Patents

Literature

1032results about How to "Simple algorithm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

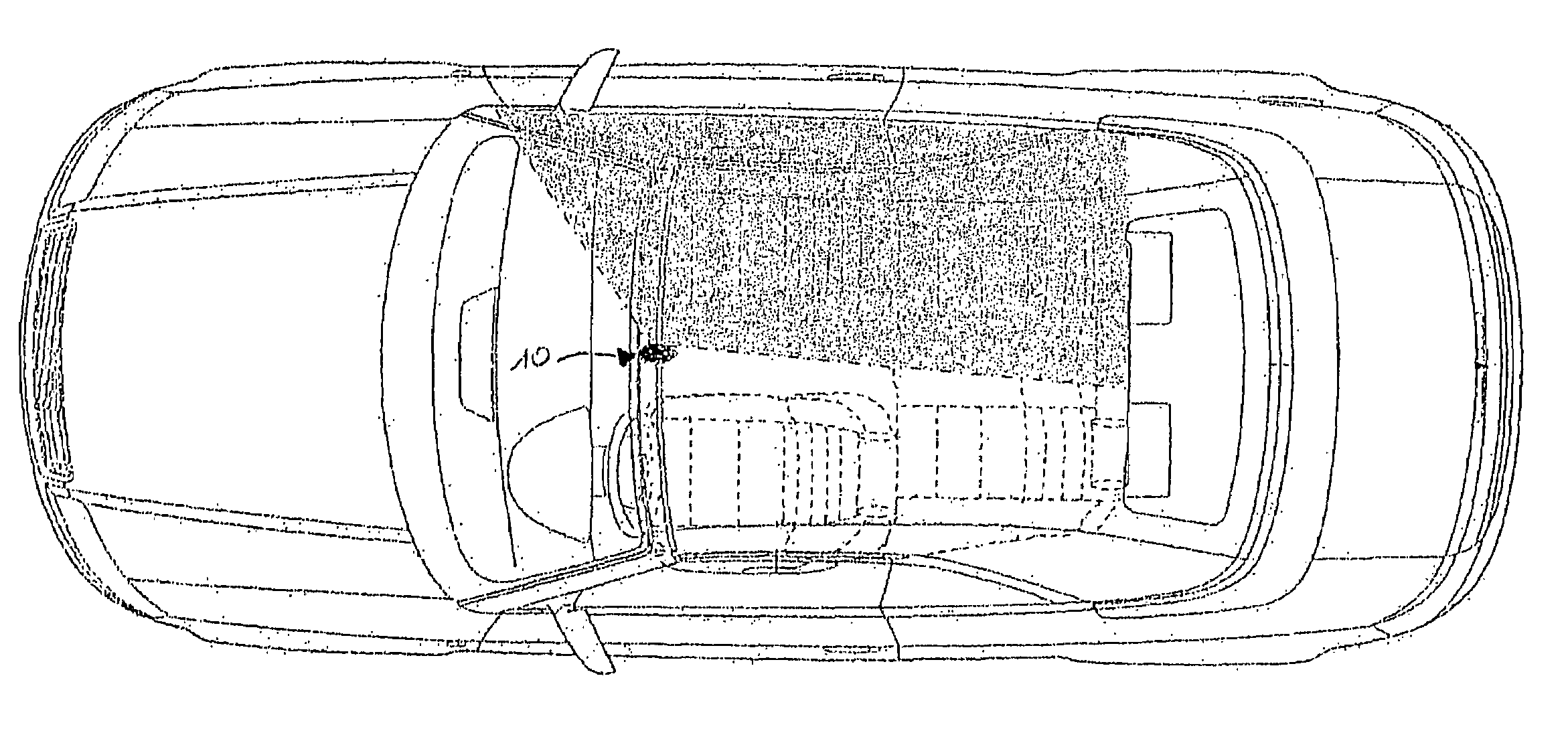

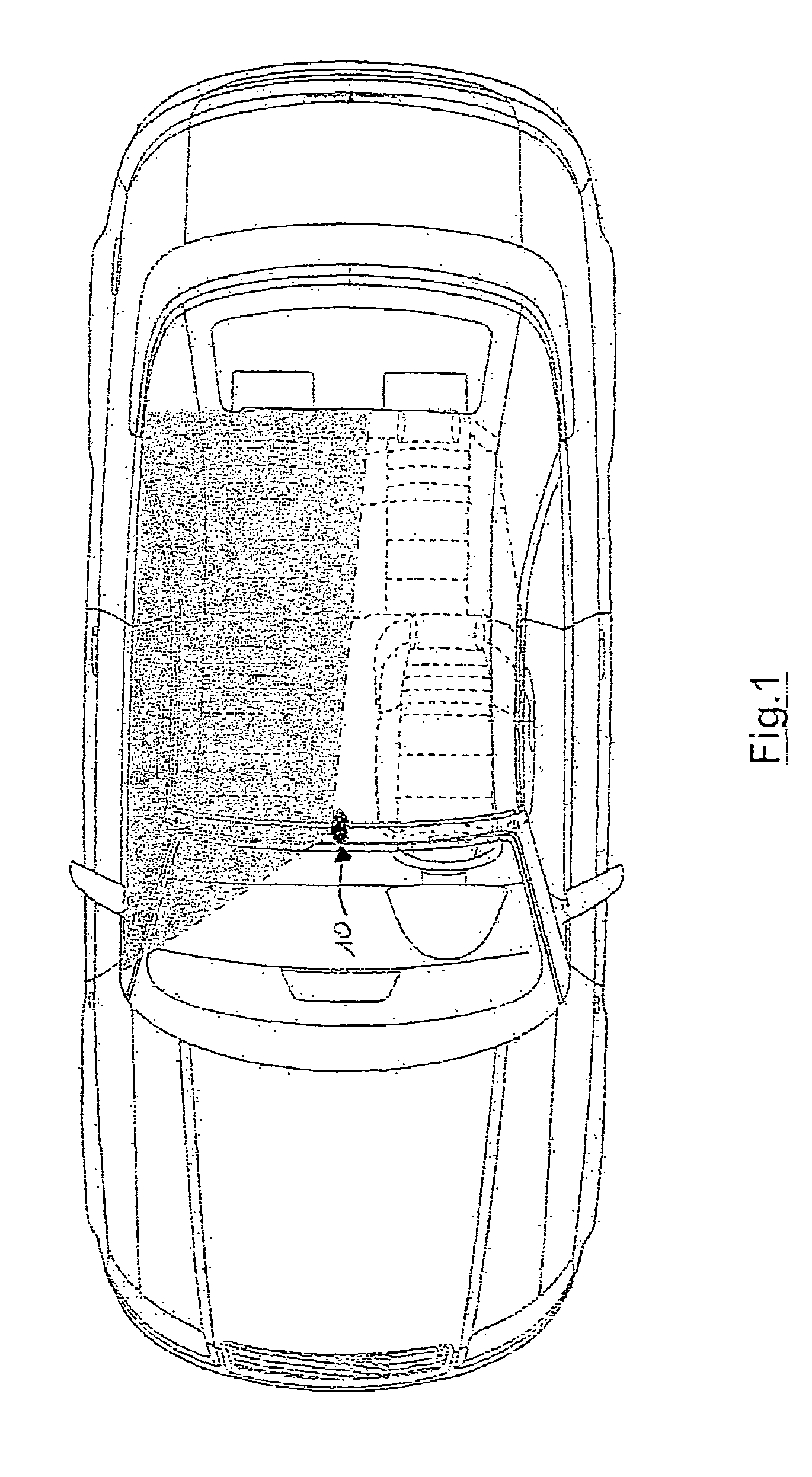

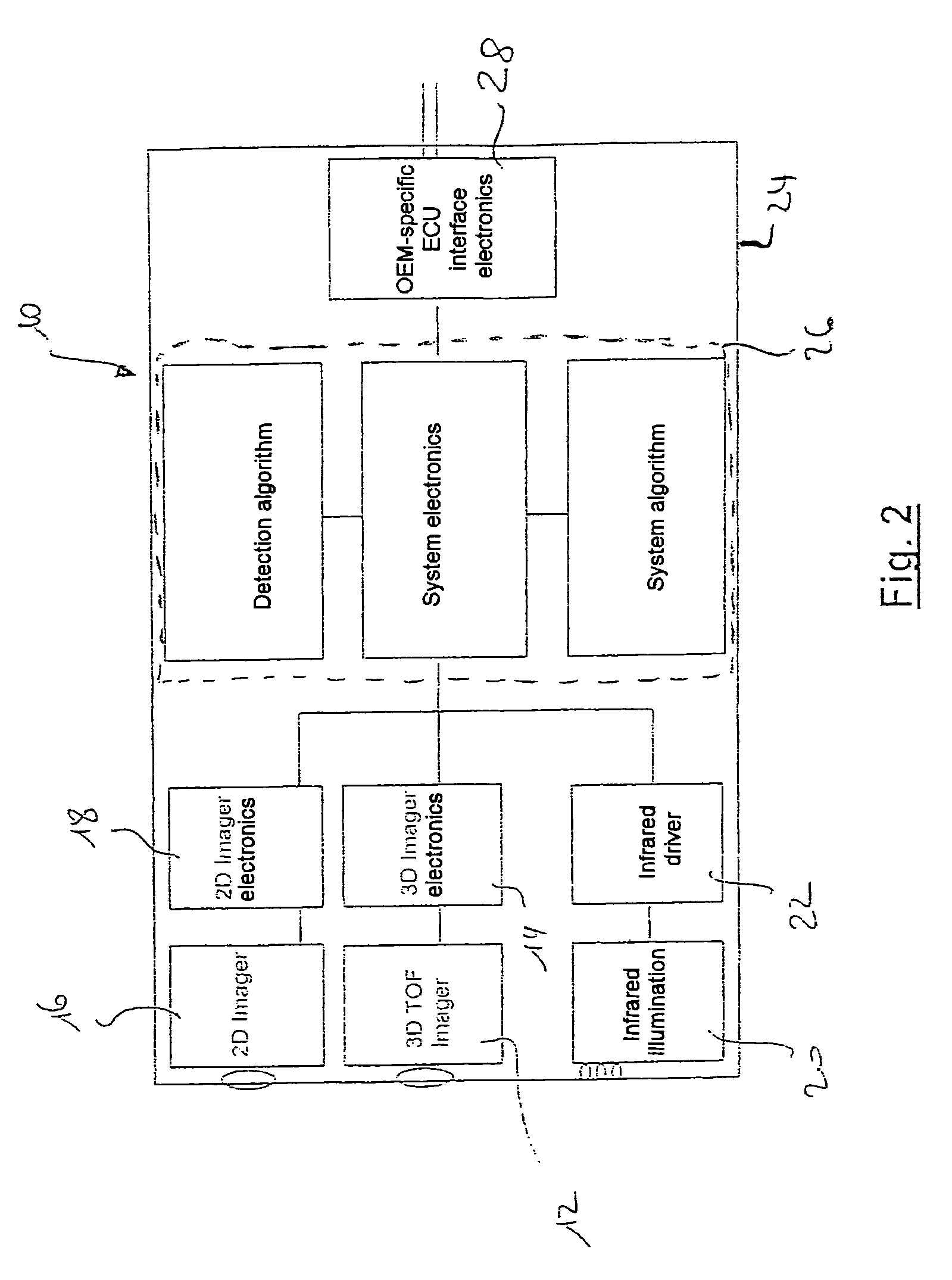

Safety device for a vehicle

ActiveUS7607509B2Low imageObject detectionBelt control systemsPedestrian/occupant safety arrangement3d cameraObject detection

Owner:IEE INT ELECTRONICS & ENG SA

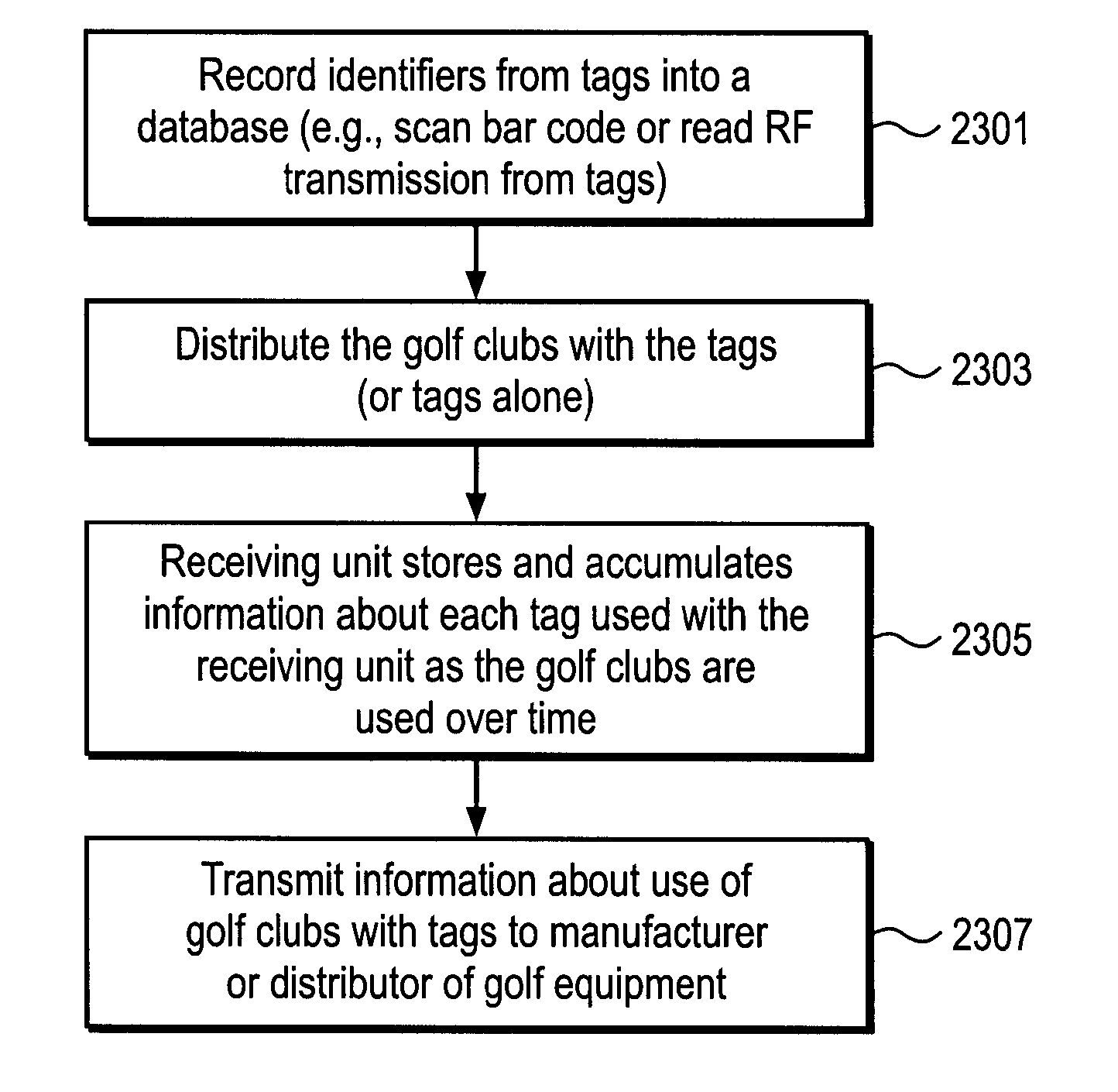

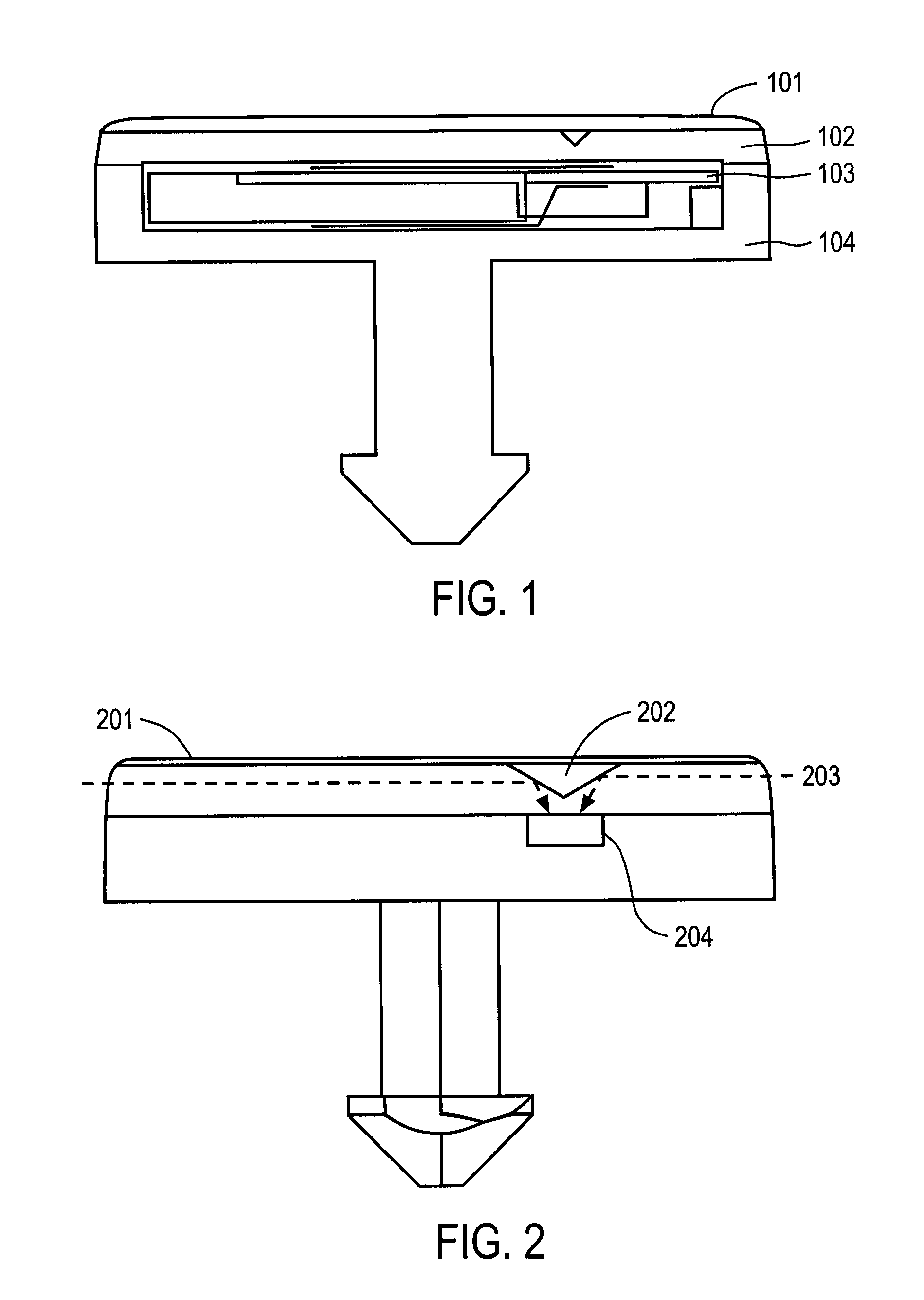

Golf club apparatuses and methods

InactiveUS20100308105A1Limit wide variationSimple algorithmMaterial analysis by optical meansPhotoelectric discharge tubesGolf course turfLight meter

Apparatuses, methods and systems related to an improved golf data collecting and golf club notification system. The system reminds golfers when a club has been mistakenly left behind on the golf course and notifies the golfer when a golf club or clubs are in or out of the golf bag. The system can notify a golfer if a club or golf bag has been removed without authorization. In one preferred embodiment an apparatus that attaches to a golf club includes dual light sensors—one light sensor configured as a switch and one light sensor configured as a light meter. Algorithms make use of the light sensor data to determine whether a golf club is in or out of a golf bag.

Owner:LEI CO LTD

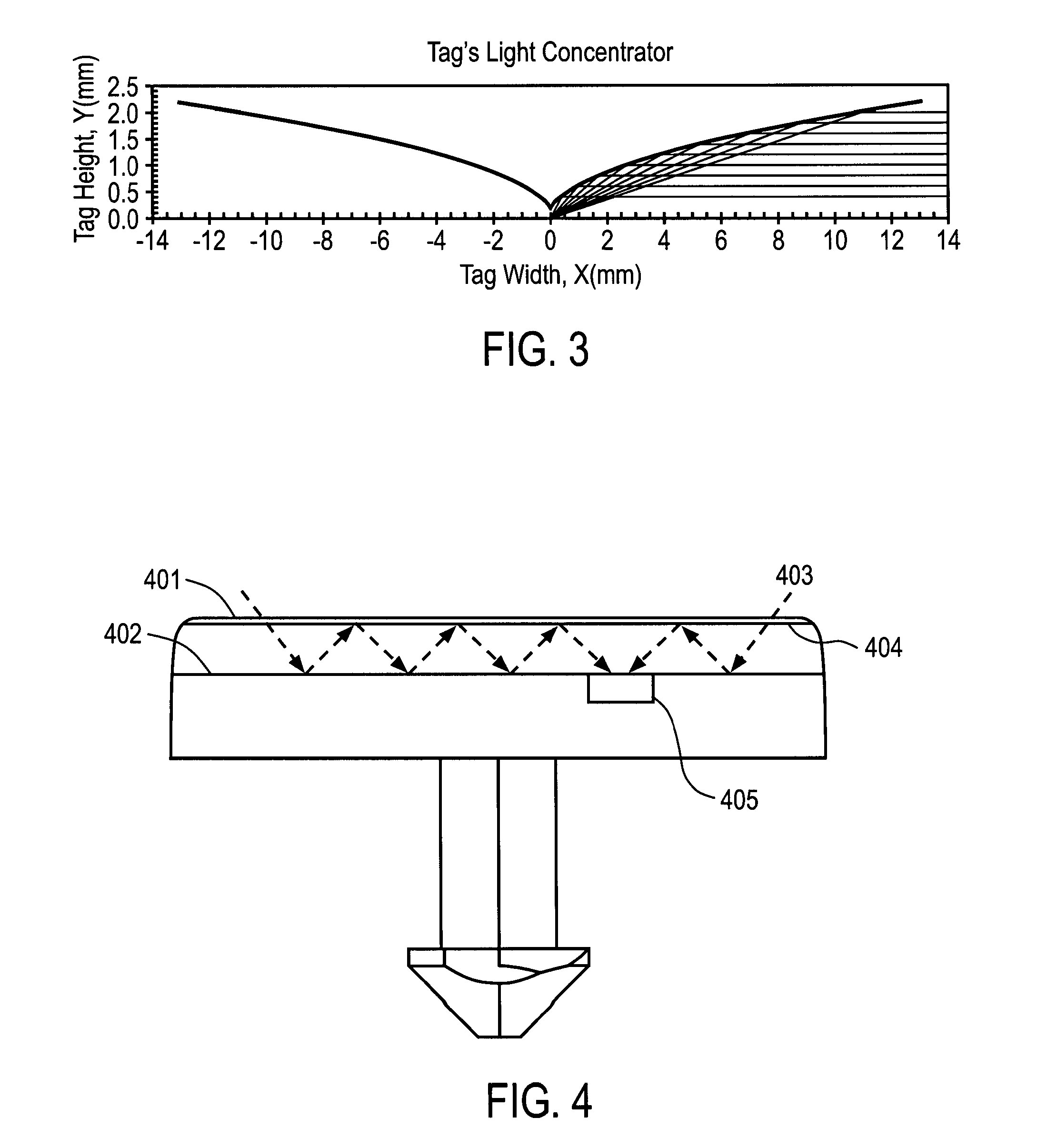

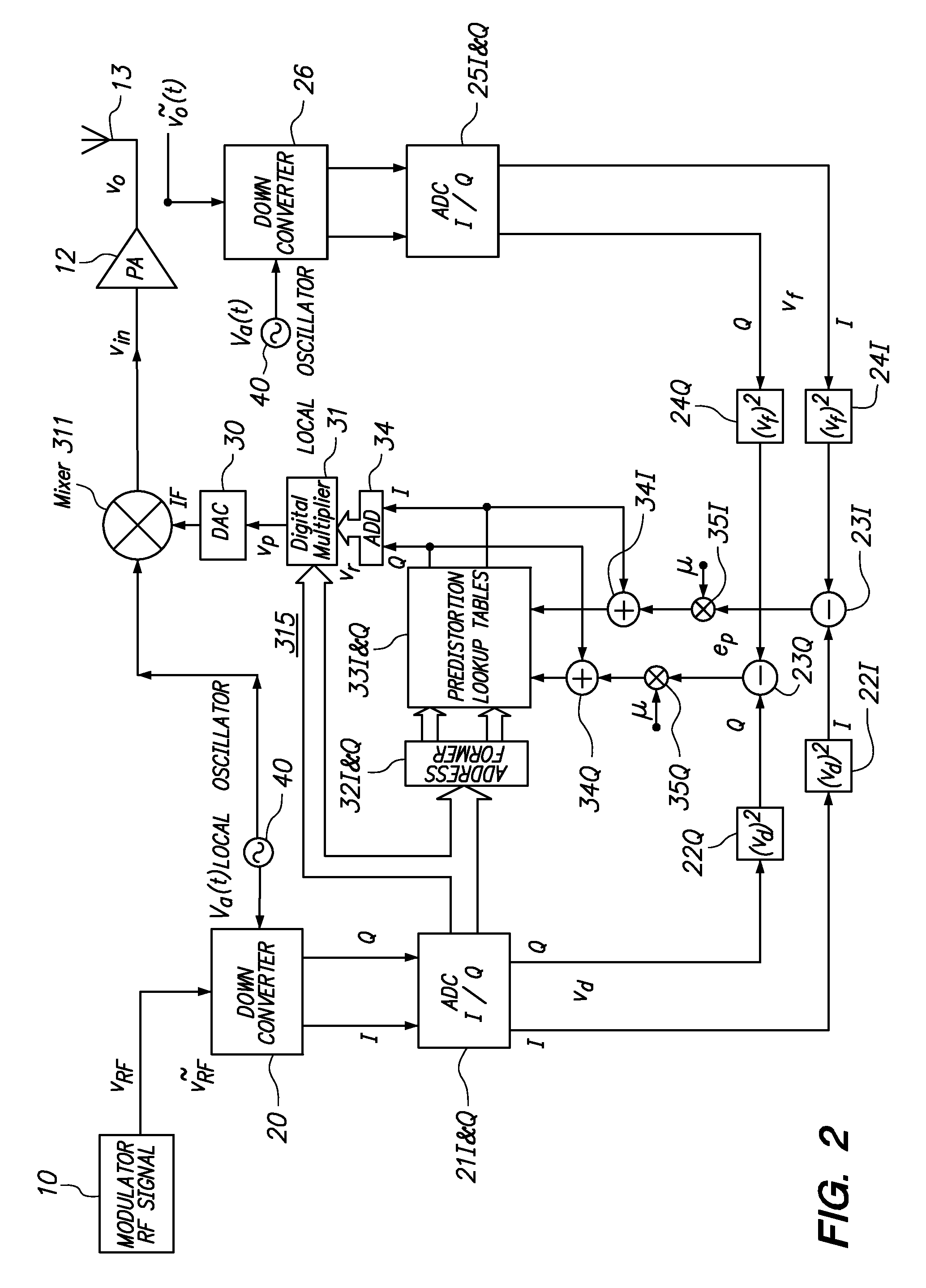

Digital Hybrid Mode Power Amplifier System

InactiveUS20080265996A1High performance and cost-effectiveImprove linearityAmplifier modifications to reduce non-linear distortionHigh frequency amplifiersPeak valueMulti carrier

A RF-digital hybrid mode power amplifier system for achieving high efficiency and high linearity in wideband communication systems is disclosed. The present invention is based on the method of adaptive digital predistortion to linearize a power amplifier in the RF domain. The power amplifier characteristics such as variation of linearity and asymmetric distortion of the amplifier output signal are monitored by the narrowband feedback path and controlled by the adaptation algorithm in a digital module. Therefore, the present invention could compensate the nonlinearities as well as memory effects of the power amplifier systems and also improve performances, in terms of power added efficiency, adjacent channel leakage ratio and peak-to-average power ratio. The present disclosure enables a power amplifier system to be field reconfigurable and support multi-modulation schemes (modulation agnostic), multi-carriers and multi-channels. As a result, the digital hybrid mode power amplifier system is particularly suitable for wireless transmission systems, such as base-stations, repeaters, and indoor signal coverage systems, where baseband I-Q signal information is not readily available.

Owner:DALI SYST LTD

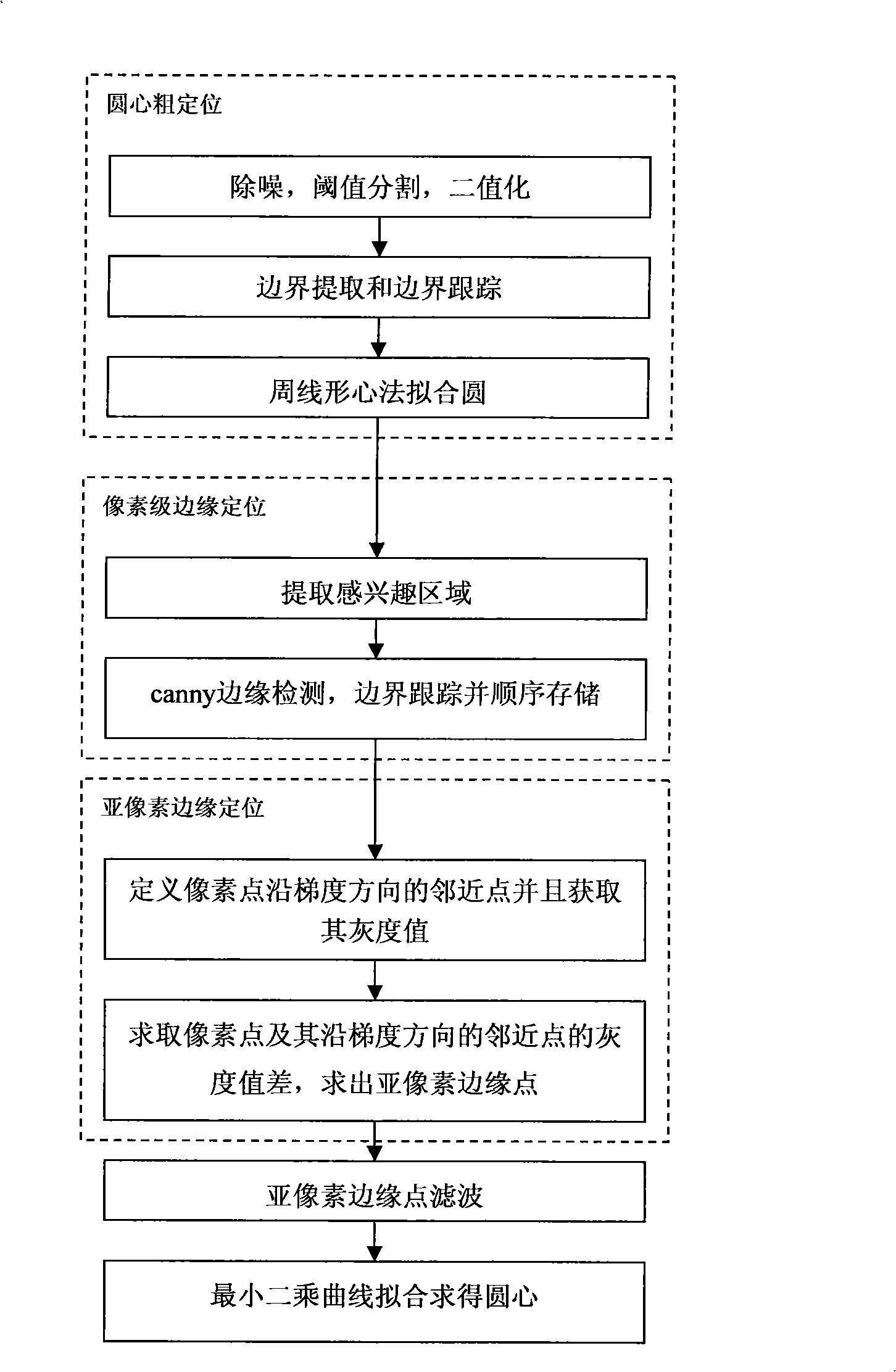

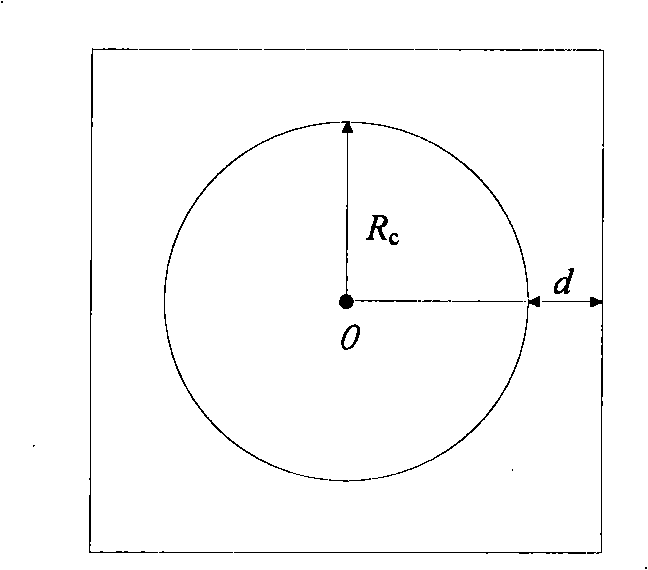

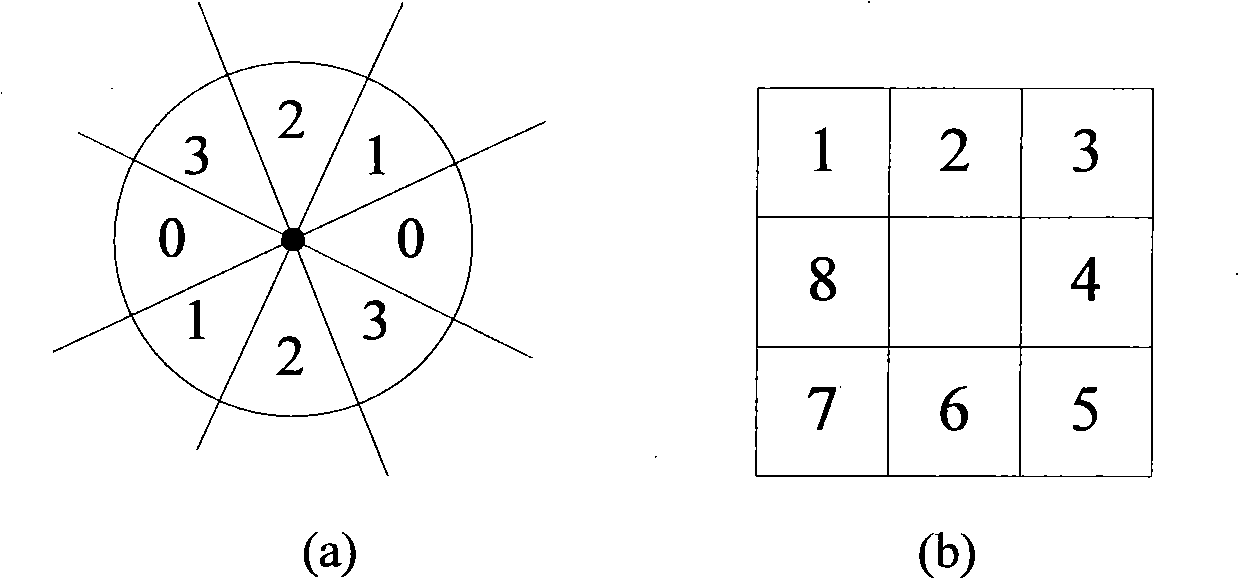

Circular target circular center positioning method

InactiveCN101334263AIncrease speedSimple calculationCharacter and pattern recognitionUsing optical meansMeasurement precisionLeast squares

The invention discloses a circle center locating method of a circular target, mainly relating to a great deal of target identification and target location. Firstly, rough circle center location is carried out to an image by using a simple contour centroid method, a key square region is extracted as a region of interest according to the information of a rough location circle center and a rough location radius, and pixel-level edge location is carried out to the circular target in the region of interest by a canny operator; then sub-pixel location is carried out to the circular target according to the geometric features and the gray information of the circle, therefore, a precise coordinate of sub-pixel edge points is obtained; after that, a curvature filtering method and an average filtering method are respectively used for filtering 'isolated points' and noise occurring in the sub-pixel edge points; finally, a least squares method is utilized to fit a circle to the filtered sub-pixel edge points so as to obtain the final circular center and radius. The method not only effectively improves the precision of circle center location, but also improves the robustness thereof, thus further improving the measurement precision of a measurement system and perfecting the stability of the measurement system.

