Patents

Literature

1230 results about "Intermediate temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The intermediate temperature range extends from 450 to 750K. The alkali metals, such as cesium, potassium and sodium, are suitable working fluids at temperatures above this range.

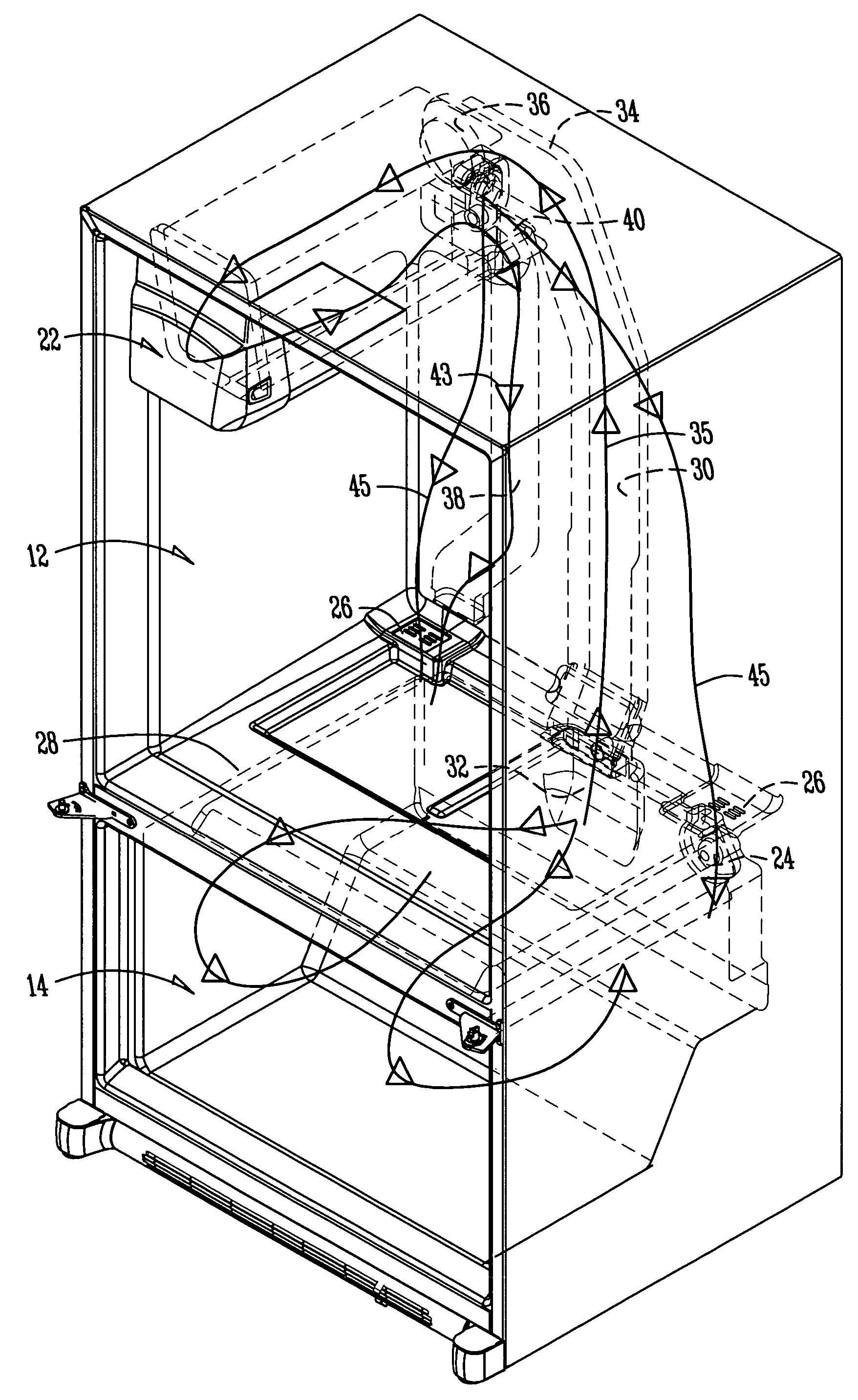

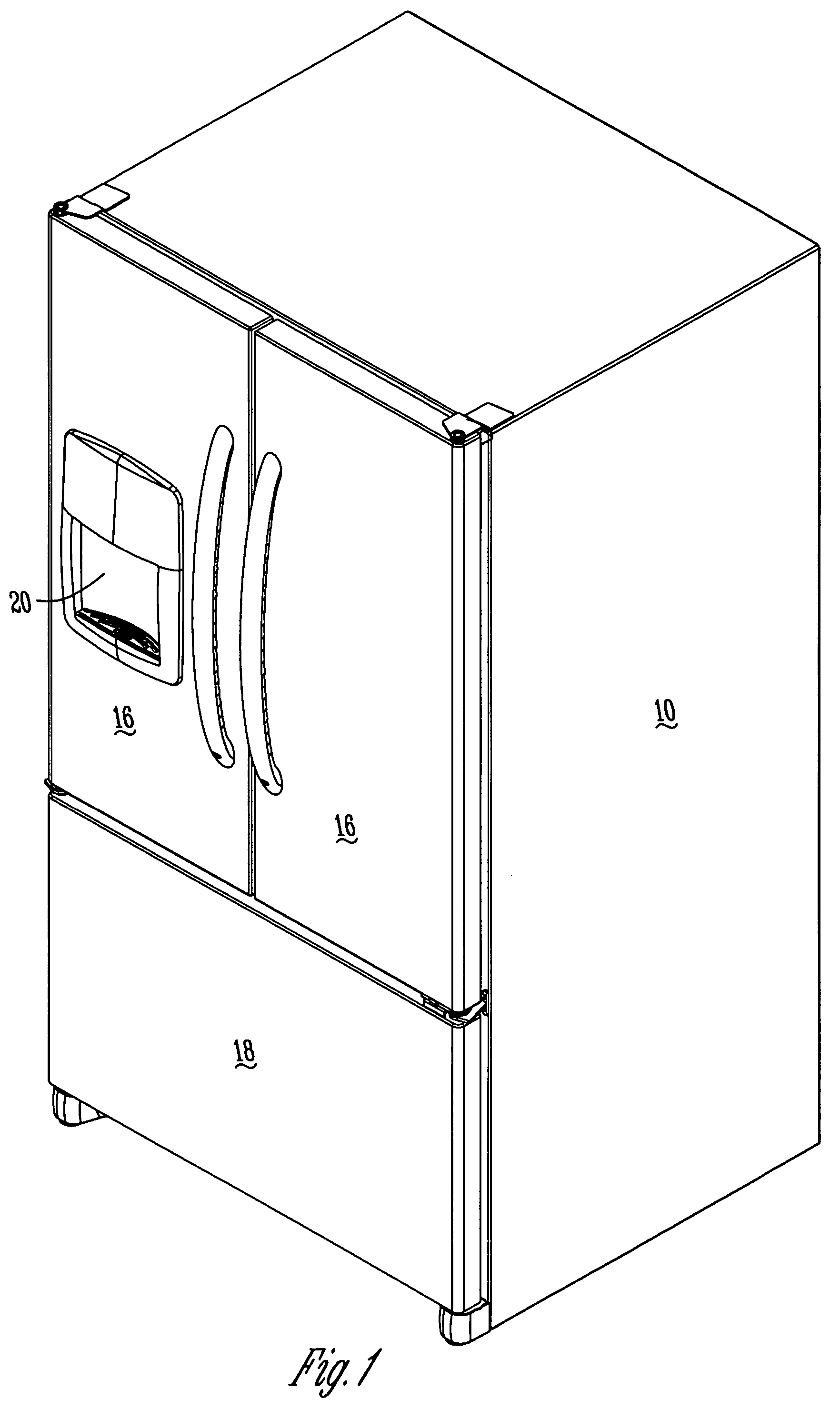

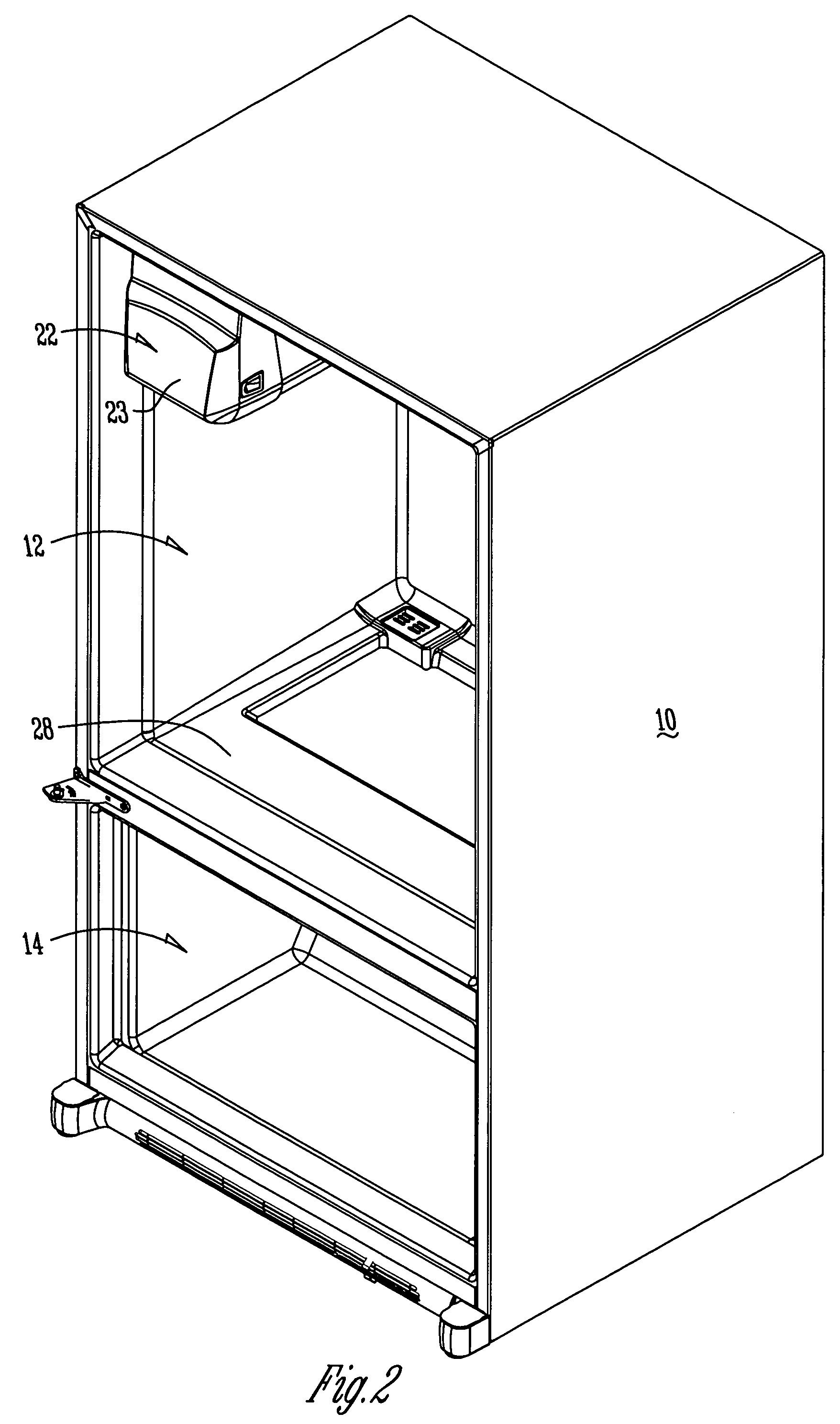

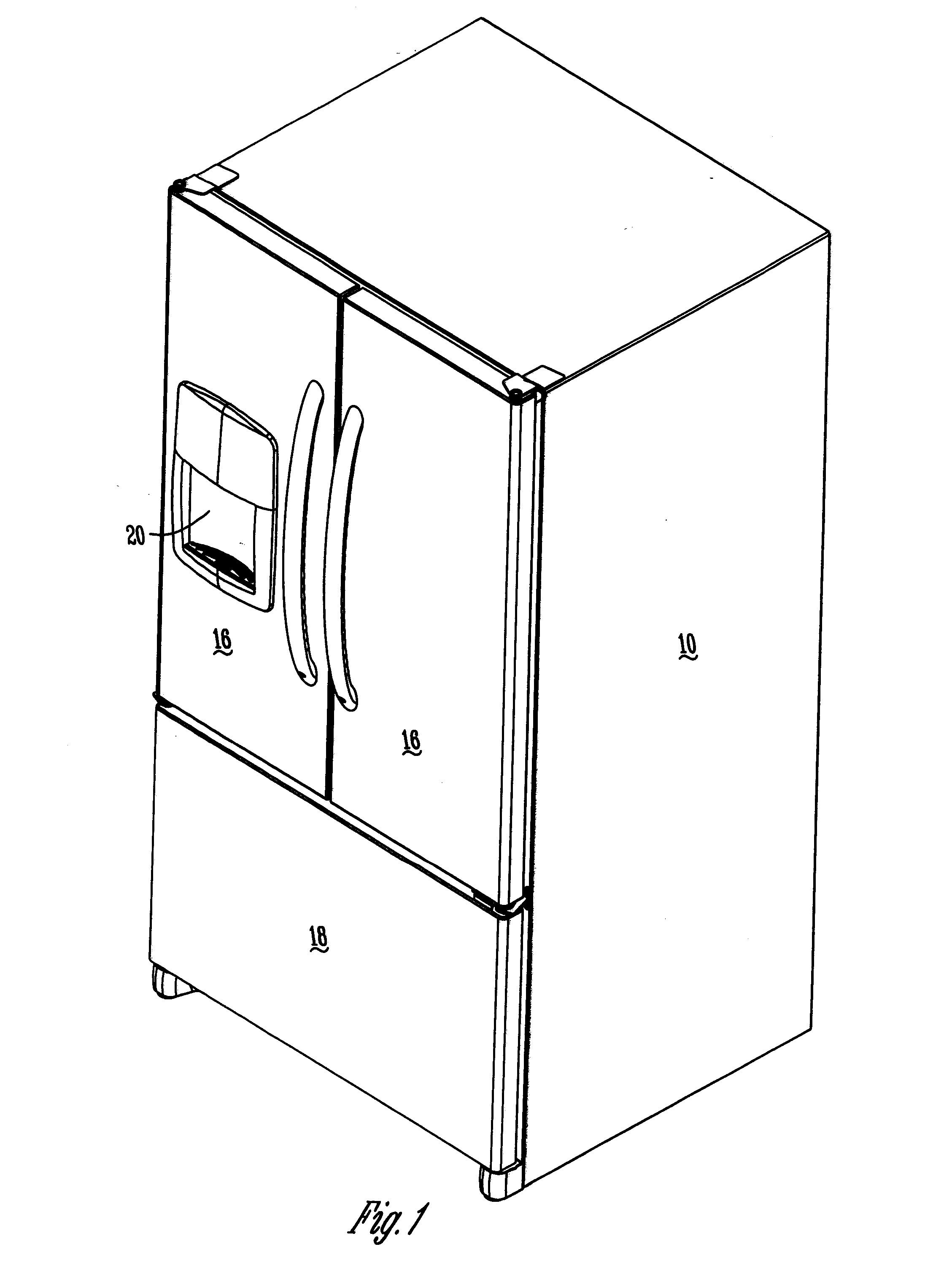

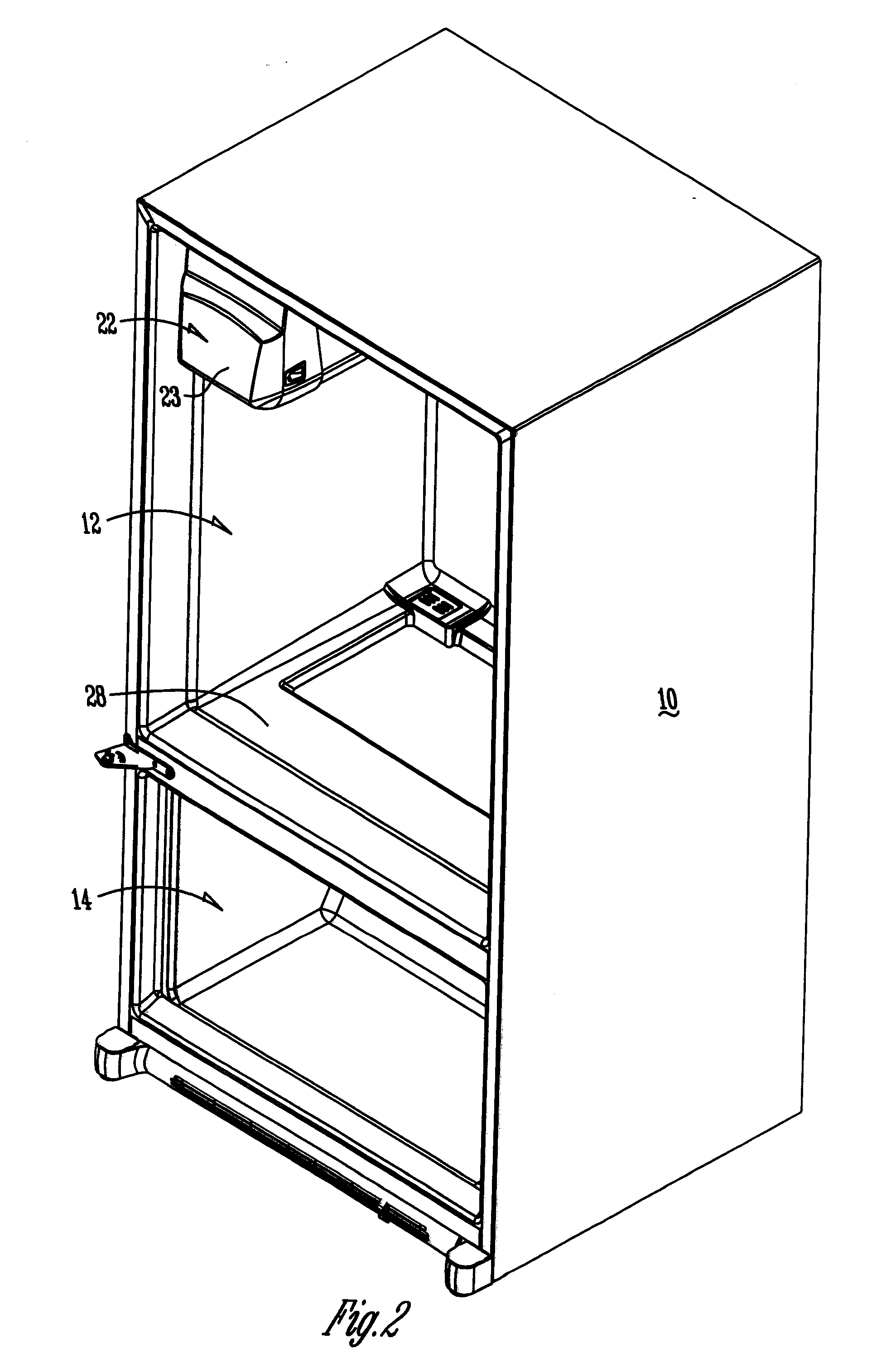

Refrigerator with intermediate temperature icemaking compartment

An icemaking compartment is provided in the refrigerator compartment of a bottom mount refrigerator. An icemaker is within the icemaking compartment. A cold air duct supplies cold air from the freezer compartment to the icemaker. The cold air duct is formed in the rear wall of the refrigerator. A fan controls the flow of air through the cold air duct. A return air duct is provided to direct a portion of the air from the icemaker back to the freezer compartment. An air vent in the icemaker directs another portion of air into the refrigerator compartment.

Owner:WHIRLPOOL CORP

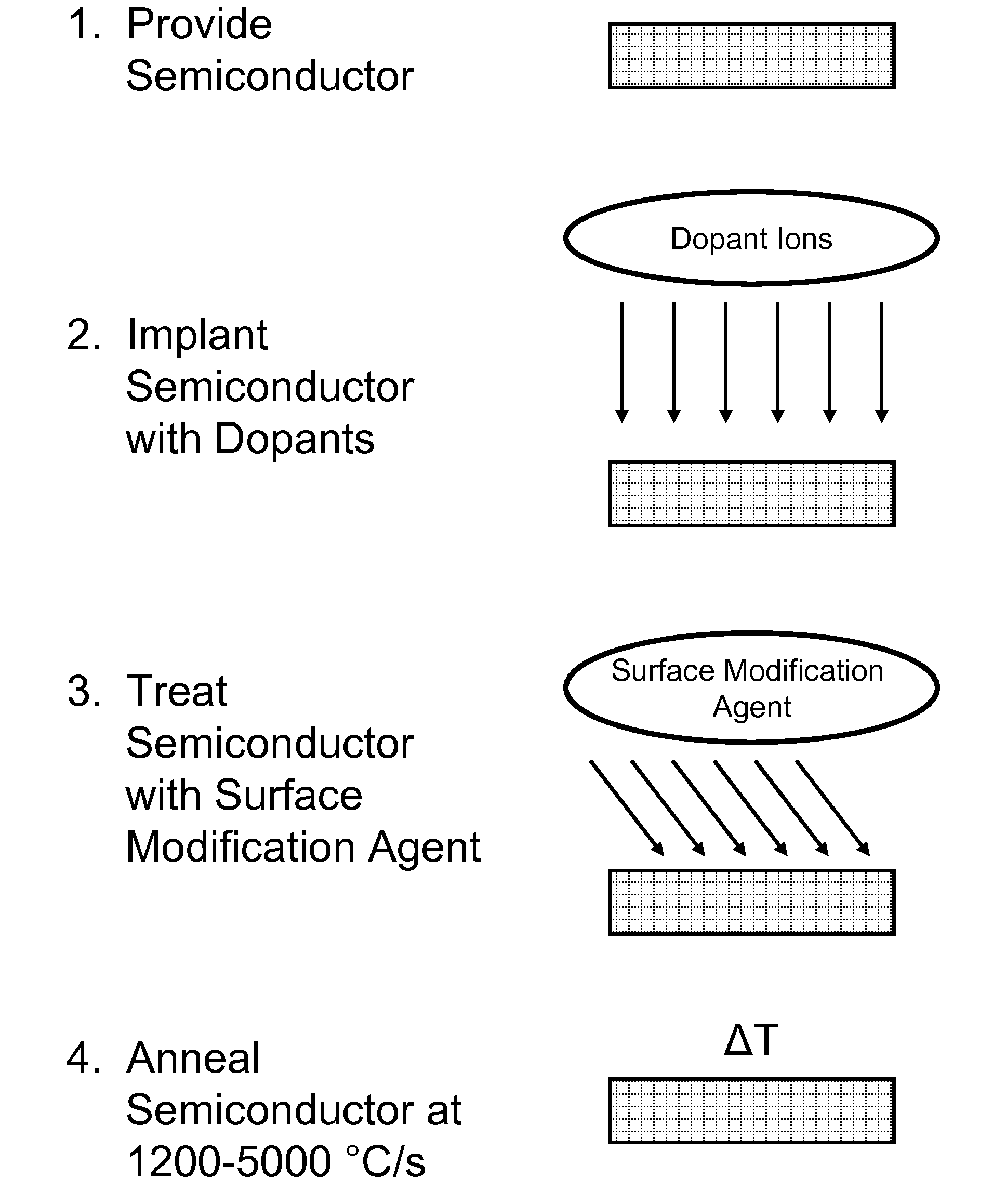

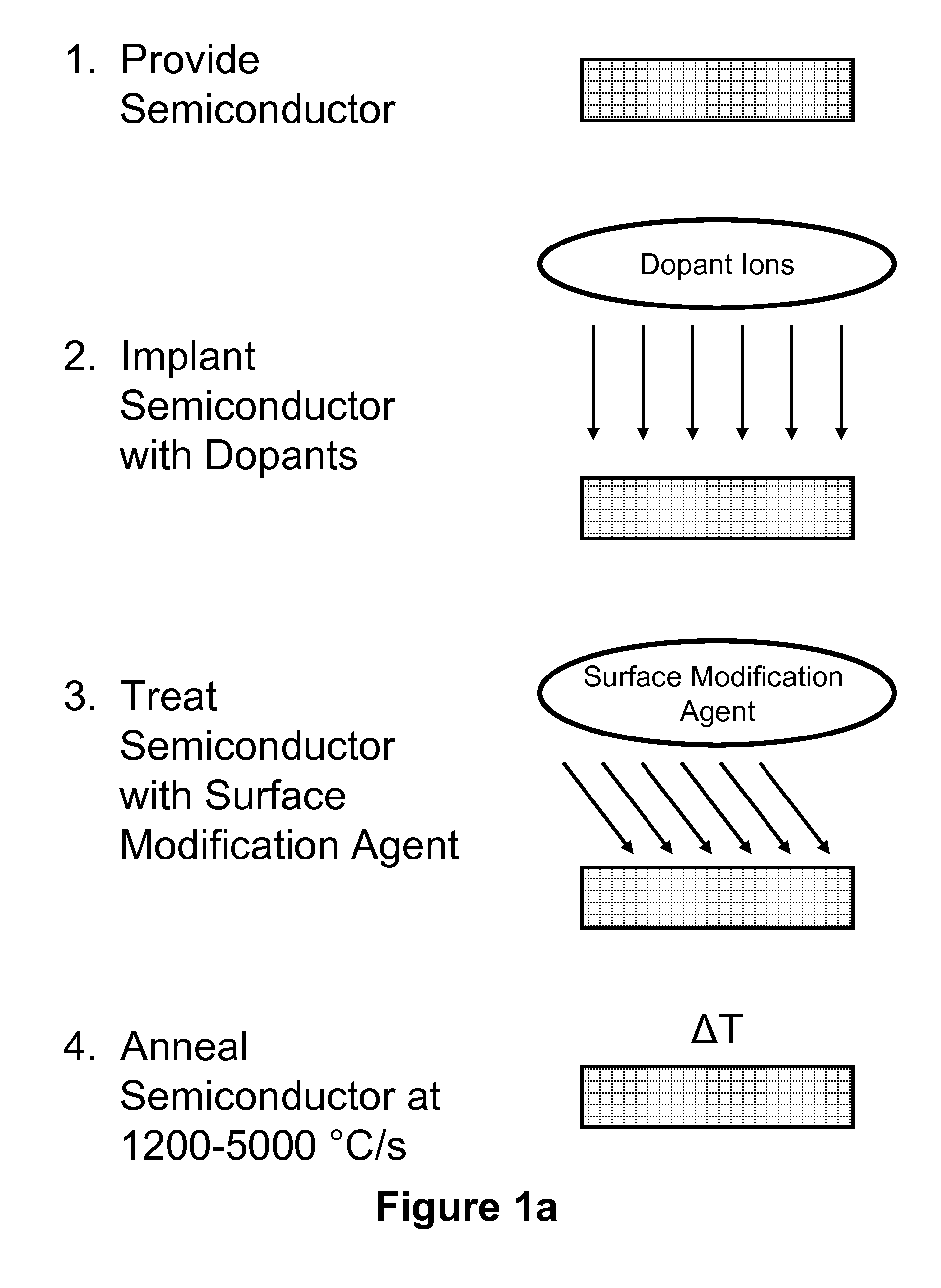

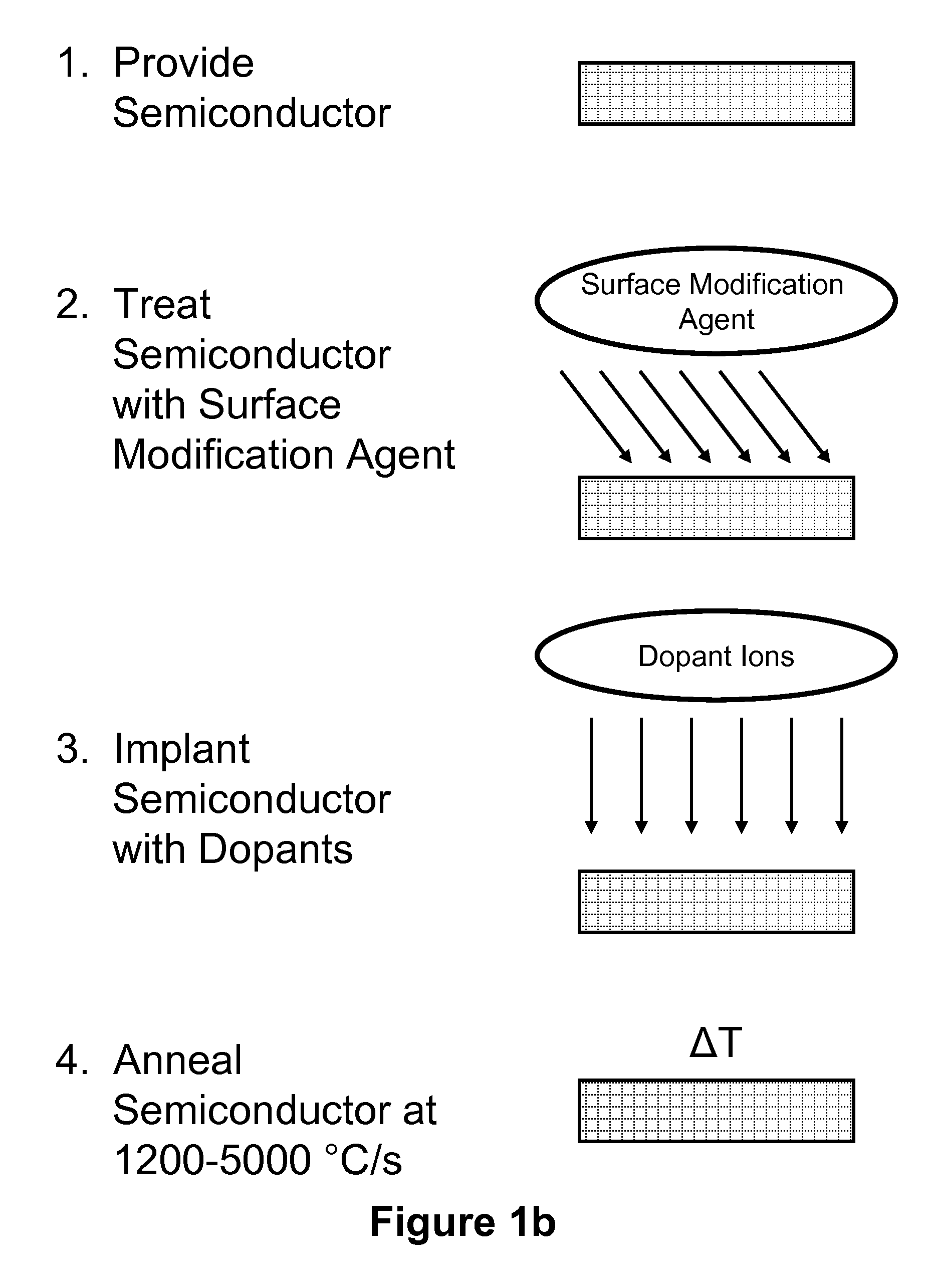

Preparation of ultra-shallow semiconductor junctions using intermediate temperature ramp rates and solid interfaces for defect engineering

ActiveUS7968440B2Increase and decrease loss rateSemiconductor/solid-state device manufacturingDopantDiffusion

Described herein are processing conditions, techniques, and methods for preparation of ultra-shallow semiconductor junctions. Methods described herein utilize semiconductor surface processing or modification to limit the extent of dopant diffusion under annealing conditions (e.g. temperature ramp rates between 100 and 5000° C. / second) previously thought impractical for the preparation of ultra-shallow semiconductor junctions. Also described herein are techniques for preparation of ultra-shallow semiconductor junctions utilizing the presence of a solid interface for control of dopant diffusion and activation.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

