Patents

Literature

3716results about "Control devices for furnaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

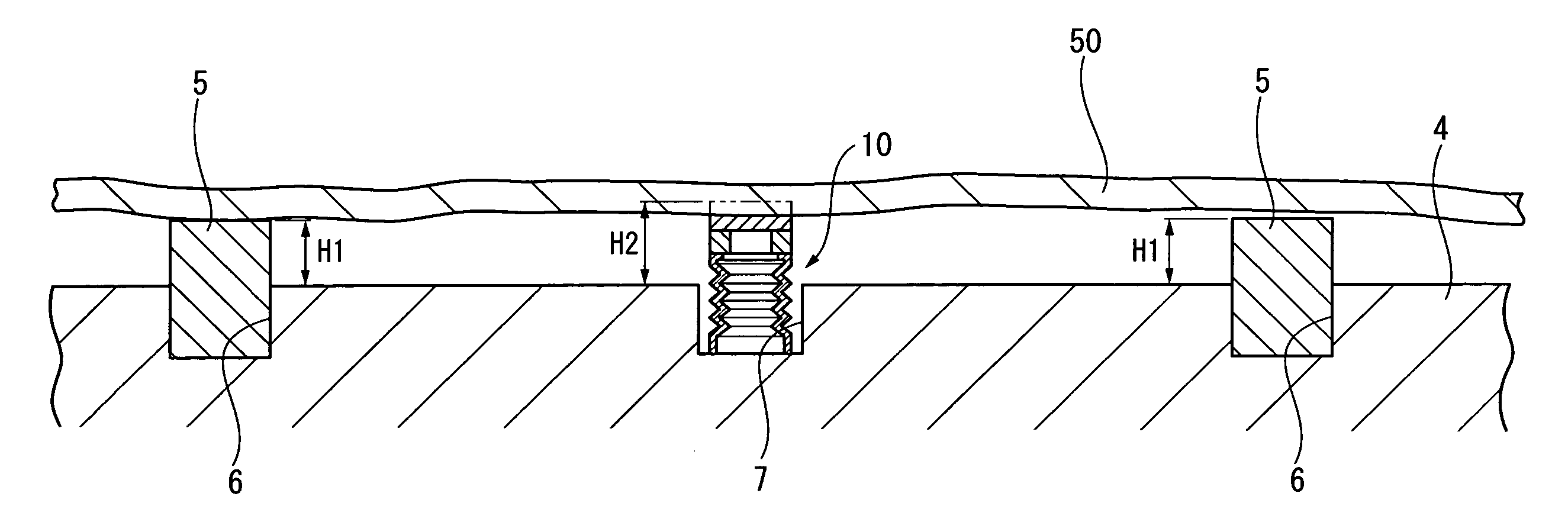

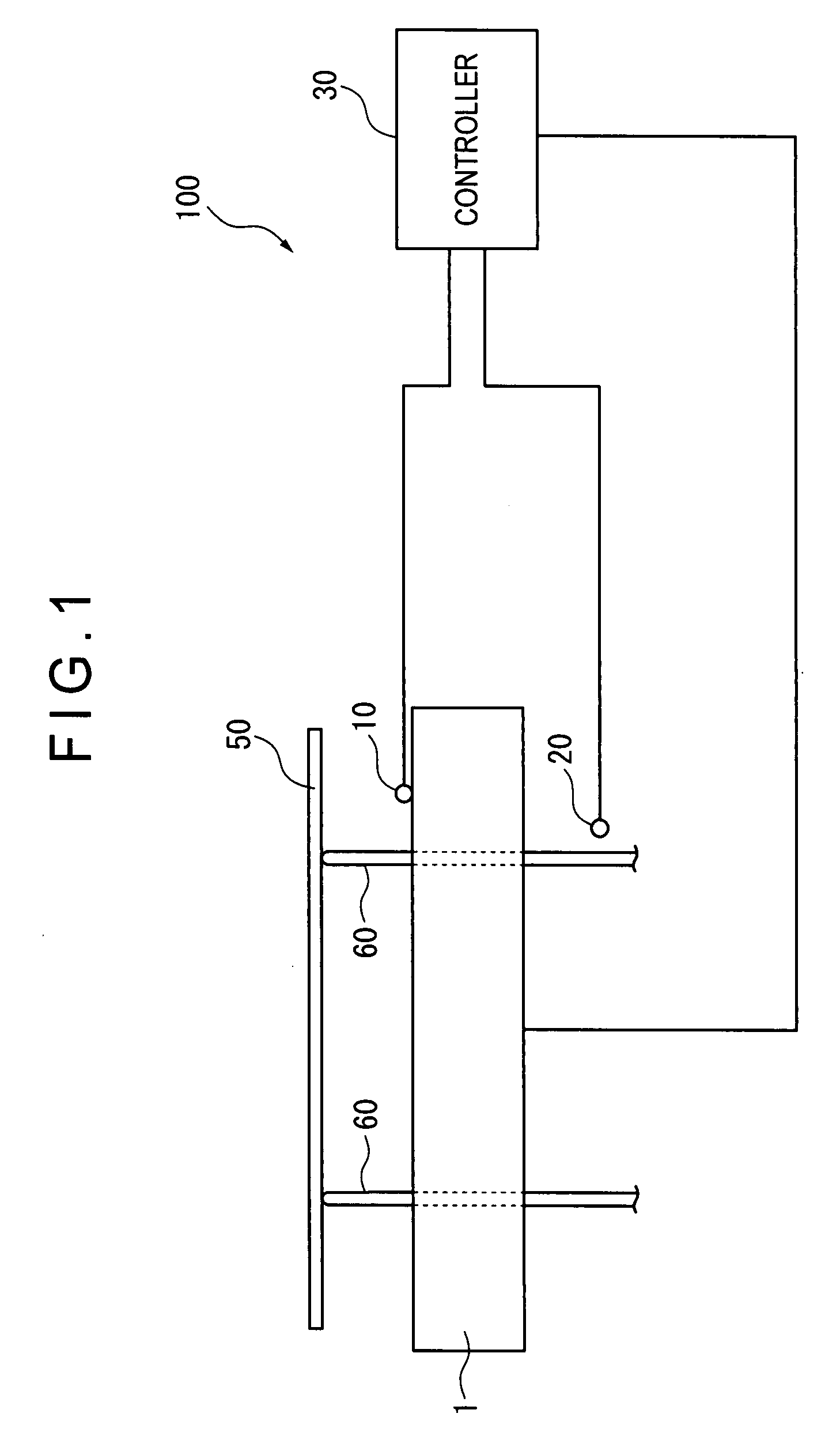

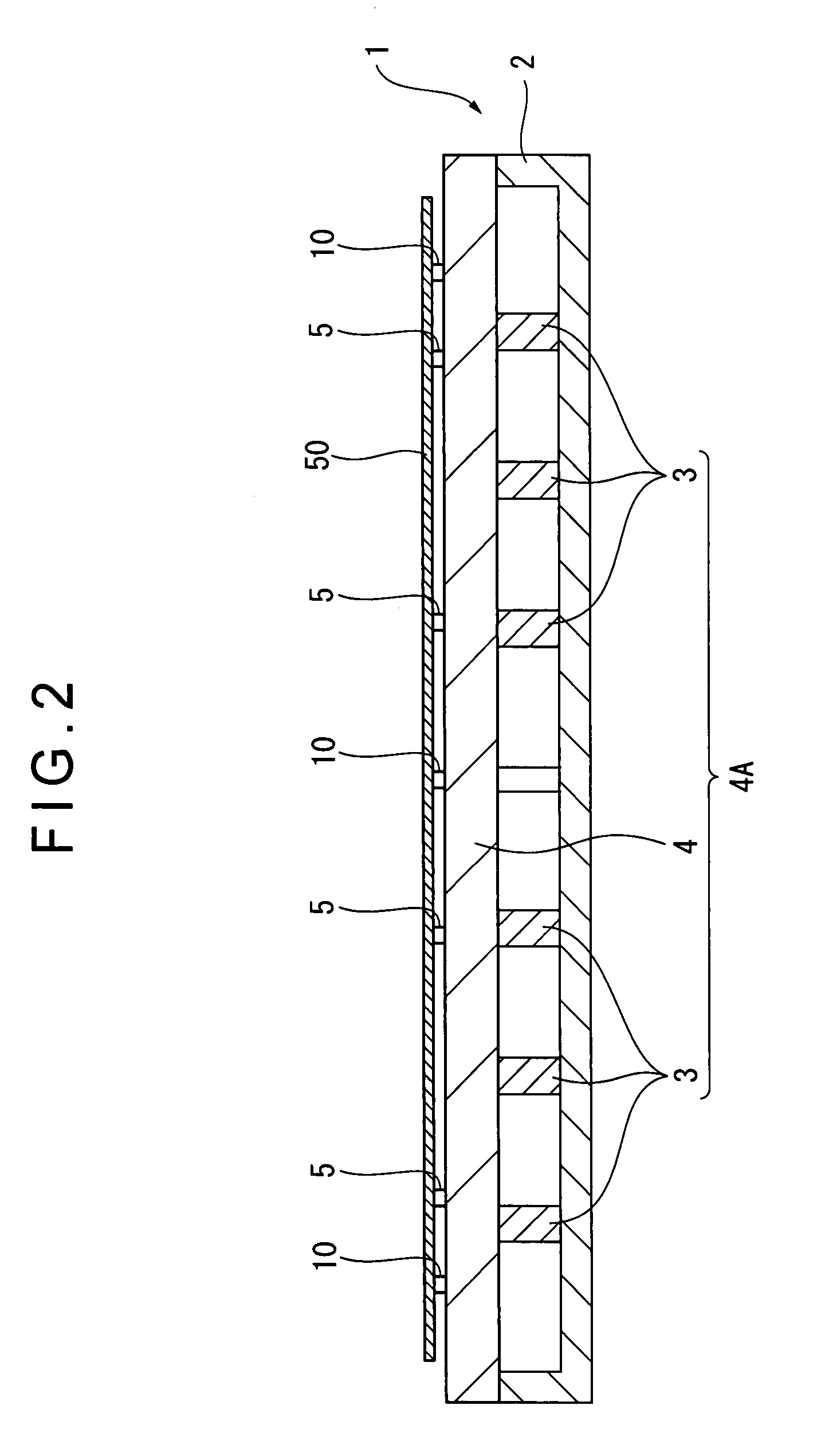

Temperature sensor, temperature control device, temperature controller and temperature-control method

ActiveUS20080043803A1High measurement accuracyThermometer detailsMechanical apparatusTemperature controlEngineering

A temperature sensor (10) includes: a temperature-sensing portion for measuring a temperature of an object (50) by contacting the object; and a supporting portion for supporting the temperature-sensing portion from a side opposite to a contact surface, the supporting portion having a space at a portion partially corresponding to the temperature-sensing portion. A temperature controller includes: a temperature control device; the temperature sensor (10) for measuring the temperature by contacting the object (50); and a controller for controlling the temperature control device. The controller includes: a mounting-state judging means for judging a mounting-state of the object (50); a switching means for switching a control gain and a target temperature of the temperature control device based on the judging result; and a control-command generating means for generating a control command based on the control gain, the target temperature and a measurement value of the temperature sensor (10).

Owner:KOMATSU LTD

LED heat lamp arrays for CVD heating

Owner:ASM AMERICA INC

Radiant shield

InactiveUS20080314892A1Thermometer detailsDrying solid materials with heatTemperature controlMetallurgy

A radiant shield and a furnace employing a radiant shield for controlled heating and treatment of material using infrared radiation. The furnace is capable of improved temperature control where material treated by the furnace may interfere with the quality of a measured temperature signal and temperature control based on that signal.

Owner:DESPATCH INDS

Method and apparatus providing separate modules for processing a substrate

InactiveUS20130189635A1Semiconductor/solid-state device manufacturingCharge manipulationComputer moduleEngineering

A method and apparatus for heat treating a photovoltaic device. The apparatus includes a heating module, a processing module, and a cooling module in which the operating temperatures of the modules may be controlled separately. The heating module is configured to pre-heat a substrate and stabilize the substrate at the desired target temperature, the processing module is configured to thermally process the substrate, and the cooling module is configured for post-treatment cooling of the substrate.

Owner:JPMORGAN CHASE BANK NA

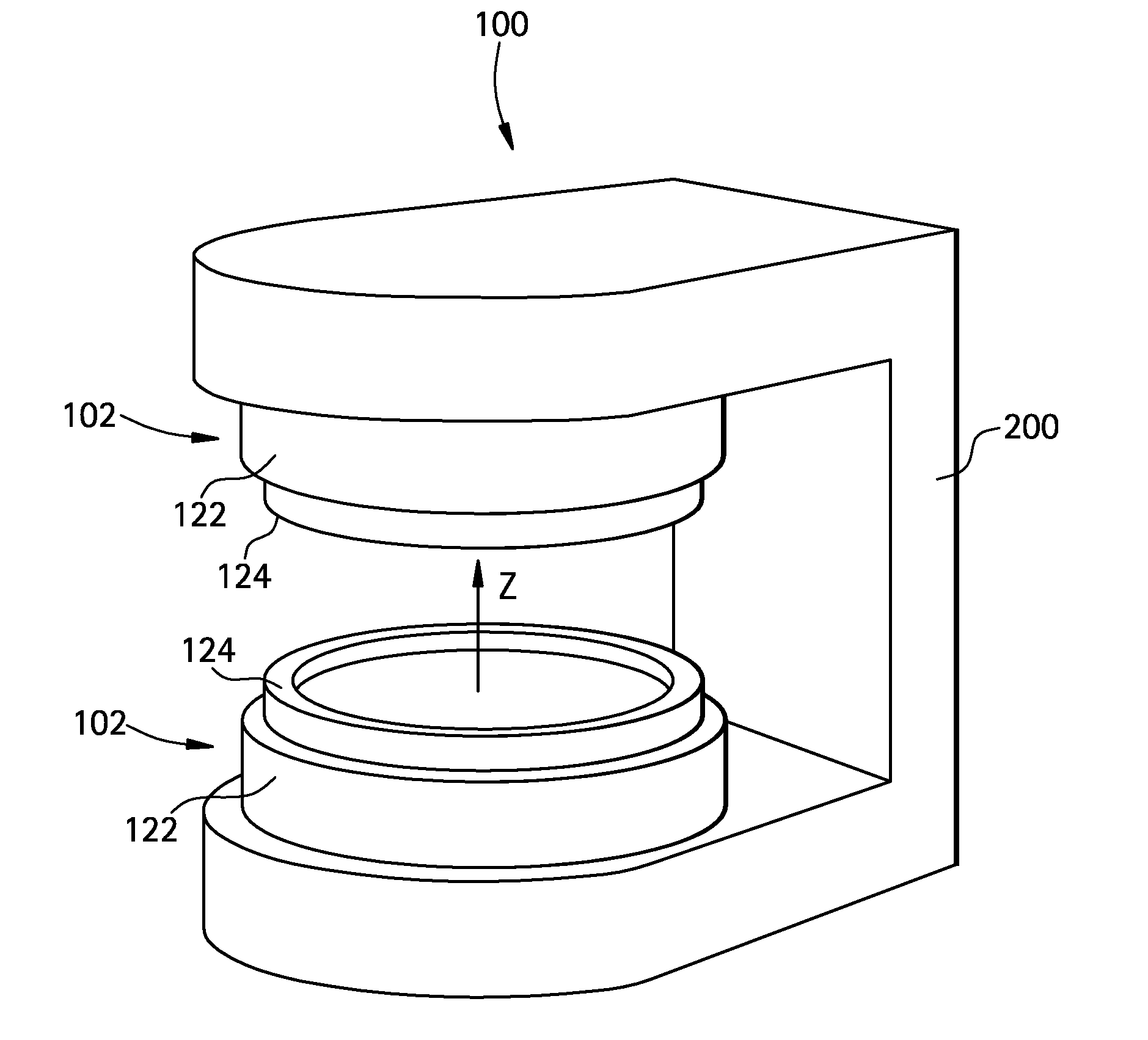

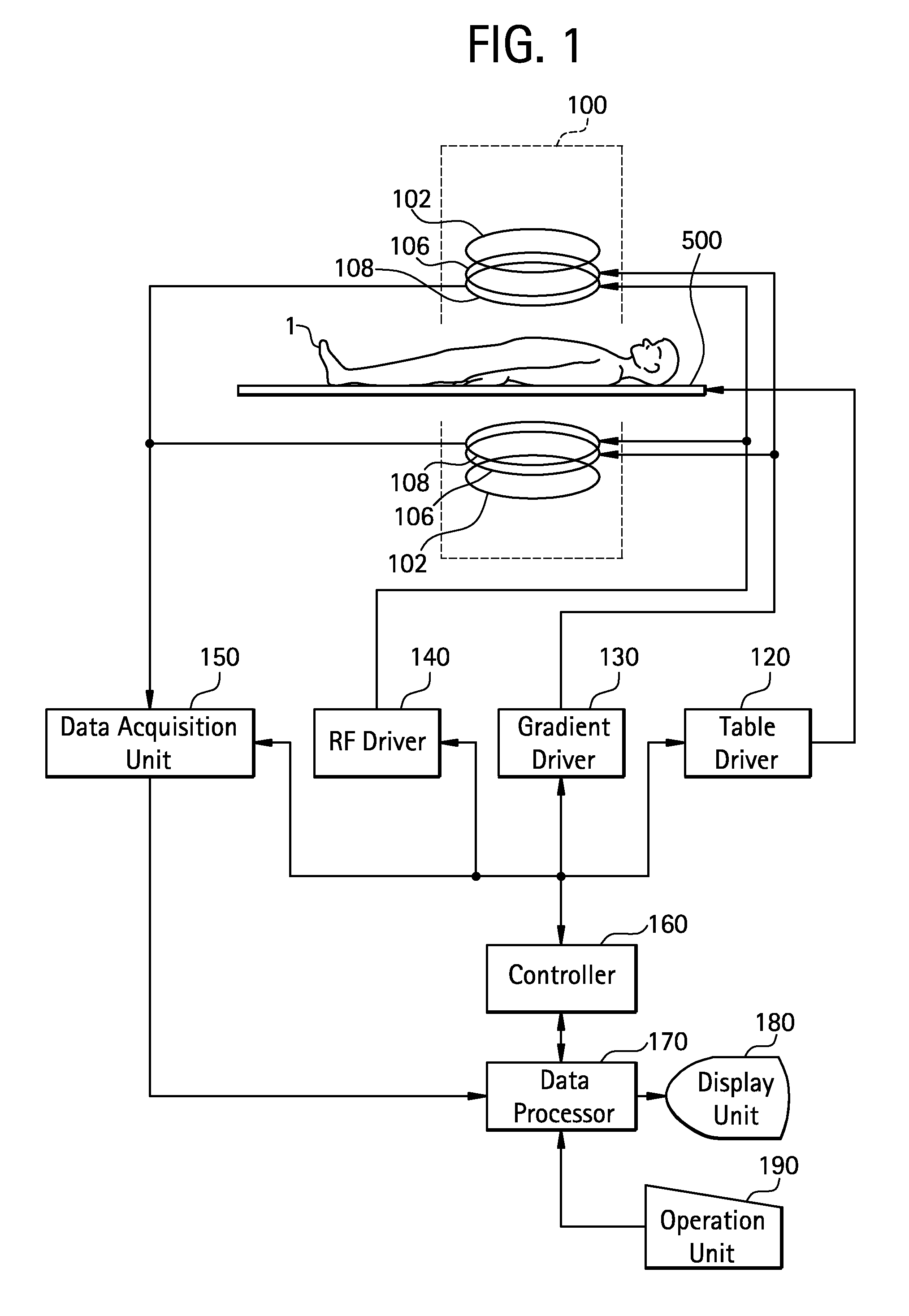

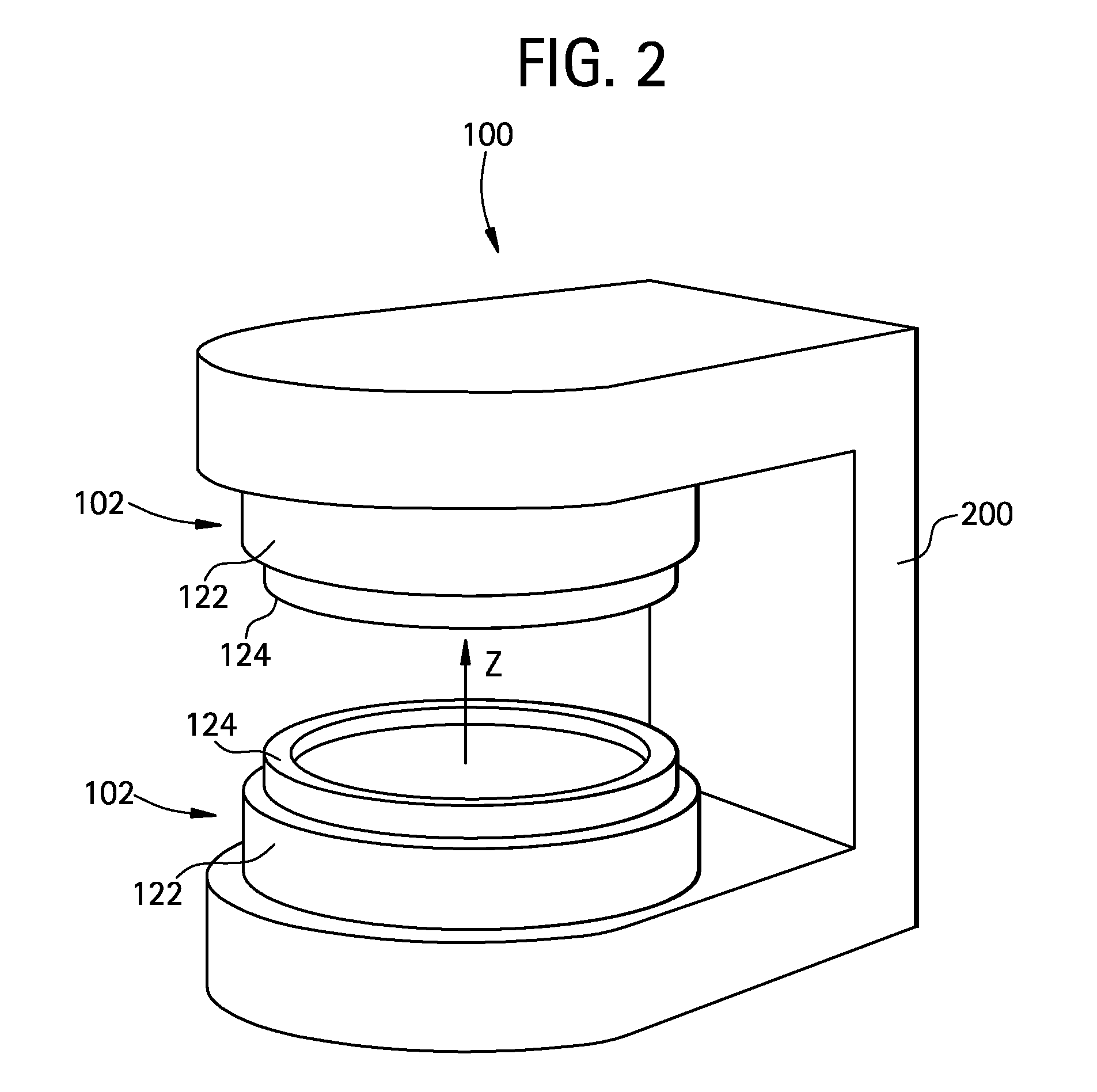

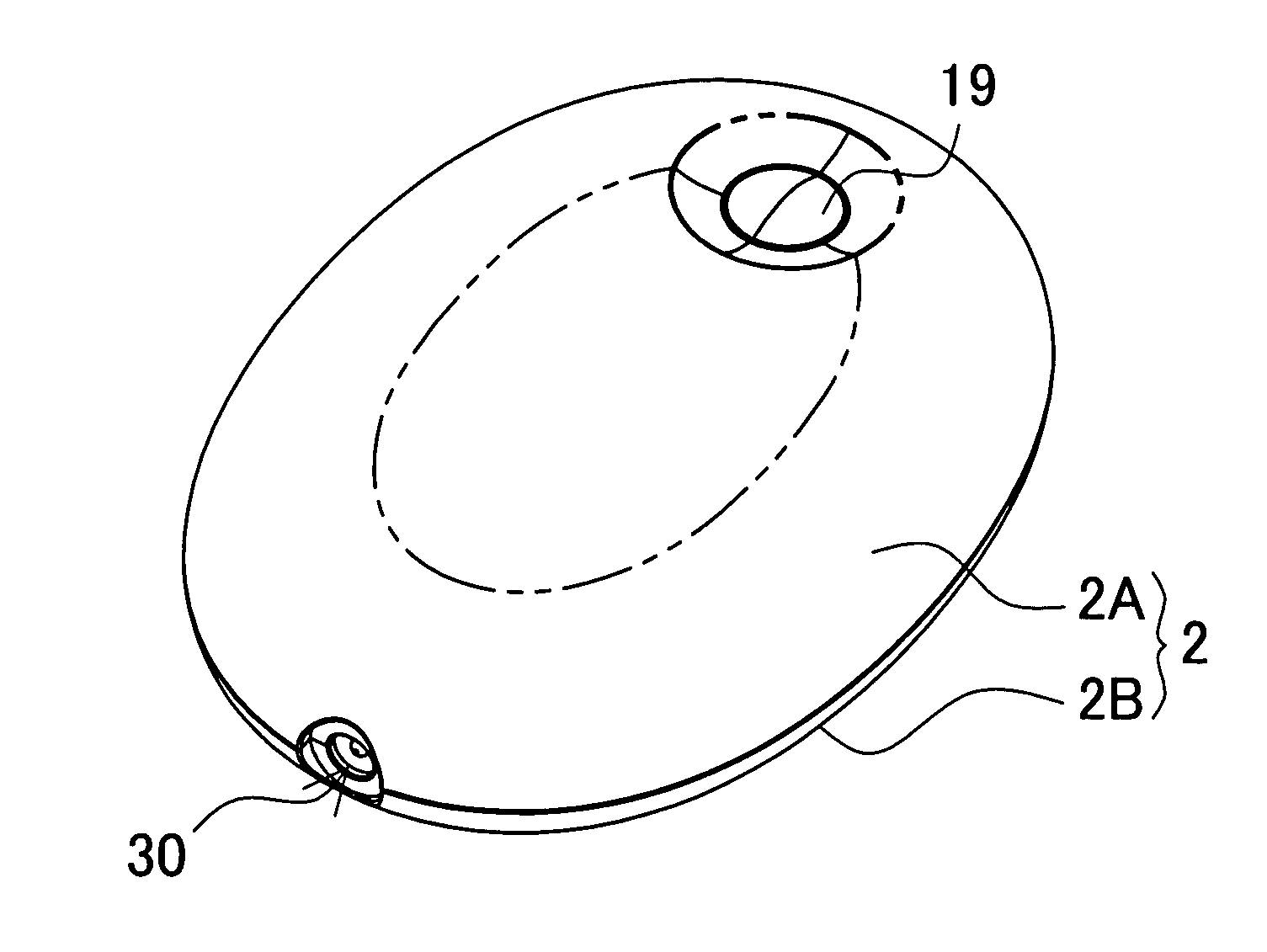

Thermal controlling method, magnetic field generator and MRI apparatus

InactiveUS20080048656A1Permanent magnetsInductances/transformers/magnets manufactureMagnetic polesRoom temperature

With a view toward implementing a thermal controlling method for making reversible a temperature characteristic of a magnetic field generator using permanent magnets small in Hcj, a magnetic field generator whose temperature characteristic is reversible, using permanent magnets small in Hcj, and an MRI apparatus provided with such a magnetic field generator, there is provided a method for controlling the temperature of a magnetic field generator having a pair of disc-shaped permanent magnets whose magnetic poles opposite in polarity to each other are opposed to each other with spacing defined therebetween, and a yoke that forms return passes for magnetic fluxes of the permanent magnets, comprising the steps of raising the temperature from room temperature to a temperature higher than the room temperature, maintaining the temperature higher than the room temperature, and lowering the temperature from the temperature higher than the room temperature to the room temperature, whereby the temperature characteristics of the permanent magnets are made reversible.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

