Patents

Literature

72results about How to "Increase the effective reaction area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Secondary aluminium cell and preparation method thereof

InactiveCN101764258ASolution areaSolve problems such as poor circulationFinal product manufactureElectrolyte accumulators manufactureQuaternary ammonium cationHalogen

The invention discloses a secondary aluminium cell and a preparation method thereof. Foamed aluminium serves as a cathode. A carbon and sulfur composite material or sulfurized polyacrylonitrile serves as an anode active material. A halogen aluminate ionic liquid formed from halogen aluminium acid and any one of halogenated quaternary ammonium salt, quaternary alkylphosphonium salt or quaternary sulfosalt is obtained by preparing electrolyte. The cell has the advantages of high energy density, good cycle performance, safety, environmental protection, no pollution in the preparation process, low cost and simple process.

Owner:无锡欧力达新能源电力科技有限公司

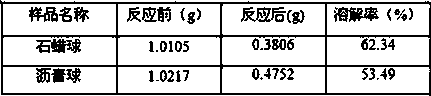

Formula of thermal battery CoS2 cathode material and processing technology

InactiveCN102544482AIncrease the effective reaction areaImprove performancePrimary cell electrodesLithium oxideMolten salt

The invention discloses a formula of a thermal battery CoS2 cathode material and processing technology. The formula comprises the following components by mass: 70.5%-85% of cobaltous sulfide CoS2, 5%-15% of lithium oxide, 16%-25% of molten salts. The processing technology of the formula comprises the following steps: adding the cathode active substance of the cobaltous sulfide CoS2 material in an enamel disc, putting in a vacuum drying oven, performing high temperature dehydration at 90 DEG C-250 DEG C; performing high temperature sintering of the dehydrated cobaltous sulfide CoS2 at 290 DEG C-500 DEG C under inert gas protection for 4 h-8 h, cooling and sieving, adding 5%-15% of lithium oxide and 16%-25% of molten salts into the cobaltous sulfide CoS2, mixing and sintering at 330 DEG C-500 DEG C for 4 h-6 h, cooling to room temperature, sieving by a 80-mesh sieve so as to prepare the high temperature resistant thermal battery cathode composite material which is bottled to keep in reserve. The invention can improve the security of thermal batteries, and increase the active substance utilization rate.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Rechargeable aluminum battery and preparation method thereof

InactiveCN101764256AIncrease the effective reaction areaWide variety of sourcesFinal product manufactureElectrolyte accumulators manufactureMicrocosmic saltSulfur

The invention discloses a rechargeable aluminum battery and a preparation method thereof. The rechargeable aluminum battery is prepared by selecting metal aluminum or an aluminum alloy, preferable foamed aluminum, as a cathode, taking vulcanized polyvinyl chloride or a carbon-sulfur compound material as an anode active substance and taking aluminic acid halide ionic liquid formed by aluminum halide and any one of quaternary ammonium salt or quaternary microcosmic salt or quaternary sulfosalt a electrolyte. The rechargeable aluminum battery has the advantages of high battery energy density, good circulation performance, safety, environmental protection, pollution-free preparation process, low cost, simple process and vast application prospect.

Owner:无锡欧力达新能源电力科技有限公司

Rechargeable aluminum-sulfur battery and preparation method thereof

InactiveCN101764255AIncrease the effective reaction areaWide variety of sourcesFinal product manufactureElectrolyte accumulators manufactureOrganic sulfide compoundMetallic aluminum

The invention discloses a rechargeable aluminum-sulfur battery and a preparation method thereof. The rechargeable aluminum-sulfur battery is prepared by adopting metallic aluminum or aluminum alloy, preferably foamed aluminum as cathode, polymeric organosulfides as anode active substances, and halogenated aluminic acid ionic liquid formed by halogenated aluminum with any one of quaternary ammonium salt, quaternary phosphor salt or quaternary sulfosalt as electrolyte. The rechargeable aluminum-sulfur battery has high energy density, good circulation performance, safety and environmental protection, no pollution in preparation process, low cost and simple technique, thus having good application prospect.

Owner:无锡欧力达新能源电力科技有限公司

Aluminium polymer secondary battery and preparation method thereof

InactiveCN101794907AIncrease capacityIncrease the effective reaction areaFinal product manufactureElectrolyte accumulators manufacturePhosphoniumSulfur

The invention discloses an aluminium polymer secondary battery and a preparation method thereof. The aluminium polymer secondary battery is prepared by taking metallic aluminium or aluminium alloy, preferably foamed aluminium as the negative pole, vulcanized polyvinyl chloride or carbon-sulfur composite materials as the positive active materials, and halogen aluminic acid ionic liquid formed by aluminum subhalide and one of hyamine, phosphonium actericideor, or sulfur actericide as the electrolyte solution. The battery has the advantages of high energy density, good cycle performance, environment protection, no pollution during the preparation, low cost, simple process and favorable application prospect.

Owner:无锡欧力达新能源电力科技有限公司

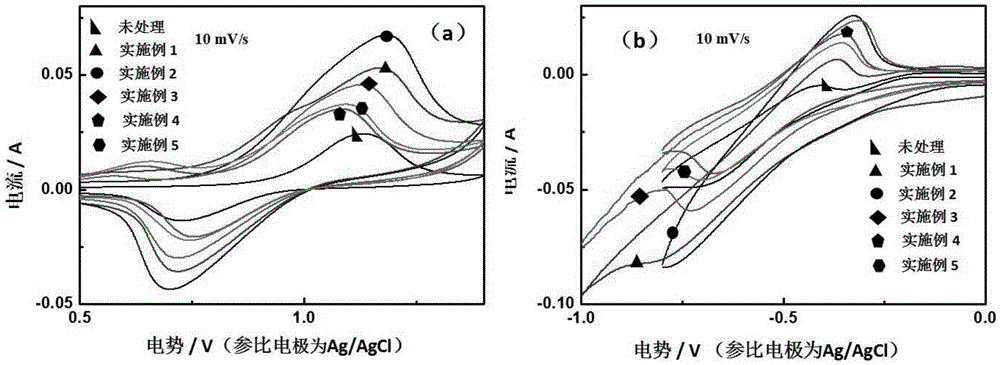

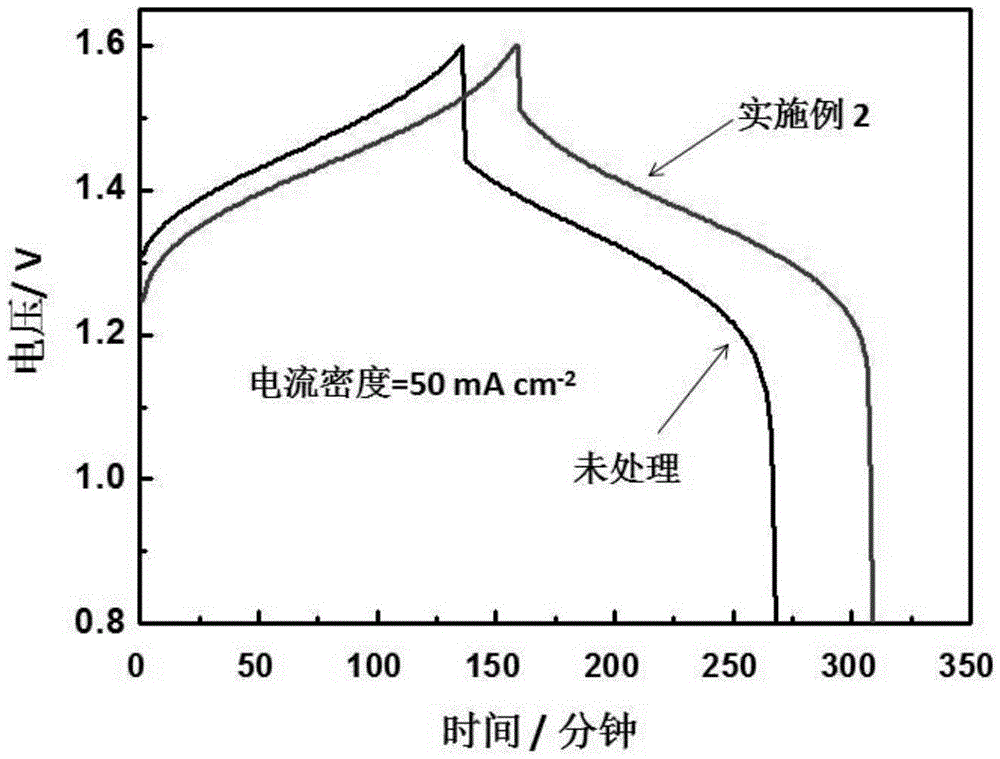

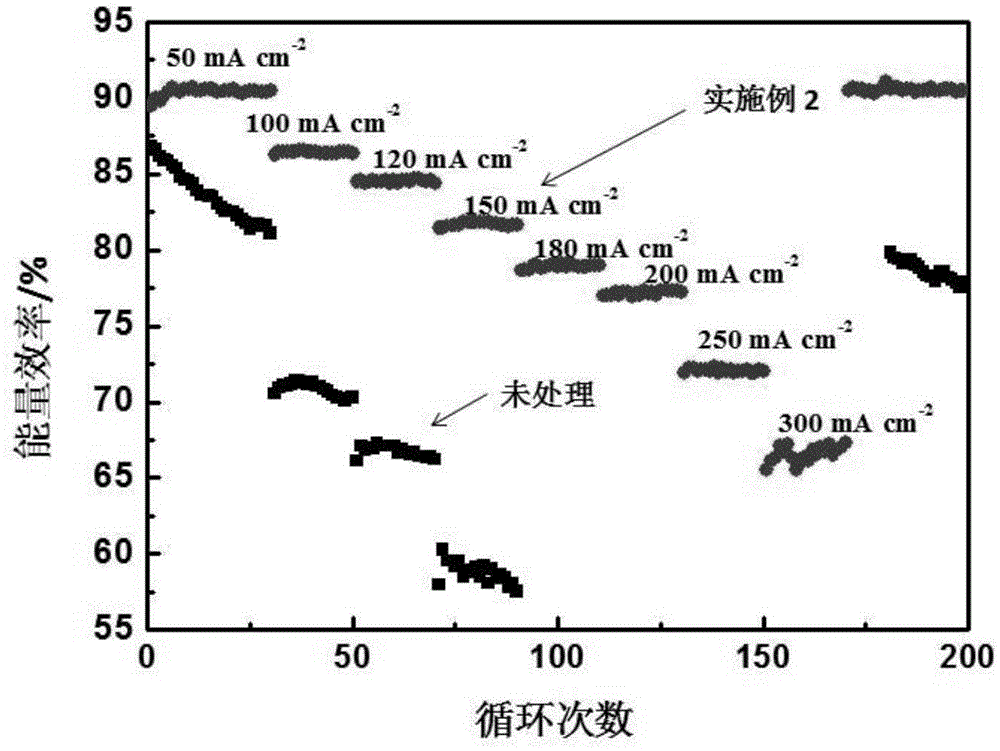

Treatment method for all-vanadium redox flow battery electrode

InactiveCN105529471AOptimize process flowEasy to operateCell electrodesRegenerative fuel cellsHigh current densityCharge discharge

The invention provides a treatment method for an all-vanadium redox flow battery electrode. The method comprises the following steps: with carbon electrode materials of a graphite felt, a carbon felt and the like as raw materials, drying the raw materials after fully soaking in an alkali liquor; carrying out high-temperature activation under protection of an inert gas; and washing and drying the product to prepare the activated carbon electrode materials. The treatment method has the advantages of being simple, simple and convenient to operate and low in cost; the surfaces of the treated carbon electrode materials are etched; the effective reaction area of vanadium ion electron pairs on the electrode surface is increased; the charge transfer impedance of an all-vanadium redox flow battery in a charge-discharge process is greatly reduced, so that the voltage efficiency and the energy efficiency of the all-vanadium redox flow battery under high current density are greatly improved.

Owner:HUNAN YINFENG NEW ENERGY

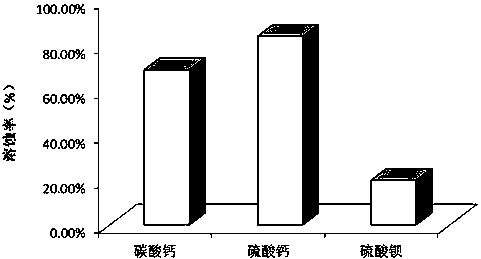

Neutral plug removal treating agent and preparation method thereof

The invention provides a neutral plug removal treating agent and a preparation method thereof. The neutral plug removal treating agent comprises the following components in percent by mass: 5 to 12 percent of an antiscaling agent, 0.5 to 1 percent of a synergist, 0.5 to 2 percent of a dispersing agent, 0.5 to 2 percent of a regulator, 5 to 10 percent of a cosolvent, and the balance of water. The neutral plug removal treating agent has the advantages that acidic materials are not added or produced during the whole process, wax, colloid and asphaltene covering the surface of sediments can be removed under a neutral low-temperature condition, and the neutral plug removal treating agent is neutral, non irritant, low-corrosion, low in transportation risk, and mild in plug removal reaction, effectively removes indissolvable inorganic scales, such as sulfate and carbonate, and achieves the purposes of elimination of transportation operation risk, reducing of tubular column corrosion rate, protection of a reservoir framework structure and improvement of the success rate of measures.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

