Patents

Literature

338results about How to "Improve hole quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

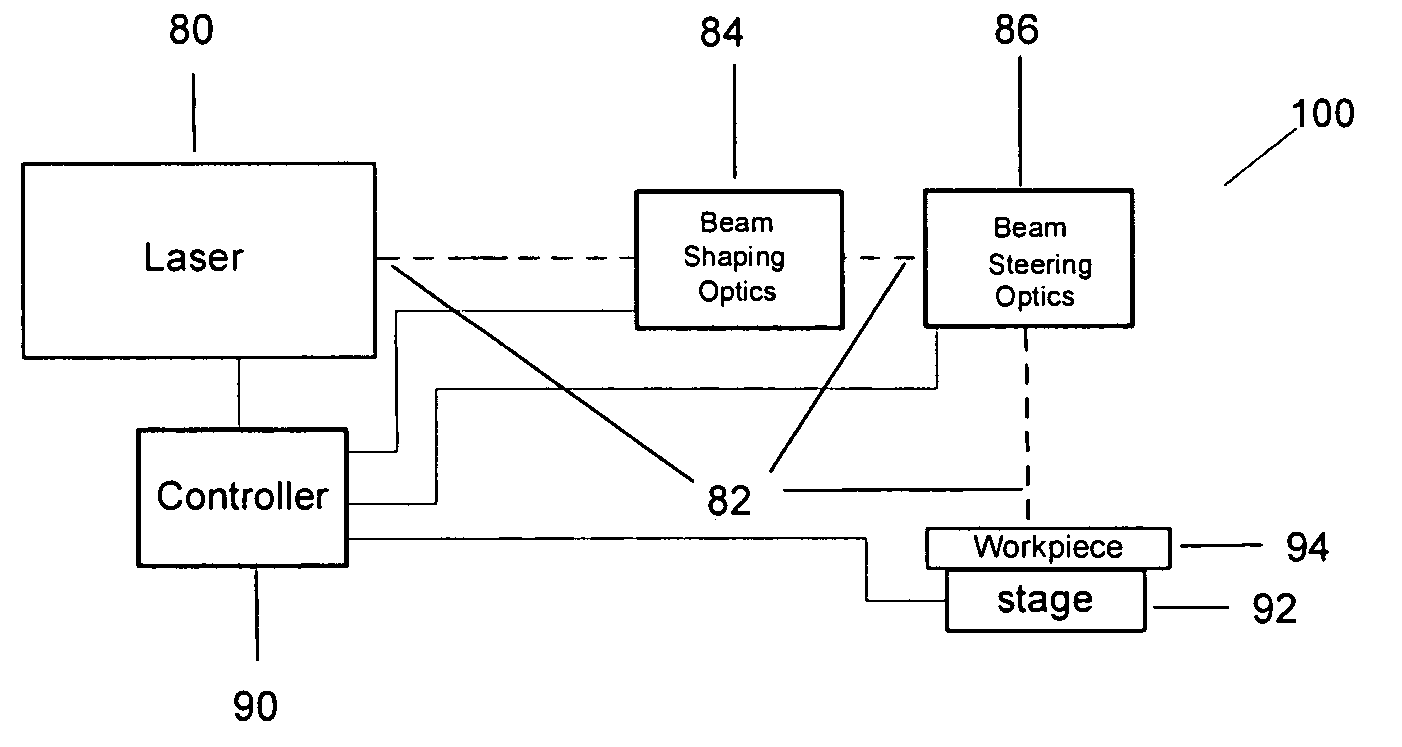

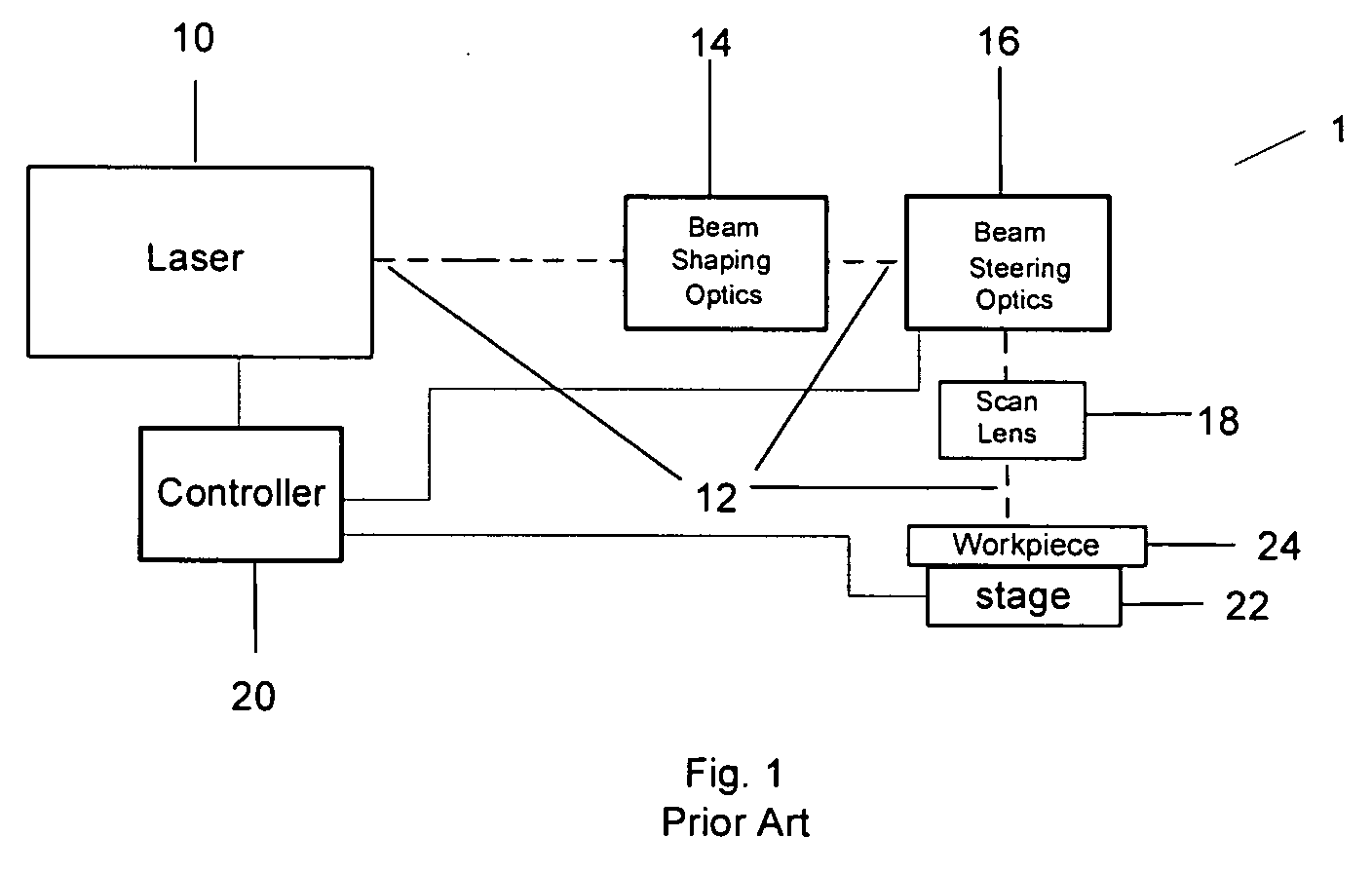

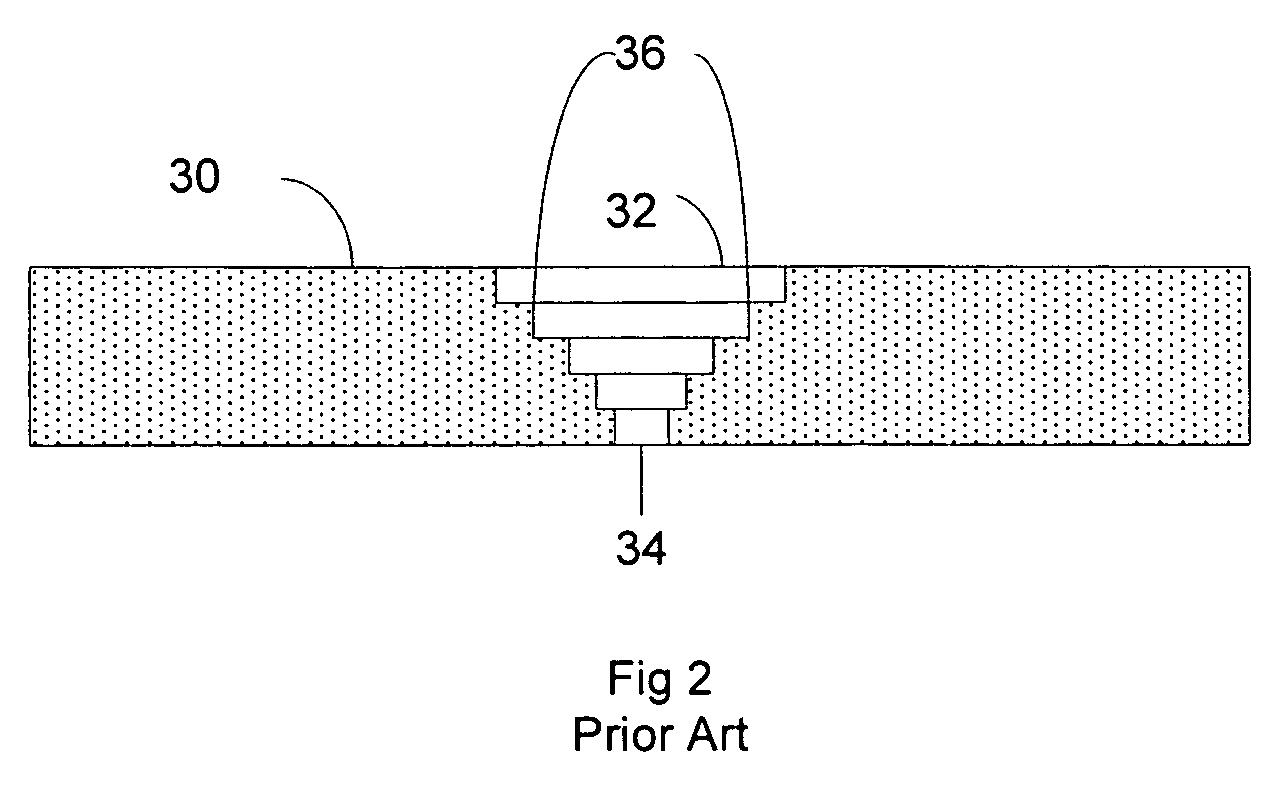

Method and apparatus for laser drilling holes with gaussian pulses

ActiveUS20090242528A1Increase path lengthDifficult to maintainWelding/soldering/cutting articlesLaser beam welding apparatusSurface finishOptoelectronics

An improved method and apparatus for drilling tapered holes in workpieces with laser pulses is presented which uses defocused laser pulses to machine the holes with specified taper and surface finish while maintaining specified exit diameters and improved system throughput. A system is described which can also drill holes with the desired taper and surface finish without requiring defocused laser pulses.

Owner:ELECTRO SCI IND INC

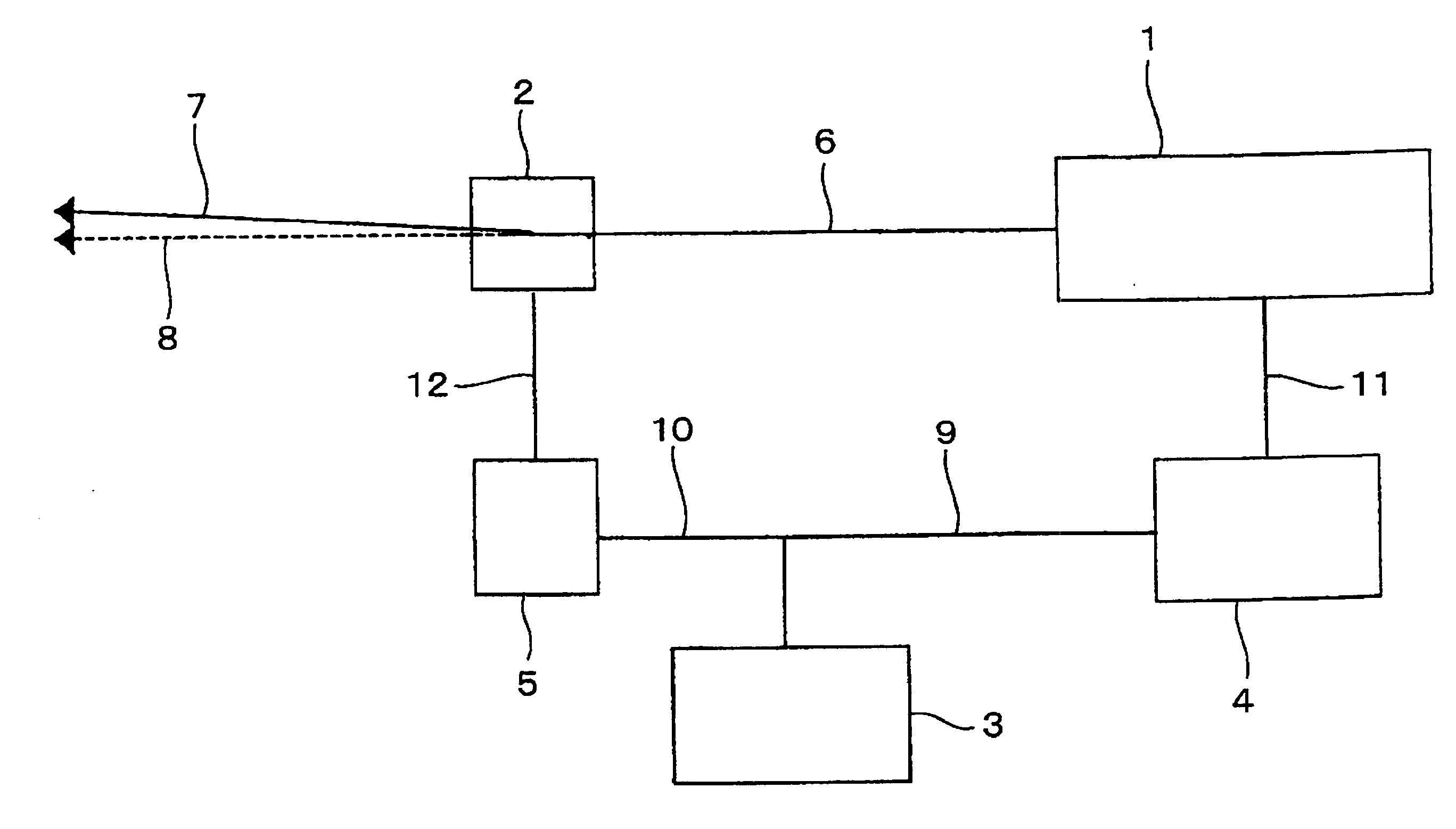

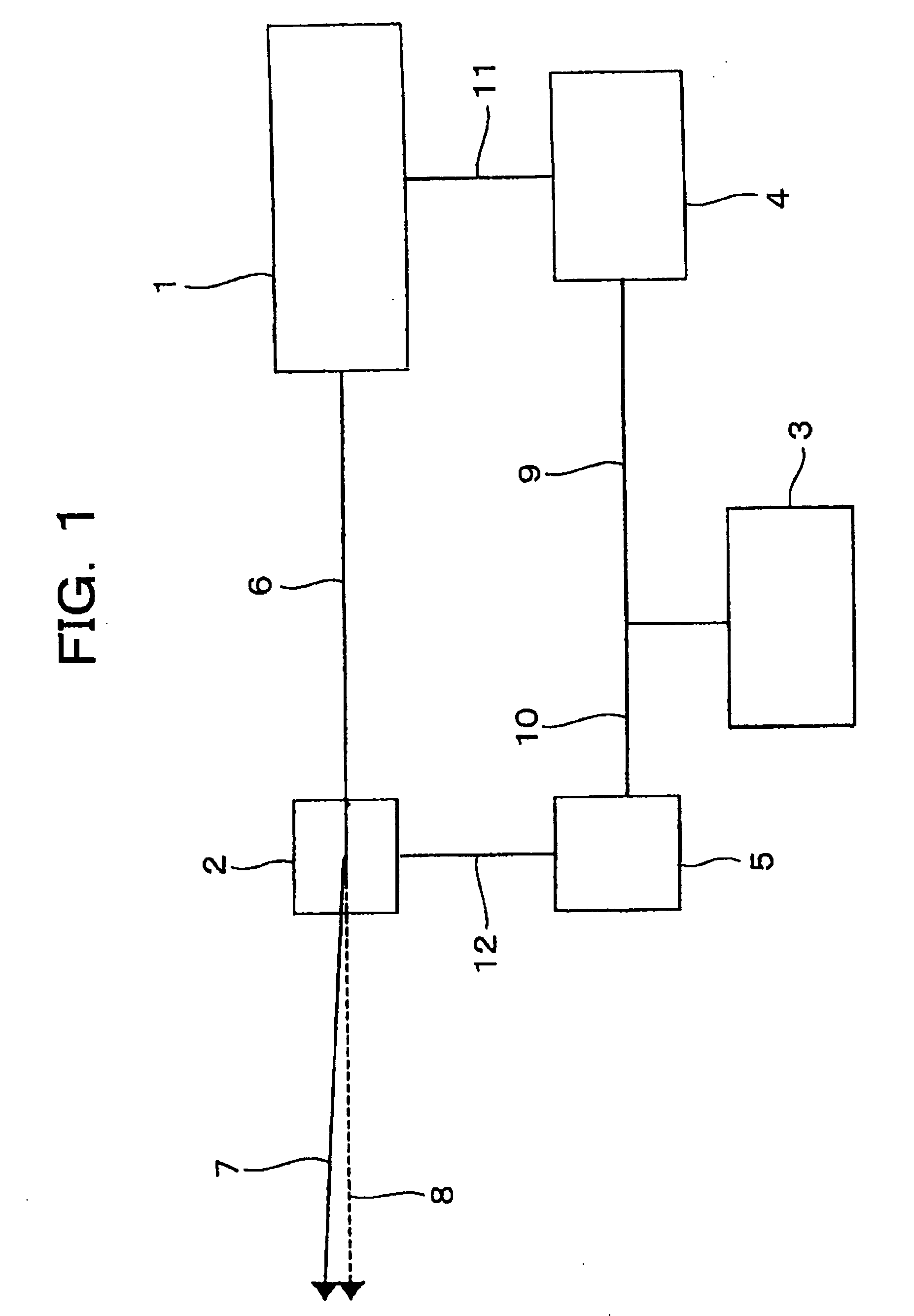

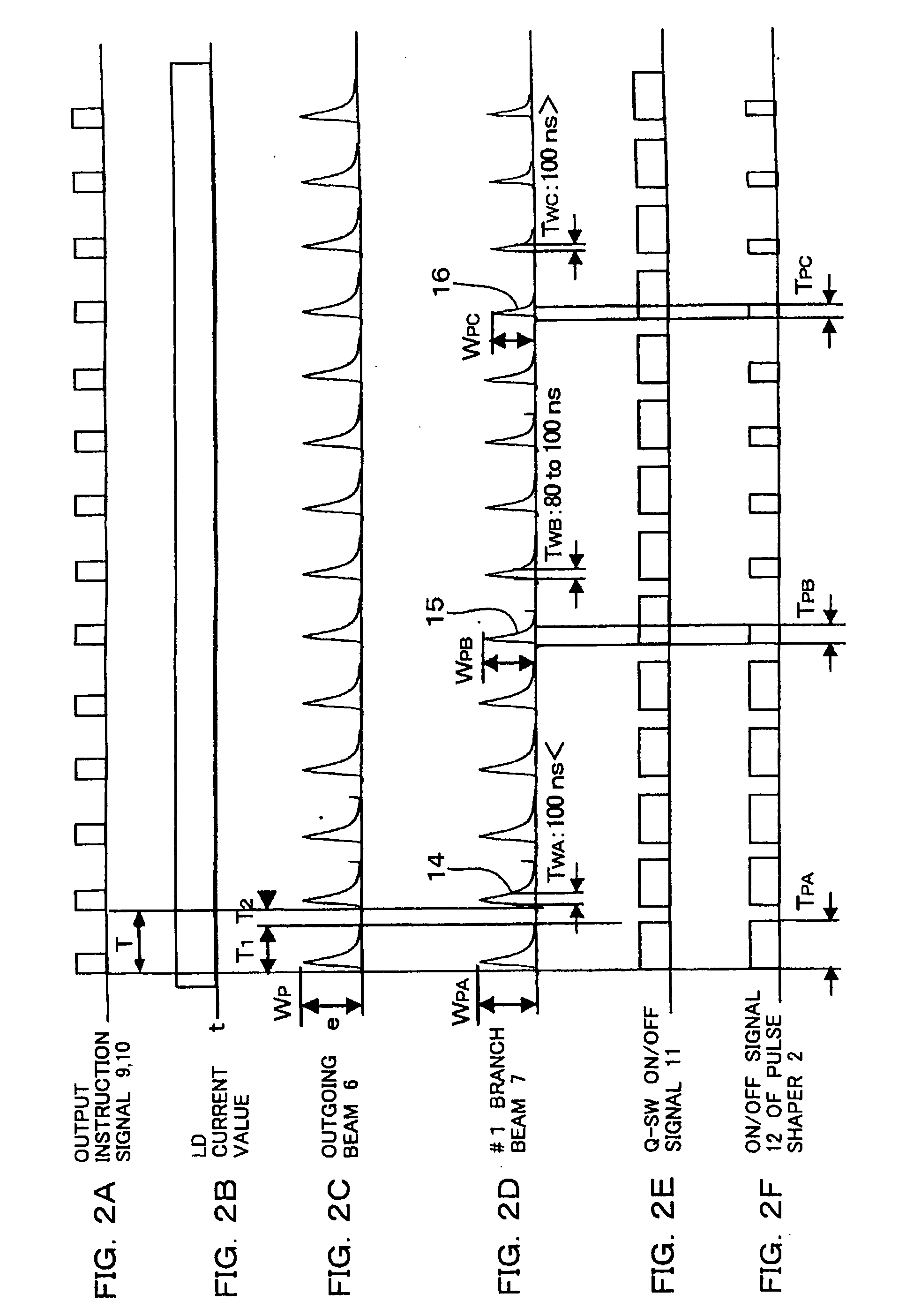

Laser machining method and laser machining apparatus

InactiveUS20050155958A1Improve hole position accuracyImprove hole qualityPrinted circuit manufactureWelding/soldering/cutting articlesLaser processingMetallic materials

A laser machining method and a laser machining apparatus superior in hole position accuracy and hole quality. An outgoing beam outputted as short pulses is shaped by a pulse shaping unit so as to form a #1 branch beam. The #1 branch beam is supplied to a portion to be machined, so as to machine the portion. In this case, the #1 branch beam may be controlled to synchronize with the outgoing beam. When a piece to be machined is made from a metal material and at least one of an organic material and an inorganic material, the metal material is machined with a laser beam shaped to have a pulse width not shorter than 100 ns, and at least one of the organic material and the inorganic material is machined with a laser beam shaped to have a pulse width shorter than 100 ns.

