Patents

Literature

1736results about How to "Small specific surface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-seepage burnon casting paint made from alcohol base or aqueous sand powder

InactiveCN1666828AExcellent anti-seepage and sticky sand effectSmall specific surface areaFoundry mouldsFoundry coresWater basedAlcohol

The invention relates to the melting coating of alcohol-base or water-base anti-penetrating sands, which uses the fireproofing bone materials, the floating agent, the felting agent, the reinforcing agent and the carrier as the preparing coating. The weight shares of the said coating are: 100,3-8,3-7,0.2-1.0 and 30-40. The invention uses chrome iron minerals as the main materials and is prior to any kinds of the traditional coating.

Owner:HUBEI UNIV OF TECH

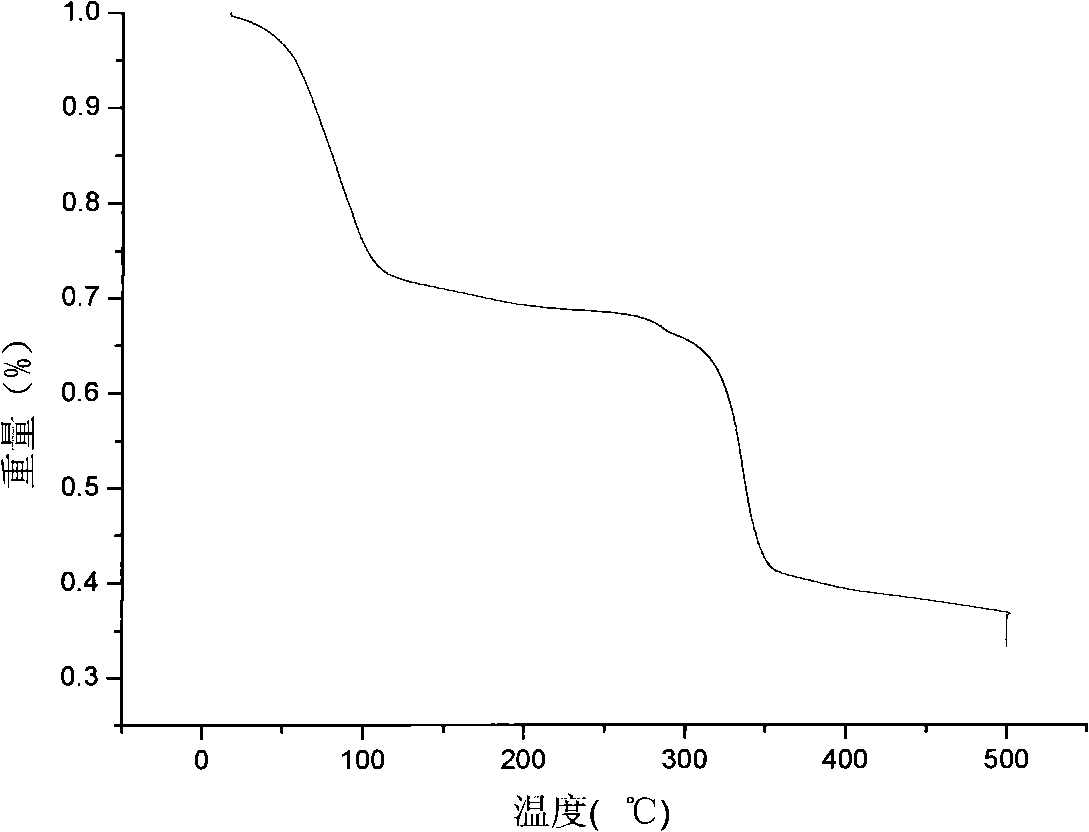

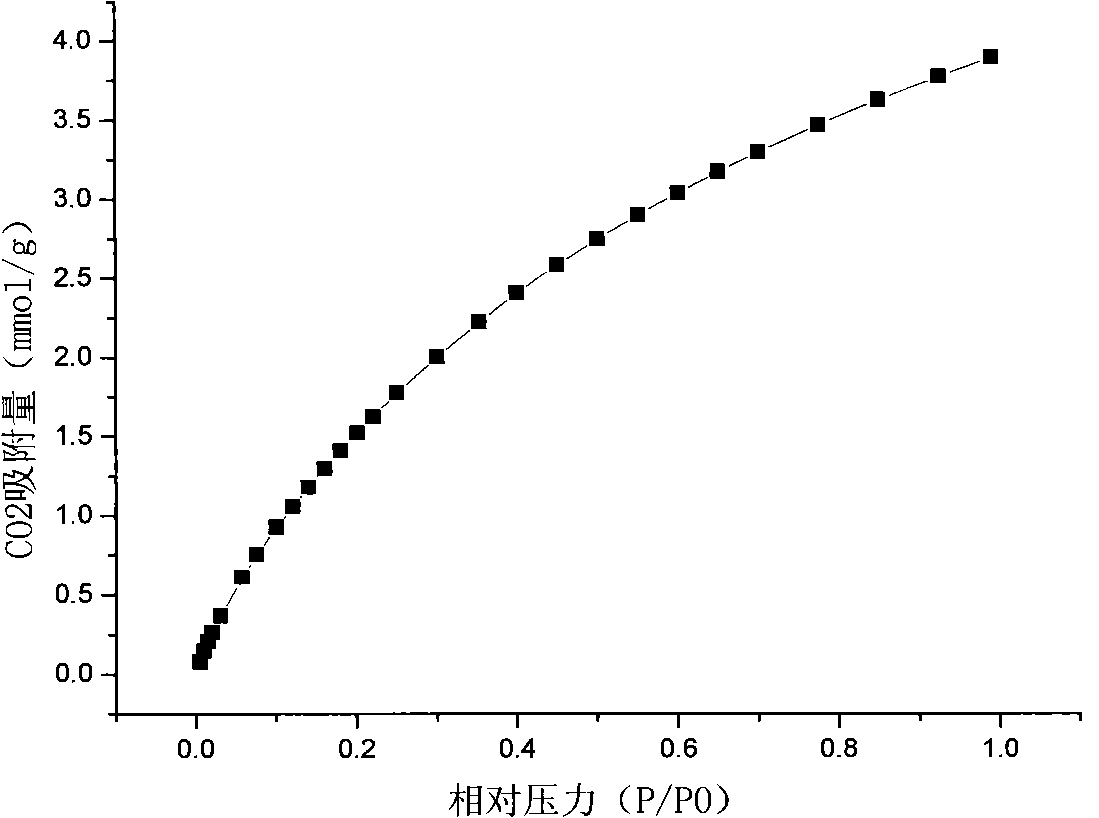

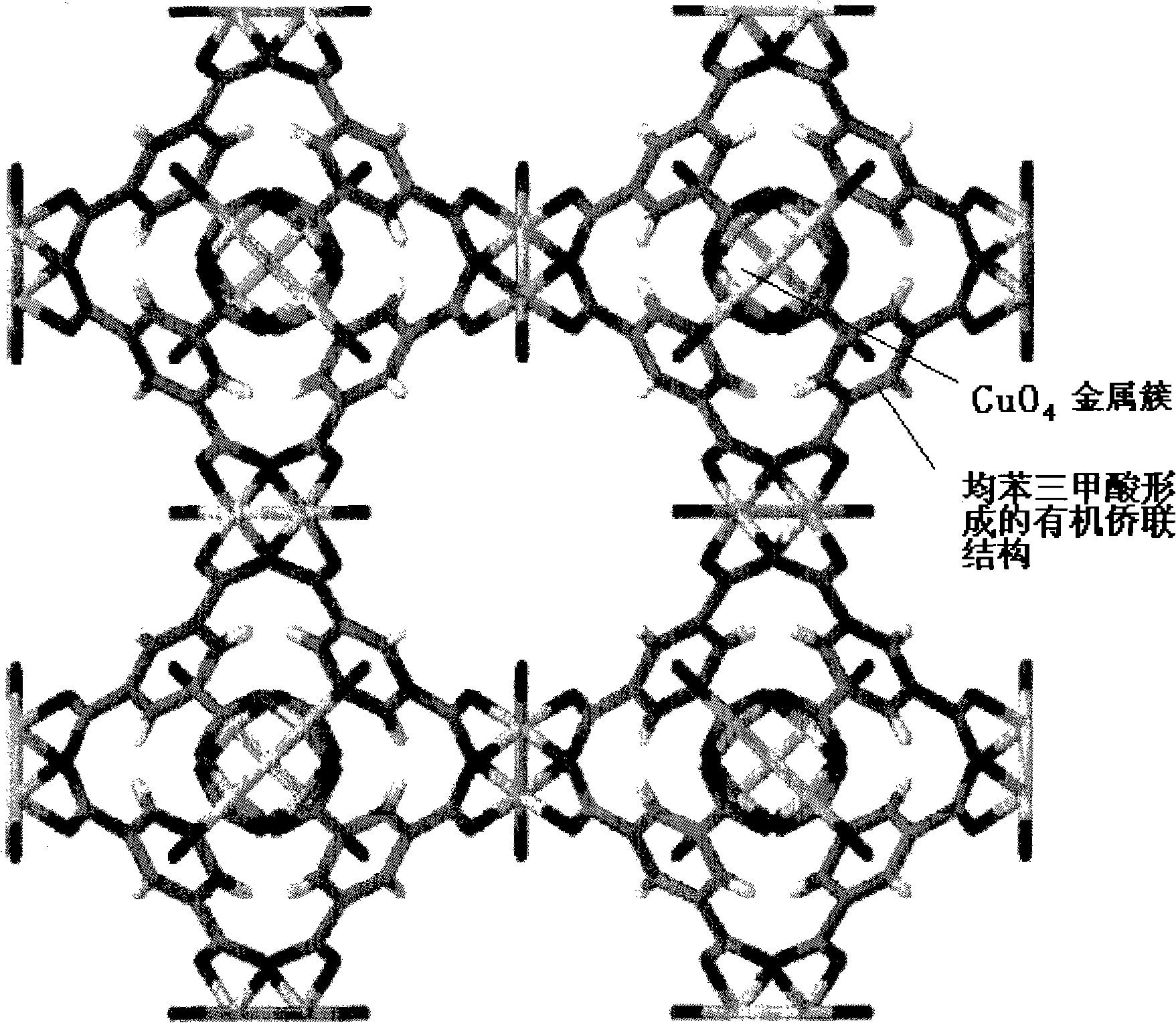

Metal organic framework material used for absorbing and separating CO2 and preparation method thereof

InactiveCN101816924ALarge specific surface areaImprove adsorption capacityProductsCarbon compoundsMetal-organic frameworkChemical measurement

The invention provides a metal organic framework material used for absorbing and separating CO2 and a preparation method thereof. The metal organic framework material is a rigid metal carboxyl compound cluster-like structure which is formed by transition metal ions and multidentate organic ligands through covalent bonds and intermolecular forces. An amine polymer is modified on the metal organic framework material; and the metal organic framework material used for absorbing and separating the CO2 has a specific surface area of 1,000 to 1,200 m<2> / g, and a pore volume of 0.4 to 0.6 cm<3> / g. The preparation method comprises the following steps of: respectively dissolving the nitrate, the chloride or the carbonate of copper or zinc and 1,3,5-trimesic acid together in a stoichiometric ratio in water or an organic solvent; mixing uniformly and sufficiently to react to obtain a BTC bridged complex crystal; and applying a product obtained by reacting an obtained BTC bridged complex crystal with the solution of polyethyleneimine to the metal organic framework material used for absorbing and separating the CO2. The material can realize selective absorption of a gas under a low pressure.

Owner:SOUTHEAST UNIV

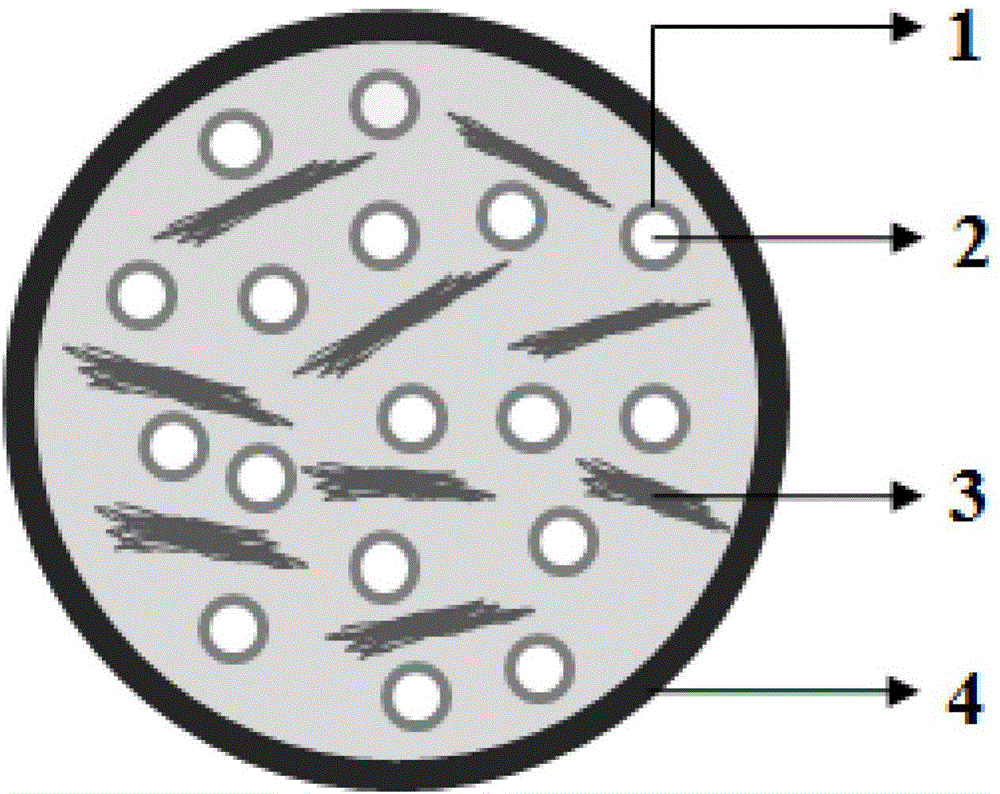

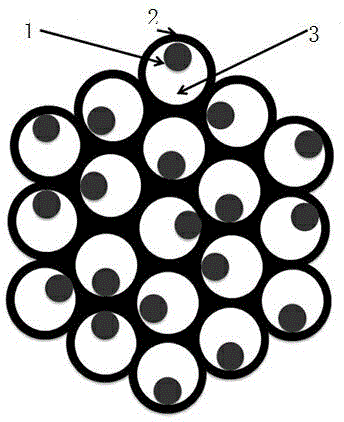

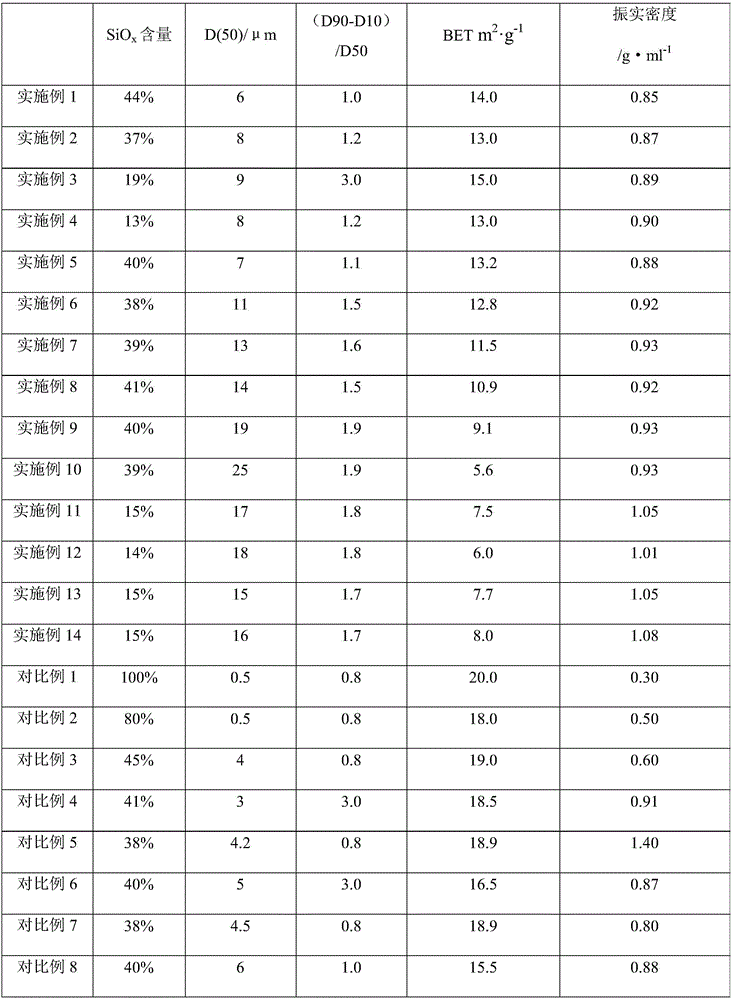

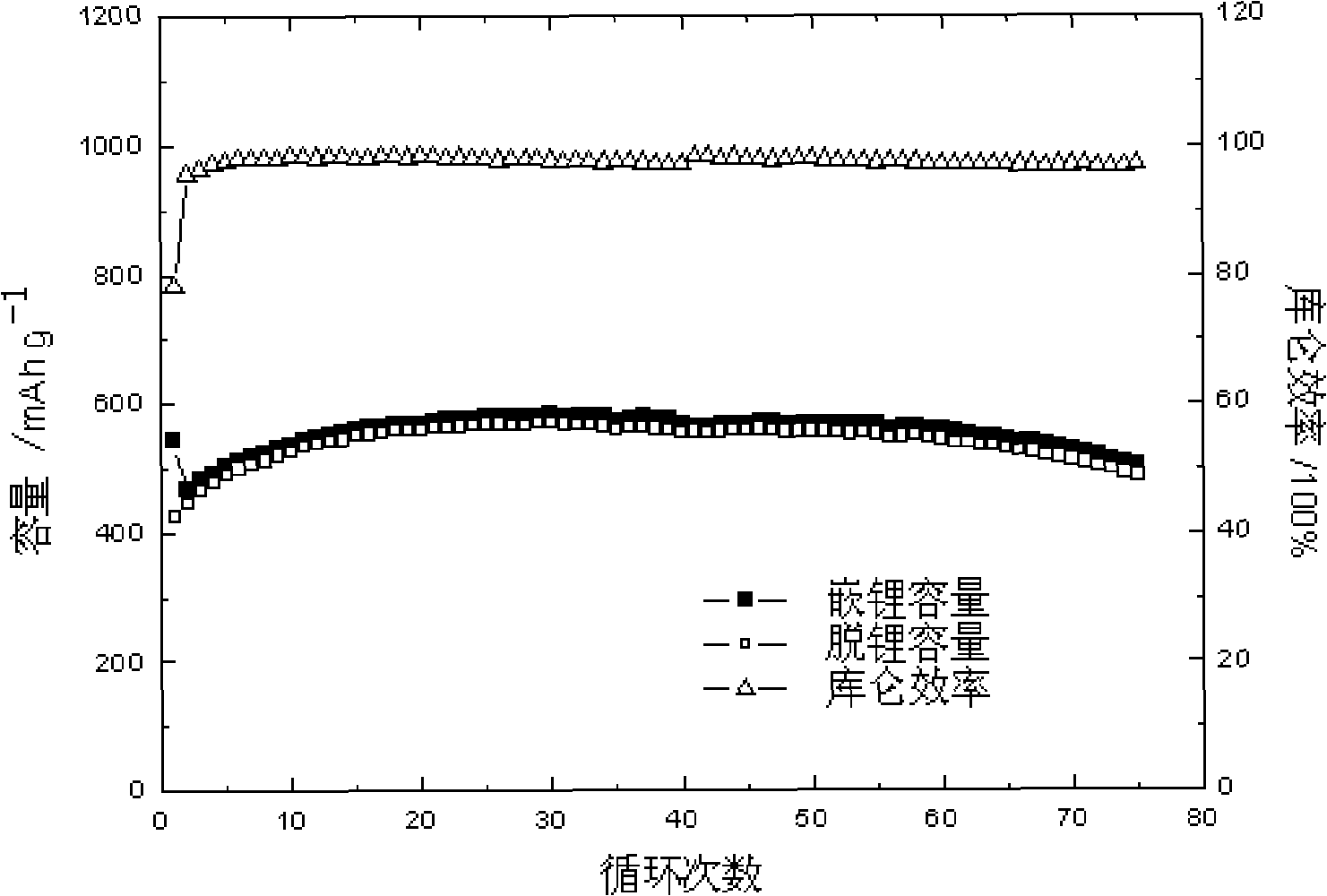

Carbon-coated nano silicon/graphene/cracked carbon layer composition material, preparation method, and lithium ion battery including the composition material

InactiveCN106067547AAchieve perfect compoundSimple processMaterial nanotechnologyCell electrodesNano siliconCarbon layer

The invention relates to a carbon-coated nano silicon / graphene / cracked carbon layer composition material, a preparation method thereof, and a lithium ion battery including the composition material. The composite material comprises spherical particles formed by uniformly dispersing carbon-coated nano silicon in graphene sheets, and a cracked carbon layer which coats the surfaces of the spherical particles. The carbon-coated nano silicon comprises nano silicon and carbon coating layer which coats the surface of the nano silicon. The method is simple, has excellent process performance and is environment-friendly. The carbon-coated nano silicon / graphene / cracked carbon layer composition material has stable structure and high compact density, has excellent performance when being used as an anode material of the lithium ion battery, has high anode capacity, excellent rate capability and cyclic performance, is more than 1500 mAh / g in first-time reversible capacity, is more than 90% in first-time coulomb efficiency and is more than 90% in 500-time cyclic capacity retention ratio and has low expansion.

Owner:BTR NEW MATERIAL GRP CO LTD

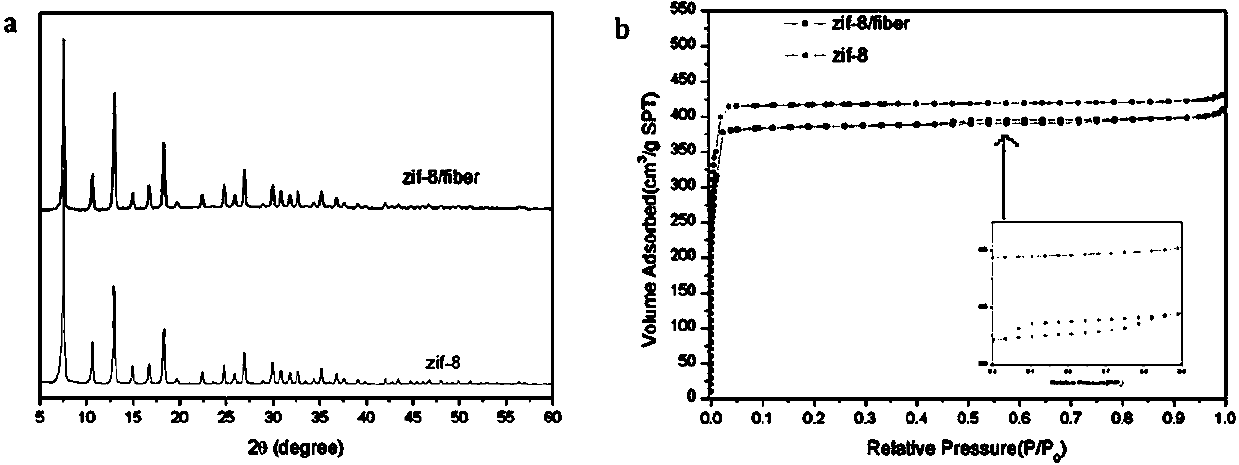

Metal organic frame composite material and preparation method thereof

InactiveCN104174388AEvenly distributedStable structureOther chemical processesAlkali metal oxides/hydroxidesIonCompound s

The invention belongs to the technical field of nano composite materials and particularly relates to a metal organic frame composite material and a preparation method thereof. The preparation method comprises the steps of adding metal ions and organic ligand into polymer nanowire solution with a core-shell structure to form mixed solution; under the room temperature, crystallizing to obtain the polymer nanowire composite with the metal organic frame / core-shell structure. The composite has the geometric shape same as that of the crystal of the pure metal frame compound, the polymer nanowires penetrate through and cover the single crystal particle, and the particles are connected by the polymer nanowires. In addition, the metal organic frame nanowire network composite growing along the polymer nanowires can be obtained. Due to addition of the polymer nanowires, functional groups or particles can be introduced, and the functionality of the metal organic frame composite material is improved. The composite material has the advantages that the preparation process is simplified, the stability of macroscopic aggregates of the material is improved and the actual application of the material is facilitated.

