Patents

Literature

1014results about How to "Realize energy saving and consumption reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biomass pyrolysis liquefied technique and double tower apparatus system thereof

InactiveCN1730177AImprove pyrolysis efficiencyWell mixedSolid waste disposalGas phaseProcess engineering

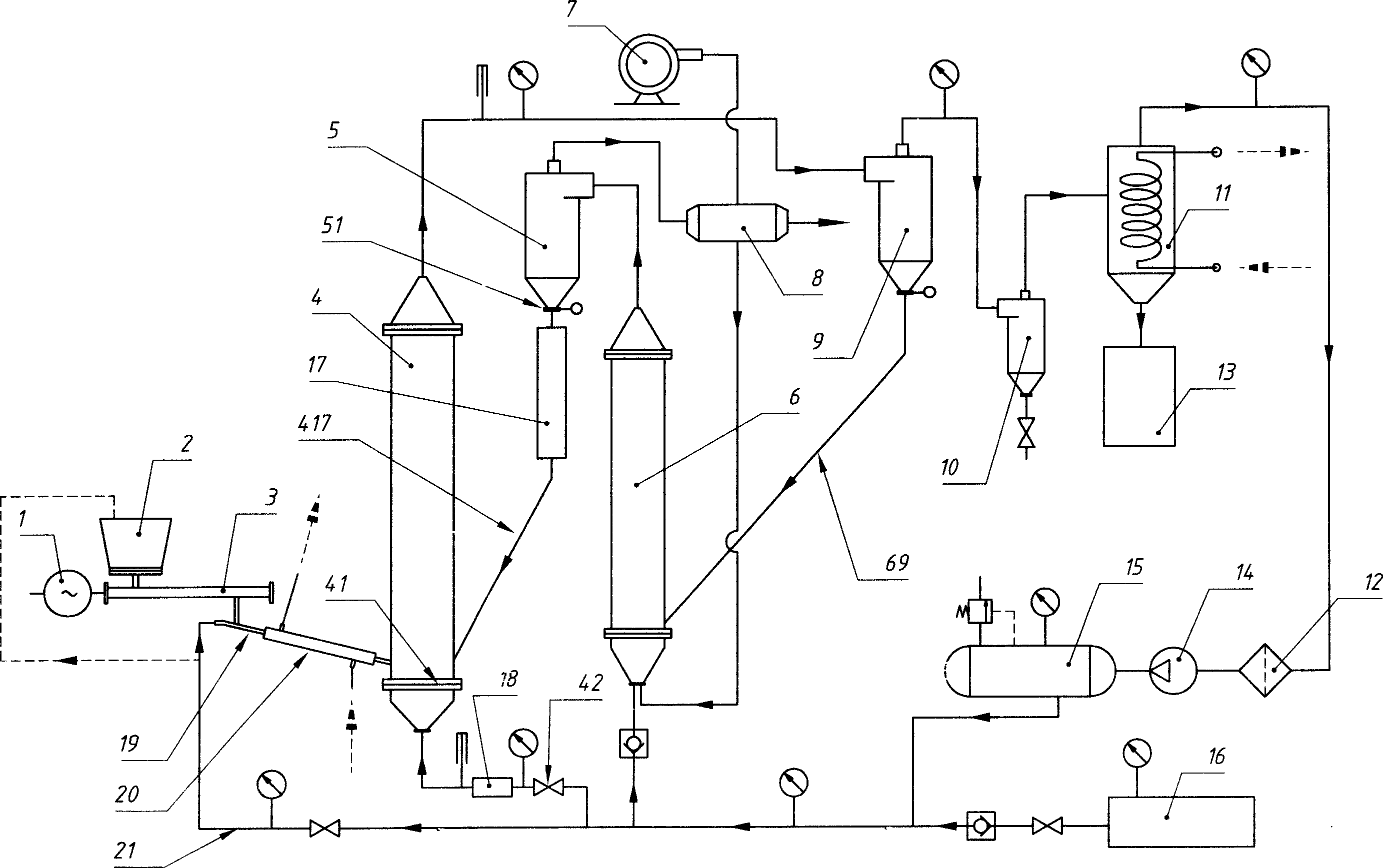

The invention relates to a biomass analgesic liquidation method and its twin-tower set system, the processes of which comprise the following steps: sending biomass to pyrolytic reaction tower and blending it with high-heat fluidized gas to subject biomass to pyrolytic cracking; separating thermal cracking gas with carbon residue and ash content in separator; and condensing thermal cracking gas to biological oil in condenser. In the process, heat-carrying agent is exported from pyrolytic reaction tower along with thermal cracking gas, carbon residue and so on, and carbon residue is used to preheat heat-carrying agent. The invention is special for heat-carrying agent heating tower to burn carbon residue and primary separator to separate heat-carrying agent, carbon residue and other materials. The invention can not only increase circulation rate to ensure uniform and stable temperature field in pyrolytic reaction tower, higher heating rates and shorter detention period of gas phase, but also make use of carbon residue as heat source by using existing apparatus.

Owner:CHONGQING UNIV

Processing method for reducing and recycling organic waste water and processing system

InactiveCN105540967AReduce foulingReduce the risk of contaminationFatty/oily/floating substances removal devicesWater contaminantsReverse osmosisWastewater

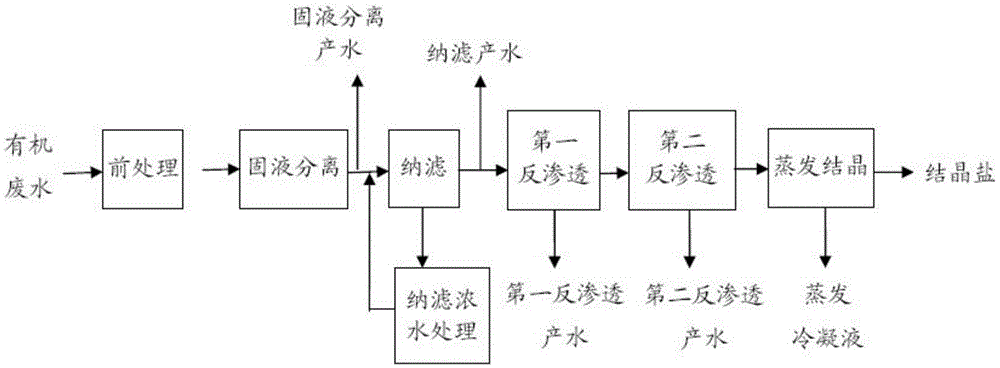

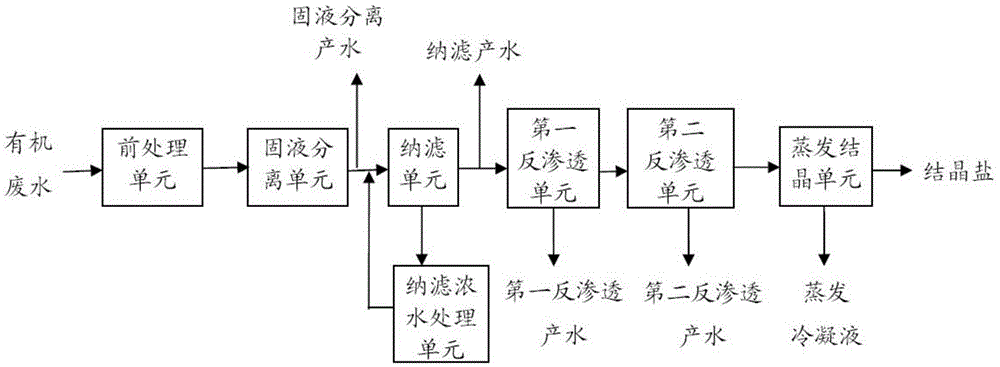

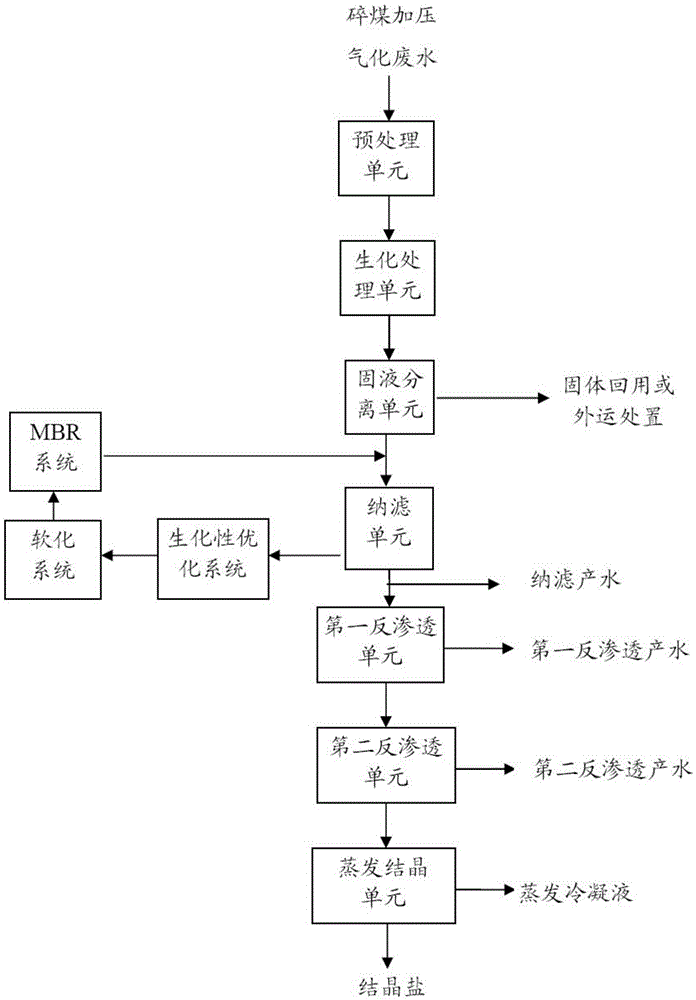

The invention provides a processing method for reducing and recycling organic waste water. The method comprises steps: (1) pre-treating waste water to obtain pre-treated out-water; (2) treating the out-water obtained from the step (1) through solid-liquid separation; (3) nano-filtering the out-water obtained from step (2); (4) treating nano-filtered concentrated water obtained from the step (3) to obtain out-water subjected concentrated water nano-filtering, returning to the step (3) for mixing the out-water subjected to concentrated water nano-filtering with the out-water subjected to solid-liquid separation, and performing nano-filtering; (5) performing first reverse osmosis treatment on out-water obtained from the step (3) through nano-filtering; (6) performing second reverse osmosis treatment on concentrated water obtained from the step (5) through first reverse osmosis treatment; and (7) evaporating and crystallizing a concentrated liquid obtained from the step (6) through second reverse osmosis treatment in order to obtain crystallized salt and evaporated concentrated water. The invention further provides a processing system of the method. Through the method and system, waste water is truly reduced and recycled.

Owner:DATANG INT CHEM TECH RESINST

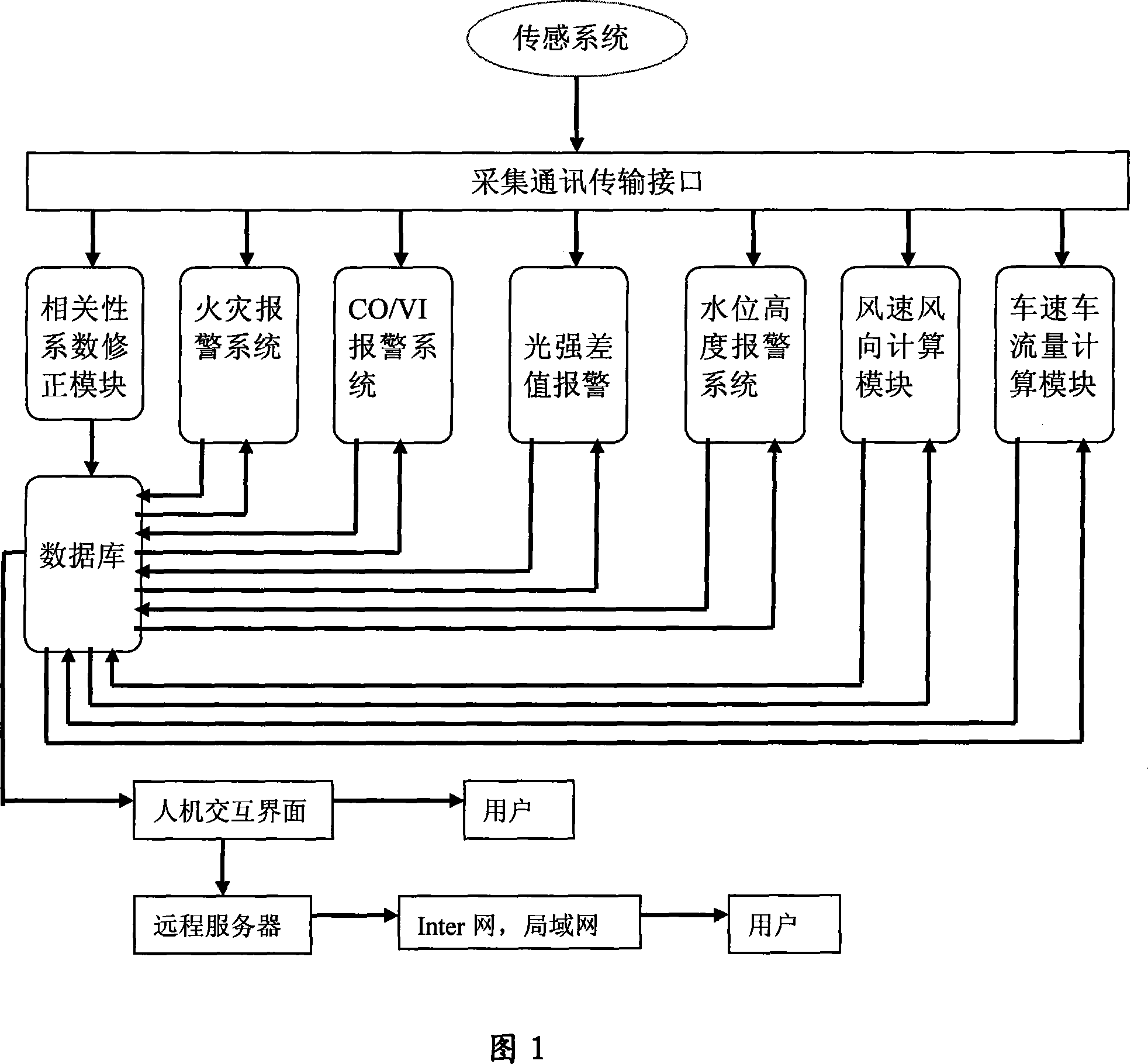

Multiple sensor integrated method for city long tunnel monitoring system

InactiveCN101105690ARealize automatic alarmGuaranteed healthy operationComputer controlSimulator controlMultiple sensorEngineering

The invention relates to a multi-sensor fusion method used in an urban long tunnel monitoring system which consists of a sensor system, a collection communication transmittance interface and database storing data; the invention is characterized in that the collection communication transmittance interface is completed by PLC; meanwhile, the collection communication transmittance interface collects analog quantity and digital quantity both of which is output by the sensor system, directly sends the analog quantity and digital quantity to the database of a supervisory computer to be implemented fusion procession; the database outputs signals to man-machine interaction interface and intelligent warning system monitoring communication environment; the intelligent warning system can send out warnings including fire warning, visibility warning, carbon monoxide density warning, traffic volume and vehicle speed warning and light intensity difference warning at tunnel entrance. The invention is characterized in that information collected by a plurality of sensors is fused and urban underground long tunnel can be monitored in real time; the self warning of health condition in the tunnel and the self warning of equipment failure can be achieved so that long time health operation of the tunnel can be guaranteed.

Owner:WUHAN UNIV OF TECH +1

Thermostable heat-isolating coating and its preparation method

The invention discloses a high-temperature proof insulating paint and making method, which comprises the following parts: 400-500g organic silica resin, 50-100g thermostable dye, 100-200g fill, 80-150 hollow ceramic microball, 30-60g bergmeal, 20-50g potassium titanate whisker, 100-150g solvent and 5-15g adjuvant.

Owner:北京国邦技术发展中心

Mineral separation process of magnetic iron ore

ActiveCN101480632AReduce energy consumptionFine Concentrate SizeSievingScreeningMagnetiteMaterials science

The invention discloses a beneficiation method for a pure magnetic iron ore. A crude ore is sequentially treated according to the steps such as first crushing, first-stage dry-type magnetic dressing, medium crushing, second-stage dry-type magnetic dressing, fine crushing and third-stage dry-type magnetic dressing, fine ore is obtained after a great amount of gangues are thrown by the third-stage dry-type magnetic dressing and sent to a grinding head sieve to be griddled and separated, granules griddled by the grinding head sieve are treated in a first-section magnetic dressing process, rough ore griddled by the grinding head sieve is treated in a first-section ball grinding and then enters the first-section magnetic dressing process; ore aggregates obtained from the first-section magnetic dressing process are treated in a second-section ball grinding after discharging gangue sands till the granularity of ore powder is -200meshes being more than or equal to 60 percent, ore powder generated from the second-section ball grinder are treated in second-section magnetic dressing, ore aggregates generated from the second-section magnetic dressing are treated in a high-frequency sieve after discharging gangue sands, products positioned on the high-frequency sieve are filtered to obtain ore concentrate, and products positioned below the high-frequency sieve are treated with desliming and then treated with floatation. The invention adopts two sections of grinding ore open-way processes and distinguishes the ore aggregates during the ore dressing process, thereby greatly reducing the energy consumption of a system, lowering the production cost and enhancing the utility ratio of equipment.