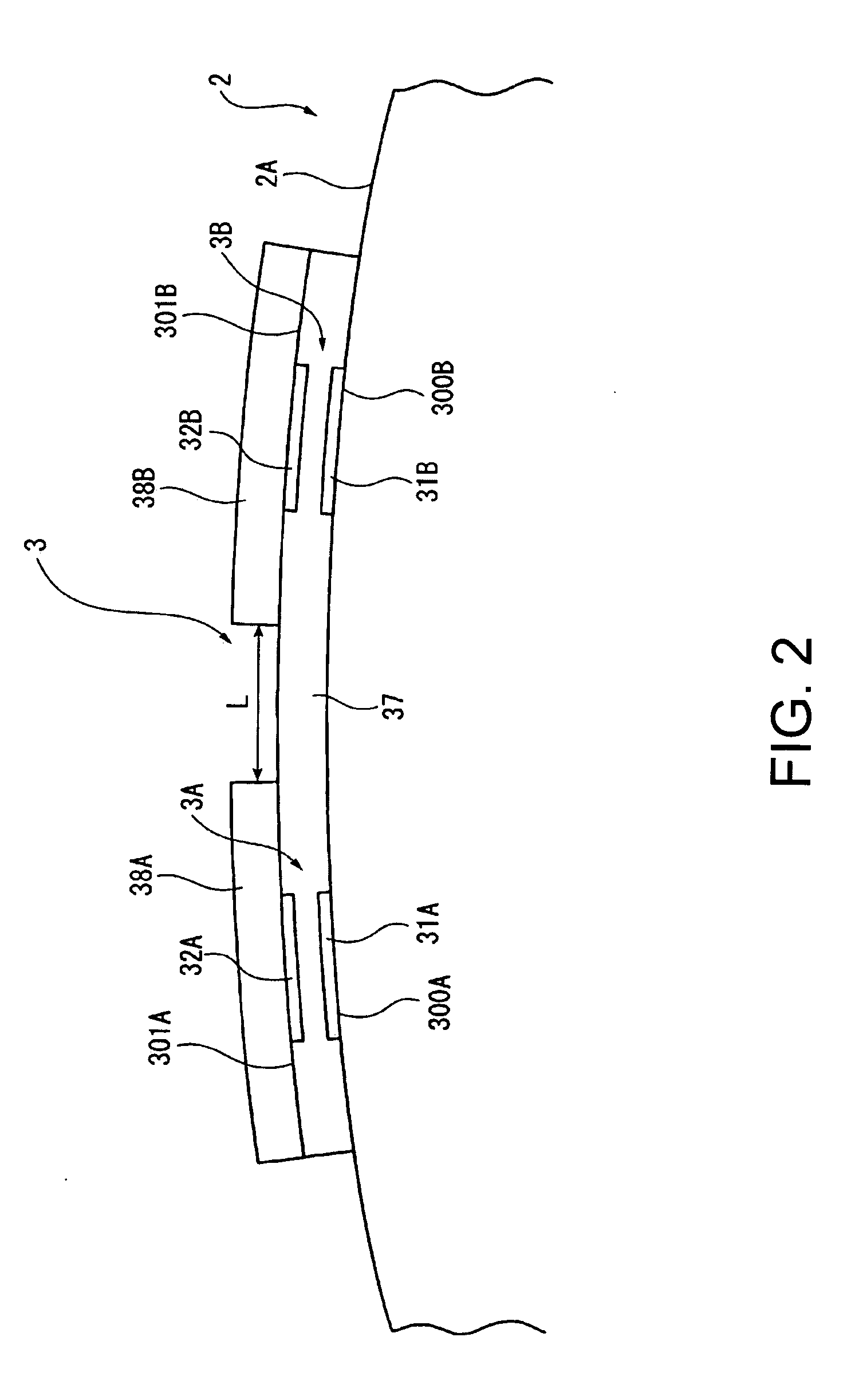

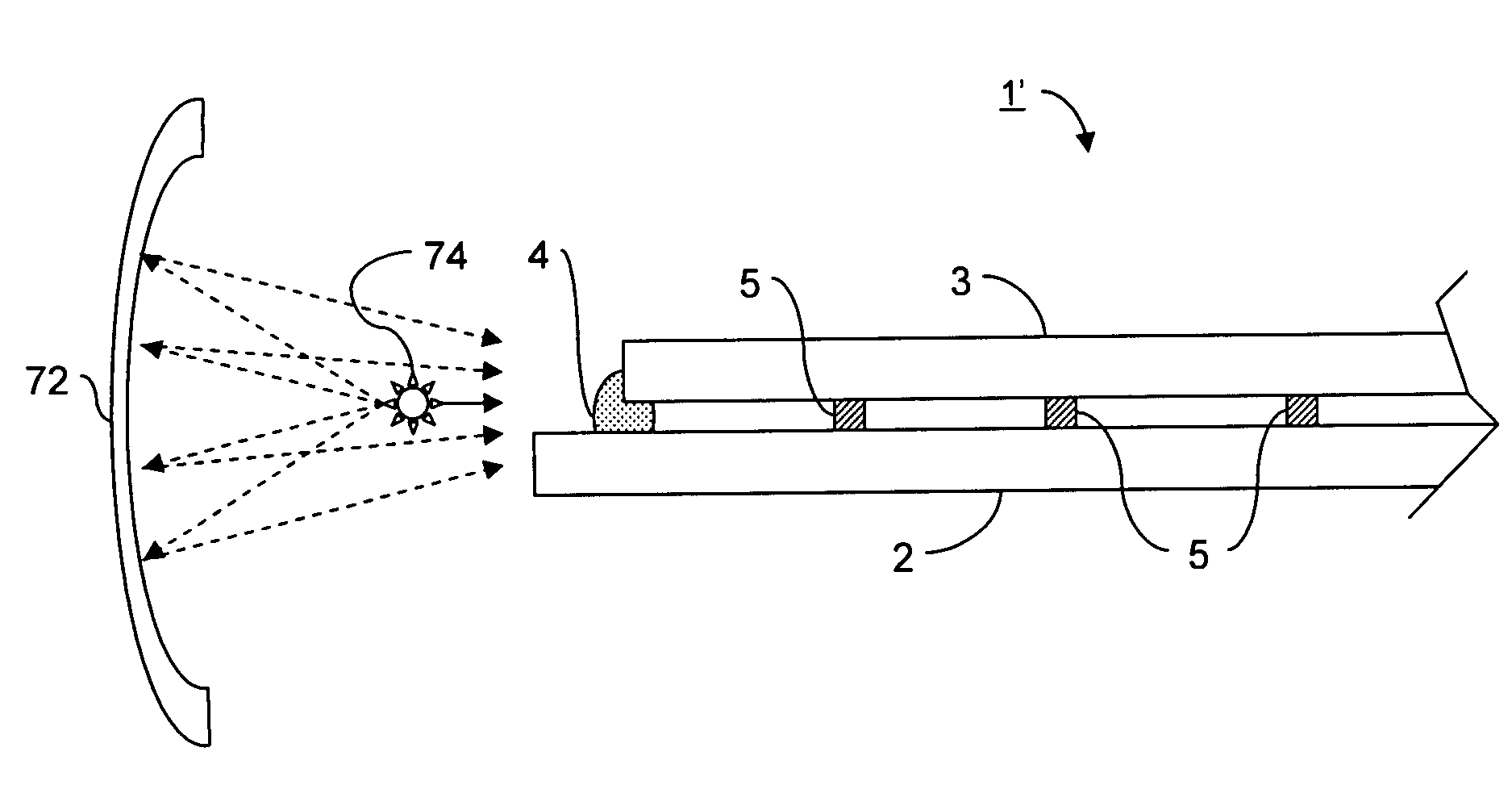

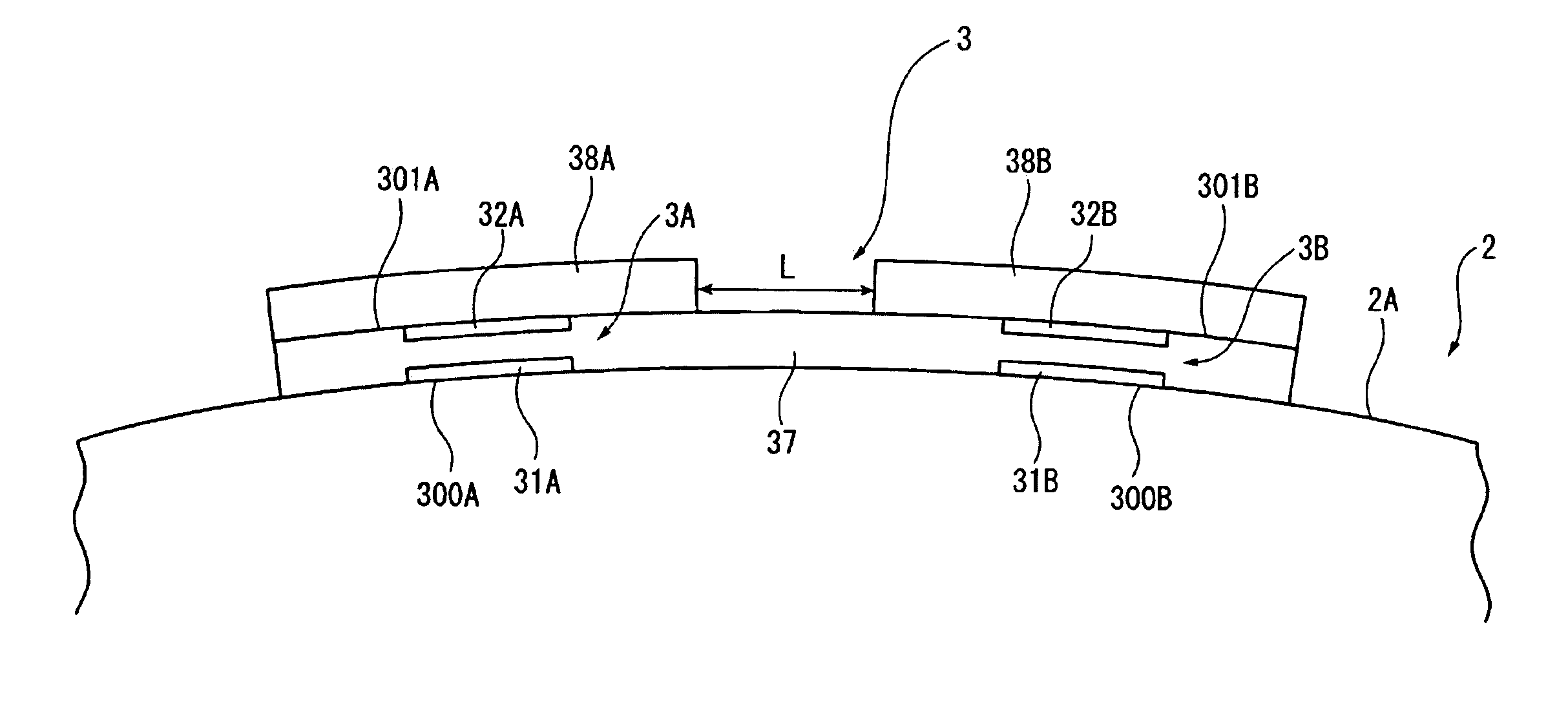

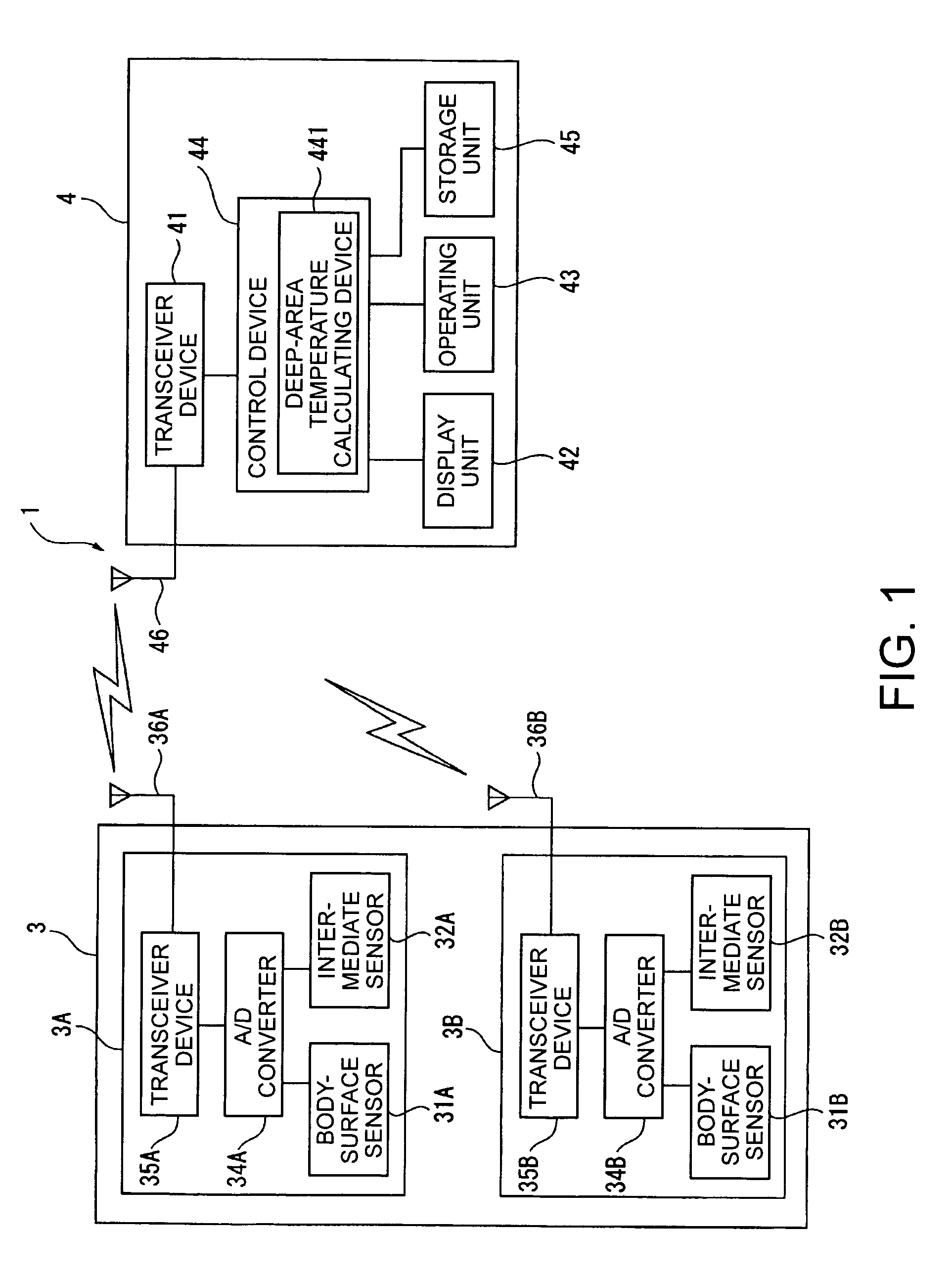

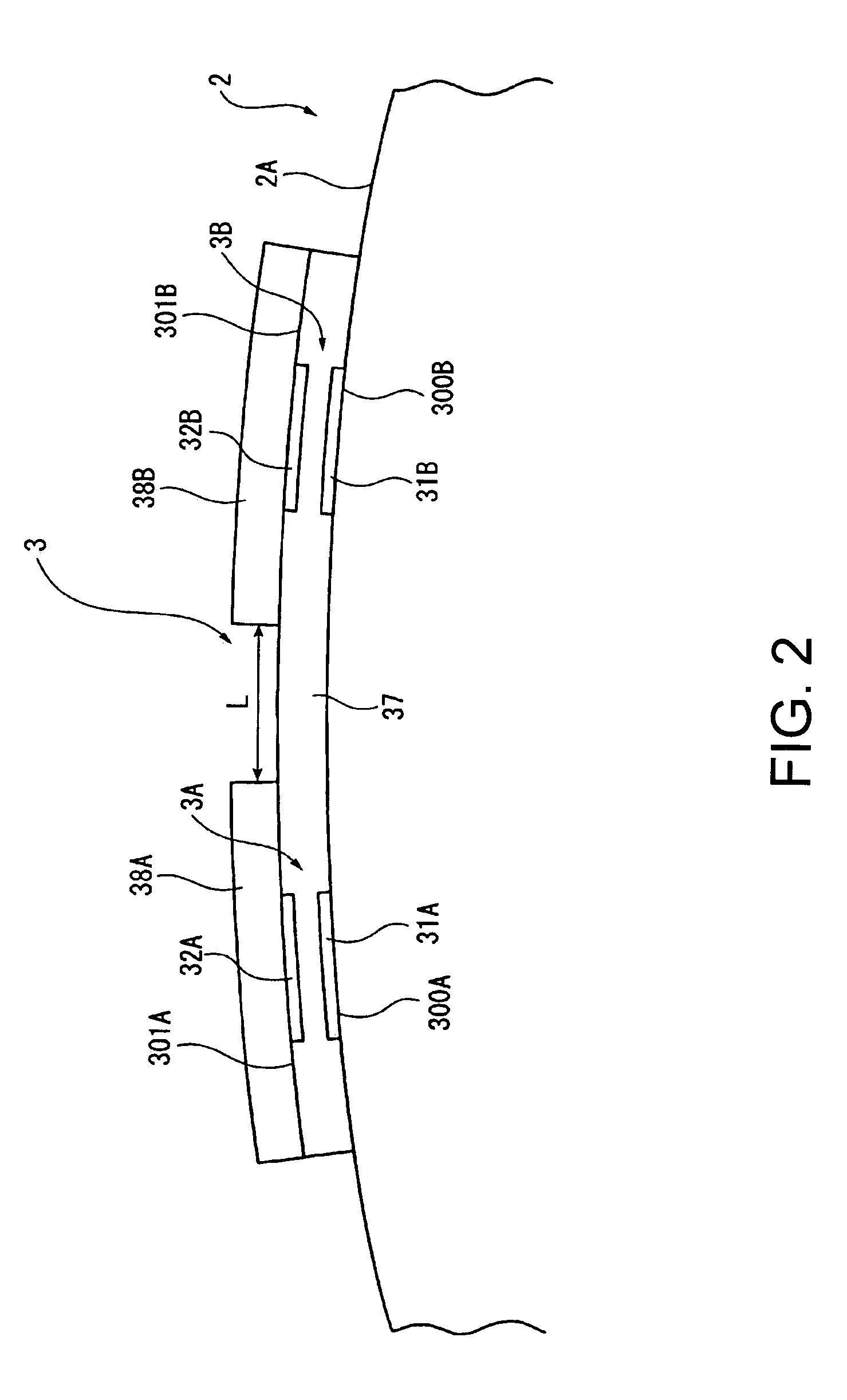

Thermometer, electronic device having a thermometer, and method for measuring body temperature

ActiveUS20060056487A1Improve accuracyThermometer detailsThermometers using electric/magnetic elementsHeat resistanceEngineering

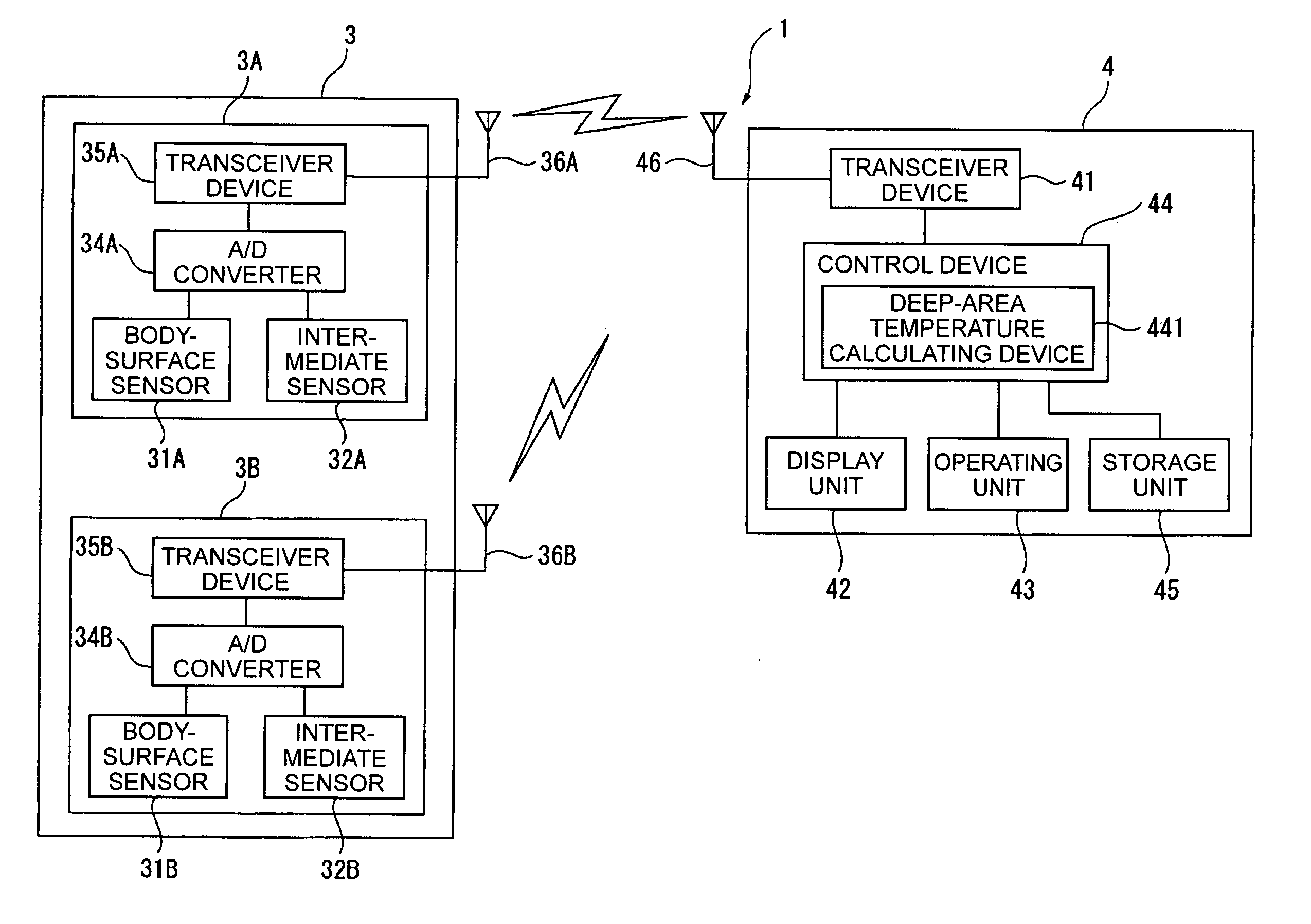

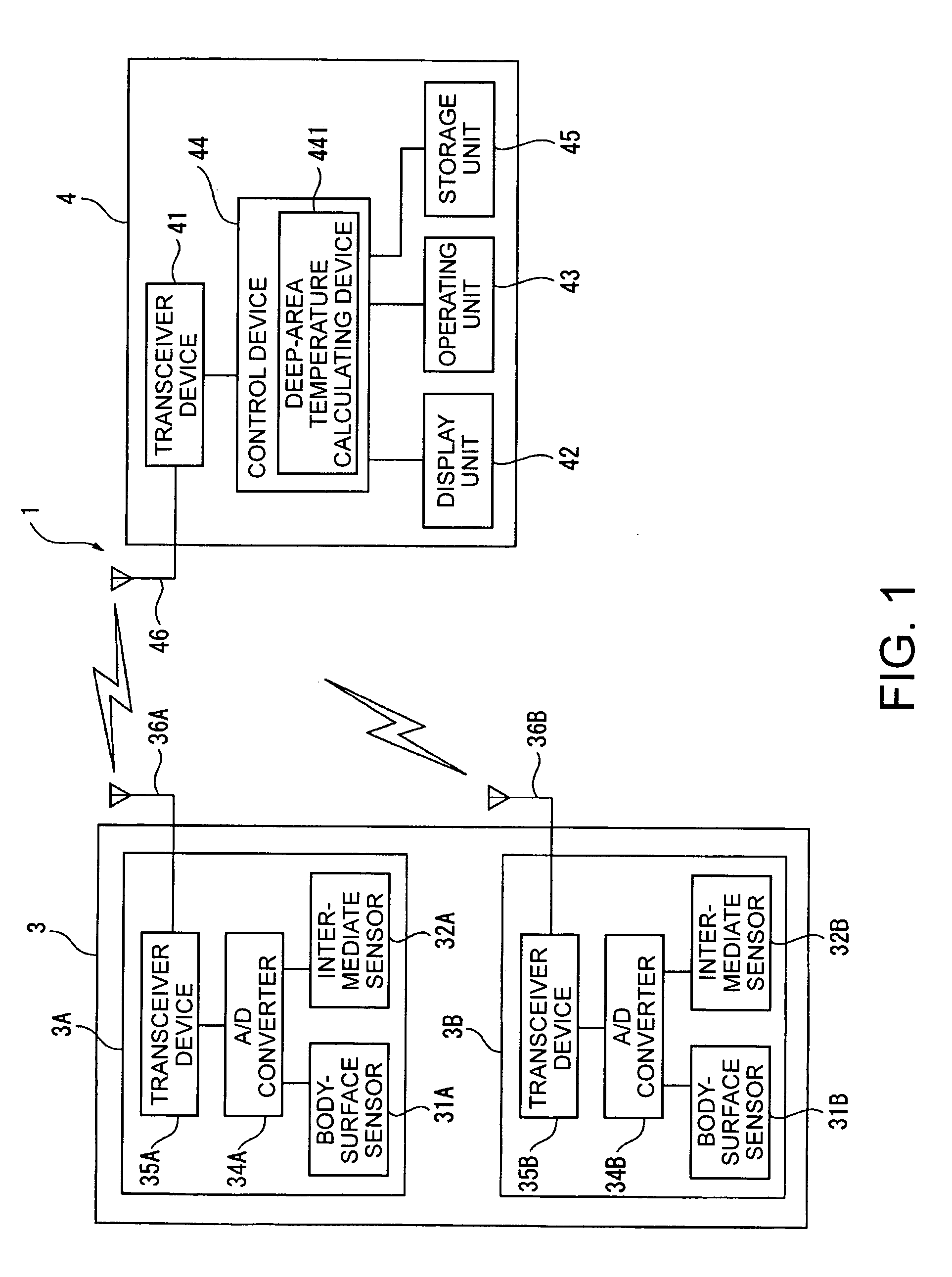

A deep-area temperature calculating device 441 calculates the temperature Tcore of a deep area on the basis of a first body-surface temperature and second body-surface temperature from body-surface sensors 31A and 31B, and on the basis of a first intermediate temperature and second intermediate temperature from intermediate sensors 32A and 32B. Since the temperature Tcore of the deep area is determined from two body-surface temperatures and two intermediate temperatures, the temperature Tcore of the deep area can be calculated regardless of the heat resistance of the thermometer without making any assumptions regarding the heat resistance of the area that extends from the deep area of the human body to the body surface. Thereby, the temperature Tcore of the deep area can be calculated and the body temperature can be measured with high precision regardless of differences in the body type or contact with clothing or bedding.

Owner:SEIKO EPSON CORP

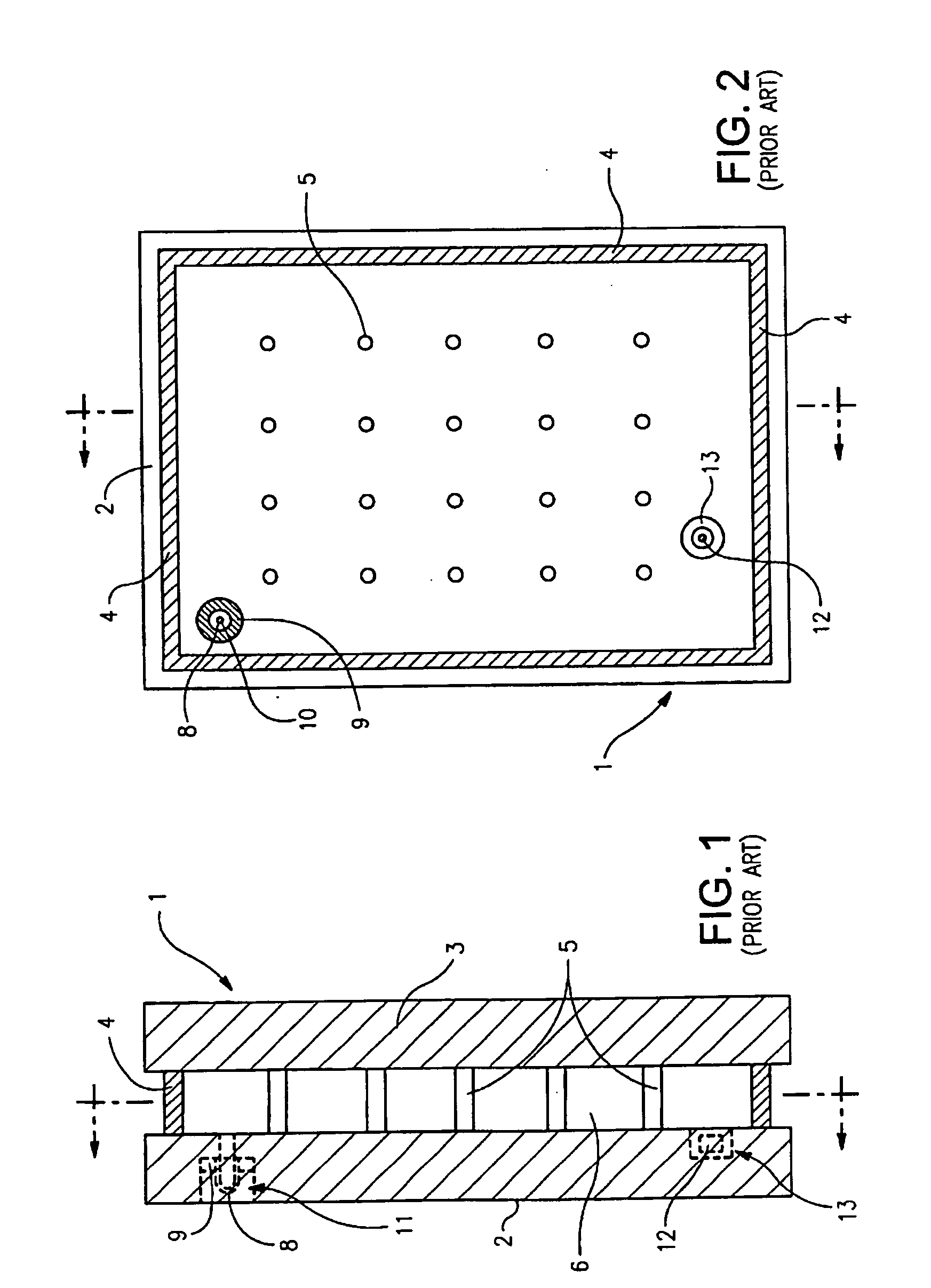

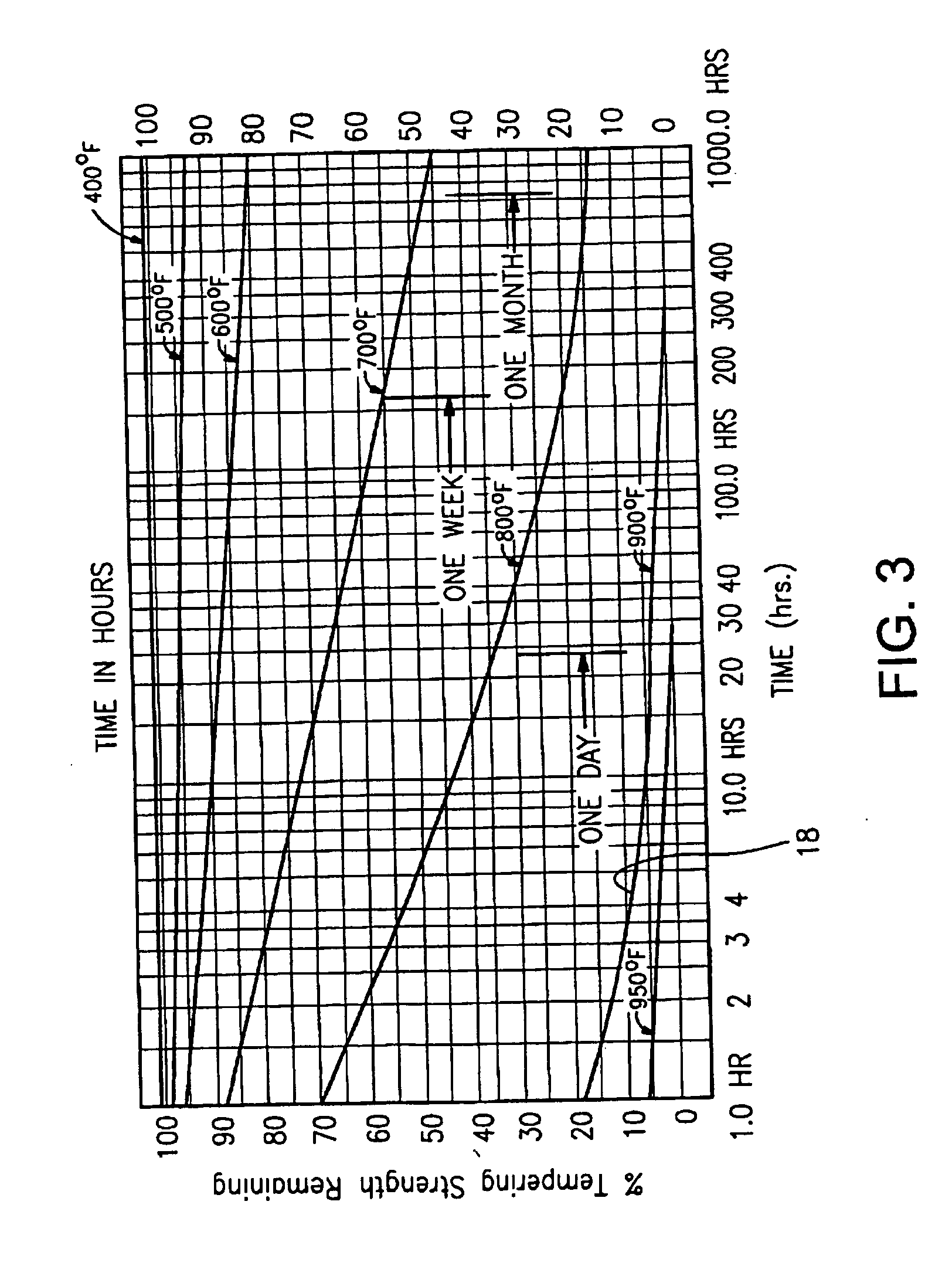

Localized heating of edge seals for a vacuum insulating glass unit, and/or unitized oven for accomplishing the same

ActiveUS20090151854A1Reduce the temperatureAccelerate breakageMechanical working/deformationClimate change adaptationEngineeringTemperature gradient

Certain example embodiments of this invention relate to edge sealing techniques for vacuum insulating glass (VIG) units. More particularly, certain example embodiments relate to techniques for providing localized heating to edge seals of units, and / or unitized ovens for accomplishing the same. In certain example embodiments, a unit is pre-heated to one or more intermediate temperatures, localized heating (e.g., from one or more substantially linear focused IR heat sources) is provided proximate to the peripheral edges of the unit so as to melt frits placed thereon, and cooled. In certain non-limiting implementations, the pre-heating and / or cooling may be provided in one or more steps. An oven for accomplishing the same may include multiple zones for performing the above-noted steps, each zone optionally including one or more chambers. Accordingly, in certain example embodiments, a temperature gradient proximate to the edges of the unit is created, thereby reducing the chances of breakage and / or at least some de-tempering of the substrates.