Owner:南通欧特建材设备有限公司 +1

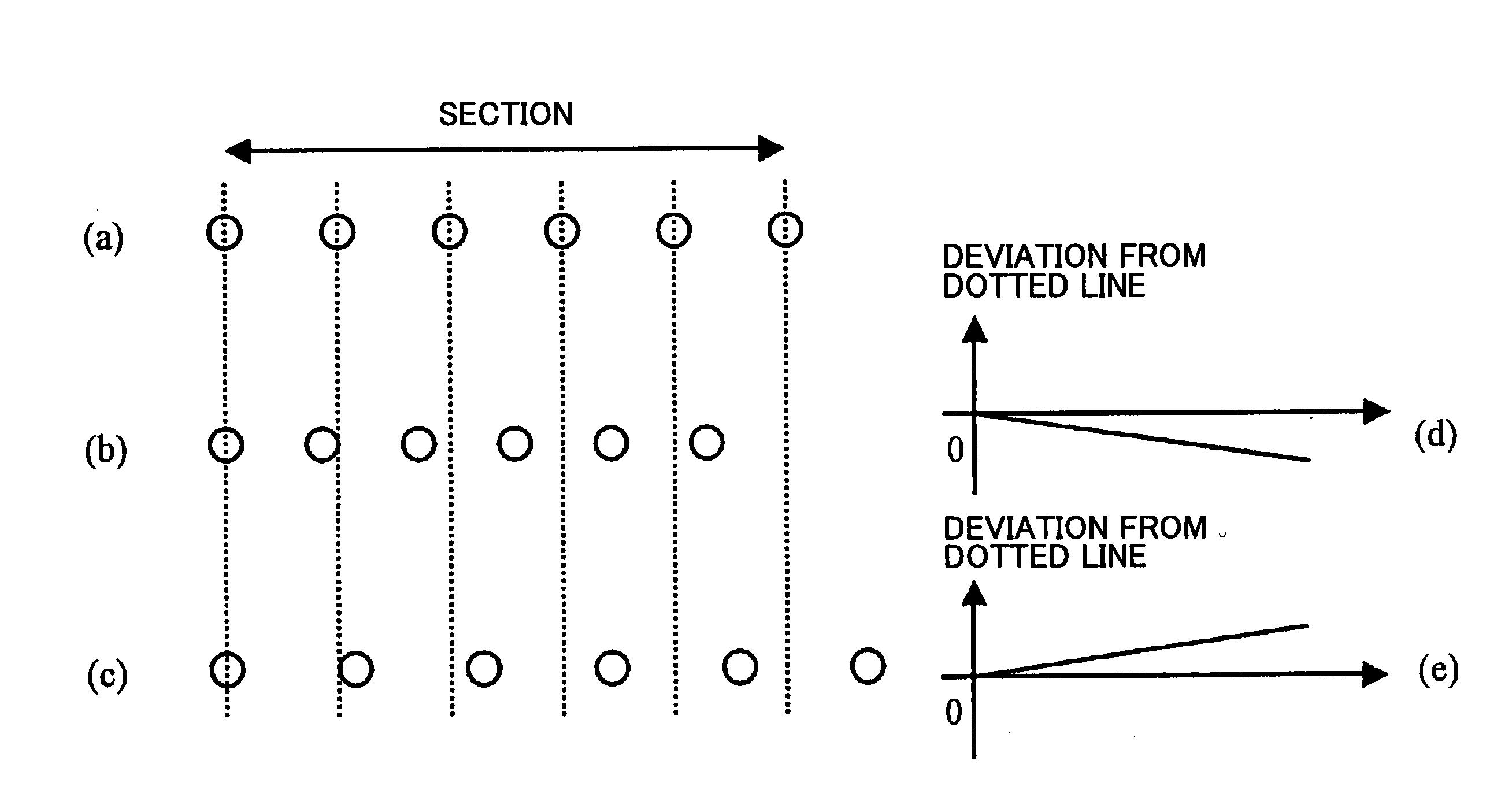

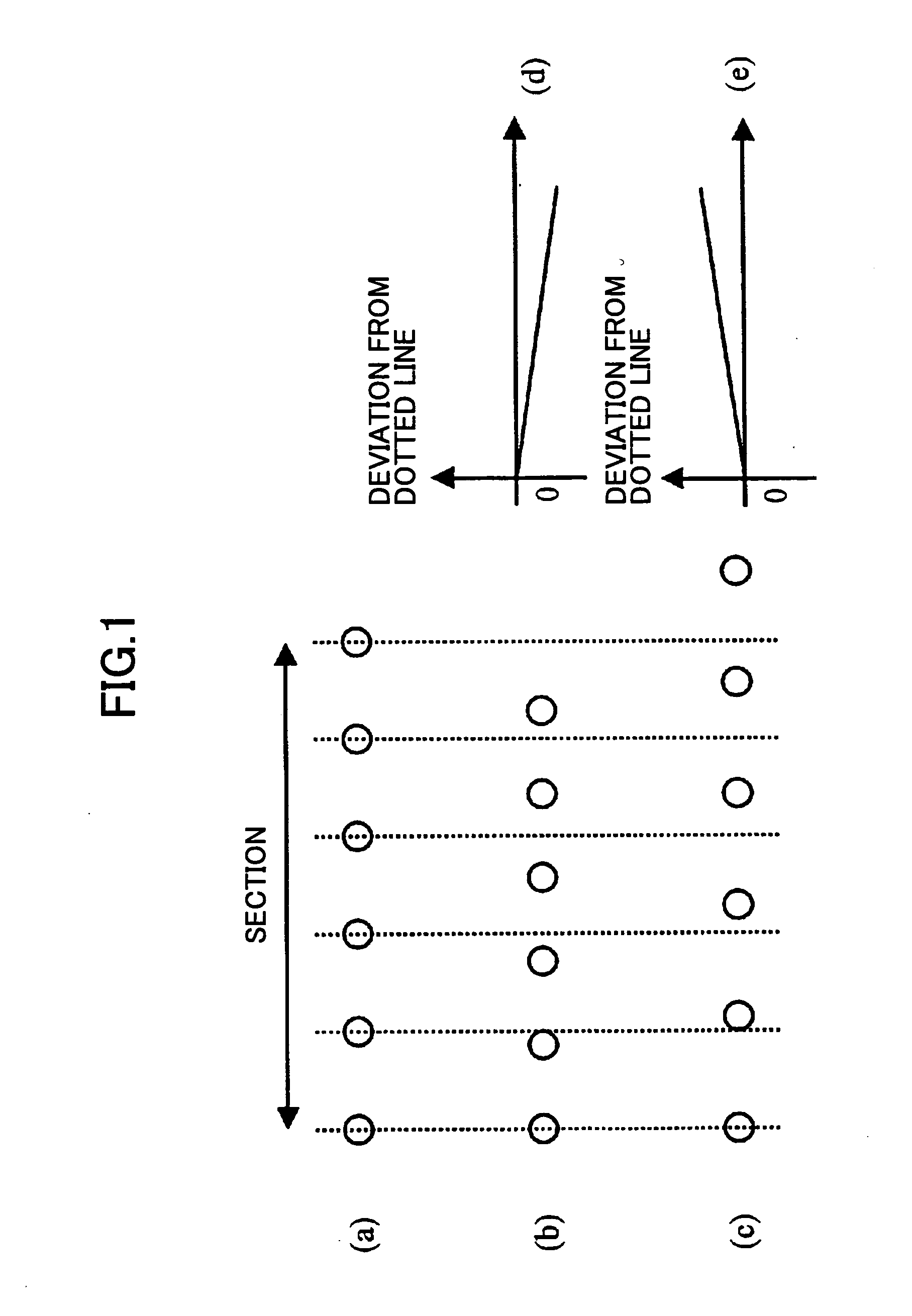

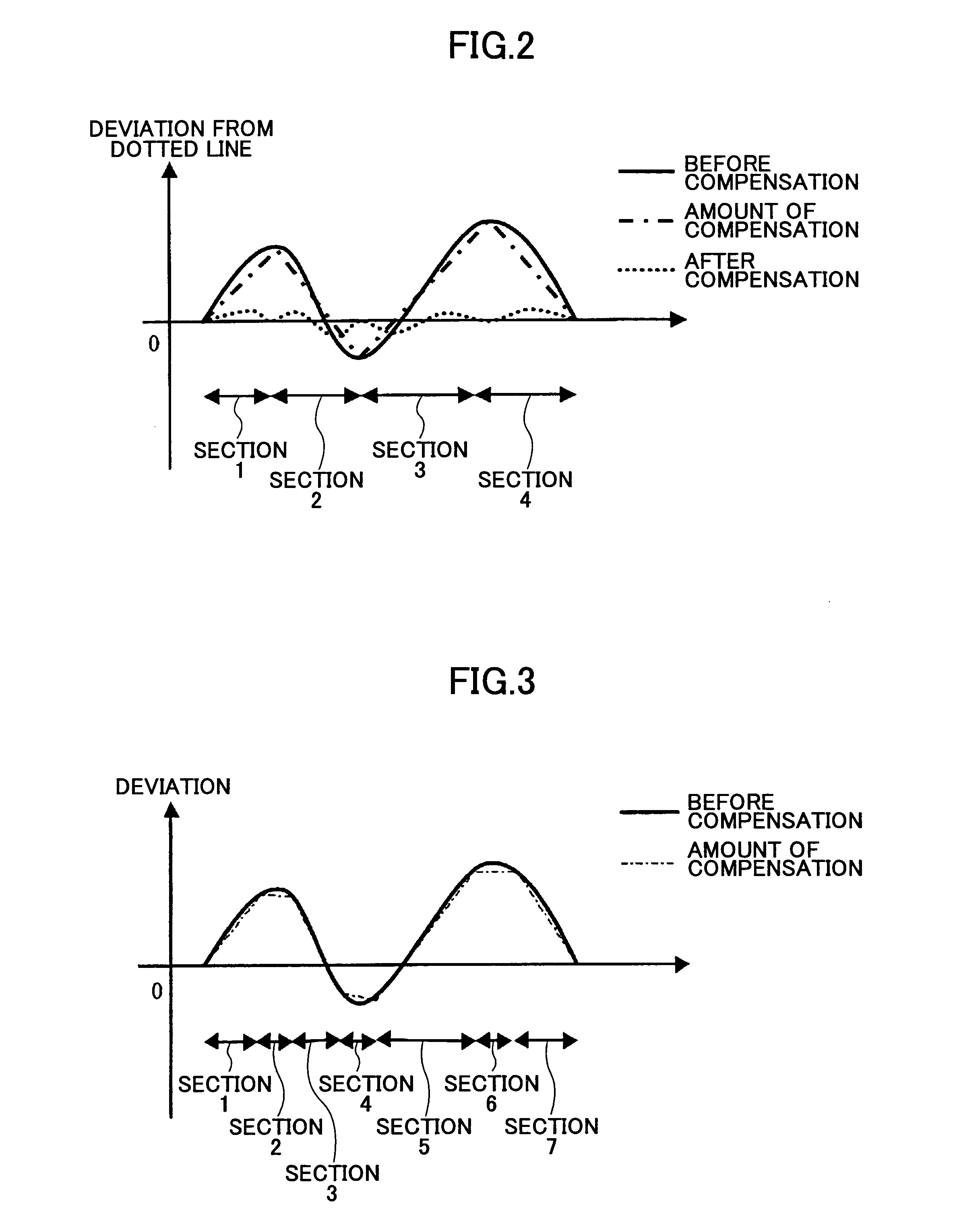

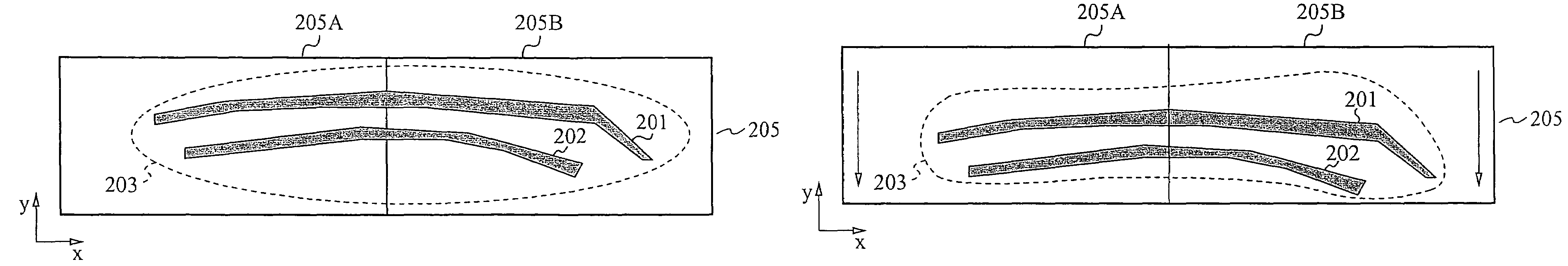

Beam-spot position compensation method, optical scanning device, and multi-color image forming device

InactiveUS20050190420A1Good image qualityFew color deviationOptical elementsOptoelectronicsLight source

In a beam-spot position compensation method for use in an optical scanning device which scans a surface of a photosensitive medium by a light beam emitted by a light source, a plurality of sections are defined by dividing a scanning region on the scanned surface. An emission timing of the light beam for every section is adjusted so that a spacing between beam-spot positions corresponding to pixels of start and end of each section is changed by a predetermined amount. The sparseness or denseness of beam-spot position spacings of the plurality of sections in the whole scanning region is compensated.

Owner:RICOH KK

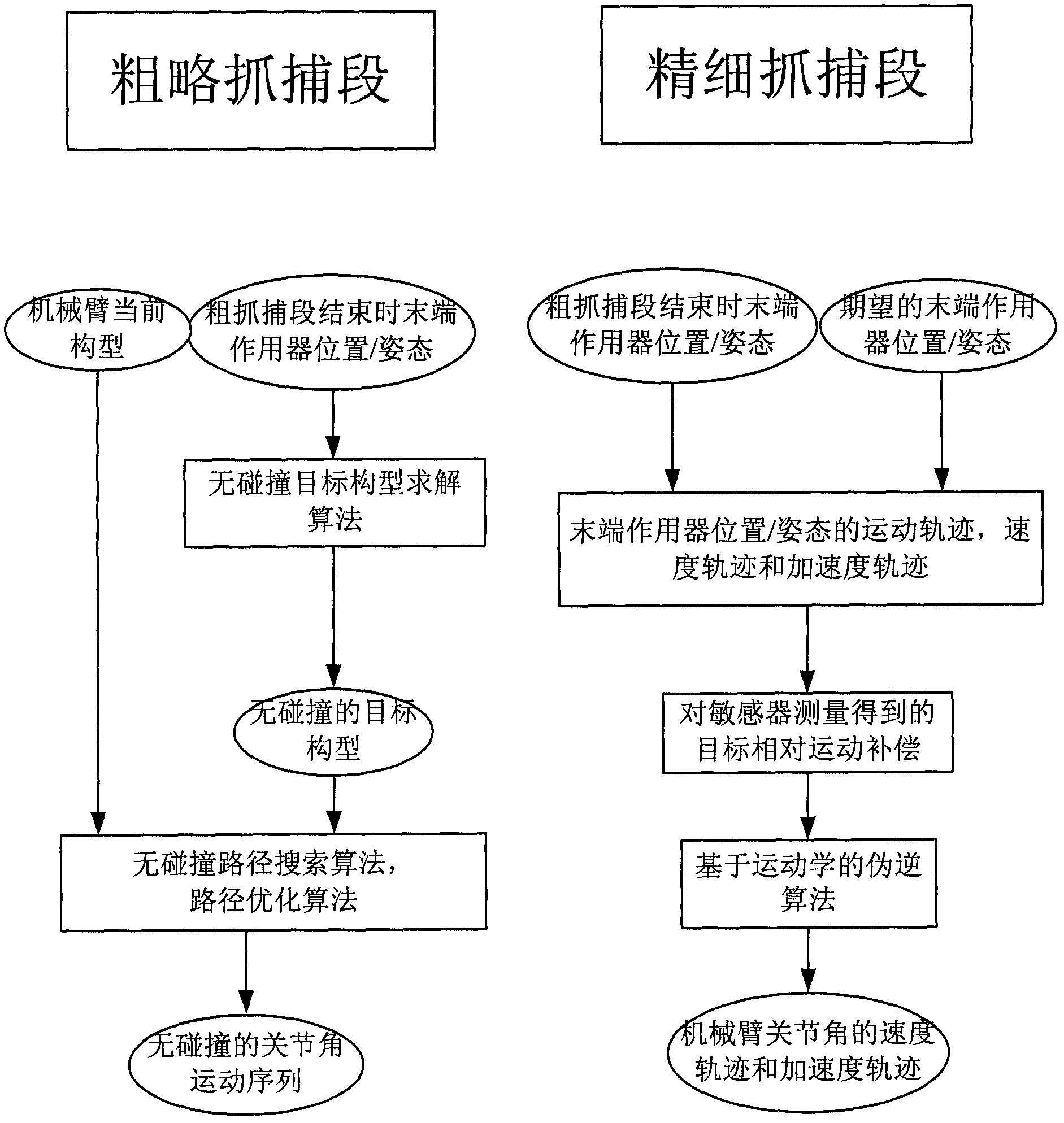

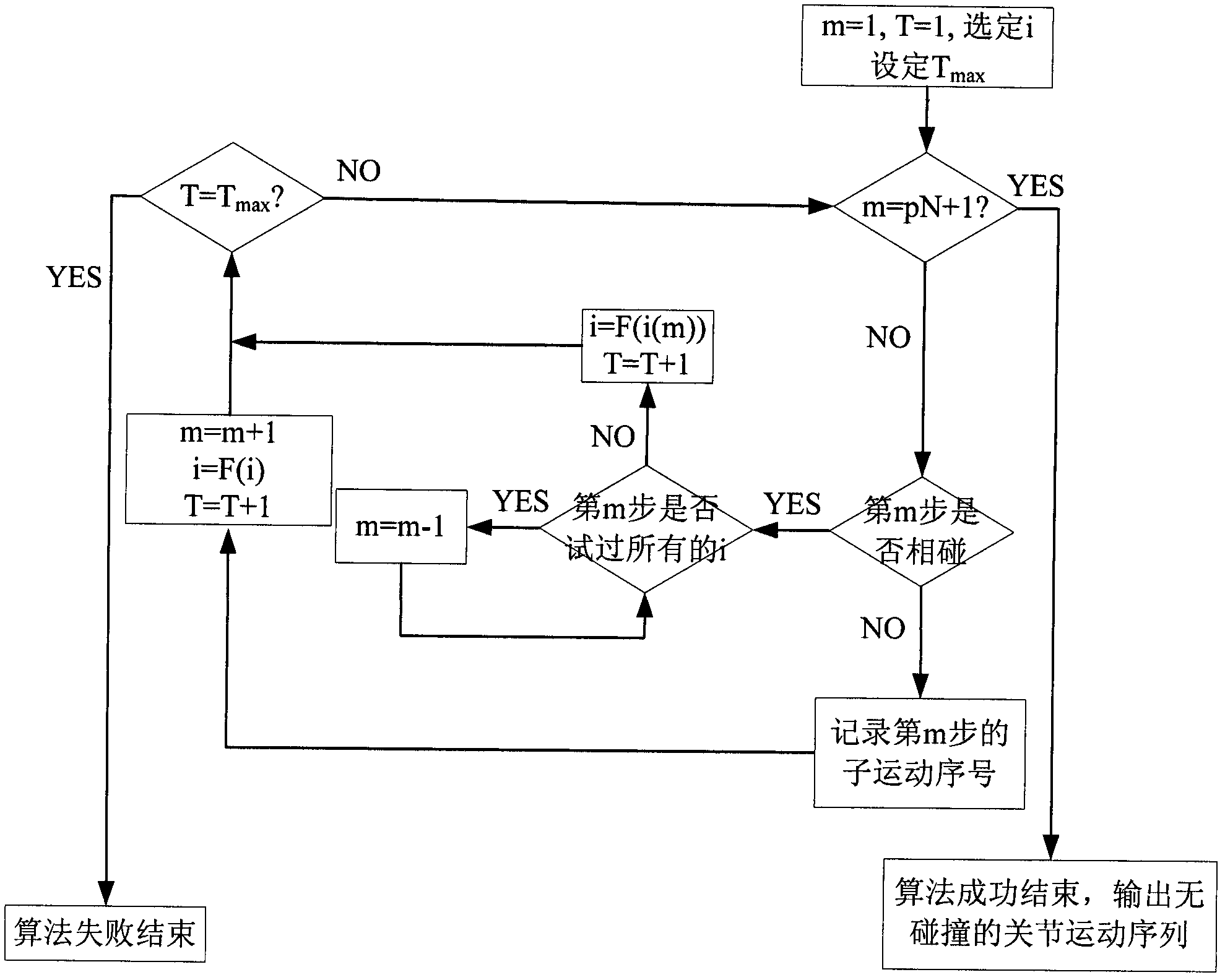

Track planning method of redundant space mechanical arm for on-track catching

ActiveCN103009389AGuaranteed accurate captureAchieve circumventionProgramme-controlled manipulatorKinematicsEngineering

The invention relates to a track planning method of a redundant space mechanical arm for on-track catching. The catching operation of the space mechanical arm is divided into a rough catching stage and a fine catching stage, so that problems are simplified. By aiming at outstanding problems of different stages, different planning algorithms are adopted. In the rough catching stage, a track searching algorithm based on configuration space is adopted, and the algorithm is based on the test in the configuration space; and in the fine catching stage, a pseudo-inverse algorithm based on kinematics is adopted, and the final precise catching is guaranteed by compensating the relative movement of a target.

Owner:BEIJING INST OF CONTROL ENG

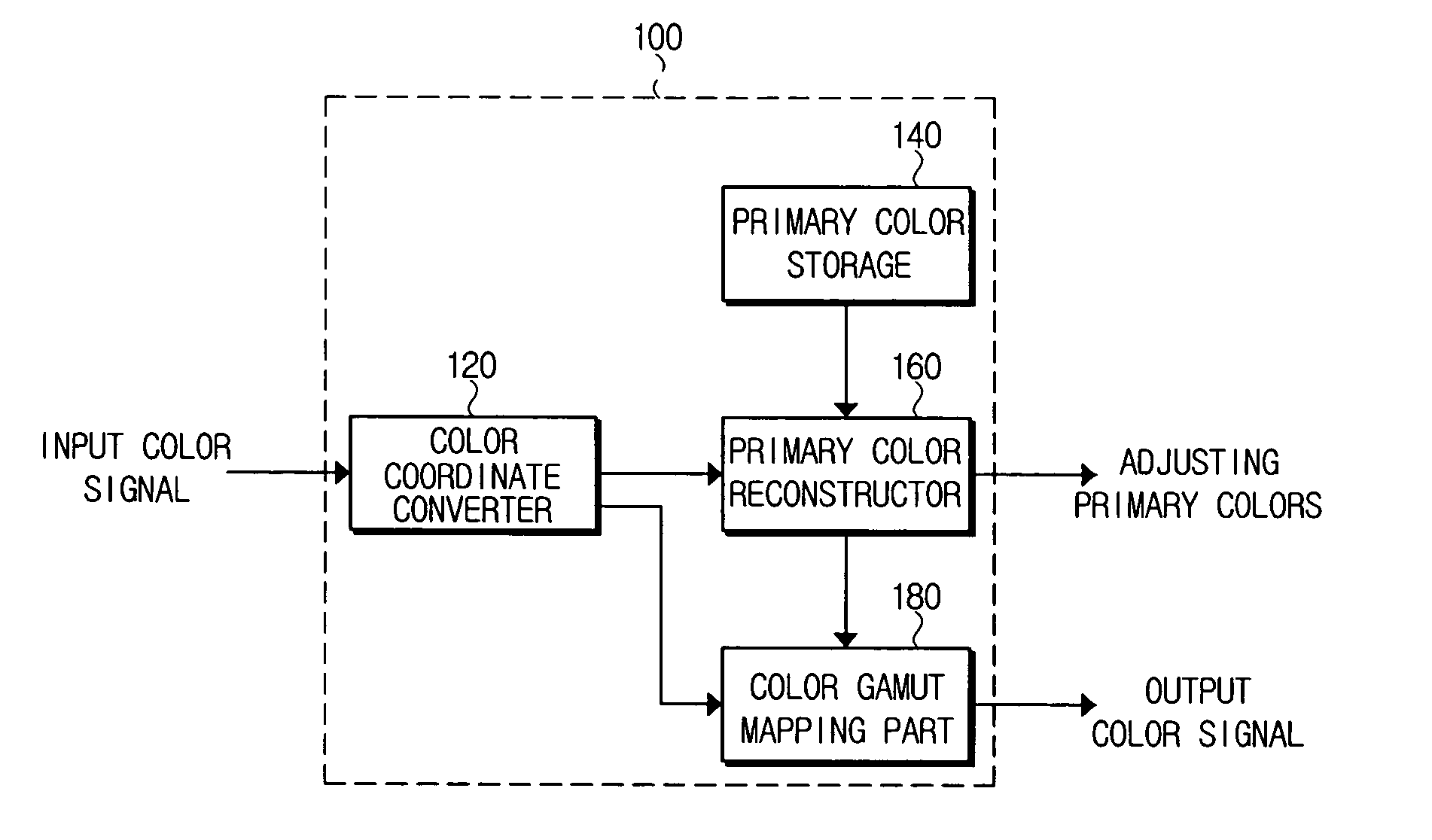

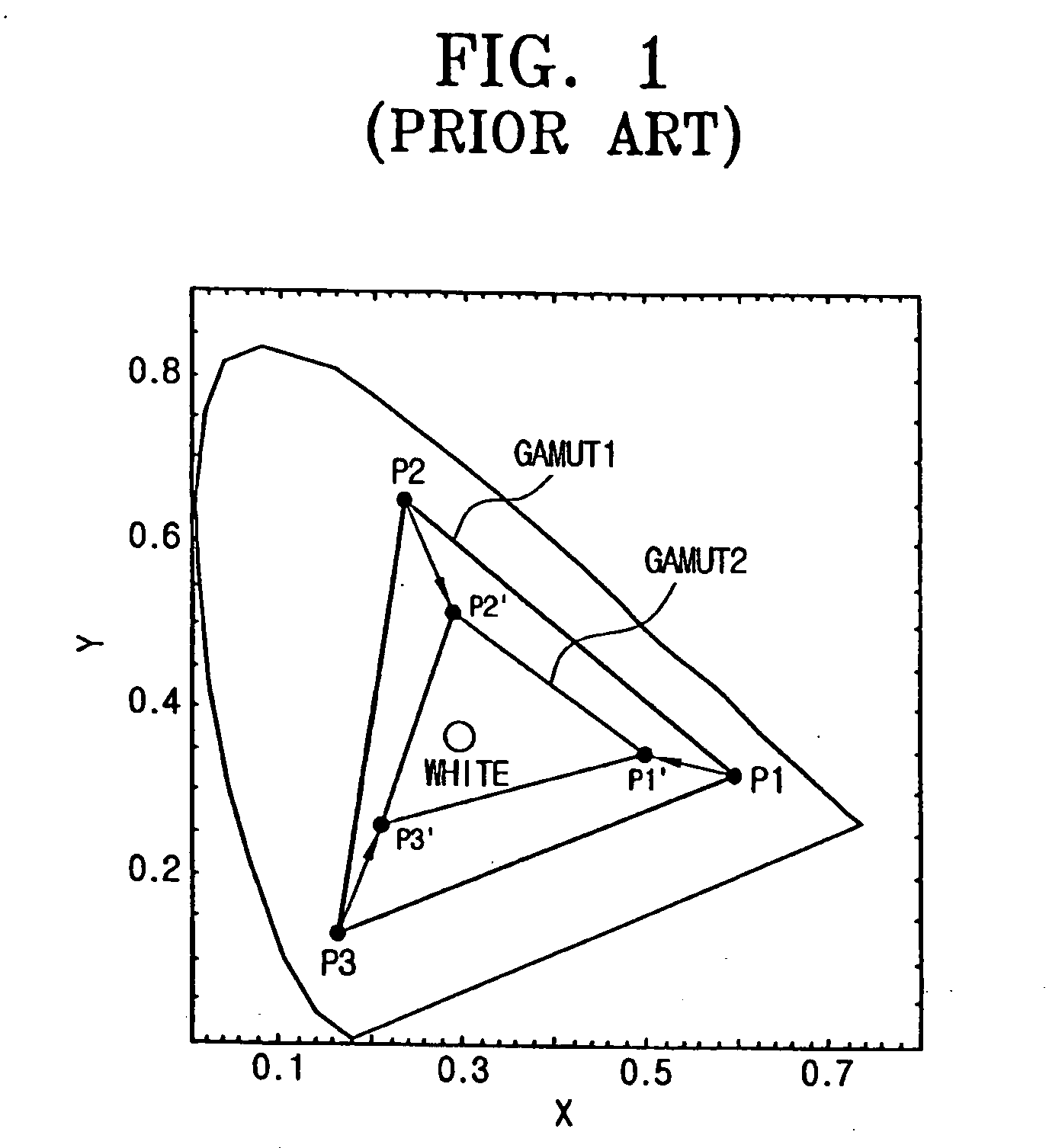

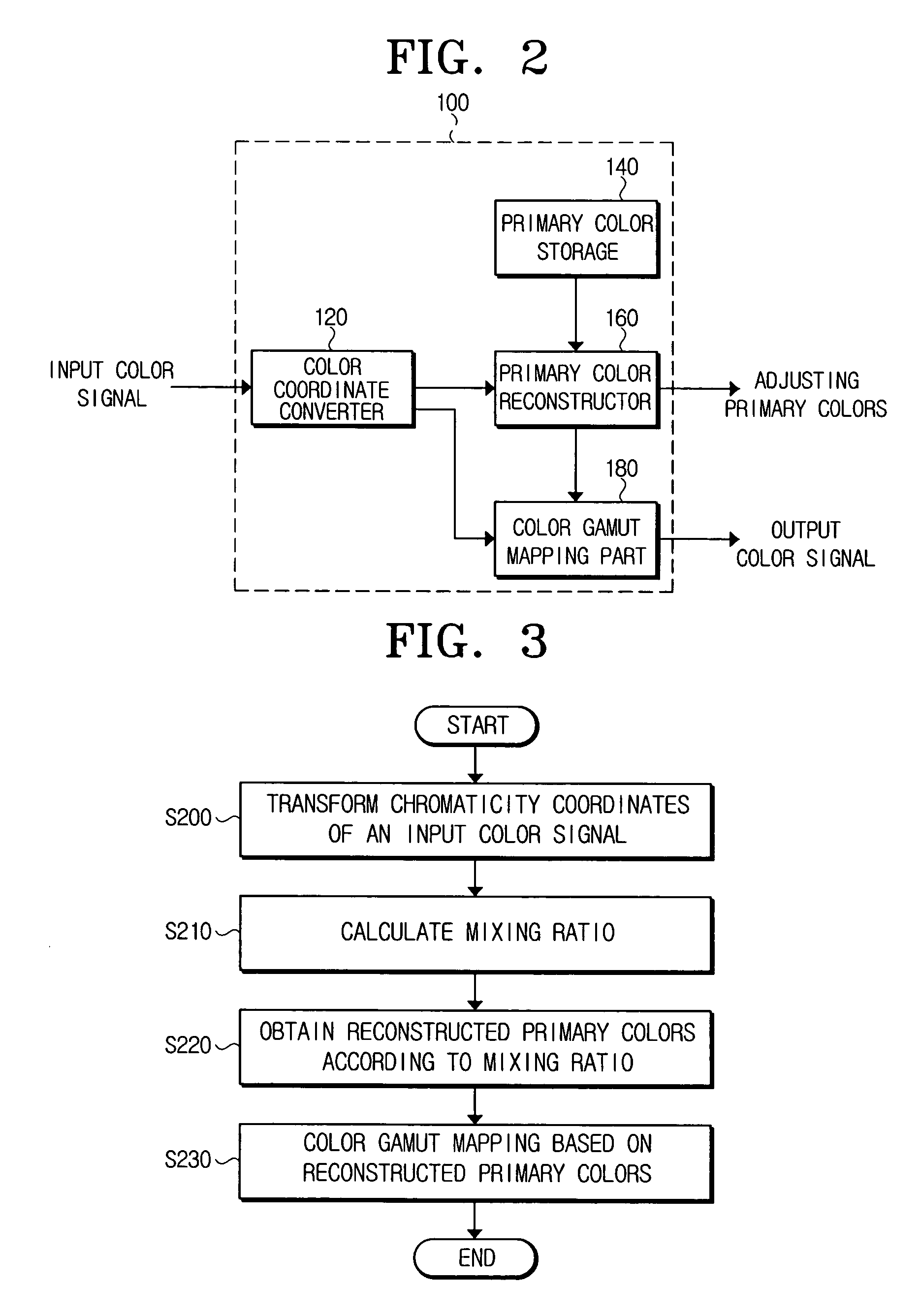

Color signal processing method and apparatus usable with a color reproducing device having a wide color gamut

InactiveUS20050280851A1Wide color gamutSimple algorithmDigitally marking record carriersColor signal processing circuitsPattern recognitionGamut

A color signal processing method includes calculating a mixing ratio for source primary colors of a color reproducing device through which an input color signal having standard primary colors is reproduced, mixing the source primary colors according to the calculated mixing ratio to obtain reconstructed primary colors, and transforming the input color signal to match a color gamut of the reconstructed primary colors and outputting the transformed color signal. Thus, the color gamut of the color reproducing device can be freely adjusted within a reproduction range thereof according to the input color signal.

