Opening method of CFRP (Carbon Fiber Reinforced Plastics) and CFRP work-piece

A workpiece and hole milling technology, which is applied in the field of composite material processing technology, can solve problems such as failure to meet CFRP processing requirements, lower tool surface strength, and failure to meet process requirements, etc., to achieve good hole quality, improved service life, and fast hole opening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

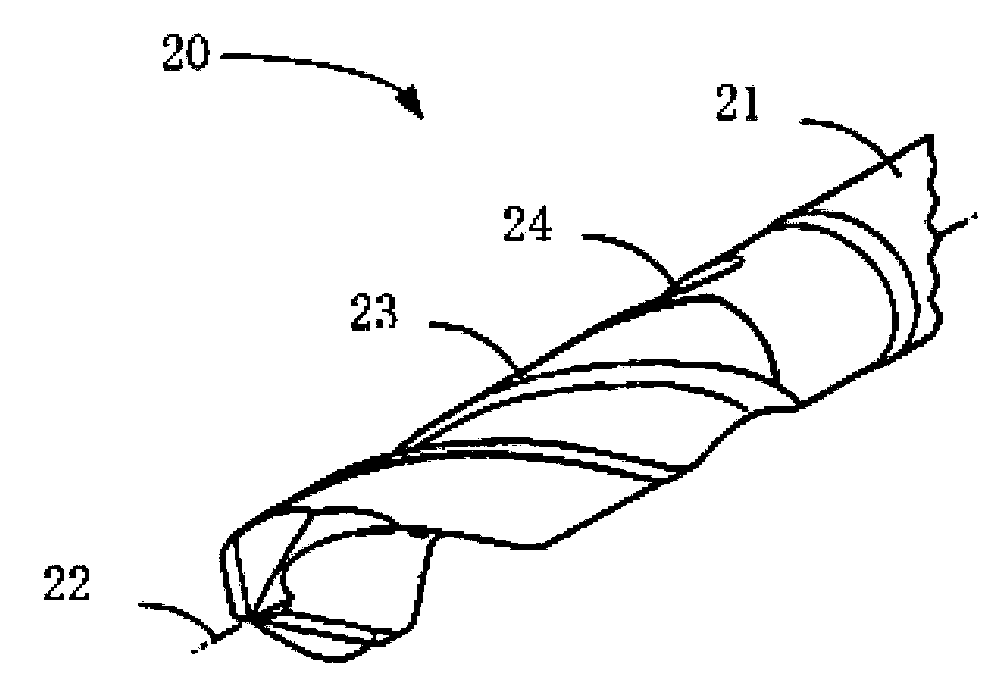

[0031] The inventor found through analysis that when the CFRP material is drilled, the heat dissipation is taken away by external cooling and product waste. Since CFRP is processed by dry cutting, the external cooling is heat dissipated and transferred to the air, which is a slow heat dissipation method. The brittle fracture can only produce little waste chips, and the heat is removed very little, so the tool temperature will be high, which will reduce the tool life.