Owner:GUARDIAN GLASS LLC

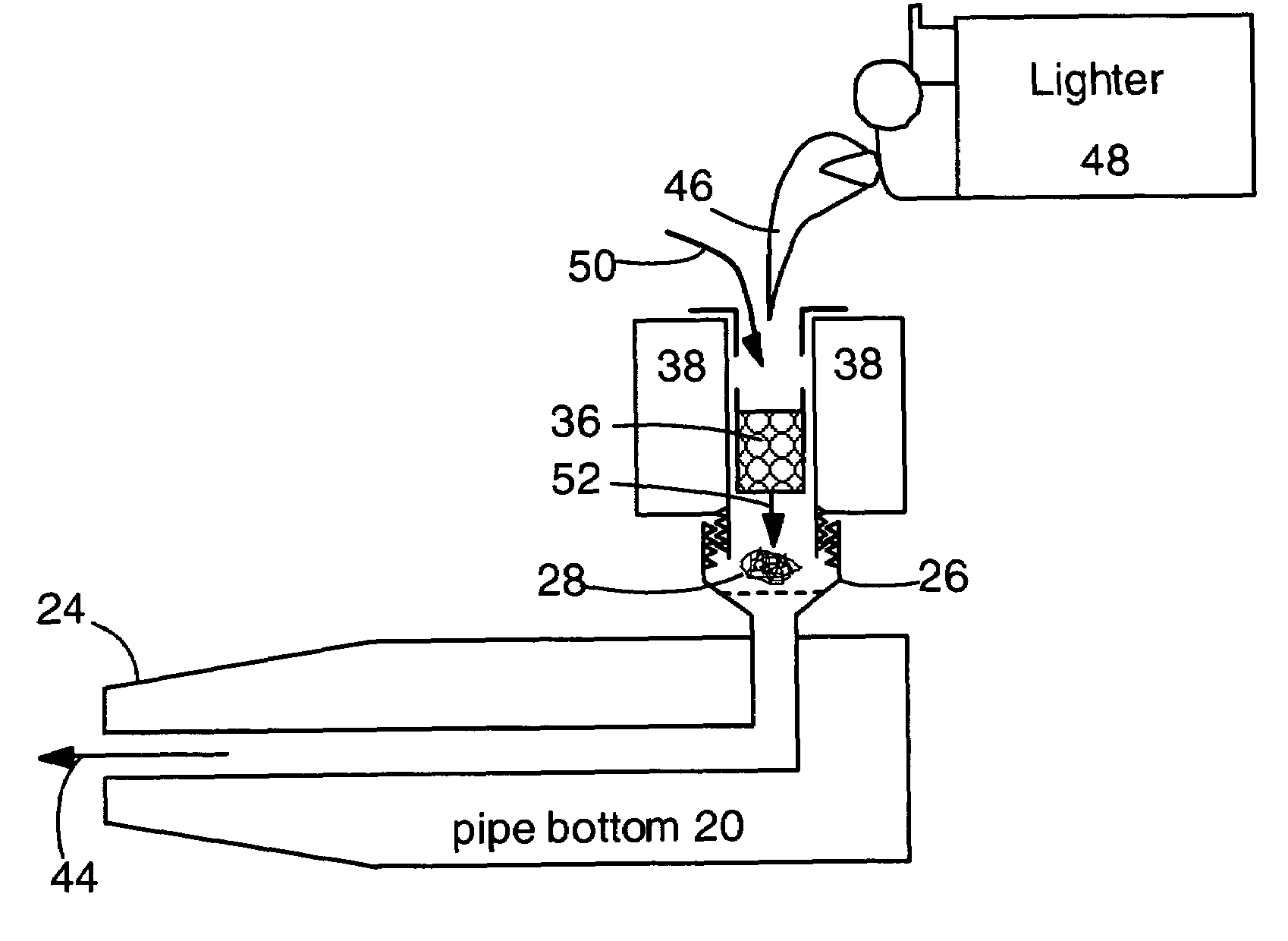

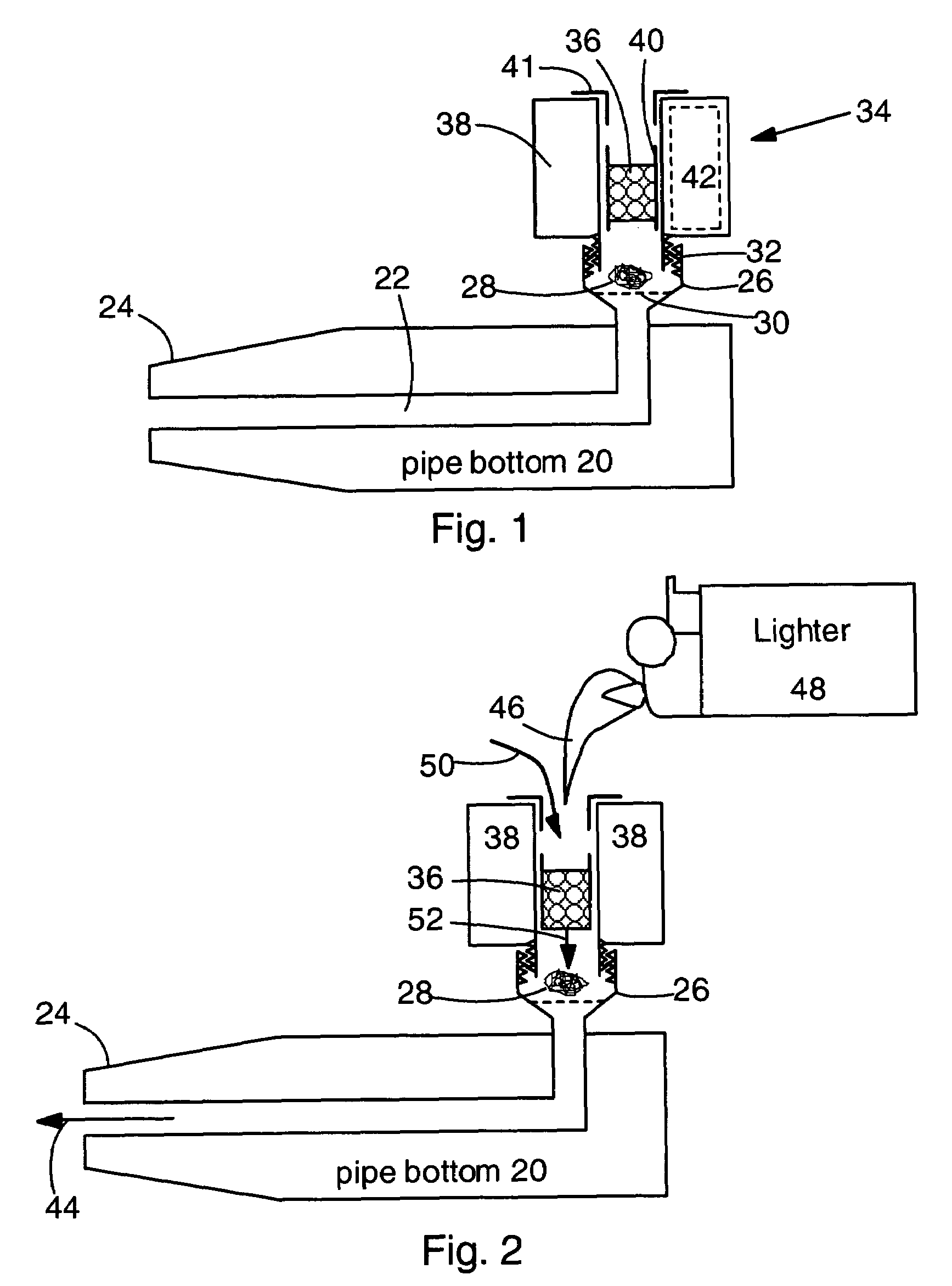

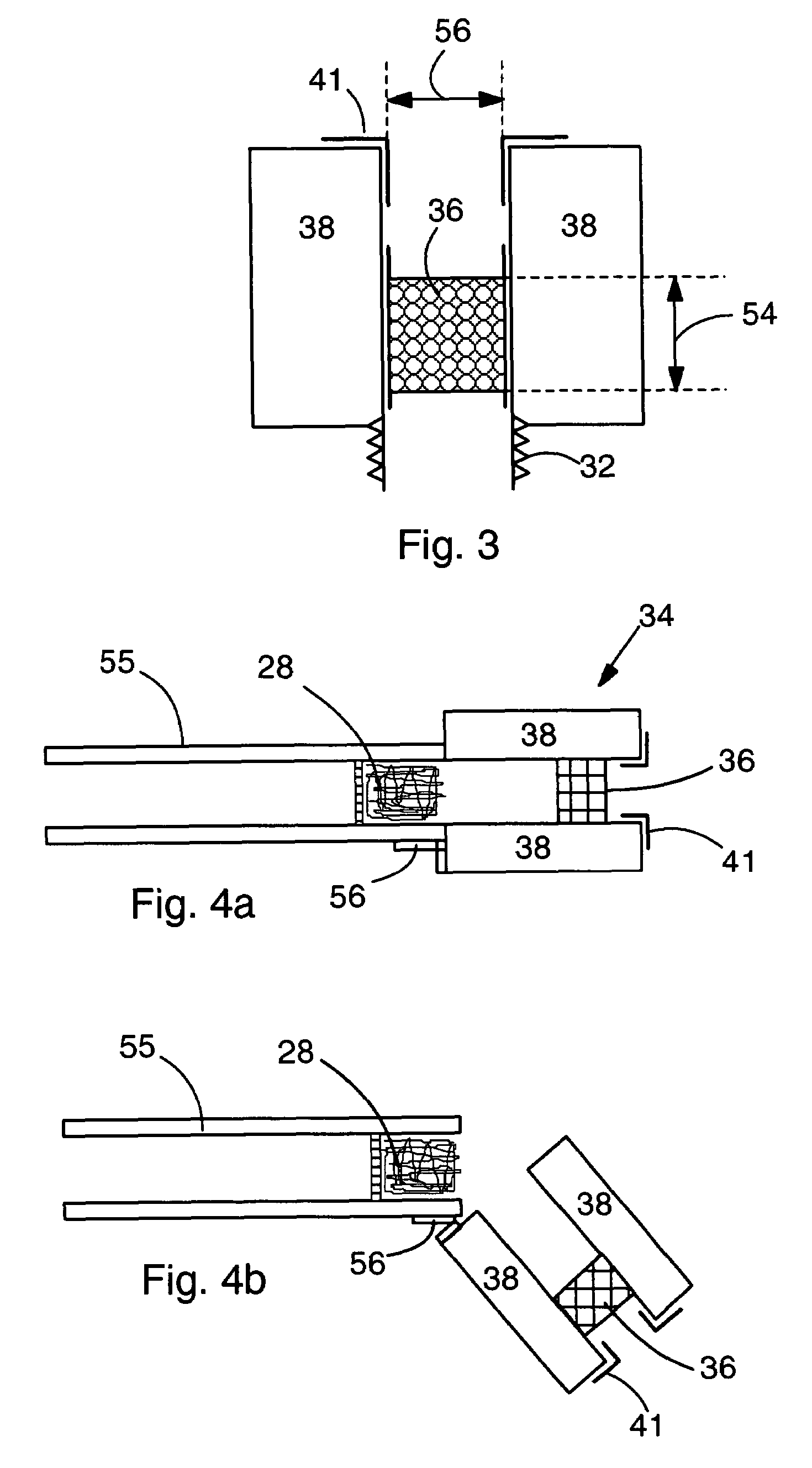

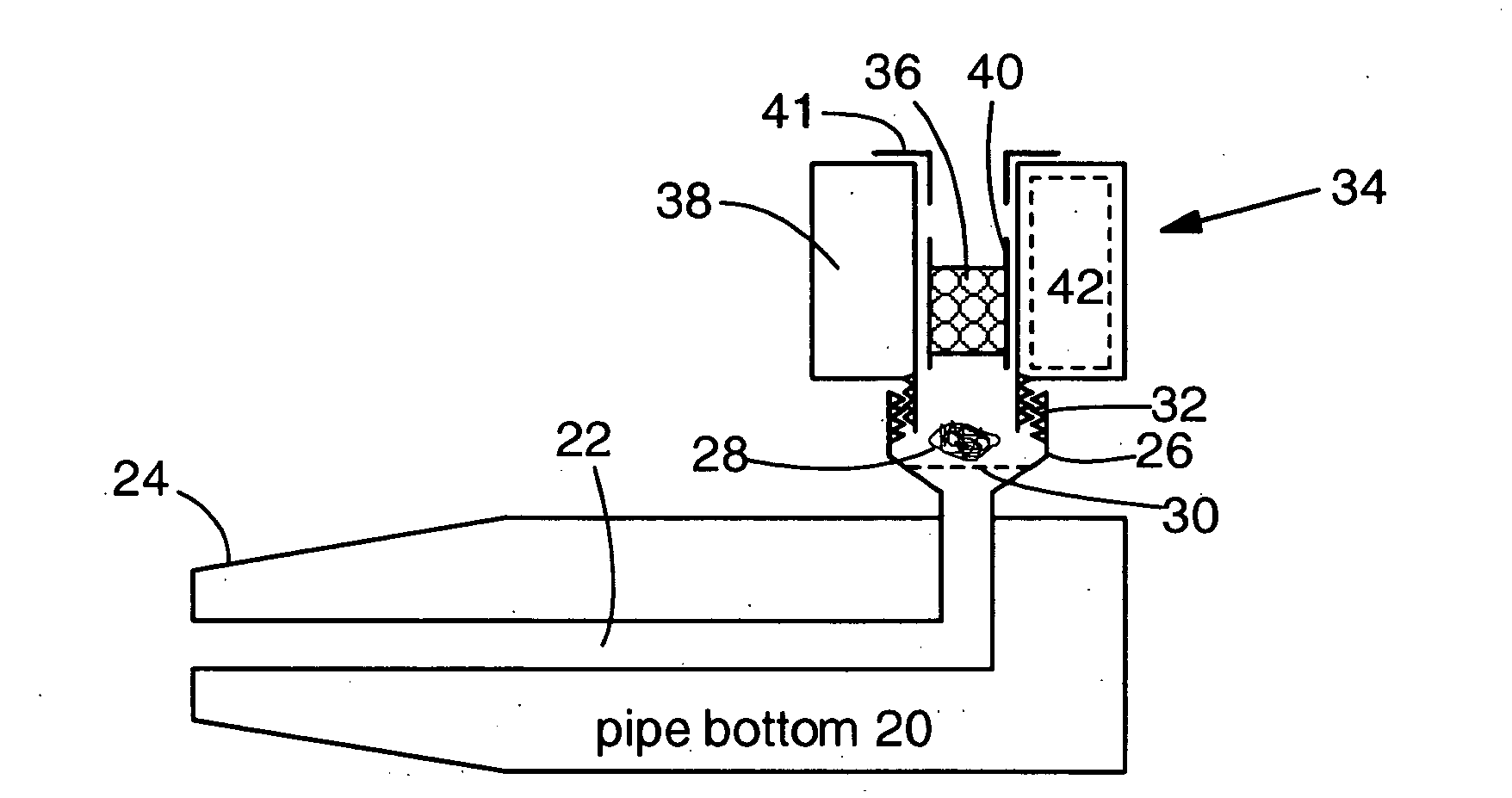

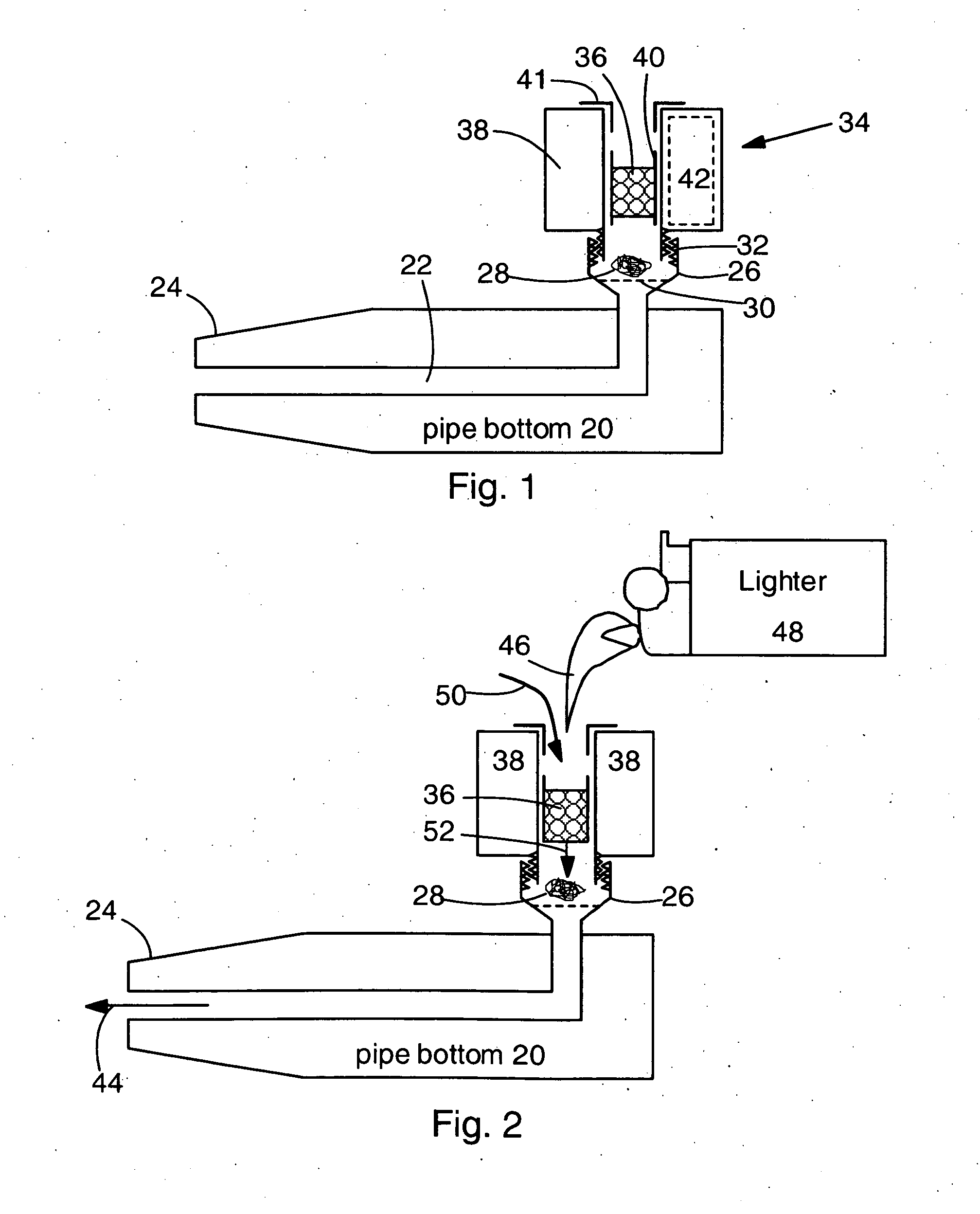

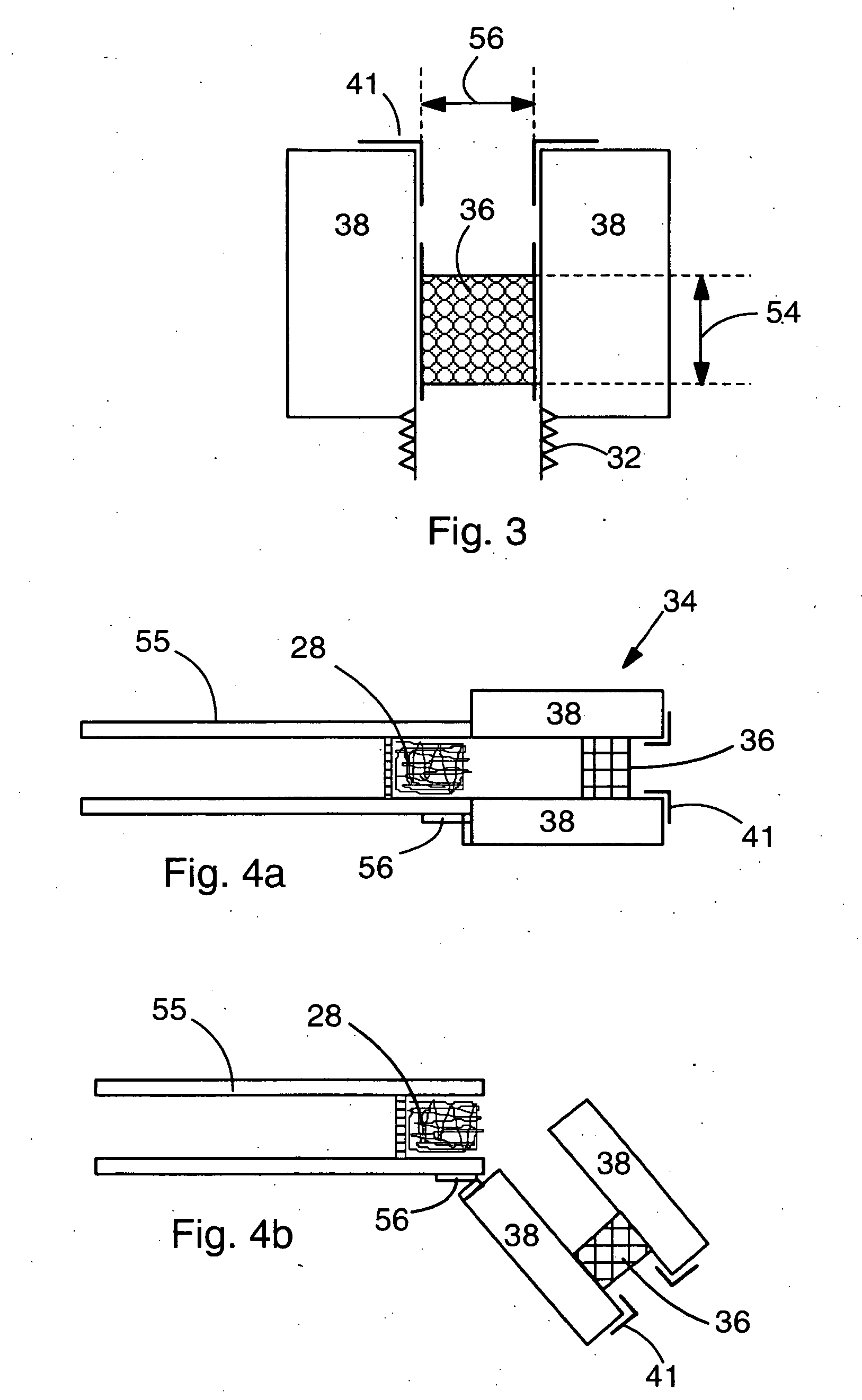

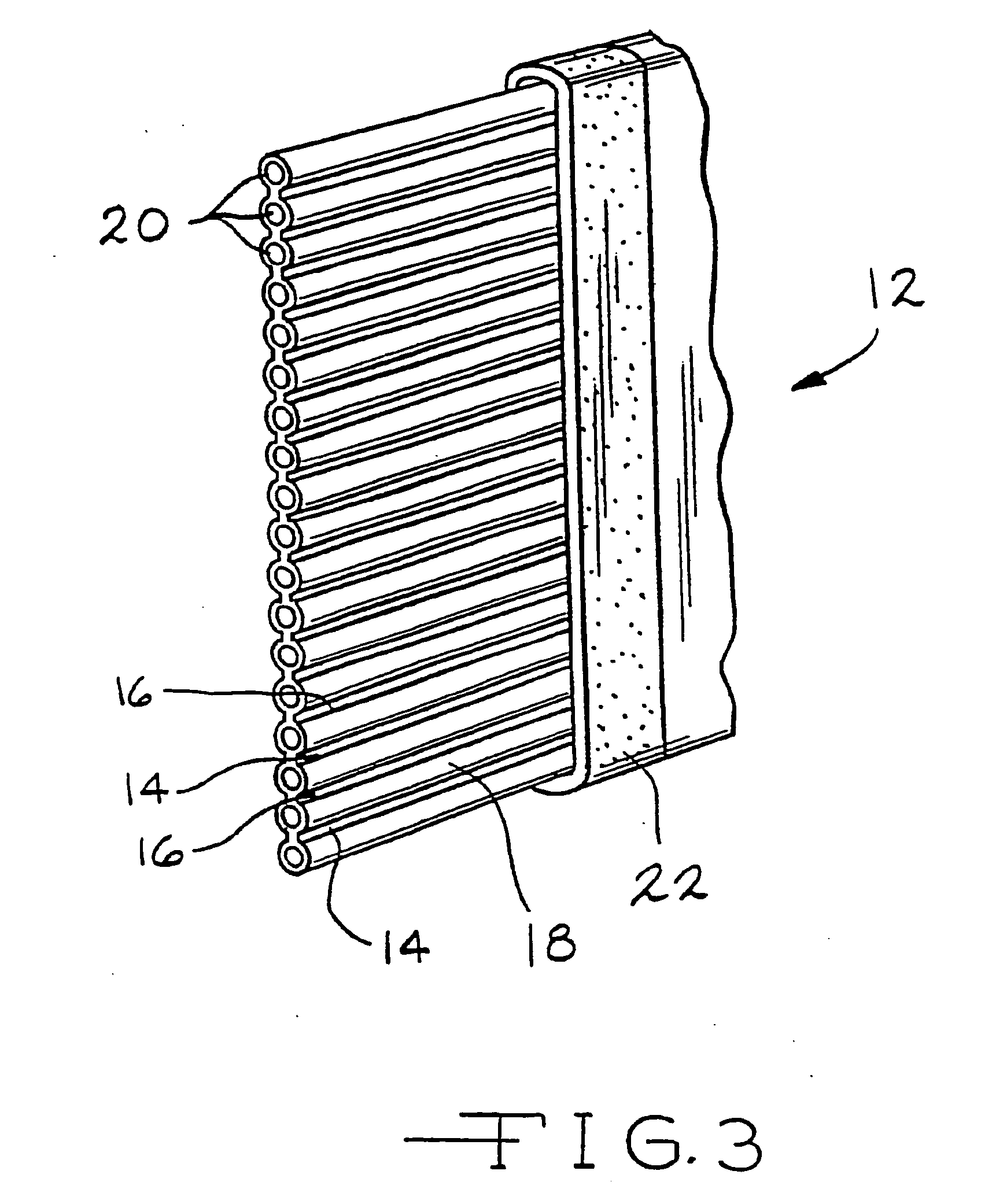

Vaporization pipe with flame filter

A vaporizer device that uses a flame for vaporizing flavor and psychoactive compounds from smoking materials such as tobacco. The present device has a filter unit 34 with a porous flame filter 36. The flame filter 36 can be made of open-cell ceramic or metal foam, sintered ceramic or metal granules or other porous, heat resistant materials. In use, flame is supplied to the flame filter, and inhalation causes ambient air to enter the flame filter as well. The flame exhaust and ambient air are mixed within the flame filter and produce an air stream of intermediate temperature. The intermediate temperature air stream is hot enough to vaporize desirable components from the smoking material, but generally is not hot enough to burn the smoking material. The temperature of the air stream can be controlled by adjusting the amount of flame supplied to the flame filter 36.

Owner:VAPORGENIE

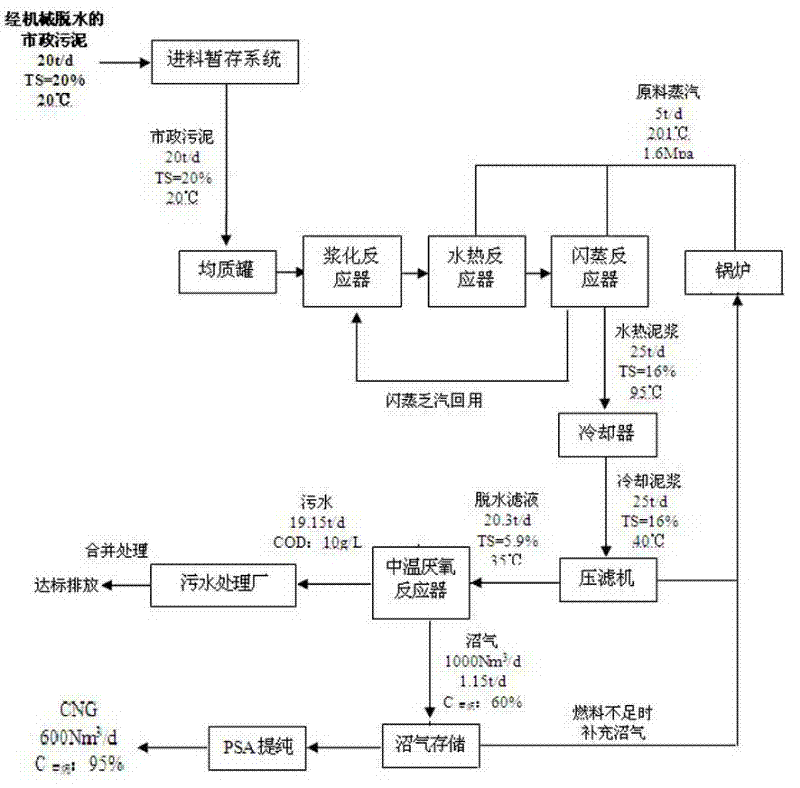

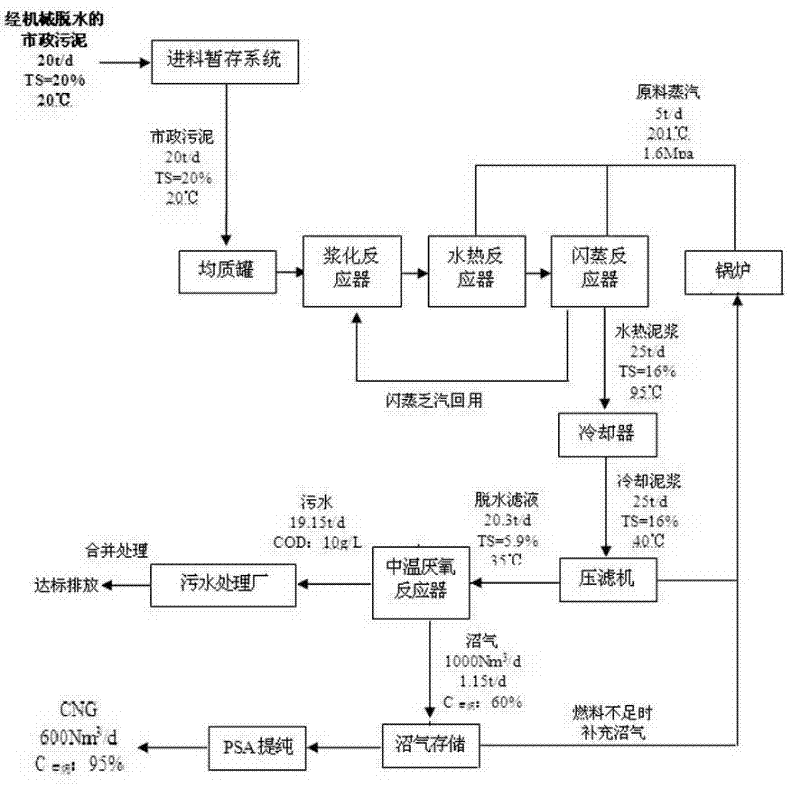

Sludge treatment process based on hydrothermal modification technology

InactiveCN102381820AAdvanced technologyHighlight energy savingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningAnaerobic reactorHigh pressure

The invention relates to a sludge treatment process based on a hydrothermal modification technology. The sludge treatment process is carried out by comprising the following steps of: (1) temporarily storing the sludge which is subjected to mechanical dehydration and has the water content of 70-85% to a pretreatment unit and deodorizing the sludge; (2) introducing to a homogeneous device, fully mixing and homogenizing, introducing the homogenized sludge to a slurrying device, introducing the slurried sludge to a hydrothermal reactor for hydrothermal reaction, and introducing the hydrothermal sludge to a flash evaporator for decompression and flash evaporation; (3) cooling to 35-45 DEG C by using a cooler, then introducing to a high-pressure diaphragm pressure filter for pressure filtering and dehydration to obtain a dehydrated mud cake with the solid content of 35-45% and dehydrated filtrate; (4) introducing the dehydrated filtrate to an intermediate temperature anaerobic reactor, wherein the residence time is for 5.5-7.5d, the inlet water temperature is controlled below 40 DEG C, and the anaerobic reaction temperature is 30-40 DEG C; and (5) preparing a biomass fuel rod by using the dehydrated mud cake, and introducing the biomass fuel rod to a boiler to provide steam for the hydrothermal reactor and the flash evaporator. The sludge treatment process has the advantages of goodtreatment effect, obvious volume reduction effect, high harmless degree, recycling of methane, good economic benefit and the like.

Owner:FUZHOU DEV ZONE SANSHUI ENVIRONMENTAL PROTECTION TECH

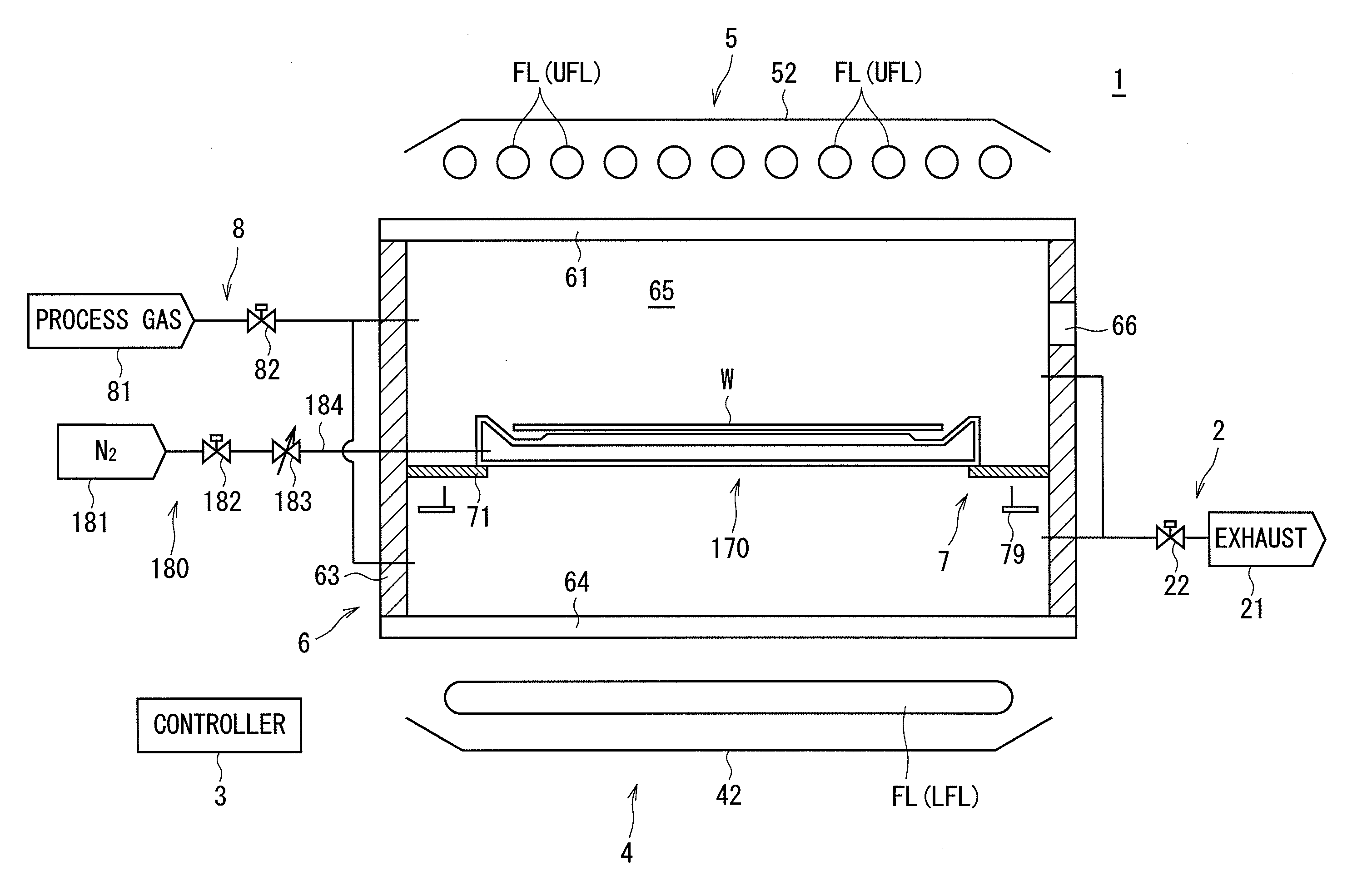

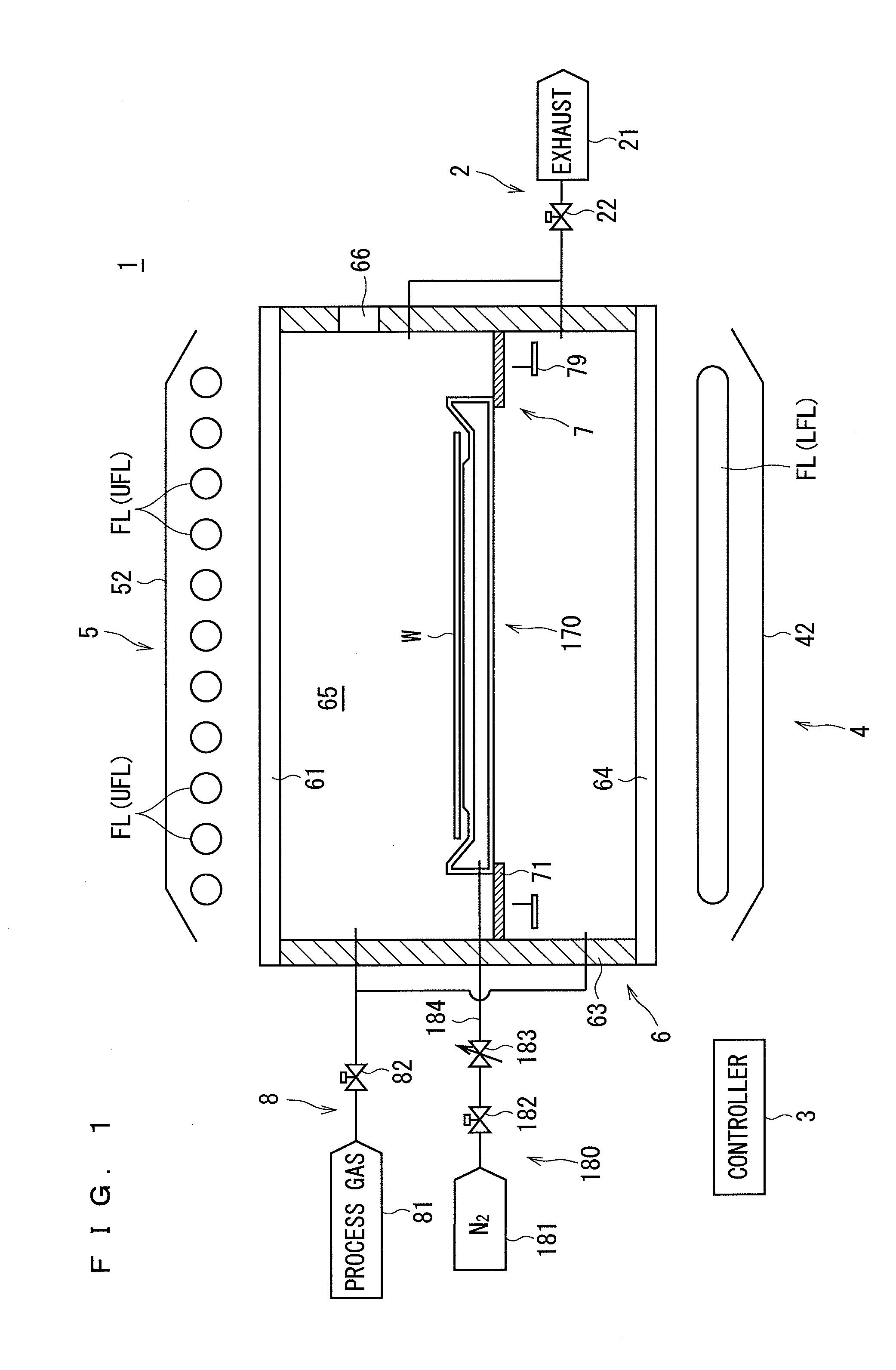

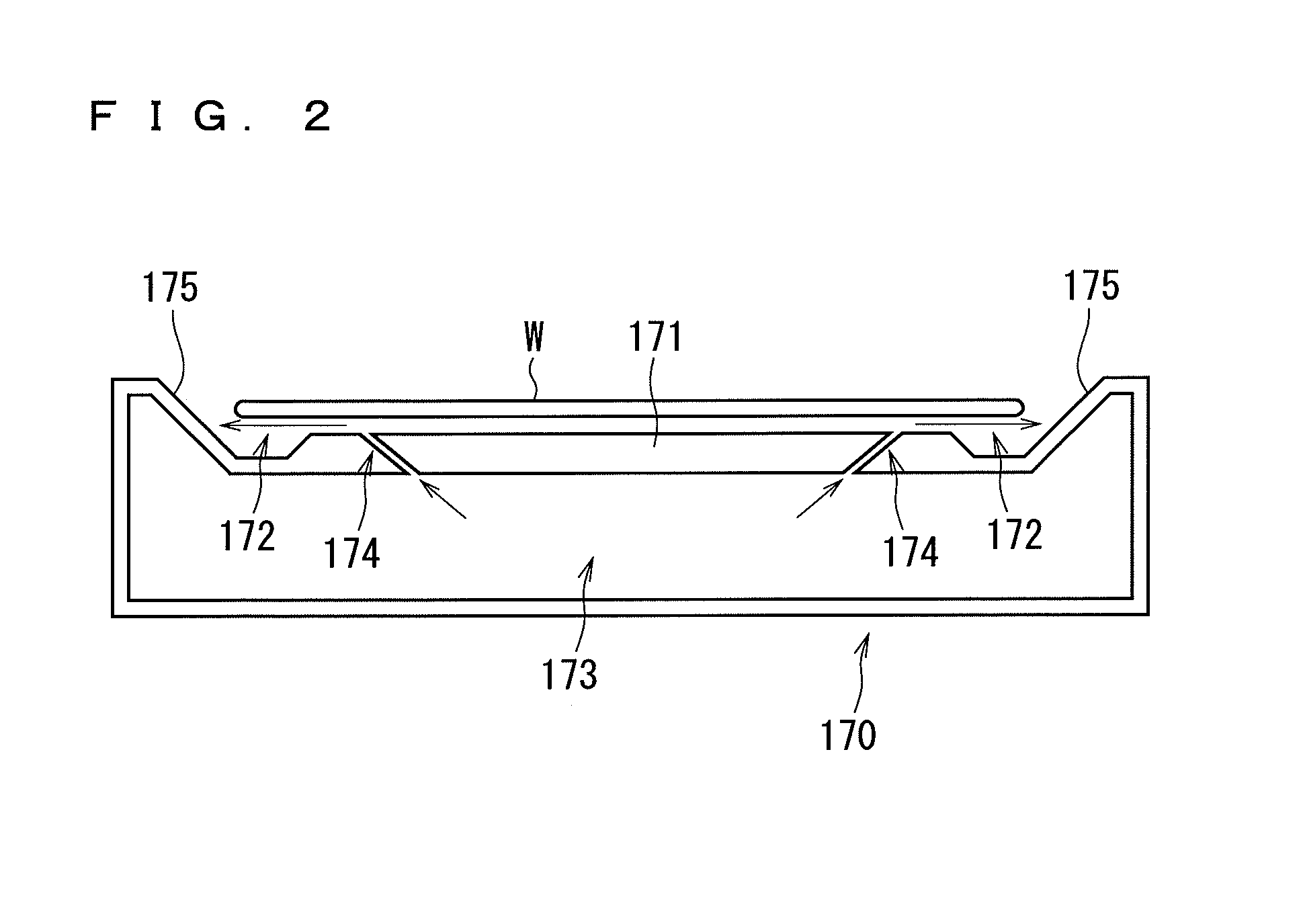

Heat treatment apparatus for heating substrate by irradiation with flashes of light, and heat treatment method

ActiveUS20130203269A1Degree of reductionAvoid crackingMuffle furnacesCharge supportsRoom temperatureEngineering

A first flash heating is performed in which a lower flash lamp irradiates a back surface of a semiconductor wafer with flashes of light, so that heat conduction from the back surface to a surface of the semiconductor wafer raises the temperature of the surface from the room temperature to an intermediate temperature. Then, a second flash heating is performed in which an upper flash lamp irradiates the surface of the semiconductor wafer with flashes of light, to raise the temperature of the surface of the semiconductor wafer from the intermediate temperature to a target temperature. Since only the irradiation with flashes of light emitted from the lower flash lamp and the upper flash lamp is used to cause the semiconductor wafer having the room temperature to reach the target temperature, all heat treatments can be completed in an extremely short time of one second or less.