Owner:FUDAN UNIV

Attapulgite clay porous ceramsite, and preparation method and purpose thereof

ActiveCN102225870AWide variety of sourcesLow priceCatalyst carriersTreatment with aerobic and anaerobic processesWater resistancePorosity

The invention discloses an attapulgite clay porous porous ceramsite, a preparation method of the ceramsite, and a purpose of the ceramsite. The ceramsite is prepared from raw materials of attapulgite clay and biomass, and a binder of industrial soluble glass. The ceramsite is prepared through calcining and oxidizing. The attapulgite clay porous ceramsite prepared by the present invention has advantages of high porosity, large specific surface area, high strength, strong water resistance, high water absorption, high catalytic activity, and the like. The porous ceramsite prepared by the presentinvention can be applied as a carrier for a catalyst, and a filling material for an aerated biological filter.

Owner:HEFEI UNIV OF TECH

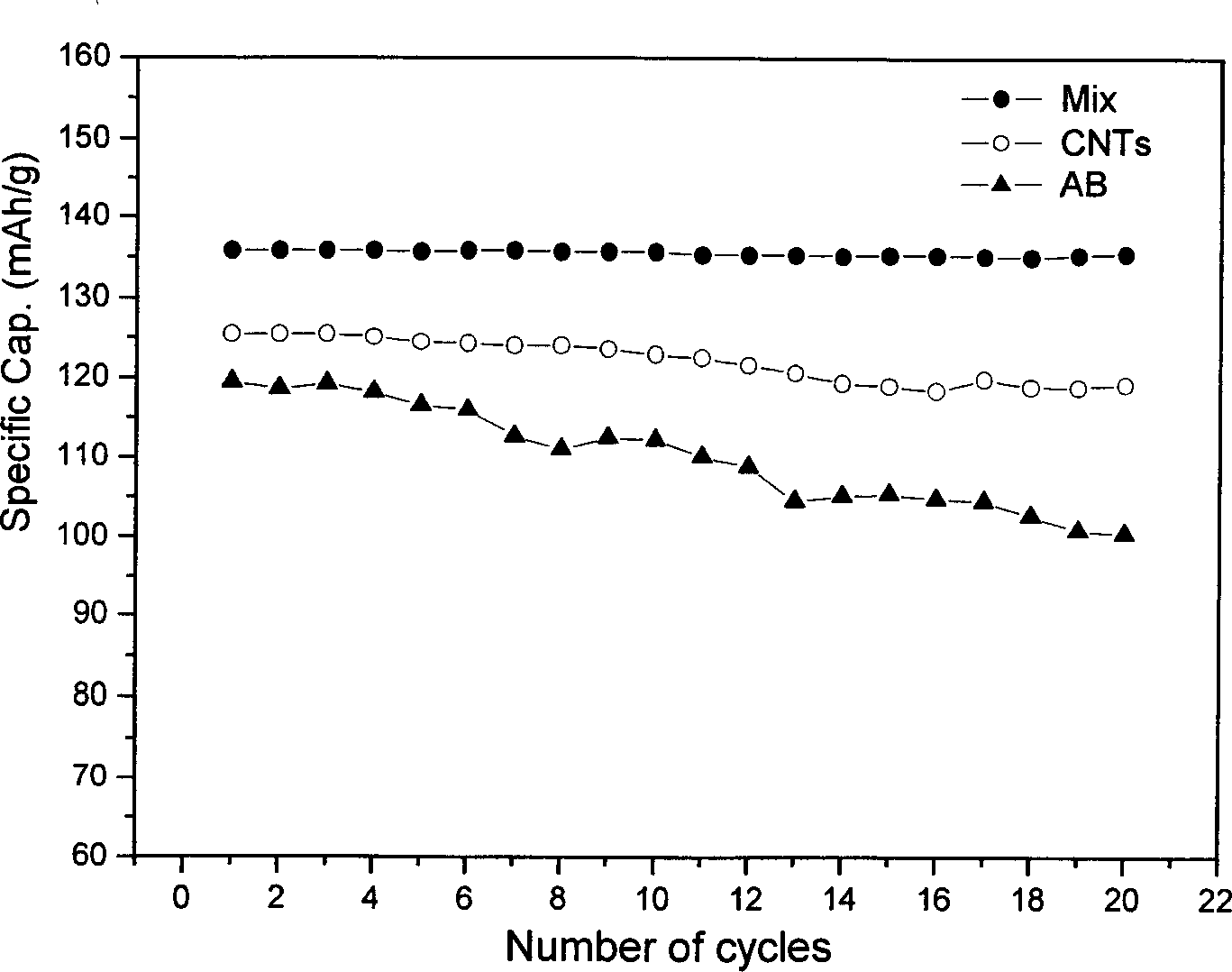

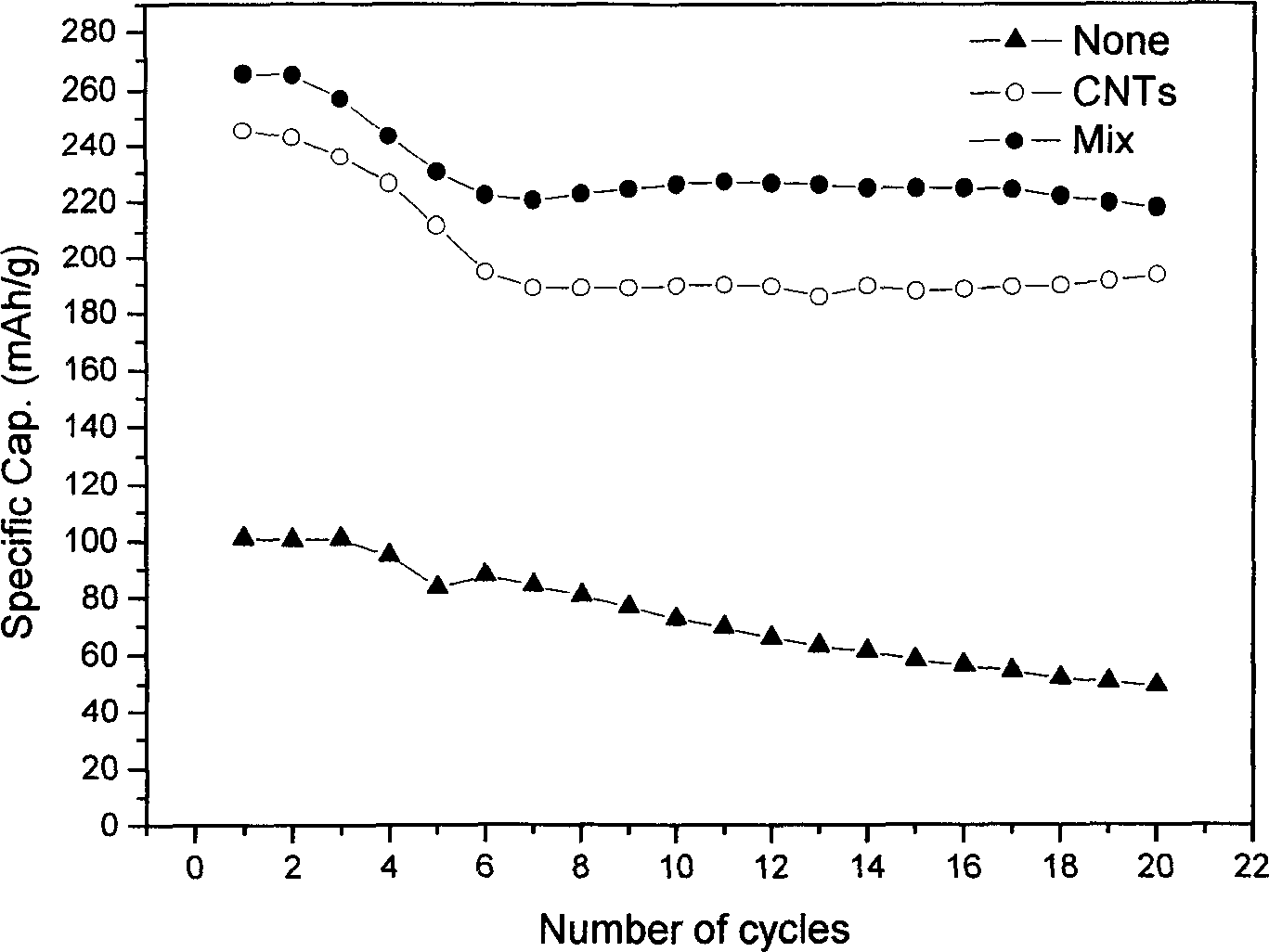

Anode, cathode material conductive agent for lithium-ion secondary battery and preparation method thereof

This invention discloses one second battery anode and negative conductive agent and its process method by use of carbon nanometer tube and acetylene black compound, wherein, the method comprises the following steps: Processing the mother liquid with concentration of 0.5 to 8 percent by adding the carbon nanometer tube and acetylene black compound into dispersion agent; or after adding the dispersion agent water or organic agent to dissipate the nanometer tube to process the low concentration mother liquid with 0.5 to 8 by adding acetylene black; The mother liquid passes filter or pressing to process compound conductive agent with dry weight of 6 to 60 percent. Comparing with conductive carbon or fiber, the nanometer tube has high capacity with high charging efficiency,

Owner:SHENZHEN SSZK NEW MATERIALS CO LTD

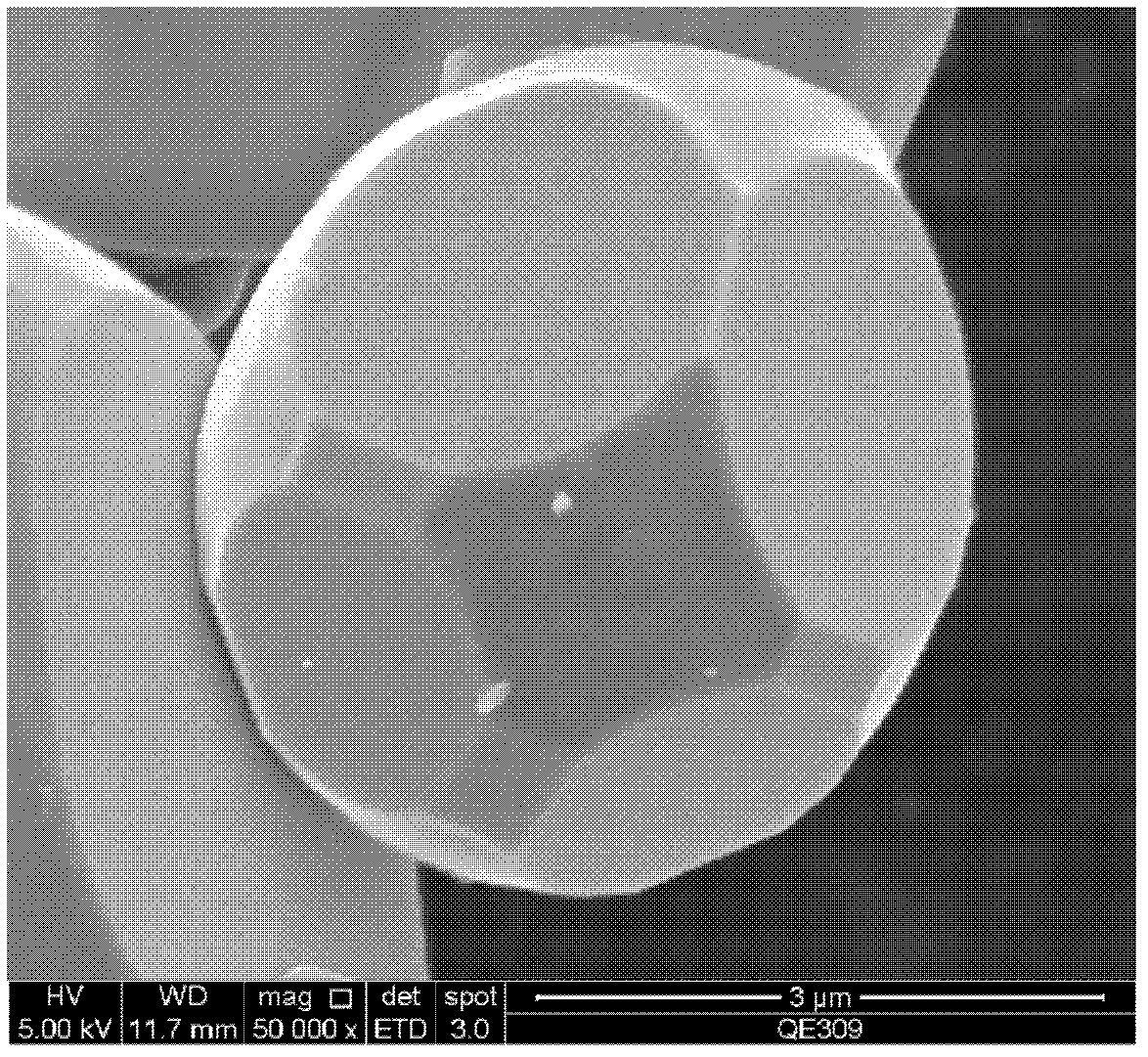

Coated-modified lithium manganese positive electrode material and preparation method thereof

The invention discloses a coated-modified lithium manganese positive electrode material and the preparation method thereof. A manganese source compound, an M source compound and a lithium source compound are taken as raw material for preparing LiaMn2 -bMbO4 particles, and then are mixed with molten solvent and A-source compound, so as to obtain coated-modified lithium manganese positive electrode material. Compared with the prior art, the LiaMn2-bMbO4 particles are similar to spheres in shape and are in crystal face connection through curved surfaces which have no clear edges; on one hand, the LiaMn2 -bMbO4 particles have very small specific surface area, so that molten solvent and coating material are more evenly dispersed on the surfaces of the particles, and the control to average thickness of a coating is facilitated; on the other hand, the features have very small surface energy, the coating material is enabled to be more easily to be combined with the LiaMn2 -bMbO4 particles to form the coating. Therefore, the coated-modified lithium manganese positive electrode material has an excellent high temperature cycling performance.

Owner:宁波富理电池材料科技有限公司

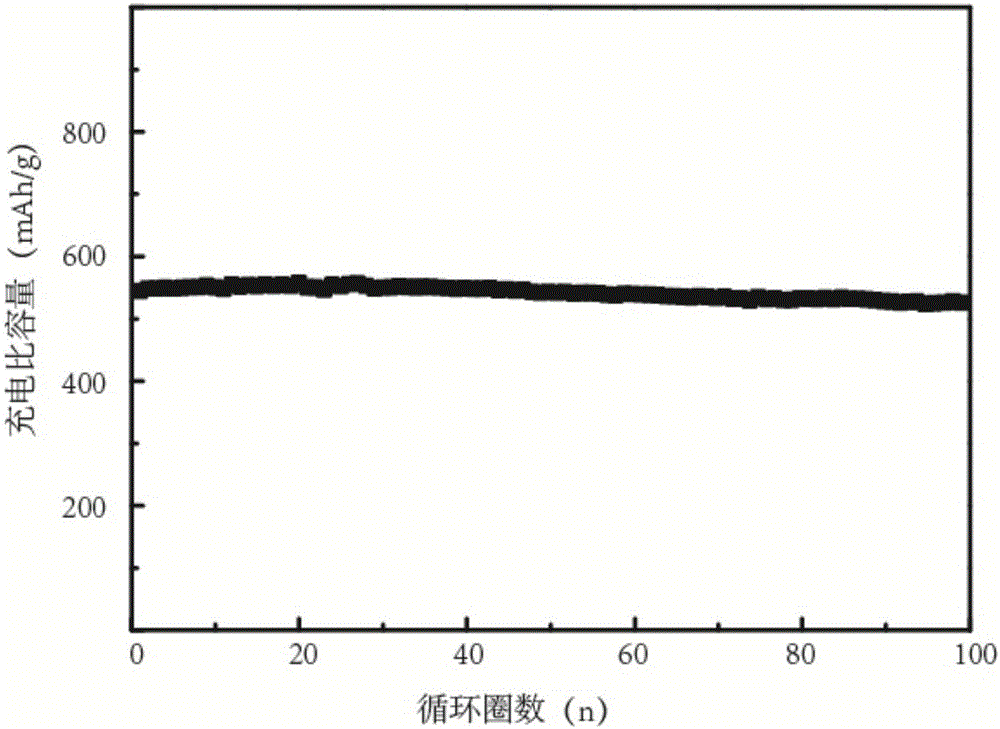

Silicon-carbon composite material and preparation method thereof and application thereof in lithium ion battery

InactiveCN106159213ASimple preparation processLow costCell electrodesSecondary cellsCarbon compositesSodium-ion battery

The invention relates to the battery field, and in particular relates to a silicon-carbon composite material and a preparation method thereof and application thereof in lithium ion battery. The following problems exist in the application of silicon-based materials in the lithium ion battery: 1. first coulombic efficiency of the lithium ion battery is low; 2, cycle life of the lithium ion battery is short; 3, the rate performance is poor; 4, the materials are low in production efficiency, and not conducive to large-scale industrial production. In order to solve the problems, the silicon-carbon composite material is provided, secondary-particles comprise a plurality of first particles containing core-shell structures, the core-shell structure comprises a carbon shell layer and silicon core particles which are completely wrapped by the carbon shell layer, and a gap is between the carbon shell layer and the silicon core particles. The preparation method of the silicon-carbon composite material and the application of the silicon-carbon composite material in the lithium ion battery are also provided.

Owner:BERZELIUS (NANJING) CO LTD

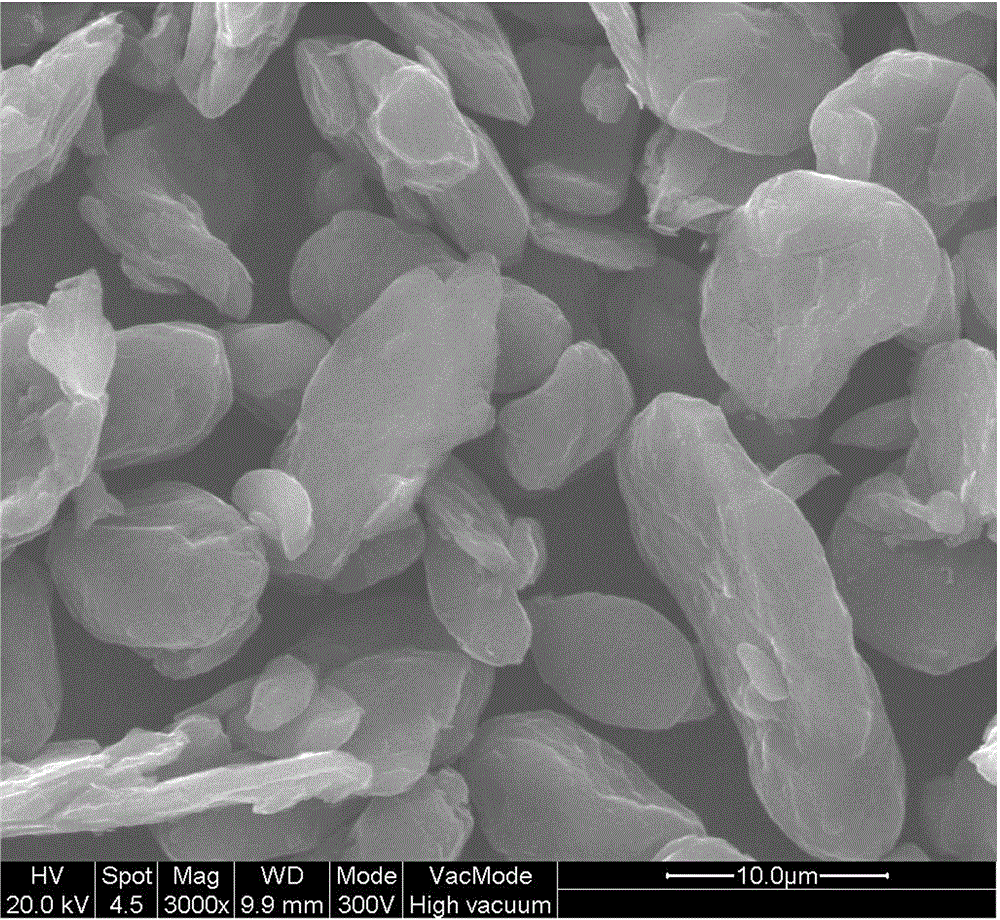

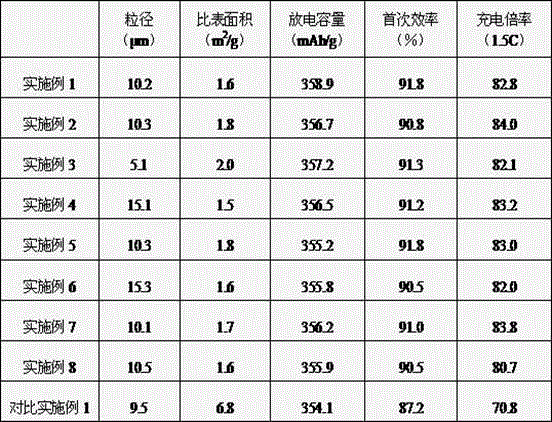

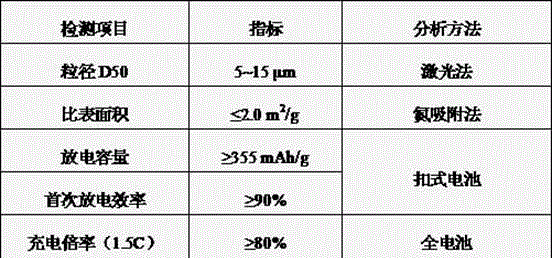

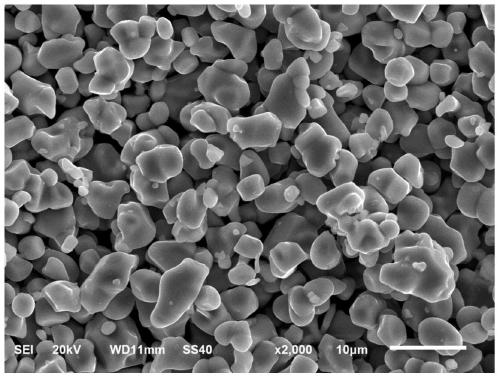

Negative electrode material for quickly rechargeable graphite lithium-ion battery and preparation method of negative electrode material

InactiveCN105024075ASmall specific surface areaIncrease charging rateCell electrodesSecondary cellsDischarge efficiencyElectrical battery

The invention discloses a negative electrode material for a quickly rechargeable graphite lithium-ion battery and a preparation method of the negative electrode material. The preparation method of the negative electrode material for the quickly rechargeable graphite lithium-ion battery comprises the following steps: (1) mixing a mixture containing a graphite precursor and bitumen and heating the mixture for kneading and crushing, wherein the mean grain size D50 of the graphite precursor ranges from 5 to 10 microns, and the mass ratio of the graphite precursor to the bitumen ranges from 50:50 to 90:10; (2) performing heat treatment at a temperature within the range of 300-700 DEG C under the protection of an inert gas; and (3) carrying out graphitizing. The mean grain size D50 of the negative electrode material prepared by use of the preparation method for the quickly rechargeable graphite lithium-ion battery is within the range of 5-15 microns and the specific surface area of the negative electrode material is below 2.0m2 / g; the first discharge capacity of a negative electrode, manufactured by use of the negative electrode material for the quickly rechargeable graphite lithium-ion battery, is more than 355mAh / g, and the initial charge-discharge efficiency of the battery is above 90%; if the battery is quickly charged (1.5C) for 45 minutes, the capacity of the battery can be above 80%; in short, the product is high in discharge capacity and charge / discharge efficiency, and good in rate capability. The invention also relates to a battery comprising the negative electrode material for the quickly rechargeable graphite lithium-ion battery.

