Patents

Literature

293 results about "Process Measures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process measures are the evidence-based best practices that represent a health system’s efforts to systematize its improvement efforts. To illustrate this, I’ll use a patient injury prevention example.

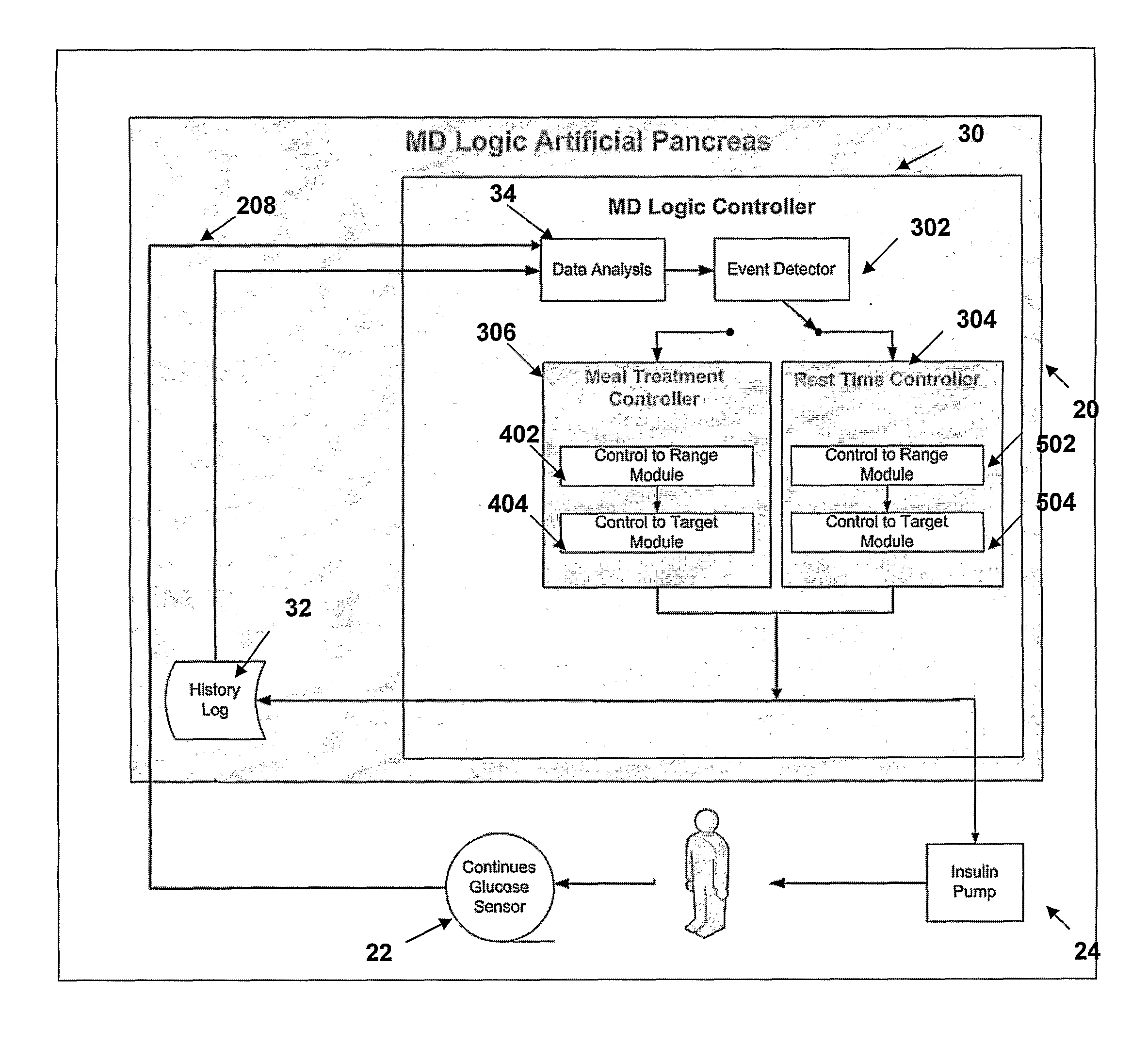

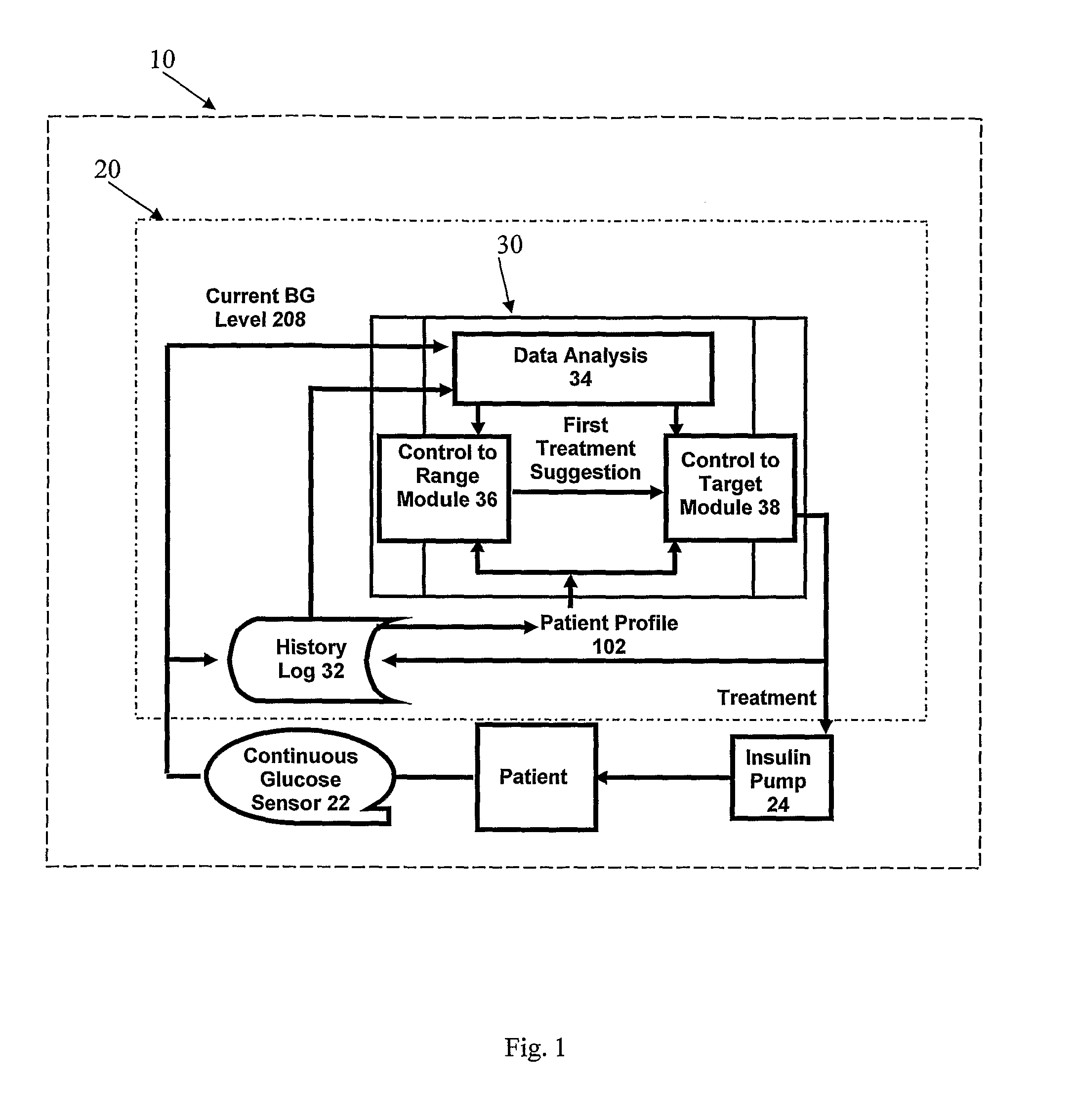

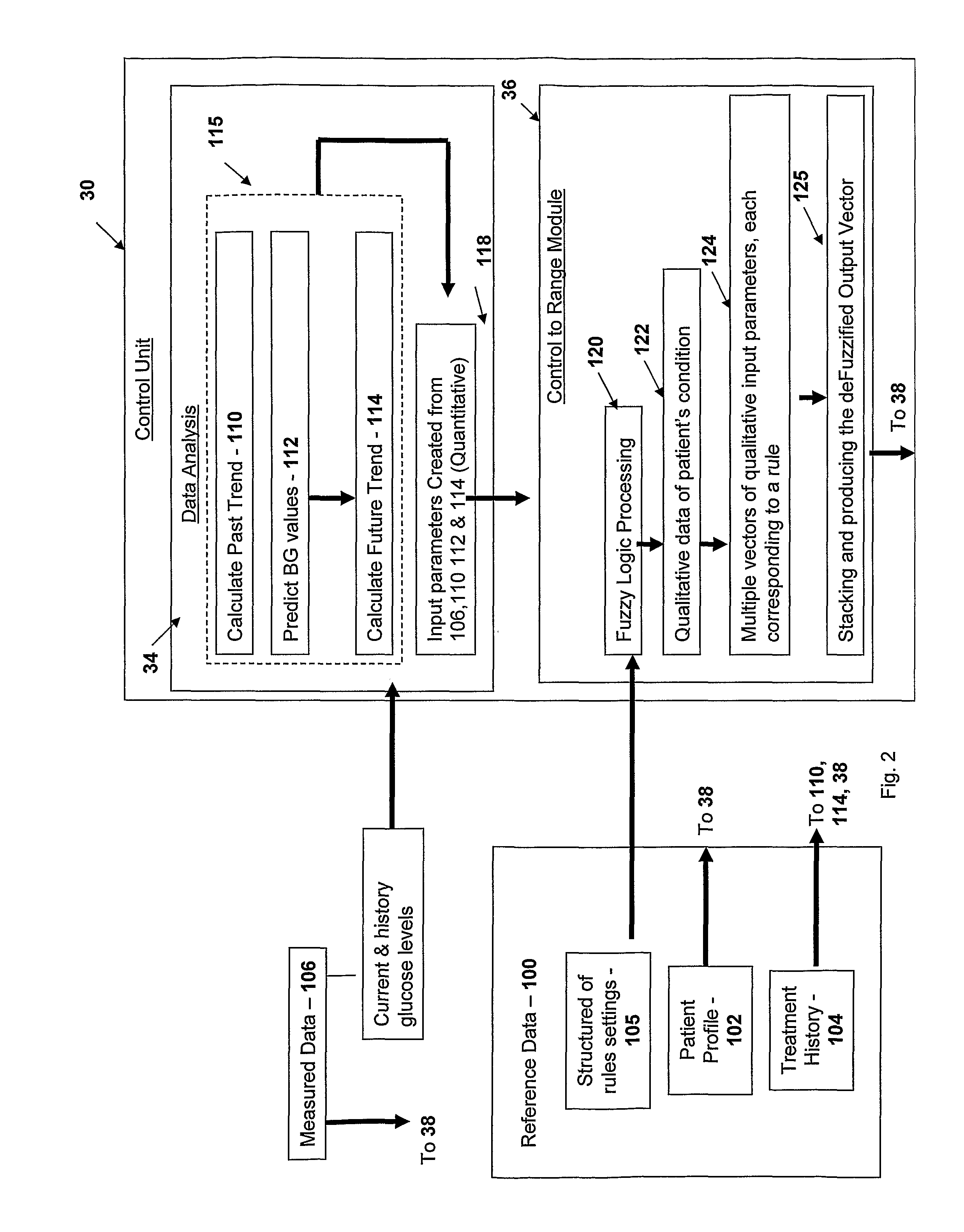

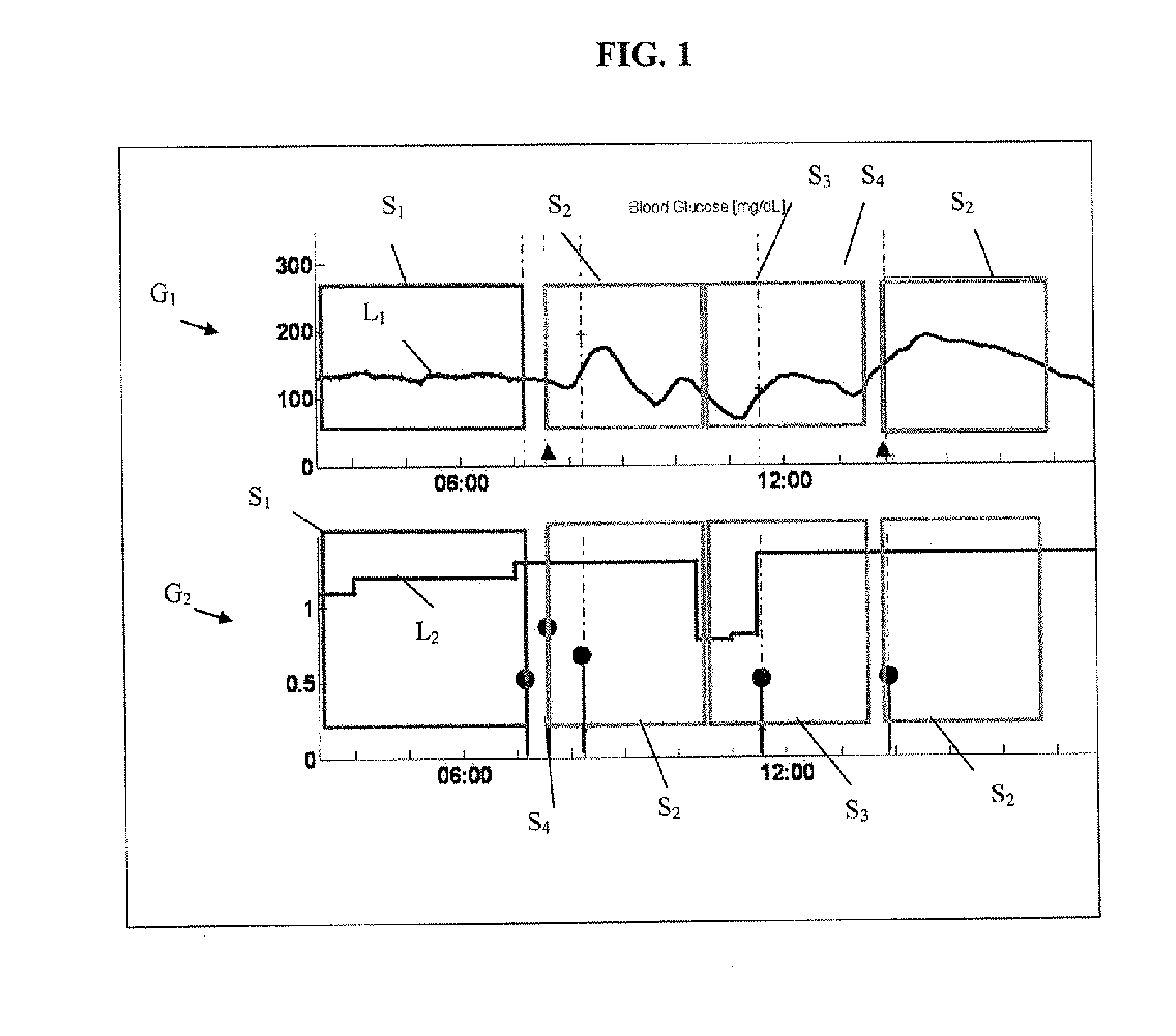

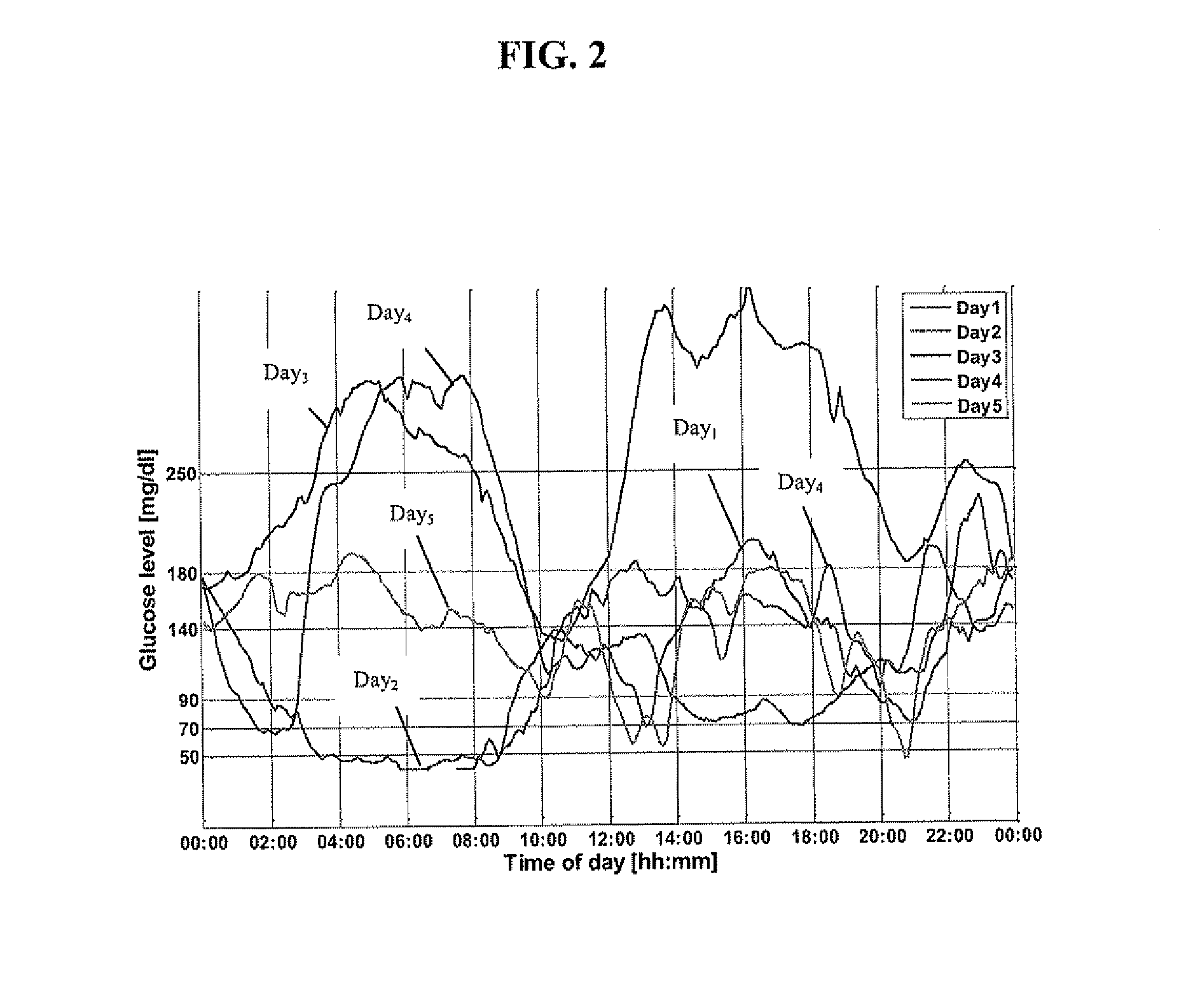

Method and system for automatic monitoring of diabetes related treatments

InactiveUS20120123234A1Easy to controlAvoiding severe hypoglycemia eventMedical simulationInfusion syringesMedicineProcess Measures

The present invention discloses a monitoring system and method for use in monitoring diabetes treatment of a patient. The system comprises a control unit comprising a first processor module for processing measured data indicative of blood glucose level and generating first processed data indicative thereof, a second processor module comprising at least one fuzzy logic module; the second processor module receives input parameters corresponding to the measured data, the first processed data and a reference data including individualized patient's profile related data, to individualized patient's treatment history related data and processes the received data to produce at least one qualitative output parameter indicative of patient's treatment parameters, such that the second processor module determines whether any of the treatment parameters is to be modified.

Owner:DREAMED DIABETES

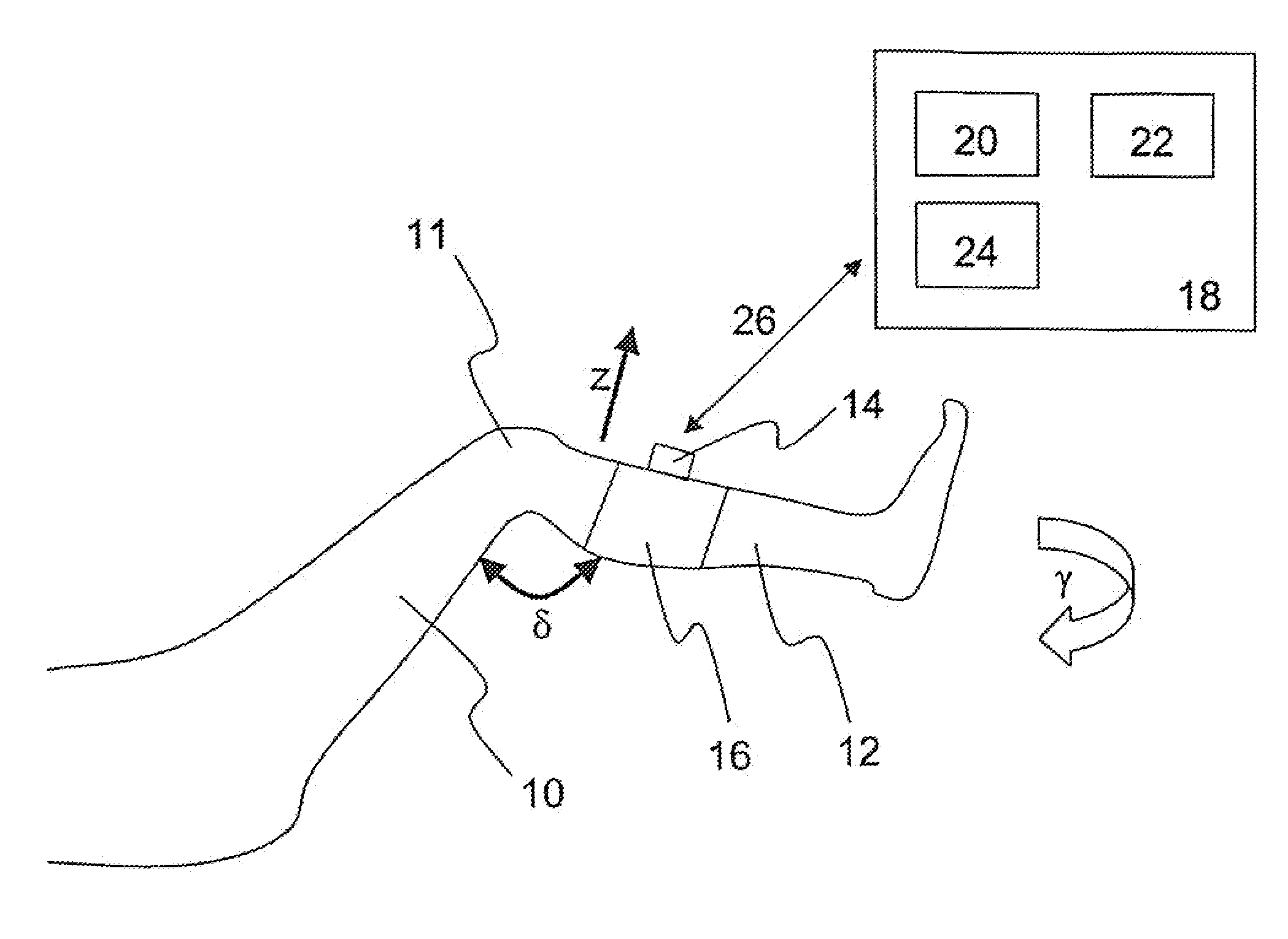

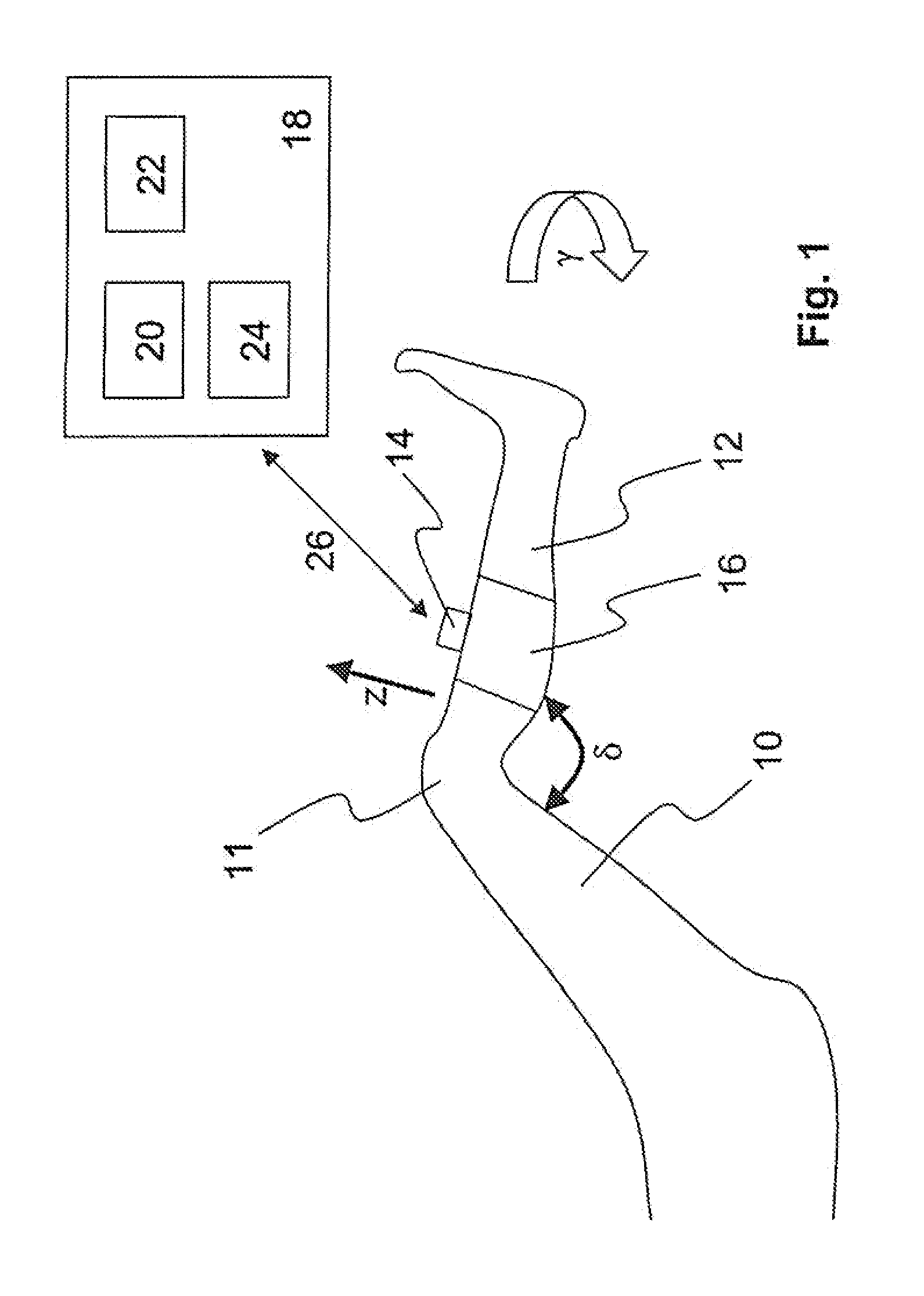

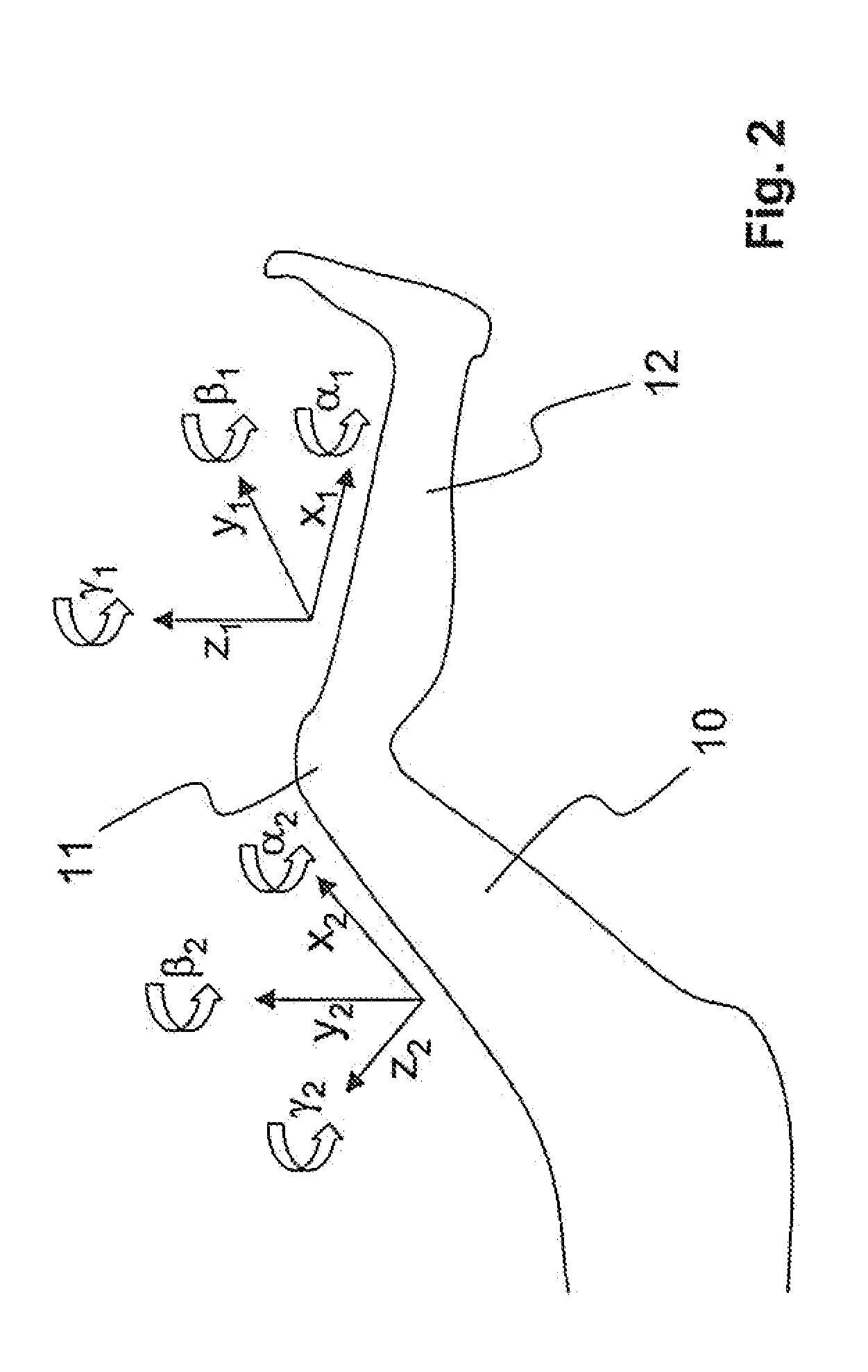

Device for determining the stability of a knee joint

InactiveUS20110213275A1Simple handlingSimple structurePerson identificationInertial sensorsPhysical medicine and rehabilitationProcess Measures

The invention relates to a device for determining the stability of a knee joint. The device comprises includes a measuring sensor (14), which can be attached via a fastening device (16) to a lower leg (12) associated with the knee joint (11). The measuring sensor (14) is designed to measure an acceleration in at least one direction (z) during a movement of the lower leg (12). Furthermore, a processing device (18) is provided for processing measured values of the measuring sensor (14) in order to infer the stability of the knee joint (11) from the processed measured values.

Owner:BORT

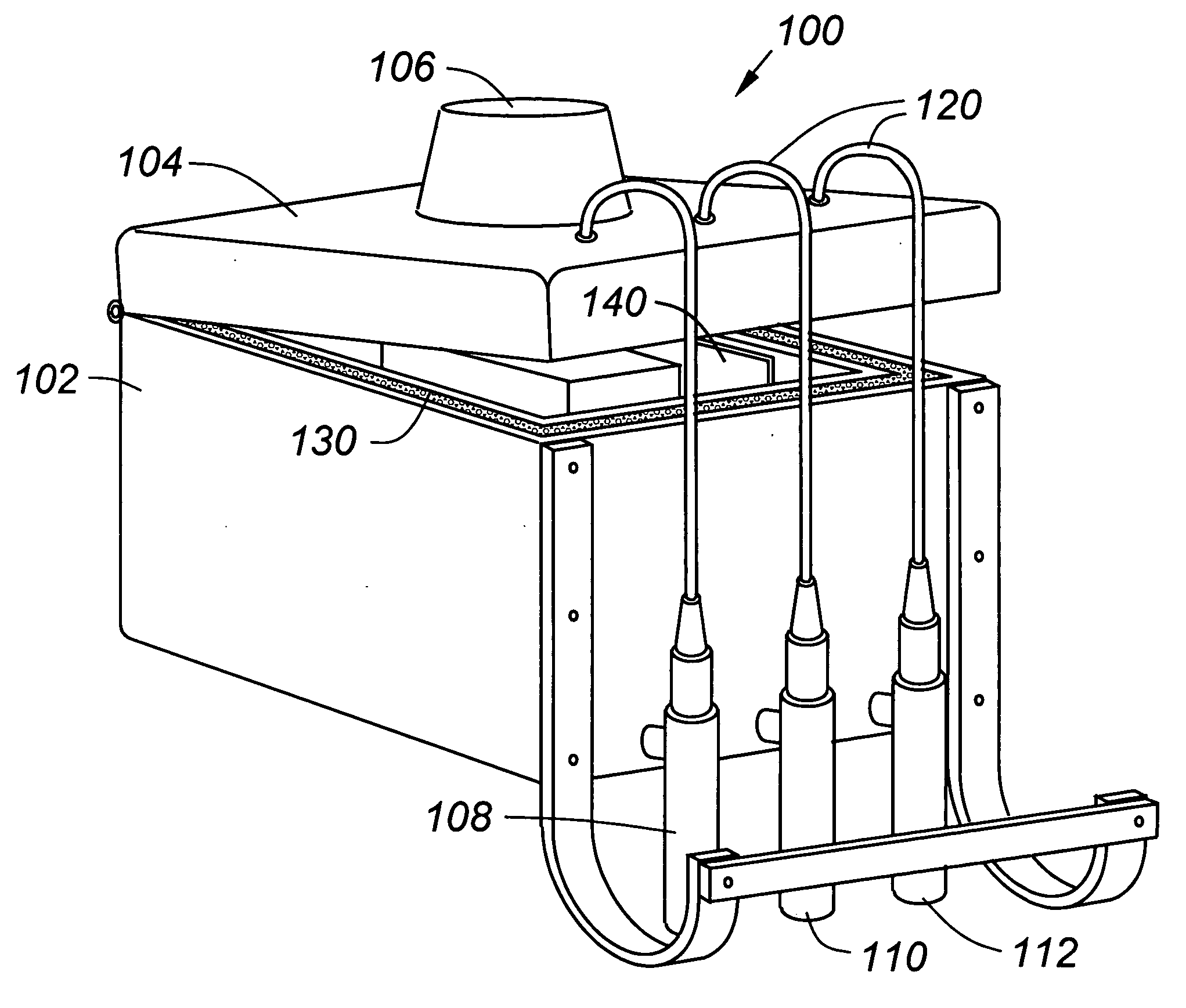

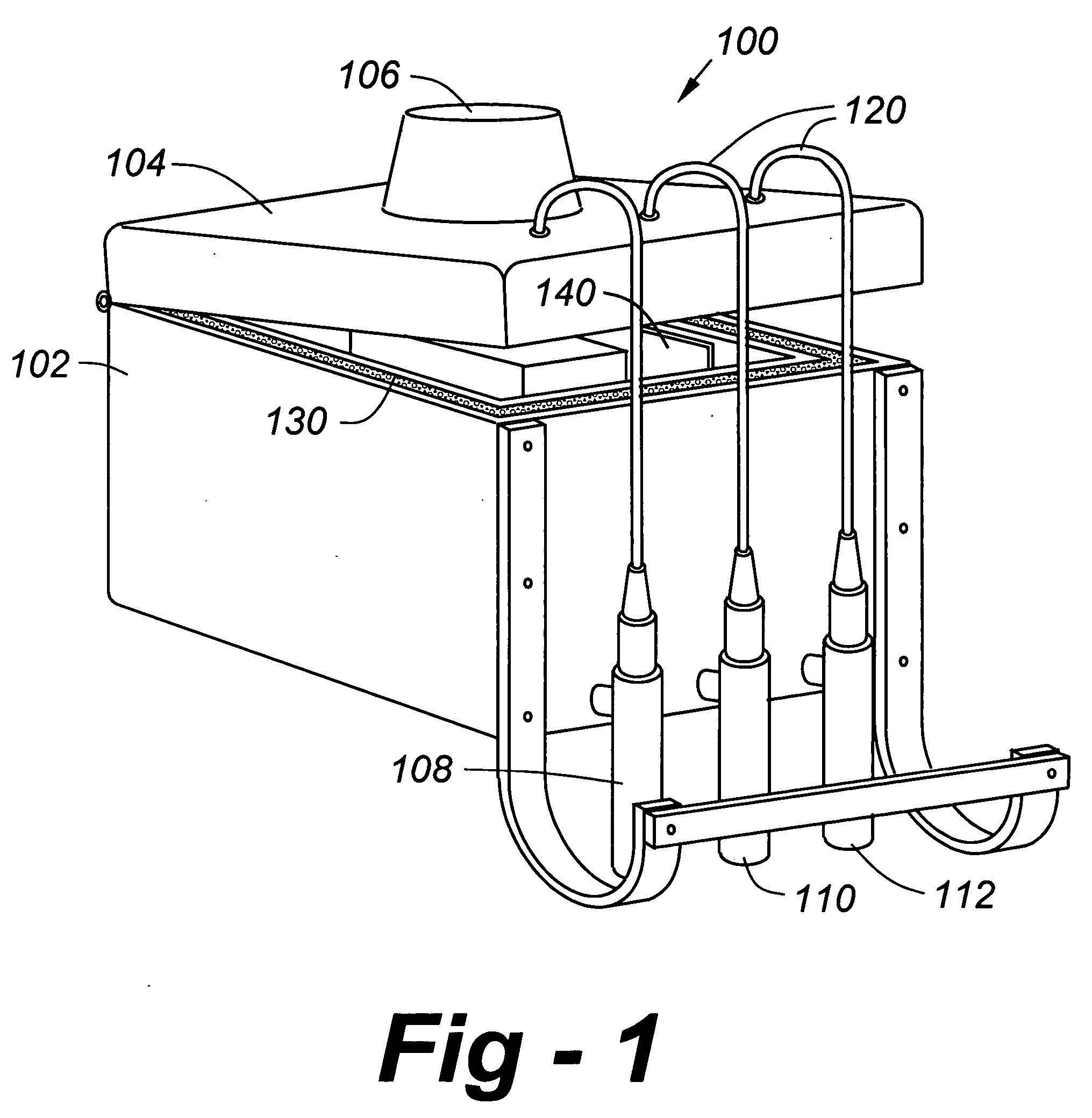

Water-quality assessment system

InactiveUS20050207939A1More transmissionExisting designTesting waterBiological testingTotal dissolved solidsPhosphate

A simple, effective and inexpensive water-quality measurement system comprises a housing suitable for travel on or in a body of water; one or more sensors for measuring water properties as the housing travels; a memory for storing information relating to the measured water properties; and software for processing measured properties. This invention combines into a single, inexpensive, and comprehensive system the sensors, computer hardware, signal-processing, Geographic Information System data, and Decision Support Software. This integration yields a system of novel and unparalleled utility. The water properties measured by the system may include: water temperature, water conductivity, pH level, dissolved oxygen, turbidity, water depth, salinity, total dissolved solids (TDS), ORP, chlorides, nitrates, and phosphates. A geographic information system (GIS) based on a global positioning satellite (GPS) technology is operative to determine geographic location and other factors, and an internal or external processor is operative to generate a map coordinating one or more of the listed characteristics to one or more of the water properties. A barometric pressure sensor may also be provided. In the preferred embodiment, the housing is a floating buoy.

