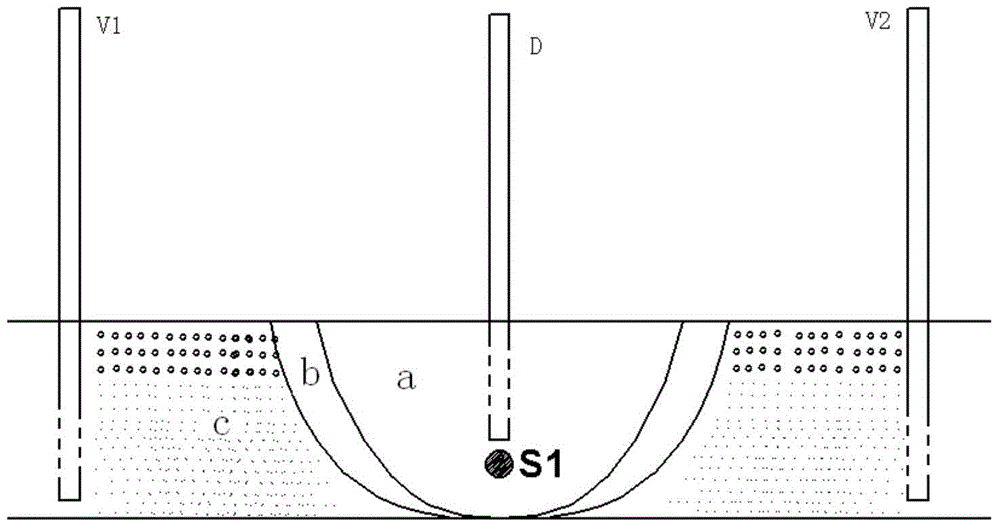

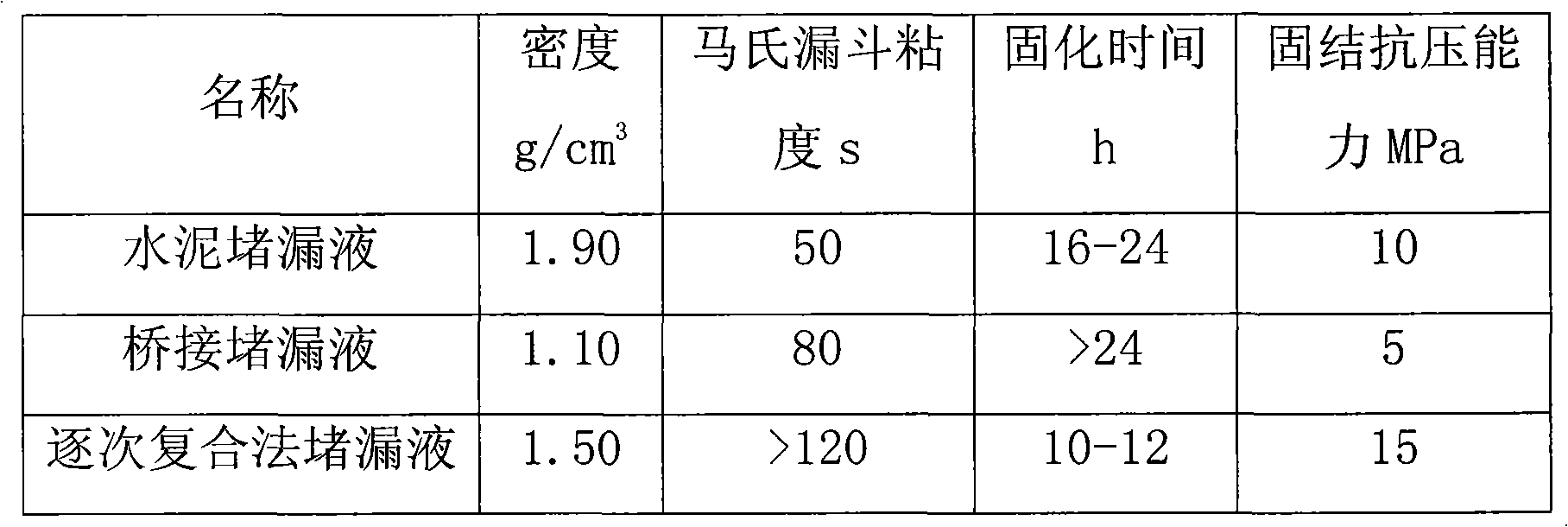

Successive-compounding-process based plugging method for well drilling

InactiveCN102434124AImprove pressure bearing capacitySolve the problem of low plugging success rateDrilling compositionSealing/packingWell drillingPorous medium

The invention discloses a successive-compounding-process based plugging method for well drilling. In the plugging method, a well-cementing cement pump or a mud pump is used for pumping two or more than two kinds of plugging fluids with different components and properties into an underground leakage zone successively in proportion. By means of the plugging method, the applicable range of the plugging fluids can be broadened, the loading capacity of a barefoot interval stratum can also be greatly increased, and the problem of low plugging success rate can be solved. According to the plugging method, a retention layer can be formed in porous media; the purpose of increasing the loading capacity and compressive strength of the stratum can be achieved by compounding the plugging fluids with different components and different properties; in addition, the construction process is simple, the plugging success rate is high, and the well drilling cost is effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