Owner:SHANGHAI SHANSHAN TECH CO LTD

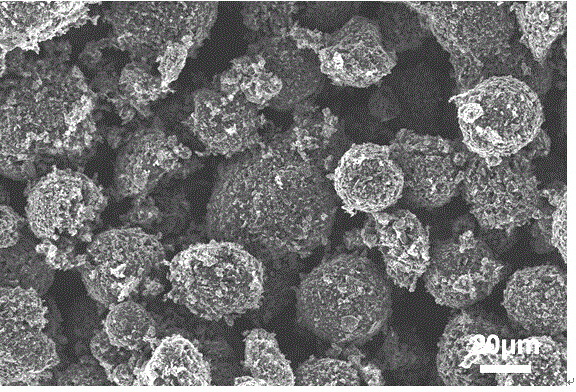

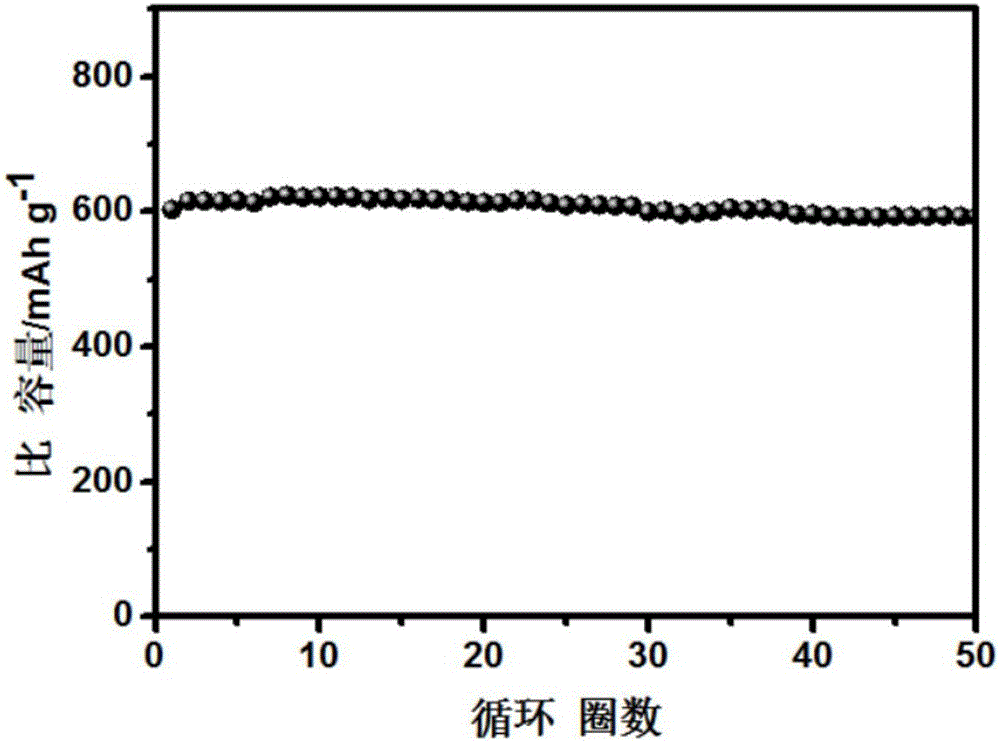

Silicon-carbon composite material for lithium ion battery and preparation method thereof

ActiveCN102891297AImprove cycle performanceIncrease capacityCell electrodesCarbon compositesCarboxymethyl cellulose

The invention discloses a silicon-carbon composite material for a lithium ion battery and a preparation method for the silicon-carbon composite material, and belongs to the field of lithium ion batteries. The silicon-carbon composite material is characterized in that carboxymethylcellulose sodium is used as a bonding agent, a liquid phase coating technology is used for silicon-carbon compounding, and a spray drying technology is used for drying granulation to prepare the silicon-carbon composite material with uniform granularity and excellent performance for the lithium ion battery. The silicon-carbon composite material and the preparation method thereof have the advantages that 1, the composite material for the lithium ion battery is prepared through a silicon-carbon compounding technology, and the capacity of the composite material is higher than that of the conventional graphite cathode material, reaches over 500mAh / g, and can meet requirements on the growing of the market of lithium ion batteries; 2, carboxymethylcellulose is used as a bonding agent which can be effectively coated and bonded on the silicon-carbon material to prevent efflorescence caused by silicon during charging and discharging, so that the cycling performance of the silicon-carbon composite material is effectively improved; and 3, the liquid phase coating and spray drying granulation technologies are adopted, so that the silicon-carbon material can be uniformly coated and bonded, has uniform granules, and is small in specific area, and the cycling performance of the silicon-carbon composite material is further improved.

Owner:JIANGXI ZHENGTUO NEW ENERGY TECH CO LTD

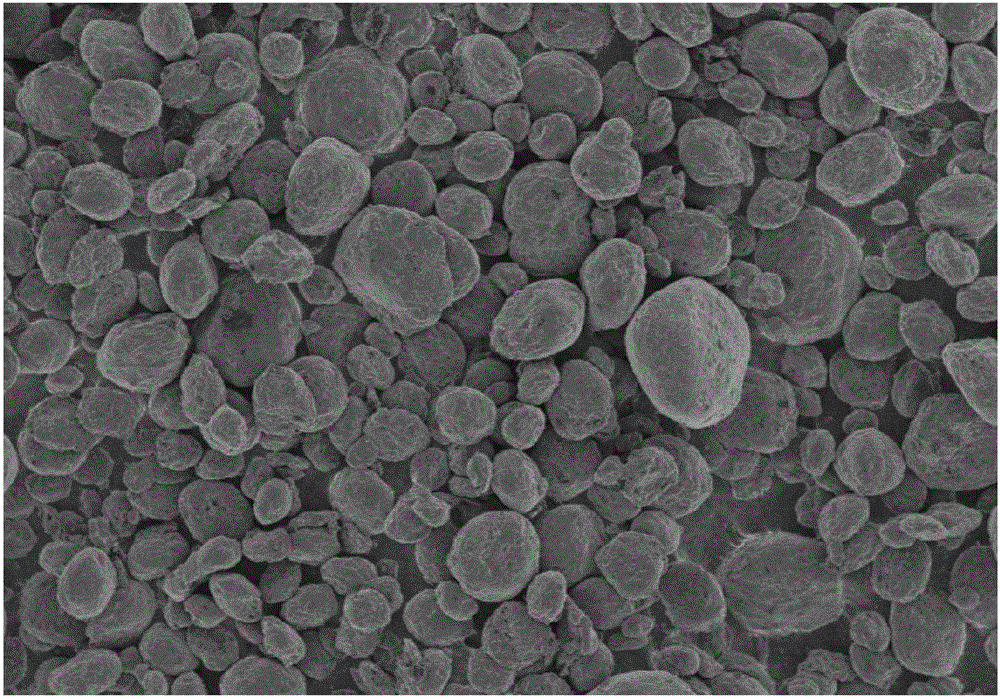

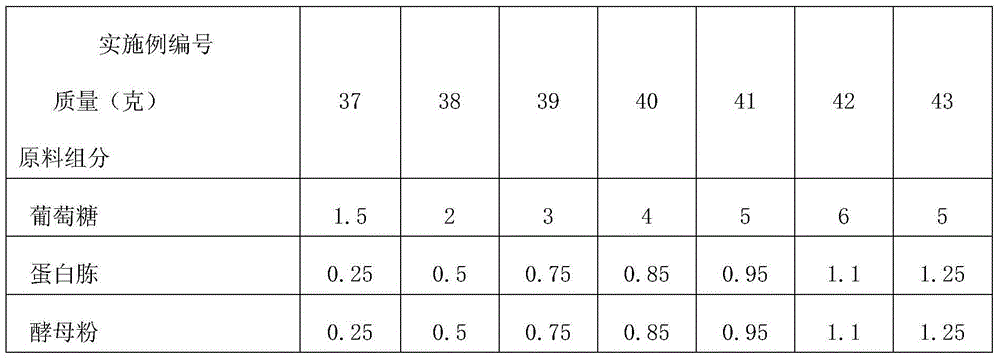

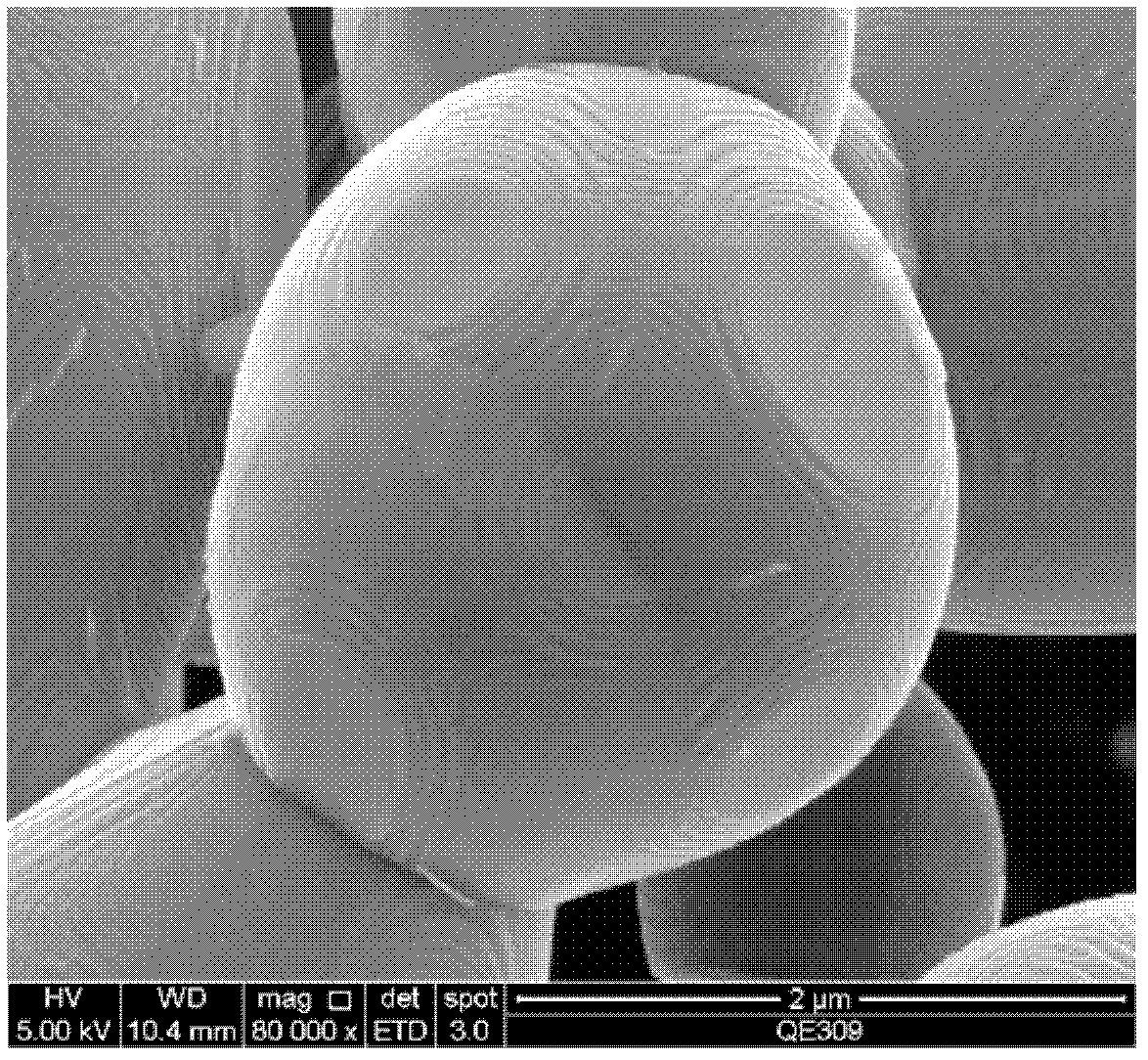

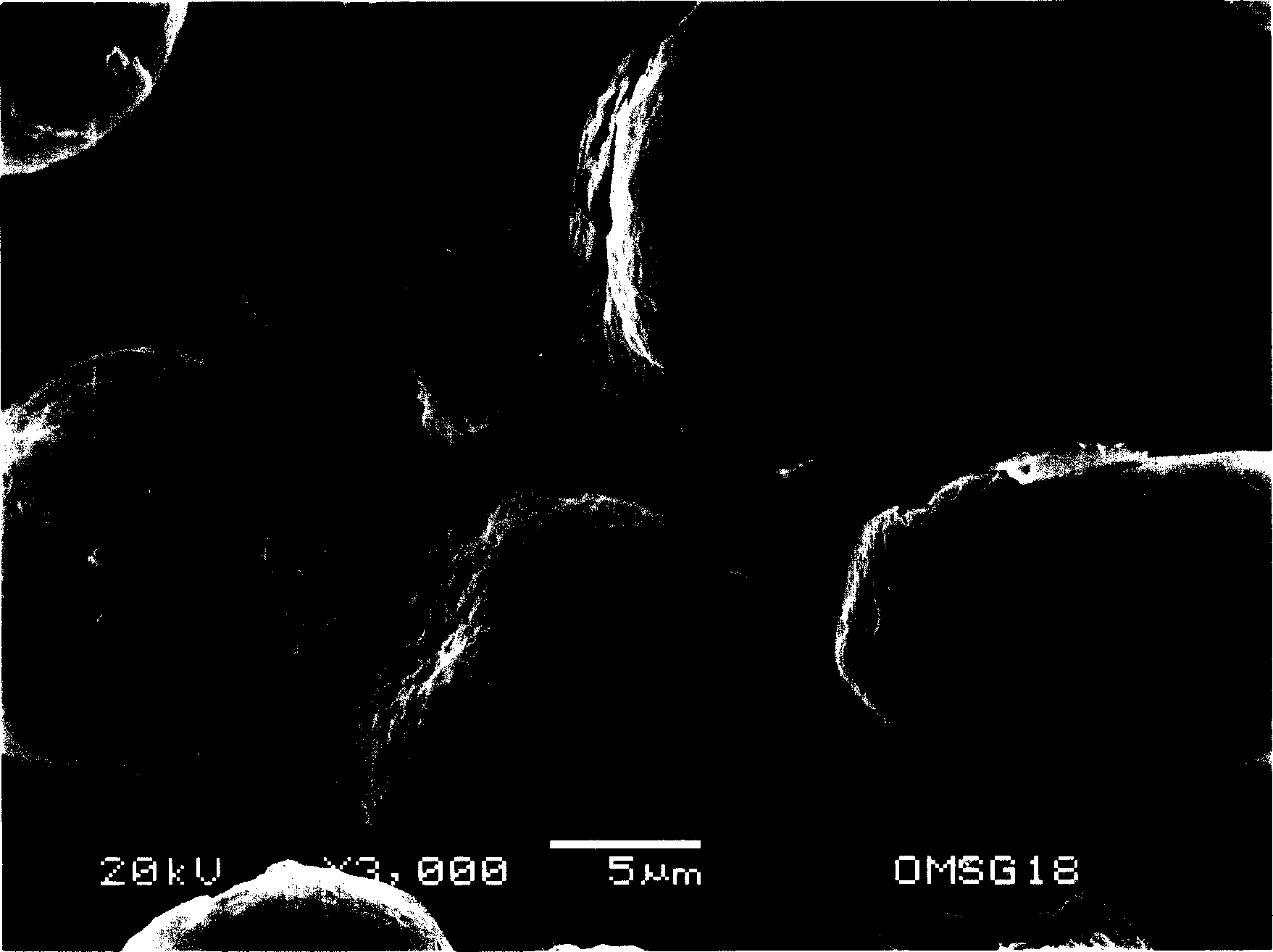

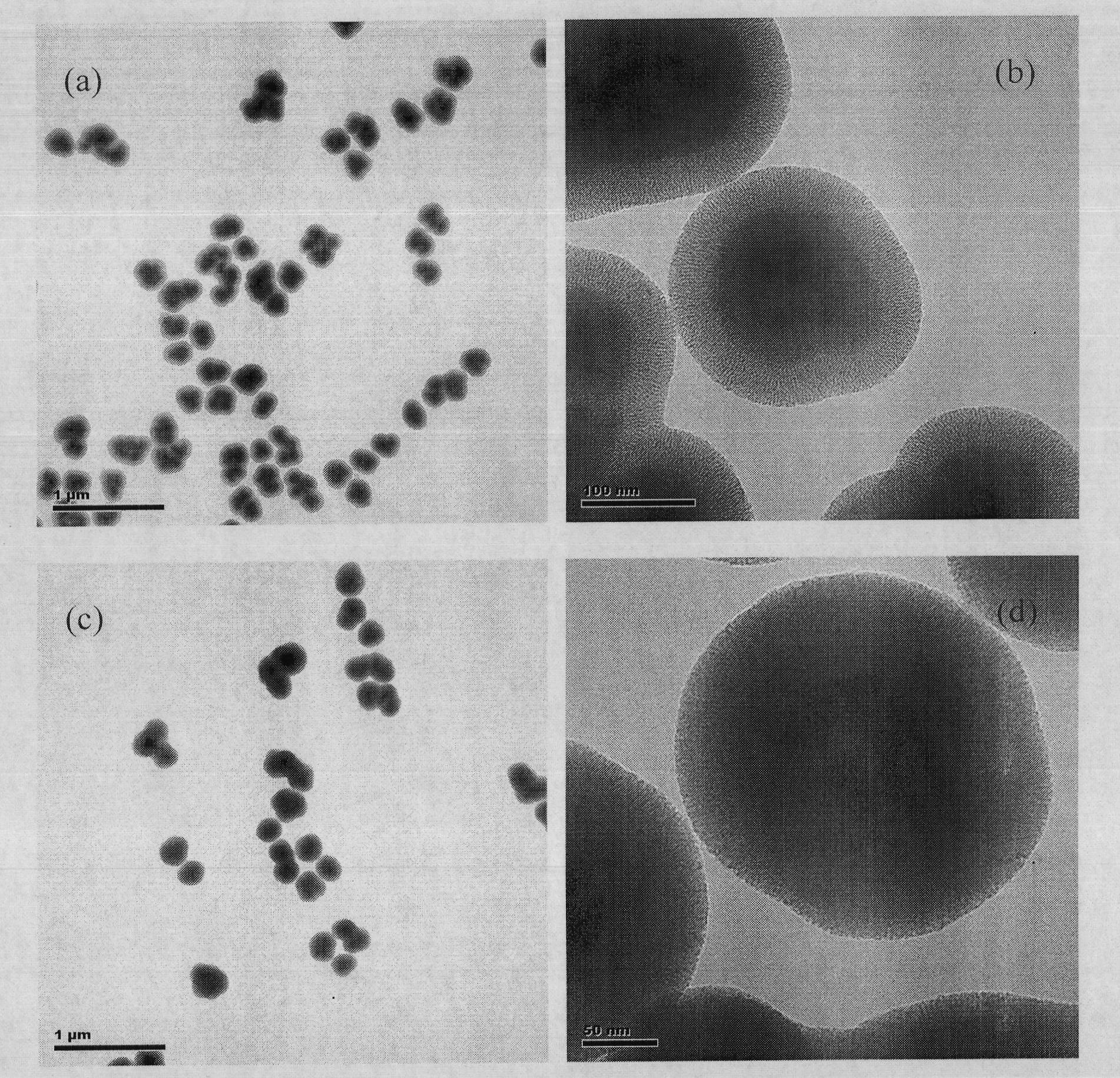

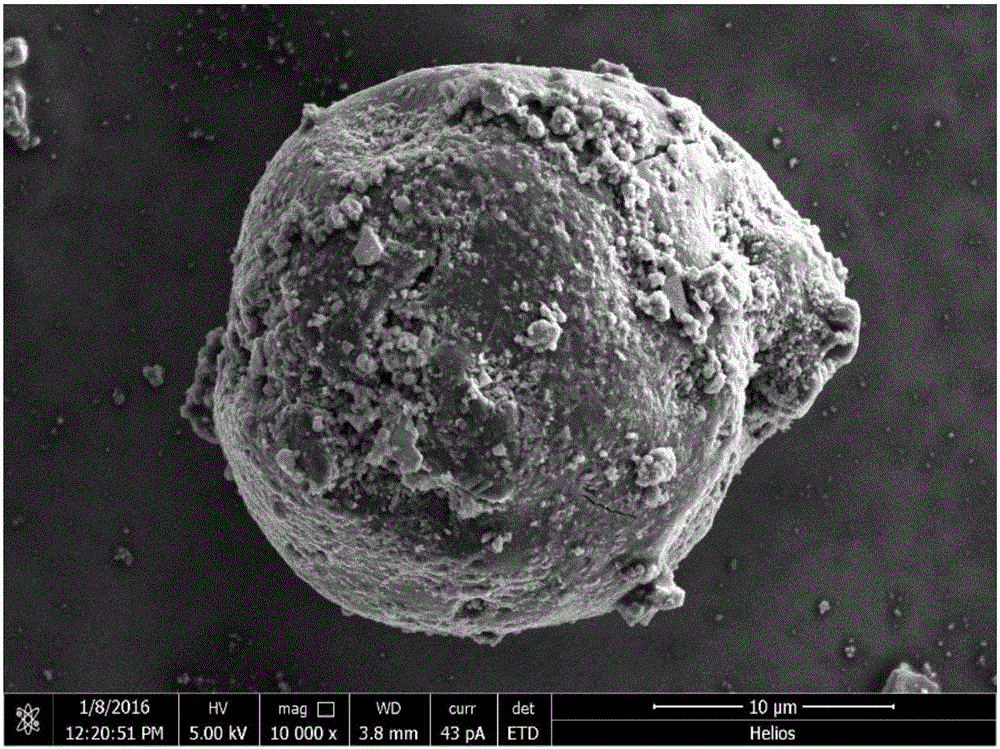

Preparation method of hypha/nanoparticle composite sphere material

InactiveCN104785216AHigh activityImprove stabilityOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationFreeze-drying

The invention discloses a preparation method of a hypha / nanoparticle composite sphere material. The preparation method is characterized by comprising steps as follows: preparing a culture medium; adding 4-20 ml of a nanoparticle aqueous solution containing 1-10 mg of nanoparticles per milliliter to the sterilized liquid culture medium, evenly mixing the mixture, inoculating the mixture with strains, culturing the mixture for 48-96 h under conditions that the temperature is 15-35 DEG C and rotating oscillation is performed at the speed of 80-200 r / min to form a hypha / nanoparticle composite sphere material, performing filtration to remove a liquid, soaking solids, namely, hypha / nanoparticle composite spheres, with a sodium hydroxide aqueous solution for 12 h, washing the spheres with deionized water until the spheres are neutral, and then performing freeze-drying to prepare the hypha / nanoparticle composite sphere material. The composite sphere material prepared with the method is applicable to fields of industrial catalysis, wastewater treatment, biomedicine and the like and has the characteristics of low cost, high activity, easiness in recovery and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