Owner:MICHIGAN TECHNOLOGICAL UNIVERSITY

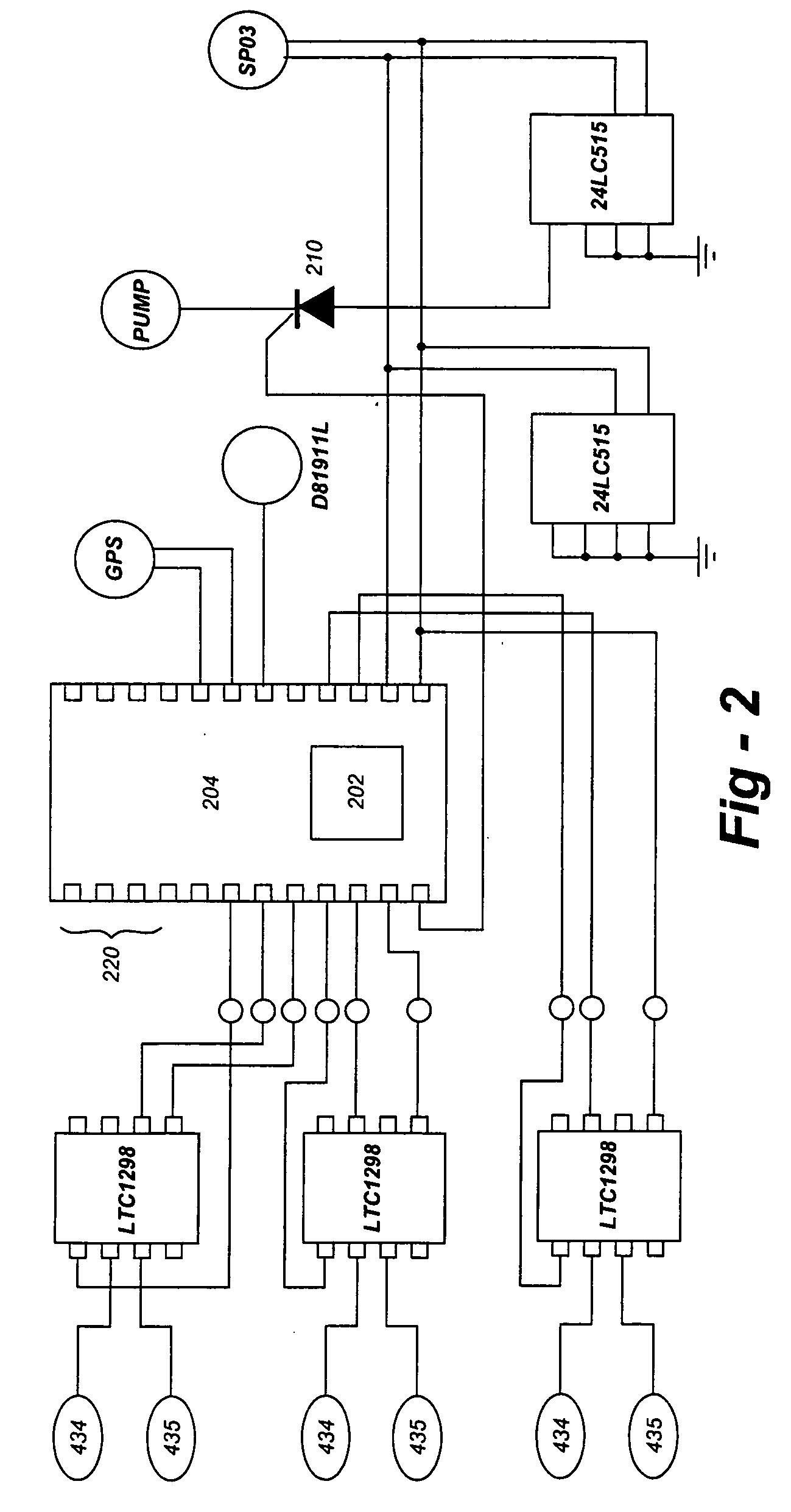

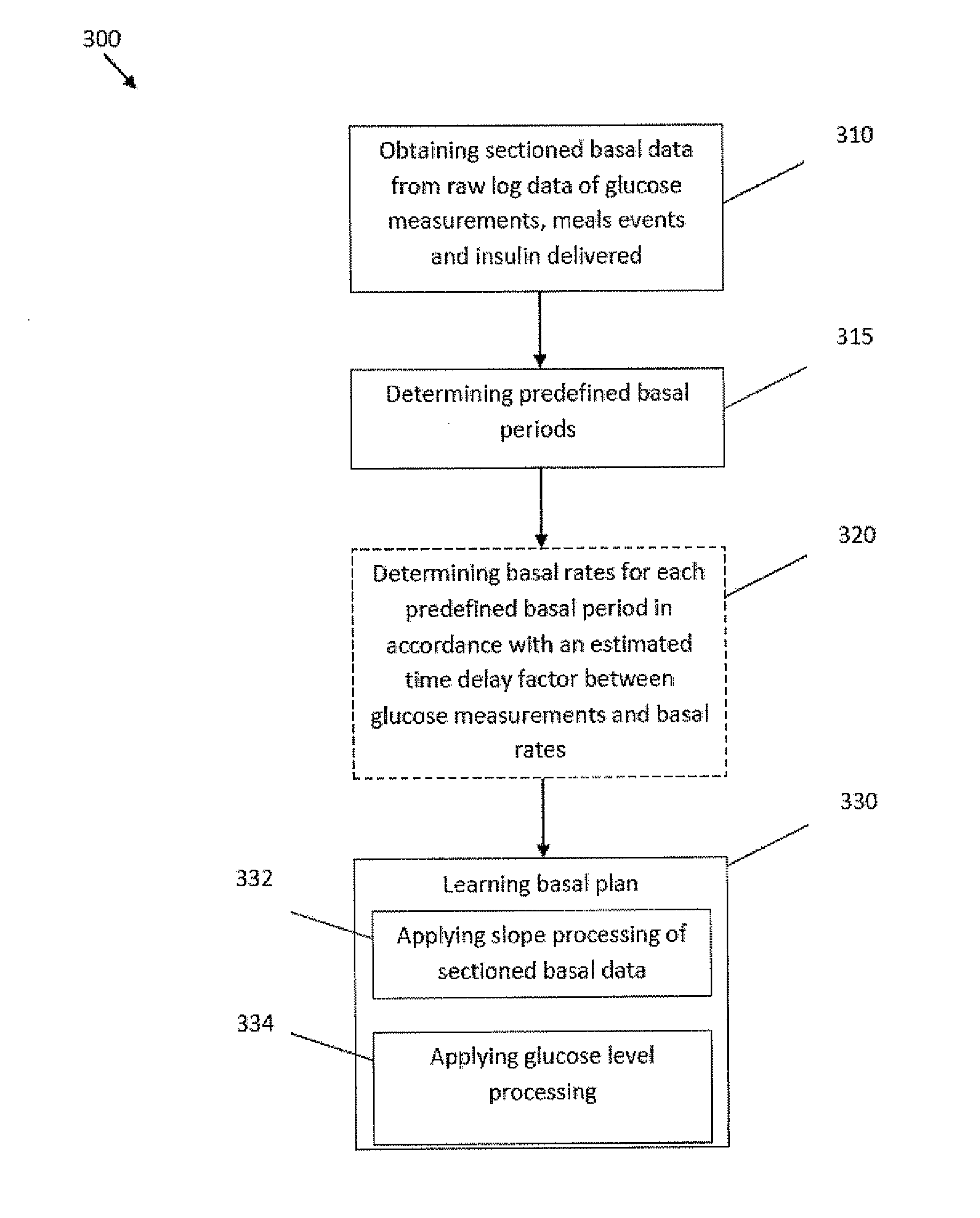

Monitoring device for management of insulin delivery

ActiveUS20120246106A1Minimize changesDrug and medicationsMedical devicesInsulin activityTreatment management

Monitoring system and method for use with diabetic treatment management. The system includes: a communication interface configured to permit access to stored raw log data, obtained over a certain time, being indicative of glucose measurements, meals consumed and insulin delivery; and a control unit including an unsupervised learning controller configured to receive and process said raw log data and determine at least one global insulin pump setting of basal rate, correction factor, carbohydrate ratio and insulin activity curve parameters. The system may include a processing unit including a first processor for processing measured data indicative of blood glucose level and generating first processed data, a second processor including at least one fuzzy logic module which receives input parameters corresponding to the measured data, the first processed data and a reference data, and processes the data to produce a qualitative output parameter to determine whether any treatment parameter should be modified.

Owner:DREAMED DIABETES

Method and computer program product for creating enterprise management systems

ActiveUS20160328217A1Software maintainance/managementModel driven codeDashboardRole-based access control

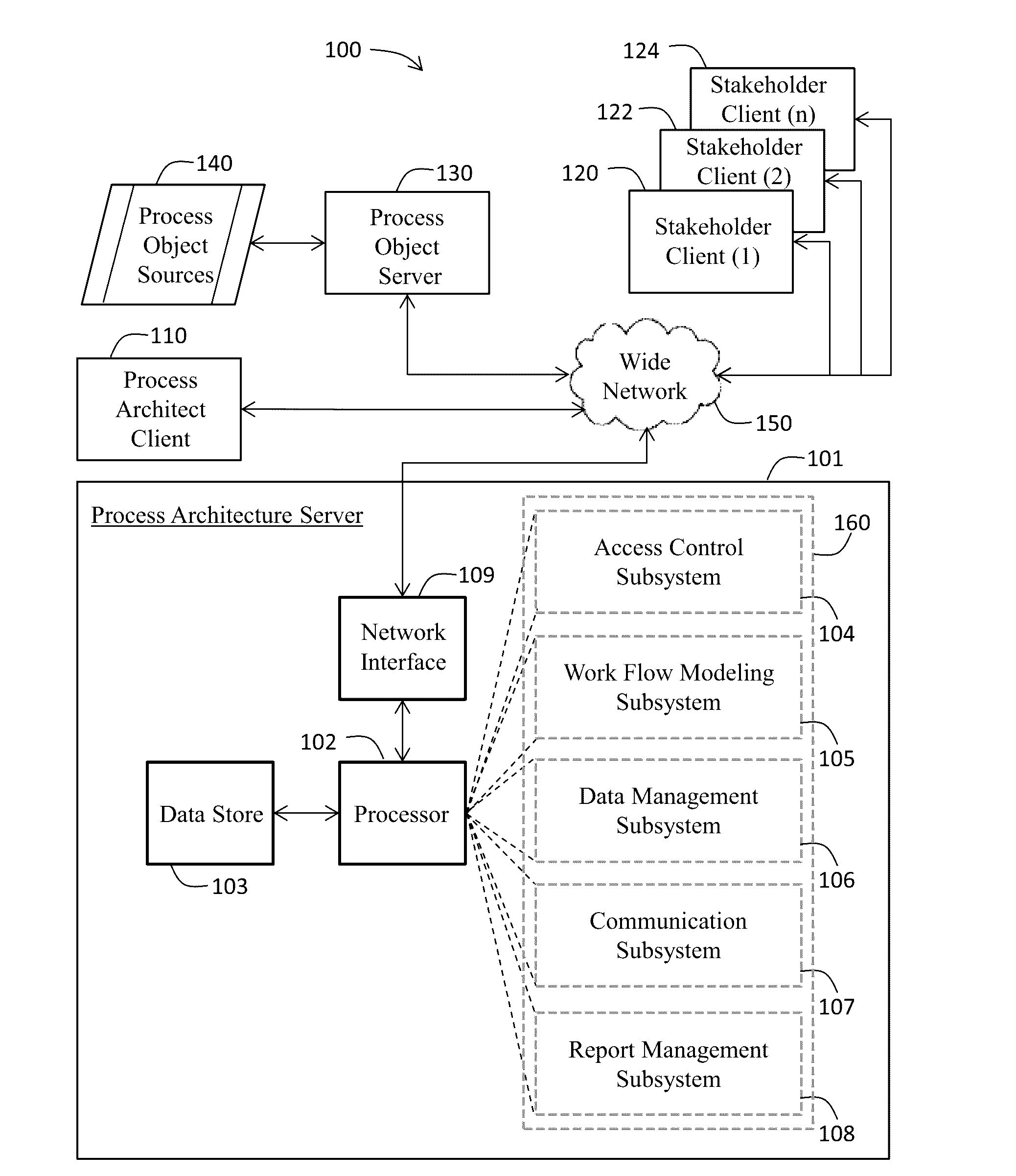

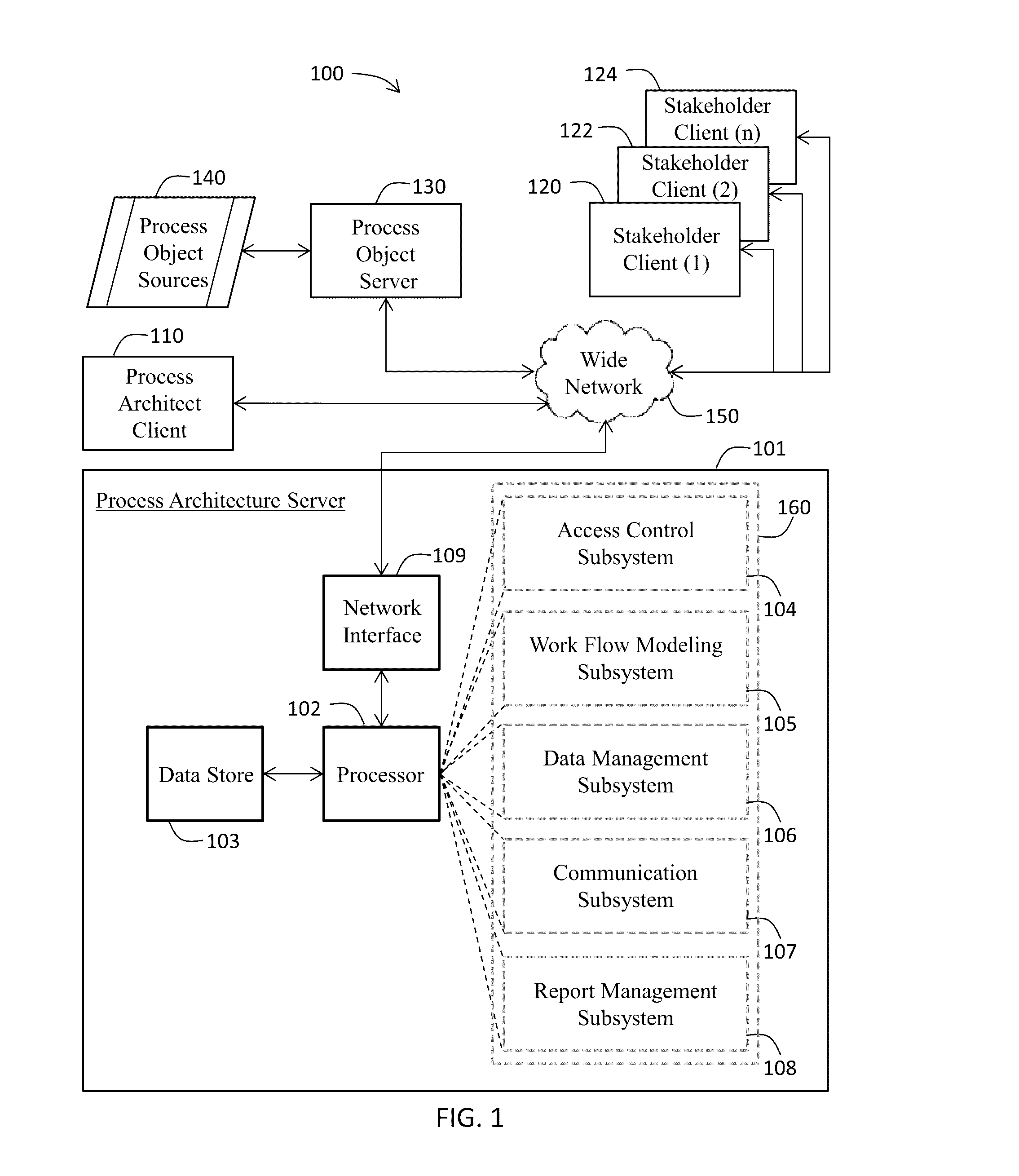

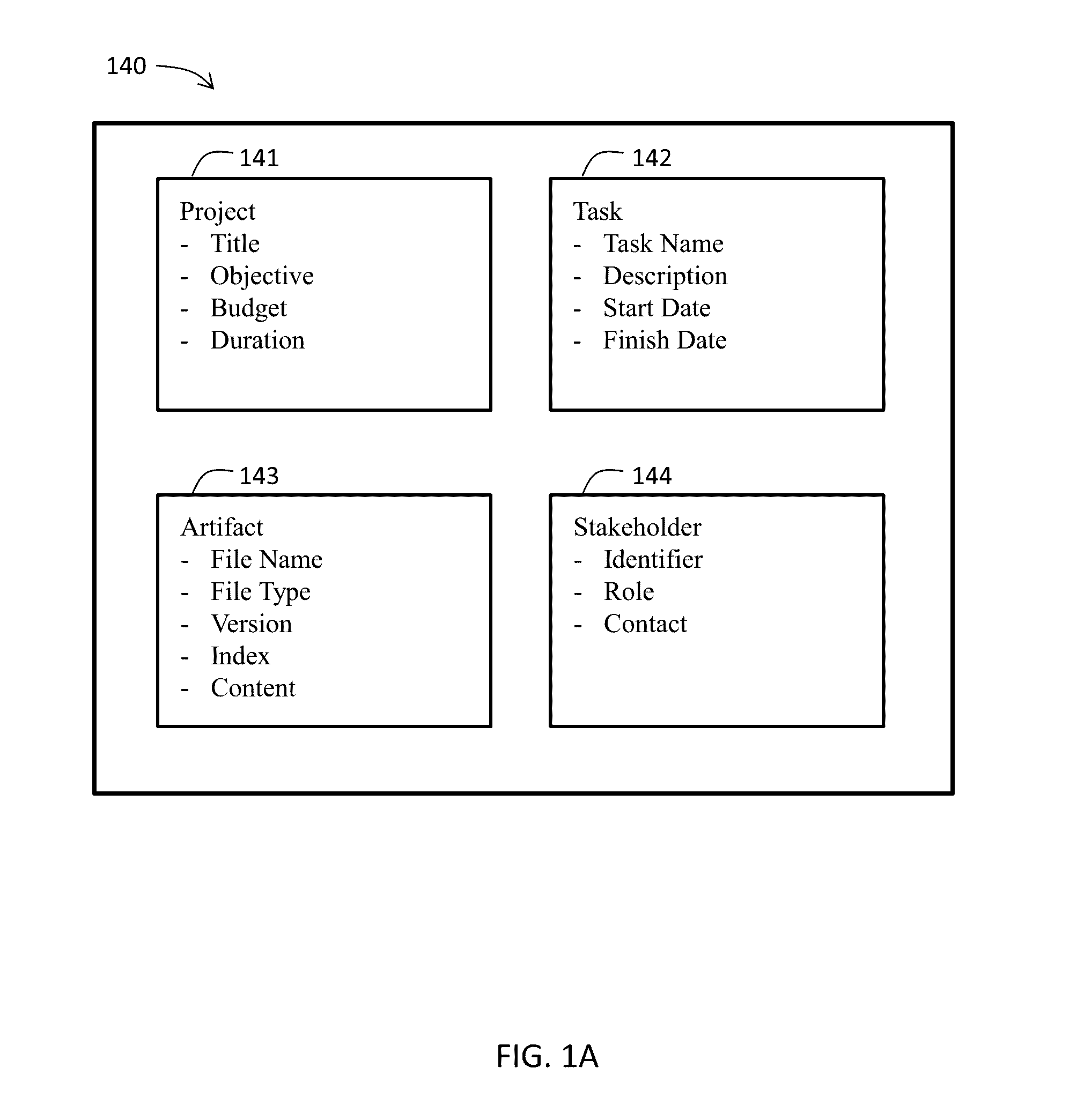

A computer program product for creating an enterprise management dashboard program, and comprising a process architecture server, a process architect client, a stakeholder client, and / or a process object server. The process architecture server includes a compiler characterized by an access control subsystem (receives role-base access control definition data), a work flow modeling subsystem (receives process model definition data), a data management subsystem (receives data structure definition data), a communication subsystem (receives communication protocol definition data), and a report management subsystem (receives report content definition data). The compiler uses the aforementioned data to create executable computer code for the enterprise management dashboard program based on modeling constructs including project sites, task pages, interface templates, report templates, and / or third-party process content. The resultant enterprise management dashboard program may be used to create and save process objects such as projects, tasks, artifacts (e.g., digital files), and process metrics.

Owner:CRAIG TECHNICAL CONSULTING INC

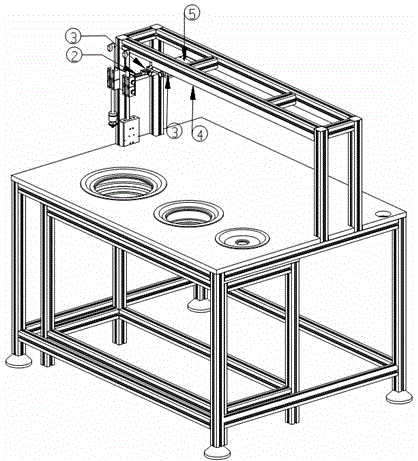

Self-calibrating method and apparatus for ultra precise workbench

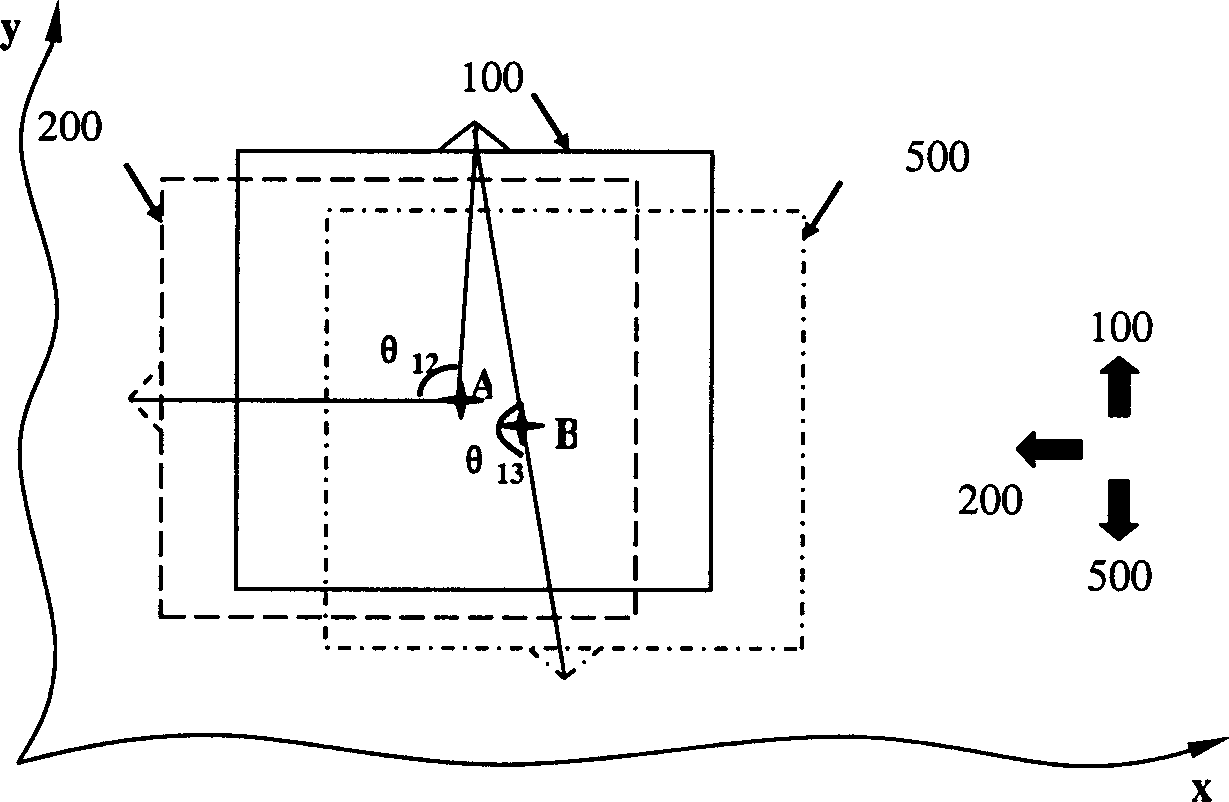

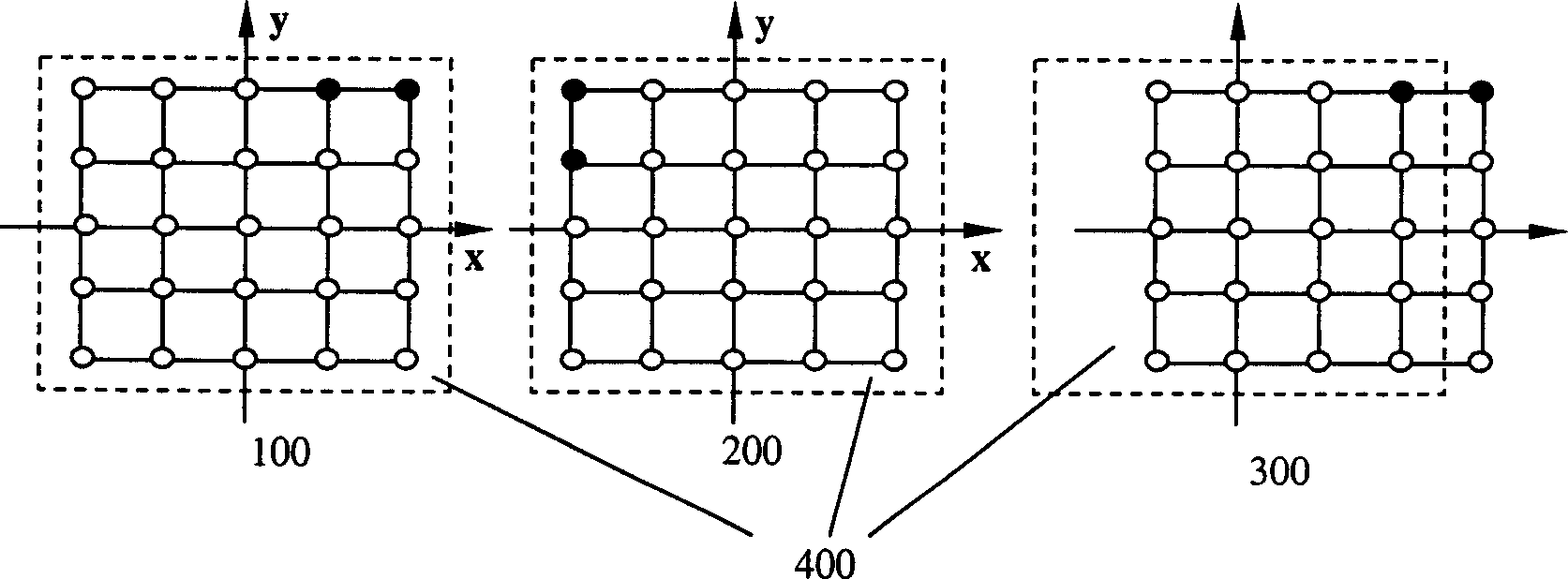

ActiveCN1667359AImprove calibration accuracyAvoid modeling errorsMeasurement devicesComplex mathematical operationsProcess MeasuresPosition error

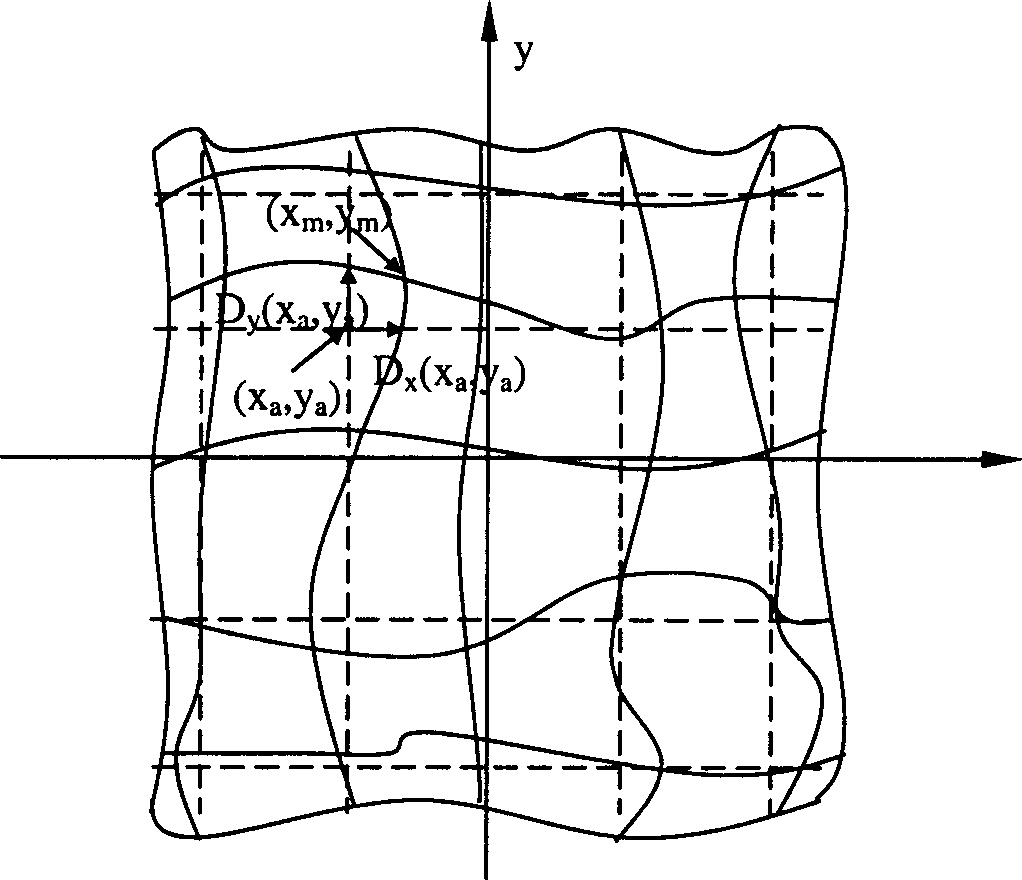

The invention discloses an automatic calibration method and apparatus applied to three-dimensional ultra-sophisticated bench. The method is to set an automatic calibration model containing error message of grid glass sheets and calibrated bench through the medium of chromed grid glass sheets, and processes measured data of grid pip in different testing position to eliminate effects of position error of grid glass sheet grid pip. The invention also discloses an automatic calibration apparatus, comprising chromed grid glass sheets with grid pulser matrix, a positioning devise with optical components and XY plane position sensor, an image-gathering card and a computer storing related program.