Owner:安徽大昌矿业集团有限公司

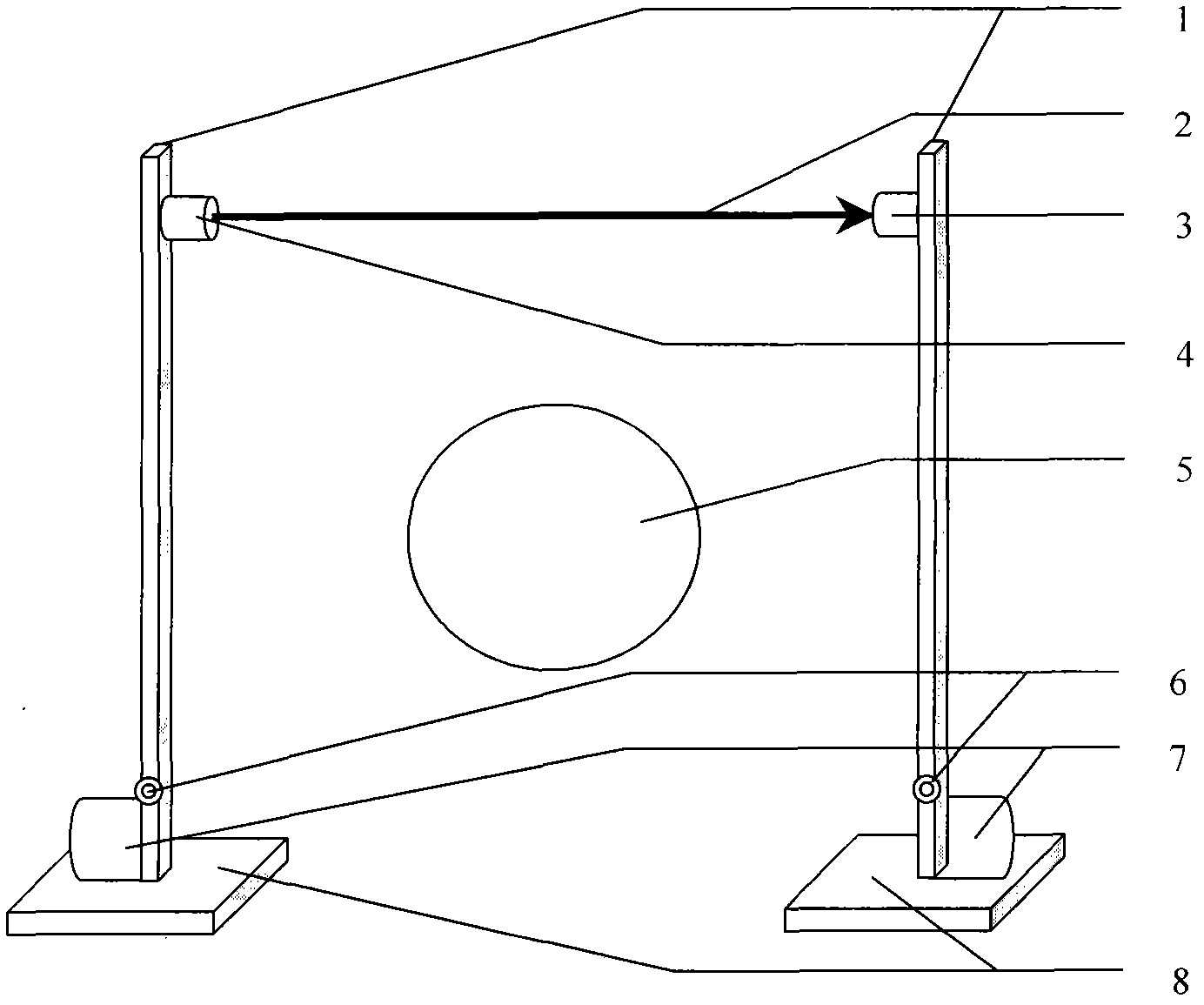

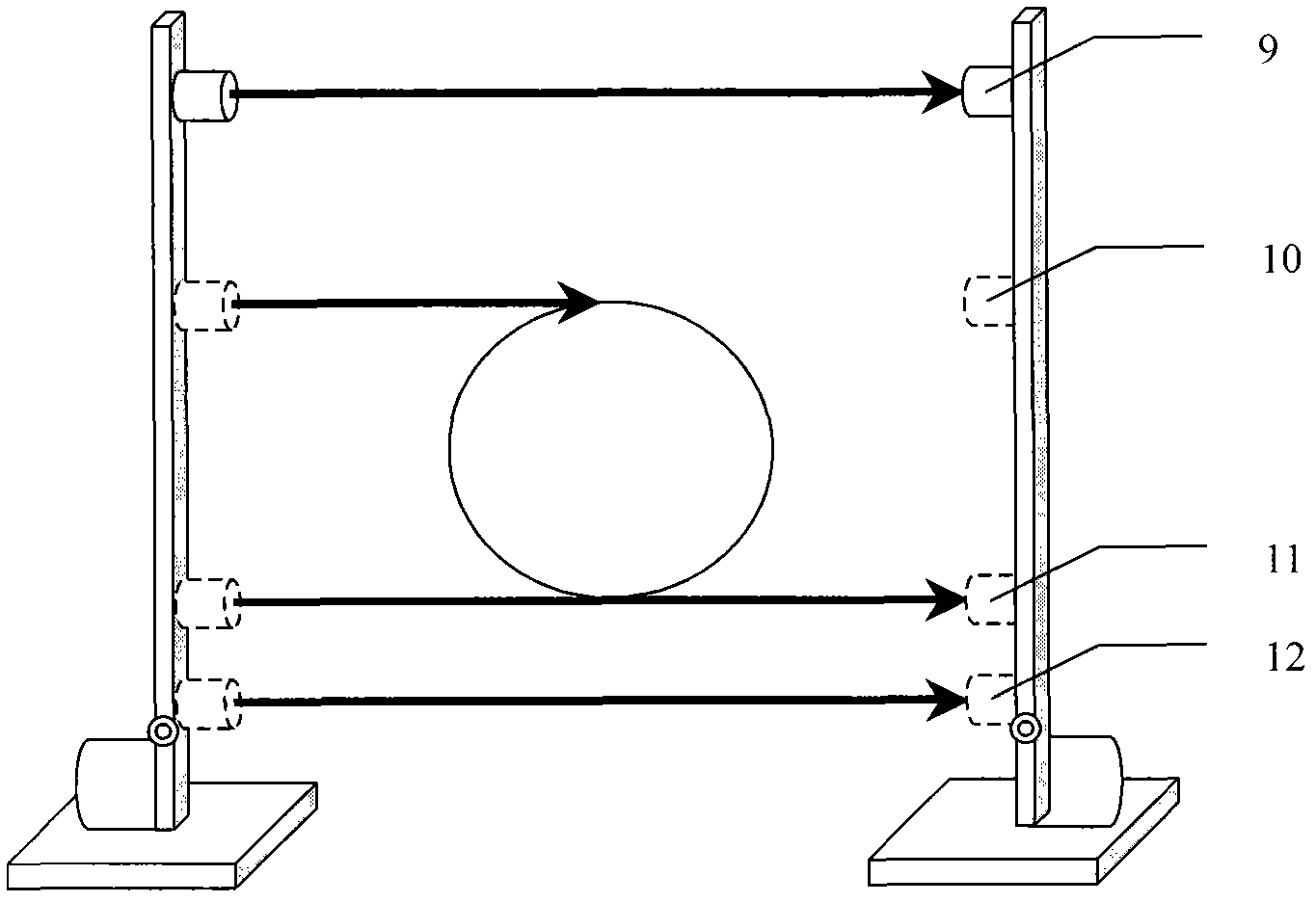

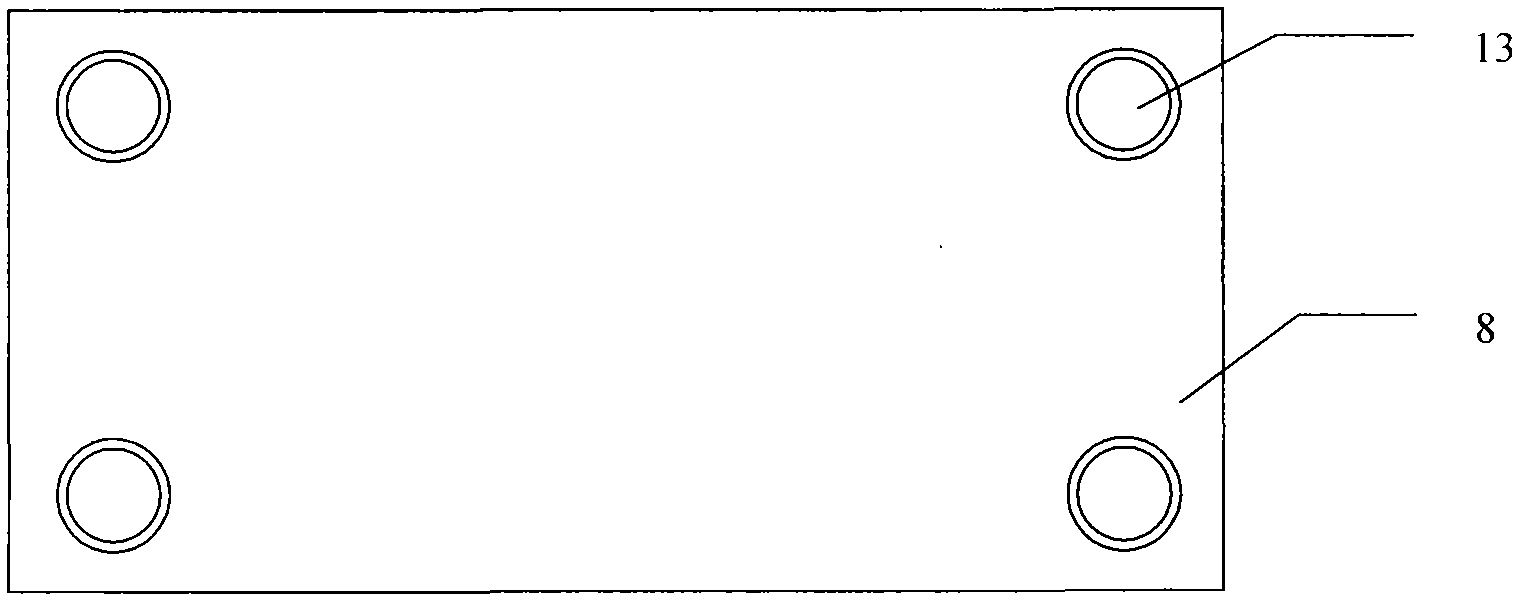

Method for measuring diameter of non-contact forging on line by using laser

InactiveCN102003943AImprove machining accuracyReduce lossUsing optical meansContact highLaser transmitter

The invention discloses a method for measuring the diameter of a non-contact forging on line by using laser. A pair of parallel linear guide rails arranged at equal altitude on the two sides of the forging is used in the method. The method is characterized in that: a laser transmitter is arranged on one guide rail, a laser receiver is arranged on the other guide rail, the laser transmitter and the laser receiver are driven to travel by two stepper motors respectively, the positions of the laser transmitter and the laser receiver are kept synchronous during the travel, the distance between the tangent point of the laser and the section circle of the forging can be computed quickly through the travel distance of the stepper motors and the connection and interruption of signals of the laser receiver, so that the diameter size of the forging can be obtained. The method has the advantages that: two mutually independent linear guide rails are adopted, so that the diameter of the forging such as a spindle of a windmill generator and metallurgic rollers in a wider range can be measured by selecting a proper guide rail length; measuring staff are not required to contact high-temperature environment, and manual measurement is avoided, so that the diameter of the current forging can be obtained quickly, precision is high, the shortcomings of long time and large error of the manual operation are overcome, and forging speed and forging precision are improved; the shortcoming of reserving relatively large cold processing allowance according to experience is effectively overcome, the allowance consumption of the forging is reduced, and the energy conservation and consumption reduction are realized.

Owner:魏青轩

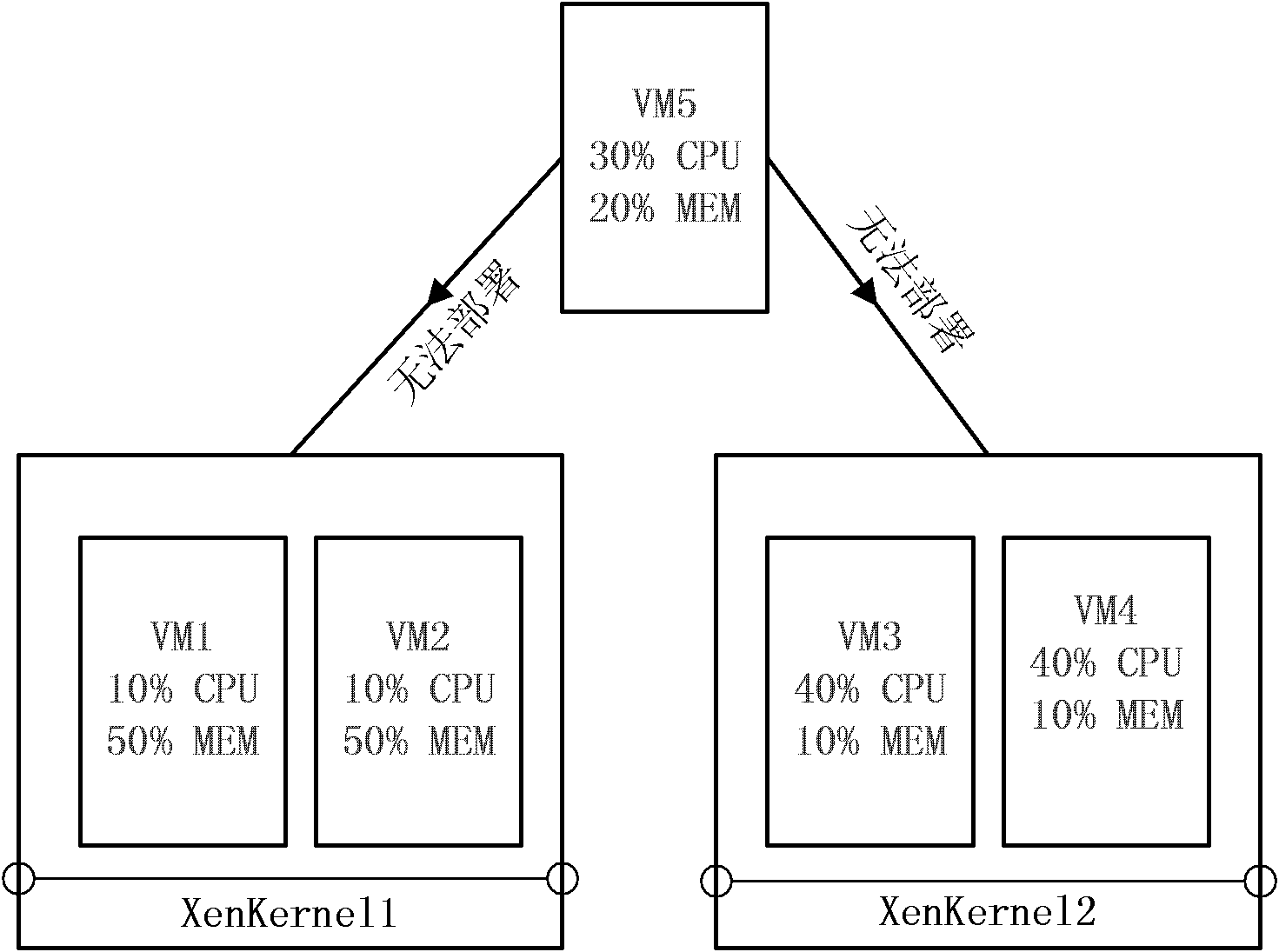

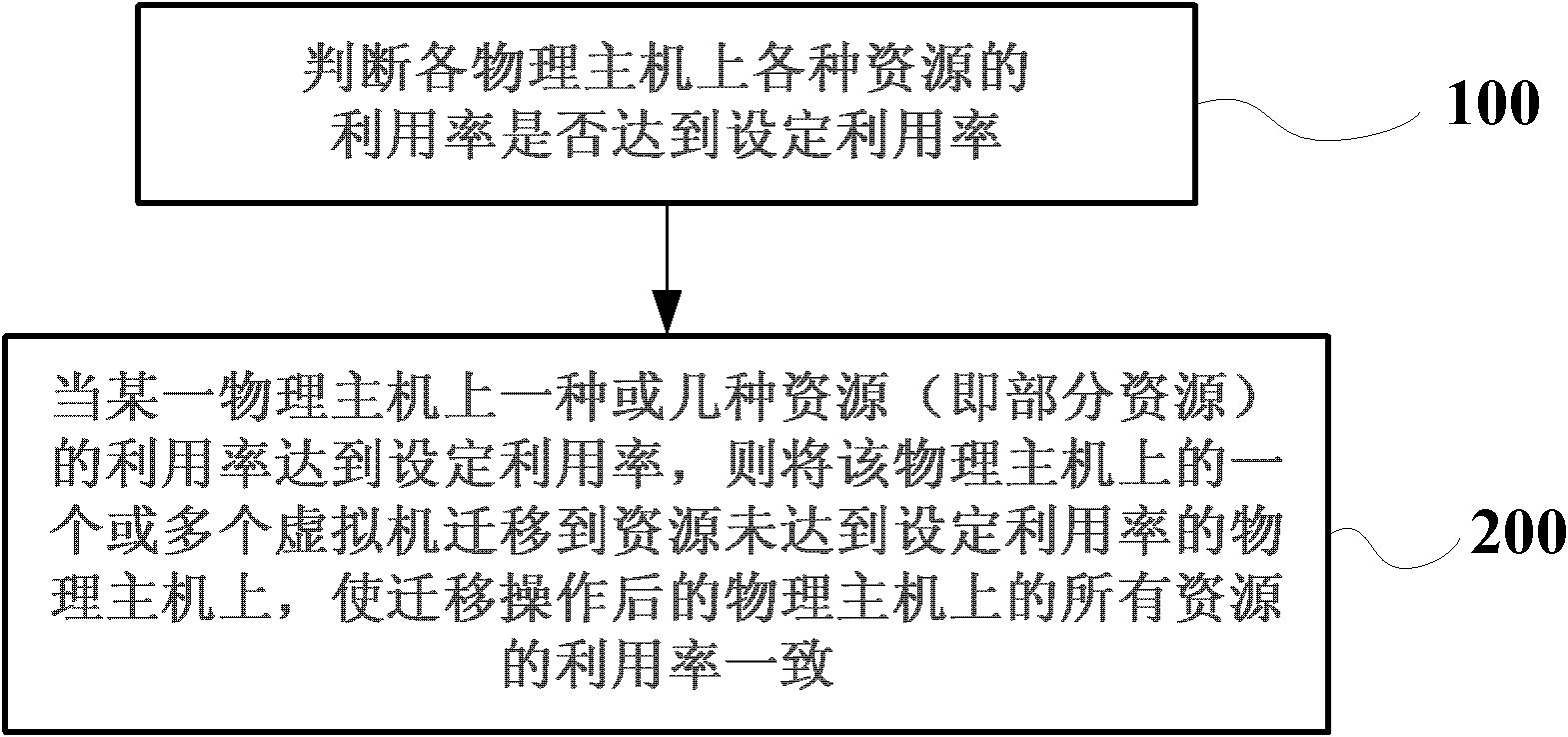

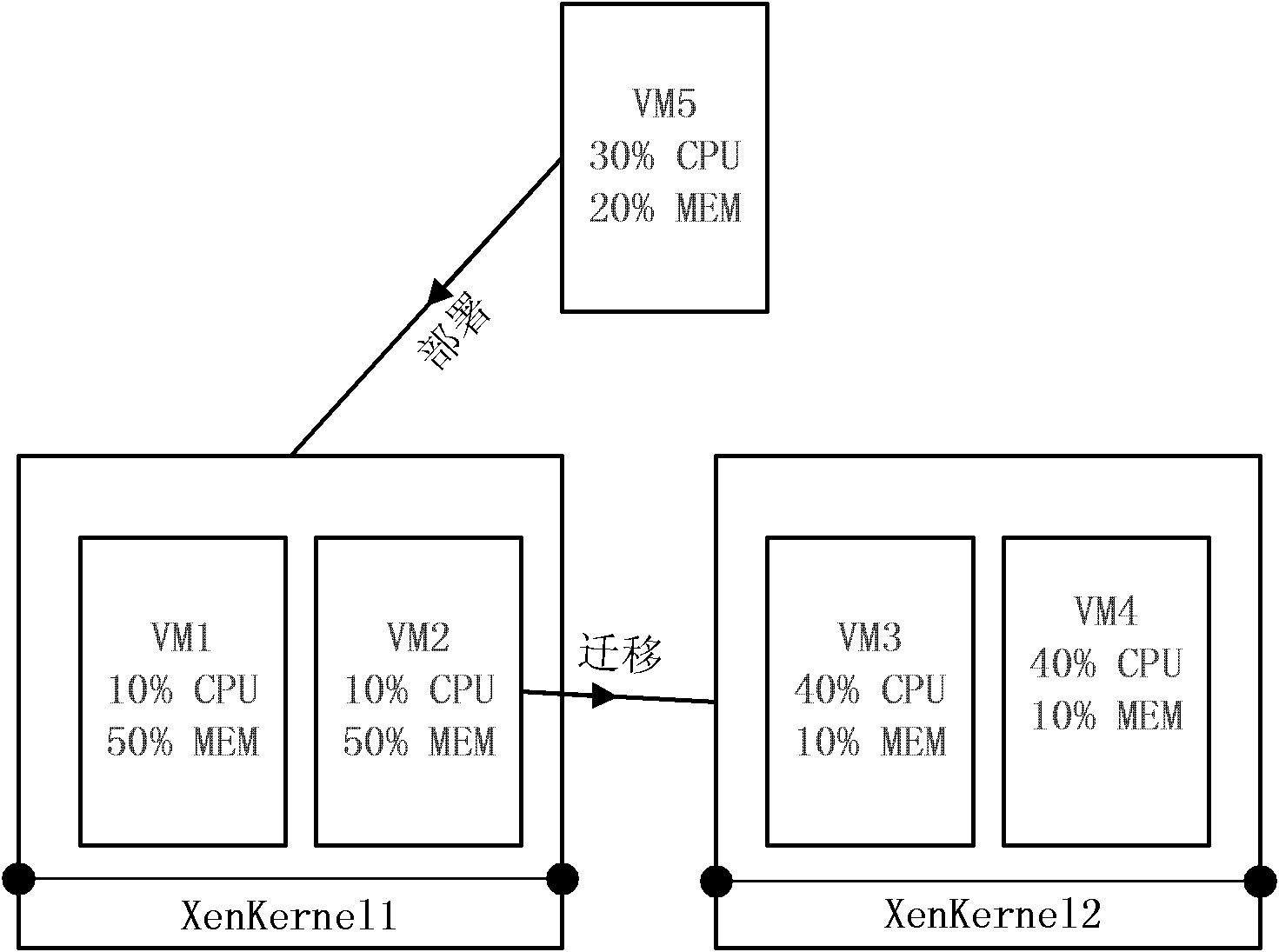

Resource dispatching system and resource dispatching method

InactiveCN102117226AImprove resource utilizationRealize energy saving and consumption reductionEnergy efficient ICTResource allocationComputer resourcesVirtual machine

The invention discloses a system and a method of resource dispatching and relates to the virtualization field of computer resources. The method comprises the following steps: when the utilization rate of one resource or a plurality of resources on a physical host reaches the set utilization rate, one virtual machine or a plurality of virtual machines on the physical host is moved to other physical hosts whose resources do not reach the set utilization rate, so that the utilization rates of all the resources on the moved physical host are consistent. Through the embodiment of the invention, the resource utilization rate of the physical host hardware is improved, and the energy conservation and the consumption reduction are realized.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

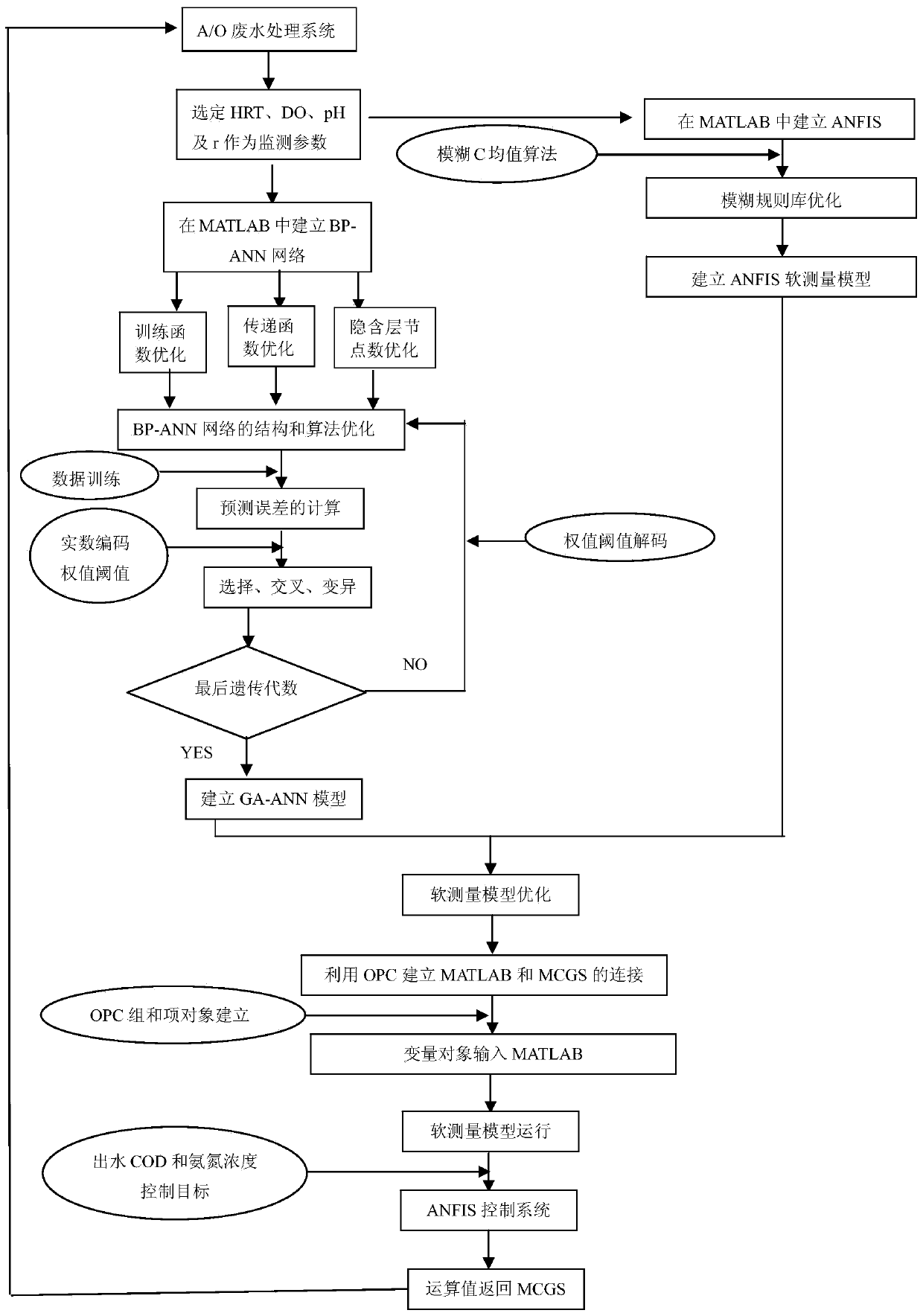

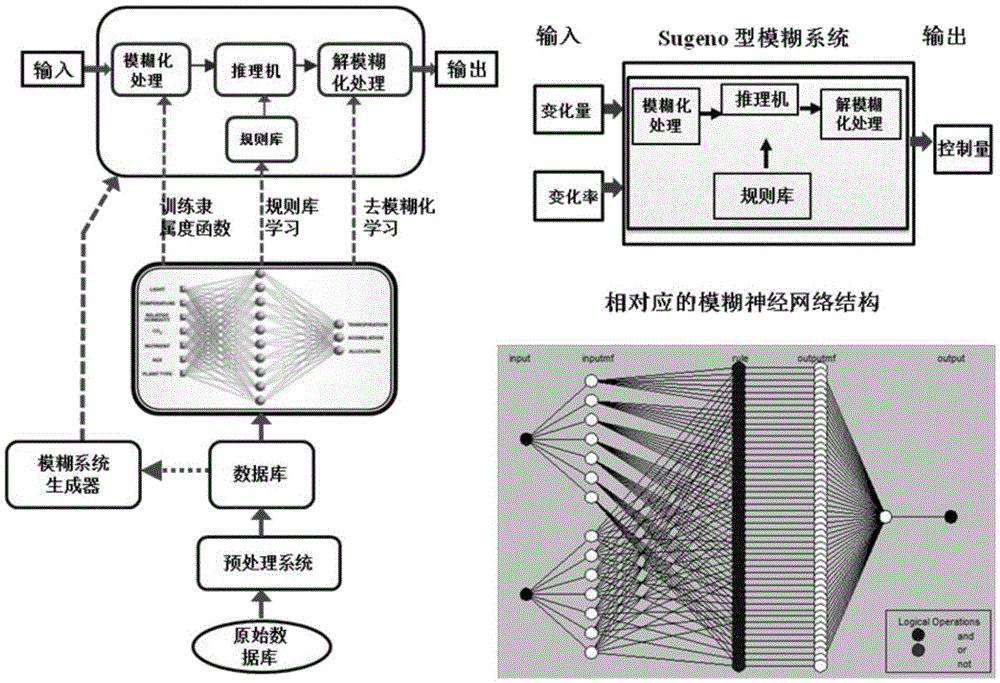

Waste water treatment monitoring method and system based on fuzzy neural network

InactiveCN103744293AImprove performanceImprove stabilityAdaptive controlChemical oxygen demandWater discharge

The invention provides a waste water treatment monitoring method based on a fuzzy neural network. According to the method, global search optimization is performed on the weight value and the threshold value of the neural network by applying a neural network structure algorithm and a real number encoding-based genetic algorithm on the basis of inspecting the influences of parameters such as the HRT (Hydraulic Retention Time) of an A / O (Anaerobic / Oxic) waste water treatment system, the DO (Dissolved Oxygen) in an aerobic pond and the reflux ratio r of mixed liquid on the COD (Chemical Oxygen Demand) and ammonia nitrogen of effluent water, so that an optimal BP-ANN (Back-Propagation Artificial Neural Network) soft measurement model and a GA-ANN (Genetic Algorithm-Artificial Neural Network) soft measurement model are built respectively. An intelligent dissolved oxygen optimization control system scheme based on the soft measurement models is built on the basis, data communication between the MATLAB (Matrix Laboratory) and MCGS (Microwave Command Guidance System) is realized in combination with an OPC (OLE for Process Control) technology, and an intelligent dissolved oxygen optimal control system is applied to dissolved oxygen optimal control in a paper-making waste water A / O technical treating process, so that energy saving and consumption reduction in paper-making waste water A / O treating engineering is realized. By adopting the waste water treatment monitoring method, the stability of the water quality of waste water discharged in the paper making industry can be increased greatly, accurate control is realized, and the chemical drug dosage and power consumption in a waste water treatment process are reduced.