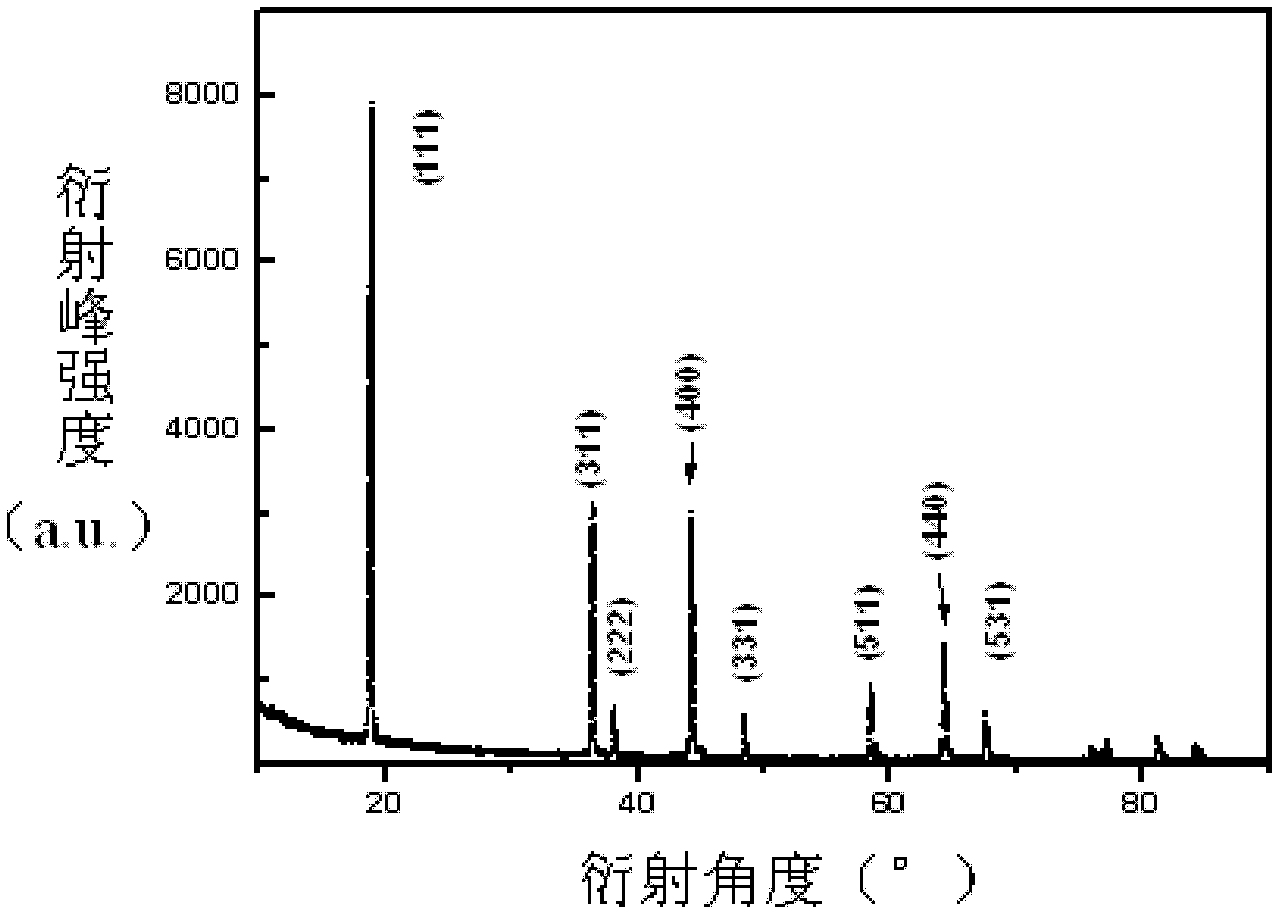

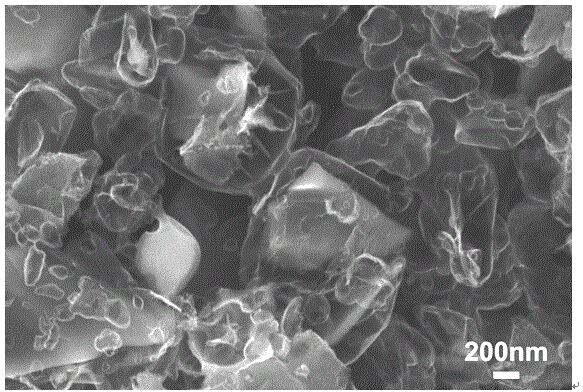

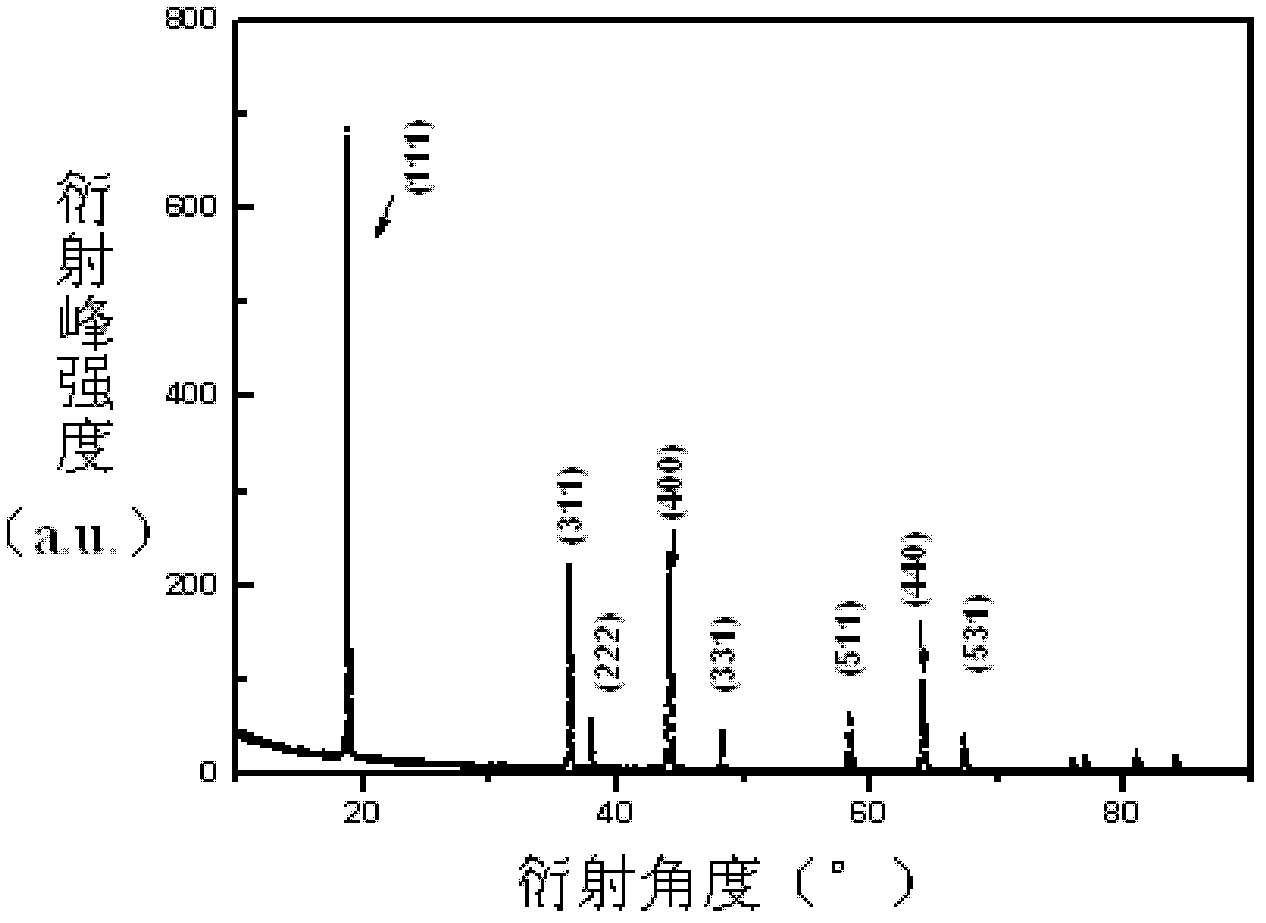

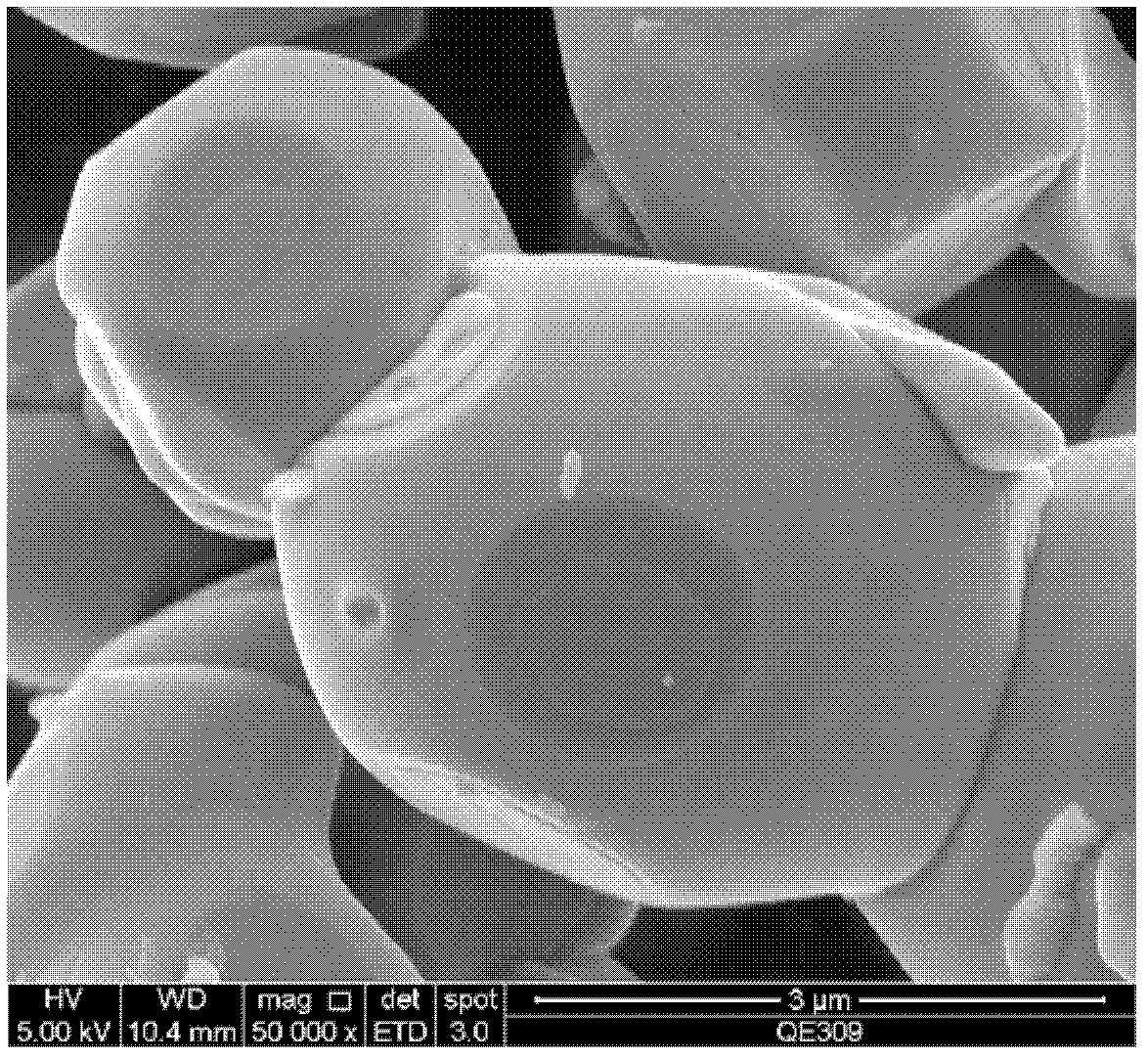

Cathode material of lithium ion battery, and preparation method thereof and lithium ion battery

ActiveCN102800840ANot easy to dissolveGood high temperature cycle performanceCell electrodesSecondary cellsTemperature cyclingLithium electrode

The invention provides a cathode material of a lithium ion battery. The cathode material is composed by the atomic ratio shown in formula (I): Lia(MxMn2-x)(O4-yZy), wherein a is greater than or equal to 0.8 and less than or equal to 1.2; x is greater than or equal to 0 and less than or equal to 1; y is greater than or equal to 0 and less than or equal to 1; M is one or more selected from Li, Na, K, Ca, Mg, Al, Ti, Sc, Ge, V, Cr, Zr, Co, Ni, Zn, Cu, La, Ce, Mn, Hf, Nb, Ta, Mo, W, Ru, Ag, Sn, Pb and Si; and Z is one or more selected from OH, halogens, N, P, S and O. Primary particles of the cathode material have sphere-like morphologies, wherein (111) face is connected with adjacent equivalent crystal face through a curved surface having no clear edges. The invention also provides a preparation method for the cathode material of the lithium ion battery and the lithium ion battery. The cathode material provided by the invention has good high-temperature cycling performance and good filling property.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

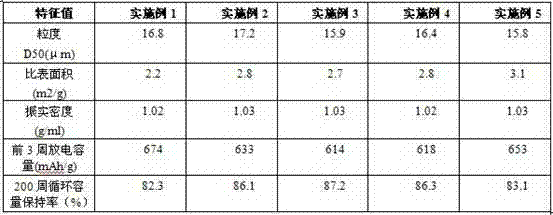

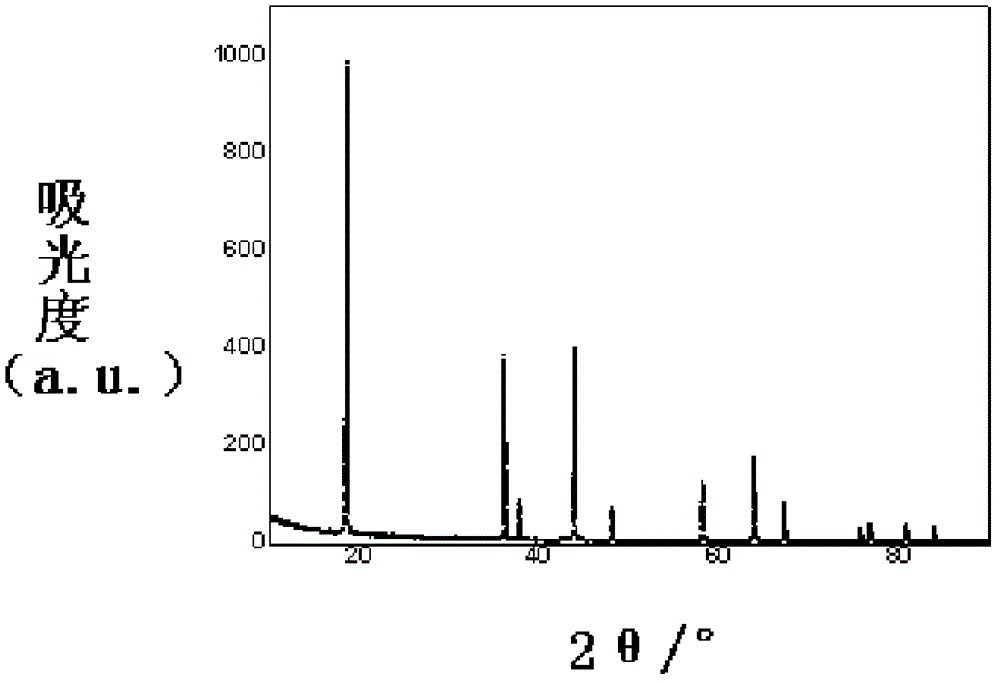

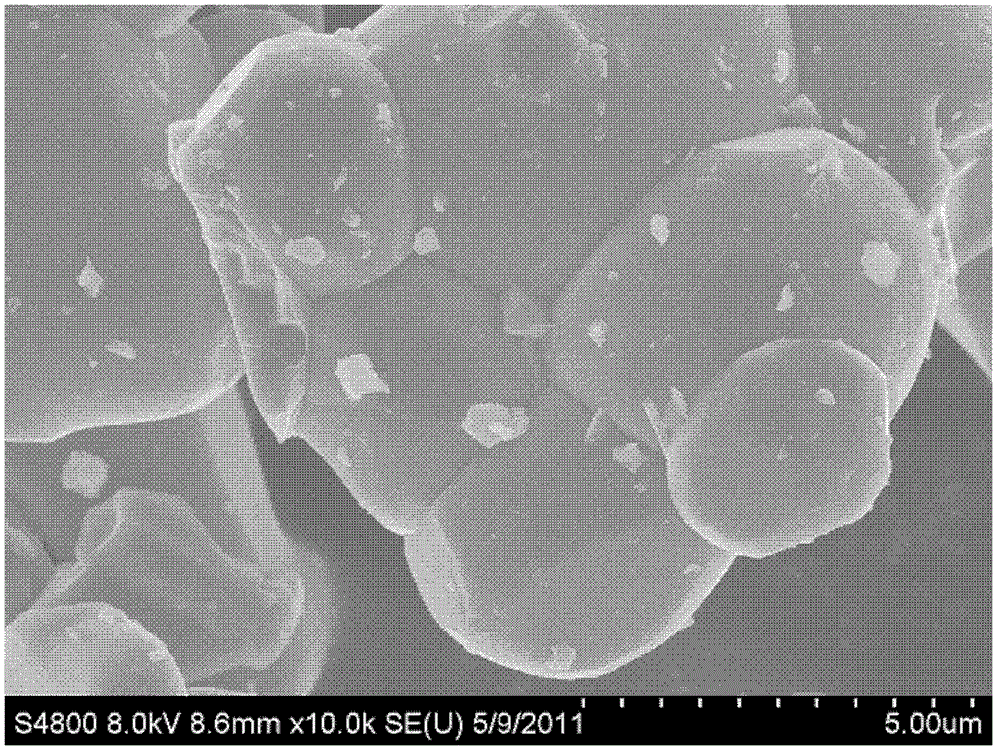

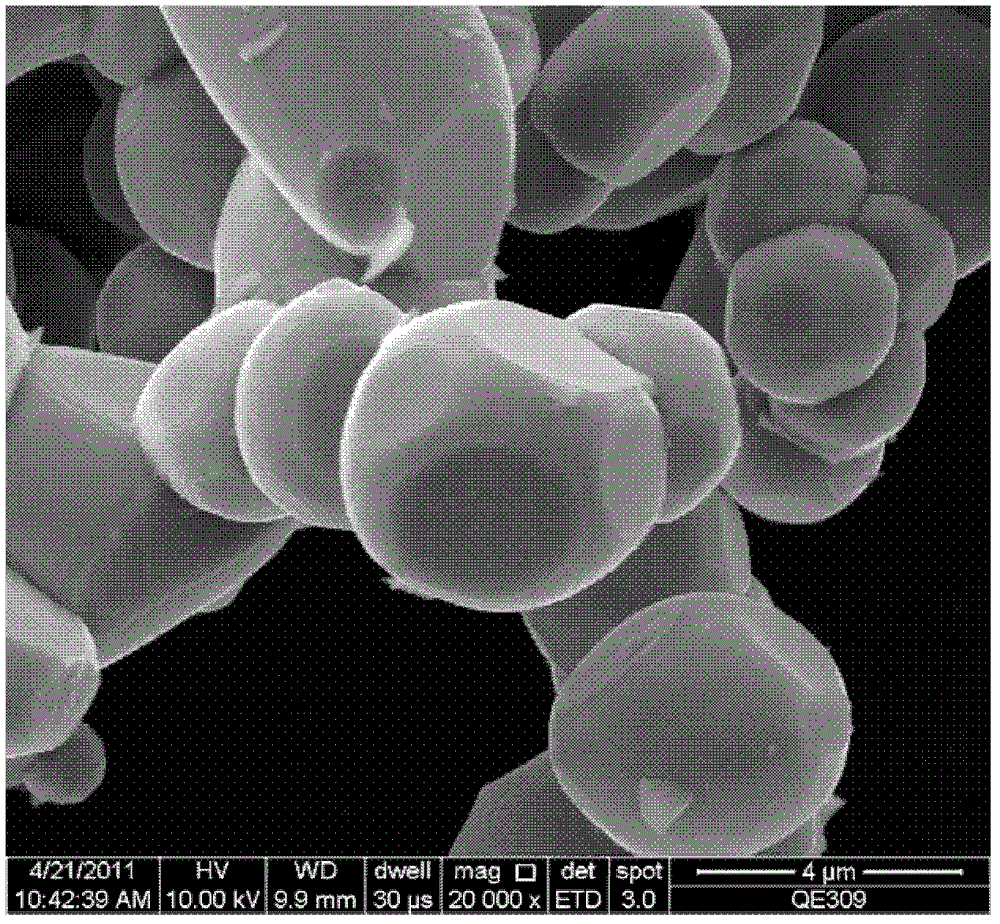

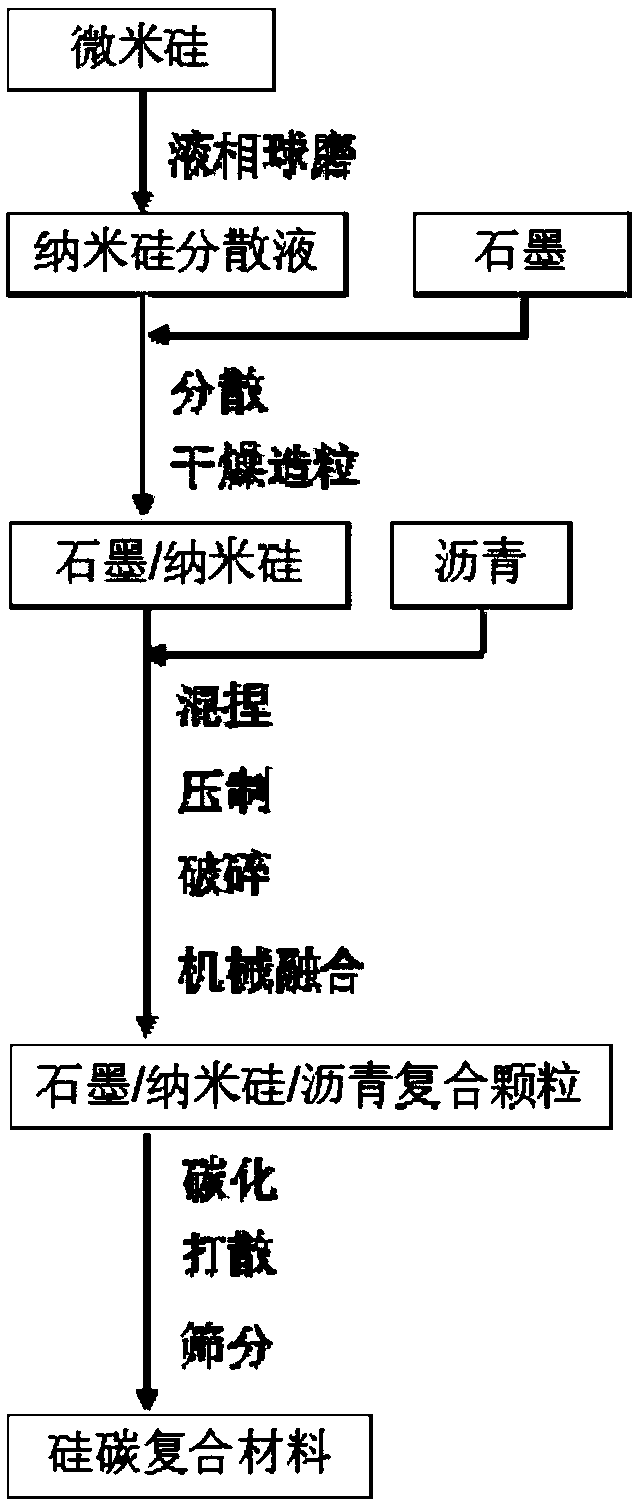

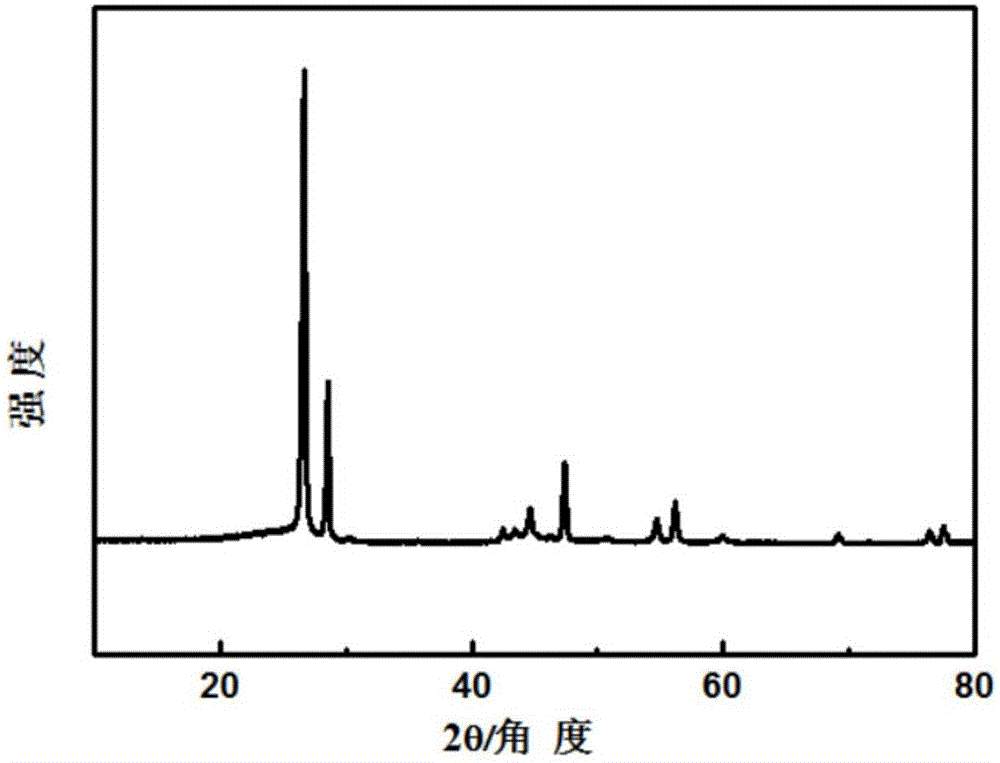

High-performance silicon-carbon cathode material and preparation method thereof

ActiveCN107785560ACover tightlyCoated evenlyNegative electrodesSecondary cellsNano siliconCarbonization