Owner:HITACHI SEIKO LTD

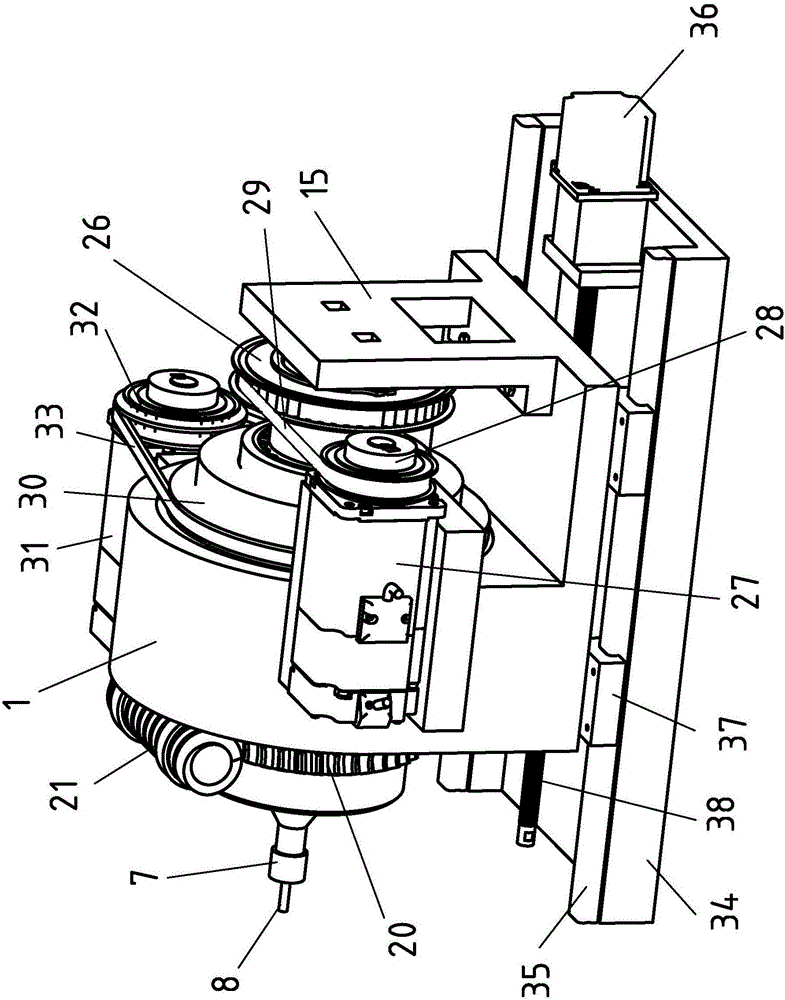

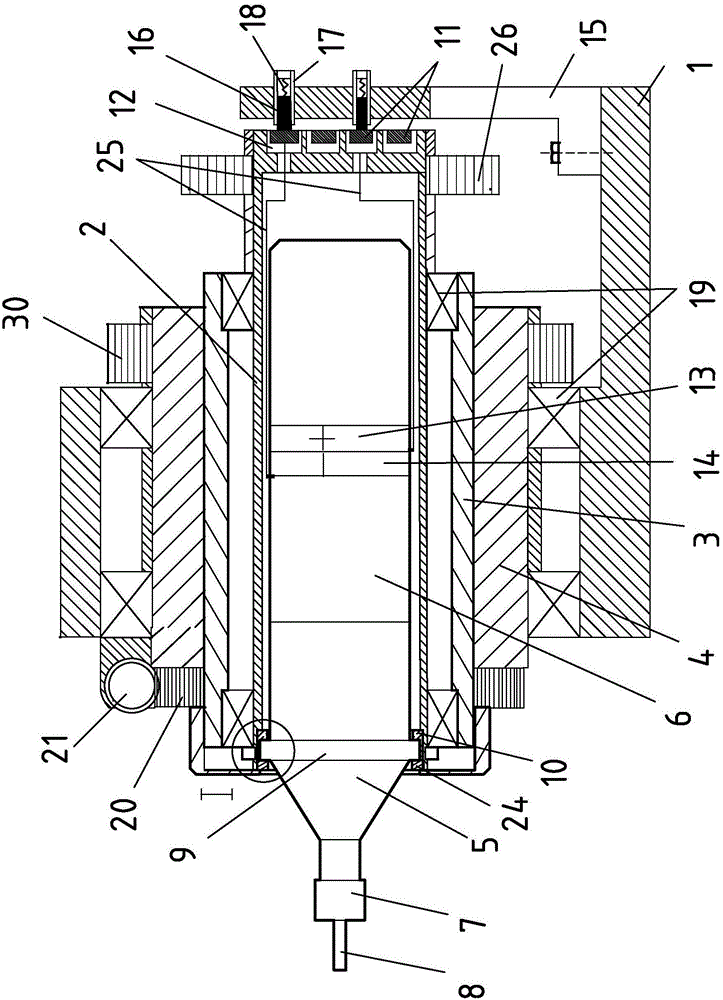

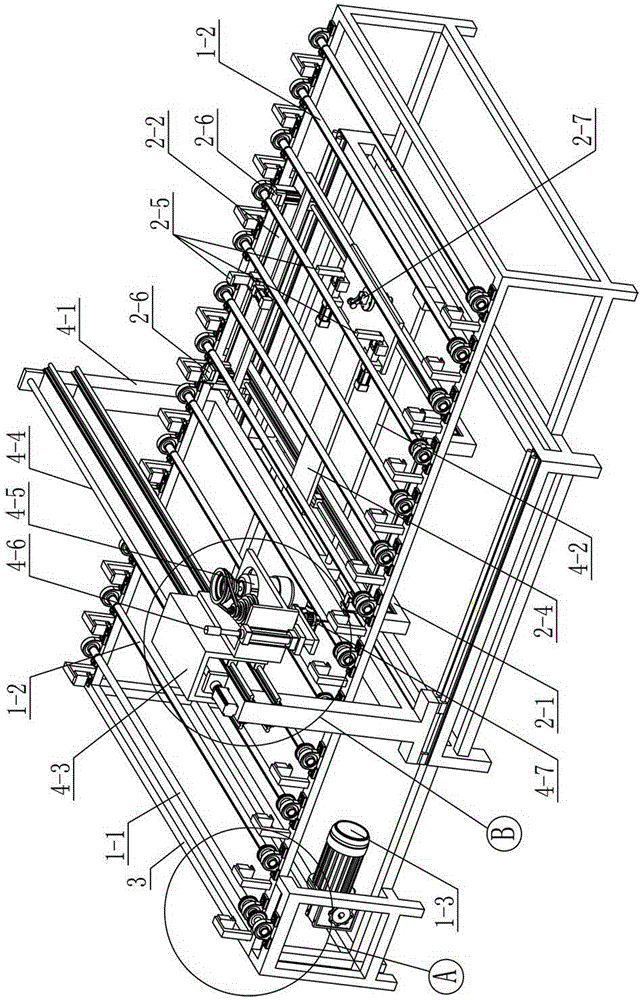

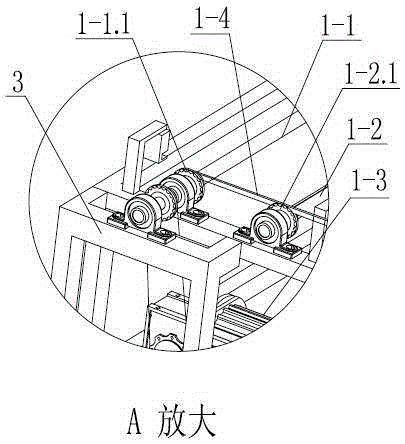

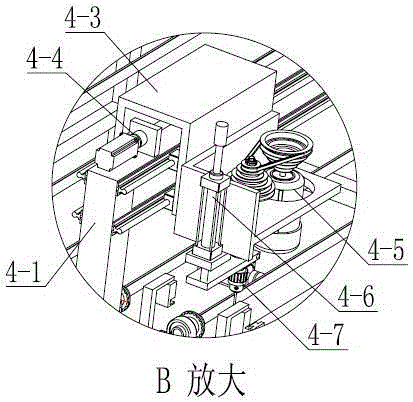

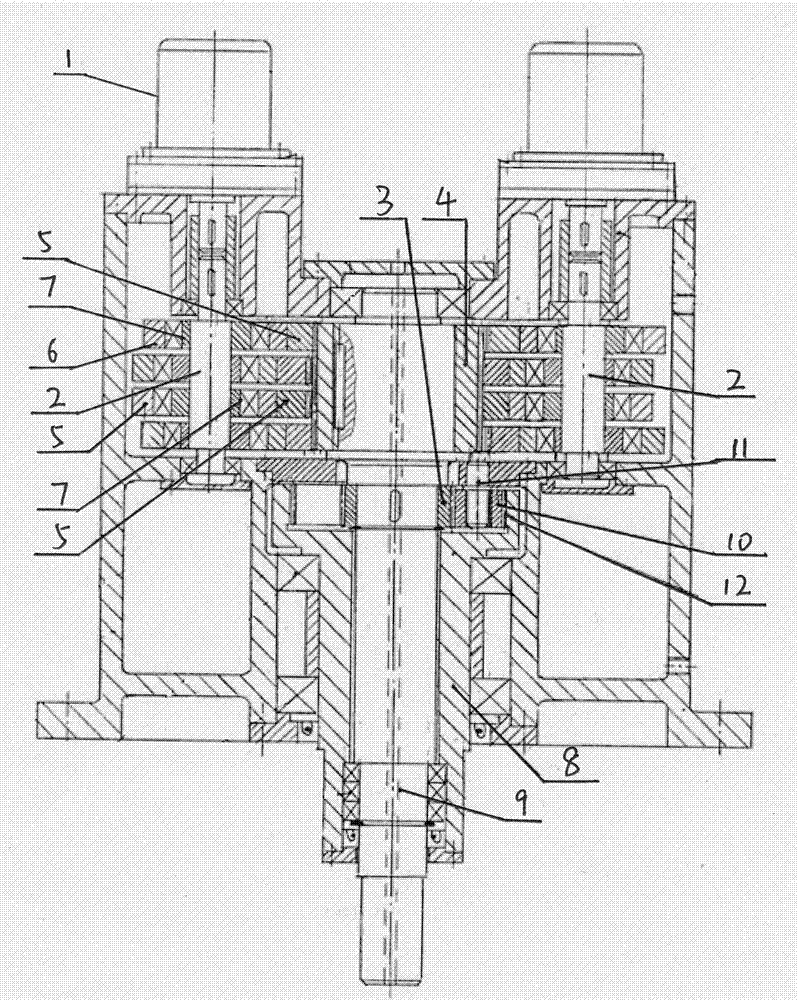

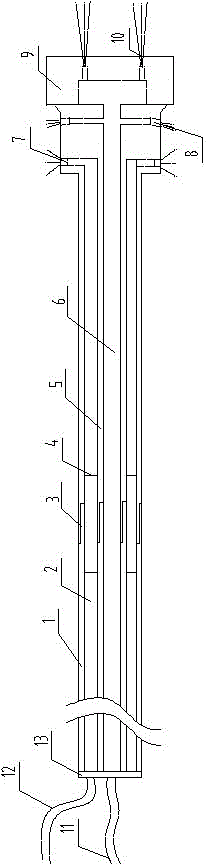

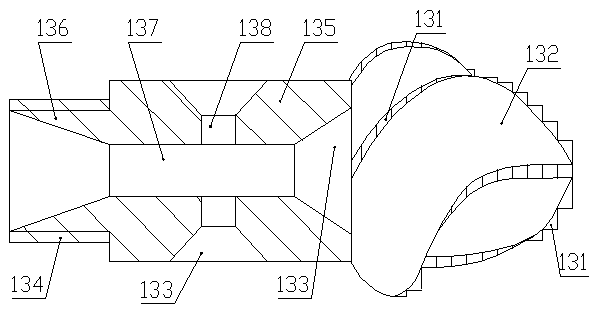

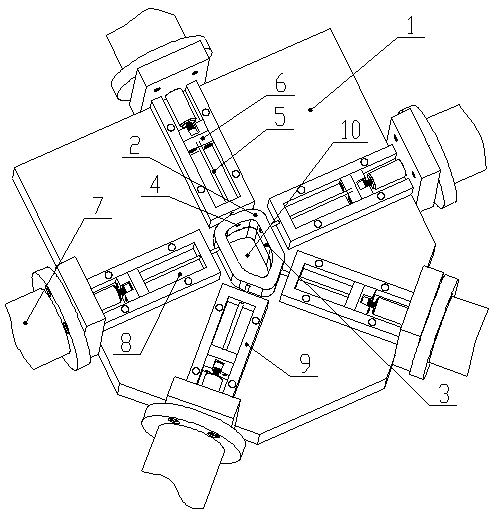

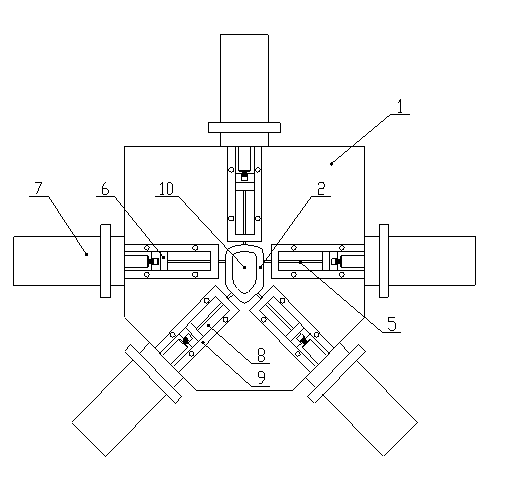

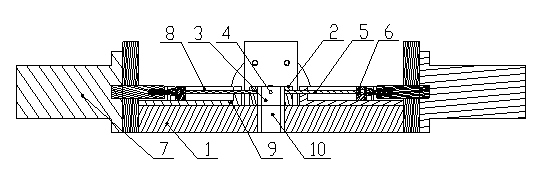

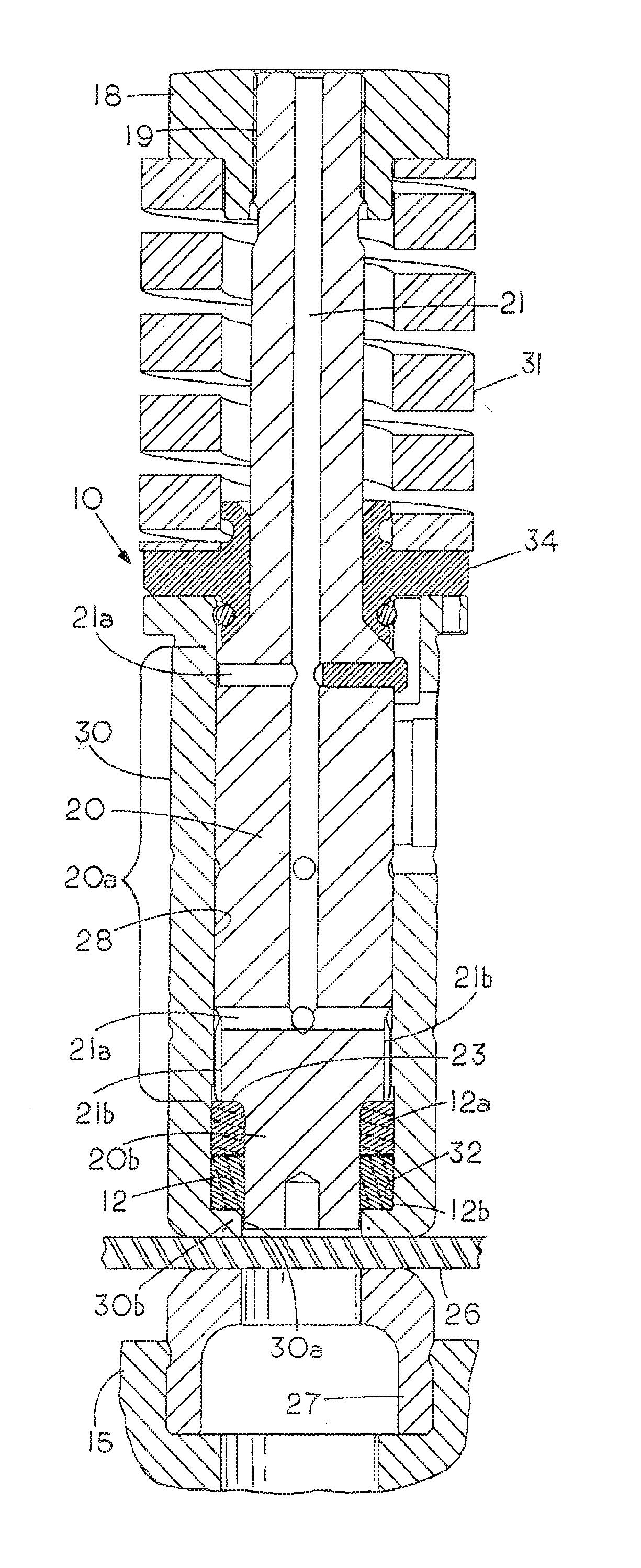

Ultrasonic helical hole milling device and machining method

ActiveCN106077774AImprove hole qualityReduce cutting forceRevolution surface grinding machinesMilling equipment detailsMilling cutterTransducer

The invention discloses an ultrasonic helical hole milling device which comprises a spindle support, an ultrasonic sleeve, an inner eccentric sleeve, an outer eccentric sleeve, an amplitude-change pole and a transducer located in the ultrasonic sleeve. The amplitude-change pole is connected with a hole forming tool through a spring chuck, and the hole forming tool is a milling cutter or a grinding wheel. The amplitude-change pole is connected with the transducer through an annular flange which is connected with the inner wall of the ultrasonic sleeve through an annular force sensor used for measuring axial and radial force borne by the annular flange. The ultrasonic helical hole milling device further comprises a helical hole-milling rotation driving device connected with the ultrasonic sleeve, a helical hole-milling revolution driving device connected with the outer eccentric sleeve and a feeding system for driving the spindle support to conduct feeding along the axis of the amplitude-change pole. The invention further discloses a machining method for conducting ultrasonic helical hole milling through the ultrasonic helical hole milling device. The ultrasonic helical hole milling device and the machining method have the advantages that the hole forming quality is high, hole forming quality consistency is good, and machining stability is good.

Owner:DALIAN UNIV OF TECH

Automatic drilling equipment for sheet metal

ActiveCN105195783ASimple structureImprove efficiencyBoring/drilling machinesAutomatic controlTransmission belt

The invention provides automatic drilling equipment for sheet metal to overcome technical defects of low drilling efficiency, high cost and poor pore-forming quality. According to the scheme, the equipment comprises an automatic control part, a rack part, a sheet metal conveying part formed by a group of passive conveying rollers, conveying motors and transmission belts which are arranged in parallel, a sheet metal positioning clamping part which is formed by a supporting plate with a guide rail, a supporting slide plate, a supporting slide plate positioning screw, a limit slide plate, a positioning clamping mechanism, a sheet metal supporting mechanism and a sheet metal lifting stopper, and an automatic drilling part which is formed by a longitudinal mobile rack, a longitudinal control screw, a transverse mobile rack, a transverse control screw, a drilling motor, a drill bit control cylinder and a drilling power head. The automatic drilling equipment has the beneficial effects of simple structure, full automatic processing process control, high efficiency, low processing cost and high pore-forming quality.

Owner:HUBEI SHUNCHANG DOOR INTELLIGENT TECH CO LTD

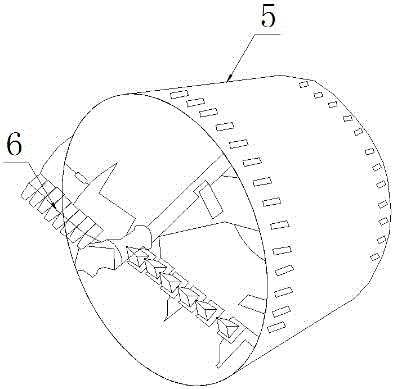

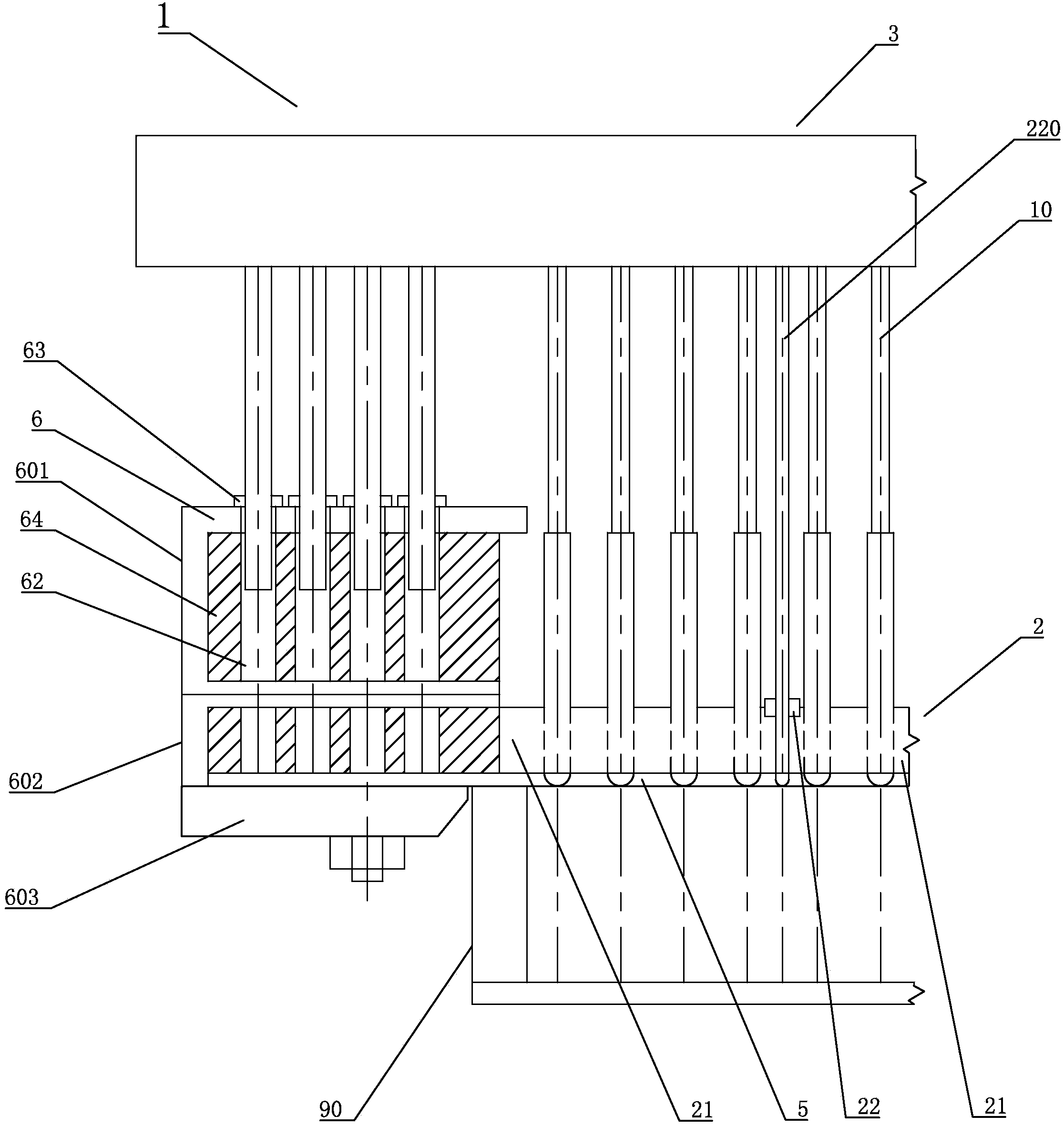

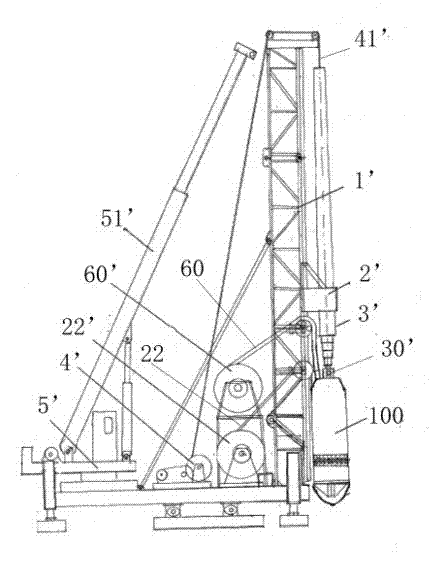

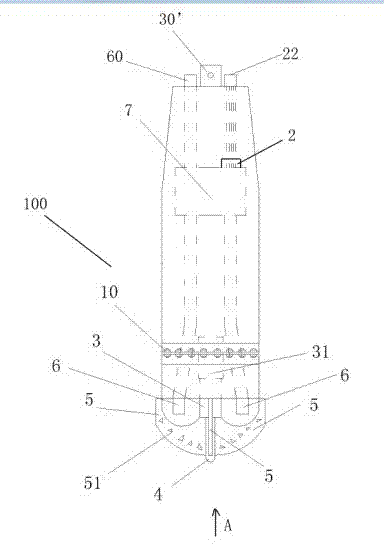

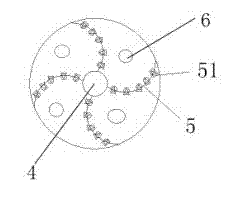

Coaxial double speed reduction forward and inverted bidirectional output spiral rock-entering drilling machine

The invention relates to a coaxial double speed reduction forward and inverted bidirectional output spiral rock-entering drilling machine which comprises double input shafts, four groups of ring plate speed reduction devices, a hollow output shaft, an outer sleeve and a planetary reduction gear. Each ring plate speed reduction device comprises a ring plate, an eccentric bearing and a ring-plate inner gear ring; each ring-plate inner gear ring is arranged in a center round hole of the corresponding ring plate and is meshed with a planet gear connected with the hollow output shaft; each eccentric bearing is arranged in symmetrical round holes at both sides of the corresponding ring plates and is connected in series with the double input shafts; the outer sleeve is coaxially sleeved with the hollow output shaft; the planetary reduction gear comprises a center wheel connected to the hollow output shaft and a uniformly distributed planet gear meshed with the center wheel; the uniformly distributed planet gear is meshed with an inner gear ring of the outer sleeve.