Owner:ZHEJIANG YONGTAI PAPER IND GROUP +1

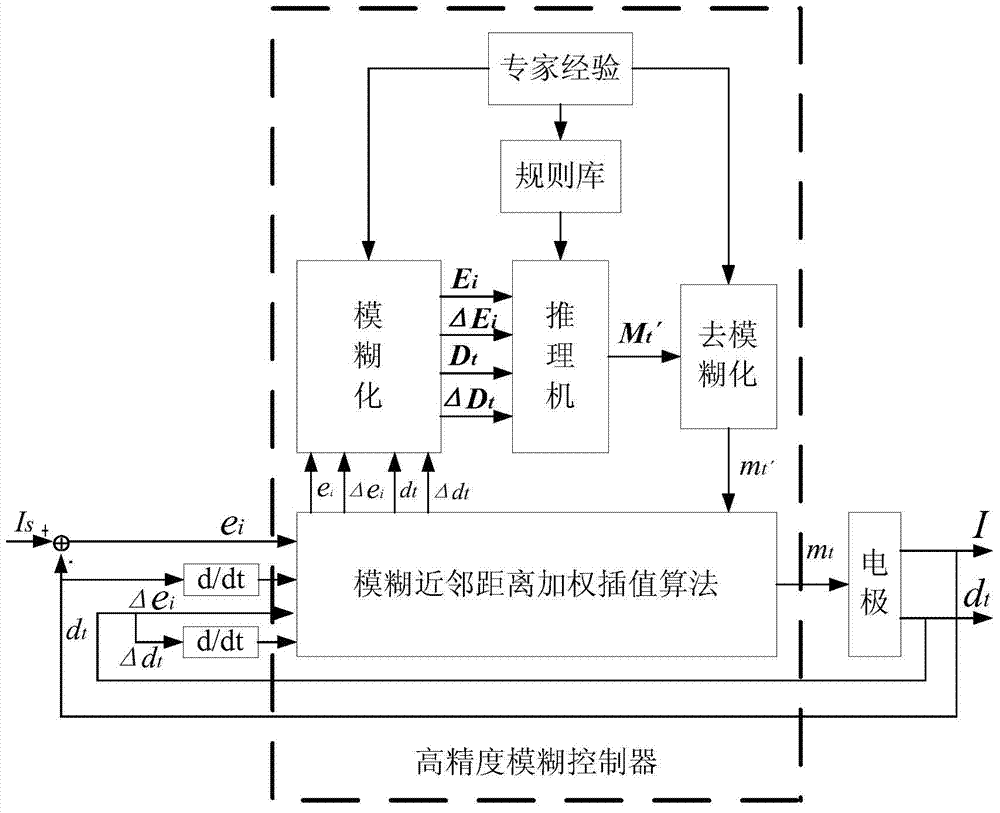

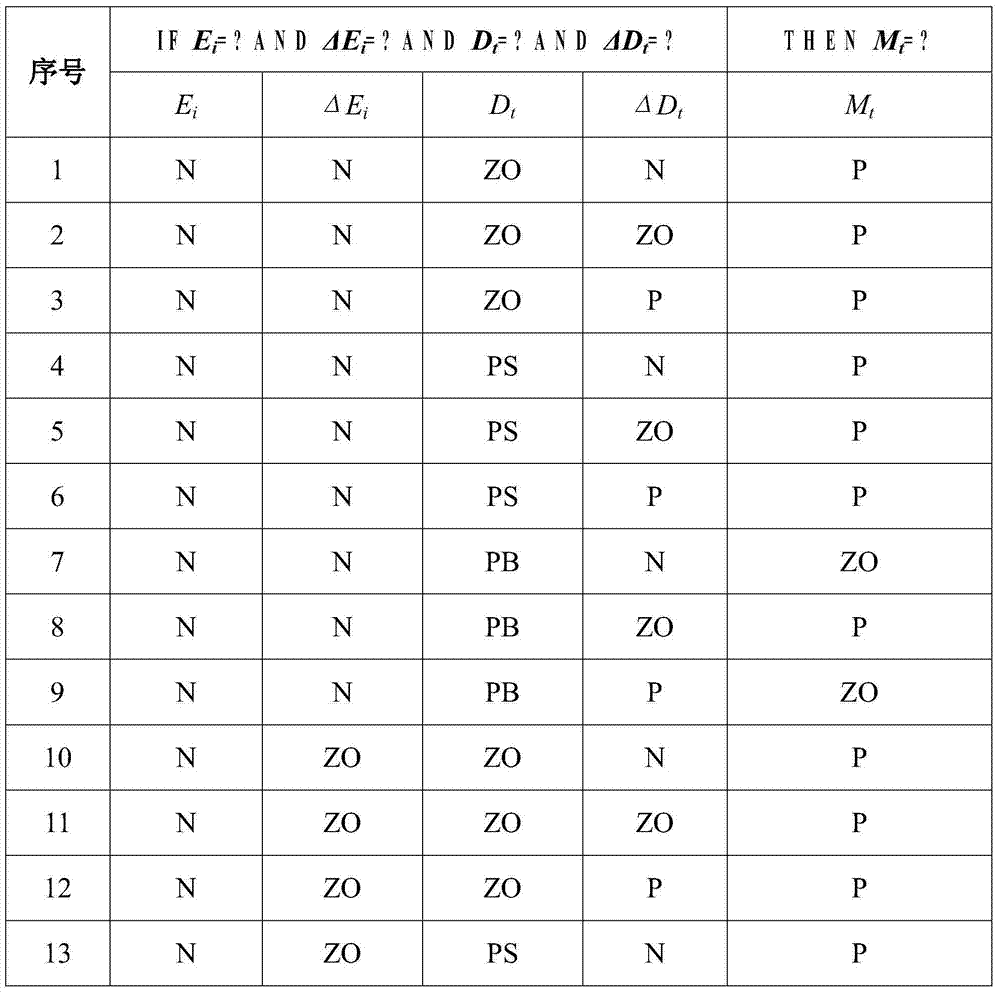

Automatic control method used for submerged arc furnace electrode and based on high-precision fuzzy control

InactiveCN103808159AHigh precisionSafe and stable operationControl devices for furnacesAutomatic controlHarmonic

The invention provides an automatic control method used for a submerged arc furnace electrode and based on high-precision fuzzy control. According to electrode current deviation ei, a change rate delta ei of the electrode current deviation, the depth dt of the electrode inserted into burden and a change rate delta dt of the depth of the electrode inserted into the burden, a high-precision fuzzy controller is adopted to adjust the variation mt of the position of the submerged arc furnace electrode, wherein a membership function and a fuzzy control rule of the fuzzy controller are obtained through expertise, and output of the controller is obtained through fuzzy neighbor distance weighted interpolation calculation, so that the control accuracy of the fuzzy controller is improved. The automatic control method used for the submerged arc furnace electrode and based on high-precision fuzzy control provides guarantee for safe and reliable operation of the submerged arc furnace which can operate in a stable manner, so that labor intensity of a worker can be reduced effectively, the maintenance quantity is reduced, the work environment is improved, and better conditions are provided for following harmonic suppression.

Owner:XI AN JIAOTONG UNIV

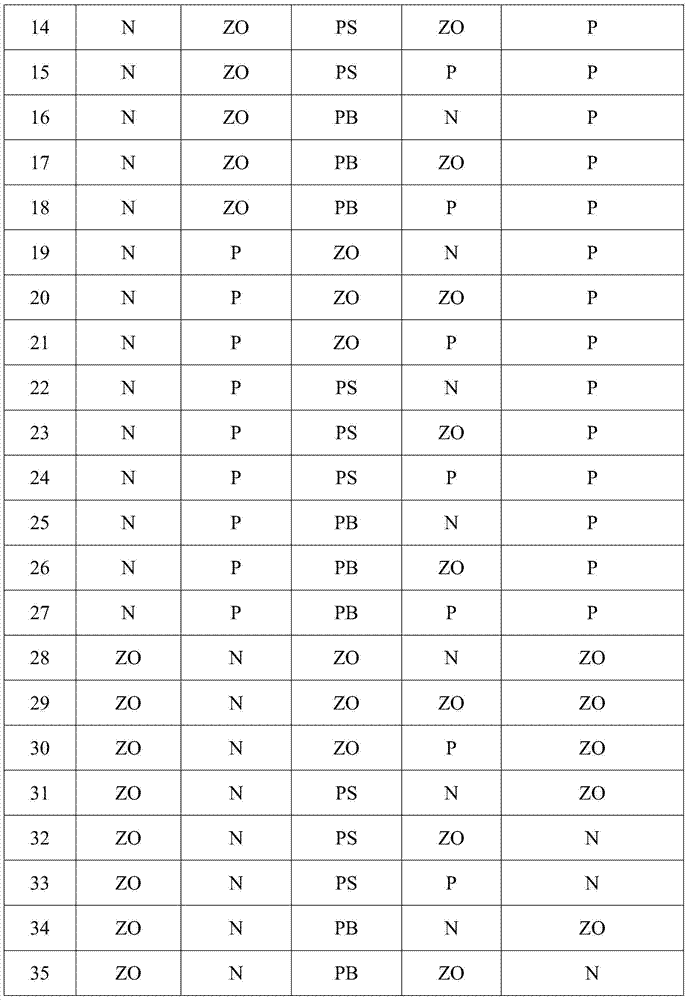

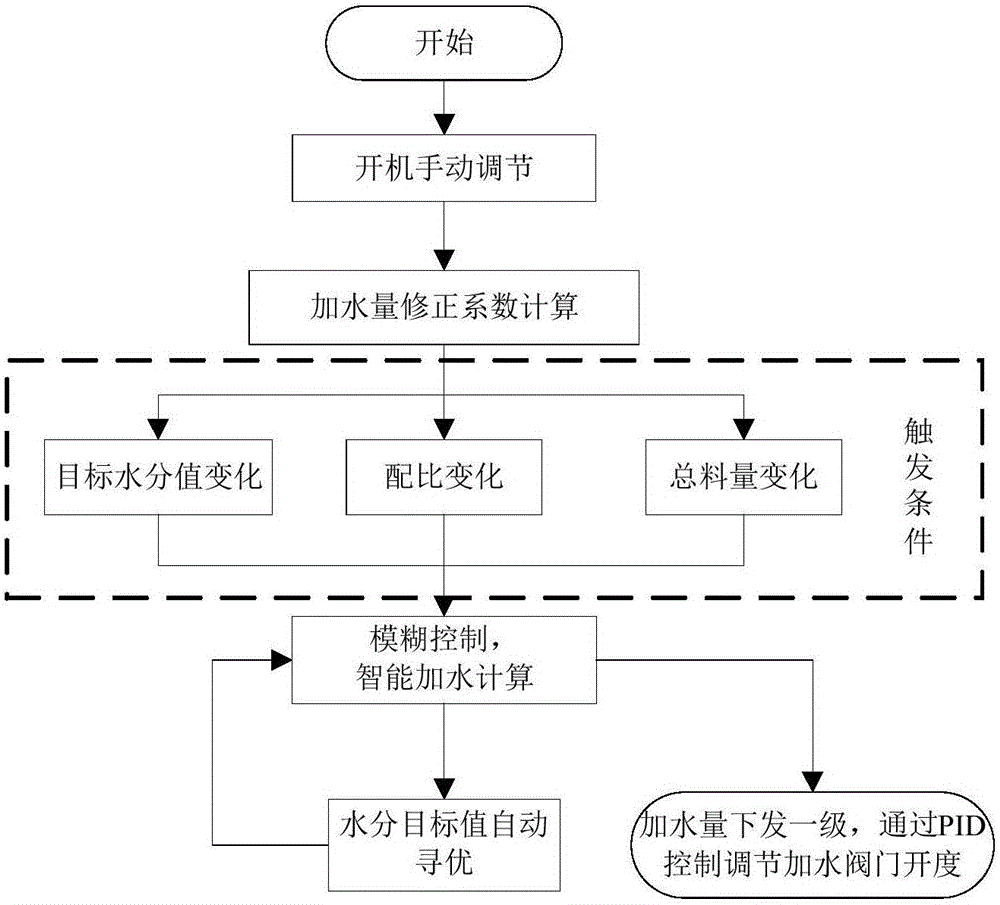

Closed loop control method of sintering mixture moisture

ActiveCN106842919ARealize closed-loop controlRealize energy saving and consumption reductionAdaptive controlAutomatic controlMicrowave

The invention provides a closed loop control method of sintering mixture moisture, belongs to the technical field of automatic sintering mixture water adding controlling, and particularly relates to a control method based on a fuzzy control theory, an automatic optimizing algorithm and a sintering water adding operation process. The control process of the method mainly comprises the steps that 1, the mixture water adding amount is automatically calculated through the target moisture and data detected by a microwave moisture testing instrument and a water adding flowmeter according to the fuzzy control theory; 2, a target moisture value is optimized regularly and automatically by establishing sintering moisture quality evaluation indexes through the automatic optimizing algorithm, and the water adding amount is precisely controlled. According to the method, the manual adjusting mode of traditional sintering mixture water adding is changed, closed loop control over the sintering mixture moisture is achieved, the control precision of sintering mixture water adding is improved, the automation level of sintering mixture water adding is increased, and the good uniform mixing and pelletizing effects and the ideal air permeability are guaranteed.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

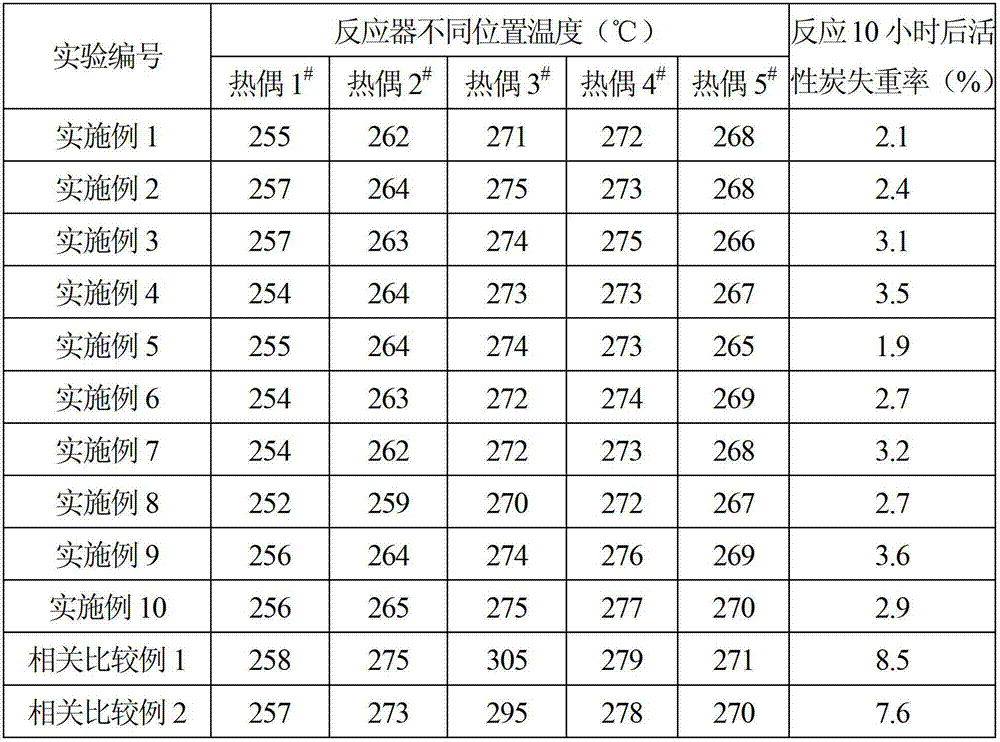

Activated carbon coating/foam silicon carbide structural catalyst and preparation method thereof

ActiveCN102814188AUniform temperature distributionSufficiently chemically inertCatalyst activation/preparationChemical reactionHeat inactivation

The invention relates to the field of structural catalysts, in particular to an activated carbon coating / foam silicon carbide catalyst with a three-dimensional communicated structure and a preparation method for the catalyst. The invention aims to solve the problems that hole opening is discontinuous, the catalyst and reaction products are separated, a heat transfer and mass transfer effect is poor and the like in the prior art. By taking foam silicon carbide as a catalyst carrier, an activated carbon coating covers on the surface of the foam silicon carbide, wherein the activated carbon coating is between 0.1 micron and 500 microns thick, and a metal catalysis active component is loaded on the activated carbon coating. The activated carbon coating is prepared on the surface of the foam silicon carbide with the three-dimensional communicated structure, then, the metal catalysis active component is loaded, and activating treatment is performed on the metal catalysis active component to obtain the catalyst. According to the activated carbon coating / foam silicon carbide catalyst, holes in the catalyst carrier are totally communicated, thus, an enclosure space does not exist, and a heat transfer and mass transfer process of the chemical reaction can be strengthened. The activated carbon coating / foam silicon carbide catalyst has the characteristics that the temperature field distribution of the catalytic reaction is uniform, the heat inactivation rate is low, the pressure drop is low and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

