Patents

Literature

159results about How to "Improve mercury removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sorbent for removal of trace hazardous air pollutants from combustion flue gas and preparation method thereof

InactiveUS20070179056A1Low costLow raw material costGas treatmentOther chemical processesSorbentToxic industrial waste

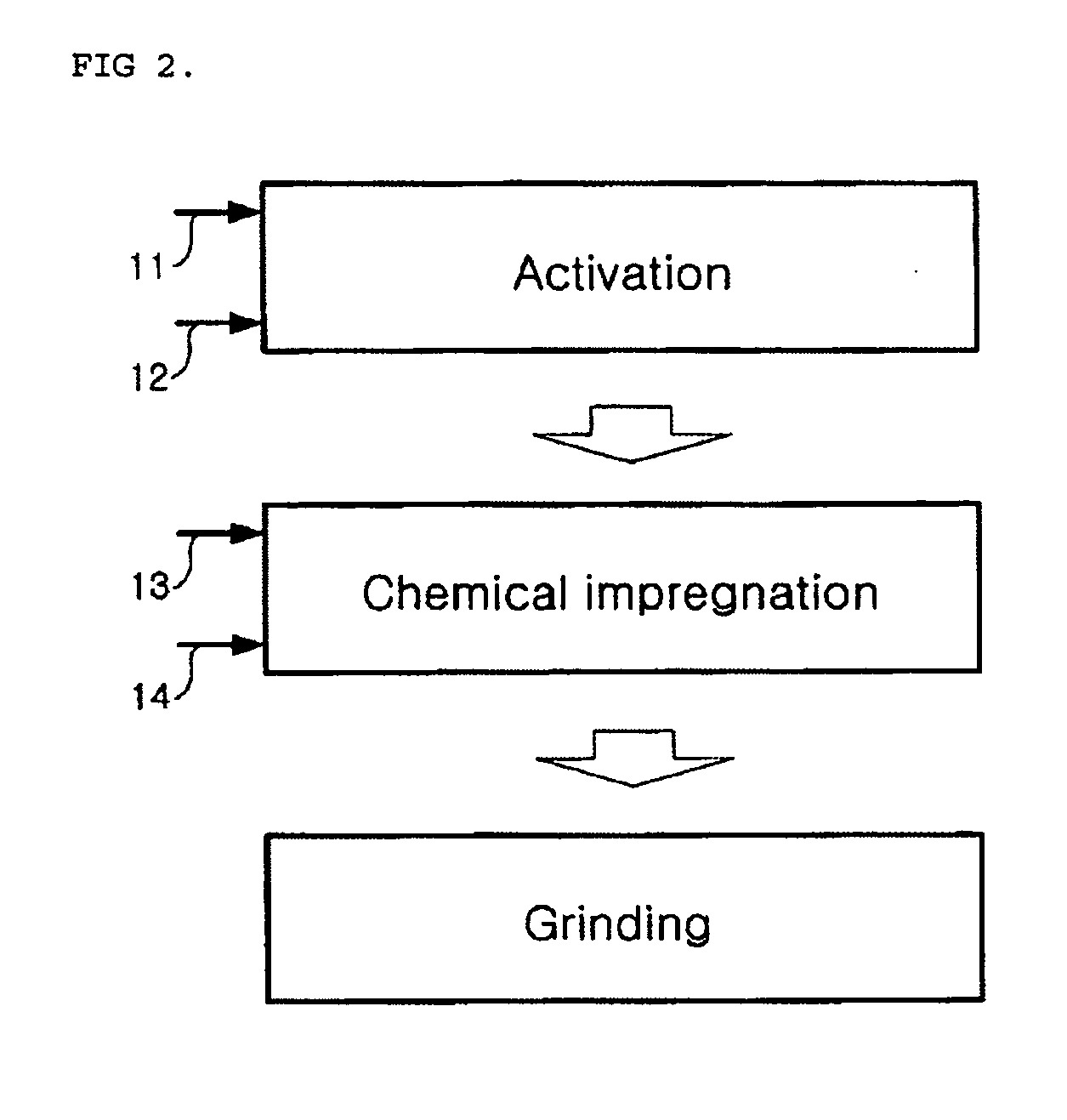

Disclosed is a sorbent for the removal of mercury from combustion flue gas and a preparation method thereof. The sorbent includes an activated heavy oil heavy ash impregnated with 0.1-30% by weight of any chemical substance selected from sulfur, iodine, bromine and chlorine. The sorbent is prepared in an economical manner using heavy oil fly ash, industrial waste generated from heavy oil-fired boilers, and has excellent sorption performance for mercury, so that a low concentration of mercury contained in combustion flue gas discharged from large-scale boilers can be removed by injection of a small amount of the sorbent. Thus, the invention can prevent a reduction in the recycling rate of coal fly ash in coal-fired power plants and minimize operation cost.

Owner:KOREA ELECTRIC POWER CORP

Preparation method of rare-earth-based composite multi-component denitrification and dioxin removal catalyst

ActiveCN104226301AImprove catalytic oxidation abilityImprove surface acidity and alkalinityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPolymerDenitrification

The invention discloses a preparation method of a rare-earth-based composite multi-component denitrification and dioxin removal catalyst. According to the preparation method, titanium dioxide (titanium white) and silicon powder as carriers and ammonium metatungstate, ammonium metavanadate, cerous nitrate and lanthanum nitrate as active components, the steps of mixing, kneading, molding, drying and roasting are carried out in the presence of auxiliary materials to prepare the catalyst, wherein the auxiliary materials include monoethanolamine, citric acid, ammonium hydroxide, lactic acid, stearic acid, glass fibers, macromolecular polymer fibers RP-CHOP, hydroxypropyl methyl cellulose, polyoxyethylene and water. The prepared catalyst can simultaneously decompose nitric oxides and dioxin and can improve the mercury removal efficiency of the existing smoke control device. The prepared catalyst is not only applicable to new power plants, but also suitable for the modification of a wet-method desulphurization device of an old power plant, 80 to 95 percent of HgO generated in a coal burning power plant can be oxidized to Hg<2+> by utilizing the prepared catalyst, and a majority of particle-state Hg<2+> can be removed by utilizing a dust removal device.

Owner:山东信义汽车配件制造有限公司

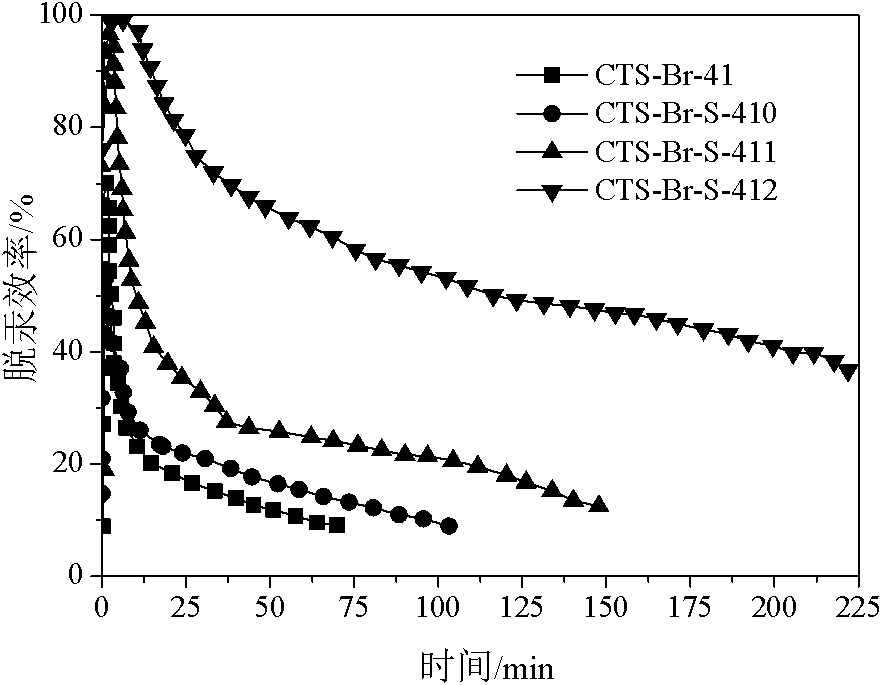

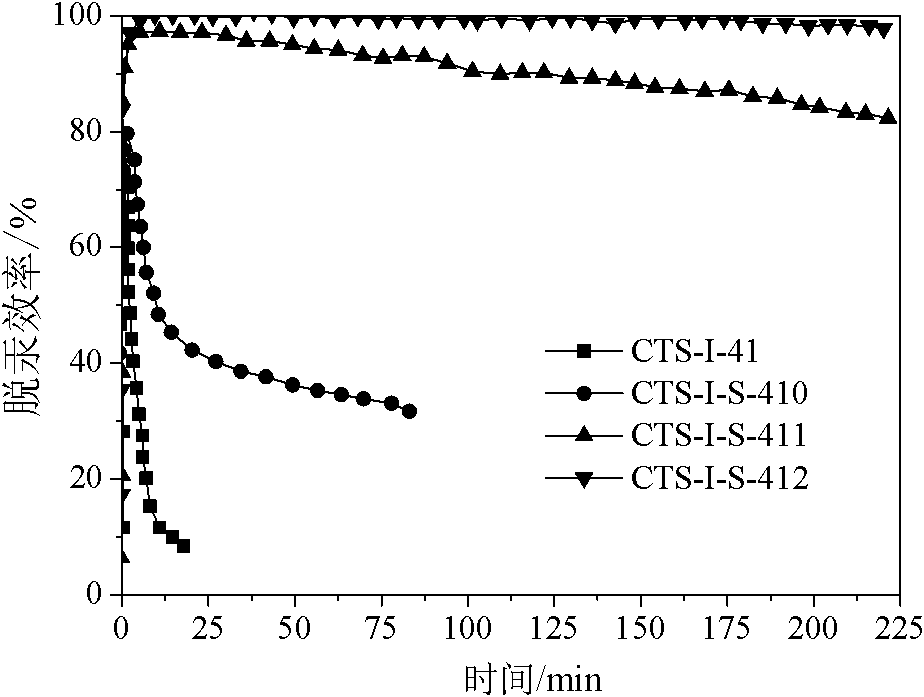

Chemically modified chitosan mercury-removing adsorbent and preparation process thereof

InactiveCN101816922AEasy to buyEasy to manufactureOther chemical processesDispersed particle separationHalogenSorbent

The invention discloses an adsorbent used for removing mercury (Hg0) in coal smoke and a preparation process thereof. The adsorbent comprises chitosan and halogen elements of bromine and iodine; as improvement, sulfuric acid is added, wherein the mass ratio of the chitosan to an iodine (bromine) compound to the sulfuric acid is (1-15):1:(0.5-5). The adsorbent is prepared by utilizing the reaction of the kali salt of the halogen elements of bromine and iodine and the sulfuric acid and better characteristics of the chitosan to the active iodine and the bromine under an acidy condition. The adsorbent has high Hg0 removal efficiency, lower cost, industrialized application and no secondary pollution of products.

Owner:HUAZHONG UNIV OF SCI & TECH

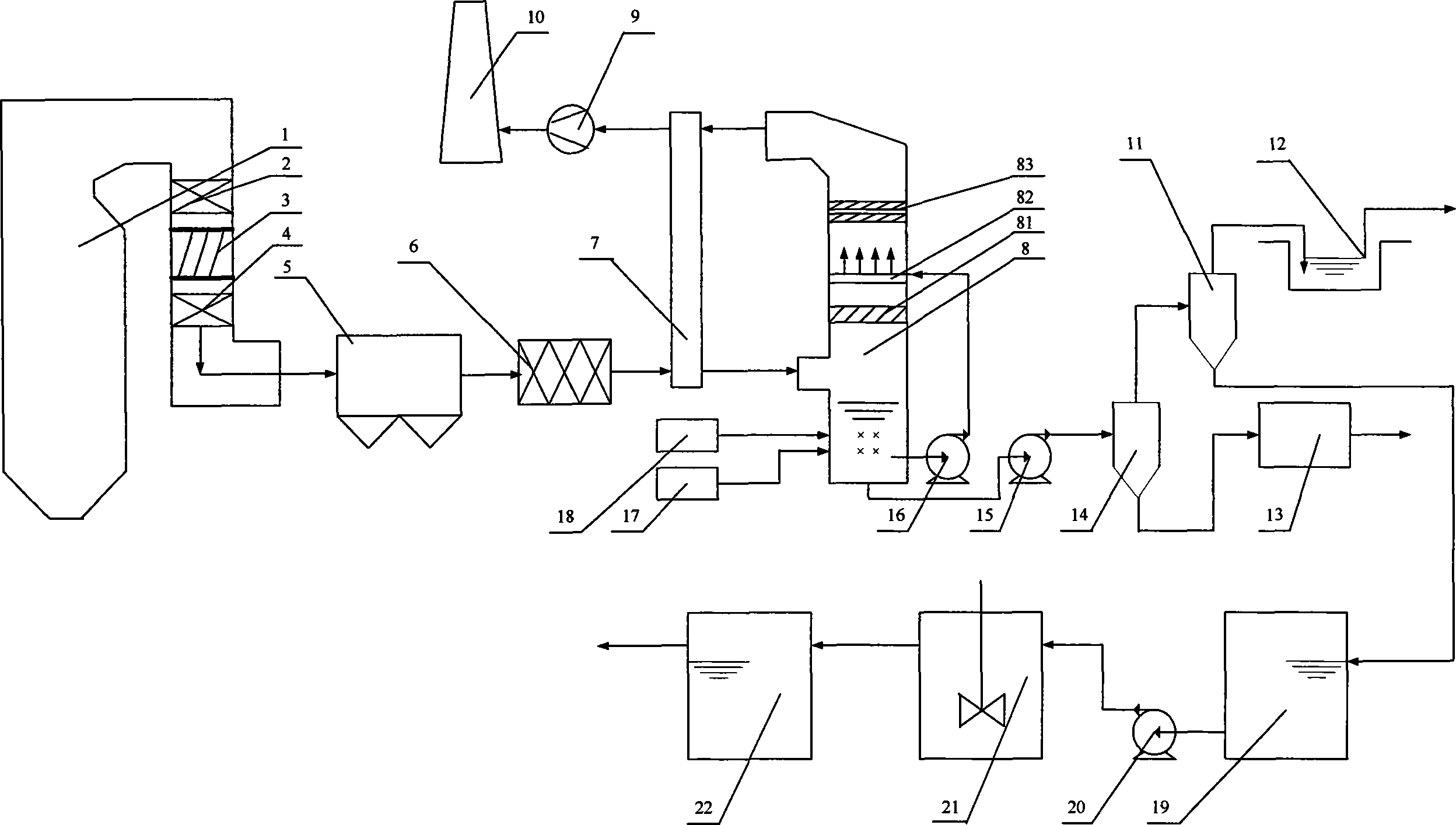

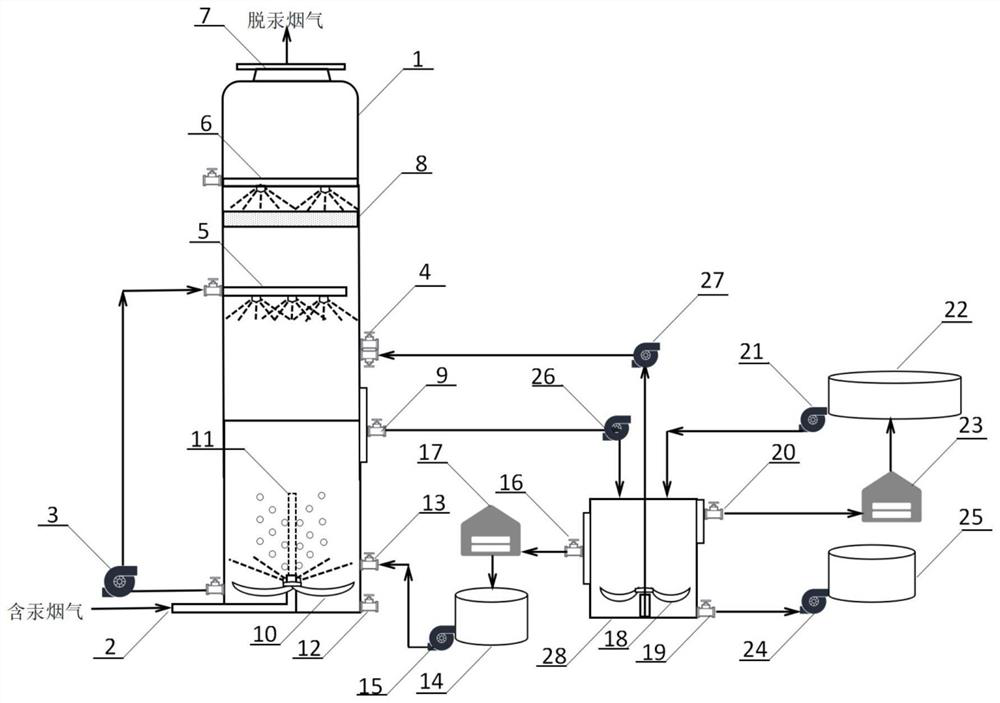

Wet flue gas desulfurizing and hydrargyrum-removing technology based on two-stage oxidation reaction and system thereof