Owner:DAINIPPON SCREEN MTG CO LTD

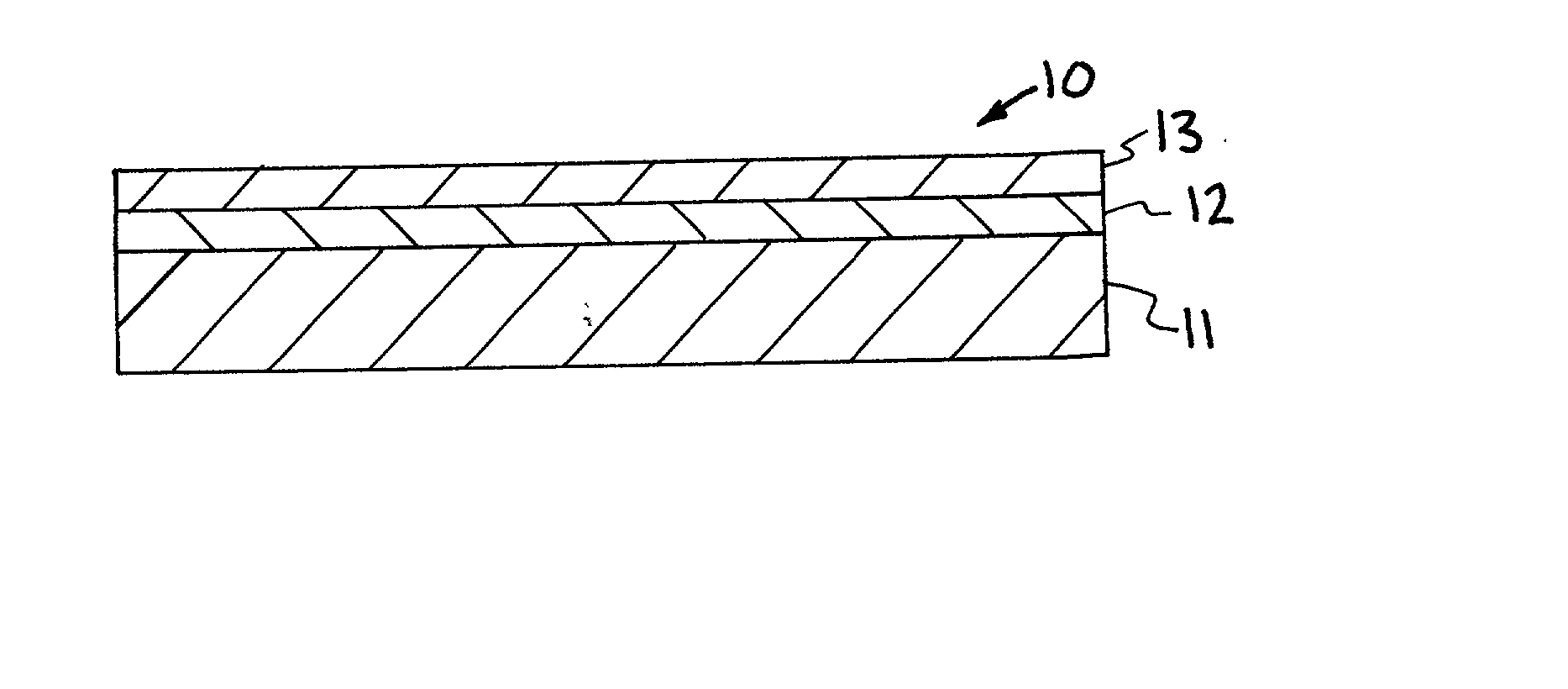

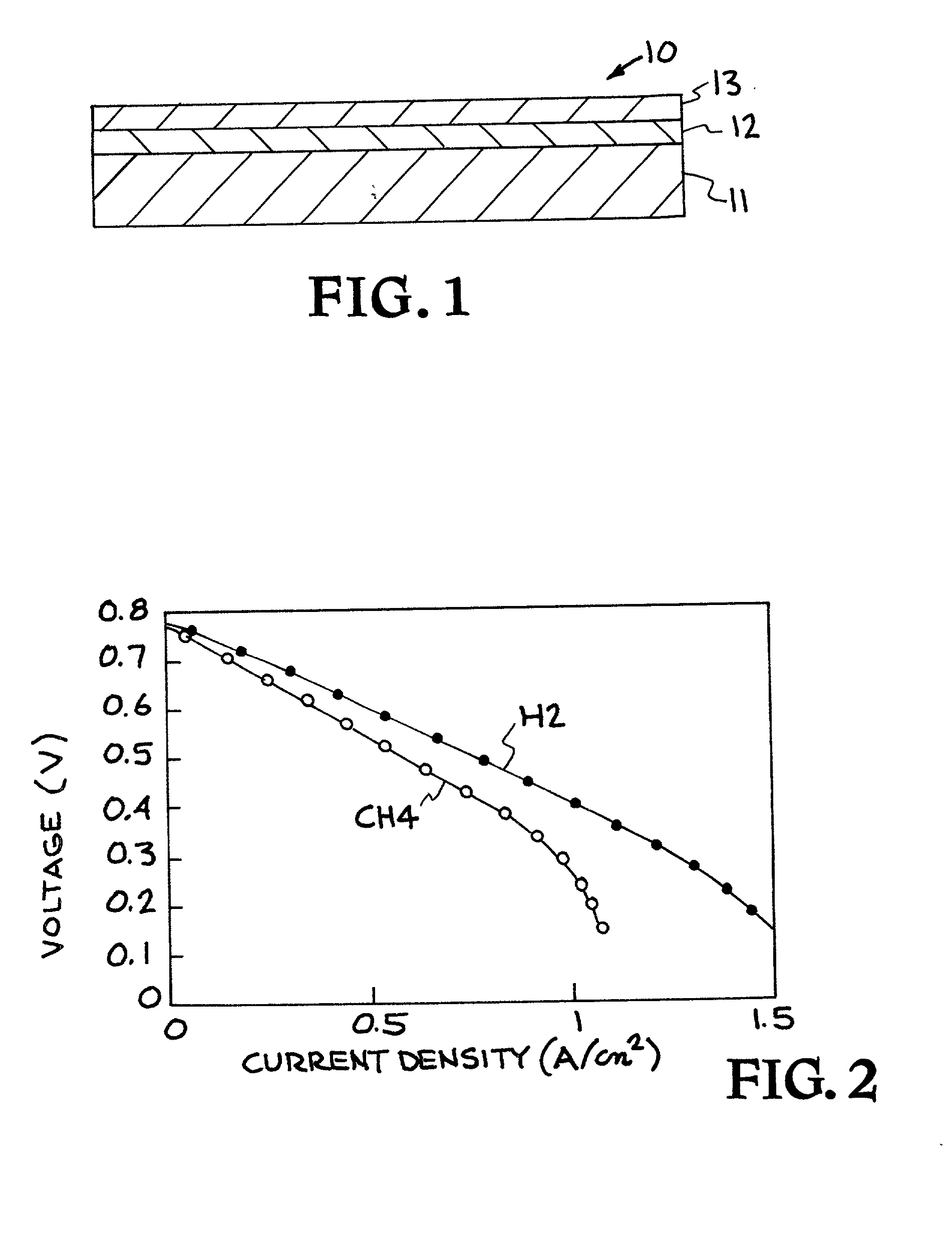

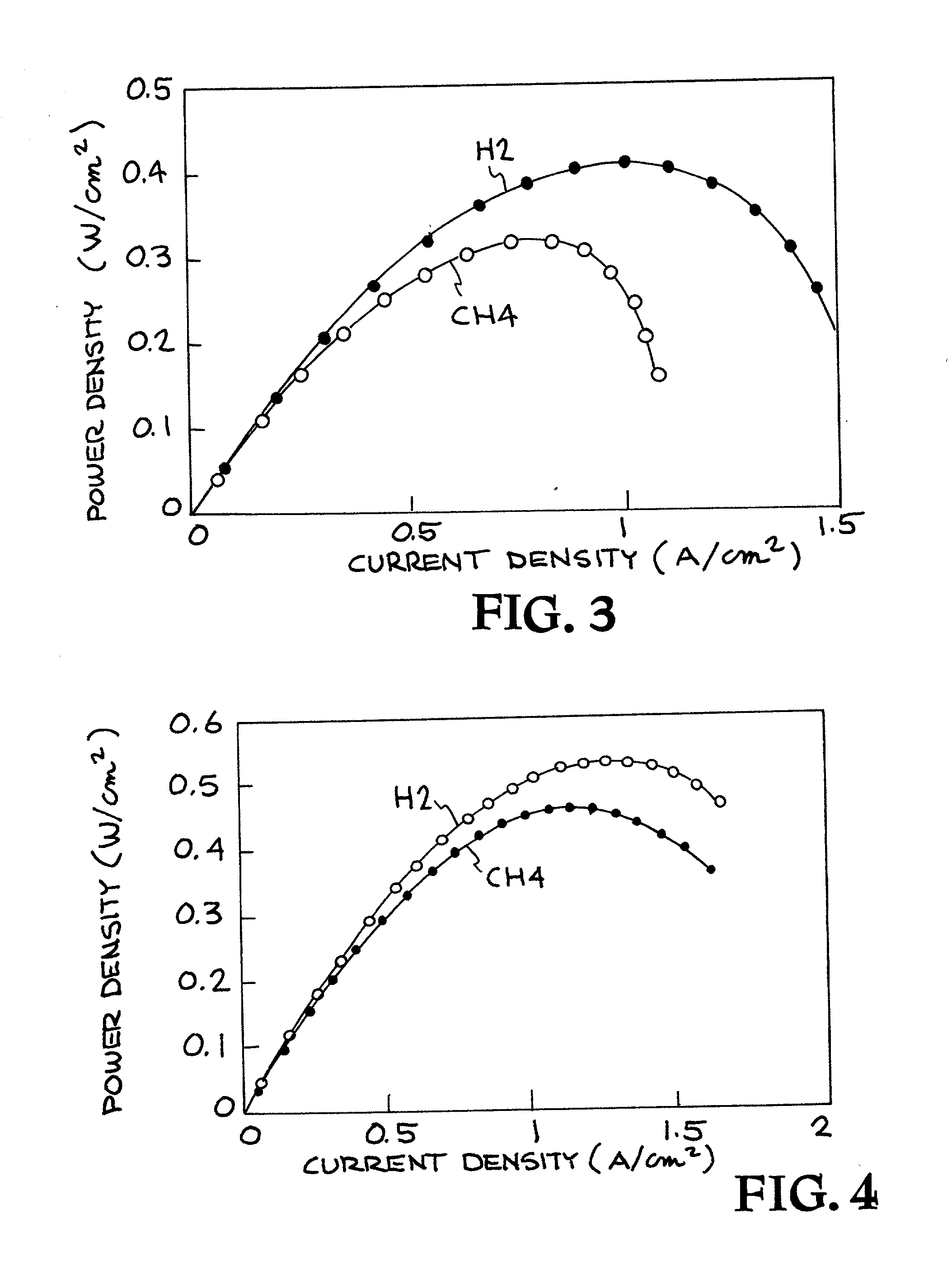

Ceria-based solid oxide fuel cells

InactiveUS20020127455A1Improve power densityMore option for sealingCell electrodesFuel cell auxillariesCerium(IV) oxideCobalt

High-performance intermediate temperature solid oxide fuel cells (SOFCs). The SOFCs are ceria-based structures that can achieve a power output of 300 mW / cm.sup.2 at an operating temperature below 600.degree. C. By way of example, the fuel cell as an anode made of NiO / doped-ceria, a thin film of doped-ceria and / or doped zirconia electrolyte is deposited on the anode, and a cathode of cobalt iron based material, such as (La, Sr)(Co, Fe)O.sub.3 or cobalt, ion, magnesium based material, is deposited on top of the electrolyte, and can operate at a temperature of 550.degree. C. The various layers may be deposited by colloidal spray deposition or aerosol spray casting.

Owner:RGT UNIV OF CALIFORNIA

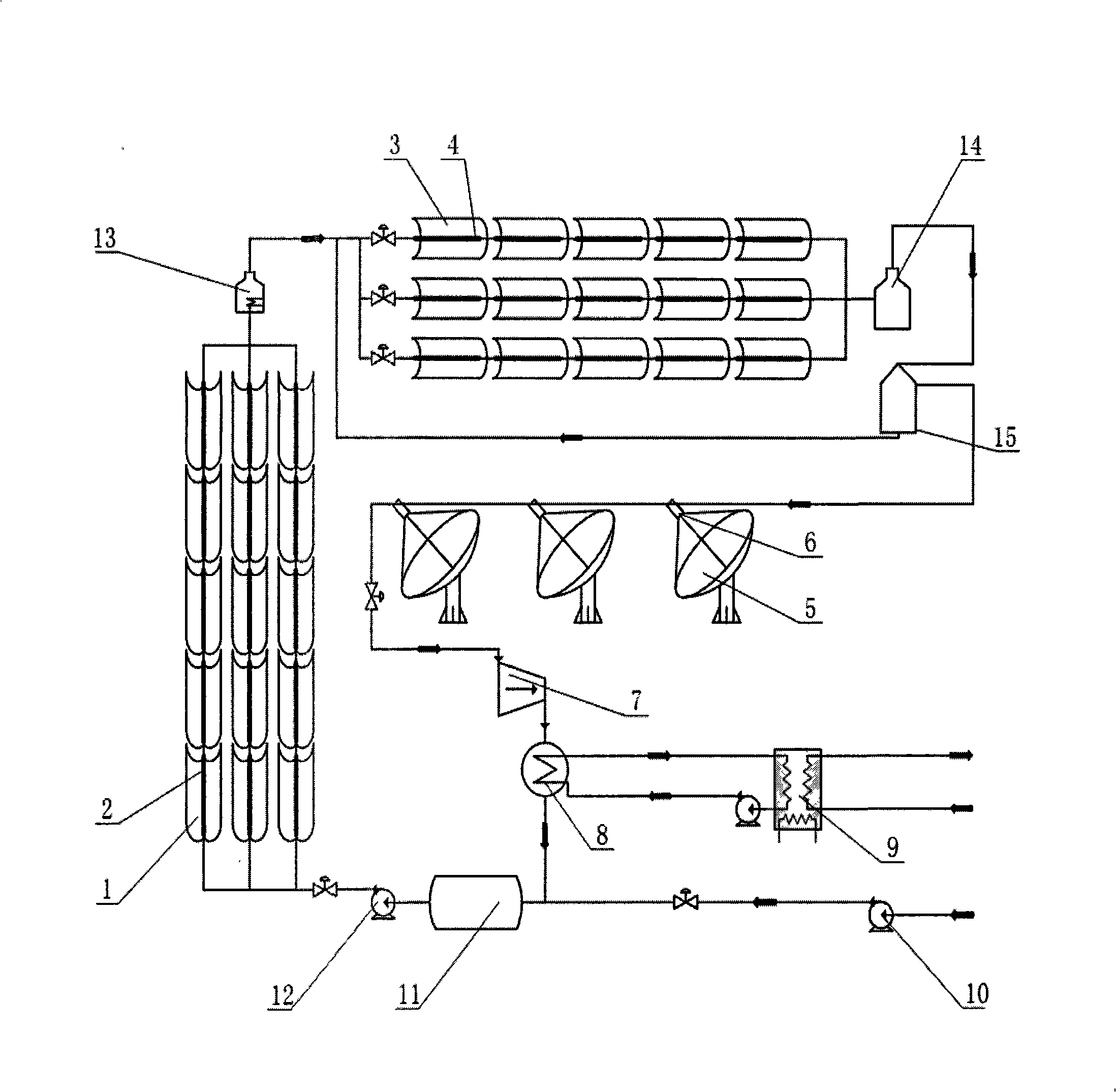

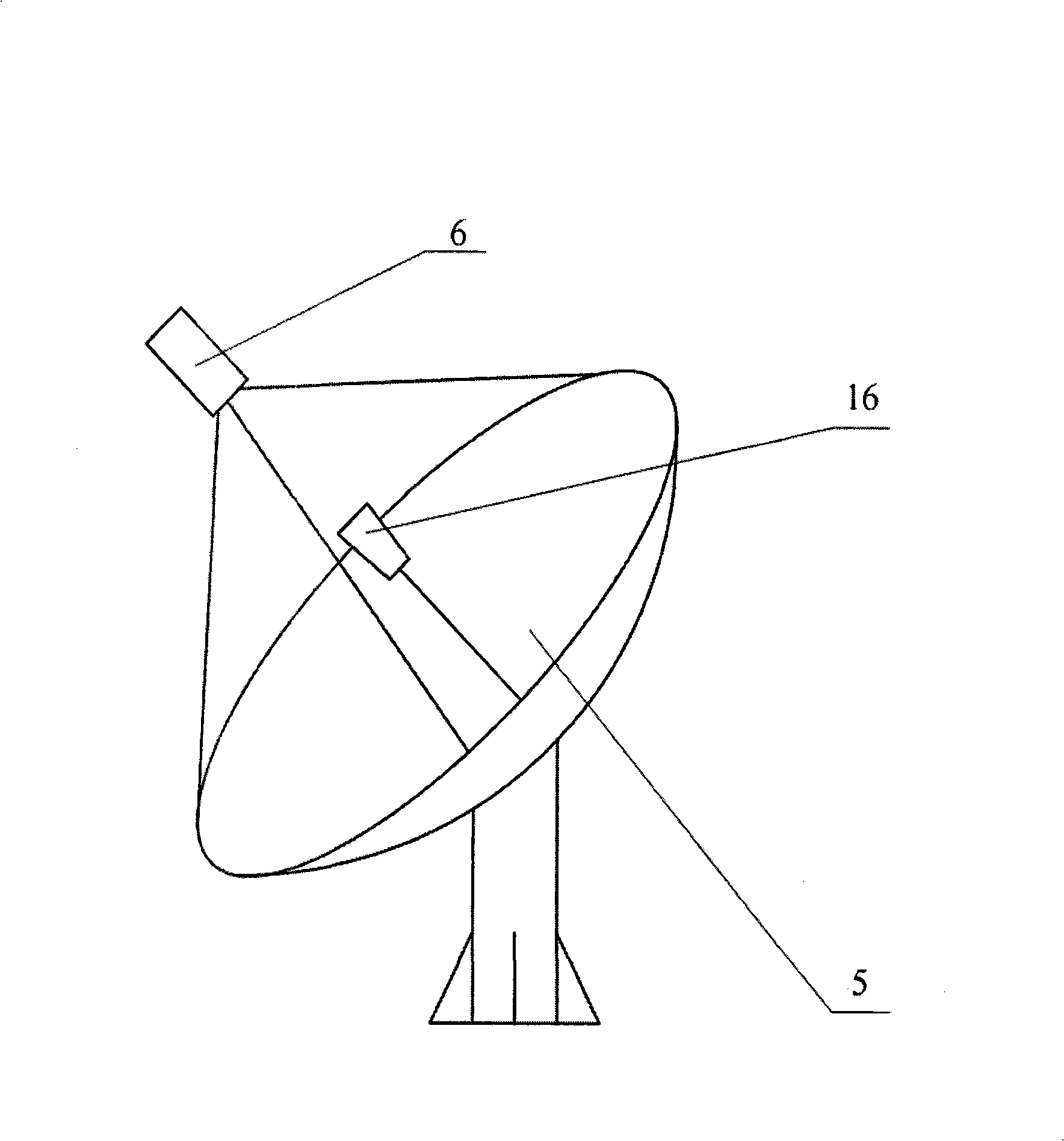

System for utilizing solar step developing heat

InactiveCN101354191AImprove reliabilityReduce thermal stressSolar heating energyFrom solar energyEngineeringSteam turbine

The invention relates to a cascade-developed heat utilization system of solar energy, which adopts that: in a low temperature section, a complex parabolic condenser is matched with a normal temperature receiver and the normal temperature receiver is output to an intermediate temperature section; in the intermediate temperature section, a parabolic trench-typed condenser is matched with an intermediate temperature receiver which is output to a high temperature section through a gas-water separator; in the high temperature section, a disk-typed condenser is matched with a high-temperature receiver which is output to a steam turbine. The cascade-developed heat utilization system of solar energy of the invention solves the defects that disk type is too expensive in manufacturing, and the trench type incurs the conflict between the reliability and the efficiency at high temperature, and the like. The effects of the cascade-developed heat utilization system of solar energy of the invention lie in that: the low temperature section adopts the complex parabolic condenser, the intermediate temperature section adopts the parabolic trench-typed condenser and the high temperature section adopts the parabolic disk-typed condenser; the three heat collecting sections are connected in series and respective advantages thereof are utilized while respective defects thereof are avoided; the three heat collecting sections are led to be combined dynamically to produce synergistic effects.

Owner:NANJING UNIV OF TECH

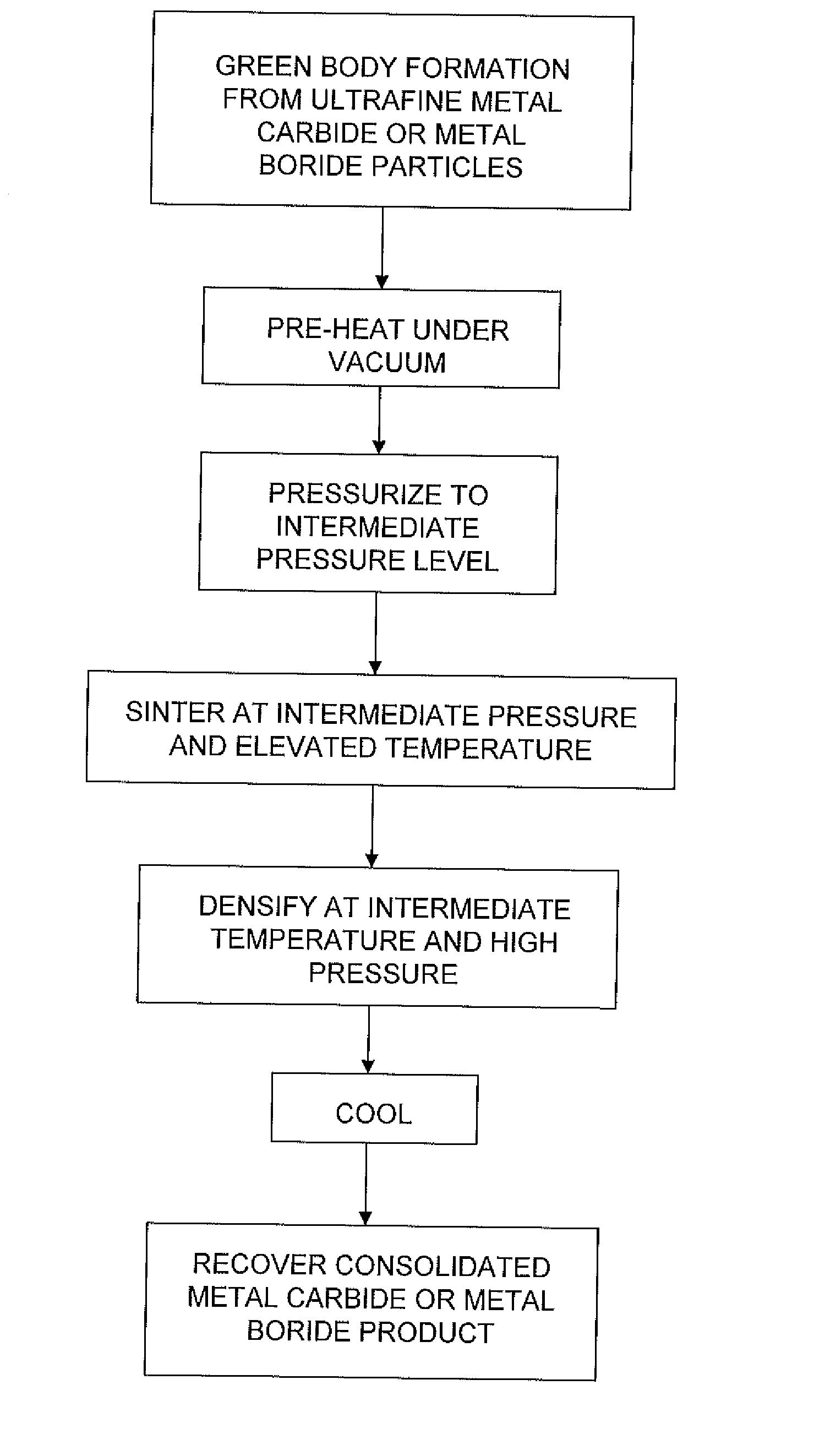

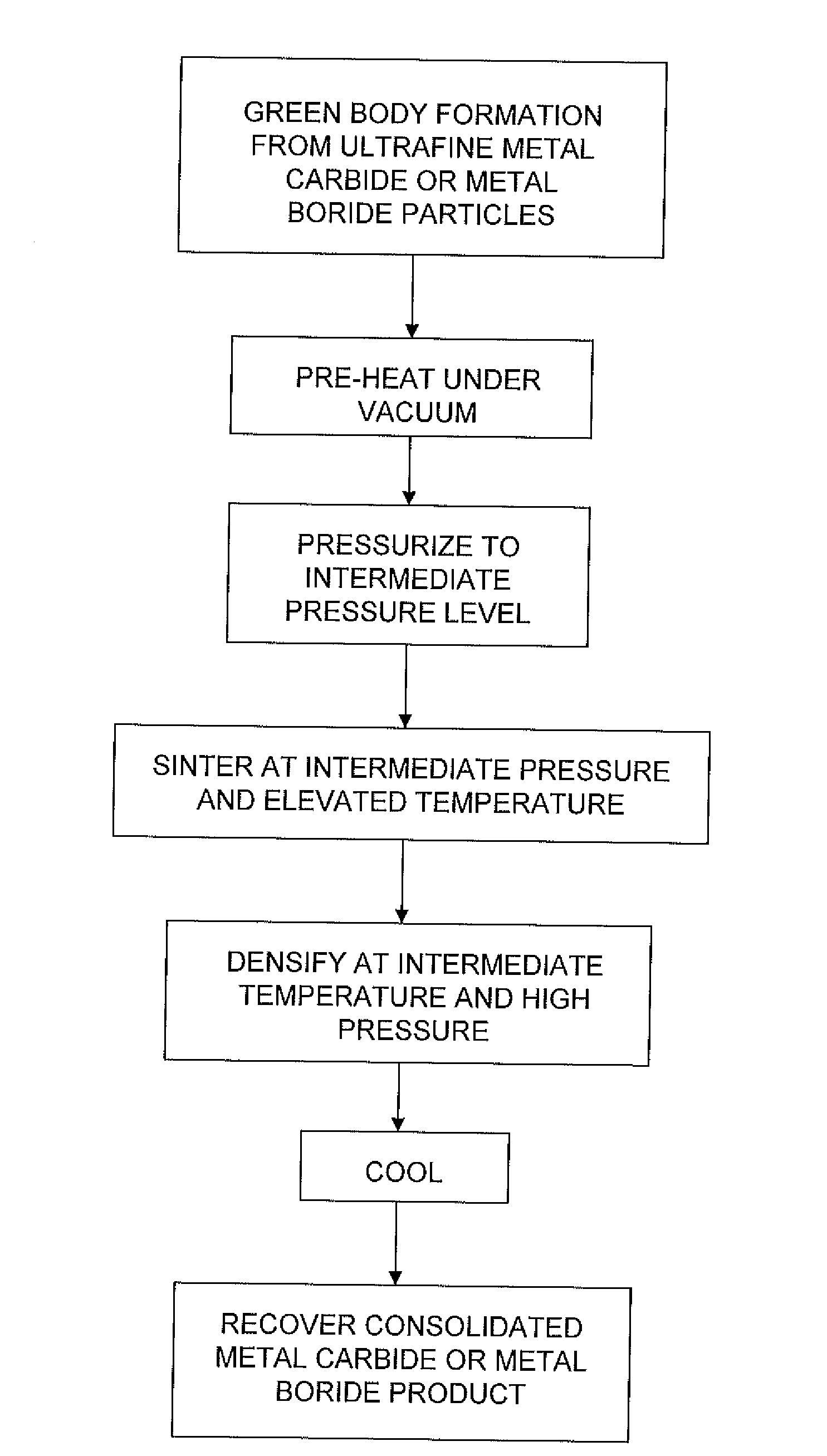

Method of consolidating ultrafine metal carbide and metal boride particles and products made therefrom

Ultrafine metal carbide or metal boride particles are consolidated by a method including sintering at intermediate pressures. A green body comprising the ultrafine metal carbide or metal boride particles may be preheated under vacuum and then pressurized to the intermediate sintering pressure. After sintering, the article may be densified at an intermediate temperature below the sintering temperature, and at an elevated pressure above the intermediate sintering temperature. The resultant consolidated metal carbide or metal boride article may then be cooled and used for such applications as armor panels, abrasion resistant nozzles, and the like.

Owner:PPG IND OHIO INC

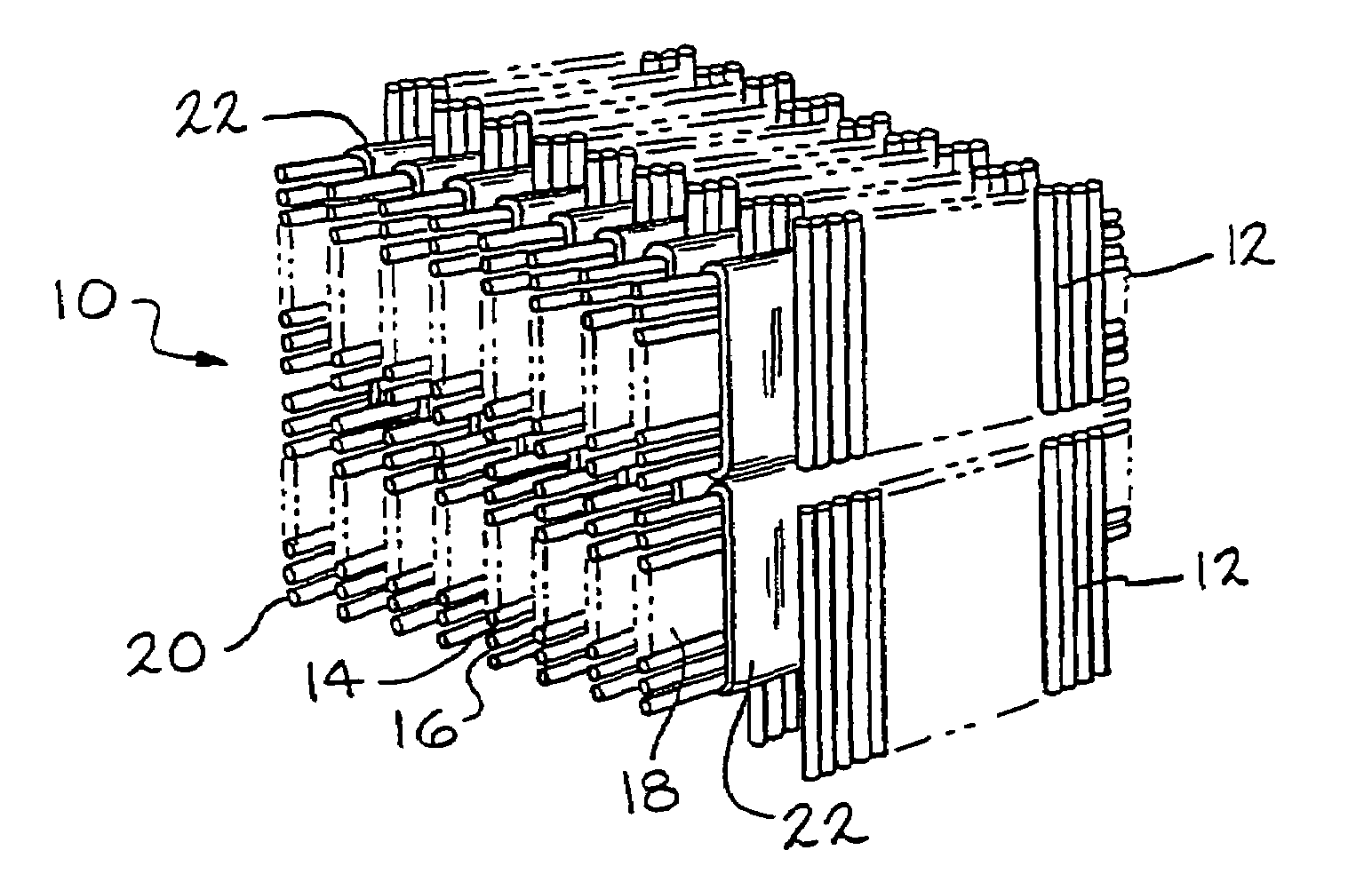

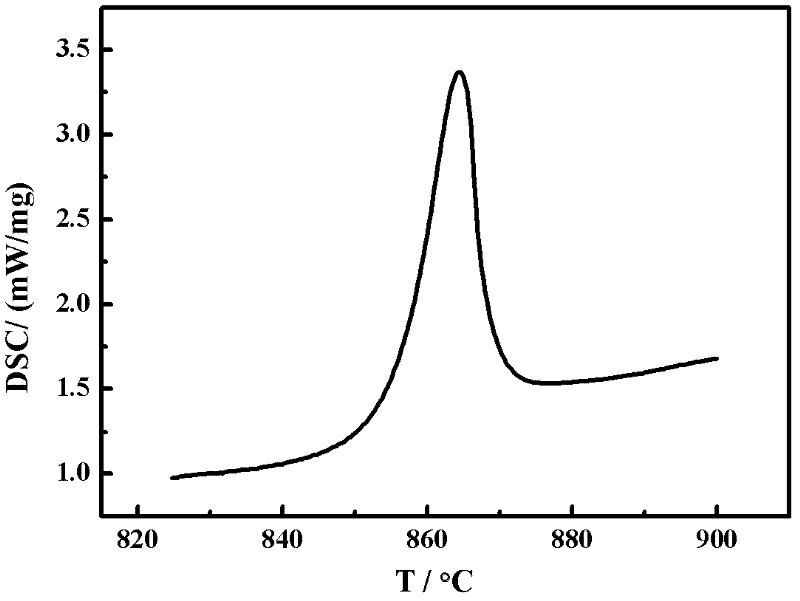

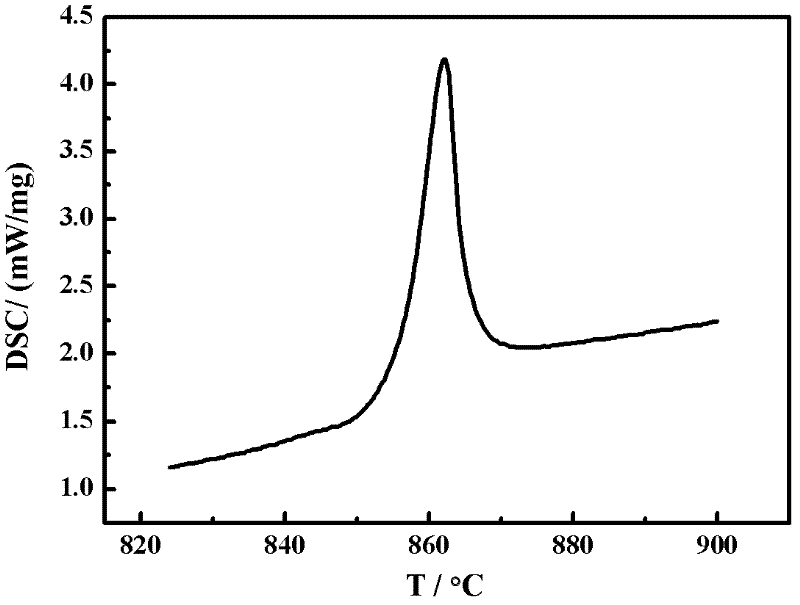

Low alkali sealing frits, and seals and devices utilizing such frits

A solid oxide fuel cell device incorporates a sealing material resistant to hydrogen gas permeation at a sealing temperature in the intermediate temperature range of 600° C.–900° C., the seal having a CTE in the 100×10−7 / ° C. to 120×10−7 / ° C., wherein the sealing material comprises in weight %, of: (i) a 80 wt % to 100 wt % glass frit, the glass frit itself having a composition comprising in mole percent of: SiO2 15–65; Li2O 0–5; Na2O 0–5; K2O 0–10; MgO 0–5; CaO 0–32; Al2O3 0–10; B2O3 0–50; SrO 0 to 25, wherein the total amount of alkalis is less than 10 mole %; and(ii) zirconia or leucite addition 0 wt % to 30 wt.