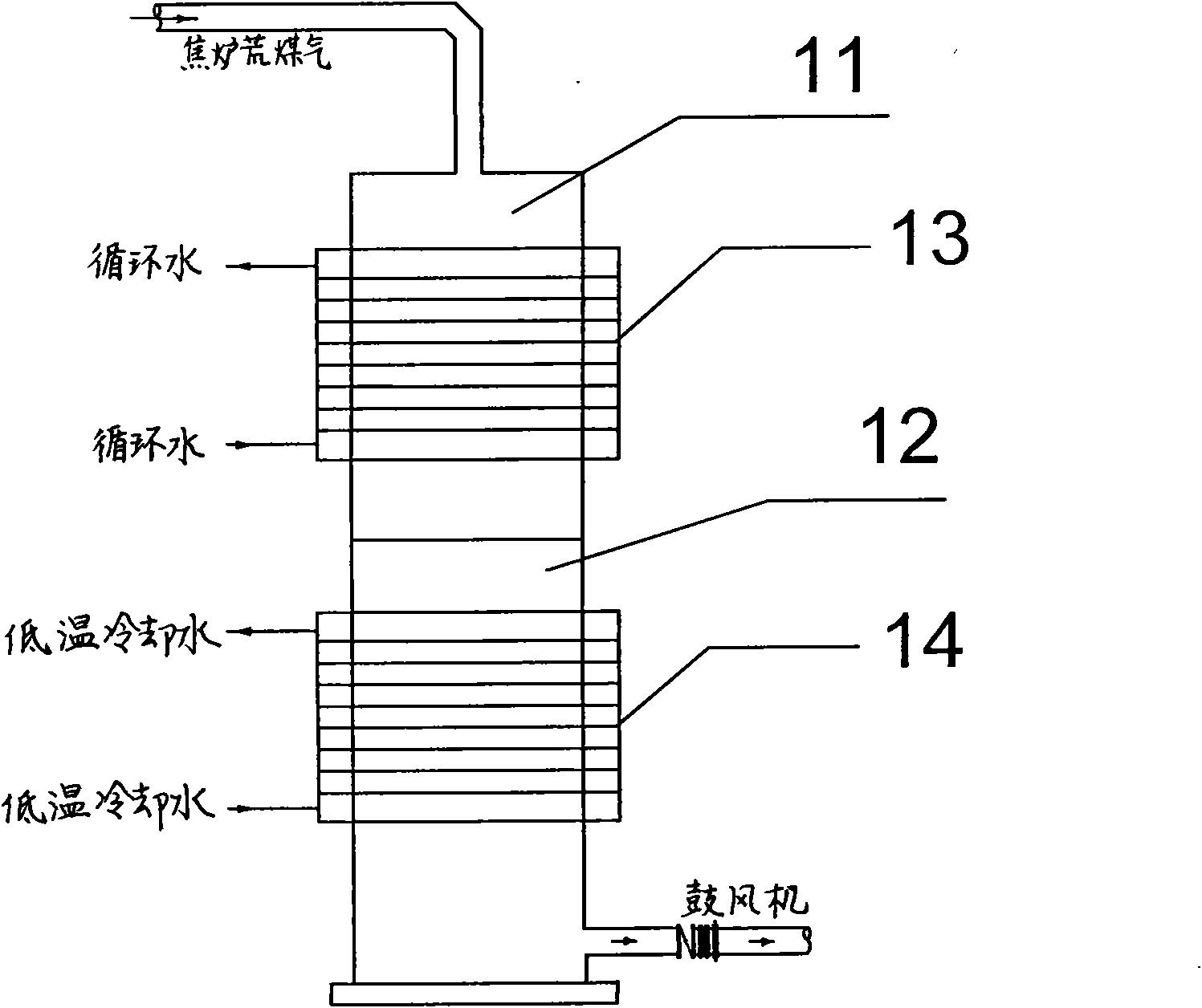

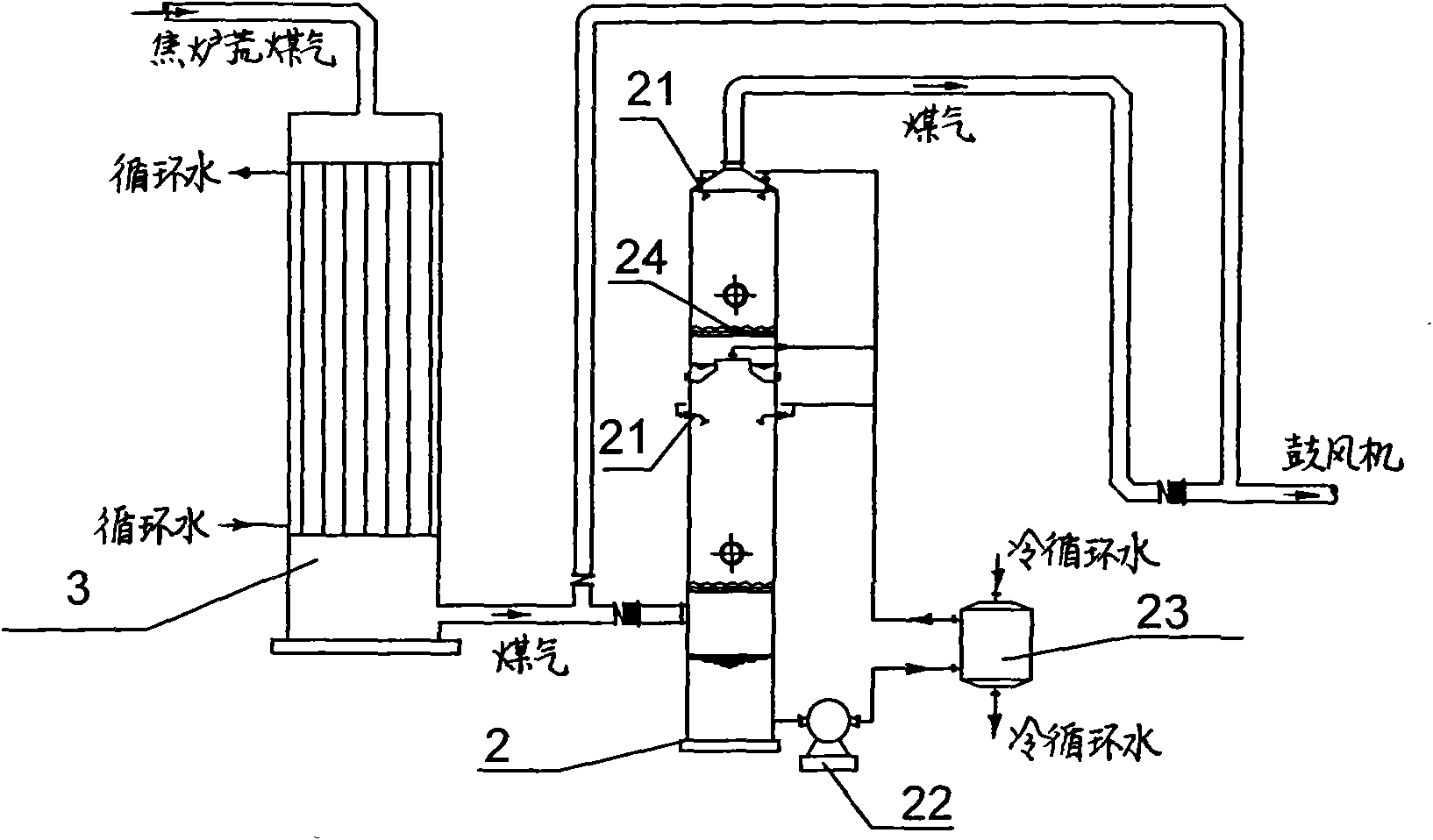

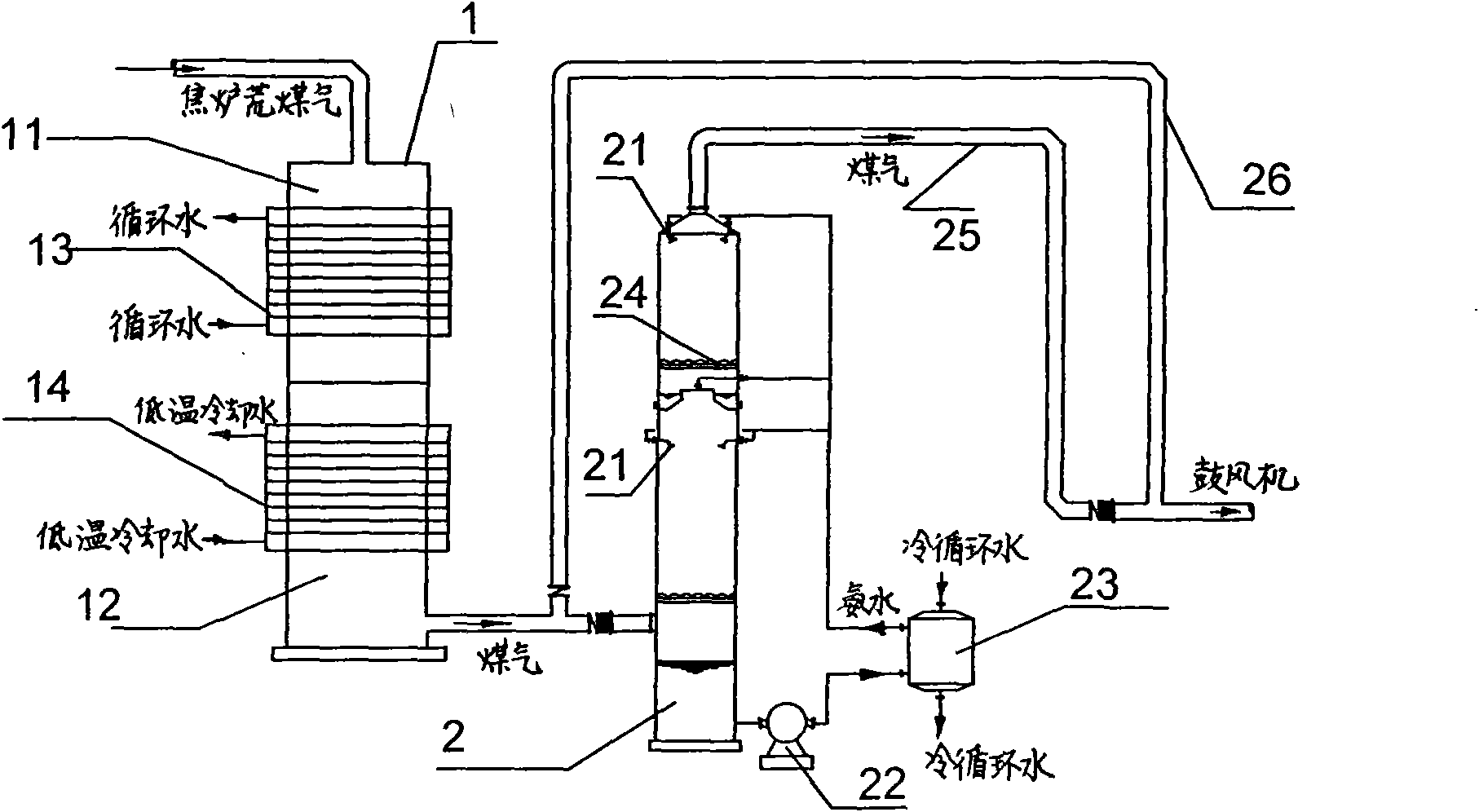

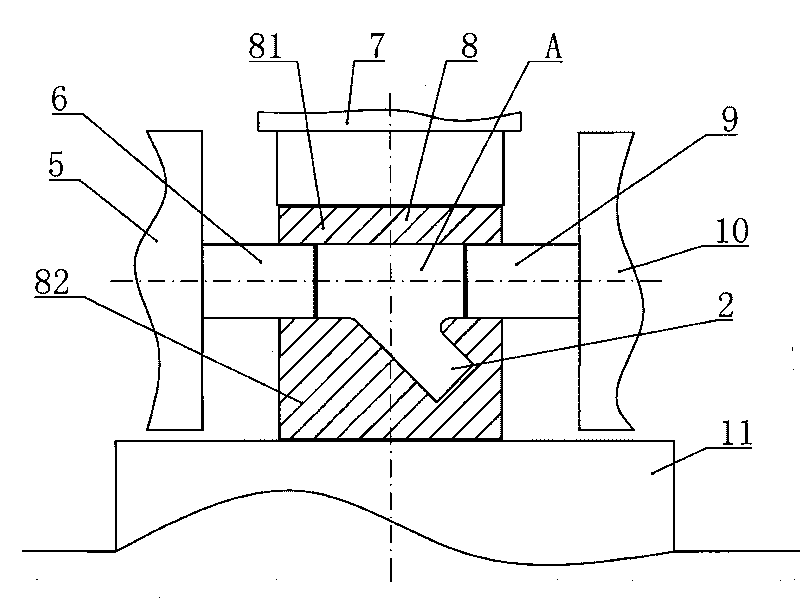

Primary cooling process for coal gas

InactiveCN101608137AImprove cooling efficiencyImprove washing effectGas purification by liquid washingGas dust removalCooling towerTar

The invention discloses a primary cooling process for coal gas. The process comprises the steps of cooling raw gas to between 20 and 30 DEG C through a horizontal-pipe primary cooler provided with a water- circulating section and a low-temperature water-cooling section, spraying the low-temperature water-cooling section of the horizontal-pipe primary cooler with coal-gas condensate of which the tar proportion is between 2 to 10 percent to remove naphthalene separated out from coal gas, and then spraying the inside of a direct-cooling tower with direct-cooling circulating fluid to wash the coal gas and remove suspended tar and dust carried by the coal gas. The process has the advantages of fully utilizing the characteristics of the high cooling efficiency and good naphthalene removal effect of the horizontal-pipe primary cooler and the good washing effect of the direct-cooling tower to perform effective process combination, performing the cooling, naphthalene removal and dust removal of the coal gas more effectively, reducing the blockage of coal-gas after-purification devices, improving equipment operating environment, saving energy and reducing consumption.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Method for implementing direct conveying and charging of high-strength low alloy steel continuously-cast bloom

ActiveCN102228968AAvoid crackingRealize energy saving and consumption reductionSteel platesSheet steel

The invention discloses a method for implementing direct conveying and charging of a high-strength low alloy steel continuously-cast bloom. The method comprises the following steps of: 1) quickly cooling the continuously-cast bloom on a continuous casting roller bed to the temperature of below 500 DEG C at the speed of 2 to 5 DEG C per second; and 2) directly charging the continuously-cast bloom into a heating furnace after quick cooling and after the temperature recovery time of over 5 minutes. By the method, the surface of a steel plate is prevented from cracking when the high-strength low alloy steel continuously-cast bloom is produced by adopting a common thermal conveying and thermal charging process, so that direct conveying and charging and even thermal conveying of the high-strength low alloy steel continuously-cast bloom become possible, and energy conservation and consumption reduction are realized. For a steel mill with limited casting blank piling site, the method can solve the contradiction between yield improvement and insufficient casting blank piling site.

Owner:CHONGQING UNIV

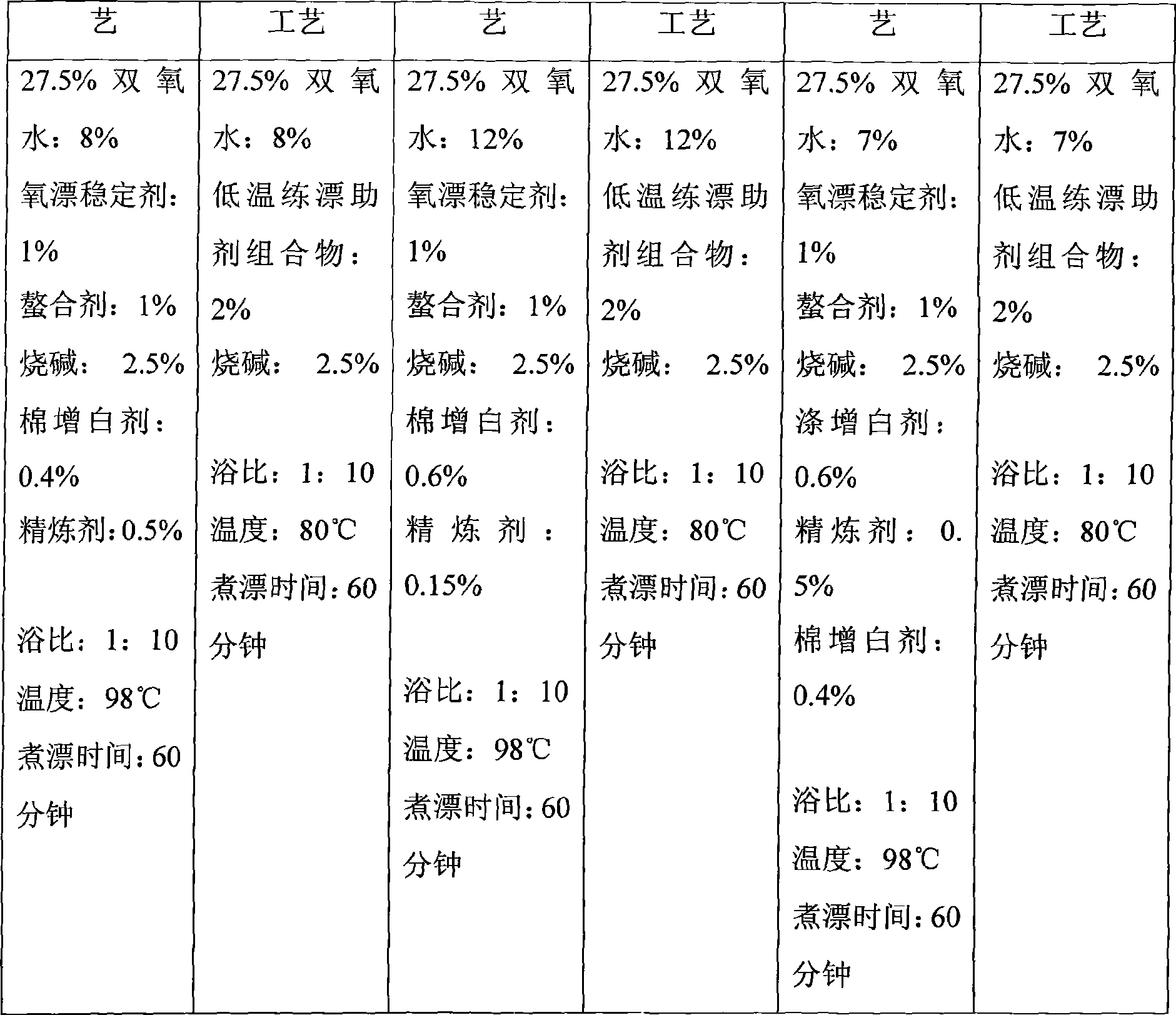

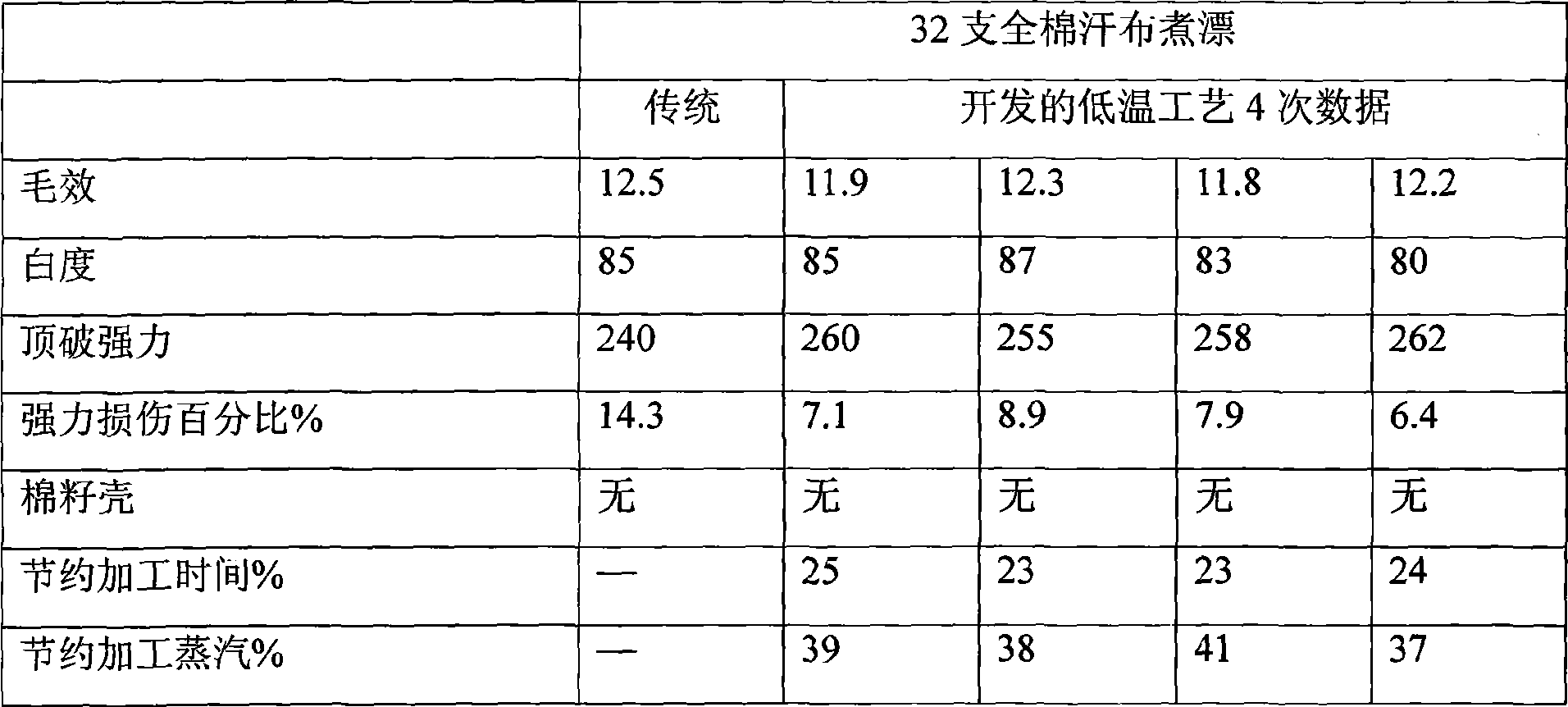

Method for environment-friendly low-temperature scouring and bleaching in spinning dyeing and finishing

ActiveCN101487183ASuitable for processingLittle loss of strengthBleaching apparatusVegetal fibresOxygenTextile dyeing

The invention relates to a method of environment-protective low-temperature scouring and bleaching used for textile dyeing and finishing, comprising the following steps: a dyeing and finishing solution which consists of low-temperature scouring and bleaching promoter composition, 25-30% of hydrogen peroxide and caustic soda, with the mass percentage of 2:8-12:2.5-3 is prepared; subsequently, the dyeing and finishing solution is used for processing cotton knitted fabric with the bath proportion of 1:8-15, the temperature of 75-80 DEG C and the time of 40-60s. The method carries out scouring and bleaching one bath processing at the temperature of 75-80 DEG C, with the scouring and bleaching effect achieving the whiteness and capillary effect standard of the traditional high-temperature alkali-oxygen one bath process at the temperature of 98-100 DEG C or even 130 DEG C; furthermore, the cost is low, the processing time is saved, and the possibility of wrinkle of cotton and cotton blended fabric (such as blended polyurethane and cotton) is reduced.

Owner:NINGBO GUANG YUAN FABRIC

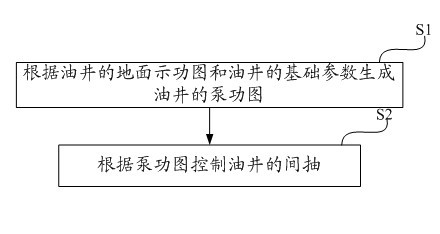

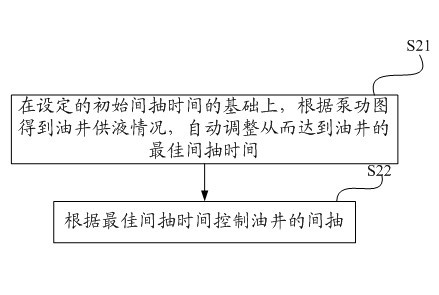

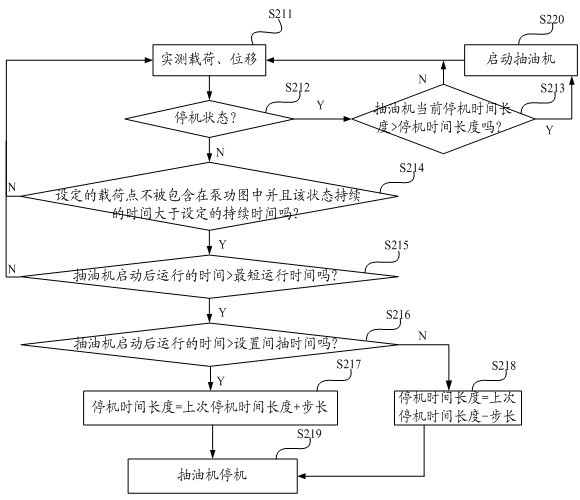

System and method for controlling interval pumping of oil well

ActiveCN102122161ARealize remote intelligent self-dynamic interval controlRealize energy saving and consumption reductionEnergy industryFluid removalStem lengthReal time analysis

The invention discloses a method for controlling interval pumping of an oil well, which comprises the following steps of: generating a pump dynamograph of the oil well according to a ground indicator diagram of the oil well and basic parameters of the oil well, wherein the basic parameters include a water content parameter of the oil well, a gas oil ratio, a viscosity, a stem diameter, a stem length, a pump diameter, a pump depth and the like; and controlling the interval pumping of the oil well according to the pump dynamograph. The invention further discloses a system for controlling the interval pumping of the oil well, which comprises an acquiring module, a ground indicator diagram generation module, a pump dynamograph generation module and an interval pumping control module. With thesystem and the method for controlling the interval pumping of the oil well, the optimal interval extraction starting point and interval extraction time can be analyzed in real time in combination with the oil production law of the oil well, remote intelligent self dynamic interval pumping control of the oil well is implemented, and consequently energy for the oil well is saved, consumption of theoil well is reduced and loss of operating apparatuses is also reduced.