Owner:TSINGHUA UNIV +1

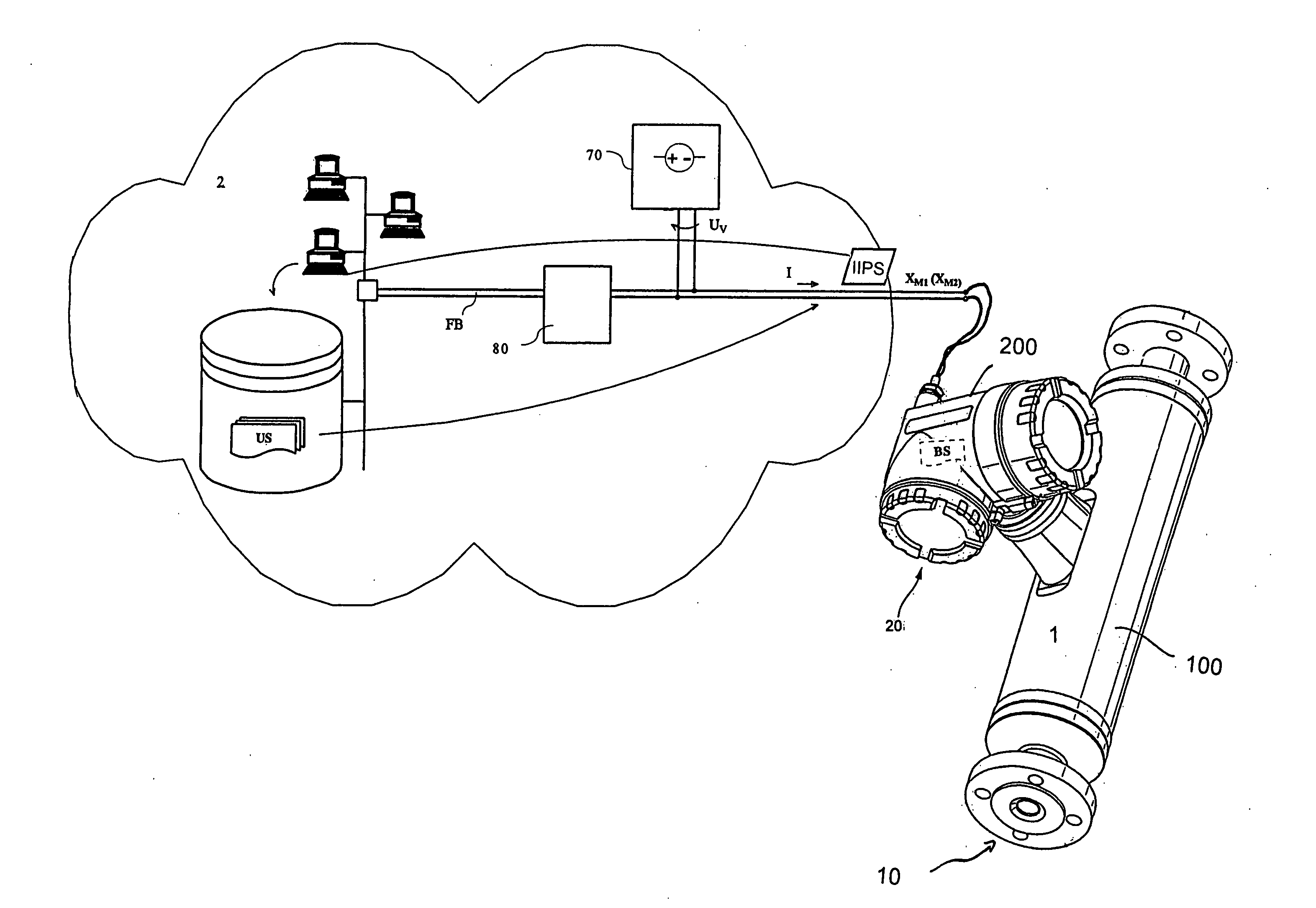

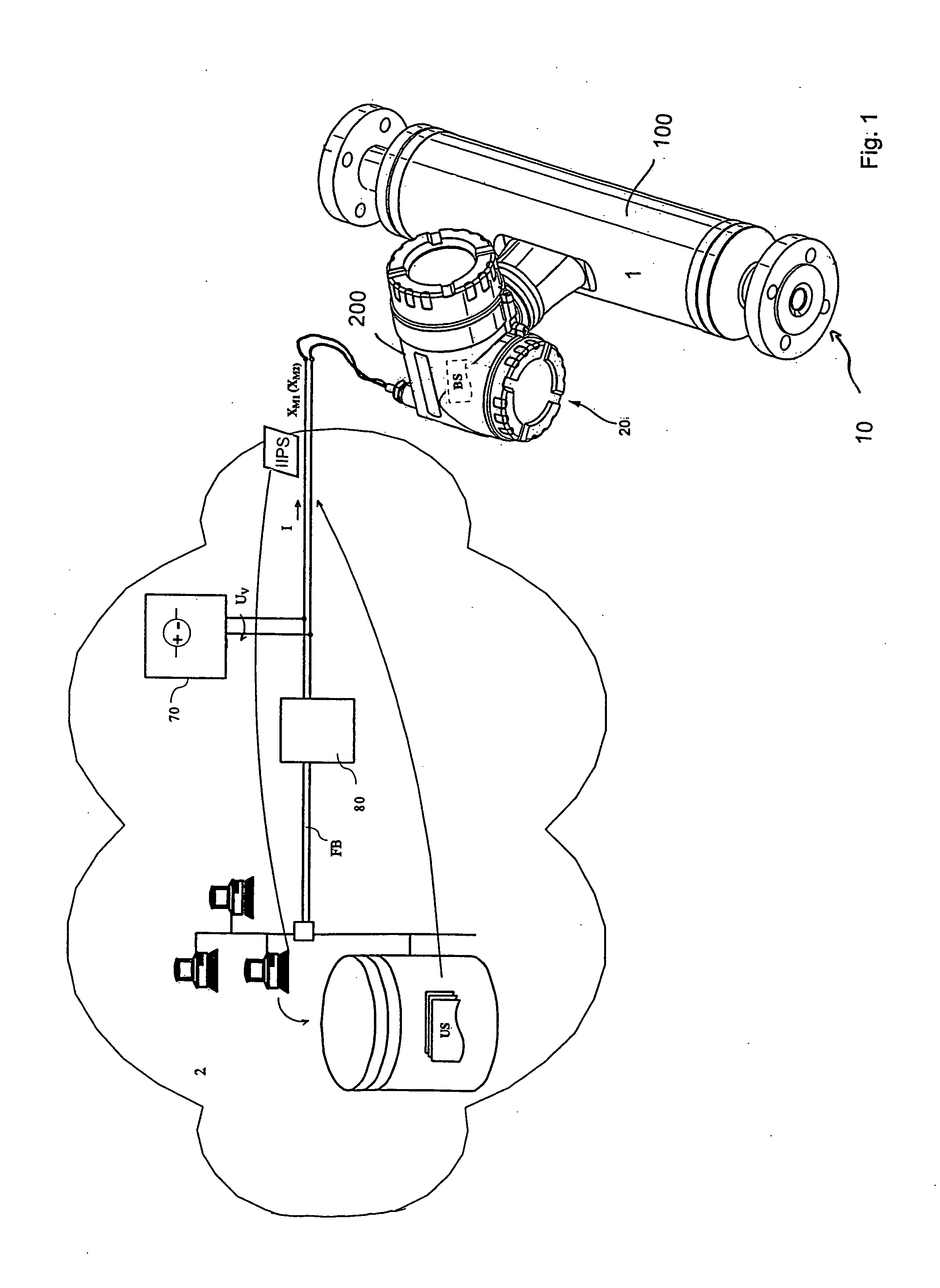

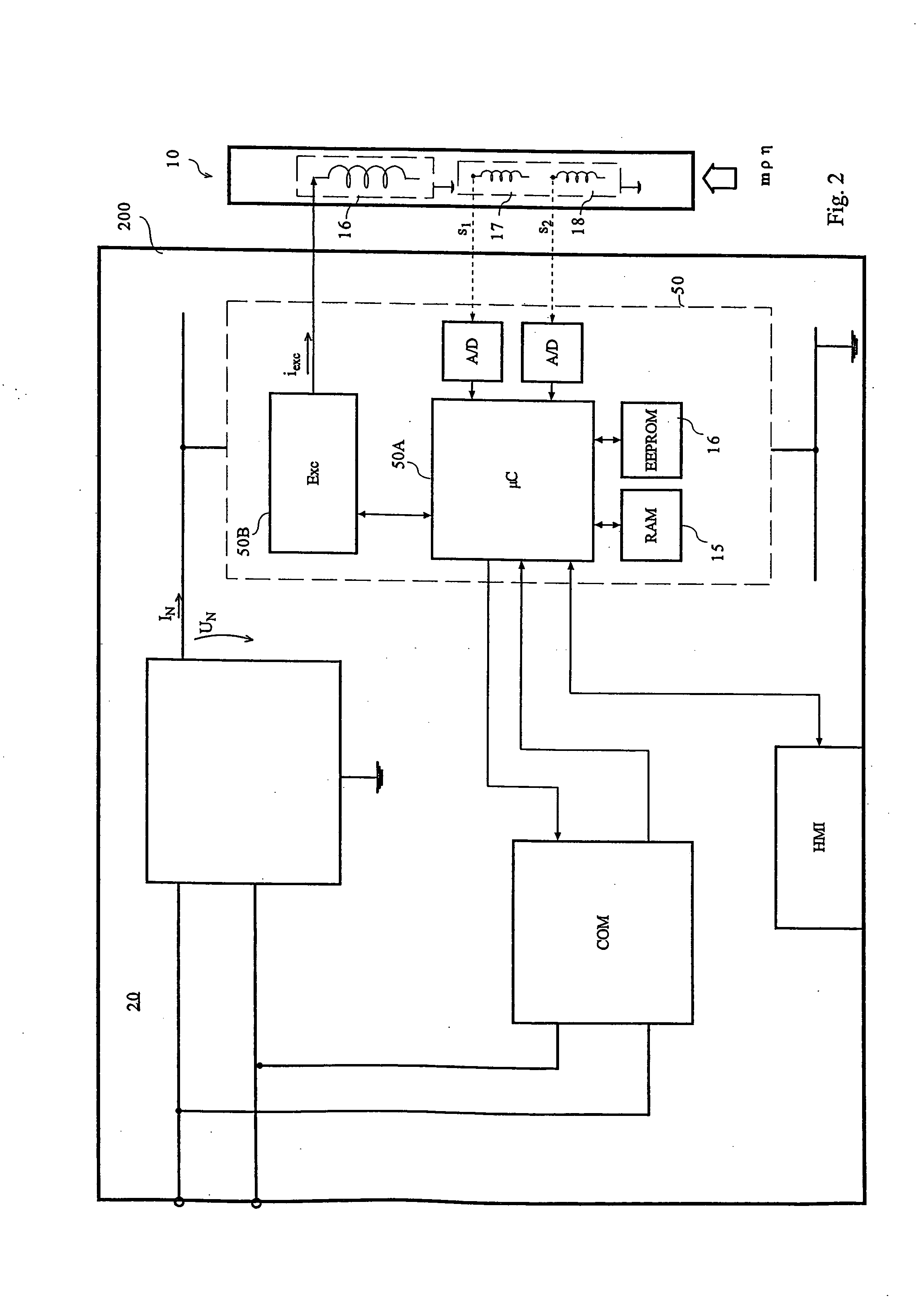

Method for start-up and/or reconfiguration of a programmable field-device

ActiveUS20080288933A1Simplify start-upImprove matchProgramme controlSpectral/fourier analysisMicrocomputerData processing system

An installed hardware of a measuring field device includes at least one transducer reacting during operation to a chemical and / or physical, measured variable of a pourable and / or flowable medium, especially a pourable or flowable bulk good, liquid, gas or the like, as well as a microcomputer communicating during operation with the transducer. The field device is first installed by means of the transducer on, and / or in a process vessel serving for conveying and / or holding pourable and / or flowable media for forming a process measuring point. Thereafter, the microcomputer is booted and a basic software held in a memory provided within the field device for providing, at least in part, basic functionalities of the field device is activated in such a manner that the basic software is executable by means of the microcomputer so that, in the interaction of basic software and hardware installed in the field device, the basic functionalities of the field device are available. Additionally, at least one initial identification parameter set held at least temporarily in the field device and at least approximately identifying the process measuring point is transferred, with application of basic software executed in the microcomputer, to a data processing system superordinated externally of the field device, and at least one upgrade software providing custom functionalities for the field measuring device going beyond the basic functionalities and held in a second memory, is selected from an ensemble of software products, taking into consideration the at least one, initial identification parameter set. A selected upgrade software fitted to the process measuring point is then transferred into a third memory provided within the field measuring device and then activated in such a manner that it is executable by means of the microcomputer, so that, in interaction of upgrade software and hardware installed in the field device, custom functionalities of the field measuring device are available.

Owner:ENDRESSHAUSER DEUTLAND AGCO

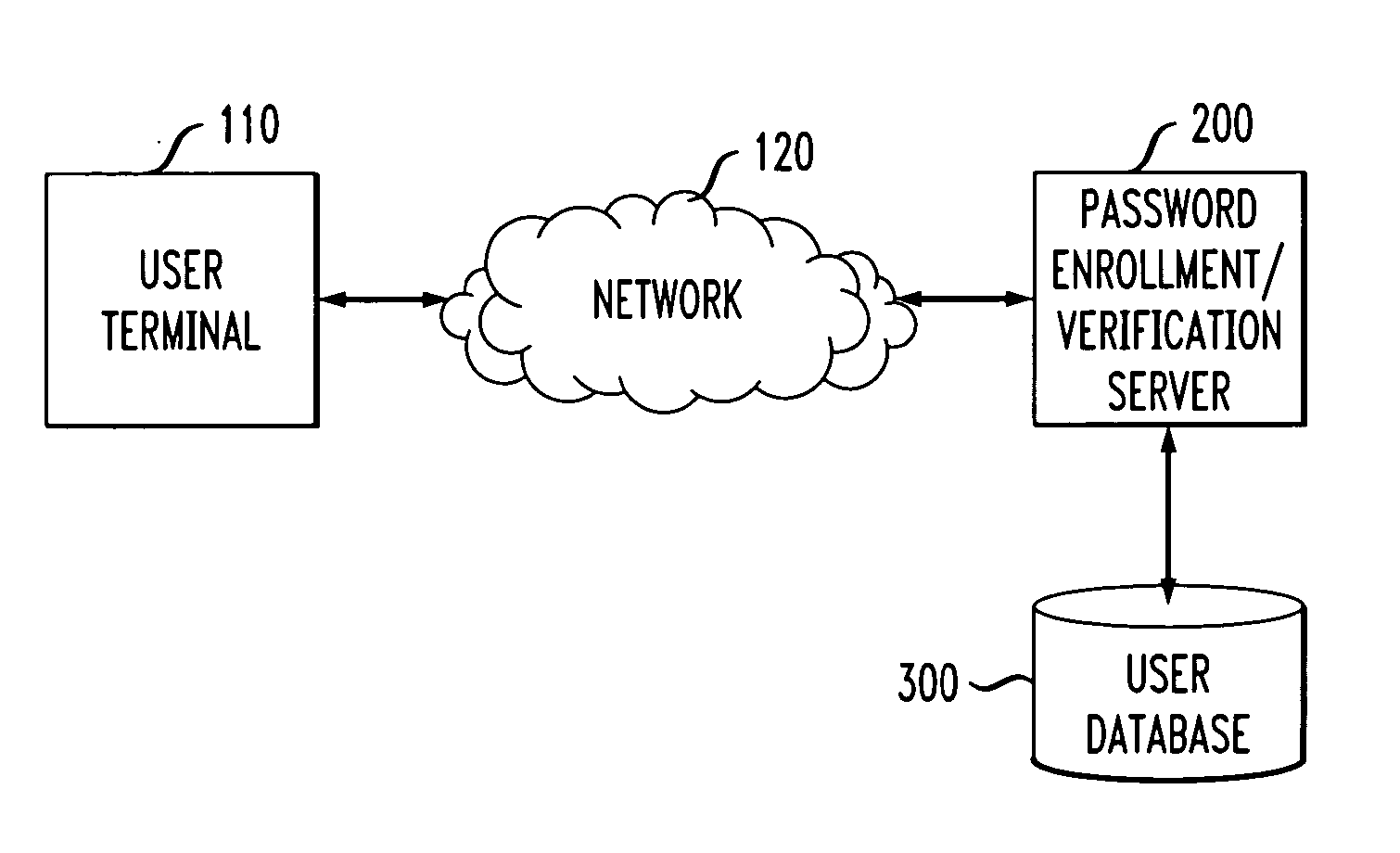

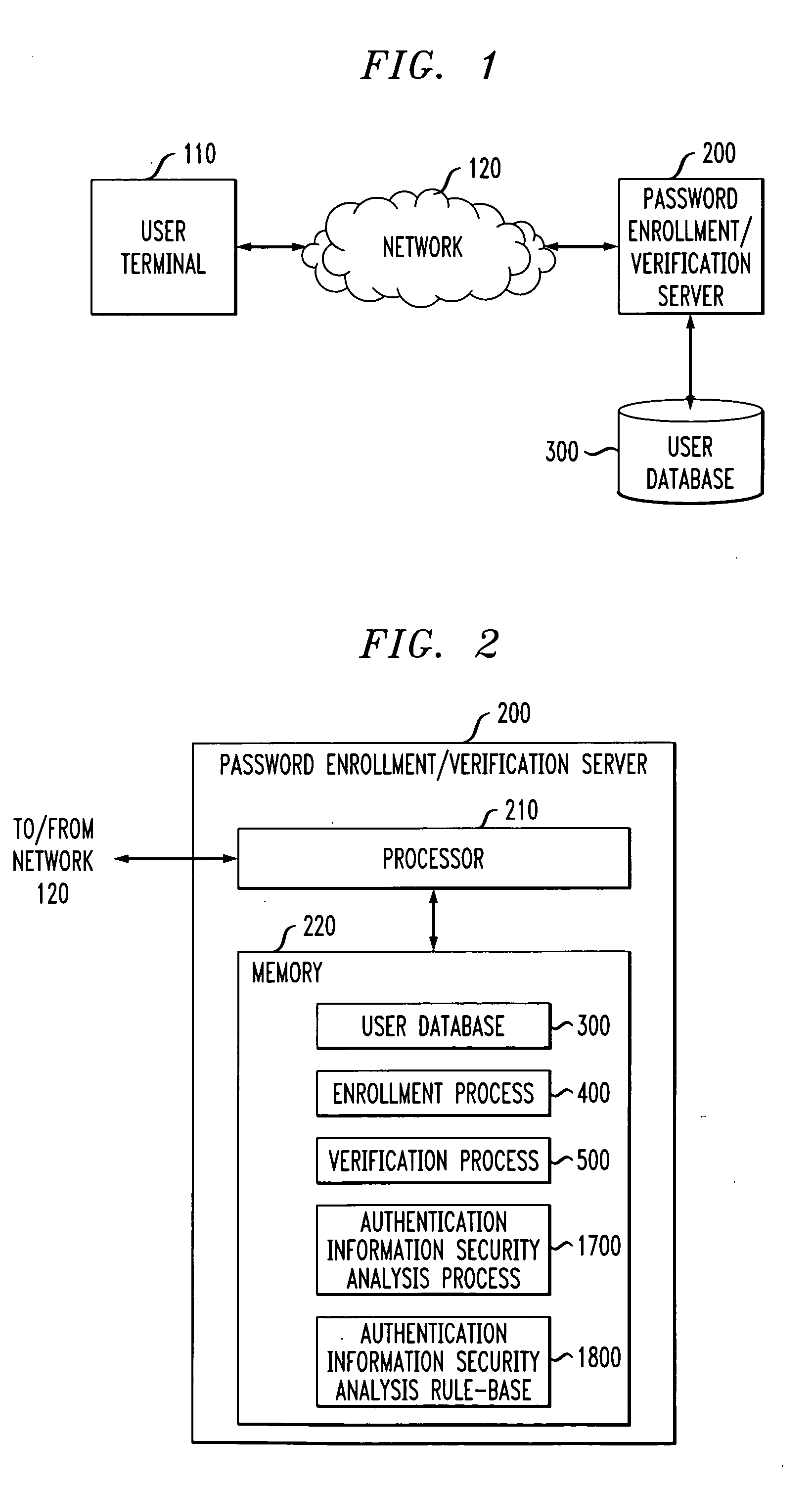

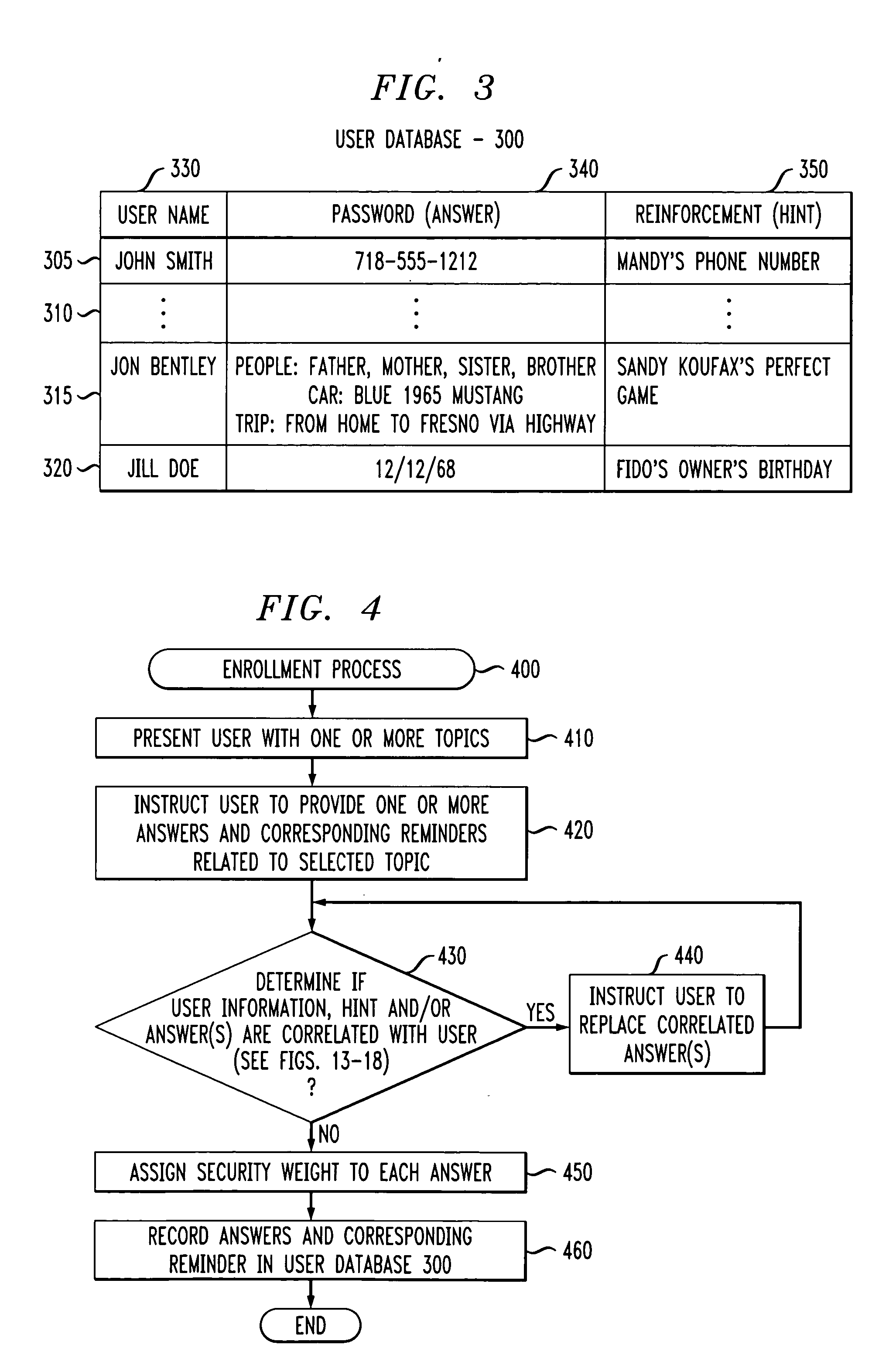

Method and apparatus for verifying security of authentication information extracted from a user

InactiveUS20050114678A1Digital data authenticationSecret communicationPersonal identification numberPassword

A method and apparatus are provided for evaluating the security of authentication information that is extracted from a user. The disclosed authentication information security analysis techniques determine whether extracted authentication information can be obtained by an attacker. The extracted authentication information might be, for example, personal identification numbers (PINs), passwords and query based passwords (questions and answers). A disclosed authentication information security analysis process employs information extraction techniques to verify that the authentication information provided by a user is not easily obtained through an online search. The authentication information security analysis process measures the security of authentication information, such as query based passwords, provided by a user. Information extraction techniques are employed to find and report relations between the proposed password and certain user information that might make the proposed password vulnerable to attack.

Owner:AVAYA INC

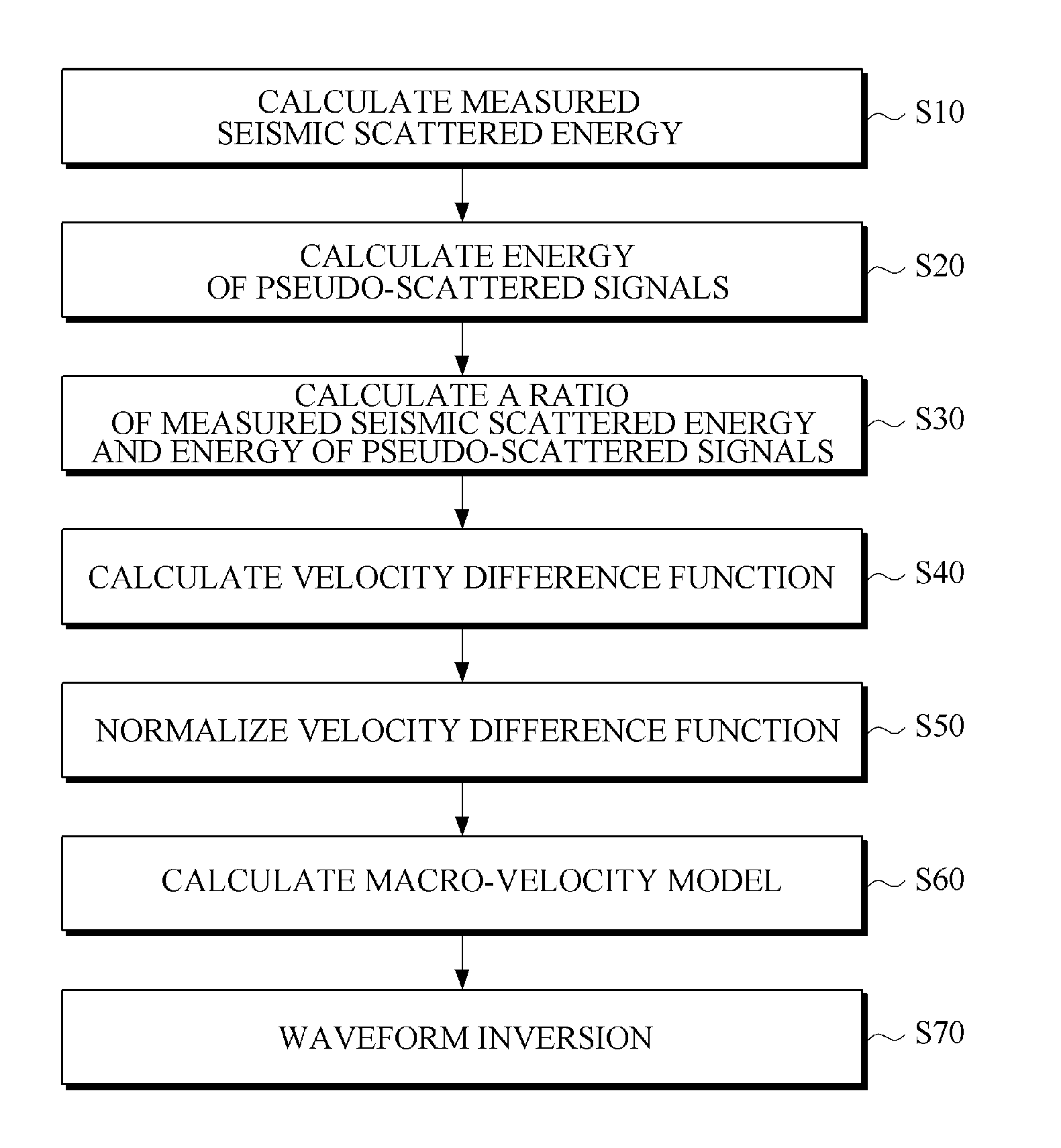

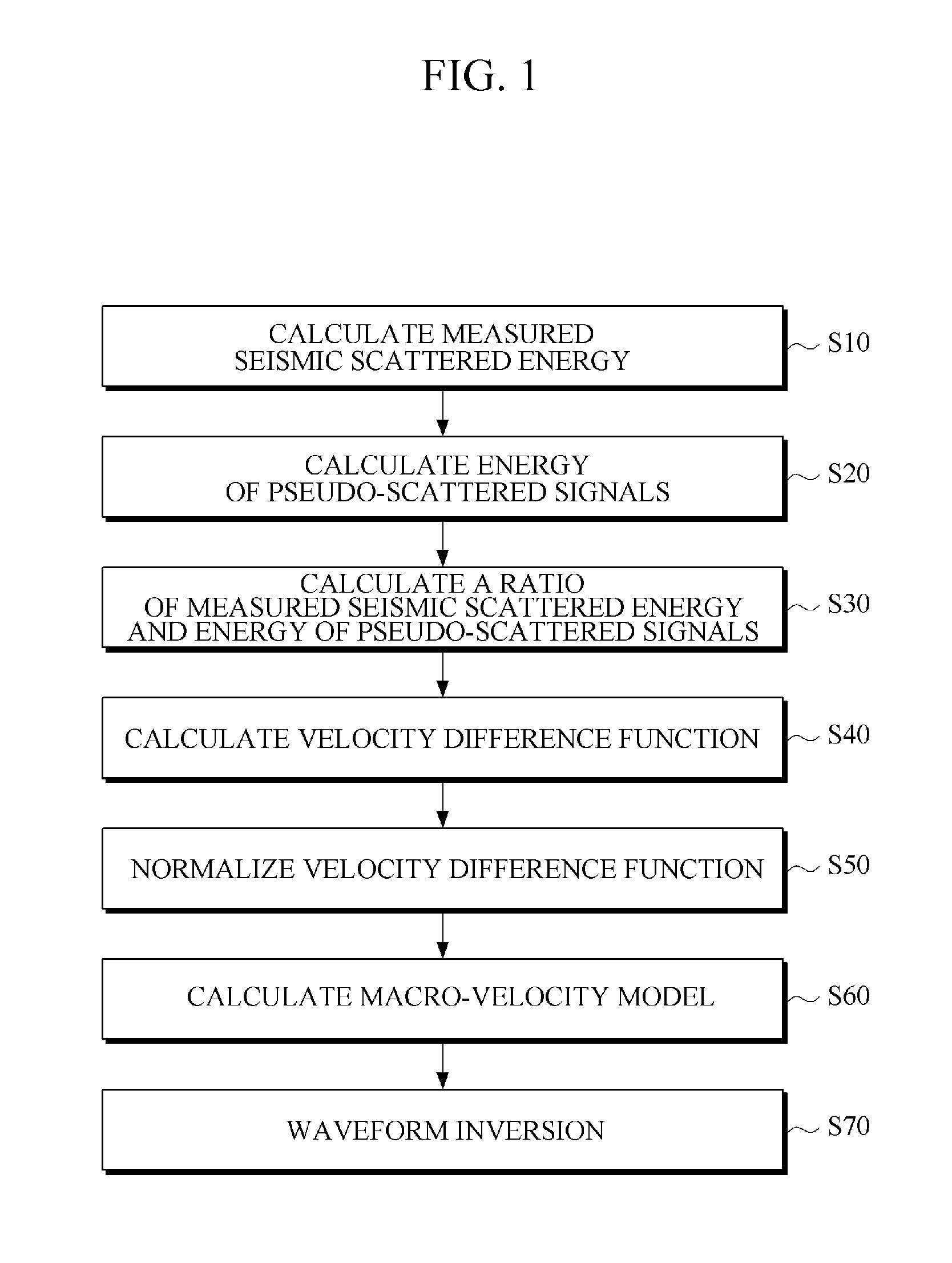

Seismic imaging apparatus utilizing macro-velocity model and method for the same

ActiveUS20120243373A1Reduce the amount of calculationHigh resolutionSeismic signal processingProcess MeasuresEnergy based

There is provided a seismic imaging technology for imaging a subsurface structure by processing measured data reflected from the subsurface structure after a wave from a source wave has been propagated to the subsurface structure. According to an aspect, there is provided a seismic imaging method for obtaining imaging data of a subsurface structure through waveform inversion using a macro-velocity model as an initial value, wherein the macro-velocity model which is used as the initial value for the waveform inversion is calculated by: calculating a velocity difference function which is a difference between a real velocity and an initial velocity model, wherein the velocity difference function is a ratio of measured seismic scattered energy and modeled scattered energy based on the initial velocity model; and calculating the macro-velocity model by updating the initial velocity model with the velocity difference function.

Owner:SEOUL NAT UNIV R&DB FOUND

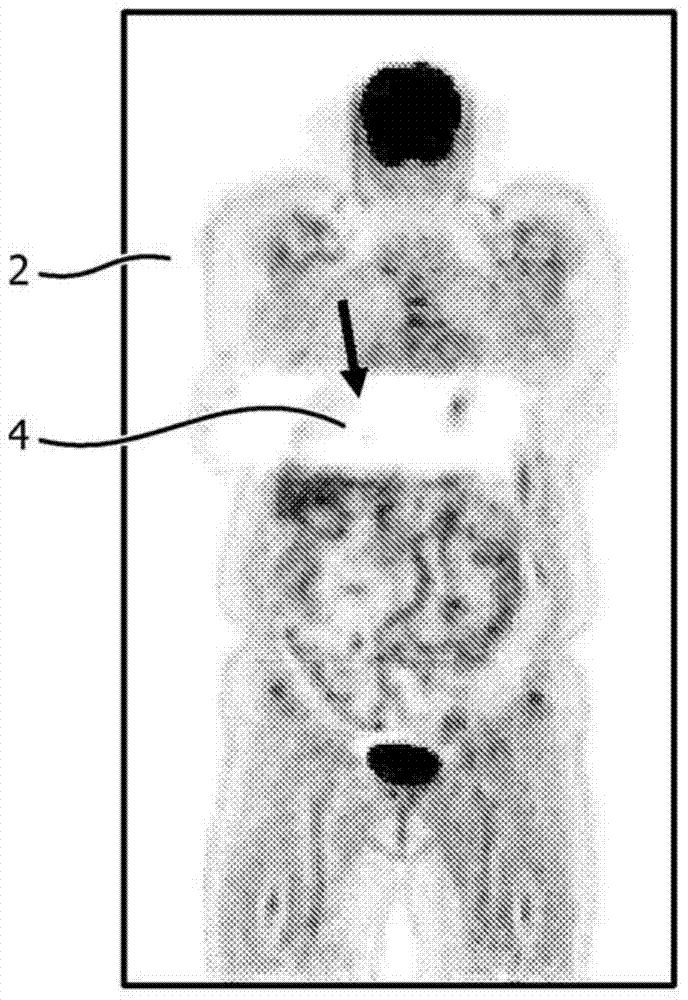

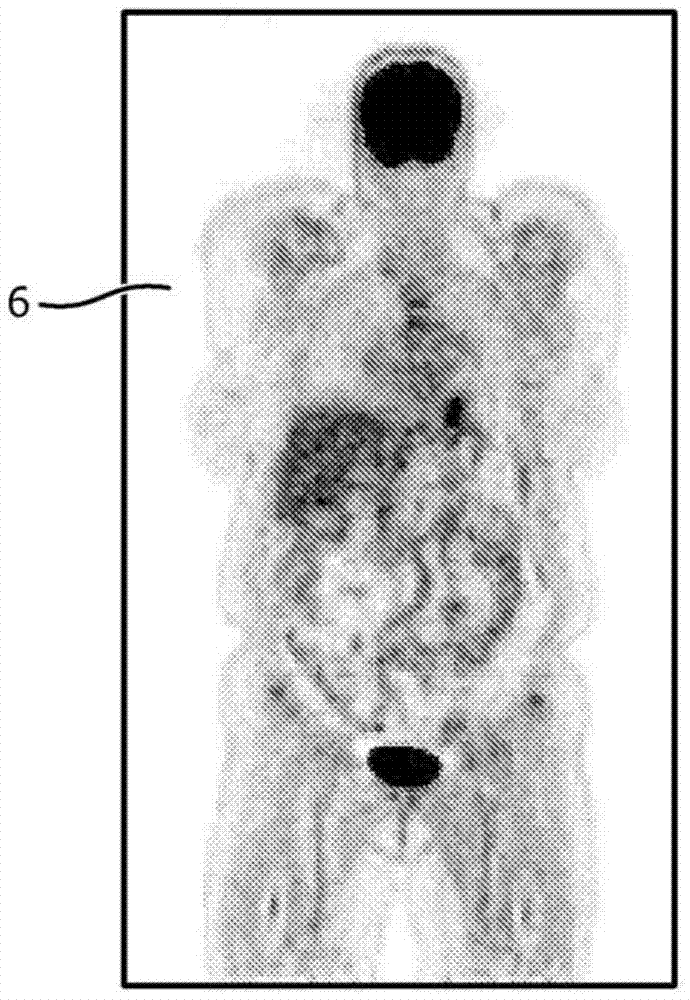

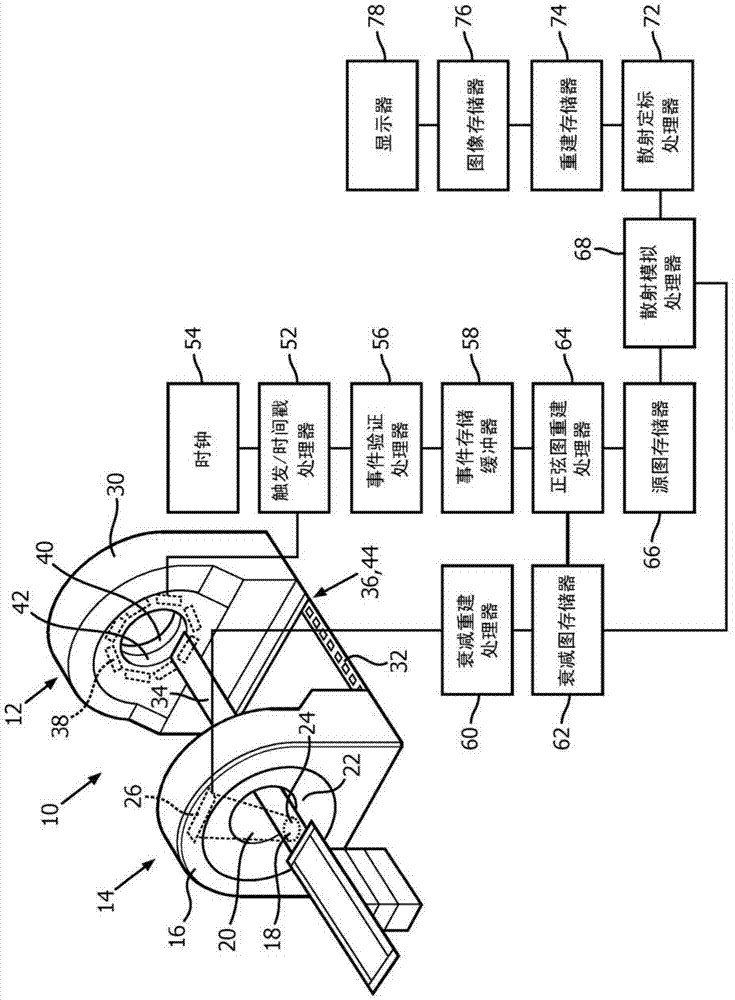

Fast scatter estimation in PET reconstruction.