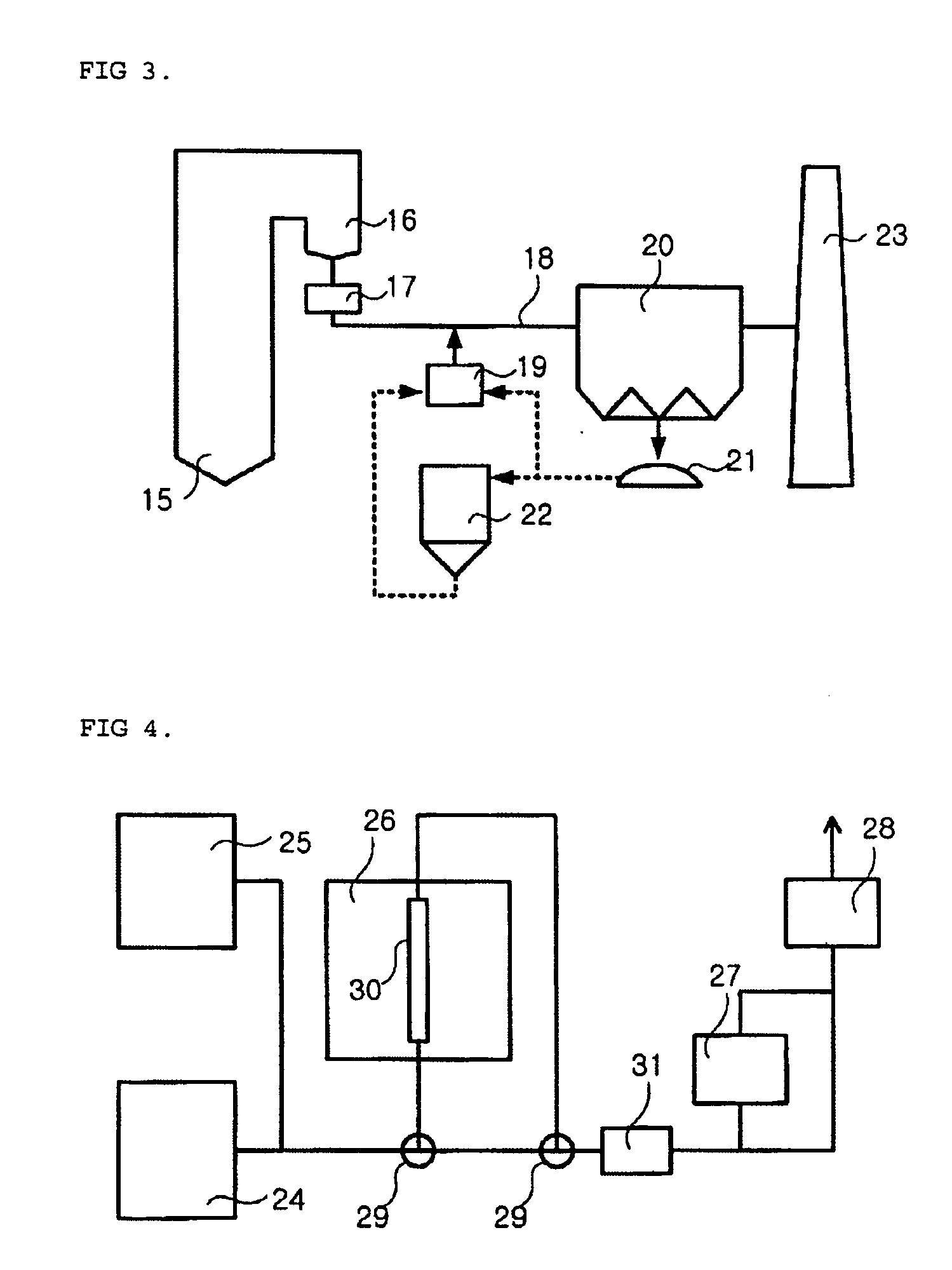

A wet flue gas desulfurization and demercuration process and a system thereof based on two-stage oxidizing reaction. The process does two-stage oxidizing treatment to the simple substance HgO in flue gas utilizing to ultraviolet radiation and oxidant of halogen series, transmutes the gas phase divalent ion Hg2+ therein to liquid phase divalent ion Hg2+ using the modified limestone-gesso wet desulfurization process, and then transmutes the liquid phase divalent ion Hg2+ to the stable mercuric sulfide-HgS deposition via stabilizer of liquid phase divalent ion Hg2+. The system comprises desulfurization and demercuration equipments such as an ultraviolet irradiator, an electrical precipitator, an oxidant spraying unit and a reaction absorber etc, gesso treatment equipments of desulfurization byproduct, and a treating equipment for mercuric sulfide-HgS deposition. The process and the system thereof can raise the oxidation rate of simple substance Hg in the flue gas effectively, and at the same time effectively overcome the reduction release of divalent ion Hg2+ to avoid secondary pollution and be capable of raise desulfurization and demercuration efficiency of limestone-gesso wet desulfurization system.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

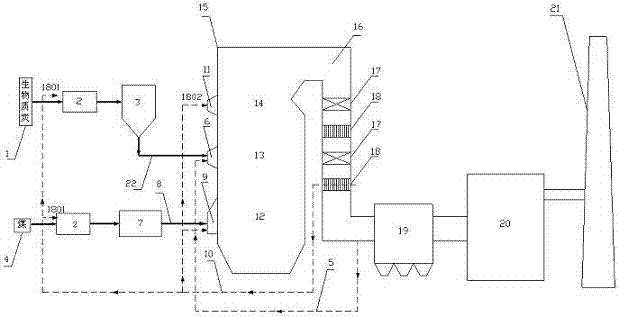

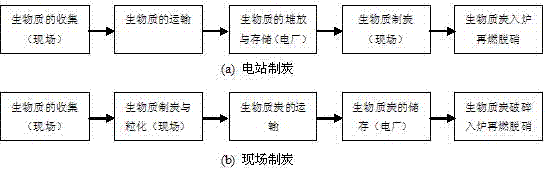

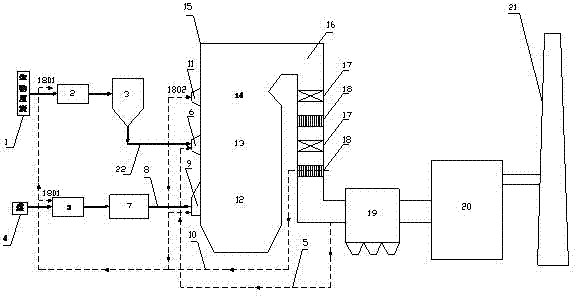

Method and system for collectively removing NOx and mercury (Hg) in coal-fired flue gas by utilizing secondary combustion of biomass charcoal

InactiveCN102364246AHigh calorific valueIncrease energy densityDispersed particle separationSolid fuel combustionLow nitrogenHigh energy

The invention discloses a method for collectively removing NOx and mercury (Hg) in coal-fired flue gas by utilizing the secondary combustion of biomass charcoal, which is characterized in that: on the basis of the secondary combustion denitrification and the recycling of flue gas, the biomass charcoal is used as secondary-combustion fuel, the characteristics of the biomass charcoal such as low sulfur, low nitrogen, chloride containing, high ash-coke activity, high energy density, zero carbon dioxide (CO2) net emission and the like are utilized, and the biomass charcoal is sent into a secondary-combustion area of a hearth, the combined removal of multiple pollutants such as NOx, Hg and the like in the coal-fired flue gas can be realized through the catalyst reduction effect of anoxic combustion and biomass charcoal as well as the catalyst oxidation effect of chloride contained flue gas and high-activity ash and coke. The invention also discloses a system for realizing the method, which comprises a biomass charcoal preparing system, a coal pulverizing system, a hearth, a combustion system of the hearth, a flue gas recycling system and a boiler tail-gas processing system. The biomass charcoal is used as the secondary-combustion fuel, so the technical advantages of the secondary combustion of the fuel and the recycling of the flue gas can be integrated, and the method and the system have the advantages that: the investment cost and the running cost are low, the denitrification efficiency and the mercury removal efficiency are high, the CO2 net emission can be reduced, and the like.

Owner:NANJING NORMAL UNIVERSITY

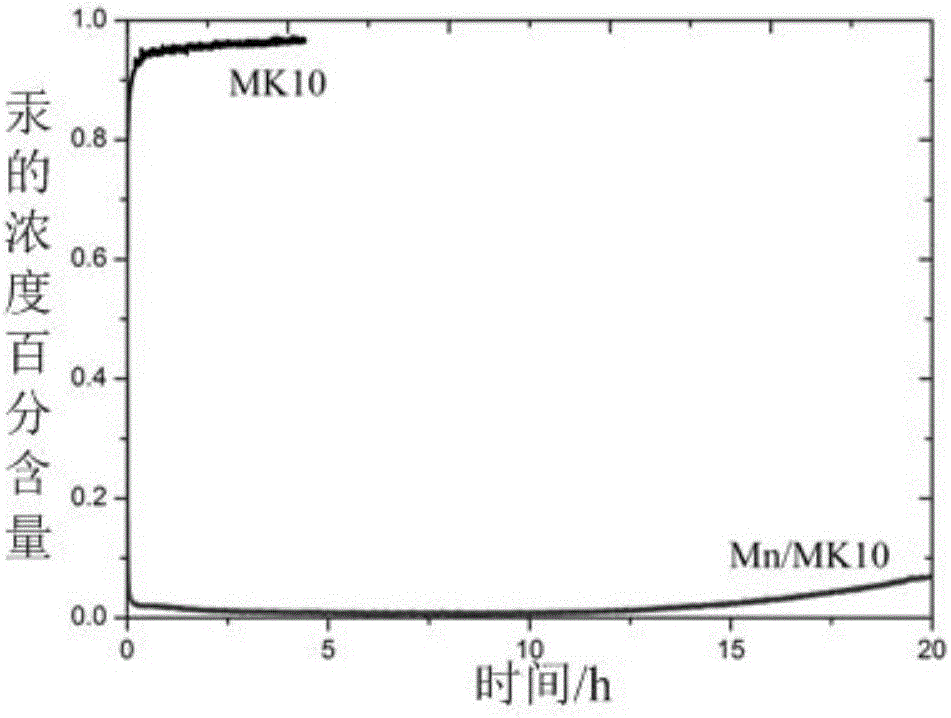

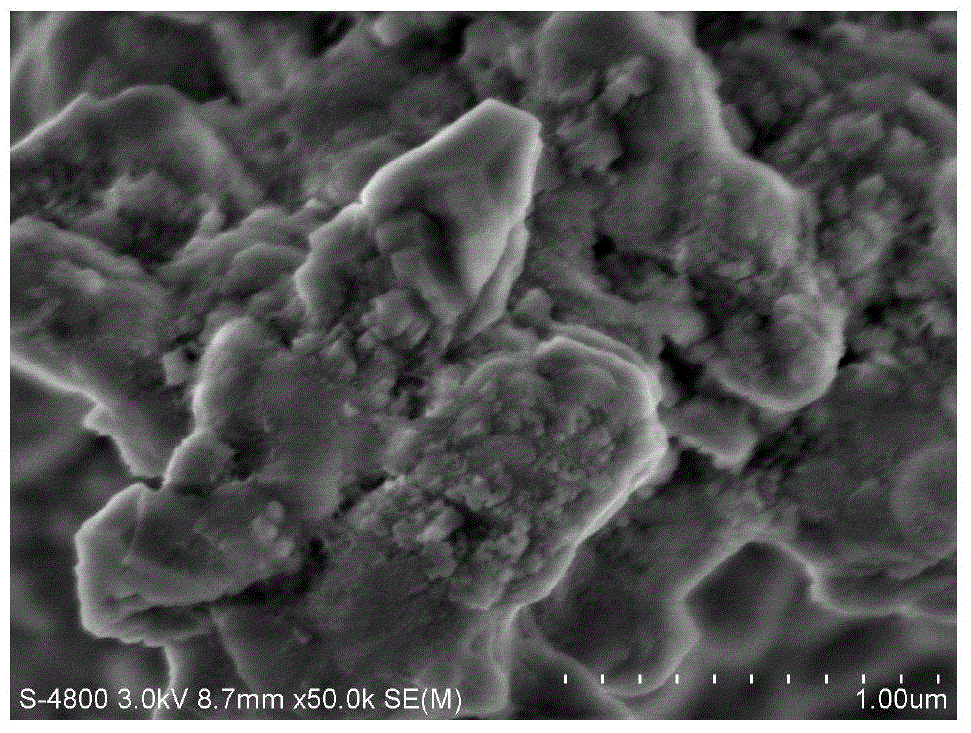

Demercuration adsorbent based on pillared montmorillonite, preparation method and application thereof

InactiveCN105664838AImproving the Ability of Adsorption and Removal of Mercury in Coal-fired Flue GasImprove thermal stabilityGas treatmentOther chemical processesMass ratioSorbent

The present invention provides a mercury removal adsorbent based on pillared montmorillonite, its preparation method and application. The adsorbent includes a carrier and an active component loaded on the carrier. The carrier is pillared montmorillonite. The active component is a metal oxide, and the ratio of the mass of the metal element to the mass of the pillared montmorillonite in the metal oxide is ≤10.0wt.%. The adsorbent makes full use of the structural characteristics of montmorillonite and the activity of the active components to adsorb elemental mercury, so that the two can play a synergistic effect; the mercury removal adsorbent not only has high thermal stability: mercury removal within 100-450 °C The efficiency reaches 99%, and it also has a high mercury removal efficiency: the inlet mercury concentration is 120ug / m 3 The mercury removal efficiency is as high as 99% within 10 hours, and over 94% even within 20 hours. It can be used to remove mercury in flue gas produced by power plants, industrial boilers or industrial kilns.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

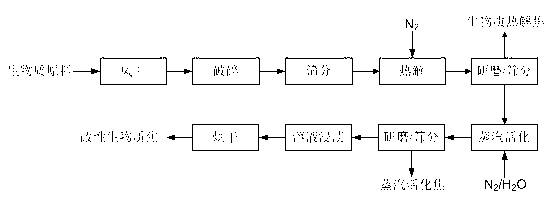

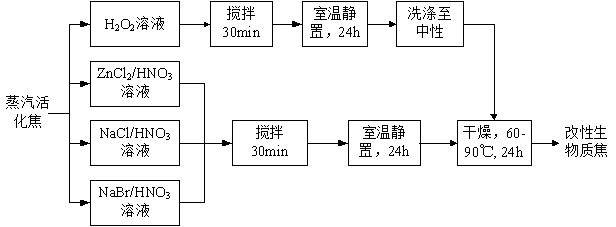

Biomass carbon-based flue gas demercuration adsorbent and preparation method thereof