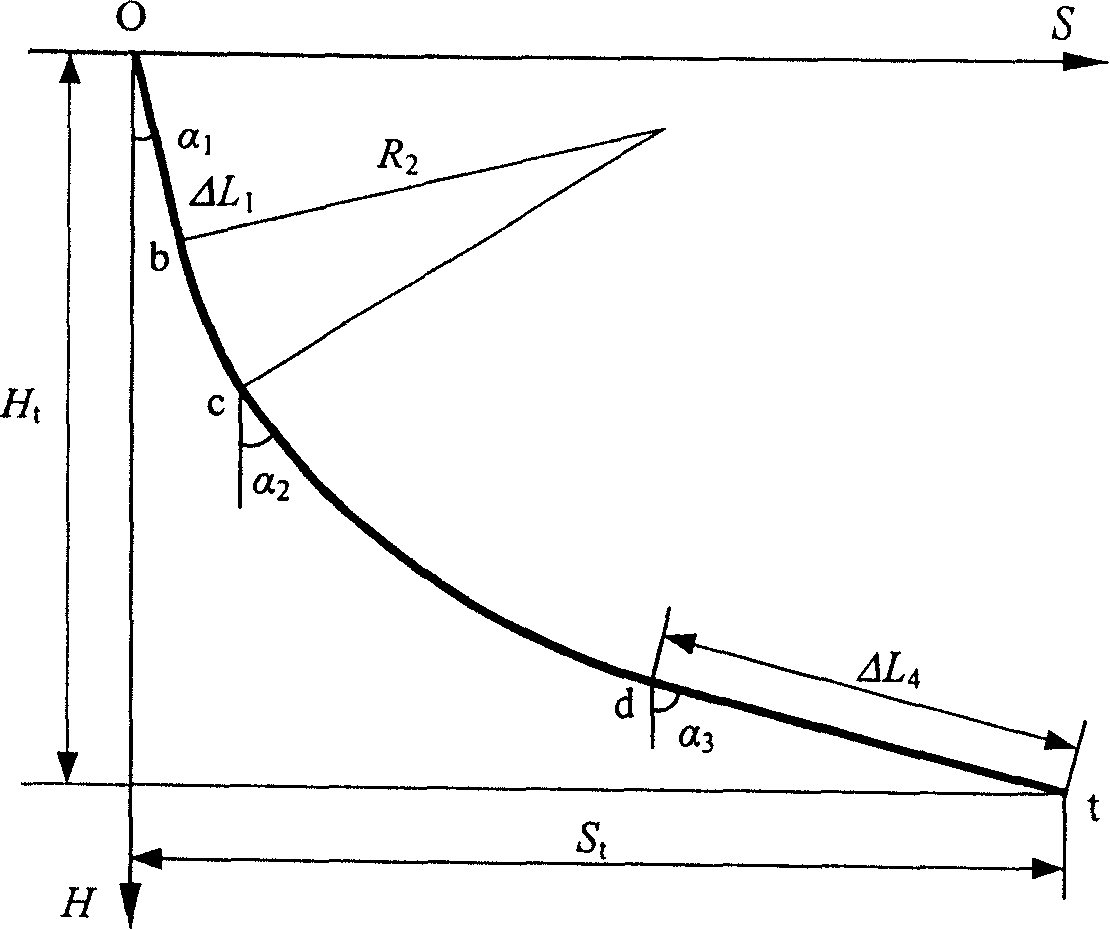

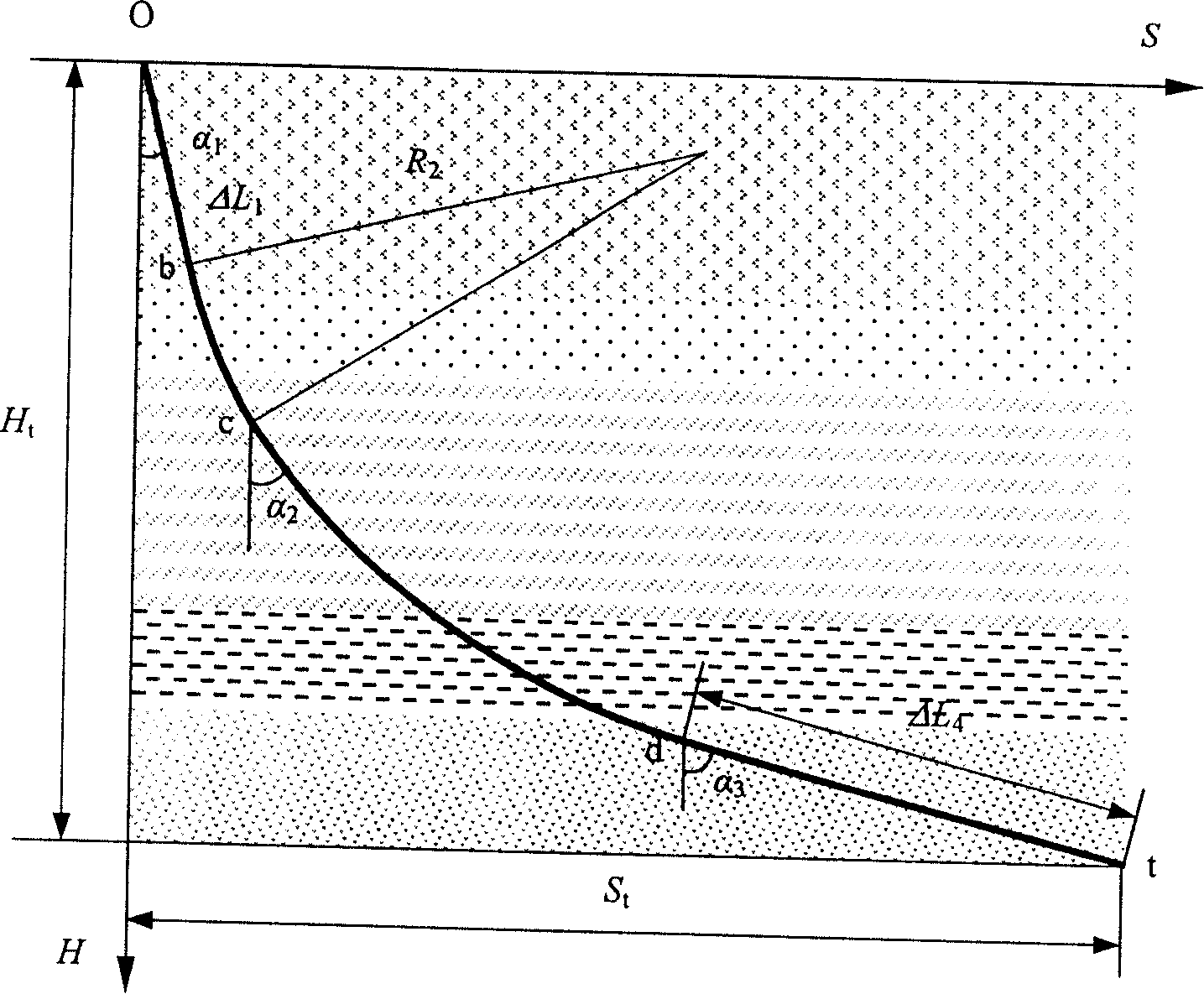

Funicular curve well drilling rail design method using stratum natural deflecting rule

ActiveCN101173598AIn line with formation conditionsRealize the designDirectional drillingSection planeThree stage

The invention relates to a drilling engineering design in the petroleum drilling engineering, in particular to wellbore trajectory optimized design and control in the highly-displacement well. For three-stage and four-stage catenary sections, the design of wellbore trajectory is finished through 12 steps. The invention puts forward a new method of two-dimensional catenary trajectory design. A plurality of units with different azimuth wander ratio is divided according to natural deviating rule of formation, which is combined to the formation condition that conforms to the actual situations of drilling engineering. On the basis of maintaining the characteristics and advantages of catenary trajectory and regarding to the influence of natural deviating rule of formation, a method of three-dimensional catenary trajectory design is put forward, which can not only scientifically work out the azimuth lead angle and initial azimuth, but also work out the trajectory parameters of every point inthe wellbore trajectory. The realization of three-dimensional wander trajectory design of catenary section has real meaning of guidance for the drilling design and construction of the highly-displacement well. The invention is used in the field of petroleum and geological exploration.