Owner:山东卓力桩机有限公司

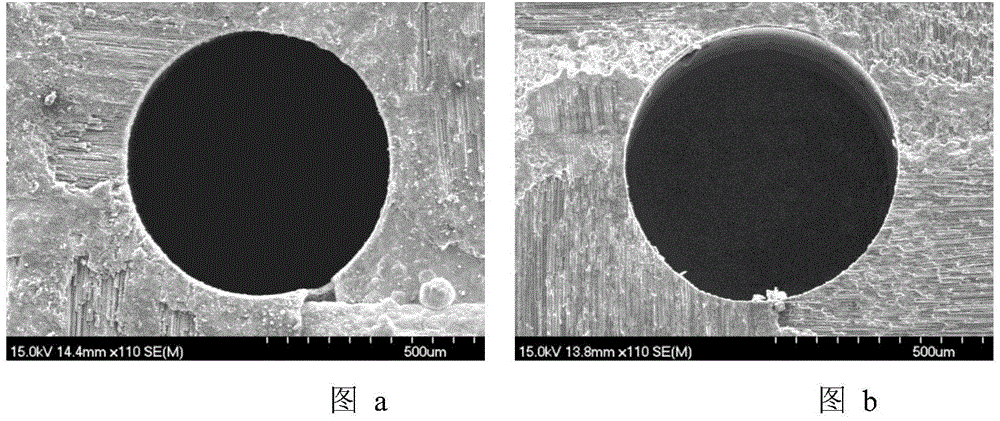

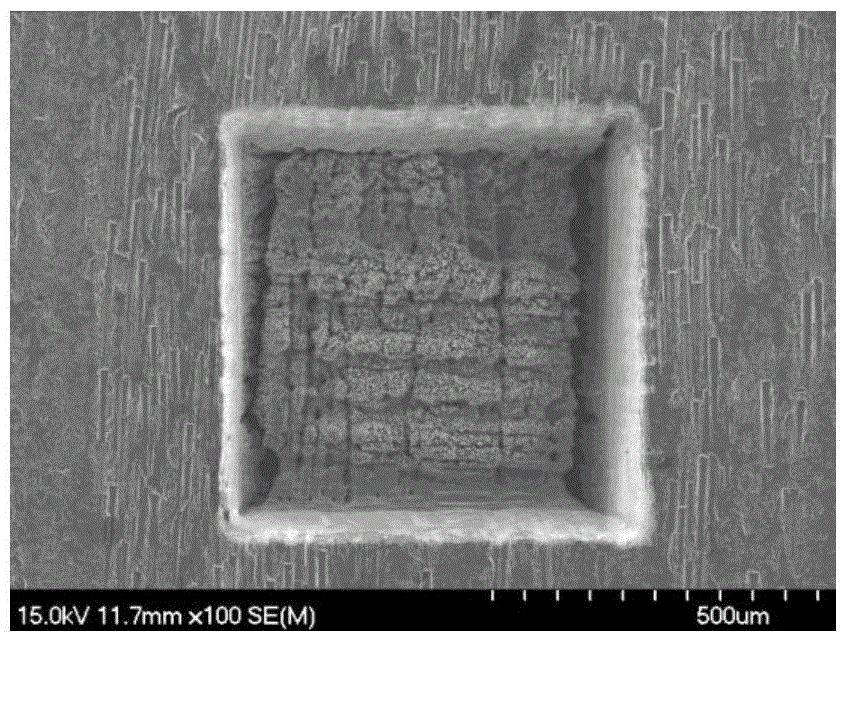

Method for machining micro holes in ceramic matrix composite through femtosecond lasers

ActiveCN104607808AHigh peak powerShort pulse widthWelding/soldering/cutting articlesLaser beam welding apparatusWavelengthLayer removal

The invention relates to a method for machining micro holes in a ceramic matrix composite through femtosecond lasers. According to the method, the silicon carbide ceramic matrix composite sample is placed on a working table and machined layer by layer in a spiral line mode through the femtosecond lasers or machined in a linear scanning mode, wherein the thickness of the sample is smaller than 3 mm; in the micro-machining process, the wave length of femtosecond laser machining ranges from 400 nm-1500 nm, the pulse width ranges from 80 fs to 500 fs, the output power of the lasers is determined according to the requirements of micro-machining and ranges from 20 mW to 20 W, and the repetition frequency of the lasers is determined according to the requirements of micro-machining and ranges from 50 K to 25 MHz; the sample is machined in a layer-by-layer removal mode, wherein the rotation speed of a machining head is 2400 rev / s. In the machining process, the method has the advantages that machining damage is small, and because material around the damage region is still in a cold state after machining, the heat effect is small; machining precision is high, energy of the femtosecond lasers is in Gaussian distribution, absorption and action of the energy in the machining process are limited within the size of which the focus center is quite small, and the machining dimension is expressed from a micro form to a sub-micro form.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

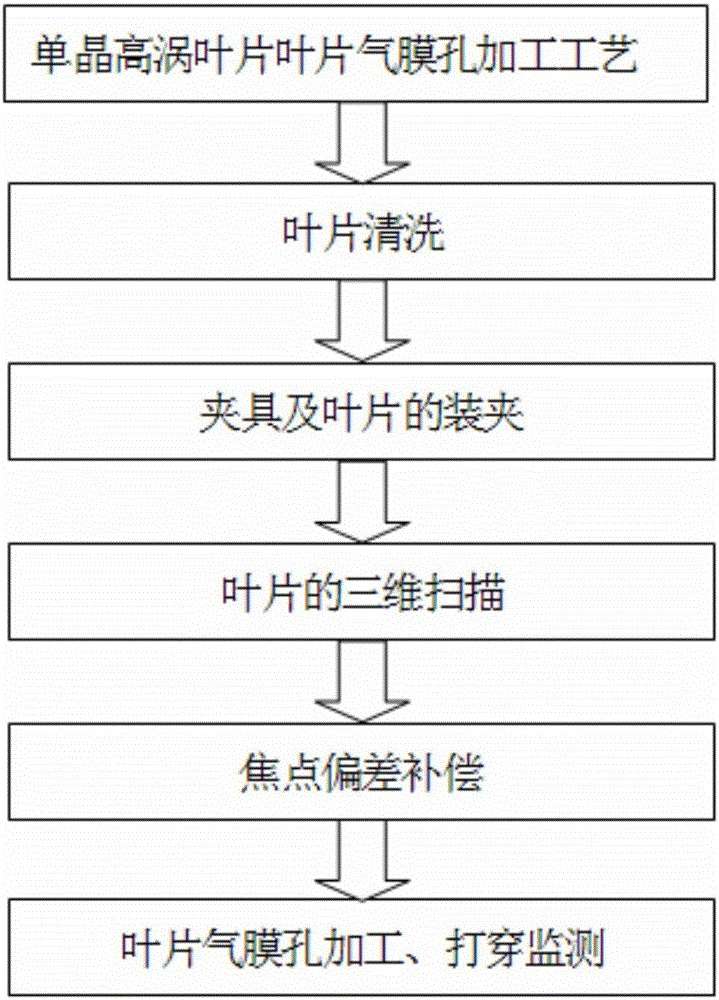

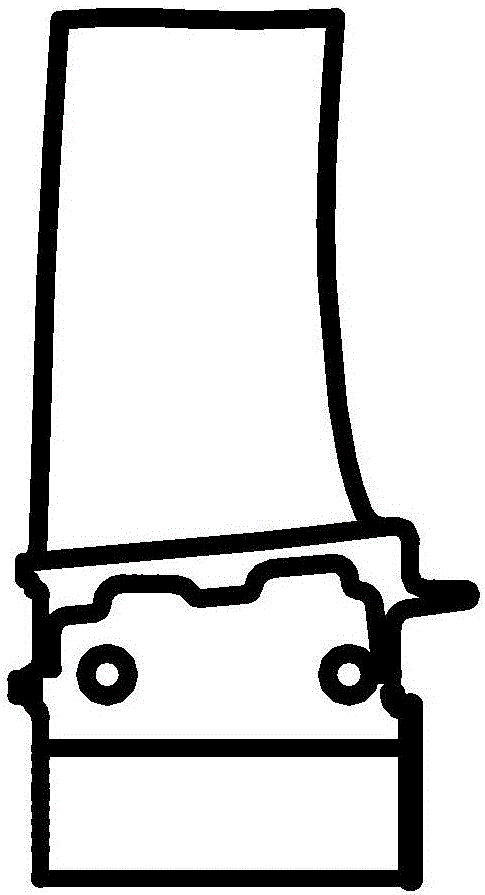

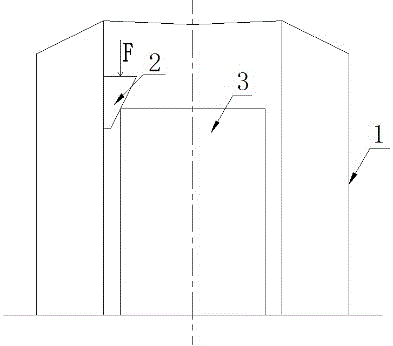

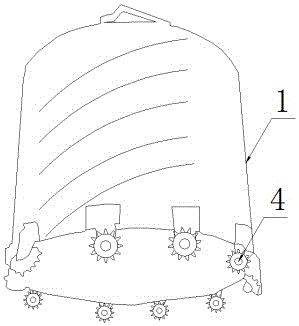

Low-damage processing method of film holes in single crystal high-pressure-turbine hollow blade of aircraft engine

ActiveCN106583949AExtend the life cycleExtended processing cycleLaser beam welding apparatusAviationEngineering

The invention provides a low-damage processing method of film holes in a single crystal high-pressure-turbine hollow blade of an aircraft engine. The low-damage processing method comprises the following steps: wiping the surface of the blade through degreasing cotton with absolute alcohol; transferring into a drying box to dry; arranging a clamp on a machine table, and aligning; assembling the dried blade on the clamp and locking; presetting scanning system parameters; scanning the blade; saving axis moving coordinate value of each hole to be processed under an automatically-generated machine coordinate system as a *.xls file; importing and generating a hole position file; performing compensative correction on the deviation value of a focus position of the hole to be processed; and setting the optimized laser processing technological parameters through a main processing interface. With the adoption of the low-damage processing method, the processed hole is outstanding in quality; a remelting layer, microcacks and recrystallization can be avoided after the single crystal material is processed, so that subsequent processing can be saved, and as a result, the fatigue life and the processing cycle of the blade can be prolonged and improved; the ablation threshold of the single crystal material can be effectively reduced; the recrystallization of the single crystal material can be avoided.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Rotary drilling method for hard rocks

InactiveCN106245626AImprove rock entry efficiencyEfficient in rockDrill bitsCore removalRock coreEconomic benefits

The invention discloses a rotary drilling method for hard rock strata, which comprises the following steps: (1) construction preparation; (2) measuring and placing pile positions; (3) processing and embedding of pile foundation steel casings; (4) rotary drilling rig Centering in place; (5) Mud preparation and circulation; (6) Drill pipe and bit type and selection; (7) Rotary drilling construction: set a wedge-shaped drill bucket on the barrel drill, using the wedge-shaped pressurization principle, wedge-shaped The pressure of the drill bucket produces radial component force on the core, and finally breaks the rock; when drilling, first use the small-diameter pick barrel core bit to loosen the core in the hole, and use the large-diameter double-bottom The rock-socketed rotary drilling bucket sweeps the hole, the pick cylinder drill bit and the double-bottom rock-socketed rotary drilling bucket are used alternately until the designed hole depth is reached; (8) Judgment and inspection of the final hole; (9) Clearing the hole; (10) Hanging the reinforcement cage and pouring underwater concrete. The invention has high rock-entry efficiency, high safety, good hole-forming quality and remarkable economic benefits.