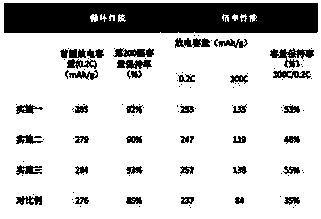

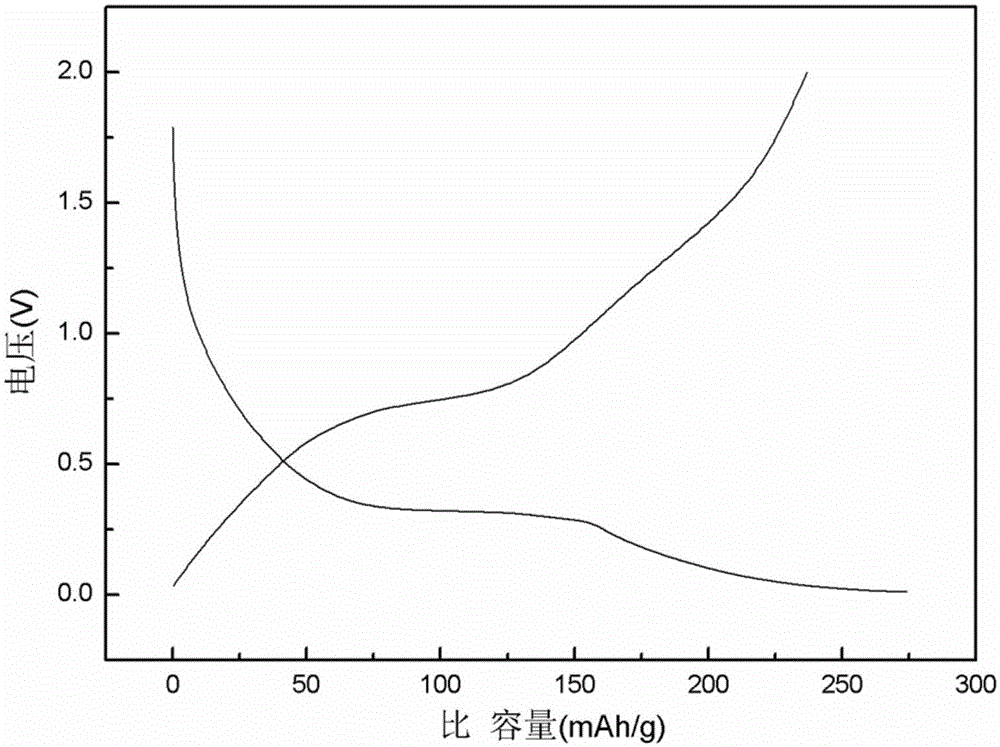

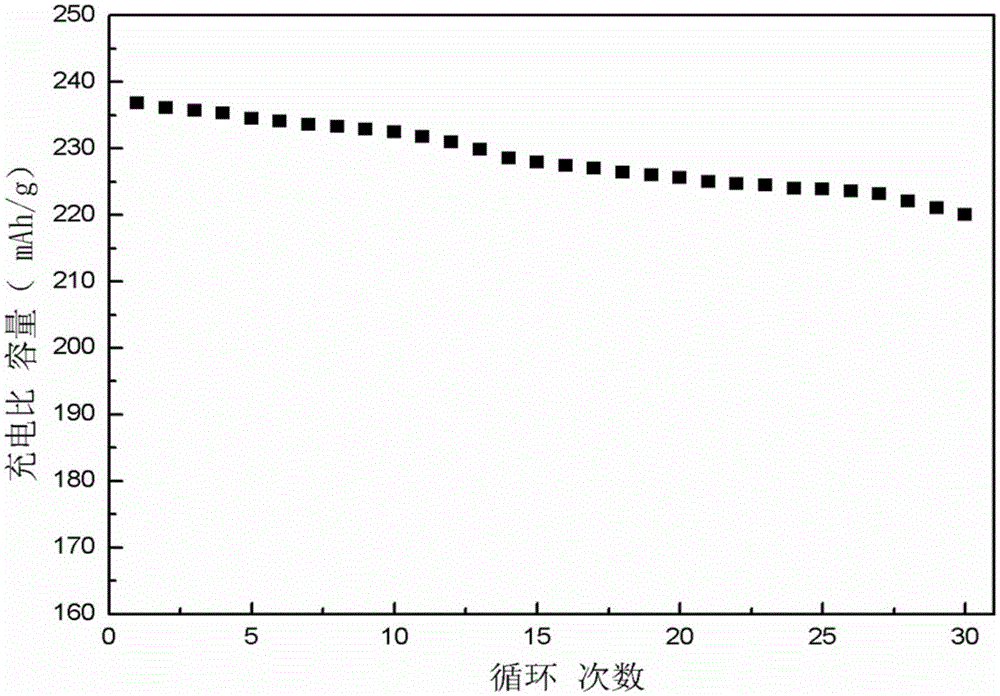

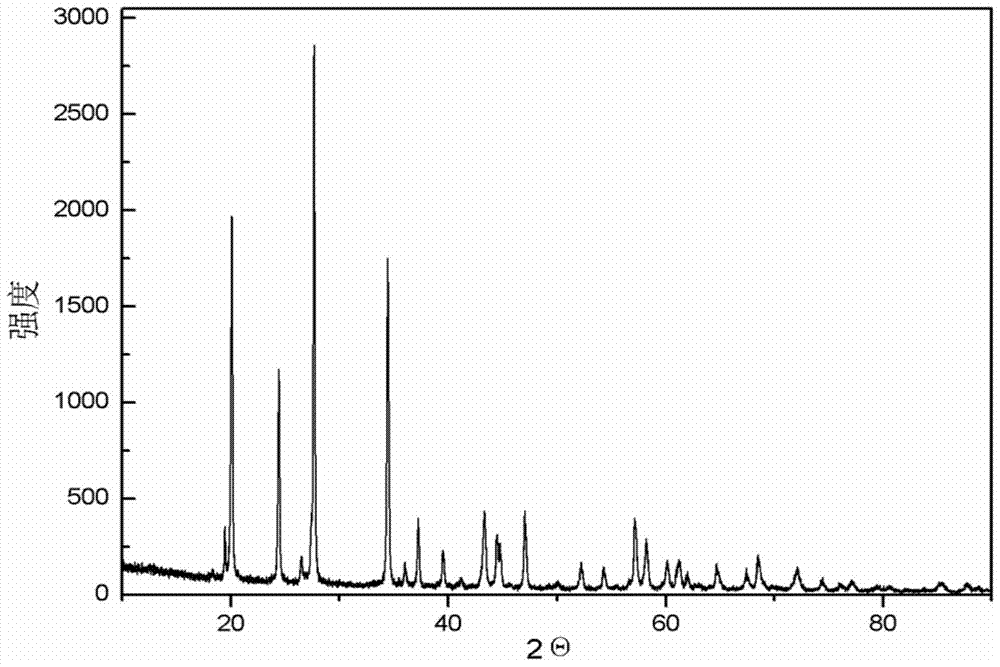

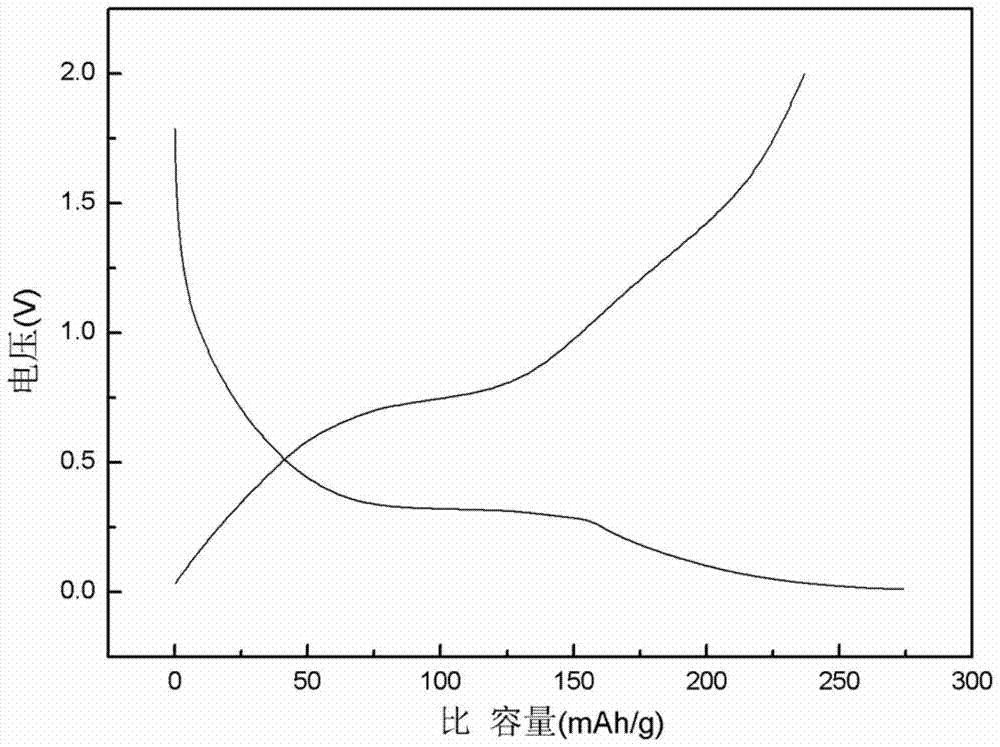

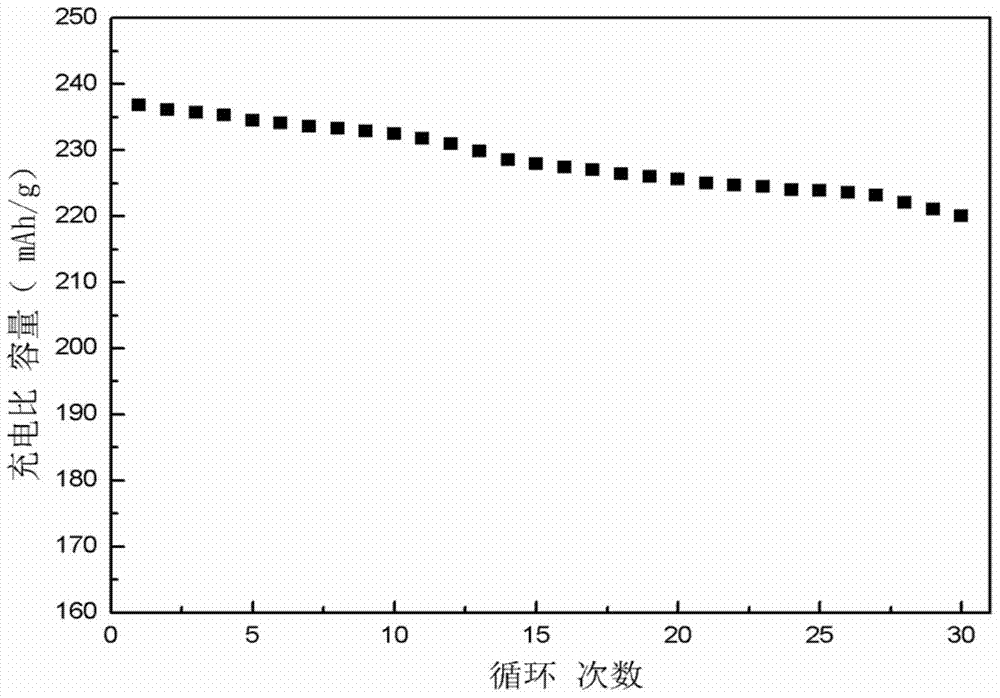

Carbon/titanium niobium oxide composite negative electrode material and preparation and application thereof

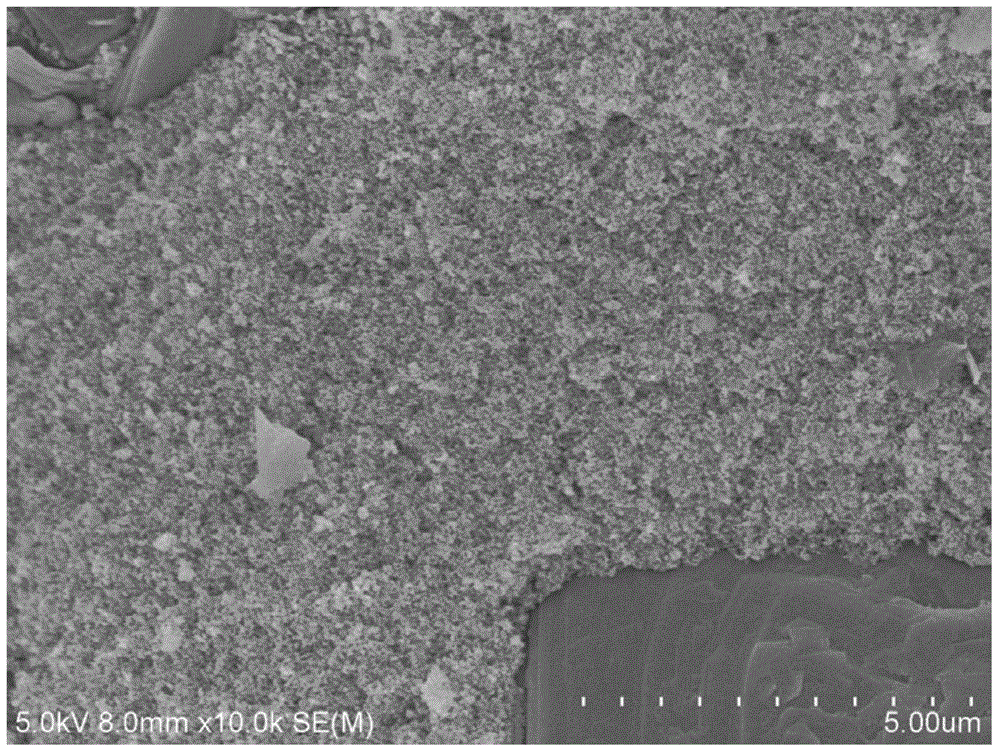

ActiveCN109859957AImprove conductivityIncrease the effective reaction areaHybrid capacitor electrodesHybrid/EDL manufactureTitaniumMass content

The invention relates to a carbon / titanium niobium oxide composite negative electrode material and preparation and application thereof. The mass content of the titanium niobium oxide in the compositenegative electrode material is 90-95%, and the mass content of carbon in the composite material is 5-10%. Compared with the prior art, the invention adopts an ultra-centrifugal effect and a sol-gel method and introduces a carbon material with high conductivity, the high-conductivity titanium niobium oxide composite material with a nano size is prepared, and nano-channels of the particles increasethe effective reaction area of the electrode and access channels of ions; and the introduction of the carbon material can form an effective conductive network in the composite material so as to improve the conductivity of the material, and meanwhile, the carbon material plays a role of supporting and coating the titanium niobium oxide, thereby improving the cycle performance of the titanium niobium oxide while improving the rate performance thereof.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

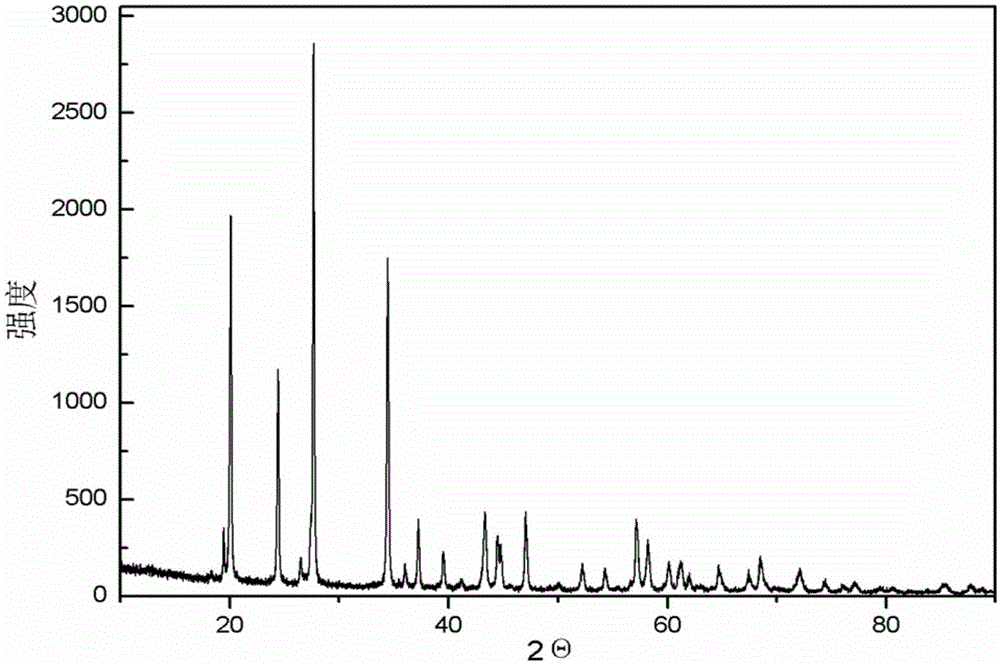

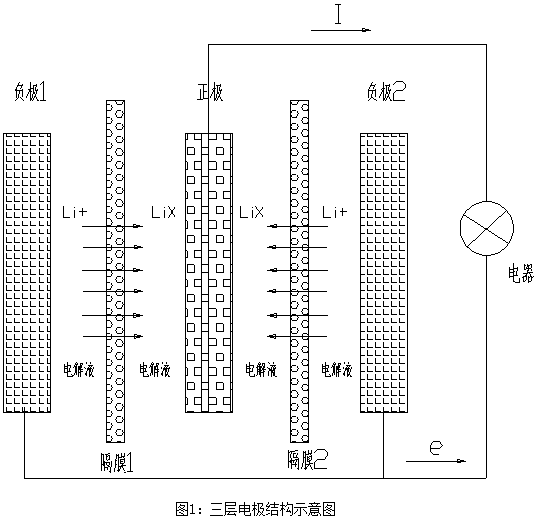

Composite lithium titanate preparation method

InactiveCN105406051AImprove conductivityIncrease the effective reaction areaCell electrodesLithiumOrganic solvent

The invention relates to a composite lithium titanate preparation method, which comprises: 1) uniformly mixing a lithium source compound, a titanium source compound and the compound of a doped modifier M according to a molar ratio of Li to Ti to M of (0.6-1):1:(0.06-0.3), dispersing in an organic solvent, carrying out ball milling for 6-12 h, sintering for 6-12 h at a temperature of 80-120 DEG C, and drying; 2) carrying out a heat treatment on the dried product obtained in the step 1) for 8-20 h at a temperature of 400-600 DEG C, and naturally cooling; and 3) carrying out mixing ball milling on the treated material obtained in the step 2) and a cladding material for 6-12 h according to a weight ratio of 100:(5-20), sintering for 8-20 h at a temperature of 700-950 DEG C under the protection of nitrogen, cooling, and screening with a 300 mesh sieve. According to the present invention, the preparation method has characteristics of rapid reaction, high product purity, low cost, and easy large-scale industrial production achieving.