Owner:CHINA PETROLEUM & CHEM CORP +1

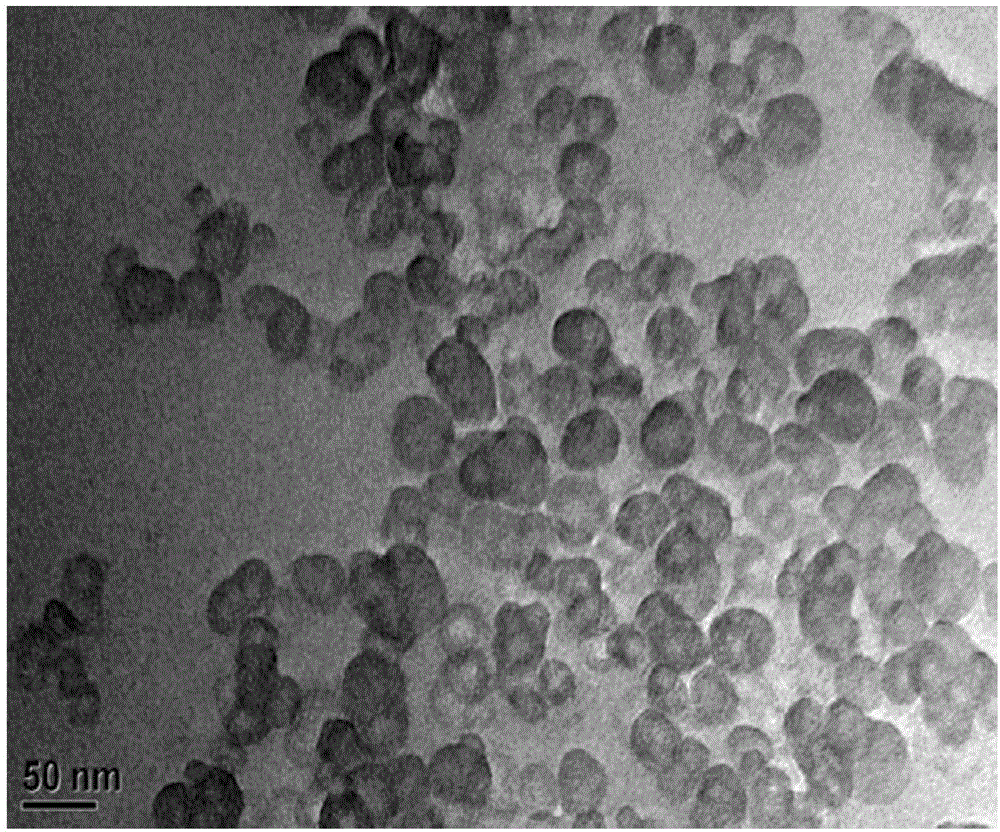

Drilling fluid additive composition application thereof and water-based drilling fluid suitable for high-bearing-pressure plugging while drilling and application thereof

ActiveCN106634878AImprove pressure bearing capacityEnhance smoothness and densityDrilling compositionWell drillingDimer acid

The invention relates to the field of well drilling in petroleum industry, in particular to a drilling fluid additive composition application thereof and a water-based drilling fluid suitable for high-bearing-pressure plugging while drilling and application thereof. The composition contains a plugging agent, a nano blocking agent, a shear strength improving agent, a bionic wall fixing agent and a bionic shale inhibitor, wherein the plugging agent is a weak crosslinking copolymer, the content of a crosslinking structure in the weak crosslinking copolymer is 0.1-1% by weight, the nano blocking agent is modified silicon dioxide nano-particles, the shear strength improving agent is a dimer acid-organic amine copolymer, and the bionic wall fixing agent is carboxymethyl chitosan grafted with groups deviated from dopamine on main chains. The composition can make a water-based drilling fluid added with the composition as an additive produce an excellent plugging effect in the process of plugging while drilling through the matching effect of the plugging agent, the nano blocking agent, the shear strength improving agent, the bionic wall fixing agent and the bionic shale inhibitor.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