ActiveCN104335247AAccurate estimateQuick estimateReconstruction from projectionImaging processingAnalog processor

An image processing apparatus includes a scatter simulation processor which processes measured sinograms generated from imaging data acquired for an imaging subject by an imaging apparatus to produce a scatter sinogram that represents a shape of scatter contribution. A scatter scaling processor utilizesa Monte Carlo simulation to determine a scatter fraction and scales the scatter sinogram to generate a scaled scatter sinogram that matches the scatter contribution in the measured sinogram. A reconstruction processor reconstructs the imaging data into an image representation using the scaled scatter sinogram for scatter correction.

Owner:KONINKLJIJKE PHILIPS NV

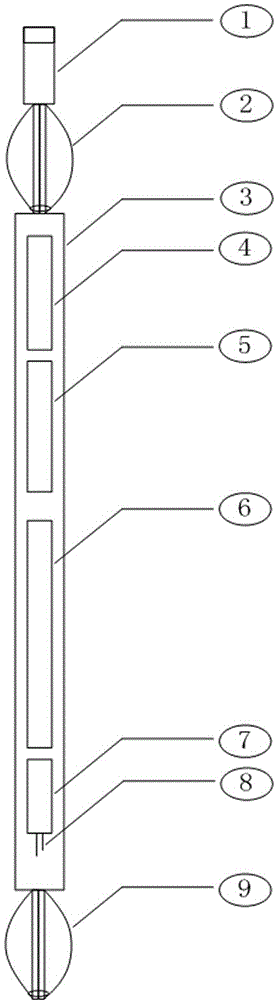

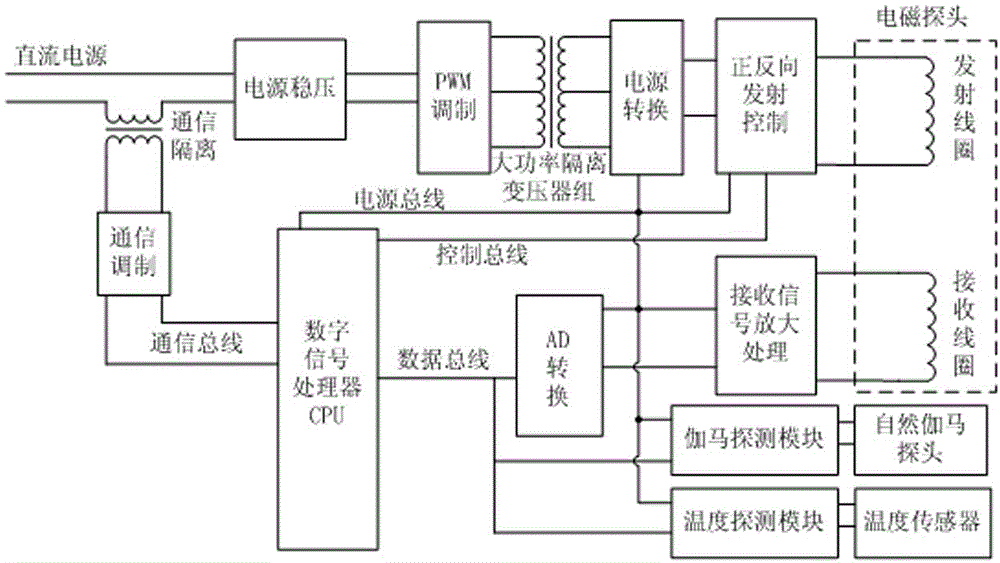

Transient electromagnetic logging instrument

ActiveCN103603650AEffectively pass throughEfficient access through casingSurveyVoltage regulator moduleElectromagnetic field

The invention relates to a transient electromagnetic logging instrument which comprises a shell, a circuit module and an electromagnetic probe system, wherein the circuit module is arranged in the shell, and the electromagnetic probe system is connected with the circuit module. The circuit module is sequentially connected with a power voltage regulator module, a PWM (pulse width modulation) module, a high-power isolating transformer bank and a power conversion module through a direct-current power supply to form a direct-current power supply circuit and a main control circuit taking a digital signal processor as a core, and a communication bus, a power bus, a control bus and a data bus are arranged on the periphery of the main control circuit. The electromagnetic probe system comprises a transmitting coil and a plurality of receiving coils, wherein the transmitting coil is provided with a magnetic core. The instrument detects casing damage and effectively measures the formation resistivity of an open hole well and a cased well in a non-contact mode. High-power transient excitation is realized by the aid of internal iron cores of the coils, the excitation intensity of a transient electromagnetic field is improved, and the formation resistivity is finally obtained by necessarily graduating and processing measured original signals.

Owner:CHINA PETROCHEMICAL CORP +2

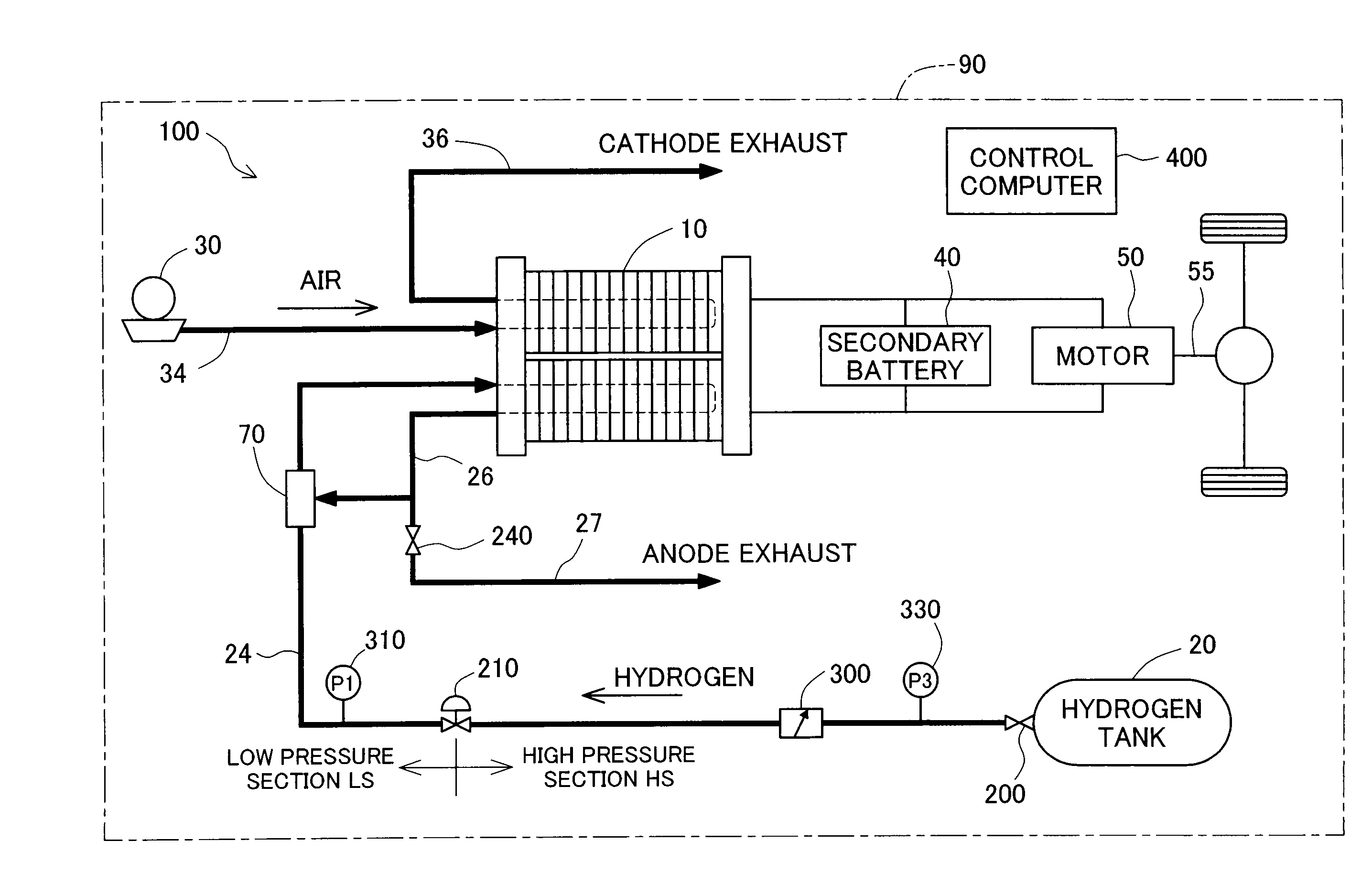

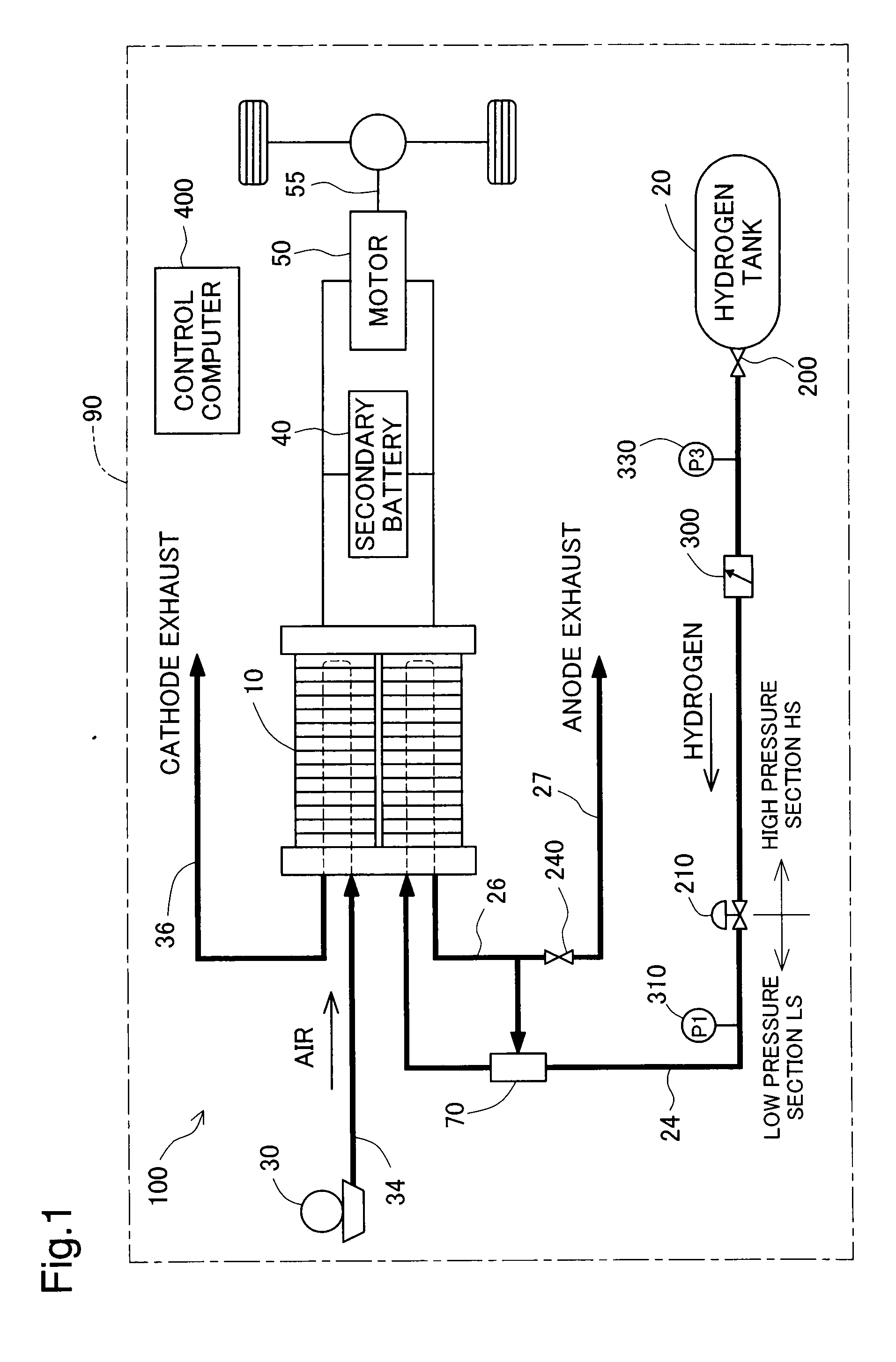

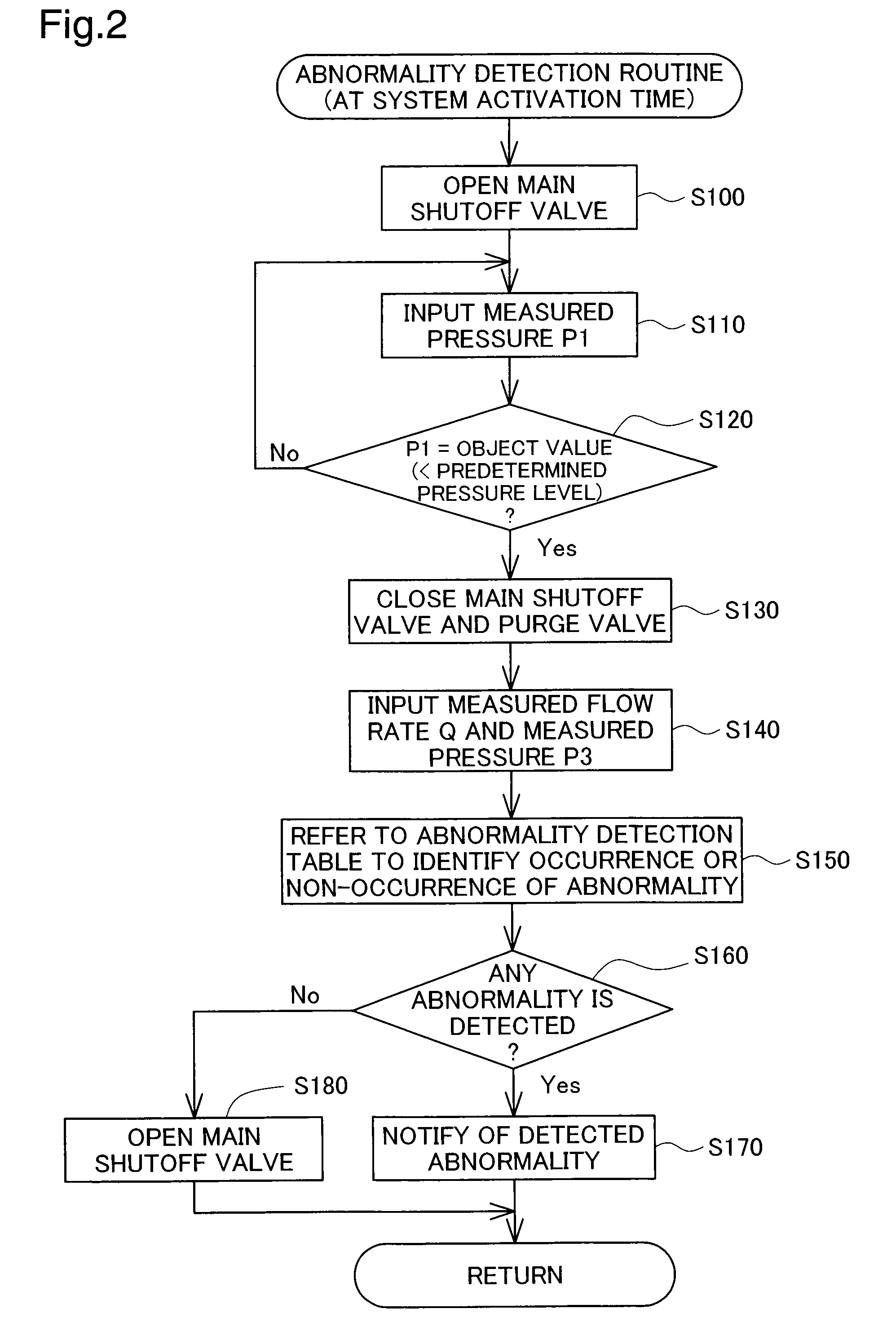

Fuel cell system

InactiveUS20090035612A1High-precision detectionAccurate detectionFuel cell auxillariesTransportation fuel cell technologyProcess MeasuresProcess engineering

In a fuel cell system of the invention, a hydrogen leakage detection process closes a shutoff valve, which shuts off a supply of hydrogen from a hydrogen supply unit into a hydrogen supply flow path, and opens a pressure regulator, which reduces a pressure of hydrogen in the hydrogen supply flow path, so as to keep the hydrogen supply flow path in a state with no pressure regulation and make the fuel cell system in a leakage detectable state. In this leakage detectable state, the hydrogen leakage detection process measures at least one of a pressure and a flow rate as a state quantity of hydrogen in the hydrogen supply flow path that feeds the supply of hydrogen to fuel cells. The hydrogen leakage detection process analyzes a detected behavior of the state quantity in the leakage detectable process and specifies the occurrence of a hydrogen leakage in the downstream of the hydrogen supply unit. This arrangement enables highly accurate detection of a hydrogen leakage in the fuel cell system with the pressure regulator provided in the hydrogen supply flow path.

Owner:TOYOTA JIDOSHA KK

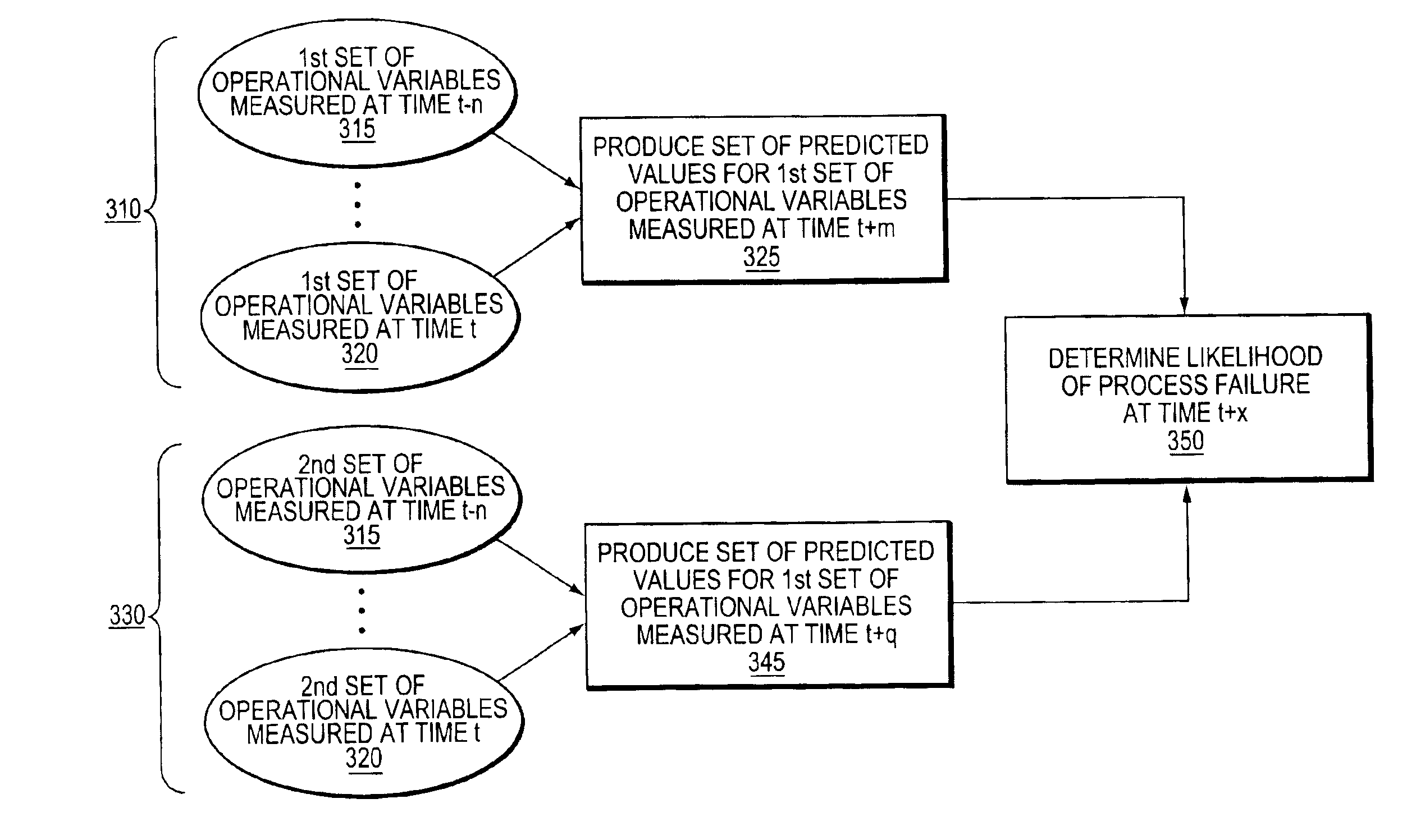

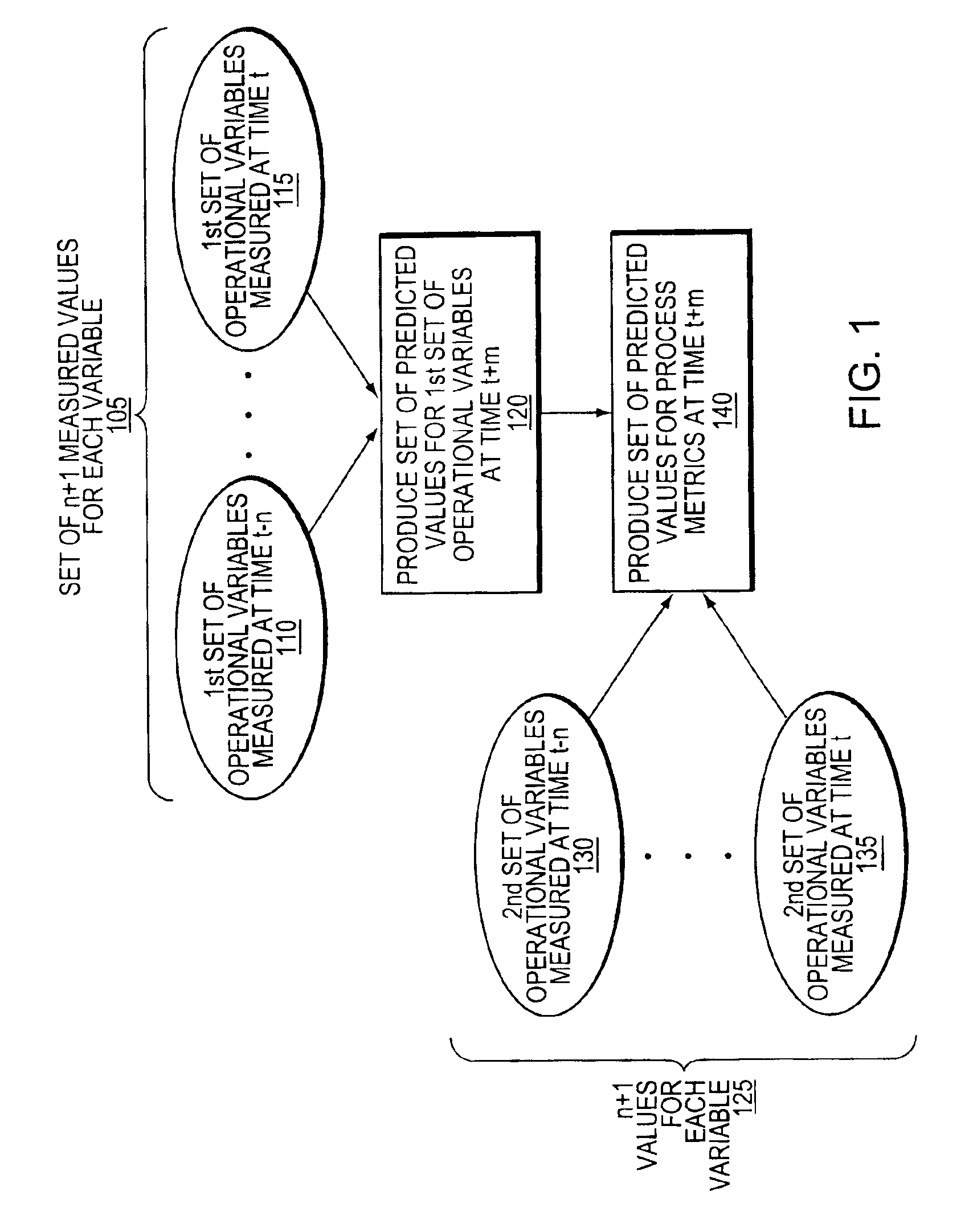

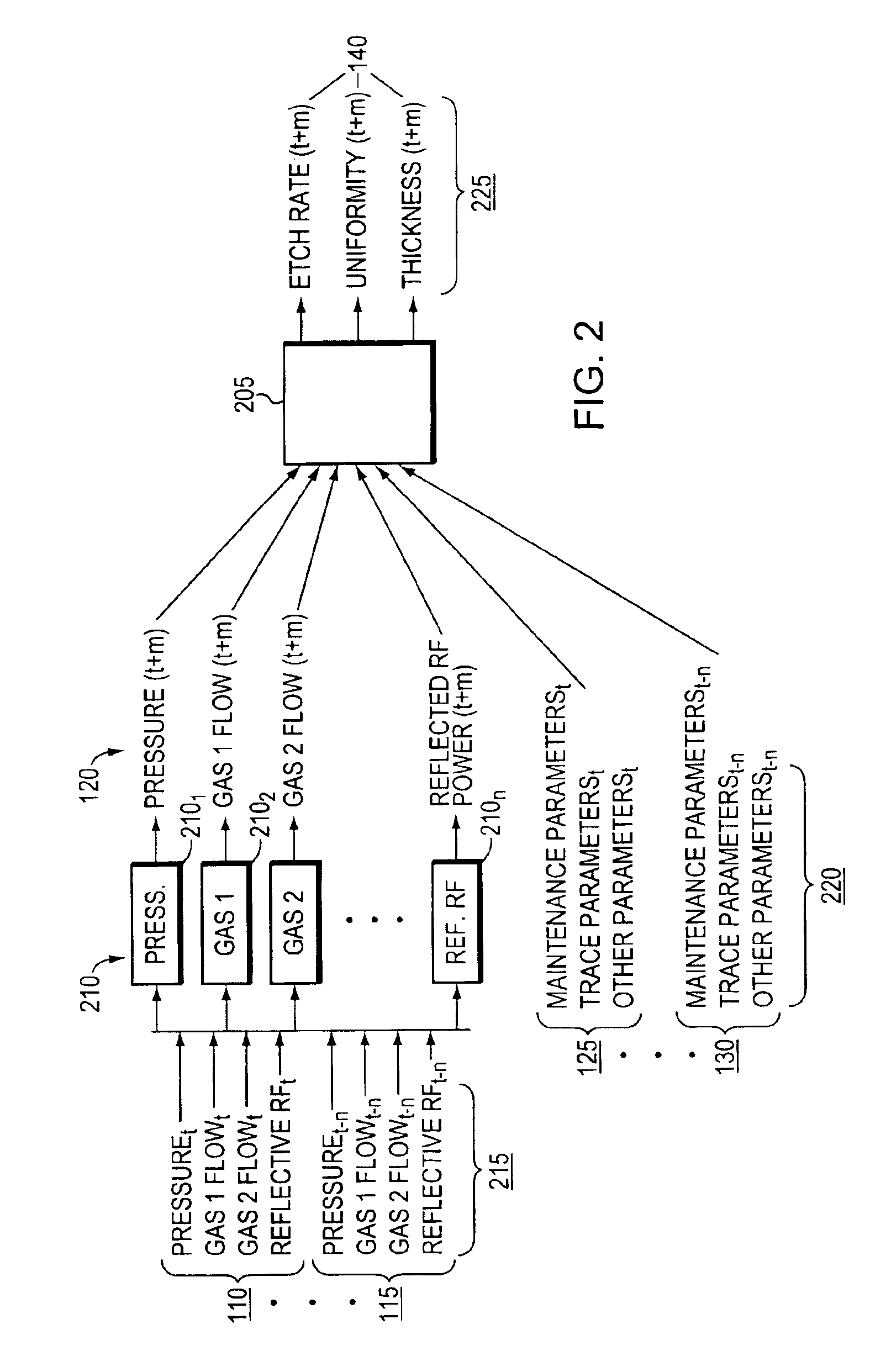

Advance failure prediction

InactiveUS6915173B2Accurate identificationCircuit-breaking switches for excess currentsElectric testing/monitoringProcess MeasuresNonlinear regression

Failure prediction for complex processes is performed utilizing one or more nonlinear regression models to relate operational variable values measured at two or more times to predicted process metric values and maintenance variable values.

Owner:IBEX PROCESS TECH

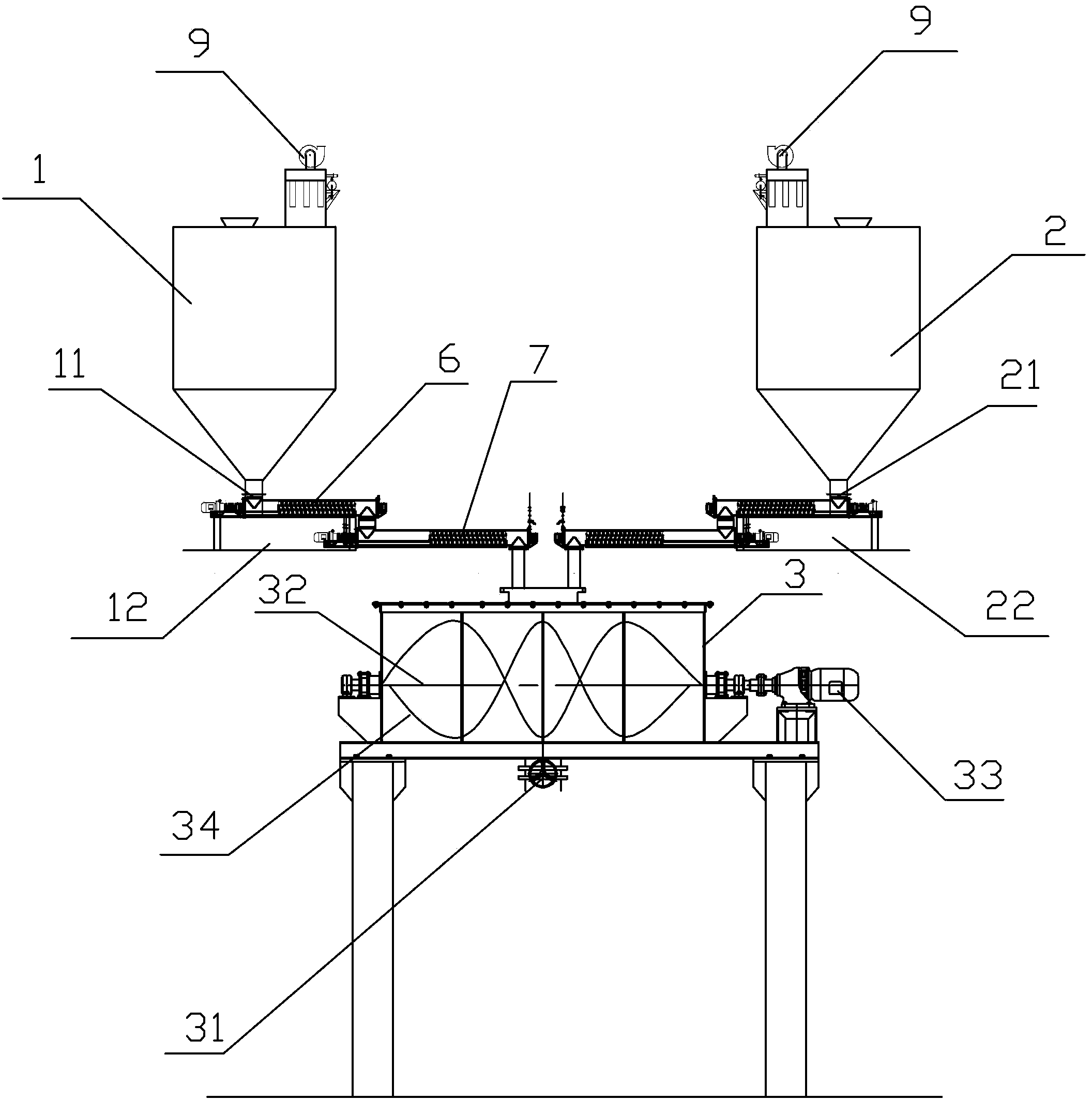

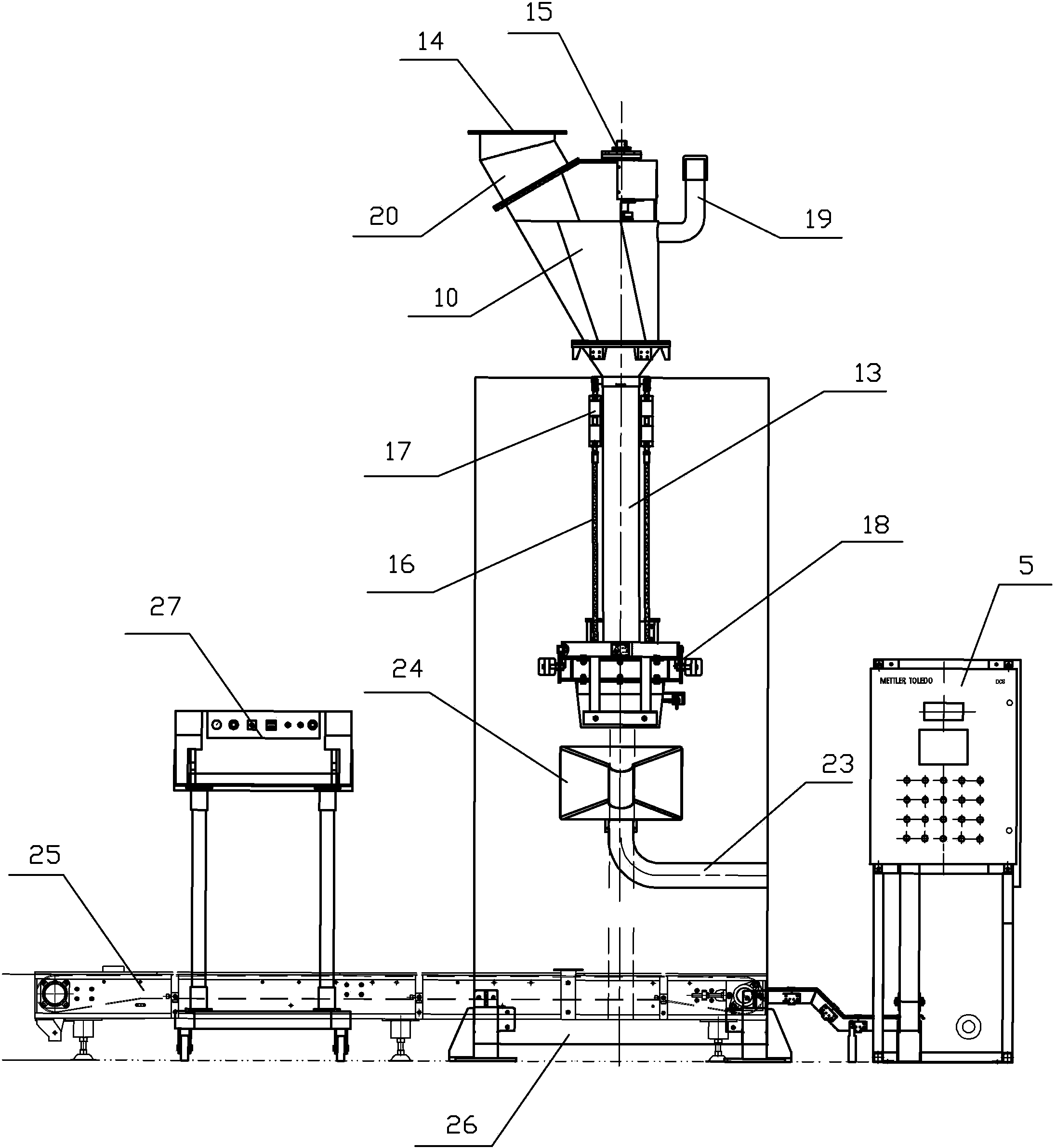

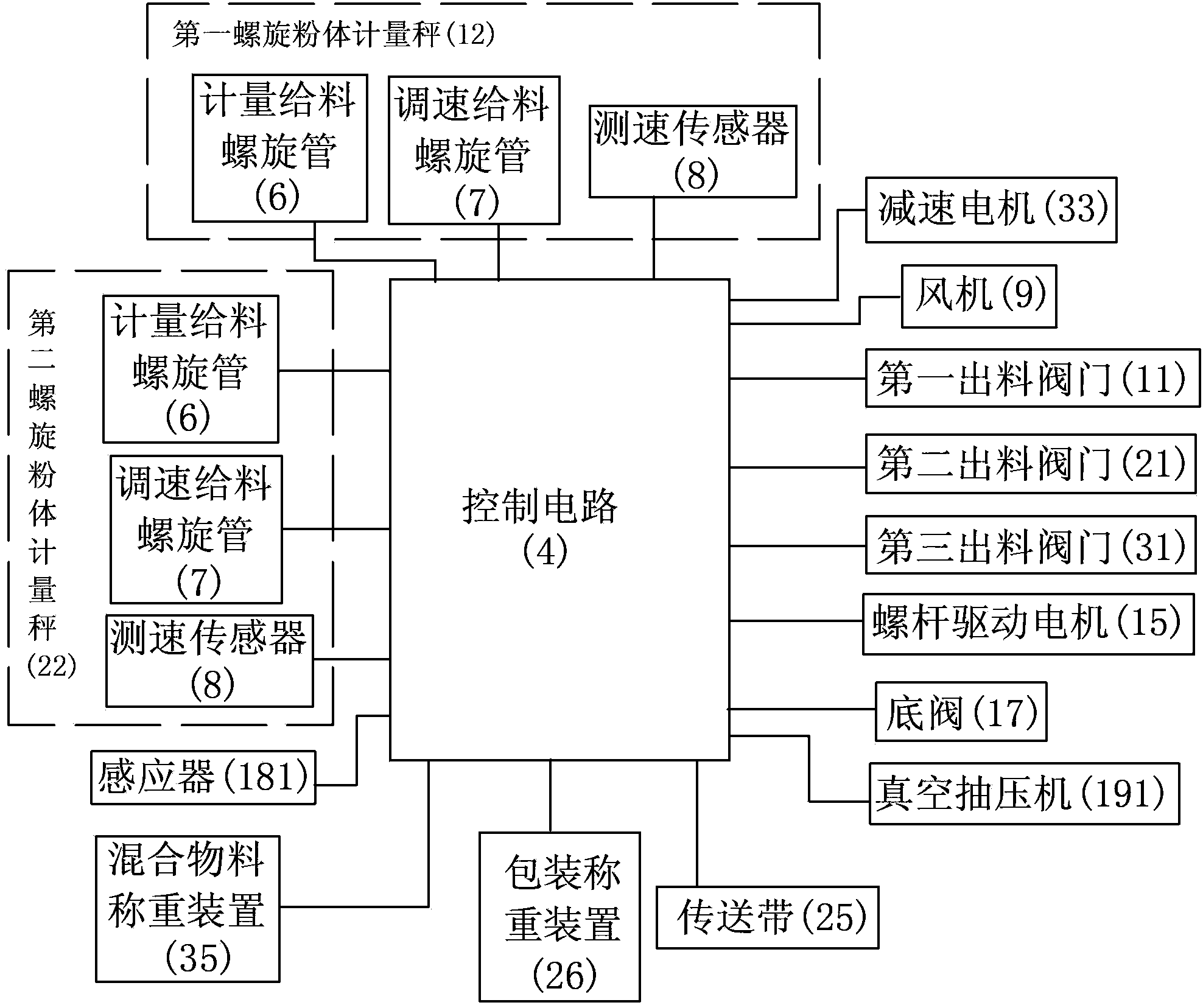

Full-automatic weighing and packaging system and control method thereof

ActiveCN103381892ARealize fully automatic controlAccurate weighingSolid materialPackaging automatic controlElectricityControl flow

The invention relates to a full-automatic weighing and packaging system and a control method thereof. A first discharging valve, a second discharging valve and a third discharging valve are respectively arranged at the bottoms of a first charging bucket, a second charging bucket and a mixture stock bin of the full-automatic weighing and packaging system; blowers are mounted at the tops of the two charging buckets; the first discharging valve and the third discharging valve are respectively connected with the mixture stock bin through a first spiral powder metering scale and a second spiral powder metering scale; the third discharging valve is connected with a packaging mechanism; the two spiral powder metering scales, the three discharging valves, the mixture stock bin and the packaging mechanism are electrically connected with a control circuit respectively. The control method comprises the step as follows: the control circuit analyzes and processes measured parameters including weight, flow and the like in real time, and sends corresponding control signals to control flow, opening / closing of valves and starting / stopping of related equipment, so as to realize full-automatization control of weighing, mixing and packaging of two materials. According to the invention, the weighing is accurate, the raised dust is reduced, the pollution and labor force are reduced, and the working efficiency is improved.

