Intermediate temperate carbonyl sulfur hydrolyst and method of preparing the same and use thereof

A hydrolysis catalyst and carbonyl sulfide technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., to achieve considerable economic and social benefits, and to overcome the effect of easy sulfation poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

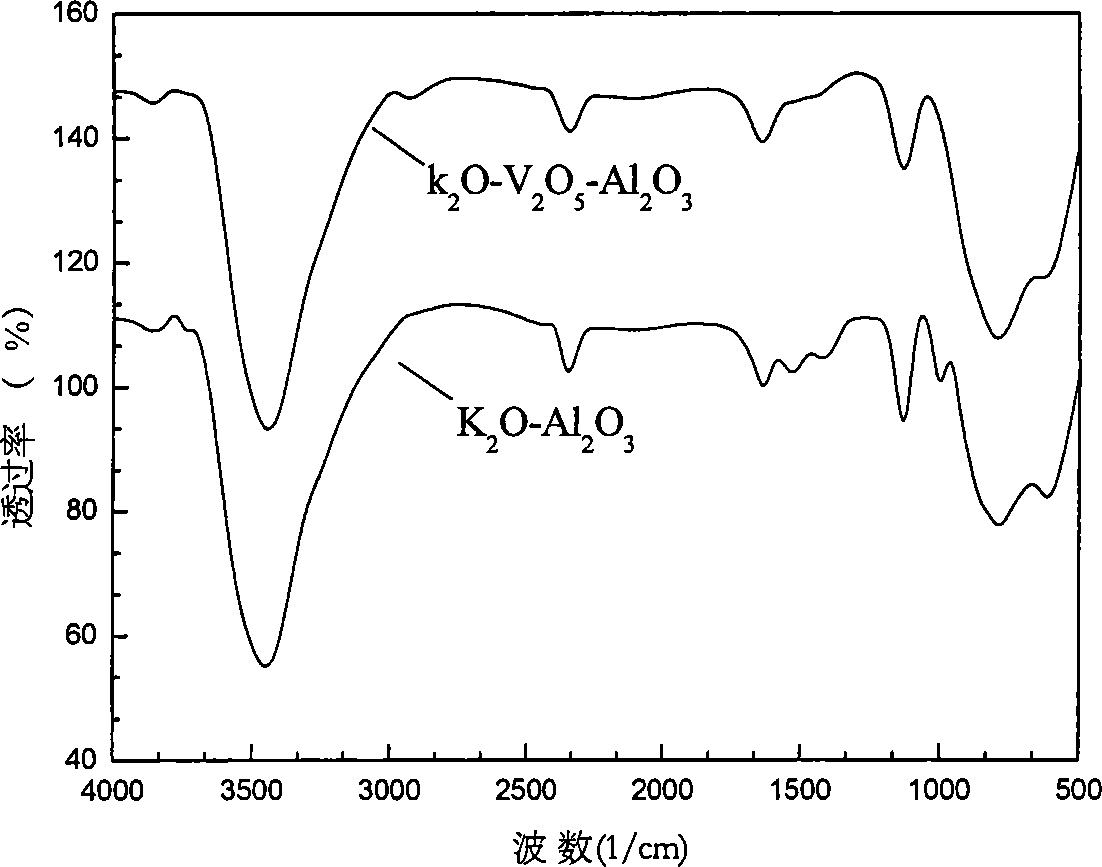

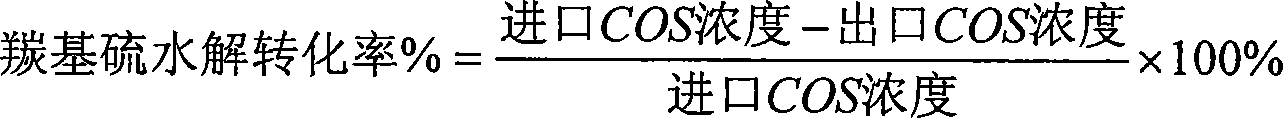

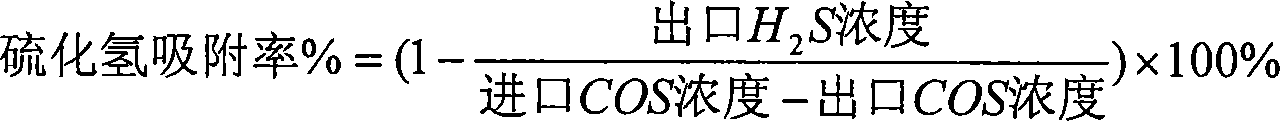

[0024] Take by weighing five parts of pseudo-boehmite that are respectively 113.8g, 110.6g, 107.5g, 104.4g, 101.2g in weight, add 10g of vanadium pentoxide and mix evenly in five parts of pseudo-boehmite, then Add 0g, 3.8g, 7.5g, 11.3g, and 15g of potassium carbonate to five parts of pseudoboehmite and vanadium pentoxide mixture, and finally add 4g of carboxymethyl cellulose, 6g of ammonium bicarbonate, 3g of A pore-forming agent composed of three components of polyvinyl alcohol, all raw materials are mixed evenly, add deionized water, and after kneading, the strips are often warm-extruded to obtain particles with a size of φ3mm×5mm, and dried at 100°C for 4 hours. Calcined at 550°C for 4 hours to obtain K 2 Five medium-temperature carbonyl sulfide hydrolysis catalysts with O contents of 0%, 2.5%, 5%, 7.5% and 10%, respectively. Catalyst at a temperature of 300°C and a space velocity of 10000h -1 , Import COS concentration 200~500mgS / m 3 Carry out carbonyl sulfide hydrolysi...

Embodiment approach 2

[0028] Take by weighing five parts of pseudo-boehmite that are respectively 113.8g, 107.5g, 101.2g, 94.9g, 88.6g in weight, add 15g of potassium carbonate in five parts of pseudo-boehmite and mix evenly, then in five parts of pseudo-boehmite Add 0g, 5g, 10g, 15g, and 20g of vanadium