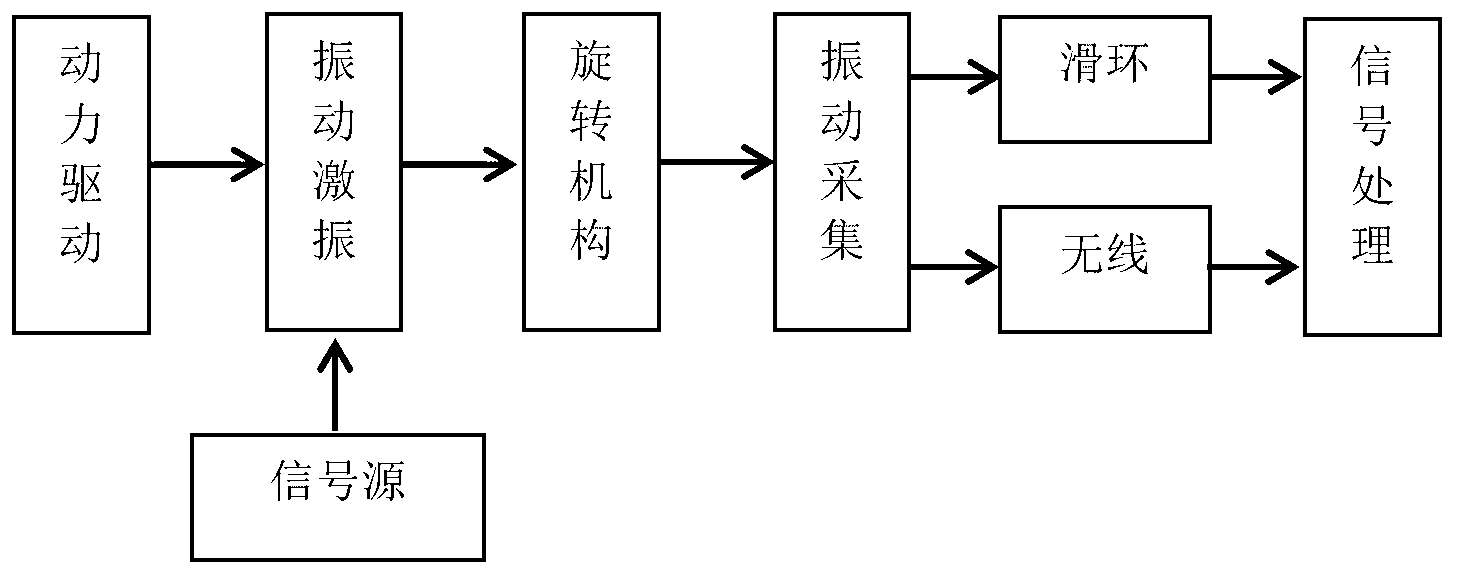

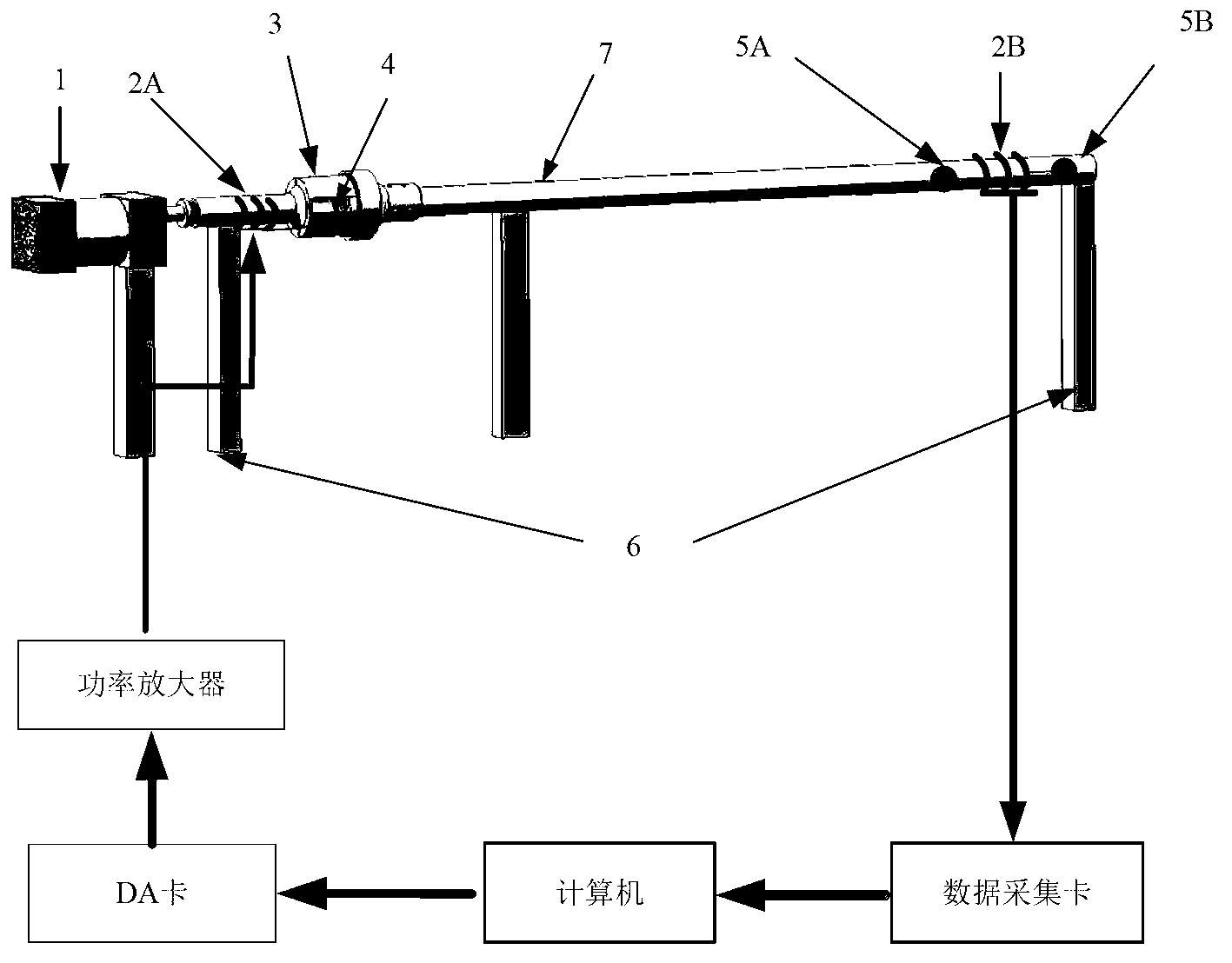

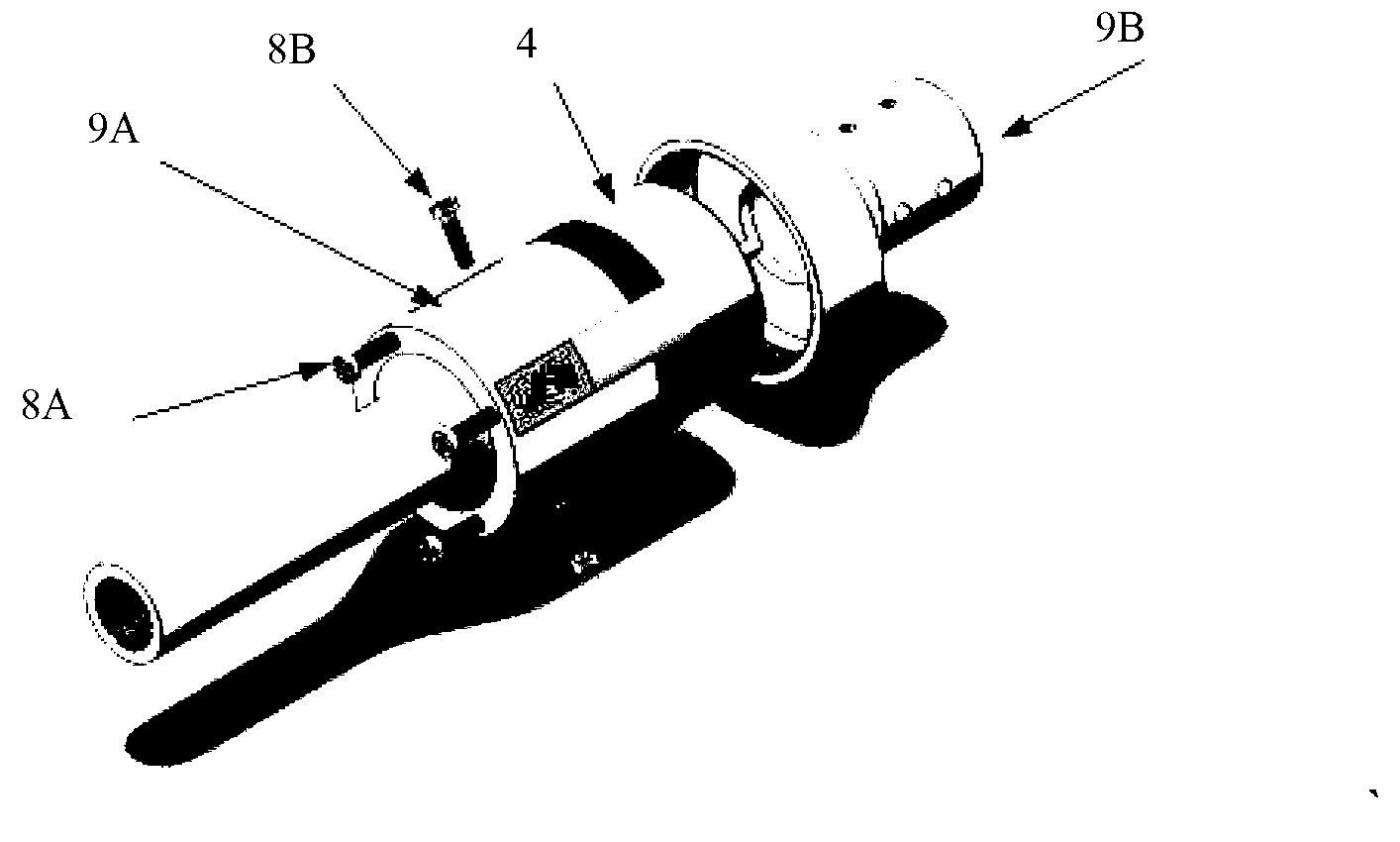

Whirling vibration excitation and dynamic measurement device

InactiveCN103323195AEasy to detectEasy transferVibration testingMeasurement deviceVibration acceleration

The invention relates to a whirling vibration excitation and dynamic measurement device mainly comprising a signal source part, a vibration signal excitation part, a vibration signal dynamic collection and transmission part, and a power drive part of a whirling mechanism. For realizing vibration excitation and signal detection of the whirling mechanism (such as a round rod and a pipe), vibration excitation with different waveforms and excitation intensities is exerted on the whirling mechanism at different rotation speeds by utilizing matching connection and coaxial rotation of a vibration exciter and the whirling mechanism, and a wired or wireless transmission mode is adopted to realize signal collection and transmission of a multichannel vibration acceleration signal to be convenient for subsequent signal analyzing and processing. The whirling vibration excitation and dynamic measurement device can work under the condition that the whirling mechanism stalls or rotates to be convenient for being in connection with a signal generator or a signal generating device designed by a user to realize the vibration excitation and detection of a complex signal, can be used for theoretical characteristics and experimental study of mechanical vibration signal measurement, vibration characteristic analysis, low-frequency acoustic data transmission and the like and is simple in structure and convenient to operate.

Owner:BEIHANG UNIV

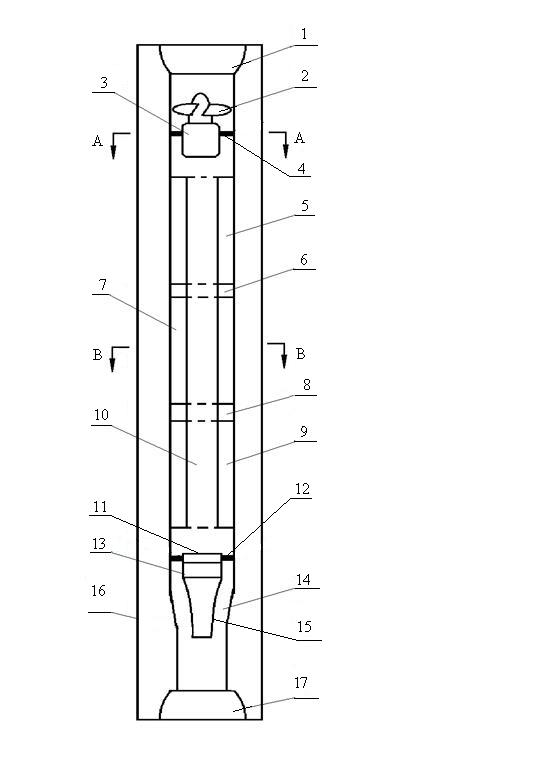

