Automatic control method used for submerged arc furnace electrode and based on high-precision fuzzy control

A technology of fuzzy control and fuzzy controller, applied in furnace control devices, furnaces, furnace components, etc., can solve problems such as difficulties, exponential increase in control rules, affecting the practical application of fuzzy controllers, and achieve the effect of improving control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

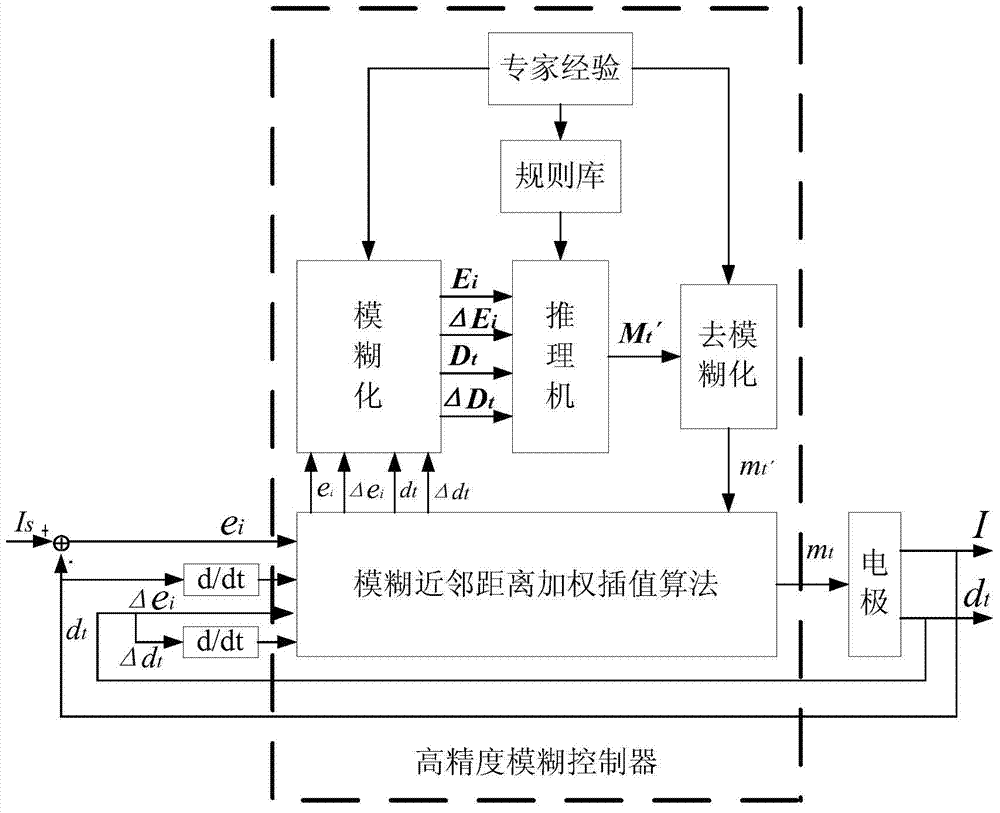

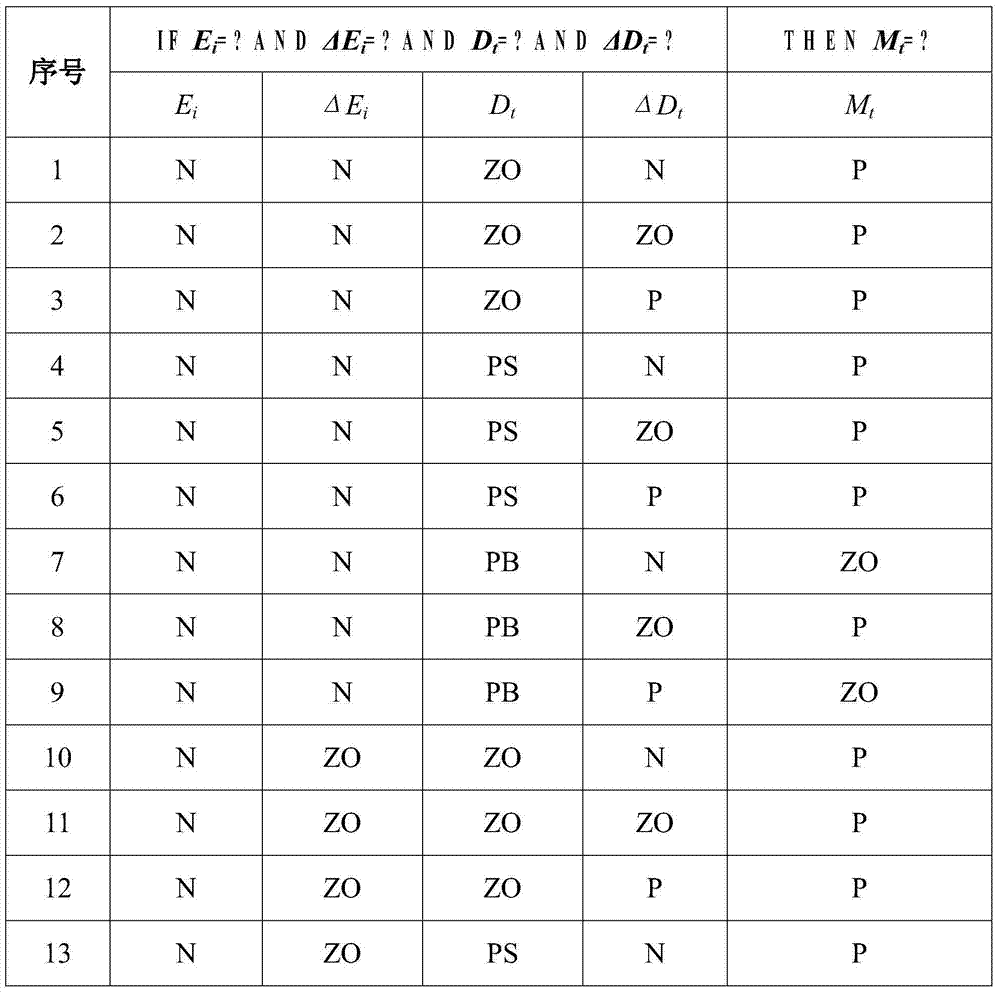

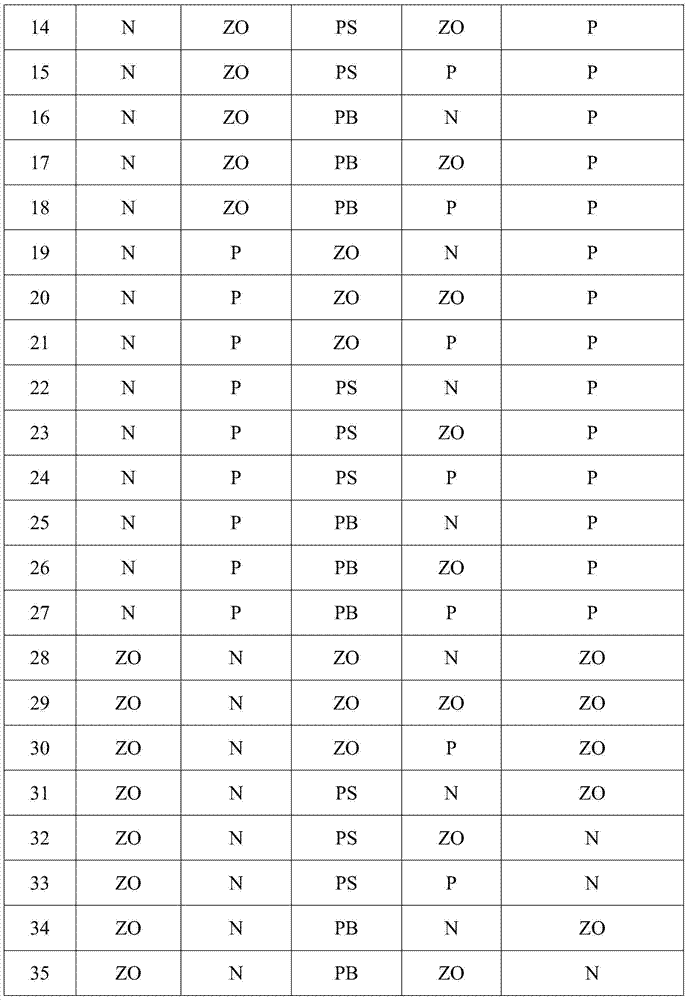

[0045] As shown in the drawings, a submerged arc furnace of a smelter is taken as an example to give a specific application of the present invention. The model of the submerged arc furnace equipped in the smelter is 25000KVA. Since the submerged arc furnace has three-phase electrodes and the controllers of each phase electrode are the same, the figure is only a diagram of the one-phase controller structure. The working process is as follows: smelting raw materials are filled into the furnace, three-phase electrodes are inserted into the furnace charge, and the arc is excited between the electrodes and high temperature is generated, thereby providing energy for the charge smelting. In order to maintain the temperature in the furnace within the desired range and evenly distribute, the depth of the electrode in the charge must be controlled during the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com