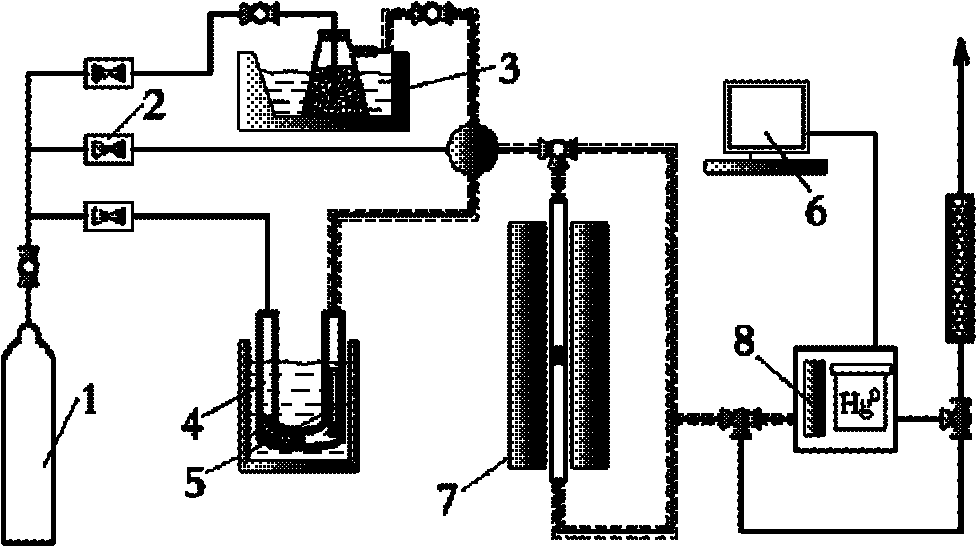

InactiveCN103252212AControl pollution dischargeRealize the double effect of protectionOther chemical processesDispersed particle separationMercury pollutionNitrogen gas

The invention discloses a biomass carbon-based flue gas demercuration adsorbent and a preparation method thereof. Based on comprehensive utilization of biomass resources and control of flue gas mercury pollutants, the emission of flue gas mercury is controlled by using modified biomass tar as the adsorbent. The biomass carbon-based flue gas demercuration adsorbent with a developed pore structure and abundant surface functional groups is prepared through treating processes of pyrogenic decomposition (at 400-800 DEG C in a nitrogen atmosphere) and steam activation (at an activation temperature of 800 DEG C with an N2-to-H2O mole ratio of 1: 1) of biomass raw material, modified reagent (H2O2, ZnCl2, NaCl or NaBr) solution dipping, and the like; and the biomass carbon-based flue gas demercuration adsorbent has the characteristics of wide adsorbent raw material source, simple preparation process, low cost, high demercuration efficiency and the like, and is suitable for coal-fired power plants and management of flue gas mercury emission in the fields of waste incineration and the like. The carbon-based flue gas demercuration adsorbent is prepared by adopting biomass, so that the emission reduction of mercury pollution can be realized, and the renewable resource of biomass can be utilized efficiently in a large scale; and the biomass carbon-based flue gas demercuration adsorbent has obvious economic benefit, environmental benefit and social benefit.

Owner:NANJING NORMAL UNIVERSITY

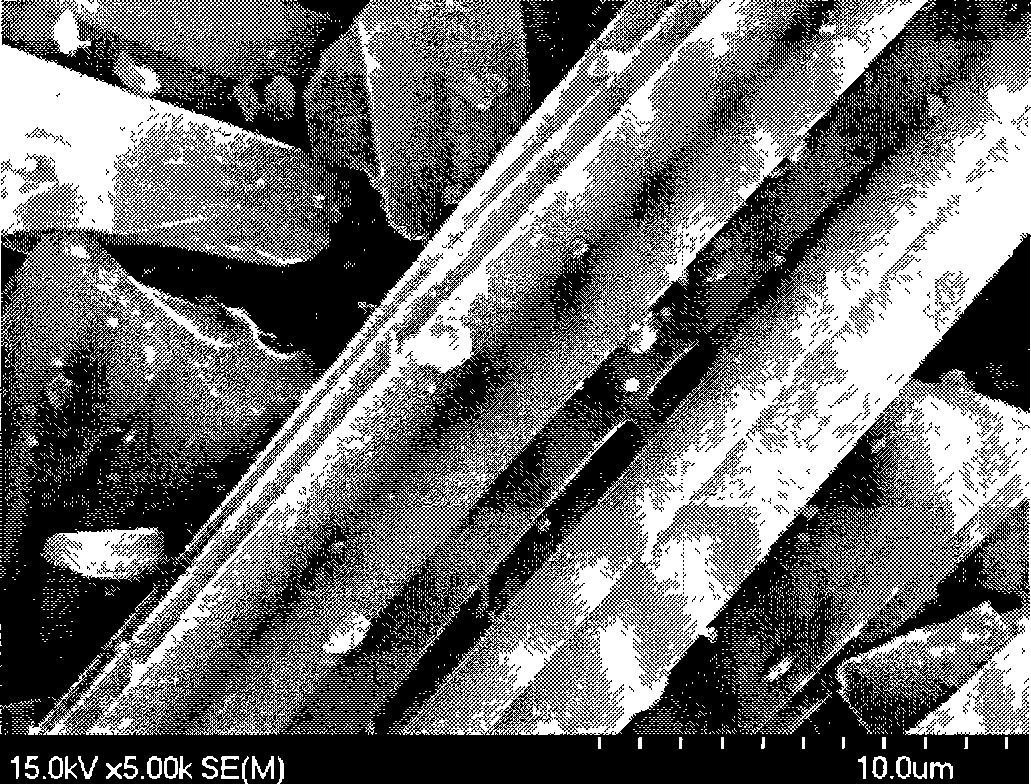

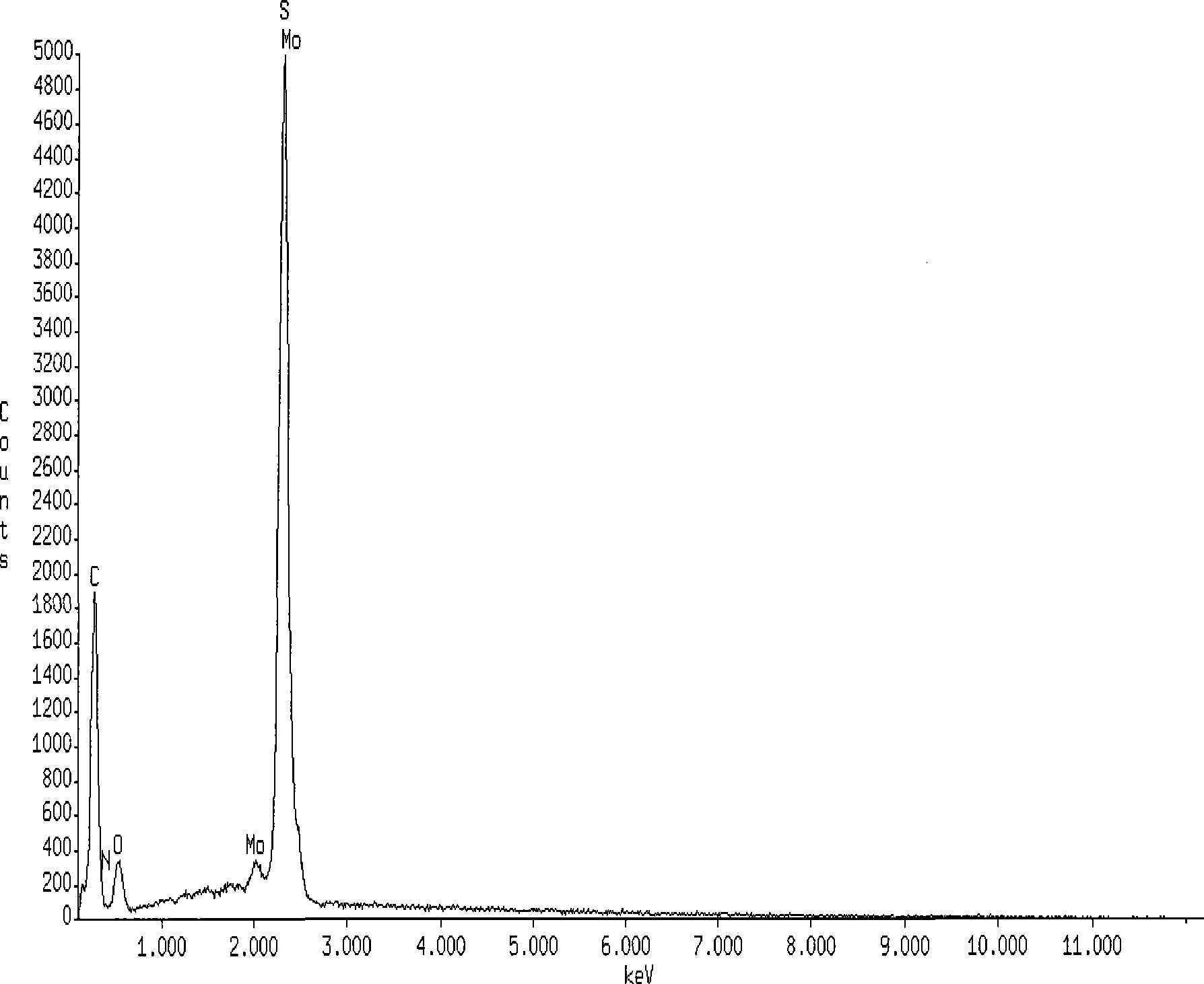

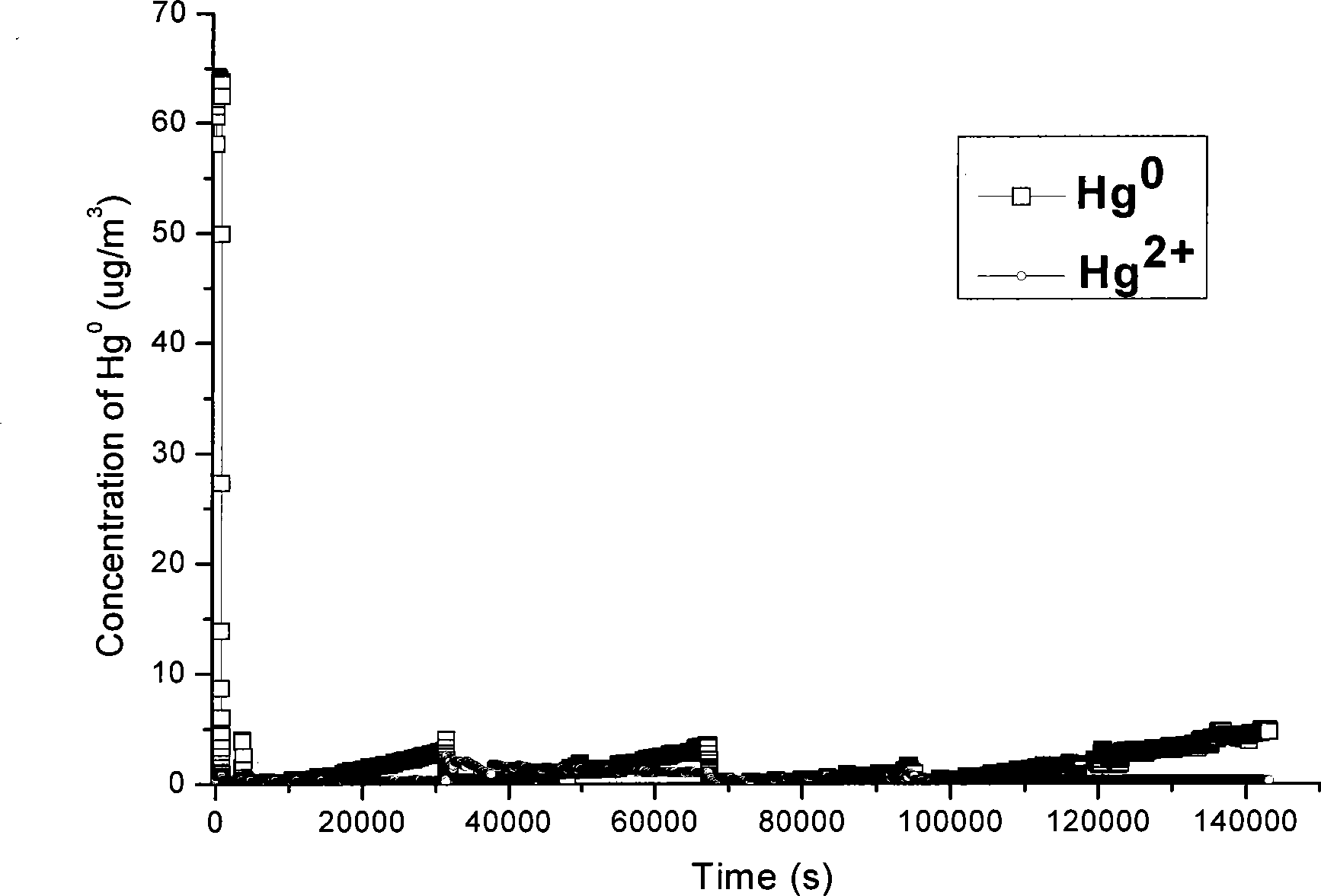

Novel activated carbon fiber adsorbing substance as well as preparation method and use thereof

InactiveCN101480605AHigh mercury removal efficiencyStrong adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesSolventIon

The invention discloses a novel activated carbon fiber adsorbent a preparation method and the application thereof. The activated carbon fiber adsorbent is characterized by carrying MoS2 on the surface of activated carbon fiber. The preparation method comprises the following steps: the activated carbon fiber is used as a carrier, ammonium molybdate is used as a precursor, and deionized water is used as a solvent to be prepared into steeping liquor, wherein the mass ratio of the activated carbon fiber to the ammonium molybdate is 1 : 0.25 to 0.3; the ammonium molybdate is carried in the activated carbon fiber by a wet immersion method, and then, the activated carbon fiber immersed with the ammonium molybdate is heated to 450 to 500 DEG C in inert atmosphere to be oxidized and decomposed to obtain MoO3-activated carbon fiber; and then, the MoO3-activated carbon fiber is heated to 800 to 825 DEG C in Ar / H2S to be sulfurized, and finally, the activated carbon fiber with the surface carried with MoS2 is prepared, i.e. the activated carbon fiber adsorbent is prepared. When the activated carbon fiber adsorbent is used for removing mercury in fume, the effect is good, and the activated carbon fiber adsorbent also has the advantages of simple preparation and easy process control.