The invention relates to a high-performance silicon-carbon cathode material and a preparation method thereof. The preparation method comprises the following steps: (1) dispersing silicon into a solvent, carrying out liquid-phase ball-milling, so as to obtain nano-silicon dispersion liquid, adding graphite, and carrying out liquid-phase ball milling so as to uniformly mix nano-silicon with graphite; (2) carrying out granulation on slurry obtained the step (1), so as to obtain graphite / nano-silicon composite particles; (3) carrying out granulation on the product of the step (2) and asphalt by virtue of a mixed kneading-pressing-crushing method, so as to obtain graphite / nano-silicon / asphalt composite particles, and carrying out mechanical fusion so as to realize spheroidization and uniform coating of the graphite / nano-silicon / asphalt composite particles in one step; and (4) carrying out carbonization, scattering and sieving, so as to obtain the high-performance silicon-carbon cathode material. The preparation method is simple and low in cost and can be used for easily producing the high-performance silicon-carbon cathode material in large scale.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Graphene modified silicon monoxide and carbon composite microsphere, and preparation method and application thereof

ActiveCN106410158AAlleviate volume expansionActive connectionCell electrodesBatteriesCarbon compositesSilicon monoxide

The invention provides a graphene modified silicon monoxide and carbon composite microsphere prepared from graphene, asphalt and silicon monoxide, and a preparation method and an application thereof. Asphalt and silicon monoxide bulk are adopted as raw materials, so the cost is low; a high temperature and high pressure reaction is adopted to obtain a silicon monoxide and carbon composite material in a liquid phase, so the technology is simple; and a dispersant can be recycled, so no waste liquid is generated, and no toxic substances are discharged. The above obtained material has a small specific surface area, and is in favor of forming a stable SEI film; a graphene two-dimensional material has an obvious modification effect, effectively connects active substances, and alleviates volume expansion of an electrode, and good dispersion and reasonable cavity of silicon monoxide make the material have excellent cycle performances.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

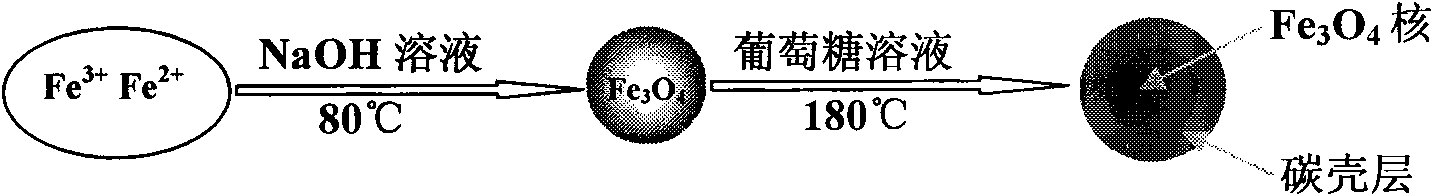

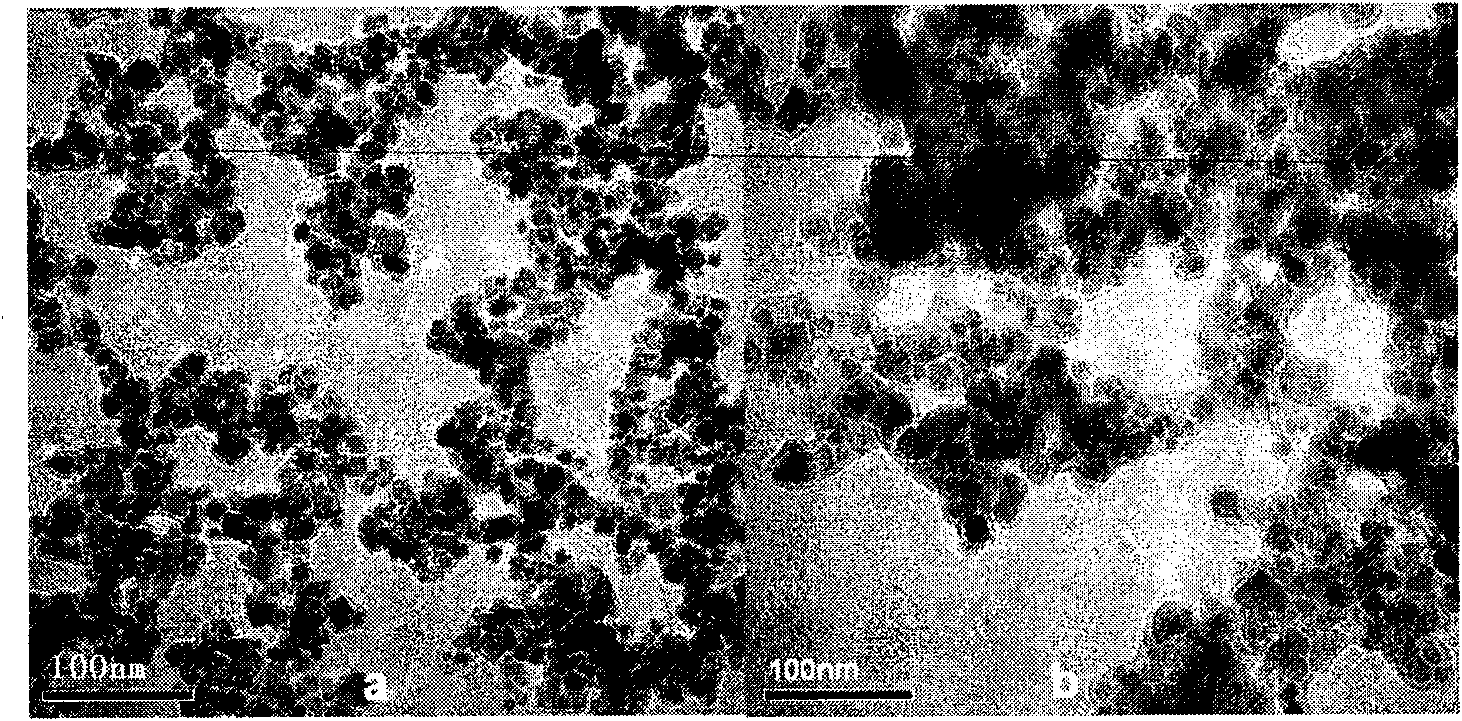

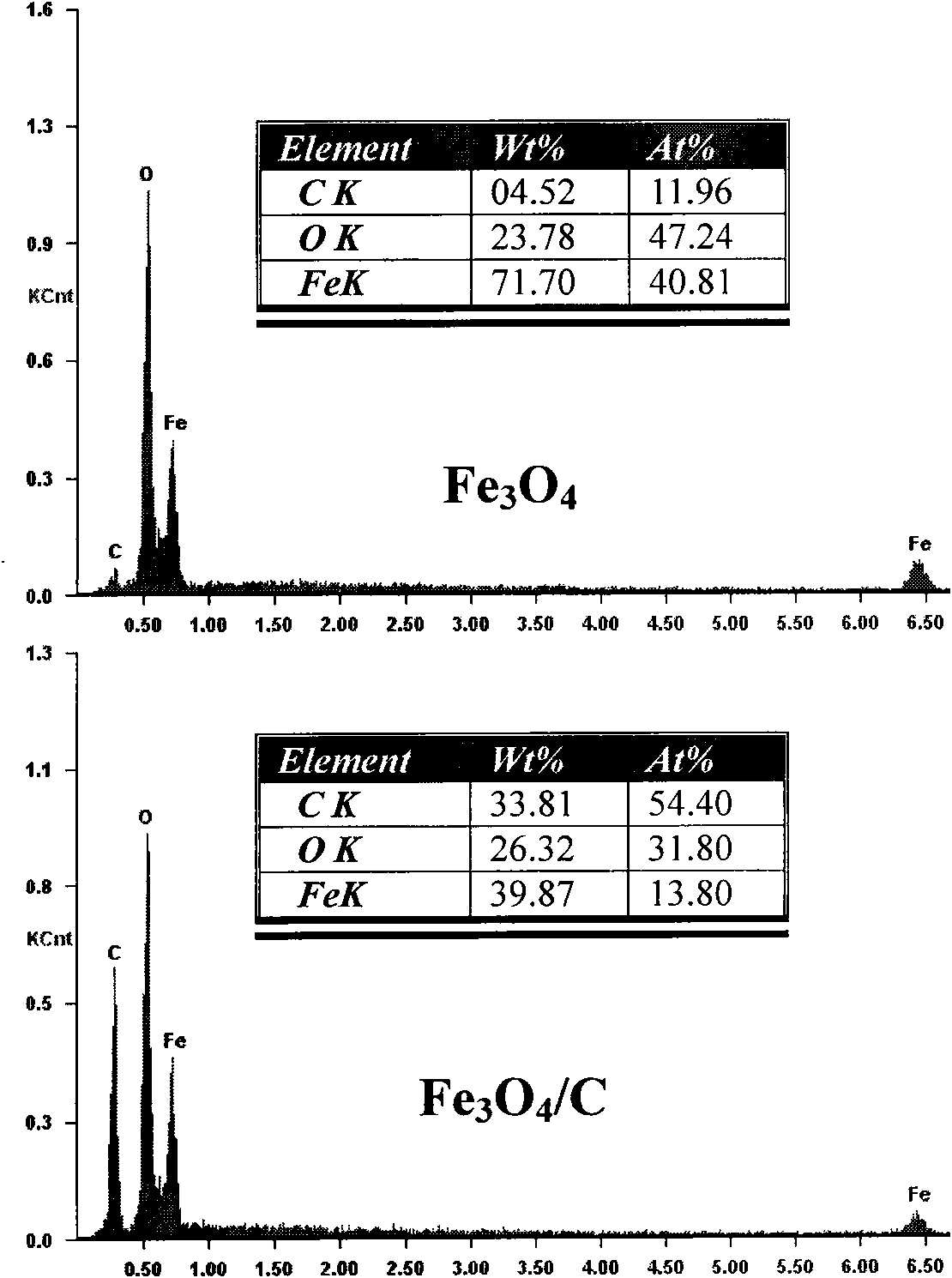

Preparation method and application of core-shell type Fe3O4/C magnetic nano solid extracting agent

InactiveCN101664668AStrong extraction abilityFast processingOther chemical processesInorganic material magnetismSolid phase extractionSorbent

The invention relates to a Fe3O4 / C magnetic nano solid extracting agent coated with a novel carbon material, belonging to the field of chemical analysis and test instruments and equipment. The extracting agent simultaneously has large special surface area of nano material, short disperse path, magnetic separation capacity of magnetic material and strong adsorption capacity of carbon material, thereby being very suitable for pretreating large-scale and large-size water samples in batch. In addition, the solid extracting agent is simple to prepare, low in raw material cost, rapid and convenientto extract and friendly to the environment and only needs using a small amount of organic solvent in the whole process.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

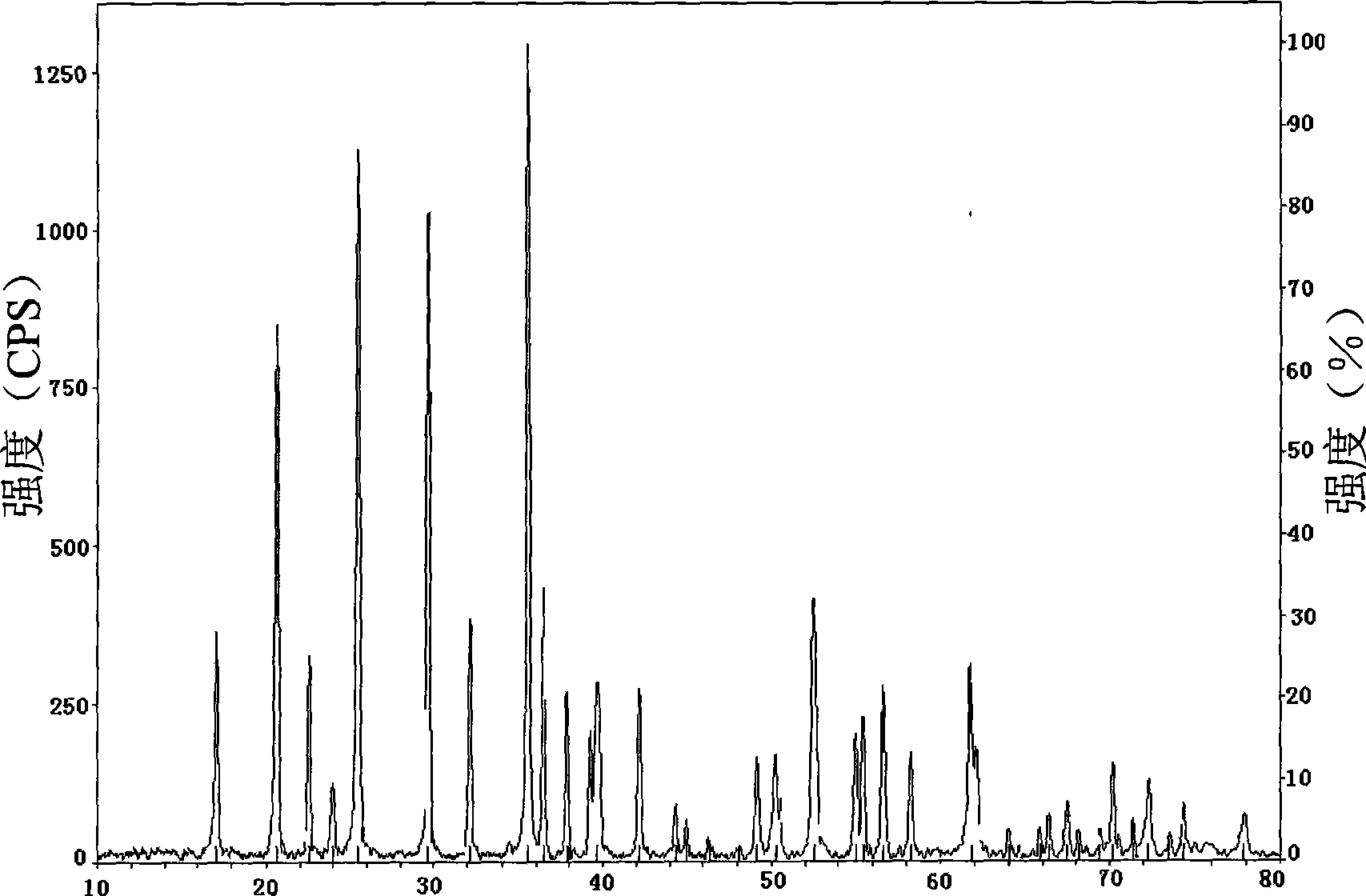

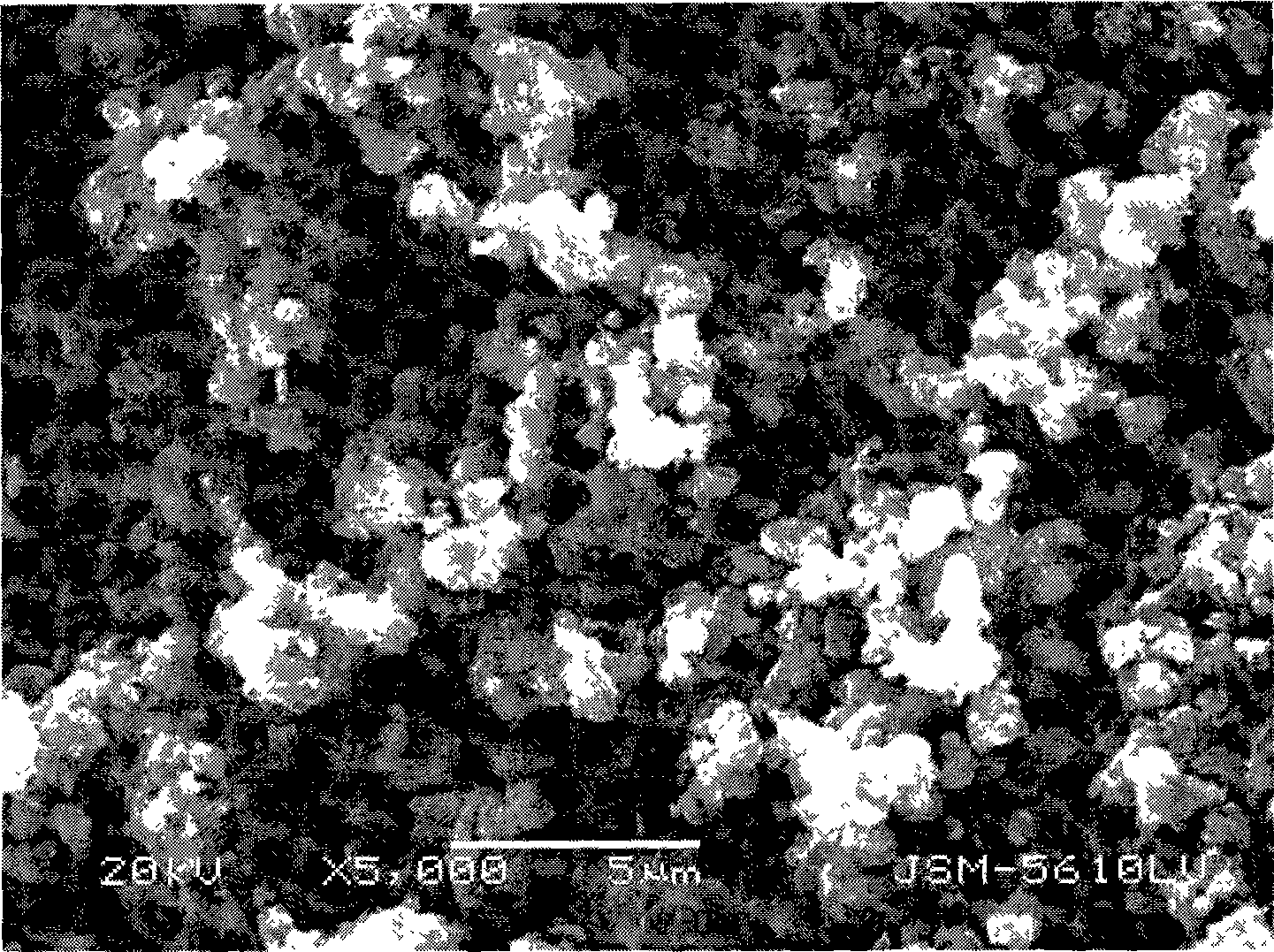

Preparing method of anode active material lithium iron phosphate for lithium ionic secondary cell

ActiveCN101399343AEasy to crushImprove high current charge and discharge performanceElectrode manufacturing processesSecondary cellsLithium iron phosphateBall mill

The invention provides a preparation method of lithium iron phosphate of a lithium-ion secondary battery positive electrode active material, the method comprises: a ferrous source compound, a phosphorus source compound, a lithium source compound and a carbon source compound are mixed, the first sintering is carried out on the obtained mixture under the protection atmosphere, products in the first sintering are ball-milled and dried, the second sintering is further carried out to obtain the lithium iron phosphate, wherein, the method further comprises the heating of the mixture at the temperature of 60-250 DEG C under the oxidation atmosphere before the first sintering or after the first sintering. The lithium iron phosphate which is obtained by adopting the method can have both high volume specific capacity and excellent high-current discharge performance.