Owner:PETROCHINA CO LTD

Photovoltaic solar energy, wind power and rainwater generating integrated generating set

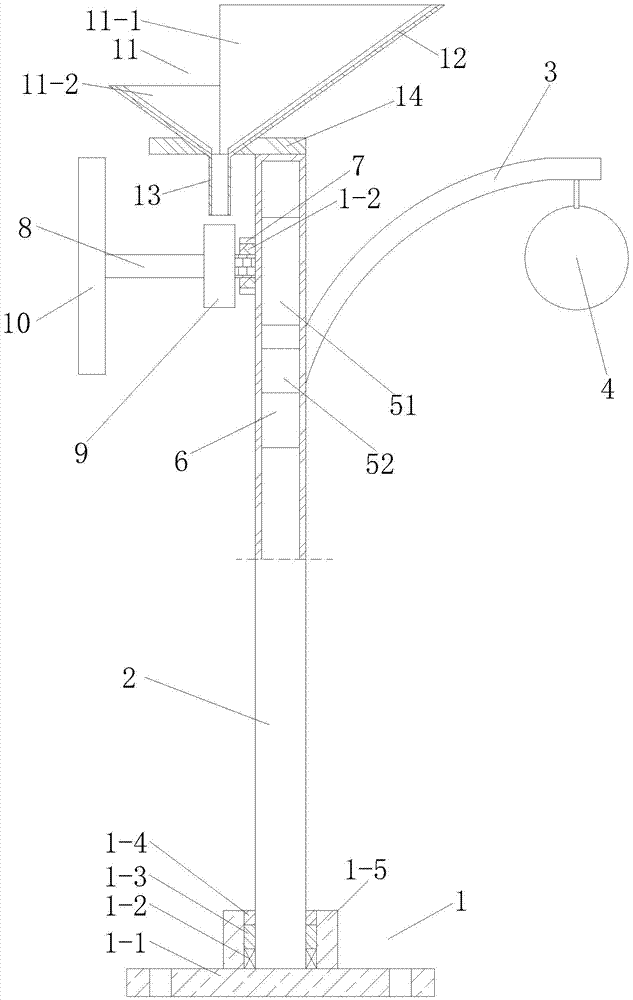

InactiveCN105443318AIncrease profitEffective continuous lightingFinal product manufacturePV power plantsImpellerPhotovoltaic solar energy

The invention relates to the technical field of solar photovoltaic generating, in particular to a photovoltaic solar energy, wind power and rainwater generating integrated generating set. The integrated generating set comprises a bottom plate body, a wind energy collecting module, a rainwater energy collecting module and a solar energy collecting module. The wind energy collecting module comprises a bearing block and fan blades. The bearing block is connected with a rotating shaft through a bearing, and one end of the rotating shaft is fixedly connected with the fan blades. The rainwater energy collecting module comprises a hopper and an impeller, the impeller is fixedly arranged on a shaft body of the rotating shaft, and the hopper is fixedly arranged on the top of a lamp supporting pole through a hopper support. A photovoltaic solar panel is fixedly arranged on the inner surface of the hopper. The rotating shaft and the photovoltaic solar panel are connected with the generating set. By means of the integrated generating set, generating is carried out through the solar energy, the wind power and the rainwater, effective continuous lighting of a streetlamp is guaranteed, the conventional energy source is saved, and pollution is reduced. The integrated generating set has the advantages of being simple in structure, reasonable in arrangement, low in manufacturing cost and the like.

Owner:苏州华安普电力科技股份有限公司

Forging process of large tee and large skew tee

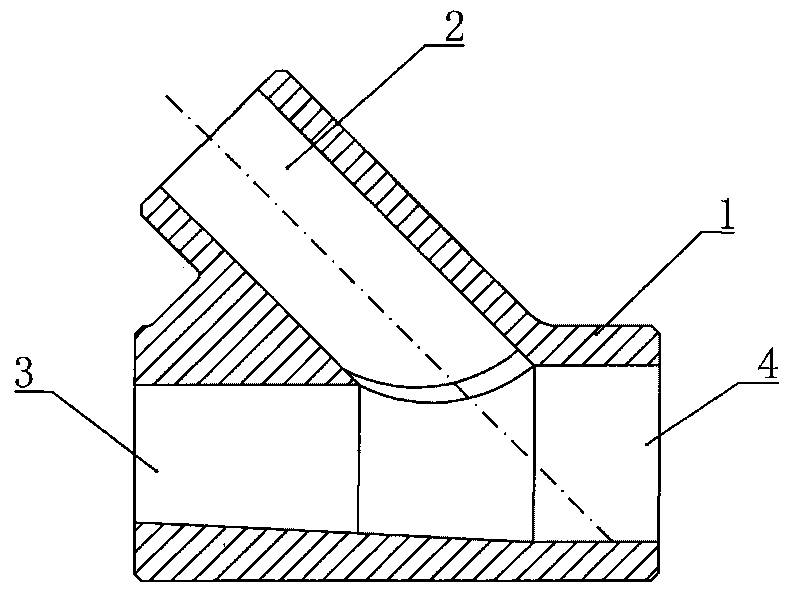

ActiveCN101695739AQuality improvementImprove mechanical propertiesForging/hammering/pressing machinesEngine componentsWater basedGraphite

The invention relates to a forging process of a large tee and a large skew tee, which comprises the steps of: putting cut blanks in a heating furnace to heat to 1200 DEG C; preheating a forging die to 200-250 DEG C, respectively coating water base graphite and glass lubricant on the forging die and the cut blanks; putting the cut blanks on a multi-direction die liquid forging press mould, moving an upper cylinder to enable an upper die to mutually press a lower die; starting an upper oil cylinder, a left oil cylinder and a right oil cylinder of a forging press for forging; releasing pressure to move the mould after molding by the forging die, taking a semi-finished product out to be put into a heat treatment furnace for furnace cooling and annealing, carrying out heat treatment, nondestructive recheck and mechanical behavior check according to the steel material requirement, and preparing for the next machining; and machining the treated semi-finished product according to the drawing requirement. The invention has the advantages of reducing energy resources and improving the production efficiency.

Owner:HEBEI FOCUS PIPING

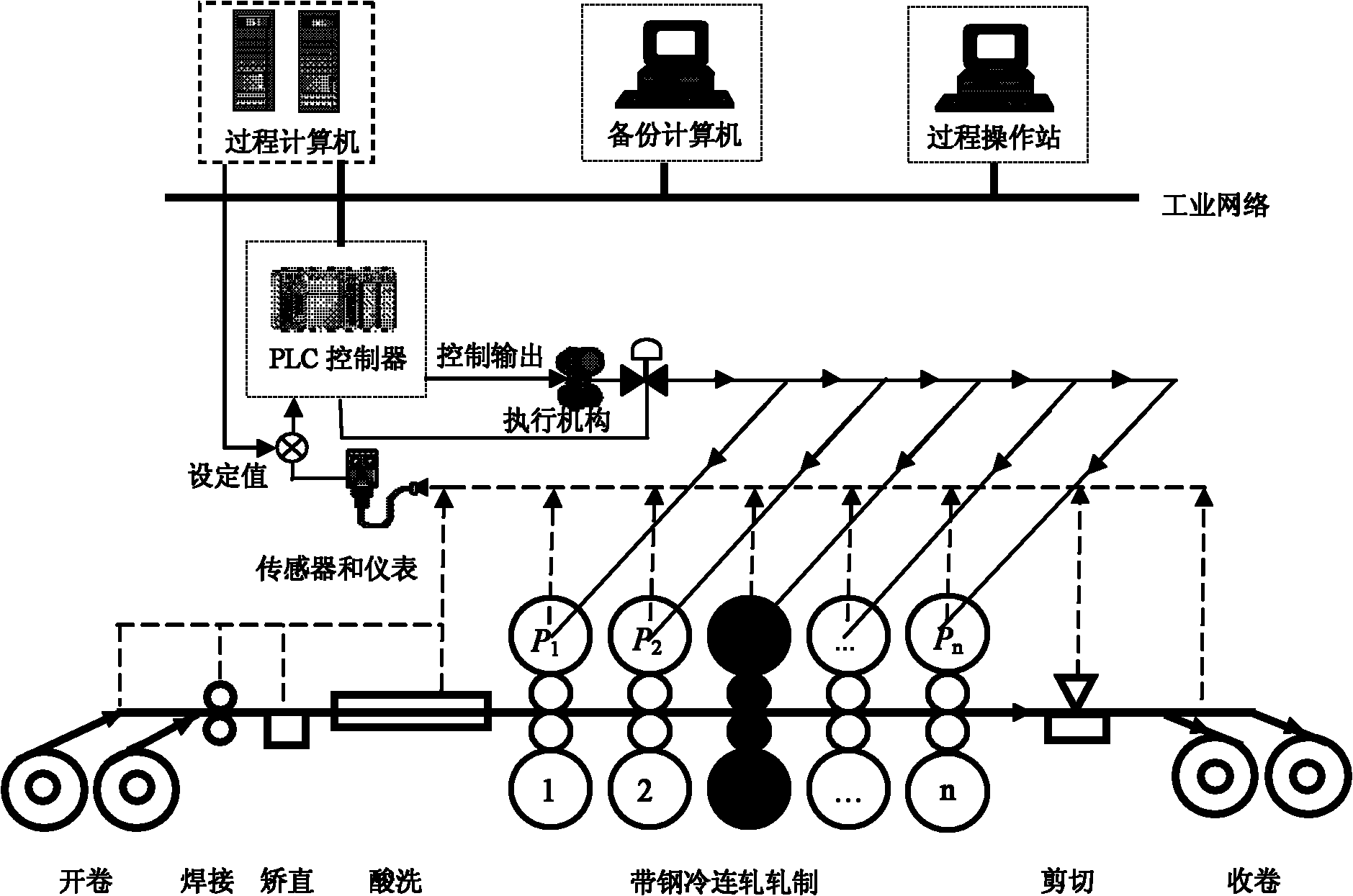

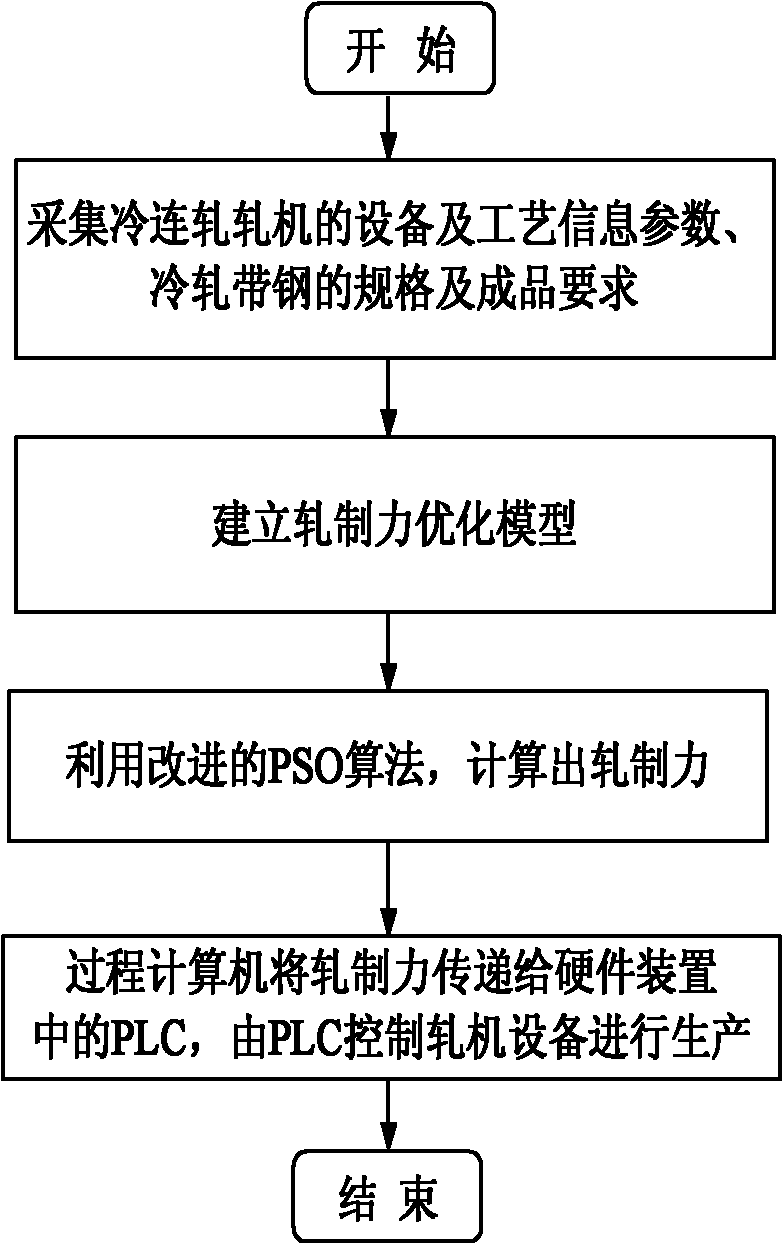

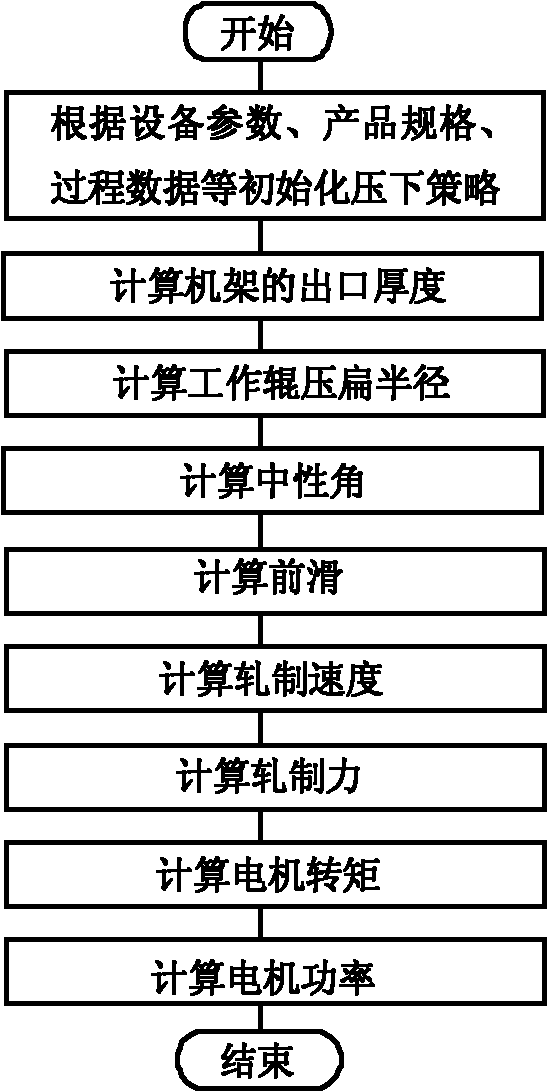

Rolling method and device for strip steel tandem cold rolling

ActiveCN102513351AQuick calculationMake full use of production capacityMeasuring devicesTension/compression control deviceElectric machineryStrip steel

A rolling method and a device for strip steel tandem cold rolling belong to the technical field of metallurgical process control. Based on site conditions of the strip steel tandem cold rolling practical production, the rolling method and the device for the strip steel tandem cold rolling fully consider reasonability of optimization calculation of rolling force, select lowest energy consumption as an optimization goal, adopt a large number of constraint conditions in the practical rolling production process, utilize an improved particle swarm optimization (PSO) optimization algorithm to carry out optimal calculation on the basis of rolling mechanism relationship, and can quickly calculate out optimized rolling schedule information to avoid extra cost caused by lack of comprehensive consideration of experience rules. By means of the rolling method and the device for the strip steel tandem cold rolling, full play to the production capacity of the whole tandem cold rolling system can be given, product quality is improved, total power of a motor of a rolling mill is reduced simultaneously, and energy saving and consumption reduction are achieved accordingly.

Owner:NORTHEASTERN UNIV

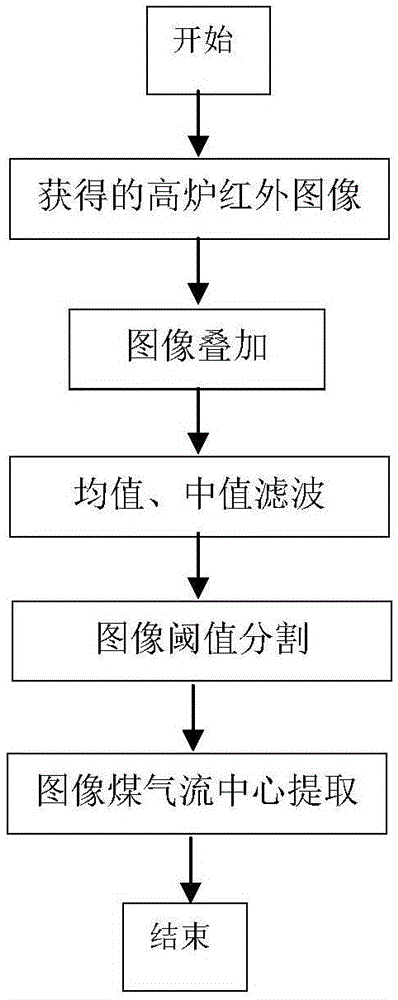

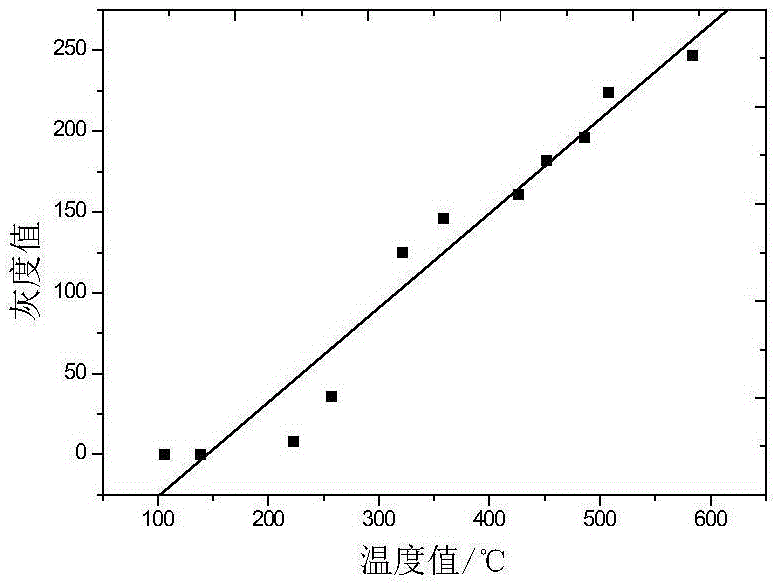

Method for processing coal gas flow center dynamic tracking and monitoring coal gas utilization rate

ActiveCN105002321ARealize dynamic trackingRealize real-time monitoringBlast furnace detailsChecking devicesData acquisitionDistribution characteristic

The invention discloses a method for processing coal gas flow center dynamic tracking and monitoring coal gas utilization rate. The method comprises the steps of 1 data collecting and processing; 2 infrared imagery processing; 3 temperature field calibration; 4 coal gas flow center dynamic tracking; 5 coal gas utilization rate monitoring. The method has the advantages that implementation is easy, temperature field calibration is achieved through the treatment on the collected infrared imagery combining crossed thermometry data and blast furnace design data, dynamic tracking on charge-level coal gas flow center fall point distribution is achieved, the coal gas flow center distribution characteristics and the corresponding coal gas utilization rates are classified, the relation between the coal gas center change and the blast furnace coal gas utilization rate is confirmed, real-time monitoring on the coal gas utilization rate is realized, the dynamic changing condition of the coal gas flow center and the relation between the dynamic changing condition of the coal gas flow center and the corresponding coal gas utilization rate can be recognized timely and accurately, on-line monitoring and visual control on the burden distribution operation of the blast furnace are achieved, and the advantages of being high in accuracy rate and strong in real-time performance are achieved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

