Patents

Literature

432 results about "Carbonyl sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbonyl sulfide is the chemical compound with the linear formula OCS. Normally written as COS as a chemical formula that does not imply its structure, it is a colourless flammable gas with an unpleasant odor. It is a linear molecule consisting of a carbonyl group double bonded to a sulfur atom. Carbonyl sulfide can be considered to be intermediate between carbon dioxide and carbon disulfide, both of which are valence isoelectronic with it.

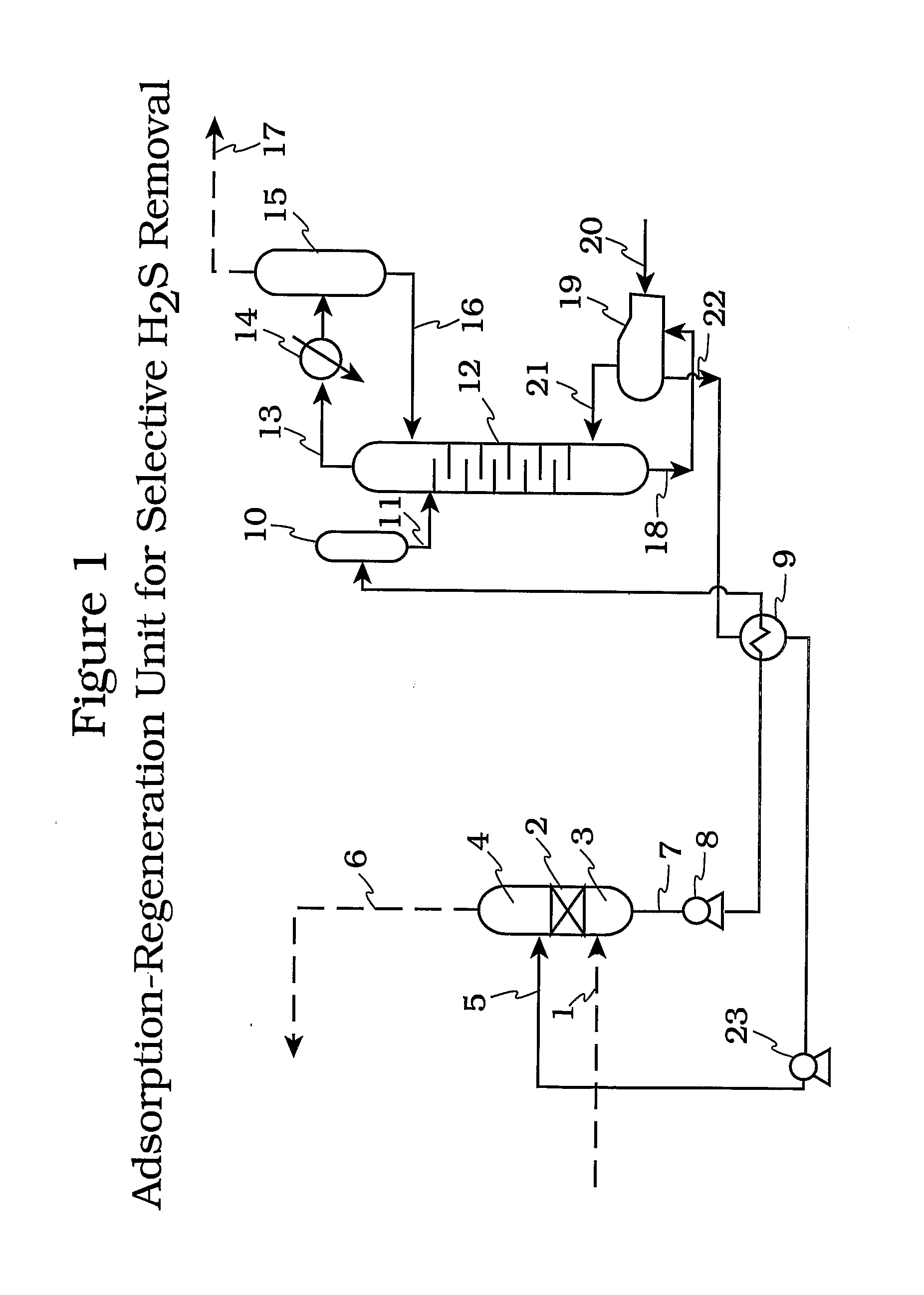

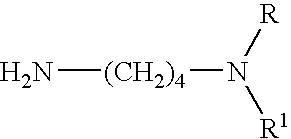

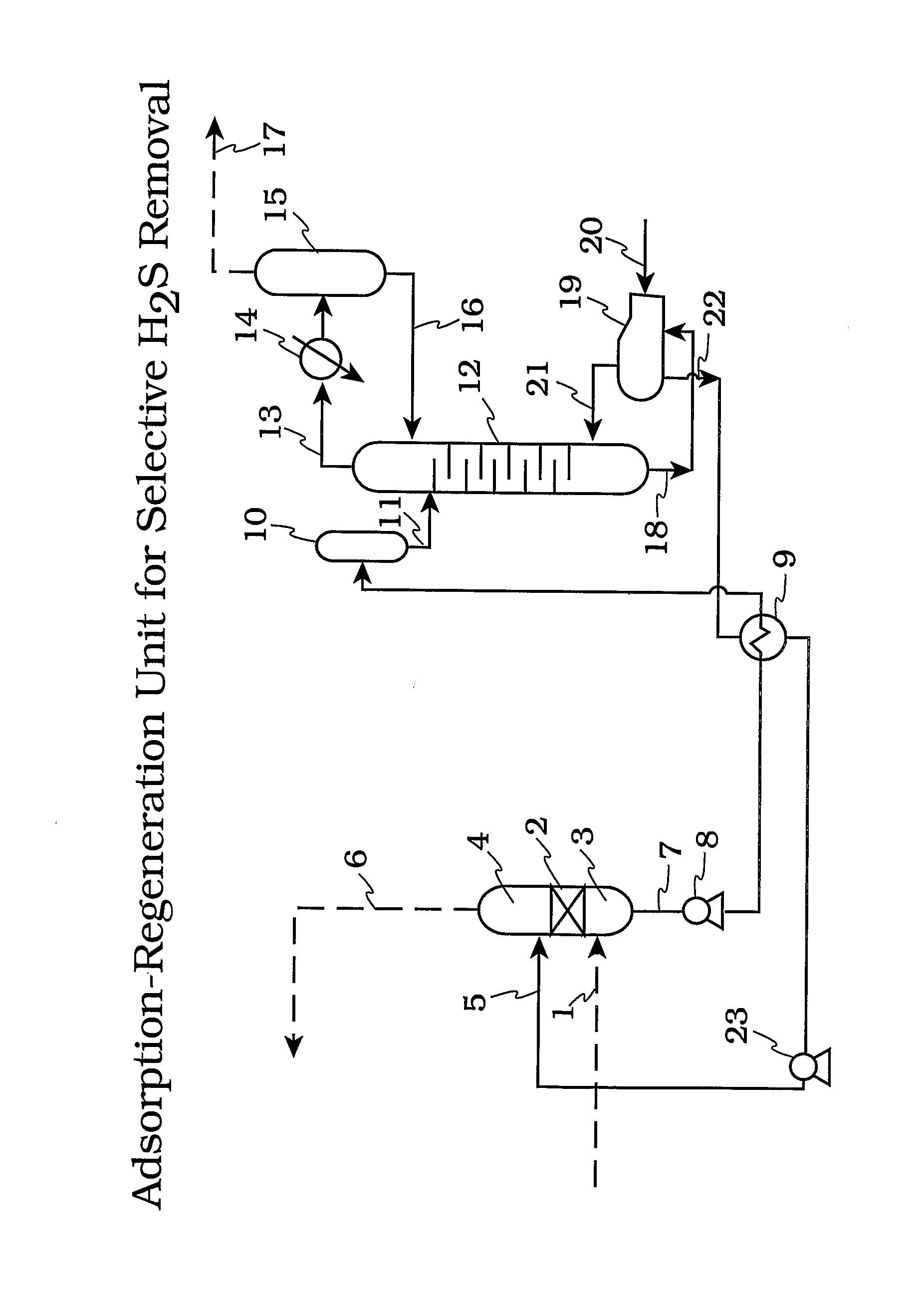

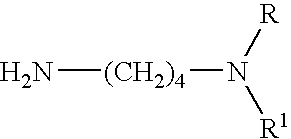

Absorbent composition containing molecules with a hindered amine and a metal sulfonate, phosphonate or carboxylate structure for acid gas scrubbing process

An acid gas absorbent comprising a metal sulfonate, phosphonate or carboxylate of a hindered amine and a process for the selective removal Of H2S as well as other acidic components such as carbon disulfide, carbonyl sulfide and oxygen and sulfur derivatives of C1 to C4 hydrocarbons from mixtures containing such acidic components and CO2 using said absorbent.

Owner:EXXON RES & ENG CO

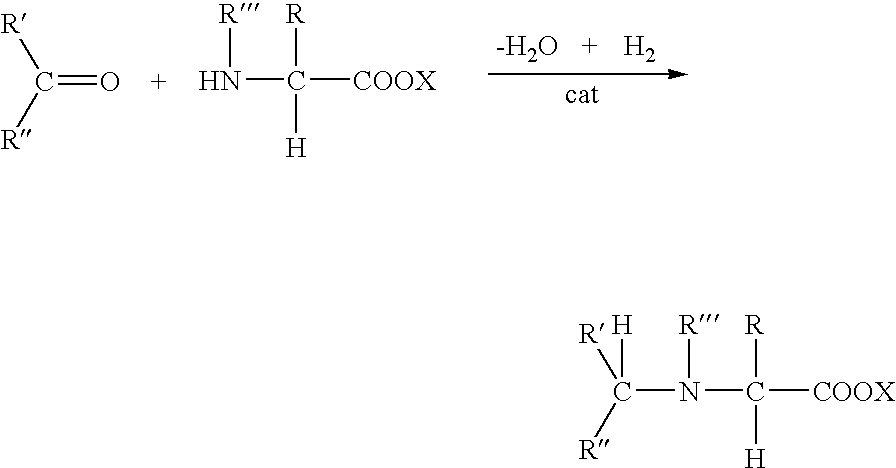

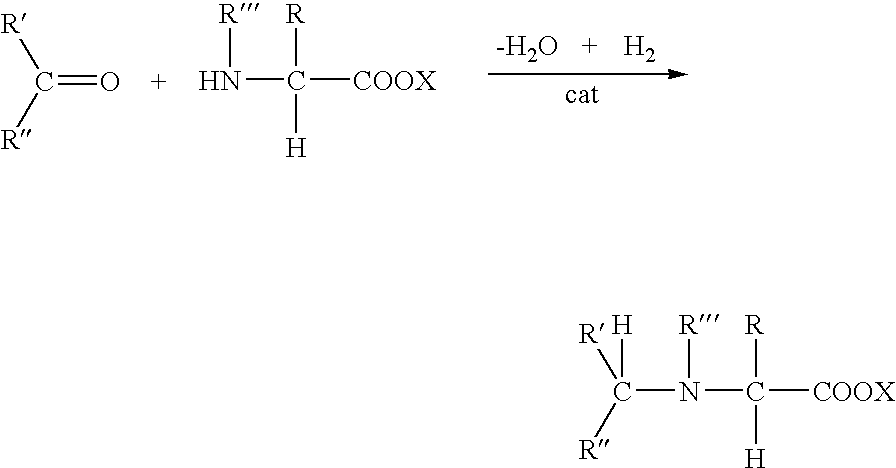

Process for the manufacture of carbon disulphide

InactiveUS7763227B2Significant costSignificant designCarbon disulfideHydrocarbon from carbon oxidesHydrogenCarbonyl sulfide

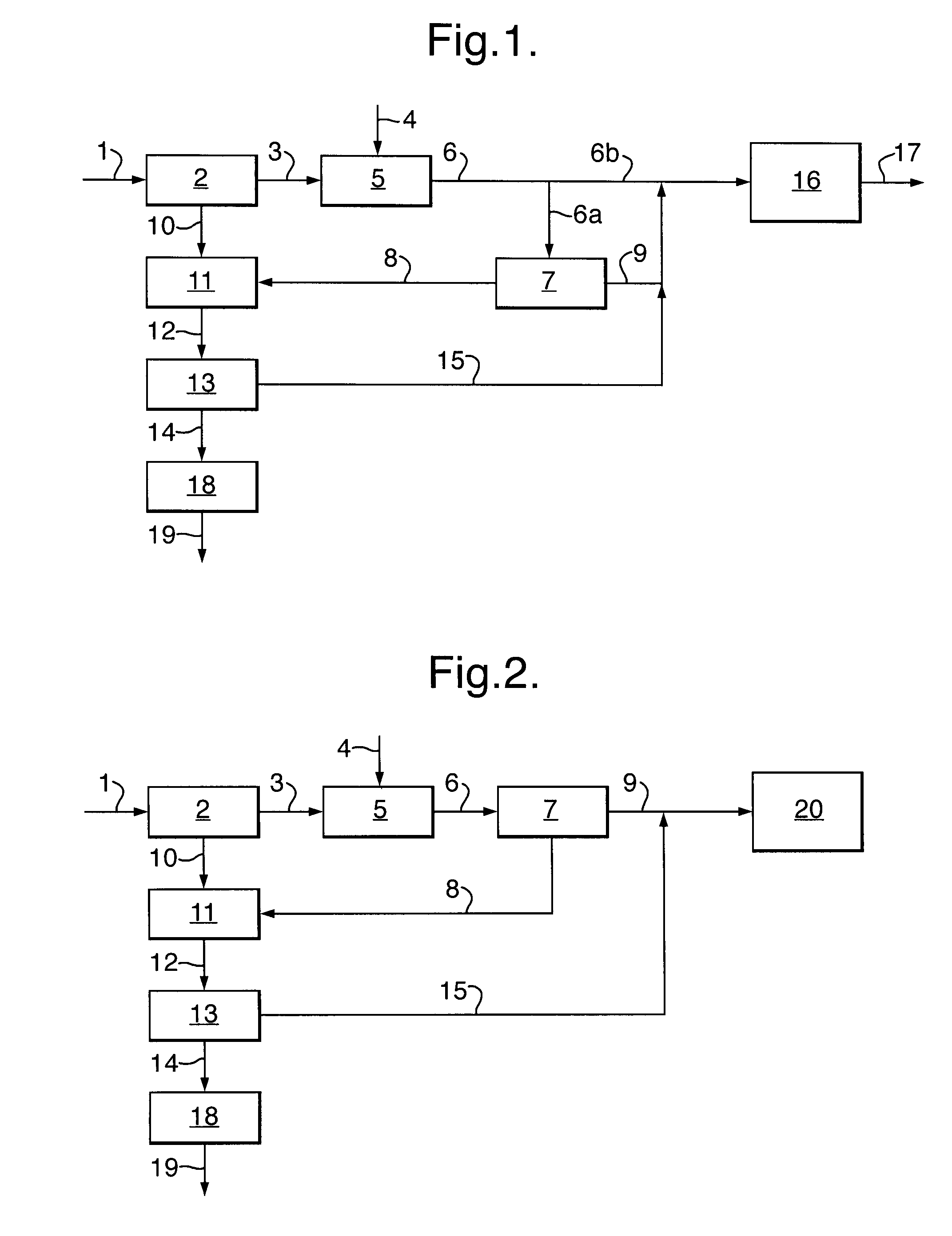

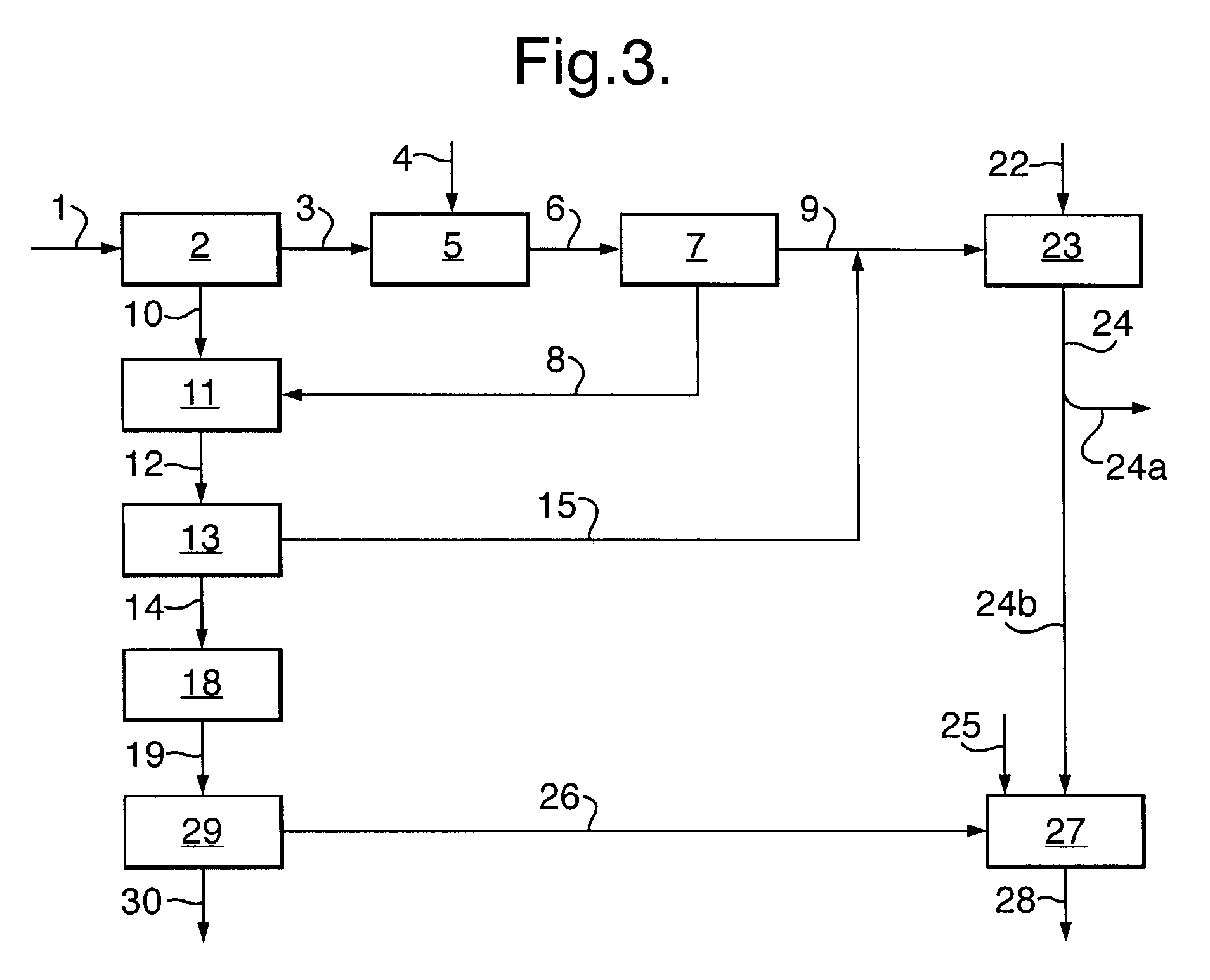

A process for the manufacture of carbon disulfide comprising the following steps: (a) reacting carbon monoxide with hydrogen sulfide to form carbonyl sulfide and hydrogen; (b) contacting the carbonyl sulfide formed in step (a) with a catalyst effective for disproportionating carbonyl sulfide into carbon disulfide and carbon dioxide.