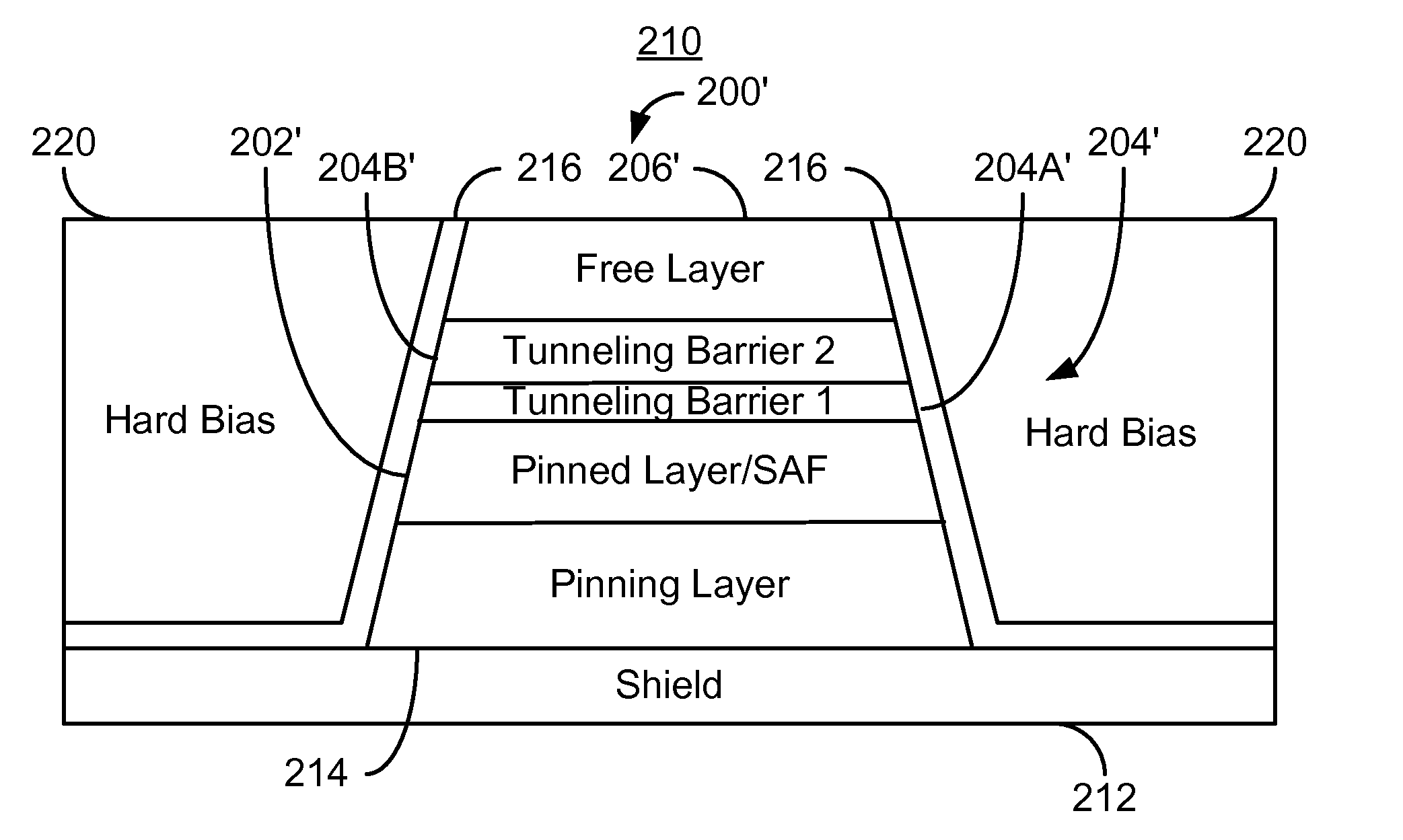

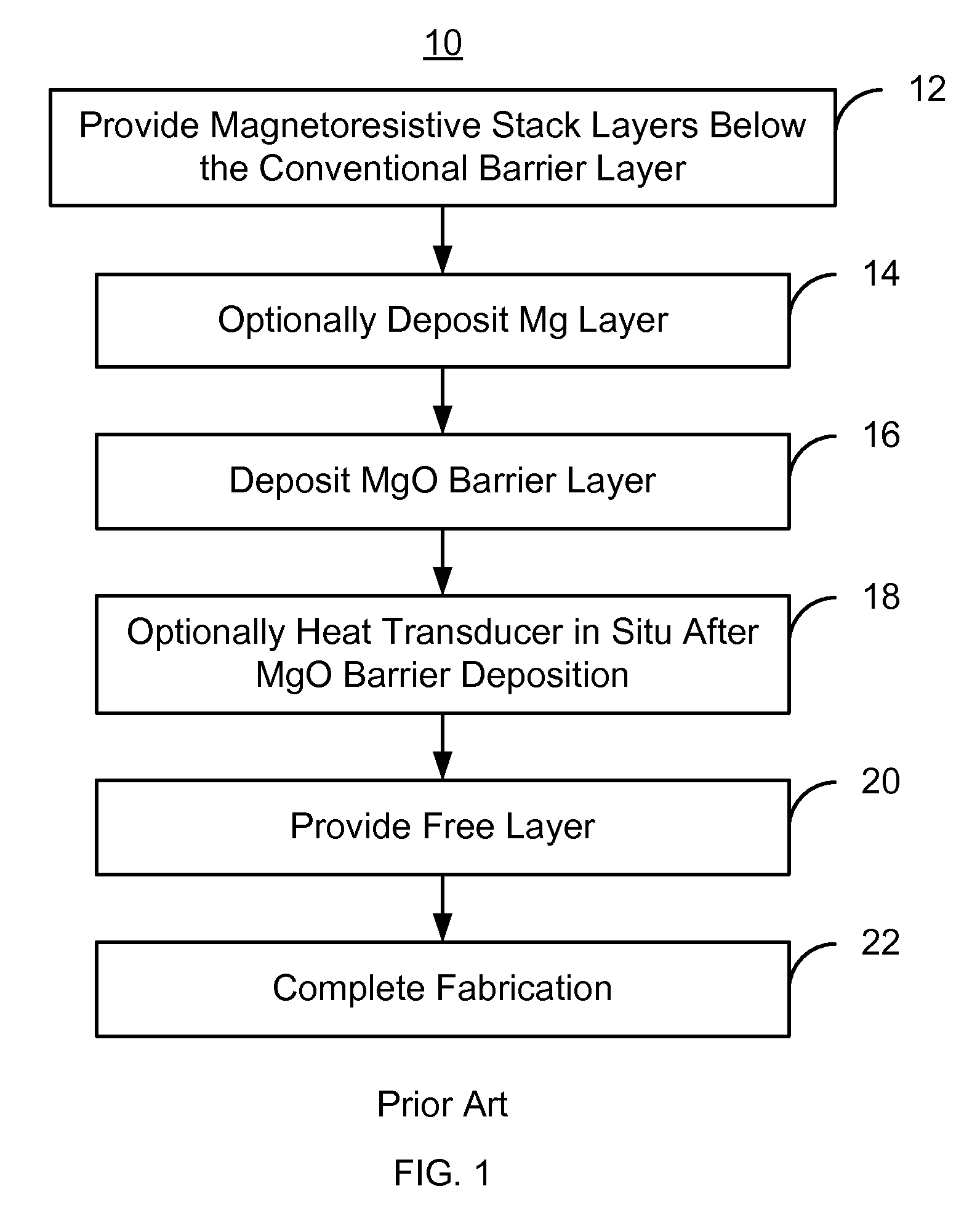

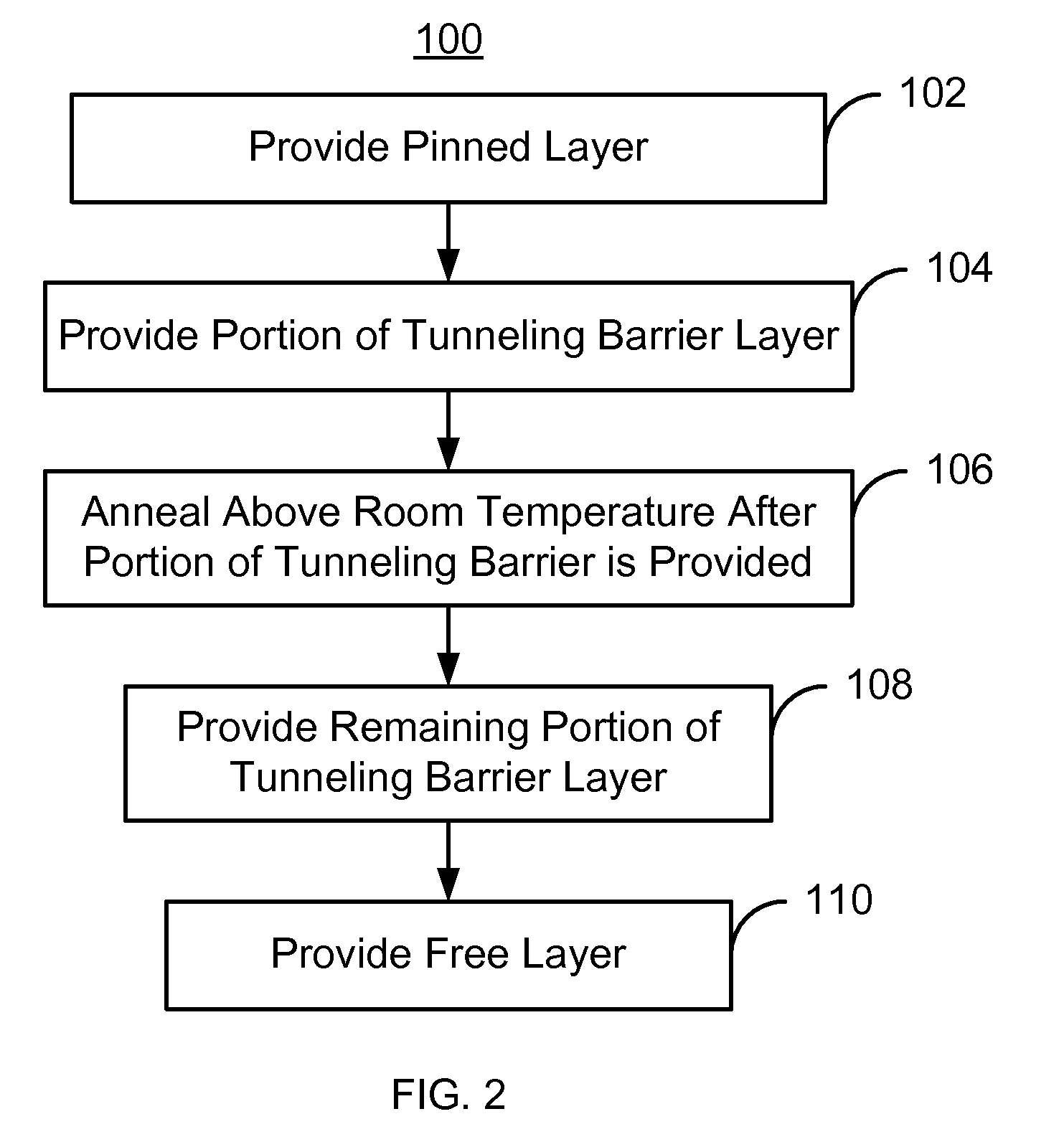

Method for providing a magnetic recording transducer

Owner:WESTERN DIGITAL TECH INC

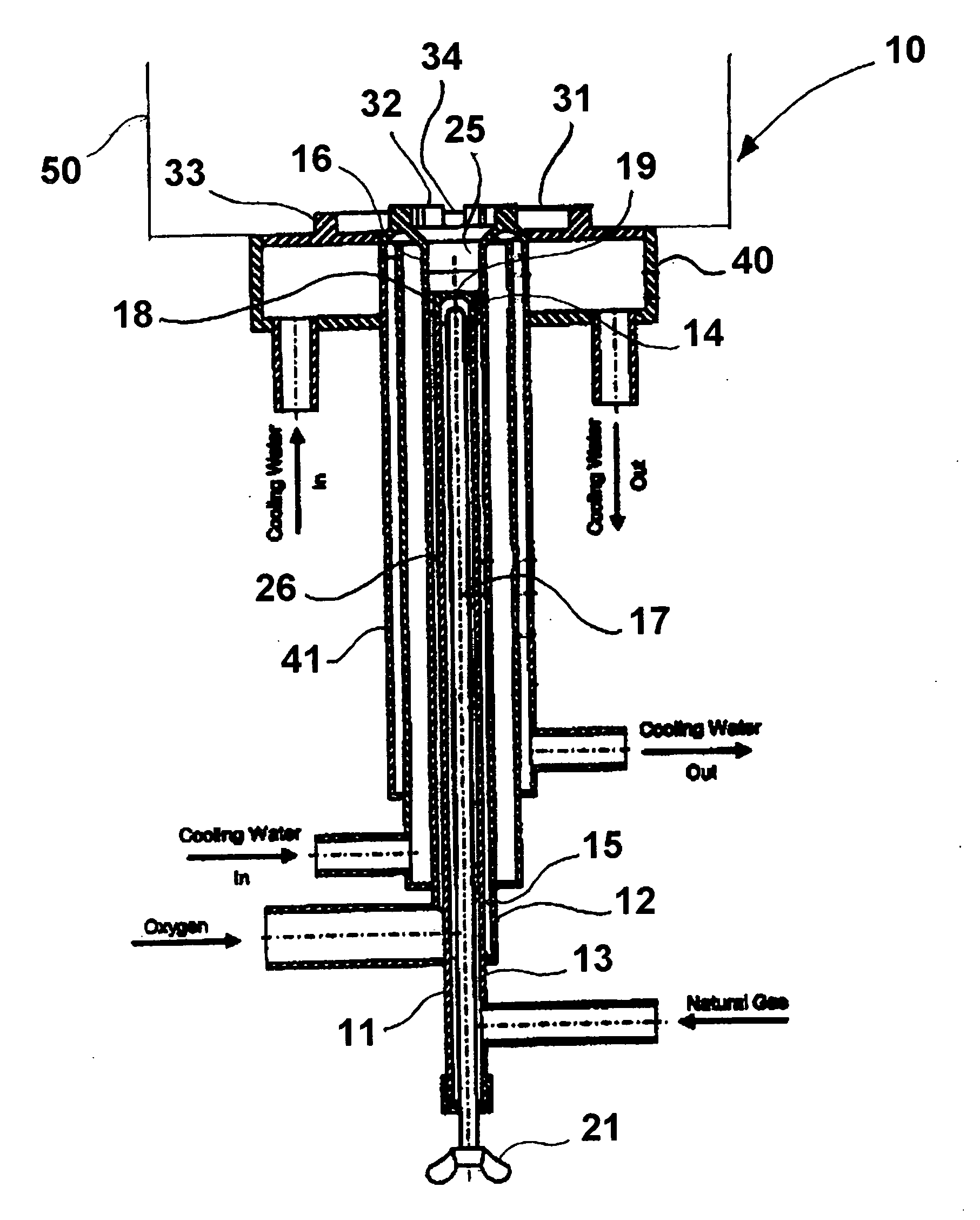

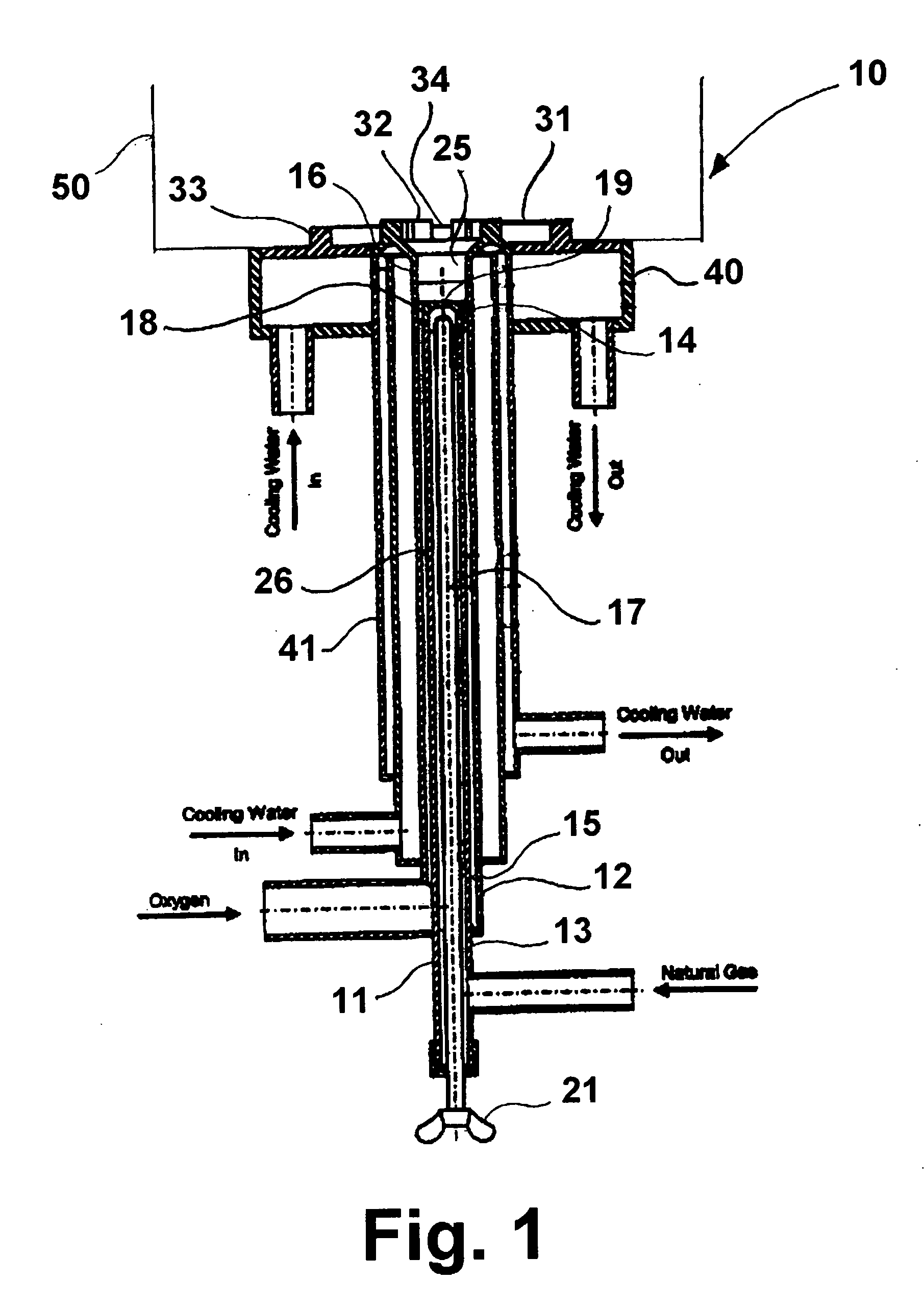

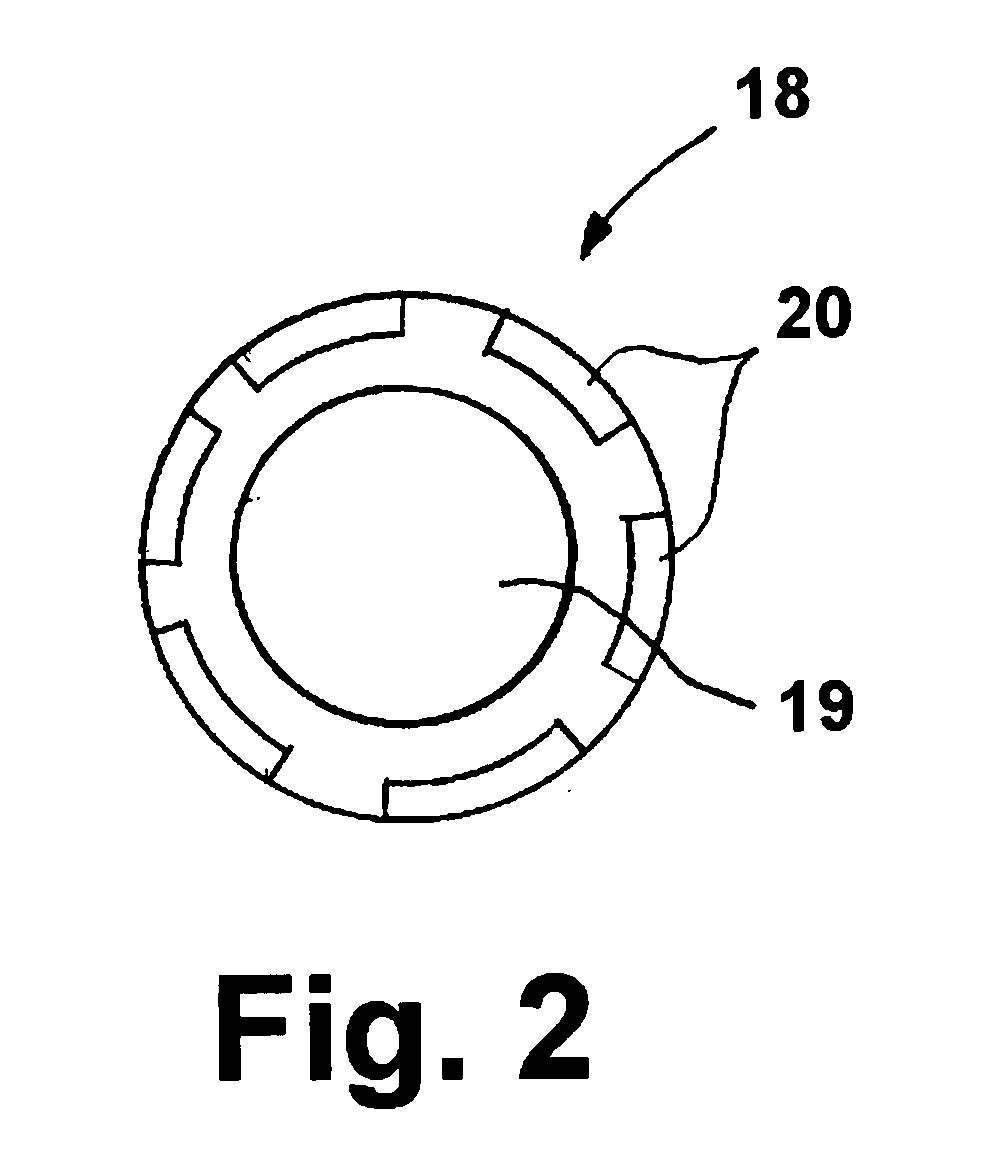

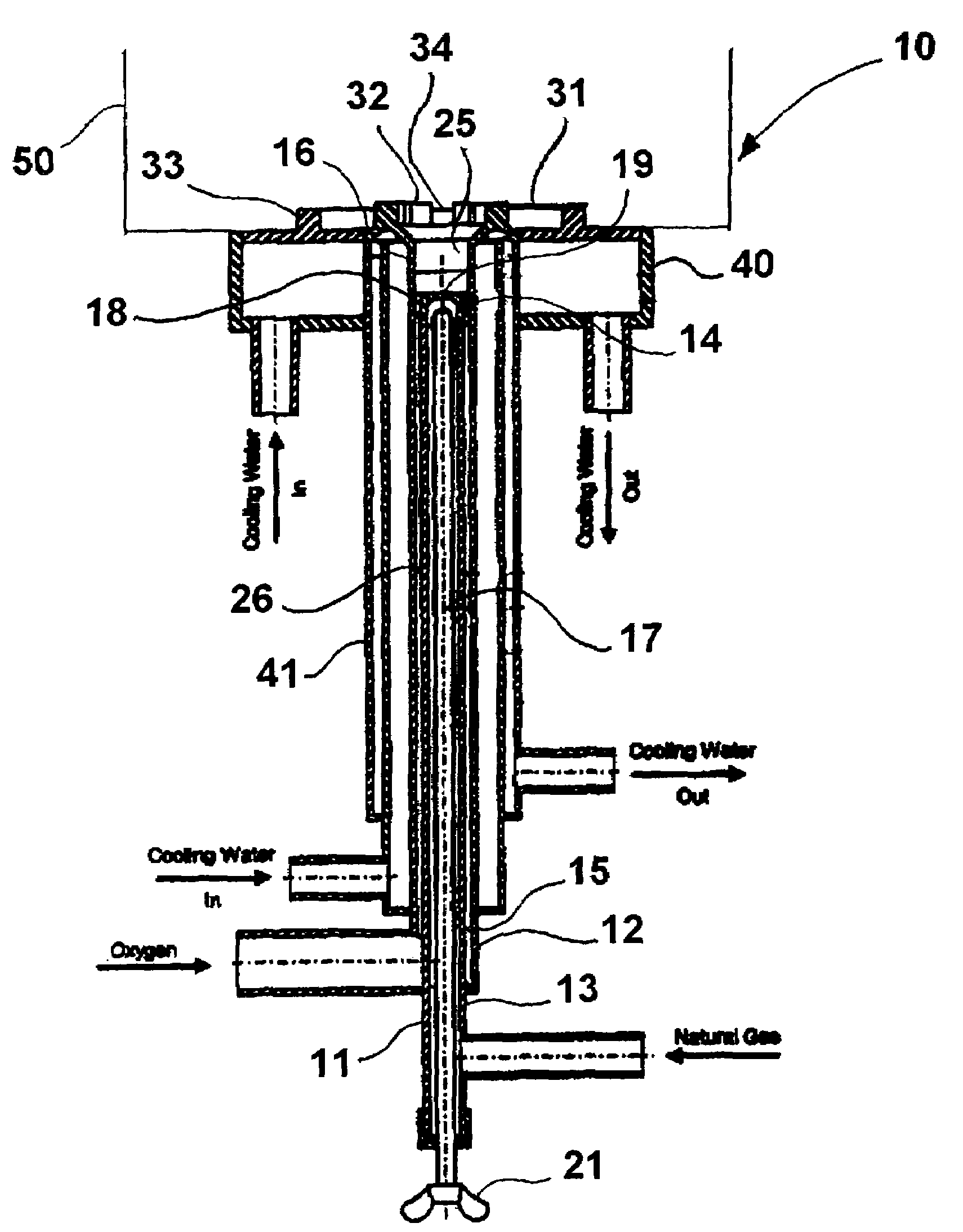

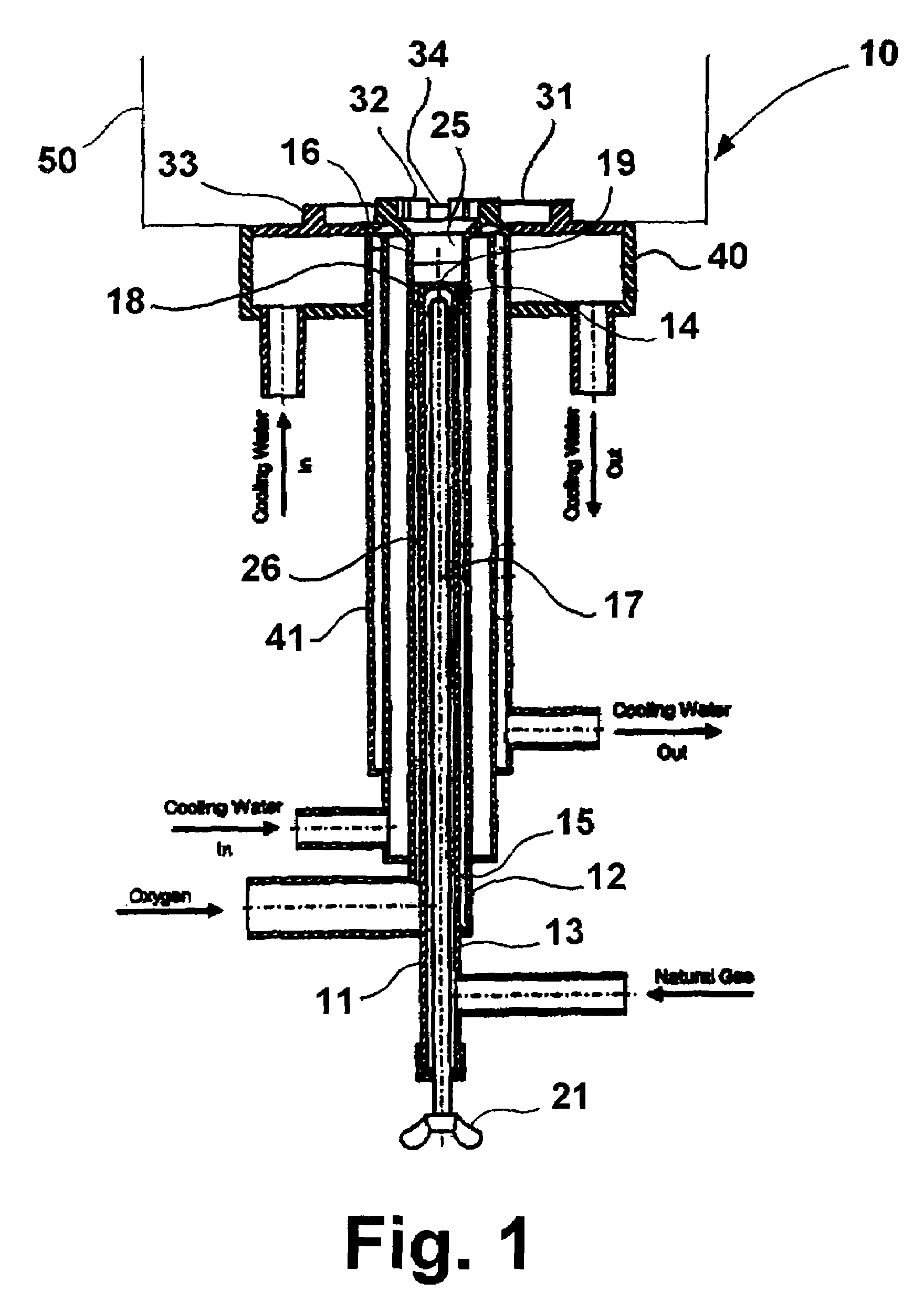

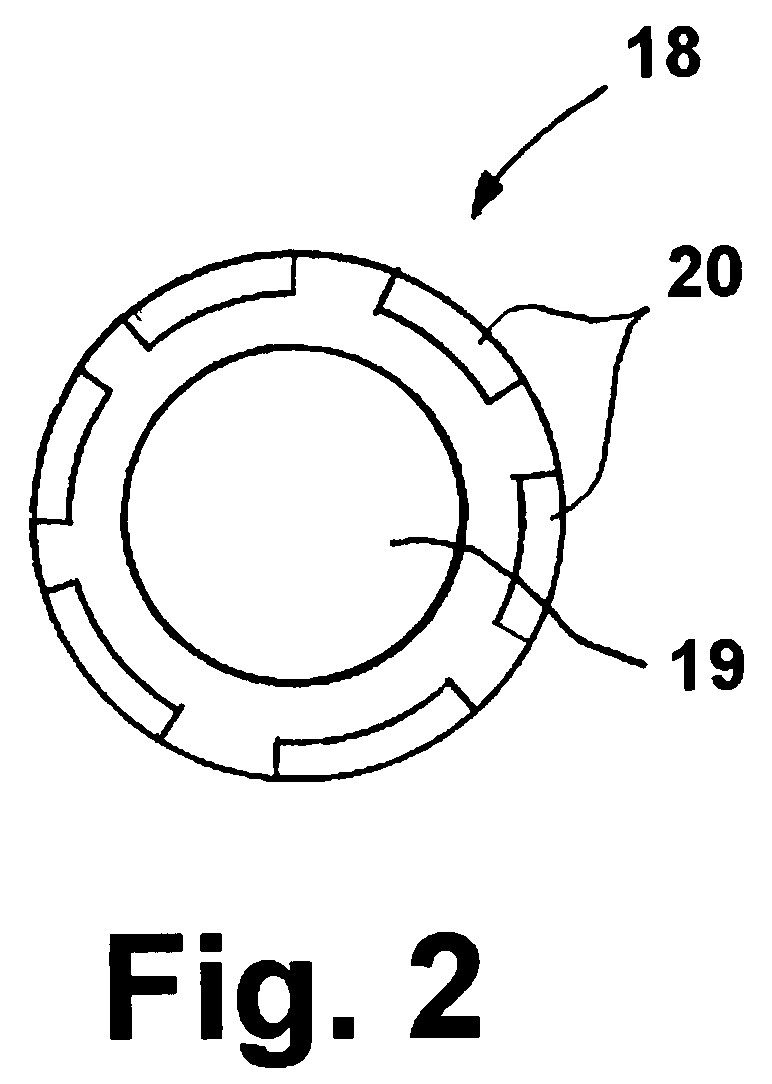

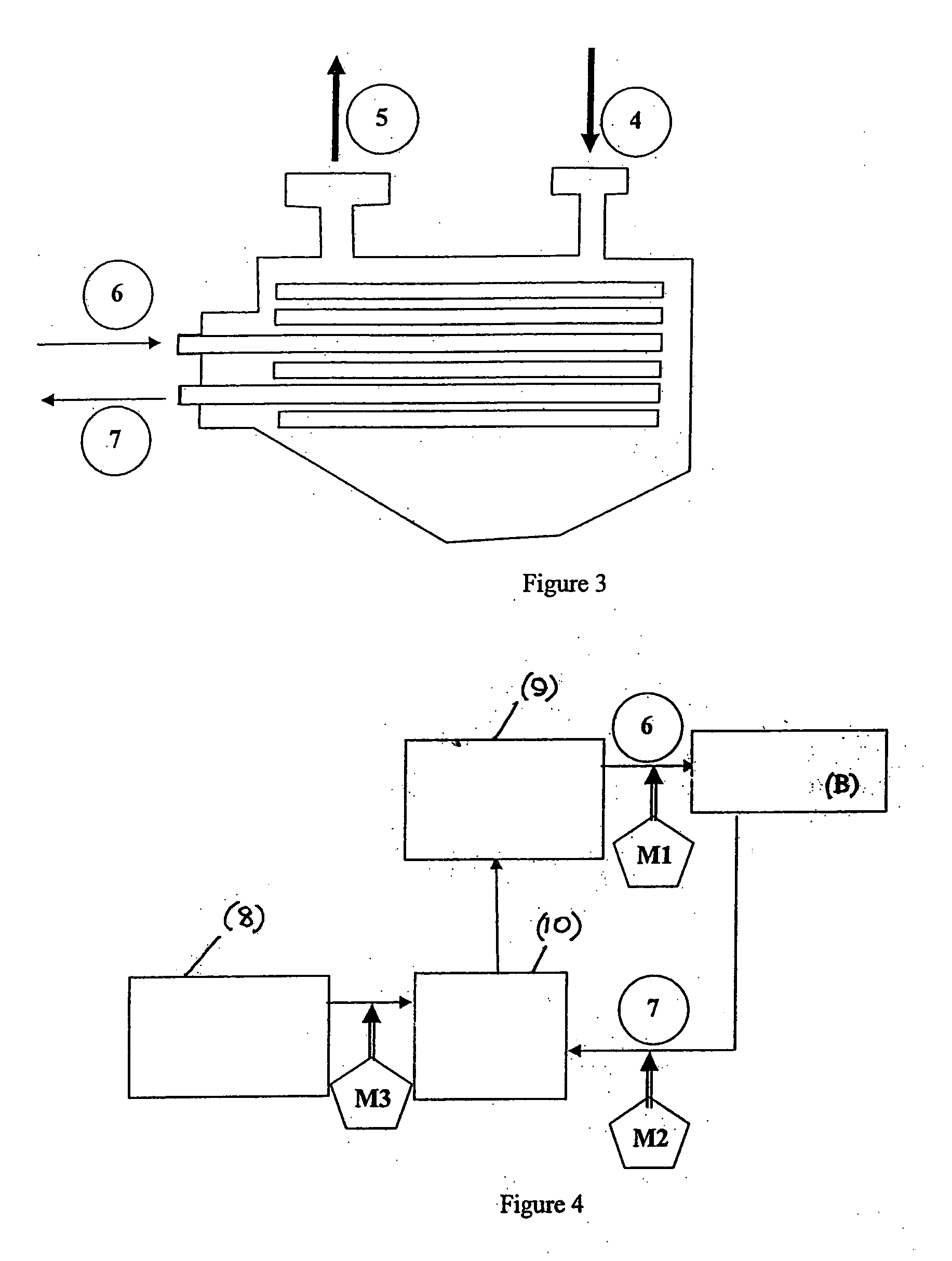

Process and apparatus for uniform combustion within a molten material

A submerged combustion burner having co-axial fuel and oxidant tubes forming an annular space therebetween, wherein the outer tube extends beyond the end of the inner tube. A burner nozzle having an outside diameter corresponding to the inside diameter of the outer tube is connected to the outlet end of the inner tube and forms a centralized opening in fluid communication with the inner tube and at least one peripheral longitudinally oriented opening in fluid communication with the annular space. In accordance with one embodiment, a longitudinally adjustable rod is disposed within the inner tube for adjustment of fluid flow therethrough, and a cylindrical insert having at least one flame stabilizer for stabilizing a flame produced by the burner is attached to the outlet end of the outer tube. In accordance with another embodiment, fluid flow through the inner tube is achieved by a flow control valve operably connected to the inner tube.

Owner:GAS TECH INST

Process and apparatus for uniform combustion within a molten material

A submerged combustion burner having co-axial fuel and oxidant tubes forming an annular space therebetween, wherein the outer tube extends beyond the end of the inner tube. A burner nozzle having an outside diameter corresponding to the inside diameter of the outer tube is connected to the outlet end of the inner tube and forms a centralized opening in fluid communication with the inner tube and at least one peripheral longitudinally oriented opening in fluid communication with the annular space. In accordance with one embodiment, a longitudinally adjustable rod is disposed within the inner tube for adjustment of fluid flow therethrough, and a cylindrical insert having at least one flame stabilizer for stabilizing a flame produced by the burner is attached to the outlet end of the outer tube. In accordance with another embodiment, fluid flow through the inner tube is achieved by a flow control valve operably connected to the inner tube.

Owner:GAS TECH INST

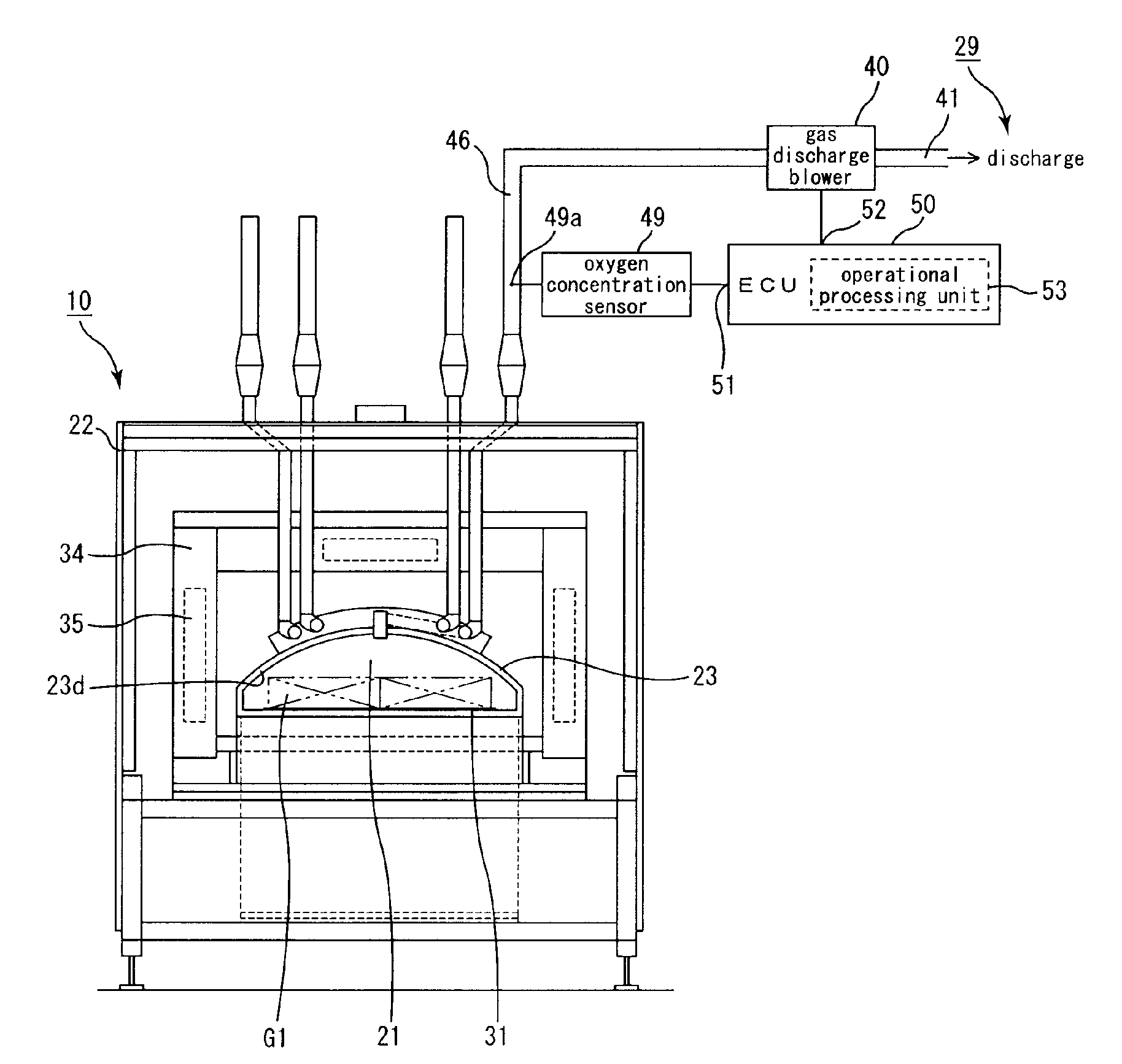

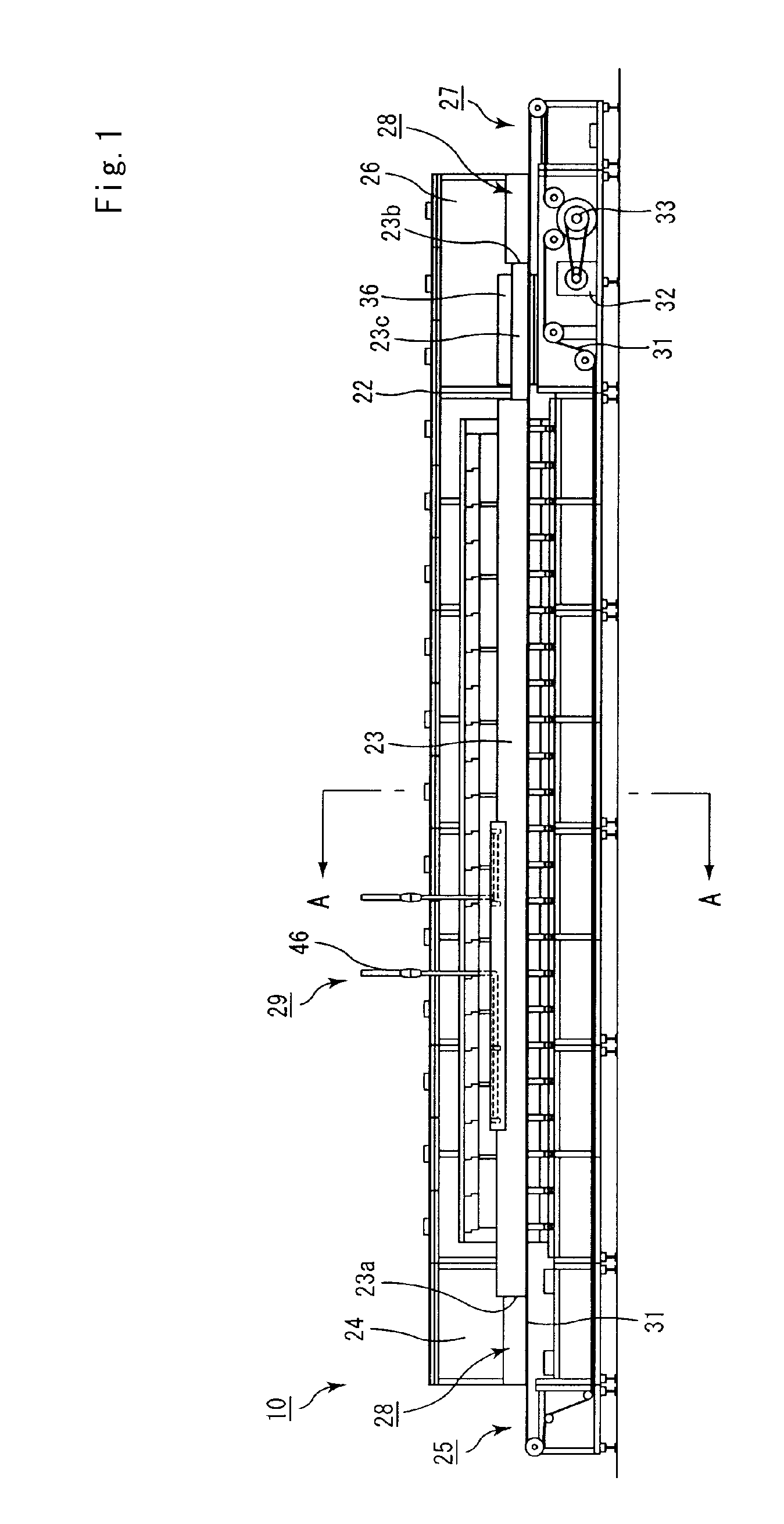

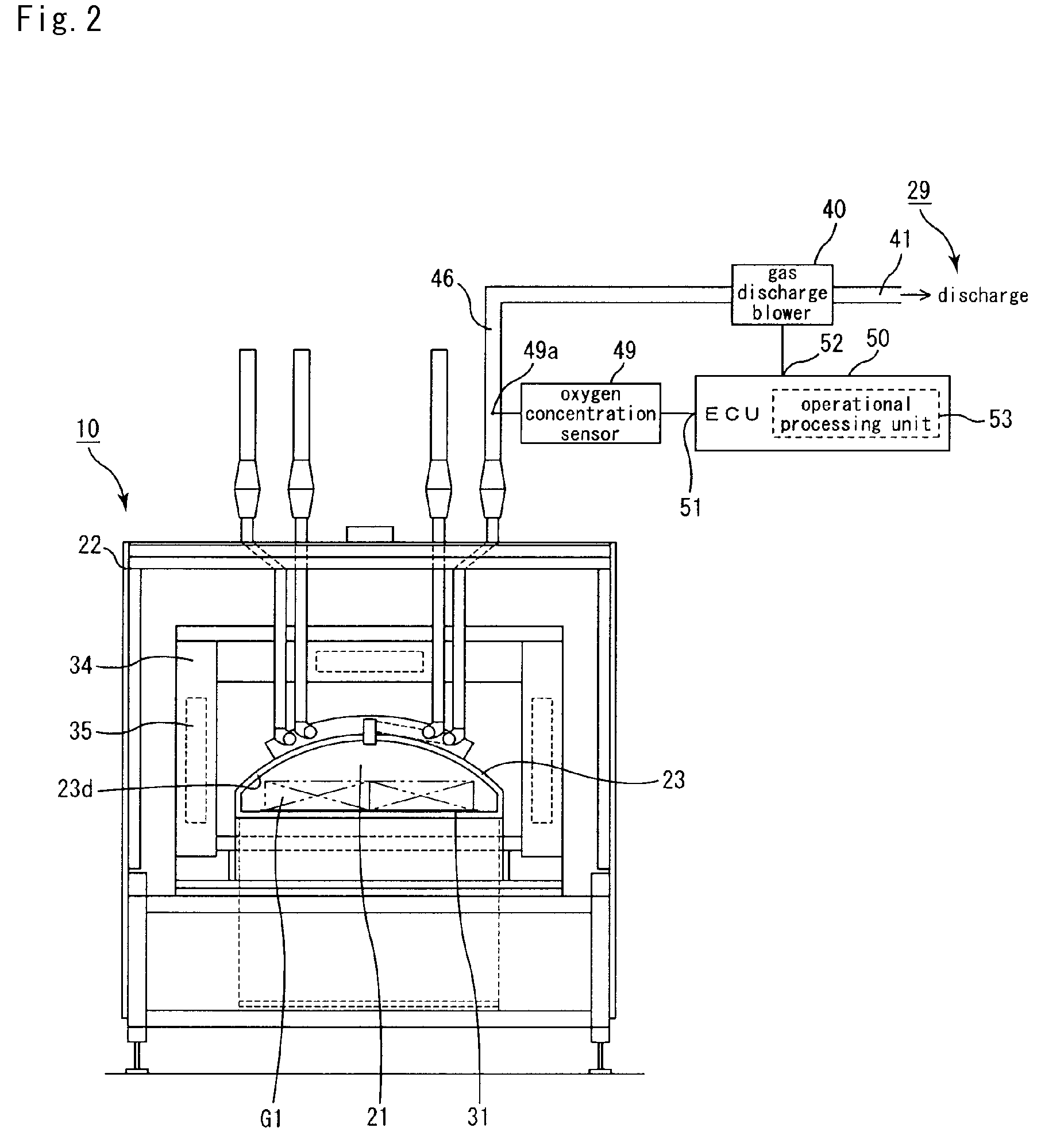

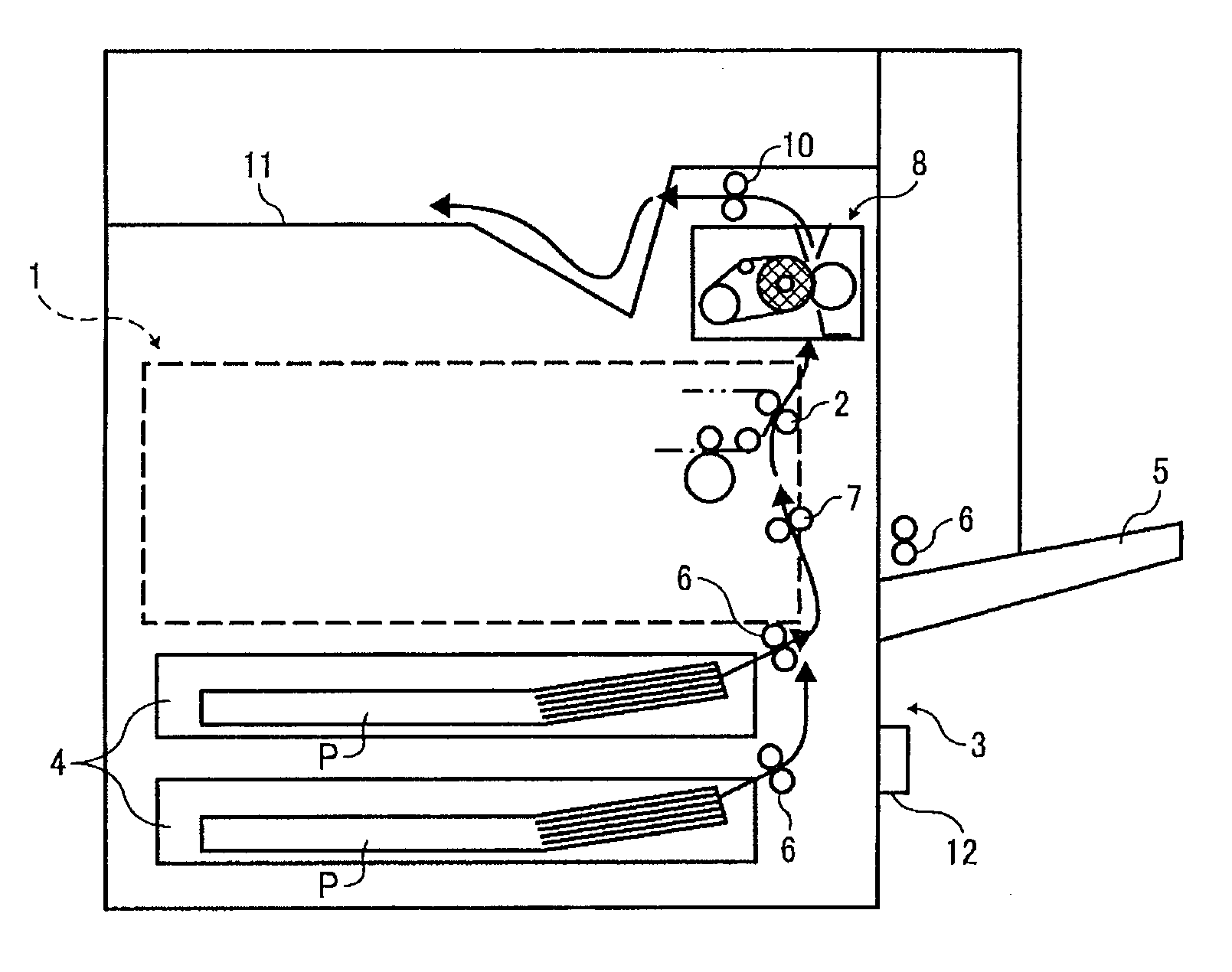

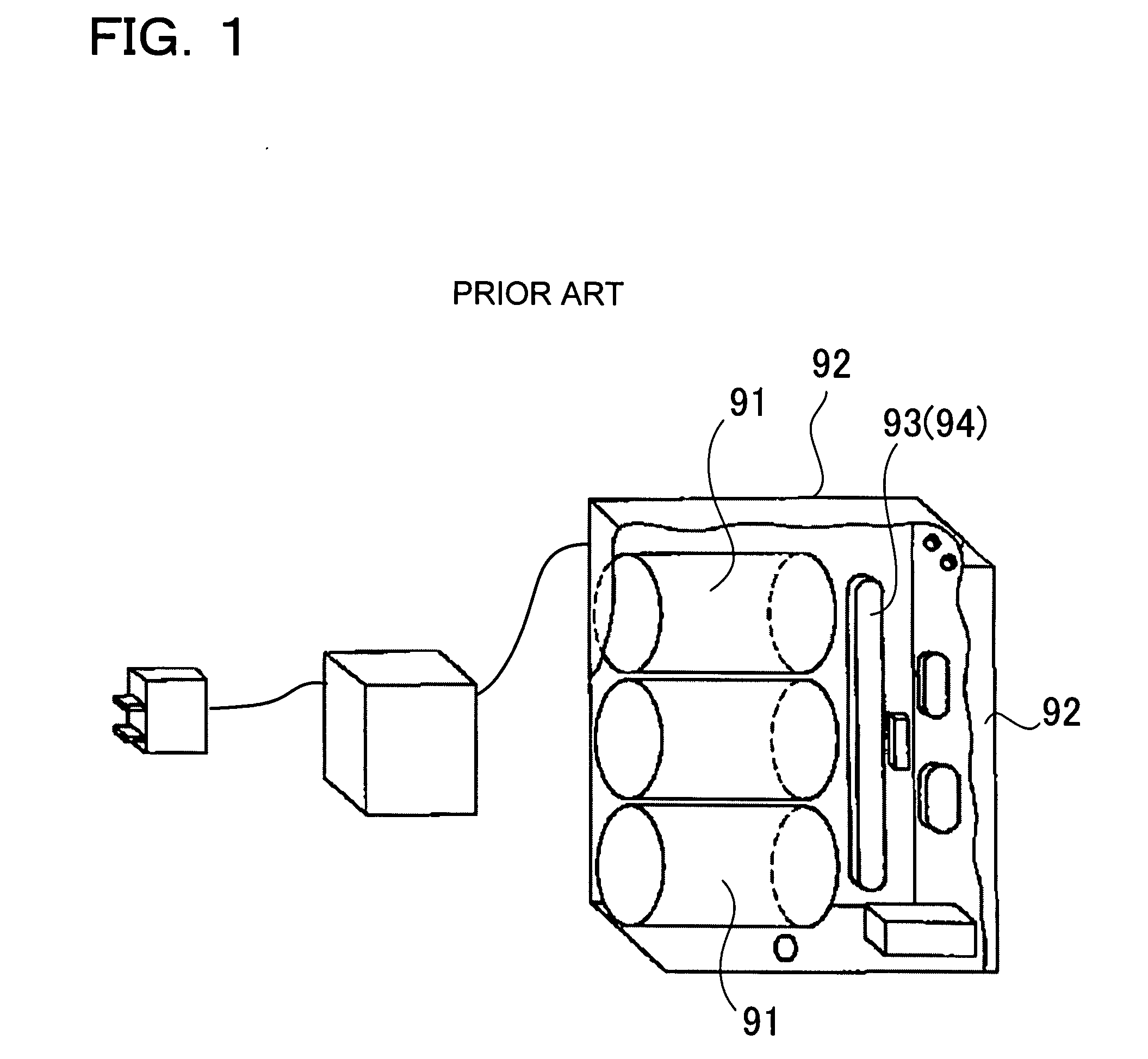

Heating furnace and method for manufacturing honeycomb structure

InactiveUS20080197544A1Increase temperatureMaintainance of heating chambersCeramic shaping apparatusMeasurement deviceHeating furnace

A heating furnace for calcining an object to be heated. The heating furnace includes a wall defining a furnace space and configured to receive the object in the furnace space, and a heating device configured to raise a temperature within the furnace space. The heating furnace also includes an oxygen supply channel configured to introduce gases containing oxygen into the furnace space. The oxygen supply channel is formed as an opening in a part of the wall surrounding the furnace space. The heating furnace further includes a gas discharge channel fluidly connected to the furnace space and configured to discharge gases in the furnace space to an outside of the furnace space, and a measurement device installed in the gas discharge channel and configured to measure properties of the gases passing through the gas discharge channel.