Owner:ZHEJIANG UNIV OF TECH

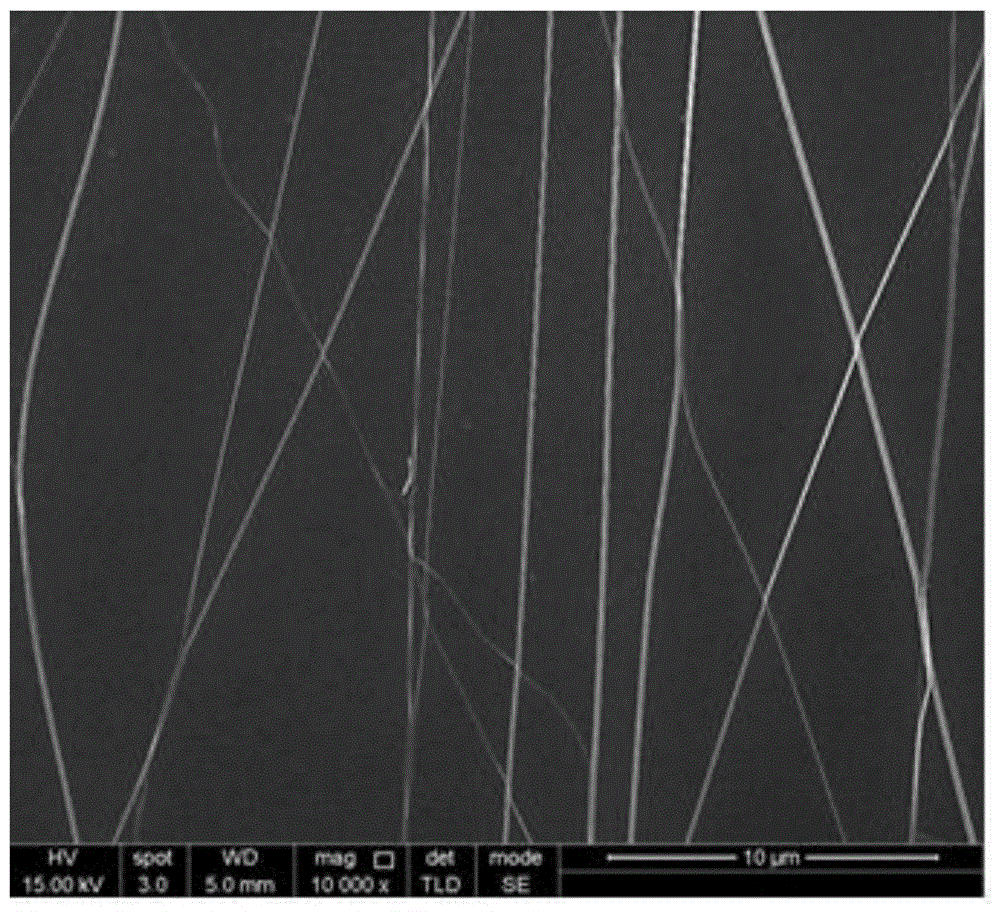

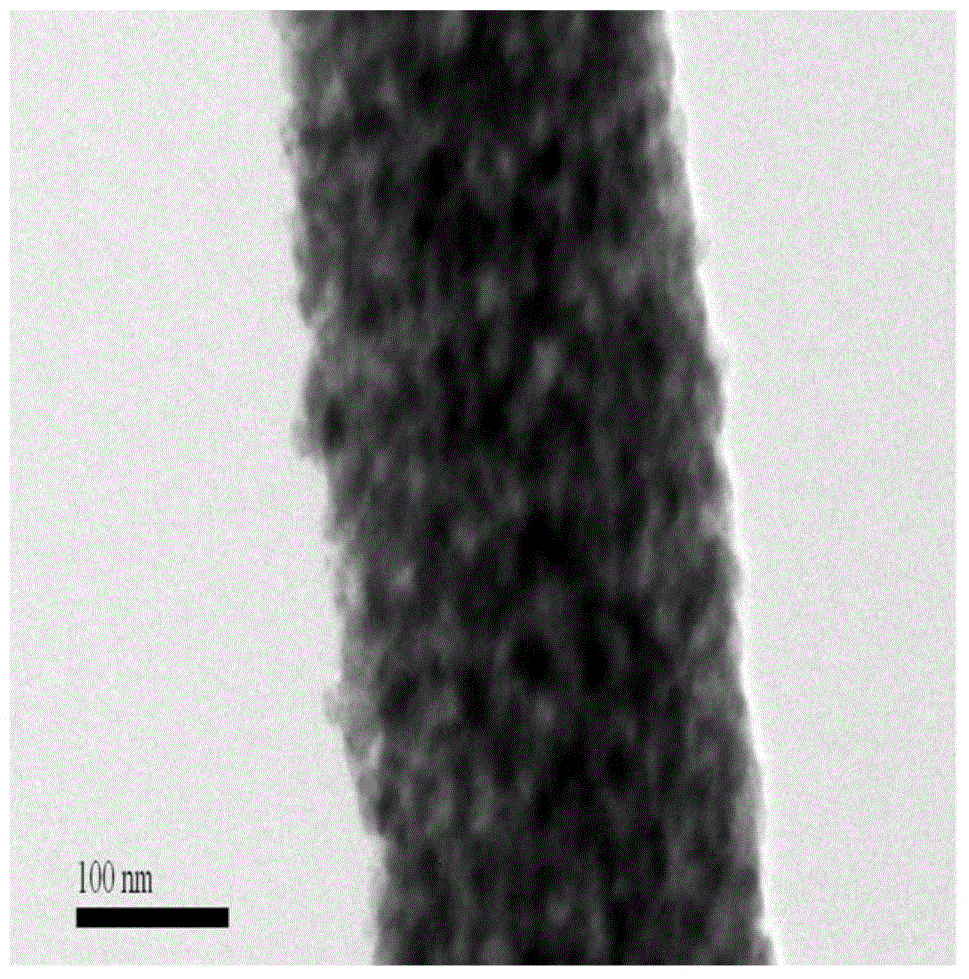

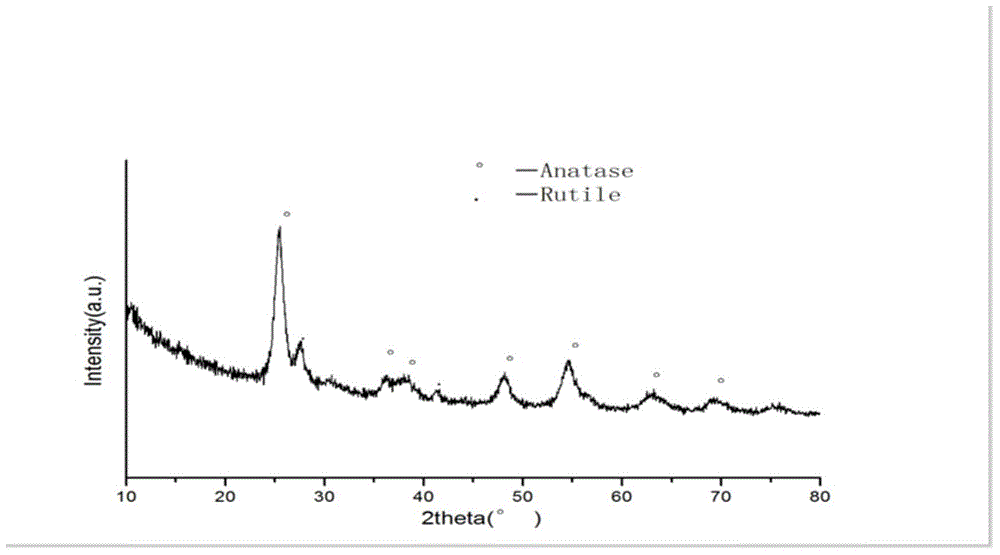

Preparation method of praseodymium-doped titanium dioxide composite nanofiber photocatalyst

InactiveCN104607171AHigh catalytic activityImprove productivityMaterial nanotechnologyDispersed particle separationAir atmosphereMuffle furnace

The invention discloses a preparation method of a praseodymium-doped titanium dioxide composite nanofiber photocatalyst. The preparation method comprises the following steps: (a) adding tetrabutyl titanate into a mixed solution of absolute ethyl alcohol and acetic acid, uniformly mixing, then sequentially adding praseodymium acetylacetone and polyvinylpyrrolidone into the mixed solution, further stirring to obtain precursor solution; (b) adding the precursor solution into an injector of an electrostatic spinning device and controlling the process condition of electrostatic spinning to prepare praseodymium-doped titanium dioxide nanoffiber non-woven fabric; (c) putting the nanofiber non-woven fabric into a muffle furnace, increasing the temperature from the room temperature to 500 DEG C under the air atmosphere to calcine, then naturally cooling to the room temperature to obtain the required composite nanofiber photocatalyst product. According to the preparation method of the praseodymium-doped titanium dioxide composite nanofiber photocatalyst, the mercury removal efficiency and performance of coal-fired flue gas can be remarkably improved; meanwhile, the method has the advantages of being convenient to operate, low in cost and low in energy consumption, so that the method is especially applicable to application places for mercury removal of smoke in a coal-fired power plant.

Owner:HUAZHONG UNIV OF SCI & TECH

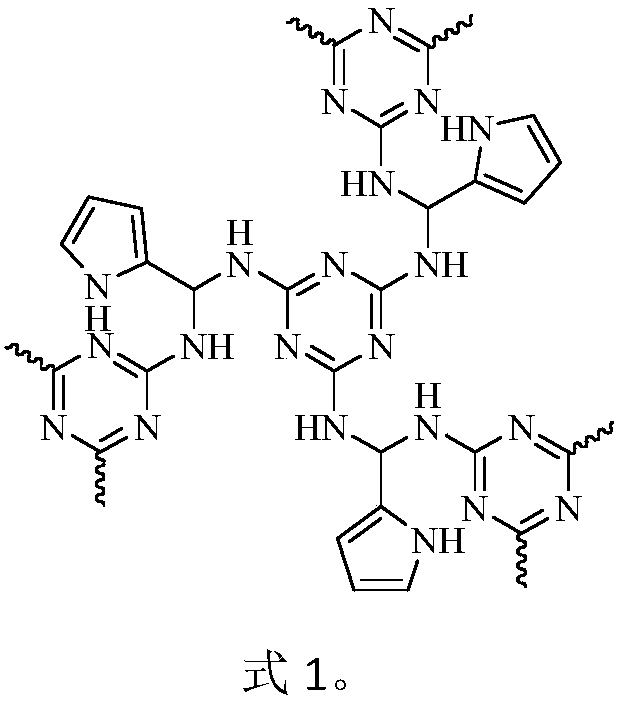

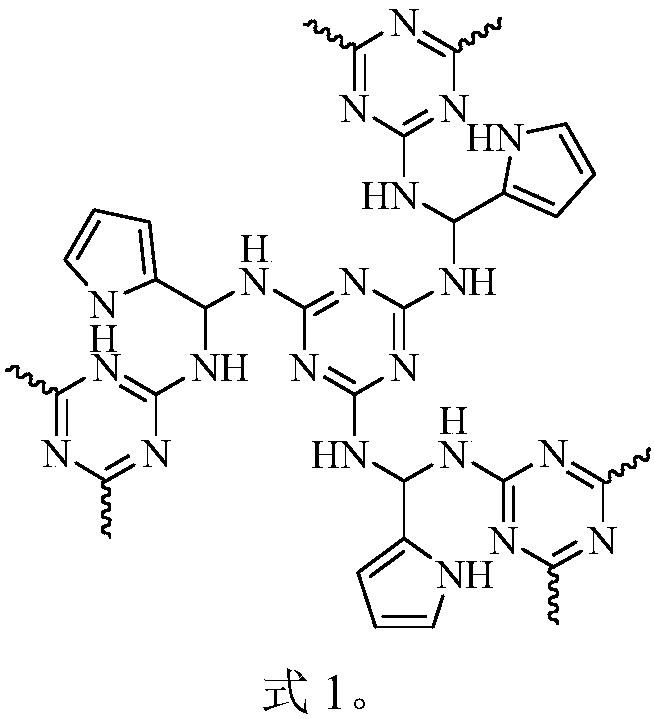

Demercuration catalyst taking metal organic framework as carrier and preparation method thereof

InactiveCN107812541ALarge specific surface areaImprove mercury removal efficiencyGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsMetal-organic frameworkNitrogen gas

The invention discloses a preparation method of a demercuration catalyst taking a metal organic framework as a carrier and belongs to the technical field of catalysts. According to the invention, trimesic acid is dissolved in an organic solvent to obtain a mixed solution A, transition metal salt is dissolved in deionized water to obtain a transition metal salt solution B, an active component and an assisting carrier salt are dissolved in the deionized water to obtain an active component aqueous solution C; adding the mixed solution A to the transition metal salt solution B for uniformly mixingwhile stirring at the temperature of 30-60 DEG C, introducing nitrogen, and then reacting for 1-3h under ultrasonic conditions; adding the active component aqueous solution C to the reaction solution, heating to 120-150 DEG C and performing thermostatic reaction for 12-36h, and cooling; and filtering, washing, drying, grinding, tabletting and sieving the reaction product to obtain the demercuration catalyst taking a metal organic framework as a carrier. The catalyst provided by the invention has relatively high adsorbing efficiency and adsorbing time.