Owner:SHELL OIL CO

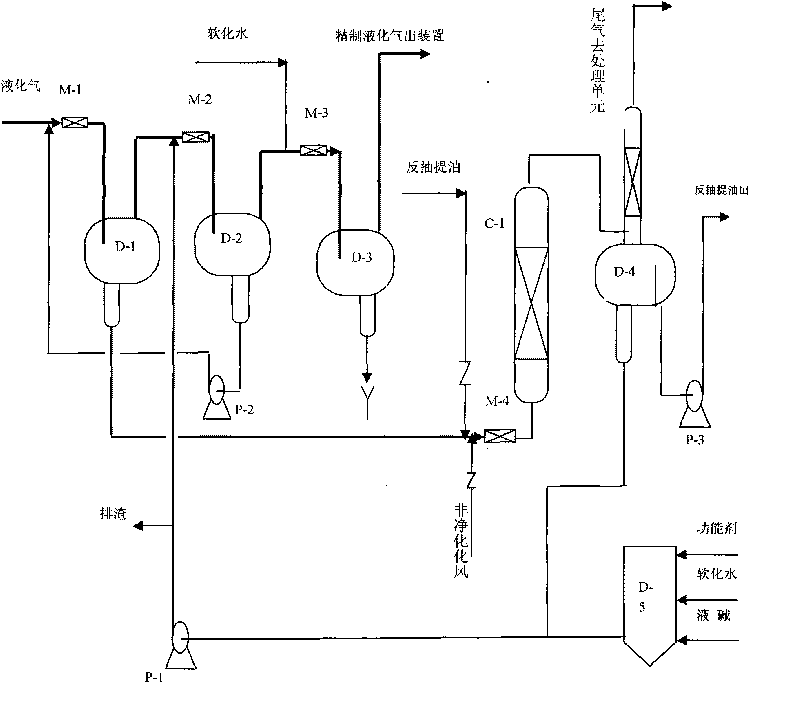

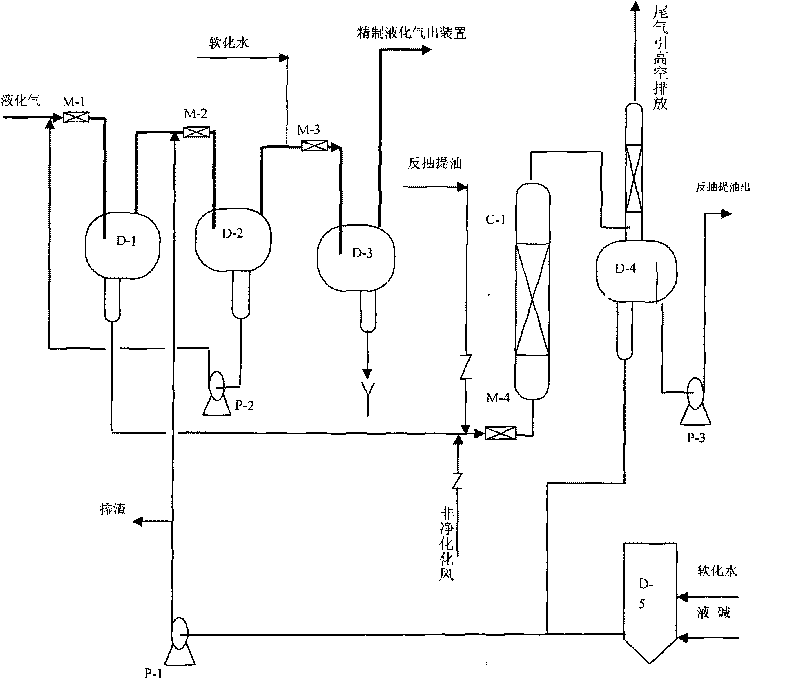

Deep desulfurization method for liquefied petroleum gas

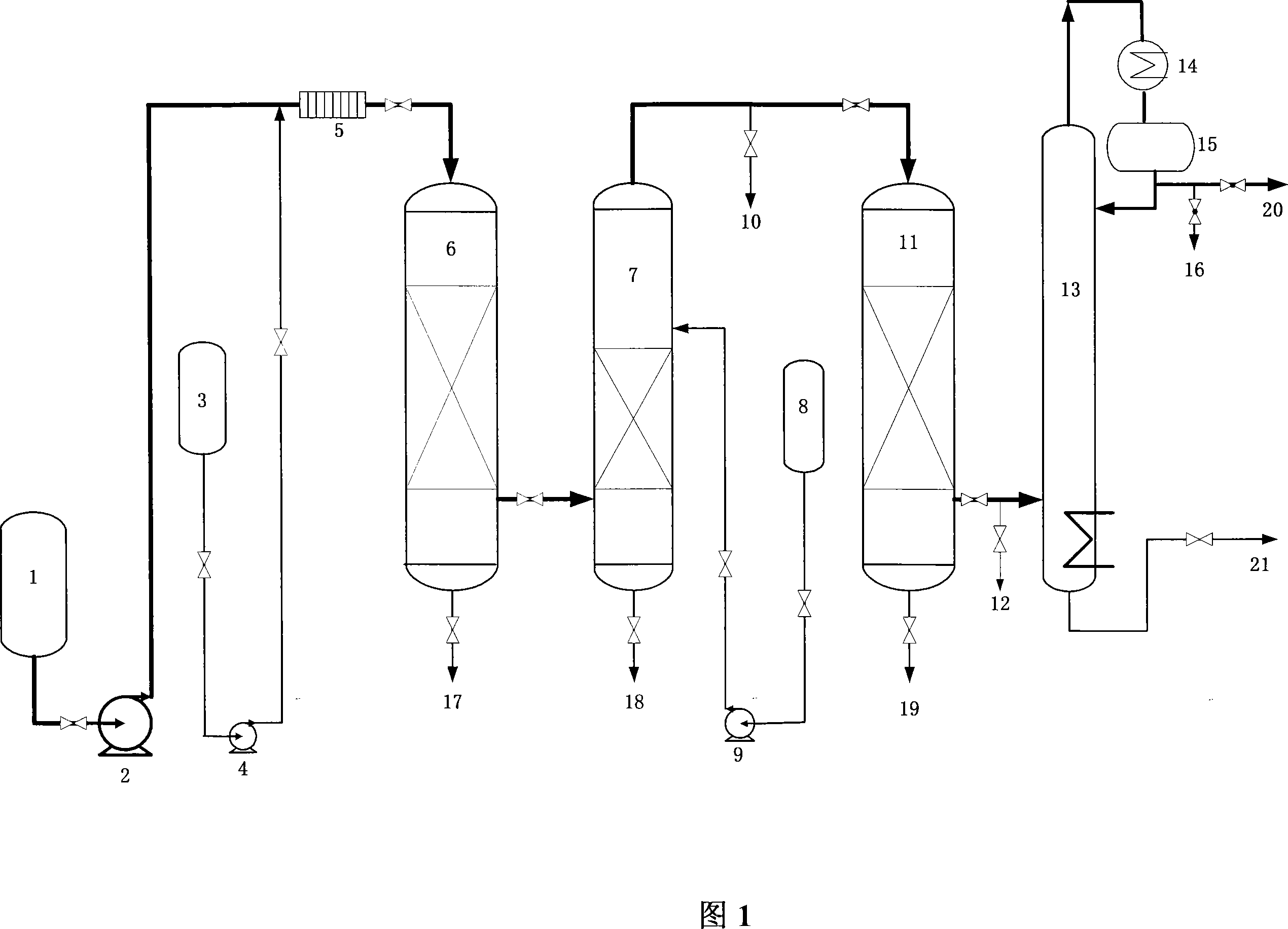

The liquefied petroleum gas deep desulfurizing process includes the following steps: mixing alcohol amine treated liquefied petroleum gas with desulfurizer aqua, feeding the mixture into a reactor with carbonyl sulfide hydrolyzing catalyst for hydrolyzing carbonyl sulfide into hydrogen sulfide and CO2 and eliminating hydrogen sulfide, regenerating the used desulfurizer, water washing the liquefied petroleum gas to eliminate residual desulfurizer with water containing dissolved oxygen or hydrogen peroxide in a water washing tower with hydrogen peroxide decomposing catalyst in the stuffing layer, eliminating mercaptan from the liquefied petroleum gas through oxidizing mercaptan into disulfide in a mercaptan eliminating reactor with catalyst, and final rectifying in a rectifying tower to eliminate disulfide. The process is simple and practical, and can lower the total sulfide content in liquefied petroleum gas to below 5 ppm.

Owner:北京石大世通科技发展有限公司

Liquid hydrocarbon mercaptan removal technique capable of deeply removing total sulfur

ActiveCN101705108AImprove abilitiesHigh activityGaseous fuelsRefining with aqueous alkaline solutionsSlagCarbonyl sulfide

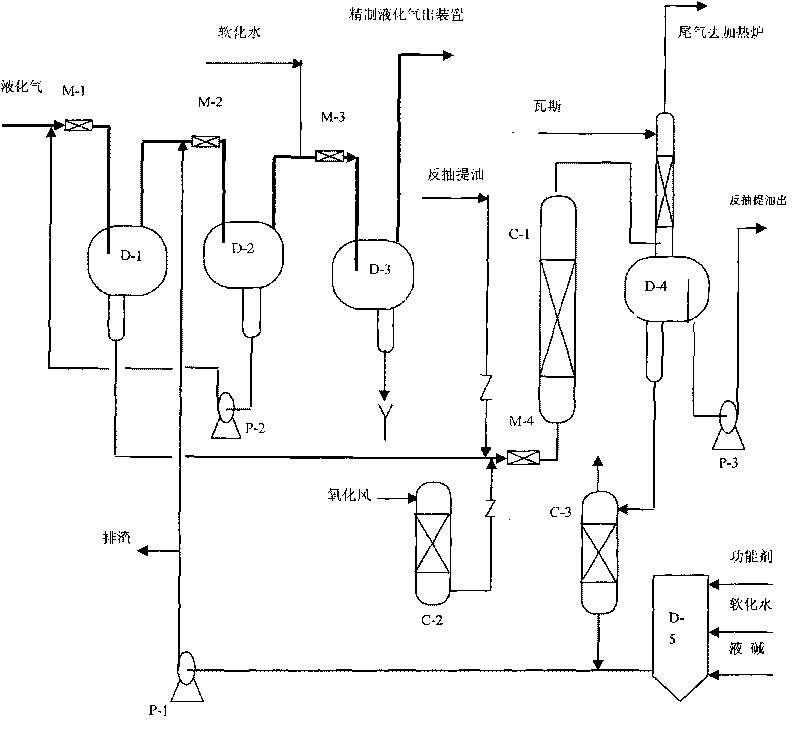

The invention relates to a liquid hydrocarbon mercaptan removal technique capable of deeply removing total sulfur, in particular to a sweetening technique for liquefied gas in an oil refinery. The oil refining liquid hydrocarbon refers to components of liquefied gas and light gasoline, wherein the liquefied gas is a raw material for producing MTBE, and the light gasoline is a component for producing high-cleanness gasoline. In order to solve the problem of high total sulfur in the oil refining MTBE and the light gasoline, according to the shape and the distribution rule of sulfocompounds in the liquid hydrocarbon, processes such as functional reinforcement of a recycle solvent, three-phase mixed reinforced regeneration, regenerated catalyst and extractant separation and recycle solvent deoxidization and the like are adopted in the conventional process of liquid hydrocarbon extraction, oxidization and mercaptan removal, so the technical effects of reinforcing the mercaptan removal depth, improving carbonyl sulfide removal rate, and avoiding forming disulphide in the extracting, saving energy and reducing emission and the like are achieved. Thus, the liquid hydrocarbon can be deeply desulfurated, the problem of high total sulfur in the oil refining MTBE and the light gasoline is solved and the slag discharging quantity in the conventional process is greatly reduced.