Owner:HANGZHOU XIAOSHAN HUADONG CHEM EQUIP

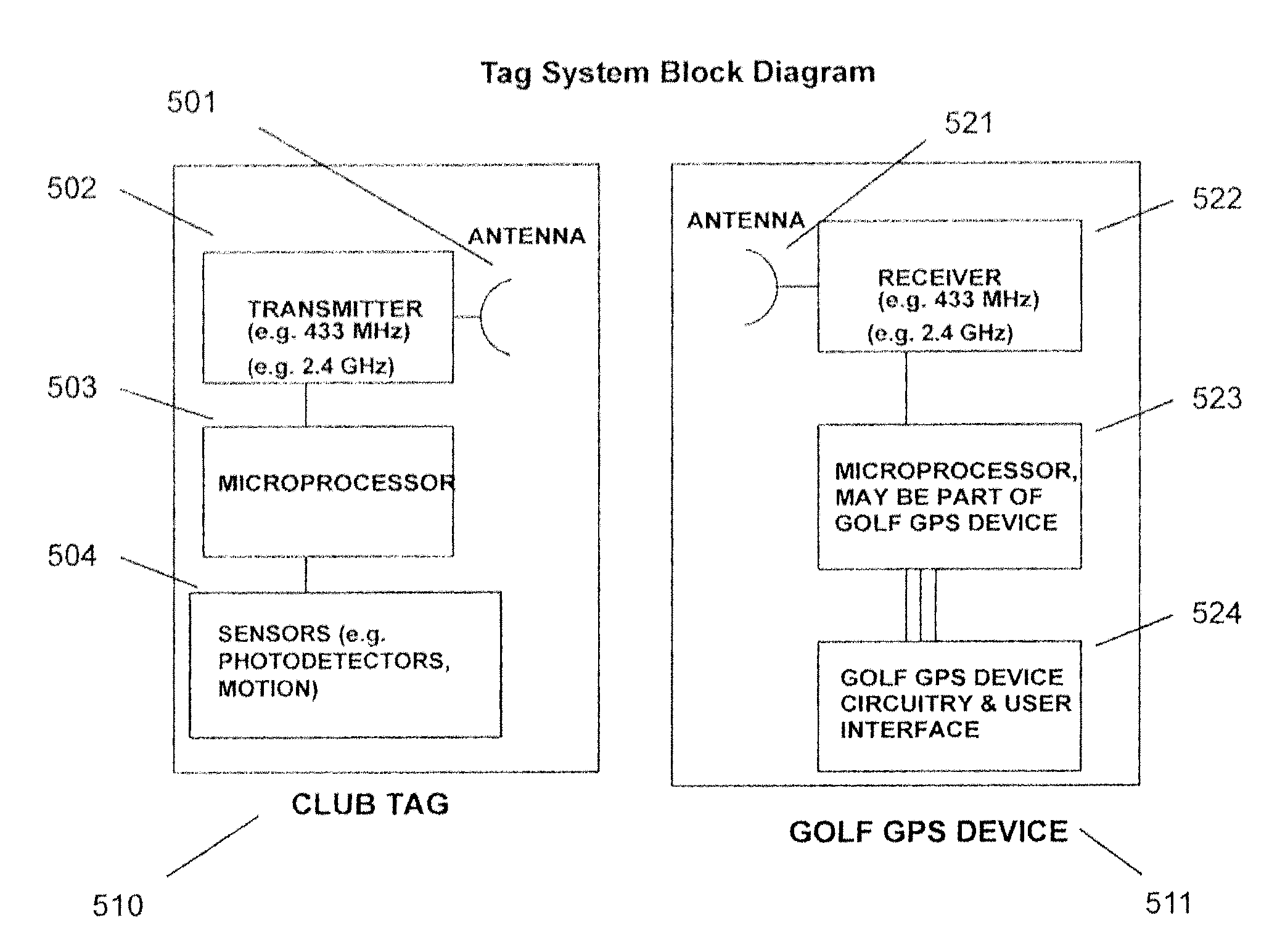

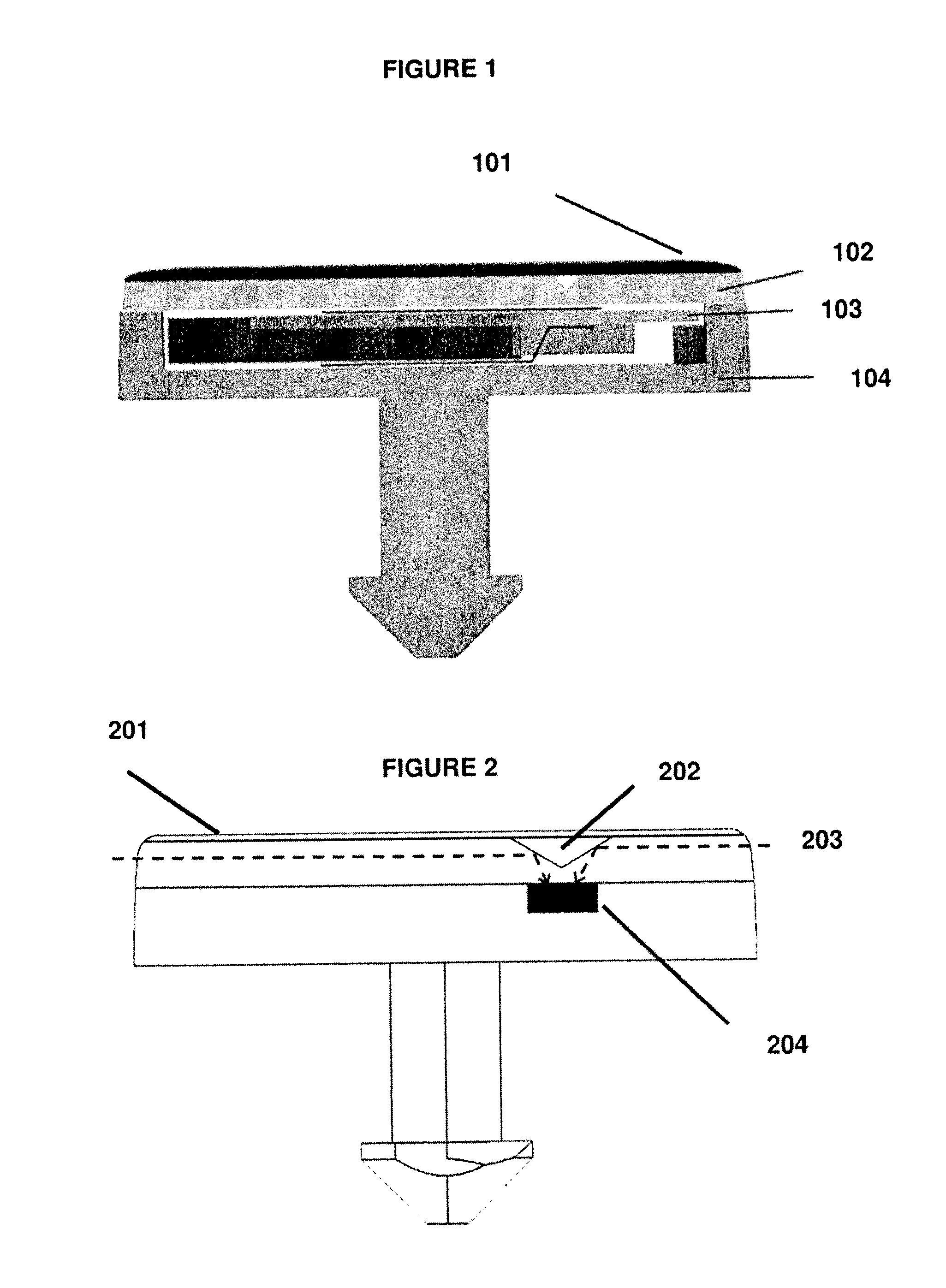

Golf club apparatuses and methods

InactiveUS20120139729A1Simple algorithmWide variationDigital data processing detailsBall sportsSleep stateProcess Measures

Methods, apparatuses, machine readable non-transitory storage media, and systems which process measured light values in order to determine the status of a golf club relative to a golf club bag are described. In one embodiment, a system uses a floating threshold, which is between a running bright average and a running dark average, to determine whether to add a current light meter value to one or the other of these running averages. In another embodiment, a system resets or re-seeds the running averages so that re-seeded averages are used after exiting from a sleep state such as a dark sleep state. In another embodiment, a system uses light sensor information or other sensor information to determine when a club is in use. In another embodiment, an active golf ball tag includes a sensor (e.g. one or more impact sensors) to detect when a golf ball is hit and to cause an RF transmitter to transmit an RF signal to an RFID reader.

Owner:LEI CO LTD

Method for producing steel for high-efficiency alloy welding wires through continuous billet casting

ActiveCN102212749AReduce consumptionEliminate blanking processWelding/cutting media/materialsSoldering mediaProcess MeasuresSmelting process

The invention relates to a method for producing steel for high-efficiency alloy welding wires through continuous billet casting, belonging to the technical field of steel making. The method comprises the following processes: providing low-sulfur molten iron and scrap steel; smelting in a top / bottom blowing converter; pulling off slag and tapping; deoxidizing the ladle; alloying the molten steel; carrying out LF (Ladle Furnace) refining; carrying out RH (Ruhrstahl Heraeus) refining; carrying out fully-protected continuous casting by a continuous billet casting machine; and checking the cast billets, wherein the key processes comprise the end point control during converter smelting, the dose of deoxidizer, the control on the oxygen activity of the molten steel in the production process, the control on the top slag during LF refining, the denitriding effect during RH refining, the regulation of sulfur and titanium contents in the refining process, the effect of protected casting and the like. The method is characterized by controlling oxygen and nitrogen contents in the molten steel through various process measures in the smelting process, thereby achieving the purpose of controlling the reaction of titanium with oxygen and nitrogen, and reducing the possibilities that a submerged nozzle is blocked and crystallizer protecting slag is agglomerated. By using the method, the steel for high-efficiency alloy welding wires, of which the titanium content is 0.15-0.22%, can be stably produced.

Owner:BEIJING SHOUGANG CO LTD

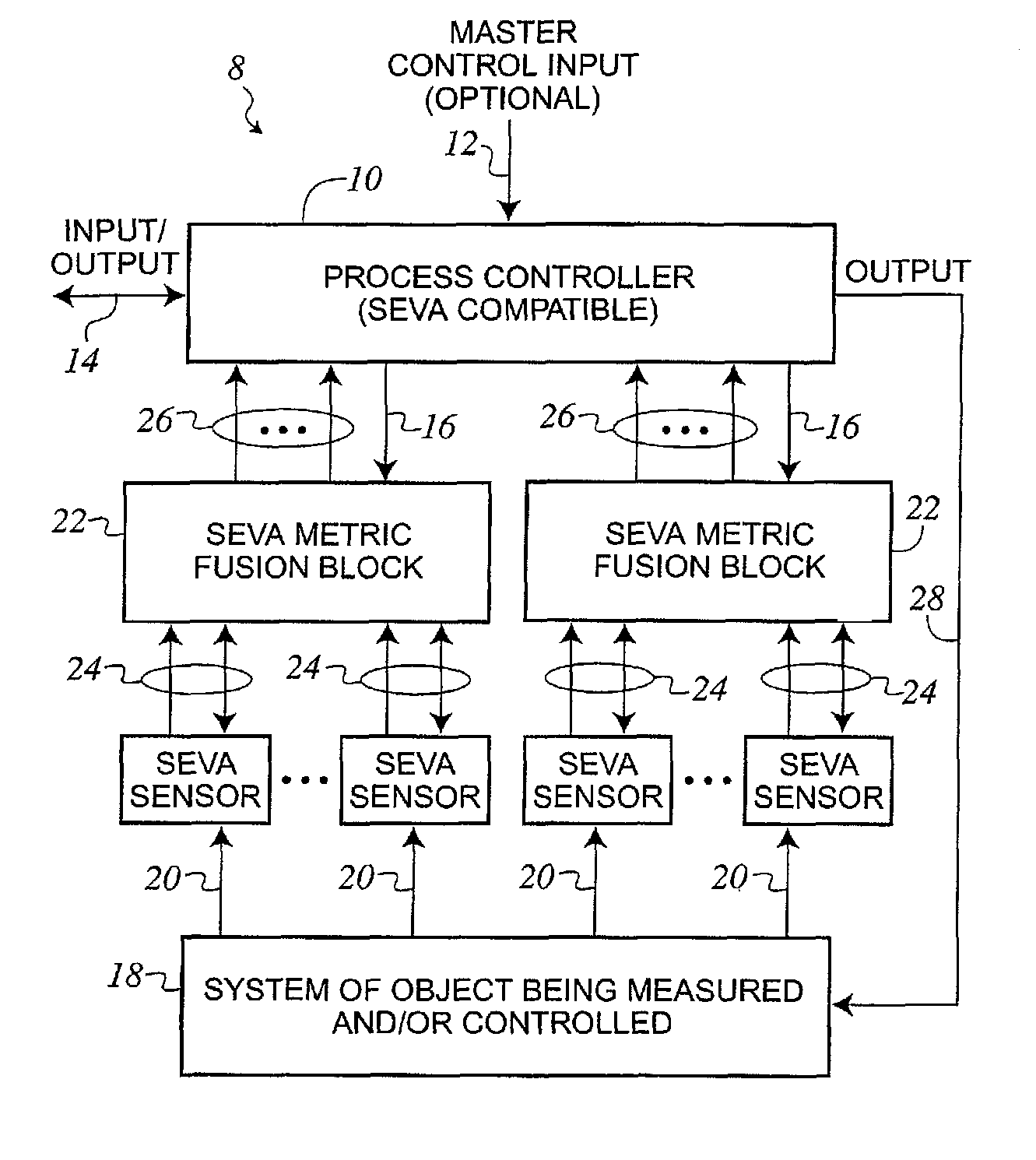

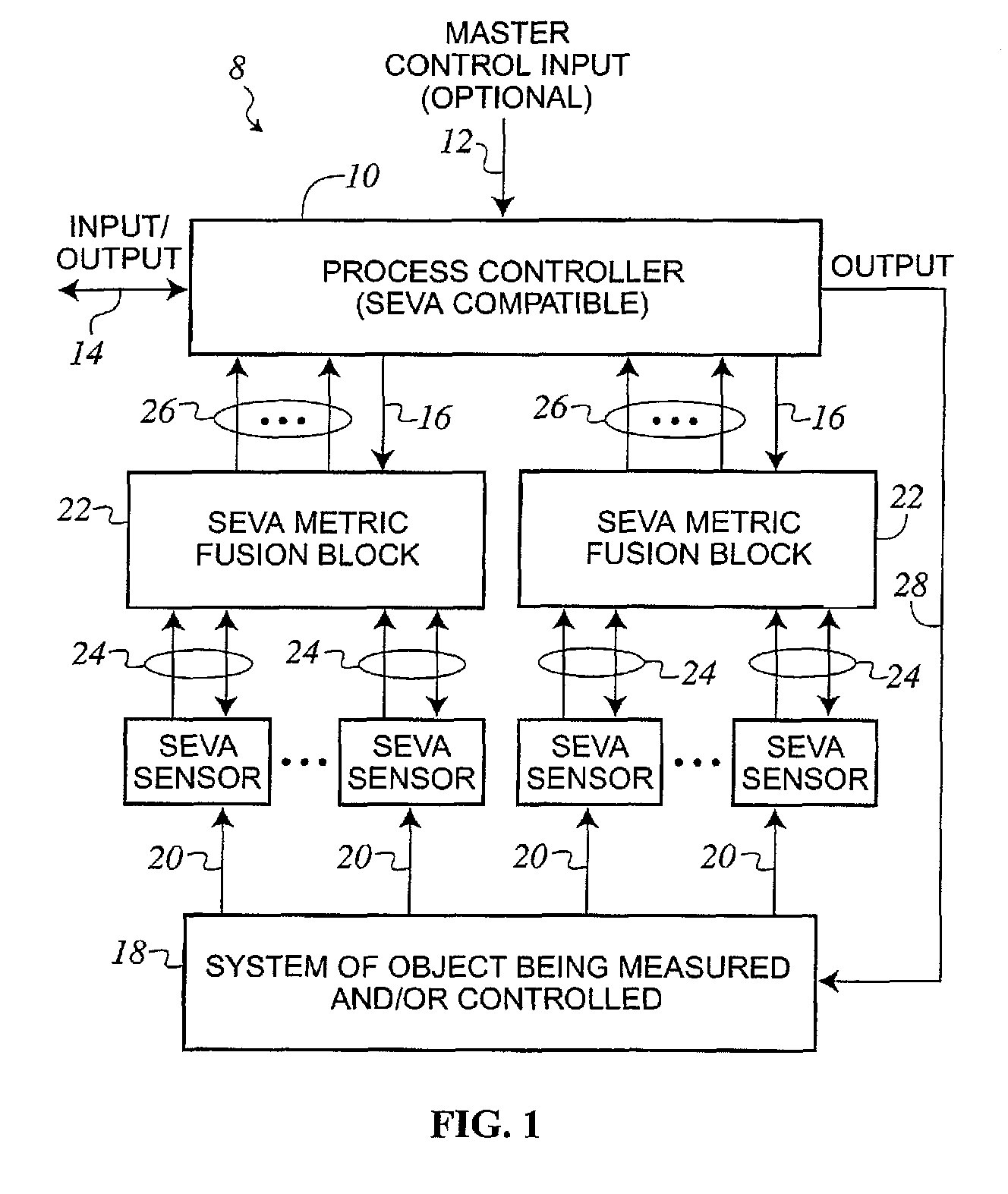

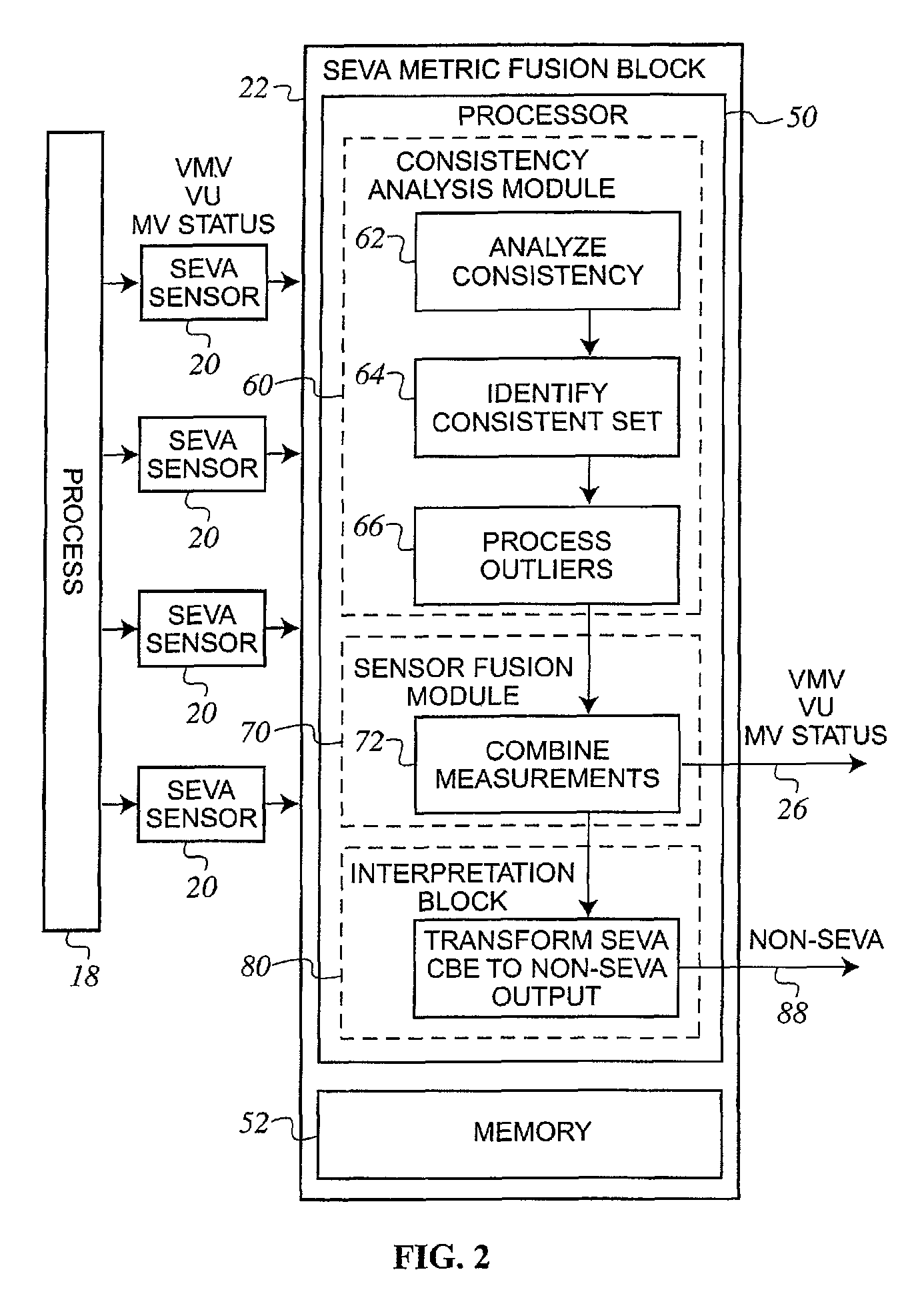

Sensor fusion using self evaluating process sensors

InactiveUS8090552B2Uncertainty in valueAccurate temperature measurementComputing operations for integral formationMeasurement arrangements for variableProcess MeasuresTransducer

A measurement processing system is disclosed for fusing measurement data from a set of independent self-validating (SEVA™) process sensors monitoring the same real-time measurand in order to generate a combined best estimate for the value, uncertainty and measurement status of the measurand. The system also provides consistency checking between the measurements. The measurement processing system includes a first process sensor and a second process sensor. Each of the first and second process sensors receive a measurement signal from a transducer and generate independent process metrics. A measurement fusion block is connected to the first and second process sensors, the measurement fusion block is operable to receive the independent process metrics and execute a measurement analysis process to analyze the independent process metrics and generate the combined best estimate of the independent process metrics.

Owner:SCHNEIDER ELECTRIC SYST USA INC

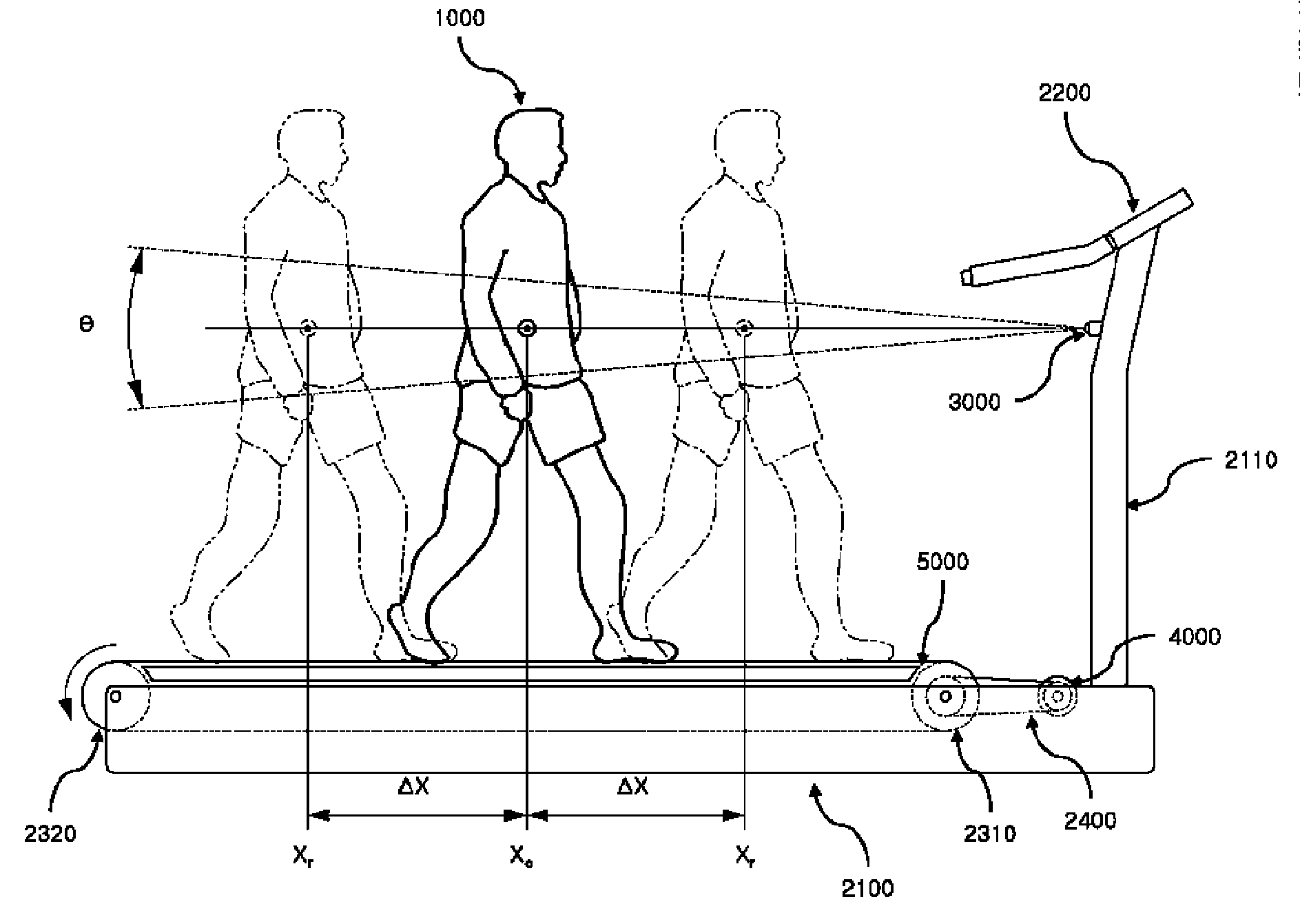

Treadmill with automatic speed control, control module of the same and control method of the same

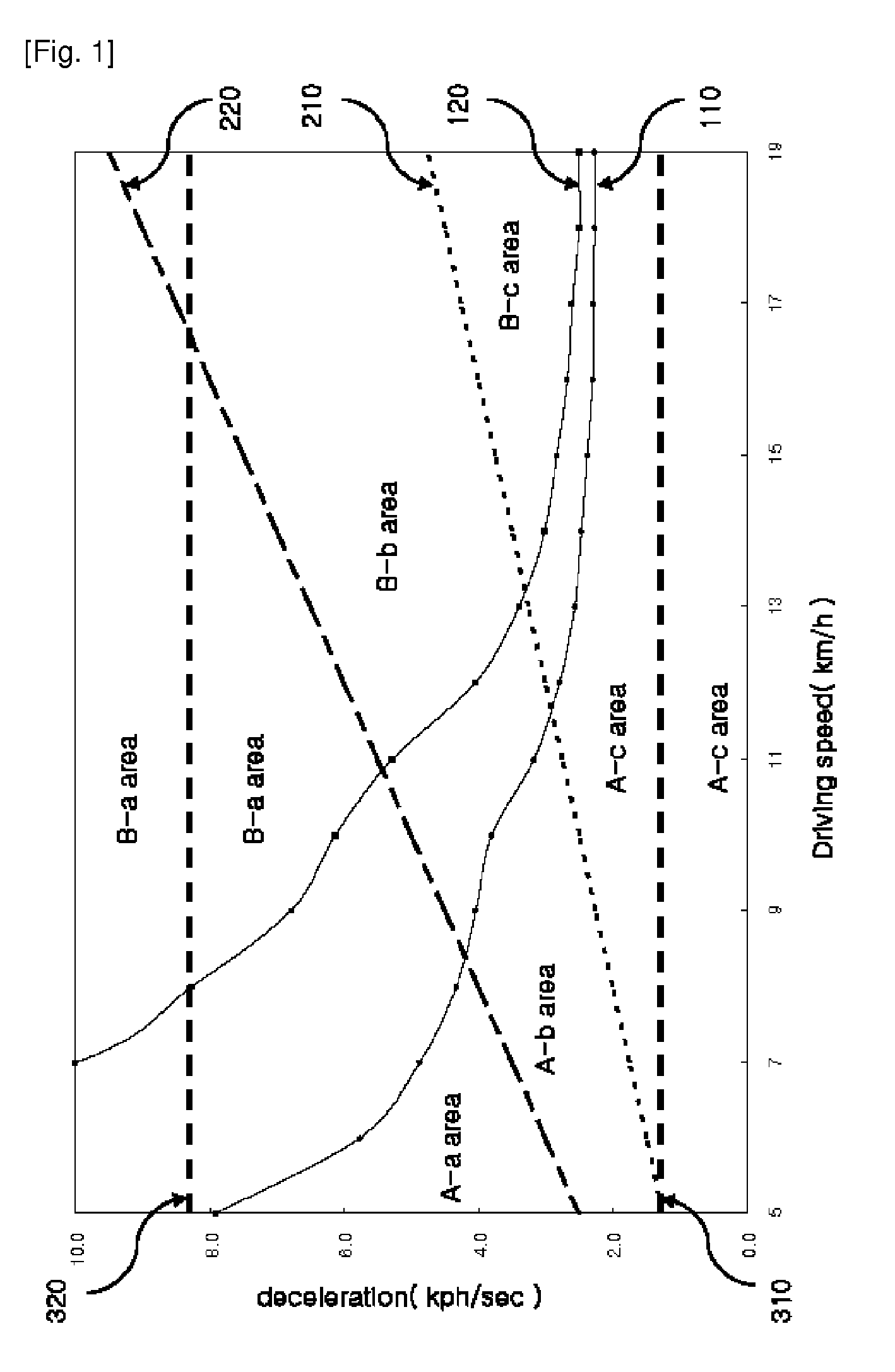

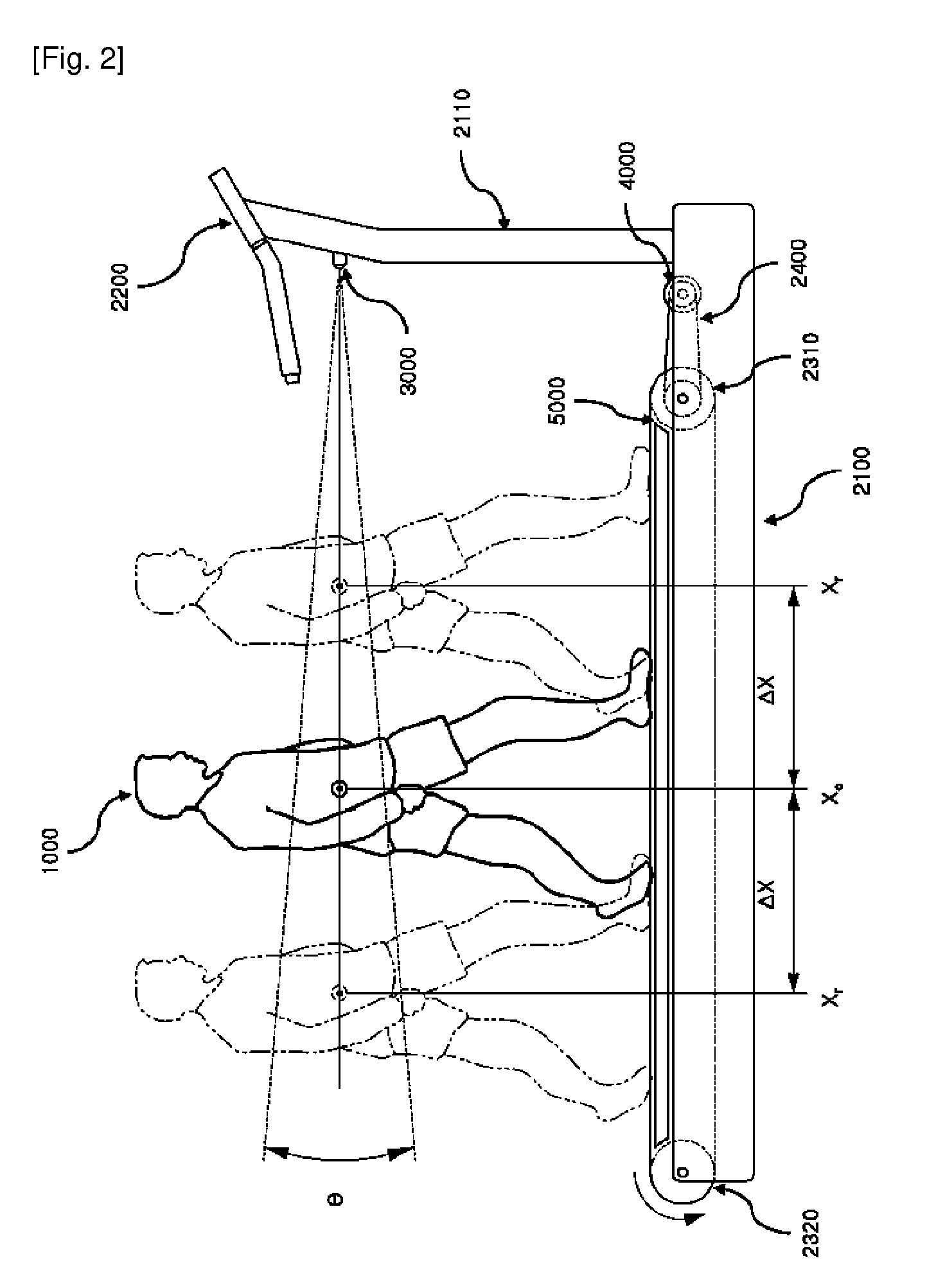

ActiveUS20100210419A1Feel goodIncrease decelerationMotor/generator/converter stoppersDynamo-electric converter controlObservational errorAutomatic control

The present invention provides a treadmill with an automatic speed control function, including: a body having a belt for supporting an exerciser; an exerciser detecting portion installed in a predetermined area of the body to detect movement of the exerciser; a driving motor coupled to the body to drive the belt; a control portion for generating a control signal for adjusting a rotation speed of the driving motor based on a signal received from the exerciser detecting portion; and a motor driving portion for adjusting the rotation speed of the driving motor according to the control signal received from the control portion, wherein a provision braking torque provided corresponding to the control signal is varied as the rotation speed of the driving motor is reduced. The treadmill quickly follows acceleration or deceleration of an exerciser, realizes a feeling like what an exerciser has while exercising on the ground to thereby improve an exerciser's exercising feeling, accepts various exercising patterns of an exerciser, resolves a problem in that a motor driving portion is tripped due to a load caused by quick deceleration, and pre-processes measured values of an exerciser's position to resolve a problem in that a speed of a belt can not be controlled due to measurement errors contained in measured values.