Owner:KUNMING UNIV OF SCI & TECH

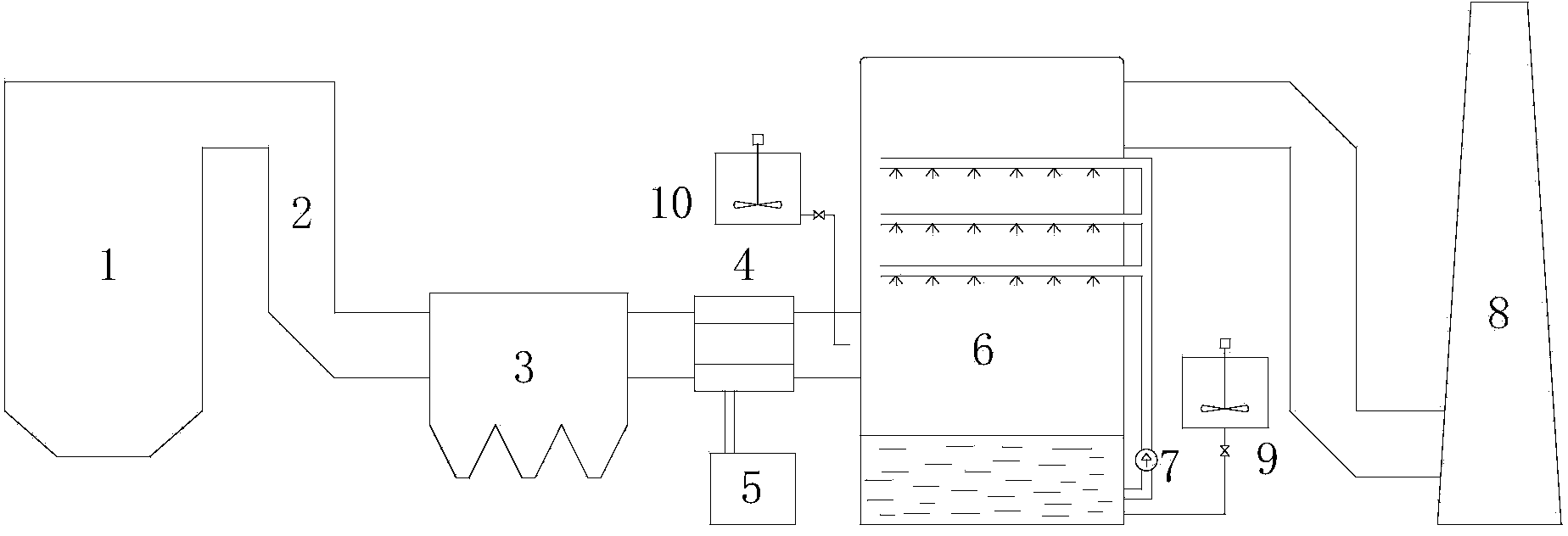

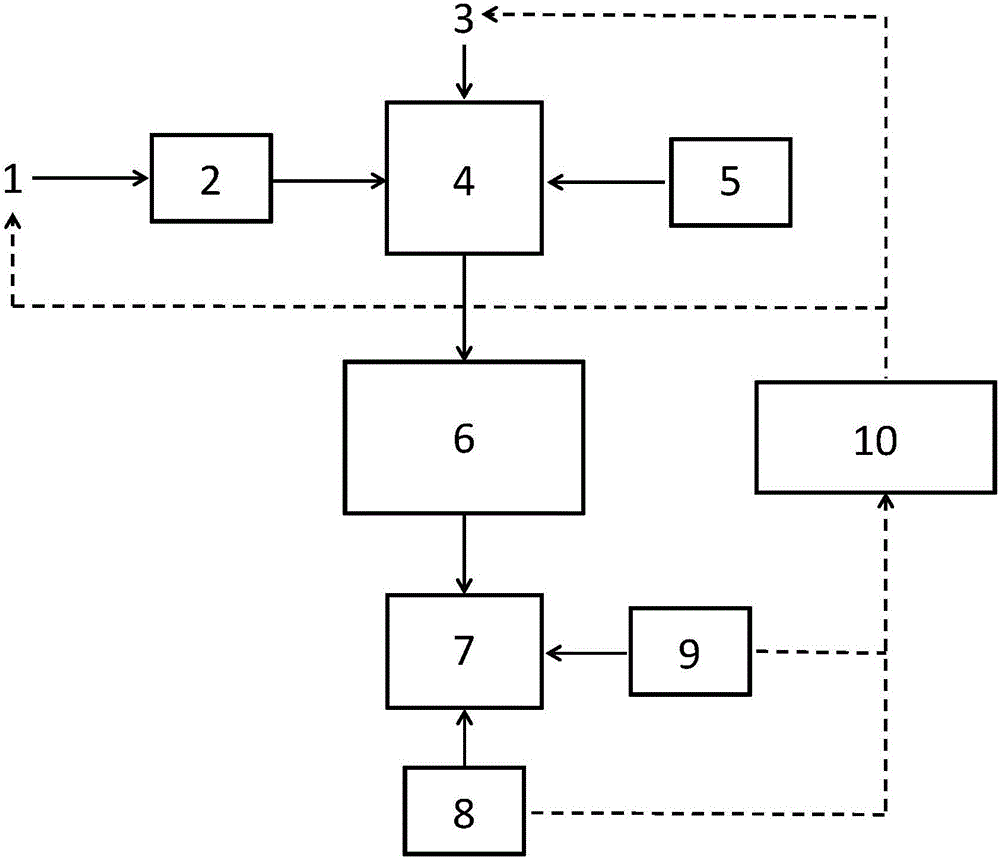

Smoke gas catalysis adsorption cooperated demercuration device and method

PendingCN106975331ASimple processEasy to operateLighting and heating apparatusDispersed particle separationParticulatesPtru catalyst

The invention provides a smoke gas demercuration method and device. According to the method, a demercuration catalyst and flue jet adsorption agent cooperated technology is used for efficient demercuration, wherein a demercuration catalyst layer is arranged at the upper stream of a denitration and ammonia spraying grille or / and the lower stream of the smoke gas denitration catalyst layer; adsorption agents are sprayed in the upper stream flue of a dust removing device; most Hg<0> in the smoke gas is converted into Hg<2+> under the effect of the demercuration catalyst and is sufficiently and uniformly mixed with the adsorption agents entering the smoke gas through spraying; reaction adsorption is performed; then, the adsorbed mercury is removed along with particle materials in the dust removal equipment; the unadsorbed mercury is further adsorbed in the absorption device, so that the mercury in the smoke gas can be effectively controlled. The smoke gas demercuration method provided by the invention has the advantages that the process is simple; the operation is convenient; the demercuration rate can reach 94 percent.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

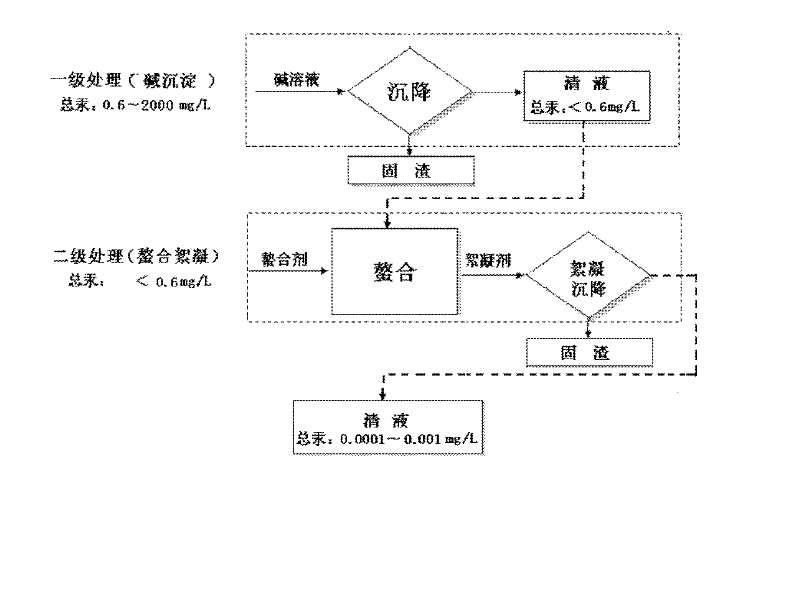

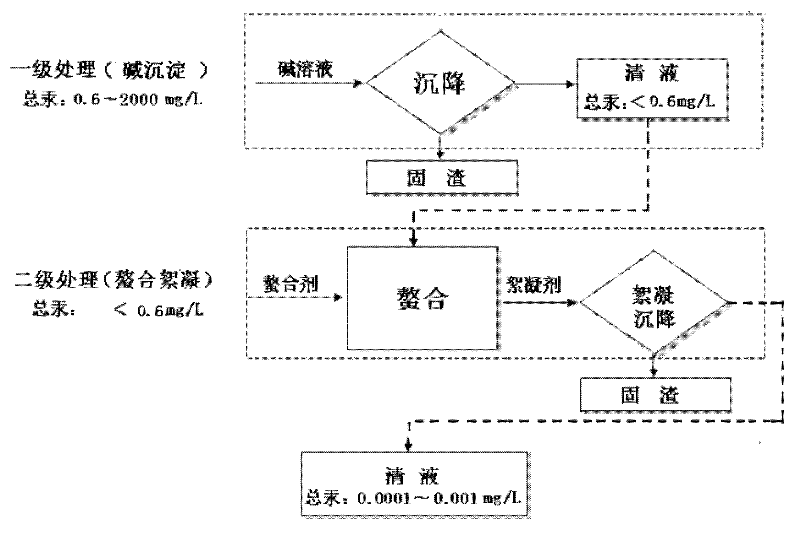

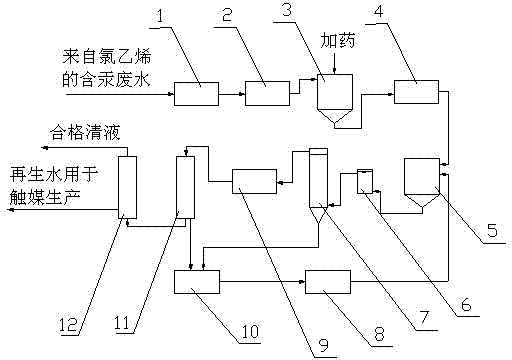

Efficient and economic mercury-containing waste water treatment method

ActiveCN102417255ALow costEasy to recycleWater contaminantsMultistage water/sewage treatmentHigh concentrationSulfur containing

the invention relates to an efficient and economic mercury-containing waste water treatment method. The efficient and economic mercury-containing waste water treatment method comprises the following steps of 1, adding an alkaline substance into high-concentration mercury-containing waste water so that the total mercury concentration is reduced to mercury concentration below 0.6mg / L, and 2, when the total mercury concentration of the high-concentration mercury-containing waste water is below 0.6mg / L, adding a sulfur-containing chelating agent into the high-concentration mercury-containing waste water according to 0.005 to 0.2% of the volume of the high-concentration mercury-containing waste water, adjusting a pH value of the mixed solution to a pH value of 3 to 7, adding 0.5 to 10% by mass of a flocculating agent into the clear solution according to a flocculating agent-clear solution volume ratio of 0.001 to 0.01 when mercury in the mixed solution is separated out, and carrying out solid-liquid separation after flocculating to obtain clarified waste water of which total mercury content is below 0.001mg / L. The efficient and economic mercury-containing waste water treatment method has the advantages that mercury removal efficiency is high; a scope of application is wide; a preparation treatment cost and a low equipment investment are low; and mercury-containing precipitates are gathered naturally and solid waste residues are treated centrally so that recovery and recycle are easy.

Owner:SHAANXI JINTAI CHLOR ALKALI CHEM CO LTD

Flue gas treatment method for simultaneous desulfurization, denitrification and demercuration by calcium and magnesium method

ActiveCN103801177AImprove denitrification performanceAchieve desulfurizationDispersed particle separationSlurryMixed gas

The invention discloses a flue gas treatment method for simultaneous desulfurization, denitrification and demercuration by a calcium and magnesium method. The method comprises the steps of (1) carrying out dust removal on the flue gas of a boiler, then enabling the flue gas to enter a static mixer, spraying ozone into the static mixer at the same time, and carrying out mixed oxidation on the flue gas of the boiler and the ozone; (2) after mixed oxidation, enabling the mixed gas to enter an absorption tower from the bottom of the absorption tower, spraying the mixed slurry of magnesium oxide and limestone or magnesium oxide and lime in a circulating way in the absorption tower, and feeding a demercuration agent into the absorption tower; (3) finally, discharging the sprayed and absorbed flue gas via a chimney from the top of the absorption tower. After the method is adopted, the denitration performance of the whole technology is maintained to be at a higher level, and high efficiency of desulfurization and demercuration is realized.

Owner:ZHEJIANG UNIV

Regeneration method of flue-gas demercuration absorbent

ActiveCN104437377AIncrease the speed of oxidation reactionImprove Chlorine RemovalOther chemical processesDispersed particle separationEnvironmental chemistryOxide

The invention discloses a regeneration method of a flue-gas demercuration absorbent composition. The regeneration method comprises the following steps: (a) washing an inactivated absorbent by using hydrogen peroxide solution, removing impurities such as flying ash on the surface of the absorbent, and converting elemental mercury absorbed on the surface of the absorbent into mercury in an oxidation state; (b) treating reacted mercury absorbent by using supercritical water and washing out the mercury absorbed; (c) further treating aqueous solution obtained in the step (b) by using sulfide solution, so as to obtain mercuric sulfide precipitate, and recovering the mercuric sulfide precipitate; (d) dipping and activating the absorbent in ferric chloride solution with the concentration being 1-3mol / L; and (e) drying, then roasting for 1-3 hours, thus obtaining the regeneration absorbent. The regeneration method disclosed by the invention is applicable to regeneration of the modified-metal-oxide-based mercury absorbent, and the recovery of the absorbing performance of the regenerated absorbent is good, so that the service life of the absorbent is prolonged and the economic and social benefits are good.

Owner:浙江大业新材料股份有限公司

Mercury removal method based on activated carbon online activation and mercury removal device based on activated carbon online activation

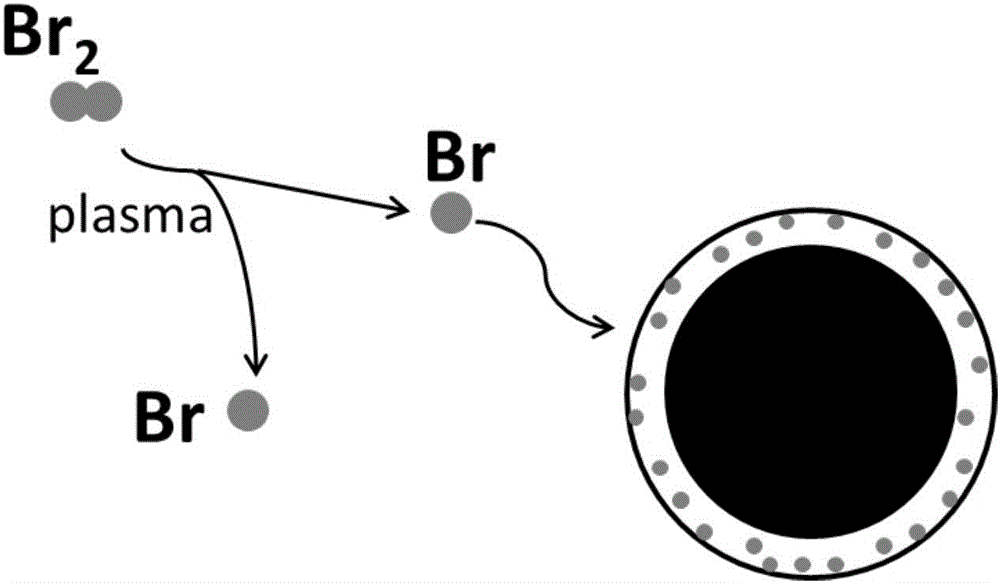

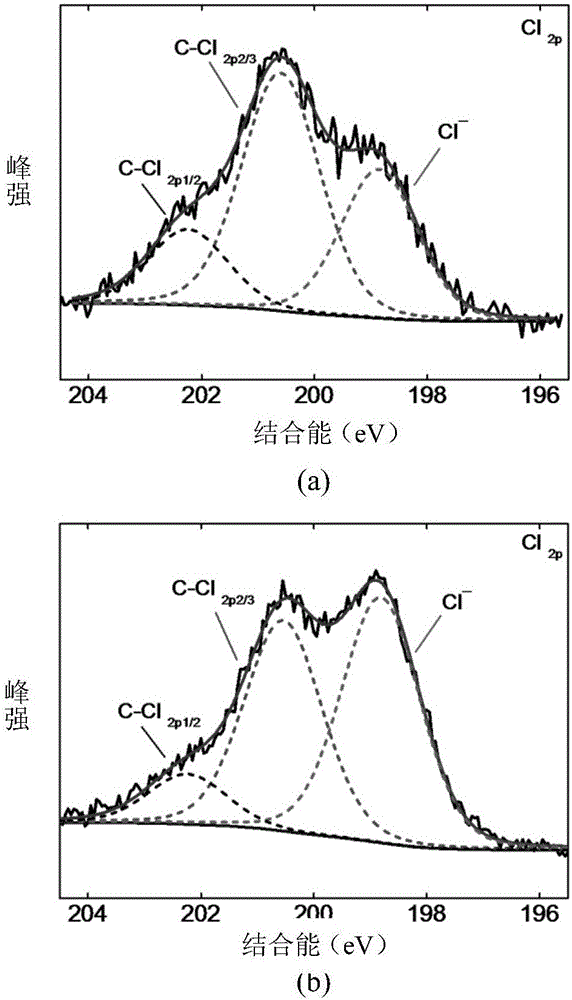

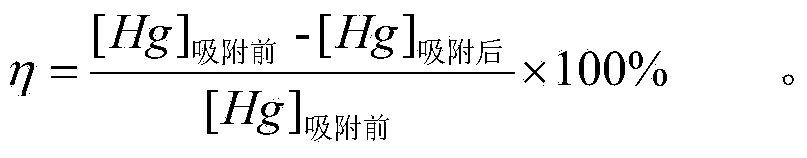

ActiveCN106040210AImprove mercury removal efficiencyOvercome the disadvantages of cumbersome operationGas treatmentOther chemical processesActivated carbonFlue gas

The invention discloses a mercury removal method based on active carbon online activation and a mercury removal device based on activated carbon online activation. Low temperature plasma treatment is carried out on active carbon and high-activity gas, so that the high-activity gas is changed into high-activity atomic or ionic state by plasma and is loaded on the active carbon, an active site is formed on the active carbon, and further online activation of the active carbon is realized; and then the online activated active carbon is fed into a flue, so as to adsorb and remove mercury in flue gas in the flue, and further mercury removal treatment of the flue gas is realized. According to the mercury removal method and device, a method for online activating the active carbon by virtue plasma is utilized for obtaining modified active carbon, mercury removal efficiency of the active carbon is improved, and the advantages of short consumed time and convenience in treatment are realized.

