Chemically modified chitosan mercury-removing adsorbent and preparation process thereof

A preparation process and adsorbent technology, applied in other chemical processes, chemical instruments and methods, separation methods, etc., can solve the problems of low removal efficiency and high economic cost, and achieve high cost performance, high mercury removal efficiency, and unique The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

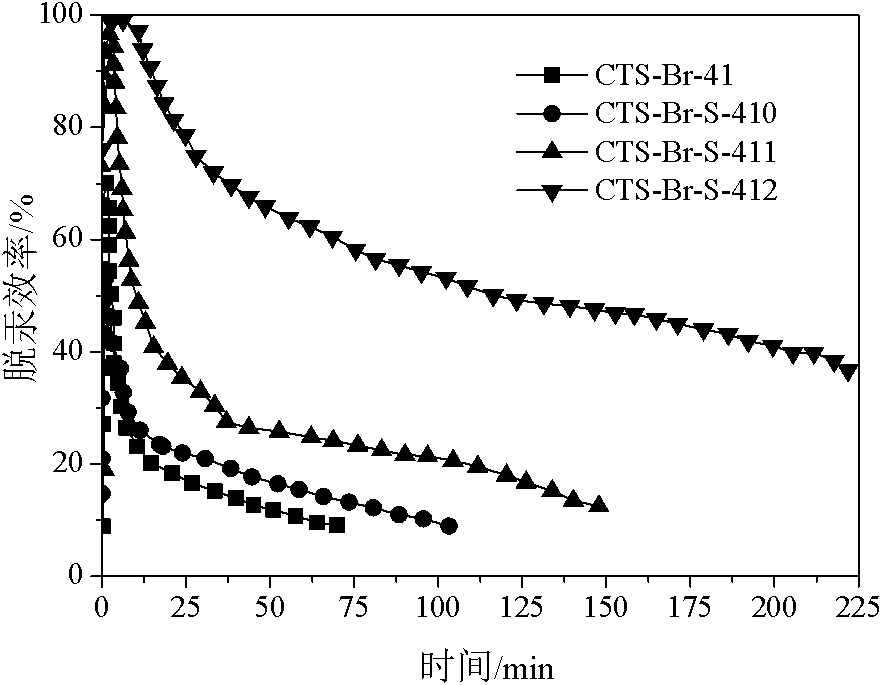

[0022] CTS-Br-S series adsorbent preparation: take by weighing 4g chitosan, put into 100mL beaker, add 30mL deionized water (appropriate amount of absolute ethanol) and 0.42g concentrated sulfuric acid (concentration is 98%), stir After 1-3 hours, add 1g KBr, stir continuously for 4-6 hours, let stand for 10-15 hours, filter with suction, dry in an oven at 80-100°C, put it in a drying dish for later use, and record it as CTS-Br-S-410. Replace the consumption of sulfuric acid in the preparation of CTS-Br-S-410 with 2g sulfuric acid, prepare adsorbent CTS-Br-S-412 (wherein S represents that sulfuric acid is added in the preparation process of adsorbent, 410 and 412 represent respectively chitosan, modifier and sulfuric acid by the mass ratio of the above preparation method).