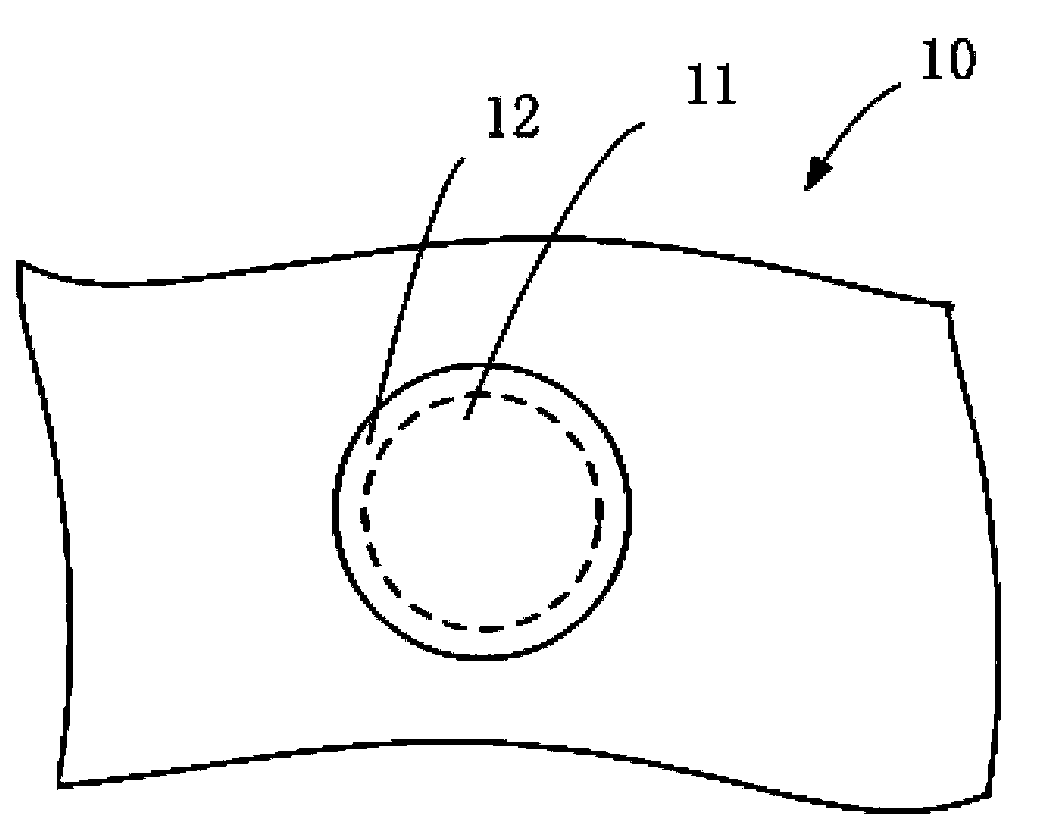

[0032] For this reason, the present invention provides a kind of drilling method of CFRP, at first with the first drill bit that has diamond coating, CFRP is drilled (the drilling at this moment is rough drilling), forms the first hole, then uses A second diamond-coated drill bit reams the first hole (reaming, ie fine drilling).

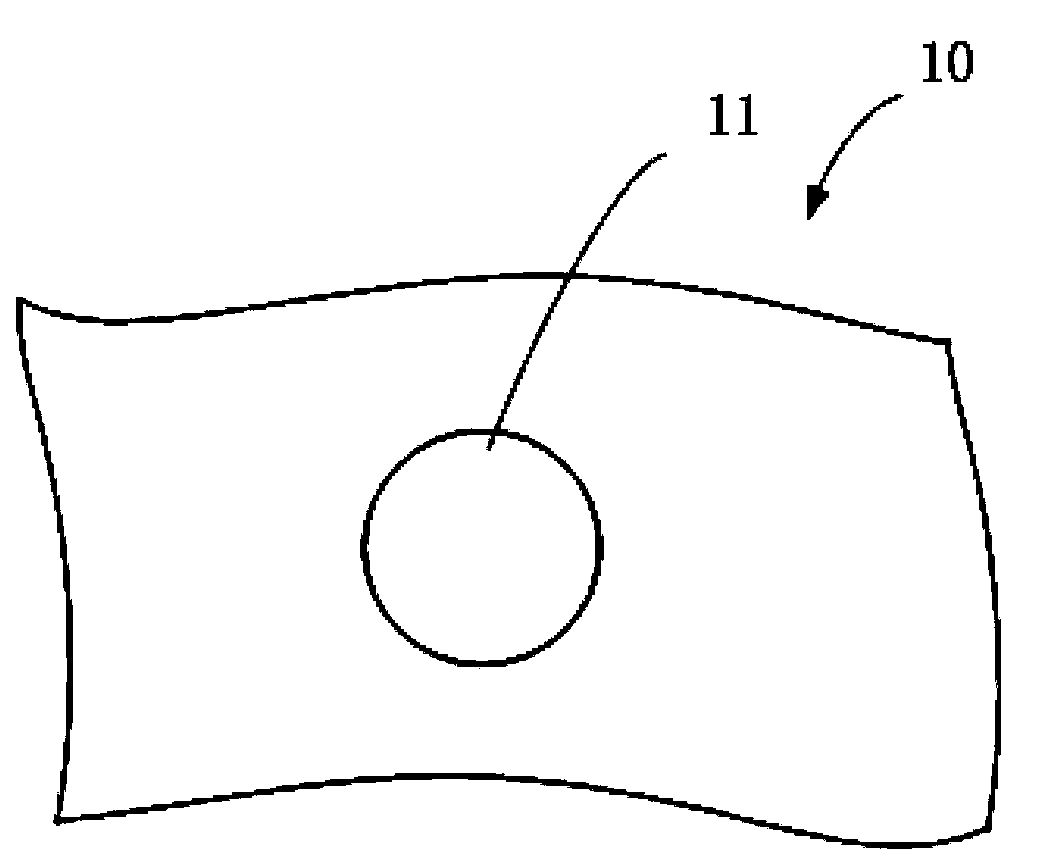

[0033] Such as figure 1 As shown, in a specific embodiment, when the CFRP plate 10 is drilled (that is, rough drilled), the rotational speed of the first drill bit can be faster, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com