Owner:CCTEB INFRASTRUCTURE CONSTR CO LTD

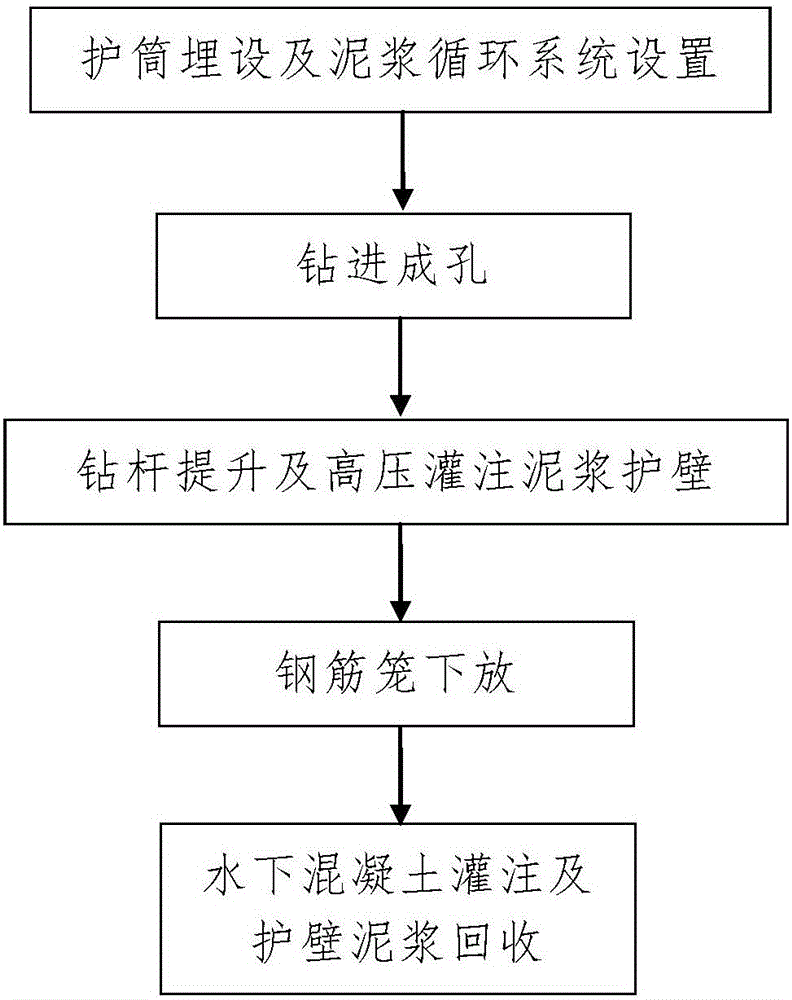

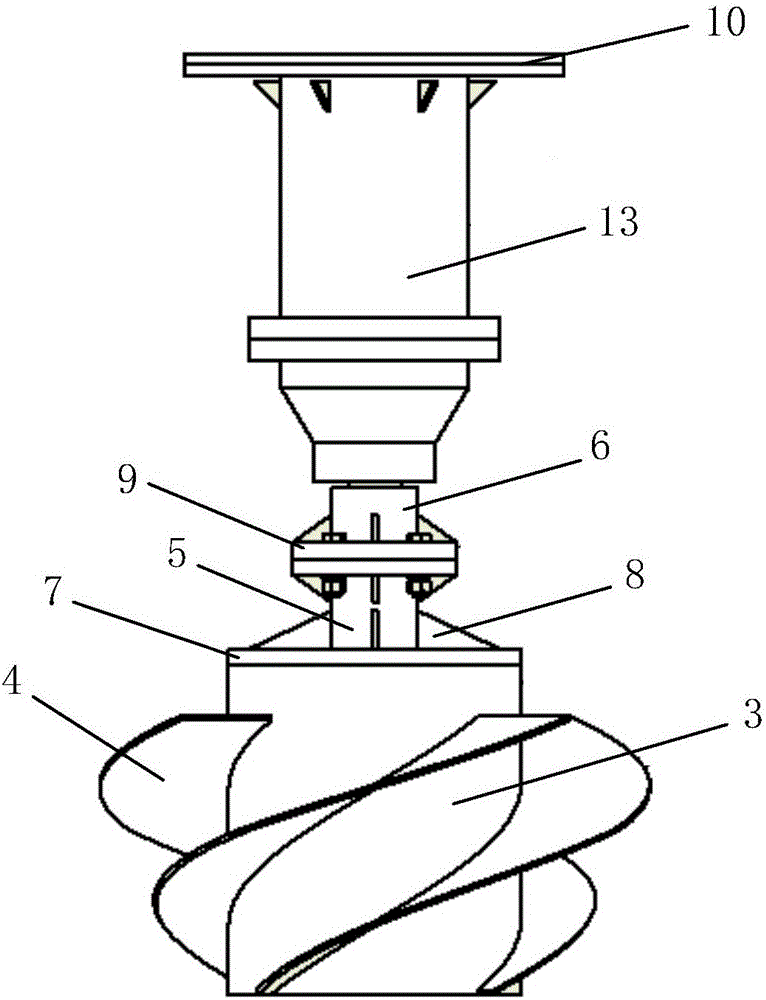

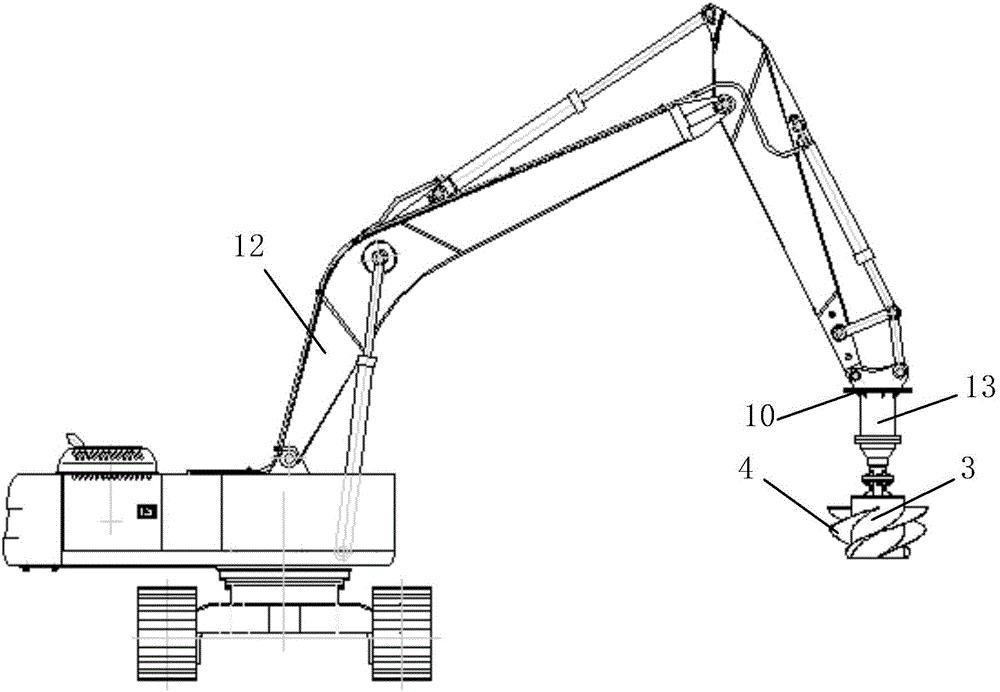

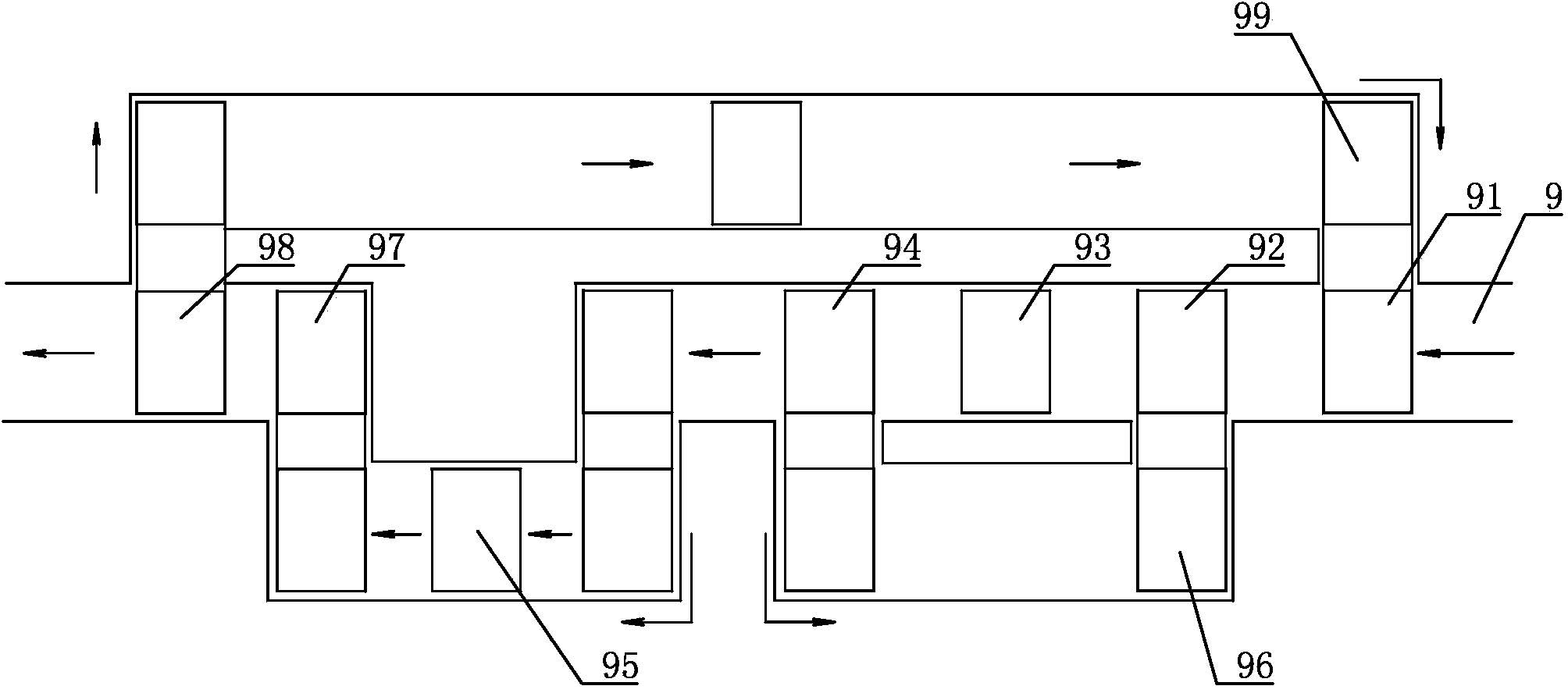

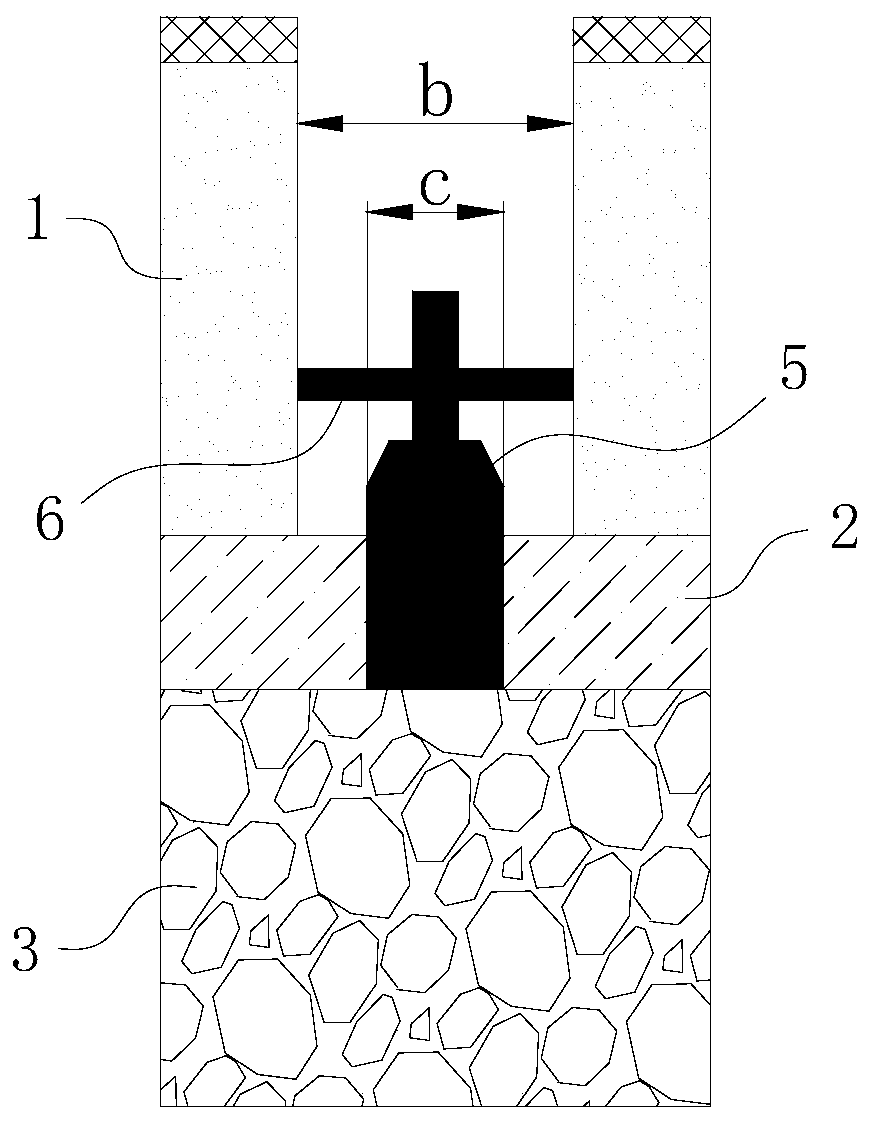

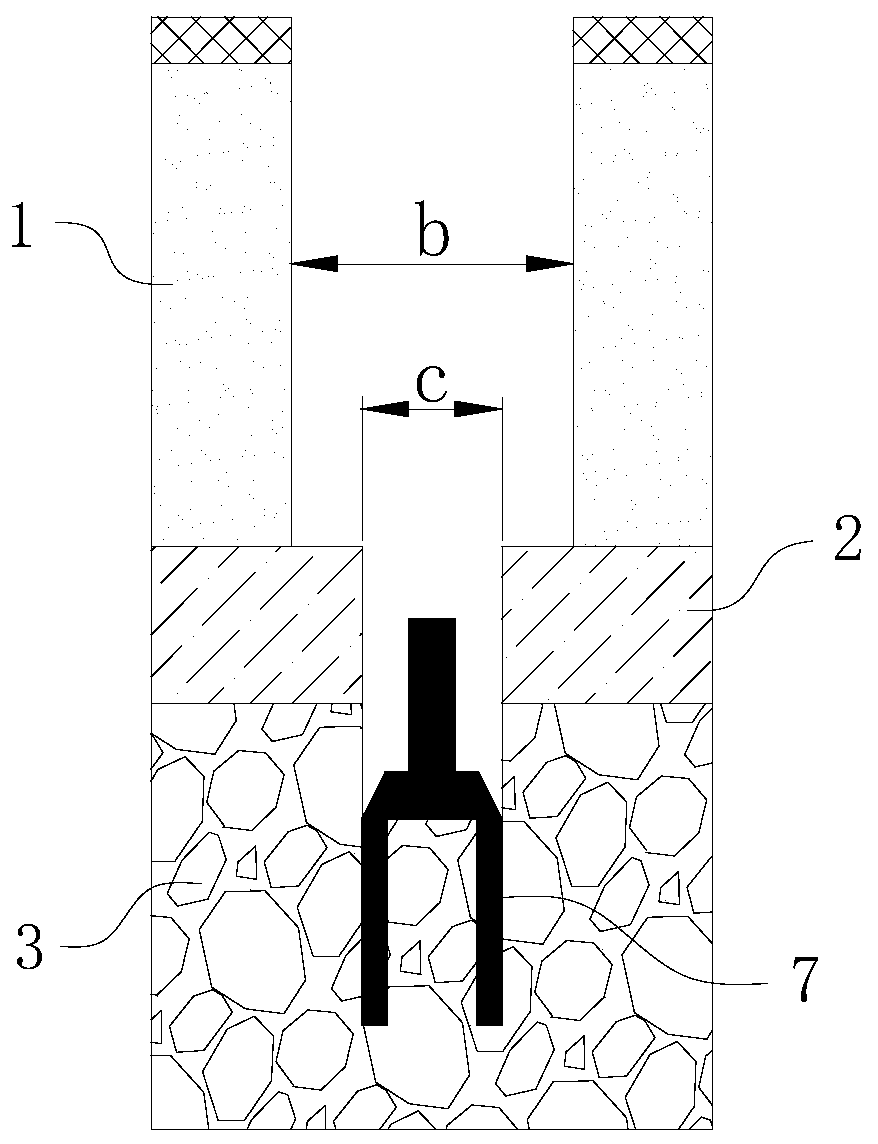

Long screw extrusion-socketed cast-in-place pile construction method based on circulating slurry breast wall

ActiveCN106284313AReasonable structural designEasy to operateBulkheads/pilesDrilling machines and methodsUnderwaterHigh pressure

The invention discloses a long screw extrusion-socketed cast-in-place pile construction method based on circulating slurry breast wall, comprising the steps of first, burying a protective barrel and setting a slurry circulating system that comprises a slurry storage tank and a slurry pumping device, with the upper portion of the protective barrel provided with an overflow hole; second, drilling to form a borehole; third, lifting a drill pipe, and casting a slurry breast wall under high pressure: lifting up the drill pipe, and continuously casting wall supporting slurry from bottom to top from the borehole bottom through the drill pipe by using the slurry pumping device; fourth, lowering a reinforcement cage; fifth, casting concrete underwater and recycling the wall supporting slurry, and recycling the wall supporting slurry discharged through the overflow hole to the slurry storage tank for backup. The method has simple steps, is easy to implement, has high hole-forming quality and good construction effect, and enables the construction of a long screw extrusion-socketed cast-in-place pile to be finished simply and quickly, and by casting the wall supporting slurry from bottom to top from the borehole bottom in a high-pressure casting manner, it is possible to effectively protect the wall and keep the borehole bottom clean with no deposit; the wall supporting slurry is reusable.

Owner:SHAANXI ZHUANGXIN CONSTR ENG +4

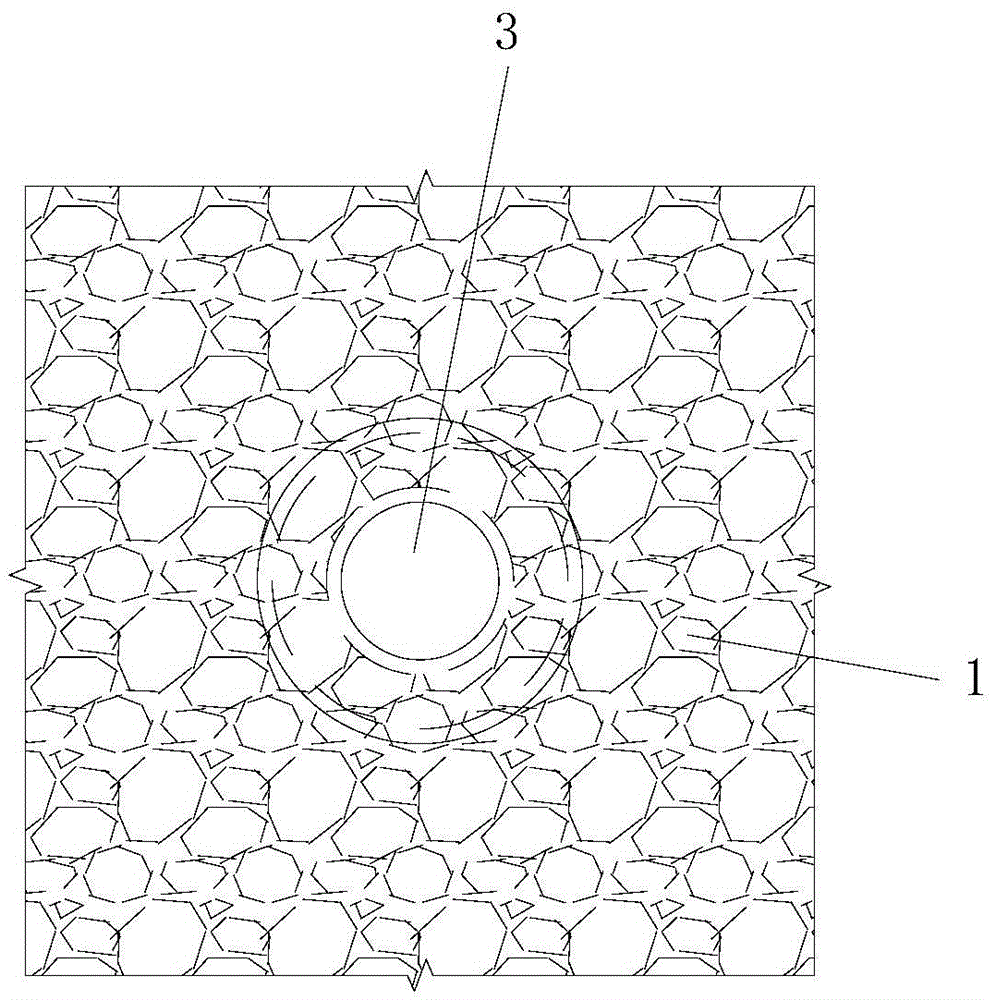

Method for preparing biomedical porous titanium and titanium alloy material

InactiveCN101948964ANo need to worry about residueSimple processProsthesisTitanium alloyPorous titanium

The invention provides a method for preparing biomedical a porous titanium and titanium alloy material, belongs to the technical field of the preparation of biomedical materials, and relates to a method for preparing porous materials, in particular the method for preparing the porous titanium and titanium alloy material. The method for preparing the porous titanium and titanium alloy material comprises the following steps of: mixing the mixture of Ti powder and 1 to 40 mass percent of Mg powder serving as a pore-forming agent in a mixer for certain time; filling the mixture in a mould; forming a set shape under certain pressure; putting green bodies into a high temperature furnace; introducing argon; heating to the temperature of between 650 and 750 DEG C; keeping the temperature for 1 to 2 hours; continuously heating the blank to the temperature of between 1,150 and 1,250 DEG C; and keeping the temperature for 3 to 7 hours and cooling to prepare the porous titanium and titanium alloy material. The method has the advantages of simple process, convenient operation, no residue or pollution of the pore-forming agent and high pore-forming quality.

Owner:DALIAN UNIV OF TECH

Soft rock and soil layer jet flow guiding hole forming-chamfering-hole collapse preventing integrated drilling method

InactiveCN104790873AImprove hole qualityImprove drilling efficiencyLiquid/gas jet drillingDirectional drillingDrill holeGeotechnical engineering

A soft rock and soil layer jet flow guiding hole forming-chamfering-hole collapse preventing integrated drilling method comprises the following steps that firstly, a soft rock and soil layer jet flow guiding hole forming-jet chamfering-hole collapse preventing guniting integrated drilling device is machined and tested; secondly, drilling technical parameters are designed; thirdly, guniting collapse preventing slurry fluid is prepared, and the solidification performance of the slurry fluid is tested; fourthly, the integrated drilling device is installed; fifthly, integrated drilling work is carried out; sixthly, after the design depth is achieved, drilling is stopped, clean water is used for cleaning a guniting pipeline and a slurry liquid nozzle, and a rod bit is pulled out; seventhly, the drilling effect is detected. The drilling efficiency and the hole forming quality of a horizontal or oblique long drill hole in the ground and an underground soft rock soil layer are greatly improved, the construction time for the horizontal or oblique long drill hole in the soft rock soil layer is shortened, and collapse destruction time of the horizontal or oblique long drill hole in the soft rock soil layer is greatly prolonged; the drilling track deviation of the horizontal or oblique long drill hole in the soft rock soil layer is reduced.

Owner:HENAN POLYTECHNIC UNIV

Preparation method of metal resin complex and metal resin complex prepared thereby

The invention provides a preparation method of an aluminum alloy resin complex and the aluminum alloy resin complex prepared thereby. The preparation method of the aluminum alloy resin complex comprises the following steps: S1, anodic oxidation: a metal substrate with a surface comprising an anodic oxidation film layer is obtained by anodic oxidation of a pretreated metal substrate, and the metal substrate is an aluminum alloy substrate or aluminum substrate; S2, treatment with an etching liquid: the metal substrate containing the anodic oxidation film layer and obtained by the step S1 is immersed in the etching liquid for treatment to obtain a surface treated metal substrate; S3, injection: the surface of the surface treated metal substrate is injected with a resin composition, and then the metal resin complex is obtained after molding; and the etching liquid contains HCl and a soluble halogen acid salt, or contains H3PO4 and a soluble phosphate. In the metal resin complex, the binding force between aluminum alloy and resin is strong, and the process is simple, and is easy for large-scale production.

Owner:BYD CO LTD

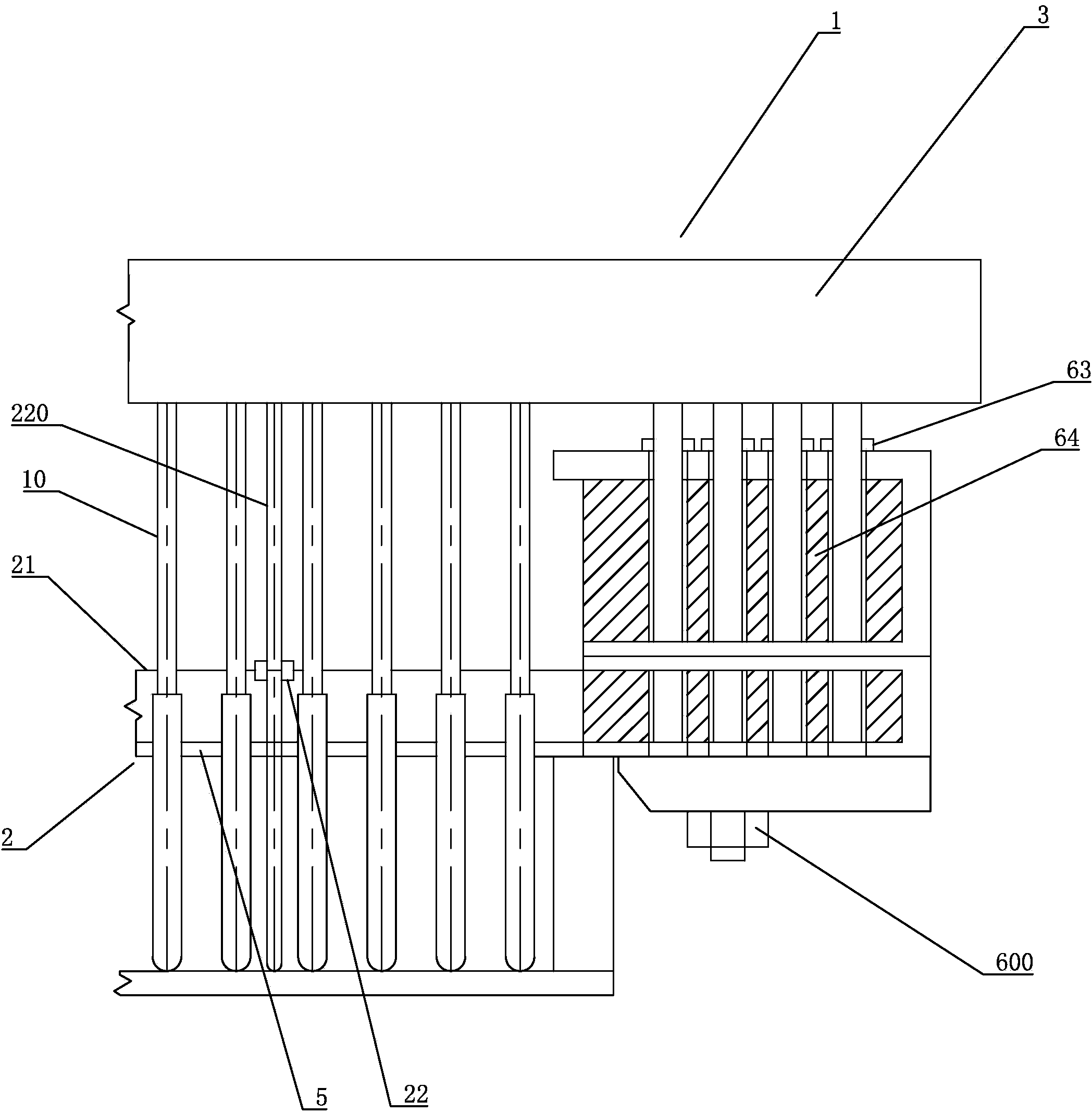

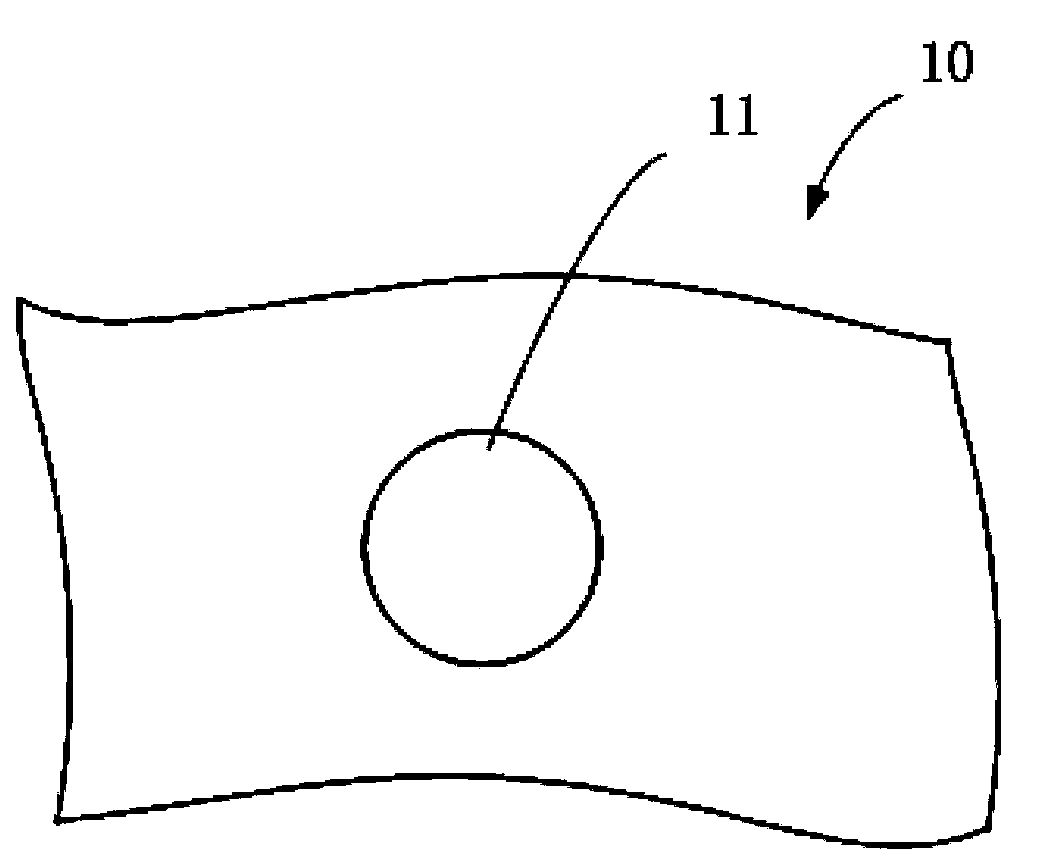

Split inserting type hole forming die and device and automatic manufacturing method of perforated brick of split inserting type hole forming die

The invention discloses a split inserting type hole forming die which comprises an upper die and a lower die. The upper die is formed by arranging a plurality of insertion rod beams which are provided with hole forming insertion rods. The lower die comprises an insertion hole board, the two ends of the lower die are provided with side boxes for supporting, and guide rods are arranged on the insertion rod beams. Annular grooves are formed in the guide rods, and guide tubes are arranged in the side boxes. The top ends of the guide tubes are fixedly connected with clamping springs, and the upper die is supported through the clamping springs and the side boxes. The insertion rod beams are divided into more than two groups according to a downwards-moving order, and each group of the insertion rod beams comprises the plurality of insertion rod beams, the insertion rod beams of the same group are driven by the same pressure vibration table, and the rods are inserted into materials in batches to form holes. The split inserting type hole forming die is combined with a pole pulling device, and therefore the hole forming process of inserting the rods and pulling the rods out of a perforated brick can be finished. According to the split inserting type hole forming die, perforated brick products are more diverse, perforated bricks with smaller holes and higher hollow rates can be obtained, and in addition, the production efficiency is high, and the shapes of the holes are complete.

Owner:桂林市城昌建材科技有限公司

Opening method of CFRP (Carbon Fiber Reinforced Plastics) and CFRP work-piece

The invention provides an opening method of a CFRP (Carbon Fiber Reinforced Plastics) and a CFRP work-piece. The opening method of the CFRP comprises the steps of using a first drill bit with a diamond coating to drill, wherein the revolving speed of the first drill bit is 2,500-3,500 / min, the feed rate is 200-280mm / min, and the cutting depth is 5-9mm, when the drilling is carried out; using a second drill bit with a diamond coating to perform broaching, wherein the revolving speed of the second drill bit is 1,500-3,500r / min, the feed rate is 120-200mm / min, and the cutting depth is 2-6mm, when the broaching is carried out. According to the opening method of the CFRP provided by the invention, the drill bits with the diamond coatings are adopted to drill, so that the CFRP can be quickly and smoothly cut, and the excessive temperature of tools can be prevented; furthermore, a way of drilling and then broaching is adopted to open the hole, and the used drill bits are adjusted according to pore sizes, so that the opening speed is fast, the hole wall of the opened hole is smooth, and the opening quality is good.

Owner:宁波江丰复合材料科技有限公司

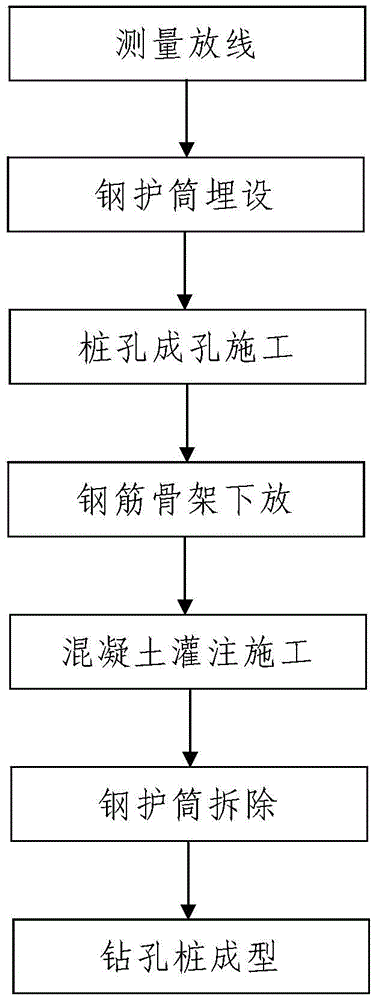

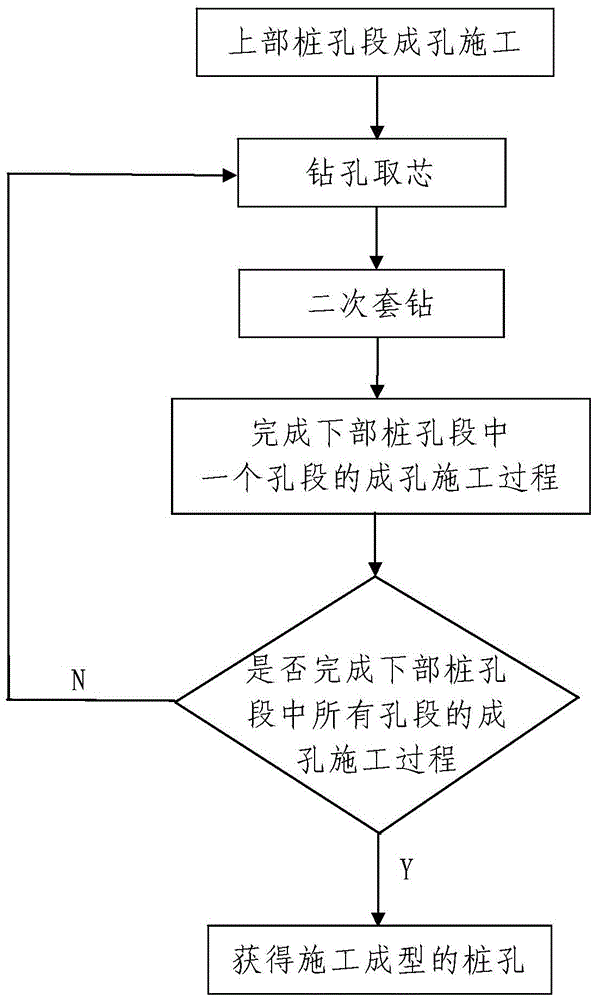

Construction method for bored pile of subway station enclosure structure of upper-soft lower-hard ground

ActiveCN105649012AThe method steps are simpleReasonable designDrill bitsCore removalSubway stationRebar

The invention discloses a construction method for a bored pile of a subway station enclosure structure of upper-soft lower-hard ground. The method includes the steps that firstly, measurement and paying-off are conducted, wherein measurement and paying-off are carried out at a pile position of the bored pile to be constructed, and the bored pile to be constructed is a cast-in-place pile constructed and formed in the upper-soft lower-hard ground; secondly, a steel casing is buried, wherein the steel casing is buried in the soft ground where the bored pile to be constructed is located; thirdly, drilling construction of pile holes is conducted; fourthly, a steel rib frame is laid down; fifthly, concrete pouring construction is conducted; sixthly, the steel casing is detached; seventhly, the bored pile is formed. Drilling construction of the pile holes includes the steps that 301, drilling construction is conducted on an upper pipe hole section and 302, drilling construction is conducted on a lower pile hole section, wherein the lower pile hole section is subjected to drilling construction by being divided into multiple pile hole section bodies from top to bottom, and when any hole section body is subjected to drilling construction, drilling for cores and secondary overcoring are conducted. The method is simple, design is reasonable, construction is easy and convenient, drilling difficulty of the pile holes is low, the use effect is good, and the bored pile construction process of the upper-soft lower-hard ground can be easily, conveniently and quickly completed.