Owner:SAMSUNG ELECTRONICS CO LTD

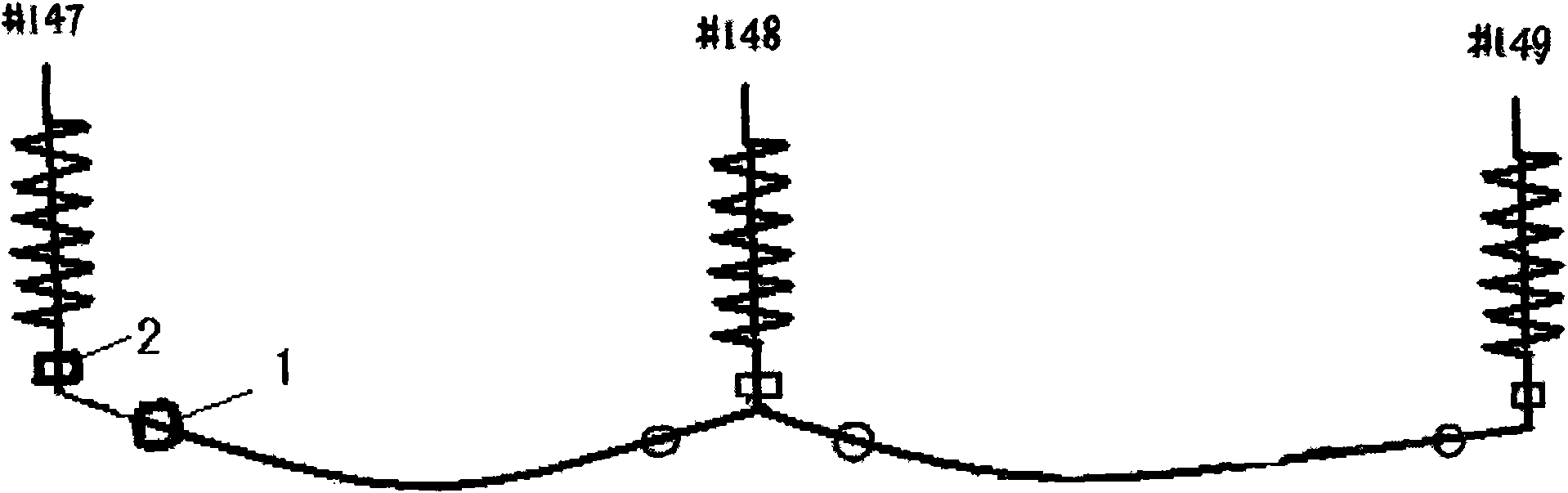

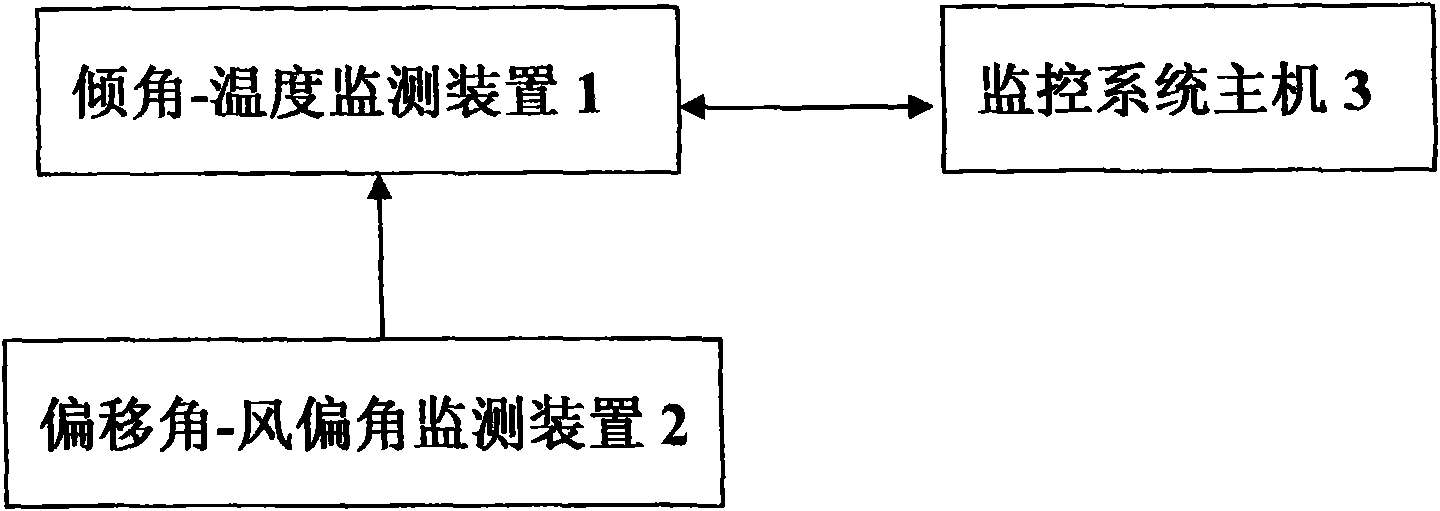

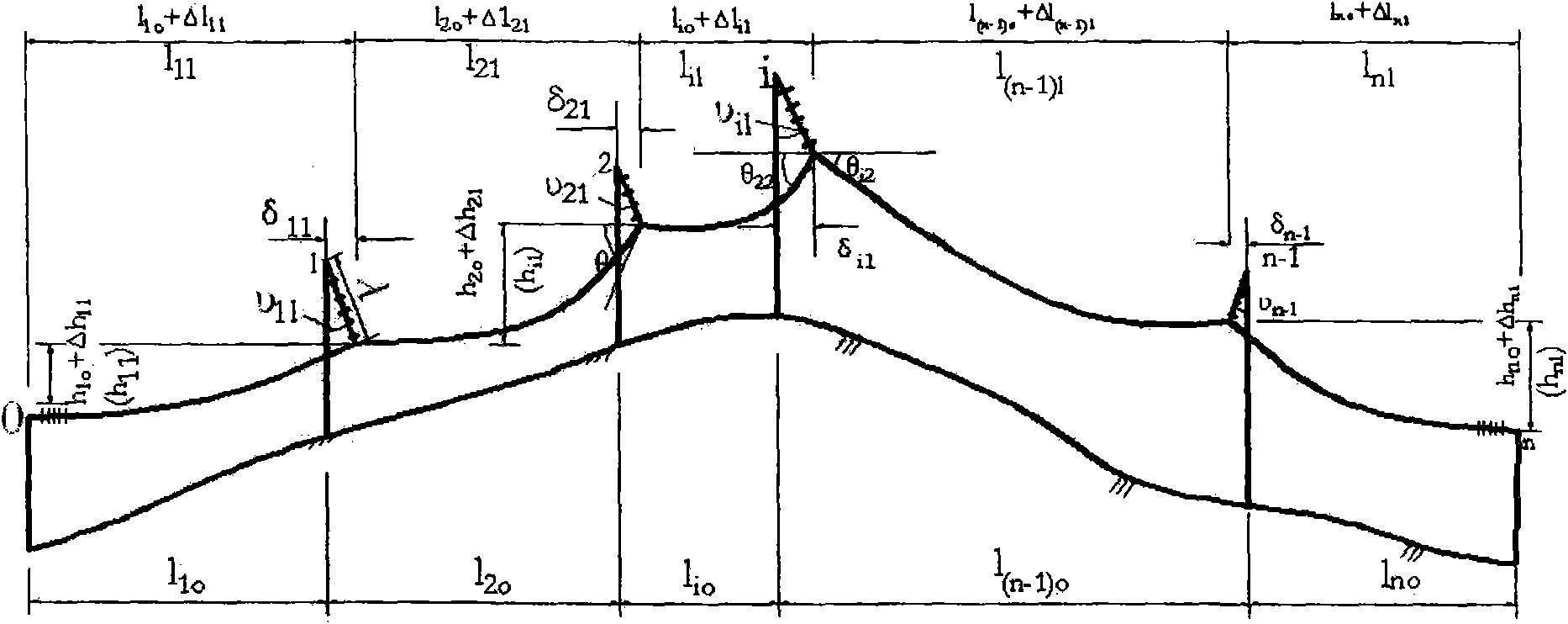

Real-time monitoring method of ice coated on overhead transmission line conductor and system

InactiveCN101556195ASimple algorithmThe result is accurateOverhead installationTension measurementDeflection angleTransmission line

The invention relates to the field of the monitoring of a transmission line conductor, in particular to a real-time monitoring method of ice coated on an overhead transmission line conductor and a system thereof. The method comprises the following steps of: firstly, arranging tilt-temperature monitoring devices on each line conductor so as to monitor the suspension point tilt and the conductor temperature of line conductors in real time; secondly, arranging deviation angle-wind deflection angle monitoring devices on each suspended insulator string so as to monitor the deviation angles of the suspended insulator strings along the conductor direction and the wind deflection angles vertical to the conductor direction in real time; and calculating the ice coating comprehensive load and the ice coating thickness of each line conductor in real time through monitoring the suspension point tilt and the conductor temperature of the line conductors and the deviation angles of the suspended insulator strings in real time. The method has the beneficial effects that not only the ice coating thickness of the conductor can be measured, but also the comprehensive load of the ice-coated conductor can be measured, furthermore, the measure is reasonable and correct, the algorithm is simple, and the result is accurate, and the method can be applied to the comprehensive load calculation of the strain section of the lines, on which ice is evenly coated or unevenly coated.

Owner:杭州甬能信息技术有限公司 +1

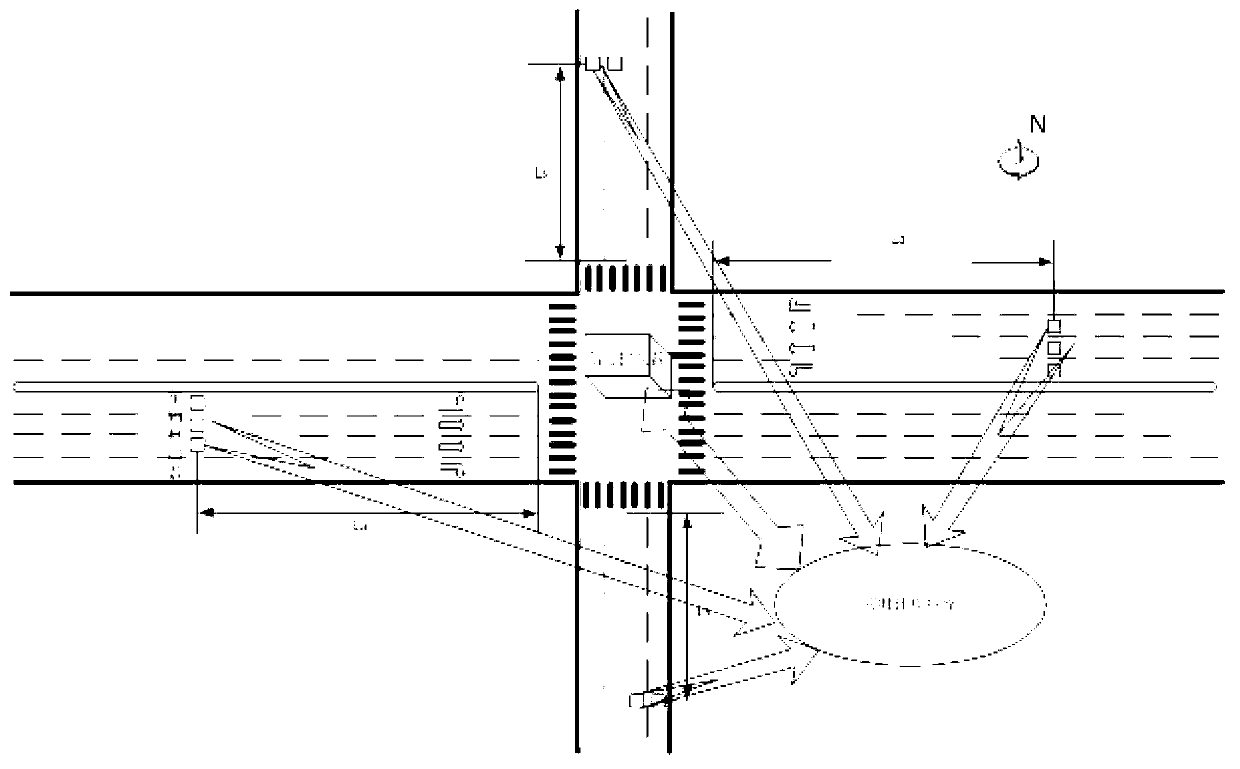

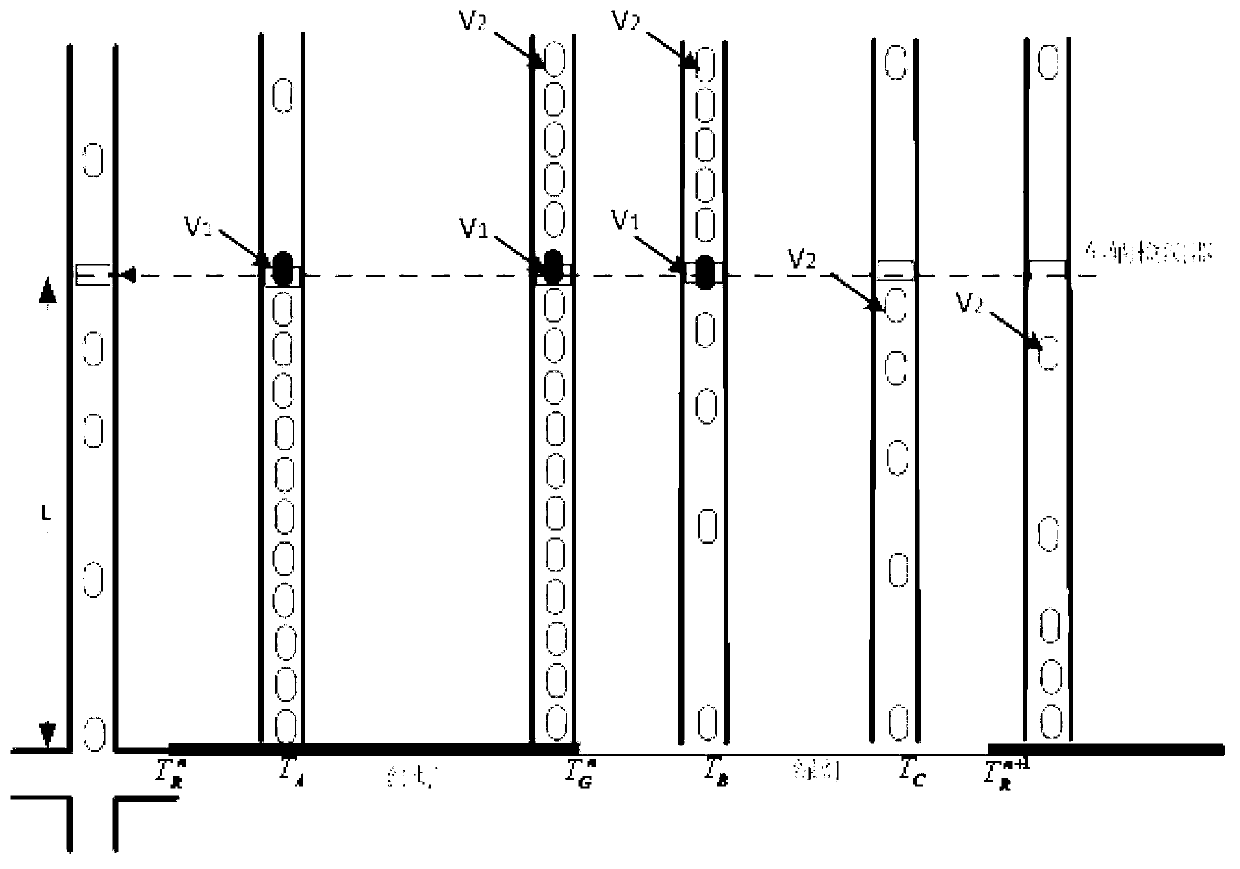

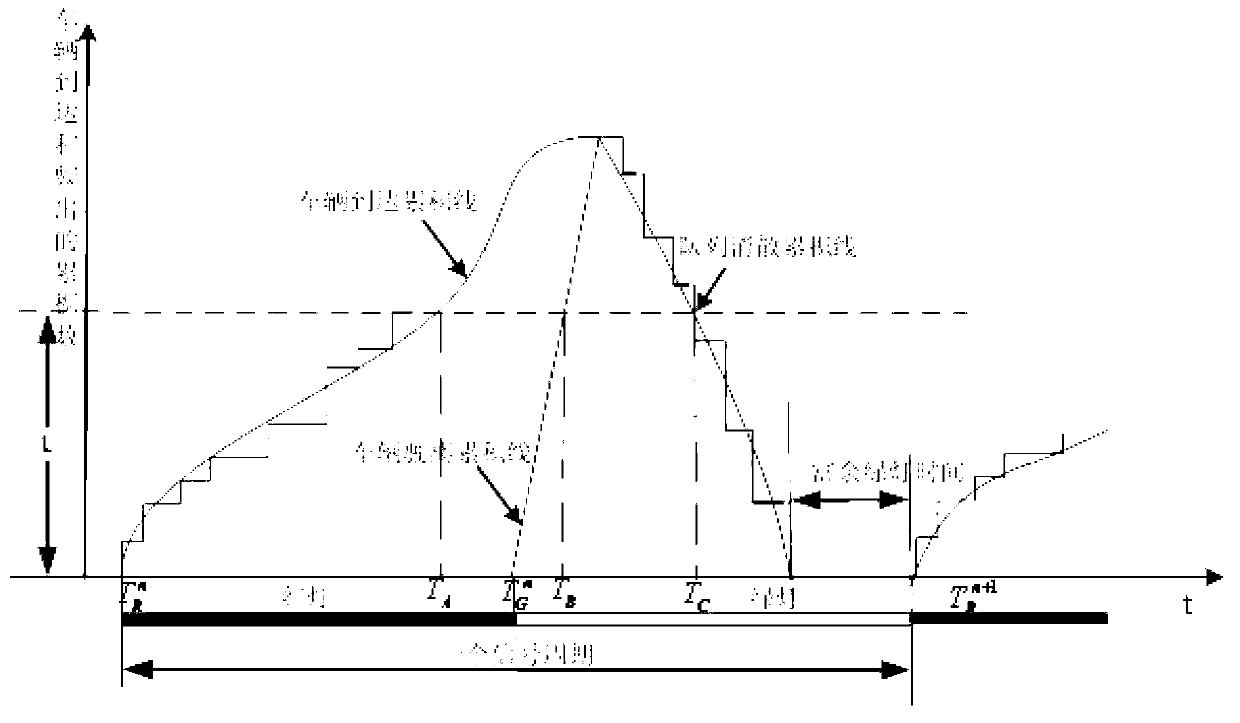

Self-adaptive intersection signal control method

InactiveCN103280113AReduce computationAchieving the purpose of adaptive controlControlling traffic signalsVehicle detectorUrban traffic control

The invention belongs to the field of urban traffic control, and provides a self-adaptive intersection signal control method. By installing vehicle monitors to detect the number of vehicles, the lengths of vehicle queues are acquired, and a signal control strategy for the next cycle is determined according to the lengths of vehicle queues at an intersection in the previous cycle. The method utilizes the vehicle detectors already arranged in a city to acquire traffic flow data and calculate the length of the queue of each lane, and the signal timing scheme of the next cycle is dynamically adjusted according to the different proportions of queue lengths. Taking a cycle as a unit, a timing scheme is calculated, the load of calculation is low, and moreover, the method also can achieve the purpose that intersection signals can be self-adaptively controlled according to the density of traffic flow. In addition, the algorithm of the method is simple, and the method has low requirement on hardware and construction quantity, and therefore is convenient to popularize.

Owner:CHANGAN UNIV

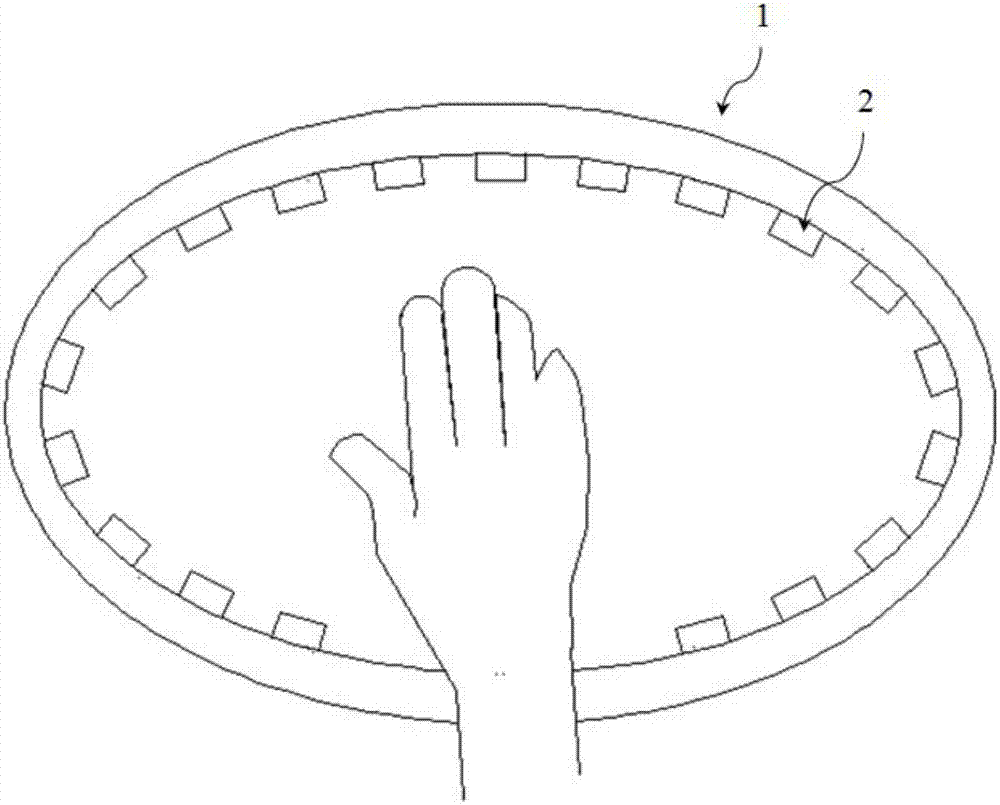

Device and method integrating gesture recognition and ultrasonic tactile feedback and application

InactiveCN107340871AStrong sense of realityImprove realismInput/output for user-computer interactionGraph readingMixed realityHand parts

The invention provides a device and method integrating gesture recognition and ultrasonic tactile feedback. The device integrates a functional unit comprising a camera, an illumination unit and an ultrasonic spray head assembly inside gloves, feeds back the hand operation in real time, achieves accurate identification and tracing to the hand actions of a user and converts tactile information fed back into forces or force moments directly acting the hands of the user, so that an operator can produce a real touch feeling in a virtual environment, and meanwhile touch feeling at multiple angle and strengths can be also simulated, the gesture recognition speed and accuracy are improved, and the fidelity and immersion degree of virtual reality experience are increased. The invention also relates to application of the device integrating gesture recognition and ultrasonic tactile feedback in virtual reality, augmented reality and mixed reality.