Owner:HENAN KELONG NEW ENERGY CO LTD

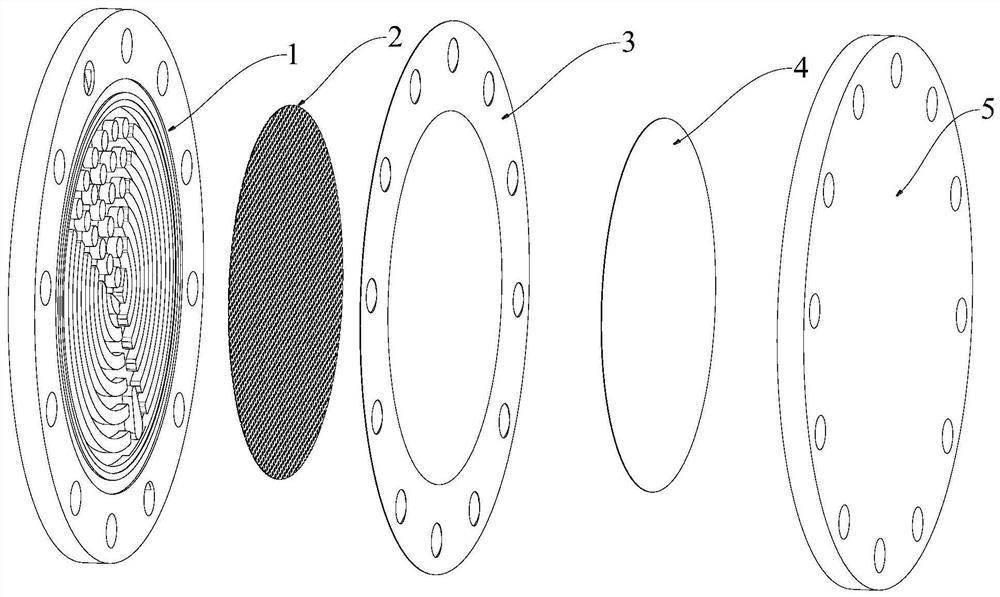

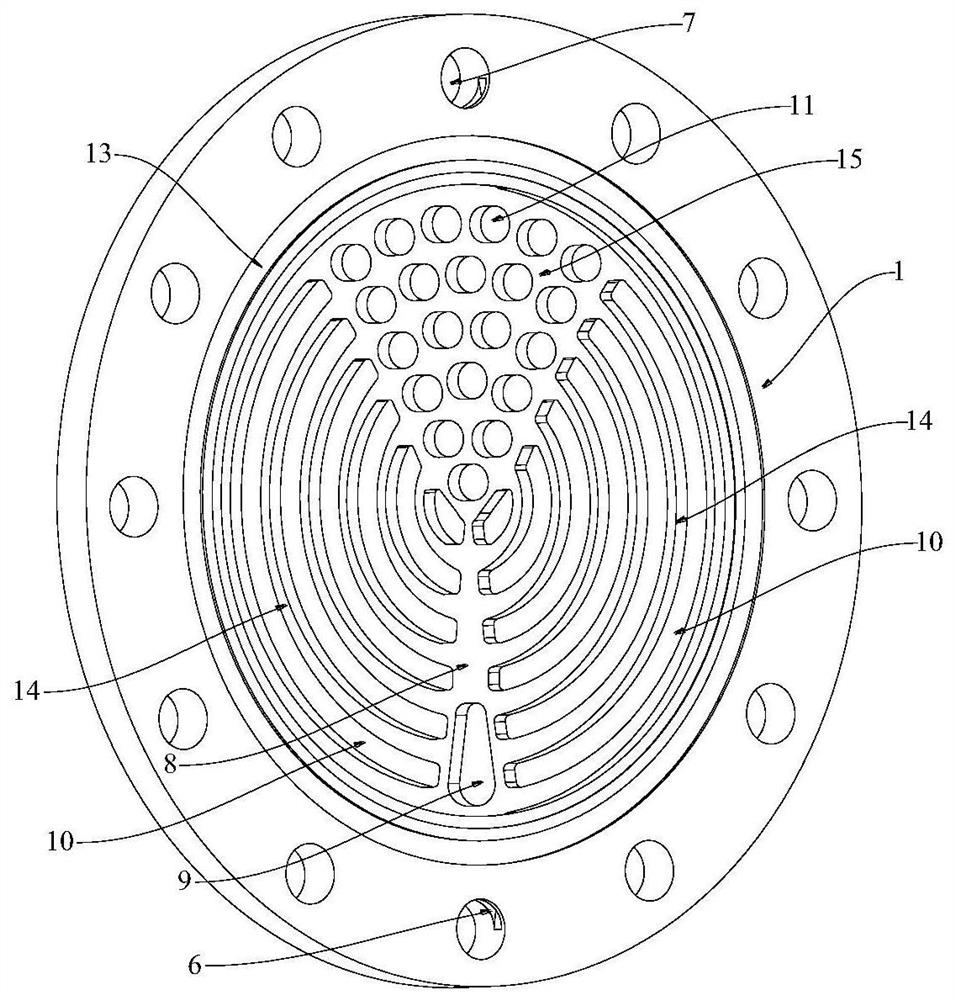

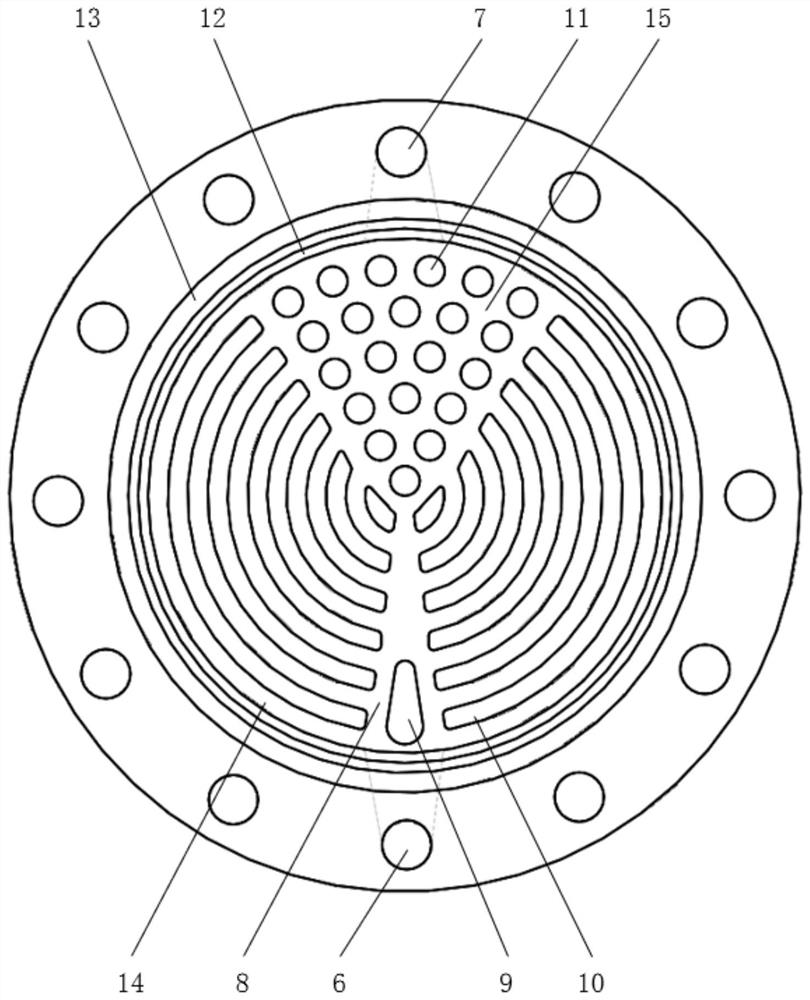

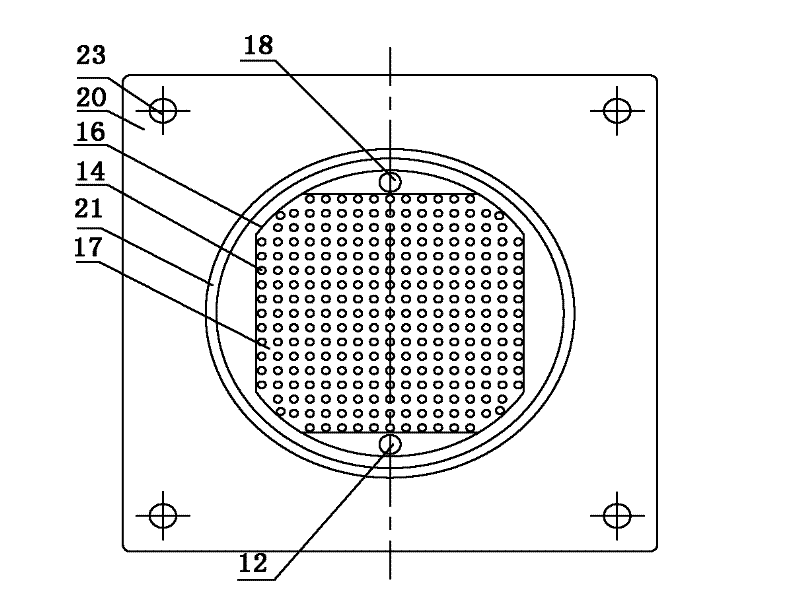

Proton exchange membrane water electrolyser structure and anode plate

The invention discloses a proton exchange membrane water electrolyser structure and an anode plate. The proton exchange membrane water electrolyser structure comprises the anode plate, an anode diffusion layer, a CCM membrane electrode, a cathode diffusion layer and a cathode plate. The anode plate comprises a fluid distribution area, an arc flow channel reaction area and a dotted flow field reaction area; and an anode plate fluid distribution area is an arc-shaped stepped flow field area which is gradually reduced from two sides to the circle center, an ellipse-like distribution structure is arranged in the middle of the area, the part, close to a water inlet, of the anode plate is an arc-shaped flow channel reaction area, and a flow field tail end area is a dot-shaped flow field reaction area. According to the invention, uniform diffusion of reaction water in each flow channel after entering a flow field is ensured by arranging the ellipse-like distribution structure in a fluid distribution area; the flow resistance of reaction water is reduced through an arc-shaped flow channel of the arc-shaped flow field, and the transmission efficiency of the reaction water is improved; and through the dot-matrix type structure of the dot-shaped flow field, formation of bubble plugs is reduced, the mass transfer capacity of reaction water is enhanced, and then the performance of the electrolytic cell is improved.

Owner:WUHAN UNIV OF TECH

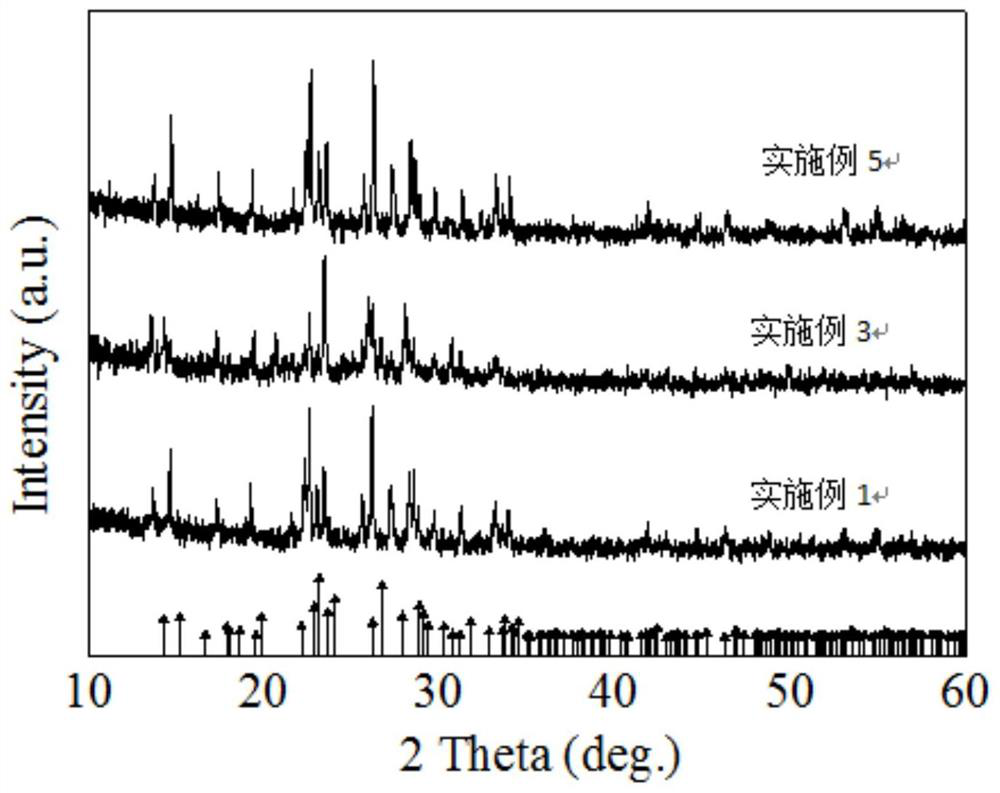

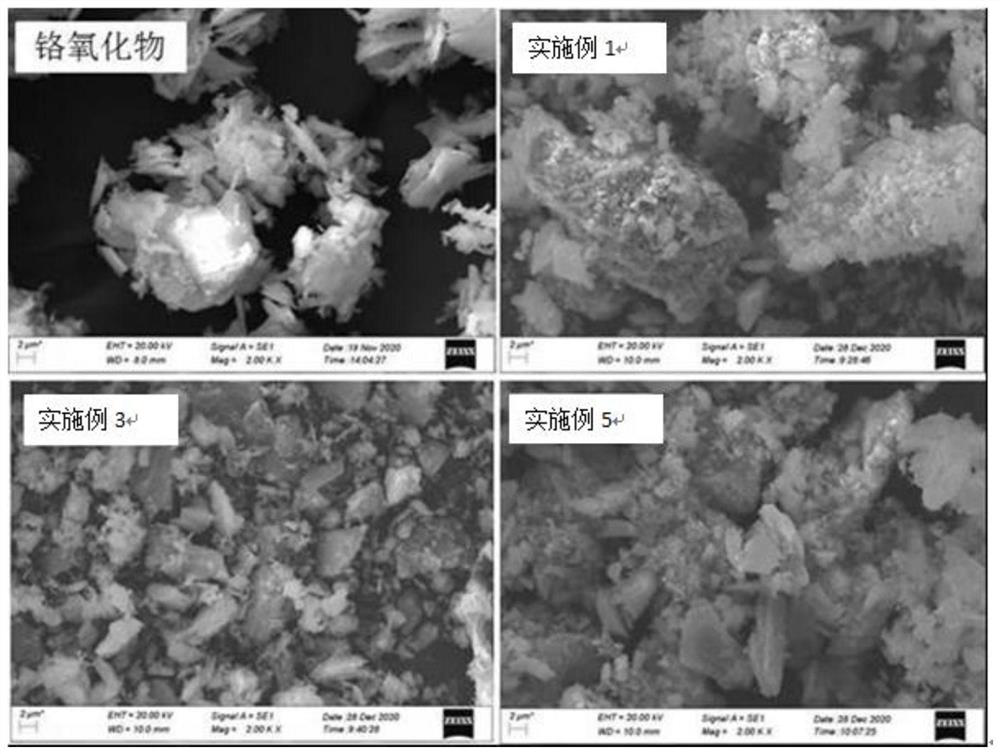

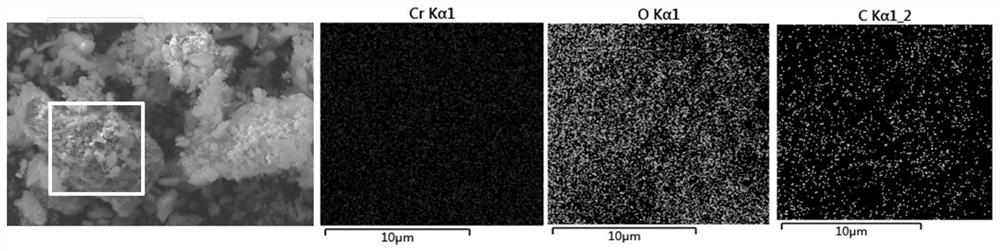

Chromium oxide/CNTS composite material and preparation and application thereof

ActiveCN112968176AImprove conductivityImprove discharge capacityOrganic electrolyte cellsPositive electrodesCarbon nanotubePrimary cell

The invention belongs to the technical field of lithium primary battery positive electrode material preparation, and particularly relates to a chromium oxide / CNTS composite material and preparation and application thereof. The chromium oxide / CNTS composite material is prepared from chromium oxide and carbon nanotubes as raw materials through a high-temperature solid-phase method or a high-energy ball milling method. The CNTS with good conductivity is compounded with the chromium oxide, so that the conductivity of the obtained composite material is obviously improved, the capacity is increased, and the rate capability is improved.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Air-breathing membrane-free fluid fuel cell provided with integrated cylindrical anode

ActiveCN109888326AHighly integratedIncrease energy densityFuel cellsChemical industrySystem integration

The invention discloses an air-breathing membrane-free fluid fuel cell provided with an integrated cylindrical anode. The air-breathing membrane-free fluid fuel cell comprises a cathode cover plate, arunner and a cell base plate, a cathode air breathing hole is formed in the cathode cover plate, and an air-breathing cathode is arranged below the cathode air breathing hole. The air-breathing membrane-free fluid fuel cell is characterized in that the runner is arranged between the cathode cover plate and the cell base plate; a cylindrical metal tube is arranged in the runner; a catalyst layer is coated on the outer surface of the cylindrical metal tube; the cylindrical metal tube is arranged parallel to the air-breathing cathode; the front part of the cylindrical metal tube is a hollow tube, and the rest part is a solid tube; a plurality of overflow ports are formed in the tube wall at a junction of the hollow tube and the solid tube along the circumferential direction; a fuel inlet isformed in the front end of the cylindrical metal tube; a waste liquor outlet is formed in the cell base plate; and the waste liquor outlet is communicated with the runner. The air-breathing membrane-free fluid fuel cell disclosed by the invention can enhance fuel transmission, system integration is facilitated, and cell performance is improved; and the air-breathing membrane-free fluid fuel cell can be widely applied to the fields of energy sources, chemical industry and environmental protection.

Owner:CHONGQING UNIV

Technology for pretreating complex and difficult-to-treat gold concentrate through utilizing industrial microware

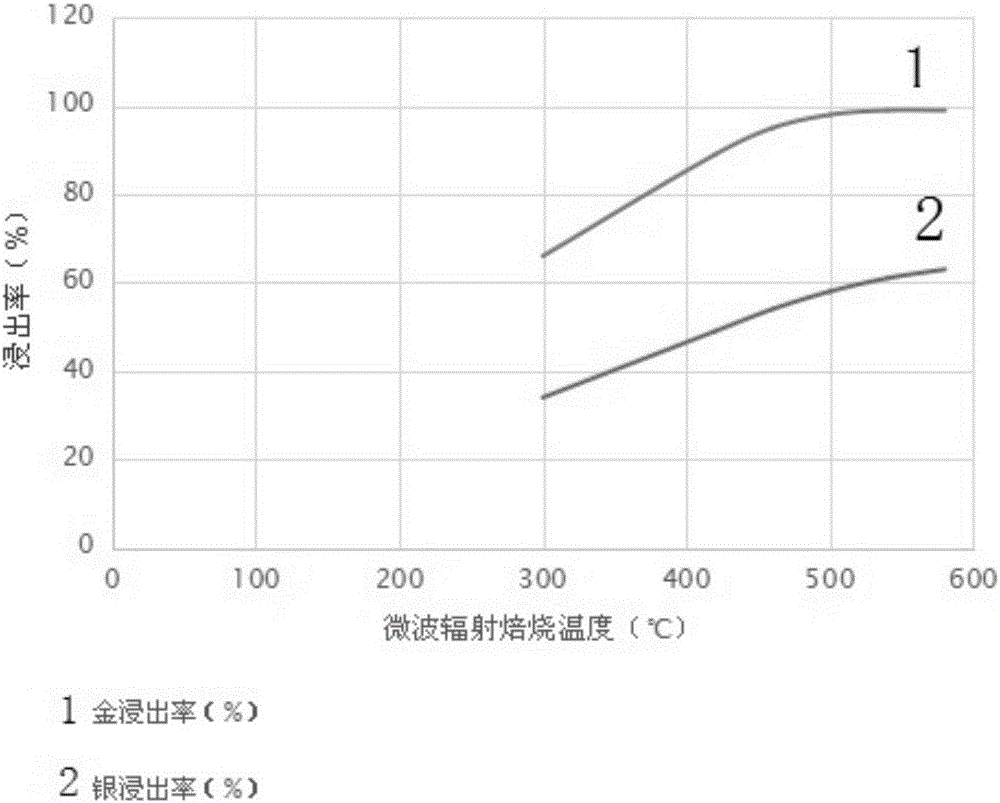

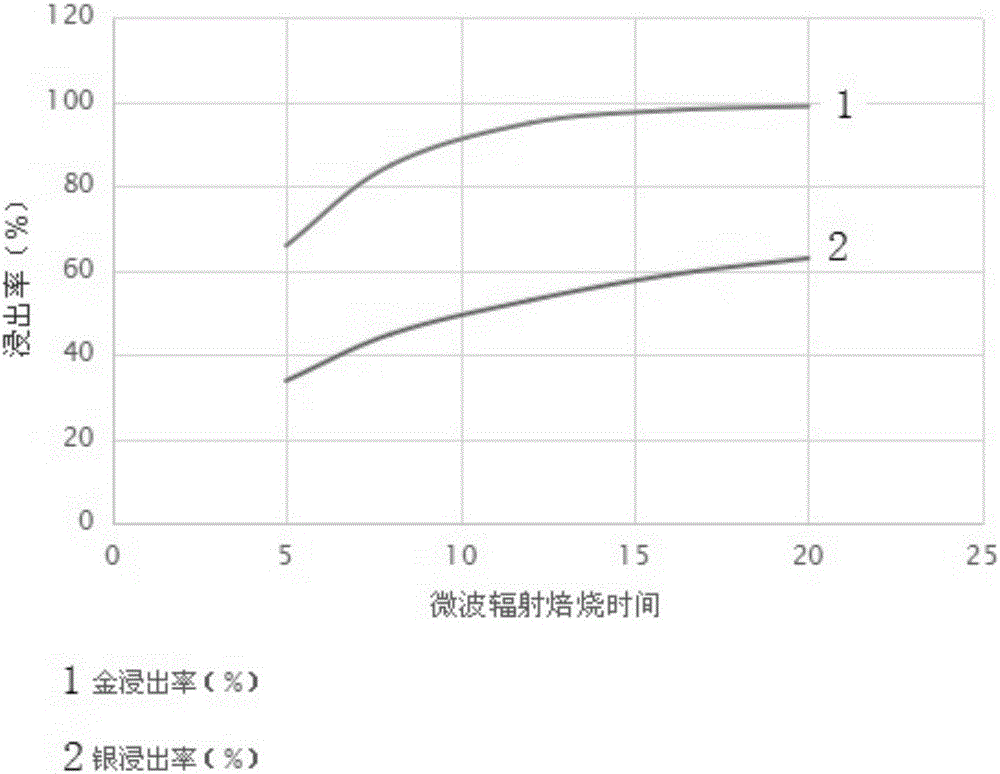

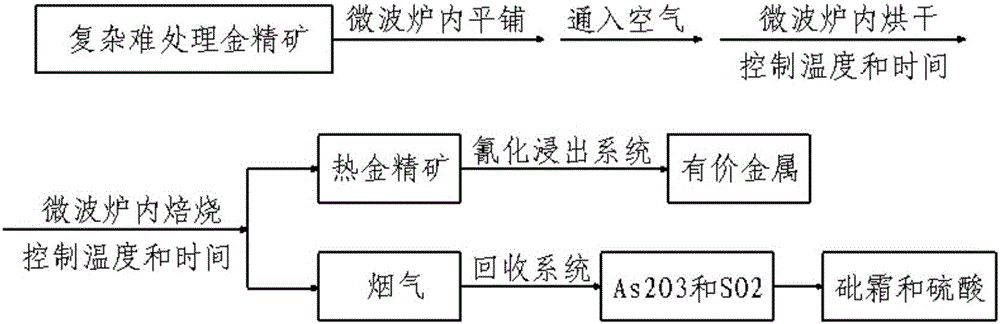

InactiveCN105936976APromote monomer dissociationIncrease the effective reaction areaArsenic oxides/hydroxides/oxyacidsSulfur compoundsMicrowave ovenCyanide

The invention relates to a technology for pretreating complex and difficult-to-treat gold concentrate through utilizing industrial microware. The technology comprises the steps of putting the complex and difficult-to-treat gold concentrate in an industrial microwave oven, and paving the complex and difficult-to-treat gold concentrate; starting a microwave oven fan, and introducing air; starting a microwave heating device to sequentially dry and bake the complex and difficult-to-treat gold concentrate; sending obtained flue gas into a recycling system to recycle As2O3 and SO2, so as to prepare arsenic and arsenic; and sending obtained hot gold concentrate to a cyanide leaching system to recycle valuable metals such as gold and silver. According to the technology, the leaching rate of gold can be greatly increased, the operation is easy, the technological process is short, the reaction temperature is decreased, the reaction time is shortened, and the production efficiency is improved.