Owner:CHINA RAILWAY FIRST GRP CO LTD

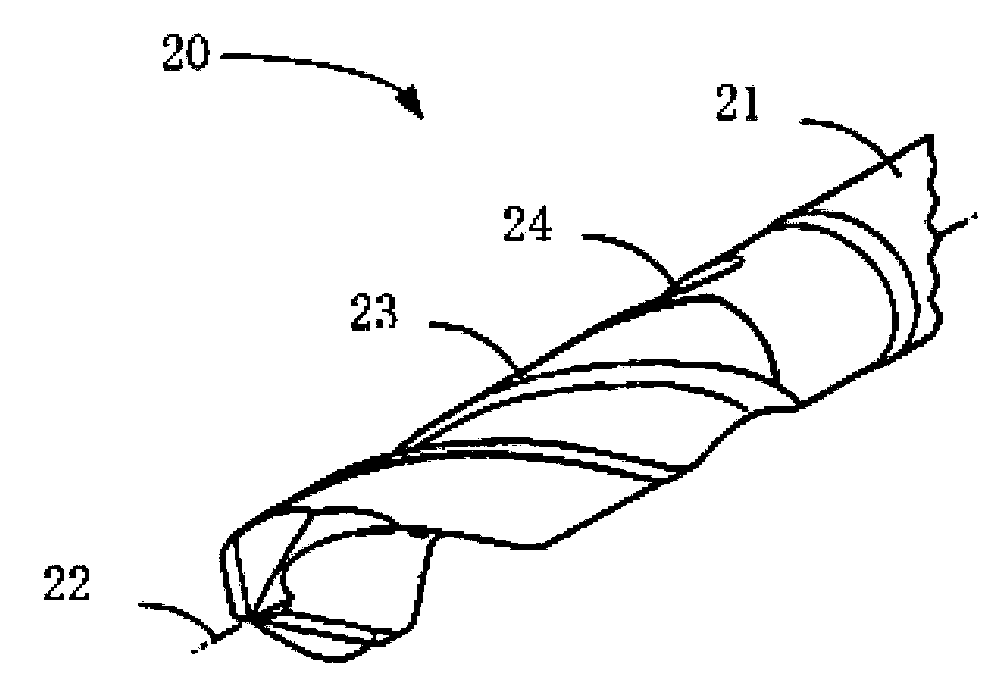

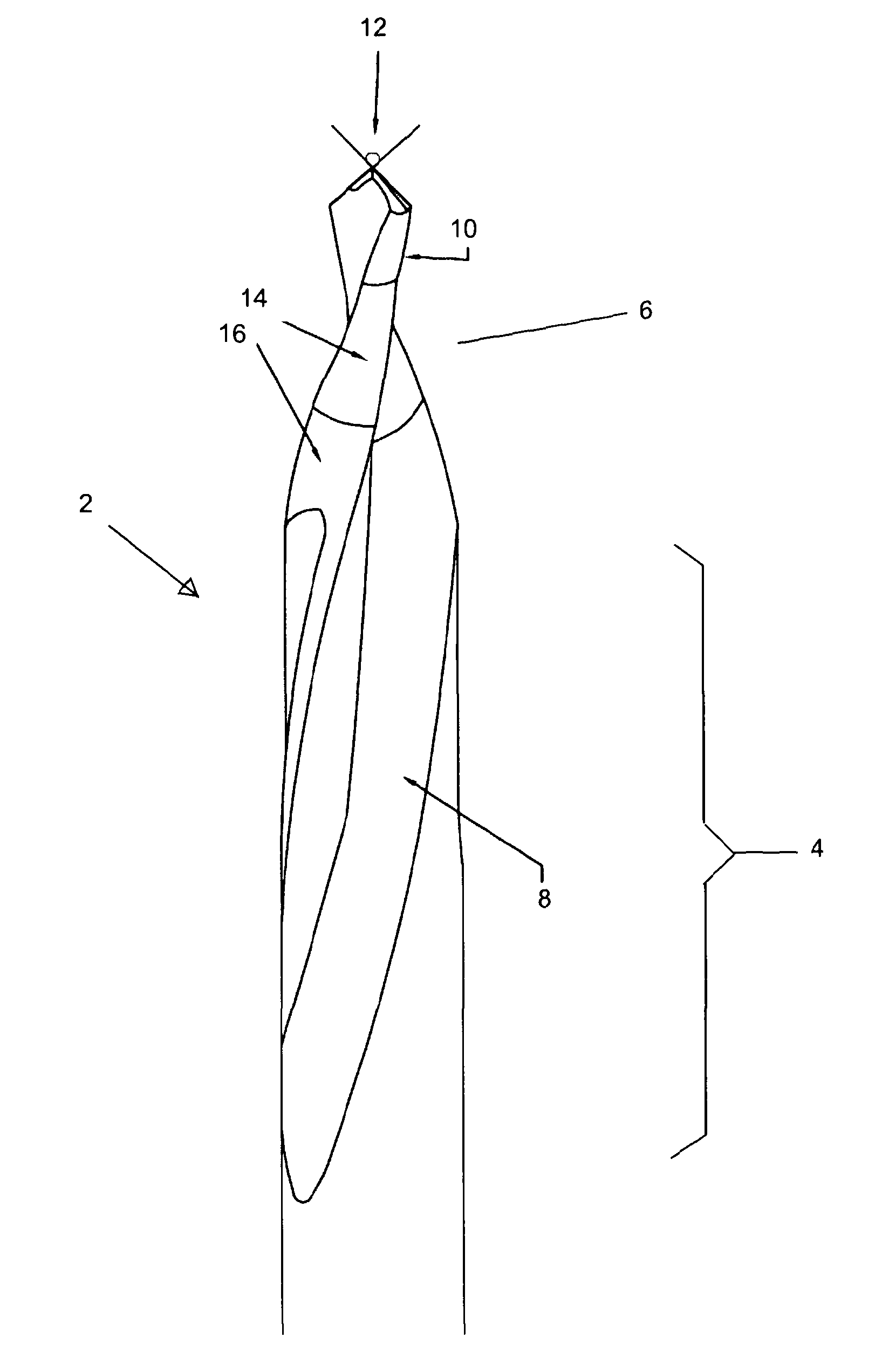

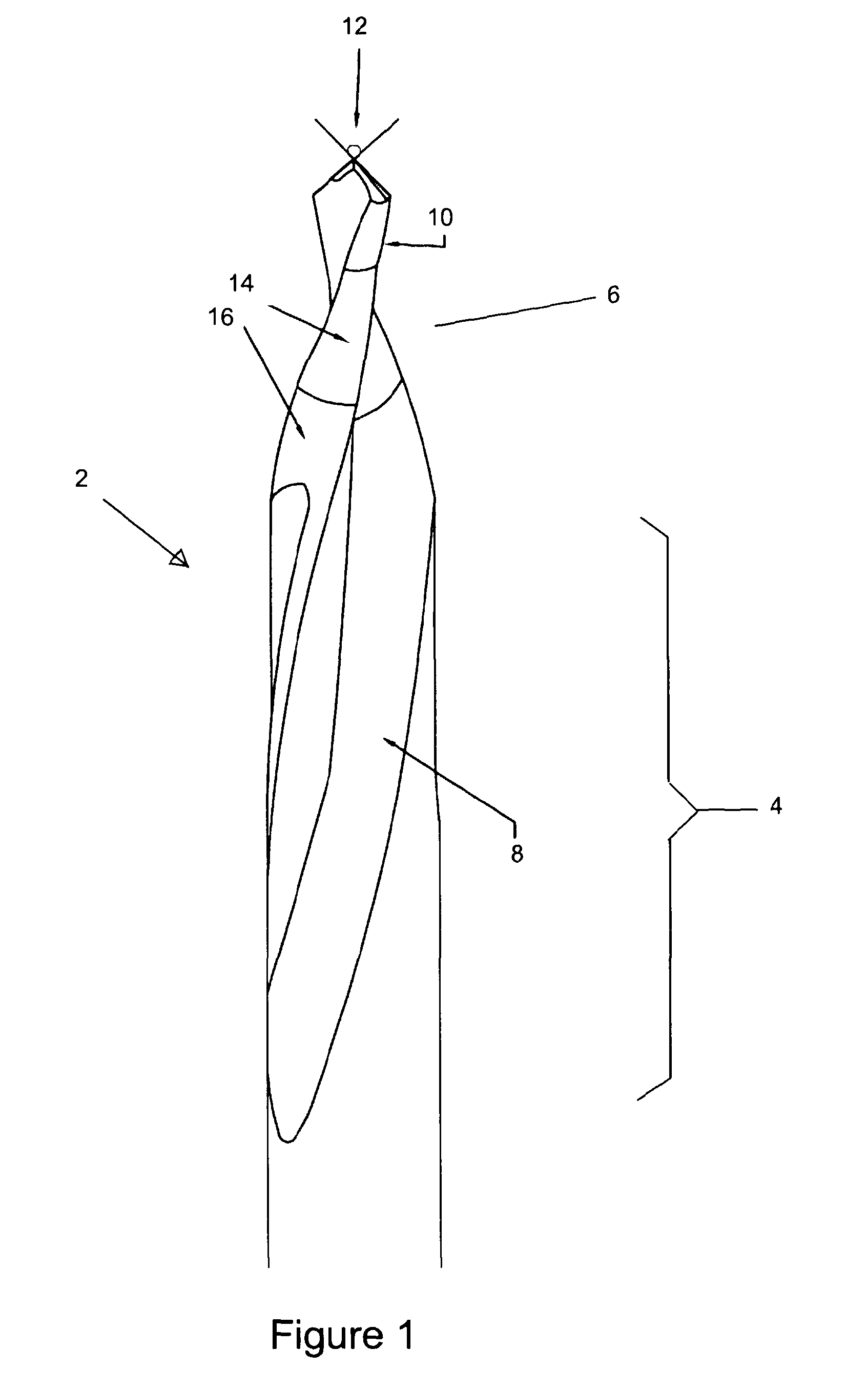

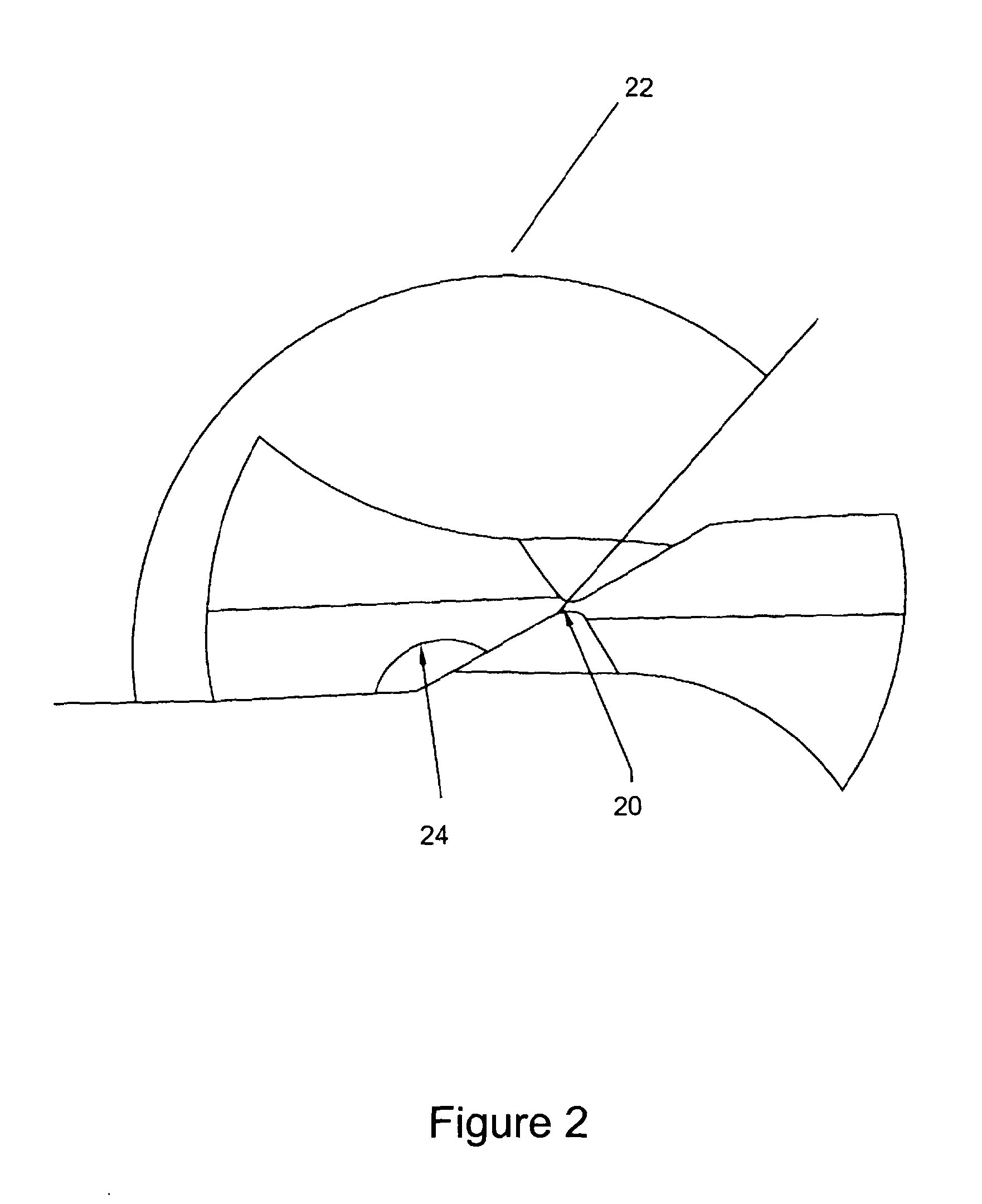

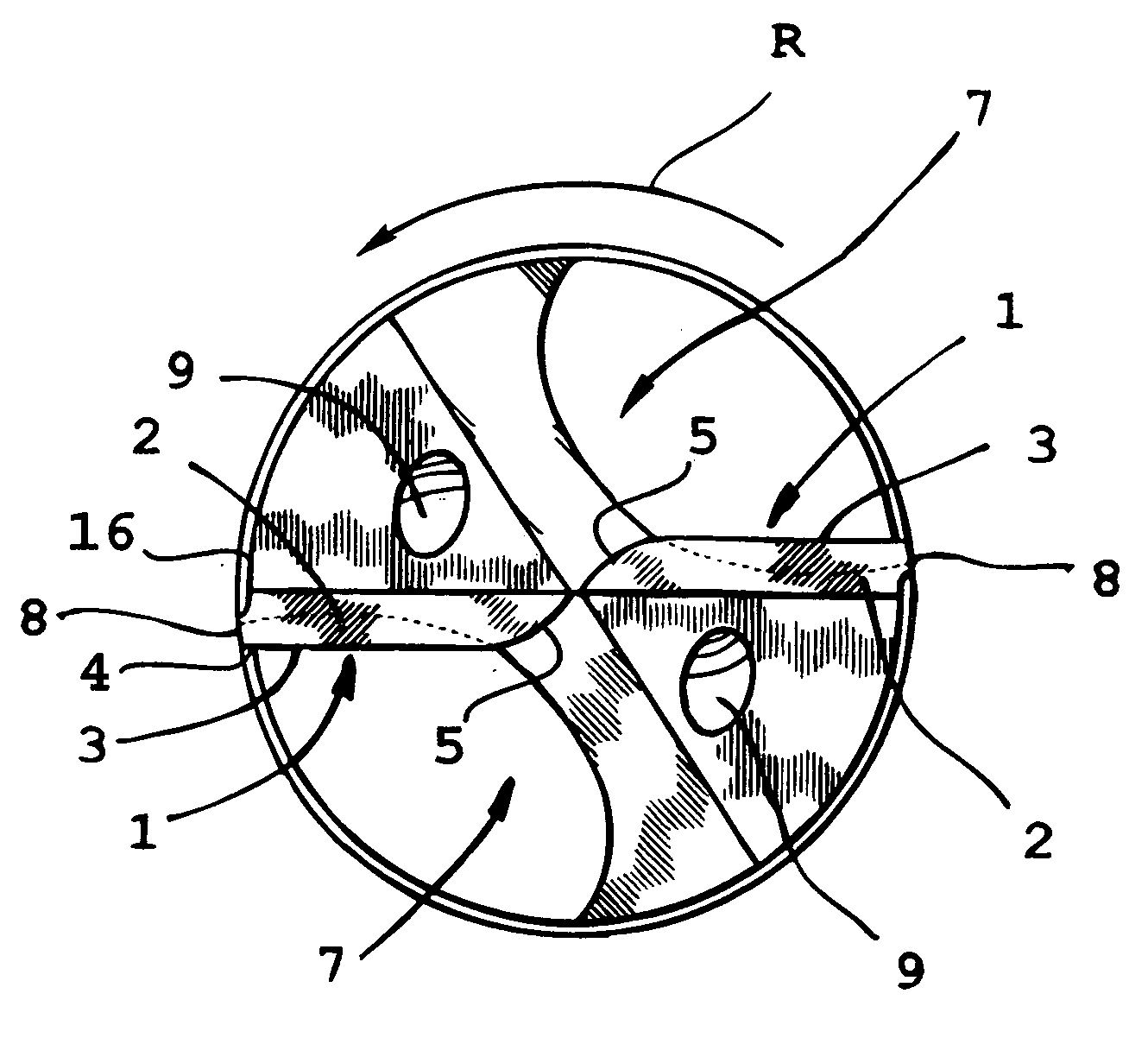

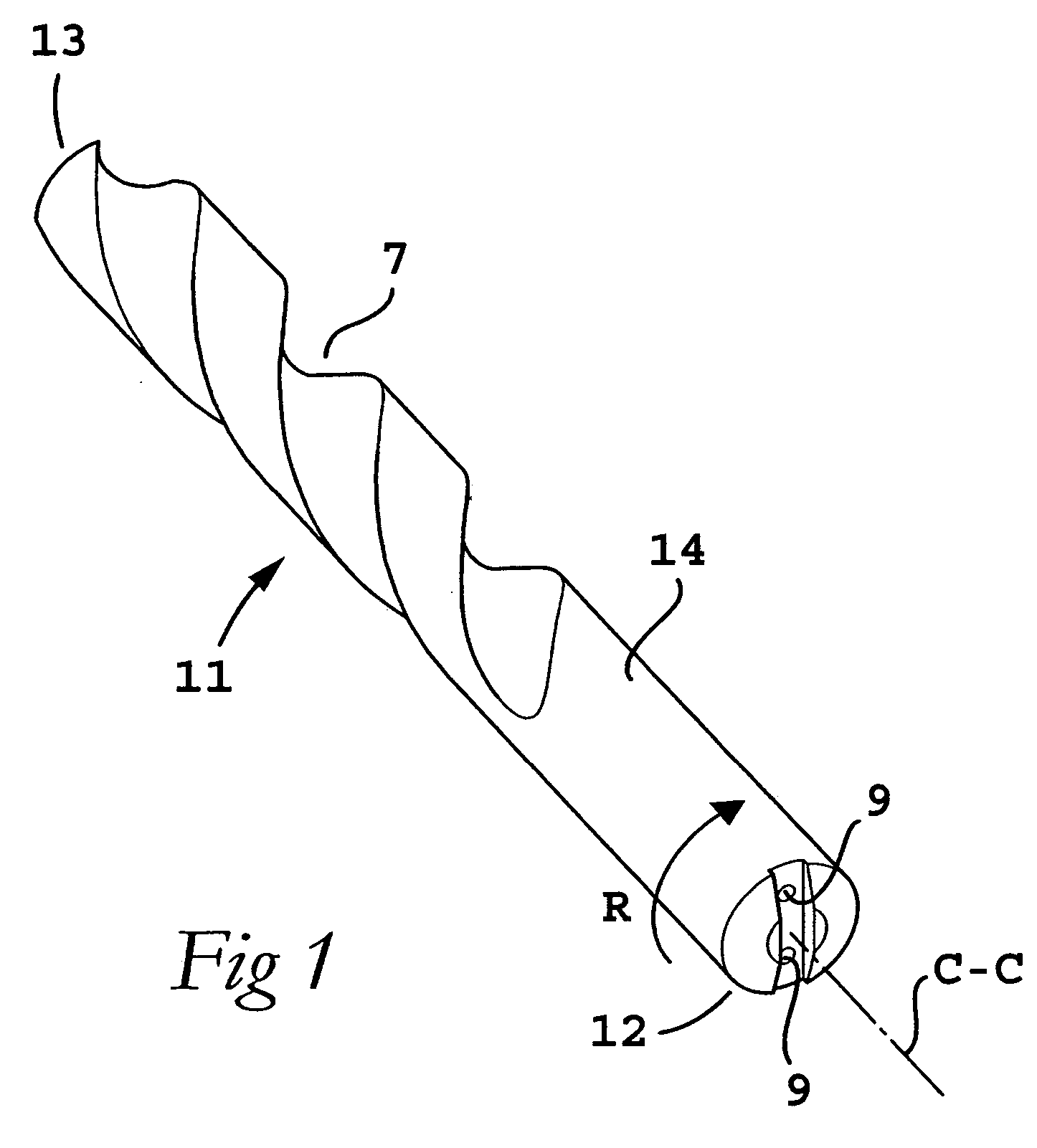

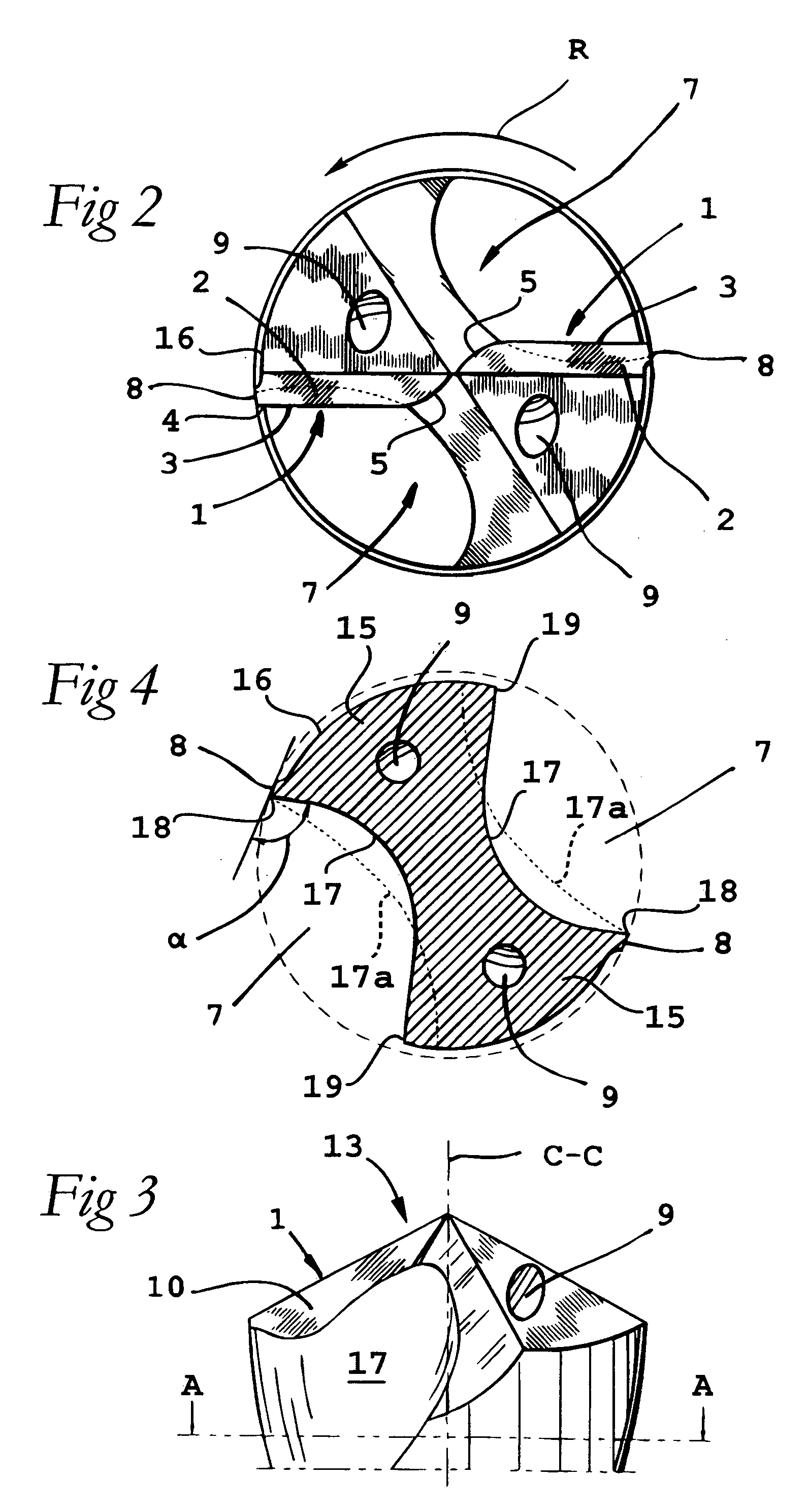

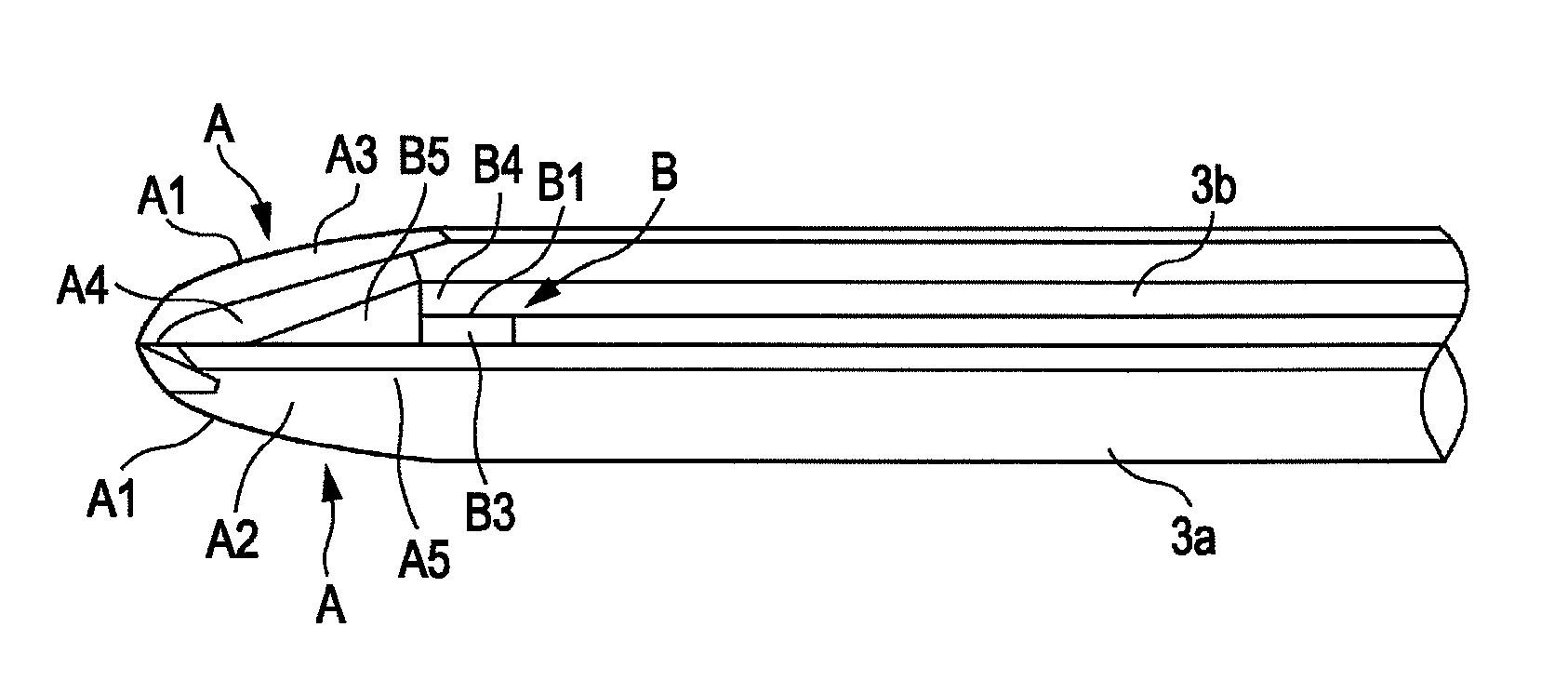

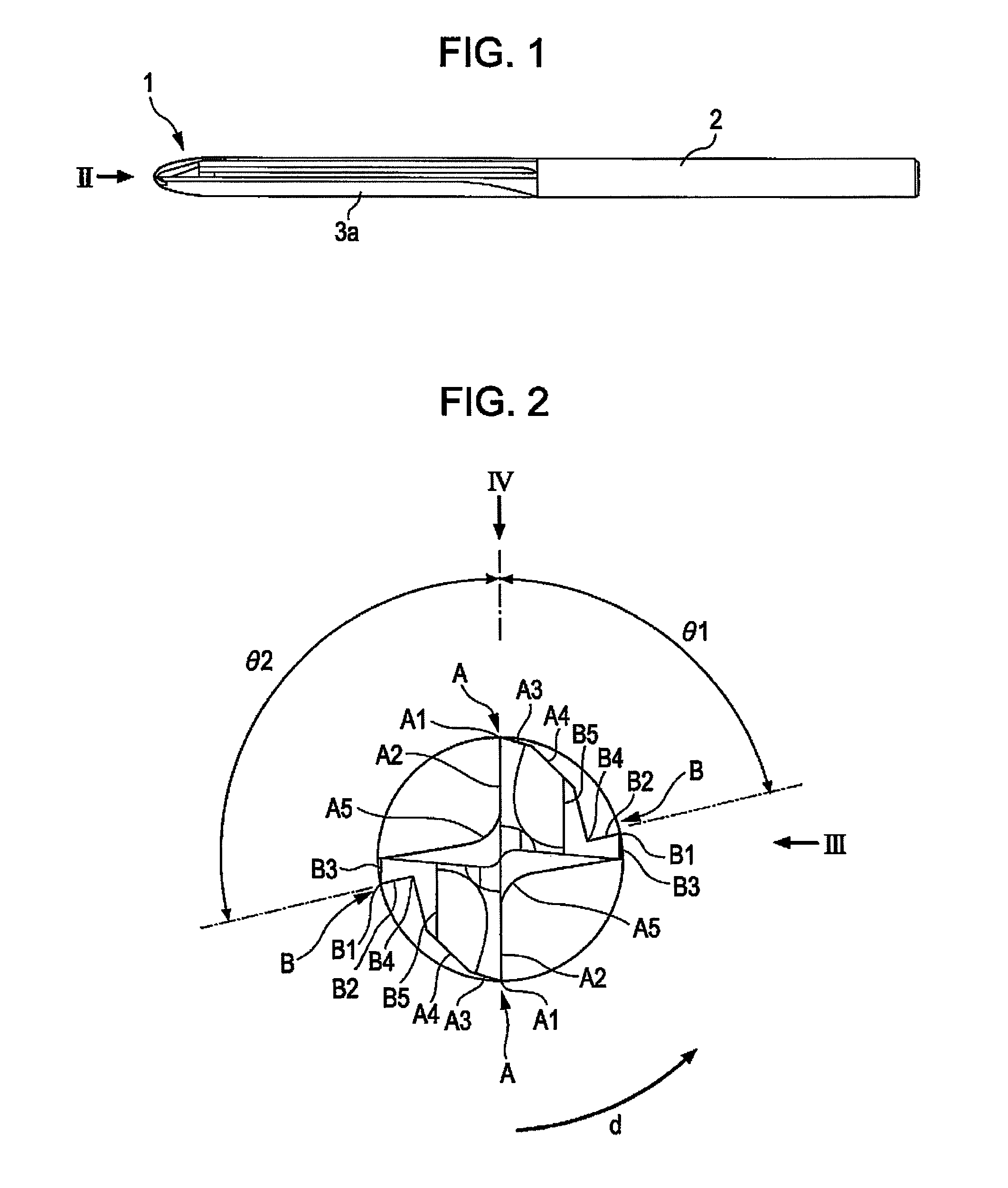

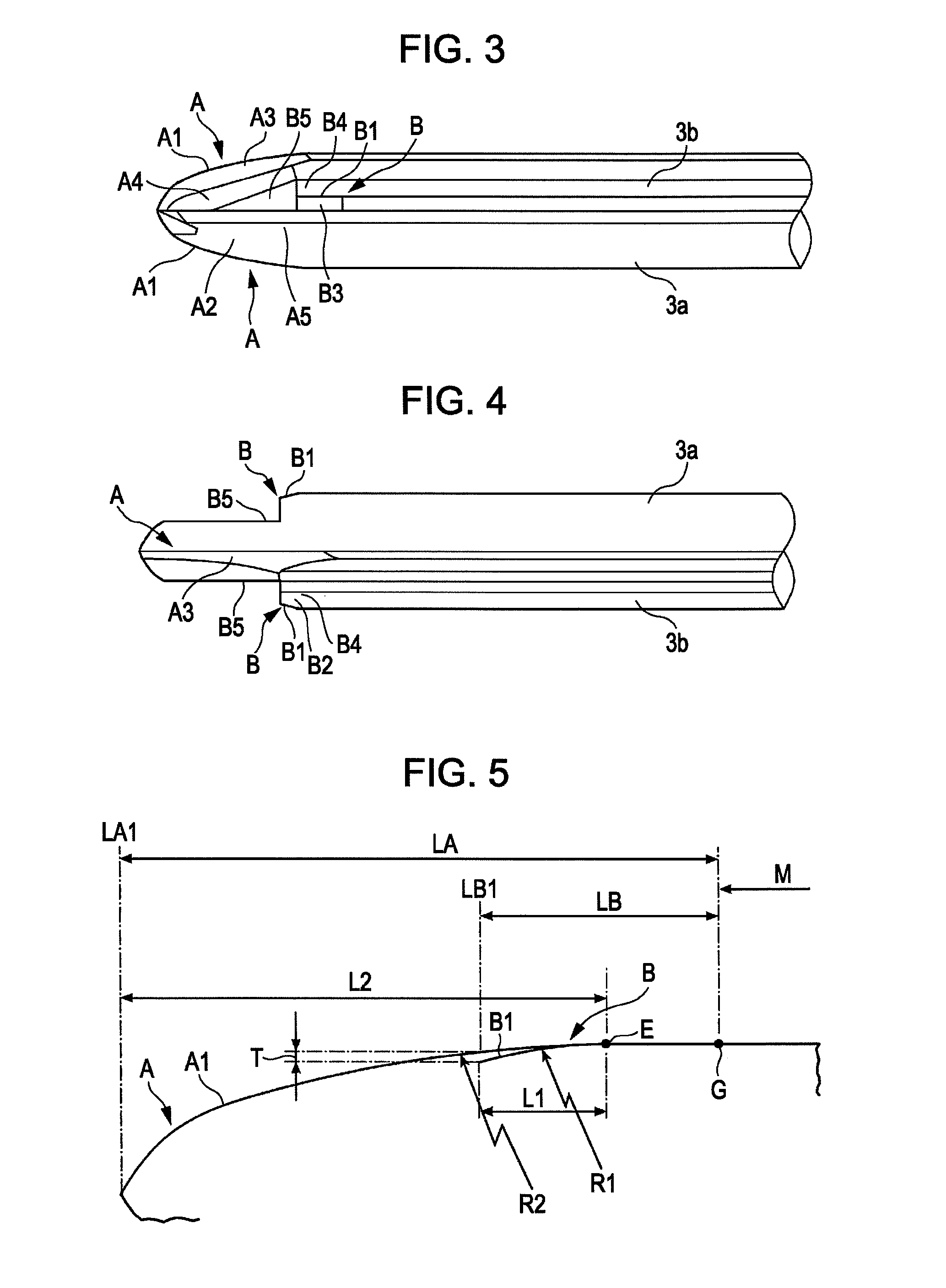

Twist drill for advanced materials

ActiveUS20130039709A1Improve hole qualityMinimize thrust forceWood turning toolsTransportation and packagingFiberGlass fiber

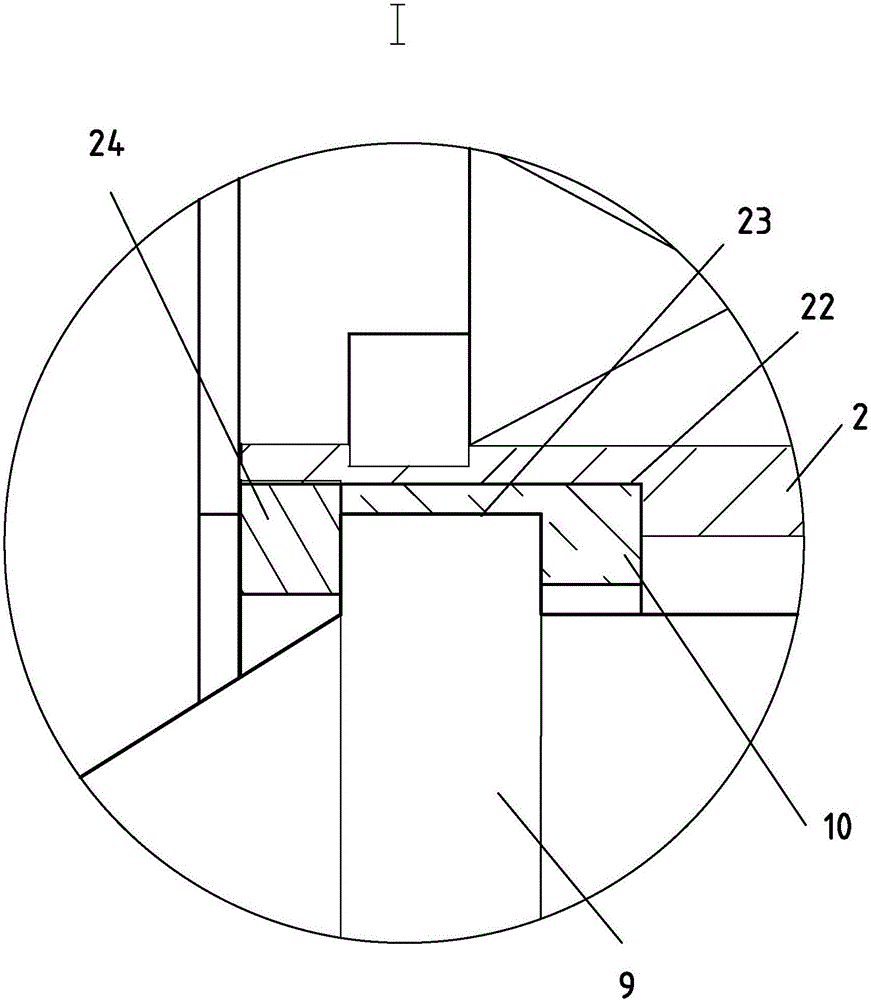

The present invention is concerned with twist drills for drilling of composite materials such as carbon fibre reinforced plastic (CFRP) and glass fibre reinforced plastic (GFRP). The present invention proposes that a twist drill (2) is provided with a variable helix having a defined start and finish helix angle, in combination with primary and secondary relief angles such that the drill (2) is adapted to minimise thrust force, particularly when used for drilling fibre—containing composite materials and especially for hand drilling. Start and finish helix angles of 50° and 10°; 50° and 30°; and 30° and 10° have been shown to provide excellent cutting performance and exit hole quality. A large secondary chisel edge angle (24) has also been found to contribute to excellent performance with composite materials, including stack machining.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

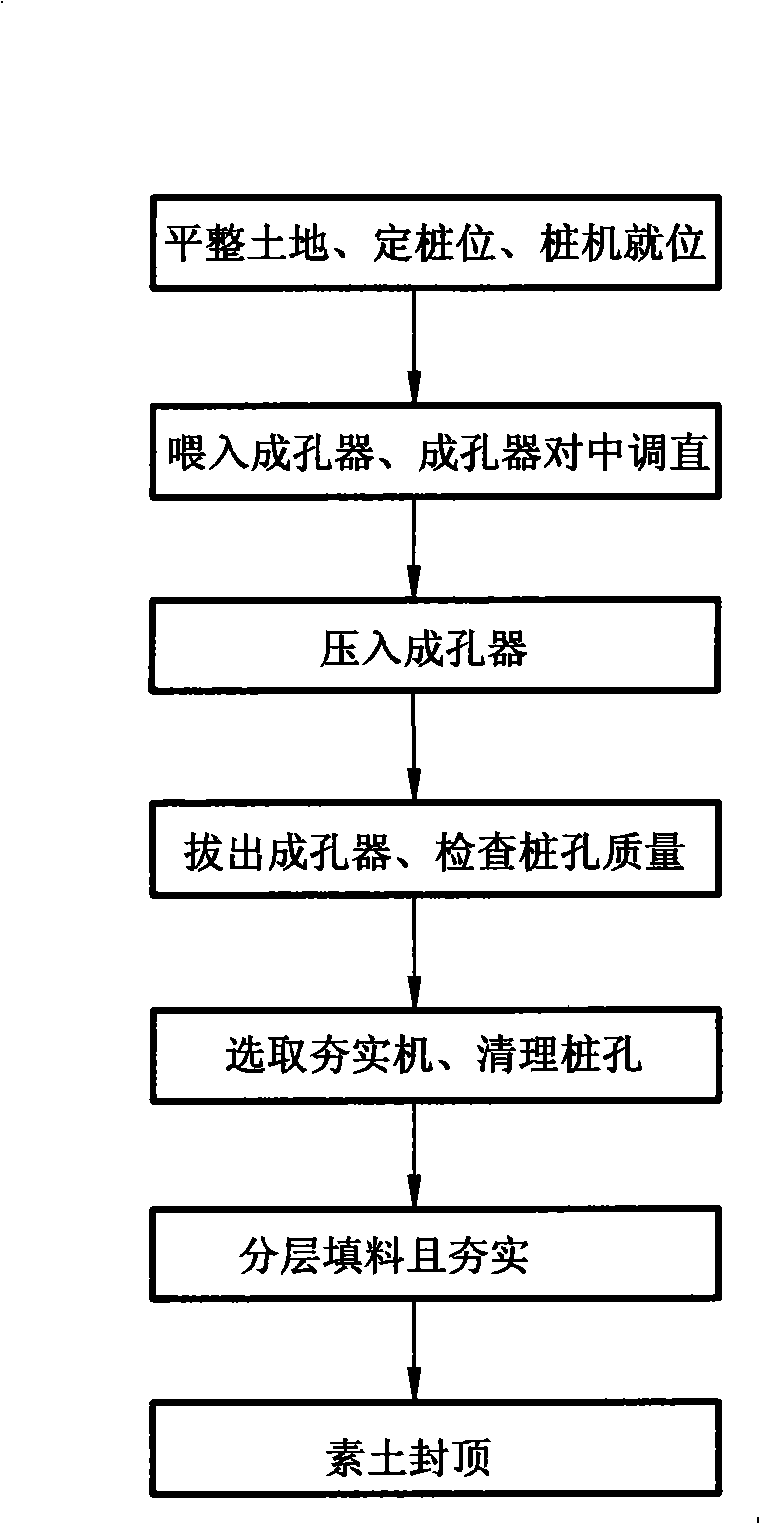

Construction method of static pressure compaction pile

InactiveCN101319500ANo pollution in the processNo noiseBulkheads/pilesSoil preservationEconomic benefitsPile driver