Owner:CORNING INC

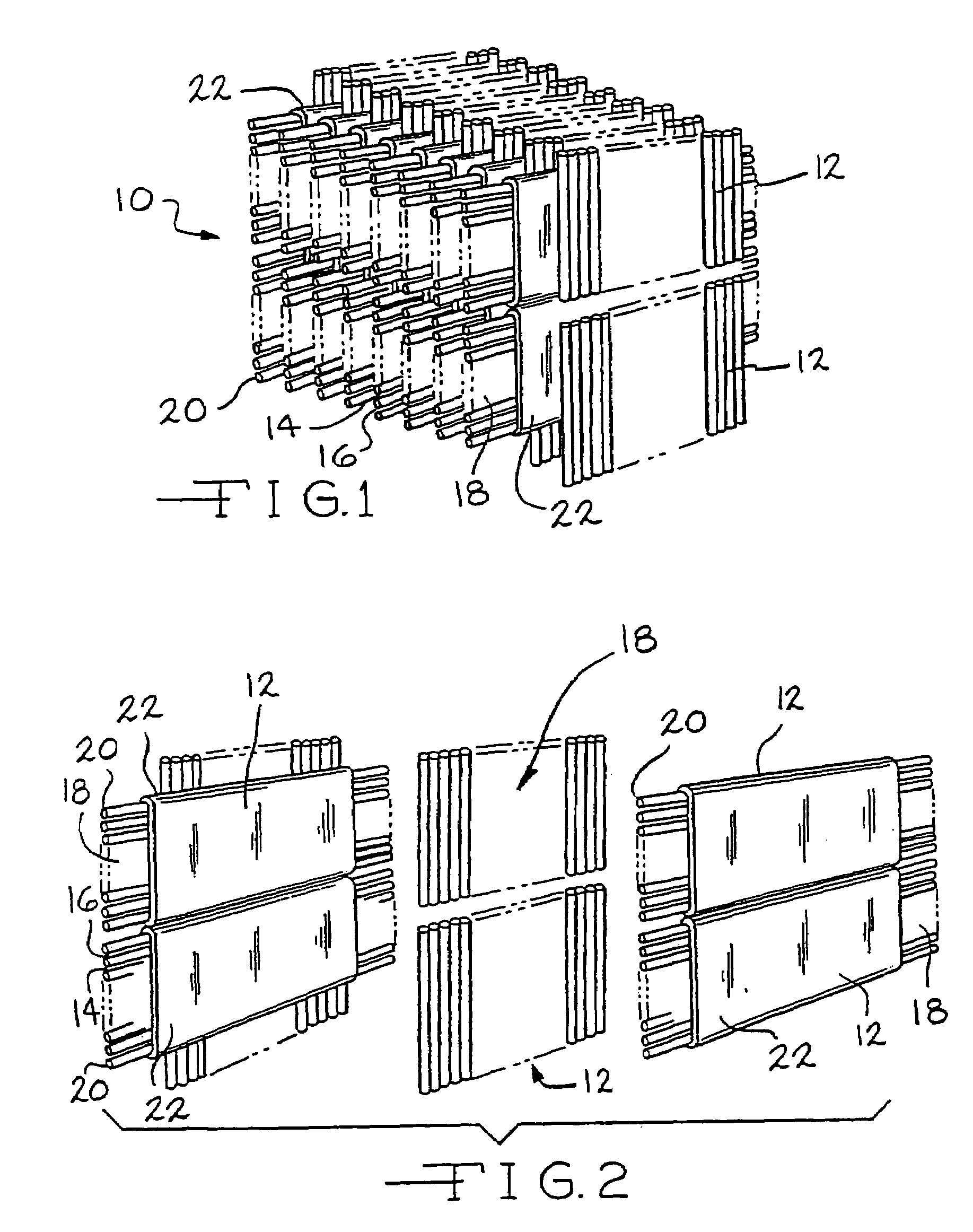

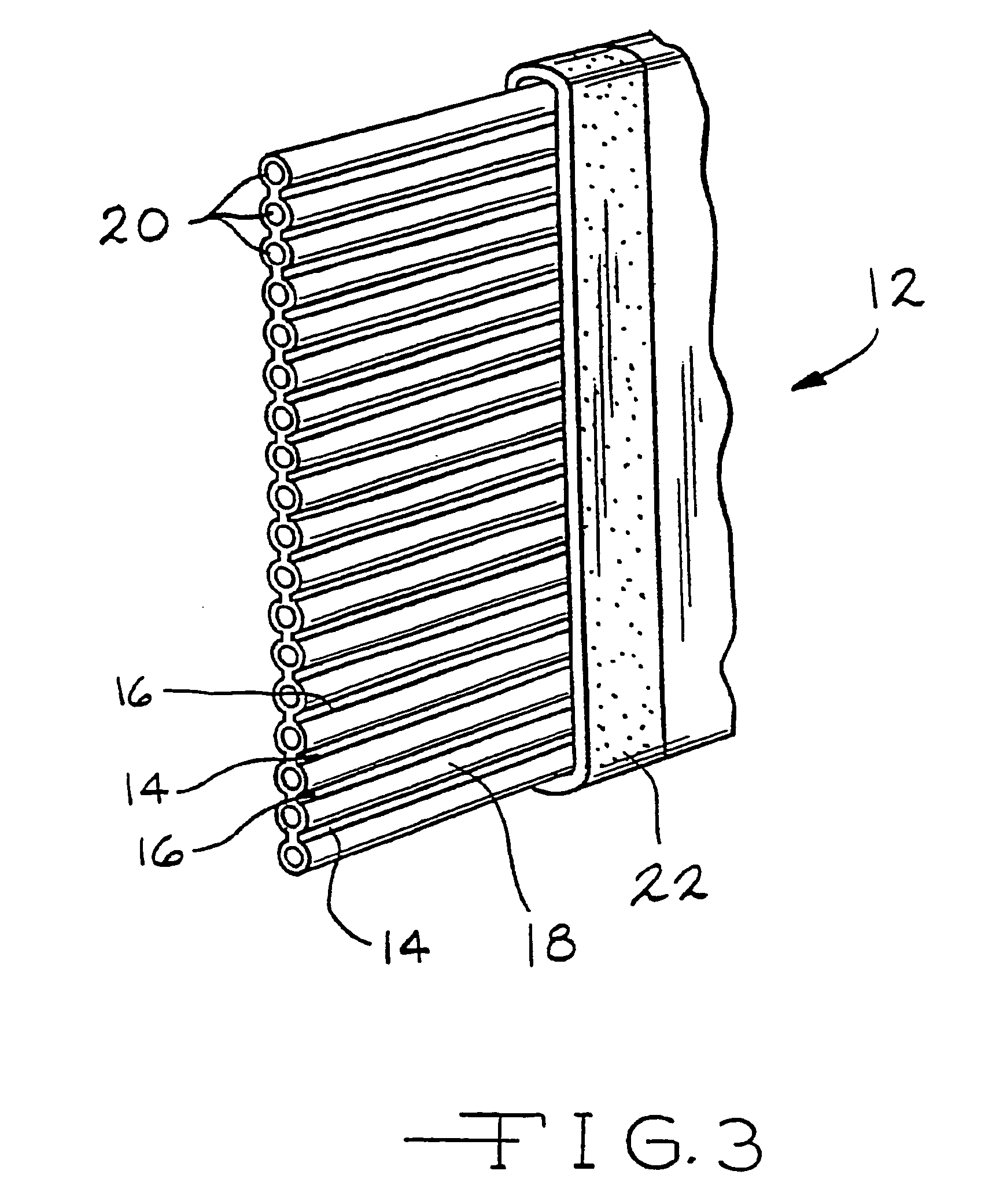

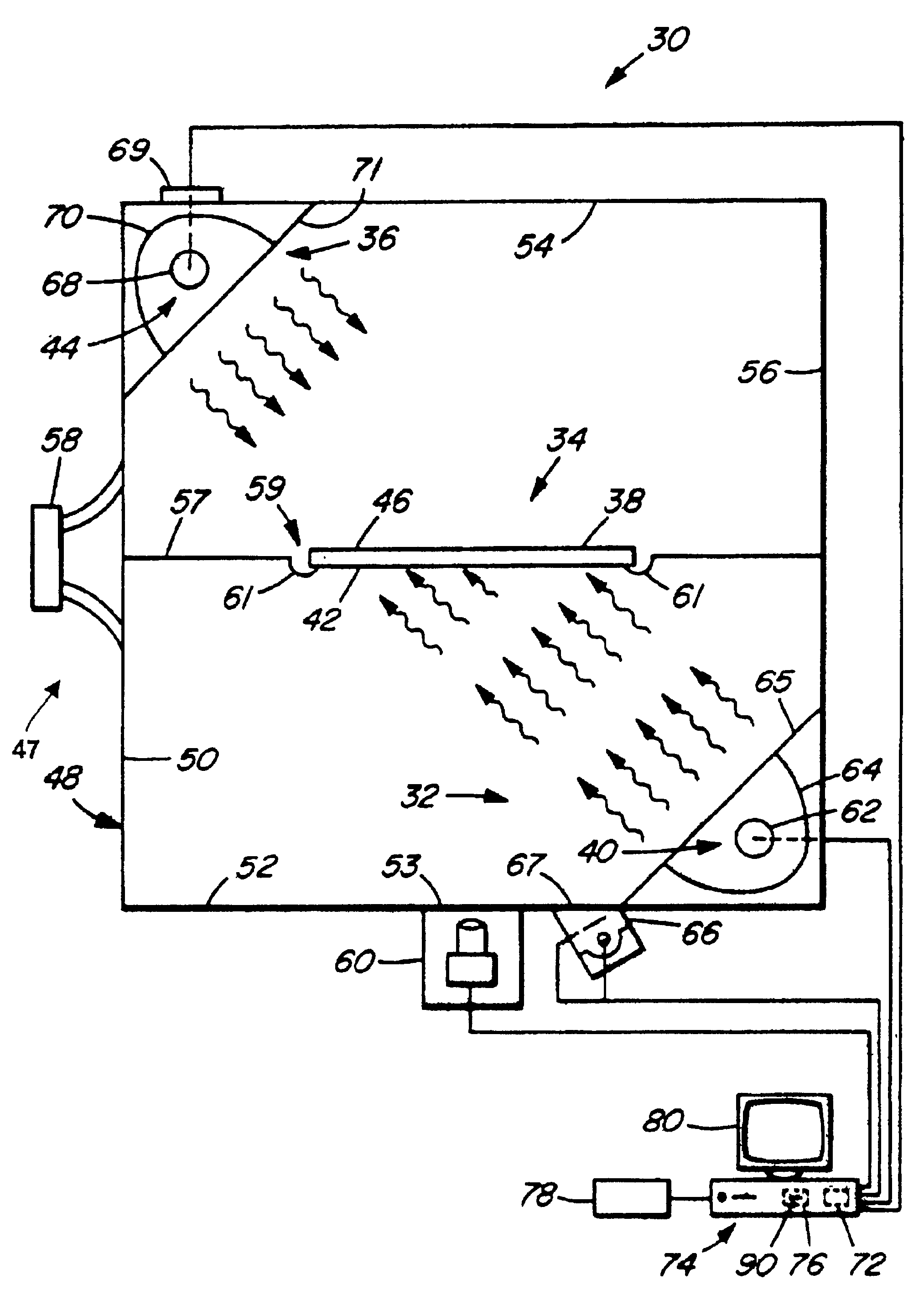

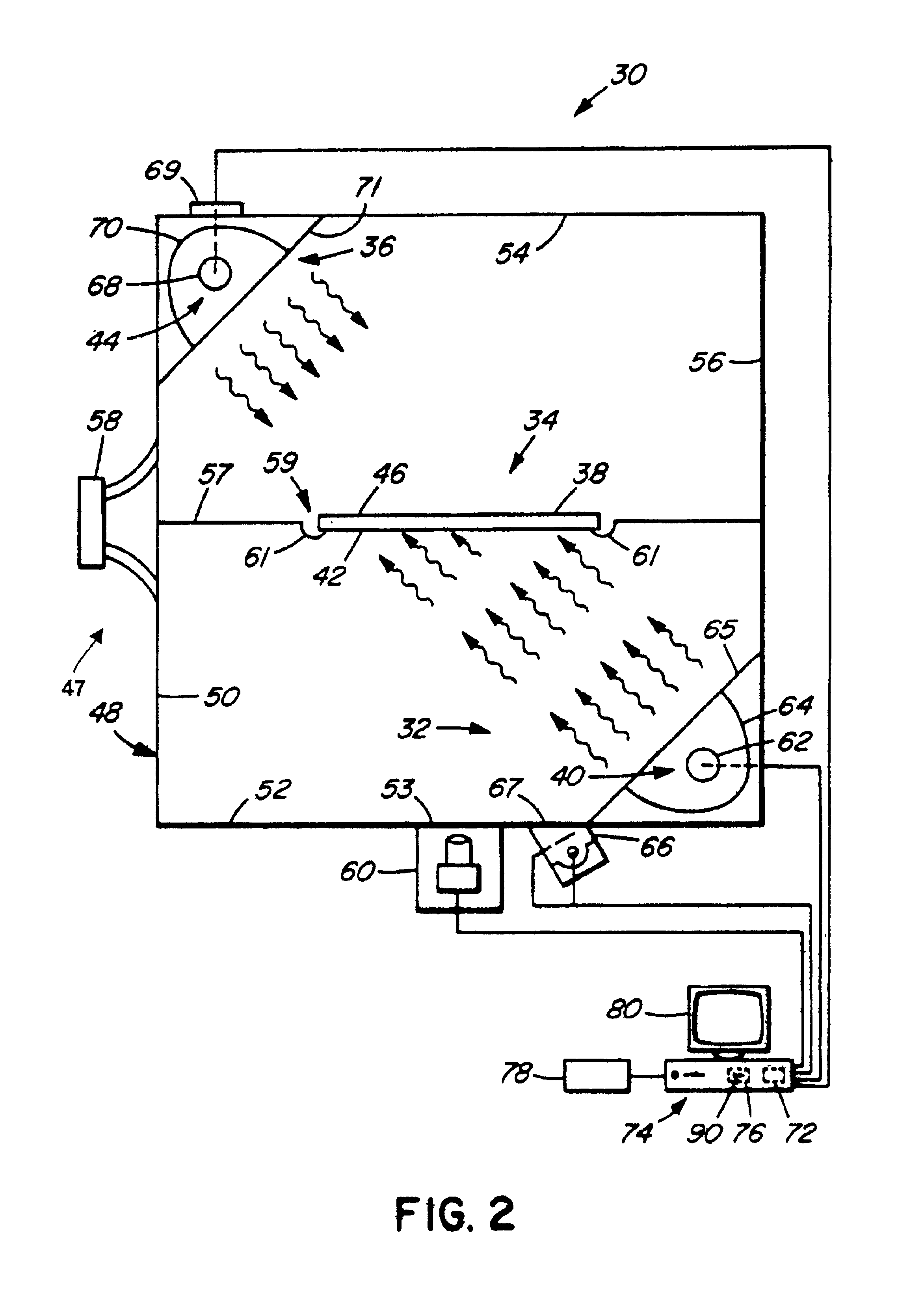

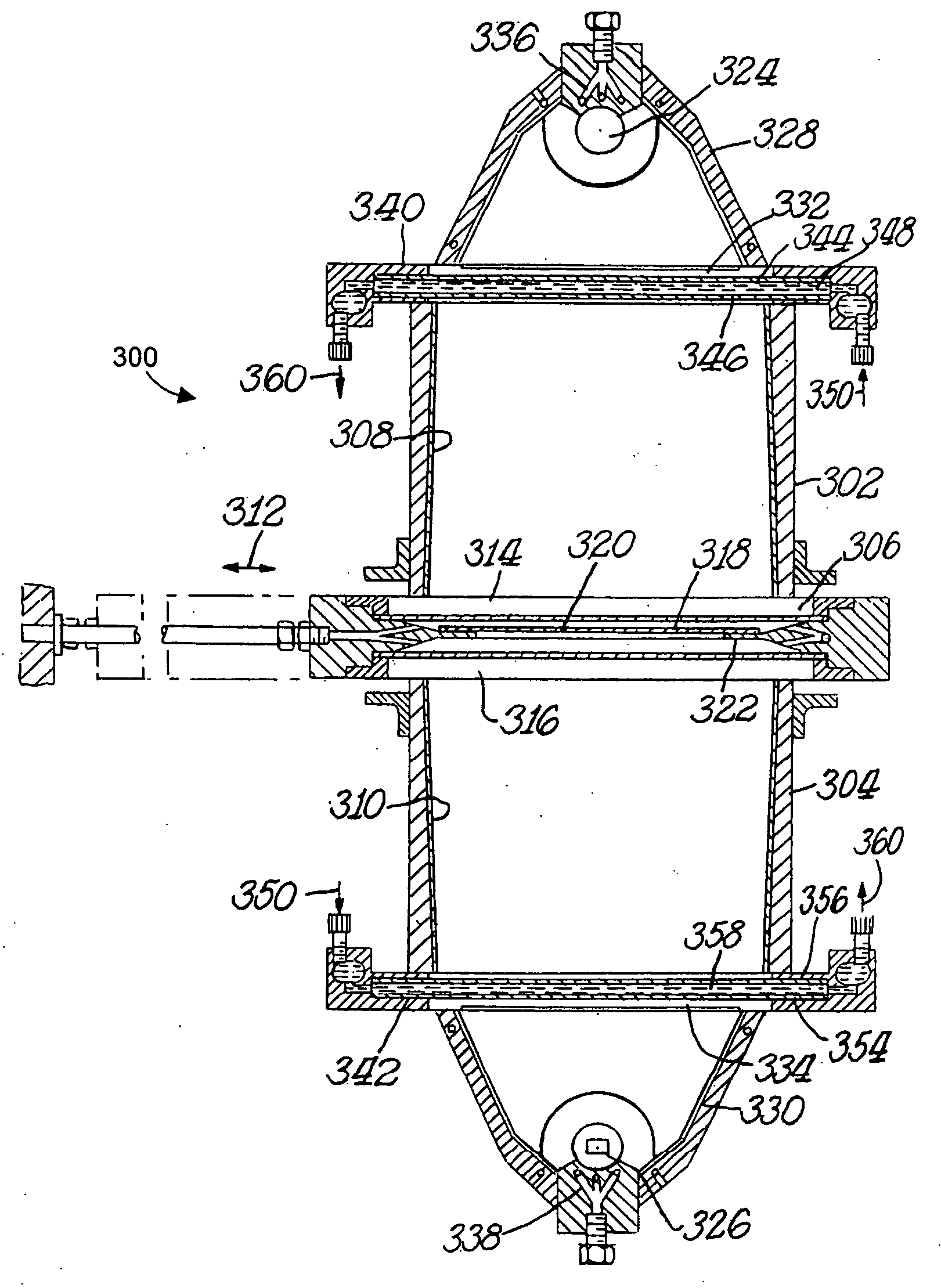

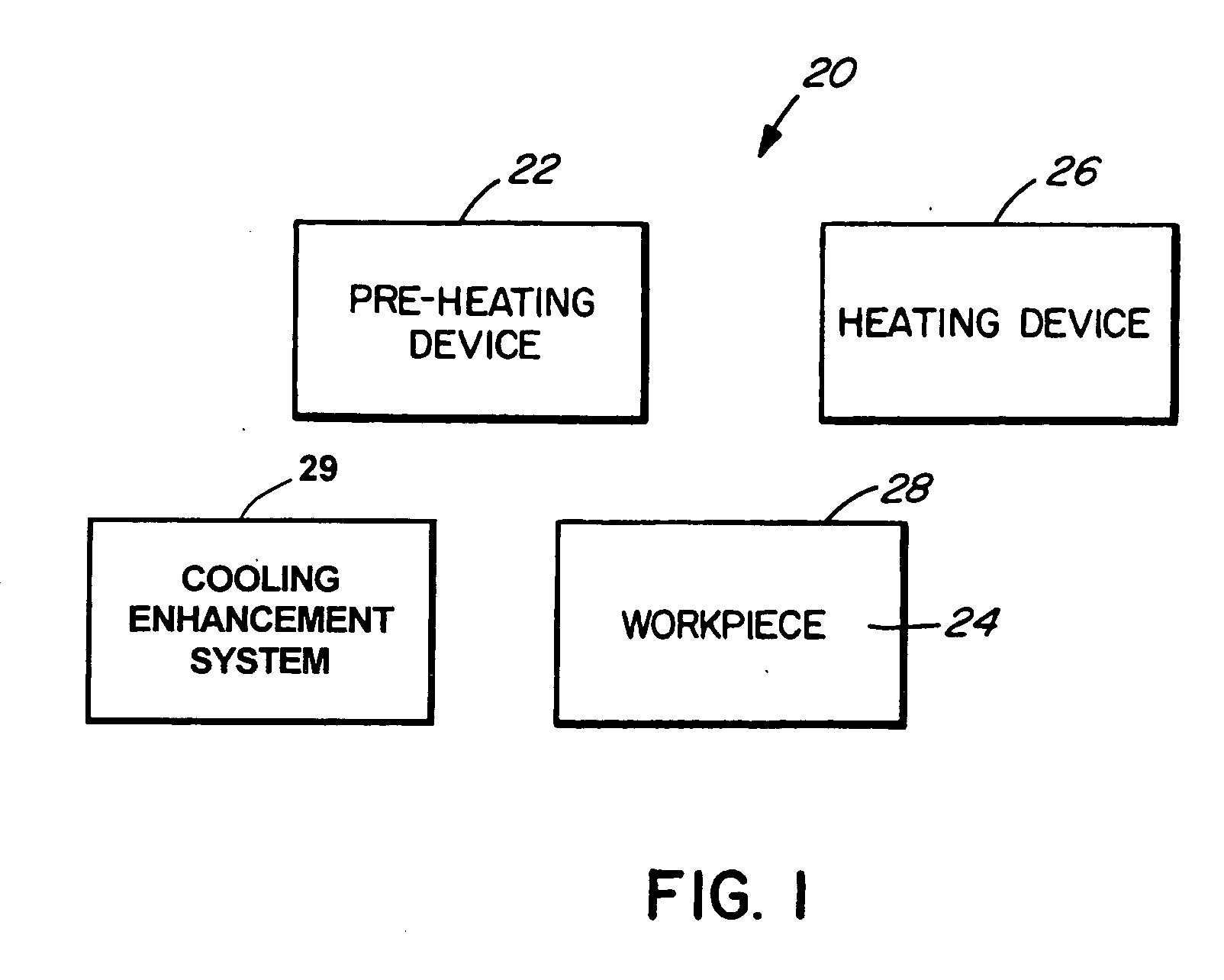

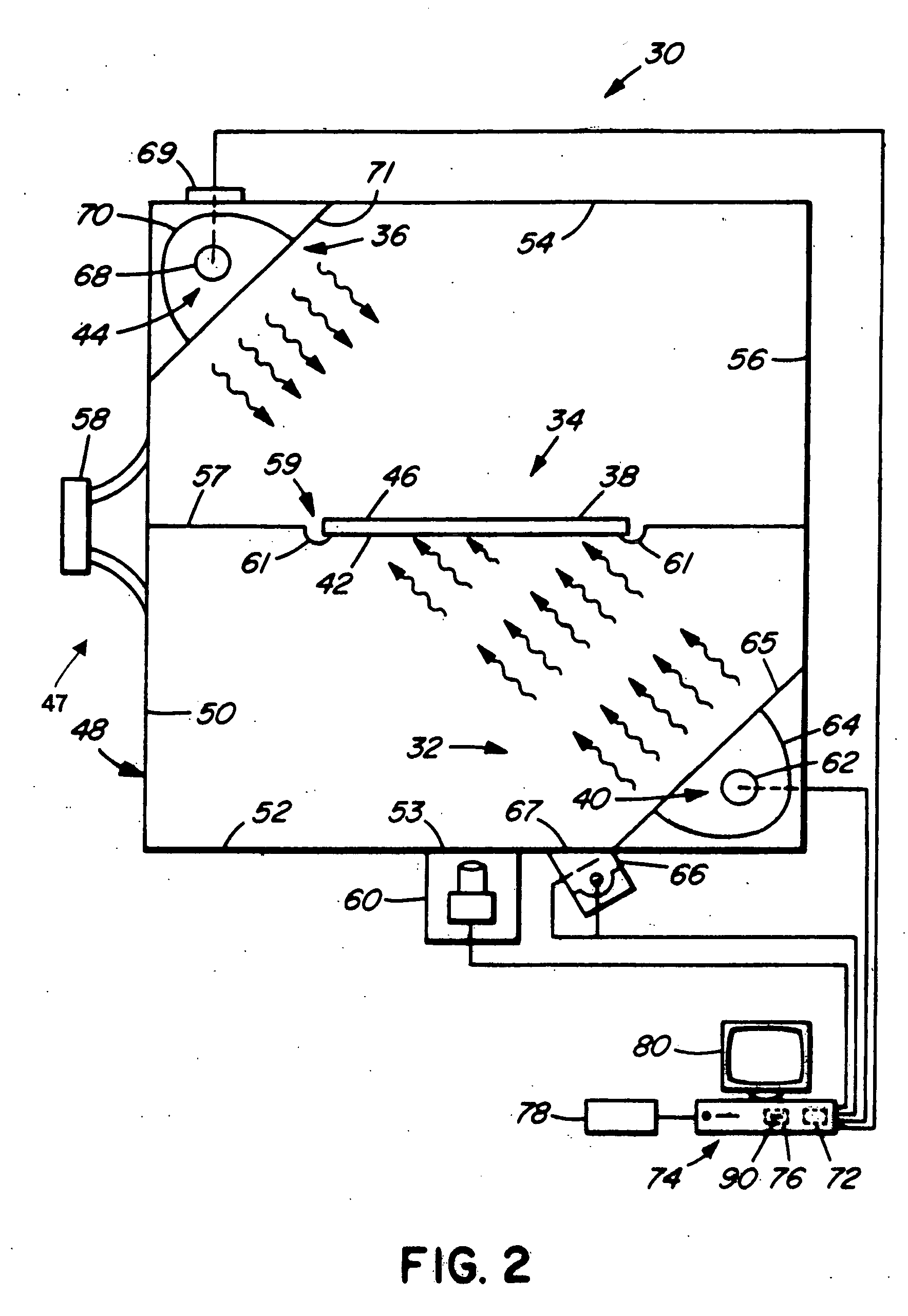

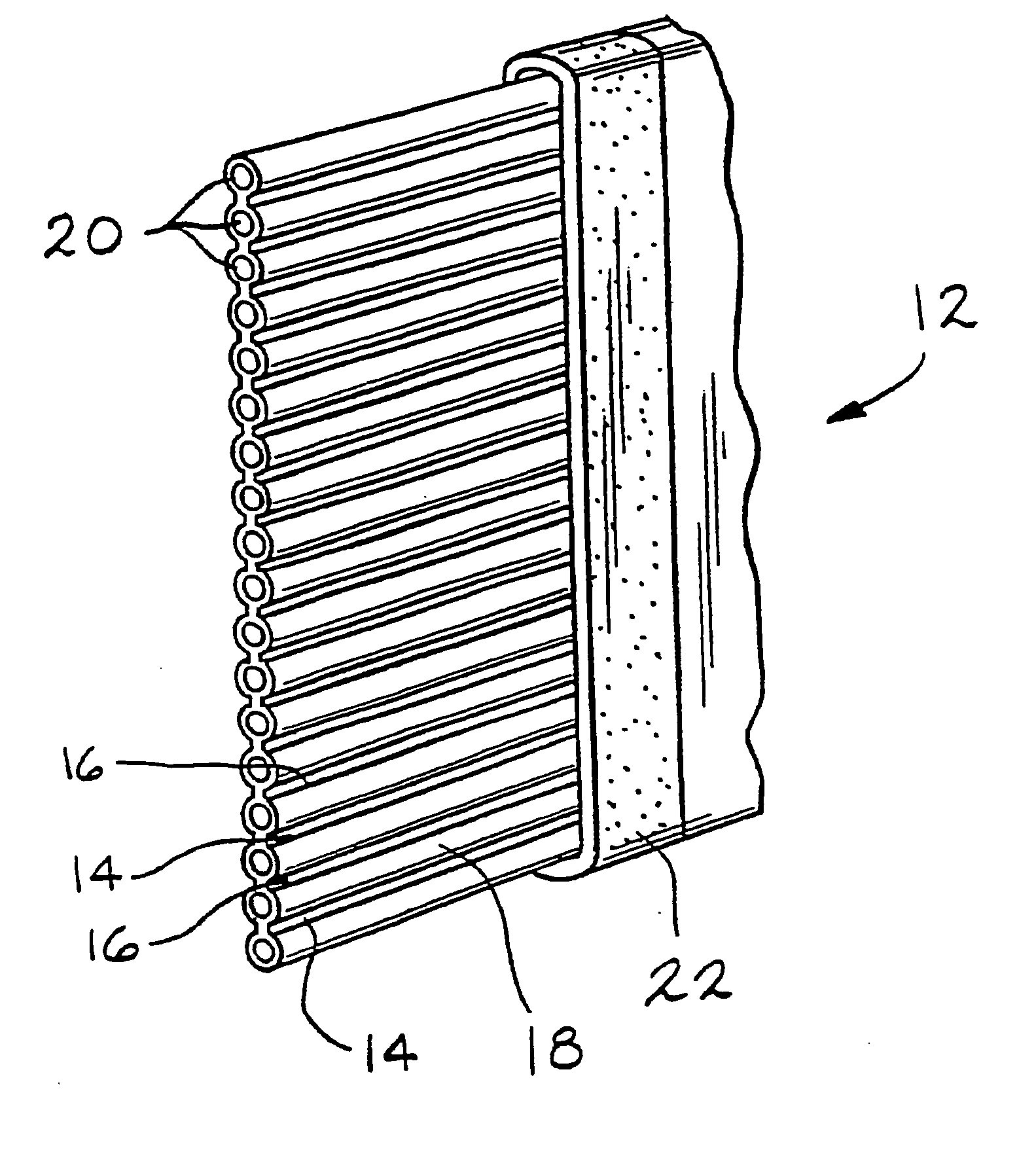

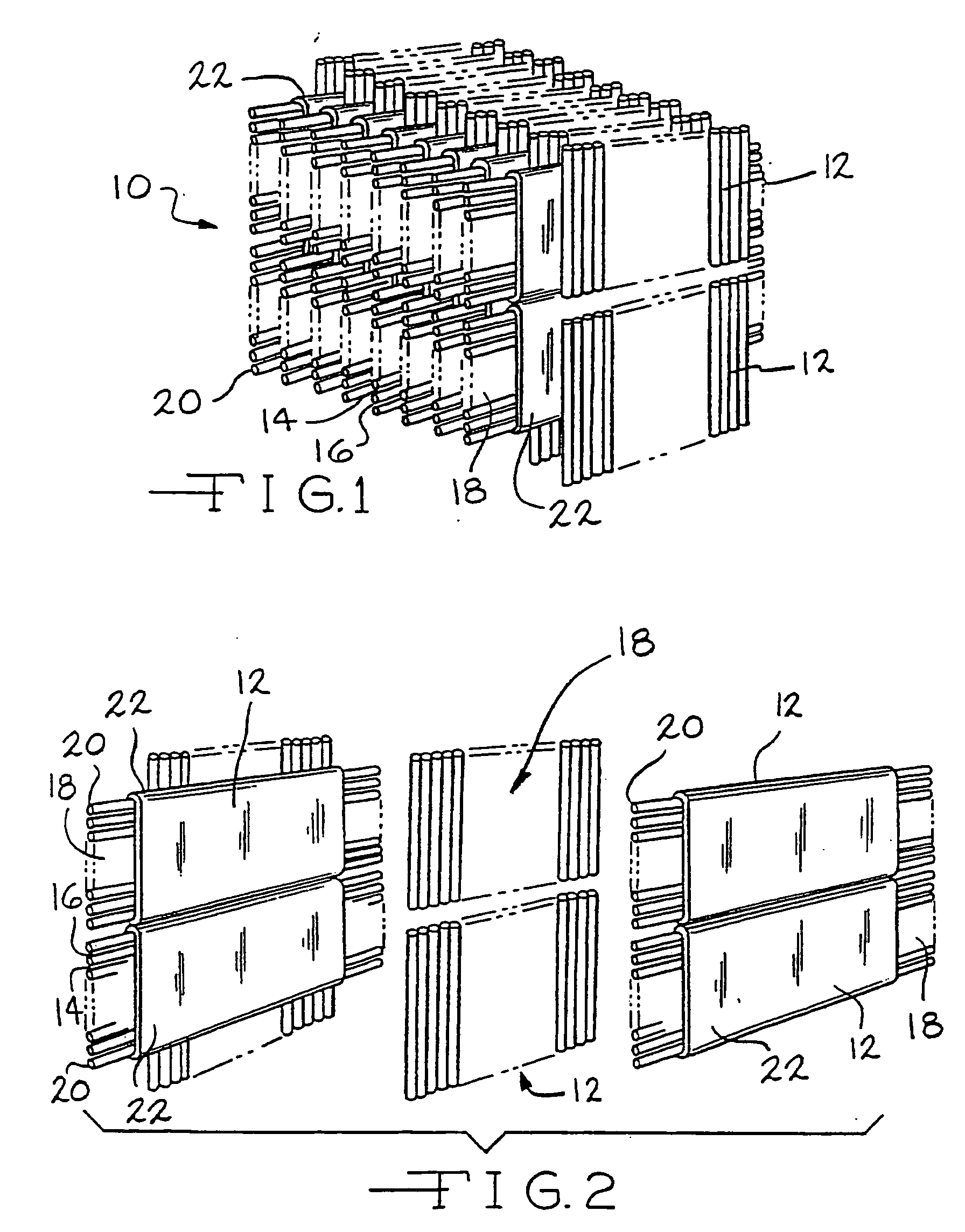

Heat-treating methods and systems

InactiveUS6941063B2Improve cooling effectWeakening rangeMechanical apparatusDrying solid materials with heatThermal radiationSemiconductor

A method involves pre-heating a workpiece to an intermediate temperature, heating a surface of the workpiece to a desired temperature greater than the intermediate temperature, and enhancing cooling of the workpiece. Enhancing cooling may involve absorbing radiation thermally emitted by the workpiece. An apparatus includes a first heating source for heating a first surface of a semiconductor wafer, a second heating source for heating a second surface of the semiconductor wafer, and a first cooled window disposed between the first heating source and the semiconductor wafer.