Owner:托里县招金北疆矿业有限公司

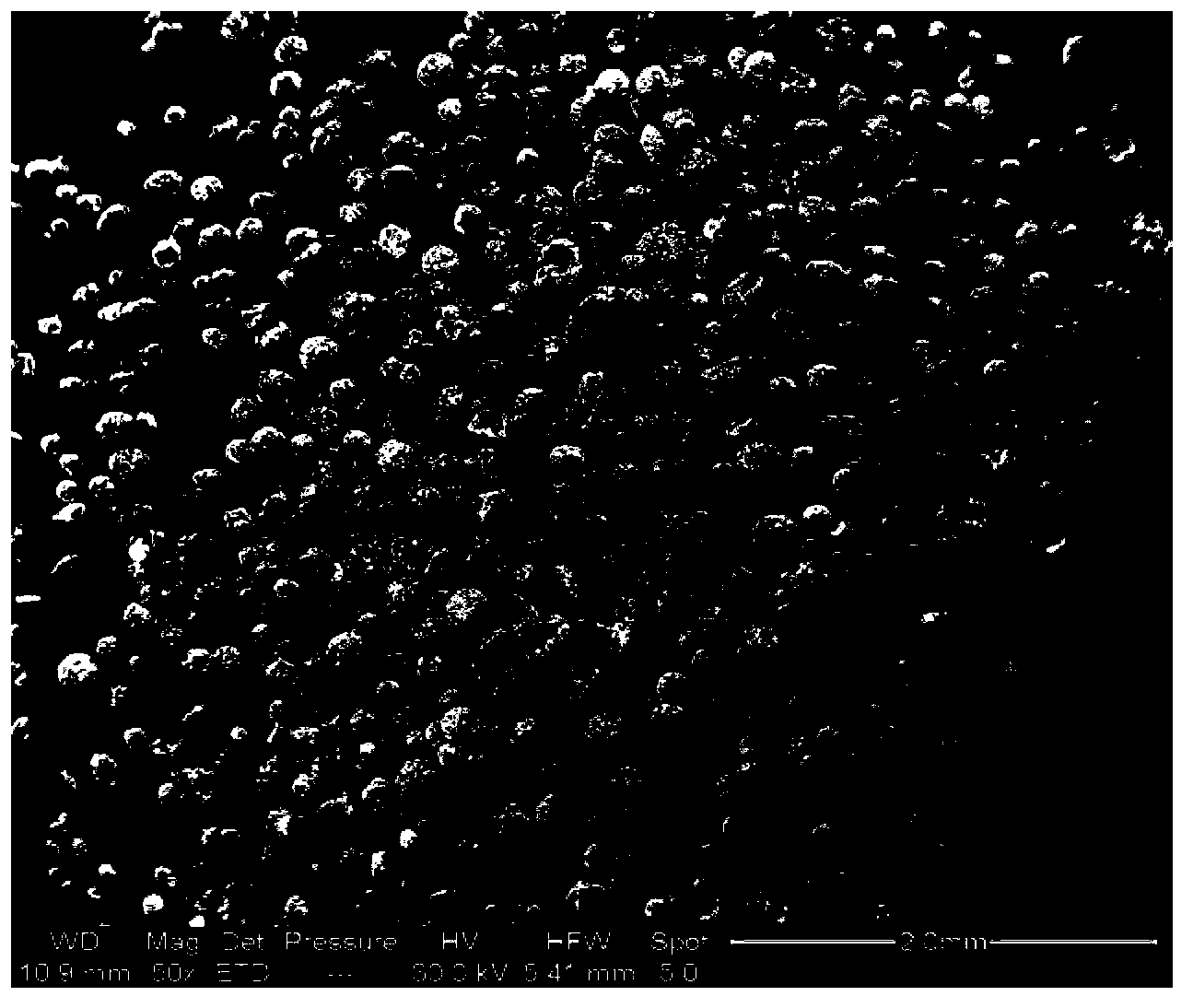

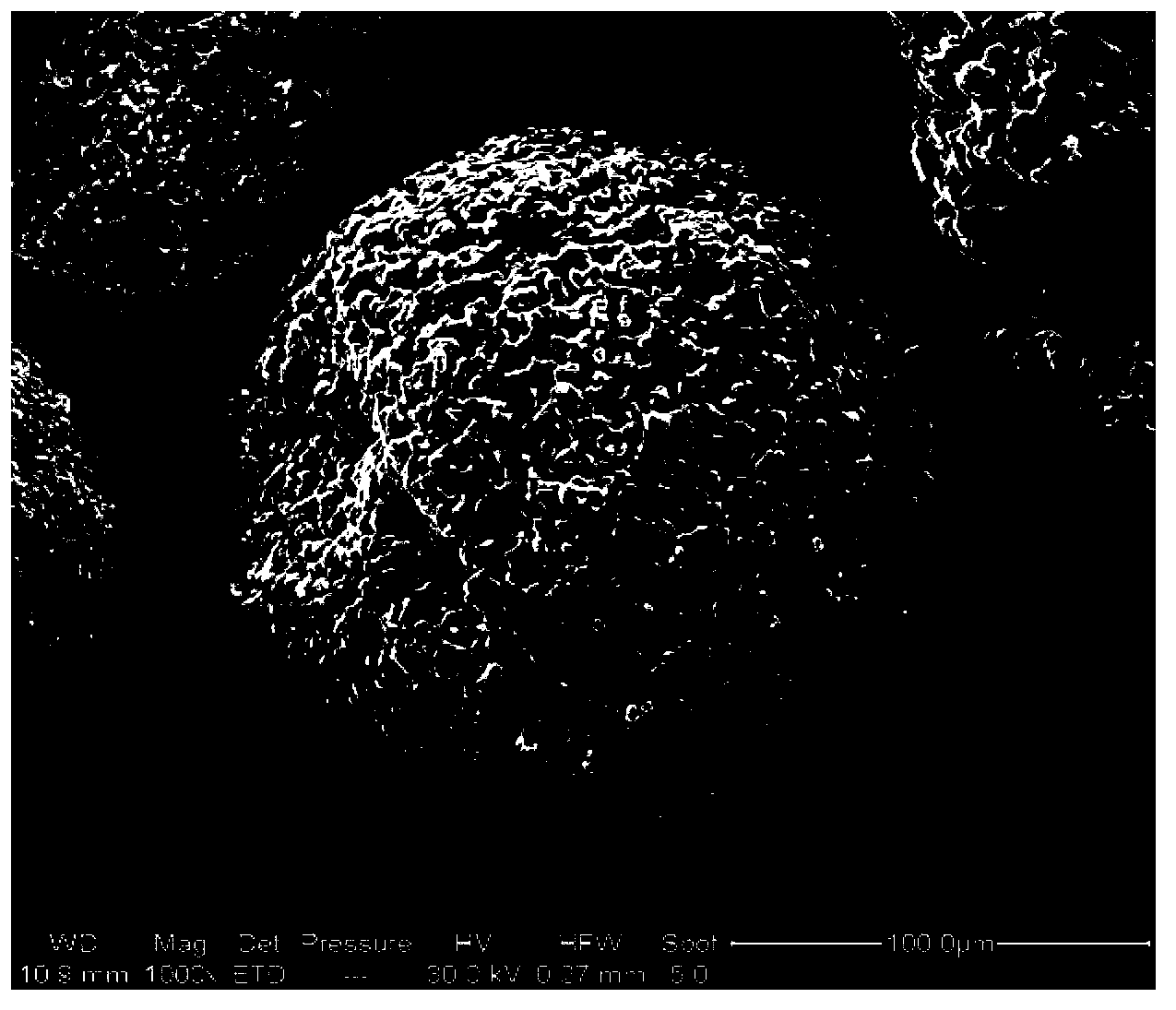

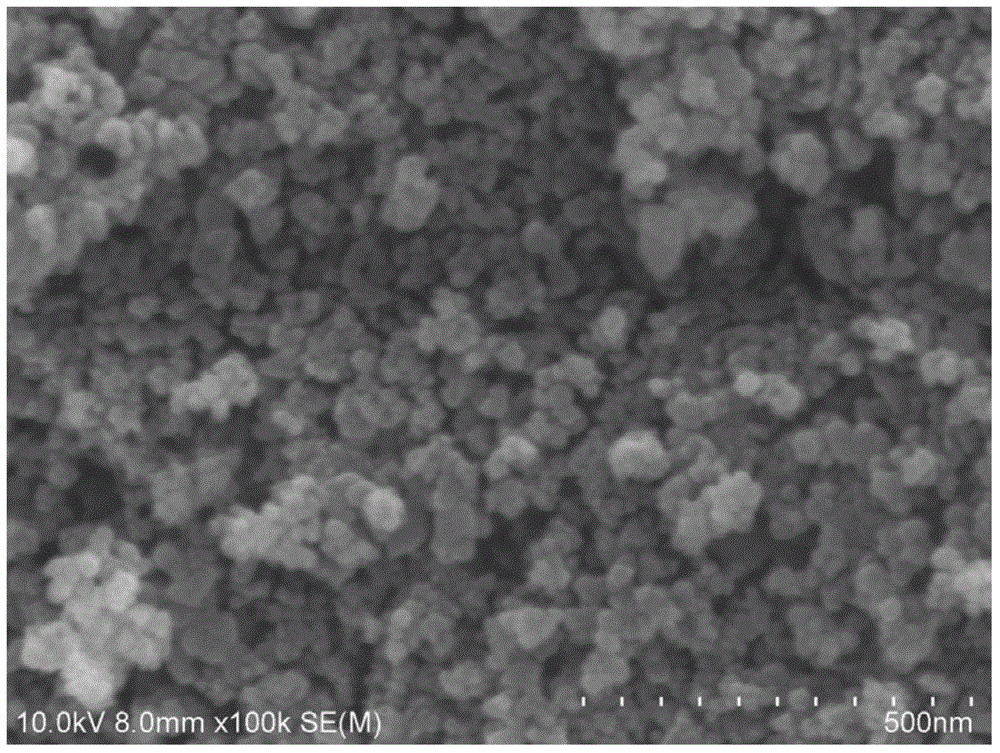

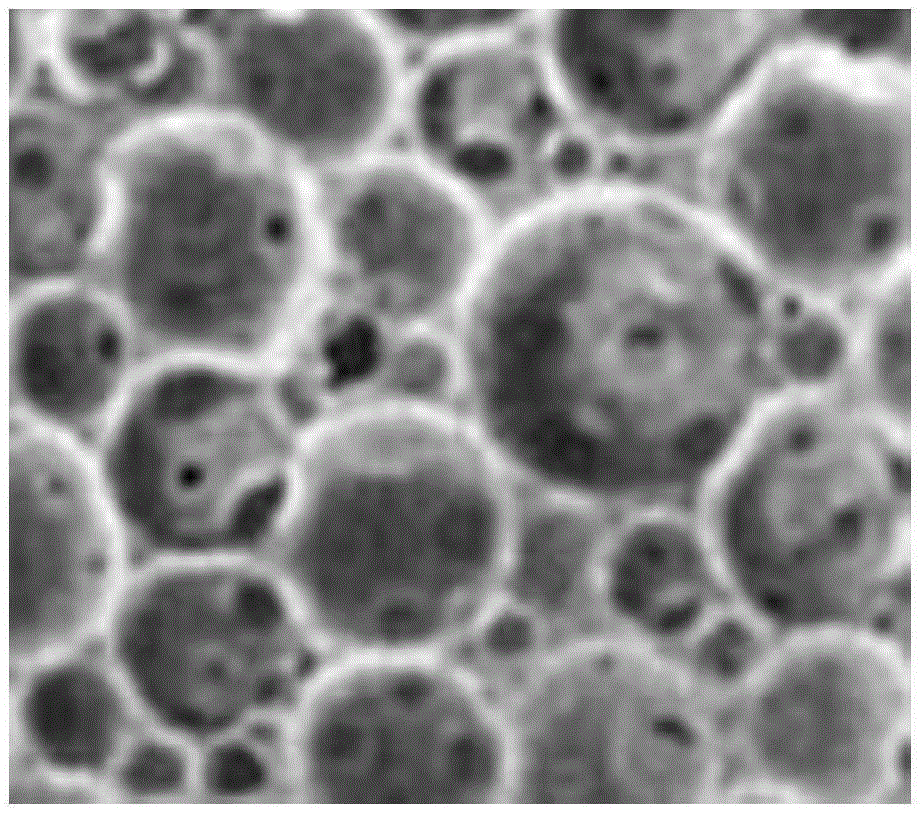

High-activity hollow-out silver powder and preparation method thereof

InactiveCN104096832AThe overall thickness is thinIncrease the effective reaction areaPorosityPower flow

The invention relates to high-activity hollow-out silver powder and a preparation method thereof and belongs to the field of preparation for high-activity silver powder. The silver powder particles are of hollow-out sphere-like shapes; the diameters of the particles are 35-150 micrometers; the specific area of the particles is not smaller than 25 square meters / gram. The silver powder disclosed by the invention is hollow-out sphere-like powder; in addition, a large quantity of nano holes exist in each particle; the inside of each particle is of a three-dimensional mesh structure; the holes are mutually communicated; by using a prepared silver oxide anode, the effective reaction area of the electrode can be effectively increased, the electric current density is reduced, further the polarization of the electrode is reduced and output performances (current and voltage) of a battery are improved; the voltage of the battery and the utilization rate of active substances are improved; in addition, under the condition that the porosity is ensured, compared with the traditional silver powder, the high-activity silver powder has the advantages that the thickness of the pressed silver oxide electrode is thinner under the condition of equal quantity, further the mass transfer efficiency is improved and the utilization rate of anode active substances is improved.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Porous flow field fuel cell monomer without bipolar plate and series-parallel electric pile structure

The invention discloses a porous flow field fuel cell monomer without a bipolar plate. Themonomer comprises an anode porous layer, an anode gas diffusion layer, a membrane electrode, a cathode gas diffusion layer, a cathode porous layer, a cathode baffle plate, a cooling porous layer and an anode baffle plate, the anode porous layer or the cathode porous layer or the cooling porous layer is formed by embedding a porous material into a solid frame, and the cathode baffle separates the cathode porous layer from the cooling porous layer. The invention also provides a series-parallel electric pile structure of a fuel cell. Through reasonable design of the structure, porosity and permeability, the flow resistance of a porous flow field is effectively reduced, and the fluid distribution uniformity is improved, so that the effective utilization rate of an electrode reaction area is increased, and the performance of the fuel cell is improved. By using the design of sharing the anode porous layer or sharing the cooling porous layer, fuel cell monomers are connected in parallel to form the Ns x Np section series-parallel electric pile structure, so that the size of an electric pile is reduced, and the power density of the electric pile is improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Preparation method of lithium titanium silicate anode material for lithium ion battery

ActiveCN105024070AImprove energy storage performanceNo pollution in the processCell electrodesSecondary cellsWater vaporElectrical battery

The invention discloses a preparation method of lithium titanium silicate anode material for a lithium ion battery. The method specifically comprises the following steps: 1) dissolving a lithium salt, a titanium source and a silicon source into an organic solvent, and uniformly mixing the lithium salt, titanium source and silicon source to obtain a mixed solution; (2) adjusting the pH value of the mixed solution to 1.5-6.5; (3) introducing water vapor carried by a carrier gas into the mixed solution obtained in the step (2) to perform a hydrolysis reaction in order to obtain a co-precipitate, and performing filtering, water washing and drying to obtain a precursor; and (4) pre-burning the precursor in an inert protection atmosphere at the temperature of 450-700 DEG C for 3-5 hours, and sintering the pre-burned precursor at the temperature of 750-950 DEG C to obtain the lithium titanium silicate anode material for the lithium ion battery. The anode material prepared with the preparation method is ideal in shape and particle size distribution, and has high electrochemical performance. The preparation method is simple in flow, high in operability, high in safety, and convenient for realizing industrialization.

Owner:CENT SOUTH UNIV

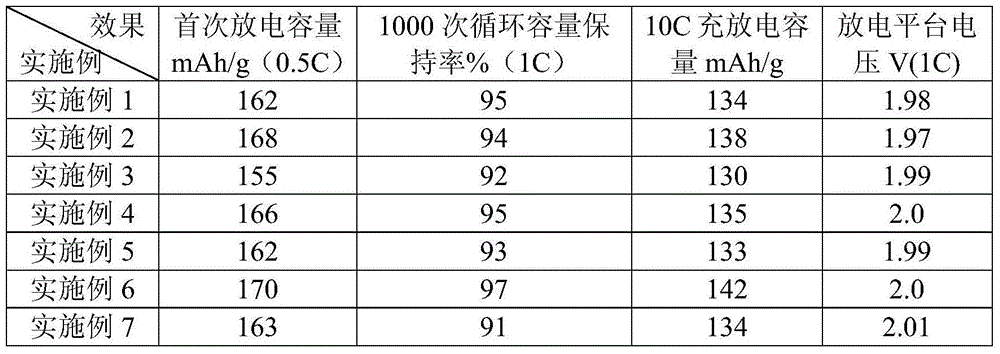

Calcium vanadate composite material as well as preparation method and application thereof

ActiveCN111268727AImprove electrochemical performanceImprove conductivityCell electrodesSecondary cellsElectrical batteryGraphite

The invention belongs to the technical field of electrochemistry, particularly relates to a calcium vanadate composite material and a preparation method thereof, and further relates to application ofthe calcium vanadate composite material. The calcium vanadate composite material is a sheet-shaped composite material formed by a graphene material and CaV4O9; the mass ratio of the graphene materialto the CaV4O9 is 1:(35-40). According to the calcium vanadate composite material disclosed by the invention, the CaV4O9 and the graphene material are compounded together, so that the calcium vanadatecomposite material has relatively good conductivity and electrochemical performance. When the calcium vanadate composite material disclosed by the invention is used as a positive electrode active material of an aqueous zinc ion battery, the calcium vanadate composite material has excellent electrochemical performance, good cycling stability and excellent rate capability.