Owner:HEBEI REFINING TECH CO LTD

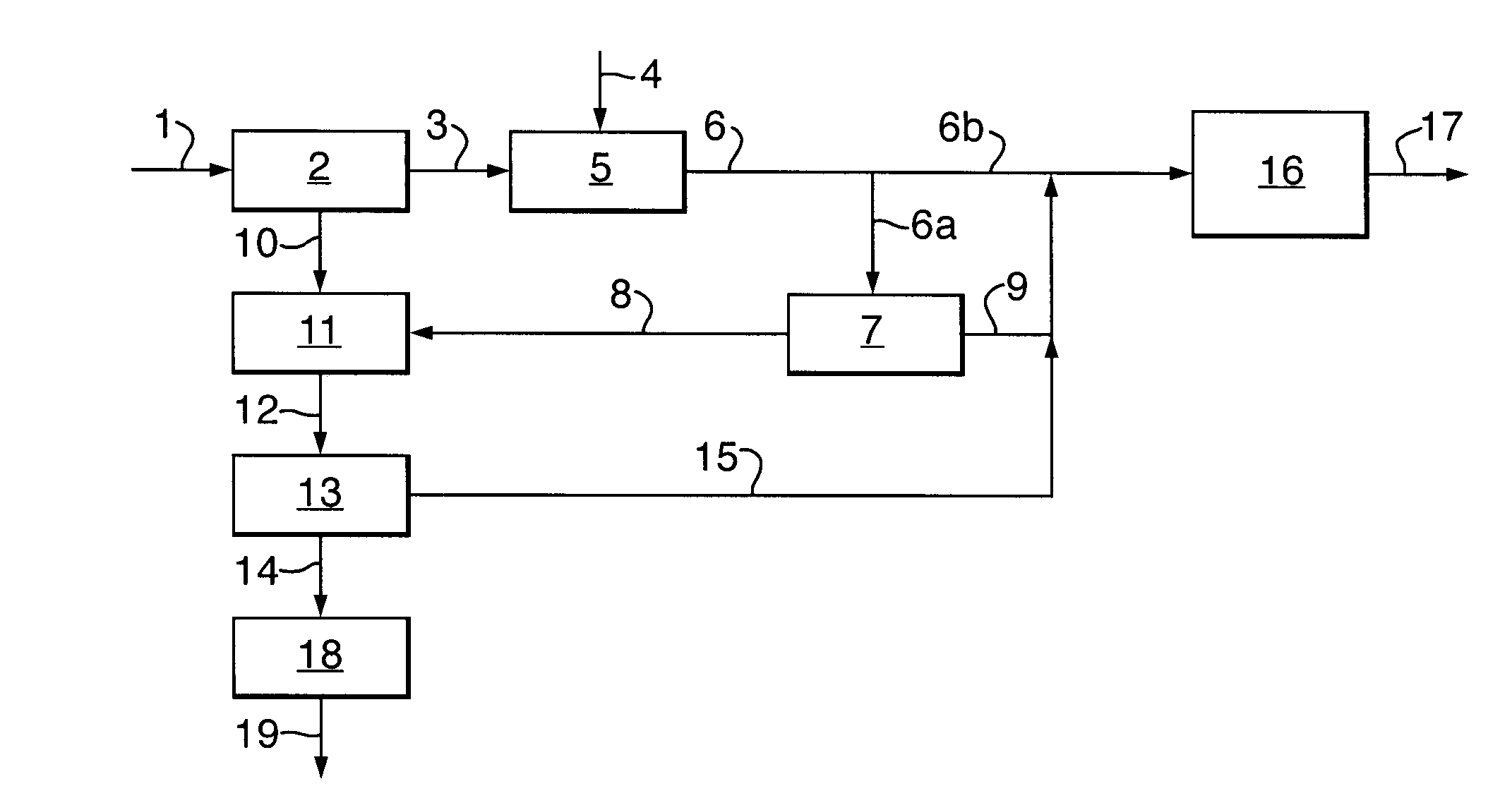

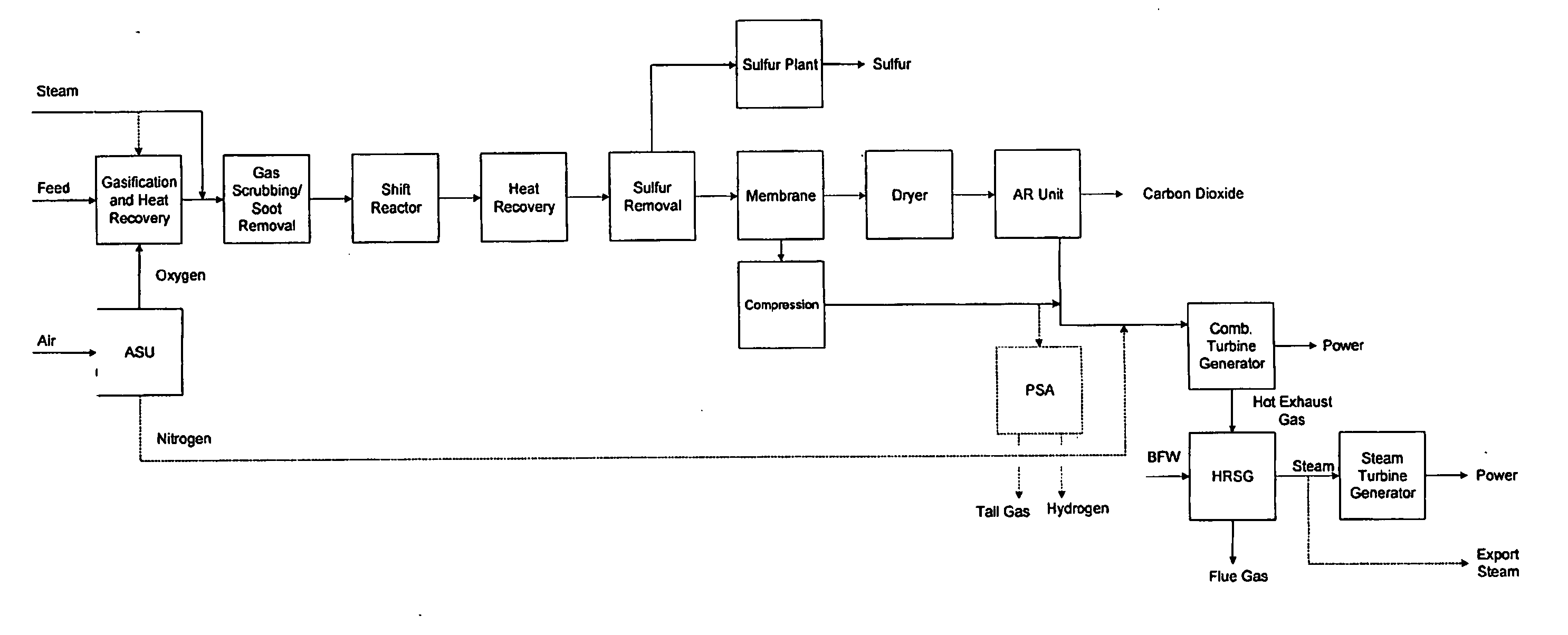

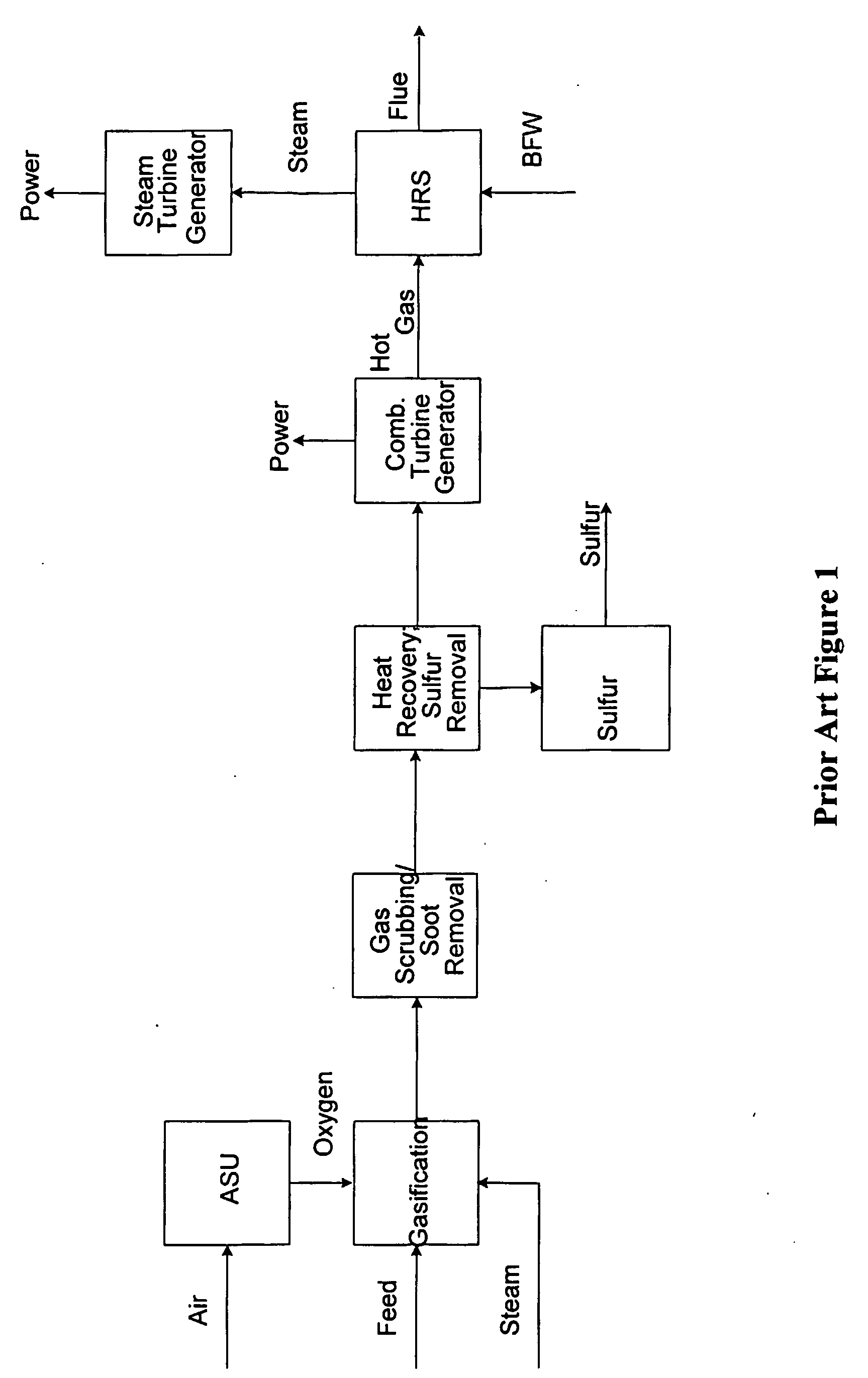

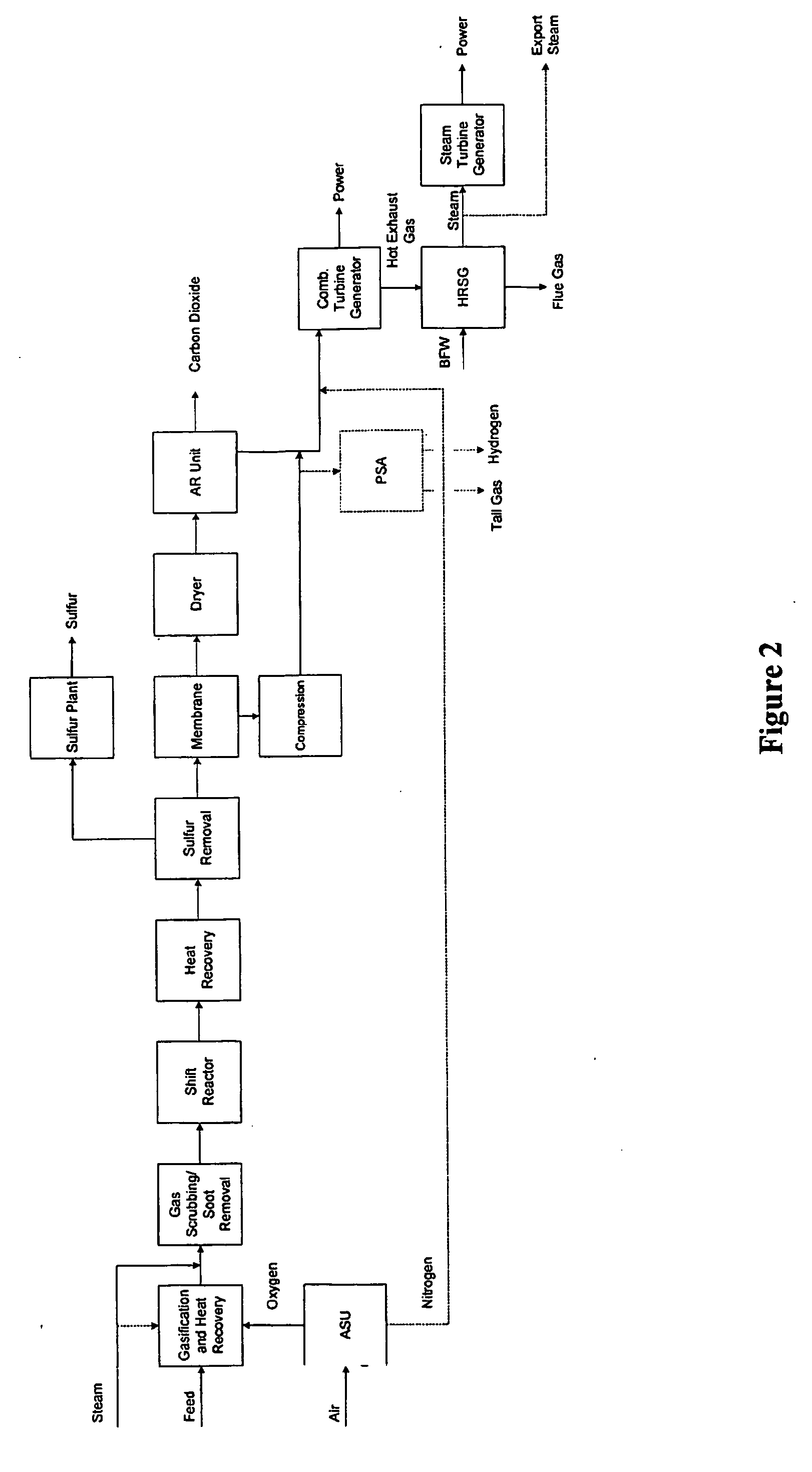

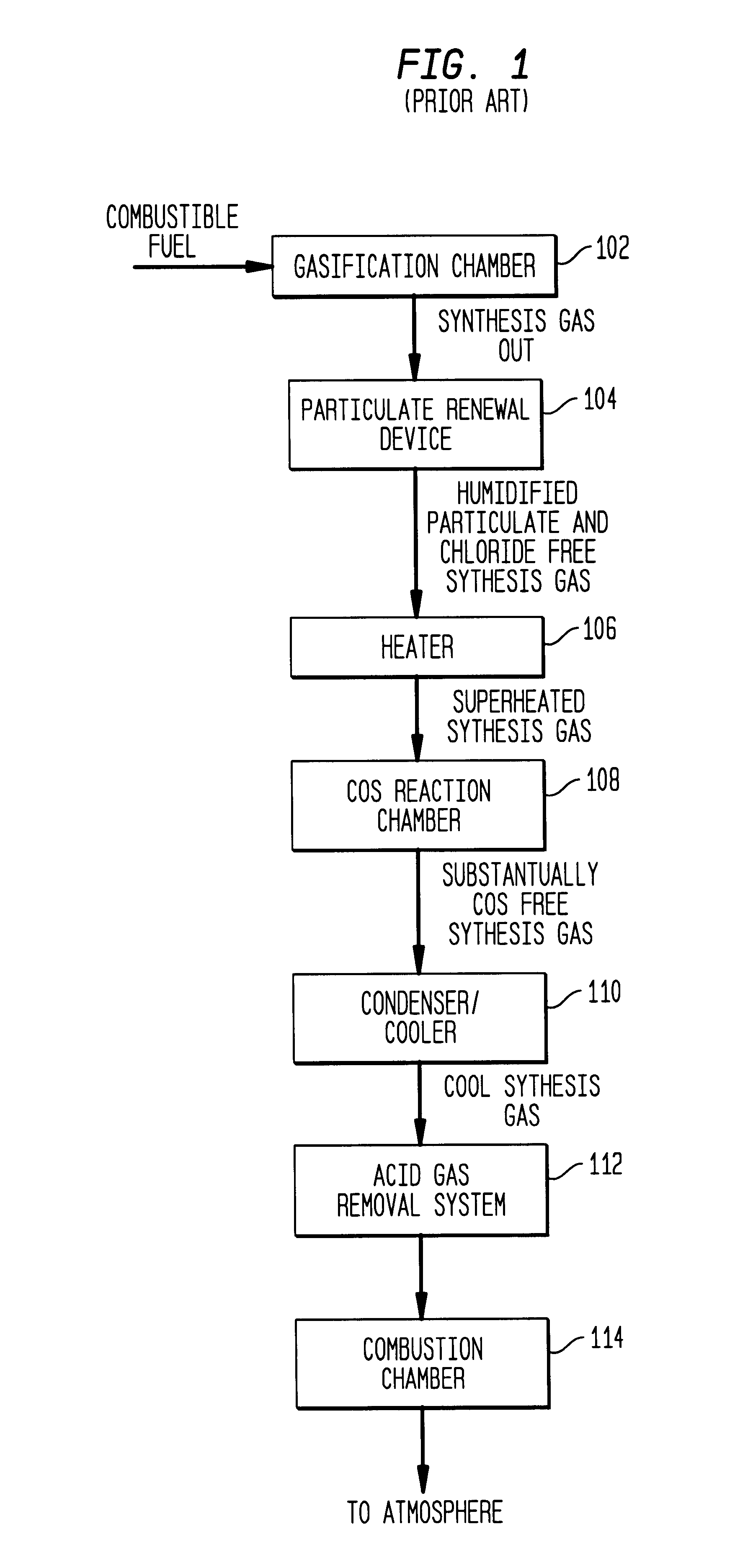

Configurations and methods of carbon capture

An IGCC plant has a precombustion decarbonization unit in which acid gas is removed from a combustion gas before the combustion gas enters a combustion turbine. In one preferred configuration, a sulfur removal unit removes hydrogen sulfide from a feed gas before the desulfurized feed gas enters an autorefrigeration unit in which carbon dioxide is removed. In another preferred configuration, hydrogen sulfide is converted to carbonyl sulfide in a dryer, and the carbonyl sulfide is absorbed in the liquid carbon dioxide that is prepared from the feed gas using autorefrigeration.

Owner:FLUOR TECHSE CORP

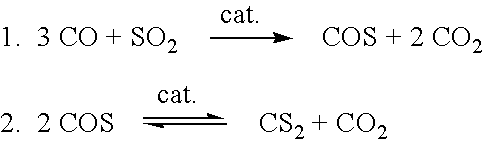

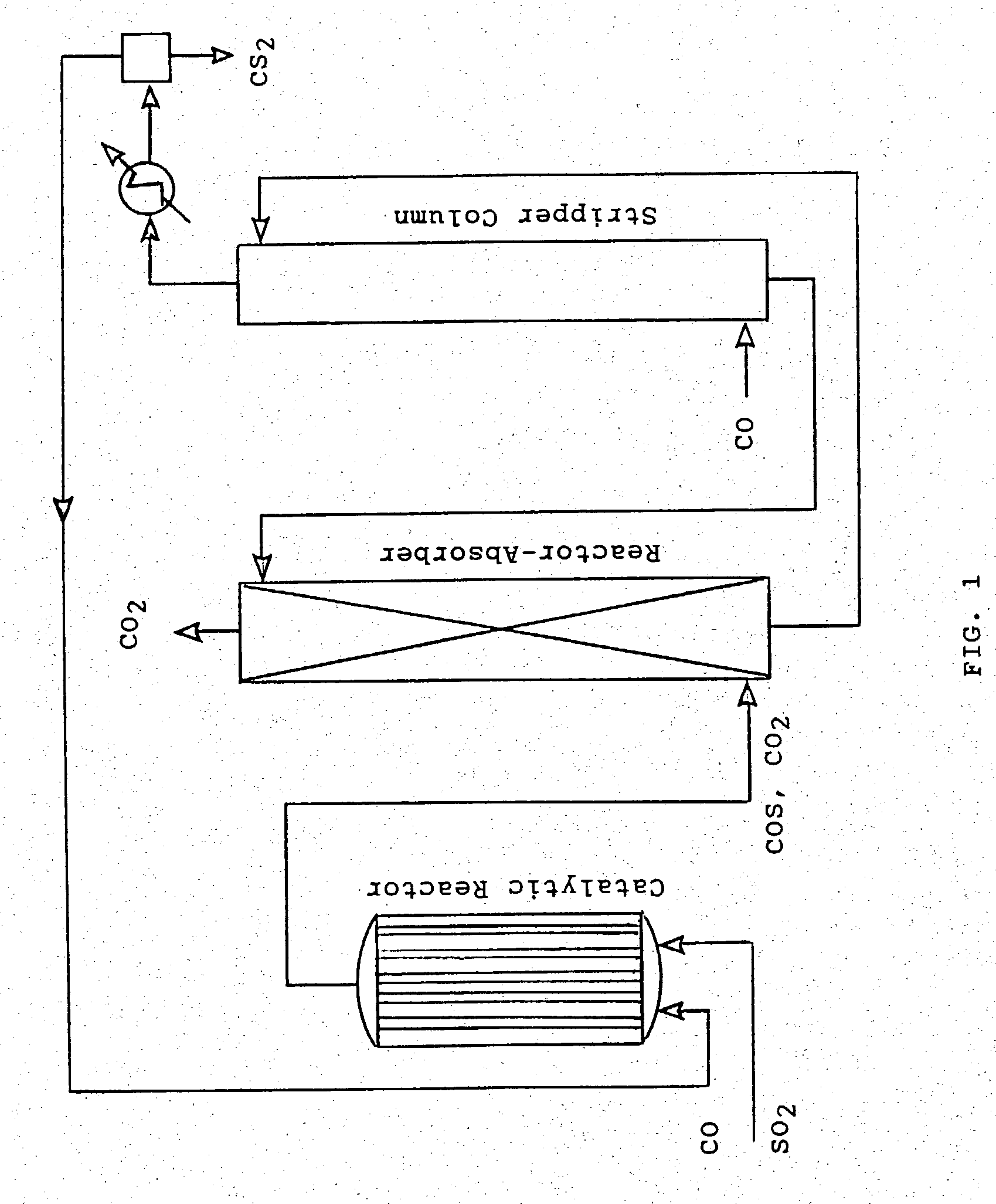

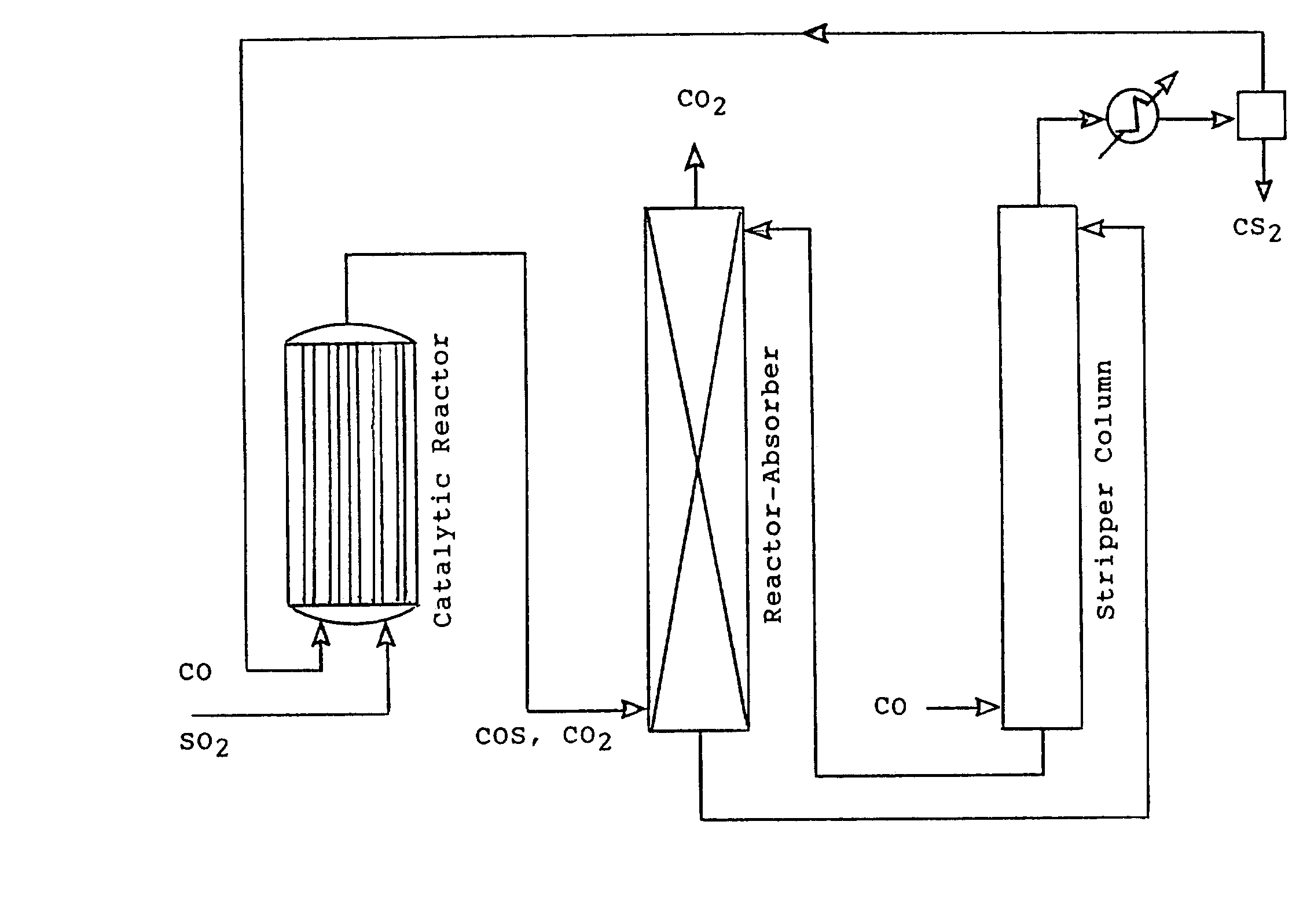

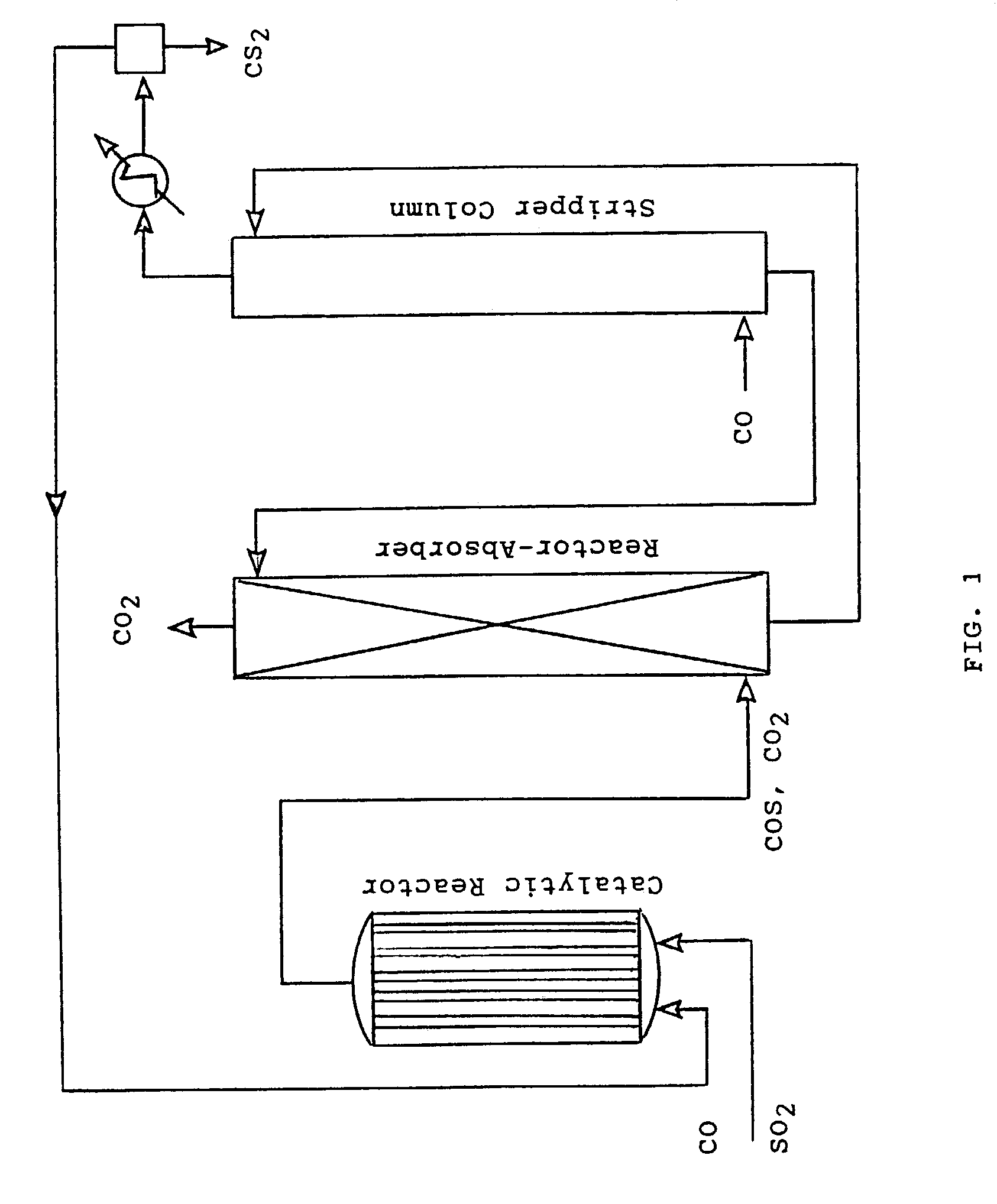

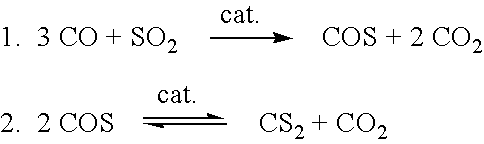

Carbon disulfide process

The specification discloses a process for the manufacture of carbon disulfide from sulfur dioxide and carbon monoxide comprising two catalytic reactions. In the first reaction, sulfur dioxide and carbon monoxide are converted to carbonyl sulfide and carbon dioxide. In the second reaction, carbonyl sulfide is disproportionated to carbon disulfide and carbon dioxide. The second reaction is conducted in the presence of a solvent, which continuously removes the carbon disulfide product so as to drive the reaction to completion.

Owner:JES TECH LLC

Absorbent composition containing molecules with a hindered amine and a metal sulfonate, phosphonate or carboxylate structure for acid gas scrubbing process