Owner:SENSES GLOBAL CORP

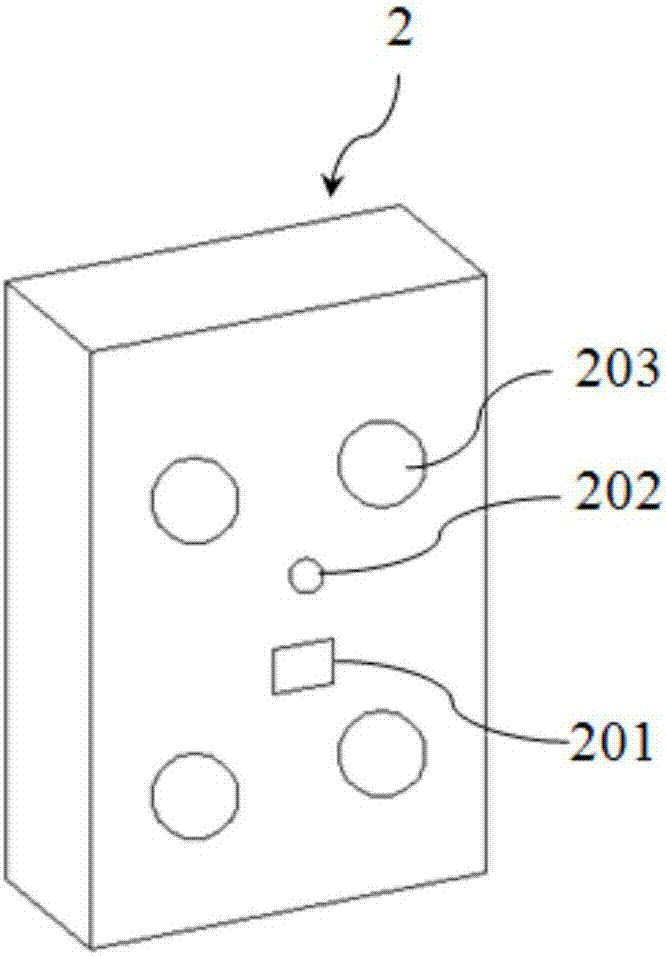

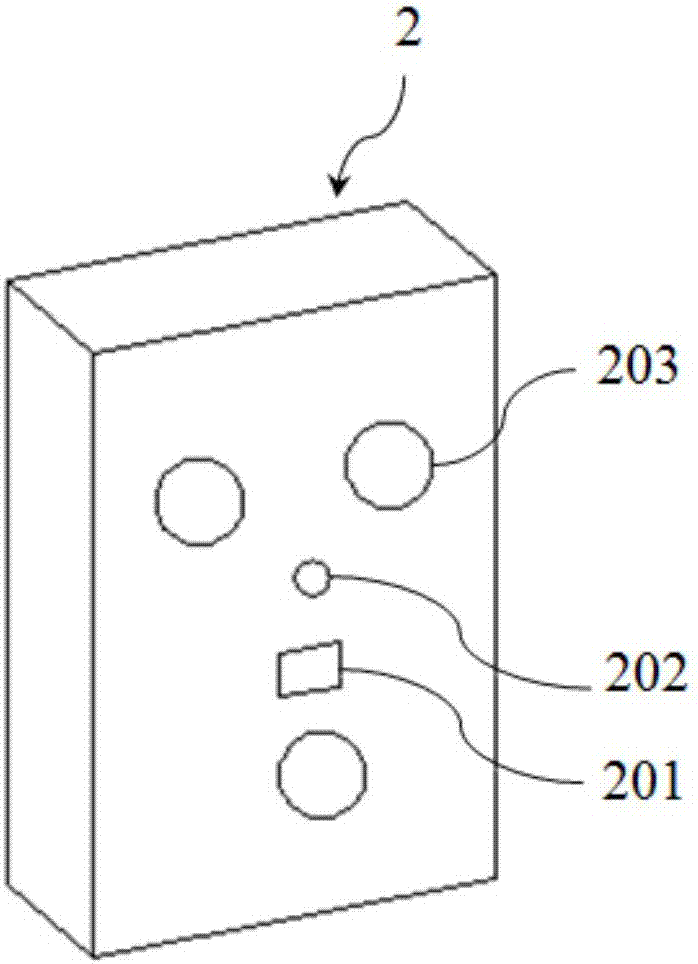

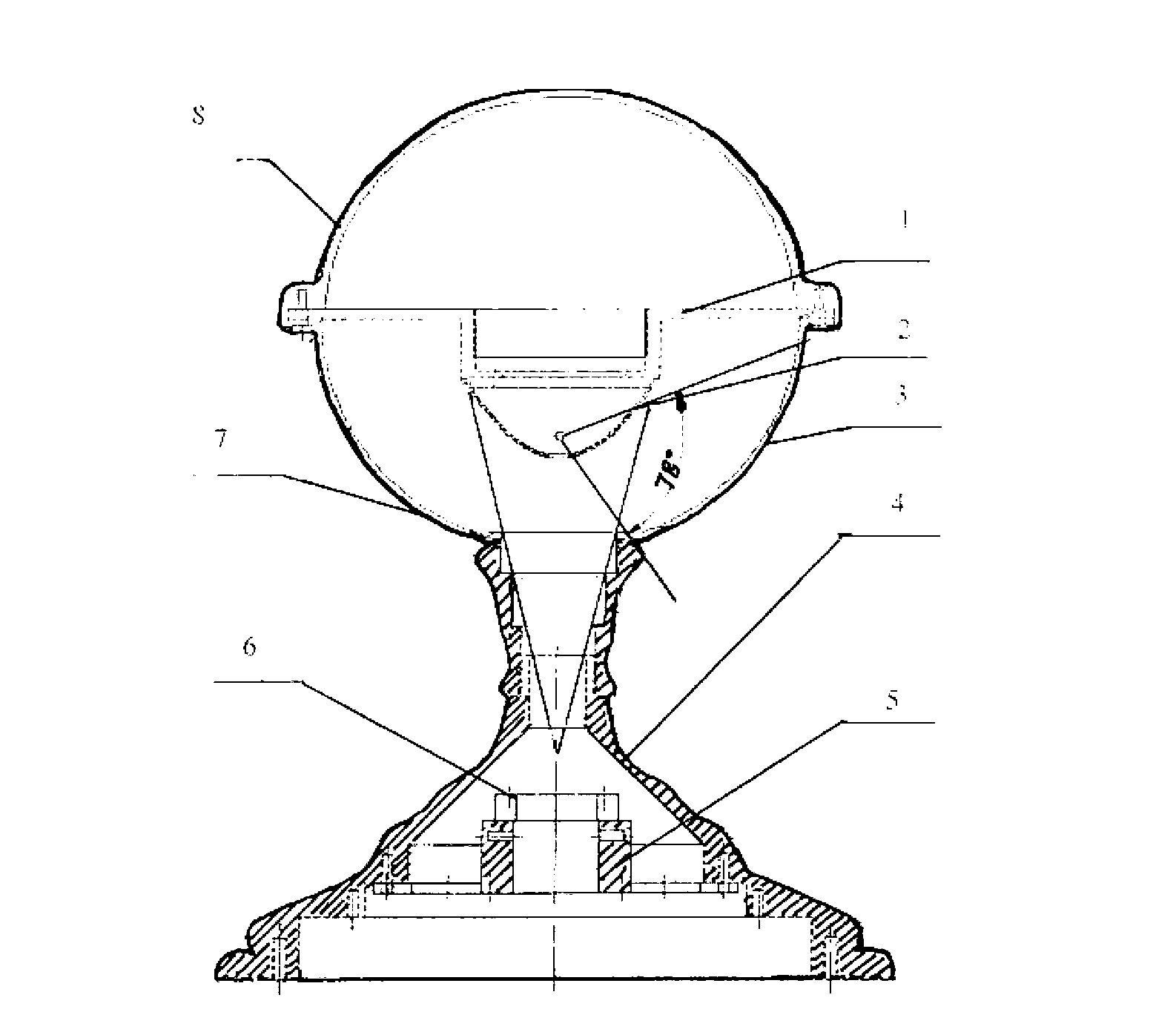

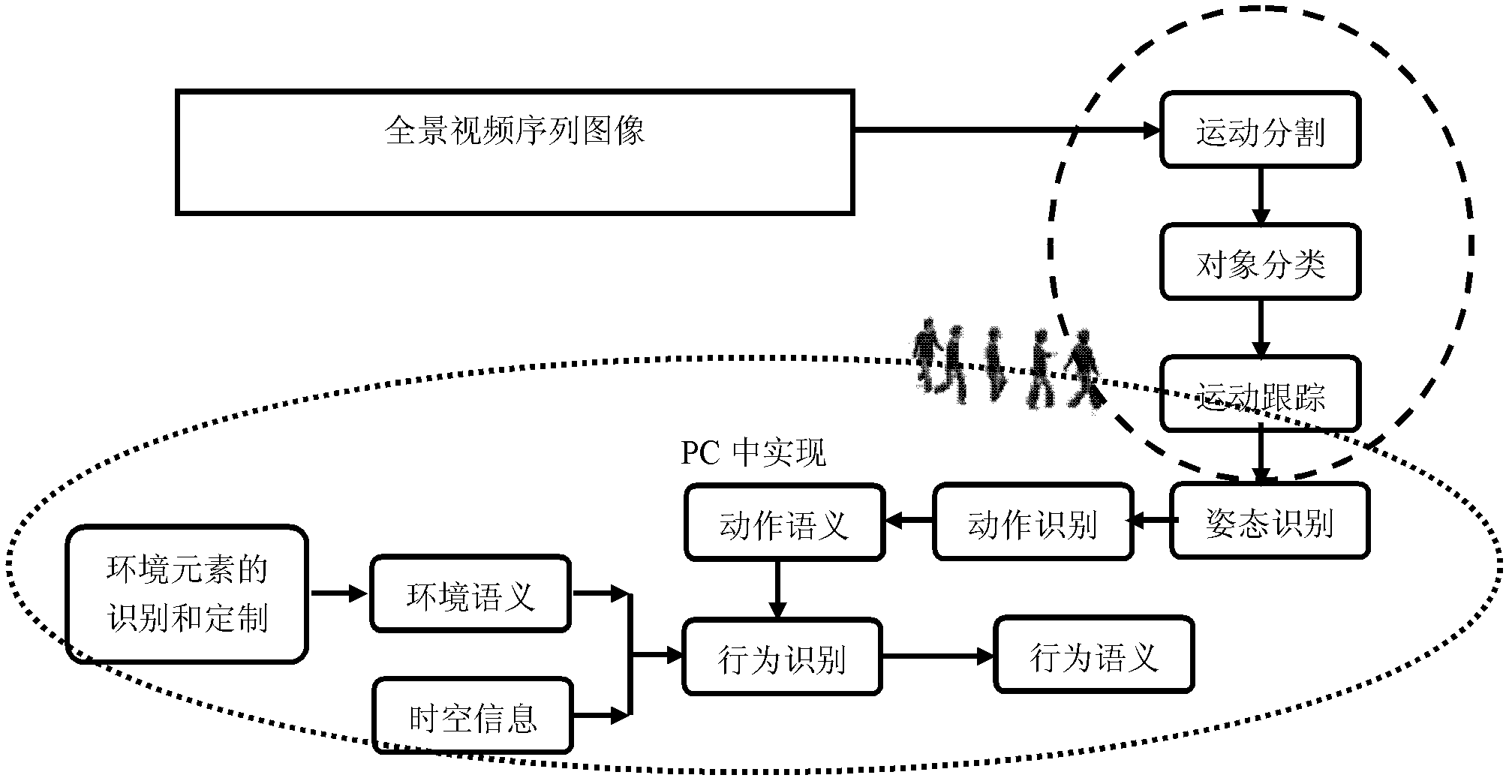

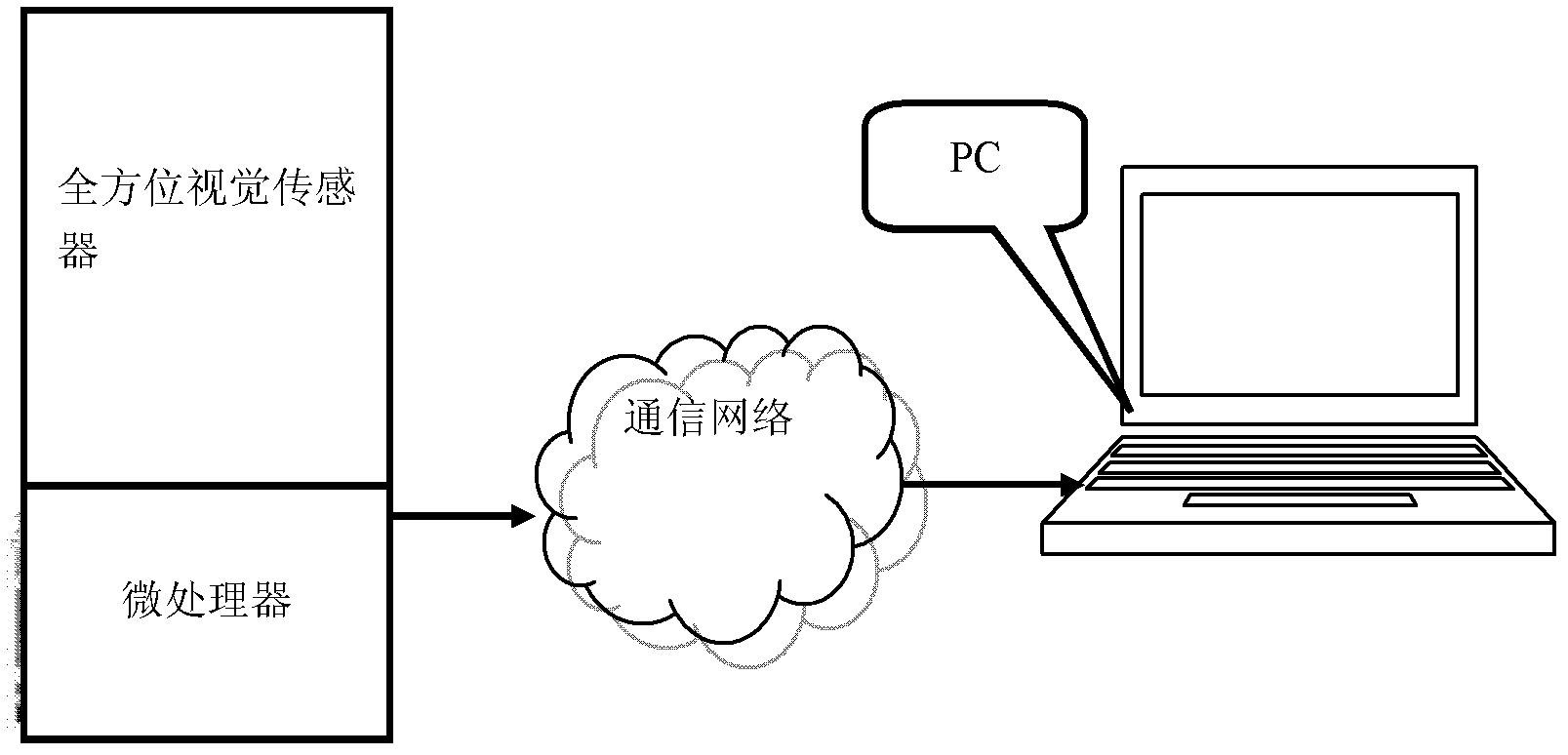

Multi-target object tracking system of panorama video sequence image

ActiveCN102999918ARemove shadowsEfficient extractionTelevision system detailsImage analysisMultiple targetMotion history

A multi-target object tracking system of a panorama video sequence image comprises a panorama camera shooting device and a microprocessor. The panorama camera shooting device is used for acquiring a scene in a large area, and the microprocessor is used for video analyzing and processing a panorama image shot by the panorama camera shooting device. During the processing process of moving target object extracting and simple multi-target object tracking, an MHoEI (motion history or energy images) algorithm which is low in computation complexity, simple in parameters and threshold value selection and convenient to realize in a system-on-chip is utilized. In order to effectively track multi-target objects in the scene in cases of shielding, separating and merging, the multi-target objects are sequentially tracked via motion characteristics, color characteristics and shape characteristics of the target objects according to matched results, and while tracking efficiency is improved, robustness for tracking the multi-target objects is improved.

Owner:ZHEJIANG UNIV OF TECH

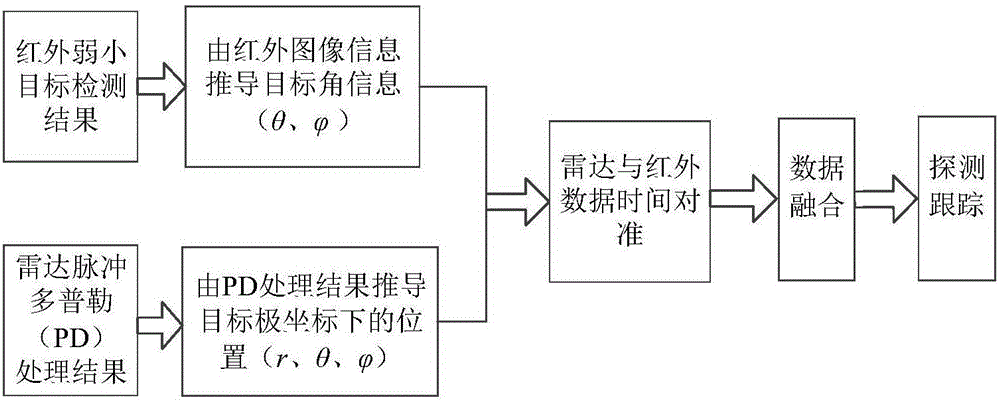

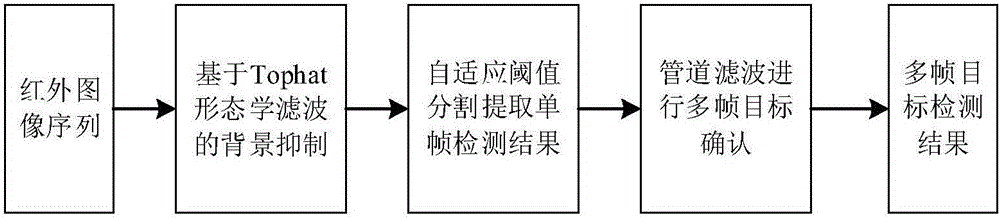

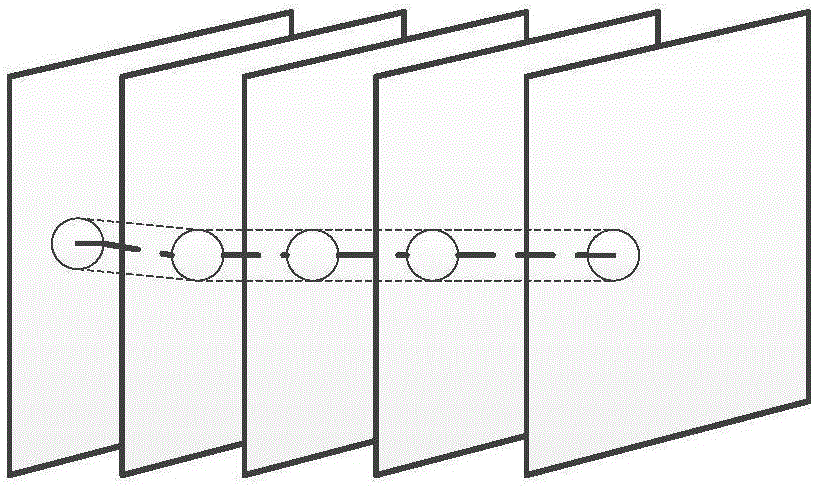

In-orbit moving target detecting method with space-based radar and infrared data fusion

InactiveCN106204629AAvoid moving out of the pipelineImprove performanceImage enhancementImage analysisRadar detectionTrack algorithm

The invention discloses an in-orbit moving target detecting method with space-based radar and infrared data fusion. The method includes the steps that when an infrared detecting system is used for detection, background suppression is carried out on each frame in an infrared image sequence by adopting a filtering method based on the morphology, self-adaptive threshold segmentation is carried out on images obtained after background suppression, a single frame detection result is extracted, a multi-frame target is determined through a tracking algorithm, and whether the detection result is a real target or not is judged to obtain the detection result of the multi-frame target; during radar detection, pulse doppler (PD) is adopted for processing. After time calibration and space calibration are carried out on the obtained infrared and radar target information, data fusion is carried out on the information by adopting a measurement fusion method, and track prediction is carried out on fused data to obtain the estimated position of the target.

Owner:XIDIAN UNIV

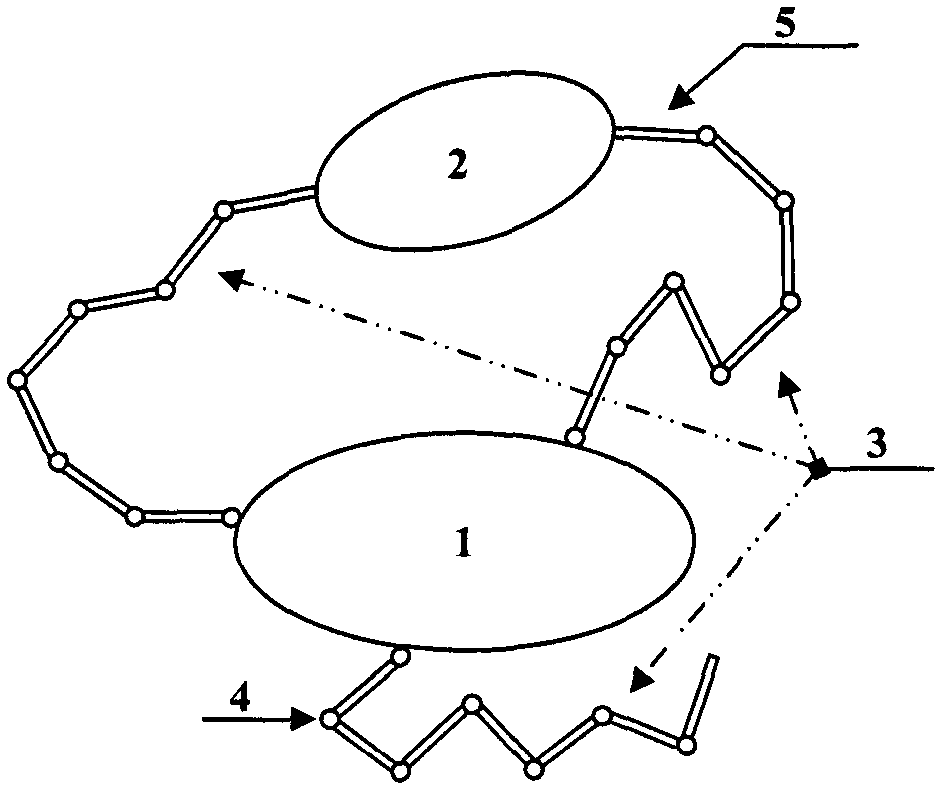

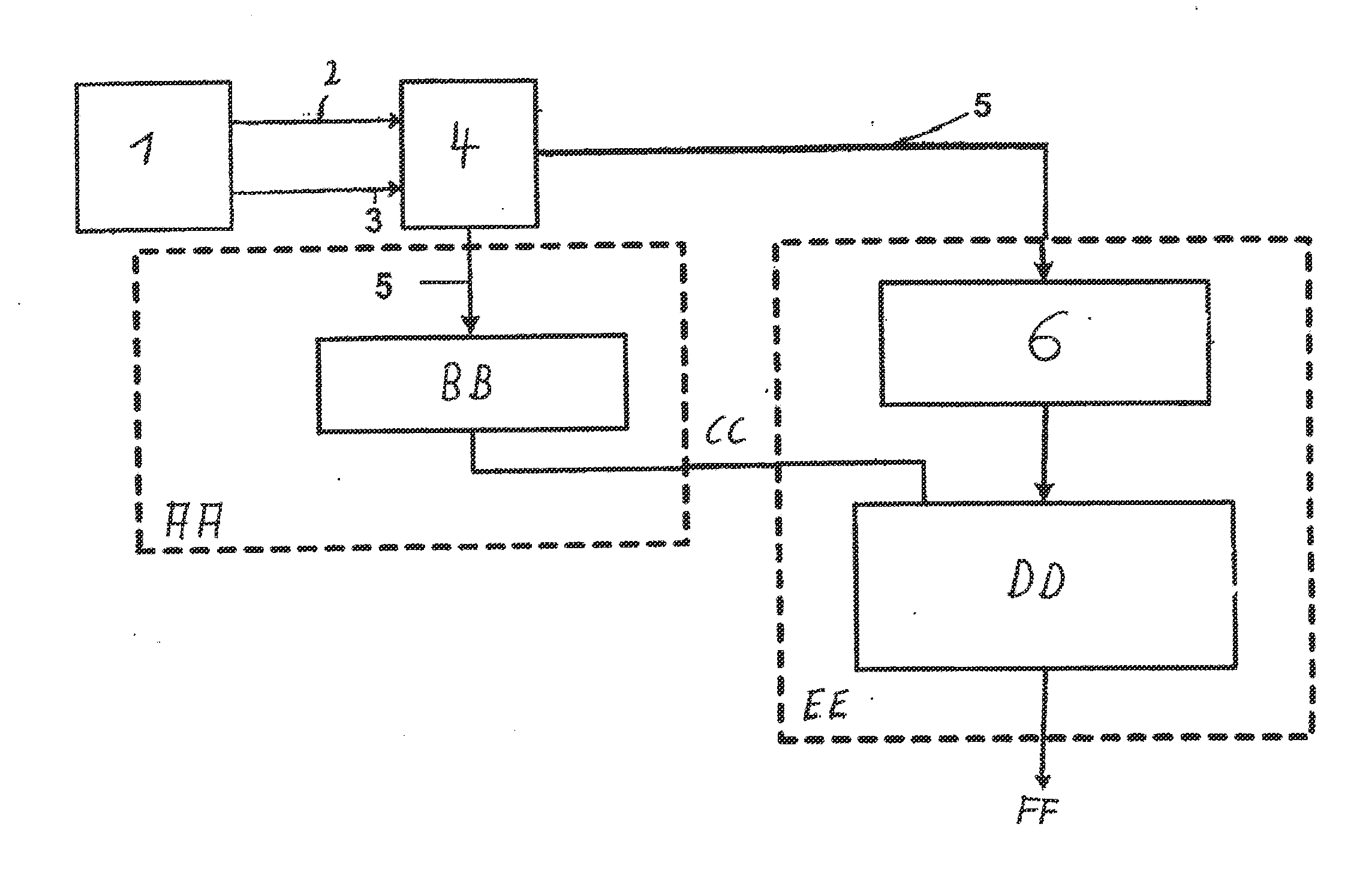

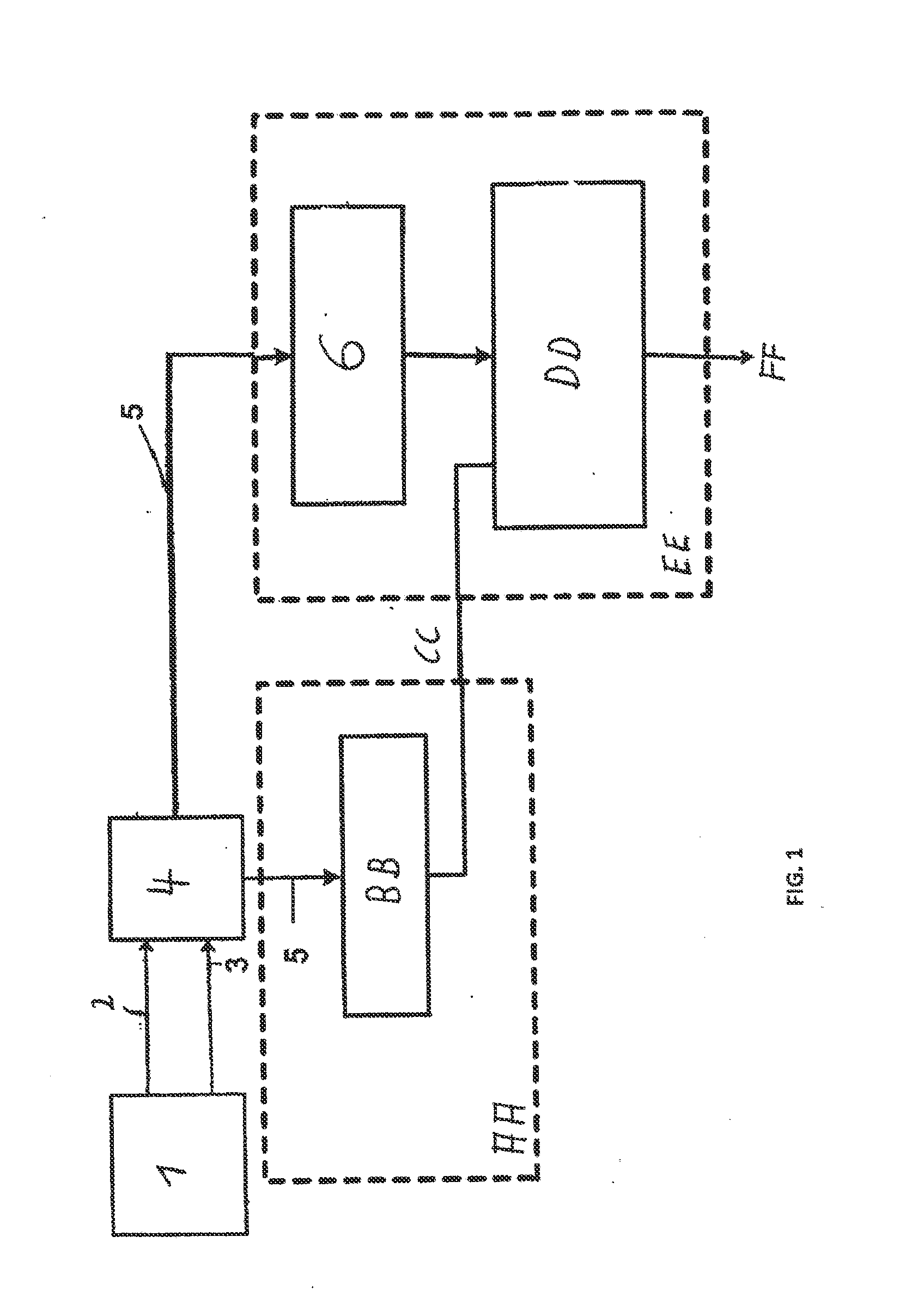

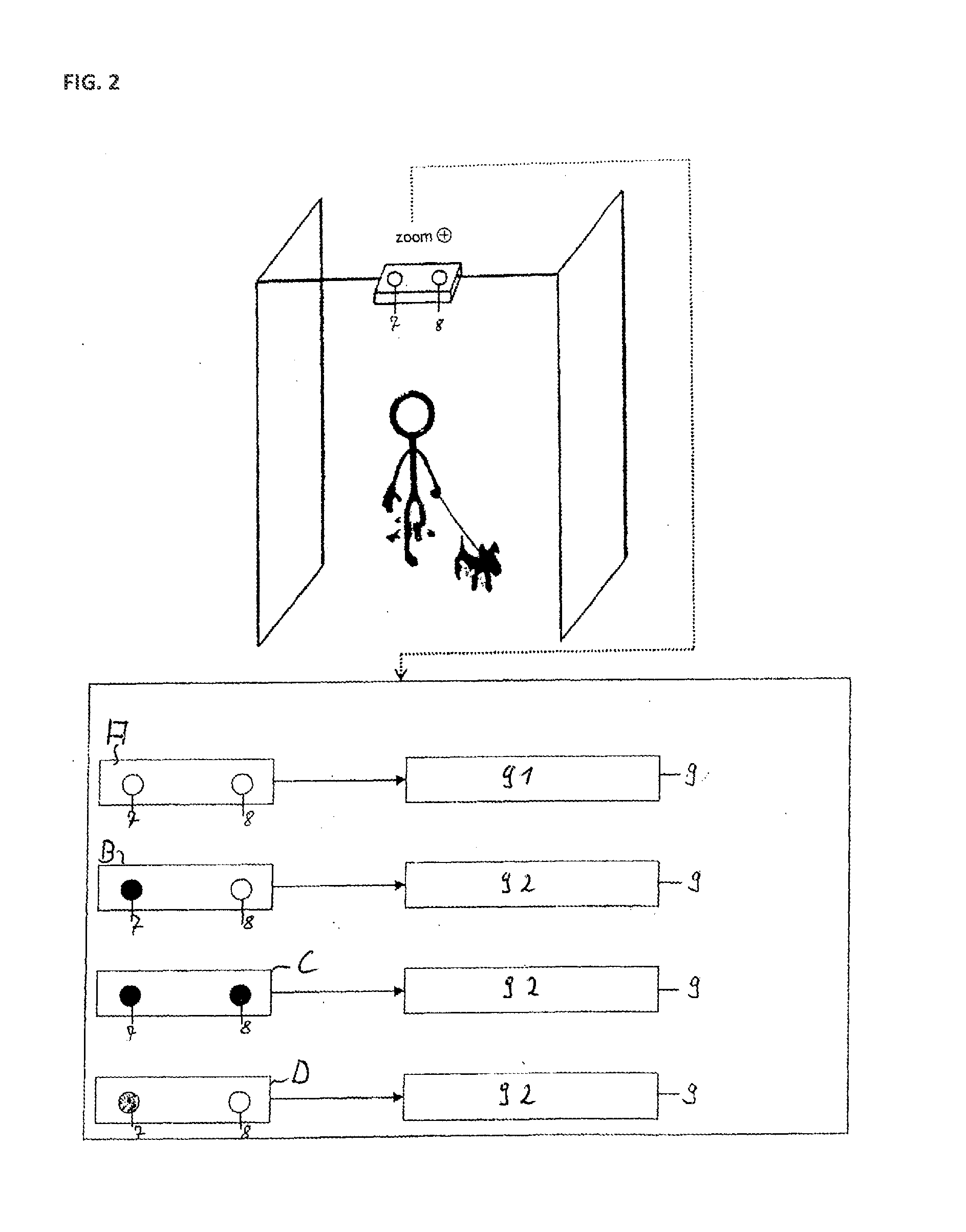

Optical Self-Diagnosis of a Stereoscopic Camera System

ActiveUS20130120536A1Simple algorithmAvoids disadvantageImage enhancementImage analysisStereo imageImage sensor

The present invention relates to a method for the optical self-diagnosis of a camera system and to a camera system for carrying out the method. The method comprises recording stereo images obtained from in each case at least two partial images (2, 3) creating a depth image, that is to say a disparity map (5) given by calculated disparity values, determining a number of valid disparity values (6) of the disparity map (5), and outputting a warning signal depending on the number of valid disparity values determined. A device for carrying out such a method comprises a stereo camera (1) having at least two lenses (7,8) and image sensors, an evaluation unit and a display unit.