Owner:MATTSON TECHNOLOGY +1

High-temperature composite phase change heat storage material and preparation method thereof

ActiveCN102585775ANo preprocessing requiredSimple manufacturing methodHeat-exchange elementsElectricityHeat conducting

The invention relates to a preparation method of a high-temperature composite phase change heat storage material, and relates to a high-temperature composite phase change heat storage material and a preparation method thereof. The method can be used for preparing high-temperature composite phase change heat storage material with high heat conductivity, so that the heat conductivity of the heat storage material is greatly improved, and the heat storage / release rate is greatly improved; and the preparation method is easy to control and simple to operate. The heat storage material can be directly obtained by sintering, without need of any bonding agent or other protectants, so that the heat-conducting property of the heat storage material is greatly improved, and the utilization ratio of the heat storage material is improved; the preparation method is simple to operate; and the prepared product can also be used for other intermediate-temperature low-temperature composite heat storage materials, as well as light heat utilization, heat-cold-electricity combined use, composite material synthesis and other many fields.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Heat-treating methods and systems

InactiveUS20050062388A1Improve cooling effectWeakening rangeMuffle furnacesDiffusion/dopingSemiconductorMaterials science

A method involves pre-heating a workpiece to an intermediate temperature, heating a surface of the workpiece to a desired temperature greater than the intermediate temperature, and enhancing cooling of the workpiece. Enhancing cooling may involve absorbing radiation thermally emitted by the workpiece. An apparatus includes a first heating source for heating a first surface of a semiconductor wafer, a second heating source for heating a second surface of the semiconductor wafer, and a first cooled window disposed between the first heating source and the semiconductor wafer.

Owner:MATTSON TECH CANADA

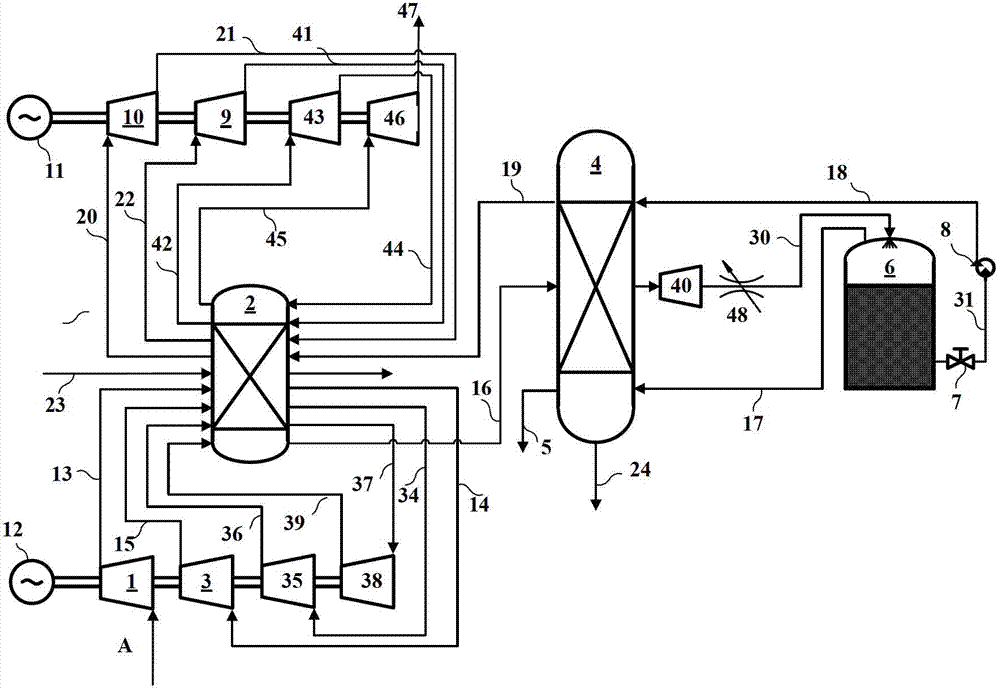

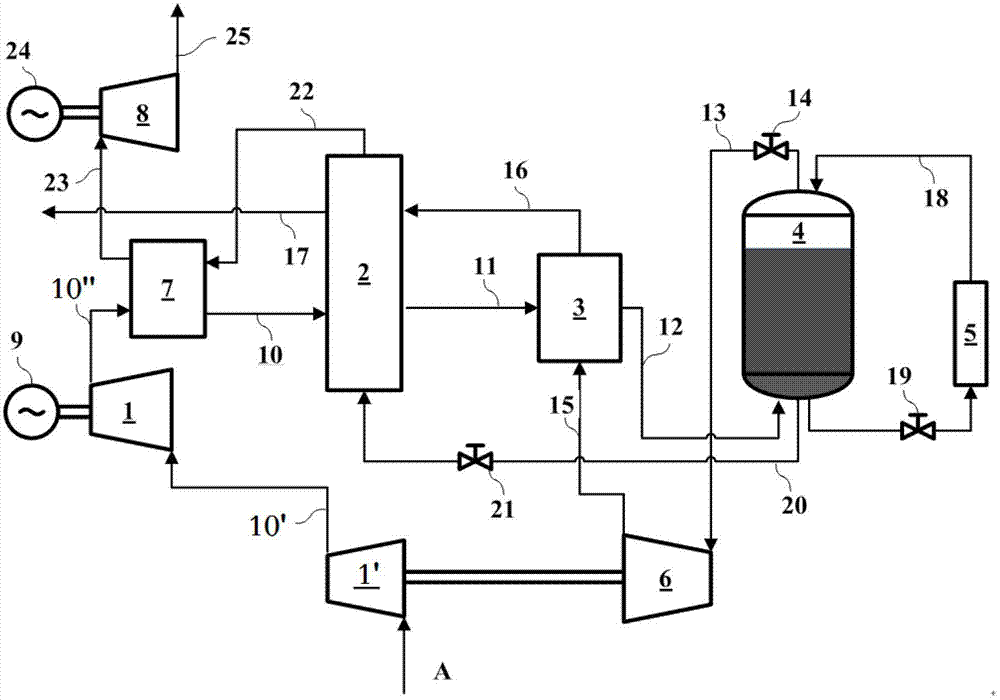

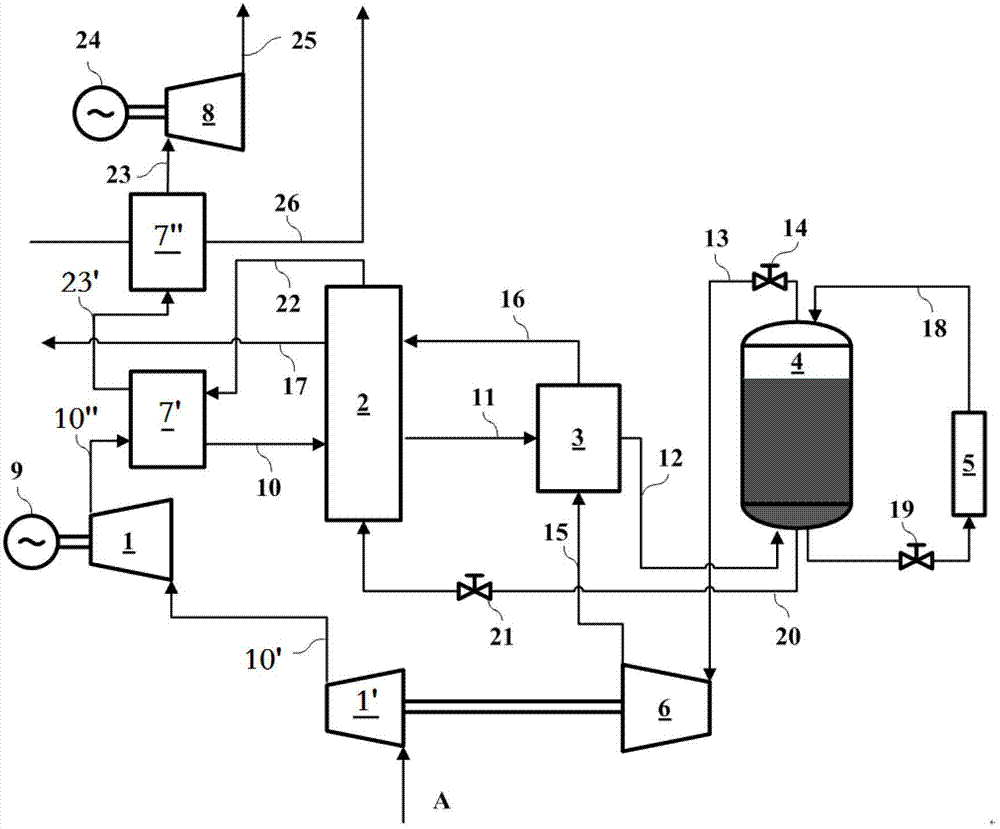

Ultra-supercritical air energy storage/release system

ActiveCN102758689AImprove efficiencyImprove energy storage efficiencyGas turbine plantsElectricityPower station

The invention discloses an ultra-supercritical air energy storage / release system, which is a novel large-scale energy storage system and relates to an energy storage technology, namely, air is compressed into an ultra-supercritical state by using off-peak electricity of a power station, heat is compression is stored simultaneously, air is cooled by using an expansion engine and simultaneously expansion work is recovered to improve the efficiency, and the ultra-supercritical air is cooled, liquefied and stored by using stored cold energy; and liquid air is pressurized and absorbs heat to reach an ultra-supercritical state at the power utilization peak and further absorb heat of compression for power generation by a turbo-generator. The ultra-supercritical air energy storage / release system disclosed by the invention has the advantages of high energy density, high efficiency, no limitation by energy storage cycle and geological conditions, suitability for various power stations, environmental friendliness, capability of recovering intermediate-temperature and low-temperature waste heat and the like.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

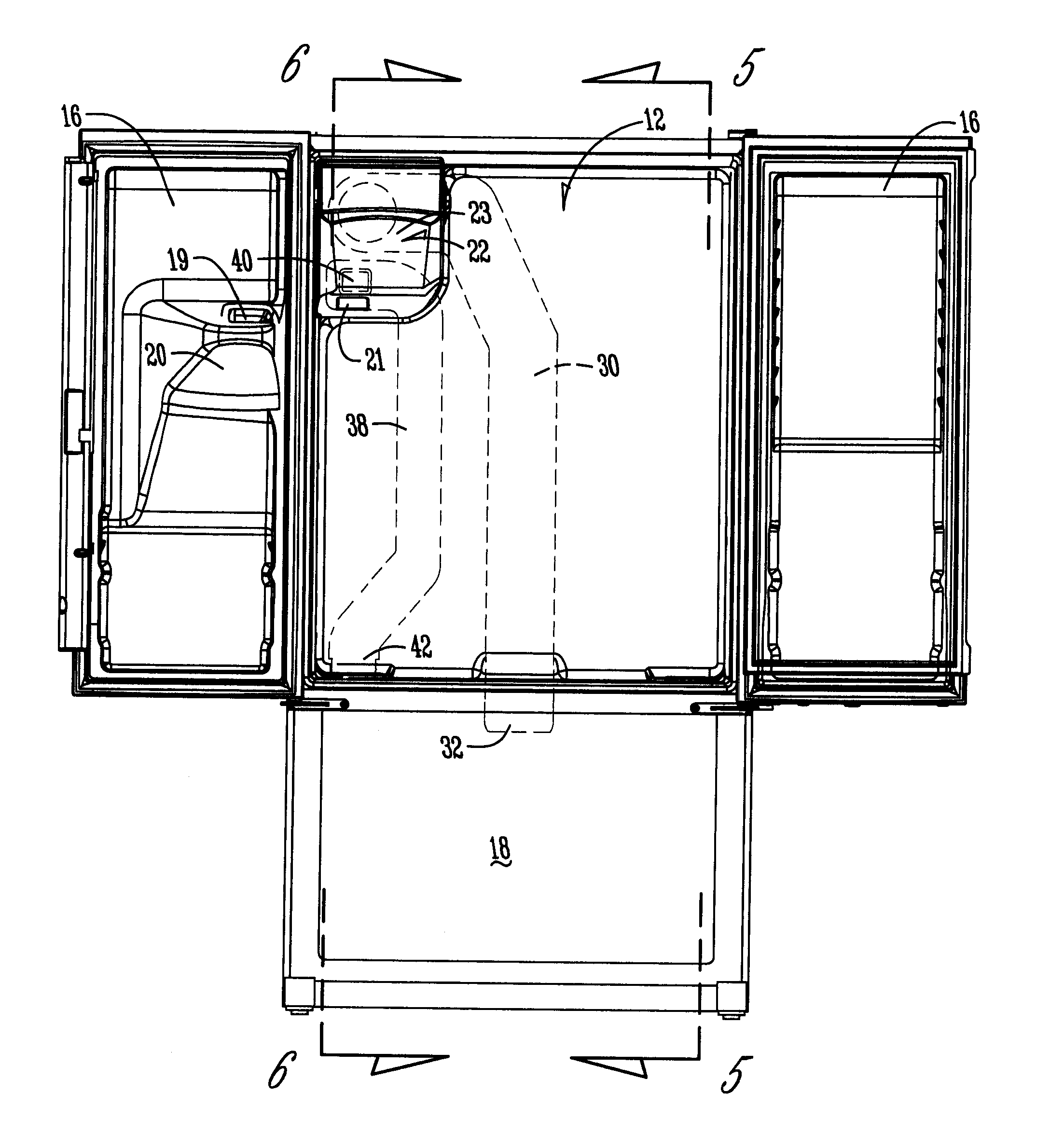

Refrigerator ice compartment with intermediate temperature

An insulated icemaking compartment is provided in the fresh food compartment of a bottom mount refrigerator. The icemaking compartment may be integrally formed with the liner of the fresh food compartment, or alternatively, may be modular for installation anywhere in the fresh food compartment. A removable bin assembly with a front cover normally seals the icemaking compartment to maintain the temperature in the compartment. A cold air duct formed in the rear wall of the refrigerator supplies cold air from the freezer compartment to the icemaking compartment. A return air duct directs a portion of the air from the icemaking compartment back to the freezer compartment. An air vent in the icemaking compartment directs another portion of air into the fresh food compartment. A control system provides for controlling refrigerator functions in a manner that promotes energy efficiency. The temperature of the ice compartment is between the temperatures of the fresh food and freezer compartments.

Owner:WHIRLPOOL CORP

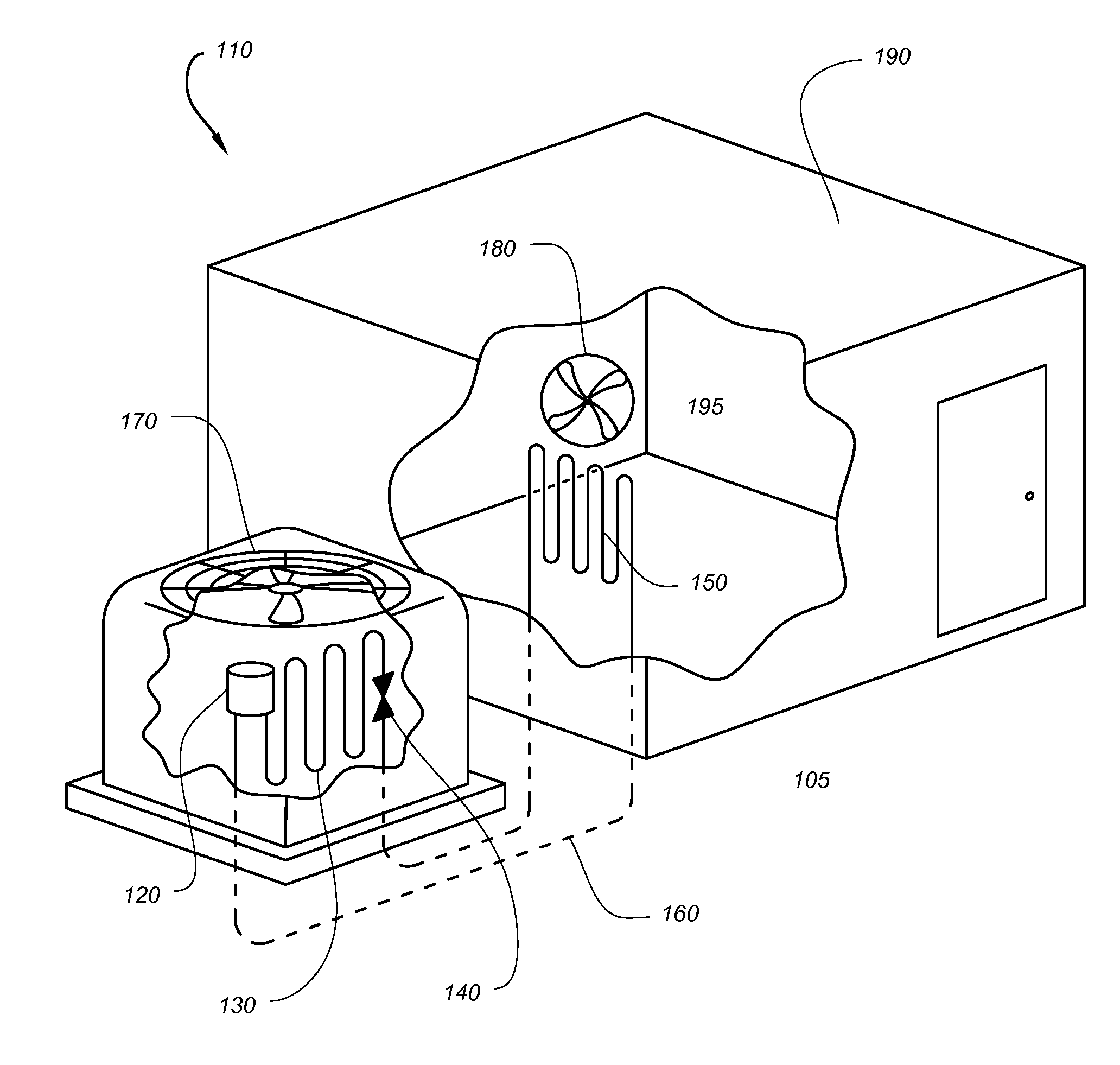

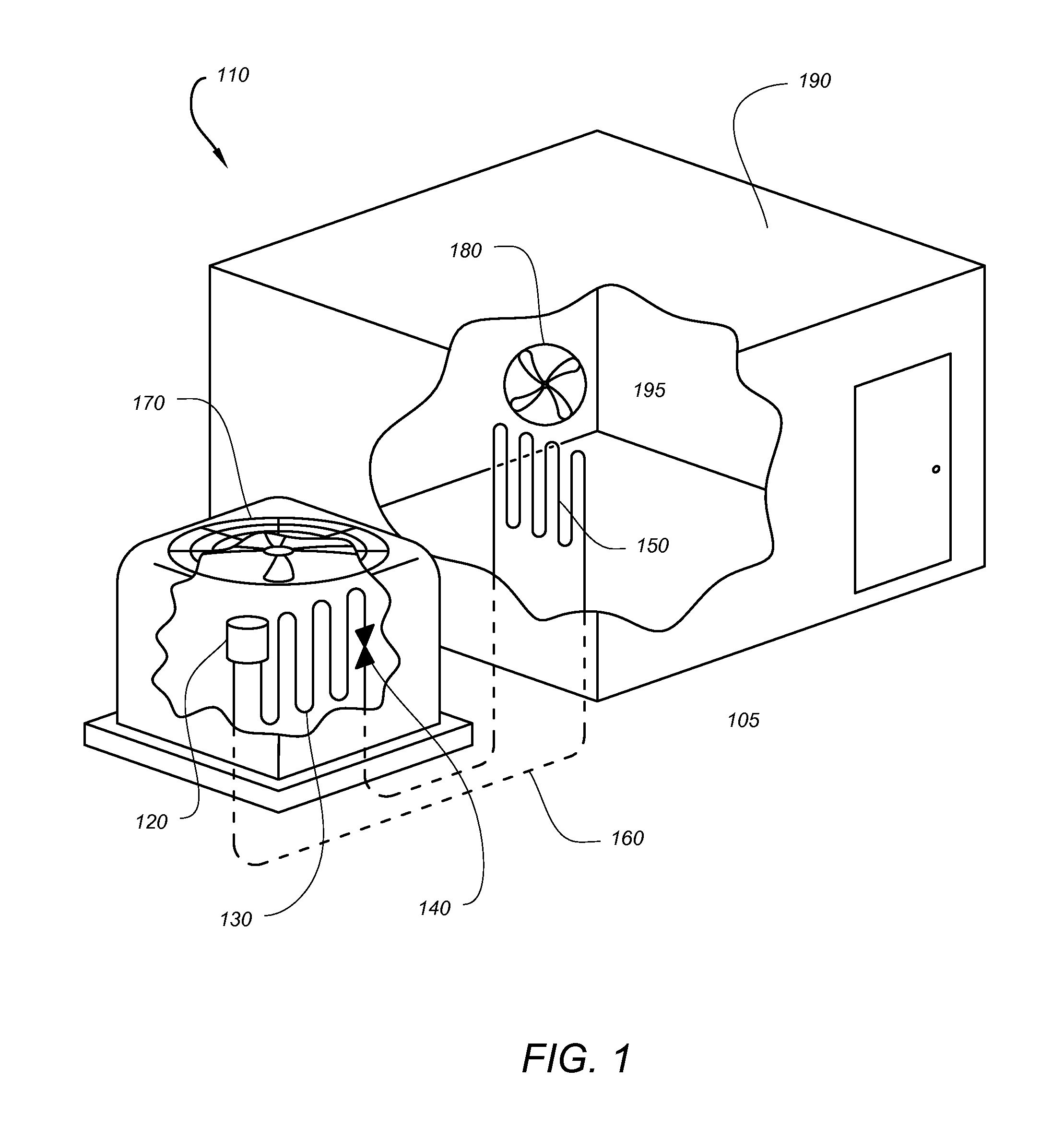

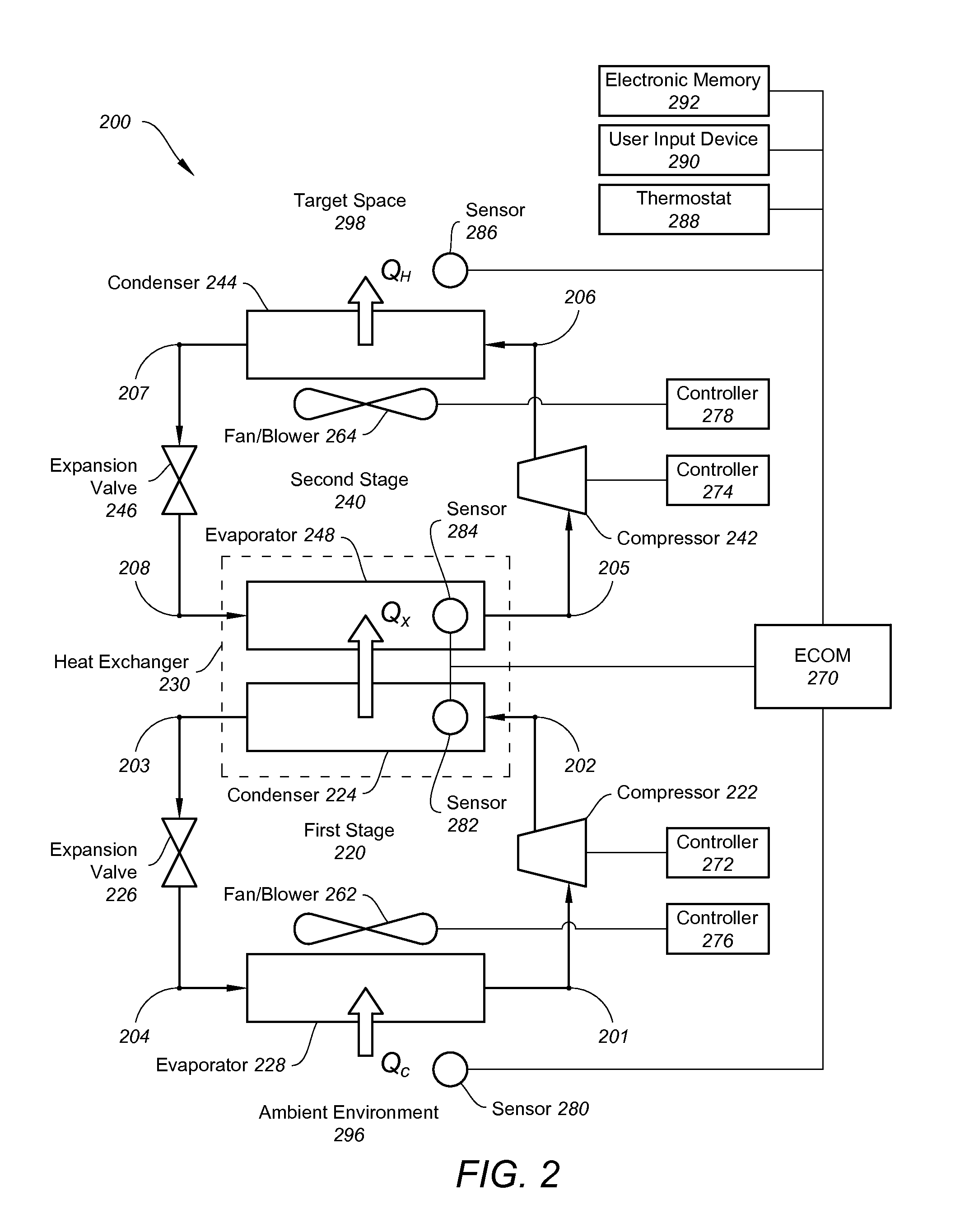

Cascade floating intermediate temperature heat pump system

ActiveUS20120210736A1Heat pumpsCompression machines with non-reversible cycleComputer moduleCoefficient of performance

A cascade heat pump system is configured with variable-speed compressors which allow operation at a high system coefficient of performance for a given thermal load. An electronic control module may be utilized to dynamically vary the speed of the compressors to achieve maximum energy efficiency. Variable-speed fans or blowers may also be used.