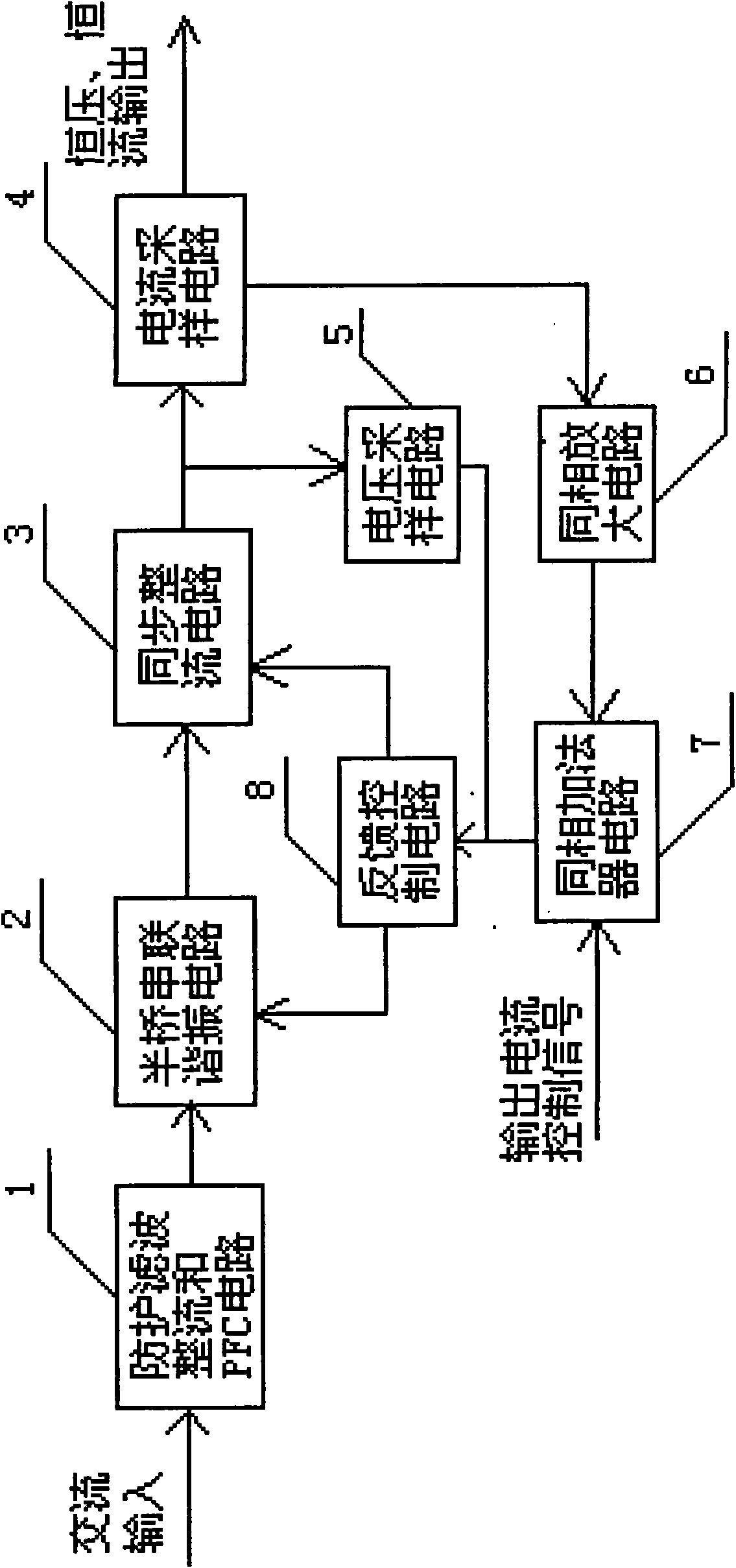

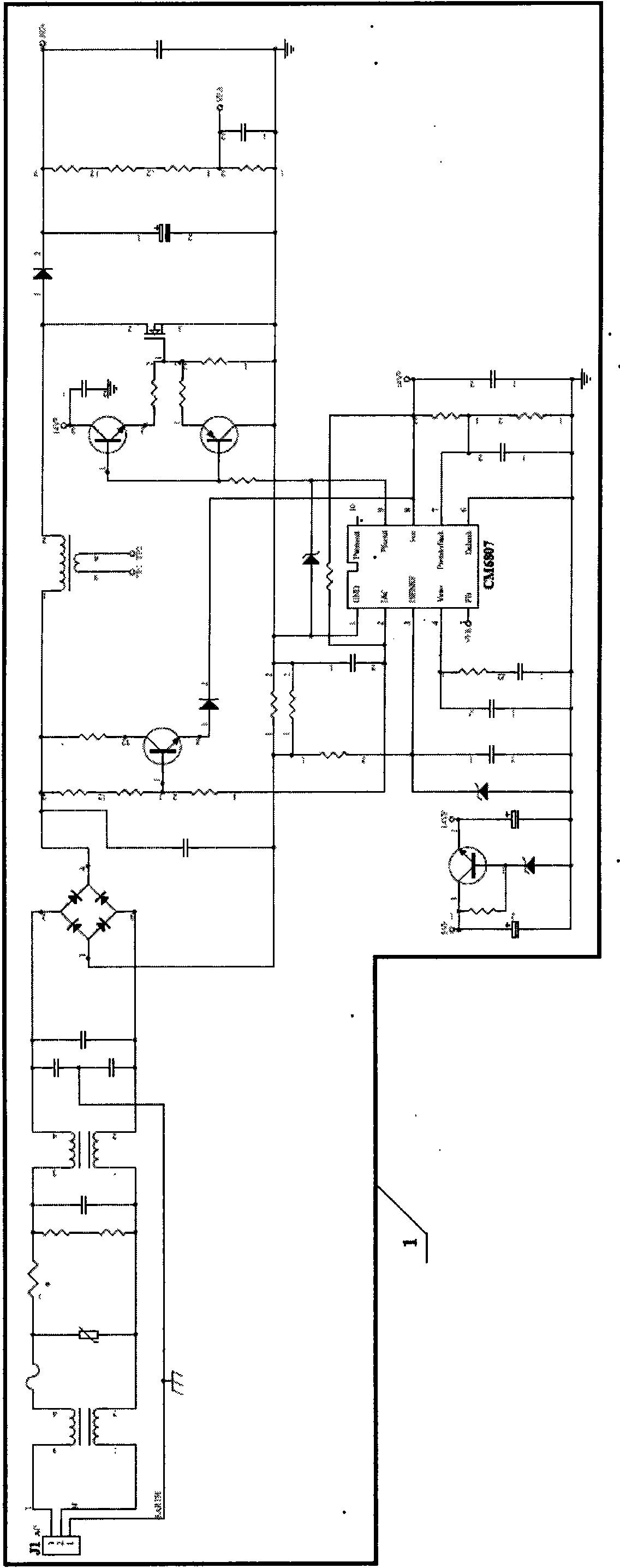

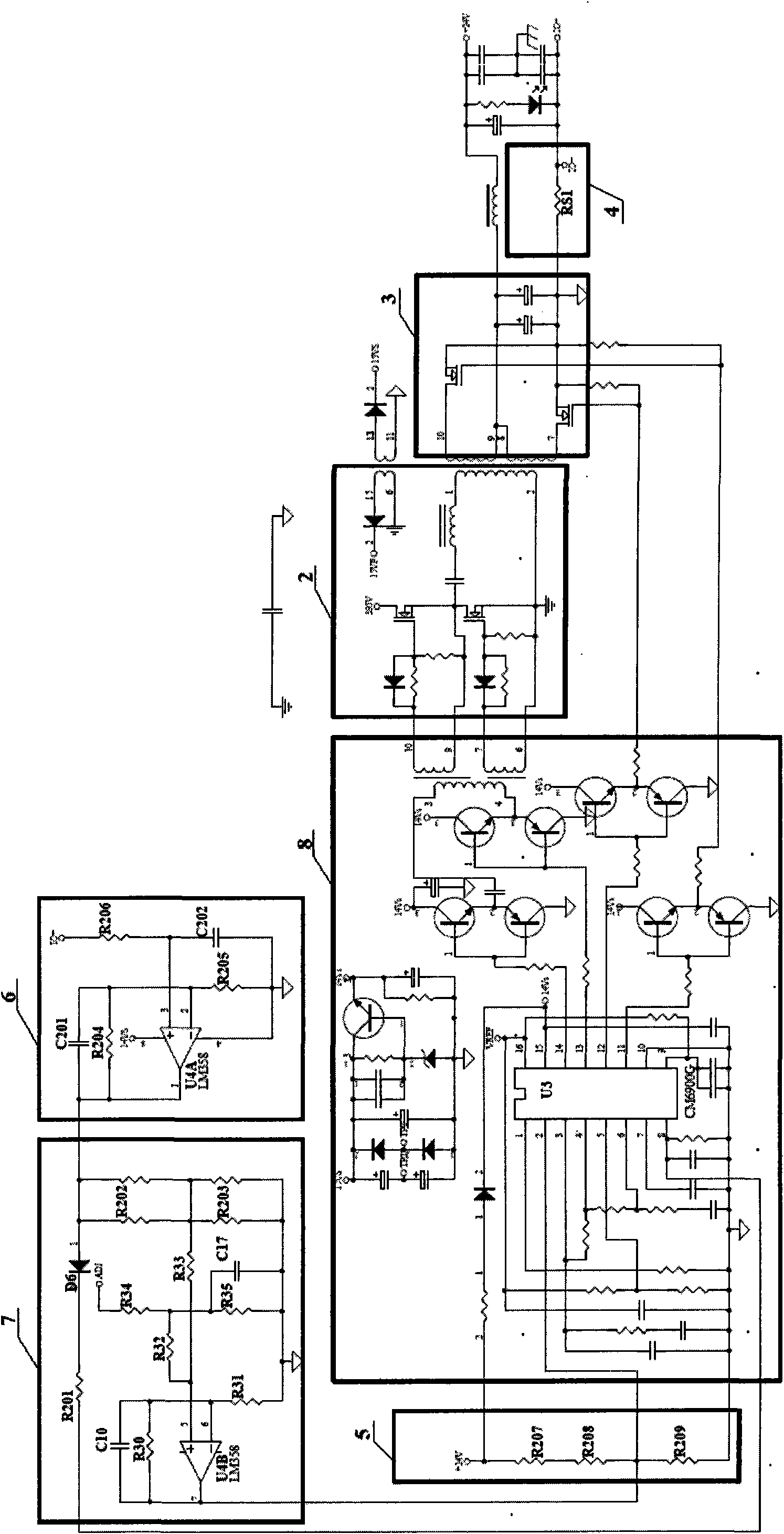

New type high-power LED driving power source

ActiveCN101621871AFacilitate intelligent dimmingRealize energy saving and consumption reductionAc-dc conversion without reversalElectric light circuit arrangementSampling circuitsEngineering

The invention discloses a new type high-power LED driving power which comprises a protection filtering rectification and a PFC circuit, the input ends of the protection filtering rectification and the PFC circuit are connected with the power source, the output ends of the protection filtering rectification and the PFC circuit are connected with a half-bridge series-resonance circuit the output end of which is connected with a synchronous rectification circuit, the output end of the synchronous rectification circuit is connected with a current sampling circuit and a voltage sampling circuit, one path output of the current sampling circuit is connected with load, the other path output of the current sampling circuit is connected with a same-phase amplifying circuit, one path input of a same phase summer circuit is connected with the output end of the same-phase amplifying circuit, the other path input is connected with a control signal of an external output circuit, the output ends of the same phase summer circuit and the voltage sampling circuit are connected with the input end of a feedback control circuit together, and two path outputs of the feedback control circuit are respectively connected with the half-bridge series-resonance circuit and the synchronous rectification circuit, the new type high-power LED driving power of the invention can regulate the size of the output current according to the external control signal, can regulate light intelligently, maximizes the realization of energy conservation and energy consumption reduction, and has the advantages of high conversion efficiency, low temperature rise and permanent constant current output and the like.

Owner:YANTAI AOXING ELECTRICAL EQUIP

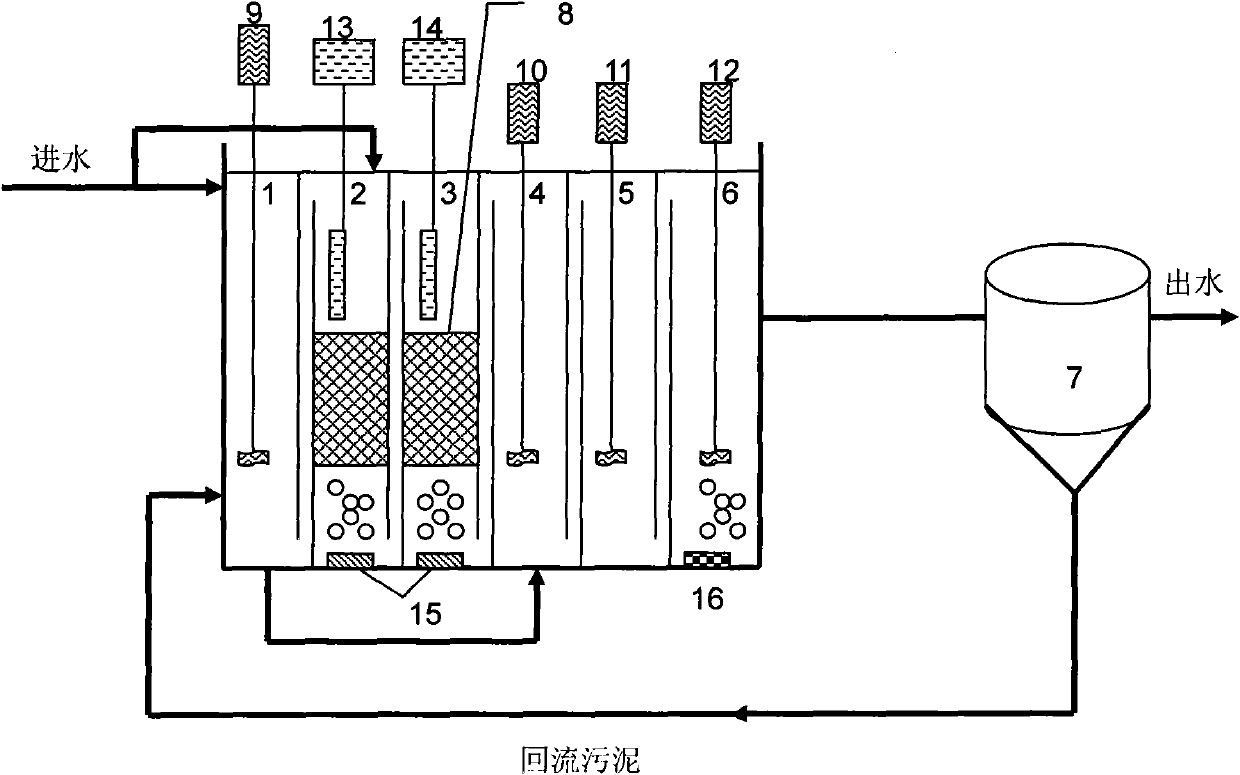

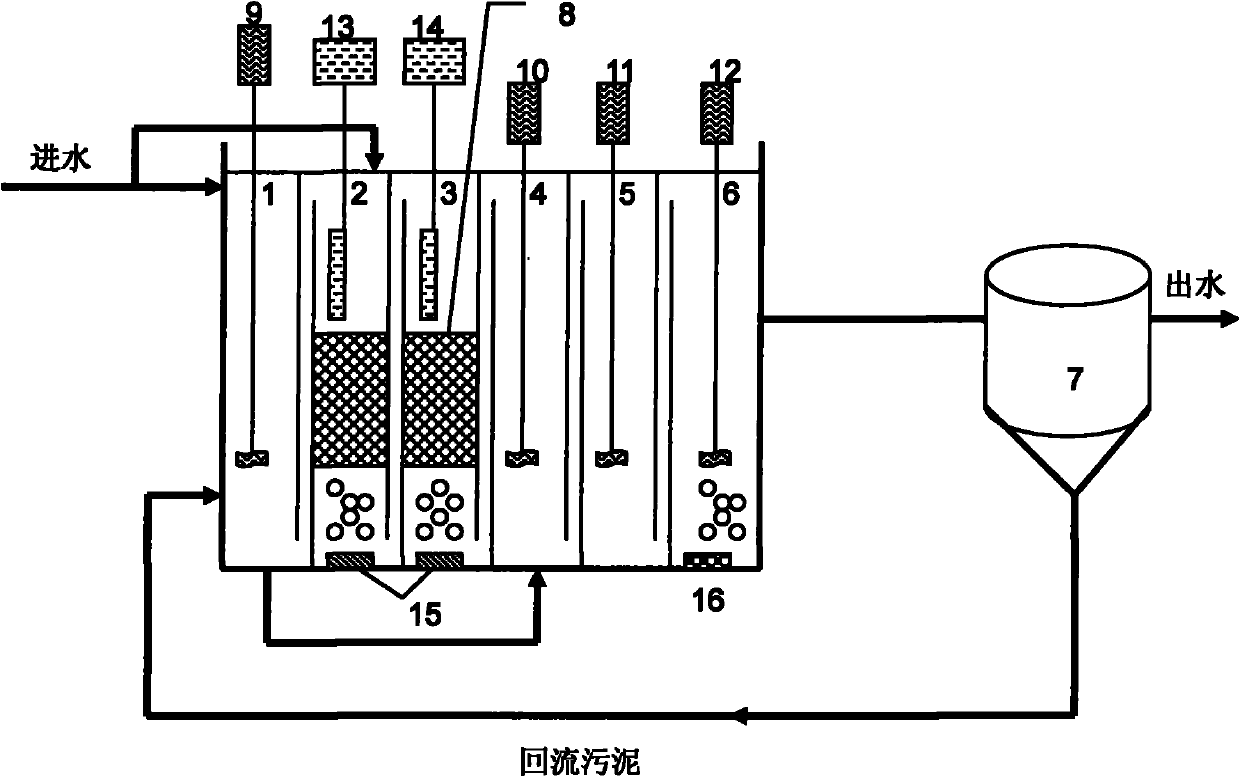

Energy-saving consumption-reducing short-range nitration dephosphorizing coupling technique with synchronous denitrification and device thereof

ActiveCN101792233AAccumulation and stabilityRealize energy saving and consumption reductionWater contaminantsMultistage water/sewage treatmentElectron donorNitration

The invention discloses an energy-saving consumption-reducing short-range nitration dephosphorizing coupling technique with synchronous denitrification and a device thereof, belonging to technical field of domestic and industrial sewage treatment. A metal carrier bed is installed in an aerobic section with integrated reaction, and is made of iron wood shaving washed through acid cleaning; and the outer part of the iron wood shaving is covered by wire netting. Under conditions of normal temperature and low dissolved oxygen, the aims of short-range nitration and synchronous denitrification can be realized; an anaerobic section is used for finishing phosphorous releasing; the aerobic section is used for finishing short-range nitration, an anoxic section is used for finishing denitrification for removing phosphorous, a fast aerobic section is used for removing remaining ammonia and nitrogen and phosphorous. The invention uses iron wood shaving with low cost to realize stable accumulation of nitrite; the aerating amount is small, the carbon source is saved, and denitrification for phosphorous removing is carried out by taking the nitrite produced via short-range nitration as electron donor, thus the nitrogen and phosphorous can be removed synchronously; and the problem that the nitrite in water could damage the environment and has toxicity is solved. The invention can realize the aims of saving energy and reducing consumption to the largest extent, and is suitable for purifying and treating domestic sewage continuously for a long time.

Owner:TSINGHUA UNIV

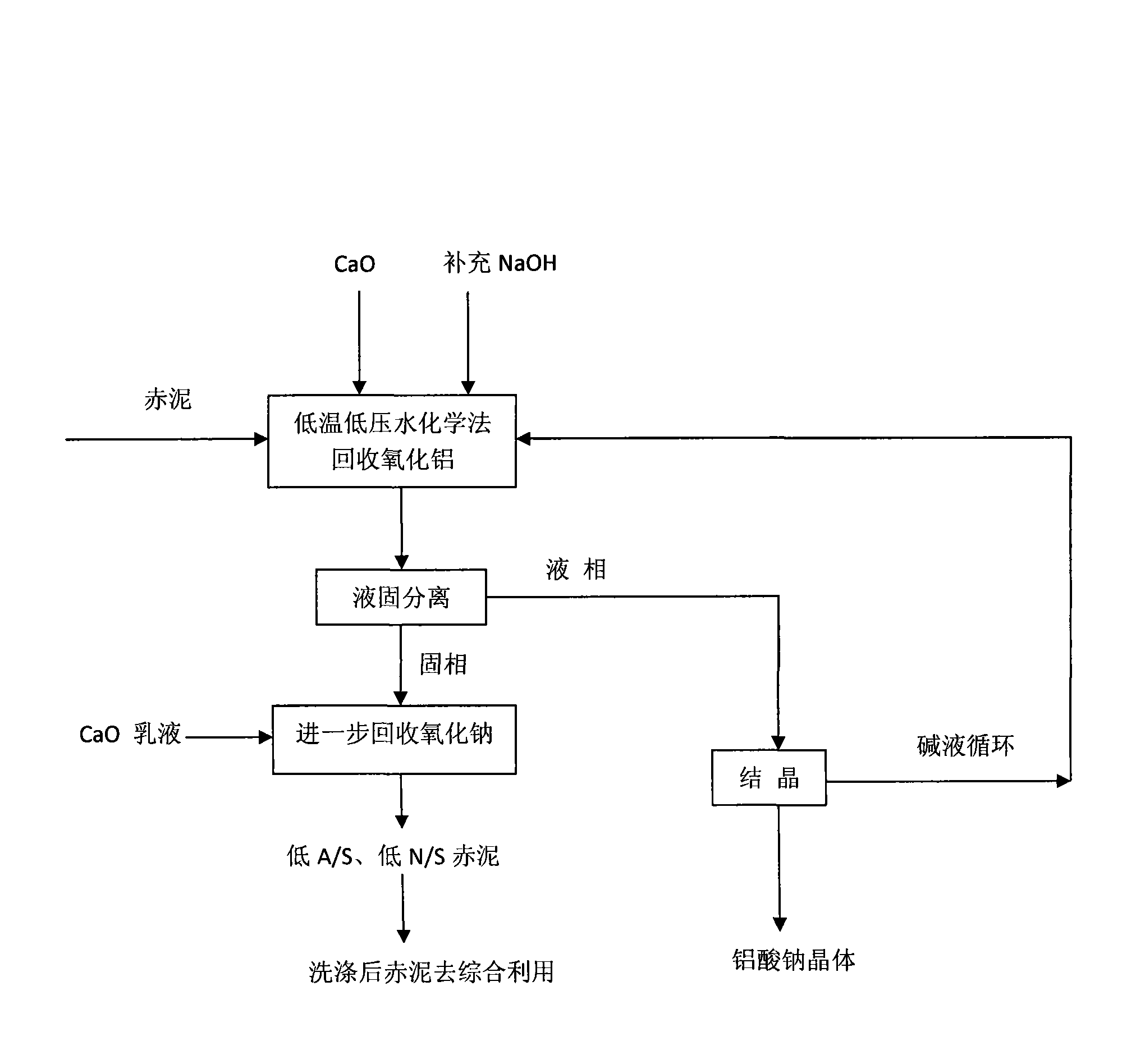

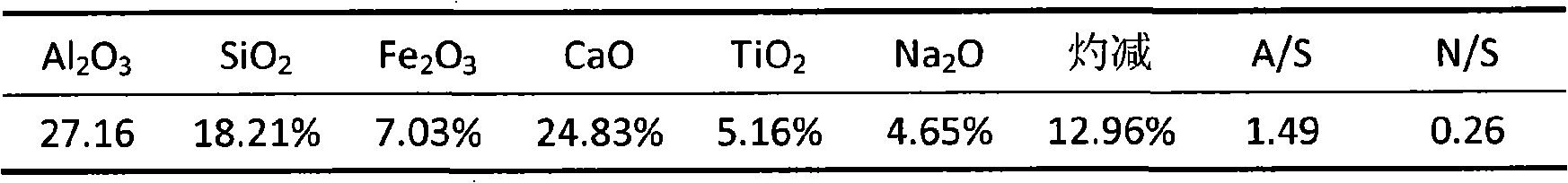

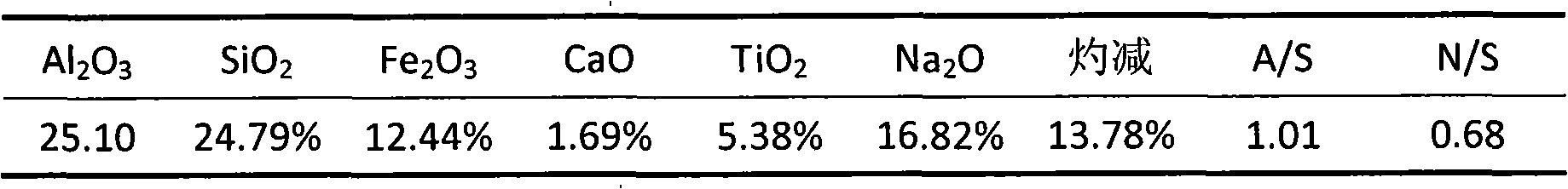

Low-temperature low-pressure hydro chemical method for recovering aluminum oxide and sodium oxide from red mud

InactiveCN101538058AHigh recovery rateEliminate pollutionAlkali metal oxidesAluminium oxides/hydroxidesResource recoveryRed mud

The invention belongs to the filed of processing, recovering and utilizing red mud waste from the production of aluminum oxide, and relates to a low-temperature low-pressure hydro chemical method for recovering aluminum oxide and sodium oxide from red mud. The method is also used for processing low-grade bauxite. The method comprises the following steps that: a red mud filter cake and lime milk are added in and evenly mixed with a concentrated solution of sodium hydroxide; the mixture is continuously stirred, heated up to the temperature of between 190 and 230 for reaction for 3 to 4h, and undergoes solid-liquid separation; the red mud filter cake undergoes deep sodium removal by the hydrothermal method, namely the red mud filter cake is added with water and lime milk and under the condition of liquid to solid ratio(L / S) of reaction pulp of 6, the mixture is reacted at a temperature of 170 DEG C for 2h, filtered and washed. By the method for processing the red mud, the A / S and N / S of the red mud are both reduced to below 0.18, so that the method provides a novel way of realizing the low-pollution emission and resource recovery of the red mud.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