High-frequency pulsed jet flow resonance well drilling device and well drilling method thereof

InactiveCN102493768AIncrease compactionBuried deepLiquid/gas jet drillingMachines/enginesSteel jacketUltrasonic sensor

The invention relates to a high-frequency pulsed jet flow resonance well drilling device and a well drilling method thereof. The high-frequency pulsed jet flow resonance well drilling device comprises an outer steel jacket, wherein one end of the outer steel jacket is connected with an upper adapter; the other end of the outer steel jacket is connected with a lower adapter; the upper adapter is connected with a drill collar by a thread; the lower adapter is connected with a drill by the thread; a small hydrogenerator, a density logger, an acoustic logger, a controller and an ultrasonic transducer are successively installed from top to bottom in the outer steel jacket; the small hydrogenerator is composed of a blade and a generator; the blade is installed above the generator; the ultrasonic transducer comprises a fixed end, a transducer and an amplitude transformer; the position on the outer steel jacket, which corresponds to the amplitude transformer, is provided with a necking section; the density logger, the acoustic logger and the controller are mutually separated by cushion blocks; and after the density logger, the acoustic logger and the controller are connected, the inner cavities of the density logger, the acoustic logger and the controller are communicated to form a well drilling fluid path. According to the high-frequency pulsed jet flow resonance well drilling device, the mechanical drilling speed is drastically improved, the improvement amplitude is 1-2 times, and the well drilling cost is effectively lowered.

