Numerical control machining method for thin-wall copper electrode

A processing method, copper electrode technology, applied in the field of mold manufacturing, to achieve the effect of reducing deformation, balancing cutting allowance, and smooth cutting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

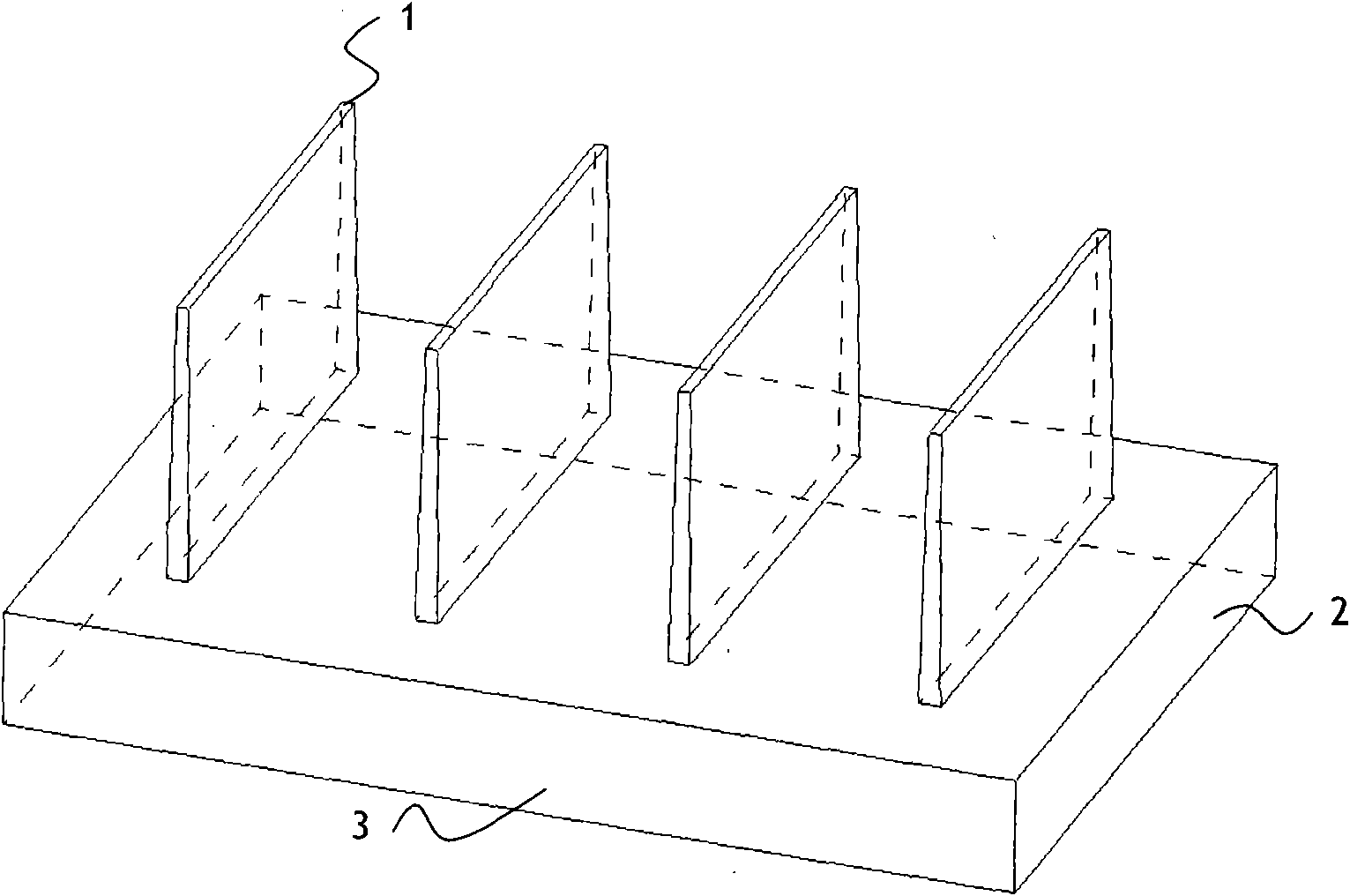

[0027] Below in conjunction with accompanying drawing, the application of the present invention is further described:

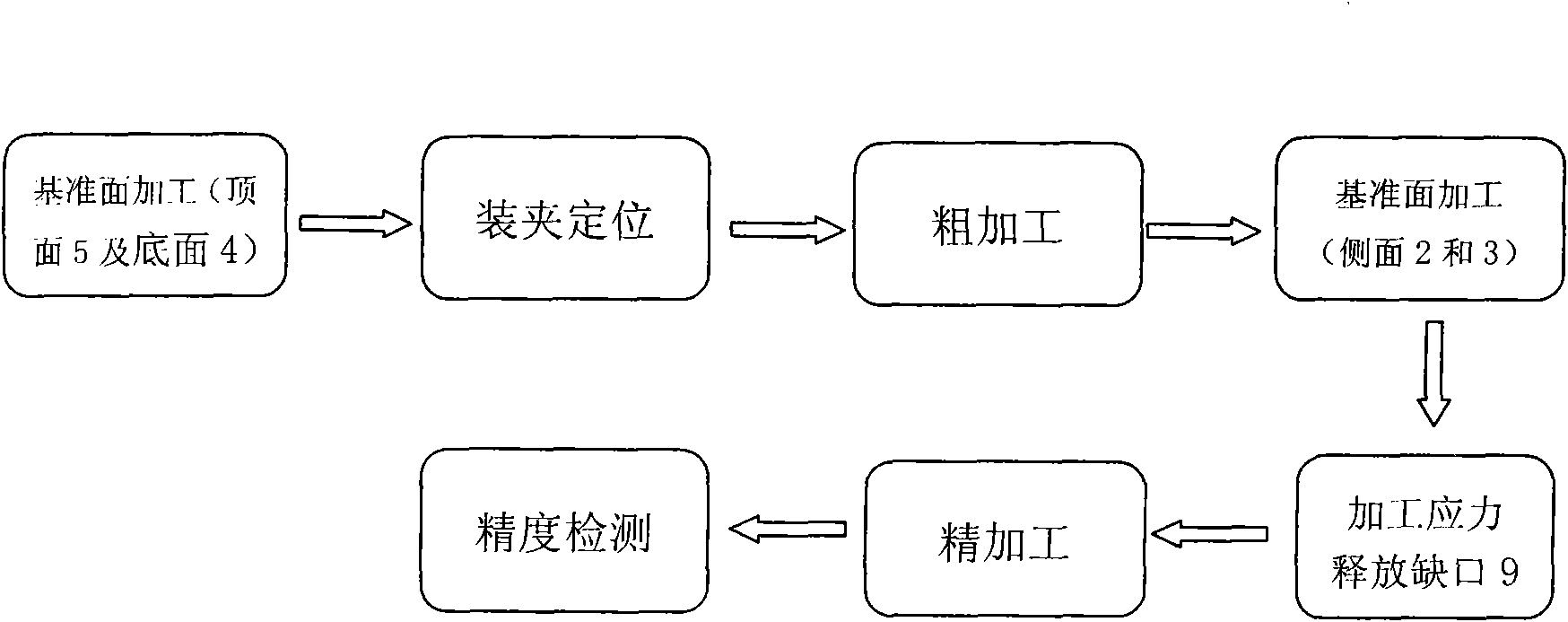

[0028] exist figure 2 In, for processing figure 1 The process of the workpiece in the middle is arranged. That is to say, from first to last: datum plane machining (datum plane 5 and datum plane 4), clamping and positioning, rough machining, datum plane machining (sides 2 and 3), machining stress relief notch 9, finishing machining, precision testing.

[0029] The specific processing method is as follows:

[0030] 1. Reasonable selection of fixtures and tools.

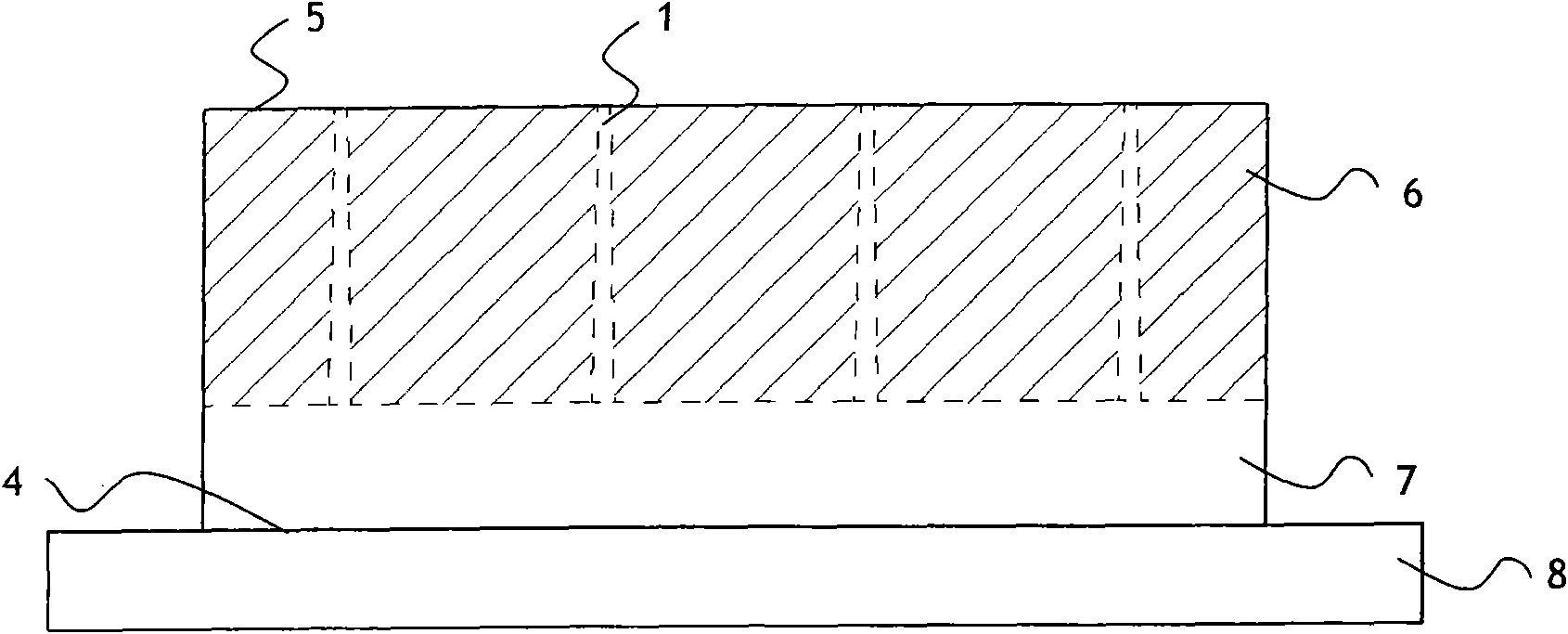

[0031] refer to image 3 , considering the accuracy of the benchmark during EDM, the workpiece blank is pre-processed with the top surface 5 and the bottom surface 4, and then fastened on the pressure plate 8 with screws, and then the pressure plate 8 together with the workpiece blank is fixed on the machine tool table.

[0032] refer to Figure 4 , Appropriately increasing the rake angle and r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com