Owner:IBIDEN CO LTD

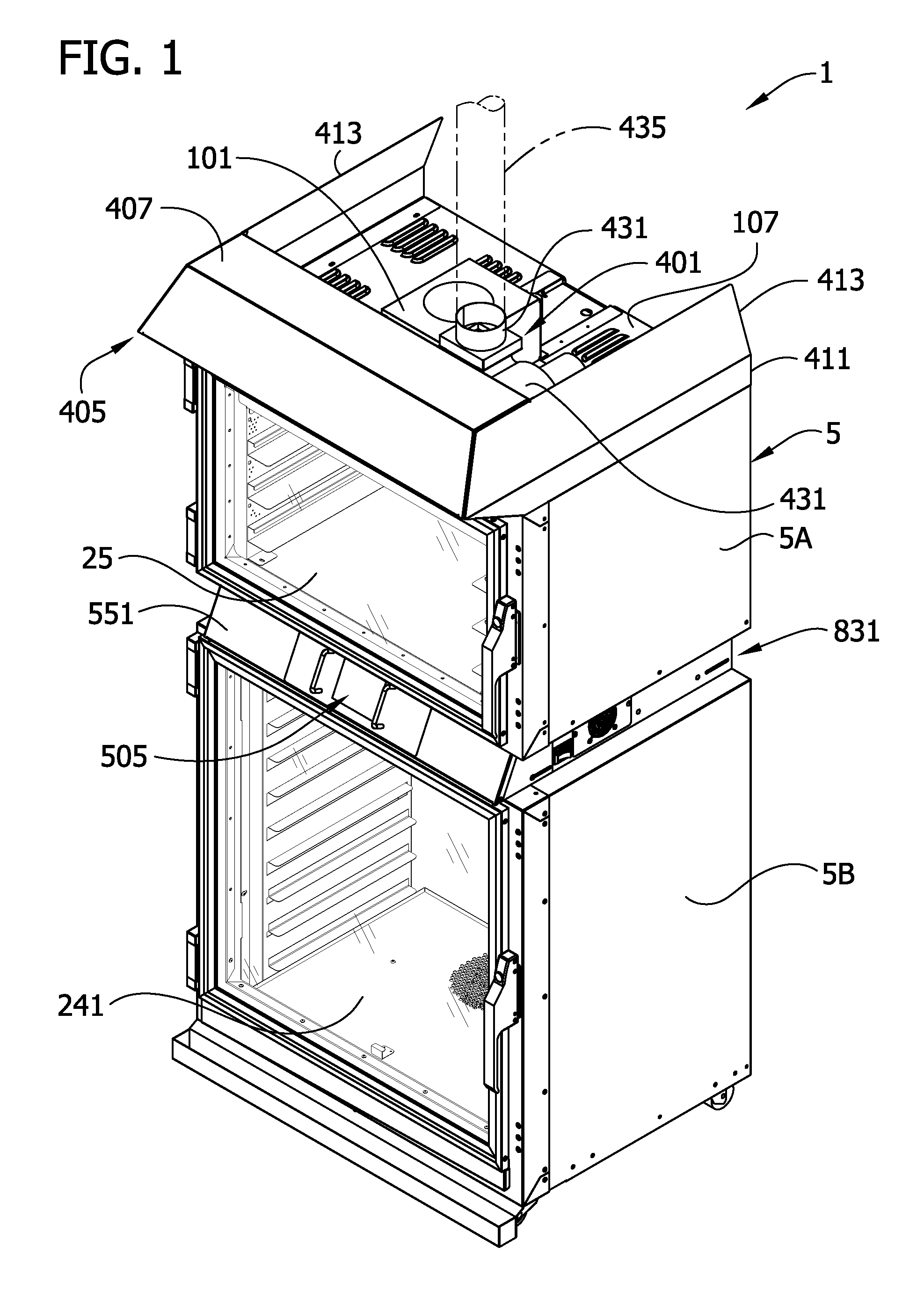

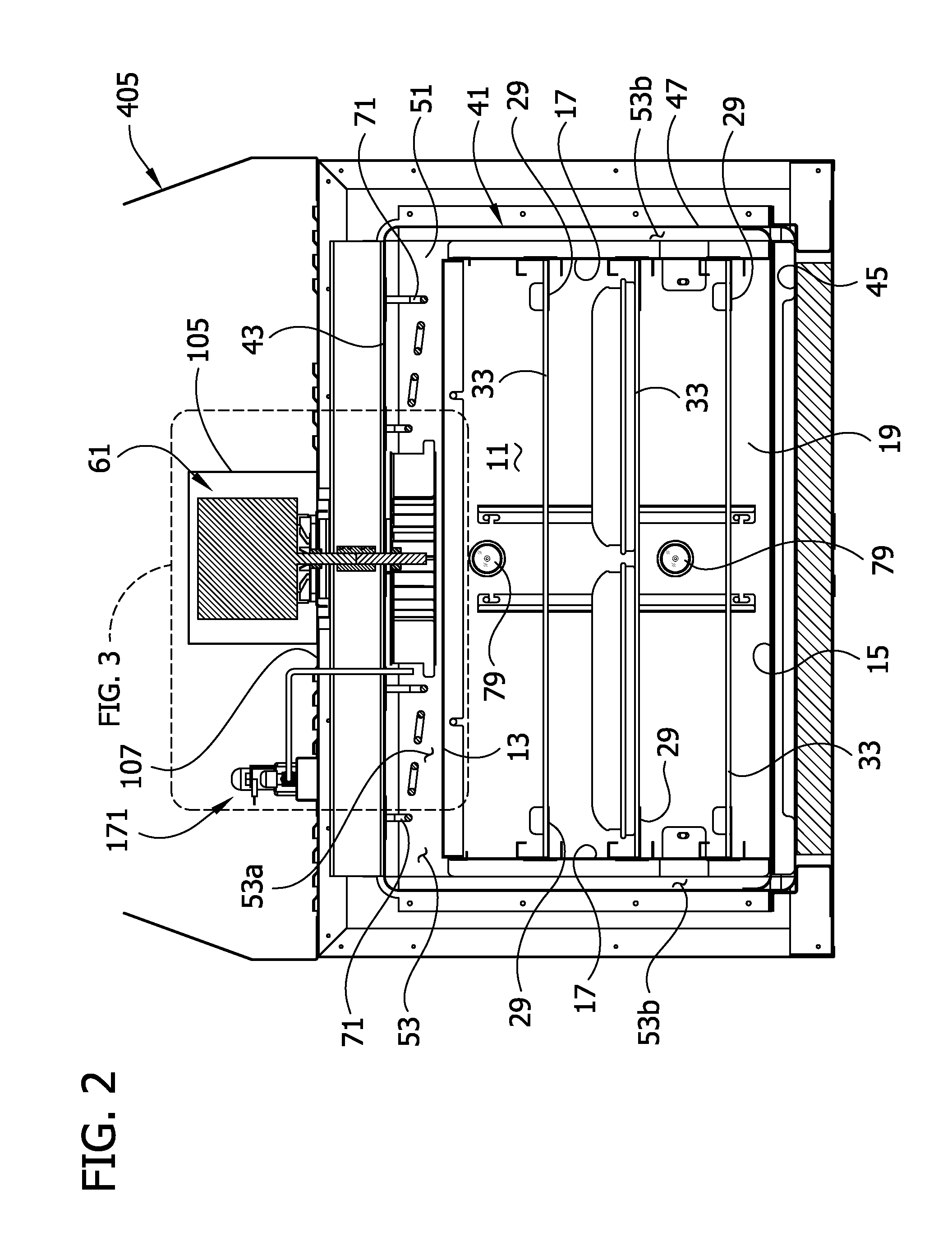

Convection oven

ActiveUS8378265B2Easy accessSelf-cleaning stoves/rangesElectrical heating fuelImpellerLiquid-crystal display

Owner:DUKE MANUFACTURING COMPANY

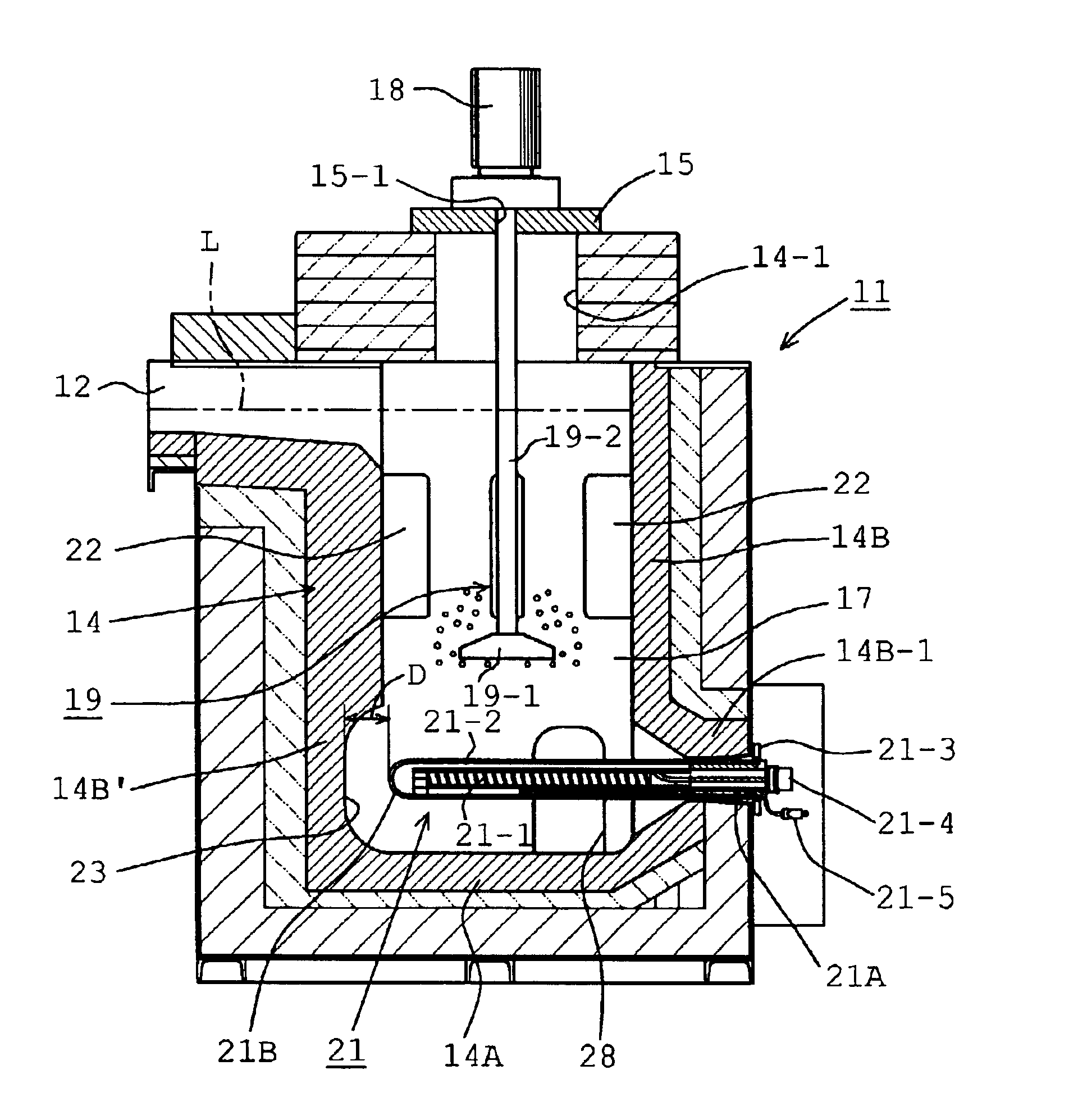

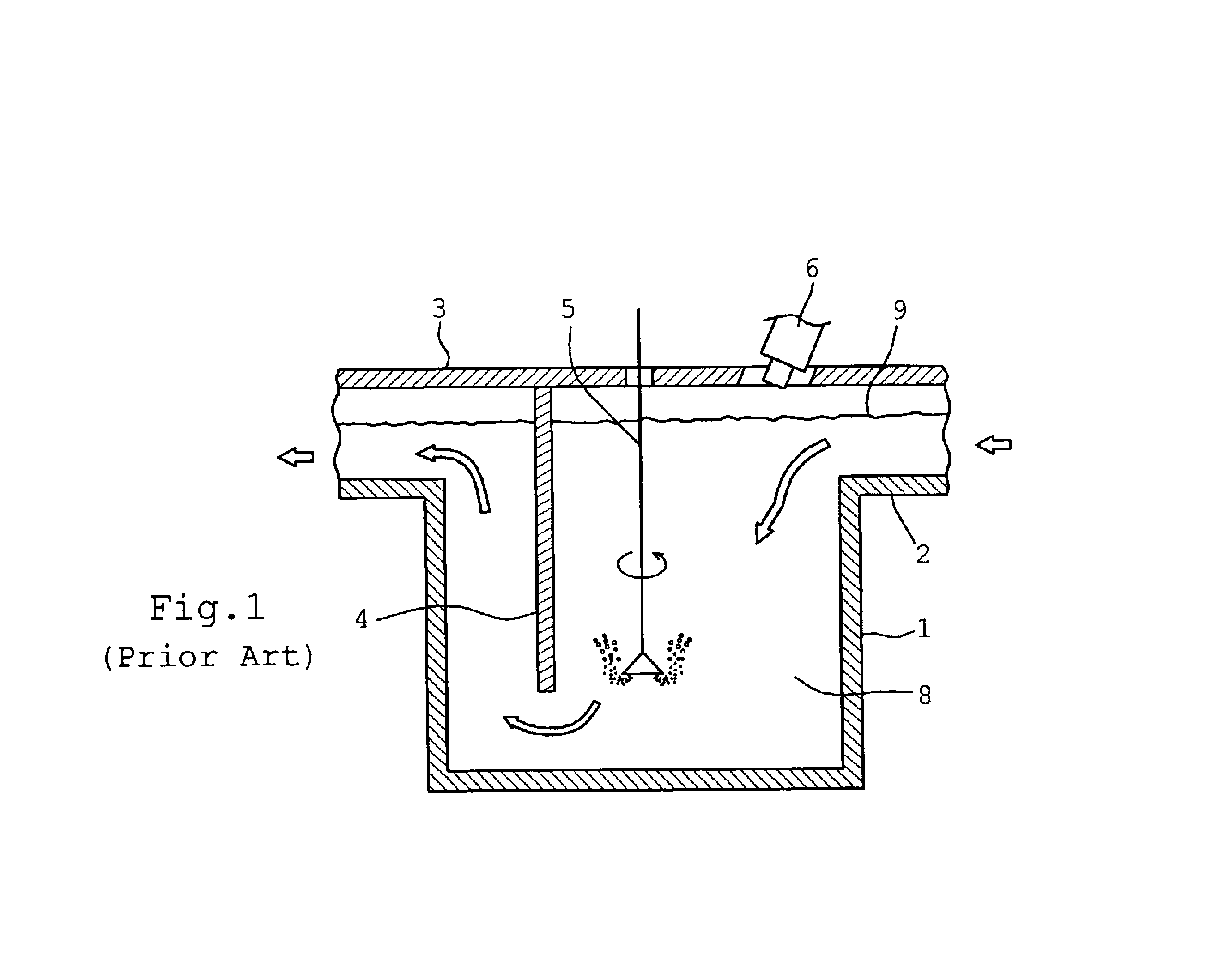

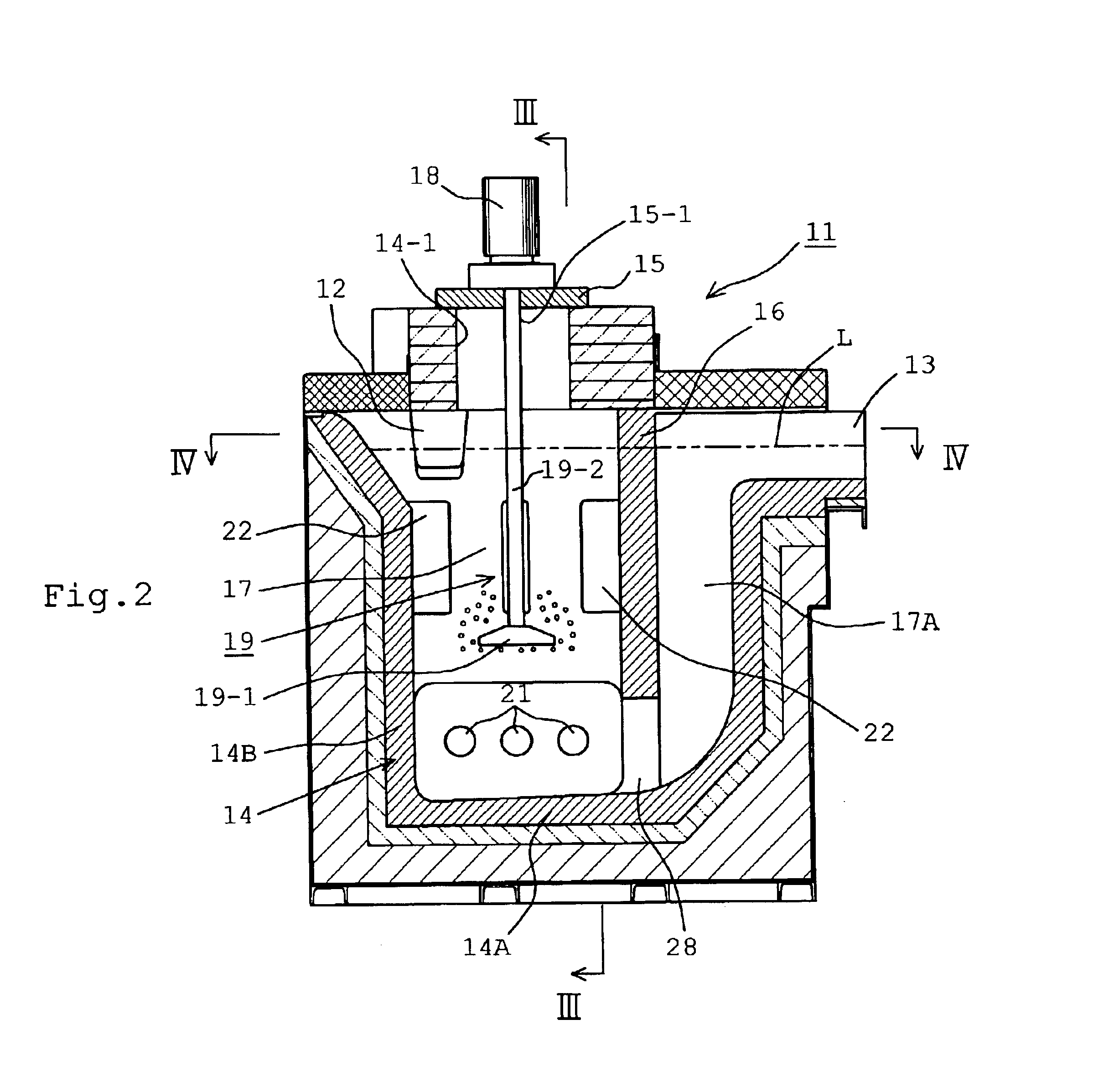

Inline degassing apparatus

InactiveUS6887424B2Reduce the amount requiredSmall volumeMelt-holding vesselsMechanical apparatusNon-metallic inclusionsSolid solution

An inline degassing apparatus for removing solid solution gases as well as nonmetallic inclusions from molten metal in a degassing container, to which the molten metal is continuously introduced for degassing operation and from which the degassed molten metal is continuously removed. A rotary diffusing device is arranged in the degassing container for generating bubbles of inert gas diffused into the molten metal, thereby entrapping solid solution gases as well as nonmetallic inclusions into the bubbles, which are then floated and separated. Heaters are provided, which extend, in a cantilever fashion, from a side wall of container at a position adjacent the bottom wall of the container substantially parallel to the bottom wall.