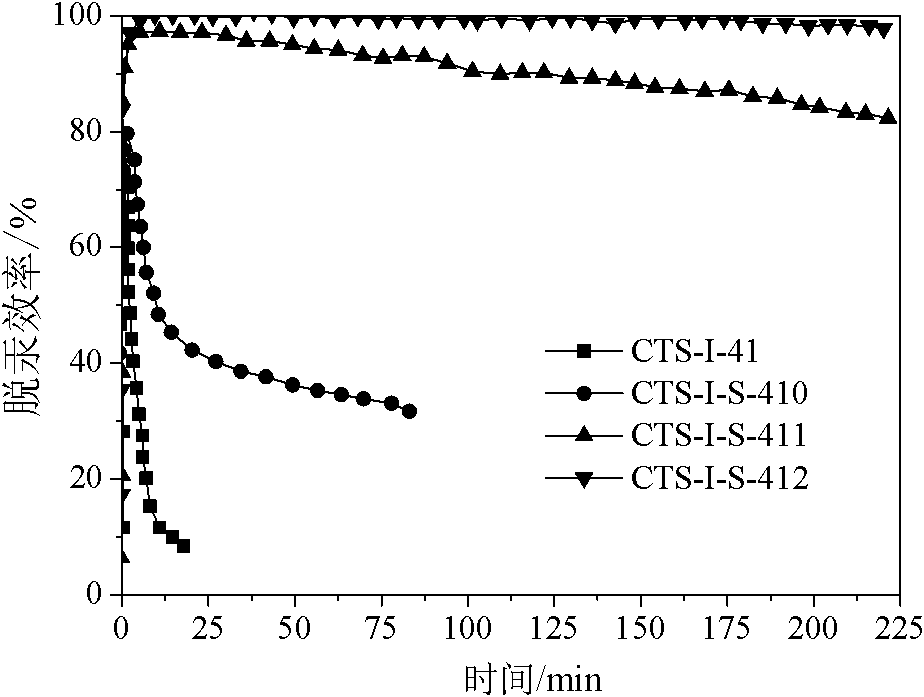

[0023] CTS-I-S series adsorbent preparation: Weigh 4g chitosan, put it into a 100mL beaker, add 30mL deionized water (appropriate amount of absolute ethanol) and 0.59g concentrated sulfuric acid (concentra...

Embodiment 2

[0025] CTS-Br-S-813 adsorbent: Weigh 8g chitosan, put it into a 100mL beaker, add 30mL deionized water (appropriate amount of absolute ethanol) and 3g sulfuric acid (concentration is 98%), stir for 1~ After 3 hours, add 1g of KBr, stir continuously for 4-6 hours, let stand for 10-15 hours, filter with suction, dry in an oven at 80-100°C, put it in a drying dish for later use, and record it as CTS-Br-S-813.

[0026] CTS-I-S-813 supplement: Weigh 8g chitosan, put it into a 100mL beaker, then add 30mL deionized water (appropriate amount of absolute ethanol) and 3g sulfuric acid (concentration: 98%), stir for 1-3h , add 1gKI, stir continuously for 4-6 hours, let stand for 10-15 hours, then filter with suction, dry in an oven at 80-100°C, put it in a drying dish for later use, and record it as CTS-I-S-813.

Embodiment 3

[0028] CTS-Br-S-1514 adsorbent: take by weighing 15g chitosan, put into 600mL beaker, then add 100mL deionized water (appropriate amount of absolute ethanol) and 4g concentrated sulfuric acid (concentration is 98%), stir for 1 ~3h later, add 1gKBr, stir continuously for 4h, let it stand for 10h, filter with suction, dry in an oven at 80-100°C, put it in a drying dish for later use, and record it as CTS-Br-S-1513.

[0029] CTS-I-S-1514 adsorbent: Weigh 15g chitosan, put it into a 600mL beaker, add 100mL deionized water (appropriate amount of absolute ethanol) and 4g concentrated sulfuric acid (concentration: 98%), stir for 1-3h Finally, add 1g KI, stir continuously for 4 hours, let it stand for 10 hours, filter it with suction, dry it in an oven at 80-100°C, put it in a drying dish for later use, and record it as CTS-I-S-1513.

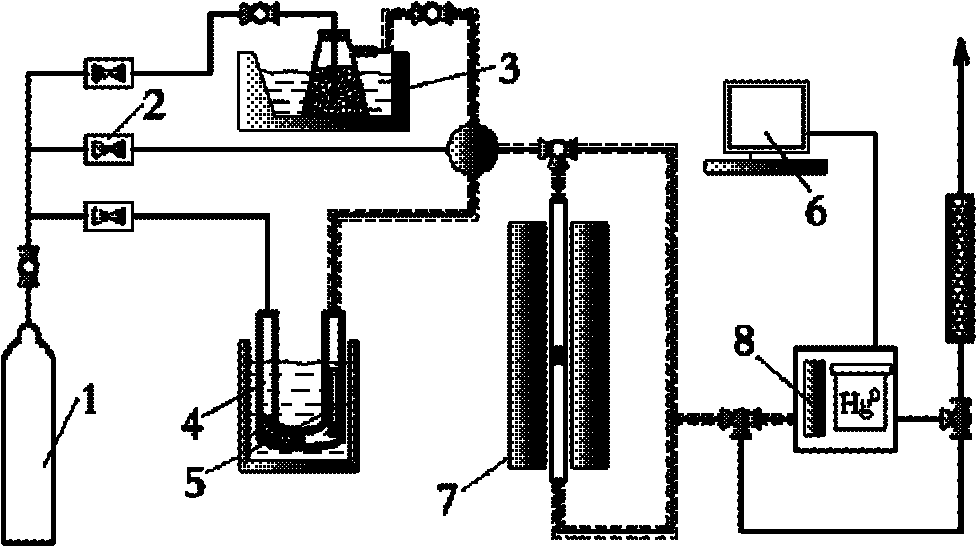

[0030] In order to understand the performance of the adsorbent of the present invention, especially in nitrogen (N 2 ) atmosphere to study its effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com