Owner:HUAZHONG UNIV OF SCI & TECH

Environment-friendly active carbon catalyst as well as preparation method and application thereof to flue gas mercury removal

InactiveCN104289232AReduce manufacturing costReduce use costPhysical/chemical process catalystsDispersed particle separationAdhesiveFlue gas

The invention discloses a preparation method of an environment-friendly active carbon catalyst. The preparation method comprises the following steps: (1) mixing an active carbon precursor, a simple substance or a compound containing at least one VIA family element, and an inorganic adhesive, performing extrusion forming after kneading, and drying to obtain a formed material; (2) preparing steeping fluid of a compound containing at least one of a IA family element, a IIA family element, a IB family element, a IIB family element, a VIIB family element, a VIII family element and a La family element, steeping the formed material obtained in step (1), and drying; and (3) activating the formed material treated in step (2) in a CO2 or H2O atmosphere to obtain the environment-friendly active carbon catalyst.

Owner:南京正森环保科技有限公司

Supported mercury remover and preparation method thereof

ActiveCN103418231AEasy to prepareLow costDispersed particle separationActive componentMetallic sulfide

The invention discloses a supported mercury remover. The active components at least comprise MSSH and carriers, wherein M is a metal which can generate a trivalent ion. The invention further discloses a preparation method of the mercury remover on the basis of the disclosure of the mercury remover. The mercury remover has a very high binding force for mercury, the binding strength between the mercury remover and mercury is stronger than that between the metal sulfide and mercury, and thus the problem of low utilization rate of metal sulfide in the mercury removing process, causing by the bad binding force between the metal sulfide and mercury and low mercury capacity during the mercury removing process, is solved.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

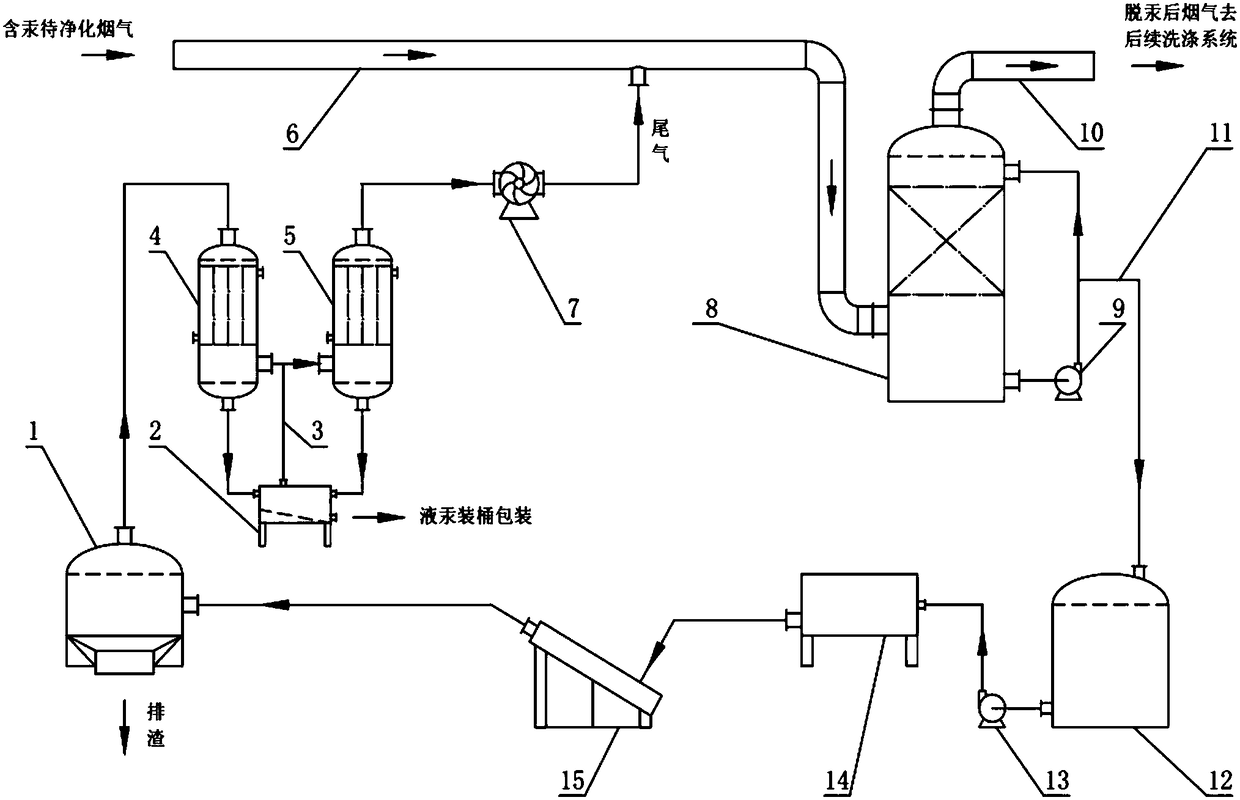

Method for recovering mercury in situ from mercury fume in non-ferrous metal metallurgy

ActiveCN108310955AAchieving flocculation recoveryAvoid pollutionGas treatmentDispersed particle separationNon-ferrous extractive metallurgySmall footprint

The invention discloses a method for recovering mercury in situ from mercury fume in non-ferrous metal metallurgy. The method comprises the following steps: performing absorption and mercury removal on mercury fume to obtain mercury-containing acid mud, and performing flocculation concentration and dehydration on the mercury-containing acid mud to obtain mercury-containing mud residues; pre-treating the mercury-containing mud, performing incineration, and recovering liquid mercury in a centralized manner by virtue of a multistage mercury condensation and collection device. The method is simple, low in cost, small in occupied area and high in efficiency of collecting and recovering the metal mercury, construction can be performed nearby a mercury fume production area of non-ferrous metal metallurgy, and environmental risk existing in the process of shipping out and treating the mercury-containing acid mud and during transportation can be avoided. Moreover, tail gases containing trace mercury can be introduced into a mercury fume purification system in non-ferrous metal metallurgy to be subjected to mercury removal again, a special tail gas treatment device does not need to be constructed, secondary pollution is effectively prevented from being avoided, and the method is simple and can be used on a large scale.

Owner:湖南西林环保材料有限公司

Method for advanced treatment of mercury-containing wastewater

InactiveCN103936187ALow priceExtended service lifeWater contaminantsWater/sewage treatment bu osmosis/dialysisSludgePolyvinyl chloride

A method for the advanced treatment of mercury-containing wastewater comprises the following steps: collecting mercury-containing wastewater, adjusting the pH value, chemically settling, carrying out advanced treatment, carrying out sludge concentration, carrying out solid-liquid separation, collecting the separated liquid, and carrying out bagging sealing collection of the separated solid. The method solves a problem of environmental pollution caused by bad treatment effect of mercury-containing wastewater generated in the production of polyvinyl chloride resin through a calcium carbide technology, and has the advantages of thorough treatment, small pollution, reasonable and simple process, continuous and rapid treatment, easy implementation and fast effectiveness. The method allows the mercury-containing wastewater to be thoroughly treated and have small pollution, and an advanced treatment material used in a system has a long service life and a low price, and can be recycled, so the method has the advantages of small investment and easy implementation; and the process is simple and reasonable, and can effectively realize energy saving, emission reduction and environmental protection.

Owner:XINJIANG TIANYE GRP +2

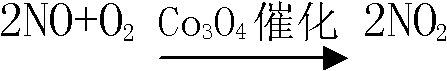

Method for removing mercury from smoke in coal fired power plant and mercury removing agent used by same

The invention discloses a method for removing mercury from smoke in a coal fired power plant and a mercury removing agent used by the same. In the term of the weight percent, the mercury removing agent is prepared from cobalt oxide and copper chloride in a mass ratio of (5-10):1000 through mixing. The mercury removing agent adopted in the invention can be directly used in a limestone- gypsum wet desulphurization system, is simple in use and convenience for use without reconstructing the traditional equipment and is low in cost; and the method for removing mercury by using the mercury removingagent has the advantages of high mercury removing efficiency, difficulty in corrosion to the device, and no generation of secondary pollution, can be used for oxidizing NO in the smoke into NO2 easily dissolved into water, and realizes the effect of removing mercury and NOx simultaneously.

Owner:HUADIAN ENVIRONMENTAL PROTECTION ENG & TECH +1

Absorbent for removing mercury out of coal burning smoke and preparation method thereof

InactiveCN103566900AImprove mercury removal efficiencyLow costOther chemical processesDispersed particle separationSodium BentoniteAbsorption capacity

The invention relates to an absorbent for removing mercury out of the coal burning smoke. The absorbent is prepared from the following raw materials in parts by weight: 80 to 90 parts of bentonite, 4 to 6 parts of potassium iodate, 6 to 9 parts o chitosan, 3 to 5 parts of dilute sulfuric acid, 2 to 4 parts of sodium citrate, 2 to 4 parts of sodium tartrate, 4 to 5 parts of modified diatomite and an appropriate amount of water. According to the absorbent, bentonite is used as an absorbent base material, the absorption capacity is good, an antibactieral, deodorizing, moisture absorption and mildew preventing functions also can be realized, and organisms also can be catalyzed and decomposed; the absorbent is high in mercury removal efficiency, low in cost, free of secondary pollution and capable of meeting the industrial application requirement.

Owner:BENGBU HUAFANG FILTER

Preparation method for flue gas mercury-removing active carbon

ActiveCN104148013AIncrease loadHigh mercury removal efficiencyOther chemical processesDispersed particle separationHalogenActive carbon

The invention provides a preparation method for flue gas mercury-removing active carbon. The preparation method comprises the following steps: step 1, removing a surface chemical group of a raw material: washing the particle active raw material with 10.wt%-30.wt% NaOH solution and drying the raw materials at 100-120 DEG C; step 2, immersing halide salt: mixing, immersing and agitating the raw material active carbon with an oxygen-containing group on the surface and a halide salt solution according to the mass ratio ranging from 1:1 to 1:5 for 4-12 hours; filtering and drying to obtain active carbon carrying the halide salt, wherein the concentration of the halide salt solution is 10wt.%-50wt.%; step 3, loading halogen: putting the active carbon carrying the halide salt into a U-shaped pipe to form a filling layer; inputting air with the halogen from the top of the filling layer at the speed of 100-500mL / min and keeping the heat for 1-10 hours at room temperature to obtain saturated halogen-loaded active carbon; and step 4, heating the saturated halogen-loaded active carbon at the temperature in a range of 80-120 DEG C to remove the volatile halogen to prepare the flue gas mercury-removing active carbon.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Demercuration absorption liquid

InactiveCN103877844AImprove mercury removal efficiencyWide liquid rangeDispersed particle separationMass ratioIonic liquid