Owner:HELLA KGAA HUECK & CO

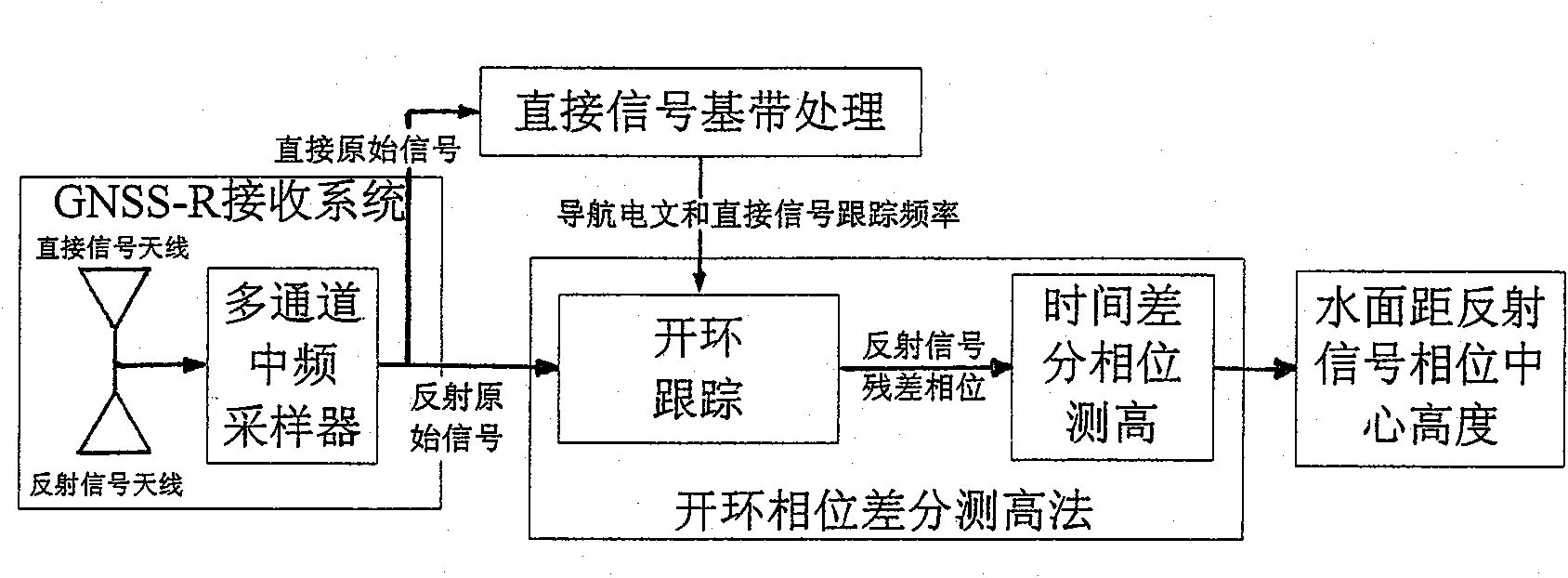

Carrier phase height measurement device based on GNSS-R technology and method thereof

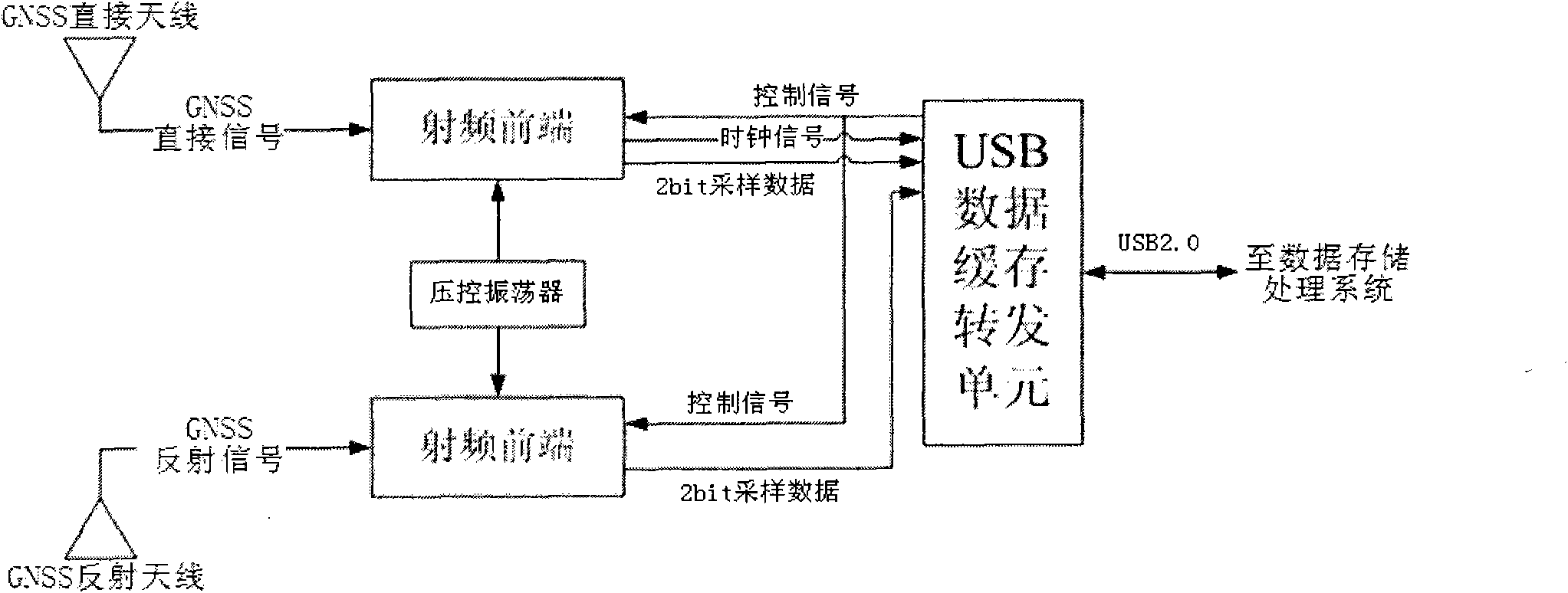

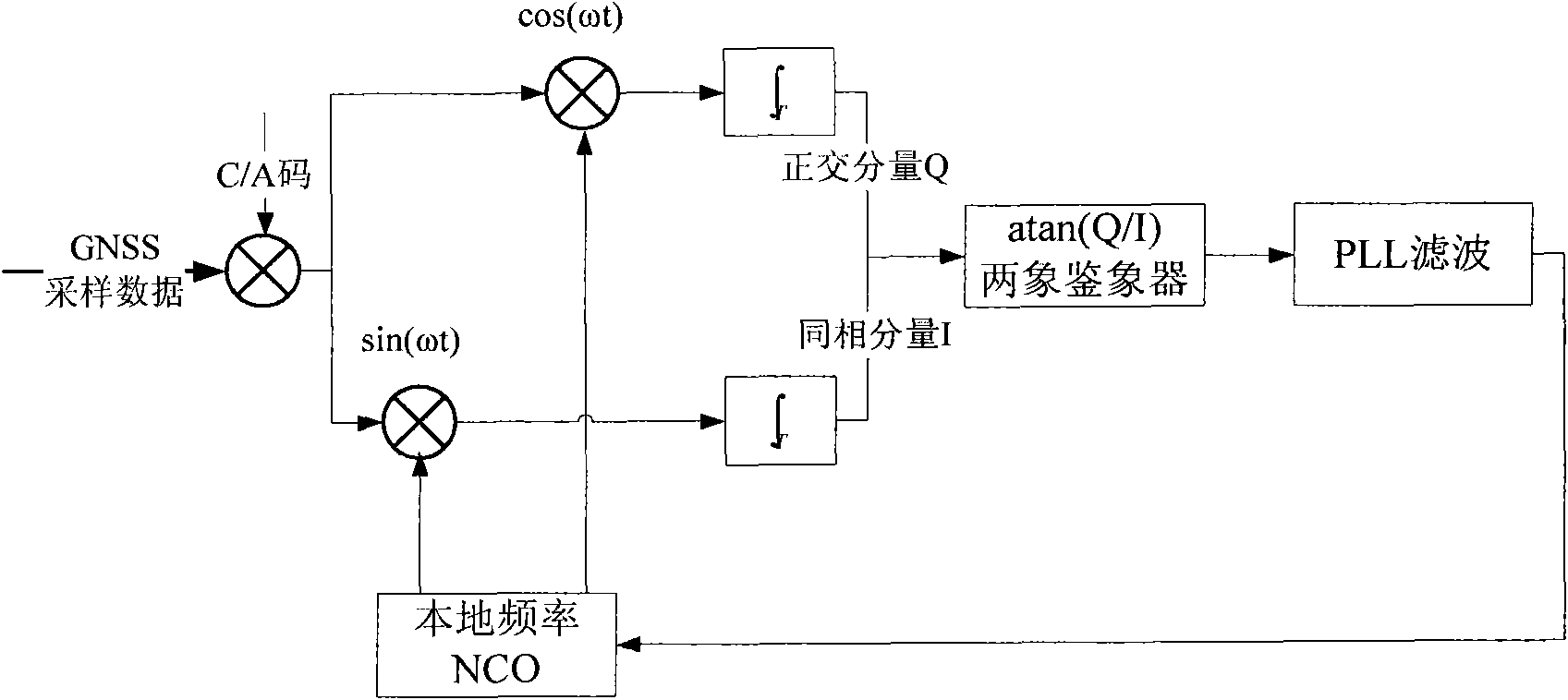

InactiveCN101846746AOvercome the effects of drastic amplitude changesEffective Phase ObservationSatellite radio beaconingRadio wave reradiation/reflectionDifferential phaseMeasurement device

The invention relates to a carrier phase height measurement device based on a GNSS-R technology and a method thereof. The device comprises a GNSS-R receiving module, a direct signal processing module, a reflected signal processing module and a reflected signal carrier phase height measurement module, wherein the reflected signal carrier phase height measurement module comprises an open-loop tracking unit and a time differential phase height measurement unit; the open-loop tracking unit takes the direct signal tracking frequency as the local reference frequency so as to effectively track the GNSS reflected signal and obtain the reflected signal carrier phase observed quantity; and the time differential phase height measurement unit utilizes the single-frequency reflected signal phase observed quantity obtained by the open-loop tracking unit to invert accurate water level in a time differential phase height measurement method. The height measurement method accurately measures the water level by the GNSS water surface reflected signal carrier phase, and effective reflected signal phase observed quantity can be obtained by open-loop tracking. A time differential phase height measurement algorithm is simple and can realize high-accuracy height measurement of the water level within a short time.

Owner:NAT SPACE SCI CENT CAS

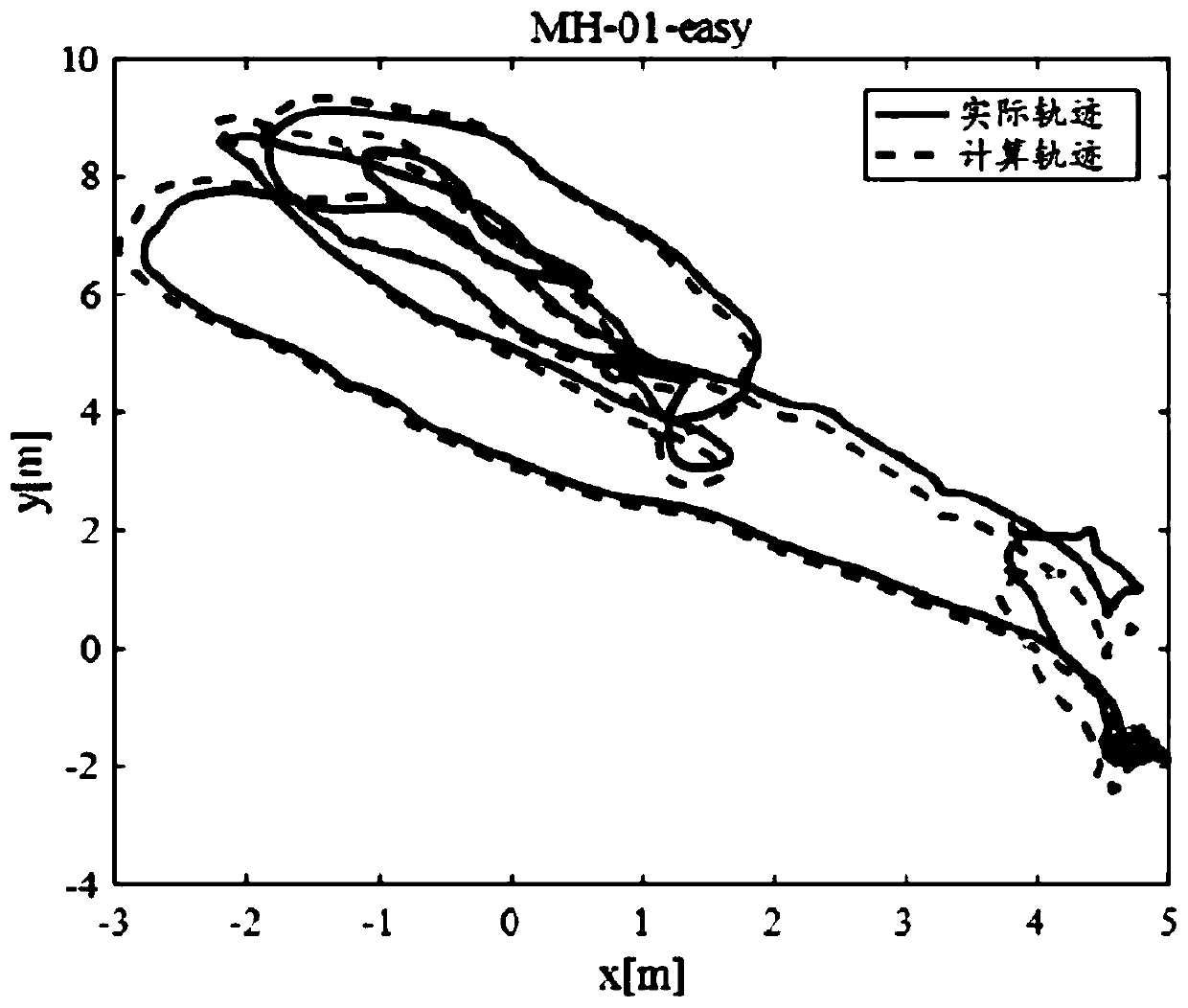

Robot positioning and mapping method, computer device and computer readable storage medium

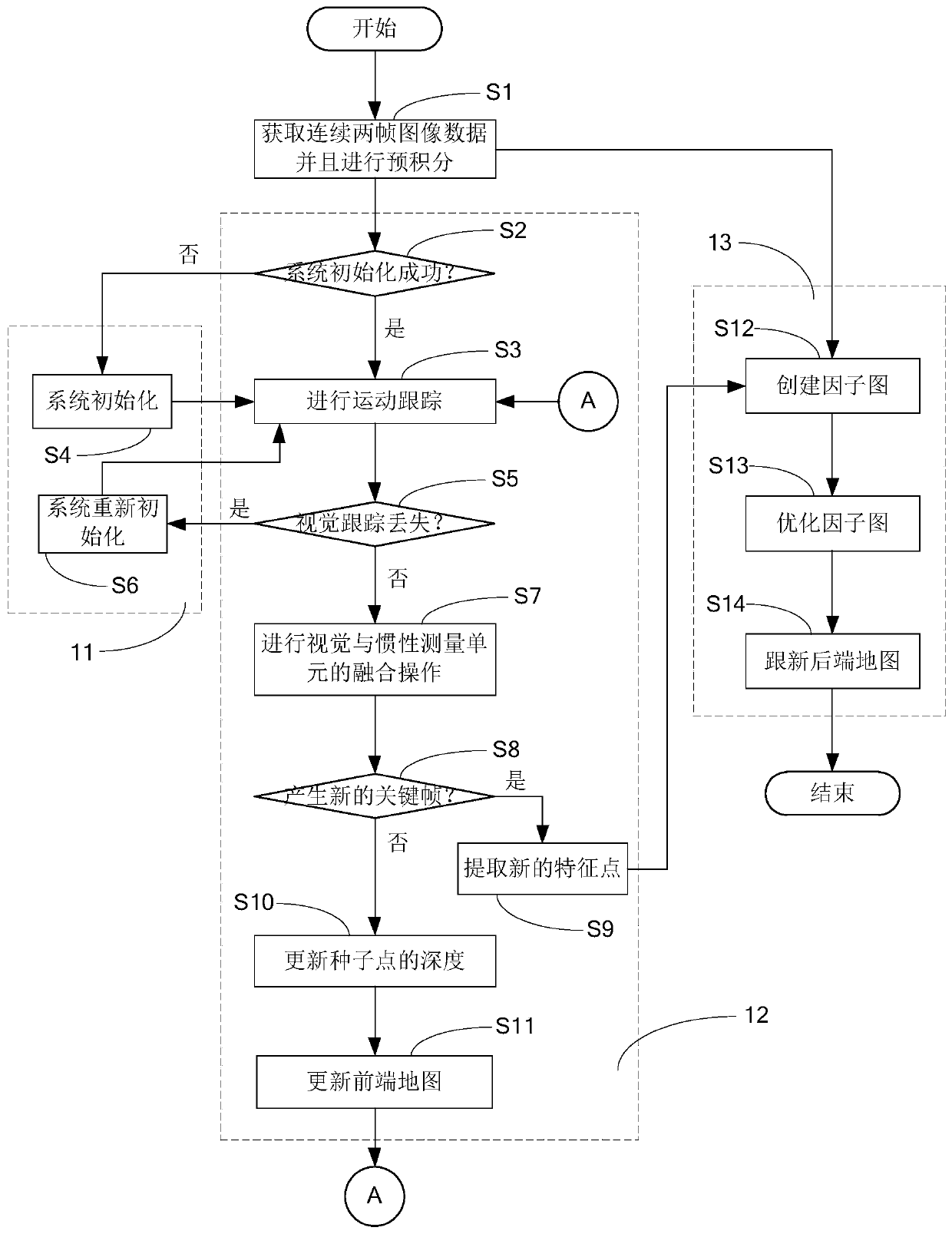

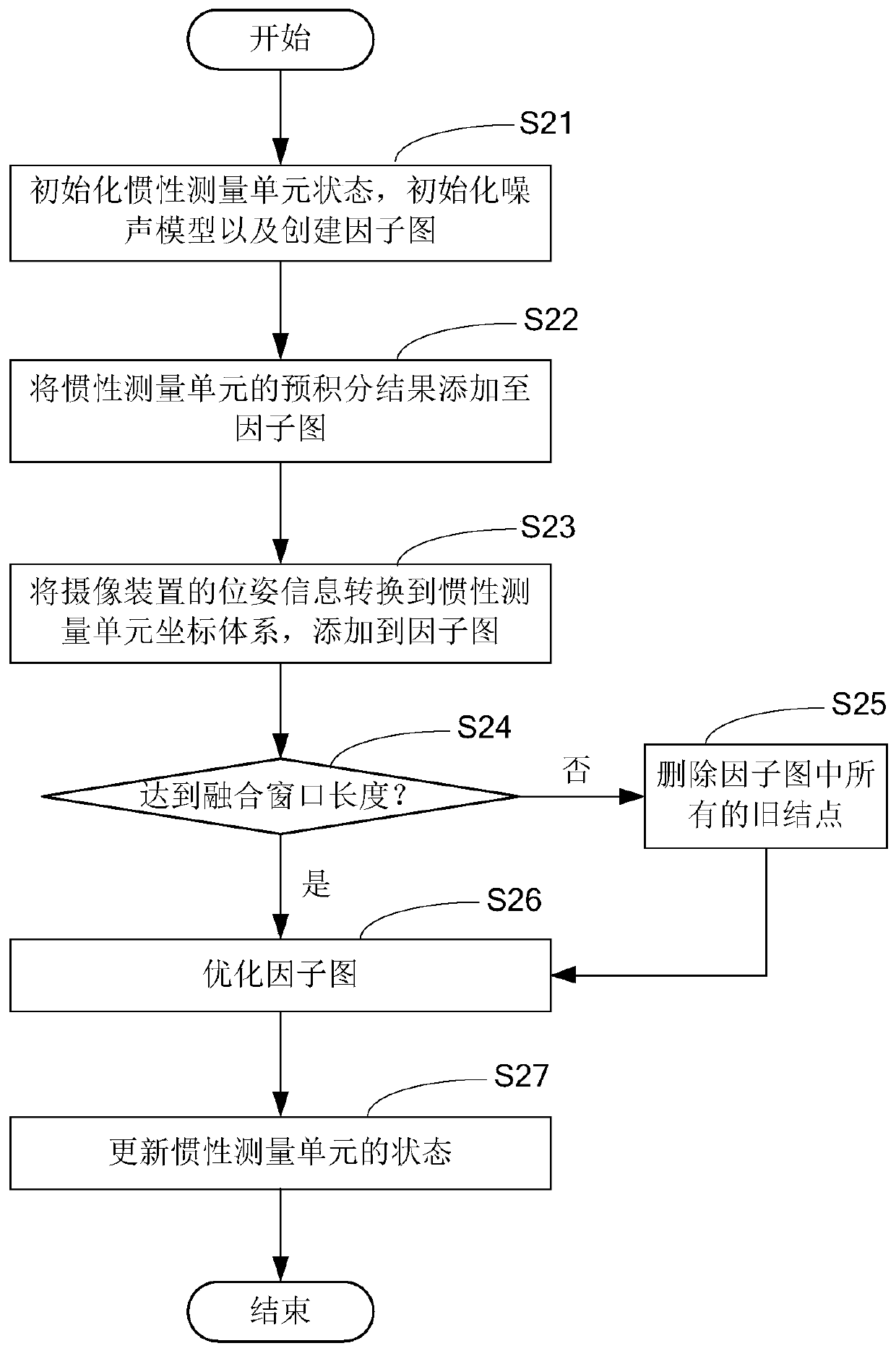

PendingCN109816696AAchieve high-precision positioningRun fastImage analysisCharacter and pattern recognitionInertial measurement unitComputer device

The invention provides a robot positioning and mapping method, a computer device and a computer readable storage medium. The method comprises the following steps of pre-integrating information acquired by an inertial measurement unit by utilizing information acquired by a camera device and information acquired by the inertial measurement unit; using the front end module to carry out motion tracking by utilizing pre-integrated relative pose information, and judge whether a visual tracking loss condition occurs or not, if the visual tracking loss condition does not occur, carrying out the visualand inertial measurement fusion operation, and updating the state information of an inertial measurement unit; and when a new key frame is generated, using the rear end module to acquire the pose information of the key frame acquired by the front end module and the corresponding relation information of the feature points, create and optimize a factor graph, and update a rear end map by using theacquired pose information and the depth information of the 3D points. The invention also provides a computer device for realizing the method and a computer readable storage medium. According to the invention, the positioning and mapping of the robot can be realized efficiently and accurately.

Owner:西安全志科技有限公司

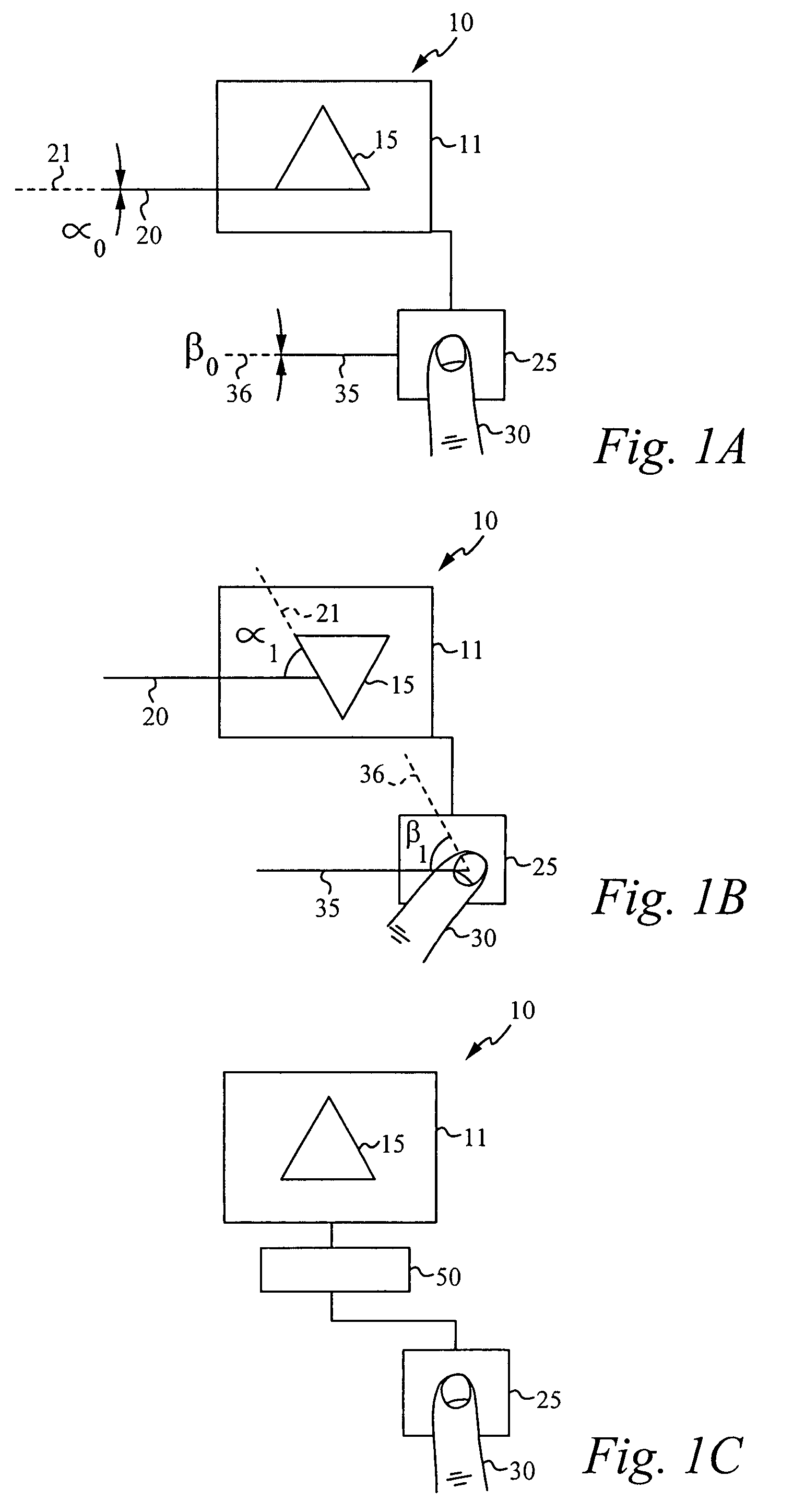

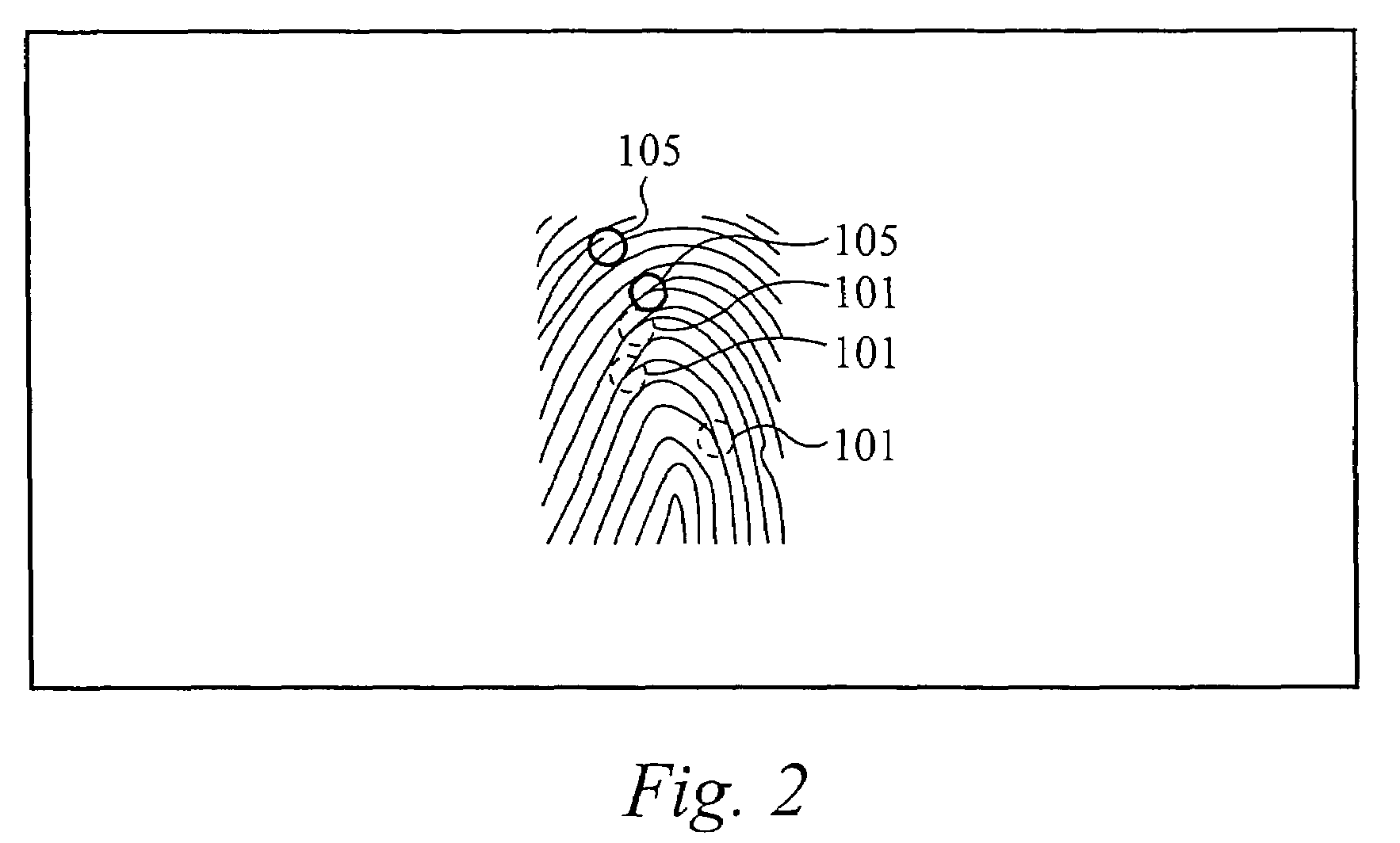

System for and method of generating rotational inputs

ActiveUS7587072B2Easy to useSmall footprintCharacter and pattern recognitionCathode-ray tube indicatorsSteering wheelJoystick

A system for and method of obtaining rotation information is disclosed. The method comprises capturing a plurality of patterned images from a plurality of locations, correlating the plurality of patterned images to generate sets of linear differences, and using the sets of linear differences to generate the rotation information. Preferably, the plurality of locations comprise a first part of a fingerprint swipe sensor and a second part of the fingerprint swipe sensor, each part configured to capture a part of a fingerprint image. Each part captures a part of the fingerprint image at two positions and correlates the parts at the two positions to determine one set of linear differences. Together, the sets of linear differences are used to calculate the rotation information, which can be used to emulate a rotational device such as a steering wheel, a joystick, or a navigation bar.

Owner:APPLE INC

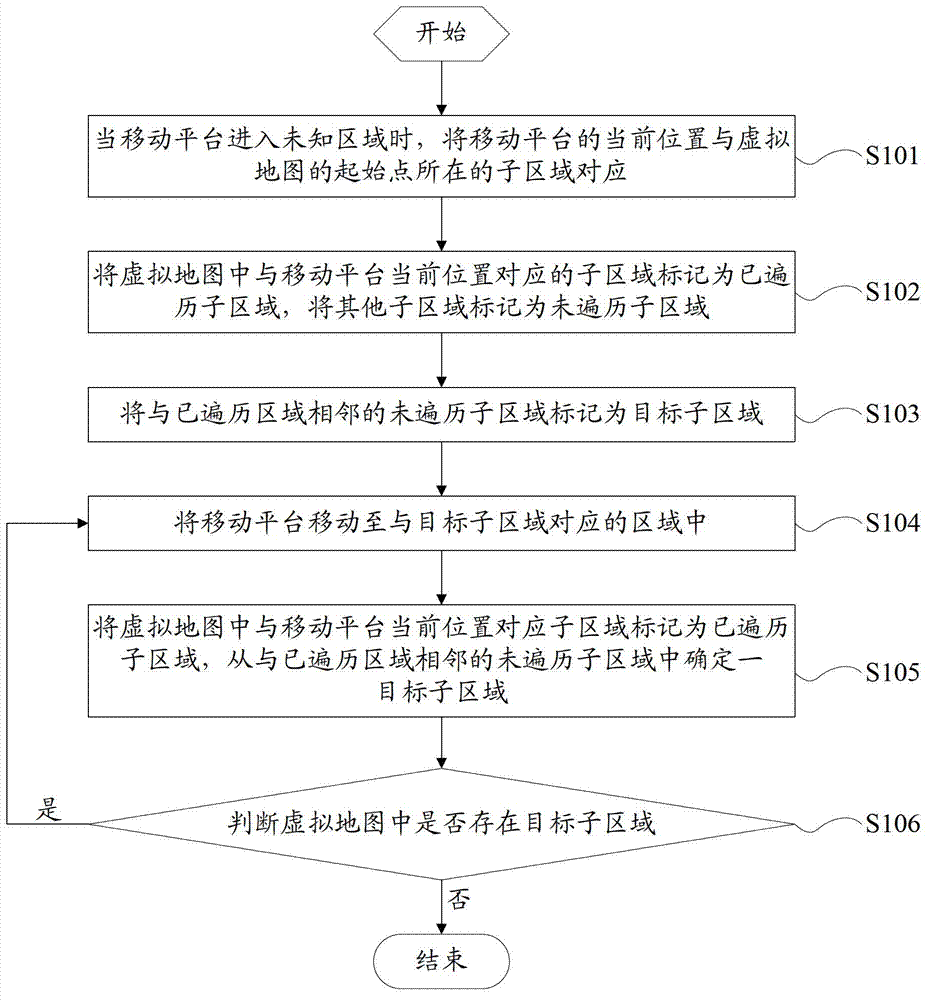

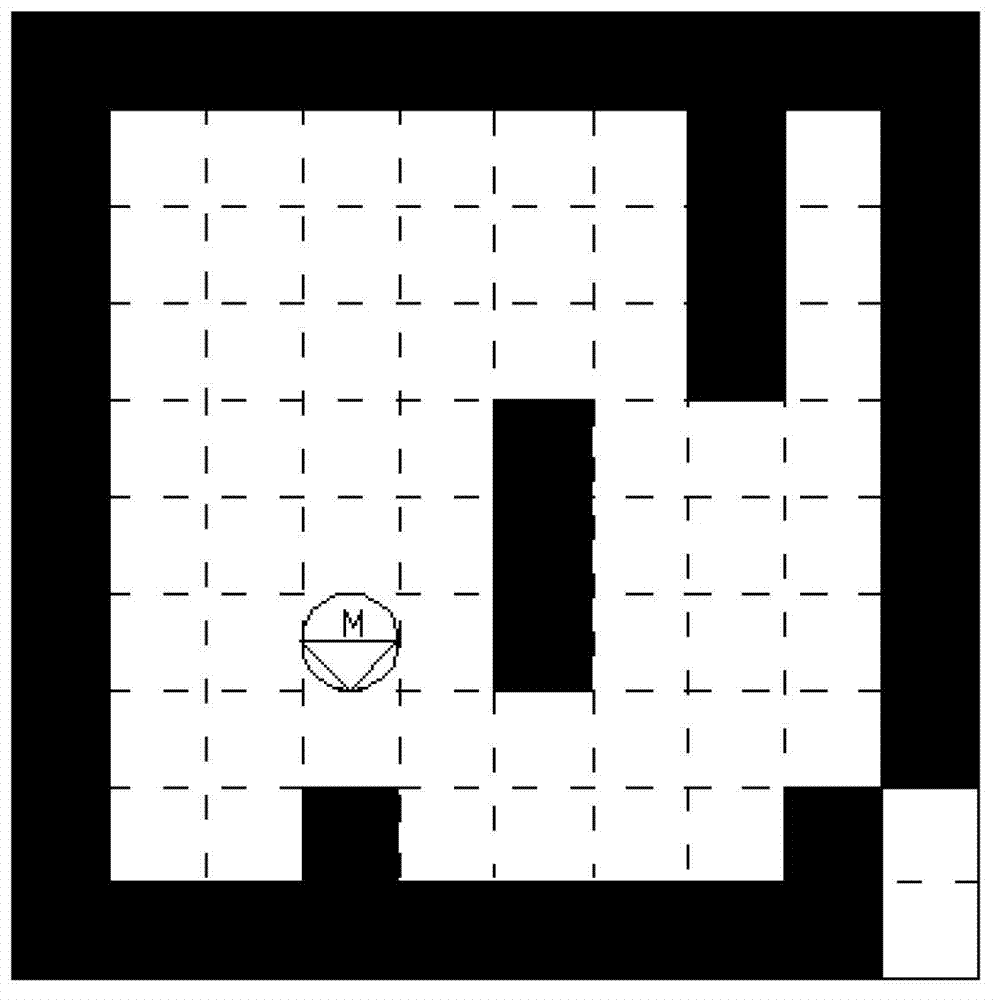

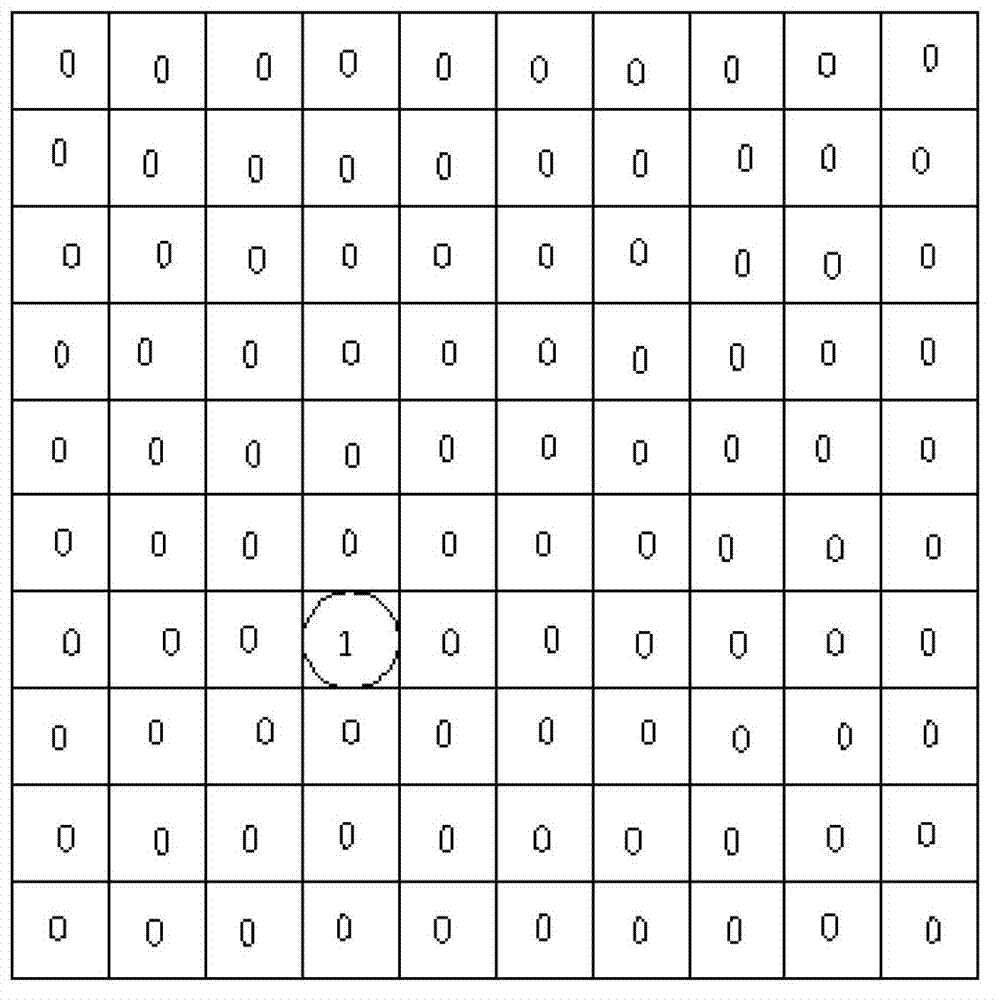

Covering method of map self-established by mobile platform in unknown region

InactiveCN102968122AReduce Duplicate CoverageSimple algorithmInstruments for road network navigationFloor sweeping machinesComputer science