Owner:PYROTEK JAPAN +1

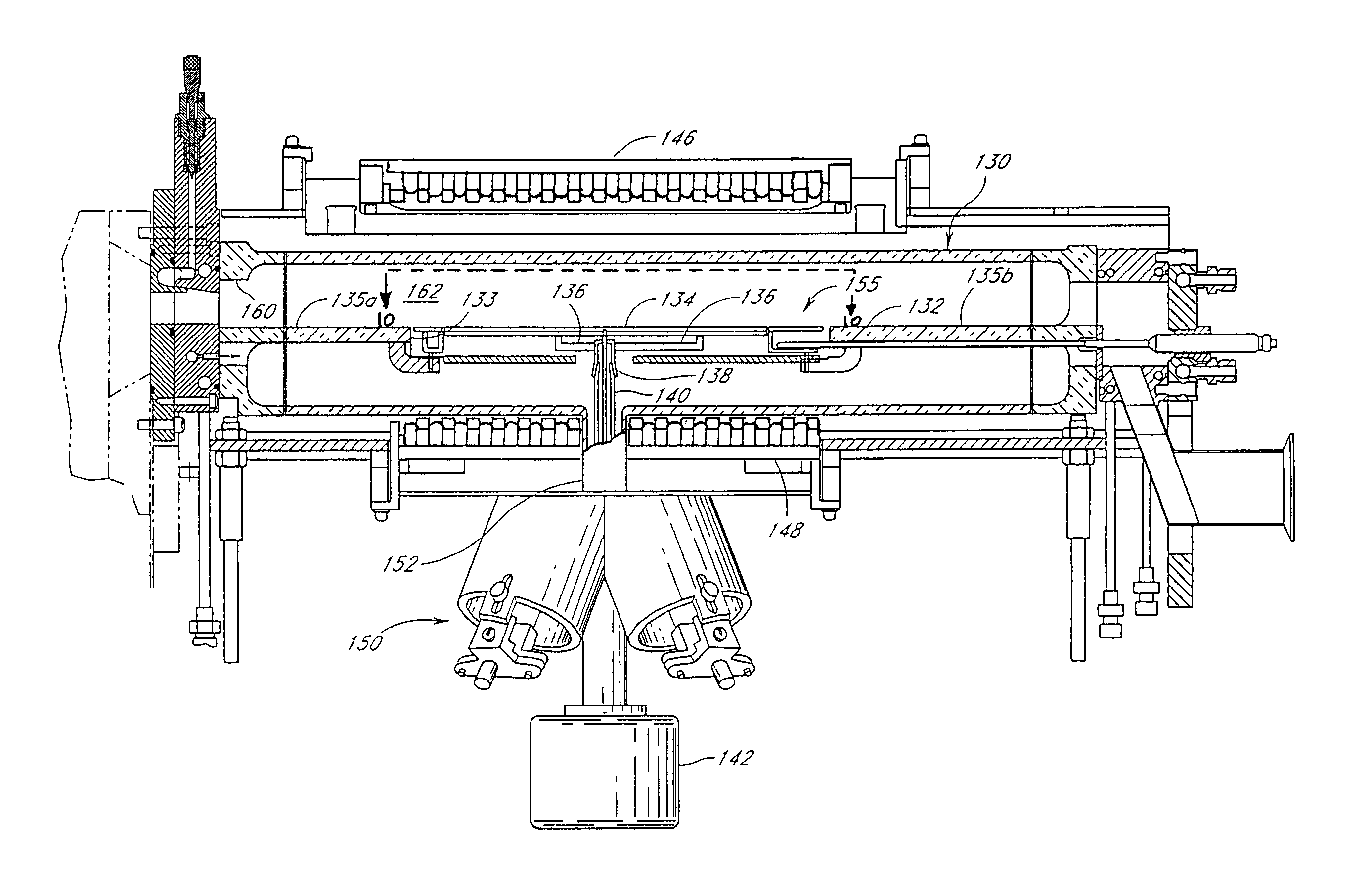

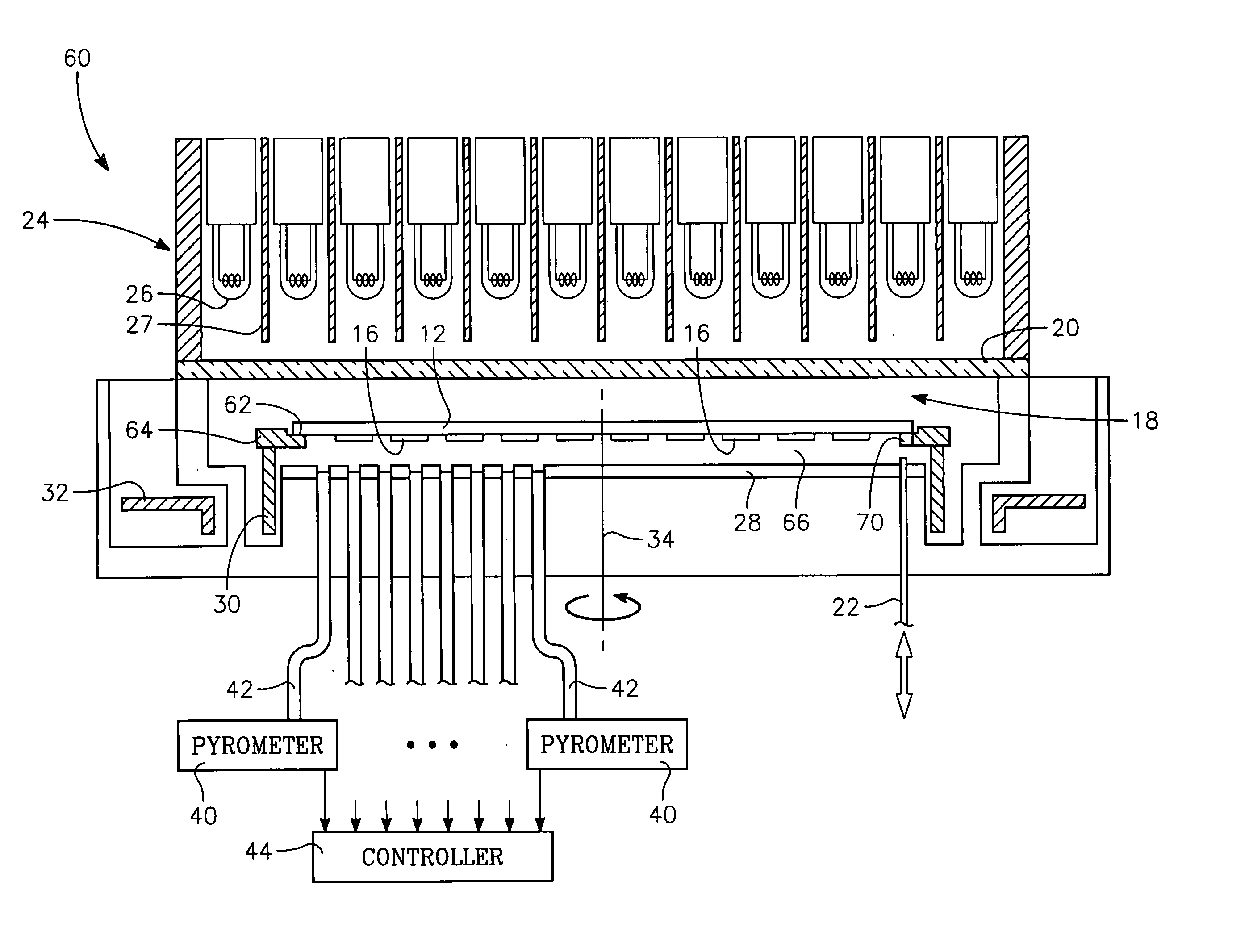

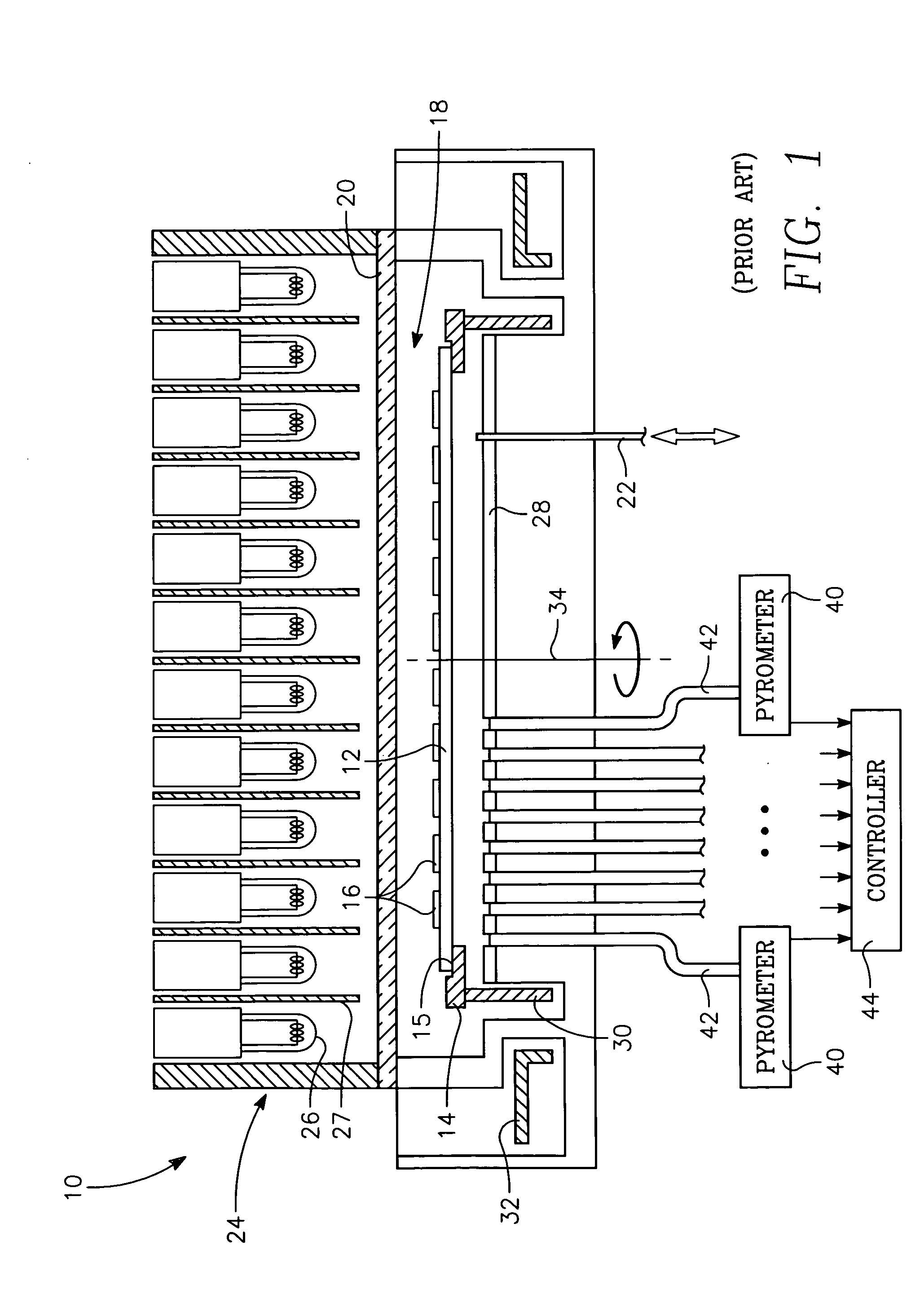

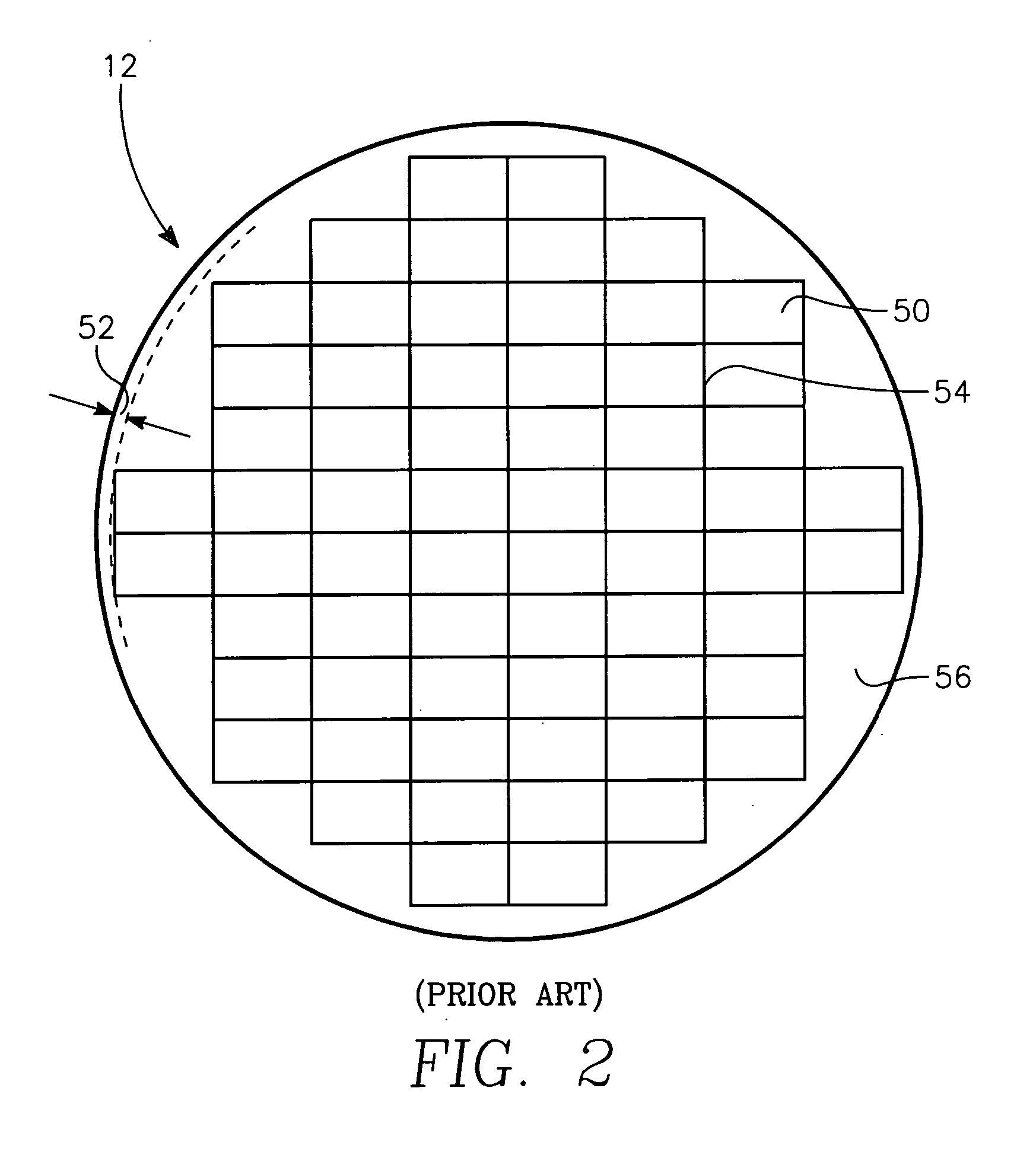

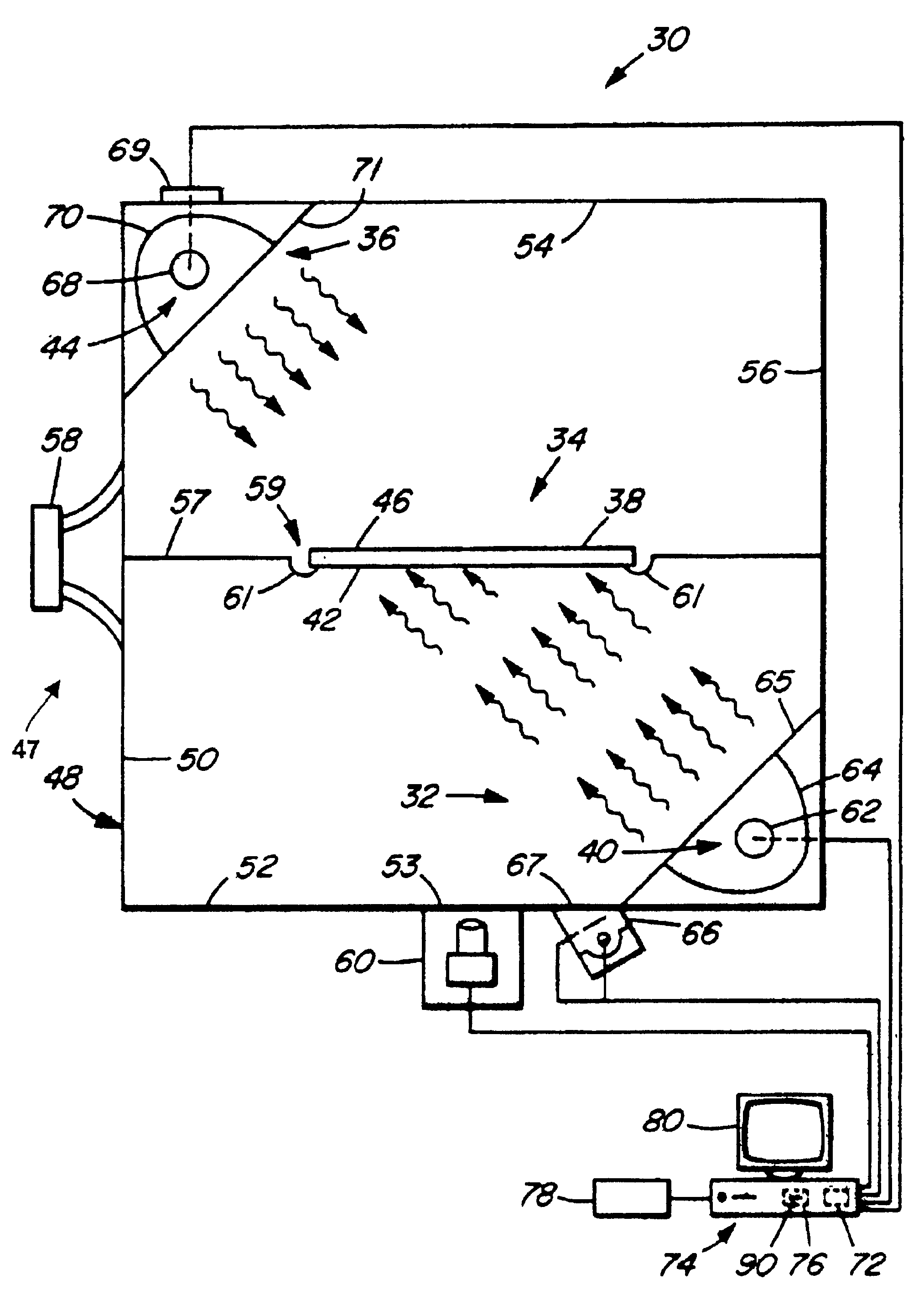

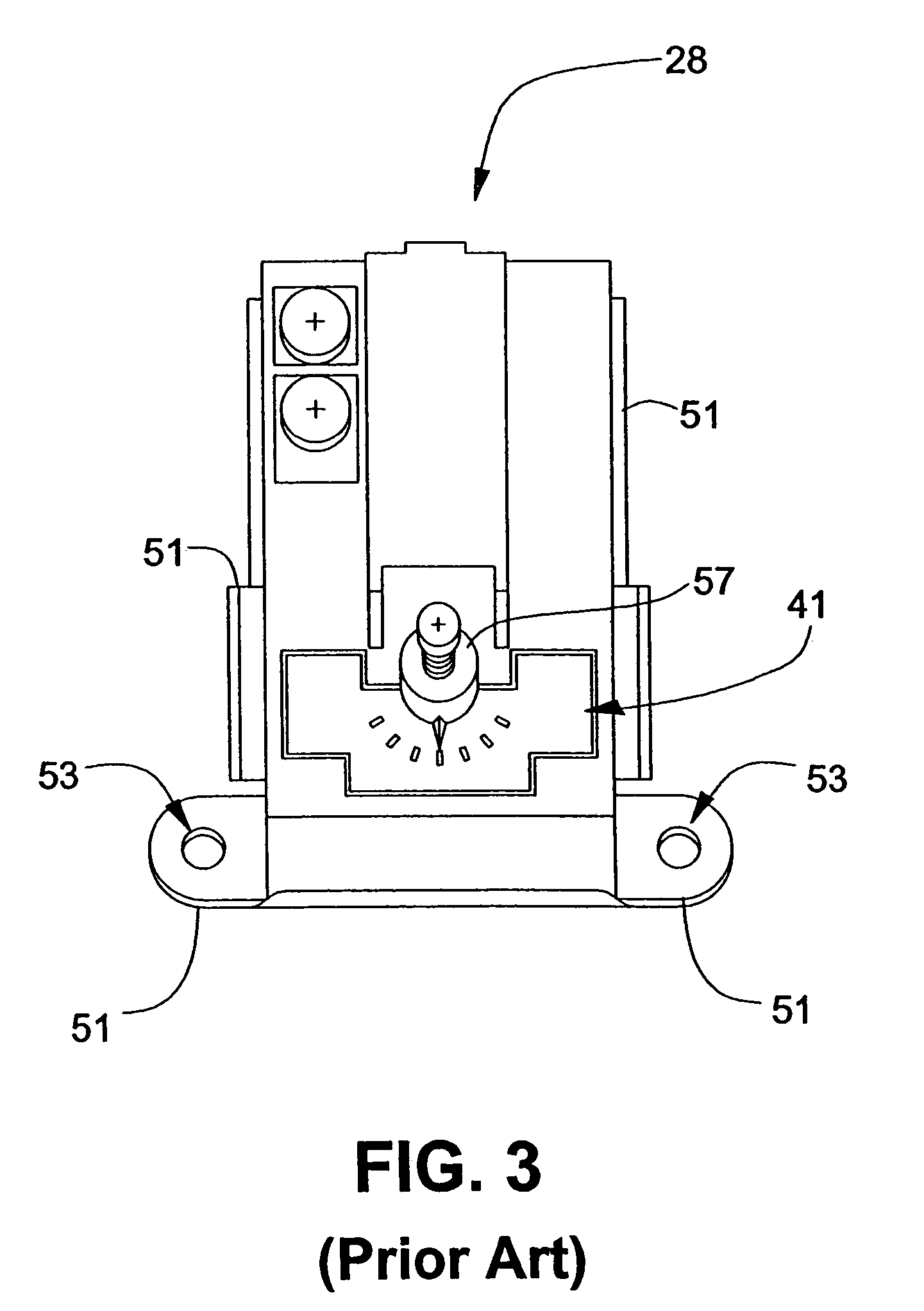

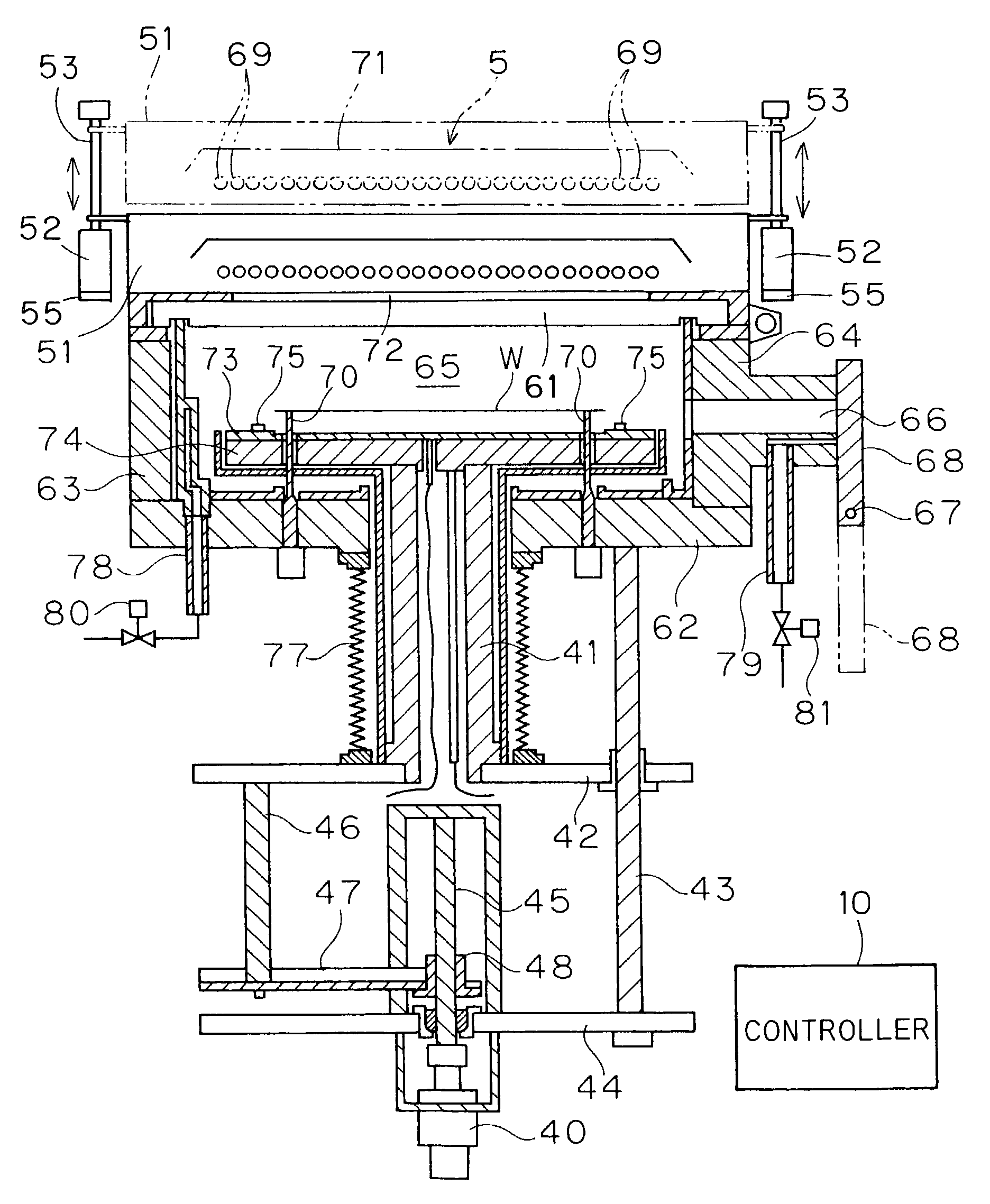

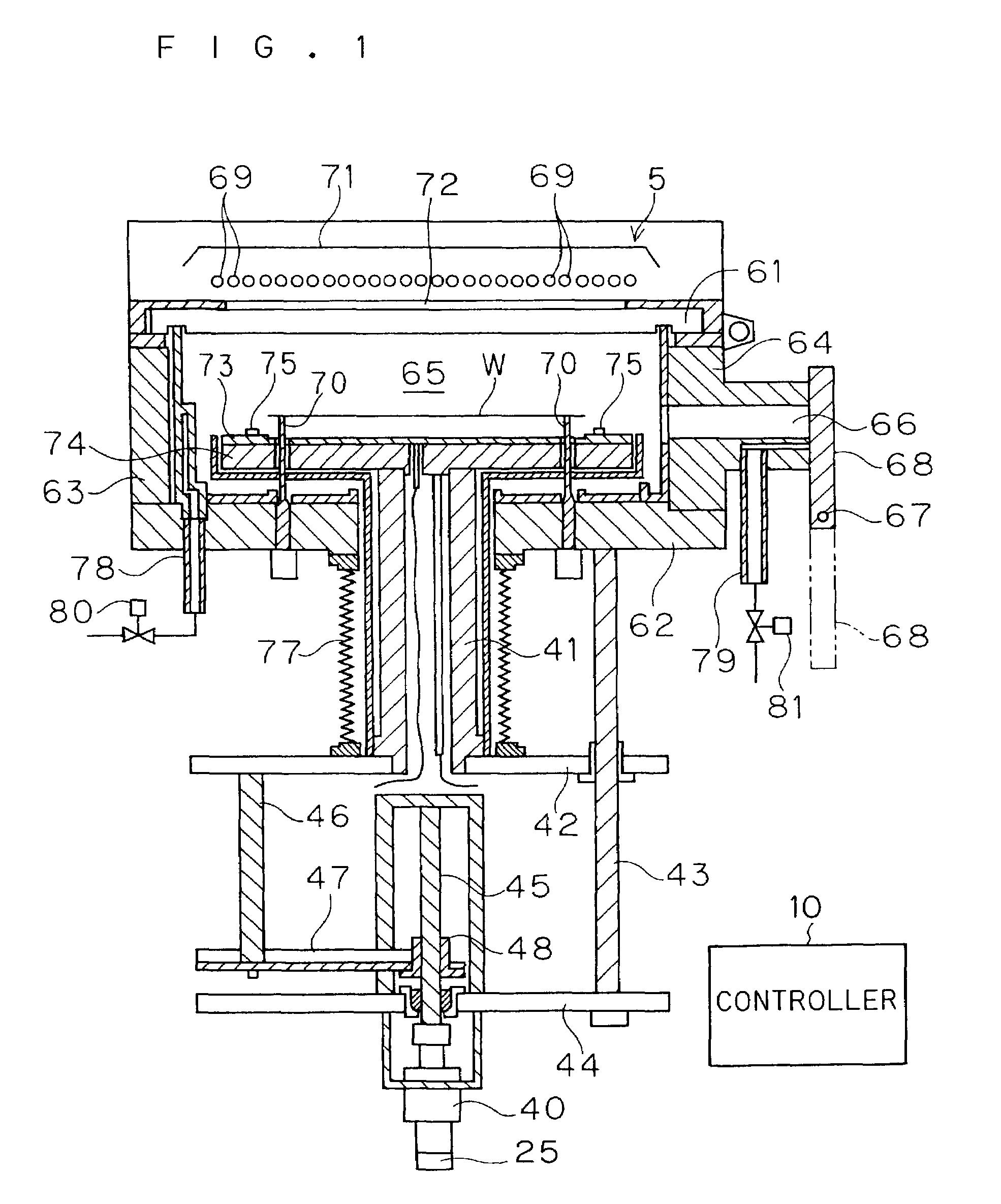

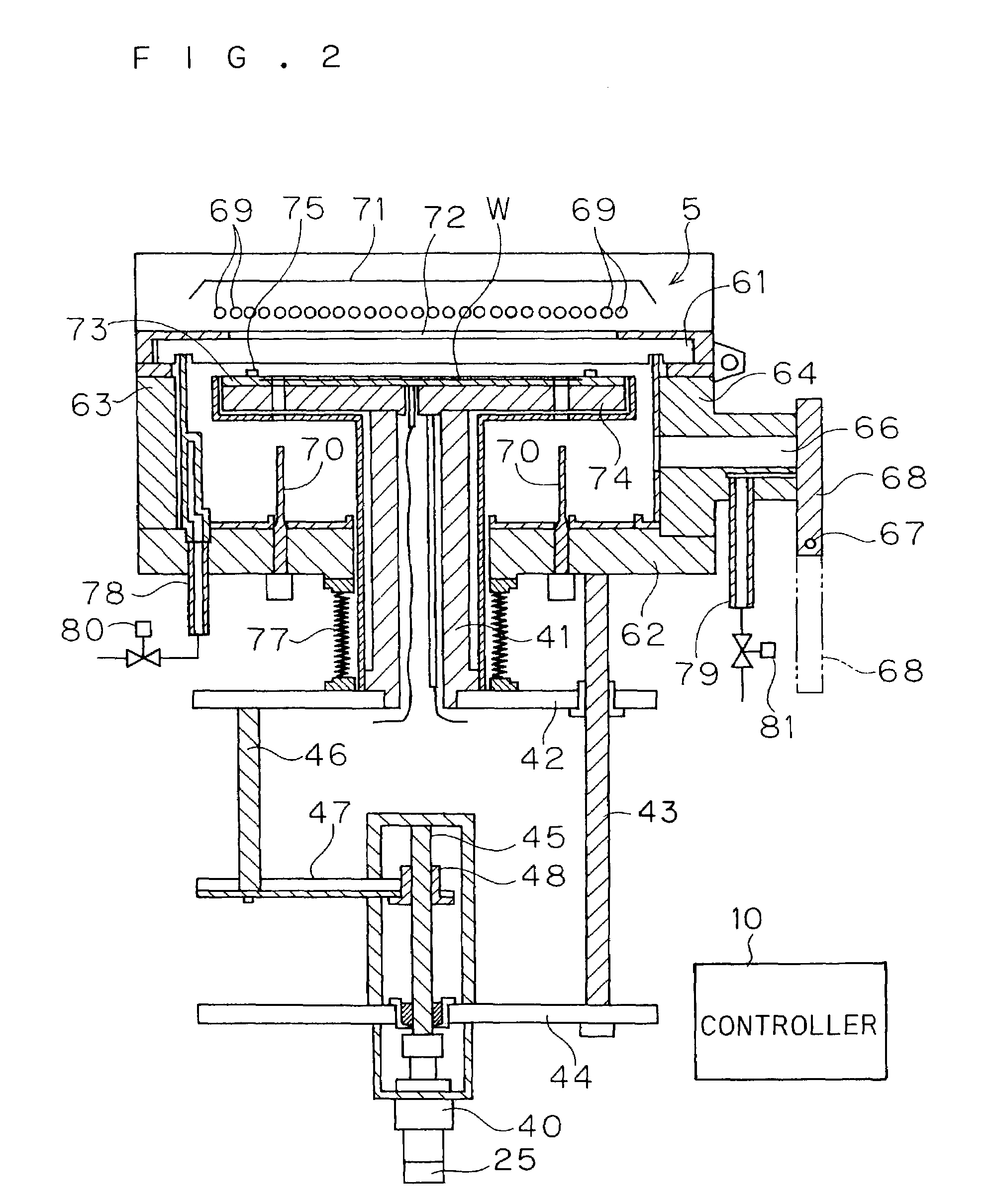

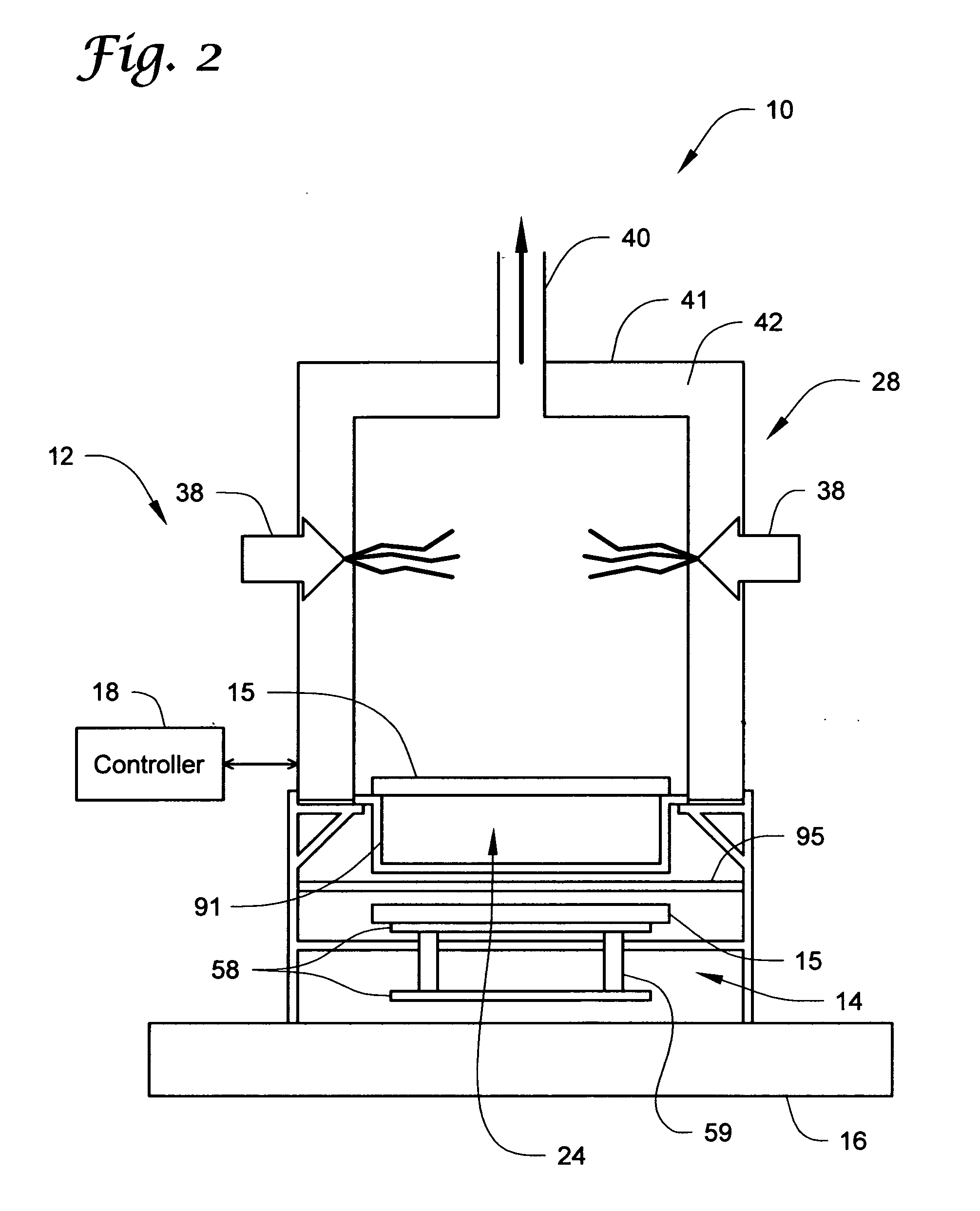

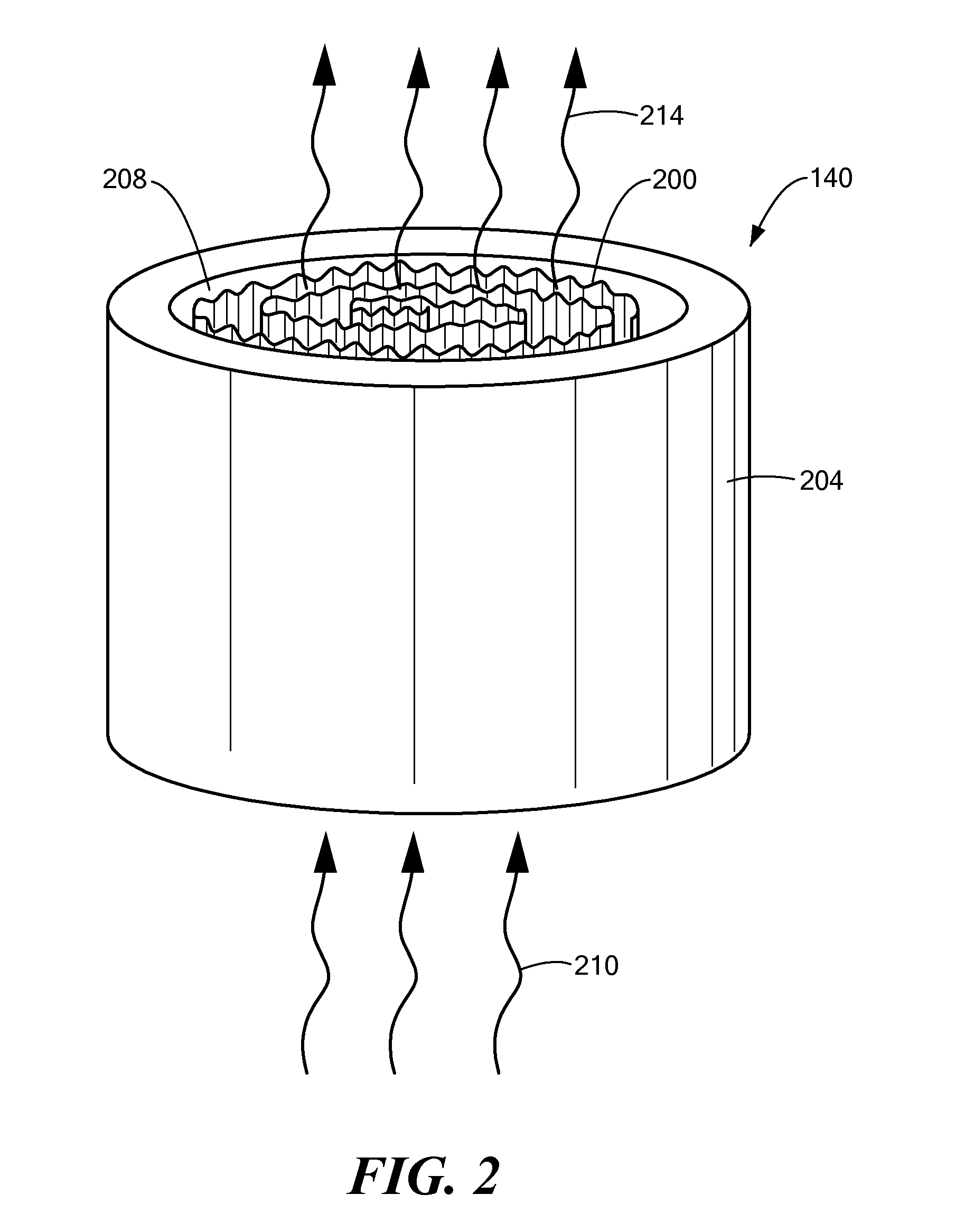

Backside rapid thermal processing of patterned wafers

A apparatus and method of thermally treating a wafer or other substrate, such as rapid thermal processing (RTP). An array of radiant lamps directs radiation to the back side of a wafer to heat the wafer. The front side of the wafer on which the patterned integrated circuits are being formed faces a radiant reflector. The wafer is thermally monitored for temperature and reflectivity from the side of the reflector. When the lamps are above the wafer, an edge ring supports the wafer in its edge exclusion zone. Alternatively, a reactor includes upwardly directed lamps and a reflector above and facing the front side of the wafer.

Owner:APPLIED MATERIALS INC

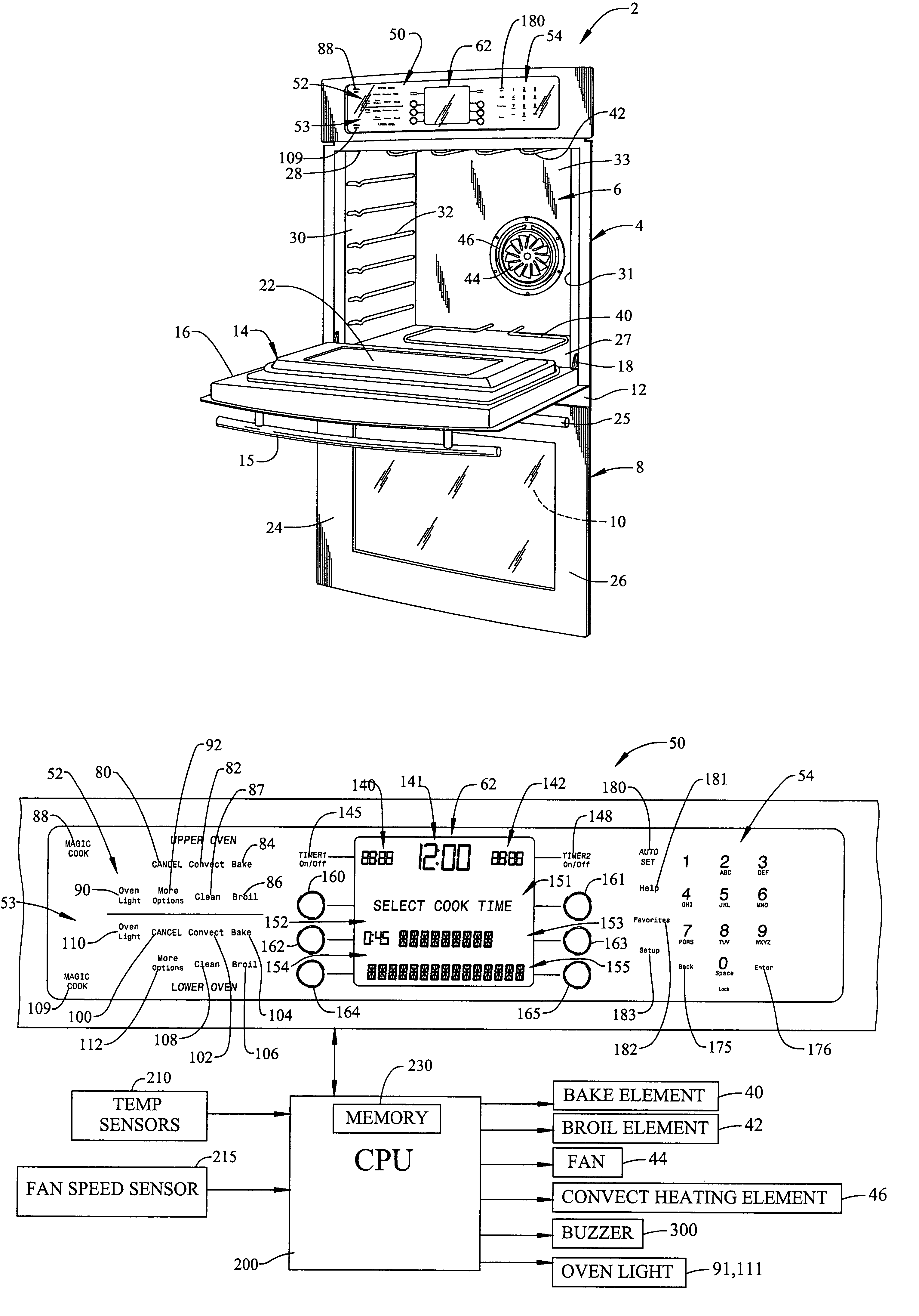

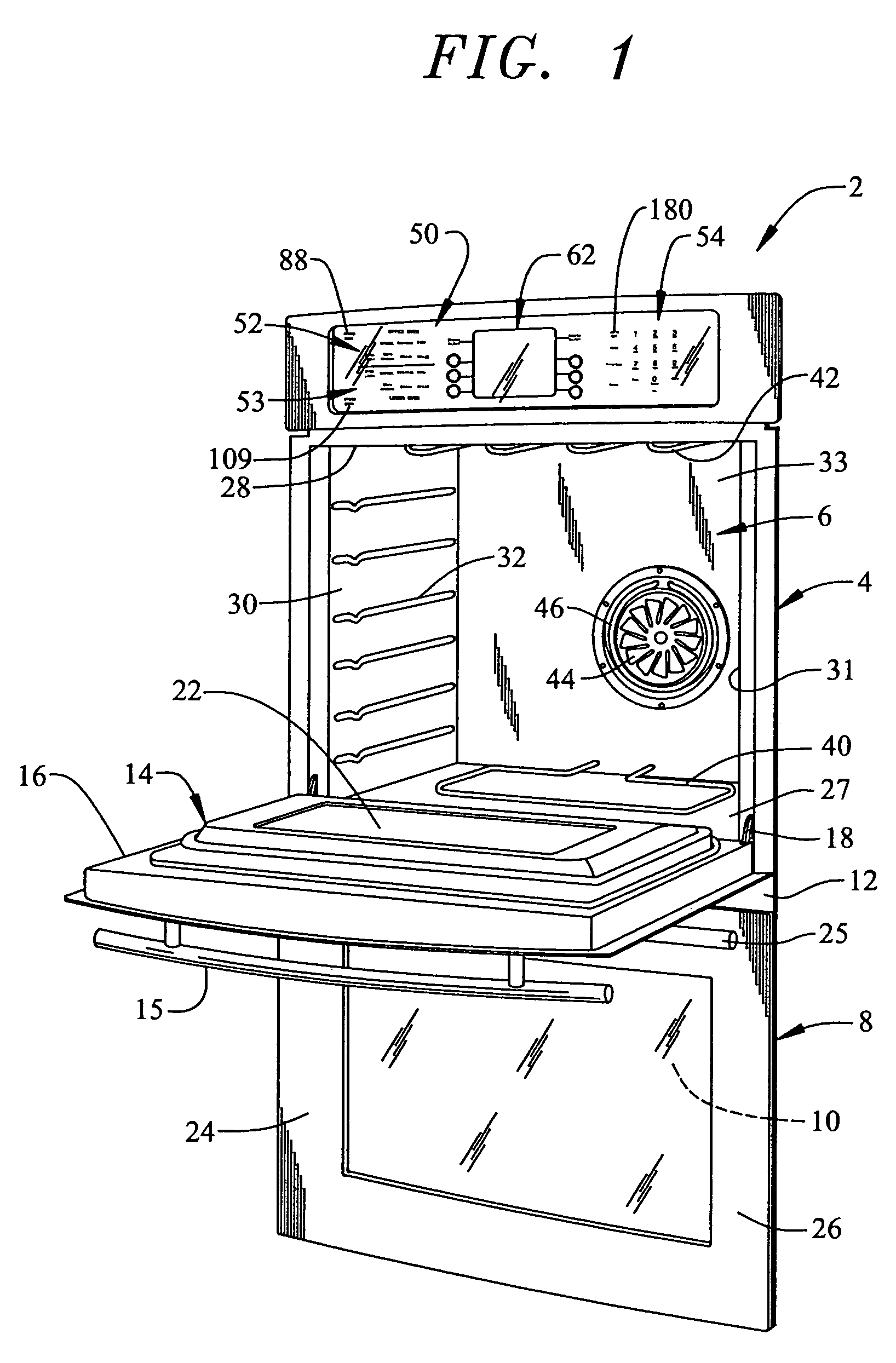

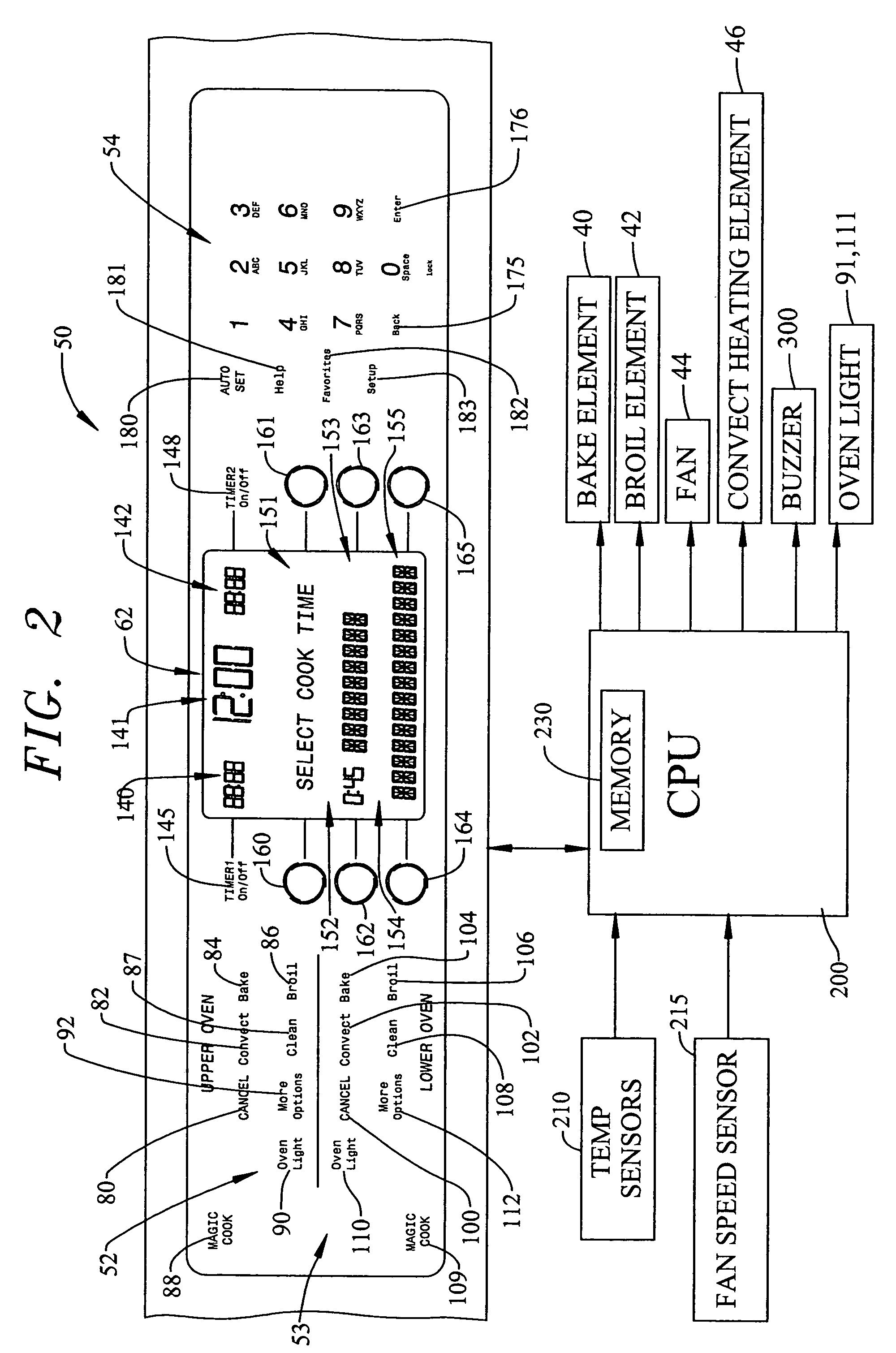

Cooking appliance control system

A control system for a cooking appliance enables a consumer to selectively program a cooking appliance through a control panel in a conventional mode based on established cooking times and temperatures, as well as in a simplified mode incorporating a minimal number of programming steps. In the simplified mode, the consumer selects a first, non-temperature related special features button and inputs a cook time. Immediately following input of the cook time, the control system starts a cooking operation. If the selected time is greater than a predetermined value, the control system automatically operates the cooking appliance in a cold start mode. An override is provided to disable the cold start mode if so desired. In addition, the control system allows a consumer to input both minimum and maximum cook times for the cooking operation.