Owner:TAICANG RONGCHI MOTOR

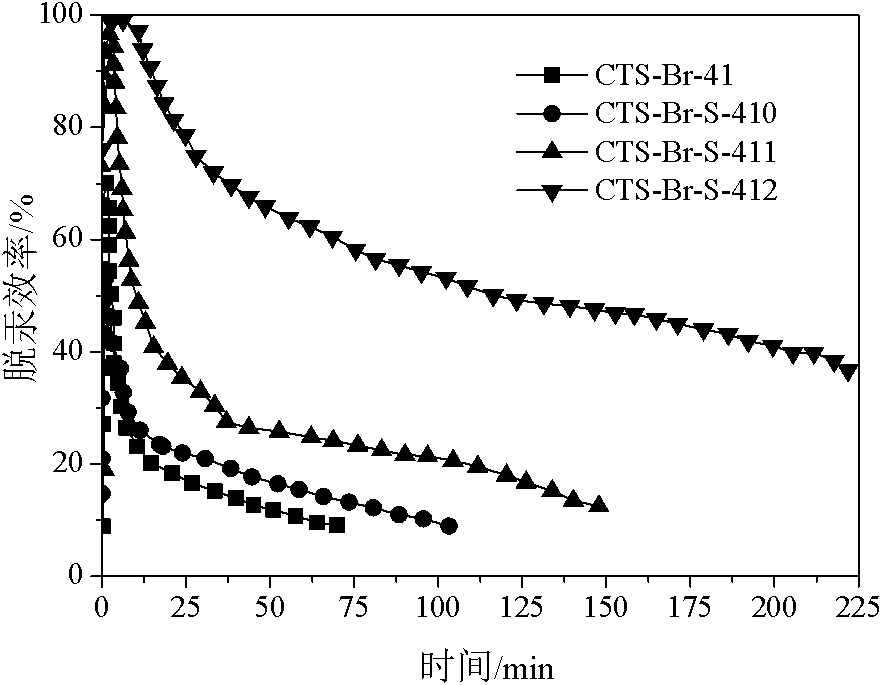

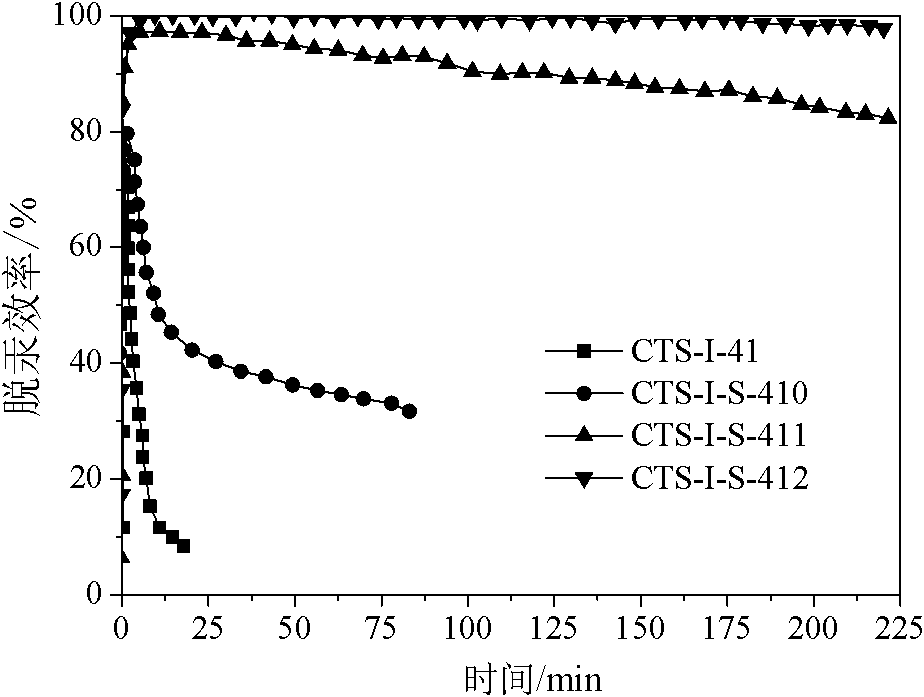

Chemically modified chitosan mercury-removing adsorbent and preparation process thereof

InactiveCN101816922AEasy to buyEasy to manufactureOther chemical processesDispersed particle separationHalogenSorbent

The invention discloses an adsorbent used for removing mercury (Hg0) in coal smoke and a preparation process thereof. The adsorbent comprises chitosan and halogen elements of bromine and iodine; as improvement, sulfuric acid is added, wherein the mass ratio of the chitosan to an iodine (bromine) compound to the sulfuric acid is (1-15):1:(0.5-5). The adsorbent is prepared by utilizing the reaction of the kali salt of the halogen elements of bromine and iodine and the sulfuric acid and better characteristics of the chitosan to the active iodine and the bromine under an acidy condition. The adsorbent has high Hg0 removal efficiency, lower cost, industrialized application and no secondary pollution of products.

Owner:HUAZHONG UNIV OF SCI & TECH

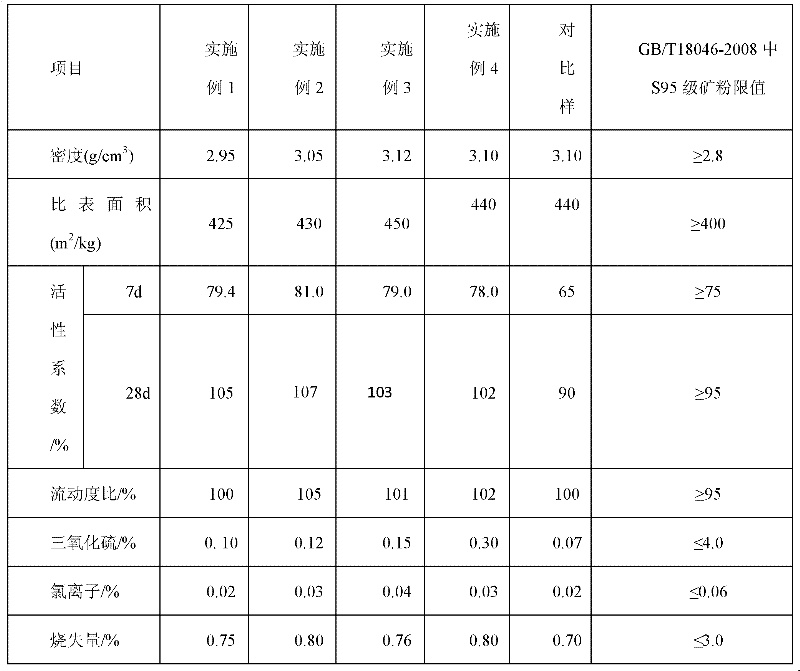

Modified steel slag composite admixture and preparation method thereof

InactiveCN102491664AOvercoming stability issuesImprove early activitySolid waste managementWork performanceSlag

The invention discloses a modified steel slag composite admixture and a preparation method thereof. The modified steel slag composite admixture comprises 55-75wt% of micro mineral slag powder, 20-40wt% of micro steel slag powder, and 1-5wt% of sintering desulphurization slag. Concrete prepared by mixing the modified steel slag composite admixture of the invention with cement has the following characteristics: the seven day active index is greater than 75%, the twenty-eight day active index is greater than 100%, the specific surface area is equal to or greater than 400m<2> / kg, the sulfur trioxide content is equal to or less than 4.0%, the chloride ion content is equal to or less than 0.06%, the ignition loss amount is equal to or less than 3.0%, and the autoclaving stability is qualified. The modified steel slag composite admixture which allows a low early strength disadvantage of steel slag composite admixtures to be overcome, working performances of concrete to be effectively improved, the strength and the endurance of concrete to be improved, and energy consumption required by slag grinding to be effectively reduced and is in favor of the low carbon economy realization, is a resource use type concrete admixture.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

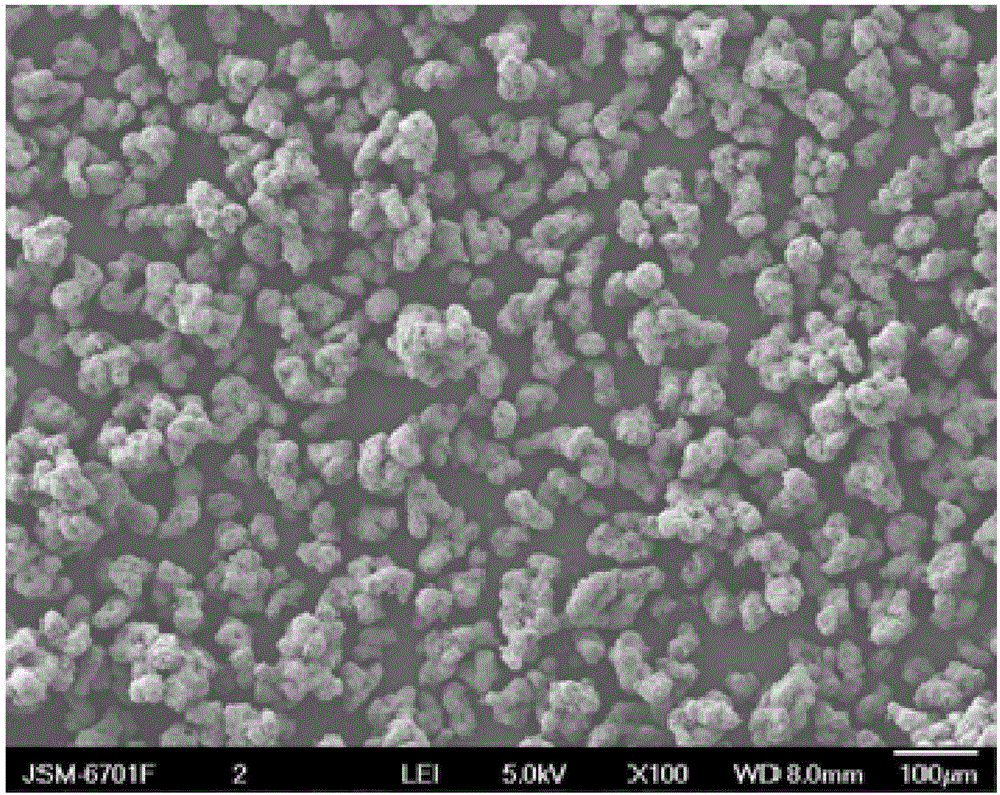

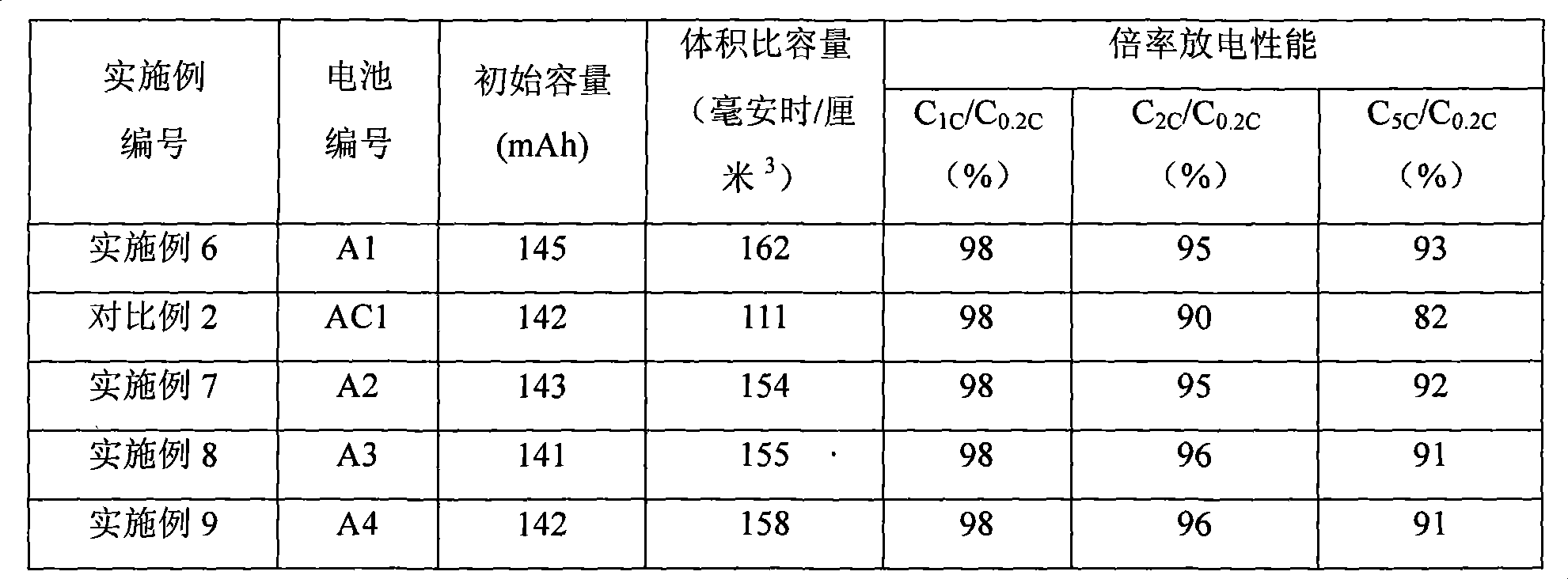

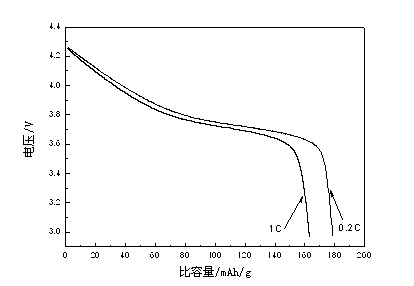

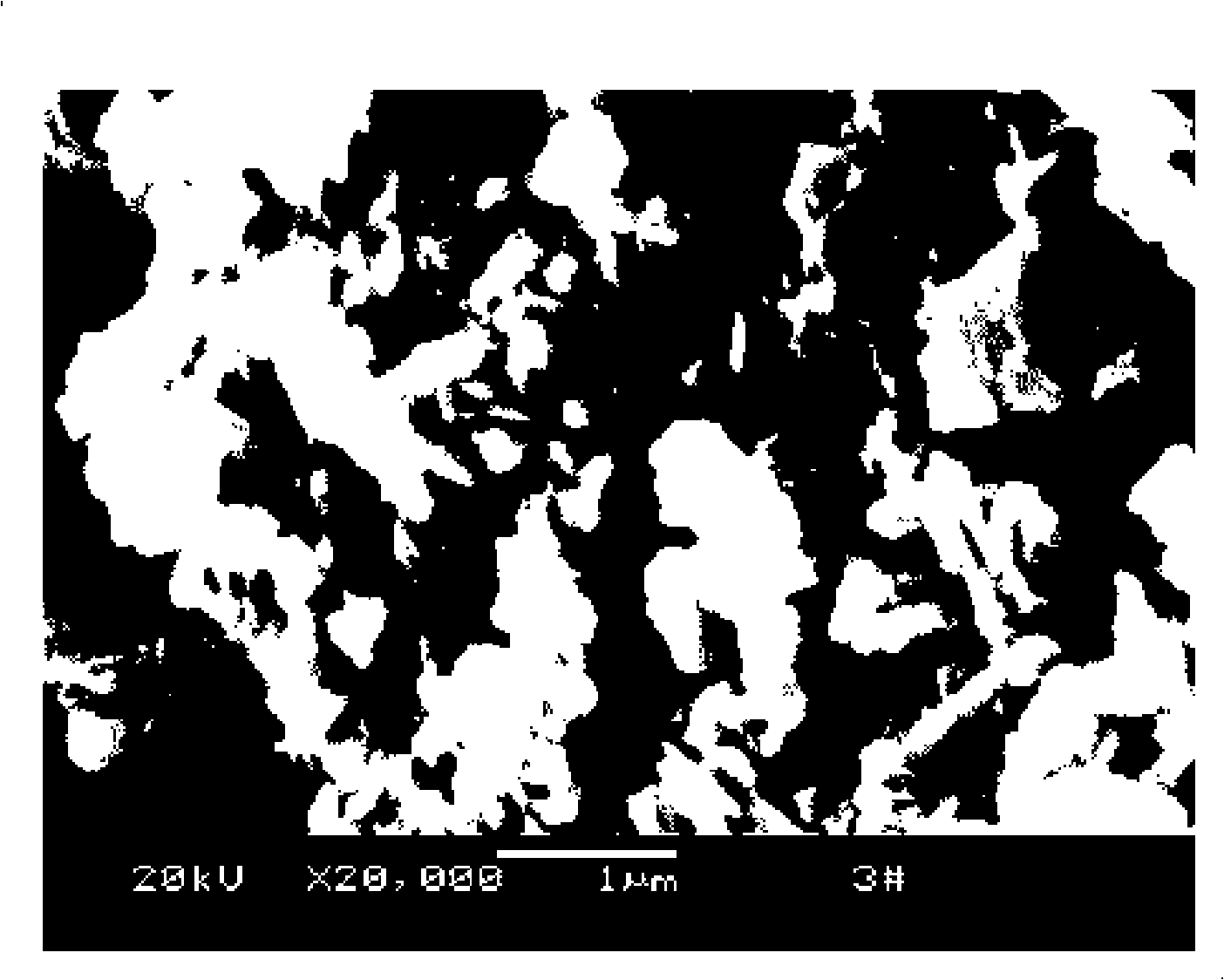

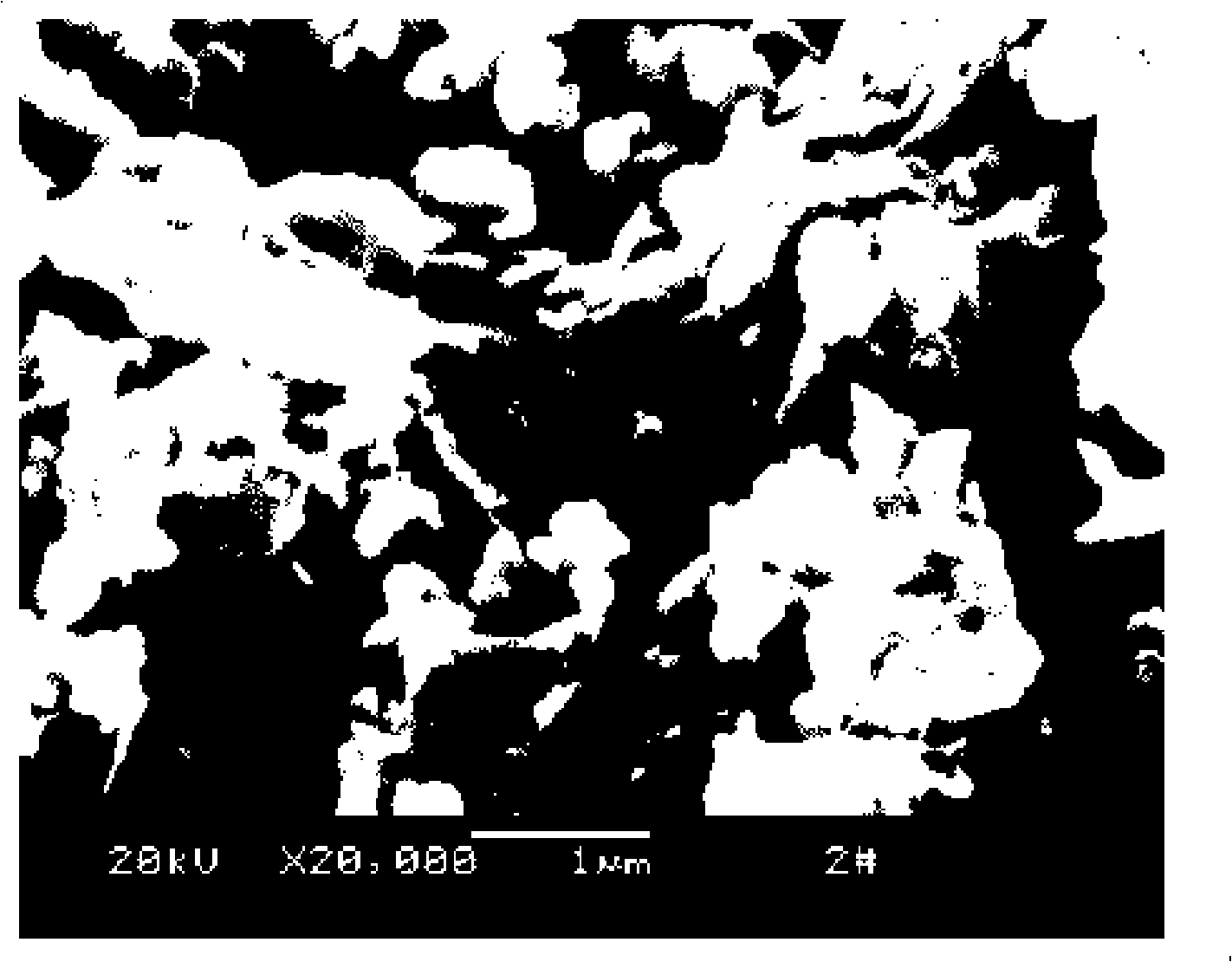

Nickel cobalt lithium manganate composite cathode material and preparation method of nickel cobalt lithium manganate composite cathode material

The invention relates to a nickel cobalt lithium manganate composite cathode material and a preparation method of the nickel cobalt lithium manganate composite cathode material. The nickel cobalt lithium manganate composite cathode material has the chemical formula of Li(NixCoyMn<1-x-y>)O2. The preparation method comprises the steps that after soluble nickel salts, cobalt salts, manganese salts and complexing agents are uniformly mixed, sodium hydroxide precipitating agents are added, the reaction is carried out in a stirring reactor with an ultrasonic device, composite hydroxides of nickel cobalt manganate are obtained, then, the composite hydroxides, water soluble macromolecular compounds and lithium source compounds are placed in the stirring reactor with the ultrasonic device, the spray drying is carried out in the ultrasonic reinforced stirring mixing process, and nickel cobalt lithium manganate precursors are obtained, the precursors are subjected to primary sintering under the certain atmosphere protection, and nickel cobalt lithium manganate products are obtained. When the nickel cobalt lithium manganate composite cathode material and the preparation method are adopted, the prepared product particles are uniform, the morphology is regular, the specific surface area is small, the tap density is high, the electrochemical performance is excellent, the processing performance is good, the cost is low, the environment-friendly effect is realized, and the environment pollution is avoided.

Owner:CENT SOUTH UNIV

Composite cathode material for lithium ion cell and preparing method thereof

ActiveCN101286560AEvenly dispersedWell mixedElectrode manufacturing processesChemical/physical/physico-chemical processesComposite cathodeGraphite

The invention relates to a lithium ion battery composite cathode material and a preparation method thereof, which belongs to the technical field of lithium ion battery. The invention aims at improving the cycle performance of silicon cathode material at the same time when keeping the high ratio volume of lithium ion battery silicon cathode material. The proposal of the invention is that silica-based material coated by disordered carbon is treated with surface modification processing by utilizing lithium salt, namely, the lithium salt is coated on the surface of Si / G / DC (silicon / graphite / disordered carbon) to be prepared into the composite cathode material, therefore, the lithium-embedding and removing depth of the silicon can be effectively controlled, and the material is the lithium ion battery composite cathode material which has high specific capacity and good cyclical stability; furthermore, the material is safe and pollution-free, and presents higher thermal stability in various lithium salt electrolytes and solvents.

