Preparation method of praseodymium-doped titanium dioxide composite nanofiber photocatalyst

A technology of composite nanofibers and nanophotocatalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low mercury removal efficiency of photocatalysts and manufacturing processes Difficult to control, high production cost and other problems, to achieve the effect of short cycle, low cost and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Measure acetic acid and ethanol with a graduated cylinder, add 10 g of tetrabutyl titanate to 100 ml of a mixed solution of acetic acid and ethanol (for example, a volume ratio of 1:1), and stir vigorously on a magnetic stirrer to mix evenly. Then, for example, 100ml of ethanol solution of praseodymium acetylacetonate can be prepared by constant volume method, wherein the content of praseodymium acetylacetonate is 3.14g, which is added into the mixed solution of tetrabutyl titanate, acetic acid and ethanol, and then 5g of polyethylene glycol is weighed with a balance. Pyrrolidone is added to it, and it is vigorously stirred on a stirrer until a uniformly mixed, transparent liquid with a certain viscosity is obtained, which is the spinning precursor solution.

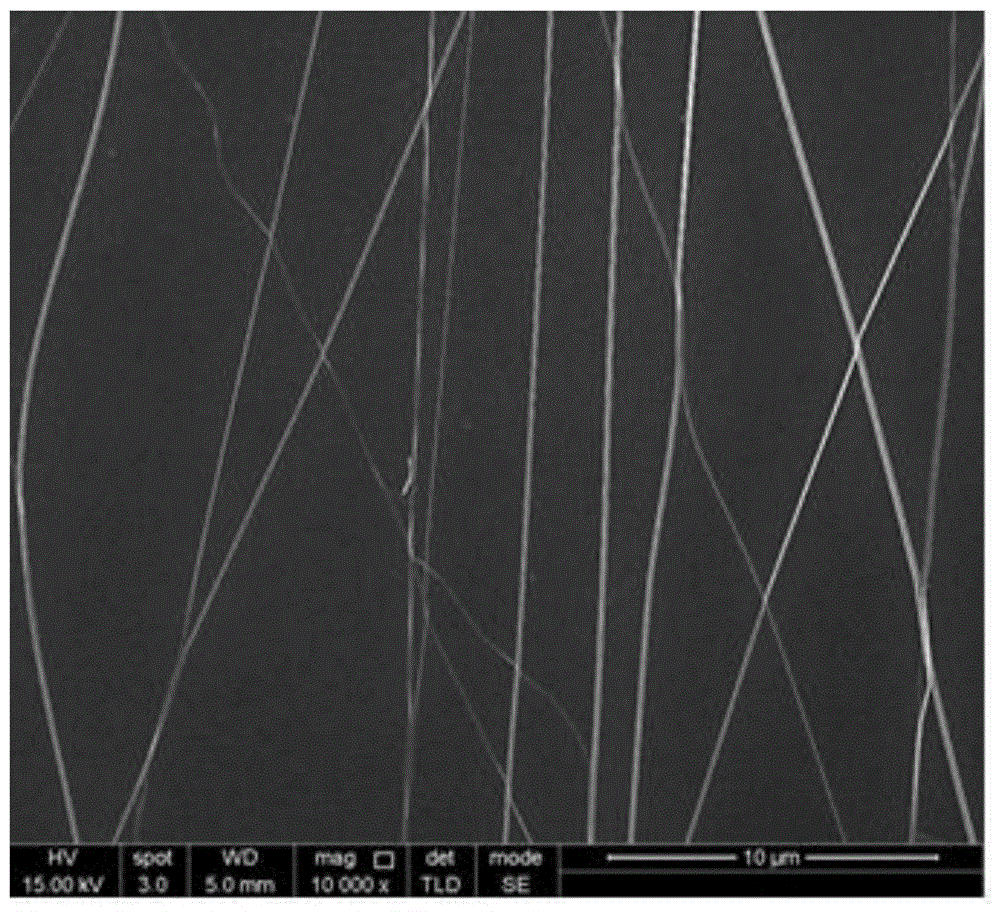

[0028] Next, put the spinning precursor solution into a 5ml syringe, connect it to a stainless steel spinneret through a polyethylene tube, and the inner diameter of the spinneret can be selected as 0.5 mm, and fix...

Embodiment 2

[0030] Measure acetic acid and ethanol with graduated cylinders. Add 14.28 g of tetrabutyl titanate into 100 ml of a mixed solution (for example, a volume ratio of 2:5) composed of acetic acid and ethanol, and vigorously stir and mix evenly on a magnetic stirrer. Then, for example, 100ml of ethanol solution of praseodymium acetylacetonate can be prepared by constant volume method, wherein the content of praseodymium acetylacetonate is 26.68g, which is added into the mixed solution of tetrabutyl titanate, acetic acid and ethanol, and then 6g of polyethylene glycol can be weighed with a balance. Pyrrolidone is added to it, and it is vigorously stirred on a stirrer until a uniformly mixed, transparent liquid with a certain viscosity is obtained, which is the spinning precursor solution.

[0031]Next, put the spinning precursor solution into a 5ml syringe, connect it to a stainless steel spinneret through a polyethylene tube, and the inner diameter of the spinneret can be selected...

Embodiment 3

[0033] Measure acetic acid and ethanol with graduated cylinders. Add 16 g of tetrabutyl titanate into a mixed solution of acetic acid and ethanol (for example, a volume ratio of 2:1), and vigorously stir and mix evenly on a magnetic stirrer. Then, for example, 100ml of ethanol solution of praseodymium acetylacetonate can be prepared by constant volume method, wherein the content of praseodymium acetylacetonate is 35g, which is added into the mixed solution of tetrabutyl titanate, acetic acid and ethanol, and then 7g of polyvinylpyrrolidone can be weighed with a balance Add it and stir vigorously on the stirrer until a uniformly mixed, transparent liquid with a certain viscosity is obtained, which is the spinning precursor solution.

[0034] Next, put the spinning precursor solution into a 5ml syringe, connect it to a stainless steel spinneret through a polyethylene tube, and the inner diameter of the spinneret can be selected as 0.6 mm, and fix it on the pinhole plate with a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com