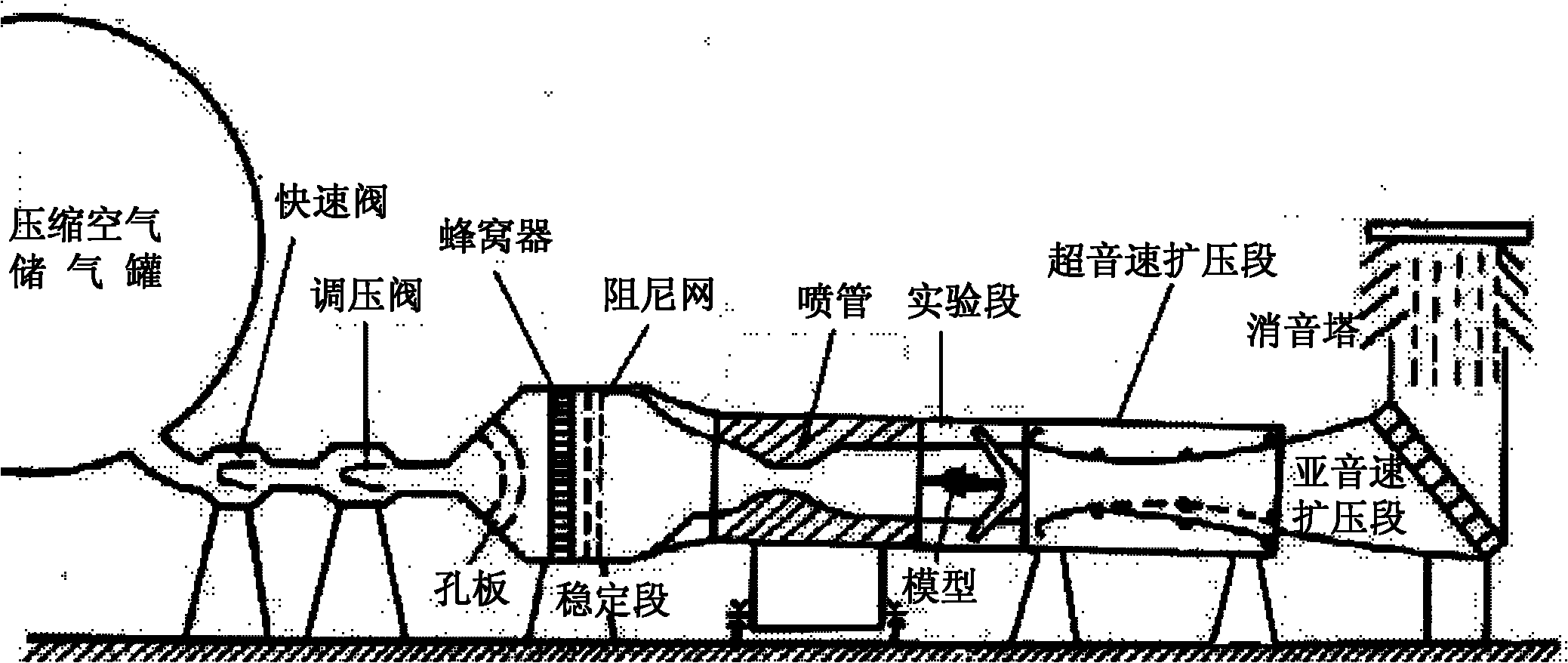

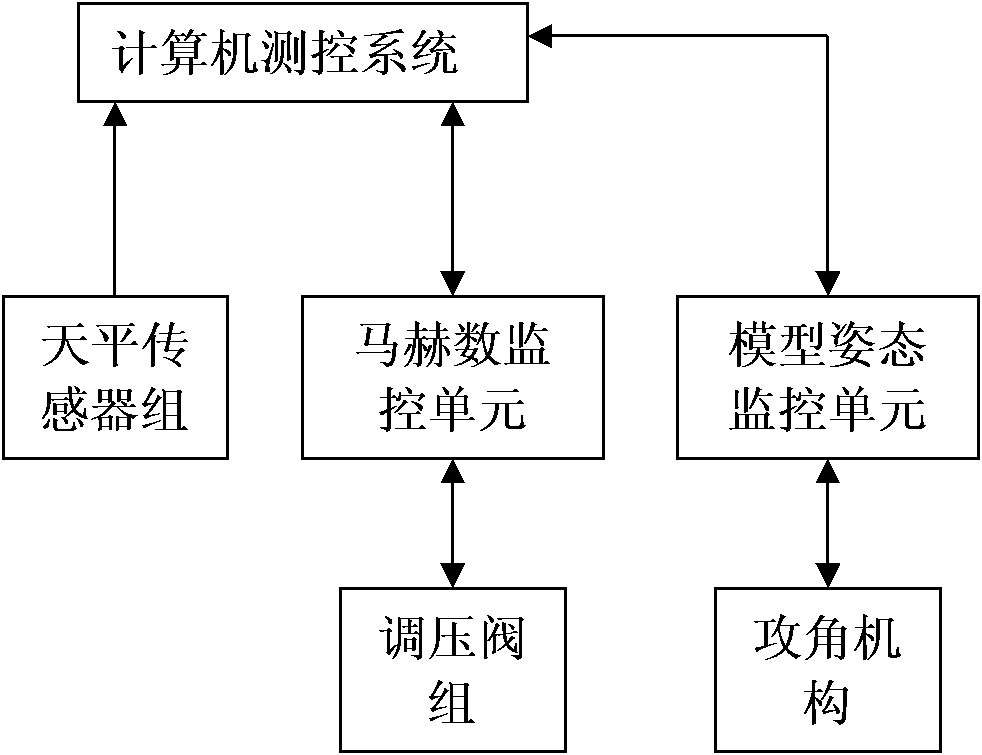

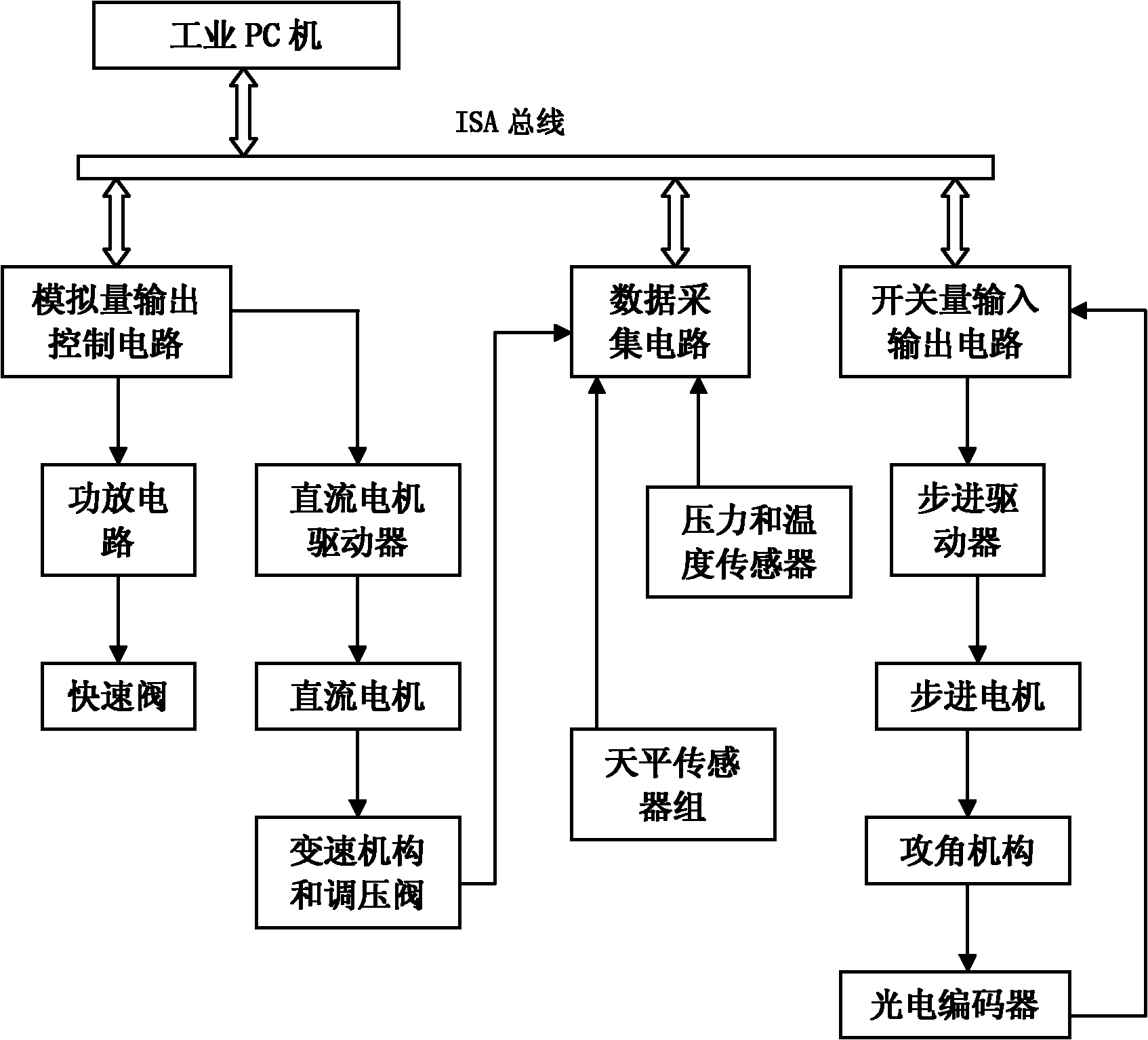

Mach number controller in wind tunnel

ActiveCN101887267ARealize energy saving and consumption reductionMeet control precision requirementsEnergy industryTotal factory controlPower parameterData acquisition

The invention relates to a mach number controller in a wind tunnel with higher characteristics and flow field precision. Firstly, a fuzzy control method with self-adjusting factors is adopted to control the mach number of the air stream in the test section of the wind tunnel in the starting stage of the test of the wind tunnel, when the actual mach number Ma of the air stream in the test stage is not more than 3 DeltaMW, a PID control method is adopted to control the mach number of the air flow in the test stage; secondly, when an industrial PC (personal computer) judges that the actual mach number Ma is within the DeltaMW for five successive times and an attack angle of the test model is in place, namely, the condition of the test model is arranged in the preset condition, the industrial PC acquires a plurality of air power parameters acted on the test model by a data acquisition circuit; , the test model is controlled to be changed to the next attack angle, and / or the air stream in the test stage is controlled to be changed to the next mach number, and the control of the mach number and the acquisition process of the air power parameter data are repeated.

Owner:JIANGSU XINPENG HEAVY ELECTROMECHANICAL MFG +1

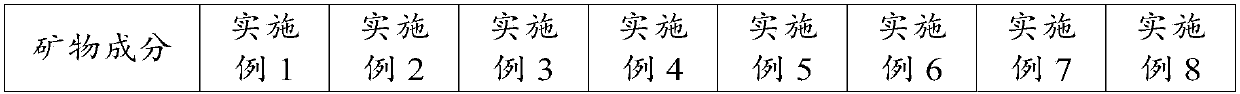

High-bending-strength supersulfate cement and preparation method thereof

ActiveCN107827379AHigh activityAccelerate the rate of hydration hardeningSolid waste managementCement productionGypsumSlag

The invention provides high-bending-strength supersulfate cement and a preparation method thereof and relates to the field of building materials. The high-bending-strength supersulfate cement comprises granulated blast-furnace slag, gypsum and high-belite sulfate aluminum cement clinker. By utilizing the high-bending-strength supersulfate cement, the problem that existing supersulfate cement is low in hydration and hardening speed and early strength and prone to sand shedding caused by the fact that excitants cannot fully excite granulation blast-furnace slag activity in the prior art is solved, and bending strength of the cement is improved greatly; the high-bending-strength supersulfate cement has the advantages of high early-later strength and is ultrahigh in bending strength especially.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

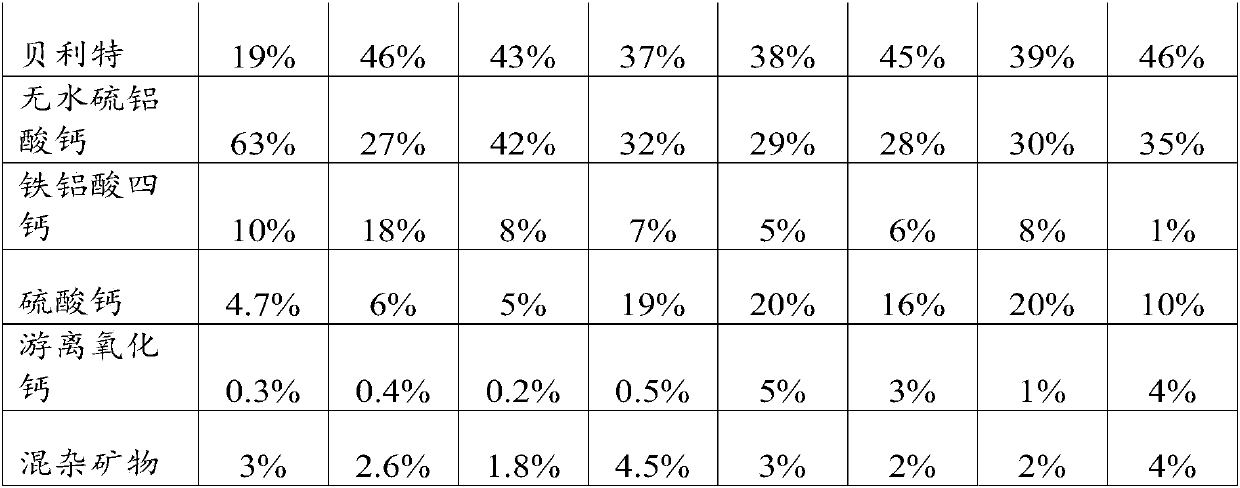

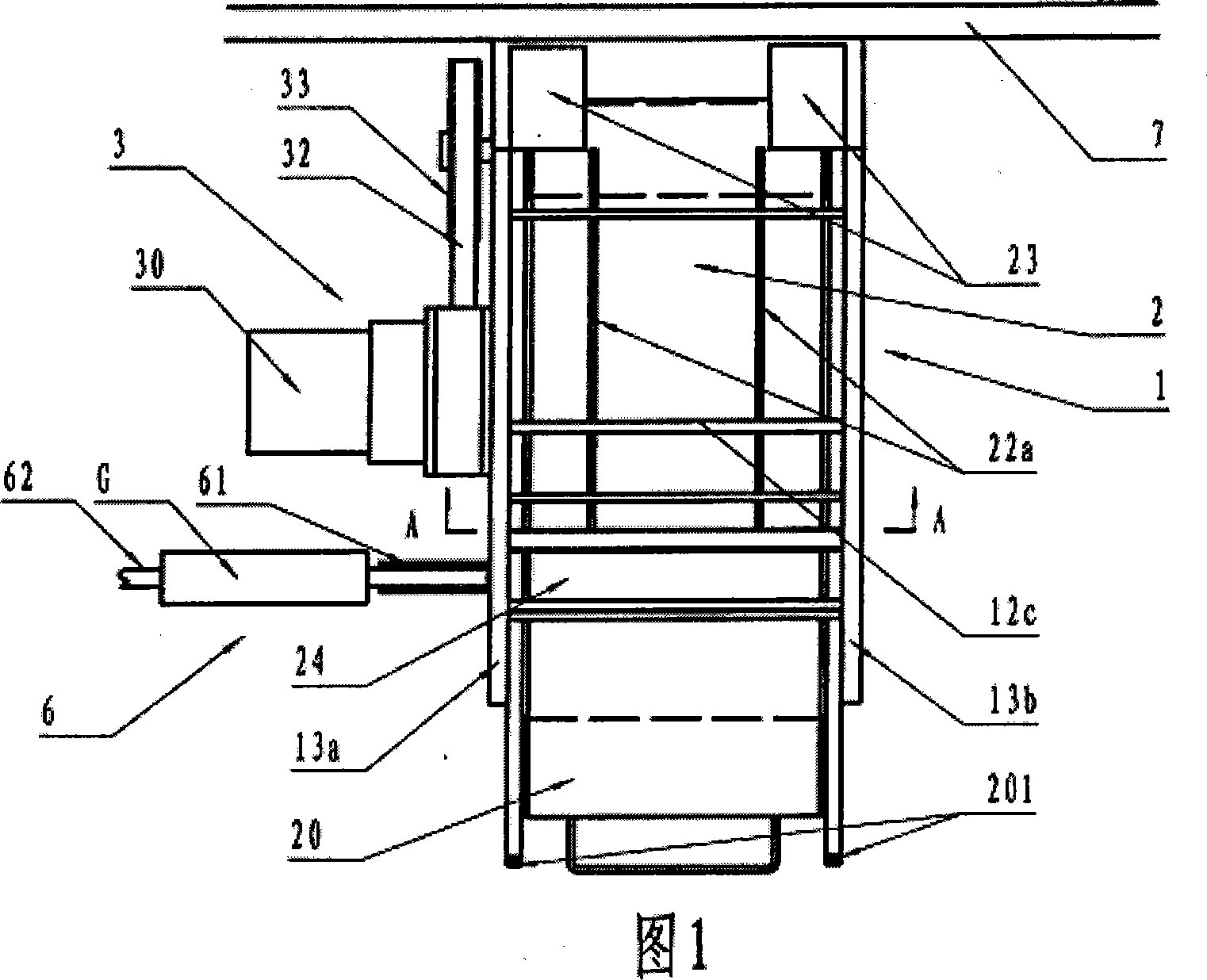

Equipment for transporting flexible pipe

InactiveCN101045334AOptimize structural configurationReduce scrap rateConveyorsControl devices for conveyorsEngineeringWork in process

A short flexible tube transferring apparatus for transferring the semi-finished flexible tubes to next workstation where the flexible tube is installed to a tube shoulder is composed of a flexible tube transferring unit driven by driver unit and able to change the transfer direction by using the transfer tracks, a flexible tube storage cabin, and a flexible tube locator.

Owner:天津市普飞特机电技术有限公司

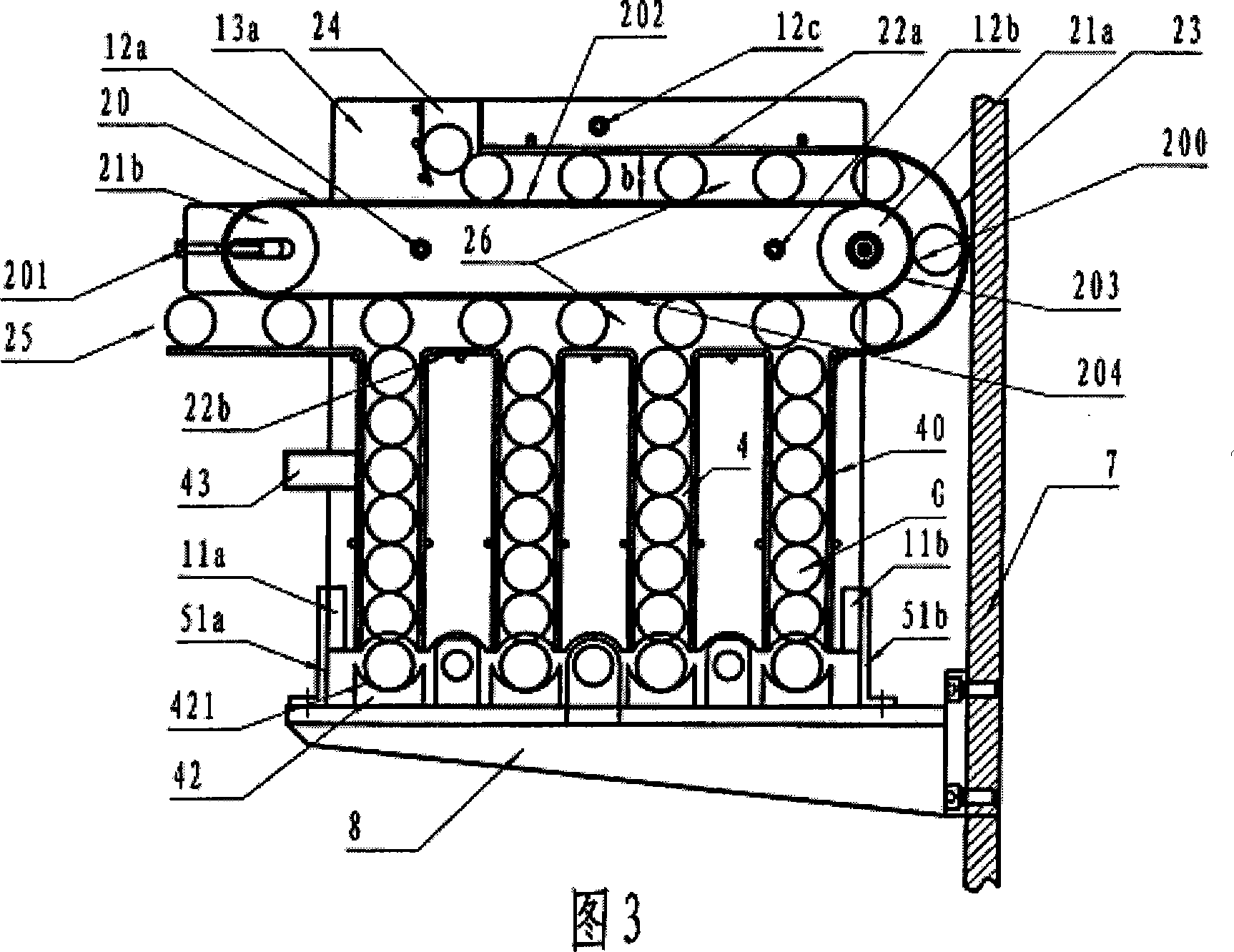

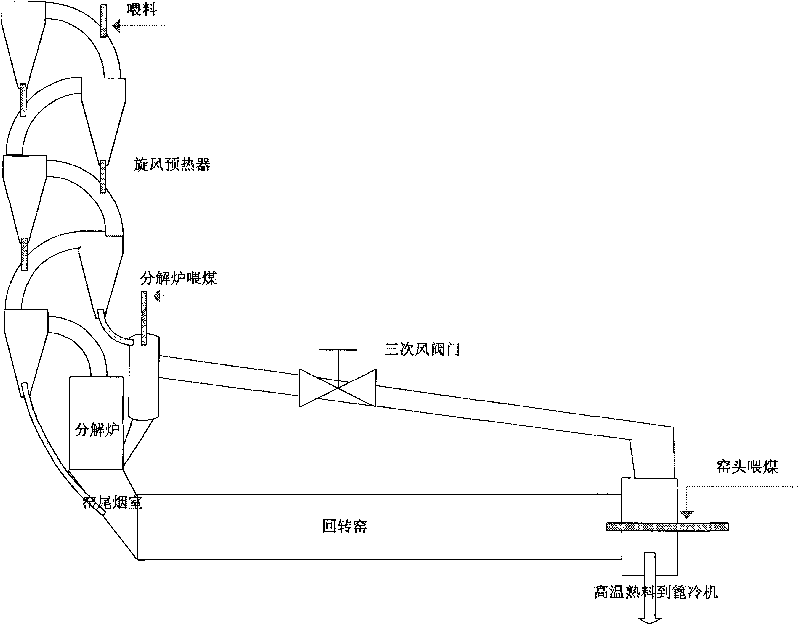

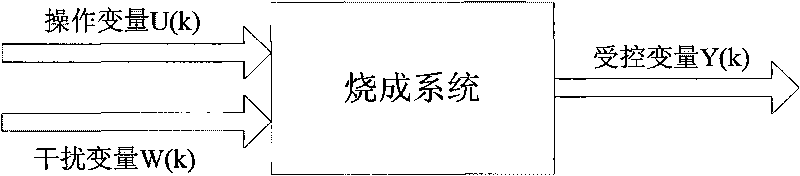

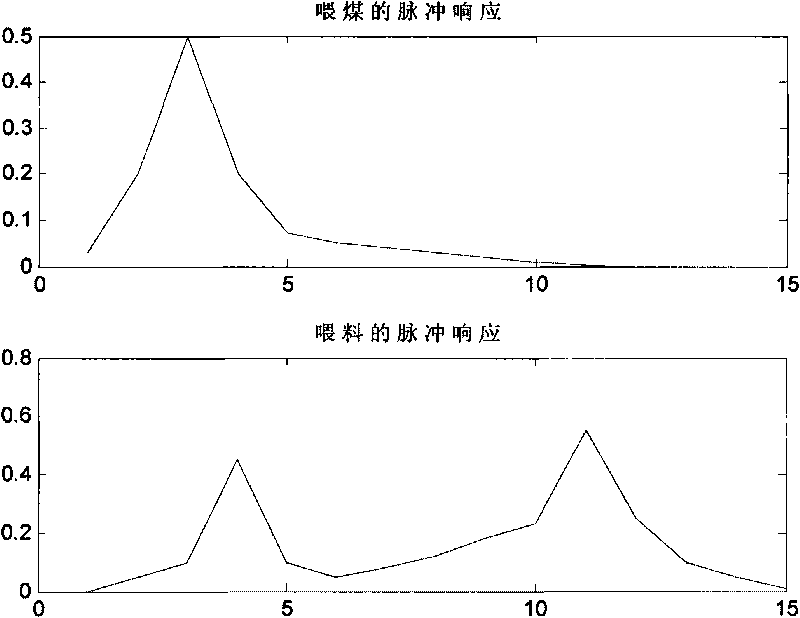

Multivariable predictive control method with firing system based on pulse response die

InactiveCN101750964ASimplify the modeling stepsImprove robustnessAdaptive controlAutomatic controlPrediction system

The present invention discloses a multivariable predictive control method with a firing system based on a pulse response die, which belongs to the field of industrial automatic control. The multivariable predictive control method with a firing system based on a pulse response die mainly comprises the steps of the building of the pulse response die and the design of a predictive control loop. The pulse response die based on a constrained least square method is built according to the on-site data and the system mechanism of the firing system. The future time output of the firing system is predicted by the pulse response die according to the current input and output of the firing system and the input of a future time system, and the better operating value of the current time of the firing system is obtained by solving a quadratic optimal problem according to a predictive control mechanism by combining set value output by the firing system and constrained conditions; after the better operating value is filtered, the better operating value is applied to the firing system to enable the firing system to work in the optimal state and finish one control circulation; the above step is repeated at the nest time to finish the rolling optimization of predictive control and ensure the stable and optimal running of the firing system in concrete production.

