Method for advanced treatment of mercury-containing wastewater

A technology for advanced treatment of waste water, applied in natural water body treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of environmental pollution, poor treatment effect of mercury-containing wastewater, etc., and achieve high mercury removal efficiency, The price can be recycled and reused, and the effect of thorough treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

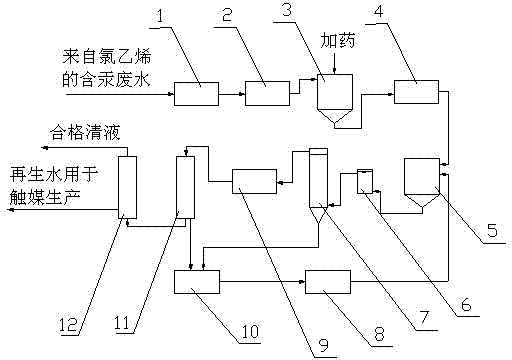

[0024] Refer to attached figure 1 , a method for the advanced treatment of mercury-containing wastewater. After the mercury-containing wastewater is collected, it undergoes pH adjustment, chemical sedimentation, pressure filtration, and microfiltration in sequence, and then undergoes sludge concentration and solid-liquid separation. Collection, the separated solids are bagged and sealed, and the steps are as follows: First, the mercury-containing wastewater is collected in the collection pool 1 for collection; the collected mercury-containing wastewater is pumped into the pH adjustment pool 2, and the pH is adjusted to 9-11; The mercury-containing wastewater after pH adjustment is pumped into the reaction tank 3 for chemical precipitation reaction, and Na 2 The S solution is fully reacted, and then the flocculant Fe is added 3+ The mercury-containing waste water after the reaction enters filter press 4 and carries out pressure filtration, and the mercury-containing waste wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com