pentoxide to the mixture of pseudoboehmite and potassium carbonate in sequence, and finally add 4g of carboxymethyl cellulose, 6g of ammonium bicarbonate, and 3g of polyvinyl alcohol three A pore-forming agent composed of three components, all the raw materials are mixed evenly, add deionized water, and after kneading, the strips are often warm-extruded to obtain particles with a size of φ3mm×5mm, dried at 100°C for 4 hours, and roasted at 550°C Get V in 4 hours 2 o 5 Five medium-temperature carbonyl sulfide hydrolysis catalysts with content of 0%, 5%, 10%, 15% and 20% respectively. Catalyst at a temperature of 300°C and a space velocity of 10000h -1 , Import COS concentration 200~500mgS / m 3 Ca...

Embodiment approach 3

[0032] Take by weighing 101.2g of pseudo-boehmite, add 15g of potassium carbonate to the pseudo-boehmite and mix evenly, then add 10g of vanadium pentoxide to the mixture of pseudo-boehmite and potassium carbonate, and finally add 4g Carboxymethyl cellulose, 6g of ammonium bicarbonate, and 3g of polyvinyl alcohol are three components of a pore-forming agent. All raw materials are mixed evenly, and deionized water is added. The particles of ×5mm were dried at 100°C for 4 hours and calcined at 550°C for 4 hours to obtain a medium-temperature carbonyl sulfide hydrolysis catalyst. The catalyst is at a space velocity of 10000h -1 , COS concentration is 200~500mgS / m 3 Under these conditions, the hydrolysis conversion rate of carbonyl sulfide and the adsorption rate of hydrogen sulfide were measured at five different temperatures of 200°C, 250°C, 300°C, 350°C, and 400°C. Table 3.

[0033] Table 3 Hydrolysis conversion rate of carbonyl sulfide and hydrogen sulfide adsorption rate on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com