Owner:MAYTAG

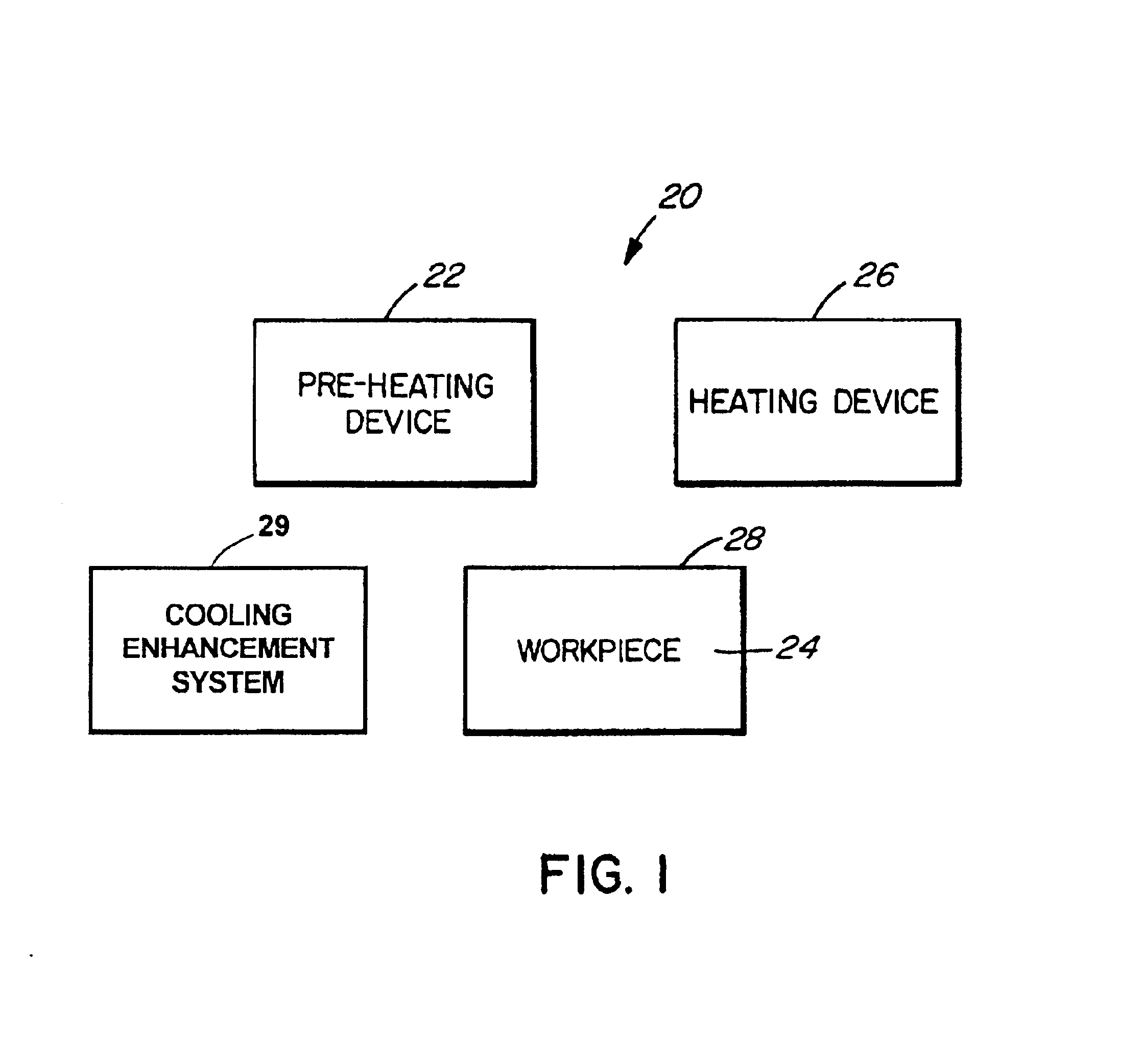

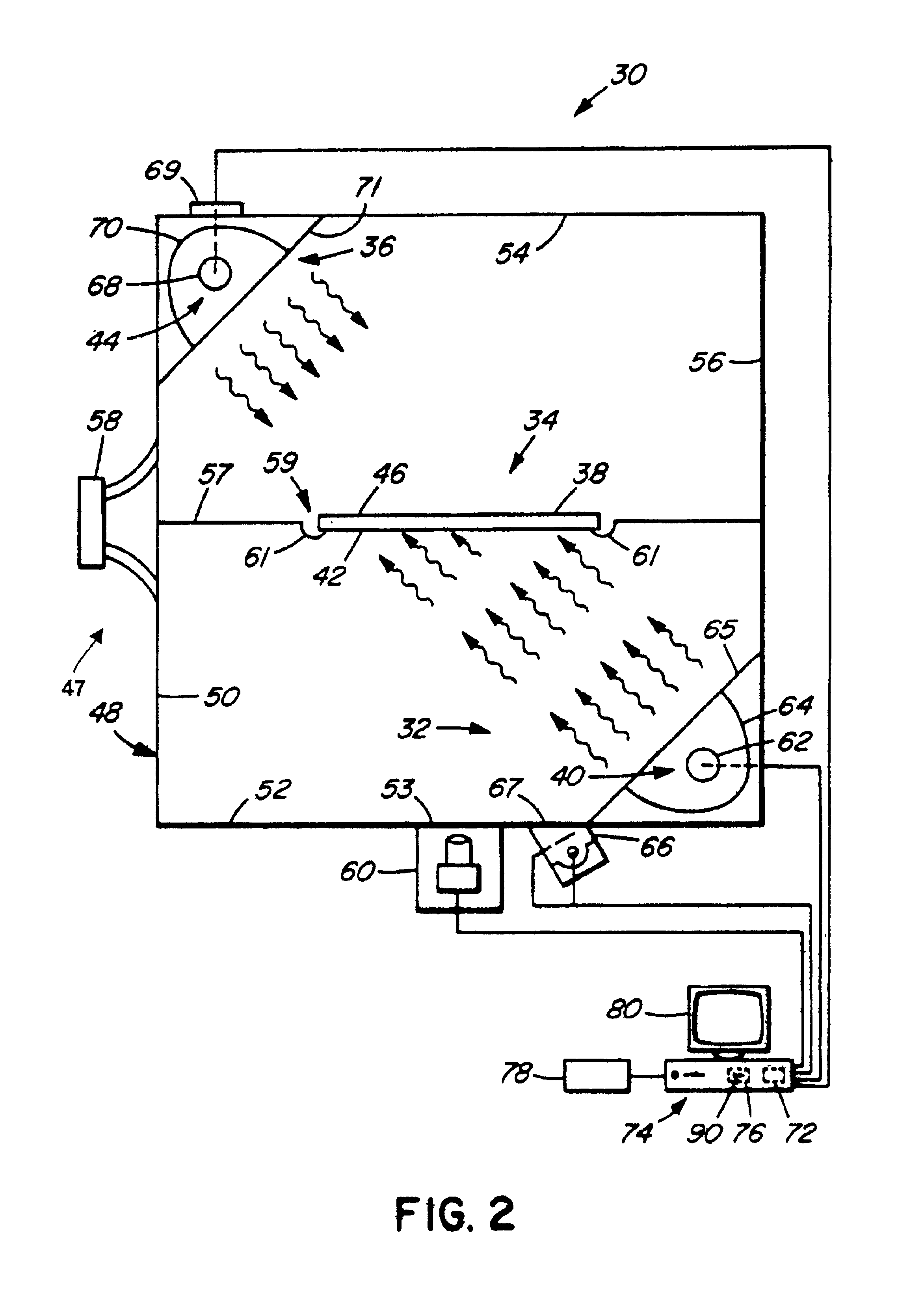

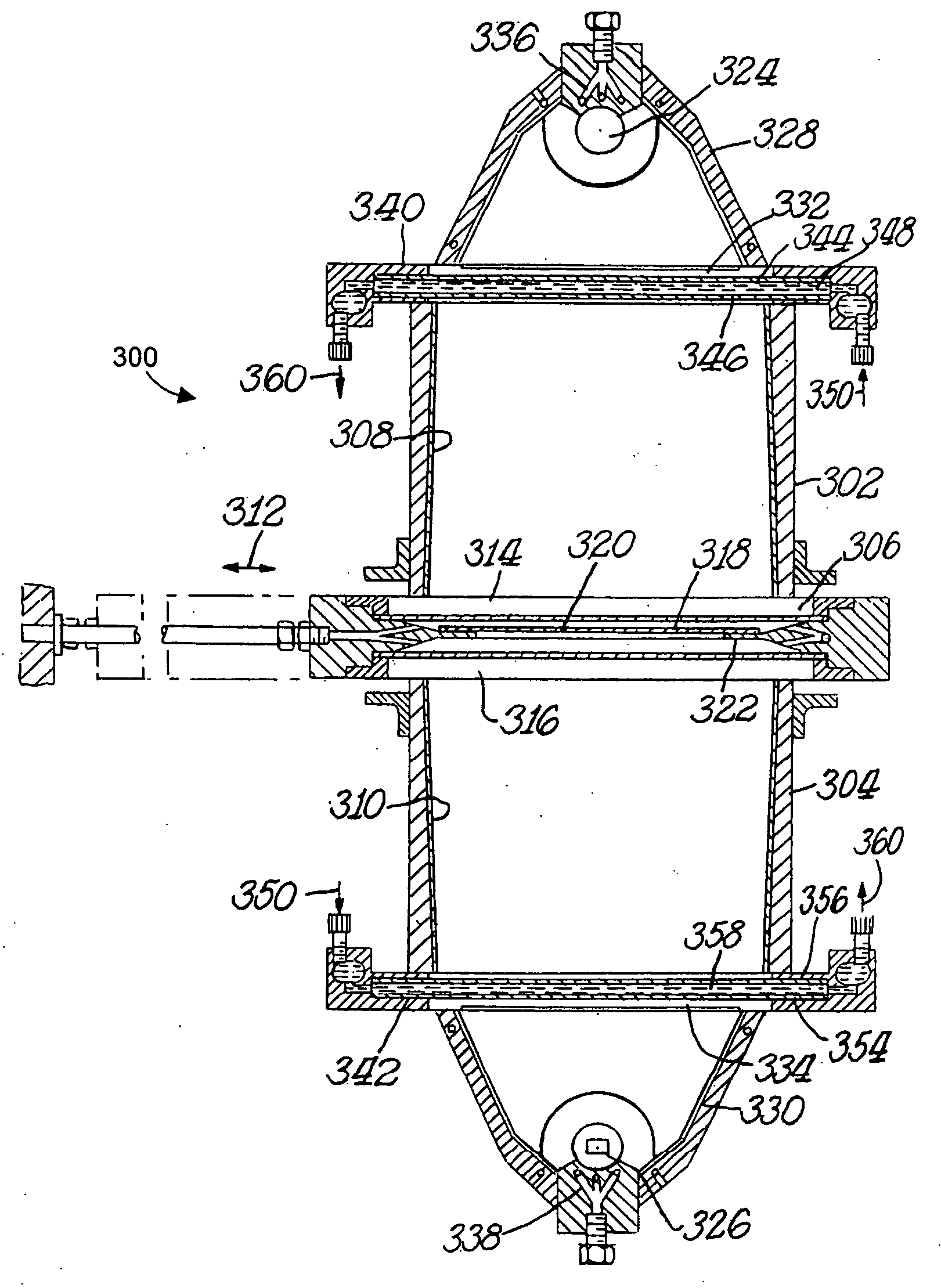

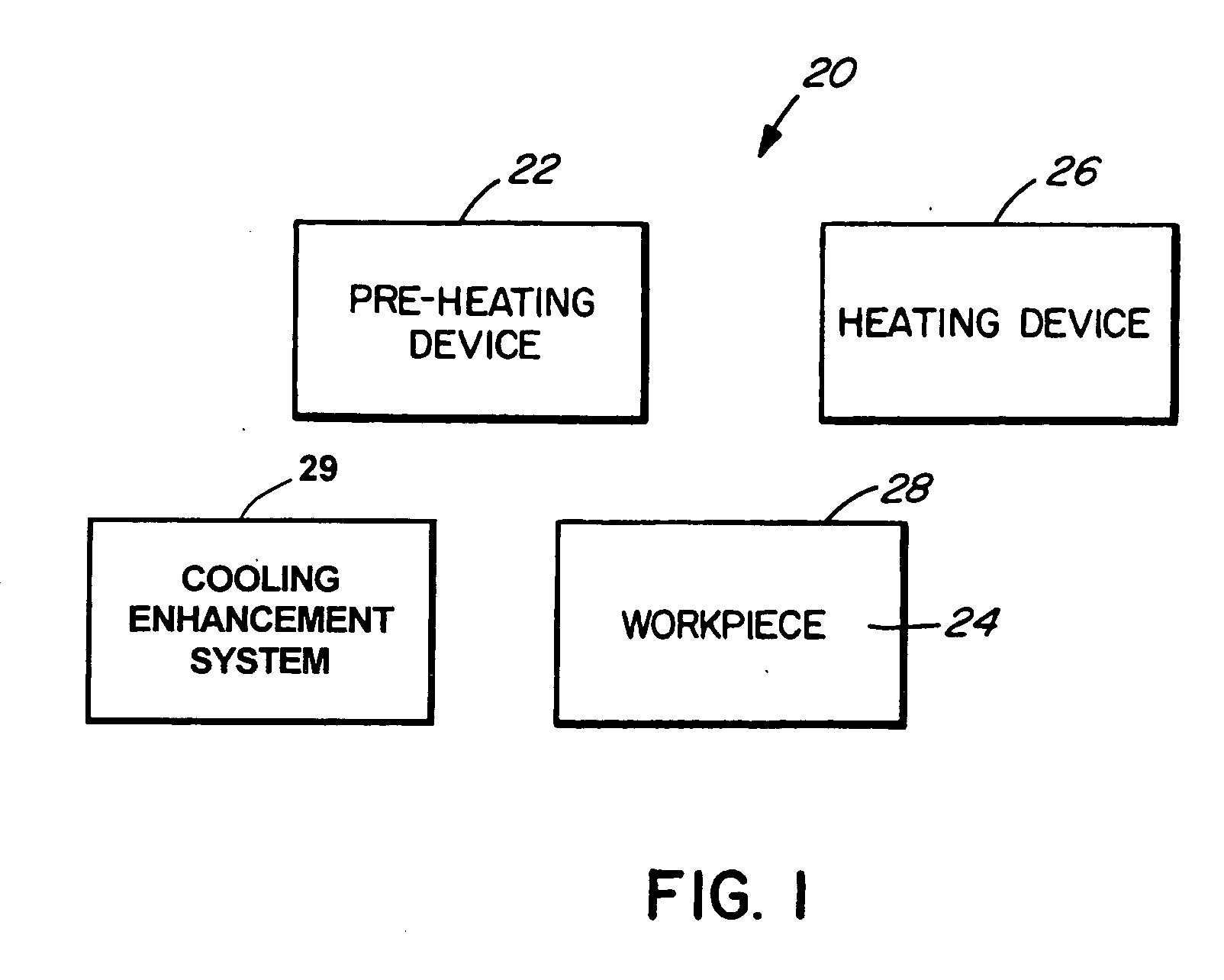

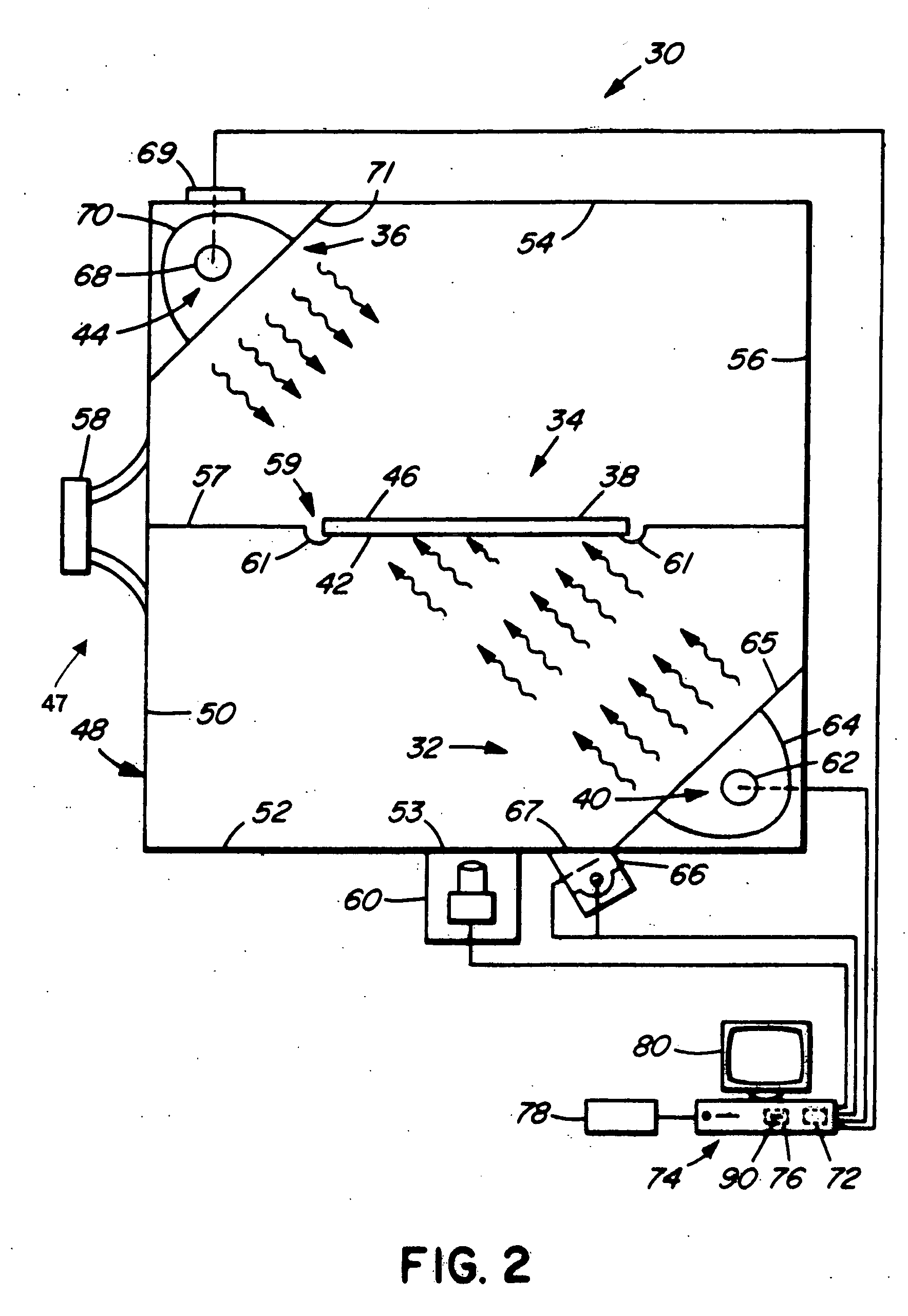

Heat-treating methods and systems

InactiveUS6941063B2Improve cooling effectWeakening rangeMechanical apparatusDrying solid materials with heatThermal radiationSemiconductor

A method involves pre-heating a workpiece to an intermediate temperature, heating a surface of the workpiece to a desired temperature greater than the intermediate temperature, and enhancing cooling of the workpiece. Enhancing cooling may involve absorbing radiation thermally emitted by the workpiece. An apparatus includes a first heating source for heating a first surface of a semiconductor wafer, a second heating source for heating a second surface of the semiconductor wafer, and a first cooled window disposed between the first heating source and the semiconductor wafer.

Owner:MATTSON TECHNOLOGY +1

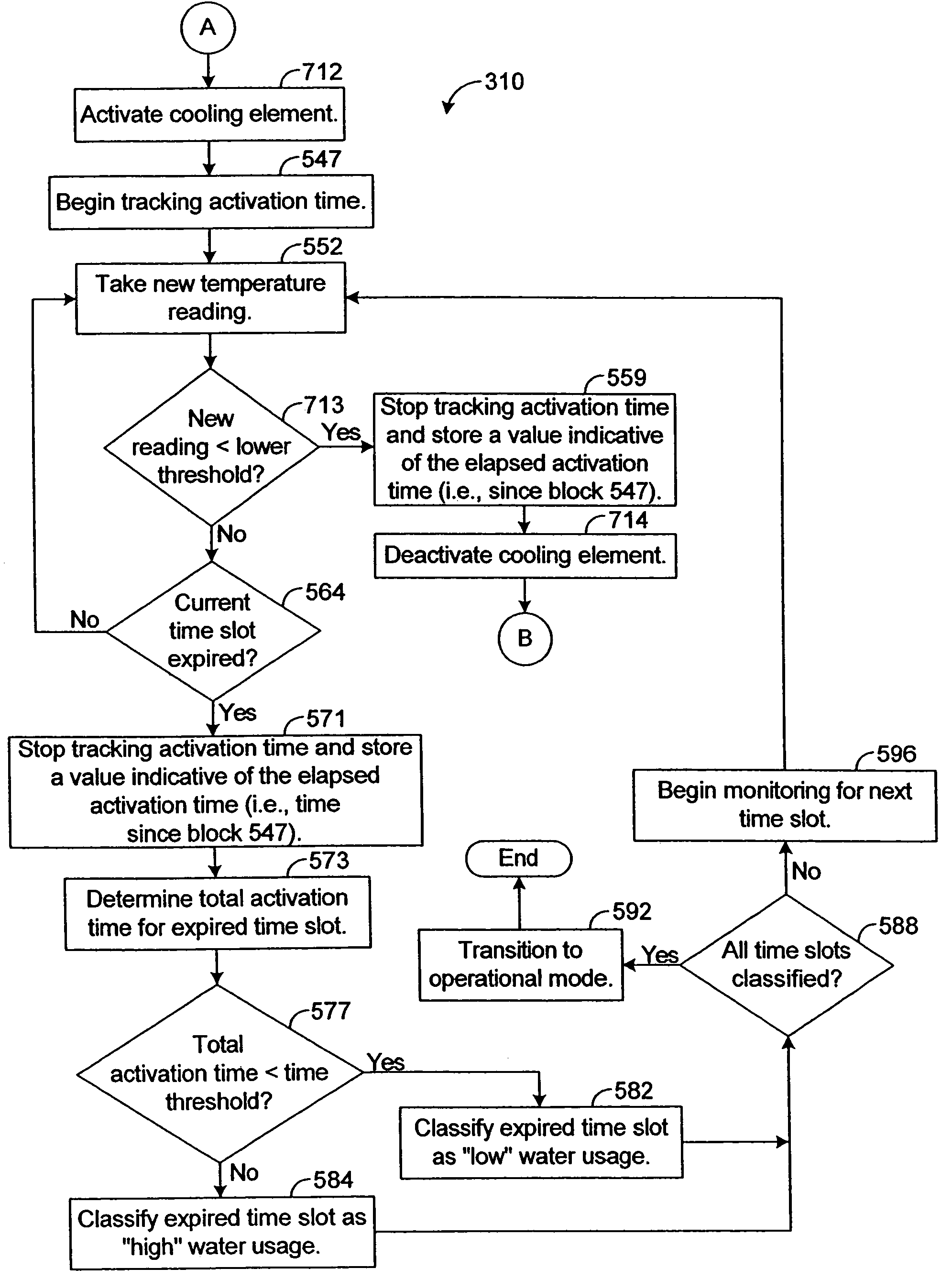

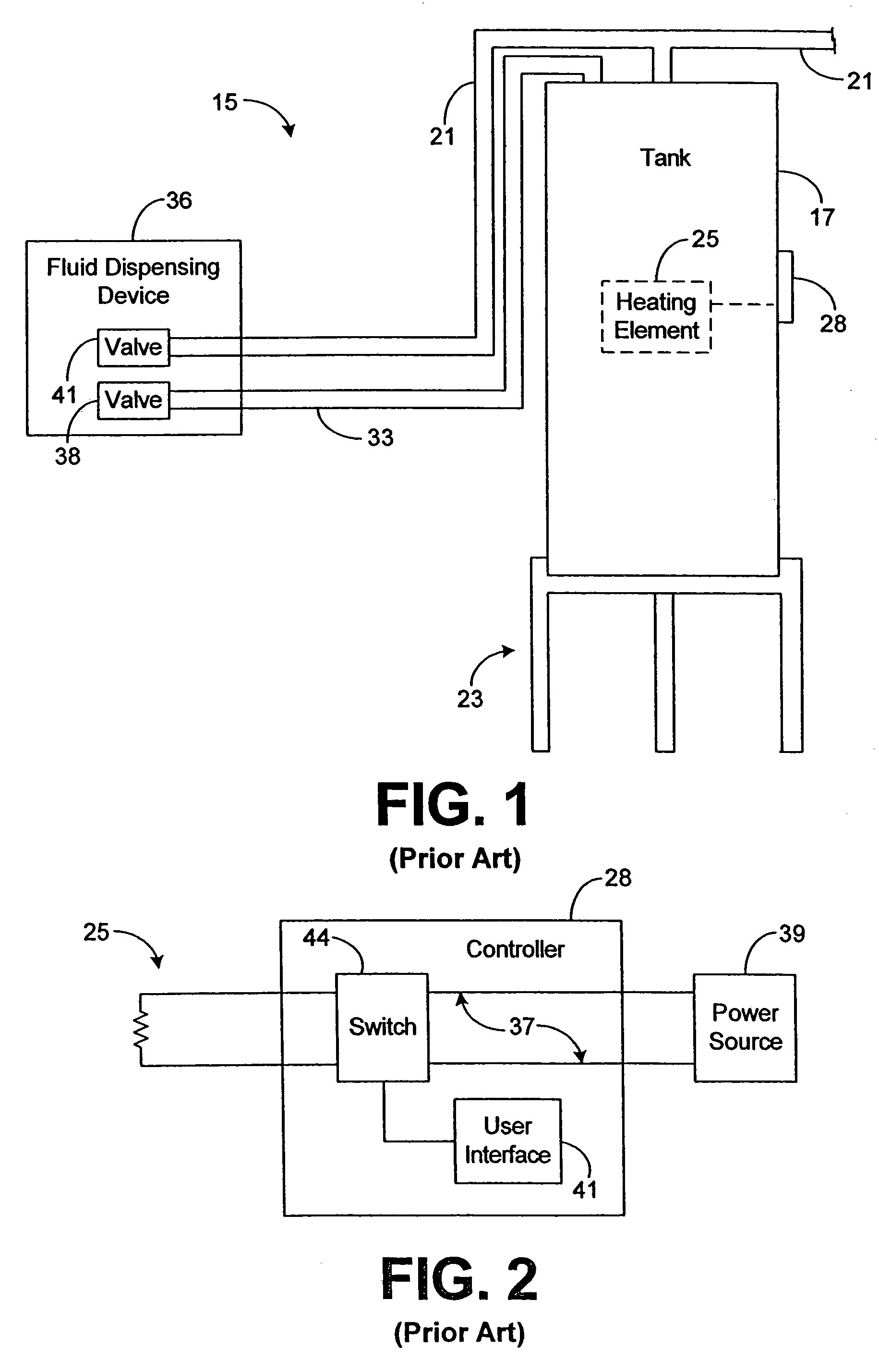

System and method for controlling temperature of a liquid residing within a tank

InactiveUS7065431B2Temperature control using digital meansThermometers using electric/magnetic elementsTemperature controlLiquid temperature

A system for controlling a temperature of a liquid residing within a tank comprises a temperature sensor, a temperature control element, memory, and logic. The temperature sensor is configured to detect the temperature of the liquid residing within the tank, and the temperature control element is coupled to the tank. The memory stores data indicative of a usage history of the tank, and the logic is configured to automatically control the temperature control element based on the data.

Owner:A O SMITH

Thermal processing apparatus and thermal processing method

InactiveUS6998580B2Easy to controlDrying solid materials with heatMuffle furnacesUltimate tensile strengthIrradiation

Owner:DAINIPPON SCREEN MTG CO LTD

Heat-treating methods and systems

InactiveUS20050062388A1Improve cooling effectWeakening rangeMuffle furnacesDiffusion/dopingSemiconductorMaterials science

A method involves pre-heating a workpiece to an intermediate temperature, heating a surface of the workpiece to a desired temperature greater than the intermediate temperature, and enhancing cooling of the workpiece. Enhancing cooling may involve absorbing radiation thermally emitted by the workpiece. An apparatus includes a first heating source for heating a first surface of a semiconductor wafer, a second heating source for heating a second surface of the semiconductor wafer, and a first cooled window disposed between the first heating source and the semiconductor wafer.

Owner:MATTSON TECH CANADA

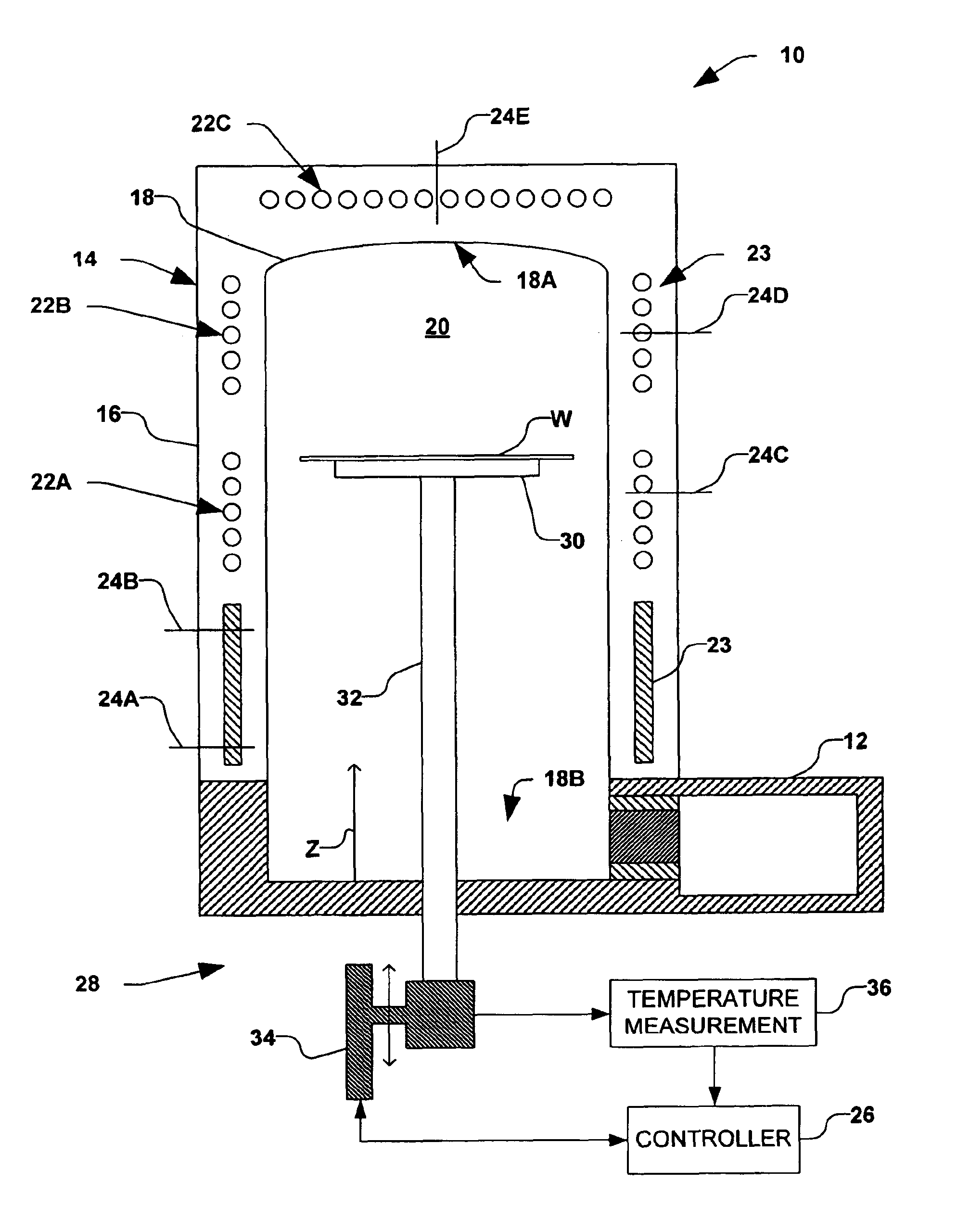

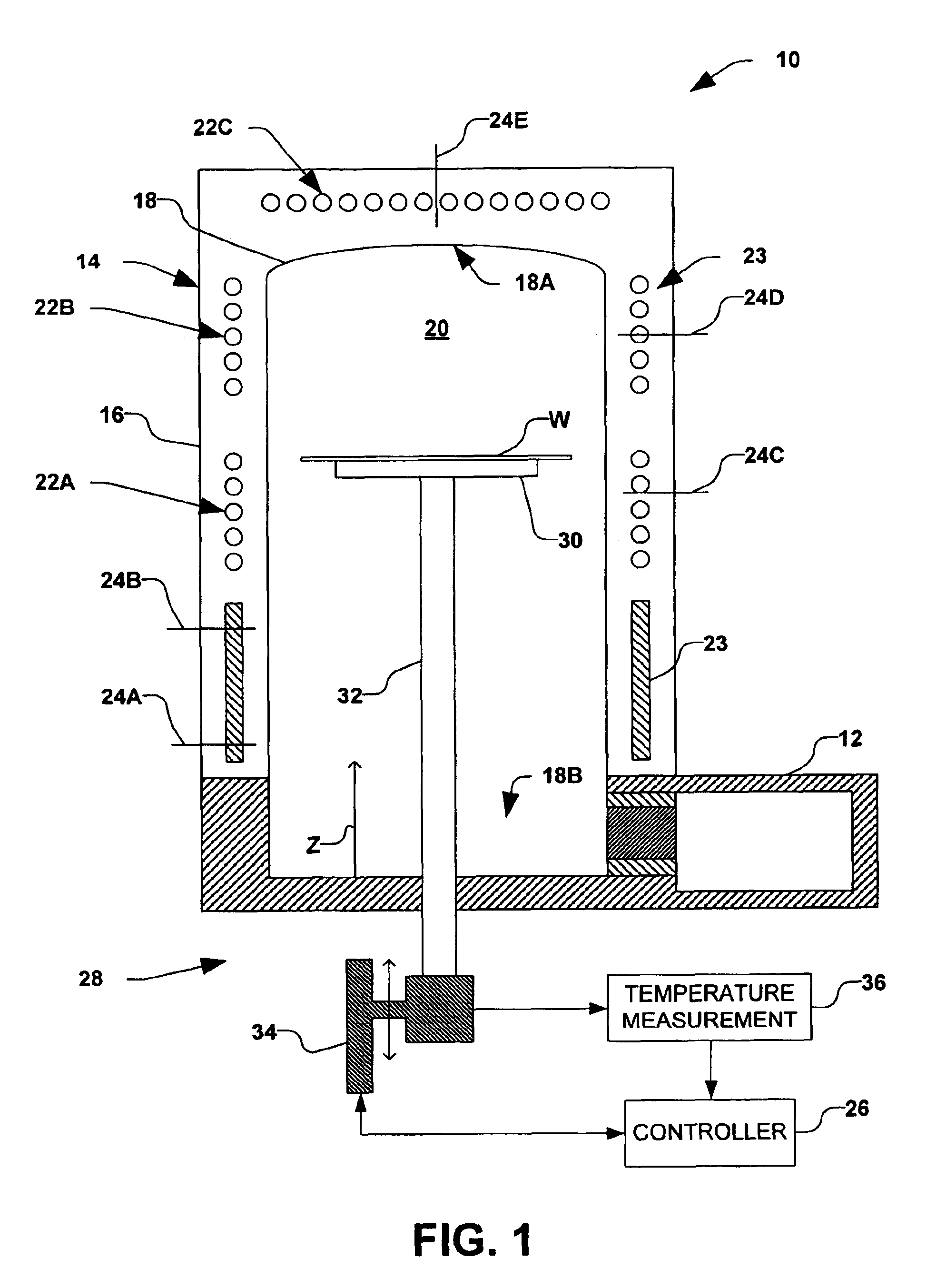

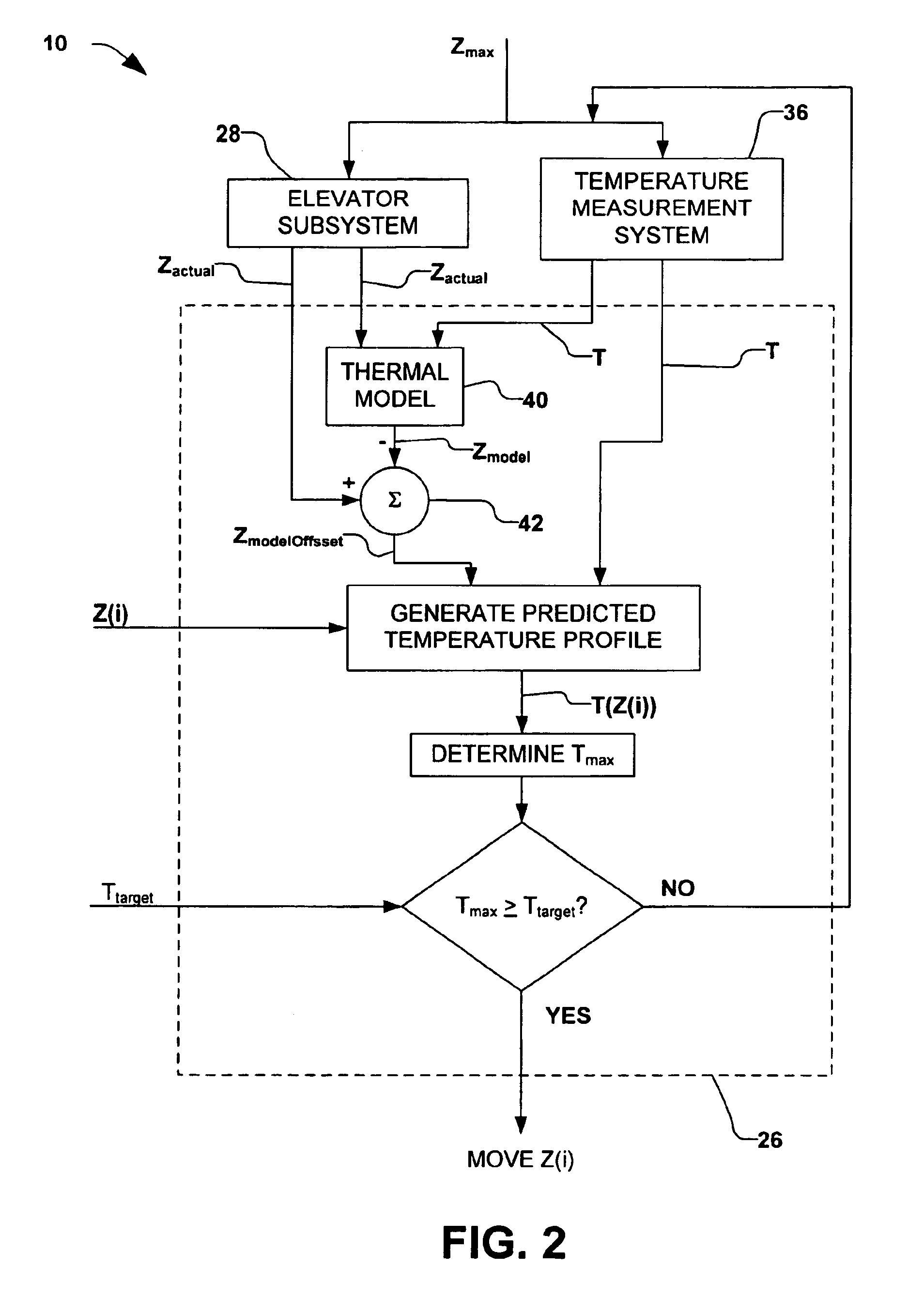

Wafer temperature trajectory control method for high temperature ramp rate applications using dynamic predictive thermal modeling

InactiveUS6855916B1Minimize error amountAmount of errorDrying solid materials with heatMuffle furnacesPosition dependentEngineering

A method for thermally processing a substrate provides a target substrate temperature and generates a move profile of the substrate within a thermal processing system. An amount of heat is provided to the substrate, and one or more temperatures associated with one or more respective locations on the substrate are measured. A predicted temperature profile is further generated, wherein a predicted temperature of the substrate is based on the amount of heat provided and the one or more measured temperatures. The amount of heat provided to the substrate is further regulated, based on the predicted temperature profile, wherein the substrate is thermally processed generally according to the intended substrate temperature profile. The amount of heat provided to the substrate can be further regulated by controlling a position of the substrate within the thermal processing system.

Owner:AXCELIS TECHNOLOGIES

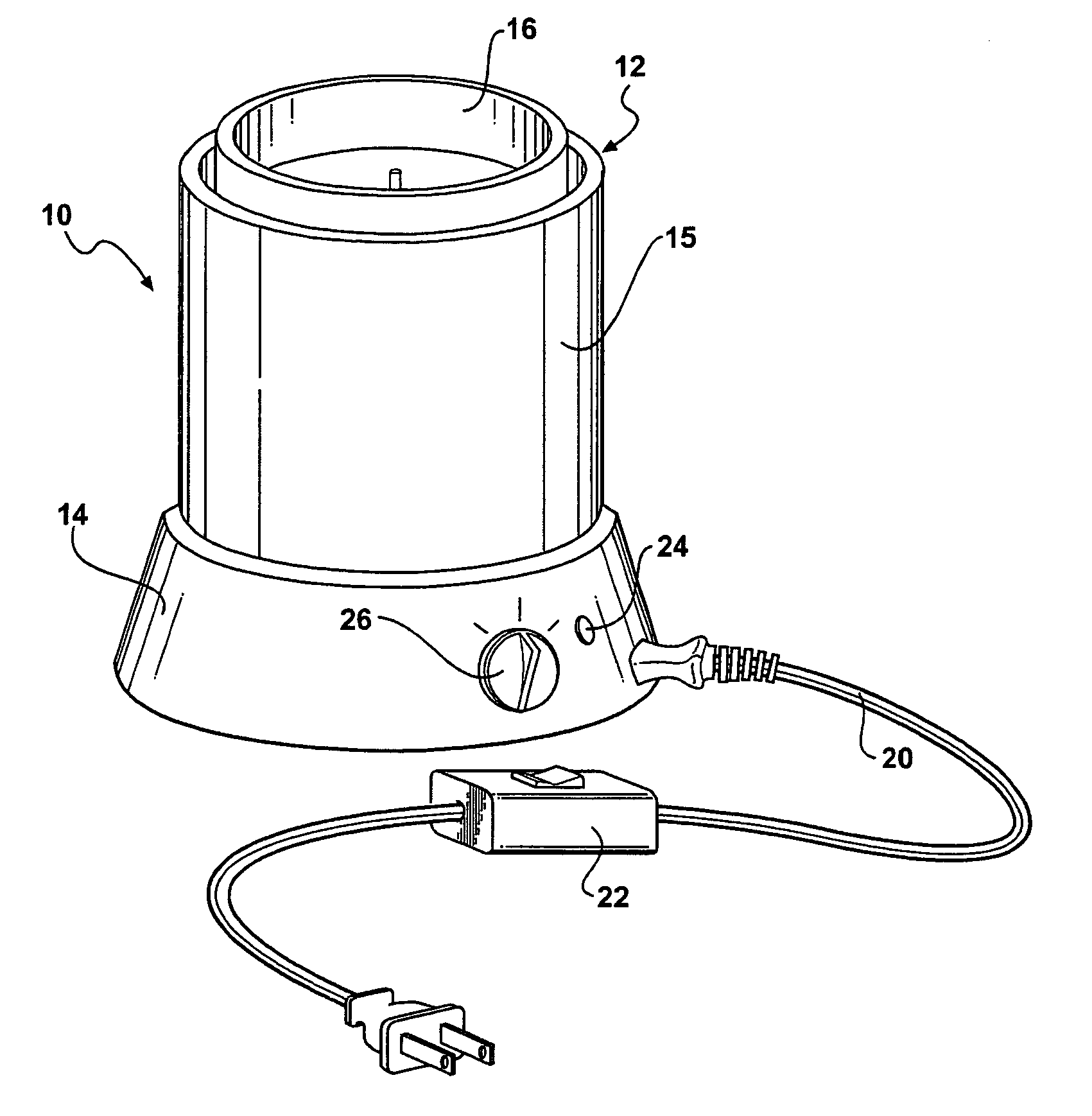

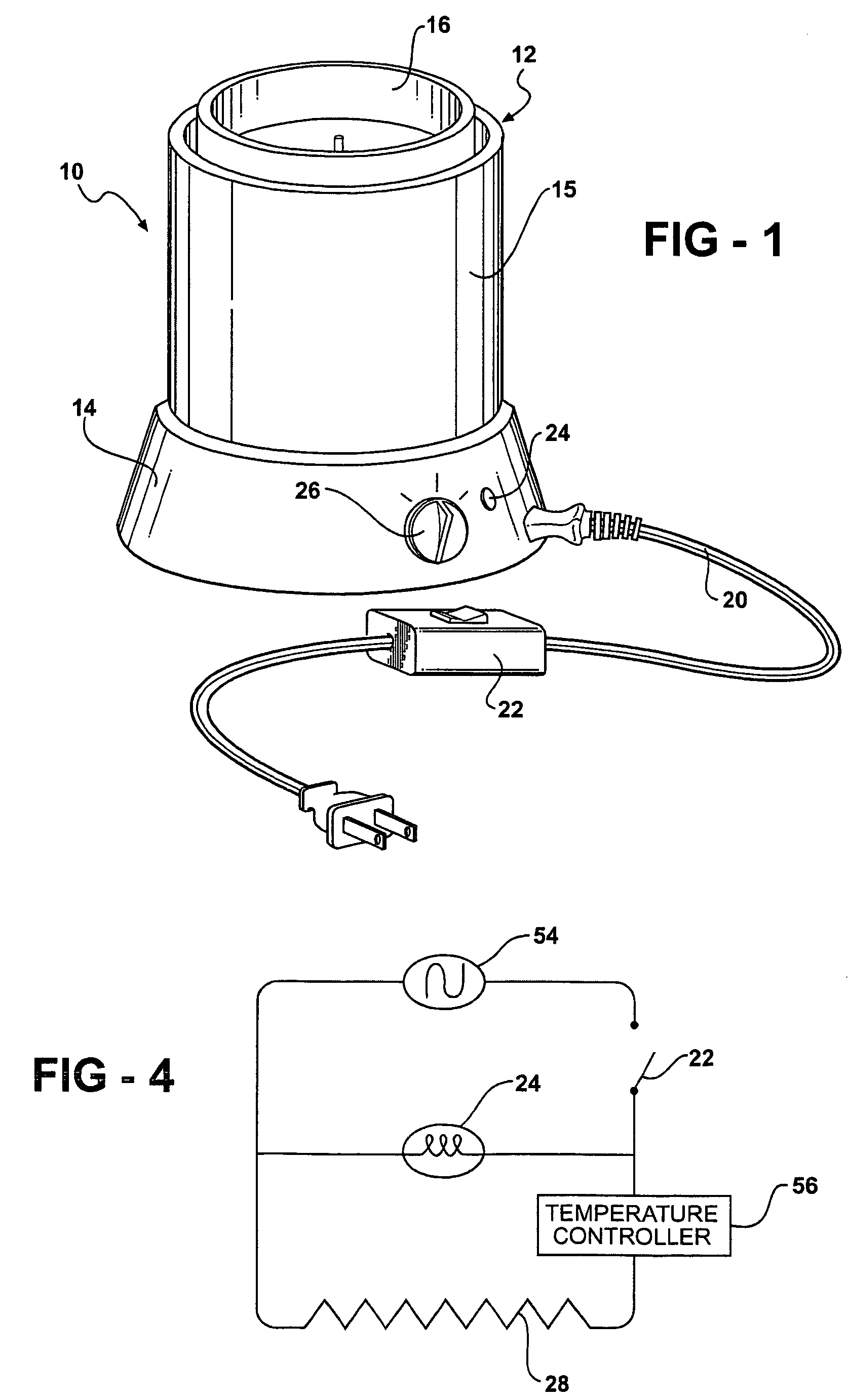

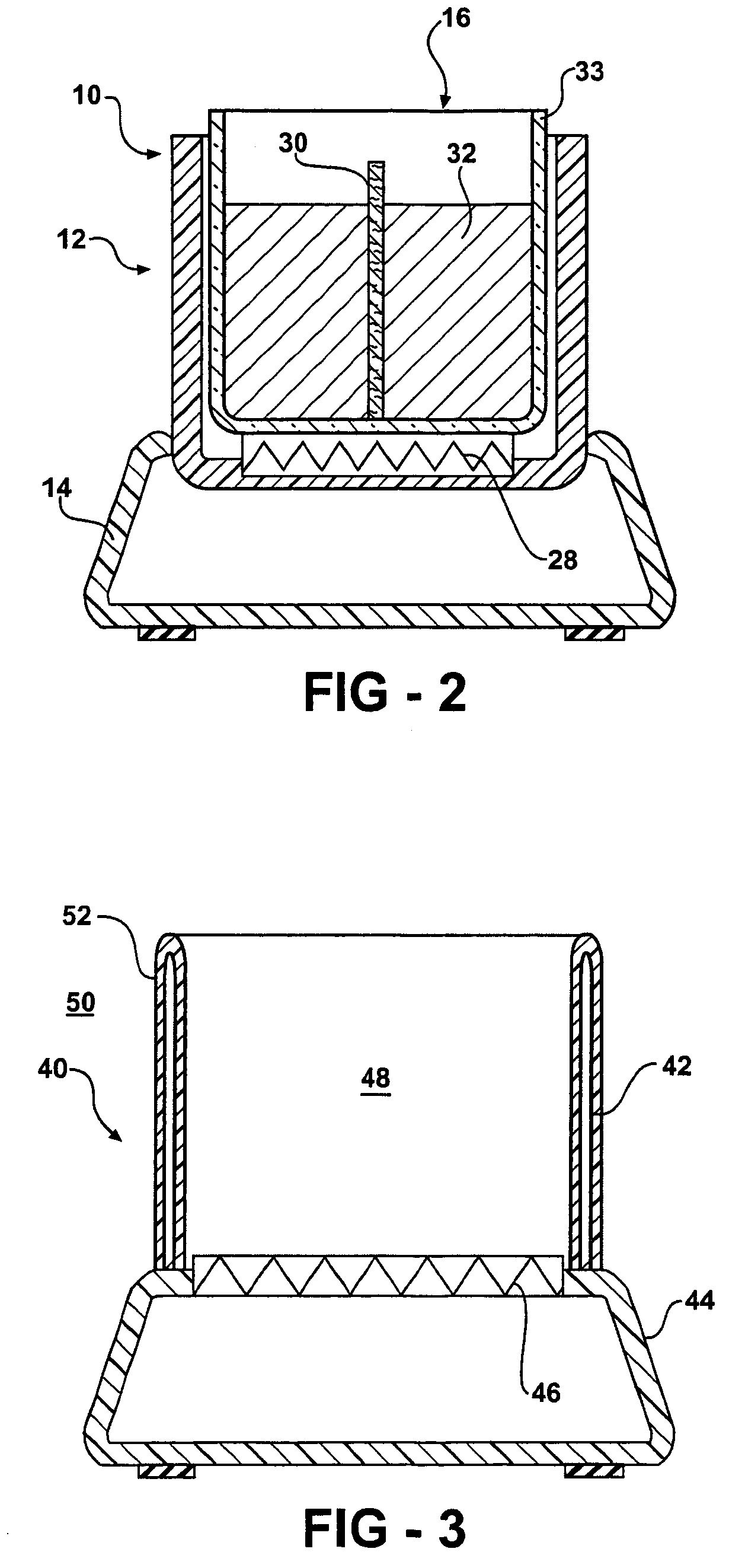

Heater for scented candles

Disclosed herein is a device for heating a scented candle so as to release scent therefrom in the absence of an open flame. The device includes a housing for retaining the candle. The housing is fabricated from a material having a low thermal conductivity. The device further includes an electrical heater in thermal communication with the housing. The heater warms the candle, and the low thermal conductivity housing aids in retaining heat in the candle thereby causing scent to be released therefrom.