The invention discloses a construction method for static-pressure compaction piles. The construction method comprises the following construction steps of leveling land, measuring, positioning, putting a pile driver in position, leveling, lifting a pore-forming device in, centering and aligning a pile body, starting a static-pressure pore-forming device, stopping and pulling out the static-pressure pore-forming device, inspecting a pile hole; displacing the pile driver, putting a rammer machine in position, cleaning the hole, filling and capping with plain soil. The construction method adopts the hydraulic static-force pile driver for static-pressure pore formation, has no noise or air pollution, can ensure the environment-friendly construction of geotechnical engineering, is fast in construction speed, guarantees construction quality, is little in disturbance to surrounding soil, produces no hole shrinkage, is high in pore-forming quality, stable in construction quality, wide in application range, capable of constructing in hard strata and foundations, easy to popularize, favorable for saving energy and increasing efficiency and good in social and economic benefits.

Owner:THE THIRD ENG CO LTD OF CHINA RAILWAY SEVENTH GRP +1

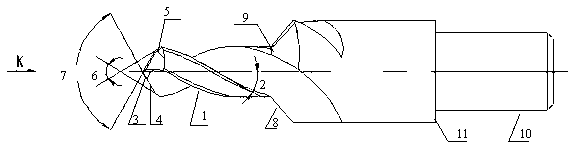

Compound tool applicable to high-speed and accurate holing on aircraft panel

InactiveCN102794486AReduce dosageImprove coaxialityTransportation and packagingTrepanning drillsChiselSurface roughness

The invention discloses a compound tool applicable to high-speed and accurate holing on an aircraft panel. The compound tool is provided with a double-helical side edge, the helical angle of the side edge is 30-40 degrees, a bottom edge is divided into three sections, i.e., a chisel edge, rough machining edges and finish machining edges; the included angle of the two rough machining edges is 120-150 degrees, and the included angle of the two finish machining edges is 60-65 degrees; a dimpling edge is connected with the helical side edge; and after holes are drilled through, the tool is fed continuously, and the dimple machining is finished by utilizing the dimpling edge. The compound tool disclosed by the invention has the advantages that the hole drilling, hole reaming and dimpling can be finished once without need of tool change, and the roughness of the machining surfaces of the holes reaches Ra1.6.