Owner:HENAN UNIV OF SCI & TECH

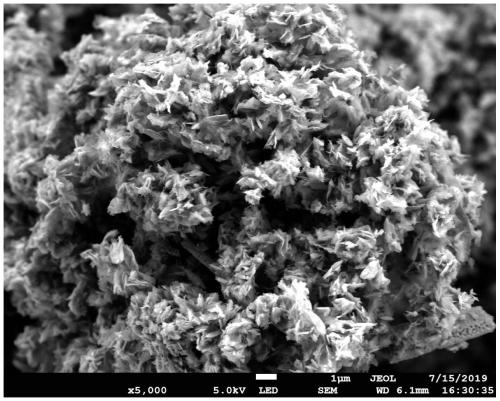

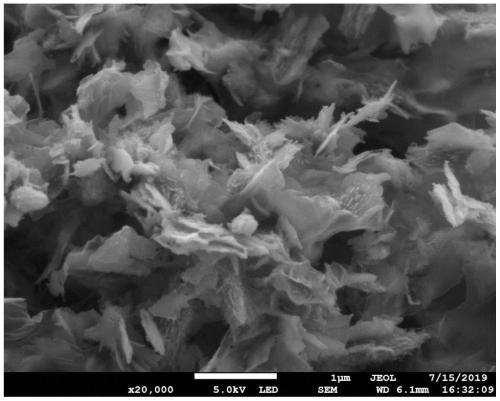

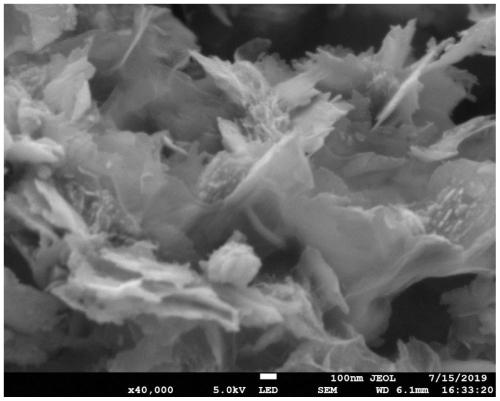

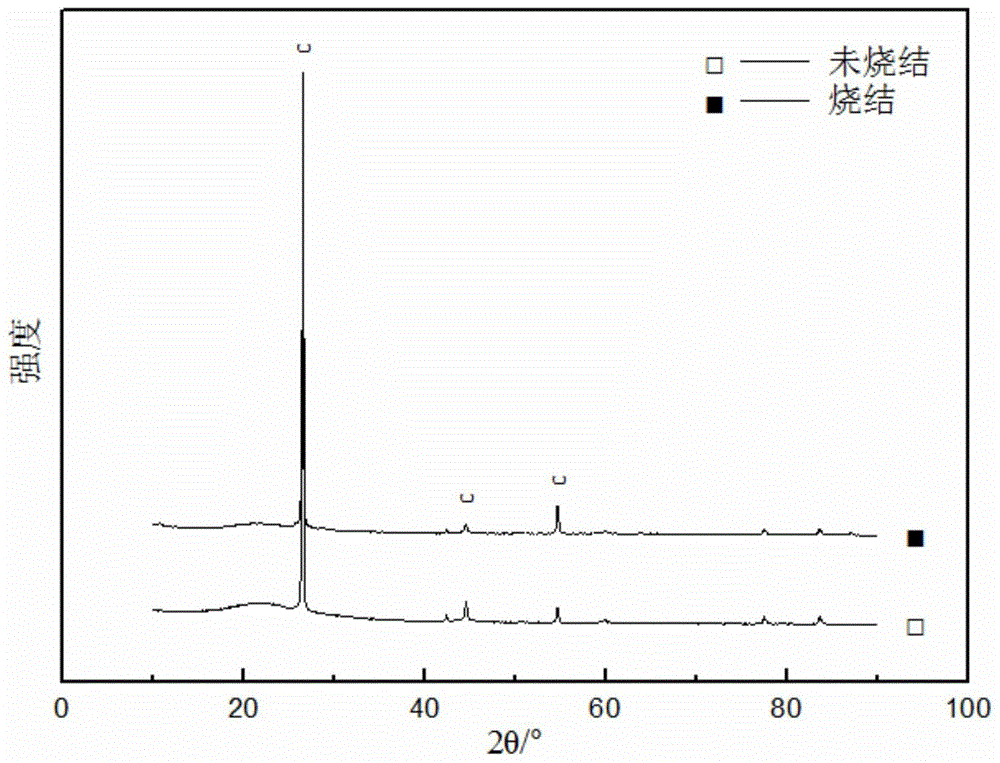

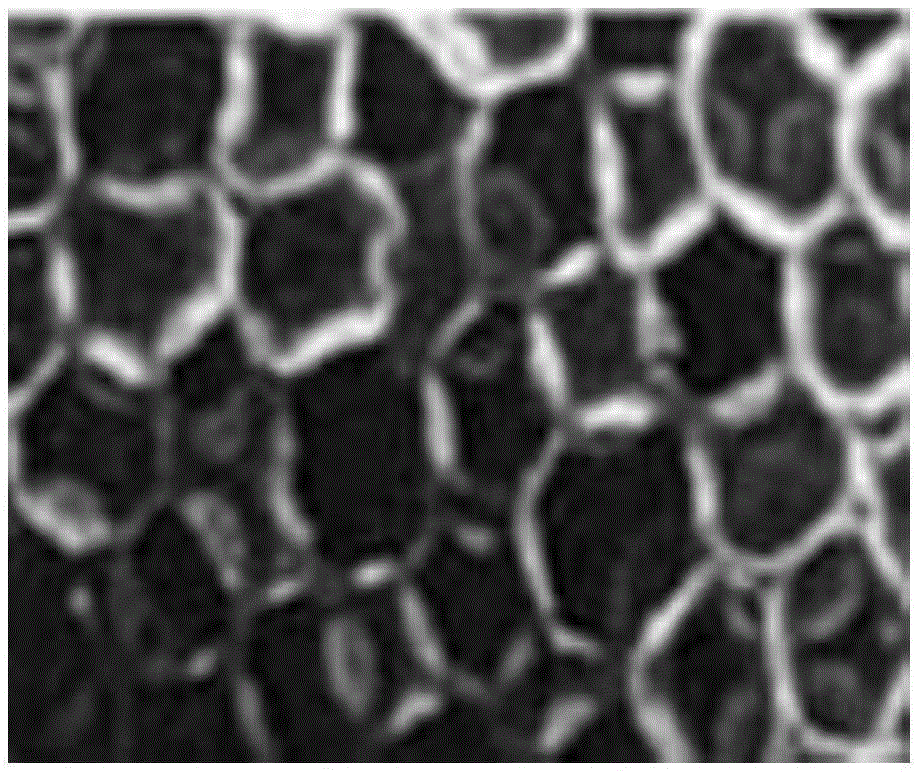

Crystal silicon dioxide/carbon porous composite material and preparation method thereof

ActiveCN105018956ATightly boundLow resistivityPolycrystalline material growthElectrode shape/formsSilica particleTetragonal crystal system

The invention discloses a crystal silicon dioxide / carbon porous composite material and a preparation method thereof. Three-dimensional network-shaped crystal silicon dioxide is evenly distributed on the surfaces of carbon particles, so that the crystal silicon dioxide / carbon porous composite material is formed. The silicon dioxide is tetragonal crystals and belongs to a P41212 space group, a=b=4.973, and c=6.924. The porosity of the crystal silicon dioxide / carbon porous composite material is 40%-80%, the peso-position hole diameter is 100-2000 nm, and the electrical resistivity is 0.10-80 ohmcm. The crystal silicon dioxide / carbon porous composite material comprises, by mass, 30%-90% of silicon dioxide and 10%-70% of carbon materials. The preparation method at least includes the following steps of mixing, forming and sintering. According to the step of mixing, the silicon dioxide particles, the carbon materials and a fluxing agent are evenly mixed, so that a powder-like mixture is obtained. According to the step of forming, the powder-like mixture is formed so that a porous block body can be obtained. According to the step of sintering, the obtained porous block body undergoes high-heat treatment in an inert atmosphere, and after the fluxing agent is removed, the three-dimensional network-shaped crystal silicon dioxide / carbon porous composite material is obtained.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

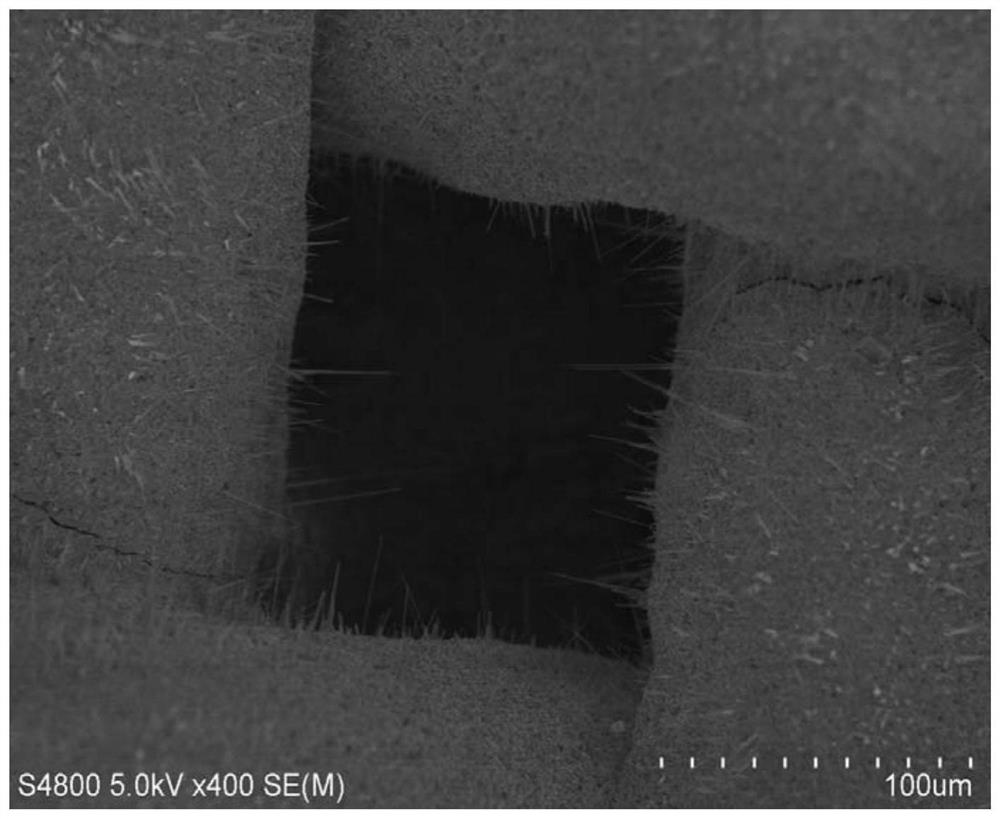

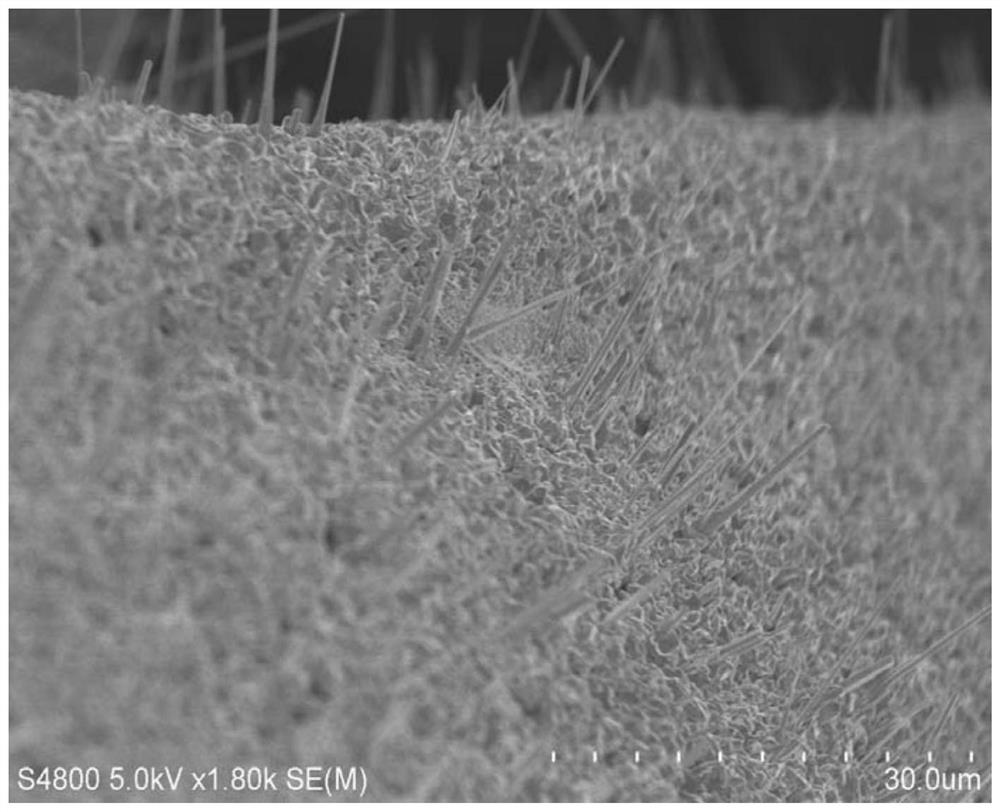

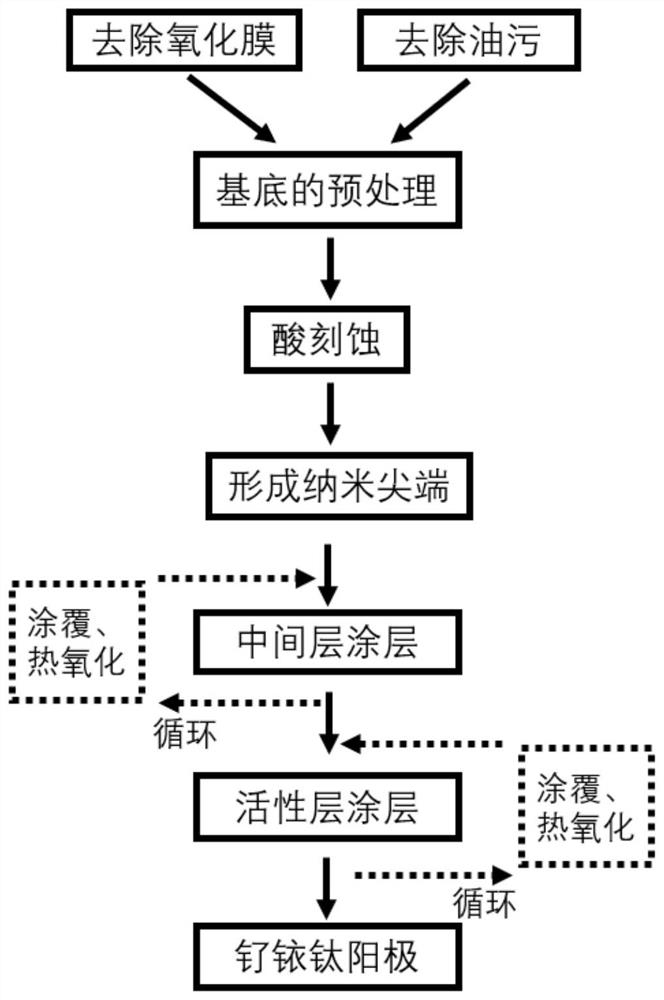

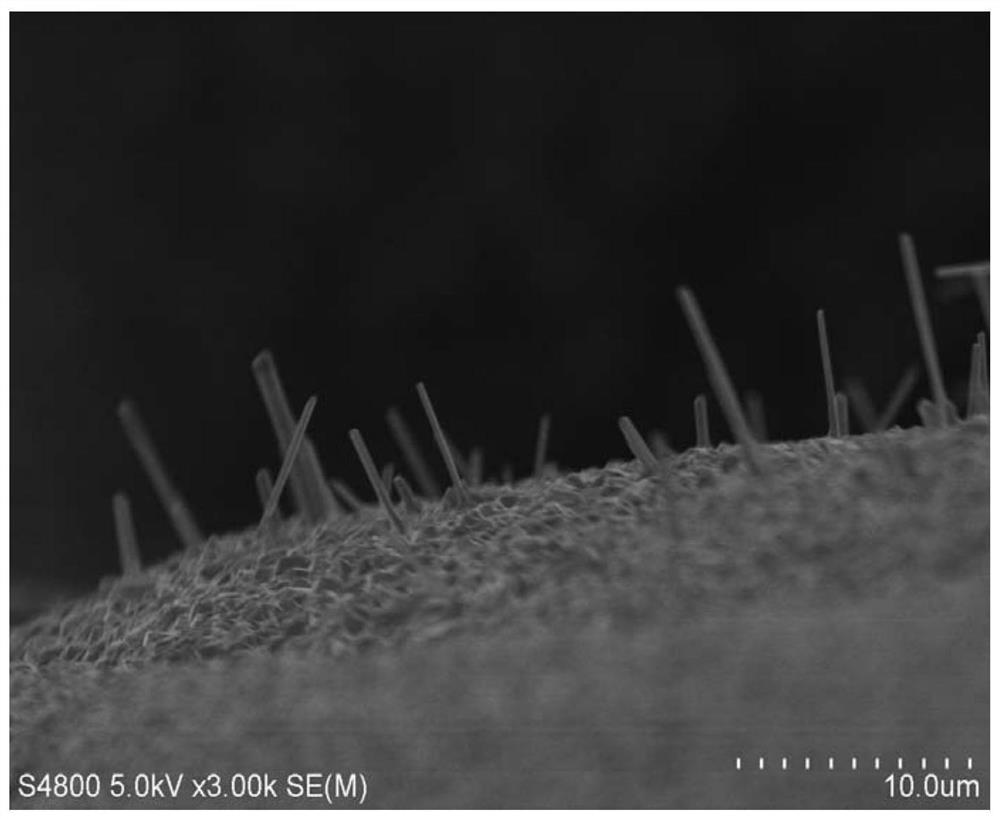

Preparation method of ruthenium-iridium-titanium ternary metal mesh electrode containing nano tip structure

ActiveCN113716658AIncrease the effective reaction areaImprove reaction efficiencyWater/sewage treatmentAcid etchingIridium

The invention belongs to the field of preparation of electrochemical electrodes, and discloses a preparation method of a ruthenium-iridium-titanium ternary metal mesh electrode containing a nano tip structure; the method comprises the following steps: (1), performing pretreatment of a titanium wire mesh substrate, including removal of a substrate oxide film and removal of oil stains; (2), performing acid etching; (3), forming a nano tip; (4), performing preparation, coating and thermal oxidation of middle-layer coating liquid; and (5), performing preparation, coating and thermal oxidation of an active layer coating solution. The surface of the prepared electrode channel contains a large number of nano tip structures, the effective reaction area of the electrode is increased, the collision opportunity of reactants and the surface of the electrode is increased, and mass transfer is promoted. The method is low in equipment requirement, low in production cost, simple to operate and easy to regulate and control. Meanwhile, the invention also discloses application of the ruthenium-iridium-titanium metal mesh electrode containing the nano-tip structure prepared by the invention to total nitrogen removal performance evaluation and control experiments in actual production wastewater, and high total nitrogen removal efficiency and low cost and energy consumption of wastewater treatment are realized.