Owner:ROCKY RES INC

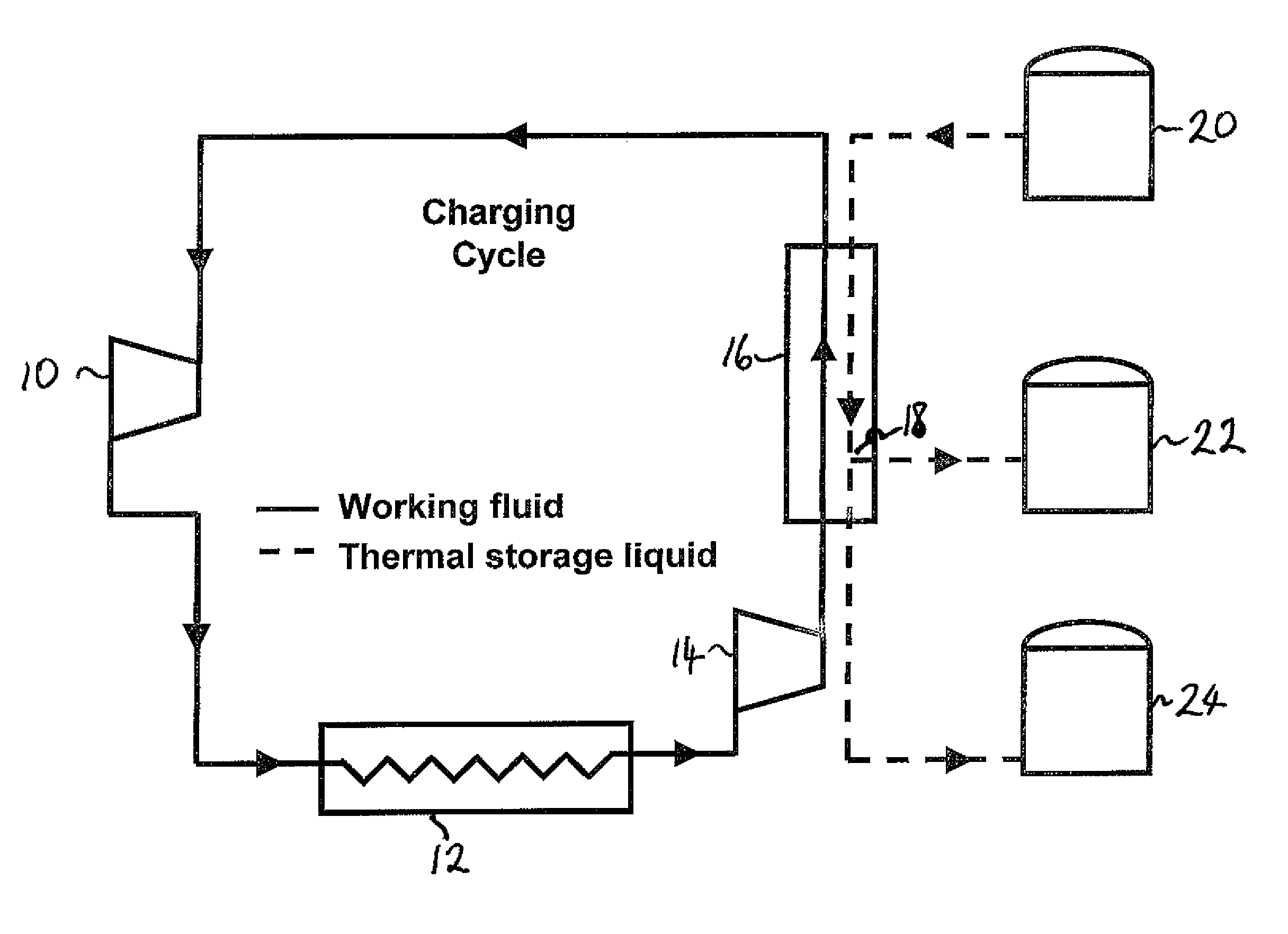

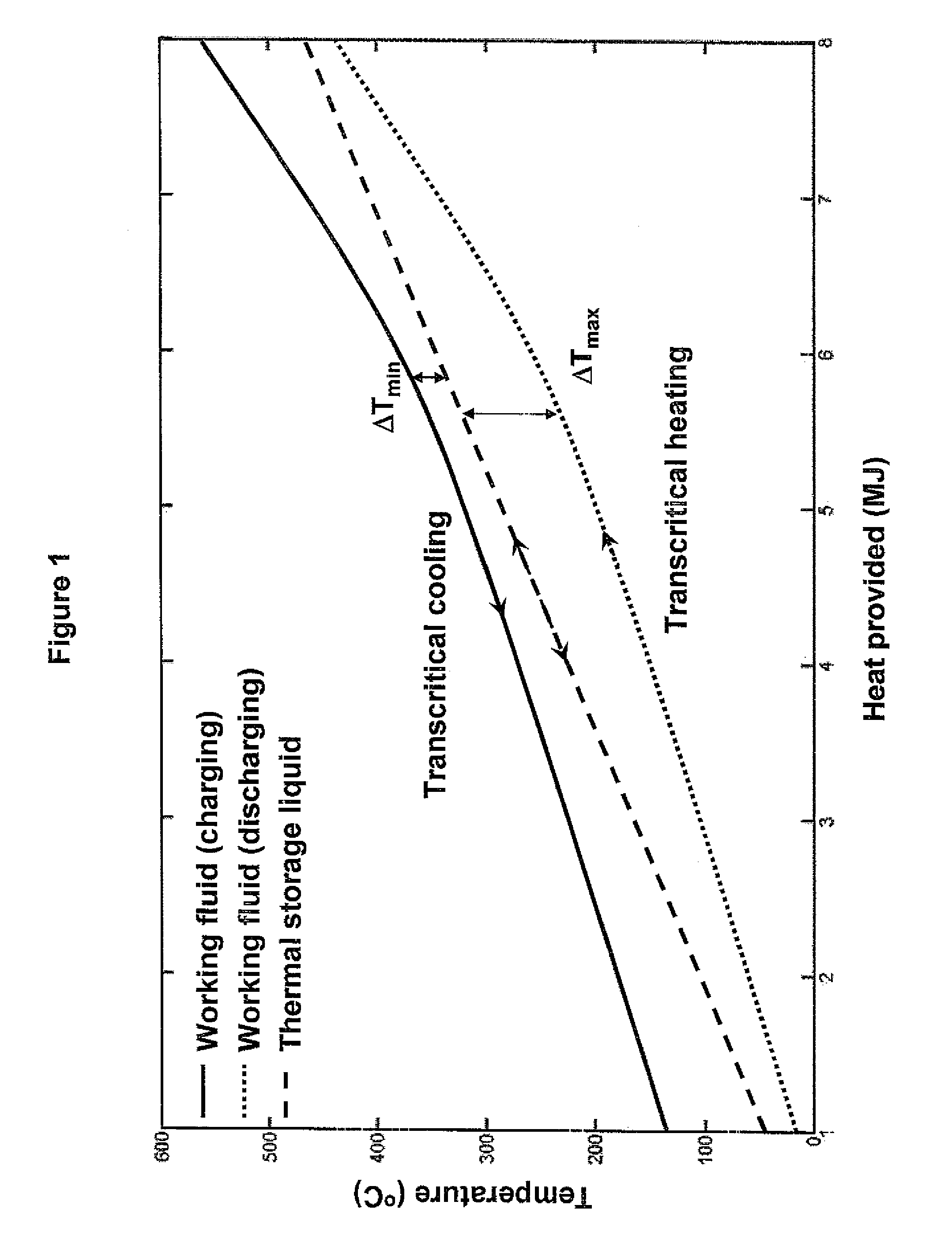

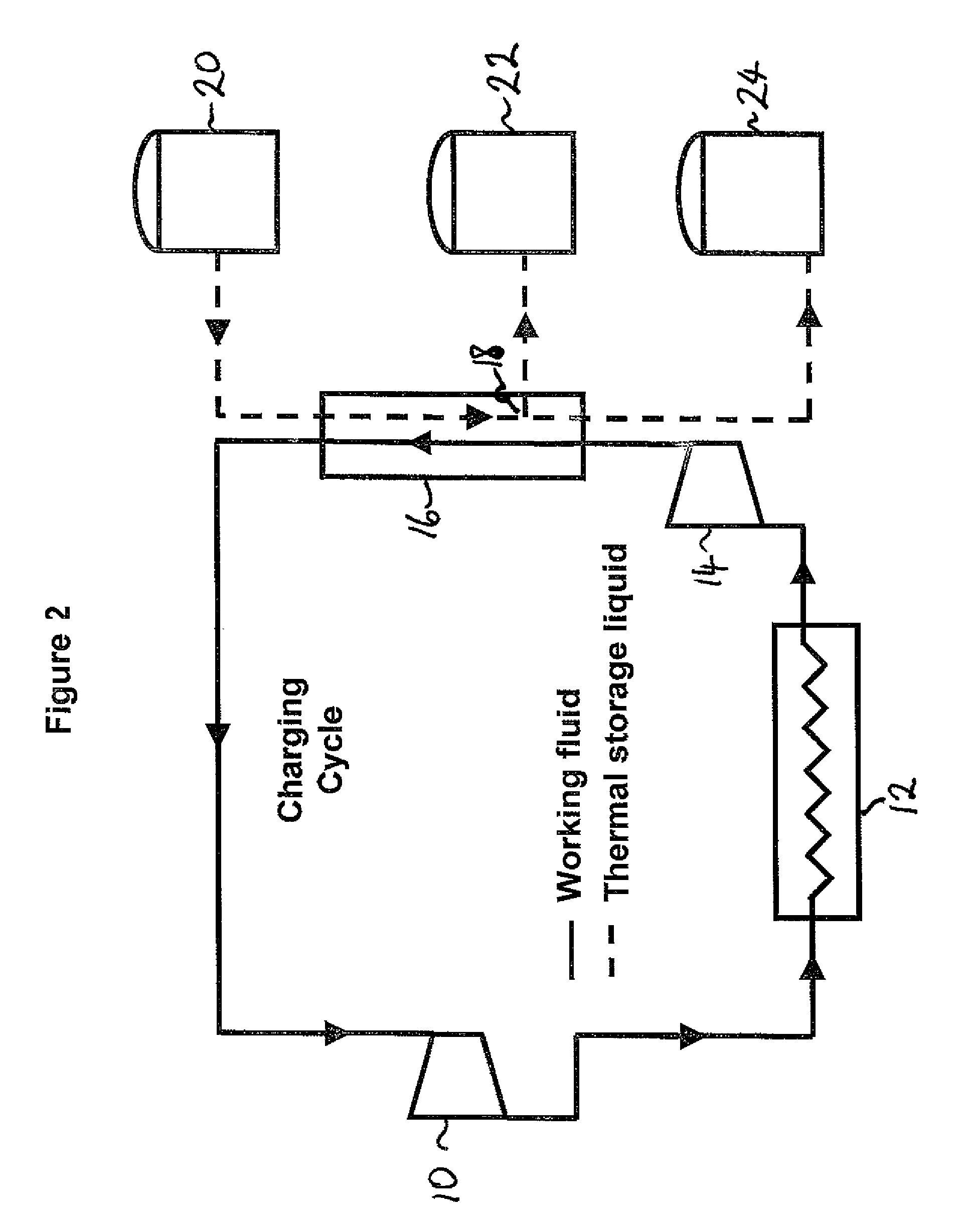

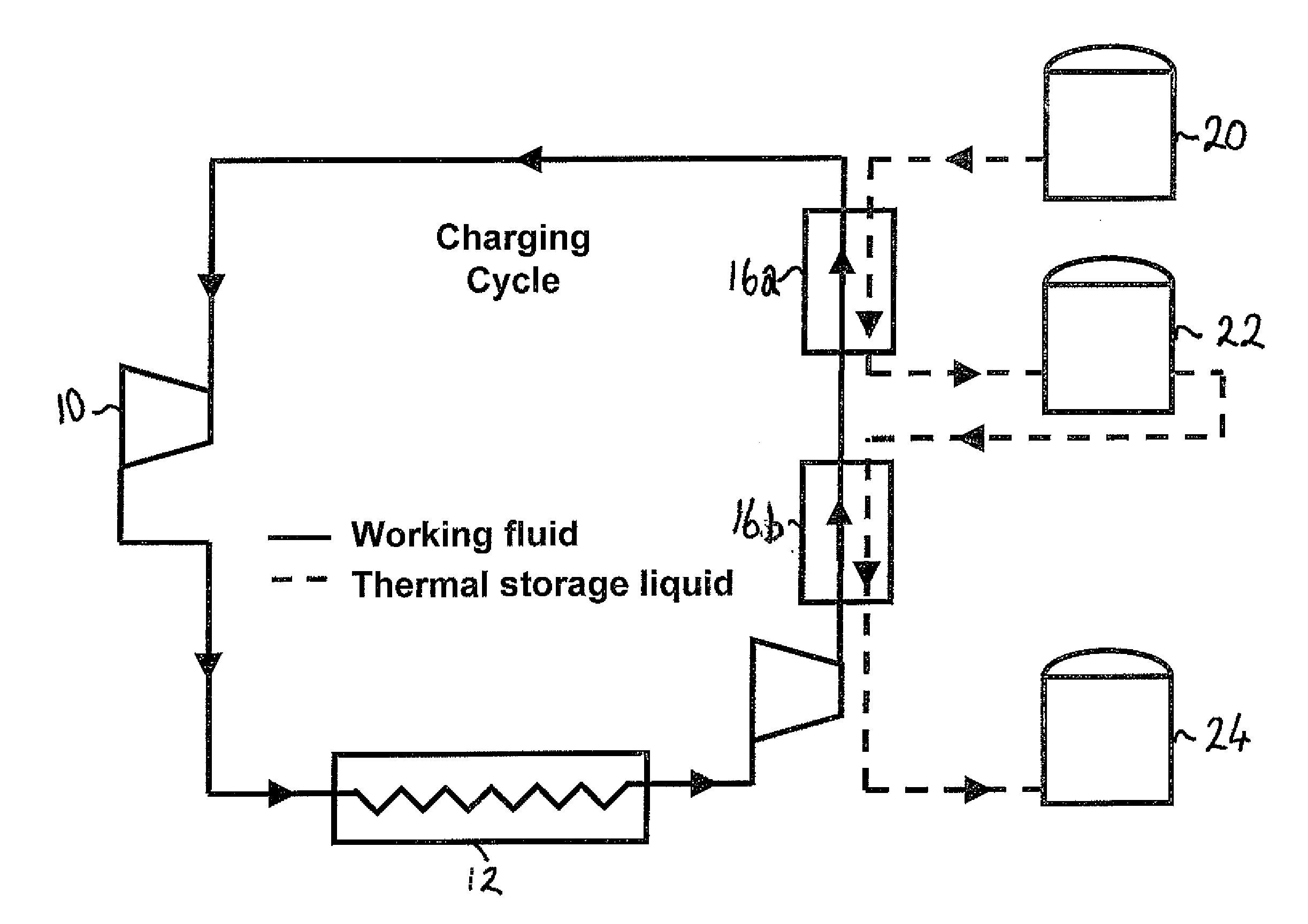

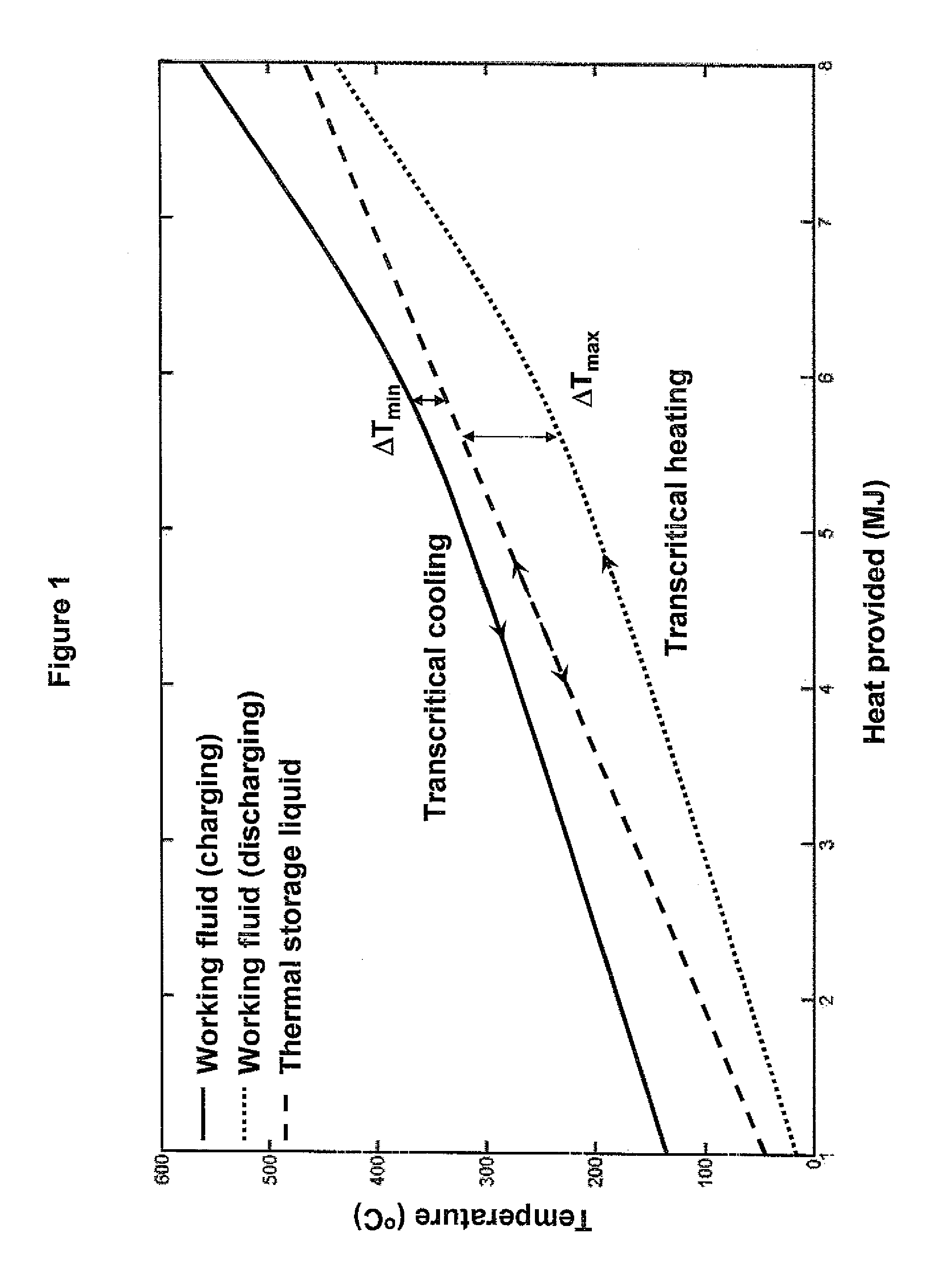

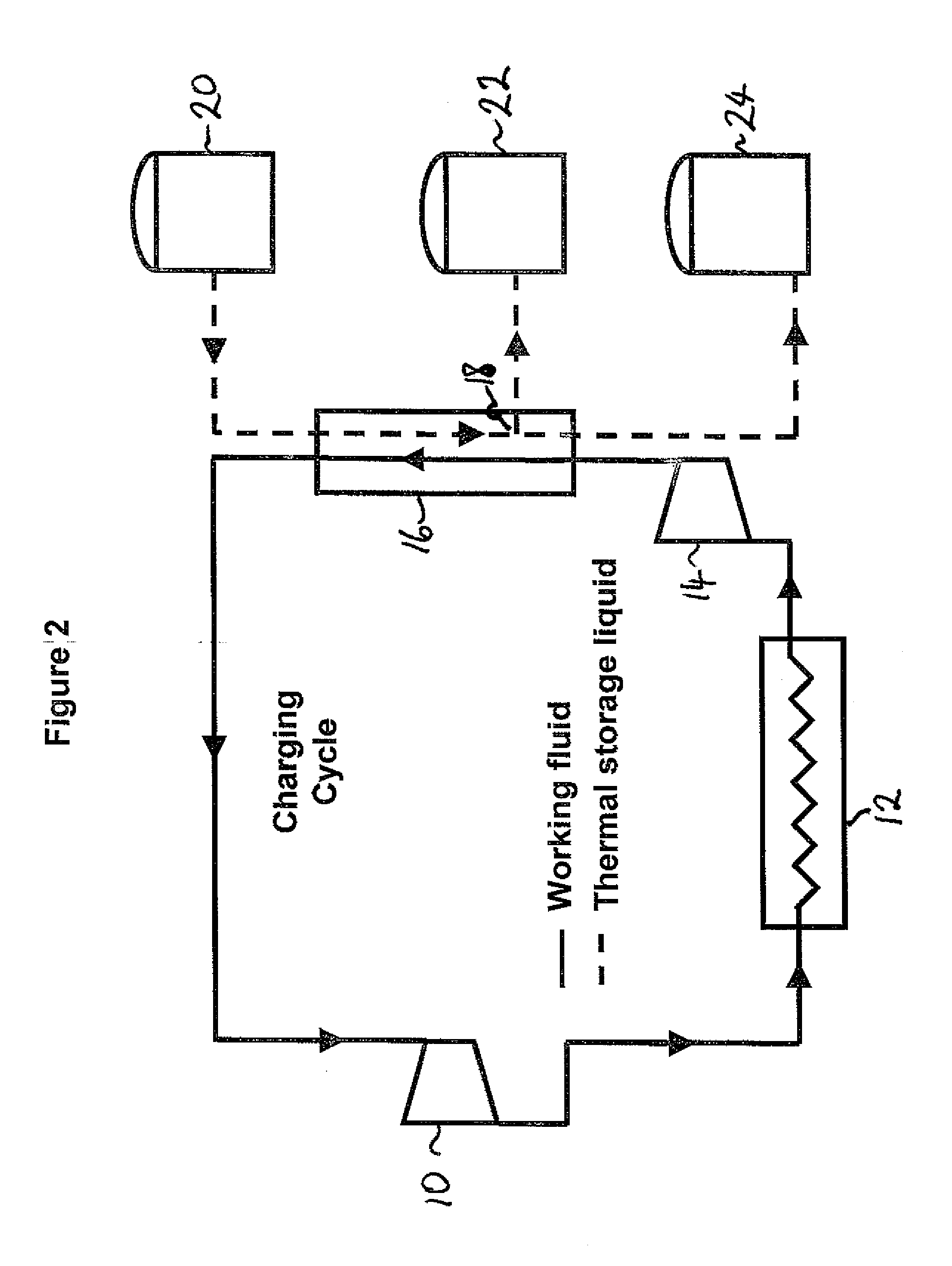

Thermoelectric energy storage system with an intermediate storage tank and method for storing thermoelectric energy

ActiveUS8904793B2Suitable for storageSolar heating energySteam generation heating methodsThermal energyWorking fluid

Owner:ABB (SCHWEIZ) AG

Vaporization pipe with flame filter

A vaporizer device that uses a flame for vaporizing flavor and psychoactive compounds from smoking materials such as tobacco. The present device has a filter unit 34 with a porous flame filter 36. The flame filter 36 can be made of open-cell ceramic or metal foam, sintered ceramic or metal granules or other porous, heat resistant materials. In use, flame is supplied to the flame filter, and inhalation causes ambient air to enter the flame filter as well. The flame exhaust and ambient air are mixed within the flame filter and produce an air stream of intermediate temperature. The intermediate temperature air stream is hot enough to vaporize desirable components from the smoking material. The filter unit and pipe can attach with a ground glass joint.

Owner:STEINBERG DAN A

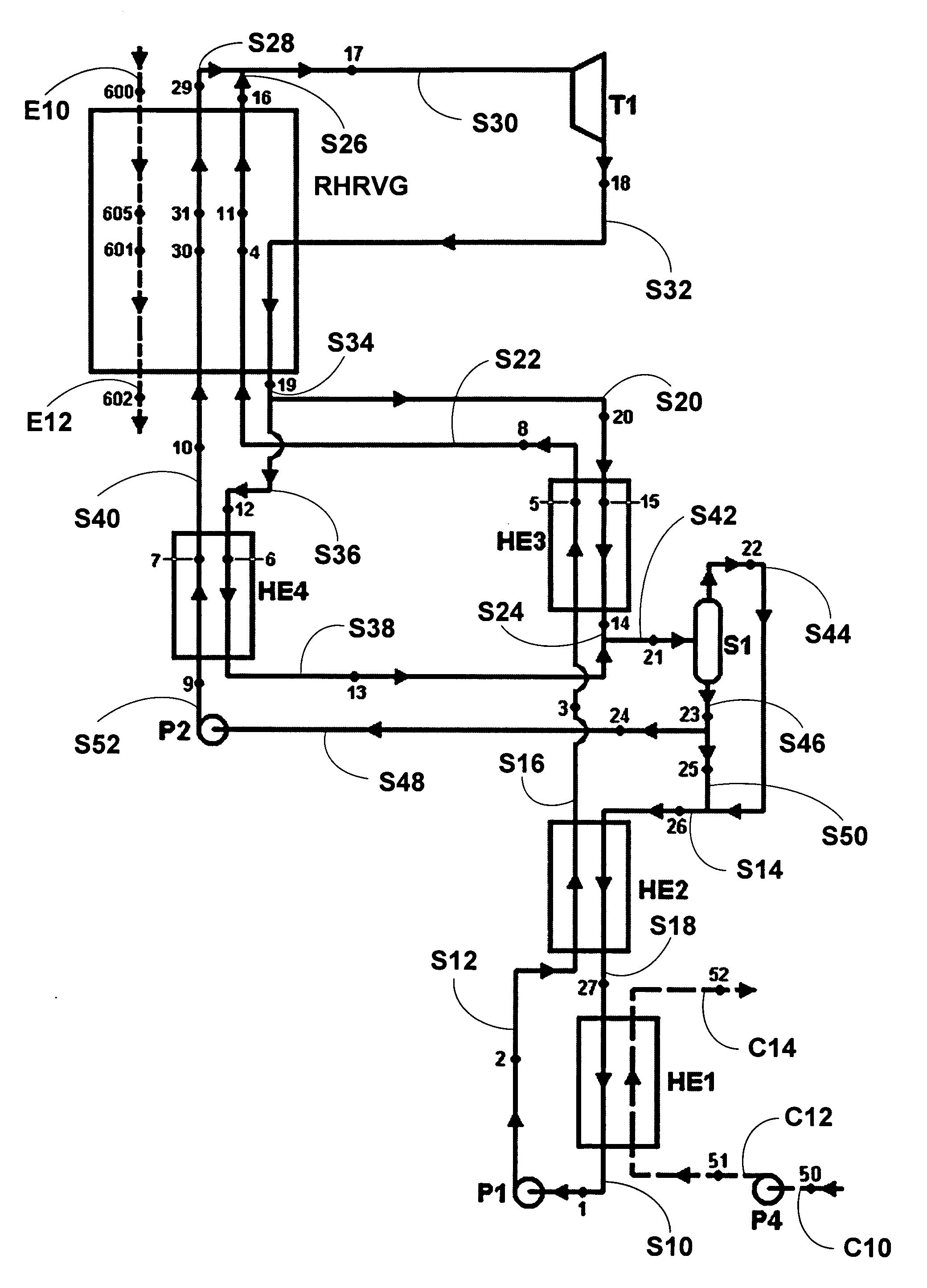

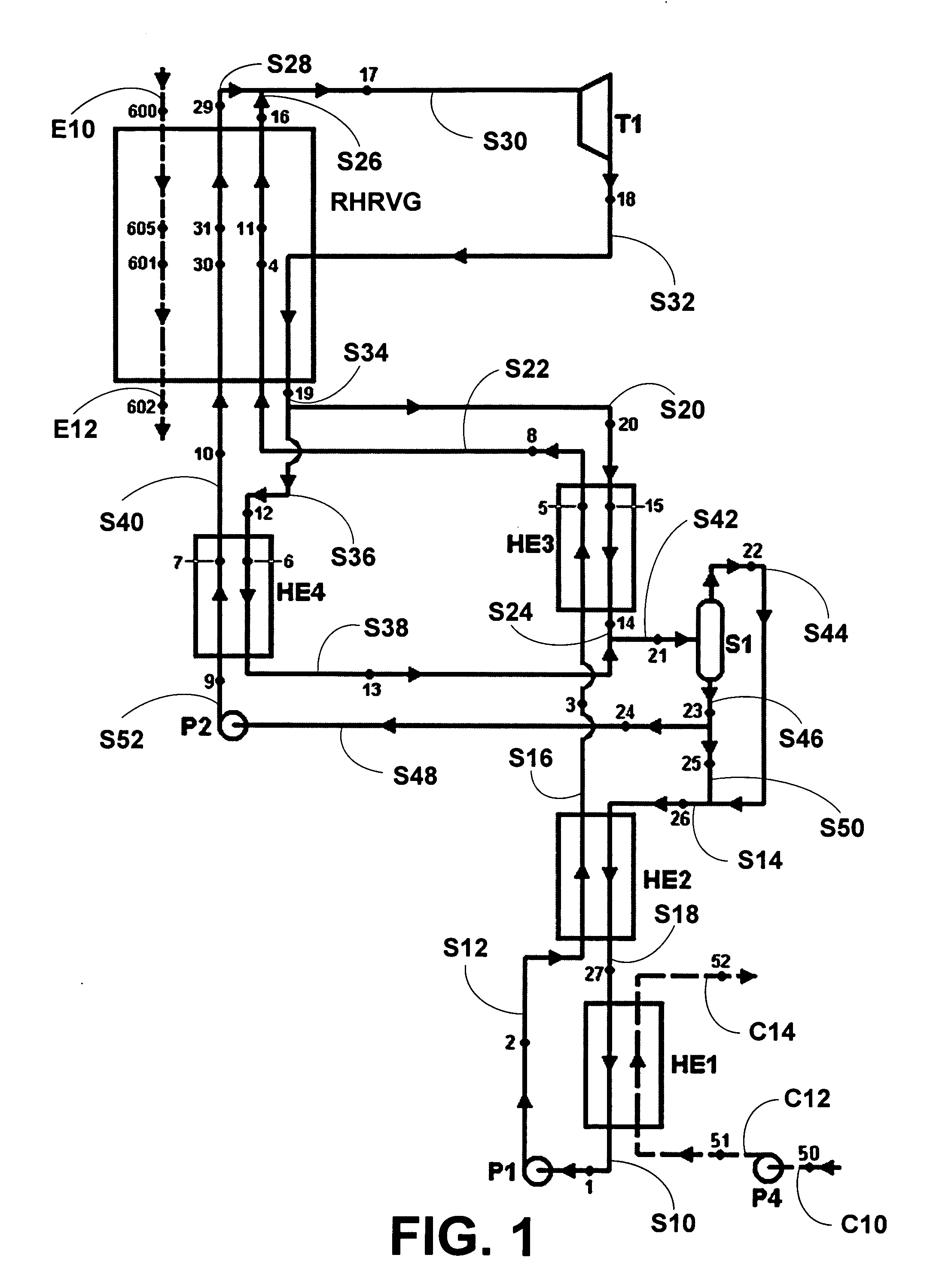

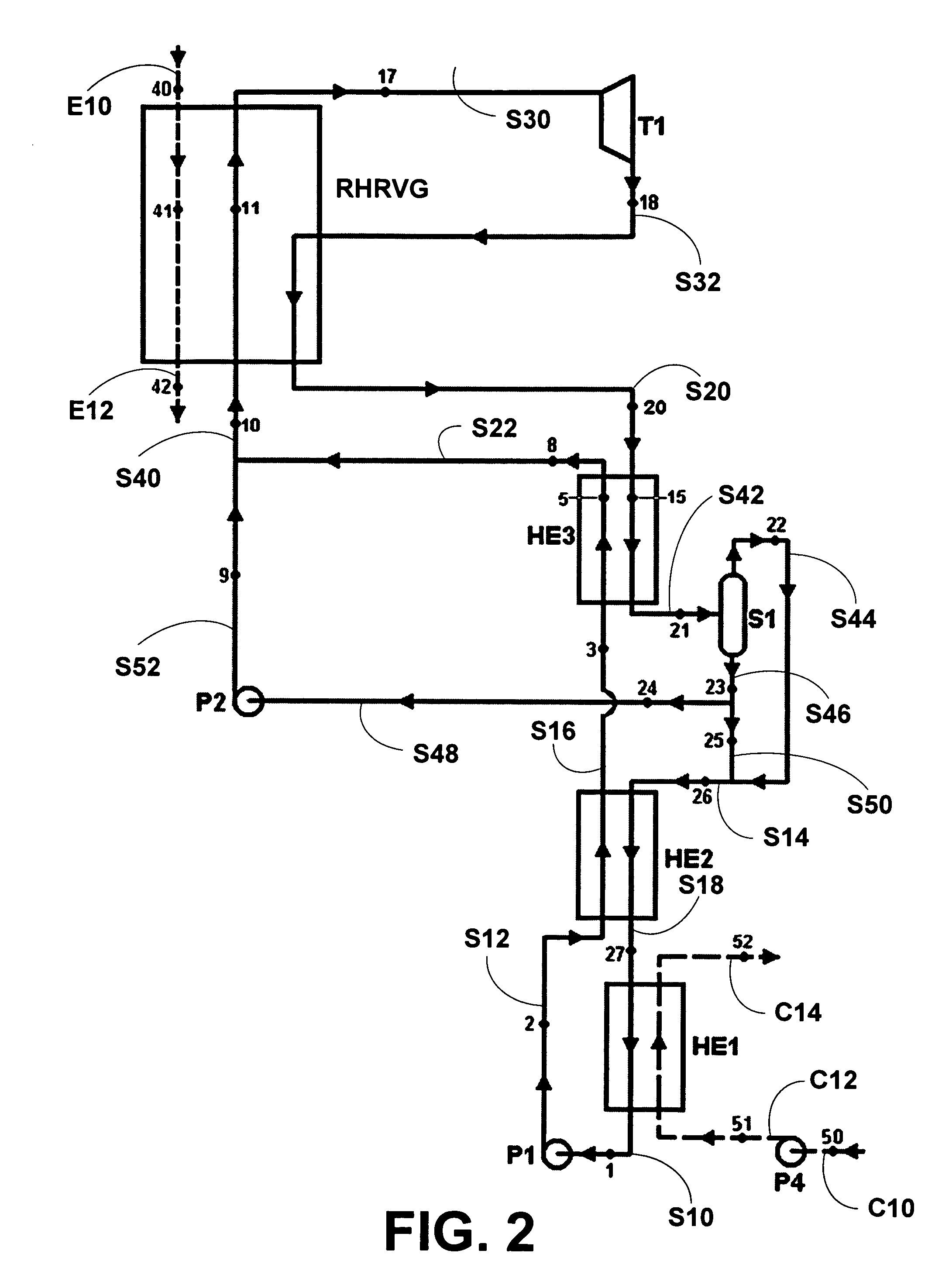

Power system and apparatus utilizing intermediate temperature waste heat

ActiveUS20080053095A1Simple bottoming cycleSteam generation heating methodsCombustion technology mitigationThermal energyForms of energy

system and method is disclosed to increase the efficient of internal combustion engines using to generate electric power, where the system and method converts a portion of thermal energy produced in the combustion process to a usable form of energy.

Owner:KALINA POWER LTD

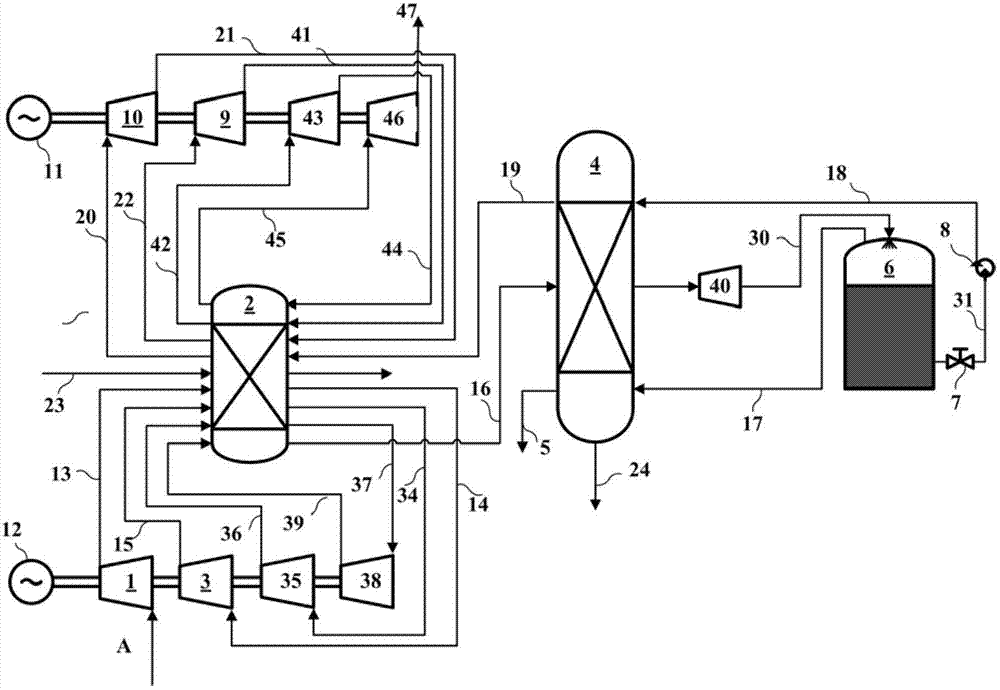

Thermoelectric energy storage system with an intermediate storage tank and method for storing thermoelectric energy

ActiveUS20120080168A1Suitable for storageSolar heating energySteam generation heating methodsThermal energyWorking fluid

A system and method are provided for storing electric energy in the form of thermal energy. A thermoelectric energy storage system includes a working fluid circuit for circulating a working fluid through a heat exchanger, and a thermal storage medium circuit for circulating a thermal storage medium. The thermal storage medium circuit includes at least one hot storage tank, an intermediate temperature storage tank, and a cold storage tank connected together via the heat exchanger. A proportion of the storage medium is redirected to or from the intermediate storage tank from or to the hot or cold storage tank, joining another proportion which flows directly between the cold and hot storage tank.

Owner:ABB (SCHWEIZ) AG

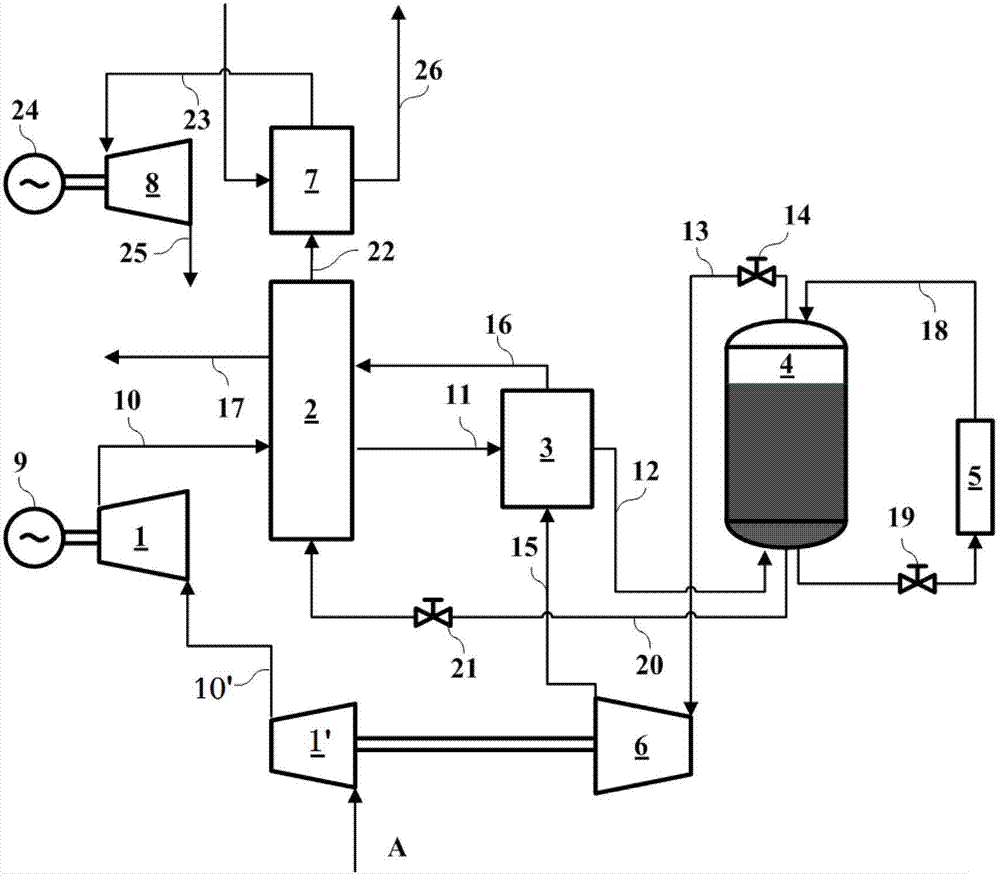

Efficient high-pressure liquid air energy storage/release system

ActiveCN102758690AIncrease energy densityImprove efficiencyGas turbine plantsPower stationHigh energy

The invention discloses an efficient high-pressure liquid air energy storage / release system, which comprises an energy storage subsystem and an energy release subsystem; in the energy storage subsystem, a low-pressure compressor set (1'), a high-pressure compressor set (1), a cold accumulator (2), a low-temperature heat exchanger (3), a high-pressure low-temperature storage tank (4), a low-temperature expansion machine set (6) and a low-temperature heat exchanger (3) are communicated in sequence; a driving unit (9) drives the high-pressure compressor set (1), and the low-temperature expansion machine set (6) drives the low-pressure compressor set (1'); the energy release subsystem comprises a self-pressurization unit (5) and an acting unit; and the high-pressure and low-temperature storage tank (4), the cold accumulator (2), a heat accumulator / heat exchanger (7) and a main expansion machine set (8) are connected in sequence, and the main expansion machine set (8) drives a power generator (24). The energy storage system disclosed by the invention has the advantages of high energy density, high efficiency, no power consumption in the power generation stage, suitability for various power stations, no greenhouse gas generation, capability of recovering intermediate-temperature and low-temperature waste heat and the like.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