Owner:ZHEJIANG UNIV

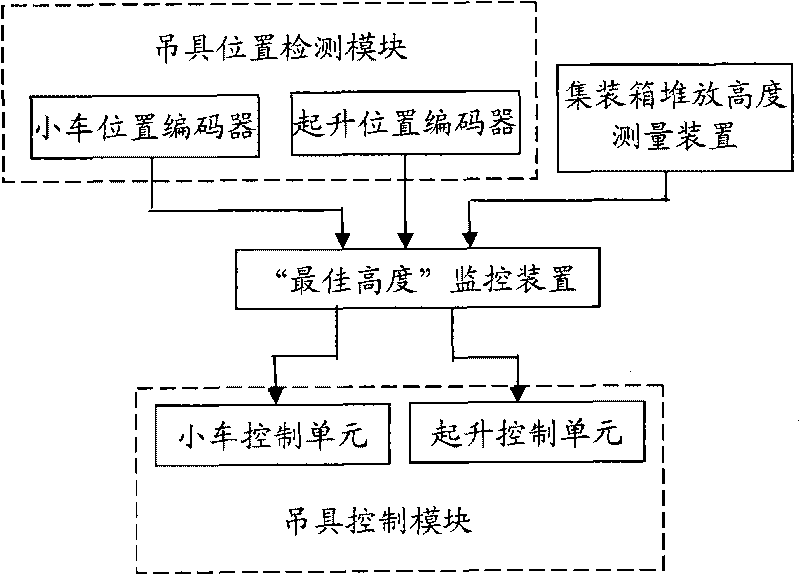

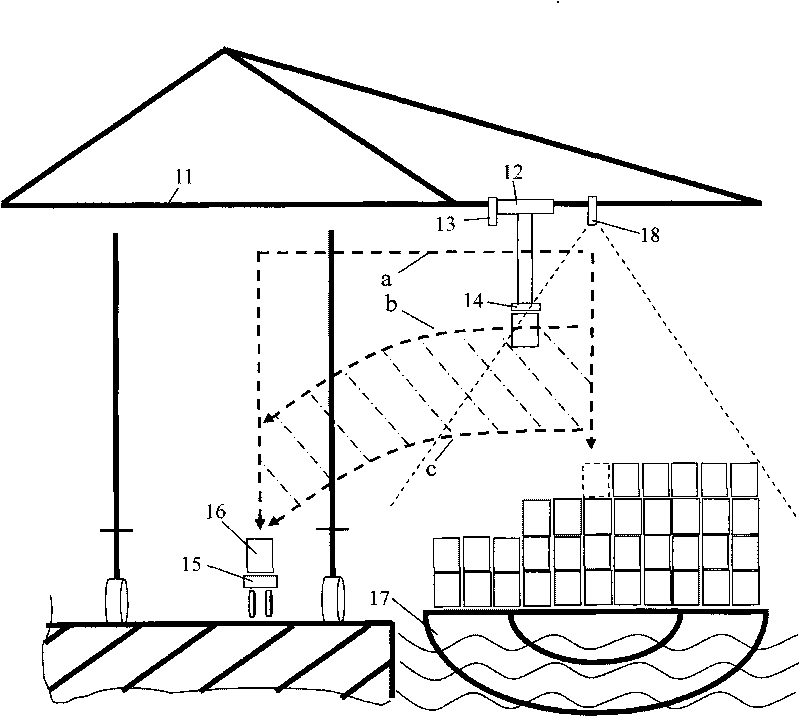

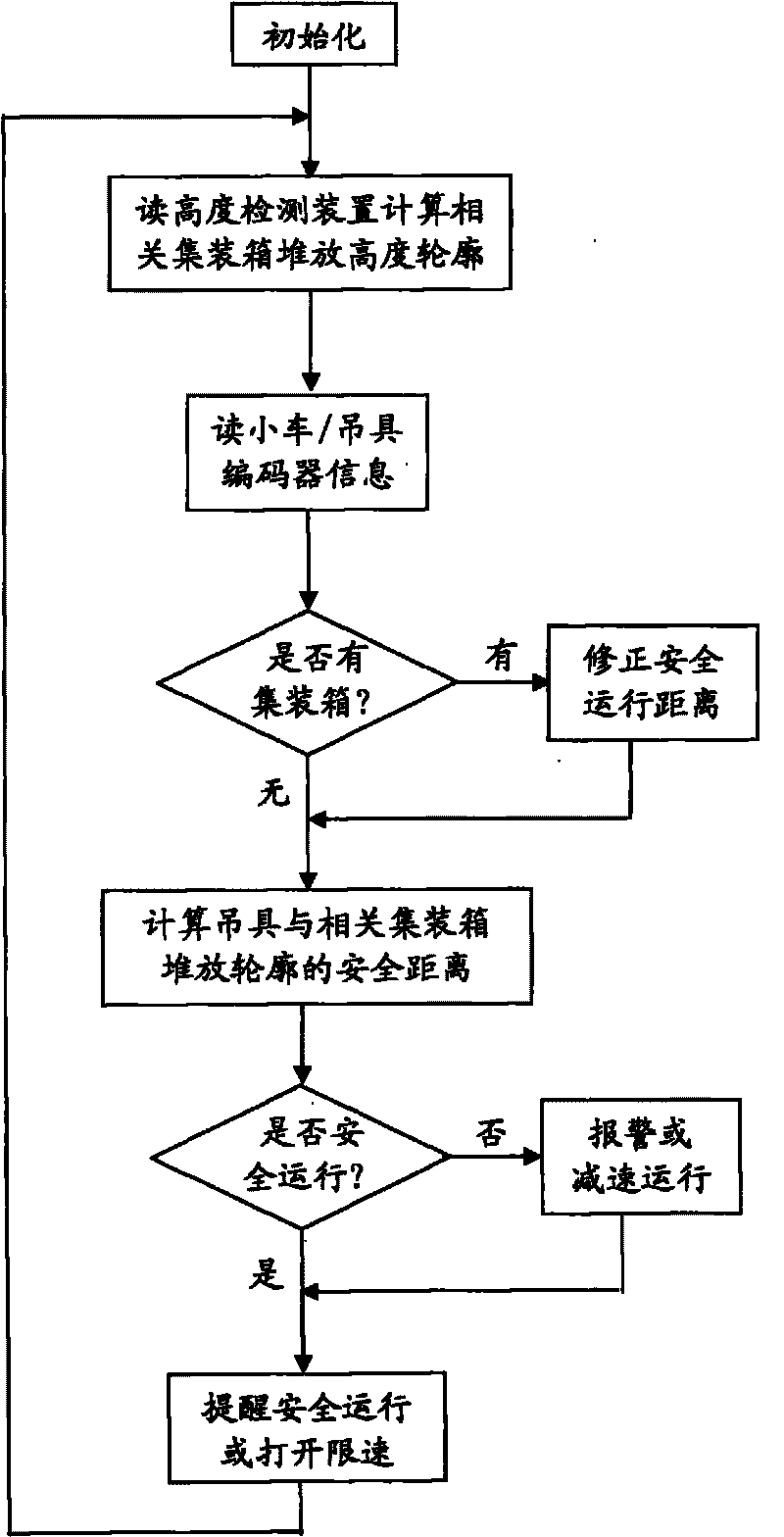

System and method for monitoring optimum hoisting height of shore bridge container

The invention relates to a monitoring system of the optimum hoisting height of a shore bridge container. The monitoring system comprises a hanger position detection module, a container piling height measurement module, an optimum height monitoring device, a hanger control module and / or a warning device, wherein the hanger position detection module and the container piling height measurement device are electrically connected with the hanger control module and / or the warning device respectively through the optimum height monitoring device; and preferably, the hanger position detection module comprises a trolley position coder and a hoisting position coder. The invention also relates to a relevant monitoring method. The monitoring system is compact and novel and can monitor a distance between a hanger and the piled outline height of a container, warns a driver to realize the operation state of the optimum hoisting height, reduces the hoisting height, saves resources, guarantees high-speed hoisting and safe operation, improves the operation efficiency, reduces the mechanical wear, prolongs the service life of steel wires, reduces the labor intensity, has safety and reliability and is suitable for large-scale popularization.

Owner:上海能港电气工程科技有限公司

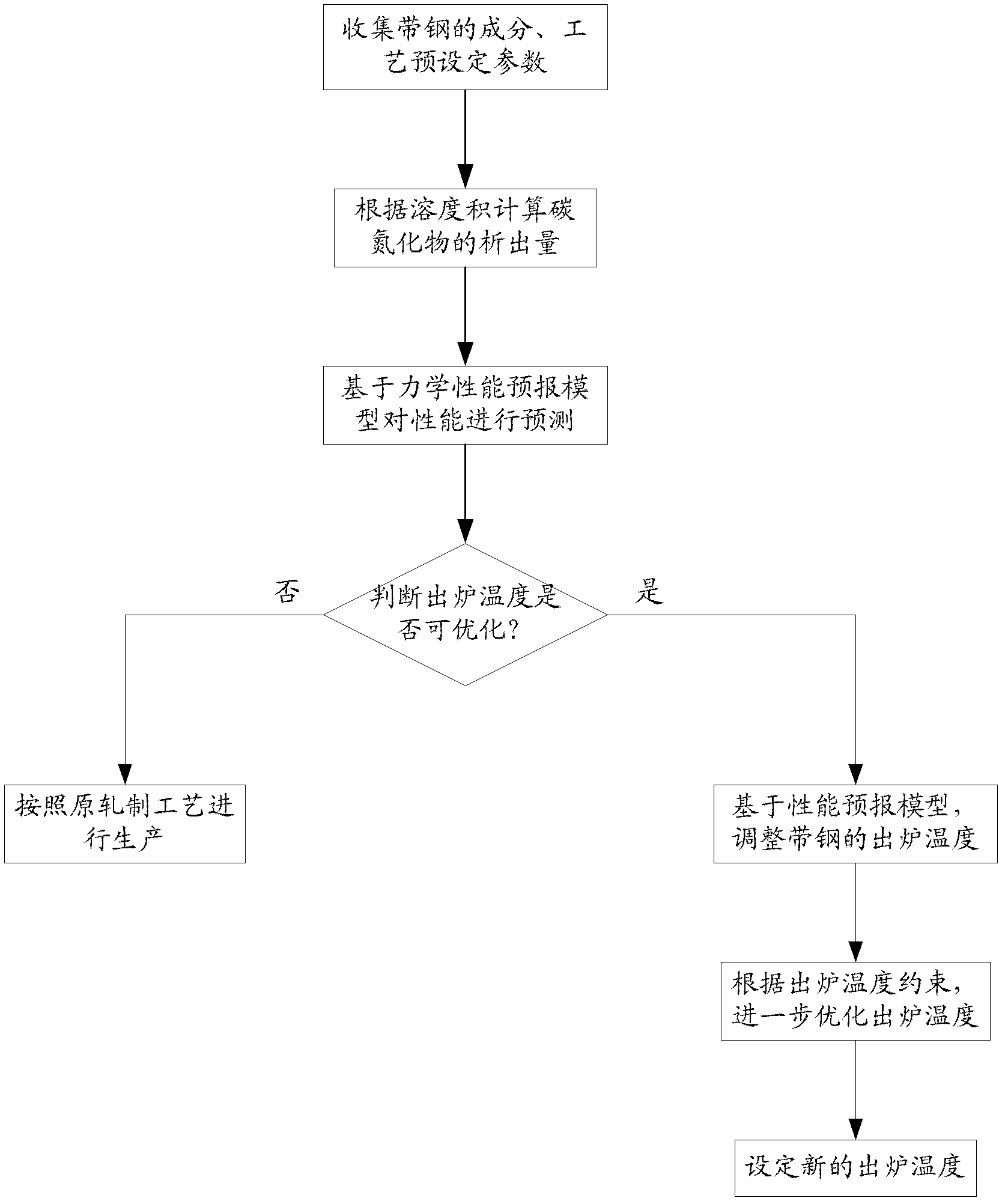

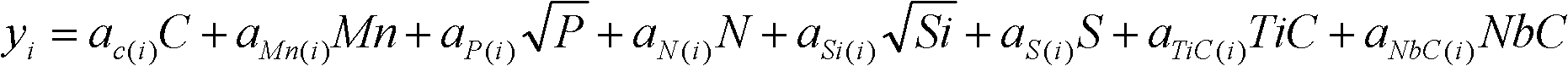

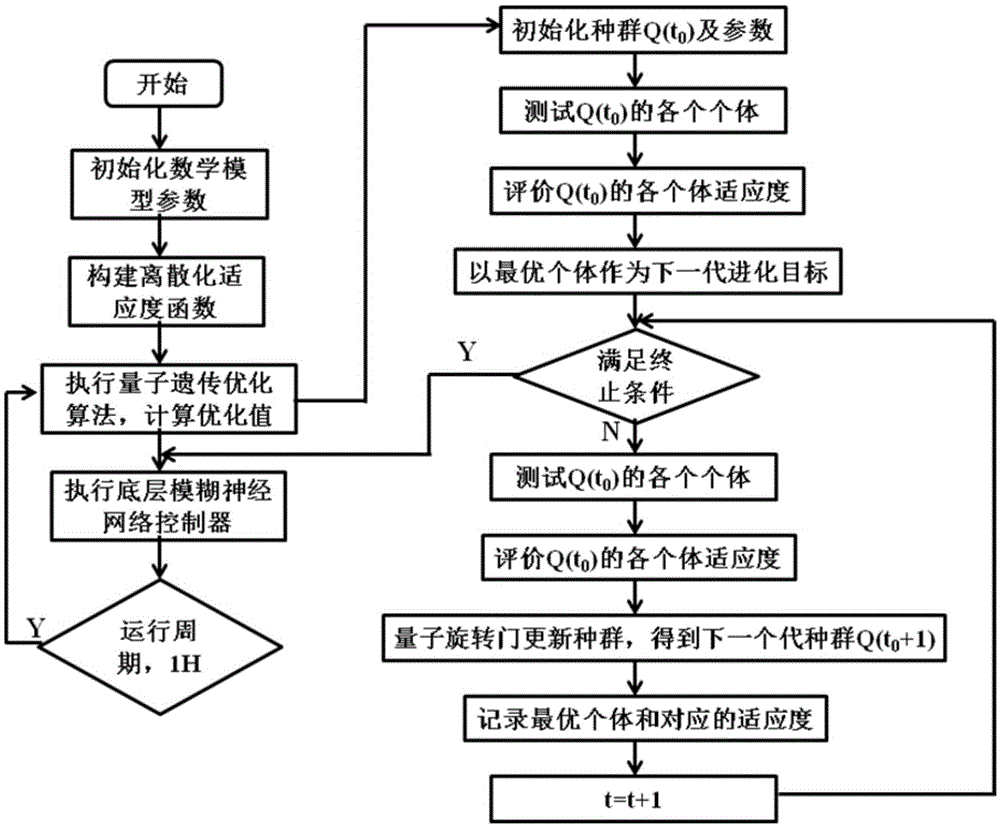

Heating furnace energy-saving control method based on strip steel mechanical property forecasting model

ActiveCN102560081AProcess temperature optimization controlRealize energy saving and consumption reductionFurnace typesHeat treatment process controlFurnace temperatureMechanical property

A heating furnace energy-saving control method based on a strip steel mechanical property forecasting model belongs to the field of process control and comprises the following steps: controlling the furnace temperature of a heating furnace on the basis of a process control computer, and establishing an industrial forecasting model for mechanical properties of a hot-rolled strip steel; before an ingot blank enters the heating furnace, forecasting the mechanical properties of the rolled strip steel according to chemical components and preset technical parameters; if the forecasted values of the mechanical properties are greater than the target values of the mechanical properties, optimizing the strip steel discharging technical temperature; and on the premise of ensuring the mechanical properties of the strip steel and not going against other necessary constraints, reducing the fuel gas consumption of the heating furnace by reducing the discharging temperature, so that the strip steel discharging technical temperature is optimized and controlled, and the fuel gas consumption of the heating furnace or the energy consumption of a unit product is reduced. The control method has a wide steel variety adapting range and can be widely applied to the field of temperature control of heating furnaces in slab blank hot rolling production lines.

Owner:BAOSHAN IRON & STEEL CO LTD

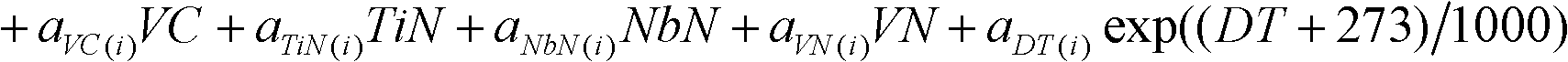

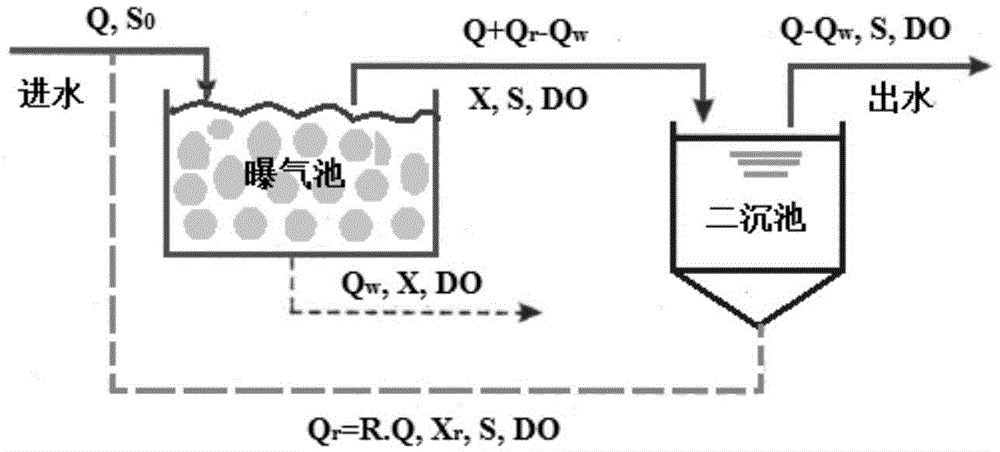

Sewage treatment process energy-saving optimization control method based on quantum genetic algorithm

The invention belongs to the environmental protection technical field and control field and specifically relates to a sewage treatment process energy-saving optimization control method based on a quantum genetic algorithm. The method is characterized in that, with effluent quality, aeration, pumping energy consumption and sludge and waste treatment cost being taken into overall consideration, quantum state vector expression is introduced to genetic encoding to express chromosomes, and evolutionary search is achieved by utilizing quantum gate effect and update so as to optimize operating cost of sludge and waste treatment, backflow and aeration energy consumption and the like of a sewage treatment system; and aeration intensity of an air blower and sludge pump backflow amount are adjusted by a fuzzy neural network controller in real time based on a set value after optimization so as to realize optimization control of the sewage treatment process, thereby reducing the operating cost while ensuring the effluent quality, reducing the sewage treatment cost and promoting efficient and stable operation of a sewage treatment factory.

Owner:SUN YAT SEN UNIV

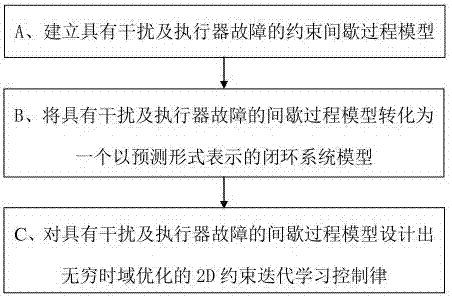

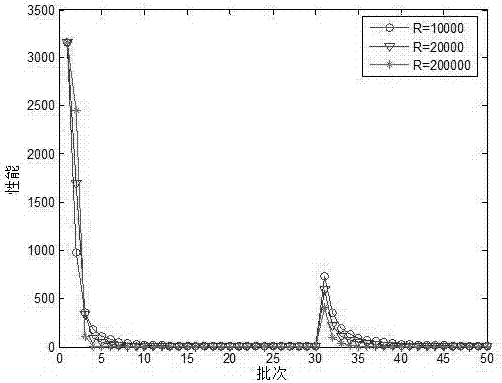

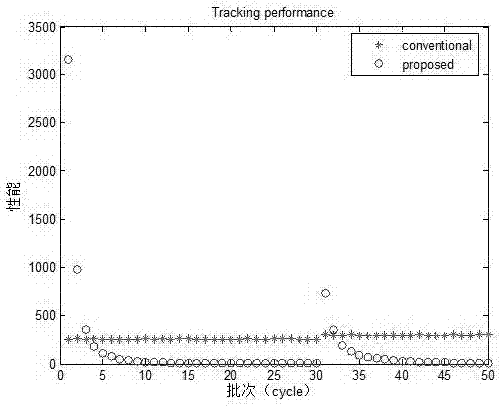

Batch process 2D constraint fault-tolerance control method through infinite time domain optimization

ActiveCN107976942ARealize energy saving and consumption reductionAchieve energy saving and consumption reductionProgramme controlComputer controlLyapunov stabilityFault tolerance

The present invention belongs to the field of automation technology advanced control, and especially relates to a batch process 2D constraint fault-tolerance control method through infinite time domain optimization. An iteration learning control law is designed for a constraint fault control system model with interference, state errors and output errors are introduced, a Roesser model is employedto convert a dynamic model of an original system to a closed-loop system model expressed by a prediction mode, and the designed iteration learning control law is converted to a determined constraint update law; and according to the designed infinite optimization performance index and a 2D system Lyapunov stability theory, giving an update law real-time online design which can ensure the asymptotically stable closed loop system robustness in a linear matrix inequality (LMI) mode. The problem is solved that the control performance cannot be improved with the batch progressive increasing and theproblem of initial value indetermination batch process is solved, and finally, energy saving and consumption reduction are achieved, the cost is reduced, and the generation probability of accidents being harmful for personal safety.

Owner:HAINAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com