Owner:EXXON RES & ENG CO

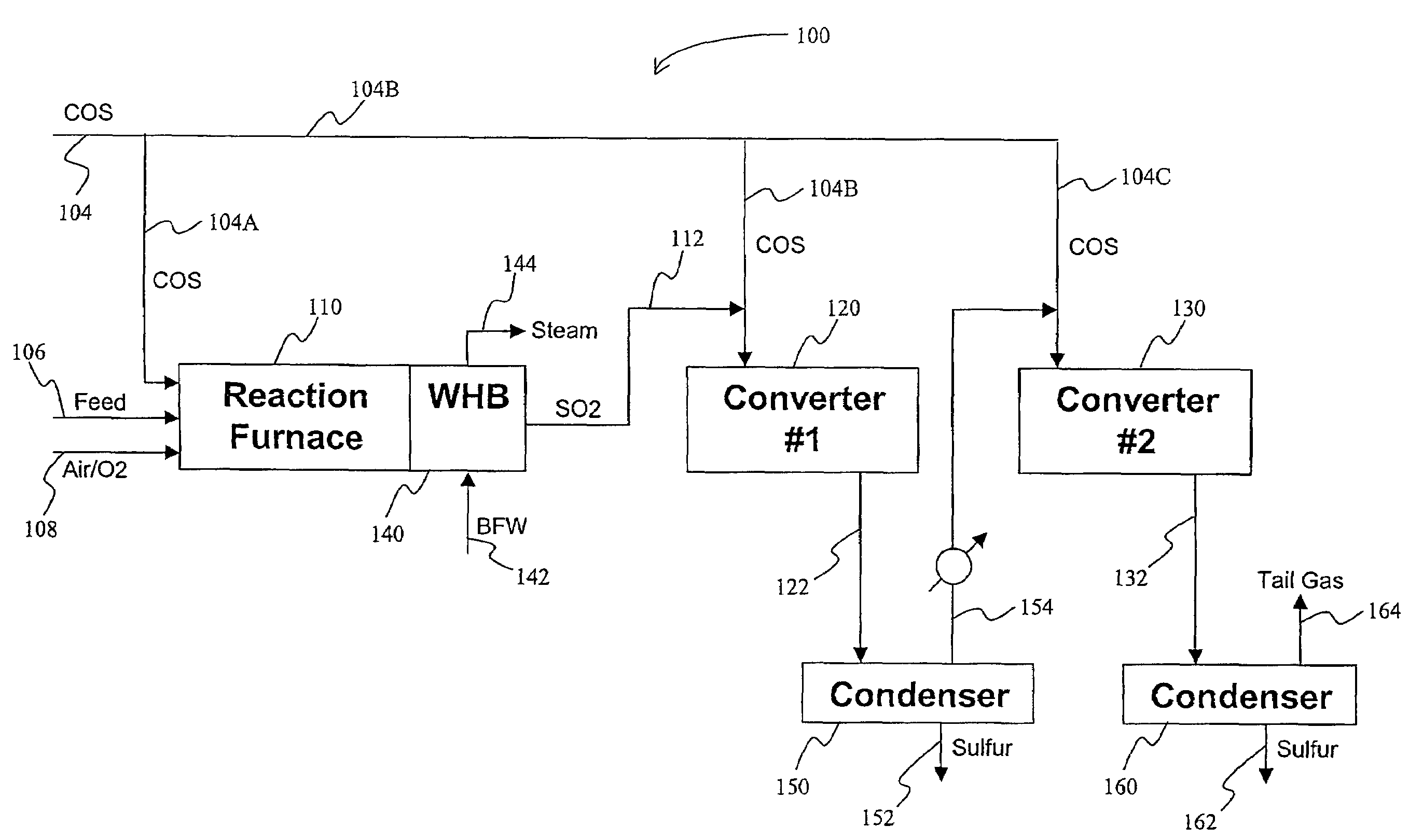

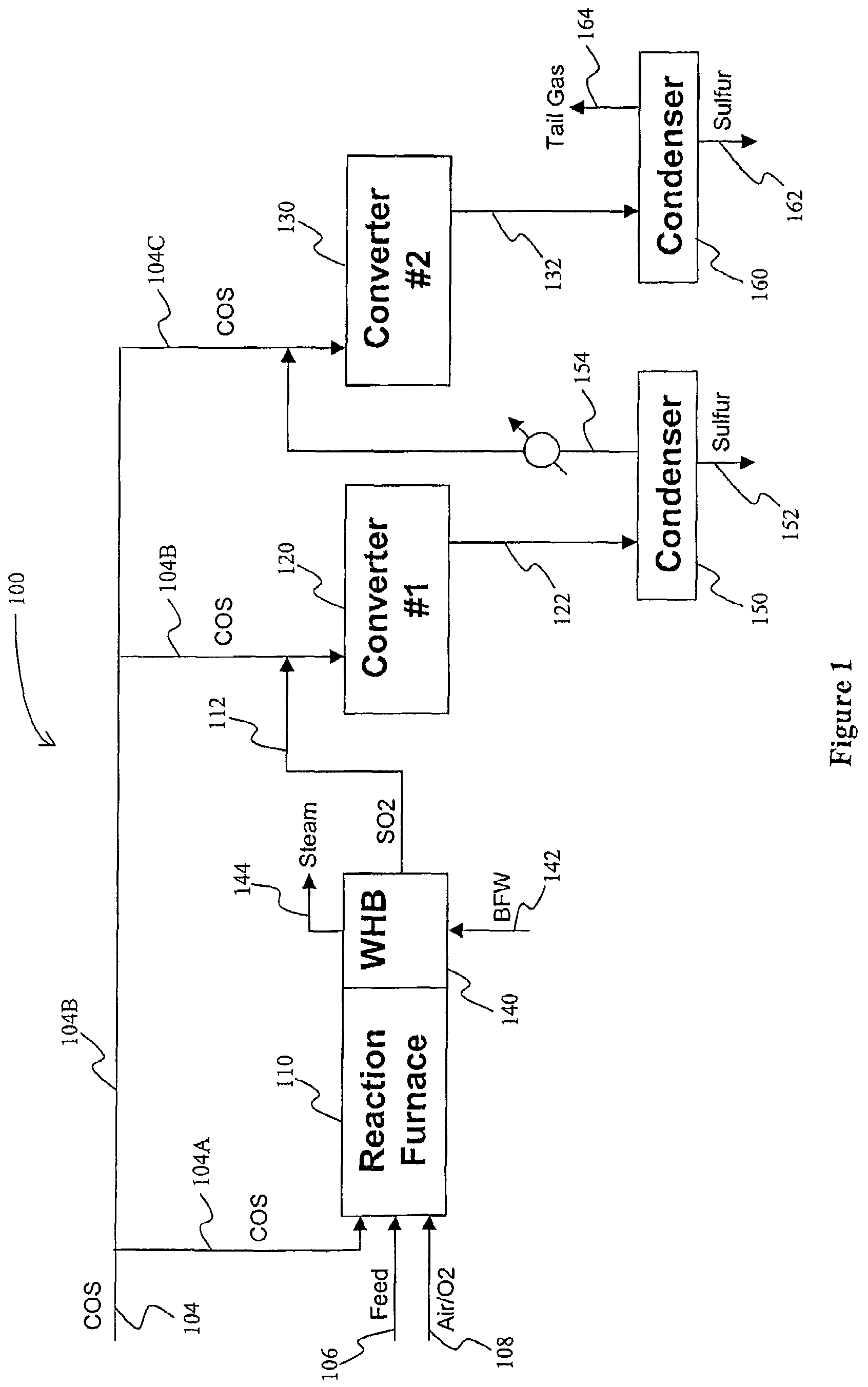

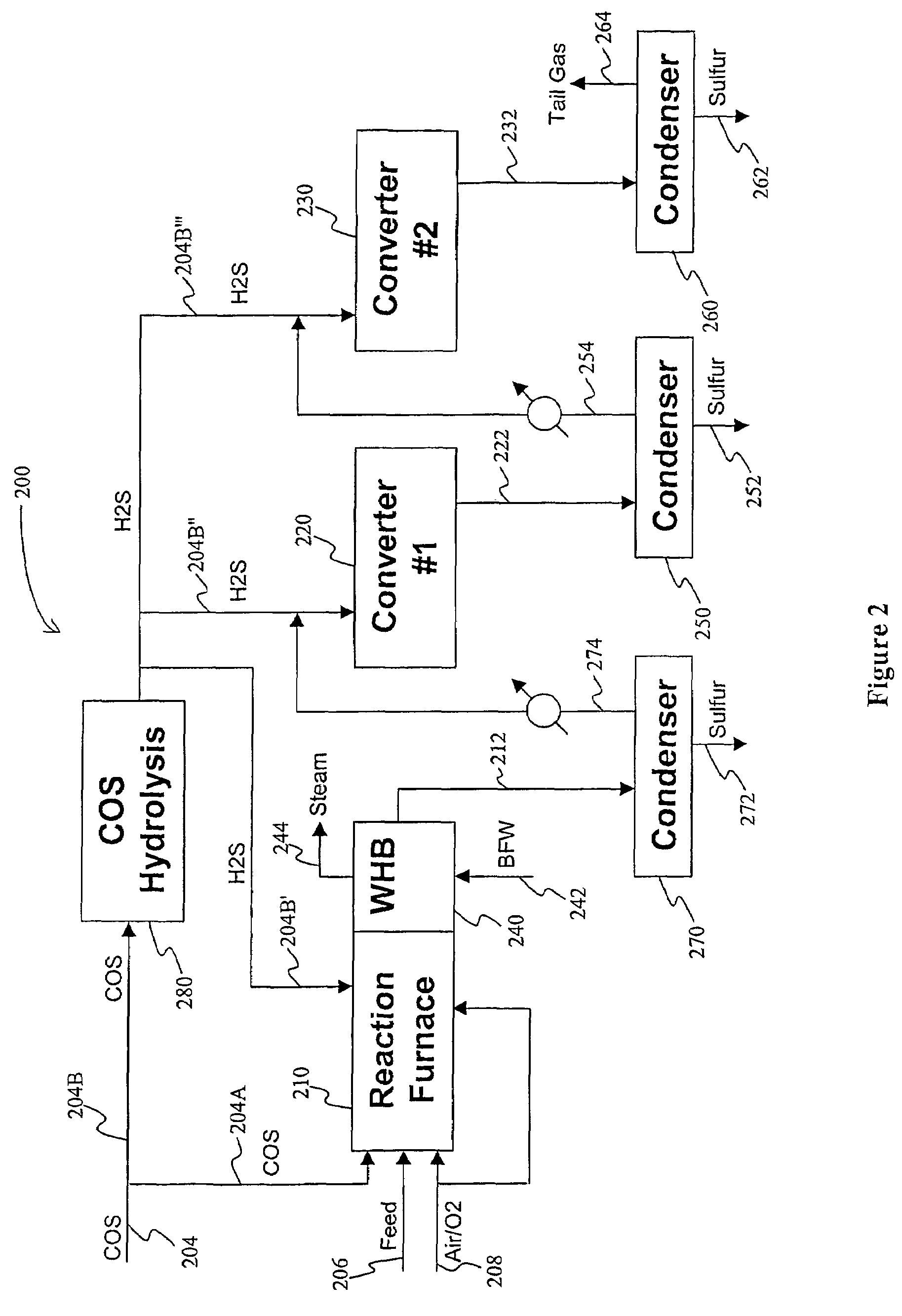

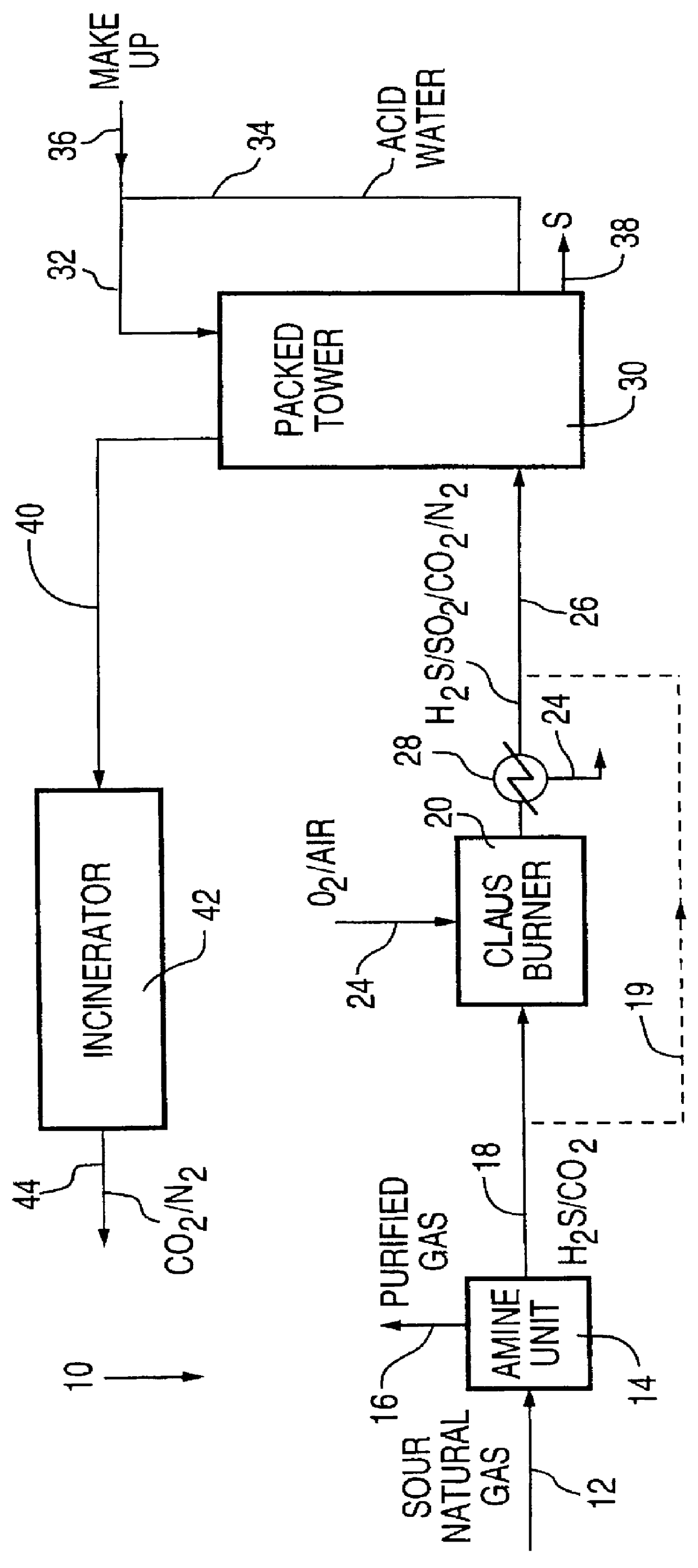

COS-Claus configurations and methods

ActiveUS7648692B2Dispersed particle separationSulfur preparation/purificationCarbonyl sulfideSubject matter

Carbonyl sulfide (COS) from a COS-containing stream (106) is convened in a Claus plant (100) to elemental sulfur (152, 162) by oxidation of a first portion of the COS-containing stream to SO2 and by hydrolysis of a second portion of the COS-containing stream to H2S. In preferred aspects of the inventive subject matter, hydrolysis and / or oxidation of the COS is performed in the reactor furnace (10), while hydrolysis of the COS is performed in the reactor furnace (10), a hydrolysis reactor, and / or a catalytic converter (120, 130, 150).

Owner:FLUOR TECH CORP

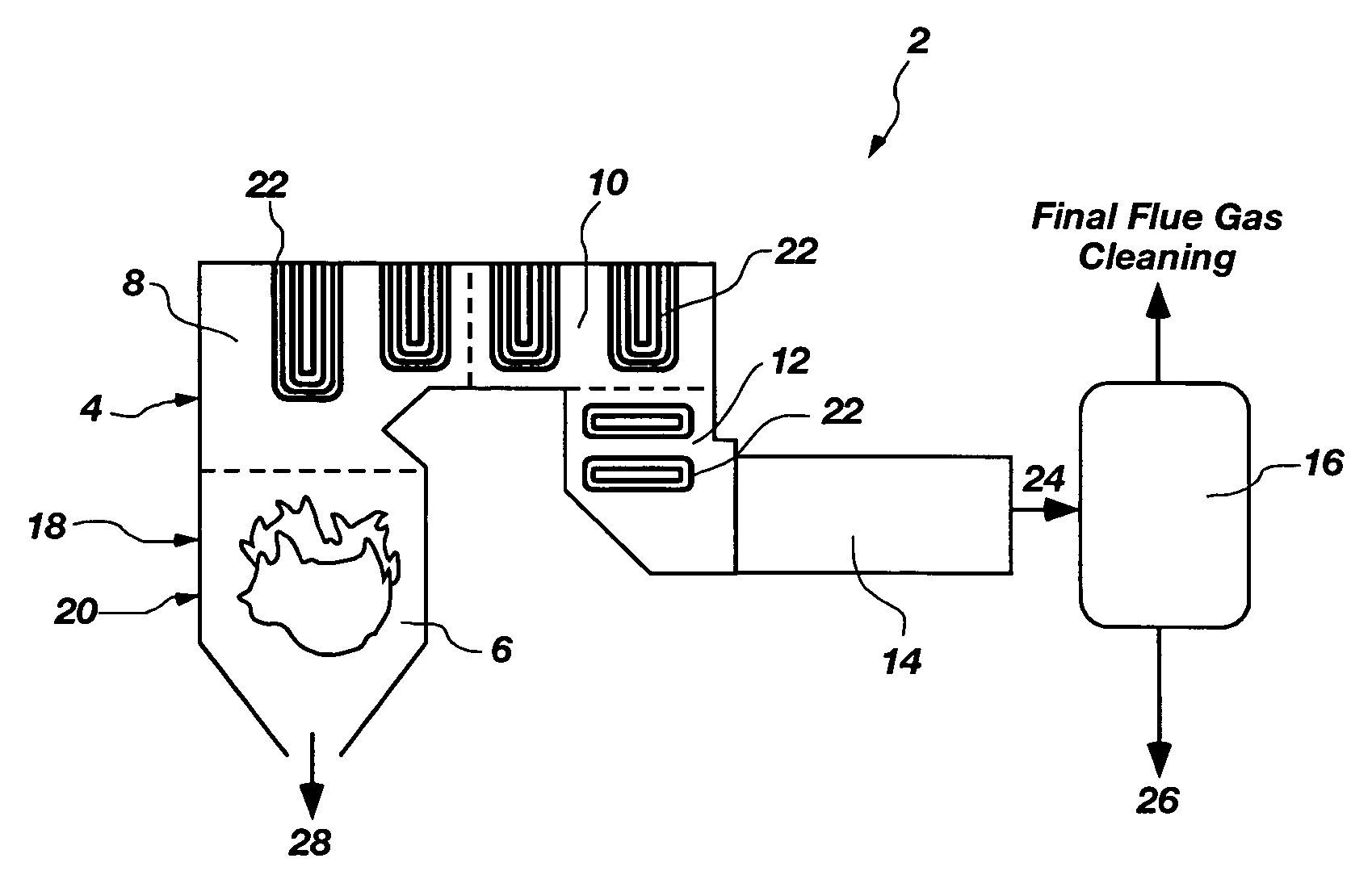

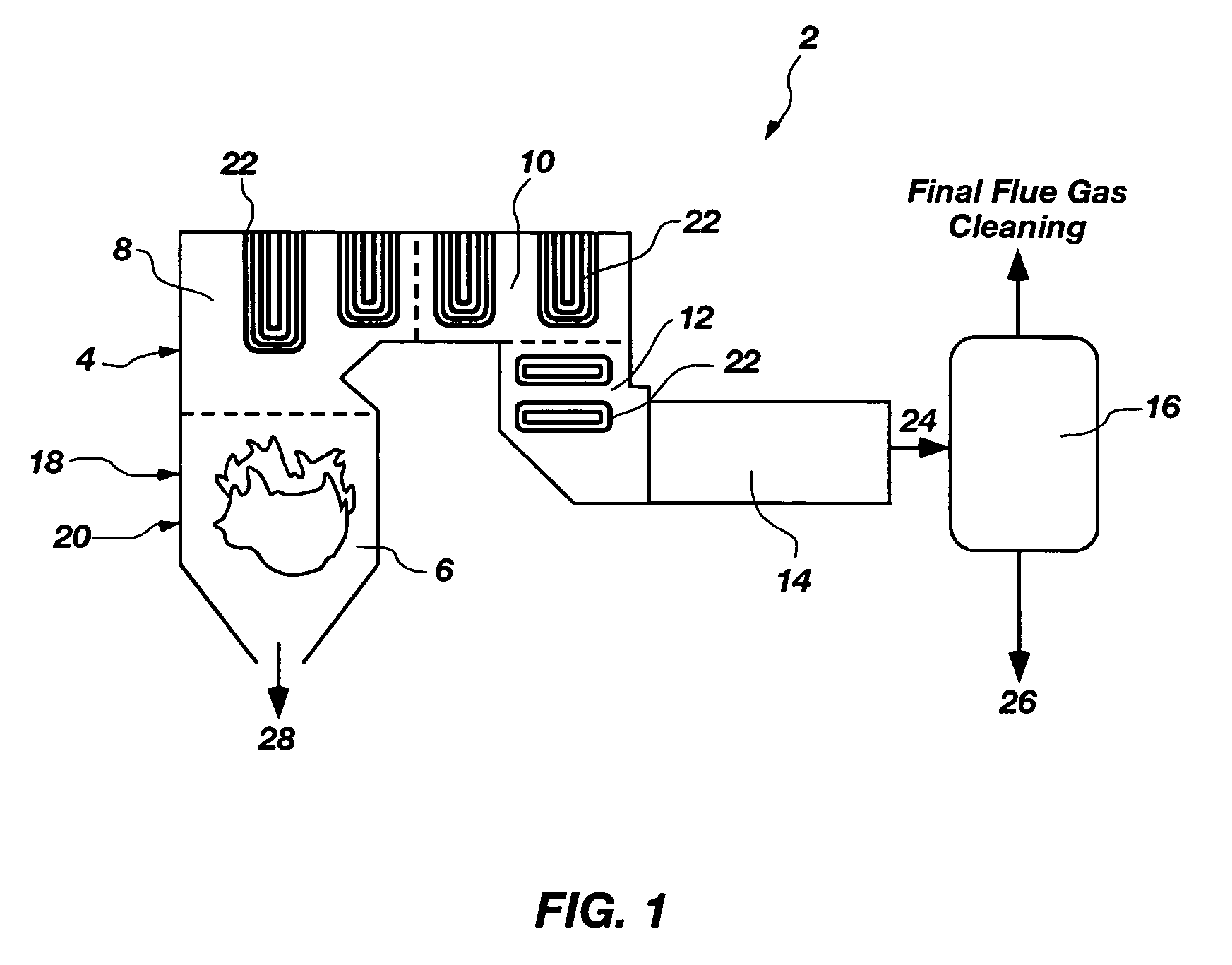

Method for oil shale pollutant sorption/NOx reburning multi-pollutant control

A method of decreasing pollutants produced in a combustion process. The method comprises combusting coal in a combustion chamber to produce at least one pollutant selected from the group consisting of a nitrogen-containing pollutant, sulfuric acid, sulfur trioxide, carbonyl sulfide, carbon disulfide, chlorine, hydroiodic acid, iodine, hydrofluoric acid, fluorine, hydrobromic acid, bromine, phosphoric acid, phosphorous pentaoxide, elemental mercury, and mercuric chloride. Oil shale particles are introduced into the combustion chamber and are combusted to produce sorbent particulates and a reductant. The at least one pollutant is contacted with at least one of the sorbent particulates and the reductant to decrease an amount of the at least one pollutant in the combustion chamber. The reductant may chemically reduce the at least one pollutant to a benign species. The sorbent particulates may adsorb or absorb the at least one pollutant. A combustion chamber that produces decreased pollutants in a combustion process is also disclosed.

Owner:BATTELLE ENERGY ALLIANCE LLC

Iron-base desulfurizer for catalyzing, translating and absorbing carbonyl sulfur at middle-low temperature and preparation thereof

InactiveCN101054538AHigh breakthrough sulfur capacityHigh precisionCombustible gas purificationSyngasSecondary component

The invention relates to a preparation of catalyzing and transforming-absorbing Fe-desulphurizer by high accuracy carbonyl sulfur at medium and low temperature, which has a good hydrogenation effect to the carbonyl sulfur and absorbs the produced carbonyl sulfur. The invention can be used to accurately remove the carbonyl sulfur in the ammonia material gas, coke oven gas, natural gas and composed gas. The desulphurizer is provided with primary active components Fe2O3, CeO2, MnO2, Ni2O3, and secondary components CuO, ZnO, MgO, K2O and etc, and the carriers are Al2O3, ZrO2, and residual binding agent and expanding drilling agent, and water. The process has a reacting temperature of 150-350 DEG C, an airspeed of 500-2000h-1, a carbonyl sulfur concentration in the gas from minim to 5000ppm. The inventive desulphurizer has a high catalytic transforming capacity with a carbonyl sulfur converting ratio more than 99%.