Owner:CRAZY MOUNTAIN IMPORTS

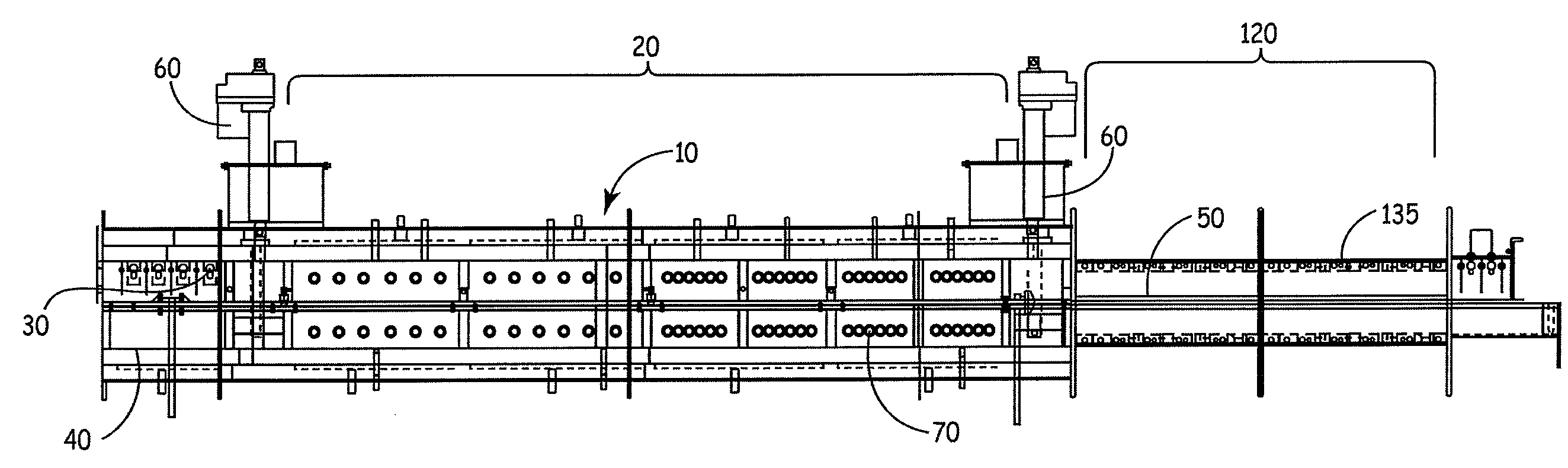

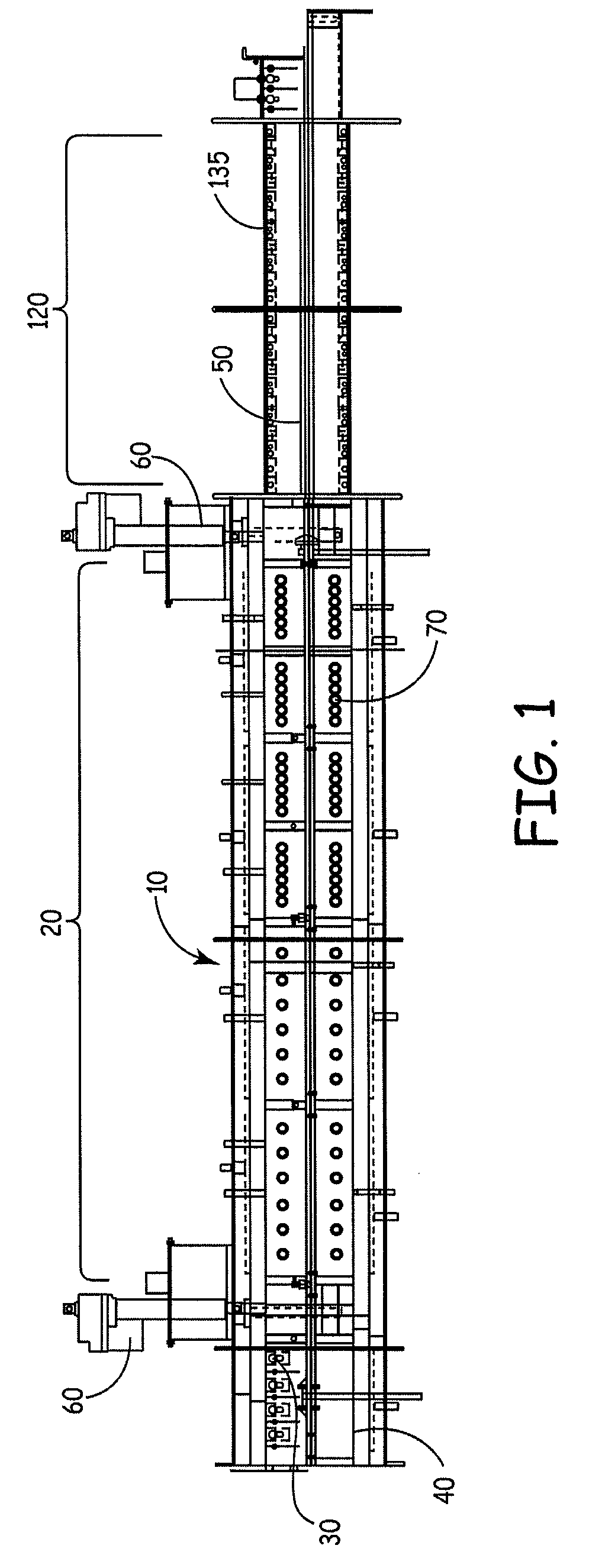

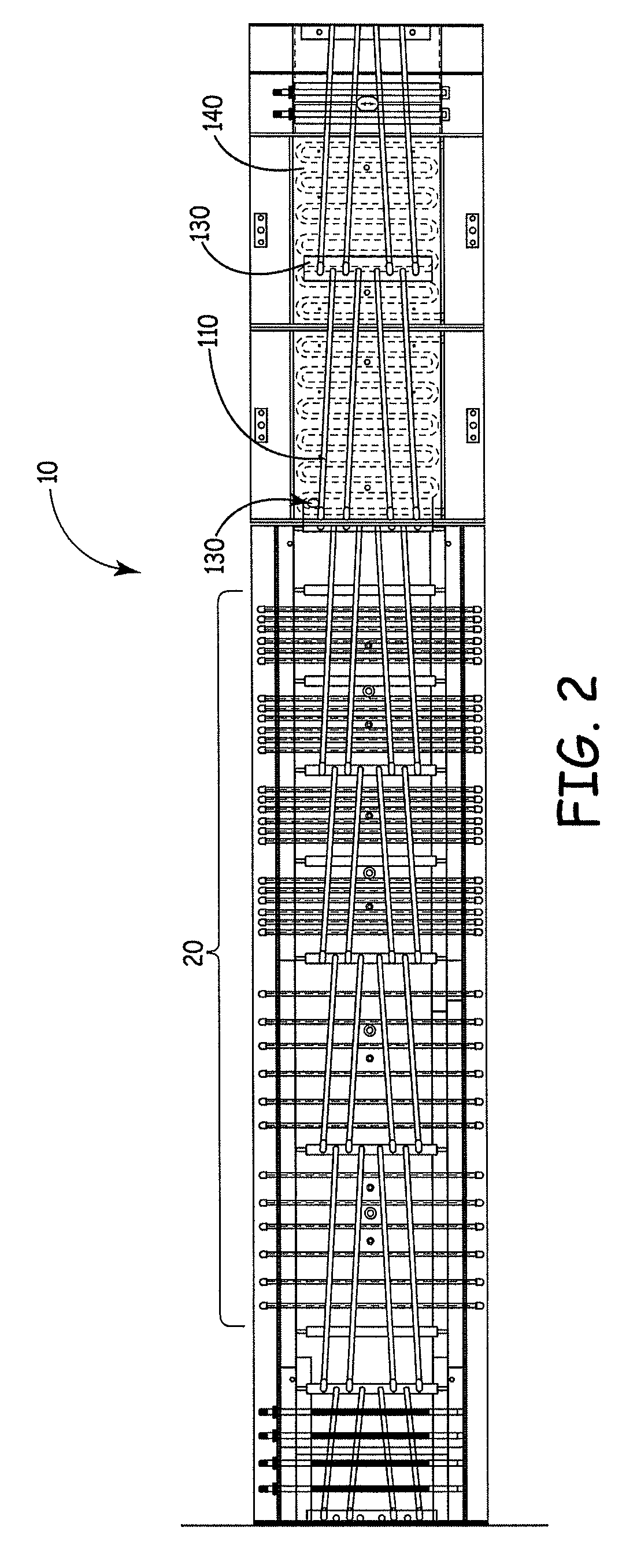

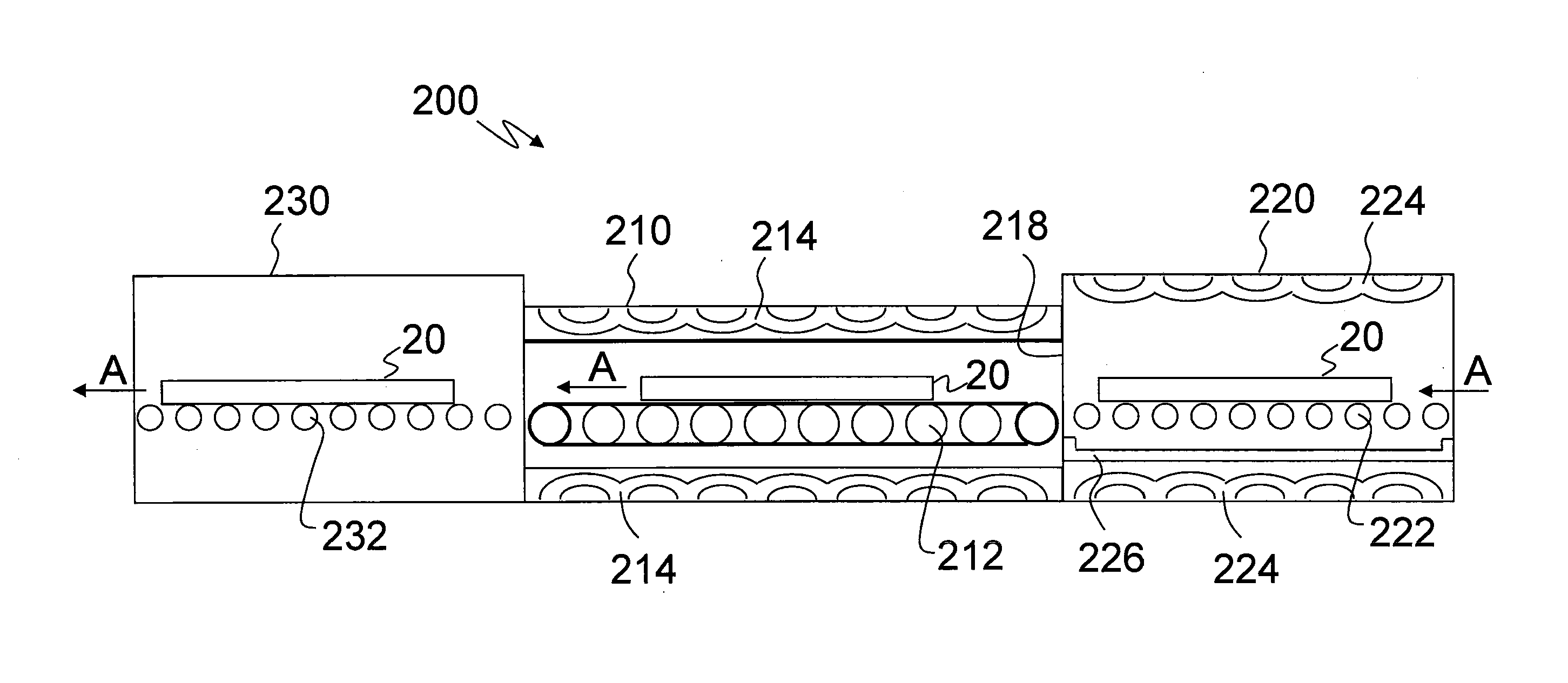

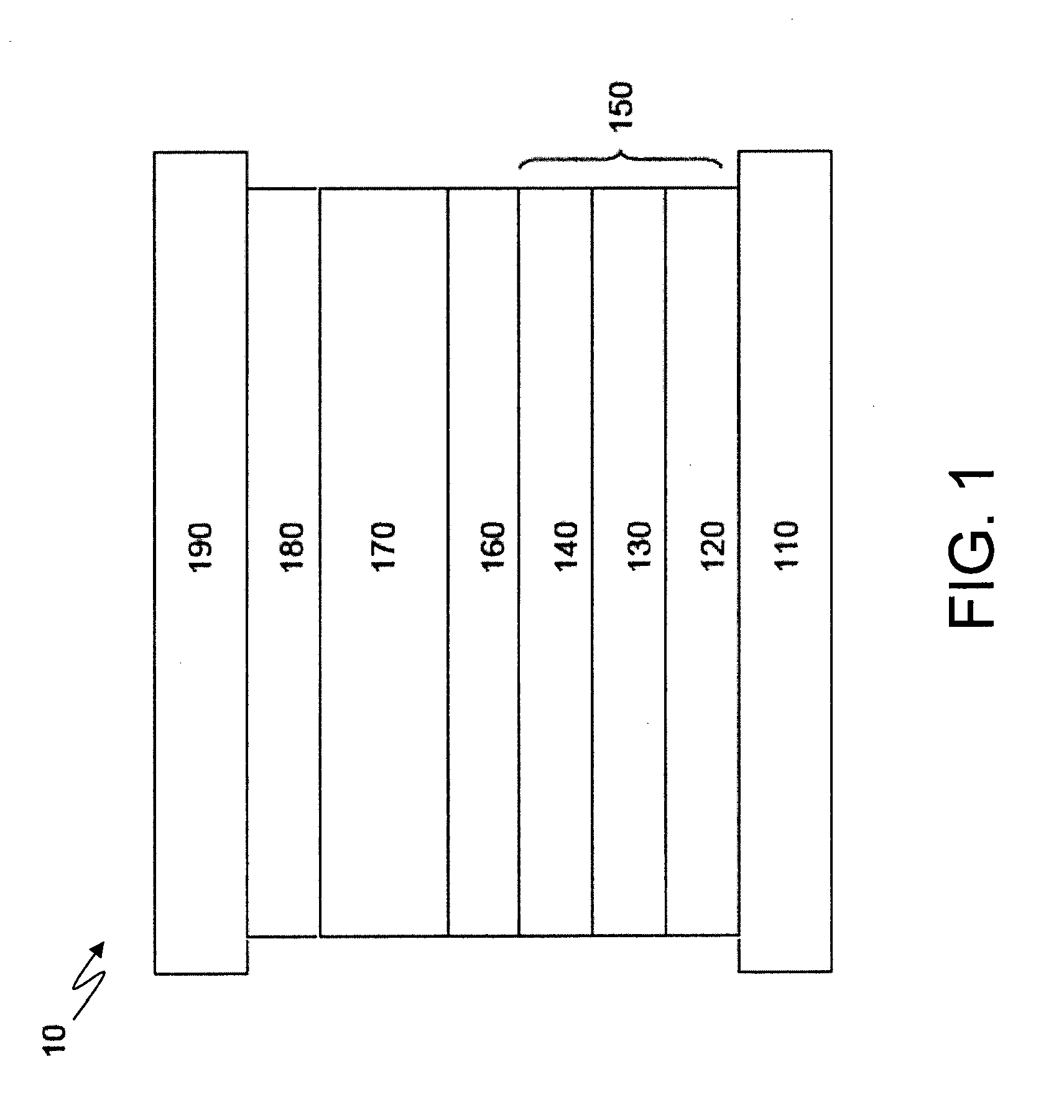

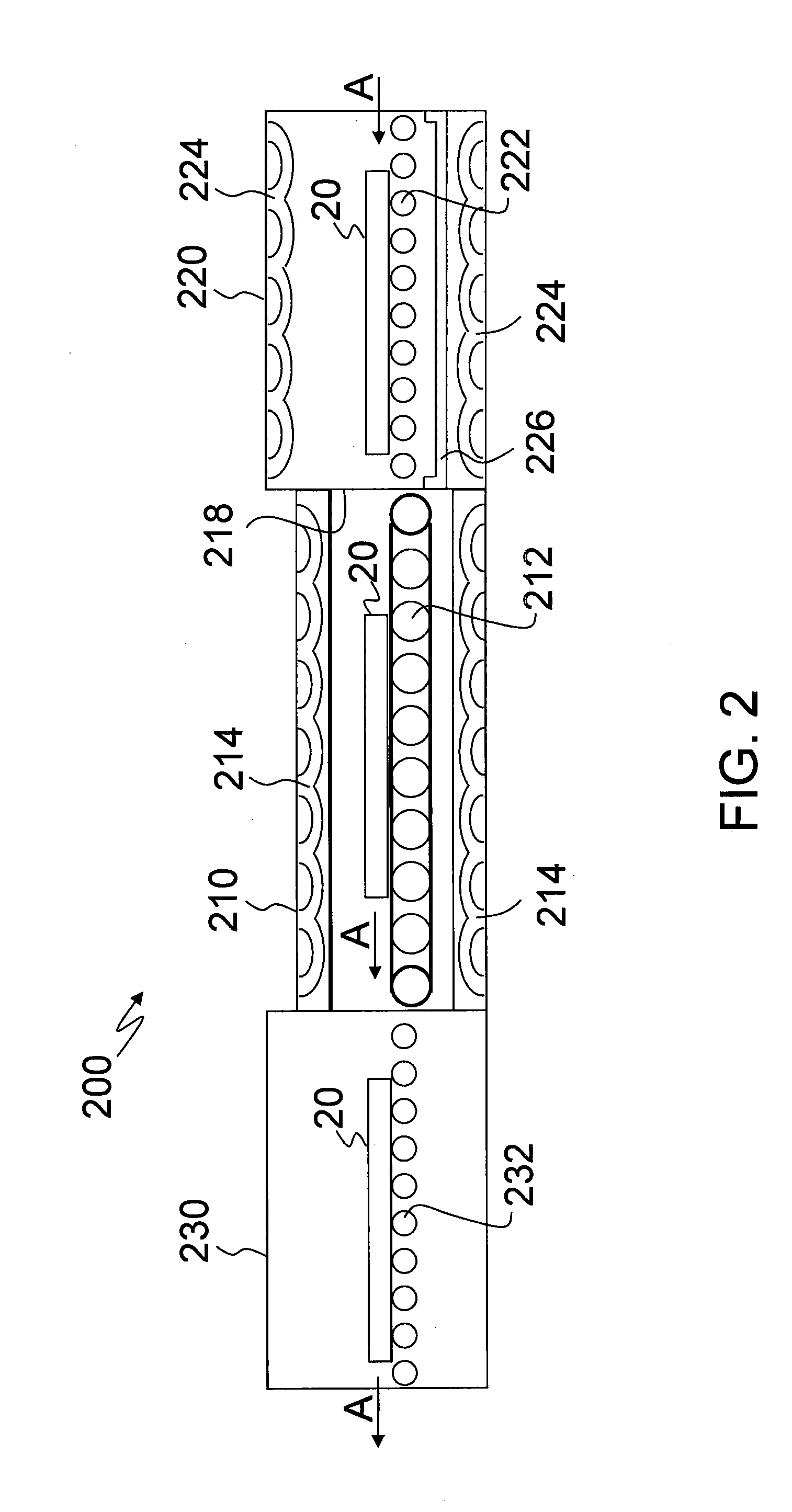

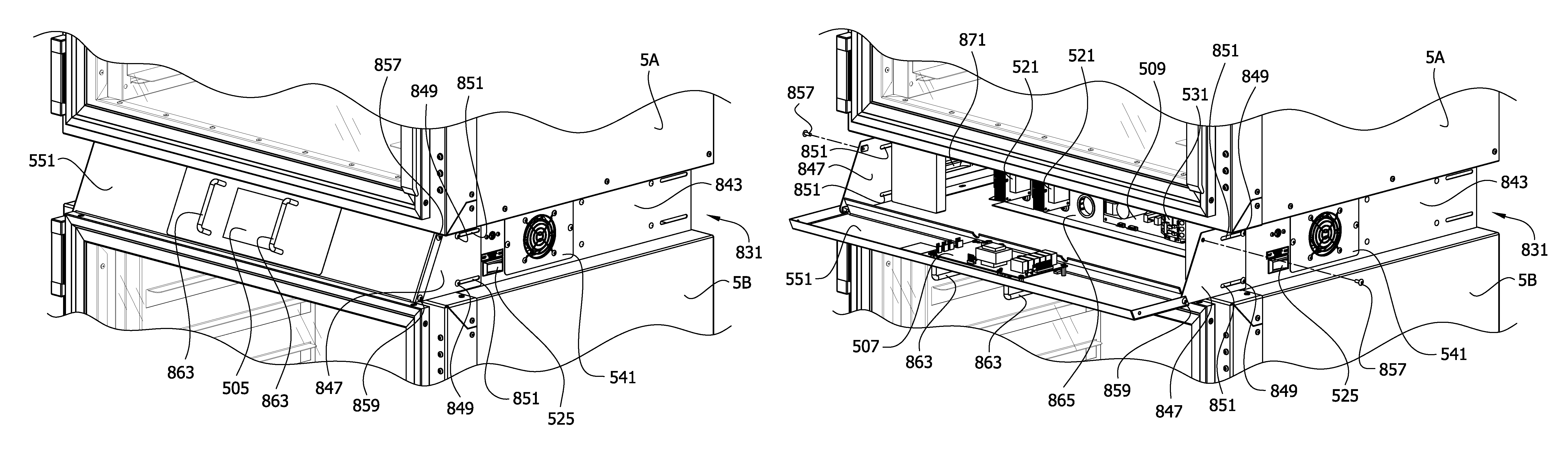

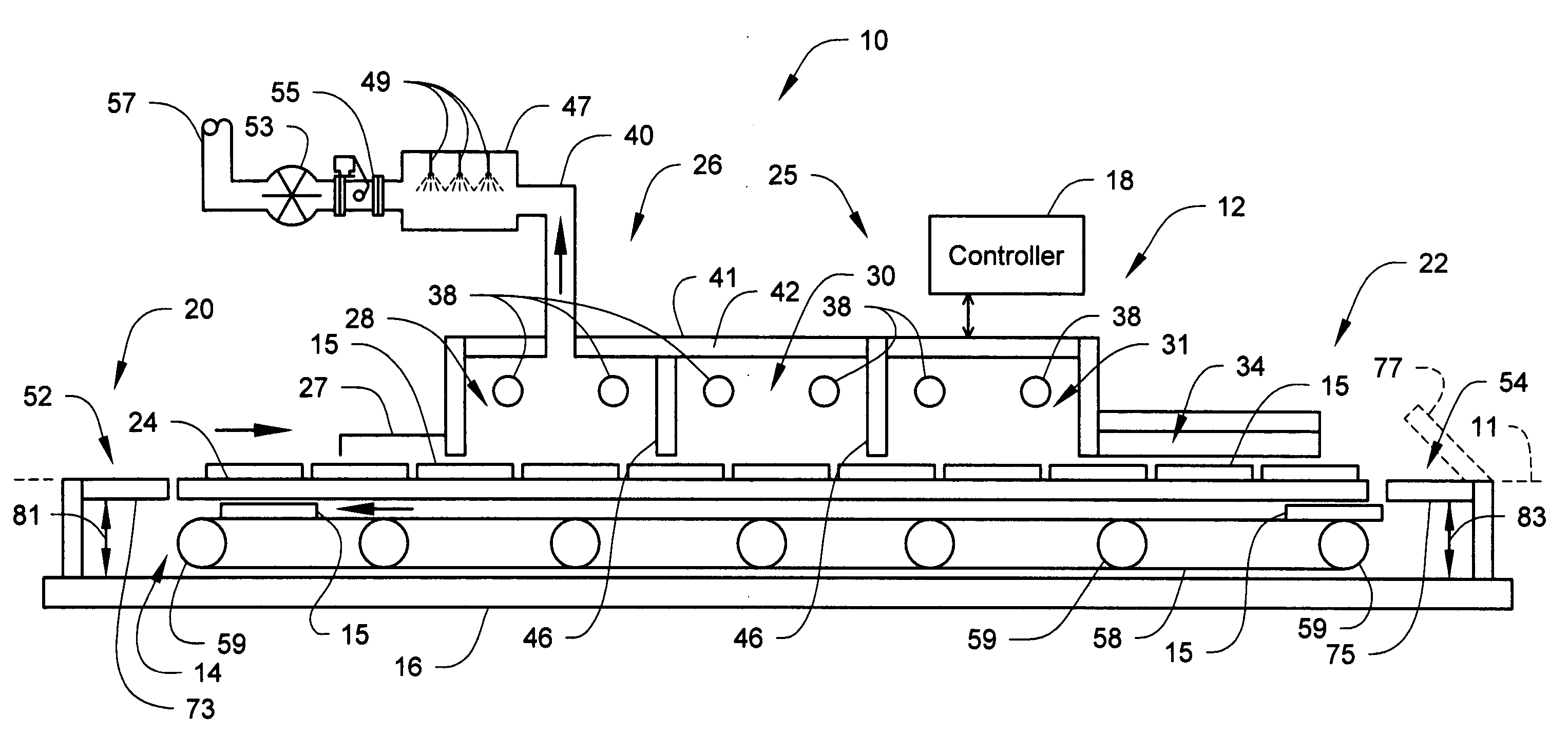

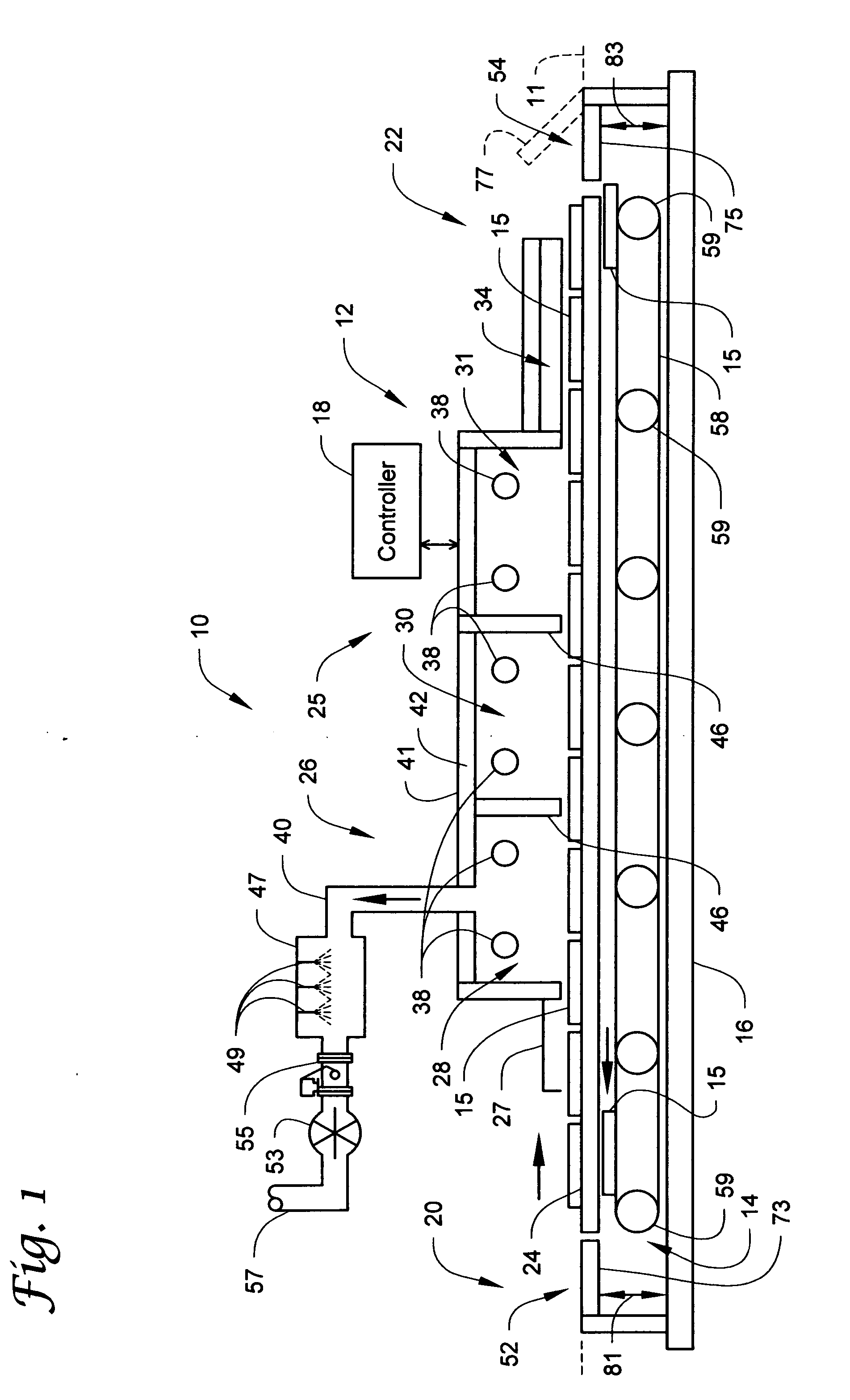

Linear hearth furnace system and methods regarding same

Systems and methods for use in processing raw material (e.g., iron bearing material) include a linear furnace apparatus extending along a longitudinal axis between a charging end and a discharging end (e.g., the linear furnace apparatus includes at least a furnace zone positioned along the longitudinal axis). Raw material is provided into one or more separate or separable containers (e.g., trays) at the charging end of the linear furnace apparatus. The separate or separable containers are moved through at least the furnace zone and to the discharging end where the processed material is discharged resulting in one or more empty containers. One or more of the empty containers are returned to the charging end of the linear furnace apparatus to receive further raw material.

Owner:NU IRON TECH LLC

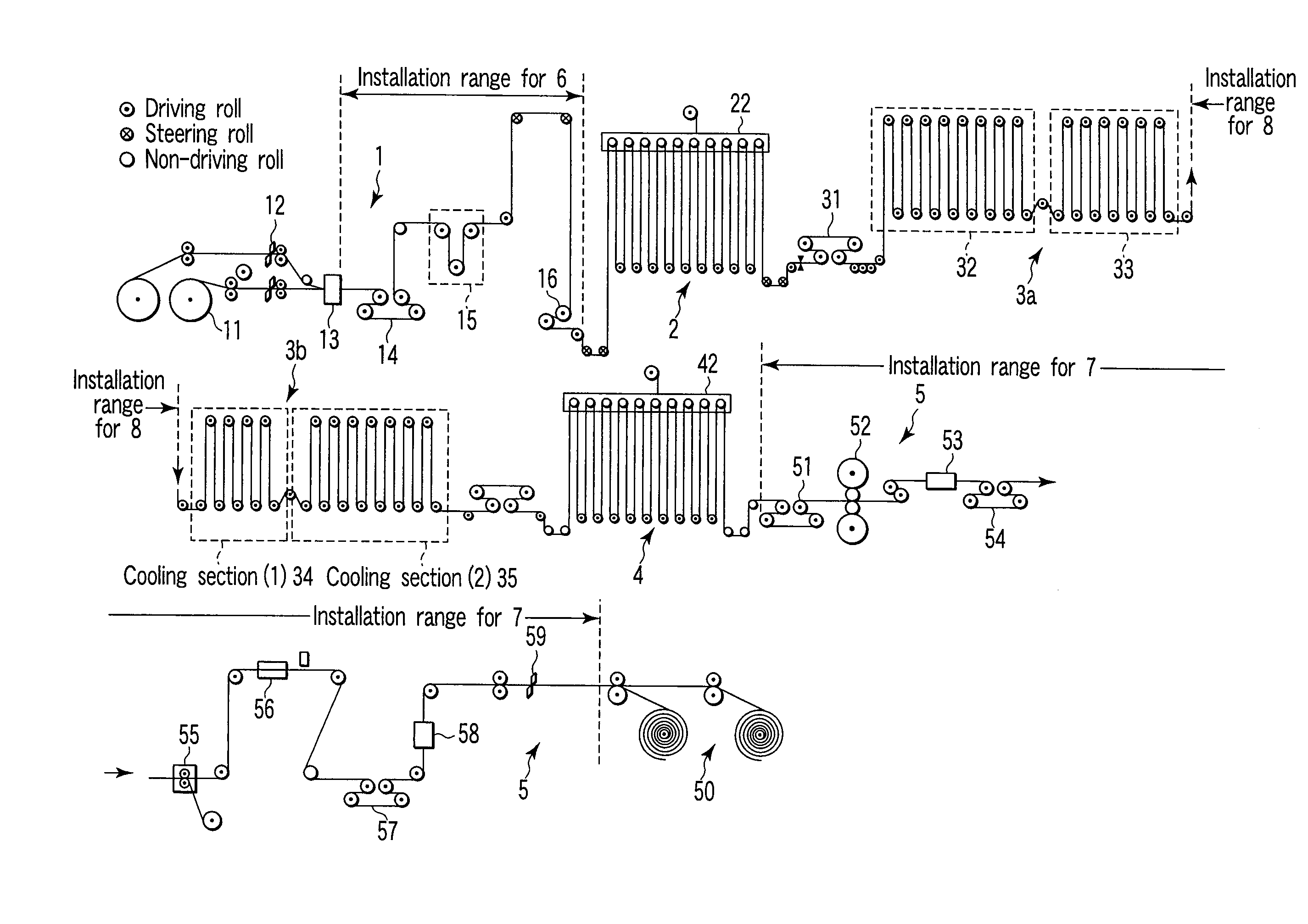

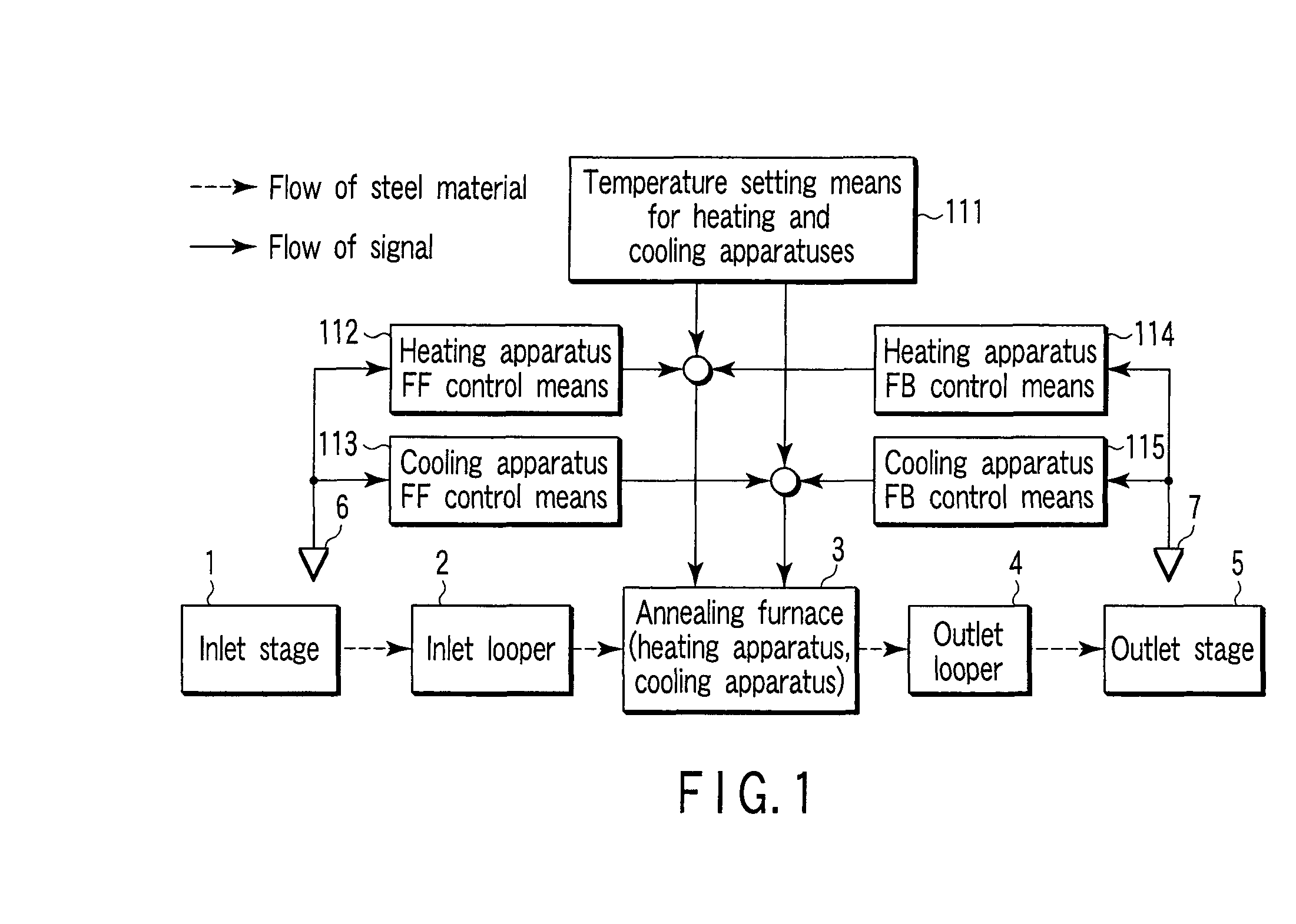

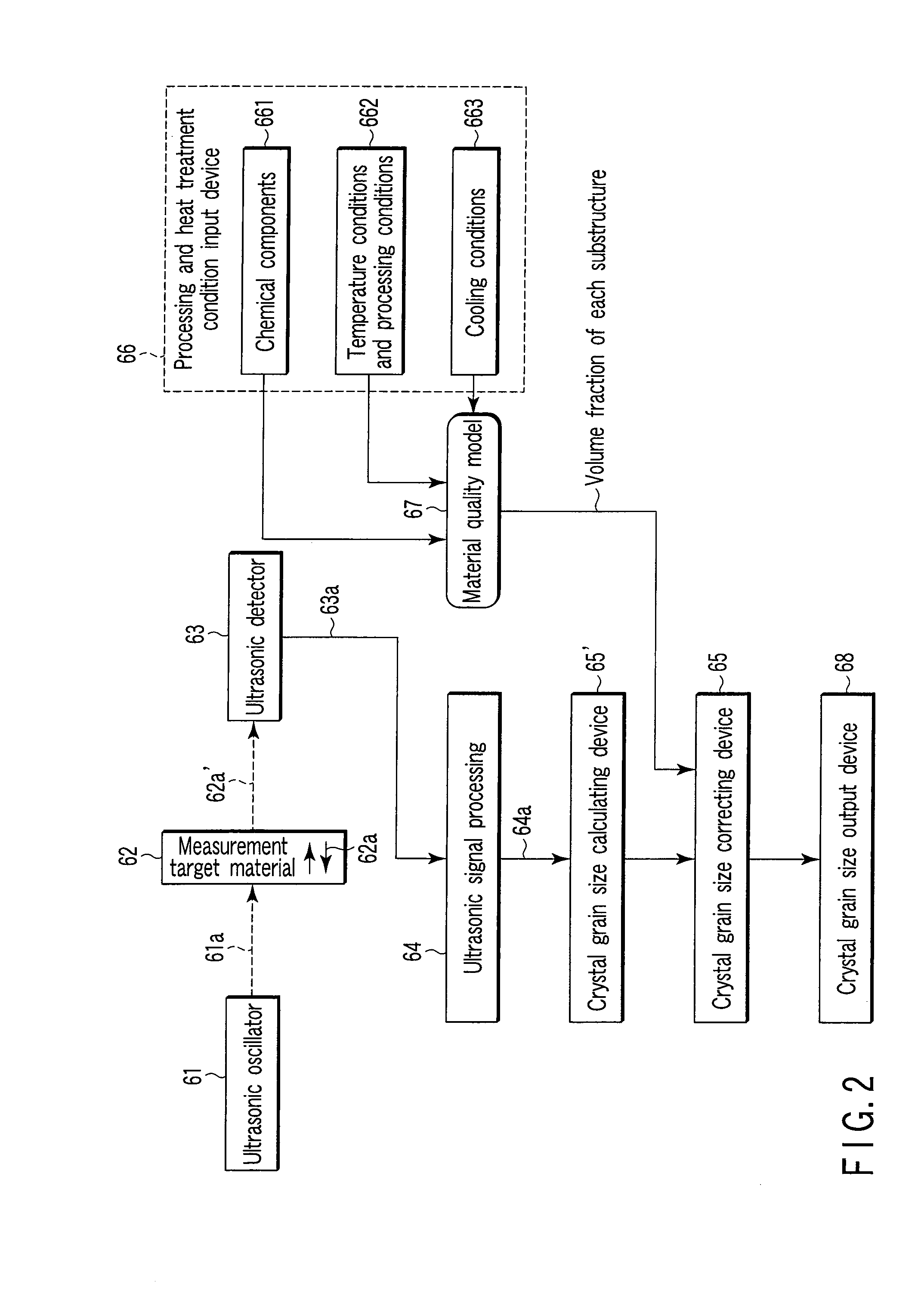

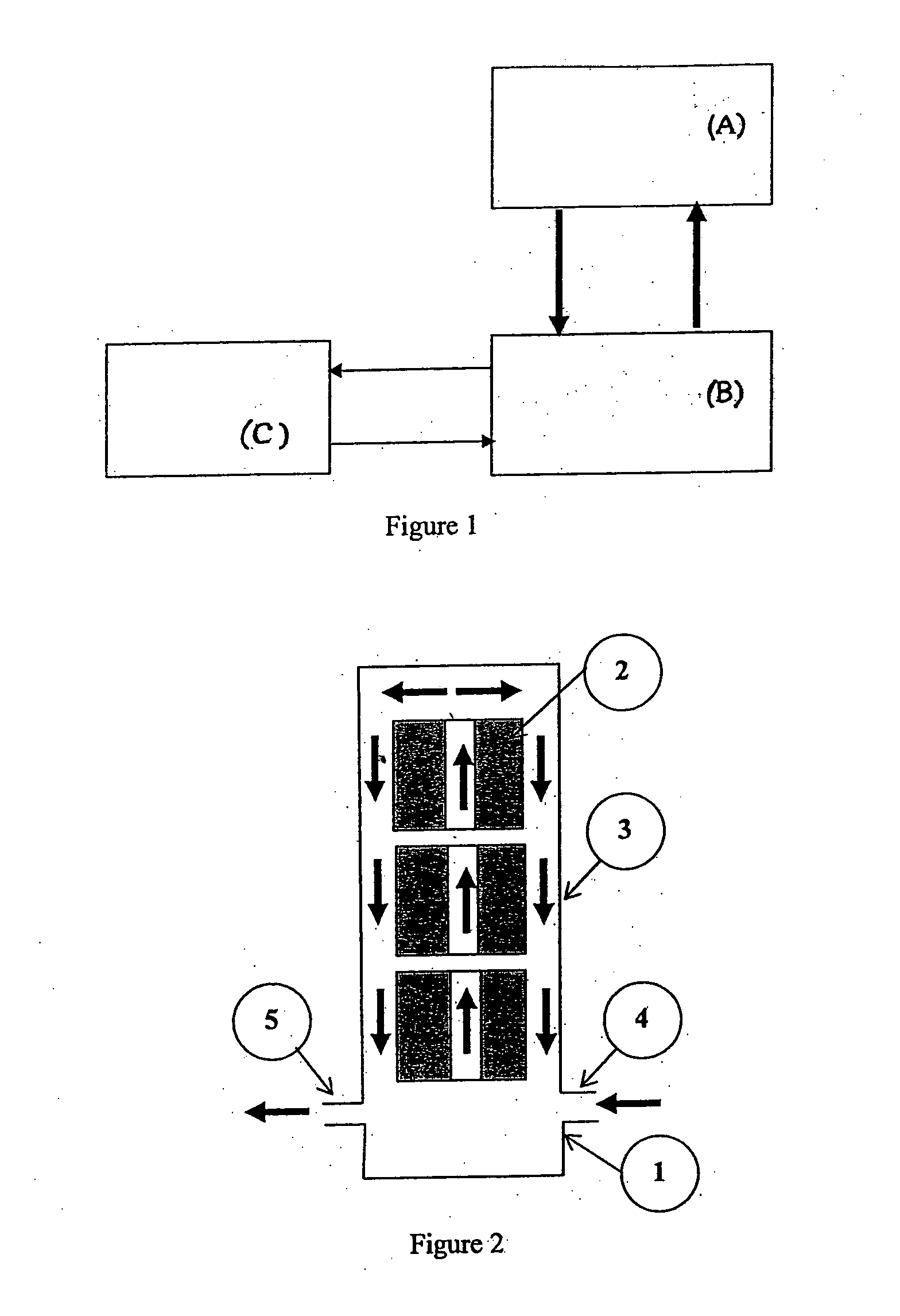

Process line control apparatus and method for controlling process line

InactiveUS20100219567A1Quality improvementHot-dipping/immersion processesFurnace typesProduction lineValue set

A process line control apparatus which controls a process line including an annealing furnace (3) including a heating process apparatus executing a heating process and a cooling process apparatus executing a cooling process, the heating and cooling processes being continuously executed on a steel material, the apparatus having feed forward control means (112, 113) for measuring quality of the steel material by a material quality measuring apparatus (6) installed in an inlet stage (1) preceding the heating process in the annealing furnace (3), and on the basis of measurement results, determining modifications for respective temperature set values set by temperature setting means (111) for the heating and cooling apparatuses in the annealing furnace (3), and feedback control means (114, 115) for measuring the quality of the steel material by a material quality measuring apparatus (7) installed in an outlet stage (5) succeeding the cooling process in the annealing furnace (3), and on the basis of measurement results, determining modifications for the respective temperature set values set by the temperature setting means (111) for the heating and cooling apparatuses in the annealing furnace (3).