Owner:SHENZHEN SILVER STAR INTELLIGENT TECH CO LTD

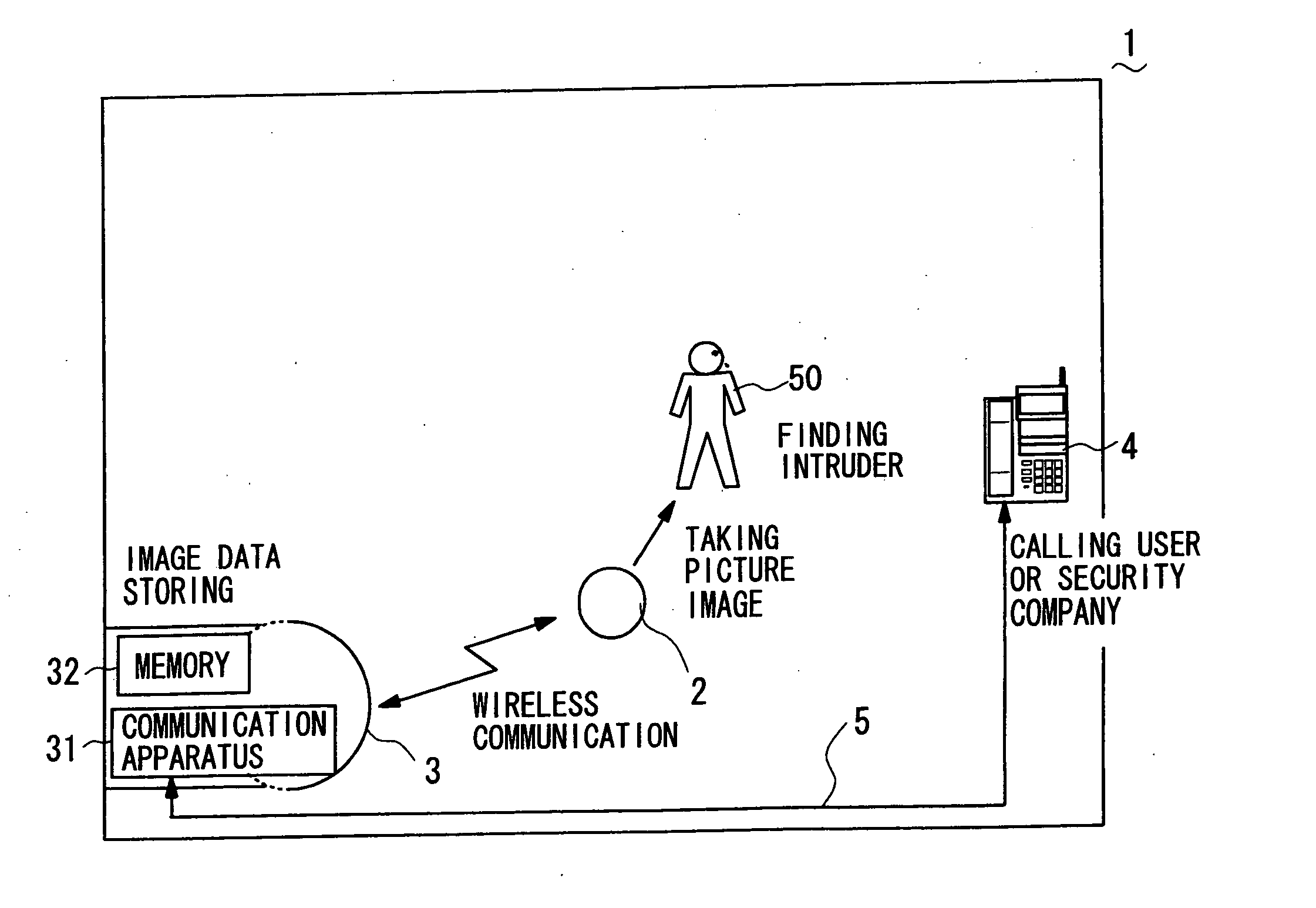

Self-directed dust cleaner

InactiveUS20050120505A1Low costReduce power consumptionAutomatic obstacle detectionTravelling automatic controlWireless lanMobile device

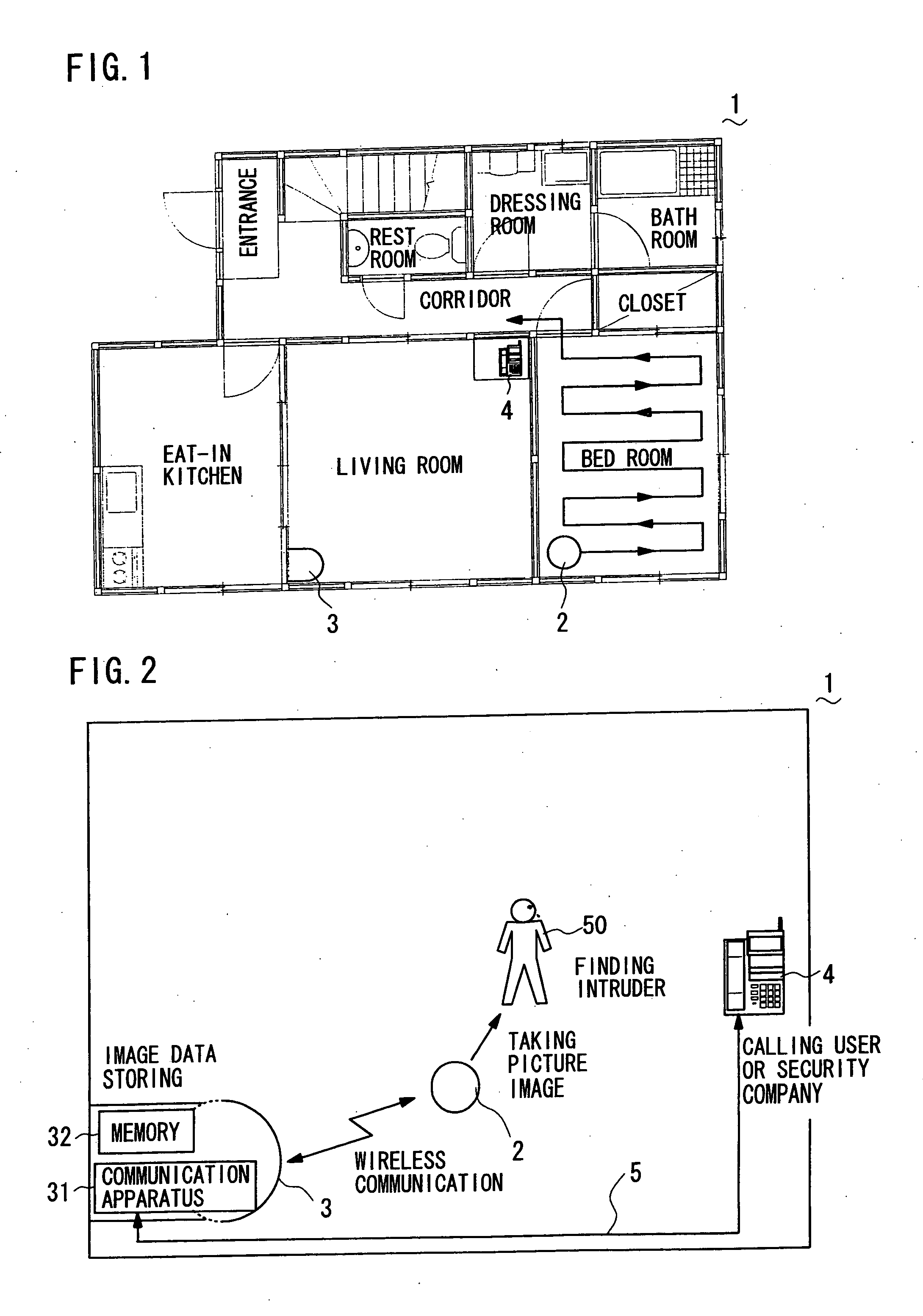

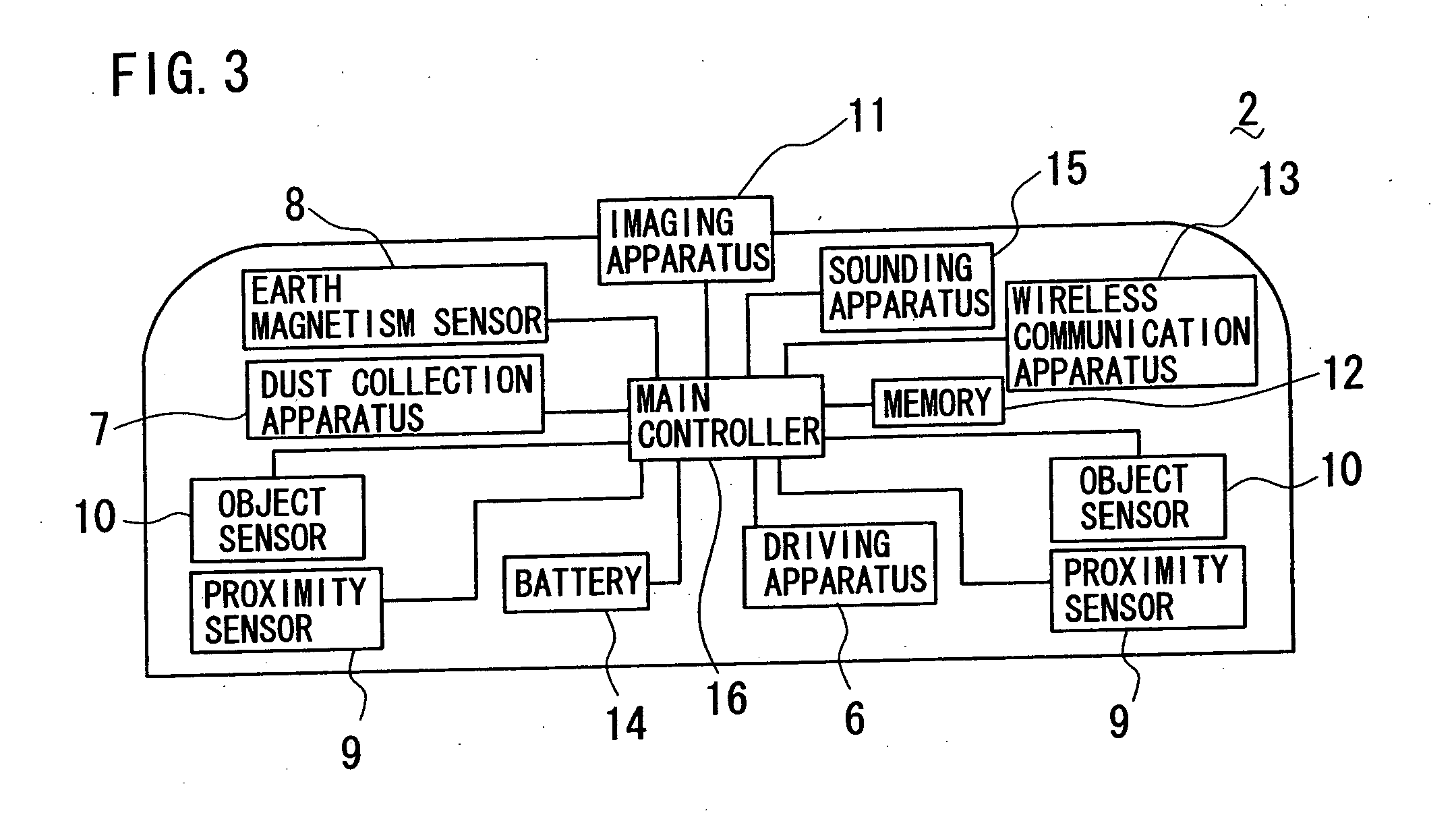

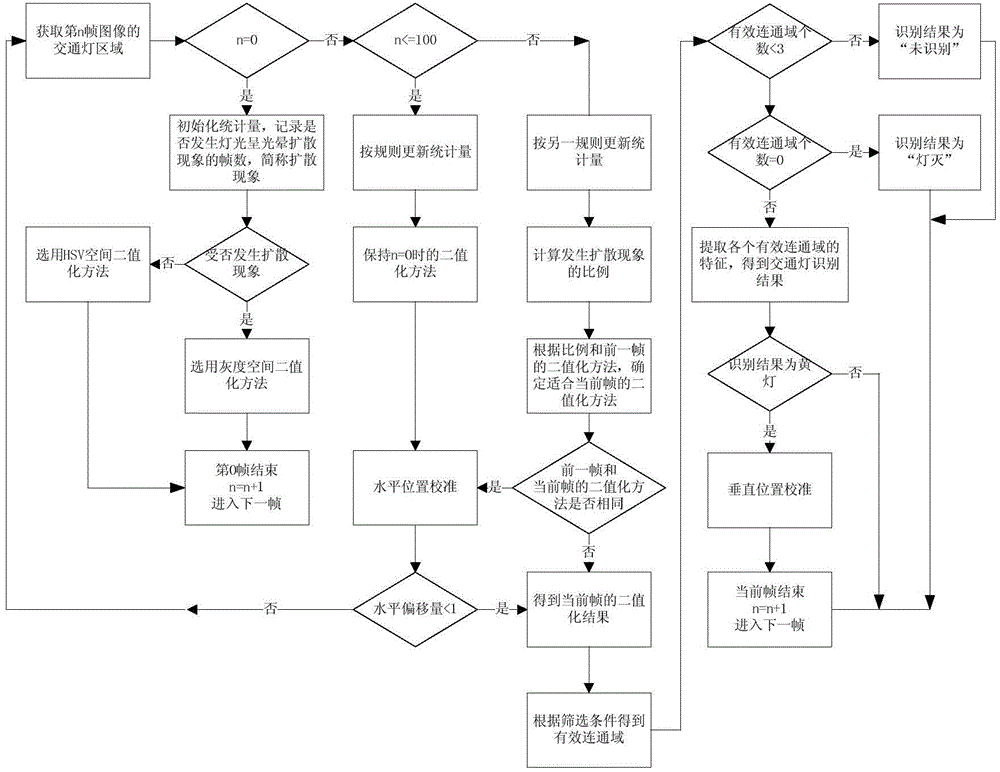

In a self-directed dust cleaner with surveiling function, when an object sensor senses existence of an object supposed as an intruder, a main controller controls that a driving apparatus to rotate a movable body to orient a lens of an imaging apparatus to the object. The imaging apparatus takes a picture image including the object, and an image data outputted from the imaging apparatus is transmitted to a telephone communication apparatus via a wireless LAN and a LAN cable. The telephone communication apparatus calls a mobile equipment of a user so as to transmit the image data taken by the imaging apparatus. Judgment whether unusual situation such as an intruder has occurred or not is entrusted to the user, so that an algorithm executed in the main controller becomes simple.

Owner:FUNAI ELECTRIC CO LTD

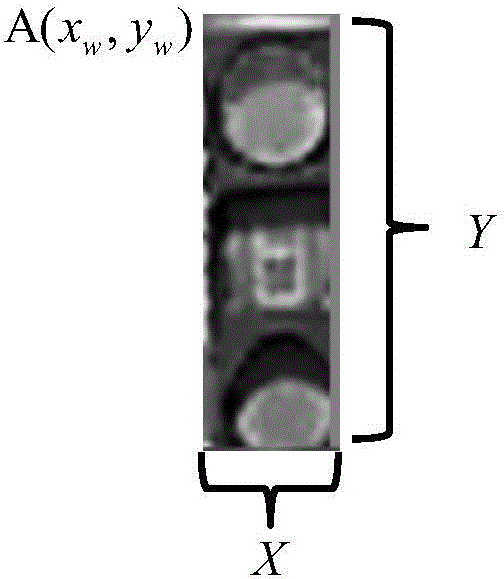

Traffic light recognition method

ActiveCN104574960ASimple adaptationAccurate identificationDetection of traffic movementCharacter and pattern recognitionColor spaceBrightness perception

The invention discloses a traffic light recognition method. The method comprises steps as follows: performing binarization on the brightness component of the HSV color space of a traffic light target area in advance, acquiring a binarization result and extracting connected domains representing a traffic light bright area from the result through switching between an RGB space gray binarization method and an HSV color space binarization method on the basis of the area characteristic of the maximum connected domain, meanwhile, calibrating horizontal coordinates of a traffic light target by using difference between bright components of traffic light images in front and back frames, then designing a classifier, acquiring a classification recognition result of the traffic light target according to the number, colors and position characteristics of the extracted connected domains, and finally, when the traffic light is a yellow light, calibrating the vertical position of the traffic light target by using the vertical coordinate of the yellow light. The method has the advantages that the method is simple to implement, high in recognition accuracy, high in adaptability to different crossroad environments and low in computational complexity, fewer resources are occupied, and positions of the traffic lights can be calibrated.

Owner:宁波中国科学院信息技术应用研究院

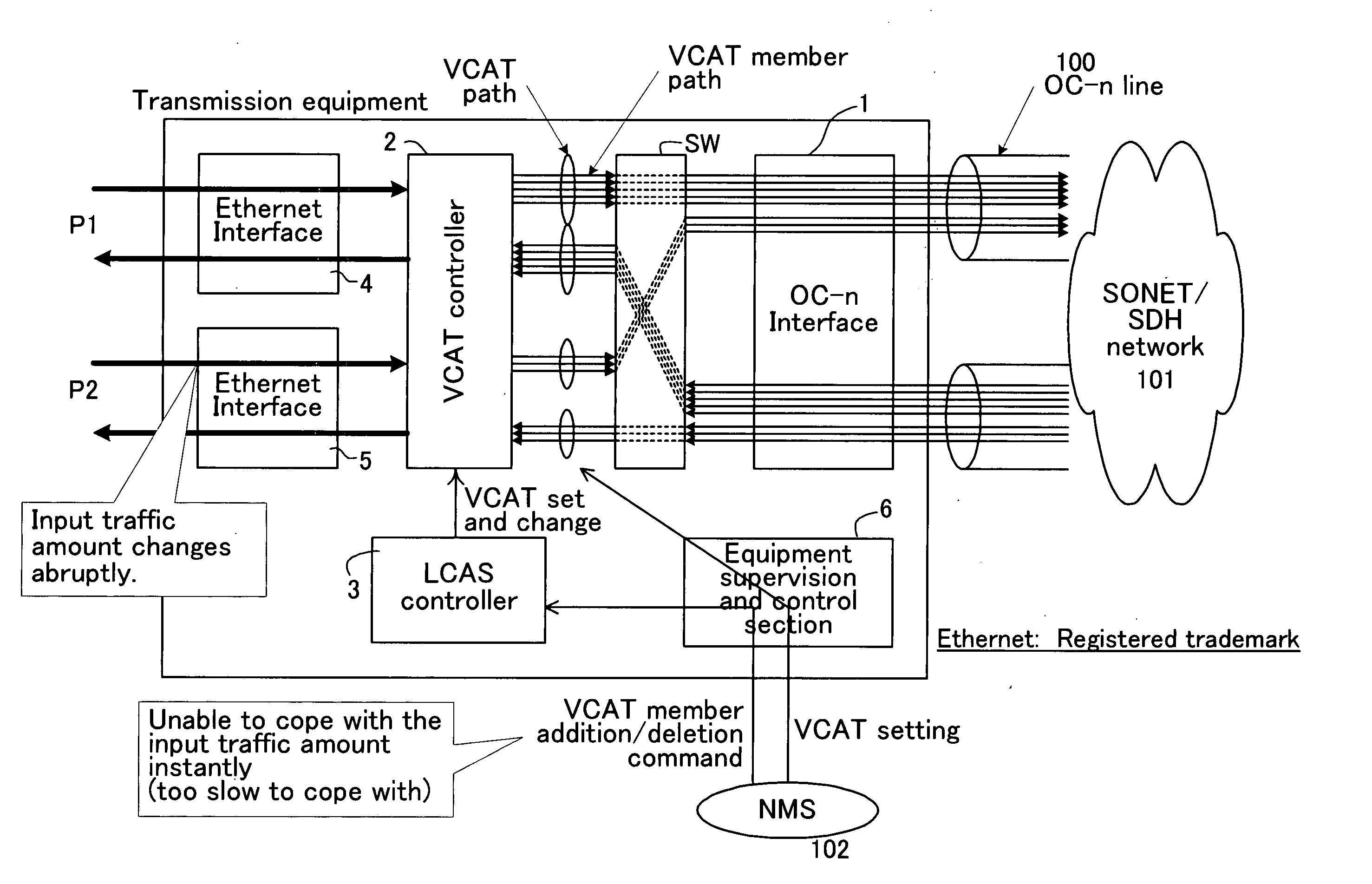

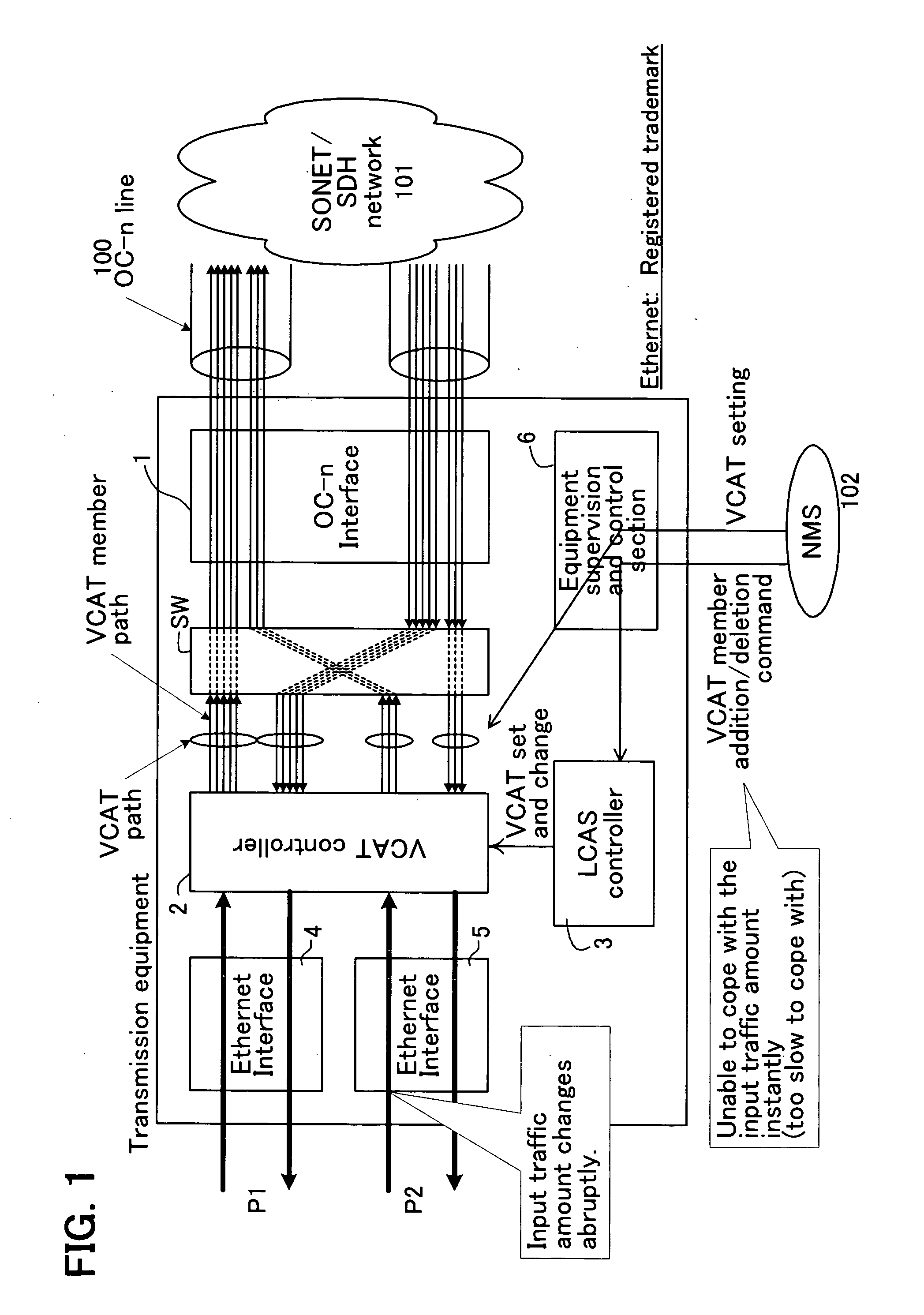

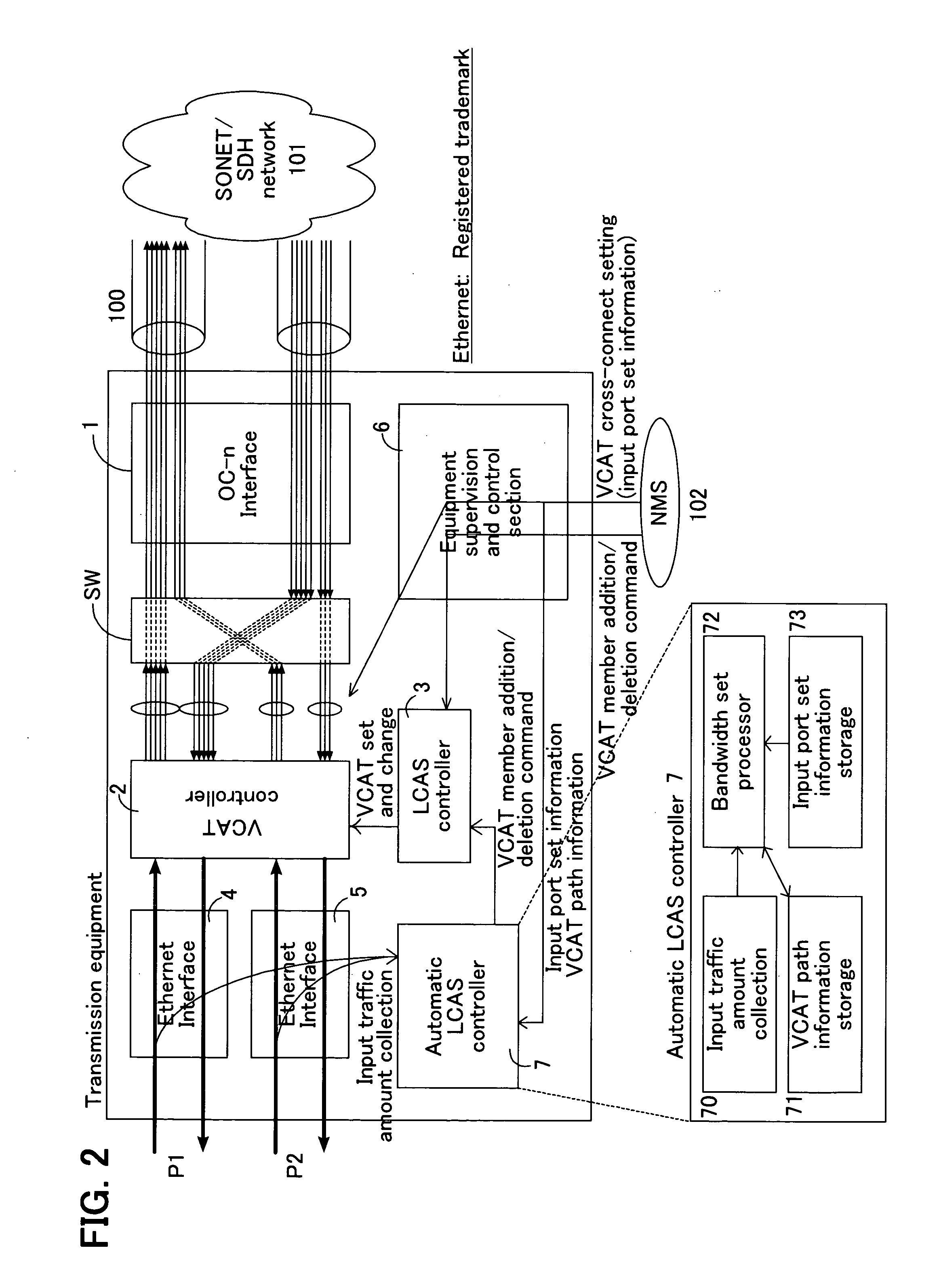

Automatic change method of virtual concatenation bandwidth

InactiveUS20050135435A1Simple algorithmPossible changeTime-division multiplexData switching by path configurationTraffic volumeTraffic capacity

Equipment enables an improved efficiency in network bandwidth usage, and an improved upper-layer throughput even when abrupt change occurs in input traffic. The equipment includes an input traffic collector which collects and retains an input traffic amount of each input port for one period at preset periods; a bandwidth set processor which calculates a bandwidth for use in each input port from the input traffic amount retained in the input traffic collector, and calculates the corresponding number of virtual concatenation member paths from the difference of the bandwidth in use and a virtual concatenation path bandwidth having been allocated to the input port, and issues an addition command or a deletion command for adding or deleting the virtual concatenation member paths for the calculated number; a virtual concatenation controller which sets a virtual concatenation path bandwidth against the traffic input from the plurality of ports; and a link capacity adjustment scheme controller which sets and changes the virtual concatenation to the virtual concatenation controller, based on the addition command or the deletion command of the virtual concatenation member paths issued by the bandwidth set processor.

Owner:FUJITSU LTD

Method for measuring diameter of non-contact forging on line by using laser

InactiveCN102003943AImprove machining accuracyReduce lossUsing optical meansContact highLaser transmitter

The invention discloses a method for measuring the diameter of a non-contact forging on line by using laser. A pair of parallel linear guide rails arranged at equal altitude on the two sides of the forging is used in the method. The method is characterized in that: a laser transmitter is arranged on one guide rail, a laser receiver is arranged on the other guide rail, the laser transmitter and the laser receiver are driven to travel by two stepper motors respectively, the positions of the laser transmitter and the laser receiver are kept synchronous during the travel, the distance between the tangent point of the laser and the section circle of the forging can be computed quickly through the travel distance of the stepper motors and the connection and interruption of signals of the laser receiver, so that the diameter size of the forging can be obtained. The method has the advantages that: two mutually independent linear guide rails are adopted, so that the diameter of the forging such as a spindle of a windmill generator and metallurgic rollers in a wider range can be measured by selecting a proper guide rail length; measuring staff are not required to contact high-temperature environment, and manual measurement is avoided, so that the diameter of the current forging can be obtained quickly, precision is high, the shortcomings of long time and large error of the manual operation are overcome, and forging speed and forging precision are improved; the shortcoming of reserving relatively large cold processing allowance according to experience is effectively overcome, the allowance consumption of the forging is reduced, and the energy conservation and consumption reduction are realized.