Owner:NORTHEAST GASOLINEEUM UNIV

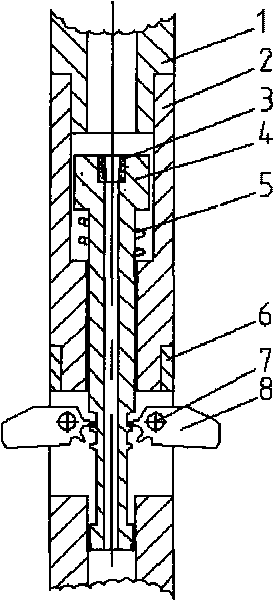

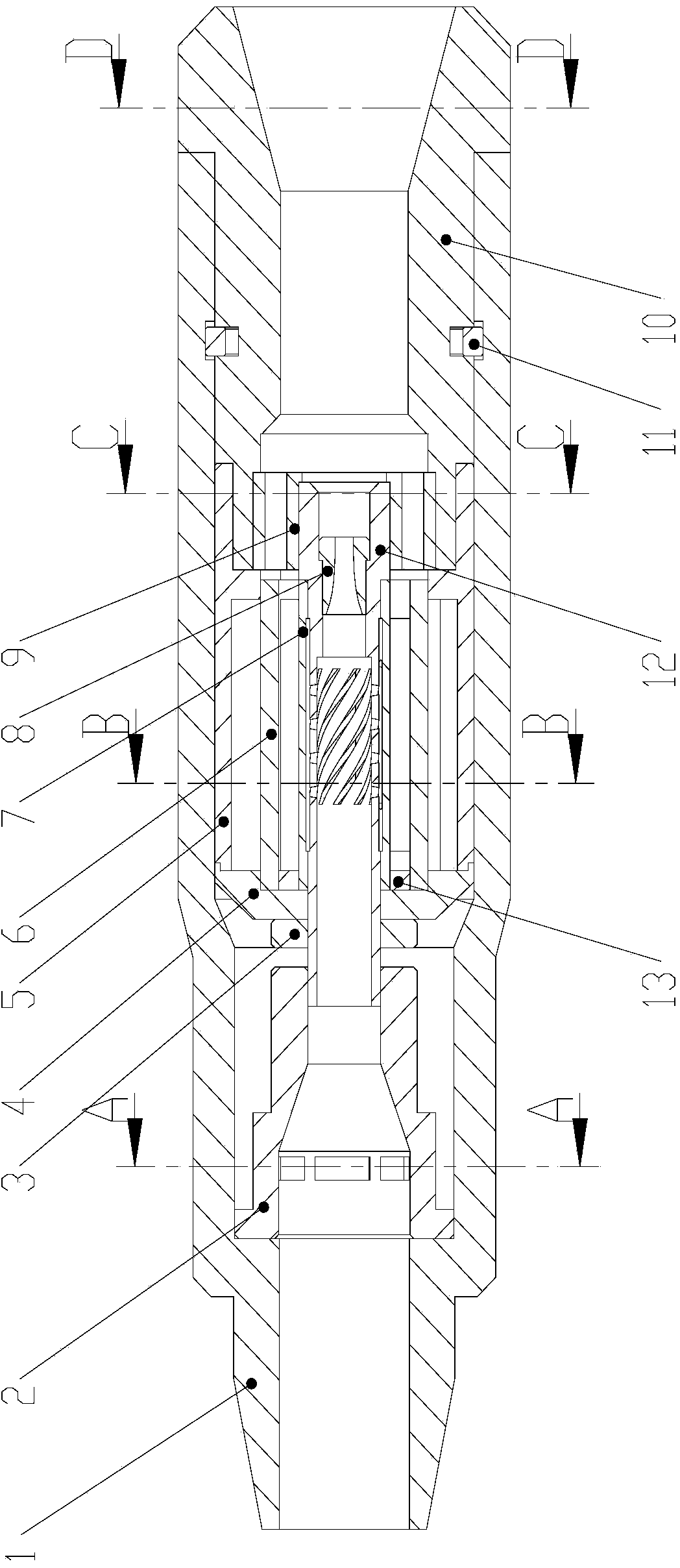

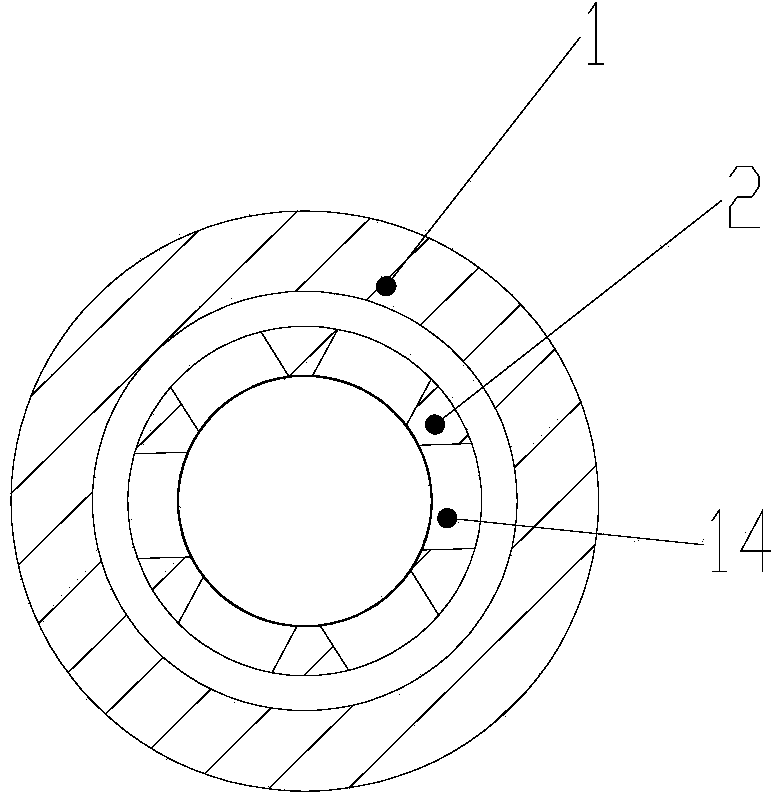

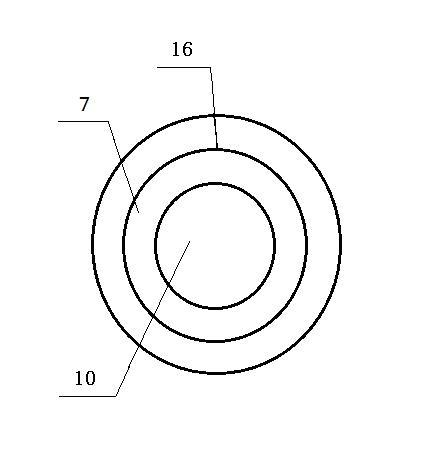

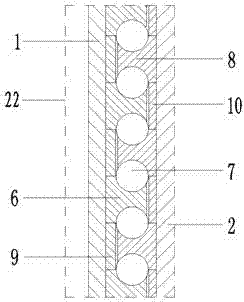

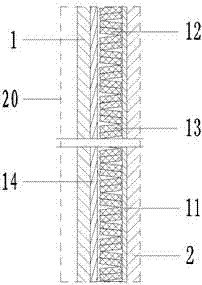

A driving shaft assembly of a screw drilling tool with a vibration damping function

ActiveCN102268961ASimple structureShorten the lengthRotating vibration suppressionDrilling rodsDrive shaftScrew thread