Owner:CHENGDU ZHONGKE LAIFANG POWER SCI & TECH CO LTD

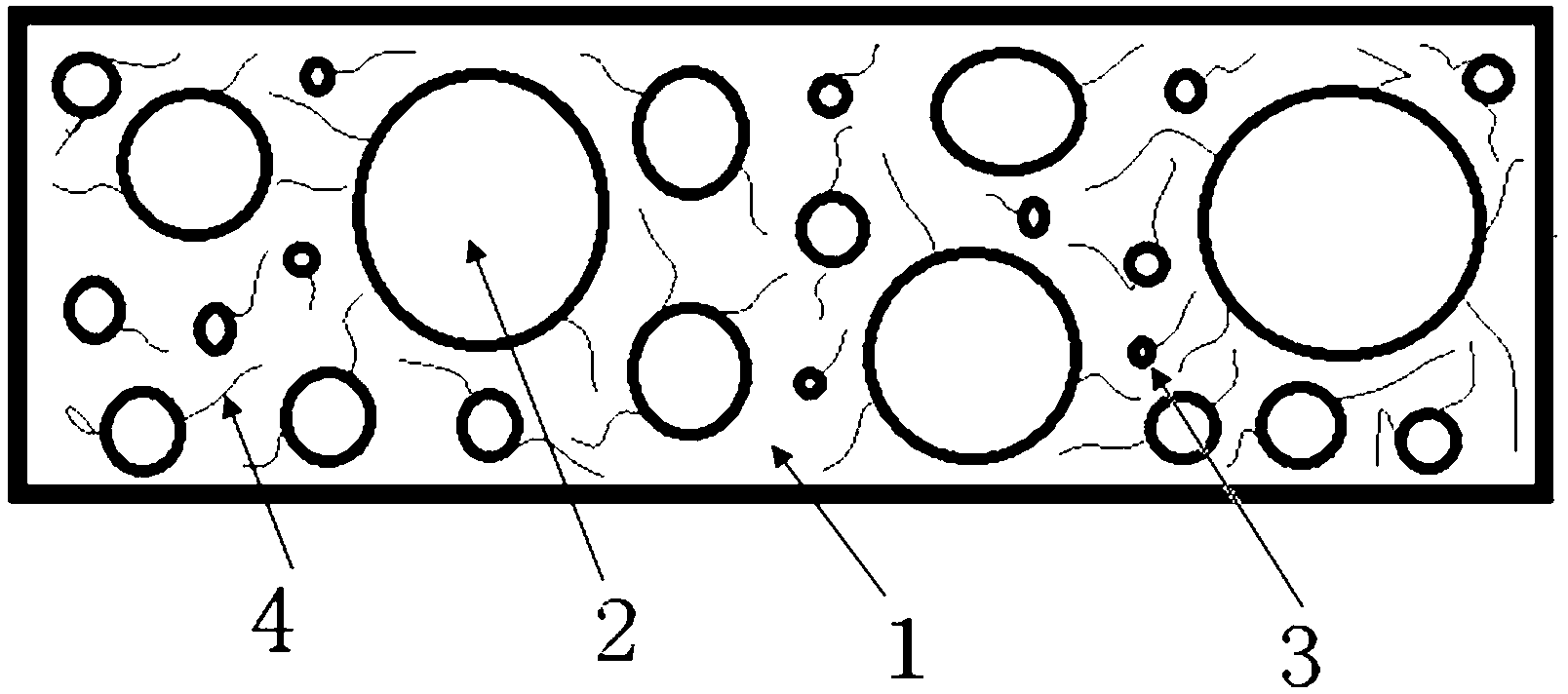

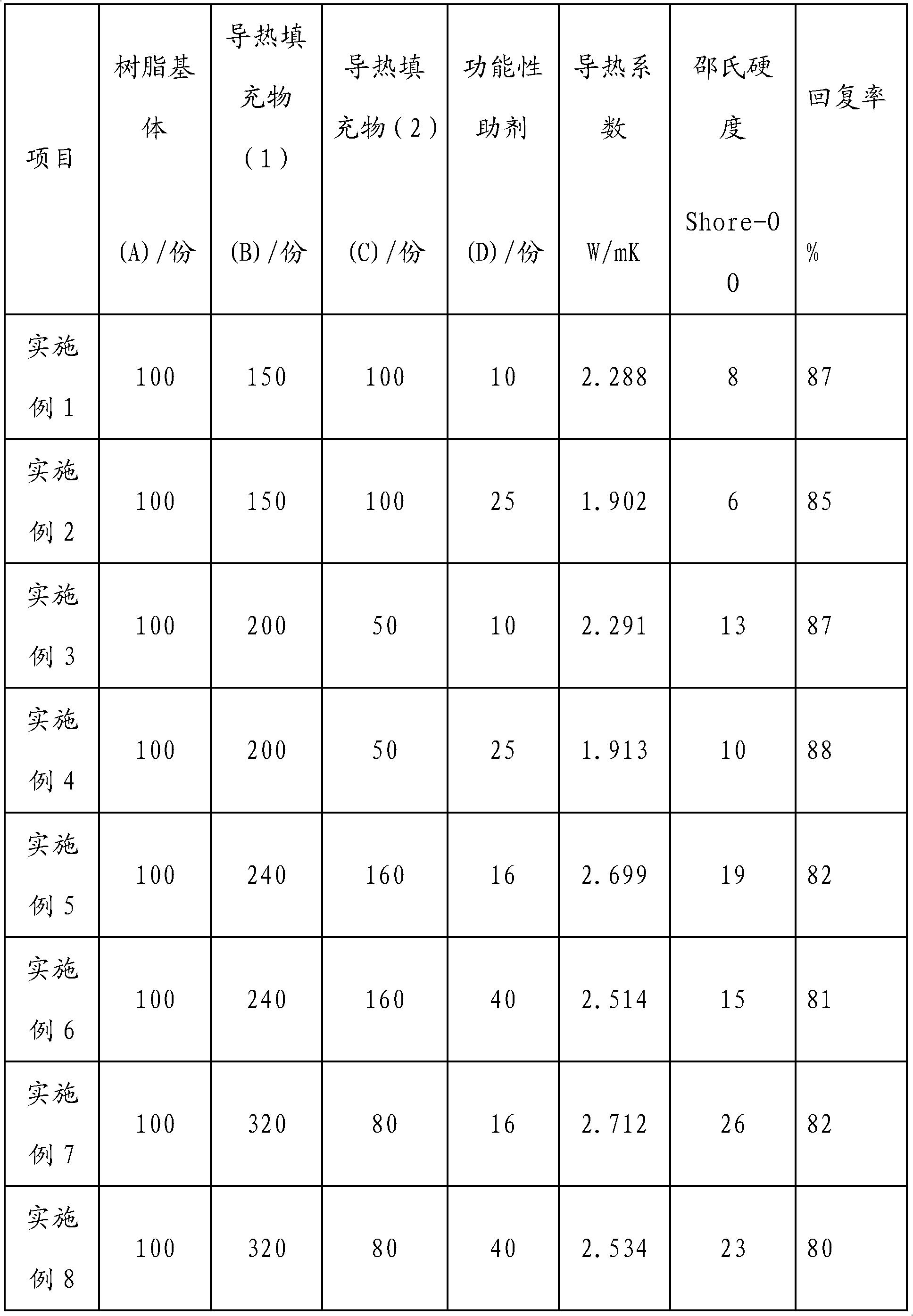

Heat-conductive gap interface material and preparation method thereof

The invention relates to a heat-conductive gap interface material and a preparation method thereof. The heat-conductive gap interface material comprises 100 parts by weight of a resin matrix and 250-400 parts by weight of heat-conductive fillers, and also comprises an assistant; and the preparation method comprises the following steps: adding the assistant and the resin matrix into a stirrer, and carrying out first stirring to obtain a mixture; and adding a heat-conductive filler (2), carrying out second stirring, adding a heat-conductive filler (1), carrying out third stirring, and curing to obtain the heat-conductive gap interface material. The heat-conductive gap interface material has a small hardness, can avoid damages caused in the assembling process of microelectronic components, and can also fully fill the gaps of the microelectronic components.

Owner:SHENZHEN DARBOND INTERFACE MATERIALS

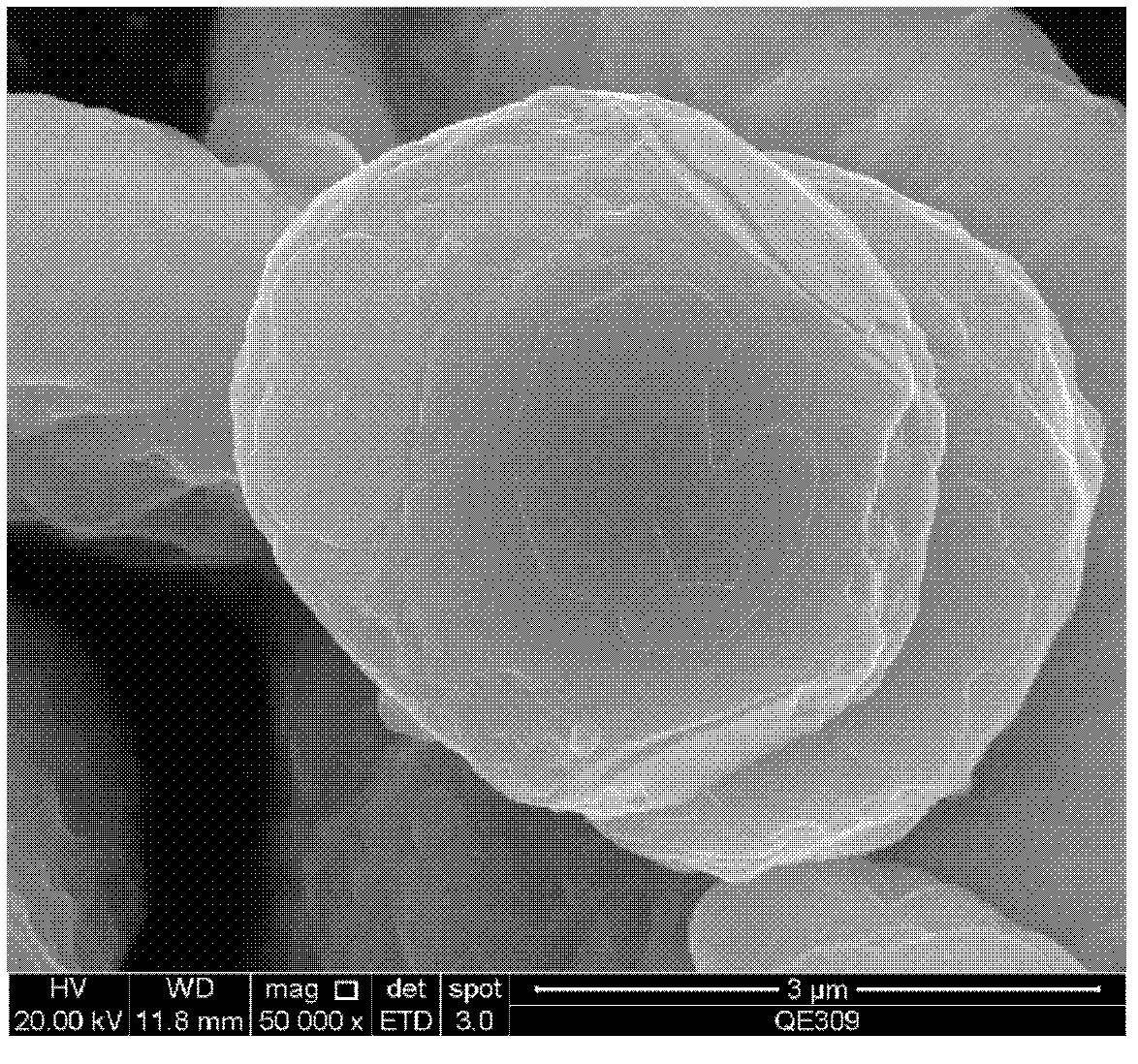

Cathode material of lithium ion battery and preparation method of cathode material

ActiveCN102683669ASmall specific surface areaGood high temperature cycle performanceCell electrodesManganesePhysical chemistry

The invention discloses a cathode material of a lithium ion battery. The cathode material has an atomic ratio of LiaMxMn(2-x)O(4-y)Zy. Primary particles of the cathode material of the lithium ion battery are substantially spherical, and the surface of each primary particle consists of 2 to 120 multilayer crystal dislocation frustums. The invention provides a preparation method of the cathode material of the lithium ion battery. The cathode material of the lithium ion battery is prepared by annealing, cooling and grinding a lithium manganate precursor in a roasting treatment mode of repeatedly changing roasting temperature. The invention has the advantages that by repeatedly changing the roasting temperature in the roasting process, the prepared cathode material of the lithium ion battery has a dislocation structure, and the mobility of ions and electrons from the inner part of the material to the outer part of the material is improved, and the magnification performance of a lithium manganate material is improved. Because the cathode material is substantially spherical, the specific surface area of the lithium manganate material is reduced, and manganese is difficult to dissolve, so the cathode material of the lithium ion battery is high in high-temperature cycle performance.

Owner:宁波富理电池材料科技有限公司

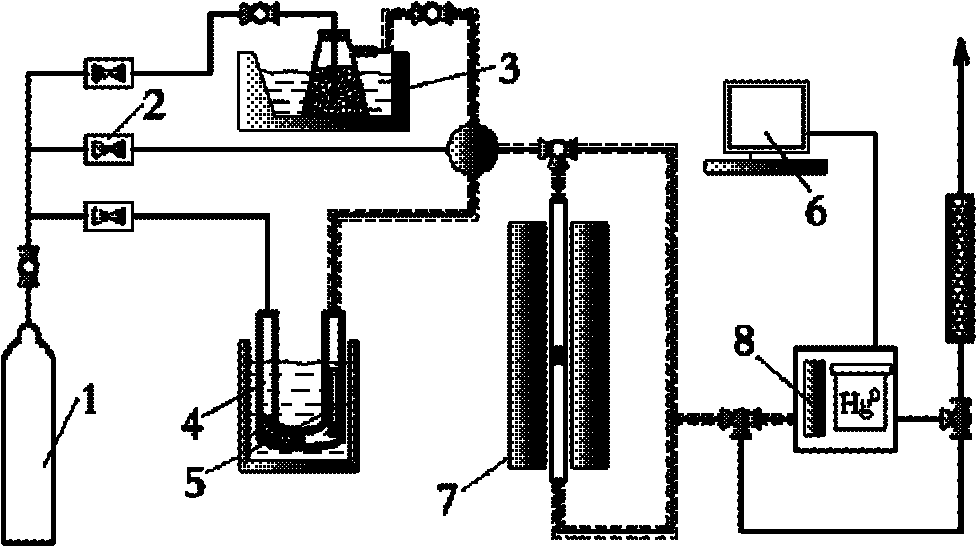

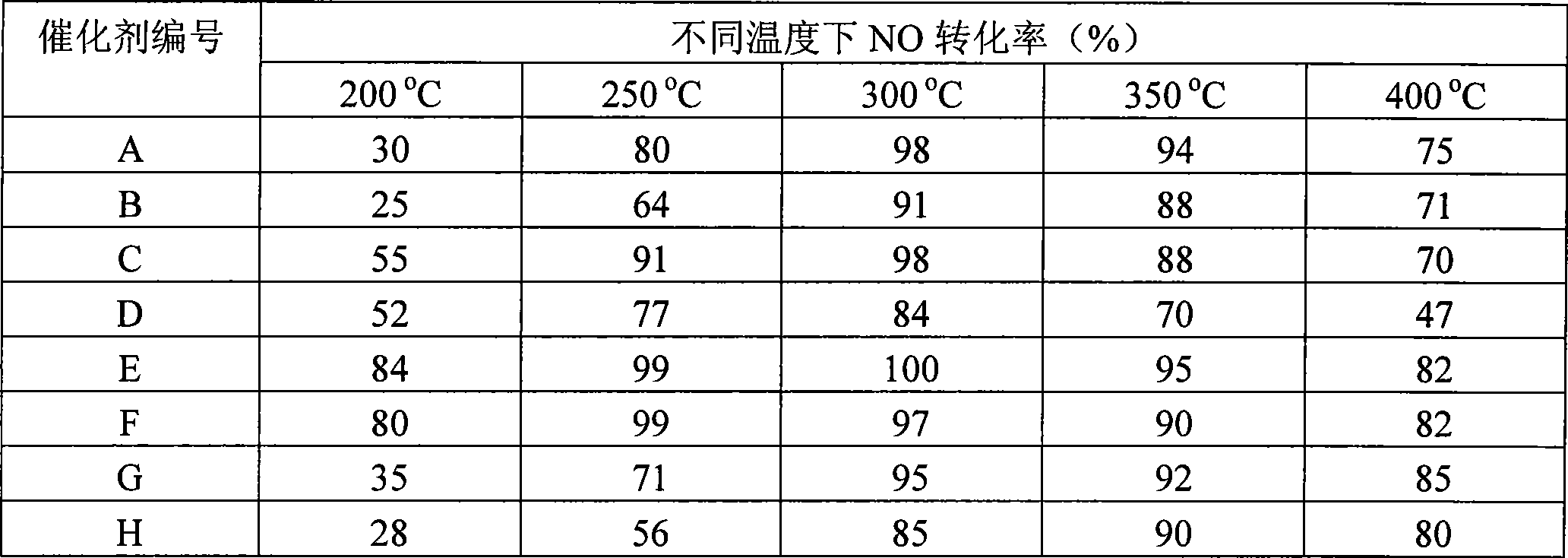

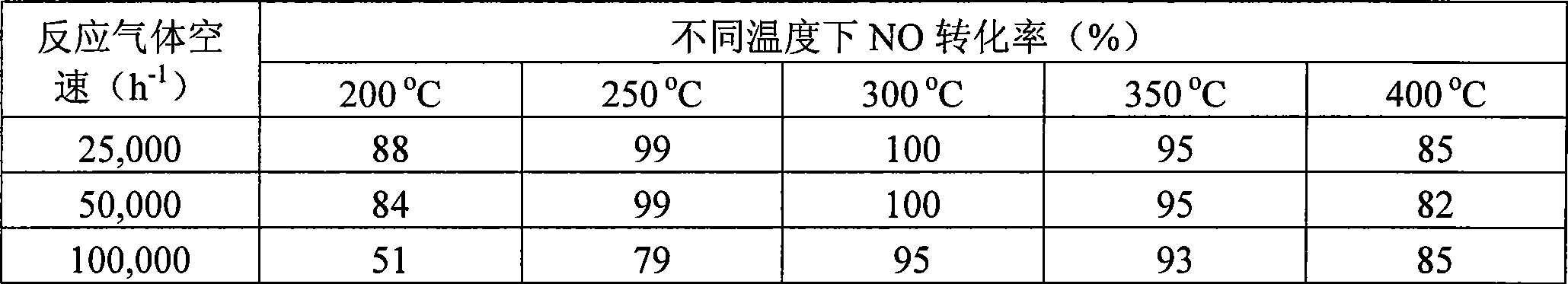

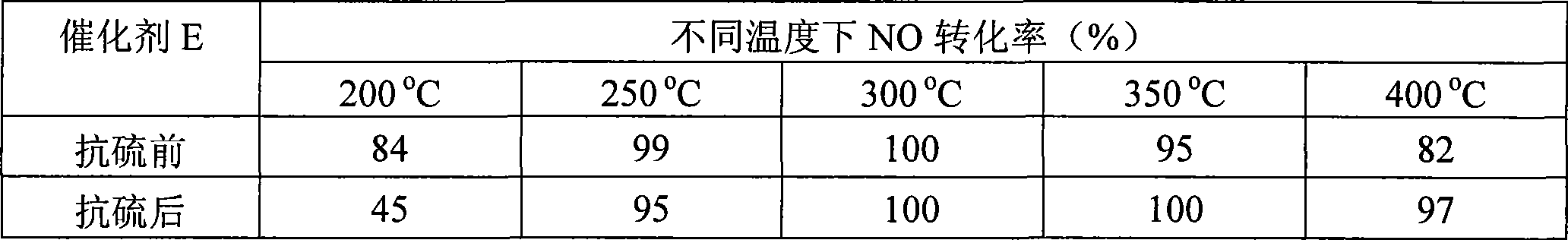

Ferrotitanium composite oxides catalyst for ammonia selective reduction nitric oxides

ActiveCN101380578ALow priceSimple preparation processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitric oxideHigh activity

The invention relates to a catalyst of selective reduction of nitrogen oxide by ammonia, which mainly solves the existing problems that the commonly used NH3-SCR catalyst system is toxic to environment and human body, the anti-SO2 poisoning ability of the catalyst system is poor in the reference and the catalyst system can not adapt to the conditions of high space velocity. The invention adopts cheap and non-toxic raw materials to prepare a Fe-Ti oxide catalyst with high activity, selectivity, stability and anti-S2 poisoning ability by the simple and practicable co-precipitation method, which can better solve the existing technical problems. If the catalyst is loaded on honeycomb ceramics after being made into pulp, the catalyst is hopeful to be put into practical application of flue gas denitrification of coal-fired power plants.

Owner:江西中科鸿虔新材料有限公司

Cathode material of Li-ion battery and preparation method, battery cathode, battery thereof

ActiveCN1702893AImproved charge and discharge coulombic efficiencyImprove electrochemical performanceElectrode manufacturing processesSecondary cellsMaterials processingCrystallinity

This invention discloses one lithium battery negative electrode materials and its process method, wherein, the battery negative electrode, battery, lithium battery negative material comprise sphere natural graphite and the irregular shape carbon with low crystal degree; the natural graphite core has the radius proportion of one to three micro characteristics. The process method comprises the following steps: grinding the natural graphite and shaping and purification processing; surface decoration and mixture with the carbon materials; mixture materials processing.