Owner:DALIAN UNIV OF TECH

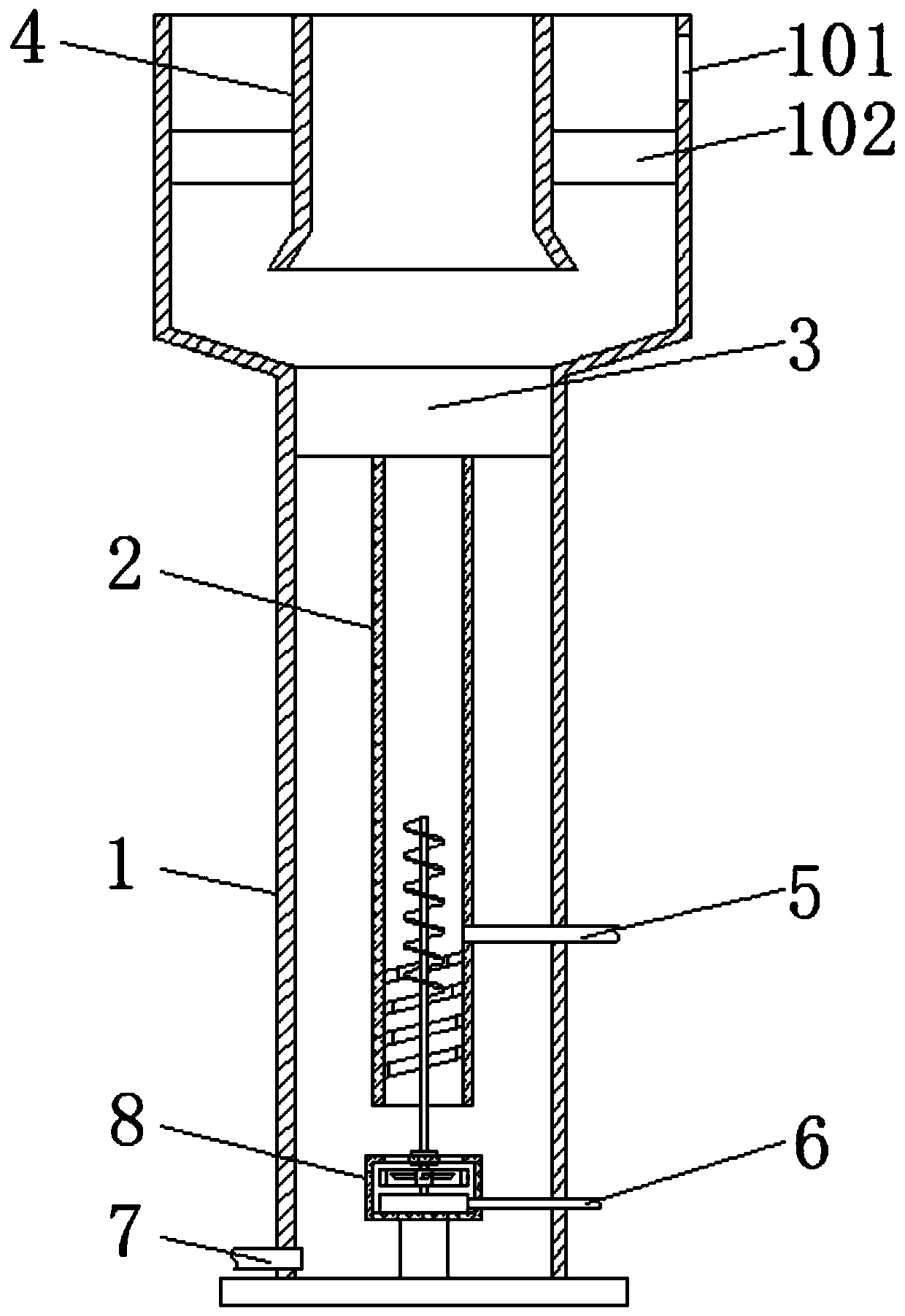

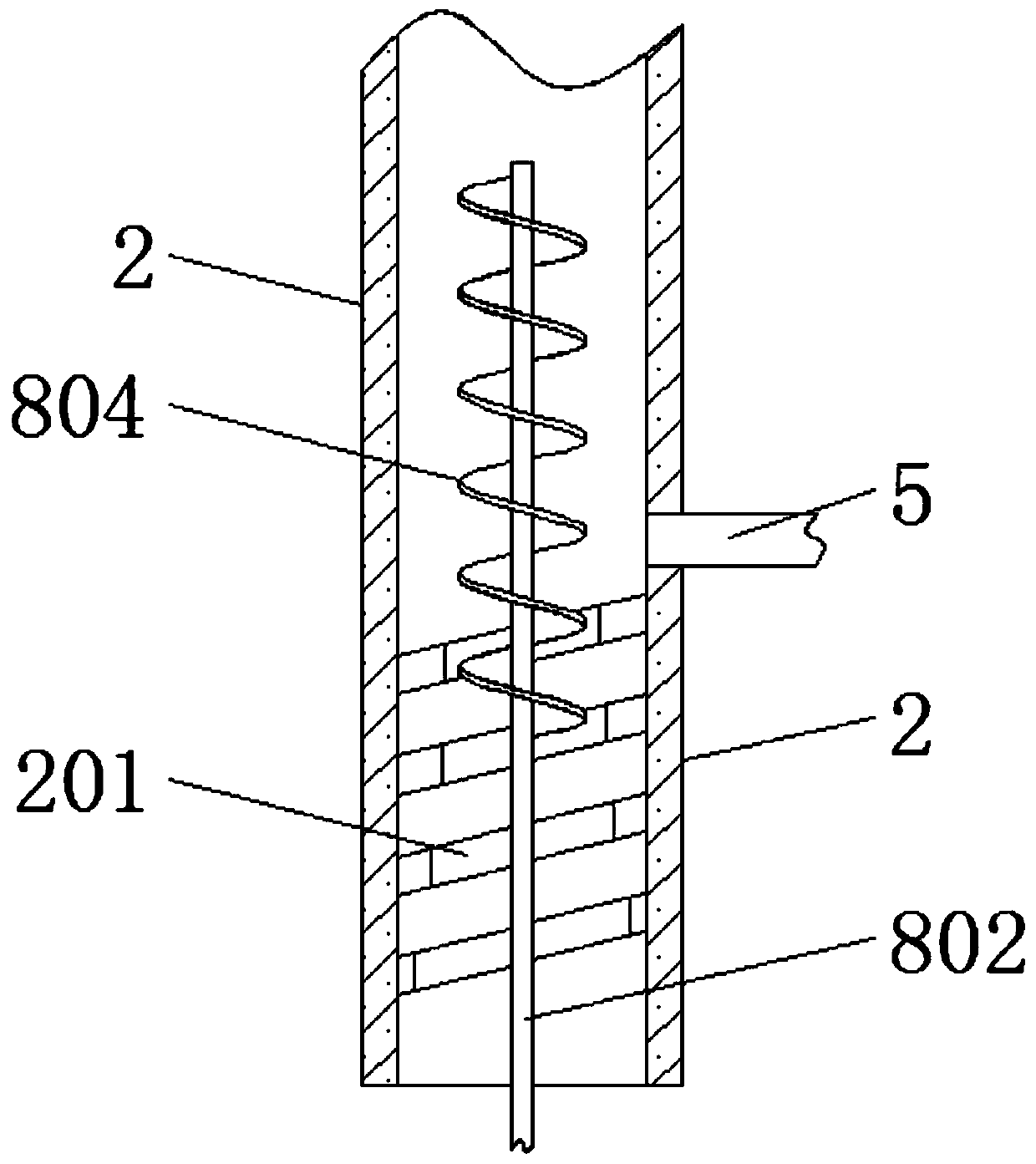

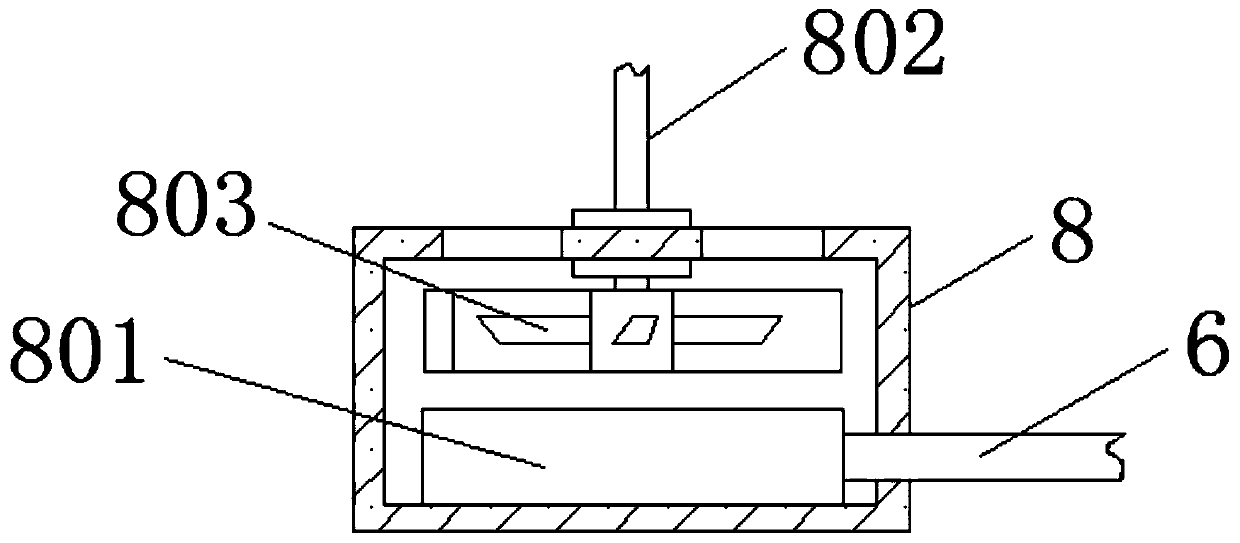

Three-phase fluidized bed for sewage treatment

InactiveCN110655274AImprove processing efficiencyEasy to handleWater contaminantsTreatment involving filtrationFluidized bedSewage treatment

The invention relates to the field of sewage treatment equipment, and discloses a three-phase fluidized bed for sewage treatment. The three-phase fluidized bed for sewage treatment comprises a separator pipe body, a flow isolating pipe, a three-phase separator, an exhaust pipe, a water inlet pipe, an air inlet pipe and a blow-off pipe; the flow isolating pipe is fixedly arranged in the middle of an inner cavity of the separator pipe body, the top end of the flow isolating pipe is fixedly connected with the bottom of the three-phase separator in a sleeving mode, and the three-phase separator isarranged at the top of the inner cavity of the separator pipe body. According to the three-phase fluidized bed for sewage treatment, through the design of the water inlet pipe located in the flow isolating pipe, a spiral packing auger is driven to rotate by the air intake power of the air inlet pipe; fluid in the flow isolating pipe upwells under the rotating action of the spiral packing auger, so that the fluid in the flow isolating pipe overcomes the gravity and resistance of the fluid to keep an up-flow state, the lifting efficiency of the fluid in the inner cavity of the flow isolating pipe is effectively guaranteed, the effective reaction area of the fluid is guaranteed to be kept in a large state, and the treatment effect of the three-phase fluidized bed is good.

Owner:曾新凤

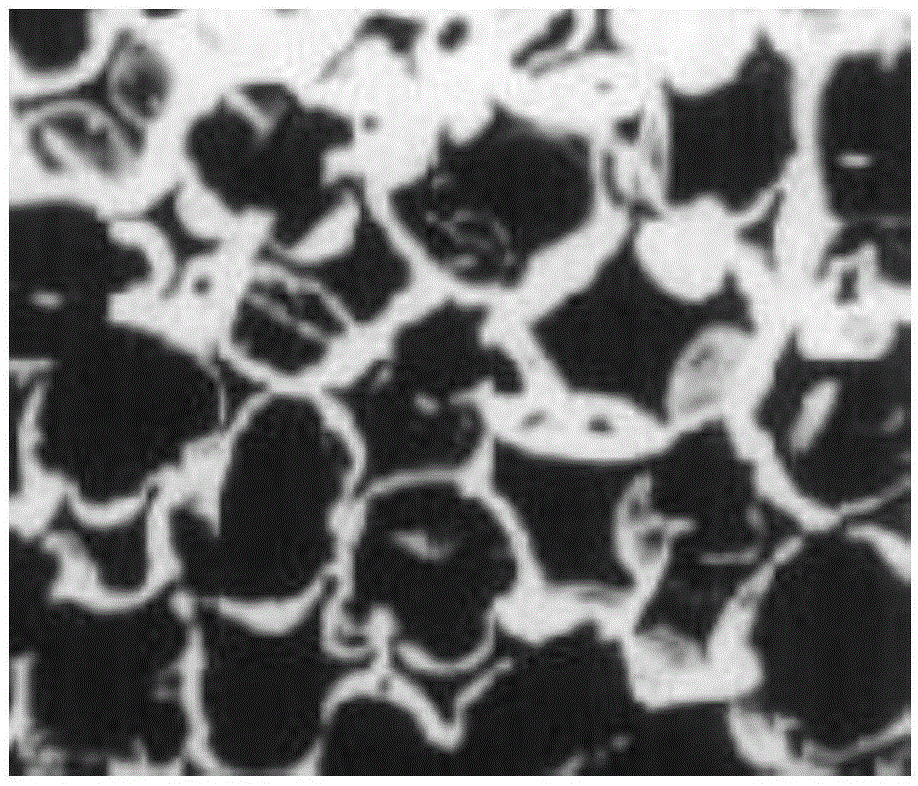

Material used for preparing rigid foamed plastic, and preparation method of rigid foamed plastic

The invention discloses a material used for preparing a rigid foamed plastic, and a preparation method of the rigid foamed plastic. According to the preparation method, a polyester polyol, an isocyanate, a catalyst 1, a catalyst 2, a physical foaming agent, a foam stabilizer, and a cross-linking agent are taken as raw materials; the degree of functionality of the polyester polyol is high, and ranges from 2.8 to 3.0, the viscosity of the polyester polyol at 25 DEG C ranges from 7000 to 10000mPa.S, hydroxyl value ranges from 380 to 450mgKOH / g, and acid value ranges from 0.1 to 2mgKOH / g; the foam stabilizer is a mixture of two organosilicon surfactants; organic combination of two key technologies, high efficiency emulsifying and nucleation, in rigid foamed plastic processing is realized, and the rigid foamed plastic with a compression strength and a bending strength of 500KPa or higher, and a dimension changing rate (80 DEG C, 48h) of 0.4% or lower is prepared. The rigid foamed plastic can be widely applied to the fields such as building and building material, communication and transportation, and refrigerating plants such as refrigerators, and cold storages.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

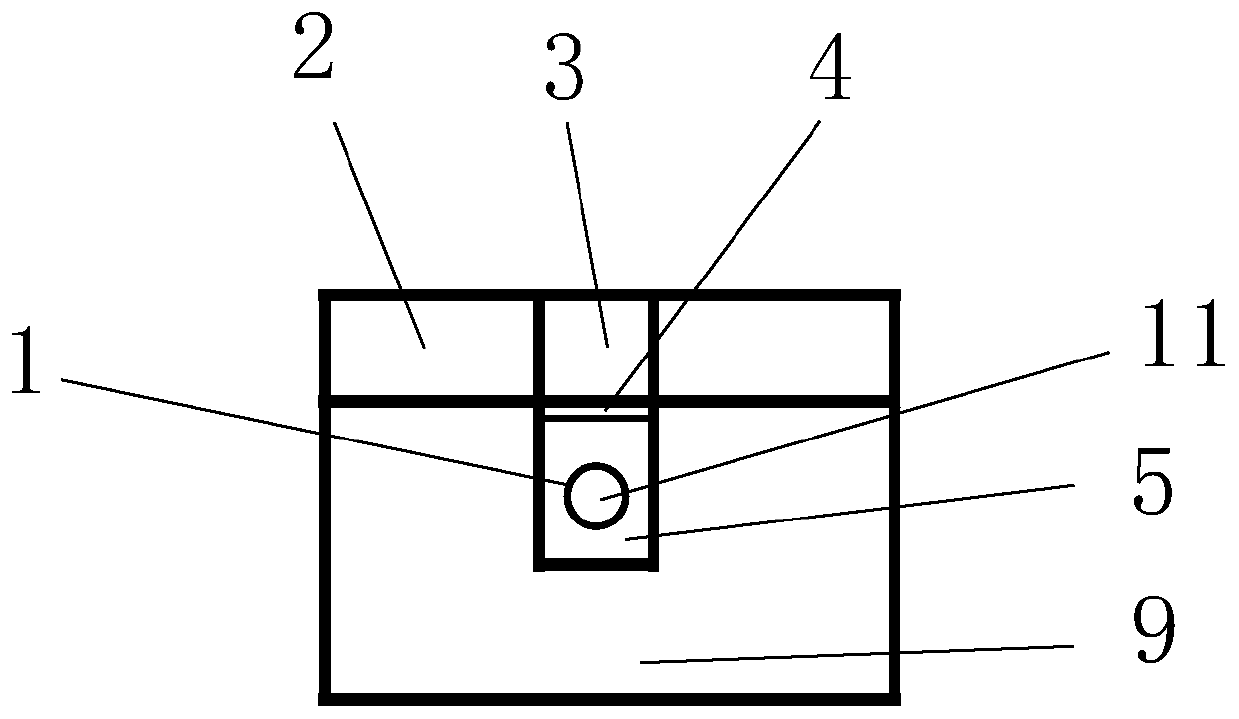

Electrochemical filter for removing total nitrogen in water

ActiveCN113772787AIncrease the effective reaction areaAdd reactive sitesWater contaminantsWater/sewage treatmentElectrochemical responseTotal nitrogen

The invention belongs to the technical field of water treatment, and discloses an electrochemical filter for removing total nitrogen in water. A water body to be treated is continuously pumped into a cathode reaction chamber through a water inlet, sequentially flows through a three-dimensional nano tip porous cathode and an anode under certain current and voltage, and reacts for a certain period of time, and finally, nitrate nitrogen, ammonia nitrogen and nitrite nitrogen in the water body are converted into nitrogen. The mass transfer distance from a substance to the surface of an electrode can be shortened by utilizing a micron-sized aperture electrode, the collision opportunity of pollutants and the electrode in the liquid flowing process is increased by the nano-tip structure in the pore channel, and meanwhile, reaction ions are limited in the internal channel of the three-dimensional nano-tip porous electrode; and the repulsive interaction of like ions under the action of electric field force is weakened, and the problems that a traditional electrochemical reactor electrode is small in effective reaction area, too large in distance between two electrodes, low in mass transfer efficiency and low in reaction efficiency, reactants are rejected by the electrode, reactant gas is accumulated, and the reactor is difficult to amplify are solved.