Owner:EAST CHINA UNIV OF SCI & TECH

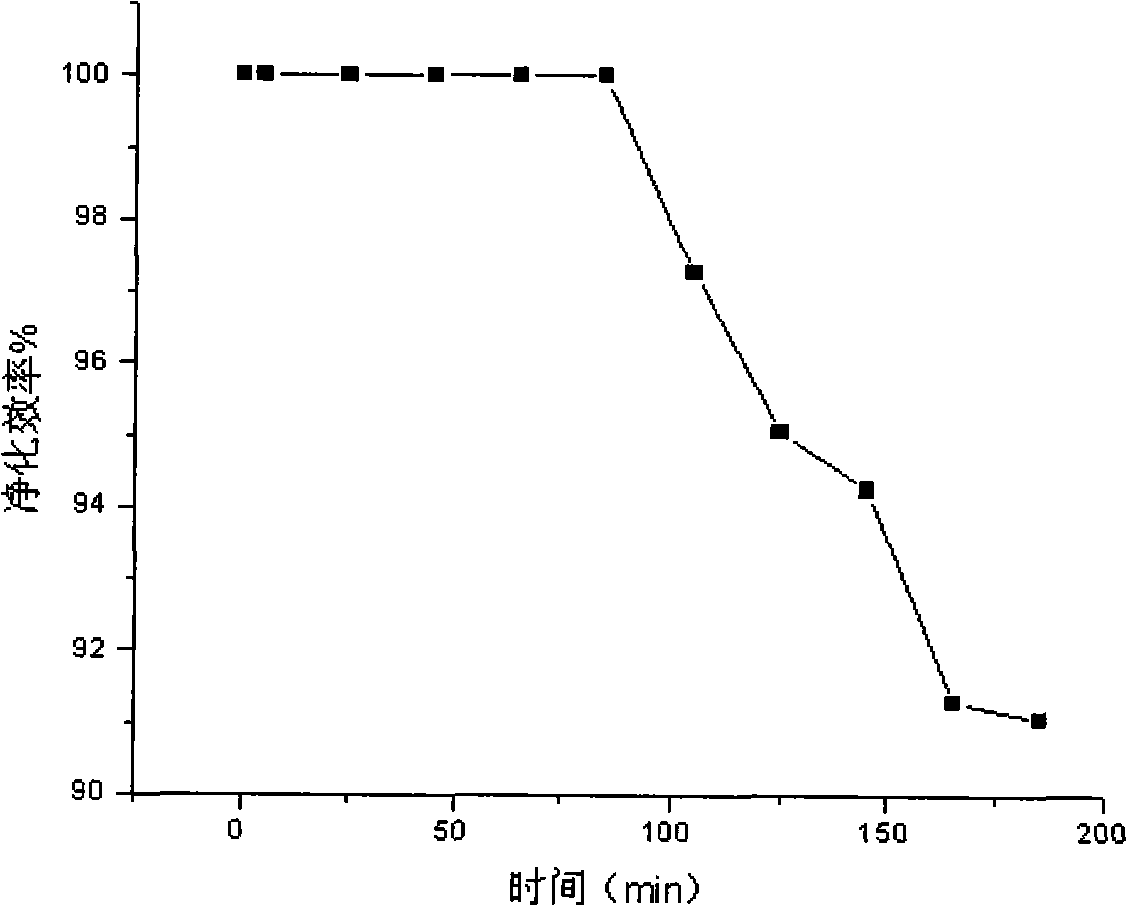

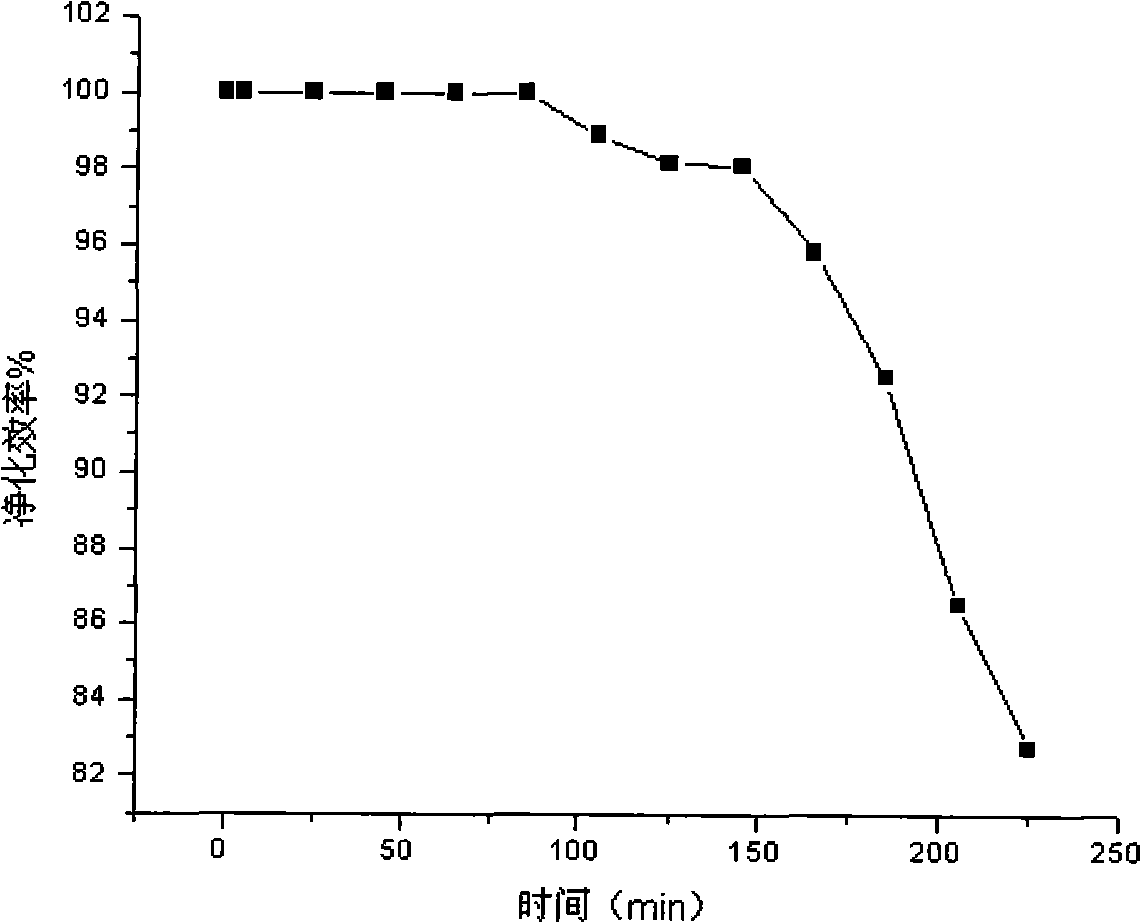

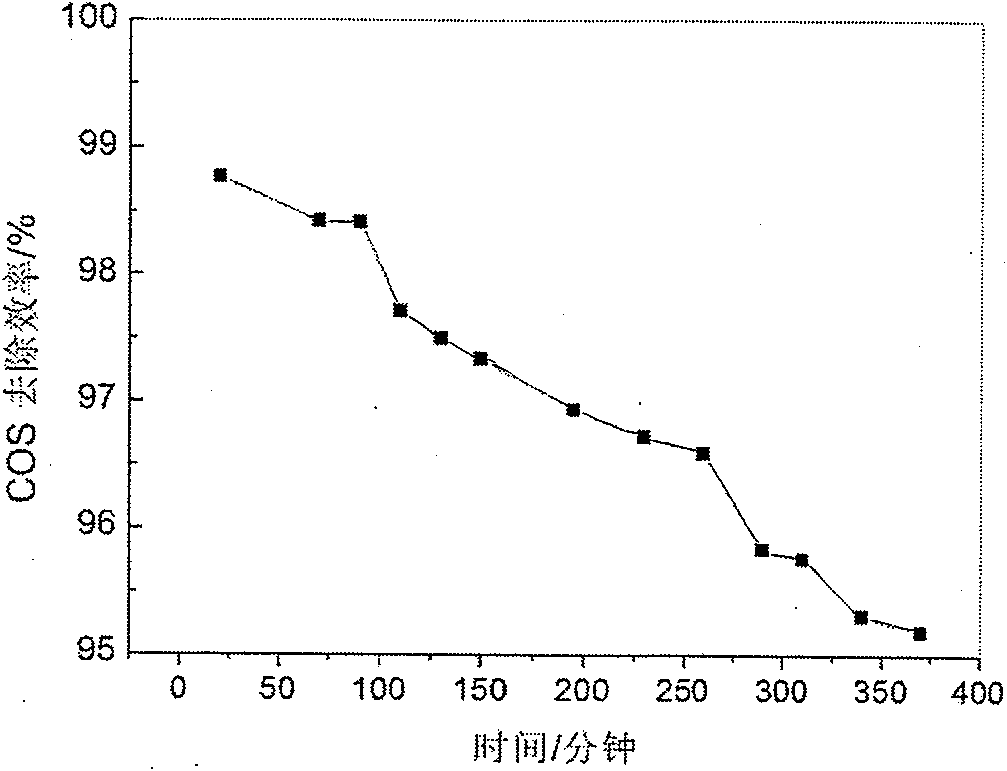

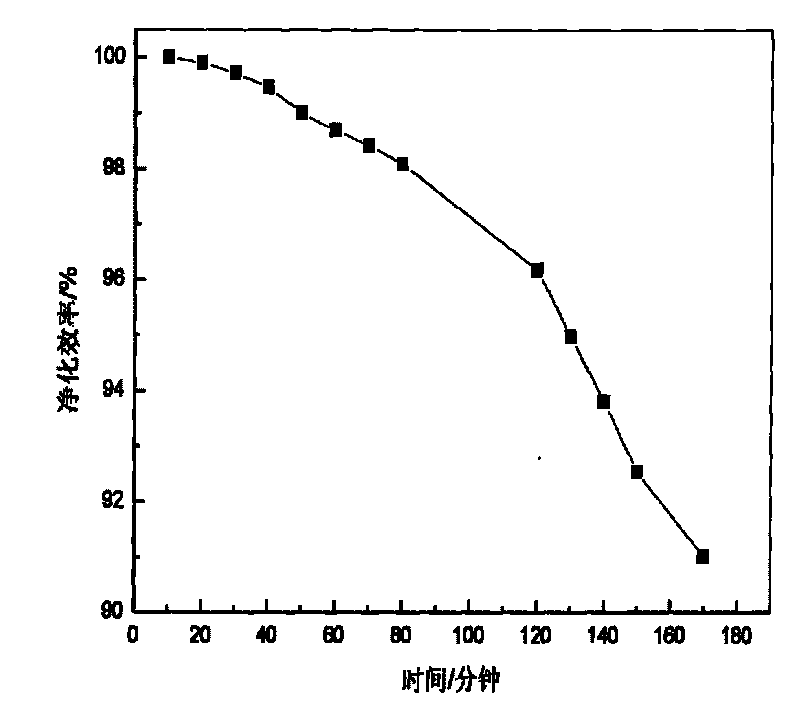

Absorbent charcoal based catalyst for hydrolyzation and catalysis of carbonyl sulphur in low-temperature and preparation method thereof

InactiveCN101318130AWide concentration rangeHigh desulfurization precisionOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationActivated carbonAlcohol

The invention provides an active carbon based catalyst for hydrolyzing and catalyzing carbonyl sulfur in low temperature, which is characterized in that the catalyst takes active carbon as a carrier and is prepared by the following method: washing the active carbon, drying the active carbon for 2-4 hours under 100-140 DEG C; impregnating the active carbon in the (A) step for 6-12 hours with the impregnation liquid of alkaline substances or metal oxides or organic alcohol amine, wherein, the mass content of the alkaline substances or the metal oxides or the organic alcohol amine accounts for 5-30 percent of that of the active carbon; drying the impregnated active carbon for 2-6 hours under the constant temperature of 100-140 DEG C and then activating the active carbon for 2-4 hours under the temperature of 300-500 DEG C and the protection of N2. The catalyst can be used for catalyzing and hydrolyzing COS and removing H2S; furthermore, the catalyst can remove the COS in the gas under the temperature of 30-100 DEG C, ensure the conversion rate of the COS to be larger than 90 percent and remove the H2S generated in hydrolysis at the same time. The COS concentration which is between 100-1500ppm has a wide adaptive range, high desulfurization accuracy and higher breakthrough sulfur capacity.

Owner:KUNMING UNIV OF SCI & TECH

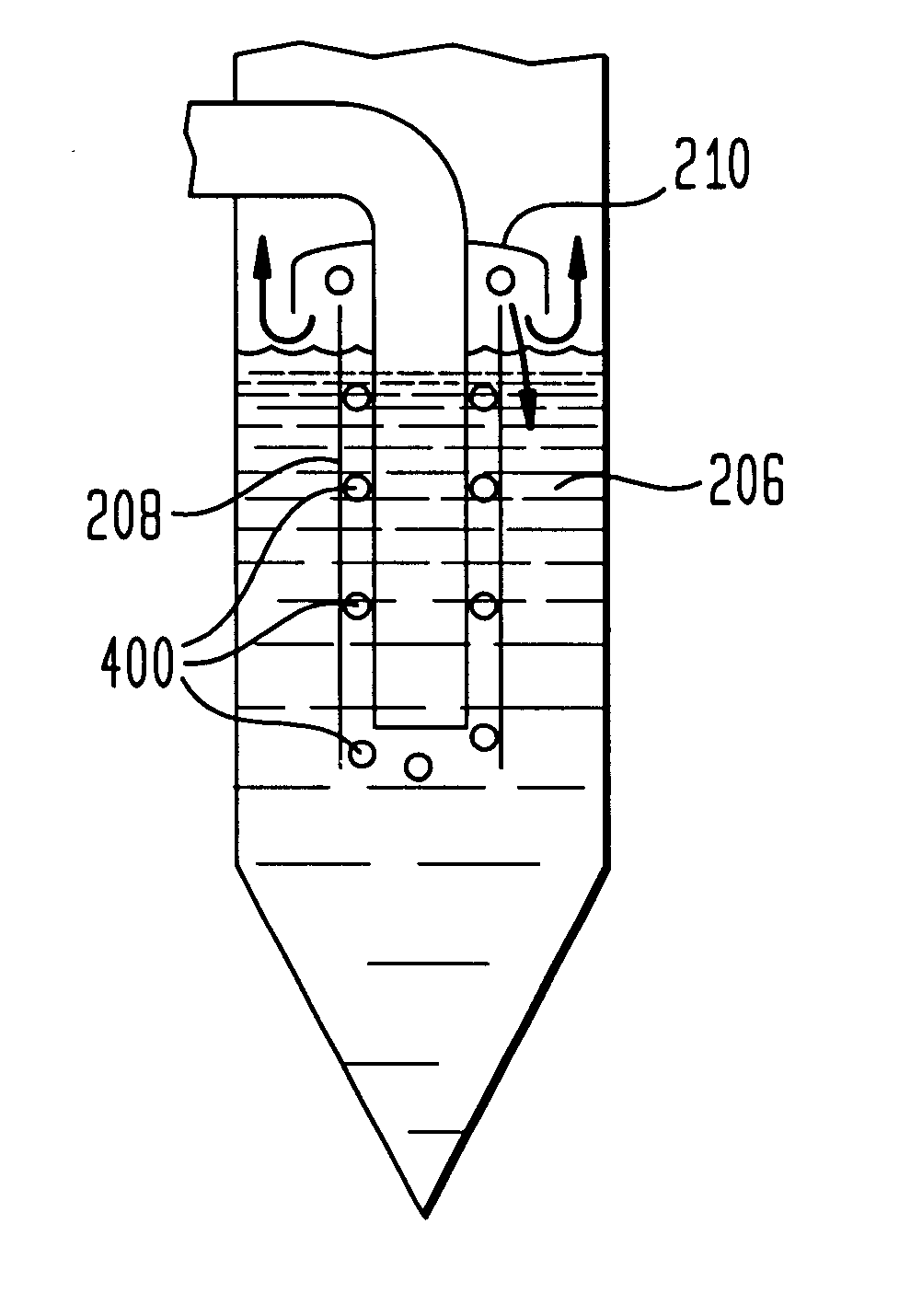

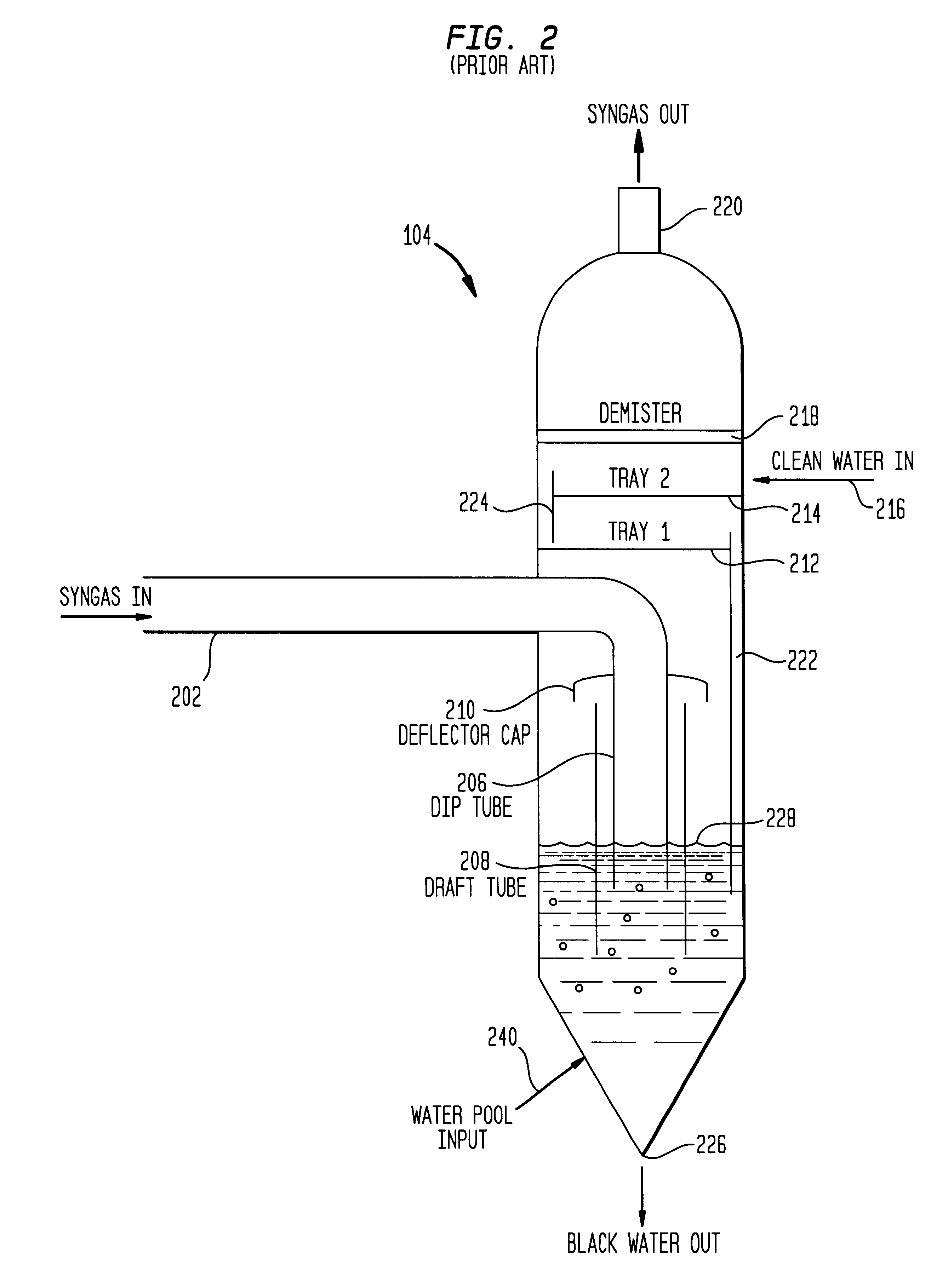

Method and apparatus for removing carbonyl sulfide from a gas stream via wet scrubbing

InactiveUS6322763B1Weaken energyLower Level RequirementsGas treatmentUsing liquid separation agentCarbonyl sulfideWater flow

Methods for removing carbonyl sulfide (COS) from a synthesis gas stream are disclosed. The method entails raising the water level of a wet scrubber so that hydrolysis of the COS may occur in the scrubber itself instead of a COS reduction chamber and no additional catalysts other than those naturally occurring in the production of the synthesis gas need be introduced into the scrubber. The water is raised, in one example, to a level such that water within an inner tube of the wet scrubber flows over an upper end of the inner tube. Raising the water level in the scrubber ensures intimate and vigorous interaction between the water, the COS, and the naturally occurring catalyst, and promotes the hydrolysis of the COS. In one example, the naturally occurring catalyst (e.g., alumina oxide) is present in the coal ash produced when coal is the fuel gasified that creates the synthesis gas stream.