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

Taste-masked film-type or wafer-type medicinal preparation

InactiveUS20050163830A1Reducing and suppressing unpleasant tasteUnpleasant tasteInorganic non-active ingredientsOrganic non-active ingredientsOral medicationPharmaceutical formulation

The invention relates to thin film-shaped or wafer-shaped pharmaceutical preparations for oral administration of active substances. The preparations contain at least one matrix-forming polymer which has at least one active substance and at least one carbon dioxide-forming substance dissolved or dispersed therein.

Owner:LTS LOHMANN THERAPIE-SYST AG

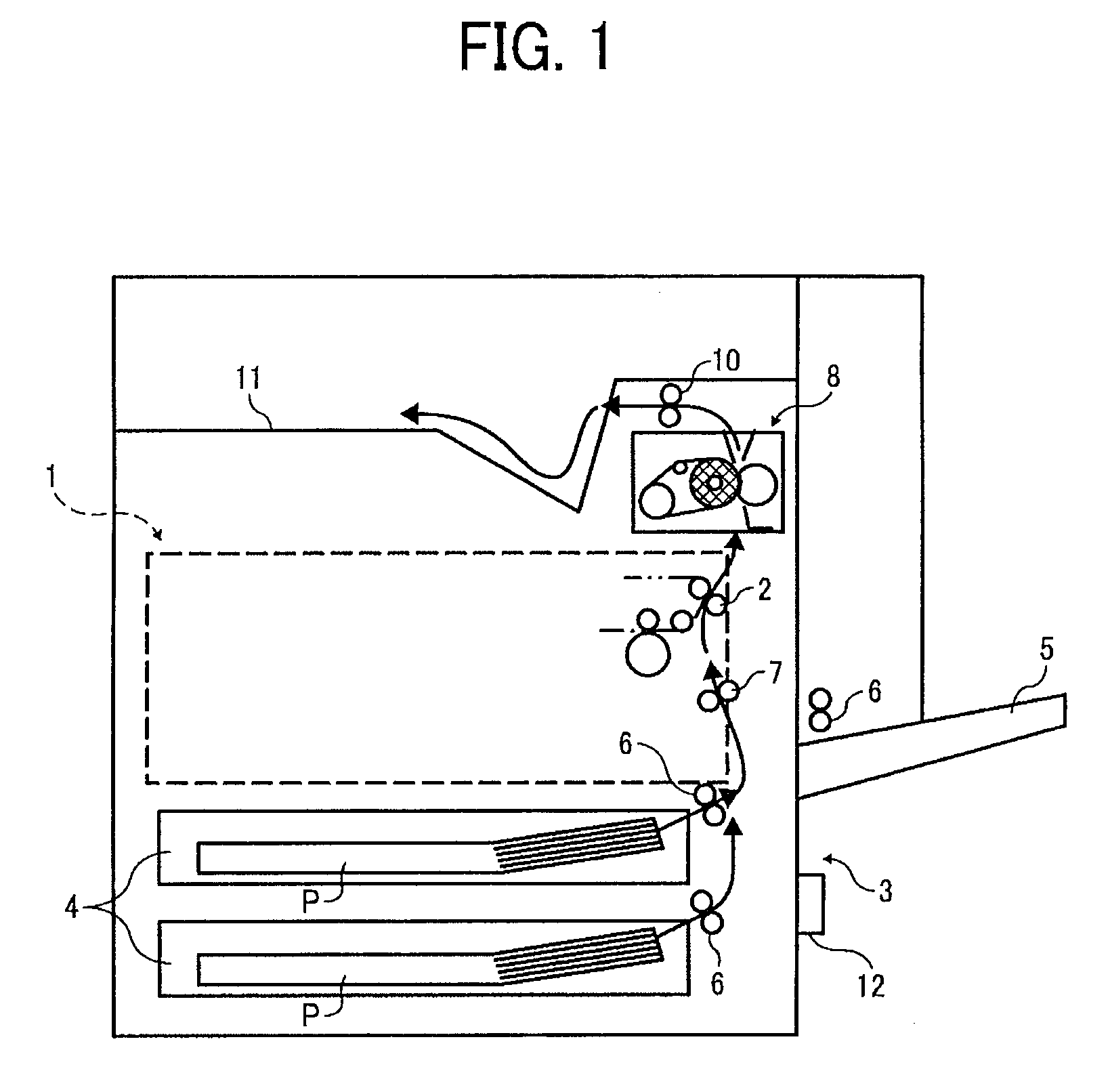

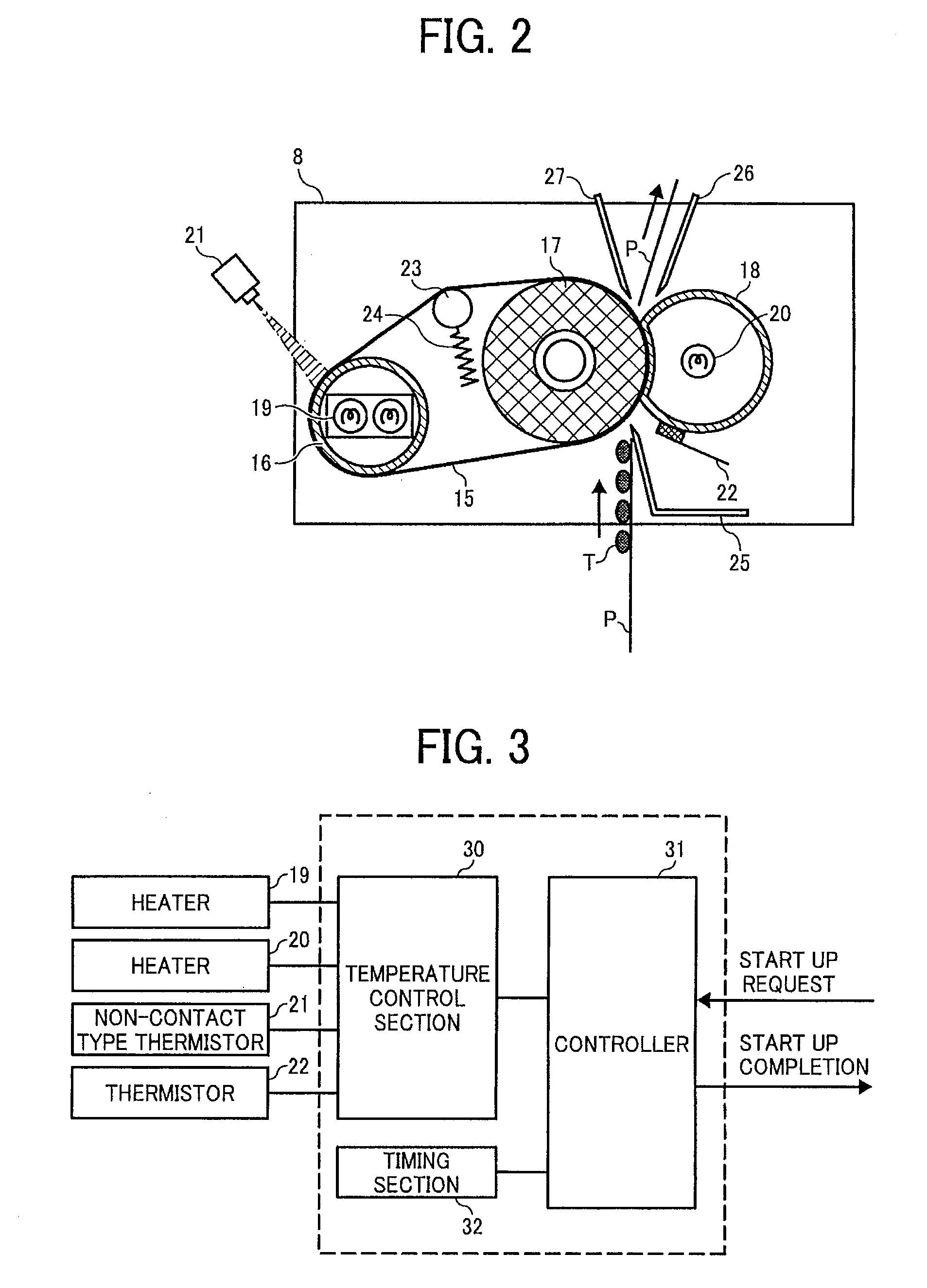

Heating device, fixing apparatus, and image forming system

InactiveUS20090003867A1Increase heightControlling laminationLaminationStart upElectrical and Electronics engineering

A heating device includes a heat applying member heated by a heat source, a pressure applying member pressure contacting the heat applying member with a prescribed pressure, and a temperature detection device that detects temperature of the heat applying member. A timing device is provided to count time elapsing from when the heat source starts heating the heat-applying member. A control device is provided to determine that heat application as a start up operation to the heating member is completed when the temperature detected by the temperature detection device reaches a prescribed threshold and the elapsing time counted by the timing device reaches a prescribed threshold.

Owner:RICOH KK

Method and Apparatus for Achieving Higher Cooling Rates of a Gas During Bypass Cooling in a Batch Annealing Furnace of Cold Rolling Mills

ActiveUS20120024516A1Improve cooling effectWork treatment devicesIndirect heat exchangersNanofluidAqueous medium

A method and apparatus to increase the cooling rate of gas used in a batch annealing furnace of cold rolling mills under bypass cooling. The invention makes use of the higher heat transfer capacities of nanocoolants developed by a high-shear mixing of nanoparticles and stabilizers in a basic aqueous medium for cooling heated hydrogen flowing through a heat exchanger during bypass cooling of the batch annealing furnace. The nanofluid is prepared in a nanofluid preparation unit.

Owner:TATA STEEL

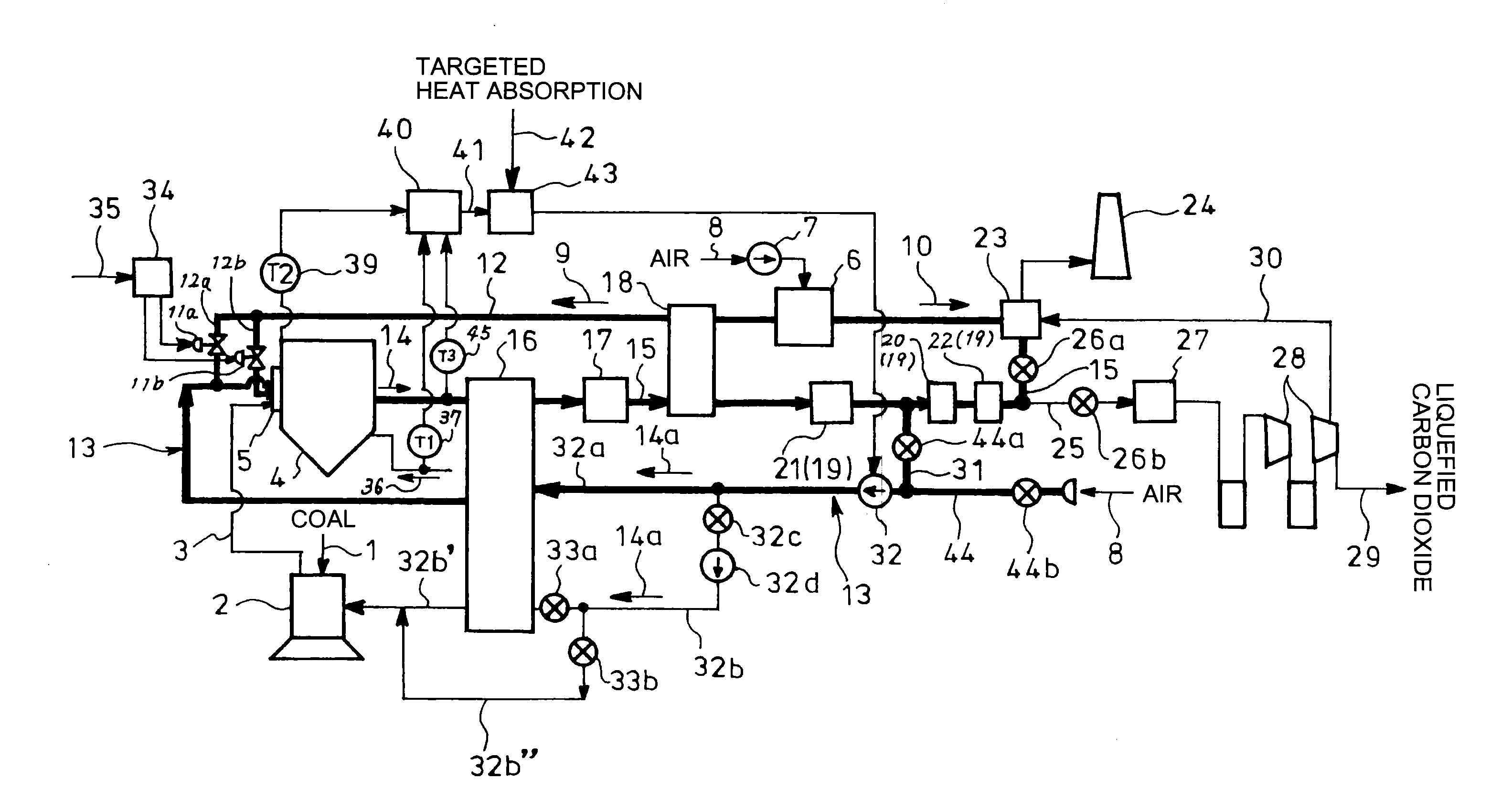

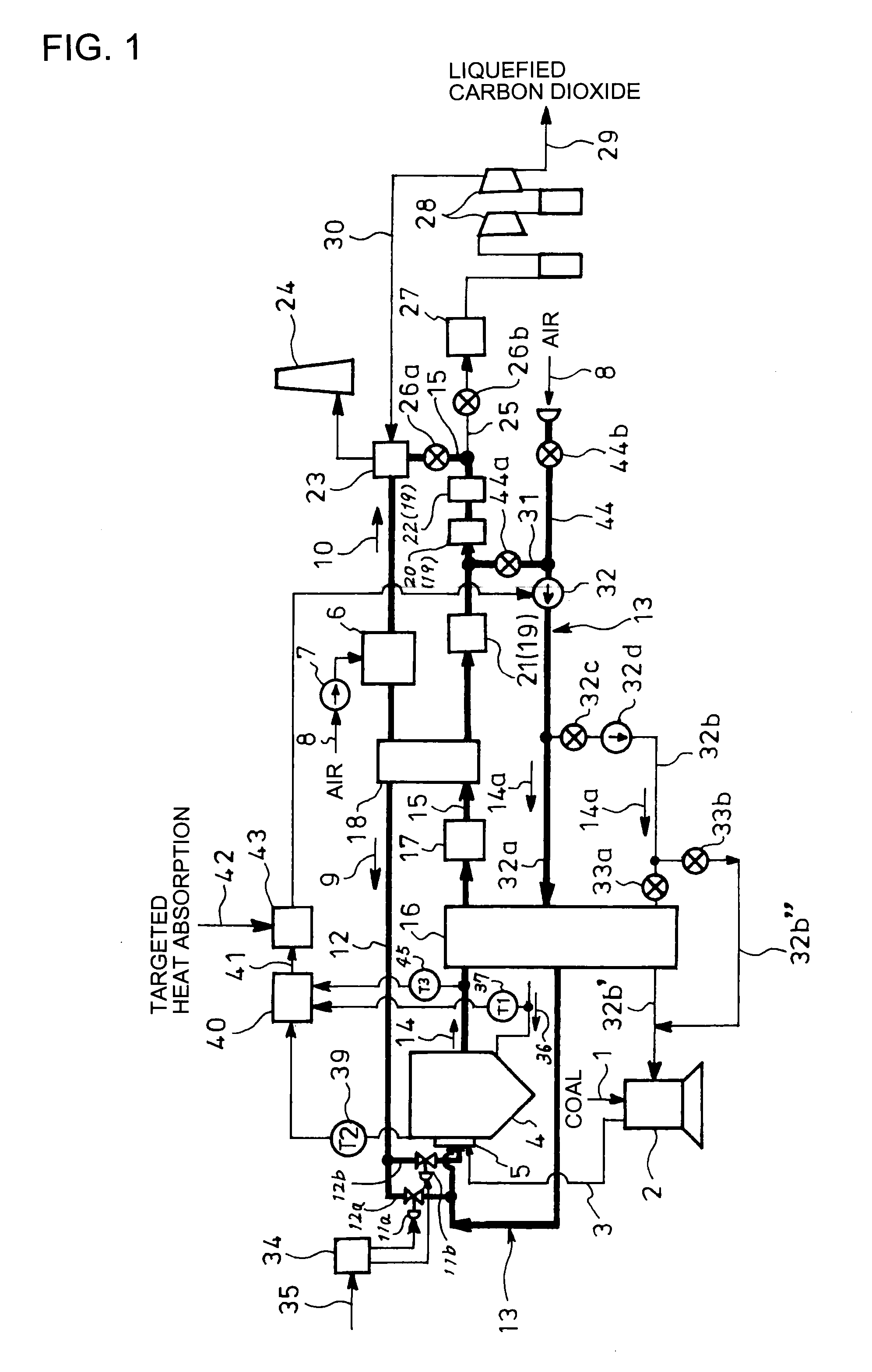

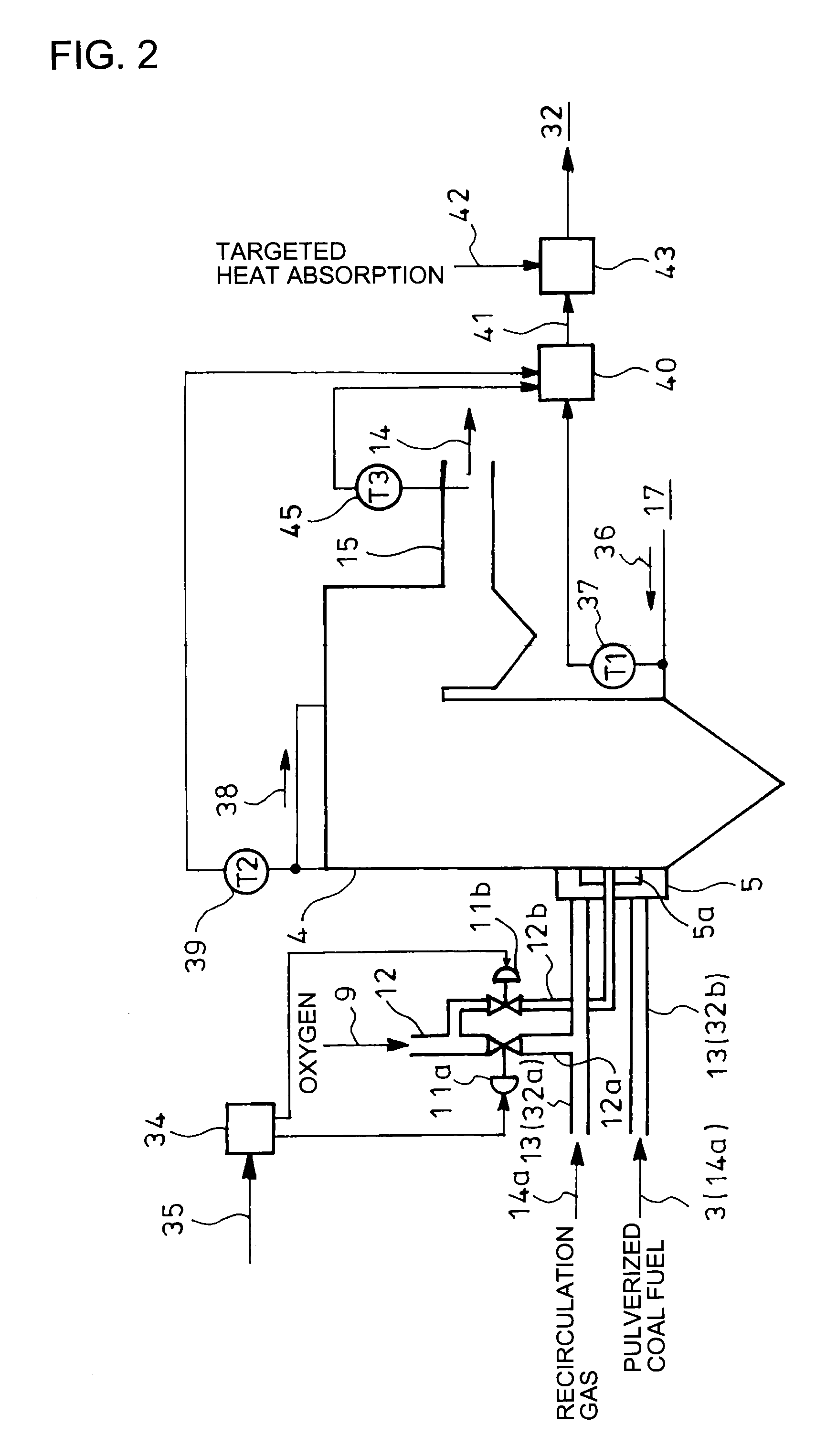

Method and apparatus for controlling combustion in oxygen fired boiler

ActiveUS20090272300A1Great advantageGood effectMechanical apparatusFluegas recirculationCombustionEngineering

Provided are a method and an apparatus for controlling combustion in an oxygen fired boiler which are easily applicable to an existing air fired boiler for easy and stable control of the combustion.Oxygen with a setting amount in accordance with a boiler load demand 35 is supplied to a boiler body 4. Heat absorption amount of the boiler is measured from inlet temperature of feedwater supplied to the boiler body 4 and outlet temperature of steam. Recirculation flow rate of combustion exhaust gas 14a is controlled such that heat absorption amount 41 of the boiler body 4 becomes equal to a targeted heat absorption amount 42 to thereby control oxygen concentration in all gas guided to the boiler body 4.

Owner:ELECTRIC POWER DEVELOPMENT COMPANY +1

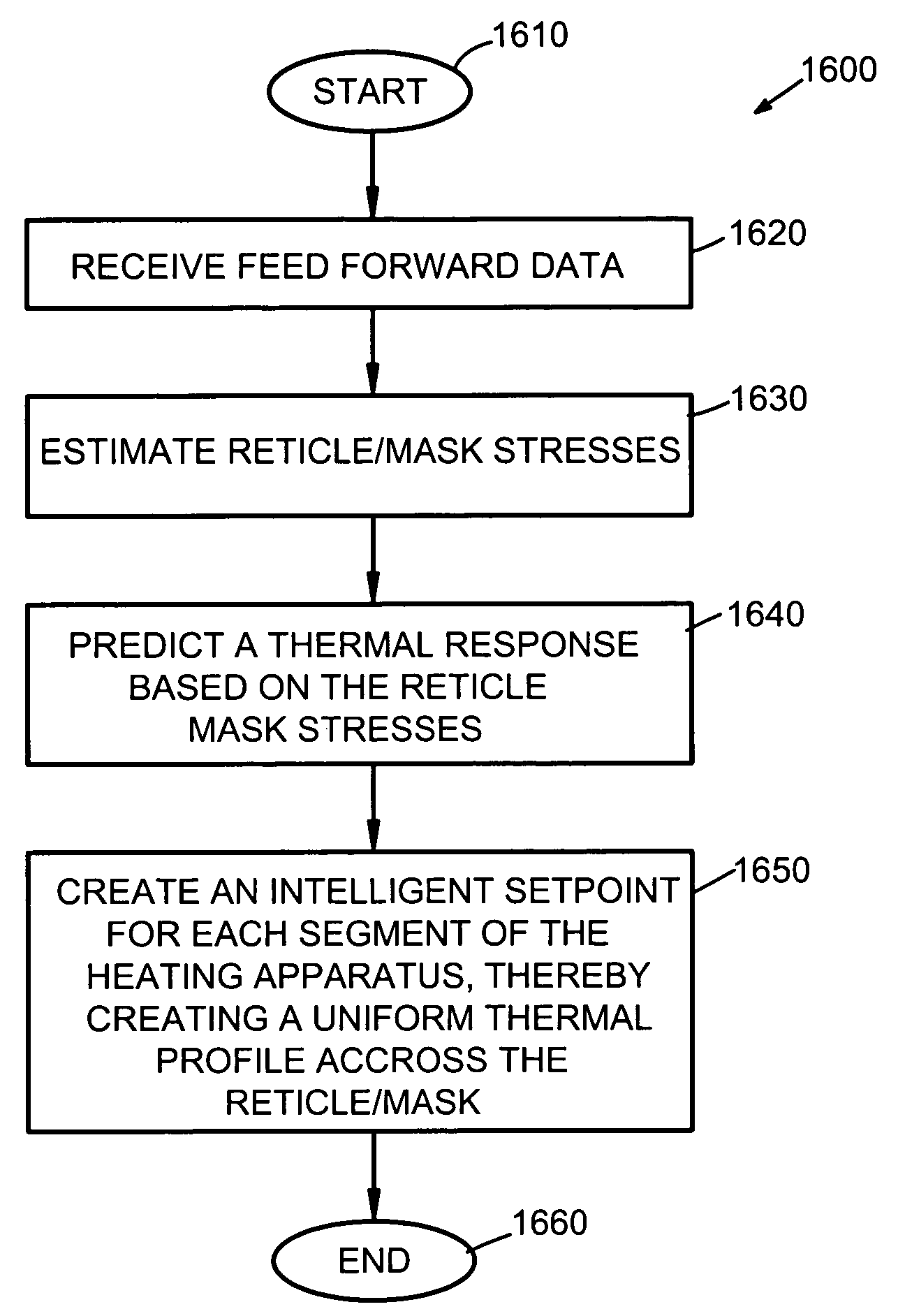

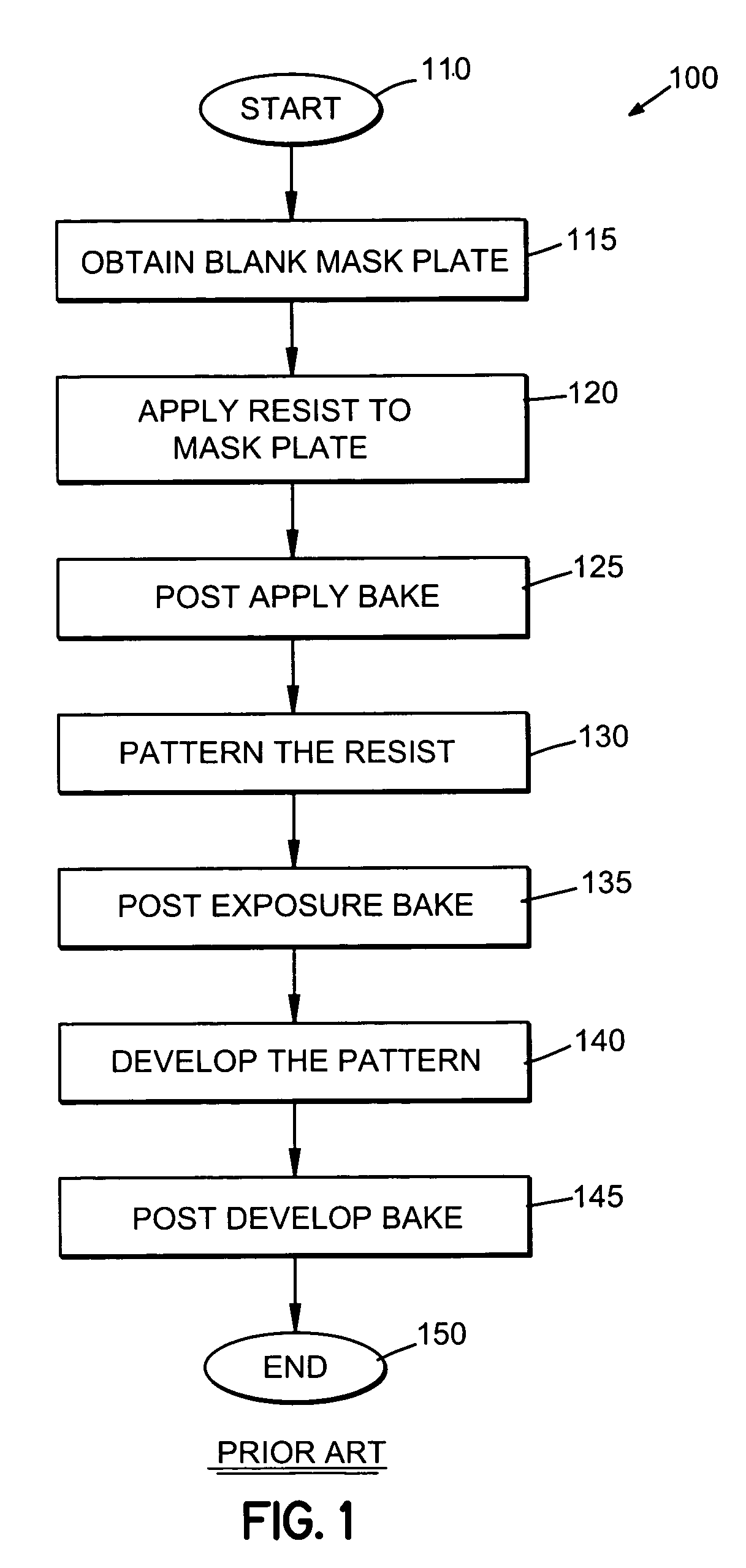

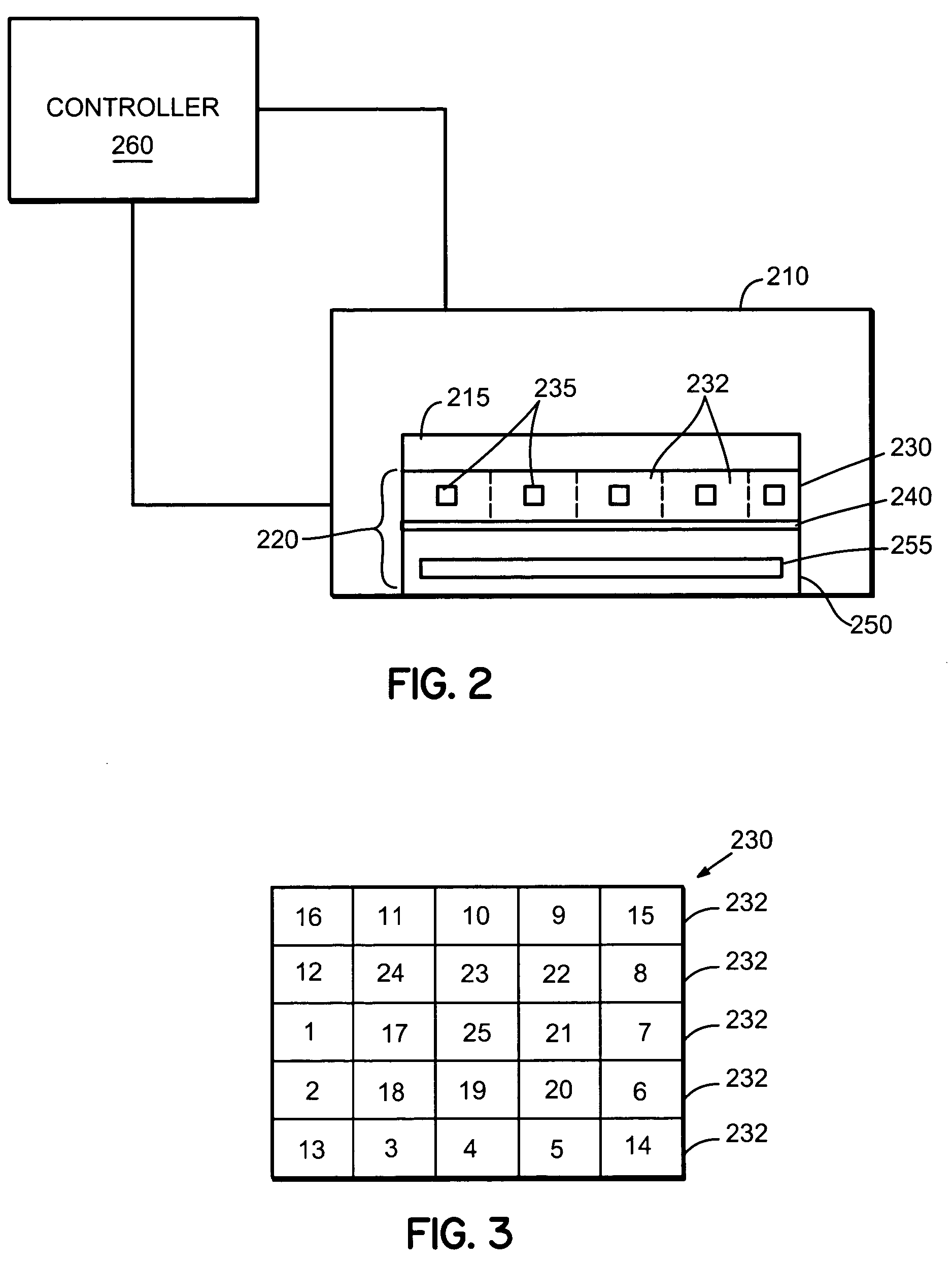

Adaptive real time control of a reticle/mask system

InactiveUS7025280B2Uniform temperature profileEasy to controlSpace heating and ventilationTemperatue controlDiffusionDynamic models

An adaptive real time thermal processing system is presented that includes a multivariable controller. Generally, the method includes creating a dynamic model of the thermal processing system; incorporating reticle / mask curvature in the dynamic model; coupling a diffusion-amplification model into the dynamic thermal model; creating a multivariable controller; parameterizing the nominal setpoints into a vector of intelligent setpoints; creating a process sensitivity matrix; creating intelligent setpoints using an efficient optimization method and process data; and establishing recipes that select appropriate models and setpoints during run-time.