The invention discloses a screw drill transmission shaft assembly which is used in oil and gas drilling and can reduce the drill vibration, prolong the service life of the drill and improve the mechanical drilling rate. The screw drill transmission shaft assembly consists of a shell, an upper transmission shaft, an upper radial bearing static sleeve, an upper radial bearing dynamic sleeve, a loadbearing group, a vibration reducing device, a lower transmission shaft, a lower short section, a central spindle and the like. The technical scheme is that: the upper transmission shaft is mounted inthe shell; the upper radial bearing static sleeve and the upper radial bearing dynamic sleeve are cooperatively mounted in an annular space formed by the shell and the upper transmission shaft; the load bearing group is mounted at the lower ends of the upper radial bearing static sleeve and the upper radial bearing dynamic sleeve; the vibration reducing device is mounted at the lower end of the load bearing group; when in work, a spline slot of the upper transmission shaft is matched with a spline of the lower transmission shaft; the lower short section is in threaded connection with the shell; and the central spindle is in threaded connection with the upper transmission shaft. The screw drill transmission shaft assembly disclosed by the invention does not increase the length of the lowerdrill, brings relatively little influence on the bottom drill combination, and can be applied to the angle building operation and curved borehole.

Owner:SOUTHWEST PETROLEUM UNIV

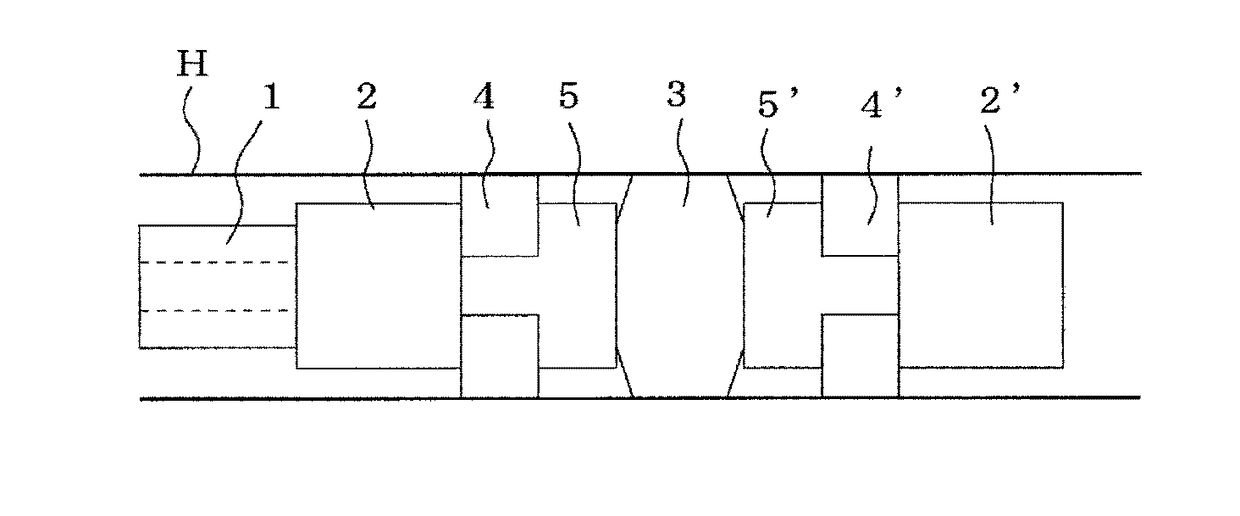

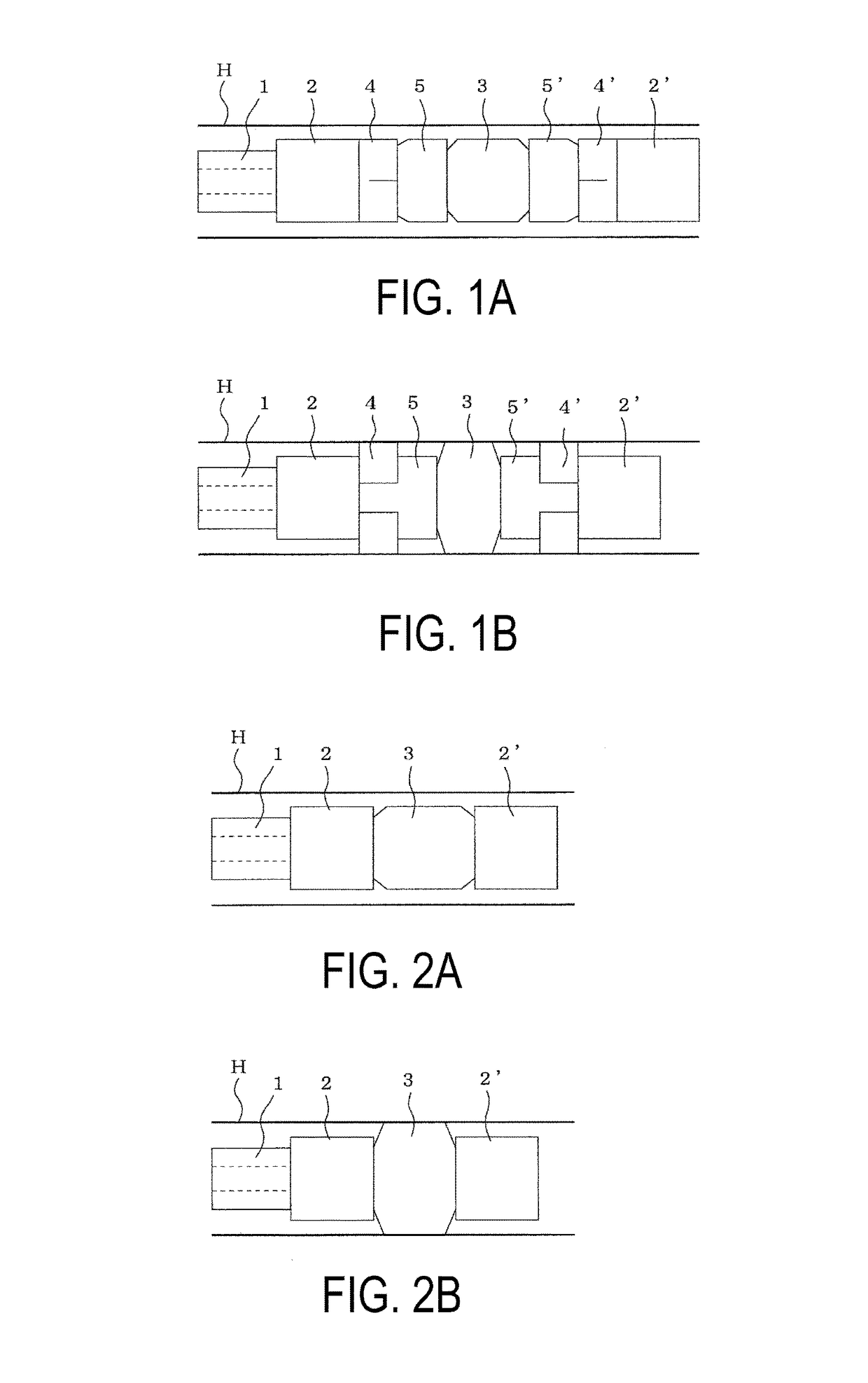

Plug for well drilling process provided with mandrel formed from degradable material