Owner:DALIAN UNIV OF TECH

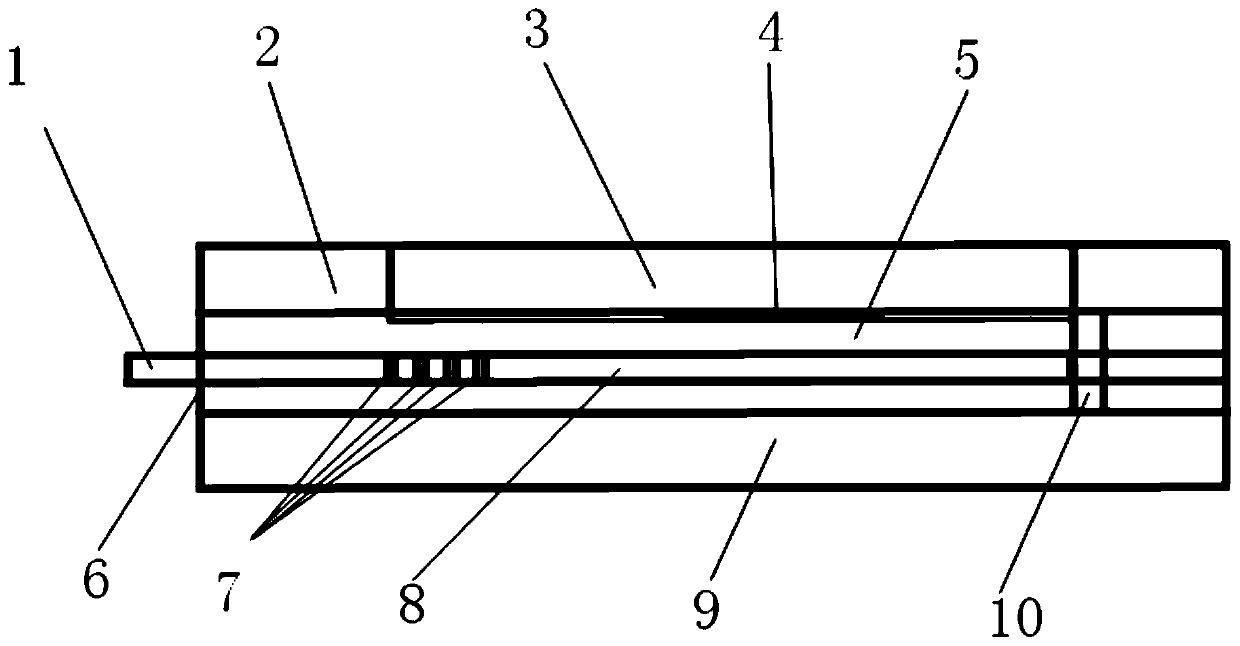

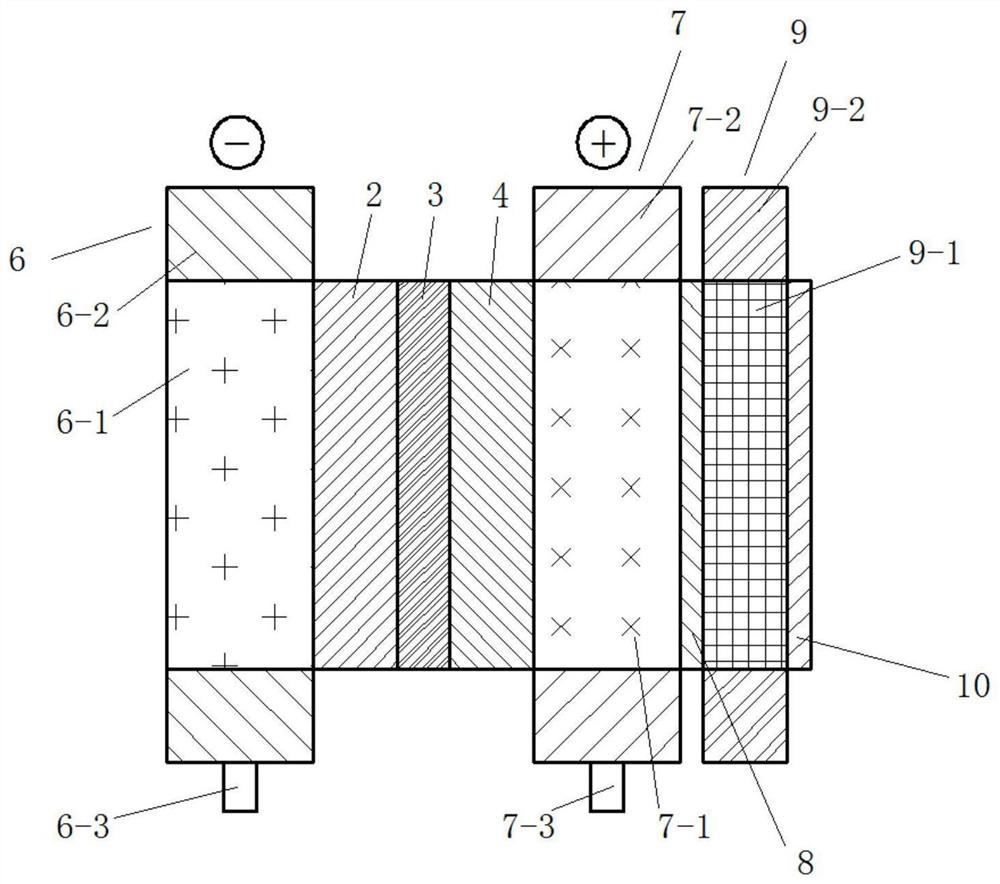

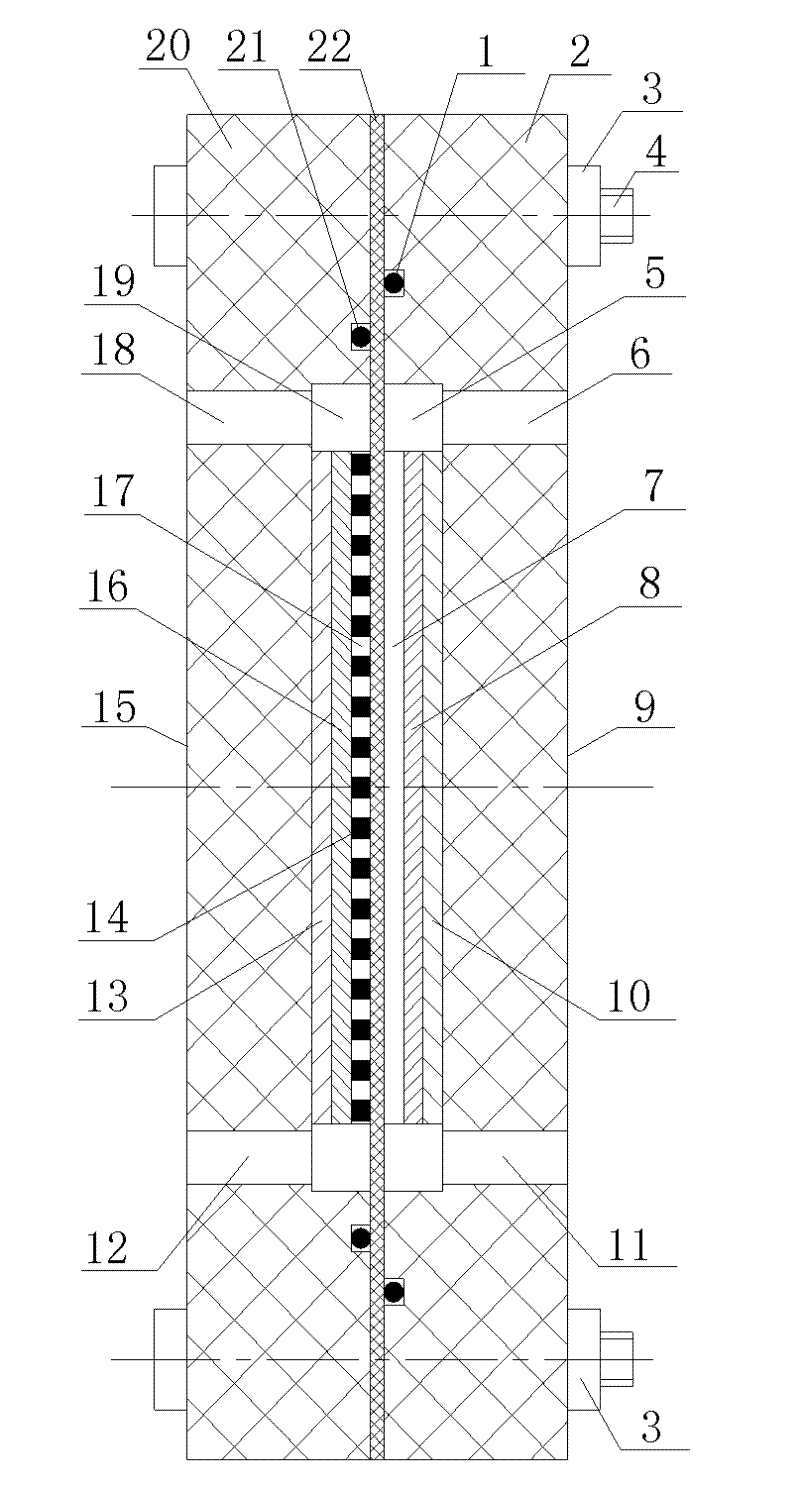

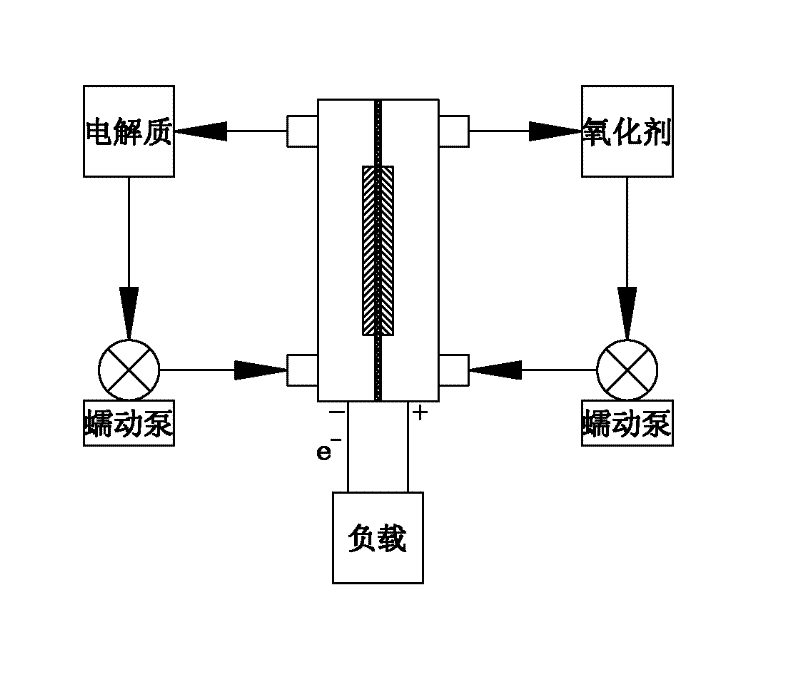

Method for preparing aluminum/hydrogen peroxide monomer batteries

ActiveCN102340017AIncrease the effective reaction areaIncrease energy densityCell electrodesRegenerative fuel cellsIon-exchange membranesAluminium

The invention discloses a method for preparing aluminum / hydrogen peroxide monomer batteries, and the method is used for hermetically and fixedly assembling an anode part and a cathode part into an integral monomer battery, wherein the anode part and the cathode part are successively prepared; and the method is characterized in that granular spacers are fully adhered to one surface of the anode part at a certain interval, and the interval is used as an anode channel; and a through trough is pressed on one surface of a cathode substrate of the cathode part and used as a cathode channel. In the invention, an anode channel is formed by using granular spacers, thereby reducing the weight of the battery, reducing the pressure loss of an electrolyte flowing through the anode part, better facilitating the discharge of hydrogen and reaction products AlO2<->, and improving the specific energy and energy density of the battery; a cathode channel is pressed on the cathode part so as to form a catalyst layer-flow field plate two-in-one structure, thereby reducing the thickness and weight of the battery; an oxidizing agent can directly flow in the three-dimensional catalyst layer, and the mass transfer of hydrogen peroxides is smooth, thereby improving the specific energy of the battery; and an ion exchange membrane achieve an effect of transformation between a double chamber structure and a single chamber structure of the battery, and is suitable for energy type power battery packs of low speed underwater equipment.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

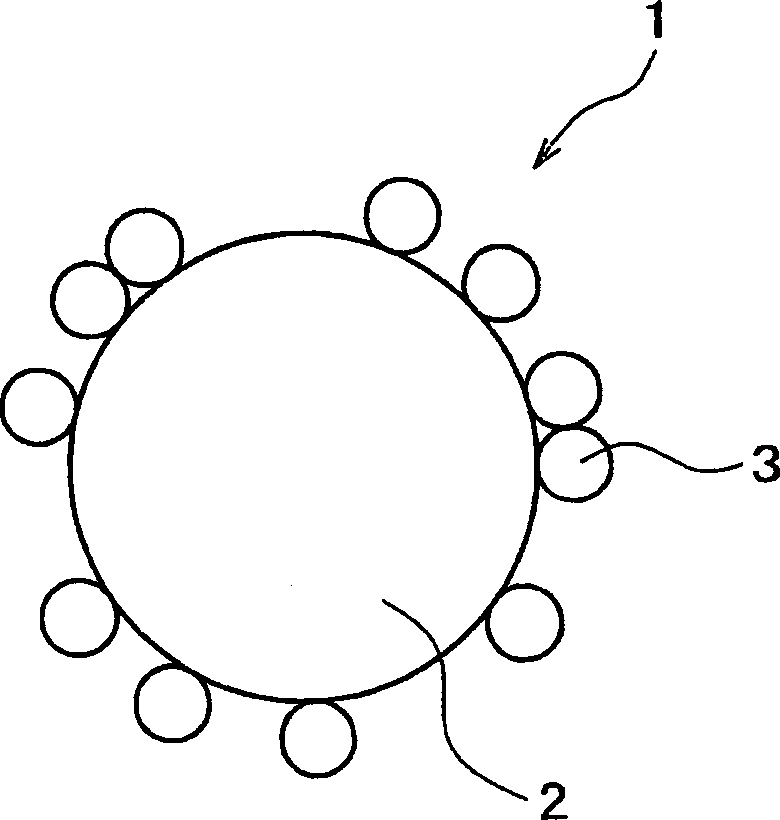

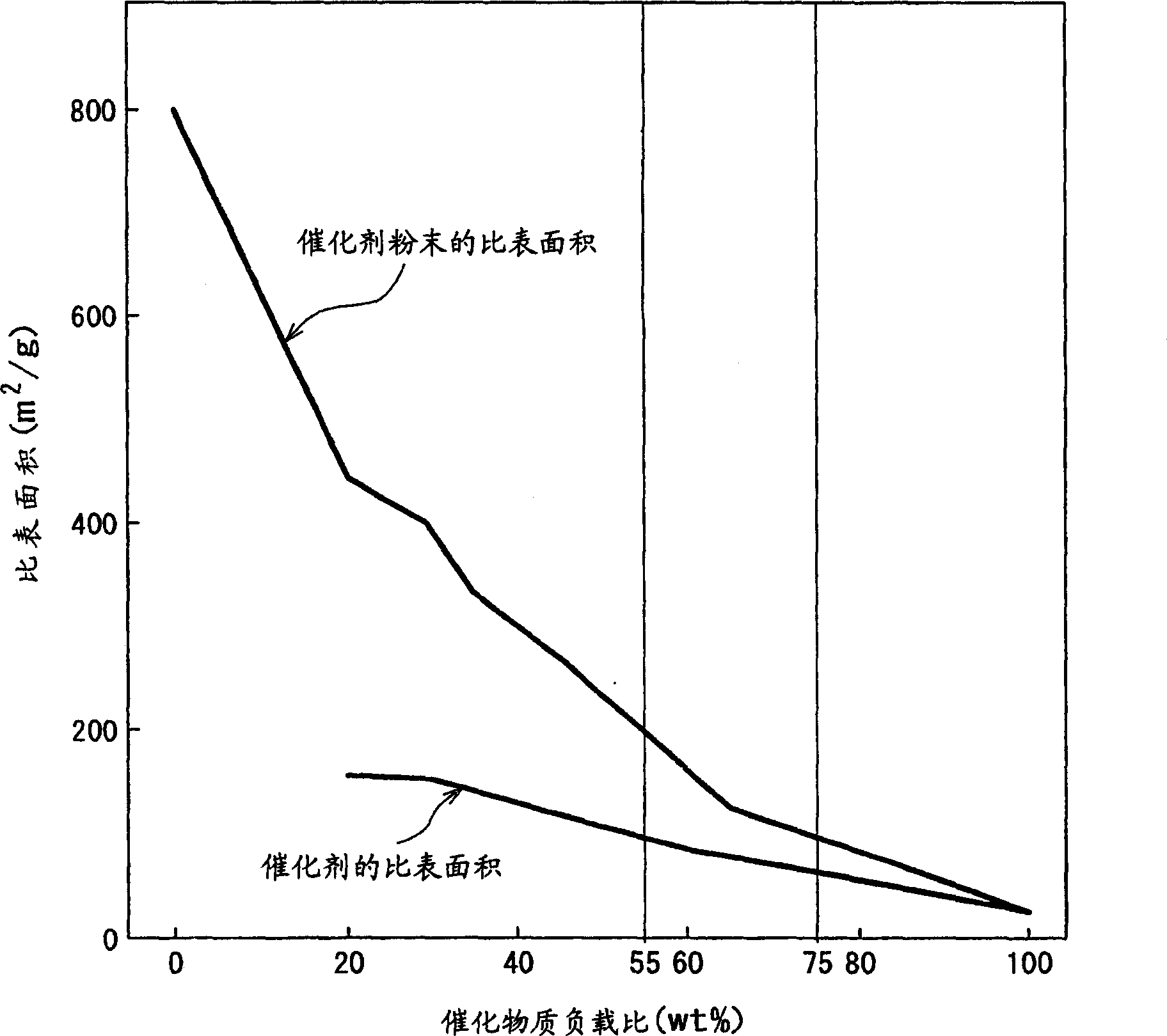

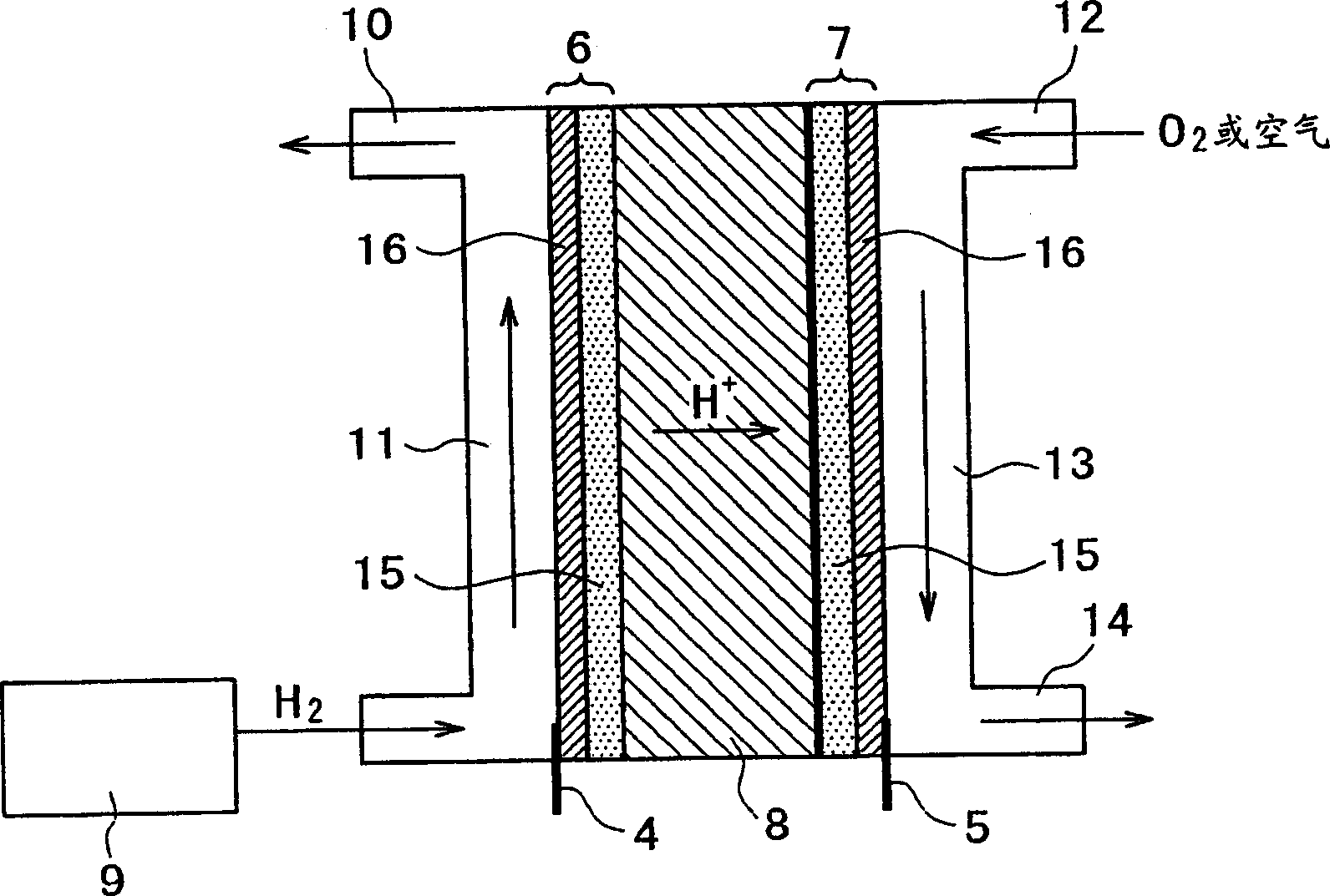

Catalyst powder, catalyst electrode and electrochemical device

InactiveCN1536695AIncrease the effective reaction areaImprove output characteristicsCell electrodesSolid electrolyte fuel cellsPolymer electrolytesElectrochemical cell

Disclosed is a catalyst powder (1) contained in an electrode, wherein the catalyst powder includes a catalytic substance (3) supported on a conductive powder (2), the catalytic substance being comprised of at least a catalyst, the weight ratio of the catalytic substance to the catalyst powder is in the range of 55 to 75 wt%, and the areal density of the catalytic substance is in the range of 1 to 3 mg / cm 2 . Also disclosed is a catalyst electrode including the catalyst powder and a solid polymer electrolyte. Further disclosed is an electrochemical device including a plurality of electrodes, and an ionic conductor sandwiched between the electrodes, wherein the above-mentioned catalyst electrode constitutes at least one of the plurality of electrodes.

