Method for measuring diameter of non-contact forging on line by using laser

A non-contact, laser receiving technology, used in measuring devices, optical devices, instruments, etc., can solve the problems of production efficiency and forging quality, increase cold working allowance, poor working conditions, etc., to avoid cold working allowance, The effect of reducing forging allowance loss and simple algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

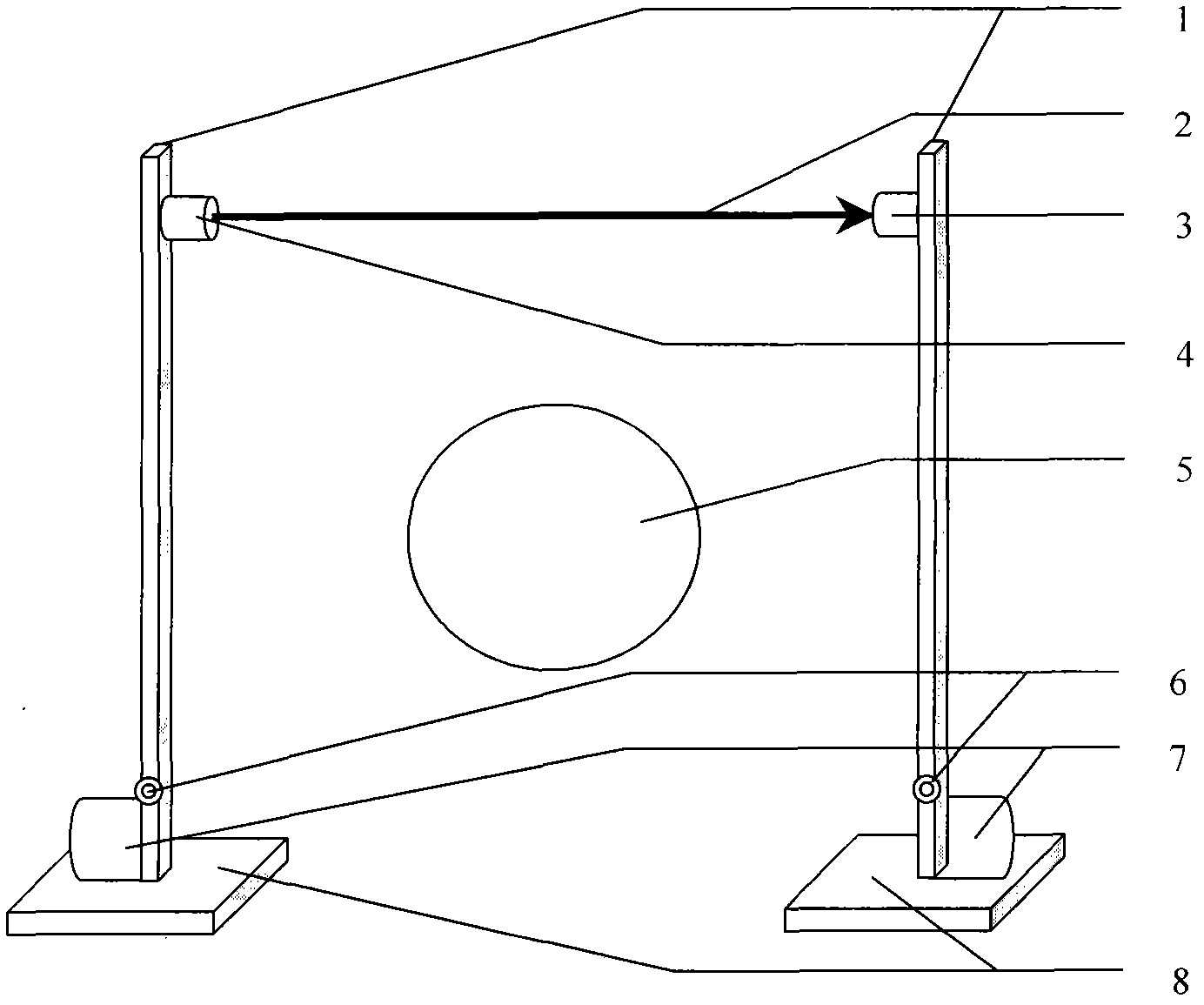

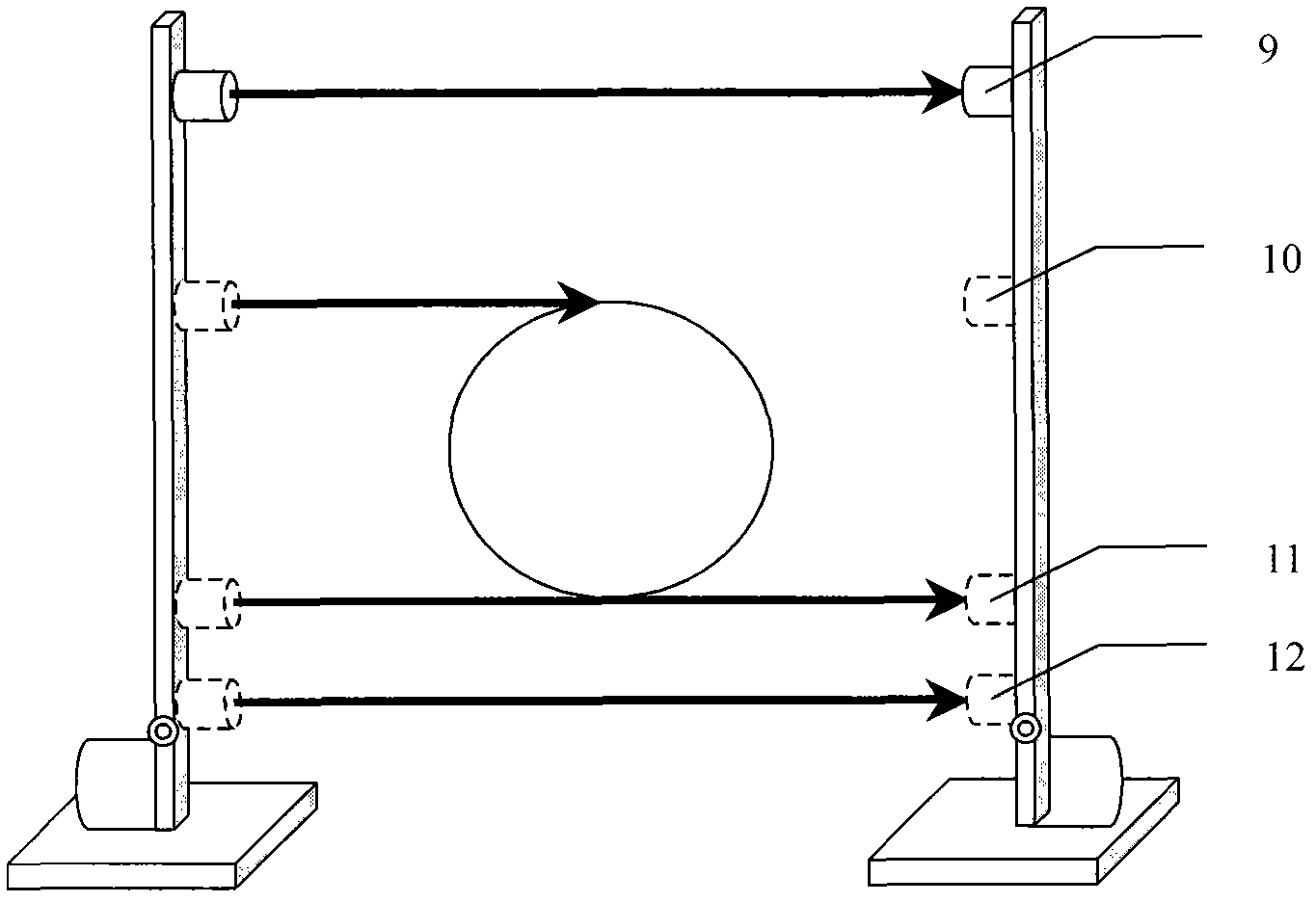

[0020] Example: figure 1 As shown, this embodiment is carried out in the forging plant of Xingtai Machinery Roll Co., Ltd. of Sinosteel Group. The length of the two linear guide rails is 3000mm, and they are installed and fixed on both sides of the forging with a distance of 25 meters. The transmission part that converts the rotary motion of the stepping motor into linear motion adopts the screw transmission mode. The length of the screw is 3000mm. One end of the screw is directly connected to the motor shaft, and the other end is fixed on the guide rail bracket through the bearing support. Installed on the guide rail There is a slider, when the guide rail rotates, the slider moves linearly along the guide rail, the laser emitting device 4 and the laser receiving device 3 are respectively fixed on the sliders of the two lead screws, and the linear guide rail 1 is the laser emitting device and the laser receiving device 3 respectively. The laser receiving device provides a mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com