Owner:KAESUN SPORTS

Method and system for measuring resonant frequency of loudspeaker part

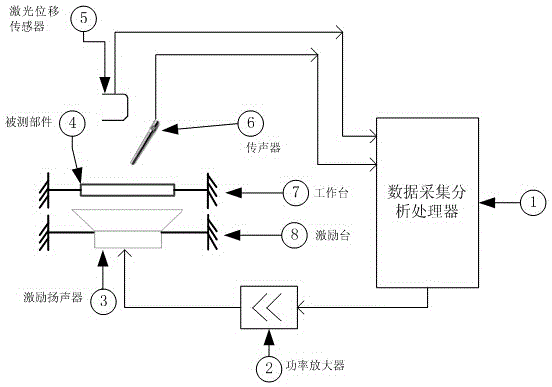

ActiveCN105050018AAccurate measurementEasy to measureElectrical apparatusSound sourcesProcess Measures

The present invention provides a method and a system for measuring the resonant frequency of a loudspeaker part. The system comprises a data acquisition and analysis processor, a power amplifier, an excitation sound source, a to-be-tested loudspeaker part, a laser displacement sensor, a microphone, an operation workbench, an excitation workbench, a tool clamp and the like. The excitation sound source is mounted on the top of the excitation workbench. The excitation workbench is arranged below the operation workbench. The downward-side excitation sound source is right facing the loudspeaker part above the excitation sound source. The laser displacement sensor and the microphone are fixed on an upward-side multifunctional bracket. The multifunctional bracket is capable of freely moving up and down, front and back, or left and right in a space above the top of the operation workbench. The data acquisition and analysis processor is used for generating excitation signals, acquiring, analyzing and processing measured signals, storing a measurement result and displaying the measurement result. Due to the adoption of the compensating means for the frequency response, the amplitude adjustment means for the vibration displacement and other means in an acoustic measurement environment, the resonant frequency of a diffuser (a vibrating diaphragm) with a centering disk can be accurately and conveniently measured.

Owner:ZHEJIANG ELECTRO ACOUSTIC R&D CENT CAS +1

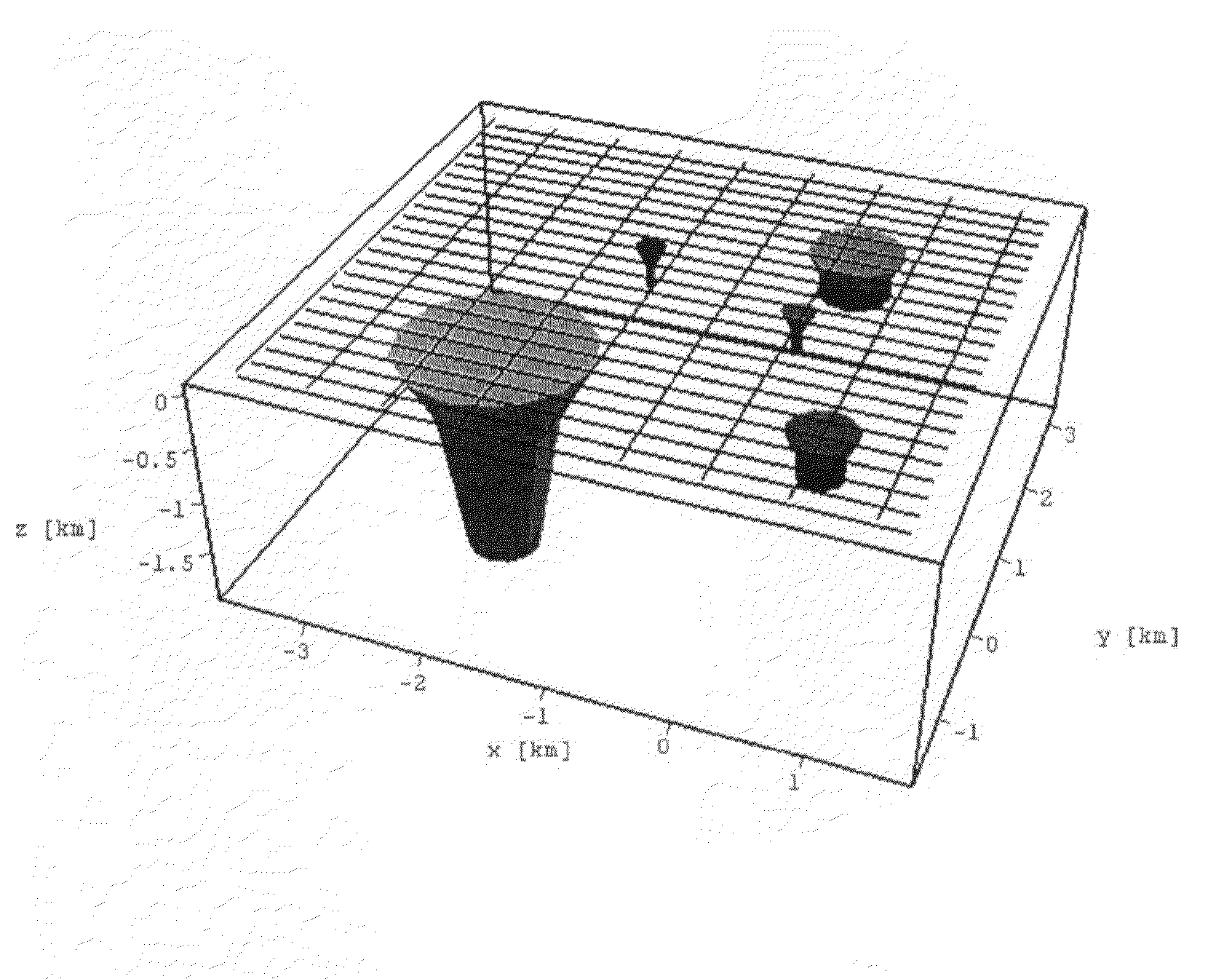

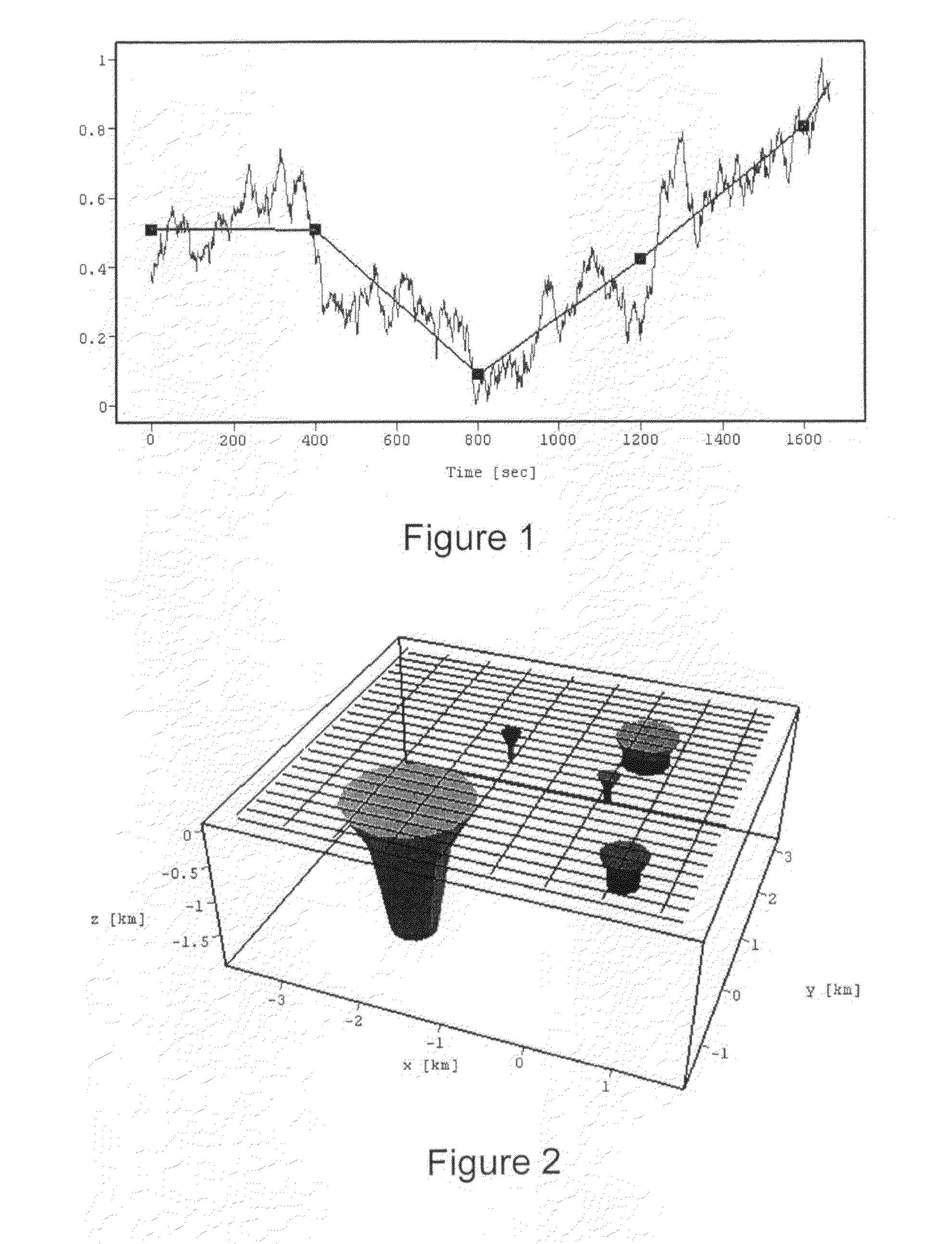

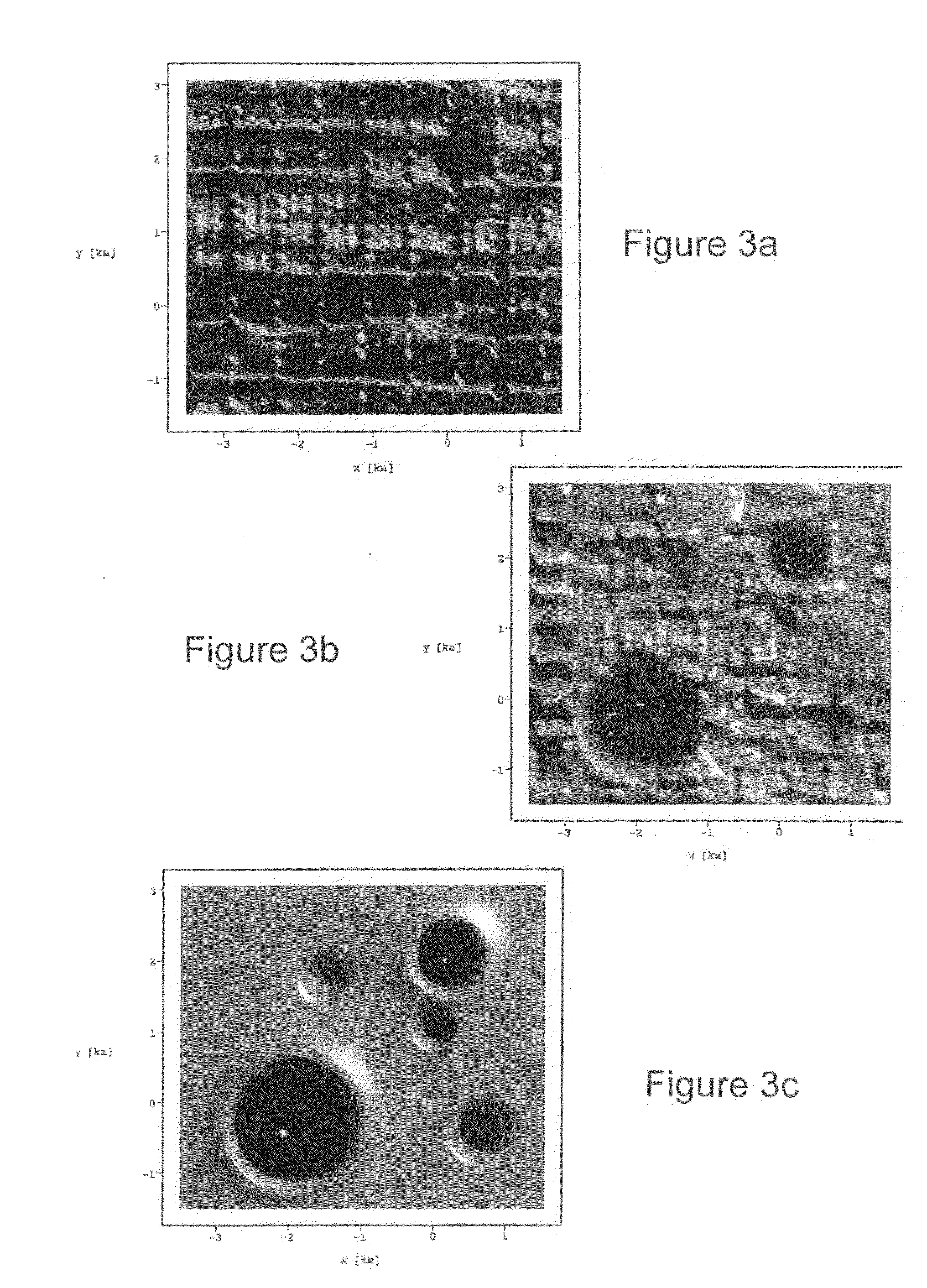

Gravity survey data processing

InactiveUS20090287464A1Amplifier modifications to reduce noise influenceResistance/reactance/impedenceTime domainPotential field

This invention relates to improved techniques for processing potential field measurement data from airborne surveys such as gravity surveys, and to methods, apparatus and computer program code for such techniques. We describe a method of processing measured potential field data from an airborne or marine potential field survey to determine a set of field mapping parameters for mapping a field, the method comprising: inputting said measured potential field data, said measured potential field data comprising data defining a plurality of potential field measurements each with an associated measurement position and measurement time; and determining said set of field mapping parameters using a model comprising a combination of a spatial part representing a spatial variation of said potential field and a temporal part representing time domain noise in said measured potential field data, wherein said determining comprises fitting said measured potential field data to both said spatial and temporal parts of said model.

Owner:ARKEX

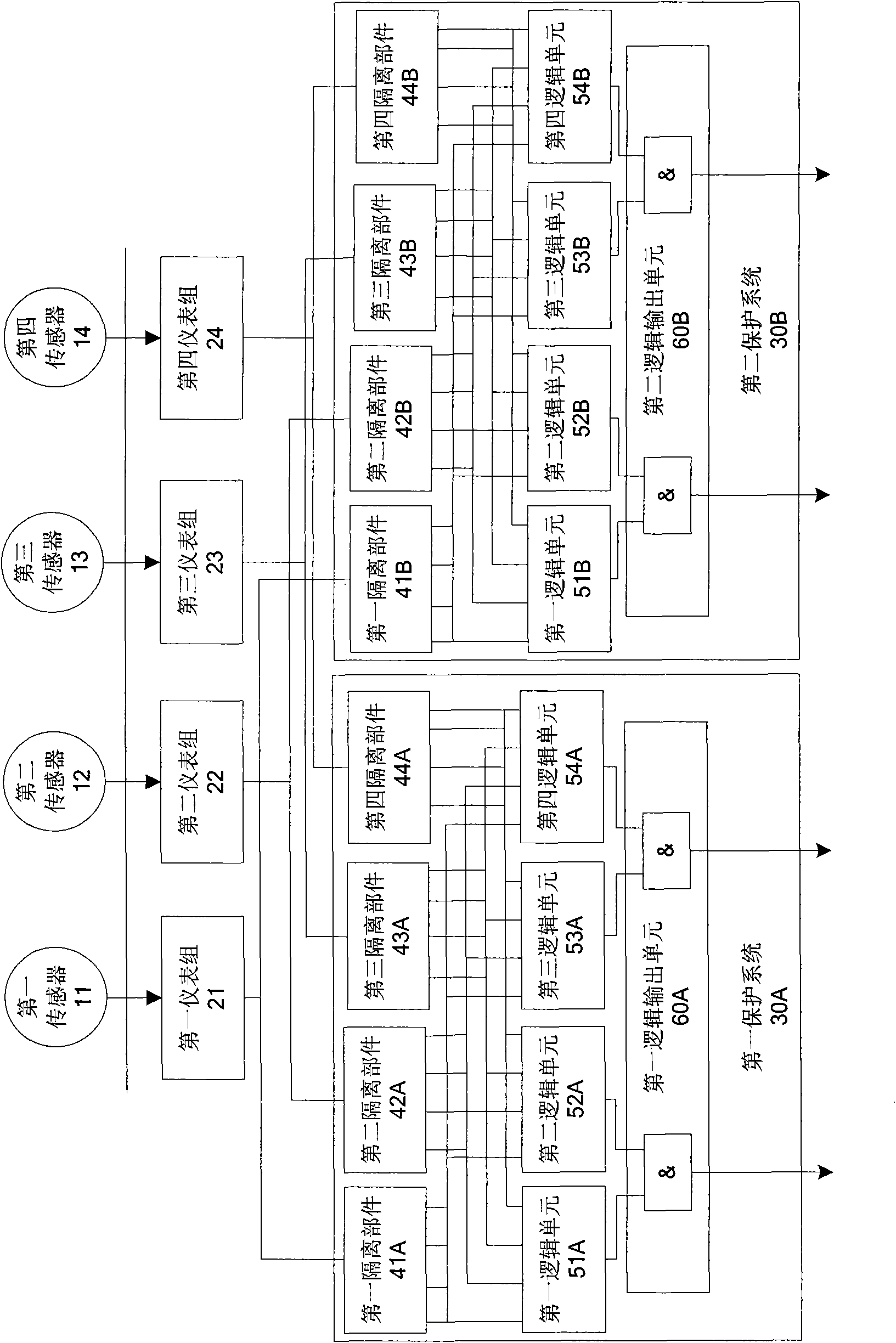

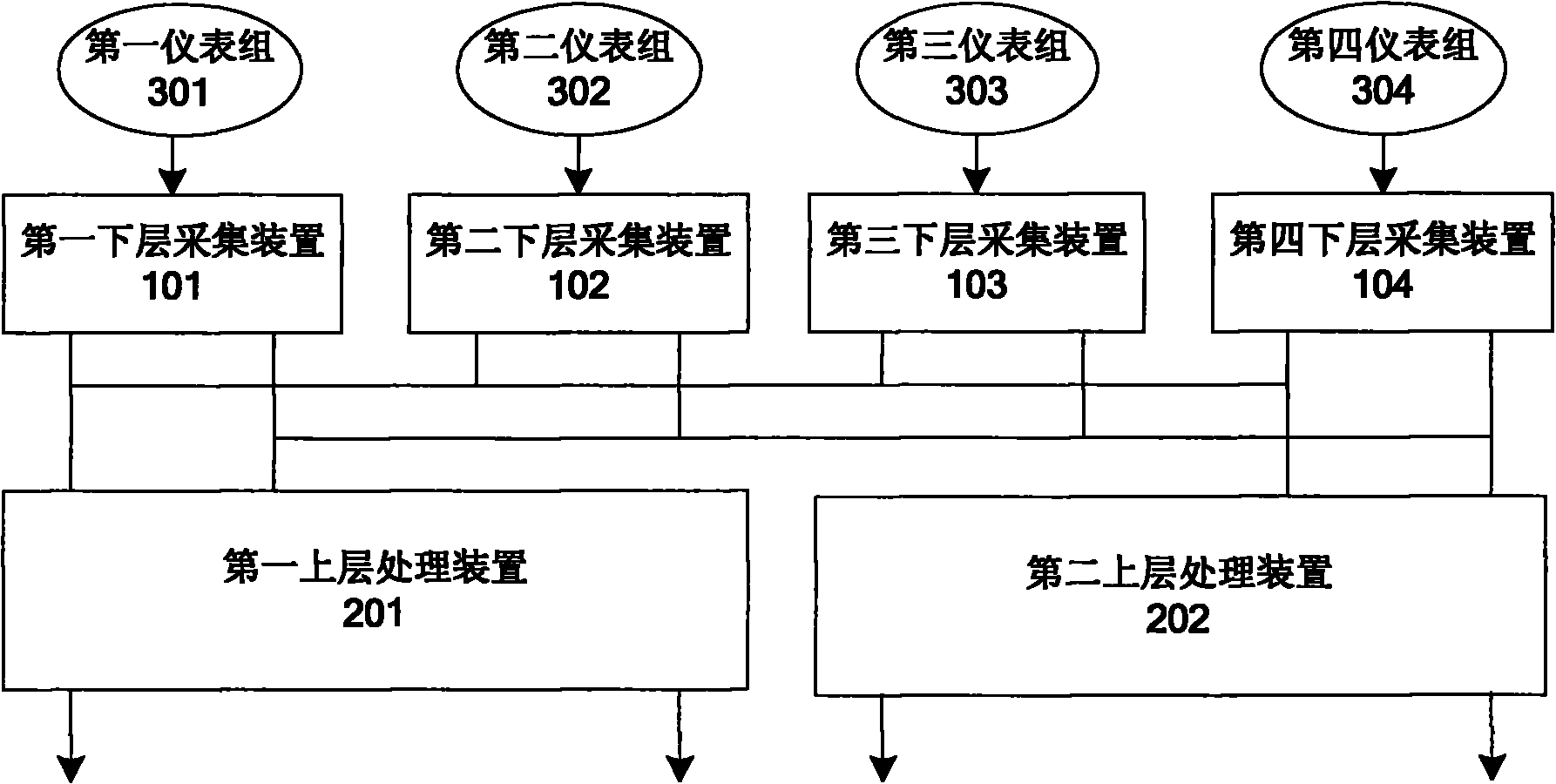

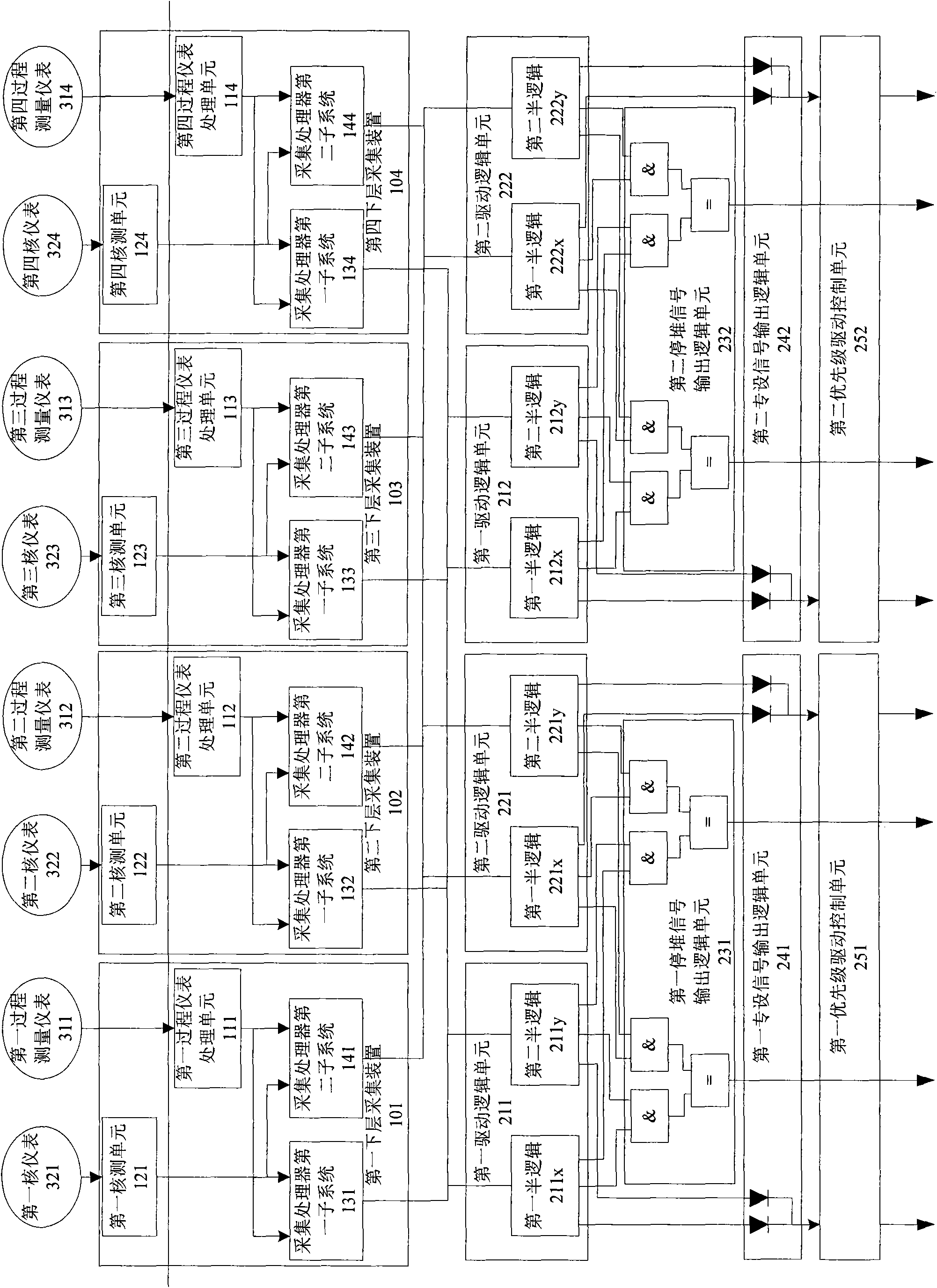

Protecting system of nuclear power station reactor

ActiveCN101968974AImprove usabilityImprove reliabilityNuclear energy generationNuclear reaction controlMeasuring instrumentMaintainability

The invention relates to a protecting system of a nuclear power station reactor, comprising at least one lower-layer acquisition device and an upper-layer processing device, wherein the lower-layer acquisition device is connected with an instrument group of the nuclear power station reactor; the instrument group comprises a process measuring instrument and a nuclear instrument; the lower-layer acquisition device acquires and processes a process signal of the process measuring instrument and a nuclear power signal generated by the nuclear instrument, and compares the process signal and the nuclear power signal respectively with a set process signal threshold and a set nuclear power signal threshold to generate digital quantity signals; and the upper-layer processing device is connected with the lower-layer acquisition device and is used for receiving the digital quantity signals generated by the lower-layer acquisition device and carrying out preset logic processing on the digital quantity signals and then generating a shut-down signal and a special driving signal. By carrying out digital processing on a reactor signal, compared with a simulation technique, the implemented protecting system of the nuclear power station reactor has high automation degree and has greater advantages in the aspect of improving usability, reliability, maintainability, economical efficiency, obsolescence resistance and flexibility.

Owner:中广核工程有限公司 +1

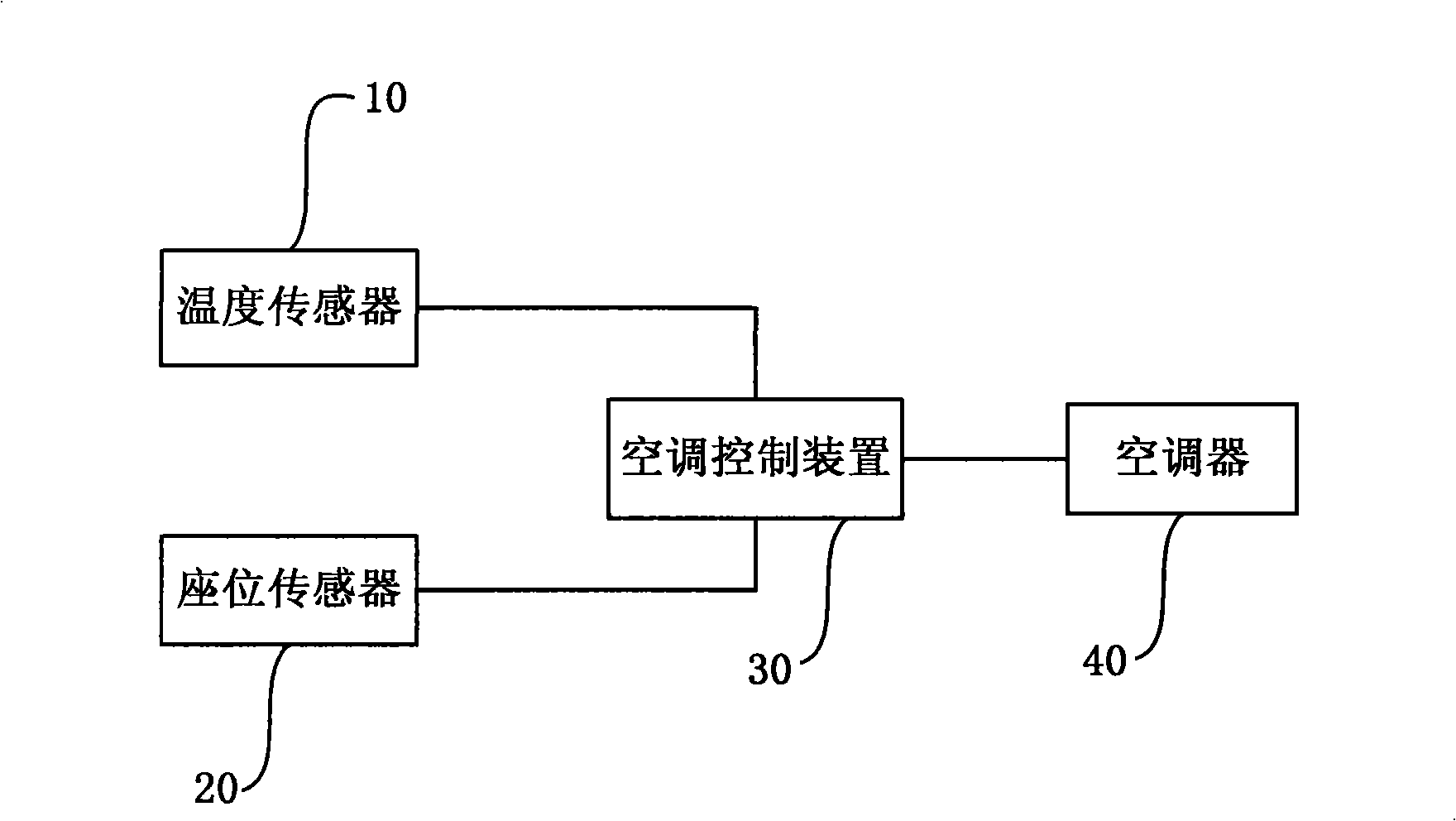

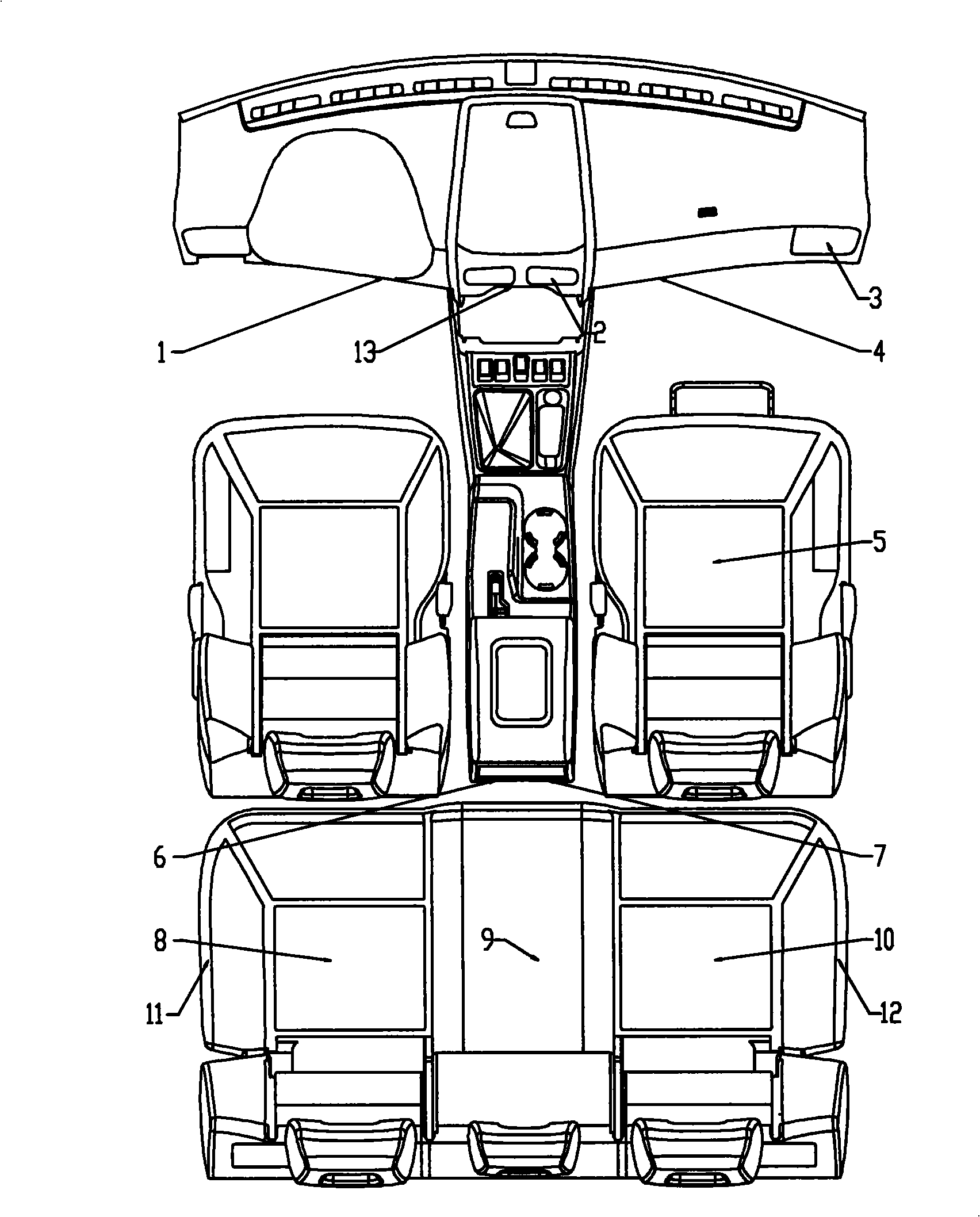

Intelligent air-conditioning system

InactiveCN101259824AReduce unnecessary wasteMeet temperature requirementsAir-treating devicesSpace heating and ventilation safety systemsControl signalProcess Measures

The invention discloses an intelligent air conditioning system comprising an air conditioner with an air outlet, a temperature sensor, a seat sensor which can sense the situation of the passenger load and an air conditioner controlling device. The air conditioner controlling device receives and processes measuring data provided by the temperature sensor and the seat sensor, and output control signals for adjusting the air conditioning power and the air outlet direction of the air outlet. The intelligent air conditioning system can automatically adjust the air conditioning power and the air outlet direction of the air outlet according to the situation of the passenger load and temperature in the automobile so as to reduce the meaningless waste of the power of the air conditioner while the requirement for inside temperature by passenger is met, thus saving energy resources.