Owner:MTI INSULATED PROD

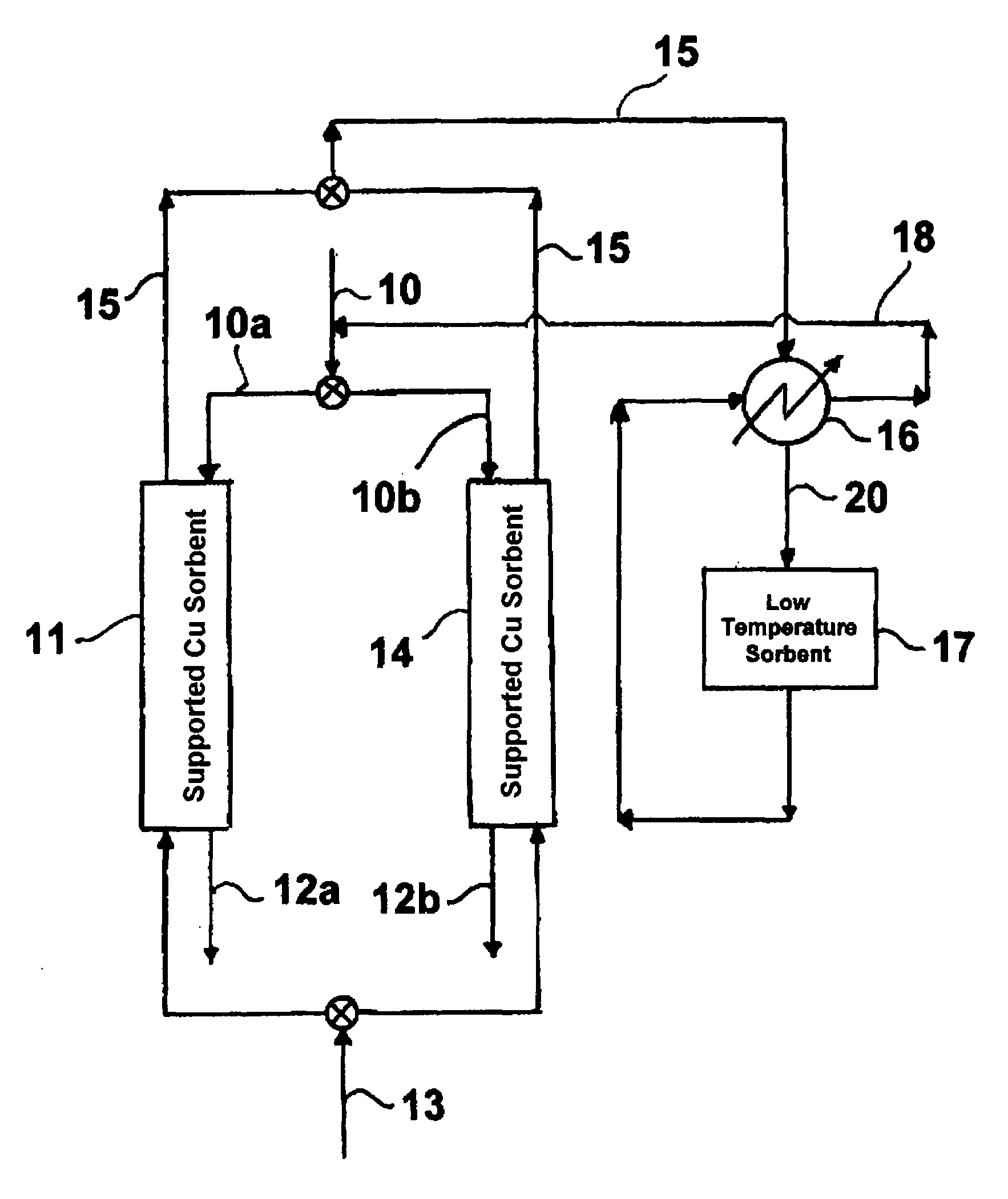

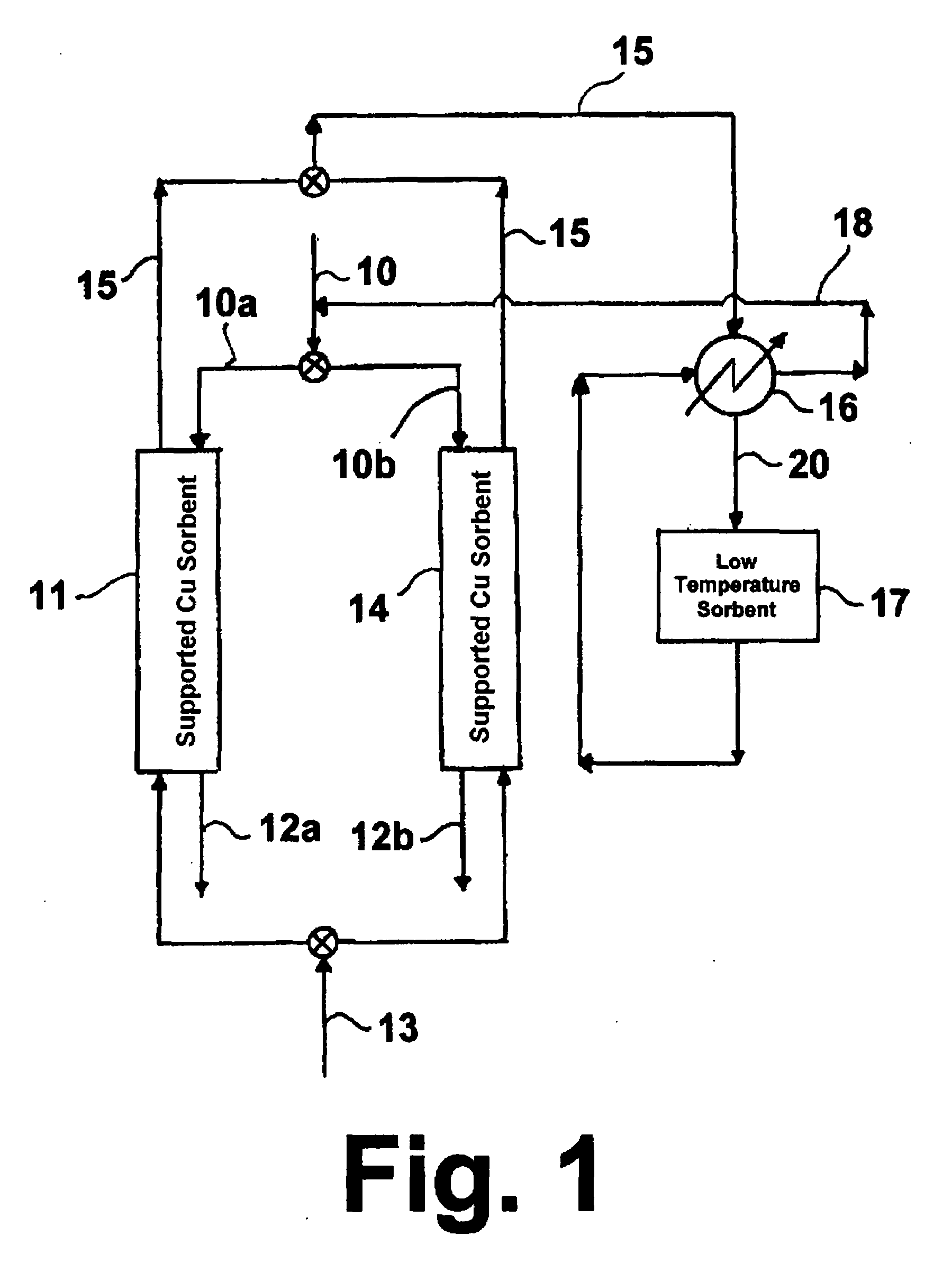

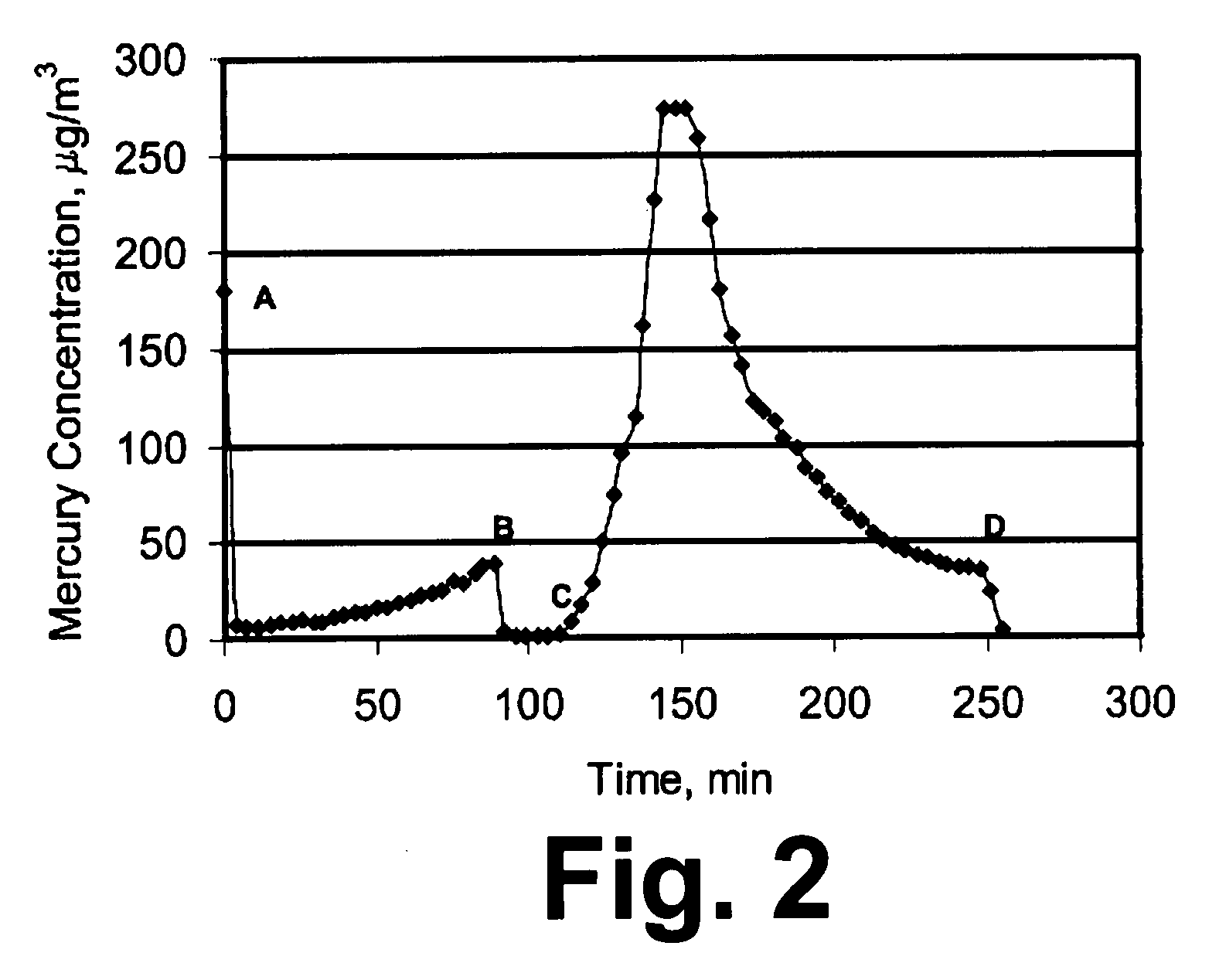

Regenerative process for removal of mercury and other heavy metals from gases containing H2 and/or CO

ActiveUS20080184884A1Increase release rateRaise regeneration temperatureGas treatmentIsotope separationSorbentCarbonyl sulfide

A method for removal of mercury from a gaseous stream containing the mercury, hydrogen and / or CO, and hydrogen sulfide and / or carbonyl sulfide in which a dispersed Cu-containing sorbent is contacted with the gaseous stream at a temperature in the range of about 25° C. to about 300° C. until the mercury concentration in the gaseous stream after contacting the sorbent exceeds a predetermined breakthrough level, signaling a spent sorbent. Arsenic, cadmium and selenium present in the gaseous stream may also be captured along with the mercury. The spent sorbent is then contacted with a desorbing gaseous stream at a temperature equal to or slightly higher than the temperature at which the mercury adsorption is carried out, producing a regenerated sorbent and an exhaust gas comprising released mercury. The released mercury in the exhaust gas is then captured using a high-capacity sorbent, such as sulfur-impregnated activated carbon, at a temperature less than about 100° C. The regenerated sorbent may then be used to capture additional mercury from the mercury-containing gaseous stream. The process may be carried out at pressures in the range of about 1 bar to about 200 bar.

Owner:GAS TECH INST

Method for removing sulfur compound in hydrocarbon-containing gas

ActiveUS20060108262A1Readily and efficiently removingEfficient removalHydrogen/synthetic gas productionHydrocarbon oils refiningSteam reformingPartial oxidation

Provided are a method for removing sulfur compounds contained in a hydrocarbon-containing gas in which in feeding a hydrocarbon-containing gas to a desulfurizing bed to remove sulfur compounds contained in the above gas, used is the desulfurizing bed constituted from a desulfurizing agent A comprising zeolite and a desulfurizing agent B comprising at least one selected from a metal element, a metal oxide and a metal component-carried oxide, and a production process of hydrogen for a fuel cell in which a hydrocarbon-containing gas subjected to desulfurization treatment by the above method is brought into contact with a partial oxidation reforming catalyst, an autothermal reforming catalyst or a steam reforming catalyst. According to the method of the present invention, combined use of two kinds of the desulfurizing agents having different desulfurizing performances and use of a raw material gas having a low concentration of carbonyl sulfide make it possible to efficiently remove all of sulfur compounds contained in a hydrocarbon-containing gas to a low concentration even at a room temperature. Further, hydrogen for a fuel cell can economically advantageously be produced by subjecting the desulfurization-treated hydrocarbon-containing gas obtained by the method described above to reforming treatment.

Owner:IDEMITSU KOSAN CO LTD

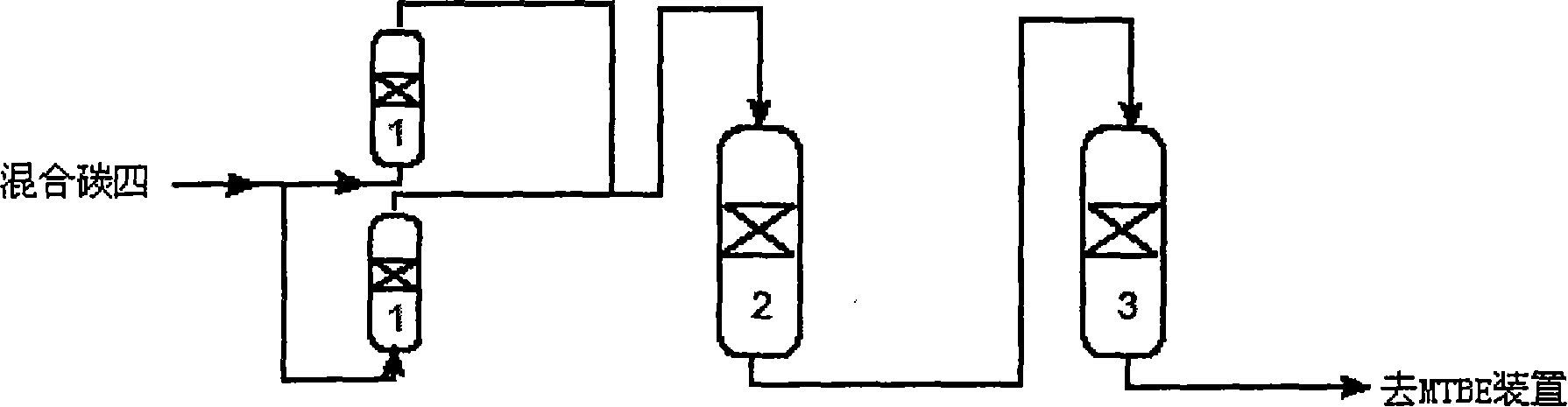

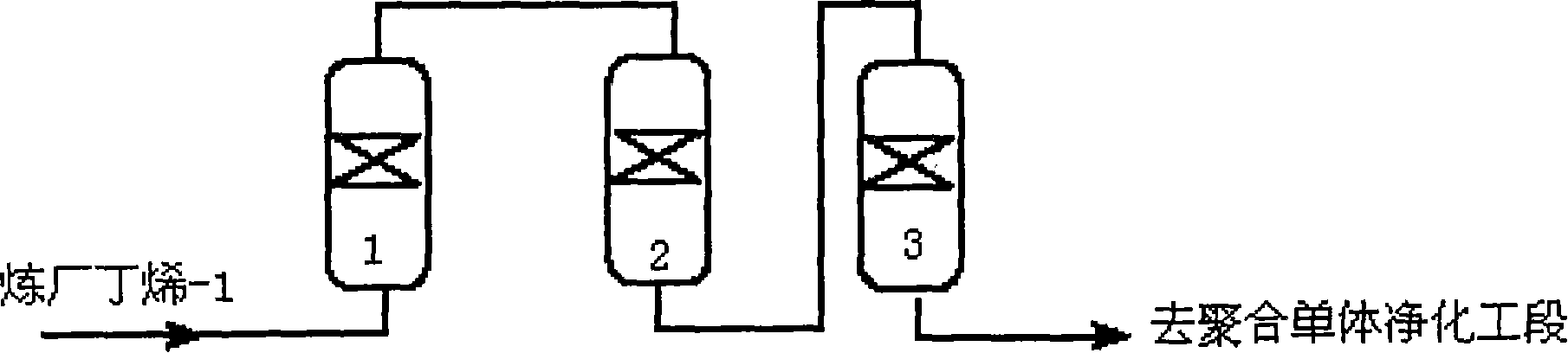

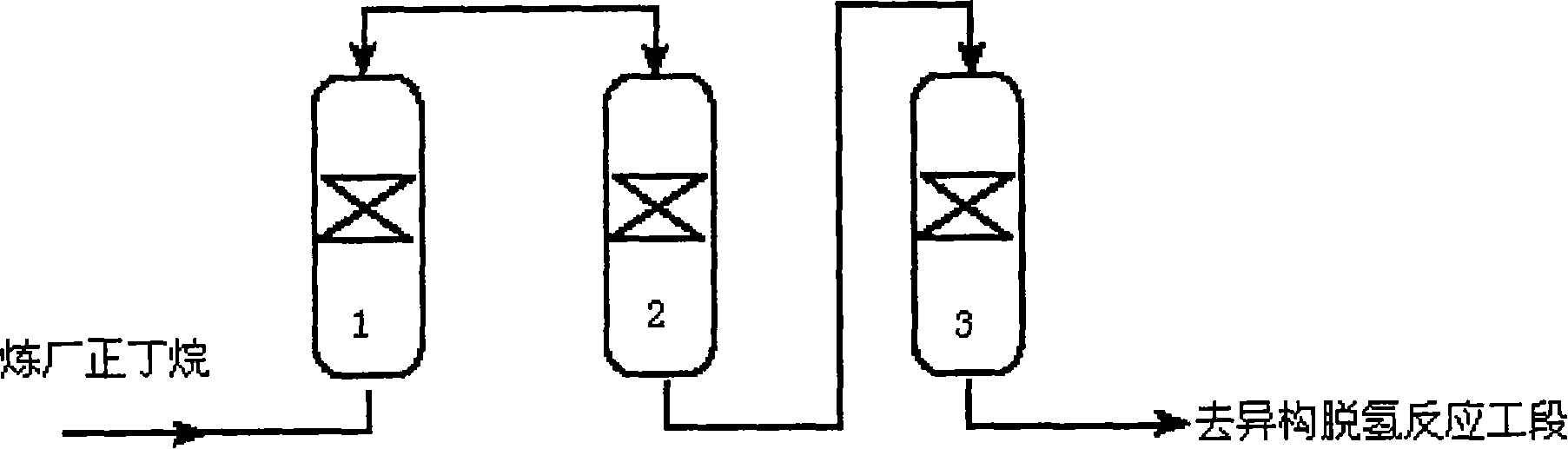

Fine desulfurize method for carbon four components of refinery

InactiveCN101249366AAchieve removalAvoid affecting downstream processesDispersed particle separationThiolCarbonyl sulfide

The invention relates to a method for fine desulphurization of C4 in a refinery, which comprises the following steps that: C4 is coarsely desulfurized through solid alkali in the refinery; the C4 coarsely desulfurized touches a carbonyl sulfur absorbent in the refinery and most of carbonyl sulfur and thiol in C4 are absorbed and removed; and C4 of the refinery touches a fine desulphurization absorbent again to absorb and remove the remaining sulfur. The total sulfur content of C4 in the refinery is reduced to less than 1mg / m<3> after C4 is finely desulfurized according to the method provided by the invention, thus meeting the requirement for C4 to be used as industrial raw material. The desulfurized C4 is free of impurity such as carbon dioxide and so on, so as not to influence subsequent processes. The fine desulphurization method provided by the invention achieves industrial production of desulphurization of C4 in the refinery, and ensures complex utilization of C4 in the refinery.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

RE sulfide catalyst for hydrolysis of carbonyl sulfide and its prepn

InactiveCN1403197AHigh activityGreat operating flexibilityPhysical/chemical process catalystsSulfateCarbonyl sulfide

The RE oxysulfide catalyst has the chemical expression of Re2O2S, where Re is La, Ce, Pr, Nd, Sm, Eu, Gd, Dy, Ho and Er. The preparation process of the catalyst includes hydrolysis of RE oxide and activation with the mixed gas of SO2 and CO at 400-700 deg.c. The catalyst has excellent hydrolysis effect on COS and other organic sulfide, certain sulfate resistance and oxygen poison resistance, and under the reaction condition including temperature 100-250 deg.c, COS content 150-300 ppm, space velocity 5,000-10,000 / Hr it results in a COS conversion rate higher than 90%.

Owner:EAST CHINA UNIV OF SCI & TECH

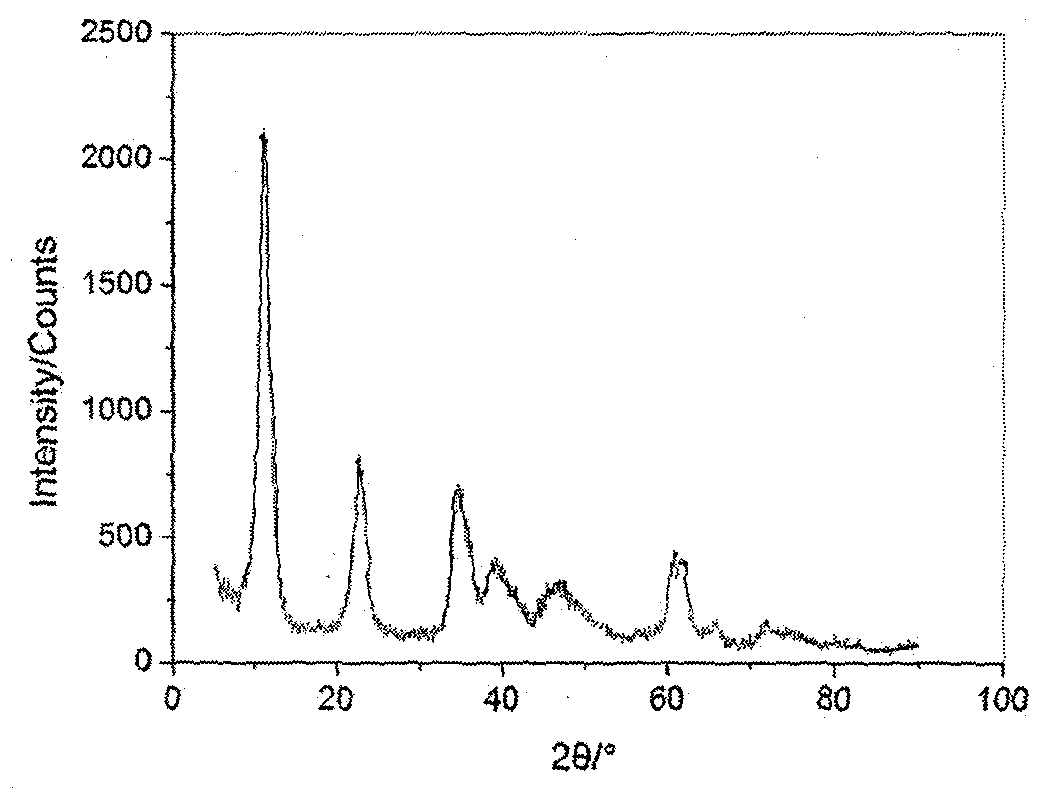

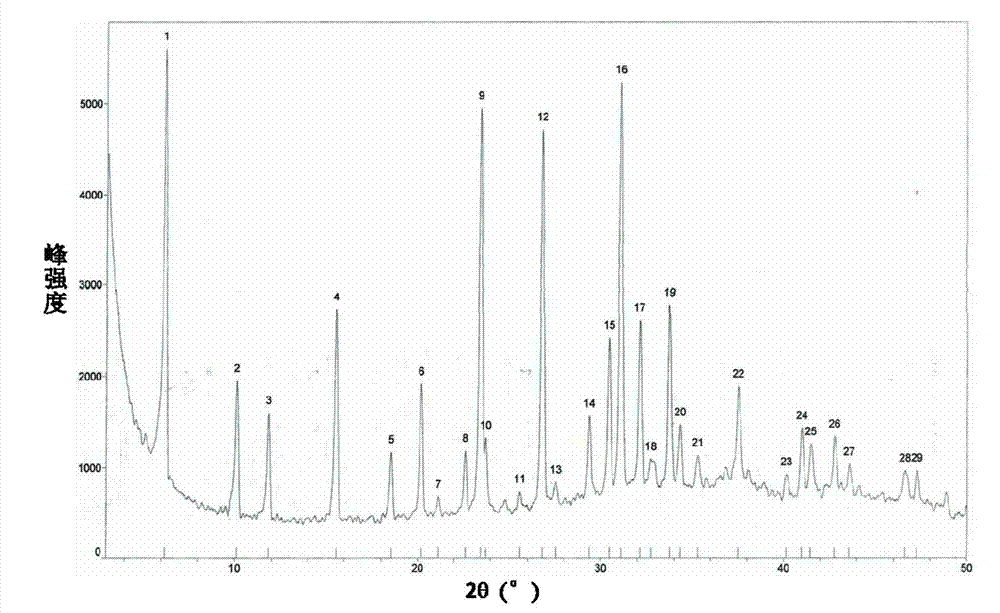

Carbonyl sulfide hydrolysis catalyst prepared by using cobalt(Co)-nickel(Ni)-aluminum(Al) hydrotalcites as precursor and preparation method thereof

InactiveCN101811051AHigh desulfurization precisionReduce energy consumptionMetal/metal-oxides/metal-hydroxide catalystsWater bathsFiltration

The invention provides a carbonyl sulfide hydrolysis catalyst prepared by using Co-Ni-Al-like hydrotalcite as a precursor and a preparation method thereof. The preparation method comprises the following steps of: at room temperature, dissolving cobalt nitrate, nickel nitrate and aluminum nitrate in distilled water to prepare solution A, wherein the total metal molar number is 0.75mol, n(Co2+):n(Ni2+) is equal to 0.25 to 1, and n(Co2++Ni2+):n(Al3+) is equal to 1.5 to 4; by using NaOH and Na2CO3 as precipitators, dissolving 0.05 moles of the NaOH and the Na2CO3 in the distilled water to prepare solution B; adding the solution A into the solution B dropwise to obtain suspension; and crystallizing the suspension in water bath, and then performing vacuum filtration, washing the crystals by the distilled, drying the crystals, baking the crystals in air, milling the crystals, tabletting the powder and screening the powder to obtain the hydrotalcite derivational compound oxide catalyst. The hydrolysis catalyst prepared by the method can be remove COS in gases, and simultaneously remove H2S generated in hydrolysis, and the desulfurization precision is high; and the hydrolysis catalyst can be used at the low temperature, the operational temperature is between 30 and 80 DEG C, and the energy consumption is low.