Owner:BTR NEW MATERIAL GRP CO LTD

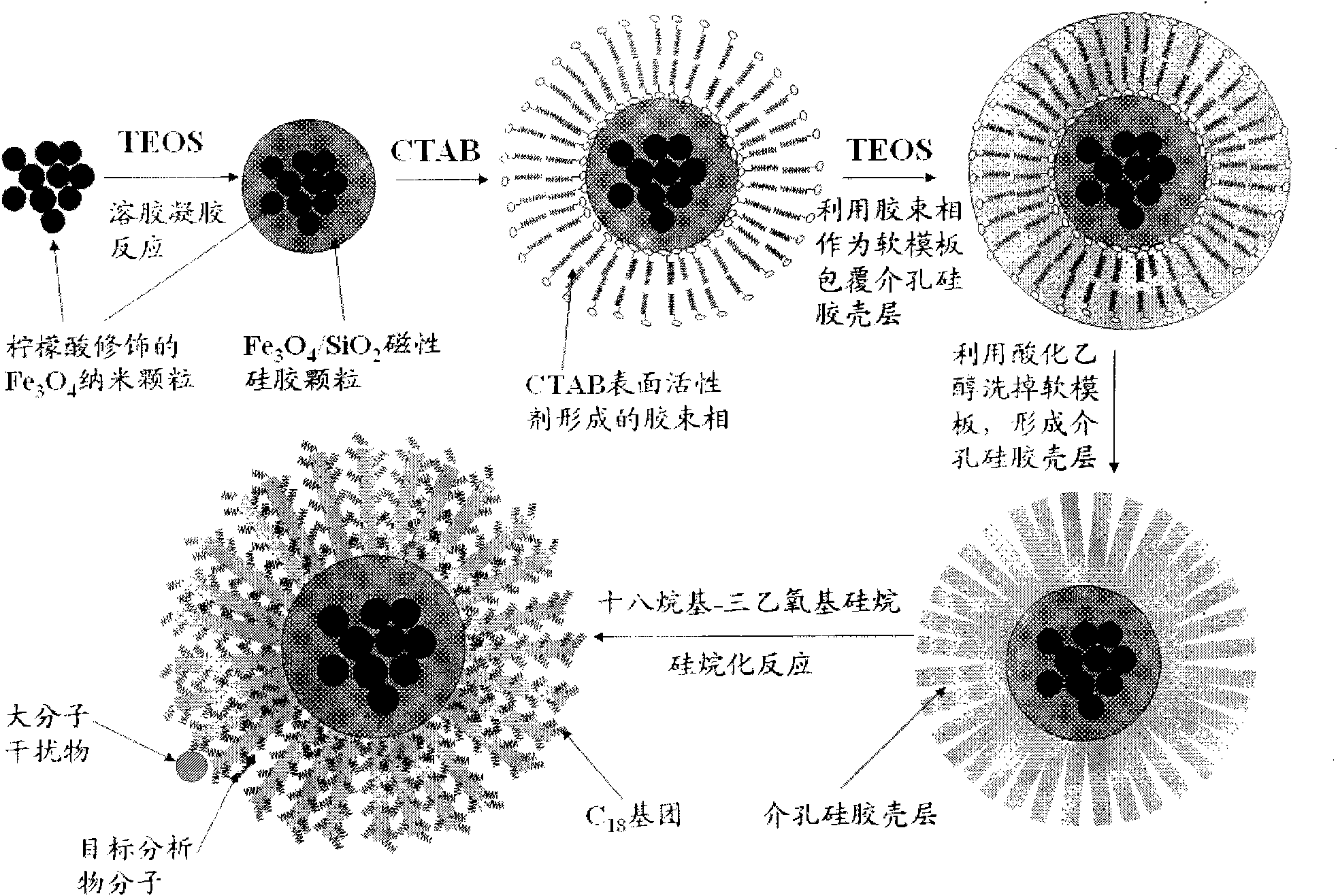

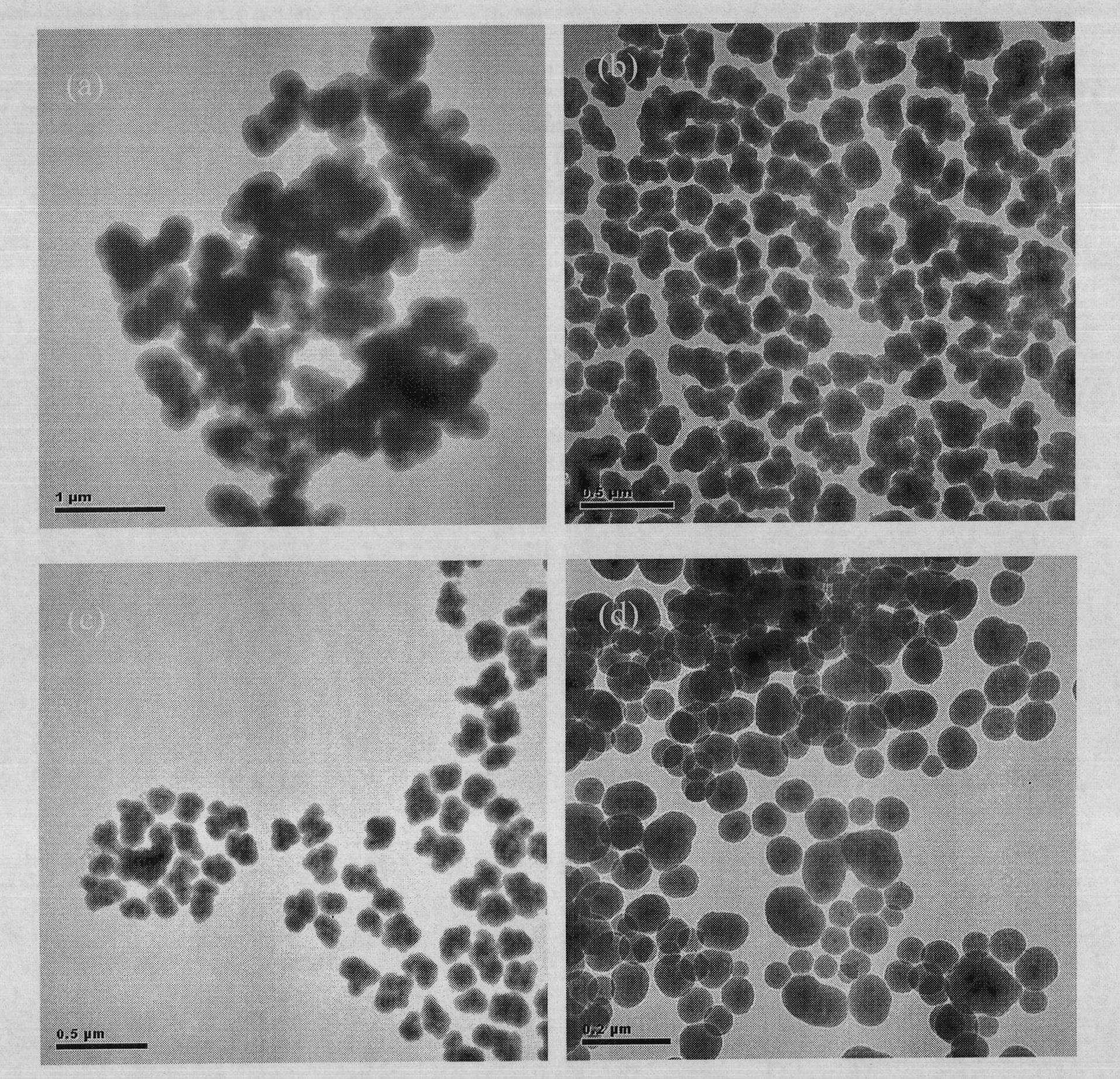

Preparation and application of high-capacity magnetic mesoporous silica gel solid phase extracting agent

InactiveCN102091605AIncrease surface areaStrong superparamagnetismIon-exchange process apparatusOther chemical processesMicrosphereMesoporous silica

The invention provides a magnetic mesoporous silica gel material extracting agent used for enriching and / or separating trace organic pollutants in an environment water sample, and a preparation method thereof. A core of the extracting agent provided by the invention is a silicon gel microsphere (i.e. magnetic silicon gel microsphere) wrapped with a plurality of Fe3O4 magnetic nano particles, and a shell of the extracting agent is a mesoporous silicon gel shell layer with inner and outer surfaces modified by C18 silanization. The extracting agent integrates huge special surface area, excellent extracting capacity and ultrahigh extracting volume of a mesoporous material, magnetic separating capacity of a magnetic material, strong extracting capacity of C18 groups and special volume exclusion function of a vertical channel of the mesoporous material. In addition, the extracting agent provided by the invention has the advantages of high extracting efficiency, low preparation cost and simple preparation method, and is very suitable for preprocessing samples of the trace organic pollutants in a bulk-mass water sample.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

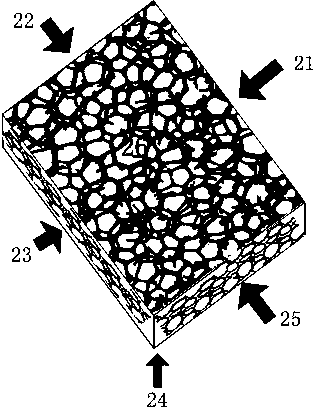

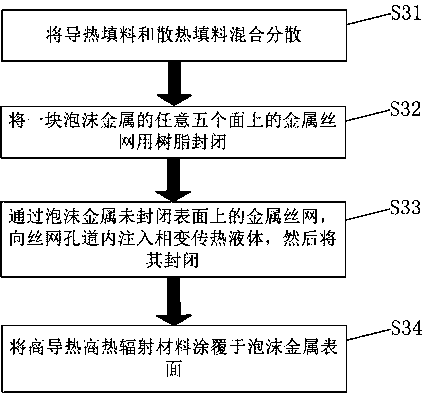

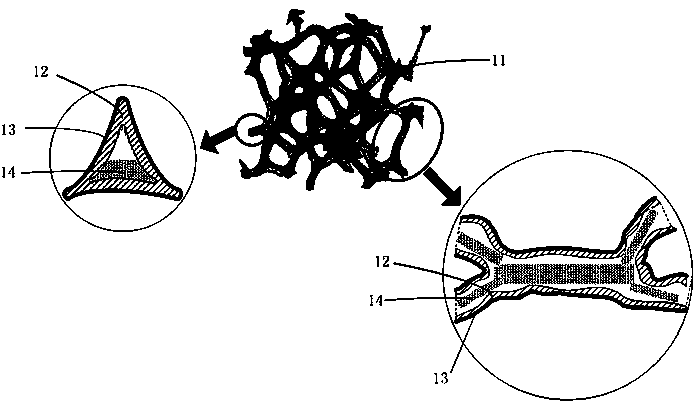

Three-dimensional network porous heat-conducting heat radiation device and preparation method thereof

PendingCN107936777AImprove thermal conductivitySmall specific surface areaSemiconductor/solid-state device detailsSolid-state devicesHeat conductingElectron

The invention relates to a three-dimensional network porous heat-conducting heat radiation device and a preparation method thereof. The three-dimensional network porous heat-conducting heat radiationdevice comprises foam metal, high-heat-conduction high-heat-radiation material and a phase-changing heat transferring material, wherein the heat transferring performance is improved by virtue of the phase-changing heat transferring material filling pores inside a foam metal skeleton wire net, the heat radiation performance is improved by virtue of the high-heat-conduction high-heat-radiation material smeared on the surface of the foam metal skeleton, and the three-dimensional network porous heat-conducting heat radiation device is suitable for the electron industry and solves the heat radiation problem of heating elements and devices.

Owner:WUZHOU HGP ADVANCED MATERIALS TECH CORP

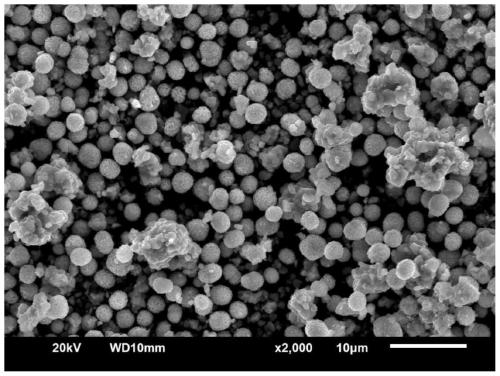

Silicon carbon composite microsphere, and preparation method and application thereof

ActiveCN106384825ASmall specific surface areaImprove cycle stabilityCell electrodesSecondary cellsCarbon compositesMicrosphere

The invention provides a silicon carbon composite microsphere, and a preparation method and application thereof. The method comprises the following steps that (1) silicon dispersion liquid is prepared: 30 to 95 percent of asphalt and 5 to 70 percent of silicon are used as raw materials, and are dispersed in an organic solvent; ball milling is performed; (2) other carbon sources are added into grinding liquid; the ball milling is further performed; (3) the dispersion liquid obtained through the ball milling is added into a high-temperature high-pressure reactor; high-temperature high-pressure reaction is performed under the inert gas protection; (4) products obtained in the third step are subjected to suction filtration to obtain solid particles; (5) the solid particles obtained in the fourth step are subjected to high-temperature carbonizing treatment in inertia non-oxidizing atmosphere to obtain the silicon carbon composite microsphere. The method has the advantages that the asphalt and the micron silicon are used as raw materials; the raw materials are cheap and are easy to obtain; a dispersing agent is nontoxic and can be recovered; the process is simple; the sphericity degree of the obtained material is good; the tap density is high; the specific surface is small; a stable SEI membrane is favorably formed; the circulation stability is excellent.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

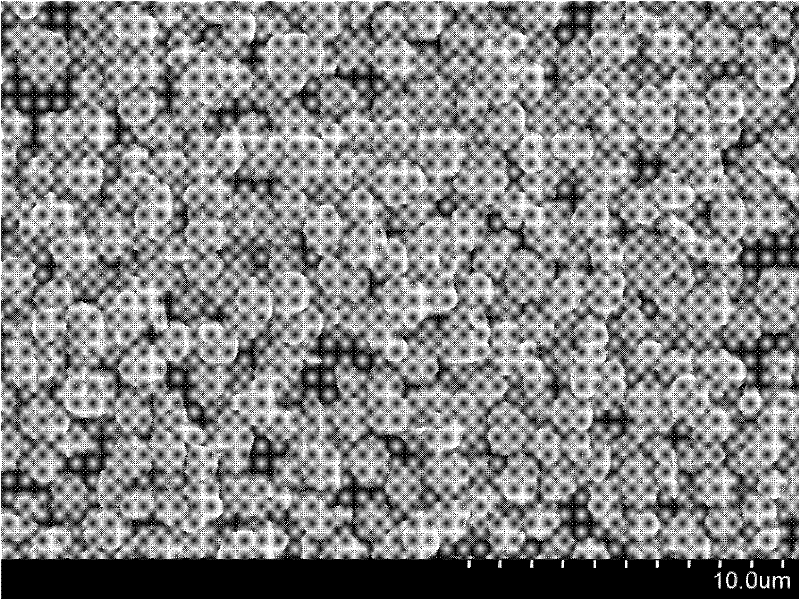

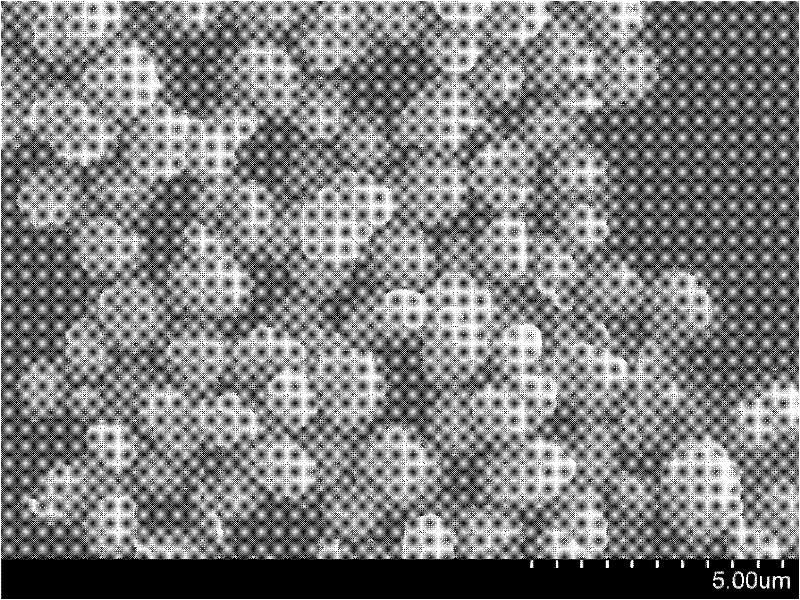

High-nickel ternary positive electrode material with single crystal morphology and preparation method of high-nickel ternary positive electrode material

InactiveCN111463411AIncrease productionImprove product qualitySecondary cellsPositive electrodesDopantPhysical chemistry

The invention discloses a high-nickel ternary positive electrode material with single crystal morphology and a preparation method of the high-nickel ternary positive electrode material. The positive electrode material is formed by a base material and a coating layer, wherein the base material is prepared from a high-nickel ternary precursor, a lithium source and a doping agent; the doping agent comprises a doping element, the doping element is a metal element, the coating layer is formed by a coating material, the coating material comprises a coating element, and the coating element is a metalelement and / or a non-metal element. The positive electrode material is obtained by mixing the high-nickel ternary precursor, the lithium source and the doping agent, performing primary sintering, then mixing with the coating material, and performing secondary sintering. The high-nickel ternary positive electrode material disclosed by the invention has the advantages of single crystal morphology,smooth surface, small specific surface area and high compaction density, and the single crystallization of the high-nickel ternary positive electrode material improves the specific capacity and cycleperformance of the positive electrode material and prolongs the service life of the positive electrode material. The preparation method is simple in process, easy to implement and beneficial to industrial large-scale production.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

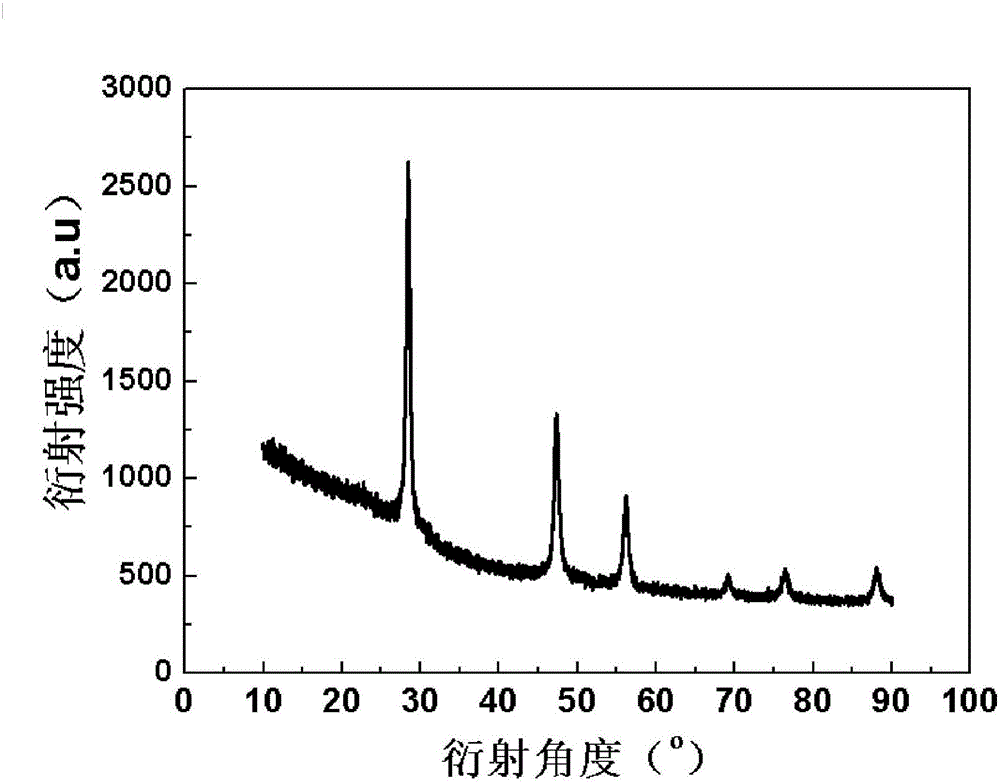

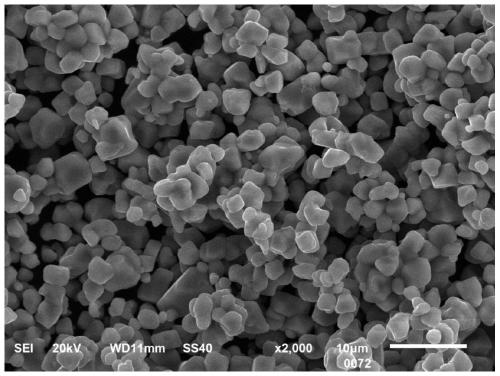

Method for preparing monodispersed silver powder with high tap density and low agglomeration

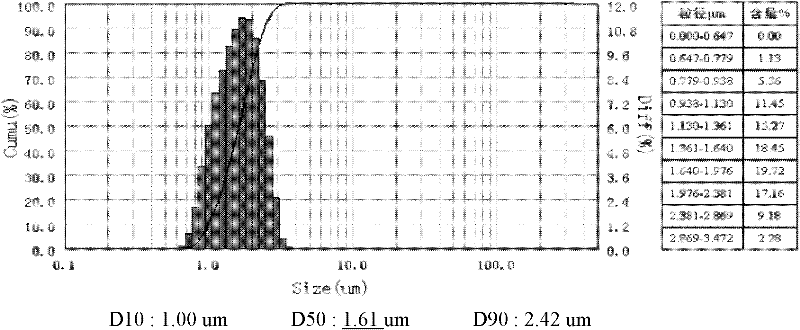

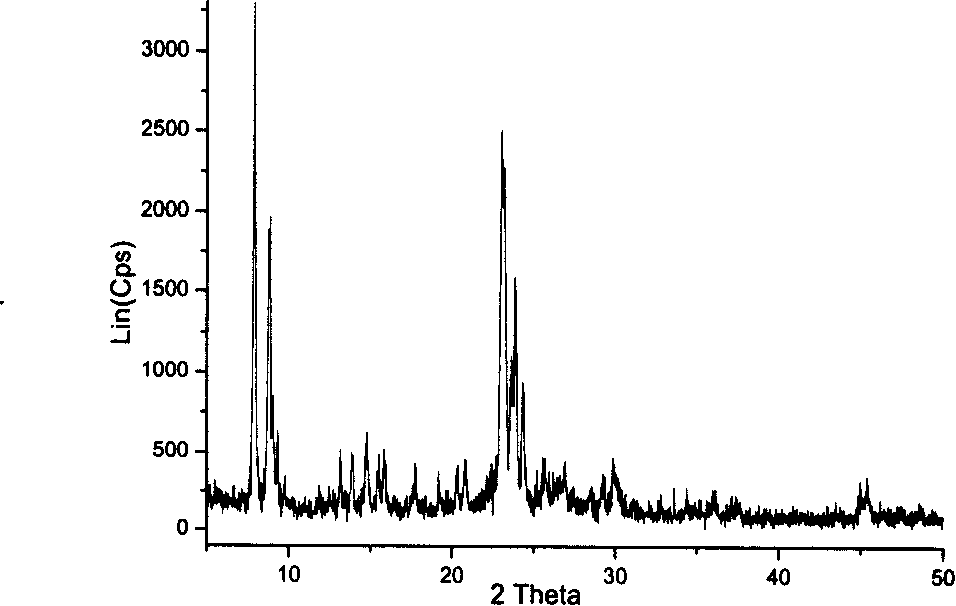

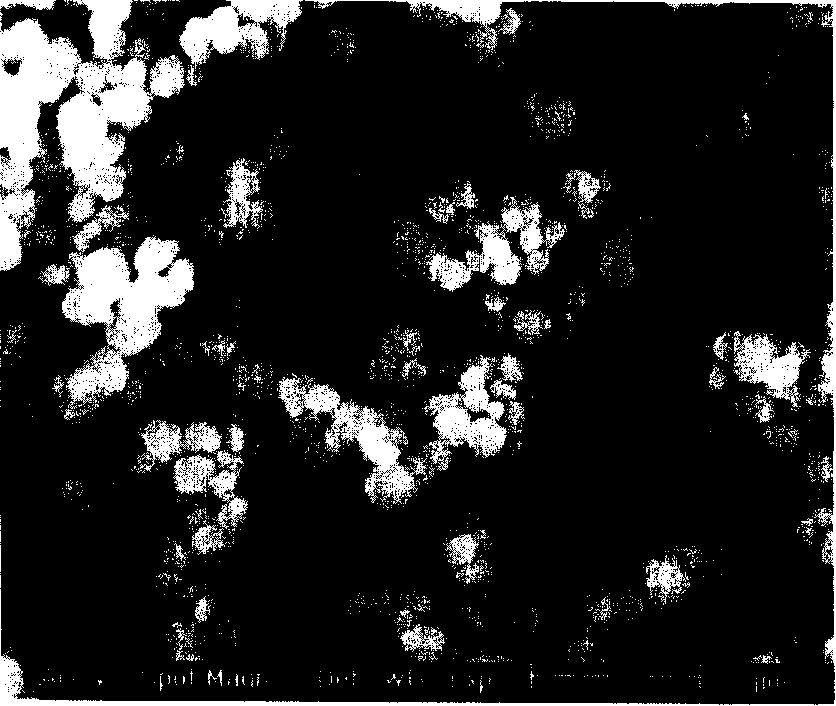

InactiveCN102343441AHigh tap densityNarrow particle size dispersionAscorbic acidVolumetric Mass Density

The invention relates to a method for preparing monodispersed silver powder with high tap density and low agglomeration, and the method is implemented through the following steps of uniformly mixing an acidic silver salt solution with a mixed reducing solution containing a L-ascorbic acid, a protective agent and a surfactant, and stirring the obtained mixture for reaction; and cleaning and then drying the obtained precipitate so as to obtain the monodispersed silver powder with high tap density and low agglomeration. Compared with the prior art, the silver powder prepared by using the method disclosed by the invention is high in tap density, small in particle diameter and dispersive range, high in degree of sphericity of particles, smooth in surface, small in specific surface area and easy for realization of mass production.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing fine grain ZSM-5/mordenite composite molecular sieve

ActiveCN101190418ALarge specific surface areaSmall specific surface areaMolecular sieve catalystsBulk chemical productionNaphthaMordenite

The invention relates to the preparation method of a small crystal ZSM-5 / mordenite composite molecular sieve, mainly solving the problems in the existing preparation process of ZSM-5 / mordenite composite molecular sieve of bigger crystal of the composite molecular sieve, low catalytic activity and fast activity loss in the reaction in which ethene and propylene are prepared by the catalyzing and cracking of naphtha. The invention well resolves the problems by adopting the technical proposal that the ZSM-5 with decent silica alumina ratio and the crystal seed of mordenite is added in the synthetic process of the molecular sieve and the PH value of the molecular sieve raw material solution system is adjusted to 9-14 in the preparation process. The ZSM-5 / mordenite composite molecular sieve prepared by the method can be applied in the industrial production, in which ethene and propylene are prepared by the catalyzing and cracking of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com