Owner:HUANENG POWER INT INC +2

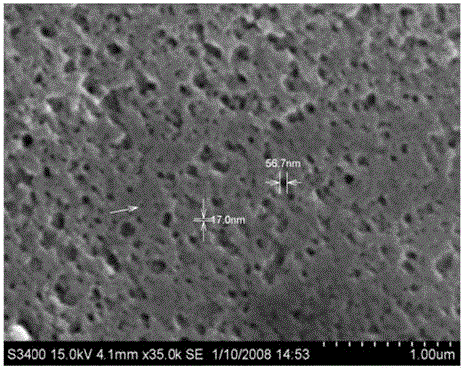

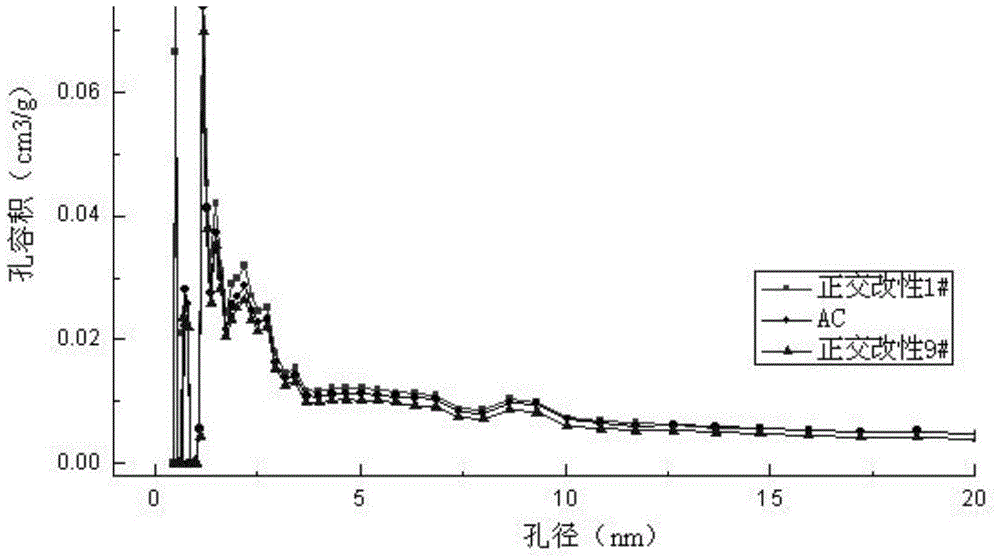

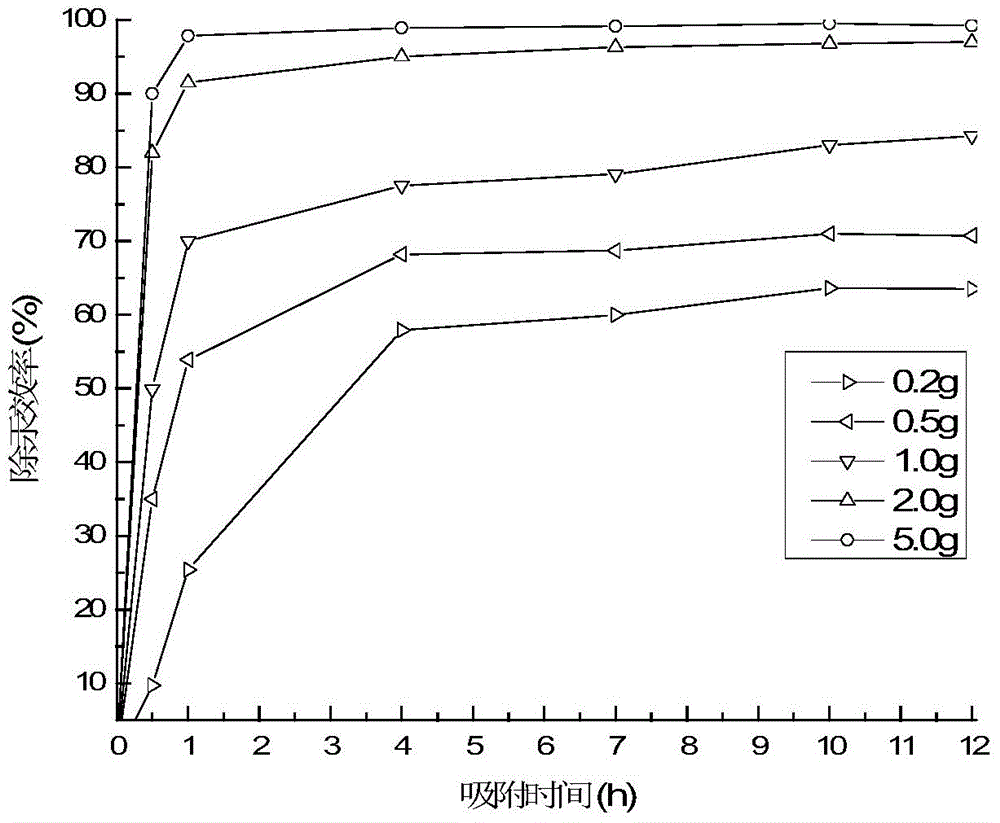

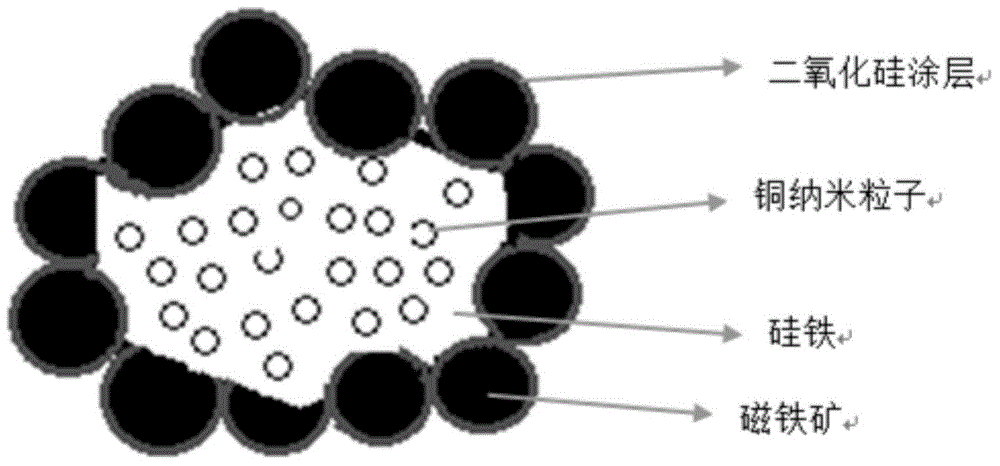

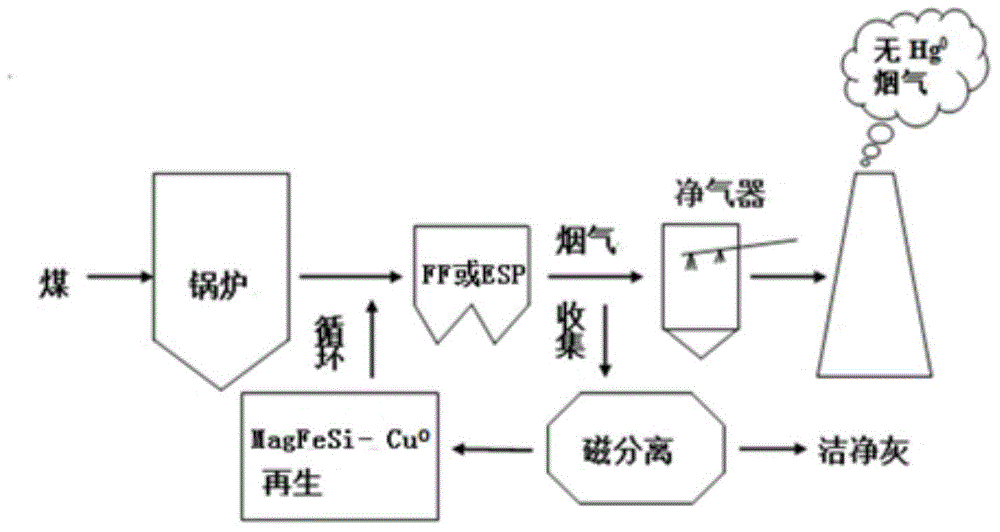

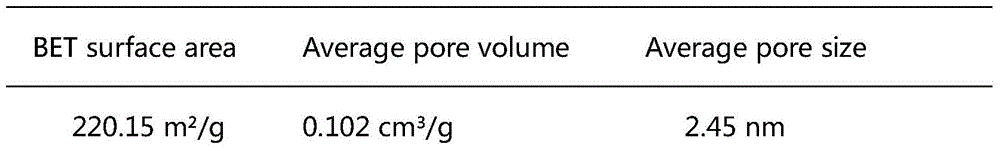

Magnetic adsorbent for removing Hg0 from flue gas and preparation and application of magnetic adsorbent

ActiveCN104525093AReduce manufacturing costImprove mercury removal efficiencyGas treatmentOther chemical processesSorbentSilica coating

The invention relates to a magnetic adsorbent for removing Hg0 from flue gas and preparation and application of the magnetic adsorbent. The magnetic adsorbent is MagFeSi-Cu0. The preparation method includes the first step of putting Fe3O4 nano particles in deionized water, adding Na2SiO3, adding a mixture into ethyl alcohol, adding NH3*H2O for a sol-gel reaction, conducting steam treatment and conducting drying to obtain magnetic particles of a silicon dioxide coating; the second step of introducing copper nano particles into the surface of silicon iron and sintering the magnetic particles of the silicon dioxide coating and the silicon iron to obtain the magnetic adsorbent. The magnetic adsorbent is applied to removing Hg0 from the flue gas. An adsorbent of mercury is the magnetic adsorbent, the coal-fired flue gas passes through a filter material, the mercury in the flue gas is caught by the magnetic adsorbent in the filter material, a dry drum magnetic separator is used for adsorbent spending and flying ash extraction, the used magnetic adsorbent MagFeSi-Cu0 will be regenerated and cycled, and therefore use cost of the adsorbent will be lowered.

Owner:DONGHUA UNIV +1

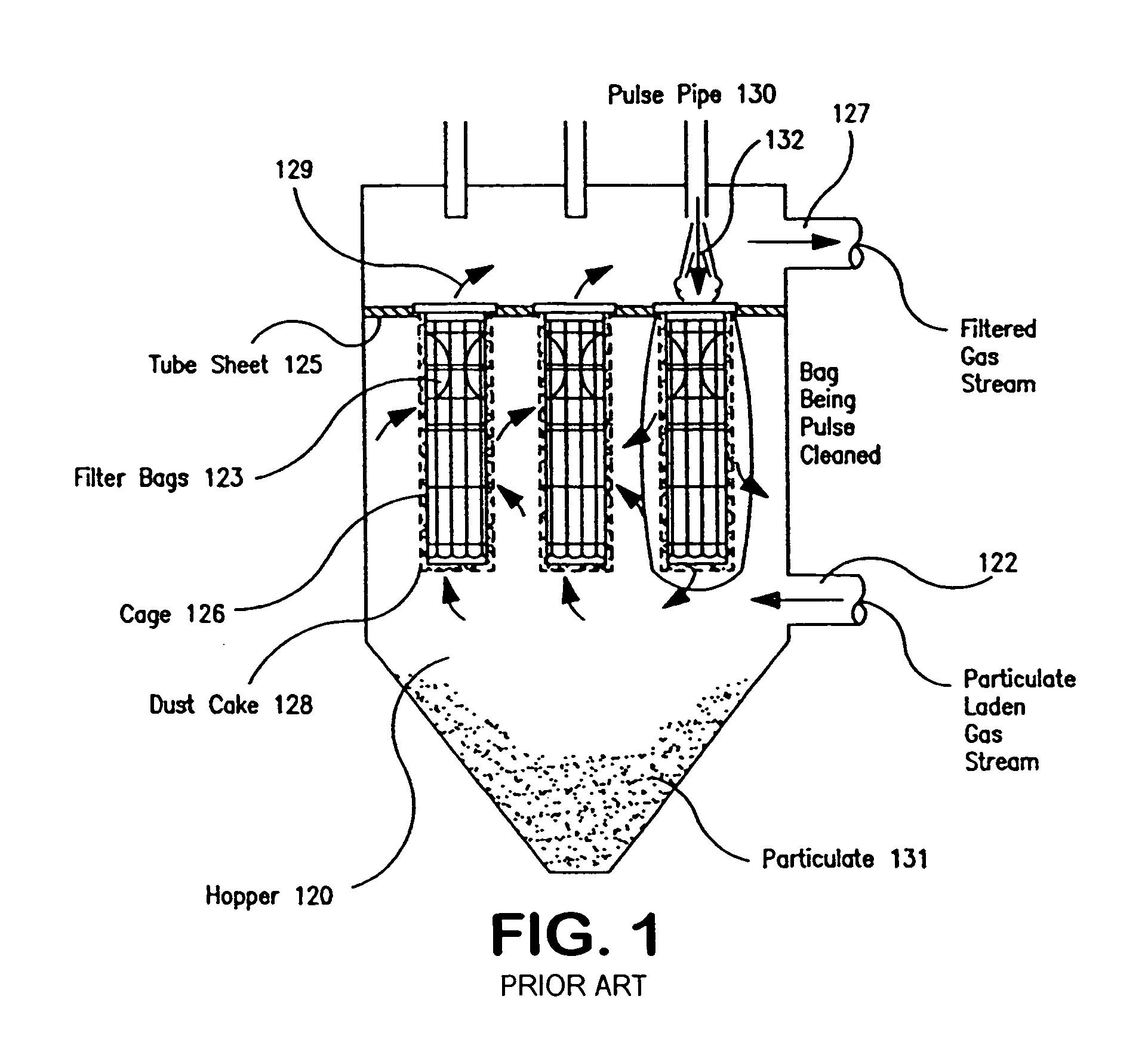

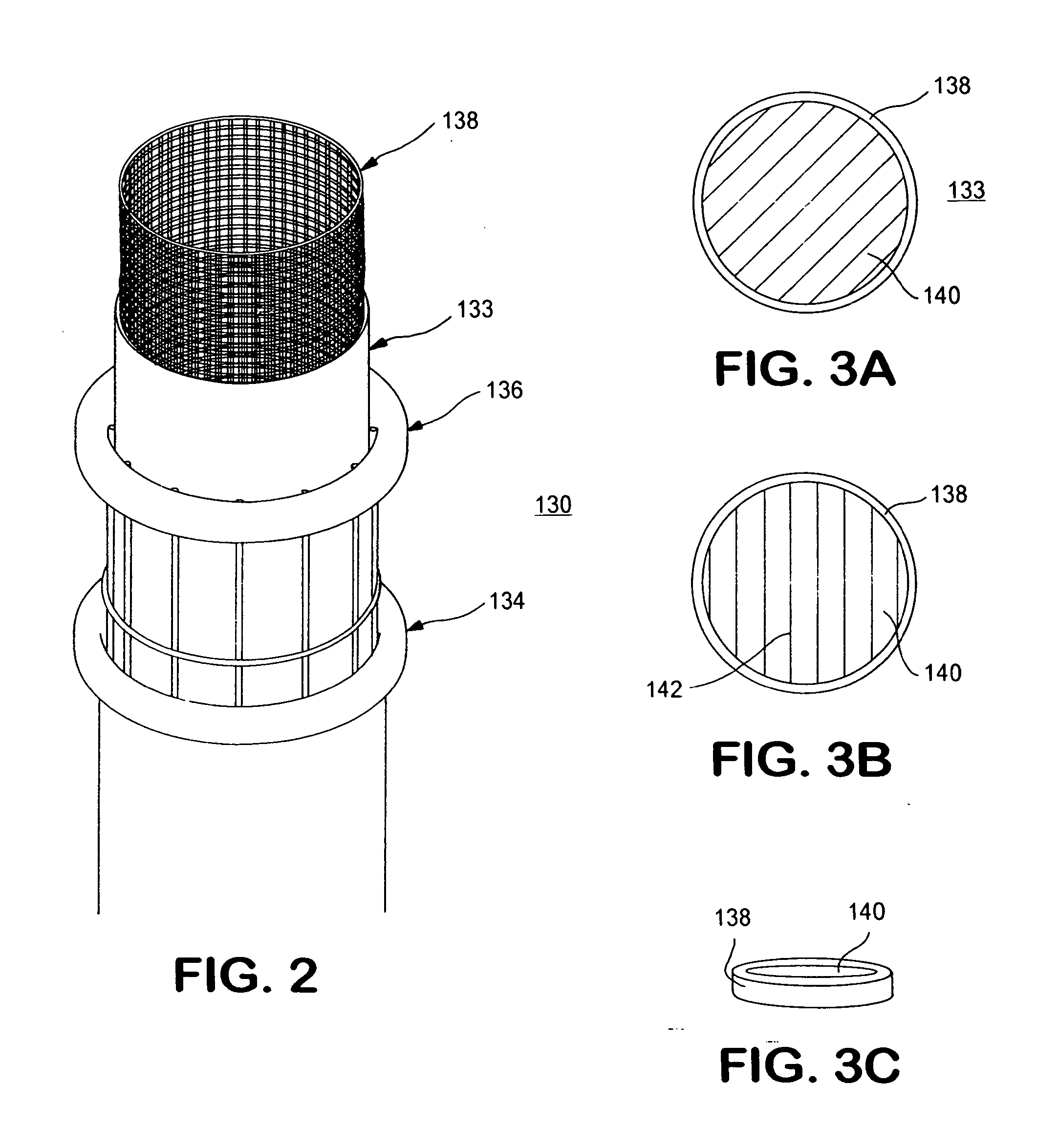

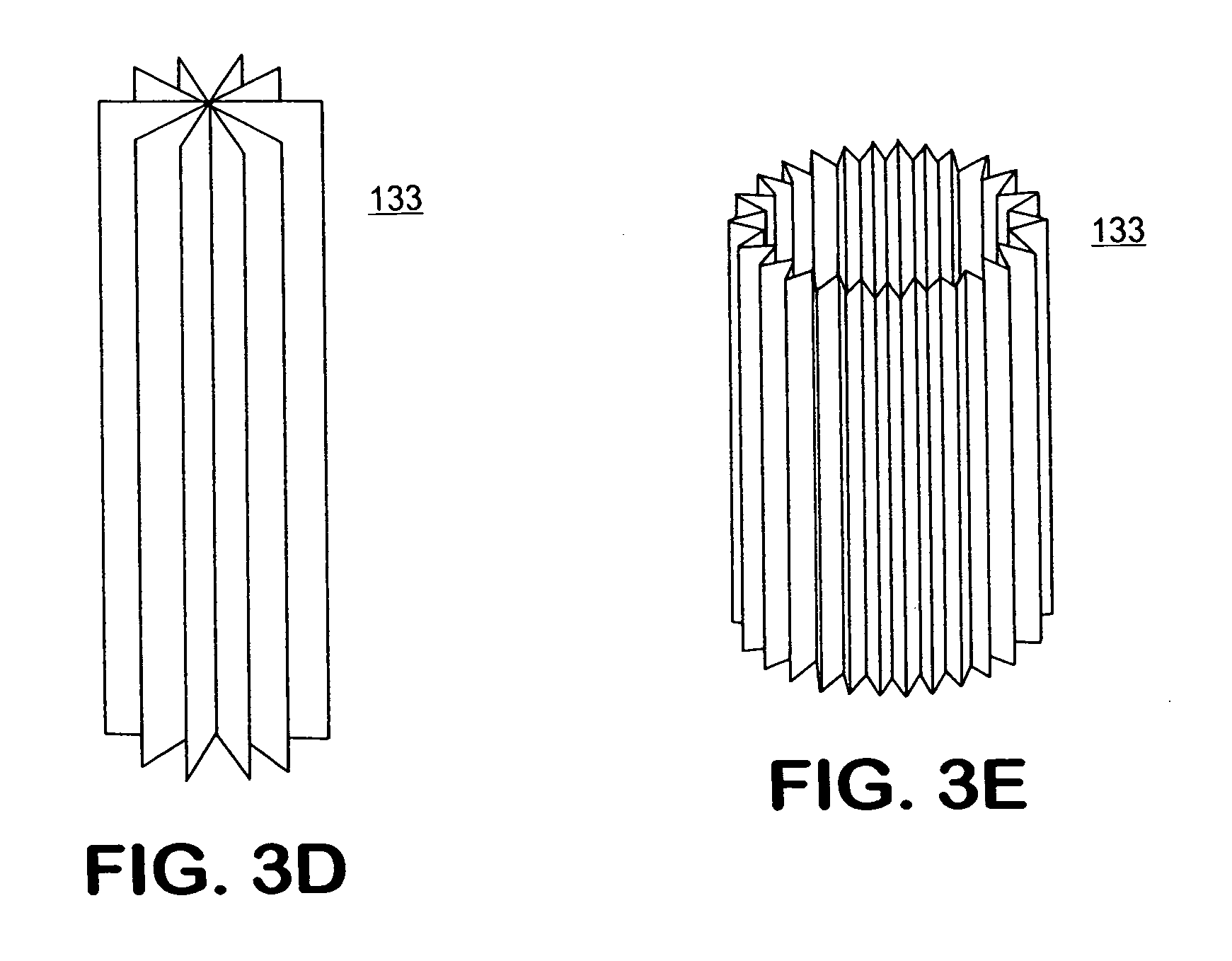

Filter system

InactiveUS20050148465A1Easily inserted into and attachedImprove mercury removal efficiencyOther chemical processesUsing liquid separation agentChemical compositionFiltration

The present invention is an improved filtration system, filtering method and unique chemical composition for capturing mercury and other pollutants in flue gases generated by process gas streams. The improved filtration system may take various forms depending on the type of filter system most desired for a particular application; however, the filter system includes at least a filter element or elements and an adsorbent component having a composition suitable for capturing mercury on the downstream side of the filter element.