Owner:魏青轩

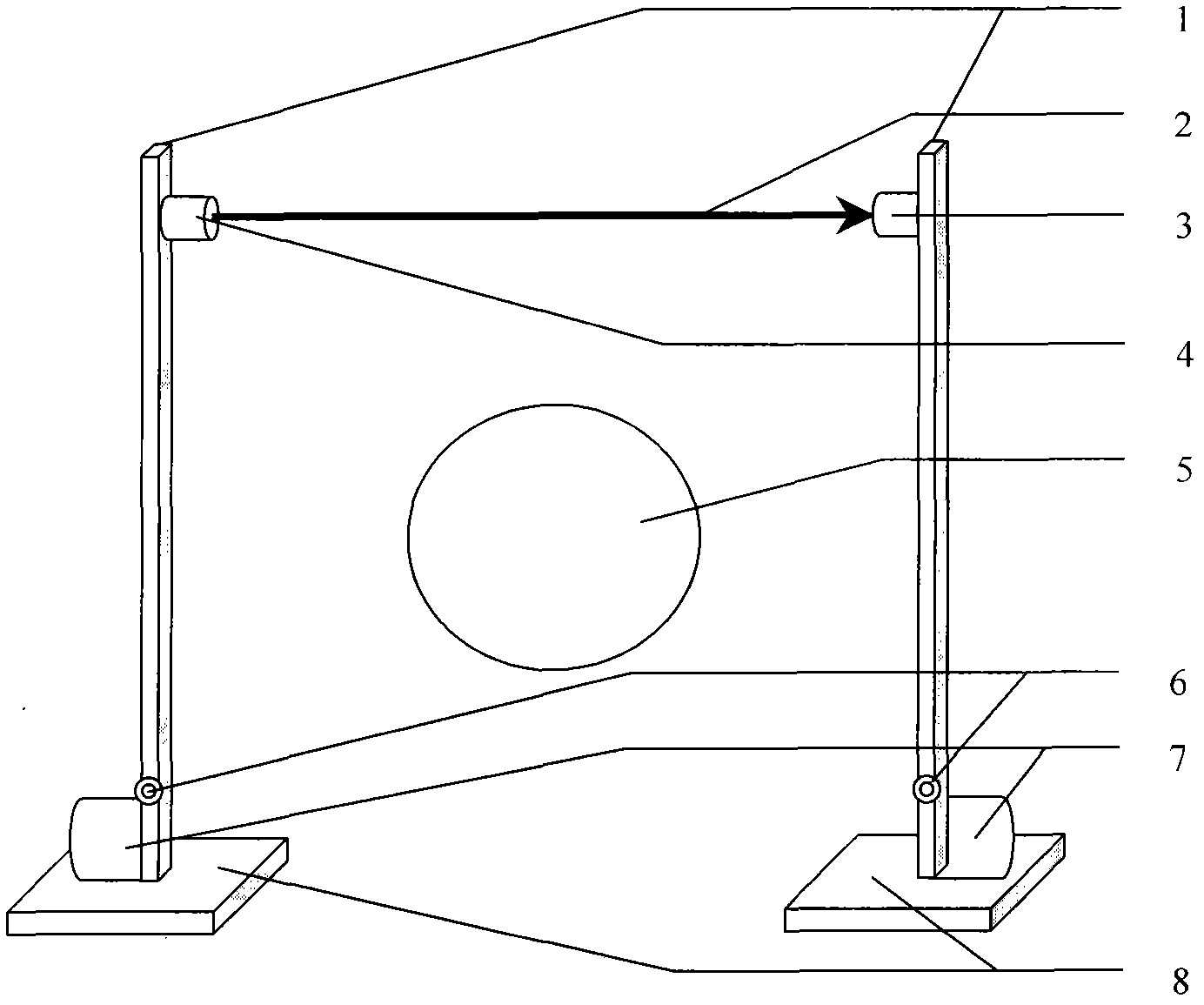

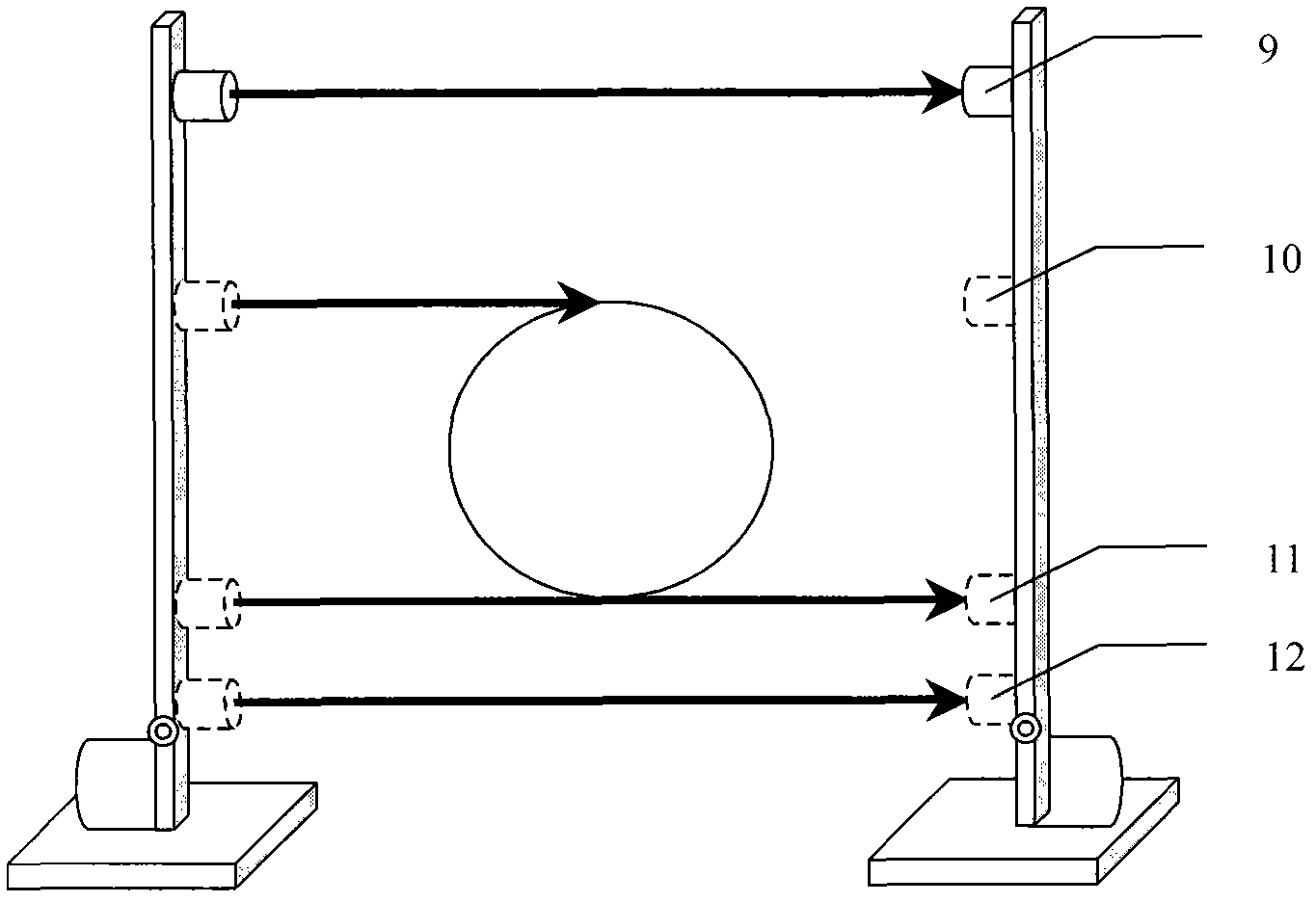

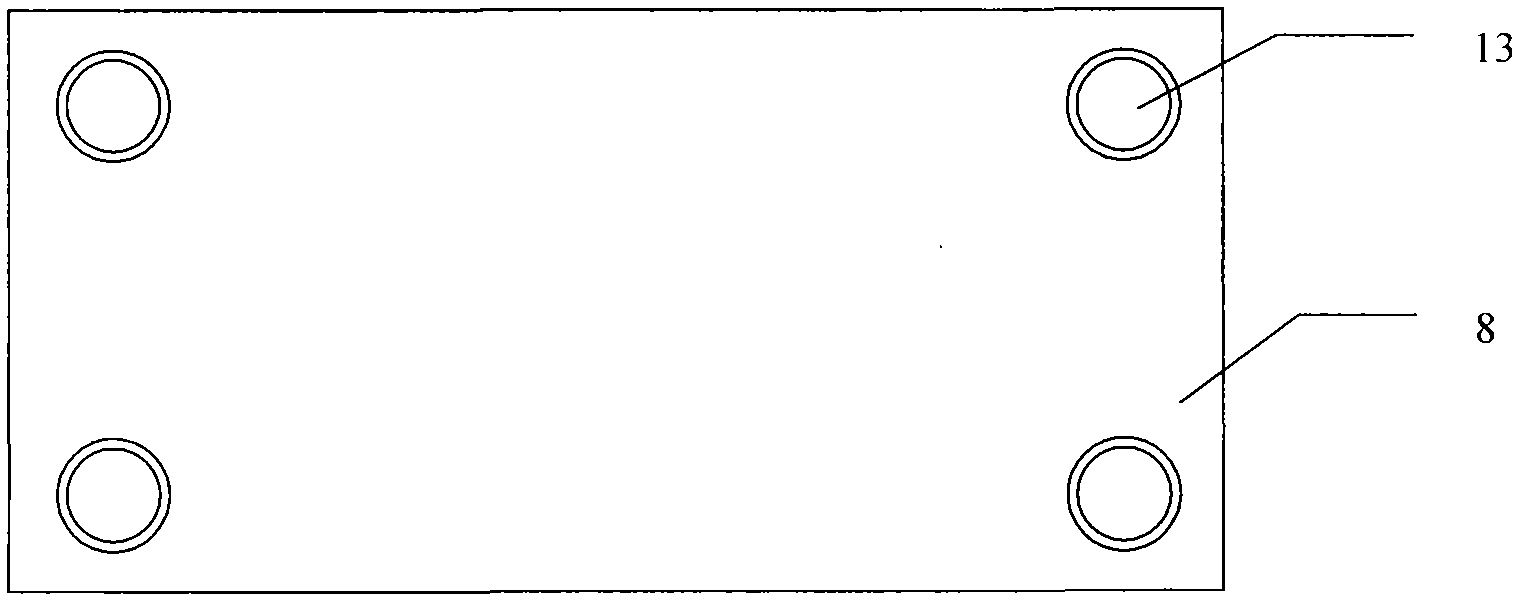

Calibration device based on rotary type two-dimensional laser three-dimensional reconstruction system

InactiveCN104656097AEasy to manufactureImprove the accuracy of 3D reconstructionElectromagnetic wave reradiationRadarComputer module

The invention provides a calibration device based on a rotary type two-dimensional laser three-dimensional reconstruction system. The calibration device comprises a data acquisition module, an acquisition assistant module, a data transmission module and a data analysis and processing module, wherein the data acquisition module comprises a two-dimensional laser radar and a calibration module, and the calibration module consists of three mutually vertical non-transparent square planes; the acquisition assistant module comprises a support frame and a rotating cradle head arranged on the support frame, the two-dimensional laser radar is arranged on the rotating cradle head, and the rotating cradle head is controlled by the data analysis and processing module. The calibration device can effectively carry out once data acquisition, and the complex degree of calibration is reduced; moreover, a two-dimensional laser coordinate system is quickly and accurately fused with a word coordinate system, and the calibrated result is applied to large-scale scene three-dimensional reconstruction.

Owner:WUHAN UNIV OF TECH

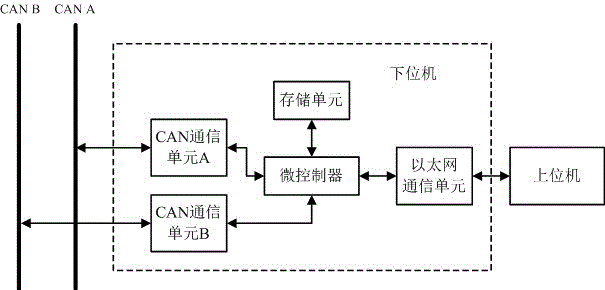

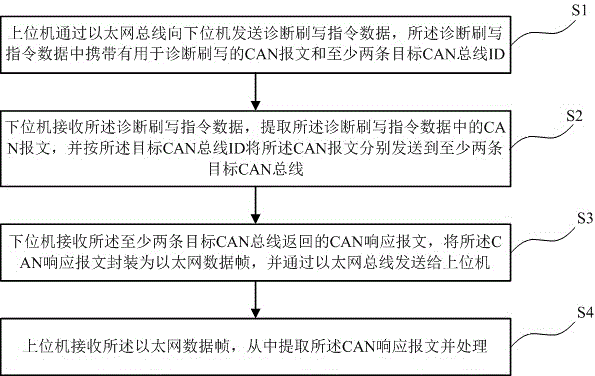

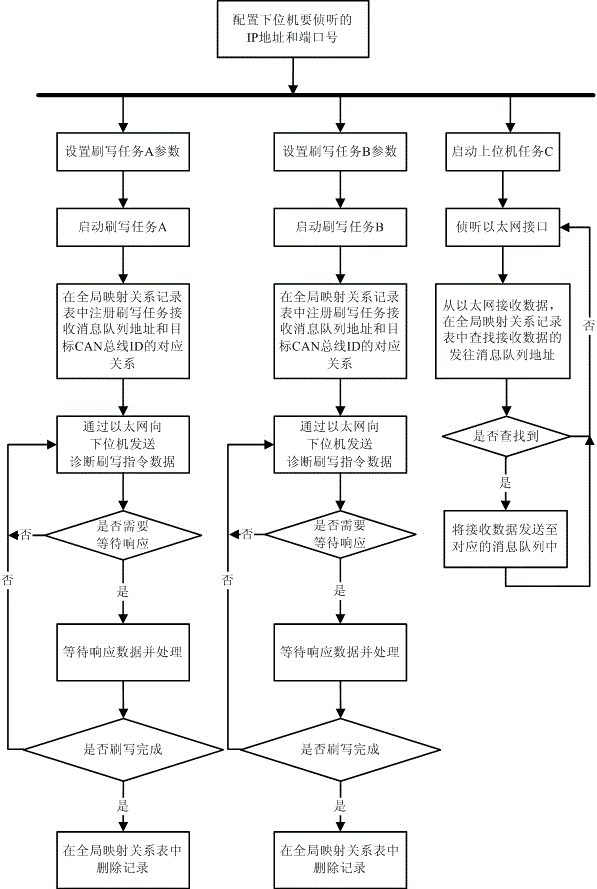

Method and system for diagnosing and flashing electronic control unit of vehicle

ActiveCN106375175AImprove offline production efficiencyIncrease productivityBus networksUser Datagram ProtocolEthernet

The invention provides a method and a system for diagnosing and flashing the electronic control unit of a vehicle. The method comprises the following steps: an upper computer sends diagnosing and flashing instruction data to a lower computer via an Ethernet bus, wherein the diagnosing and flashing instruction data carries a CAN message for diagnosing and flashing and at least two target CAN bus IDs; the lower computer receives the diagnosing and flashing instruction data, extracts a CAN message in the data, and sends the CAN message to at least two target CAN buses according to the target CAN bus IDs; the lower computer receives a returned CAN response message, packages the CAN response message into an Ethernet data frame, and sends the Ethernet data frame to the upper computer via the Ethernet bus; the upper computer receives the Ethernet data frame, extracts the CAN response message from the Ethernet data frame, and processes the CAN response message; and the upper computer and the lower computer communicate via a user datagram protocol UDP. The electronic control units on multiple CAN buses can be flushed at the same time, and thus, the production efficiency is improved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

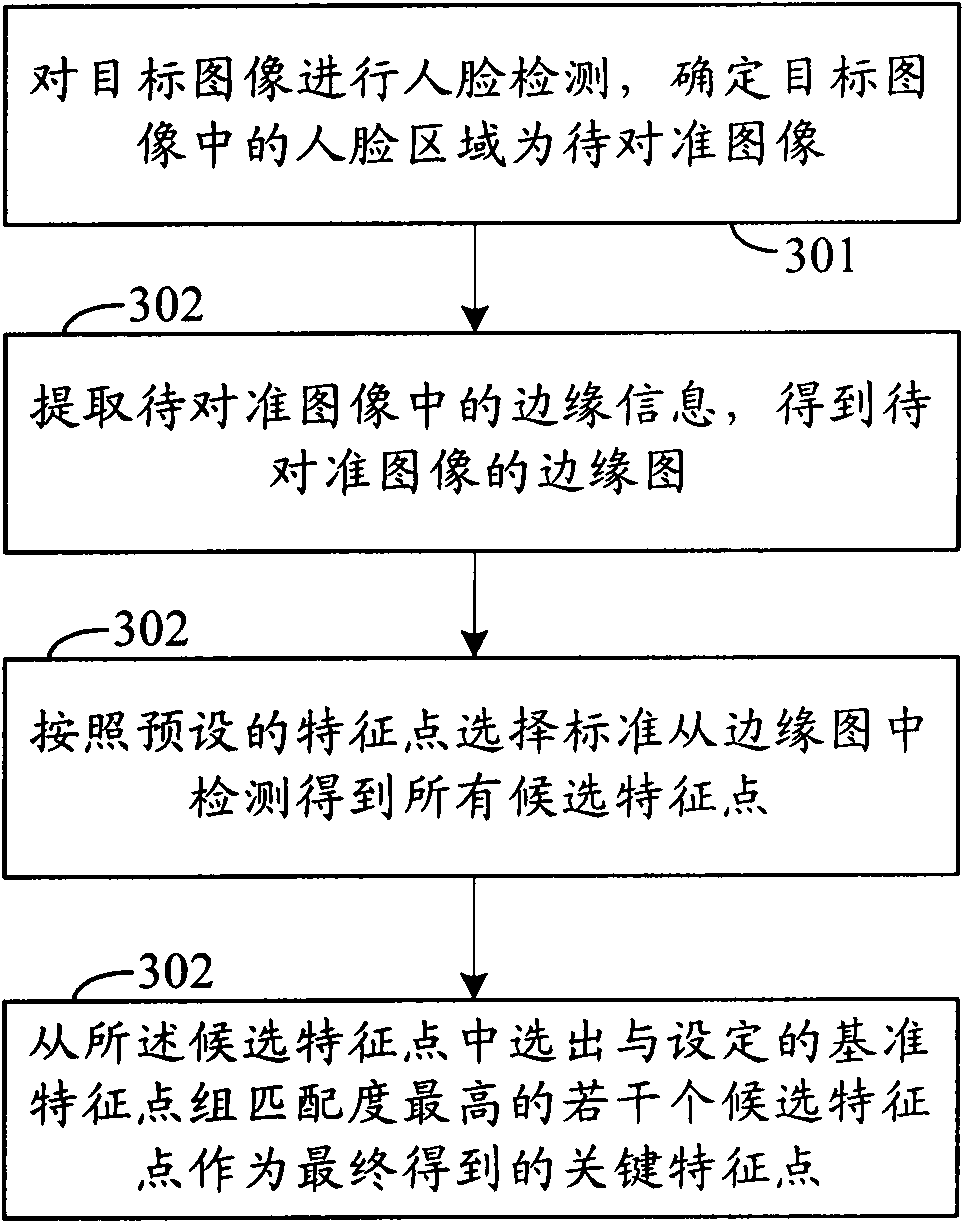

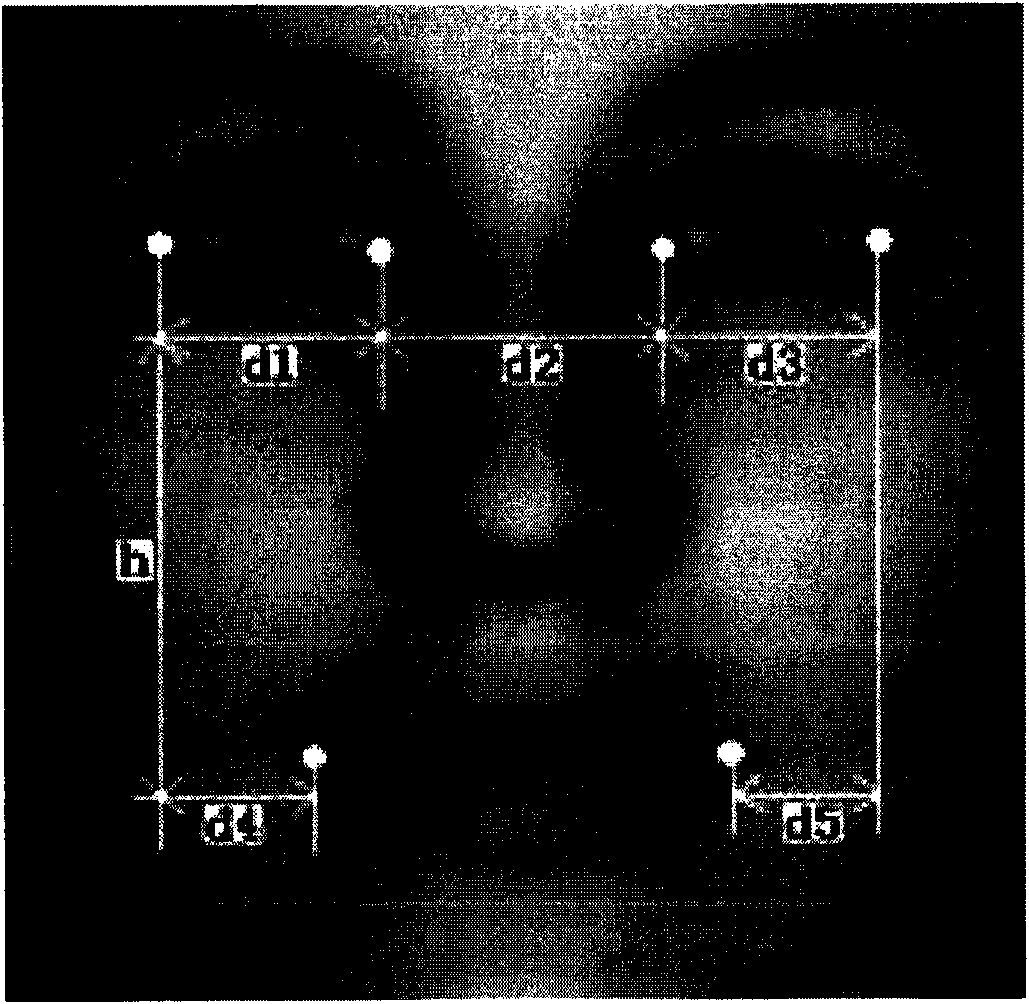

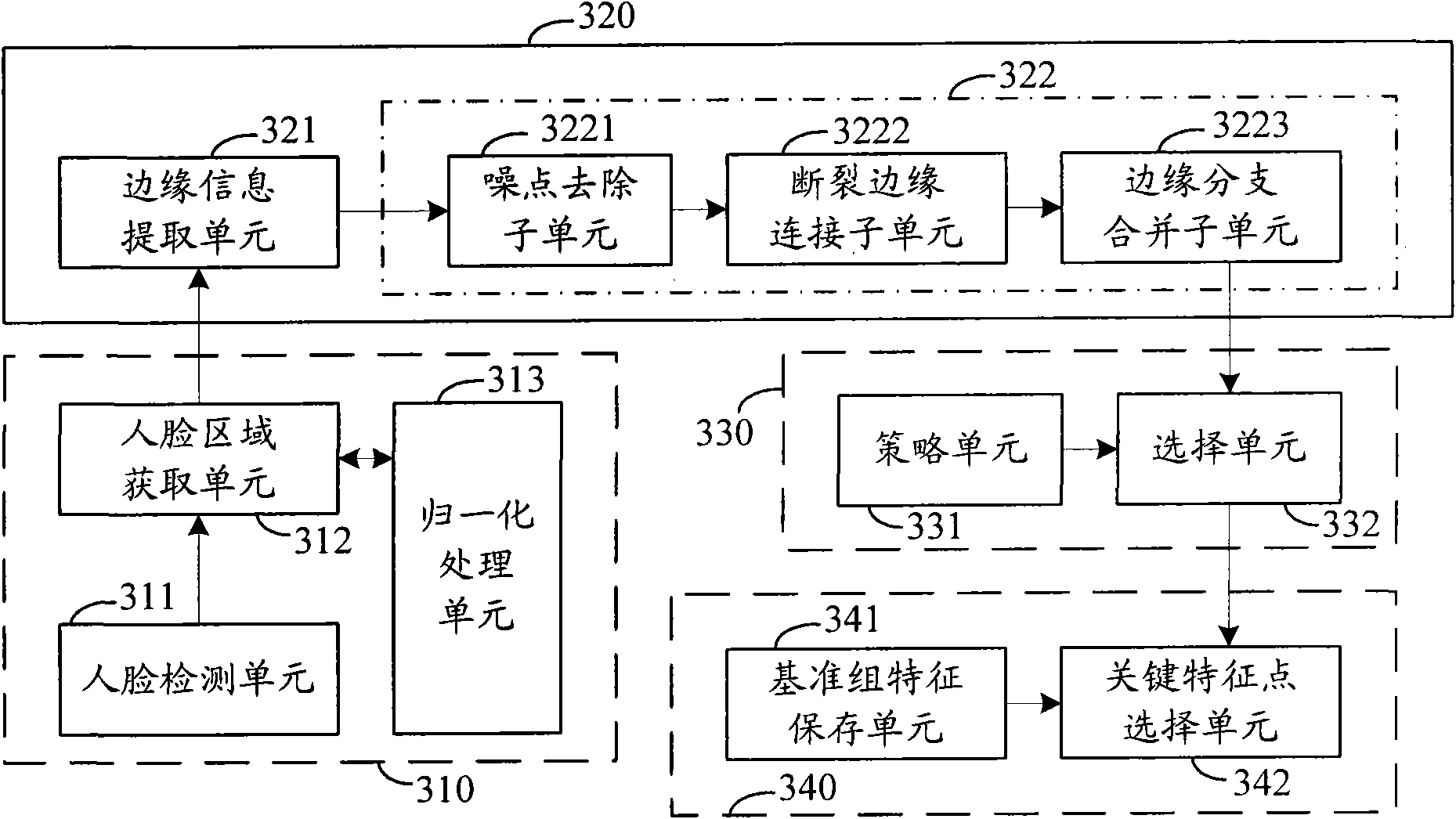

Method and device for positioning key feature point

InactiveCN101877055ARapid positioningAchieve accurate positioningCharacter and pattern recognitionPattern recognitionComputer vision

The invention discloses a method for positioning a key feature point, which comprises the following steps: detecting a face in a target image and determining the face area in the target image as an image to be aligned; extracting the edge information in the image to be aligned to obtain an edge graph of the image to be aligned; detecting all candidate feature points from the edge graph according to a pre-set feature point selecting standard; and selecting a plurality of candidate feature points with the highest match degree with a set reference feature point from the candidate feature points to serve as the finally obtained key feature points. The invention further discloses a device for positioning the key feature point, which comprises an image to be aligned determining module, an edge graph acquiring module, a candidate point determining module and a key feature point determining module. The method and device of the embodiment of the invention can accurately position the key feature point in the face area, and the algorithm of the scheme has the advantages of simplicity, small calculation amount and fast implementation.

Owner:VIMICRO CORP

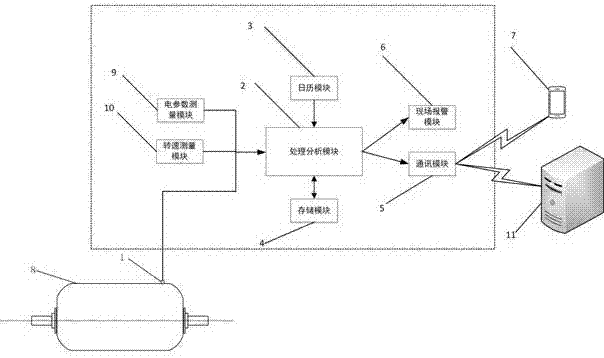

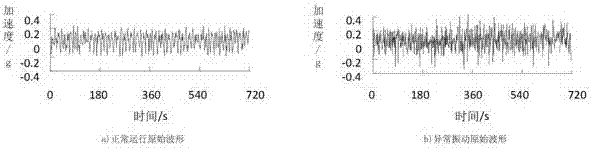

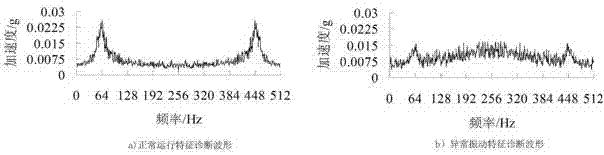

Online monitoring and early warning system for vibration of intelligent motor

PendingCN107064796ASimple algorithmLow hardware requirementsSubsonic/sonic/ultrasonic wave measurementDynamo-electric machine testingElectricityChanging trend

The invention relates to an online monitoring and early warning system for vibration of an intelligent motor, which belongs to the field of intelligent motor monitoring. The system comprises a vibration sensor, a processing and analysis module, a calendar module, a storage module, a communication module, a field alarming module and a portable device. the vibration sensor measures the real-time vibration data of the motor, the data are transmitted to the processing and analysis module, the operation and the working state of the motor are analyzed and judged in combination of data measured by an electric parameter measuring module and a rotation speed measuring module, and in view of abnormal vibration features under different load rates, field alarming or early warning to the portable device is carried out. Besides, early warning is also carried out for the changing trend of the vibration frequency and the changing trend of the amplitude. The system can realize online vibration monitoring and early warning when the motor is abnormal or in an abnormal working state, timely finding and timely processing are carried out, expanding of motor fault can be effectively avoided, the maintenance efficiency is greatly improved, the structure is simple, the cost is low, the measurement is accurate, and the system can be widely applied to intelligent and online vibration monitoring on middle and small-sized motors.