Owner:TOKYO ELECTRON LTD

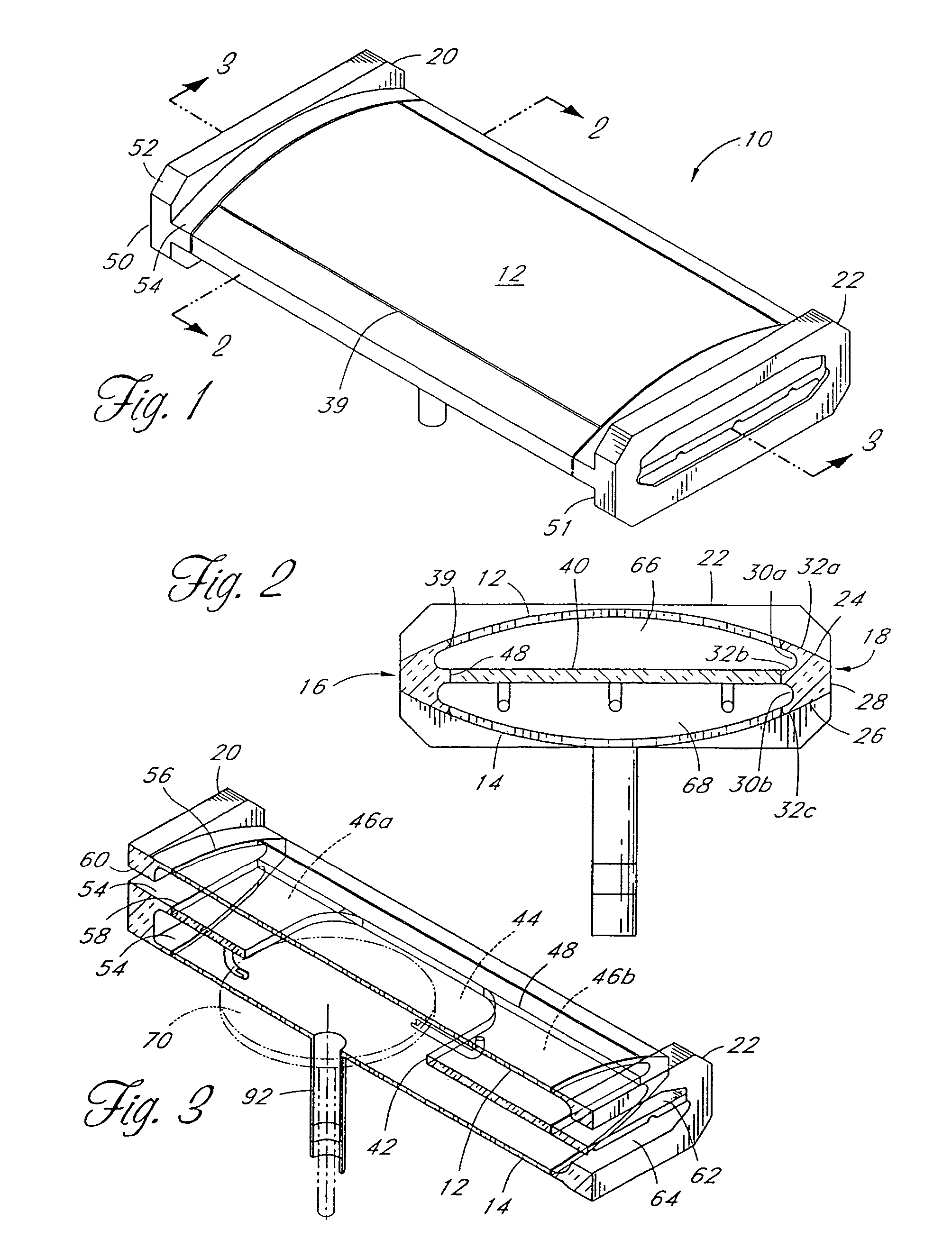

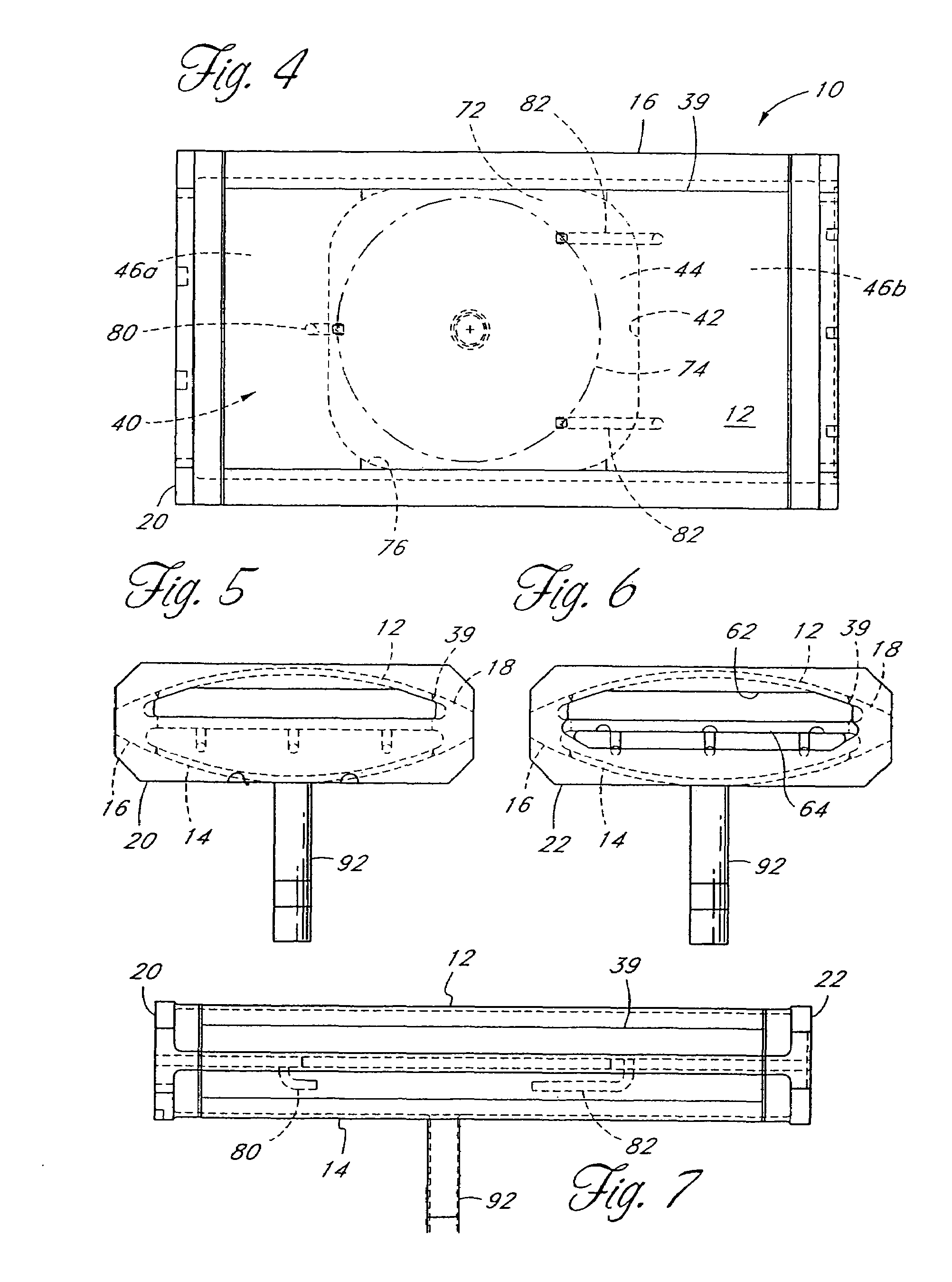

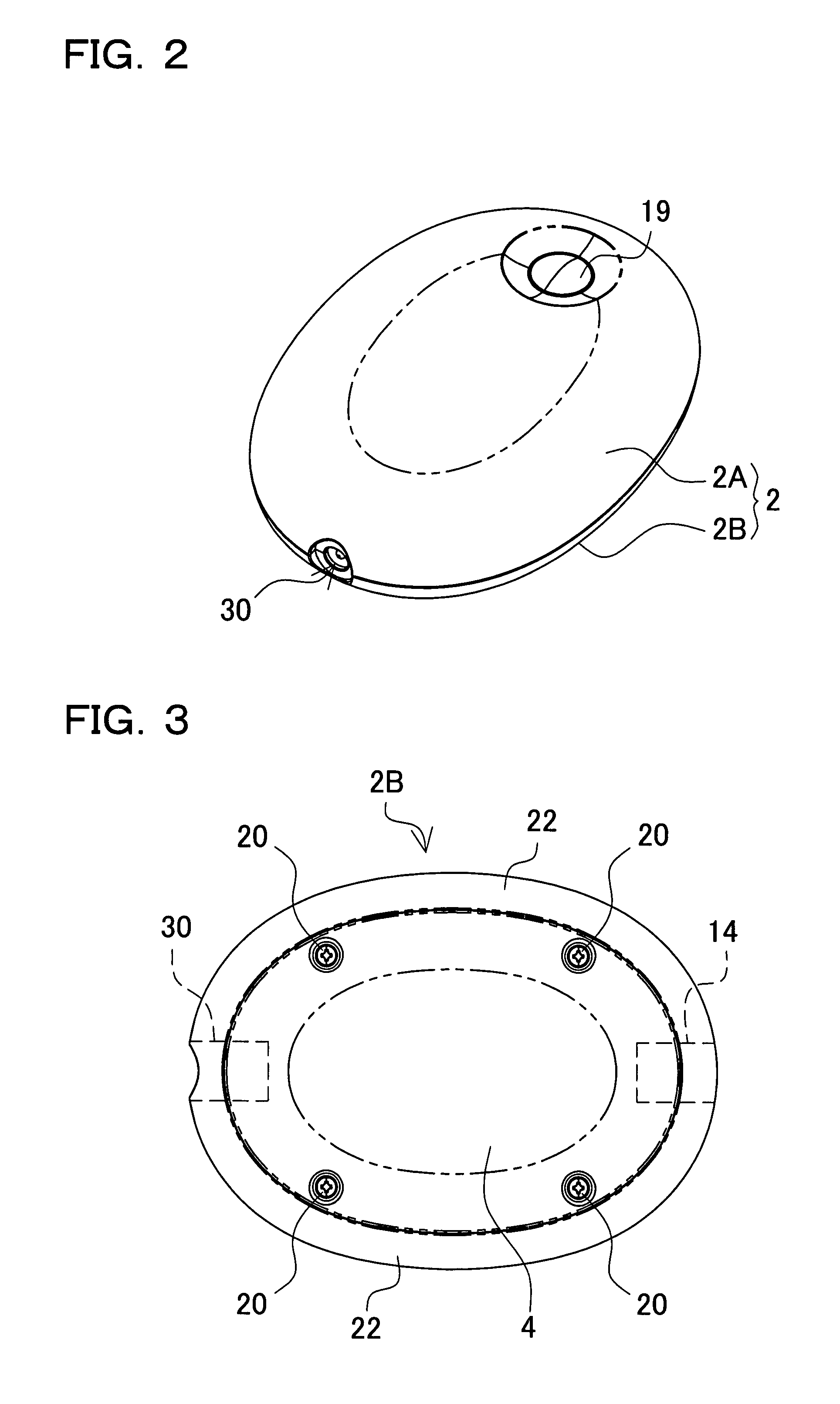

Hand warmer

InactiveUS20080053979A1Avoid failureImprove the temperature environmentMechanical apparatusSurgeryElectrical batteryRechargeable cell

In a hand warmer, a heat dissipating plate is thermally coupled to a heater that is supplied with current by a battery that is accommodated in a case. The battery is a box-shaped rechargeable battery of a box-shaped rechargeable lithium-ion battery or lithium-polymer battery that has flat surfaces opposed to each other. The heater is a heating element that is opposed to the flat surface of the battery. A shielding plate is arranged between the heating element and the flat surface of the battery. The heat dissipating plate that is thermally coupled to the heating element is secured to the case on the surface side of the case. In the hand warmer, the flat surface of the box-shaped rechargeable battery, the shielding plate and the heat dissipating plate are arranged in a stack structure. The heat dissipating plate is heated by the heating element.

Owner:SANYO ELECTRIC CO LTD

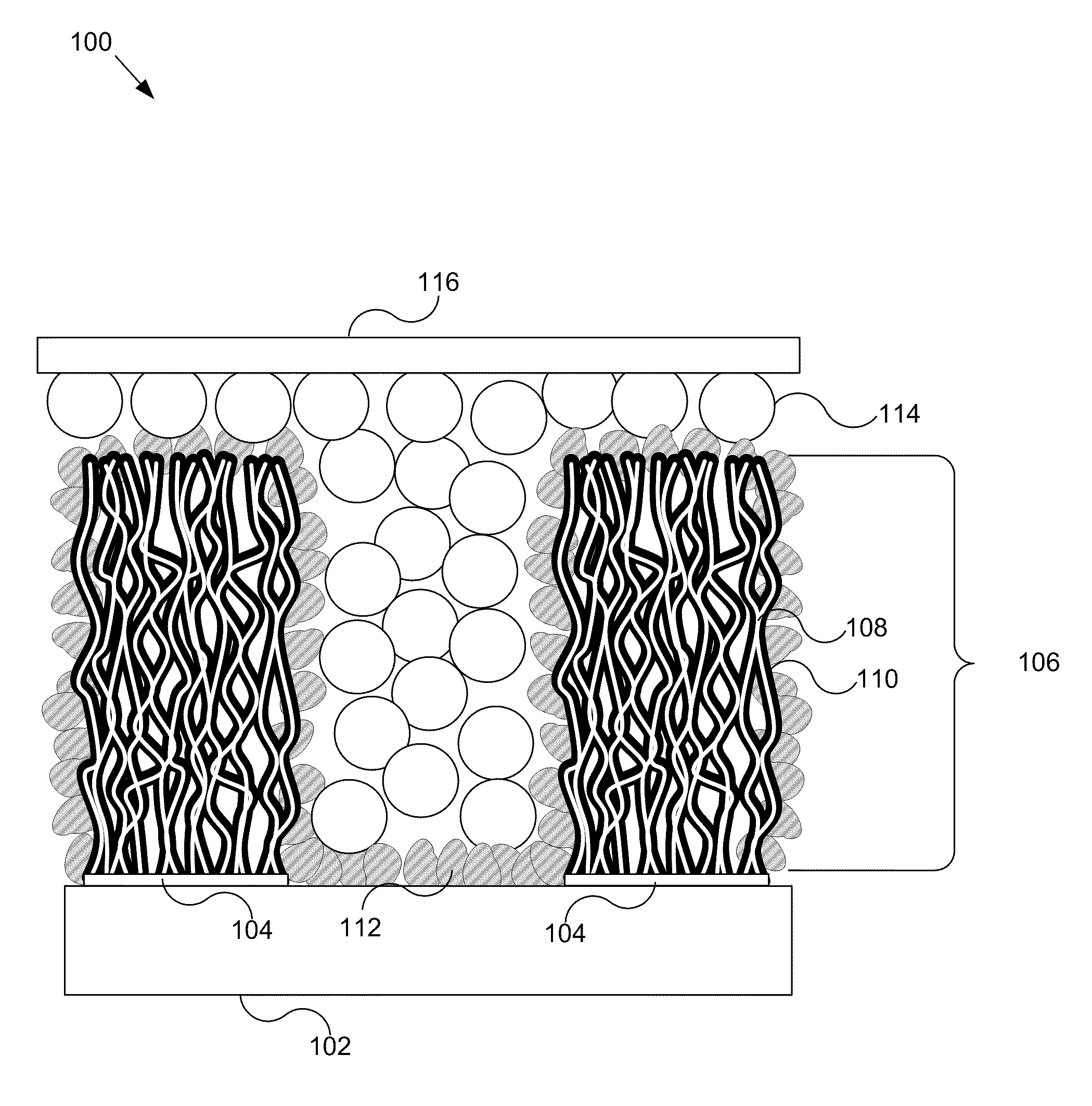

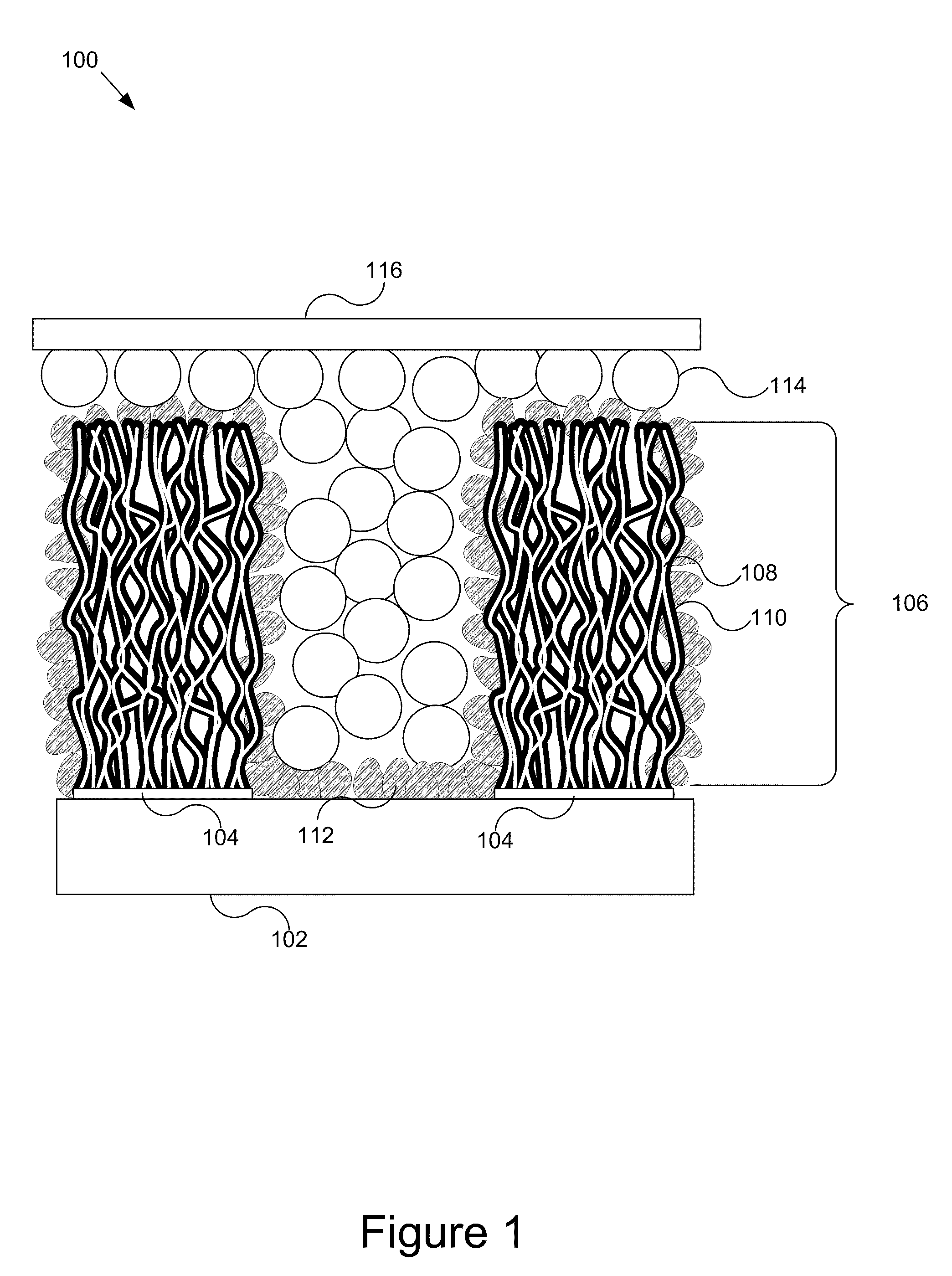

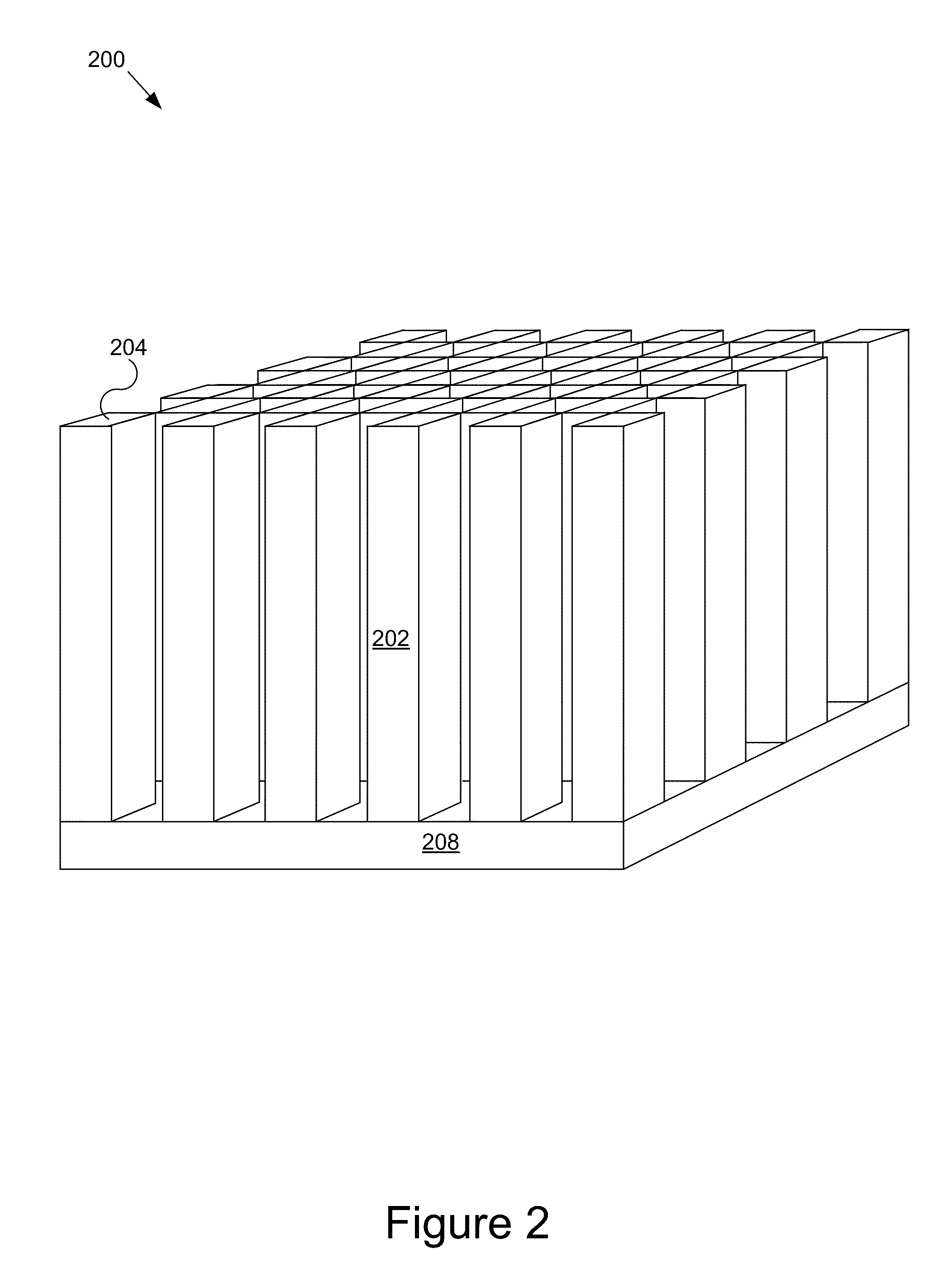

Apparatus, system, and method for carbon nanotube templated battery electrodes

InactiveUS20110183206A1Material nanotechnologyElectrode carriers/collectorsParticulatesCarbon nanotube

An apparatus, system, and method are disclosed for a carbon nanotube templated battery electrode. The apparatus includes a substrate, and a plurality of catalyst areas extending upward from the substrate, the plurality of catalyst areas forming a patterned frame. The apparatus also includes a carbon nanotube forest grown on each of the plurality of catalyst areas and extending upward therefrom such that a shape of the patterned frame is maintained, and a coating attached to each carbon nanotube in the carbon nanotube forest, the coating formed of an electrochemically active material. The system includes the apparatus, and a particulate cathode material distributed evenly across the apparatus such that the particulate cathode material fills the passages, a current collector film formed on top of the particulate cathode material, and a porous spacer disposed between the apparatus and the cathode.

Owner:BRIGHAM YOUNG UNIV

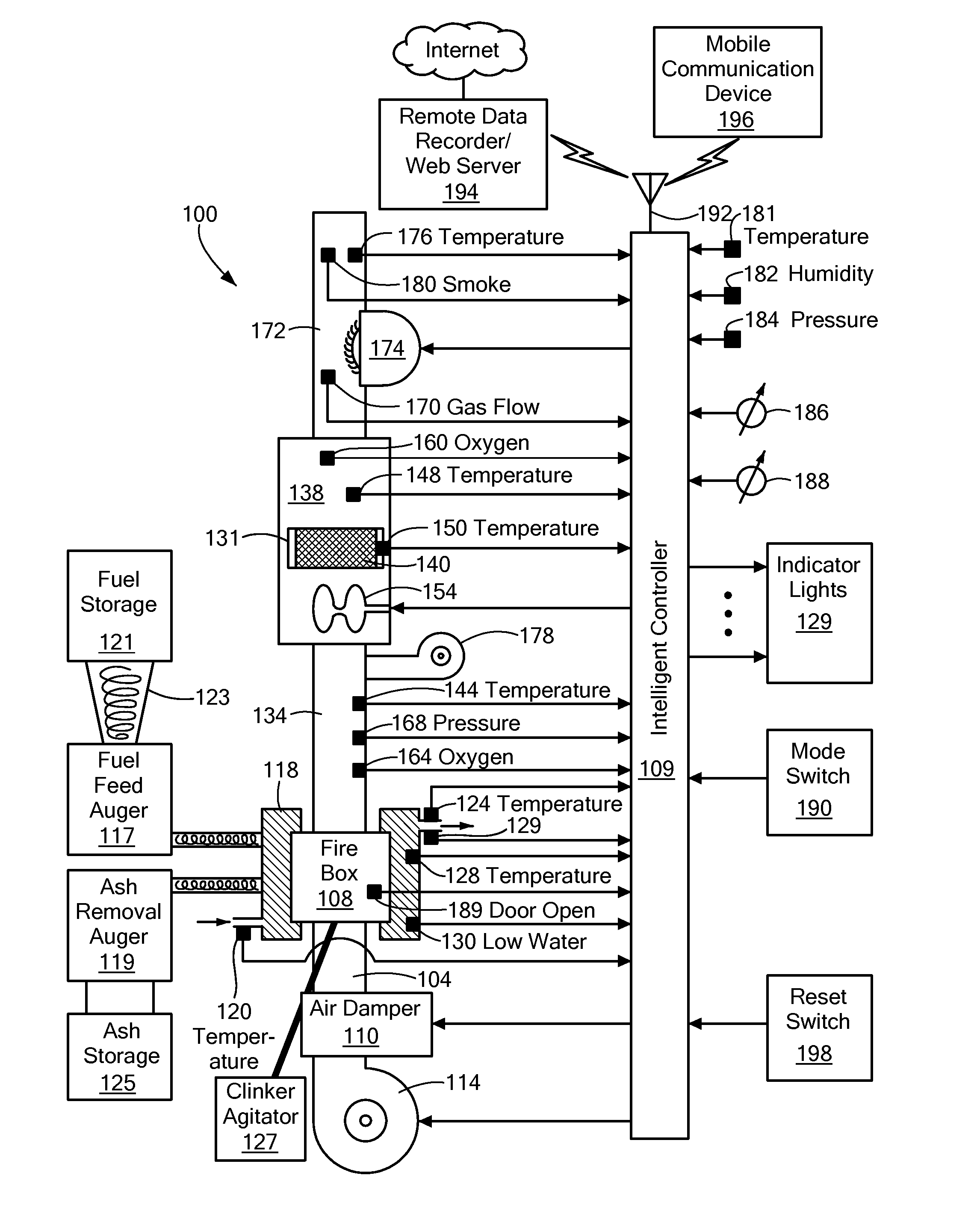

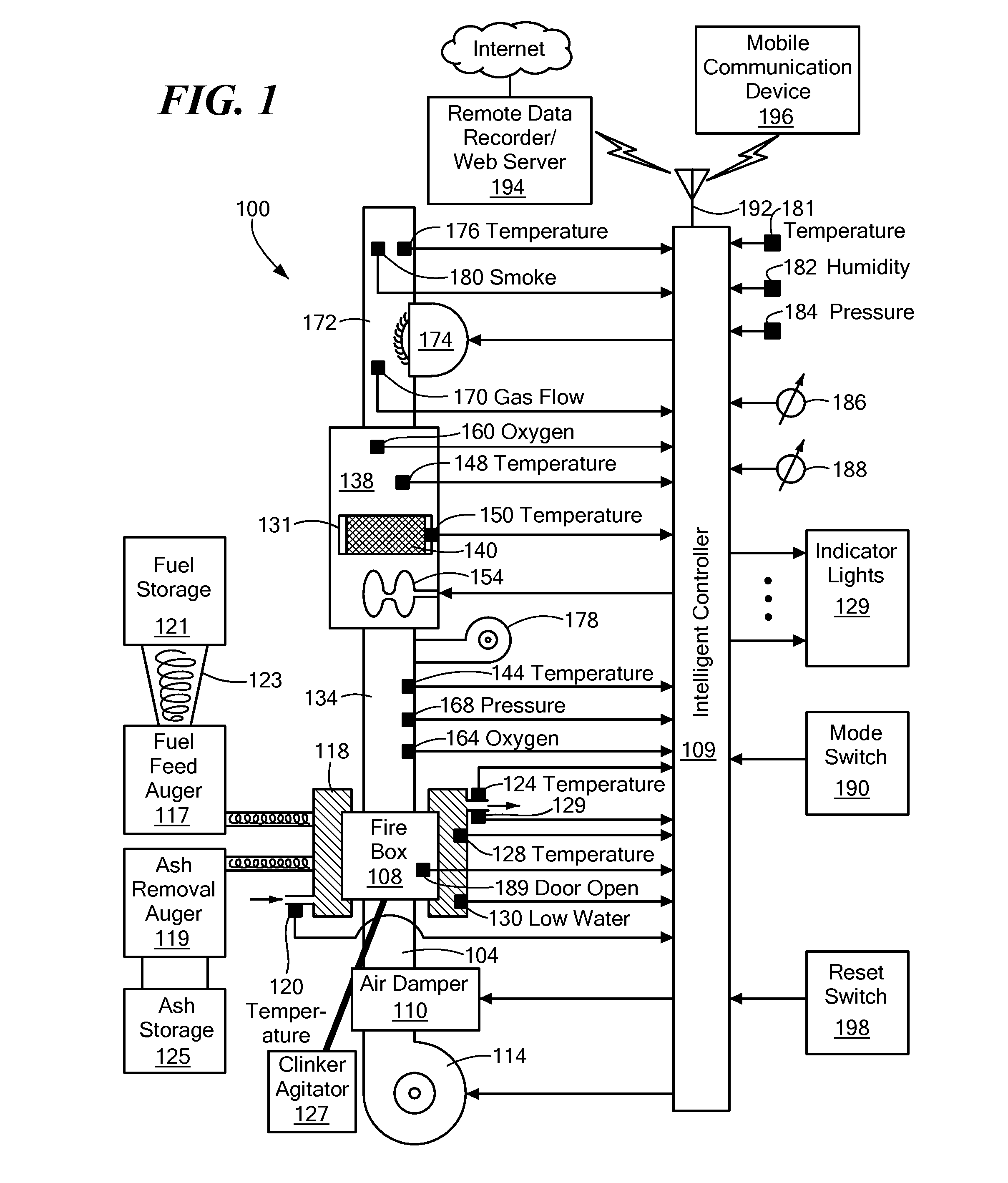

Fuel Feed and Air Feed Controller for Biofuel-Fired Furnace

A microprocessor-based controller manages delivery of BTUs or power by determining an amount of thermal heat or power needed through sensors and, in response, controls a batch or continuous feed of biofuel fuel and / or air to a biofuel furnace. The controller controls the fuel and air required to operate the furnace efficiently.

Owner:BIOMASS CONTROLS PBC

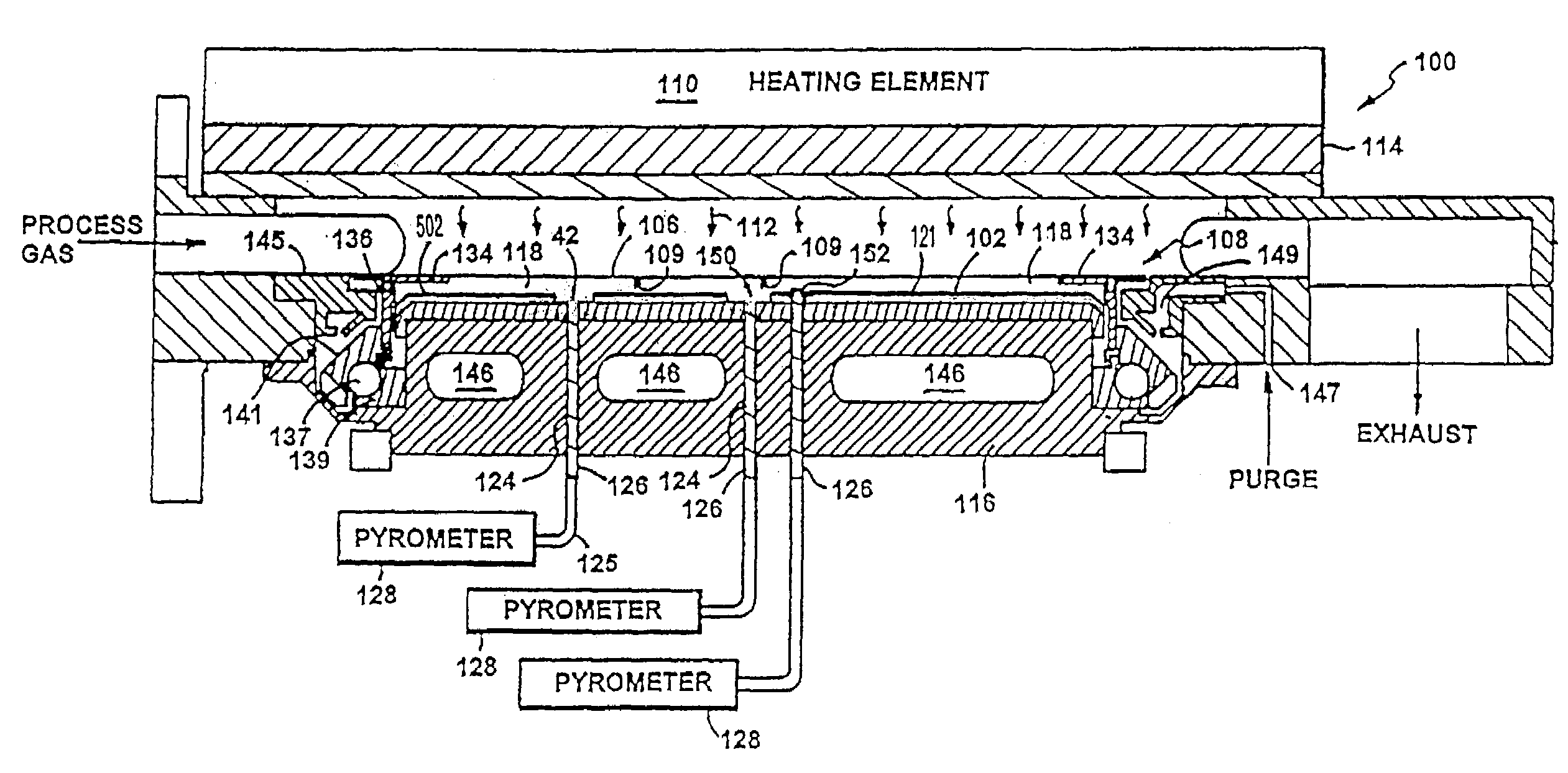

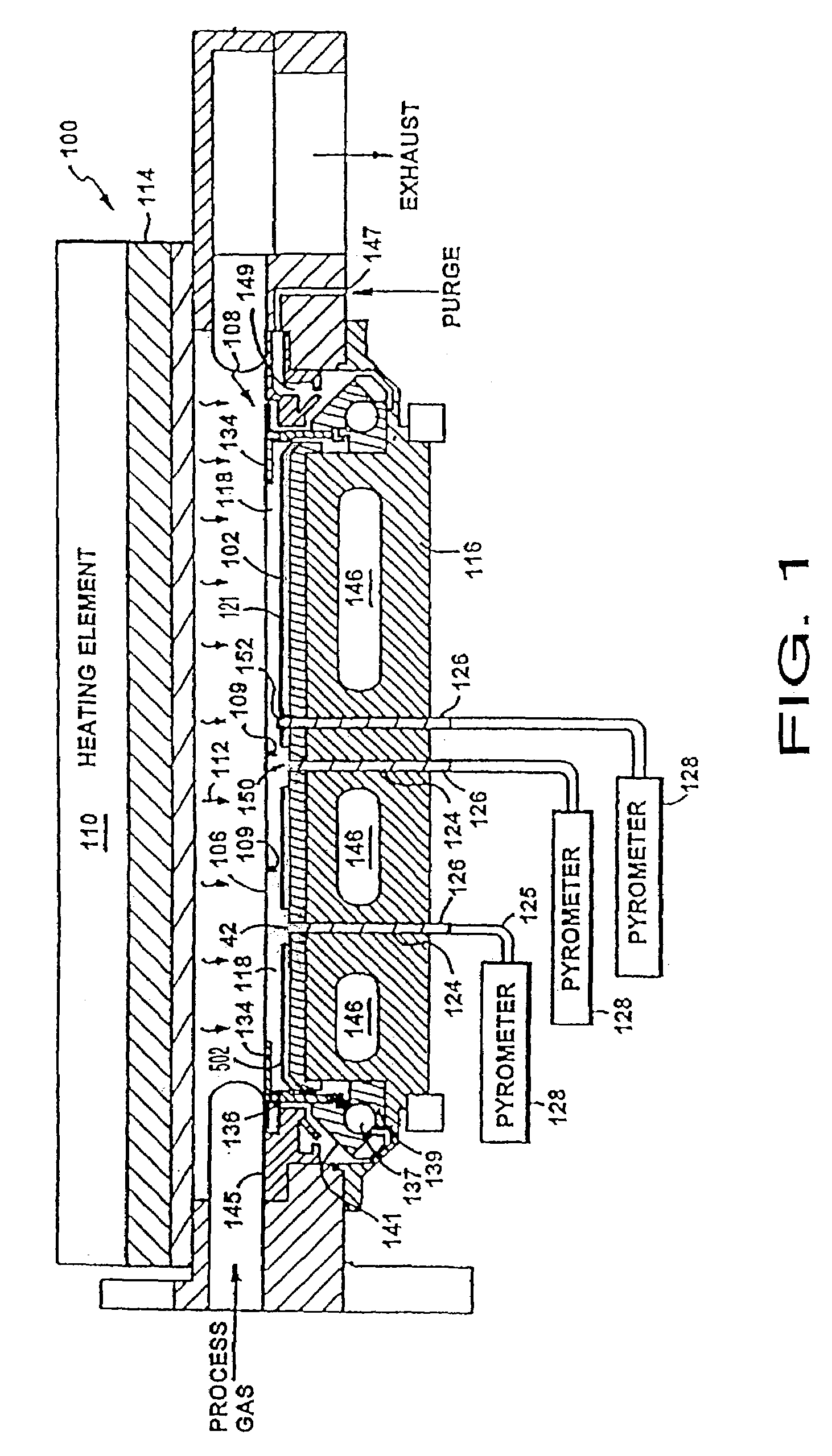

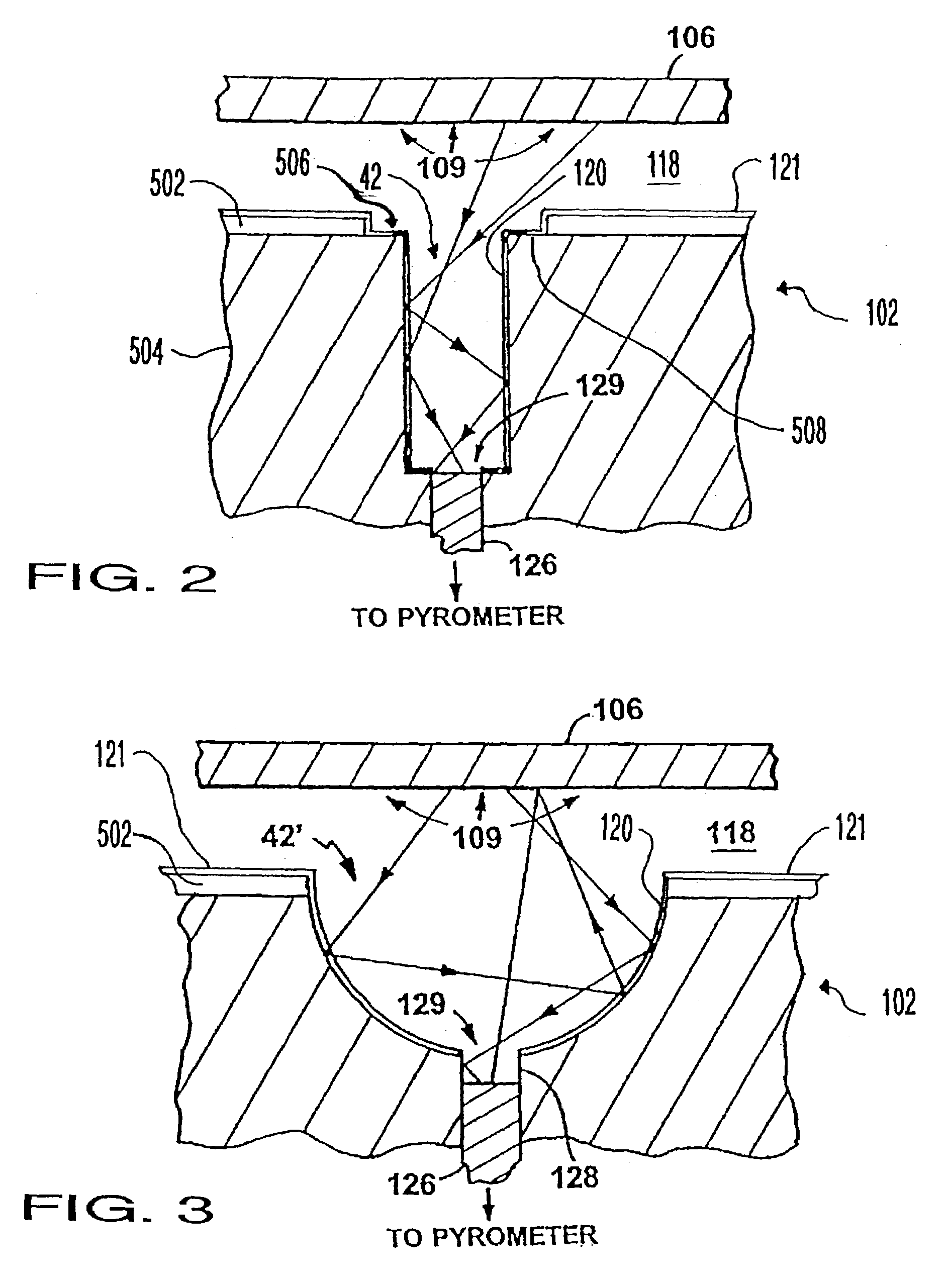

Stepped reflector plate

InactiveUS7041931B2Improve performancePromote rapid coolingDrying solid materials with heatMuffle furnacesSemiconductorHeat treated

In a system for thermal processing of a semiconductor substrate, a reflector plate has a stepped surface facing the substrate during heating and cooling of the substrate. The raised surface of the reflector plate has reduced reflectivity, providing advantages during, among other things, cooling of the substrate. The reflector plate also includes a number of recesses to which one or more pyrometers are coupled. These recesses have a highly reflective surface, providing advantages in the performance of the pyrometers.

Owner:APPLIED MATERIALS INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com