Owner:CHERY AUTOMOBILE CO LTD

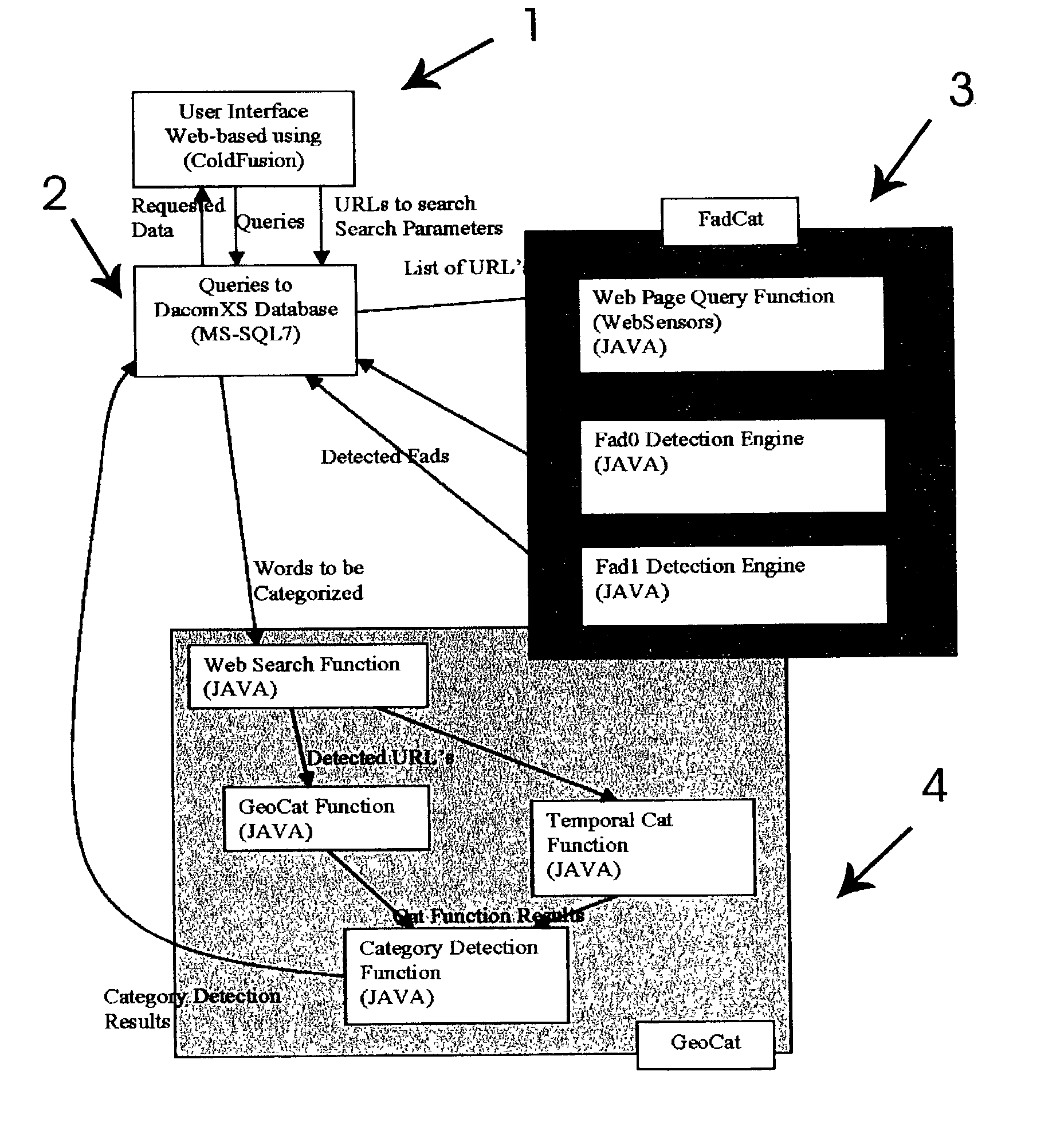

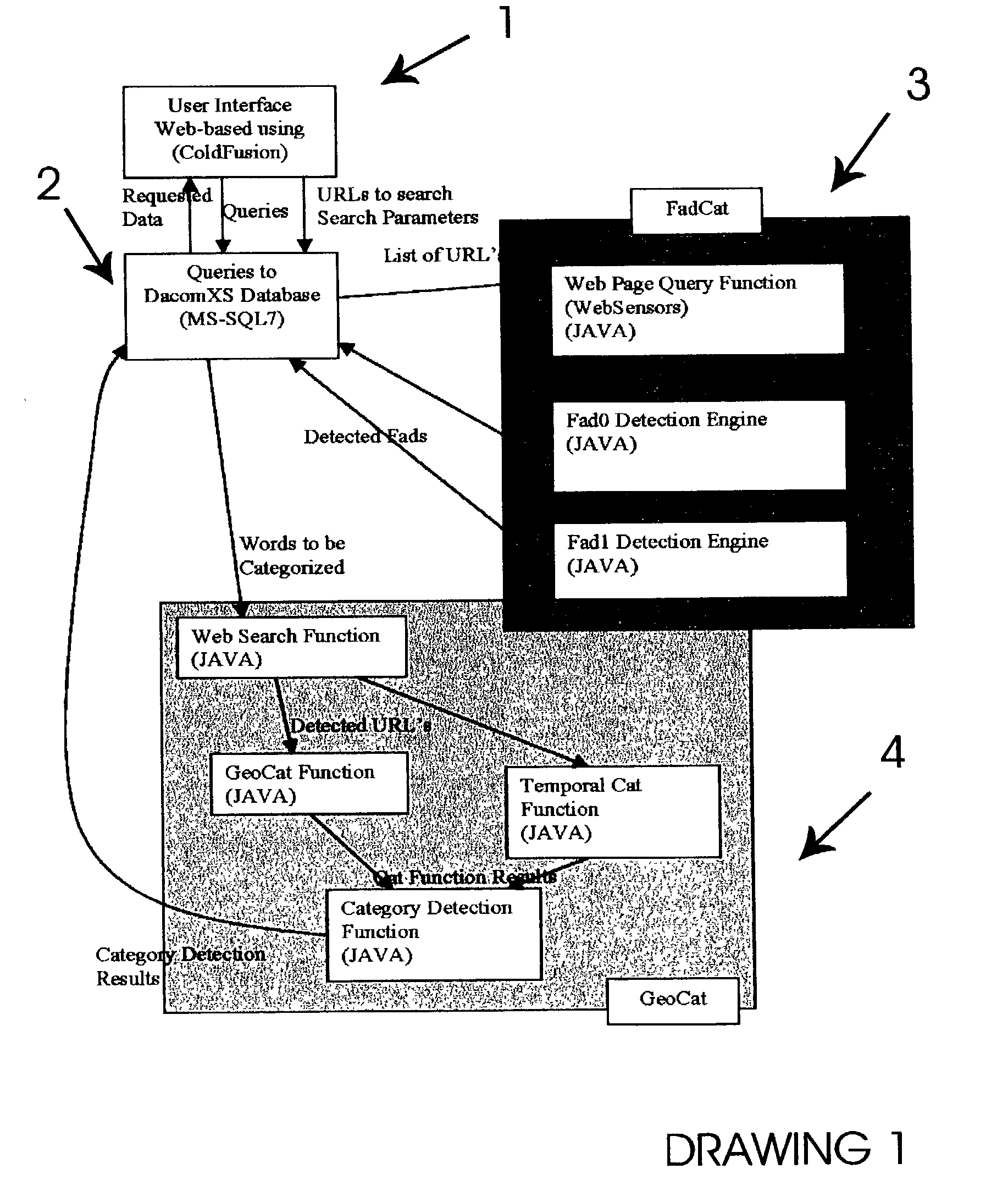

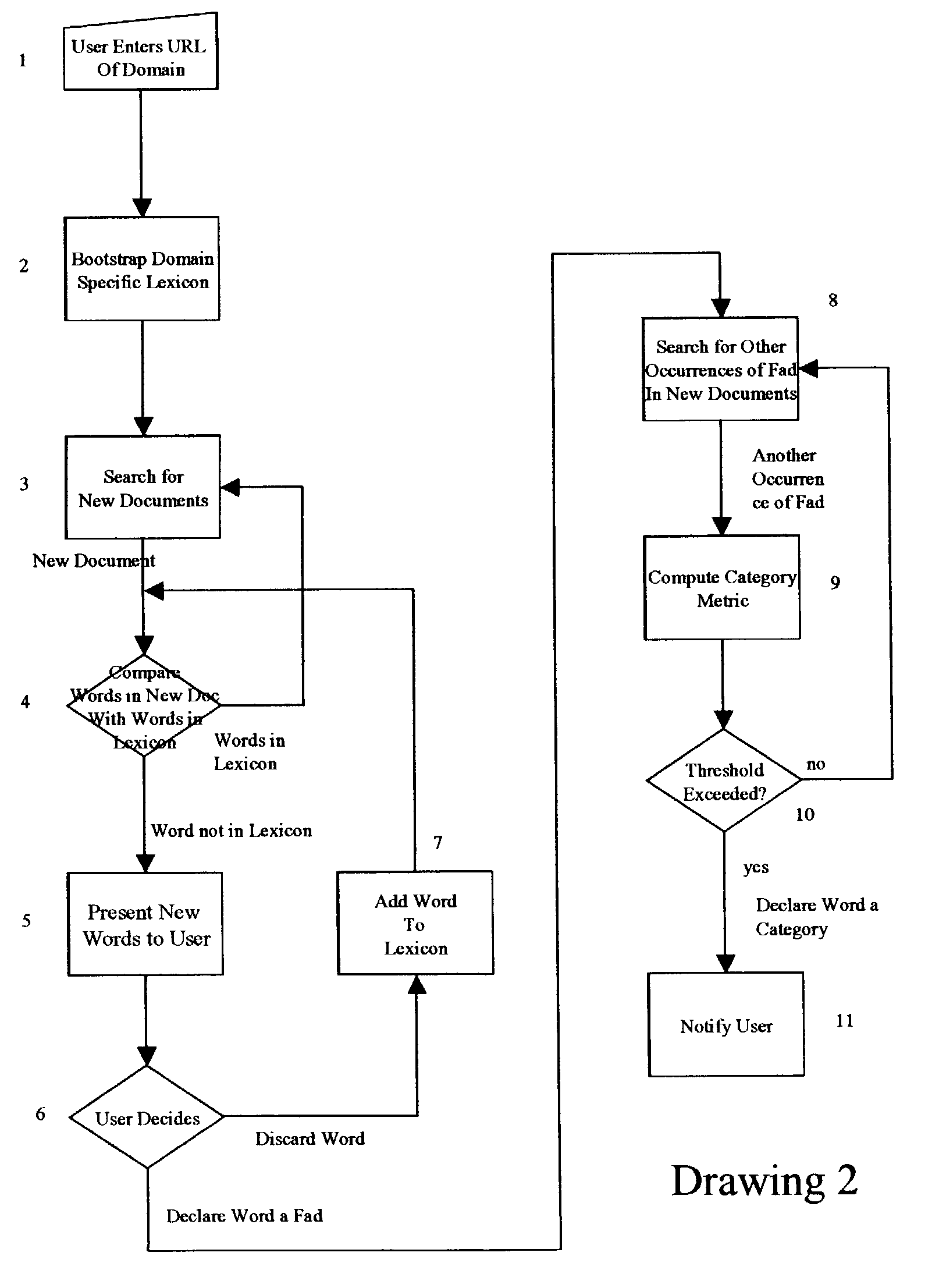

Lexicon-based new idea detector

ActiveUS7024624B2Natural language data processingSpecial data processing applicationsProcess MeasuresCourse of action

A method and apparatus for detecting the occurrence of new ideas in documents or communications. The method is comprised of three processes. The first process lexiconizes all words or symbols in a set of documents. The second process compares all words in a second set of documents to the words in the lexicon. Words not already in the lexicon are presented to a user who takes one of two courses of action, 1) lexiconizes the word, or, 2) declares it a “fad” indicating that the word is to be further analyzed. The third process measures the spatial and temporal spread of said fad by searching a third set of documents and computing metrics based on additional occurrences of said fad, said metrics being used to determine when a fad has achieved a level of interest denoted as a category. When a category is detected, a user is notified.

Owner:HINTZ KENNETH JAMES

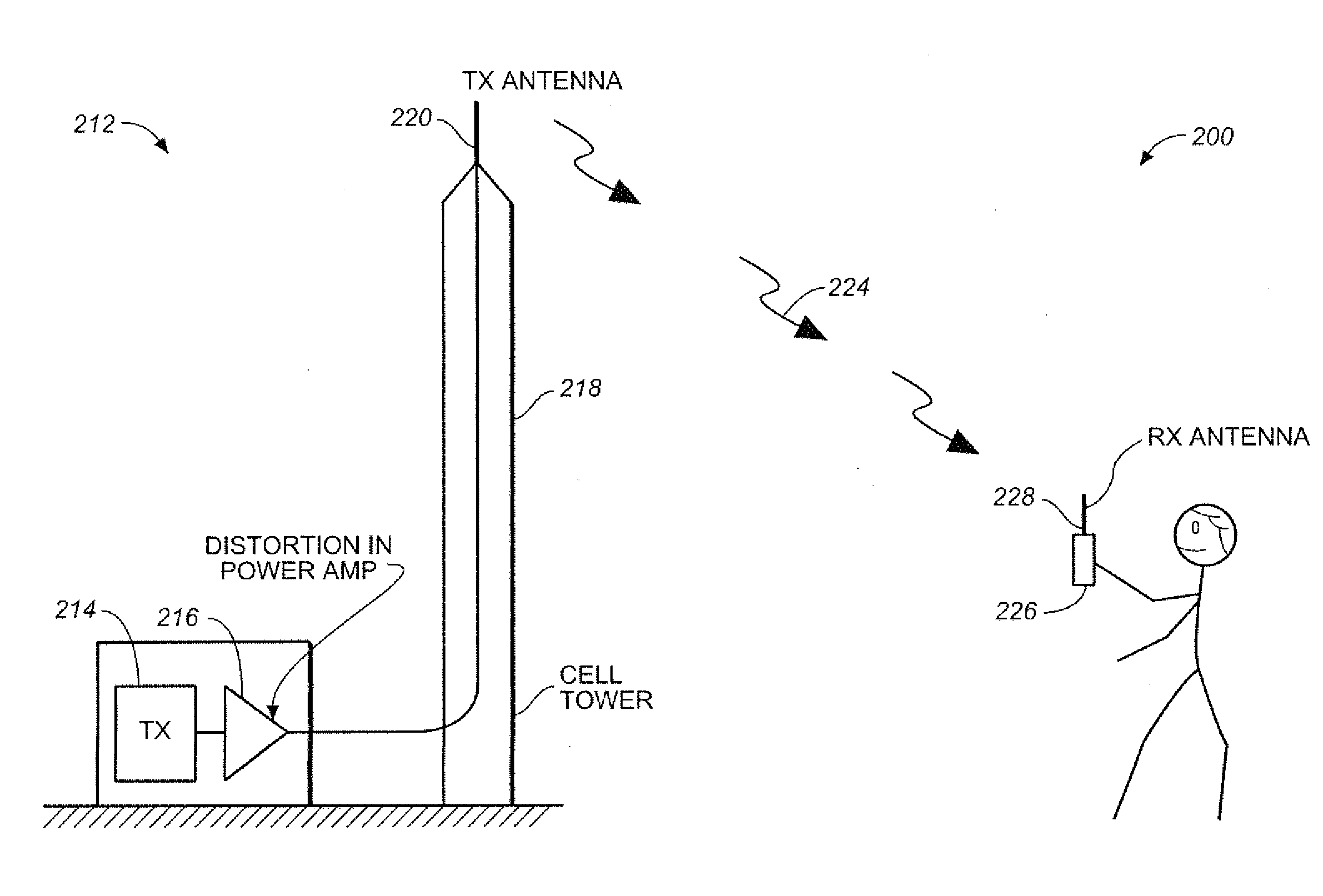

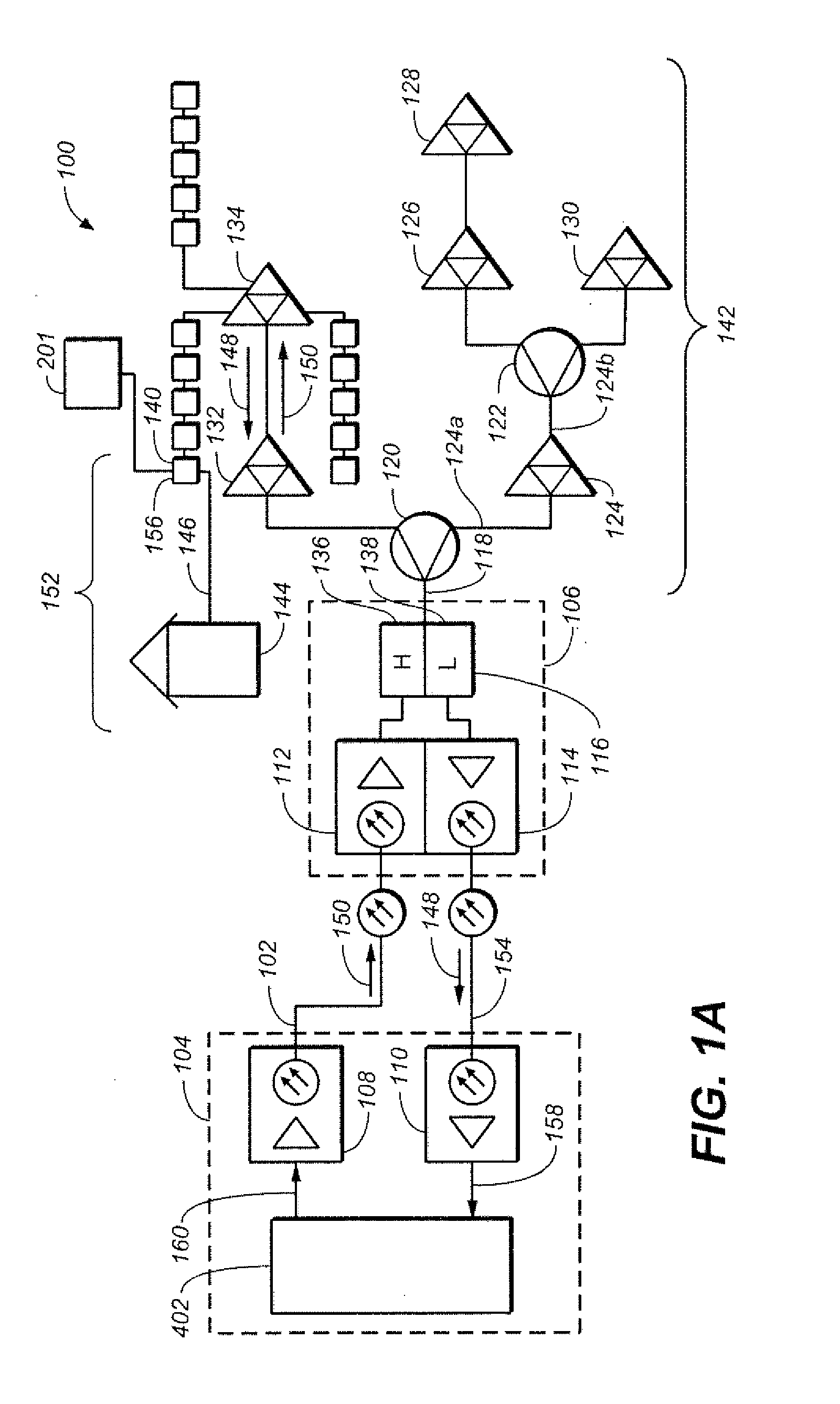

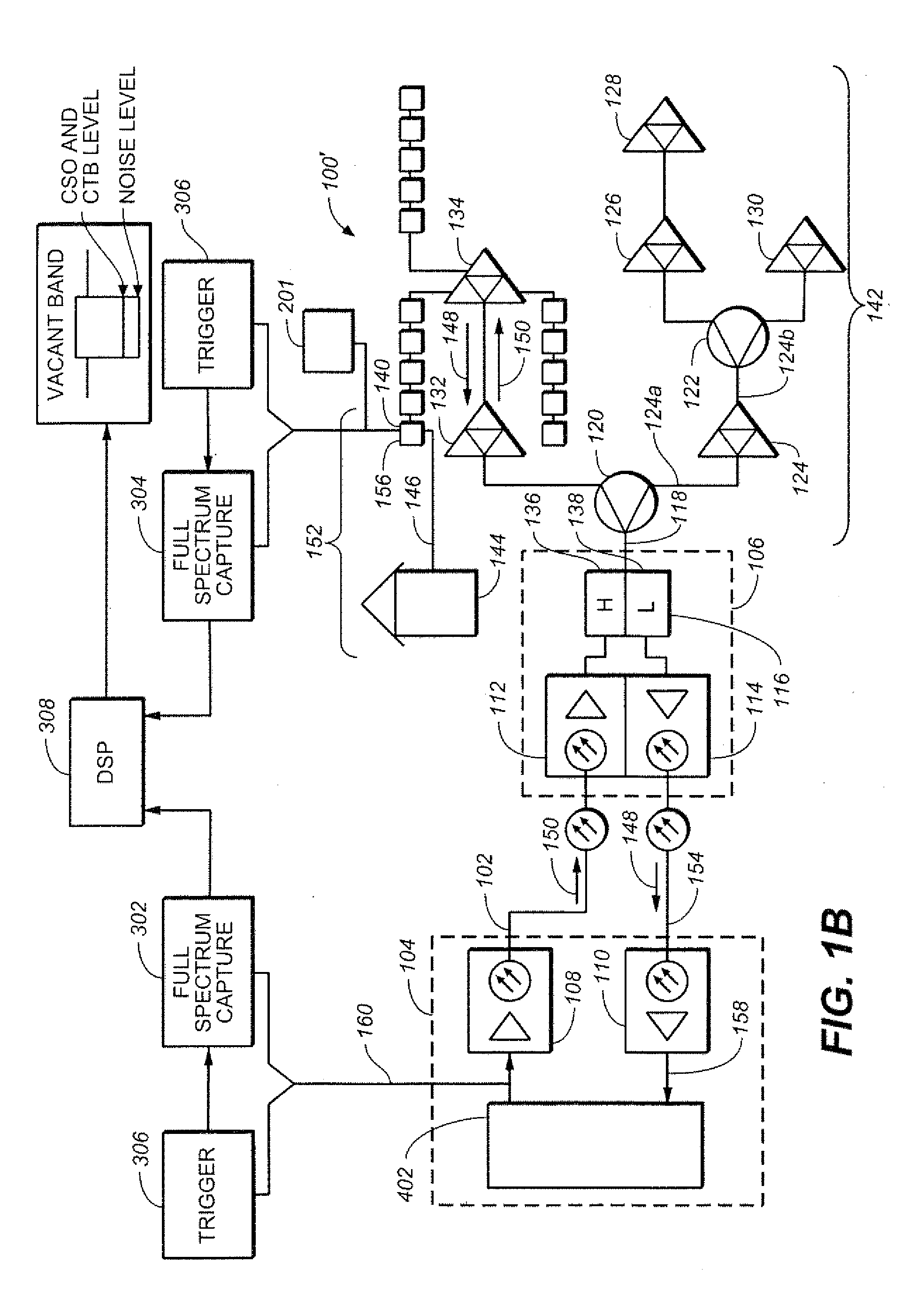

Analysis of Captured Random Data Signals to Measure Linear and Nonlinear Distortions

ActiveUS20150043626A1Transmission monitoringElectromagnetic transmissionNonlinear distortionDigital signal processing

A method to capture random data signals at an end point in a broadband network and process them via digital signal processing (DSP) techniques to determine both linear distortions and nonlinear distortions. In a distribution network, such as a tree and branch cable network, the location of the impairment addition can be identified by determining location of terminals have a distortion and locations of terminals that do not have a distortion. Linear distortions may be determined by an autocorrelation of the captured signal with itself. Nonlinear distortions may be determined by processing measured energy in a vacant band with manufactured energy in the vacant band. If a vacant band is not available, one can be created by demodulating a signal occupying the band, and subtracting the demodulated signal from the measured signal plus interference in a band, leaving only the interference.

Owner:CABLE TELEVISION LAB

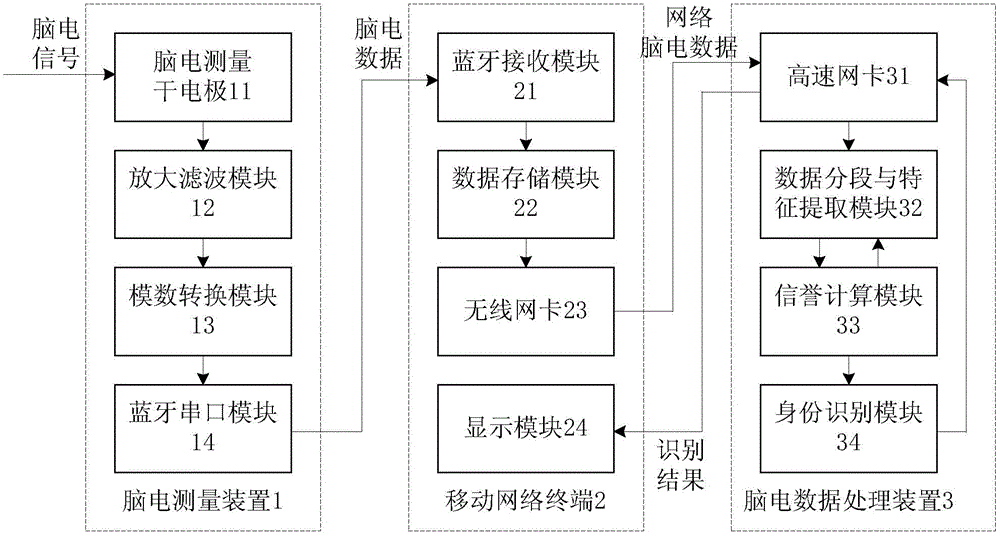

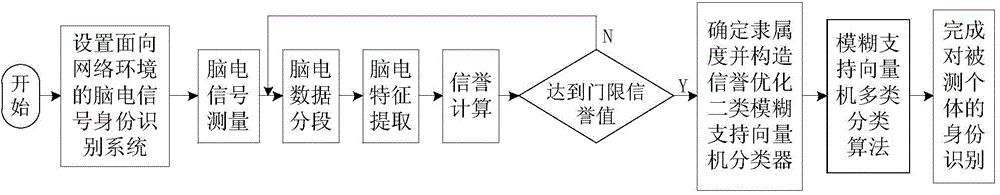

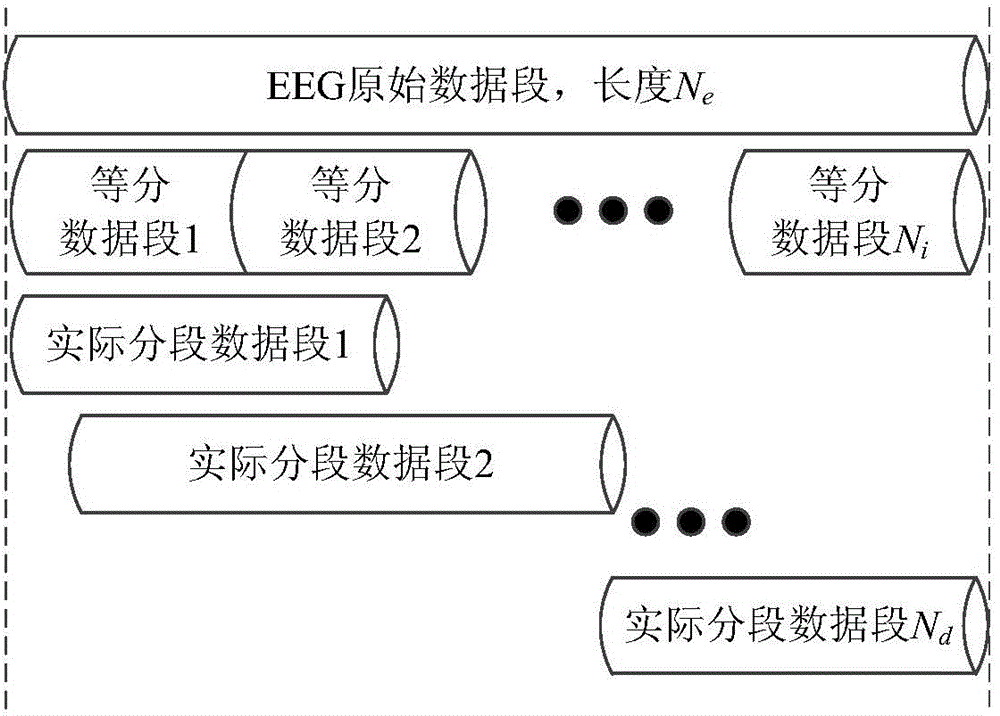

Network environment-oriented electroencephalogram identification system and network environment-oriented electroencephalogram identification method

ActiveCN103976740AReduce the difficulty of measurementShort timePerson identificationSensorsMeasurement deviceWireless network

The invention relates to a network environment-oriented electroencephalogram identification system and a network environment-oriented electroencephalogram identification method. The identification system comprises a plurality of wearable electroencephalogram measuring devices, more than one mobile network terminal and an electroencephalogram data processing device; the electroencephalogram measuring devices are used for processing measured electroencephalograms into network electroencephalogram data and transmitting the network electroencephalogram data to the electroencephalogram data processing device for processing; the electroencephalogram data processing device is used for outputting an identification result and transmitting the identification result to a mobile network terminal for displaying. The identification method comprises the steps of measuring the electroencephalograms of a tested individual by using the electroencephalogram measuring devices and processing the electroencephalograms into the network electroencephalogram data, transmitting the electroencephalogram data to the electroencephalogram data processing device by virtue of a wireless network card of the mobile network terminal, performing segment treatment on the electroencephalograms and extracting electroencephalogram characteristic information by use of the electroencephalogram data processing device, screening electroencephalogram characteristic vector training samples based on reputation computing, and determining the input sample and the degree of membership of a fuzzy support vector machine, thereby completing the identification of the tested individual and outputting the result.

Owner:TSINGHUA UNIV

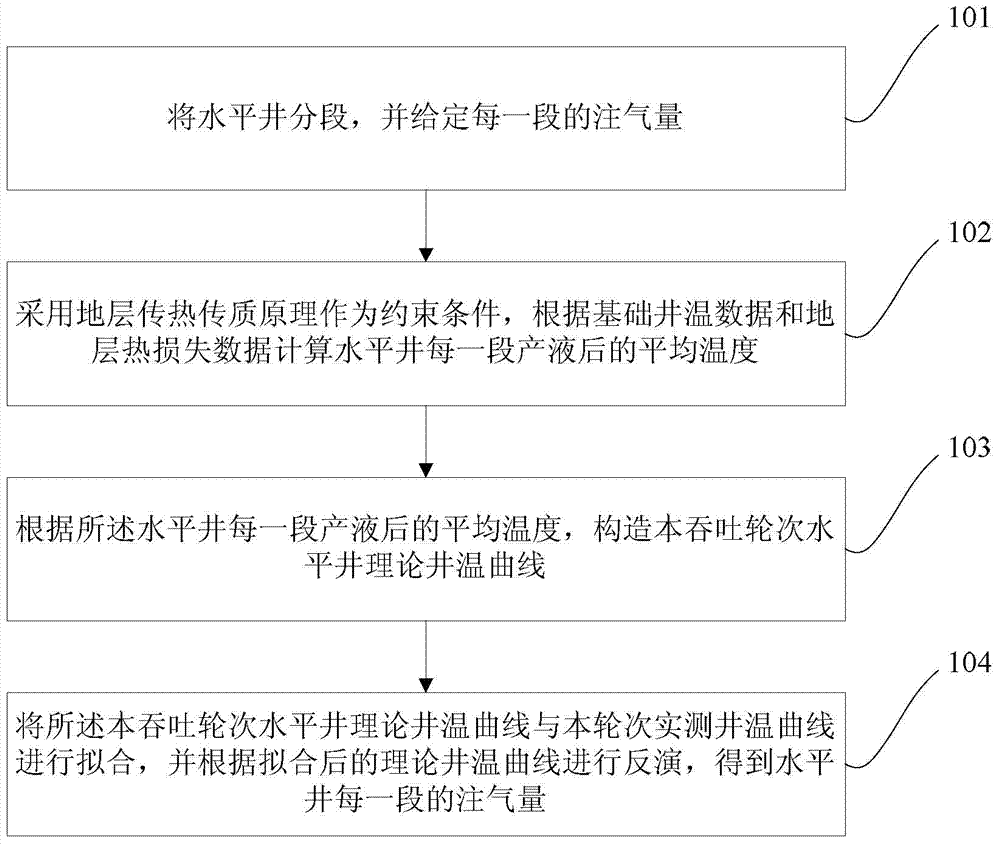

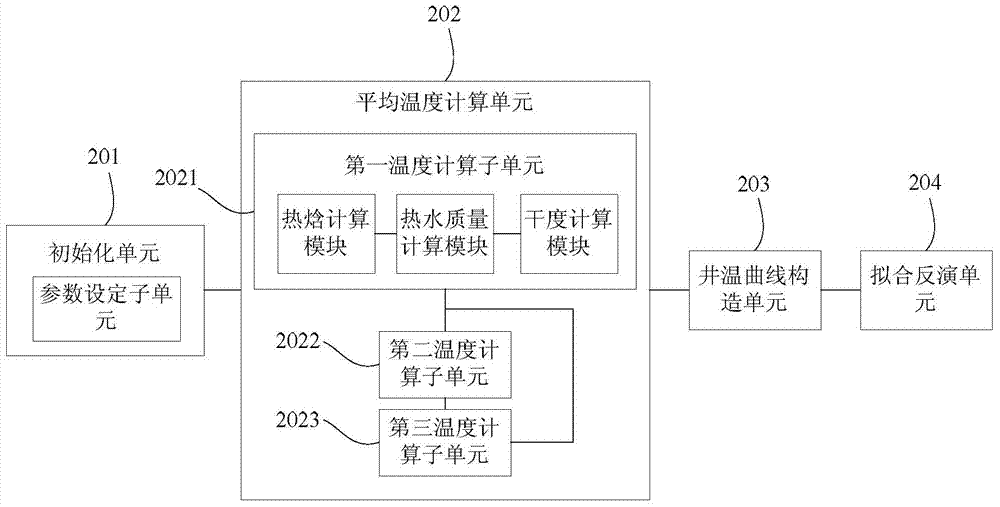

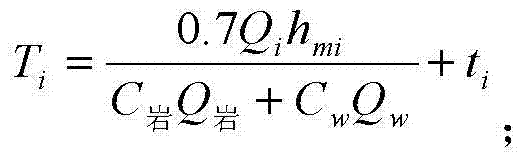

Method and system for analyzing steam suction condition of thick oil horizontal well

The invention provides a method and a system for analyzing the steam suction condition of a thick oil horizontal well. The method comprises the following steps of sectionalizing the horizontal well, and setting the gas injection volume of each section; calculating the average temperature of each section after liquid production according to basic well temperature data and stratus heat loss data by adopting stratum heat transfer and mass transfer principle as a constraint condition; constructing a theoretical well temperature curve of the horizontal well in the throughput round according to the average temperature of each section of the horizontal well after the liquid production; fitting the theoretical well temperature curve of the horizontal well in the throughput round and a measured well temperature curve of the throughput round, and performing inversion according to the fitted theoretical well temperature curve to obtain the gas injection volume of each section of the horizontal well. According to the method and the system, the use condition of the sections of the horizontal well can be evaluated, the use degree can be analyzed, and thick oil horizontal well process measure regulation and oil reservoir analysis can be guided.