Owner:ZHEJIANG UNIV

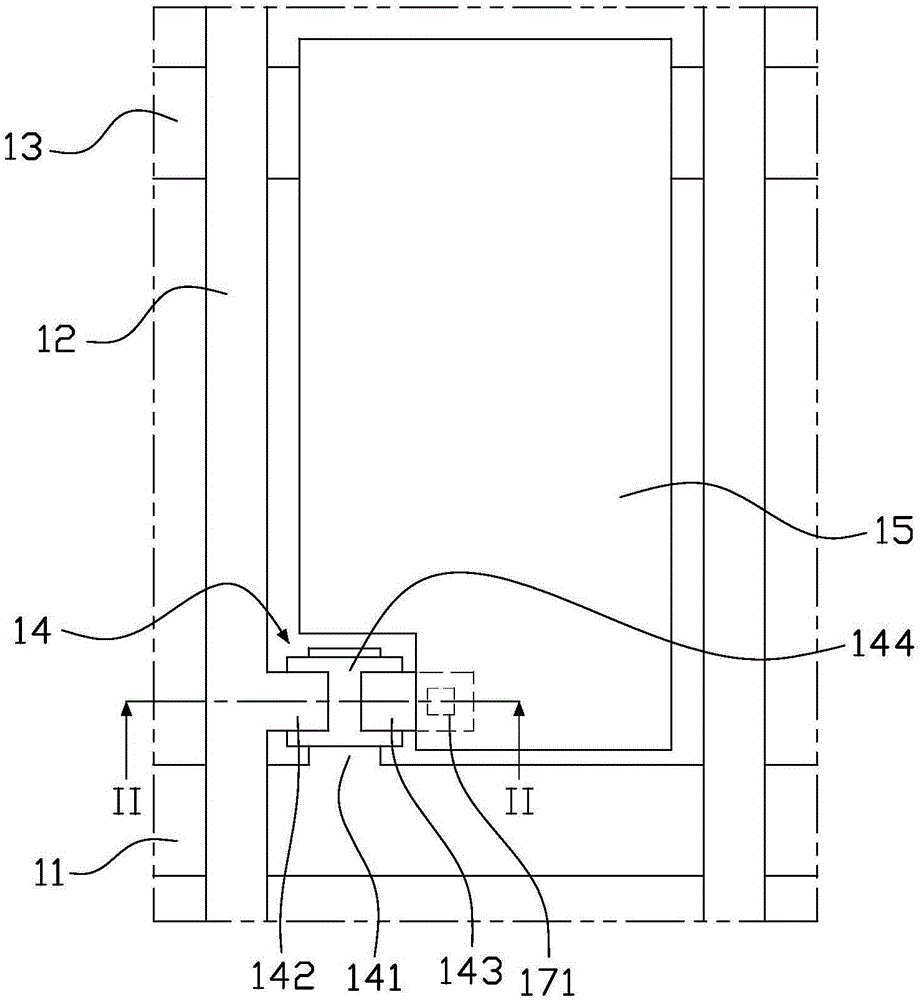

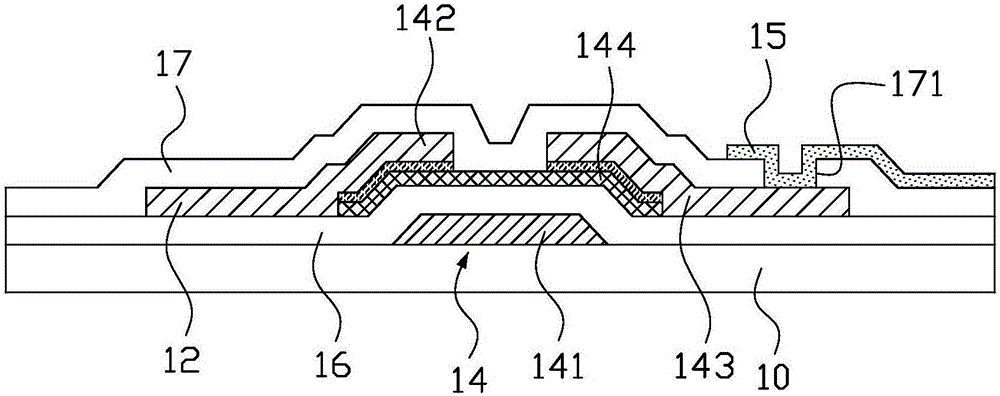

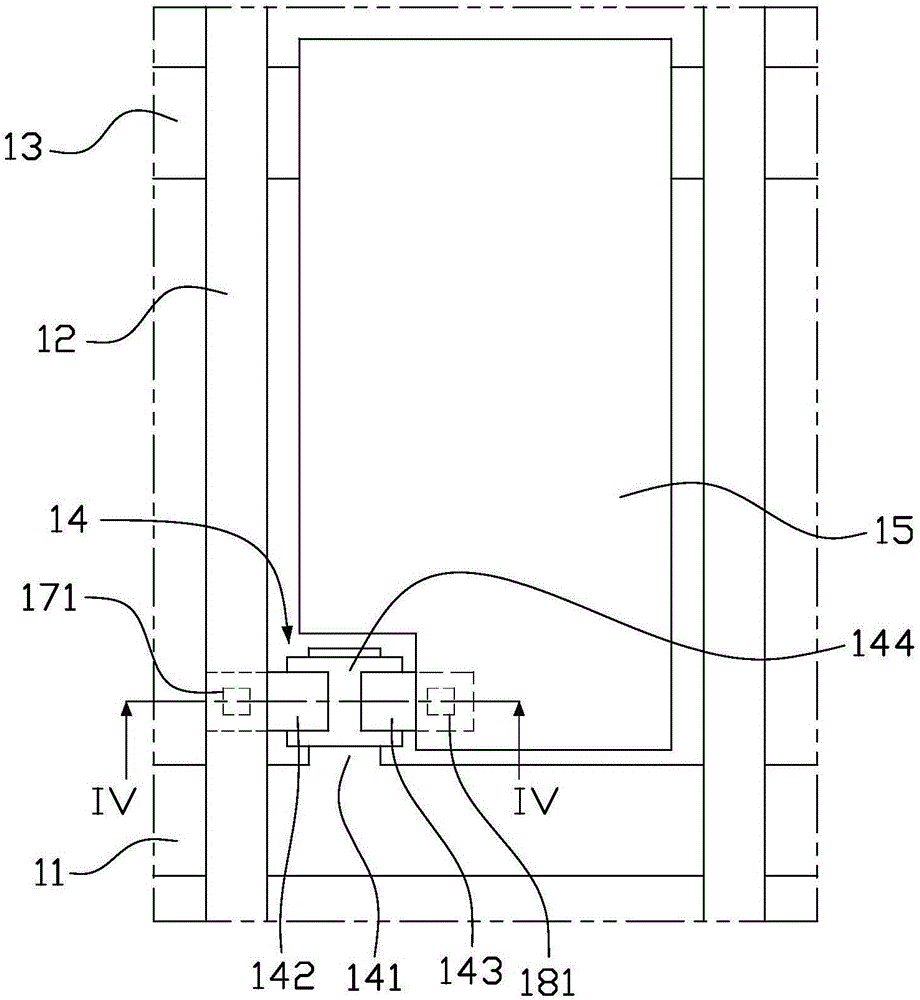

Thin film transistor array substrate, manufacturing method and liquid crystal display panel

ActiveCN106483726AIncreasing the thicknessImprove alignment accuracySolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayInsulation layer

Provided are a thin film transistor array substrate, a manufacturing method and a liquid crystal display panel. The thin film transistor array substrate comprises a substrate, a first metal layer, a first insulation layer, an active layer, a second metal layer, a second insulation layer, a third metal layer, a third insulation layer and a pixel electrode. The first metal layer is formed on the substrate and comprises a scanning line and a grid. The first metal layer is covered with the first insulation layer, and the active layer is formed on the first insulation layer. The second metal layer is formed on the first insulation layer and comprises a source electrode and a drain electrode. The second metal layer is covered with the second insulation layer, and a first contact hole and a second contact hole are formed in the second insulation layer. The third metal layer is formed on the second insulation layer and comprises a data line and a conductive block, the data line is connected with the source electrode through the first contact hole, and the conductive block is connected with the drain electrode through the second contact hole. The third metal layer is covered with the third insulation layer, and a third contact hole is formed in the third insulation layer. The pixel electrode is formed on the third insulation layer, and the pixel electrode is connected with the conductive block through the third contact hole.

Owner:KUSN INFOVISION OPTOELECTRONICS

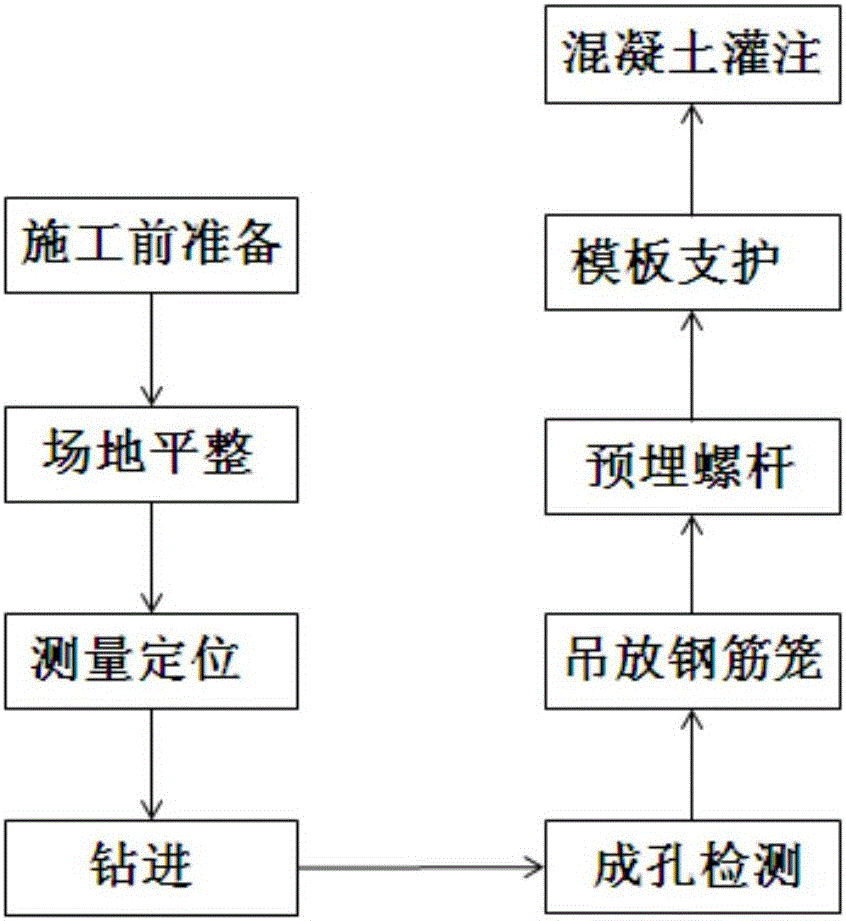

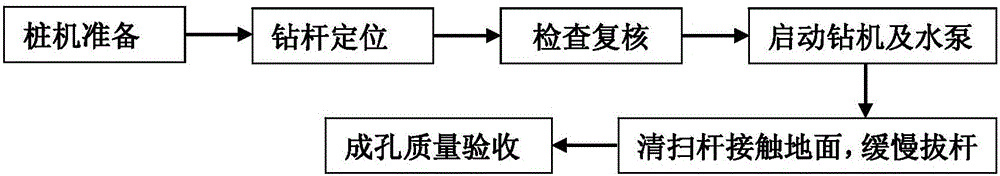

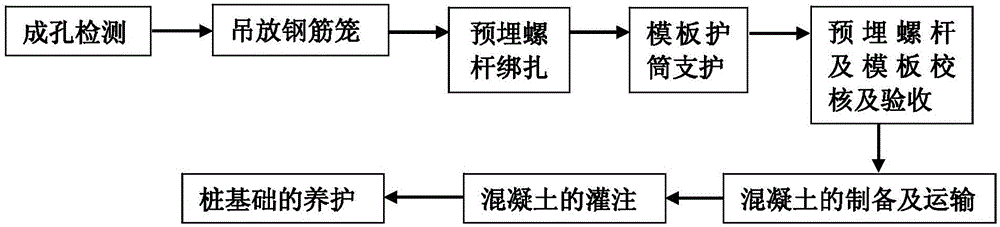

Water injection type rotary drilling construction method for cast-in-situ bored pile

The invention provides a water injection type rotary drilling construction method for a cast-in-situ bored pile. The construction method comprises following steps: preparation before construction; site formation; surveying and positioning; drilling; pore forming detection; hanging of a steel reinforcement cage; pre-embedment of screws; concrete pouring. The construction method is suitable for construction of the cast-in-situ bored pile in the desert area, the principle of the construction method is focused on a deserted special geological structure, and the sand layer is consolidated through water injection, so that the problems of frequent hole collapse and over-thick sediment in pile foundation construction of a gravel layer in the desert area are solved, and the efficiency of the pile foundation construction is improved. The construction method is simple to operate and convenient to construct, realizes formation of a drill hole prone to hole collapse, can prevent hole collapse and is particularly suitable for construction of a foundation pouring pile for a photovoltaic support in a deserted geological environment, and sediment cleaning is not required.

Owner:CHINA FIRST METALLURGICAL GROUP

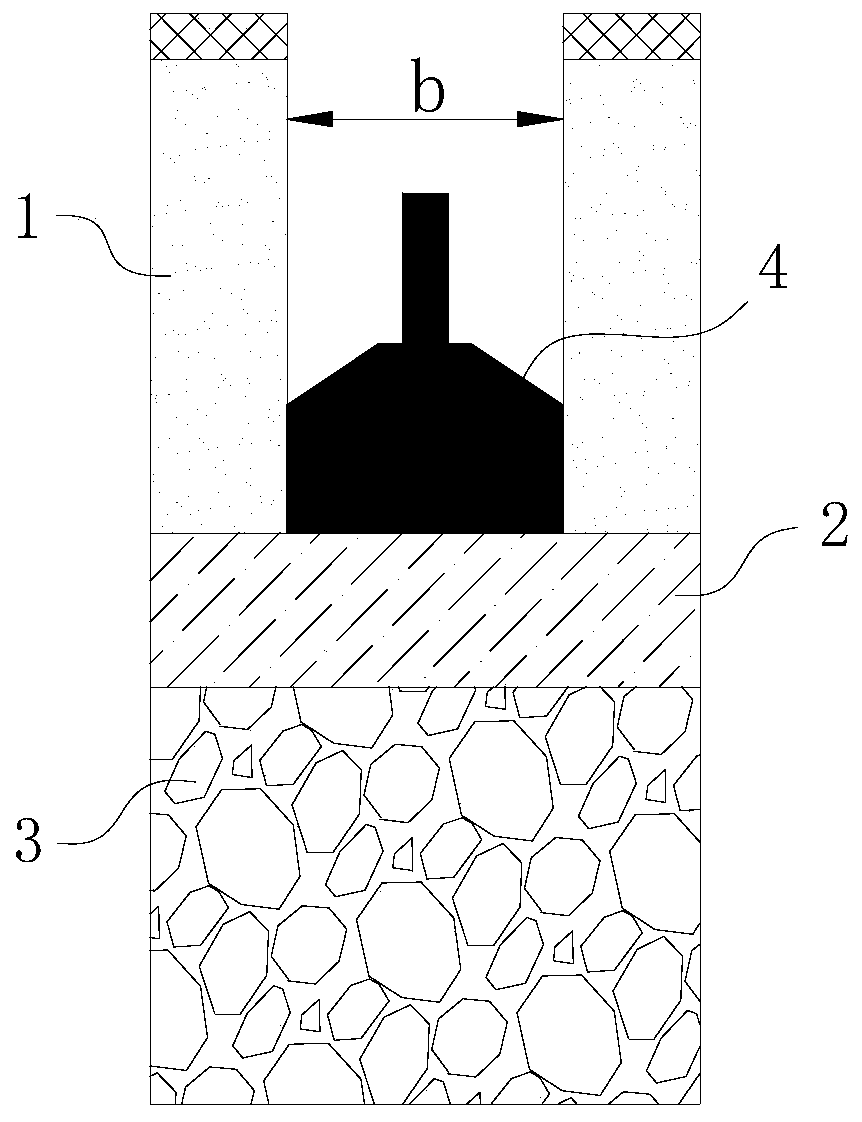

Drill for chip removing machining

ActiveUS20060171787A1Improve hole qualityImprove productivityWood turning toolsTransportation and packagingFluteEngineering

A drill for chip removing machining, including a front tip including at least one cutting edge and a chip flute. The chip flute is countersunk in an envelope surface of a body of the drill and extends rearwardly from the cutting edge. The chip flute is generally defined by a cross-section-wise concavely vaulted surface located between first and second longitudinal borders, the first longitudinal border extending from an area of a peripheral end of the cutting edge. The chip flute is deeper in an area of the first longitudinal border than in an area of the second longitudinal border such that a curve defining the cross-sectional shape of the flute surface has a radius of curvature that is smallest in the vicinity of the first longitudinal border and that increases towards the second longitudinal border. The flute surface transforms into a planar chip surface, which in turn transforms into the cutting edge.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Hole forming method for cast-in-situ bored pile

InactiveCN111379516AMake up for the shortcomings of incomplete hole cleaningQuality assuranceSurveyDirectional drillingBridge engineeringDrill hole

The invention relates to the technical field of bridge engineering, and discloses a hole forming method for a cast-in-situ bored pile. For a covering layer, a rotary drilling rig is assembled with a rotary drilling bucket for first drilling, and the construction efficiency is high; after entering rock, the rotary drilling rig is first assembled with a roller cone cylinder drill for secondary drilling, then a cutting pick cylinder drill is changed for third drilling, roller cone cylinder drills with different sizes are changed for step-by-step reaming, and at the stage, the problems of slow footage drilling, drill jamming, drill rod fracture and the like caused by insufficient torque after the rotary drilling rig enters the rock can be avoided; and after the reaming is in place, a percussion drill is changed to trim the hole shape of a primary pile hole, finally a mud circulating system is utilized to clear the formed pile hole, and it is ensured that the drilling slag at the bottom ofthe pile hole is thoroughly removed. Based on this, the hole forming method makes full use of the advantages of high hole forming efficiency of the rotary drilling rig, also makes up for the disadvantages of incomplete hole clearing of the rotary drilling rig, and has the advantages of high efficiency, low cost, small limitation, low safety risk, good hole forming quality and the like.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

Backpitch shattering and dust collecting drill bit

The invention discloses a backpitch shattering and dust collecting drill bit which comprises a connecting rod and more than three backpitch cutter wings evenly arranged. Blades are arranged on the ridge portions of the backpitch cutter wings respectively, the rear ends of the backpitch cutter wings are all connected to the front end of the connecting rod, the diameter of the rear portion of the connecting rod is smaller than that of the body of the connecting rod, a connecting portion used for connecting a drill pipe is formed, and connecting threads are arranged on the circumferential surface of the connecting portion. An axial air channel penetrating through the connecting rod in a front-and-back mode is formed in the connecting rod, and horn mouths are arranged at the front end and the rear end of the axial air channel respectively. The backpitch shattering and dust collecting drill bit can achieve efficient crushing of coal rock, the coal rock is cut down from a coal wall, is further shattered to be fine pulverized coal convenient for air to convey, and is conveyed out through the air channel, the efficient air conveying of the pulverized coal is achieved, and therefore the channel is not prone to being blocked, pore-forming speed and pore-forming quality are improved, and maintenance cost, labor cost and time cost in a drilling operation are reduced.

Owner:HENAN POLYTECHNIC UNIV

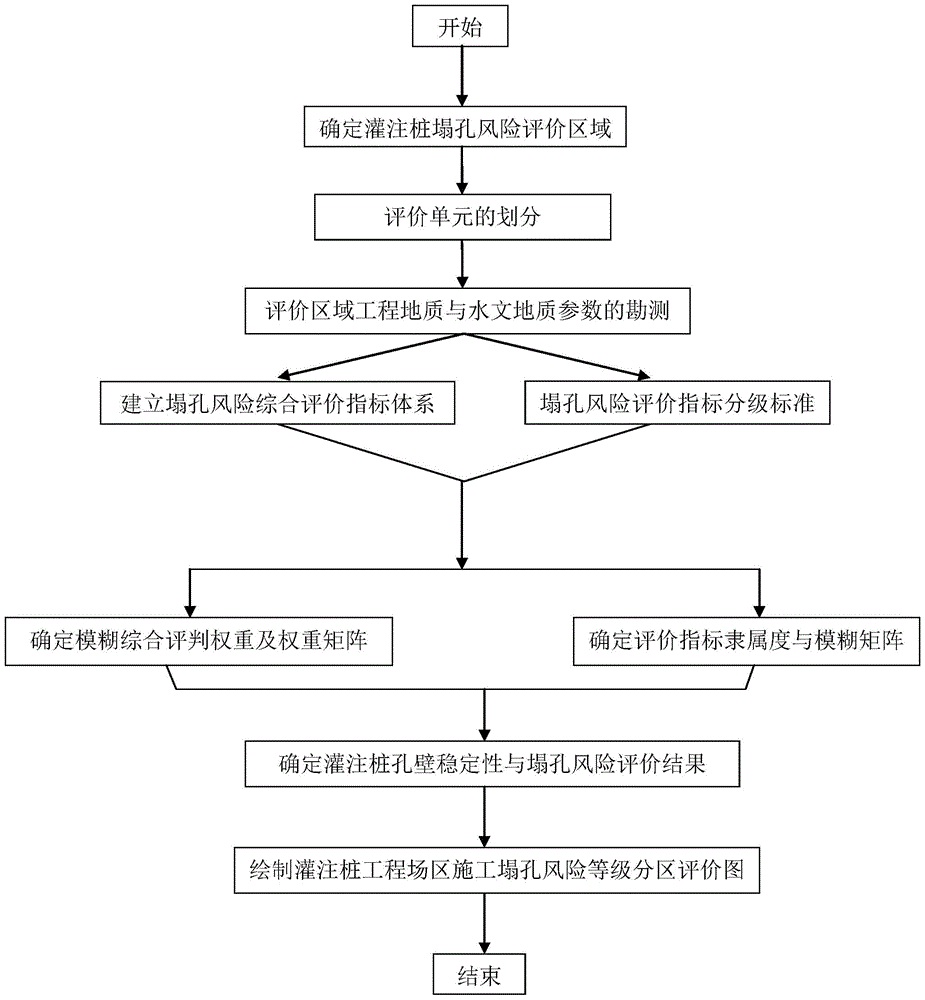

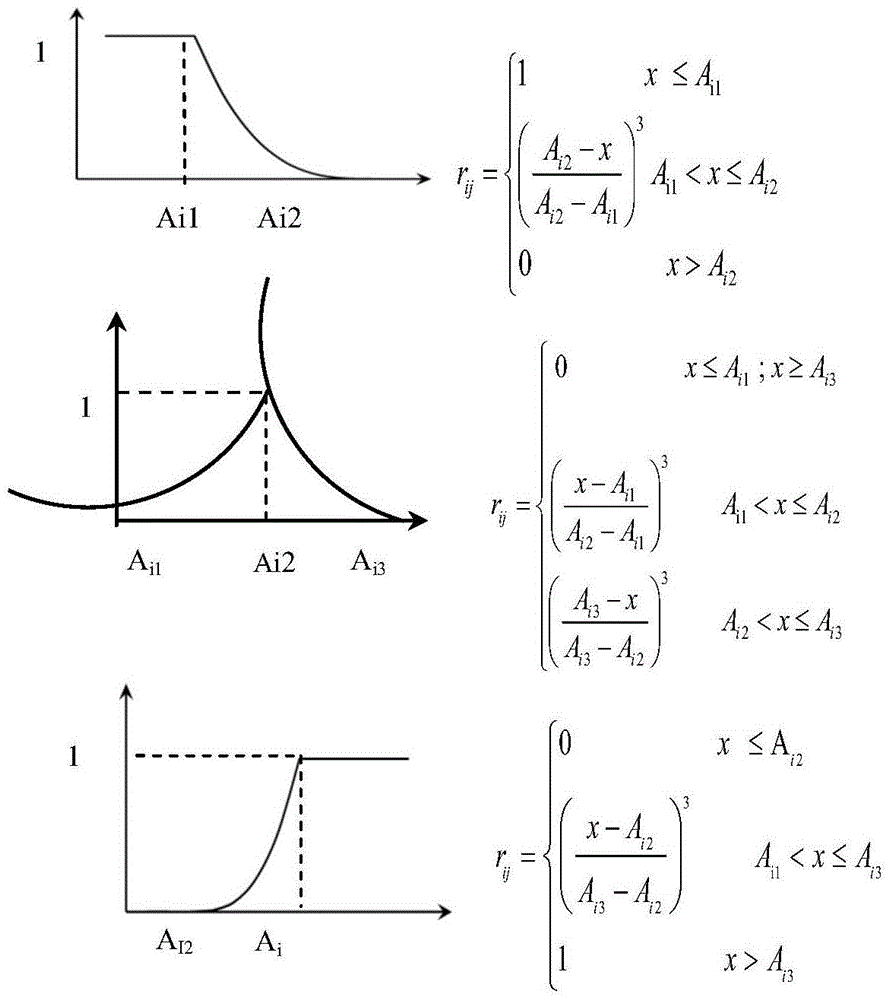

Evaluation method for hole collapse risk of foundation of cast-in-situ bored pile and application

ActiveCN105701345AImprove pore forming efficiencyImprove hole qualitySpecial data processing applicationsInformaticsMultiple factor analysisInformation quantity

The invention discloses an evaluation method for a hole collapse risk of a foundation of a cast-in-situ bored pile and application. On the basis of the basic principle of a fuzzy mathematic theory, the method is a fuzzy synthetic evaluation method for carrying out analysis and evaluation on the stability of a hole wall of the cast-in-situ bored pile and the hole collapse risk through multiple-factor analysis and evaluation. The fuzzy evaluation method not only evaluates and sorts evaluation objects according to the comprehensive scores, but evaluates the order of evaluation of the evaluation objects according to values on a fuzzy evaluation set and a maximum membership principle. The method overcomes the defect of oneness of a result of the conventional mathematical method, and the result contains abundant information quantity. The method is simple and feasible, and as for problems which cannot be subjected to number analysis from some traditional views, the problems of fuzziness and uncertainty of stability evaluation of many projects can be well solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Slurry for cross-sea bridge drilling pile drill construction and pulp making method

The invention discloses slurry used for the drilling construction of a sea-spanning bridge drilling pile, which comprises the following components: 13.5 to 16.6 percent of sea mud, 81 to 83 percent of seawater, 0.15 to 0.2 percent of slurry admixture, 1 to 3 percent of swell soil, as well as 0.4 to 0.5 percent of calcined soda; wherein, the percentage is the weight percentage; the preparing method of the slurry is as follows: the slurry admixture and the calcined soda are uniformly stirred to form the comprehensive material of the slurry admixture and the calcined soda; then after the swell soil is added into a stirring machine, the comprehensive material of the slurry admixture and the calcined soda is added and stirred uniformly; then the sea mud is added; the stirring machine is adjusted to a low-speed gear; the seawater is slowly added simultaneously when stirring; slow speed stirring is carried out for 3 to 5 minutes at first, then high speed stirring is carried out for 10 to 15 minutes, thus leading various materials to be completely decomposed and molten.

