Composite lithium titanate preparation method

A composite lithium titanate and lithium source technology, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as material cycle performance defects, improve the first Coulomb efficiency and cycle stability, high rate performance, improve The effect of high rate capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

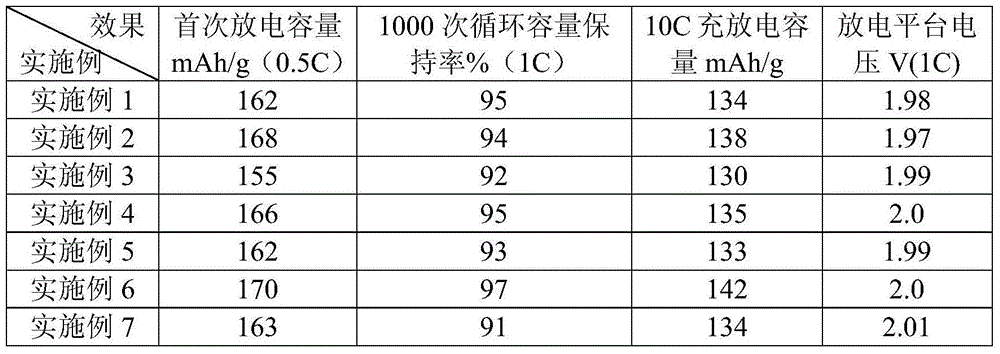

Examples

Embodiment 1

[0019] The preparation method of composite lithium titanate comprises the following steps:

[0020] 1) Lithium carbonate, titanium dioxide and chromium oxide were mixed according to the Li:Ti:Cr molar ratio of 0.6:1:0.06, dispersed in an alcohol solvent for ball milling for 8 hours, and then sintered and dried at 80°C for 6 hours;

[0021] 2) heat-treat the dried product obtained in step 1) at 400° C. for 10 hours and then cool it naturally;

[0022] 3) The heat-treated material obtained in step 2) and glucose were mixed and ball-milled at 100:10 by weight for 10 hours, then sintered at 750° C. for 15 hours under nitrogen protection, and cooled through a 300-mesh sieve.

Embodiment 2

[0024] The preparation method of composite lithium titanate comprises the following steps:

[0025] 1) Lithium carbonate, titanium dioxide and zirconia were mixed according to the Li:Ti:Zr molar ratio of 0.8:1:0.1, dispersed in acetone solvent for ball milling for 12 hours, and then sintered at 90°C for 8 hours and dried;

[0026] 2) heat-treat the dried product obtained in step 1) at 500° C. for 18 hours and then cool it naturally;

[0027] 3) The heat-treated material obtained in step 2) and furfural resin were mixed and ball-milled for 10 hours at a ratio of 100:20 by weight, then sintered at 800° C. for 16 hours under nitrogen protection, and then cooled through a 300-mesh sieve.

Embodiment 3

[0029] The preparation method of composite lithium titanate comprises the following steps:

[0030] 1) Lithium nitrate, titanium tetrachloride and zinc oxide were mixed according to Li:Ti:Zn molar ratio of 1:1:0.2, dispersed in alcohol solvent for ball milling for 8 hours, then sintered at 100°C for 8 hours and dried;

[0031] 2) heat-treat the dried product obtained in step 1) at 600° C. for 20 hours and then cool it naturally;

[0032] 3) Mix and ball-mill the heat-treated material obtained in step 2) and asphalt at a ratio of 100:10 by weight for 12 hours, then sinter at 900° C. for 18 hours under nitrogen protection, and then cool through a 300-mesh sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com