Owner:HARBIN UNIV OF SCI & TECH +2

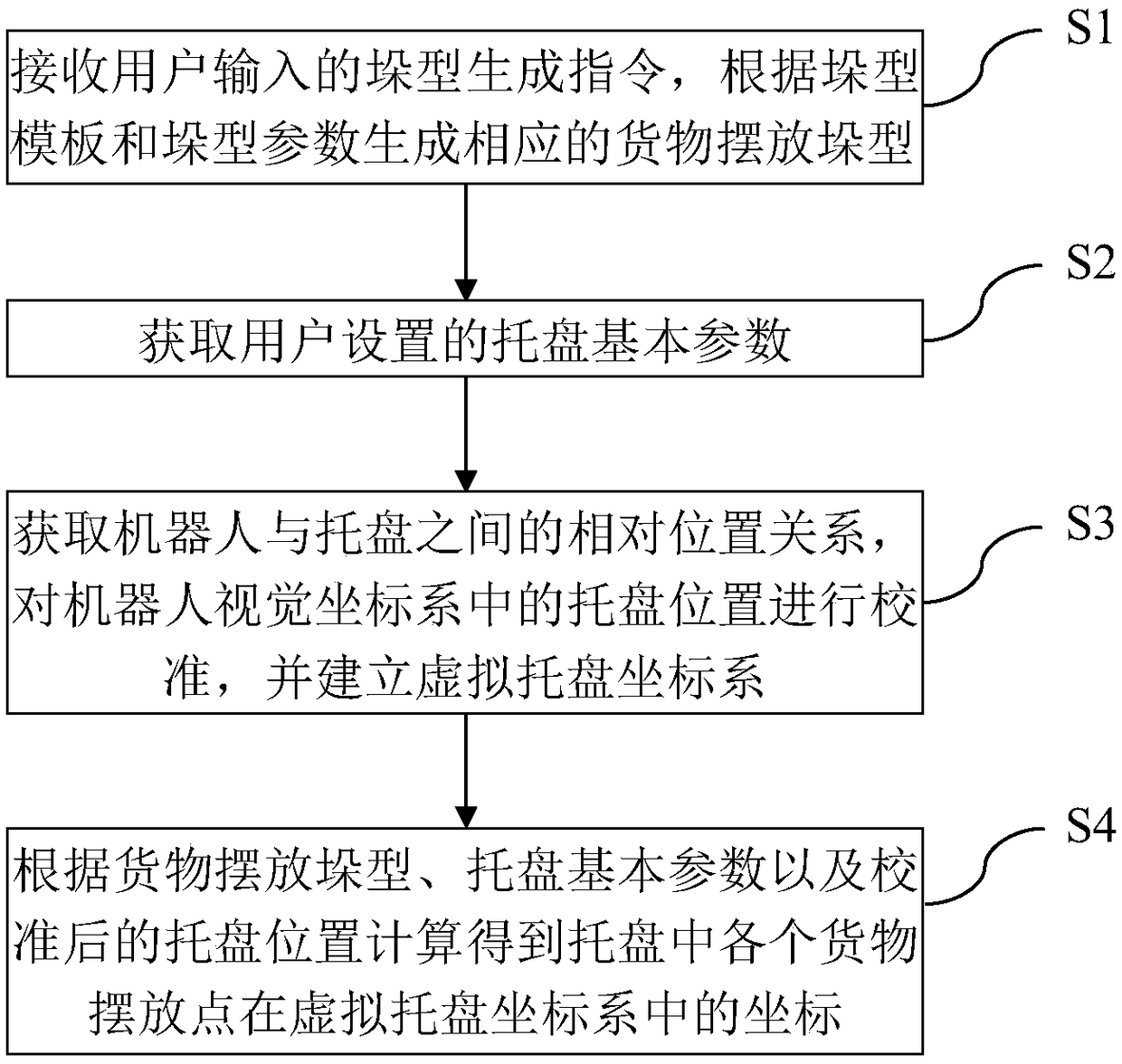

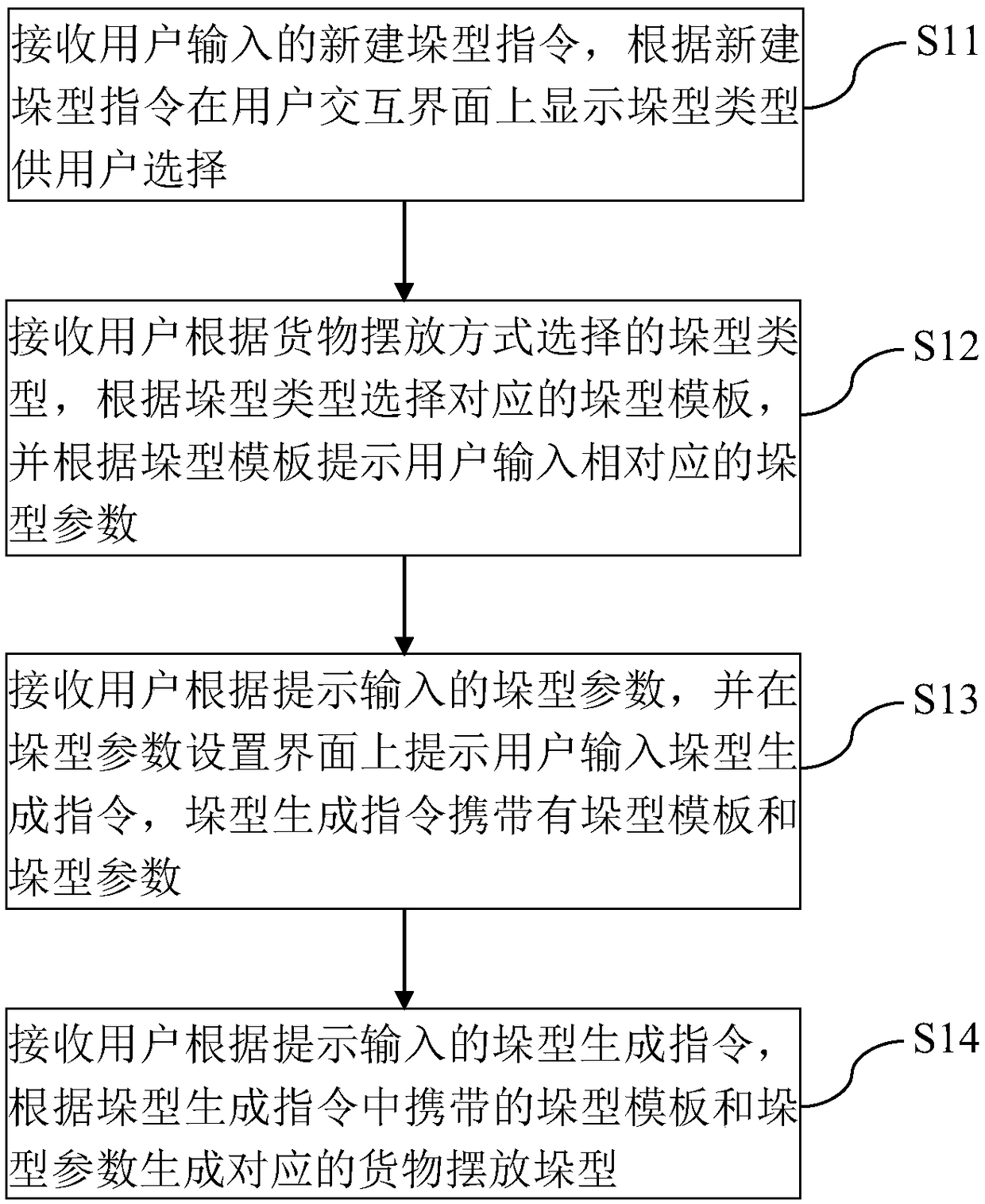

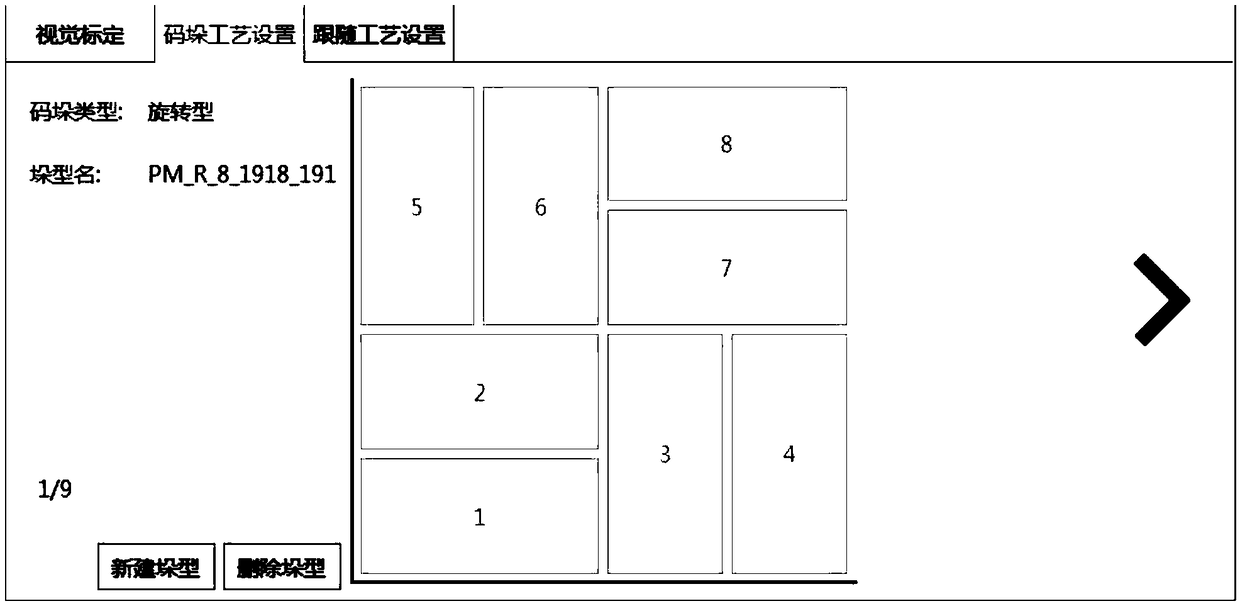

Method and device for generating a robot stacking point location and computer readable memory

ActiveCN109353833AEasy to operateSimple algorithmStacking articlesLogisticsSimulationControl engineering

The invention provides a method and device for generating a robot stacking point location and a computer readable memory. The method includes the steps that a stack type generation instruction input by a user is received, the stack type generation instruction is provided with a stack type template and a stack type parameter, and according to the stack type template and the stack type parameter, acorresponding goods placement stack type is generated; a tray basic parameter set by the user is obtained, the tray basic parameter includes the tray size and the size, the number of layers and the gap of goods to be placed on a tray; the relative position relationship between a robot and the tray is obtained, the tray position in a robot visual coordinate system is calibrated, and a virtual traycoordinate system is established; and according to the goods placement stack type, the tray basic parameter and the calibrated tray position, coordinates of goods placement points in the virtual traycoordinate system are calculated. According to the method and device for generating a robot stacking point location and the computer readable memory, complex placement of the goods can be realized.

Owner:SHENZHEN INOVANCE TECH

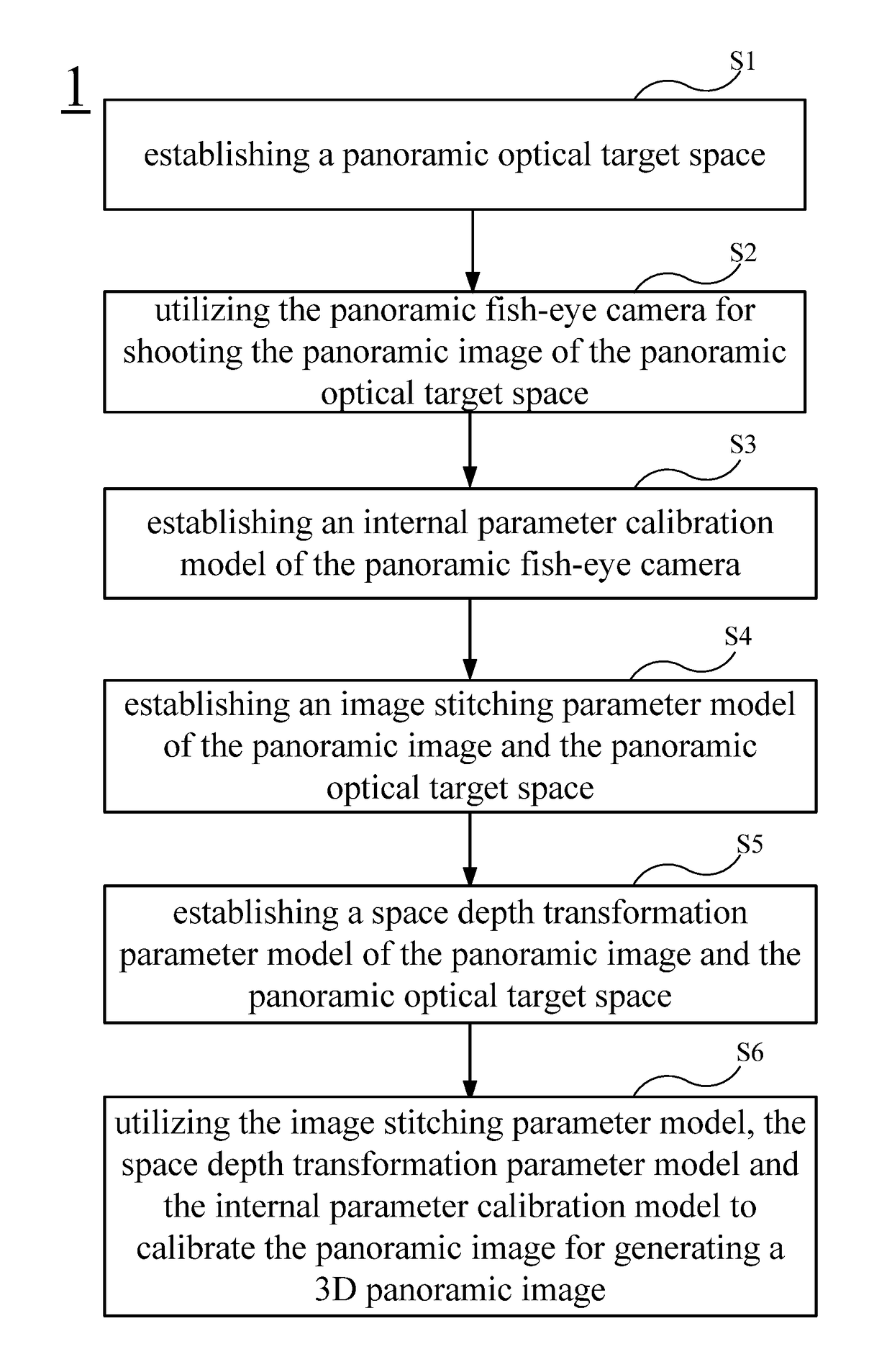

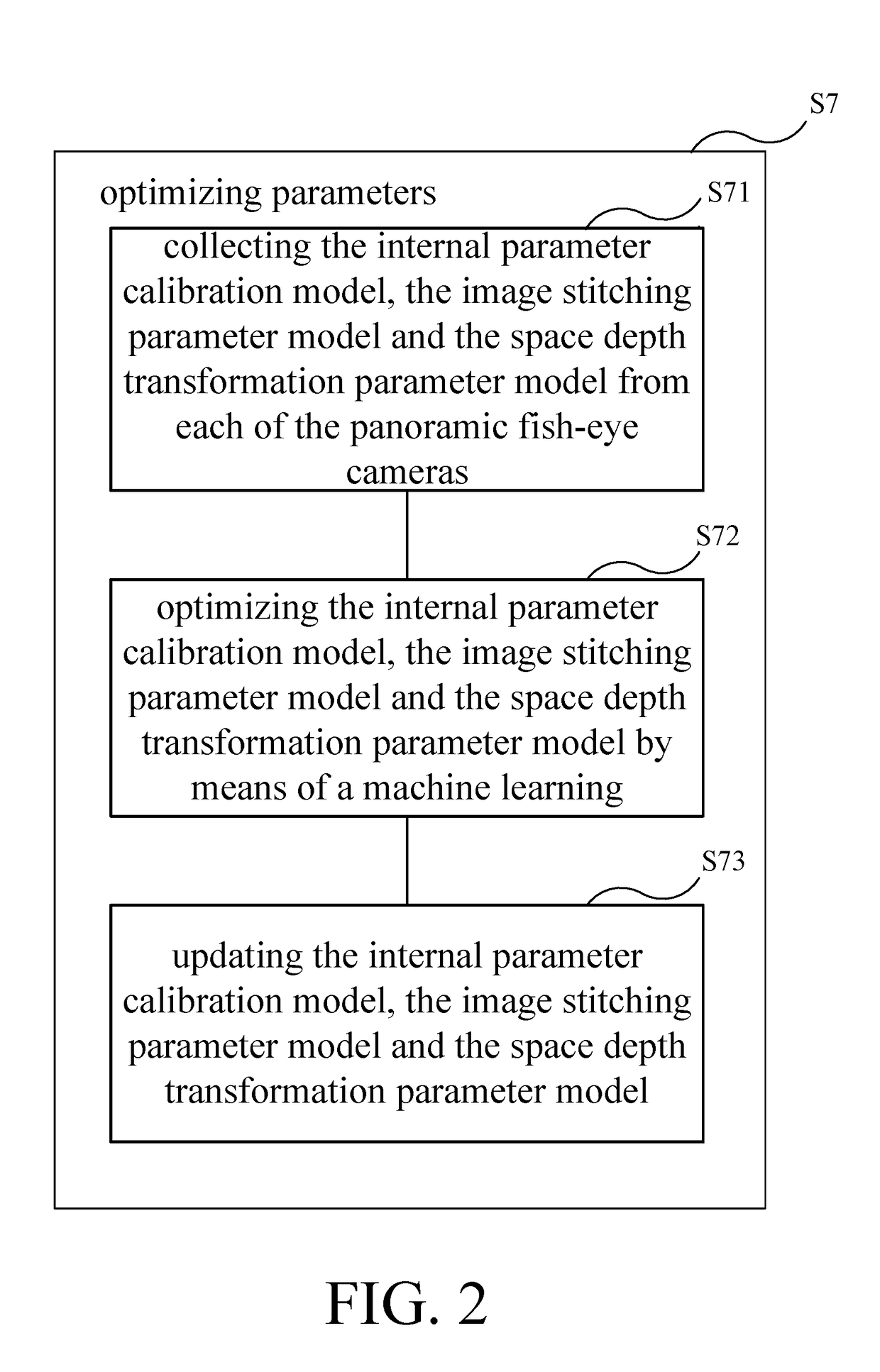

Image calibrating, stitching and depth rebuilding method of a panoramic fish-eye camera and a system thereof

InactiveUS20170127045A1Simple algorithmCalibrated instantly and portable convenientlyImage enhancementTelevision system detailsTransformation parameterComputer science

The present invention provides an image calibrating, stitching and depth rebuilding method of a panoramic fish-eye camera comprising the following steps of: establishing a panoramic optical target space; using the panoramic fish-eye camera for shooting the panoramic optical target space's panoramic image; establishing an internal parameter calibration model for the panoramic fish-eye camera; establishing an image stitching parameter model and a space depth transformation parameter model of the panoramic image and the panoramic optical target space; and using the internal parameter calibration model, the image stitching model and the depth transformation parameter model to calibrate the panoramic image for generating a 3D panoramic image. Compared to the prior art, the present invention can optimize the calibration parameters by accumulating all the camera data and executing a machine learning for increasing the computing efficiency.

Owner:HANGZHOU YUTU TECH CO LTD

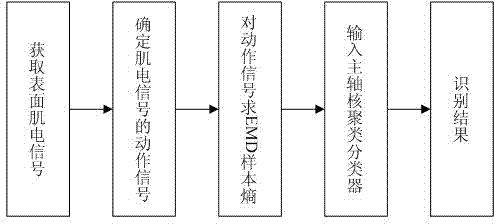

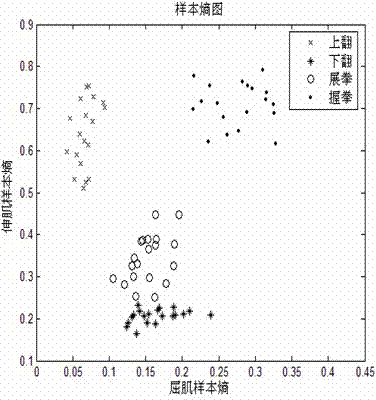

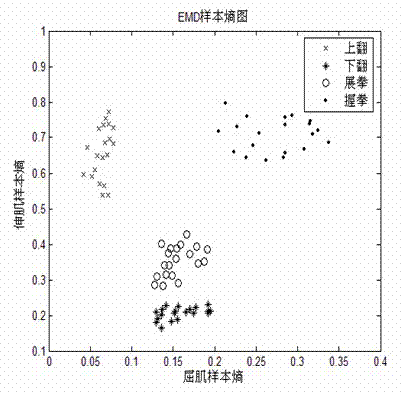

Method for identifying surface electromyography (sEMG) on basis of empirical mode decomposition (EMD) sample entropy

ActiveCN102961203AStrong anti-interference abilitySimple algorithmDiagnostic recording/measuringSensorsMachine learningElectromyography

The invention provides a method for identifying surface electromyography (sEMG) on the basis of empirical mode decomposition (EMD) sample entropy. The method comprises the following steps: acquiring the corresponding sEMG from the related muscle tissue; performing EMD by using an actuating signal of the sEMG determined by energy threshold; adaptively selecting a plurality of intrinsic mode function (IMF) components comprising electromyographic signal effective information according to a frequency availability method; superposing the IMF components to serve as effective electromyographic signals and evaluating the sample entropy; and inputting the sample entropy serving as feature vector into a clustering classifier based on a spindle kernel clustering algorithm to realize identification on an upper limb multi-locomotion mode of the electromyographic signal. The sample entropy can disclose the complexity of the sEMG from a short time sequence, represents the tiny change condition of the electromyographic signal well, has high antijamming capability, simple algorithm and high calculation speed, and is particularly suitable for real-time processing of the electromyographic signal.

Owner:HANGZHOU DIANZI UNIV

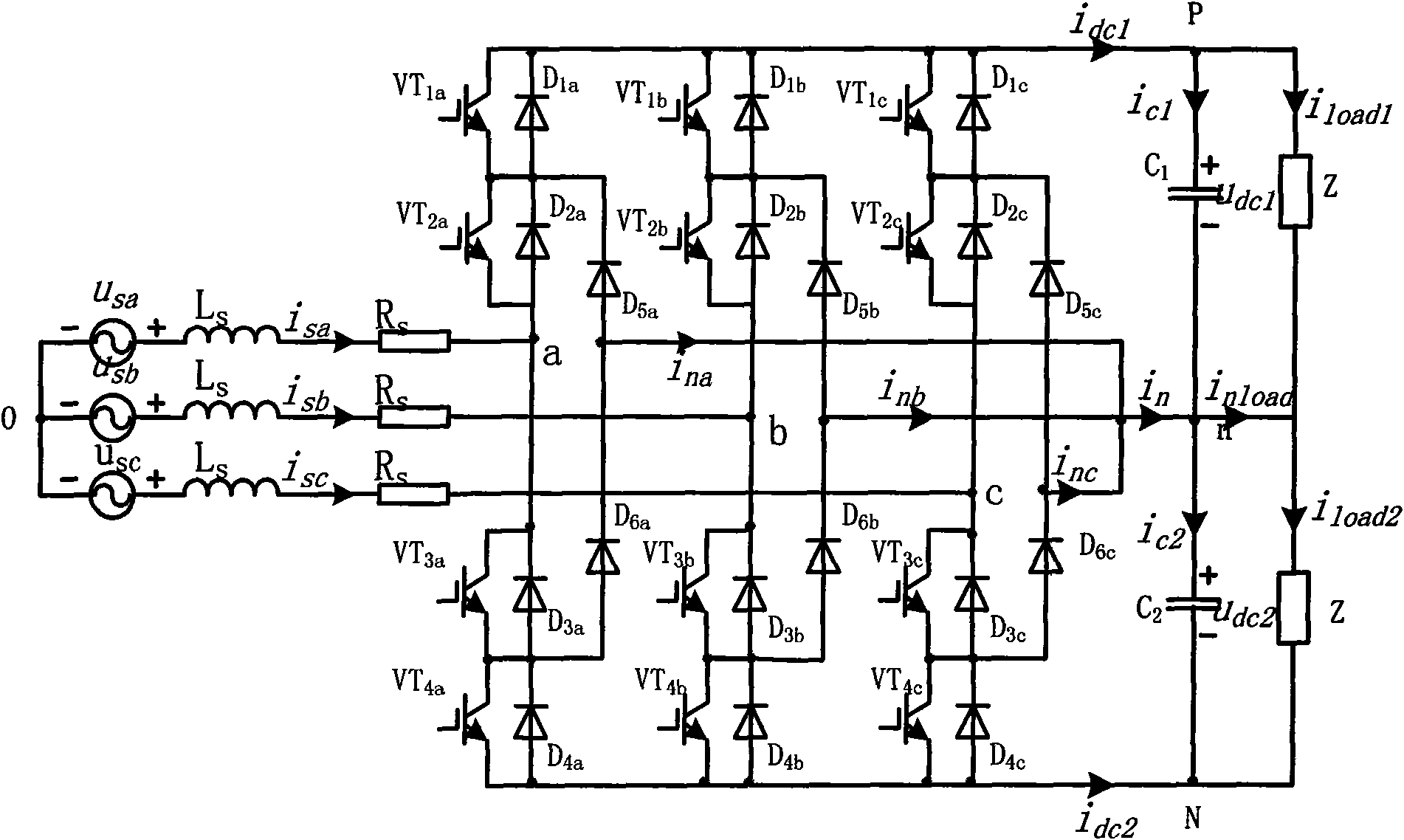

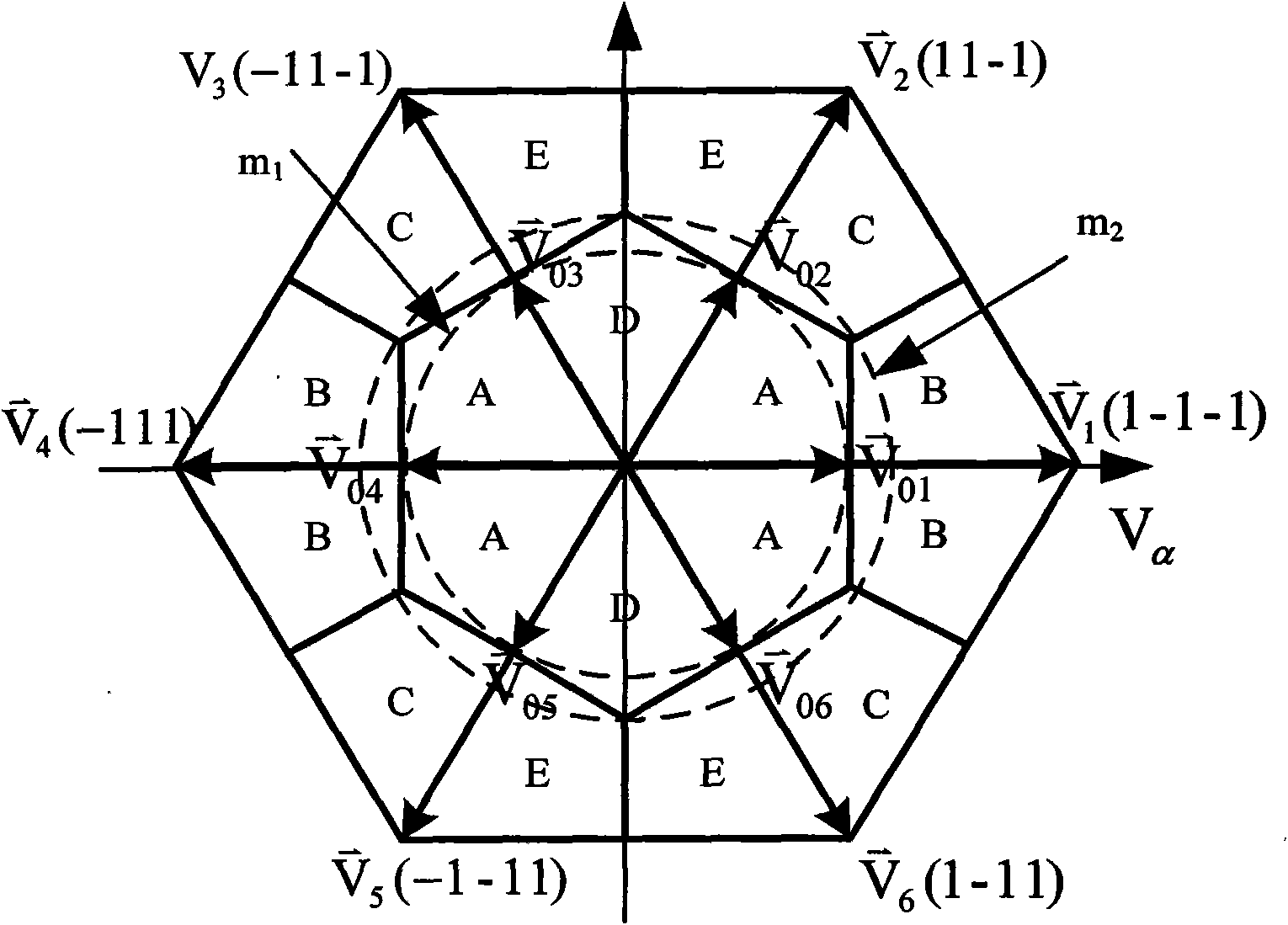

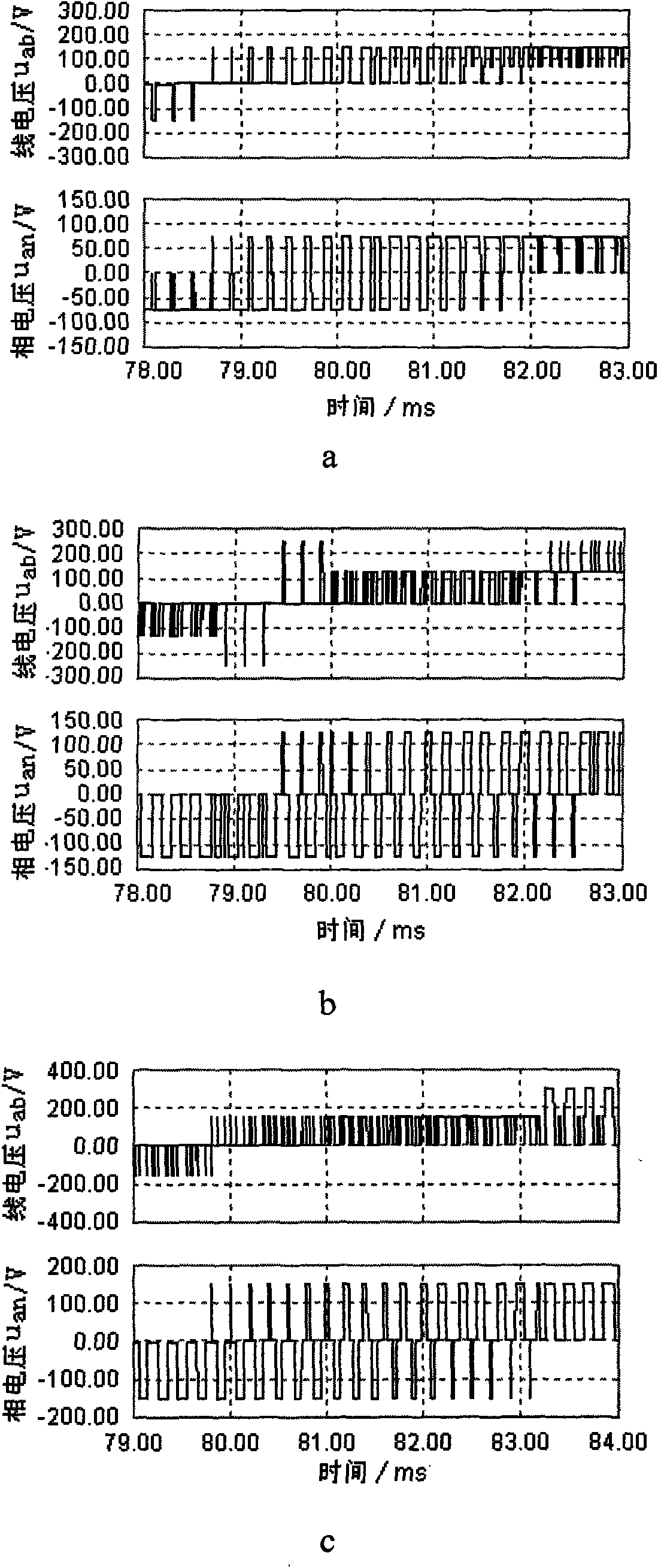

Symmetrical three-section voltage vector pulse width modulation method for three-level PWM rectifier

InactiveCN101615853AImprove balanceLess voltage vector divisionAc-dc conversionThree levelVoltage vector

The invention discloses a symmetrical three-section voltage vector pulse width modulation method for a three-level PWM rectifier, which comprises the following steps: 1. voltage vector area division: dividing one sector according to every 60 degrees, setting up three small areas in each sector, and calculating by taking quadrant as a unit; 2. voltage vector synthesis: using the adjacent three-voltage vector synthesis of each area according to the areas divided in the step one; 3. voltage vector acting time calculation: calculating the acting time of each synthesized voltage vector of each area according to V-t characteristics; and 4. voltage vector pulse width modulation: utilizing the voltage vector acting time calculated in the step three to carry out the voltage vector pulse width modulation, i.e. realizing the voltage vector pulse width modulation by a DSP+CPLD three-level PWM rectifier system based on a logical approach. The method realizes the self-balancing of the voltage vector pulse width modulation; the voltage vector subareas are fewer, and the algorithm is simple.

Owner:XIAN UNIV OF TECH

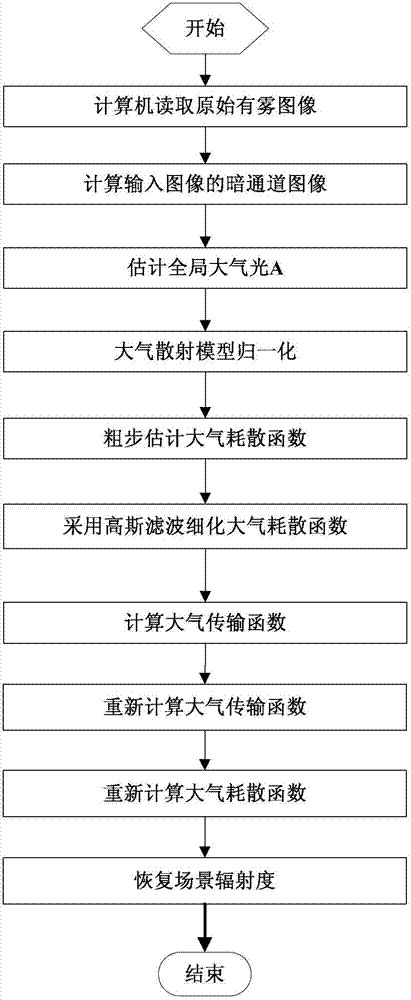

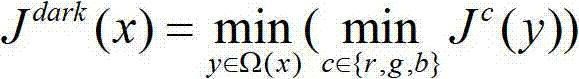

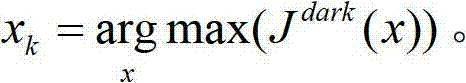

Gaussian filter-based real-time defogging method for single image

ActiveCN102831591ARestoring the real sceneSimple algorithmImage enhancementSingle imagePhysical model

The invention provides a Gaussian filter-based real-time defogging method for a single image. The method is established on the basis of a physical model and can realize real-scene recovery of a degraded quality image. The method comprises the following four main steps of: step 1, calculating, inputting a dark channel image of a fogged image and estimating an overall atmosphere light value; steps 2, primarily estimating an atmosphere dissipative function; step 3, adopting Gaussian filtering to refine the atmosphere dissipative function; and step 4, recovering a scene radiancy. With the adoption of the method, defects that an existing defogging method is slower in defogging speed and cannot be applied to a real-time processing system are overcome; and the method is good in effect of an obtained defogged image and rapid in processing speed, can be applied to a real-time system, and has a better practical value and a wide application background.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com