Owner:ROAD AND BRIDGE CONSTRUCTION

Multi-hole forming machine for section tube and using method thereof

InactiveCN103008444AEasy loading and unloadingEasy to replaceMetal-working feeding devicesPositioning devicesHydraulic cylinderPunching

The invention relates to a multi-hole forming machine for a section tube and a using method thereof. The multi-hole forming machine comprises a working platform, wherein the middle part of the working platform is provided with a bump for tight matching with the inner circumferential wall of the section tube, so that the section tube is stably erected on the working platform; the middle part of the bump is provided with a hollowed part, so that the circumferential walls of the bump are of equal wall thicknesses; the bump is provided with a plurality of through holes passing through the inner and outer peripheral sides of the bump; and the outer peripheral side of the bump is provided with a boring punching head on the axial leads of the through holes. The using method comprises the following steps of: I, sleeving the section tube on the bump and clamping the lower part of the section tube on the outer circumferential wall of the bump; and II, slightly pressing the upper part of a section tube sleeve, and starting an air cylinder or a hydraulic cylinder for driving the punching head to move simultaneously to complete boring work. The multi-hole forming machine is simple in structure, and a plurality of holes can be formed rapidly and synchronously in the section tube; and moreover, an operating method is easy, convenience is brought to attachment and detachment and the boring quality is good.

Owner:莆田市奔腾工贸有限公司

Rotary pump perforating piling machine

ActiveCN102251518AImprove compactnessWill not collapse holesDrill bitsDrilling rodsSoil horizonEngineering

The invention provides a rotary pump perforating piling machine which is characterized by comprising a rack, a drill rod is arranged on the rack, a diamond soil suction perforating drill bit is fixedly arranged at the lower end of the drill rod and is internally provided with a power pump, a rotary drill bit is arranged below the diamond soil suction perforating drill bit and connected with the power pump, soil stirring blades evenly distributed at the circumference are arranged around the rotary drill bit, soil suction pipes are arranged at the intervals among the soil stirring blades and are connected with a one-way mud pump valve which is connected with a mud pipe and a high-pressure diamond hydraulic power soil suction pressure pump, and the mud pipe is wound on a mud pipe roll which is arranged on the rack. In the invention, a soil semi-squeezing mode is adopted, namely, soil layers are beaten and stone blocks are crushed by the drill bit, weak soil is pumped to the ground by thesoil suction pipe, broken stones are squeezed and compacted on hole walls under the driving of the soil stirring blades, and the compactness of the squeezed hole walls is improved and collapse hardlyhappens; and the small stones are squeezed towards the hole walls and soil comes from the high-pressure pipe, thus high pore-forming speed and good pore-forming quality are achieved.

Owner:洪子云

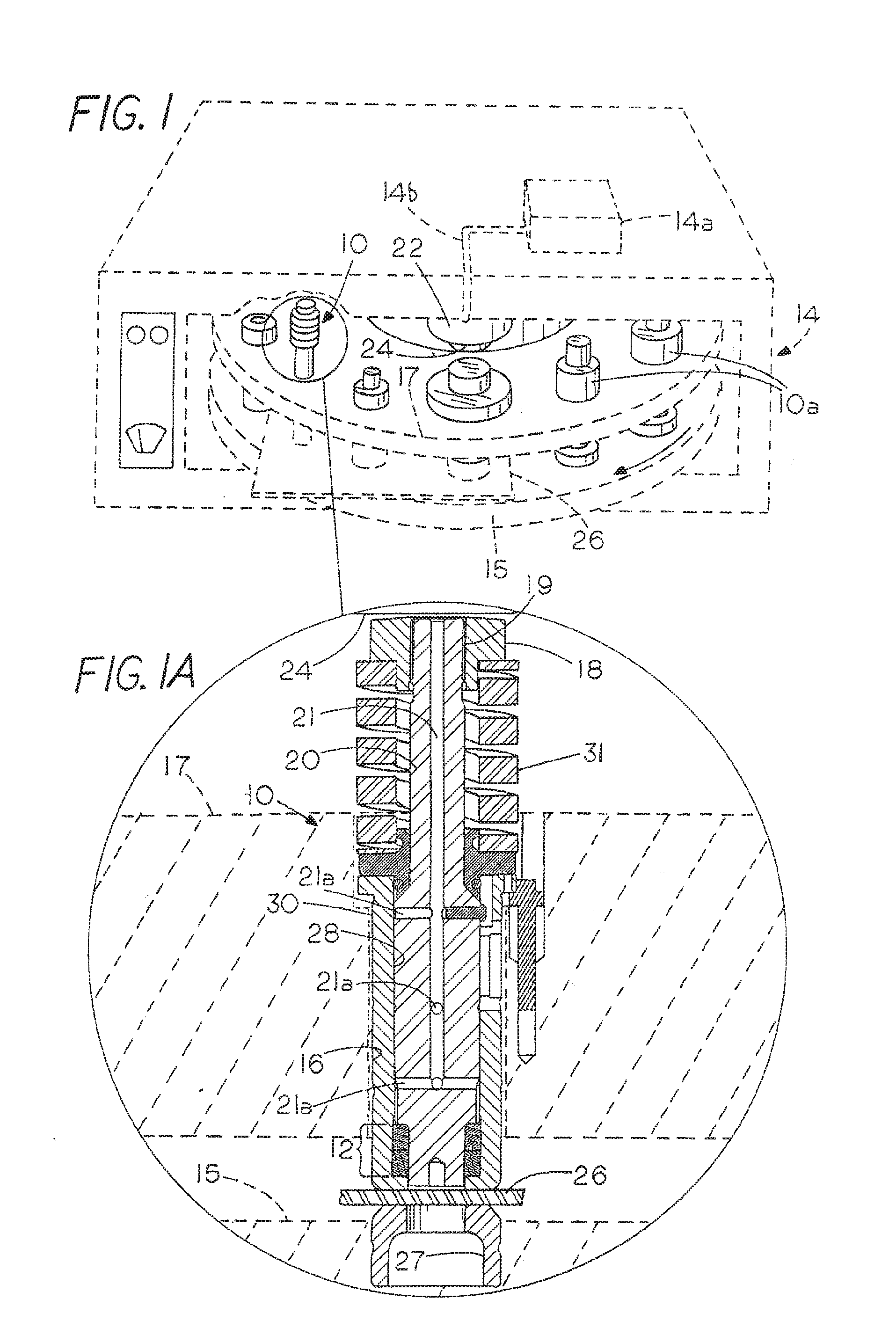

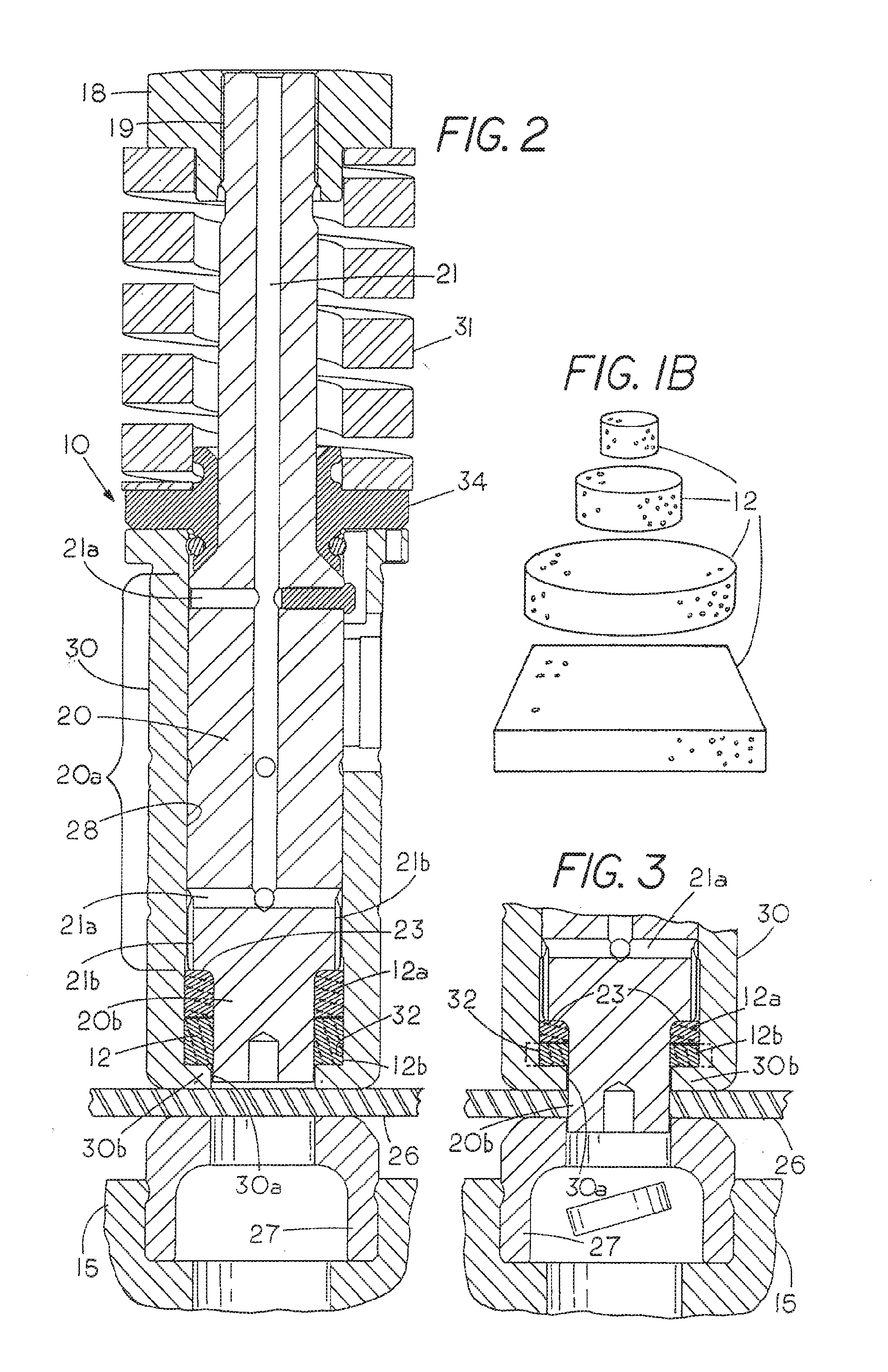

Punching and Forming Lubrication System and Lubricant Retention Matrix

InactiveUS20130047808A1Reduce and prevent in and operationReduce and prevent problemShaping toolsWork treatment devicesParticulatesReciprocating motion

A punch element is mounted for sliding movement in the guide sleeve or casing with the punch point at its lower end for forming or punching a workpiece. A stripper element is located at the lower end of the guide sleeve which defines the casing of the punch assembly, and the stripper element has an opening aligned with the punch point through which the punch point passes to engage the workpiece. A matrix placement chamber is provided within the casing between the punch point and the guide sleeve so as to at least partially surround the punch point and at least one flexible lubrication matrix body is contained in the matrix placement chamber inside the housing. The matrix which is enclosed entirely within the casing of the unitary punch assembly in which the punch reciprocates comprises an integral porous elastic multi-cellular polymeric body containing a multiplicity of hollow communicating cells adapted to hold a lubricant in fluid communication with the sidewalls of at least the point of the punch and in a preferred form completely surrounds the punch point. The lubrication matrix can also hold a cleaning agent or an abrasive in particulate form.

Owner:MATE PRECISION TOOLING

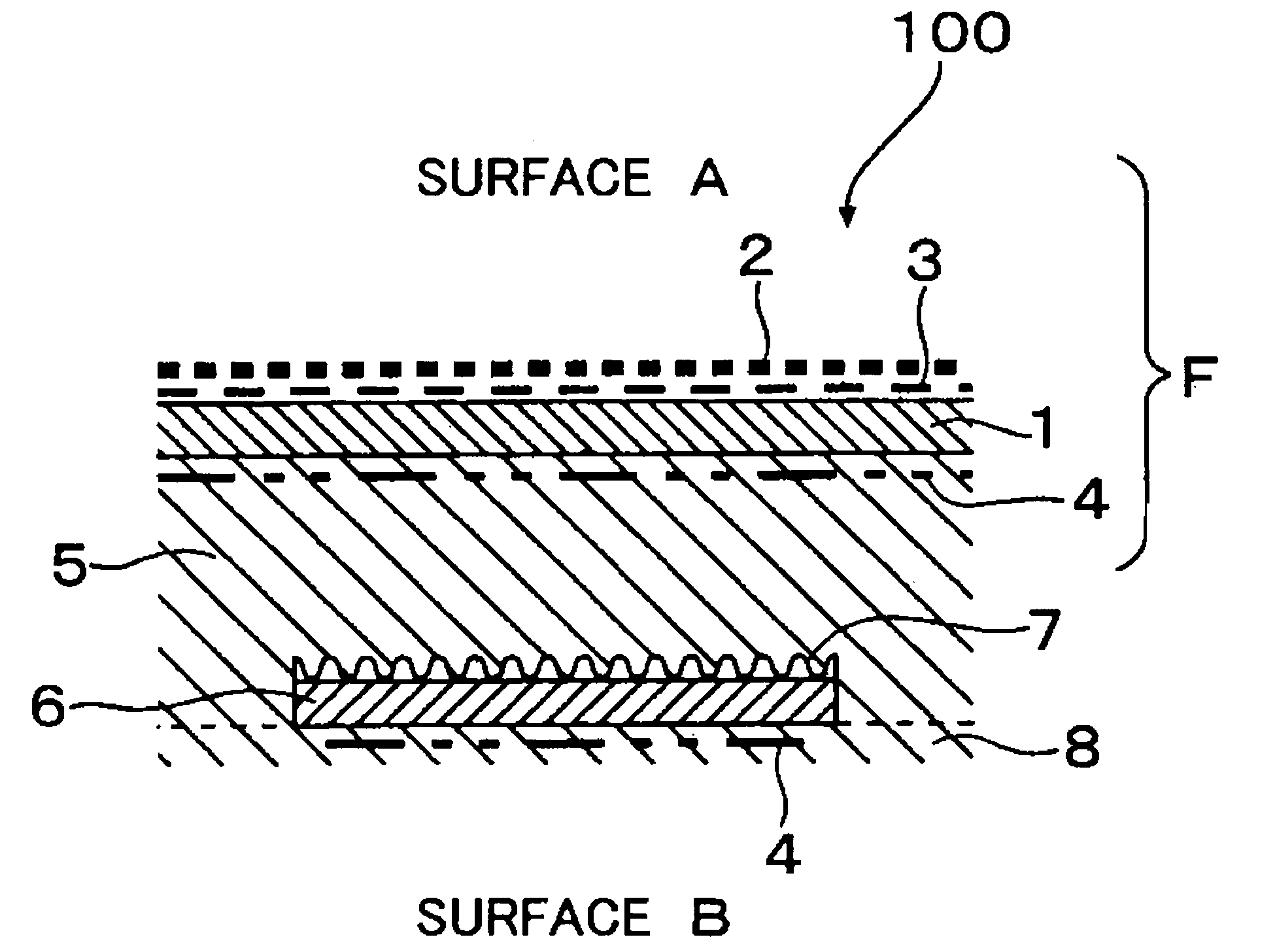

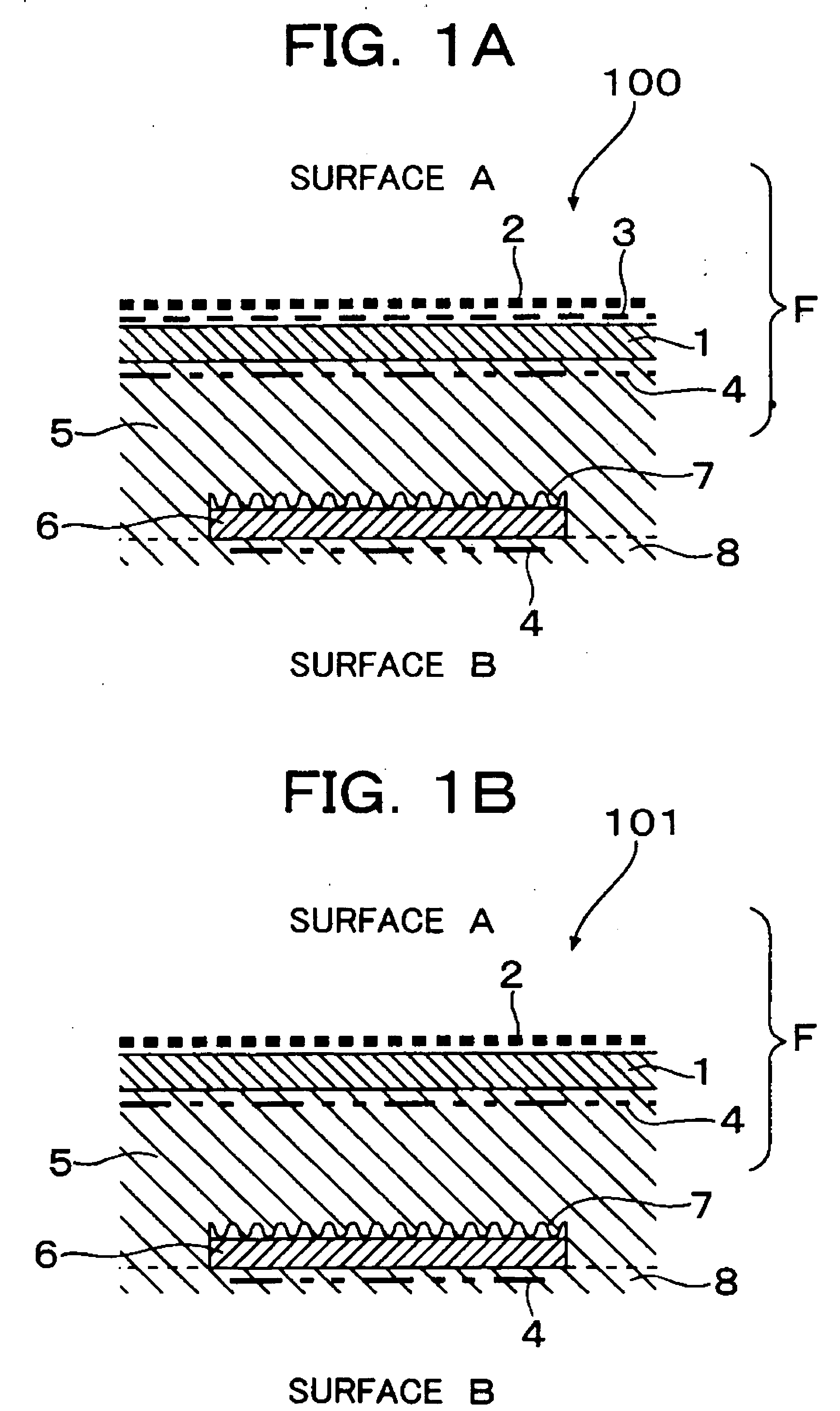

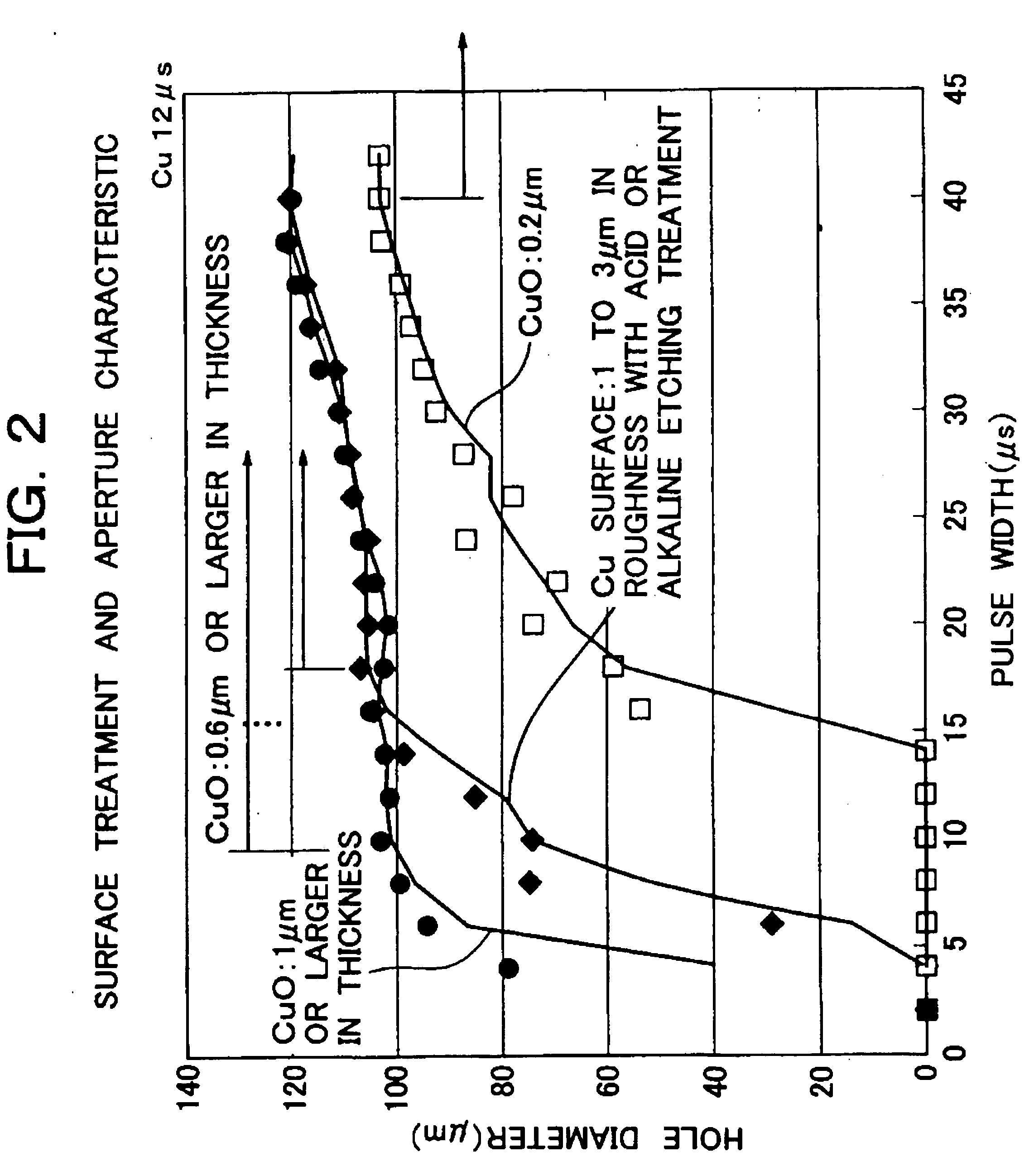

Printed circuit board and method for processing printed circuit board

InactiveUS20050244621A1Low production costUniform processing qualityLight absorption dielectricsCircuit board tools positioningLaser lightPrinted circuit board

The invention is to provide a printed circuit board in which advance of packaging density of the printed circuit board and reduction in production cost can be attained while processing quality can be made uniform, a method for processing the printed circuit board and a method for producing the printed circuit board. There is provided a printed circuit board including an alternate laminate of electric conductor layers and electrically insulating layers, wherein a coating layer capable of absorbing laser light but insoluble in an etching solution dissolving the electric conductor layers is provided on a front surface of a first one of the electric conductor layers. In this case, the coating layer may be provided on a front surface of a rear one of the electric conductor layers. Each of the electric conductor layers may contain Cu as a main component while the coating layer may contain CuO as a main component. The coating layer may have a thickness not thinner than 0.6 μm.

Owner:HITACHI SEIKO LTD

Drill

ActiveUS8734067B2Improve hole qualityExtended service lifeWood turning toolsTransportation and packagingHigh rateDistal portion

A drill includes a pair of main cutting edges extending from a distal portion of the drill to a position close to a proximal end of the drill to entirely define a two-edge configuration, and a pair of auxiliary cutting edges extending between positions at the distal and proximal sides of a maximum diameter position to partly define a four-edge configuration. A ridgeline of each auxiliary cutting edge is located within an angle smaller than 90° from a ridgeline of the corresponding main cutting edge toward the rear in a rotation direction of the drill. The point angle of the auxiliary cutting edges increases at a higher rate than the point angle of the main cutting edges in a predetermined range from the maximum diameter position toward a distal end of the drill.

Owner:SUBURU CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com