A plug for well drilling process comprising: (a) a mandrel formed from a degradable material; (b) a pair of rings placed on an outer peripheral surface existing in the orthogonal to an axial direction of the mandrel, at least one of the rings being formed from a degradable material; and (c) at least one diameter-expandable circular rubber member placed at a position between the pair of rings on the outer peripheral surface existing in the orthogonal to the axial direction of the mandrel; the percentage of mass loss in the degradable material after immersion for 72 hours in water at a temperature of 150° C. preferably being from 5 to 100%; and a well drilling method comprising the step of plugging well hole using the plug for well drilling process, wherein part or all of the plug for well drilling process degrades after the plugging.

Owner:KUREHA KAGAKU KOGYO KK

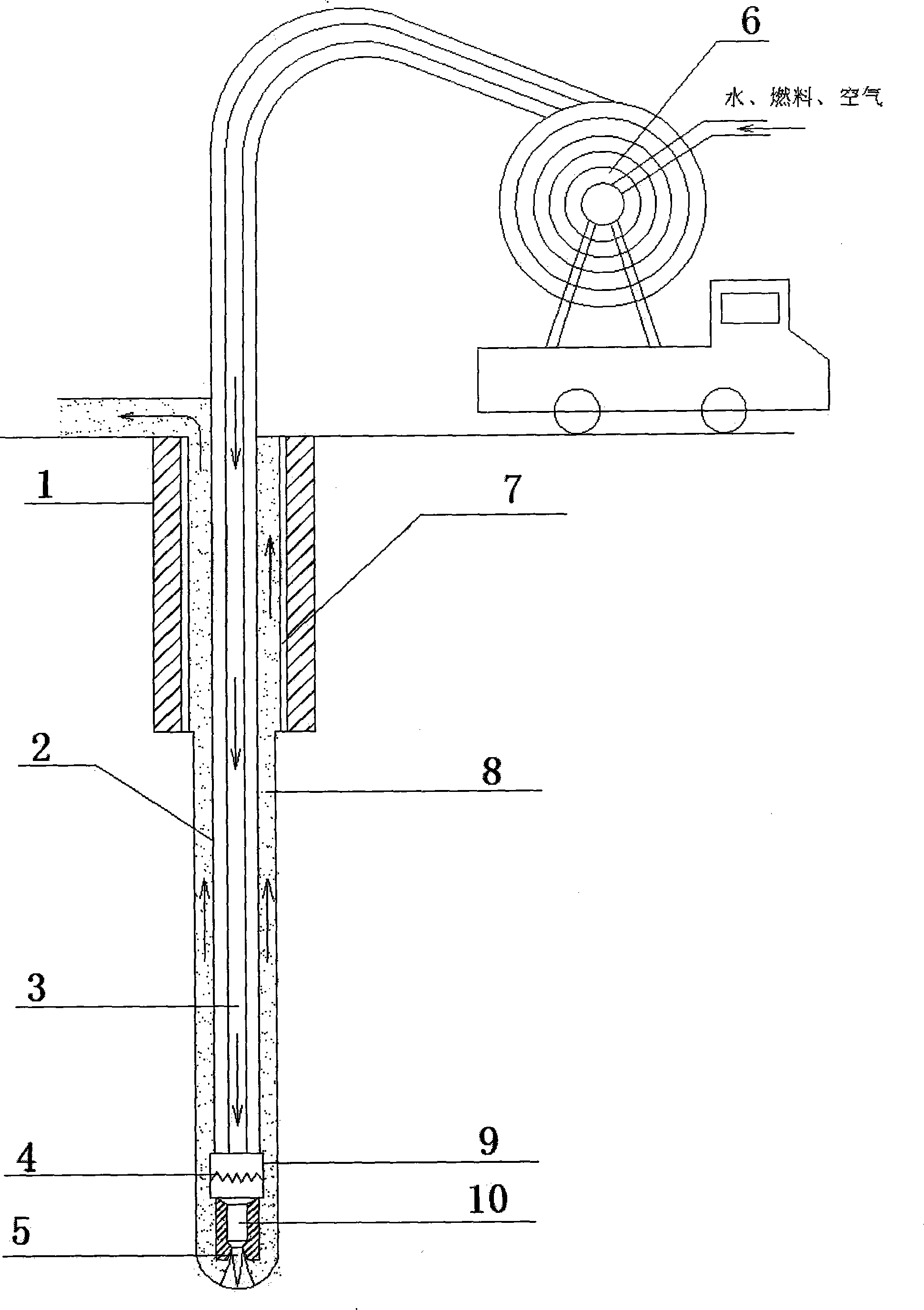

New well drilling method for efficient rock breaking by means of heating power jet flow

ActiveCN103790516AEfficient rock breakingIncrease profitLiquid/gas jet drillingElectric cablesHeating power

The invention relates to a new welling drilling method for efficient rock breaking by means of heating power jet flow, and a complete set of construction scheme. According to the system composition, a continuous coil tubing unit, an electric measuring instrument truck, a cable, an air injection pipeline, a fuel injection pipeline, a fuel reaction cavity, a heating power jet flow nozzle, a ground pump set and the like are included. According to the technology, on the basis of the principle that the continuous heated surfaces of rocks crack until the rocks are decomposed in a splitting mode, the heating power jet flow acts on the rocks on the deep well hard formation, the non-contact efficient rock breaking is achieved under heat transfer and impact force of high-temperature and high-pressure fluid media, and the energy utilization rate of the well bottom is improved; the technological process is simple, the continuous oil tube well drilling technology is combined, a drill bit does not need to be replaced, the time of the tripping operation is shortened, abrasion to a tubular column is reduced, and the cost of the drilling operation is reduced. According to the new welling drilling method for efficient rock breaking by means of heating power jet flow, the heating power jet flow technology is creatively guided into the continuous oil tube well drilling, popularization and application of the continuous tube technology are facilitated, and oil and gas resources are efficiently exploited.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com