Owner:WL GORE & ASSOC INC

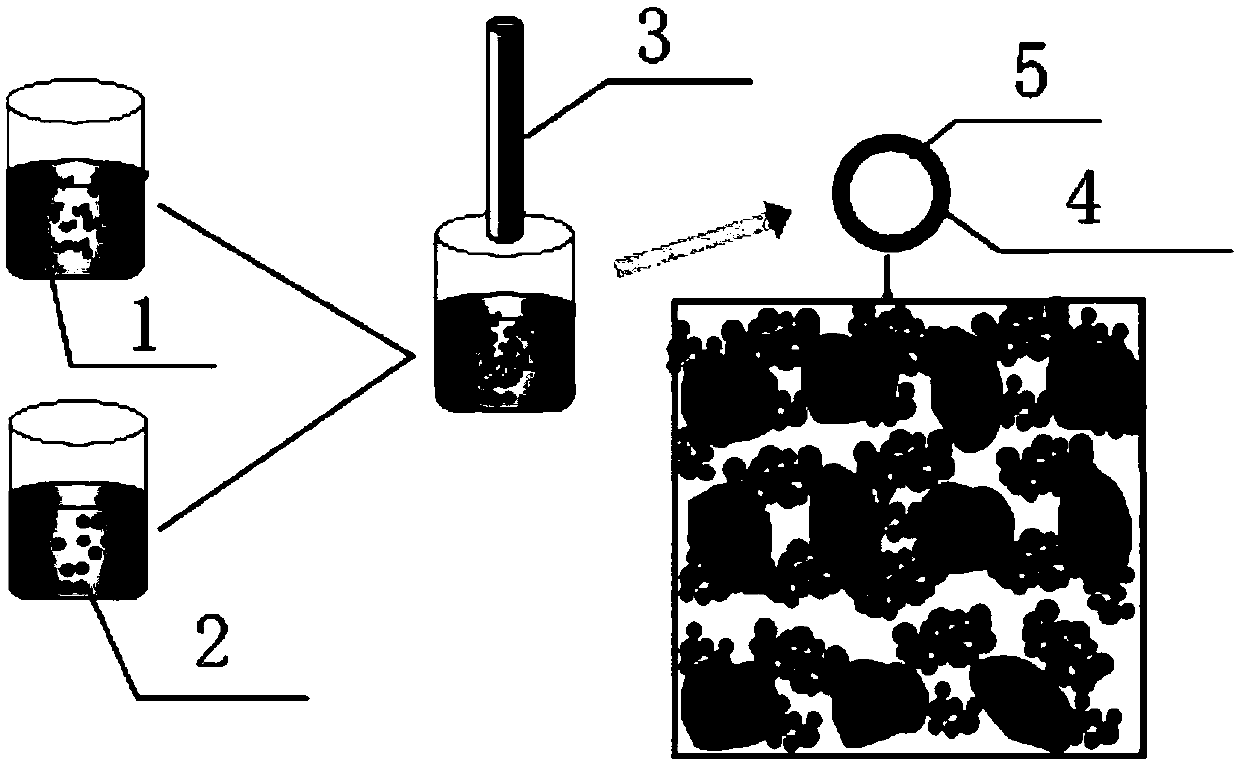

Preparation method of magnetic mercury removal adsorbent

InactiveCN106311186AImprove mercury removal efficiencyEasy to separateOther chemical processesWater contaminantsFerrite nanoparticlesSorbent

The invention discloses a preparation method of a magnetic mercury removal adsorbent. The magnetic mercury removal adsorbent adopts magnetic Mn ferrite nanoparticles, carriers are added to the magnetic nanoparticles to improve the performance, and then the magnetic nanoparticles are subjected to amino-functionalization through modification and addition of a specific solution. According to the preparation method, corresponding salt is dissolved with ionized water, a strong base solution is added, stirred and heated, a reaction product is separated by means of an external magnetic field, stirred, heated and dried, and the amino-functionalized magnetic adsorbent prepared through modification is obtained and can acquire good mercury removal performance. Two modification processes are combined, and removal of mercury ions in a solution by the adsorbent can be improved effectively.

Owner:SOUTHEAST UNIV

Mercury removal adsorbent with core-shell structure, and preparation method thereof

InactiveCN110665455AImprove mercury removal efficiencyThe process is simple and easy to controlGas treatmentPhysical/chemical process catalystsThioureaPhysical chemistry

The invention discloses a mercury removal adsorbent with a core-shell structure. The mercury removal adsorbent is characterized in that Fe3O4 nanoparticles are used as a carrier, and MoS2 nanosheets are grown on the surface of Fe3O4 in situ to form a Fe3O4@MoS2 core-shell structure in order to obtain the mercury removal adsorbent with the core-shell structure. The Fe3O4 nanoparticles are taken asa raw material, and are dispersed into deionized water, ammonium molybdate tetrahydrate and thiourea are added, and the mercury removal adsorbent, namely the MoS2 Fe3O4 nano-composite material, is prepared by using a hydrothermal technology. The composite material has the advantages of good crystallinity, controllable morphology and size, and excellent adsorption performance.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

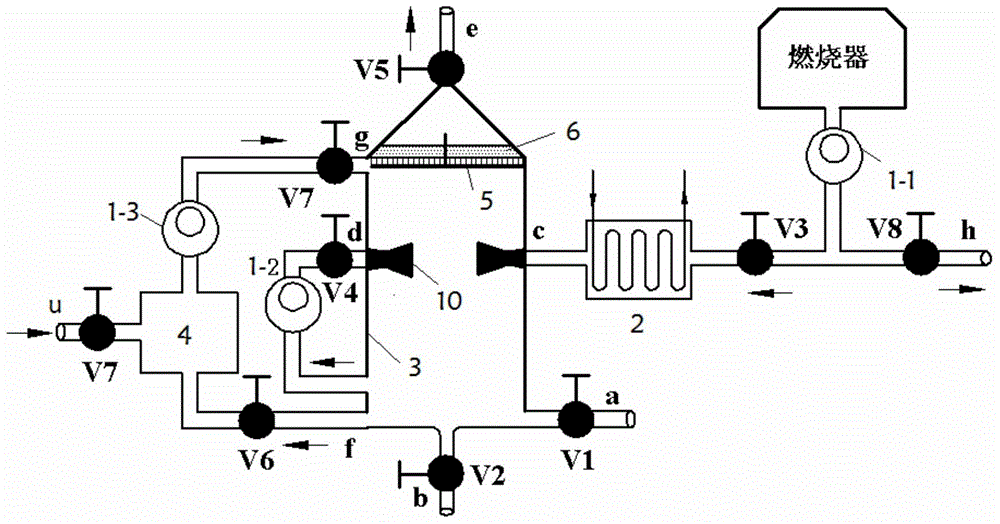

Algae-char-impact-tower-based mercury removal method and preparation method of algae char

InactiveCN104436994AImprove protectionEmission reduction benefits are obviousOther chemical processesDispersed particle separationFlue gasMercury adsorption

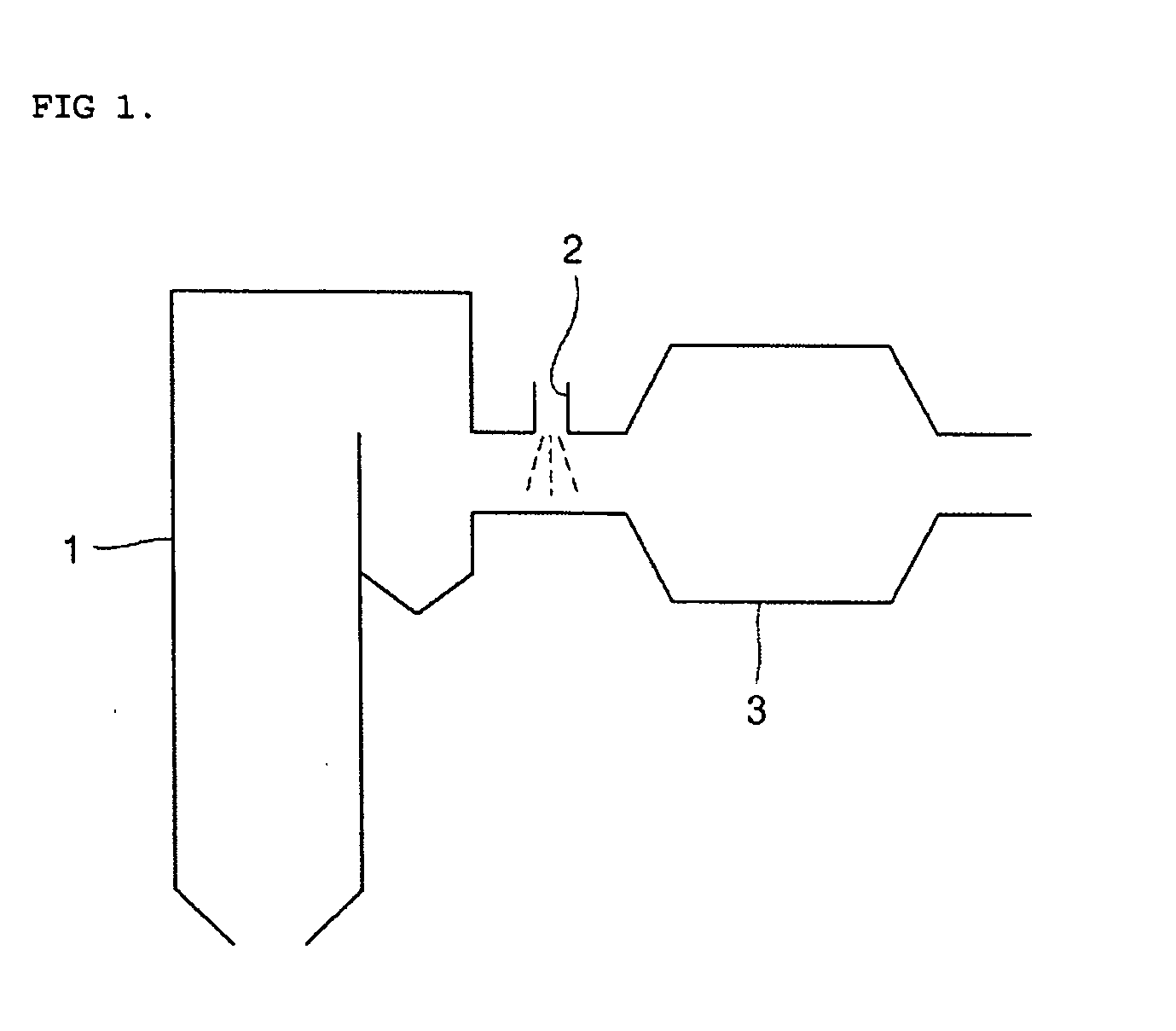

The invention relates to an algae-char impact-tower-based mercury removal method. The method comprises the following steps: performing pyrolysis on algae to prepare biomass char as a flue gas mercury removal adsorbent, and adsorbing and removing mercury in one impact tower reactor; recycling mercury resource and regenerating the adsorbent in a separator; cooling mercury-containing flue gas from a burner and spraying the flue gas into the impact tower reactor through a Laval spray pipe, spraying the algae char adsorbent into the impact tower reactor through the Laval spray pipes which are coaxially and oppositely arranged, and enabling two strands of gas flows to have opposite impact in the impact tower reactor so as to realize the adsorption and removal of mercury. When regeneration is performed in one impact tower reactor, flue gas from the burner is automatically switched and flows into the other impact tower reactor. The two impact tower reactors are alternatively used for performing regeneration. According to the method and the device, the biomass char is prepared by utilizing pyrolysis of algae and used for adsorbing and removing mercury, the removal process has no secondary pollution, the raw material of the adsorbent is a regenerative resource with wide reserves, and wide application prospects can be achieved.

Owner:南京朗洁环保科技有限公司

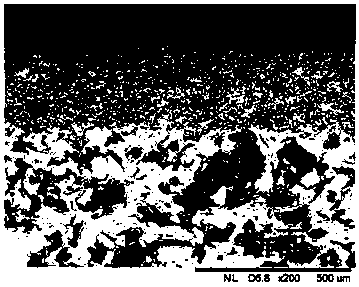

Ag and two-dimensional MXene modified high-temperature flue gas dust removal, denitration and mercury removal catalytic film and preparation method thereof

ActiveCN109603533AImprove purification effectIncrease contactPhysical/chemical process catalystsDispersed particle filtrationReactive siteAdhesive

The invention belongs to the field of air purification, in particular to an Ag and two-dimensional MXene modified high-temperature flue gas dust removal, denitration and mercury removal catalytic filmand a preparation method thereof. The catalytic film is composed of a ceramic support and an active catalytic layer spread in a hole channel of the ceramic support, the active catalytic layer comprises a two-dimensional MXene nanosheet, AgNO3, active metal, a carrier, a dispersing agent and an adhesive; according to the invention, the two-dimensional layered MXene nanosheet is used as a structural guiding agent to prepare the Ag and two-dimensional MXene modified high-temperature flue gas dust removal, denitration and mercury removal catalytic film; the introduction of the two-dimensional MXene nano material enables the catalytic layer to have a two-dimensional and three-dimensional assembly structure, more active sites are provided, the contact between gas and the catalyst is increased,and the denitration and mercury removal efficiency is improved; meanwhile, by utilizing the separation performance of the film, the dust removal, denitration and mercury removal integrated treatment can be achieved at high temperature, and the flue gas purification process is simplified.

Owner:CHINASALT JINTAN

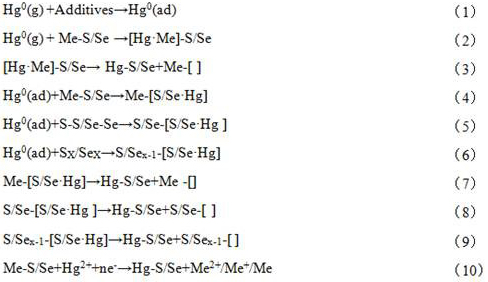

Stable suspension system for removing mercury in flue gas and recovery method of suspension system

ActiveCN112755764AImprove mercury removal efficiencyLarge capacityGas treatmentDispersed particle separationFlue gasControl system

The invention discloses a stable suspension system for removing mercury in flue gas and a recovery method of the suspension system. Metal sulfur, a selenide mercury removal agent and an additive are pretreated to form a stable suspension, the mercury-containing flue gas is in contact with the suspension, gaseous mercury (Hg0) is converted into stable mercuric sulfide or mercury selenide, and efficient removal of gaseous mercury in the flue gas is achieved. According to the method, existing pollutant control systems in various industries can be utilized, and the cost is low; the suspension system is simple to recover and separate and can be recycled; mercury can be recycled as a product; and the market prospect is wide.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com