Owner:PETROCHINA CO LTD

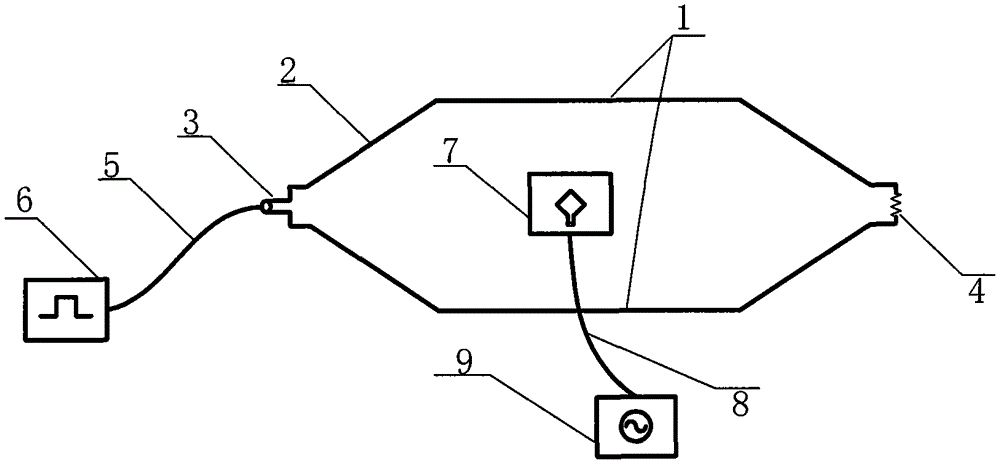

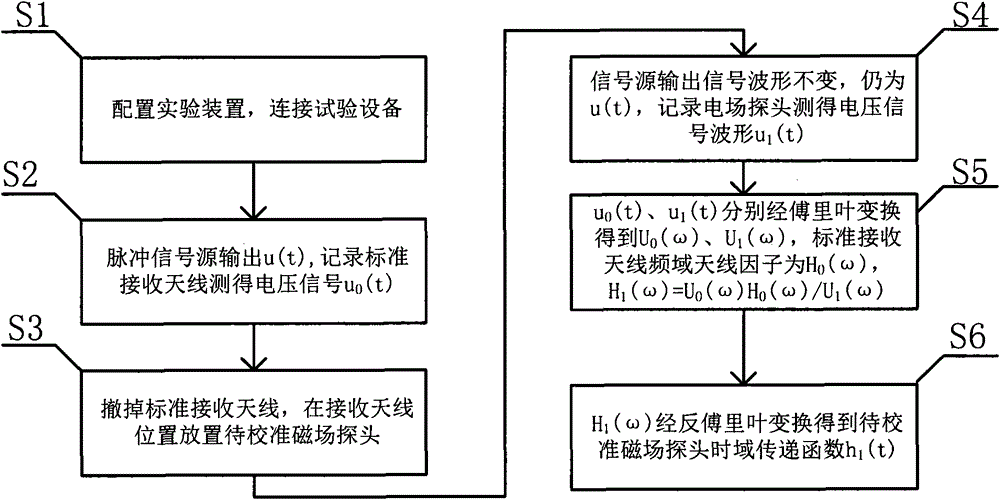

Time-domain calibration method for electromagnetic pulse magnetic-field probe

ActiveCN105093148AAchieving Time Domain CalibrationCalibration work is easy and convenientElectrical measurementsParallel plateElectromagnetic pulse

The present invention relates to a time-domain calibration method for an electromagnetic pulse magnetic-field probe. The method is used for calibrating an electromagnetic pulse magnetic-field probe in the time domain. The method comprises the steps of conducting the calibration test in a transmission line parallel-plate working space, connecting the tapered transition section of a parallel-plate transmission line and a pulse signal source with an adapter via coaxial cables, connecting the terminal of the parallel-plate transmission line with a matched load, connecting a digital oscilloscope with a standard antenna or a to-be-calibrated probe via a shielding radio frequency signal line, feeding a pulse voltage signal of the pulse signal source in the parallel-plate transmission line, forming a pulsed magnet field in the transmission line parallel-plate working space, recording a voltage signal waveform measured by the standard receiving antenna or the to-be-calibrated magnetic-field probe by the digital oscilloscope, and processing measured voltage signals according to a certain algorithm to obtain the time-domain transfer function of the to-be-calibrated magnetic-field probe. In this way, the time-domain calibration on the to-be-calibrated magnetic-field probe that is the same with the standard receiving antenna in frequency band can be realized.

Owner:中国人民解放军63973部队

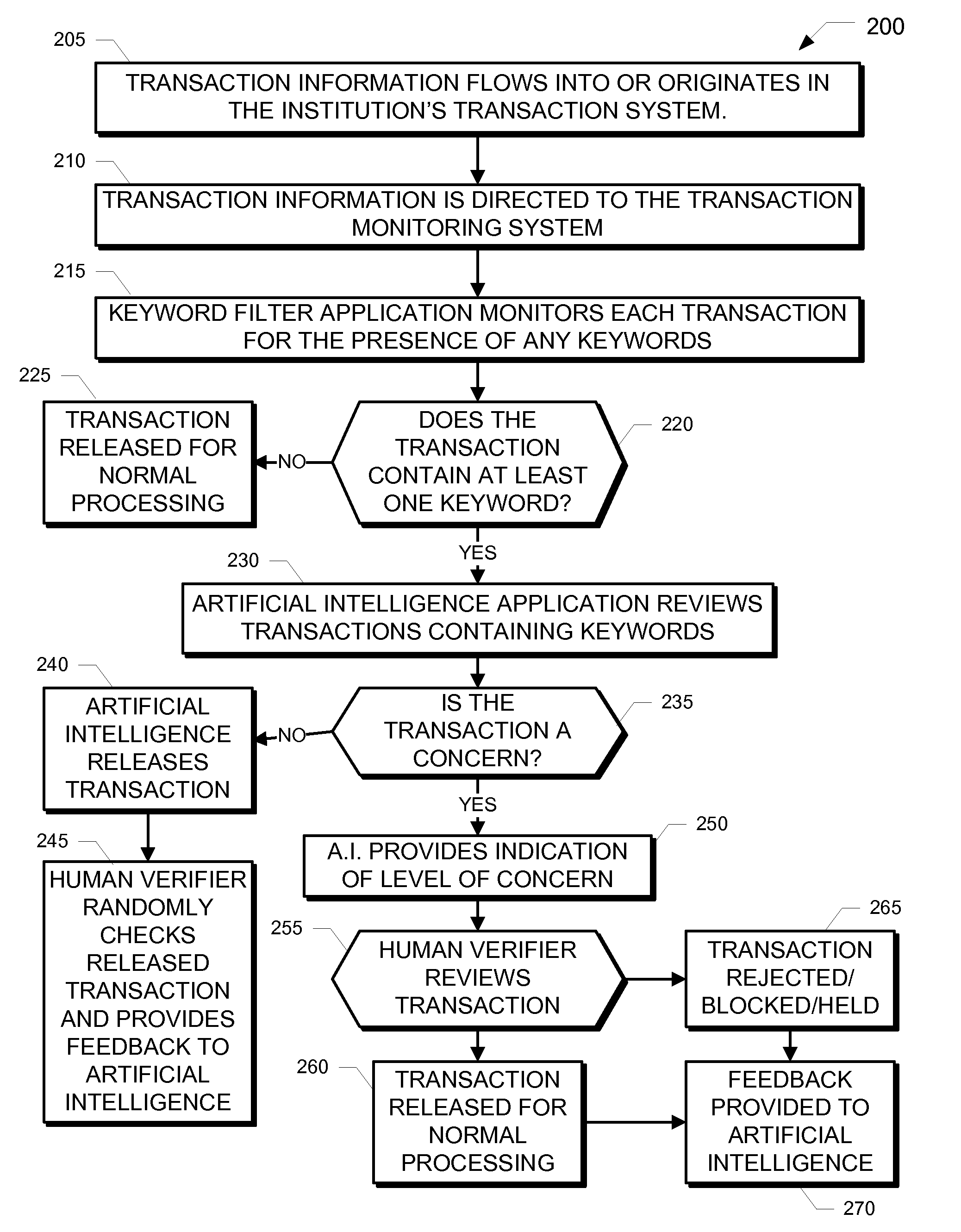

System update management

ActiveUS8838474B2Learn capacity and toleranceAnticipate overcapacity problemsComplete banking machinesFinanceCommunication interfaceProcess Measures

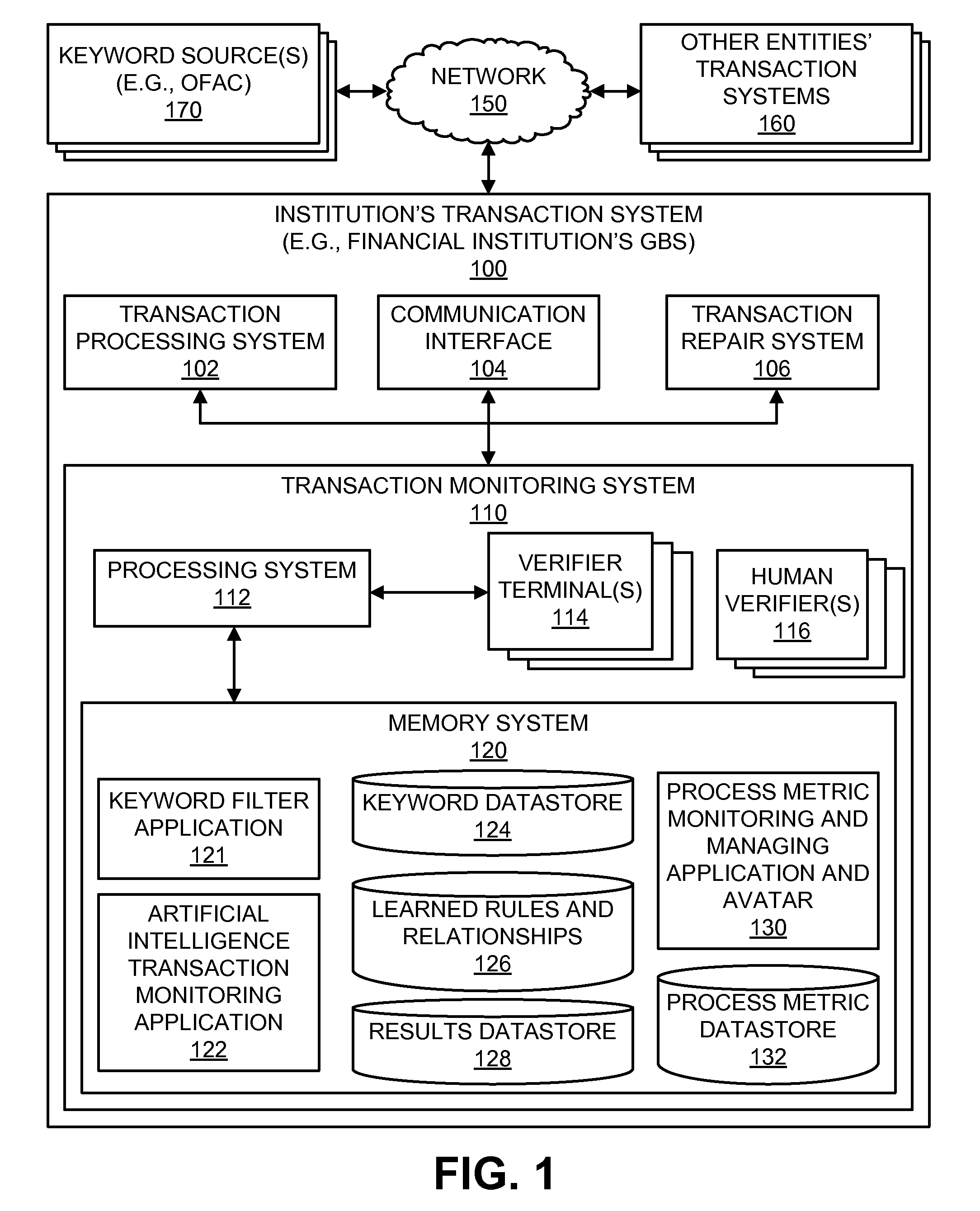

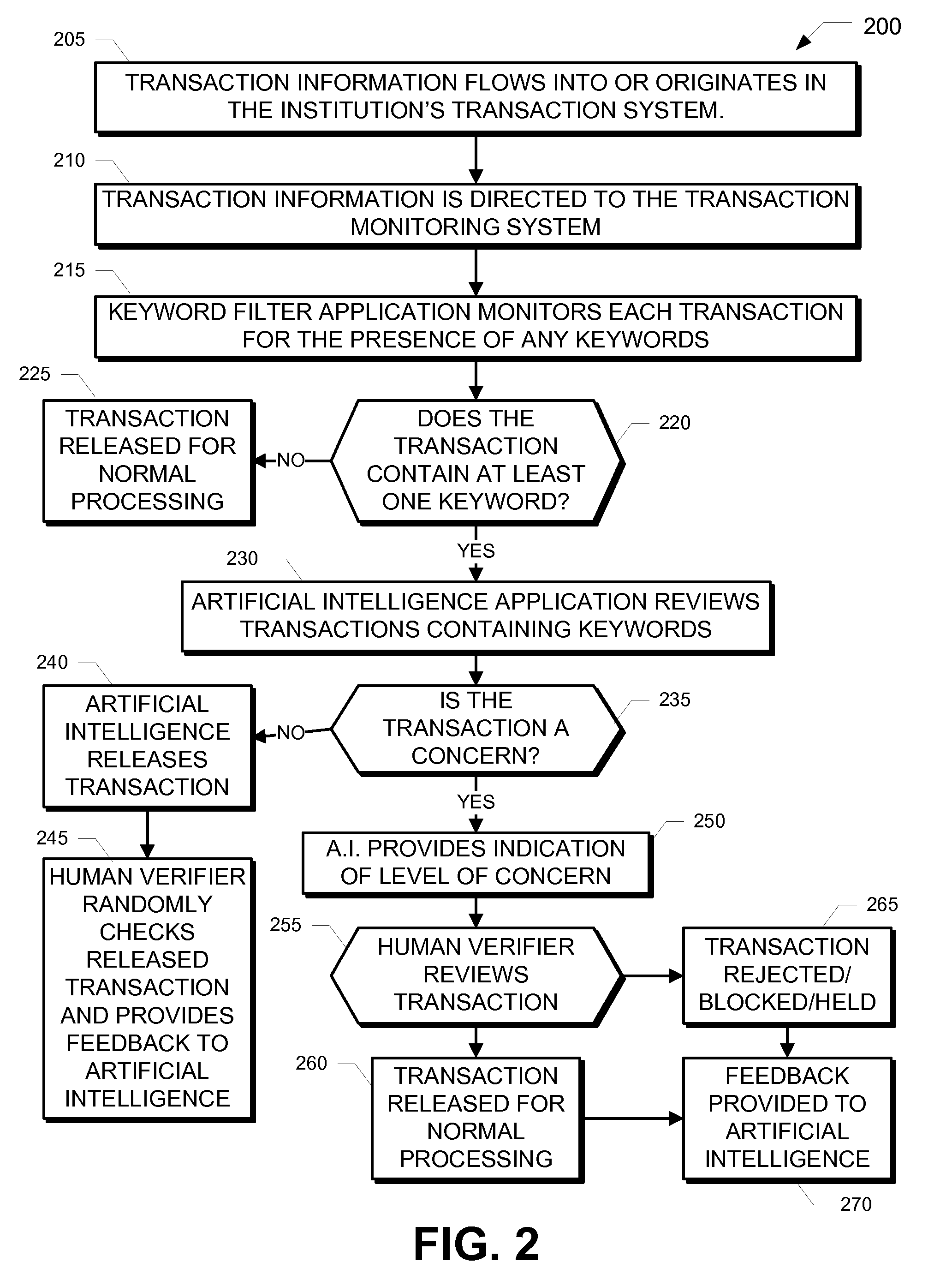

Embodiments of the invention provide systems and methods for managing updates to a financial transaction monitoring system, wherein the financial transaction monitoring system is configured to specially handle any financial transactions involving an entity identified in a list of entities. In one embodiment, the system includes a communication interface configured to receive an update to the list of entities, the update including one or more new keywords. The system may further include a memory device having information about a plurality of transactions. In one embodiment, the system includes a processor configured to: determine the number of transactions in the plurality of transactions that can properly be associated with at least one of the new keywords; and determine whether the update will impact the financial transaction monitoring system based at least partially on process metrics and the determined number of transactions in the plurality of transactions that can properly be associated with at least one of the new keywords.

Owner:BANK OF AMERICA CORP

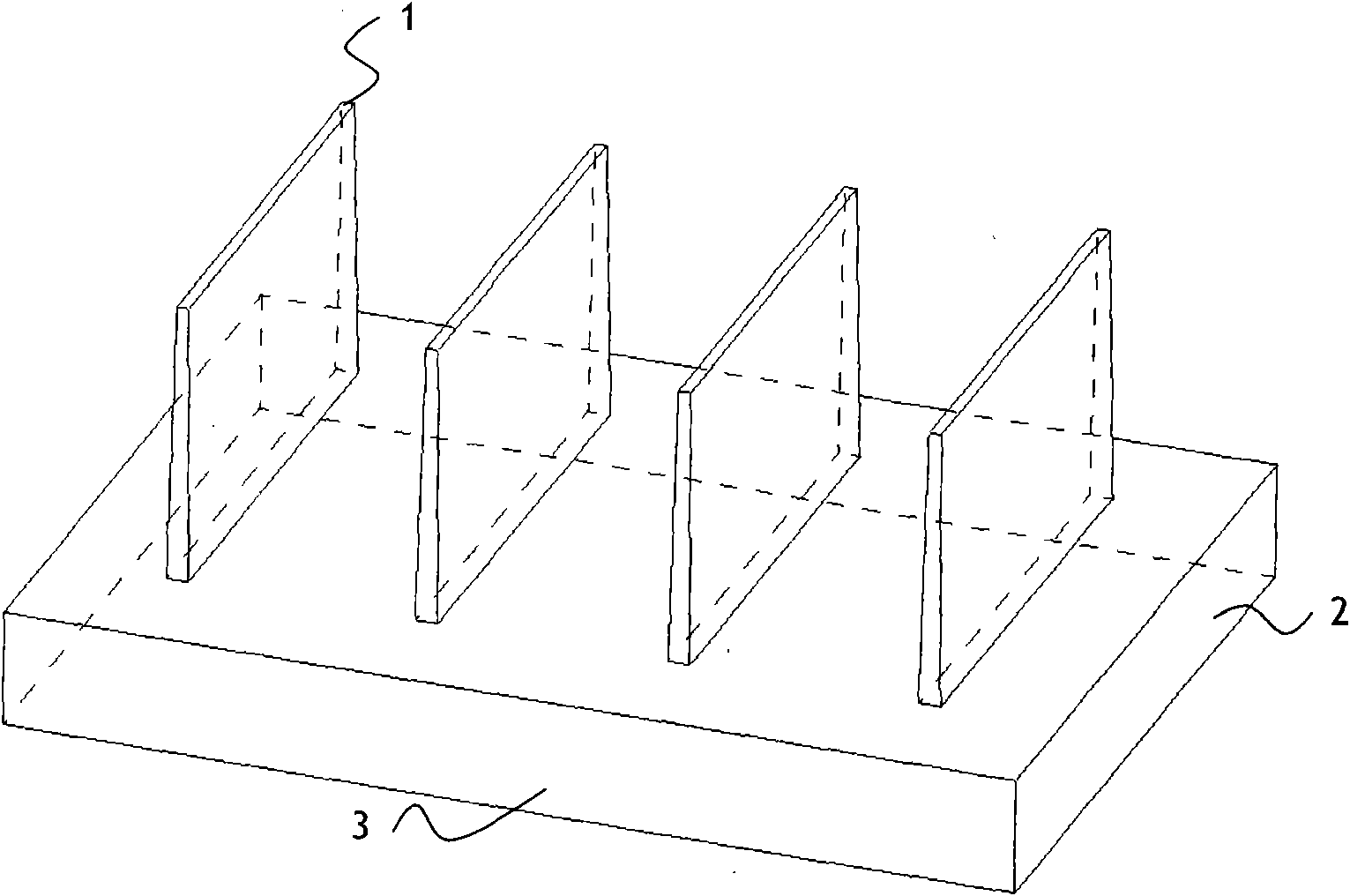

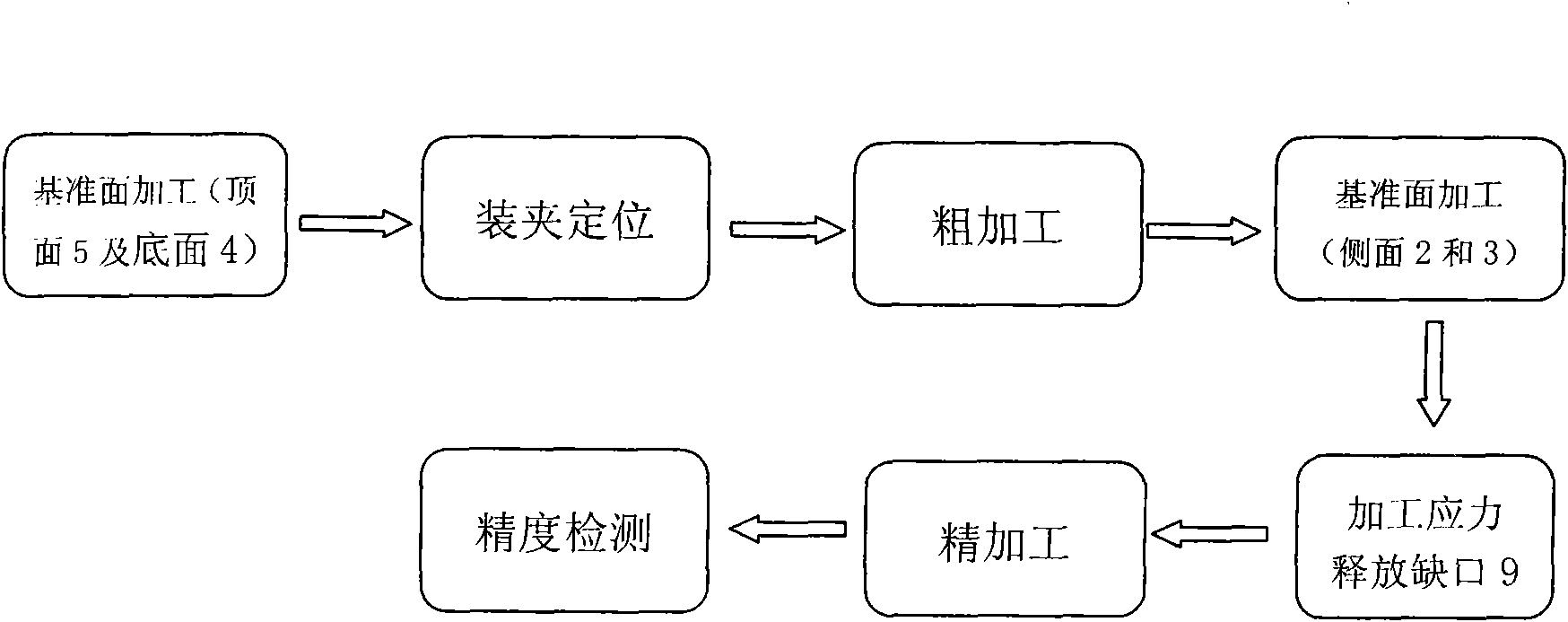

Numerical control machining method for thin-wall copper electrode

The invention relates to a numerical control machining method for a thin-wall copper electrode, which comprises the following steps of: reasonably selecting a clamp, a cutter and a cutting parameter for improving the working efficiency; reasonably distributing the step and a feed route; controlling the deformation of a workpiece; after rough machining is finished, mounting a residual stress release notch at the side surface of the workpiece; eliminating deformation caused by residual stress during rapid rough machining, wherein a rough machining cutter adopts a ball end milling cutter instead of a generally used flat end vertical milling cutter; and carrying out symmetrical machining on the design of the feed route. The method for machining the workpiece sequentially comprises the steps of machining a reference surface 5 and a reference surface 4, clamping for positioning, roughly machining, machining a reference surface 2 and a reference surface 3, machining a stress release notch 9, finely machining and detecting precision. By adopting a plurality of process measures for controlling deformation, the invention has the advantages of greatly reducing the deformation of machining parts and effectively improving the precision and the stability of the parts. By actually measuring the workpiece on a three-coordinate measuring machine, a surface roughness value can be reduced to minimum and can completely meet the requirement on products.

Owner:潘建新 +1

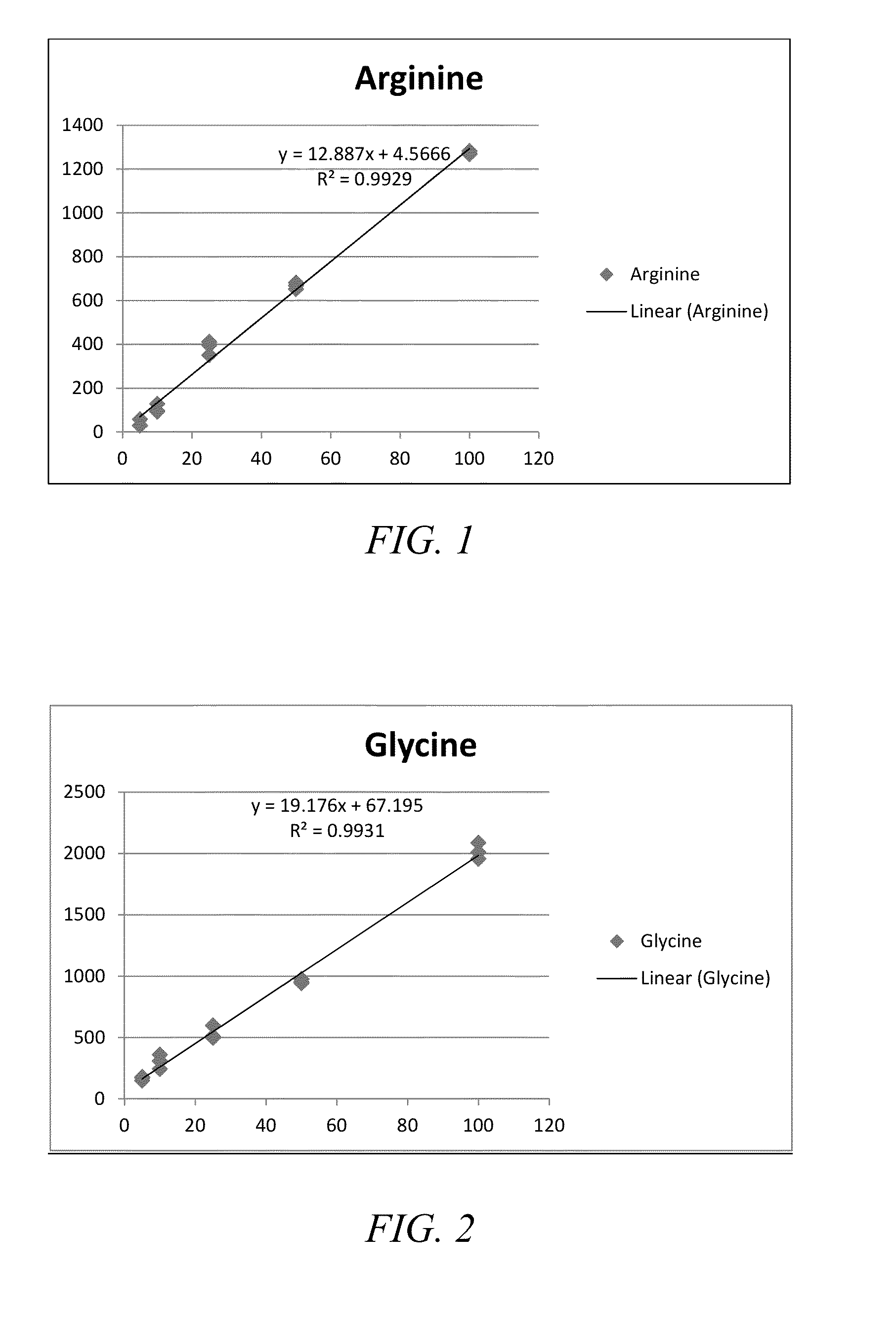

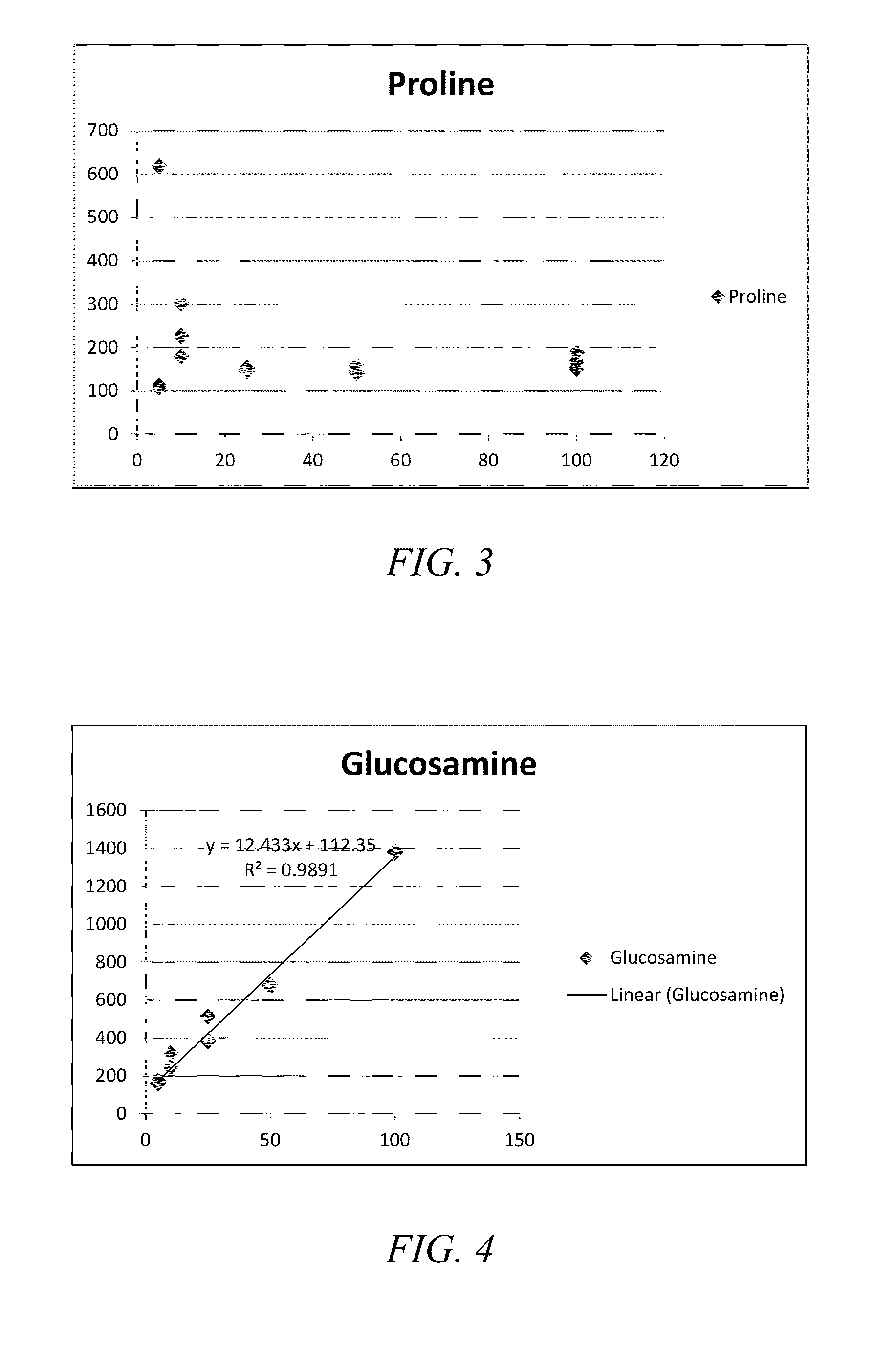

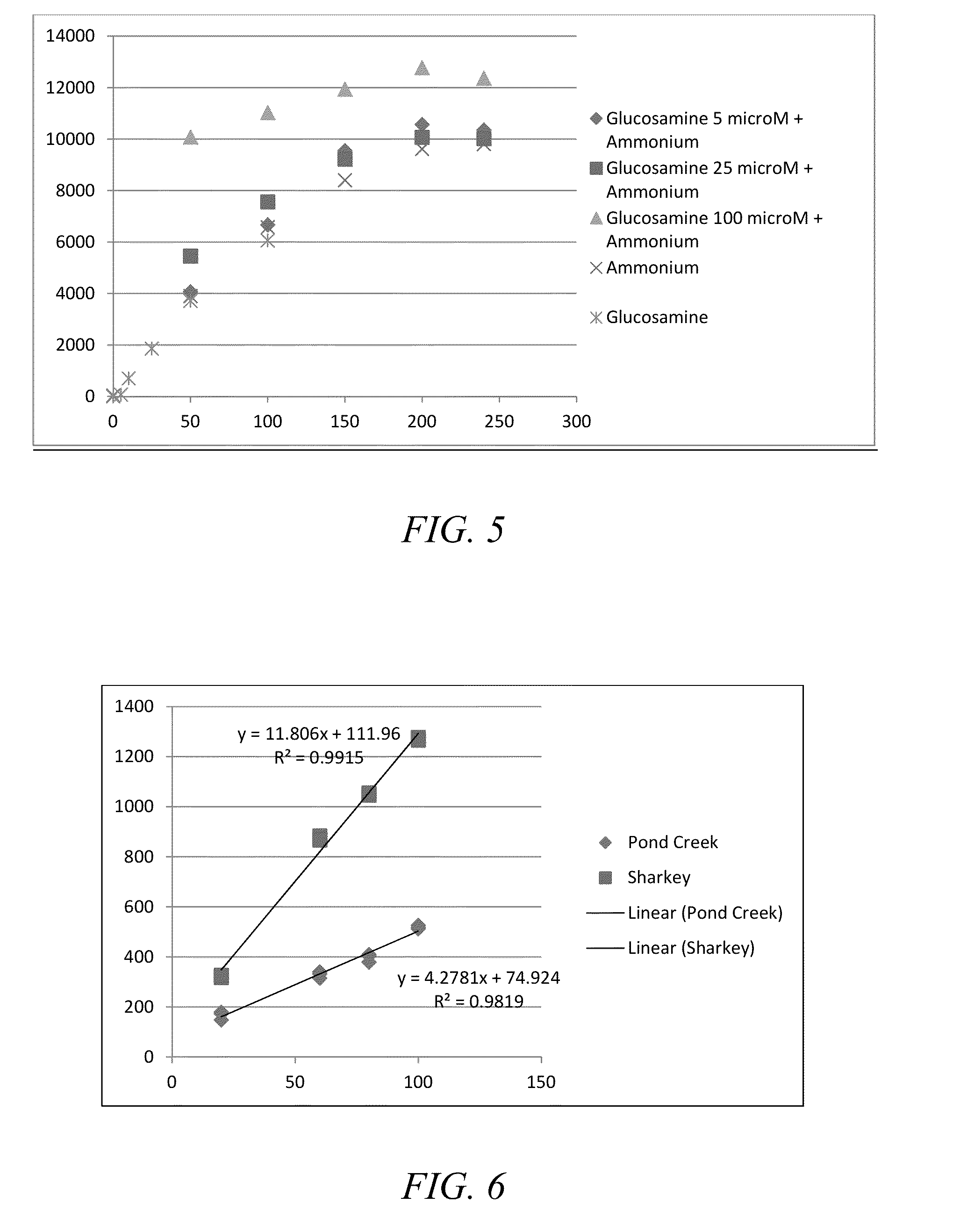

System and process for quantifying potentially mineralizable nitrogen for agricultural crop production

ActiveUS20140273253A1Material analysis by optical meansEarth material testingFluorescenceProcess Measures

The invention is generally directed to a system and process for fluorometrically quantifying potentially mineralizable nitrogen for agricultural crop production. The soil analysis process measures potentially mineralizable nitrogen and calibrates the application of soil-based nitrogen for site or field specific management of nitrogen fertilizers for crops grown on a wide variety of soil textures including sandy loam, silt loam and clay soils. The spectrofluorometric system and process may be utilized for routine soil testing with a lower sample to sample variability, and the automation of the spectrofluorometric system and process allows for simultaneous determination of potentially mineralizable soil organic nitrogen, ammonium and nitrate.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com