Owner:SONY CORP

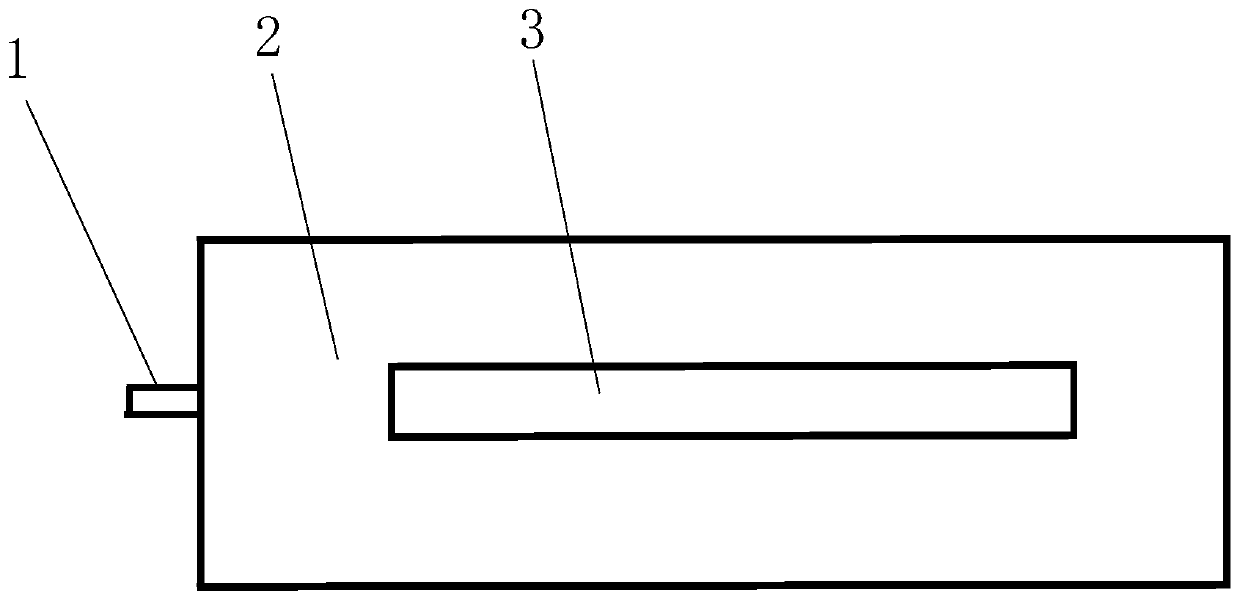

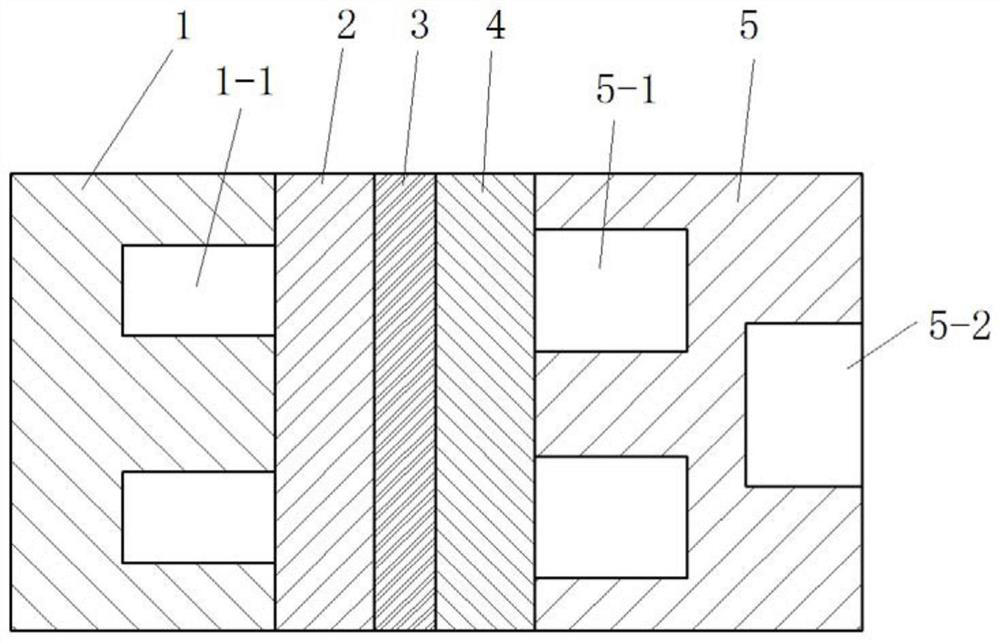

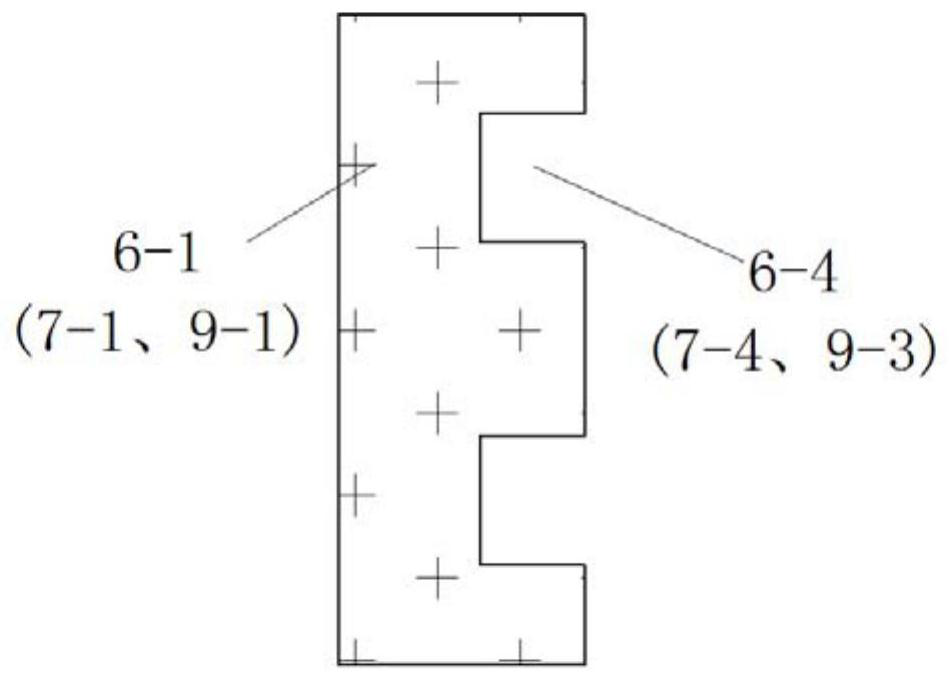

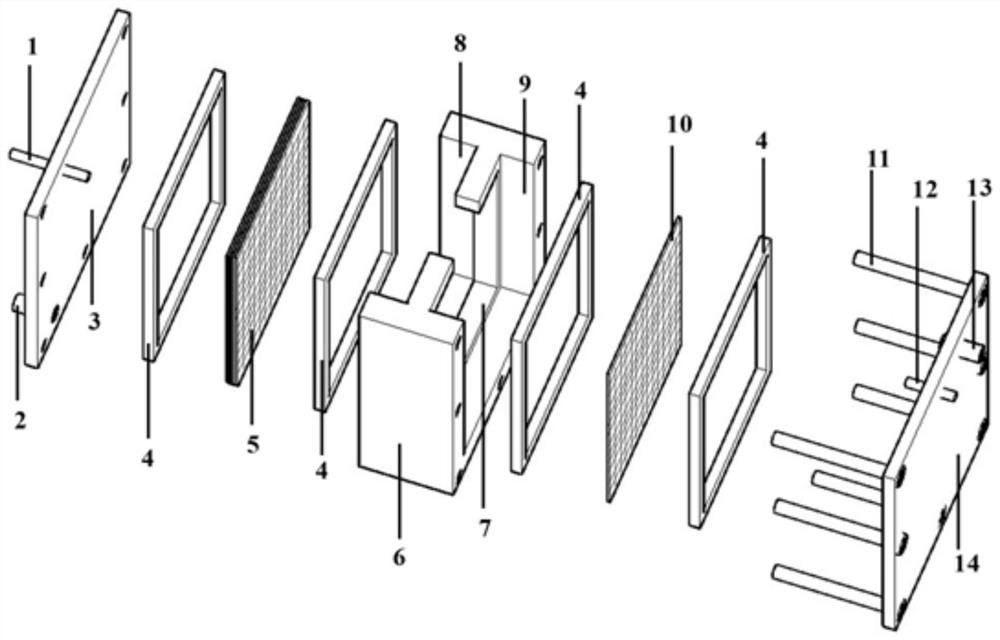

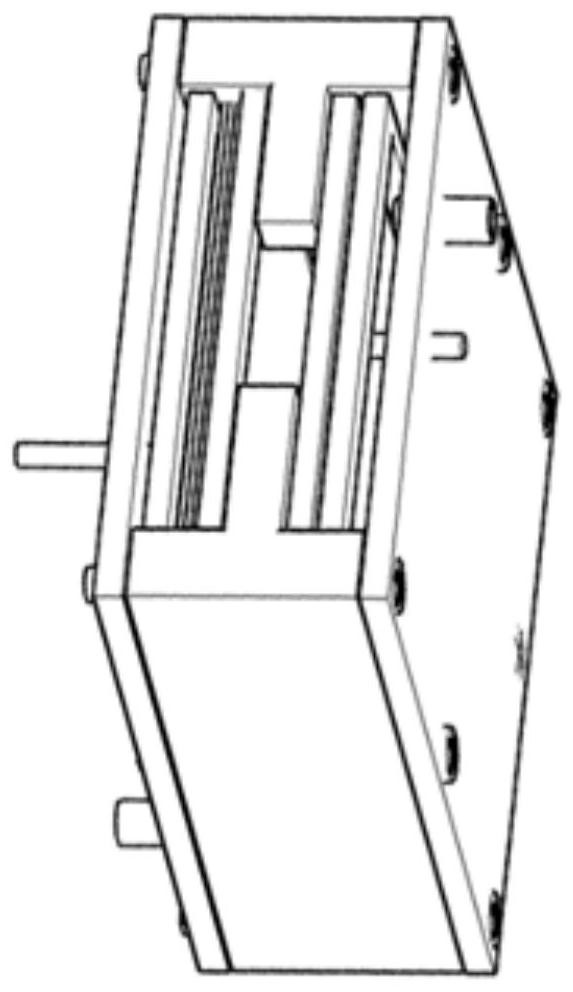

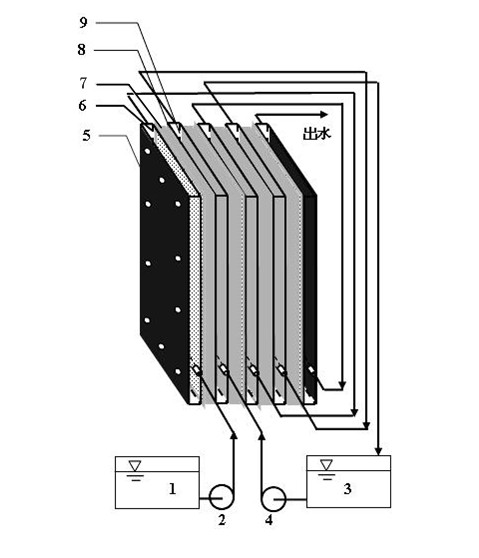

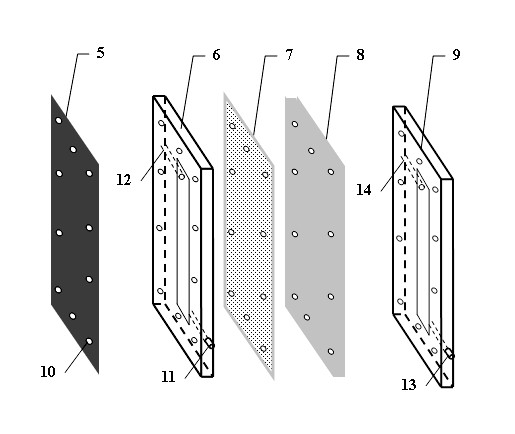

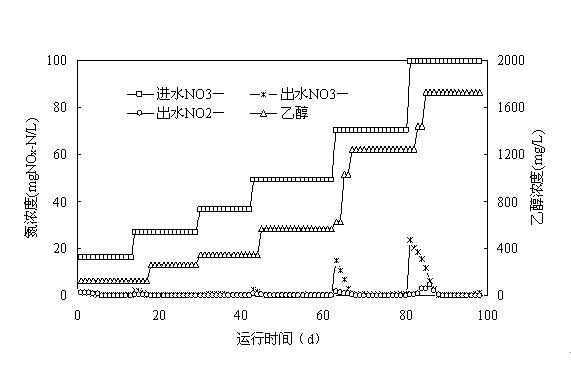

Plate-frame immobilized cell membrane bioreactor and application thereof

InactiveCN102173509AEliminate the effects ofStrengthen the degree of disturbanceTreatment with anaerobic digestion processesMembrane bioreactorAdverse effect

The invention discloses a plate-frame immobilized cell membrane bioreactor. The bioreactor is characterized in that cover plates are arranged on the outmost layers; the middle part is formed by successively arranging and assembling frames and flat-shaped immobilized cells; the frames include W frames and a C frame; the W frames represent the frames for the underground water to flow; the C frame represents the frame for the ethanol water to flow; the arrangement sequence of the cover plates, the frames and the flat-shaped immobilized cells is as follows: one cover plate, one W frame, one flat-shaped immobilized cell, the C frame, the other flat-shaped immobilized cell, the other W frame and the other cover plate; the lower and upper ends of the W frames and the C frame are respectively provided with inlets and outlets; and bolt holes are arranged around the cover plates and the frames. The bioreactor has the following advantages: the oxygen in the air is avoided from being dissolved in the underground water and ethanol water in the reactor, thus reducing the adverse effects of the dissolved oxygen on denitrification; at the same time, the effective reaction area of the immobilized cell in unit volume and the treatment capability in unit volume are obviously improved; and besides, recycling of the carbon source of denitrification is also realized, thus reducing waste of the carbon source of denitrification.

Owner:EAST CHINA UNIV OF SCI & TECH

Rechargeable aluminum battery and preparation method thereof

InactiveCN101764256BIncrease the effective reaction areaWide variety of sourcesFinal product manufactureElectrolyte accumulators manufactureMicrocosmic saltSulfur

The invention discloses a rechargeable aluminum battery and a preparation method thereof. The rechargeable aluminum battery is prepared by selecting metal aluminum or an aluminum alloy, preferable foamed aluminum, as a cathode, taking vulcanized polyvinyl chloride or a carbon-sulfur compound material as an anode active substance and taking aluminic acid halide ionic liquid formed by aluminum halide and any one of quaternary ammonium salt or quaternary microcosmic salt or quaternary sulfosalt a electrolyte. The rechargeable aluminum battery has the advantages of high battery energy density, good circulation performance, safety, environmental protection, pollution-free preparation process, low cost, simple process and vast application prospect.

Owner:无锡欧力达新能源电力科技有限公司

Full-through-hole metal fiber sintered body fuel cell bipolar plate and fuel cell stack

The invention discloses a full-through-hole metal fiber sintered body fuel cell bipolar plate and a fuel cell stack, the full-through-hole metal fiber sintered body fuel cell bipolar plate comprises a conductive partition plate and a flow field plate, the flow field plate is arranged on one side or two sides of the conductive partition plate, and the flow field plate is made of a metal fiber sintered body; the flow field plate and the conductive partition plate are in integrated sintering connection, welding connection or cementing connection. According to the all-through-hole metal fiber sintered body fuel cell bipolar plate and the fuel cell stack provided by the invention, the metal fiber sintered body is adopted as the flow field plate, so that fluid diffusion is uniform, the effective reaction area of gas is doubled, and the power density of the cell is improved; the metal fiber felt serves as a cooling channel of the cell stack, so that the cooling efficiency is improved; the cell stack volume is reduced; and the cell stack volume power is improved.

Owner:WESTERN METAL MATERIAL

Method for preparing nano carbon electrode

ActiveCN103746091AEffective contactReduce usageMaterial nanotechnologyHybrid capacitor electrodesNitrogen gasCopolymer

A method for preparing a nano carbon electrode comprises the following steps: 1) forming a precursor gas; 2) weighing raw materials; 3) putting a precursor obtained in the step 2) in a 60-70 DEG C vacuum oven, drying for 10-30 hours, then putting into a tube type vacuum furnace with atmosphere protection, placing on a conductive substrate, then introducing nitrogen gas or argon gas, and next introducing the precursor gas; 4) preparing a dispersion powder from the product obtained in the step 3), carrying out isopyknic immersion of the dispersion powder with a phenolic resin-P123 macromolecule copolymer-ethyl orthosilicate sol, and carrying out full condensation; 5) depositing the product obtained in the step 4 on a thin metal layer; and 6) depositing an electrolyte on the thin metal layer. The method can reduce the cost, and also improves the performance.

Owner:GUIZHOU TELIDA NANO CARBON SCI & TECH +1

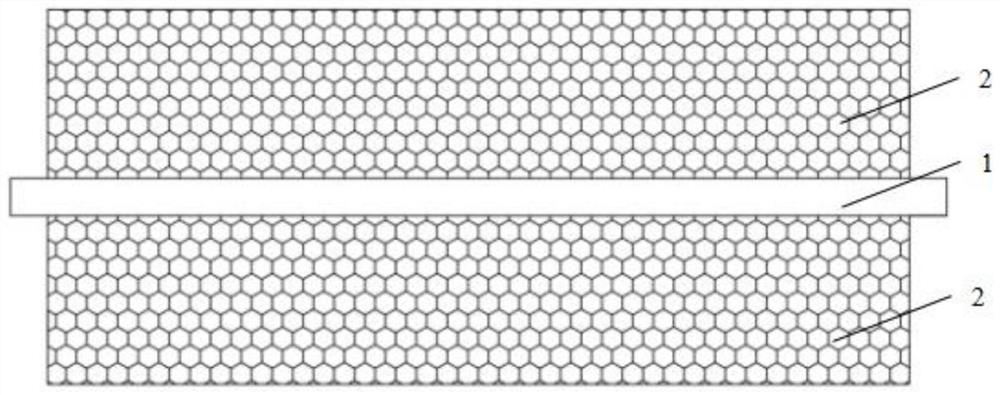

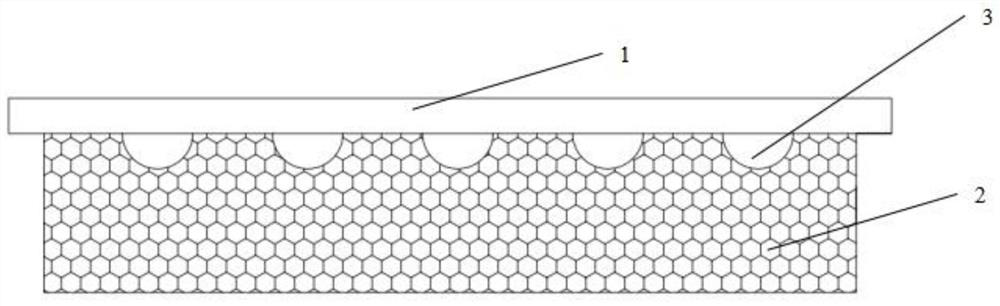

Efficient battery with three-layer electrode structure

InactiveCN108470942AIncrease productivityLow costFinal product manufactureSecondary cellsInternal resistancePerformance index

The invention aims at providing a novel battery structure. Laminated winding of anodes, electrolytes, partition membranes and cathodes is usually adopted in preparation of current ion batteries, and this mode has an obvious defect that the utilization rate of anode materials is not high, and correspondingly the density of battery energy is not high enough, so that the demand of electric cars cannot be met. It can be shown by a principle of a battery that by increasing the effective reaction area of electrodes and reducing internal resistance of the battery, the battery performance index can beeffectively upgraded. The utilization rate of the electrodes is increased, the internal resistance of the battery is lowered, and compared with a battery structure of a traditional mode, the batterystructure remarkably improves the performance of the battery.

Owner:孙备宽

A kind of preparation method of titanium silicate lithium lithium ion battery negative electrode material

ActiveCN105024070BImprove energy storage performanceNo pollution in the processCell electrodesSecondary cellsWater vaporHydrolysis

The invention discloses a preparation method of lithium titanium silicate anode material for a lithium ion battery. The method specifically comprises the following steps: 1) dissolving a lithium salt, a titanium source and a silicon source into an organic solvent, and uniformly mixing the lithium salt, titanium source and silicon source to obtain a mixed solution; (2) adjusting the pH value of the mixed solution to 1.5-6.5; (3) introducing water vapor carried by a carrier gas into the mixed solution obtained in the step (2) to perform a hydrolysis reaction in order to obtain a co-precipitate, and performing filtering, water washing and drying to obtain a precursor; and (4) pre-burning the precursor in an inert protection atmosphere at the temperature of 450-700 DEG C for 3-5 hours, and sintering the pre-burned precursor at the temperature of 750-950 DEG C to obtain the lithium titanium silicate anode material for the lithium ion battery. The anode material prepared with the preparation method is ideal in shape and particle size distribution, and has high electrochemical performance. The preparation method is simple in flow, high in operability, high in safety, and convenient for realizing industrialization.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com