Owner:KUNMING UNIV OF SCI & TECH

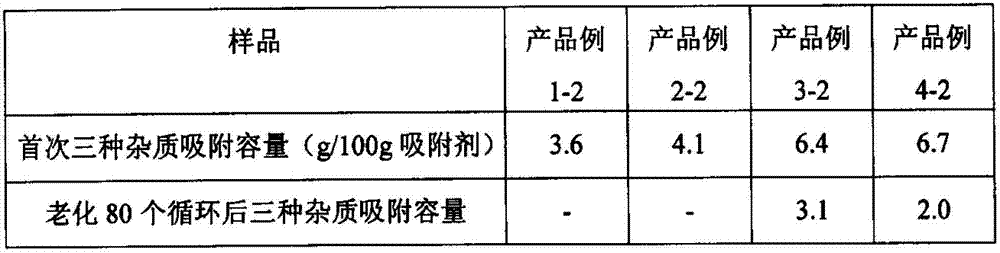

Preparation method of absorbent used for removing impurities from olefin flows

ActiveCN102921373AUniform distribution of poresEvenly distributedOther chemical processesAdsorption purification/separationPore distributionSorbent

The invention relates to a preparation method of an absorbent used for removing impurities from olefin flows. The absorbent contains components of zeolite molecular sieves, activated alumina and metal oxides. The preparation method adopts an in-situ synthesis method and an ion exchange method: the zeolite molecular sieves are synthetized on an activated alumina carrier, and then the metal oxides are loaded on the absorbent through ion exchange. Compared with the prior art, the absorbent prepared by adopting the preparation method has the advantages of even pore distribution and low absorption heat effect, performs a deep absorption function, can be used for removing one or more mixtures from carbon dioxide, hydrogen sulfide, carbonyl sulfide, methanol, mercaptan, ammonia, or other impurity compounds containing O, S or N from the olefin flows of ethylene, propylene, or the like.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

Purification technique for producing propylene by refinery plant

InactiveCN101255089ALower production productMeet the requirements of cracking propyleneChemical modification purification/separationSorbentAntichlor

The invention provides a purification process for propone produced in refinery, wherein the raw material is propone produced in refinery, and the process comprises: passing a carbonyl sulfide hydrolytic reactor containing carbonyl sulfide hydrolytic agent therein and a zinc oxide desulfurization reactor containing zinc oxide desulfurization agent therein; passing a fine desulfurization reactor containing fine desulfurization agent therein; passing a dechlorination reactor containing an inorganic antichlor and an organic antichlor; passing a dearsenization and dephosphorization reactor containing dearsenization and dephosphorization agents, passing a de- oxygen-containing and nitrogen-containing compound reactor containing oxygen-containing and nitrogen-containing compound adsorbents therein; obtaining a purified product. The product can take place cracking propone for polymerizing monomer and catalytically synthesizing organic compounds, to increase value of propone produced in refinery, and to expand the application ranges of propone produced in refinery.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

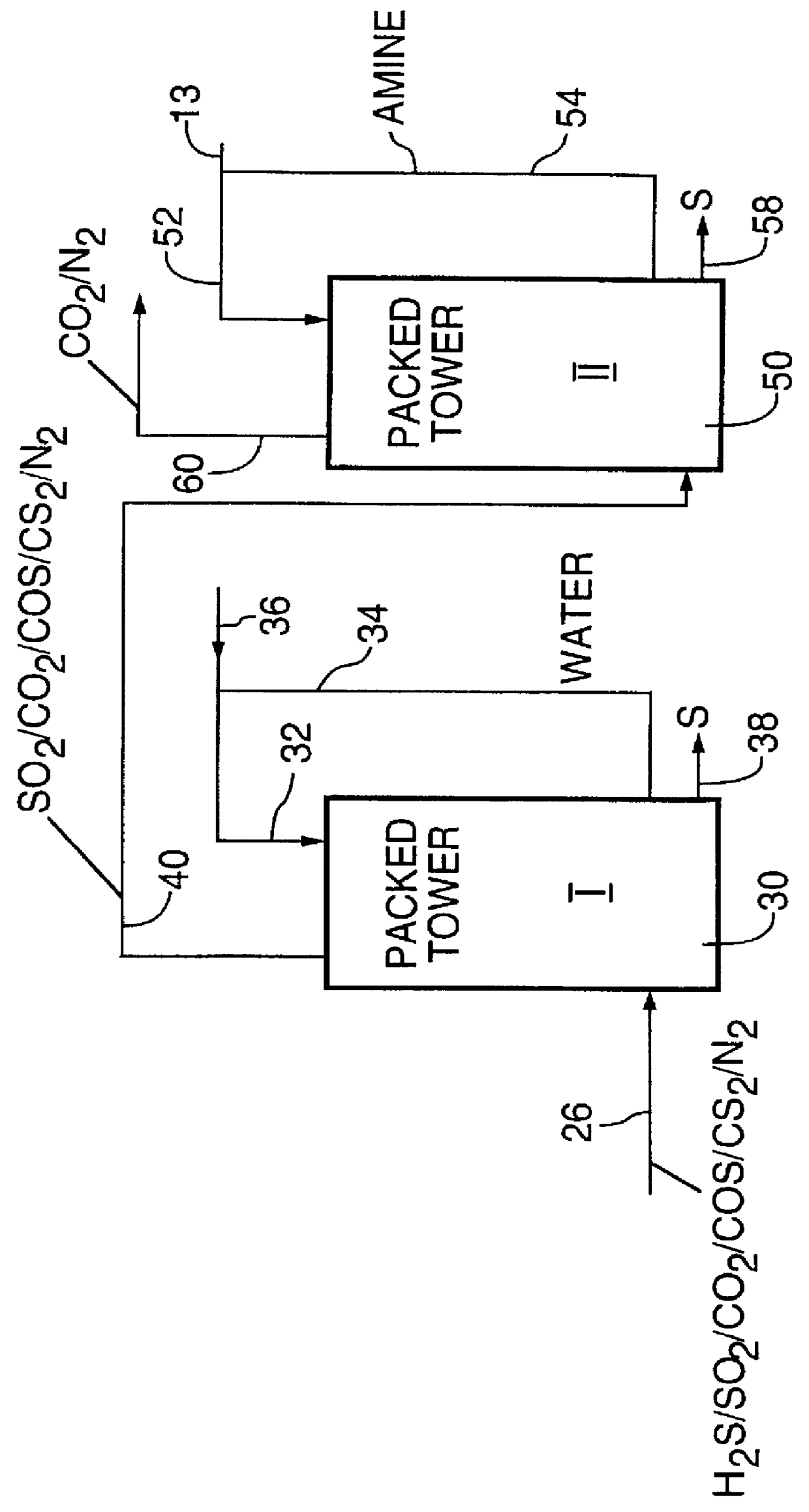

Natural gas treatment process

PCT No. PCT / CA97 / 00536 Sec. 371 Date Jul. 15, 1998 Sec. 102(e) Date Jul. 15, 1998 PCT Filed Jul. 28, 1997 PCT Pub. No. WO98 / 04337 PCT Pub. Date Feb. 5, 1998Hydrogen sulfide is removed from gas streams by reaction with sulfur dioxide in an autogeneously-formed aqueous acid medium according to the equation: SO2+2H2S->2H2O+3S the sulfur being removed from the aqueous phase. Carbonyl sulfide and / or carbon disulfide is removed from gas streams by hydrolysis to hydrogen sulfide in the presence of a weak organic base catalyst, such as quinoline, with the hydrogen sulfide reacting with sulfur dioxide to form sulfur.

Owner:APOLLO ENVIRONMENTAL SYST

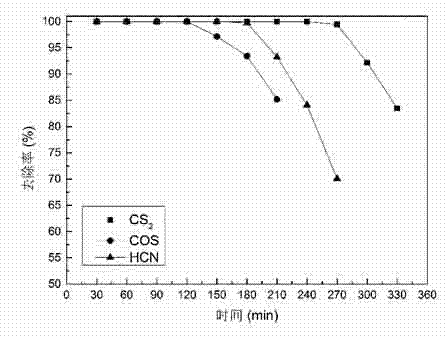

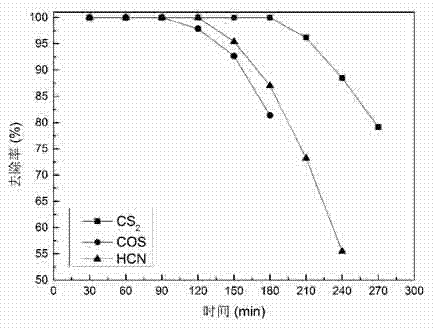

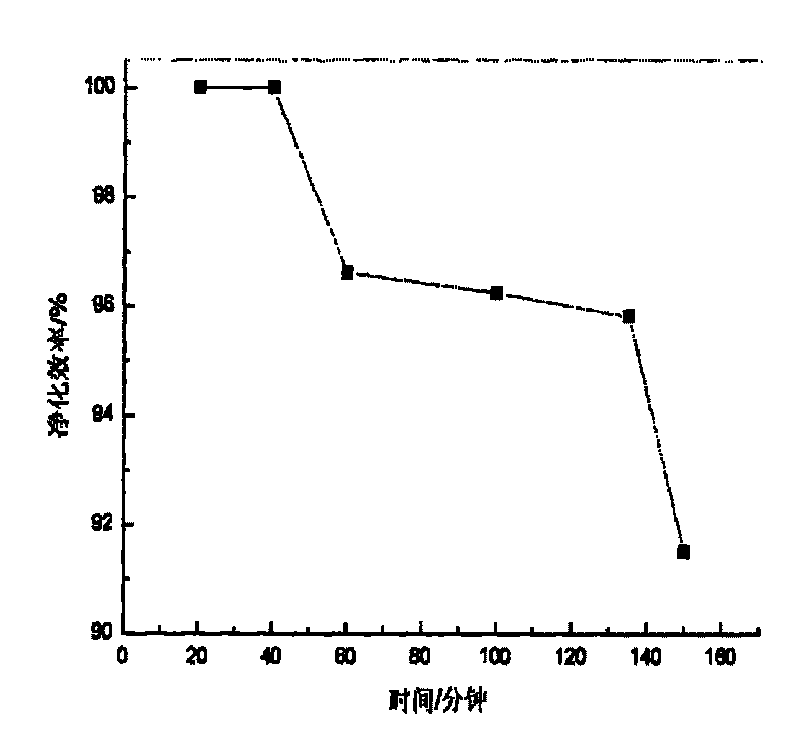

Preparation method of modified bio-charcoal based catalyst

InactiveCN104772146AImprove removal effectFully removedDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCarbonyl sulfide

Owner:KUNMING UNIV OF SCI & TECH

Method for removing acidic gases through biological technology

ActiveCN106310890AAchieve co-removalAchieve recyclingDispersed particle separationWaste water treatment from gaseous effluentsCarbonyl sulfidePollution

The invention belongs to the field of environmentally-friendly purification, and relates to a method for removing acidic gases through a biological technology. The method is mainly used to remove acidic gas flow containing carbon dioxide, hydrogen sulfide, carbonyl sulfide, carbon disulfide and mercaptan. A chemical absorption, microbial oxidation regeneration and biotrickling filter three-tower technology is adopted, and the chemical absorption characterized in that an alkaline solution is used to absorb carbon dioxide, hydrogen sulfide and a small amount of organic sulfur which are introduced to the alkaline solution; the microbial oxidation regeneration realizes biological oxidation of sulfides into biological sulfur under aeration conditions and alkaline solution regeneration; and biotrickling filter purification of organic sulfur is used for removing carbonyl sulfide, carbon disulfide, mercaptan and other organic sulfurs. The method adopting carbon dioxide fixation, sulfur resource recovery, absorption liquid recycling and organic sulfur deodorizing purification realizes acidic gas integral treatment, and solves the environmental protection problem of acidic gas pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

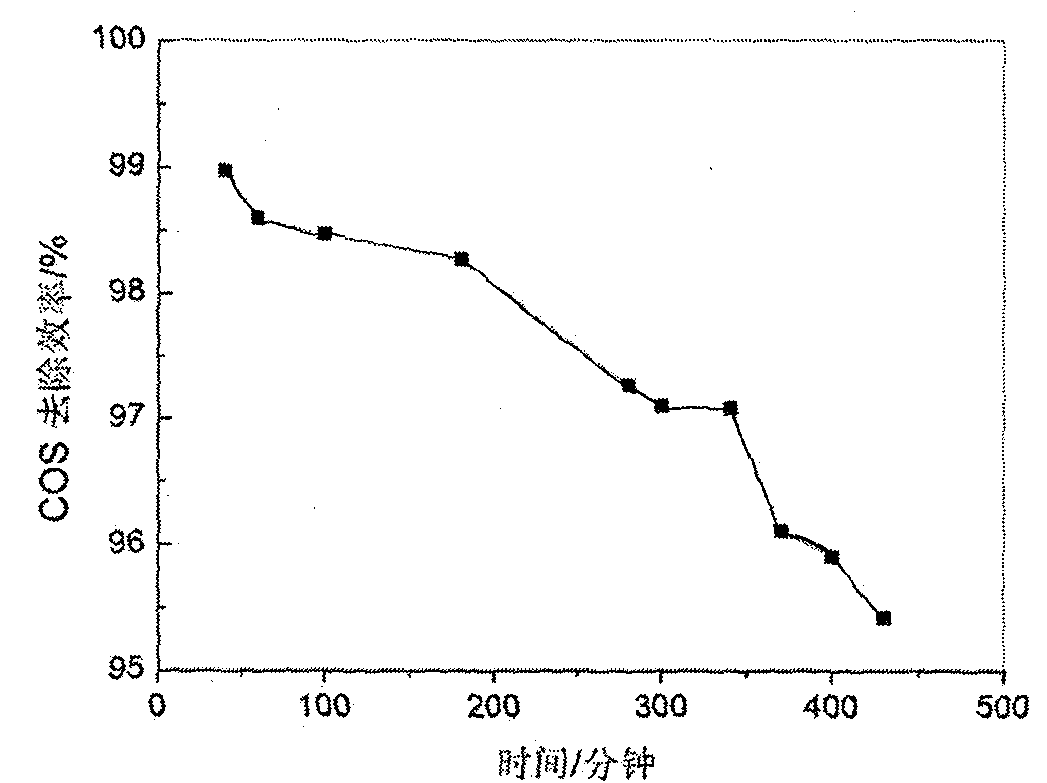

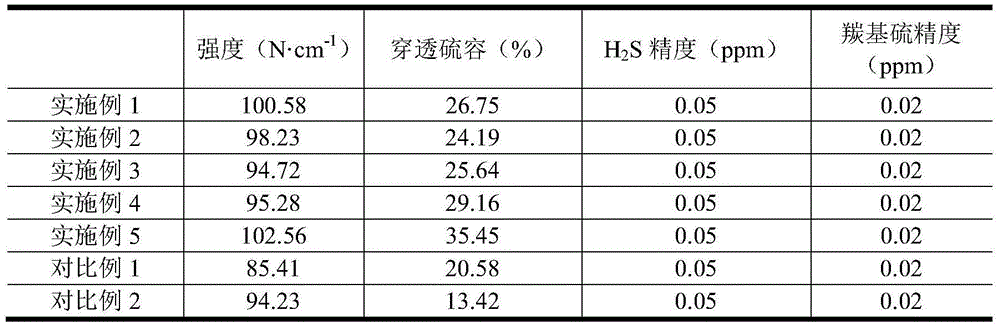

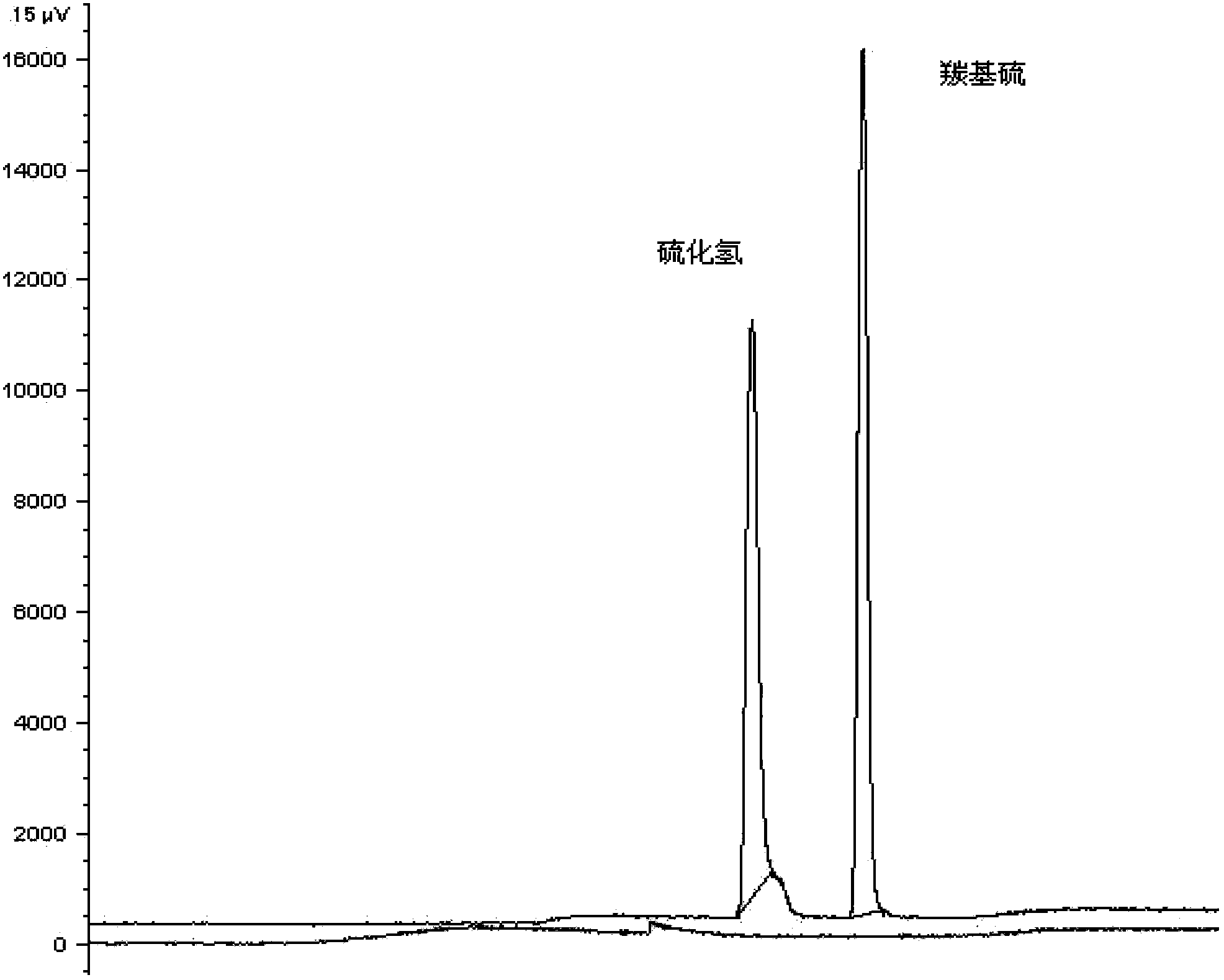

Desulfurizing agent for removing hydrogen sulfide and carbonyl sulfide at the same time

ActiveCN104437074AHigh mechanical strengthEvenly distributedDispersed particle separationCarbonyl sulfideAccelerant

The invention discloses a desulfurizing agent for removing hydrogen sulfide and carbonyl sulfide at the same time. The desulfurizing agent is prepared through the following steps that S1, a compound containing zinc, a binder and an accelerant are mixed, kneaded and formed; S2, a mixture formed after mixing, kneading and forming in the S1 is dried, and then a dried desulfurizing carrier precursor is obtained; S3, the desulfurizing carrier precursor obtained in the S2 is calcinated, and then a desulfurizing agent carrier is obtained; S4, the desulfurizing agent carrier is impregnated in a first copper salt solution, and copper active components are loaded on the desulfurizing agent carrier, wherein the first copper salt solution is an ammonium hydroxide solution of basic cupric carbonate; S5, an impregnated sample obtained in the S4 is dried and calcinated, and then the desulfurizing agent for removing hydrogen sulfide and carbonyl sulfide at the same time is obtained. The obtained desulfurizing agent is high in strength and not prone to pulverization, the impregnation effect of the active components is better, and hydrogen sulfide and carbonyl sulfide impurities in a high-temperature industrial gas source can be efficiently removed at the same time.