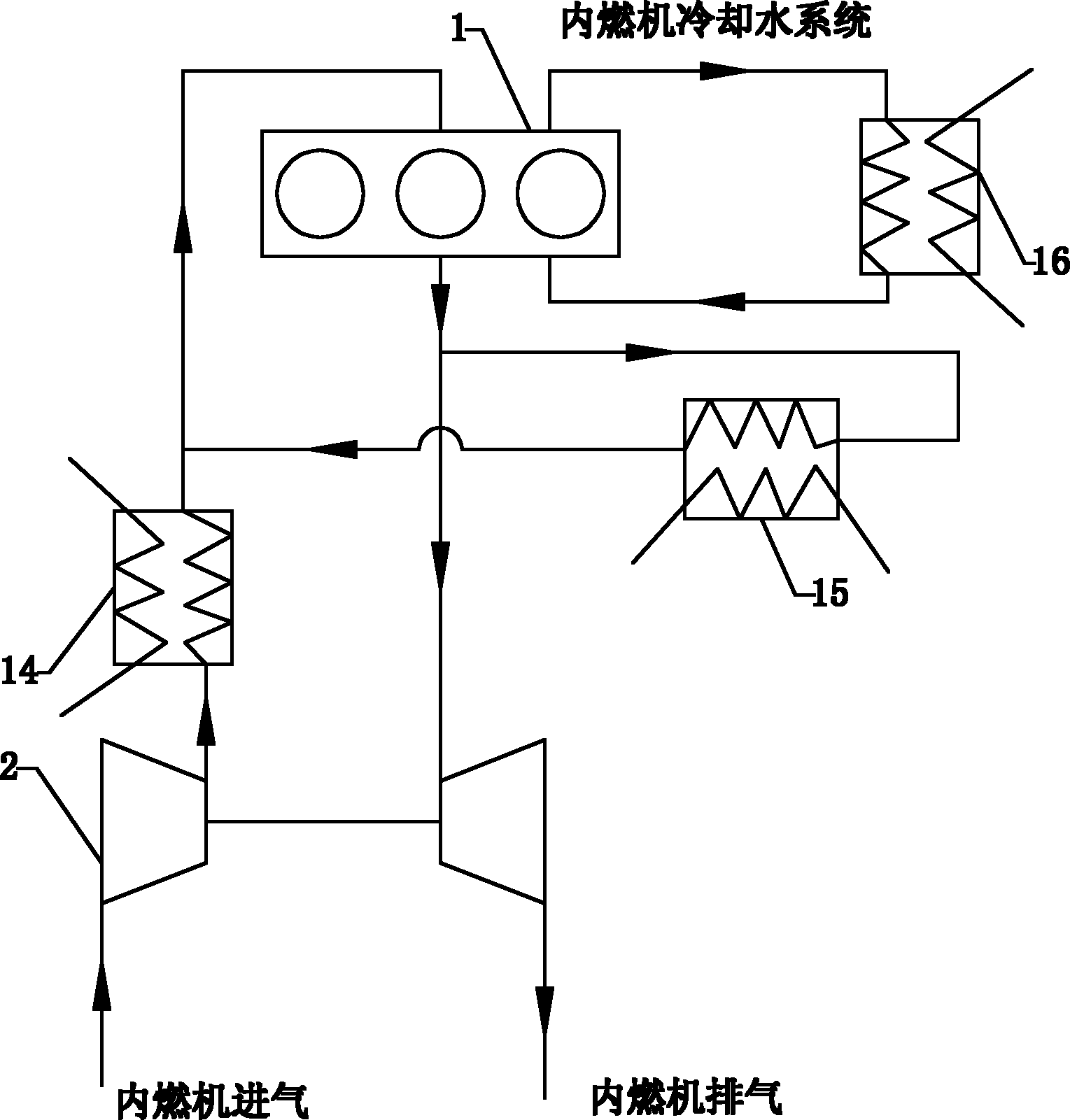

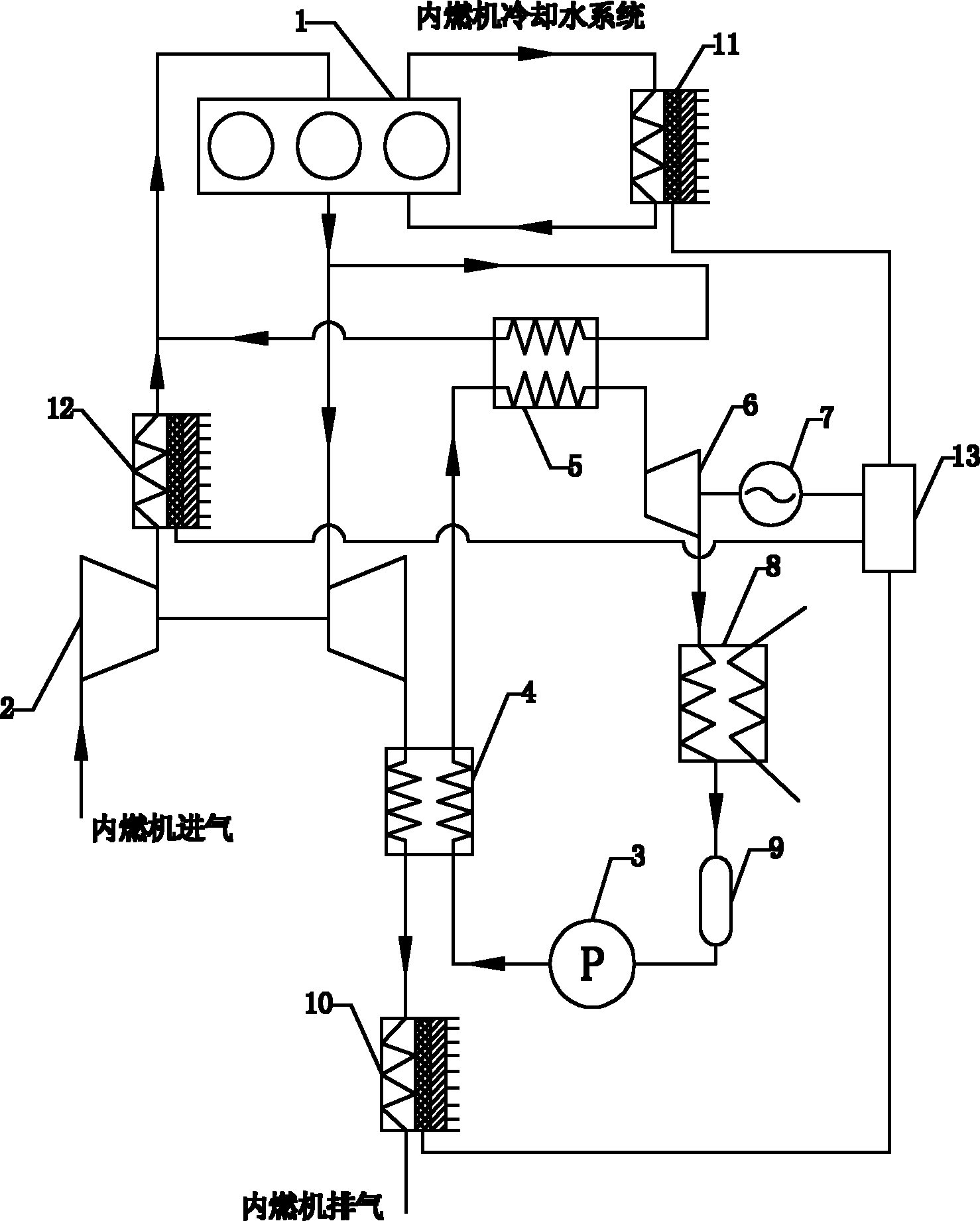

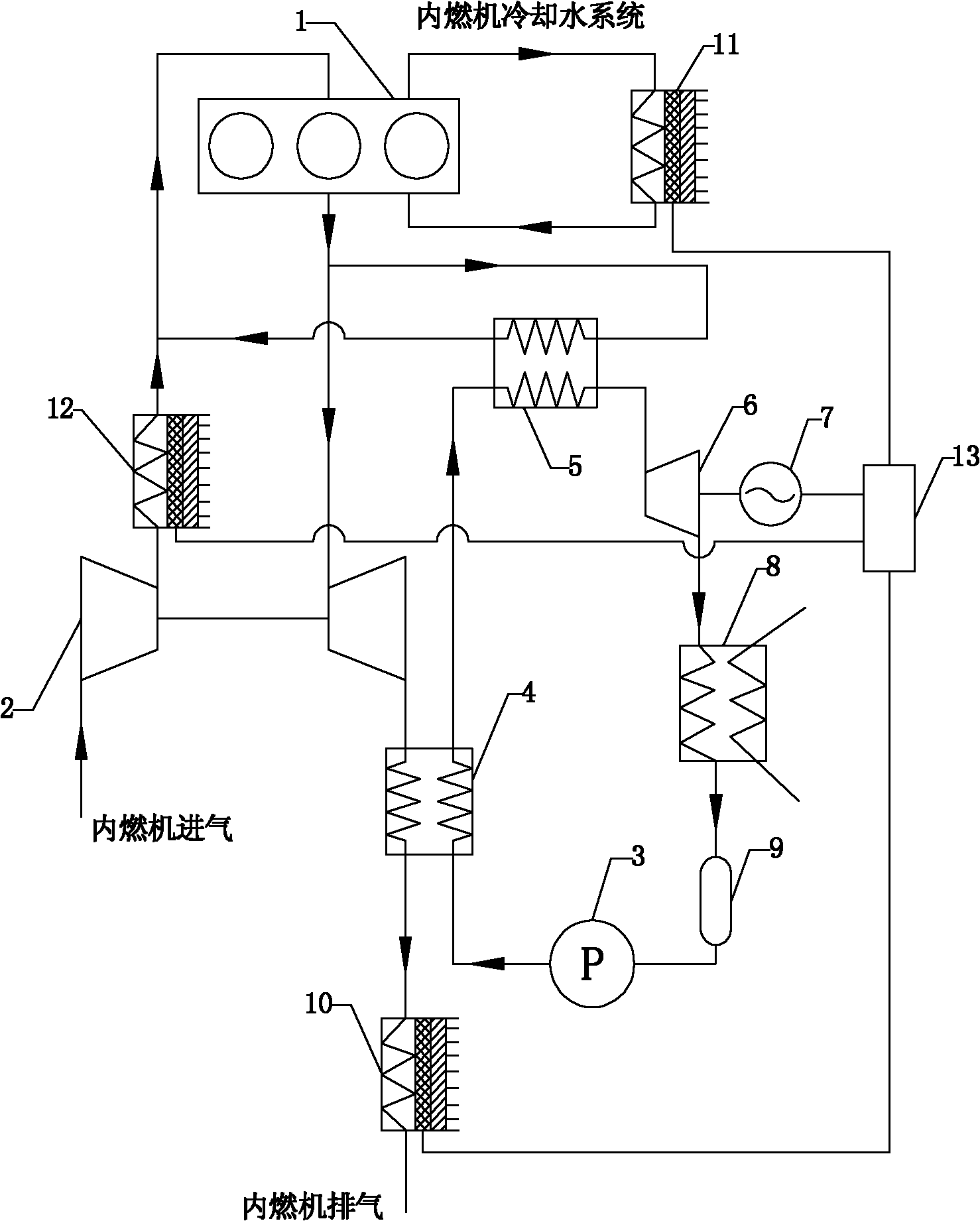

Combined-type residual heat recovery system suitable for internal combustion engine

InactiveCN102182583AImprove fuel economyGuaranteed efficiencyInternal combustion piston enginesEngine componentsTurbochargerExternal combustion engine

The invention discloses a rankine cycle and temperature difference power generating module combined-type residual heat recovery system suitable for an internal combustion engine. The system comprises an intermediate temperature residual heat recovery subsystem and a low temperature residual heat recovery subsystem; a hydraulic pump, an evaporator, an over-heating device, an expander, a condenser and a liquid storage device in the intermediate temperature residual heat recovery subsystem are sequentially connected, and the intermediate temperature residual heat in the internal combustion engine is recycled by adopting a rankine cycle technology by the intermediate temperature residual heat recovery subsystem; tail gas emitted by a turbine end of a turbosupercharger is taken as a heat source for the evaporator; tail gas of an EGR (exhaust gas recirculation) system of the internal combustion engine is taken as a heat source for the over-heating device; the expander is connected with a power generator through a crankshaft of the expander, and the power energy output end of the power generator is connected with an energy recovery device; and in the low temperature residual heat recovery subsystem, three semi-conductor temperature difference power generating modules are adopted to recycle the tail gas heat at the outlet end of the evaporator of the intermediate temperature residual heat recovery subsystem, the heat of the supercharge air at the end port of a gas compressor of the turbosupercharger and the heat of the cooling water of a motor. According to the invention, the rankine cycle and the temperature difference power generating module are adopted to be combined to recycle the residual heat of the internal combustion engine, so that not only is the fuel oil economy of the internal combustion engine improved, but also the volume of the integral residual heat recovery system is reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

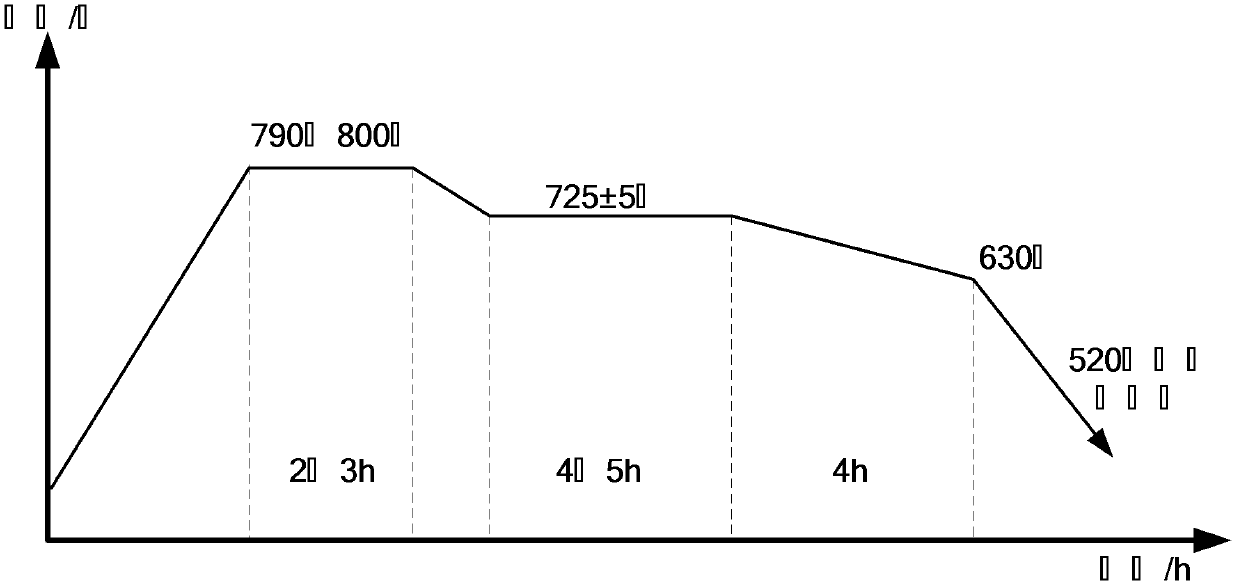

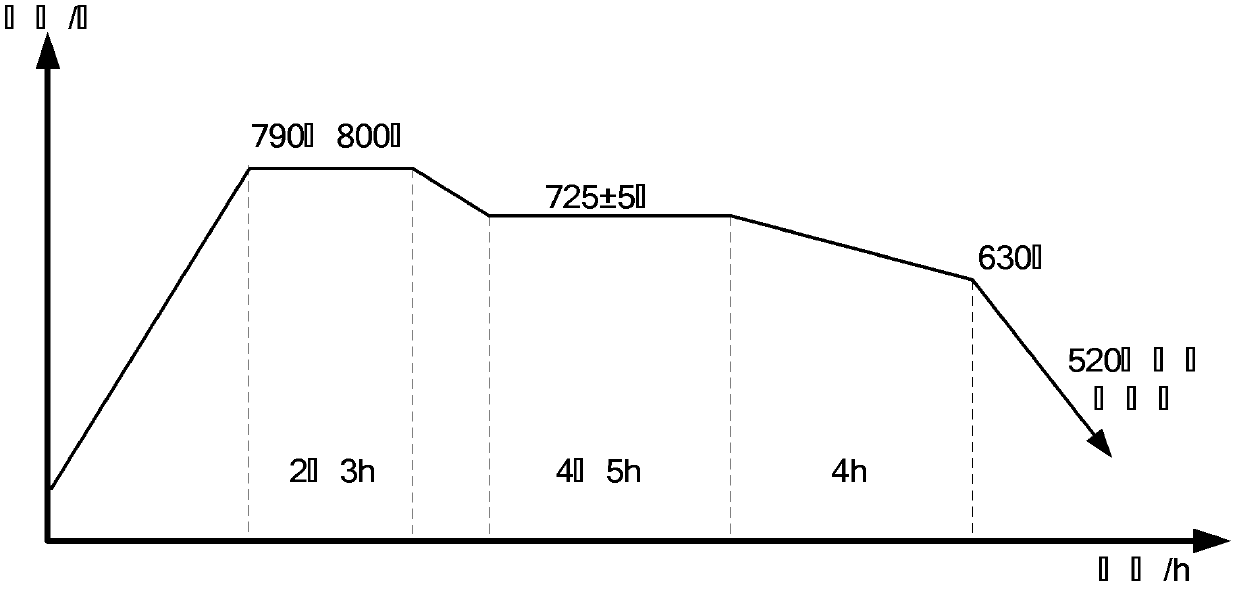

Spheroidized annealing technology for GCr15 bearing steel

The invention relates to a spheroidized annealing technology for GCr15 bearing steel. The GCr15 bearing steel comprises the following components in percentage by mass: 0.95 to 1.05 percent of C, 0.25 to 0.45 percent of Mn, 0.15 to 0.35 percent of Si, less than or equal to 0.025 percent of S, less than or equal to 0.025 percent of P, 1.40 to 1.65 percent of Cr, less than or equal to 0.10 percent of Mo, less than or equal to 0.30 percent of Ni, less than or equal to 0.25 percent of Cu, less than or equal to 0.50 percent of Ni and Cu, and the balance of Fe. The spheroidized annealing technology for the GCr15 bearing steel is characterized by comprising the following steps of: heating the components to the temperature of between 790 and 800 DEG C together with a furnace, and performing high-temperature heat preservation at the temperature; cooling the heated components to the temperature of 725+ / -5 DEG C, and performing intermediate-temperature heat preservation; and slowly cooling to thetemperature of 630 DEG C, quickening the cooling rate, cooling to the temperature of below 520 DEG C, discharging and performing air cooling. The technology is simple, the structure and the mechanical properties of the GCr15 bearing steel are suitable for subsequent plastic processing forming, and a structure preparation is made for final quenching and tempering.

Owner:WISDRI WUHAN WIS IND FURNACE

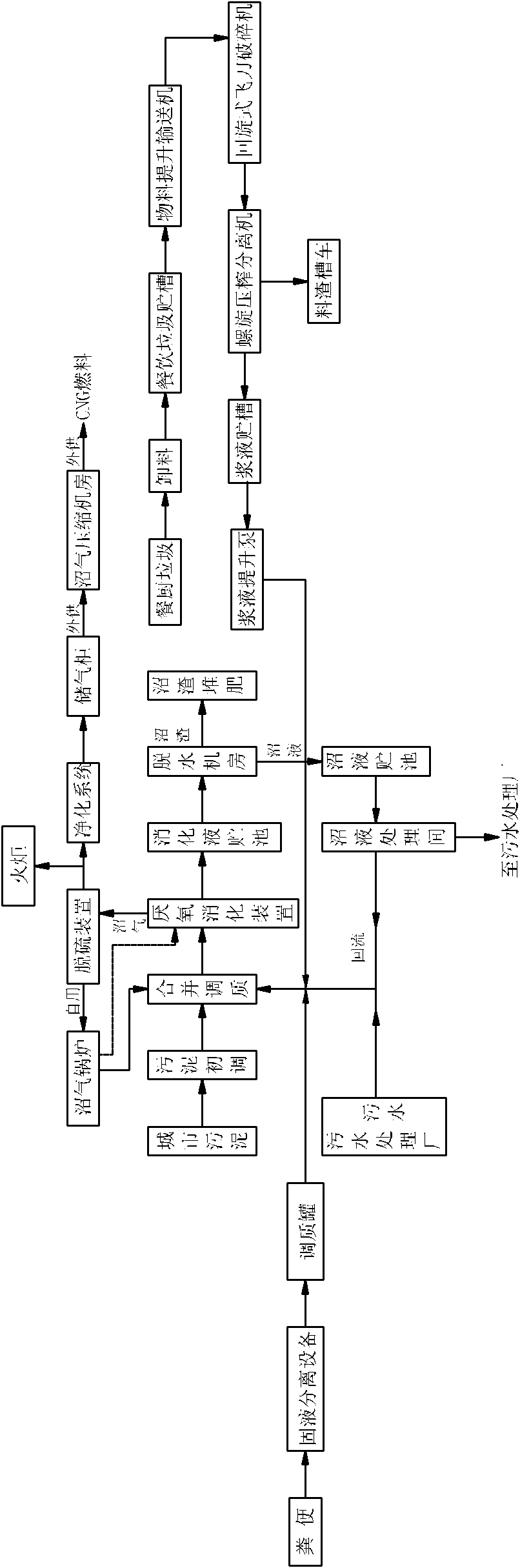

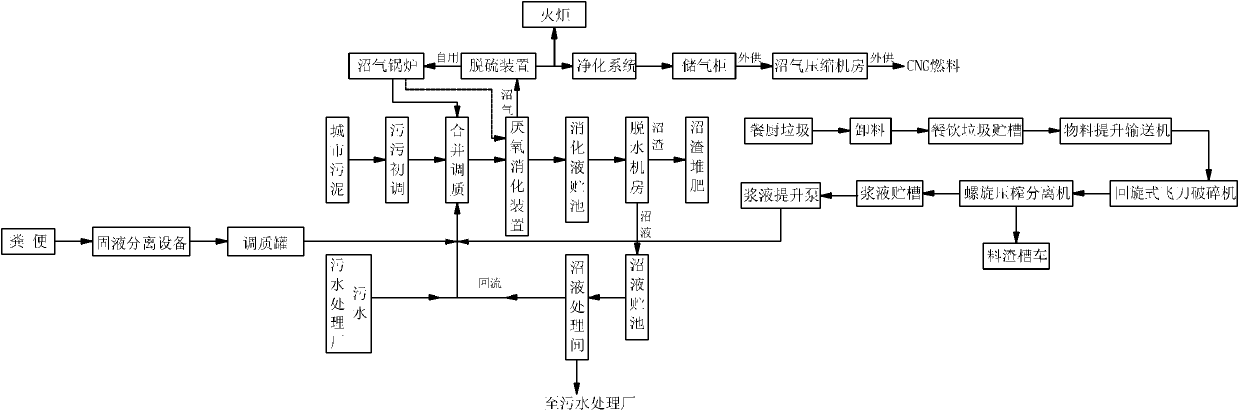

Urban sludge, excrement and kitchen garbage combined treatment process

ActiveCN102167486ASave engineering investmentSmall footprintWaste based fuelTreatment with anaerobic digestion processesEngineeringPre treatment

The invention relates to an urban sludge, excrement and kitchen garbage combined treatment process as a novel process, in particular to an urban sludge, excrement and kitchen garbage combined treatment process under the demands of lower investment from government, less occupying area and lower running cost. In the combined treatment process, a pretreatment unit, a combined tempering unit, an intermediate-temperature anaerobic digestion unit, a digestive juice dewatering unit, a methane purifying unit and a biogas treating unit are included. The invention provides a novel treatment process in order to solve the problems of pollution from urban sludge, excrement and kitchen garbage.

Owner:DALIAN MUNICIPAL DESIGN & RES INST

Thermometer, electronic device having a thermometer, and method for measuring body temperature

ActiveUS7249883B2Improve accuracyHigh precision measurementThermometer detailsThermometers using electric/magnetic elementsHeat resistanceEngineering

A deep-area temperature calculating device 441 calculates the temperature Tcore of a deep area on the basis of a first body-surface temperature and second body-surface temperature from body-surface sensors 31A and 31B, and on the basis of a first intermediate temperature and second intermediate temperature from intermediate sensors 32A and 32B. Since the temperature Tcore of the deep area is determined from two body-surface temperatures and two intermediate temperatures, the temperature Tcore of the deep area can be calculated regardless of the heat resistance of the thermometer without making any assumptions regarding the heat resistance of the area that extends from the deep area of the human body to the body surface. Thereby, the temperature Tcore of the deep area can be calculated and the body temperature can be measured with high precision regardless of differences in the body type or contact with clothing or bedding.

Owner:SEIKO EPSON CORP

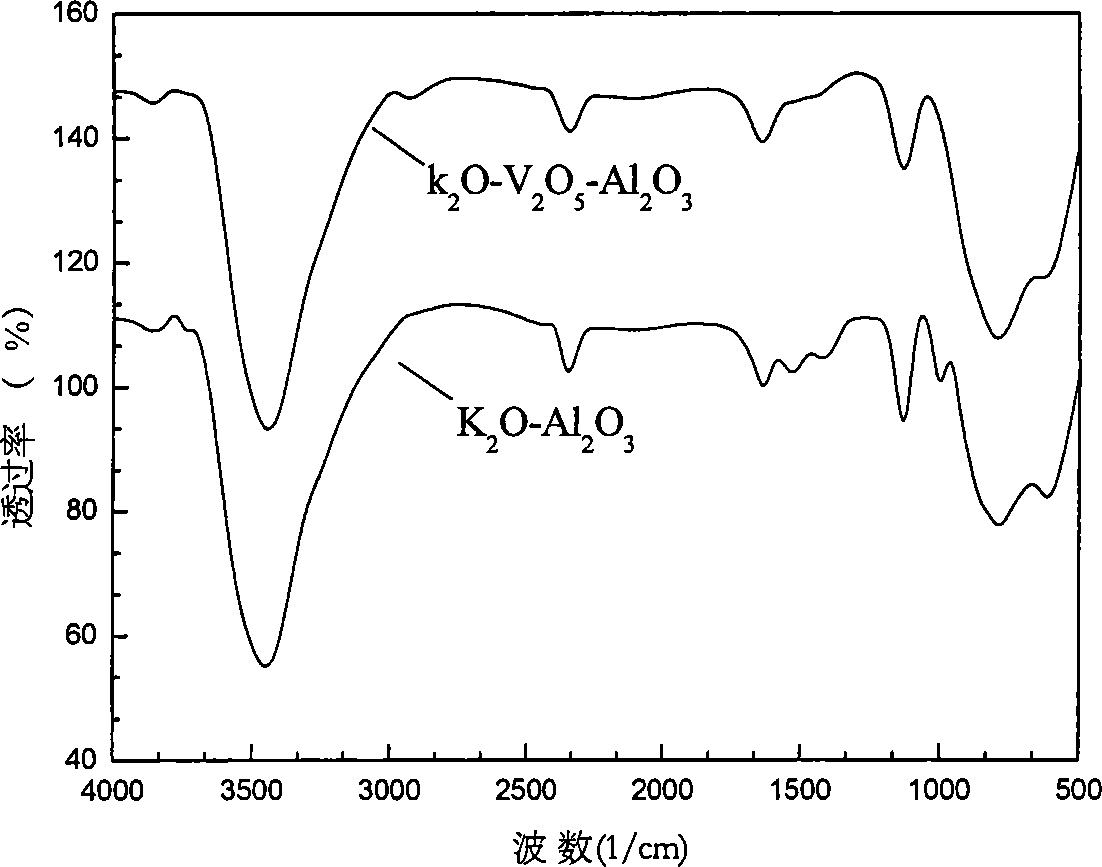

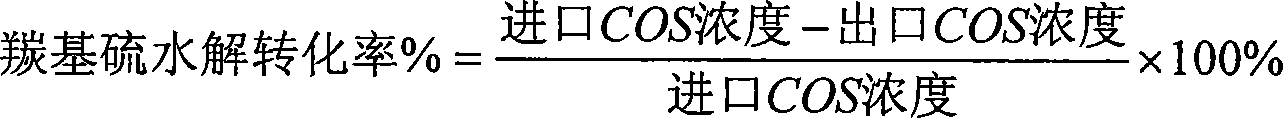

Intermediate temperate carbonyl sulfur hydrolyst and method of preparing the same and use thereof

InactiveCN101108339AOvercome the deficiency of easy sulfation poisoningDispersed particle separationGas purification by catalytic conversionSulfateSulfur

An intermediate temperate carbonyl sulfur hydrolysis catalyst and the preparation method and use is provided, which belongs to the technology field of catalyst and the preparation method and use. The invention is mainly improving the anti-sulfate performance of the catalyst under intermediate temperature by adding modifier V2O5 to change the composite of the catalyst, the preparation method is that: mix the components of catalyst with porous materials components evenly, add water or nitric acid to knead, extrude to forming, then dry and activate. When the catalyst is Phi 3mm multiple 5mm industrial grain, under the normal pressure, the reaction temperature is 200 to 400 DEG C., the airspeed is 4000 to 10000h-1, the concentration of COS is lower than 500mgS / m3. The catalyst in the invention has high COS hydrolysis activity and anti-sulfate performance, the COS hydrolysis conversion rate is more than 99 per cent, which can be used in 200 to 400 DEG C. COS hydrolysis conversion in the feed gas with a 0 to 12 per cent of 02 content.

Owner:TAIYUAN UNIV OF TECH

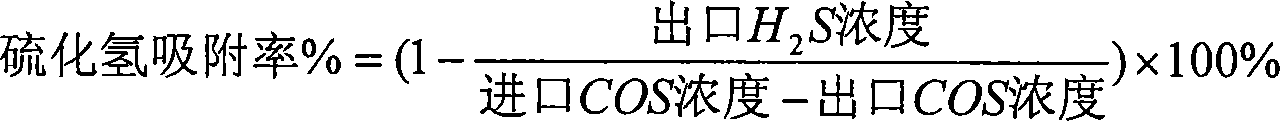

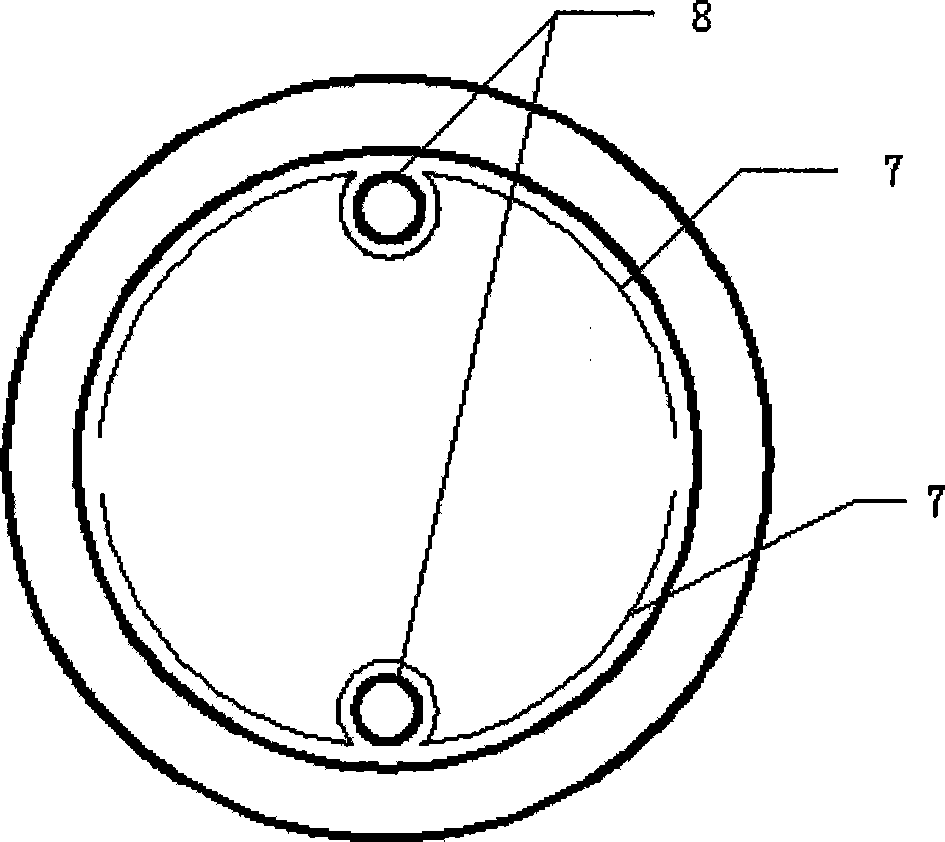

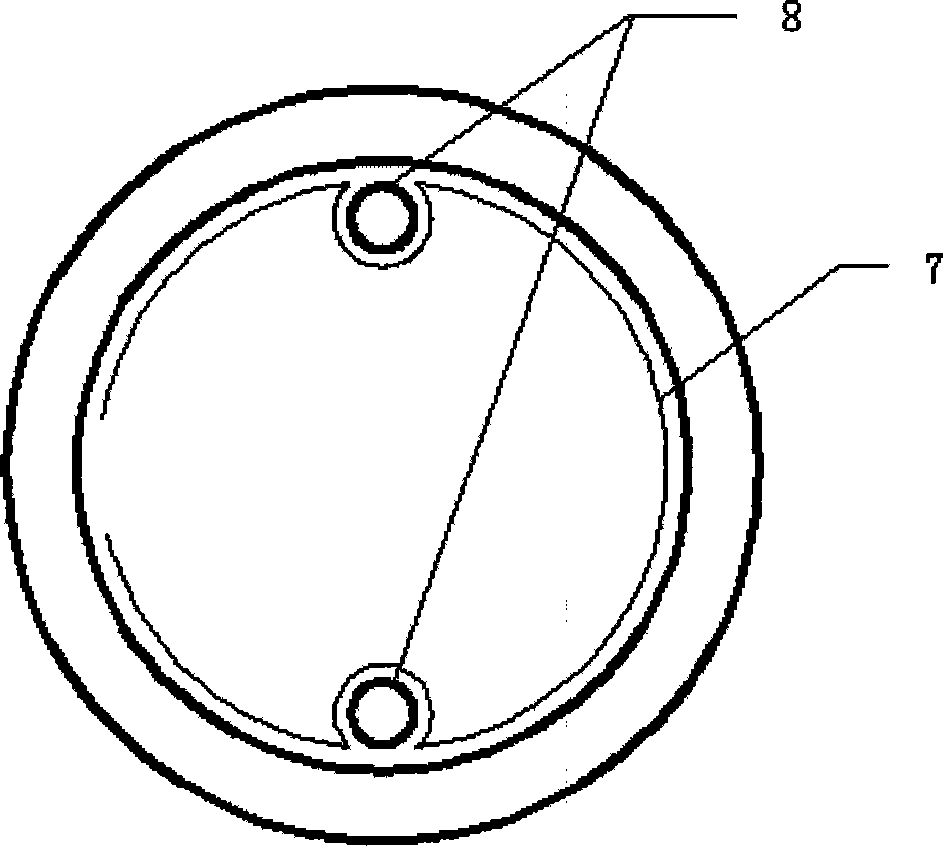

Medium temperature glass-metal structure solar vacuum thermal-collecting tube

InactiveCN101392965AMeet solar air conditioningFulfil requirementsSolar heating energySolar heat devicesMaterials scienceMetallic Nickel

The invention discloses an intermediate temperature glass-metallic structure solar vacuum thermal-collecting tube, which belongs to the technical field of solar utilization, wherein a layer of temperature-resistant anti-oxidation film is plated on the outer surface of a heat-transfer pipe provided with a heat-conductive wing in the intermediate temperature glass-metallic solar vacuum thermal-collecting tube, and the film layer is aluminum or zinc or nickel or chromium or stainless steel; the heat-conductive wing is a thin aluminum plate which is coiled into the shape of an opening cylinder or a semicircular cylinder, and is tightly connected or welded with a U-shaped copper tube or a copper heat pipe of the temperature-resistant anti-oxidation film; and a heat-conductive wing tube is arranged inside the all-glass solar vacuum thermal-collecting tube, and closely contacts the inner wall of the all-glass solar vacuum thermal-collecting tube. A non-evaporable getter can be arranged inside a vacuum interlayer of the all-glass solar vacuum thermal-collecting tube, thereby improving the vacuum service life of the all-glass solar vacuum thermal-collecting tube after the long-term operating temperature is extended to more than 140 DEG C. The invention is a novel intermediate temperature glass-metallic solar vacuum thermal-collecting tube with high cost performance, and can meet the requirements of solar air-conditioners and industrial heat.

Owner:TSINGHUA UNIV

Low alkali sealing frits, and seals and devices utilizing such frits

A solid oxide fuel cell device incorporates a sealing material resistant to hydrogen gas permeation at a sealing temperature in the intermediate temperature range of 600° C.-900° C., the seal having a CTE in the 100×10−7 / ° C. to 120×10−7 / ° C., wherein the sealing material comprises in weight %, of: (i) a 80 wt % to 100 wt % glass frit, the glass frit itself having a composition comprising in mole percent of: SiO2 15-65; Li2O 0-5; Na2O 0-5; K2O 0-10; MgO 0-5; CaO 0-32; Al2O3 0-10; B2O3 0-50; SrO 0 to 25, wherein the total amount of alkalis is less than 10 mole %; and (ii) zirconia or leucite addition 0 wt % to 30 wt.

Owner:CORNING INC

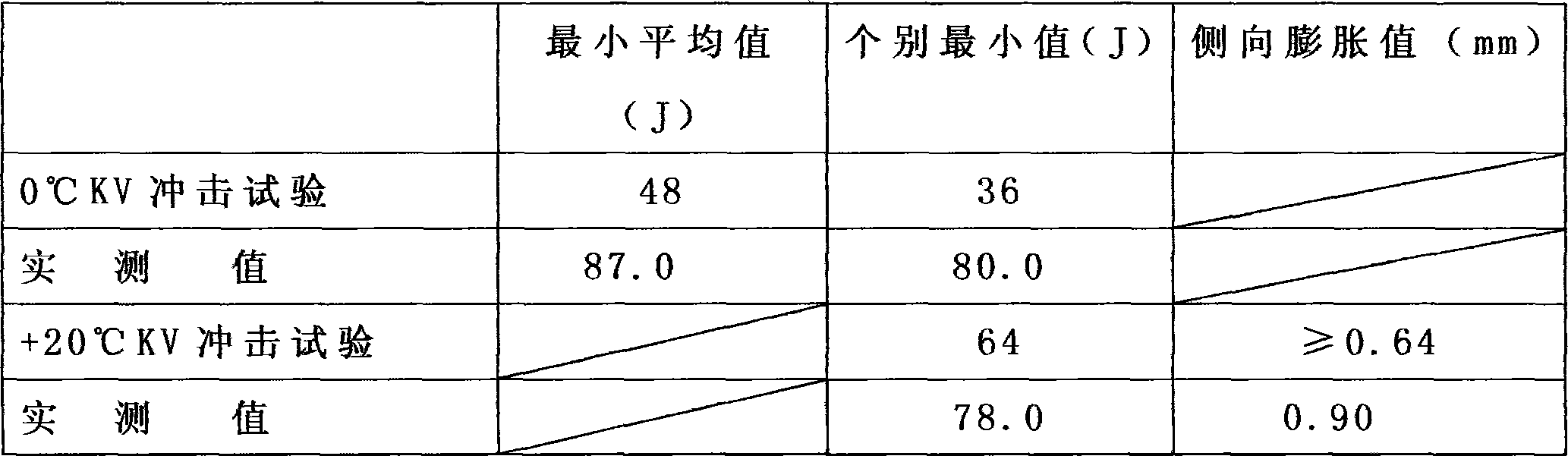

Million - kilowatts class nuclear power station reactor main bolt production process

ActiveCN101169150AUniform tissueFully heatedNuclear energy generationScrewsNuclear engineeringNuclear power

The invention discloses a pile main bolt manufacturing technique of a million kilowatt grade nuclear power station. The manufacturing technique includes material-selecting, melting, heating, forging, cooling, after-forging heat treatment, defect-detecting, and forging capability heat treating. When selecting the material, the microelement content of the materials is controlled, the heat preserving duration in the intermediate temperature stage is prolonged, the heat raising and the heat preserving duration in the high temperature stage are reduced, the distortion volume in the course of the forging is controlled between 30 percent and 70 percent, the forging rate reaches 5 above; after-forging heat treatment, ultrasonic defect detecting, and forging capacity heat treating are conducted when the forging is finished. The main bolt produced according to the manufacturing technique of the invention can improve the impact value under the circumstance that the intensity keeps unchanged, theproduct can meet the RCC-M standard requirements completely, and the reliability and the safety of the pile pressure container using the main bolt of the million kilowatt grade nuclear power station can be ensured.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com