Owner:SHENYANG SANJUKAITE CATALYST

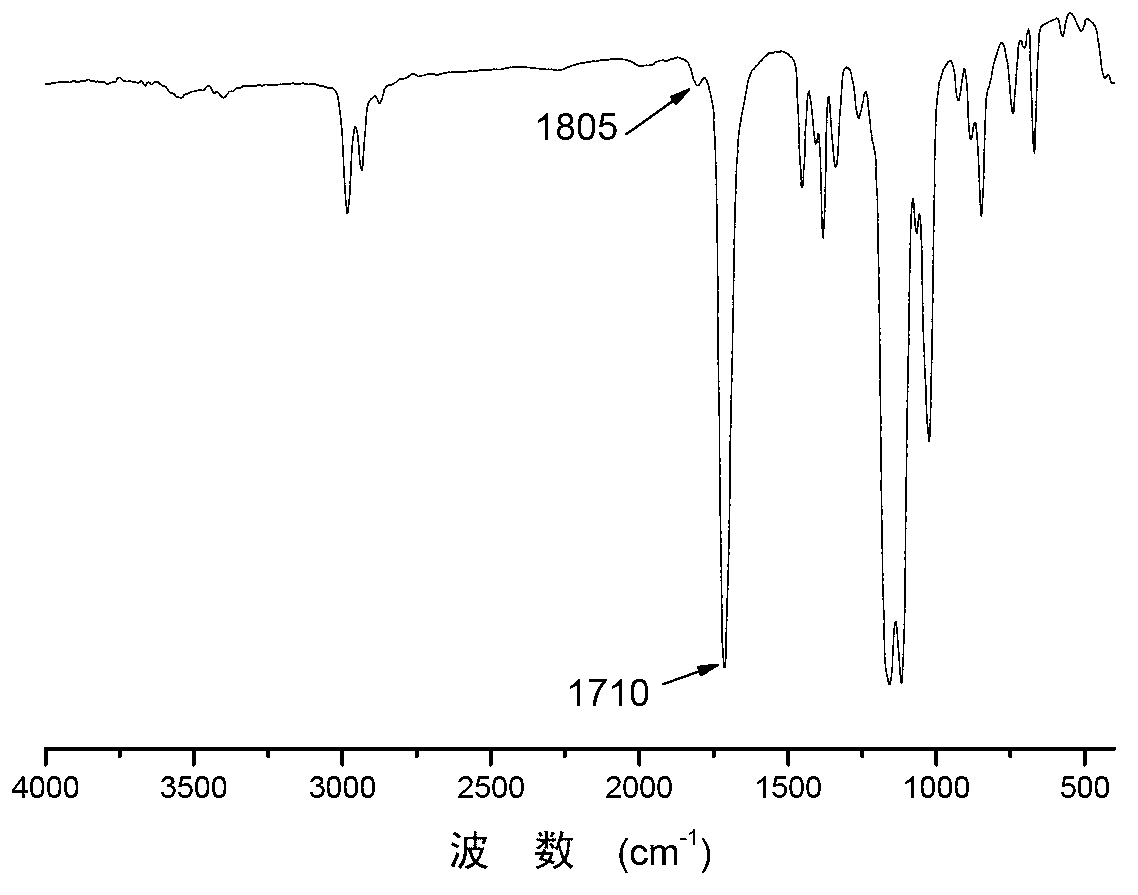

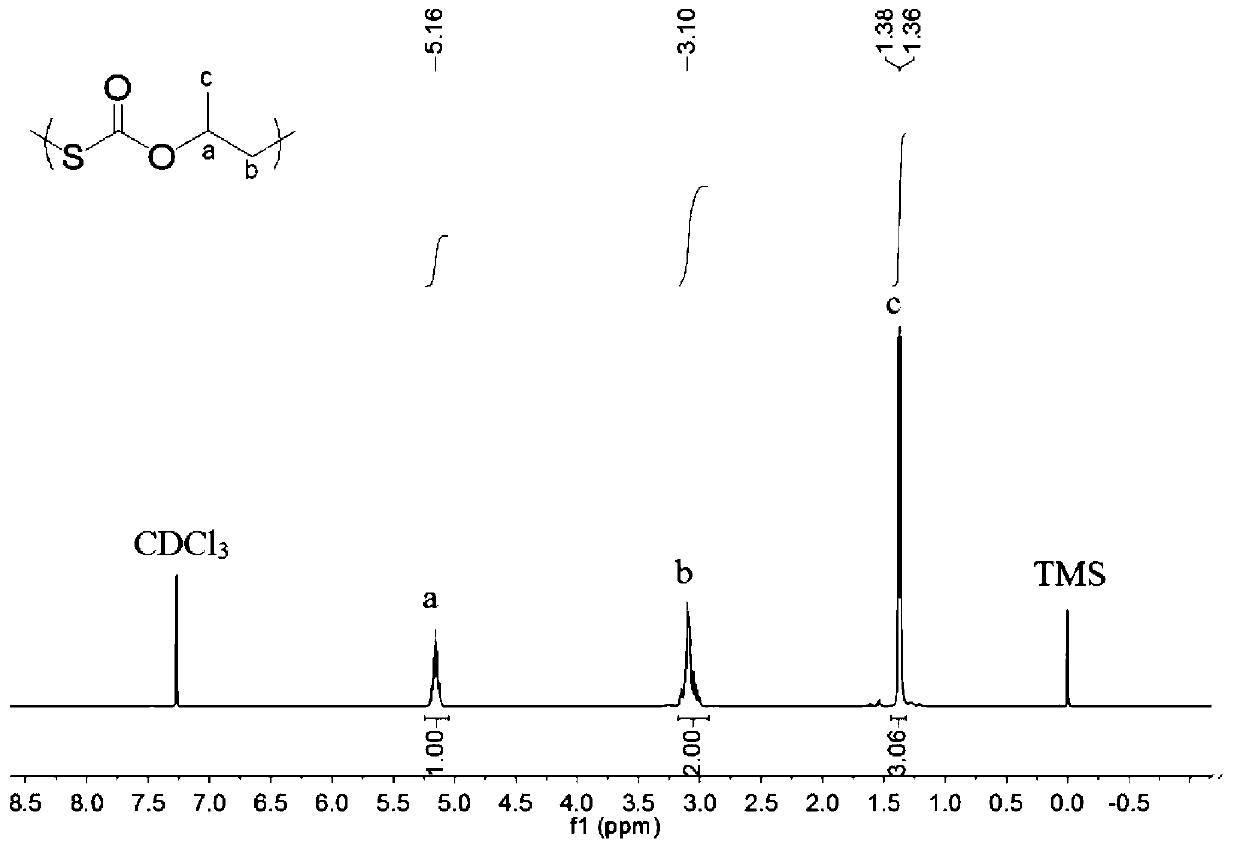

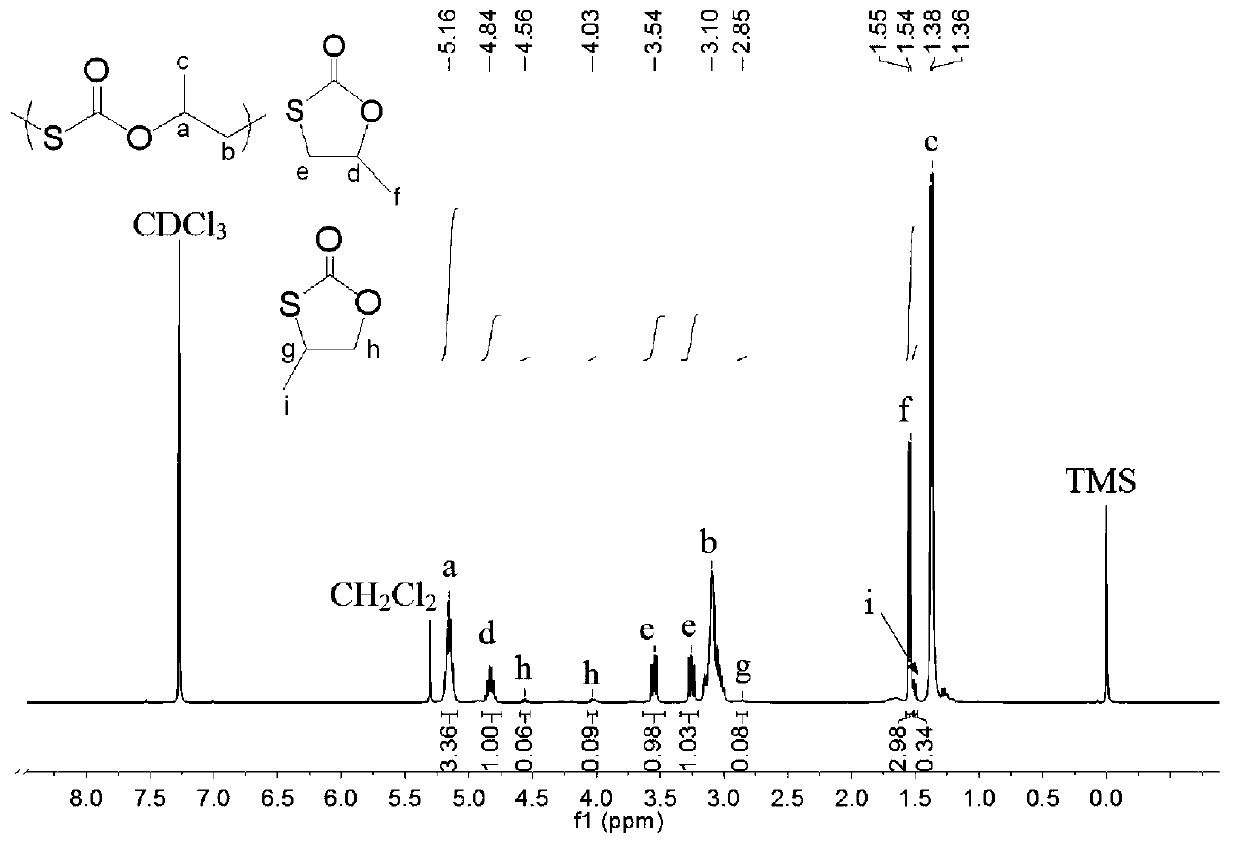

Preparation method of polymonosulfo-carbonate with regular chain structure

The invention relates to the field of synthesis of a high polymer material and aims to provide a preparation method of polymonosulfo-carbonate with a regular chain structure. The preparation method comprises the following steps of: adding epoxide, carbonyl sulfide, a catalyst and a catalyst promoter to a dry high-pressure reaction kettle, reacting for 0.5 hour -12.0 hours under self pressure at 0 DEG C-80 DEG C; and purifying and drying to obtain polymonosulfo-carbonate. The catalyst adopted by the preparation method disclosed by the invention has very high catalytic efficiency, and the method which is provided by the invention is different from a ring opening polymerization method for synthesizing polymonosulfo-carbonate in a controllable manner. The polymerization method is simple and easy to operate, and capable of accurately adjusting the polymer structure by adjusting the reaction conditions. The polymonosulfo-carbonate provided by the invention can be used more extensively; and the obtained product has a higher refractive index, for example, the COS-PO copolymer has the refractive index of 1.63, which is remarkably higher than that of the common copolymer, and therefore, the preparation method has a potential application to special optical materials such as adhesives.

Owner:ZHEJIANG UNIV

Purificant used for absorbing hydrogen sulfide and carbonyl sulfide in tail gas of natural gas and preparation method thereof

ActiveCN103506071ASimple ingredientsEasy accessOther chemical processesGaseous fuelsSimple componentChemisorption

The invention discloses a purificant for tail gas of natural gas and a preparation method thereof, especially to a purificant which removes hydrogen sulfide and carbonyl sulfide gas harmful to human beings in tail gas of natural gas produced in the process of industrial production or experiments through chemisorptions, belonging to the field of purification of atmospheric pollution. The purificant uses active carbon as a carrier and a soluble zinc salt and a soluble copper salt as active components. The preparation method for the purificant comprises the following steps: preparing an aqueous solution from the soluble zinc salt and the soluble copper salt; loading the aqueous solution on the active carbon carrier; and carrying out drying, oxidation treatment, washing with distilled water and drying. The normal temperature purificant provided by the invention is widely applicable to purification of ppm-grade hydrogen sulfide and carbonyl sulfide gas tail gas of natural gas used a factory or laboratory, and the content of hydrogen sulfide and carbonyl sulfide gas is less than 30 ppb after purification; and the purificant has the advantages of simple components, easy preparation, a low price, low usage cost and a good desulphurization effect and has a great popularization value.

Owner:CHINA PETROLEUM & CHEM CORP +1

Secondary aluminum battery and preparation method of anode thereof

InactiveCN101764254AIncrease the effective reaction areaWide variety of sourcesCell electrodesSecondary cellsHalogenCarbonyl sulfide

The invention discloses a secondary aluminum battery and a preparation method of anode thereof; the secondary aluminum battery comprises a battery anode, a battery cathode, an electrolyte, a diaphragm and a current collector; the battery cathode is made of aluminum or aluminum alloy; the battery anode is made of polystyrene polysulfide or carbonyl sulfide composite material; and the electrolyte is halogen aluminic acid ionic liquid. The preparation method of secondary aluminum battery anode material (polystyrene polysulfide) comprises the following steps: (1) preparing chlorination polystyrene; (2) preparing polystyrene polysulfide; (3) slowly dropping sodium polysulfide solution into chlorination polystyrene solution according to the proportion of Na to C1 being 1: 1 at the temperature of 50 to 150 DEG C, stirring so as to react about 24 hours. Powder product is obtained after cleaning and extracting to obtain polystyrene polysulfide product dried about 24 hours in vacuum at the temperature of 80 DEG C.

Owner:无锡欧力达新能源电力科技有限公司

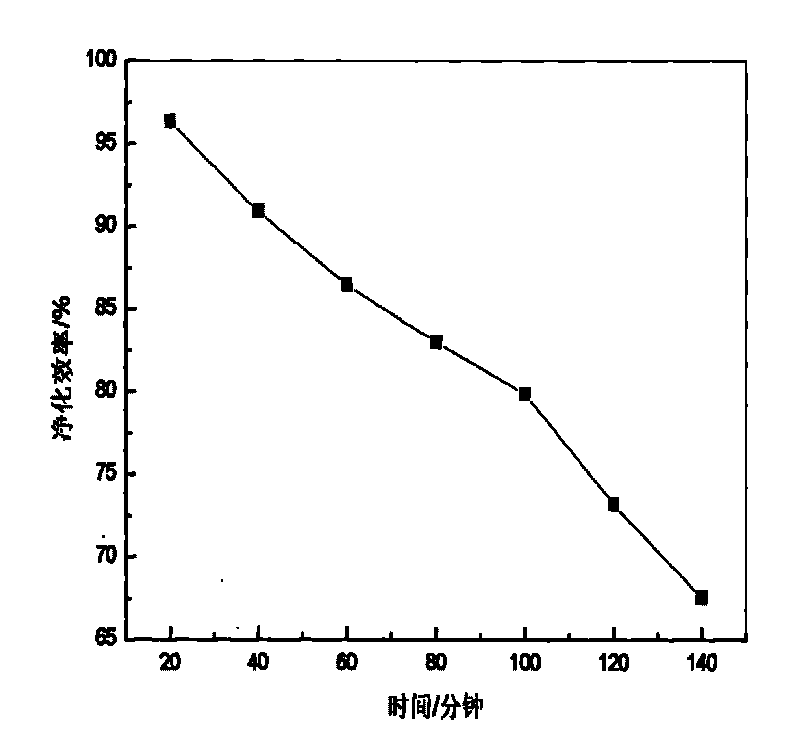

Low-temperature carbonyl sulfide hydrolysis activated carbon-supported catalyst and preparation method thereof

InactiveCN101703928ALow costHigh desulfurization precisionHydrogen sulfidesDispersed particle separationActivated carbonPtru catalyst

The invention relates to a preparation method of a low-temperature carbonyl sulfide hydrolysis activated carbon-supported catalyst. The method comprises the following steps: (1) grinding activated carbon, sieving the ground activated carbon to 40-60 meshes, washing for 3-4 times, then boiling for 1.5 h with l mol / L KOH solution, washing with distilled water until the pH value is constant, and then drying at the temperature of 120 DEG C for later use; (2) ultrasonic immersing the activated carbon in the step (1) with metal oxide immersion liquid with mass content accounting for 1-9 percent of that of the activated carbon for 30 min; (3) keeping the temperature of the activated carbon after immersing treatment in the step (2) constant for 3-6 h at the temperature of 120-170 DEG C, and then activating for 3 h at the temperature of 200-700 DEG C; and (4) ultrasonic immersing the activated carbon after activating in the step (3) with alkali solution with mass content accounting for 3-15 percent of that of the activated carbon for 30 min, and then keeping the temperature of the activated carbon constant for 3 h at the temperature of 110 DEG C to 160 DEG C to obtain the activated carbon-supported catalyst. The preparation method can remove the COS in the gas, simultaneously remove the H2S generated during the hydrolysis, has higher desulfurization precision, can obtain the low-cost raw material easily and also has the advantages of good activity at the normal and low temperature, low cost and the like.

Owner:KUNMING UNIV OF SCI & TECH

Carbon disulfide process

The specification discloses a process for the manufacture of carbon disulfide from sulfur dioxide and carbon monoxide comprising two catalytic reactions. In the first reaction, sulfur dioxide and carbon monoxide are converted to carbonyl sulfide and carbon dioxide. In the second reaction, carbonyl sulfide is disproportionated to carbon disulfide and carbon dioxide. The second reaction is conducted in the presence of a solvent, which continuously removes the carbon disulfide product so as to drive the reaction to completion.

Owner:JES TECH LLC

Anti sulfur deoxidizing catalyst, its preparing process and application method

ActiveCN1631530AStrong resistance to sulfur poisoningPhysical/chemical process catalystsActivated carbonPolymer science

The invention unfurls a kind of off O catalyst and its producing way and application. The catalyst of the invention is made of carry and the active parts on carry PtS, rate by carry weight: Pt: 0.01--0.5%(wt), S / Pt mol rate: 0.1--50, the carry is chosen in three oxide two aluminum, numerator sieve, two oxide silicon and active carbon. The invention apply the catalyst in taking off O to COS of 1--500ppm, O of 0.5 %( vacuum) of having hydrogen. Temperature is 25-450 degC, press is 1--15MPa. The catalyst of the invention has the strong ability to offence S poison, very well to be used in taking off O in the air including S.

Owner:CHINA PETROLEUM & CHEM CORP +1

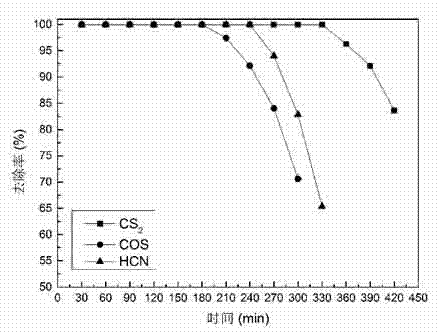

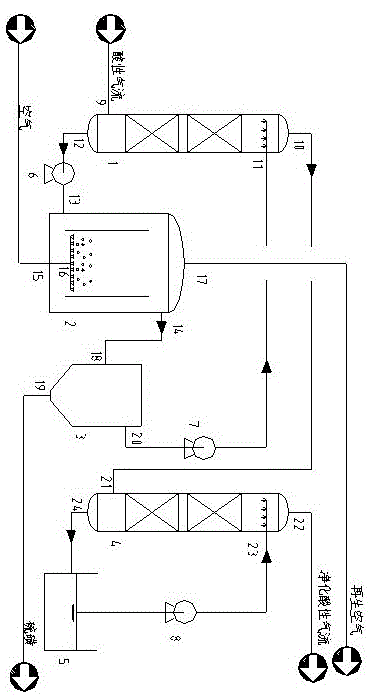

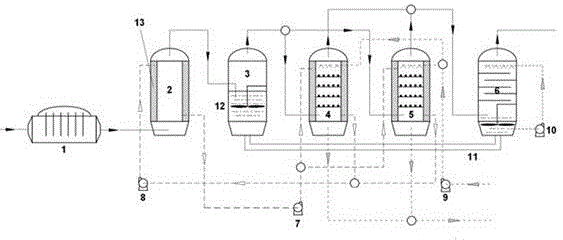

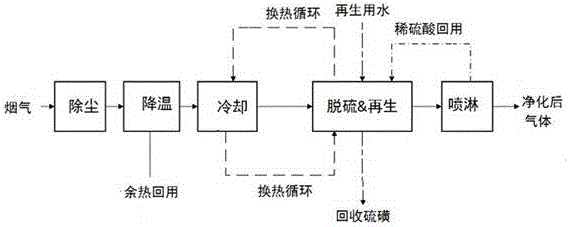

Method and device for simultaneously removing carbonyl sulfide and carbon disulfide

ActiveCN106621796AEfficient use ofModerate reaction temperatureGas treatmentDispersed particle separationCooling towerCarbonyl sulfide

The invention discloses a method and a device for simultaneously removing carbonyl sulfide and carbon disulfide. The device which is a desulfurization device comprises a heat exchange system, an assistant catalysis system, a continuous operation system, a catalyst regeneration system and the like. The heat exchange system comprises a cooling tower and fixed-bed reaction towers, the assistant catalysis system comprises a stripping tower, a spray tower and a communication pipe, the continuous operation system comprises the two fixed-bed reaction towers, and the catalyst regeneration system comprises the heat exchange system and a regeneration spray system. The method and the device have the advantages that the method is high in desulfurization efficiency, heat from high-temperature flue gas can be effectively utilized, dilute sulfuric acid which is a product can be recycled, and accordingly the catalytic reaction efficiency can be improved; the double reaction towers are respectively positioned at a catalytic reaction stage and a catalyst regeneration stage and can be switched over by the aid of electromagnetic valves in a timed manner, and accordingly continuous operation of the systems can be guaranteed; elemental sulfur on the surfaces of deactivated catalysts can be transferred into liquid phases in regeneration procedures and is convenient to extract in follow-up procedures, and the device is high in integration level and automation degree.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com